Soil slope surface model, manufacturing method and scouring test device and method

A soil slope and scour test technology, which is applied in the fields of soil slope model, production method, and scour test device, can solve problems such as uneven compaction of the soil layer, long test cycle of the slope scour test, etc., and save money and manpower consumption, shorten the test cycle, and ensure the effect of compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

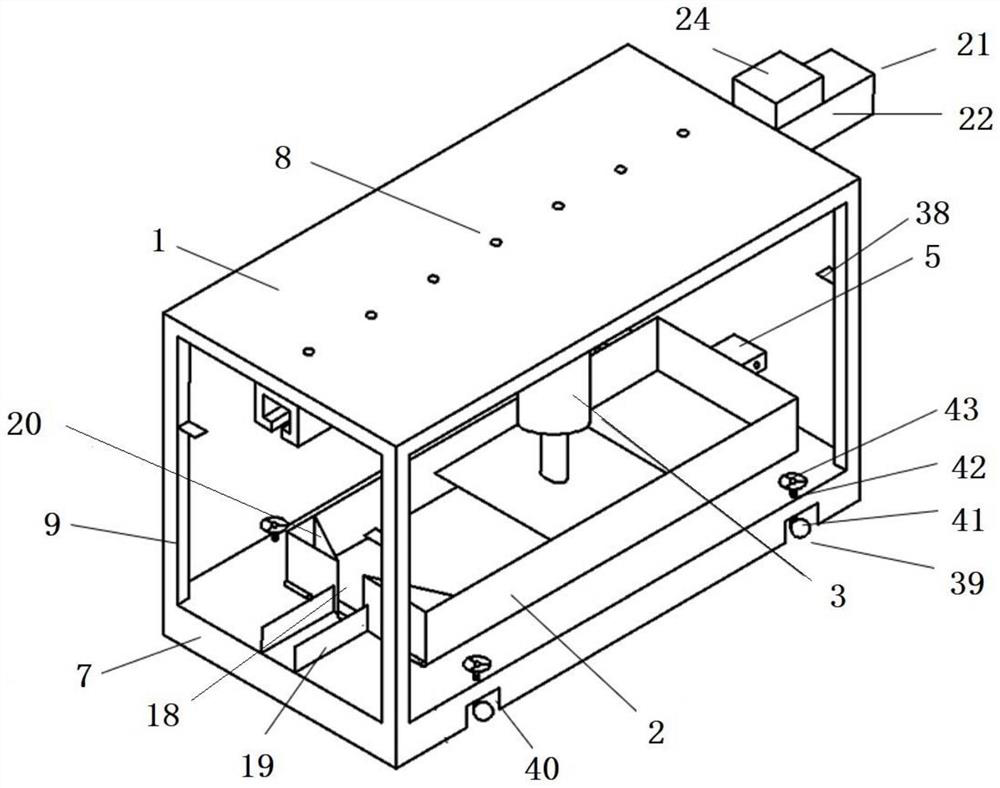

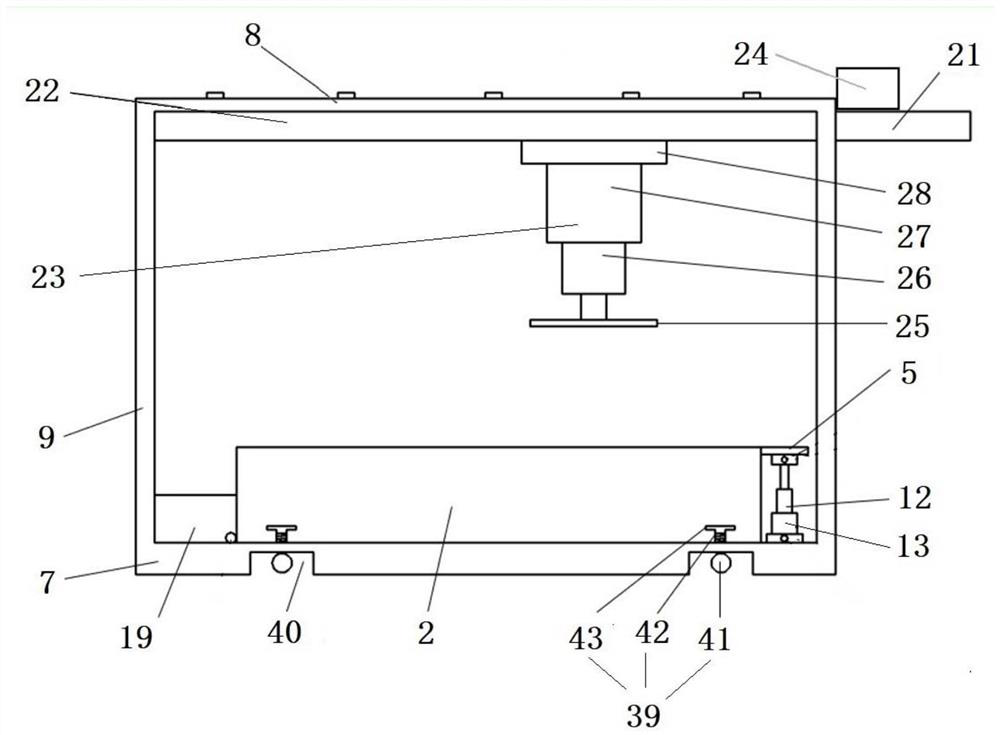

[0065] Comply with the above technical solutions, such as Figure 1 to Figure 8 As shown, the present embodiment provides a soil slope slope model scour test device, including a test box 1, and also includes a model box 2 and a loading device 3 installed in the test box 1, the test box Rainfall device 4 is also installed in 1;

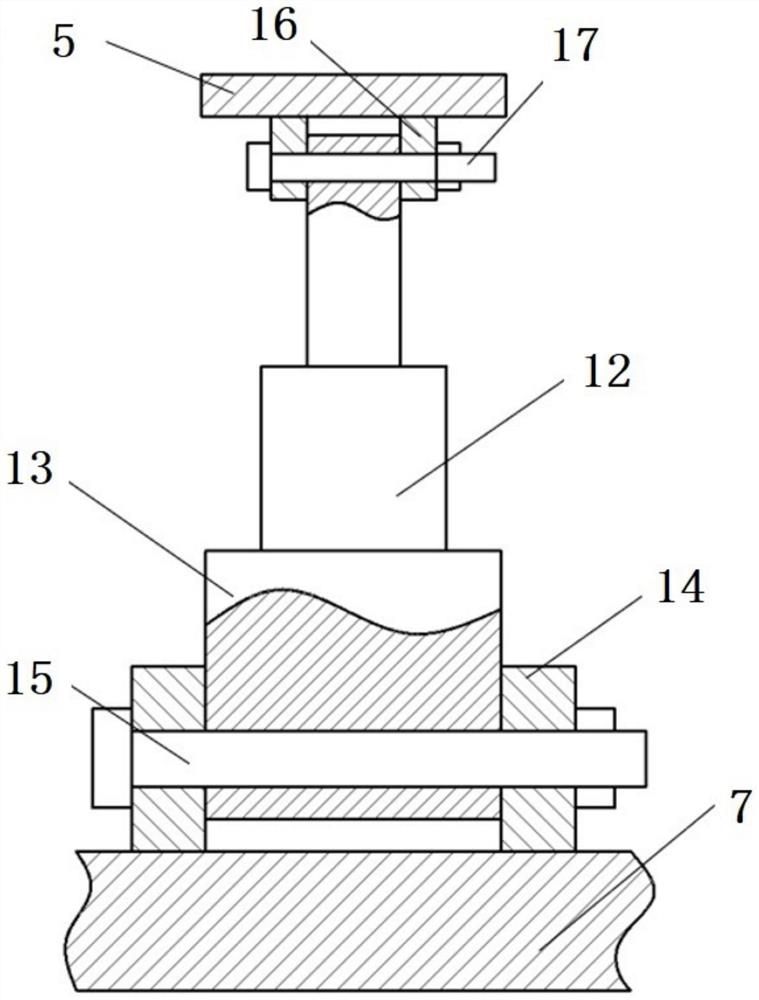

[0066] One side of the model box 2 is hinged with the test box body 1 . The other end of the hinge of the model box 2 and the test box body 1 is also equipped with a reaction force plate 5, and a model box angle changing device 6 is also connected between the described reaction force plate 5 and the test box body 1. The model box angle changing device 6 is used to lift the side of the model box 2 where the reaction force plate 5 is installed. The rainfall device 4 is used to scour the model soil in the model box 2, the loading device 3 is used to compact the model soil in the model box 2, one side of the model box 2 is hinged with the test box 1, and...

Embodiment 2

[0088] A method for making a soil slope surface model, the method is carried out by the described device for making a soil slope surface model and scouring test, and the method includes the following steps:

[0089] Step 1: Calculate the amount of soil required to achieve the required compaction degree of the test;

[0090] Firstly, the maximum dry density ρ of the test soil was obtained through the indoor compaction test max , according to the degree of compaction required by the test, combined with the maximum dry density of the test soil, the bottom area S of the model box 2 and the thickness h of the slope model to calculate the amount of soil required to make a slope model;

[0091] Step 2: Filling and compacting successively;

[0092] The soil retaining plate 11 is installed in the retaining plate retaining groove 10, since the distance between the retaining plate retaining grooves 10 is equal, the soil mass weighed according to the amount of soil required for the test ...

Embodiment 3

[0096] A soil slope surface model, prepared by the method in Embodiment 2 of the soil slope surface model. The slope surface model is made by the pressure loading device and the model box, which can accurately ensure the compaction of the slope surface model, avoid the use of large earthwork volumes, shorten the test period, and save the test capital and manpower consumption;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com