Patents

Literature

130results about How to "Guaranteed compaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

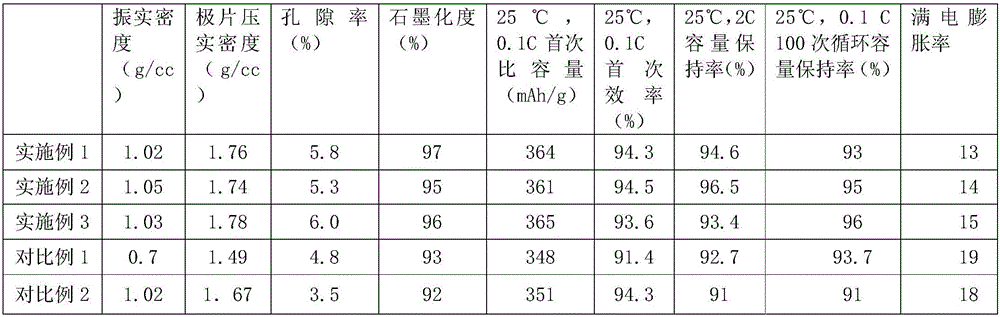

Preparation method of composite graphite, composite graphite and lithium ion battery

InactiveCN105098184ALow costHomogeneous catalytic effectCell electrodesSecondary cellsLithium electrodeGraphite

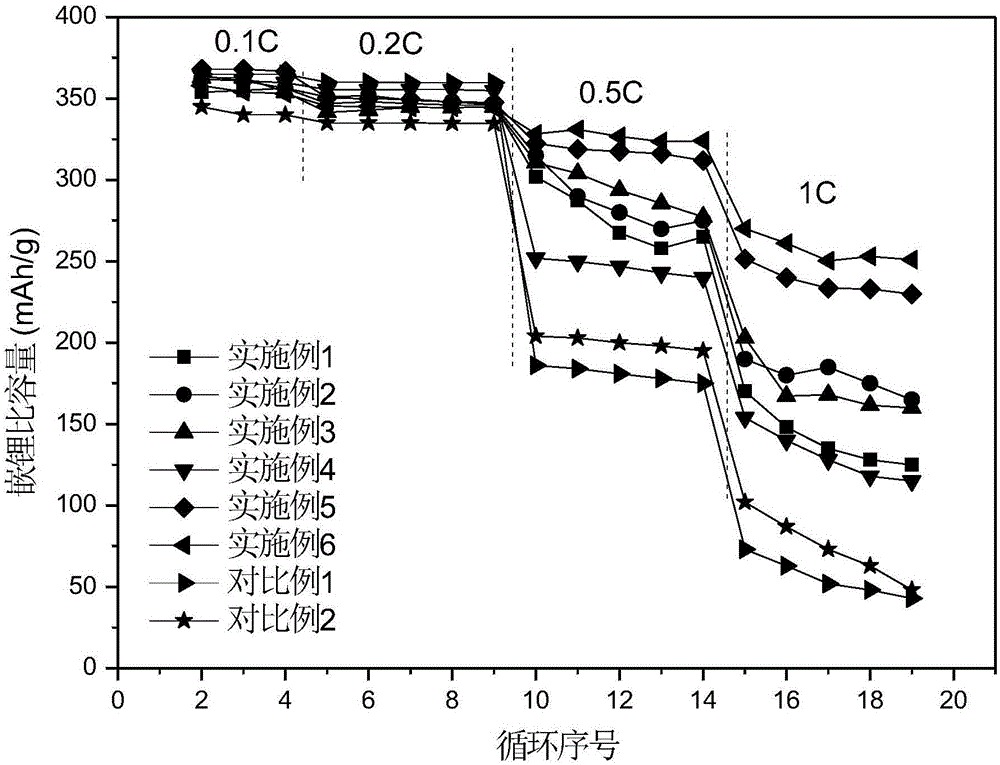

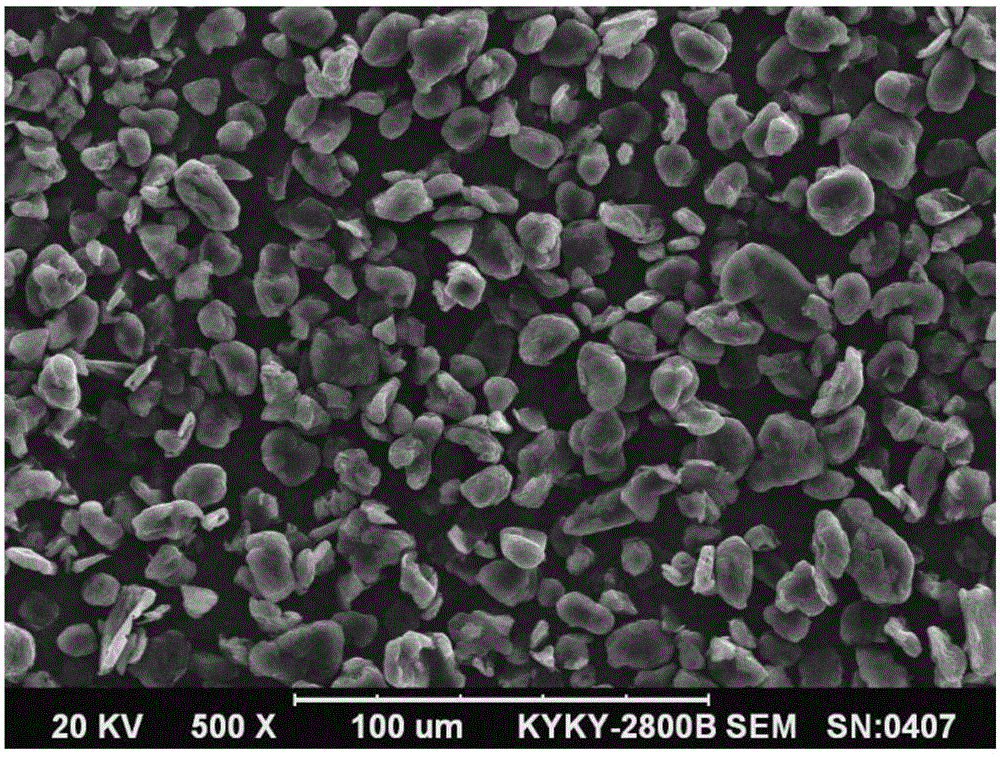

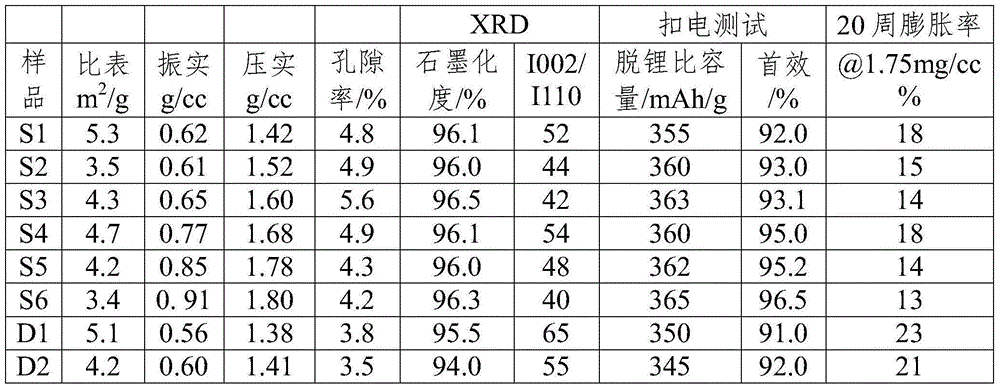

The invention provides a preparation method of composite graphite to overcome the problems that the composite graphite prepared by the method in the prior art is low in energy density, poor in high-rate charge and discharge properties and high in expansion rate in the charging and discharging processes. The preparation method comprises the following steps: (S1) providing ultrafine carbon powder, wherein the ultrafine carbon powder comprises green coke and / or mesophase carbon green microspheres; (S2) mixing the ultrafine carbon powder with a binder to obtain a mixture A, mixing the mixture A with a catalyst to obtain a mixture B, and then carrying out combined treatment on the mixture B to obtain a precursor; (S3) carrying out graphitizing treatment on the precursor to obtain a semi-finished product; and (S4) crushing, spheroidizing, wrapping and sieving the semi-finished product to obtain the composite graphite. Meanwhile, the invention further discloses the composite graphite prepared by the method and a lithium ion battery. The composite graphite provided by the invention is high in energy density, good in liquid absorption and retention properties, good in isotropic property, good in high-rate charge and discharge properties and low expansion rate in the charging and discharging processes.

Owner:BTR NEW MATERIAL GRP CO LTD

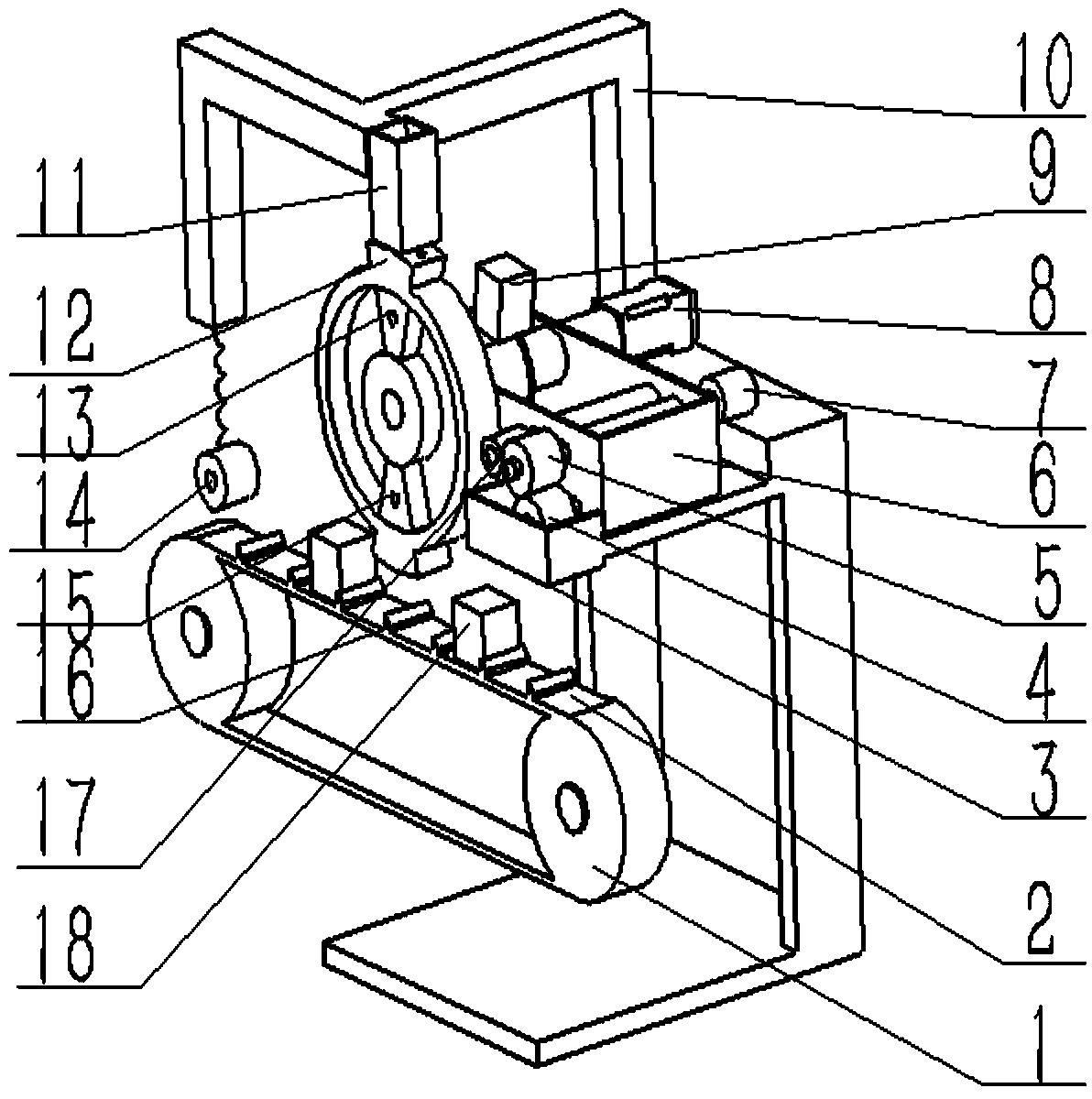

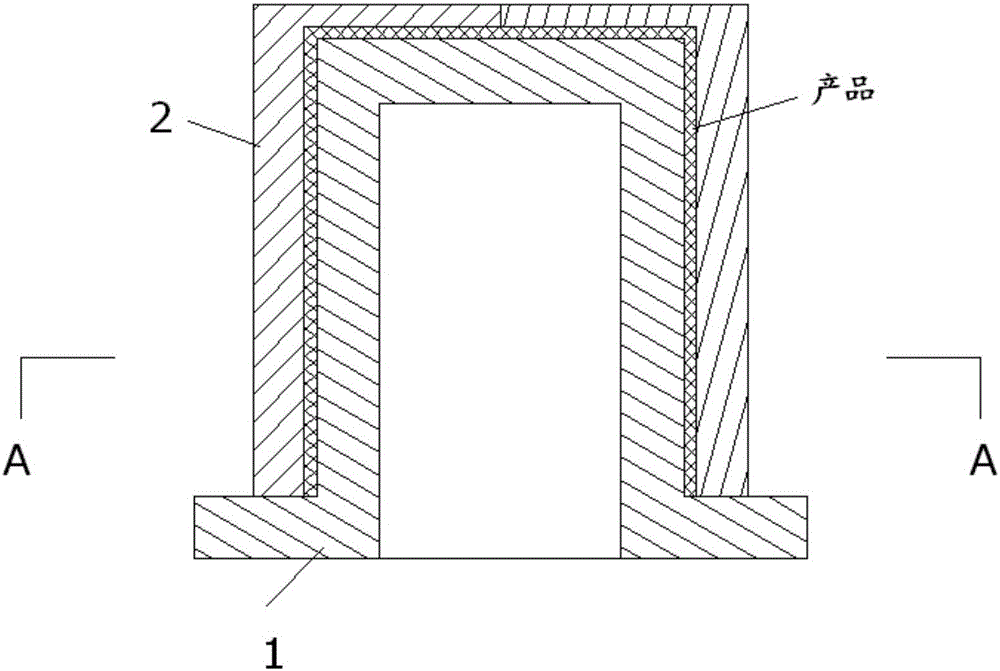

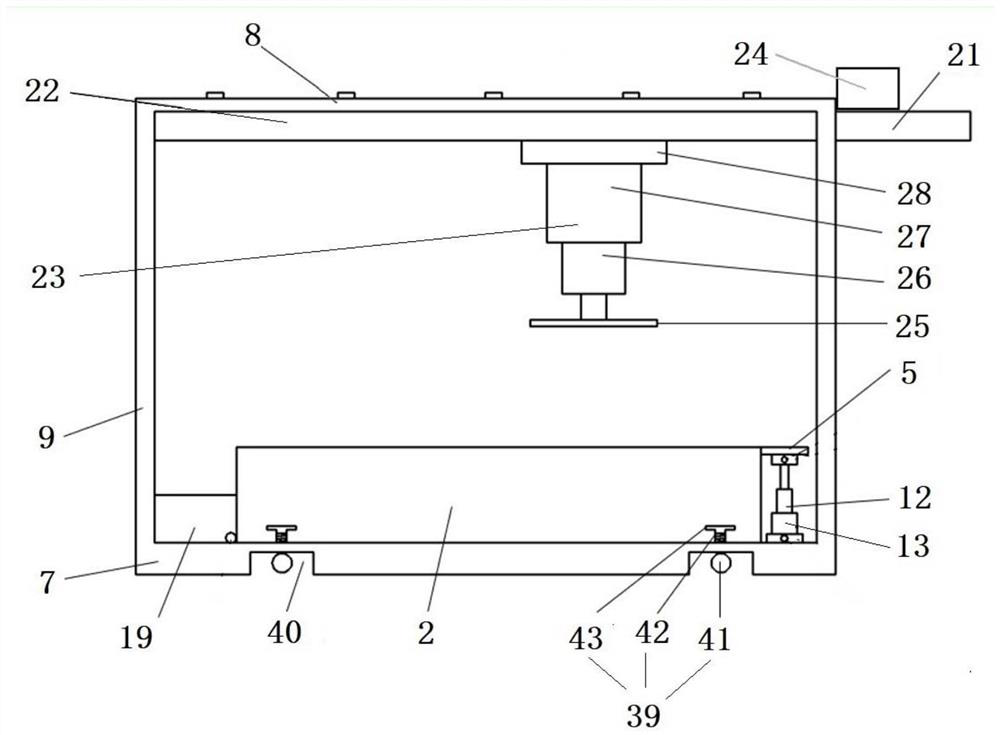

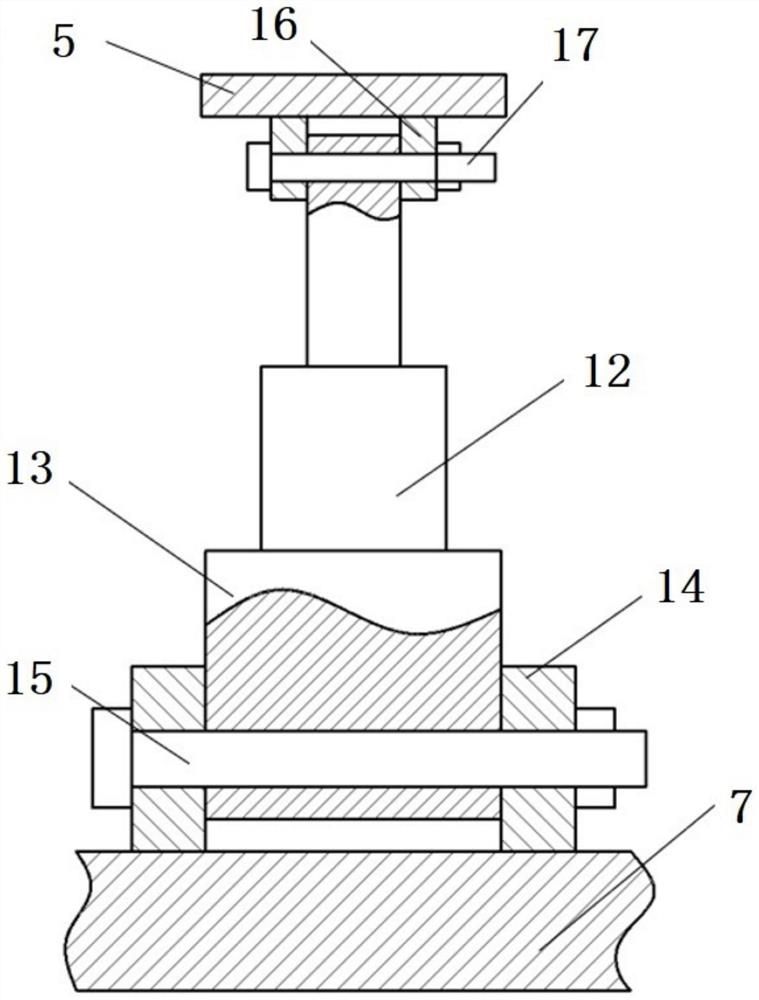

Automatic square tin can branding device

InactiveCN104139899APrecise positioningGuaranteed compactionLabelling short rigid containersLabelling machinesCouplingPulp and paper industry

The invention discloses an automatic square tin can branding device and belongs to electromechanical equipment. The automatic square tin can branding device comprises a belt pulley, a conveyor belt, a glue box, a first gluing roller, a second gluing roller, a bearing block, a motor, a stepping motor, an air pump, a rack, a paper box, a main wheel, an air suction hole, a pressure brush, an air-blowing hole, conveyor belt positioning blocks, a third gluing roller and tin cans, wherein the stepping motor arranged on a boss behind the rack is connected with the main wheel through a coupler and a shaft; the air pump is fixed on the shaft between the stepping motor and the main wheel; the motor arranged on the boss behind the rack is connected with the second gluing roller through a shaft; the glue box is welded in front of the rack; the paper box welded above the rack is positioned just above the main wheel; the air suction hole and the air-blowing hole are connected with a cylinder through an air pipe; the pressure brush is arranged at the left end of the rack; the conveyor belt is arranged under the main wheel and the pressure brush and is driven by the belt pulley; multiple positioning blocks are fixed on the conveyor belt. According to the automatic square tin can branding device disclosed by the invention, the automatic square tin can branding operation can be finished.

Owner:张凤仙

In-situ warm-mixing regenerant for bituminous pavement, preparation method and construction method of in-situ warm-mixing regenerant

ActiveCN103013144ALow costLow heating temperatureRoads maintainenceBuilding insulationsRoad surfaceMaterials science

The invention relates to an in-situ warm-mixing regenerant for a bituminous pavement, and a preparation method and a construction method of the in-situ warm-mixing regenerant. The strength of a cold-regenerating mixture is longer in formation time; a finish coat in a certain thickness is required to be paved additionally; the property of the regenerated mixture is poorer; a lower level cold mixing technology is used generally; and cement is required to be added generally, so that the durability of the level is reduced. The in-situ warm-mixing regenerant for the bituminous pavement comprises the following raw materials in parts by mass: 10-30 parts of naphthenic hydrocarbon, 20-40 parts of furfural extract oil, 30-50 parts of deionized water, 10-20 parts of microwave absorption agent, 5-10 parts of surfactant, 5-10 parts of dispersing agent and 1-5 parts of antiaging agent. According to the in-situ warm-mixing regenerant, the preparation method and the construction method, the mixing cost can be lowered; the construction efficiency is improved; a use ratio of old materials is increased; compared with in-situ heat regeneration, the ageing of a bituminous mixture is reduced; the service life of the pavement is prolonged; a cooling rate is reduced; the discharge amount of harmful gas and dust is decreased; new aggregates and new bitumen are not required to be added; and the material cost is lowered.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

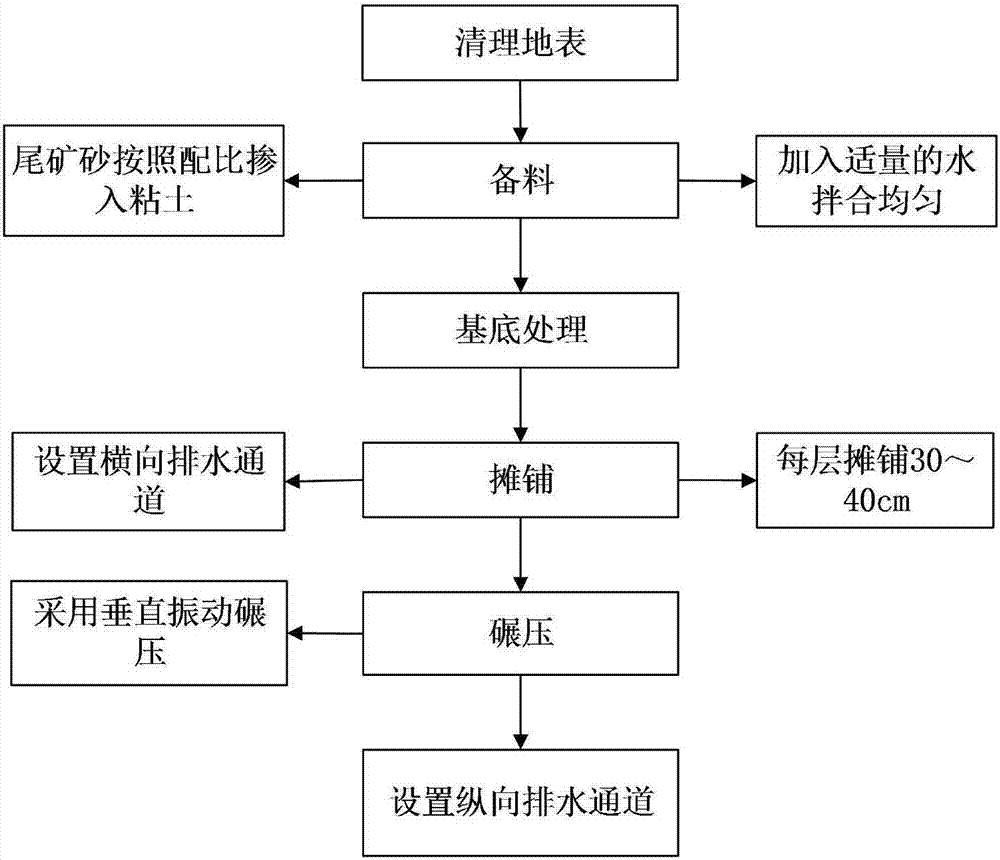

Construction method of clay-improved tailing sand roadbed filler

InactiveCN107100049ARealize resourcesRealize efficient utilizationRoadwaysEngineeringToxic industrial waste

The invention discloses a construction method of clay-improved tailing sand roadbed filler. The method comprises the following steps: 1) cleaning the ground surface; (2) preparing materials; (3) processing a substrate; (4) spreading the material; (5) rolling the filler; and (6) setting longitudinal drainage channels. The method uses the industrial waste tailings as the roadbed filler, and improves the performance of the tailing ore used for road by adding the clay, ensures the quality of roadbed, and realizes the recycling and efficient utilization of waste.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST

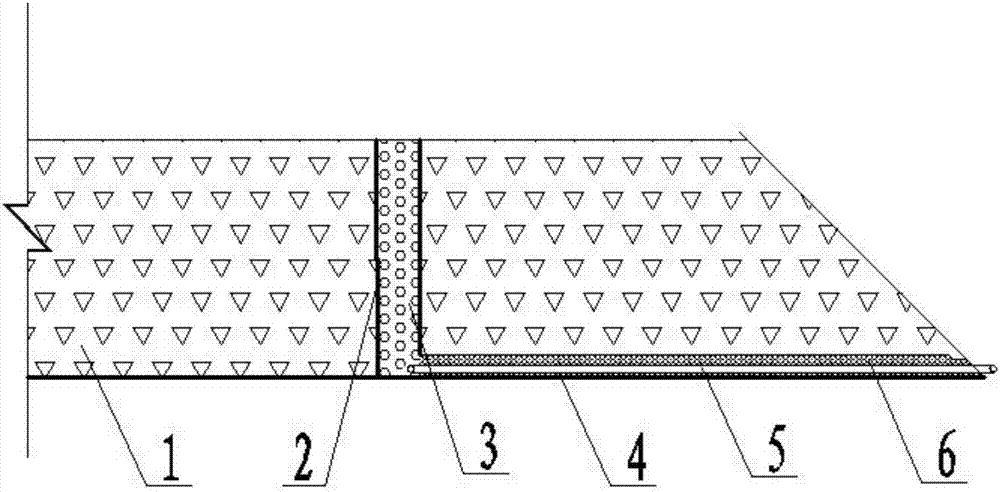

High-fill embankment filling construction process

InactiveCN112030638AImprove stabilityGuaranteed compactionRoadwaysClimate change adaptationArchitectural engineeringRoad surface

The invention provides a high-fill embankment filling construction process, and relates to the technical field of building construction processes. The high-fill embankment filling construction processspecifically comprises the following steps that S1, performing base treatment, specifically, treating a pavement foundation to be constructed; S2, performing layered filling, specifically, filling the embankment of the construction section in a layered mode, and performing filling of the next layer after filling of each layer is completed and compacted; S3, performing impact rolling; S4, arranging a temporary drainage system; S5, performing inspection and identification; S6, performing layer finishing; and S7, tampering the slope. According to the high-fill embankment filling construction process provided by the invention, the high-fill embankment can be filled in areas with poor soil and stone filler properties, much rainfall and poor roadbed stability through the construction process, and meanwhile, the situation of sedimentation after construction is completed can be avoided.

Owner:CHINA FIRST HIGHWAY ENG +2

Preparation method of high-performance graphite negative electrode material for lithium ion battery

InactiveCN105789627AEasy to processImprove cycle performanceCell electrodesSecondary cellsHigh rateMass ratio

The invention discloses a preparation method of a high-performance graphite negative electrode material for a lithium ion battery. The method comprises the following steps of 1) collecting petroleum coke micropowder in a shaper and a grinder in normal graphite production, and mixing the petroleum coke micropowder, ground expanded graphite powder, raw mesocarbon microbeads and an adhesive in a mixer for 0.5-3 hours according to a mass ratio of 1 to (0.01-0.3) to (0.7-1.5) to (0.1-0.2) to form a solid-phase coated mixture, wherein the frequency of the mixer is 30-50HZ; and 2) graphitizing the solid-phase coated mixture obtained in the step 1) to obtain the high-performance graphite negative electrode material for the lithium ion battery. The method is simple and feasible; micropowder wastes in a dust collector are recycled, so that the cost is reduced; the method is easy for large-scale industrial production; and the obtained graphite negative electrode material has the characteristics of high energy density, good liquid absorption and retention performance, good cycle performance, good isotropic performance, good high-rate charge / discharge performance and low expansion rate in a charge / discharge process.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

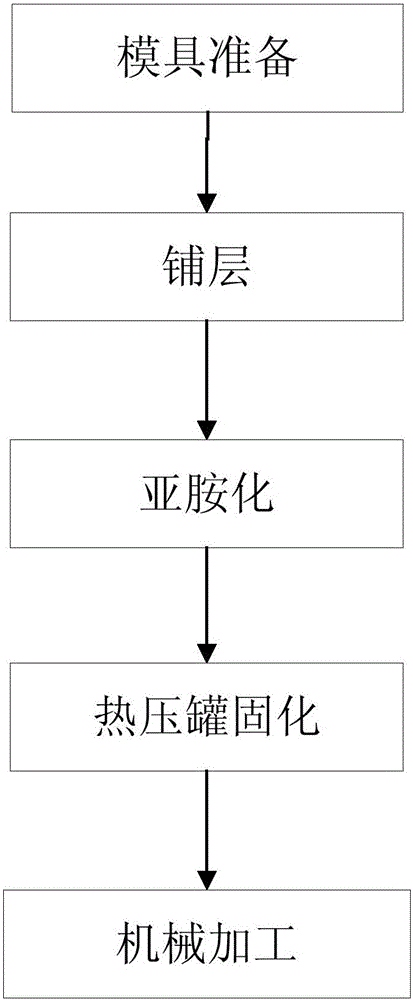

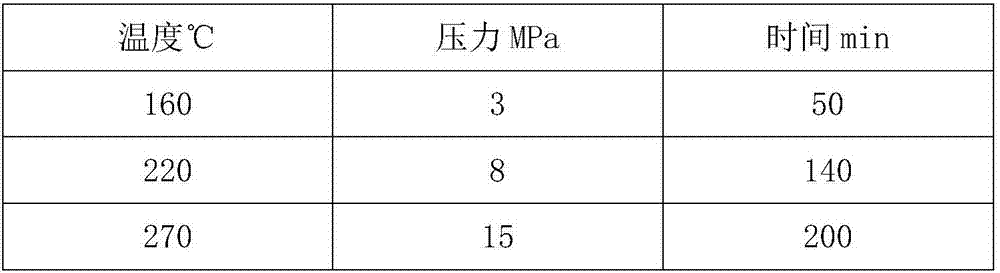

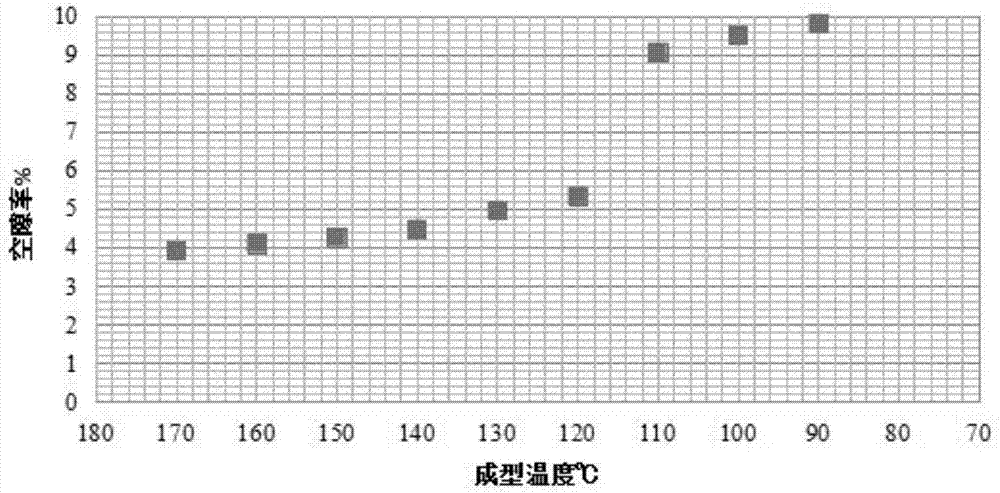

Forming method of thin-walled helical antenna supporting medium tube made of high-temperature-resistant polyimide composite

The invention relates to a forming method of a thin-walled helical antenna supporting medium tube made of a high-temperature-resistant polyimide composite, belongs to the technical field of high-temperature-resistant wave-transparent resin matrix composite forming, and particularly relates to a forming method applied in space returner GPSs and S-frequency-band antenna spiral supporting medium tubes. A thin wall refers to the wall, with the wall thickness ranging from 1.5 mm to 3 mm, of the spiral antenna supporting medium tube. According to the mechanics, wave transmissivity, heat resistance and weight reduction requirements of the high-temperature-resistant thin-walled helical antenna supporting medium tube used for air returners, a special mold is designed, materials are preferentially selected, and the prepared spiral antenna supporting medium tube has the following excellent comprehensive performance.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

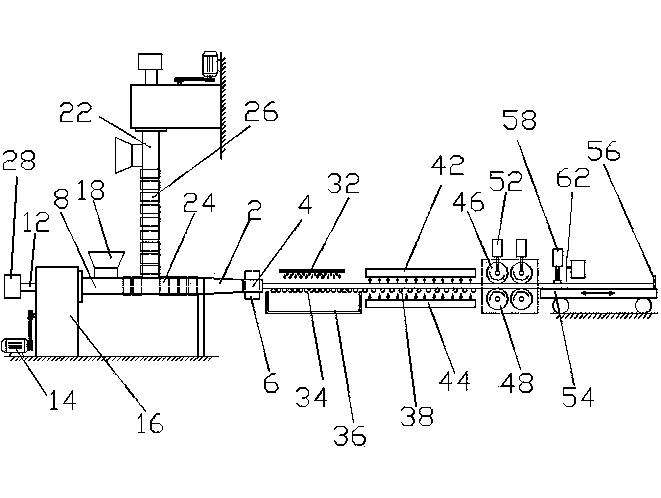

Technology for preparing micropore pipe through semi-molten continuous extrusion of high molecular powder

The invention relates to a technology for preparing a micropore pipe through semi-molten continuous extrusion of high molecular powder. The technology is characterized by comprising the following steps: (1) feeding solid powdered material in a screw extruding device through a hopper; (2) heating a barrel entering the screw extruding device, and performing initial compaction by a threaded rod at the same time so as to enable materials to be in a semi-molten state; (3) feeding the material in a handpiece for further compaction; (4) feeding the materials in a mould cavity of a neck mould of the screw extruding device to be tubular, determining inner and outer diameters under the effect of a vacuum cooling forming sleeve, and initially cooling; (5) cutting through a cutting device to obtain the micropore pipe. According to the technology, the high molecular powder is continuously extruded and formed when being in semi-molten state and the produced product does not need to be subjected to aftertreatment simultaneously when production of micropore pipes is realized, so that the production efficiency is greatly improved. According to the technology, a solvent is not used, and thus the micropore pipe is beneficial to environmental protection and health of operators.

Owner:SUZHOU KAHO POLYMER TECH CO LTD +1

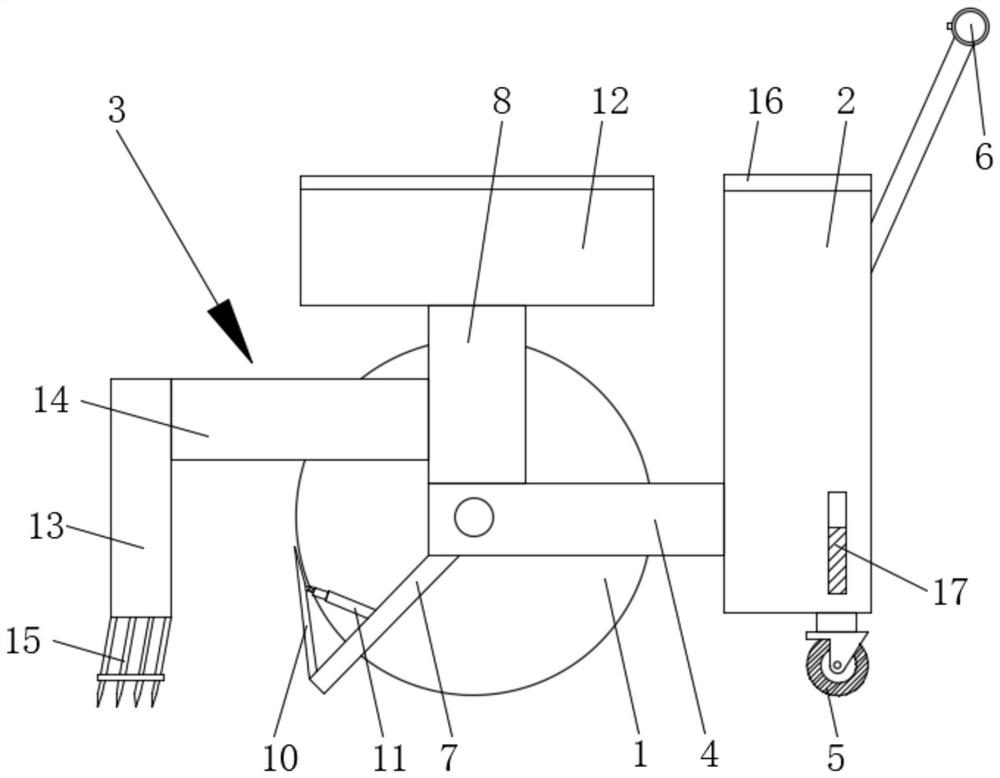

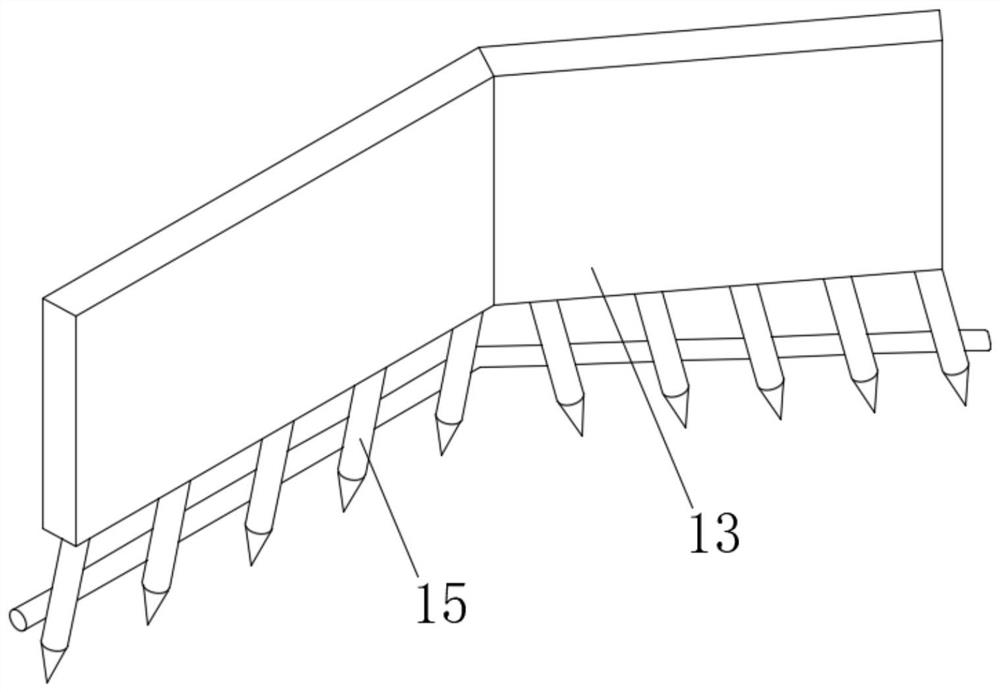

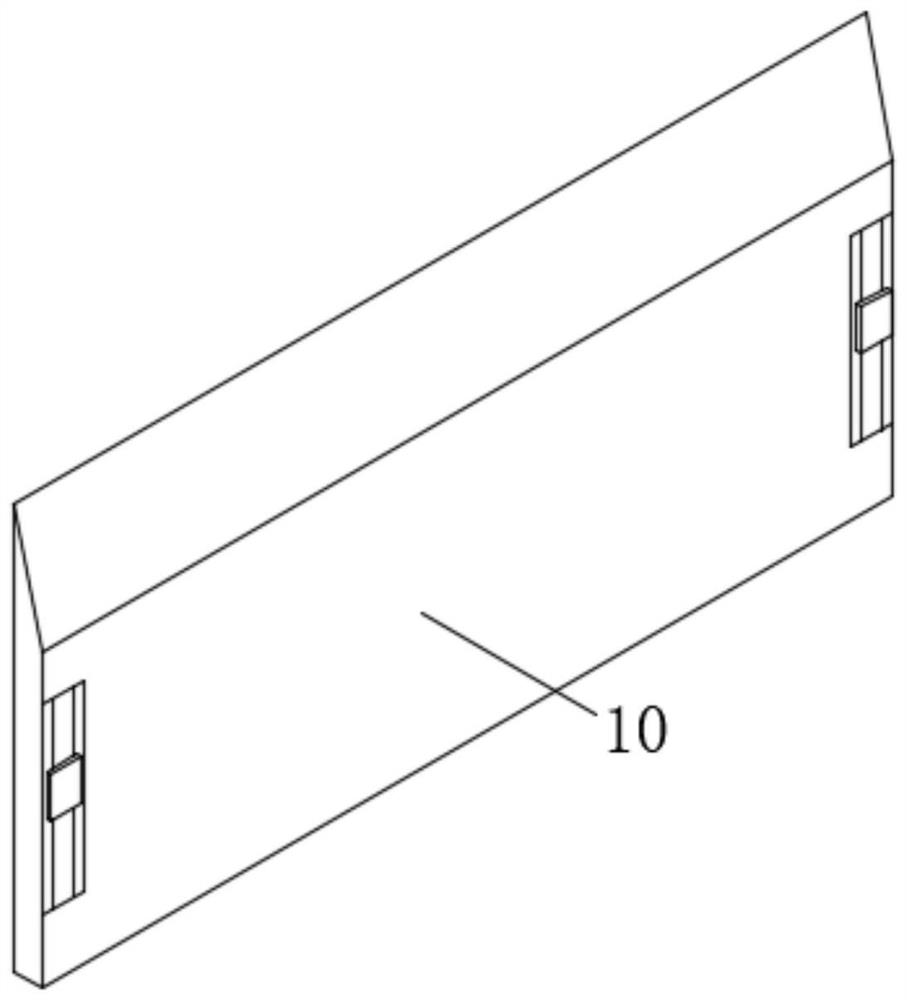

Road repairing and breaking device

InactiveCN109629386AWeight increaseImprove repair qualityRoads maintainenceCrushed stoneRoad surface

The invention belongs to the field of road equipment, and particularly discloses a road repairing and breaking device. The road repairing and breaking device comprises a cart body, a breaking mechanism, a dust collection pump and a pouring mechanism, wherein the breaking mechanism, the dust collection pump and the pouring mechanism are located in the cart body; a lever is arranged in the cart body, the dust collection pump and the pouring mechanism are fixedly connected to the two ends of the level respectively, an elastic piece is fixedly connected to the bottom of the level on one side of the dust collection pump, the dust collection pump is communicated with a sucker for absorbing road gravel particles, the sucker penetrates through the bottom of the cart body, and a sucker opening faces the lower portion of the cart body; the pouring mechanism comprises a discharging hopper containing padding, the side wall, towards one side of the dust collection pump, of the discharging hopper iscommunicated with a discharging pipe, and the discharging pipe penetrates through the bottom of the cart body to face the lower portion of the cart body. After the technical scheme is adopted, the road repairing and breaking device can automatically pour padding into road surface cracks in the road repairing process.

Owner:CHONGQING VOCATIONAL INST OF ENG

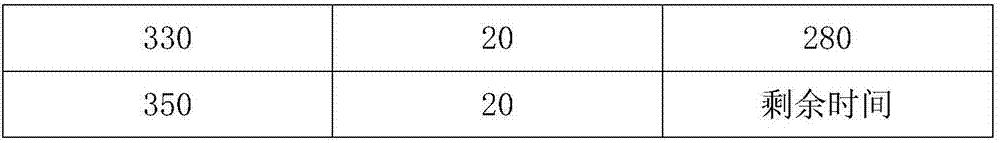

Preparation method for compact aluminum titanate ceramic

The invention belongs to the technical field of a ceramic material and specifically relates to a preparation method for a compact aluminum titanate ceramic. The method comprises the following steps: by taking tetrabutyl titanate and aluminum nitrate as raw materials, taking an alcohol solution containing a dispersing agent as a solvent and taking butyl silicate as an internal additive; introducing ammonia gas, refluxing, aerating and reacting, thereby acquiring a gel solution; by taking ferric chloride as an external additive, adding a curing agent, reducing pressure and distilling, thereby acquiring the gel; adding the gel into a mold, vibrating, heating and curing; and raising temperature in gradient, pressurizing, drying and sintering in a muffle furnace, thereby acquiring the compact aluminum titanate ceramic. The invention solves the problem of complex preparation process of the liquid phase compound in the prior art; the method provided by the invention is high in plasticity and is capable of customizing the ceramic shape according to the requirement; the prepared aluminum titanate is high in purity, fine in structure and high in uniformity.

Owner:无锡特科精细陶瓷有限公司

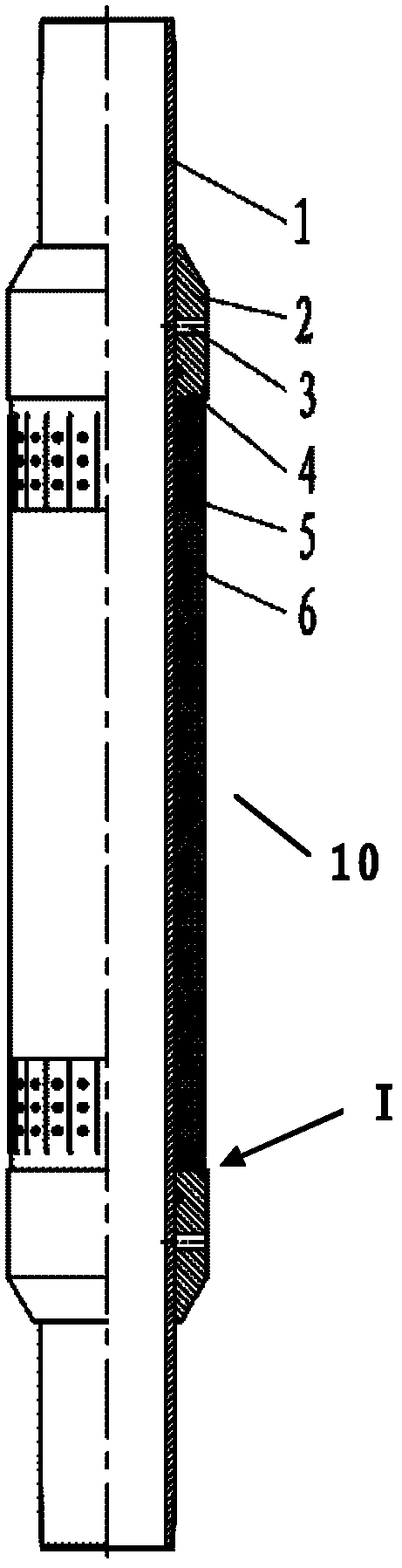

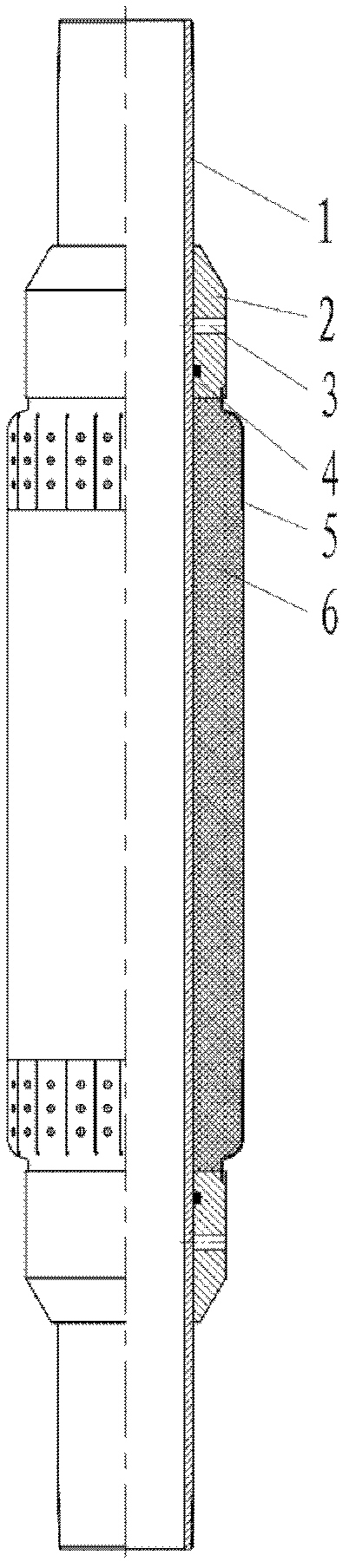

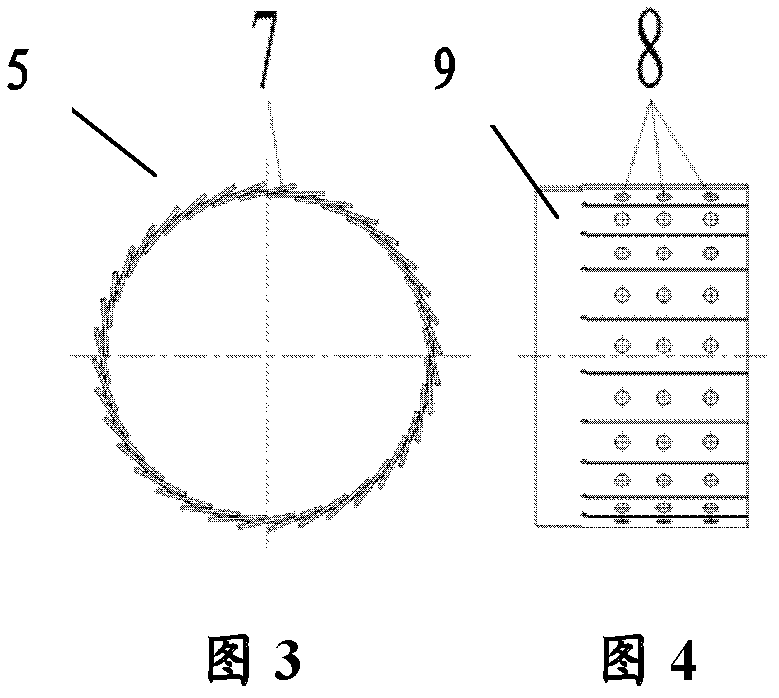

Self-expansion packer

The invention provides a self-expansion packer which comprises a base tube, a self-expansion rubber cylinder, limit end rings and bulge-preventing rings, wherein the base tube is surrounded by the self-expansion rubber cylinder; the limit end rings are fixed on the base tube and are close to two ends of the rubber cylinder; two ends of the rubber cylinder are surrounded by the bulge-preventing rings; each bulge-preventing ring comprises a base ring part and a plurality of batten parts which extend from the base ring part in the longitudinal direction of the base tube; and every strip part on the periphery of the base tube is partially overlapped with a part of an adjacent strip part. By the aid of the bulge-preventing rings, the rubber cylinder can be prevented from being extruded and torn. At the same time, the rubber cylinder can still absorb liquid in a well after seals of two ends of the rubber cylinder are expanded, so that the compactness to the well wall is maintained and reliable and stable annulus packing is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

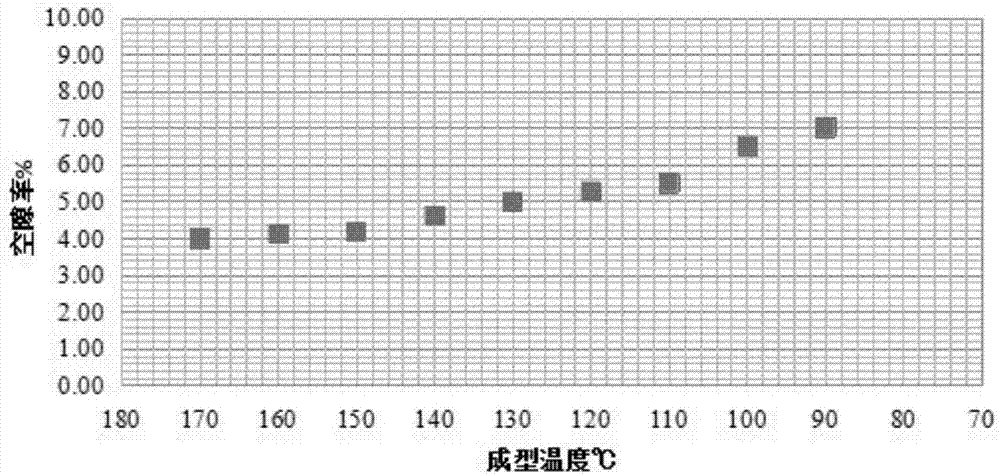

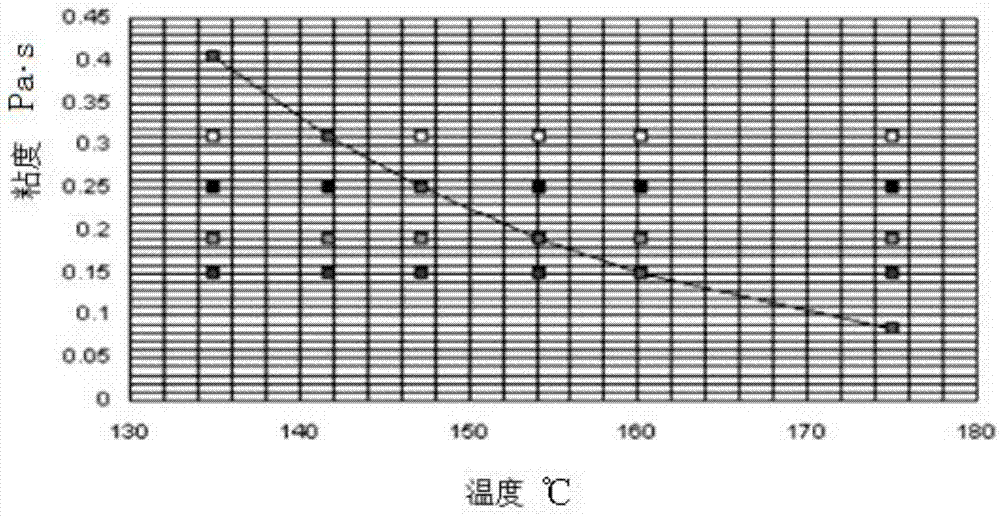

Rolling compaction process based on asphalt mixed material compaction characteristic

InactiveCN107386037AGuaranteed compactionImprove the compaction effectIn situ pavingsClimate change adaptationExperimental methodsMixed materials

The invention relates to a rolling compaction process based on asphalt mixed material compaction characteristic. The rolling compaction process comprises the following steps: 1) determining the inserting pressing temperature of the asphalt mixed material; 2) determining the final pressing temperature of the asphalt mixed material by a compaction characteristic experimental method; 3) determining the effective rolling compaction time; 4) determining the rolling compaction mode; and 5) determining rolling compaction parameters. The invention provides the rolling compaction process capable of guaranteeing complete compaction of the asphalt mixed material by considering the compaction characteristic of the asphalt mixed material and the temperature field change rule and by reasonably determining the final pressing temperature of the asphalt mixed material and the effective compaction time so as to guarantee that the compaction degree meets the requirements.

Owner:天津市国腾公路咨询监理有限公司 +2

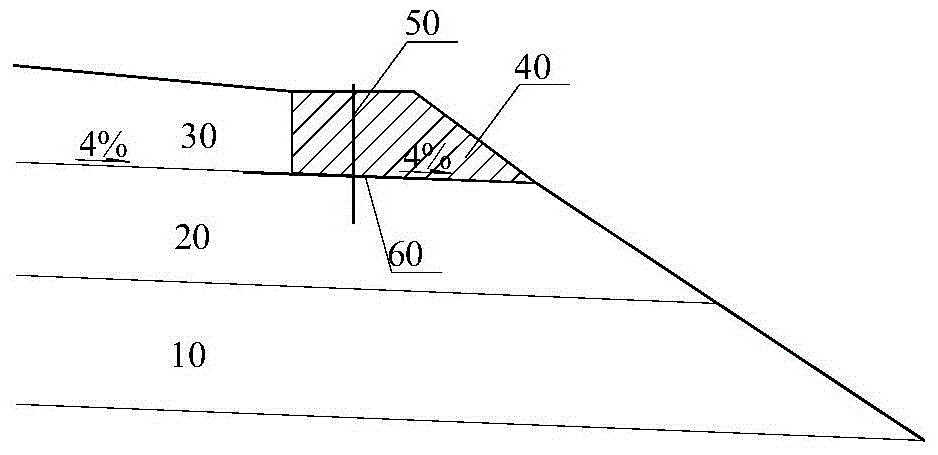

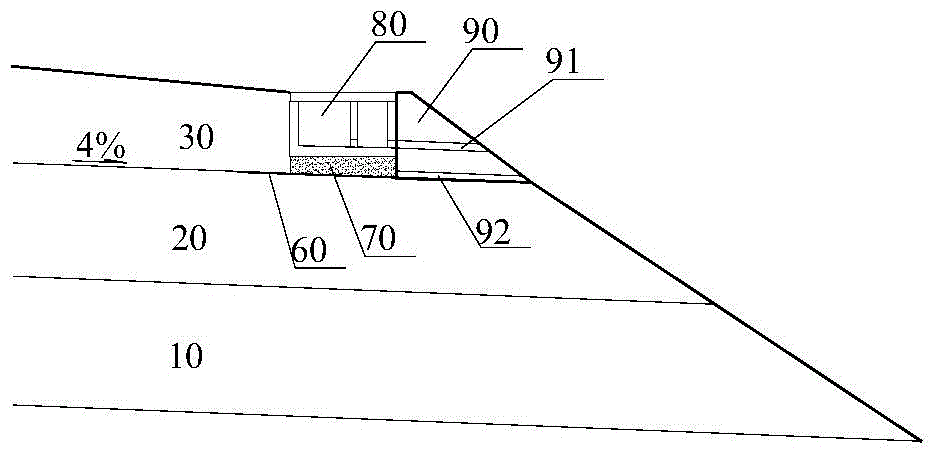

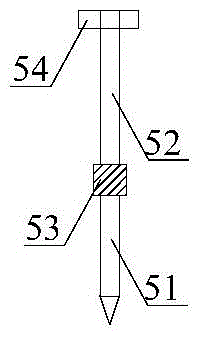

Construction method for cable trough and protective shoulder of high-speed railway roadbed

ActiveCN105672064ALow costSave engineering investmentCable installations on groundRailway tracksSubgradeSurface structure

The invention provides a construction method for a cable trough and a protective shoulder of a high-speed railway roadbed. By the adoption of the construction method for the cable trough and the protective shoulder of the high-speed railway roadbed, the problem caused by cutting of a roadbed surface structure can be effectively solved; and the construction method has the characteristics of being easy to operate, capable of saving time, economical and the like. The construction method comprises the steps that a roadbed body structure and a roadbed bottom layer structure which are located under the roadbed surface structure are filled in a layered mode; the top surface of a roadbed bottom layer structure is rolled to be flat; a composite waterproof and drainage plate is laid in the positions, corresponding to the cable trough and the protective shoulder, of the top surface of the roadbed bottom layer structure; a road shoulder mold is arranged in the positions, corresponding to the cable trough and the protective shoulder, of the composite waterproof and drainage plate, and a reserved hole is formed in the road shoulder mold; a fixing screw is inserted into the reserved hole of the road shoulder mold; the road shoulder mold is fixed to the top of the roadbed bottom layer structure by means of a movable rod on the upper portion of the fixing screw through a nut; the portion, on the inner side of the road shoulder mold, of the roadbed surface structure is filled in a layered mode; the nut on the movable rod is taken down; the road shoulder mold is dismounted; a connecting buckle in the fixing screw is opened, and the movable rod in the fixing screw is taken out; a gravel pervious bed at the bottom of the cable trough is laid; the cable trough is placed; and the concrete protective shoulder is cast in place in a layered mode.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

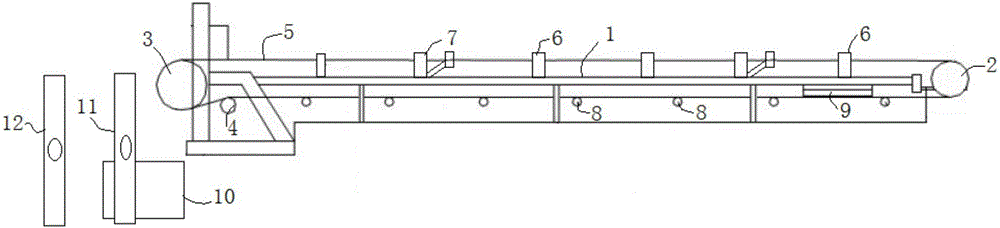

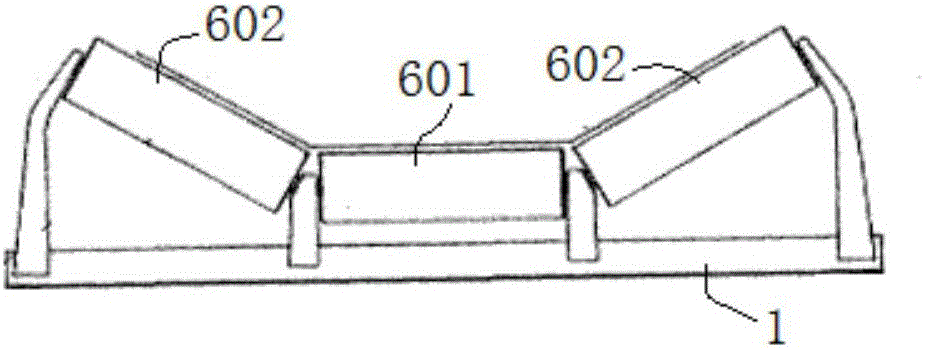

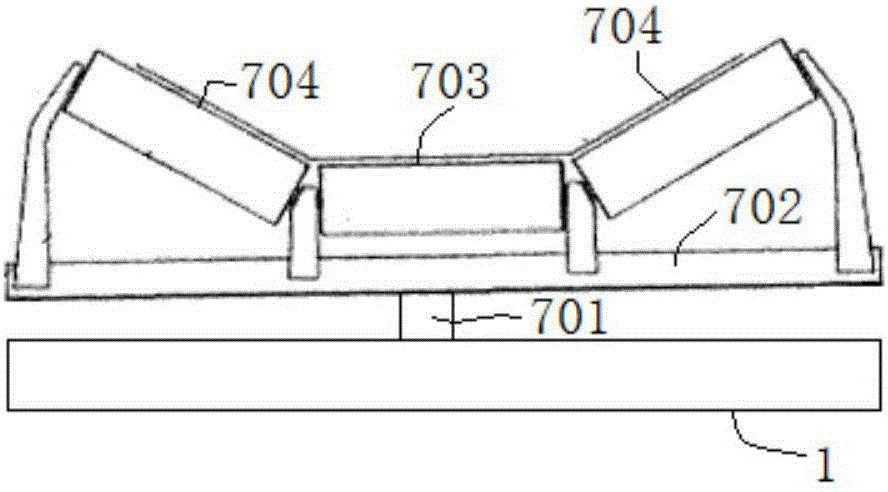

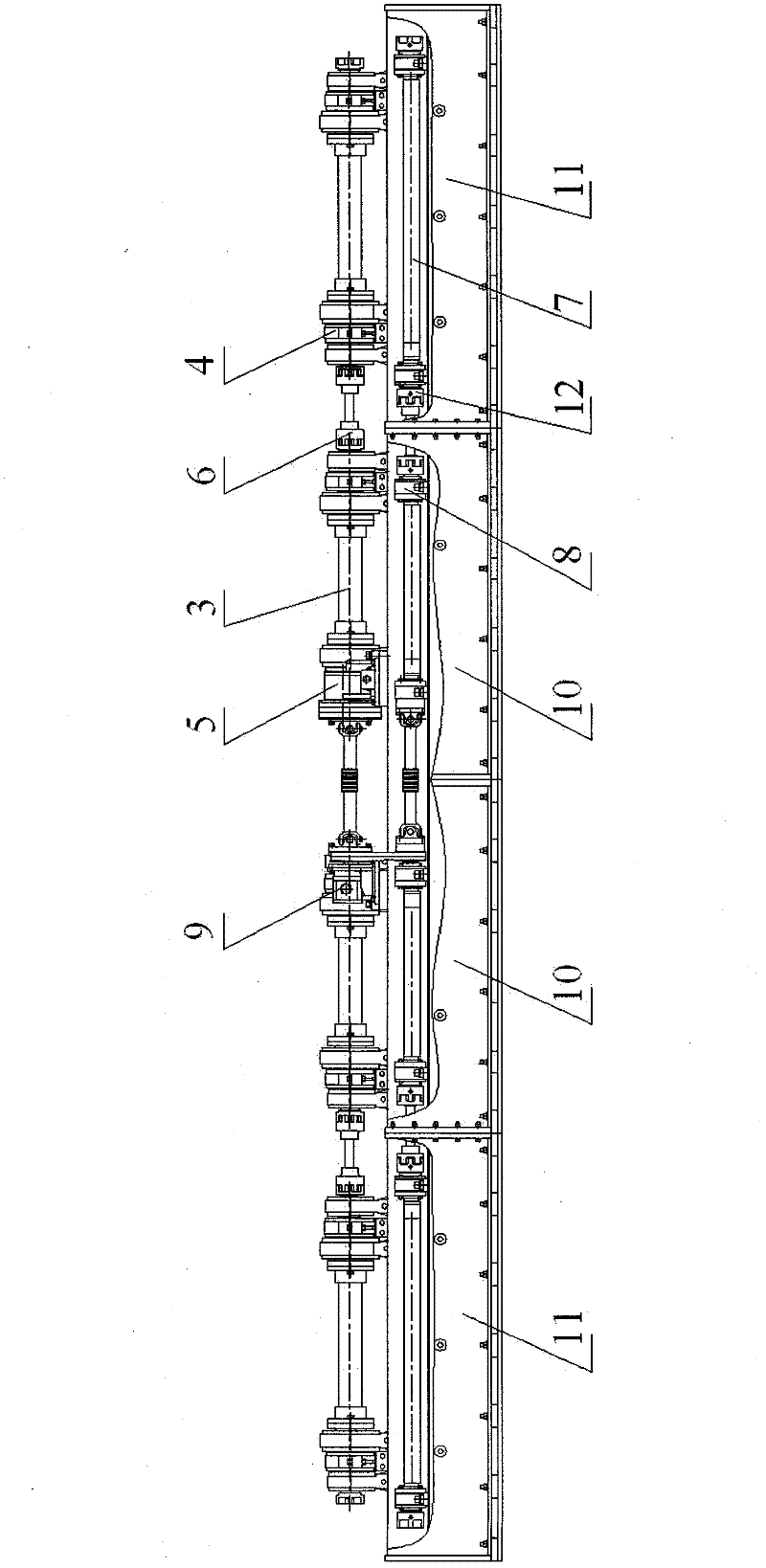

Belt conveying system for transportation of bulk materials

The invention discloses a belt conveying system for transportation of bulk materials, and belongs to the field of conveyers. The belt conveying system comprises a rack, and a driving head wheel and a driving tail wheel are arranged at the two ends of the rack respectively; a conveyer belt coats the driving head wheel and the driving tail wheel and conveys the materials around the driving head wheel and the driving tail wheel; the upper layer conveyer belt is supported by top carrier rollers; the lower layer conveyer belt is supported by bottom carrier rollers; the top carrier rollers comprise fixed carrier rollers and movable carrier rollers; a sweeper is arranged above the lower layer conveyer belt; the materials conveyed by the conveyer belt are collected by a material mover; and a primary material arranging device and a secondary material arranging device are sequentially arranged in the transportation direction of the material mover. According to the belt conveying system, flying dust can be decreased, the production environment is improved, material transportation efficiency is improved, and efficient and stable operation of the conveyers is guaranteed.

Owner:ANHUI TAIFU HEAVY IND MFG CO LTD

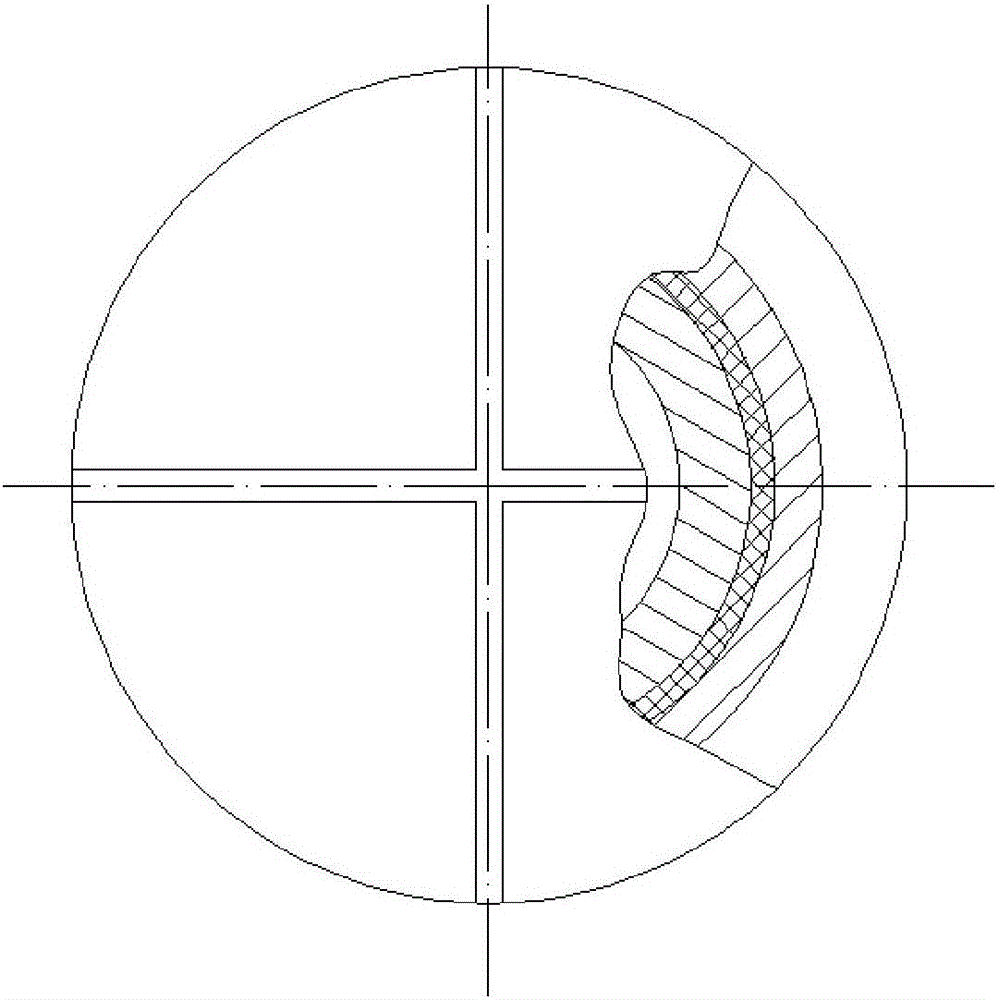

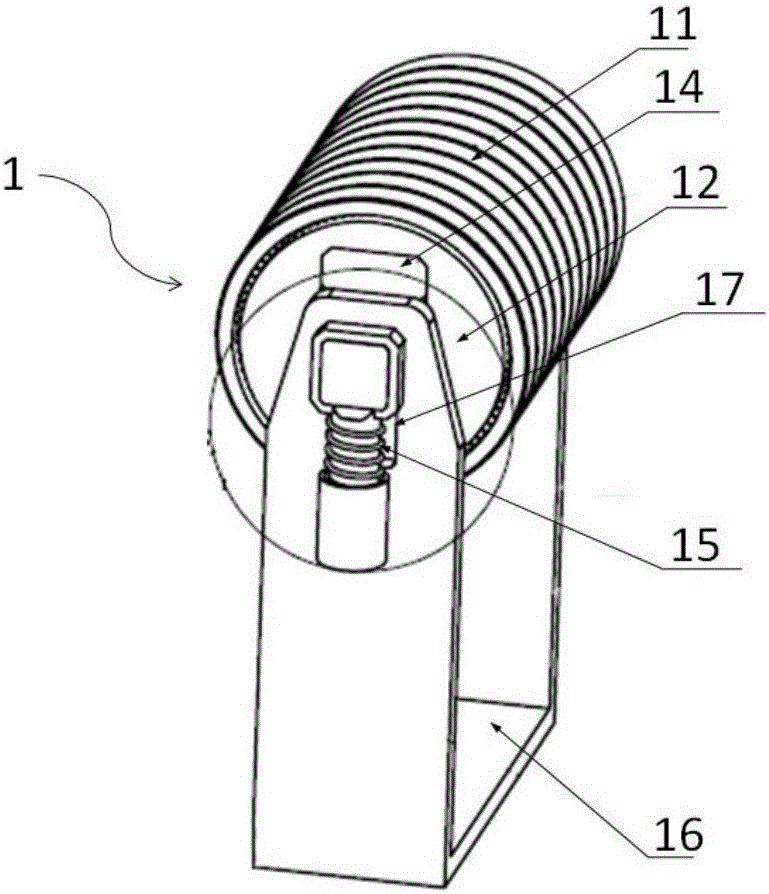

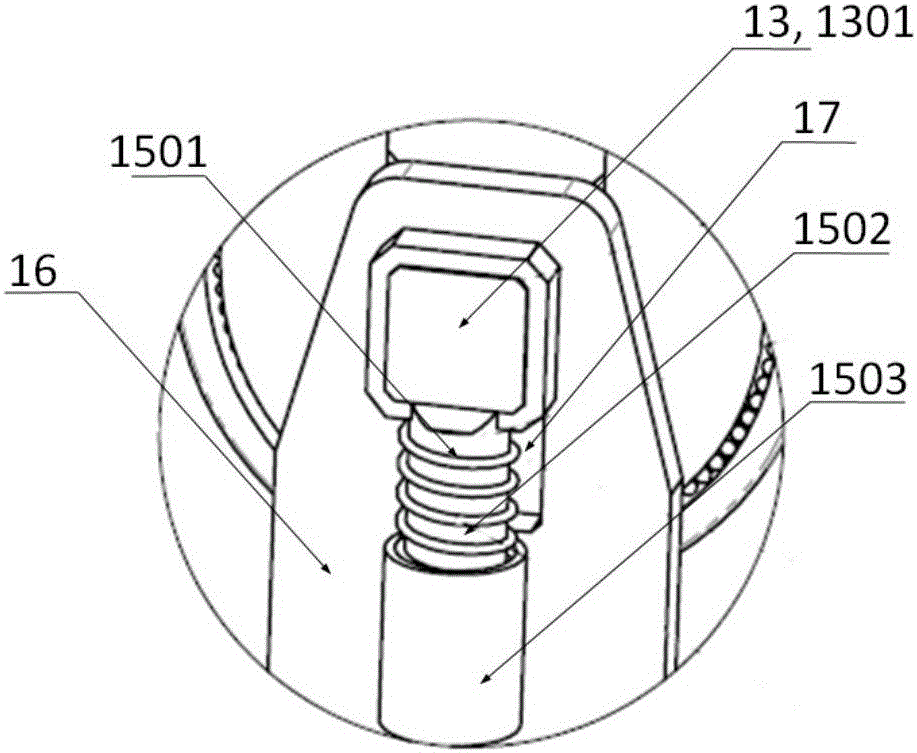

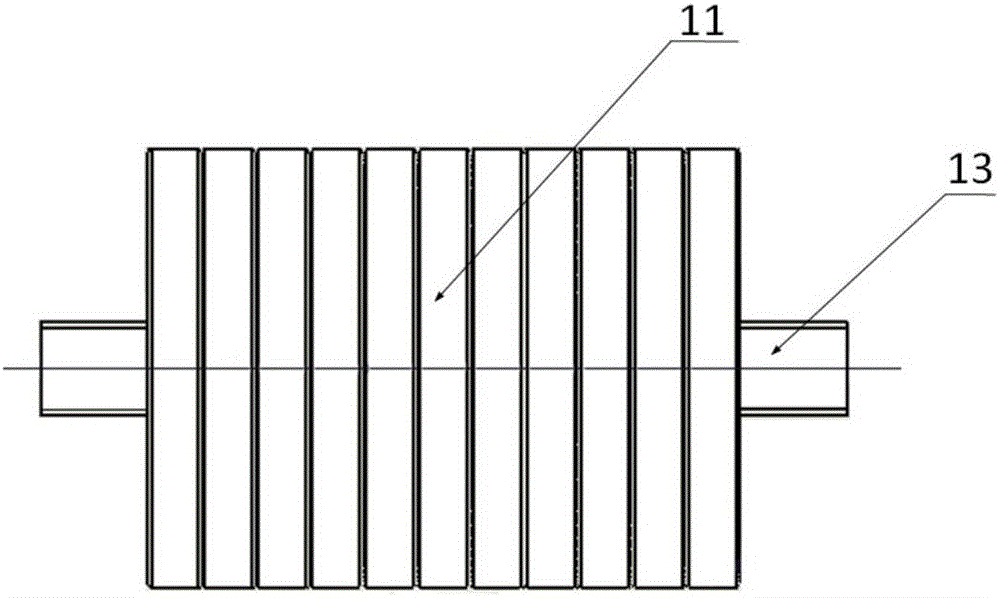

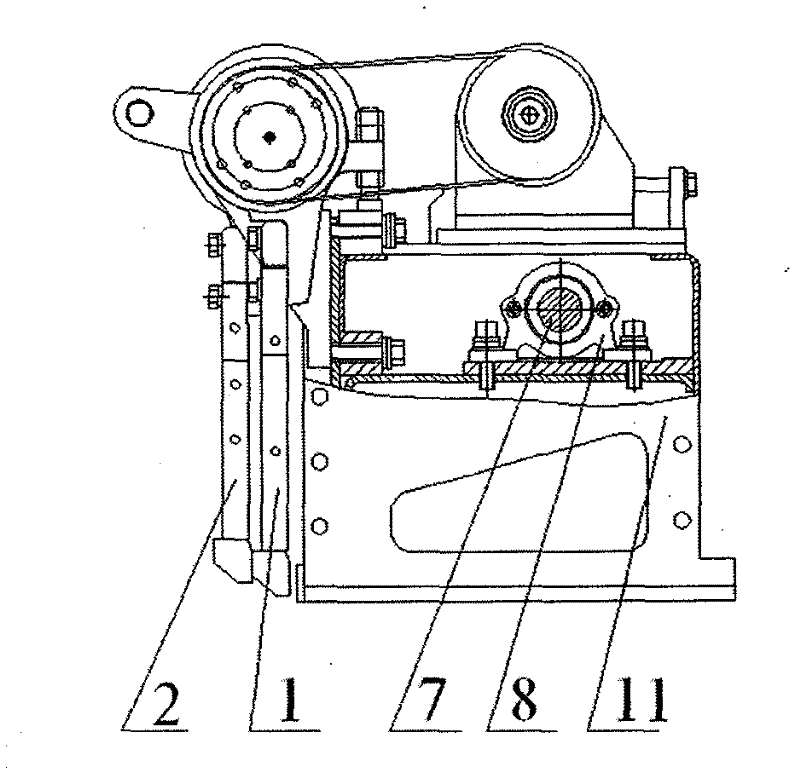

Auxiliary press roller and forming machine connector press roller with same

ActiveCN105881948AEffective contactTo achieve the effect of preloadingTyresLoad carryingTire manufacturing

The invention relates to a press roller for tire manufacturing, in particular to an auxiliary press roller and a forming machine connector press roller with the same, and belongs to the field of tire manufacturing; the auxiliary press roller comprises a roller plate, a roller barrel, a roller shaft, an elastic layer, support devices, a base and a guide channel, wherein the roller plate is arranged outside the roller barrel and encloses the roller barrel, the roller shaft is disposed in the roller barrel, and the elastic layer is disposed above or outside the roller shaft and is positioned in a covering range of the roller plate; two ends of the roller shaft are roller shaft ends, the support devices are arranged below the roller shaft ends, and the support devices are positioned on the base and are elastic so that the roller shaft can move up and down according to its load-carrying condition.

Owner:QINGDAO SENTURY TIRE CO LTD

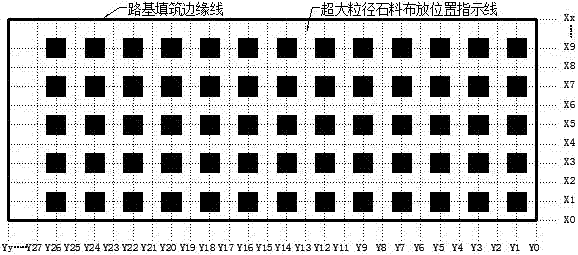

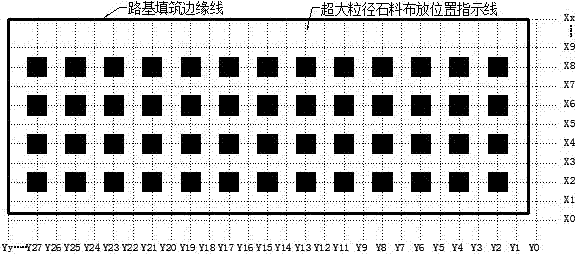

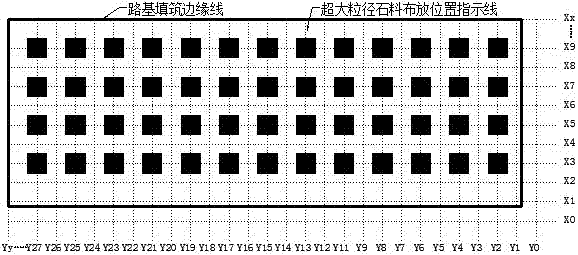

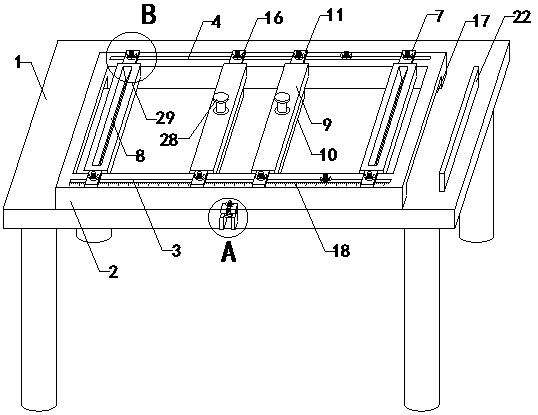

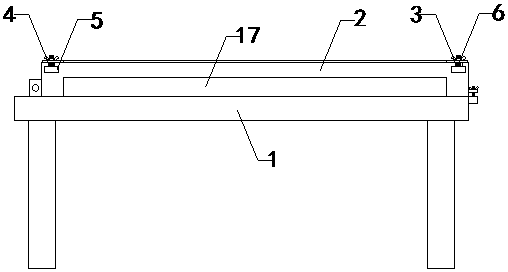

Method for filling high-filled embankment with rock blocks with superlarge particle size

The invention discloses a method for filling a high-filled embankment with rock blocks with superlarge particle size. The method includes the following steps: (1) foundation treatment; (2) laying of the rock blocks with superlarge particle size: the rock blocks with superlarge particle size are separated out; a minimum height of the super-size rocks from the top surface of a foundation is determined; a laying solution for the rock blocks with superlarge particle size is determined, including the determination of the number of laid layers and the determination of the paved length of the foundation; a laying sketch for each layer is determined, and in order to ensure that the embankment containing the rock blocks with superlarge particle size does not ununiformly settle, a method of stagger layering is adopted for laying; laying construction of the rock blocks with superlarge particle size is carried out, and the laying construction is a flow process, which includes three construction links, i.e., loading of the rock blocks with superlarge particle size, unloading of the rock blocks with superlarge particle size and laying of the rock blocks with superlarge particle size; (3) pavement and leveling of the embankment with the rock blocks with superlarge particle size; (4) layer-by-layer compaction of the embankment with the rock blocks with superlarge particle size; (5) dynamic compaction of the embankmen with the rock blocks with superlarge particle size t.

Owner:河北水利电力学院

Cutting device for new energy solar panel production

The invention relates to the technical field of solar panel production and processing accessory devices, in particular to a cutting device for new energy solar panel production. The effect on fixing apanel is improved, the panel is prevented from deviating during the cutting process, the cutting accuracy is ensured, and hands cannot be easily injured by a cutter, so that the practicability is improved; and quick positioning can be carried out according to the cutting side of the panel, so that the use reliability is improved. The cutting device for new energy solar panel production comprisesa working table, the cutter, a rectangular side frame, a cutting device and a pressing device, wherein a front sliding chute and a rear sliding chute are formed in a front side frame and a rear side frame of the rectangular side frame correspondingly; multiple groups of sliding blocks are arranged in the front sliding chute and the rear sliding chute; fastening screw rods stretching out to the upper part of the rectangular side frame are arranged at the top ends of the multiple groups of sliding blocks; the cutting device comprises a positioning plate and two groups of first positioning pieces; and the pressing device comprises a fixed plate, a pressing plate, two groups of second positioning pieces, a threaded rod, a threaded pipe and two groups of pressing springs, and further comprisesball bearings and fastening nuts.

Owner:山西云度知识产权服务有限公司

Compaction device for land consolidation

InactiveCN112492893AEasy dischargePlay a compacting roleSpadesAgricultural machinesLand consolidationBolt connection

The invention discloses a compaction device for land consolidation. The compaction device comprises a compaction roller, a storage box and a processing mechanism, the side face of the storage box is connected with a fixed lifting lug through multiple sets of countersunk bolts, the fixed lifting lug is hinged to the compaction roller through a rotating shaft, and two sets of symmetrically-arrangedsupporting legs are welded to the bottom end of the storage box; rolling wheels with power systems are welded to the bottom ends of the supporting legs, two sets of inclined rods are further welded toone side of the storage box, push rods are welded to the other sides of the two sets of inclined rods, and a processing mechanism is connected to the side face, away from the storage box, of the fixed lifting lug; and a C-shaped connecting plate is welded to the bottom end of the fixed lifting lug, a U-shaped connection plate is welded to the top end of the fixed lifting lug, a scraper is rotatably connected to the top end of the connecting plate through a hinge, and two sets of hydraulic rods are welded to the side face, close to the scraper, of the connecting plate. According to the compaction device for land consolidation, different compaction requirements can be met, and large-size stones on an advancing path can be discharged.

Owner:汨罗市大荆宏腾供销有限公司

Method for improving collapsible loess in northwest arid regions

InactiveCN111411554AGuaranteed compactionGuaranteed flatnessRoads maintainenceSoil scienceEngineering

The invention relates to a method for improving collapsible loess in the northwest arid regions. The ash mixing amount and the water content are controlled in the mode that a powder spreading vehicleand a cold regenerator are connected with a watering cart, ash mixing uniformity and the water content can be effectively controlled, the compactness, the flatness and the like of a roadbed are guaranteed, and that the roadbed is not prone to sinking when collapsible loess is used is guaranteed.

Owner:中铁二十五局集团第二工程有限公司

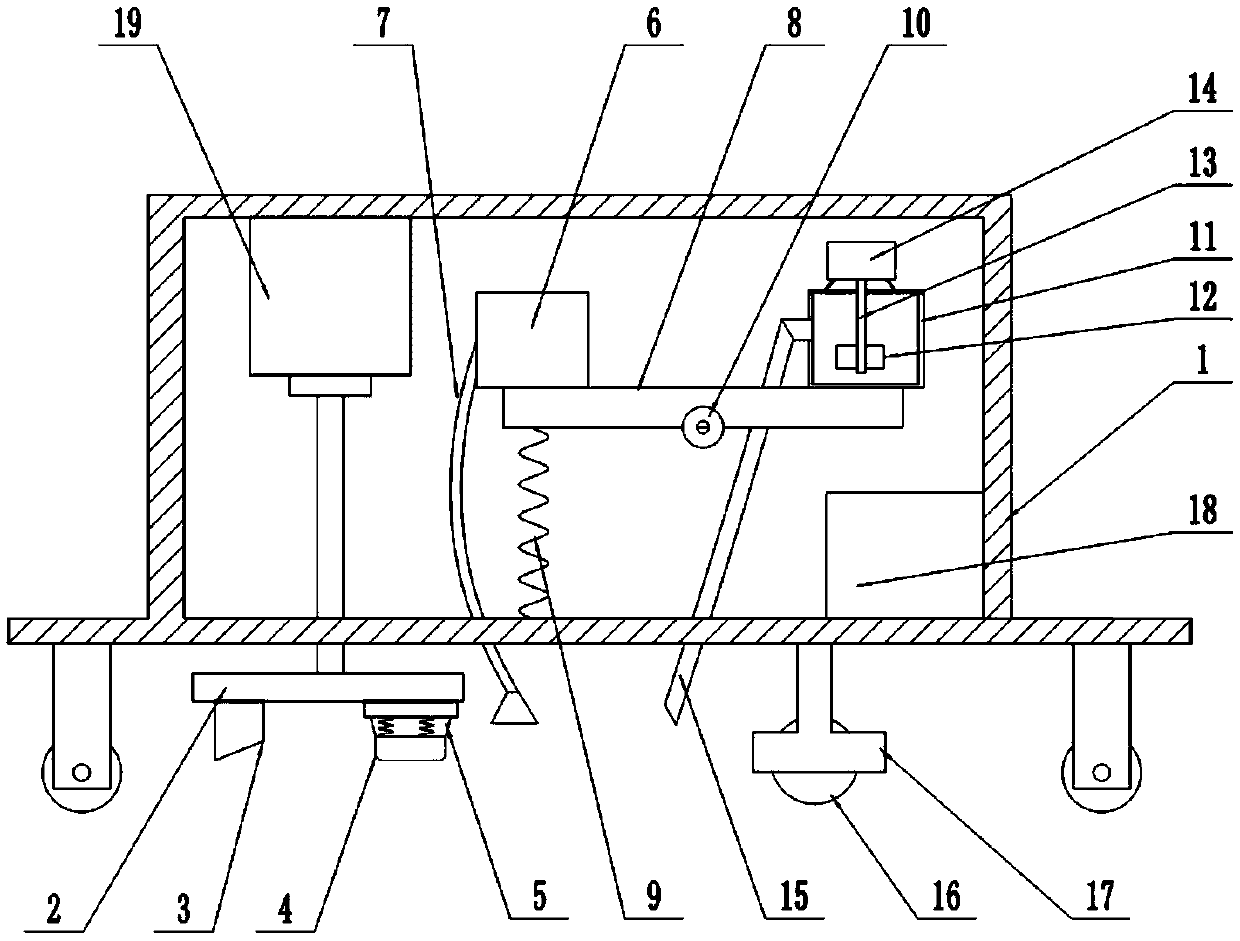

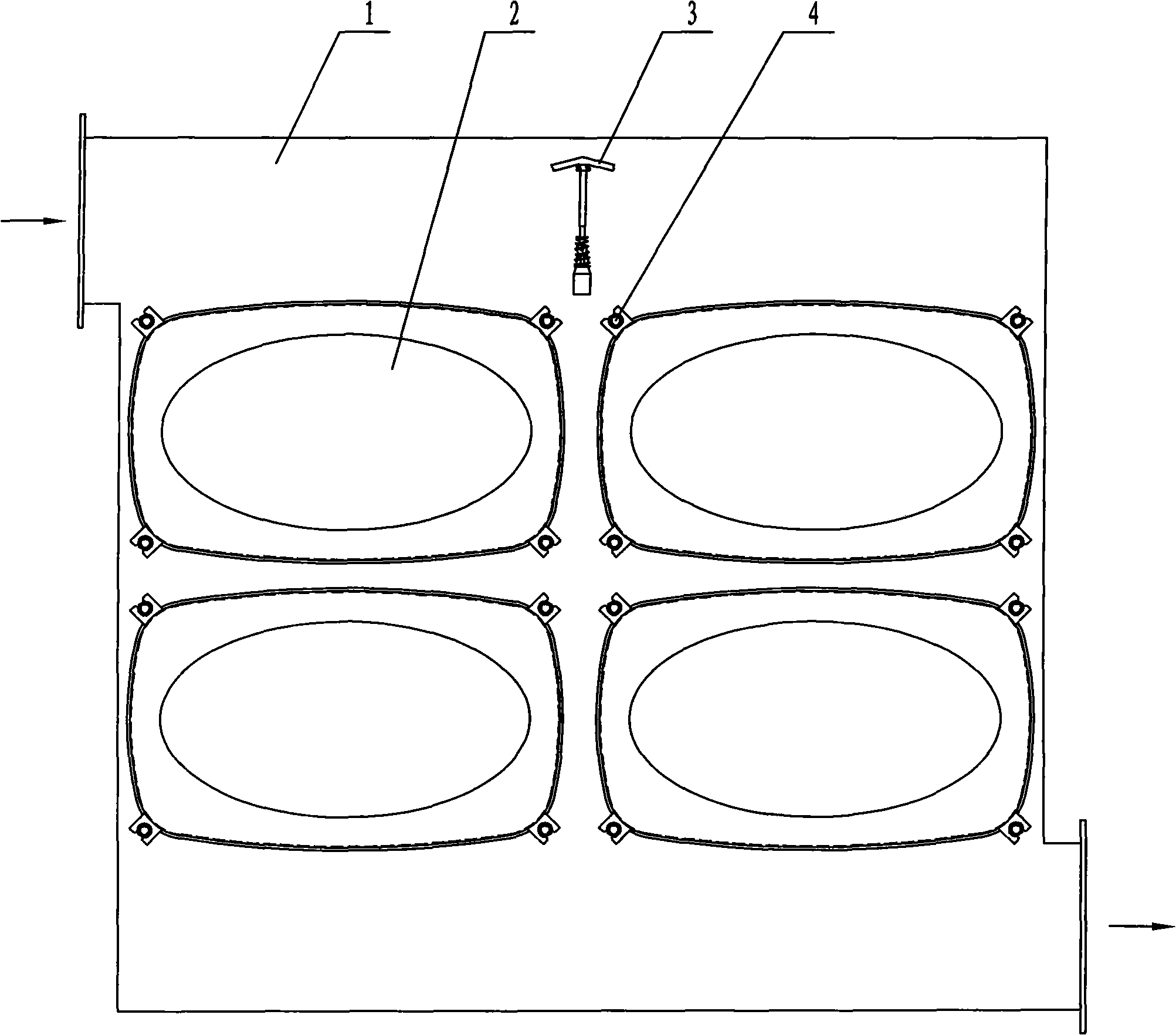

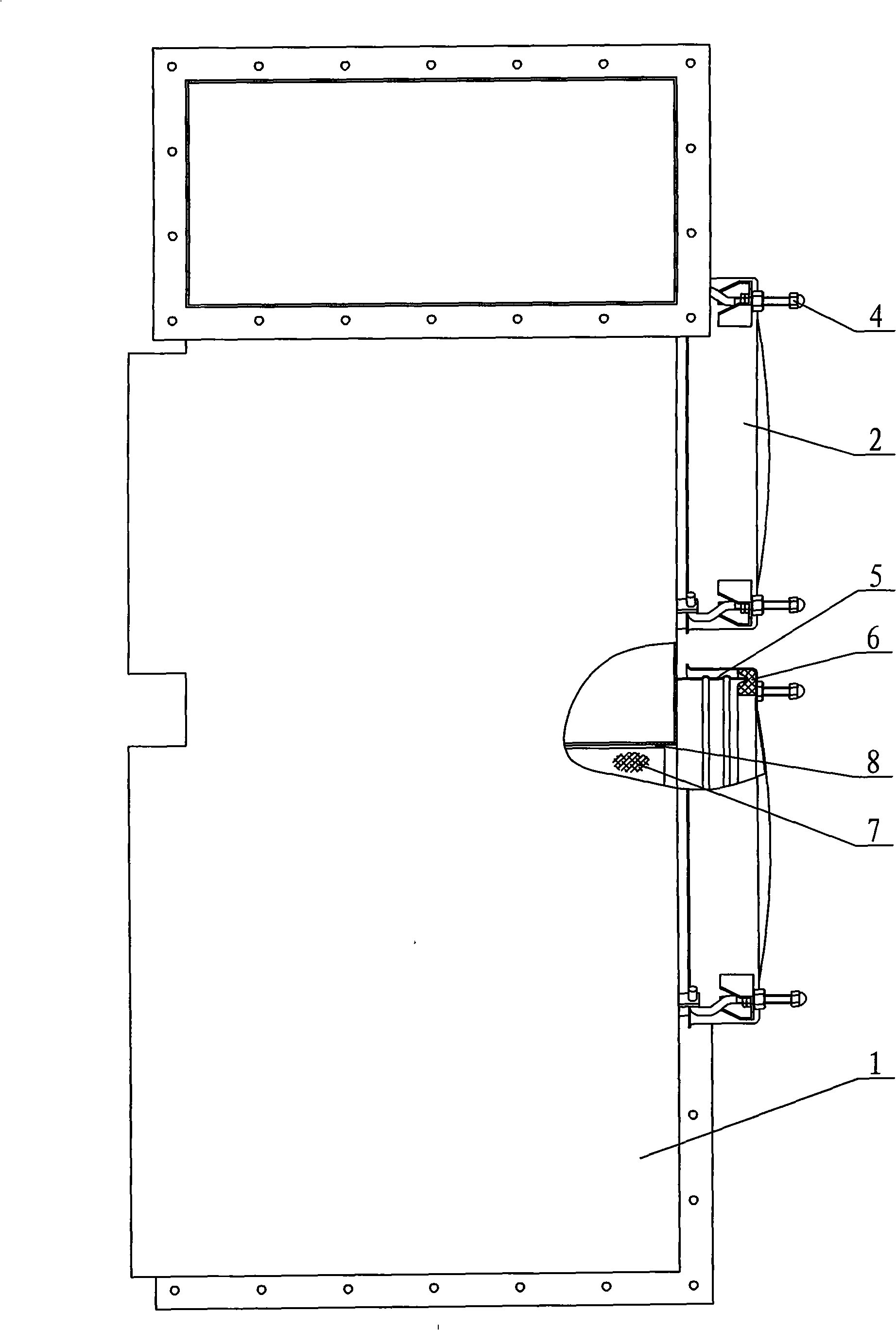

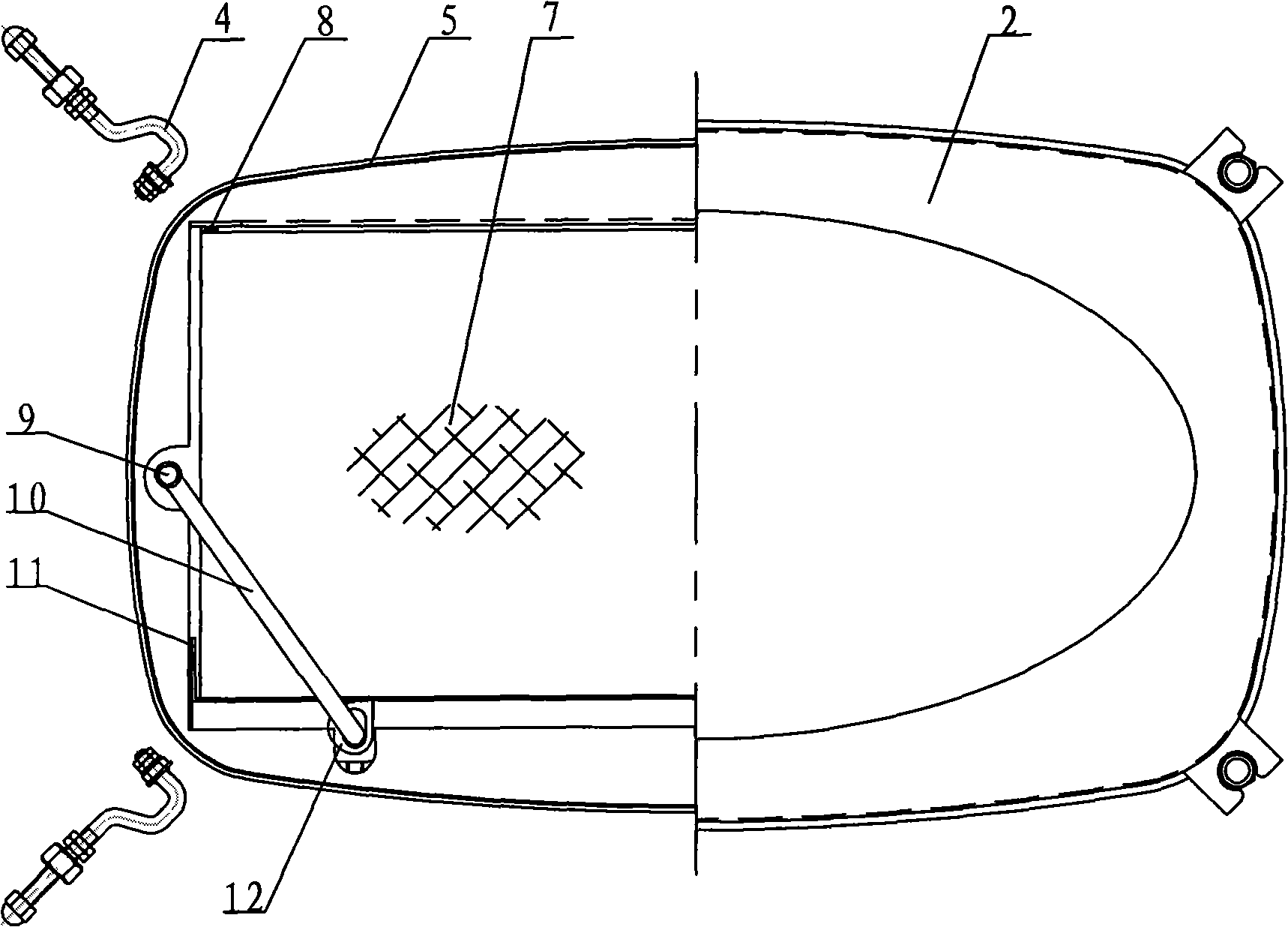

Antipollution filter box-body with quick clamp shaft

ActiveCN101357282AReduce secondary pollutionReduce changeover times and the time workers are exposed to radiationDispersed particle filtrationWrenchCam

The invention provides an anti-pollution filter box body with a fast clamp shaft. Each box body is provided with one or more filter element units inside; the filter element unit is arranged on an operation face of the box body; a mounting hole of each filter element unit is sealed by a box body cover; each box body cover is fixed on the outer shell of the box body by at least four locking elements; a socket wrench is hung on the outer shell of the box body; each socket wrench corresponds to a filter element unit and is welded at the filter element mounting hole on the operation face of the box body; the box body cover is sheathed on the socket; the box body cover is provided with a cover seal ring; the cover seal ring and the socket are sealed in a guillotine-shaped seal manner; each box body cover is fixed on the outer shell of the box body by four locking elements; a foaming PVC gasket is adhered to the contact face of the filter element and the box body; the filter element is arranged on a filter element bracket which is supported by a cam arranged on the fast clamp shaft; and an operating handle is arranged at the end of the fast clamp shaft. The box body has the advantages that sealing effect is good, efficiency of replacing the filter element is high, and the secondary pollution caused by replacing the filter element is reduced.

Owner:NANFANG VENTILATOR +1

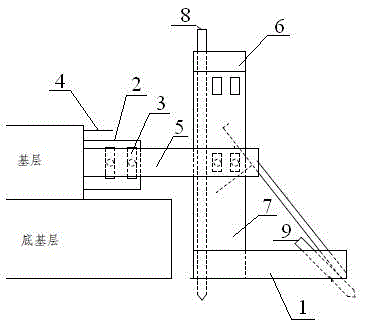

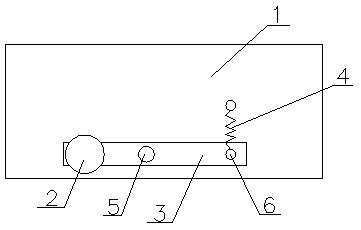

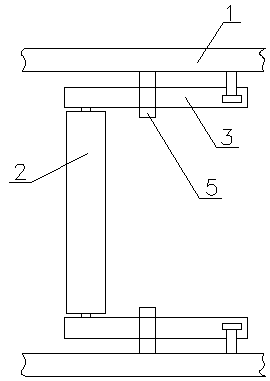

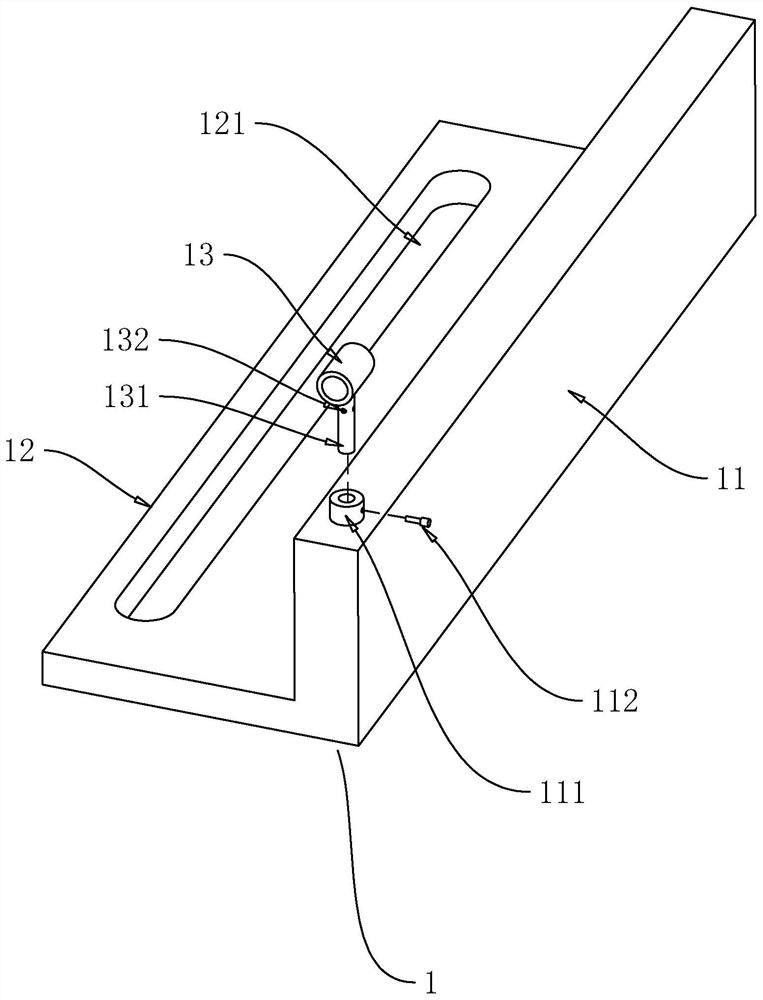

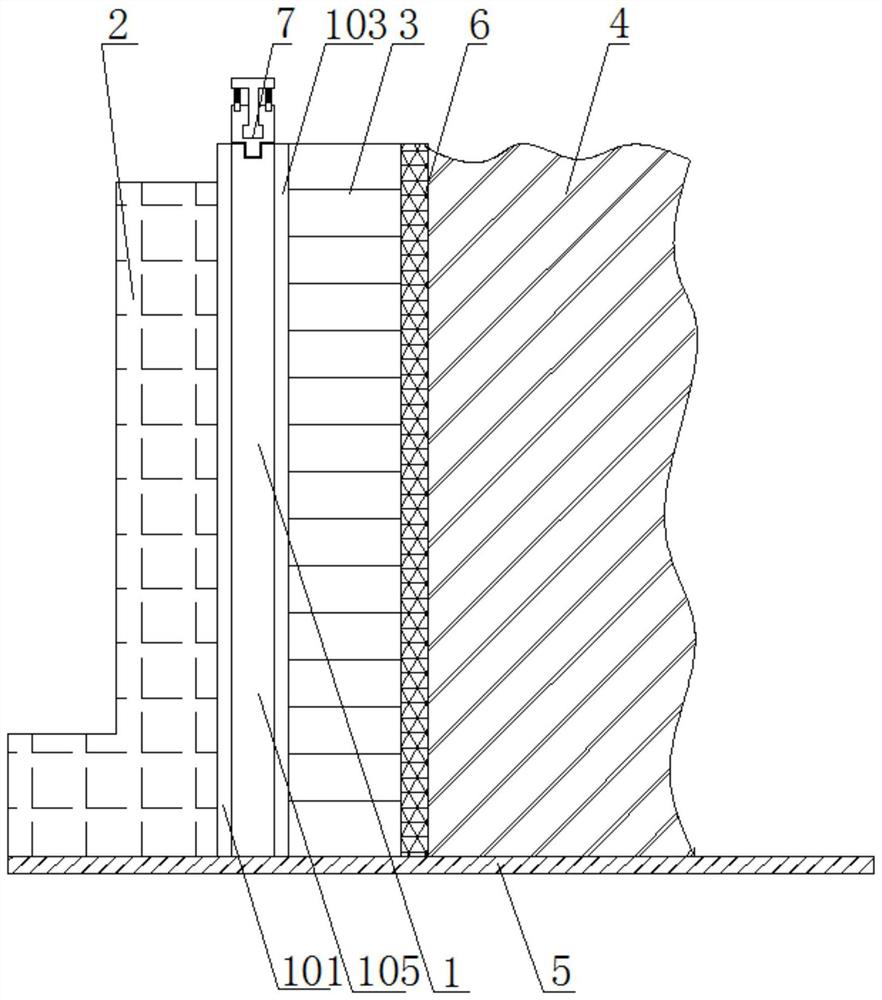

Basement layer stiffened side mold construction method

The invention relates to a basement layer stiffened side mold construction method. The method comprises the following steps: (1) a pavement width position is accurately measured before construction without deviation; (2) production of an L-shaped steel plate bracket: equal angle steel III is connected with a steel plate II through single-surface lap welding; and the steel plate II is connected with equal angle steel I through a reinforcement II by using the single-surface lap welding to form the L-shaped steel plate bracket; (3) one ends of a steel chisel I and a steel chisel II penetrate through the equal angle steel III and the equal angle steel I to be embedded under a roadbed by 25 cm; (4) 16# channel steel is used as a side mold at a water stable edge part; the length of single side mold is an adjustable line type with a length of 3 m; a steel plate I is welded with a sleeve; a reinforcement I is arranged in the sleeve; two ends of the reinforcement I are respectively welded with the channel steel; and (5) the channel steel is welded on the L-shaped steel plate bracket through equal angle steel II; and the equal angle steel II is connected with the steel plate I through a M18 high-strength screw rod. The method is high in working efficiency, saves the cost, and is convenient and practical in operation.

Owner:GANSU SHUNDA ROAD & BRIDGE CONSTR +1

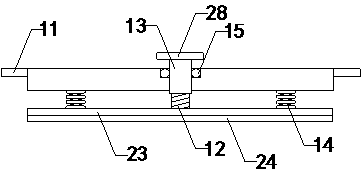

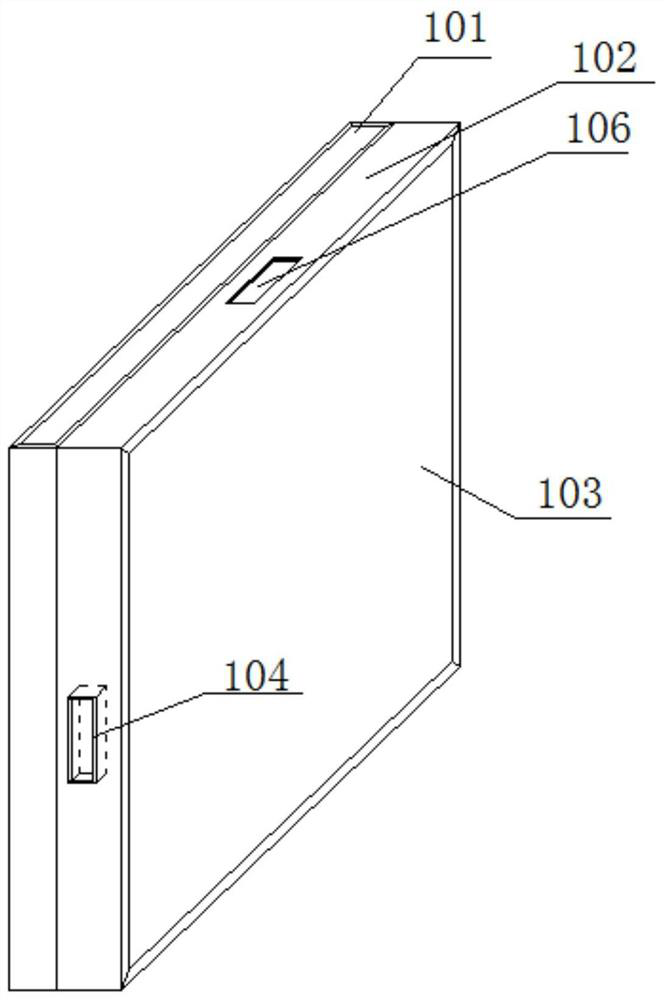

Paper mounting machine corrugated paper compaction device

InactiveCN107662445AGuaranteed compactionSimple structurePaperhangingPulp and paper industryEngineering

The invention relates to a compacting device for corrugated paper of a laminating machine. It includes two machine wall plates, a pressure roller is arranged between the two machine wall plates, connecting rods are connected at both ends of the pressure rollers, the middle part of the connecting rod is hingedly connected with the machine wall plate, and the other part of the connecting rod One end is connected with a spring, and the other end of the spring is connected with the machine wall plate above it. The invention has a simple structure, and the lower end of the spring can generate a pressure on the pressure roller through the other end of the connecting rod in real time, thereby ensuring the compaction of corrugated paper, good compaction effect and durability.

Owner:YIZHENG JINQUAN MACHINERY

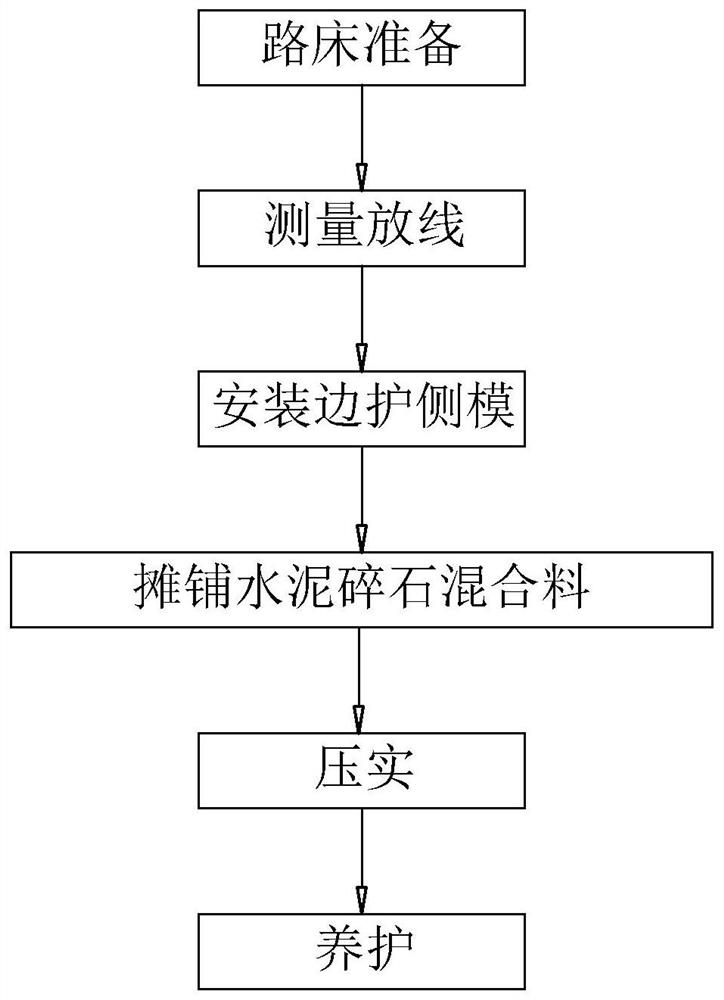

Cement stabilized macadam base construction method

PendingCN112482119AAccurate connectionAvoid horizontal expansionRoads maintainenceArchitectural engineeringStructural engineering

The invention relates to a cement stabilized macadam base construction method. The method comprises the following steps: S1, preparing a roadbed; S2, surveying and setting out; S3, installing an edgeprotection side form; S4, paving a cement and macadam mixture; S5, performing compaction; and S6, maintaining. The construction method has the effects that the quality of the cement macadam roadbed slope is guaranteed, and the quality of the constructed cement macadam roadbed is guaranteed.

Owner:LANHAI CONSTR GRP CO LTD

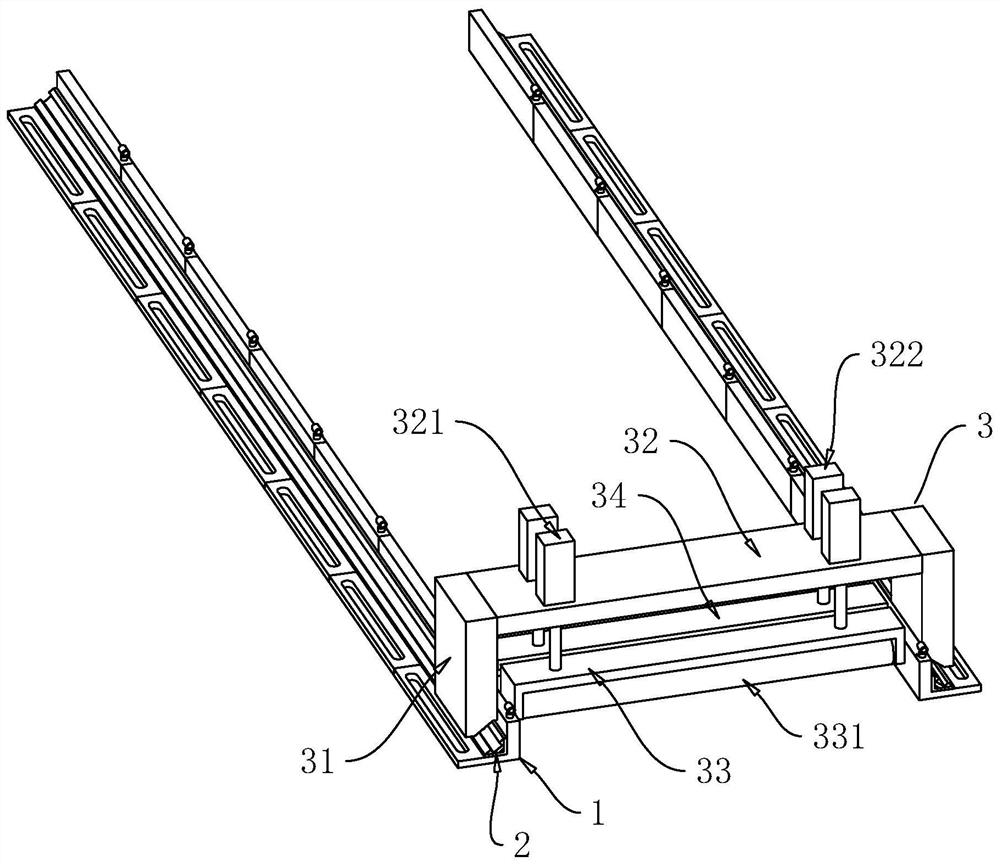

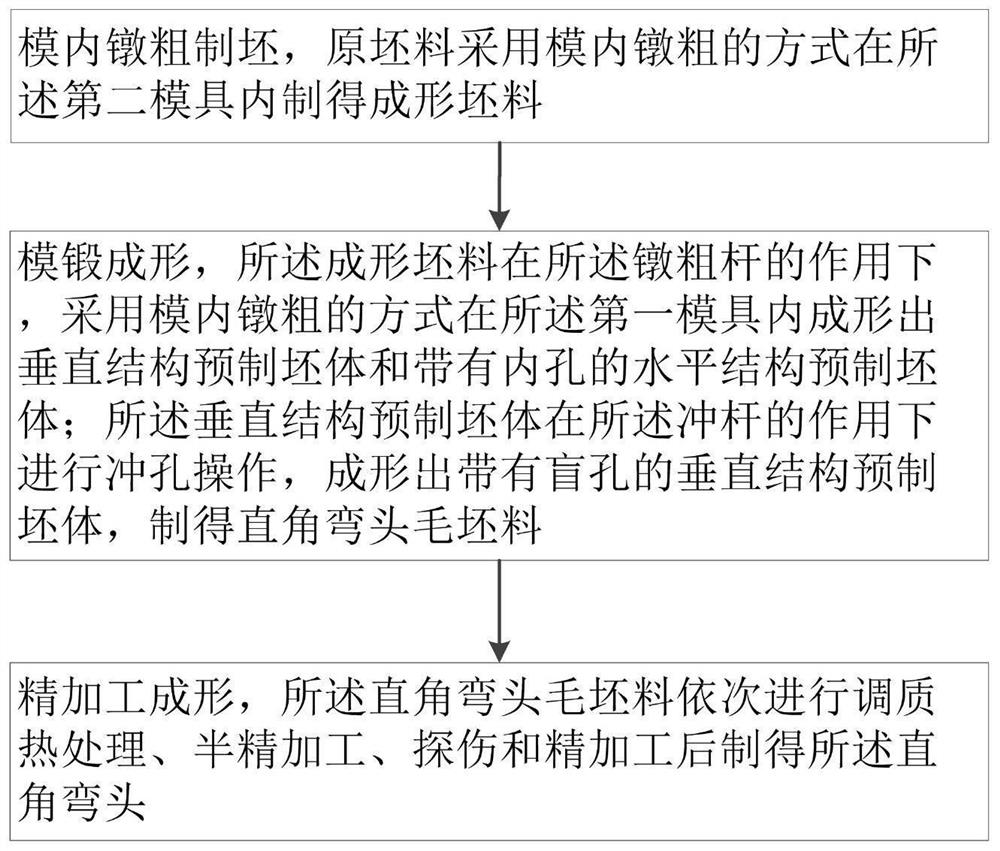

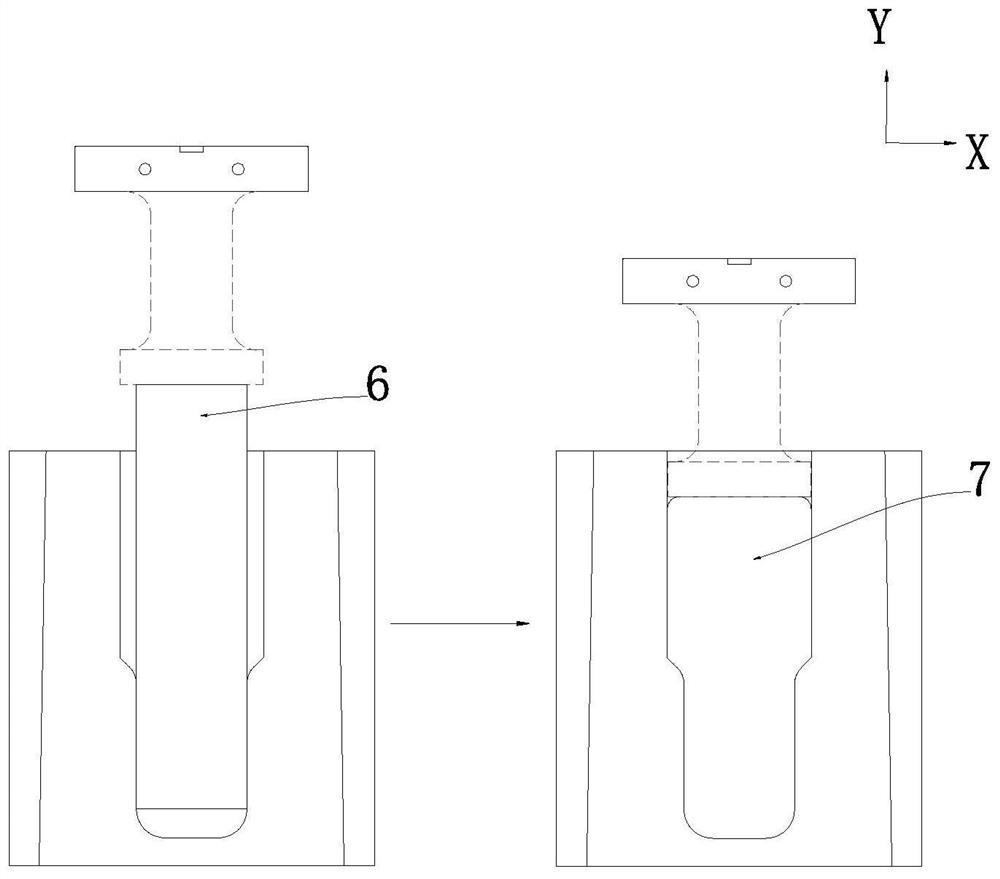

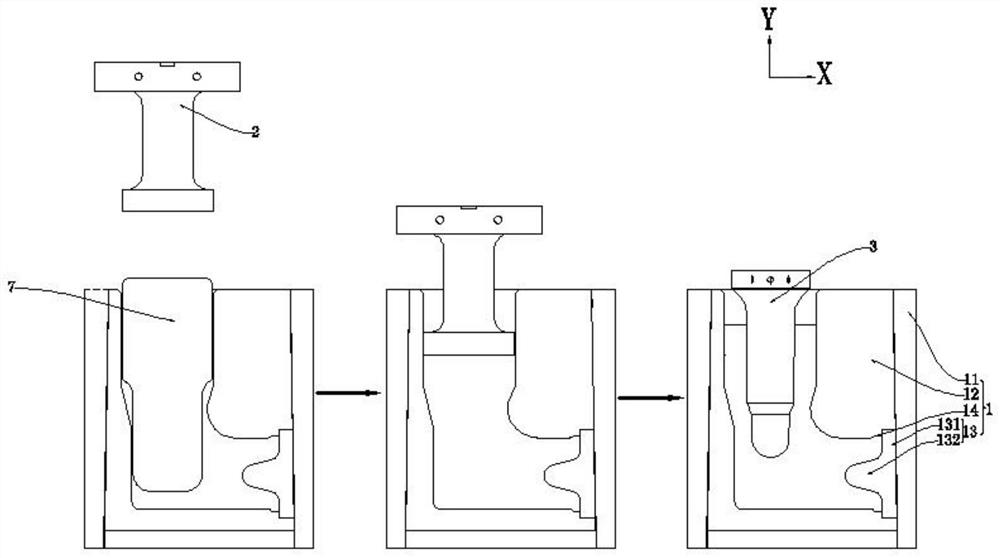

Die-forging forming die and method for ultra-large square elbow

ActiveCN112775378ASimple structureImprove stabilityForging/hammering/pressing machinesPunchingManufacturing engineering

The invention provides a die-forging forming die and method for an ultra-large square elbow, and belongs to the technical field of die-forging forming. The die-forging forming die for the ultra-large square elbow comprises a first die used for die-forging forming and a second die used for in-die upsetting blank making; the first die comprises a bottom die, an upsetting rod and a punching rod; a die-forging impression matched with a square elbow blank material in outline shape is arranged in the bottom die; the upsetting rod is used for stretching into the die-forging impression to conduct in-die upsetting; the punching rod is used for stretching into the die-forging impression to conduct punching operation; the bottom die comprises an outer die, an inner die and a side plug matched with the inner die; the side plug is embedded in the end of the inner die; and the inner die and the side plug are sleeved with the outer die. According to the die-forging forming die and method, the product quality level, the quality stability and the material yield of square elbow forged pieces can be increased, the service stability of the forged pieces is greatly improved, and the service life of the forged pieces is greatly prolonged.

Owner:CHINA FIRST HEAVY IND +2

Filling-soil compactor for forestry afforestation use

InactiveCN111108875AReduce labor intensityImprove work efficiencySoil-working equipmentsClimate change adaptationForest industrySoil science

The invention discloses a filling-soil compactor for forestry afforestation use. The filling-soil compactor for the forestry afforestation use comprises a snap sleeve, a support frame, and a compaction mechanism; a connecting plate is connected to an outer wall of the snap sleeve; the snap ring is connected with one end, far away from the snap sleeve, of the connecting plate; a slider is connectedto an outer wall of the snap ring; a first support plate and a second support plate are separately connected to a top wall of the slider; a soil filling mechanism and a first compacting mechanism areseparately connected to a bottom wall of the first support plate; a second compacting mechanism is connected to a bottom wall of the second support plate; a third support plate is connected to an outer wall of the second compacting mechanism; a turning disk is connected to an outer wall of the third support plate; a first connecting rod and a second connecting rod are separately connected to an outer wall of the turning disk; the first connecting rod is connected with the second compacting mechanism; and the second connecting rod is connected with the first compacting mechanism. The filling-soil compactor for the forestry afforestation use is simple in structure, convenient to use, and capable of performing effective filling-soil compacting operation on a transplanting pit as well as achieving uniform soil compaction density so as to facilitate water penetration during watering; and moreover, the filling-soil compactor for the forestry afforestation use is also capable of effectivelyreducing labor intensity, and improving work efficiency.

Owner:李沙沙

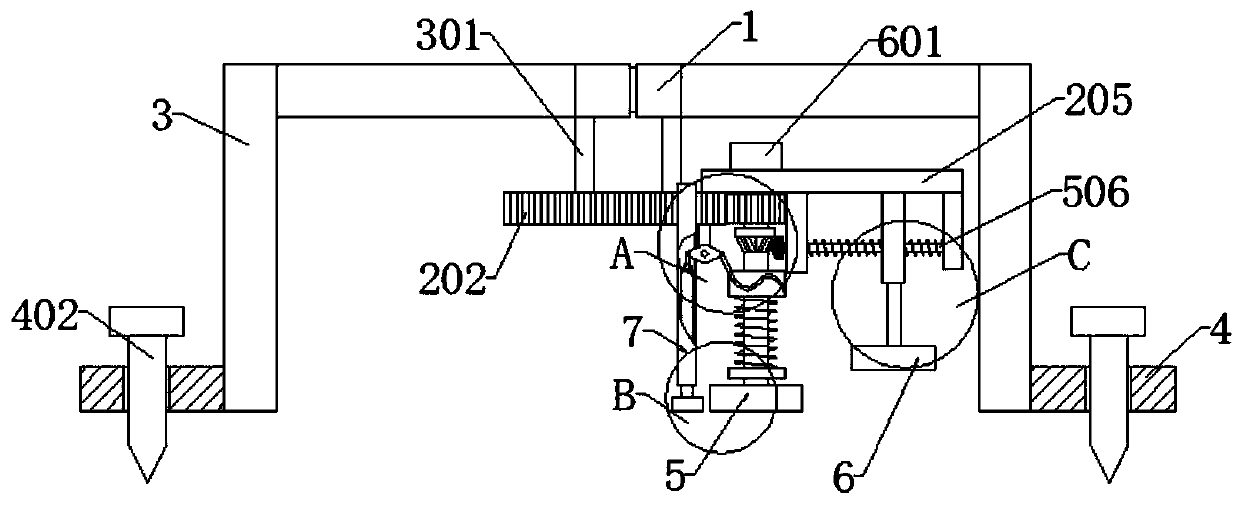

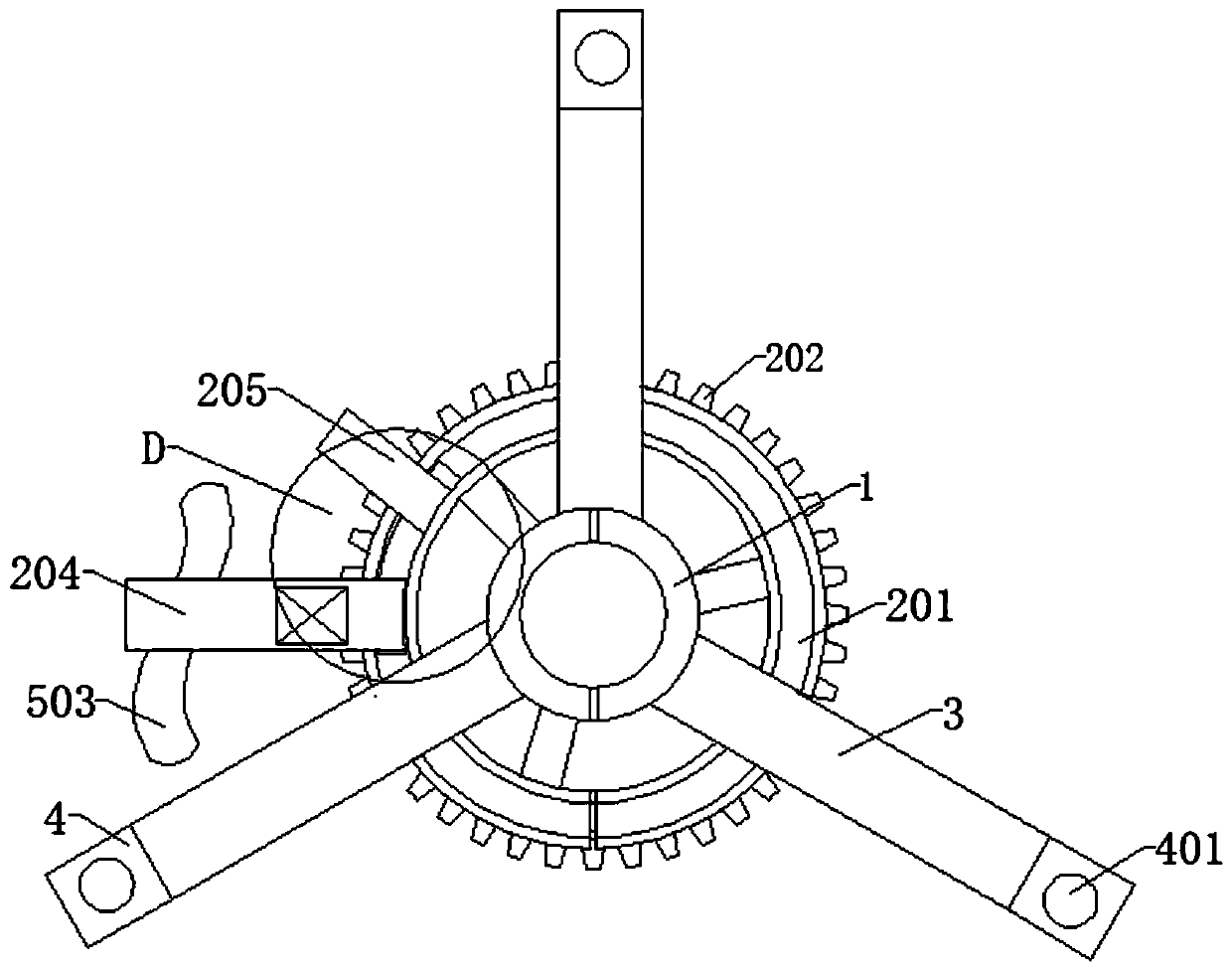

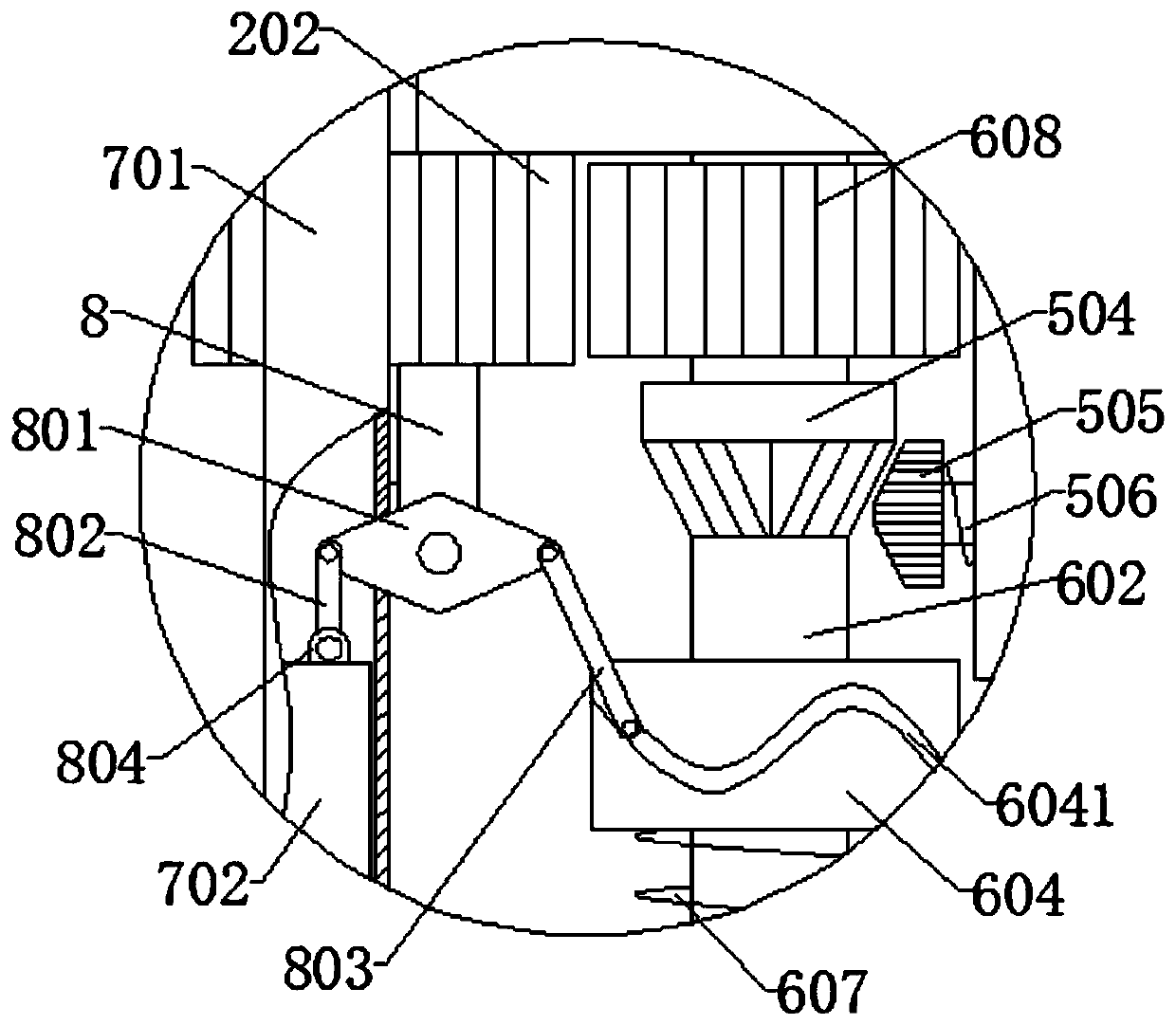

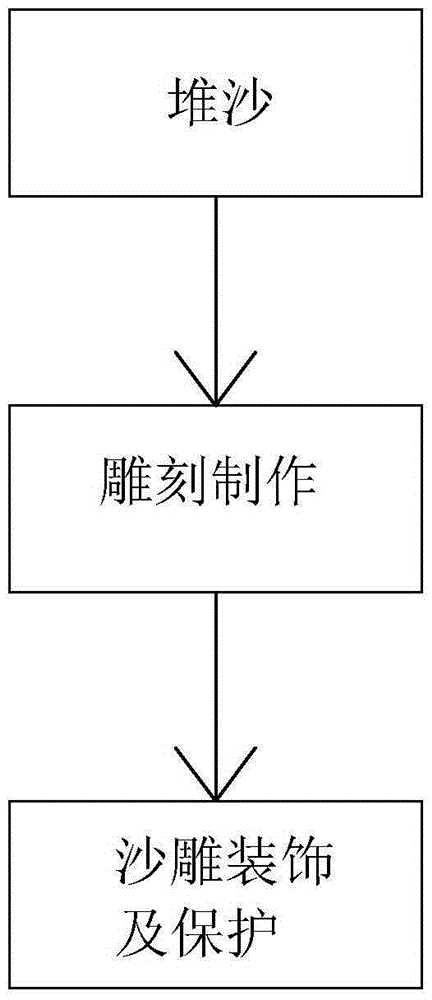

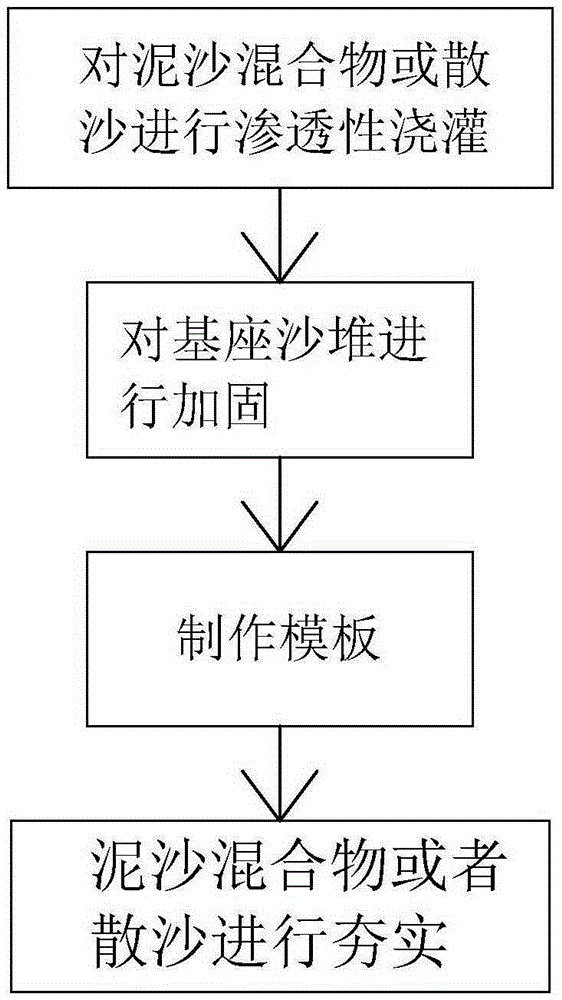

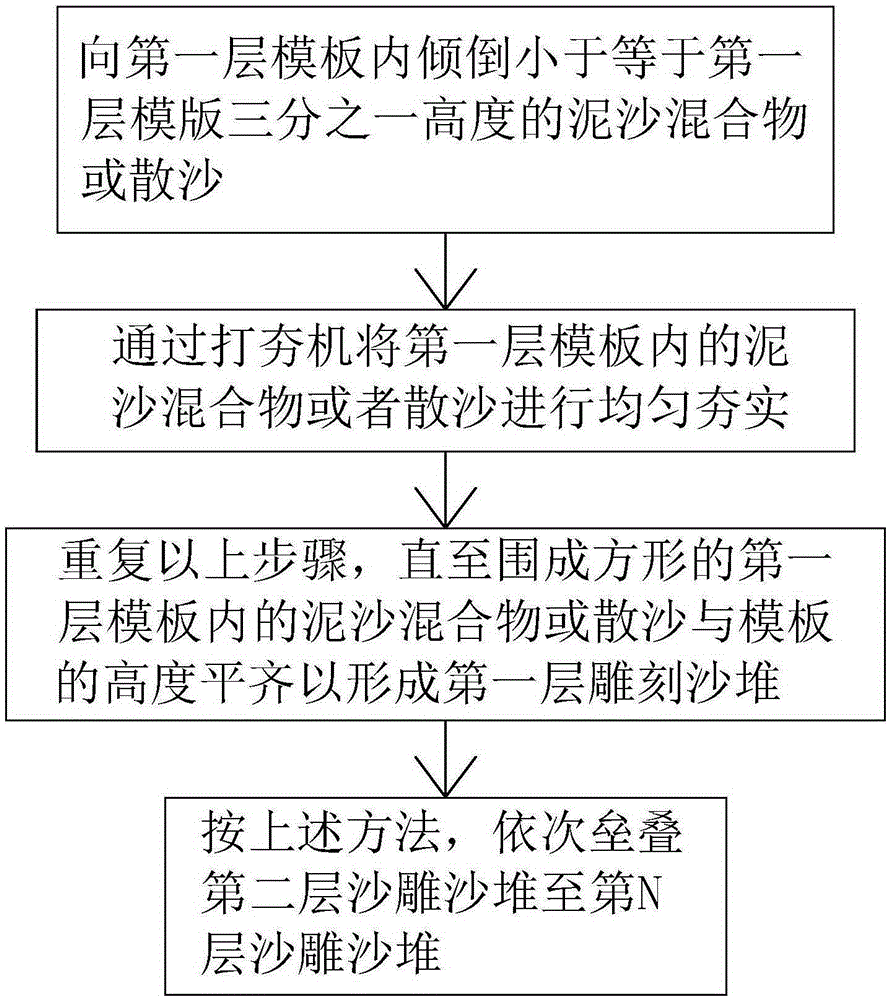

Sand sculpture manufacturing method

ActiveCN105346325ASolve the low mud contentThe solver sand itself is too largeOrnamental structuresStructural stabilityMaterials science

The invention discloses a sand sculpture manufacturing method. The method solves the problem that a sculpture sand pile is loose, so that a sand sculpture is prone to collapsing. According to the technical scheme, loose sand smaller than or equal to one third of the height of a first layer template is poured into a first layer template defining a square ; the loose sand in the first layer template is evenly tamped through a tamping machine; the steps are repeatedly executed until the loose sand in the first layer template defining the square is aligned to the template to form a first layer sculpture sand pile; and the method is adopted in the second layer sculpture sand pile to the Nth layer sculpture sand pile for tamping. According to the sand sculpture manufacturing method, by adoption of the method, the loose sand in each layer template can be tamped at at least three times, loose sand in each layer is firmer, and is not prone to loosening and collapsing, and the structural stability is improved; and meanwhile, the more tamped loose sand is more easily sculptured, and the sculpture precision is improved.

Owner:舟山市普陀区朱家尖柒区原创沙雕制作中心

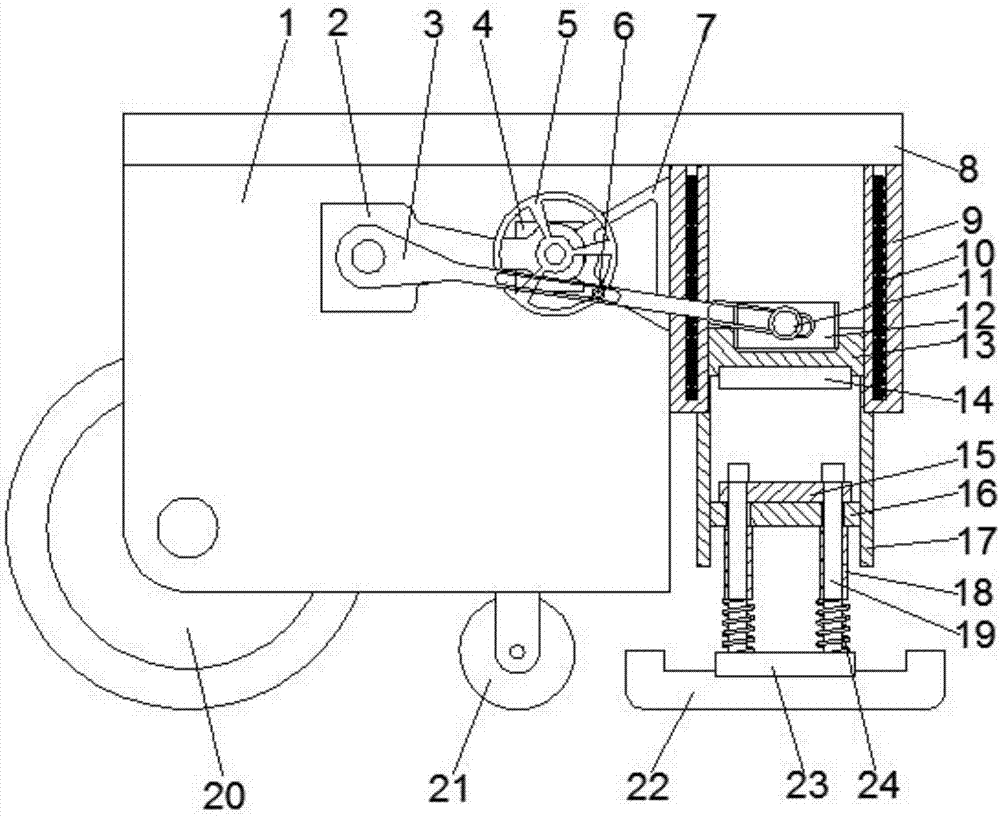

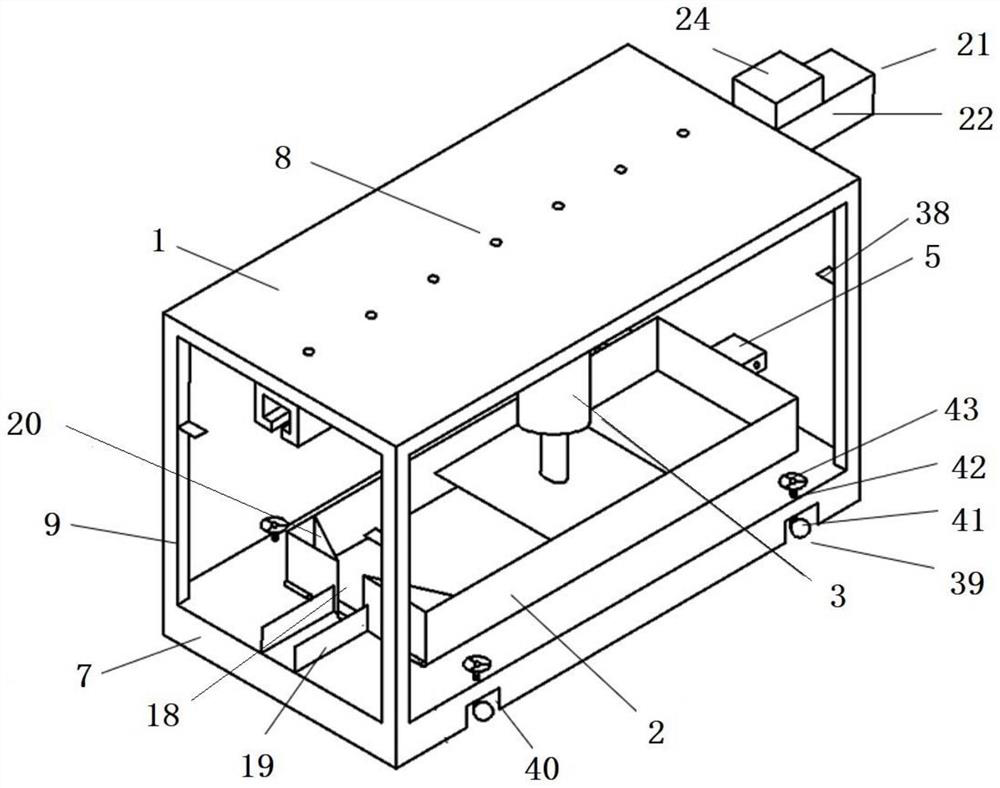

Ground ramming device

InactiveCN107989021AGuaranteed compactionAvoid lower maintenance costsSoil preservationEngineeringFlywheel

The invention discloses a ground ramming device. The ground ramming device comprises a machine box, a tank body is fixedly connected to one end of the machine box, a cover plate is fixedly connected to the upper ends of the machine box and the tank body, and a supporting frame is welded inside the machine box; a tripod is welded to the inner side wall, close to the tank body, of the machine box, and the tripod and the supporting frame are fixedly connected; and a motor is fixedly connected to the end, close to the supporting frame, of the machine box, a swing rod is rotationally connected to one end of the supporting frame and is fixedly connected with an output shaft of the motor, a flywheel is rotationally connected to the connecting position between the supporting frame and the tripod,a first limiting wheel is rotationally connected to the flywheel, and a first hollow groove and a second hollow groove are formed in the swing rod. According to the device, the structure is novel, theoperation is stable, a hammer body can move up and down in a reciprocating mode to ram the ground through the transmission of the flywheel and the swing rod, the ground ramming device is higher in efficiency, the use of hydraulic transmission is avoided, so that the maintenance cost is reduced, the practicability is high, and the popularization is facilitated.

Owner:HEFEI XIAKANG ELECTRONICS COMMERCE CO LTD

Soil slope surface model, manufacturing method and scouring test device and method

PendingCN111707533AGuaranteed compactionShorten the test cyclePreparing sample for investigationInvestigating abrasion/wear resistanceStructural engineeringTest chamber

The invention provides a soil slope surface model manufacturing and scouring test device which comprises a test box body, and further comprises a model box and a loading device which are mounted in the test box body, and a rainfall device is further mounted in the test box body. One side of the model box is hinged to the test box body, the other end of the model box, which is hinged to the test box body, is also provided with a counter-force plate, and a model box angle changing device is also connected between the counter-force plate and the test box body. A slope surface model is manufactured through the pressure loading device and the model box, the compactness of the slope surface model can be accurately guaranteed, the use of a large amount of earthwork is avoided, the test period isshortened, and the capital and manpower consumption of the test is saved; and the inclination angle of the model box can be adjusted through the model box angle changing device, and the test requirements of slopes with different inclination angles can be met. The rainfall intensity, the rainfall duration and the rainfall type can be adjusted through a rainfall flow control device, and slope rainfall erosion tests with different rainfall parameters can be achieved.

Owner:CHANGAN UNIV +1

Screed possessing uniform amplitude of spreader

InactiveCN102518026AGuaranteed flatnessGuaranteed compactionRoads maintainenceClassical mechanicsRoad surface

The invention discloses a screed possessing uniform amplitude of a spreader, which is characterized in that an analysis for uniformity of the amplitude of the screed is carried out by calculating the amplitude value of each point on the screed; the design parameter of a vibrator and a vibration beam of a compacting system of the spreader can be optimized, under the prerequisite that the mean value of amplitude of the screed is ensured, the difference value of the maximum amplitude and the minimum amplitude of the screed can be effectively reduced, thereby the purposes of ensuring the transverse flatness and the compactness of the pavements can be reached.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Retaining wall system capable of reducing construction influence and construction method for retaining wall system

ActiveCN112240031AAvoid damageReduce instabilityArtificial islandsRoadwaysRetaining wallGrounding line

The invention discloses a retaining wall system capable of reducing the construction influence and a construction method for the retaining wall system, and relates to the field of engineering construction. The retaining wall system comprises an air pressure energy dissipation layer, an air pressure partition plate and a ground line, a retaining wall is arranged above the left side of the ground line, the air pressure energy dissipation layer is arranged on the right side of the retaining wall, and a sand bag layer is arranged on the right side of the air pressure energy dissipation layer; andan inverted filter geotextile is arranged on the right side of the sand bag layer, and embankment filling soil is arranged on the right side of the inverted filter geotextile. According to the retaining wall system capable of reducing the construction influence, through cooperation of the air pressure energy dissipation layer and an energy dissipation device, ramming force generated during embankment filling construction is effectively absorbed, and the situation that the retaining wall is damaged due to vibration generated by the ramming force during construction is avoided.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com