Patents

Literature

80results about How to "Short maturation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potato crisp utilizing micro wave processing and its processing method

InactiveCN1891072AEasy to storePreserve nutrientsFood preservationFood preparationChipped potatoesMicrowave

The present invention discloses a kind of potato crisps processed by microwave and its processing method. Said processing method includes the following steps: washing potato flakes, scalding said potato flakes in boiling edible salt water, cooling, draining, freezing, drying, adding palm oil and egg yolk powder, mixing them with potato flakes, uniformly stirring them, roasting them by using microwave and spraying flavouring material so as to obtain the invented product.

Owner:HUNAN AGRICULTURAL UNIV

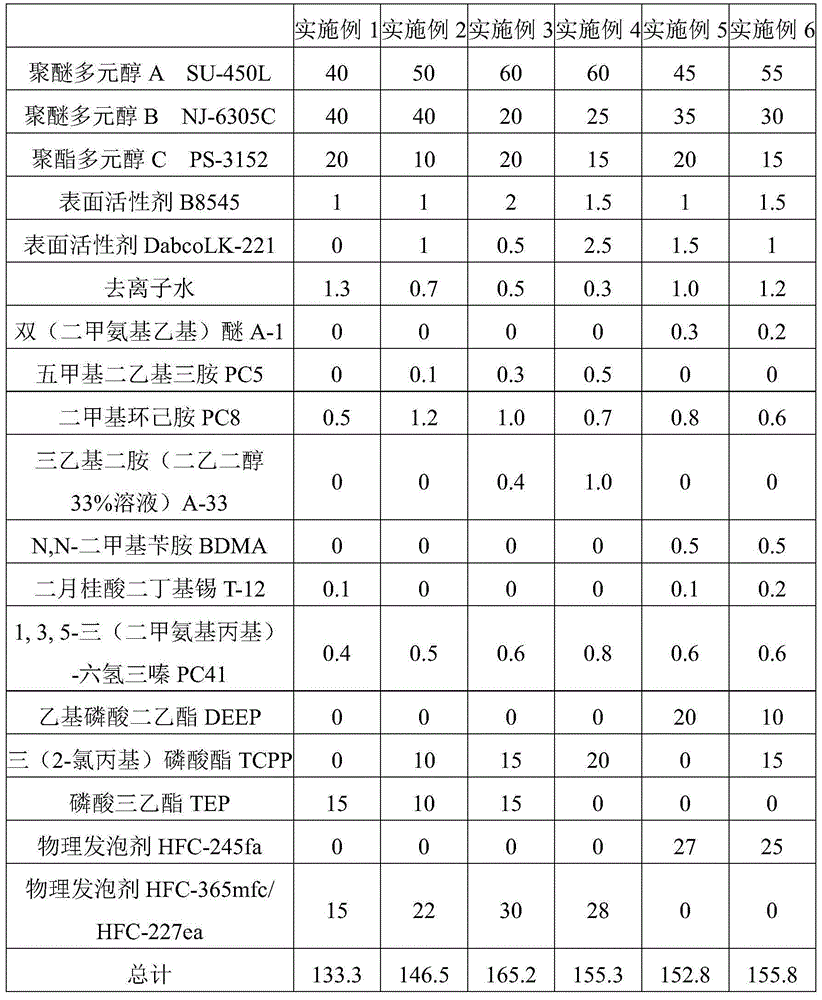

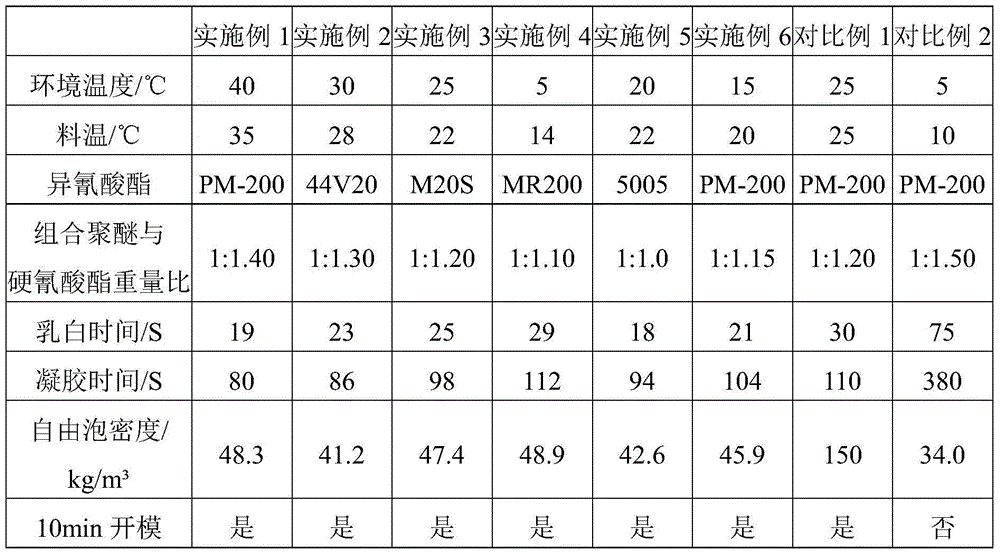

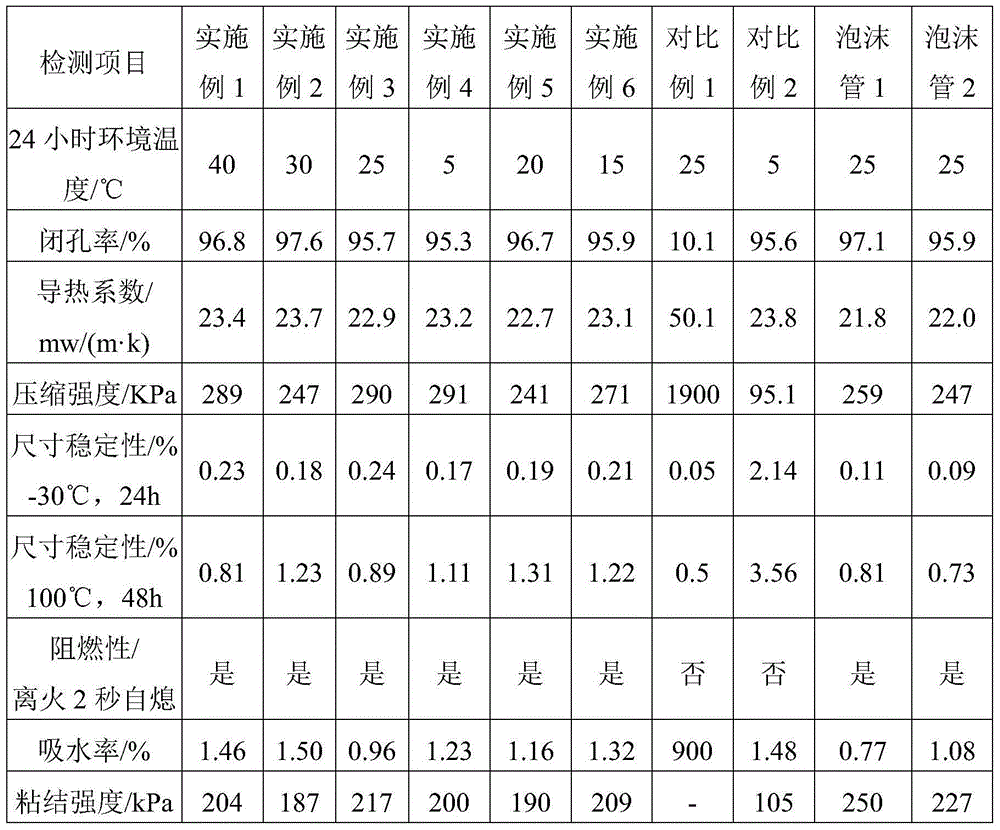

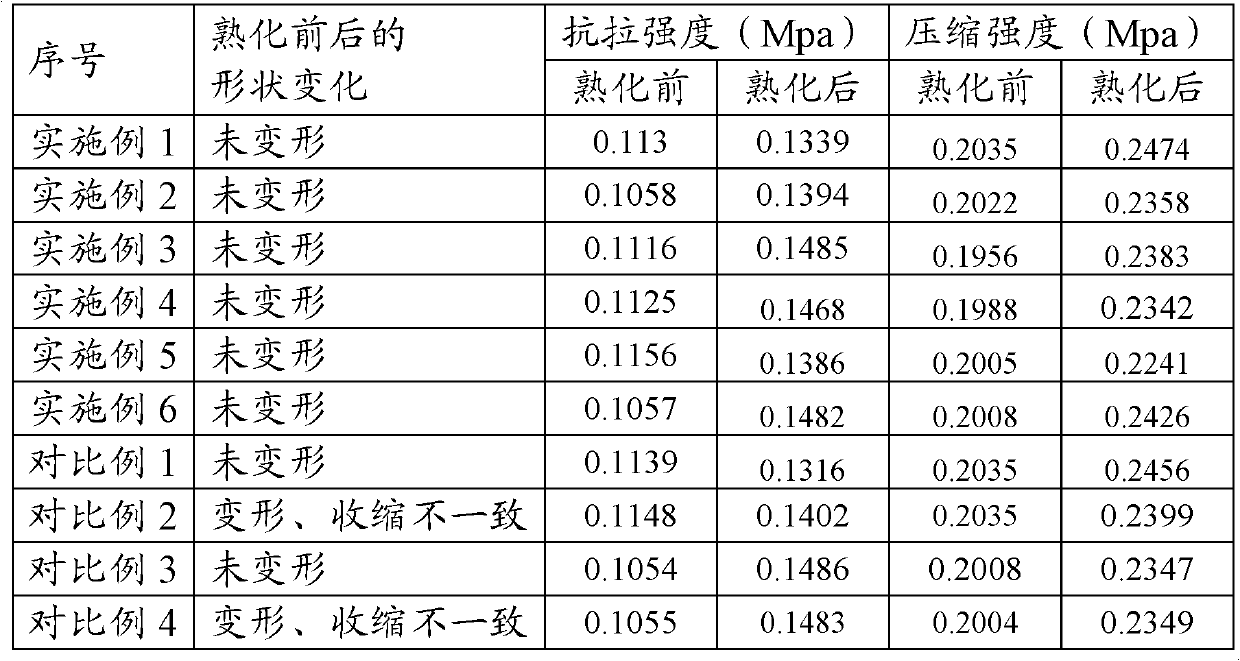

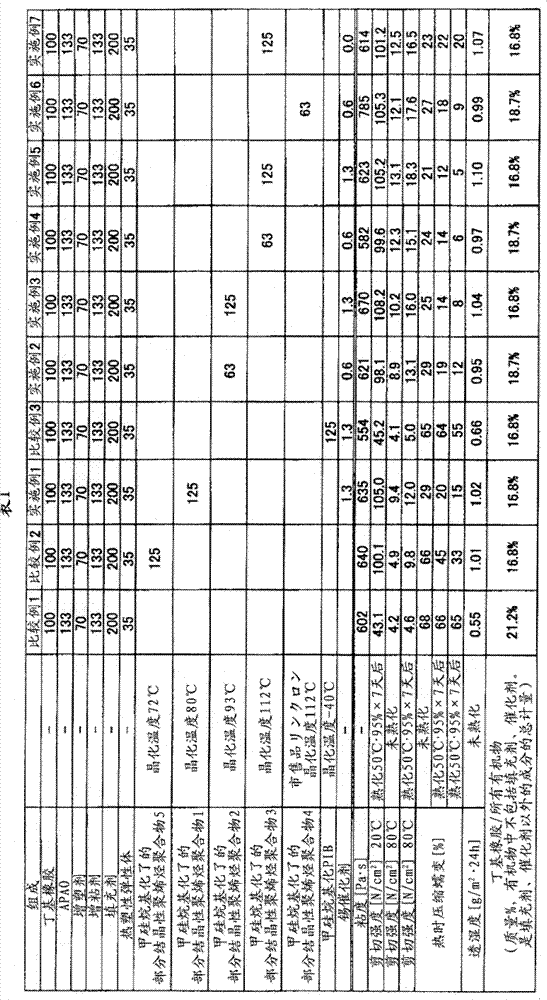

Combined polyether, raw material composition, polyurethane foam as well as preparation method and application thereof

ActiveCN104592471ALow thermal conductivityHigh compressive strengthThermal insulationPipe protection by thermal insulationPolyesterPolyol

The invention discloses combined polyether, a raw material composition, polyurethane foam as well as a preparation method and application thereof. The combined polyether comprises the following components in parts by weight: 100 parts of polyol, 1-4 parts of a surfactant, 0.3-1.3 parts of a chemical foaming agent, 1-3 parts of a catalyst, 15-30 parts of a flame retardant and 15-30 parts of a physical foaming agent, wherein polyol is a mixture of 40-60 parts of polyether polyol A, 20-40 parts of polyester polyol B and 10-20 parts of phthalic anhydride polyol. The foam has the advantages of excellent comprehensive property, low cost, a certain thermal insulation fire-retardant property and is simple in preparation method, safe to operate and wide in application range, high in construction and foam curing speed and short in time from mixing to foam molding curing ( only 10 minutes) and can be used in high-temperature, wind, cold and other 5-40 DEG C terrestrial environments.

Owner:SHANGHAI DONGDA POLYURETHANE

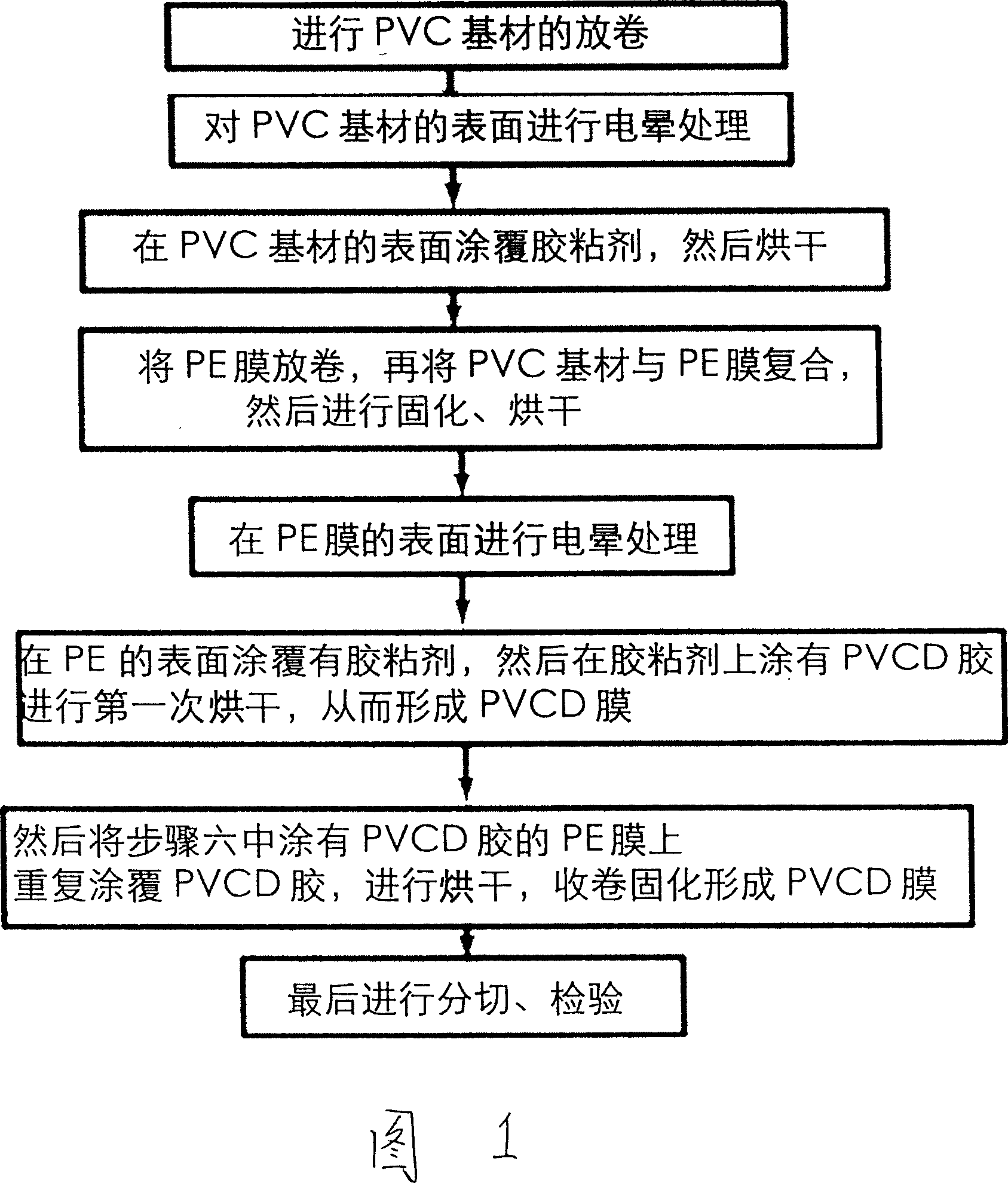

Technology for preparing high-separation, low solvent residue and low resolving-out matter PVC/PE/PVCD solid medicinal composite hard sheet

InactiveCN101024325ASolvent resistantUV resistantLamination ancillary operationsSynthetic resin layered productsManufacturing technologyAdhesive

The invention discloses PVC / PE / PVCD solid medicine using composite hard sheet manufacturing technology. It includes the following steps: unreeling for PVC basis material; corona treatment for its surface; coating adhesive; drying; unreeling for PE film; compositing the PVE basis material and PE film; solidifying; dying; corona treatment for the PE film surface; coating adhesive; coating PVCD glue; drying to form PVCD film; repeating coating the PVCD glue on the PE film; drying; rolling, solidifying to form PVCD film again; patting cut and detecting.

Owner:徐小圣

Low quantitative coating type food package raw paper, and preparation method thereof

The invention discloses a low quantitative coating type food package raw paper, and a preparation method thereof. The preparation method comprises following steps: firstly, cationic starch is added into a PCC suspension solution, uniform mixing is carried out, then gelatinization is carried out so as to form a partically-crosslinked gel substance, and normal temperature cooling and dispersion treatment are carried out so as to obtain a starch coated PCC filling material; bleached sulfate softwood pulp, and bleached sulfate hardwood pulp are subjected to mixing pulping, the starch coated PCC filling material, a wet strength agent, a sizing agent, and a retention agent are added, and concentration adjusting, slag removing, and sieving are carried out so as to obtain a slurry for wet loadingpaper making; the slurry is subjected to fourdrinier dehydration moulding and squeezing, and pre-drying; and at last, paper surface glue applying, soft calendaring, and rolling are carried out to obtain a finished product. According to the preparation method, no expensive titanium dioxide is adopted as a filling material, production cost is low, the retention rate of the filling material and finefiber is high, environment pollution caused by white water discharge is reduced, the obtained paper is uniform, full width tightness is constant, paper surfaces are flat and fine, surface strength andwet tensile strength are high, and water based coating quality requirements are satisfied.

Owner:ZHEJIANG HENGDA NEW MATERIAL CO LTD

Fast food rocessing method for fresh chilled vegetables by microwave curing

InactiveCN102845691AGuaranteed FreshnessKeep the tasteFood preparationMicrowave ovenMicrowave curing

The invention discloses a fast food rocessing method for fresh chilled vegetables by microwave curing. The method comprises the following steps of: a, cleaning raw materials, b, cooking sauce, c, treating by boiled water, d, pouring sauce, e, cooling, f, subpackaging, g, refrigerating and transporting, and h, curing by microwave: cooking for 18s to 22s by the microwave at the cooking temperature of 92 DEG C to 98 DEG C by using a microwave oven. The fast food rocessing method for fresh chilled vegetables by microwave curing, provided by the invention, has the advantages that the microwave cooking speed is high, the cooking efficiency is high, the vegetable is unlikely to turn yellow, the color of the fast food is bright, the pleasant taste of the vegetable is maintained, the taste is authentic, and only a small part of nutrition is lost.

Owner:深圳市慈浩餐饮科技有限公司

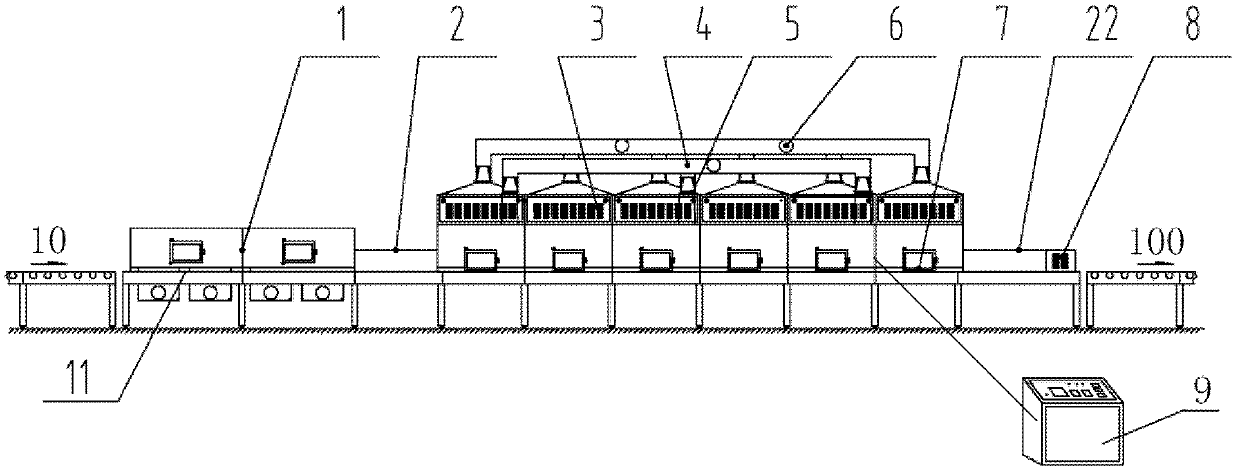

Method and equipment for curing phenolic aldehyde foam material

The invention discloses a method and equipment for curing a phenolic aldehyde foam material. The method for curing the phenolic aldehyde foam material comprises the steps of radiating the phenolic aldehyde foam material to be cured by using microwaves and cooling the phenolic aldehyde foam material. The equipment for curing the phenolic aldehyde foam material has the advantages that moisture, residual foaming agents and formaldehyde inside the phenolic aldehyde foam material are evaporated rapidly, and a chemical reaction inside the phenolic aldehyde foam material is greatly accelerated, so that the curing time is shortened. The microwaves are penetrable, so that the surface and inside of the phenolic aldehyde foam material are subjected to microwave radiation at the same time; and polar molecules absorb the energy of electromagnetic waves and generate uniform heat, so that the product quality is guaranteed, and the phenomenon that the phenolic aldehyde foam material shrinks discordantly, cracks or deforms is avoided.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

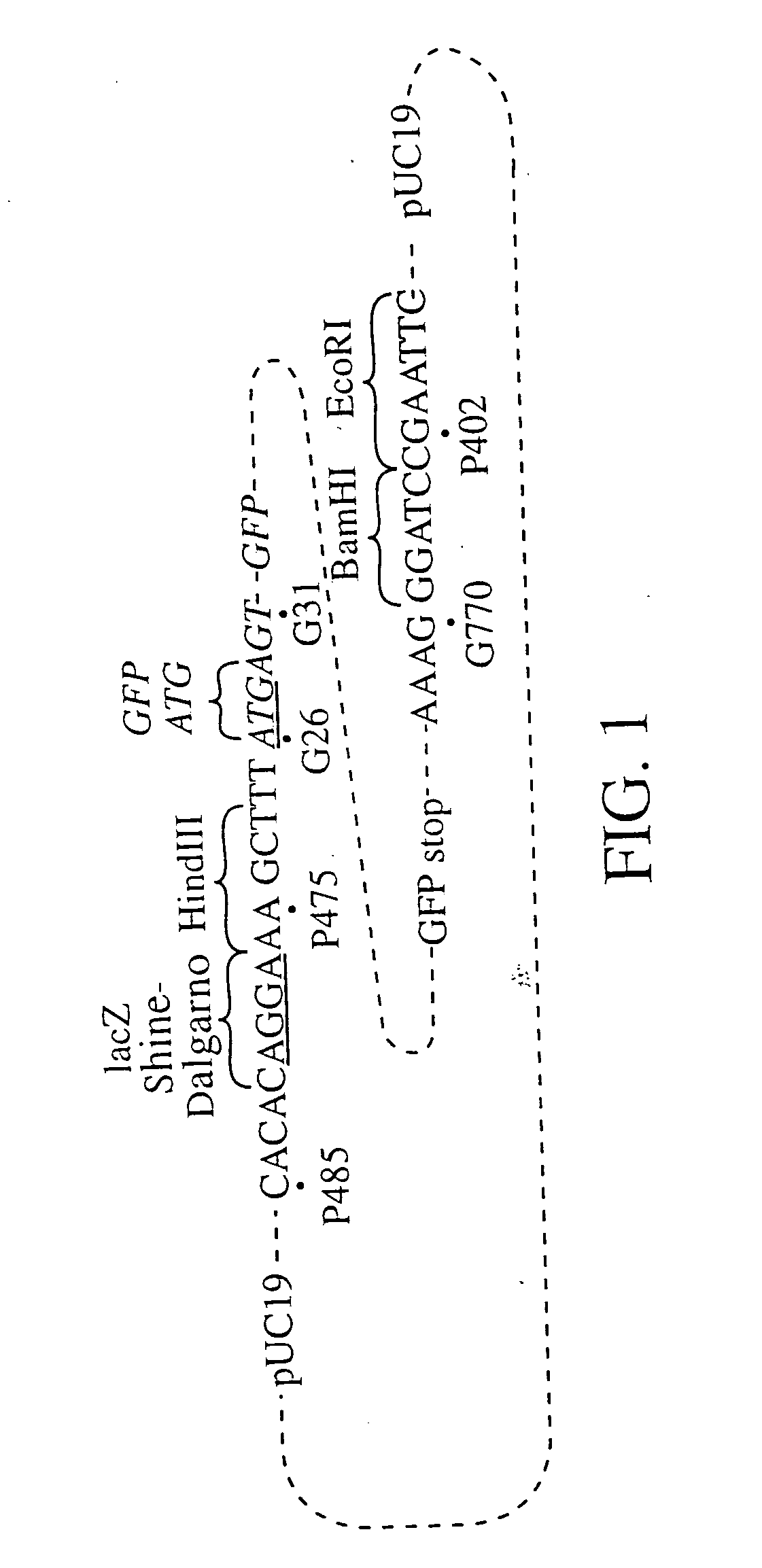

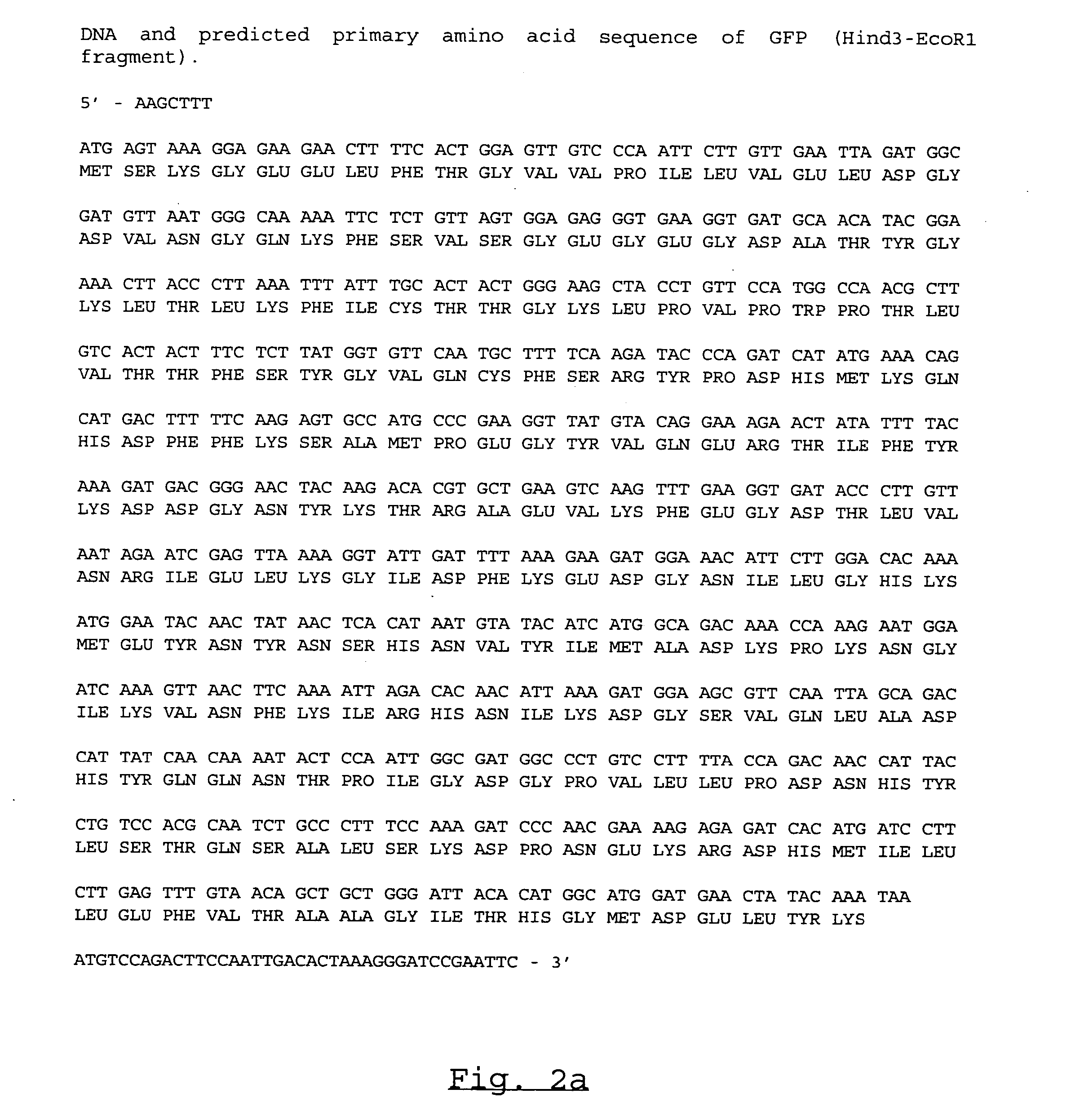

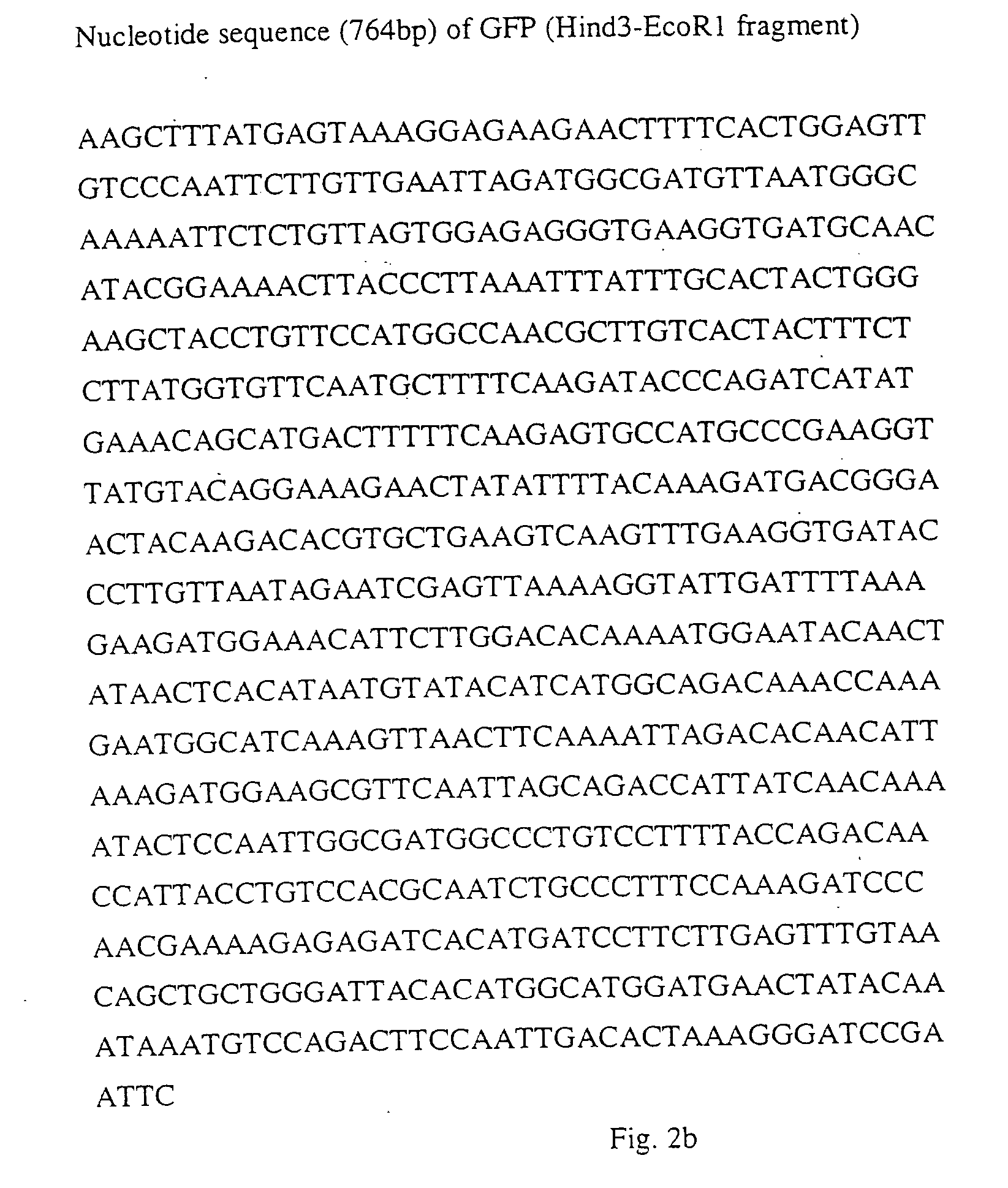

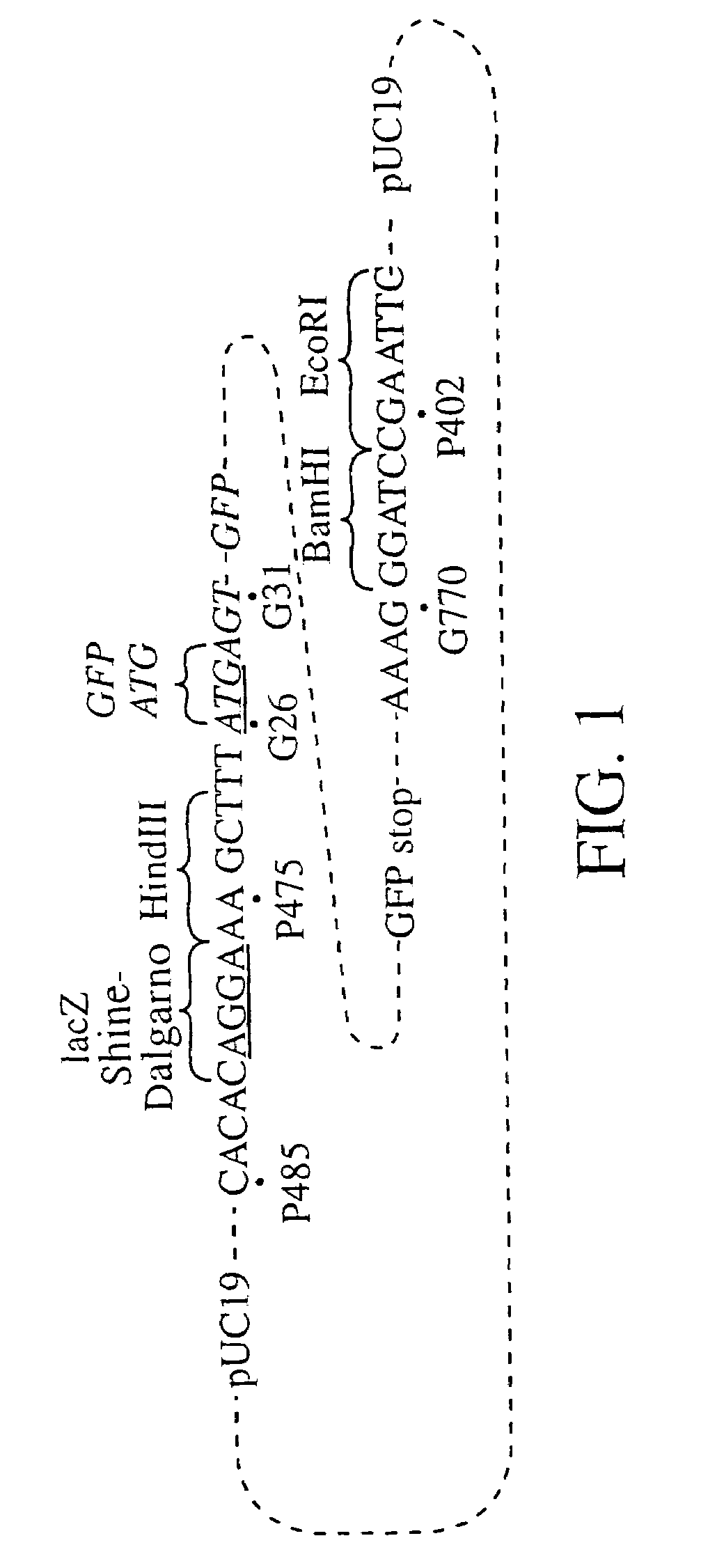

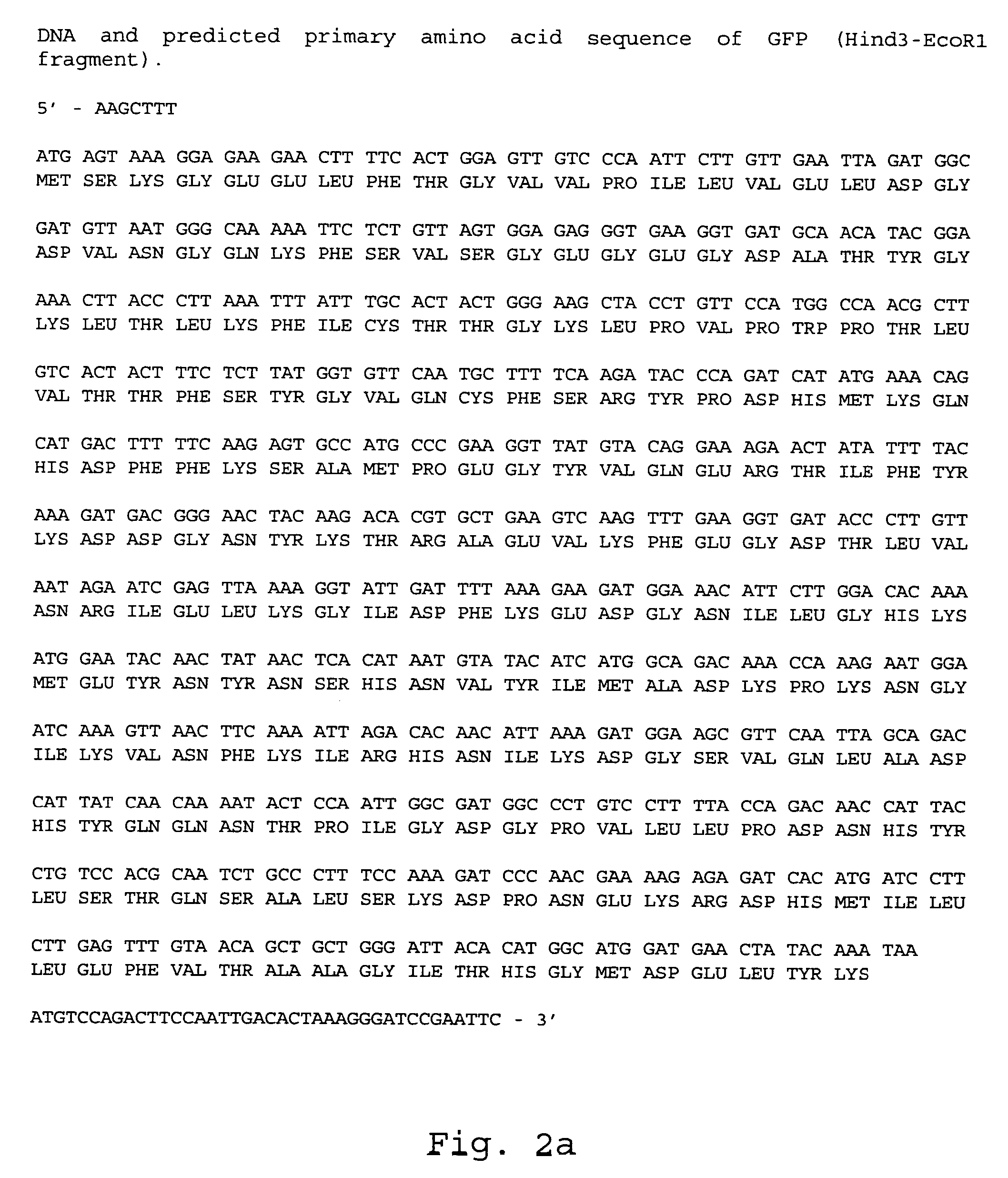

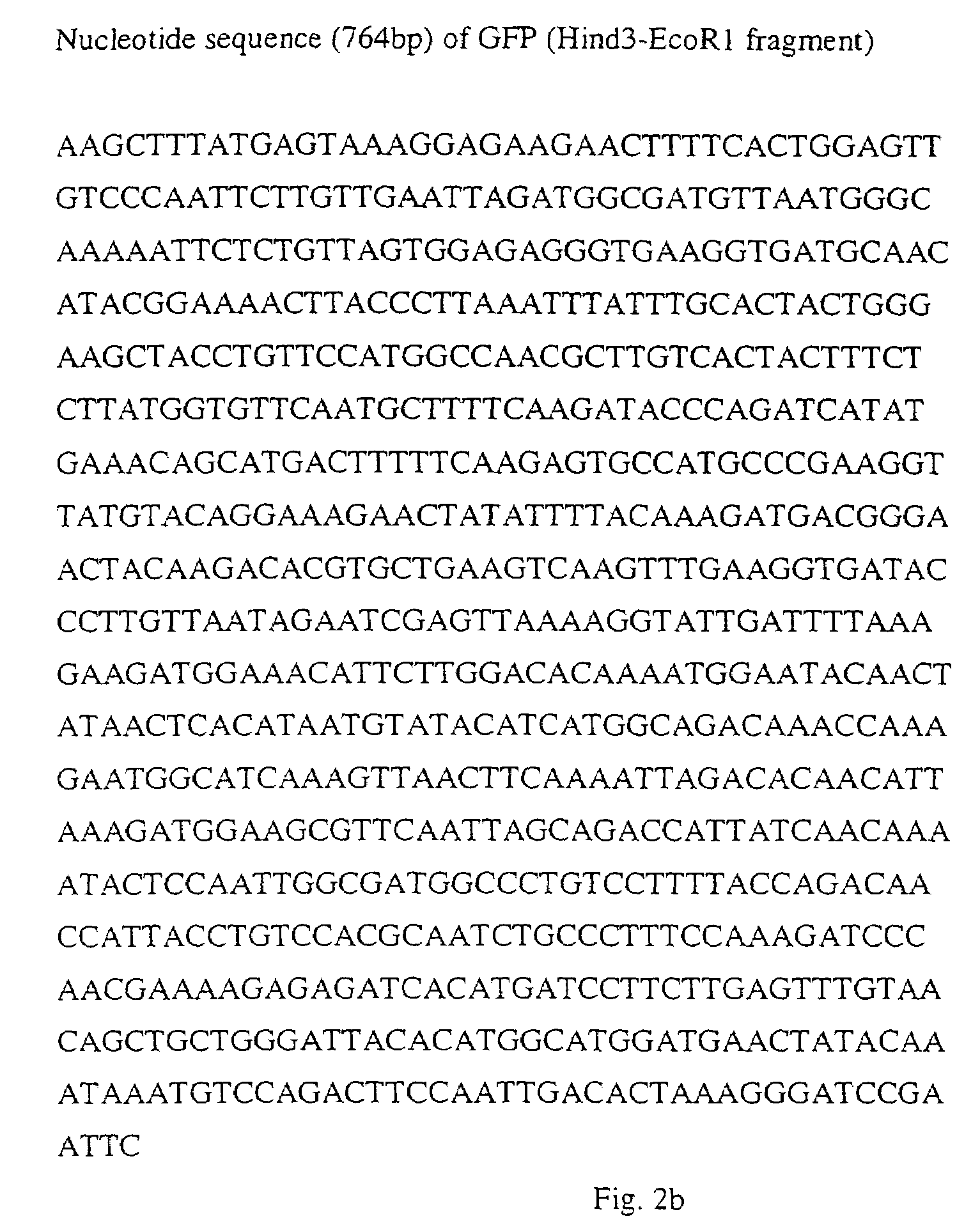

Novel fluorescent proteins

InactiveUS20050054050A1Improve practicalityEasy accessFungiBacteriaFluorescenceCombinatorial chemistry

The present invention relates to novel variants of the fluorescent protein GFP having improved fluorescence properties.

Owner:FISHER BIOIMAGE

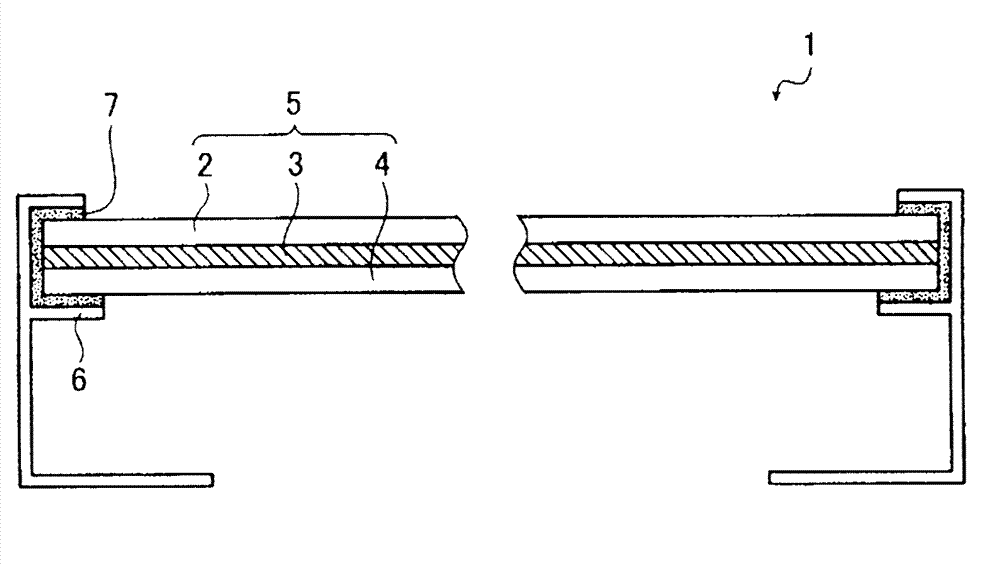

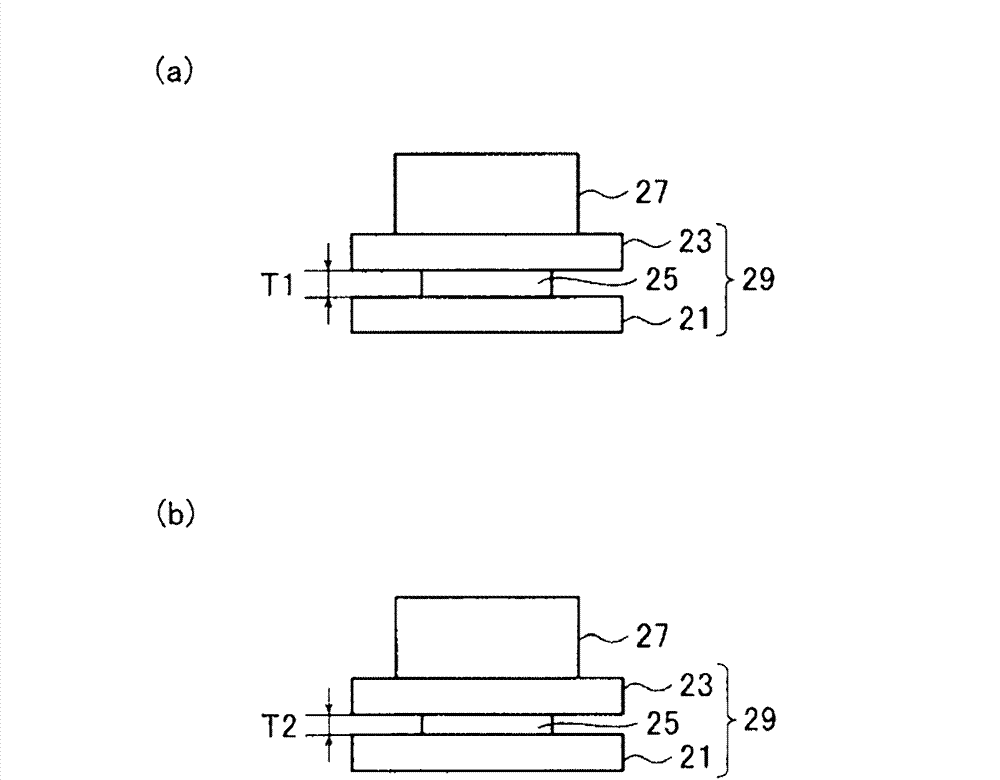

Reaction type hot melting sealing agent composition for solar cell

InactiveCN102786896AImprove heat resistanceShort maturation timeOther chemical processesAdhesivesPolyolefinHeat resistance

The invention provides a reaction type hot melting sealing agent composition for a solar cell advantaged by excellent heat resistance and short curing time. The invention provides a reaction type hot melting sealing agent composition for a solar cell comprising butyl rubber and a part of silylanizing crystalline polyolefin polymers with the crystalline temperature of 80-130 DEG C, and provides a solar cell module using the reaction type hot melting sealing agent composition for the solar cell to bond a cell and a frame.

Owner:THE YOKOHAMA RUBBER CO LTD

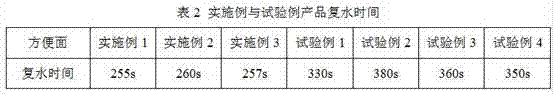

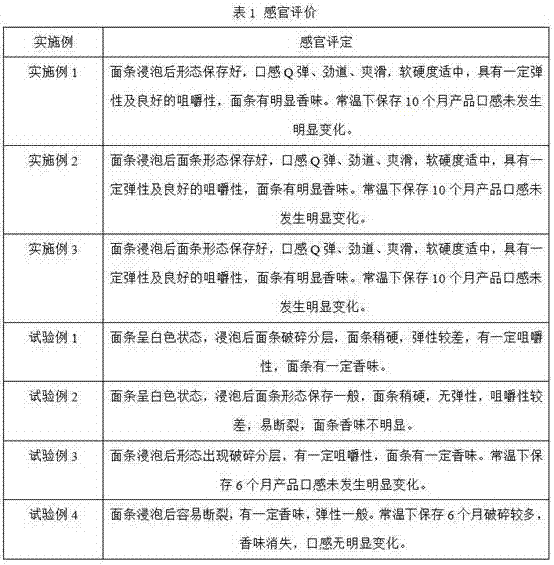

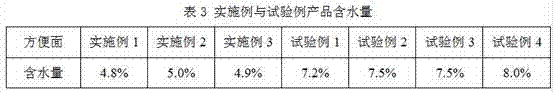

Non-fried instant wide noodle and preparation method of same

InactiveCN107279725AFast water absorptionBright colorFood preservationDough mixing/kneading machinesAge methodWheat gluten

The invention discloses a method for producing non-fried instant wide noodles through a screw extrusion heat-aging method. The non-fried instant wide noodles is prepared from 70-80 parts of flour, 20-25 parts of drinking water, 1-3 parts of wheat gluten, 1-2 parts of salt, and 0.1-0.25 parts of dietary alkali. The method includes the steps of: fully kneading the raw materials through a high-speed stirring and kneading apparatus to make dough and transporting the dough into a screw extrusion aging device to further stir the dough, and heat and age the dough and pre-shape noodles; performing sectional low-temperature hot air drying to the shaped noodles in an automatic hot air drying manner, and performing hot-shrink-packaging to obtain a finish product. The non-fried instant wide noodles produced through the screw extrusion aging and shaping method is tough and chewy, contains less fat and completely remains nutritional substances, has good rehydration effect and is low in breaking rate, is free of being mixed with soup, and has long shelf life. The method is simple in operations and achieves automatic, standardized and large-scale production.

Owner:四川白家阿宽食品产业股份有限公司

Composite sizing agent for coating paper in machine and sizing method

ActiveCN101381974APromote absorptionImprove qualityWater-repelling agents additionPolystyreneWater resistant

The invention provides a composite sizing agent for coating paper in a machine and a sizing method. The composite sizing agent comprises the following compositions in weight percentage: 5 to 20 percent of an alkyl ketene dimer neutral sizing agent, 0.1 to 5.0 percent of a polystyrene acrylic acid emulsion, 0.1 to 5.0 percent of a polystyrene acrylic ester emulsion, 0.1 to 5.0 percent of polyaluminium chloride and the balance being water. Through controlling the water resistant and liquid resistant performances of base paper, the method improves the absorption to painting in the paper coating process, achieves the aim of improving the quality of coating paper after the coating paper is coated and improving the competitiveness of a product on the market. The sizing method has the advantages of simple operation, low cost and considerable application prospect. Compared with the prior art, the sizing method also has the advantages of short curing time and small amount for a sizing paper sample and the like.

Owner:SHANGHAI DONGSHENG NEW MATERIALS +1

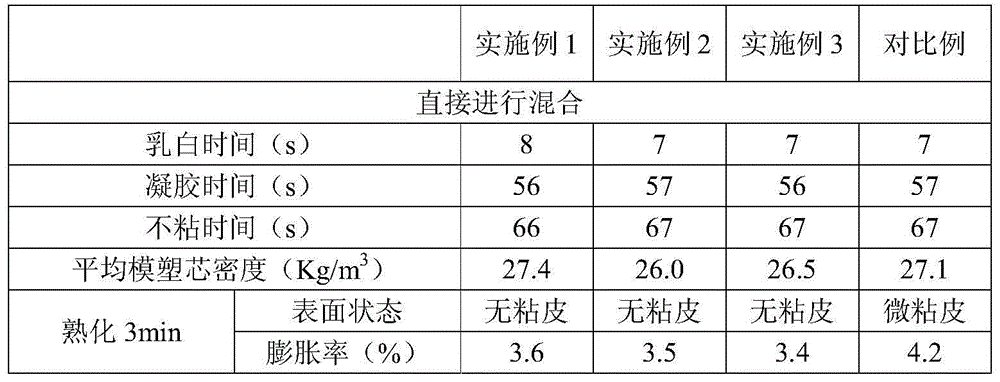

Composition, rigid polyurethane foam material and refrigeration device

The invention discloses a composition, rigid polyurethane foam and a refrigeration device. The composition comprises combined polyether and isocyanate, wherein the combined polyether contains polyol, a foaming agent and a catalyst composition, wherein the foaming agent contains trans-1-chloro-3, 3, 3-trifluoropropene, and the catalyst composition contains N-methyldicyclohexylamine, N, N-dimethylcyclohexylamine and (2-hydroxypropyl) trimethylammonium formate. The composition has long-term storage stability; and furthermore, the foam material obtained by adopting the composition has the characteristics of low heat conduction coefficient, high strength, short curing time and the like, so that an obtained product has a relatively good energy-saving effect.

Owner:HEFEI HUALING CO LTD

Sweet peppery taste salted egg and its production method

A salted egg is prepared from eggs of fowls, liquor with high alcohol content, white sugar, hot pepper and flavouring through boiling eggs, adding white sugar and said liquor, loading the eggs and soup in a ceramic container, sealing and preserving.

Owner:TIANJIN CHINESE & BRITISH NANOMETER TECH DEV

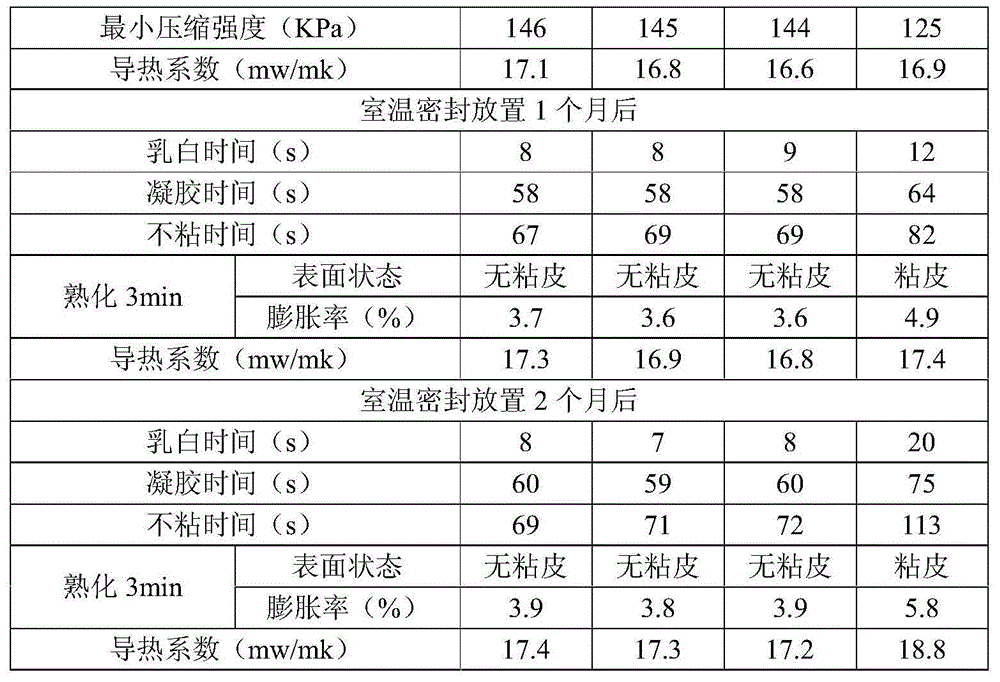

Method for producing feed grade calcium hydrophosphate

The invention discloses a method for producing feed grade calcium hydrophosphate III. The method comprises the steps as follows: slag field tank water and lime milk are mixed in a reactor and defluorinated, and after the obtained slurry is deposited, an supernatant liquid and the lime milk react in the reactor to obtain feed grade calcium hydrophosphate I, then react with phosphoric acid, and are dried, filtered and separated to obtain feed grade calcium hydrophosphate III. Compared with other methods of preparing feed grade calcium hydrophosphate III with wet process phosphoric acid, the method produces the feed grade calcium hydrophosphate I by utilizing phosphogypsum slag filed tank water with a low phosphorous content, treating and improving the content of the phosphorus are needless, the feed grade calcium hydrophosphate I can be directly produced only after purity removal, the product process is simple, and the phosphorus resource can be effectively reused. Moreover, the method is short in curing time, easy to control the process, and free of waste discharge during the whole process.

Owner:WENGFU (GRP) CO LTD

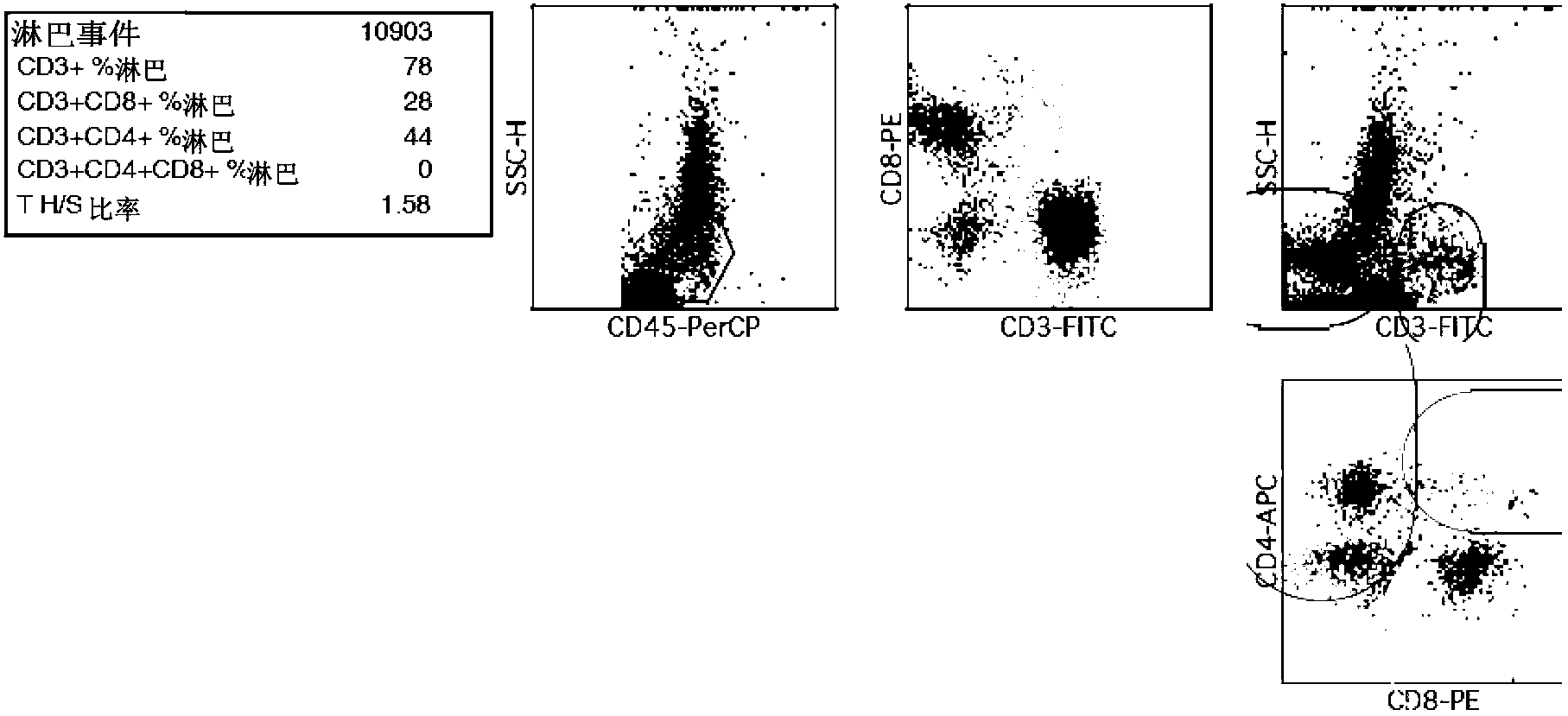

Method for in-vitro culture of killer T cells

ActiveCN103013914AHigh kill rateShort maturation timeBlood/immune system cellsLymphocyteBiological Immunotherapy

The invention relates to a method for in-vitro culture of killer T cells. Specifically, IL-2 and an anti-CD3 monoclonal antibody are combined with indigowoad leaf decoction for costimulation of lymphocytes taken from 50ml of in-vitro blood so as to get the T cells with cytotoxin activity by induction; and the T cells with the cytotoxin activity, which are obtained by an induction culture method, have the advantages of large proliferation number and good vitality, and the number of the CD8-positive T cells can be increased from 20%-30% to 80%-90%. Simultaneously, the method disclosed by the invention has the advantages of low taking quantity of the blood, simple operation steps, low cost of a reagent and short maturation time of the cells, above 1*10<9> cells can be achieved by 8 days and used for performing continuous intravenous infusion on a patient six times, and above 1*10<9> cells can be infused every time. The method is suitable for a clinical biological immunotherapy of the patients with tumors and can be widely popularized and applied.

Owner:JILIN TUO HUA BIOTECH

Catalytic purification composite material and preparation method and application thereof

ActiveCN106582701AShort maturation timeImprove catalytic degradation efficiencyOther chemical processesWater contaminantsPorous carbonImpurity

The invention provides a catalytic purification composite material and a preparation method and application thereof. Activated carbon loaded manganese sand particles are used as a basic framework of the material, and mixed metal oxides as active components are loaded on the outermost layer of the framework. The preparation method of the material comprises the following steps: pretreating manganese sand and removing impurities on the surface of the manganese sand; taking wooden activated carbon or shell activated carbon as an activated carbon precursor; roasting in an inert atmosphere; preparing a porous carbon structure which uses the manganese sand as a framework; and modifying the surface of the manganese sand-porous carbon structure by using the metal oxides to form the novel composite purification material with adsorption and electro-catalyst composite functions. When the catalytic purification composite material is used, the composite material effectively adsorbs and catches low-concentration organic matters in micro-polluted raw water at first, so that pollutants are adsorbed on the surface of the material, then the composite material with adsorption saturation is guided into an electrolytic bath for electrochemical oxidation, the pollutants on the surface of the composite material are desorbed and decomposed, and are thoroughly mineralized into carbon dioxide and water, and meanwhile, recycling of the composite material is realized.

Owner:南京朗科环保科技有限公司

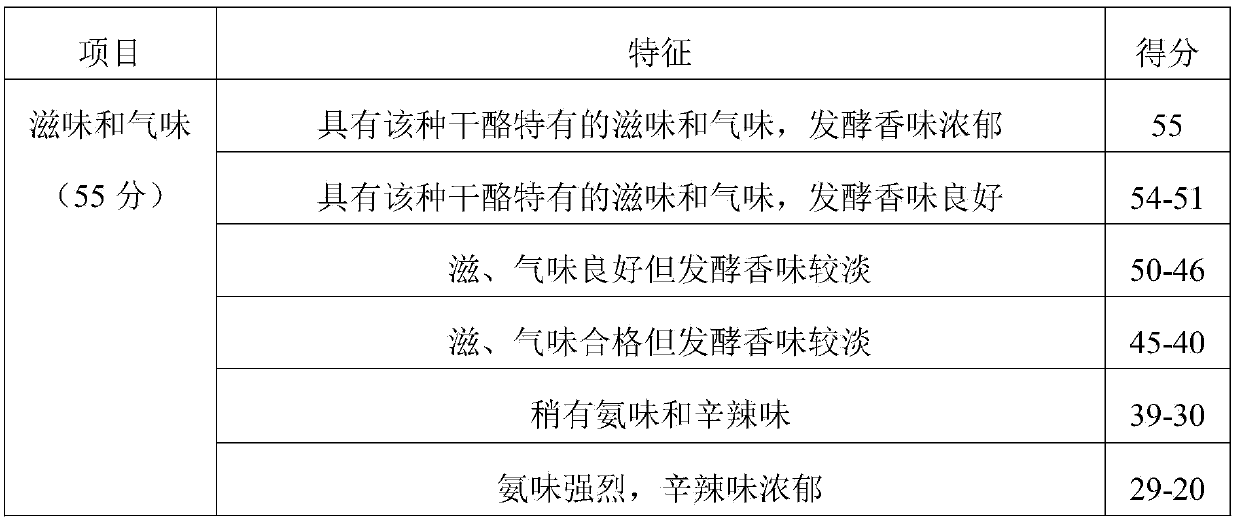

Preparation method of mold cheese

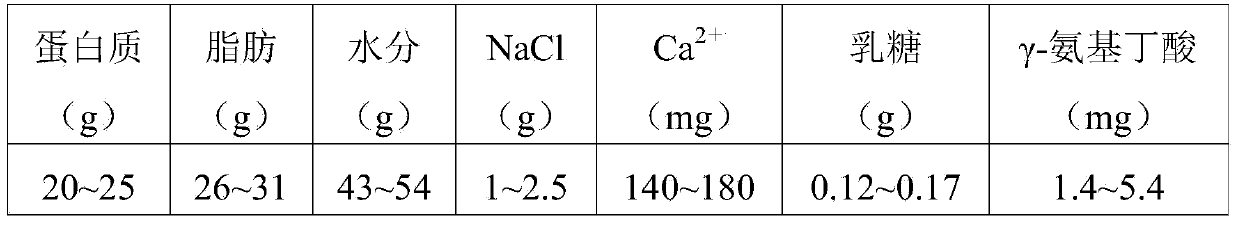

ActiveCN103734352AFlavor is easy to be accepted by consumersRich in nutritional valueCheese manufactureSporeAdditive ingredient

The invention discloses a preparation method of a mold cheese. The method comprises the following steps: (1) inoculating a lactic acid bacteria starter and a monascus spore solution in sterilized raw milk at the temperature of 28-32 EDG C, and carrying out acidizing fermentation until the pH value is 6.2-6.4; (2) adding chymosin, stirring for 5-10min, carrying out milk curding for 25-30min so as to obtain milk curd; (3) cutting the milk curd, stirring for 15-30min, so as to obtain a milk curd block; (4) carrying out whey removal on the milk curd block until the pH value is 5.4-5.8, adding salt, sizing in a die and overturning at fixed period; (5) inoculating a mucor spore solution, and maturing. The mold cheese prepared by adopting the method is soft, contains ingredients such as monacolin-K and gamma-aminobutyric acid, and has the functions of regulating blood fat, lowering blood pressure, controlling cholesterol, regulating human immunity, and the like; the preparation method disclosed by the invention can be conveniently applied to industrial generalization and production.

Owner:BRIGHT DAIRY & FOOD

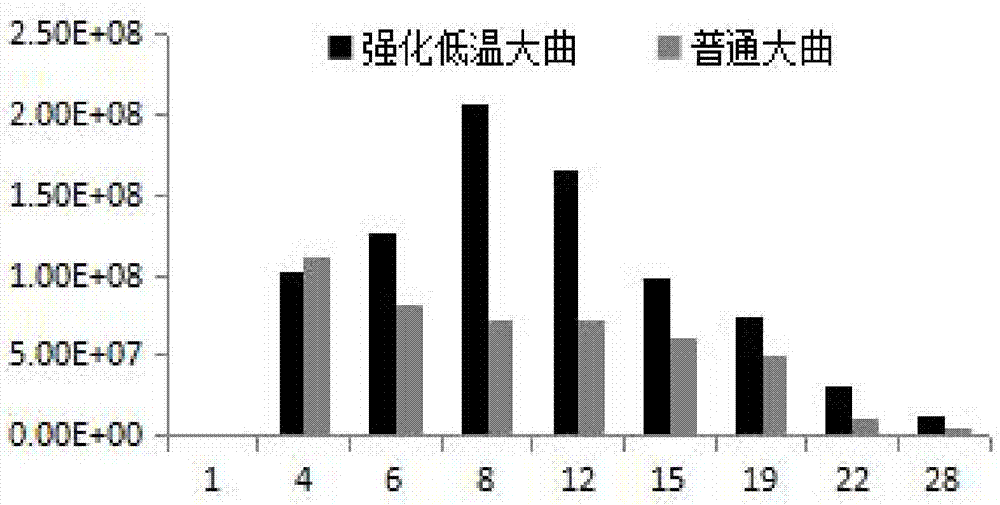

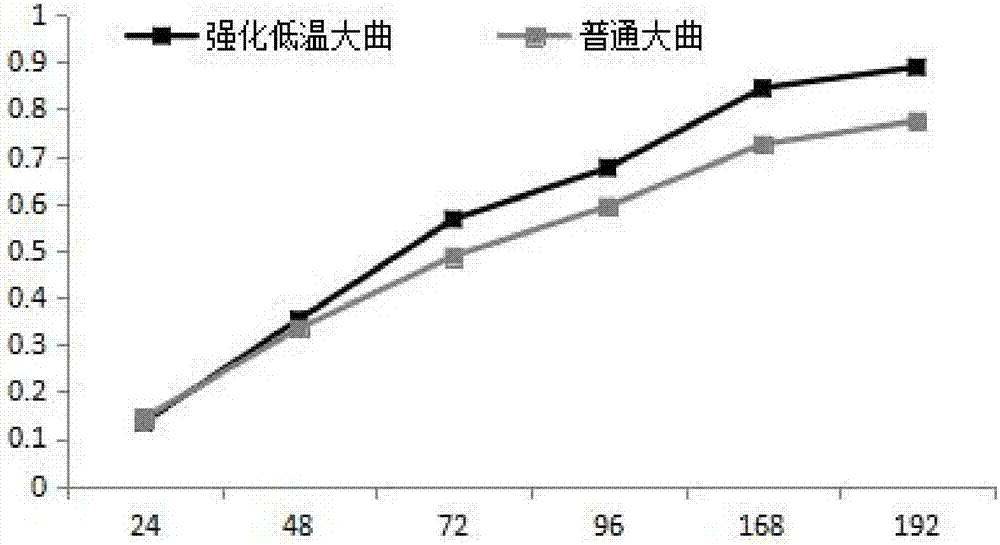

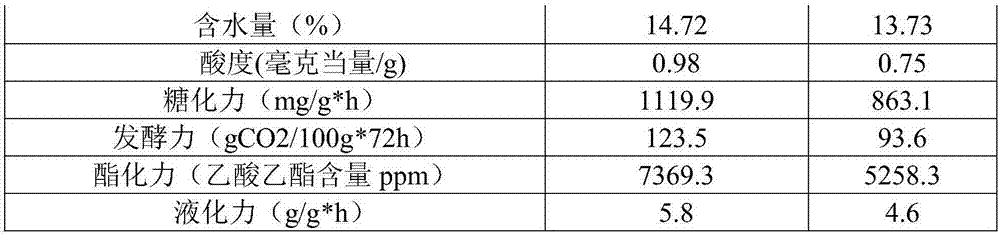

Wickerhamomyces anomalus GJYD15 and application of wickerhamomyces anomalus GJYD15 in preparing low temperature yeast

ActiveCN107488602APromote growthEasy temperature controlFungiAlcoholic beverage preparationYeastTemperature control

The invention discloses wickerhamomyces anomalus GJYD15 and an application of wickerhamomyces anomalus GJYD15 in preparing low temperature yeast and relates to the technical field of fermentation engineering. the low temperature yeast used for preparing faint scent flavor liquor is prepared by preparing a seed solution, a primary seed solution, a secondary seed solution and a tertiary seed solution containing the wickerhamomyces anomalus GJYD15 from the wickerhamomyces anomalus GJYD15, and performing raw material breaking, strain addition, yeast block preparation and room culture. Low temperature rack yeast preparation is adopted; at the same time, multiple grain proportions are used; the flavor formation of the yeast, strain growth and temperature control during yeast culture are more facilitated; a total bacteria count and biological diversity of the low temperature yeast prepared by a technology are increased and improved; an ester flavor of the yeast is obvious; the temperature of the yeast is increased relatively quickly; the problems of increase of a bitter taste of basic liquor and influence on the quality of the basic liquor caused by infection with infectious microbes such as hair moulds due to too slow temperature rise and long yeast preparation time in winter are effectively avoided; at the same time, the maturity time of the yeast is short; the production efficiency is improved; and the production cost is lowered.

Owner:ANHUI RUISIWEIER TECH

Novel fluorescent proteins

The present invention relates to novel variants of the fluorescent protein GFP having improved fluorescence properties.

Owner:FISHER BIOIMAGE

All-seawater larval rearing and indoor industrialized culture method for trachidermus fasciatus heckel

InactiveCN105557584AImprove farming outputImprove survival rateClimate change adaptationPisciculture and aquariaTrachidermus fasciatusBroodstock

The invention belongs to the technical field of fish breeding and culture. In order to overcome the technical defects in an existing larval rearing and culture method for trachidermus fasciatus heckel, the invention provides an all-seawater larval rearing and indoor industrialized culture method for trachidermus fasciatus heckel. The method comprises the following steps of (1) catching parent fishes; (2) rearing and acclimating the parent fishes; (3) performing spawning and fertilization; (4) performing incubation; (5) performing larval rearing; and (6) performing indoor industrialized culture of adult fishes. With the adoption of the technical scheme provided by the invention, the problem of reduced yield due to blocked migration route of trachidermus fasciatus heckel at present can be effectively solved; and through indoor industrialized artificial culture, the controllability of culture conditions is improved, the culture yield of the trachidermus fasciatus heckel is greatly increased, and the mariculture industry is promoted to develop in high yield, high quality and high efficiency.

Owner:RONGCHENG FISHERY TECH PROMOTION STATION

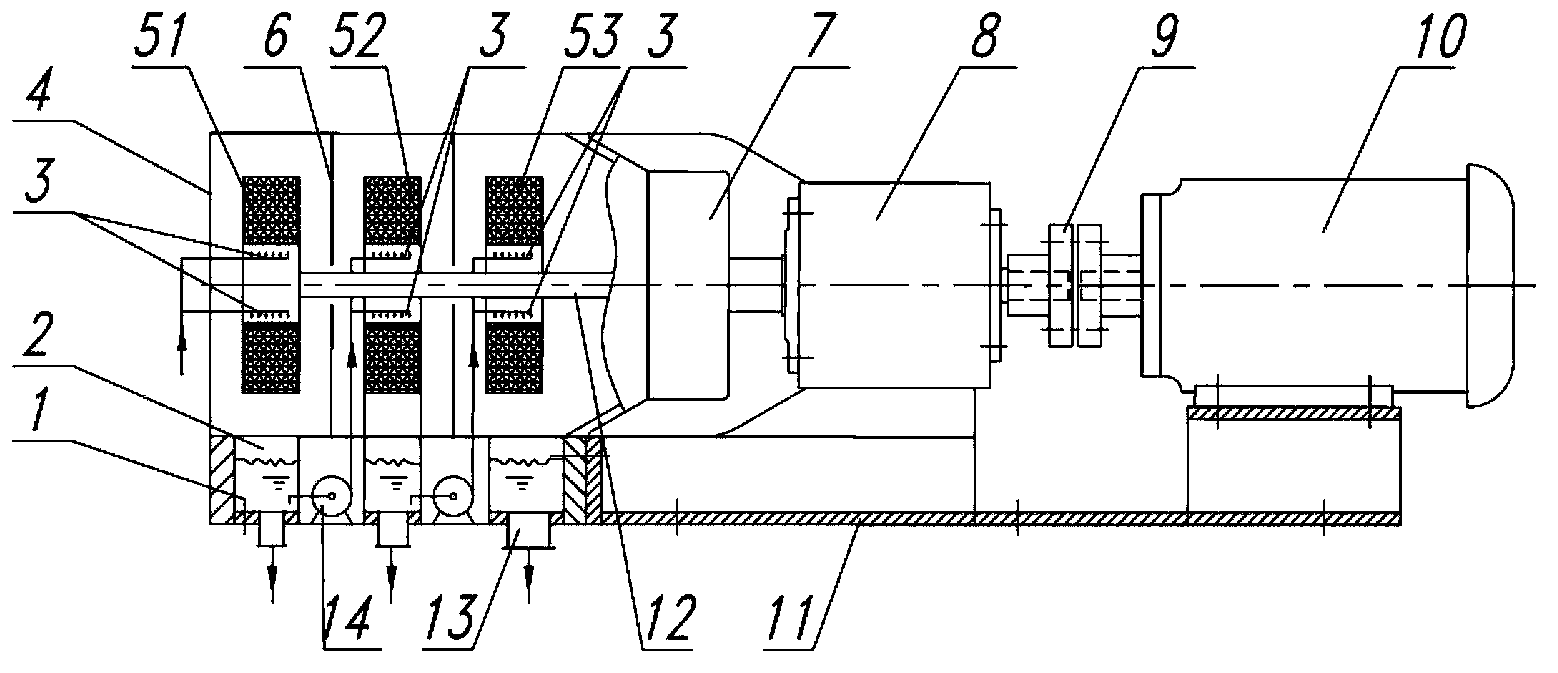

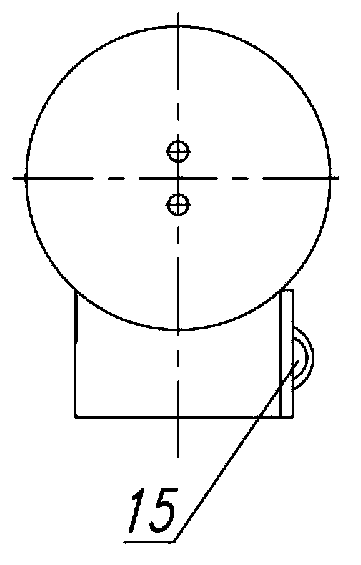

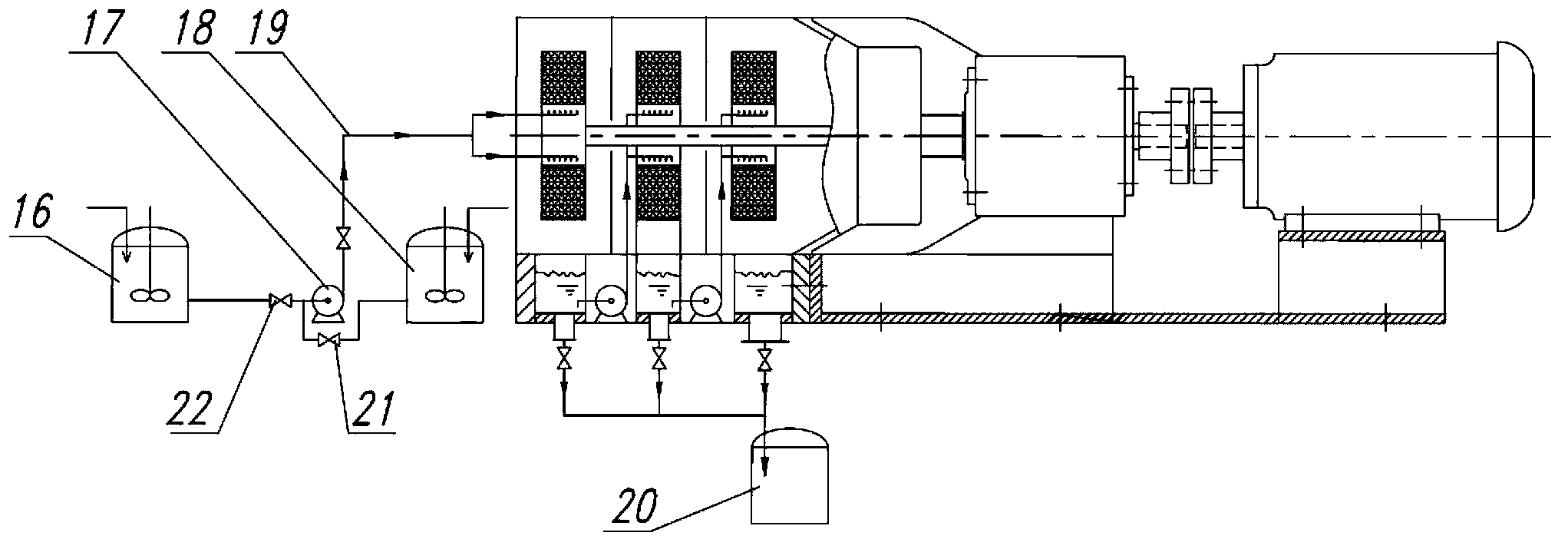

Revolving bed device and method for quickly mixing and dissolving polymers

ActiveCN103406035AReduce resistanceImprove efficiencyRotary stirring mixersDissolvingCouplingEngineering

The invention discloses a revolving bed device for quickly mixing and dissolving polymers. The revolving bed device comprises a motor, a coupling connected with an output shaft of the motor, a bearing pedestal fixedly connected with the coupling, a revolving bed housing fixedly connected with the bearing pedestal, and a sealing system, wherein a liquid inlet and a liquid outlet are formed in the revolving bed housing; at least two stages of rotors are arranged in the revolving bed housing; the liquid inlet is communicated with the inner edge of the rotors through liquid inlet spraying pipes; liquid storage cabins are correspondingly arranged below each stage of rotor; each stage of liquid storage cabin is communicated with an inlet end of a liquid inlet pump through a pipeline; an output end of the liquid inlet pump is communicated with the inner edge of the next stage of rotor through a spraying pipe; the liquid storage cabin below the last stage of rotor is connected with the liquid outlet; the sealing system is arranged between the last stage of rotor and the bearing pedestal. The revolving bed device has the advantages of short curing time, small occupied space, high efficiency and the like.

Owner:BEIJING UNIV OF CHEM TECH +1

Special organic fertilizer for meinong muskmelons and preparation method of special organic fertilizer

InactiveCN104725159AImprove water retentionImprove fat retentionBio-organic fraction processingAnimal corpse fertilisersBiotechnologyMicrobial agent

The invention discloses a special organic fertilizer for meinong muskmelons. The special organic fertilizer is prepared from the following raw materials in parts by weight: 10-15 parts of peanut cakes, 30-50 parts of pig manure, 12-16 parts of sesame seed cakes, 6-8 parts of cotton seed hulls, 4-6 parts of potassium fulvate, 5-6 parts of weathered coal, 4-5 parts of JT microbial agent, 5-8 parts of ammonium nitrate, 6-10 parts of ammonium phosphate, 3-5 parts of sweet potato stems, 6-7 parts of furfural residues, 4-5 parts of pine needle leaf powder, 4-5 parts of macrobrachium shells, 6-8 parts of potato starch, 4-5 parts of sodium sulfate, 30-40 parts of a soil conditioner and a proper amount of water. The fertilizer disclosed by the invention is prepared from a great number of organic matters serving as main raw materials so as to restore oil, maintain ecological capacity and enhance the water retaining, fertilizer retaining and fertilizer making functions of soil; meanwhile, all the raw materials are reasonably proportioned, so that all the components can more sufficiently take effects, and furthermore the fertilizer effect is higher; and the aims of reducing the product cost and increasing the economic incomes of fruit farmers because the raw materials are cheap and available are achieved on the premise of ensuring the fertilizer effect.

Owner:MAANSHAN QUANRUN AGRI SCI & TECH

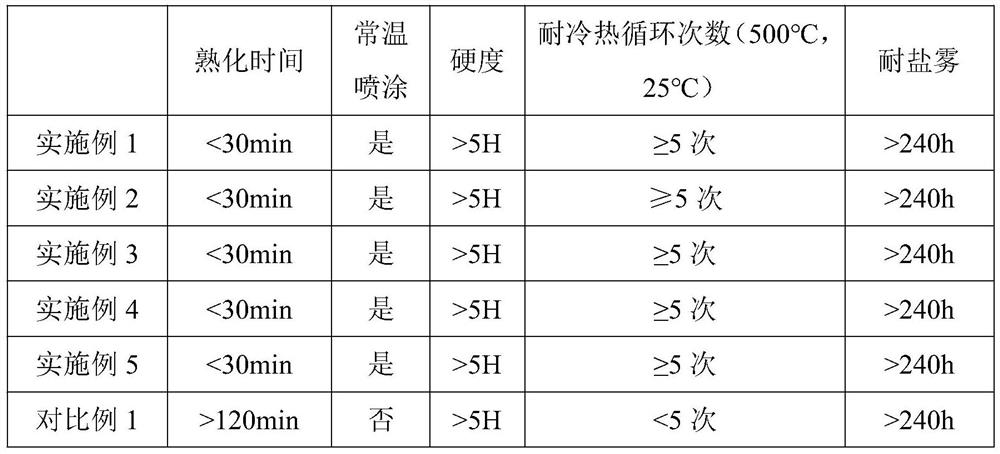

Water-based polysiloxane ceramic simulating coating

InactiveCN111909616AShort maturation timeSimple curing processAnti-corrosive paintsPtru catalystMetallic substrate

The invention relates to the technical field of coatings, in particular to a water-based polysiloxane ceramic simulating coating. The water-based polysiloxane ceramic simulating coating is composed ofa component A, a component B and a component C, wherein the component A is composed of water-based nano sol, filler, pigment, an anti-sagging agent, a leveling agent and a dispersing agent, the component B is a catalyst, the component C is a silane coupling agent, and the mass ratio of the component A to the component B to the component C is 10: (1-10): (0.1-5). The water-based polysiloxane ceramic simulating coating has the advantages of being good in stability before curing, simple in curing process, short in curing time, capable of being sprayed at normal temperature, long in shelf life after curing, resistant to hot and cold circulation, high in hardness, resistant to corrosion and the like, and can meet the requirement for long-term use of various metal base materials in complex andchangeable environments.

Owner:无锡米克新材料有限公司

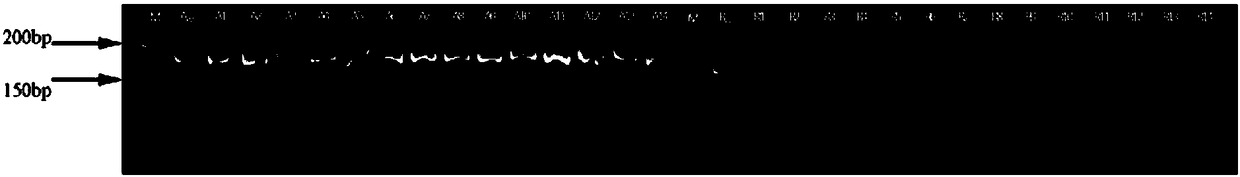

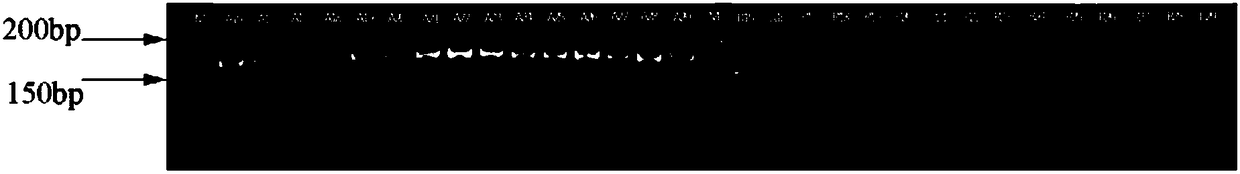

Primer pair, kit comprising same, application of primer pair and method for detecting medicago truncatula ecotypic A17 and R108

ActiveCN108411030AAvoid false positivesAvoid false negativesMicrobiological testing/measurementDNA/RNA fragmentationDNA fragmentationRepeatability

The invention provides a primer pair, a kit comprising the same, application of the primer pair and a method for detecting medicago truncatula ecotypic A17 and R108 and relates to the field of biotechnology. The primer pair comprises a primer NST480-F and a primer NST480-R, which have sequences separately shown as SEQ ID NO.1 and SEQ ID NO.2 and meanwhile can simultaneously amplify DNA (deoxyribonucleic acid) fragments of different lengths of the medicago truncatula ecotypic A17 and R108, so that a user can distinguish whether a sample to be detected contains the medicago truncatula ecotypic A17 and R108 through one amplification. When applied to detecting the medicago truncatula ecotypic A17 and R108, the primer pair has the advantages of being high in sensitivity, accuracy and repeatability, rapid, convenient and the like and solves the problem that the prior art lacks a rapid and accurate method for detecting and identifying the medicago truncatula ecotypic A17 and R108.

Owner:LANZHOU UNIVERSITY

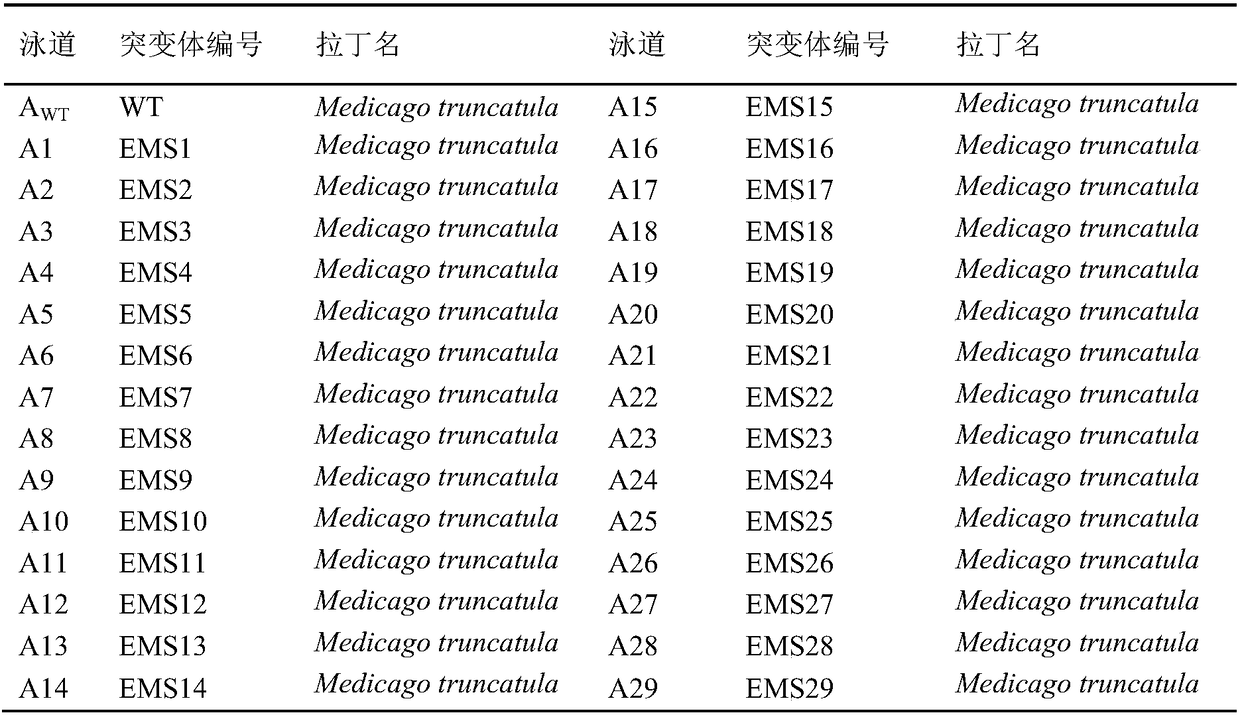

Processing method beef squid salad salami

InactiveCN102415583AImprove organizational structureResidue reductionFood preparationHigh fatFood flavor

The invention provides a processing method of beef squid salad salami. The method comprises steps of: raw material pretreatment, acerbity removal treatment on peeling squid by a sodium bicarbonate solution, beef preserving by a dry preserving method, meat rubbing, chopping, loading, fermentation, sausage sootiness, drying, vacuum package and low temperature storage. The method of the present invention overcomes disadvantage of high fat content in fermented meat product, improves disadvantage of single flavor and develops a beef squid salad salami with characteristics of short maturation time, high safety, low fat, high protein, abundant nutrition and suitability for taste of consumers in our country.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Single-waterproof temperature-sensitive label-use paper

InactiveCN103132373AShort maturation timeShort waterproof functionSpecial visual effect coatingsCoatingsProcess engineeringPolycarbonate

The invention provides a single-waterproof temperature-sensitive label-use paper which is characterized in that the label-use paper is composed of the components of a temperature-sensitive color-development layer, a pre-coating layer, and a high-quality base paper layer, which are sequentially arranged from top to bottom. According to the single-waterproof temperature-sensitive label-use paper, pre-coating liquid and temperature-sensitive color-development layer coating liquid are pumped into a coating machine feeding tank, and are used for coating the high-quality base paper. One-step coating is finished, and the paper is fetched and cut, such that finished product is obtained. The temperature-sensitive color-development layer coating liquid adopts a polycarbonate-grade phenolic substance or a diphenyl sulfone substance as a color developing agent. Compared with prior arts, coated and fetched finished product paper of the single-waterproof temperature-sensitive label-use paper is already aged. The aging time is short, and the paper has higher waterproof functions, wherein fading is prevented when the paper is wetted and abraded. With the paper, color-development capacity preservation time of temperature-sensitive paper is longer. No protective layer is needed to be coated, such that production processes are reduced. The label-use paper has the characteristics of improved production efficiency, fast production speed, lower cost, and more stable product characteristics.

Owner:JIANGSU WANBAO RUIDA HI TECH CO LTD

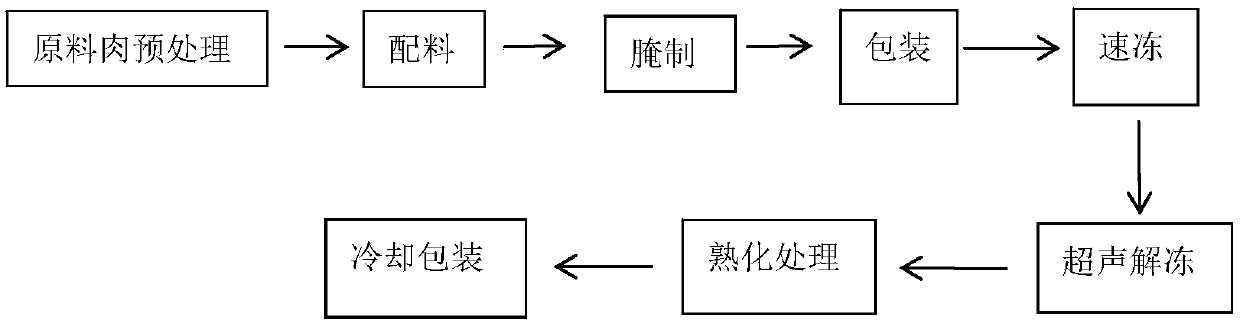

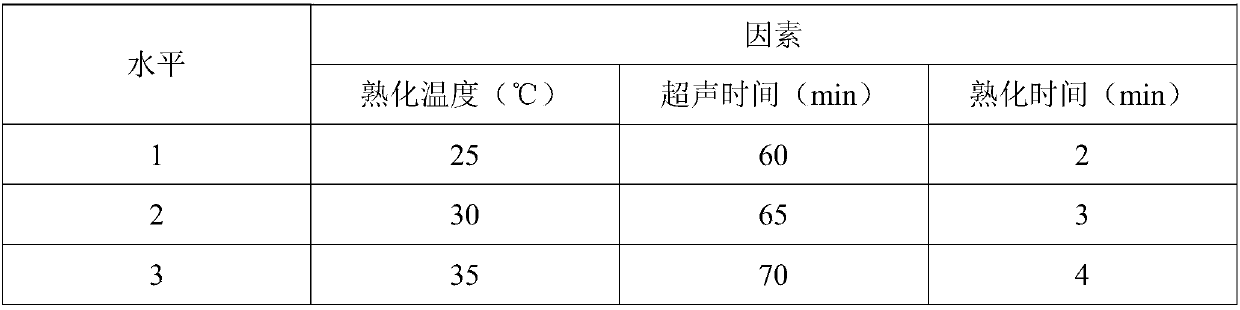

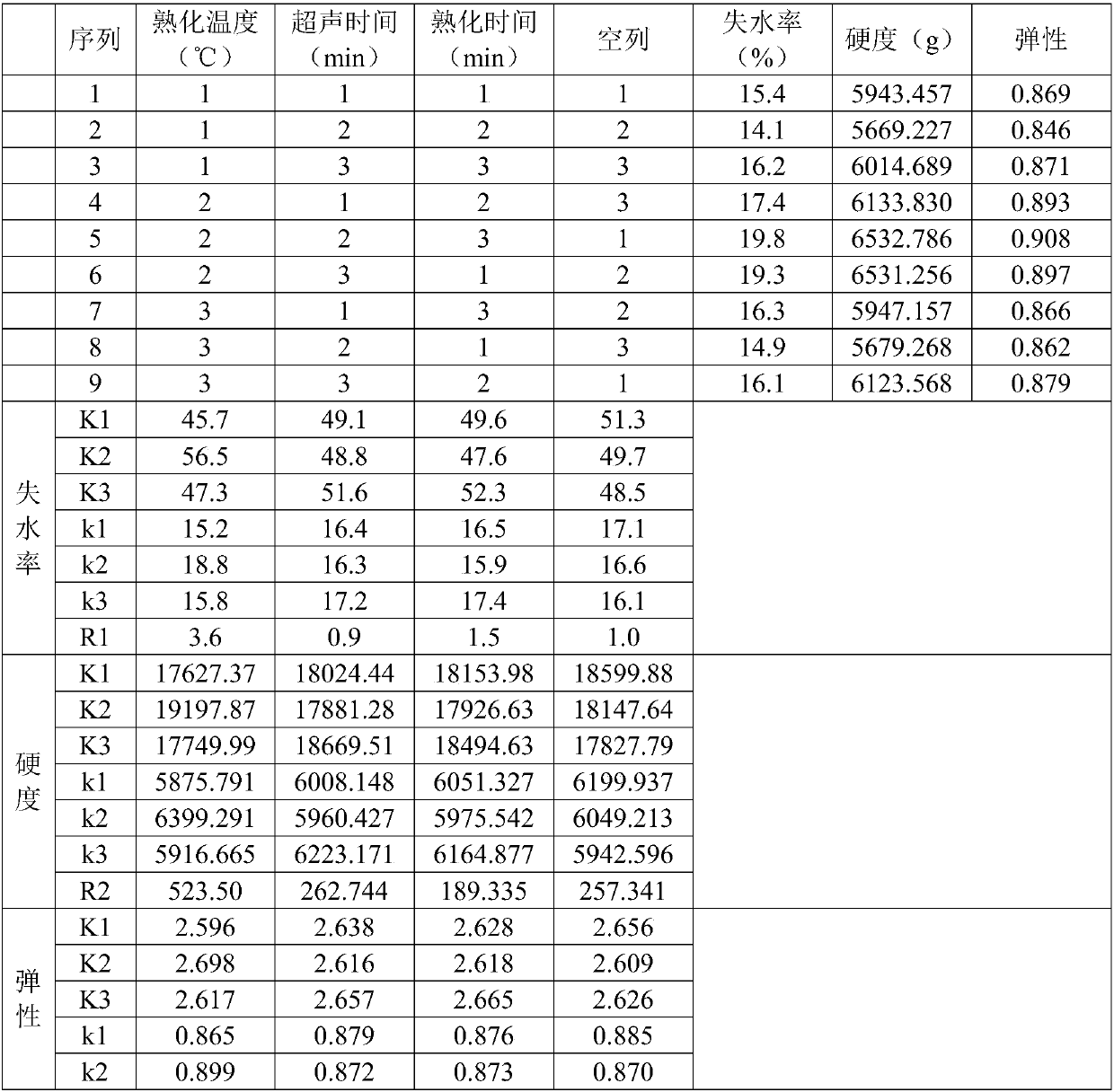

Preparation method of low-temperature cured prefabricated meat product

The invention discloses a preparation method of a low-temperature cured prefabricated meat product. The method comprises the following steps: slicing raw material meat, and pickling meat slices to obtain pickled meat; subjecting the pickled meat to vacuum packaging and freezing to obtain frozen meat; subjecting the frozen meat to ultrasonic treatment and curing to obtain cured meat; subjecting thecured meat to vacuum packaging to obtain a finished product. With the preparation method of the invention, curing time is short; the produced meat product is suitable in saltiness and moderate in acidity; remnant nitrite is less than 2 ppm; and pickling is complete, and is prepared for subsequent deep processing.

Owner:HUNAN AGRICULTURAL UNIV

Functional foods and process for producing functional food

InactiveUS20050249780A1Improve enhance flavorShort maturation timeMilk preparationPharmaceutical non-active ingredientsGramFunctional food

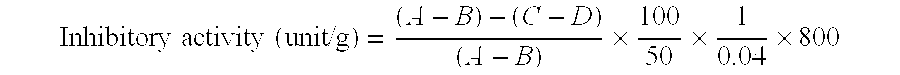

Functional food including milk products from which an antihypertensive effect is obtained in a more natural way, more specifically functional food of which ACE inhibitory activity is enhanced by adding EMC preferably with ACE inhibitory activity of 9,000 units or more is provided. ACE inhibitory activity of this functional food is made 5,000 units or more per daily standard intake of the product. For example, in case of processed cheese, ACE inhibitory activity is made 350 units per gram or more assuming daily intake to be approximately 15 g.

Owner:MEIJI CO LTD

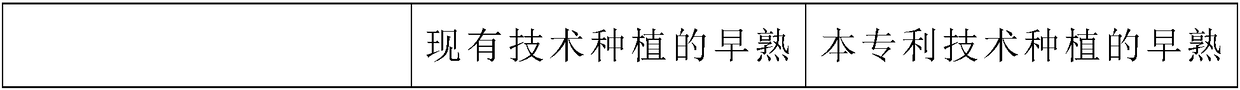

Method for planting Chinese cabbage in planting factory

InactiveCN108293721AShortened maturation timeSpeed up maturation timeSeed and root treatmentSaving energy measuresPlant factoryBlue light

The invention belongs to the agriculture planting field and relates to a method for planting Chinese cabbage in a planting factory, light emitted by an LED lamp with the proportion of red-blue light being 60%-99% is used for irradiating the Chinese cabbage, the planting method sequentially comprises the following steps of a sowing and germination acceleration stage, a seedling stage, a seedling slowing stage, a rosette stage, an early pacing stage, a middle pacing stage, a later pacing stage and a harvesting stage, illumination is performed alternatively during the seedling stage, the seedlingslowing stage, the rosette stage, the early pacing stage, the middle pacing stage, the later pacing stage and the harvesting stage, and in the harvesting stage, continuous illumination is performed one day before harvesting. The method for planting the Chinese cabbage in the planting factory has the advantages that the planting cost is low, and the maturing time is quick.

Owner:ZHEJIANG TIANYUE TECH CO LTD

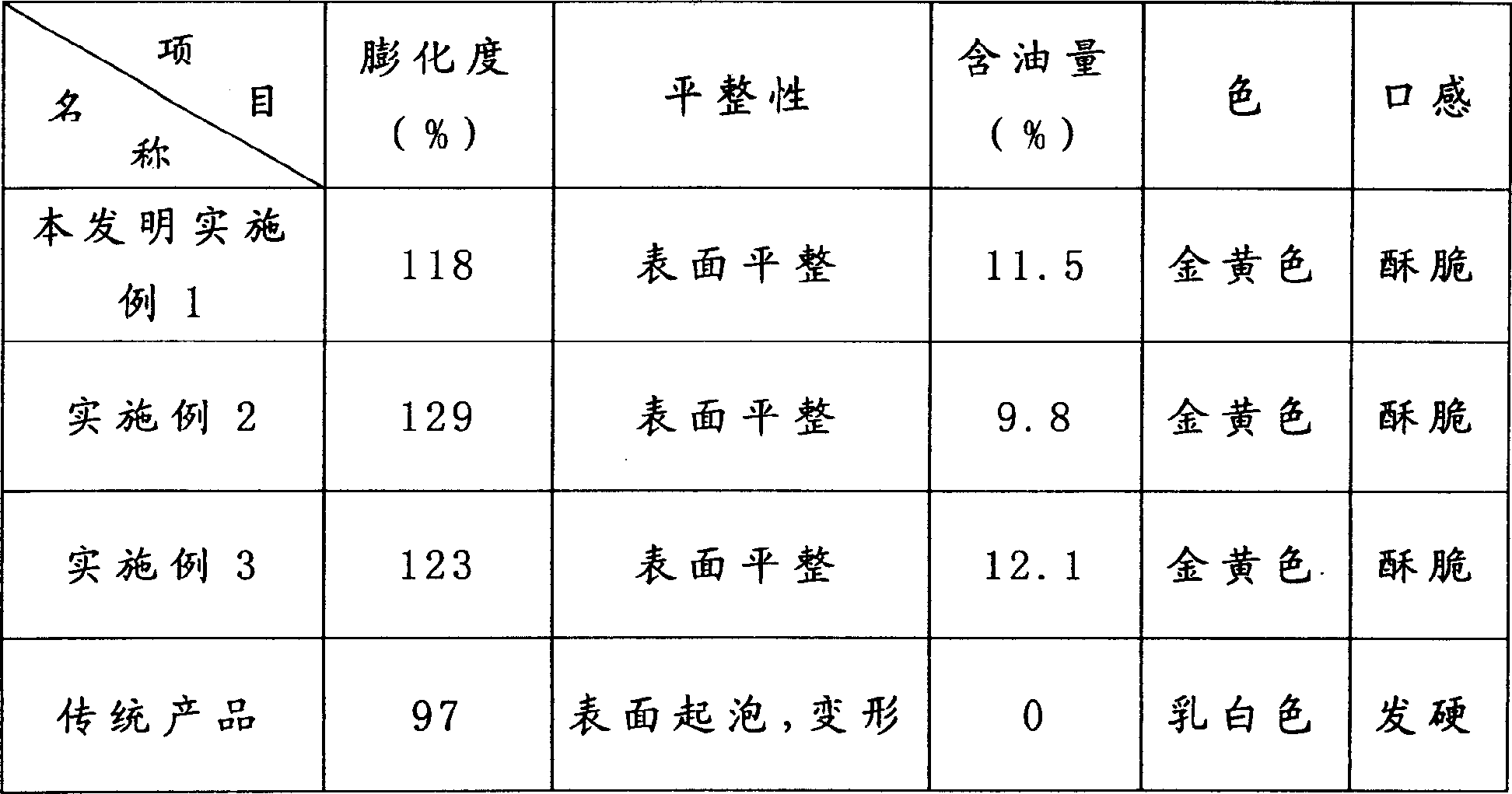

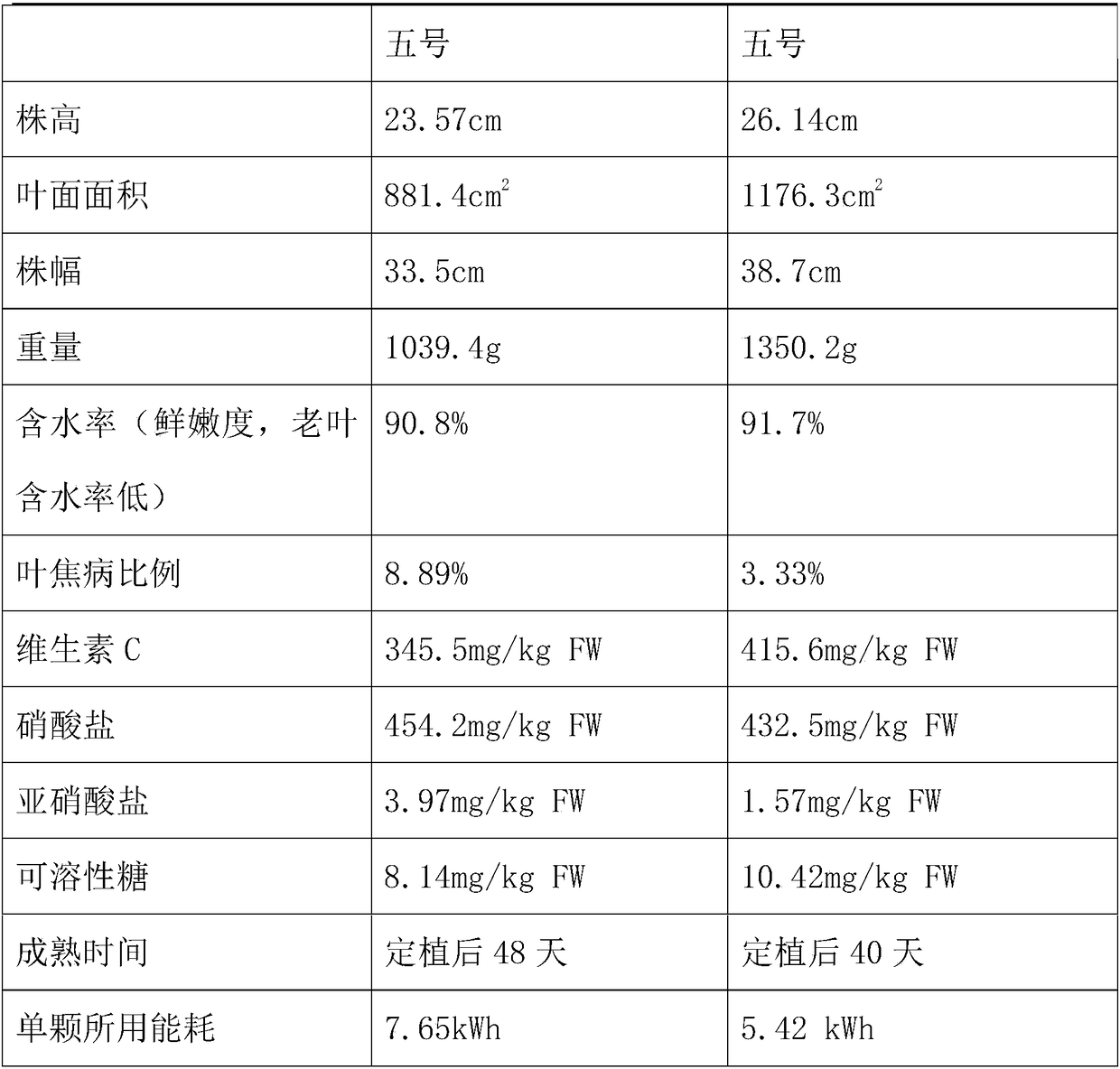

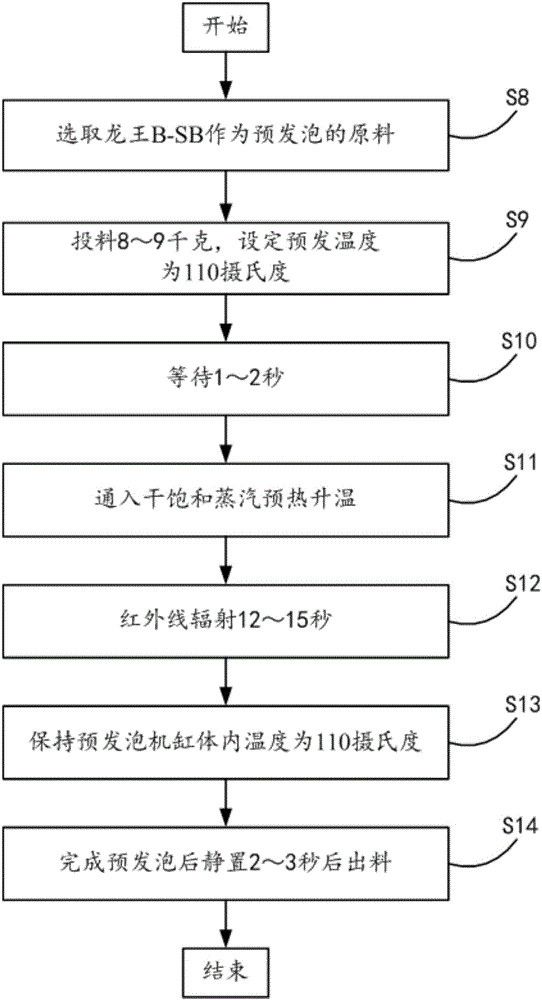

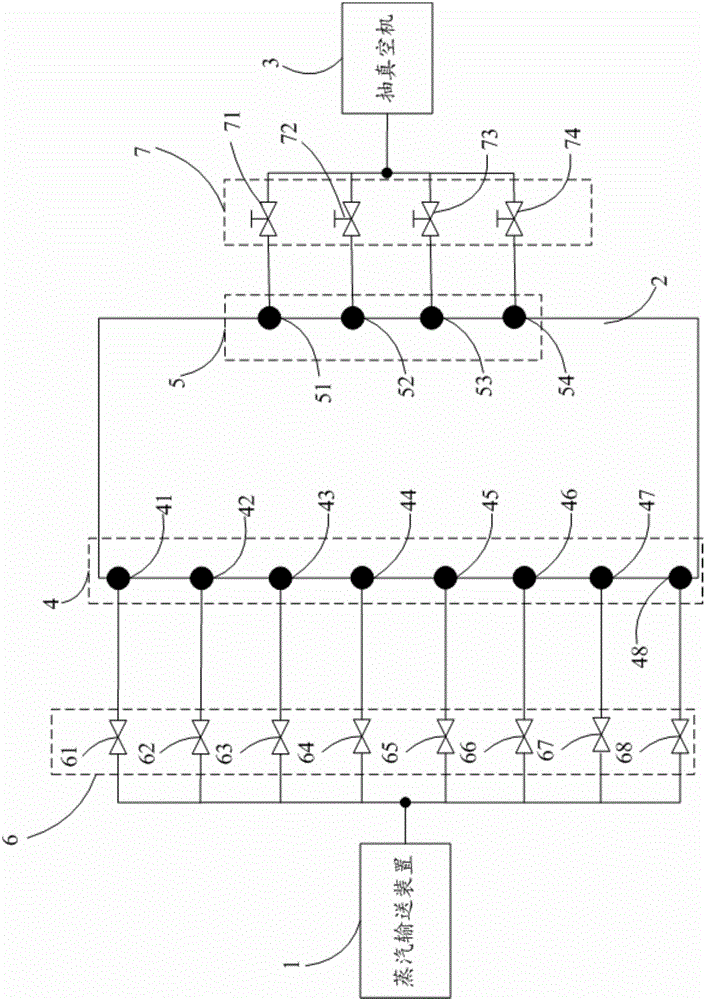

EPS foam packing box production process

The invention discloses an EPS foam packing box production process. The EPS foam packing box production process comprises pre-foaming, curing and forming procedures, wherein in the curing procedure, EPS foam particles are conveyed to a pressure-loading tank; hot air of which the pressure is 0.4-0.6 kilogram force per square centimeter and the temperature is 35-45 DEG C is injected into the tank body of the pressure-loading tank; the pressure and the temperature of hot air in the tank body are kept unchanged, and the EPS foam particles are stored for 0.5-1 hour; hot air is injected into the tank body again, thereby increasing the internal pressure of tank body to 0.8-1.2 kilogram force per square centimeter; the internal pressure and temperature of the tank body are kept unchanged, and the EPS foam particles are stored for 0.8-1.2 hours; hot air is injected into the tank body for the third time, thereby increasing the internal pressure of tank body to 1.8-2.2 kilogram force per square centimeter; and the internal pressure and temperature of the tank body are kept unchanged, the EPS foam particles are stored for 0.8-1.2 hours, and then the curing treatment is completed. According to the EPS foam packing box production process, a pressurizing and warming mode is adopted for the curing treatment, the curing effect is good, and the cell internal negative pressure recovery rate reaches 99%.

Owner:福建南安艺洋泡沫制品有限公司

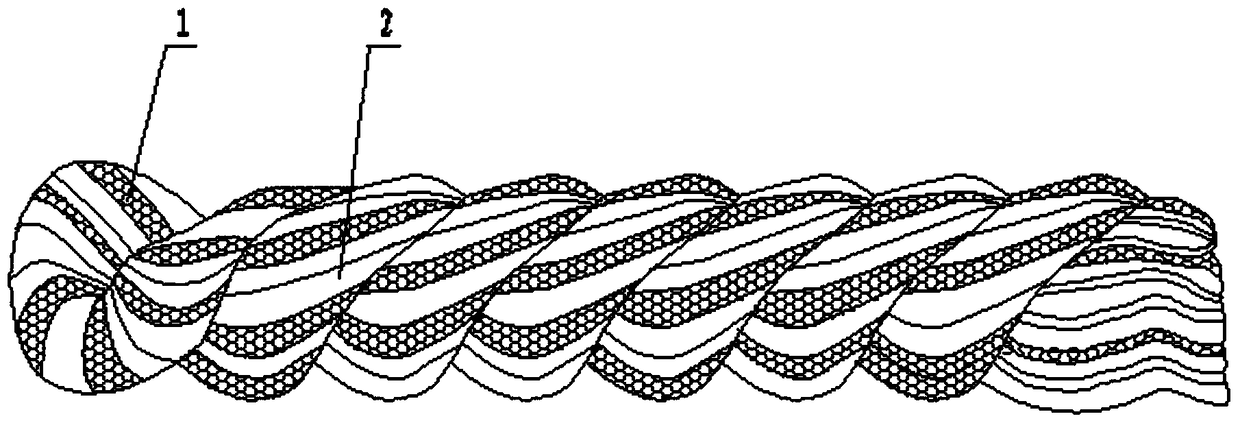

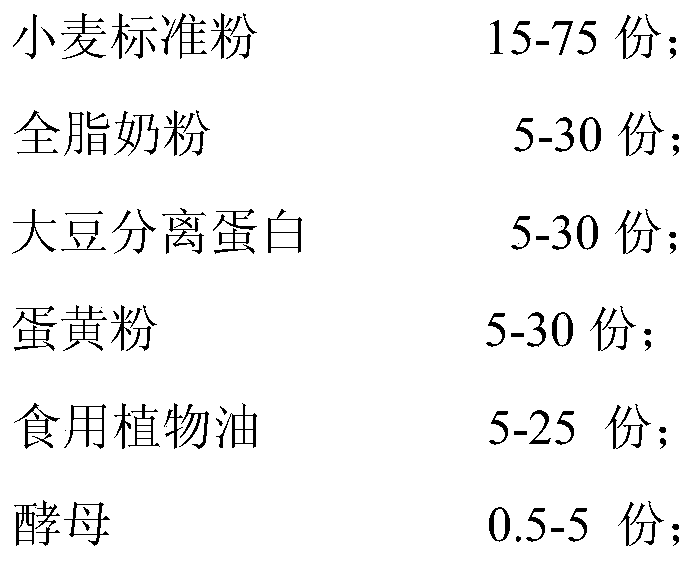

Twist twist with high and high-quality protein content and preparation method thereof

ActiveCN104996513BIncrease varietyRaise the ratioDough treatmentDeep-fried productsFilling materialsWhole milk

The invention relates to a twisted doughnut with high-quality protein content, which comprises twisted noodle strips, sesame strips and stuffing, and the ratio of the mass of the twisted noodle strips to the sesame sticks and the mass of the stuffing is 10:2-8. In terms of main ingredients, the twisted dough twist of the present invention is compounded with wheat standard flour, whole milk powder, egg yolk powder and soybean protein isolate, the protein content is higher than 12%, and the amino acid pattern of the contained protein is close to FAO / WHO, and the amino acid score reaches more than 80. It is beneficial to human body absorption; in the production process, through the optimization of the proportion of each component, the stretching performance of the twist noodle strips is enhanced, and the operability is good. The filling has good expansion during the frying process, which improves the quality of the finished twist. The fried dough twist of the invention retains the characteristics of sweetness, crispness, and long-term preservation, and further improves the protein content of the twisted dough twist, filling the gap in the market.

Owner:天津桂发祥十八街麻花食品股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com