Patents

Literature

97results about How to "Improve high current charge and discharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

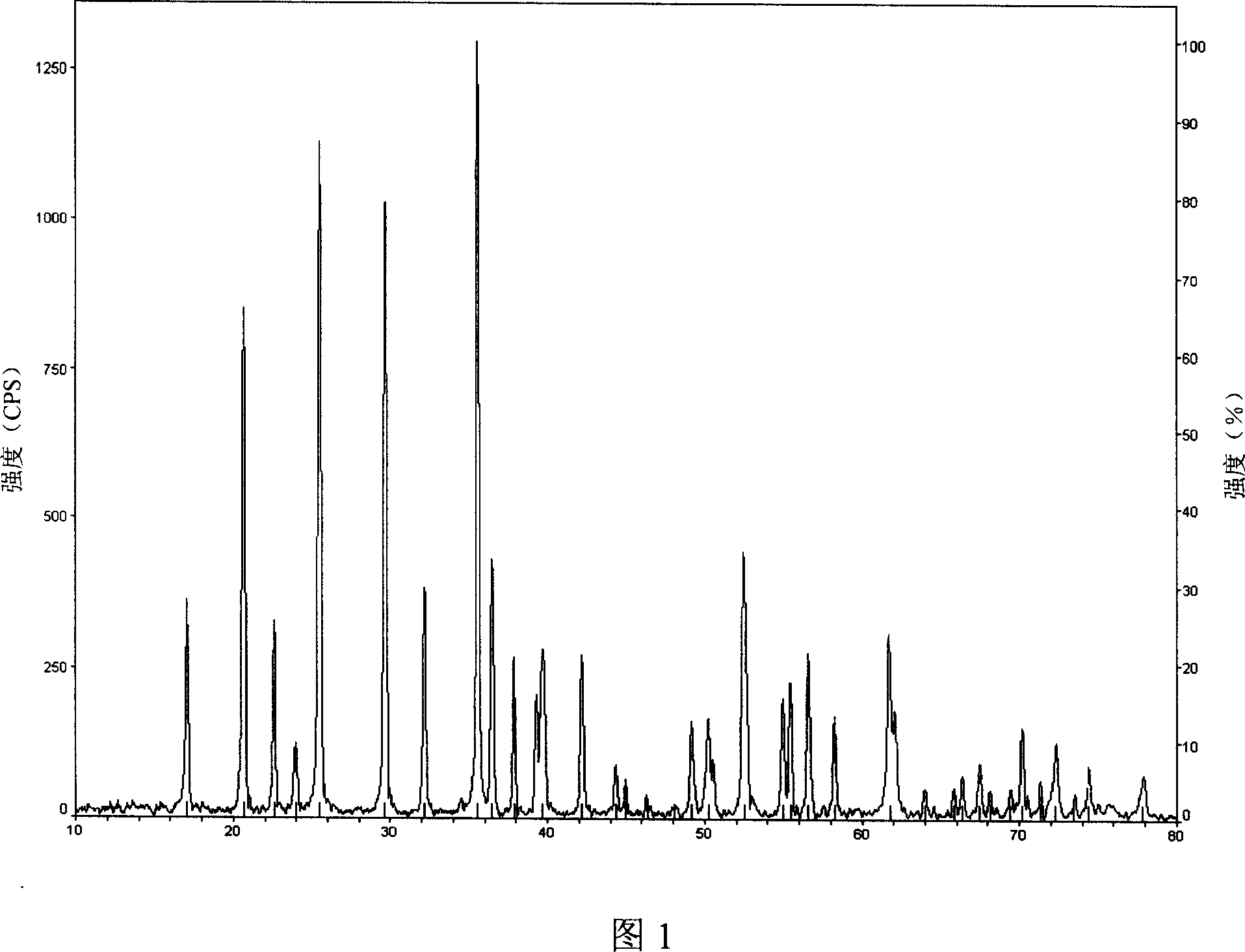

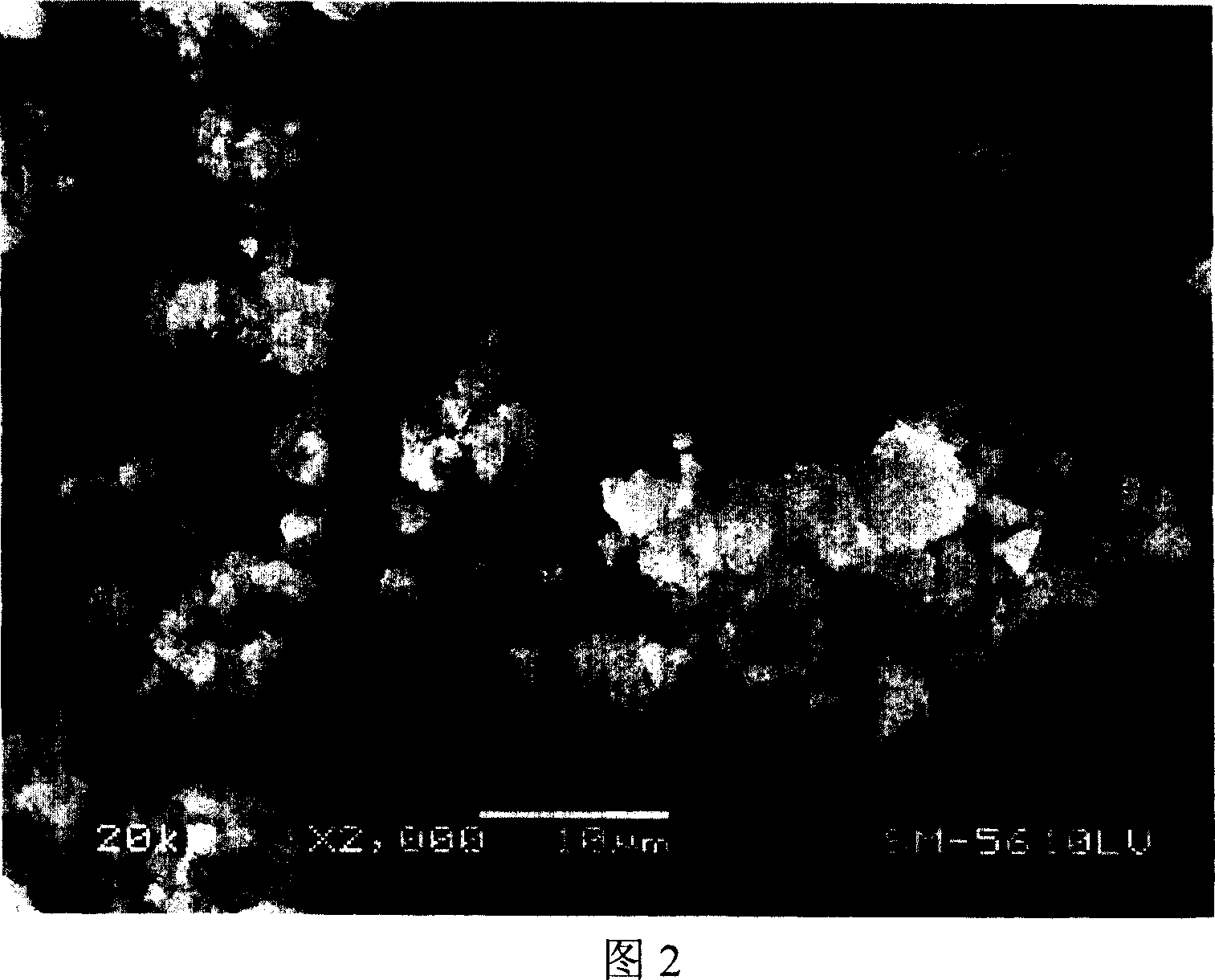

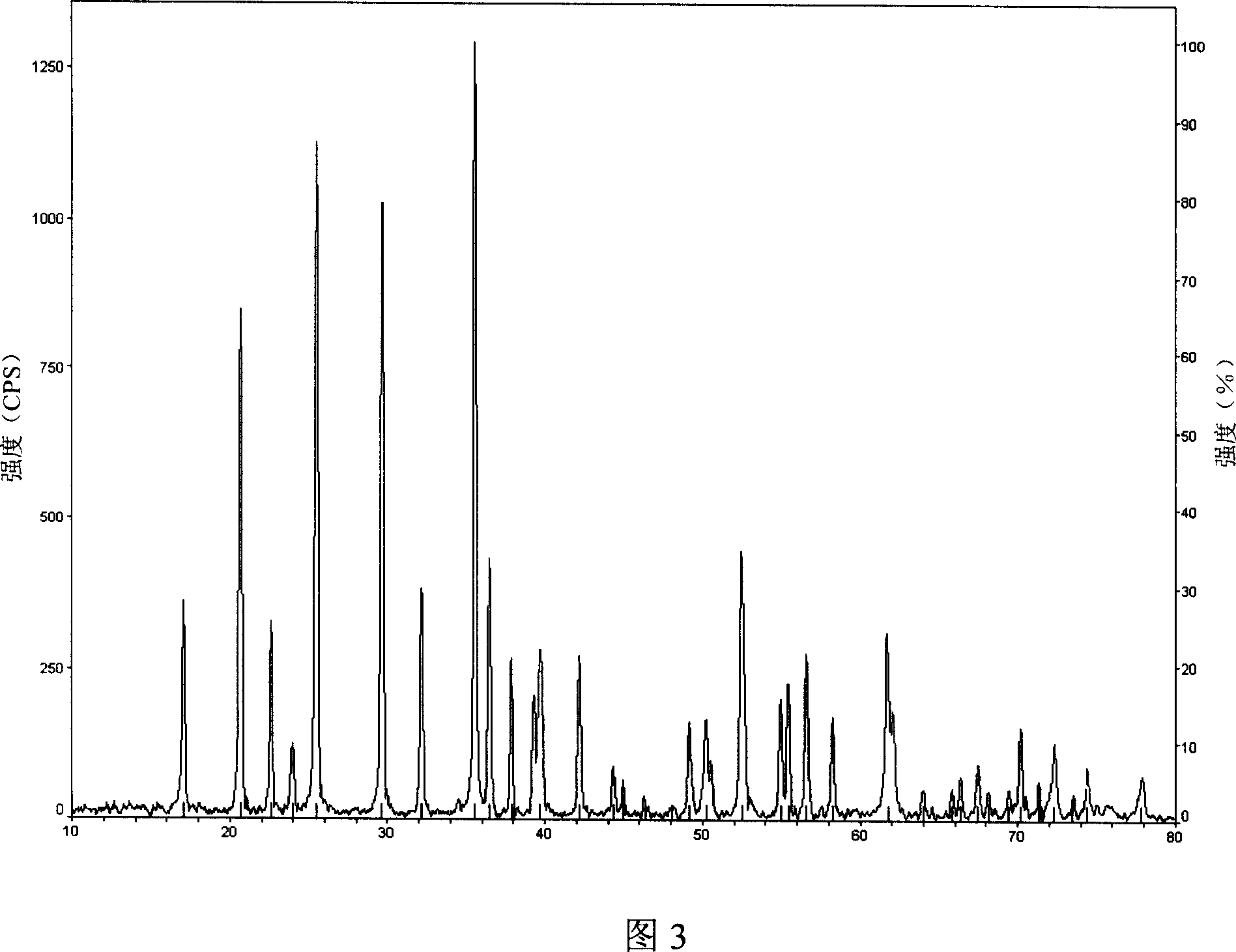

Preparing method of anode active material lithium iron phosphate for lithium ionic secondary cell

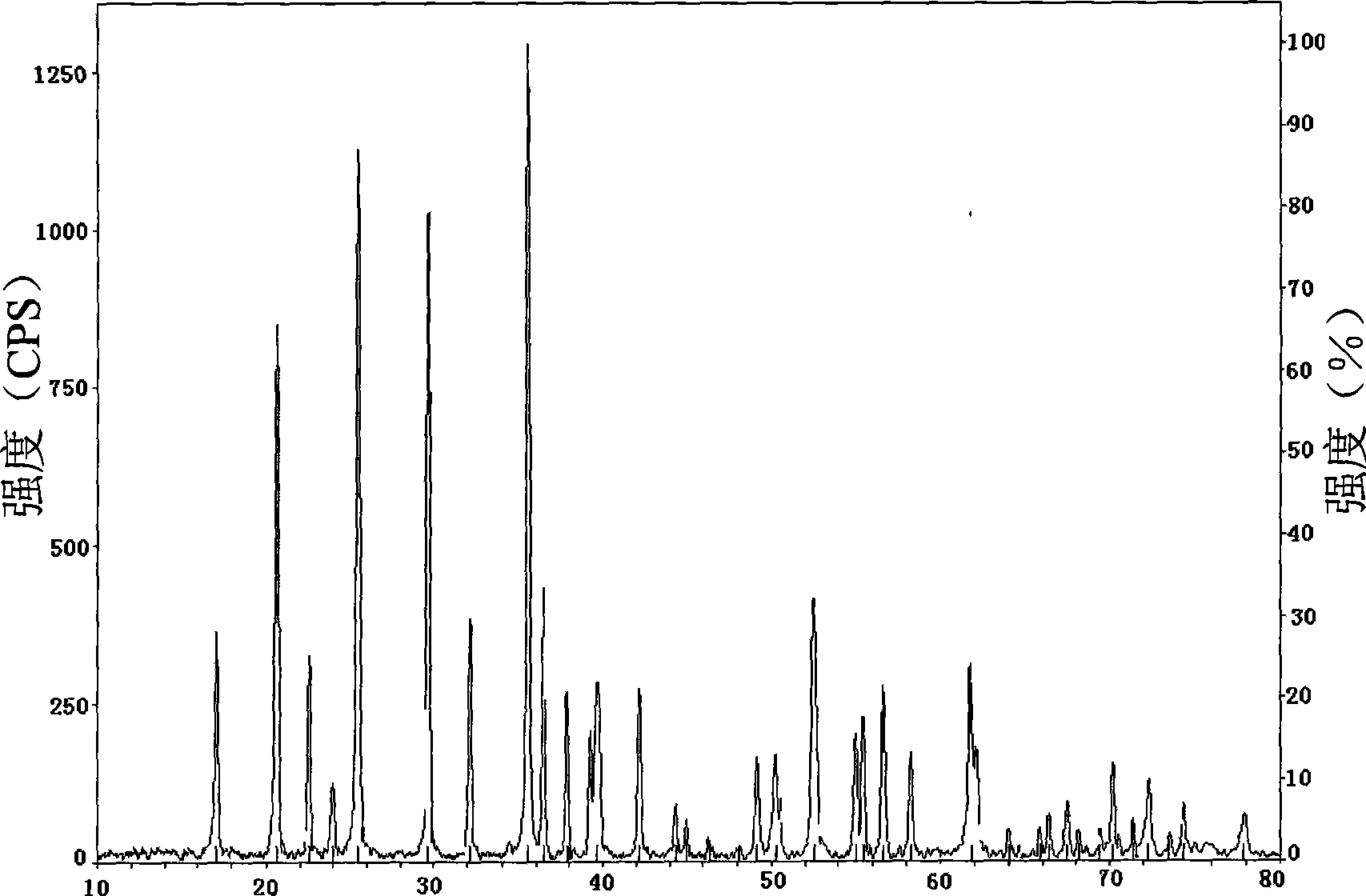

ActiveCN101399343AEasy to crushImprove high current charge and discharge performanceElectrode manufacturing processesSecondary cellsLithium iron phosphateBall mill

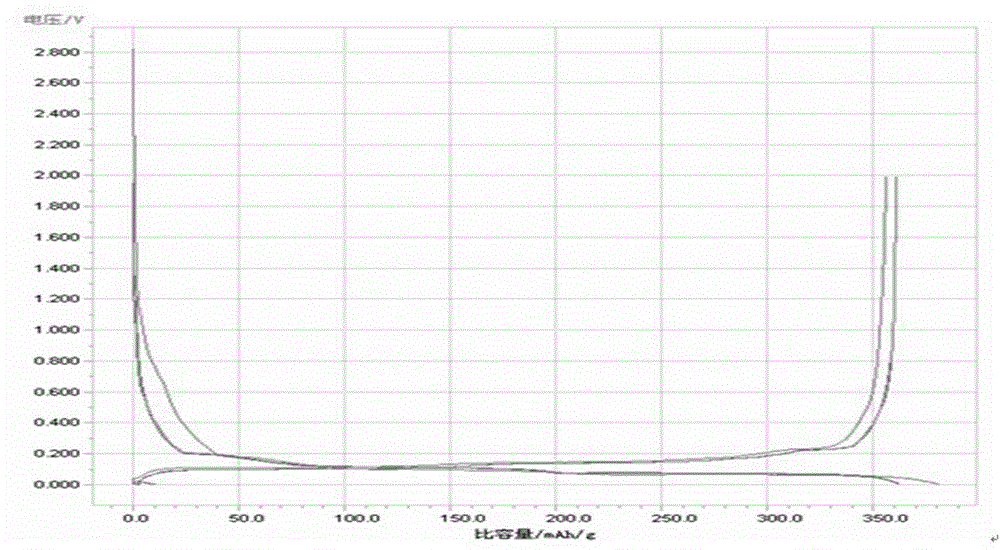

The invention provides a preparation method of lithium iron phosphate of a lithium-ion secondary battery positive electrode active material, the method comprises: a ferrous source compound, a phosphorus source compound, a lithium source compound and a carbon source compound are mixed, the first sintering is carried out on the obtained mixture under the protection atmosphere, products in the first sintering are ball-milled and dried, the second sintering is further carried out to obtain the lithium iron phosphate, wherein, the method further comprises the heating of the mixture at the temperature of 60-250 DEG C under the oxidation atmosphere before the first sintering or after the first sintering. The lithium iron phosphate which is obtained by adopting the method can have both high volume specific capacity and excellent high-current discharge performance.

Owner:TAICANG RONGCHI MOTOR

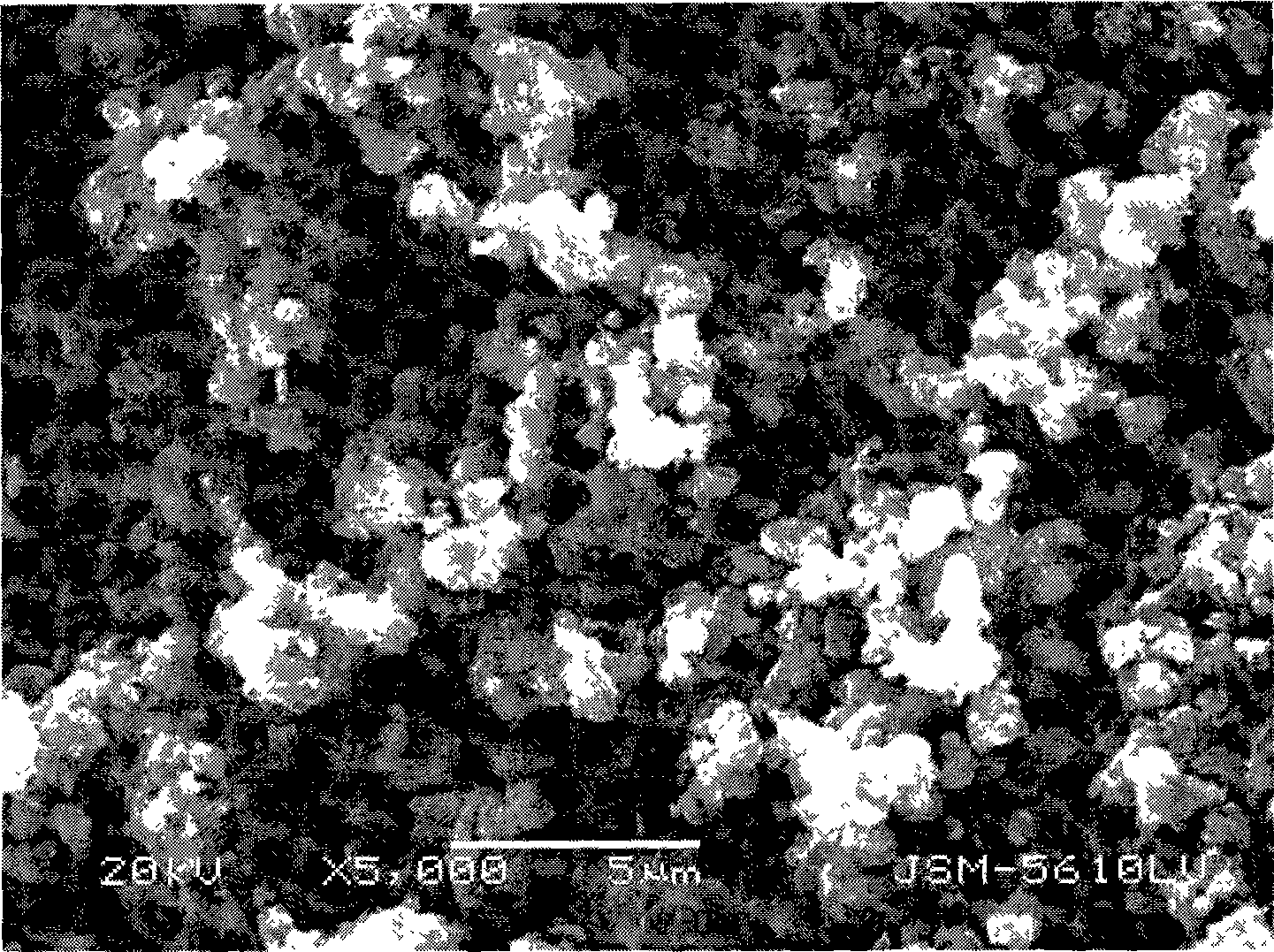

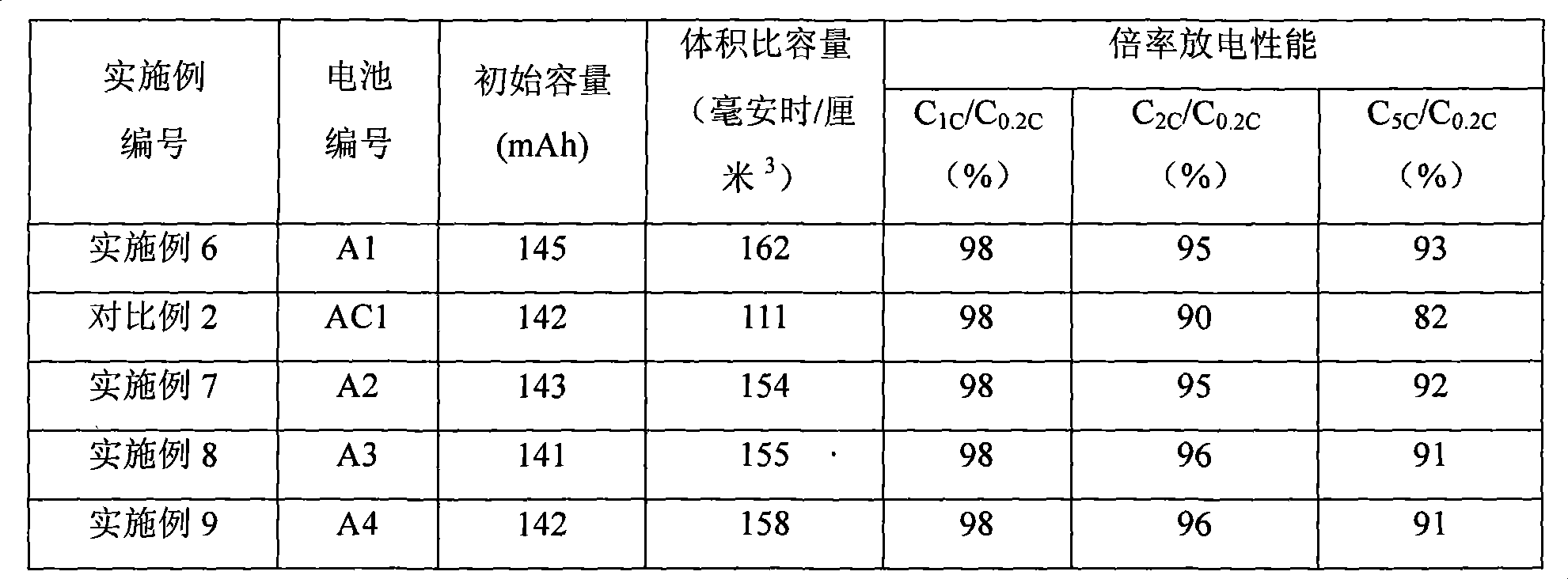

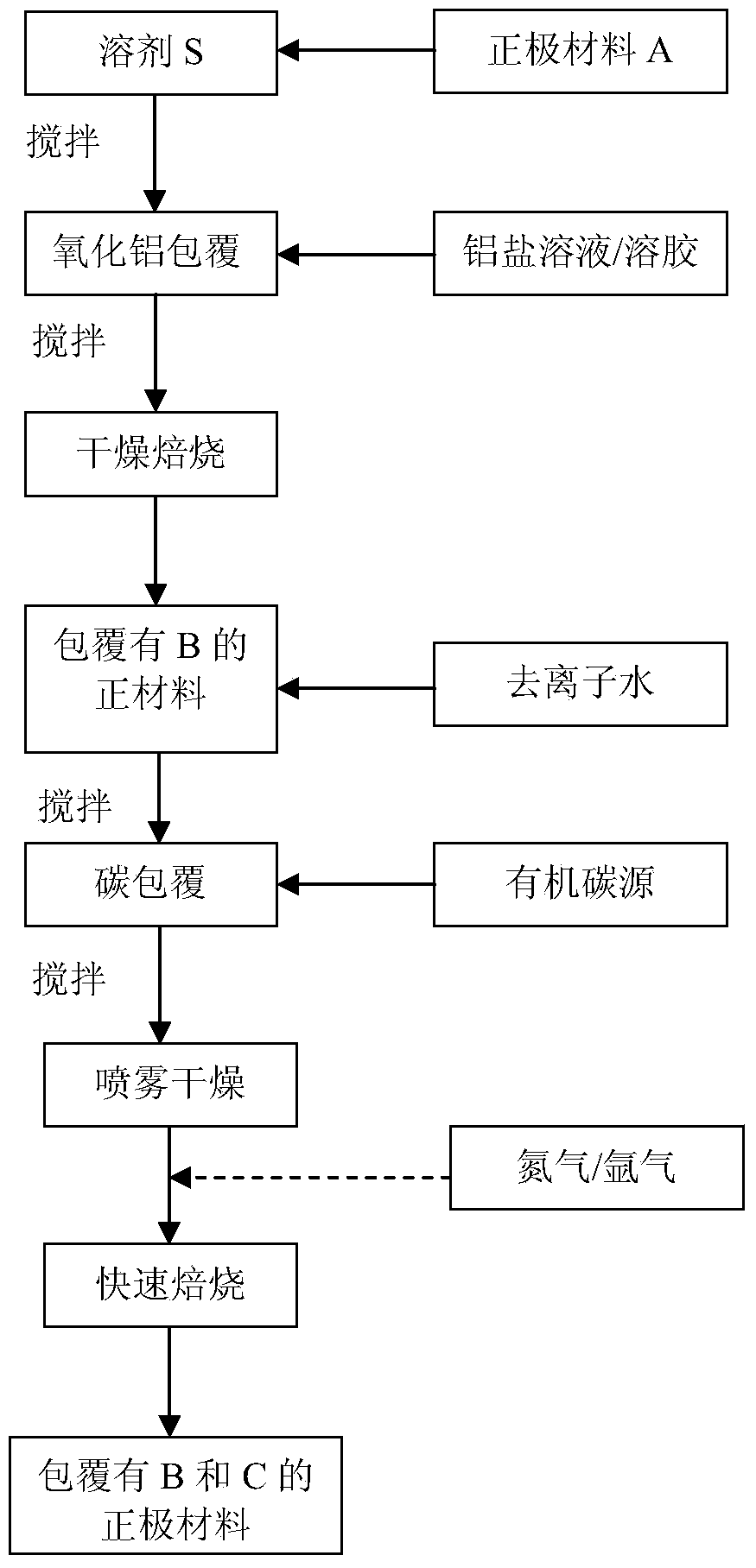

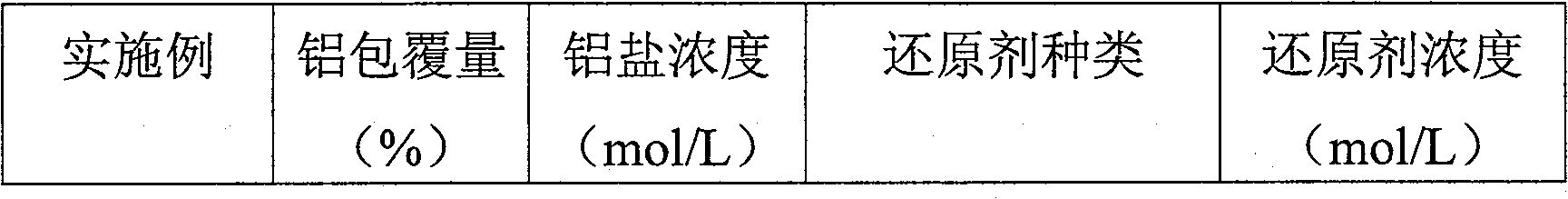

Lithium ion battery anode material and preparation method thereof

ActiveCN103647073AAvoid metal reductionQuick releaseElectrode thermal treatmentSecondary cellsCarbon coatingCarbon source

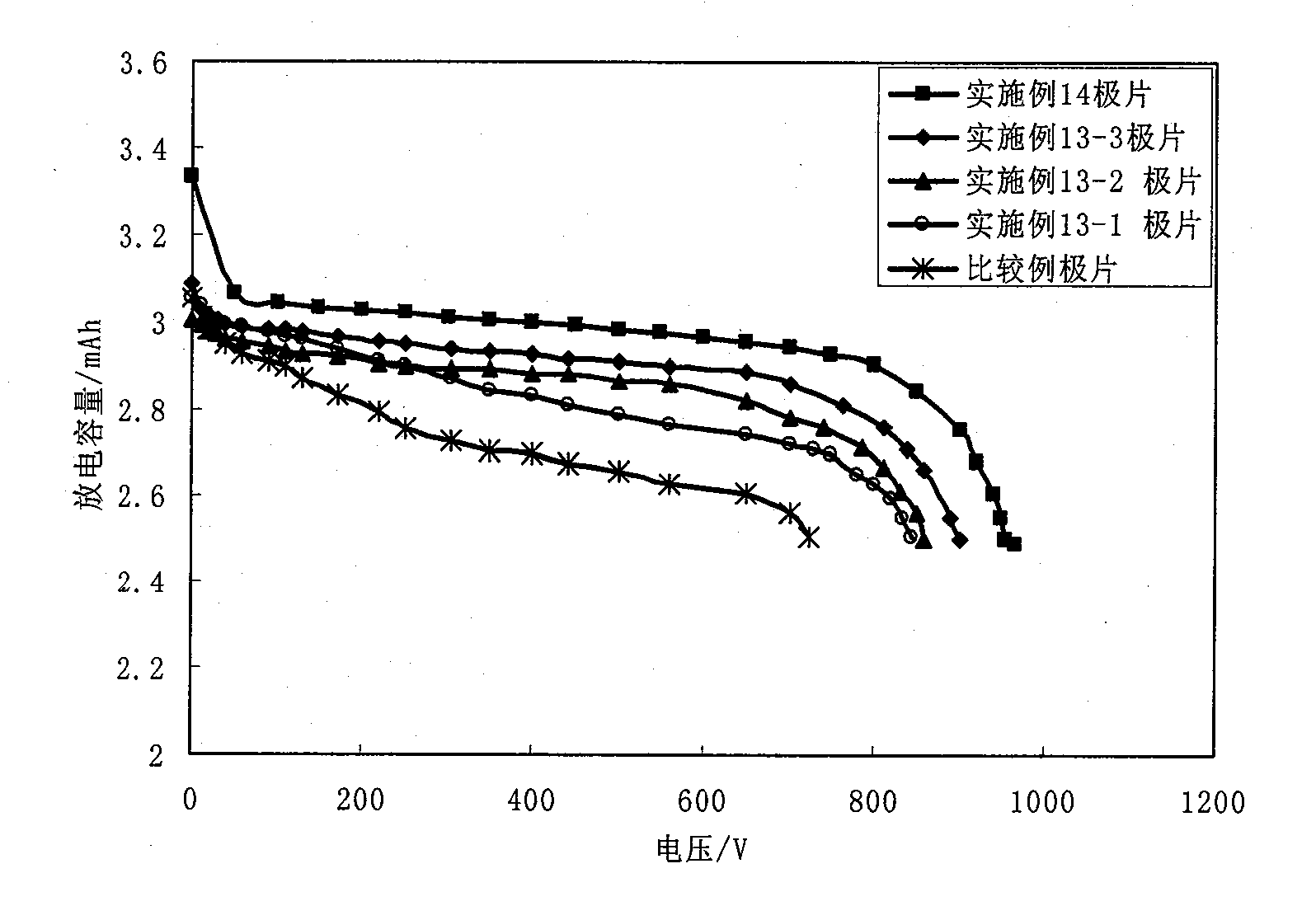

The invention discloses a preparation method of a lithium ion battery anode material. The method is characterized in that the outer surface of the existing lithium ion battery anode material is sequentially coated with an aluminum oxide layer and a carbon layer, wherein the coating condition is liquid-phase coating, in the coating process of the aluminum oxide, the addition sequence of the existing lithium ion battery anode material and aluminum salt is adjusted, and the coating substance organic aluminum salt is added under the continuously stirring condition, so that a hydrolytic product is uniformly adsorbed onto the surface of an active substance. The carbon coating is carried out through a spray drying and rapid sintering way in the inert gas atmosphere, so that the problems that the metal is reduced due to the high-temperature carbon coating and the organic carbon source is difficultly carbonized in low temperature can be avoided. The invention also discloses a lithium ion battery anode material prepared through the method. The energy density and power density of the battery can be remarkably improved, and the cycling performance, the capacity retention rate and the safety performance of the battery can be improved.

Owner:EVE ENERGY CO LTD

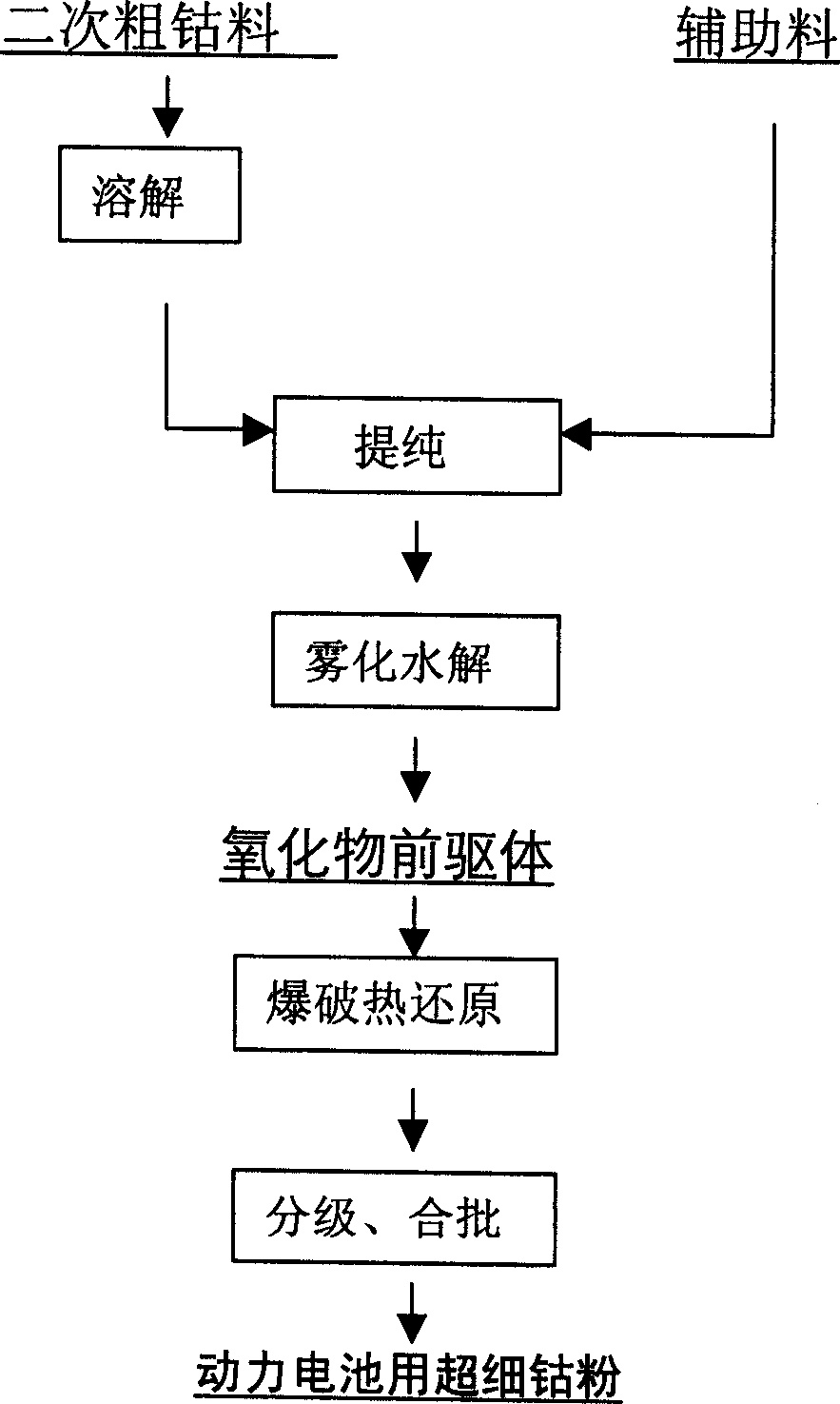

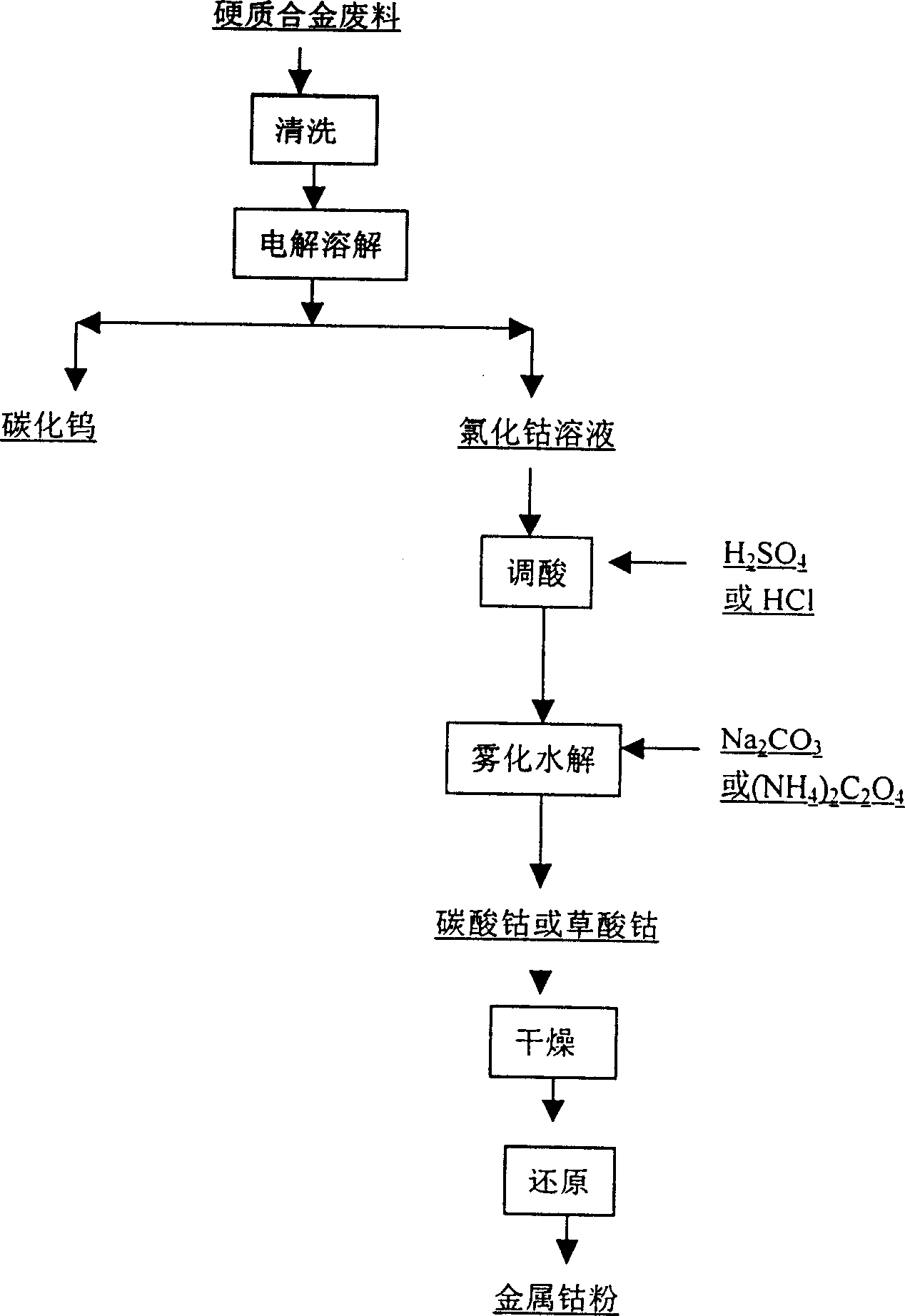

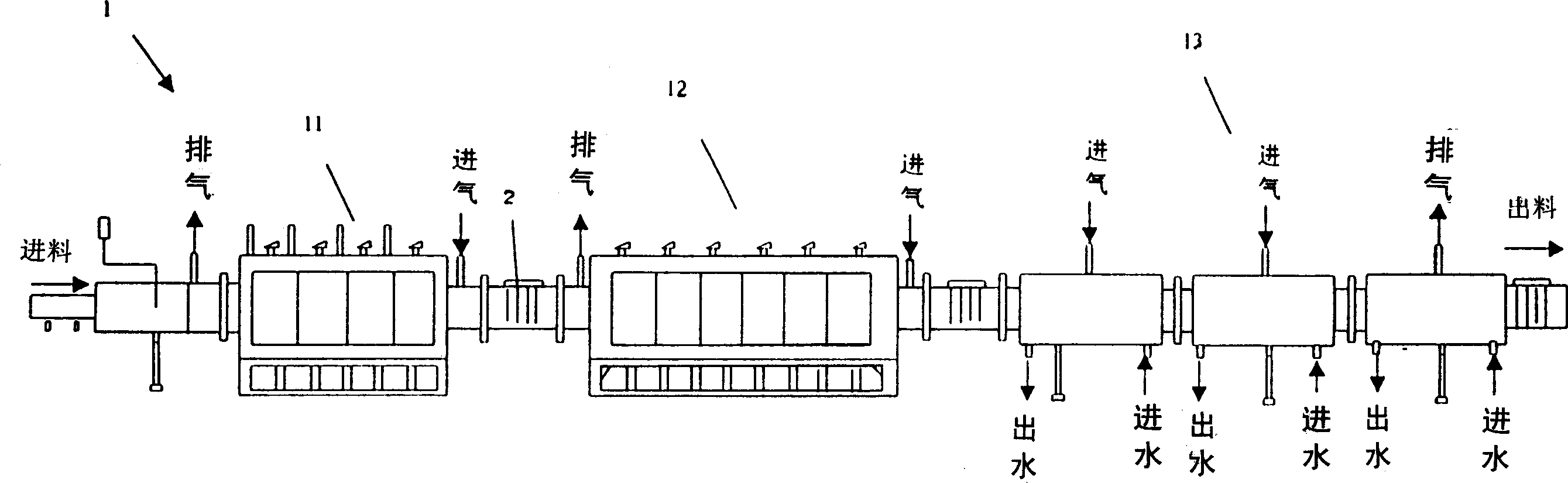

Production and producing apparatus for super fine cobalt powder by circulating technology

A process for preparing superfine spherical or fibrous Co particles from used battery by the circulation technique includes such steps as extracting twice for purifying, atomizing, hydrolyzing, depositing to obtain the Co compound precursor, and exploding for thermal reduction at multiple temp segments to obtain the superfine Co particles (0.1-0.2 microns) used for power battery and powder metallurgy. Its apparatus is also disclosed.

Owner:JINGMEN GEM NEW MATERIAL

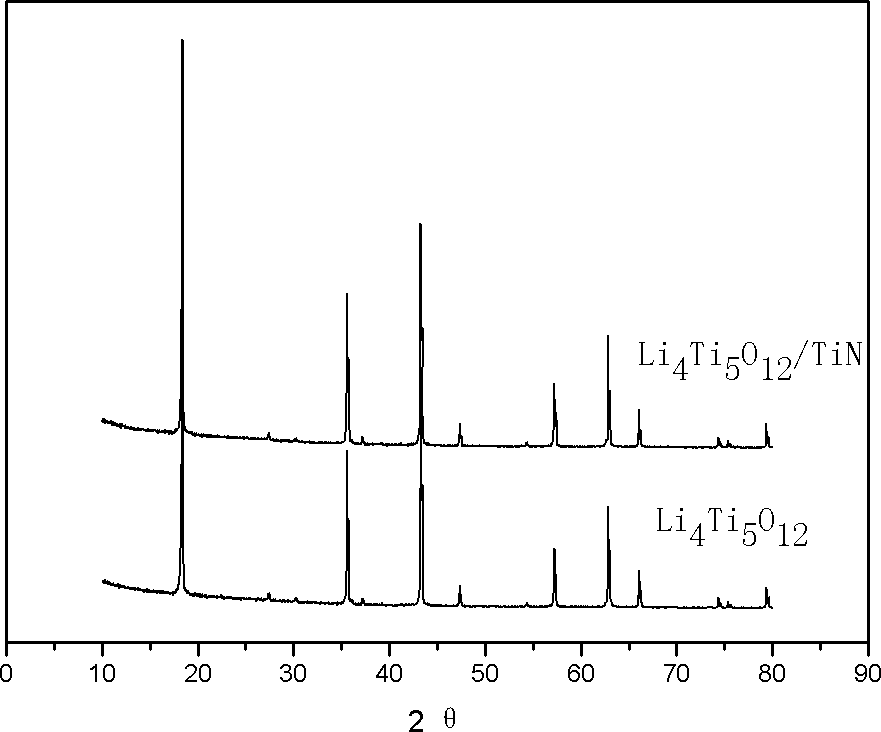

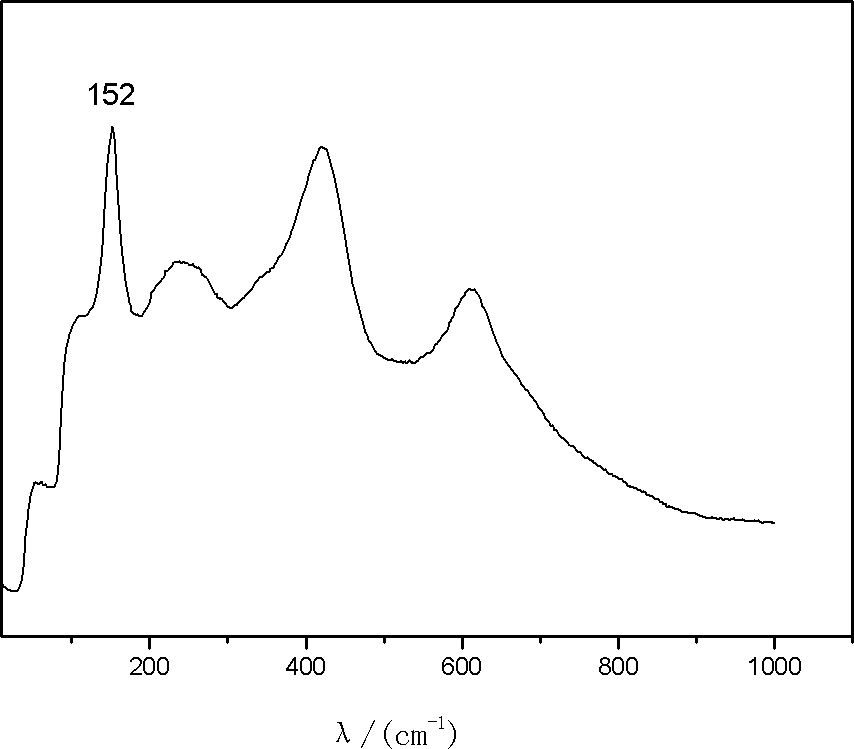

Method for preparing lithium titanate/titanium nitride composite material

The invention belongs to the field of battery materials, and particularly relates to a cathode material for a lithium battery. The invention discloses a method for preparing a lithium titanate / titanium nitride composite material, which comprises the following steps of: grinding titanium dioxide serving as a titanium source, lithium titanate and solid nitrogen source uniformly in a disperse medium, drying at the temperature of between room temperature and 120 DEG C, and grinding; and firing under the protection of vacuum or inert gas, and then naturally cooling to obtain the lithium titanate / titanium nitride composite material, wherein the nitrogen source is selected from one or mixture of more than two (comprising two) of urea, biuret, cyanamide, dicyandiamide, melamine, cyanuric acid monamide and cyanuric acid diamide. The method for directly preparing the Li4Ti5O12 / TiN composite electrode material by adding the solid nitrogen source into the raw materials for preparing Li4Ti5O12 does not increase the preparation process, has low cost, simple process and low energy consumption, and is easy to realize scale production.

Owner:SUZHOU UNIV

Preparation method and applications of battery graphene-base current collector

InactiveCN104347881AIncrease effective contactLower internal resistanceElectrode carriers/collectorsFiltrationElectrical battery

The invention discloses a preparation method and applications of a battery graphene-base current collector, and belongs to the field of electrochemical battery. The provided current collector is suitable for lithium ion battery and lithium-sulfur battery, is prepared by dispersing graphite, subjecting graphite to suction filtration, and rolling the graphite, has a thickness of 15 to 25 [mu]m, and has high mechanical strength. When the provided graphene-base current collector is applied to a lithium ion battery or a lithium-sulfur battery, the weight of the lithium ion battery or the lithium-sulfur battery is effectively reduced, the energy density of the lithium ion battery or the lithium-sulfur battery is improved. Moreover, the provided current collector has a very strong electrolyte absorbing and storing performance, so the strong current charging / discharging performance of battery using the provided current collector is improved, and the properties of multiple electrode materials are all largely improved. The preparation process of the provided current collector is simple and controllable, and furthermore the preparation method can be applied to massive and low-cost industrial production, and thus has a high application value.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Modified ferrous lithium phosphate as anode material for lithium ion batteries and its production

InactiveCN1585168AStable structureImprove performanceElectrode manufacturing processesLithium compoundsOlivineLithium electrode

The invention is to supply a positive pole material for the lithium ion battery with the property of excellent performance and low cost, apply the olivine type modification lithium ferrous phosphate as positive material, its molecular formula is presented as LiFl-xMxPO4, in which the M is one or two of the elements as below: Cr, Co Mn, Mg, Ni, La. The producing method mixes the lithium iron modification element M with the phosphor after warming-up and igloss processing in the inert gases, the modification lithium ferrous phosphate with stable structure is produced.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP +1

Lithium ion power battery with good safety performances

ActiveCN103746139AImprove cycle lifeImprove securityElectrode carriers/collectorsSecondary cellsElectrolytic agentPower battery

The invention relates to the technical field of lithium ion power batteries, and particularly relates to a lithium ion power battery with good safety performances. The lithium ion power battery includes a positive pole, a diaphragm, a negative pole and an electrolyte, the negative pole comprises a negative pole current collector and a negative pole active material layer, the negative pole active material layer includes a negative pole active material and a conductive material, the negative pole active material is lithium titanate, and the ratio of the negative pole cathode and the positive pole capacity is 0.65-0.68. The lithium ion power battery effectively increases the battery cycle life, the battery safety performances and the battery large-current charge and discharge performances.

Owner:东莞维科电池有限公司

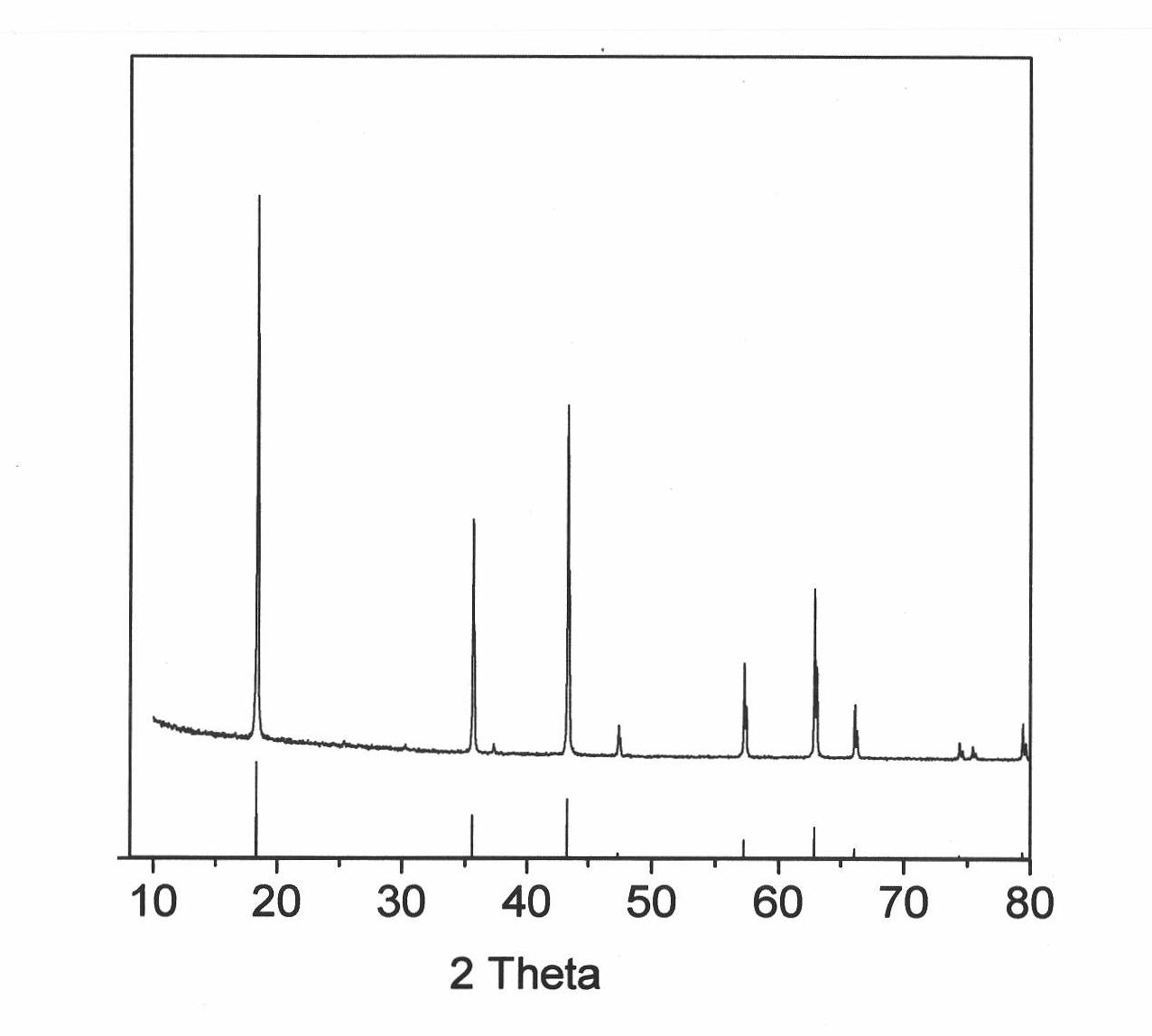

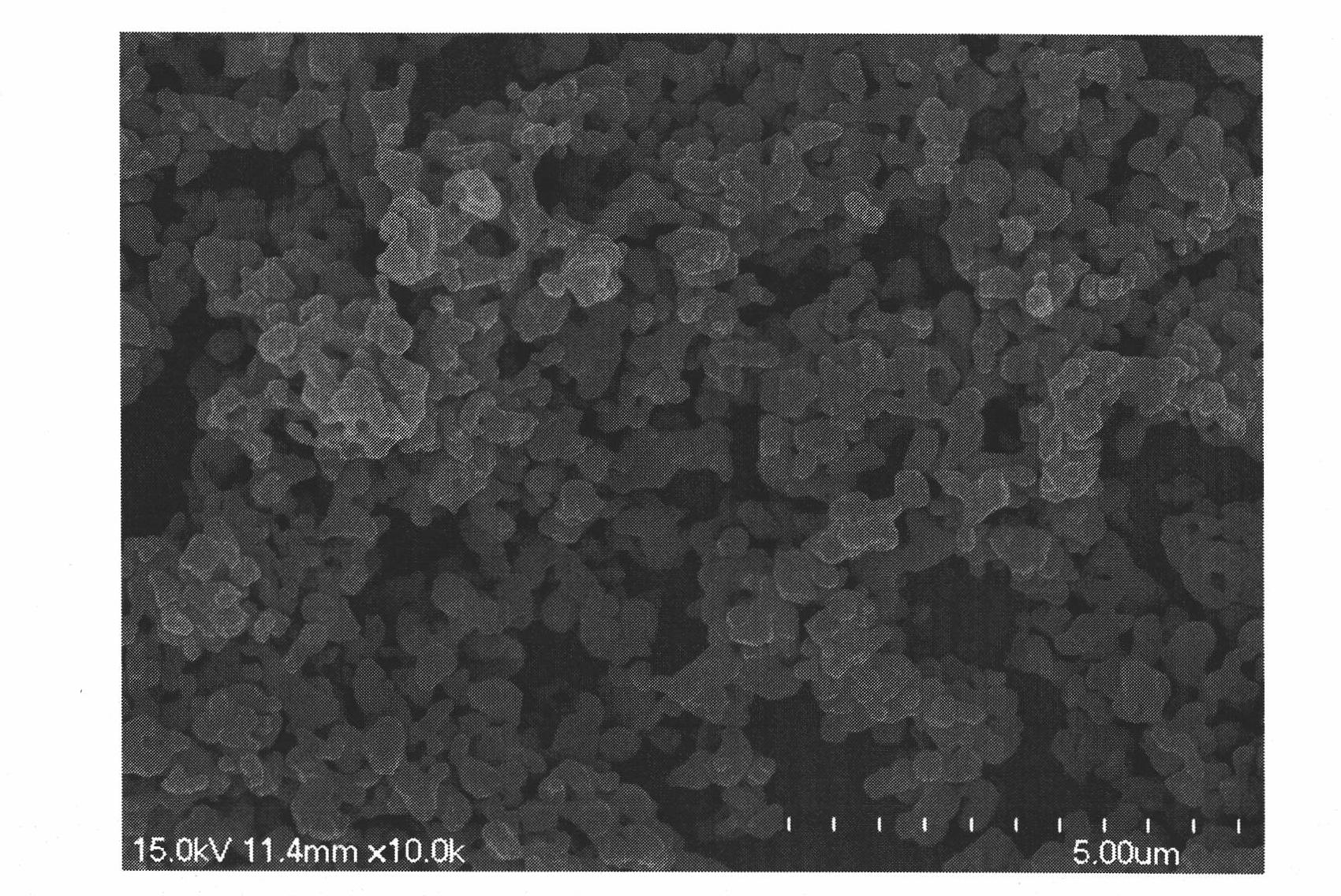

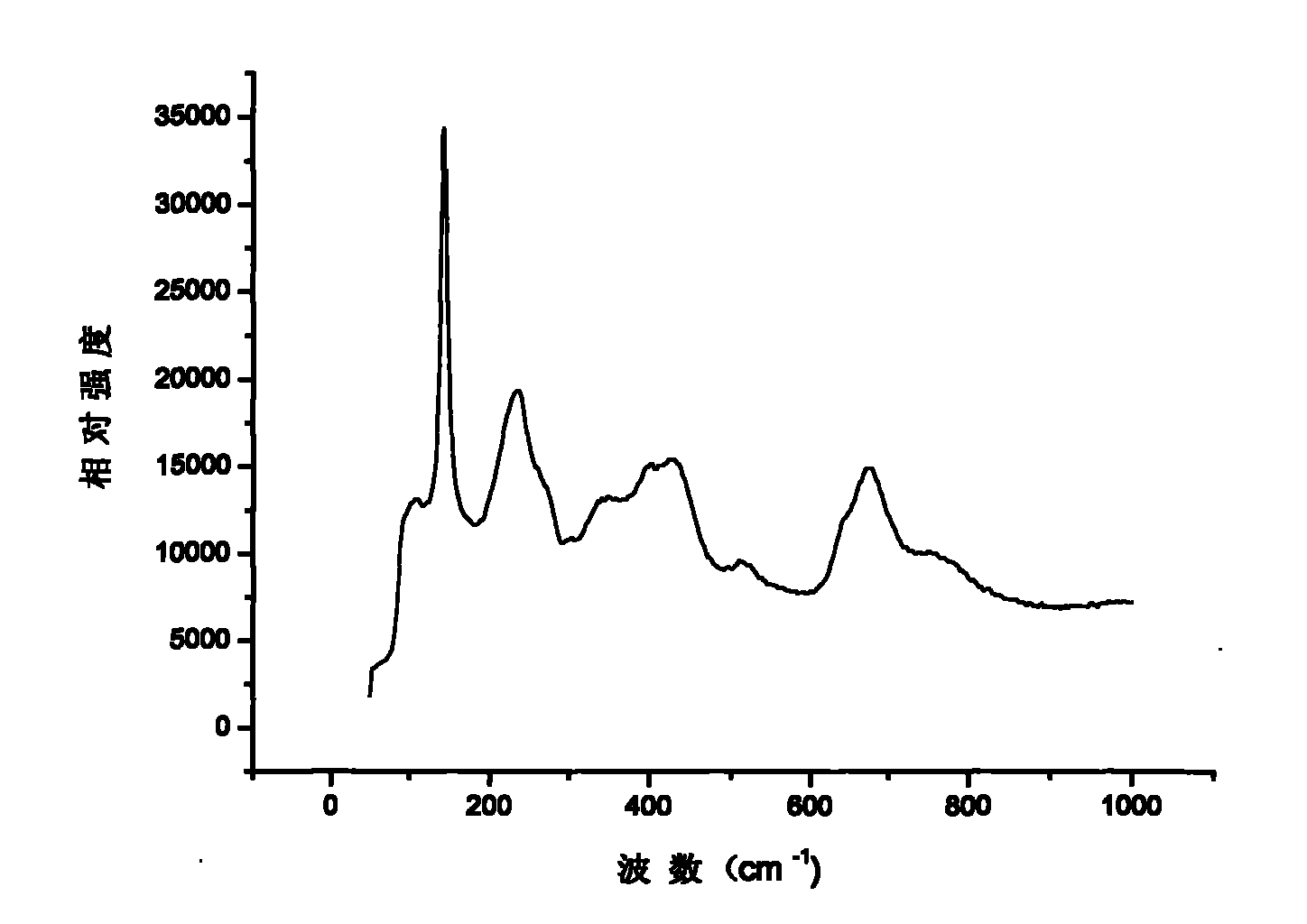

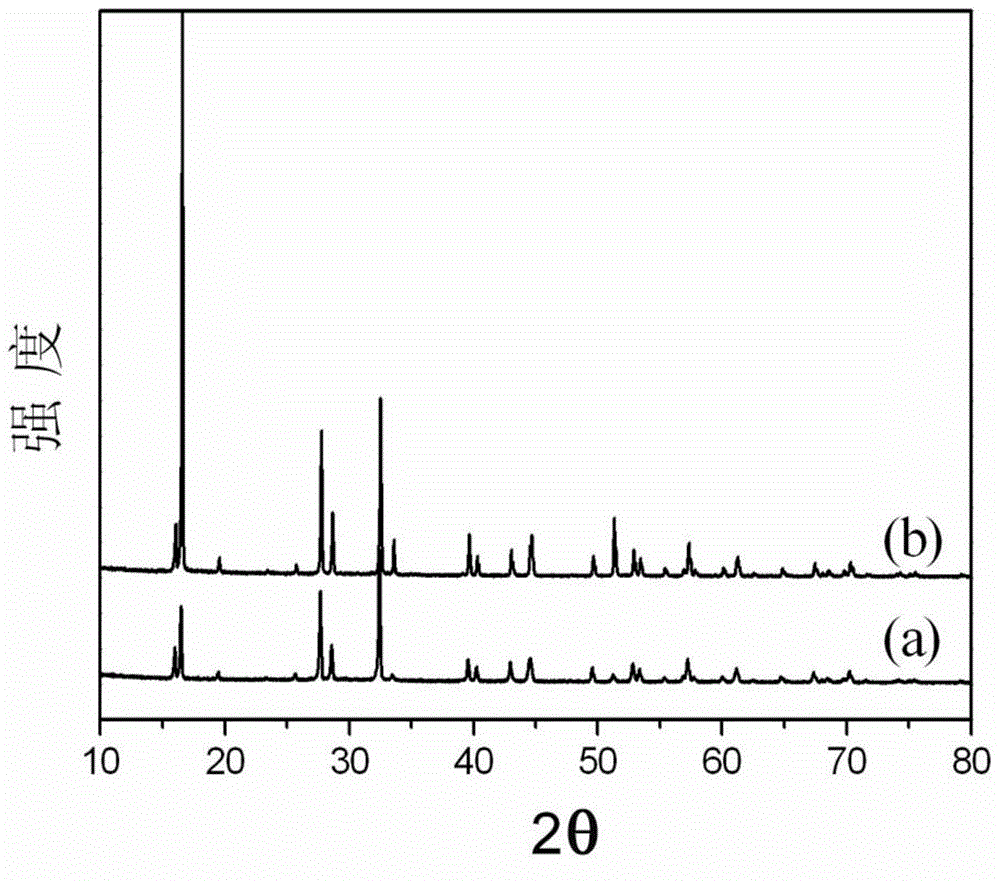

Method for manufacturing spinelle lithium titanate for lithium ionic cell cathode material

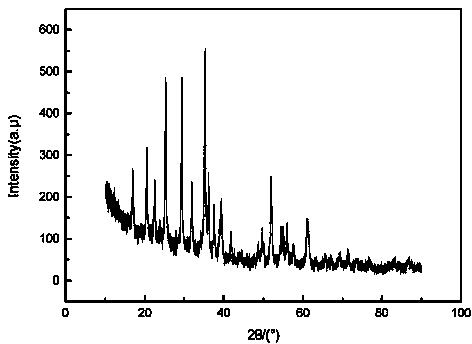

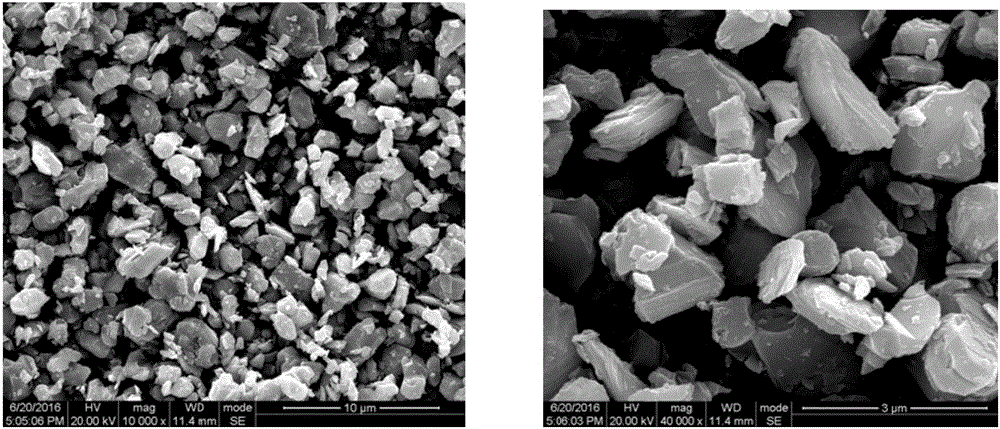

InactiveCN101391806AImprove high current charge and discharge performanceSmall particle sizeCell electrodesLithium compoundsLithium carbonateSolid-state

The invention provides a method for preparing spinel lithium titanate used for the negative electrode materials of lithium ion batteries, which comprises the following steps of: mixing compounds of metatitanic acid and lithium according to an atomic ratio of lithium to titanium between 0.8 and 0.88; adding into carbon or powder former body of the carbon; carrying out an even mixing for 5 to 72 hours in a medium and then drying the mixture; carrying out treatment for 2 to 20 hours under the temperature between 200 and 500 DEG C; then synthesizing for 2 to 72 hours under the temperature between 600 and 900 DEG C, to acquire spinel-structure lithium titanate for the negative electrode materials of the lithium ion batteries. Adopting the cheap metatitanic acid as the raw materials and adding into the carbon or powder former body of the carbons, the method for preparing spinel lithium titanate for the negative electrode materials of the lithium ion batteries realizes the synthesis of spinel-structure lithium titanate with grains diameter less than 500 nanometers under lower temperatures and greatly improves the rate capacity, while the traditional high-temperature solid state method, with a sintering temperature generally between 800 and 100 DEG centigrade, only produces larger lithium carbonate particles at micron levels. With simple technique and strong operability, the method for preparing spinel lithium titanate for the negative electrode materials of the lithium ion batteries is easy to realize large-scale production.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Composite graphite cathode material and preparation method thereof

ActiveCN104609400AImprove cycle performanceGood high current charge and discharge performanceCell electrodesCarbonizationGraphite particle

The invention discloses a composite graphite cathode material and a preparation method thereof. The composite graphite cathode material comprises graphite particles a and b, wherein the graphite particles a are secondary artificial graphite particles formed by granulating, coating and bonding oil-based petroleum coke; the graphite particles b are secondary composite graphite particles, adopting core-shell structures, formed by removing impurities from small-particle diameter natural graphite balls, and spherodizing, coating and bonding the small-particle diameter natural graphite balls; the composite graphite material is prepared by mixing the graphite particles a and b, adding a binding agent, coating, bonding and performing high temperature carbonization. By compounding the two secondary graphite particles with different characteristics to prepare the composite graphite material, the capacity of graphite is improved and the problems that the graphite is poor in rate capability, poor in high-current charge and discharge performance, poor in compacting performance are solved.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

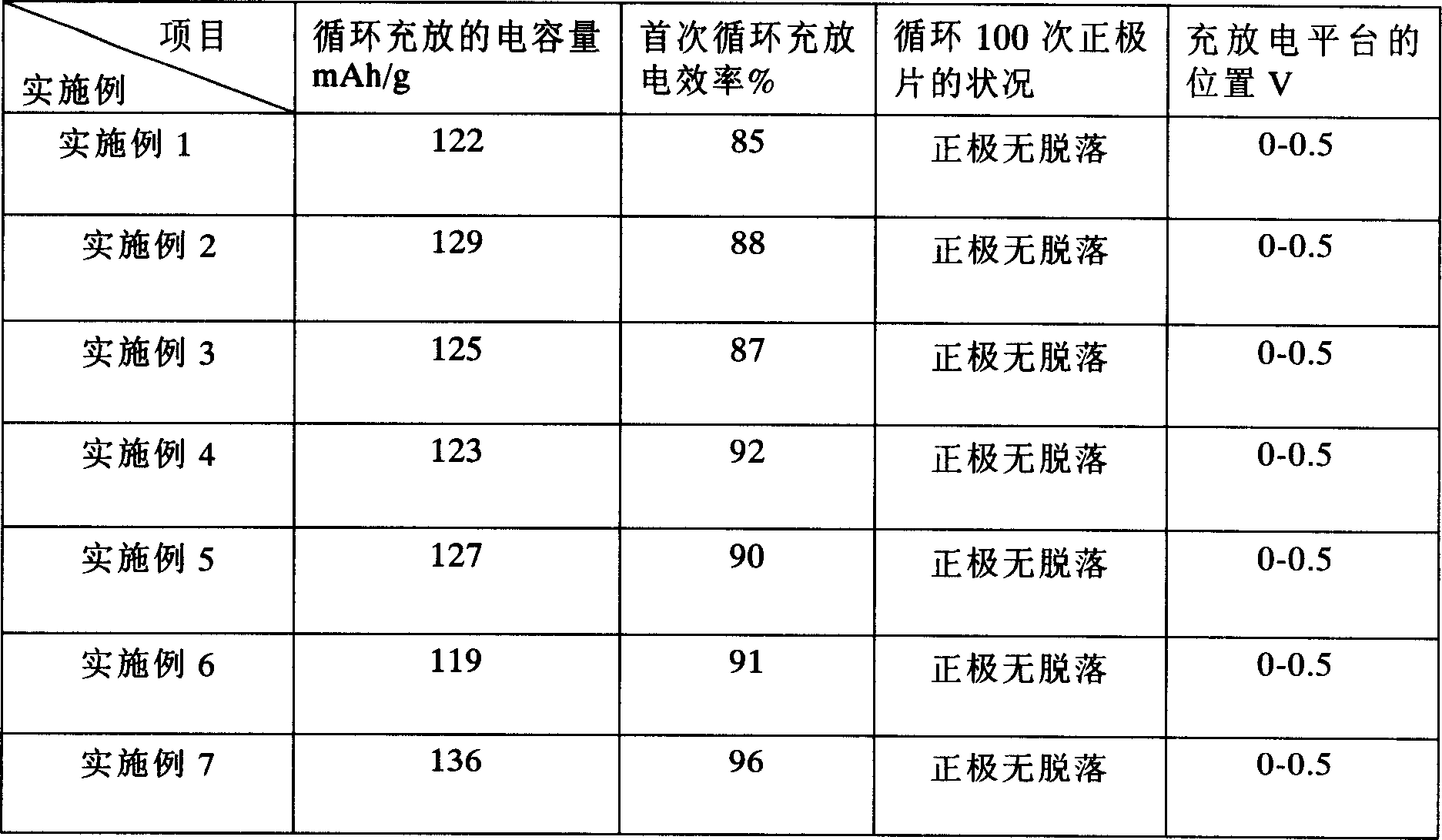

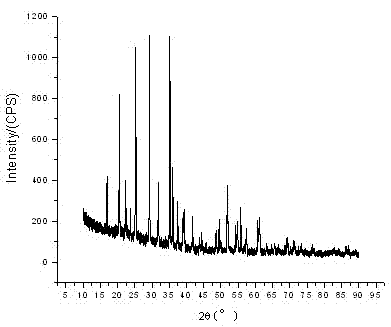

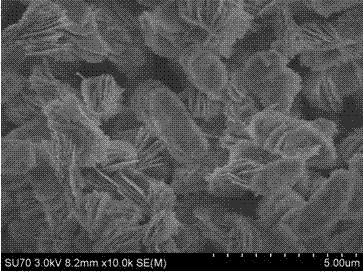

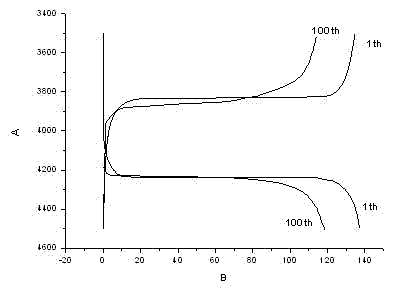

Preparation method of LiFePO material, lithium ion battery and positive plate thereof

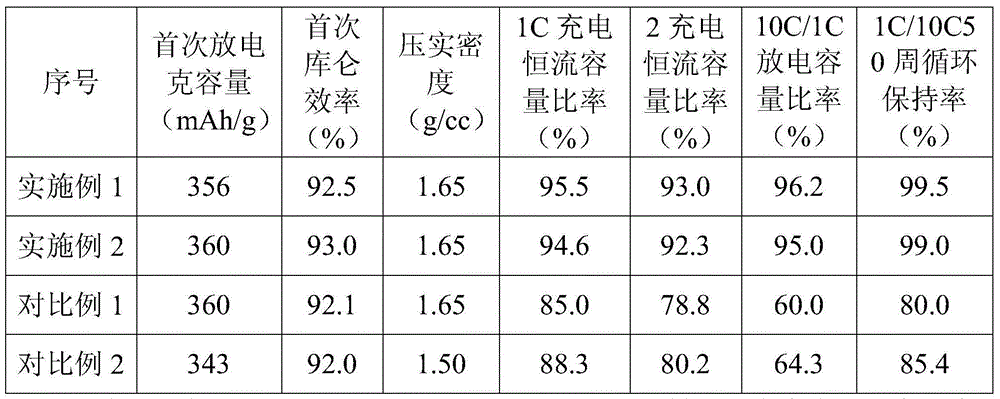

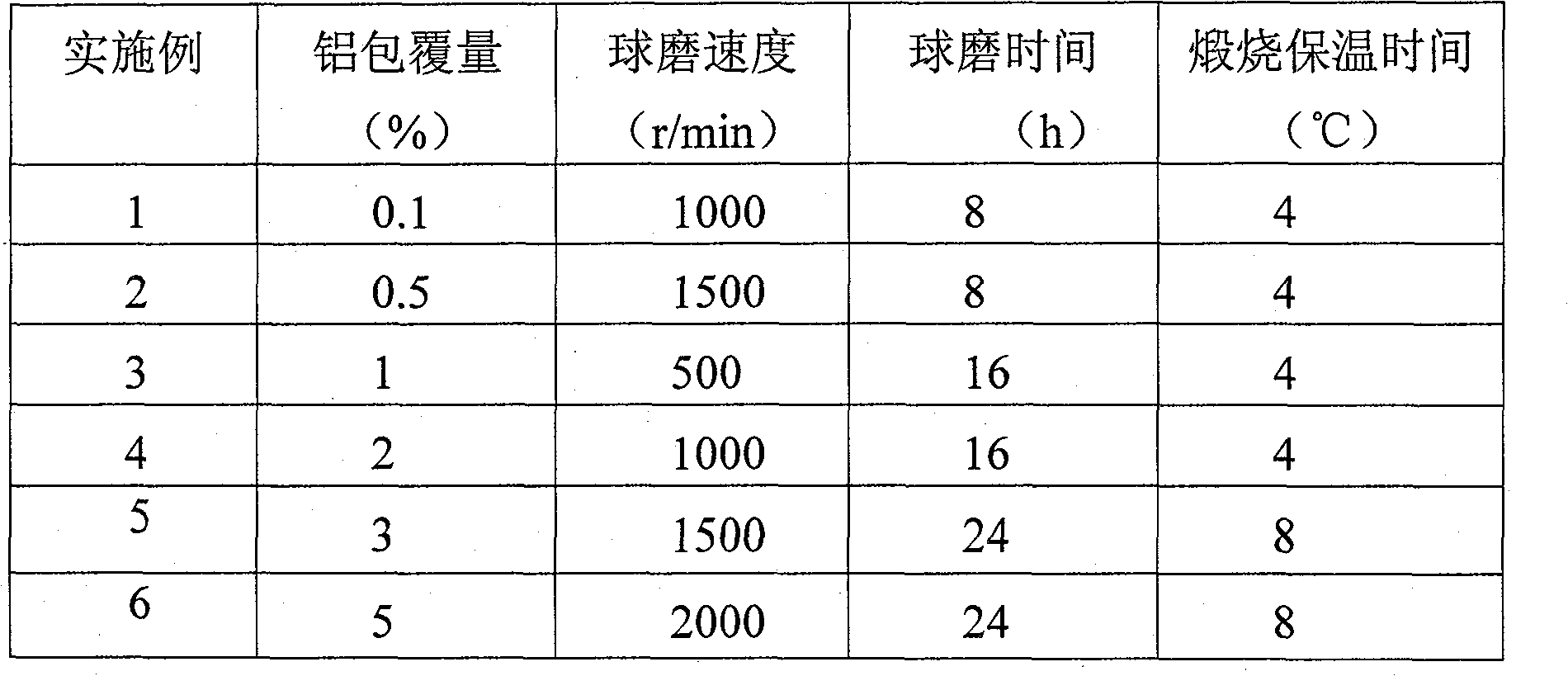

ActiveCN101891179ALower internal resistanceImprove high current charge and discharge performanceCell electrodesSecondary cellsAluminium-ion batteryInternal resistance

The invention discloses a preparation method of a LiFePO material, a lithium ion battery using the material and a positive plate thereof. The preparation method comprises the following steps: sintering to prepare LiFePO powder; cladding aluminum on the surface of the LiFePO powder particle to form a LiFePO-Al composite material. Compared with the prior art, the LiFePO material prepared by the invention and the cladding aluminum can carry out homodisperse and surface cladding at the molecule level; the conductivity of the electrode plate prepared by the invention is improved by 101-10001 times; and the internal resistance of the LiFePO lithium ion battery is reduced greatly, and the large-current charge-discharge property is obviously improved, thus the material is particularly suitable for a high power lithium ion battery. Compared with the other cladding elementary metal, Al metal is cheaper, has lighter mass, lower melting point, more stable electrochemistry property and the like; and in additional, the aluminum in the composite material and a positive pole current collector are made of the same material, so that primary battery corrosion effect can not be formed.

Owner:STARZEON ELECTRONICS DONGGUAN +1

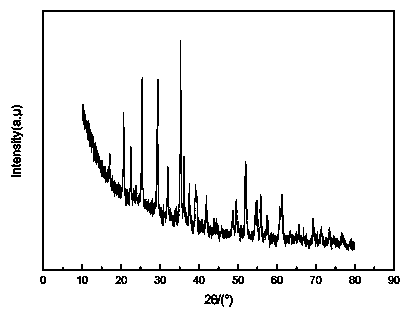

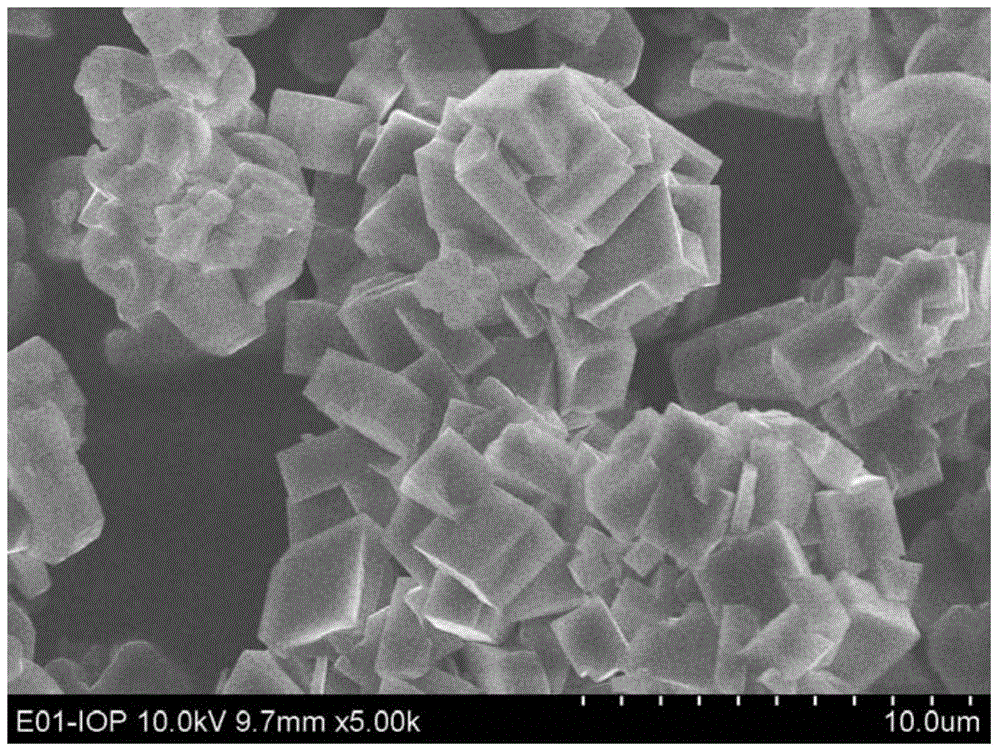

Preparation method for manganese phosphate lithium nanosheet

InactiveCN102903918AGood dispersionFacilitated DiffusionCell electrodesMANGANESE ACETATEPolyethylene glycol

The invention relates to a preparation method for a manganese phosphate lithium nanosheet. According to the preparation method, glycol and water are used as a solvent, and polyethylene glycol is introduced, so that the formation of crystal nucleus and the growth of crystal are influenced, and as a result, the thermosynthesis of the solvent of the manganese phosphate lithium nanosheet can be achieved. The preparation method comprises the following steps of: dissolving ascorbic acid in the water / glycol solvent; then dissolving into phosphoric acid and manganese acetate in sequence; dropwise adding the water / glycol solution of manganese acetate to the previous solution containing phosphoric acid, lithium acetate and ascorbic acid; then introducing proper polyethylene glycol; fully mixing to obtain a precursor for water / solvent thermal reaction; transferring the precursor into a reaction kettle system to be sealed; thermally processing at 160 to 240 DEC G; and carrying out thermal reaction to the solvent to obtain the manganese phosphate lithium nanosheet. By adopting the preparation method, products are stable in quality, high in purity and high in dispersion of particles; the lithium ions can be dispersed well; the electrochemical performance of a lithium ion battery can be improved; and the preparation method is simple in technical process, easy to control, free of pollution, low in cost, and easy for mass production.

Owner:ZHEJIANG UNIV

Anode material for lithium ion battery and preparation method thereof

InactiveCN102354748AImprove conductivityImprove high current charge and discharge performanceCell electrodesTitanium compoundsLithium electrodeLithium battery

The invention discloses a preparation method of an anode material for a lithium ion battery, which comprises the following steps of: mixing titanium dioxide with lithium carbonate to be ball-milled evenly, carrying out heat preservation for 10-180 minutes at the temperature of 750-850 DEG C and cooling to obtain lithium titanate; and mixing the lithium titanate with a solid-state nitrogen source compound to be calcined with the protection of protective gas, and obtaining the anode material for the lithium ion battery after reaction. In the step of preparing the lithium titanate, the time for heat preservation of raw materials at high temperature is greatly shortened, the aggregation of material particles caused by long-time ignition is avoided, the particle size of the lithium titanate is greatly reduced, and the modification area of TiN after the lithium titanate is nitrided is increased, so that the conductivity performance of the prepared anode material for the lithium ion battery is improved. In addition, due to the reduction of the particle size of the lithium titanate, the migration distance of lithium ions in a charge-discharge process of the lithium ion battery is reduced, and thus the large current charge-discharge performance of the anode material for the lithium ion battery is improved.

Owner:SUZHOU UNIV

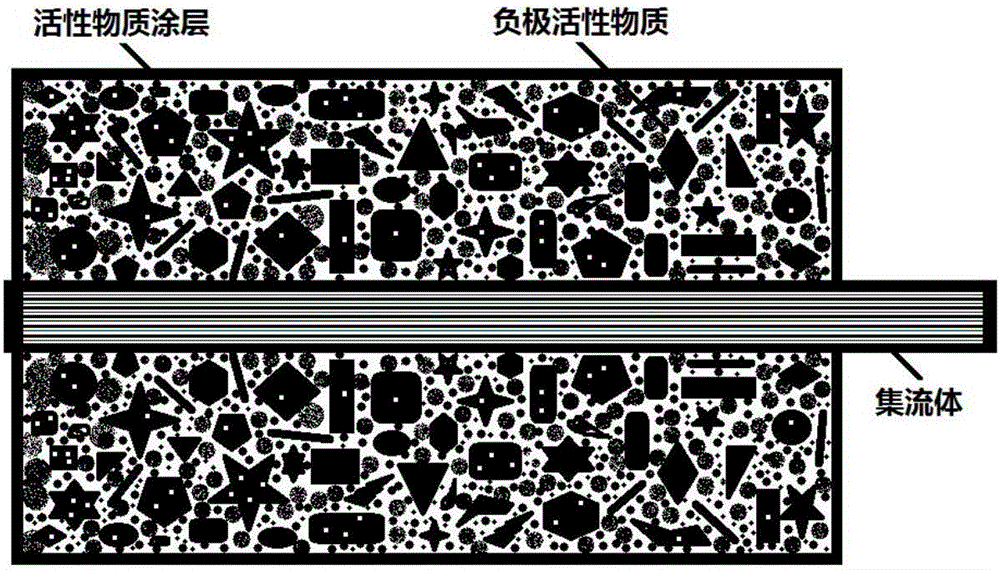

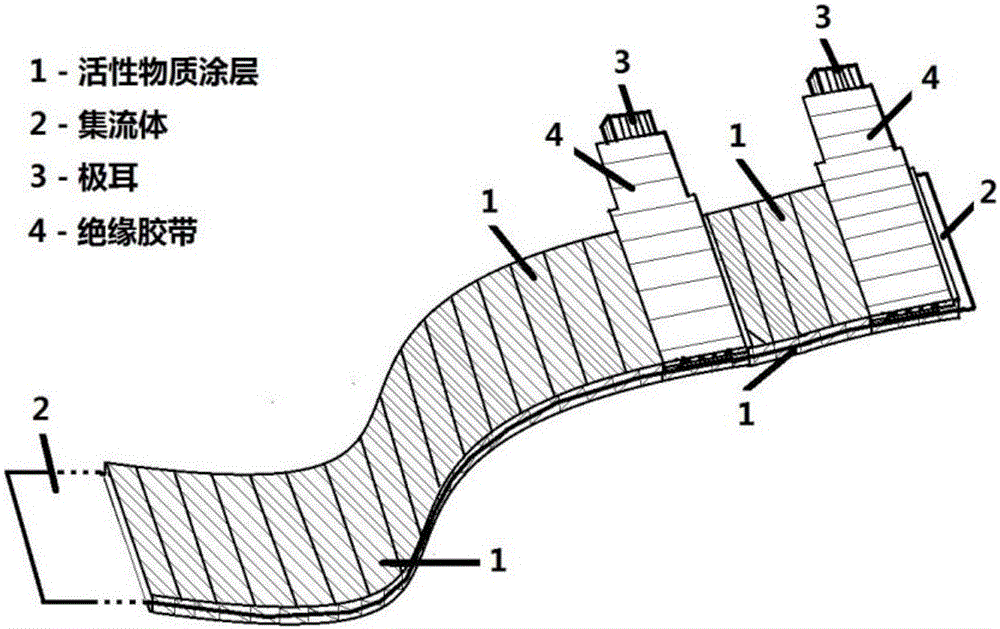

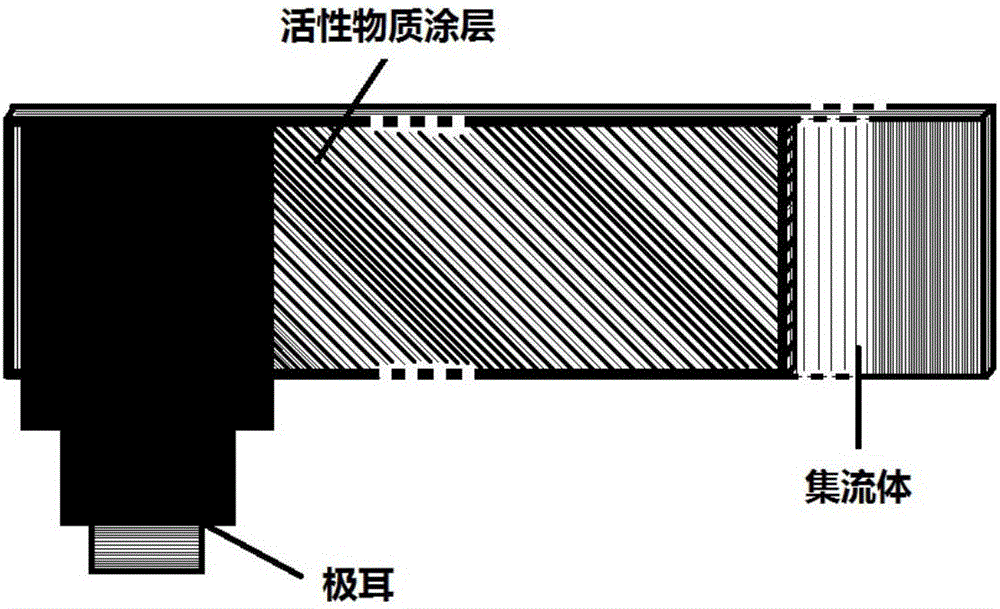

Manufacturing method of negative plate of safety lithium-ion battery

InactiveCN106450169AGood thermal stabilityStable performance during charge and discharge cyclesSecondary cellsElectrode collector coatingCopper foilCurrent collector

The invention discloses a manufacturing method of a negative plate of a safety lithium-ion battery. The method comprises the steps of mixing a negative active material with a conductive agent at a certain mass ratio to obtain a mixture A; carrying out ball-milling and mixing on an additive B and the mixture A at a certain mass ratio to form a mixture C; preparing a certain mass percent of water solution from CMC which accounts for a certain mass ratio of the mixture C, carrying out constant-temperature stirring, adding an SBR which accounts for a certain mass ratio of the mixture C in batches, simultaneously adding an NMP which accounts for a certain ratio of the mixture C and carrying out constant-temperature stirring to form a sizing material D; adding the mixture C to the sizing material D in batches, controlling the solid content of the mixture C and stirring to obtain slurry; adding a proper amount of water, adjusting, controlling the viscosity and stirring to obtain negative slurry E; employing copper foil as a current collector F, intermittently coating a single side or double sides of the current collector F with the negative slurry E, reserving a certain current collector, carrying out drying, controlling the surface density, carrying out rolling and controlling the compactness and the thickness of the negative plate; and dividing, cutting, welding and pasting a tab adhesive tape to obtain the negative plate of the safety lithium-ion battery. The lithium-ion battery assembled by the negative plate has good electric cycle performance and safety performance.

Owner:HUBEI UEE ENERGY TECH CO LTD

Method for producing active substance ferrous lithium phosphate as lithium-ion battery anode

ActiveCN1982208AEasy to operateEasy to controlCell electrodesPhosphorus compoundsPhysical chemistryLITHIUM PHOSPHATE

Production of lithium-ion battery positive active substance ferro-lithium phosphate is carried out by mixing polymer, phosphate-source compound with ferro-source compound and lithium-source compound in solution, sintering to obtain the mixed solution, removing solvent to obtain the gel and sintering. It's simple and convenient, the battery has excellent discharge capacity and circulation performance, and the ferro-lithium phosphate is solid, homogeneous and has better conductivity.

Owner:BYD CO LTD

Preparation method of hierarchical pore carbon foam used for supercapacitor electrode

InactiveCN103449396AExcellent electrochemical performanceImprove high current charge and discharge performanceCarbon preparation/purificationParaffin waxCapacitance

The invention relates to a preparation method of a hierarchical pore carbon foam used for a supercapacitor electrode. The method comprises: firstly taking formaldehyde, resorcinol, silicon dioxide nanoparticles and water according to a mass ratio of 1:1-2:0.1-1:0.5-10, mixing them uniformly and taking the mixture as a water phase; adopting liquid paraffin as an oil phase, using Span 80 and Tween 80 as emulsifiers, weighing Span 80, Tween 80, the oil phase and the water phase according to a mass ratio of 2:3:8-20:15-30, mixing the water phase, the oil phase and the emulsifiers under stirring to obtain an oil-in-water type emulsion, adding a catalyst to solidify make the emulsion, conducting drying, then performing high temperature carbonization, removing the silicon dioxide nanoparticles from the carbonized material by dissolution in an HF solution with a mass percent of 40%, thus obtaining carbon foam, mixing the carbon foam with KOH in a mass ratio of 3-7:1, then conducting activation at 800-1000DEG C, thus obtaining the hierarchical pore carbon foam. When the hierarchical pore carbon foam provided in the invention is used as a supercapacitor electrode, high specific capacitance can be effectively maintained, and simultaneously the large current charge-discharge performance of the electrode can be improved.

Owner:TONGJI UNIV

Lithium manganese phosphate nano-ellipsoids and preparation method thereof

InactiveCN104183847AGood dispersionFacilitated DiffusionMaterial nanotechnologyCell electrodesMANGANESE ACETATEPhosphoric acid

The invention discloses lithium manganese phosphate nano-ellipsoids. The nano-ellipsoids are mono-like prepared from lithium manganese phosphate monocrystal particles with the diameter of 3-6nm, and have the major diameter of 0.8-2.8 microns and the minor diameter of 0.5-1.8 microns. A preparation method of the nano-ellipsoids comprises the steps that a solvent, required for solvent thermal reaction, is prepared from ethylene glycol, manganese acetate, lithium acetate and phosphoric acid are taken as reacting materials, potassium hydroxide is taken as a mineralizer, so as to promote nucleation and growth, heat treatment is carried out at high temperature and high pressure, and then, the lithium manganese phosphate nano-ellipsoids are obtained. The lithium manganese phosphate nano-ellipsoids and the preparation method thereof have the advantages that the lithium manganese phosphate nano-ellipsoids are stable in quality, high in purity and good in particle dispersibility and are beneficial to the diffusion of lithium ions and the improvement of the electrochemical properties of a lithium-ion battery, and the preparation process is simple in process, easy to control and low in cost and is pollution-free, so that the large-scale production is facilitated.

Owner:ZHEJIANG UNIV

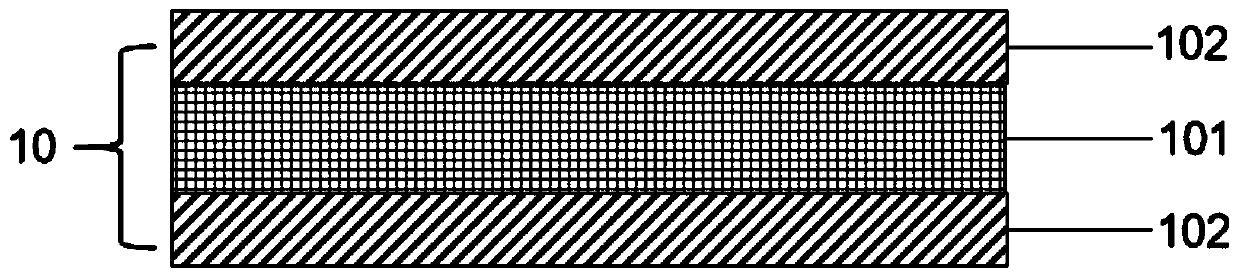

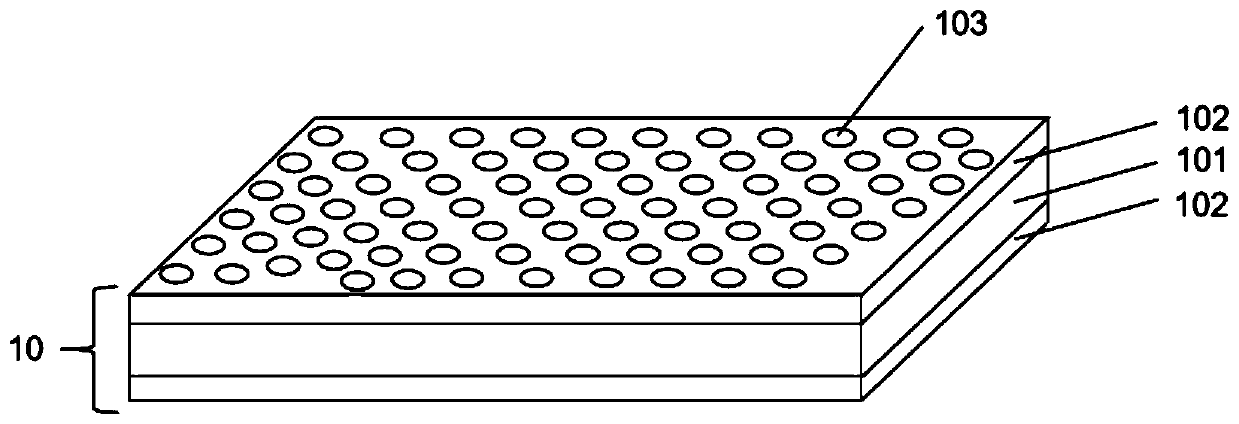

Ultra-light conductive current collector

InactiveCN111384404AReduce weightIncrease energy densityElectrode carriers/collectorsLithium-ion batteryPolymer

The invention belongs to the technical field of lithium ion batteries, and particularly relates to an ultra-light current collector. The ultra-light conductive current collector is characterized in that the current collector is of layered porous structure and formed by laminating a supporting layer and a conductive enhancement layer, the supporting layer is a polymer PTC plastic film, the conductive enhancement layer is a graphene film, and after the graphene film is deposited on the polymer PTC plastic film, laser drilling is carried out to form the graphene / polymer PTC plastic film current collector with the layered porous structure. According to the current collector provided by the invention, the mass of the battery current collector can be effectively reduced, and the thermal runawayprobability of the battery in case of short circuit or over-high temperature can be reduced.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

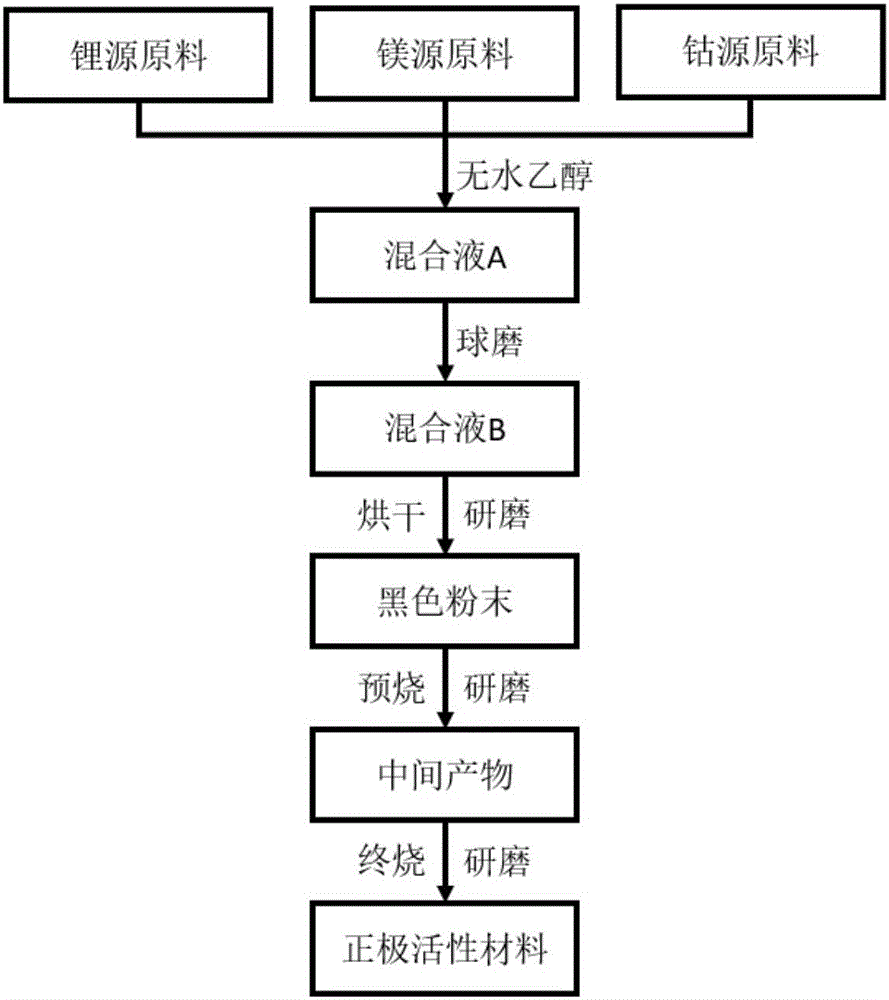

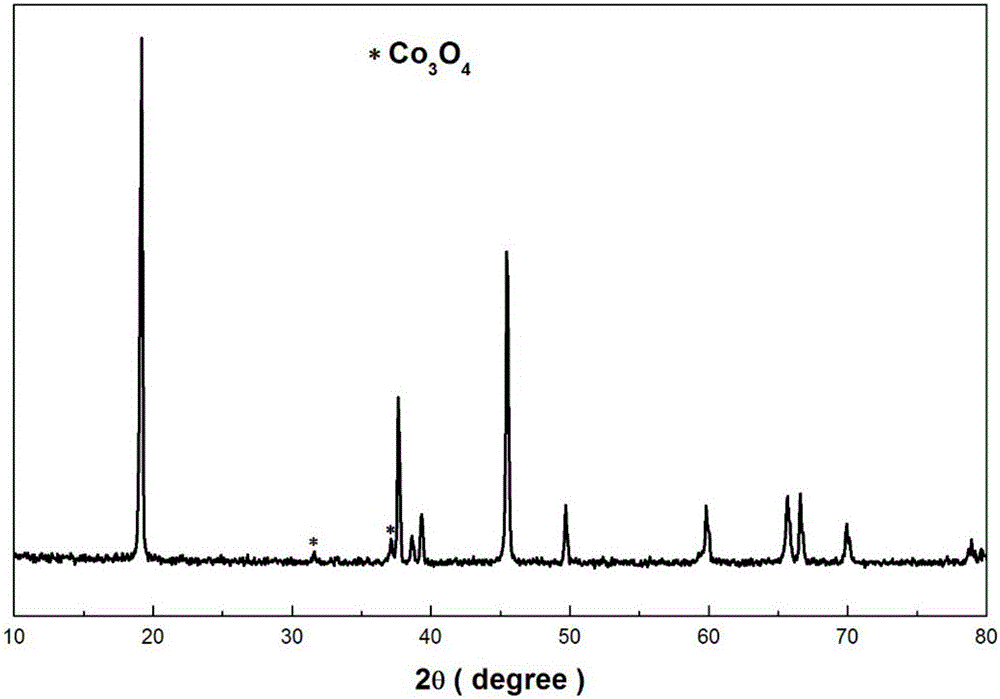

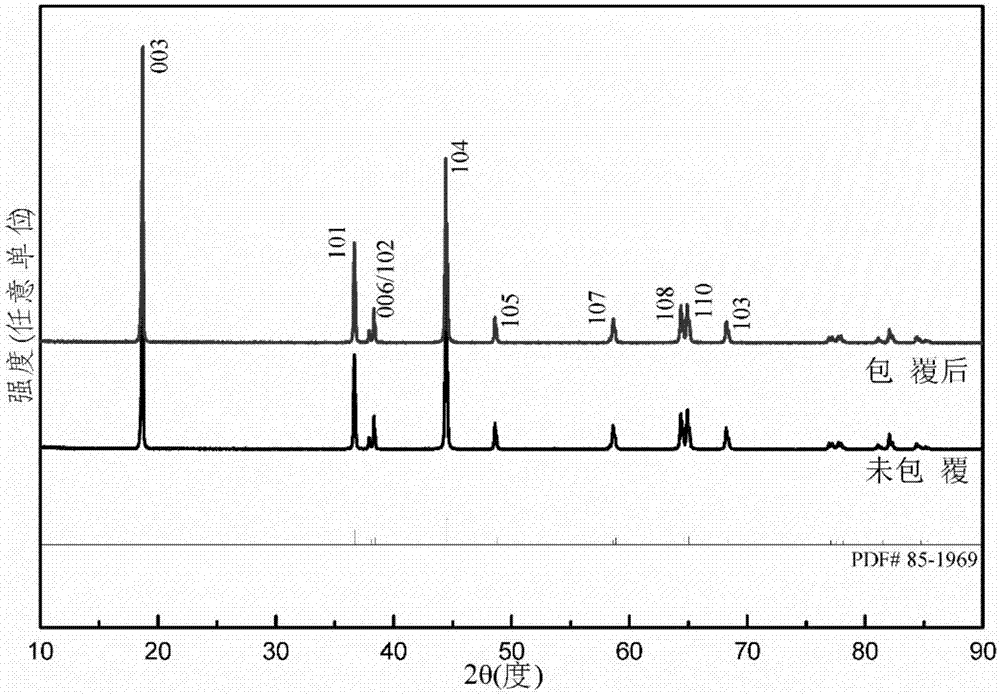

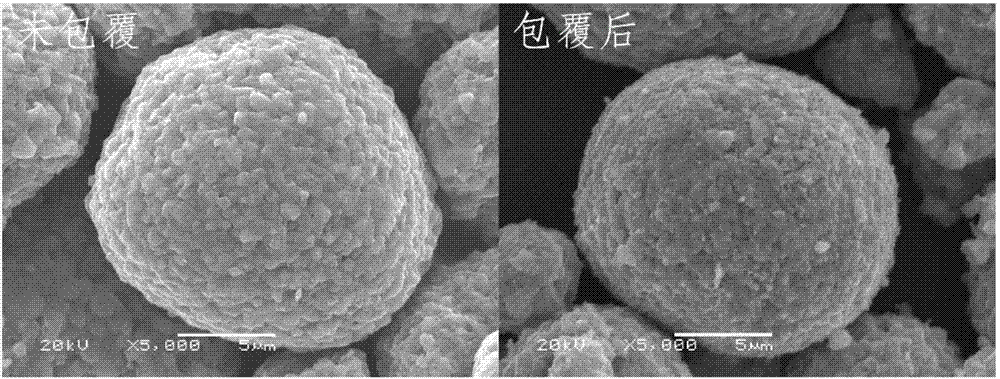

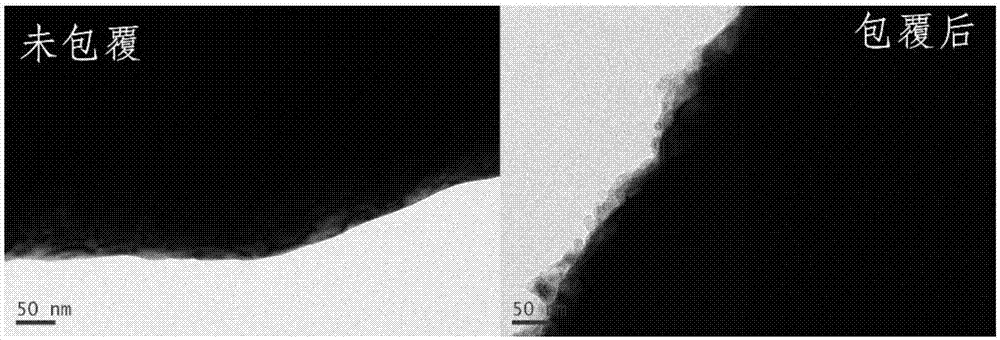

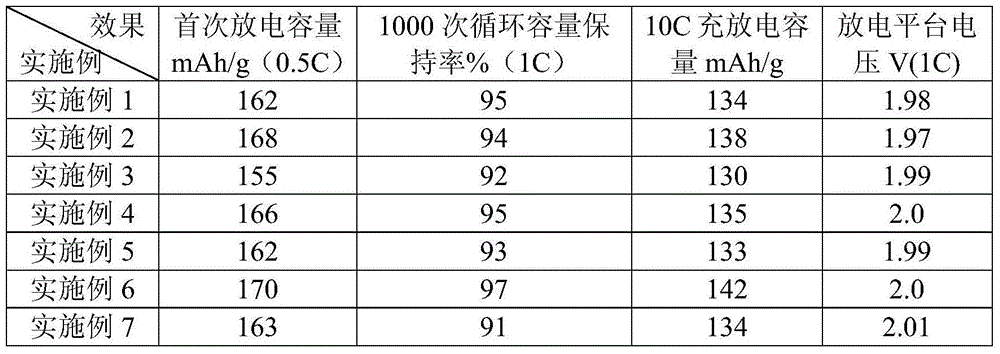

High-voltage cathode material Li delta Co(1-x)MgxO2@AlF3 of lithium ion battery and preparation method of high-voltage cathode material

ActiveCN106099098AImprove conductivityImprove high current charge and discharge performanceCell electrodesHigh voltage cathodeLithium electrode

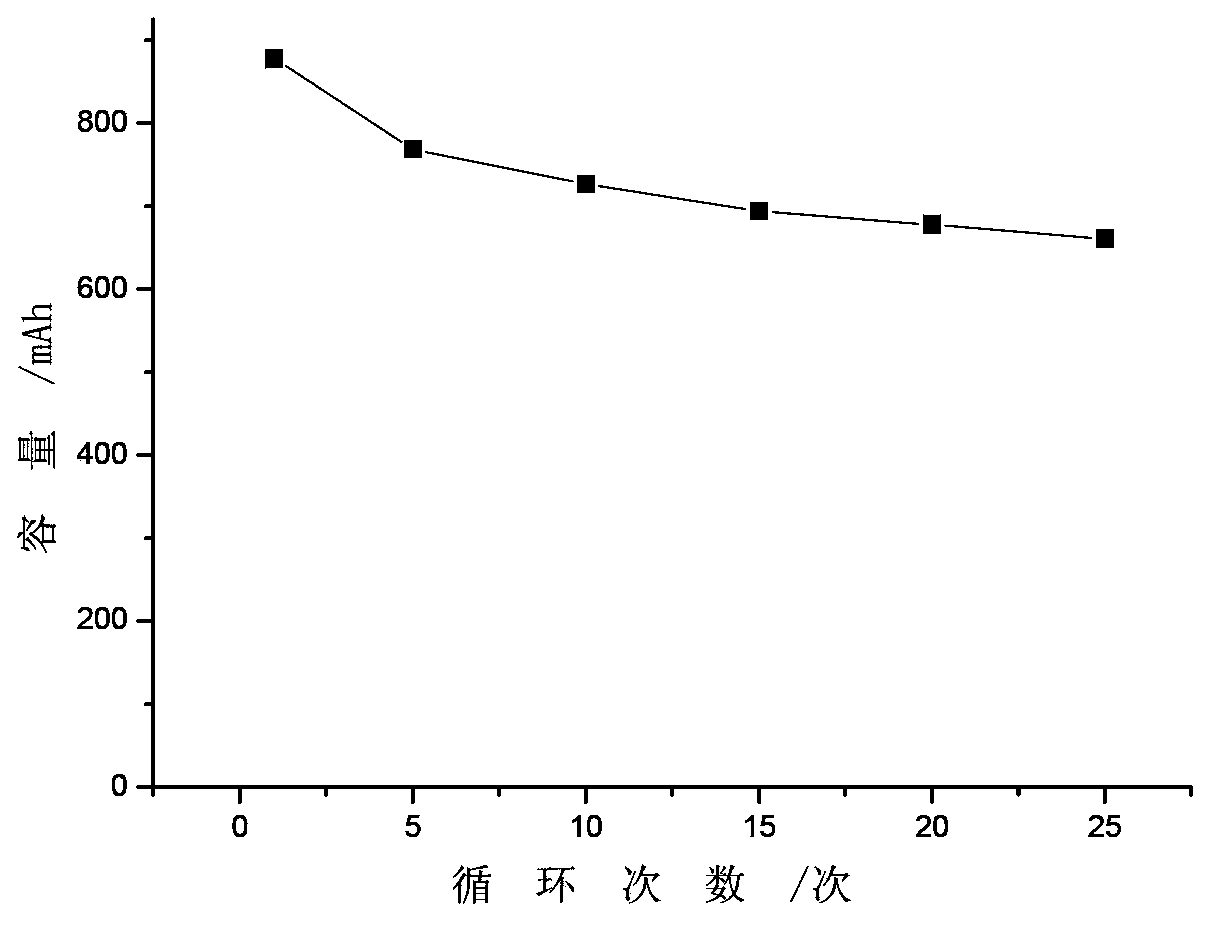

The invention belongs to the field of lithium ion batteries, and provides a cathode material Li delta Co(1-x)MgxO2@AlF3 of a lithium ion battery and a preparation method of the cathode material. According to the cathode material Li delta Co(1-x)MgxO2@AlF3, delta is larger than or equal to 1 and smaller than or equal to 1.05, x is larger than 0 and smaller than or equal to 0.05, and the defect of poor electrochemical performance of laminar LiCoO2 under high potential is overcome. The bulk-phase doping modification and surface coating combined laminar cathode material Li delta Co(1-x)MgxO2@AlF3 has higher specific discharge capacity and very stable circulation performance; at the room temperature, at 0.5 C rate and within the charge-discharge voltage range of 2.75-4.4 V (vs.Li / Li<+>), the first specific discharge capacity can reach 187.6 mAh / g, the 3.8V platform capacity approaches 100%, the capacity can reach 180 mAh / g after 30 times of circulation, and the capacity retention ratio is 96%. Besides, the provided material preparation method adopts a simple preparation process, the preparation cost is low, and large-scale industrial production is easy to realize.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

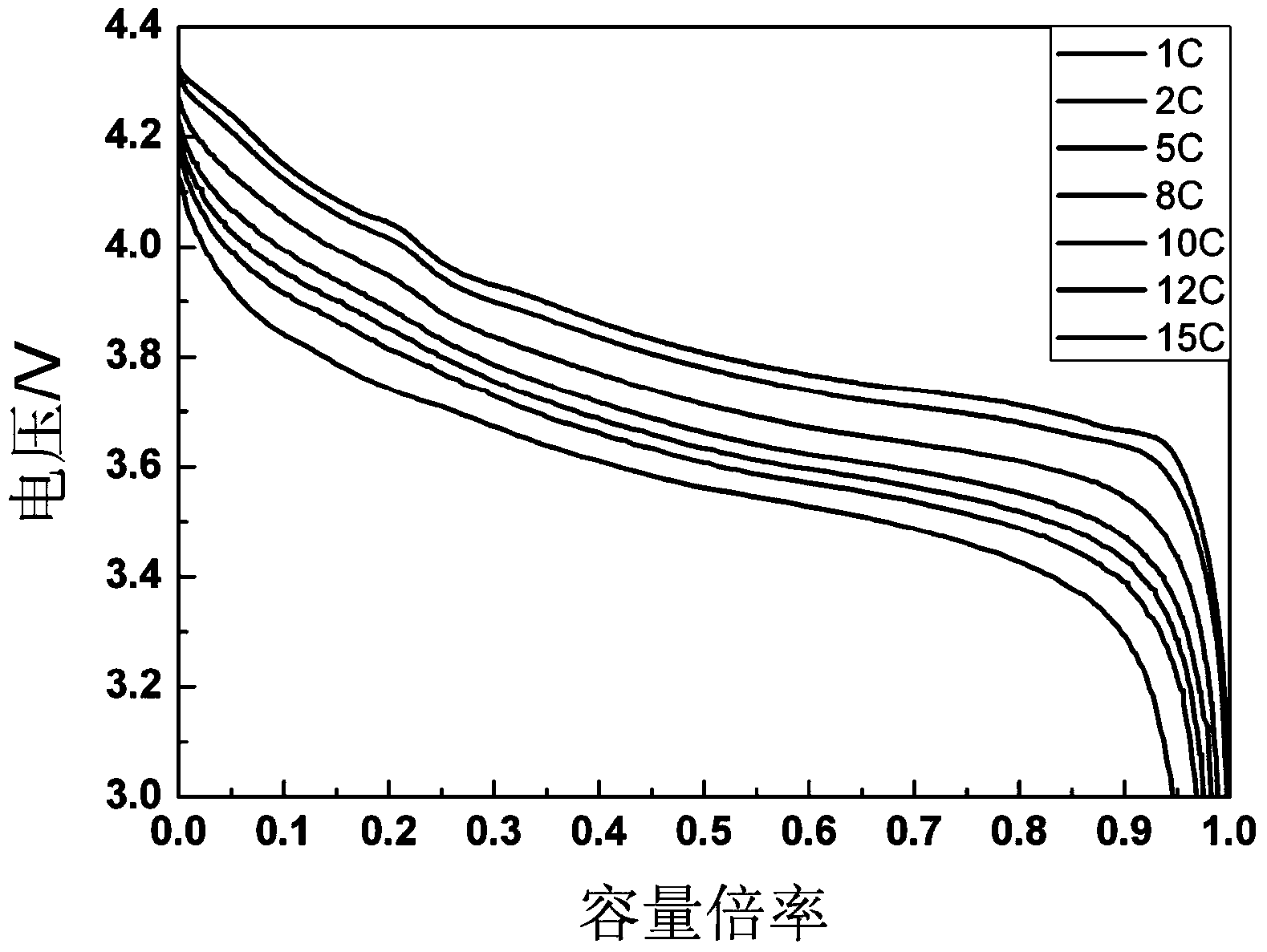

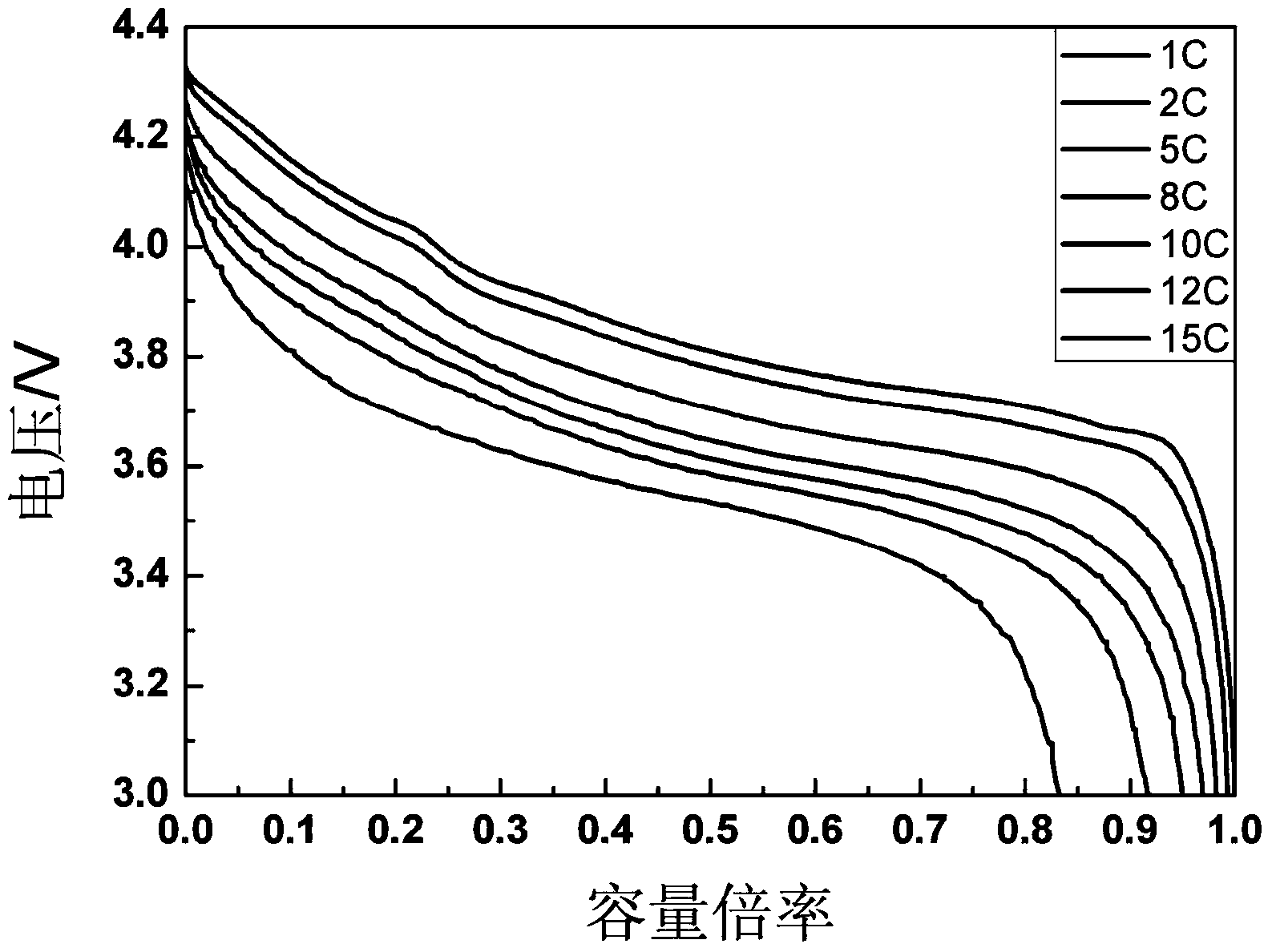

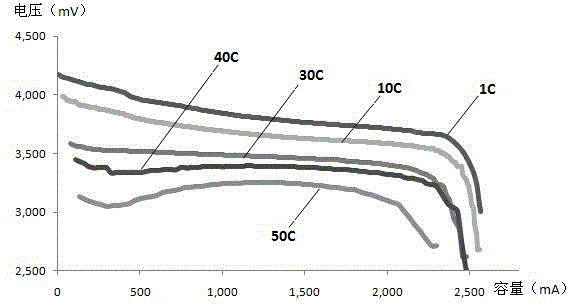

Lithium ion battery with high-rate charge-discharge performance

InactiveCN104900908AImprove conductivityImprove high current charge and discharge performanceSecondary cellsNegative electrodesHigh rateAluminium-ion battery

The invention discloses a lithium ion battery with high-rate charge-discharge performance. According to the lithium ion battery, high-rate lithium cobalt oxide is taken as an anode, high-rate intermediate carbon microspheres are taken as a cathode, and graphene is taken as a conductive additive. Cathode and anode material systems with the high-rate properties are adopted, the surface density and the compaction density of pole pieces of the anode and the cathode are controlled, high conductivity of the pole pieces is guaranteed, and the high-current charge-discharge performance of the battery is improved. The graphene with the high conductivity is taken as the conductive additive, the defect that the proportion of active materials for the anode and the cathode is reduced due to heavy addition of a conventional conductive additive is overcome, and the volume energy density of the battery is increased. An electrolyte containing a PC (polycarbonate) solvent with a high solidifying point and high electric conductivity is adopted, so that the heat dissipation problem of the battery under the high-current charge and discharge condition is effectively solved, and the cyclic stability of the battery is further guaranteed. The lithium ion battery is simple in process, and the performance of the prepared lithium battery is excellent.

Owner:田东

Composite positive elelectrode material of lithium ion cell and its prepn. method

InactiveCN1564347AEffect of Small Volume Energy DensityLittle change in tap density before and afterElectrode manufacturing processesSecondary cellsLithiumReducing agent

Molecular formula of composite anode material is as following: LiMxFe1-x / (C+M'), where M is Co, Mn, Cr, Ni, Cu, Ag or Au; M' is Co, Mn, Cr, Ni, Cu, Ag or Au, 0 C01D 15 / 02 C01G 1 / 02 H01M 4 / 04 H01M 4 / 48 H01M 4 / 58 0 8 2 2004 / 3 / 15 1564347 2005 / 1 / 12 000000000 Huanan Tech Univ. Guangzhou 510640 Zhou Zhentao Lu Zhengzhong yu xiaomeng 44102 The Patent Agency of Guangdong Provincial Institutions of High learning No.72 Nonlinxia Road, the City of Guangzhou, Guangdong Province 510080

Owner:SOUTH CHINA UNIV OF TECH

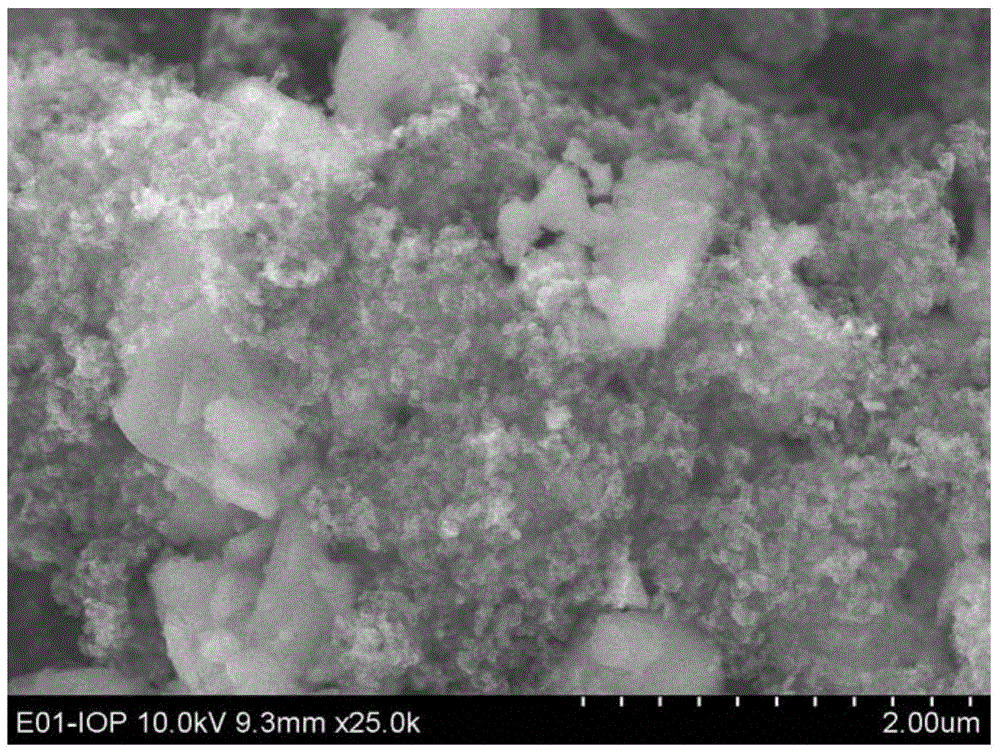

Lithium manganese phosphate nanoparticles and preparation method thereof

InactiveCN104183845AGood dispersionFacilitated DiffusionMaterial nanotechnologyCell electrodesArgon atmospherePhosphoric acid

The invention discloses lithium manganese phosphate nanoparticles. The nanoparticles have the size of 50-100nm. A preparation method of the nanoparticles comprises the steps that a solvent, required for solvent thermal reaction, is prepared from ethylene glycol, manganese acetate tetrahydrate, lithium acetate dihydrate and phosphoric acid are taken as reacting materials, P123 is taken as a surfactant, so as to influence nucleation and growth, heat treatment is carried out at high temperature and high pressure, then, segmented calcining is carried out at the temperature of 300-400 DEG C and 550-650 DEG C under the protection of a nitrogen or argon atmosphere, and then, the lithium manganese phosphate nanoparticles are obtained. The lithium manganese phosphate nanoparticles and the preparation method thereof have the advantages that the product is stable in quality, high in purity and good in particle dispersibility and is beneficial to the diffusion of lithium ions and the improvement of the electrochemical properties of a lithium-ion battery, and the preparation process is simple in process, easy to control and low in cost and is pollution-free, so that the large-scale production is facilitated.

Owner:ZHEJIANG UNIV

Nickel-based material, preparation method of nickel-based material, and lithium ion battery

InactiveCN106876697AImprove stabilityImprove thermal stabilityCell electrodesSecondary cellsOrganic solventSilanes

The invention provides a nickel-based material. The nickel-based material comprises a core material represented by the FORMULA (I) and a Li<4>SiO<4> coating layer coated on the surface of the core material. The invention further provides a preparation method of the nickel-based material. The preparation method of the nickel-based material comprises the following steps of: mixing methyl silane with an organic solvent, then, adjusting the pH value, and reacting to obtain coating liquid; mixing the coating liquid with a precursor material represented by the FORMULA (II) to stir, so that an initial nickel-based material is obtained; and, performing high-temperature solid-phase reaction after mixing the initial nickel-based material with lithium salt, so that the nickel-based material is obtained. Li<4>SiO<4> is coated on the surface of the core nickel-based material; the obtained nickel-based material is used as the cathode material; and thus, a lithium ion battery has better cycle performance and rate capability.

Owner:四川浩普瑞新能源材料股份有限公司

Composite lithium titanate preparation method

InactiveCN105406051AImprove conductivityIncrease the effective reaction areaCell electrodesLithiumOrganic solvent

The invention relates to a composite lithium titanate preparation method, which comprises: 1) uniformly mixing a lithium source compound, a titanium source compound and the compound of a doped modifier M according to a molar ratio of Li to Ti to M of (0.6-1):1:(0.06-0.3), dispersing in an organic solvent, carrying out ball milling for 6-12 h, sintering for 6-12 h at a temperature of 80-120 DEG C, and drying; 2) carrying out a heat treatment on the dried product obtained in the step 1) for 8-20 h at a temperature of 400-600 DEG C, and naturally cooling; and 3) carrying out mixing ball milling on the treated material obtained in the step 2) and a cladding material for 6-12 h according to a weight ratio of 100:(5-20), sintering for 8-20 h at a temperature of 700-950 DEG C under the protection of nitrogen, cooling, and screening with a 300 mesh sieve. According to the present invention, the preparation method has characteristics of rapid reaction, high product purity, low cost, and easy large-scale industrial production achieving.

Owner:HENAN KELONG NEW ENERGY CO LTD

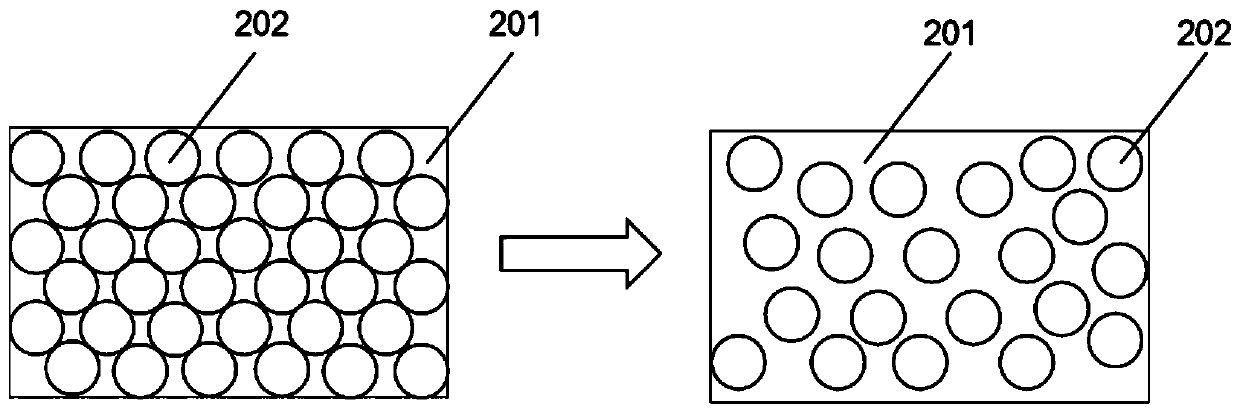

Quick-charging and safe low-temperature lithium ion battery and manufacturing method thereof

InactiveCN111370752AIncrease contact areaEliminate the "partition wall effect"Final product manufactureSecondary cellsInternal resistanceFast charging

The invention discloses a quick-charging and safe low-temperature lithium ion battery and a manufacturing method thereof. The battery is prepared by putting a dry battery cell into a shell, injectingelectrolyte, forming, sealing and grading capacity, and the dry battery cell is formed by winding a positive plate, a ceramic diaphragm, a negative plate and a ceramic diaphragm. The positive / negativeelectrode active substance is secondary micron particles formed by primary nanoparticles, and the nanoscale particles can effectively shorten the migration distance of lithium ions and improve the migration speed of the lithium ions in the charging and discharging process of the battery. Meanwhile, the multiple tabs led out from the positive and negative plates of the dry battery cell are gathered and then are welded with the planar metal sheet current collector to form a full tab. The internal resistance and the temperature rise of the battery in the charging process are effectively reduced,the problem of high-rate quick charging of the battery is solved, the high-current charging and discharging performance of the battery is improved, and the safety stability and the low-temperature electrochemical performance of the battery are also improved.

Owner:LONG POWER SYST NANTONG CO LTD

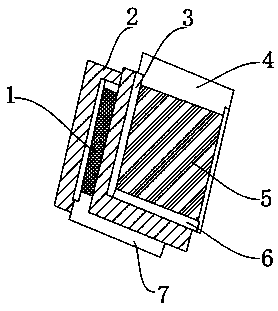

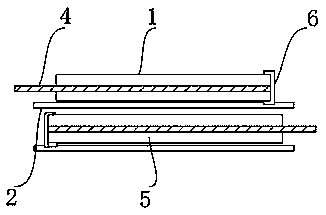

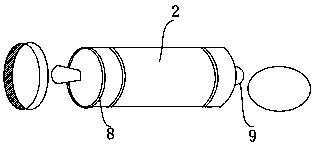

Soft pack lithium ion battery and manufacturing method of same

InactiveCN107293809AIncreasing the thicknessIncrease productivityFinal product manufactureCurrent conducting connectionsPower flowElectrical battery

The invention relates to a soft pack lithium ion battery including a cell assembly and a soft pack shell. The cell assembly comprises a plurality of single cell bodies, which are connected in parallel. Each single cell body is a coiled-type cell body. The thickness of the cell assembly is larger than 1 cm. The coiled-type cell body is higher in production efficiency and lower in production cost. Due to the structure that the single cell bodies are stacked in a parallel-connected manner, a problem of high internal resistance of the coiled-type cell body can be avoided. The structure also solves a problem of poor flatness frequently appearing in charge / discharge process of a thick coiled cell structure in later period, wherein the thickness of the cell assembly is larger than 1 cm when the single cell bodies are connected in parallel, so that the cell assembly is higher in capacity. The soft pack lithium ion battery is high in production efficiency and low in production cost, has high energy density, large capacity, and is improved in large-current charge / discharge performance. The invention also discloses a manufacturing method of the soft pack lithium ion battery.

Owner:GREE ELECTRIC APPLIANCES INC

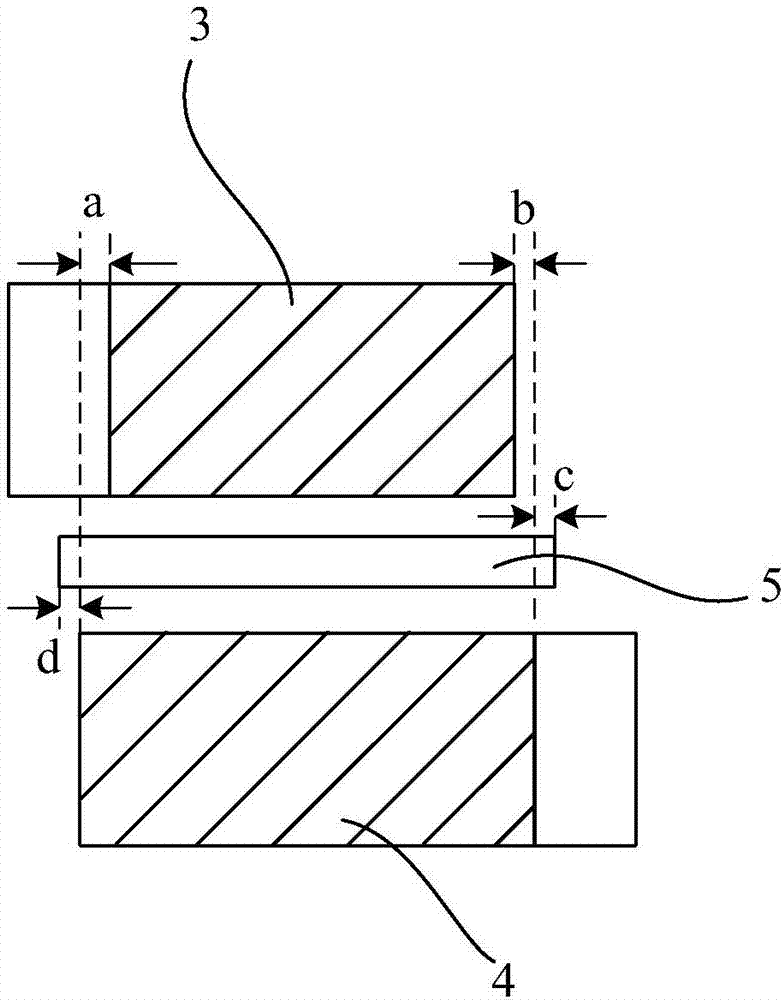

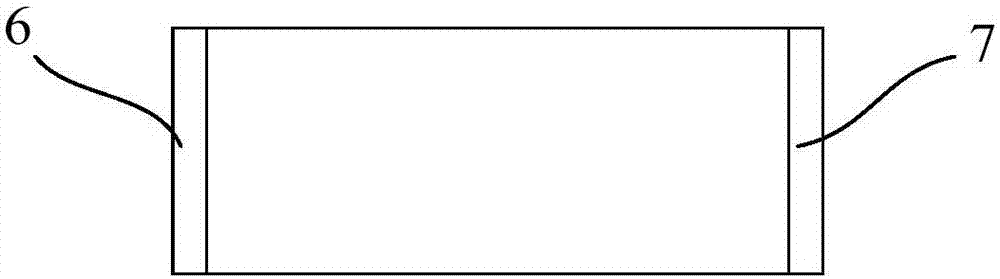

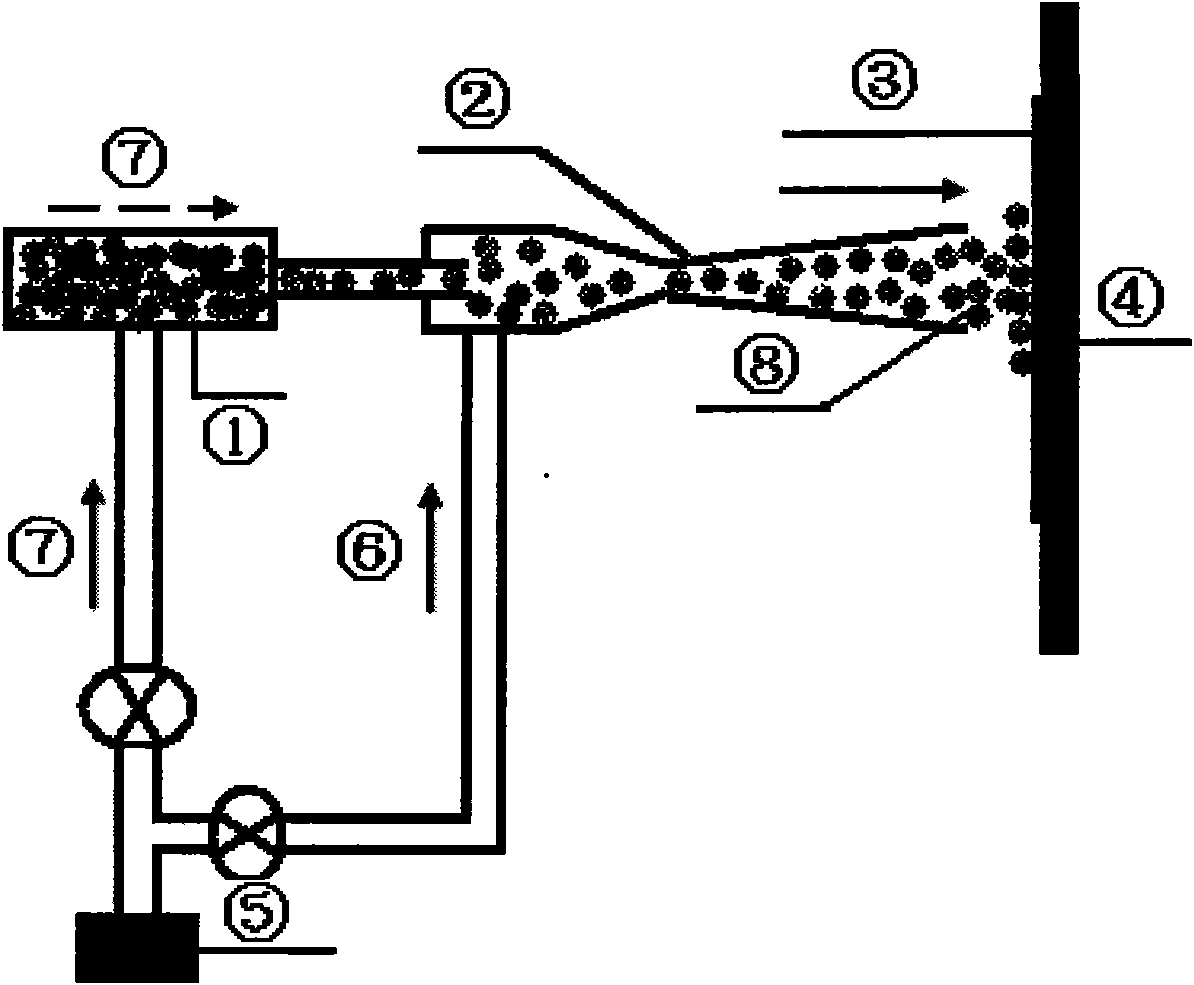

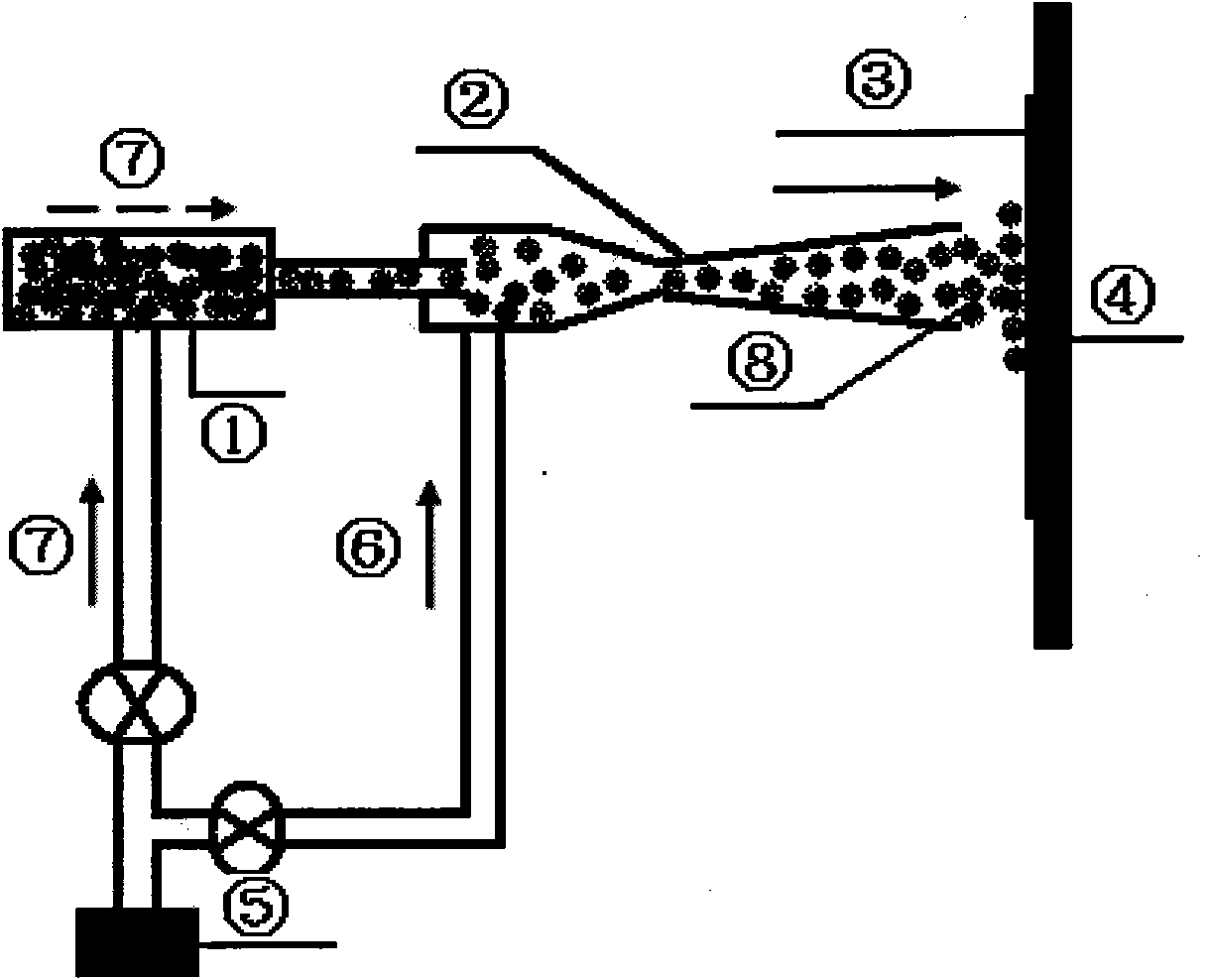

Preparation method for lithium ion battery anode piece, and anode piece prepared by the same

The present invention belongs to the technical field of lithium ion battery preparation, and discloses a preparation method for a lithium ion battery anode piece, and an anode piece prepared by the method. According to the present invention, a cold spray coating technology is adopted to deposit a mixture comprising an anode active material and a conductive agent on an anode current collector to prepare the lithium ion battery anode piece. With adopting the lithium ion battery anode piece prepared by the method of the present invention, the problems of cost and pollution of the anode piece preparation method in the prior art can be solved; the gap between the active material and the current collector, and the gap between the active material particles can be reduced so as to significantly reduce the porosity of the electrode piece, increase the bulk density, reduce the transmission distance of the electrons and the lithium ions in the active material particles, reduce the resistance of the internal resistance of the electrode piece, and improve the high-current charge-discharge performance of the lithium battery. At the same time, with adopting the lithium ion battery anode piece prepared by the method of the present invention, the surface roughness of the electrode piece can be increased, the polarizability of the electrode can be reduced, and the lithium ion battery prepared by using the lithium ion battery anode piece of the present invention has good cycle performance under the high current density.

Owner:甘肃大象能源科技有限公司

Polymer lithium ion battery preparation technique and products

ActiveCN101098025AReduce manufacturing costRealize large-scale productionFinal product manufactureSecondary cellsBoiling pointSlurry

The invention discloses a novel polymer lithium battery and a relative preparation method. The invention modifies the baffle membrane of general liquid lithium battery, adds chemical crosslink agent monomer with high boiling point into anode slurry and cathode slurry used for preparing liquid lithium battery, fills liquid lithium battery electrolyte with thermal initiator, to process thermal solidification, to obtain a novel polymer lithium battery. The invention can use general production process and device of prior liquid lithium battery, with the support for batch production of polymer battery, while the novel battery has same electric property of liquid battery.

Owner:广东风华新能源股份有限公司

Preparation method of low temperature graphite anode material for lithium ion battery

ActiveCN106276910AHigh degree of isotropySwell and shrinkCell electrodesGrapheneSolventWater soluble

The invention discloses a preparation method of a low temperature graphite anode material for a lithium ion battery. The preparation method comprises the following steps: (1) dispersing graphite, a dispersant and a first carbon source into a water-soluble solvent, and carrying out ultrasonic treatment to obtain mixed liquor; (2) grinding the mixed liquor obtained in the step (1) by the use of a sand mill, and adding a water-soluble solvent; (3) drying the mixed liquor obtained after grinding in the step (2) by the use of spray dryer into a powder so as to obtain a agglomeration granulation object; (4) adding a second carbon source and a water-insoluble solvent into the agglomeration granulation object obtained in the step (3) and adding the mixture into a high speed mixer, and stirring and mixing; and (5) carrying out high-temperature graphitization treatment on the agglomeration granulation object coated with the second carbon source in a graphitization furnace so as to obtain the low temperature graphite anode material. By a simple and efficient spray drying process for agglomeration granulation, a porous graphite secondary particle agglomerate is obtained; and by secondary surface coating, the low temperature graphite anode material for a lithium ion battery is obtained.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Aluminum oxide solid diaphragm, preparing method of aluminum oxide solid diaphragm, electrochemical battery or capacitor

InactiveCN103964821AHigh melting pointNo shrinkageElectrolytic capacitorsCell component detailsElectricityHeat resistance

The invention provides an aluminum oxide solid diaphragm and a preparing method of the aluminum oxide solid diaphragm. The preparing method comprises the following steps that aluminum oxide powder with the average particle diameter being 0.1 to 1mum is mixed with pore forming agents according to a mass ratio being 4:6 to 8:2, ball milling is carried out, and mixed powder is formed; the mixed powder is sieved by a sieve being 1000 to 5000 meshes, and dispersed mixed powder is obtained; then, dry pressing forming or isostatic pressing forming is carried out, and biscuits are obtained; the biscuits are placed in an air or oxygen atmosphere sintering furnace, the temperature is raised to 800 to 1000 DEG C at the speed being 1 to 10 DEG C / minute, after heat insulation is carried out for 1 to 12 hours, the temperature is continuously raised to 1300 to 1800 DEG C at the speed being 5 to 20 DEG C / minute, heat insulation is carried out for 2 to 6 hours, cooling is carried out, and the aluminum oxide solid diaphragm is obtained. The aluminum oxide solid diaphragm has the advantages that the pore diameter is proper, the heat resistance performance is good, and the safety is high, so the safety of an electrochemical battery or a capacitor is effectively improved. The invention also provides an electrochemical battery or a capacitor using the aluminum oxide solid diaphragm.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Composite material containing fluorine-containing titanium phosphate compound as well as preparation method and application of composite material

ActiveCN104577111AExcellent rate performanceImprove high current charge and discharge performanceNegative electrodesSecondary cellsLow voltageSodium-ion battery

The invention provides a composite material containing a fluorine-containing titanium phosphate compound as well as a preparation method for the composite material. The composite material comprises the following raw materials in percentage by weight: 60-99 percent of the fluorine-containing titanium phosphate compound and 1-40 percent of an electronic conductive material, wherein the chemical formula of the fluorine-containing titanium phosphate compound is Na3[Ti2P2O10F]. The invention further provides a lithium ion battery anode material containing the composite material, a sodium-ion battery anode material containing the composite material and corresponding batteries. Furthermore, the invention further relates to application of the composite material containing the fluorine-containing titanium phosphate compound in a lithium ion battery and a sodium-ion battery, and particularly application in a room-temperature lithium ion battery and a room-temperature sodium-ion battery. The composite material disclosed by the invention has the advantages of low cost, low voltage, high capacity, environment friendliness and the like.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com