Retaining wall system capable of reducing construction influence and construction method for retaining wall system

A retaining wall and anti-filter geotextile technology, which is applied in the field of engineering construction, can solve the problems of reducing the quality of the "V"-shaped backfill area, longitudinal cracks in the subgrade, and the quality of the drainage and anti-filter layer of the compact retaining wall cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

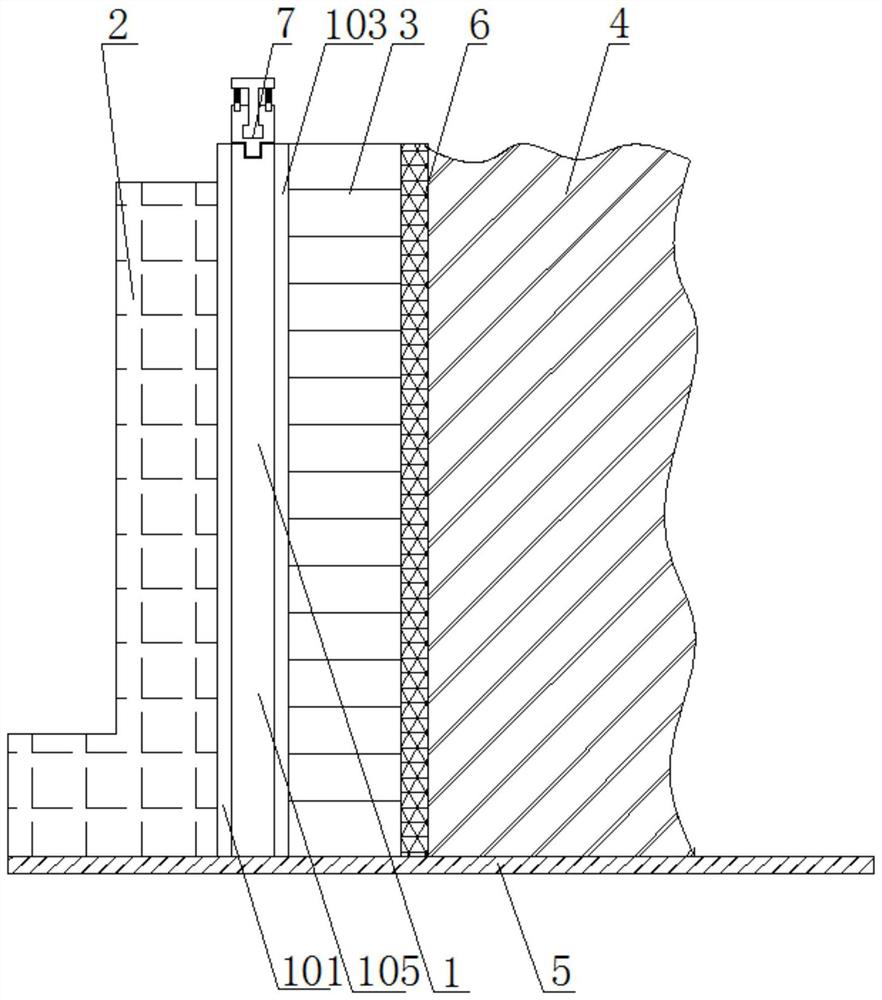

[0037] see Figure 1-4 , a retaining wall system for reducing the impact of construction, comprising an air pressure energy dissipation layer 1, an air pressure partition 105 and a ground line 5, a retaining wall 2 is arranged above the left side of the ground line 5, and an air pressure is arranged on the right side of the retaining wall 2 Energy dissipation layer 1, sandbag layer 3 is arranged on the right side of air pressure energy dissipation layer 1, and sandbag layer 3 is formed by stacking several sandbags, and filter geotextile 6 is arranged on the right side of sandbag layer 3. The right side of the cloth 6 is provided with an embankment fill 4 .

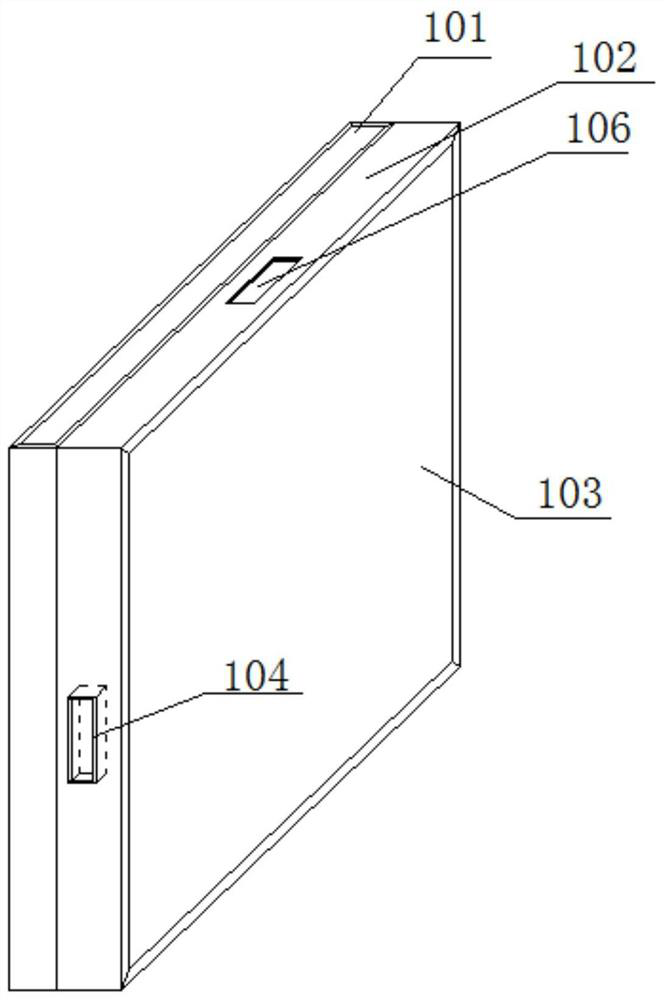

[0038] The air pressure energy dissipation layer 1 includes a packing channel 101, a metal frame 102, a rubber surface 103, a connecting slot 104, an air pressure partition 105 and a communication slot 106; the outer wall of the air pressure partition 105 is respectively wrapped with a metal frame 102 and a rubber surface ...

Embodiment 2

[0042] see Figure 1-4 , the construction method of the retaining wall system to reduce the construction impact is as follows:

[0043] S1. According to the design drawings of the retaining wall 2, stake out on site, excavate the foundation and check the bearing capacity of the groove base;

[0044] S2. Set up the formwork and pour concrete for the retaining wall, and maintain the concrete for the retaining wall until the strength reaches the requirement;

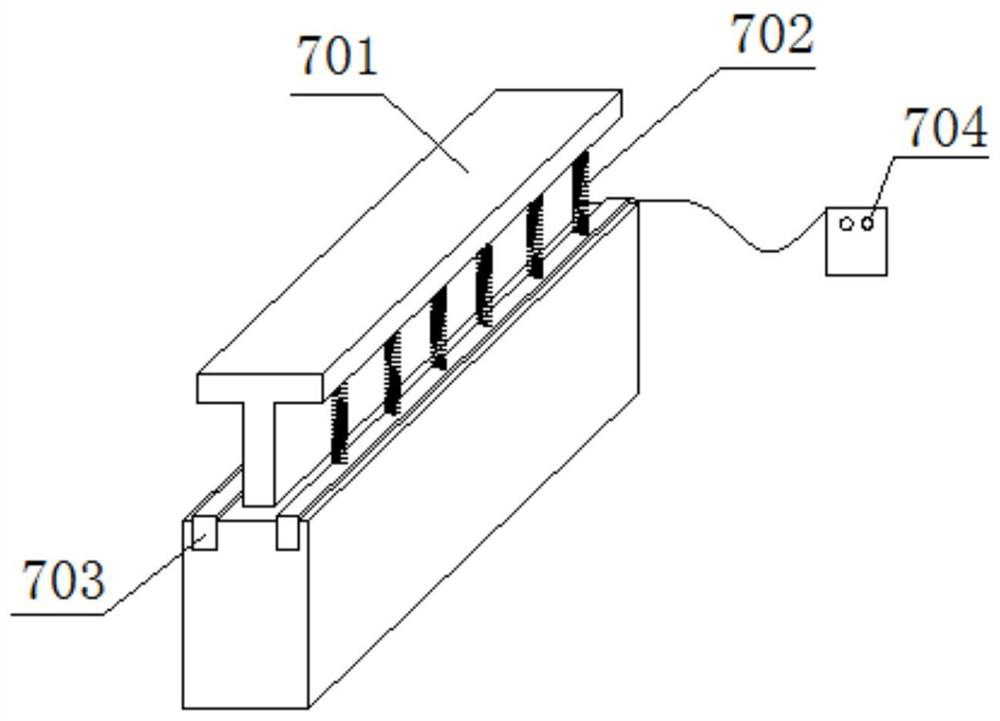

[0045] S3, install the air pressure energy dissipation layer 1, and connect the air pressure partition 105 according to the length of the filling and paving;

[0046] S4. Use an air pressure pump to inject air into the air pressure partition 105, use the air pressure monitoring device to monitor the internal air pressure, and maintain the internal pressure of the air pressure partition 105;

[0047] S5. The sandbag layer 3 is placed on the right side of the air pressure energy dissipation layer 1, and the filter geotextil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com