Patents

Literature

648results about How to "High sintering activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing shrinkage-matched ceramic composites

InactiveUS6576182B1Large particle sizeHigh sintering activitySemi-permeable membranesOther chemical processesCeramic matrix compositeMetallurgy

A process for producing a composite, containing at least one shrinkage-matched ceramic layer, wherein a starting material for the ceramic layer(s) has shrinkage behavior on sintering which is matched to remaining layer(s), and which is selected such that the ceramic-forming constituent of the same contains at least one ceramic powder of a specific size, and which process entails joining the layers of the composite by sintering.

Owner:NASS RUEDIGER

Lead-free and cadmium-free electrode silver slurry for piezoelectric ceramics and preparation method thereof

ActiveCN102751000AAchieve lead-freeImprove adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesion forceSlurry

The invention discloses a lead-free and cadmium-free electrode silver slurry for piezoelectric ceramics. The lead-free and cadmium-free electrode silver slurry for piezoelectric ceramics is prepared from the following raw materials in percentage by weight: 50 to 75 percent of conducting silver micro powder, 0.5 to 5 percent of inorganic additive, 1 to 15 percent of lead-free glass powder and 15 to 45 percent of organic carrier. The lead-free and cadmium-free electrode silver slurry is technologically advantaged in that a boron-bismuth-silicon-zinc-titanium glass system is designed, the traditional lead-containing glass can be completely substituted, a lead-free product is realized, the system glass can react with a piezoelectric ceramic substrate to form a firm interface between an electrode and the substrate, and the adhesion force of the interface is more than 15N / mm<2>.

Owner:HEFEI SHENGDA ELECTRONIC TECH IND CO LTD

Aluminium nitride ceramics material and preparation method thereof

ActiveCN101386539ADoes not significantly affect colloidal propertiesGood dispersion propertiesAluminium acetylacetonateNano al2o3

The invention discloses an aluminium nitride ceramic material and a preparation method thereof. The method is to add nano-alumina to raw materials in the prior preparation method for preparation according to the prior preparation process. In-situ growing nano-alumina can be obtained directly through adding the nano-alumina, or indirectly through adding organic aluminum, such as aluminium secondary butylate, aluminium isopropoxide or aluminium acetylacetonate, and by means of low-temperature decomposition of the organic alumina. The method can be applied to dry pressing and tape casting shaping, can obtain slurry with good dispersing characteristic and even mixing of the aluminium nitride and the nano-alumina by the ceramic preparation process, such as normal pressure, hot pressed sintering or the like, and is favorable for the improvement of sintering activity of materials, the reduction of sintering temperature, the improvement of luster uniformity, planeness and roughness for a ceramic substrate, and the reduction of production cost. The aluminium nitride ceramic material and the preparation method thereof can be widely applied to the field of aluminium nitride ceramic production.

Owner:无锡海古德新技术有限公司

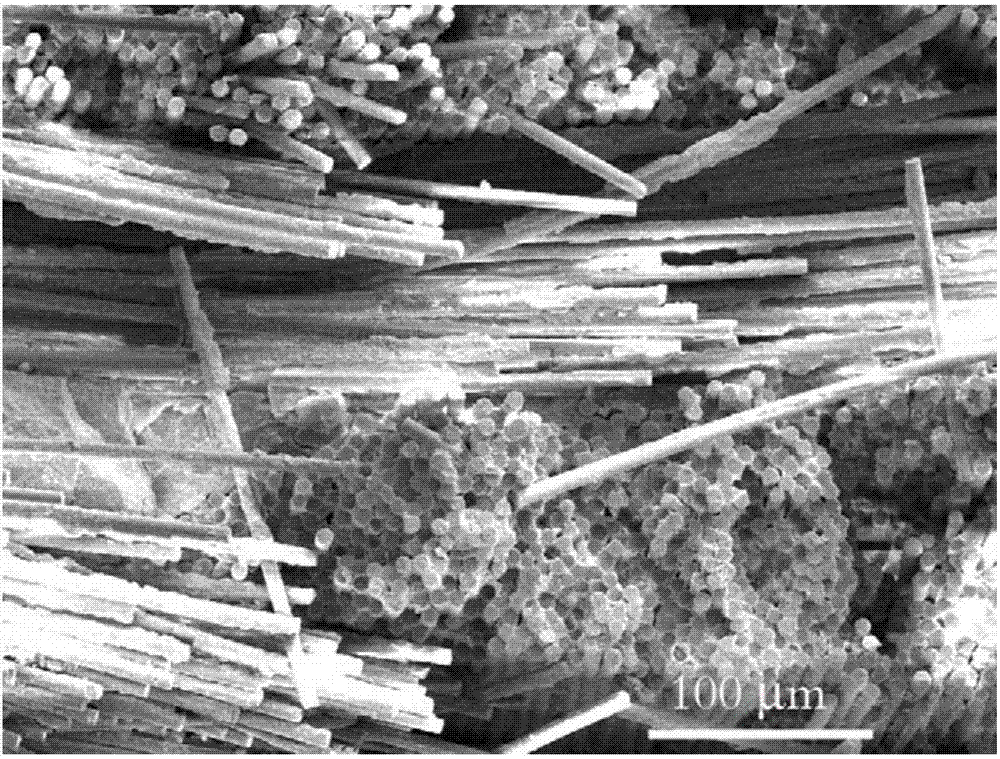

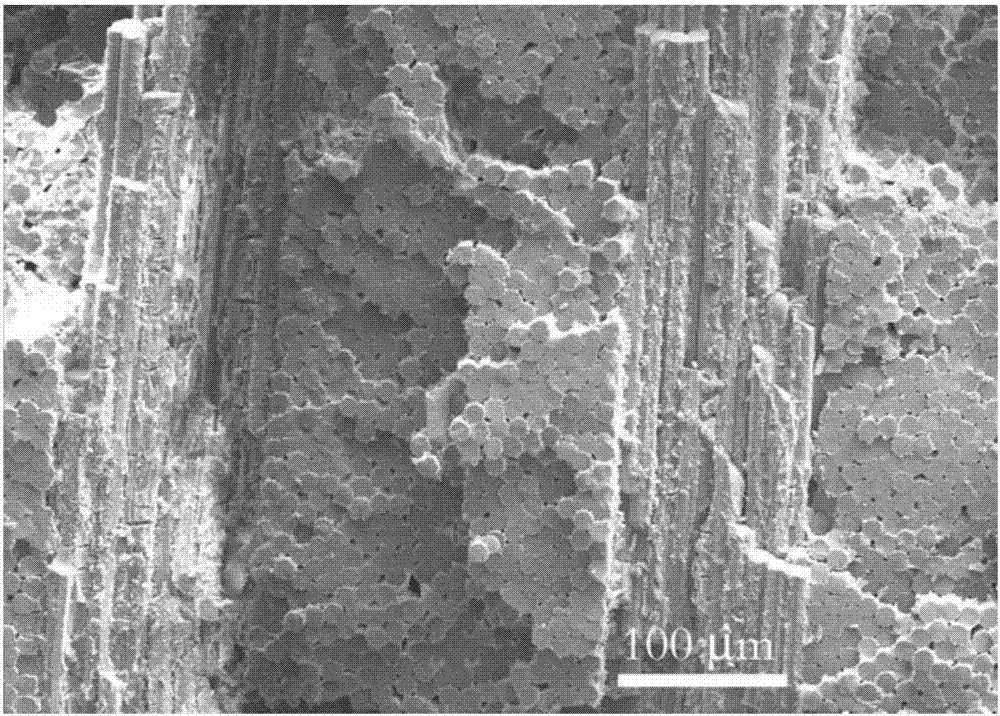

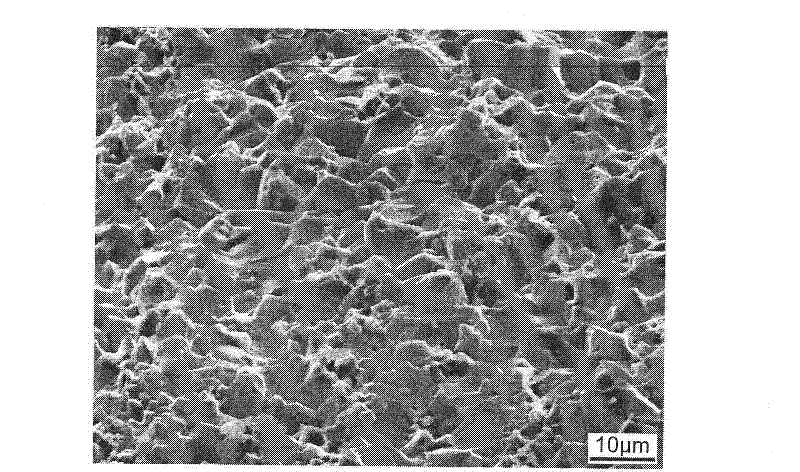

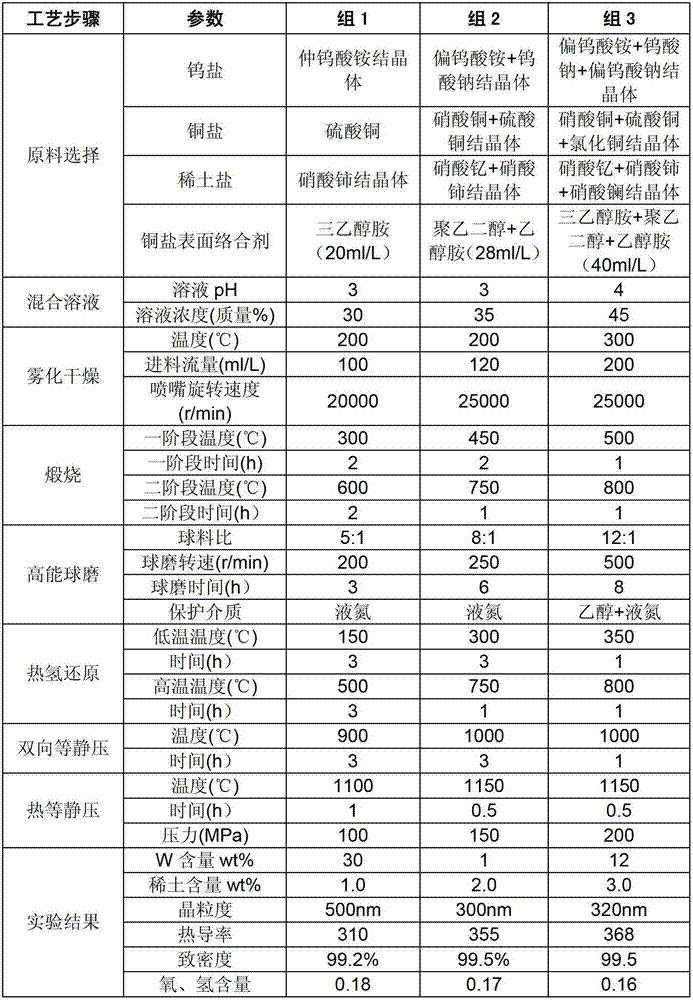

Method for preparing rare-earth oxide dispersion strengthened fine-grained tungsten material

ActiveCN105518169AGood compatibilityEvenly distributedTransportation and packagingMetal-working apparatusRare-earth elementTungstate

A method for preparing a rare-earth oxide dispersion strengthened fine-grained tungsten material, comprising: according to a condition that a mass percentage of rare-earth oxide is 0.1-2%, and the remaining composition is W, weighing soluble rare-earth salt and tungstic acid salt, and respectively preparing 50-100 g / L of rare-earth saline solution and 150-300 g / L of tungstic acid saline solution; adding a minor amount of alkali into the rare-earth salt to control the pH to be 7-8, adding an organic dispersing agent, and stirring to enable the rare-earth salt to form uniformly suspending R(OH)3 colloidal particles (R represents a rare-earth element); adding the tungstic acid saline solution into the R(OH)3 colloidal particles, adding a minor amount of acid to control the pH to be 6-7, adding the organic dispersing agent, stirring to enable the tungstic acid salt to form tungstic acid micro-particles, precipitating and coating the R(OH)3 colloidal particles with the R(OH)3 colloidal particles as a core, and forming coprecipitated coated colloidal particles; conducting spray drying on the coprecipitated coated colloidal particles to obtain a composite precursor powder of tungsten and rare-earth oxide; calcining, conducting thermal reduction via hydrogen, and preparing superfine nanometer tungsten powder having a particle size of 50-500 nm; and conducting normal high-temperature sintering after a general pressing forming. The high-performance fine-grained tungsten material dispersed and strengthened by a minor amount of rare-earth oxide prepared by the above method has a density approximate to full density (>=98.5%), and uniform and small tungsten grains having an average size of 5-10 [mu]m; in addition, rare-earth oxide particles having a particle size of 100 nm - 500 nm are uniformly distributed in a tungsten crystal or a crystal boundary.

Owner:长沙微纳坤宸新材料有限公司

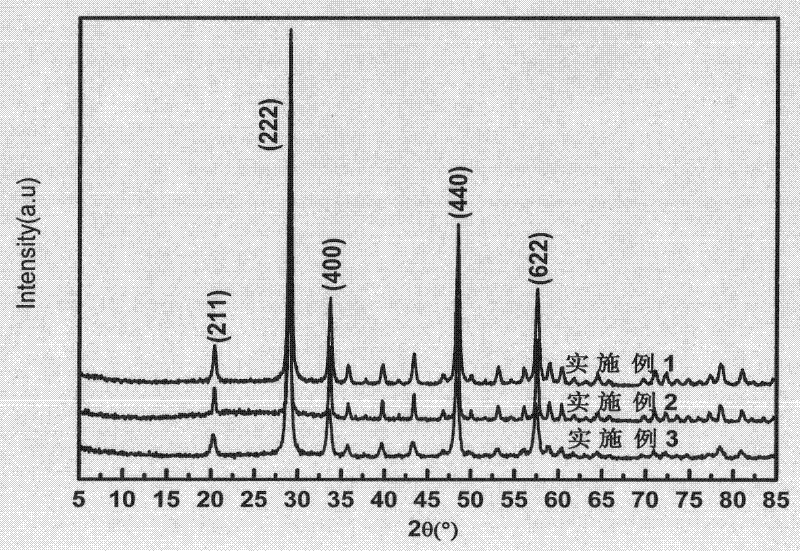

Yttria-stabilized zirconia powder and preparation method thereof

The invention relates to yttria-stabilized zirconia powder and a preparation method thereof. The yttria-stabilized zirconia powder has the composition characteristics that yttria is taken as a stabilizer of a zirconia material; the powder comprises a doping system formed by one or more following third components: alumina, ceria, lanthana, copper oxide, magnesium oxide and calcium oxide, wherein the weight of the yttria is 2-8mol%, and the total doping weight of the alumina, the ceria, the lanthana, the copper oxide, the magnesium oxide and the calcium oxide is 0-5wt%. According to the yttria-stabilized zirconia powder and the preparation method, the deficiencies of an existing liquid phase preparation process of nanometer zirconia powder are overcome, and the prepared nanometer ZrO2 composite powder has the performance of uniformity in dispersion of components, uniform grain size, super-fineness, high sintering activity, good liquidity and the like. Furthermore, the preparation method is simple in process and low in cost and is easy to industrialize.

Owner:YAAN YUANCHUANG CERAMIC

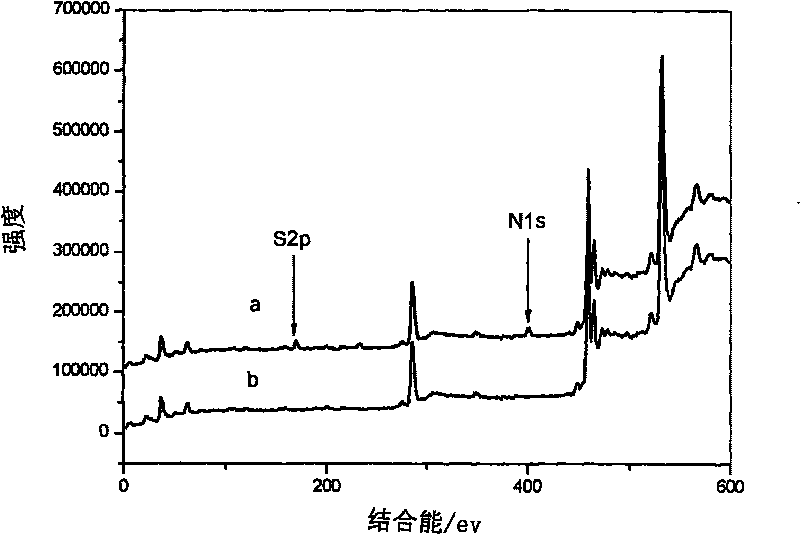

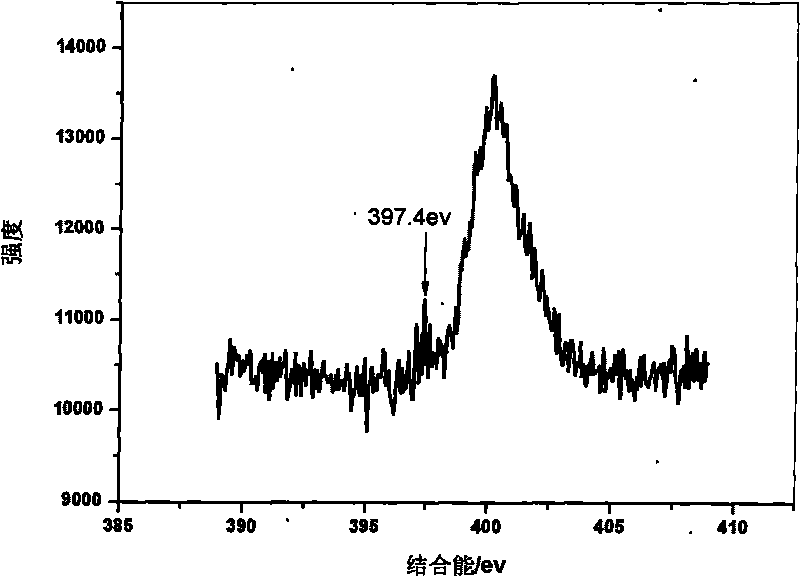

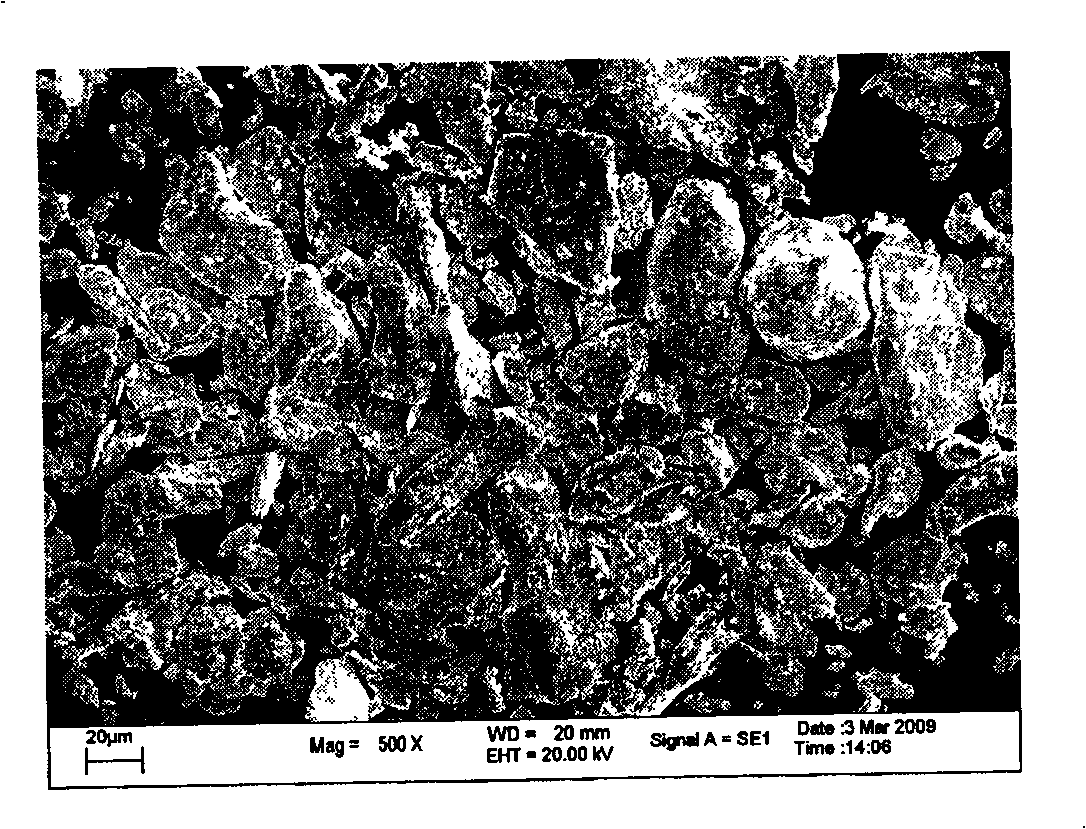

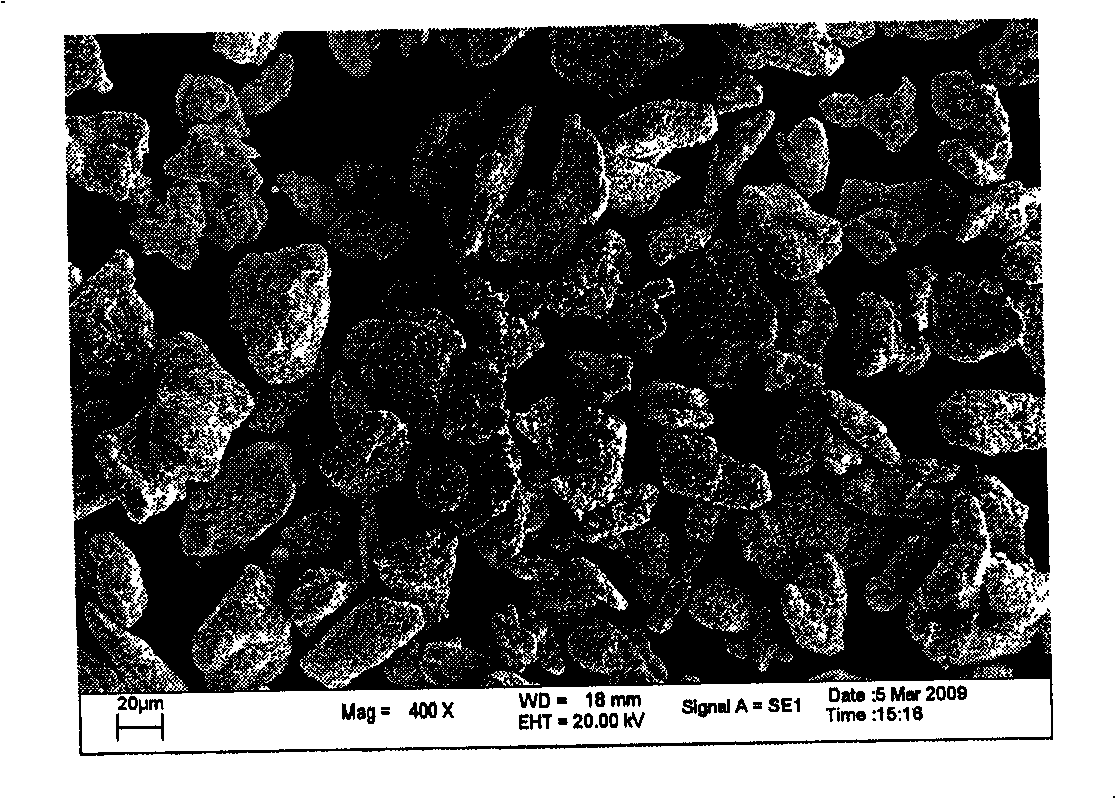

Method for preparing sulfur and nitrogen co-doped titanium dioxide with visible light catalytic activity

InactiveCN101721985AReduce consumptionHigh doping contentPhysical/chemical process catalystsThioureaPhotocatalytic degradation

The invention provides a method for preparing sulfur and nitrogen co-doped titanium dioxide with visible light catalytic activity, which adopts a sol-gel method and comprises the following steps: hydrolyzing titanium ester and introducing sulfur and nitrogen sources to obtain a titanium dioxide sol, wherein the sulfur and nitrogen sources are from thiourea solution; in a sol system, dropwise adding 1 to 5 percent saturated aqueous solution of thiourea to perform the hydrolysis reaction to obtain the sol; then performing aging and volatilizing a diluent to obtain a titanium dioxide gel; drying the titanium dioxide gel and grinding into powders; performing heat treatment on the solid powder; and calcinating to obtain sulfur and nitrogen co-doped titanium dioxide nano powder. In the method, the thiourea is used as the raw materials of the nitrogen and sulfur sources, the sulfur and the nitrogen are simultaneously introduced in the process of the hydrolysis reaction of the sol to achieve synergistic effect and improve the reaction efficiency, raw material consumption is less, the process is simplified, the absorption range of visible light is effectively improved, the wavelength of the visible light is expanded to about 650nm, and the sulfur and nitrogen co-doped titanium dioxide has obvious visible light activity in the photocatalytic degradation reaction of organic pollutant molecules.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of copper-coated tungsten composite powder

InactiveCN101537491AHigh sintering activityUniform thicknessLiquid/solution decomposition chemical coatingWater bathsBipyridine

The invention discloses a preparation method of copper-coated tungsten composite powder, belonging to the technical field of powder metallurgy. Corresponding tungsten powder and blue vitriod are employed according to the weight ratio of composite powder to be prepared and the tungsten powder is pre-treated; copper sulphate and seignette sol are dissolved into solution; bipyridine is added and NaOH is used to adjust pH value to 12-14; an appropriate amount of formaldehyde solution and the tungsten powder are added; the mixture is heated and then stirred continuously in constant-temperature bathing at 30-60 DEG C until the tungsten powder is red; the tungsten powder is washed, dried, reduced and annealed, thereby obtaining copper-coated tungsten composite powder. The preparation method of copper-coated tungsten composite powder has wide application range and is applicable to tungsten-powder coating coppers with different finenesses and shapes. The preparation method of copper-coated tungsten composite powder prepares copper-coated tungsten composite powder in different content ratios according to different requirements. The copper-coated tungsten composite powder obtained by the method of the invention has excellent sintering activity, thereby improving the combination property of tungsten copper alloy.

Owner:UNIV OF SCI & TECH BEIJING

PEN multilayer film of middle temperature solid oxide fuel cell and its producing method

InactiveCN1409427ALow resolutionHigh strengthFinal product manufactureCell electrodesSolid oxide fuel cellRelative density

This invention relates to PEN multilayer film of warm solid oxide full cell and its processing method characterized by multiple doctor-blading layer by layer or stratified doctor-blading and multi-layer co-rolling, then lour-temp. co-senlering to obtain anode / electrolyte double-layer film, after that, preparation of cathode layer and PEN multilayer, film, in which the thickness of NiO+DCO porous anode layer is 0.5-1 mm, NiO content or crysal size expressing graded distribution along the thickness direction. Weight content varies from 70-80% to 50-60%, crystal size varies from 5-8 um to 1-3 um, DCO electrolyte thickness is 20-150 um, with relative density higher than 96%, and thickness of LaCoO3 porous cathode layer of 30-50 um.

Owner:UNIV OF SCI & TECH OF CHINA

Alumina ceramic and preparation method thereof

The invention provides alumina ceramics and a manufacturing method of the alumina ceramics. The main materials of the alumina ceramics are as follows: alumina micro mist or a superfine alumina micro mist which is formed by Gamma alumina and an Alpha alumina with an particle diameter of between zero point one to three point five micron and a purity of ninety-nine point nine percent or more than ninety-nine point nine percent according to certain proportion. One or a mixture of a small quantity of magnesia, yttria, lanthana, thulia and yttria stabilized zirconia is added into the micro mist as sinter accessory ingredient and is subject to dry pressing, grouting and isostatic cool pressing after being even mixed evenly, thus ceram green pressing is obtained. Only a little organic addition agent is needed to be added. After drying, the green pressing body does not need to be roasted and can be directly introduced to an ordinary high temperature si-mo rod resistance furnace or a continuous type si-mo rod electrothermal tunnel kiln to be sintered for one to three hours at a temperature below one thousand six hundred and seventy Celsius system. Therefore, the alumina ceramics can be obtained with high tightness, mechanical property and good dielectric property and with a nonconventional structure and a placode the size of which is zero point two to two hundred millimeter and a purity of ninety nine to ninety-nine point nine percent.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

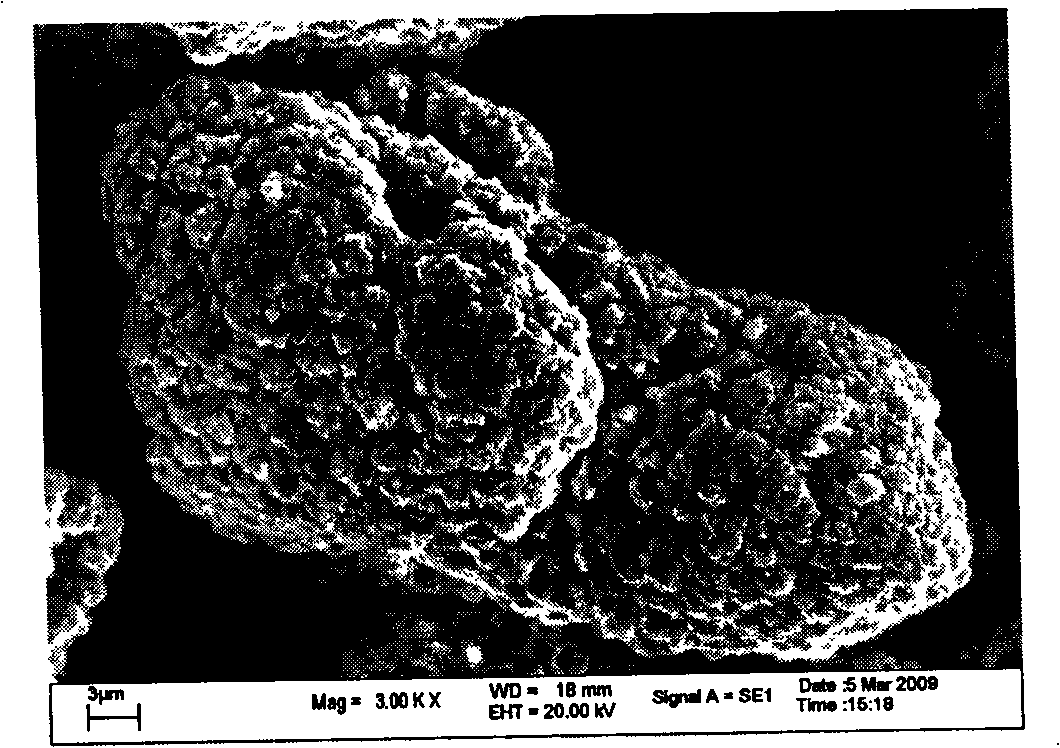

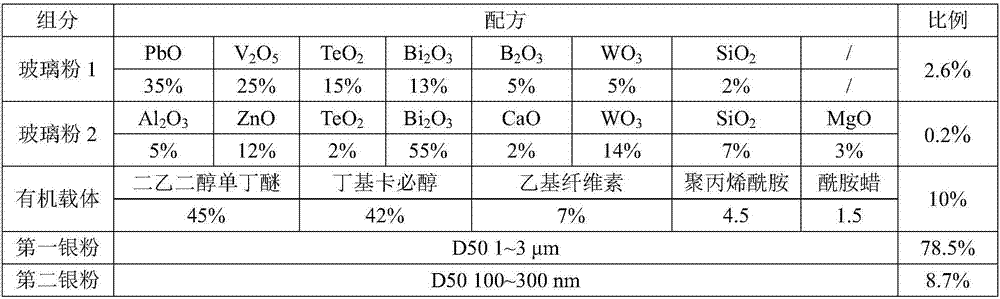

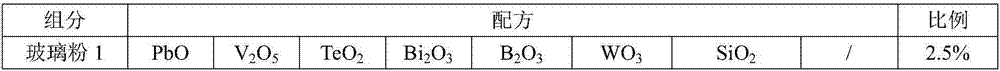

Positive electrode silver paste for back passivation silicon solar cell and preparation method thereof

ActiveCN107195354AHigh sintering activityImprove liquidityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicon solar cellColloidal particle

The invention discloses positive electrode silver paste for a back passivation silicon solar cell and a preparation method thereof. The positive electrode silver paste comprises, in mass percent, 3%-15% of organic carriers, 80%-95% of silver powders and 1%-5% of inorganic glass materials. The inorganic glass materials are prepared by compounding Pb-V-Te glass and Bi-W-Si glass; and the silver powders are prepared by compounding first silver powders and second silver powders. Through introduction of nanometer silver powders, sintering activity of a silver powder system is improved, and compactness of silver grid lines under low-temperature sintering is improved; by adjusting softening temperature, viscosity and surface tension of the glass materials, liquidity and wetting ability of glass liquid are improved, etching capacity of the glass liquid to a front-surface antireflection layer is ensured and silver powder fusion and reprecipitation capability is improved; precipitation of silver nanometer colloid particles on the surface of a silicon wafer helps to promote the glass layer to form good ohmic contact with the silicon wafer, and thus conversion efficiency is improved; and through introduction of the second component glass powders, bonding strength between the glass layer and a silicon substrate is enhanced.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

High-temperature-resistant high-strength aluminum oxide fiber enhanced composite material and preparation method thereof

The invention relates to a high-temperature-resistant high-strength aluminum oxide fiber enhanced composite material and a preparation method thereof. The preparation method comprises the following steps of: by taking a two-dimensional cloth paving layer and 2.5D woven or orthogonally three-dimensional woven continuous aluminum oxide fiber preform as an enhancer, preparing a matrix through a double nano composite impregnation liquid where silicon dioxide and aluminum oxide are uniformly mixed; and finally obtaining the aluminum oxide fiber enhanced composite material through the process of vacuum pressure impregnation, micro-positive pressure medium and low temperature pre-curing, micro-positive pressure curing and atmosphere temperature programming sub-sectional thermal treatment, wherein the mass ratio of silicon dioxide to aluminum oxide in the composite material is (19:1)-(12:8), and the volume content of the aluminum oxide fibers is 30-60%. The prepared composite material has a high-temperature-resistant property and a high-temperature mechanical property, and is high in compactness; the room temperature tensile strength of the material reaches 310+ / -30MPa, the tensile strength at 1100 DEG C reaches 135+ / -20MPa, and the tensile strength at 1200 DEG C reaches 90+ / -10MPa; and compared with a similar quartz fiber enhanced silicon dioxide oxide / oxide composite material, the performance is improved by 4-5 times.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Sintering preparation method of boron carbide ceramic

The invention discloses a sintering preparation method of boron carbide ceramic, which comprises the following steps: 1. sintering: carrying out mixing and ball milling on boron carbide powder, carbon powder, metal powder, a dispersant, an adhesive and deionized water to make a slurry, carrying out spray granulation, pressing into a biscuit, presintering for debonding, and carrying out thermal-insulation sintering at lower sintering temperature (slightly higher than the melting point of metal), thereby implementing primary shrinkage sintering of the product by utilizing the surface tension of the molten metal in the system; and 2. sintering: continuing enhancing the sintering temperature, carrying out in-situ reaction to generate metal carbide, metal boride or metal boro-carbide and nano B4C which have higher sintering activity, and forming a solid solution with boron carbide granules by using the metal carbide, metal boride or metal boro-carbide and nano B4C as sintering assistants to promote the further shrinkage sintering of the system, thereby obtaining the high-performance boron carbide ceramic. The method has the advantages of both the normal-pressure sintering technique and the reactive sintering technique.

Owner:NINGBO VULCAN TECH CO LTD

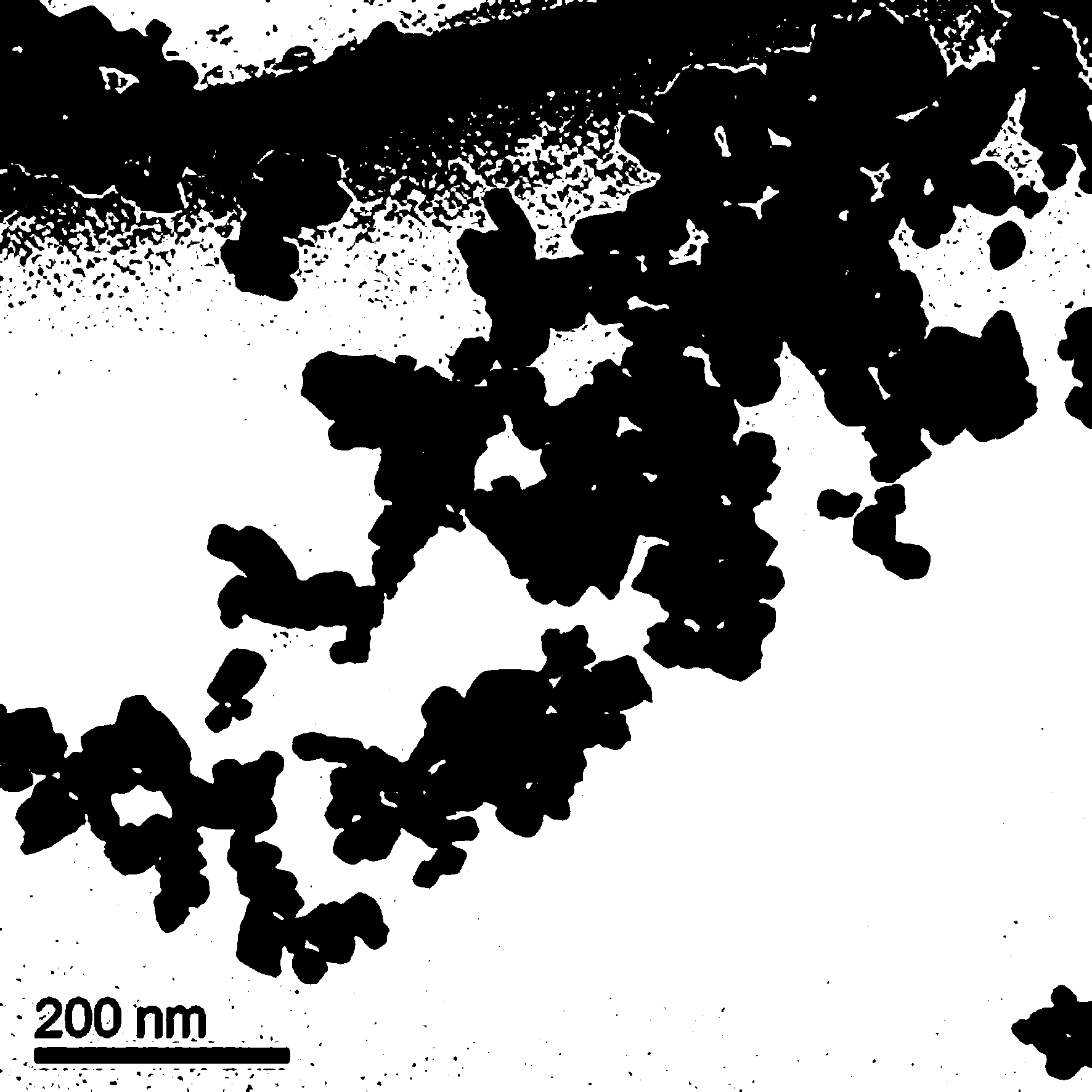

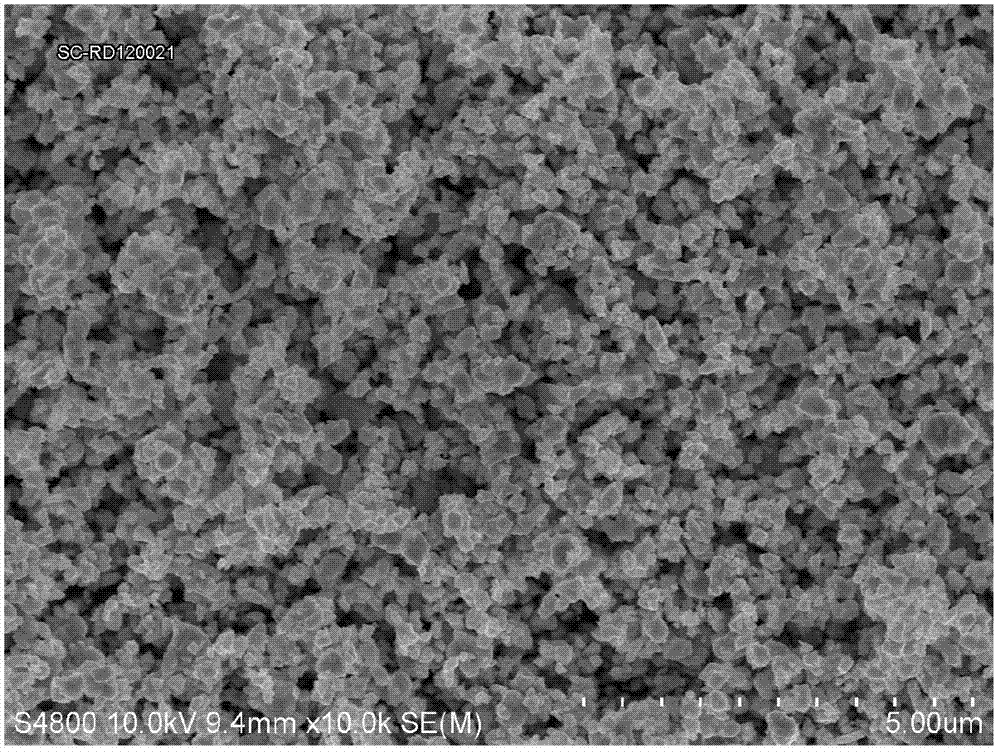

Preparation of micron/nano-scale high purity tungsten powder

The invention relates to a preparation method of micro / nano-high-purity tungsten powder. Tungstate is dissolved in deionized water, excessive dilute nitric acid or hydrochloric acid is added to allow the mixture to fully generate yellow precipitation, dilute ammonia water is added to fully convert the yellow precipitation to transparent colloid under the stirring condition, a surfactant is added and is evenly dissolved by strong stirring; the hydrothermal reaction is carried out, a product after the hydrothermal reaction uses the deionized water or ethanol for cleaning and filtering, precursor powder is obtained by drying; and the precursor powder is carried out the reduction to obtain the high-purity micro / nano-tungsten powder. The micro / nano-tungsten powder which is prepared by using the invention is characterized by fine particle size, even distribution of the components and high purity, the specific surface particle size and the powder morphology analyzing particle size after the diffusion are less than 80nm, the tungsten particle size of the powder is 20 to 30nm, the powder is spherical or nearly spherical, the oxygen content is lower than 0.18 percent, the tungsten content is more than 99.5 percent, and the powder has good formability and sintering activity.

Owner:CENT SOUTH UNIV

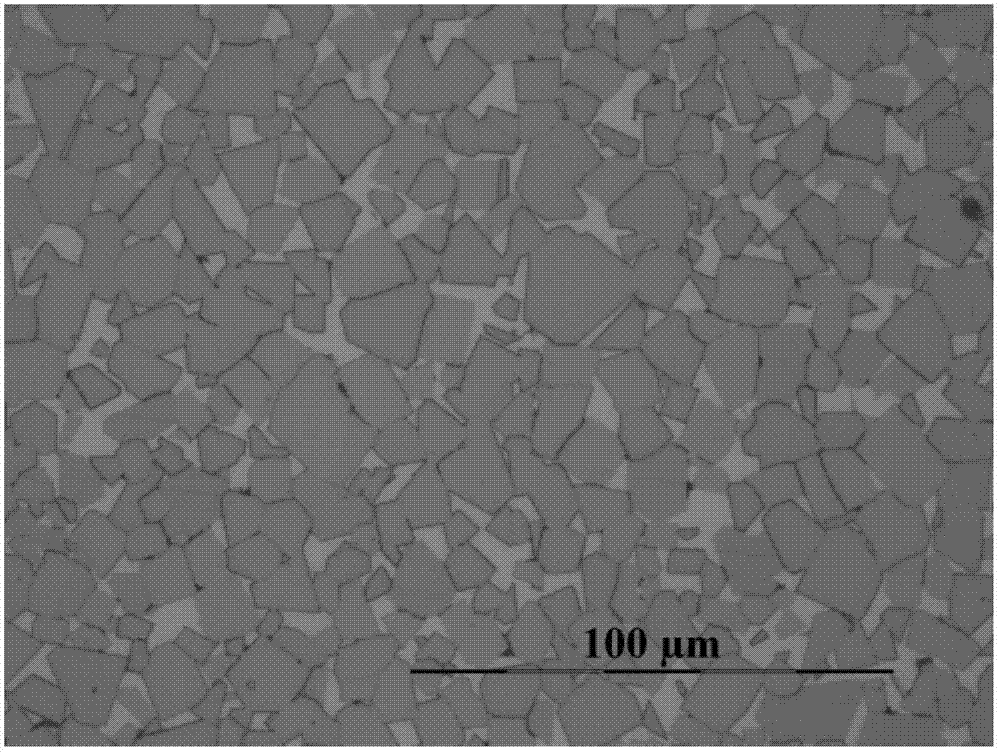

Preparation method for super coarse crystal WC-Co hard alloy

The invention discloses a preparation method for a super coarse crystal WC-Co hard alloy. According to the preparation method, a proper amount of fine tungsten carbide powder is added into a raw material, and the super coarse crystal WC-Co hard alloy is prepared by proper ball milling and sintering processes, so that the super coarse crystal hard alloy with the grain size of 6.0 to 14.0 microns can be prepared successfully. The preparation method has the characteristics that the process is simple, the process is easy to control, the production cost is low, and the WC grain size distribution in the alloy product is uniform.

Owner:XIAMEN TUNGSTEN +1

Nano ceramic cutter and preparation method thereof

ActiveCN103708832AImprove anti-aging propertiesPrimary particle size ultra-fineNanoceramicYttria-stabilized zirconia

The invention relates to a nano ceramic cutter and a preparation method thereof. The composition of the nano ceramic cutter can be yttrium oxide stabilized zirconium oxide including synergic doping of one or more third components among aluminum oxide, magnesium oxide, calcium oxide and titanium oxide; and the nano ceramic cutter specifically comprises the following components: 80-95wt% of zirconium oxide, 2-8wt% of yttrium oxide, 0-20wt% of aluminum oxide, 0-5wt% of magnesium oxide, 0-4wt% of calcium oxide, 0-0.5wt% of titanium oxide and 0-2wt% of other rare-earth oxides. After the green body of the nano ceramic cutter prepared through the method is calcined at 1300-1350 DEG C, the theoretical density is up to 99.7%; the nano ceramic cutter is high in bending strength and favorable in fracture toughness; and the process is simple and easy to realize large-scale production.

Owner:YAAN YUANCHUANG CERAMIC

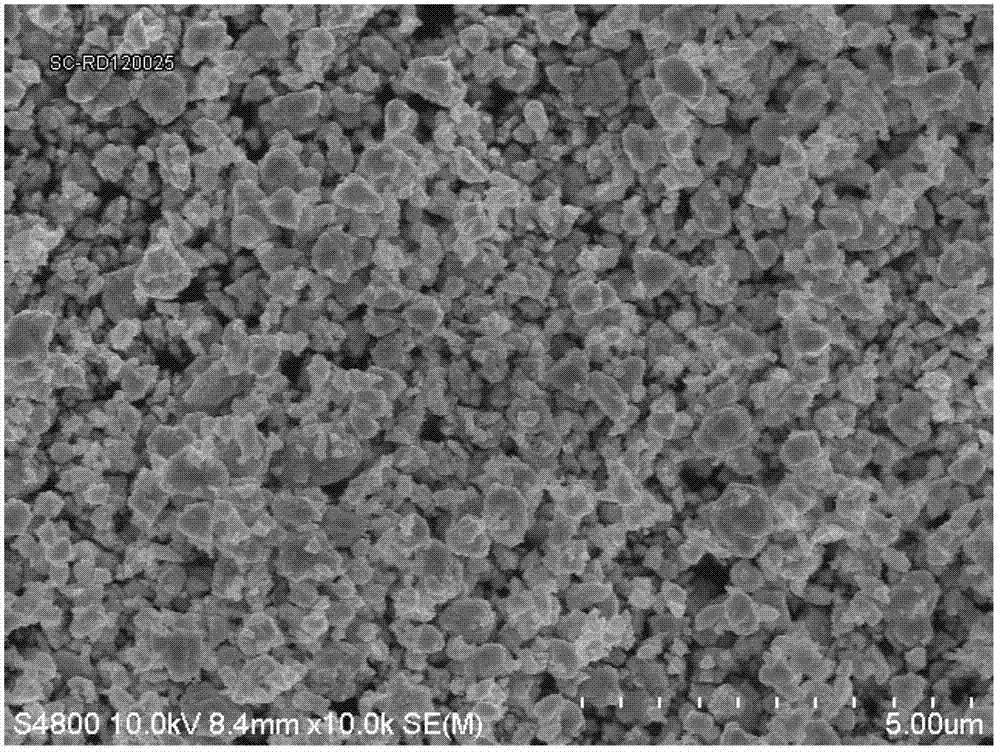

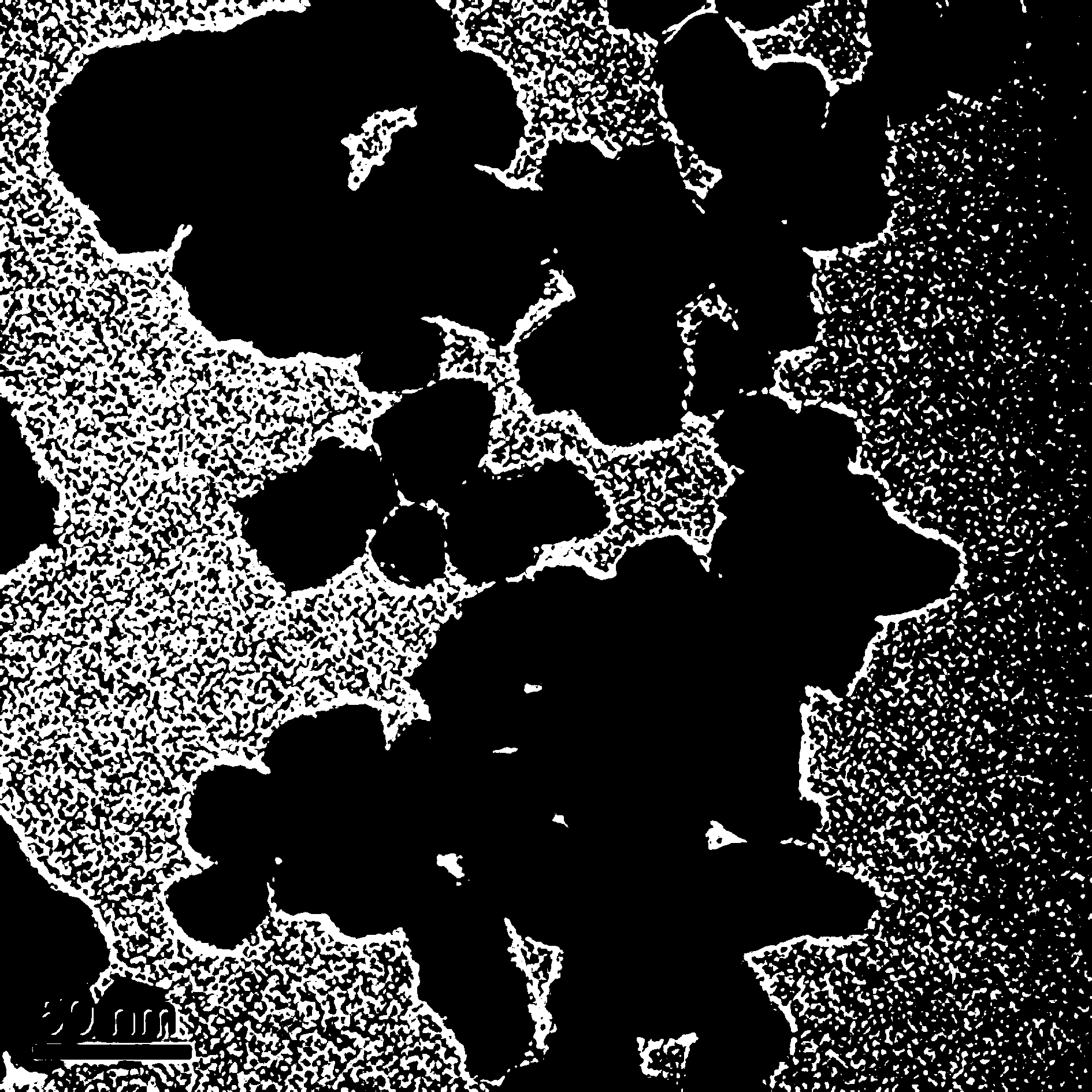

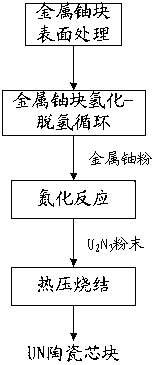

Preparation method of uranium nitride fuel powder and pellet

ActiveCN103466568AHigh purityHigh sintering activityNuclear energy generationNitrogen-metal/silicon/boron binary compoundsSurface cleaningDehydrogenation

The invention relates to a preparation method of uranium nitride fuel powder and a pellet, which comprises the following steps: (1) carrying out surface cleaning treatment on a pure metal uranium lump; (2) hydrogenating the pure metal uranium lump in hydrogen at 150-300 DEG C for 2-16 hours, dehydrogenating in a vacuum, and repeating the hydrogenation-dehydrogenation several times to obtain metal uranium powder; (3) nitridizing the metal uranium powder in nitrogen at 200-600 DEG C for 6-24 hours to obtain U2N3 powder; (4) denitrifying the U2N3 powder in a mold, keeping the system vacuum, pressurizing the mold to 30-60 MPa, sintering at 1450-1620 DEG C for 1-2 hours, and cooling to obtain the UN ceramic pellet. The method provided by the invention is simple in technique and easy to control; and the obtained intermediate product U2N3 powder has higher purity and higher sintering activity, and can be finally subjected to hot pressed sintering to obtain the UN fuel pellet of which the TD is up to 98.9%.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

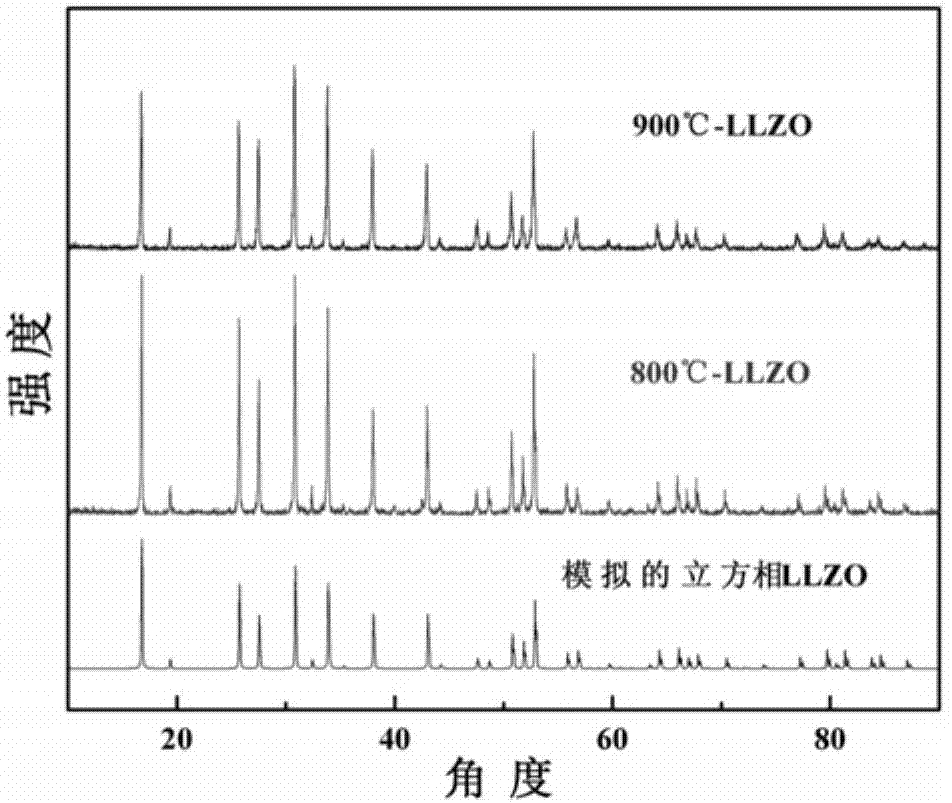

Method for preparing solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder

ActiveCN104124467ACalcination temperature is lowHigh sintering activitySecondary cellsElectrical batteryElectrochemistry

The invention discloses a method for preparing a solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder. The method specifically comprises the steps of dissolving a certain amount of lanthanum nitrate and zirconium nitrate into water, adding a precipitator, namely ammonium carbonate, controlling the pH value to ensure that La<3+> and Zr<4+> ions are simultaneously precipitated, and filtering and washing the precipitate; weighing a certain amount of lithium oxalate, dissolving lithium oxalate into water, adding the precipitate into the lithium oxalate solution, stirring, evaporating, crystallizing, and separating out lithium oxalate crystal on the surface of the precipitate to form precursor powder with a coated structure. The prepared powder has the advantages of uniform mixing, fine grains, high purity and the like; through the formed specific coated structure, the calcination temperature of the powder is low, the sintering time of the powder is short, and the room-temperature lithium ion electric conductivity of the sintered lithium lanthanum zirconium oxide is more than 2.2*10<-4>S / cm. According to the method, the process is simple, the cost is low, the preparation conditions are easy to control, and the prepared solid electrolyte is good in electrochemical stability and high in electric conductivity and can be used for preparing all-solid-state lithium ion batteries.

Owner:WUHAN UNIV OF TECH

Method for preparing Mo-Cu composite material

The invention relates to a method of preparing a Mo-Cu composite material. A mixture ball consisting of 85 to 95 weight percent Mo powder, 4.65 to 14.5weight percent Cu powder and 0.35 to 0.5weight percent Ni powder is milled into mechanical alloying composite powder; after pressing and shaping, the Mo-Cu composite material is made after the power is sintered in a hydrogen sinter furnace. The Mo-Cu composite material of the invention has relative density of up to 98percent, which not only meets the use requirements of materials of parts of high-performance engines and other heat sink materials, but also is characterized by oxidation resistance, corrosion resistance, creep resistance, fatigue resistance and tiny deformation at high temperature.

Owner:ZHONGBEI UNIV

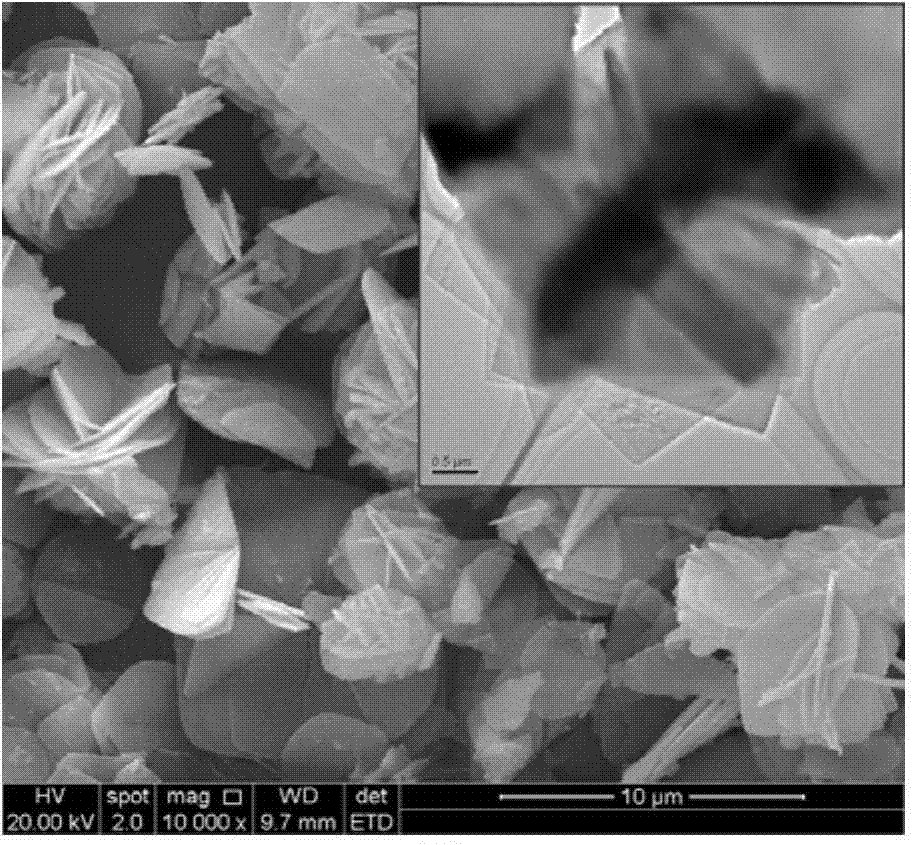

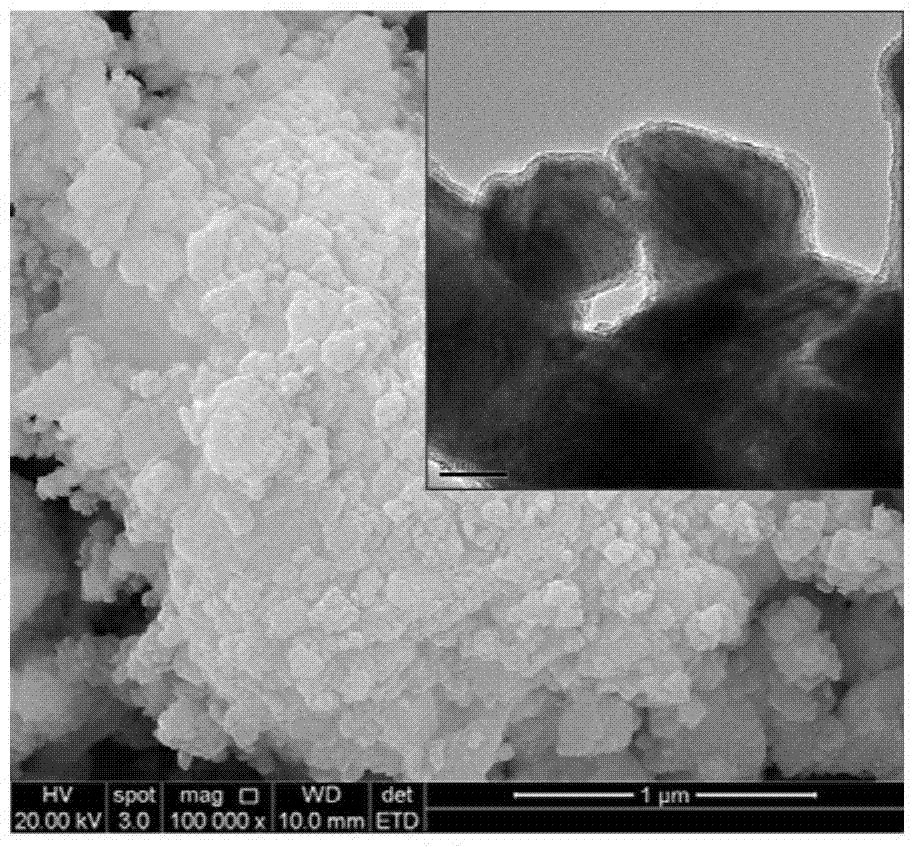

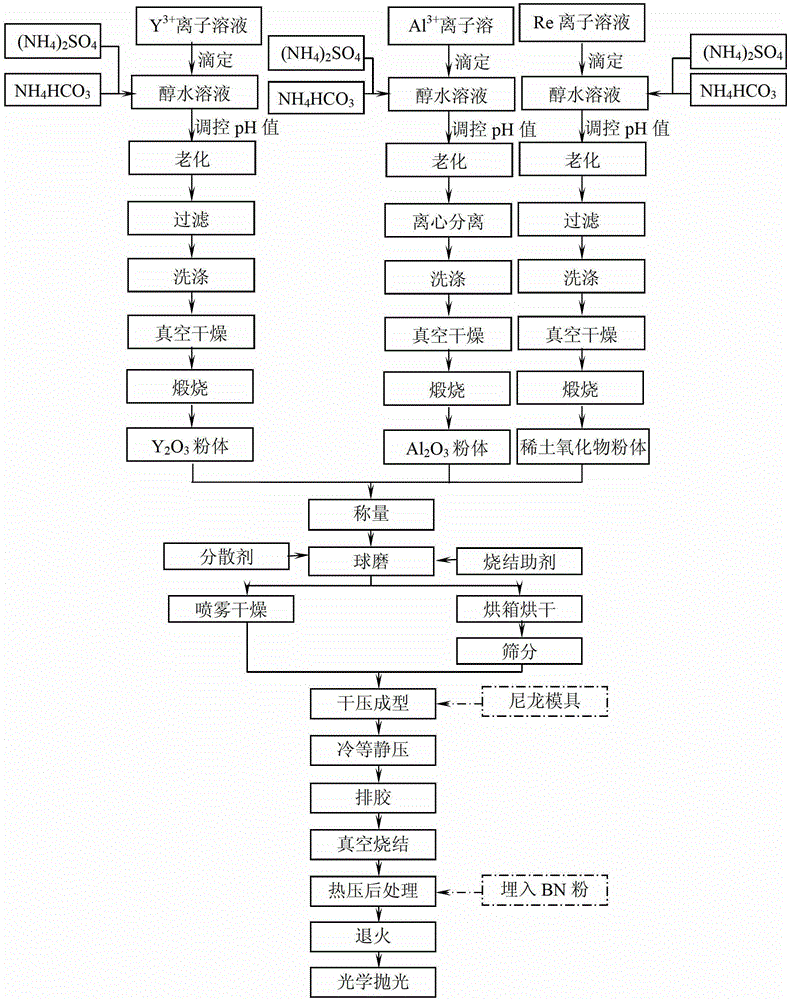

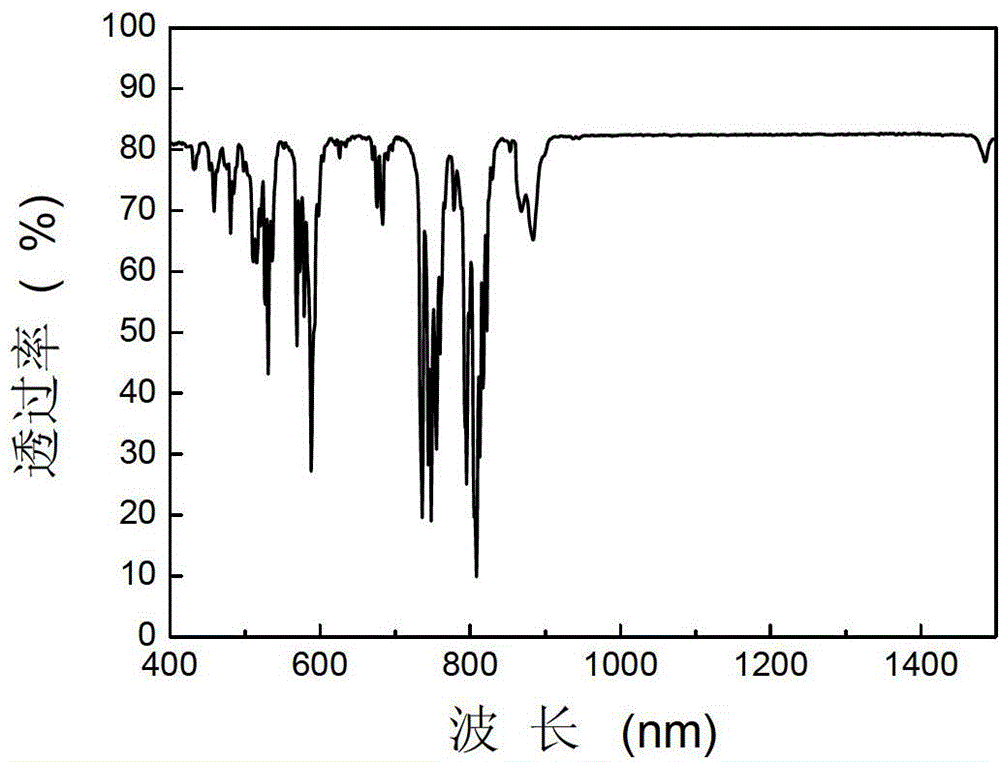

Preparation method of yttrium aluminium garnet doped transparent laser ceramics

The invention discloses a preparation method of yttrium aluminium garnet doped transparent laser ceramics. The method includes using an alcohol-aqueous system stepping chemical co-precipitation method to firstly prepare high-dispersity and high-activity nanometer Y2O3 oxide powders, Al2O3 oxide powders and rare earth (Re) oxide powders, weighing raw materials of the powders according to a stoichiometric ratio of Y<3-x>RexAl5O12 when the powders are prepared, placing the powders, sintering aids, dispersing agents and absolute ethyl alcohol into a ball-milling tank for ball milling, drying ball-milling mixing slurries into powders, forming the powders into green bodies with certain shapes by dry pressing, and then subjecting the green bodies to isostatic cool pressing to obtain ceramic biscuits. The ceramic biscuits are subjected to binder removing, vacuum sintering, powder-burying hot-pressing post-processing, annealing and optical polishing to obtain Re:YAG transparent ceramics. The preparation method has the advantages of being controllable, high in repeatability, low in cost and high in transmittance.

Owner:北京雷生强式科技有限责任公司

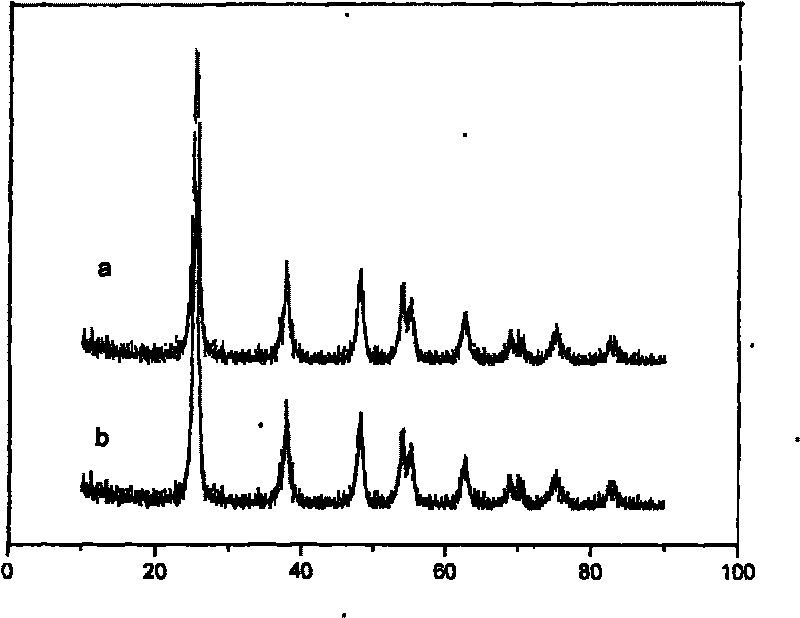

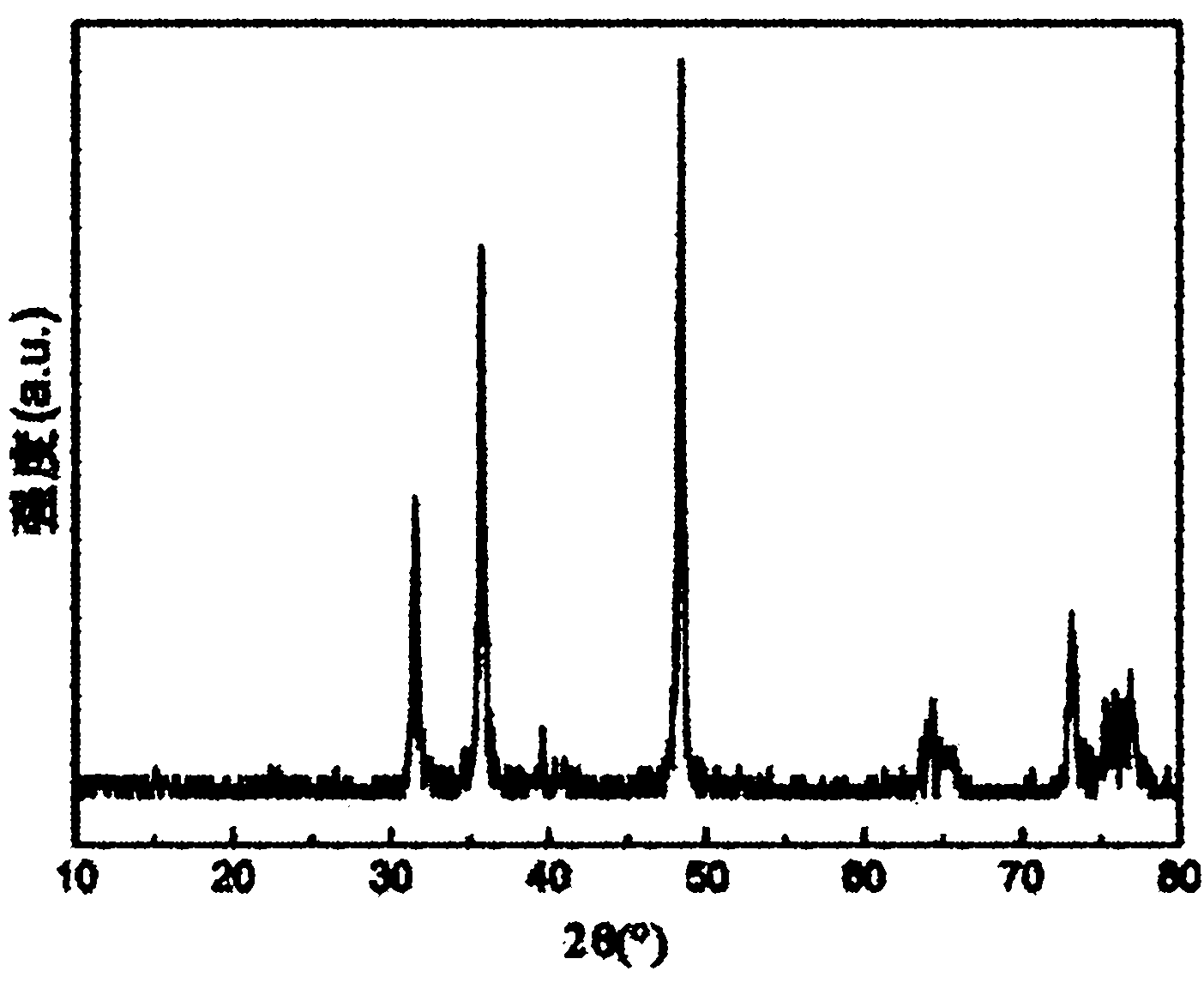

A NiZnCu ferrite material and preparing method thereof

InactiveCN101552074AHigh sintering activityImprove permeabilityInorganic material magnetismMetallurgyInorganic oxide

The invention discloses a NiZnCu ferrite material, which is a ferrite material made by adding organic additives and inorganic oxide additives in the base raw material prescription of Fe[2] O [3], NiO, or Ni [2] O [3], CuO, ZnO. The reparing method includes: adding the raw material and the organic additives into the inorganic oxide additives, mixing with water, drying, sifting; presintering; joining the organic additives again, adding water for ball milling, mixing; drying and then sifting, to obtain the inventive NiZnCu ferrite material. Granulation, molding and sintering is required during manufacturing magnet ring. Compared with the existing technology, this invention adds organic additives twice to make the prescription and process simpler, reduce the cost and presintering temperature, improve the sintering activity of the presintering material so that the sintering temperature scope becomes wider, and obtain a NiZnCu ferrite material with a good consistency of production batches, suitability for industrial production, high magnetic permeability and Q value stability.

Owner:贵阳晶华电子材料有限公司

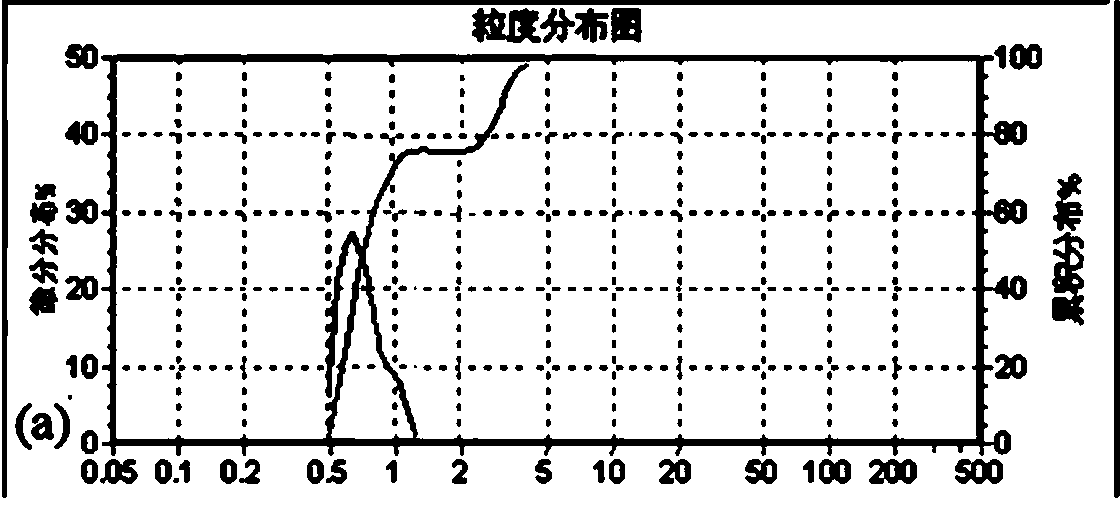

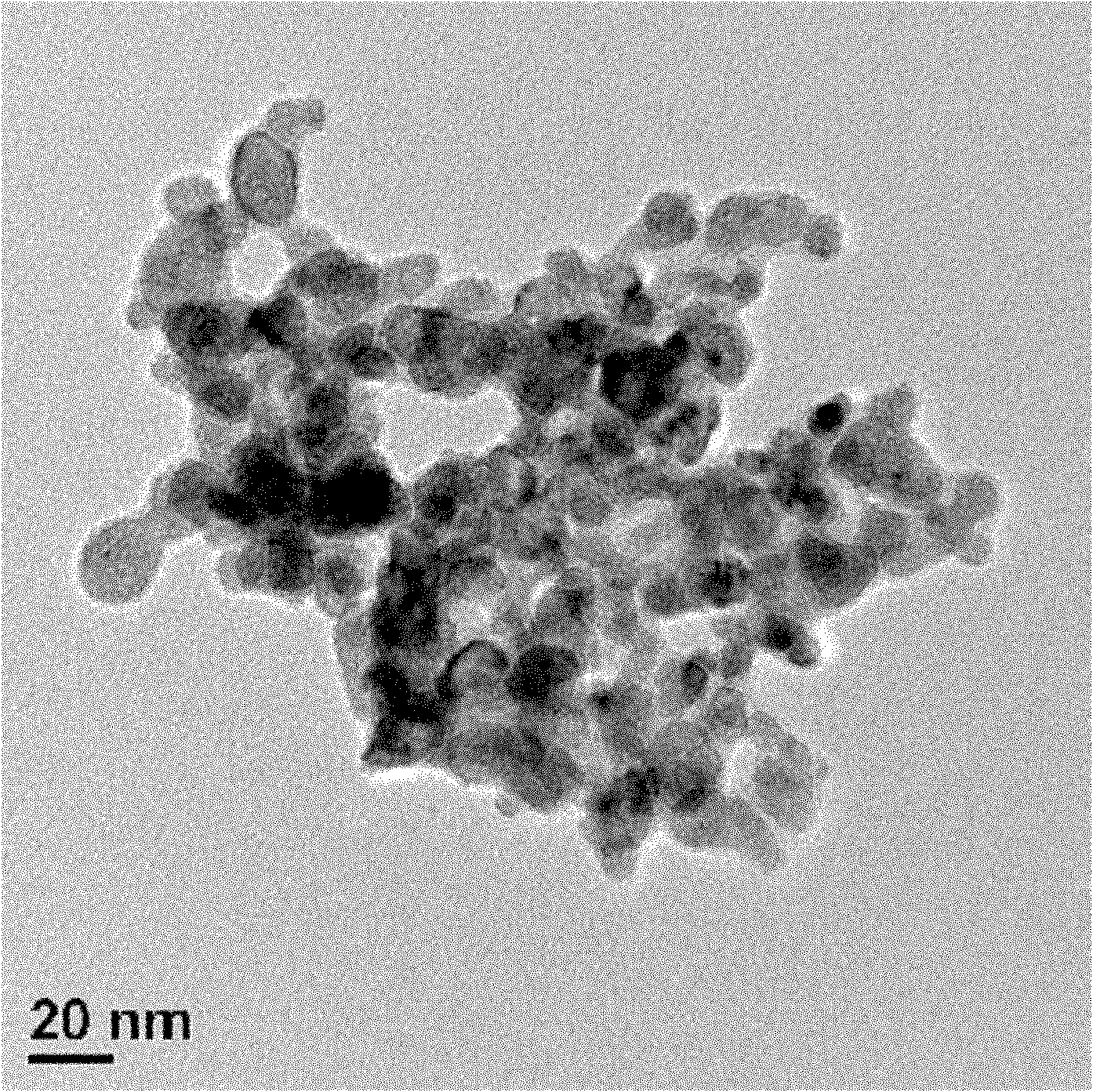

Preparation method of nano-tungsten powder

InactiveCN102019429ASimple preparation processThe preparation process is practicalAir atmosphereAmmonium metatungstate

The invention discloses a preparation method of nano-tungsten powder. The preparation method comprises the following steps: preparing ammonium metatungstate and citric acid into clear mixed aqueous solution; performing complex reaction at the temperature of 60 to 90 DEG C; filtering and drying to obtain the precursor of tungsten oxide; calcining in air to obtain tungsten oxide (WO3) powder; introducing ammonia gas to the tungsten oxide powder for nitridation to obtain tungsten nitride (W2N) powder; and finally performing thermal treatment on the tungsten nitride powder to obtain the nano-tungsten powder. The preparation process disclosed by the invention is simple and practical and has the high operability and is easy in implementation of scale production; the prepared powder has small particle size of which the average particle size is 20-50 nm; the particle size distribution is uniform; and the degree of aggregation is low and high sintering activity is realized. The technology disclosed by the invention can promote the progress of high-quality tungsten material in China and the performance level, and provide means for transforming advantages in tungsten ore resources into industrial and economical advantages.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

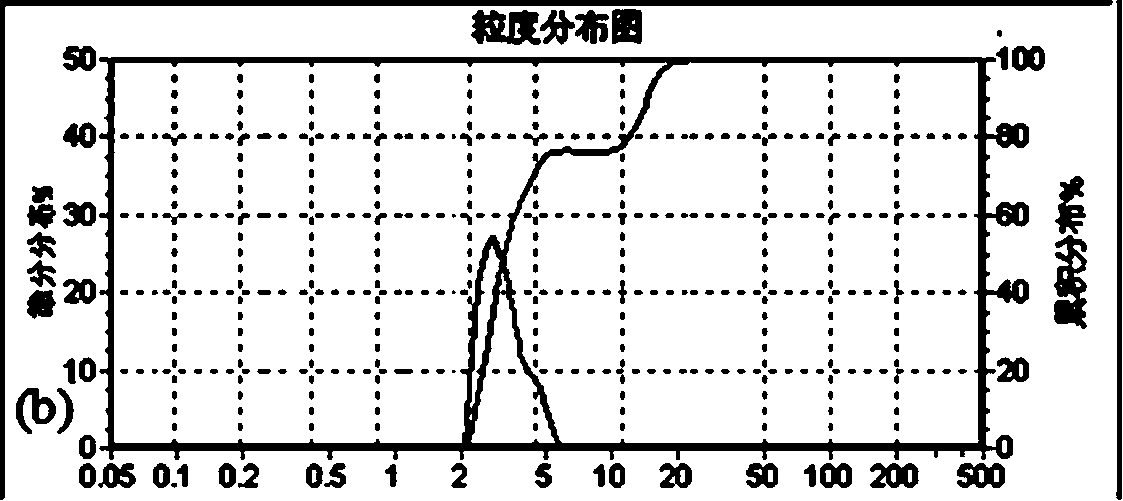

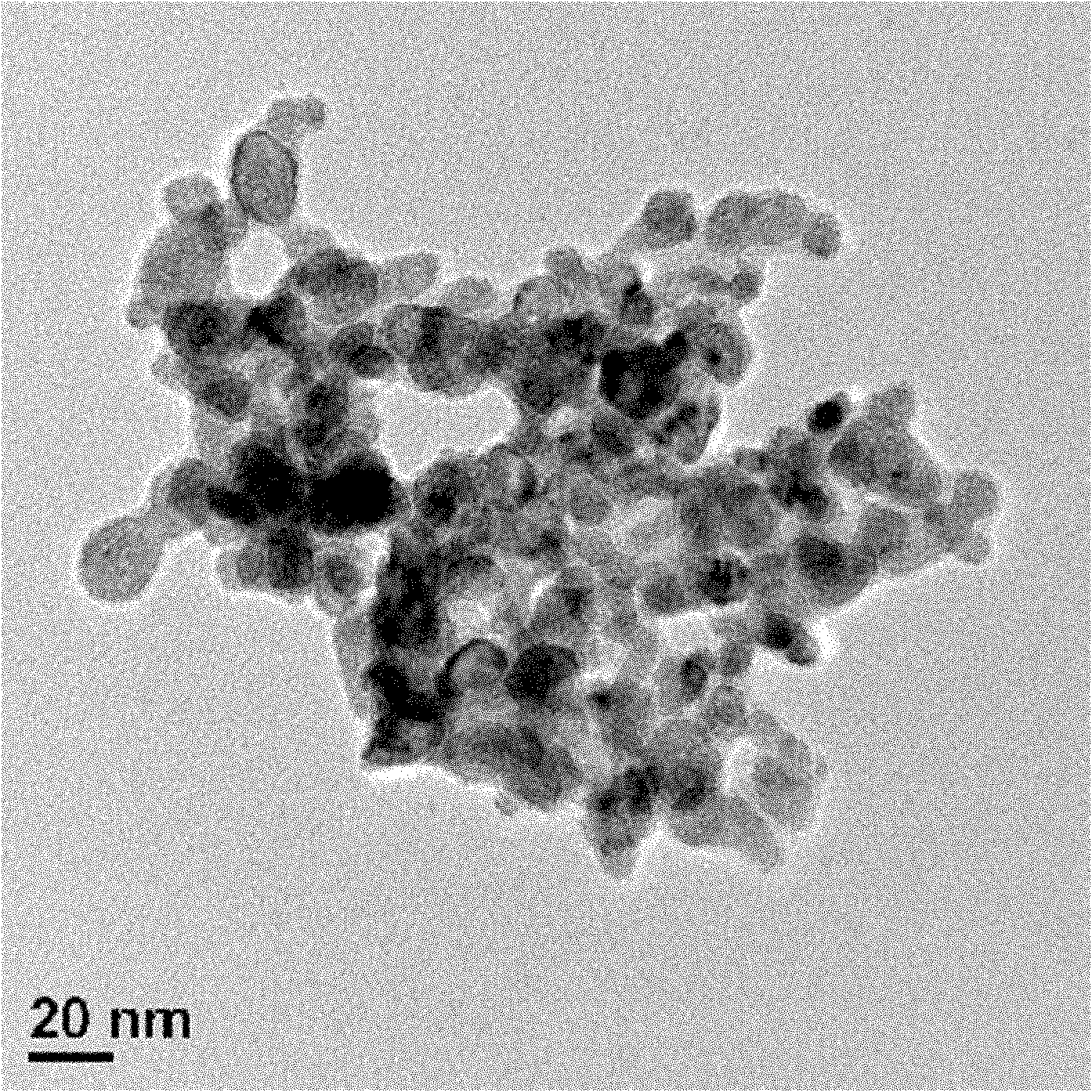

Method for preparing tungsten carbide nano-powder

InactiveCN101985356ASimple preparation processStrong maneuverabilityTungsten/molybdenum carbideAir atmosphereIon

The invention discloses a method for preparing tungsten carbide nano-powder. The method comprises the following steps of: dissolving ammonium paratungstate and citric acid in deionized water, and performing complexation in water bath; filtering and drying to obtain a precursor of tungsten oxide, and calcining under air atmosphere to obtain tungsten oxide powder; putting the obtained tungsten oxide powder in a tube furnace, introducing ammonia and nitriding to obtain tungsten nitride powder; mixing the obtained tungsten nitride powder and carbon black, performing ball milling, performing rotary evaporation drying and performing heat treatment under the air pressure of less than 200 Pa or inert atmosphere; or putting the obtained tungsten nitride powder in the tube furnace, and introducing the mixed gas of methane and hydrogen and carbonizing to obtain the tungsten carbide nano-powder. The preparation process of the method is simple, practical, and high in controllability and can easily realize large-scale production; the particle size of the prepared powder is small, the particle size distribution is uniform and the aggregation degree is low; and the method has high sintering activity, and densification can be realized by performing hot pressing sintering at the temperature of 1,700 DEG C.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

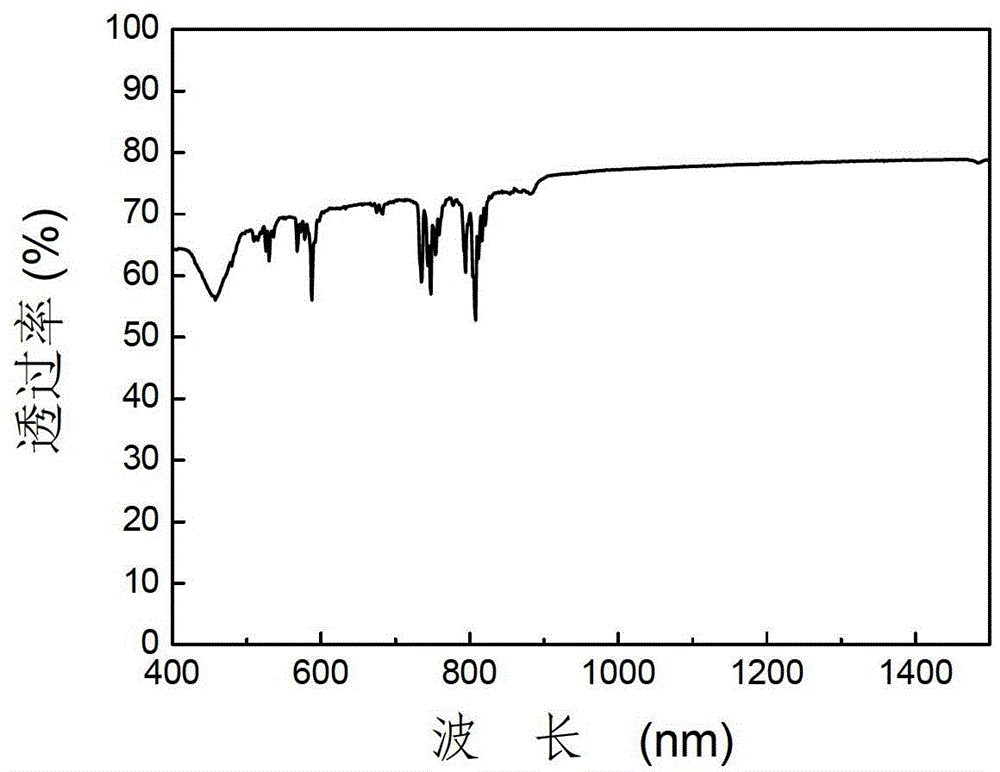

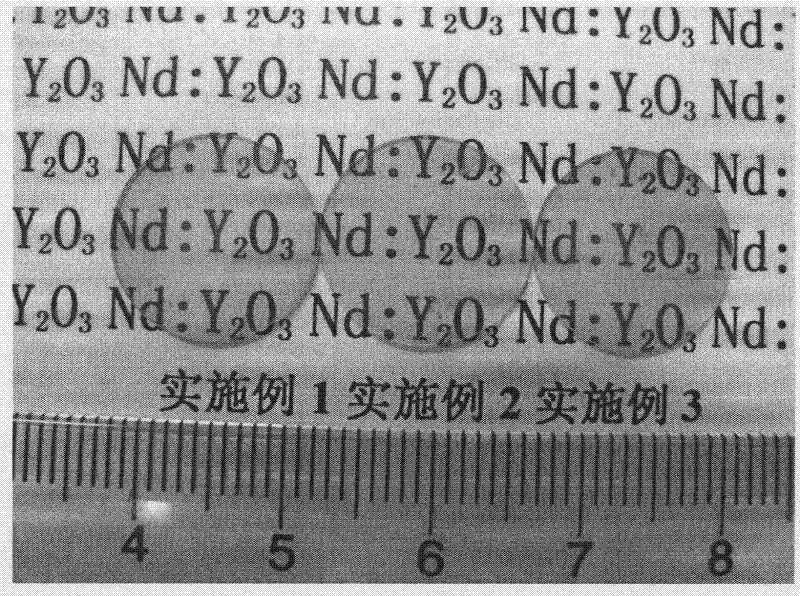

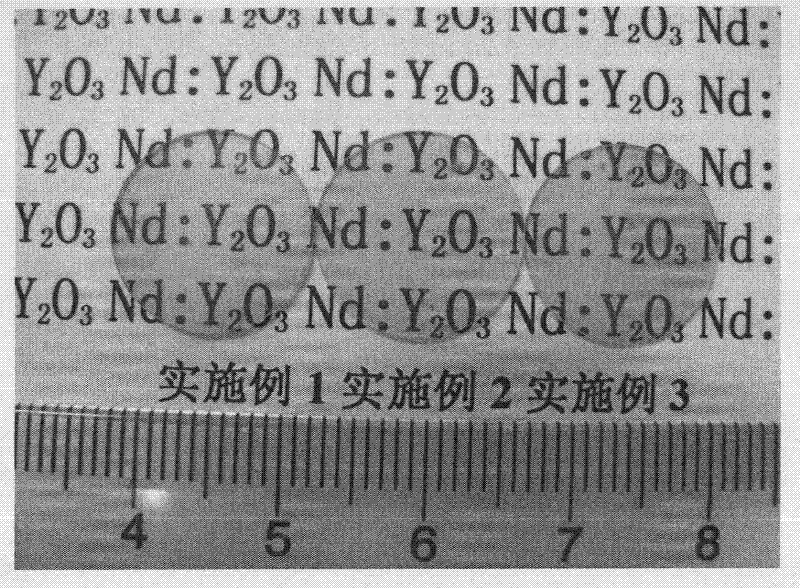

Preparation method of transparent yttria ceramic

The invention discloses a preparation method of transparent yttria ceramic, in particular relates to an ammonium bicarbonate co-precipitation method of Nd:Y2O3 nano powder. The method comprises the following steps: slowly dropwise adding a precipitator ammonium bicarbonate solution in a mixed solution prepared from yttrium, doped rare earth ion, (NH4)2SO4, polyacrylic acid (PAA) and MgSO4.7H2O at room temperature by using a positive-titration method so as to prepare a precursor, washing and drying; then calcining; carrying out preliminary press molding, cold isostatic pressing, vacuum sintering, annealing and polishing to obtain the transparent yttria ceramic. In the method, self-made high-activity nano powder is used for preparing the transparent yttria ceramic at low temperature; and the process is simple and practicable, and the prepared transparent yttria ceramic has a good optical property.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

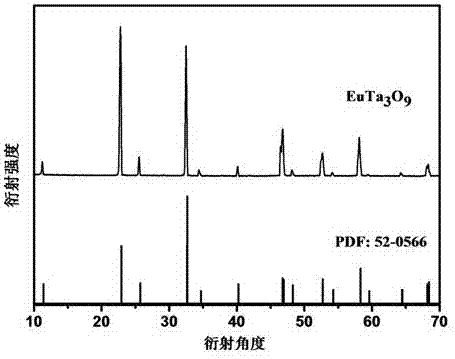

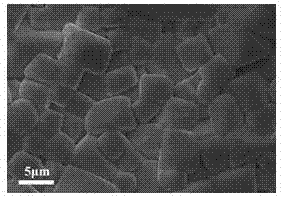

Preparation method of rare-earth tantalate high-temperature ceramic

The invention discloses a preparation method of rare-earth tantalate high-temperature ceramic. Adding RE2O3 into concentrated nitric acid, reacting to obtain a mixture, then adding TaOCl3 for mixing and stirring for 0.5 hour, adding mass of strong ammonia water to control the pH value of the reaction system to be 9 to 11, stirring to obtain a precipitated colloid, and performing filtration ,washing, drying, roasting, tabletting and sintering on the precipitated colloid to obtain the rare-earth tantalate high-temperature ceramic. According to the preparation method provided by the invention, the process purity is high, the impurity content is low, the sample is compact, the product preparation cost is low, the preparation method is suitable for production in batch, and the target product is likely to be used as a novel ceramic material with high temperature-resistance, oxidation resistance and wear-resistance.

Owner:KUNMING UNIV OF SCI & TECH

Pressureless sintering preparation method for boron carbide ceramic

The invention relates to a pressureless sintering preparation method for boron carbide ceramic, and coarse particle powder with the particle size larger than 2 micrometers is taken as raw materials. The method comprises the following steps that 70-80 wt % of boron carbide powder (D50>=2 micrometers), 4-8 wt% of carbon powder and 0.7-2 wt% of yttrium oxide powder are put into a ball mill mixing container, ball mill slurrying is performed after binding agents, dispersing agents and deionized water are added, and the solid phase content of obtained slurry is 25-45 wt%; the obtained slurry is prepared into granulating powder with a spray drying granulating machine; the granulating powder is pressed into green bodies by adopting a dry-pressing molding technology or isostatic cool pressing molding technology at 100-200 MPa; the green bodies are placed in a vacuum furnace, a vacuum or normal pressure sintering mode is adopted, heat preservation is performed for 0.5-5 h at the temperature of 2000 DEG C-2300 DEG C, sintering is completed, and then the boron carbide ceramic is obtained. According to the pressureless sintering preparation method for the boron carbide ceramic, due to the fact that the coarse particle boron carbide powder which is low in cost is adopted as the raw materials and the pressureless sintering technology capable of achieving scale production is adopted, the preparation cost of the boron carbide ceramic can be greatly lowered, and therefore the method is suitable for the fields of nuclear power, semiconductor equipment, armor protection and the like.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

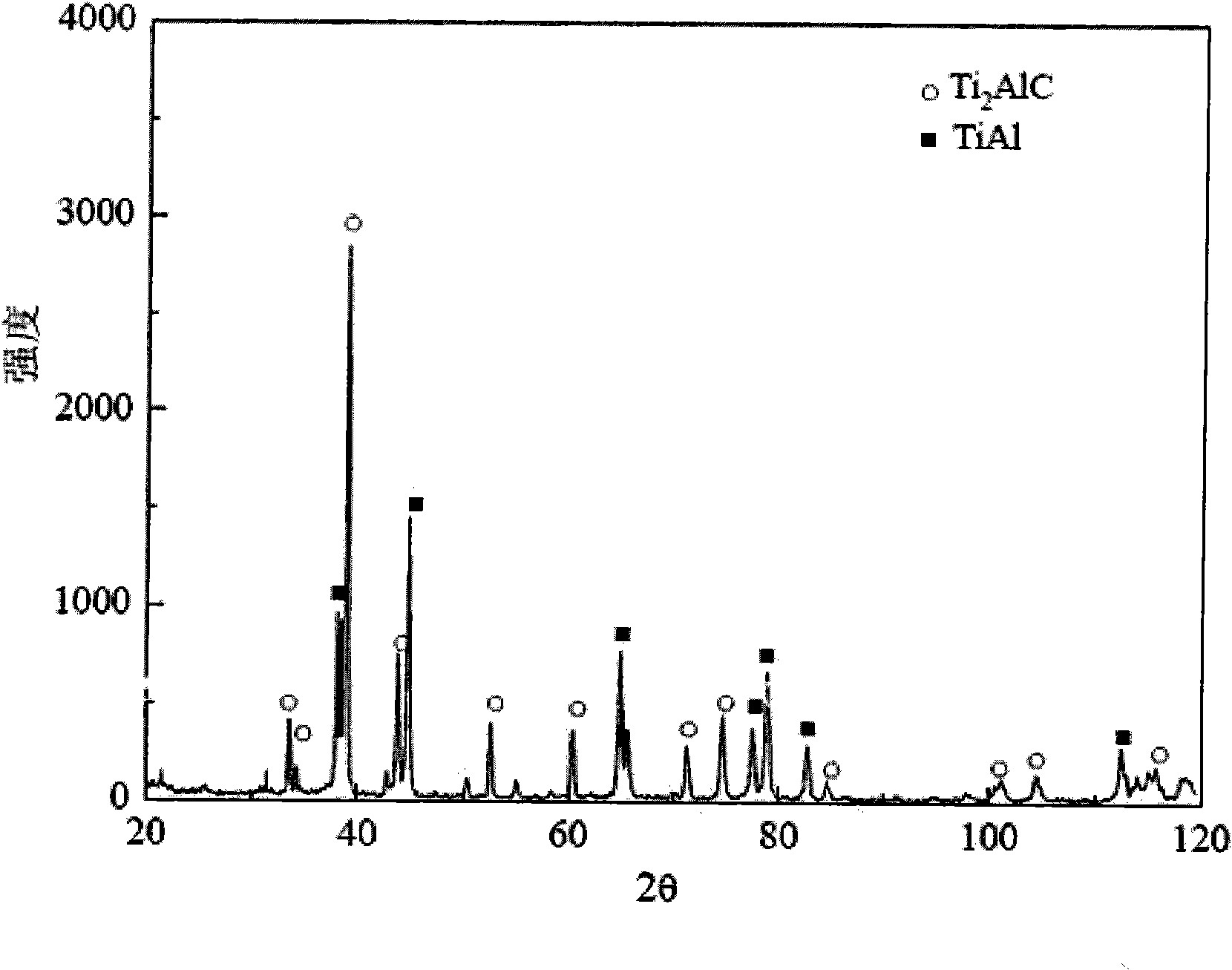

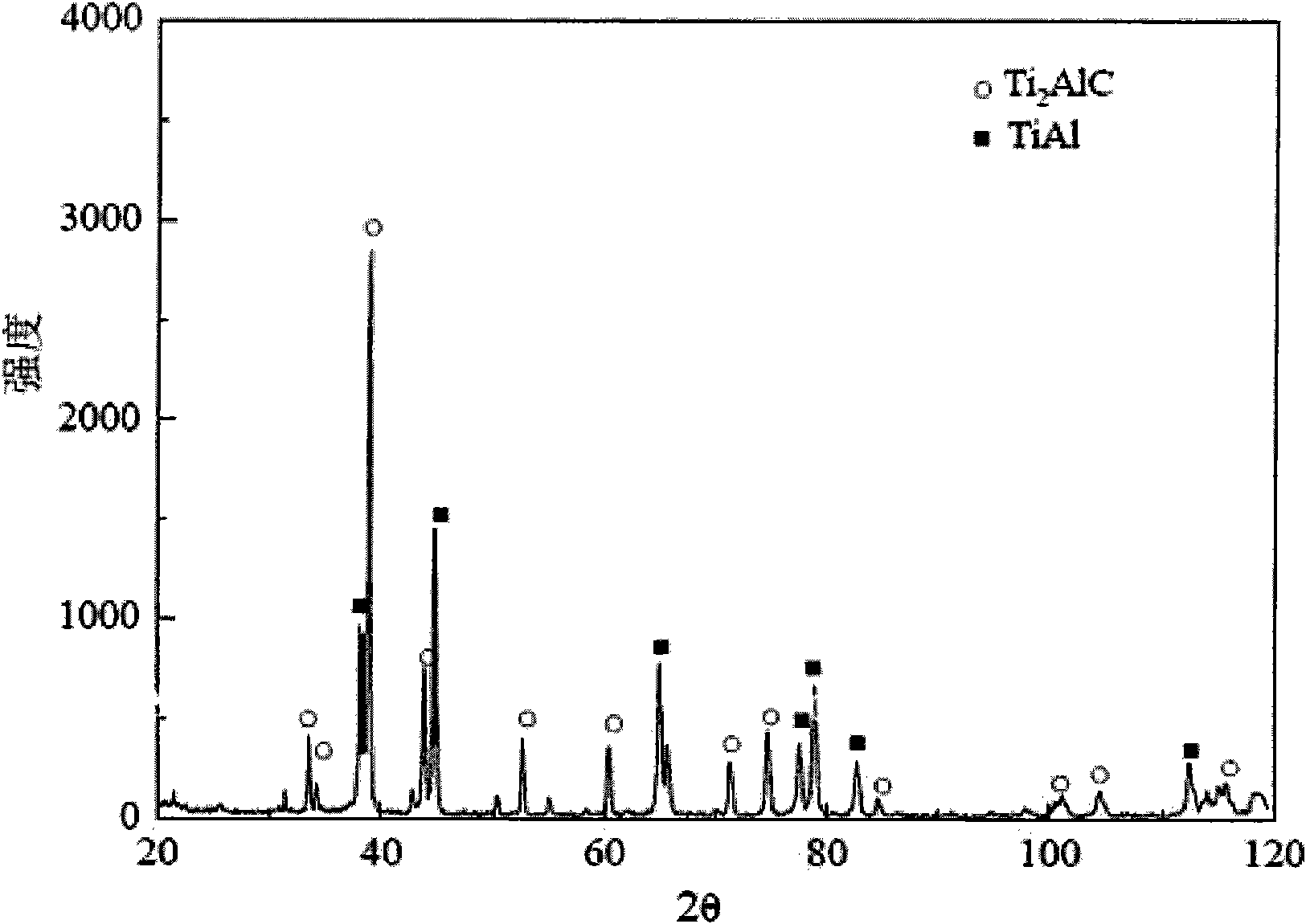

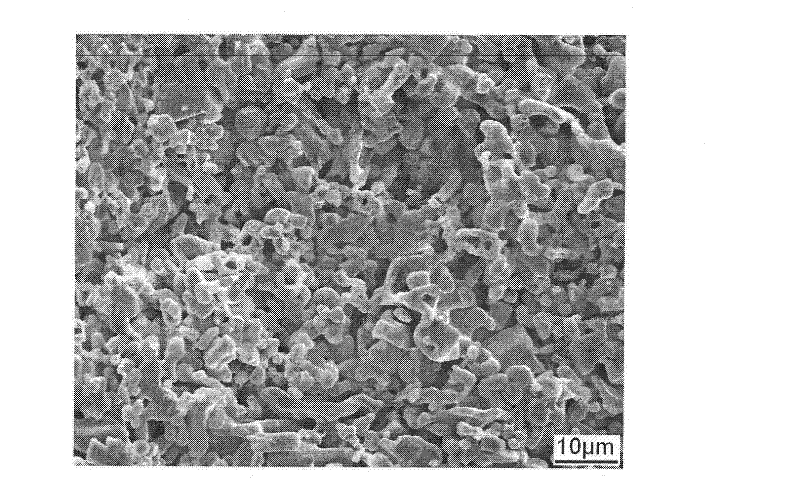

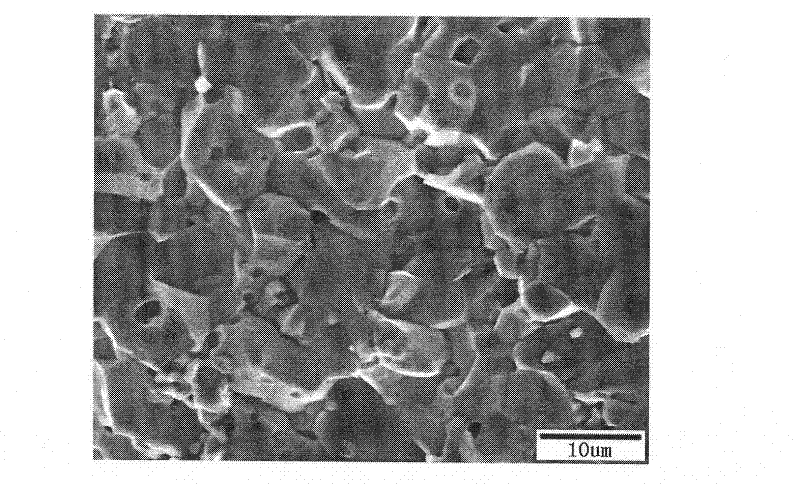

Method for preparing Ti2AlC self-lubricating and heat-resisting structural material

The invention relates to a method for preparing a Ti2AlC self-lubricating and heat-resisting structural material, which is characterized by comprising the following steps of: 1, batching Ti powder and Al powder according to an atomic ratio, and performing ball milling; performing physical dispersing on the TiAl powder subjected to the ball milling and a carbon nano tube or powdered graphite; and performing plasma sintering consolidation on the TiAl / carbon nano tube or the TiAl / powdered graphite which is subjected to the physical dispersing. In the method, the consolidation time is between 700 and 1,100 DEG C, and is about 300 to 700 DEG C lower than that of the prior art, so the Ti2AlC self-lubricating and heat-resisting structural material can be prepared at a low temperature.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

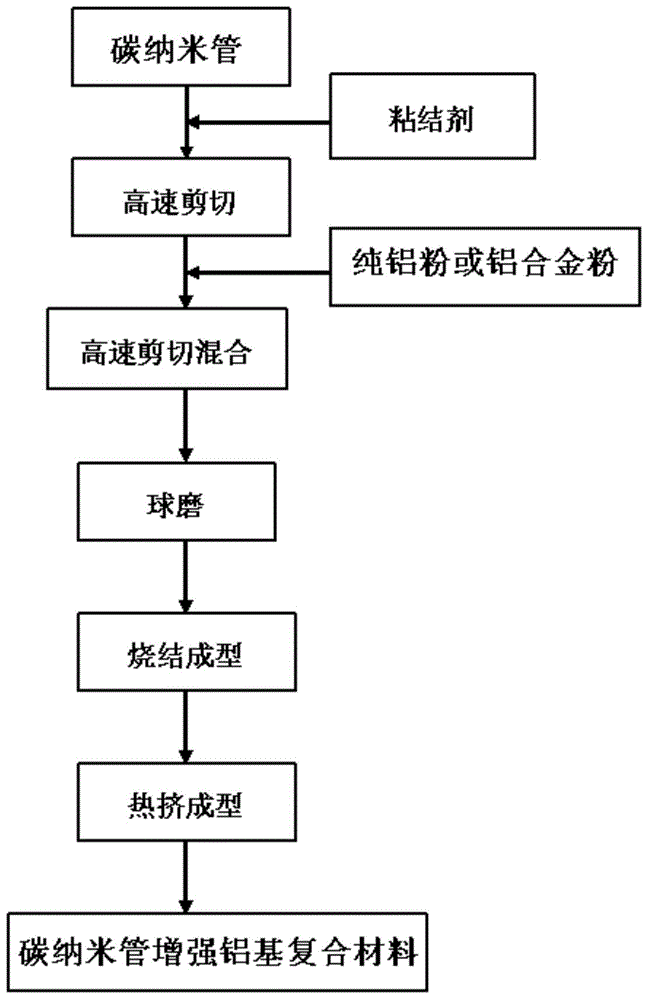

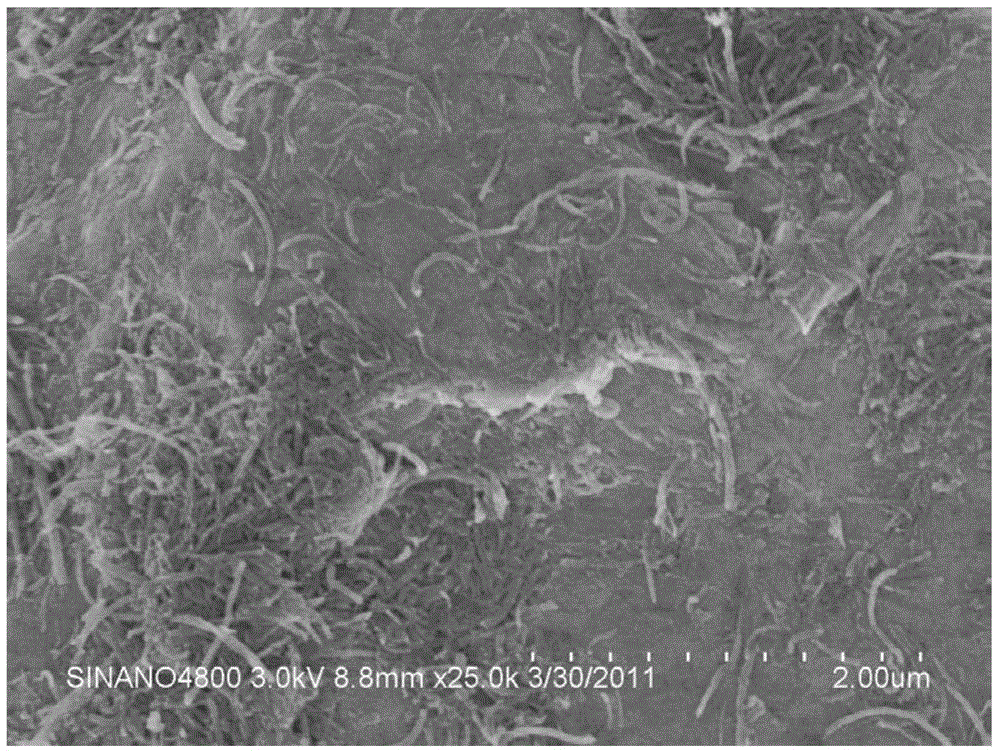

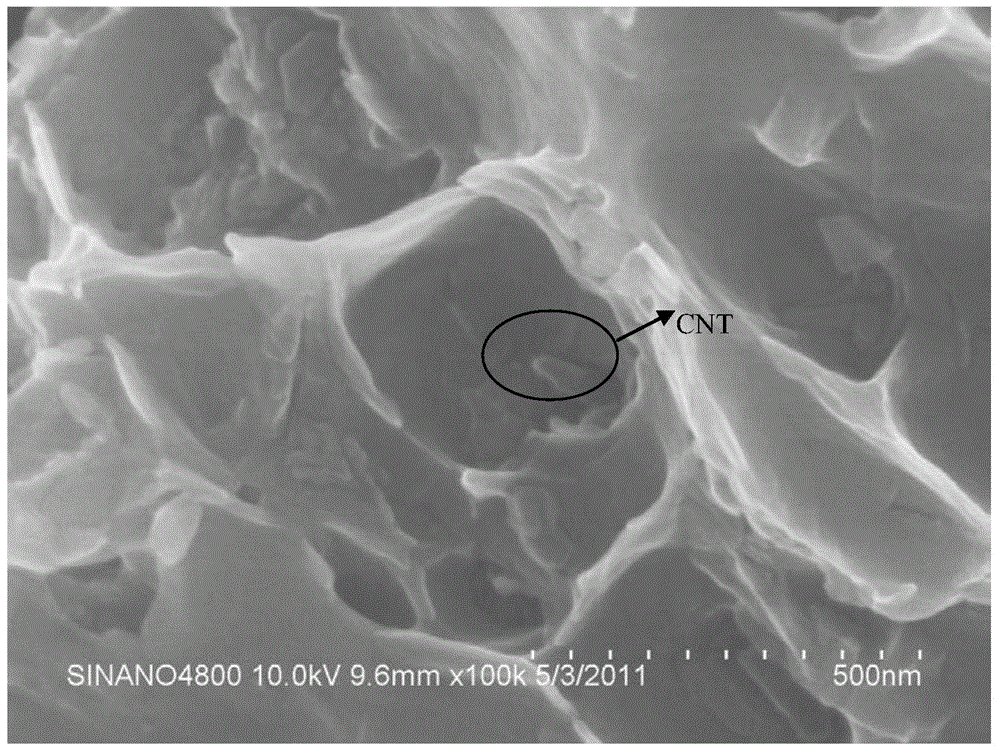

Carbon-nanotube-reinforced aluminum-base composite material

The invention discloses a carbon-nanotube-reinforced aluminum-base composite material which is prepared by the following steps: 1) carrying out high-speed shear mixing on predispersed carbon nanotubes and an adhesive until the adhesive is uniformly coated on the carbon nanotube surface, adding pure aluminum powder or aluminum alloy powder, and carrying out high-speed shear mixing until the carbon nanotubes are uniformly distributed on the pure aluminum powder or aluminum alloy powder surface, thereby obtaining first composite powder; 2) carrying out ball milling on the obtained first composite powder to obtain second composite powder; and 3) sequentially carrying out sinter molding and hot extrusion molding to obtain the carbon-nanotube-reinforced aluminum-base composite material. The adverse factors capable of resulting in stratification due to density variation are eliminated, so that the CNTs (carbon nanotubes) and the aluminum powder are uniformly mixed while keeping favorable sintering activity, and the bonding strength between the CNTs and aluminum powder is enhanced to obtain favorable interfacial combination. The combined action of work hardening and grain refining reinforcement on the base can be utilized to enhance the aluminum base, so that the tensile strength and wear resistance of the composite material are greatly enhanced.

Owner:STATE GRID CORP OF CHINA +2

Preparation method of polycrystalline cubic boron nitride (PcBN) composite material

The invention relates to a preparation method of a polycrystalline cubic boron nitride (PcBN) composite material, which comprises the following steps: by using nonstoichiometric titanium nitride (TiNX, 0.3<=x<=0.6) as the basic component of a binder in the PcBN composite material, constituting a binder with one or both of aluminum nitride (AlN) and titanium carbide (TiC), and sintering with monocrystalline cubic boron nitride (cBN) under the conditions of high temperature and high pressure to prepare the PcBN composite material, wherein the pressure is 4-6.5GPa, the temperature is 1400-1650 DEG C, and such pressure and temperature are kept for 1-25 minutes. Since the PcBN composite material is prepared from the cBN and the binder mainly composed of the nonstoichiometric titanium nitride (TiNX, 0.3<=x<=0.6), the polycrystal does not contain any simple substance element or alloy phase, thereby avoiding the existence of soft spot. The hardness of the obtained PcBN composite material is up to 38-55GPa, and the fracture toughness is up to 3.31-4.12MPa.m1 / 2.

Owner:YANSHAN UNIV

Preparation method for promoting to sinter zirconium boride or zirconium carbide ceramics by using reaction aids

The invention provides a preparation method for promoting to sinter zirconium boride or zirconium carbide ceramics by using reaction aids. Two-phase sintering aids capable of being reacted, namely Zr powder and C powder, or Zr powder and B4C powder, are added, and a material is promoted to be compact and crystals of a matrix are inhibited from growing by zirconium carbide / zirconium boride second phase particles with higher sintering activity, which are generated through in-situ reaction between the sintering aids. The ZrB2 or ZrC-based bulk material prepared by the method has the relative density of over 97 percent, the room temperature bending strength of 500-800MPa, the fracture toughness of 3.5-6.5MPa.ml / 2, and the hardness of 14-20GPa. The second phase generated through the in-situ reaction has the same melting point as the matrix, and the sintering acids cannot bring adverse effect to the high temperature mechanical properties of the material.

Owner:江苏先进无机材料研究院

W-Cu composite material with high Cu content and preparation method of W-Cu composite material

The invention relates to a W-Cu composite material with high Cu content and the preparation method of the W-Cu composite material. The W-Cu composite material is characterized in that due to the improvement of raw materials and a technology, the prepared composite material has high Cu content reaching up to more than 70% and has the characteristics of uniform structure and high compactness.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com