Flat electrode supported ceramic electrolyte battery and preparation method thereof

A ceramic electrolyte, flat-plate technology, used in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve the problems of difficult to obtain materials, low battery strength, and difficult production, to reduce the preparation cost, improve the battery strength, The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

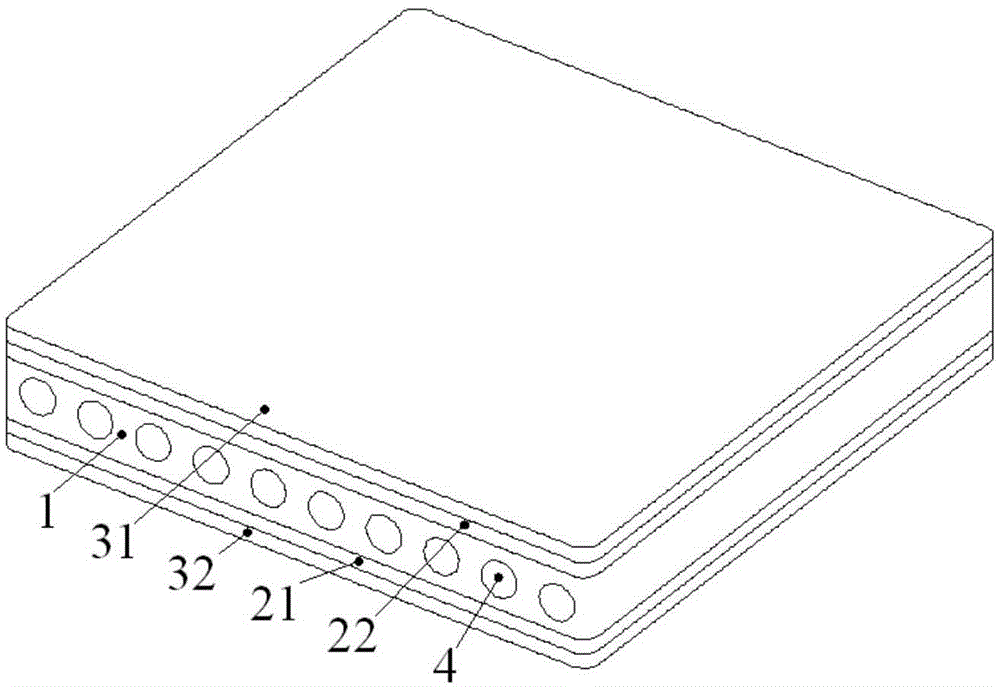

[0041] In this embodiment, the schematic diagram of the structure of the ceramic electrolyte battery supported by flat electrodes is as follows figure 1 As shown, the supporting electrode layer 1, the electrolyte layer and the unsupported electrode layer are stacked up and down along the thickness direction, the supporting electrode is an anode, and the unsupported electrode is a cathode. The electrolyte layer includes a first electrolyte layer 21 and a second electrolyte layer 22 , the first electrolyte layer 21 is located on the upper surface of the supporting electrode layer 1 , and the second electrolyte layer 22 is located on the lower surface of the supporting electrode layer 1 . The unsupported electrode layer includes an upper first unsupported electrode layer 31 and a second unsupported electrode layer 32, the first unsupported electrode layer 31 is located on the upper surface of the first electrolyte layer 1, and the second unsupported electrode layer 32 is located o...

Embodiment 2

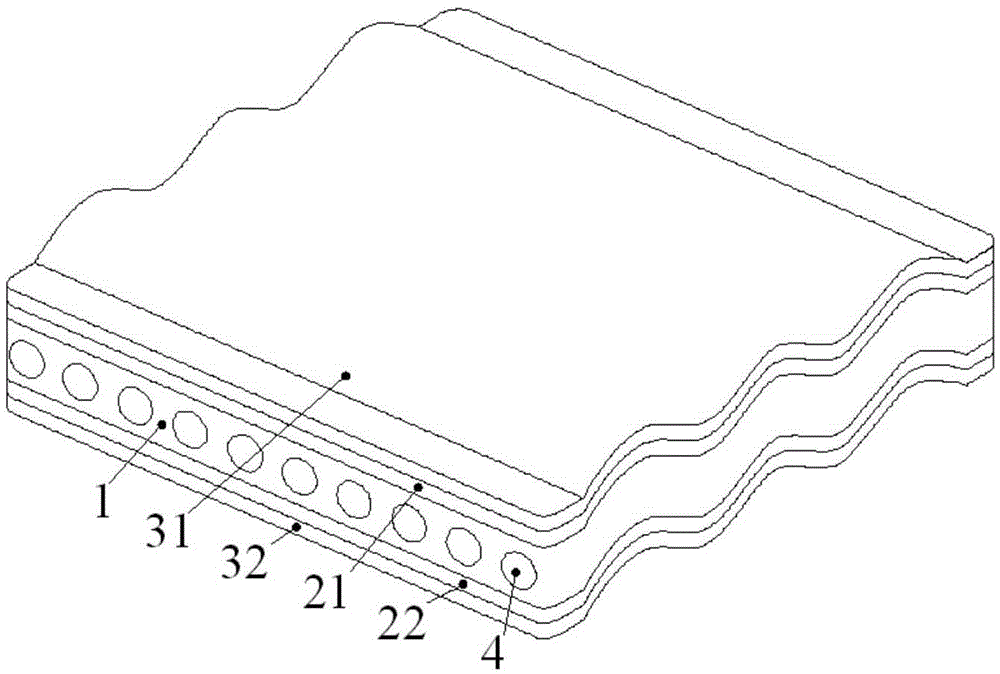

[0053] In this embodiment, the schematic diagram of the structure of the ceramic electrolyte battery supported by flat electrodes is as follows figure 2 shown. The structure is the same as figure 1 The structures shown are basically the same, except that the upper and lower surfaces of the supporting electrode layer 1, the upper and lower surfaces of the first electrolyte layer 21, the upper and lower surfaces of the second electrolyte layer 22, the upper and lower surfaces of the first unsupported electrode layer 31, and the second The upper and lower surfaces of the non-supporting electrode layer 32 are both uneven and wavy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com