Potato crisp utilizing micro wave processing and its processing method

A potato and crisp technology, applied in application, food preservation, food preparation, etc., can solve problems such as affecting product taste and food safety, increasing consumers' economic burden, and detrimental to consumers' health, and reducing oil-soluble nutrition. Loss of ingredients, shortened heating time, and quick heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1, after the rinsed potato chips were blanched with 2% salt water under boiling, cooled to normal temperature and drained; the drained potato chips were frozen at -20°C for 10 hours; then at 50°C Dry at temperature for 30 minutes. Mix 4kg of palm oil and 2kg of egg yolk powder evenly with 100kg of dried potato chips, and finally microwave at 100% power for 3 minutes, then bake at 60% power for 2 minutes, and then spray 3kg of lobster powder seasoning.

Embodiment 2

[0028] Example 2, after the rinsed potato chips were blanched with 2.5% salt water under boiling, cooled to normal temperature and drained; the drained potato chips were frozen at -25°C for 12 hours; then at 45°C Dry at temperature for 35 minutes. Mix 4.2kg of palm oil and 3kg of egg yolk powder evenly with 120kg of dried potato chips. Finally, microwave with 100% power for 3 minutes, then use 60% power for 2.5 minutes, and then spray 3.6kg of spicy beef flavor. seasoning.

Embodiment 3

[0029] Example 3, after the rinsed potato chips were blanched with 1.8% salt water under boiling, cooled to normal temperature and drained; the drained potato chips were frozen at -15°C for 12 hours; then at 50°C Dry at temperature for 35 minutes. Mix 3.6kg of palm oil and 1.2kg of egg yolk powder evenly with 80kg of dried potato chips, and finally microwave with 100% power for 2.5 minutes, then use 60% power for 3.5 minutes, and then spray 2.4kg of spicy chicken wings flavor seasoning.

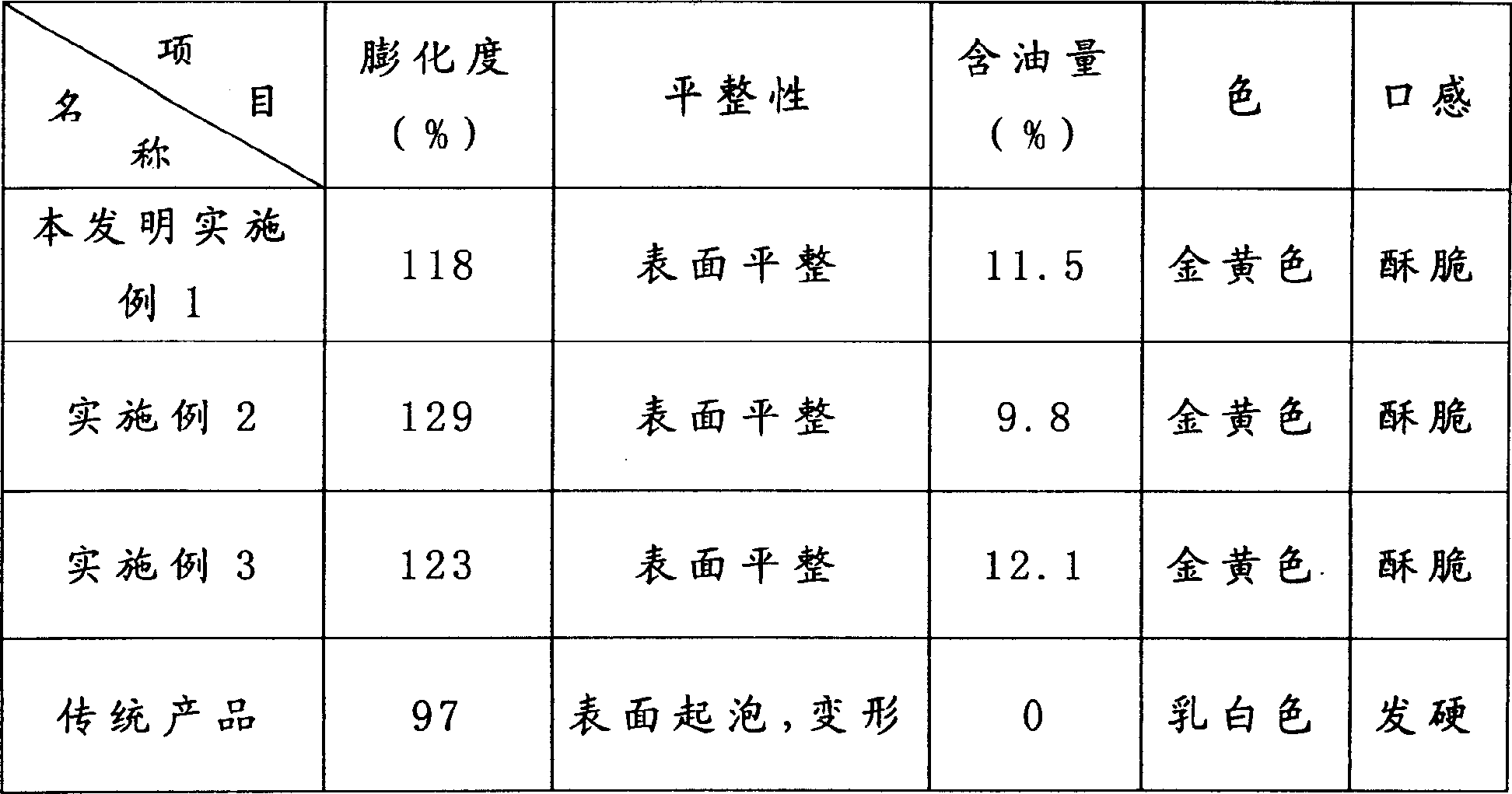

[0030] The above-mentioned embodiment gained finished product and the finished product comparison result of traditional microwave technology are shown in Table 1:

[0031]

[0032] The mouthfeel column in the above table is the evaluation result of a 5-person panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com