Patents

Literature

1433results about How to "Improve charge and discharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

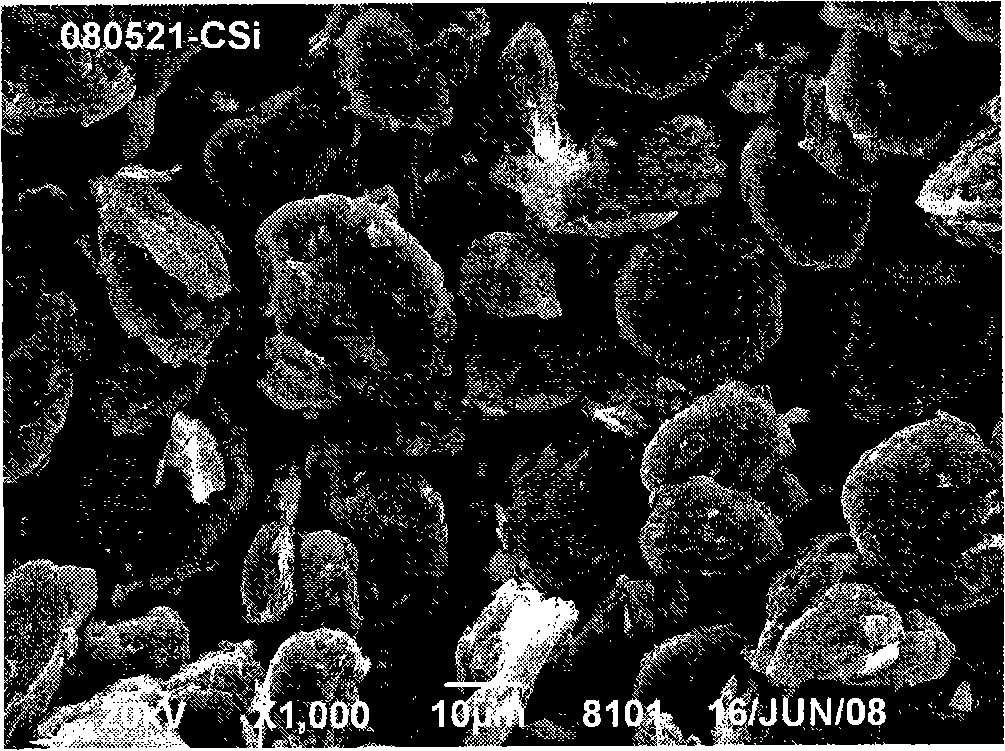

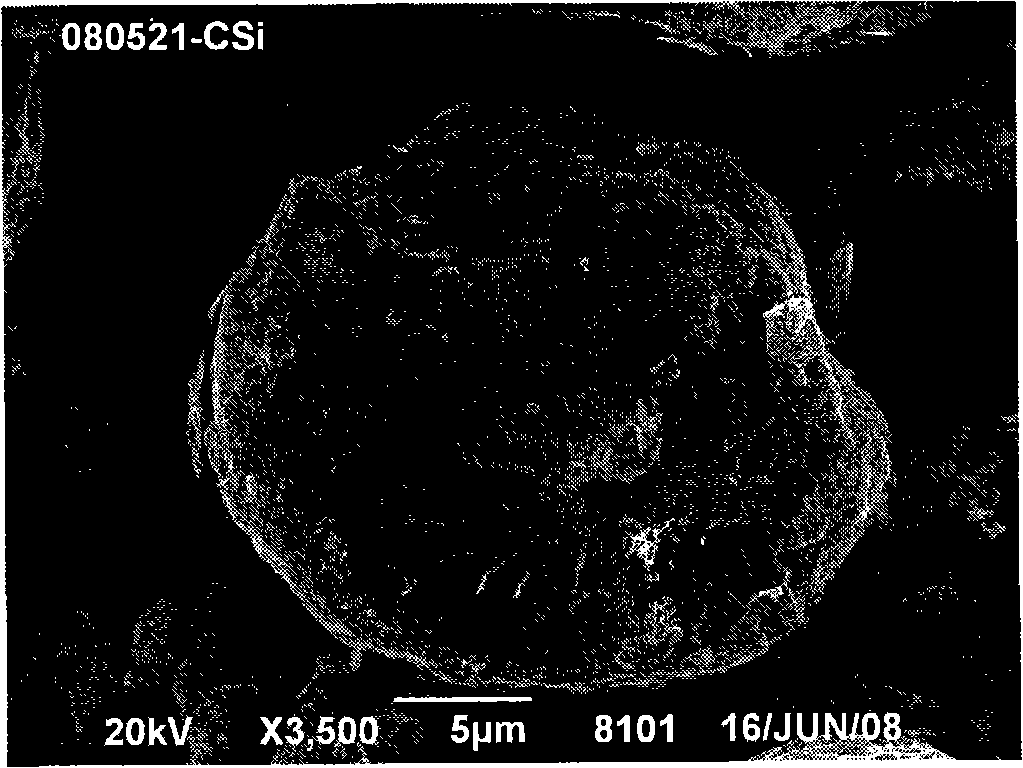

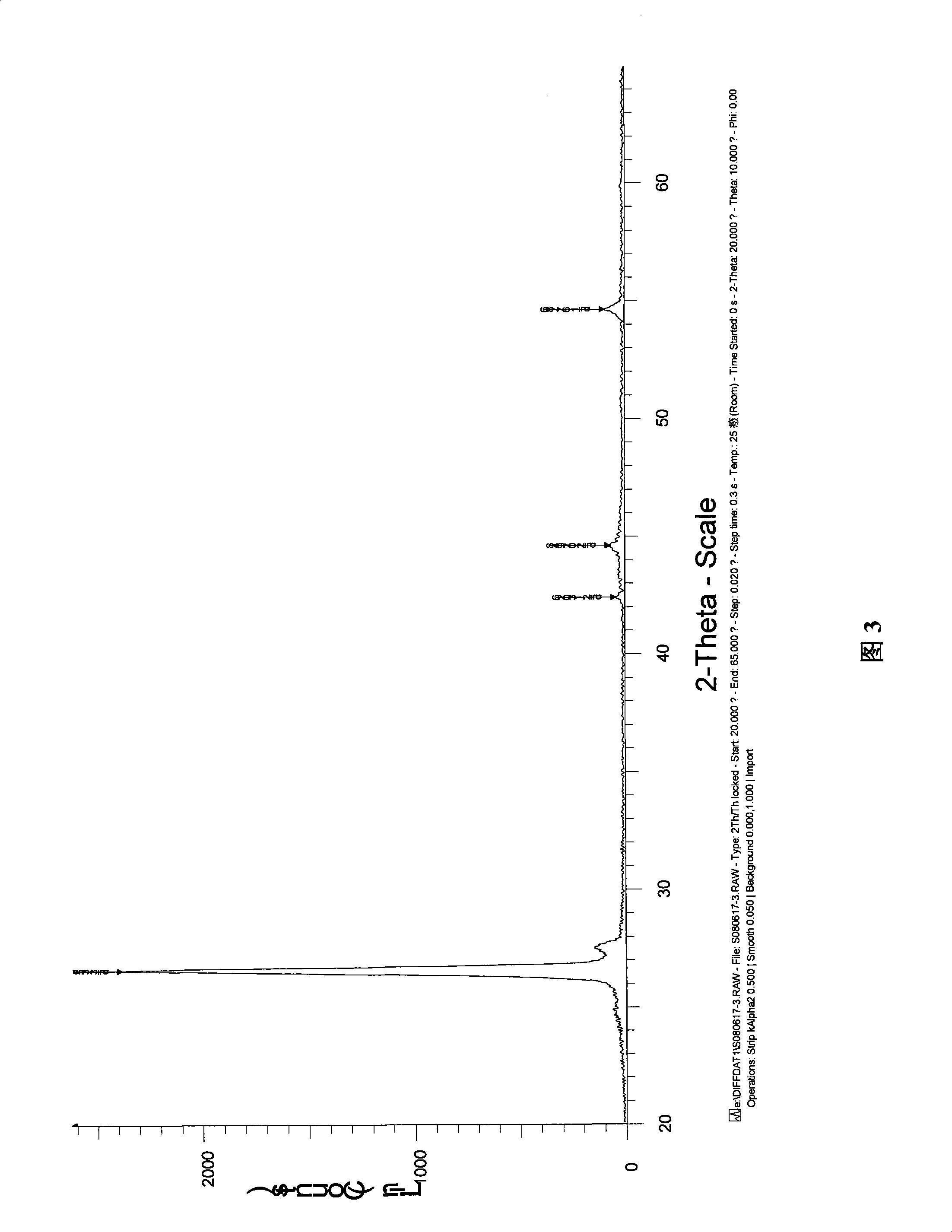

Silicon-carbon composite cathode material of lithium ion battery and preparation thereof

InactiveCN101339987AImprove battery energy densityImprove cycle performanceElectrode manufacturing processesChemical/physical/physico-chemical processesCarbon compositesCarbonization

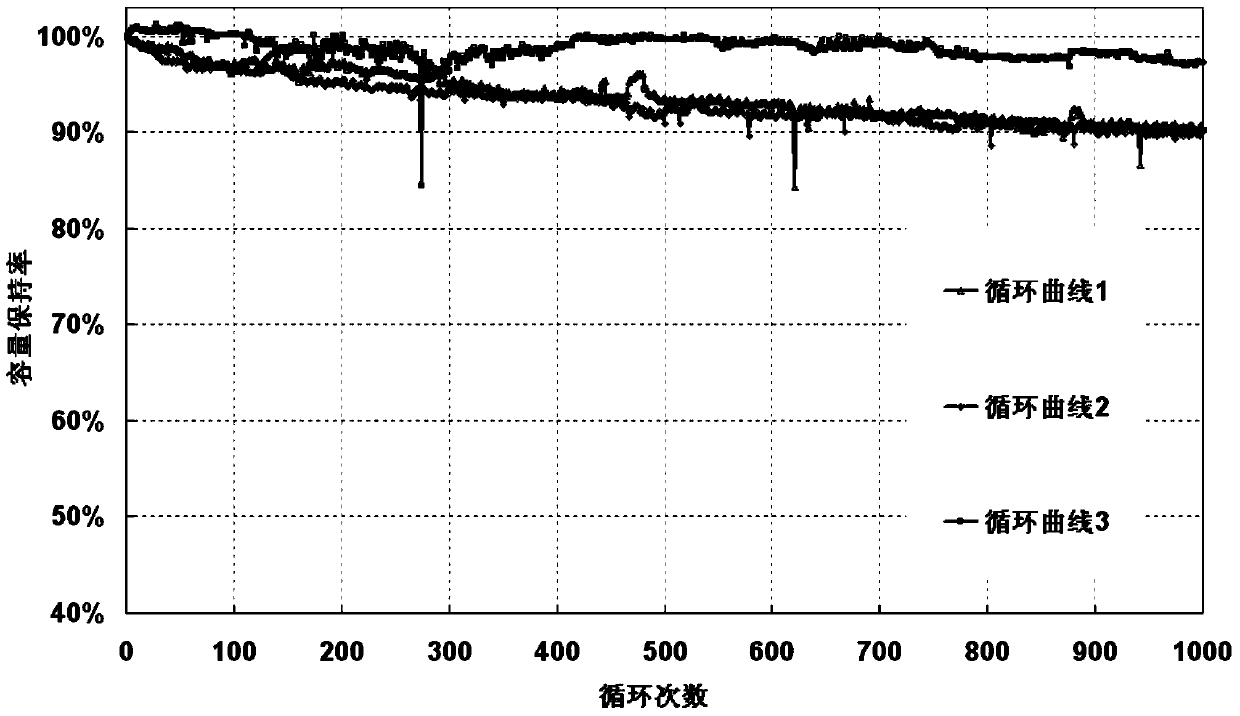

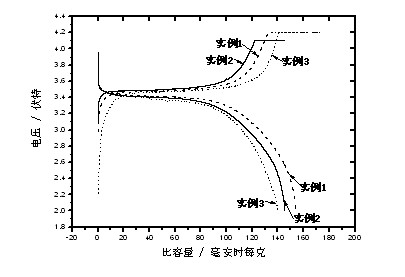

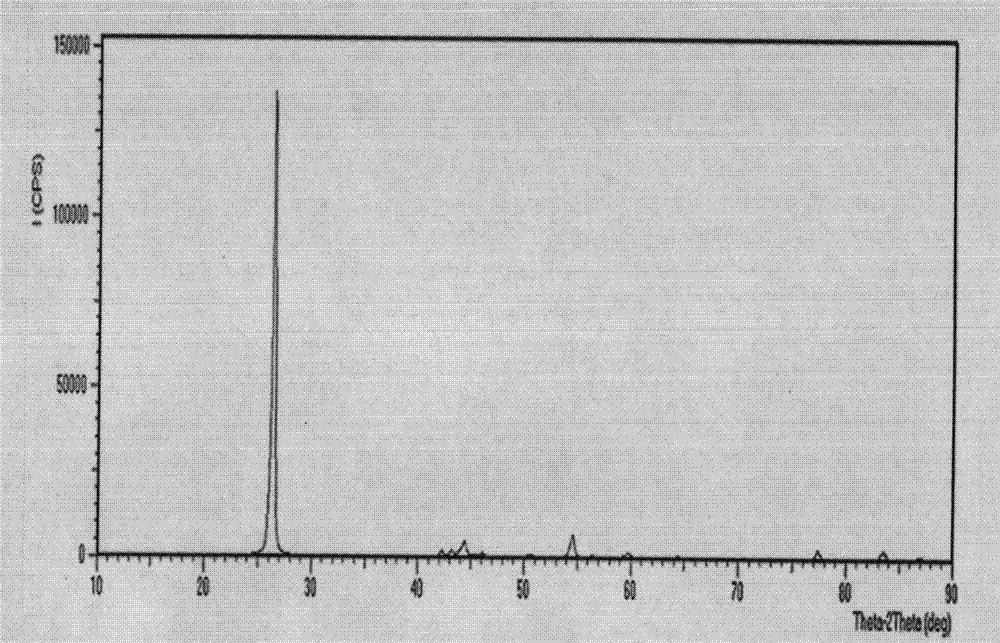

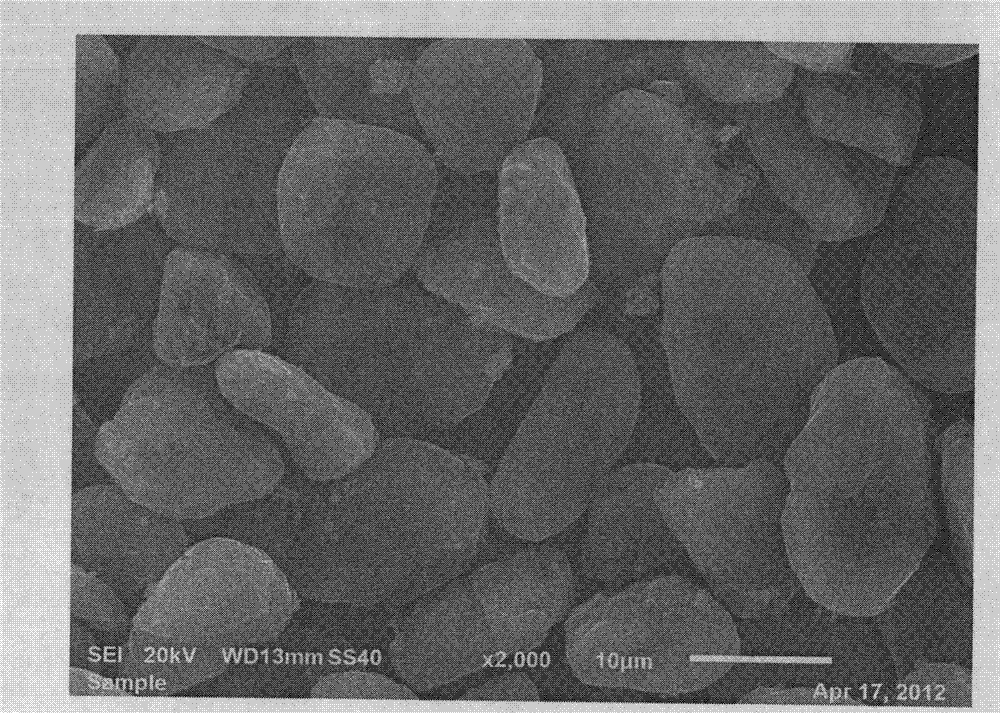

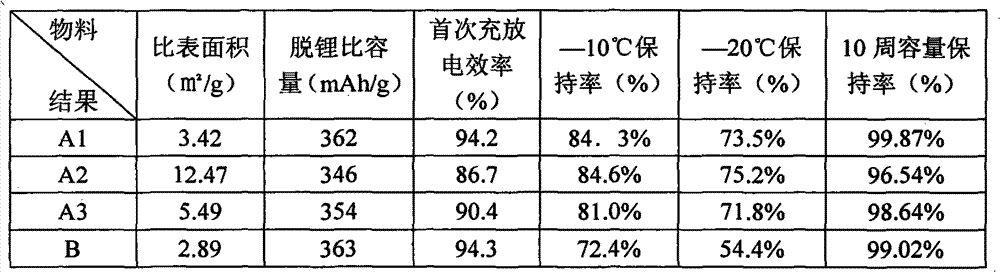

The invention provides a silicon-carbon composite cathode material for preparing a lithium-ion battery at the room temperature and a preparation method thereof. The composite cathode material is a material with a nuclear shell structure and comprises the following proportional elements: 0.01-10% of simple substance silicon and 90-99.9% of carbon. With regard to the preparation method, silicon powder and graphite are mixed for ball grinding and then added with bitumen or polymer cladding material for ball grinding again, after the treatment of carbonization, the mixture is crushed and sieved to obtain the material containing 0.01-10wt% of silicon and 10-99.9% of carbon. The capacity of the material is more than 350mAh / g, the cycle efficiency of the material is larger than 90% for the first time, and keeps larger than 80% after 200 cycles, and the material has good charging and discharging property.

Owner:湖南海容新材料有限责任公司

High-performance lithium ion battery and preparation process thereof

InactiveCN102347475AImprove electronic conductivityImprove charge and discharge performanceCell electrodesSecondary cellsAluminium foilCopper foil

The invention relates to a high-performance lithium ion battery. According to the battery, an electrode material is subjected to a nano-composite treatment of grapheme and polyaniline; an anode current collector comprises aluminium foil; a cathode current collector comprises copper foil; a conductive agent comprises superconducting carbon black, conductive graphite or acetylene black; a binding agent comprises styrene butadiene rubber, carboxymethylcellulose sodium, polytetrafluoroethylene, polyvinylidene difluoride or hydroxy propyl methylcellulose; a electrolyte comprises liquid electrolyte or a polymer electrolyte containing a conductive polymer, a nano-material, or a mixture comprising the conductive polymer and the nano-material; a membrane is subjected to a high temperature resistant insulation coating treatment, or directly adopts a high temperature resistant insulating porous polymer matrix. A preparation process for the high-performance lithium ion battery comprises: material preparing, coating, drying, rolling, slicing, coil winding or sheet stacking, assembling, liquid injecting, formation and capacity distributing. The lithium ion battery provided by the present invention has characteristics of excellent charge and discharge performance at the large rate, small capacity fading, good heat stability, good safety performance and long electrode cycle life, and can be widely applicable for the fields of electric bicycles, electric motorcycles, electric cars and the like.

Owner:LUNAN RES INST OF COAL CHEM

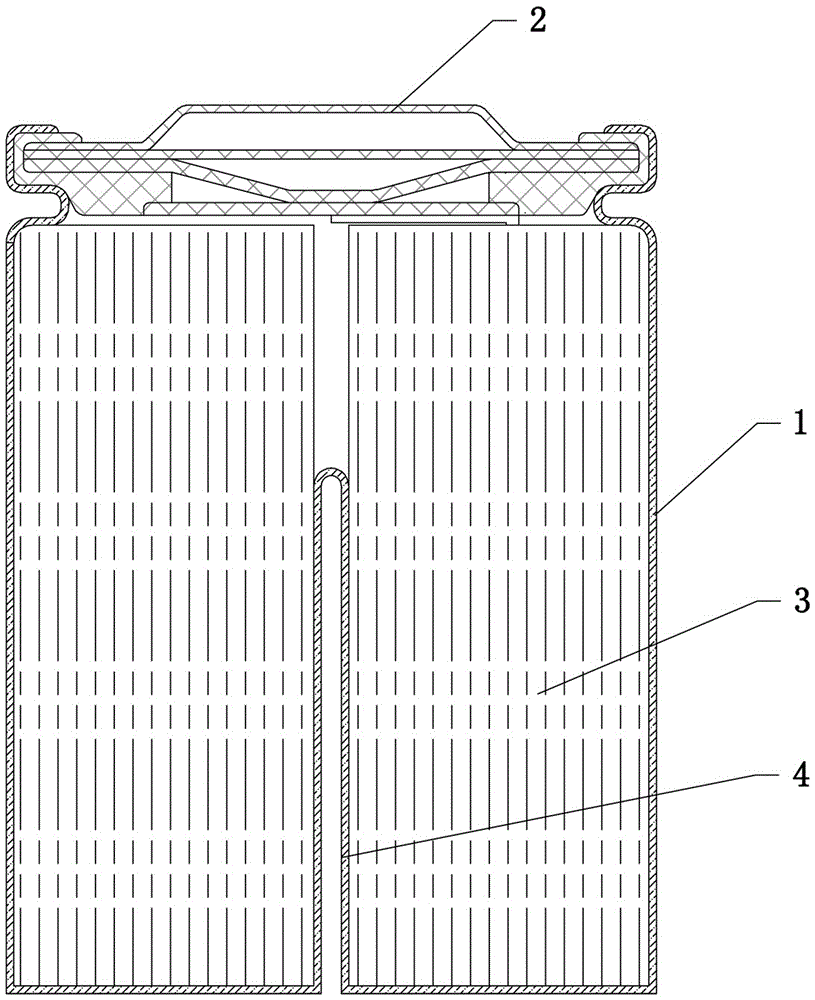

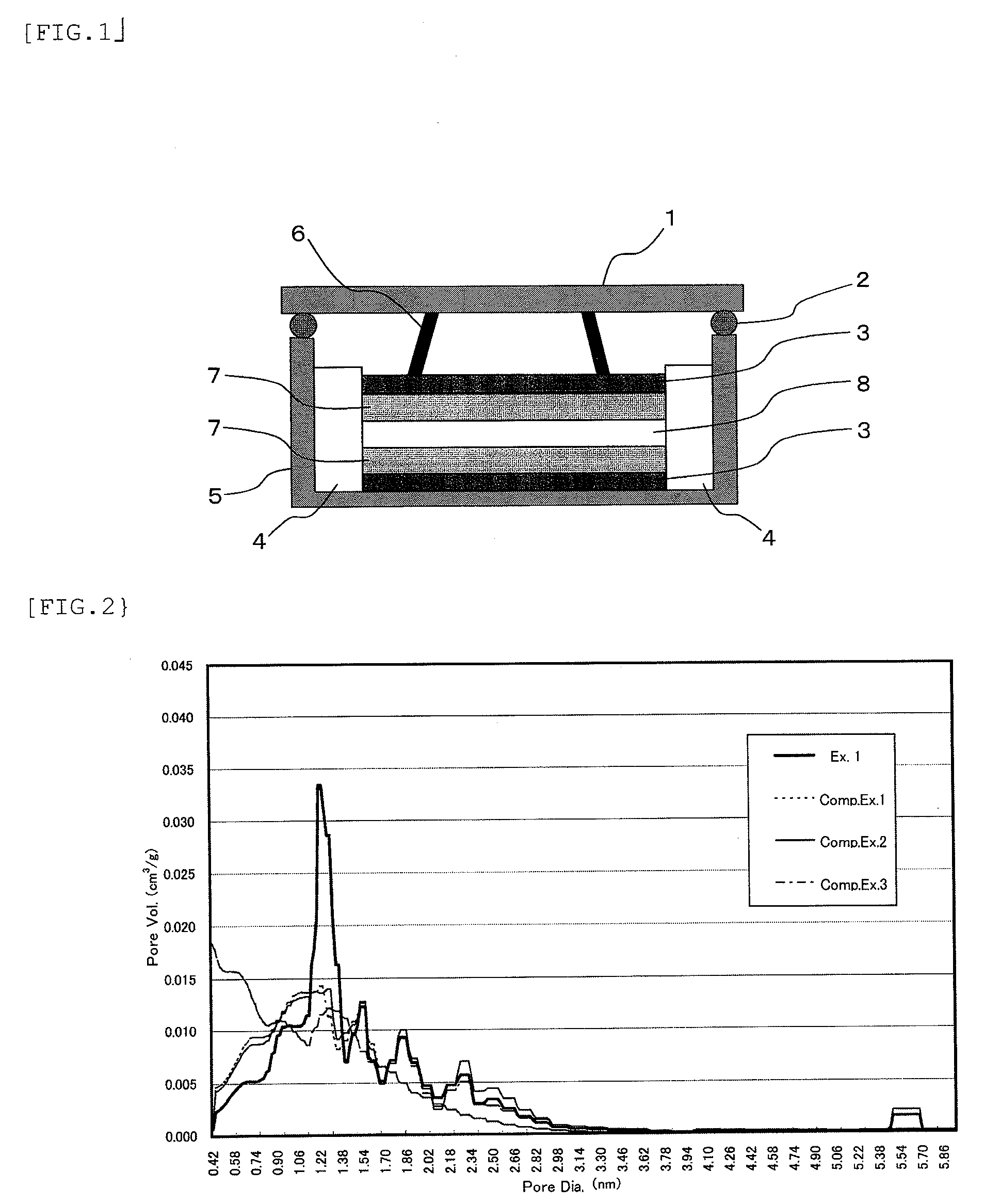

Cylindrical lithium ion battery and manufacturing method therefor

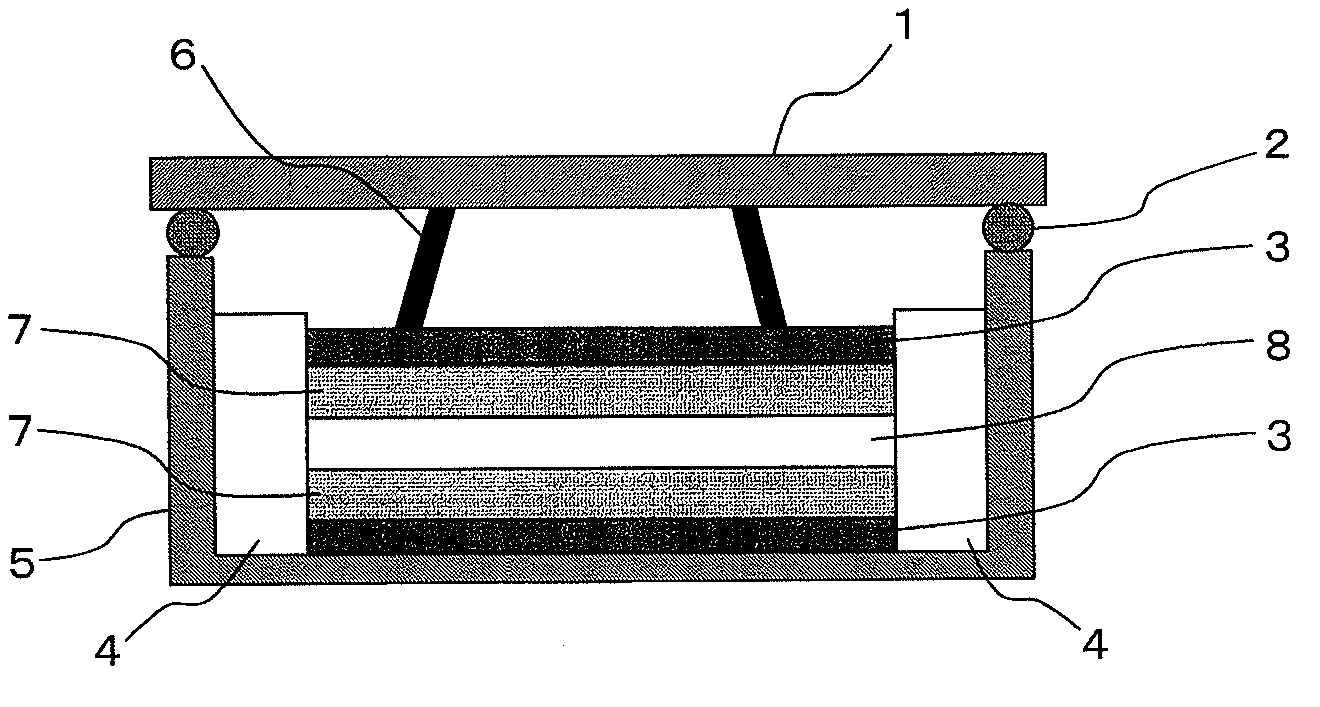

ActiveCN105470558AAvoid deformationImprove securityFinal product manufactureSecondary cellsElectrical polarityEngineering

The invention belongs to the technical field of lithium batteries and discloses a steel shell type cylindrical lithium ion battery and a manufacturing method therefor. The technical scheme adopted by the invention is as follow: the cylindrical lithium ion battery comprises a cylindrical steel shell, a positive plate, a negative plate and a diaphragm, wherein two sides of each of the positive plate and the negative plate are coated with active substances with corresponding activities; the positive plate, the negative plate and the diaphragm are arranged at intervals and wound into a battery cell; the battery is characterized in that a negative current collector is further arranged on an outer layer of the positive plate, the negative plate and the diaphragm arranged at intervals and is wound into the battery cell together with the positive plate, the negative plate and the diaphragm; a tube body is arranged in the middle of the steel shell; the upper part of the tube body is sealed; the periphery of the lower part of the tube body is hermetically connected with the bottom surface of the steel shell; a lower opening of the tube body is communicated with the outside; two short edges and a long edge of the negative plate are left as uncoated regions; the positive plate is provided with a tab; the diaphragm is longer than a coated region on the negative plate at the starting end of winding and wider than the coated region on the negative plate; the center of the battery cell is inserted in the tube body; and the tab of the positive electrode is opposite to the uncoated region of the negative plate in direction.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

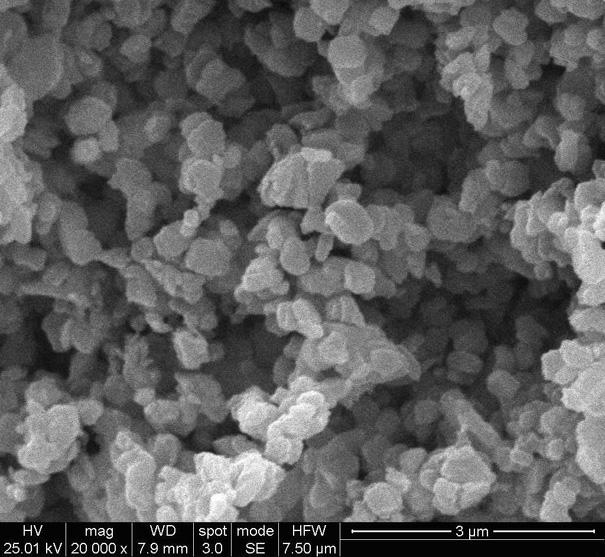

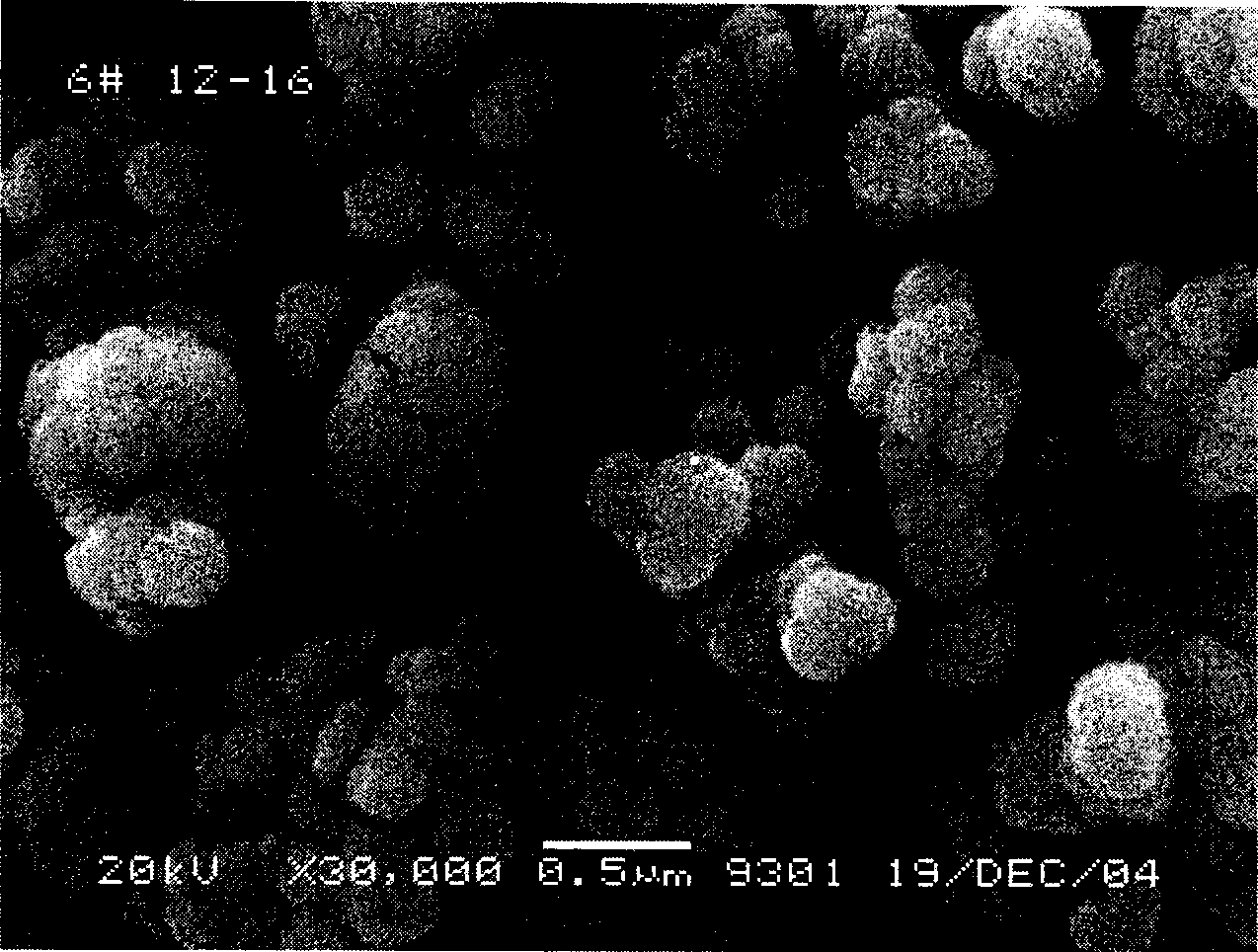

Preparation method of nano positive material for lithium ion battery

InactiveCN102386381AShort heat treatment timeReduce energy consumptionNanostructure manufactureCell electrodesNickel saltElectrical battery

The invention belongs to the field of preparation techniques of nanophase materials and green energy resources, and relates to a preparation method of a nano positive material LiNi1 / 3Mn1 / 3Co1 / 3O2 applied to a lithium ion battery. By using the method, the defects that the calcining temperature needed by a current synthetic material is high, the calcining time is long, the particle sizes of a product are not uniform, and the like, are mainly solved. The preparation method comprises the following steps: adding a certain amount of template agent in a mixed aqueous solution of a nickel salt, a manganese salt and a cobalt salt, and then, dripping a precipitant and a complexing agent into the obtained mixture to form a precipitate; subjecting the precipitate and the mixed aqueous solution to a high-pressure thermal reaction in a hydrothermal kettle, cleaning and baking the obtained product to be dry, so as to obtain a nickel manganese cobalt oxide; and finally, uniformly mixing the nickel manganese cobalt oxide with the lithium salt to prepare a final product by calcining and cooling. By using the preparation method, the product with favorable electrochemical performance can be obtained within a shorter calcining time; the energy consumption is decreased; and the preparation method has obvious economic benefit in the large-scale application of industrial synthesis.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +2

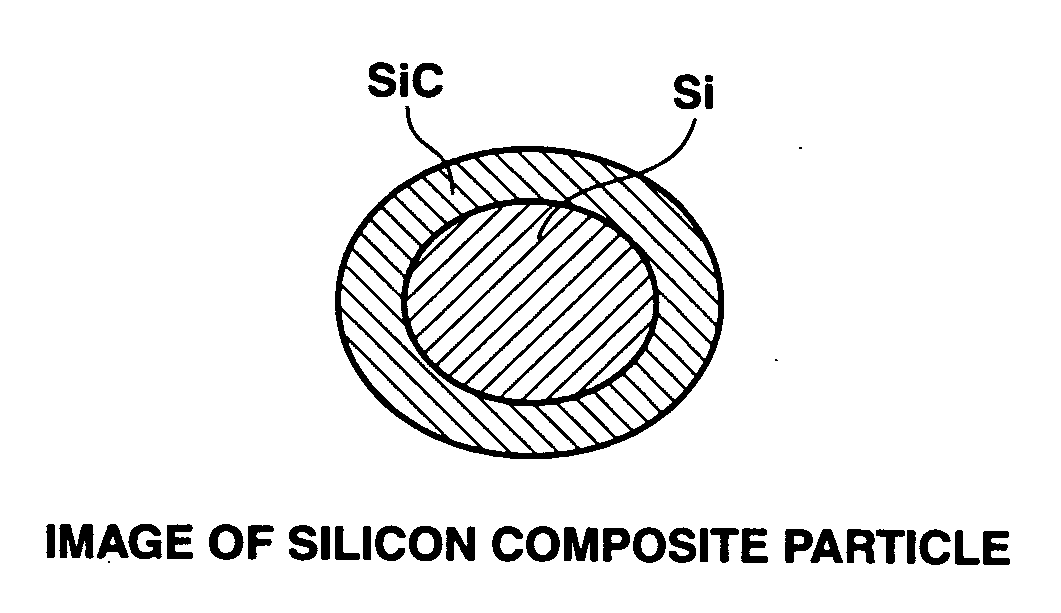

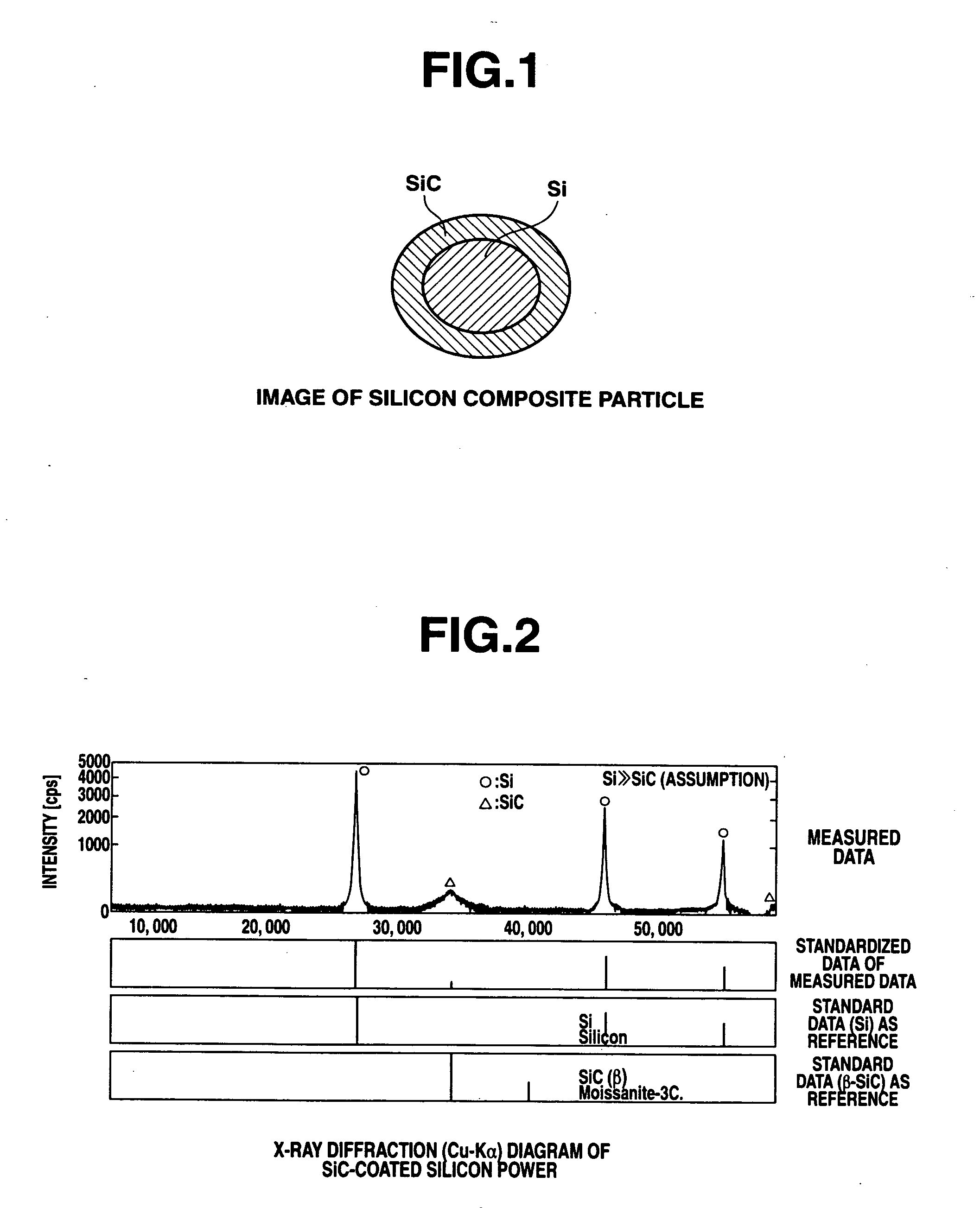

Silicon composite, making method, and non-aqueous electrolyte secondary cell negative electrode material

InactiveUS20060003227A1Improve initial efficiencyImprove cycle performanceFinal product manufactureSecondary cells charging/dischargingCarbon layerDecomposition

A silicon composite comprises silicon particles whose surface is at least partially coated with a silicon carbide layer. It is prepared by subjecting a silicon powder to thermal CVD with an organic hydrocarbon gas and / or vapor at 900-1,400° C., and heating the powder for removing an excess free carbon layer from the surface through oxidative decomposition.

Owner:SHIN ETSU CHEM IND CO LTD

Power and energy storage lithium-ion battery and preparation method thereof

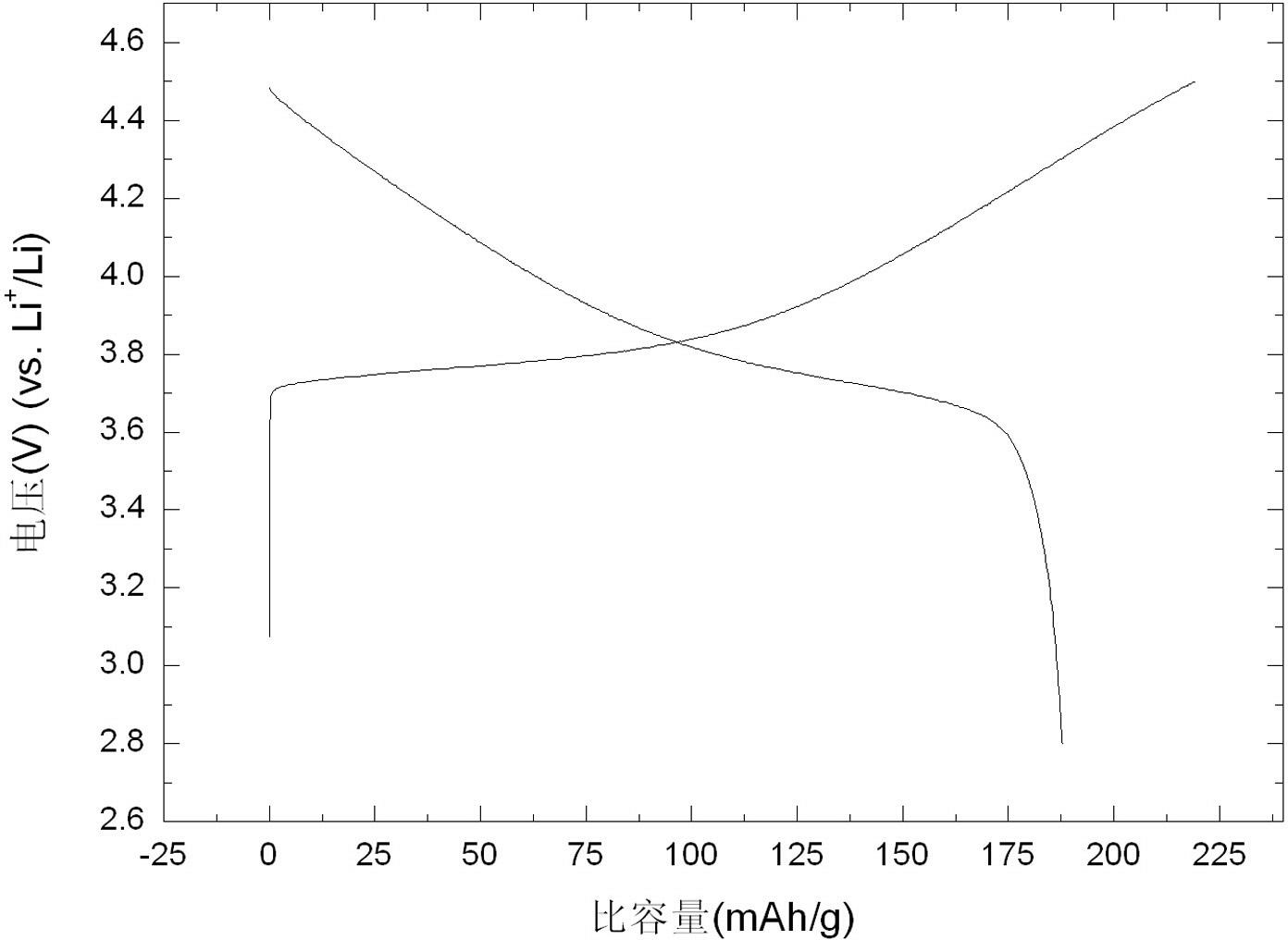

ActiveCN103441305AImproved gram capacity playIncrease capacityFinal product manufactureElectrolyte accumulators manufactureGramEngineering

The invention relates to a preparation method of a power and energy storage lithium-ion battery. A negative active substance of the power and energy storage lithium-ion battery comprises soft carbon, hard carbon, a mixed material of soft carbon and graphite and a mixed material of hard carbon and graphite. The designing method of the battery comprises the steps of designing the gram volume of the negative active substance as the primary lithium-embedding gram volume, designing the gram volume of the positive active substance as the primary lithium-removal gram volume, designing the ratio of the capacity of the positive electrode and the capacity of the negative electrode to be (1: 1) to (1.5: 1). By adopting the designing method, the capacity and comprehensive performance of the battery can be remarkably improved, and excellent lithium-embedding and lithium-removal capacity of the soft carbon material and the hard carbon material can be adequately exerted. Compared with the existing lithium battery technology, the prepared power lithium battery has long service life, high multiplying power, high safety performance and excellent low-temperature performance and can be widely applied to the fields such as electric tools, various portable devices, spaceflight, starting power supply and the like.

Owner:BTR NEW MATERIAL GRP CO LTD

Battery heating circuits and methods using voltage inversion based on predetermined conditions

ActiveUS20130134945A1Reduce battery capacityIncreased polarizationCharge equalisation circuitPropulsion by batteries/cellsEngineeringEnergy storage

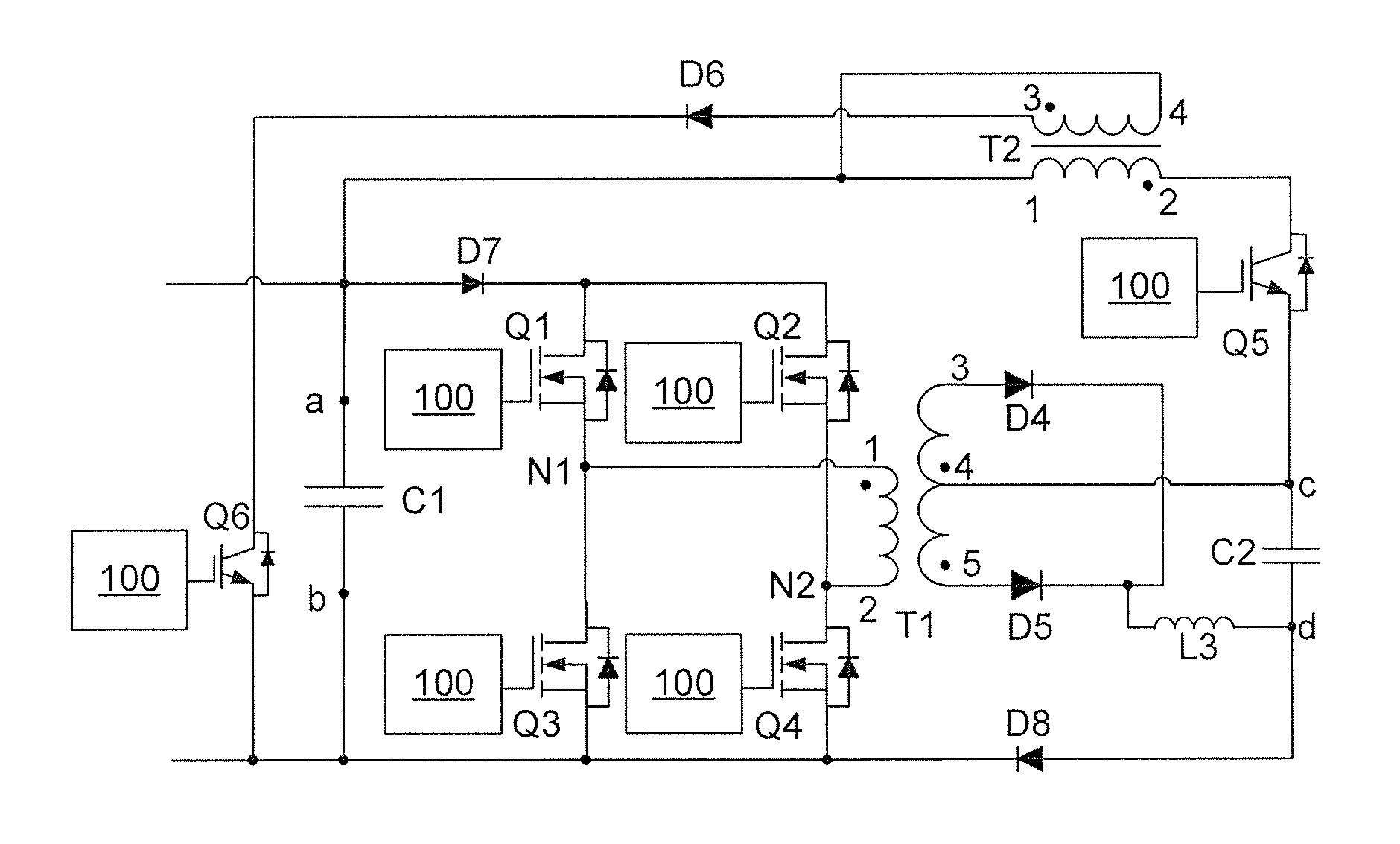

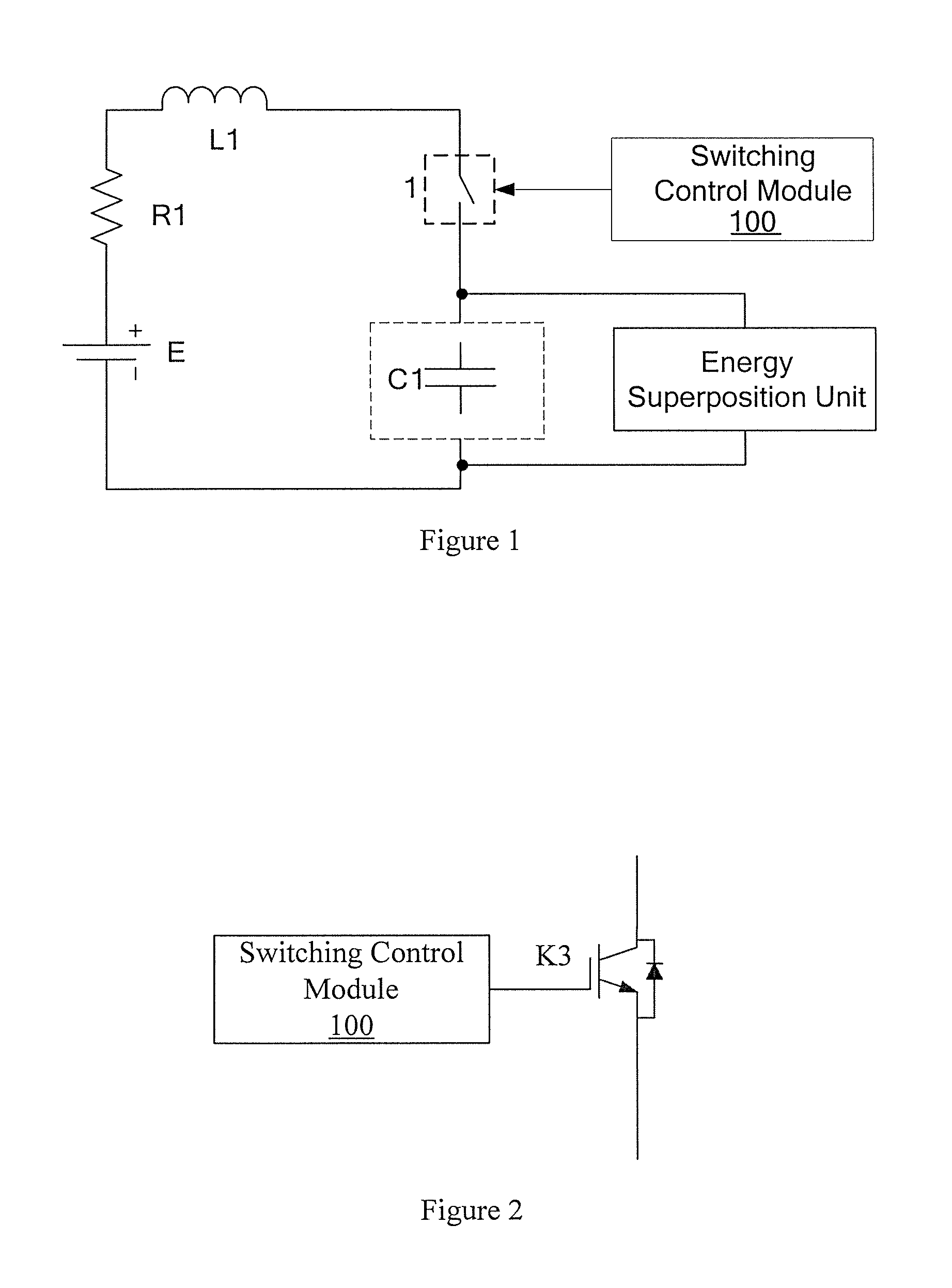

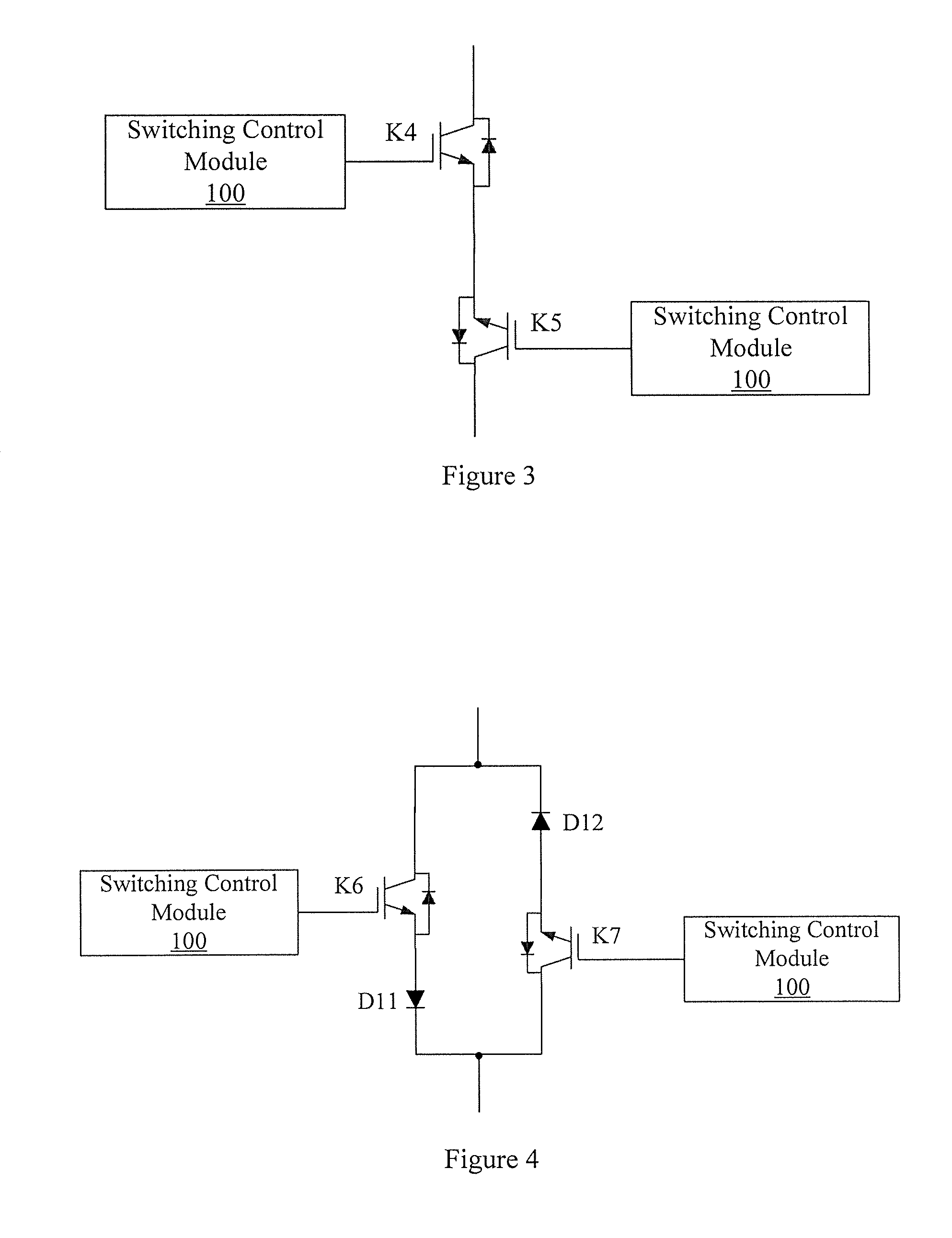

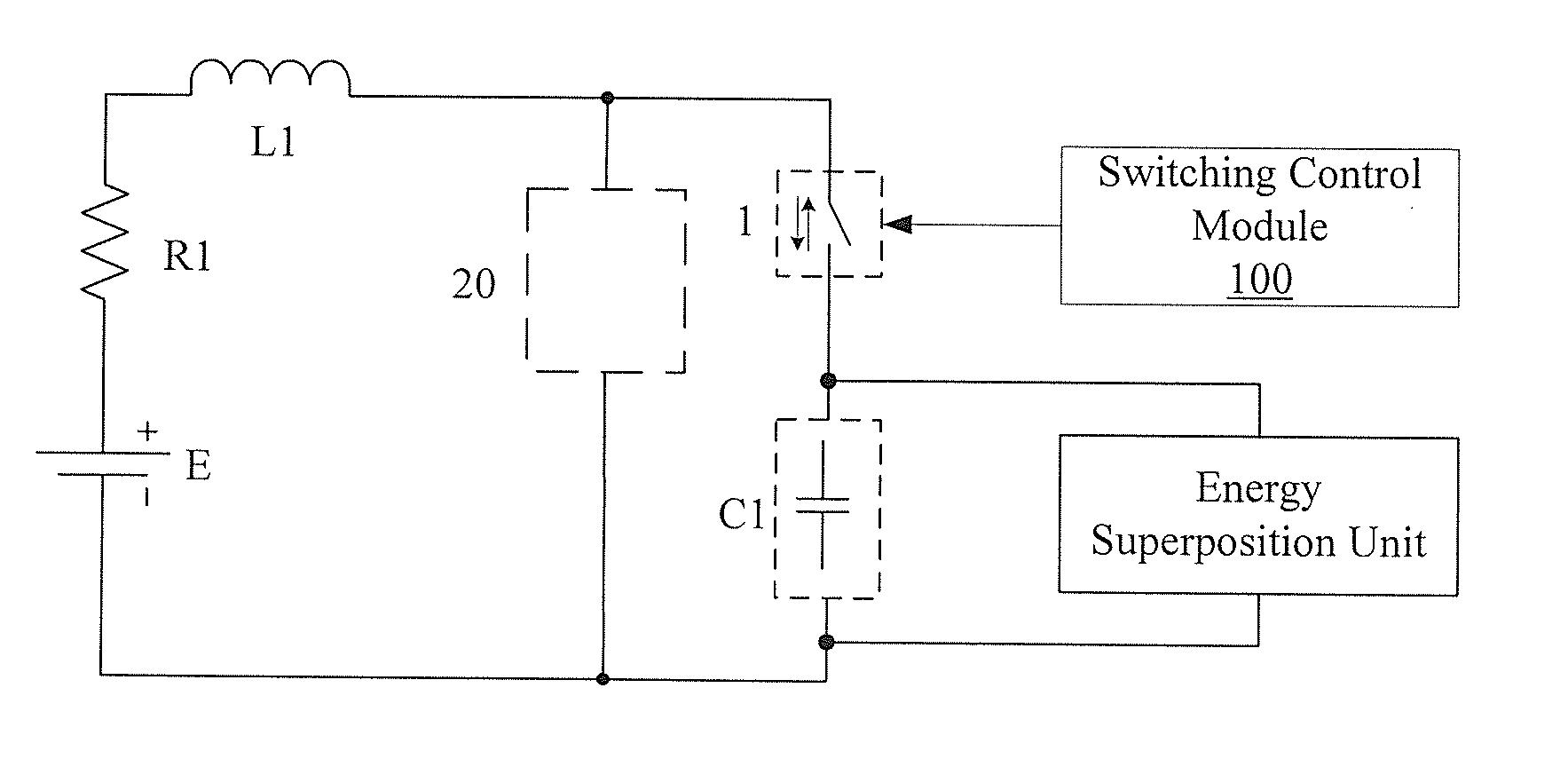

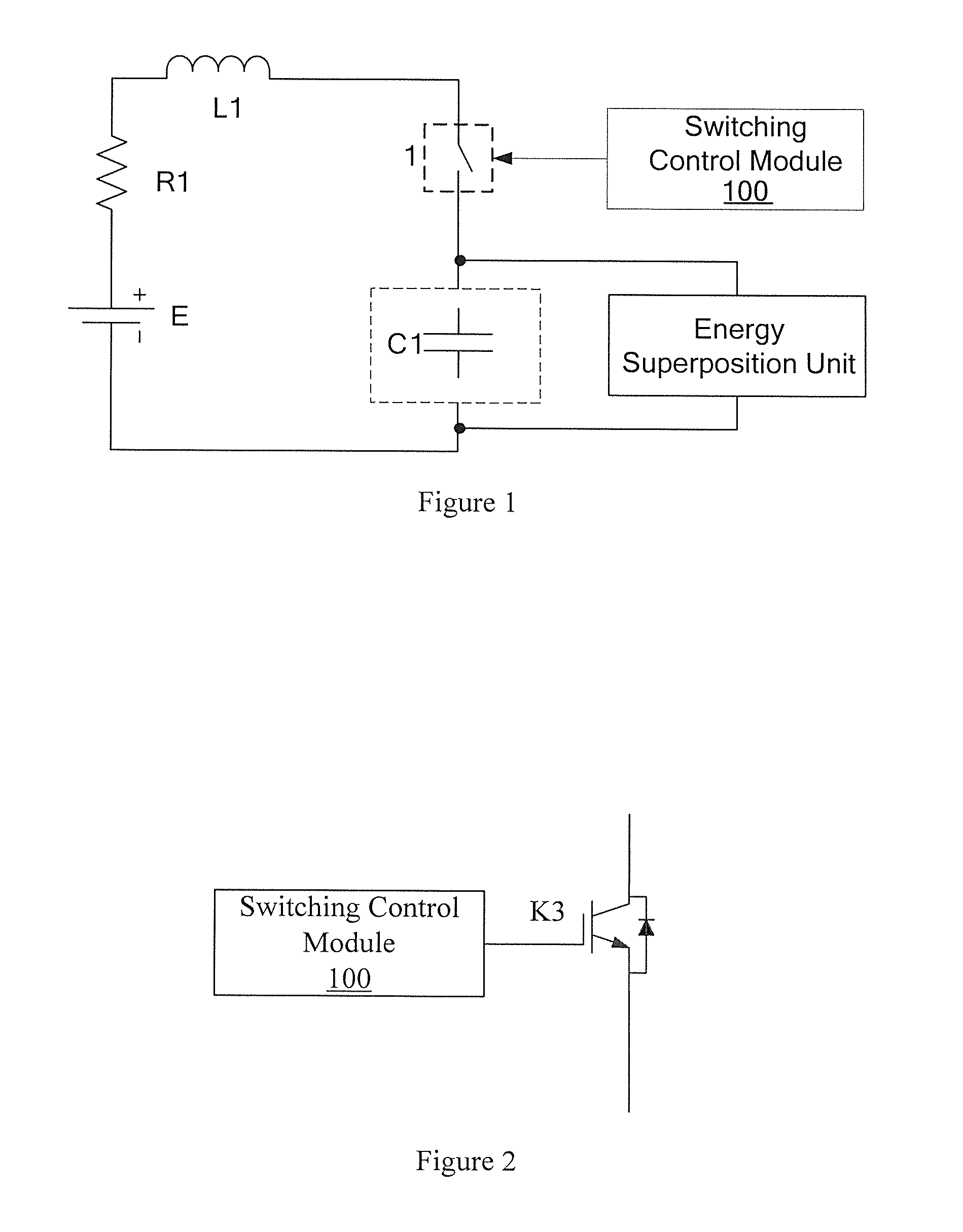

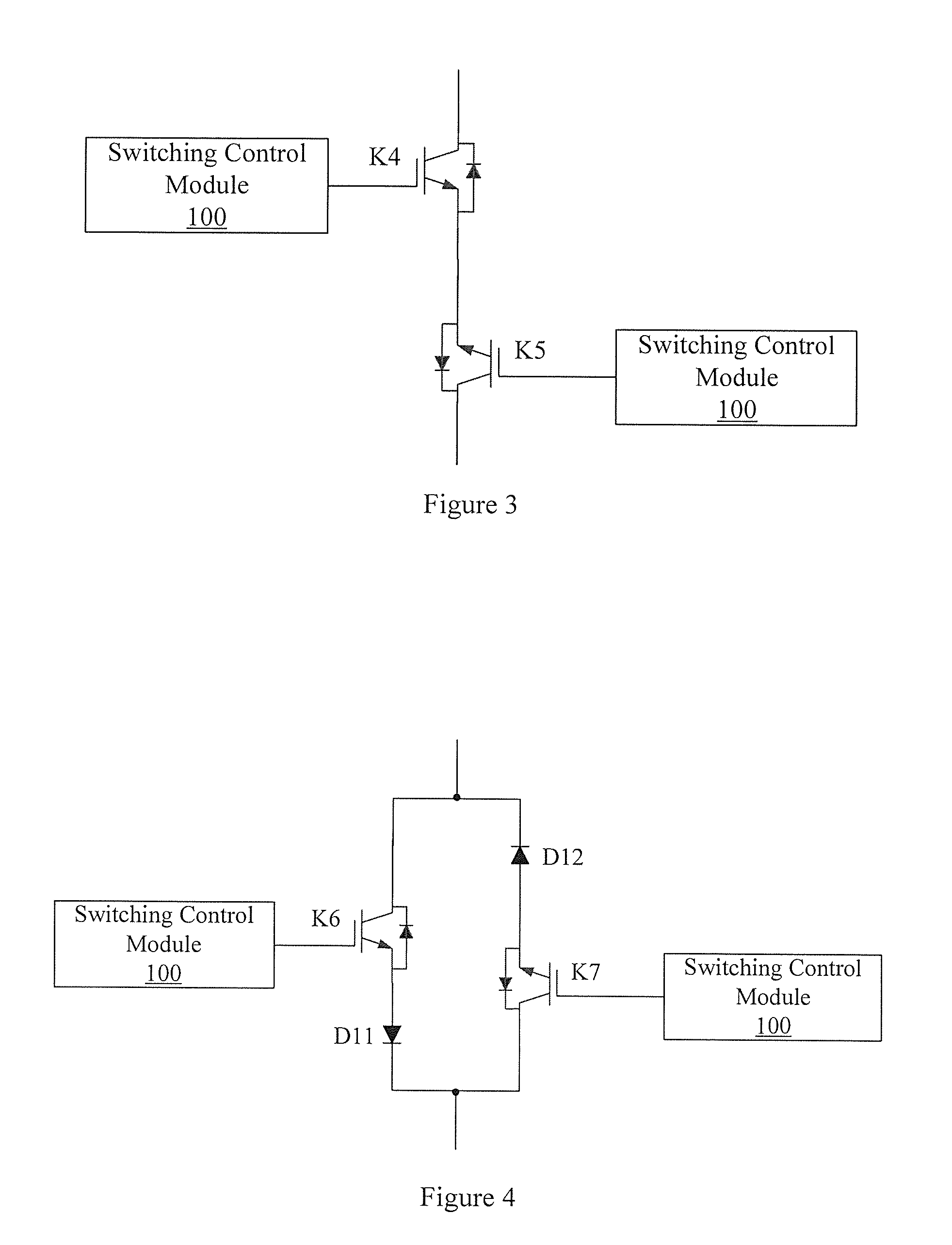

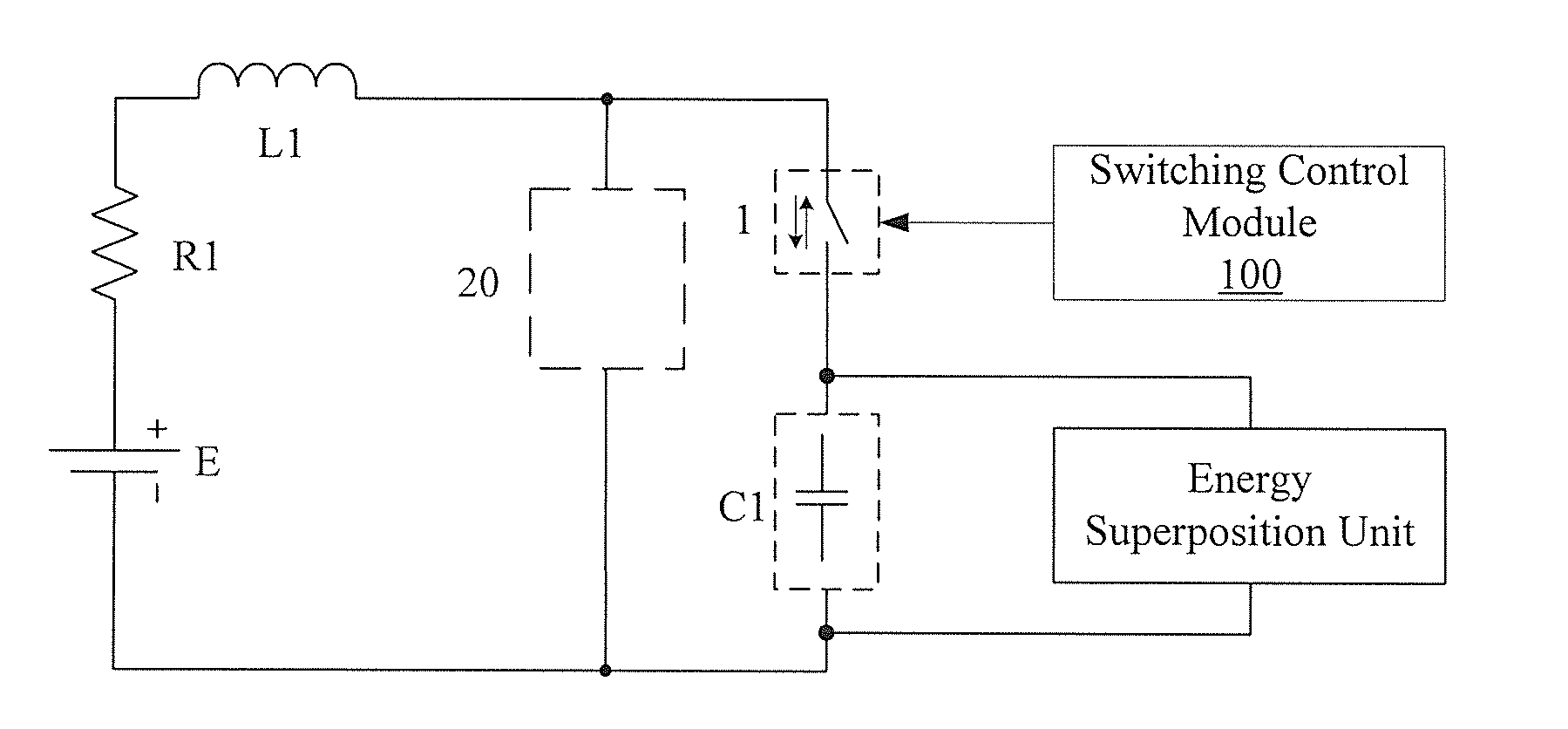

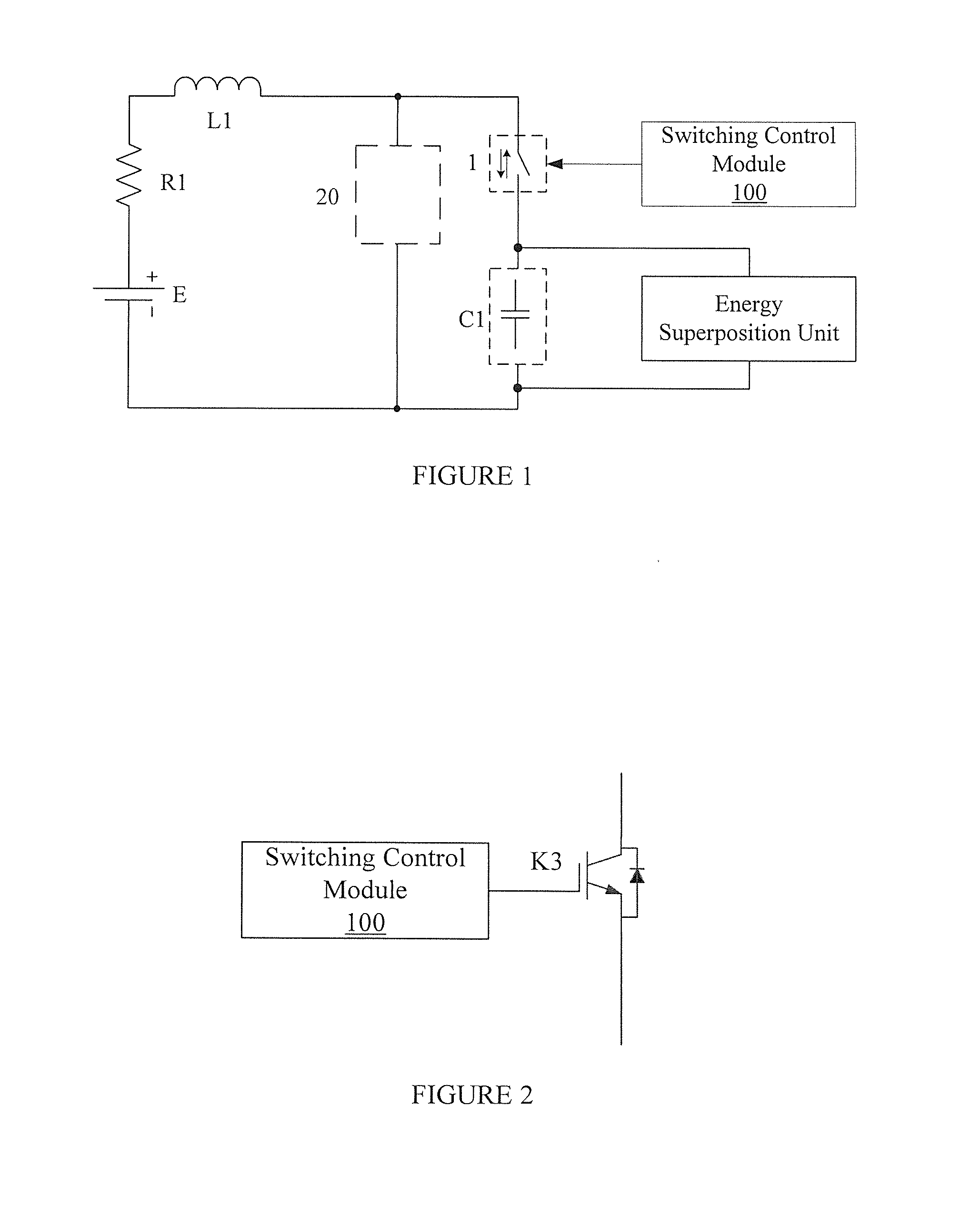

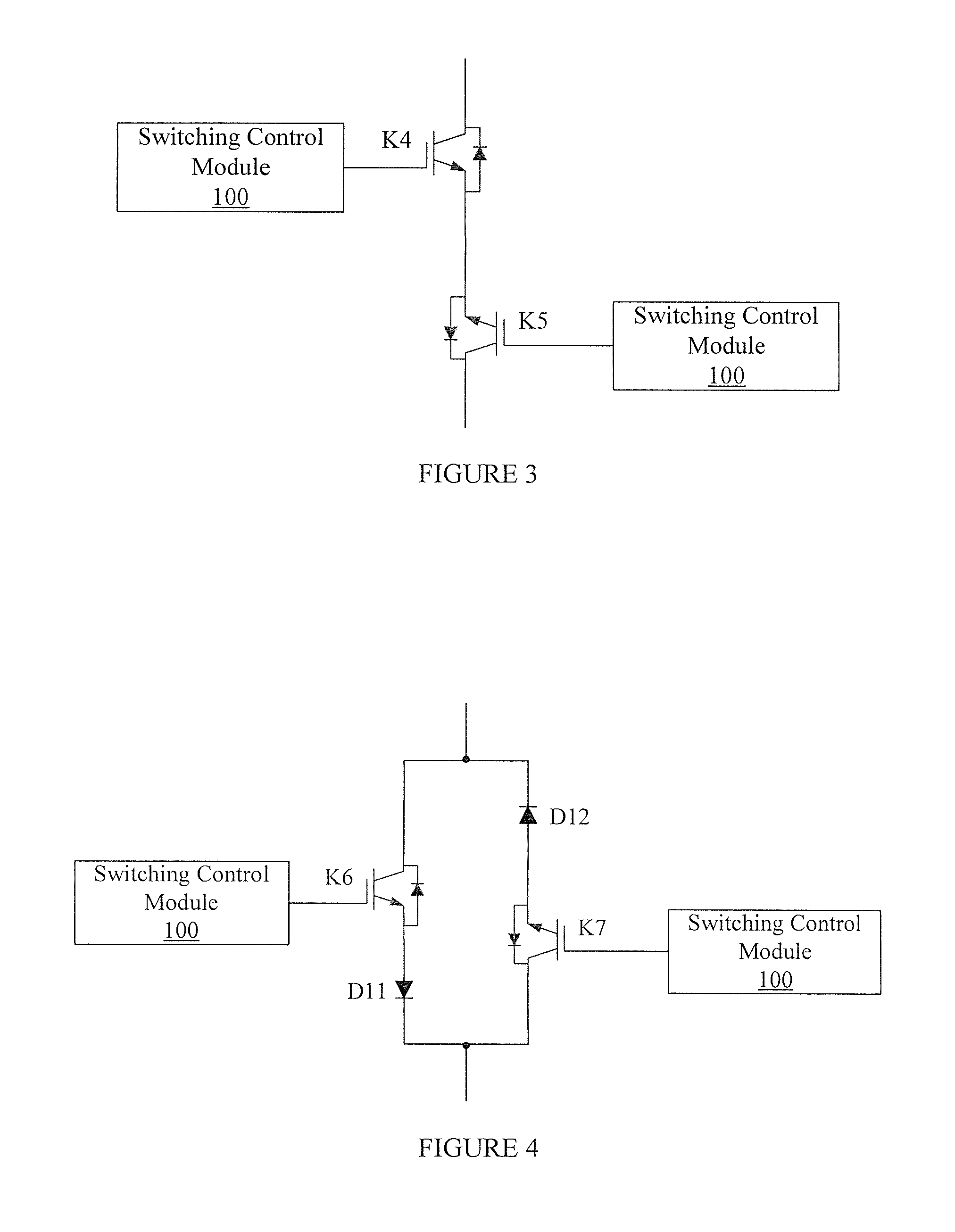

Certain embodiments of the present invention provide a battery heating circuit, comprising a switch unit 1, a switching control module 100, a damping component R1, an energy storage circuit, and an energy superposition unit; the energy storage circuit is configured to connect with the battery to form a loop, and comprises a current storage component L1 and a charge storage component C1; the damping component R1, the switch unit 1, the current storage component L1, and the charge storage component C1 are connected in series; the switching control module 100 is connected with the switch unit 1, and is configured to control ON / OFF of the switch unit 1, so as to control the energy flowing between the battery and the energy storage circuit.

Owner:BYD SEMICON CO LTD

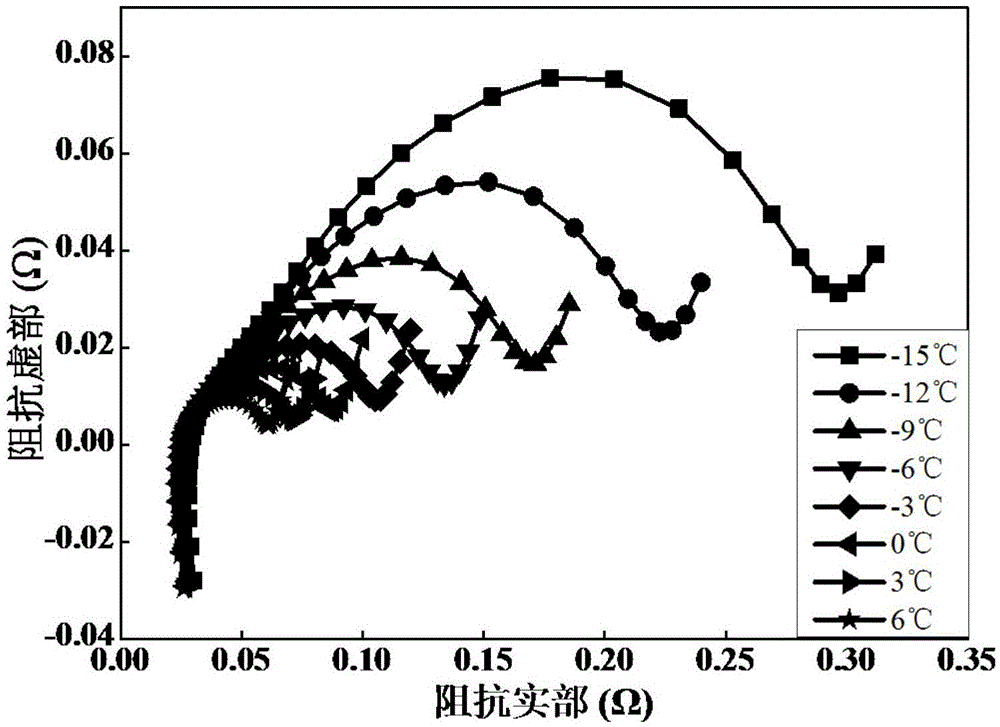

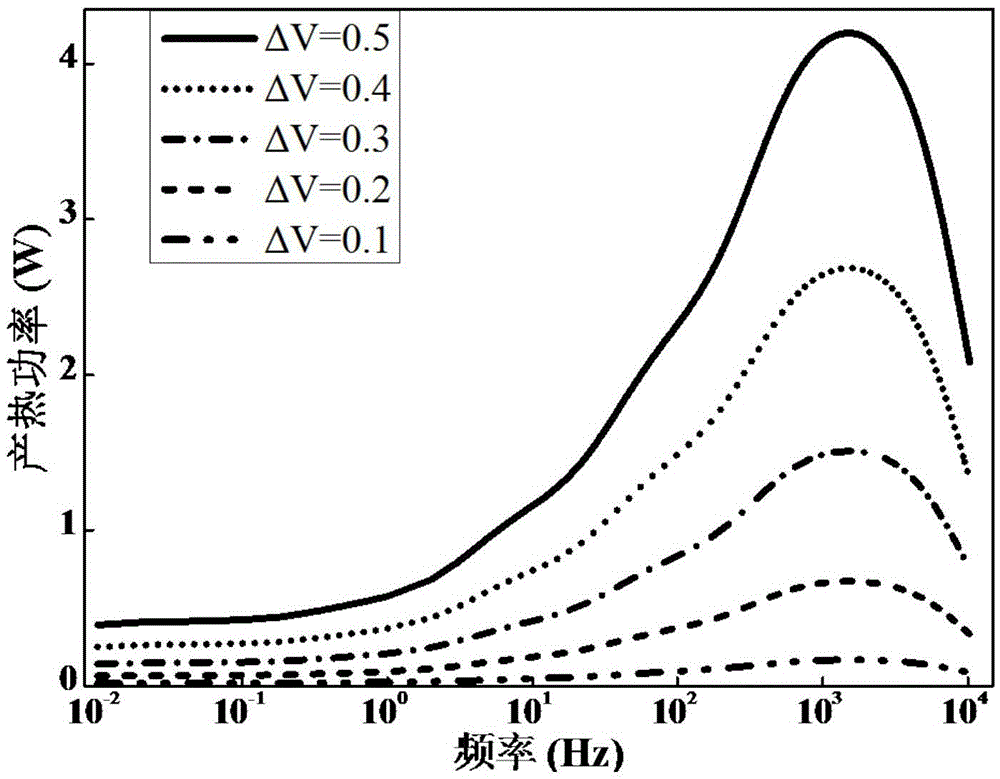

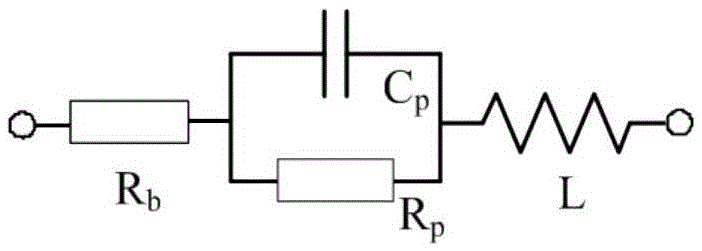

Low-temperature rapid self-heating method for lithium-ion battery

ActiveCN105680114ADetermining the Polarization Voltage Amplitude RangeNo effect on lifespanSecondary cellsVoltage amplitudeElectrical battery

The invention relates to a low-temperature rapid self-heating method for a lithium-ion battery. The method comprises the following steps: (S1) determining a polarization voltage amplitude range which does not have influence on the service lifetime of the lithium-ion battery and is safely used, and selecting a sine AC voltage amplitude according to the range; (S2) calculating the relationship between heat production power and frequency and obtaining a frequency point, namely the optimal heat production frequency point, with the maximum heat production power according to the relationship between battery impedance and frequency under the selected sine AC voltage amplitude; and (S3) carrying out heating free of lifetime loss on the battery by a sine AC signal according to the amplitude determined in the step (S1) and the frequency determined in the step (S2). The low-temperature rapid self-heating method for the lithium-ion battery has the effects of being high in heating rate, obvious in low-temperature performance improvement, free of an influence on the service lifetime of the lithium-ion battery, good in heating temperature uniformity and the like; and the target of reducing the influence on the service lifetime of the lithium-ion battery to the maximal extent is achieved.

Owner:BEIJING BEIJIAO NEW ENERGY TECH CO LTD

Battery heating circuits and methods with resonance components in series using voltage inversion based on predetermined conditions

ActiveUS20120032642A1Reduce battery capacityIncreased polarizationCharge equalisation circuitSemiconductor/solid-state device detailsEngineeringVoltage rating

Certain embodiments of the present invention provide a battery heating circuit, comprising a switch unit (1), a switching control module (100), a damping component R1, an energy storage circuit, and an energy superposition unit, the energy storage circuit is configured to connect with the battery to form a loop, and comprises a current storage component L1 and a charge storage component C1; the damping component R1, the switch unit (1), the current storage component L1, and the charge storage component C1 are connected in series; the switching control module (100) is connected with the switch unit (1), and is configured to control ON / OFF of the switch unit (1), so as to control the energy flowing between the battery and the energy storage circuit; the energy superposition unit is connected with the energy storage circuit, and is configured to superpose the energy in the energy storage circuit with the energy in the battery when the switch unit (1) switches on and then switches off; the switching control module (100) is also configured to control the switch unit (1) to switch off after the first positive half cycle of current flow through the switch unit (1) after the switch unit (1) switches on, and the voltage applied to the switch unit (1) at the time the switch unit (1) switches off is lower than the voltage rating of the switch unit (1).

Owner:BYD SEMICON CO LTD

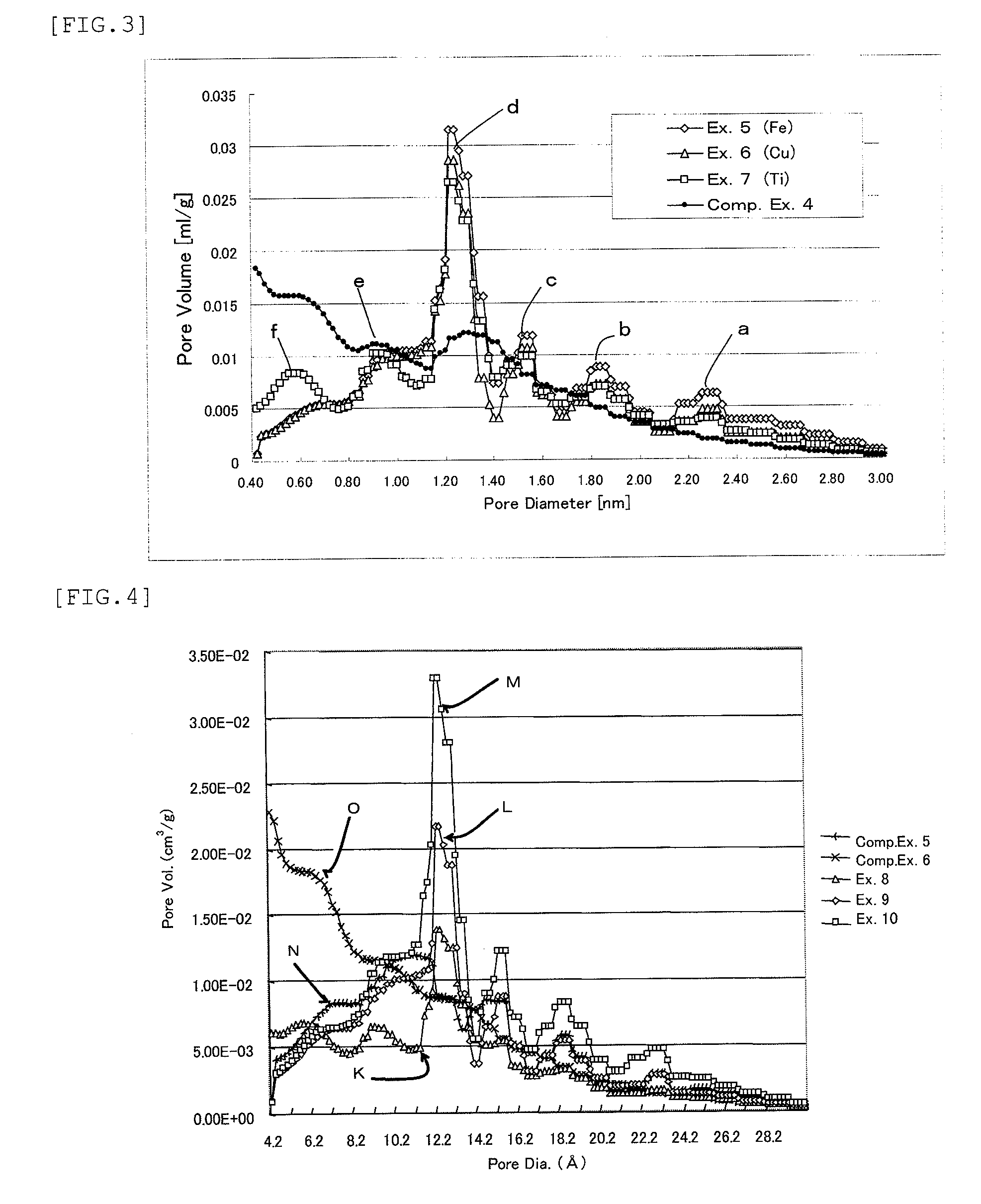

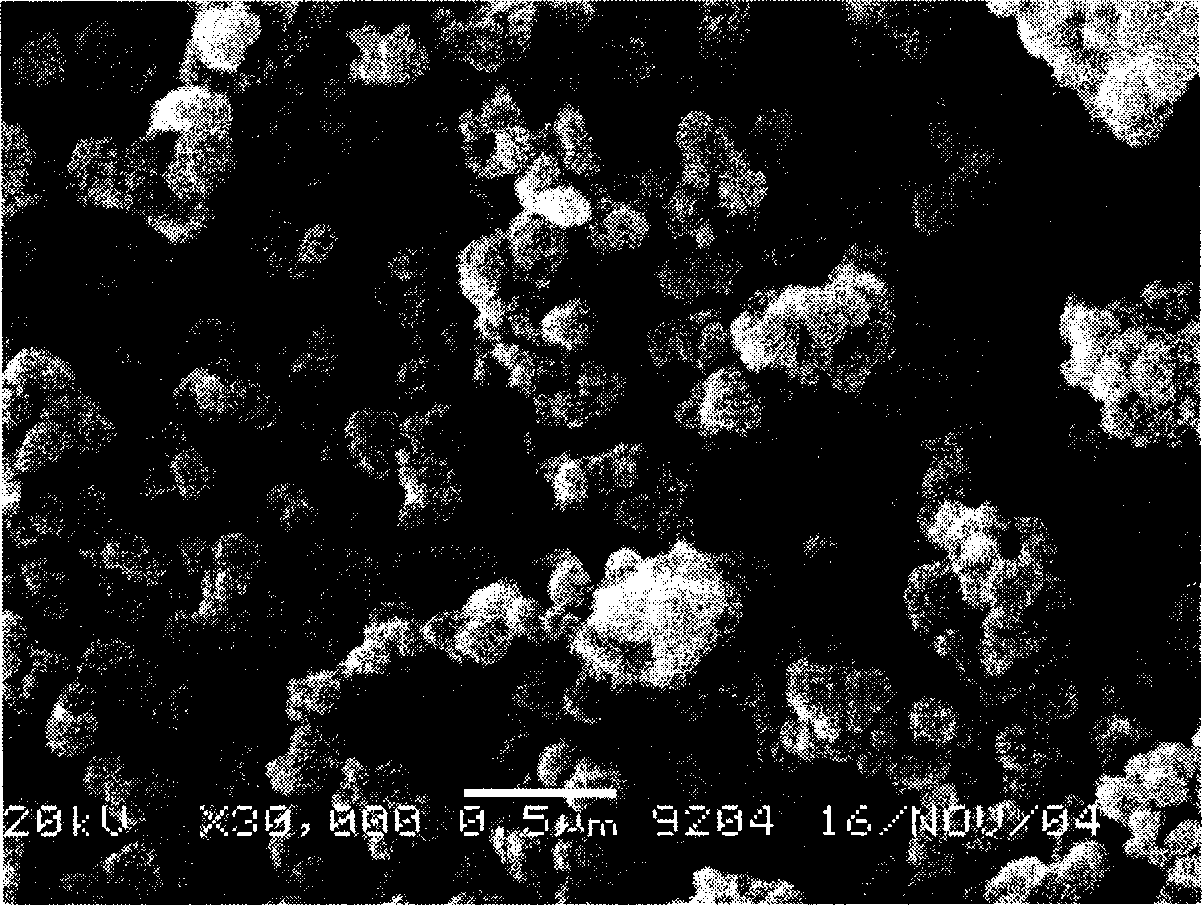

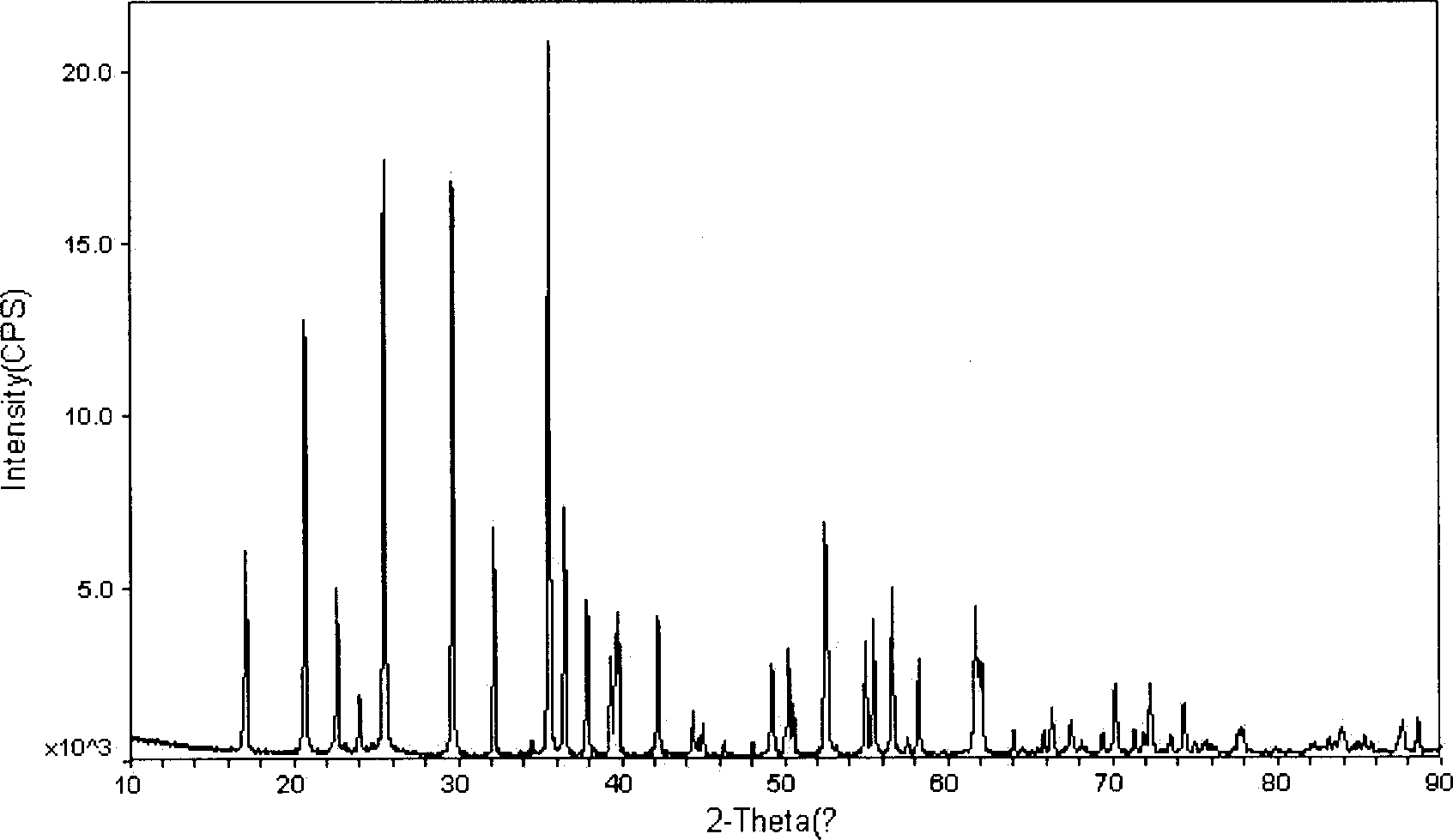

Activated carbon and process of making the same

InactiveUS20090080142A1High electrolytic ion mobilityLower internal resistanceCarbon compoundsOther chemical processesFiberActivated carbon

An activated carbon having the highest peak D within the range of 1.0 nm to 1.5 nm, in which the peak D is from 0.012 to 0.050 cm3 / g and is from 2% to 32% to a total pore volume, in pore size distribution as calculated by BJH method from N2-adsorption isotherm at 77.4 K. An electric double layer capacitor comprising the polarizable electrode which comprises the activated carbon, carbon fiber, carbon black, and binder.

Owner:SHOWA DENKO KK

Mixed cathode diachylon of superbattery and preparation method thereof

The invention discloses mixed cathode diachylon of a superbattery and a preparation method thereof. The diachylon is prepared by mixing the following raw materials in parts by weight: 100 parts of lead powder, 4-10 parts of sulfuric acid, 0.1-8 parts of organic binder, 0.1-2 parts of barium sulfate, 0.01-2 parts of hydrogen separating inhibitor, 1-7 parts of active carbon, 0.1-3 parts of heterodromous graphite, 0.05-1 part of acetylene black, 1-4 parts of humic acid, 5-15 parts of red lead, 12-21 parts of water and 0.1-0.2 part of short fiber. By adding the hydrogen separating inhibitor, the active carbon maintains high-performance capacitance characteristics, so that an electrode has high capacitance. In a part of charge state, the recycling service life of the superbattery is improved by more than 10 times compared with a common lead-acid storage battery.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU +3

Method for improving heavy-current discharge performance of iron phosphate lithium

InactiveCN1805181AImprove high-current discharge performanceSolve easy oxidationElectrode manufacturing processesLithium compoundsLithium iron phosphatePhosphate

The invention relates to a method for preparing the lithium anode material which is characterized in that: mixing the bivalence iron compound, doping metallic compound, phosphor compound and oxidant, to be reacted in the mixing reactor with temperature of 20-100Deg. C and the pH =1-8 for 0.5-24 hours; drying in 30-160Deg. C; mixing attained leading element, the lithium compound and the deoxidize carbon; heating in non-oxygenation condition to 400-800Deg. C in the temperature increase speed of 1-40Deg. C / min to be calcined in constant temperature for 2-35 hours; decreasing the temperature in the speed of 1-20Deg. C / min to attain the final product. The invention uses the carbon heating to deoxidize the trivalent iron which can solve the oxygenation problem of ferrous iron ion; and uses the mixed ferric phosphate and doping phosphate as leading elements to solve the uniform mixing problem of doping elements and improve the conductivity of material to improve the big current (o.8C) discharge / charge property, with short preparation time, easy control, lower energy consumption and lower cost.

Owner:CENT SOUTH UNIV

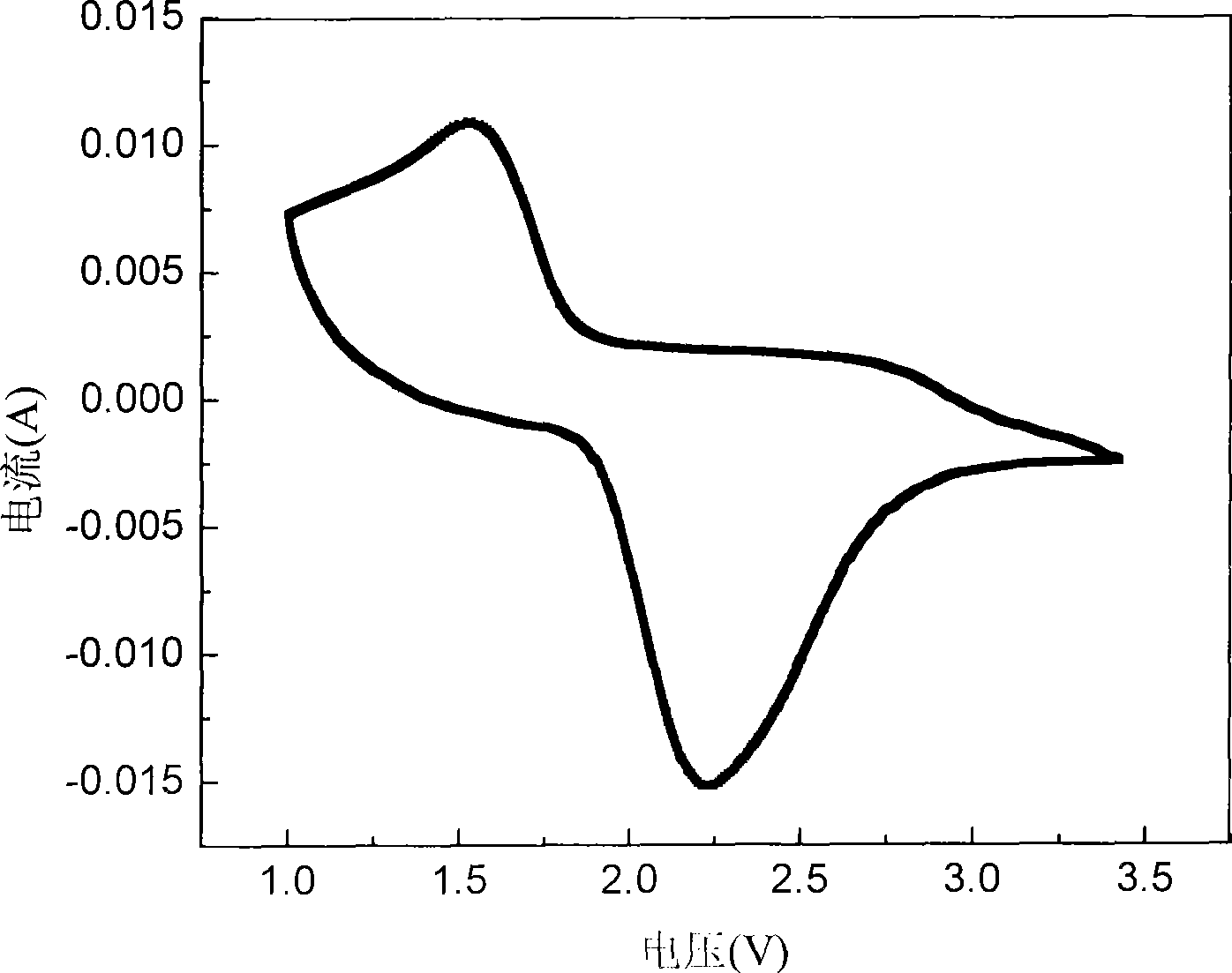

High-reliability vanadium ion electrolyte

InactiveCN102110836AInhibit precipitationImprove stabilityRegenerative fuel cellsCharge and dischargeSulphate Ion

The invention provides a high-reliability vanadium ion electrolyte, which is composed of vanadium sulphate, sulfuric acid, water and an additive, wherein the additive comprises at leas one material selected from the group consisting of an alkali metal salt, a hydroxyl-containing material and a surfactant. The high-reliability vanadium ion electrolyte provided by the invention, the deposition of V (V) and the oxidization of V (II) are effectively controlled by adding a novel additive composition into vanadium ion electrolyte and using the synergistic effects among the components of the additive, the stability of the electrolyte is greatly improved, and the charge and discharge properties and circulation stability of a vanadium battery effectively are improved by applying the vanadium ion electrolyte obtained to the vanadium battery.

Owner:上海林洋储能科技有限公司

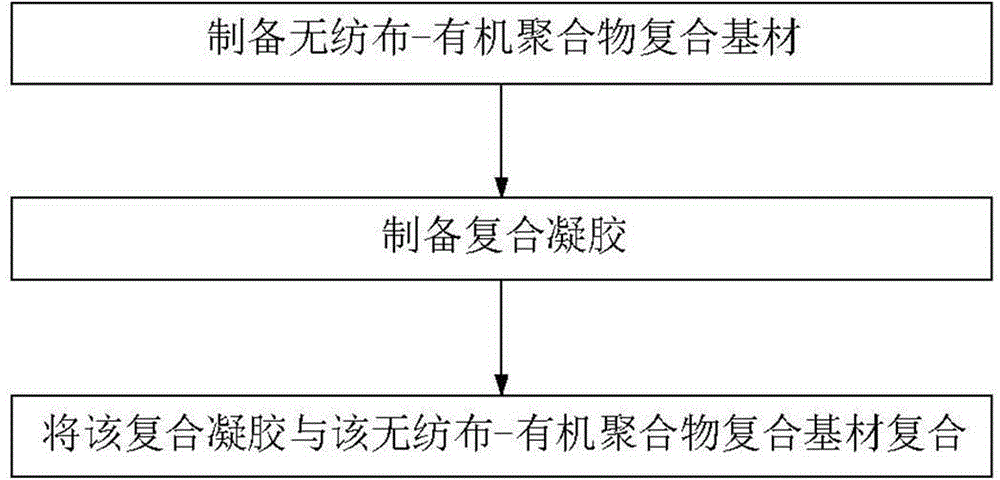

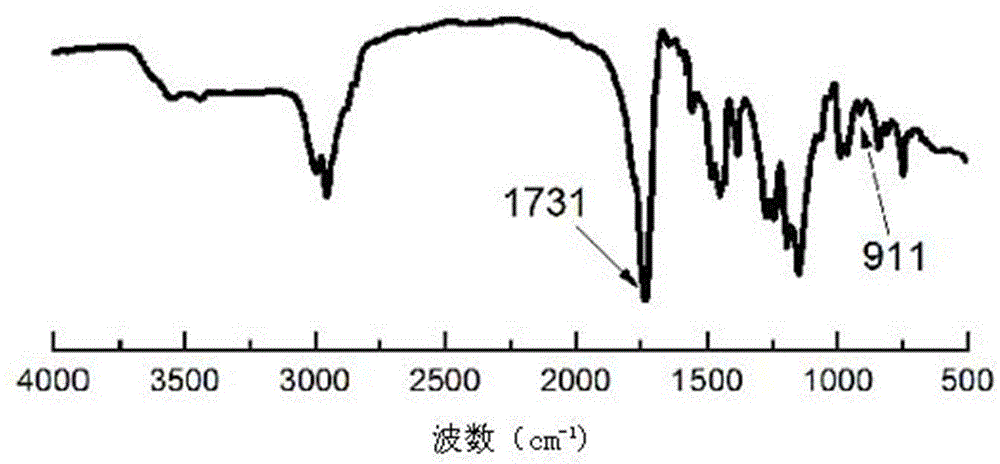

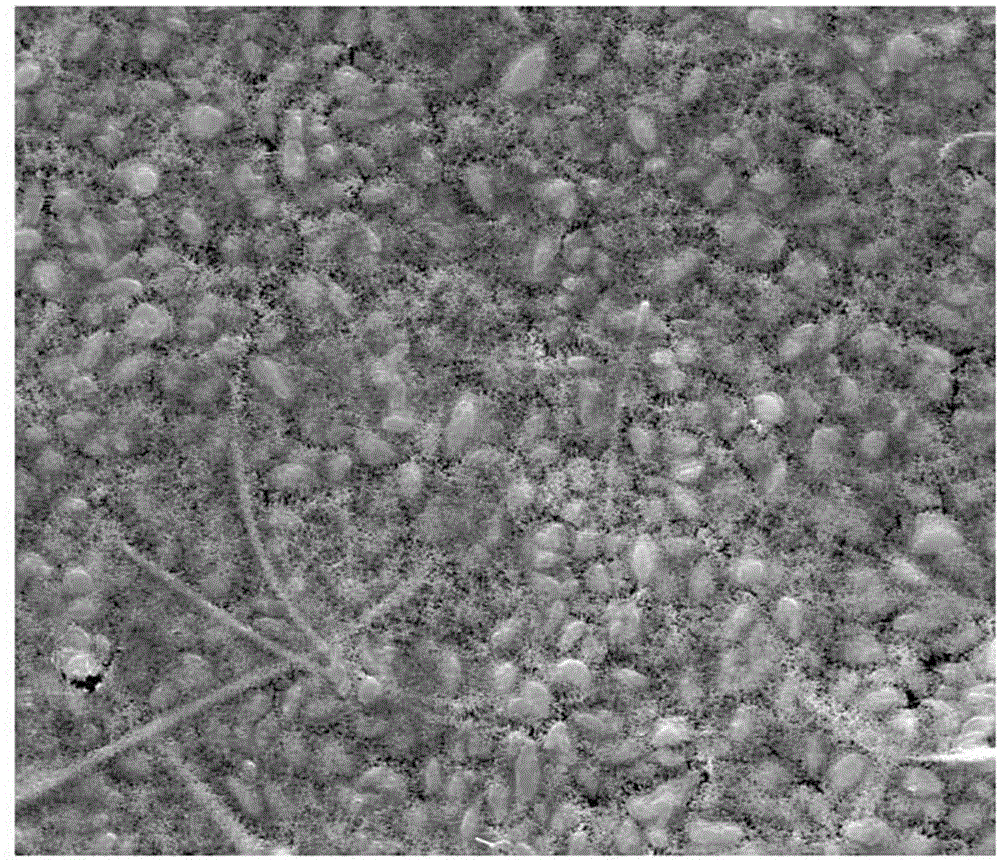

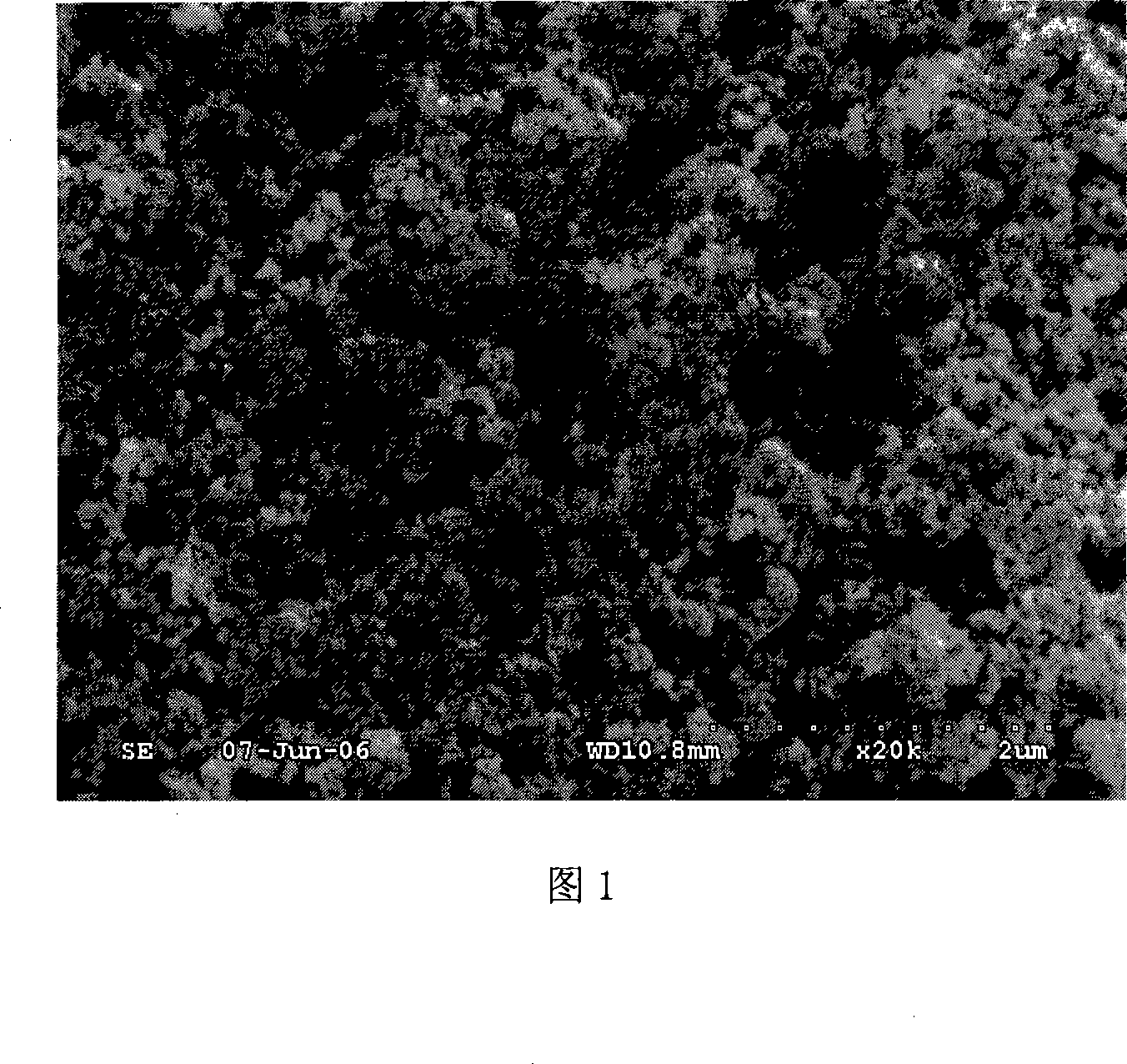

Composite diaphragm, preparation method thereof and lithium ion battery

ActiveCN104088155AGood thermal dimensional stabilityImprove safety and charge and discharge performanceFibre typesSecondary cellsMethyl methacrylateSilane coupling

The invention relates to a composite diaphragm. The composite diaphragm comprises a non-woven fabric-organic polymer composite base material, and a composite gel compounded with the non-woven fabric-organic polymer composite base material, wherein the non-woven fabric-organic polymer composite base material comprises a non-woven fabric and a cross-linked polymer, and the cross-linked polymer is formed by copolymerization of a polymer monomer containing alkenyl and alkoxy silane containing alkenyl in the presence of a catalyst and a cross-linking agent; the composite gel comprises a gel polymer and inorganic modified nano powder, and the inorganic modified nano-powder comprises a polymer formed by copolymerization of methyl methacrylate and a silane coupling agent containing C=C groups, and further comprises a nano-sol connected with the alkoxy silane by virtue of condensation reaction. The invention also relates to a preparation method of the composite diaphragm and a lithium ion battery.

Owner:JIANGSU HUADONG INST OF LI ION BATTERY +1

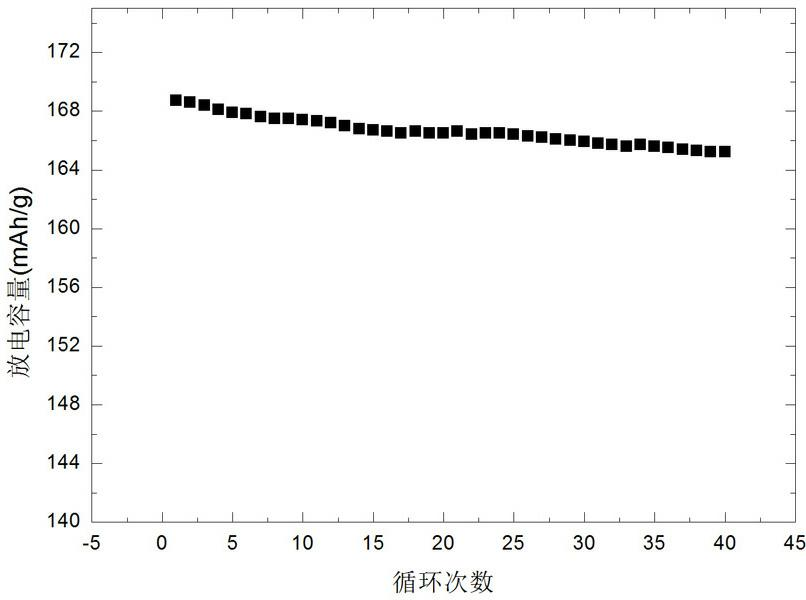

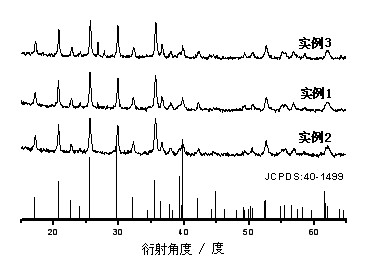

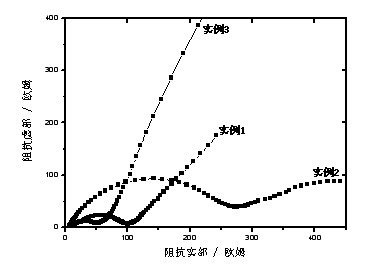

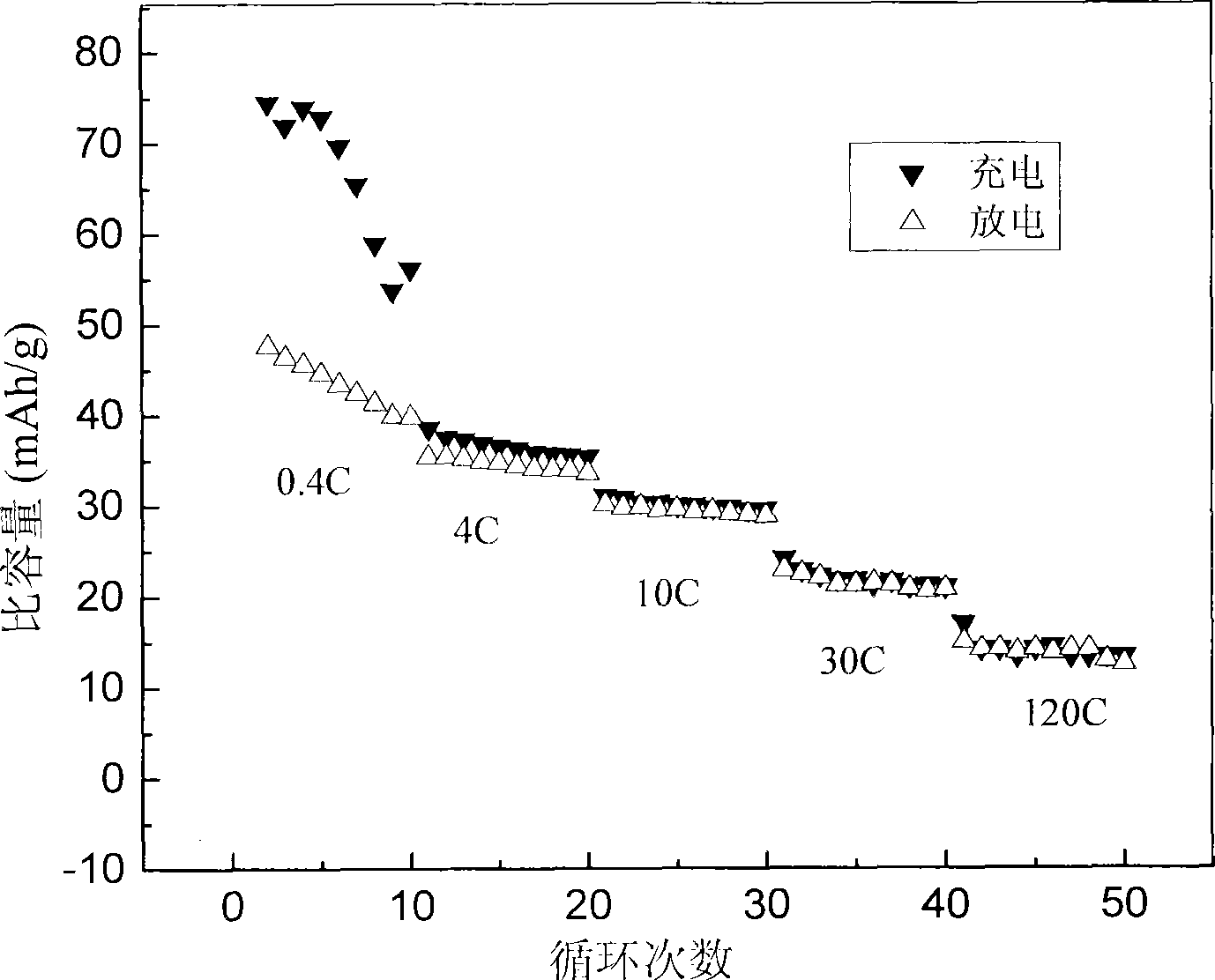

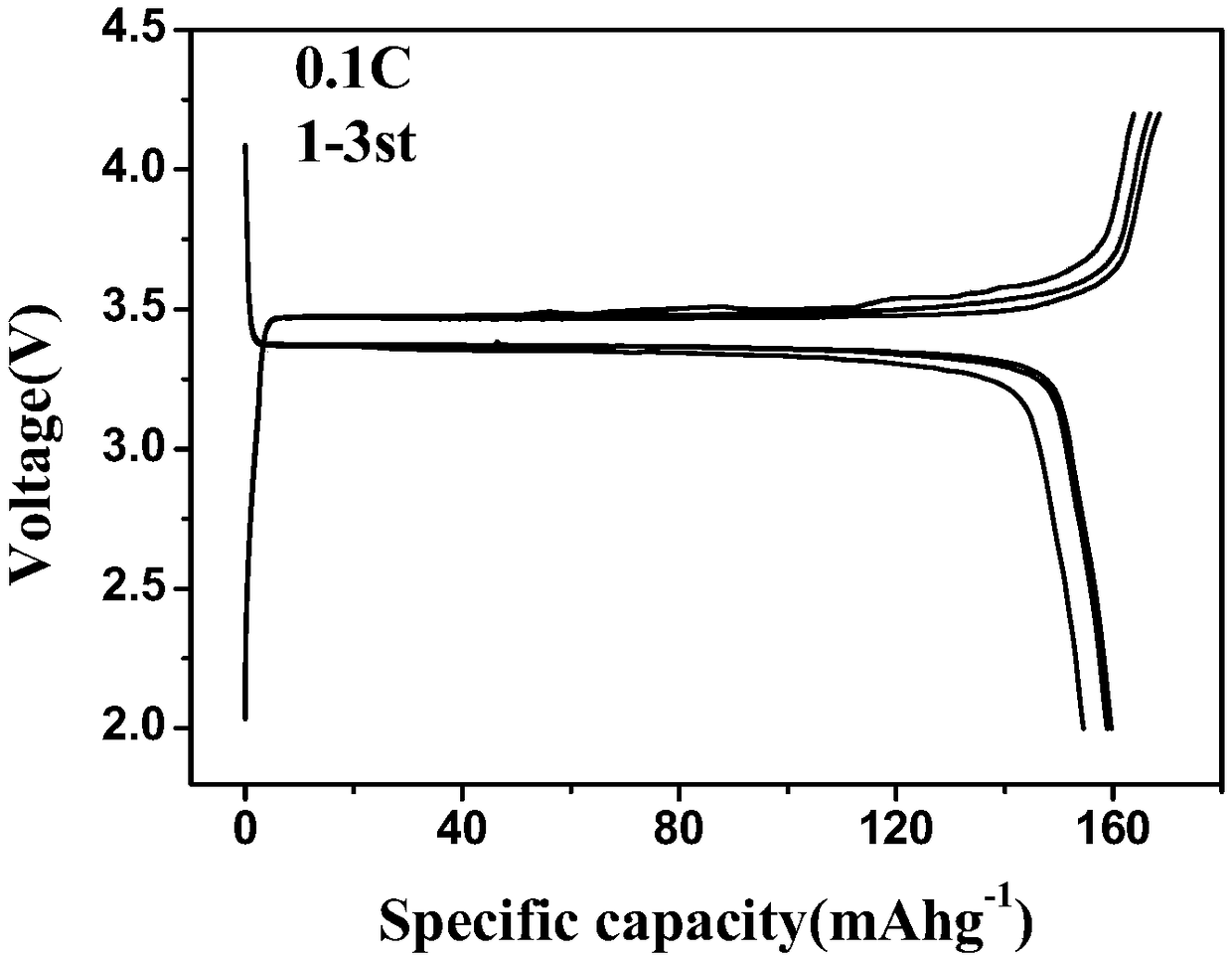

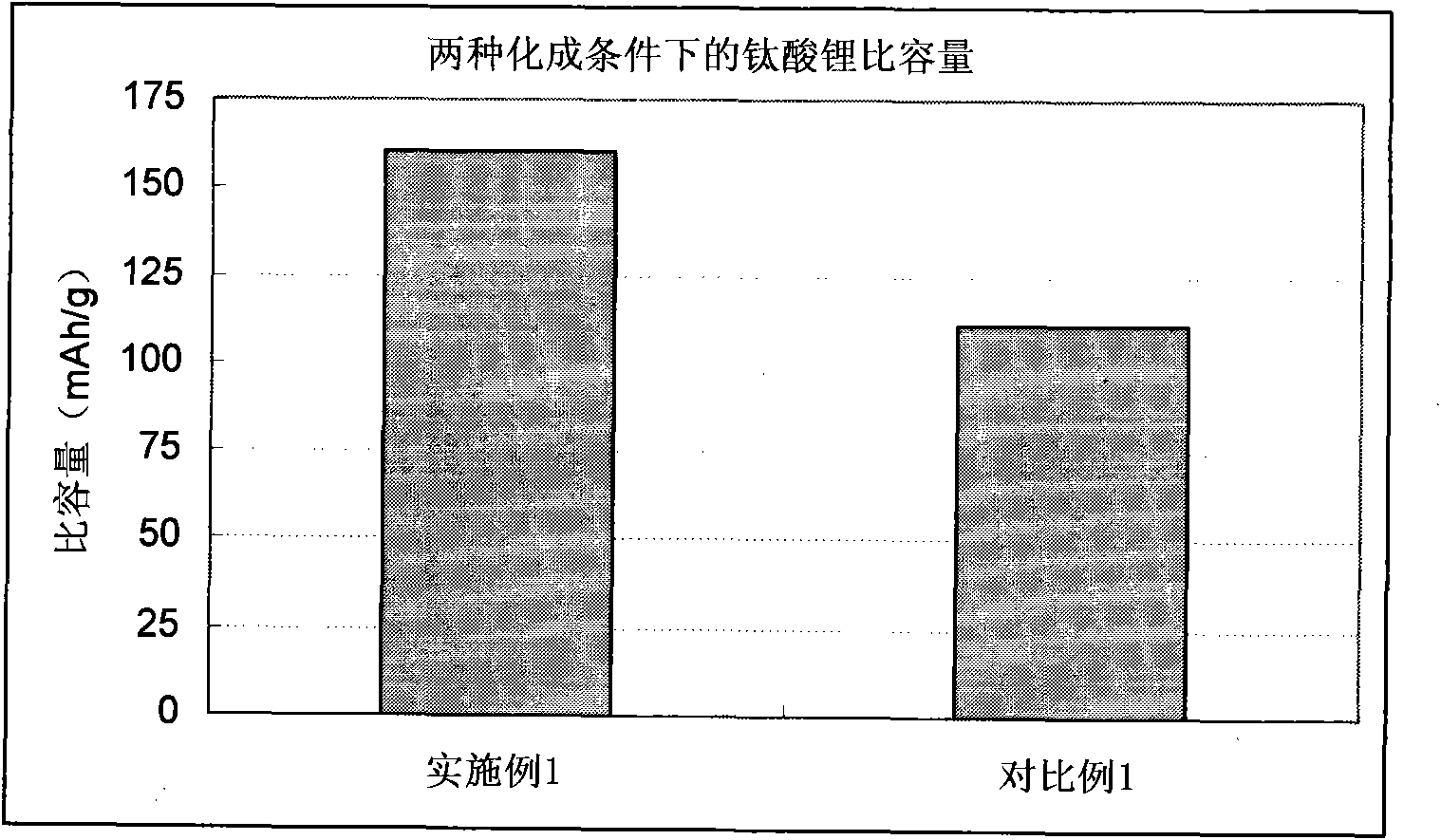

Method for preparing nano-crystal lithium-titanium composite oxide

InactiveCN101058438ARich reservesReserves are cheapNanostructure manufactureCell electrodesCapacitanceWater baths

The invention discloses a making method of nanometer crystal Li-Ti composite oxide, which comprises the following steps: adopting titanium powder or titanium compound as raw material; blending the materials with 30% hydrogen peroxidate under low temperature; adding certain quantity of lithium salt solution and moulder; stirring evenly; reacting under water bath condition at 50-100 deg. c completely; drying the composite system directly to produce predecessor; proceeding heat disposal for the predecessor at 200-400 deg. c for 2-6h; heating to 600-1000 deg. c; sintering 8-36h; cooling; grinding; obtaining the nanometer crystal Li-Ti composite oxide with spinel structure and the content of Li4Ti5O12 over 90%; controlling the even grain size of the product between 15nm and 100nm and specific surface area between 10 and 100m2 / g due to different aperture shape of moulds, sintering time and temperatures; making the reversible specific capacity of the product over 160mAh / g under 0. 1C charging and discharging condition; keeping the capacity maintaining rate between 50% and 70% under discharging condition at 100deg. c as ideal negative electrode material of lithium ion dynamic battery and lithium ion super-capacitance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method of lithium iron phosphate/carbon nanotube composite material

InactiveCN102569796AImprove conductivityProne to clusteringMaterial nanotechnologyCell electrodesElectrical batteryActive agent

The invention provides a preparation method of a lithium iron phosphate / carbon nanotube composite material. The preparation method comprises the steps of: dissolving a lithium source and a phosphate source in a mixed liquor agent prepared from alcohol and water to prepare a reaction solution, then adding a ferrous source and a reducing agent, then adding a surfactant, finally adding carbon nanotubes, reacting for 6-8h in a polytetrafluoroethylene high-pressure reaction kettle at 160-200 DEG C to obtain a precursor, calcining the obtained precursor at 600-800 DEG C under the protection of inert gas to prepare the lithium iron phosphate / carbon nanotube composite material with favorable performance. The lithium iron phosphate prepared according to the invention has the advantages of high purity, small grain size, regular shapes and the like, and the carbon nanotubes are embedded into the interiors or cladded onto the surfaces of lithium iron phosphate particles to play a role of electric conductive network, so that the composite material achieves an excellent electrochemical property and is an ideal cathode material for preparing the lithium ion battery.

Owner:SOUTHEAST UNIV

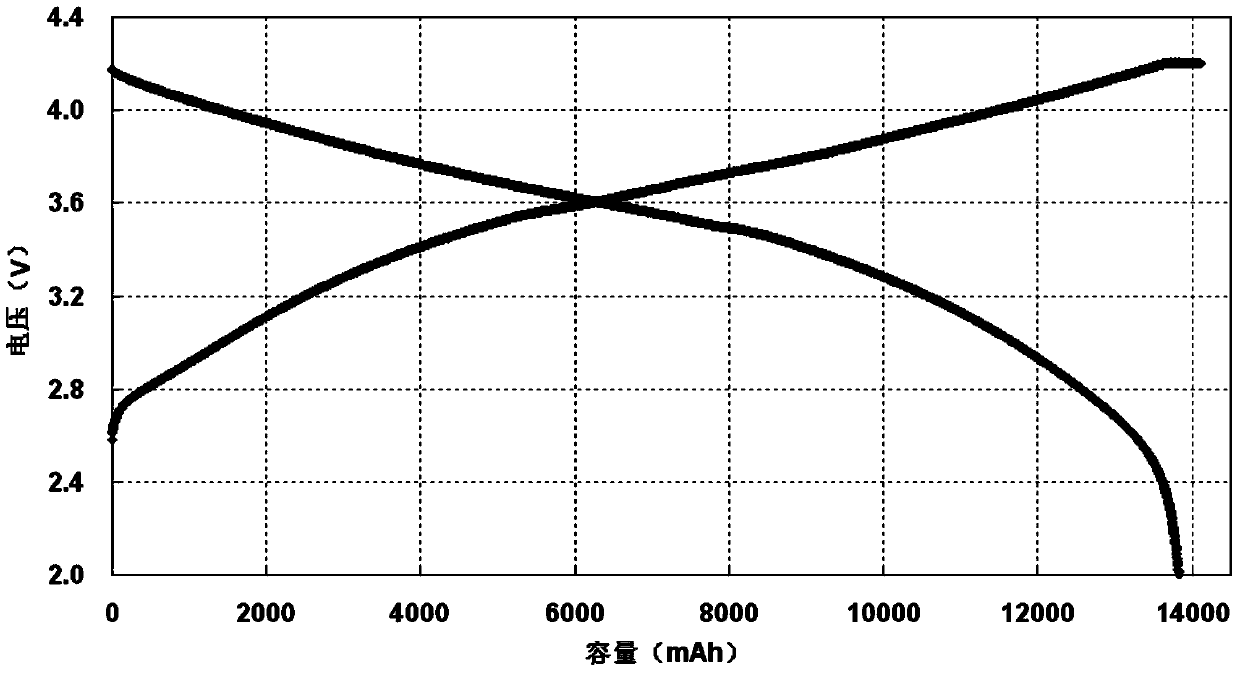

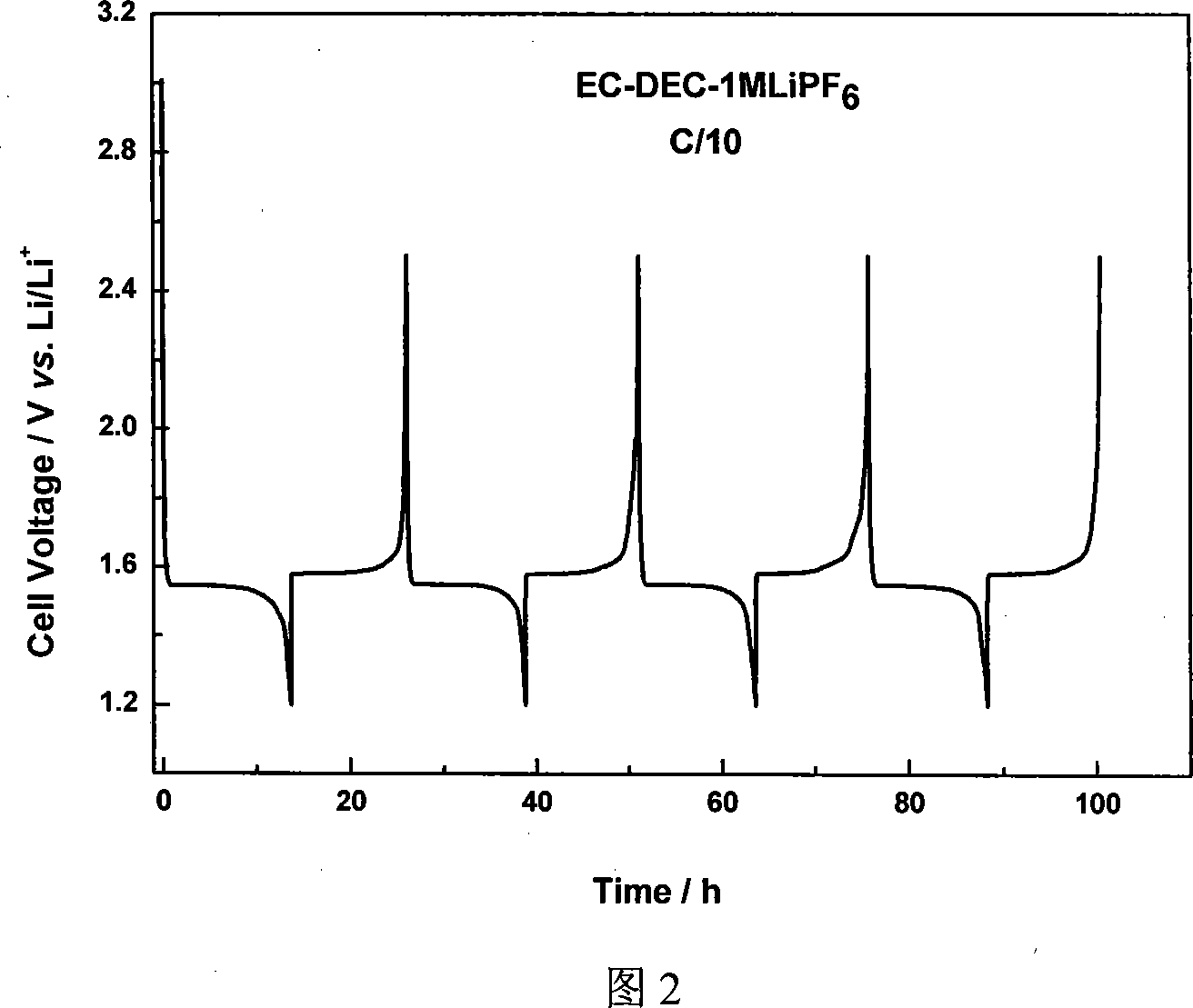

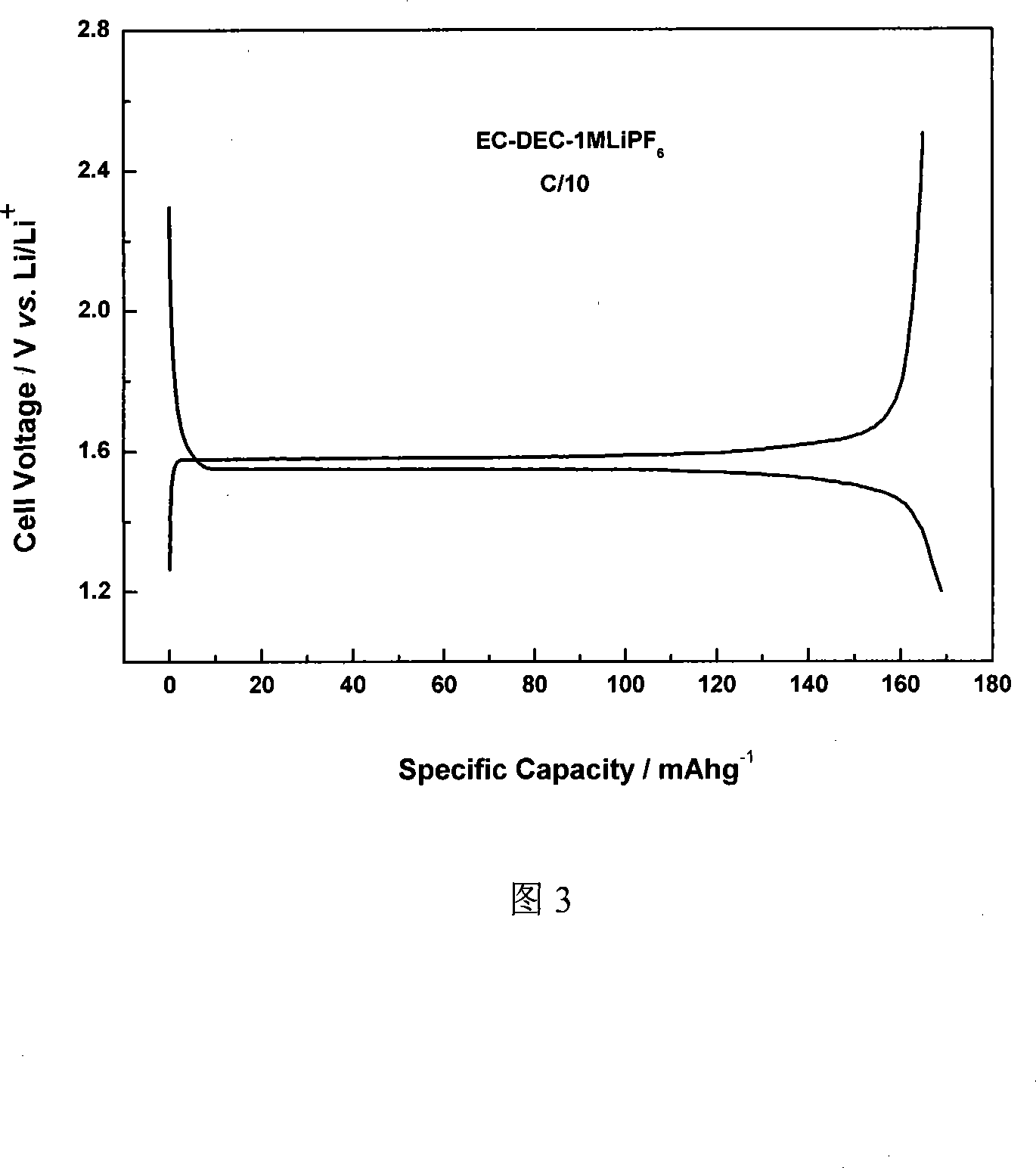

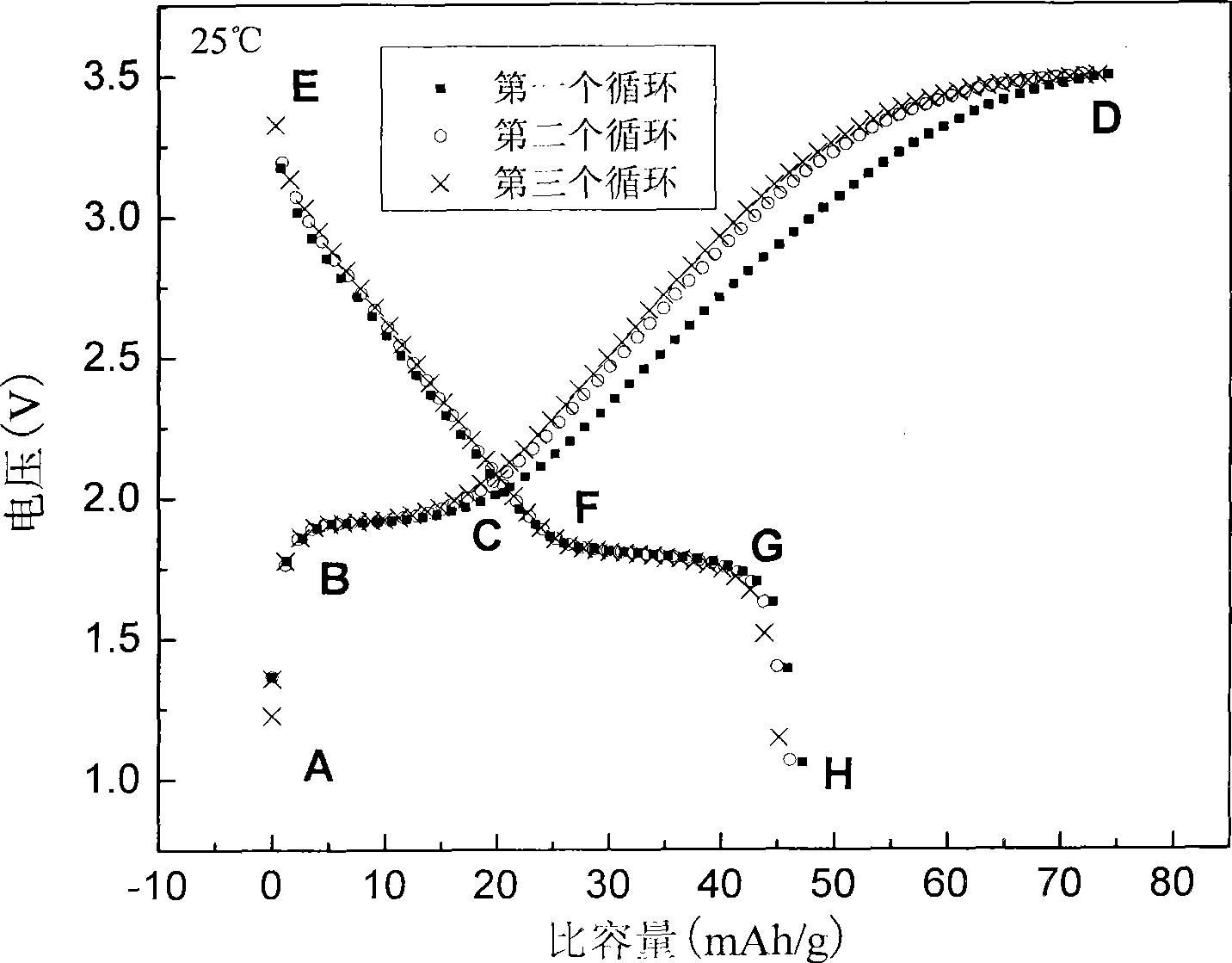

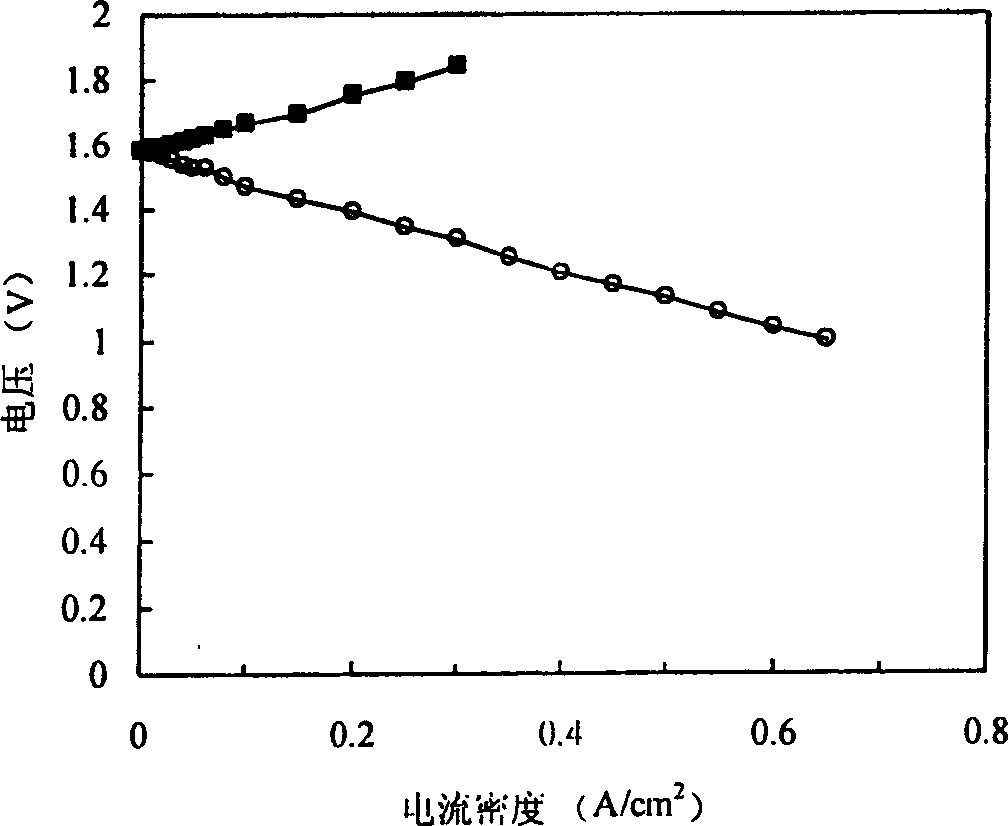

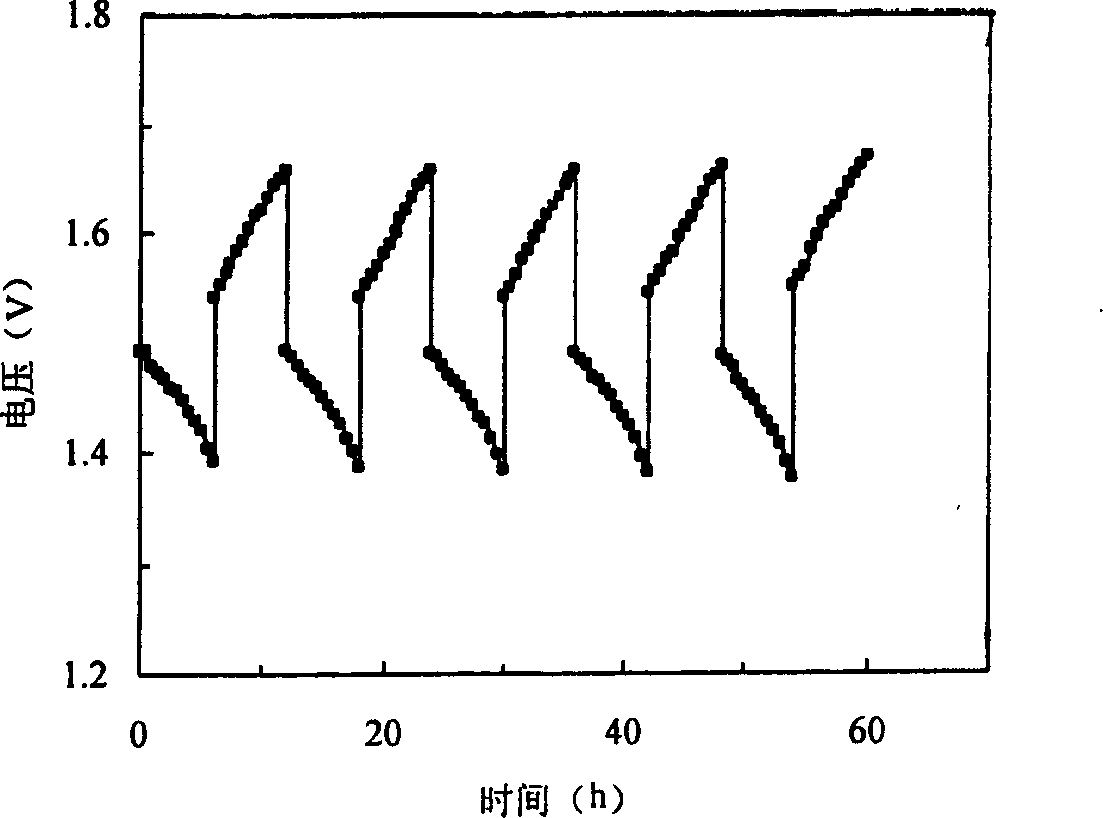

Asymmetric lithium iron phosphate cell using lithium titanate as main active substance of negative pole

InactiveCN101488584AImprove charge and discharge performanceHigh specific powerFinal product manufactureCell electrodesPolyvinylidene fluorideActivated carbon

The invention discloses an unsymmetrical lithium iron phosphate battery, the negative pole of which takes lithium titanate as the main active substance, belonging to the technical field of non water electrolysis liquid lithium ion battery or hybrid battery. The battery comprises an anode, a cathode, a diaphragm and electrolyte; wherein the main active substance of the anode is lithium iron phosphate powder, lithium iron titanate powder added with activated carbon or lithium iron phosphate powder added with carbon nanotube, the anode material also comprises caking agent, conductive agent and dispersing agent; the main active substance of the cathode is lithium titanate powder, compound copper, argentum, or lithium titanate powder or semi-conductive modified lithium titanate power, the cathode material also comprises the caking agent, the conductive agent and the dispersing agent. The caking agent is polyvinylidene fluoride, the conductive agent is acetylene black, and the dispersing agent is N-methyl pyrrolidone. The invention has good discharging property under heavy current, and can maintain high specific power and high specific energy.

Owner:TSINGHUA UNIV

Battery heating circuits and methods with resonance components in series using voltage inversion and freewheeling circuit components

ActiveUS20120031890A1Reduce battery capacityIncreased polarizationCharge equalisation circuitSemiconductor/solid-state device detailsResonanceComputer module

Certain embodiments of the present invention provide a battery heating circuit, comprising a switch unit (1), a switching control module (100), a damping component R1, an energy storage circuit, a freewheeling circuit (20), and an energy superposition unit, the energy storage circuit is configured to connect with the battery to form a loop, and comprises a current storage component L1 and a charge storage component C1; the damping component R1, the switch unit (1), the current storage component L1, and the charge storage component C1 are connected in series; the switching control module (100) is connected with the switch unit (1), and is configured to control ON / OFF of the switch unit (1), so as to control the energy flowing between the battery and the energy storage circuit; the energy superposition unit is connected with the energy storage circuit, and is configured to superpose the energy in the energy storage circuit with the energy in the battery when the switch unit (1) switches on and then switches off; the freewheeling circuit (20) is configured to form a serial loop with the battery and the current storage component L1 to sustain current flow in the battery after the switch unit (1) switches on and then switches off.

Owner:BYD SEMICON CO LTD

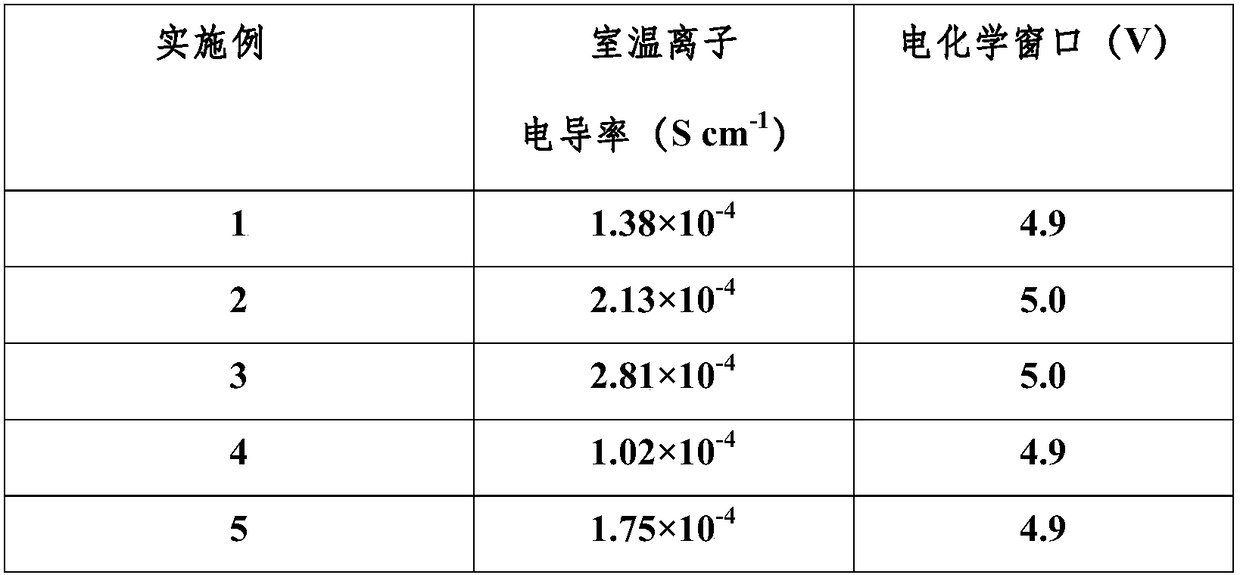

Preparation and application of organic-inorganic composite solid-state electrolyte

ActiveCN108878959AImprove mechanical propertiesImprove thermal stabilitySolid electrolytesSecondary cellsSolid state electrolytePtru catalyst

The invention relates to preparation and application of an organic-inorganic composite solid-state electrolyte, and relates to the technical field of a lithium ion battery electrolyte. The organic-inorganic composite solid-state electrolyte is prepared by selecting an isocyanate compound having rigid characteristic, a flexible chain segment compound capable of complexing and dissociating with lithium ions, inorganic nanoparticles, a conductive lithium salt and an organic solvent and adding a tin catalyst for crosslinking and curing. With the isocyanate compound, the mechanical property and thethermal stability of the composite solid-state electrolyte can be improved; by the flexible chain segment compound and the inorganic nanoparticles, the ion conductivity, the ion transfer number and the wide electrochemical window of the composite solid-state electrolyte can be improved, the charge-discharge performance of the lithium ion battery is improved, and the interface contact of the solid-state lithium ion battery is improved; and the organic-inorganic composite solid-state electrolyte has the advantages of excellent interface stability, wide electrochemical window, wide working temperature range, high ion conductivity and versatile shapes and is applicable to a lithium ion polymer battery.

Owner:BEIJING UNIV OF TECH

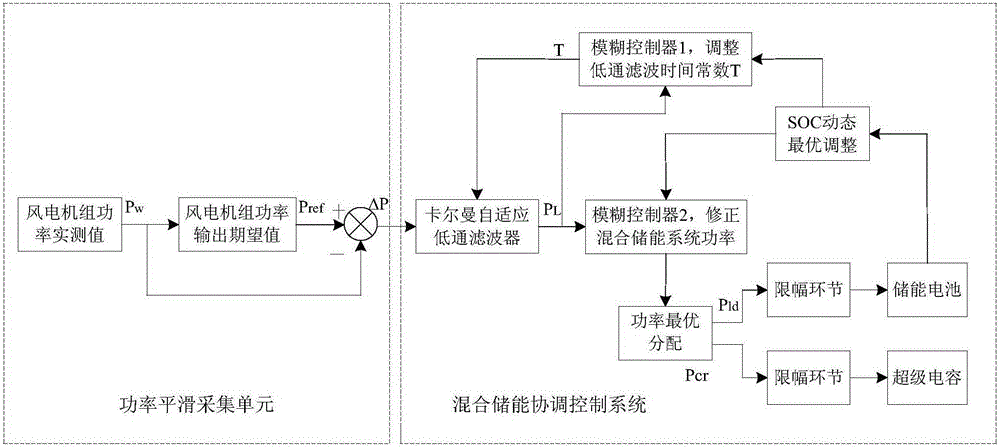

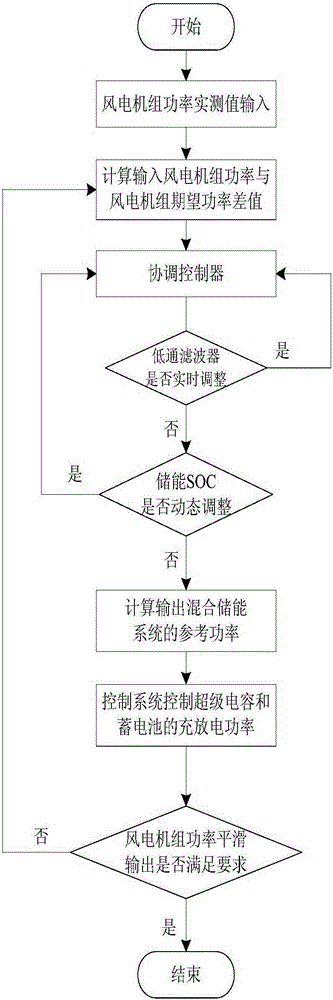

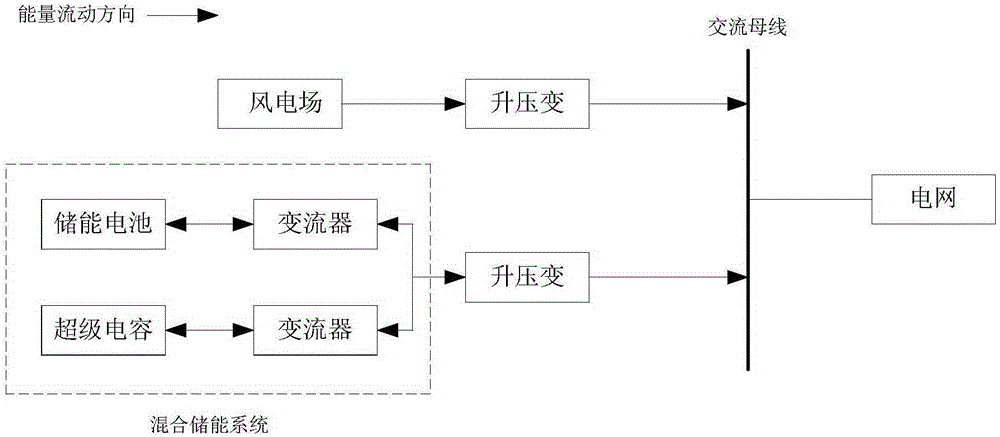

Hybrid energy storage control system for stabilizing wind power fluctuation and control method

ActiveCN105162147ASmooth out output power fluctuationsImprove charge and discharge performanceSingle network parallel feeding arrangementsEnergy storageAutomotive engineeringCapacitance

The invention discloses a hybrid energy storage control system for stabilizing wind power fluctuation and a control method. The system comprises a power smooth acquisition unit and a hybrid energy storage coordination control unit. Wind power set power can be acquired by the power smooth acquisition unit in real time, the wind power set power is contrasted with a desired output power value of a wind power set, after amplitude limit processing, the wind power set power is sent to the hybrid energy storage coordination control unit, Karman adaptive low pass filtering is carried out by the hybrid energy storage coordination control unit according to a power deviation value to acquire a power output value of a wind power set, a first fuzzy controller is for adjusting time constant of a Karman low pass filter, correction on a power output value of the hybrid energy storage system is carried out by a second fuzzy controller after output power of the Karman low pass filter and energy storage cell state-of-charge SOC are acquired by the second fuzzy controller, after the amplitude limit stage, optimum power output is acquired by an energy storage cell and a super capacitor, so over-discharging and over-charging of the cell are avoided, and thereby safety operation of the energy storage system and the optimum wind power fluctuation stabilizing effect are realized.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +3

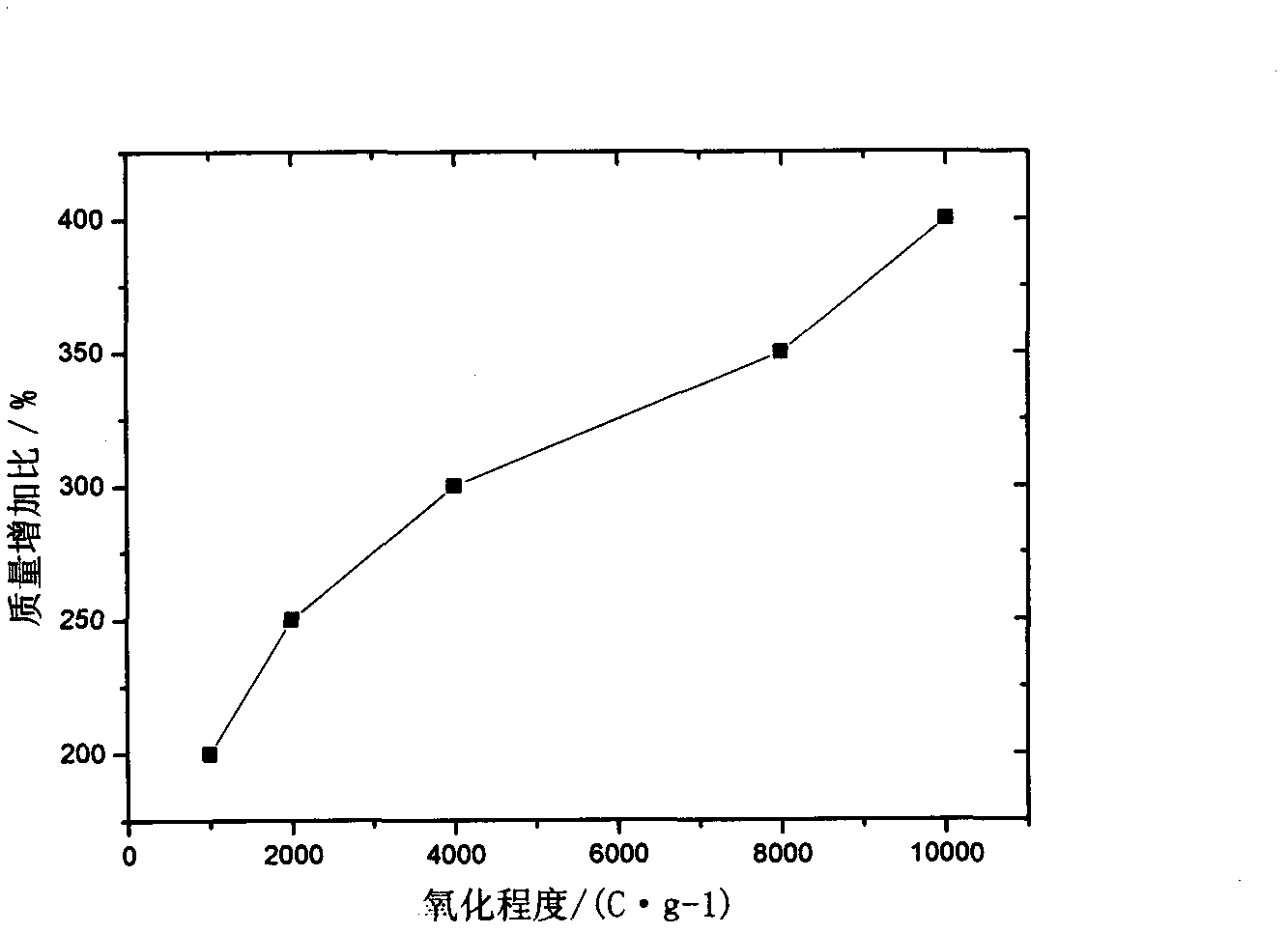

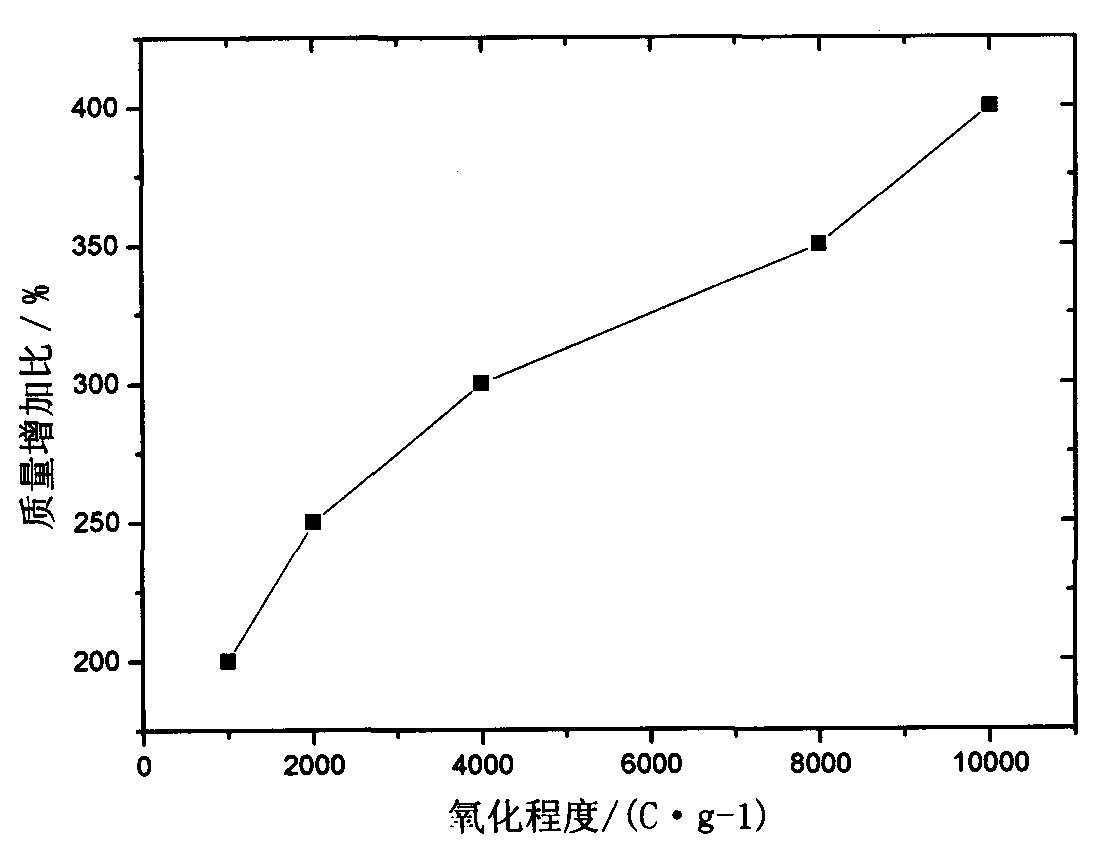

Modified method of graphite felt used for full-vanadium fluid flow battery electrode

ActiveCN102136579AControl the rate of oxidation reactionIncrease the reaction areaCell electrodesFenton reagentDistilled water

The invention relates to a modified method of a graphite felt used for a full-vanadium fluid flow battery electrode. Firstly a graphite felt is processed by an air oxidation method, and then the graphite felt processed by the air oxidation method is modified by utilizing hydrogen peroxide or an Fenton reagent. The modified method comprises the following steps: a. air oxidation processing: placingthe washed graphite felt into a heating device for heating; oxidizing in the hot air environment; naturally cooling to room temperature in the heating device after oxidation; and washing the cooled graphite felt; b. hydrogen peroxide or Fenton reagent modified processing: placing the washed graphite felt into the hydrogen peroxide or the Fenton reagent to be modified to obtain the modified graphite felt; and c. processing residues on the surface of the graphite felt: washing the graphite felt after being processed by a hydrogen peroxide solution or the Fenton reagent by utilizing distilled water; and removing the hydrogen peroxide or the Fenton reagent residual on the surface of the graphite felt. The modified method provided by the invention has the advantages of being simple and feasible in operation and low in cost and environment-friendly.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

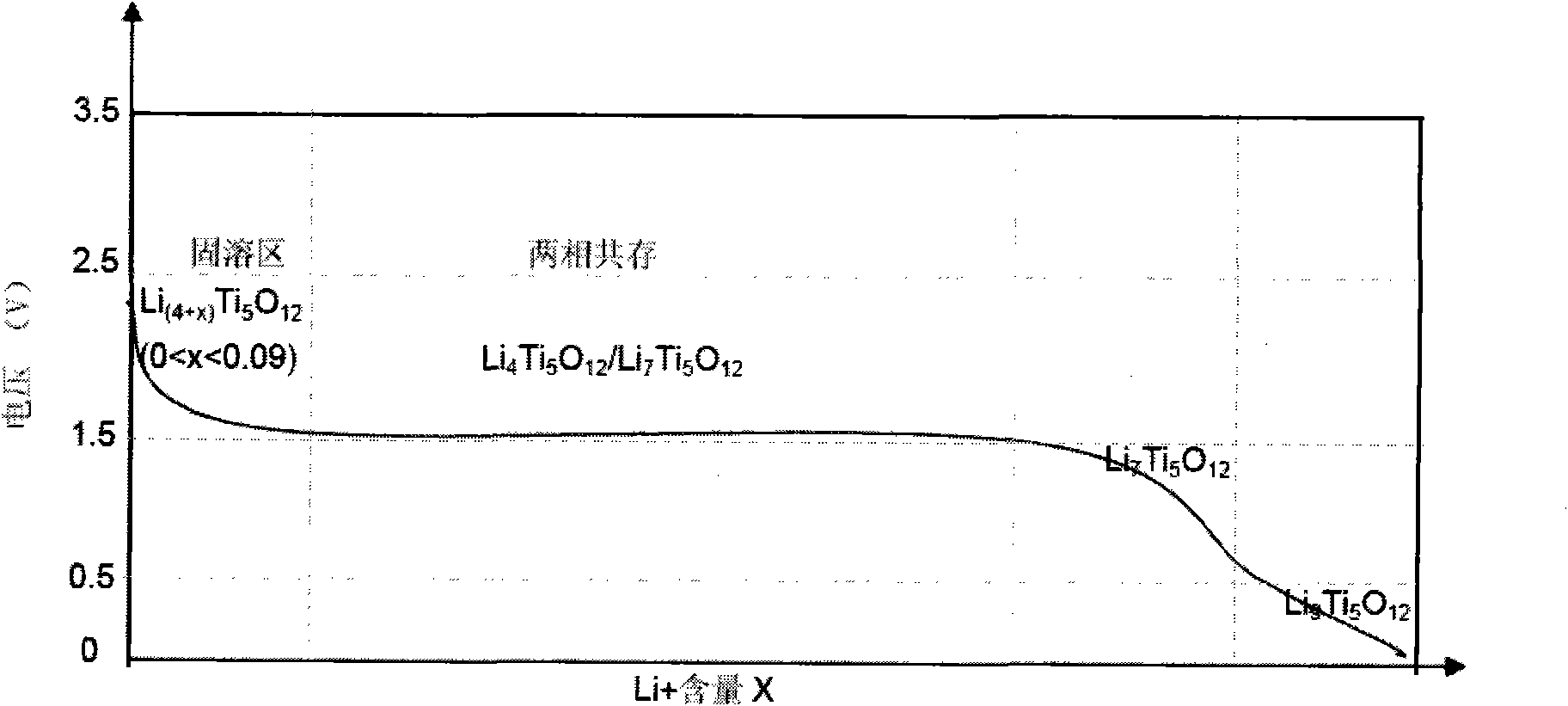

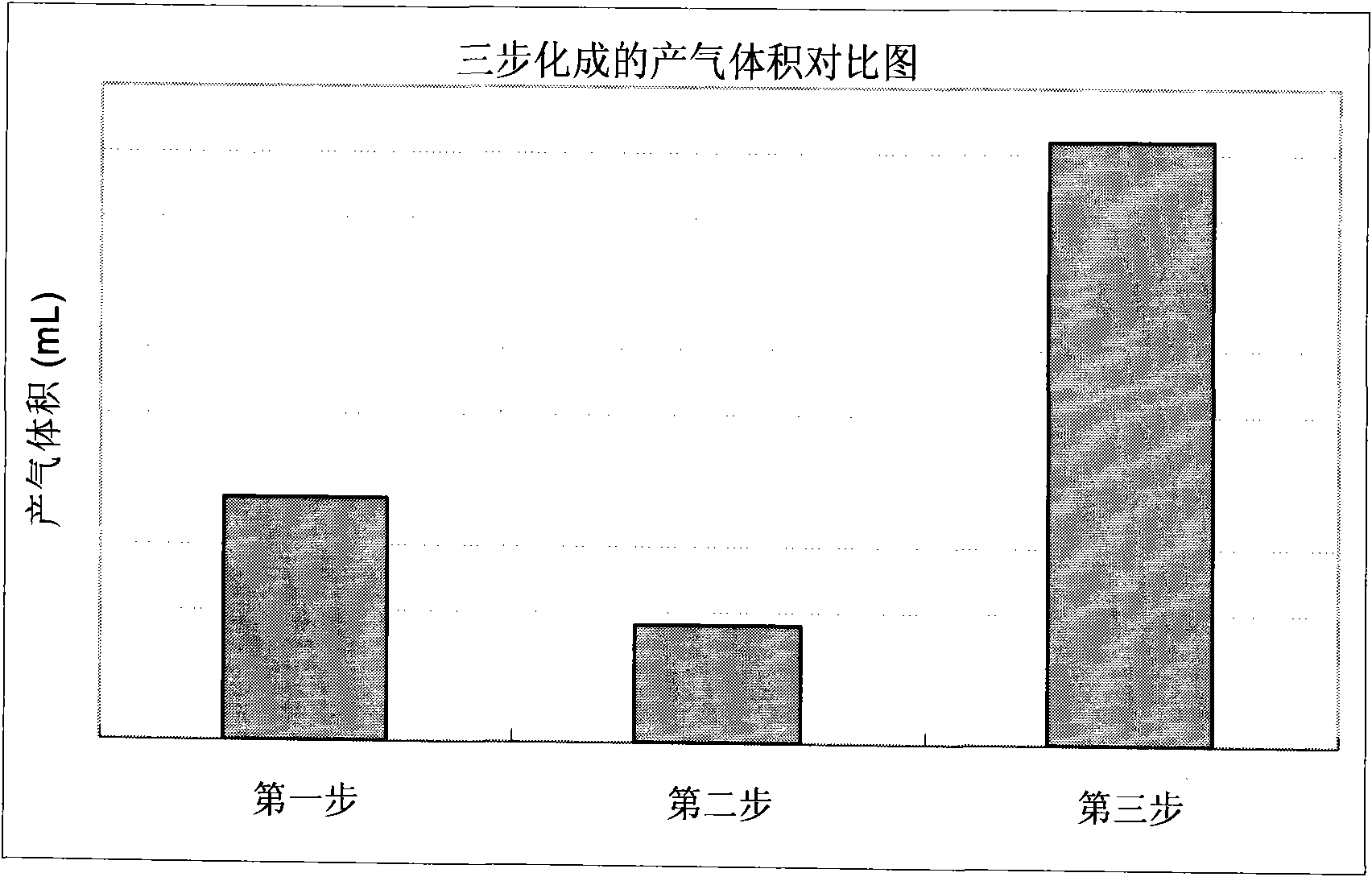

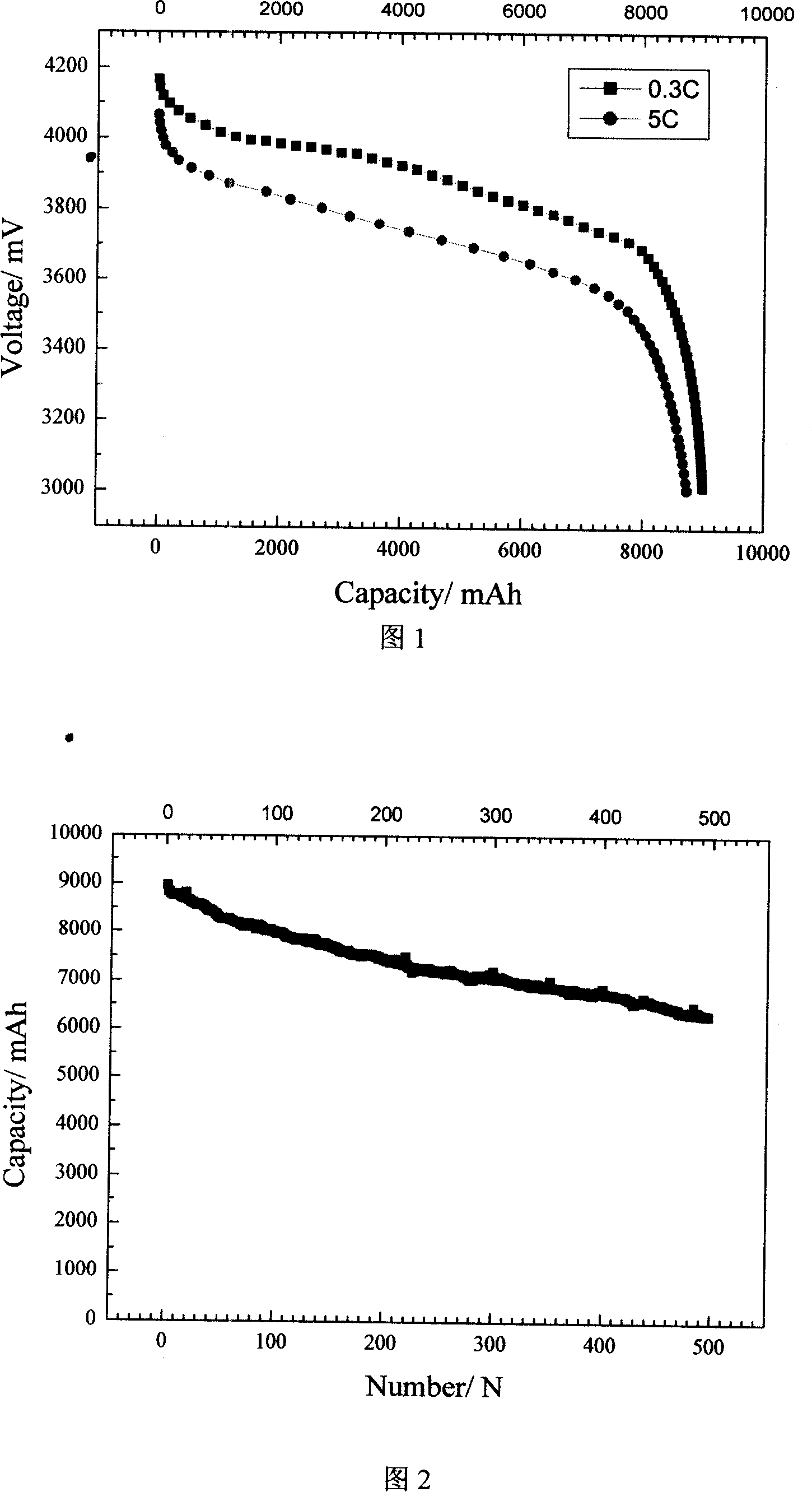

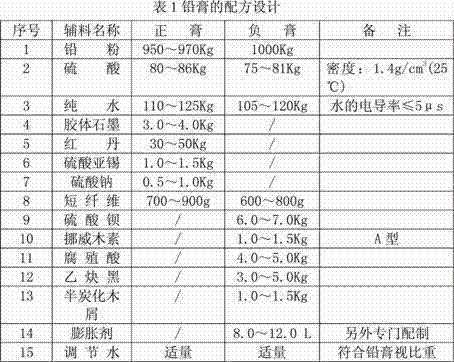

Lithium ion secondary battery

ActiveCN101958428AImprove cycle performance and safety performanceGood charge and discharge performanceCell electrodesFinal product manufactureElectrochemistryLithium electrode

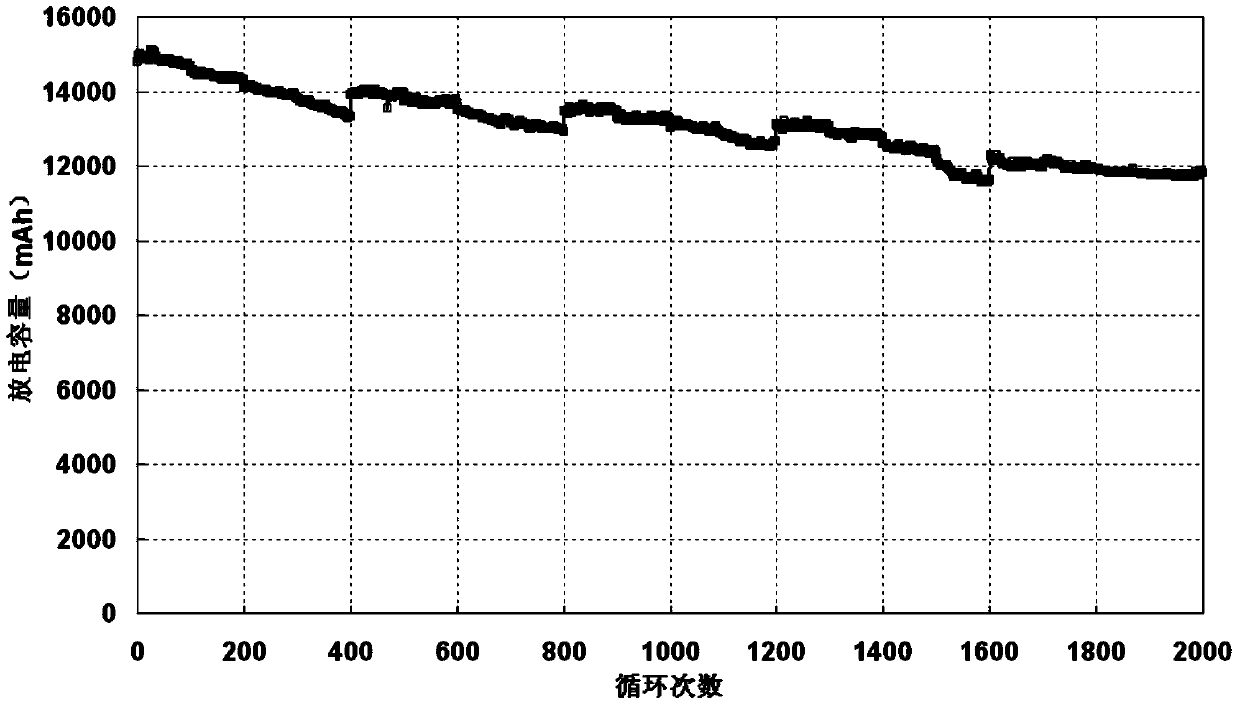

The invention belongs to the technical field of lithium ion batteries, and particularly discloses a lithium ion secondary battery. The lithium ion secondary battery comprises a cathode, an anode, an isolation membrane and electrolyte, wherein the cathode comprises cathode active substance, adhesive and conductive carbon; the anode comprises a lithium titanate active material, adhesive and conductive carbon; base materials for a cathode plate and an anode plate are aluminum foils; and the ratio of the anode capacity to the cathode capacity is 0.70 to 1.00. The lithium ion secondary battery comprises the following activation steps of: 1, charging the battery with constant current of 0.2C to 5C to change lithium titanate into Li4+xTi5O12 from Li4Ti5O12, wherein the x is more than 0.09 and less than or equal to 2.50; 2, charging the battery changed in the first step with constant current of 0.1C to 5C so that the x in the Li4+xTi5O12 is more than 2.50 and less than or equal to 3.00; and 3, charging the battery changed in the second step with constant voltage for 0.2 to 12 hours, and pumping the gas generated in each step until vacuum. The lithium ion secondary battery has excellent electrochemical performance, and meanwhile, the circulation performance and the high-temperature storage performance of the lithium ion secondary battery are improved.

Owner:DONGGUAN AMPEREX TECH

High power gel polymer lithium ion power cell and method of producing the same

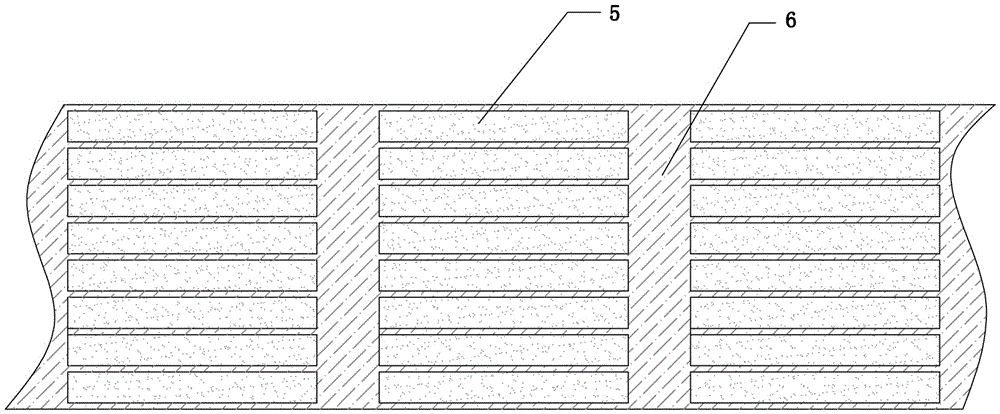

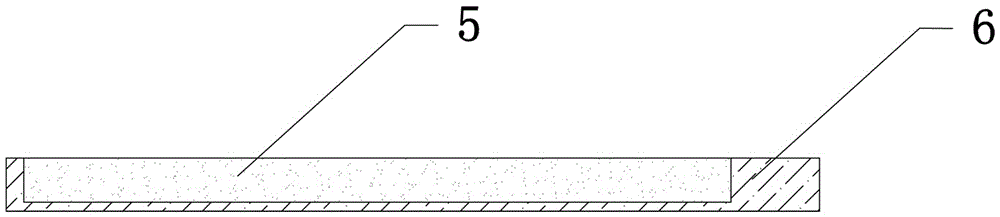

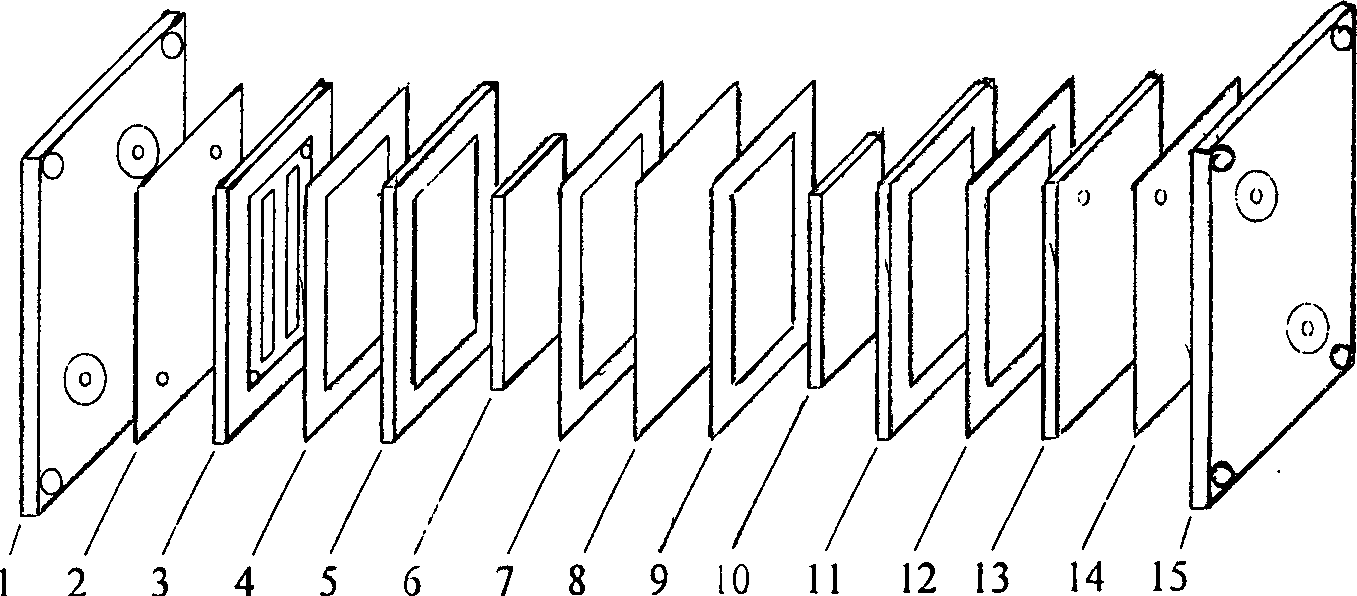

InactiveCN101154750AIncrease capacityLow manufacturing costFinal product manufactureOrganic electrolyte cellsPolymer electrolytesPower battery

The invention relates to a lithium ion battery and the manufacturing method thereof, particularly relating to a high multiplying power gel polymer lithium ion power battery and the manufacturing method thereof. Mainly aiming at resolving the technical problems of safety performance, etc., which exists in the prior art, the invention provides the high multiplying power gel polymer lithium ion power battery, which has the advantages of reasonable design, simple structure, high safety performance and low cost, and the manufacturing method thereof. The main technical proposal of the invention is that the lithium ion power battery consists of a cathode mass flow liquid, an anode mass flow liquid, a cathode membrane, an anode membrane, a membrane and electrolyte, wherein, the membrane is the gel polymer electrolyte, the cathode membrane and the anode membrane are evenly coated or hot-pressed on the cathode mass flow liquid and the anode mass flow liquid; the cathode mass flow liquid, the cathode membrane, the membrane, the anode membrane and the anode mass flow liquid are orderly overlaid, forming a square single bag.

Owner:万向电动汽车有限公司

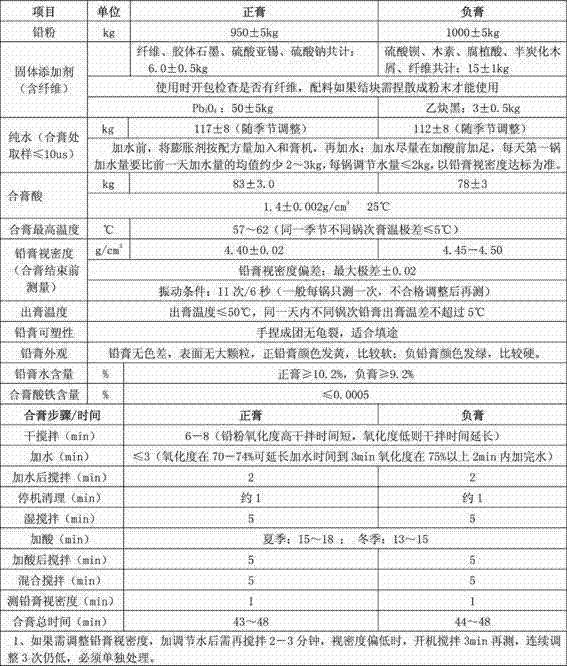

Lead plaster for low temperature resistant lead storage battery for electric scooter and preparation method of lead plaster

ActiveCN103779557AInhibition of \"shrinkage\"Inhibit \"passivation\"Cell electrodesFiberElectrical battery

The invention relates to a lead plaster for a low temperature resistant lead storage battery for an electric scooter and a preparation method of the lead plaster. The lead plaster comprises an anode lead plaster and a cathode lead plaster, wherein the anode lead plaster comprises the following components in parts by weight: 950-970 parts of lead powder, 80-86 parts of 1.3-1.4g / cm<3> sulfuric acid, 110-125 parts of pure water, 3.0-4.0 parts of colloidal graphite, 30-50 parts of red lead, 1.0-1.5 parts of tin sulfate, 0.5-1.0 part of sodium sulfate and 0.7-0.9 part of short fiber; the cathode lead plaster comprises the following components in parts by weight: 1000 parts of lead powder, 75-81 parts of 1.3-1.4g / cm<3> sulfuric acid, 105-120 parts of pure water, 0.6-0.8 part of short fiber, 6.0-7.0 parts of barium sulfate, 1.0-1.5 parts of Norway lignin, 4.0-5.0 parts of humic acid, 3.0-5.0 parts of acetylene black and 1.0-1.5 parts of semi-carbonized saw dust. According to the lead plaster and the preparation method thereof, the acceptance performance when the battery is charged at low temperature is improved and the discharge capacity is increased; the lead plaster disclosed by the invention is applicable to low-temperature environment and is especially suitable for northeast and northwest regions in China.

Owner:河北超威电源有限公司

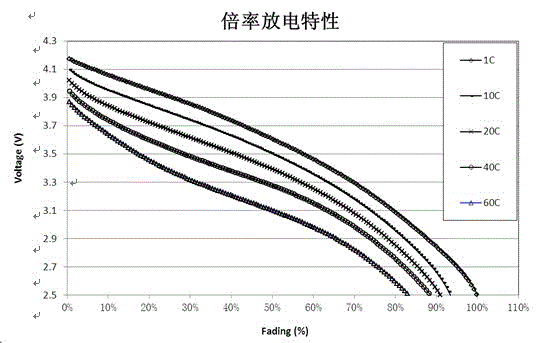

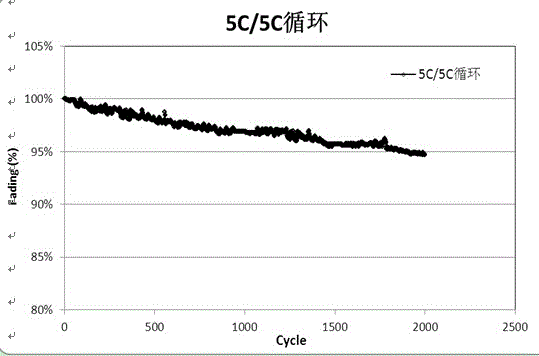

Lithium ion battery capable of being subjected to high-rate charge and discharge and preparation method thereof

InactiveCN102983355AWith high rate charge and discharge characteristicsMeet power requirementsCell electrodesFinal product manufactureFiberHigh rate

The invention discloses a lithium ion battery capable of being subjected to high-rate charge and discharge and a preparation method thereof. The lithium ion battery capable of being subjected to high-rate charge and discharge comprises a positive pole, a negative pole and a diaphragm, wherein the positive pole comprises the following components in percentage by weight: 80-98% of positive active material, 1-19% of conductive agent and 1-19% of binder; the negative pole comprises the following components in percentage by weight: 80-98% of negative active material, 1-19% of conductive agent and 1-19% of binder; the positive active material includes one or two of Li(NiCoMn)O2 and lithium manganate; the negative active material includes one or two of hard carbon and soft carbon; the conductive agent is one of superconducting carbon black, carbon fiber, crystalline flake graphite and a carbon nanotube; and the binder is one of kynar, butadiene styrene rubber, sodium carboxymethylcellulose and hydroxypropyl / carboxymethyl cellulose. According to the lithium ion battery capable of being subjected to high-rate charge and discharge and the preparation method thereof disclosed by the invention, the lithium ion battery has high-rate charge and discharge characteristics, and is good in charge and discharge characteristics, wide in temperature application range, excellent in low-temperature charge performance, long in cycle life and high in safety.

Owner:TIANJIN ENERGIES

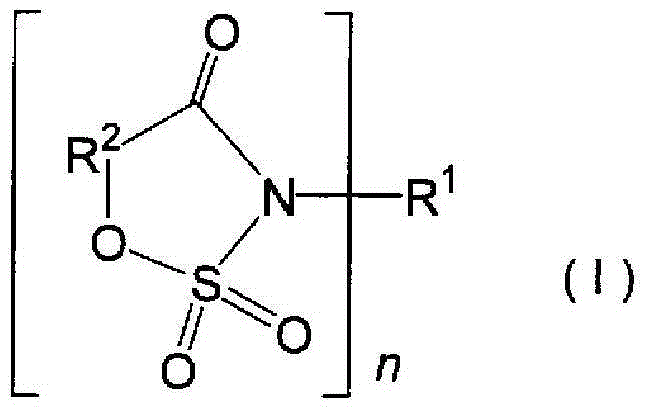

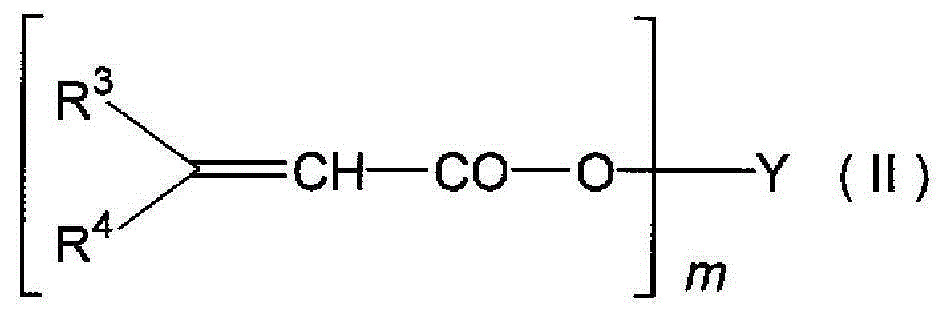

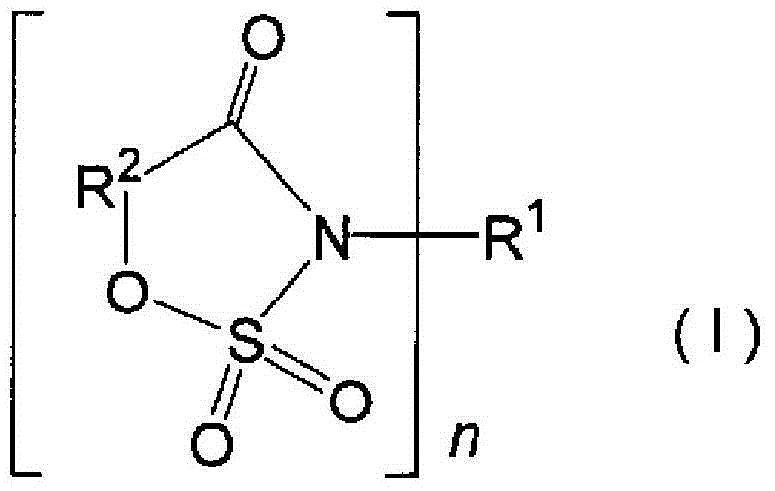

Nonaqueous electrolyte solution for secondary batteries and nonaqueous electrolyte secondary battery

InactiveCN105009347AExcellent charge and discharge characteristicsImprove thermal stabilityCell electrodesLi-accumulatorsHalogenAlkaline earth metal

[Solution] With respect to a nonaqueous electrolyte solution for secondary batteries containing an electrolyte, a solvent and an additive, and a nonaqueous electrolyte secondary battery which is provided with the nonaqueous electrolyte solution, the additive contains a compound represented by formula (I). (In formula (I), n represents an integer of 1-4; R1 represents a halogen atom or the like if n = 1, represents an alkaline earth metal atom or the like if n = 2, represents a trivalent transition metal atom or the like if n = 3, and represents a tetravalent transition metal atom or the like if n = 4; and R2 represents an alkylene group having 1-6 carbon atoms or an alkenylene group having 2-6 carbon atoms.) [Effect] A nonaqueous electrolyte secondary battery using a nonaqueous electrolyte solution for secondary batteries according to the present invention has high low-temperature characteristics, while having high high-temperature characteristics.

Owner:SHOWA DENKO KK

Method for preparing vanadium nitride

InactiveCN101717076AAvoid agglomeration or crystallizationWide variety of sourcesNitrogen-metal/silicon/boron binary compoundsCapacitanceMaterials science

The invention discloses a method for preparing vanadium nitride. In the preparation method, a vanadium-containing compound is mixed with organic nitride, and the mixture is calcinated in nitrogen-containing gas to obtain the vanadium nitride. The vanadium nitride prepared by the method has small grain diameter, and has higher specific capacitance and good cycle performance. The method for preparing the vanadium nitride has the advantages of wide source of raw materials, low production cost, simple operation and low requirement on equipment, meets the requirement of modern industry on energy conservation and emission reduction, and is favorable for industrial production. When the method is used for preparing super capacitors, the super capacitors have high specific capacitance and good cycle performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

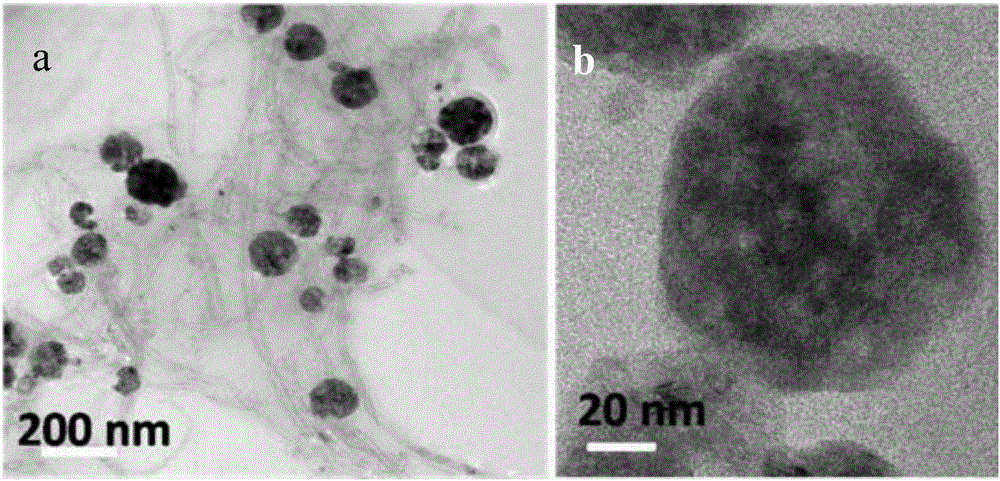

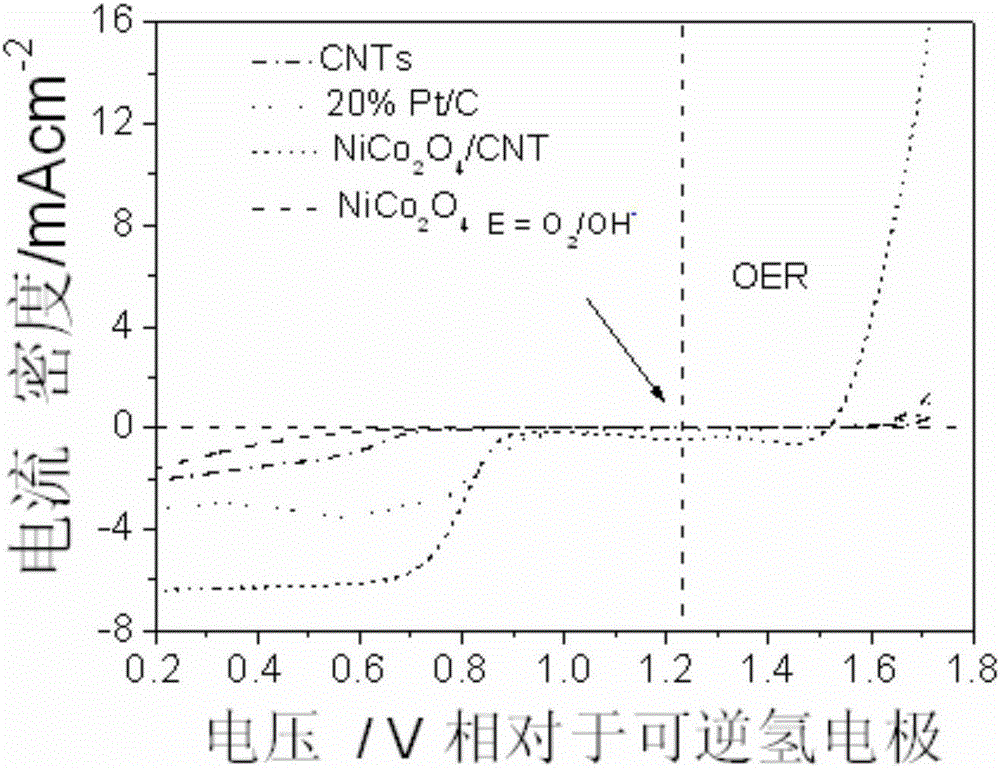

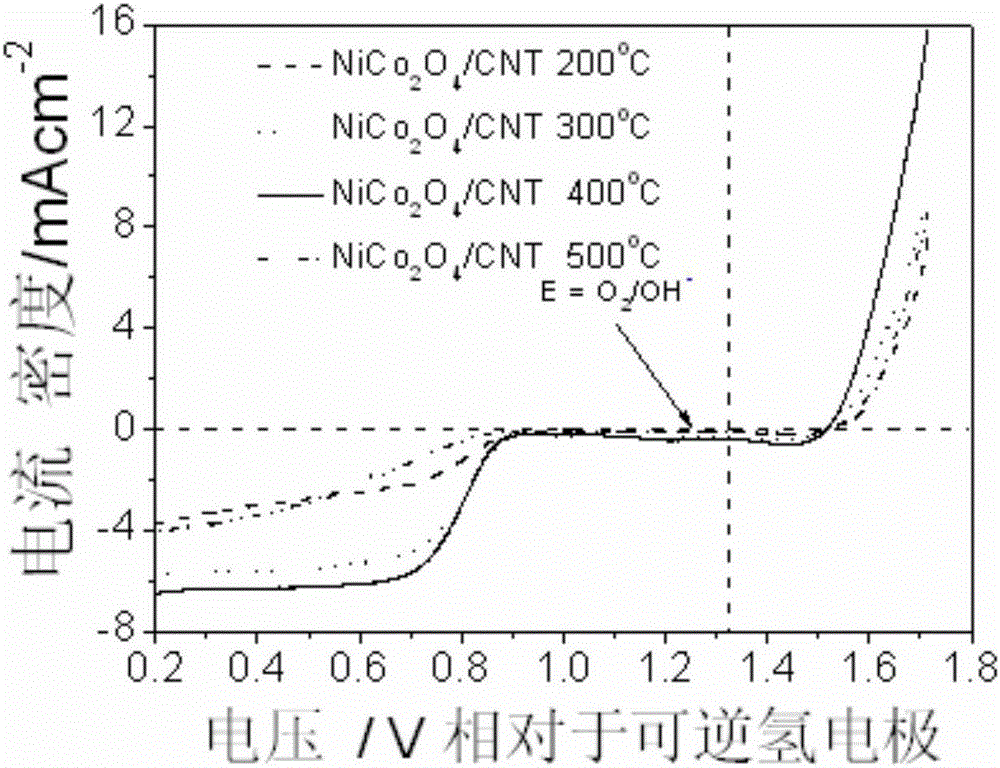

Nickel cobalt oxide/carbon nanotube composite catalyst, preparation and application thereof

InactiveCN105289617AImprove electrochemical performanceImprove charge and discharge stabilityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCarbon nanotubeCarbon nanotube supported catalyst

The invention relates to a nickel cobalt oxide / carbon nanotube composite catalyst, a preparation and an application thereof. The bi-functional catalyst comprises carbon nanotube and nickel cobalt oxide NiCo2O4 spinel; according to the preparation, nickel acetate, cobalt nitrate and carbon nanotube are respectively weighed, and then dissolved in ammoniacal liquor and the obtained material is performed with ultrasonic dispersion, then is subjected to a hydrothermal reaction at temperature of 140-160 DEG C for 3-6 hours, the obtained product is cooled to room temperature, cleaned and dried, calcined and ground to obtain the bi-functional catalyst. The invention also provides an application of the bifunctional catalyst in preparation of an air electrode of a metal air battery. The bi-functional catalyst has efficient oxygen reduction performance and efficient oxygen evolution performance in air.

Owner:DONGHUA UNIV

Carbon anode material for lithium ion battery and preparation method for carbon anode material

InactiveCN102832378AIrreversible specific capacity is lowImprove cycle stabilityCell electrodesCarbonizationCarbon nanotube

The invention discloses a carbon anode material for a lithium ion battery and a preparation method for the carbon anode material. The carbon anode material comprises core-shell structured composite particles. Each core-shell structured composite particle comprises a substrate, a substrate coating layer and a carbon nano tube embedded into the substrate and the substrate coating layer. Each substrate is natural graphite. Each substrate coating layer is an organic pyrolytic carbon coating layer. The preparation method comprises the following steps of: mixing organic pyrolytic carbon coating layer raw materials and a solvent, heating and melting a mixture, and adding the carbon nano tubes to form a uniform disperse system; adding the natural graphite for mixing, and performing oil bath stirring, evaporative drying, crushing and granulation treatment; and sequentially performing small molecule removal, organic pyroytic carbon cracking and free radical-based treatment, thermal polymerization, high-temperature carbonization and micro-crystallization treatment in a non-oxidizing atmosphere. The anode material is high in first charging and discharging efficiency, cycling stability, heavy-current charging and discharging performance and low-temperature performance. Moreover, a preparation process for the anode material is simple, free of pollutant emissions and environment-friendly, totally-enclosed reaction is adopted, the solvent is recycled, and the anode material can be produced in a large scale.

Owner:ZHEJIANG WELLY ENERGY CORP

Method for producing electrode of sodium polysulfide/bromine novel energy storage cell

InactiveCN1474470AHigh mechanical strengthImprove conductivityCell electrodesSodium polysulfideChemistry

An electrode process method for multiple Na / Br sulfide type energy storage battery is to mix carbon loading transition metal catalyst and perfluorinated sulfonic acid resin uniformly to be coated on the supporting carbon paper or felts as the negative pole, and mix carbon loading Pt catalyst and perfluorinated sulfonic acid resin evenly to be coated on carbon paper or felts as the positive pole. The inverted electrodes have rather high mechanical strength, good conductance.

Owner:DALIAN RONGKE POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com