Green high-strength and high-toughness concrete and preparation process thereof

A high-strength toughness, concrete technology, applied in the field of concrete, can solve problems such as easy to load a large amount of mortar, rough surface, and affect the strength of concrete, and achieve sustainable development, high mechanical strength, and improved density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

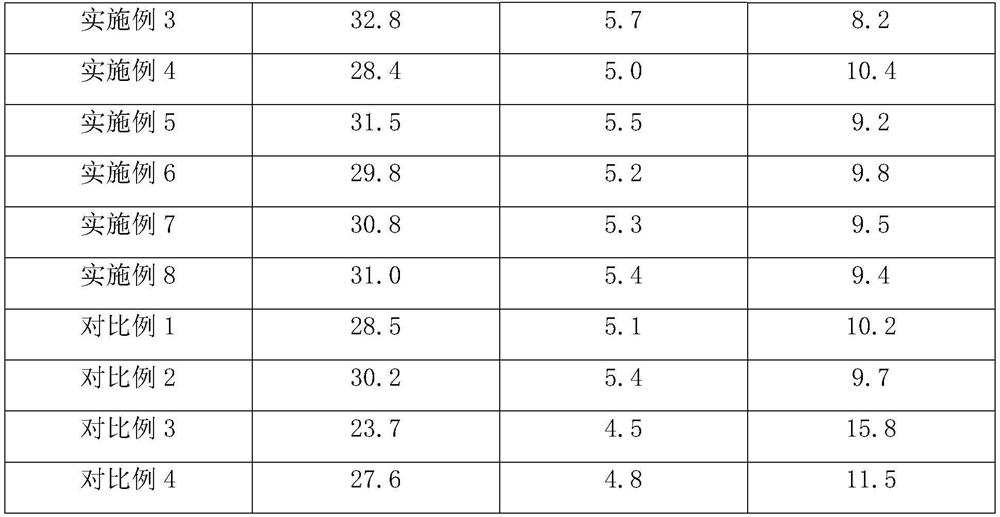

Examples

preparation example 1

[0045] Preparation Example 1: Modified recycled aggregates are prepared by the following method:

[0046]Weigh waste concrete blocks and go through primary crushing, secondary crushing, cleaning, grading, and drying to obtain recycled aggregates. The recycled aggregates are composed of recycled crushed stone and recycled sand with a weight ratio of 2.8:1. The particle size of the recycled crushed stone is 5-10cm, mud content 0.3%, porosity 42%, crush index 8%, surface density 2510kg / m 3 ;Reclaimed sand fineness modulus 2.1, mud content 3%, porosity 42%, surface density 2460kg / m 3 ;

[0047] Weigh the regenerated aggregate and place it in a 0.5% sodium gluconate aqueous solution by mass fraction, the weight ratio of the regenerated aggregate to the sodium gluconate aqueous solution is 1:2.5, soak for 15min at a stirring speed of 300r / min, then take out the regenerated aggregate, drain Dry the surface moisture, and make semi-finished products after drying;

[0048] Put the se...

preparation example 2

[0049] Preparation example 2: The modified recycled aggregate is prepared by the following method:

[0050] The waste concrete blocks are weighed and subjected to primary crushing, secondary crushing, cleaning, grading, and drying to obtain recycled aggregates. The recycled aggregates are composed of recycled crushed stone and recycled sand with a weight ratio of 2:1. The particle size of the recycled crushed stone is 5-10cm, mud content 0.3%, porosity 42%, crush index 8%, surface density 2510kg / m 3 ;Reclaimed sand fineness modulus 2.1, mud content 3%, porosity 42%, surface density 2460kg / m 3 ;

[0051] Weigh the regenerated aggregate and place it in a 0.1% sodium gluconate aqueous solution by mass fraction, the weight ratio of the regenerated aggregate to the sodium gluconate aqueous solution is 1:2.5, soak for 15min at a stirring speed of 300r / min, then take out the regenerated aggregate, drain Dry the surface moisture, and make semi-finished products after drying;

[005...

preparation example 3

[0053] Preparation example 3: The modified recycled aggregate is prepared by the following method:

[0054] Weigh waste concrete blocks and go through primary crushing, secondary crushing, cleaning, grading, and drying to obtain recycled aggregates. The recycled aggregates are composed of recycled crushed stone and recycled sand with a weight ratio of 3.2:1. The particle size of the recycled crushed stone is 5-10cm, mud content 0.3%, porosity 42%, crush index 8%, surface density 2510kg / m 3 ;Reclaimed sand fineness modulus 2.1, mud content 3%, porosity 42%, surface density 2460kg / m 3 ;

[0055] Weigh the regenerated aggregate and place it in a 1% sodium gluconate aqueous solution by mass fraction, the weight ratio of the regenerated aggregate to the sodium gluconate aqueous solution is 1:2.5, soak for 15min at a stirring speed of 300r / min, then take out the regenerated aggregate, drain Dry the surface moisture, and make semi-finished products after drying;

[0056] Put the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com