H-shaped four-crawler-belt slipform paver

A slip-form paver and four-track technology, which is applied to roads, road repairs, roads, etc., can solve the problem of ensuring the stability and smoothness of the main machine driving and paving operations, and the most effective match between machine quality and driving force , Unfavorable problems such as uniform distribution of machine quality, to achieve the effect of fast and convenient replacement of cutter wheel, flexible and diverse adjustment methods, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

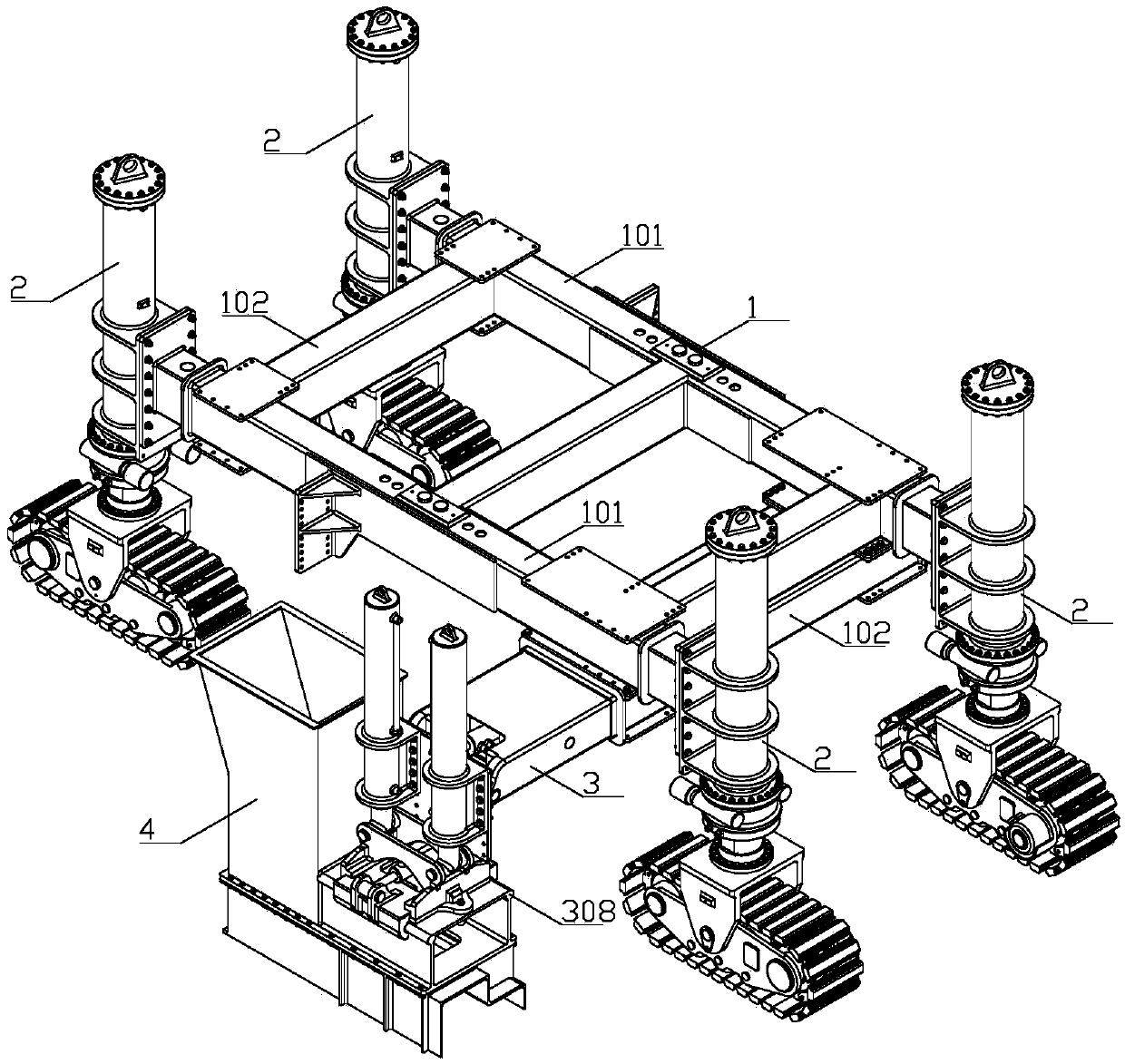

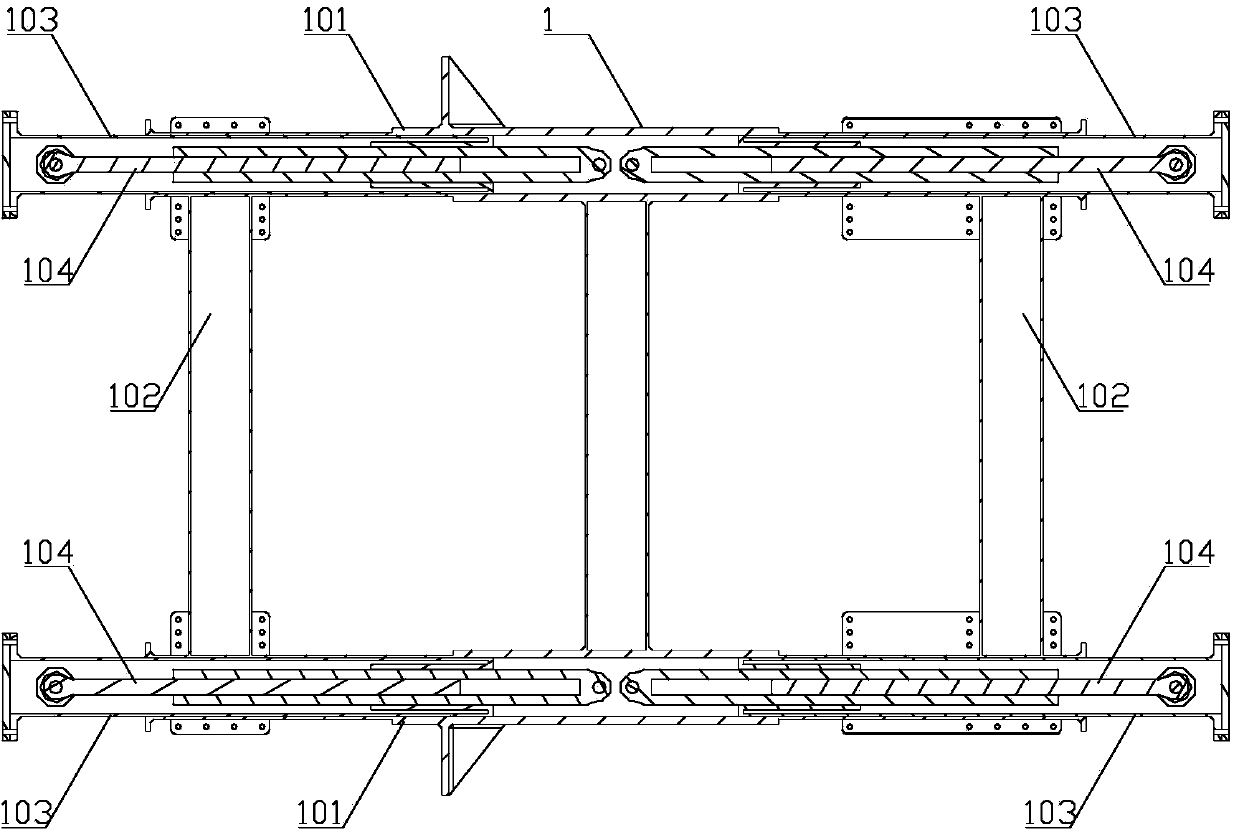

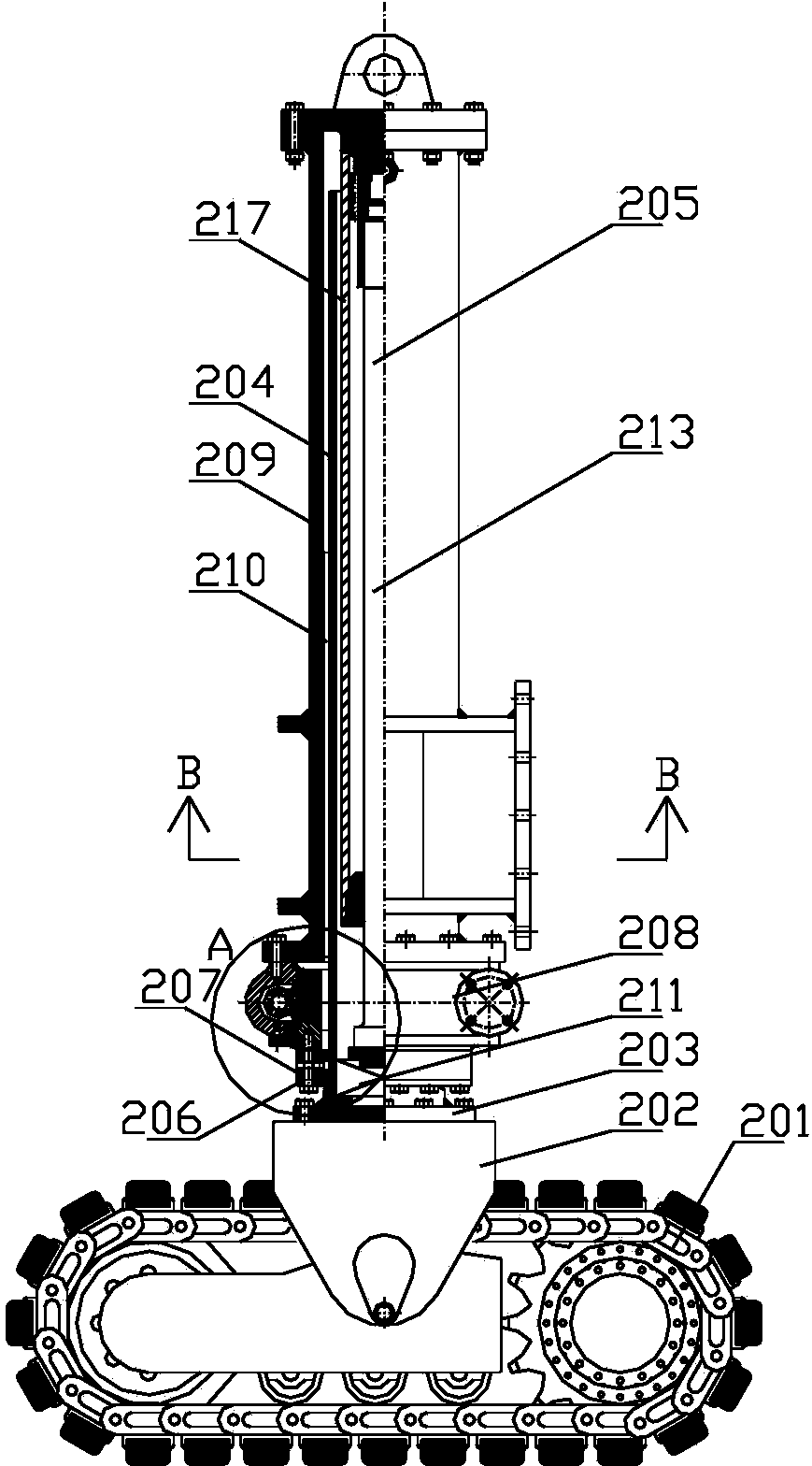

[0042] Embodiment 1: as figure 1 As shown, the H-type four-track slipform paver includes an H-type telescopic chassis 1 and a crawler-type lifting and steering device 2, such as figure 2 As shown, the H-shaped telescopic chassis 1 includes two hollow longitudinal main beams 101, two transverse main beams 102, and four hollow telescopic beams 103; Two transverse main beams 102 are respectively fixed between the top ends, two longitudinal main beams 101 and two transverse main beams 102 form a square frame-shaped main body, and telescopic beams are movably inserted at both ends of each longitudinal main beam 101 103, one end of each telescopic beam 103 is placed in the inner cavity of the longitudinal main beam 101; the outer end of each telescopic beam 103 is provided with a crawler lifting steering device 2; each telescopic beam 103 is provided with a telescopic beam oil cylinder 104, The top of the piston rod of the telescopic beam oil cylinder 104 is fixedly connected with...

Embodiment 2

[0043] Embodiment 2: as Figure 12 As shown, the H-type four-track slipform paver includes an H-type telescopic chassis 1 and a crawler-type lifting and steering device 2. The H-type telescopic chassis 1 includes two hollow longitudinal main beams 101, two transverse main beams 102, Four hollow telescopic beams 103; between two longitudinal main beams 101 bottoms, a side-mounted sliding form mold holder 3 is fixed; its overall structure is the same as in embodiment 1, and the difference is that, as Figure 13 with 14 As shown, the piston rod of the lifting cylinder 302 stretches out upwards, and the sliding form fixture is an upper suspension sliding form fixture 320, such as Figure 15As shown, the upper hanging sliding form fixture 320 includes a fixture bottom plate 321, a movable splint B322, a splint limit block B323, a fixture cylinder B324, and a sliding form connecting plate B325; the bottom of the fixture bottom plate 321 and the piston rod of the lifting cylinder 30...

Embodiment 3

[0044] Embodiment 3: as Figure 16 with 17 As shown, the H-type four-track slipform paver includes an H-type telescopic chassis 1 and a crawler-type lifting and steering device 2. The H-type telescopic chassis 1 includes two hollow longitudinal main beams 101, two transverse main beams 102, Four hollow telescopic beams 103; between the bottoms of the two longitudinal main beams 101, a side-mounted sliding form mold holder 3 is fixed; A material conveyor fixing frame 5 is fixed between one end of the beam 101; Figure 18 As shown, the material conveyor fixed frame 5 includes a fixed frame main beam 501, a fixed frame movable arm 502, a fixed frame oil cylinder 503, and a conveyor connecting seat 504. The fixed frame main beam 501 is fixed on the bottom of the two longitudinal main beams 101, One end of the fixed frame movable arm 502 is slidingly inserted in the fixed frame main beam 501, and the outer end of the fixed frame movable arm 502 is vertically provided with a conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com