Patents

Literature

138results about How to "Uniform bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

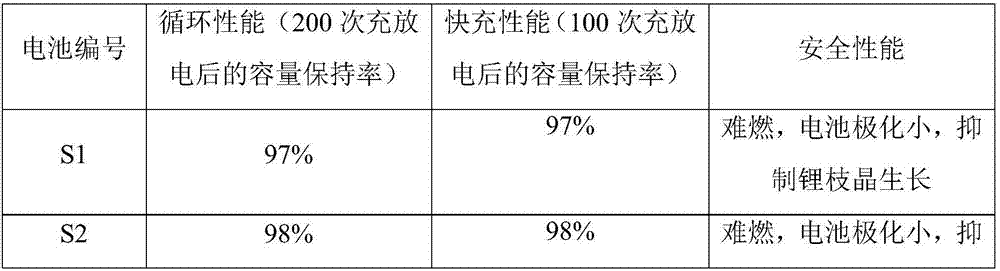

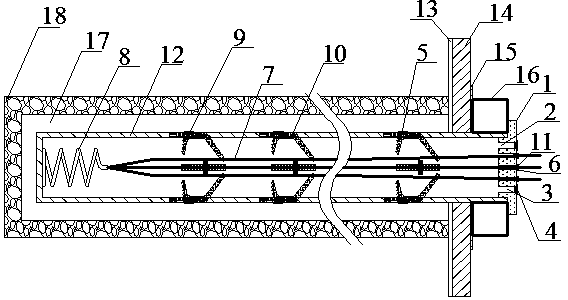

Inorganic/organic composite thin film solid-state electrolyte for lithium metal battery and preparation method of inorganic/organic composite thin film solid-state electrolyte

ActiveCN107394261AImprove ionic conductivityImprove flexibilityLi-accumulatorsLithium electrodeInorganic electrolyte

The invention belongs to the technical field of a lithium metal battery, and particularly relates to an inorganic / organic composite thin film solid-state electrolyte for the lithium metal battery. The inorganic / organic composite thin film solid-state electrolyte comprises a ceramic nanowire network framework, an inorganic electrolyte and a polymer electrolyte, wherein the inorganic electrolyte is combined with the ceramic nanowire network framework by a magnetron sputtering method, and the polymer electrolyte is combined with the inorganic electrolyte and the ceramic nanowire network framework in an in-situ way. Compared with the prior art, the ceramic nanowire network framework with a unique structure is used, and the multi-layer network-structure inorganic / organic composite thin film solid-state electrolyte is prepared on the basis; and moreover, by optimizing and improving the interface compatibility and stability of the inorganic / organic composite thin film solid-state electrolyte and a metal lithium electrode, rapid ion transmission is achieved, the growth of lithium dendrites is suppressed, the penetrating of the lithium dendrites is prevented, and the cycle stability and the safety of the lithium metal battery are improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

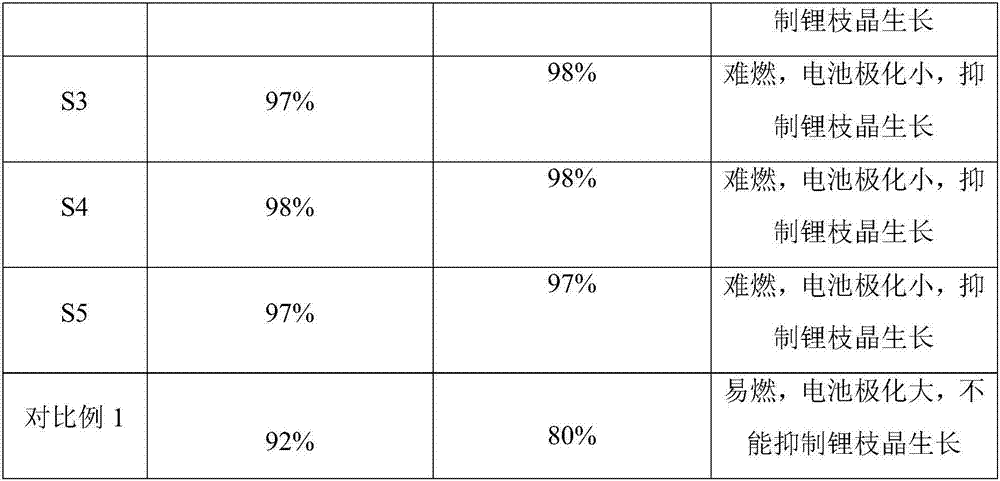

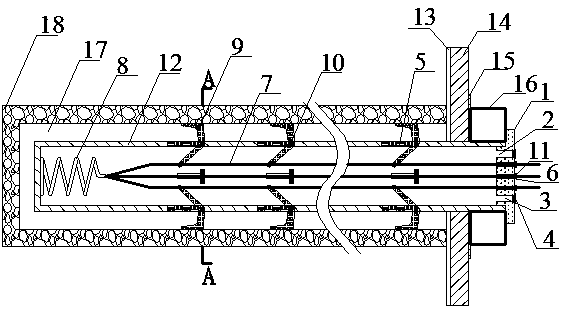

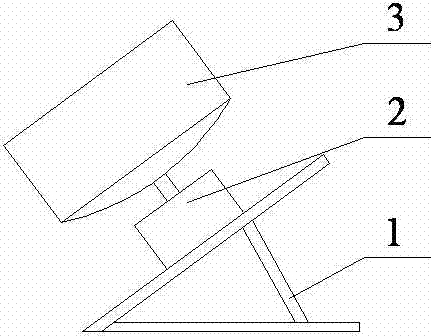

Novel anchoring grouting anchor rod and construction method thereof

ActiveCN108979692ASolve the anchorSolve the problem of insufficient groutingAnchoring boltsClimate change adaptationPre stressPre stressing

The invention discloses a novel anchoring grouting anchor rod and a construction method thereof. The novel anchoring grouting anchor rod is formed by a grouting system, an anchoring system and a fastening system. The grouting system comprises a cover, a vent hole, a grouting hole, a slurry plug, and overflow holes and various parts work together to ensure that slurry is full and tightly bonded. The anchoring system is formed by anchoring holes, a steel strand, a high-strength spring, an anchor claw, a rotating shaft and a steel strand clamp, initial anchoring force can be provided for the anchor rod, the anchor claw has barbs and rotates under the traction of the steel strand and closely attaches to a surrounding rock, and anchor removal is effectively prevented. The fastening system is formed by an anchor rod body, a slurry stop pad, a tray, a washer and a high-strength nut. After the slurry is solidified, the pre-stress can be provided for the grouting anchor to control the deformation of the surrounding rock. According to the invention, an anchor claw rotation design is employed, the anchor claw closely attaches to the surrounding rock, sufficient anchoring force is provided toprevent the anchor removal, and vent holes are set to ensure a pouring effect. The application defect of an existing grouting anchor is solved, and the novel anchoring grouting anchor rod and the construction method have the advantages of anchor removal prevention, high adaptability and good grouting effect.

Owner:SHANDONG UNIV OF SCI & TECH

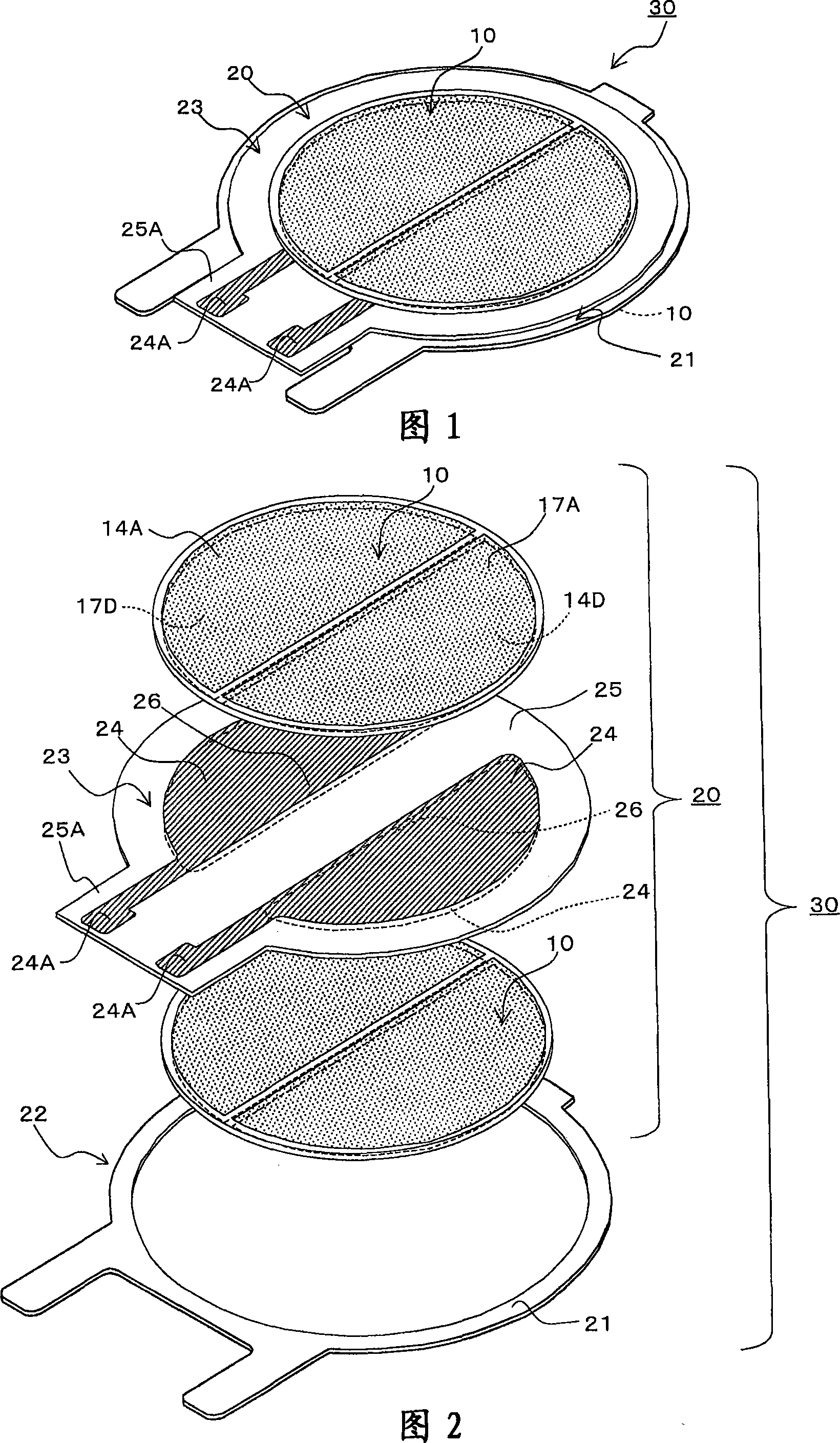

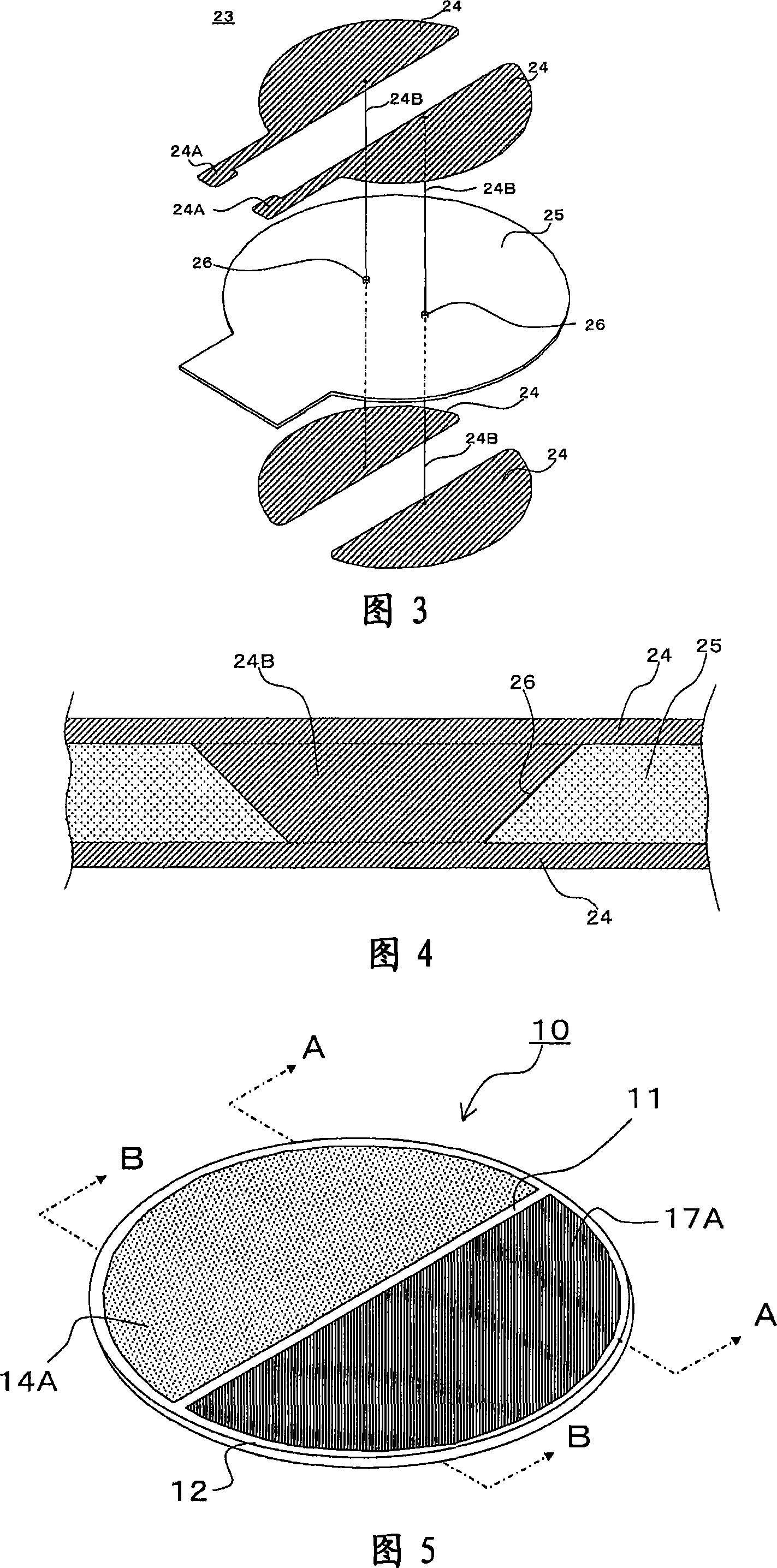

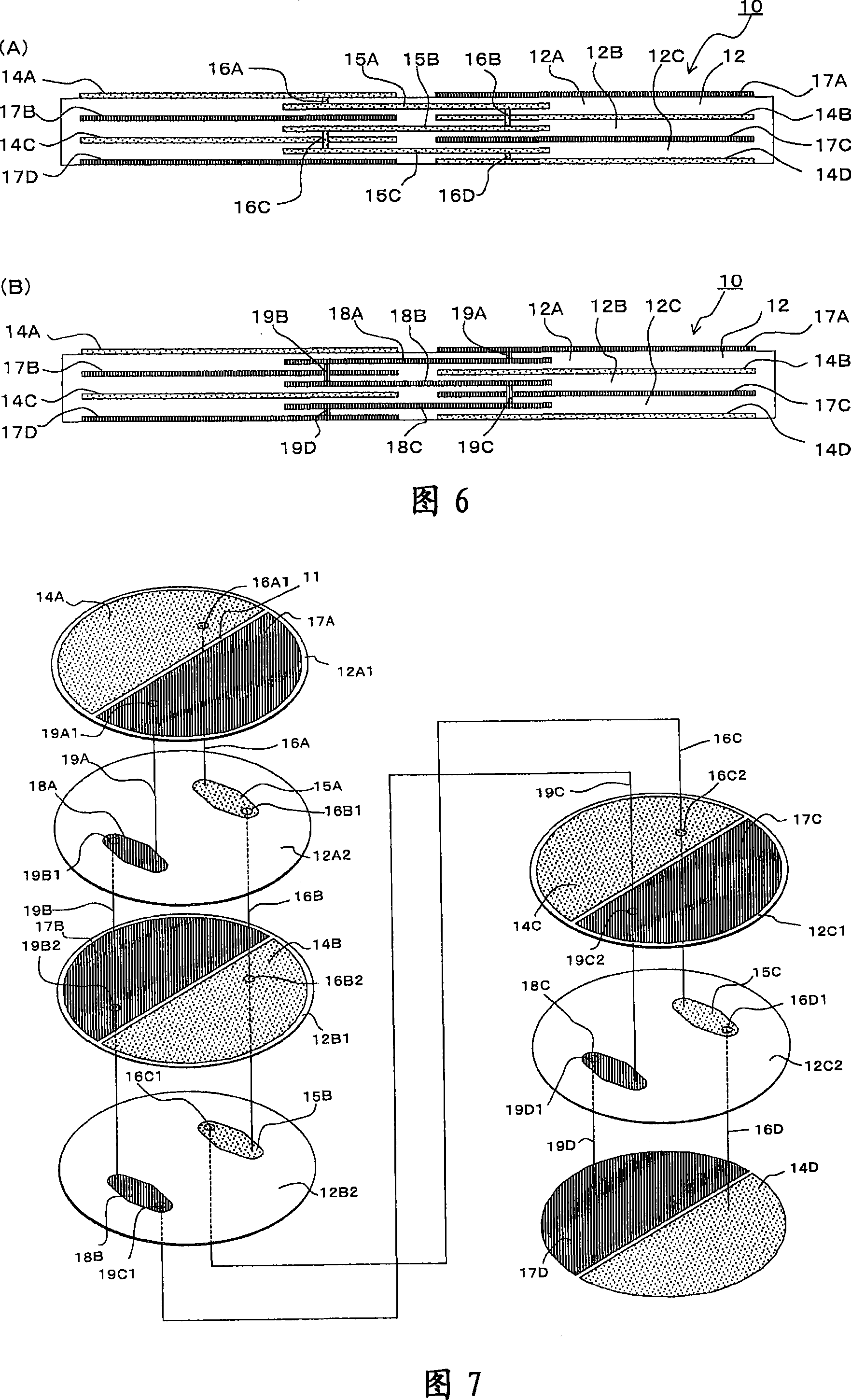

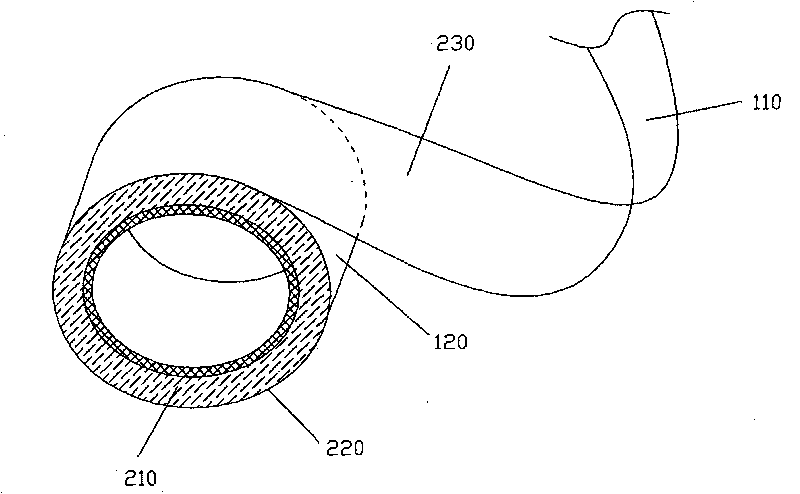

Piezoelectric type electroacoustical transformer

InactiveCN101102621AUniform bondingImprove reliabilityPiezoelectric/electrostrictive transducersMouthpiece/microphone attachmentsElectrical conductorTransformer

The invention provides a piezoelectric electro-acoustic converter. The piezoelectric electro-acoustic converter has: a pair of piezoelectric elements with an outer electrode on one main surface; piezoelectric vibration plate arranging between a pair of piezoelectric elements and attaching on two main surfaces of the insulated base plate; a supporting body having the circular supporting portion along the edge portion of the piezoelectric vibration plate, in which a through hole conductor on the vibration plate is arranged in the inner area surrounded by the circular supporting portion, the connecting electrodes at two main surfaces of the vibration plate are connected mutually and a set of lead-out portion respectively connected with the electrode are formed near the edge portion of another main surface. Therefore, the invention is unnecessary to set the lead-out portion near the edge portion of the vibration plate and on the binding face of the supporting portion for connecting the electrodes, meanwhile the edge portion of the vibration plate along the whole circumference is uniformly binding to the circular supporting portion of the supporting body.

Owner:TAIYO YUDEN KK

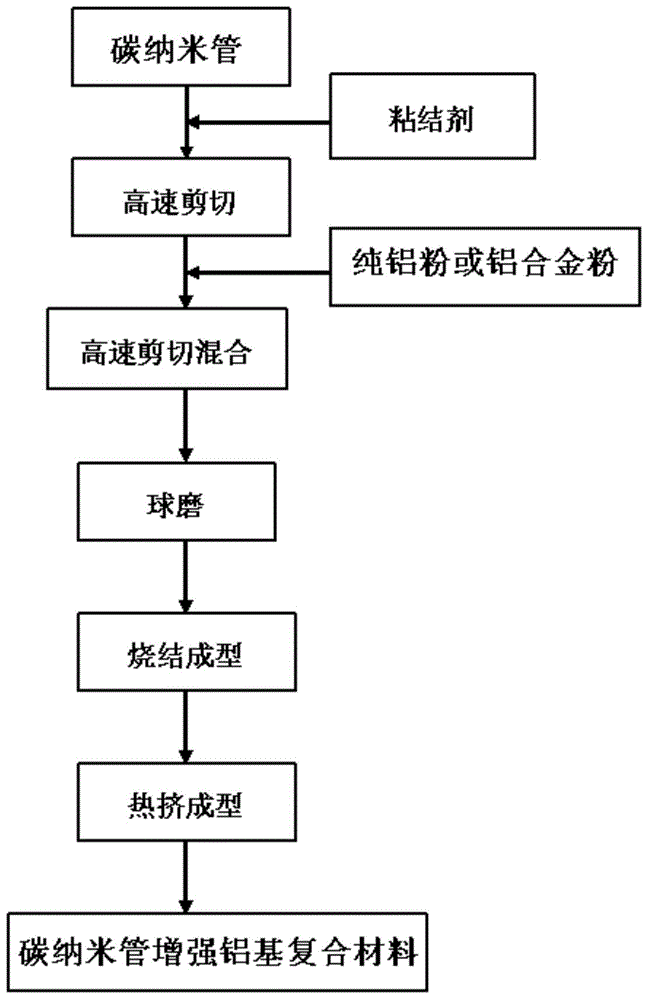

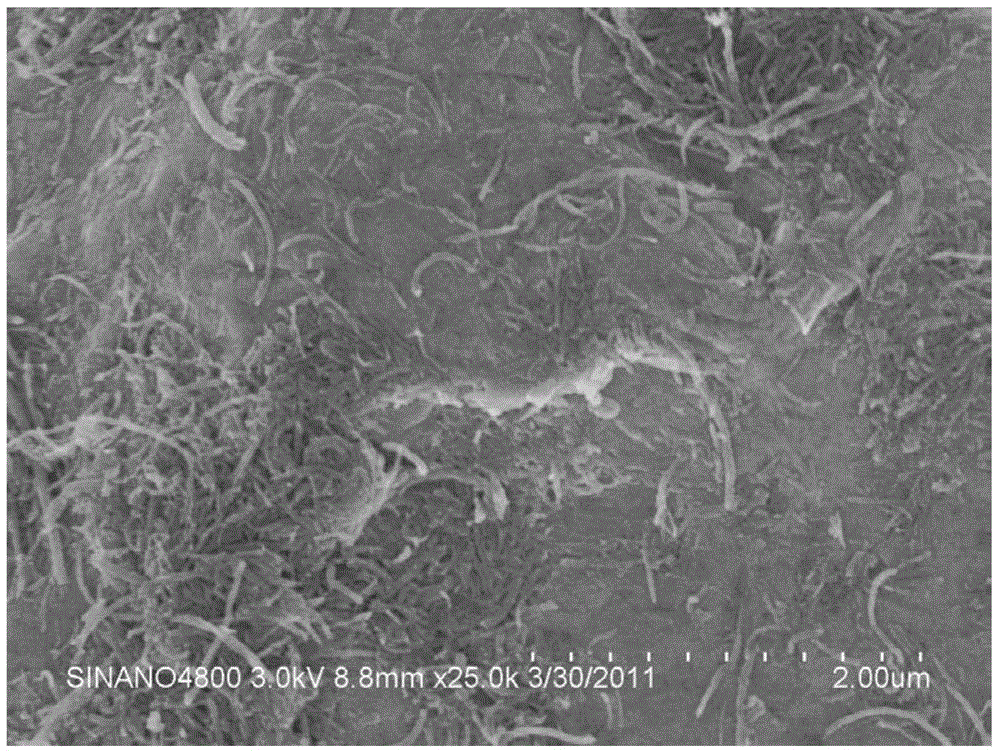

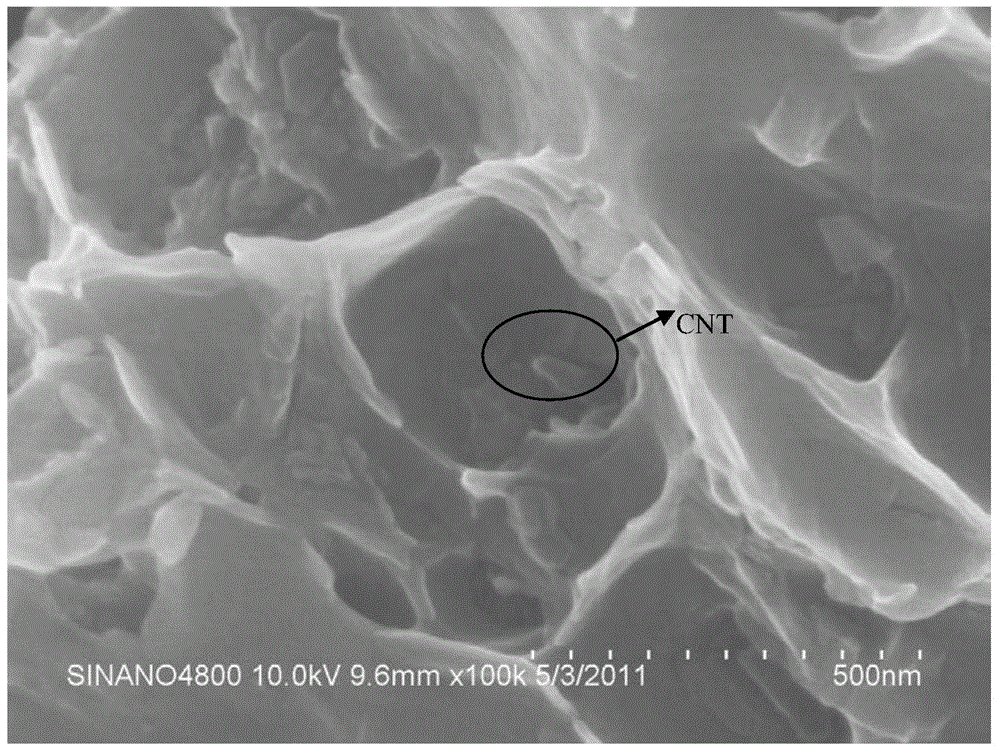

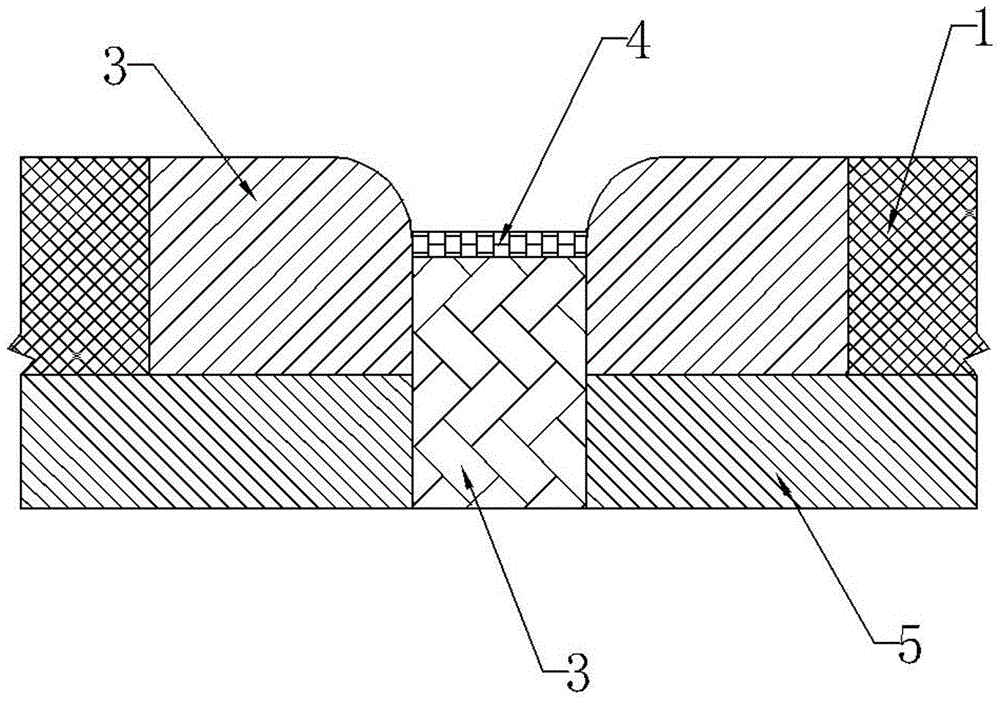

Carbon-nanotube-reinforced aluminum-base composite material

The invention discloses a carbon-nanotube-reinforced aluminum-base composite material which is prepared by the following steps: 1) carrying out high-speed shear mixing on predispersed carbon nanotubes and an adhesive until the adhesive is uniformly coated on the carbon nanotube surface, adding pure aluminum powder or aluminum alloy powder, and carrying out high-speed shear mixing until the carbon nanotubes are uniformly distributed on the pure aluminum powder or aluminum alloy powder surface, thereby obtaining first composite powder; 2) carrying out ball milling on the obtained first composite powder to obtain second composite powder; and 3) sequentially carrying out sinter molding and hot extrusion molding to obtain the carbon-nanotube-reinforced aluminum-base composite material. The adverse factors capable of resulting in stratification due to density variation are eliminated, so that the CNTs (carbon nanotubes) and the aluminum powder are uniformly mixed while keeping favorable sintering activity, and the bonding strength between the CNTs and aluminum powder is enhanced to obtain favorable interfacial combination. The combined action of work hardening and grain refining reinforcement on the base can be utilized to enhance the aluminum base, so that the tensile strength and wear resistance of the composite material are greatly enhanced.

Owner:STATE GRID CORP OF CHINA +2

Manufacturing method of diffused alloy steel powder

A process for preparing diffusion-type alloy steel powder uses water-atomized pure iron powder and powdered alloy elements as raw materials, and includes mixing and diffusion steps. It can be used for high-density and high-strength powder metallurgy with the advantages of low cost and excellent performance.

Owner:山东鲁银新材料科技有限公司

Surface treatment solution for manufacturing solid electrolytic capacitor

InactiveCN101819889AIncrease capacityHigh leakage pass rateSolid electrolytic capacitorsElectrolysisElectrolytic capacitor

The invention provides surface treatment solution for manufacturing a solid electrolytic capacitor, which at least comprises a coupling agent for connecting an anode body surface oxide film medium with a solid electrolyte in the solid electrolytic capacitor, wherein the surface treatment solution also comprises a surfactant for reducing the surface tension of solution of the coupling agent, and improving the effect of the solution of the coupling agent for wetting the anode body surface oxide film medium to ensure that the coupling agent is more uniformly covered on the surface of the anode body surface oxide film medium, so the bonding between the anode body surface oxide film medium and the solid electrolyte is more uniform, and the bonding area and the bonding strength are improved.

Owner:FUJIAN GUOGUANG ELECTRONICS SCI & TECHCO

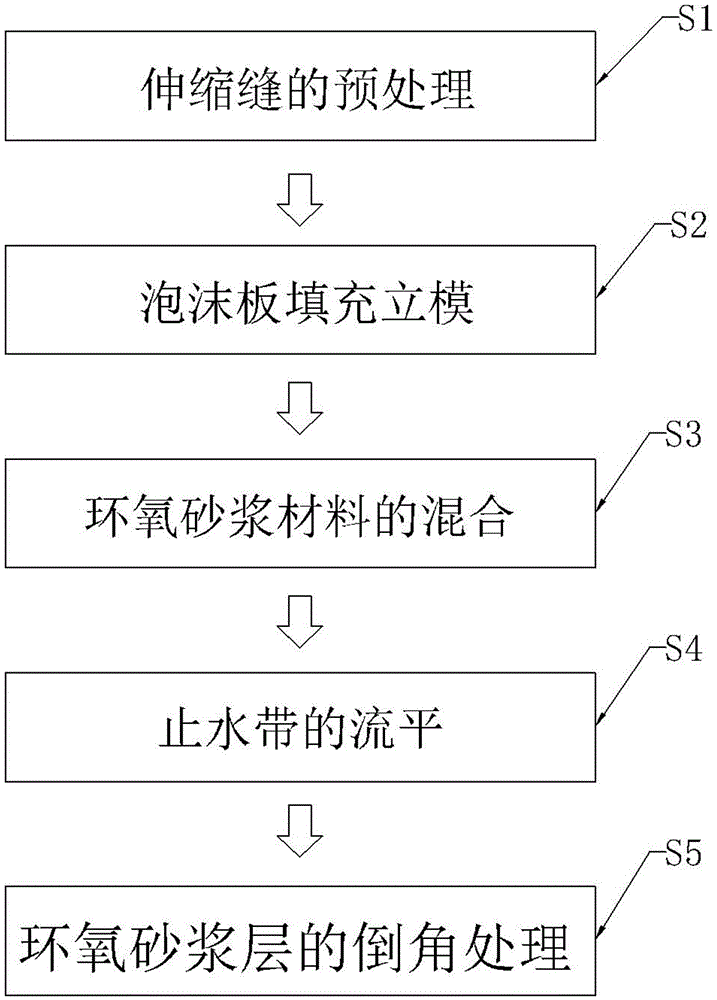

Epoxy mortar for bridge expansion joints and construction method thereof

InactiveCN105541180ALow viscosityHigh viscositySolid waste managementBridge structural detailsFirming agentArchitectural engineering

The invention relates to an epoxy mortar for bridge expansion joints and construction method thereof, and belongs to the technical field of building materials. The epoxy mortar material consists of a liquid A, a liquid B and a filler; and diamines D2000 and D230 are mixed as an epoxy curing agent. The curing agent has low viscosity, good compatibility with the epoxy resin, long working life, high bonding strength, good flexibility and thermal shock resistance, and can be applied to the epoxy mortar material capable of absorbing the stress. The epoxy mortar material mixed from the liquid A, liquid B and filler for construction of bridge expansion joints changes the condition that rigid concrete, which can to be easily damaged under impact stress, needs profile steel for protection in the traditional bridge expansion joint; epoxy mortar material substitutes the rigid concrete in traditional expansion joints, avoids a steel structure, and has good waterproof and seal performance; the expansion joints have color consistent with the color of the adjacent concrete or asphalt, so that the bridge is more beautiful; the expansion joints cannot cause vibration of vehicles when the vehicles pass by the expansion joints; and the noise generated by the vehicles is lower.

Owner:HEERON TECH (WUHAN) NEW MATERIALS CO LTD

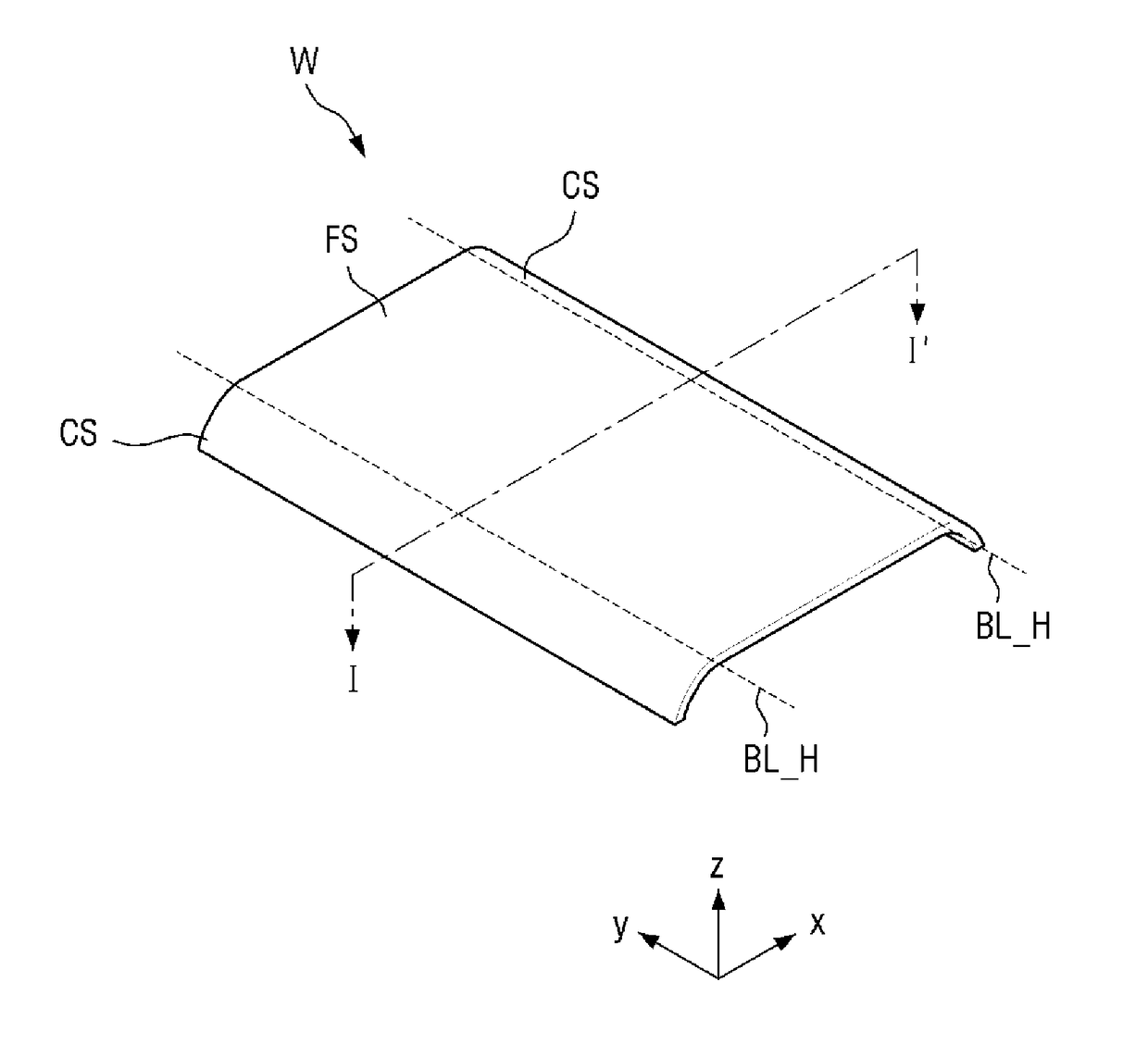

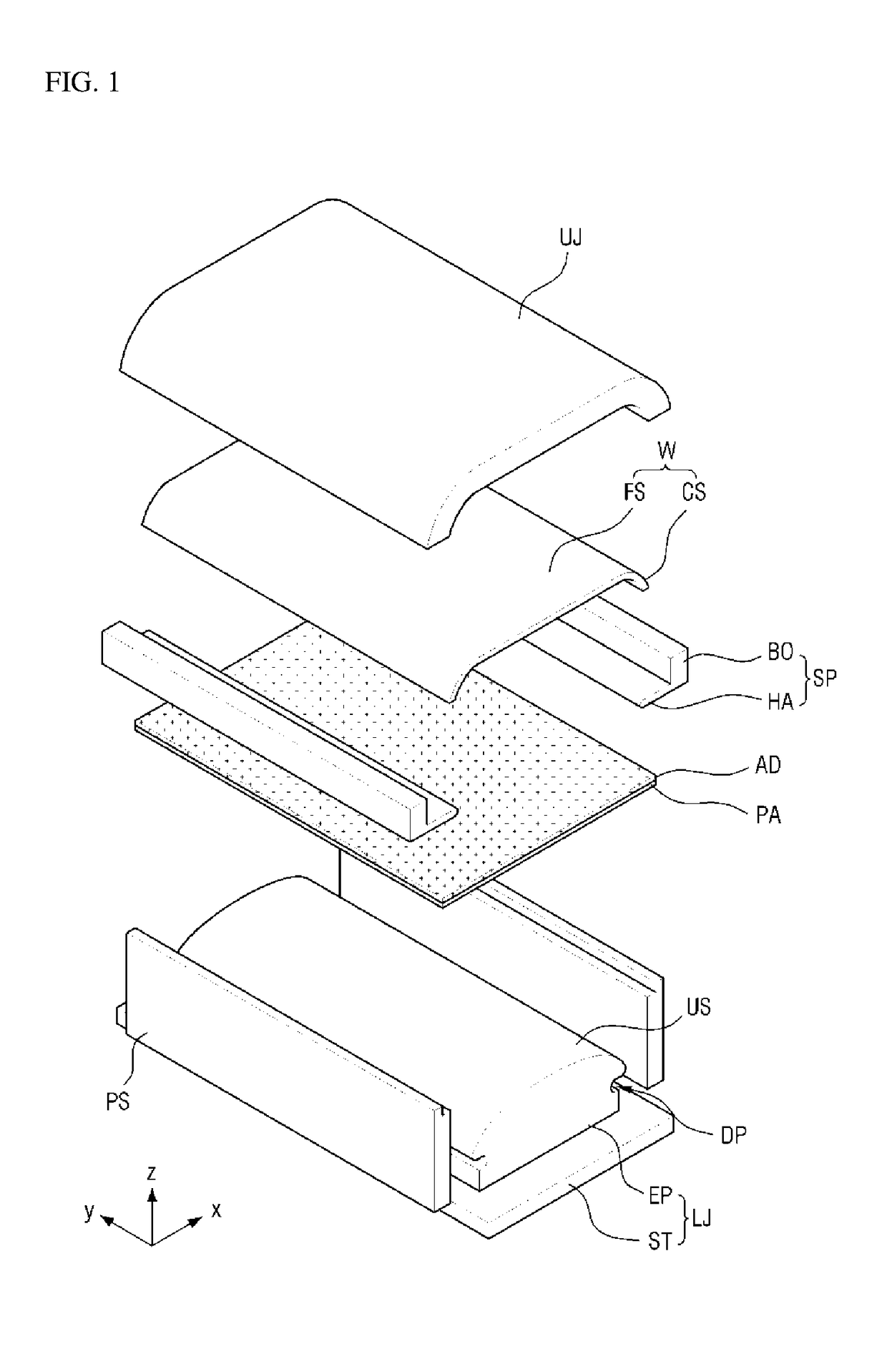

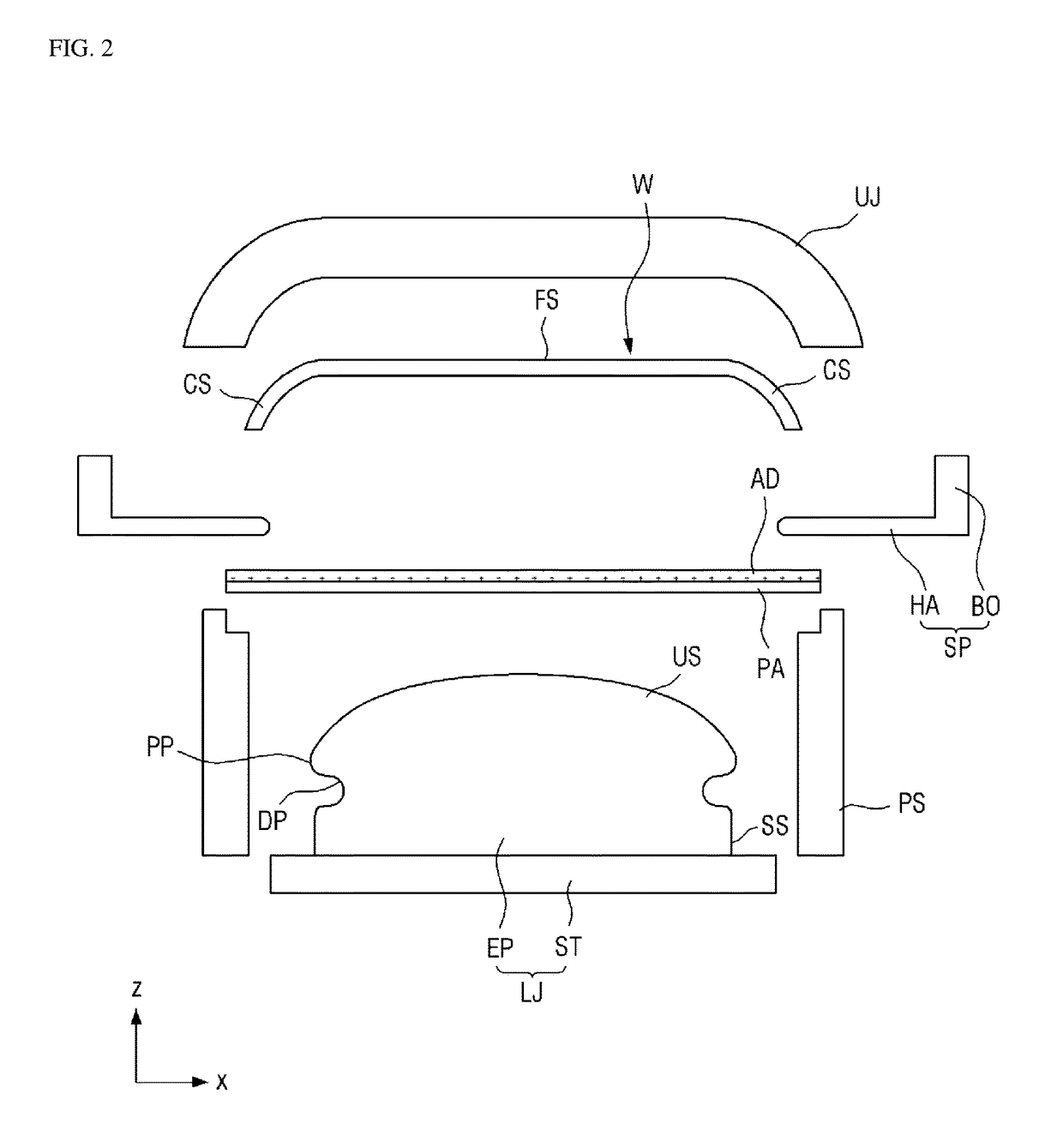

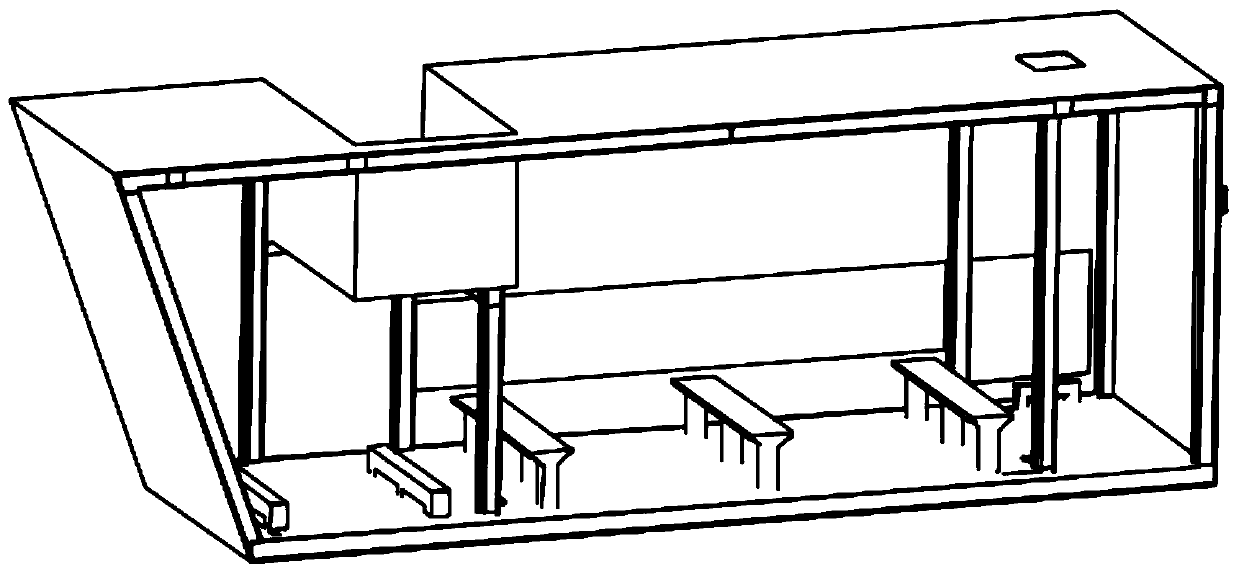

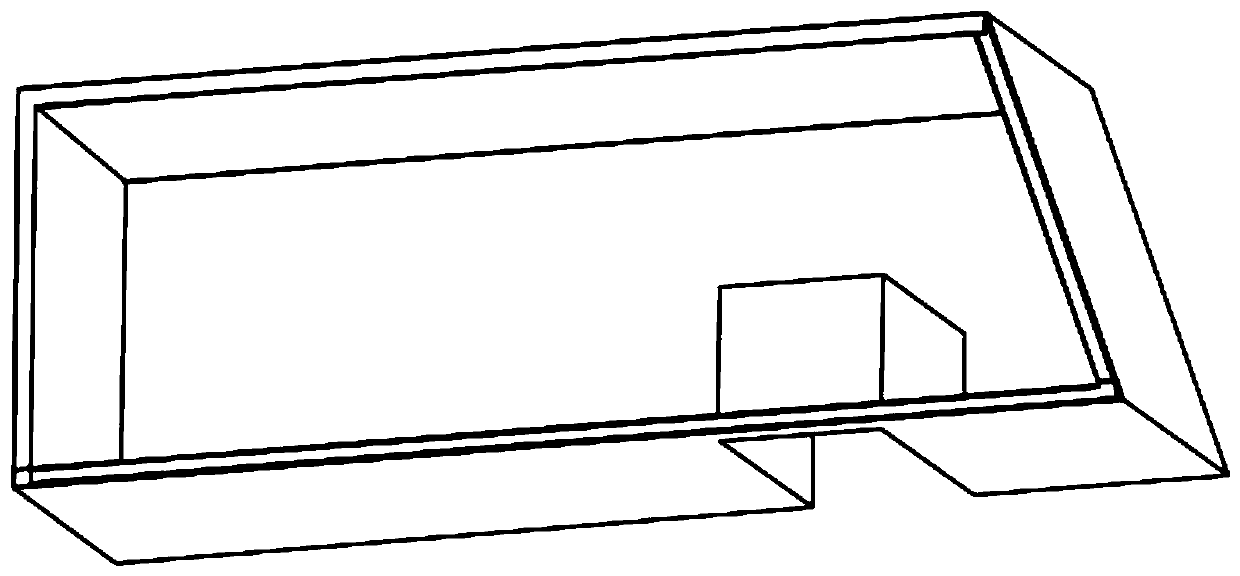

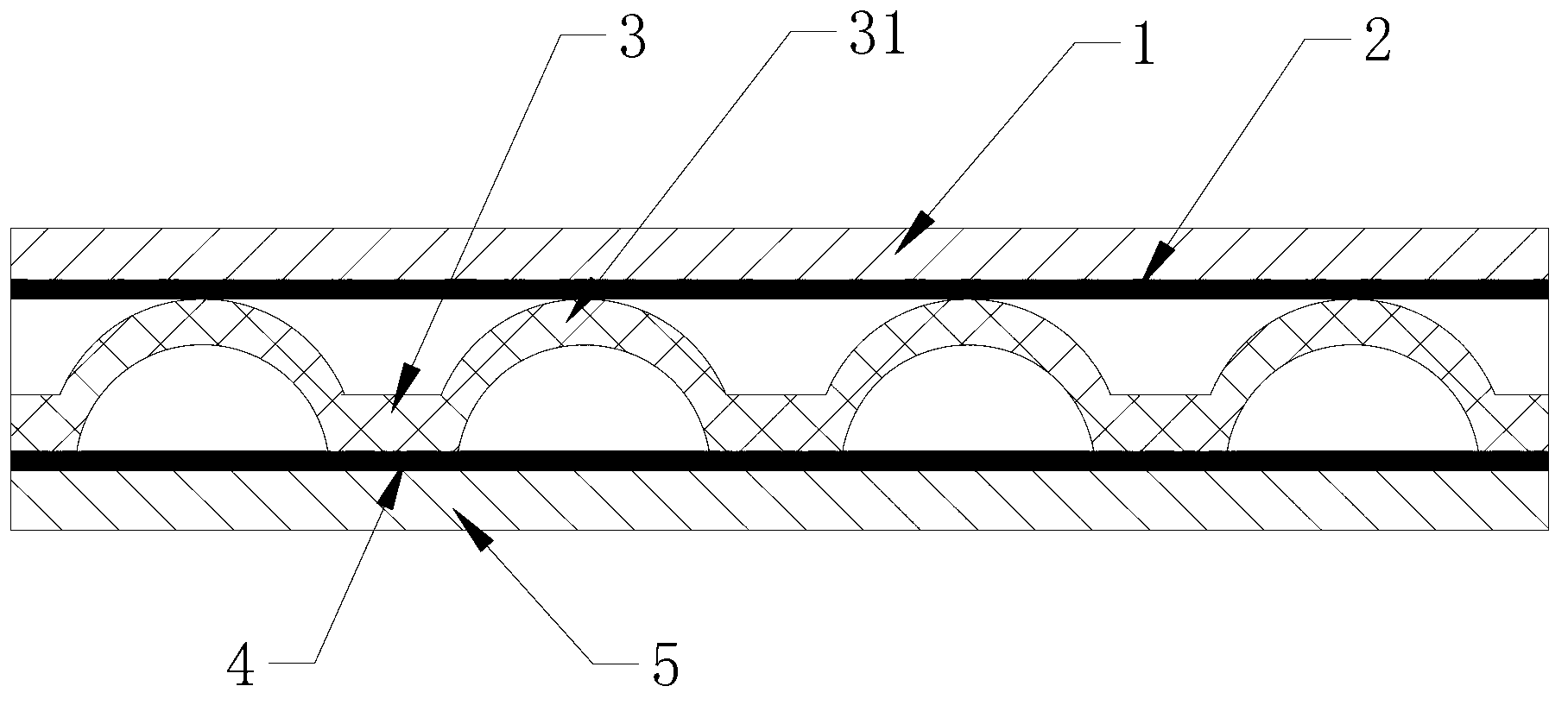

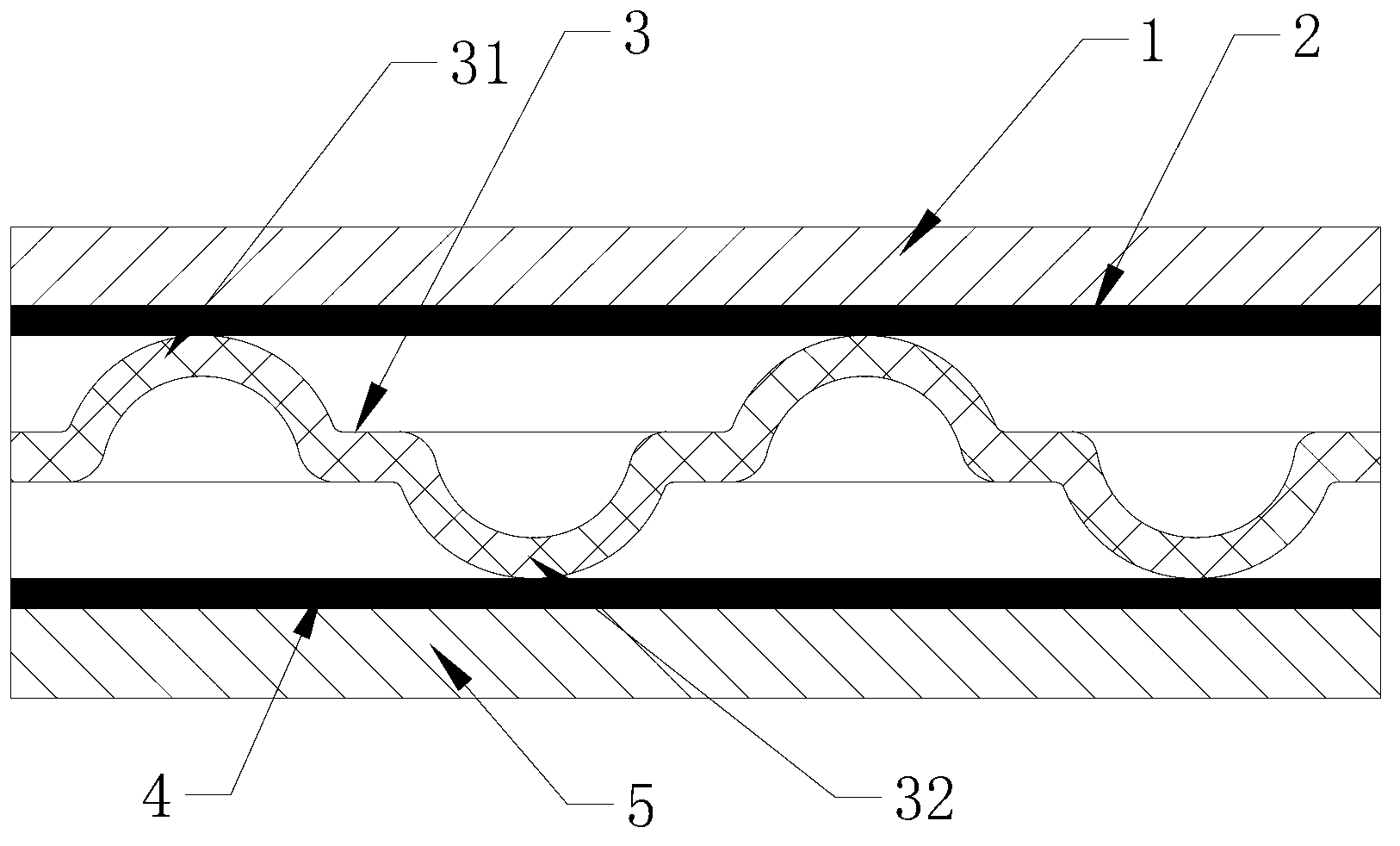

Laminating apparatus and method of fabricating display device using the same

ActiveUS20180056638A1Uniform bondingEvenly bondedLamination ancillary operationsSolid-state devicesBiomedical engineeringDisplay device

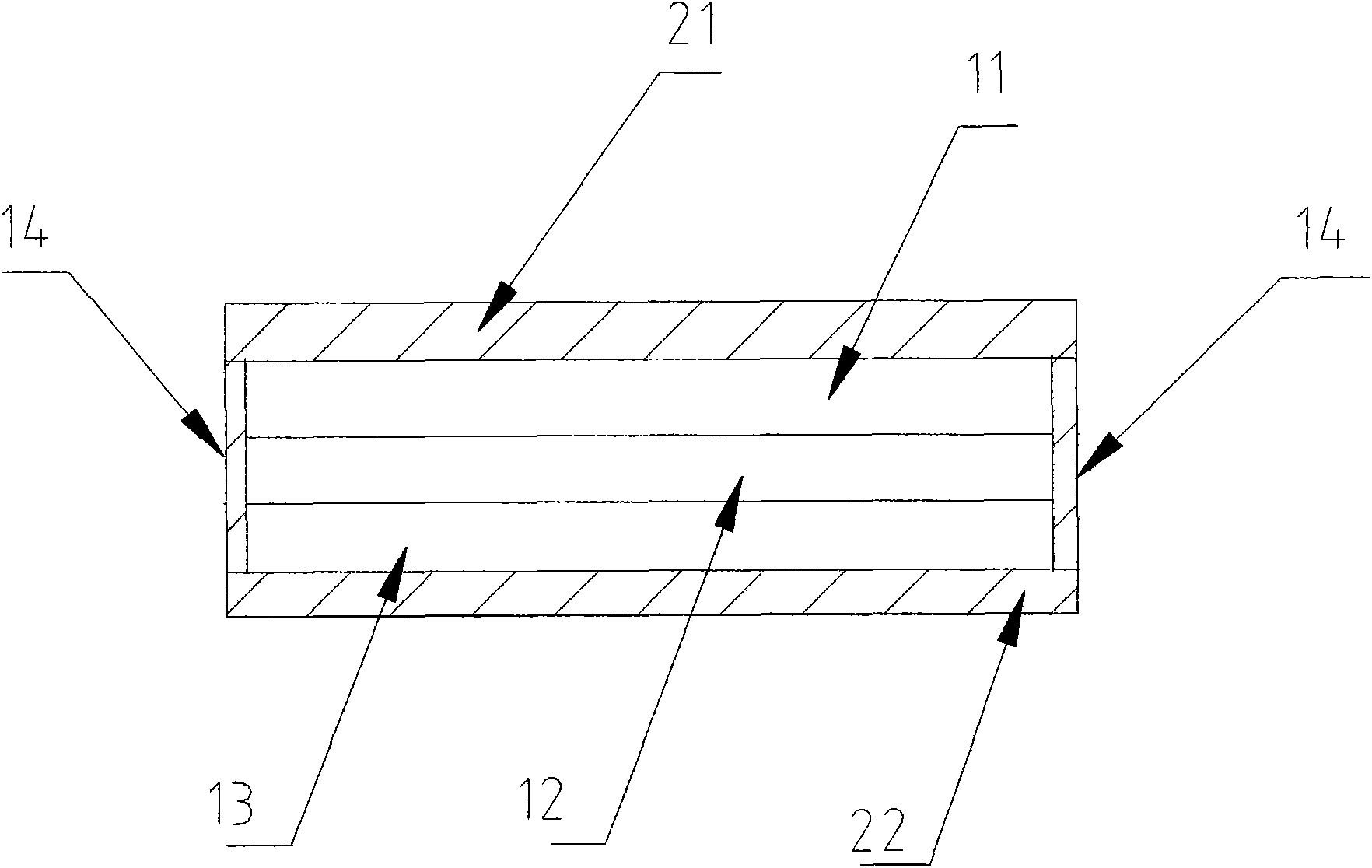

A laminating apparatus and method of fabricating a display device are provided. According to an exemplary embodiment of the present disclosure, the laminating apparatus includes a first jig, which is configured to fix a window having curved surfaces, and a second jig, which includes a pressure pad facing the first jig. The pressure pad includes a top surface, which is convex toward the first jig, and depressed portions, which are inwardly depressed from side surfaces, respectively.

Owner:SAMSUNG DISPLAY CO LTD

High strength ultraviolet resistant PE/ PET composite material and preparation method thereof

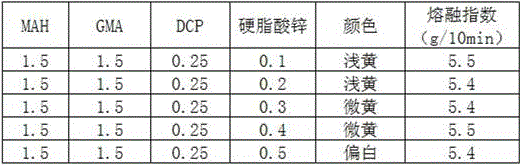

The invention belongs to the field of polymer materials, and particularly relates to an efficient PE / PET composite material interface compatibilizer, a high strength ultraviolet resistant PE / PET composite material and a preparation method thereof. The high strength ultraviolet resistant PE / PET composite material is prepared from, by weight, 100 parts of high density polyethylene, 0.5-2.0 parts of maleic anhydride, 0.5-2.0 parts of glycidyl methacrylate, 0.05-0.3 part of initiator, and 0.1-0.5 part of heat stabilizer. The efficient PE / PET composite material interface compatibilizer include the materials of, by weight, 100 parts of high density polyethylene, 1.2-1.5 parts of maleic anhydride, 1.2-1.5 parts of glycidyl methacrylate, 0.2-0.3 part of initiator, and 0.3-0.5 part of lubricants. Maleic anhydride and glycidyl methacrylate are grafted with high density polyethylene to form an efficient interface compatibilizer. The effect of the application of the efficient PE / PET composite material interface compatibilizer in the PE / PET composite material is better than the effect of either of HDPE-G-MAH and HDPE-G-GMA used alone in the PE / PET composite material. The efficient PE / PET composite material interface compatibilizer has good heat resistance, large filling capacity, and good processing performance, and can effectively improve the mechanical properties of the PE / PET composite material.

Owner:SHENYANG KETONG PLASTIC

Preparation method of PVC (Polyvinyl Chloride) sectional material with surface coated with metal film

InactiveCN103722861AHigh bonding strengthUniform and strong bondingSynthetic resin layered productsLaminationPolyvinyl chlorideSizing

The invention relates to a preparation method of a PVC (Polyvinyl Chloride) sectional material with surface coated with a metal film. The PVC sectional material with the surface coated with the metal film is prepared by material mixing, co-extrusion, vacuum cooling and sizing, coating of an aluminum film on the surface of the sectional material, cutting and molding. According to the preparation method provided by the invention, a PVC raw material and hot melt adhesive are compounded together by a way of co-extrusion, so that the bonding strength of the hot melt adhesive is high, the bonding of the metal film is uniform and strong, the bonding strength is high, delamination is unlikely to occur, and the continuous production of the hot melt adhesive, PVC raw material powder and PVC sectional material products with the surfaces coated with the metal films can be realized.

Owner:山东华信塑胶股份有限公司

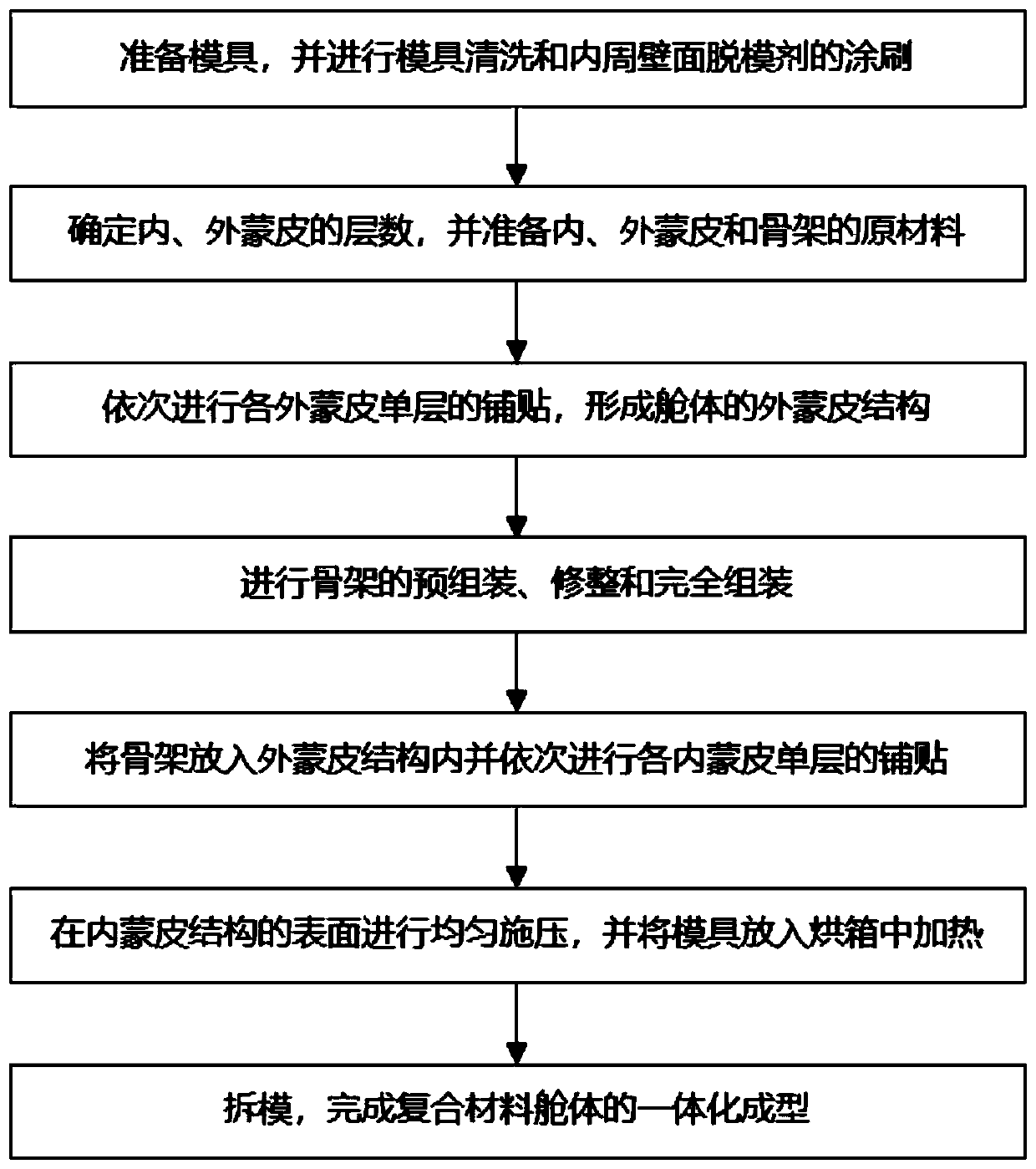

Integrated forming method for composite material cabin

The invention discloses an integrated forming method for a composite material cabin, and belongs to the technical field of cabin forming. According to the integrated forming method, a die corresponding to the cabin in shape is arranged and internally and sequentially provided with an outer skin structure, a framework and an inner skin structure; through layering paving and pasting of inner and outer skin materials, the framework can be effectively wrapped in the inner skin structure and the outer skin structure, an integrated integral structure is formed, and the weight of the cabin is greatlyreduced under the situation that the structure strength of the cabin is guaranteed. According to the integrated forming method for the composite material cabin, the steps of the integrated forming method are simple, operation is simple and convenient, integrated forming of the composite material cabin can be effectively achieved, and it is ensured that the cabin has good integral performance after being formed; and the weight of the cabin is greatly reduced compared with an existing metal cabin, the maneuverability of a weapon system loading the cabin is effectively improved, and good application prospects and popularization value are achieved.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

Negative electrode slurry for lithium ion batteries

InactiveCN106558702AImprove adhesionUniform bondingCell electrodesSecondary cells servicing/maintenanceCarbon nanotubeSlurry

Relating to the technical field of lithium ion battery manufacturing, the invention discloses a negative electrode slurry for lithium ion batteries. The negative electrode slurry for lithium ion batteries is prepared from a negative electrode active material, a conductive agent, a negative electrode binder, 20-25 parts of a solvent and other raw materials, wherein the negative electrode active material is spherical graphite, the conductive agent is carbon nanotube, and the solvent is N-methyl pyrrolidone. The binder added in the negative electrode slurry provided by the invention has good binding performance, can bind the negative electrode active material together better and more evenly, and also is suitable for batteries needing higher cycle performance. The negative electrode slurry binder used in the invention can improve the safety performance of the negative electrode slurry, so that assembled lithium ion batteries can automatically stop heat generation reaction at high temperature to ensure the safety of lithium ion batteries during use. The negative electrode slurry provided by the invention has more excellent cycle performance, the prepared lithium ion batteries have higher capacity, and also has the characteristic of automatic cut-off of heat generation reaction at high temperature.

Owner:长兴天晟能源科技有限公司

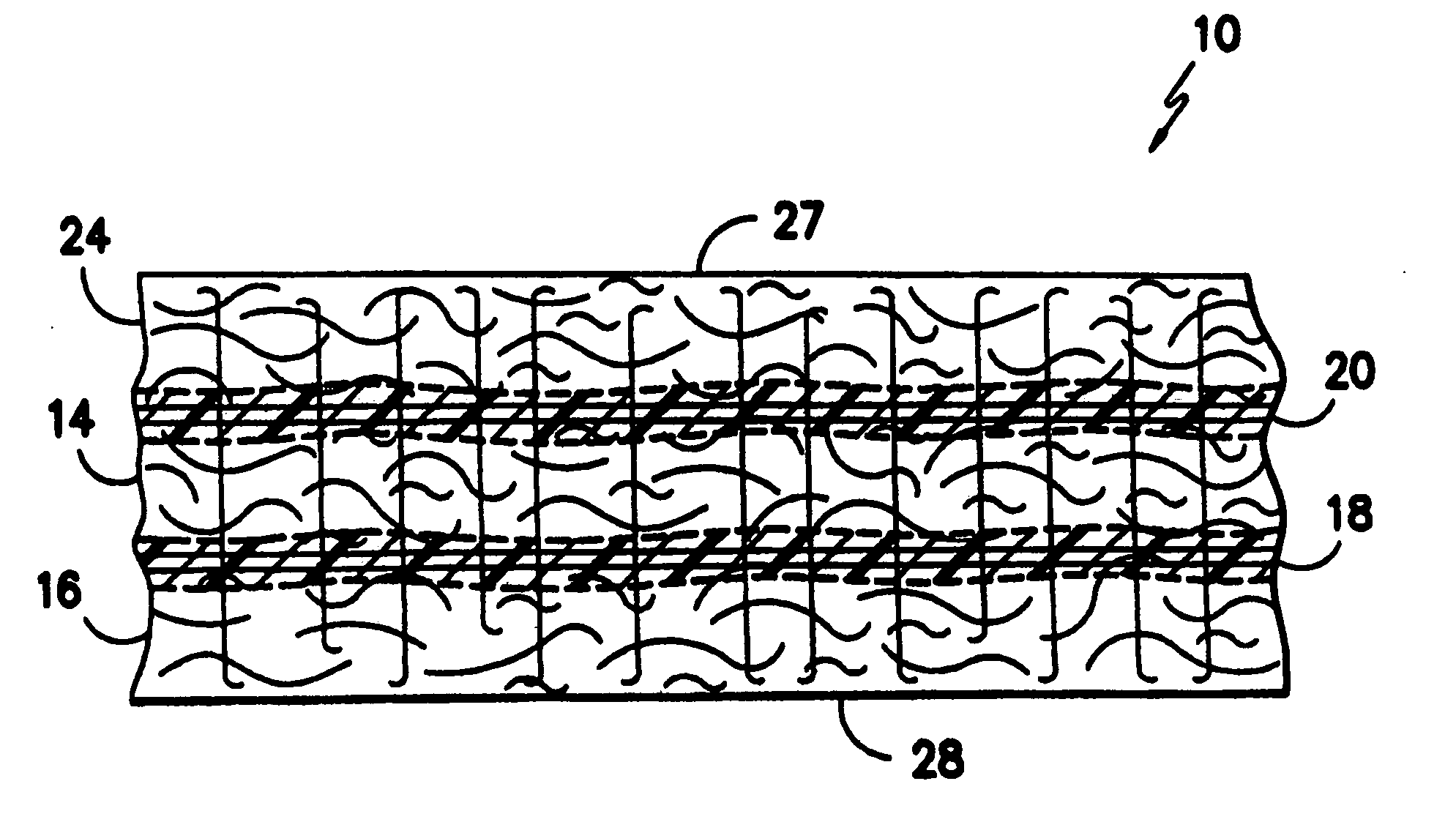

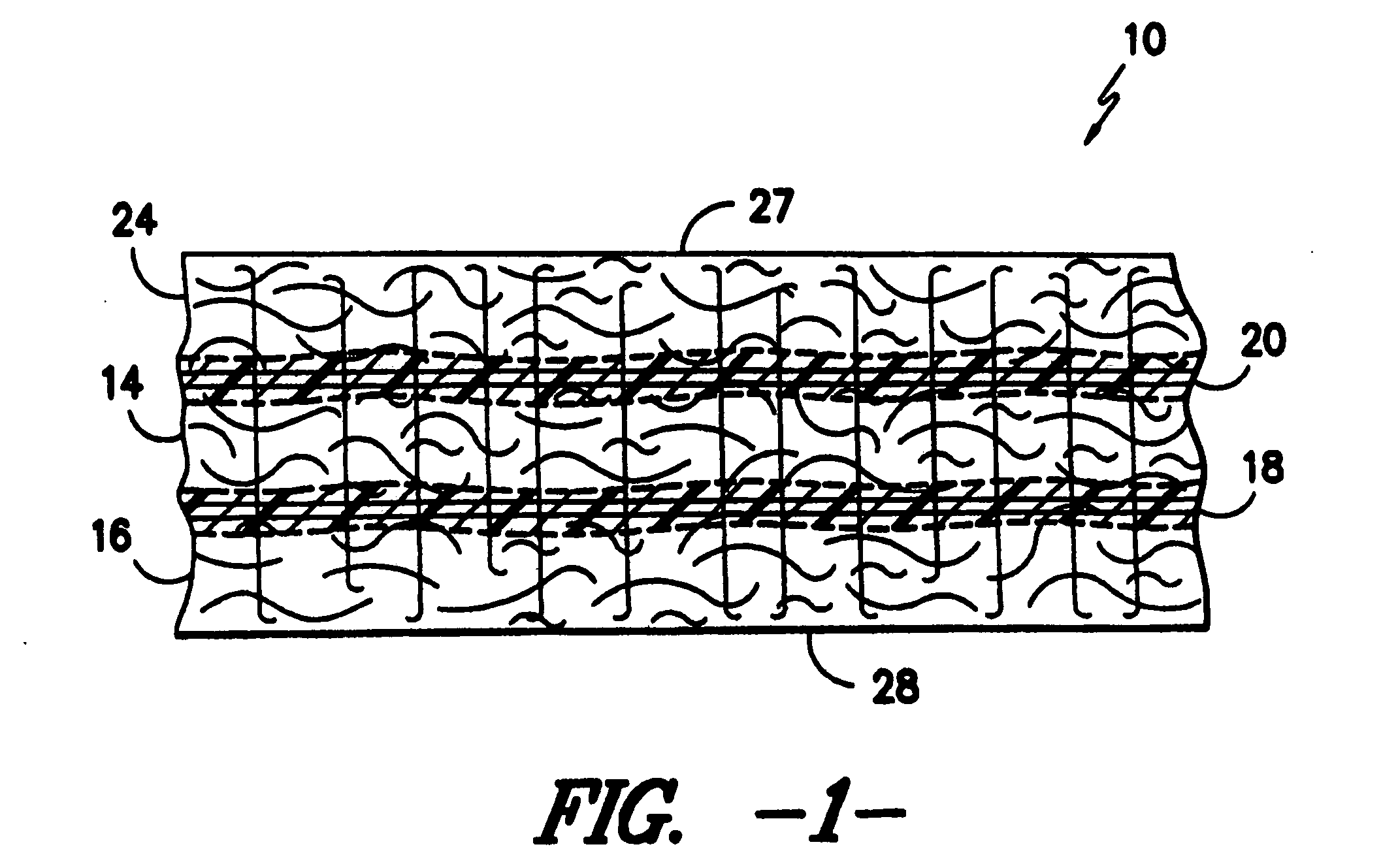

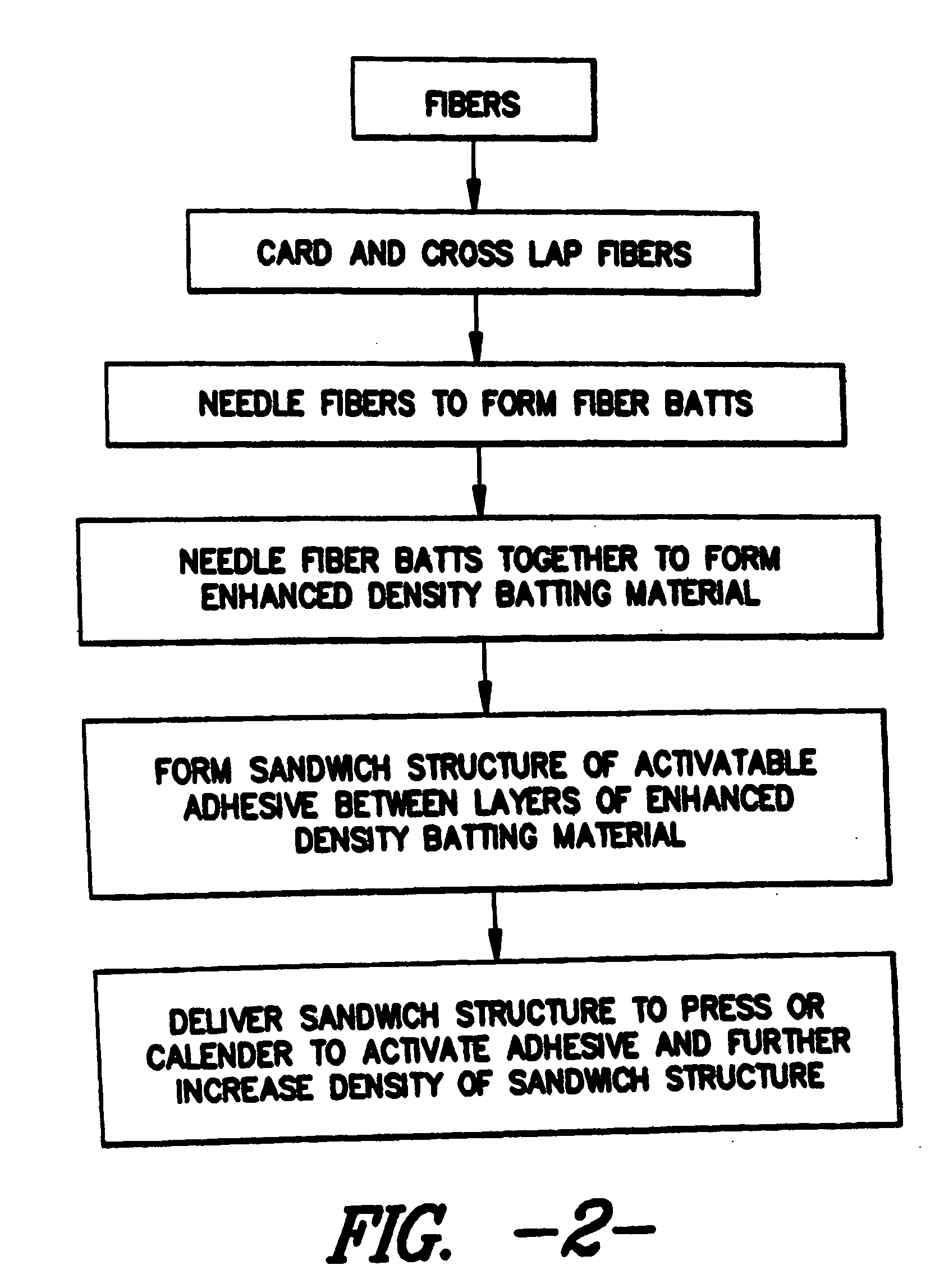

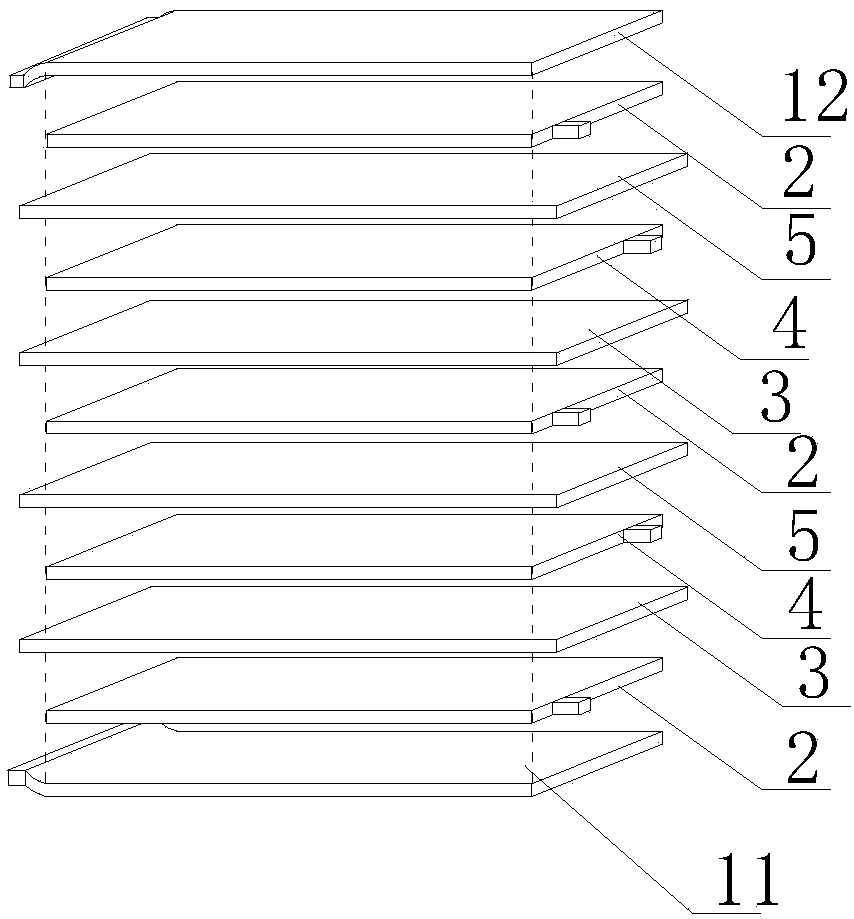

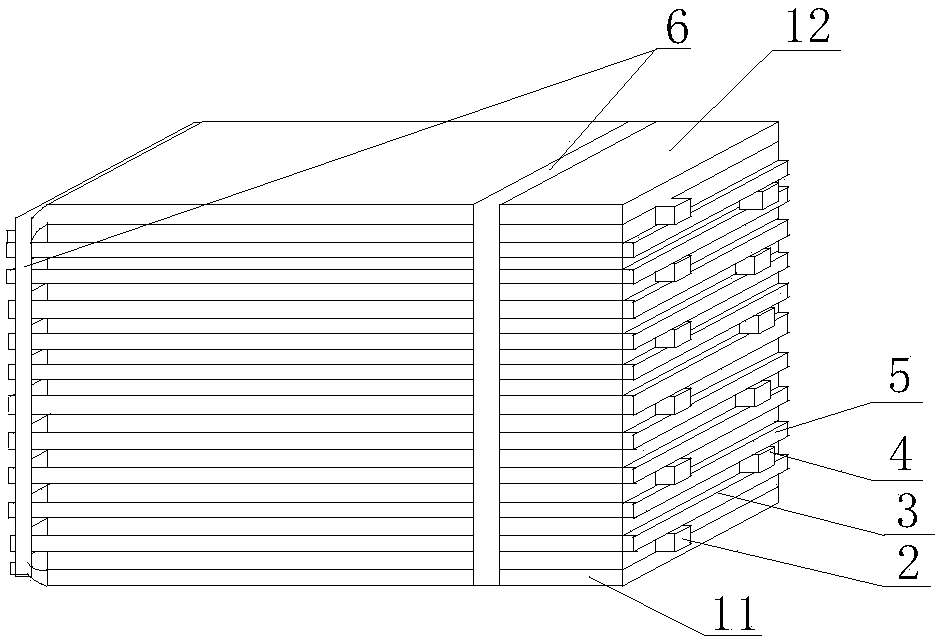

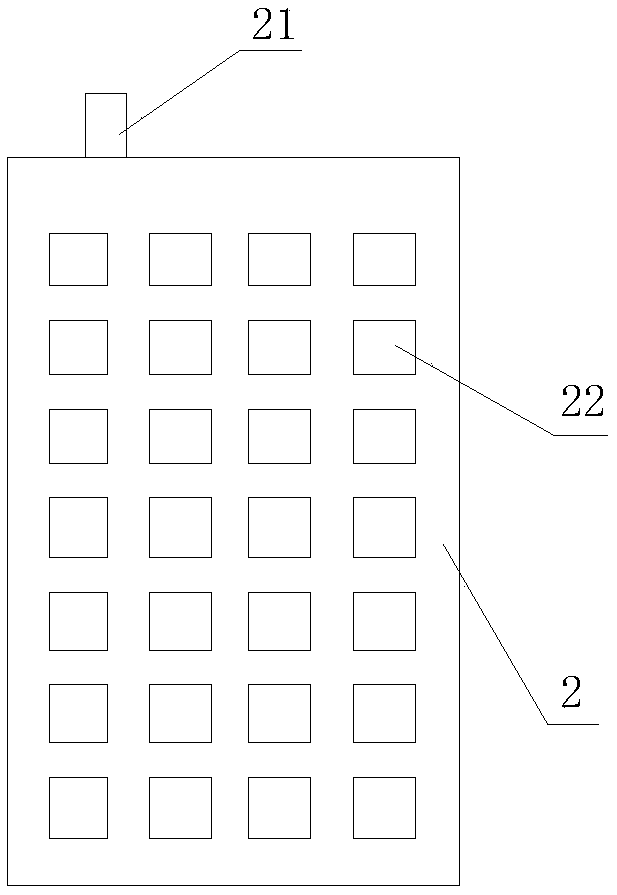

Nonwoven laminate structure

InactiveUS20060194496A1High structural densityLarge thicknessLayered productsCleaning equipmentFiberBiological activation

A nonwoven composite structure having a plurality of layers of nonwoven fiber batting bonded in laminating relation to one another by a localized adhesive disposed between the layers. The adhesive between the layers of fiber batting preferably extends across the interface between the adjacent layers so as to at least partially penetrate each of the layers thereby enhancing the bond strength between the layers. The bond strength between the layers and the uniformity of the resultant bonded structure may be further enhanced by forcibly extending fibers from at least one layer of batting through the material forming the adhesive such as by needling prior to activation of the adhesive such that a portion of the fibers forming the layers of batting extends across the adhesive between the bonded layers.

Owner:THE FELTERS

Surface processing solution for manufacturing solid electrolytic capacitor

InactiveCN101819887AUniform bondingIncrease bonding areaSolid electrolytic capacitorsSurface oxidationAnode

The invention provides surface processing solution for manufacturing a solid electrolytic capacitor. The surface processing solution at least comprises a coupling agent, wherein the coupling agent is used for connecting an anode surface oxidation film medium and a solid electrolyte in the solid electrolytic capacitor; the coupling agent is at least one of or combination of more of a titanate coupling agent, an aluminate coupling agent, a duplex metal coupling agent, a lignin coupling agent and a tin coupling agent; and the mass concentration of the coupling agent is 0.001 to 50 percent. Through the surface processing solution, the adhesion between the anode surface oxidation film medium and the solid electrolyte is more uniform and the adhering area and the adhering strength are larger, so that the capacity of the solid electrolytic capacitor is increased and the equivalent series resistance of the solid electrolytic capacitor is reduced; and at the same time, the protective effect on the anode surface oxidation film medium is better and the creepage qualification rate of the solid electrolytic capacitor is higher.

Owner:FUJIAN GUOGUANG ELECTRONICS SCI & TECHCO

Preparation method of sealed high-energy-storage lead-acid storage battery with quick charging and discharging function

ActiveCN108400391AReduce thicknessIncrease energy densityFinal product manufactureLead-acid accumulator electrodesHigh energyTrickle charging

The invention discloses a preparation method of a sealed high-energy-storage lead-acid storage battery with a quick charging and discharging function. The storage battery mainly comprises a storage battery box body, a plurality of integrated ultra-thin polar plate groups, a circuit connecting piece, an electrolyte and an anti-expansion sleeve. By virtue of the technology, the conventional procedures of processing of the lead-acid storage battery are overturned, and through innovation of a continuous spraying process of fluid lead paste, one-time combination of each polar plate group in a wet soft state can be completed, so that adhesion of lead paste and a partition plate can be reinforced; and the polar plate groups are tightly assembled and plugged into a polar plate cavity in a wet softstate to be subjected to overall curing and drying, so that integration of the polar plate groups is realized, falling off of the lead paste is prevented effectively, the thicknesses of the polar plates and the partition plate are greatly lowered, the polar plate spacing is greatly reduced, lamination of the lead paste and a grid is reinforced, the area of the polar plates and the current collecting grid within the unit space is multiplied, and the energy density and charging and discharging speed of the storage battery are greatly improved.

Owner:JIESHOU JINGHUA TECH INFORMATION CONSULTING SERVICE CO LTD

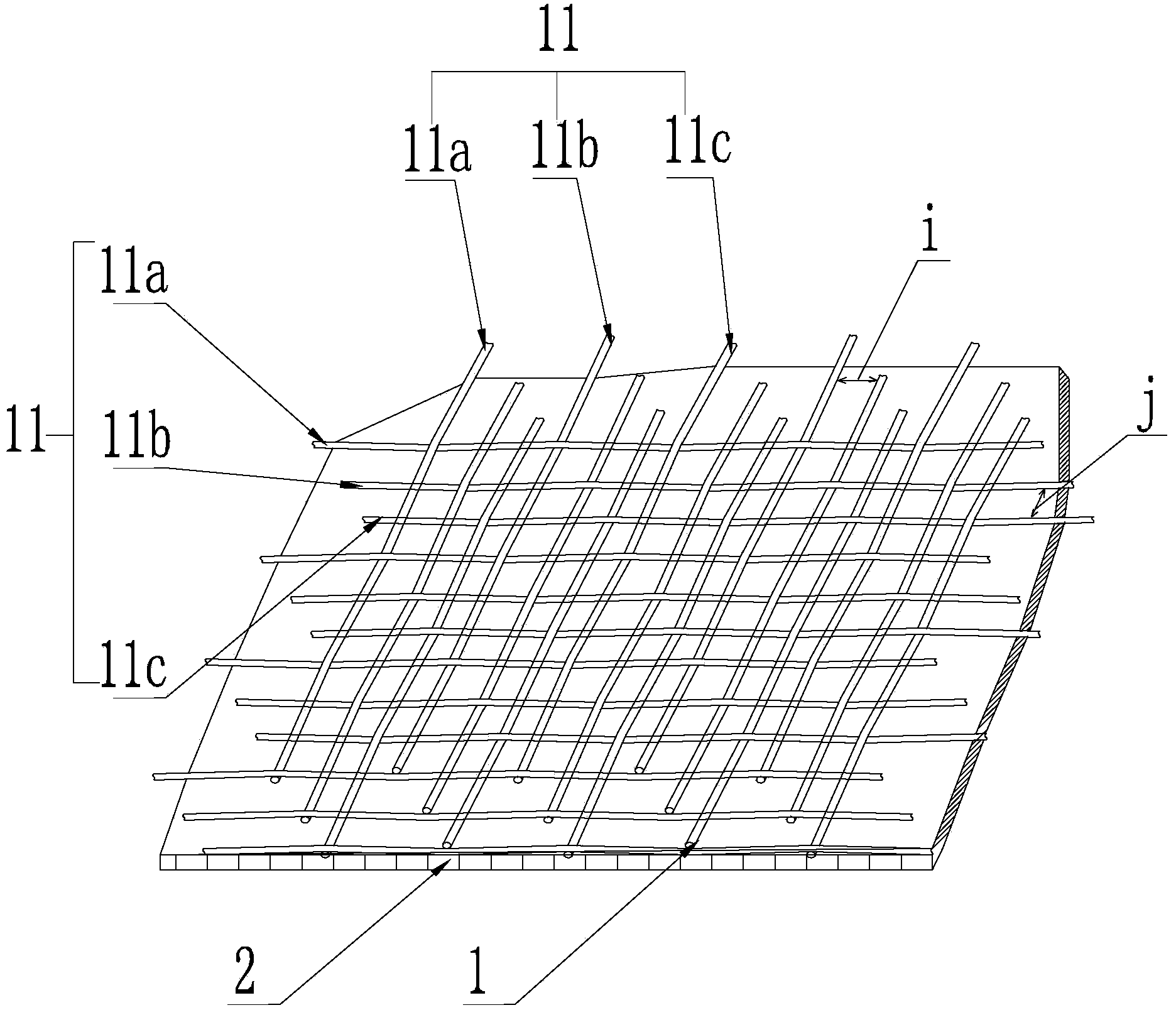

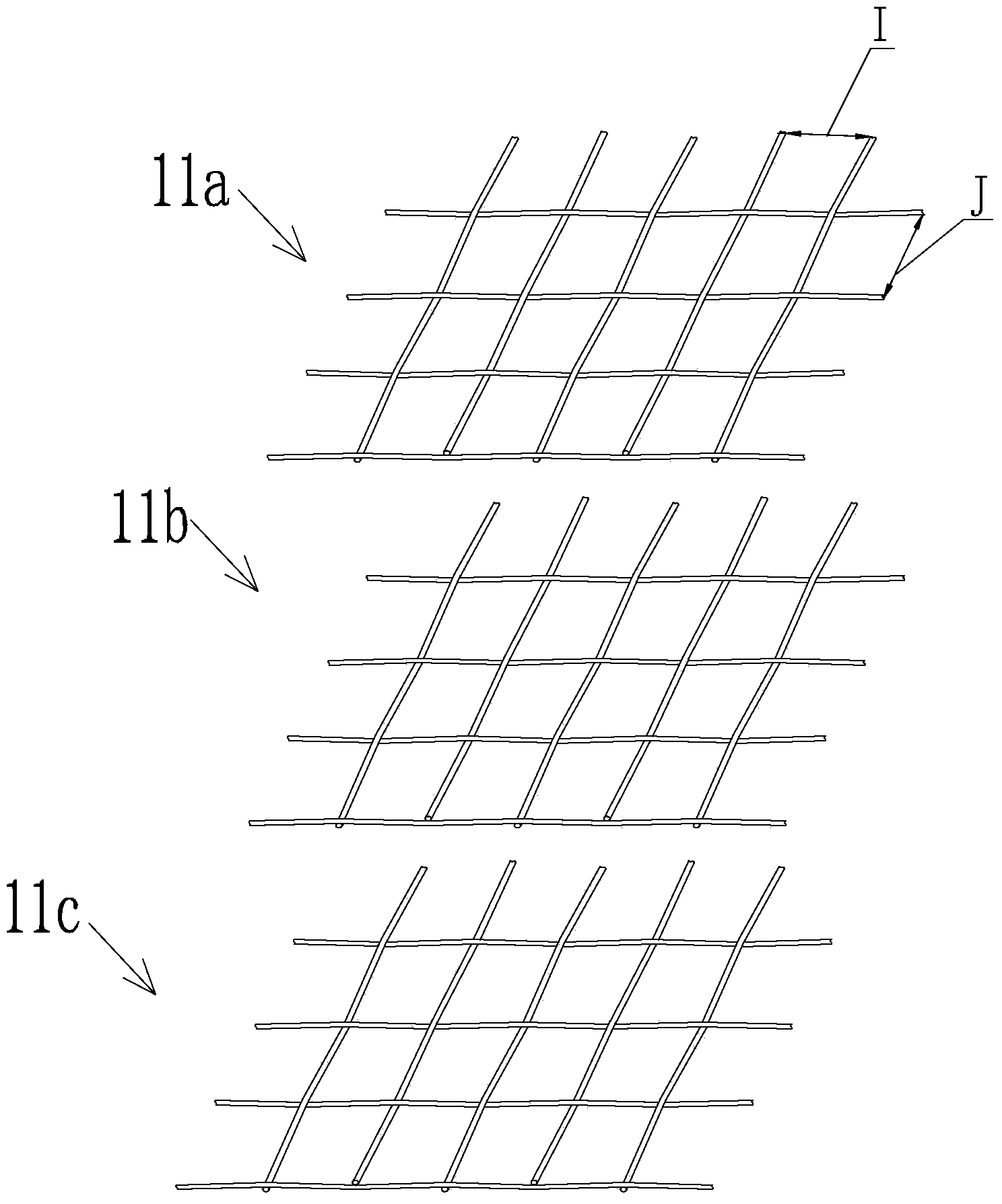

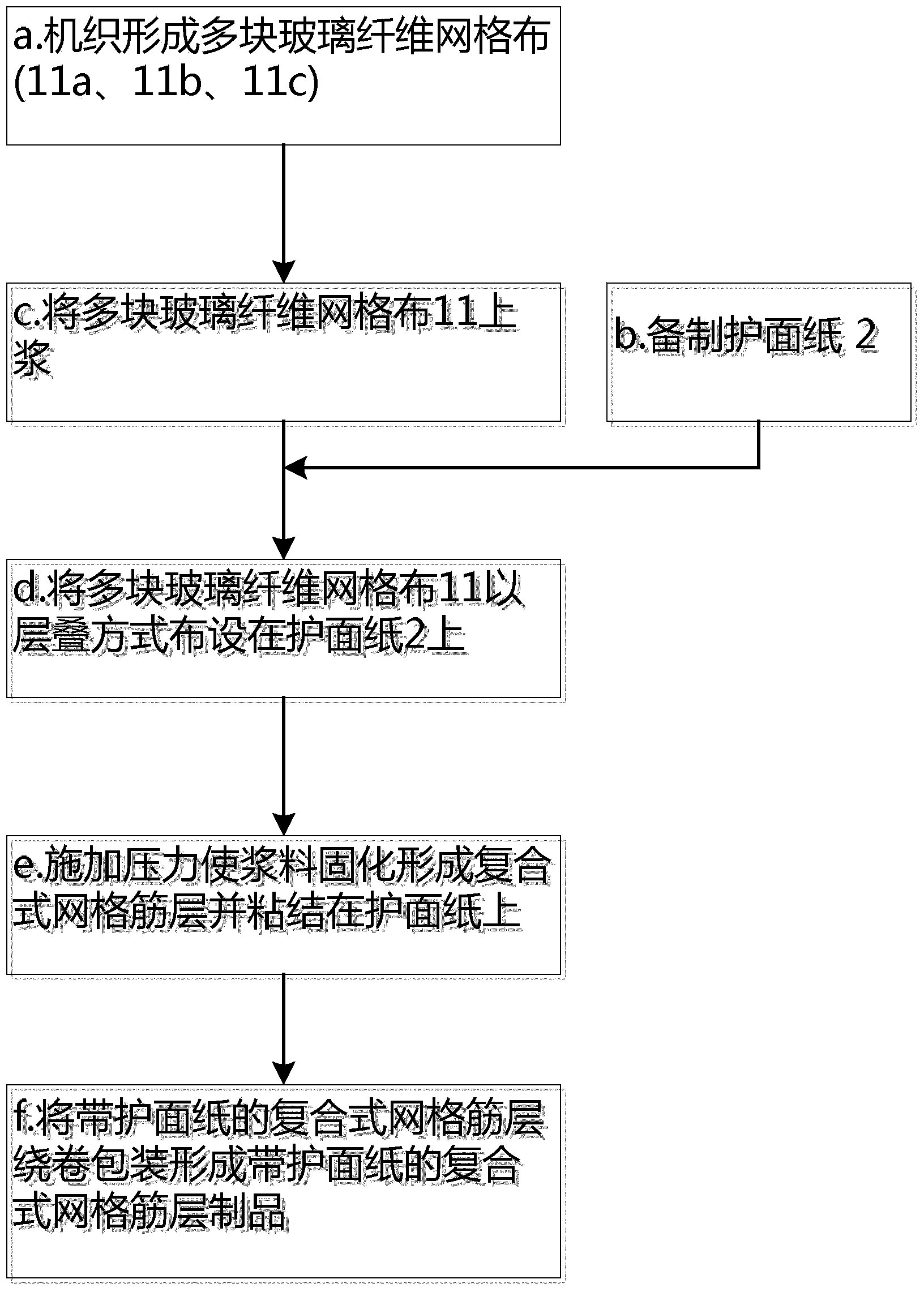

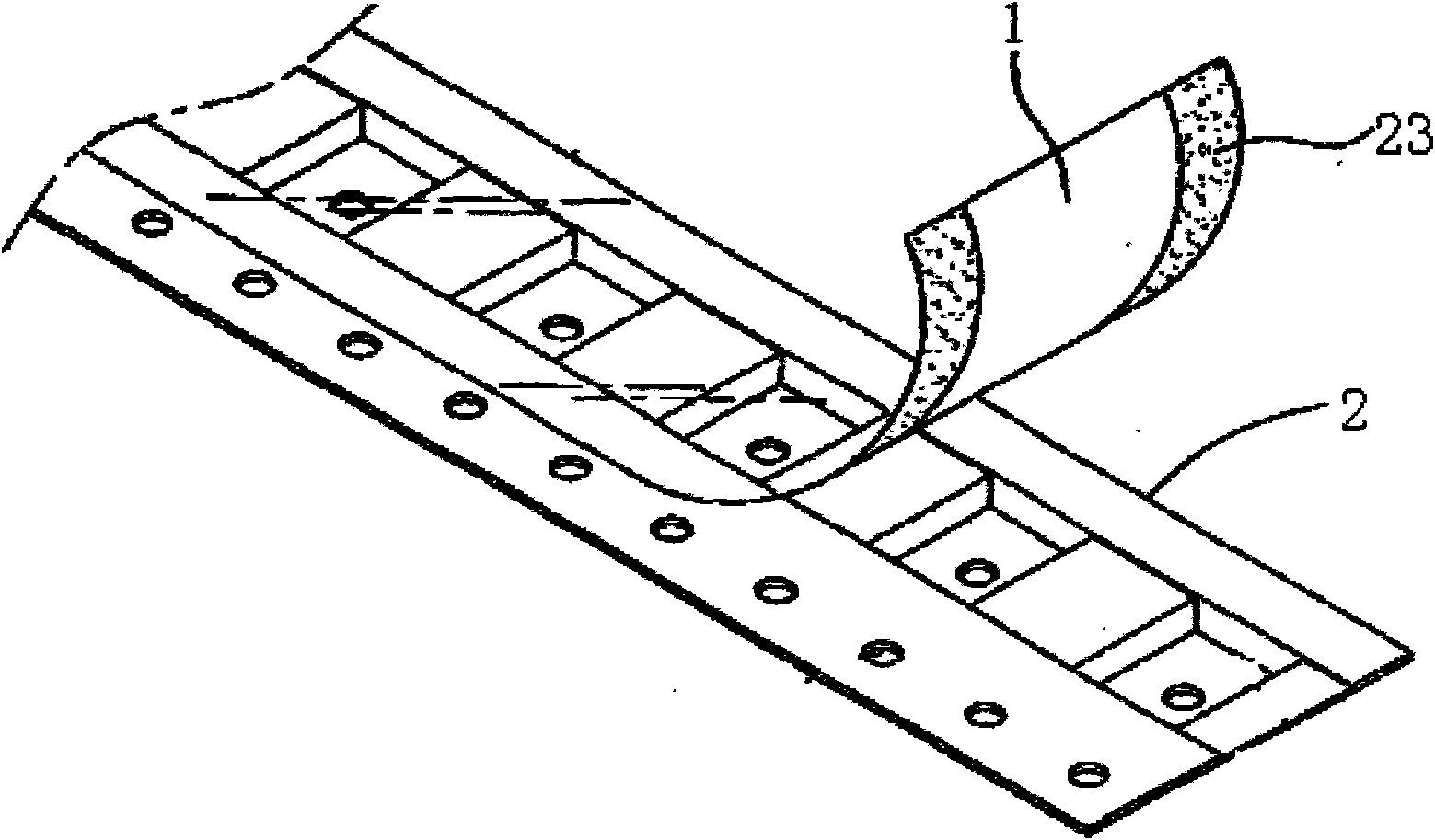

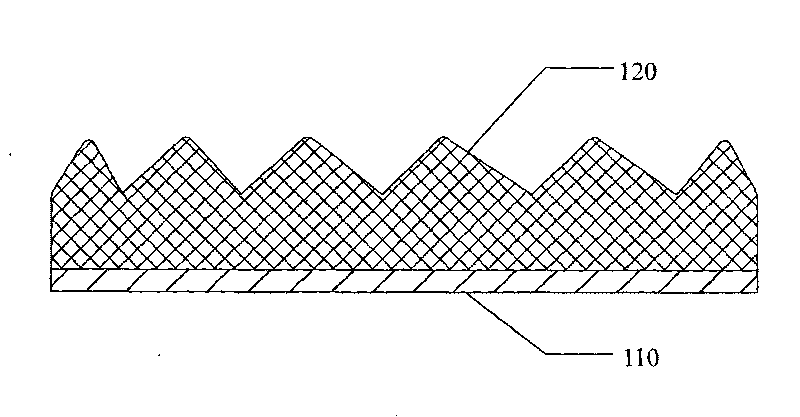

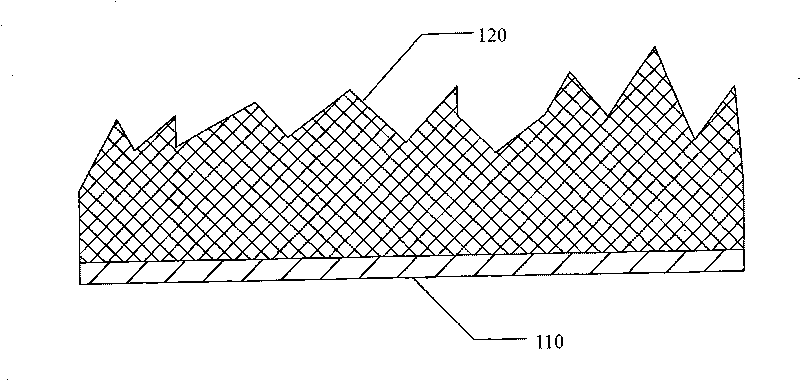

Compound gridding rib layer product with surface protecting paper and preparation method thereof

InactiveCN103953177AHigh strengthImprove stabilityCovering/liningsLaminationFiberglass meshGlass fiber

The invention discloses a compound gridding rib layer product with a piece of surface protecting paper and a preparation method thereof. The compound gridding rib layer product comprises a compound gridding rib layer and the piece of surface protecting paper, wherein the compound gridding rib layer comprises layers of fiber glass meshes; each layer of the fiber glass mesh is bonded by a sizing agent; the fiber glass meshes are compounded to form the compound gridding rib layer in a stacking manner; the compound gridding rib layer and the surface protecting paper are bonded in the stacking manner. The invention aims to overcome the defects in the prior art, and provides the compound gridding rib layer product with the piece of surface protecting paper, which is high in mechanical strength and uniform in rib distribution, and the preparation method thereof.

Owner:JINGTAI COUNTY JINLONG CHEM BUILDING MATERIALCO

Environmental-protection straw light wall board production method

InactiveCN107498681AUniform bondingImprove waterproof performanceConstruction materialCeramic shaping apparatusAdhesiveSilicon oxygen

The invention discloses an environmental-protection straw light wall board production method. The production method comprises the preparation steps of: preparation of raw materials-surface treatment through physical and chemical combination methods-uniform glue mixing-pavement-hot pressing molding in a mold-fixed length cutting-accumulation protection curing-inspection-products; in preparation of the raw materials, the raw materials are divided into two types: one is surface layer raw materials, and the other one is middle layer raw materials; in the surface treatment step, wax on the surfaces of straws are treated by adopting physical and chemical combination methods; chemical raw materials containing silicon-oxygen chemical bond structures similar to wax structures on the surfaces of the straws and being 0.01-0.5 mass% of the straws are added; then, adhesives capable of forming hydrogen bonds or chemical bonds with polyhydroxyl structures are added; and in uniform glue mixing, strengthening materials are added in glue mixing of the middle layer raw materials. No harmful gas is discharged from boards prepared by the method; and the boards are smooth, unified and beautiful in textures and high in strength, flame retardance, sound insulation and damp prevention.

Owner:河南安朝板材科技有限公司

Method for dissipating charges on end face of cover tape

InactiveCN101648622AQuick exclusionNo falling phenomenonFlexible coversWrappersAntistatic agentSurface layer

The invention discloses a method for dissipating charges on the end face of a cover tape, which is used in the process of producing the electronic parts for the electronic carrier tapes and the covertapes. The cover tape comprises an upper surface layer, an intermediate layer and a heat sealing layer from top to bottom in sequence. The heat sealing layer can be bonded with a carrier tape. When bonding is carried out, first antistatic agents are coated on the upper surface of the upper surface layer, the end faces at both sides of the cover tape and the lower surface of the heat sealing layer,so that the end faces of the cover tape, the upper surface of the upper surface layer and the lower surface of the heat sealing layer are connected to form a whole antistatic layer. In the previous method, when static electricity appears, the static electricity generated above can only be dissipated by the upper surface layer and the static electricity generated below can only be dissipated by the lower surface layer. The method of the invention is characterized by dissipating the static electricity as a whole due to upper and lower connection, doubling the dissipation speed and further ensuring the uniformity of the bonding strength of the cover tape and the carrier tape, and effectively improves the adhesiveness and antistatic property, which can not be reached by the previous method.

Owner:LIANMENG ELECTRONICS TECH KUSN

Composite foam mortar, and preparation and construction method thereof

ActiveCN101412608AWater retentionFunctionalSolid waste managementCeramicwareCrack resistanceMicrosphere

The invention relates to a composite foam mortar, which is prepared from the components by the following weight percentage through mechanically and evenly stirring: 20 to 30 percent of ordinary Portland cement, 5 to 8 percent of white lime, 8 to 10 percent of fly ash, 15 to 20 percent of light aggregate, 30 to 40 percent of heavy aggregate, 1.6 to 2.0 percent of foam initiator, and 3.0 to 5.0 percent of strength-keeping rubber powder, wherein the light aggregate is an inorganic vitrification hollow microsphere material; the heavy aggregate is a mixture of sand and coarse whiting powder; and the foam initiator is a mixture of an anionic surfactant and a foam stabilizer. The 30 to 50 weight percent of composite foam mortar is diluted by water, is constructed on a wall surface by a mortar mixer with instant mixed spray coating, and is scraped evenly by a running rule or a putty knife. The composite foam mortar can be constructed by adopting a mechanical guniting technology, thus the construction efficiency and the construction quality are improved, the material dosage on a unit area is reduced, and the cost is reduced. The composite foam mortar also has the advantages of water resistance and heat insulation, improved crack resistance, good compatibility with base layer brickworks, and simple and practical process; besides, the composite foam mortar is applicable to waterproof and heat insulation decoration engineering on the inner and outer surfaces of the outer walls of all buildings, in particular to the moist environments with high requirements on water resistance and heat insulation in south China.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Anode slurry binding agent used for lithium ion batteries

InactiveCN106571469AImprove adhesionGood effectCell electrodesSecondary cells servicing/maintenancePolyvinyl alcoholSlurry

The invention belongs to the technical field of lithium ion battery manufacturing, and discloses an anode slurry binding agent used for lithium ion batteries. The anode slurry binding agent is prepared from raw materials including polyvinyl alcohol, polyacrylic acid, sodium carboxymethylcellulose, sodium alginate, and a binding agent additive; the binding agent additive is prepared from polyvinylidene fluoride, Ketjen black, and polymethyl acrylate. The anode slurry binding agent possesses excellent binding performance, is capable of realizing better and more uniform binding of anode active materials, is suitable for batteries with requirements on higher cycling performance, and is capable of improving safety performance of anode slurry, realizing automatic stop of exothermic reaction of assembled lithium ion batteries at high temperature, and ensuring the safety of lithium ion batteries in applications.

Owner:长兴天晟能源科技有限公司

Process for coating diamond particles by cobalt powder

The invention relates to a process for coating diamond particles by cobalt powder. The key points are as follows: the process comprises the steps of: blending a diluted agent, blending isopropanol and acetone according to a mole ratio of (3.5-4.5):1, and mixing the blended diluted agent with glue according to a weight ratio of (7-9):1 to form a binding agent; placing the diamond particles into a coating device; and spraying the blended binding agent into the coating device, sprinkling metal powder into the coating device, roll-dispersing the diamond particles evenly, thus completing the coating process. The process has the advantages that the process procedures are simple, and the cost can be lowered by more than 50% by adopting a technology of coating diamond particles by cobalt powder to substitute the mode that the cobalt powder is directly used as binding materials of a wear-resistant material in the prior art; and the new type blended diluted agent has low cost, the coating effect is obviously promoted by proportion of the diluted agent and the glue, thus finally leading the produced diamond products to be perfect.

Owner:HEBEI HANGHUA DIAMOND PROD

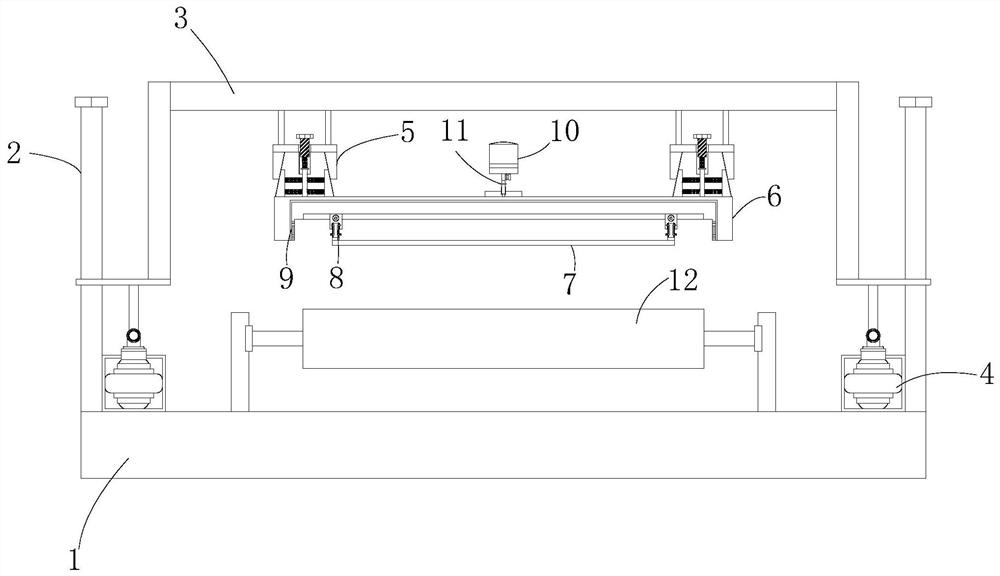

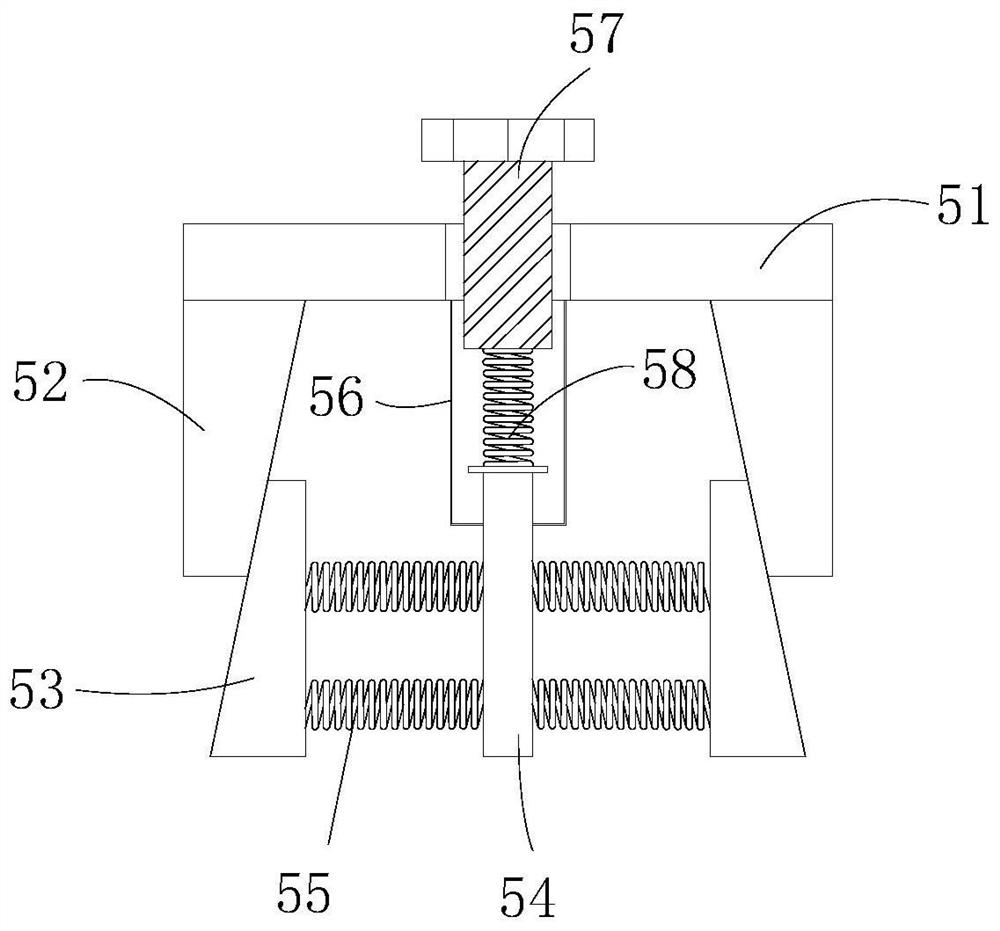

Seamless hot pressing device for down jacket fabric

ActiveCN113812711AUniform bondingHigh degree of mechanizationDirt cleaningClothes making applicancesStructural engineeringMechanical engineering

The invention belongs to the technical field of down jacket fabric processing equipment, and particularly relates to a seamless hot-pressing device for down jacket fabric. The device comprises a base, a guide column and a hot-pressing lifting support arranged on the guide column in a sleeving mode, the hot-pressing lifting support is driven by a telescopic air cylinder to ascend and descend, a fabric containing plate is arranged on the upper end face of the base, and a pressing plate is movably arranged at the position, corresponding to the fabric placing plate, of the hot-pressing lifting support through a hot-pressing adjusting mechanism; and the hot-pressing adjusting mechanism comprises a fixing plate fixedly connected with the hot-pressing lifting support. The down jacket fabric is attached through the hot-pressing technology, the pressing force and the pressing buffering stroke can be adjusted according to different hot-pressing requirements of different clothes, meanwhile, the pressing plate can be conveniently replaced through the fixing mechanism, the application scene and durability of the device are increased, and the device is simple in structure, high in stability, reasonable in design and convenient to industrial popularization and use.

Owner:GAOFAN (ZHEJIANG) INFORMATION TECH CO LTD

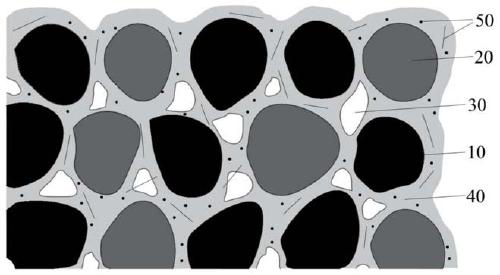

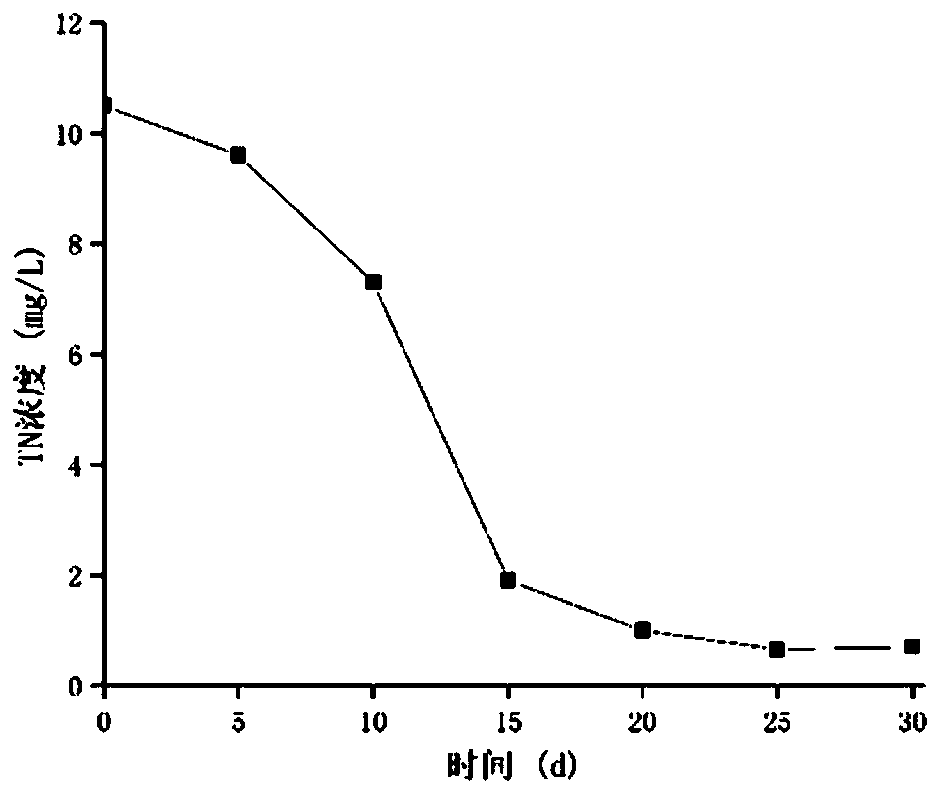

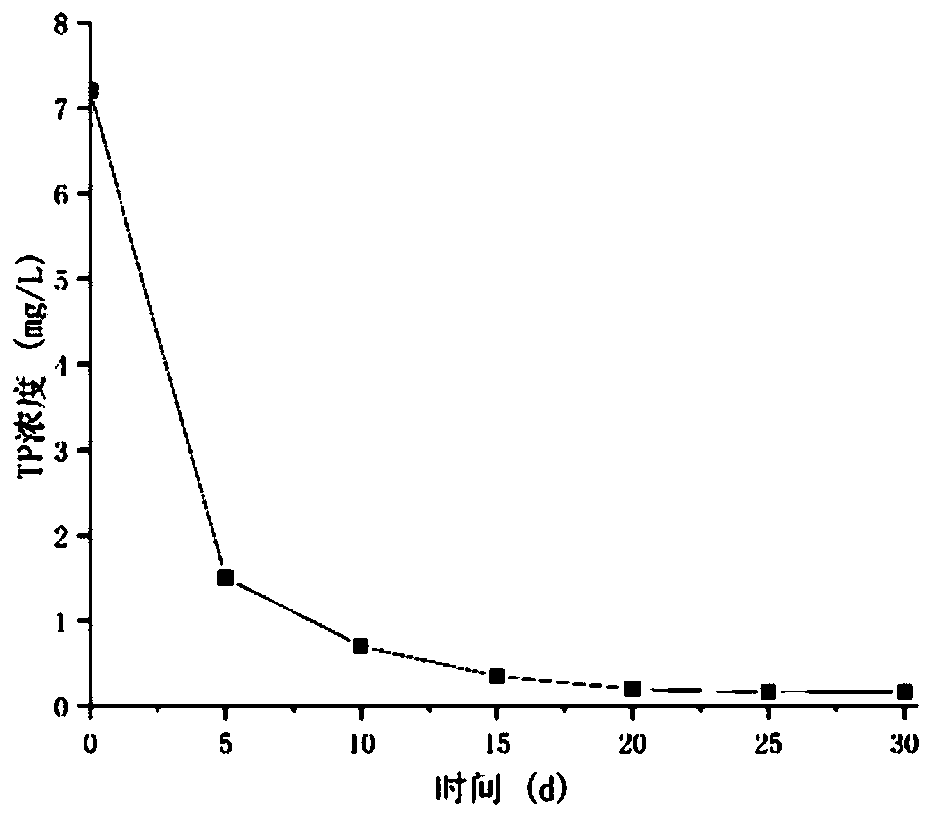

Nitrogen and phosphorus removal ecological permeable material and preparation method thereof

ActiveCN111039620AAvoid hardening and cloggingEfficient removalBreakwatersQuaysNitrogen removalEngineering

The invention discloses a nitrogen and phosphorus removal ecological permeable material and a preparation method thereof, and belongs to the fields of environmental functional materials and water purification. The ecological permeable material comprises a slow-release skeleton structure and permeable holes; the slow-release skeleton structure a skeleton is formed by pyrite particles of which the surfaces are coated with a mixture of a binding material and fiber reinforced ribs and aggregate particles of which the surfaces are coated with a mixture of the binding material and fiber reinforced ribs, the permeable holes are uniformly distributed in the slow-release skeleton structure, and the channels of the holes enable the water permeability coefficient of the ecological permeable materialto be not less than 10 mm / s. The nitrogen and phosphorus removal ecological permeable material has the characteristics of good water permeability, high molding degree, high specific surface area, highstrength, easiness in microbial biofilm formation and the like, can slowly release calcium ions and iron ions to remove phosphorus, realizes autotrophic nitrogen removal, and has a good purificationeffect on pollutants in water, especially total nitrogen and total phosphorus.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

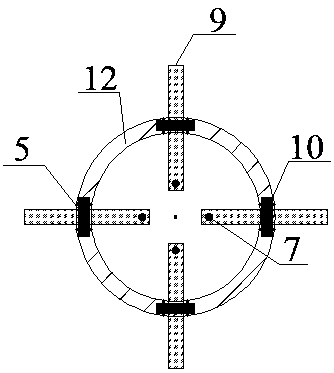

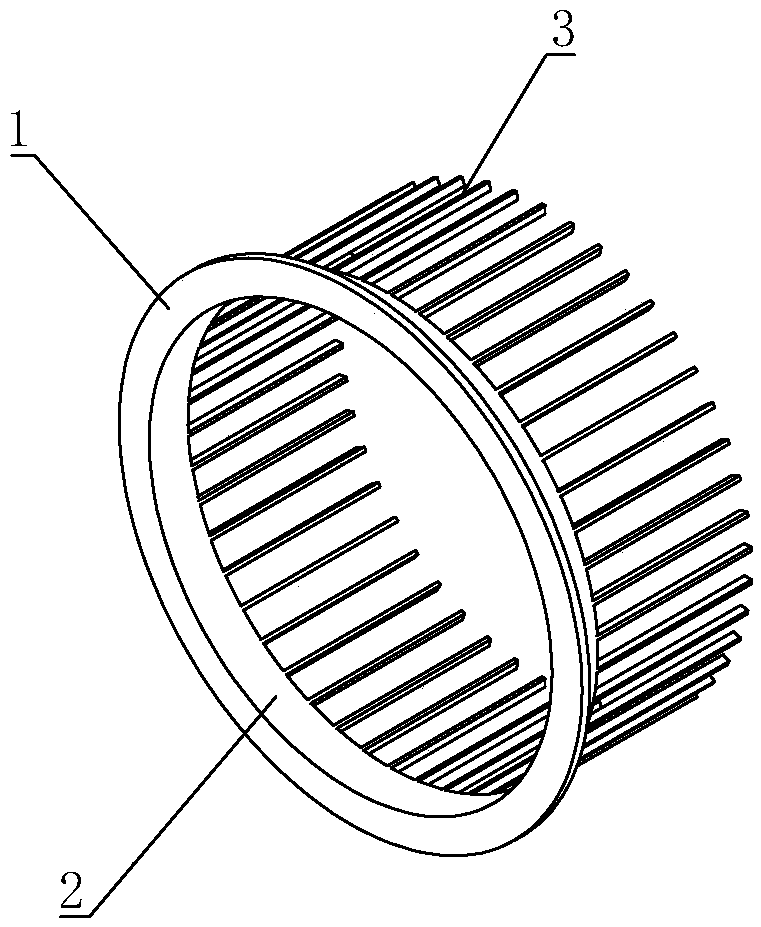

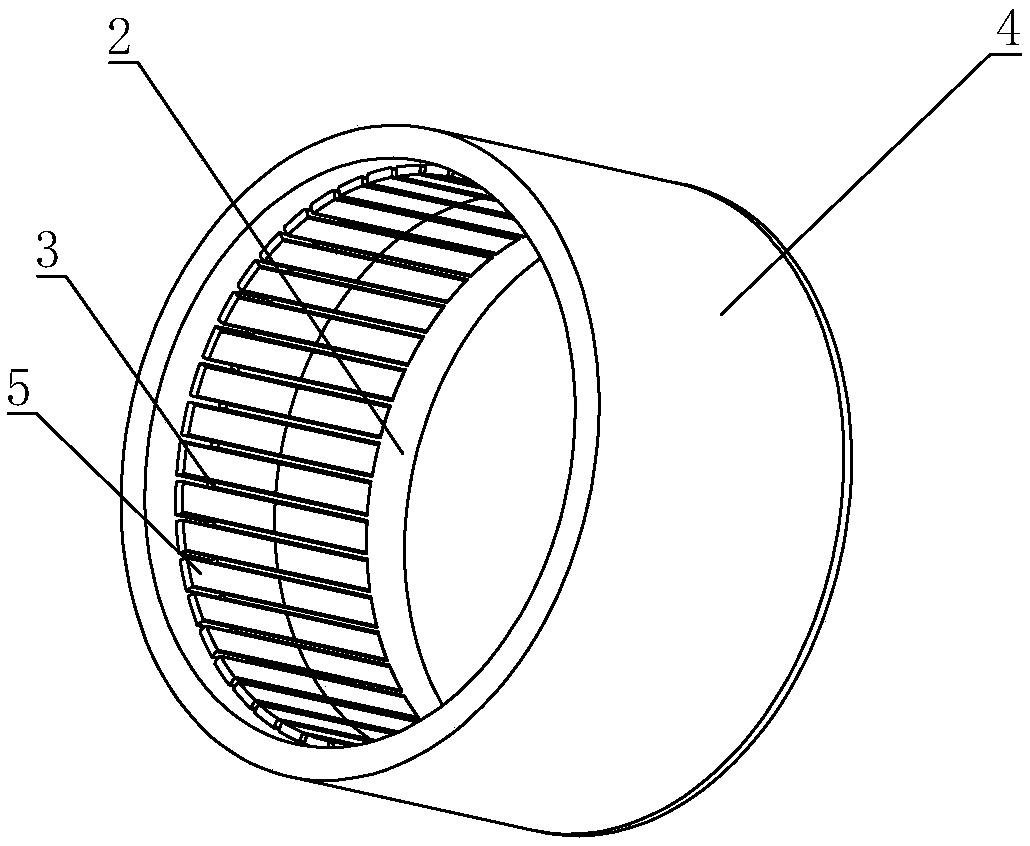

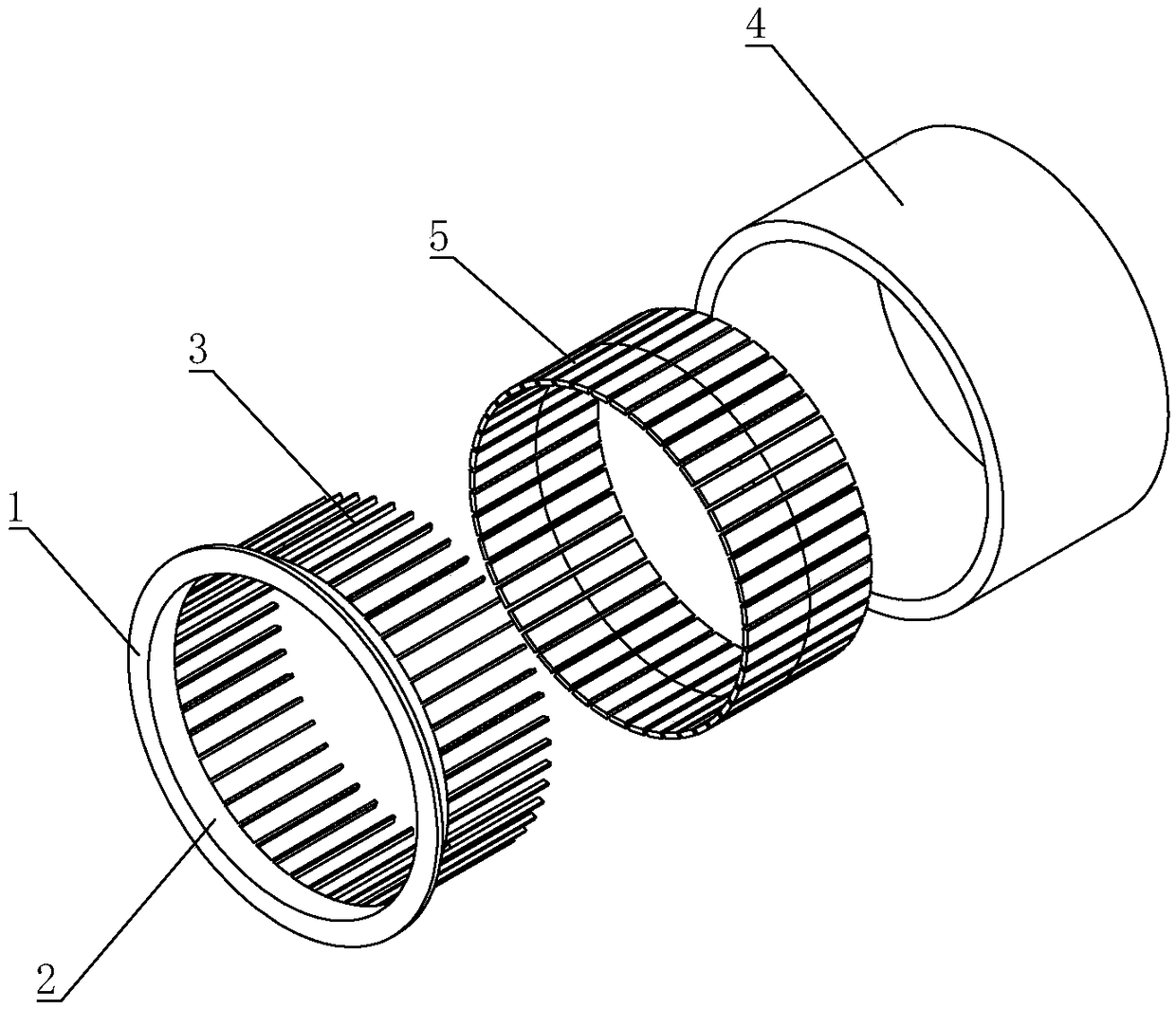

Outer rotor brushless motor magnetic steel adhesion tool

PendingCN108631523AUniform bondingHigh speedManufacturing stator/rotor bodiesBrushless motorsEngineering

The invention discloses an outer rotor brushless motor magnetic steel adhesion tool which comprises a positioning ring, wherein a connecting ring is vertically connected in a circumferential directionon the inner edge of the positioning ring; the axis line of the positioning line is accordant with that of the connecting ring; the outer diameter of the connecting ring is accordant with the inner diameter of a casing; the outer diameter of the positioning ring is greater than the inner diameter of the casing; a plurality of stripy positioning columns are connected at intervals in an axial direction on an end surface, away from the positioning ring, of the connecting ring; the gap between every two adjacent positioning columns is accordant with the width of magnetic steel to be adhered; thenumber of the magnetic steel to be adhered is set as n; the number of the positioning columns is n+1. By adopting the outer rotor brushless motor magnetic steel adhesion tool disclosed by the invention, magnetic steel can be adhered uniformly and adhered to the bottom directly, the magnetic steel adhesion speed is increased, and the magnetic steel adhesion quality is improved.

Owner:宣城坚腾智能传动设备有限公司

Processing technology of copper enameled wire with high painting fastness

ActiveCN113223777ADry fastGood adhesionApparatus for feeding conductors/cablesApparatus for heat treatmentCopper wireSurface roughness

The invention belongs to the technical field of enameled wire production technologies, and particularly relates to a processing technology of a copper enameled wire with high painting fastness. The processing technology specifically comprises the steps of wire drawing, paying off, annealing, cleaning, painting, baking and curing, and taking up. Wire drawing and paying off are carried out for many times to obtain a copper wire, then the cooper is annealed, and the annealed copper ispolished and cleaned to remove surface burrs of the copper wire and increase the surface roughness, so paint adhesion is facilitated; and the paint and the surface of the copper wire are tightly and uniformly bonded through multiple times of painting and two times of pressurization, meanwhile, drying of the surface of the paint is accelerated by increasing the temperature in a pressurization machine, and finally the paint is more stable through baking and curing, so the prepared enameled copper wire is uniform and stable in paint layer, high in fastness, not easy to fall off and high in breakdown strength.

Owner:江西泰和百盛实业有限公司

Method for processing coiled BOPP film adhesive tape

The invention discloses a method for processing a coiled BOPP film adhesive tape, which comprises a coiled tape adhering step. The coiled tape adhering step comprises the following operations: firstly, performing surface structure homogenized treatment on an adhered surface of the adhesive tape to ensure that the surface tension of the adhered surface is 35 to 45 dynes; and while adhering a loweradhesive tape to an upper adhesive tape, uniformly extruding the surface of the upper adhesive tape along the rotary coiling opposite direction of the tape. Through the surface structure homogenized treatment, the adhered surface of the tape has uniform structural distribution, and the surface of the upper adhesive tape is extruded during coiling the tape to discharge the air between the adheringsurface and the adhered surface, so adhesion between the upper and lower tapes of the coiled BOPP film adhesive tape is quite uniform, the noise produced by the tapes is greatly reduced during drawing and breaking the tape in use, and the noise of the tape can be reduced to below 30 decibels through detection.

Owner:BOLEX SHENZHEN ADHESIVE PROD

Aluminum composite plate

InactiveCN103213343AIncreasing the thicknessHigh strengthMetal layered productsSurface layerEngineering

The invention discloses an aluminum composite plate comprising a core-layer plate as well as a bottom-layer plate and a surface-layer plate which are adhered to two sides of the core-layer plate, wherein the core-layer plate, the bottom-layer plate and the surface-layer plate are made of aluminum; a plurality of first bulges are uniformly formed on the core-layer plate in a pressing manner; the protruding heights and the protruding directions of the first bulges are same; and the bottom-layer plate and the surface-layer plate are adhered to the core-layer plate through adhesive layers. The aluminum composite plate has the advantages of good flatness and processability, high strength, light weight and fire prevention.

Owner:ZHANGJIAGANG MUZI MACHINERY TECH

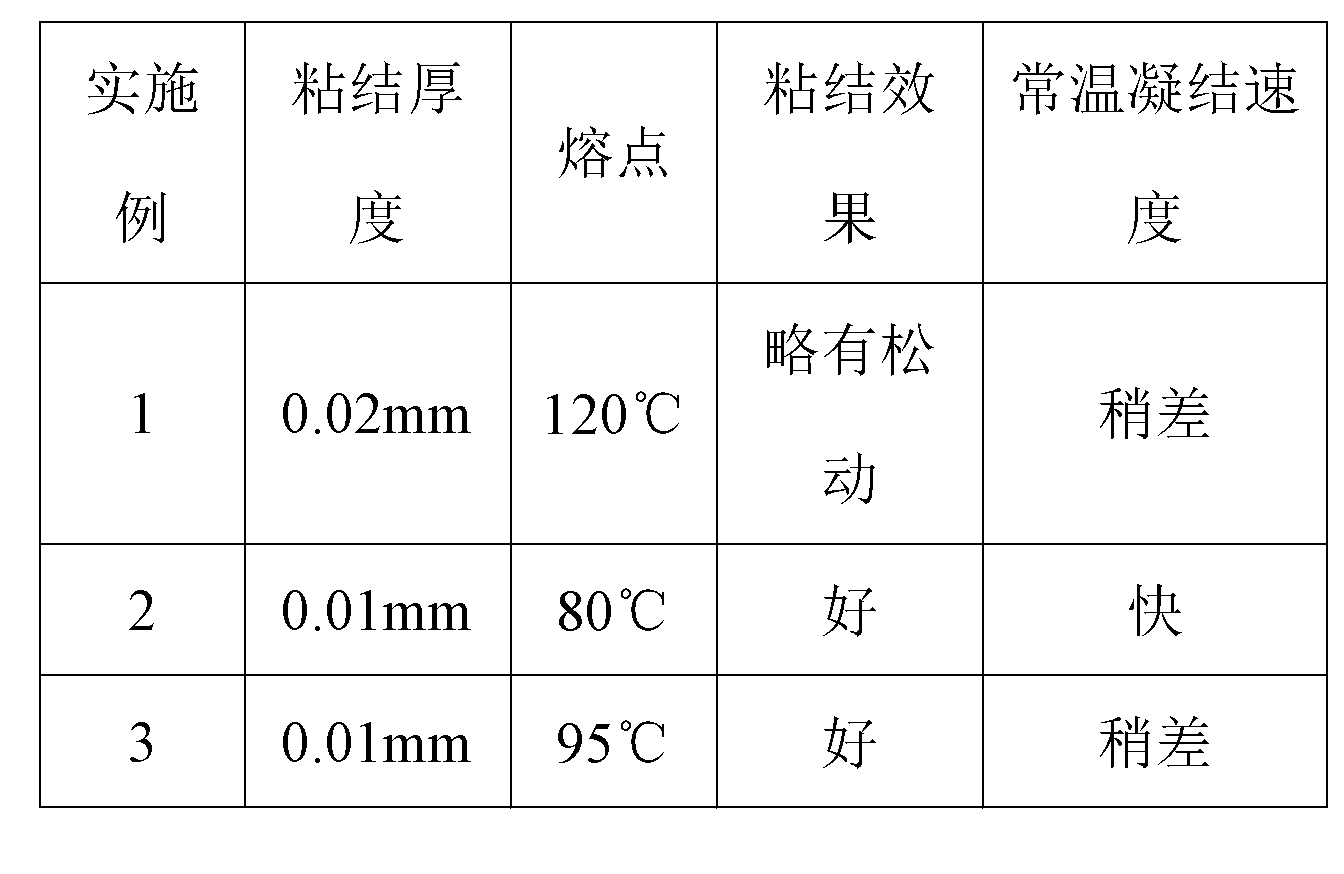

Formula of paraffin adhesive for bonding special ceramics and iron plate

ActiveCN103232833ADamage reduction statusEfficient processingWax adhesivesAldehyde/ketone condensation polymer adhesivesParaffin waxAdhesive

The invention relates to a formula of a paraffin adhesive for bonding special ceramics and an iron plate. The paraffin adhesive aims to solve the problems of lack of favorable bonding property in the bonding of the special ceramic part and iron part, incapability of ensuring high efficiency in the working process, and poor permeability, and the problem that people can encounter some difficulties and risks in the concrete production process. The invention is characterized by comprising the following components in percentage by weight: 55.5-57.0% of high-temperature high-purity paraffin, 15-16.5% of high-purity rosin, 3.0% of polyethyleneglycol, 3.0% of synthetic resin, 9.5-10% of sibutramine intermediate and 11.0-12% of curing accelerator. The bonding thickness can be controlled at 0.01mm; and the paraffin adhesive has the advantages of excellent bonding effect for special ceramics of zirconium oxide, aluminum oxide, silicon carbide and the like and iron parts, high cooling speed, low loosening tendency at normal temperature, and strong hard impact resistance.

Owner:衢州飞瑞特种陶瓷有限公司

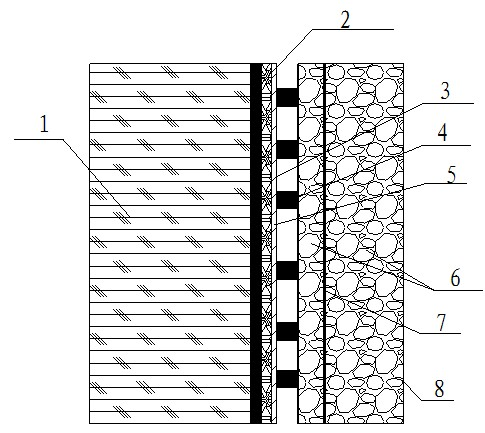

Old wall surface refurbishment and installation system

The invention relates to an old wall surface refurbishment and installation system. A main body comprises a wall surface, a plastering layer painted on an outer layer of the wall surface, and a painting agent adhesive layer and an old tile surface which are arranged outside the plastering layer, wherein an adhesive layer is arranged on an outer layer of the old tile surface; a thermal insulation plate is adhered outside the adhesive layer; a coating panel is arranged on the thermal insulation plate; adhesives on the adhesive layer are adhered to the old tile surface in array distribution; a distance between adjacent adhesives is 2 to 5cm; and an enhanced aluminum plate is arranged at 1 / 3 of the left side of the thermal insulation plate. In the process of refurbishing the wall surface, the old tile surface is knocked by hard objects and is chiseled into a pitted surface, the chiseling depth reaches the painting agent adhesive layer inside the old tile surface, novel adhesives are painted and are uniformly adhered, novel tiles can be decorated on the coating panel, environment-friendly, safe and material-saving effects are achieved, not all the old tiles are required to be knocked, and the novel adhesives are saved.

Owner:SUZHOU CITY BANGCHENG ELECTRICITY TECH

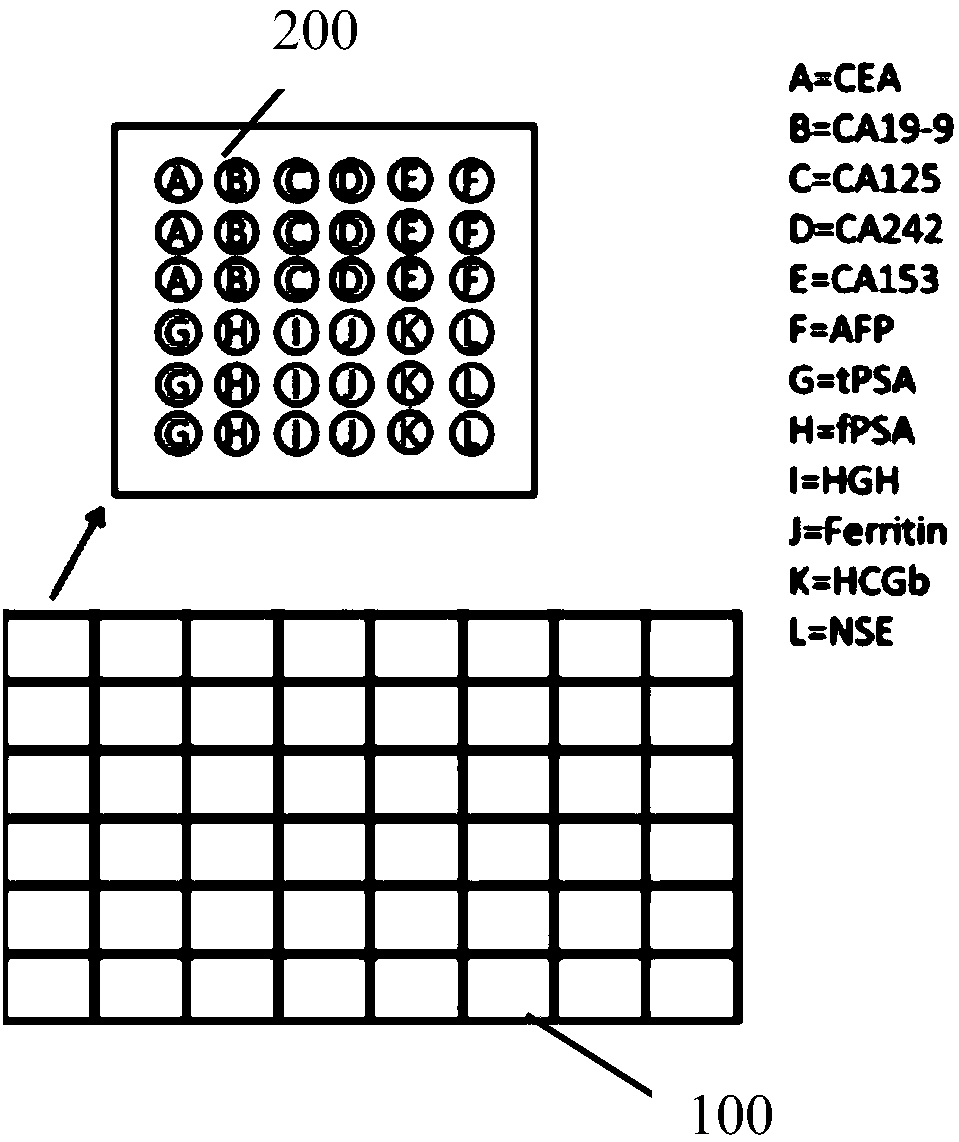

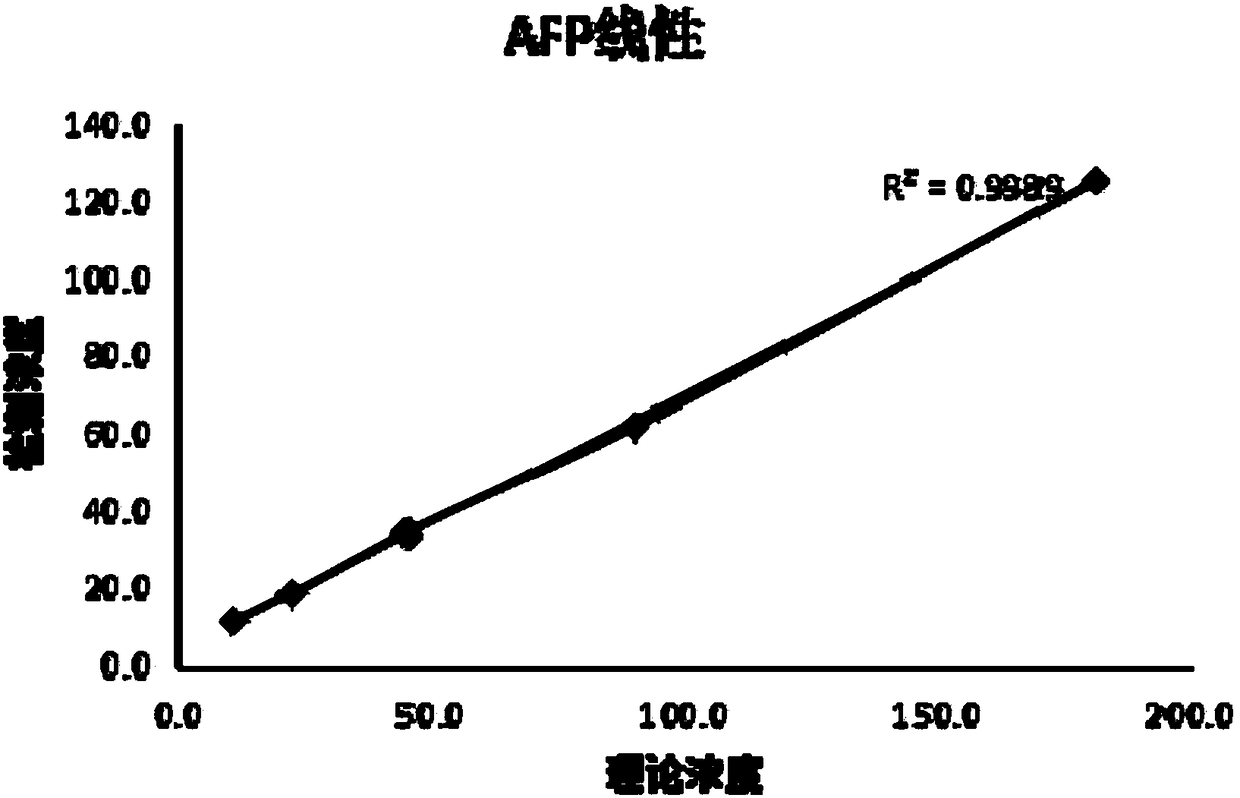

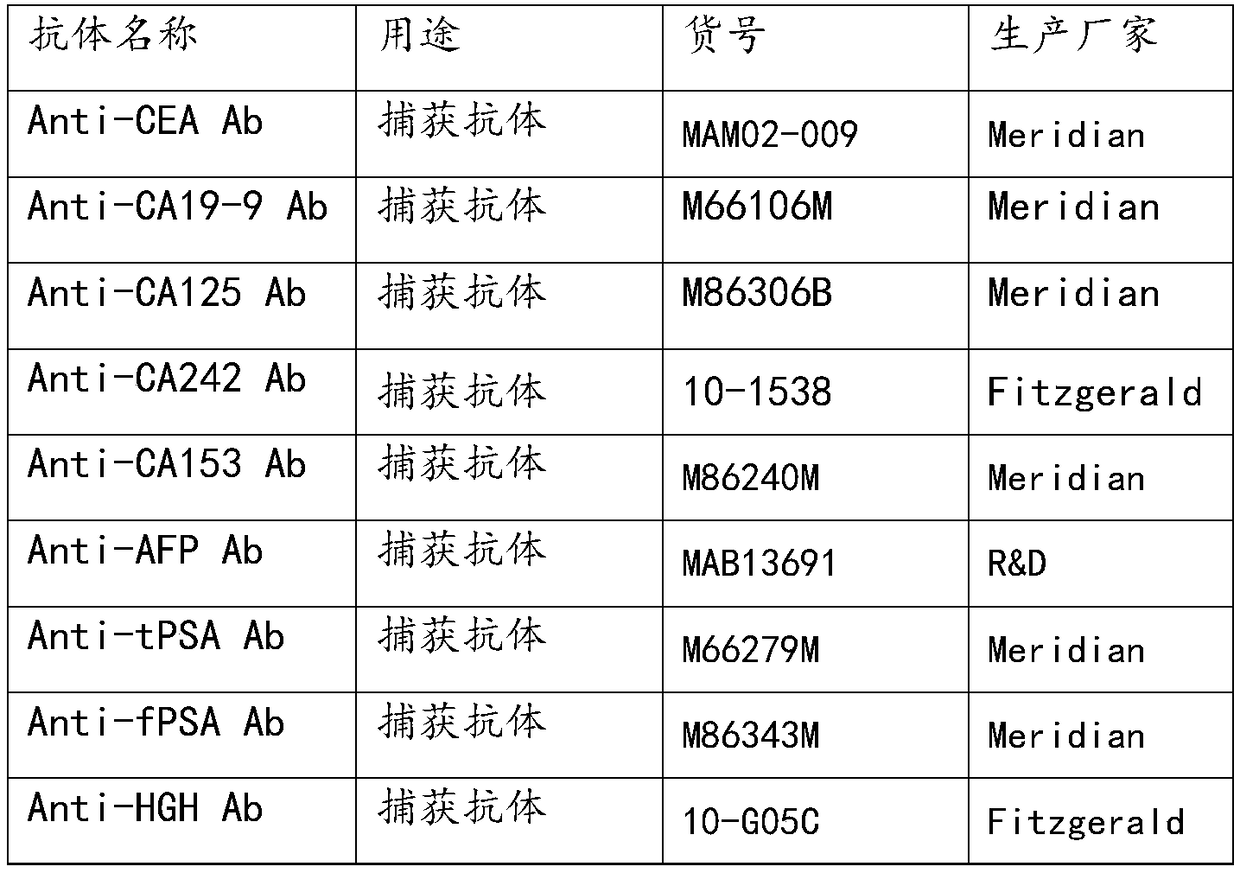

Antibody chip kit for early screening and diagnosis of tumors

The invention discloses an antibody chip kit for early screening and diagnosis of tumors. The detection is realized based on an enzyme lined immunosorbent assay (ELISA); the antibody chip kit comprises an antibody chip and an antigen standard substance mixture of multiple tumor markers, wherein the antibody chip comprises a base membrane and capture antibodies, fixed on the base membrane, of the multiple tumor markers; the base membrane is a polydimethylsiloxane (PDMS) membrane having a surface containing hydrophilic groups. On the premise of maintaining the characteristics of high sensitivity, large flux, much information and the like, the base membrane adopted by the invention is good in stability, strong in biological compatibility, good in flexibility, easy to clean and convenient to use; chip substrates of the capture antibodies of the tumor markers are fixed.

Owner:上海铭源数康生物芯片有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com