Patents

Literature

82results about How to "High structural density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technology of full-dry desulfurizing gypsum building material product

The invention relates to a production technique of a total drying desulfurizing gypsum building material product, which comprises the following steps: desulfurizing gypsum, phosphor gypsum or natural gypsum are taken as the raw materials, through roasting, sieving, adding water and inorganic silicon water repellent compound, the raw materials are still dry powder; then the gypsum building material product with high consistency is obtained through installing by a paver and shaped by high pressure. The product has high strength, good rigidity, without shrinkage and no need of release agent. The gypsum product needs no drying to produce and greatly saves energy, and the energy-saving effect is good. The gypsum product having simple production technique saves energy consumption without discharge of contamination, and has no poison and damage with very low production cost. The invention can completely satisfy various requirements of users.

Owner:重庆金仓龙新型建材有限公司

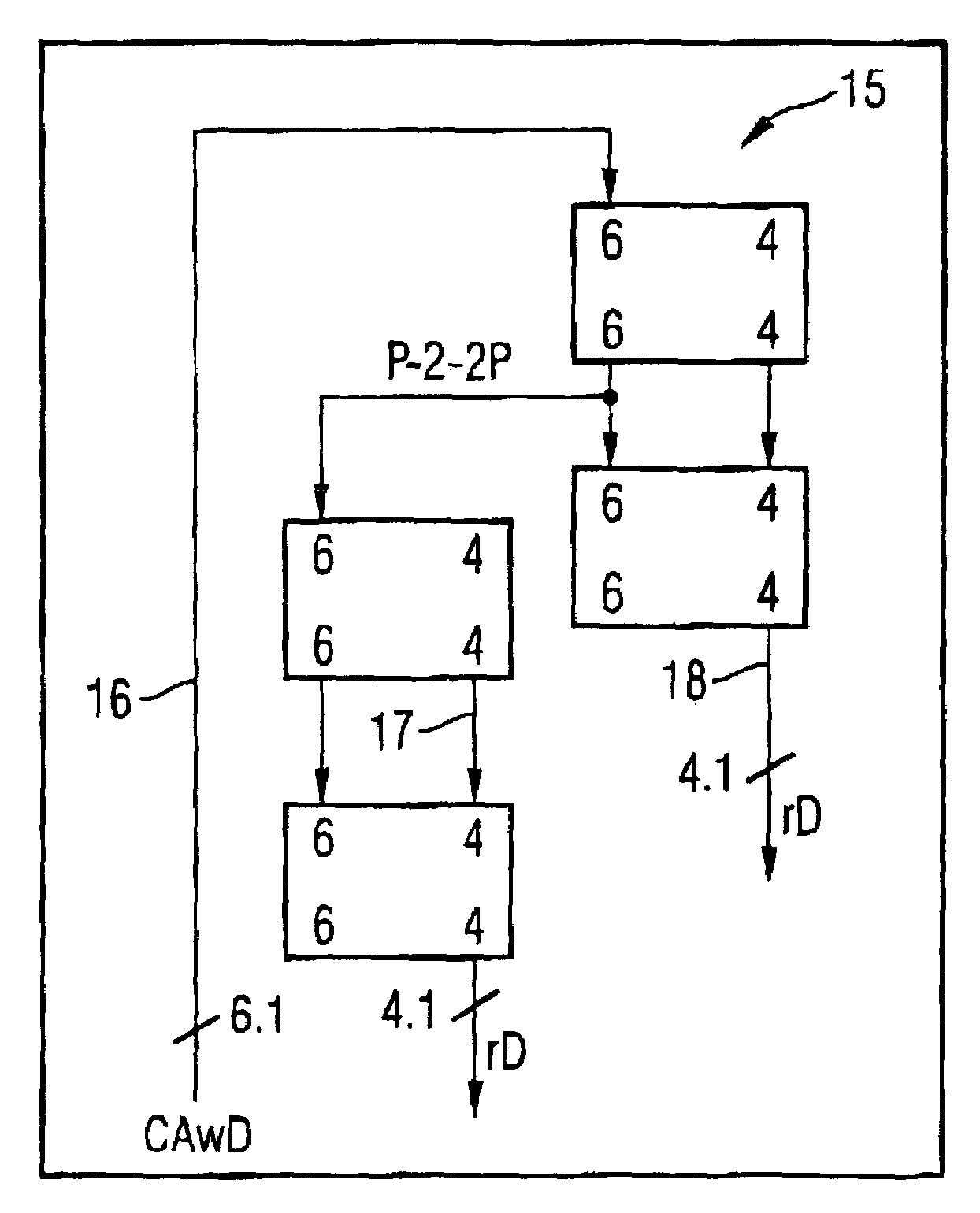

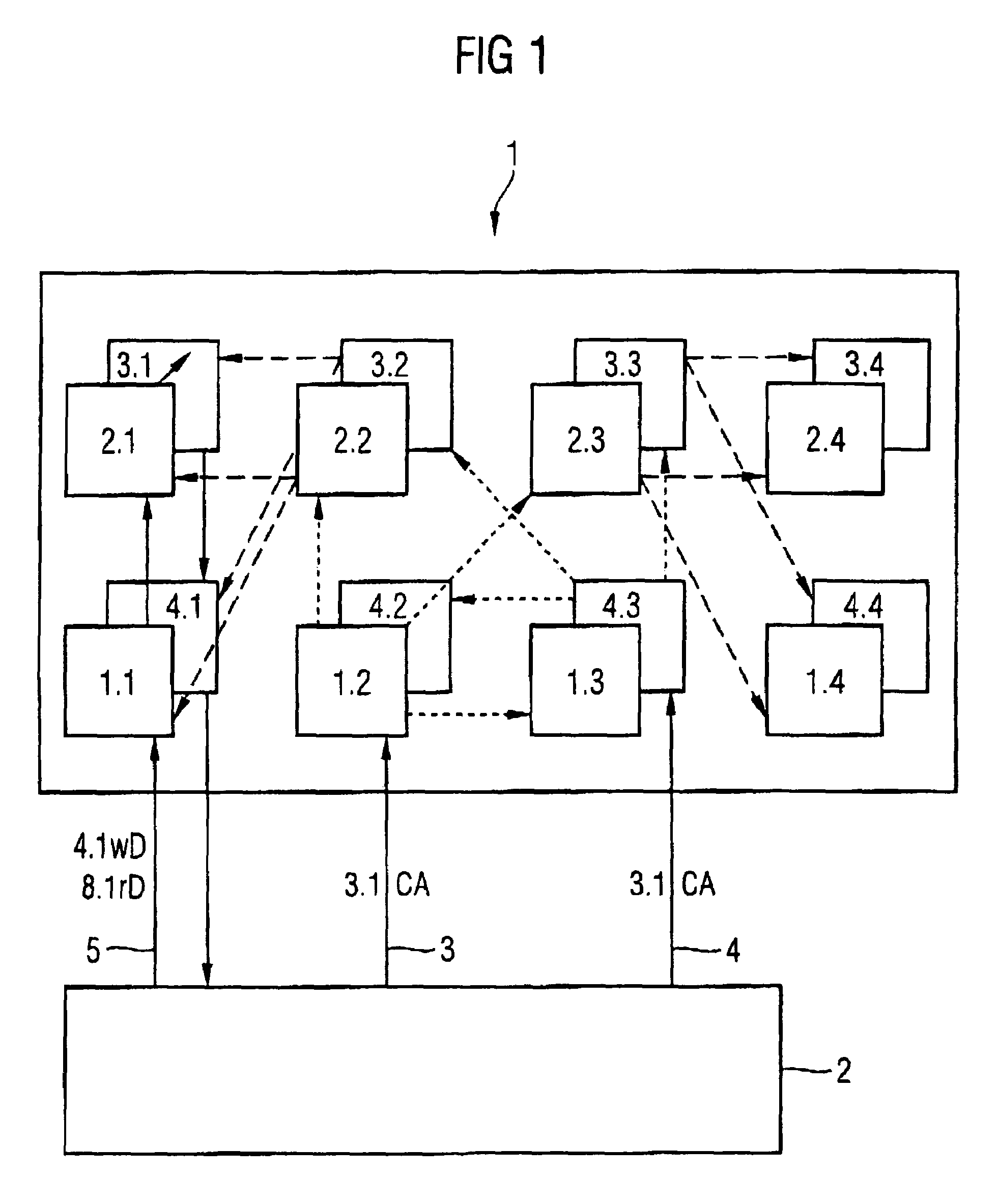

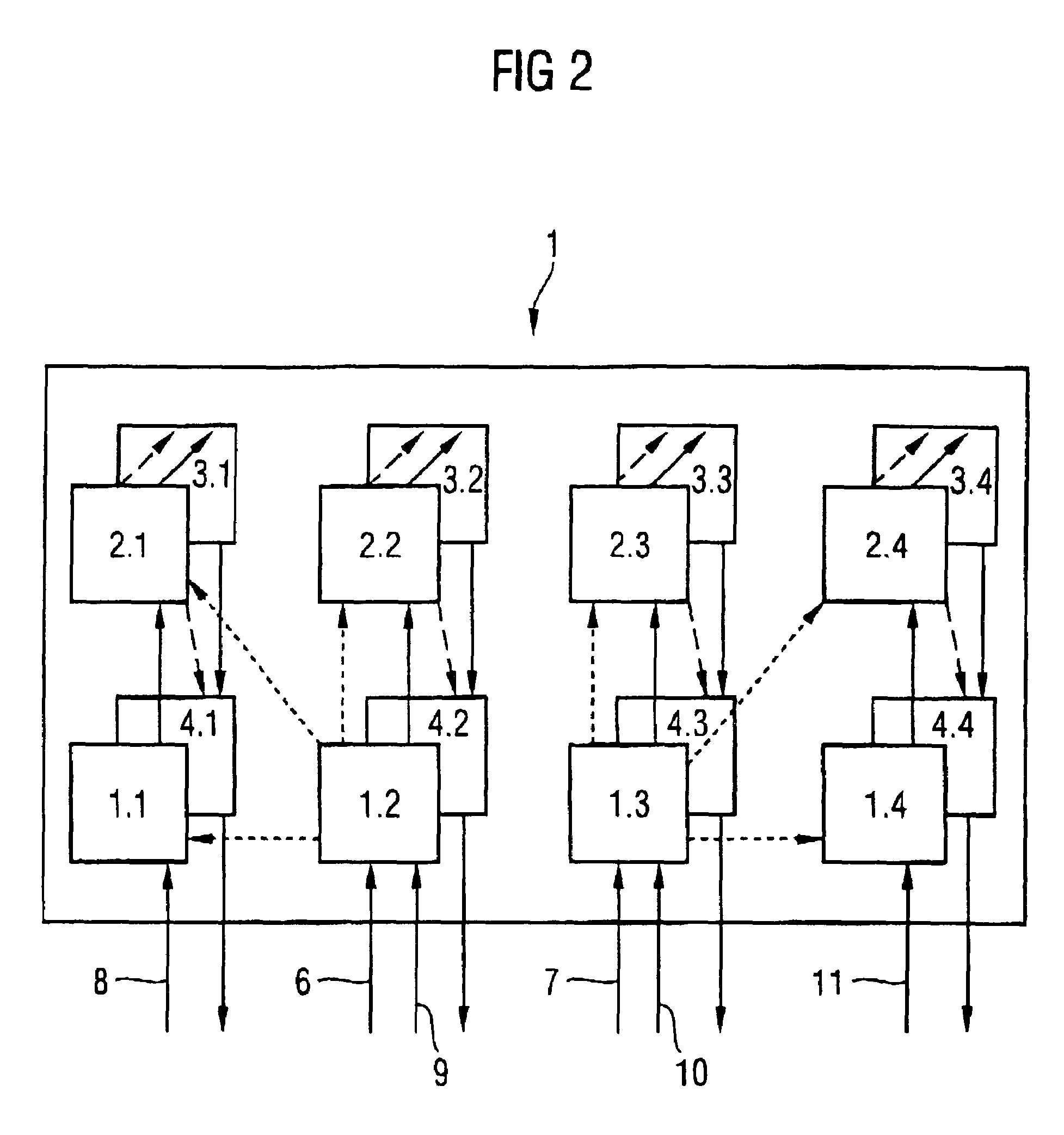

Semiconductor memory arrangement with branched control and address bus

A semiconductor memory arrangement for operation in a data memory system with at least one semiconductor memory chip for the storage of user data includes a memory controller for control of the at least one semiconductor memory chip, and at least one unidirectional signal line bus for control and address signals connected with the memory controller and branching at least once. The at least once branching bus directly connecting at least one semiconductor memory chip with the memory controller and connecting the semiconductor memory chips among each other.

Owner:POLARIS INNOVATIONS

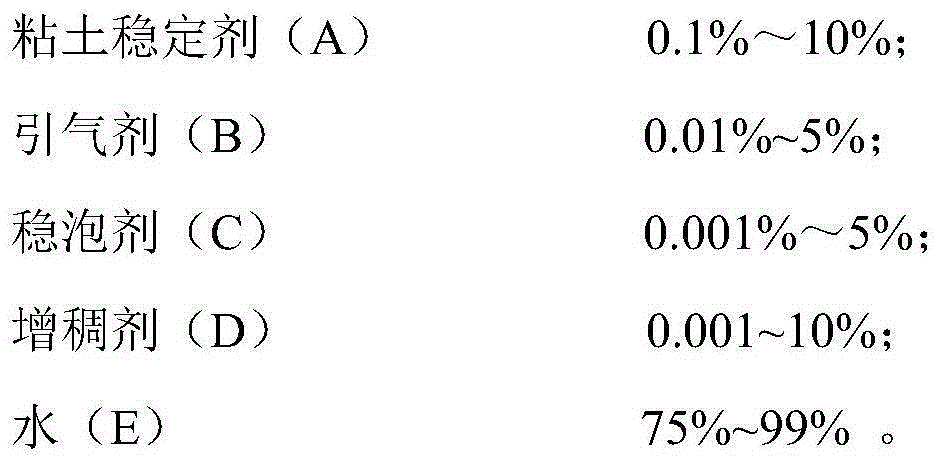

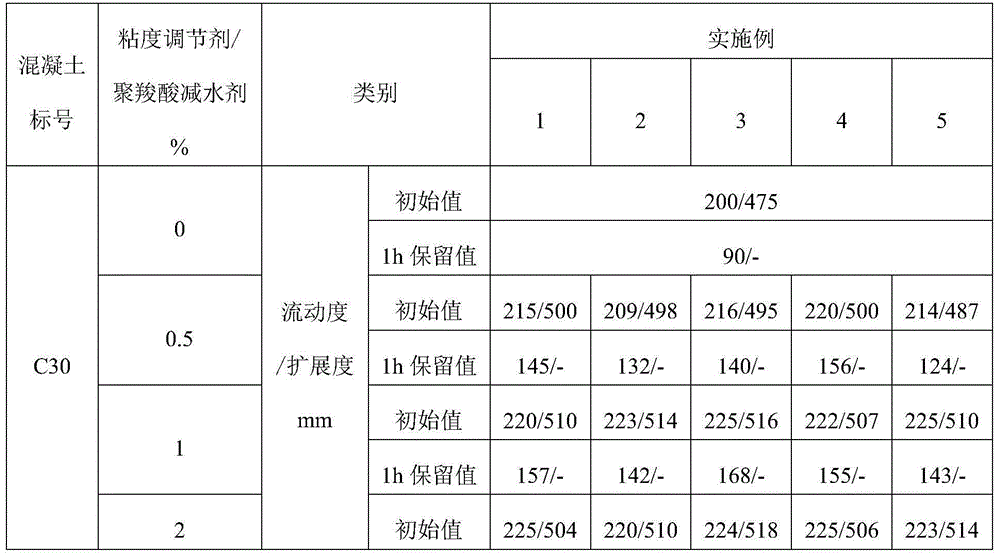

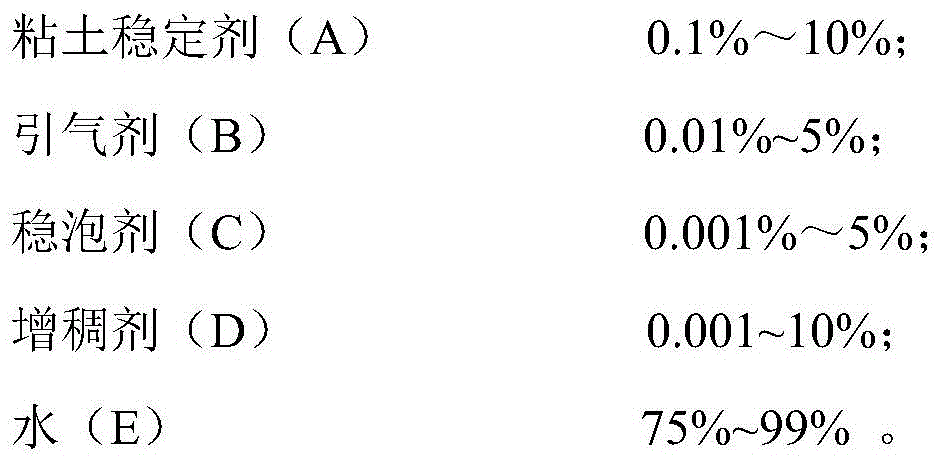

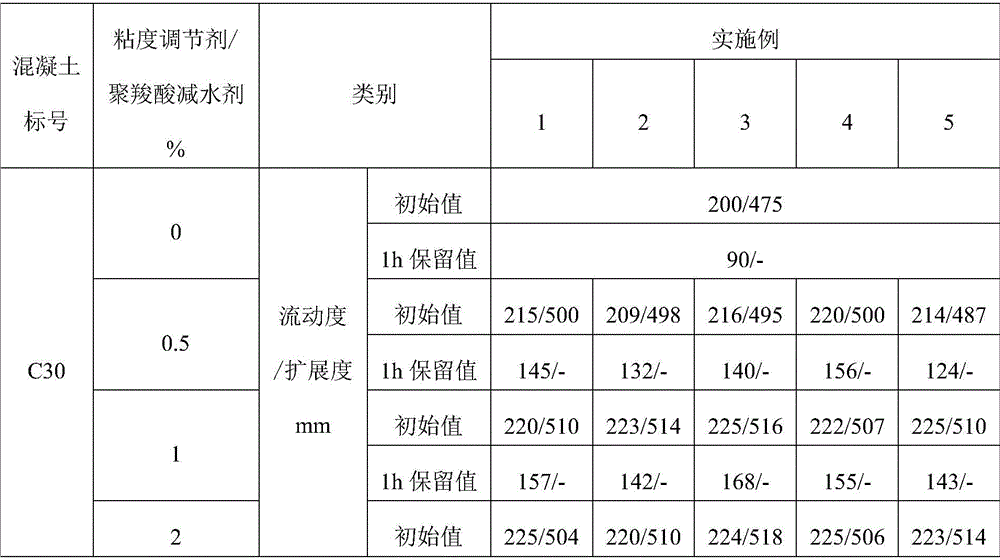

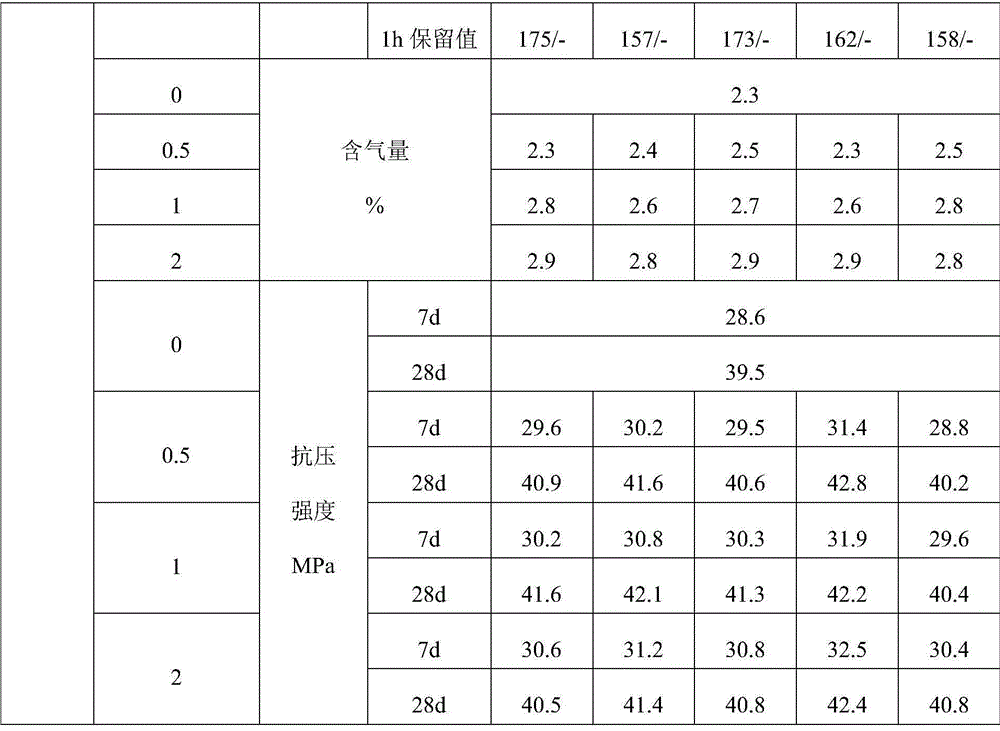

Concrete viscosity regulator suitable for compatible use with polycarboxylic acid water reducer and preparation method thereof

The invention discloses a concrete viscosity regulator suitable for compatible use with a polycarboxylic acid water reducer and a preparation method thereof; the concrete viscosity regulator comprises the components by the weight percentage: 0.1%-10% of a clay stabilizer, 0.01%-5% of an air-entraining agent, 0.001%-5% of a foam stabilizer, 0.001-10% of a thickener, and 75%-99% of water. The preparation method comprises the steps: firstly, adding water to a stirrer, fully mixing evenly other components, starting up the stirrer, after running smoothly, slowly adding the materials, and thus obtaining the concrete viscosity regulator when the materials are fully dissolved and stirred evenly. With cooperative use of the prepared viscosity regulator with the polycarboxylic acid water reducer, the polycarboxylic acid water reducer can be promoted to be adsorbed on cement particle surfaces to form a water film lubrication layer, a cement slurry steric-hinerance effect and rheological properties (the cement slurry has low plastic viscosity and higher yield stress) are effectively increased, wrapping performance on aggregates is increased while the viscosity of the concrete slurry is reduced, and thus the concrete construction performance is improved.

Owner:NANJING HYDRAULIC RES INST

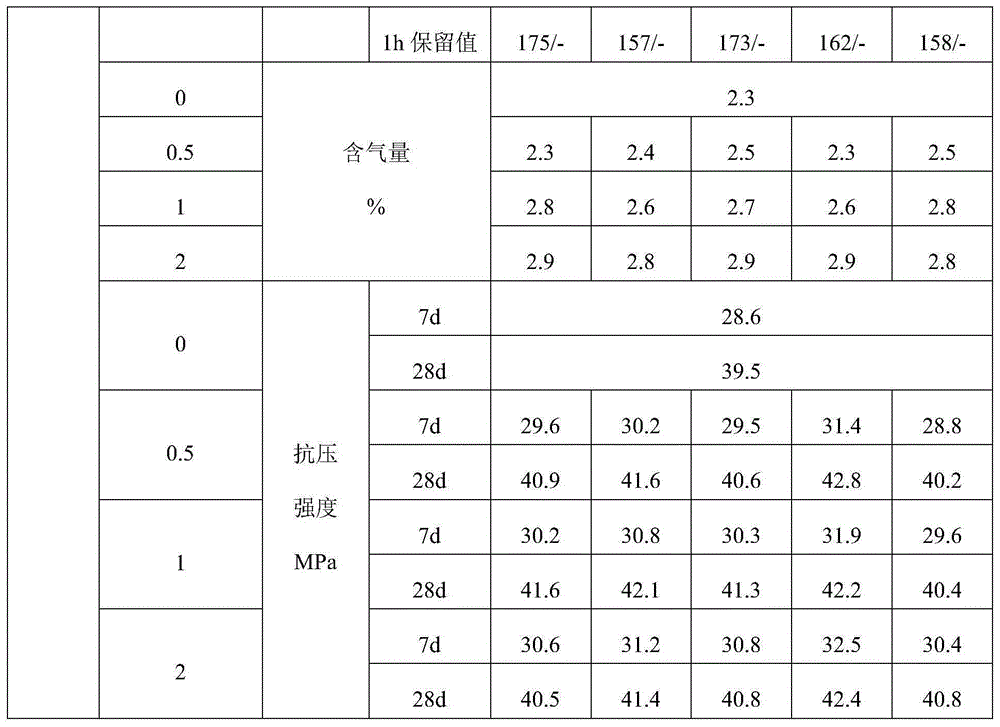

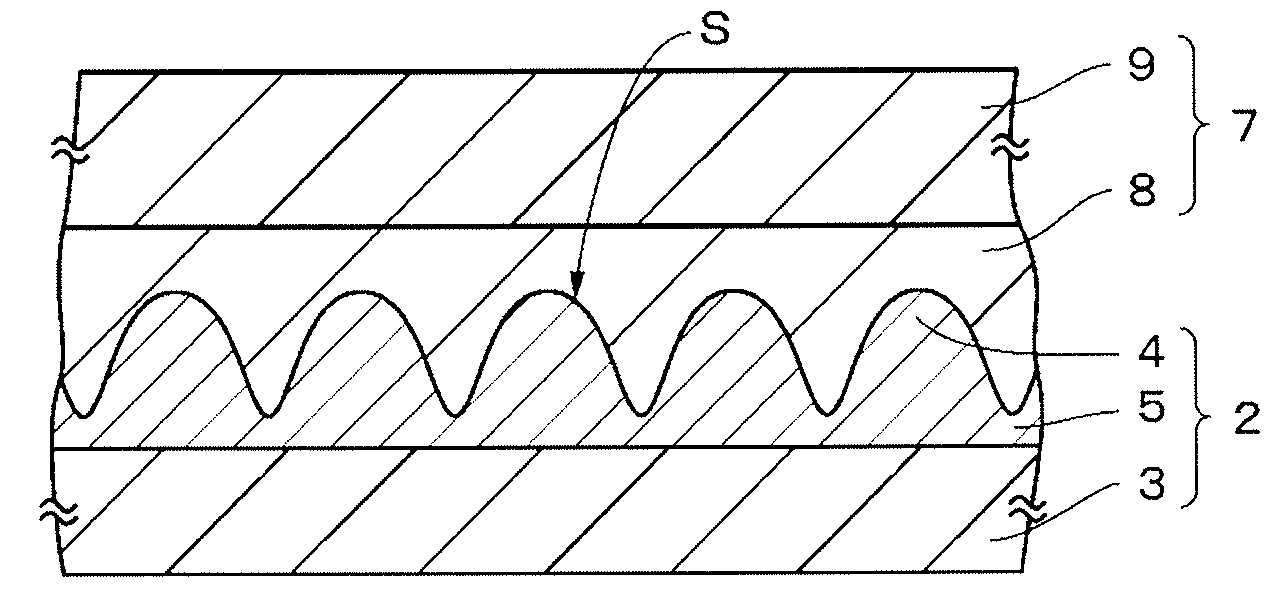

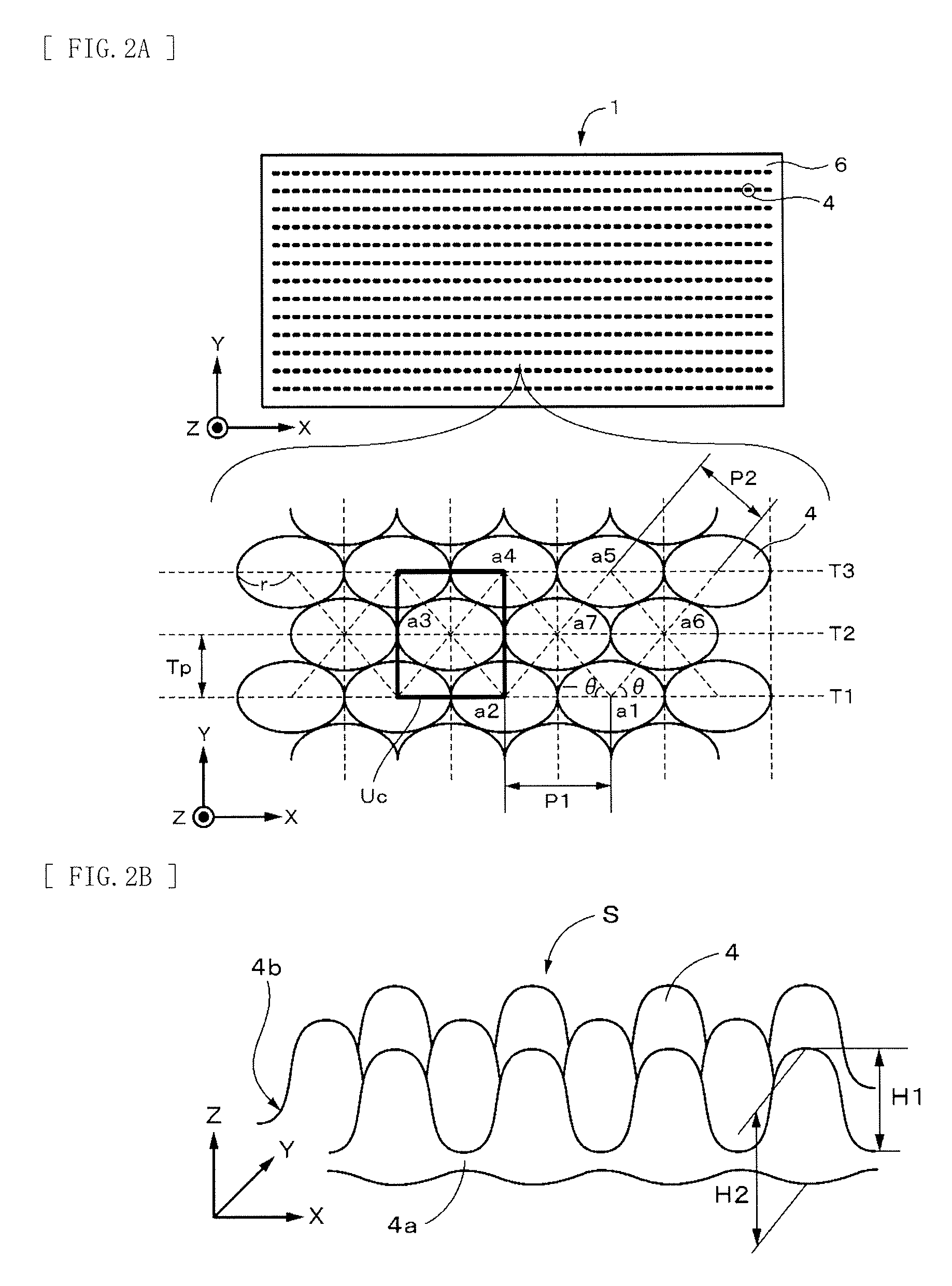

Conductive optical device, input device, and display device

InactiveUS20150223328A1High structural densityExcellent optical propertiesDigital data processing detailsOptical articlesRefractive indexDisplay device

A conductive optical device includes: a base; a plurality of structures supported by the base, and arranged at a pitch that is equal to or shorter than a wavelength of visible light; and a transparent conductive layer provided on a surface-side of the structures, and having a shape that follows along a surface shape of the structures. The following relational expressions are satisfied:y≧−1.785x+3.238y≦0.686where x is a refractive index and y is an aspect ratio, of each of the structures.

Owner:DEXERIALS CORP

A concrete viscosity modifier suitable for use in combination with polycarboxylate water reducer and preparation method thereof

Owner:NANJING HYDRAULIC RES INST

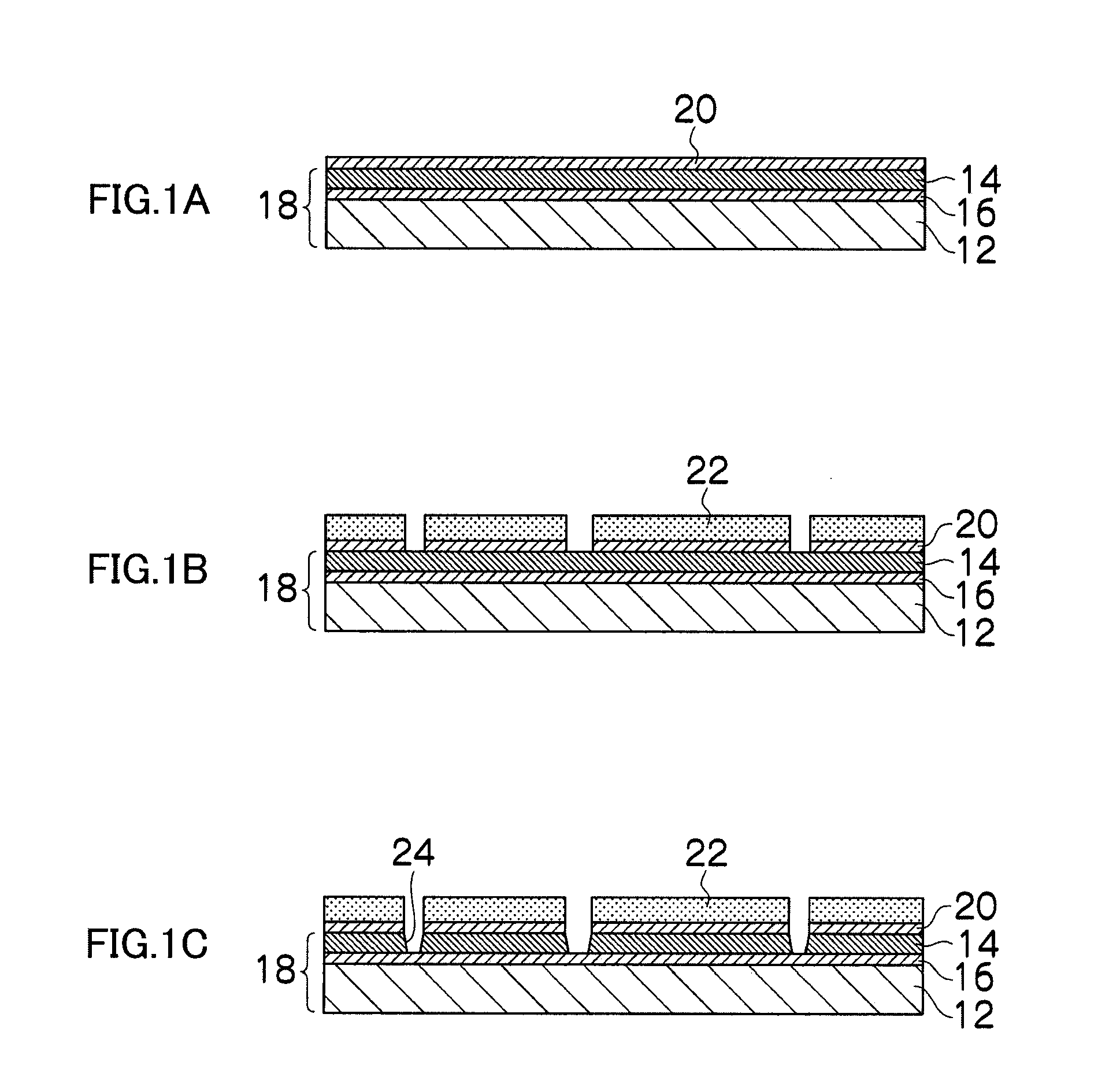

Method of manufacturing inkjet head and inkjet recording apparatus

InactiveUS20100214354A1High structural densityImprove adhesionInking apparatusSemiconductor/solid-state device manufacturingThermal oxideNozzle

The method of manufacturing an inkjet head, includes: an opening section forming step of forming, with respect to a SOI substrate having a first silicon layer, a second silicon layer and a first thermal oxide film between the first silicon layer and the second silicon layer, nozzle opening sections passing through the second silicon layer and the first thermal oxide film and reaching the first silicon layer; after the opening section forming step, a first silicon layer removing step of removing the first silicon layer; and after the first silicon layer removal step, a liquid-repellent film forming step of forming a liquid-repellent film on a surface of the first thermal oxide film that has been exposed in the first silicon layer removal step.

Owner:FUJIFILM CORP

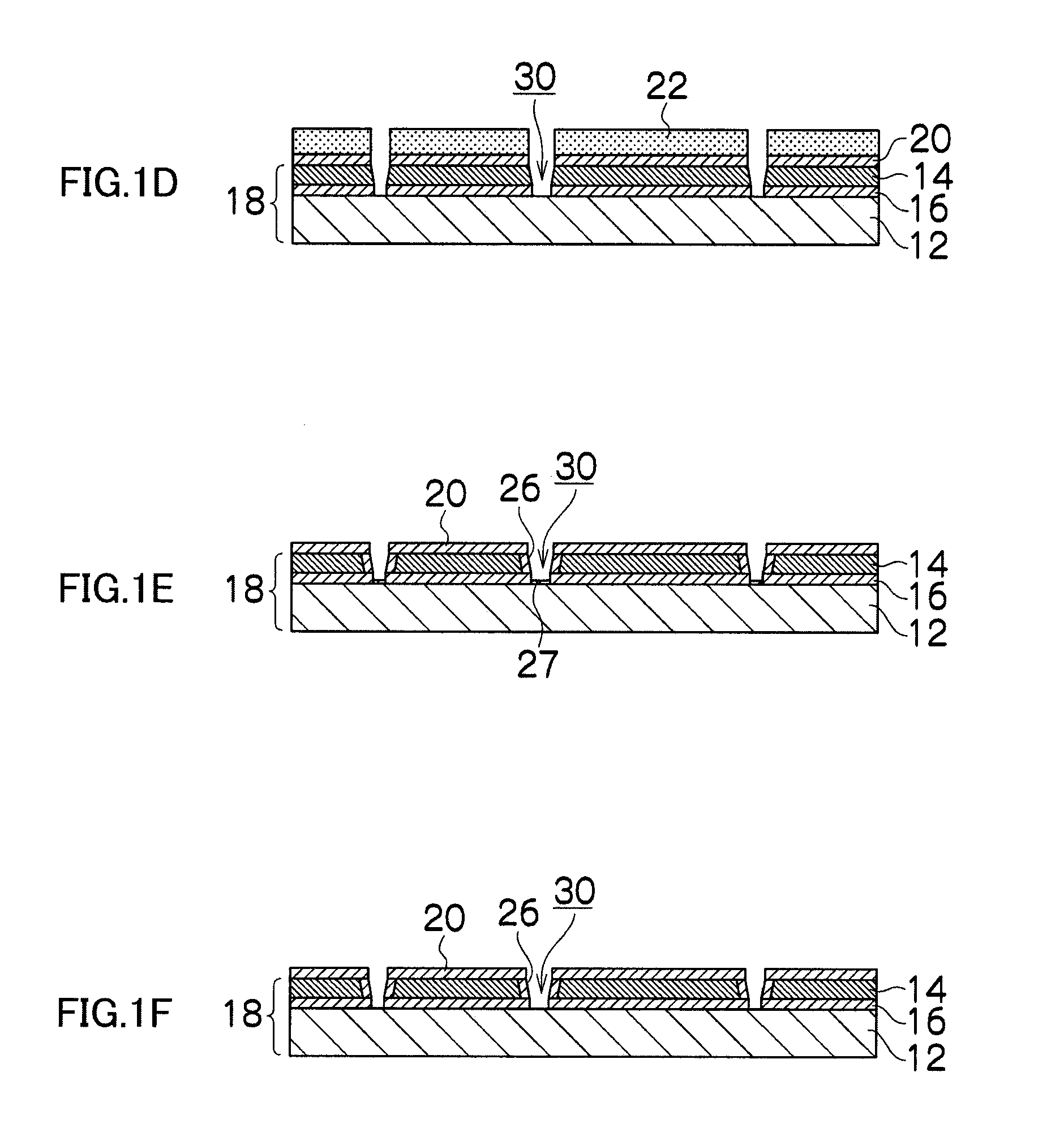

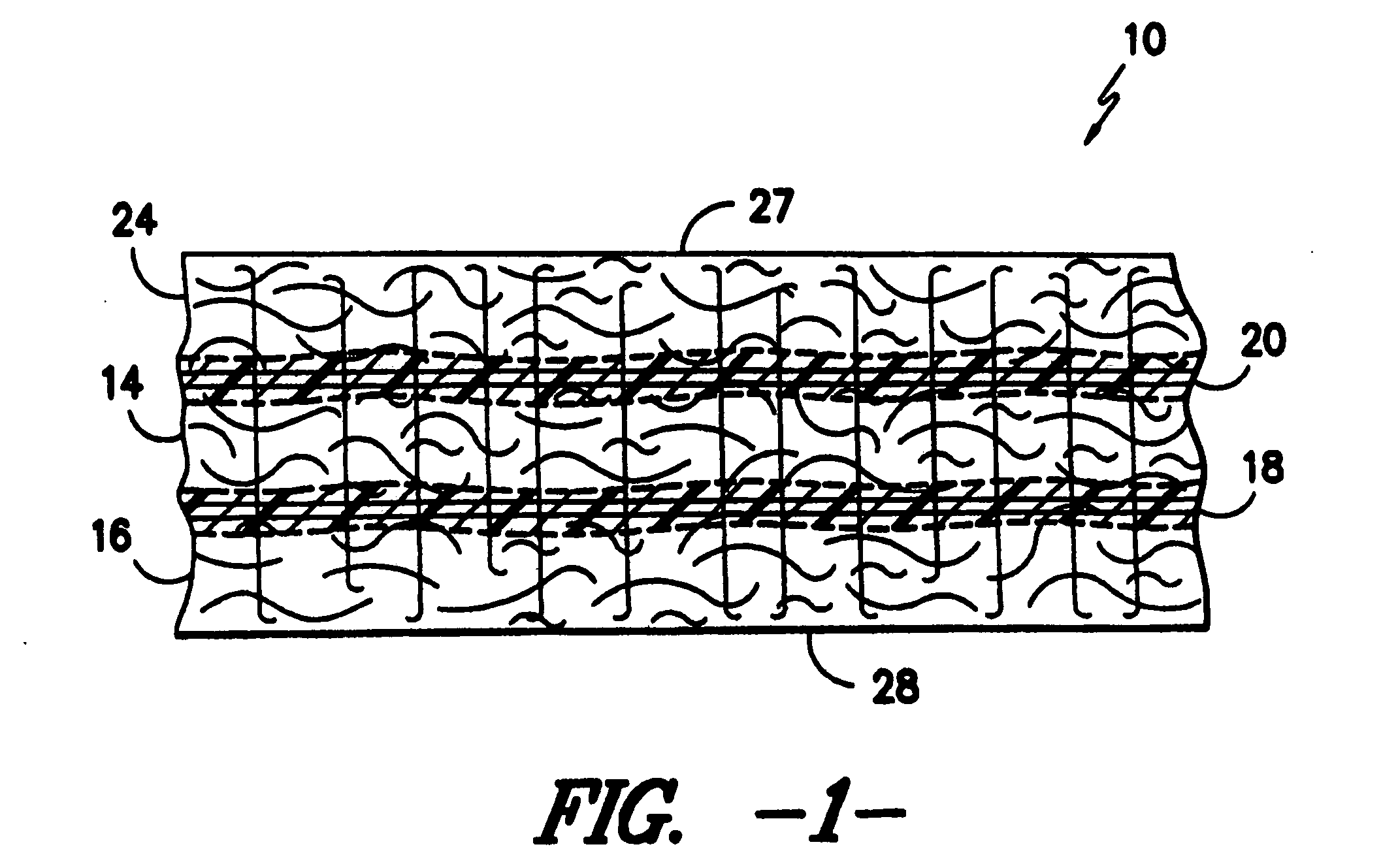

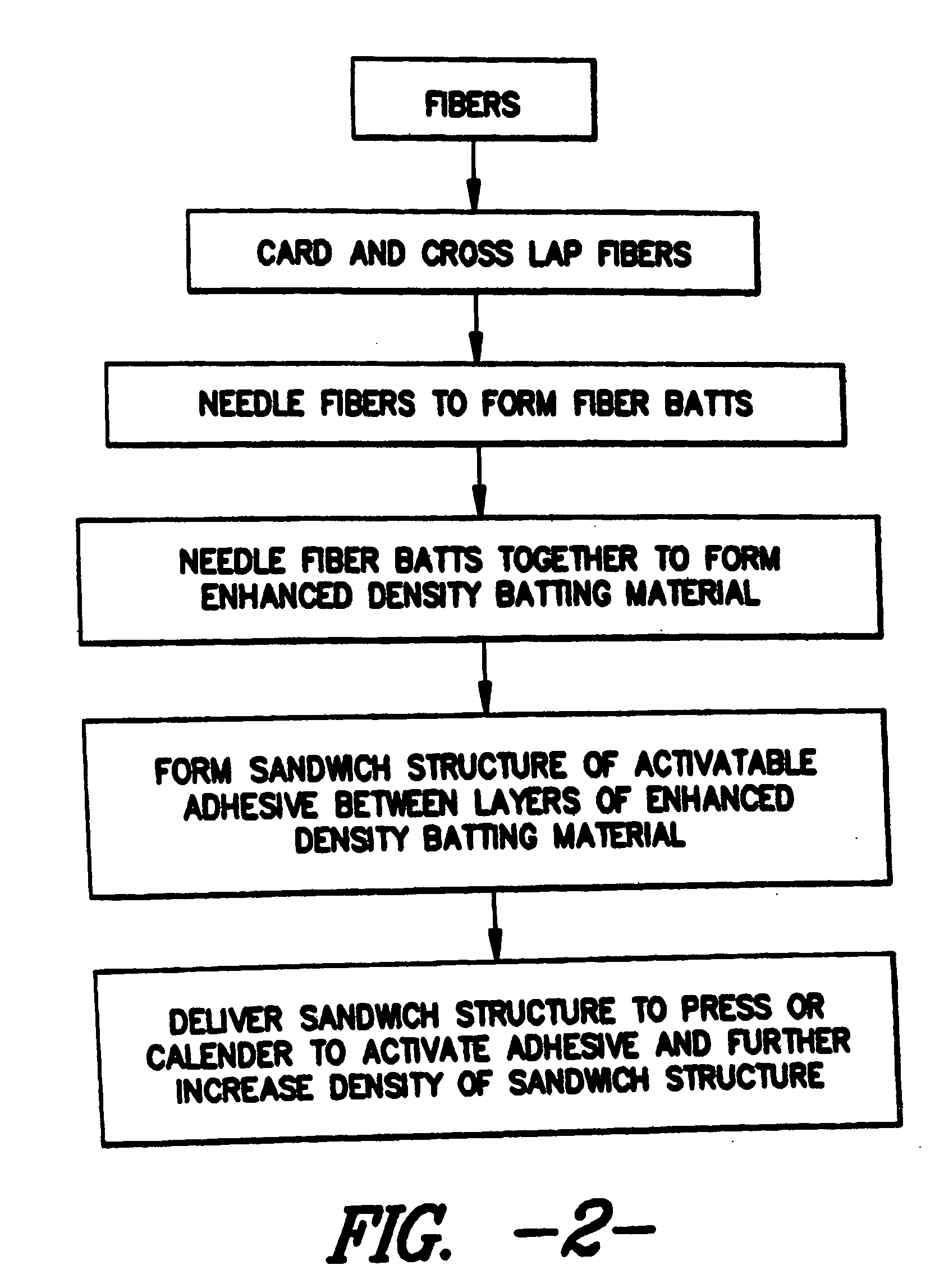

Nonwoven laminate structure

InactiveUS20060194496A1High structural densityLarge thicknessLayered productsCleaning equipmentFiberBiological activation

A nonwoven composite structure having a plurality of layers of nonwoven fiber batting bonded in laminating relation to one another by a localized adhesive disposed between the layers. The adhesive between the layers of fiber batting preferably extends across the interface between the adjacent layers so as to at least partially penetrate each of the layers thereby enhancing the bond strength between the layers. The bond strength between the layers and the uniformity of the resultant bonded structure may be further enhanced by forcibly extending fibers from at least one layer of batting through the material forming the adhesive such as by needling prior to activation of the adhesive such that a portion of the fibers forming the layers of batting extends across the adhesive between the bonded layers.

Owner:THE FELTERS

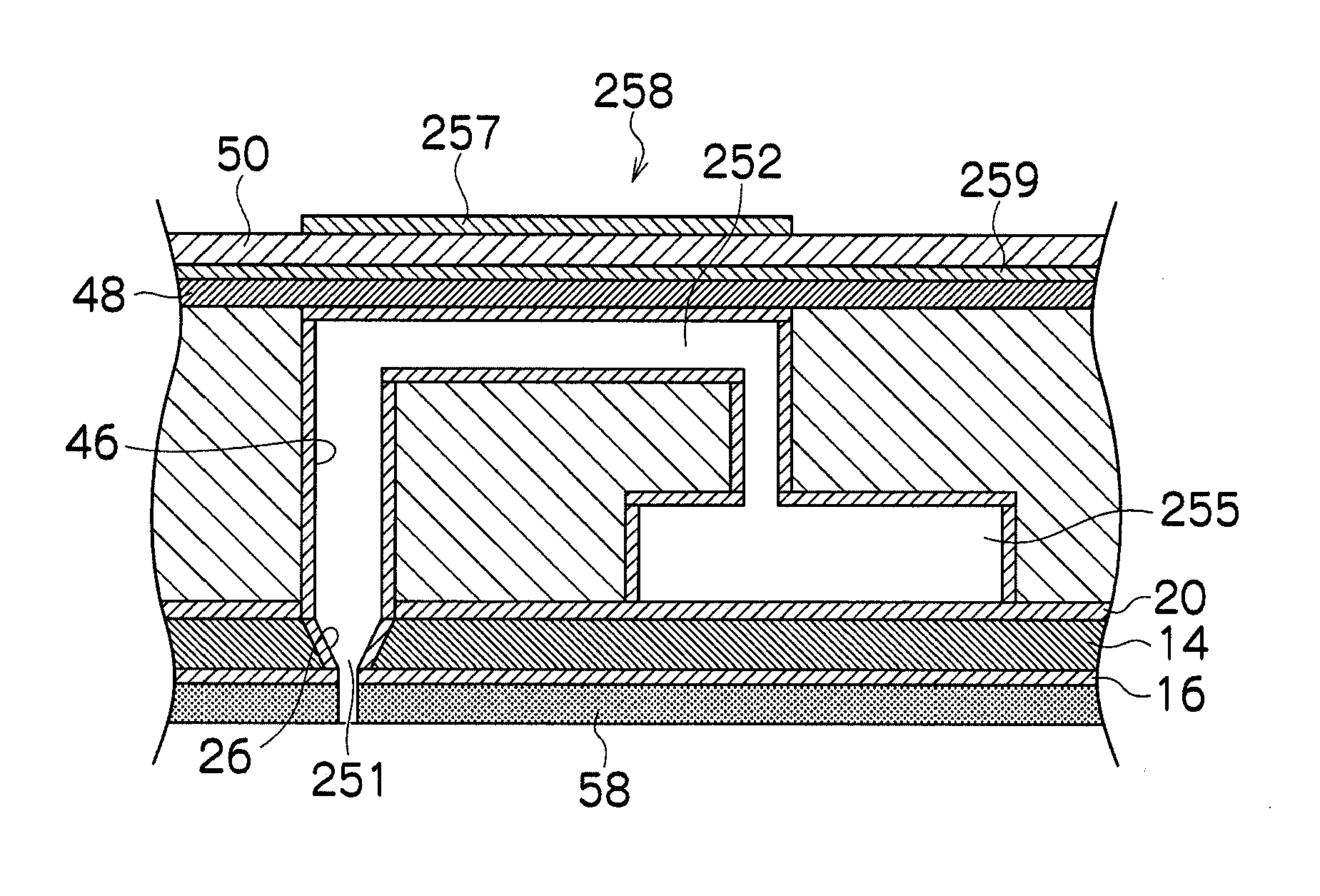

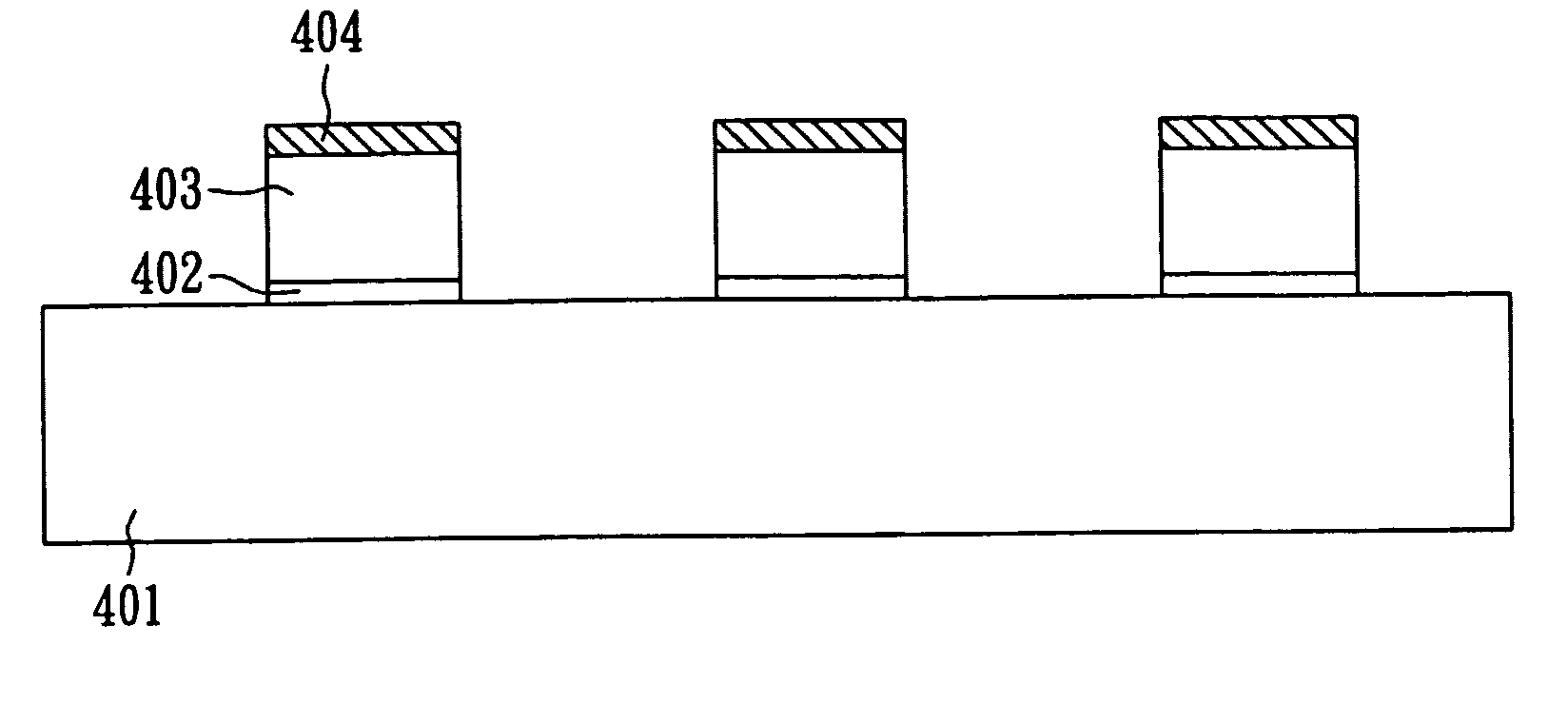

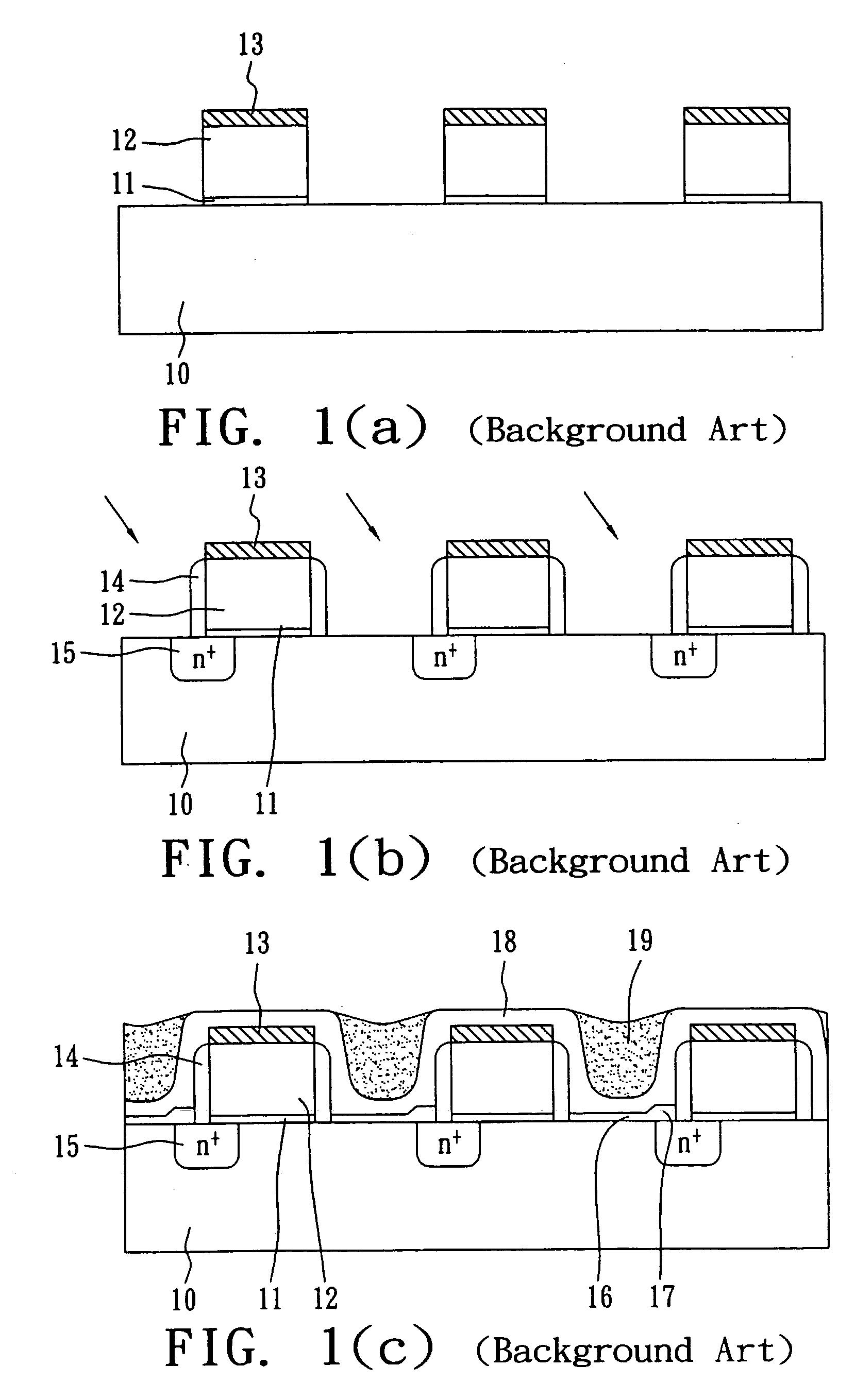

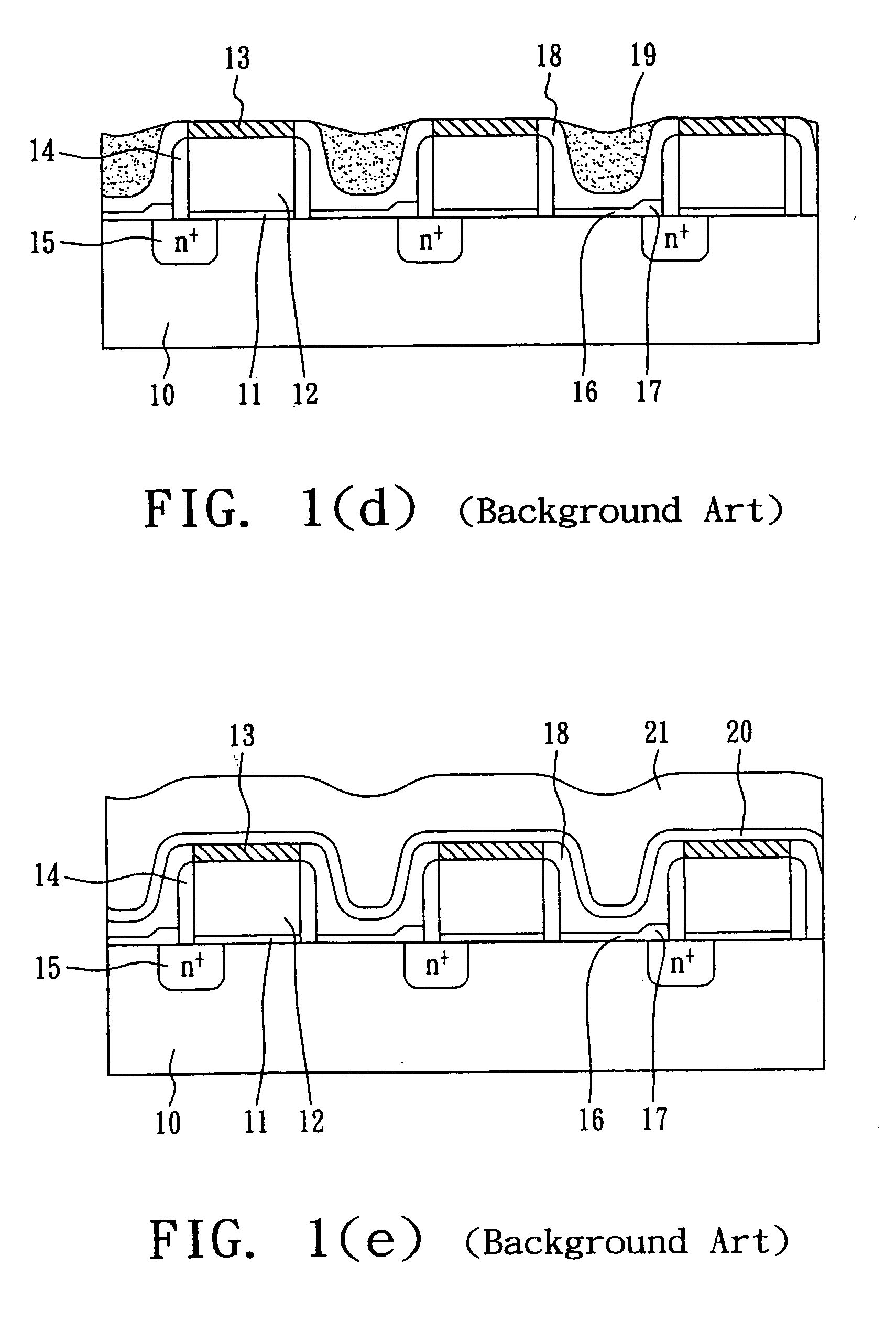

Memory structure and manufacturing as well as programming method thereof

InactiveUS20060073702A1Flexible operationHigh structural densitySolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricNitride

A memory structure includes a floating gate and a nitride gate dielectric on a semiconductor substrate, wherein the floating gate and nitride gate dielectric function as two memory cells. In addition to the floating gate and nitride gate dielectric, the memory structure further comprises two bitlines and a select gate. The two bitlines are formed in the semiconductor substrate, the floating gate and the select gate are formed above the semiconductor substrate and transversely disposed between the two bitlines, and the nitride gate dielectric is formed between the select gate and the semiconductor substrate.

Owner:SKYMEDI CORPORATION

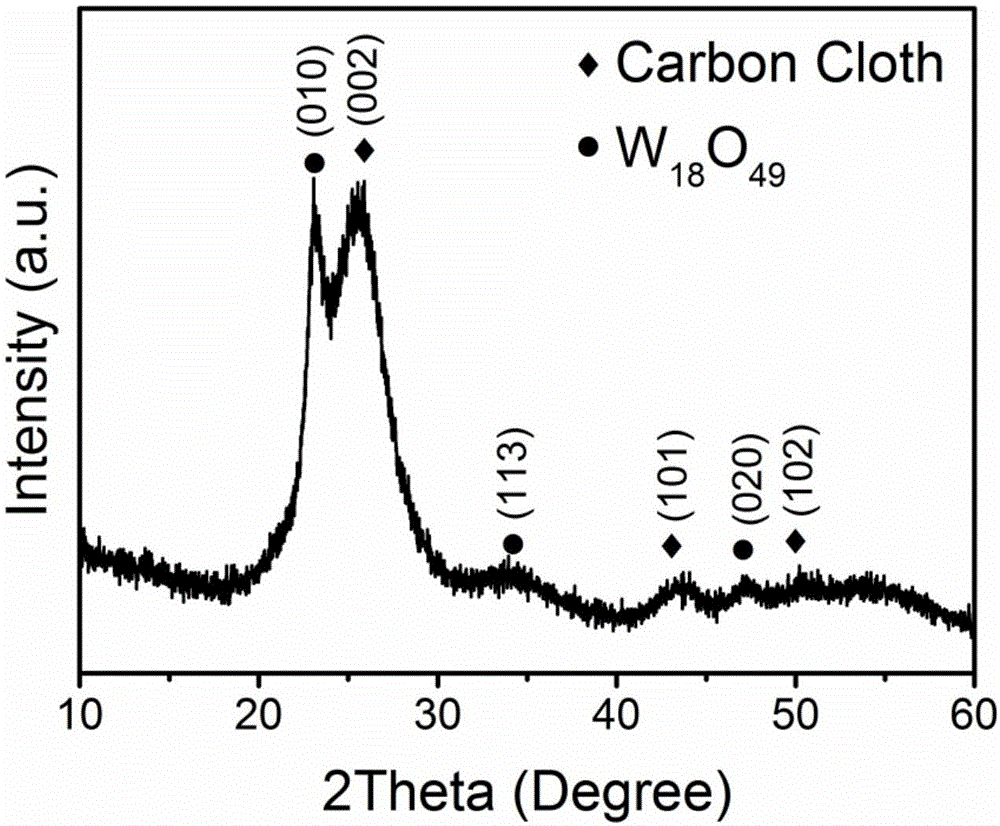

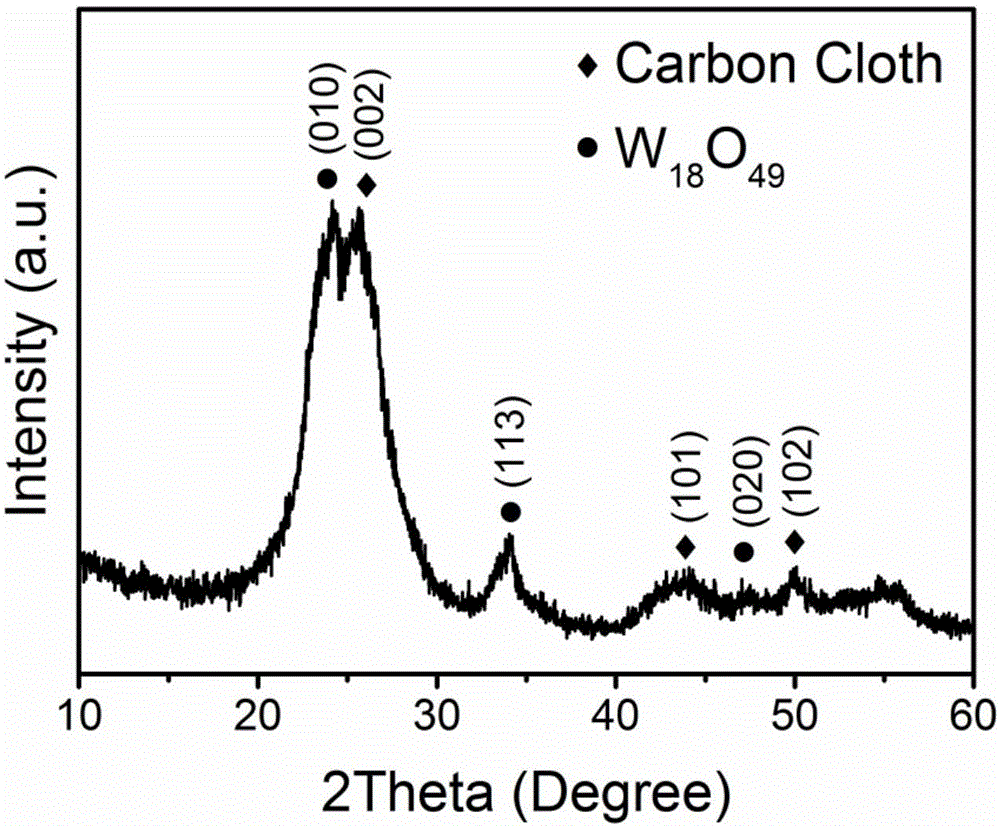

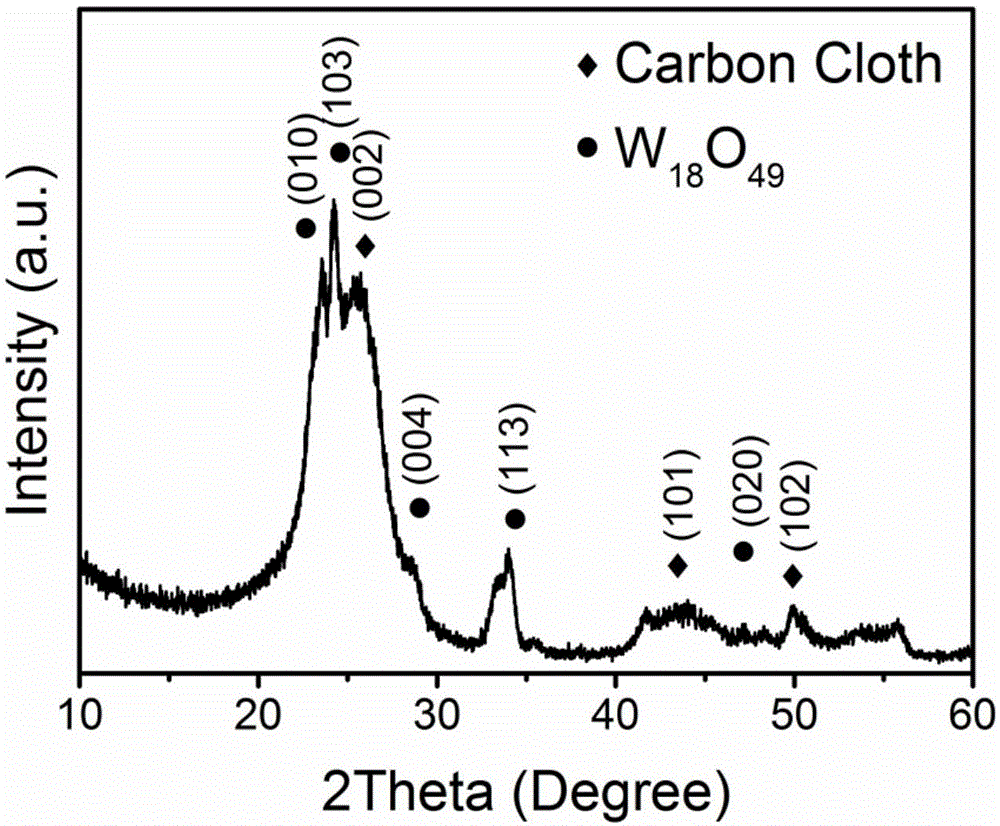

W18O49 coated carbon fiber composite material and preparation method thereof

The invention discloses a W18O49 coated carbon fiber composite material and a preparation method thereof. The W18O49 coated carbon fiber composite material takes carbon fibers as a reaction source and the W18O49 coated carbon fiber composite material is produced by adopting a solvothermal method; a monoclinic W18O49 nano-material grows on the carbon fibers through the solvothermal method in a coating manner; in a solvothermal preparation process, any template and any catalyst are not needed; the technology is simple, the yield is high and the cost is low, so that the W18O49 coated carbon fiber composite material is suitable for batch production; the W18O49 nano-material directly grows on carbon cloth and the prepared nano composite material has a uniform shape and coating tightness and can be used as photocatalysis, electrocatalysis, solar cell, flexible sensor, field emission and lithium-ion battery negative electrode materials.

Owner:NORTHWEST UNIV

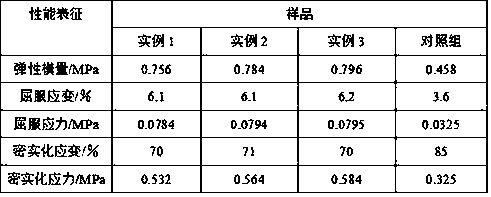

Green high-strength and high-toughness concrete and preparation process thereof

ActiveCN114230289AClosely connectedHigh structural densitySolid waste managementFiberAggregate (composite)

The invention relates to the field of concrete, and particularly discloses green high-strength and high-toughness concrete and a preparation process thereof. The green high-strength and high-toughness concrete is prepared from the following raw materials in parts by weight: cement, fly ash, mineral powder, natural aggregate, modified regenerated aggregate, water, an additive and composite fibers, a preparation method of the modified regenerated aggregate comprises the following steps: weighing waste concrete blocks, pretreating to obtain regenerated aggregate, putting the regenerated aggregate into a sodium gluconate solution, stirring and soaking, then taking out the regenerated aggregate, and performing drying post-treatment to obtain the modified regenerated aggregate; the preparation method comprises the following steps: weighing the cement, the fly ash and the mineral powder, mixing and stirring to obtain a premix; weighing the natural aggregate, the modified regenerated aggregate and the composite fiber, stirring and mixing to obtain a mixture; weighing the water, the additive, the premix and the mixture, mixing and stirring to obtain a mixture, and pouring and curing to obtain the concrete, the concrete has the advantages of greenness, high strength and high toughness.

Owner:深圳市深建混凝土有限公司

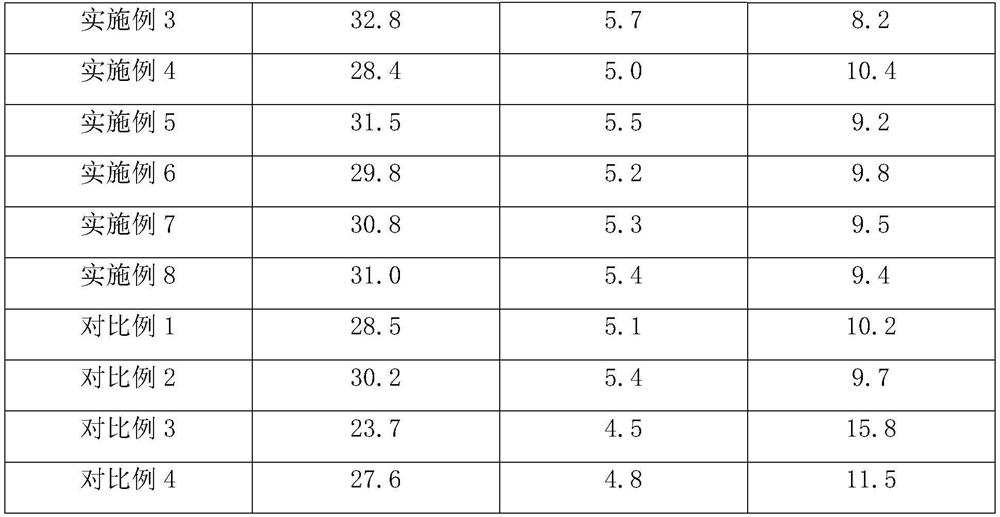

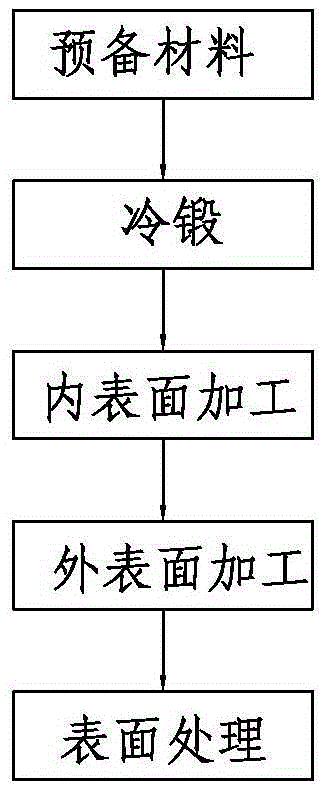

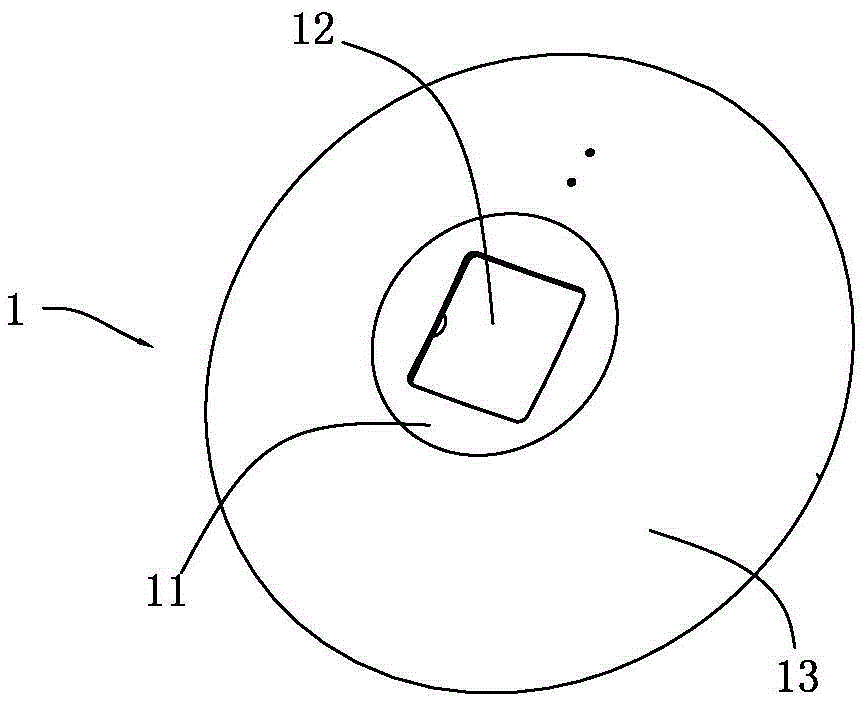

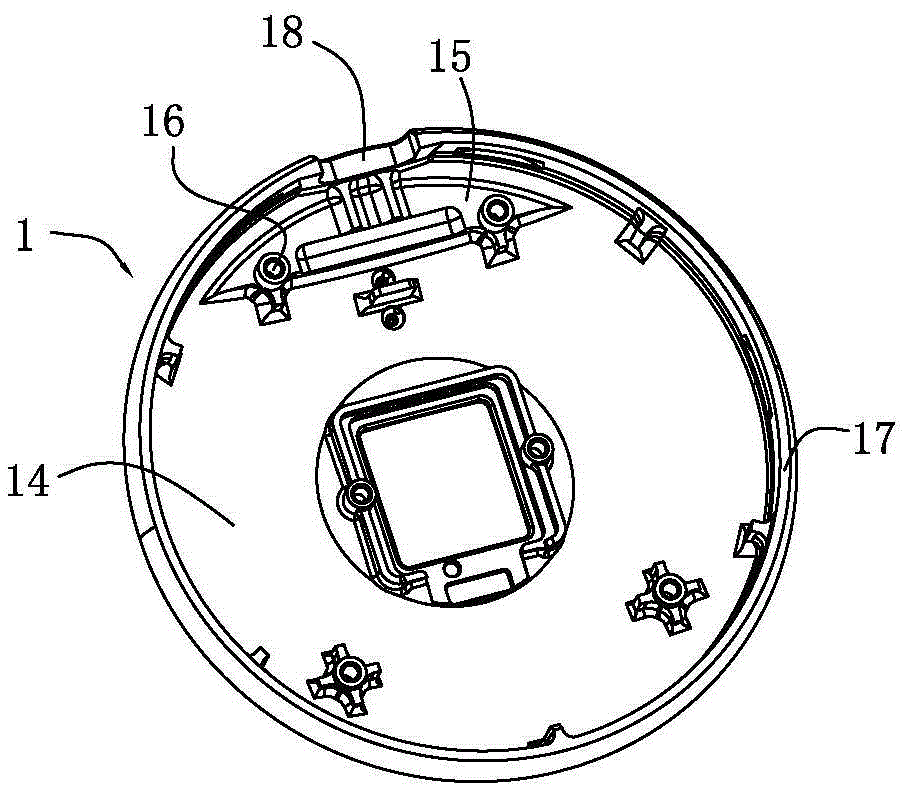

Electronic product aluminum shell cold forging (cold heading) method and product thereof

InactiveCN105397491AHigh structural densitySimple processOther manufacturing equipments/toolsDomestic articlesPressure castingUltimate tensile strength

The invention discloses an electronic product aluminum shell cold forging (cold heading) method and a product thereof. The method comprises the following steps that (1), an aluminum board is prepared; (2), a cold forging mould carries out cold forging on the aluminum board and an aluminum shell blank in a needed shape is moulded; (3), the inner surface of the aluminum shell blank is machined; and (4), the outer surface of the aluminum shell blank is machined, and an electronic product aluminum shell product is obtained. The method is simple in process, the cold forging procedure replaces a pressure casting procedure and is easy to implement, the production period is greatly shortened, the production efficiency is high, and the cost is low. The structural density of the prepared product is large, the overall structural intensity is improved effectively, the heat conduction and heat dissipation properties are good, the comprehensive performance is good, and the application range is wide, for example, the electronic product aluminum shell cold forging (cold heading) method and the product thereof can be used for producing radiators, mechanical and electrical product end covers, communication cavities, USB flash disk cover bodies, fingerprint product cover bodies, cover bodies of other electronic products and the like.

Owner:余千军

Microemulsion water base construction water proof material and its preparation method

InactiveCN1410503AEnvironmentally friendlyImprove permeabilityOther chemical processesChemistrySilicone polymer

A water-proof water-base microemulsified material for building is prepared through modifying the organosilicone polymer containing active group with-sulfuryl chloride containing hydrophobic group under the action of catalyst, adding emulsifier and emulsifying assistant to water, and microemulsifying in water.

Owner:SICHUAN UNIV

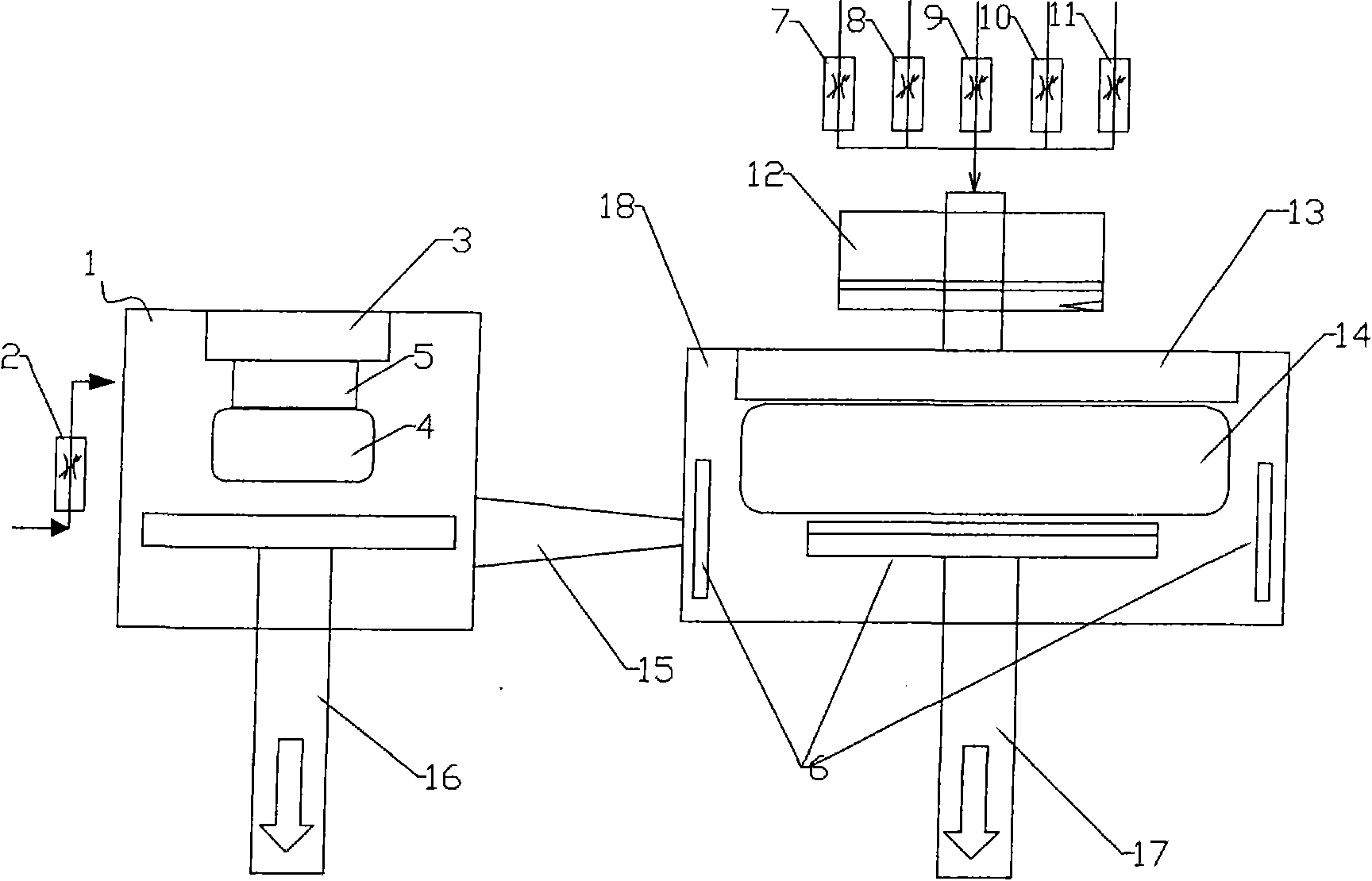

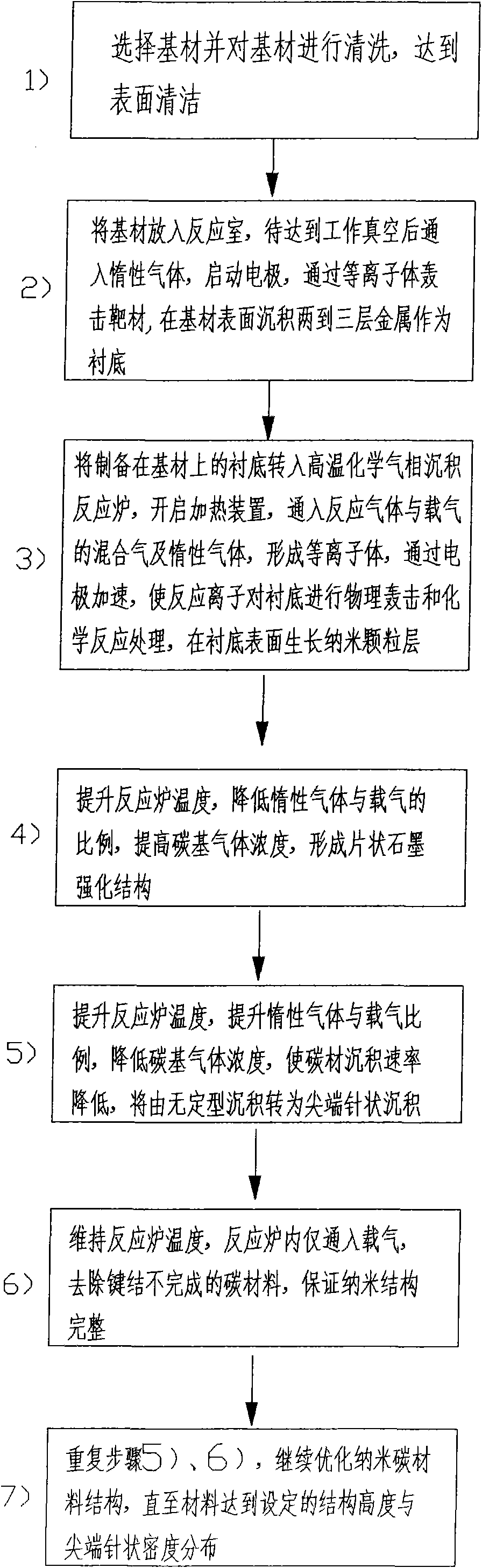

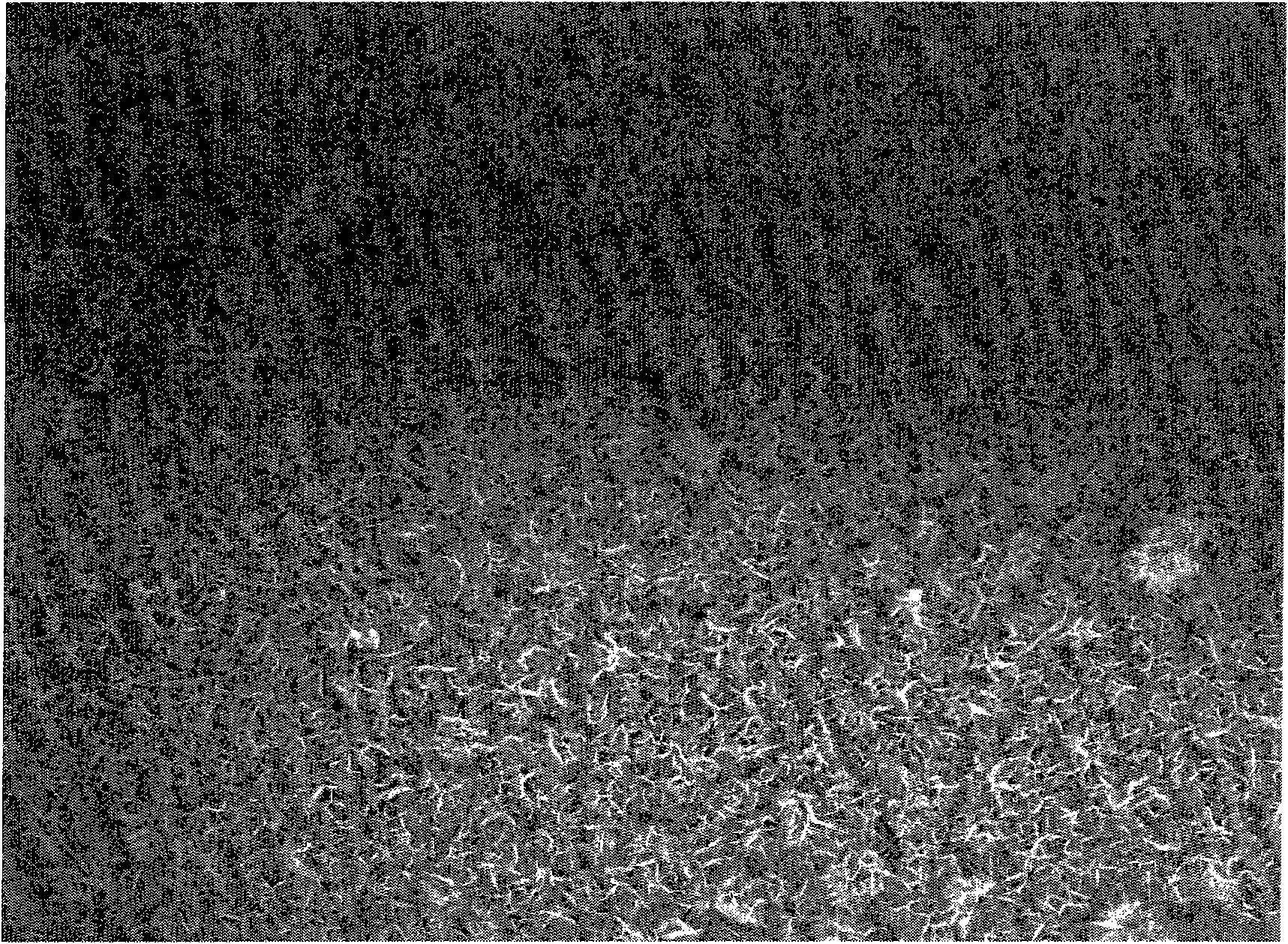

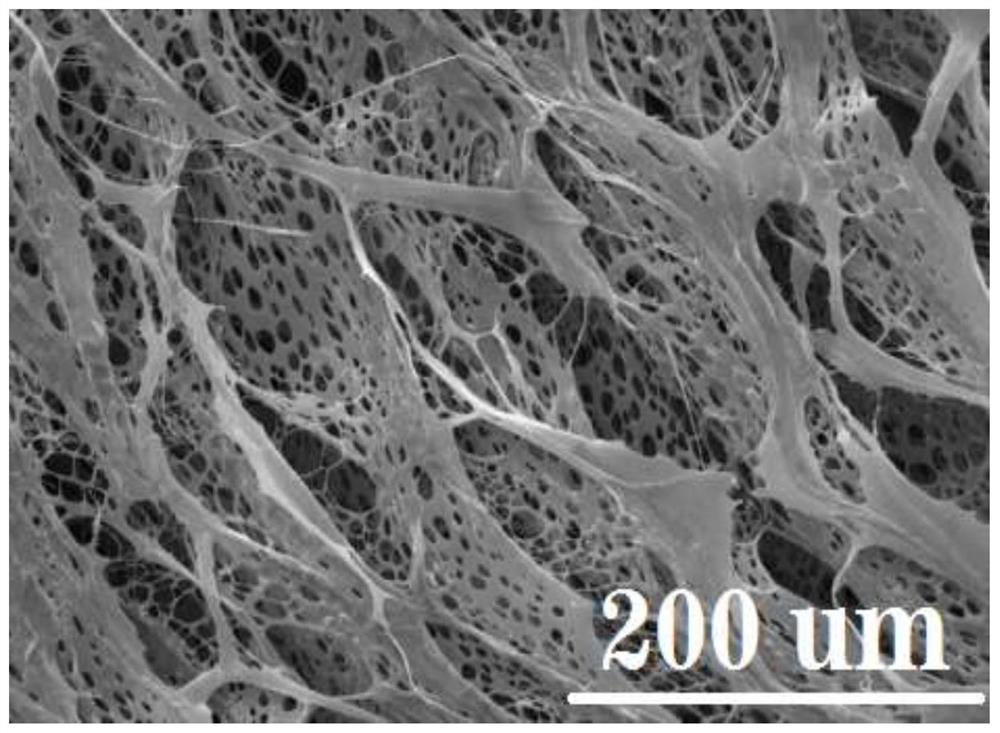

Carbon-based nano novel field electron emission material in areatus layered structure and preparation method thereof

ActiveCN101887828AHigh aspect ratioHigh structural densityIndividual molecule manipulationDischarge tube/lamp detailsCarbon based nanomaterialsCurrent distribution

The invention discloses a carbon-based nano novel field electron emission material in areatus layered structure. The nano material is formed by the way that nano film in areatus structure is deposited on a substrate and then dense nano microtubules are grown at the edge point of the nano film, the nano microtubules are grown at the point of the areatus structure, wherein the height of the areatusstructure is 0.5-5Mum, the included angle of the long side of the areatus structure and the normal of the surface of the substrate is less than or equal to 20 degrees, and the height of the nano microtubule is 1-1000nm. The novel field electron emission carbon-based nano material is subject to recombination and optimization on structural characteristic thereof and can overcome the problems that single-wall and multi-wall carbon-based nano tubes manufactured by the prior art are poor in degree of graphitization and low in texture density and have crystal defects; emission efficiency and current distribution requirements are met, and the application thereof in multiple fields can be effectively widened; besides, the invention also provides a preparation method of the material.

Owner:CHONGQING XINHE QIYUE TECH CO LTD

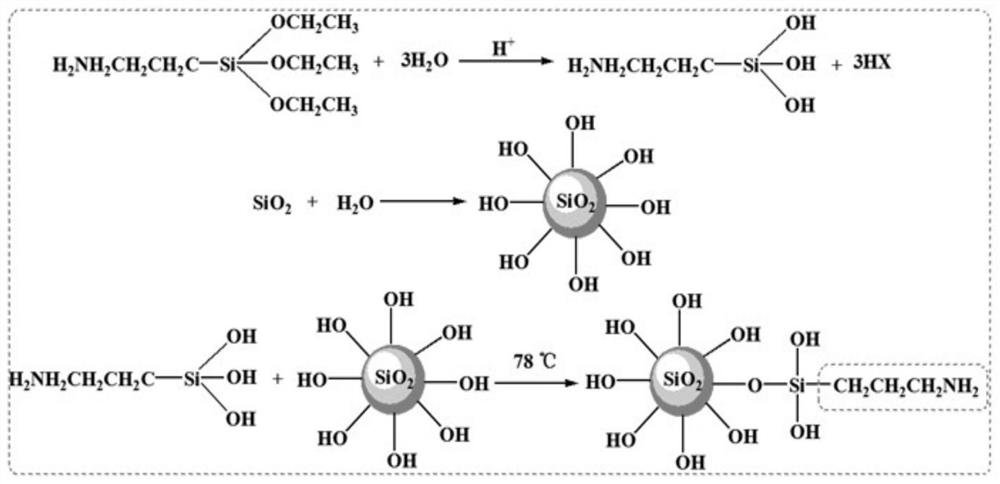

Temperature-resistant and salt-tolerant high-efficiency filtrate reducer for drilling fluid and preparation method thereof

ActiveCN112876606AGood temperature and salt resistanceImproved temperature and salt resistanceDrilling compositionMeth-Materials science

The invention discloses a temperature-resistant and salt-tolerant high-efficiency filtrate reducer for drilling fluid. The temperature-resistant and salt-tolerant high-efficiency filtrate reducer is prepared by blending a zwitterionic polymer and modified nano-SiO2; the zwitterionic polymer is prepared from 2-acrylamido-2-methylpropanesulfonic acid, maleic anhydride, methacryloyloxyethyl trimethyl ammonium chloride, sodium p-styrenesulfonate, calcium sulfate whiskers, ammonium persulfate and deionized water. The invention also discloses a preparation method of the filtrate reducer, and the method comprises the following steps of: firstly, preparing the zwitterionic polymer through free radical polymerization of an aqueous solution; then, adopting KH-550 for surface hydrophobization modification on the nano-SiO2; and finally, blending the zwitterionic polymer and the modified nano-SiO2 so as to obtain the filtrate reducer. The temperature-resistant and salt-tolerant high-efficiency filtrate reducer for the drilling fluid is excellent in temperature resistance and salt tolerance, and the filtration performance of a drilling fluid system can be effectively improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

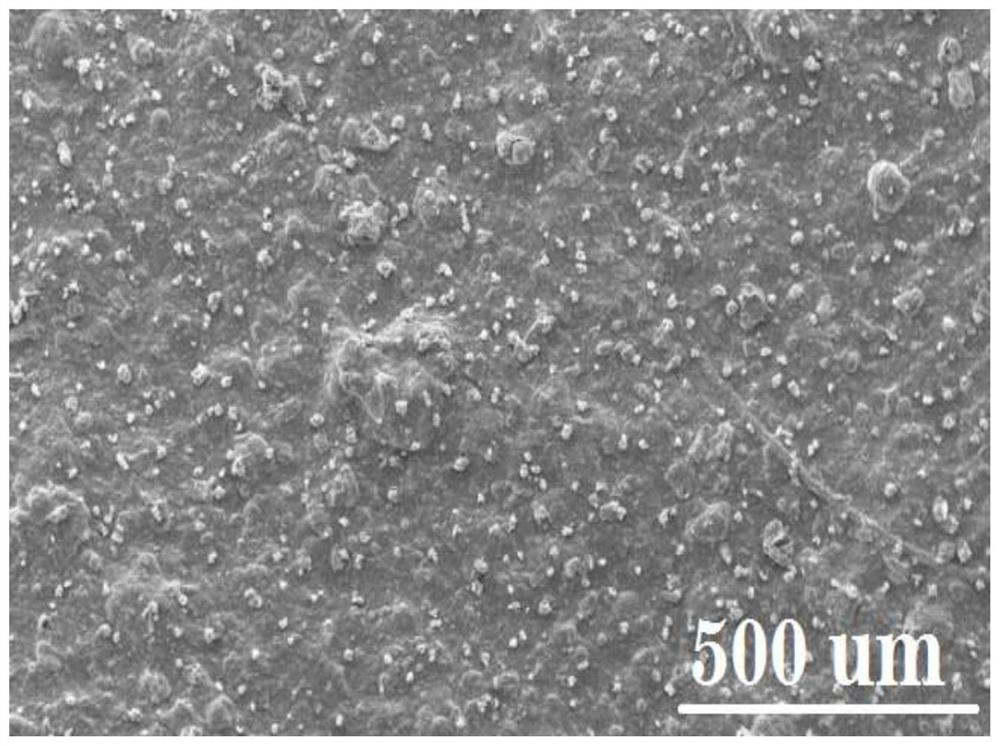

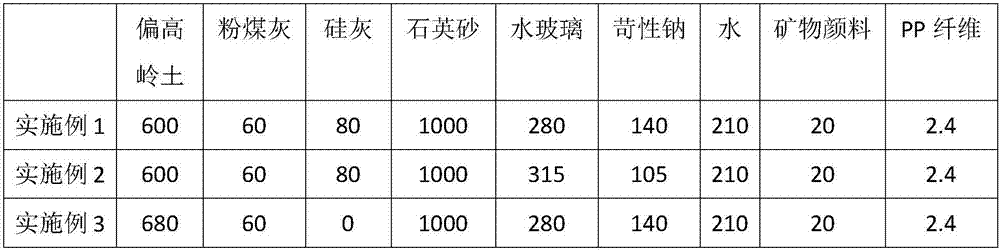

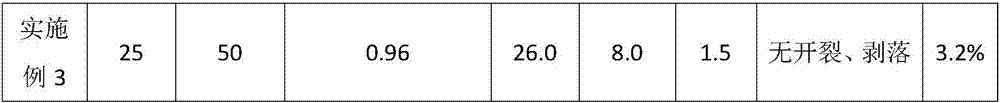

Waterproof and anti-alkali decorating mortar and preparation method thereof

The invention belongs to the technical field of building materials and particularly relates to waterproof and anti-alkali decorating mortar and a preparation method thereof. The decorating mortar is prepared from the following raw materials in percentage by mass: 20%-30% of metakaolin, 2%-3% of coal ash, 3%-5% of silica fume, 40%-55% of quartz sand, 5%-15% of water glass, 3%-7% of caustic soda, 6%-15% of water, 0.2%-1.2% of an inorganic mineral pigment and 0.1%-0.3% of PP fiber. The waterproof and anti-alkali decorating mortar is low in whiskering risk, high in structural compactness and strength, good in water resistance and excellent weather resistance.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

Improved quick high vacuum densification soft foundation treatment method

InactiveCN102828499AEasy dischargeHigh structural densitySoil preservationVacuum pumpingStructural engineering

The invention discloses an improved quick high vacuum densification soft foundation treatment method, belonging to the technical field of geotechnical engineering. The method comprises the following steps of: 1, inserting a plurality of groups of plastic draining plates wrapped with geotextile into a soft foundation to be treated, connecting the upper ends of the plastic draining plates to level horizontal pipes, and then connecting the horizontal pipes to vacuum pumping equipment, and embedding the level horizontal pipes into the surface soil of the soft foundation to be treated; and 2, starting the vacuum pumping equipment, and carrying out high-energy dynamic consolation in each direction of the surface layer of the soft foundation at a plurality of times, so as to keep the soft soil in a high vacuum state which is also a high pressure differential state together with the vacuum pumping construction. The method has low cost, short construction period, controllable quality and pure physical construction and is environment friendly and is capable of quickly consolidating the soft foundation.

Owner:SHANGHAI HARBOUR SOFT SOIL TREATMENT ENG CO LTD +2

Preparation method of high-strength type foaming and cushioning packaging material

The invention relates to a preparation method of a high-strength type foaming and cushioning packaging material and belongs to the technical field of preparation of packaging materials. The preparation method provided by the invention is characterized in that bamboo pulp is taken as a main body and is subjected to pulping treatment and then fermentation modification; by virtue of fermentation treatment, internal pores of the material are greatly increased, and the specific surface area is increased; furthermore, by virtue of fermentation, bamboo pulp fibers are effectively decomposed and saccharified, and the formed saccharified liquid improves the gel network of the starch material, increases the expansion properties of the material, effectively increases the structure density of the gelmaterial and modifies the mechanical properties of the composite material; by performing pulping treatment on the bamboo pulp fibers, the fibers are cut off and are mutually extruded to generate a large number of fine fibers; and because the fine fibers contain a large number of hydroxyl groups, the hydrogen bonding degree among the fibers is effectively increased, the bonding strength among the fibers is effectively increased, the formed fiber network is richer, and the curl degree and the adhesive force of the fibers are effectively increased, thereby greatly increasing the mechanical properties of the material.

Owner:常州杰轩纺织科技有限公司

Automobile plastic soundproof plate and preparation method thereof

The invention discloses an automobileplasticsoundproofplate which is prepared from, by weight, 30-35 parts of quartz sand, 16-20 parts of aerosol, 22-28 parts of nano calcium carbonate, 10-15 parts of nano silver, 26-30 parts of graphene, 40-46 parts of polyvinyl chloride, 20-25 parts of polyurethane, 10-15 parts of acrylic cotton, 7-9 parts of silicon oil, 17-21 parts of fatty acid amide, 5-10 parts of oleamide, 5-12 parts of erucyl amide, 14-20 parts of sodium polyacrylate, 25-26 parts of hydroxypropyl methyl cellulose, 7-13 parts of methyl acrylate, 4-8 parts of lead sulfate tribasic, 2-8 parts of aluminum stearate, 11-15 parts of ceramic microbead, 14-18 parts of vermiculite powder and 7-8 parts of tetrapod-like zinc oxide whisker. The automobile plastic soundproof plate is high in structural density and good in soundproof effect, has certain water absorbing performance, is long in service life and has an antibacterial function.

Owner:芜湖天鸿汽车零部件有限公司

Formula of glossy putty powder for exterior wall

The invention provides a formula of glossy putty powder for exterior wall decoration. With the adoption of the formula, structural compactness can be effectively improved, bonding strength and constructability are improved, and while construction quality is improved, construction efficiency can be substantially improved and economic benefit of construction is increased. The formula is characterized in that the glossy putty powder is prepared from components in percentage by mass as follows: 30%-35% of cement, 5%-8% of ash calcium powder, 60%-65% of ground calcium carbonate powder, 4 permillage-5 permillage of hydroxypropyl methyl cellulose, 10 permillage-15 permillage of latex powder, 2 permillage-2.5 permillage of wood fiber and 0.3 permillage-0.6 permillage of starch ether.

Owner:浙江杰林新材料科技股份有限公司

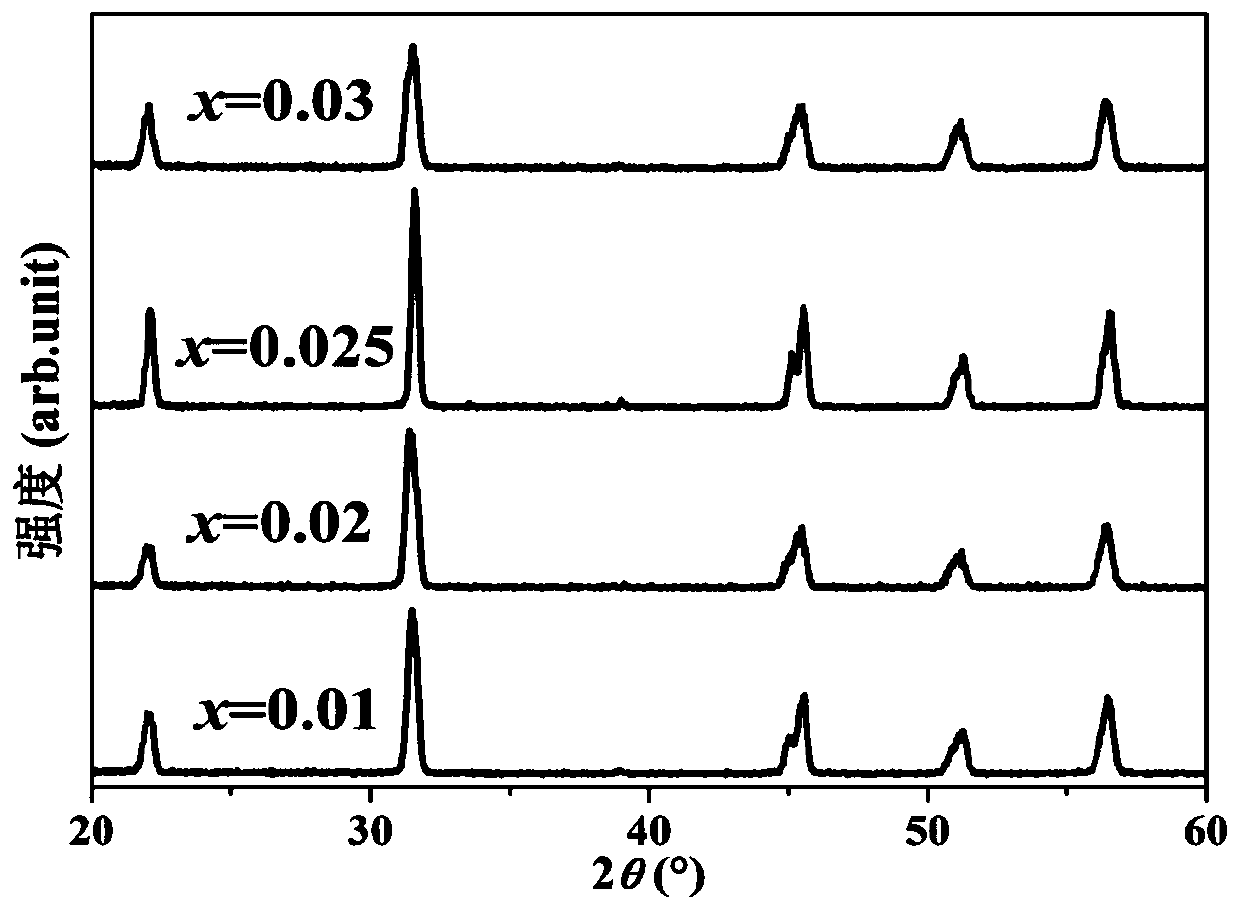

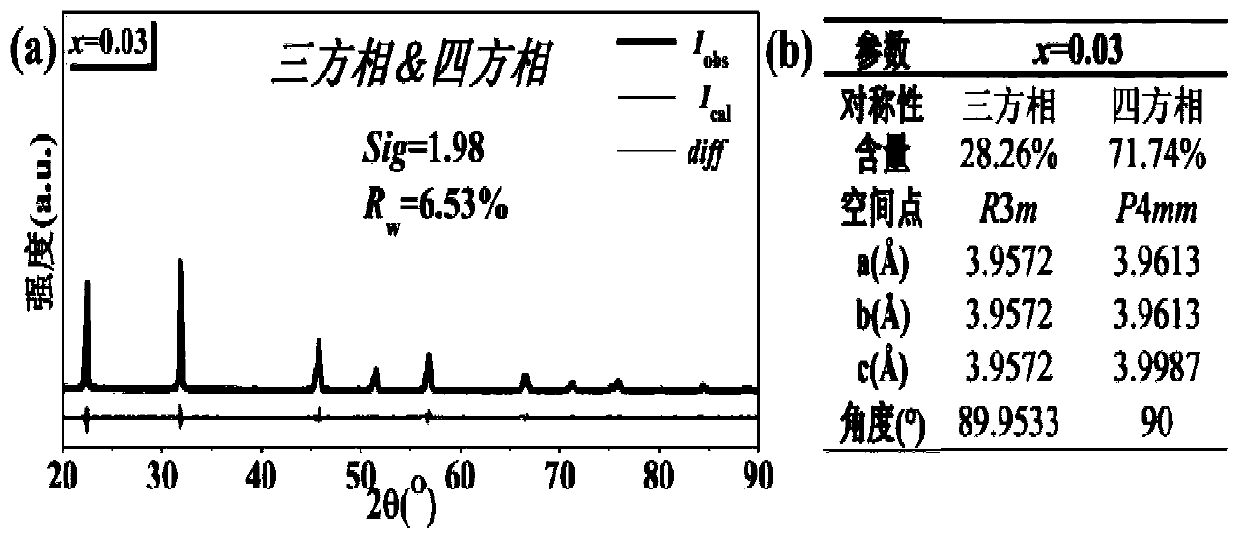

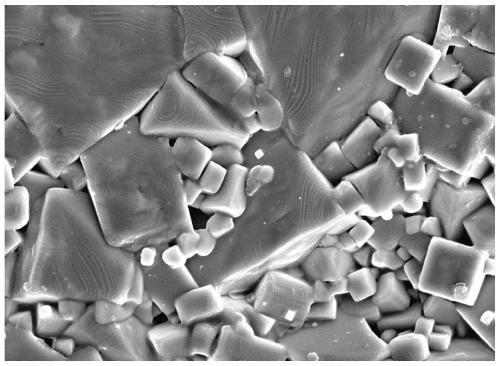

High-voltage high-curie-point potassium sodium niobate-potassium sodium antimonate series lead-free piezoelectric ceramic and preparation method thereof

ActiveCN111548155AExcellent piezoelectric propertiesImprove temperature stabilityPhysical chemistryPiezoelectric sensor

The invention discloses a high-voltage high-curie-point potassium sodium niobate-potassium sodium antimonate series lead-free piezoelectric ceramic and a preparation method thereof. The lead-free piezoelectric ceramic is represented by a general formula of 0.965[(1-x)K0.54Na0.476NbO3-xK0.54Na0.476SbO3]-0.01Bi2O3-0.0025Fe2O3-0.03ZrO2, wherein x is greater than or equal to 0.01 and less than or equal to 0.03. The high-voltage high-curie-point potassium sodium niobate-potassium sodium antimonate series lead-free piezoelectric ceramic is prepared by adopting a two-step method through a traditionalceramic preparation technology; the high-temperature-resistant piezoelectric ceramic prepared by the method has the advantages of grain size inclusion, compact microstructure, tetragonal phase content up to 70% or above, favorable piezoelectric properties, favorable temperature stability and higher Curie temperature, has wide applicability in the field of piezoelectric sensors, and can be used inthe field of high-temperature sensing.

Owner:成都迪迈斯科技有限公司

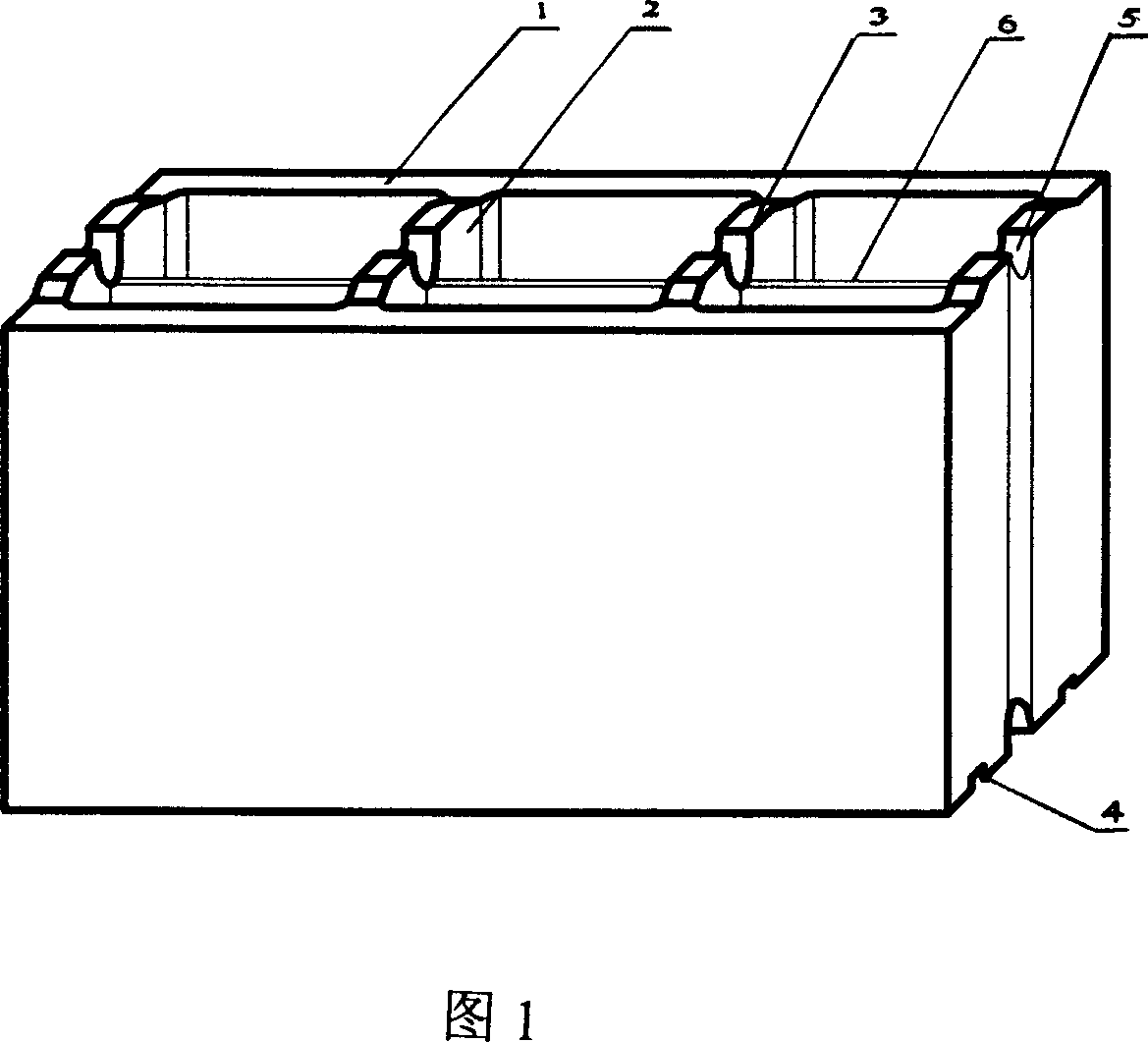

Phosphous plaster double-row-hole energy-saving building brick and all-dry production method thereof

InactiveCN1936227AHigh strengthHigh structural densityConstruction materialCeramic shaping apparatusFluteBrick

The invention discloses a phosphogypsum double-row bore building blocks and the optimum drying producing method. It adopts phosphogypsum as raw material, and taking high pressure molding. The main body includes main wall, rib and protruding rib. The flute matched to protruding rib is set at the bottom of rib. And semicircle orifice is set on the protruding rib. Hard polystyrene clapboard is set between the main paralleled walls. The product has the advantages of high intension, high hollow ratio, good energy saving effect, rapid construction, light weight, and non-shrinking. It decreases drying processes, energy consumption of device and the cost of producing.

Owner:重庆金仓龙新型建材有限公司

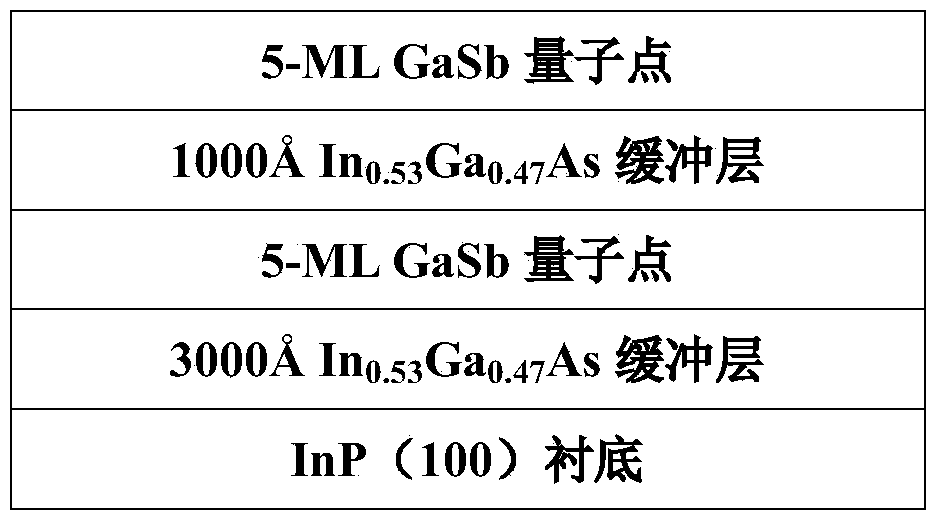

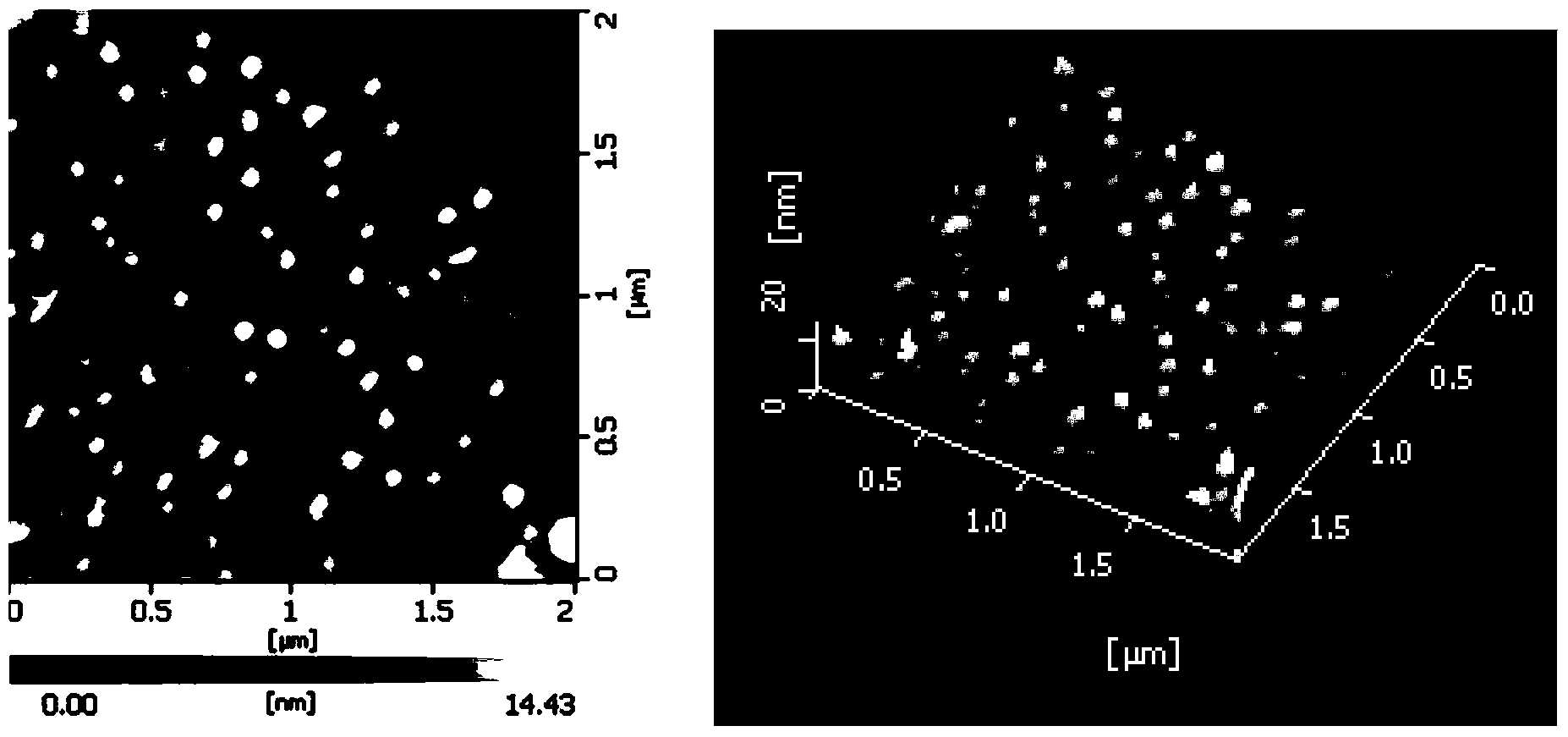

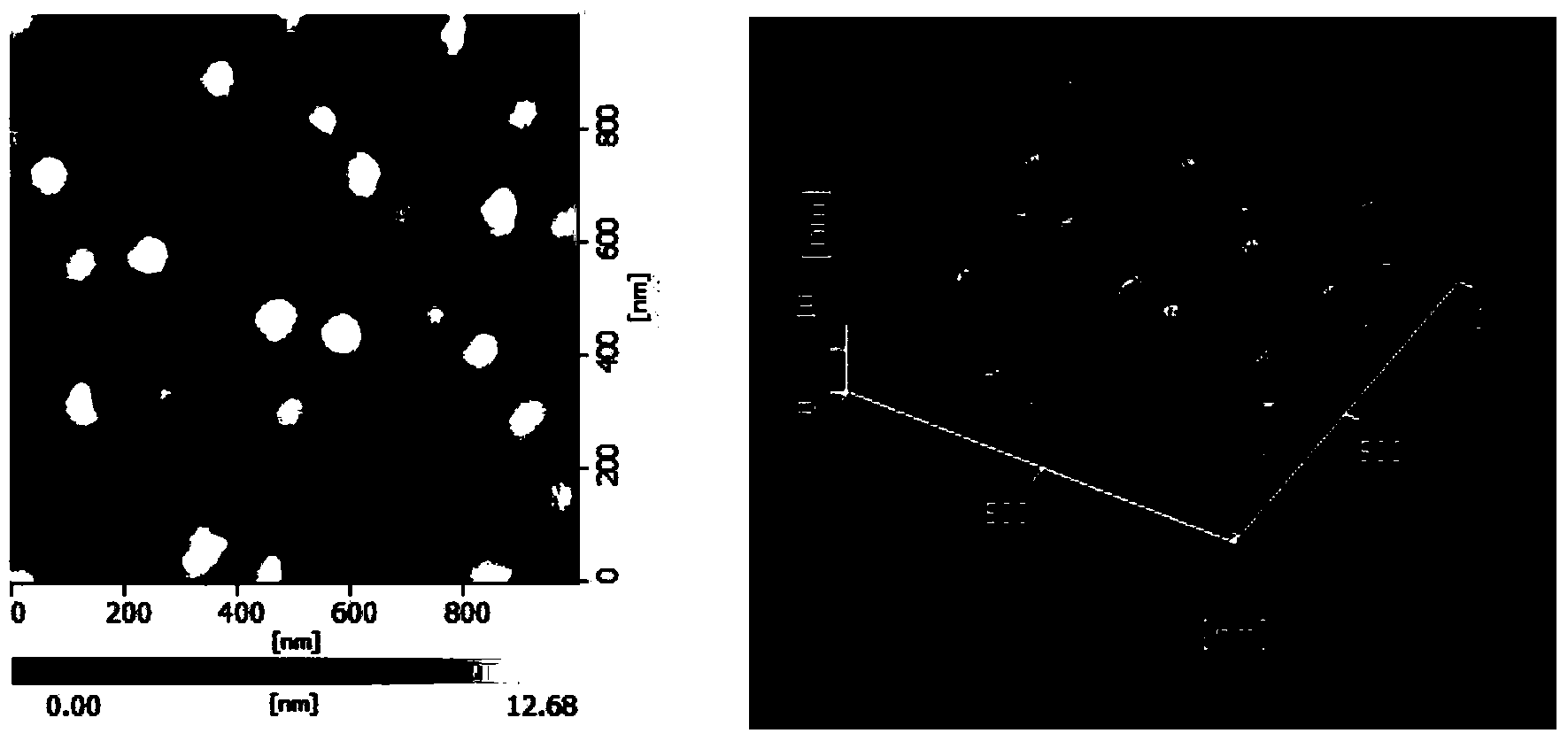

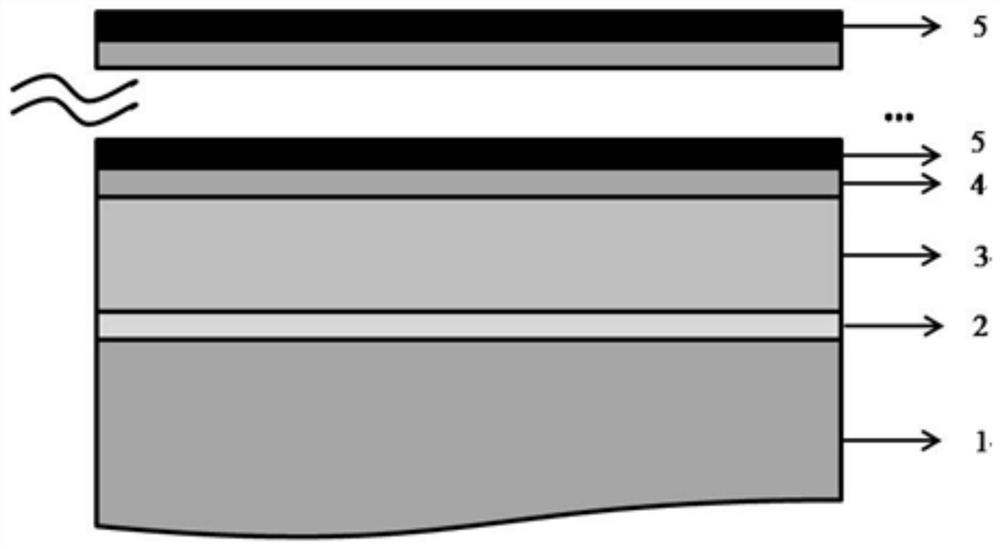

Method for epitaxial growth of II-type GaSb/InGaAs quantum point on InP substrate

ActiveCN103820848AImprove shape qualityGood optical performancePolycrystalline material growthNanotechnologyLattice mismatchQuantum dot

The invention discloses an II-type GaSb In 0.53 Ga 0.47 As quantum point superlattice material and a growth method. According to the invention, a first layer of the superlattice material is a In 0.53 Ga 0.47 As buffer layer grown on an InP substrate, a second layer is GaSb quantum dot; a third layer is the In 0.53 Ga 0.47 As buffer layer and a fourth layer is GaSb quantum dot; the growth method is characterized in that the buffer layer is grown on the surface of the InP substrate, 4-5ML GaSb quantum point is grown, then the buffer layer is grown, and the 4-5ML GaSb quantum point is finally grown. According to the invention, a MBE technology is employed to obtain the GaSb In 0.53 Ga 0.47 As quantum point grown by a S-K mode on the InP substrate, and the GaSb In 0.53 Ga 0.47 As quantum point has good morphology quality and better optical performance. The method can effectively avoid the As-Sb exchange, and the crystal lattice mismatch degree and Ga atom migration can be obviously reduced.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

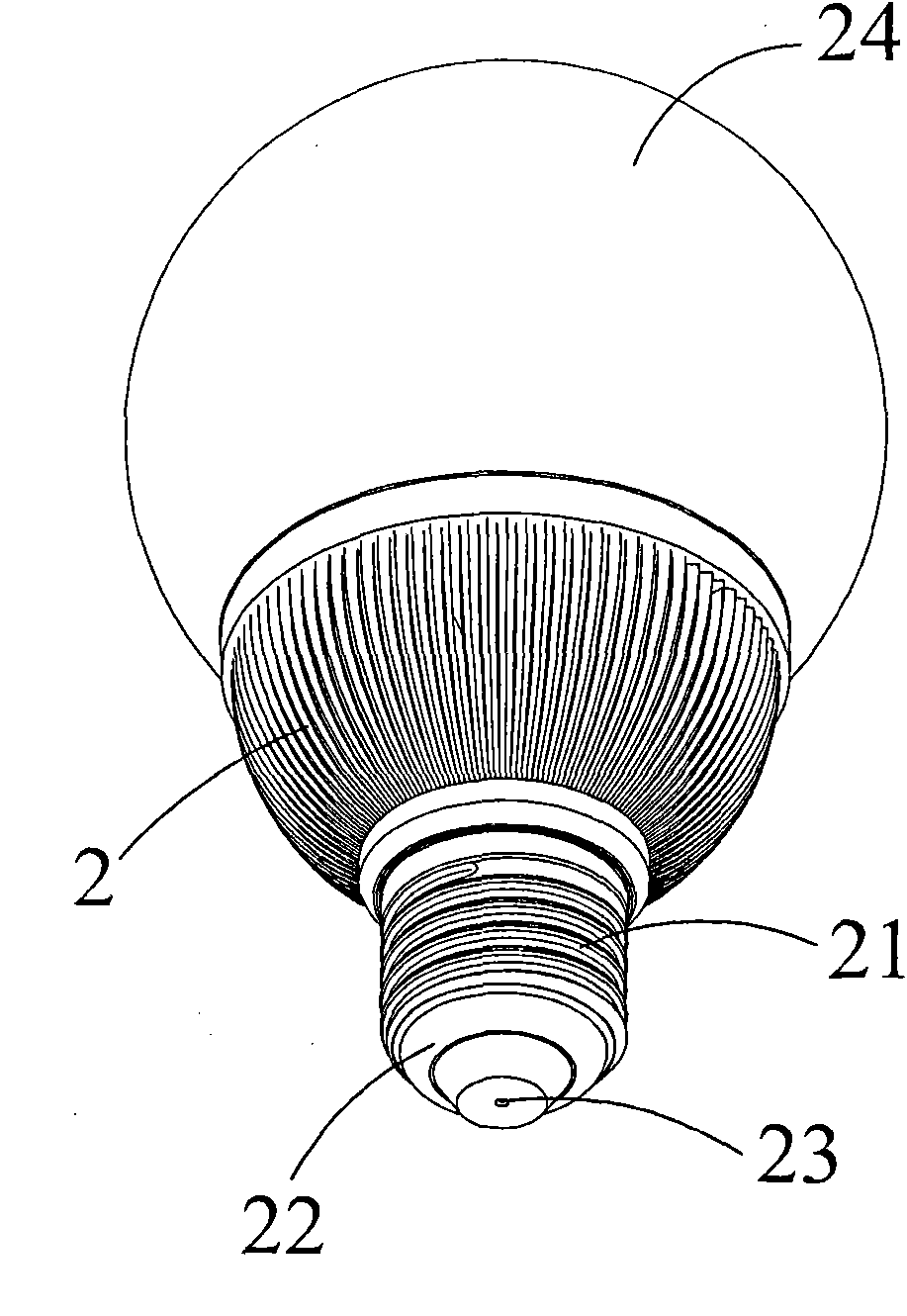

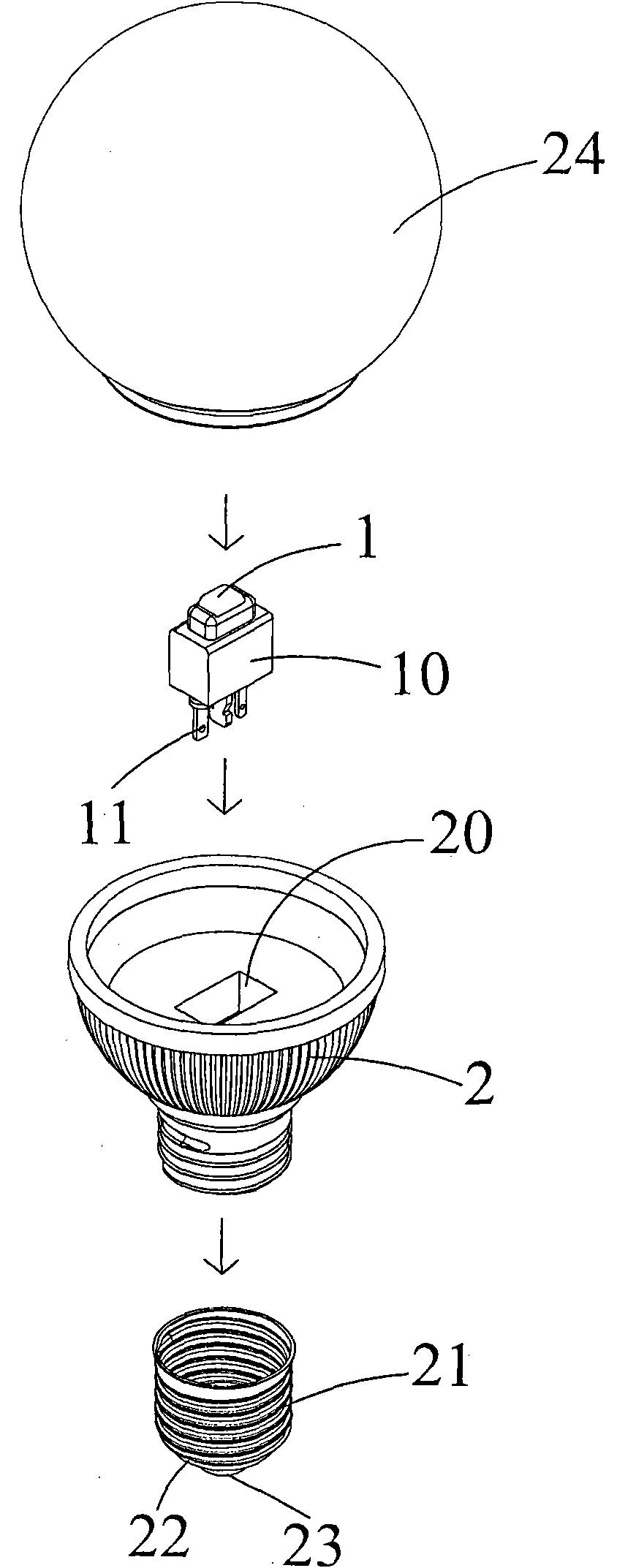

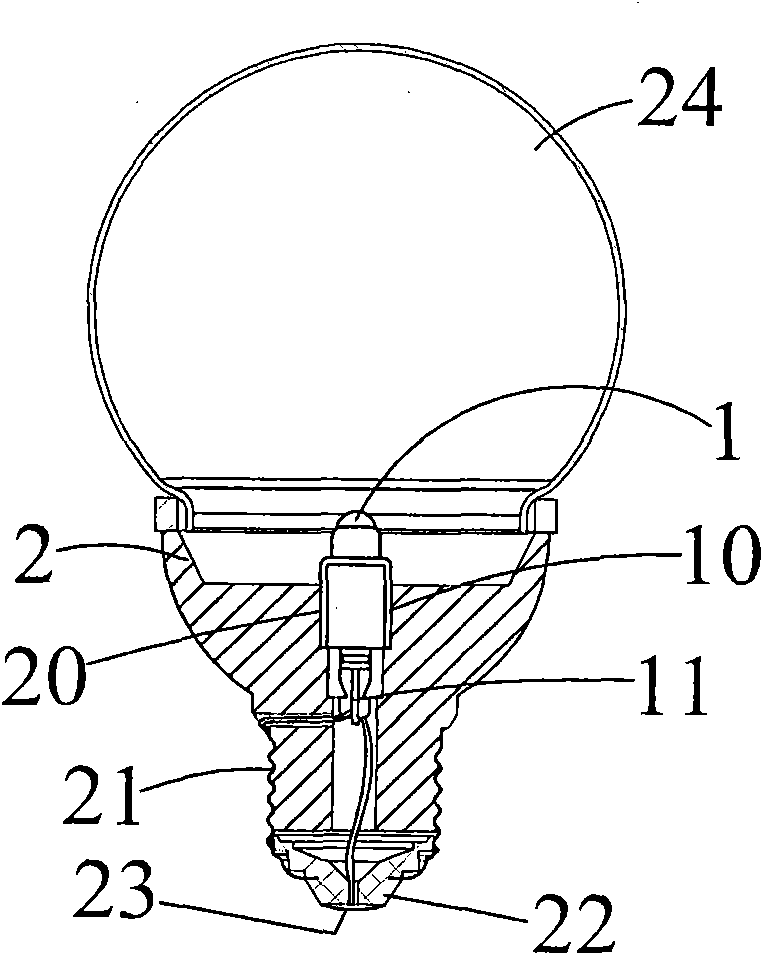

High-efficient LED (light emitting diode) lamp

InactiveCN102052581AImprove cooling effectHigh structural densityPoint-like light sourceElectric circuit arrangementsEngineeringThermal diffusivity

The invention discloses a high-efficient LED (light emitting diode) lamp which mainly comprises an alternating current LED module and a radiating lamp seat, wherein the alternating current LED module is provided with a heat conducting part and an electric connection part; the radiating lamp seat is made of nonmetal which has good thermal diffusivity and is in a porous structure, can be directly molded into a shape of the lamp seat, and is provided with an indented part used for accommodating the alternating current LED module; the heat conducting part of the alternating current LED module is combined with the indented part of the radiating lamp seat; and the electric connection part is connected with an external power source. The high-efficient LED lamp provided by the invention also comprises a heat conducting fin, wherein the heat conducting fin is arranged between the heat conducting part of the LED module and the radiating lamp seat; and when the LED is illuminated, the heat generated by the LED can be conducted promptly by the heat conducting fin, thus the heat on the heat conducting fin can be conducted promptly to the radiating lamp base for radiating. The heat radiating lamp seat in the invention can be directly molded into a shape of a common lamp seat, and has the functions of heat radiating and electrical insulation efficiency; and the high-efficient LED lamp can be used for replacing a known lamp bulb, and can be directly used for replacing a lamp bulb without replacing the light fitting.

Owner:秦文隆

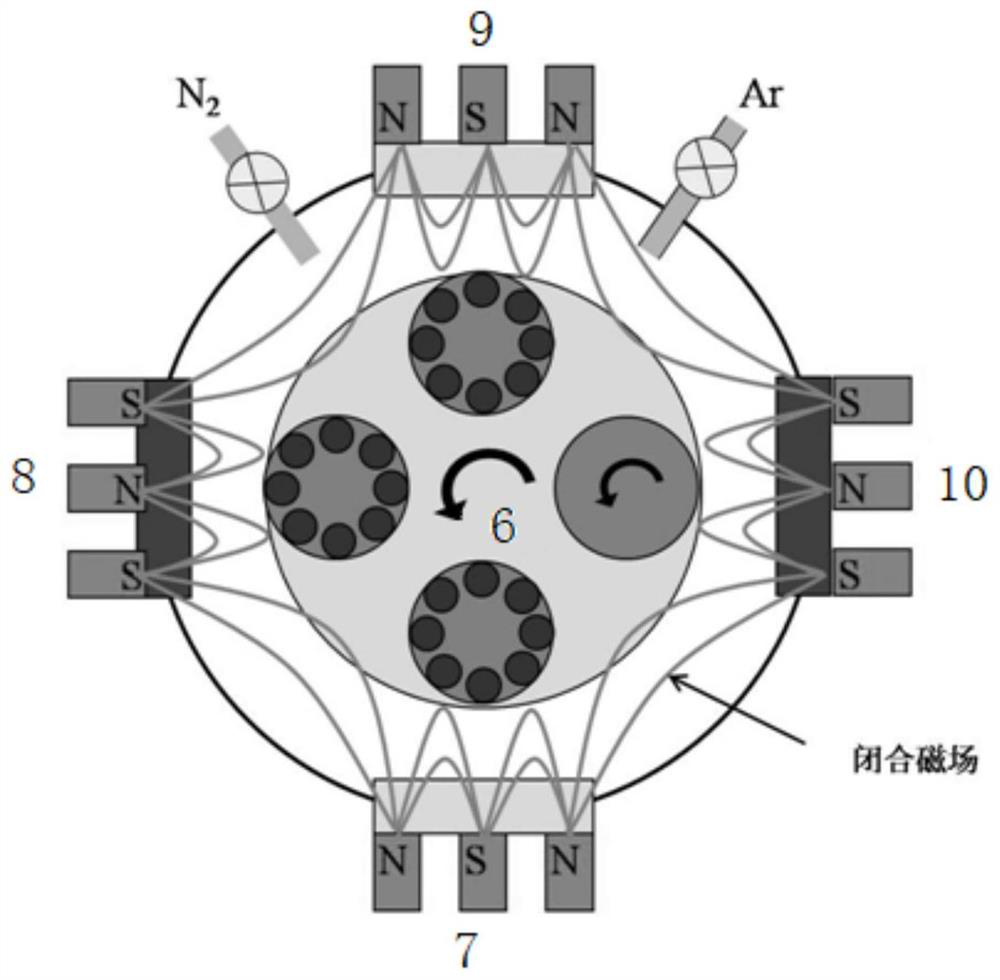

Nano multi-layer composite solid lubricating film layer with long service life under space irradiation and preparation thereof

ActiveCN112760607AExcellent resistance to space radiationHigh densityVacuum evaporation coatingSputtering coatingAlloy substrateComposite material

The invention discloses a nano multi-layer composite solid lubricating film layer with a long service life under space irradiation and preparation thereof. The nano multi-layer composite solid lubricating film layer composed of a Ti binding layer, a TiN bearing layer and an AgTiNi / MoS2Ti nano multi-layer lubricating functional layer is deposited on a titanium alloy substrate, an aluminum alloy substrate, a stainless steel substrate, a bearing steel substrate and the like by adopting a closed magnetic field unbalanced magnetron sputtering technology. The nano multi-layer composite film layer can reliably serve for a long time in strong space irradiation environments such as low-orbit high atomic oxygen density, medium-high-orbit high electron proton density and high ultraviolet irradiation dose, and is high in bearing capacity and low in friction coefficient, thus, the service life of a moving part of a spacecraft exposed in the space irradiation environments can be greatly prolonged, and the reliability of the moving part is improved. In addition, the preparation method has the characteristics that the process is environment-friendly and flexible, the film thickness is uniform, the compactness is good, the preparation process of the film layer is controlled in a programmed manner, the modulation period of the film layer is easy to regulate and control, and batch treatment can be realized, industrial production is easy to realize, and the good application prospect is achieved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

High-surface smoothness CBN grinding wheel with ultrafine granularity and containing nanometer carbon spheres and preparation method thereof

InactiveCN105127914AGood dispersionGood wettabilityNon-macromolecular adhesive additivesAbrasion apparatusAdhesiveHigh surface

The invention discloses a high-surface smoothness CBN grinding wheel with ultrafine granularity and containing nanometer carbon spheres; firstly, CBN abrasives with ultrafine granularity and microcrystal ceramic abrasives are pretreated in the preparation process of the grinding wheel; the treated abrasives are improved in mechanical performance, and are better in bonding effect with adhesive; abrasives treated by solution prepared by sodium polystyrenesulfonate and polyethyleneimine are excellent in dispersibility, are not easy to be agglomerated, and are formed to a stable system without being precipitated and flocculated in the solution; dried powder and adhesive are better in wettability and compatibility, and are tight and firm in bonding; the added nanometer carbon spheres effectively improve the heat dissipation and heat conduction performances of the grinding wheel, and improve the structural compactness; fluorine carbon resins serve as adhesive to enable the surface of the grinding wheel to become more smooth; waste chips are not easy to be bonded, and are easy to be removed; and the grinding wheel is high in strength, smooth and compact in surface, quick in cooling and not easy to damage workpieces, resists both wear and corrosion, and can be applied to the grinding of metal parts with high precision.

Owner:安徽威铭耐磨材料有限公司

Archaized brick and preparation method thereof

The invention provides an archaized brick and a preparation method thereof. The archaized brick is at least prepared from raw materials in parts by weight as follows: 100-200 parts of cement, 100-260 parts of diamond, 80-160 parts of potash feldspar and soda feldspar, 80-120 parts of bentonite, 3-10 parts of titanium dioxide, 1-6 parts of copper sulfate, 6-12 parts of silicon dioxide and 10-40 parts of vinyl ester resin. All the components are well compatible, and the prepared brick has high structural density and has the advantages of improved tensile strength, shear strength and pressure intensity as well as reduced deformation, elongation and thermal expansion coefficient.

Owner:贞丰县恒山建材有限公司

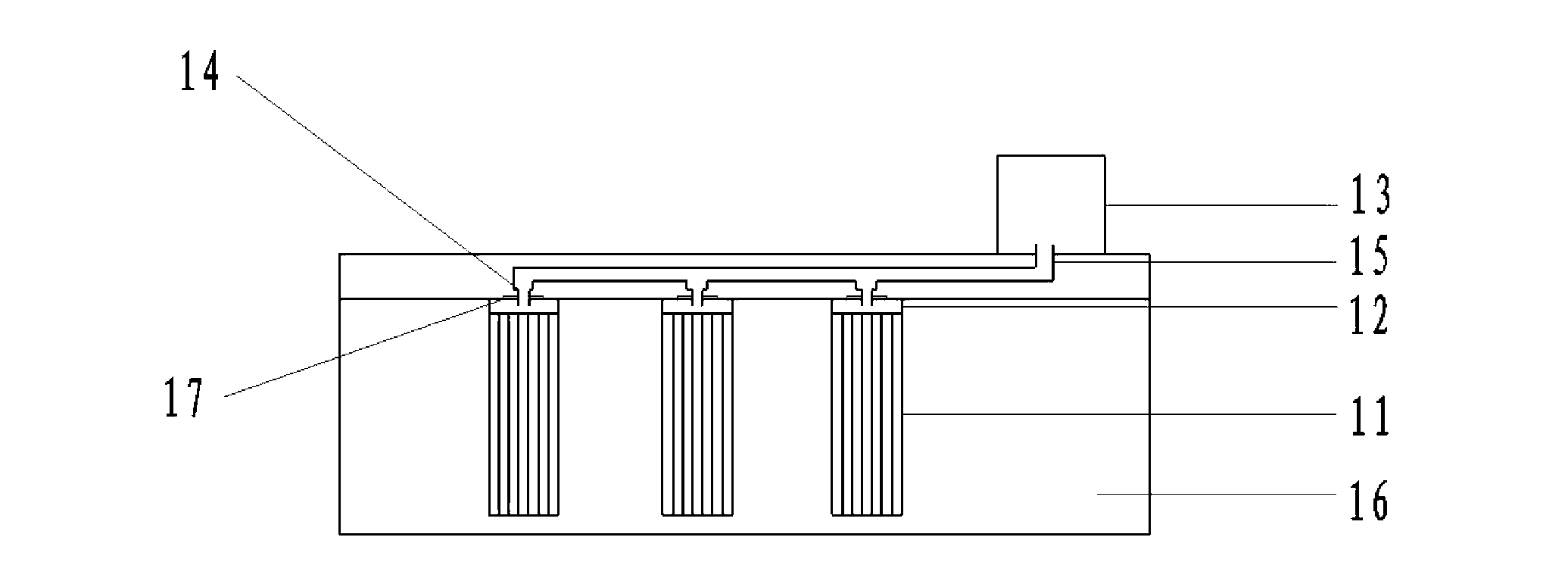

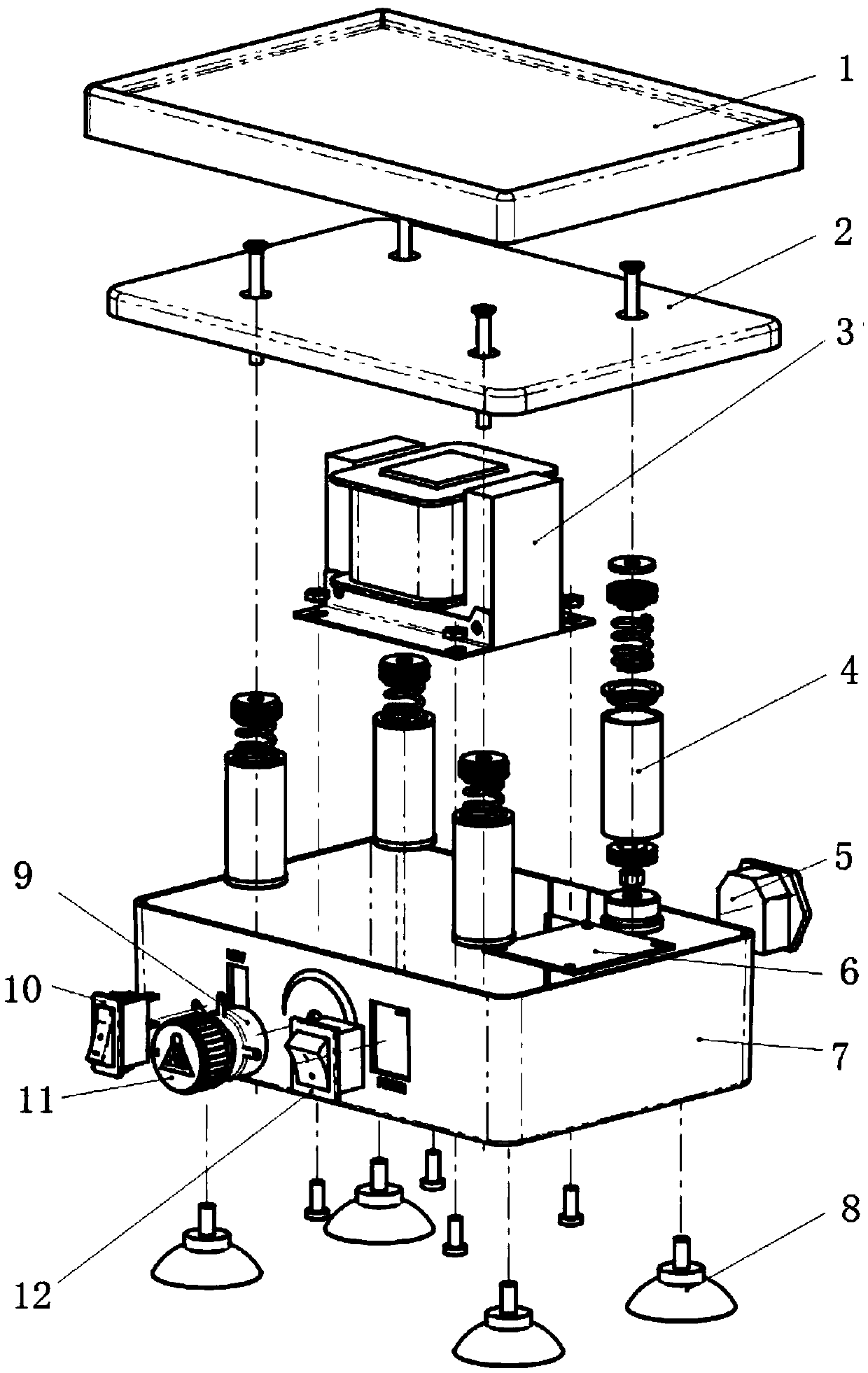

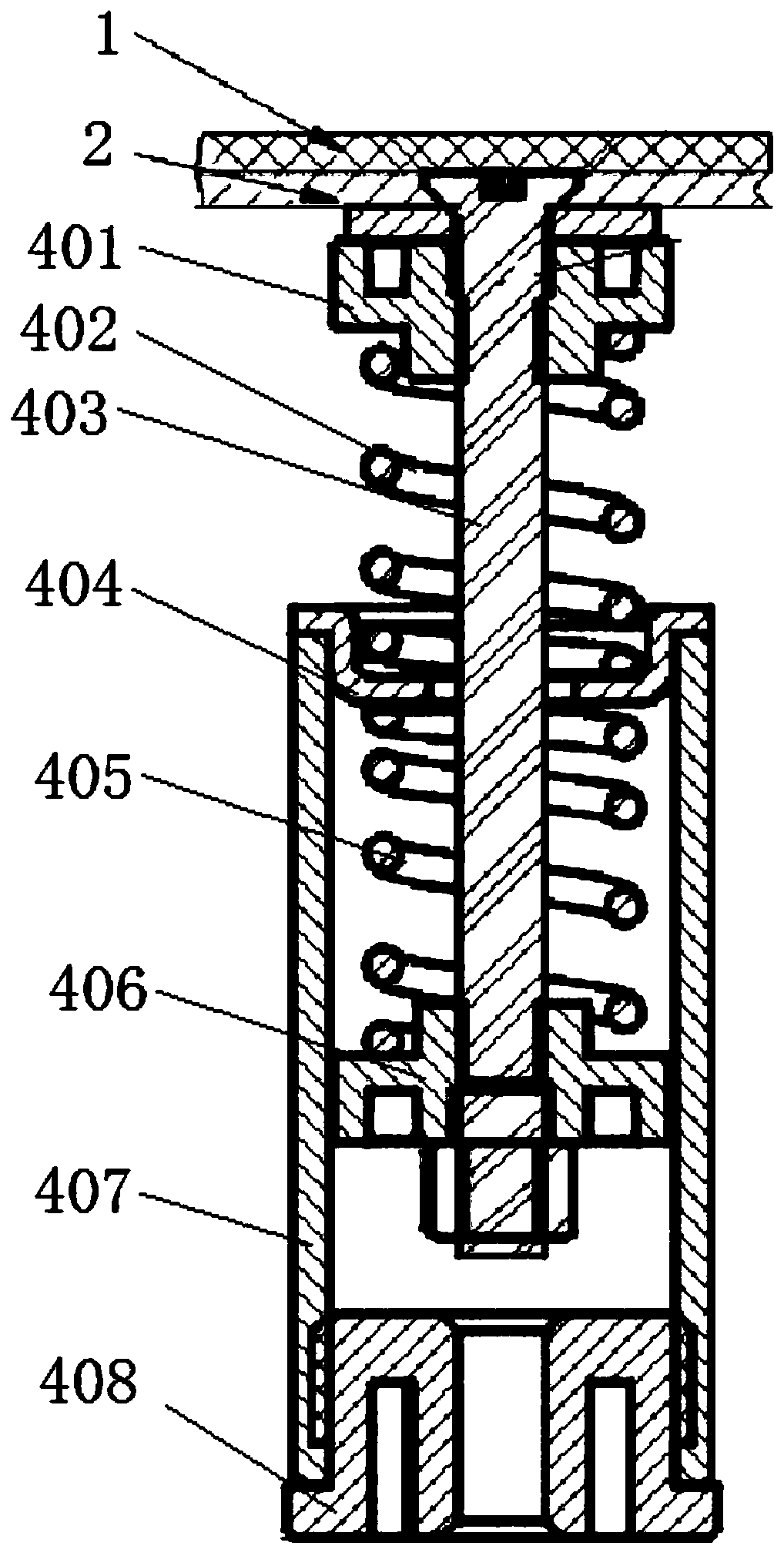

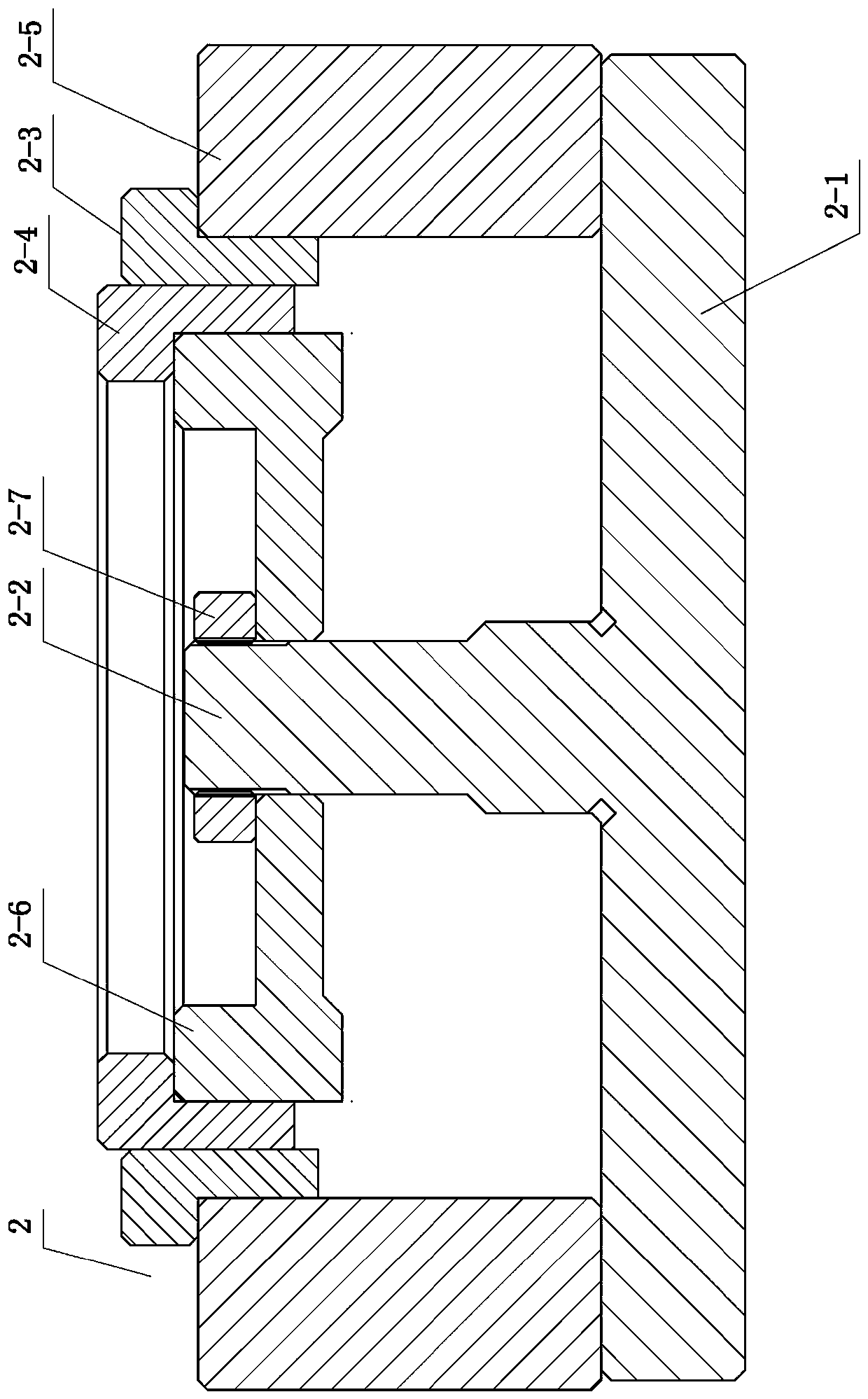

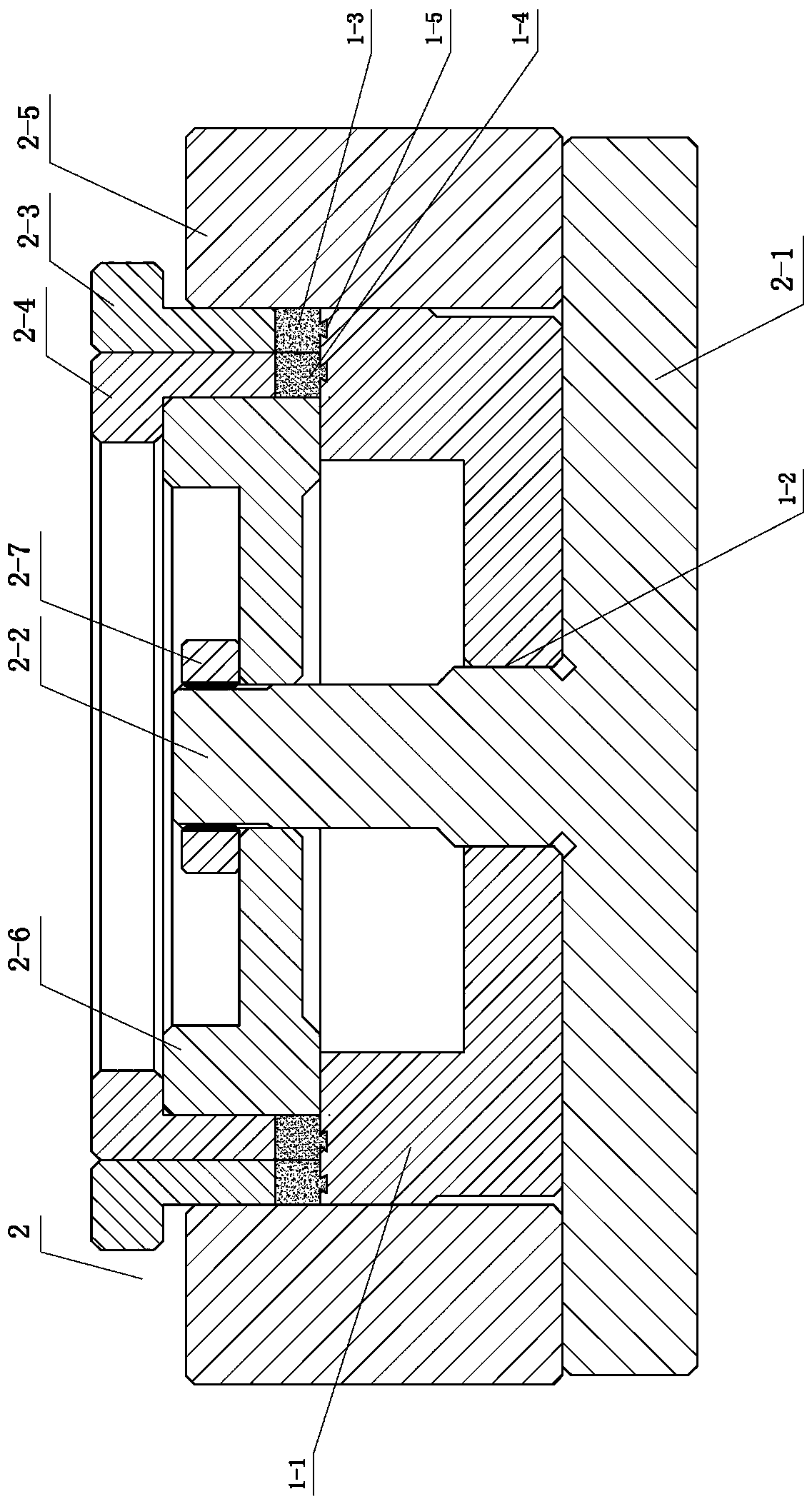

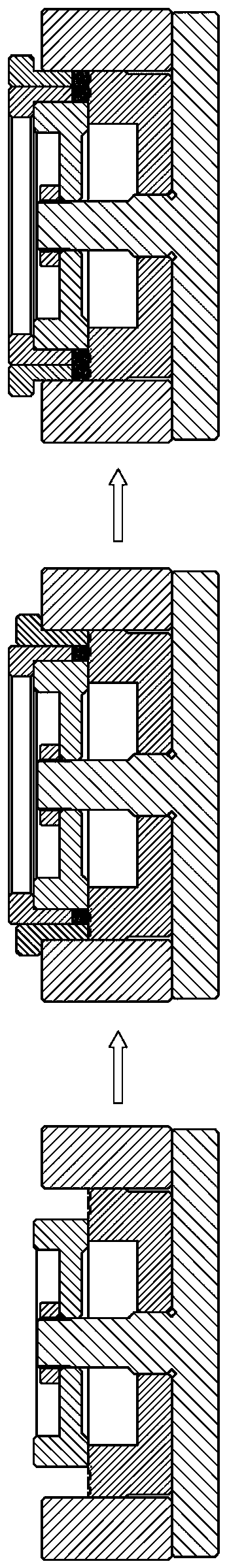

Vibration device for vibrating gypsum in denture processing

PendingCN109567965AHigh densityImprove work efficiencyAuxillary shaping apparatusDental prostheticsGypsumVibration based

The invention discloses a vibration device for vibrating gypsum in denture processing. The vibration device comprises a vibration base, wherein the vibration base is internally provided with a plurality of groups of vibration assemblies and a transformer; a platform is arranged at the upper end of the vibration base; the platform is connected with the vibration assemblies; each vibration assemblycomprises an upper spring, a lower spring, a vibration rod capable of moving up and down and a barrel body; a cap cover is fixed at the upper end of each barrel body and the lower end of each barrel body is connected with the vibration base; the top of each vibration rod is connected with the platform and the lower end of each vibration rod penetrates through the corresponding cap cover and stretches into an inner cavity of the corresponding barrel body to be connected with a sliding block; each sliding block is in slippage match with an inner wall of the corresponding barrel body; each upperspring sleeves the upper end of the corresponding vibration rod and is located between the platform and the corresponding cap cover; each lower spring sleeves the lower part of the corresponding vibration rod and is located between the corresponding cap cover and the corresponding sliding block. When the vibration device is used, gypsum to be processed is placed on the platform so that the structural density of the gypsum is improved; the working efficiency is improved and the processing quality of a product is also ensured.

Owner:武汉金光医疗科技有限公司

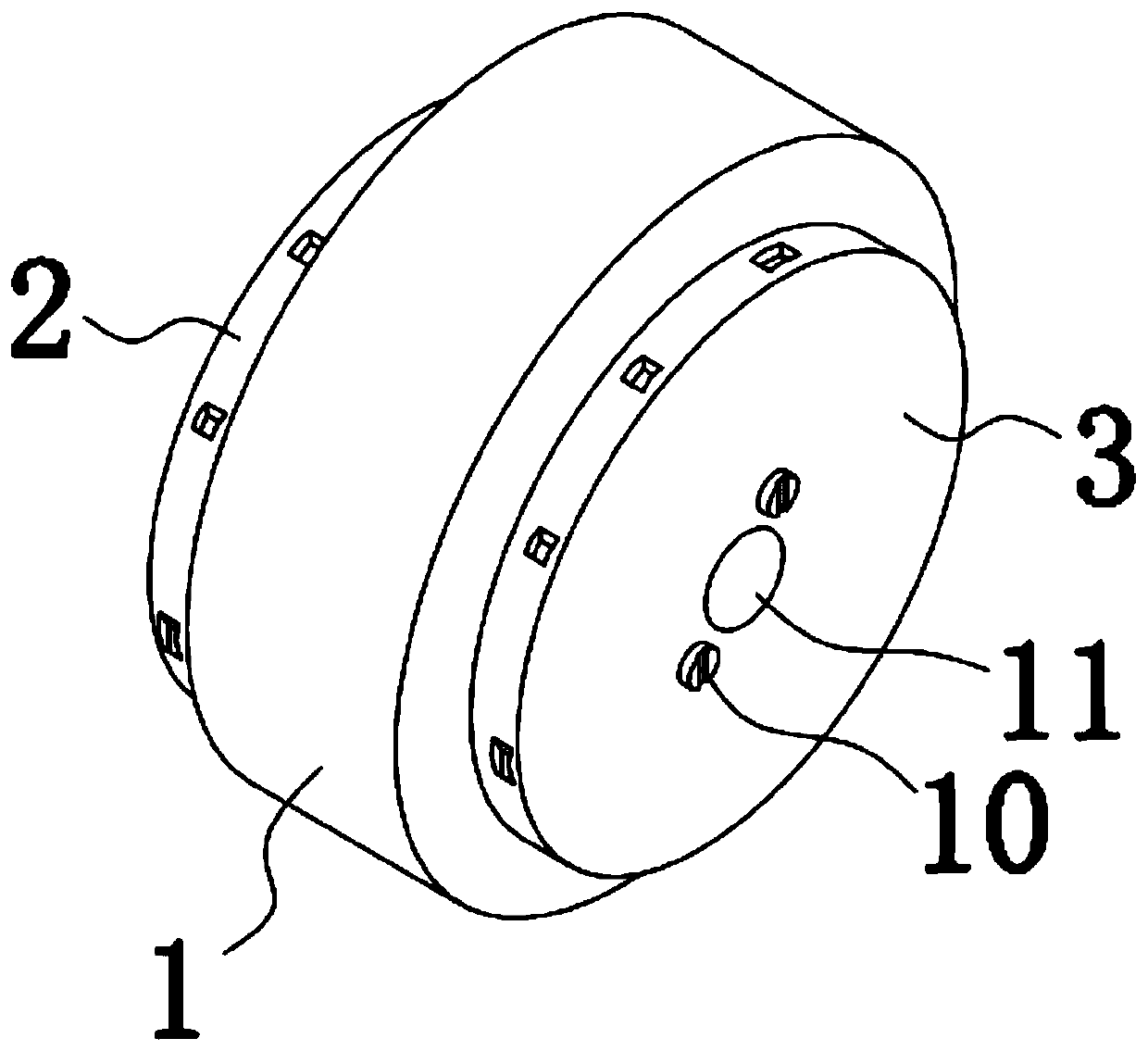

High-strength PE electric conduit and preparation method thereof

ActiveCN114716714AHigh structural densityHigh strengthGeneral water supply conservationPolyurea/polyurethane coatingsFiberCarbide silicon

The invention relates to the field of power cable accessory preparation, and particularly discloses a high-strength PE power conduit and a preparation method thereof. The high-strength PE electric conduit comprises a PE pipe, an adhesion promoting layer and an epoxy resin layer, the adhesion promoting layer is prepared from a polyurethane hot melt adhesive and modified silicon carbide fibers; the epoxy resin layer is prepared from the following raw materials: epoxy resin, an amine curing agent, a toughening agent, modified composite fibers, filling micro powder, a flatting agent and an anti-ultraviolet additive; the preparation method comprises the following steps: hot-melting the polyurethane hot melt adhesive, and mixing with the modified silicon carbide to obtain an adhesion-promoting coating; weighing epoxy resin, an amine curing agent, a toughening agent, modified composite fibers, filling micro powder, a flatting agent and an anti-ultraviolet additive, and mixing to obtain an epoxy resin coating; the surface of the PE pipe is sprayed with an adhesion-promoting coating, then the surface of the PE pipe is sprayed with an epoxy resin coating, and after curing, the adhesion-promoting coating is cured into an adhesion-promoting layer; the epoxy resin coating is cured into an epoxy resin layer; the invention has the advantages of improving the mechanical strength of the electric conduit and prolonging the service life of the electric conduit.

Owner:广东中讯通讯设备实业有限公司

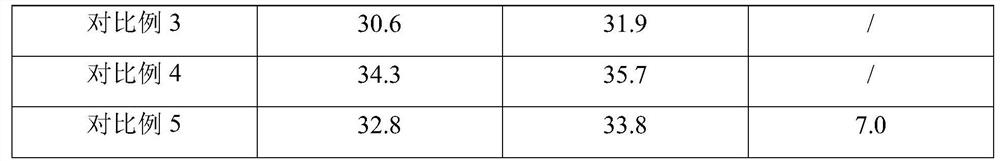

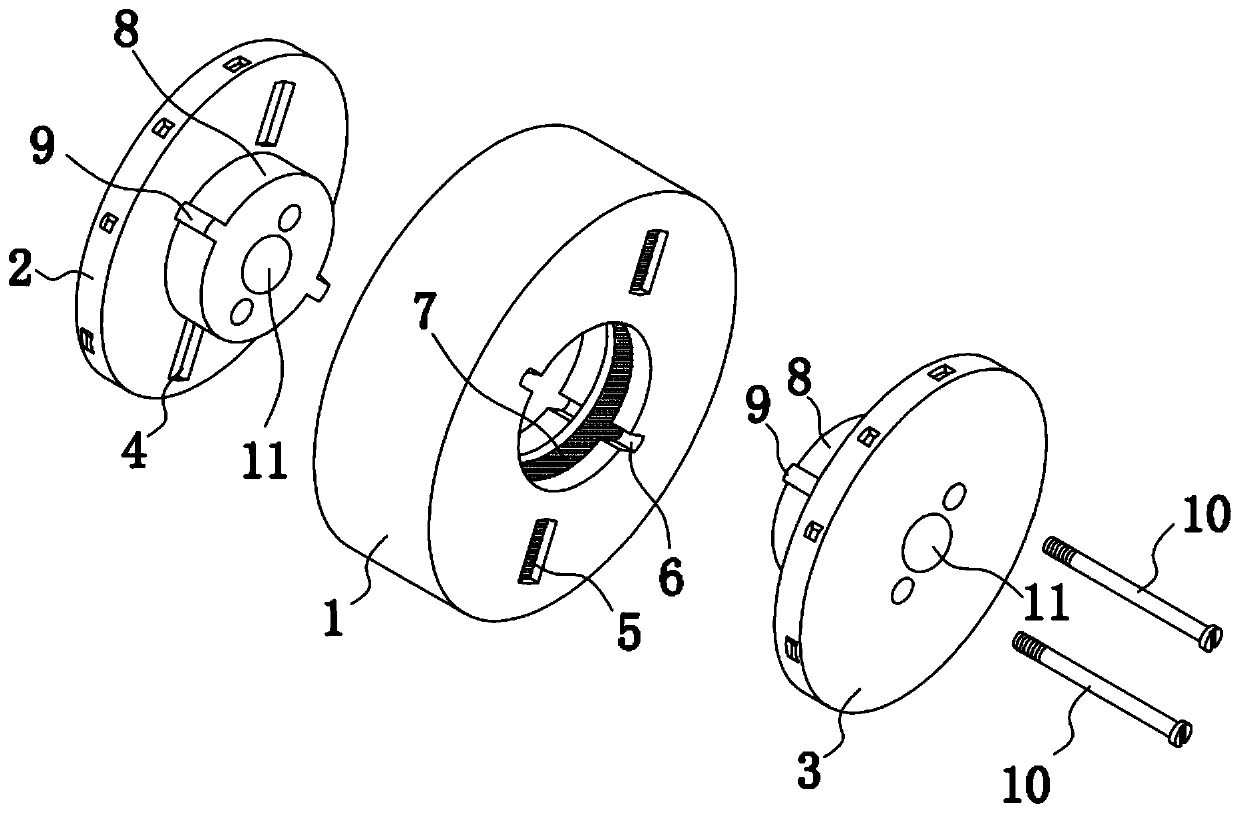

Compound diamond grinding wheel for lens polishing and preparation method thereof

InactiveCN110788767AHigh structural densityPlay a protective effectBonded abrasive wheelsGrinding devicesStructural engineeringMechanical engineering

The invention discloses a compound diamond grinding wheel for lens polishing. The grinding wheel comprises a grinding wheel body, a left end cover and a right end cover, wherein the left end cover andthe right end cover are fixed in the middle of the left side and the middle of the right side of the grinding wheel body, a round hole is formed in the middle of the grinding wheel body, the side edge of the round hole is provided with positioning grooves, the side surface of the grinding wheel body is provided with clamping grooves, and cylindrical insertion protrusions for being inserted into the round hole are arranged in the middle of the right end of the left end cover and in the middle of the left end of the right end cover. Positioning protrusions matched with the positioning grooves are arranged on the surfaces of the cylindrical insertion protrusions, and clamping protrusions matched with the clamping grooves are arranged on the surface of the right end of the left end cover andon the surface of the left end of the right end cover. The positioning protrusions are matched with the positioning grooves, and the clamping protrusions are matched with the clamping grooves so thatpolishing can be carried out when the grinding wheel body rotates at a high speed, and the grinding wheel body is protected.

Owner:启东蓝威金刚石科技有限公司

A kind of diamond resin grinding wheel and mold and method for processing the grinding wheel

ActiveCN108714860BAchieve inhibitionEasy to operateBonded abrasive wheelsGrinding devicesRough surfaceGrinding wheel

The invention relates to a diamond resin wheel and a mold and a method for machining the resin wheel. The resin wheel comprises a base body and abrasive material layers, wherein the abrasive layers are at least two abrasive layers which are fixed on the surface or the outer circle of a base body through extrusion and hot pressing, and each abrasive layer is formed by mixing and pressing differentcoarse and thin diamond particles and a binding agent; and the bonding position of the abrasive material layers and the base body are adopted with a dovetail-type structure, and the bonding faces arefurther processed into rough surfaces; the mold comprises a positioning base, a mold frame and a center mold, wherein the inner wall of the mold frame and the bottom face of the center mold form a placement area of the diamond resin wheel base body, a gap for installing a pressure head is arranged between the inner wall of the mold frame and the outer wall of the center mold, and the center mold is assembled with an assembling rod in a fixed mode through a fastening nut to be limited; the method for machining the resin wheel comprises the following steps that 1) the resin wheel base body is prepared; 2) the base body is fixed; 3) the abrasive material layers are pressed in advance; 4) hot-pressing forming is carried out; and 5) shaping and manufacturing are carried out. According to the method, a specially designed mold and a machining mode are adopted, so that the resin wheel with multiple utilization can be produced, and the grinding efficiency is improved.

Owner:湖南鑫星凌金刚石工具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com