Screed possessing uniform amplitude of spreader

A screed and paver technology, which is applied in the directions of roads, road repairs, roads, etc., can solve the problems such as the inability to meet the requirements of the horizontal amplitude uniformity of the screed, and achieve the effect of ensuring the horizontal flatness and compaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

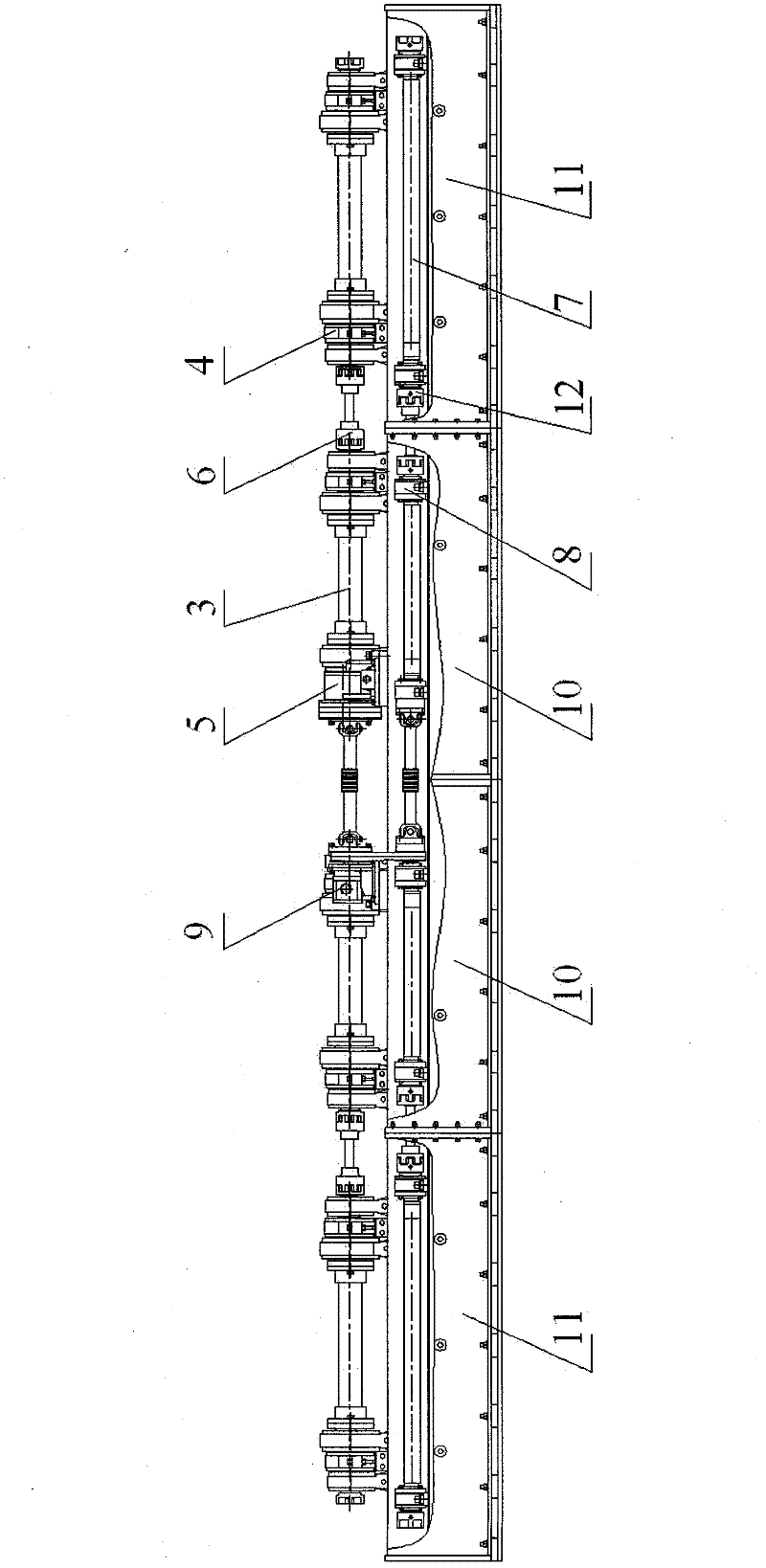

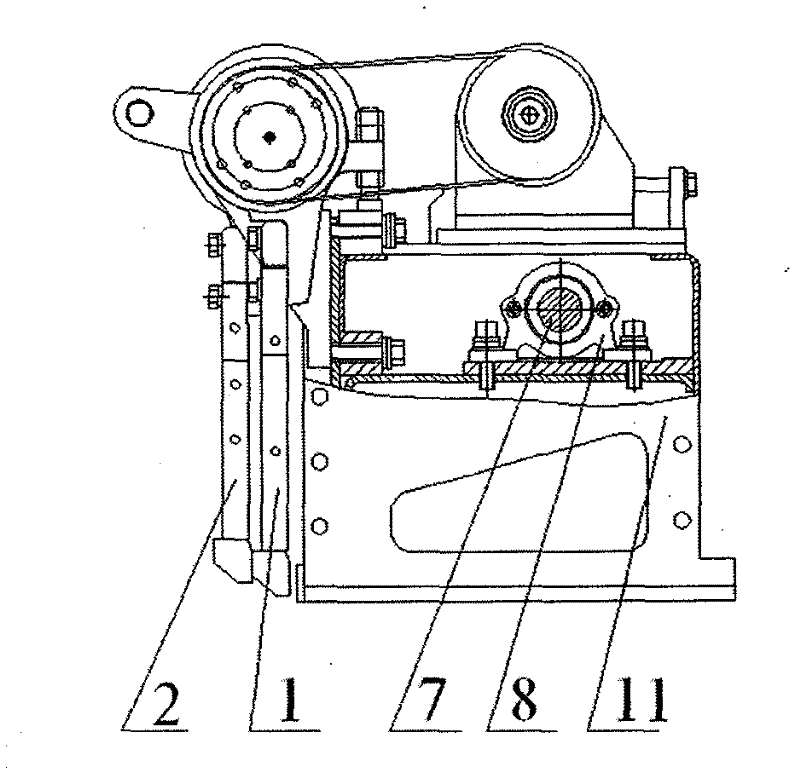

[0025] The paver includes a compaction system consisting of a vibrating mechanism, a screed, and a vibrator. It is located at the rear end of the paver. The vibrating mechanism includes a vibrating beam, a vibrator driving eccentric shaft 3, a bearing and a bearing seat 4, The vibrating beam includes a main vibrating beam 1 and an auxiliary vibrating beam 2, the main vibrating beam 1 and the auxiliary vibrating beam 2 are installed on the eccentric shaft 3 of the vibrator through bearings, and the eccentric shaft 3 of the vibrator is composed of The vibrator bearing seat 4 fixed on the screed box is supported, and the vibrator motor 5 drives the eccentric shaft 3 of the vibrator to rotate, driving the main vibrating beam 1 and the auxiliary vibrating beam 2 to reciprocate up and down , there are several sections of vibrating beams arranged along the paving width direction, the vibrator eccentric shafts 3 of each vibrating beam are connected through the vibrator coupling 6, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com