Processing method beef squid salad salami

A salami and lamy sausage technology, applied in the field of food science, can solve problems such as restricting product sales and promotion, difficulty in consumer acceptance, high fat content, etc., and achieve benefits for human health, hair color, and rich nutrition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

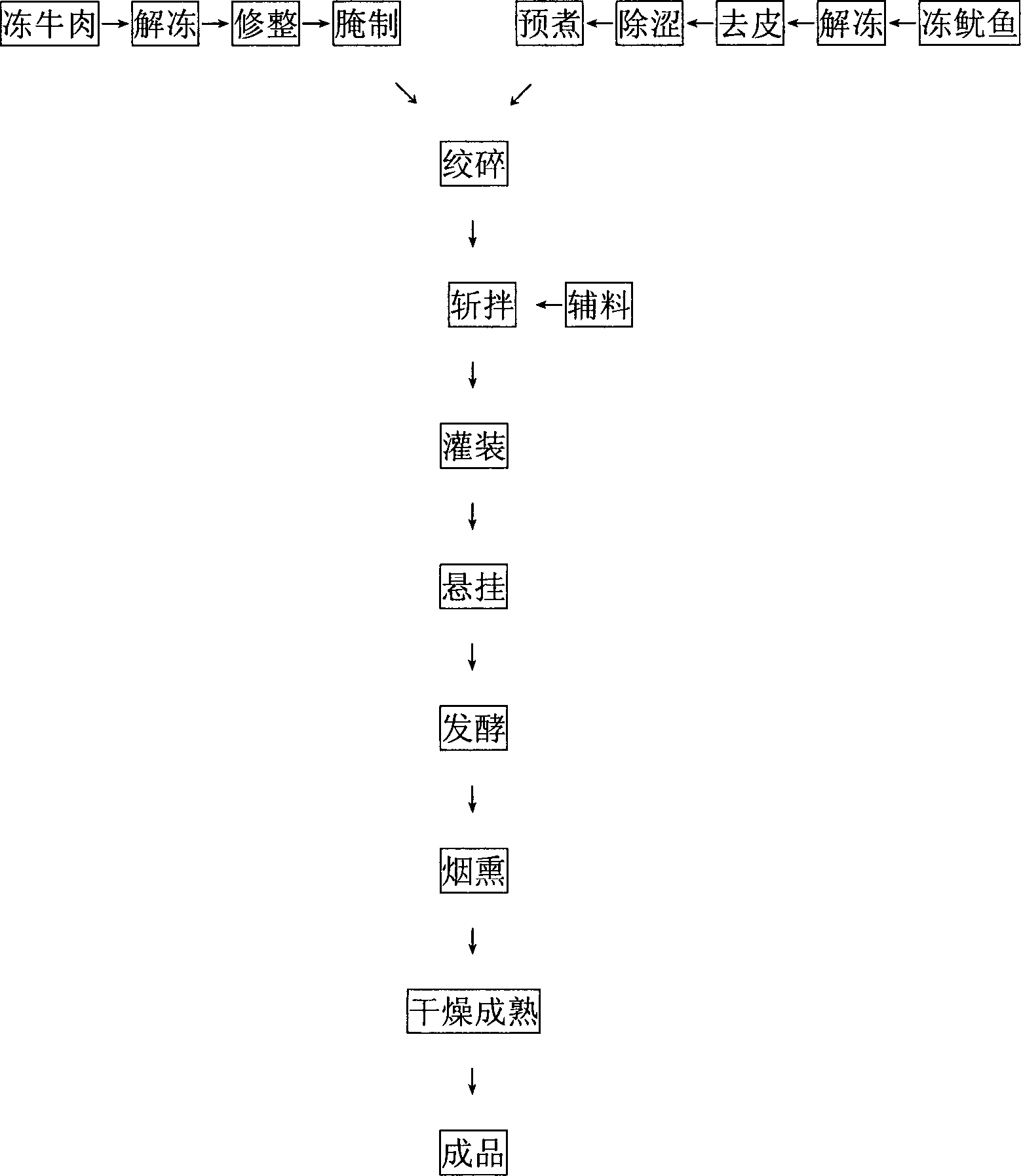

Method used

Image

Examples

Embodiment 1

[0037] (1) Place 35Kg of beef at 4°C, rinse and thaw with running cold water, then wash, peel, remove bone and connective tissue, etc.; peel the squid.

[0038] (2) Soak 15Kg squid in 0.3% sodium bicarbonate solution for 3 times the mass of squid after peeling the skin for 30 minutes, then wash with water until neutral, and boil for 50 seconds in boiling water.

[0039] (3) Preparing the salting agent in the following proportions: 1.5% of table salt, 0.015% of sodium nitrite, 0.5% of sodium ascorbate, and 0.5% of sodium iso-ascorbate. Apply the above-mentioned salting agent on the beef, and then marinate it at 4°C for about 60 hours.

[0040] (4) Put marinated beef and pre-cooked squid into a meat grinder with an aperture of no more than 4mm and grind.

[0041] (5) Put the ground beef and squid into the chopping machine at low speed and chop until the squid grains are 2mm to 3mm in size. Add other auxiliary materials while chopping: compound phosphate: 0.2%, glucose: 1%, whit...

Embodiment 2

[0049] (1) Place 35Kg of beef at 4°C, rinse and thaw with running cold water, then wash, peel, remove bone and connective tissue, etc.; peel the squid.

[0050] (2) After peeling 15Kg squid, soak it in 0.4% sodium bicarbonate solution for 30 minutes, then wash with water until neutral, and cook in boiling water for 40 seconds.

[0051] (3) prepare salting agent according to following ratio: 2% table salt, 0.015% sodium nitrite, 0.5% sodium ascorbate, 0.5% sodium iso-ascorbate. Apply the above-mentioned salting agent on the beef, and then marinate it at 4°C for about 48 hours.

[0052] (4) Put marinated beef and pre-cooked squid into a meat grinder with an aperture of no more than 4mm and grind.

[0053] (5) Put the ground beef and squid into the chopping machine at low speed and chop until the squid grains are 2-3mm in size. Add other auxiliary materials while chopping: compound phosphate: 0.2%, glucose: 1%, white sugar : 1.5%, cooking wine: 2.5%, spices 1%, etc. The meat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com