Lead plaster for low temperature resistant lead storage battery for electric scooter and preparation method of lead plaster

A technology for electric bicycles and lead-acid batteries, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of poor low-temperature performance, insufficient battery charge acceptance performance, and inability to meet environmental use requirements, and improve low-temperature discharge performance. , The effect of improving discharge capacity and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 Preparation of expansion agent

[0049] (1) Add 12.0L of sulfuric acid into the lead bucket (density at 15°C is 1.40±0.05g / cm 3 ), the lead skin barrel is heated by steam.

[0050] (2) Open the valve of the heating steam on the lead drum, and when the sulfuric acid is heated to 80°C, adjust the steam valve to keep the temperature of the sulfuric acid between 80°C and 100°C.

[0051] (3) Put 3.0Kg of cotton (pure seedless cotton) into the lead bucket within 10 minutes, and at the same time, keep stirring with a plastic rod until all the cotton is semi-carbonized into a yellow-brown slurry (it cannot be carbonized and blackened) , close the steam valve.

[0052] (4) The expansion agent can only be used when the temperature drops to no higher than room temperature by 5°C. The storage period of the prepared expansion agent shall not exceed 3 days.

Embodiment 2

[0053] Example 2 Low-temperature-resistant lead-acid battery lead paste for electric moped and preparation method thereof

[0054] Low-temperature-resistant lead-acid battery lead paste for electric mopeds, including positive lead paste and negative lead paste:

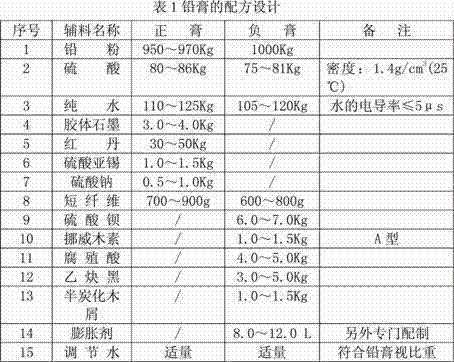

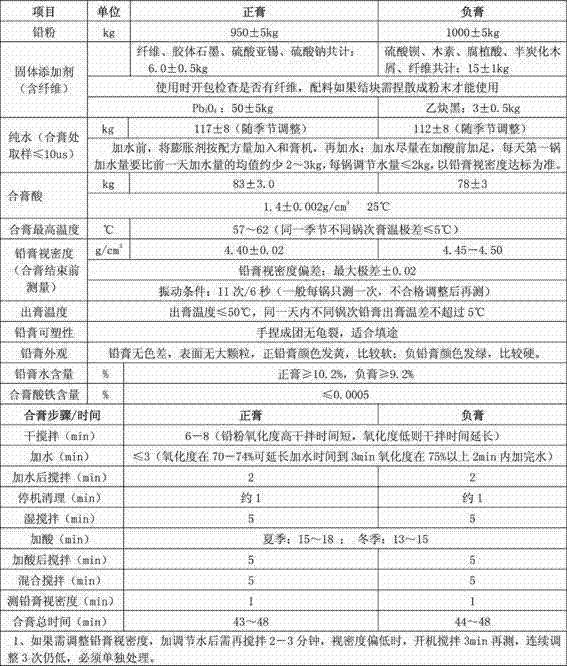

[0055] The ratio of parts by weight of each component in the positive lead paste is: lead powder 960Kg, concentration 1.3-1.4g / cm 3Sulfuric acid 80 Kg, pure water 110Kg, colloidal graphite 4.0Kg, red lead 50Kg, stannous sulfate 1.0 Kg, sodium sulfate 0.5 Kg; short fiber 0.9 Kg;

[0056] The weight-number ratio of each component in the negative lead paste is: lead powder 1000 Kg, concentration 1.3-1.4g / cm 3 75 Kg of sulfuric acid, 105 Kg of pure water, 0.6 Kg of short fibers, 7.0 Kg of barium sulfate, 1.0 Kg of Norway lignin, 5.0 Kg of humic acid, 3.0 Kg of acetylene black, 1.5 K of semi-carbonized wood chips, and 8 L of swelling agent in Example 1.

[0057] (1) Ingredients

[0058] 1.1 Weigh each raw material ac...

Embodiment 3

[0070] Example 3 Low-temperature-resistant lead-acid battery lead paste for electric moped and preparation method thereof

[0071] Low-temperature-resistant lead-acid battery lead paste for electric mopeds, including positive lead paste and negative lead paste:

[0072] The ratio of parts by weight of each component in the positive lead paste is: lead powder 950Kg, concentration 1.4g / cm 3 Sulfuric acid 80 Kg, pure water 110Kg, colloidal graphite 3.0Kg, red lead 50Kg, stannous sulfate 1.5 Kg, sodium sulfate 1.0 Kg; short fiber 0.7 Kg;

[0073] The weight / number ratio of each component in the negative electrode lead paste is: lead powder 1000 Kg, concentration is 1.4g / cm 3 75 Kg of sulfuric acid, 105 Kg of pure water, 0.6 Kg of short fiber, 7.0 Kg of barium sulfate, 1.5 Kg of Norway lignin, 5.0 Kg of humic acid, 2.5 Kg of acetylene black, 1 K of semi-carbonized wood chips, and 12 L of swelling agent in Example 1.

[0074] (1) Ingredients

[0075] 1.1 Weigh each raw materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com