Cylindrical lithium ion battery and manufacturing method therefor

A lithium-ion battery and cylindrical technology, which is applied in the field of steel shell cylindrical lithium-ion battery and its preparation, can solve the problems of unfavorable heat dissipation of the battery, difficult detection of the quality of the bottom of the steel shell by spot welding of the negative electrode lug, and poor heat dissipation, so as to improve production efficiency Consistency with the battery, improve safety performance and charge and discharge performance, and improve the effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing a cylindrical lithium-ion battery, comprising the steps of material preparation, installing batteries, rolling grooves, baking batteries, liquid injection, spot welding caps and sealing, and the material preparation includes the following steps,

[0033] Coat the active material on the negative electrode foil according to the specifications, leaving an uncoated area around the coated area;

[0034] Cut the above-mentioned negative electrode foil according to the required size into negative electrode sheets with two short sides and one long side containing uncoated areas and the rest as coated areas, and cut positive electrode sheets according to the size requirements;

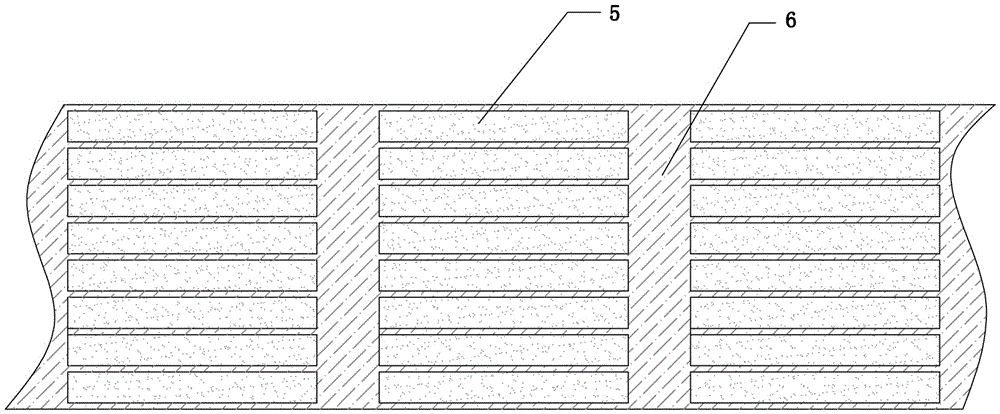

[0035] According to the outer layer is the negative electrode current collector not coated with active material, the inner layer is the separator, the negative electrode sheet, the separator and the positive electrode sheet are arranged at intervals and wound on the winding needle o...

Embodiment

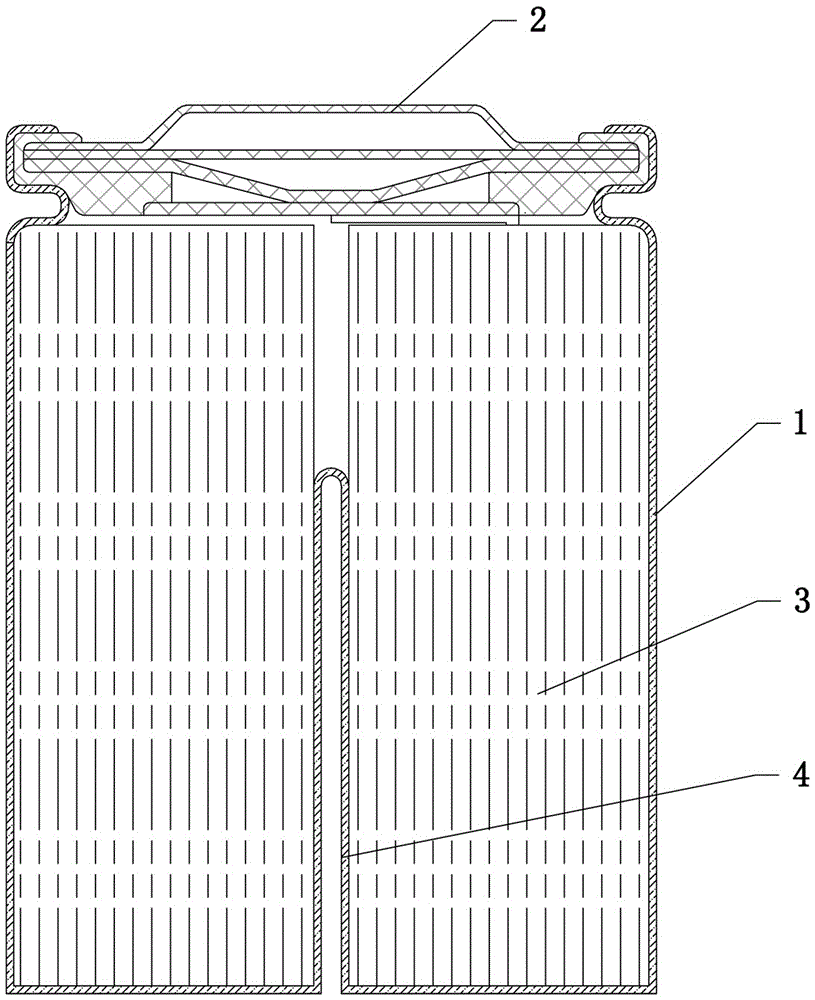

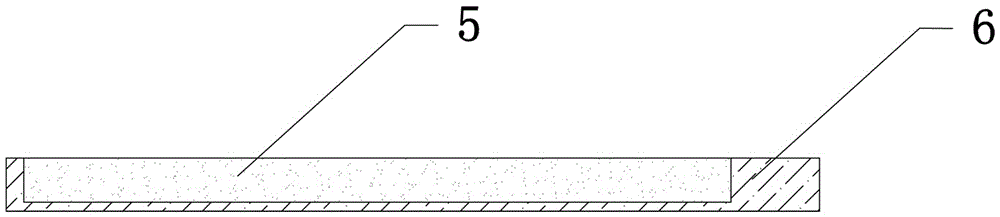

[0041] Preparation of 26650-3000mAh-3.2V lithium iron phosphate steel shell cylindrical lithium-ion battery, the side profile of the finished product is as follows figure 1 As shown, the steel shell cylindrical lithium-ion battery consists of a steel shell 1 , a cap 2 and a cell 3 . The outer diameter of the steel shell is 26.0±0.05mm, the height of the steel shell is 67.8±0.1mm, and the wall thickness of the steel shell is 0.2±0.02mm. The other end of the tube body is a sealed round head structure, the height of the tube body is 40.0±0.1mm, and the outer diameter of the tube body is 4.0±0.1mm. The cap is a common combination cap with a diameter of 25.4±0.05mm and a height of 42±0.1mm. The battery cell consists of a positive electrode sheet, a negative electrode sheet and a separator winding. The thickness of the aluminum foil of the positive electrode current collector is 16±1μm, the positive electrode is coated by a conventional gap coating process, and the density of one ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com