Preparation method of LiFePO material, lithium ion battery and positive plate thereof

A technology of lithium iron phosphate and positive electrode sheet, which is applied in the preparation of lithium iron phosphate material and the field of lithium ion battery and its positive electrode sheet, and can solve the problems that cannot satisfy the application of high power lithium ion battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0022] The following describes the process of preparing the lithium iron phosphate / aluminum composite material according to the first embodiment of the present invention by using the mechanical ball milling mixing method.

[0023] The method for preparing lithium iron phosphate / aluminum composite material according to the present invention comprises the steps of: step one, sintering to prepare lithium iron phosphate powder; step two, preparing nano-Al powder; step three, combining nano-Al powder with sintering The final lithium iron phosphate powder is subjected to high-speed ball milling and dispersion under the protection of an inert atmosphere; step 4, inert gas or reducing gas is passed into the tube furnace, and the mixture of Al powder and lithium iron phosphate powder is sintered and kept warm, so that Al is melted, so that the aluminum element is coated on the lithium iron phosphate powder particles to form a lithium iron phosphate / aluminum composite material; Step 5, the...

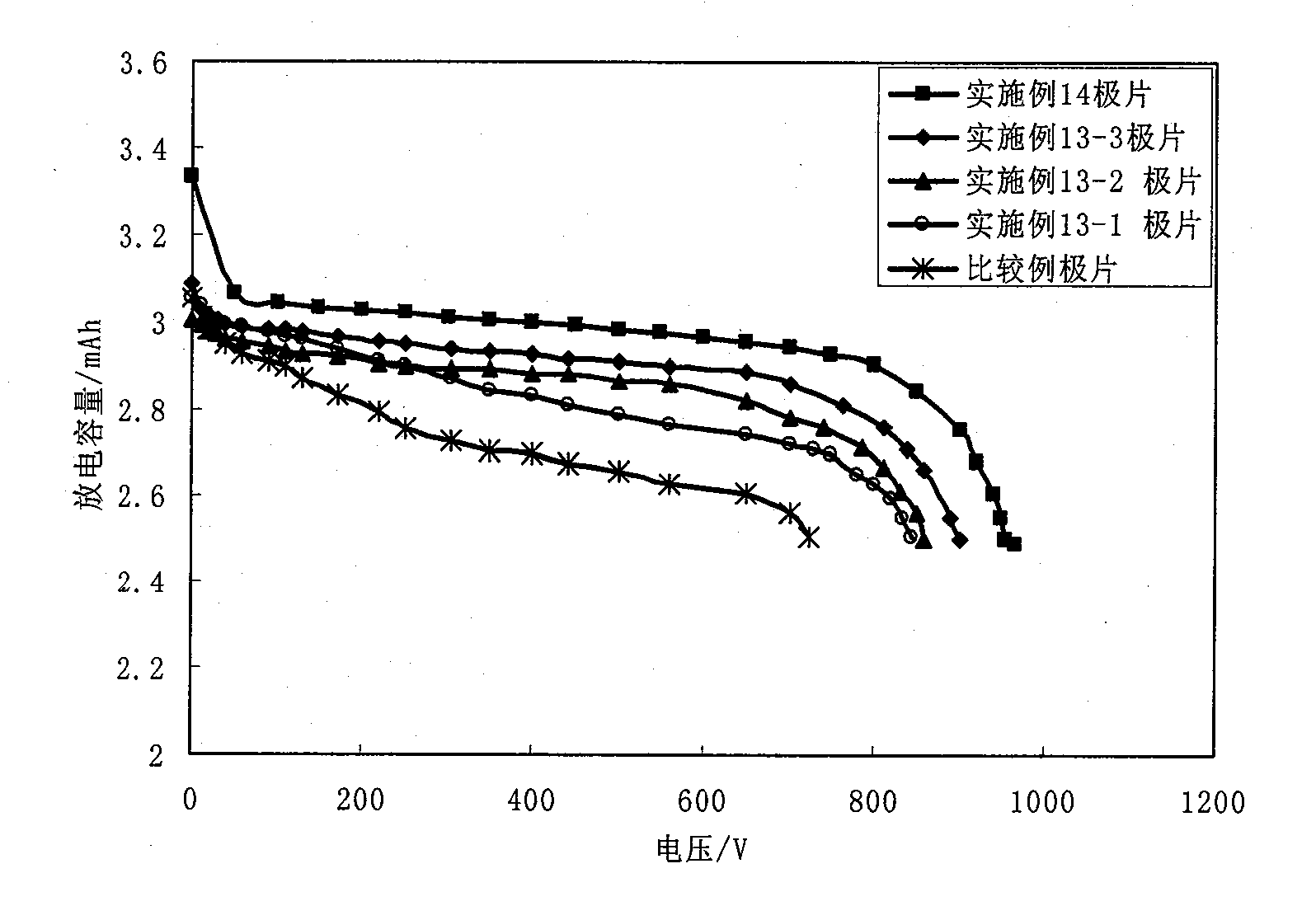

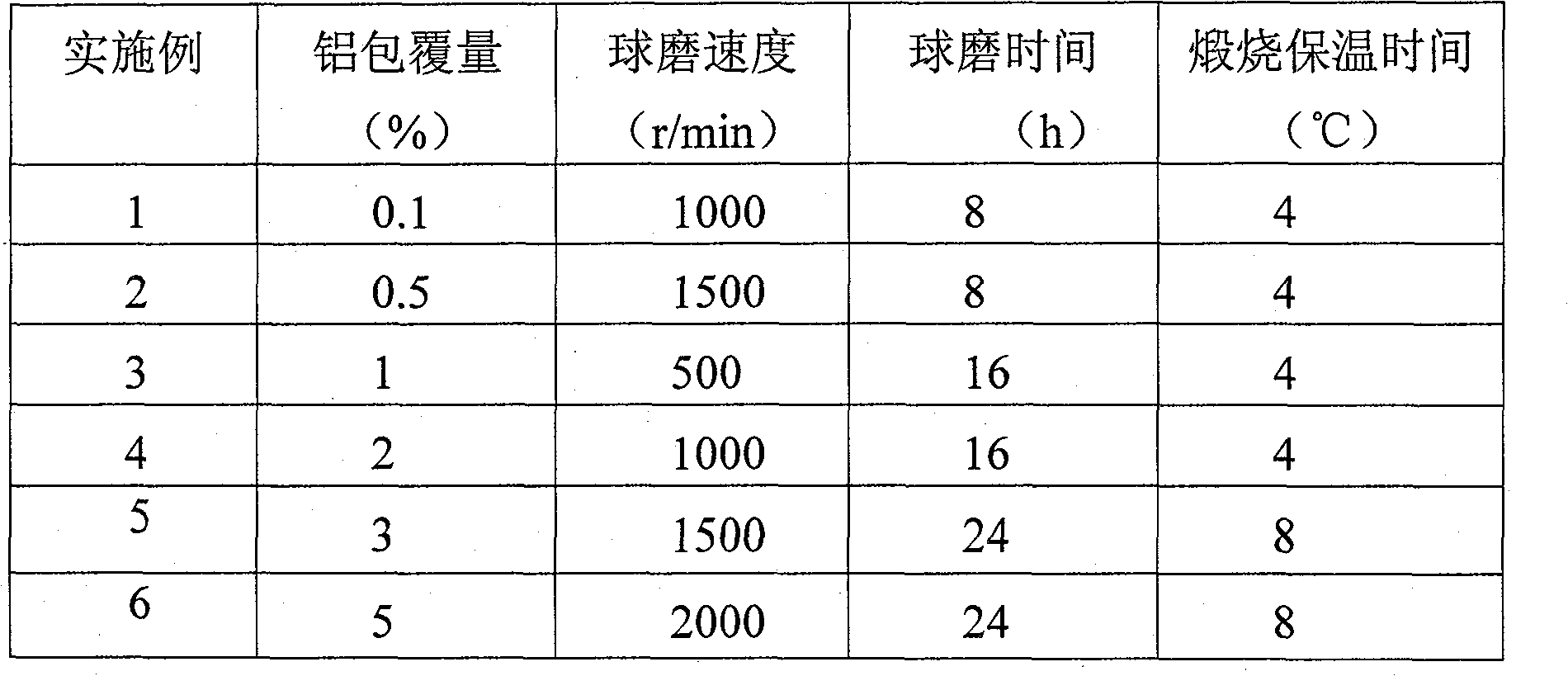

Embodiment 1~6

[0033] Preparation of LiFePO by Ball Milling 4 The specific process of the / Al composite material is as follows: 2 CO 3 , FeC 2 o 4 , NH 4 h 2 PO 4 Lithium iron phosphate LiFePO is sintered once as a raw material by high-temperature solid-state method 4 Material, the material after sintering is pulverized for the first time. According to the ball-to-material ratio of 3:1, two kinds of diameters of grinding balls Φ1 / Φ5 (in mm) are selected, and the dosage ratio is Φ1:Φ5=7:3. In an inert protective atmosphere glove box, LiFePO 4 Materials, nano-aluminum powder, grinding balls and organic solvents such as isopropanol, acetone, n-butanol, tert-butanol, and hexanediol are mixed and loaded into a ball mill tank, and the amount of aluminum powder is LiFePO 4 The amount of the material is 0.1-5%, the amount of the organic solvent is to completely cover the ball material, the liquid level is slightly higher than the ball material liquid level, the ball milling speed is 500-2000...

Embodiment approach

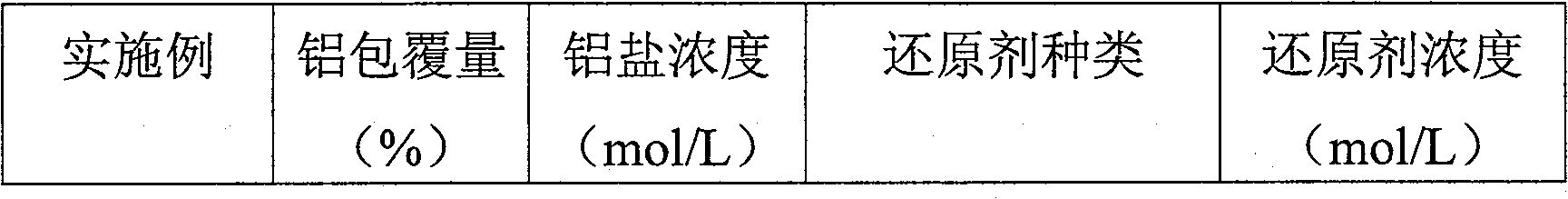

[0036] According to the second embodiment of the present invention, the process of preparing lithium iron phosphate / aluminum composite material by electroless plating will be described below.

[0037] In the method for preparing lithium iron phosphate / aluminum composite material by electroless plating according to the present invention, steps are included: Step 1, sintering to prepare lithium iron phosphate powder; Step 2, preparing aluminum metal molten salt electroplating solution, wherein the electroplating solution includes aluminum Metal room temperature molten salt, organic reducing agent, and an organic solvent that does not react with aluminum metal molten salt; step 3, prepare a chloride salt solution containing active metal Pd, Rh, Ru, etc., and add ethanol, propanol, ethylene glycol etc., prepare a mixture of alcohol and water to obtain an activation solution; Step 4, under an inert atmosphere, soak the lithium iron phosphate material in the above activation solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com