Modified ferrous lithium phosphate as anode material for lithium ion batteries and its production

A technology for lithium ion batteries and cathode materials, which is applied in the field of modified lithium ferrous phosphate cathode materials for lithium ion batteries, can solve the problems of low specific capacity, difficult industrial production, poor discharge capacity and cycle performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

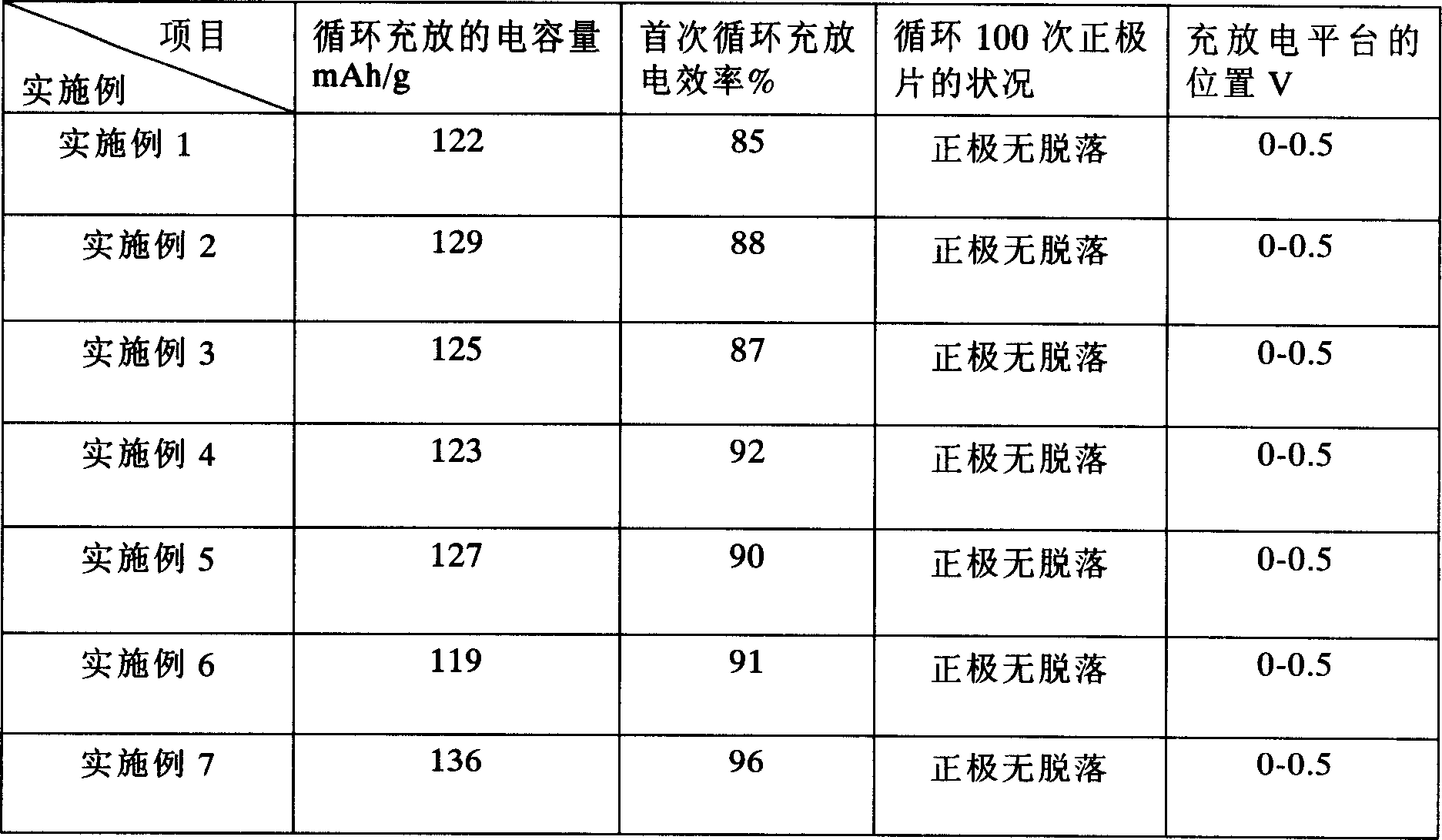

Examples

Embodiment 1

[0006] 1. Lithium carbonate, ferrous salt, chromium salt (containing chromium oxide), conductive agent and other materials with the atomic ratio of lithium, iron and M, namely Li / (Fe+M)=1.02, are mixed for 2 hours evenly.

[0007] 2. The powder material obtained in the first processing step is kept at a lower temperature of 400 degrees in an inert atmosphere for 15 hours, and cooled naturally.

[0008] 3. Mix the powder pre-calcined in the second processing step evenly again, then keep it warm at a higher temperature of 650 degrees in an inert atmosphere for 24 hours, cool and ball mill it through a 300-mesh sieve for use.

Embodiment 2

[0010] 1. Lithium carbonate, ferrous salt, chromium salt (containing chromium oxide), conductive agent and other materials with the atomic ratio of lithium, iron and M, namely Li / (Fe+M)=1.04, are mixed for 2 hours evenly.

[0011] 2. The powder material obtained in the first processing step is kept at a lower temperature of 400 degrees in an inert atmosphere for 14 hours, and cooled naturally.

[0012] 3. Mix the powder pre-calcined in the second processing step evenly again, then keep it warm at a higher temperature of 650 degrees in an inert atmosphere for 24 hours, cool and ball mill it through a 300-mesh sieve for use.

Embodiment 3

[0014] 1. Lithium carbonate, ferrous salt, chromium salt (containing chromium oxide), conductive agent and other materials with the atomic ratio of lithium, iron and M, namely Li / (Fe+M)=1.06, are mixed for 2 hours evenly.

[0015] 2. The powder material obtained in the first processing step is kept at a lower temperature of 400 degrees in an inert atmosphere for 18 hours, and cooled naturally.

[0016] 3. Mix the powder pre-calcined in the second processing step evenly again, then keep it warm at a higher temperature of 650 degrees in an inert atmosphere for 24 hours, cool and ball mill it through a 300-mesh sieve for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com