Method for preparing sulfur and nitrogen co-doped titanium dioxide with visible light catalytic activity

A technology of titanium dioxide and catalytic activity, applied in the field of preparation of titanium dioxide photocatalyst, can solve the problems of high risk and pollution, and achieve the effects of less consumption of raw materials, improved absorption range, and high sintering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

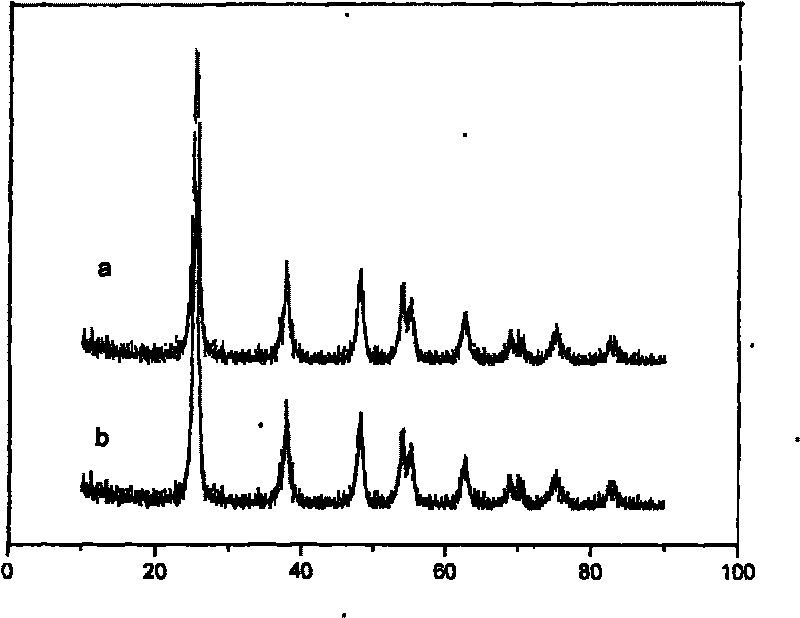

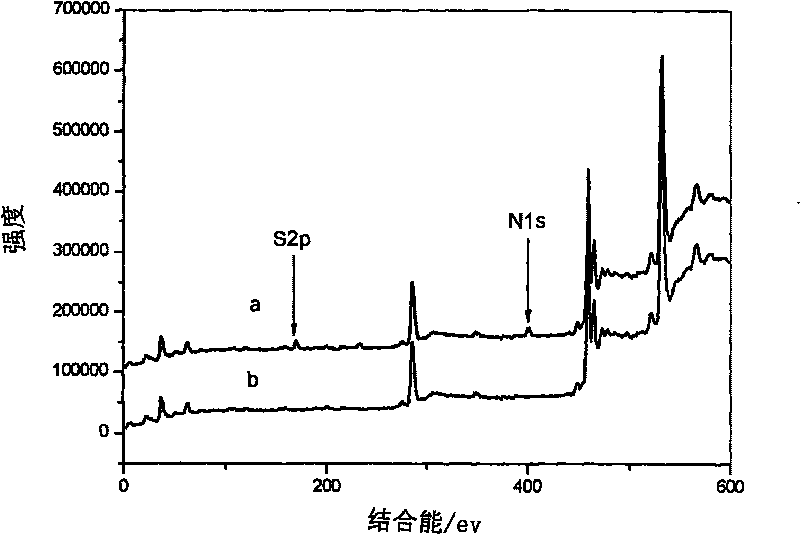

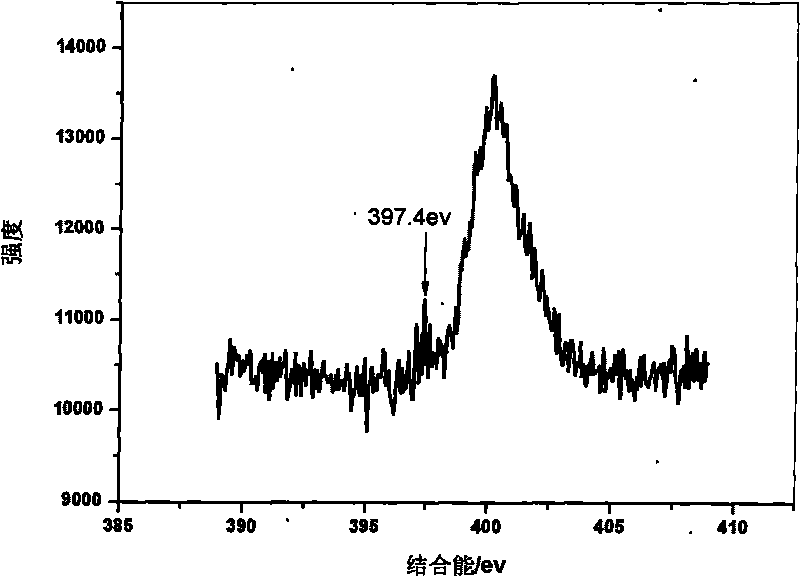

[0019] Embodiment 1: Sol-gel method prepares sulfur-nitrogen co-doped titanium dioxide: the raw material ratio (percentage by weight, total weight is 50 grams) of synthetic titanium dioxide sol: butyl titanate (analytical pure) 5%, dehydrated alcohol (analytical Pure) 88%, acetic acid (analytical pure) 5%, thiourea (analytical pure) 2%, put butyl titanate, absolute ethanol, acetic acid in the reaction flask according to the above ratio, and stir at a temperature of 15°C for 30 Minutes, then thiourea aqueous solution was added to the reaction solution, and the reaction was continued for 2 hours to obtain a titanium dioxide sol. The solvent was evaporated to obtain a gel, and the gel was dried in an air atmosphere at 100° C. for 2 hours to obtain a dried solid. Grind the dried solid, put it into a muffle furnace after grinding, heat up to 450°C at a rate of 2°C / min at room temperature, calcinate at 450°C for 2 hours, and cool down to room temperature to obtain the target product...

Embodiment 2

[0021]Embodiment 2: Sol-gel method prepares sulfur and nitrogen co-doped titanium dioxide, the raw material ratio (percentage by weight, total weight is 50 grams) of synthetic titanium dioxide sol: butyl titanate (analytical pure) 5%, dehydrated alcohol (analytical pure) 88%, acetic acid (analytical pure) 5%, thiourea (analytical pure) 1%, butyl titanate, dehydrated alcohol, acetic acid are placed in the reaction flask according to the above ratio, and stirred at a temperature of 15°C for 30 Minutes, then thiourea aqueous solution was added to the reaction solution, and the reaction was continued for 2 hours to obtain a titanium dioxide sol. The solvent was evaporated to obtain a gel, and the gel was dried in an air atmosphere at 100° C. for 2 hours to obtain a dried solid. Grind the dried solid, put it into a muffle furnace after grinding, heat up to 450°C at a rate of 2°C / min at room temperature, calcinate for 2 hours, and cool down to room temperature to obtain a sample of ...

Embodiment 3

[0022] Embodiment 3: Sol-gel method prepares sulfur and nitrogen co-doped titanium dioxide, the raw material ratio (percentage by weight, total weight is 50 grams) of synthetic titanium dioxide sol: butyl titanate (analytical pure) 5%, dehydrated alcohol (analytical Pure) 88%, acetic acid (analytical pure) 5%, thiourea (analytical pure) 3%, put butyl titanate, absolute ethanol, acetic acid in the reaction flask according to the above ratio, and stir at a temperature of 15°C for 30 Minutes, then thiourea aqueous solution was added to the reaction solution, and the reaction was continued for 2 hours to obtain a titanium dioxide sol. The solvent was evaporated to obtain a gel, and the gel was dried in an air atmosphere at 100° C. for 2 hours to obtain a dried solid. Grind the dried solid, put it into a muffle furnace after grinding, raise the temperature to 450°C at a rate of 2°C / min at room temperature, calcinate for 2 hours, and cool down to room temperature to obtain the targe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com