Patents

Literature

69 results about "Tin sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tin(IV) sulfate is a chemical compound composed of one atom of tin and two ions of sulfate, which is broken down into two atoms of sulfur and eight atoms of oxygen. It is represented by the chemical formula Sn(SO4)2.

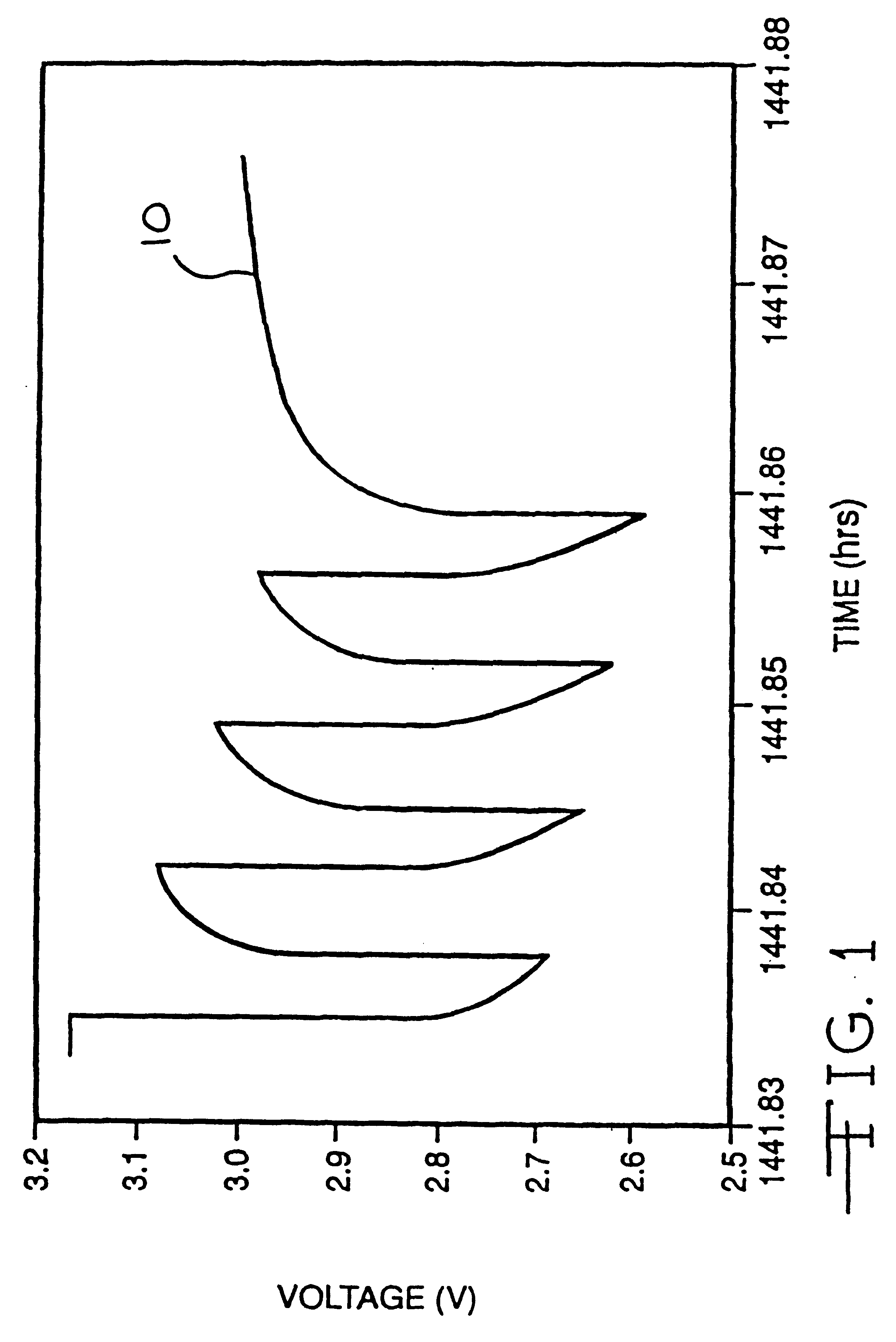

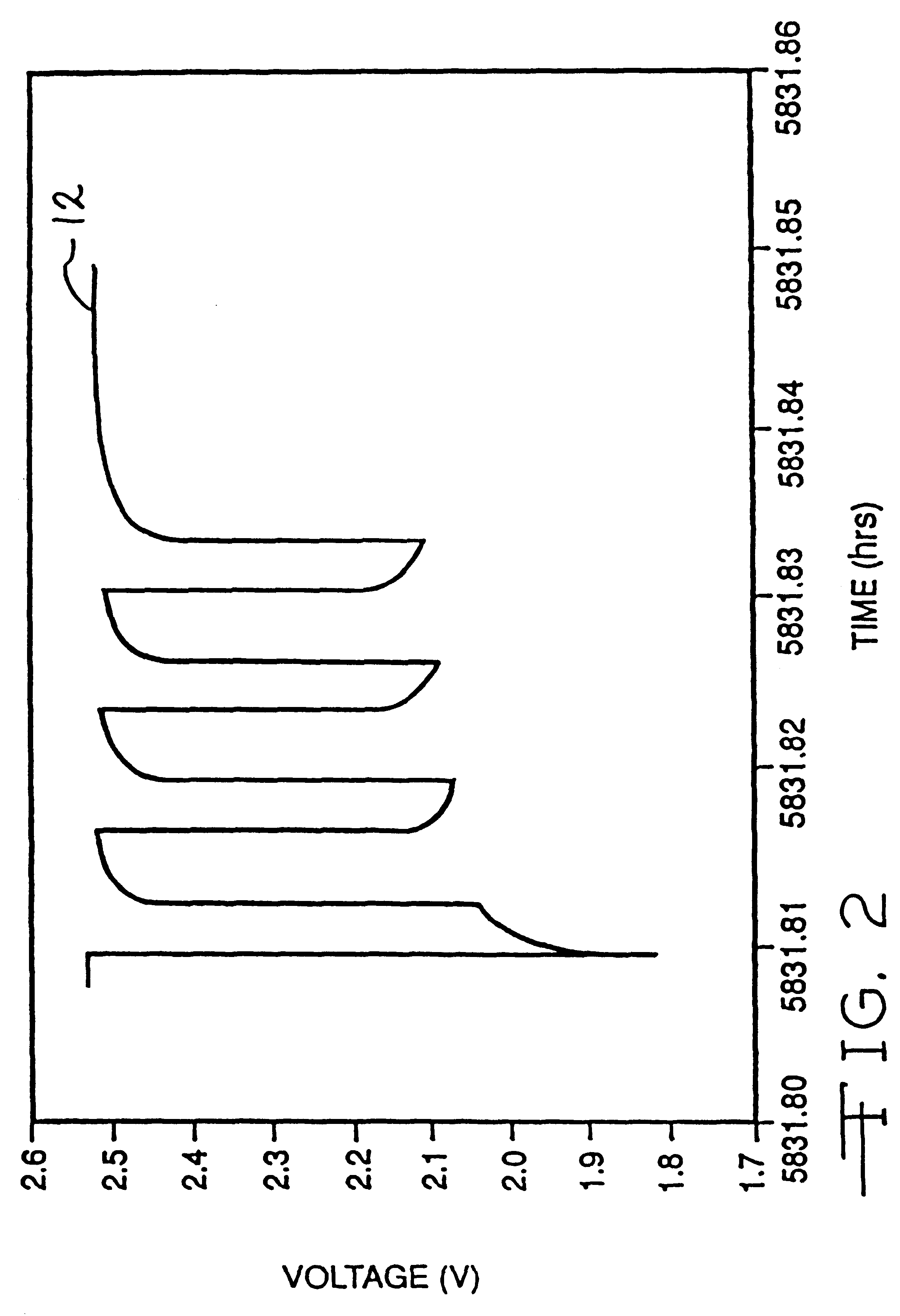

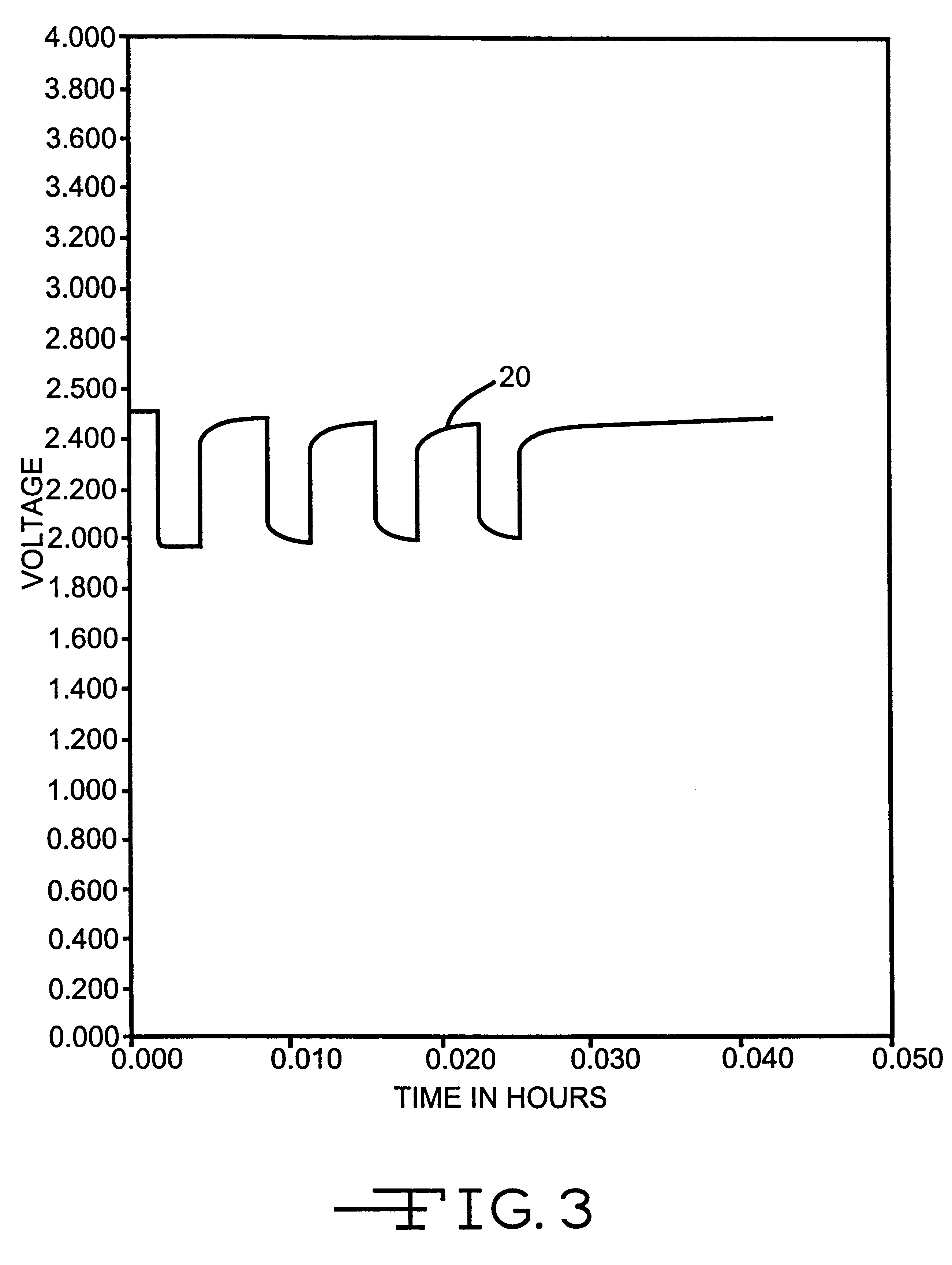

Method for reducing voltage delay in an alkali metal electrochemical cell activated with a nonaqueous electrolyte having a sulfate additive

An alkali metal, solid cathode, nonaqueous electrochemical cell capable of delivering high current pulses, rapidly recovering its open circuit voltage and having high current capacity, is described. The stated benefits are realized by the addition of at least one organic sulfate additive to an electrolyte comprising an alkali metal salt dissolved in a mixture of a low viscosity solvent and a high permittivity solvent. A preferred solvent mixture includes propylene carbonate, dimethoxyethane and a sulfate additive having at least one unsaturated hydrocarbon containing a C(sp2 or sp3 )-C(sp3) bond unit having the C(sp3) carbon directly connected to the -OSO3- functional group, or a silyl sulfate or a tin sulfate.

Owner:WILSON GREATBATCH LTD

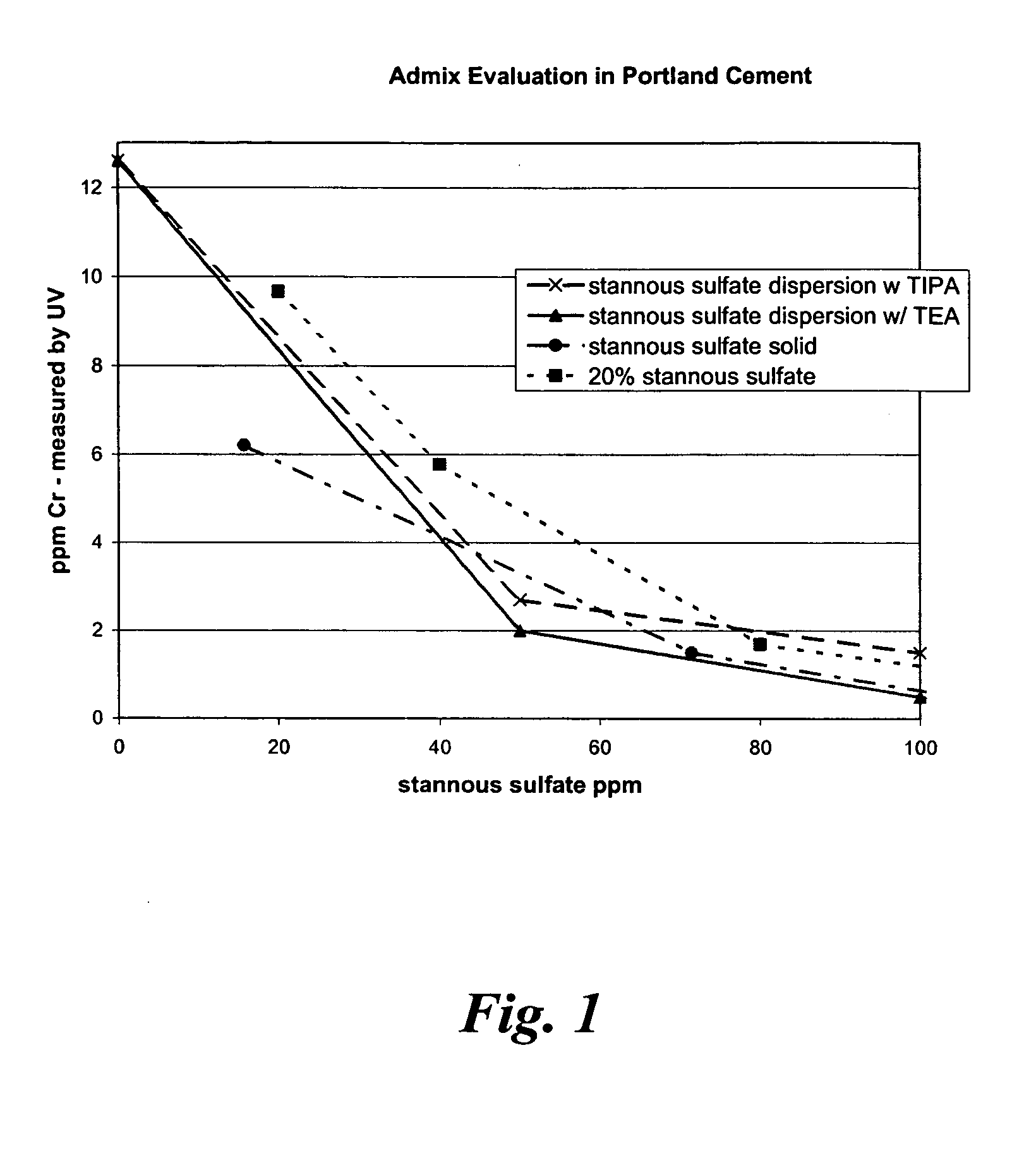

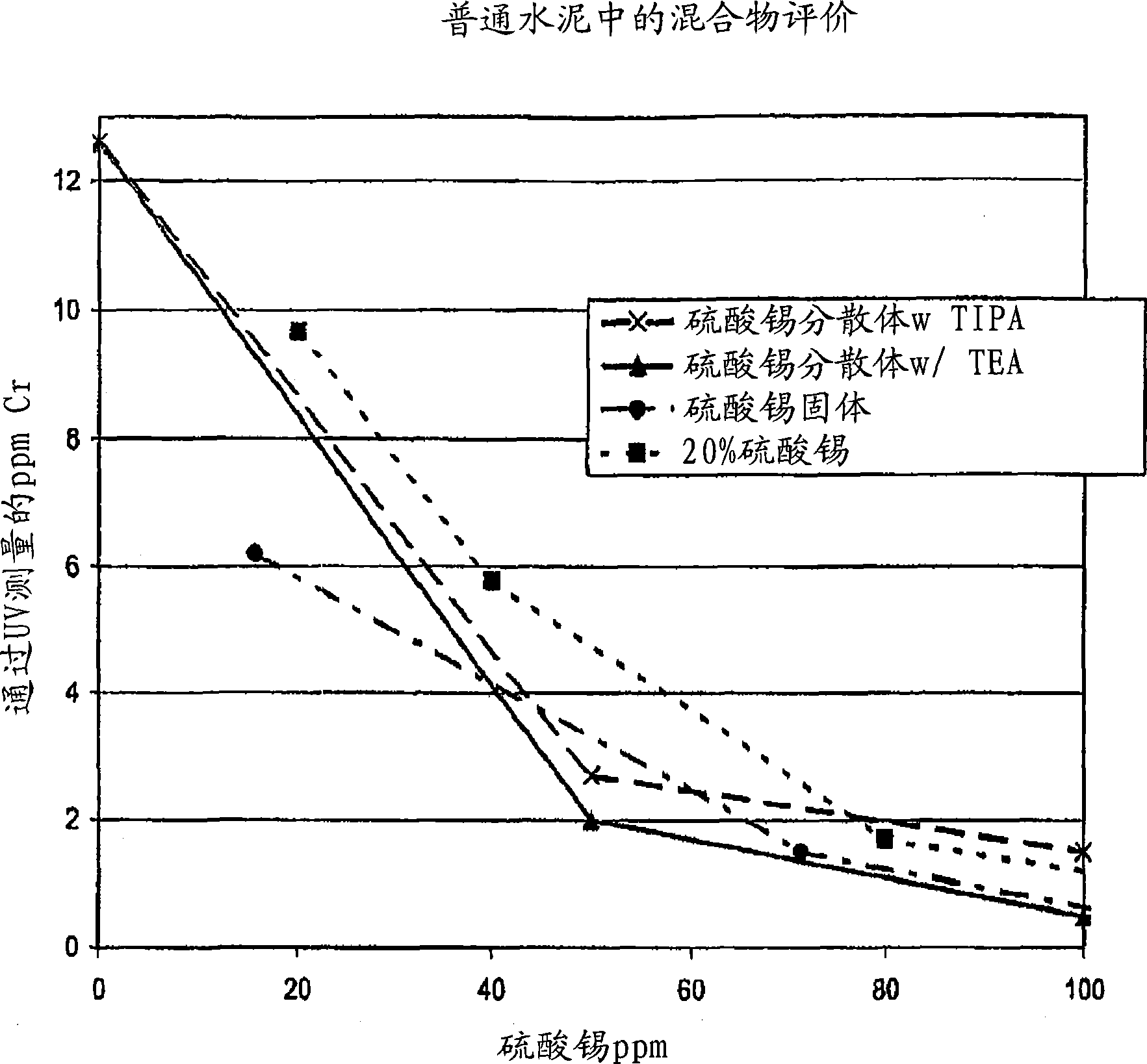

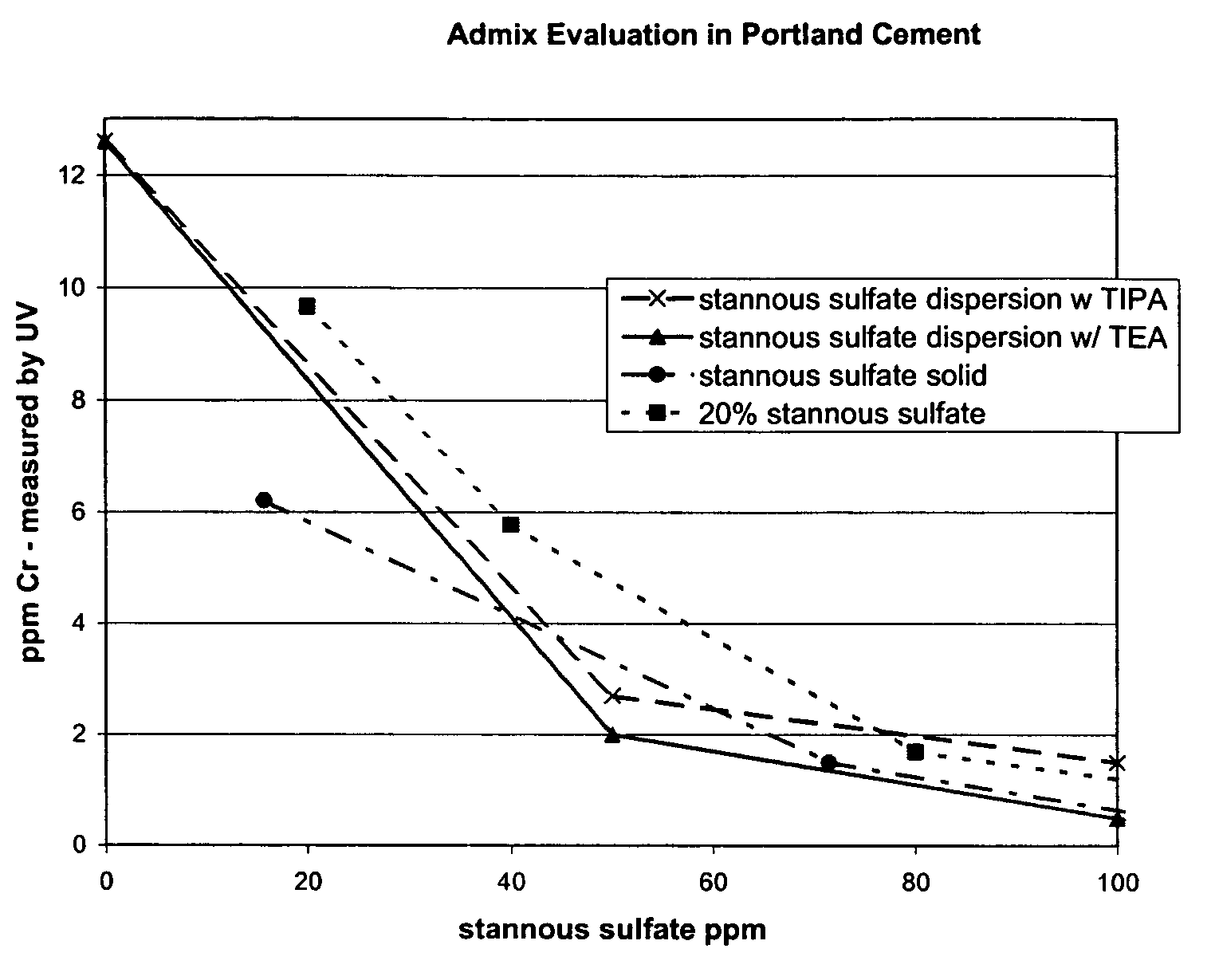

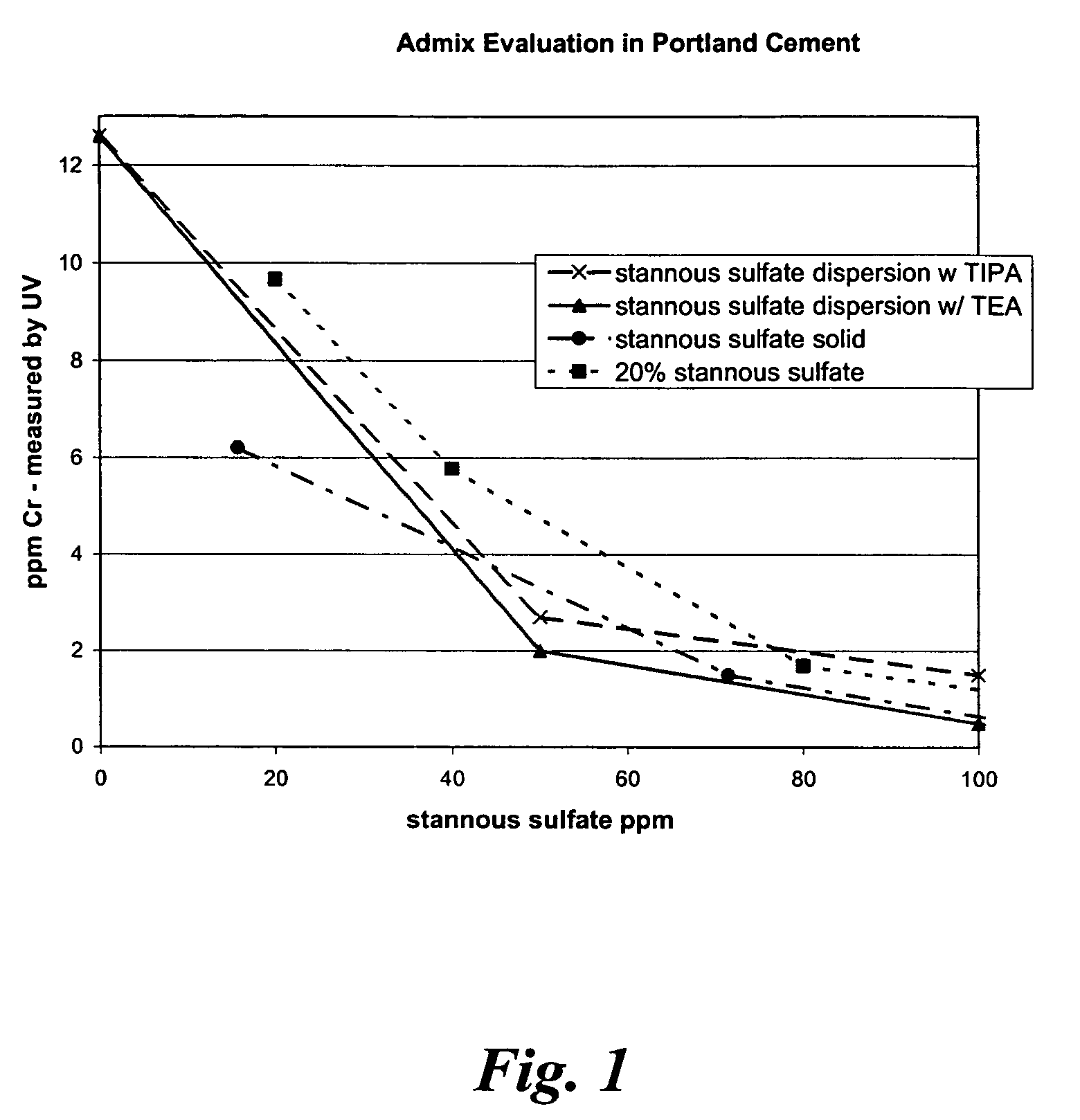

Sulfate dispersion chromate reducer

A chromium VI reducing composition comprising particles of solid material selected from the group consisting of iron (II) sulfate and tin sulfate, the particles being substantially uniformly dispersed within a liquid carrier. Methods for modifying hydratable cementitious materials using the chromium reducing composition are also disclosed and provide advantages over dry powder or dissolved forms of sulfate compositions when used in cement manufacturing.

Owner:GCP APPL TECH INC

Semi-bright lead-free chemical tinning liquid and using method thereof

InactiveCN101717929AEnables continuous autocatalytic depositionFast depositionLiquid/solution decomposition chemical coatingThioureaBenzaldehyde

The invention discloses new semi-bright lead-free chemical tinning liquid and a using method thereof. A semi-bright silver tin-copper alloy chemical plating layer is obtained on copper and copper alloy matrix. In the chemical plating liquid, tin sulfate is used as a main salt, thiourea is used as a main complexing agent, citric acid is used as an auxiliary complexing agent, sodium hypophosphite is used as a reducing agent, ethylene diamine tetraacetic acid is used as an antioxidant, sulfuric acid is used as a stabilizing agent, gelatin is used as a leveling agent, and benzaldehyde is used as an auxiliary brightening agent. The pH value of the plating liquid is 0.8 to 2.0, the temperature of the plating liquid is between 80 and 90 DEG C, the carrying capacity of the plating liquid is 0.8 to 1.5dm2 / L, and the mechanical stirring speed is 50 to 100 rpm. The continuous self-catalytic deposition of tin is implemented on the copper and copper alloy matrix, plating layers of different thicknesses can be obtained by controlling the chemical plating time, and the deposition speed is high; crystalline grains are obviously refined, the surface flatness of the plating layer is improved, and the plating surface area is large; the plating layer and the matrix are combined firmly; and after passivating treatment, the change resistance of the plating layer is high. The technology has broad application prospect in products such as deep hole pieces, blind hole pieces, small-sized electronic parts and components which are difficult to process, printed circuit boards (PCB) and the like.

Owner:KUNMING UNIV OF SCI & TECH

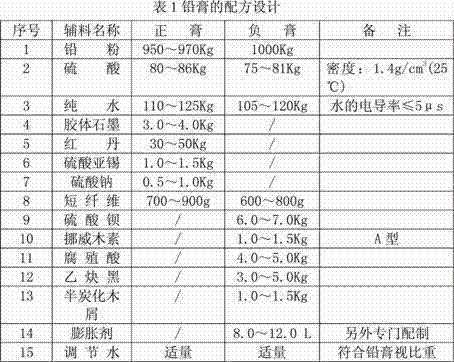

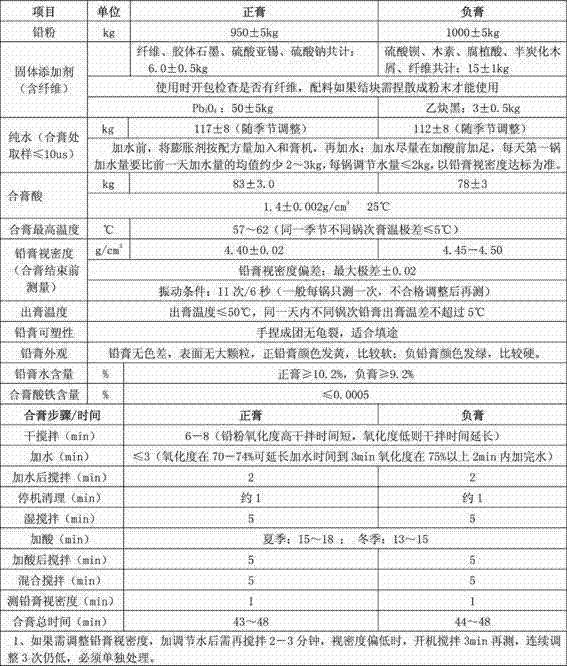

Lead plaster for low temperature resistant lead storage battery for electric scooter and preparation method of lead plaster

ActiveCN103779557AInhibition of \"shrinkage\"Inhibit \"passivation\"Cell electrodesFiberElectrical battery

The invention relates to a lead plaster for a low temperature resistant lead storage battery for an electric scooter and a preparation method of the lead plaster. The lead plaster comprises an anode lead plaster and a cathode lead plaster, wherein the anode lead plaster comprises the following components in parts by weight: 950-970 parts of lead powder, 80-86 parts of 1.3-1.4g / cm<3> sulfuric acid, 110-125 parts of pure water, 3.0-4.0 parts of colloidal graphite, 30-50 parts of red lead, 1.0-1.5 parts of tin sulfate, 0.5-1.0 part of sodium sulfate and 0.7-0.9 part of short fiber; the cathode lead plaster comprises the following components in parts by weight: 1000 parts of lead powder, 75-81 parts of 1.3-1.4g / cm<3> sulfuric acid, 105-120 parts of pure water, 0.6-0.8 part of short fiber, 6.0-7.0 parts of barium sulfate, 1.0-1.5 parts of Norway lignin, 4.0-5.0 parts of humic acid, 3.0-5.0 parts of acetylene black and 1.0-1.5 parts of semi-carbonized saw dust. According to the lead plaster and the preparation method thereof, the acceptance performance when the battery is charged at low temperature is improved and the discharge capacity is increased; the lead plaster disclosed by the invention is applicable to low-temperature environment and is especially suitable for northeast and northwest regions in China.

Owner:河北超威电源有限公司

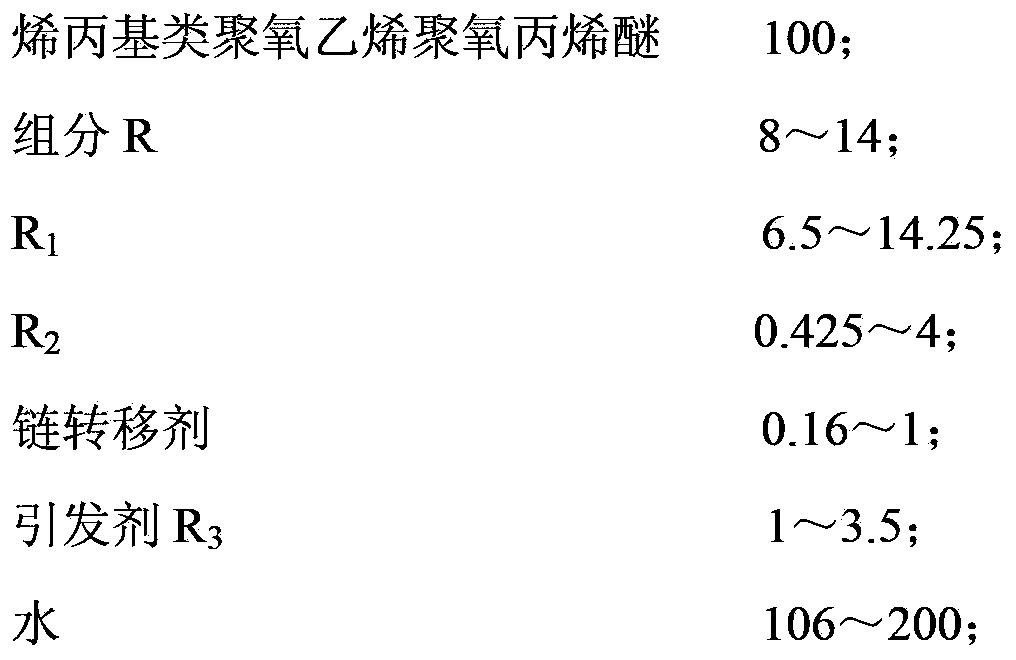

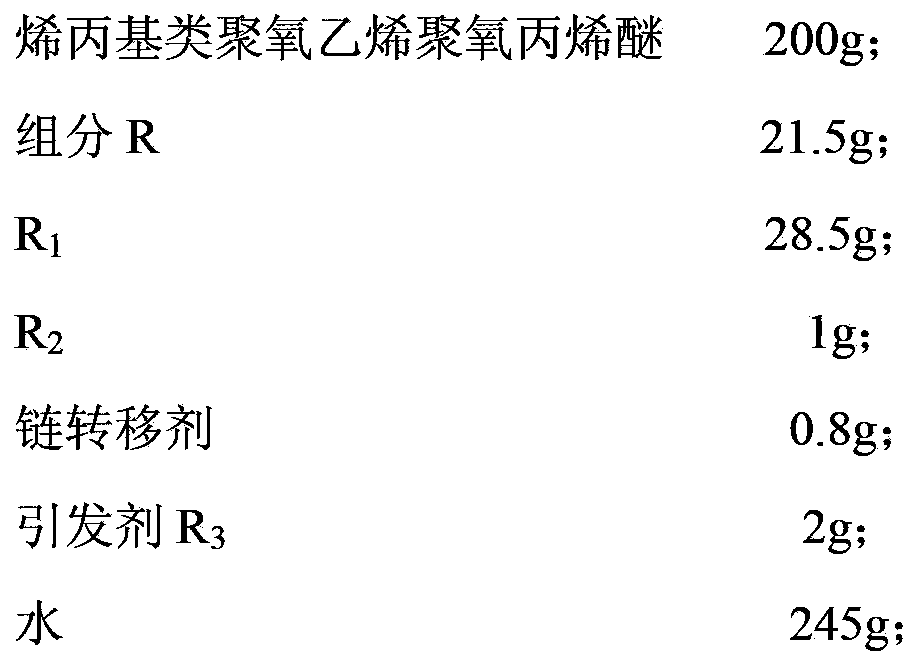

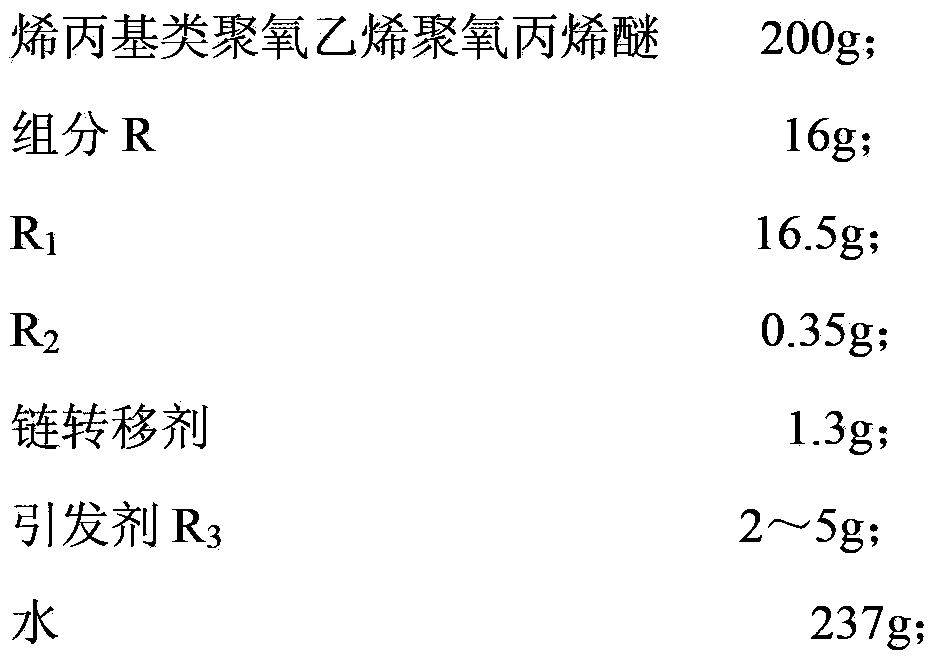

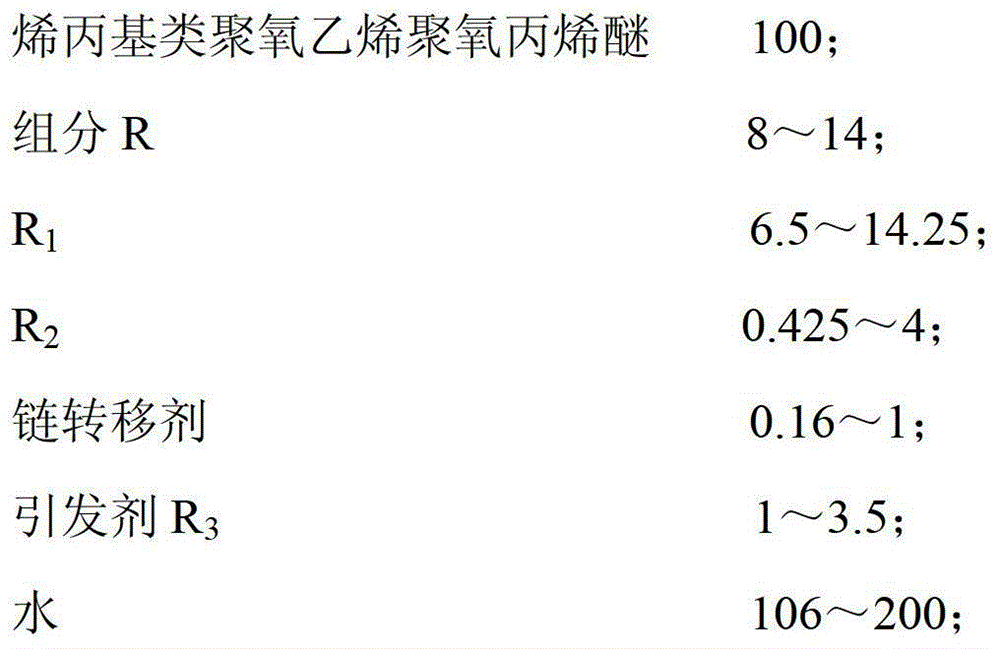

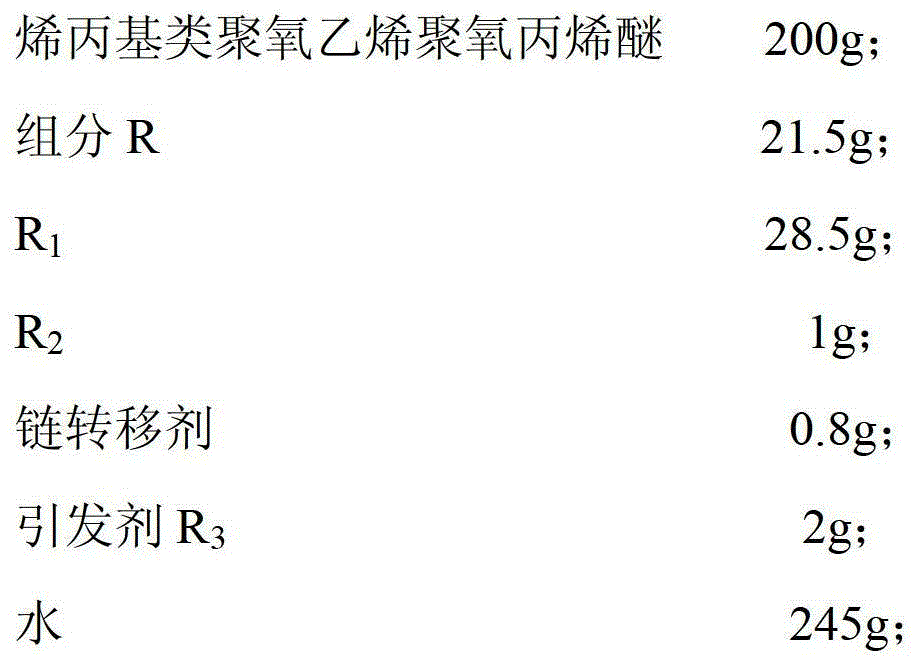

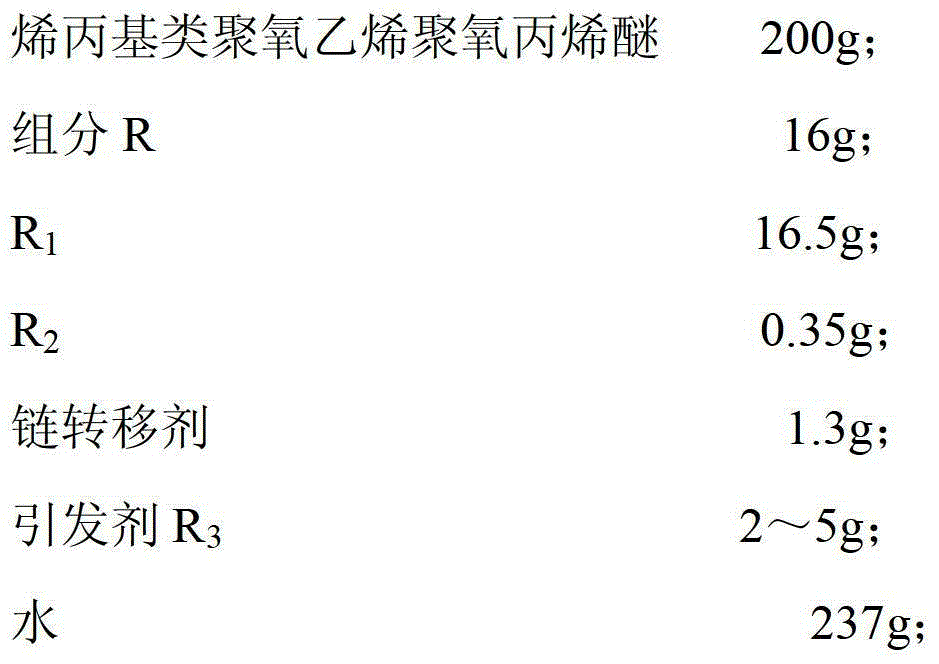

Mud-resistant polycarboxylic acid water reducer and preparation method thereof

The invention discloses a mud-resistant polycarboxylic acid water reducer which is prepared from the following components: allyl polyoxyethylene polyoxypropylene ether, components R, R1 and R2, a chain transfer agent, an initiating agent R3 and water, wherein the component R is one or more of maleic anhydride, sodium methallyl sulfonate, vinyl acetate, itaconic acid, itaconic anhydride and fumaric acid; R1 is one or a mixture of two of acrylic acid and methylacrylic acid; R2 is one or more of ascorbic acid, sodium formaldehyde sulfoxylate, ferrous sulfate, tin sulfate, sodium hypophosphite, sodium hydrogen sulfite and oxalic acid. The invention further discloses a preparation method for the mud-resistant polycarboxylic acid water reducer. The mud-resistant polycarboxylic acid water reducer has the following benefits: the water solubility and the steric hindrance of polycarboxylic acid are effectively kept; a large amount of non-hydrophilic structures on branch chains can be used for effectively preventing soil interlayer adsorption, so that the adsorption speed and effect are greatly reduced and the mud-resistant purpose is achieved.

Owner:SICHUAN TONGZHOU CHEM TECH

Sulfate dispersion chromate reducer

A chromium VI reducing composition comprising particles of solid material selected from the group consisting of iron (II) sulfate and tin sulfate, the particles being substantially uniformly dispersed within a liquid carrier. Methods for modifying hydratable cementitious materials using the chromium reducing composition are also disclosed and provide advantages over dry powder or dissolved forms of sulfate compositions when used in cement manufacturing.

Owner:WR GRACE & CO CONN

Sulfate dispersion chromate reducer

A chromium VI reducing composition comprising particles of solid material selected from the group consisting of iron (II) sulfate and tin sulfate, the particles being substantially uniformly dispersed within a liquid carrier. Methods for modifying hydratable cementitious materials using the chromium reducing composition are also disclosed and provide advantages over dry powder or dissolved forms of sulfate compositions when used in cement manufacturing.

Owner:GCP APPL TECH INC

Tin plating electrolyte

The invention discloses tin plating electrolyte. The tin plating electrolyte comprises the following components 60 to 90g / L of tin methane sulfonate, 10 to 30g / L of tin sulfate, 110 to 140mg / L of p-cresolsulphonic acid, 60 to 120mg / L of sulfosalicylic acid, 30 to 50g / L of phosphinic acid, 45 to 70mg / L of 2,2-PySSPy, 15 to 25mg / L of 8-hydroxyquinoline, 20 to 30mg / L of catechins, 10 to 15g / L of 2,2-dihydroxy diethyl sulfide, 5 to 10mg / L of hexadecylpyridinium bromide, 8 to 12 g / L of dodecyl-phenol polyoxyethylene ether, 5 to 10g / L of ethylene glycol, 4 to 8g / L of benzalacetophenone, 5 to 10g / L of sodium hexametaphosphate, 4 to 8g / L of sodium dodecyl sulfate, and the balance of deionized water. According to the tin plating electrolyte, Sn2<+> can be effectively restrained to convert into Sn4 <+> in an electrolytic process by improving an electrolyte formula, and the stability of plating solution is improved; and meanwhile, the throwing power of the electrolyte is increased, and the luminance, the corrosion resistance and the welding performance of tin coatings are improved.

Owner:郎溪县金科金属有限公司

Anode lead paste for power lead-acid storage battery and preparation method of anode lead paste

ActiveCN105140474AIncrease specific energyGood high current discharge performanceLead-acid accumulatorsCell electrodesPhysical chemistryPolyaniline

The invention discloses an anode lead paste for a power lead-acid storage battery. The anode lead paste comprises the following constituents by mass: 1,000 parts of lead powder, 90-110 parts of deionized water, 70-100 parts of sulfuric acid solution with mass percentage of 50%, 0.6-0.9 part of synthetic fiber, 10-30 parts of barium sulfate, 0.5-3 parts of lignin, 0.5-2 parts of tin sulfate, 0.5-3 parts of lignin sulfonic acid and 5-20 parts of polyaniline. The invention simultaneously discloses a preparation method of the anode lead paste for the power lead-acid storage battery. By the anode lead paste for the power lead-acid storage battery and the preparation method thereof, the low-temperature performance of the power lead-acid storage battery can be effectively improved, and the problem of a short cycle life at a low-temperature state is solved.

Owner:ANHUI CHAOWEI POWER

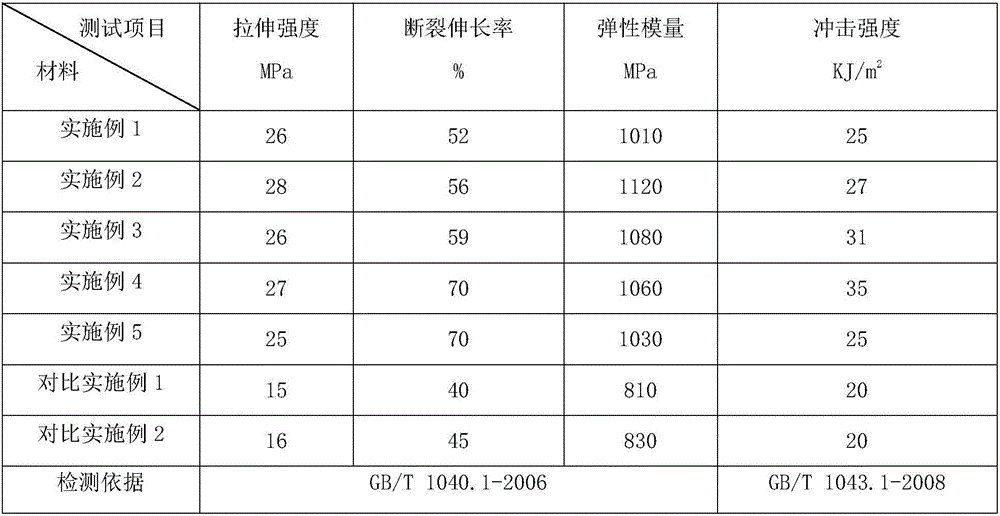

Cellulose enhanced starch plastic, preparation method and application thereof

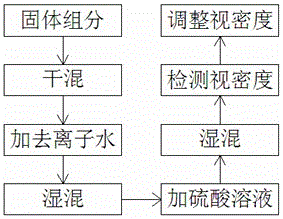

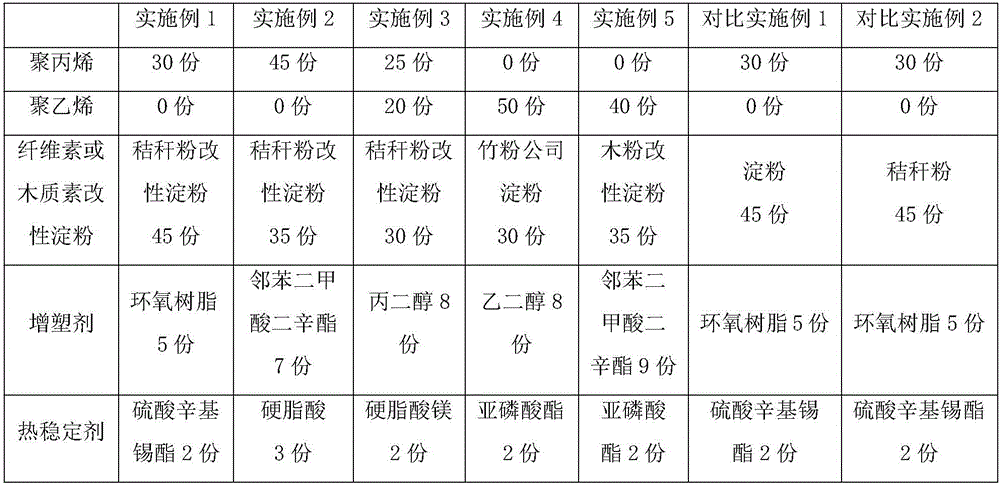

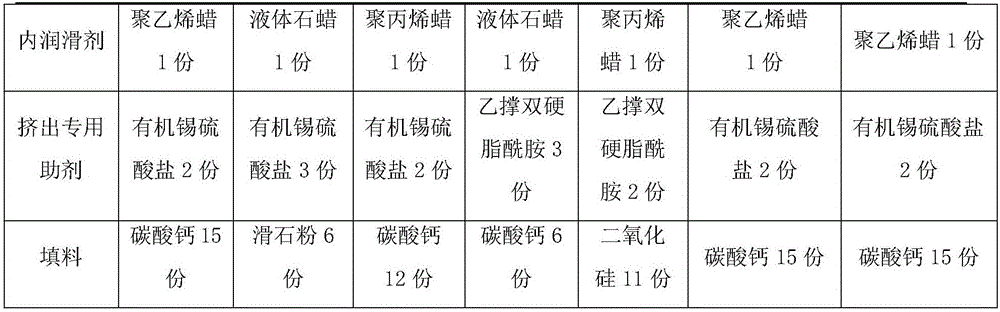

The invention provides a cellulose enhanced starch plastic which comprises the following raw materials by weight percent: 20-60% of polyolefin, 25-70% of cellulose or lignin modified starch, 5-10% of additive, 0-5% of extruding auxiliaries and 0-15% of padding, wherein the additive is one or more of a plasticizer, a heat stabilizer and an internal lubricant; the extruding auxiliaries are one or more of organic tin sulfate and ethylene stearamide; the padding is one or more of talcum powder, calcium carbonate and silicon dioxide. The invention also provides a preparation method of the cellulose enhanced starch plastic and a hollow extruding panel prepared from the cellulose enhanced starch-base plastic. According to the invention, the reproducible raw materials, such as cellulose or lignin modified starch, are mixed with polyolefin; the modified starch can be uniformly dispersed in a polyolefin matrix; compared with the plastic adopting single starch or cellulose, the acquired plastic product has an obviously increased mechanical property.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

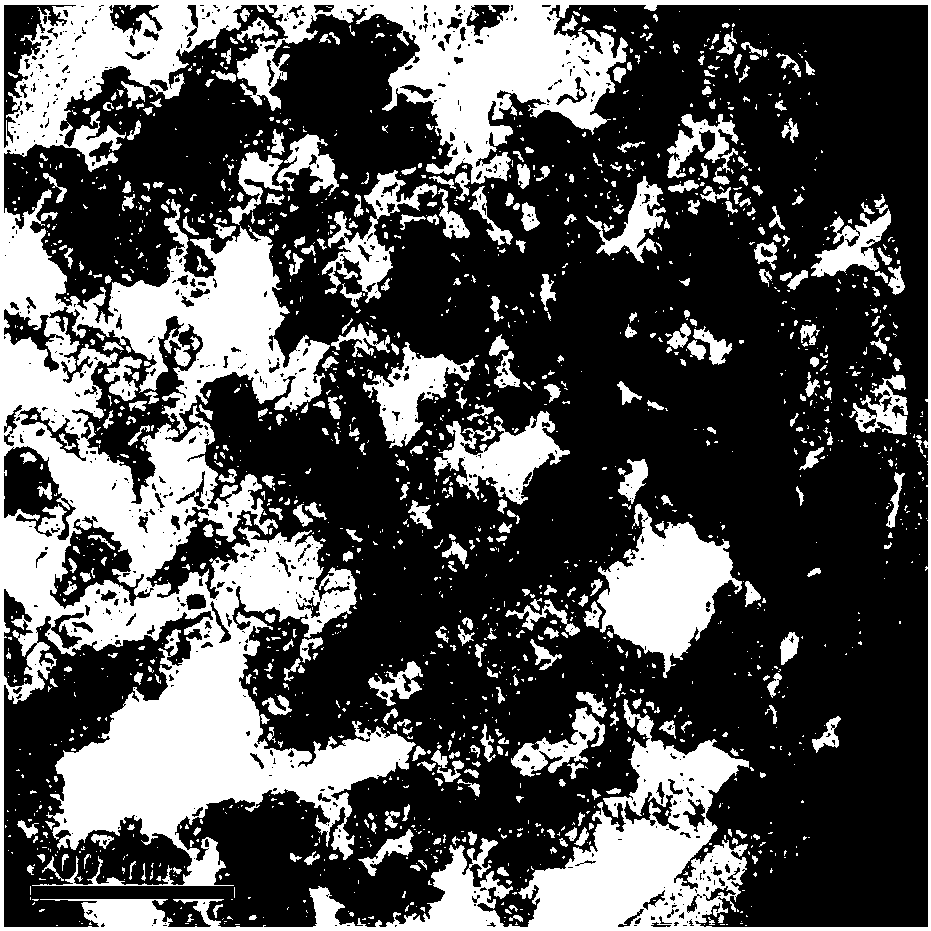

Nanometer tin/carbon composite material and preparation method thereof

InactiveCN108134091AAvoid bulky metallic tin situationsEvenly distributedMaterial nanotechnologyAlkaline accumulatorsCarbon compositesPotassium borohydride

The invention relates to a nanometer composite material, in particular to a nanometer tin / carbon composite material and a preparation method thereof. A nanometer tin and carbon compound is obtained bytaking various carbon materials as a substrate, tin nitrate, tin chloride, tin sulfate, tin acetate, tin citrate and the like as a tin source, water containing an organic complexing agent, ethylene glycol, propylene glycol or other mixture as a solvent and sodium borohydride, potassium borohydride, hydrazine hydrate and the like as a reducing agent and by an absorption-decomposition-reduction method. According to the method, a solution containing tin ions is absorbed to a surface of a carbon material, remaining solution is filtered, the tin oxide / tin and carbon compound is obtained after thermal treatment, and the nanometer tin / carbon composite material is finally obtained by reduction reaction. In the composite material obtained by the method, metal tin particles are uniformly distributed in surfaces of carbon particles in nanometer size, and a phenomenon that a large amount of tin can be agglomerated by a traditional tin reduction method is prevented.

Owner:CENT SOUTH UNIV

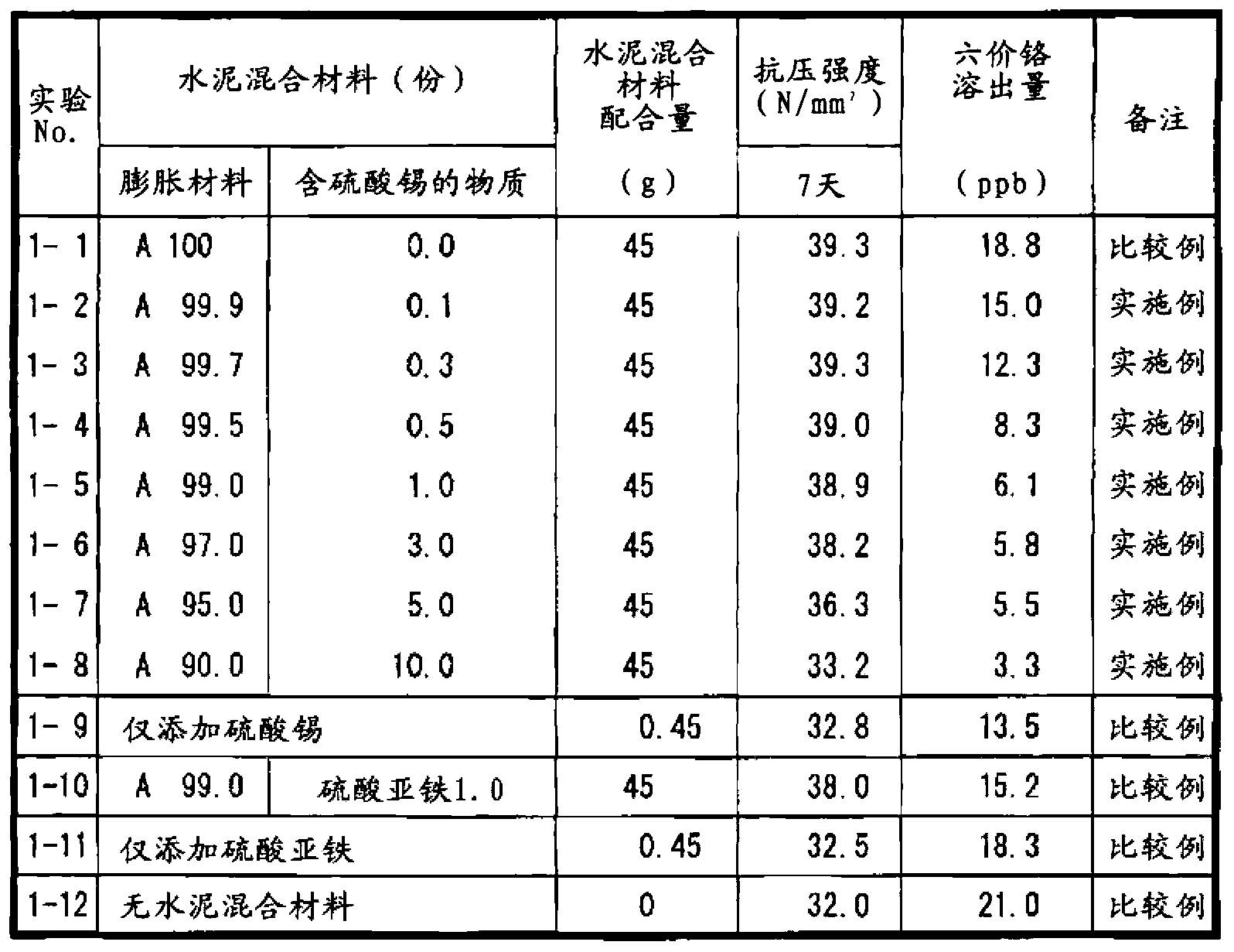

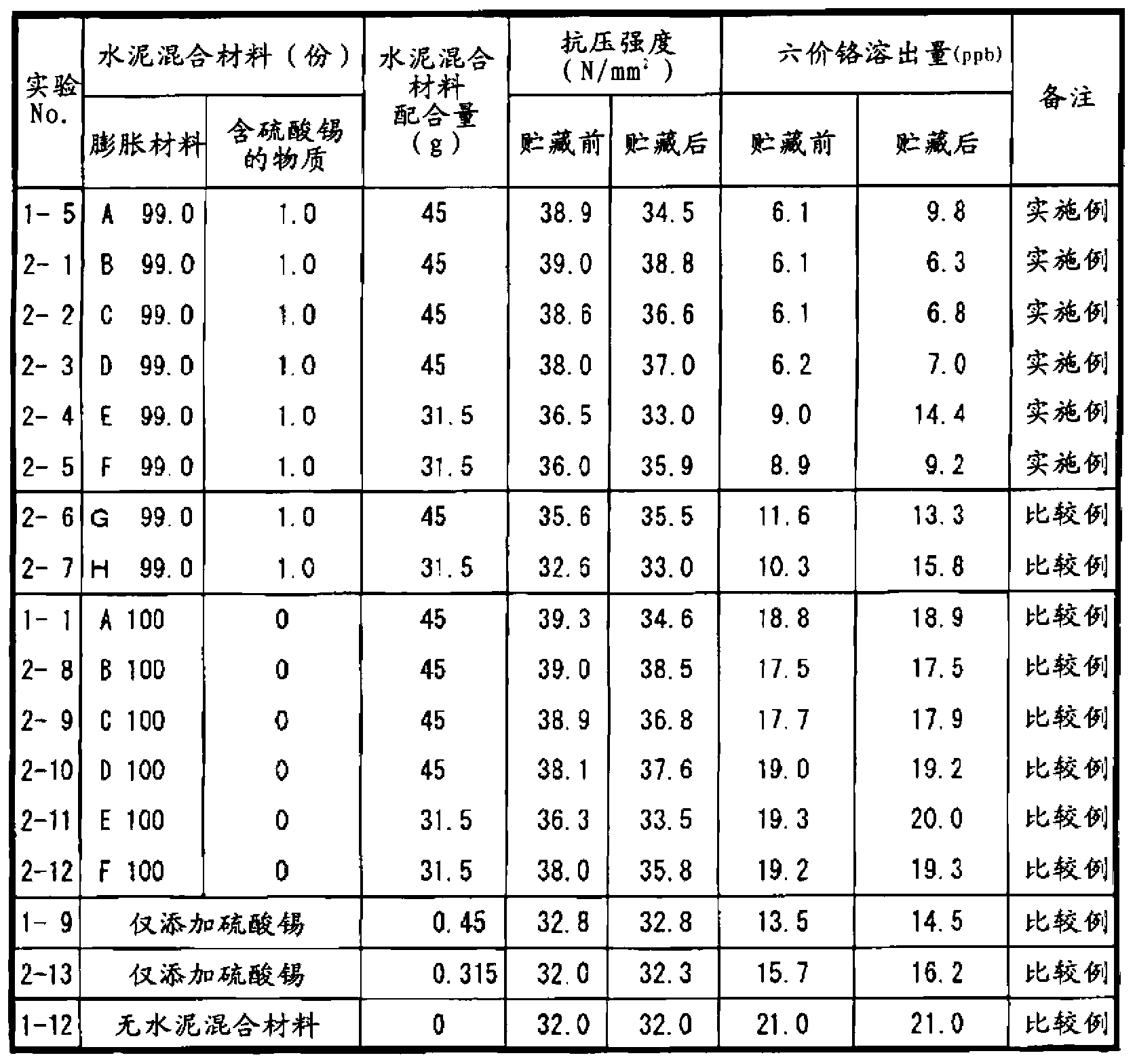

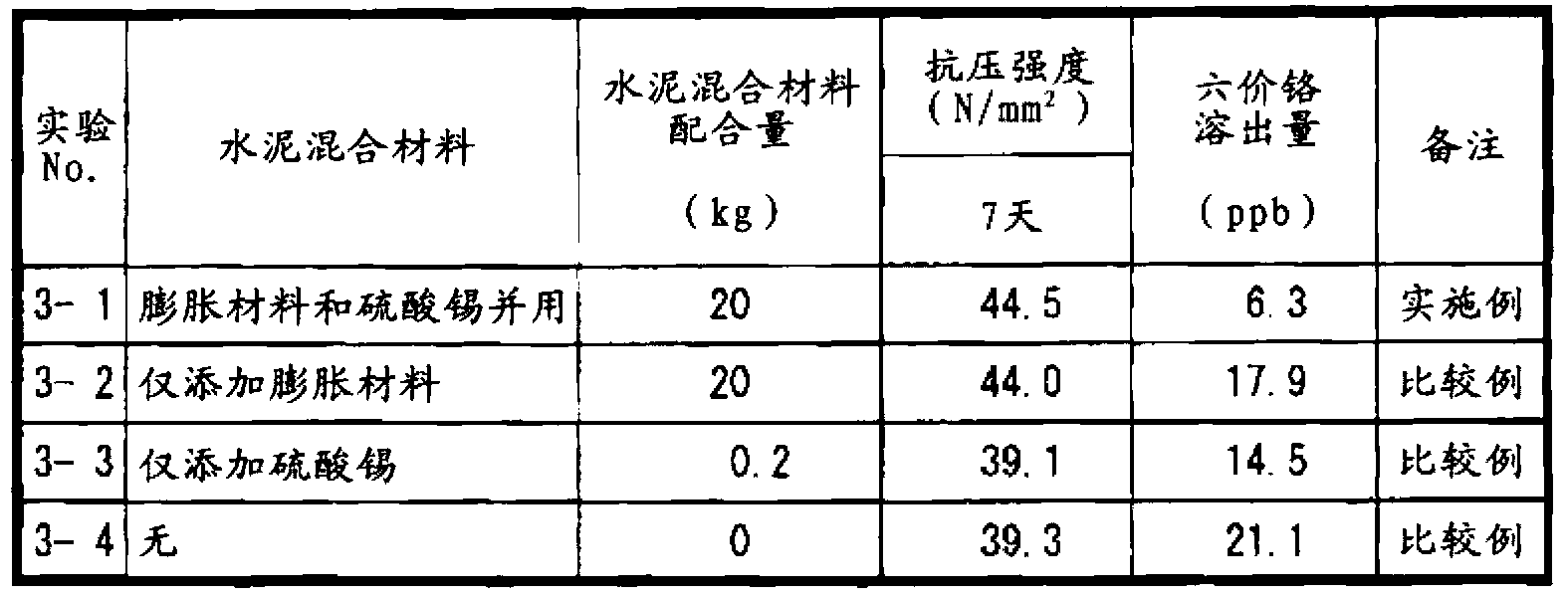

Cement admixture, cement composition, and hexavalent chromium reduction method using same

ActiveCN103261116AExcellent initial strength performanceGood reduction effectSolid waste managementReducing agentCarbon dioxide

Provided are a cement admixture and a hexavalent chromium reduction method yielding superior initial concrete strength, having high hexavalent chromium reduction effects, and exhibiting little decrease in hexavalent chromium reduction effects even when stored as a cement admixture. (1) A cement admixture including a tin sulfate-containing substance and an expansive material containing free lime, a hydraulic compound, and anhydrite; (2) the cement admixture of (1), wherein the amount of the tin sulfate-containing substance is 0.2 to 8 parts by mass in terms of tin sulfate per total 100 parts by mass expansive admixture and tin sulfate-containing substance; (3) the cement admixture of (1) or (2), wherein the expansive admixture is treated with carbon dioxide gas to generate calcium carbonate; (4) the cement admixture of any of (1) to (3), wherein the expansive admixture is surface-treated using a shrinkage reducing agent; (5) a cement composition containing the cement admixture of any of (1) to (4); and (6) a hexavalent chromium reduction method using the cement composition of (5).

Owner:DENKA CO LTD

Formula and preparation method of plating solution as well as method for plating aluminum base plate

The invention discloses a formula and a preparation method of a plating solution for plating a tin-bismuth alloy as well as a method for plating an aluminum base plate. The formula of the plating solution comprises the following components by weight: 40-60 g / l of tin sulfate, 100-130 g / l of sulfuric acids, 0.3-1.5 g / l of bismuth nitrate and 0.5-5.0 g / l of leather glues. The preparation method comprises the following steps of: firstly weighing the tin sulfate, the sulfuric acids, the bismuth nitrate and the leather glues in proportion; injecting one third of running water into a plating solution tank, and adding the sulfuric acids with half of the proportional quantity to acidize the running water; adding the tin sulfate in proportion; then adding the rest sulfuric acids and the bismuth nitrate in proportion; adding the dissolved leather glues; and adding the running water to the plating solution tank to a working solution level. The method for placing the aluminum base plate by using the plating solution comprises the following steps of: deoiling; scouring; preprocessing zincate; carrying out common watt nickel plating; and plating the tin-bismuth alloy. The invention reduces the processing cost by plating a layer of the tin-bismuth alloy on the aluminum base plate, not only has good welding performance, but also has better mechanical strength at low temperature.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

Use of polycarboxylate ethers in combination with other additives for milling cement

InactiveUS20160024307A1Improve early strengthReducing floating of rustInksCement productionIron sulfateAlkaline earth metal

Use of an aqueous composition containing at least one polycarboxylate ether as cement grinding aid, wherein the aqueous composition contains one or more additives, or the aqueous composition is used in combination with one or more additives, and wherein the additive is selected from 1,3-propanediol, a carboxylic acid, a sulfonated amino alcohol, boric acid, a salt of boric acid, a salt of phosphoric acid, sorbitol, a saccharide, a gluconate, iron sulfate, tin sulfate, an antimony salt, an alkali salt, an alkaline earth salt, lignin sulfonate, glycerol, melamine, melamine sulfonate and mixtures thereof.

Owner:SIKA TECH AG

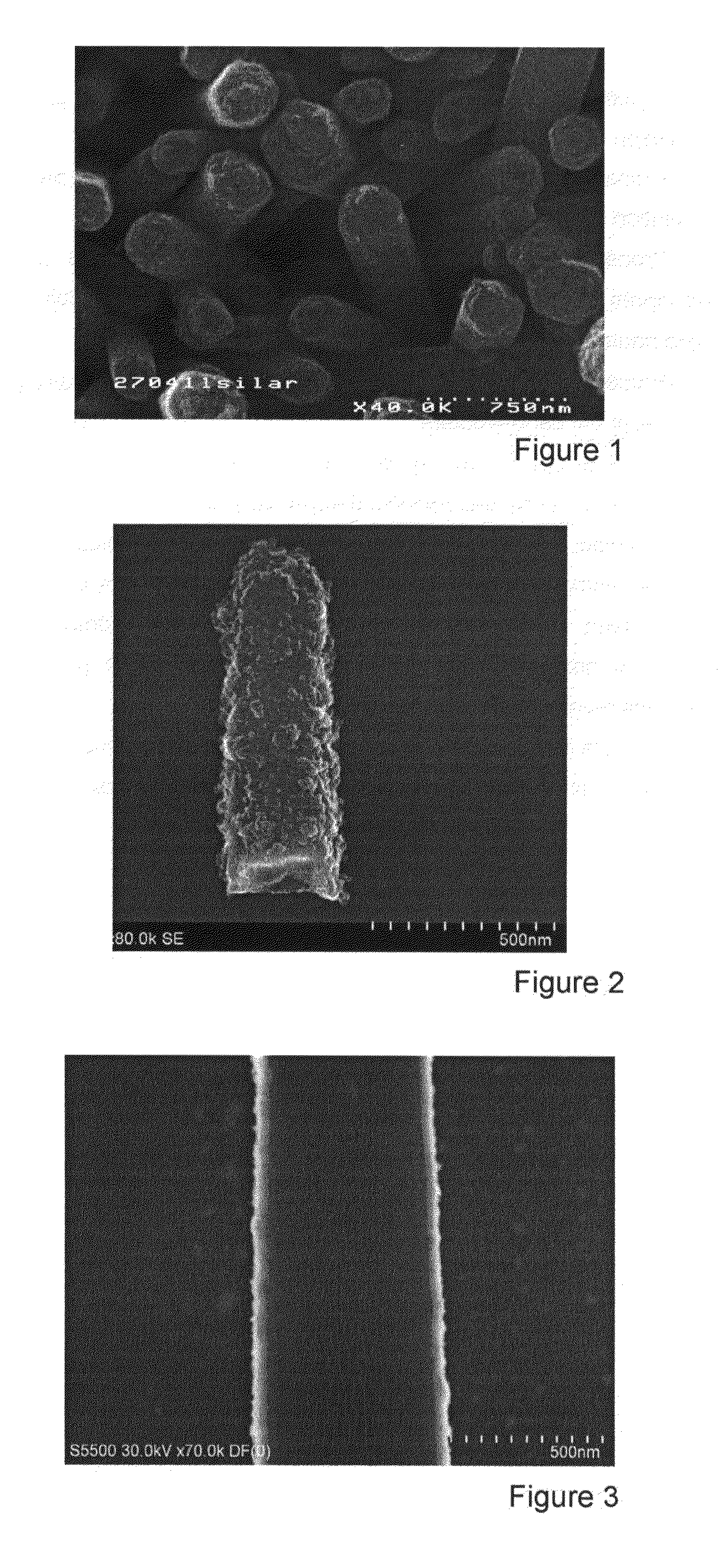

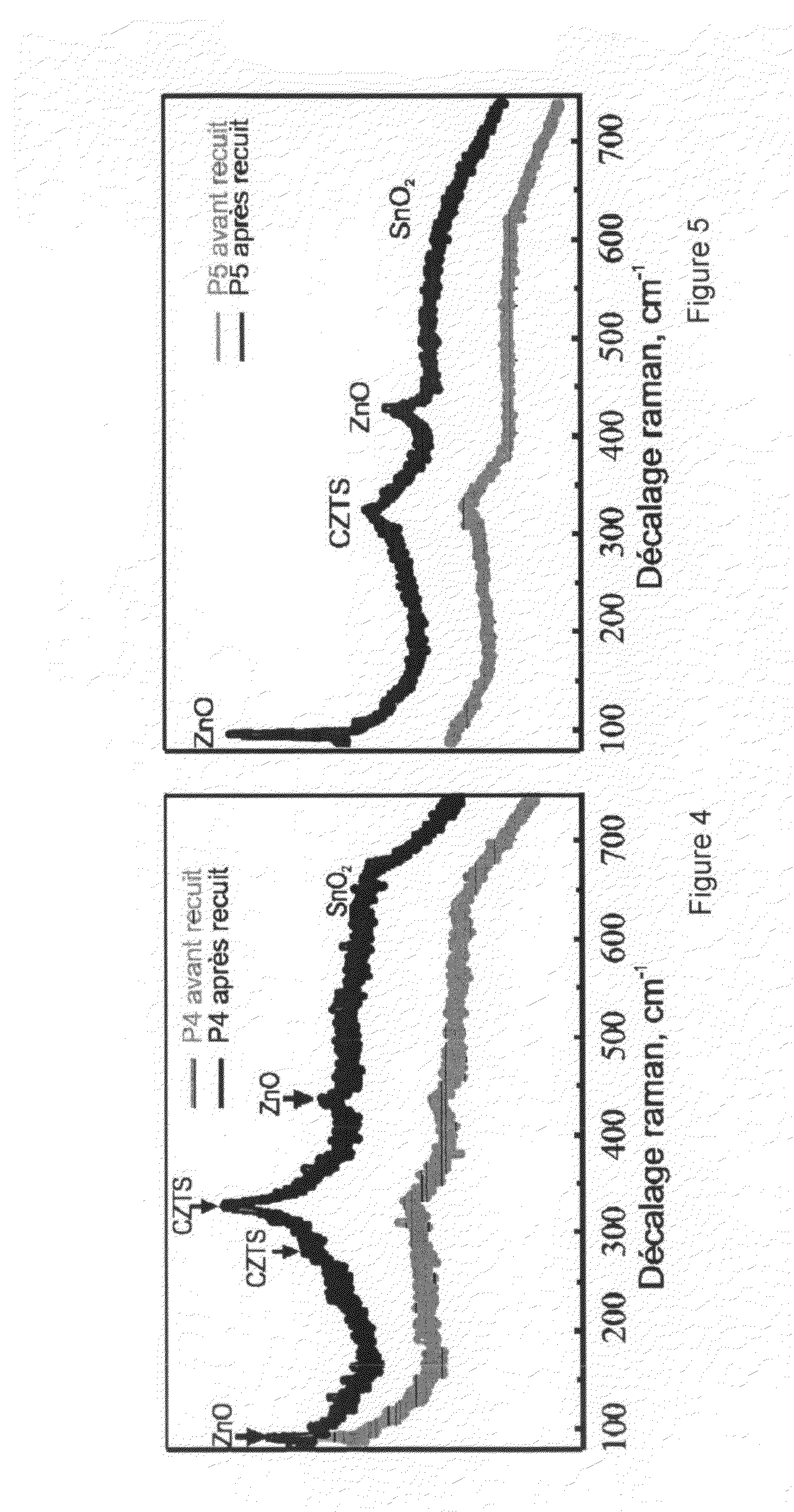

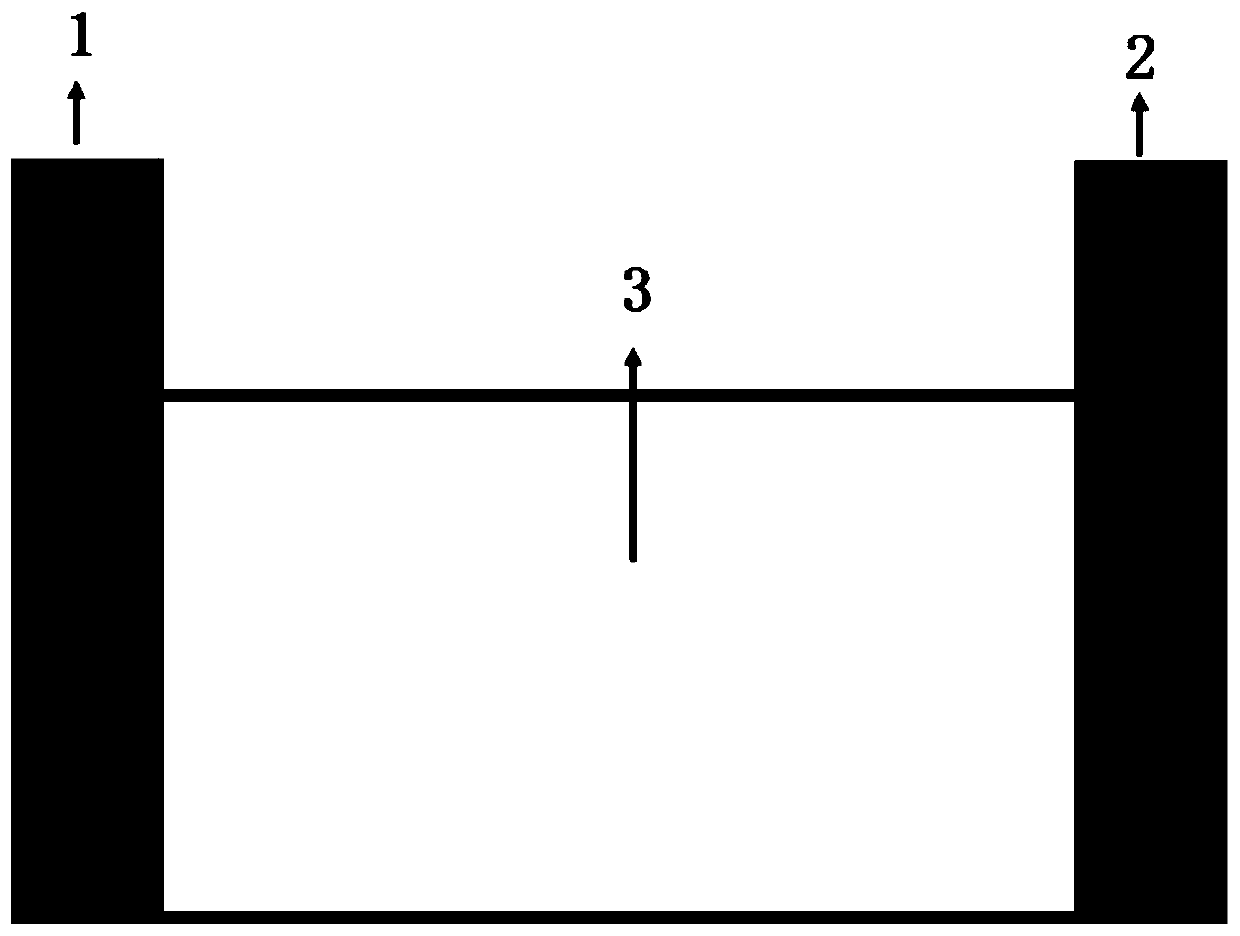

Method for producing a film by cu2znsns4 silar

InactiveUS20130302597A1Not to damageTime stableMaterial nanotechnologyHot-dipping/immersion processesSulfateSulfur

The present invention relates to a method for manufacturing a film of Cu2ZnSnS4 (CZTS) on a metal or metal oxide substrate by successive ion layer adsorption and reaction (SILAR), characterized by the fact that it comprises at least two cycles, each cycle comprising the following successive steps: immersion of the substrate in a cationic solution comprising copper sulfate (CuSO4), tin sulfate (SnSO4) and zinc sulfate (ZnSO4), referred to as the precursors; rinsing by immersion of the substrate in deionized water; immersion of the substrate in an anionic solution comprising sodium sulfide (Na2S); rinsing by immersion of the substrate in deionized water; the concentration ratio of the copper (Cu2+), zinc (Zn2+) and tin (Sn2+) cations and of the sulfur (S2−) anion is 1:1:1:1 or 1:0.5:0.5:1.The invention will be applicable more particularly in the photovoltaic field, especially for production of thin-film, especially nanostructured photovoltaic cells, such as the ETA (Extremely Thin Absorber) cell.

Owner:AUX ENE ALT COMMISSARIAT A LENERGIE ATOMIQUE

High-temperature valve control lead-acid storage battery and preparation method thereof

ActiveCN107146890AImprove performanceImprove corrosion resistanceFinal product manufactureElectrode carriers/collectorsAlloyMetal

The invention belongs to the technical field of a lead storage battery, and particularly relates to a high-temperature valve control lead-acid storage battery and a preparation method thereof. In the high-temperature valve control lead-acid storage battery, metal elements La, Ce and Ag are added into high-tin alloy of a positive grid, 4BS, Bi2O3, Co3O4, Lu2O3 and Na2SO4 are added into a positive active substance, 2-naphthalenesulfonate, cabot carbon black and Beta-naphthol are added into a negative active substance, and tin sulfate and ammonium sulfate are added into an electrolyte. By the high-temperature valve control lead-acid storage battery, the corrosion resistance of the positive grid under a high-temperature environment is improved, the age hardening speed of the grid is reduced, the strength of the positive active substance is improved, the contraction of a negative electrode is reduced, the conductivity of the active substances is improved, the charging efficiency is improved, so that the service lifetime of the battery under an environment of 50-70 DEG C is prolonged than that of an existing battery by about 1.5 times; and the preparation method is scientific, reasonable, simple and practical.

Owner:ZIBO TORCH ENERGY

Sn-b plating solution and plating method using it

InactiveUS20100038255A1Generation of whisker is also preventedImprove electrical durabilityWhiskersBorane

Owner:ILJIN COPPER FOIL

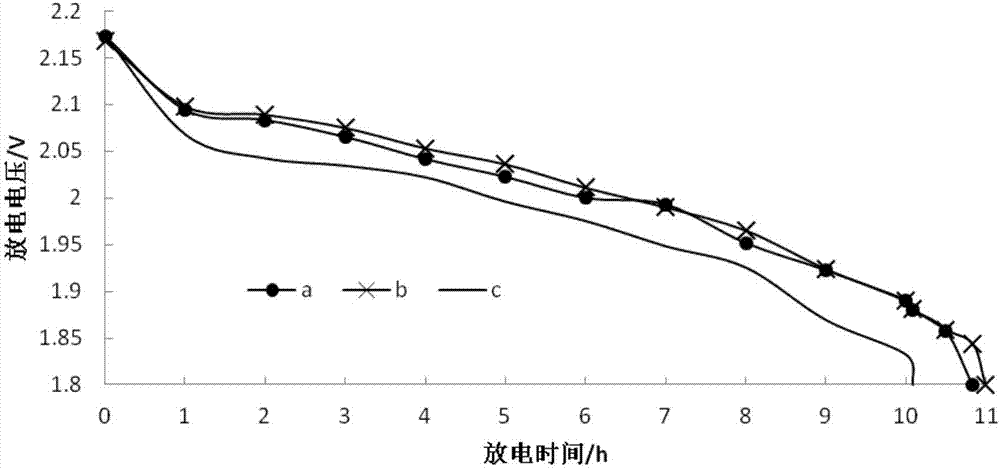

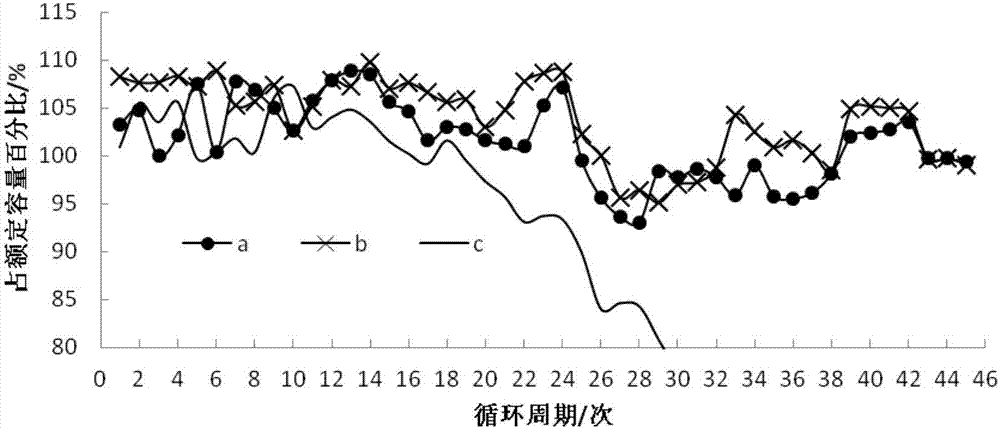

Manganese dioxide battery based on electrochemical metallurgy principle

InactiveCN111342148AIncrease energy densityImprove cycle performanceCell electrodesSecondary cellsManganese sulphateO-Phosphoric Acid

The invention discloses a manganese dioxide battery based on an electrochemical metallurgy principle, and relates to the technical field of batteries. The manganese dioxide battery comprises a manganese dioxide electrode, an electrolyte and a cathode, wherein the electrolyte is one or more of sulfuric acid, acetic acid, phosphoric acid and nitric acid containing additives, and the additives comprise one or more of manganese sulfate, tin sulfate, cadmium sulfate and copper sulfate. The invention aims to obtain a battery with high energy density and high circularity by introducing an electrochemical metallurgical reaction into the battery. The manganese dioxide positive electrode material and the manganese dioxide negative electrode material disclosed by the invention can generate reversibledissolution and deposition processes in charging and discharging processes. By using an electrochemical metallurgical reaction system, a high-circularity aqueous battery is obtained. The manganese dioxide battery based on the electrochemical metallurgy principle, which has high circularity and high energy density, can be obtained, and has great scientific research and social and economic benefits.

Owner:湖南源达新材料有限公司

Lithium ion battery positive electrode material and preparation method thereof

InactiveCN107910556AUniform particlesHigh specific capacityCell electrodesLi-accumulatorsLithium hydroxideLithium-ion battery

The invention discloses a lithium ion battery positive electrode material. The lithium ion battery positive electrode material comprises the following raw materials based on parts by weight: 100-110 parts of lithium hydroxide, 20-30 parts of manganese sulfate, 4-6 parts of cobalt oxide, 2-3 parts of conductive bonding liquid, 7-9 parts of zinc oxide, 0.1-0.2 part of sodium carboxymethyl celluloseand 0.08-0.1 part of tin sulfate. The positive electrode material prepared by the method has the advantages of uniform particle, high specific capacity, good cycle property and the like, industrial production is easy, graphite powder is processed by triethylamine and is mixed with rosin, the lithium ion battery positive electrode material has better electrical conductivity and is high in viscosity, and the stability of the finished product of the electrode material can be effectively improved.

Owner:安徽智森电子科技有限公司

Tin electroplating solution and preparation method and application thereof

The invention provides a tin electroplating solution and a preparation method and application thereof. The tin electroplating solution per liter comprises, by mass, 10-50 g of tin sulfate, 50-200 g ofsulfuric acid, 0.05-5 g of a wetting agent, 0.01-2 g of an antioxidant and 0.01-2 g of a grain refiner, wherein a solvent of the tin electroplating solution is water, and the crystal refiner is a flavonoid compound. According to the tin electroplating solution, tin sulfate is adopted as a main salt, sulfuric acid is used as an electrolyte to increase conductivity, the wetting agent, the antioxidant and the grain refiner are further added, and then the components are mutually matched to play a synergistic effect, so that the production efficiency is greatly improved and tin source is saved under the condition that the same plating thickness is achieved; and meanwhile, the compactness of a tin plating layer is improved, and the tin plating layer has good alkaline corrosion resistance.

Owner:上海天承化学有限公司

Tin plating method for metal surface

InactiveCN110735132AUniform filmLight levelingLiquid/solution decomposition chemical coatingChemical reactionThiourea

The invention relates to a tin plating method for a metal surface. The method comprises the following steps: enabling a tin-free part to be in contact with a repairing solution for chemical reaction,wherein the heating temperature during chemical reaction is 30-40 DEG C; and washing and drying after the tin-free part is reacted with the repairing solution, wherein the solute of the repairing solution is tin sulfate, thiourea and sodium chloride, and the solvent of the repairing solution is water. The novel method for realizing rapid tin plating is uniform in film formation, smooth in light quantity and good in conductivity.

Owner:BEIJING SHUGUANG AERO ELECTRICAL

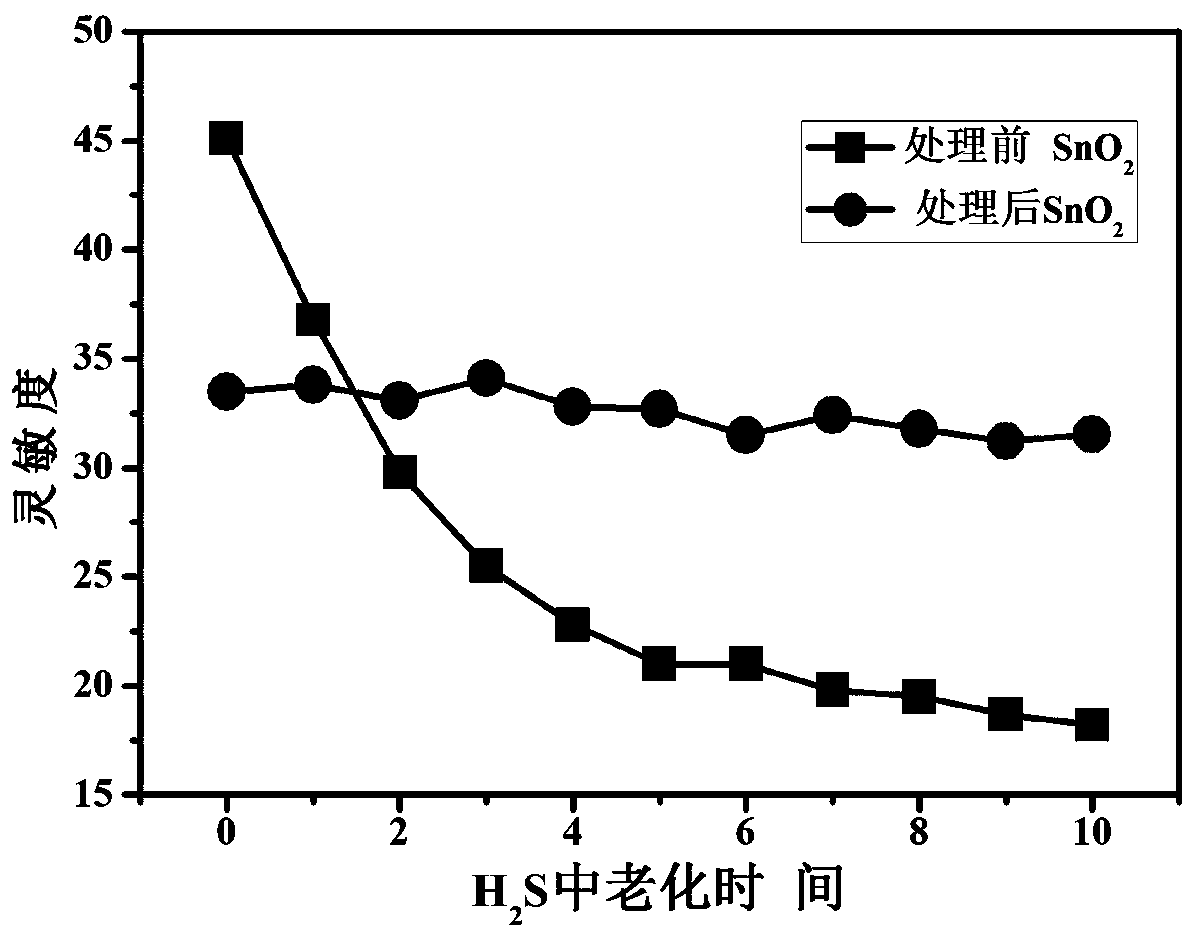

Method for improving stability of hydrogen sulfide-sensitive tin dioxide gas sensor material

ActiveCN107831269AGuaranteed stabilityImprove performanceMaterial nanotechnologyMaterial analysisTin dioxideHigh energy

The invention discloses a method for improving the stability of a hydrogen sulfide-sensitive SnO2 gas sensor material. The method comprises the following steps: preparing an aqueous solution of a sulfur salt and SnCl4.5H2O, placing the SnO2 gas sensor material in the above solution, performing stirring, and adding an appropriate amount of a complexing agent; placing the above obtained solution ina reactor, and performing a reaction for 3-5 h; cooling the reactor to room temperature, and centrifuging and drying the obtained sample; and placing the obtained powder precursor in a high-energy ball mill, performing ball milling, placing the ball-milled powder precursor in a muffle furnace, and performing calcination to obtain a tin sulfate- modified SnO2 nano-powder with a porous surface. Themethod, aiming at the problem of poor stability of the SnO2 gas sensor material in the H2S gas detection process, uses the sulfur salt to preprocess the gas sensor material to form a porous sulfate film on the surface of SnO2 in order to effectively prevent the SnO2 from reacting with sulfide during use, it is expected to ensure the long-term stability of the sensor in the H2S gas atmosphere. Themethod has the advantages of simple preparation process, realization of mass production, realization of stable performances, and broad application prospect.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

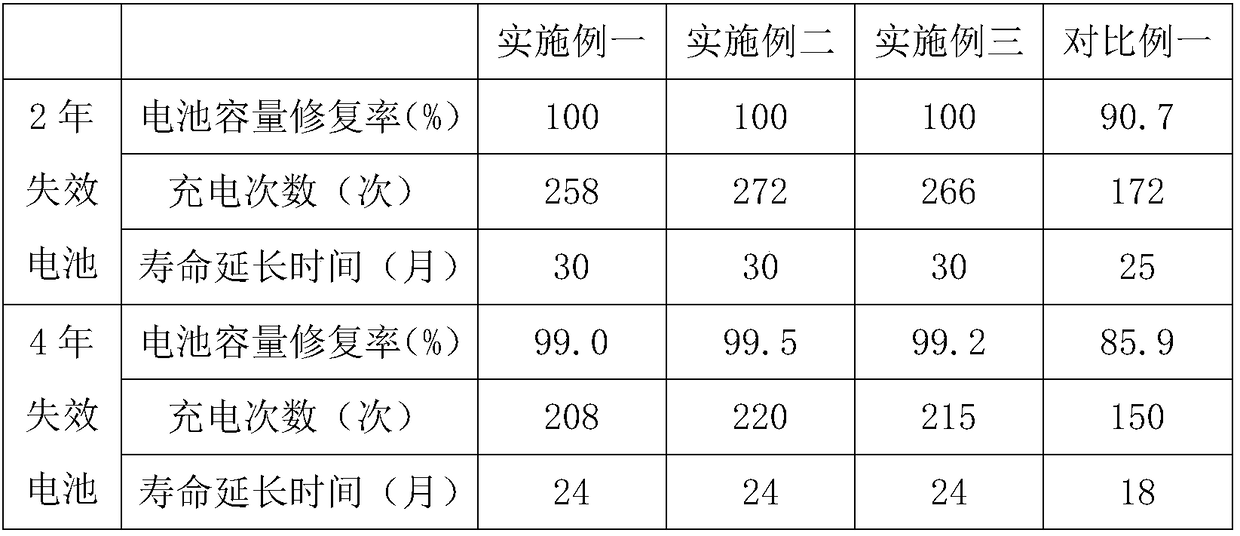

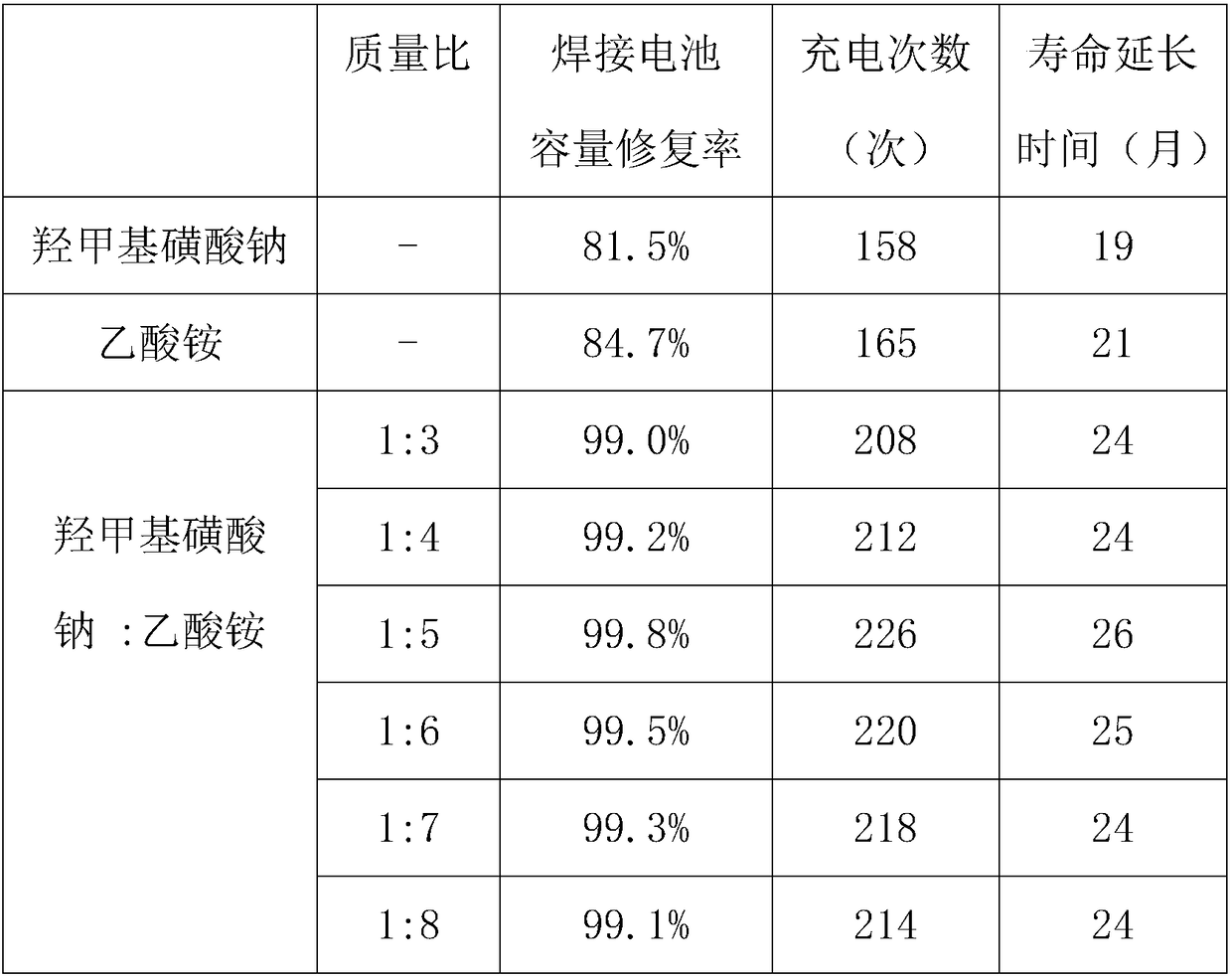

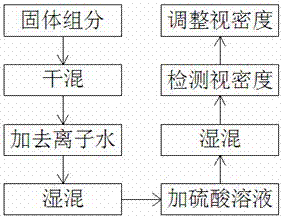

Efficient active agent of lead-acid storage battery and preparation method of active agent

ActiveCN108470949AImprove activation abilityLower internal resistanceLead-acid accumulatorsElectrolyte/reactants regenerationTin dioxideHigh activation

The invention belongs to the technical field of a storage battery, particularly an efficient active agent of a lead-acid storage battery and a preparation method of the active agent, and solves the problems of incomplete repair function, and poor repair effect, easily formed battery micro short circuit and low battery repair rate caused by destructive current impact to lead sulfate caused by purebattery capacity increasing of the active agent of the lead-acid storage battery in the prior art. The efficient active agent of the lead-acid storage battery comprises the following raw materials: sulfate, tin sulfate, tin dioxide, a sulfuric acid solution, polyethylene potassium sulphate, 1- allyl-3-methylimidazole chlorine salt, ammonium polyacrylate, sodium lignin sulfonate, hydroxylmethyl sodium sulfonate, ammonium acetate and distilling water. The efficient active agent of the lead-acid storage battery provided by the invention has safe and environment friendly raw materials, low dosage,100% of lead-acid storage battery capacity repair rate, high activation, complete repair functions, easy realization of industrial production and worth popularizing.

Owner:TIANNENG GRP HENAN ENERGY TECH

A negative lead paste for power lead-acid battery and preparation method thereof

ActiveCN105140474BIncrease specific energyGood high current discharge performanceLead-acid accumulatorsCell electrodesPolyanilineBarium sulfate

The invention discloses an anode lead paste for a power lead-acid storage battery. The anode lead paste comprises the following constituents by mass: 1,000 parts of lead powder, 90-110 parts of deionized water, 70-100 parts of sulfuric acid solution with mass percentage of 50%, 0.6-0.9 part of synthetic fiber, 10-30 parts of barium sulfate, 0.5-3 parts of lignin, 0.5-2 parts of tin sulfate, 0.5-3 parts of lignin sulfonic acid and 5-20 parts of polyaniline. The invention simultaneously discloses a preparation method of the anode lead paste for the power lead-acid storage battery. By the anode lead paste for the power lead-acid storage battery and the preparation method thereof, the low-temperature performance of the power lead-acid storage battery can be effectively improved, and the problem of a short cycle life at a low-temperature state is solved.

Owner:ANHUI CHAOWEI POWER

A kind of silicon solar cell electrode silver-coated copper paste and preparation method thereof

ActiveCN104157331BLow costImprove stabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureCeriumSilicon solar cell

The invention relates to a silicon solar cell electrode silver coated copper sizing agent and a preparing method of the silicon solar cell electrode silver coated copper sizing agent. Conductive component micro silver coated copper powder is the spherical micro metal powder with copper serving as the core, silver serving as the shell, and copper-tin-silver alloy serving as the middle layer, the copper content is 50 percent to 60 percent, the silver content is 30 percent to 40 percent, the tin content is 3 percent to 10 percent, the particle size is 1-3 microns, the tap density is 4.0-5.5 g / ml, the specific surface area is 0.5-1.5 m<2> / g, and the conductive component micro silver coated copper powder is prepared under the alkaline condition with glyoxylic acid or glyoxal serving as a reducing agent to conduct step-by-step reduction on copper sulfate, tin sulfate and a silver nitrate solution. A bismuth-silicon-boron-zinc-cerium-molybdenum system is adopted in lead-free glass powder, the softening temperature of the glass powder is 400-600 DEG C, the micro silver coated copper powder serves as the conductive component, a large amount of silver powder is saved, and the raw material cost of the conductive sizing agent is greatly reduced.

Owner:TIANJIN ZHONGKE CHEM

Low-expansion building ceramic material and preparation method thereof

The invention discloses a low-expansion building ceramic material. The low-expansion building ceramic material comprises, by weight, 5-10 parts of alumina, 7-10 parts of magnesium oxide, 3-7 parts of titanium dioxide, 4-8 parts of germanium pentoxide, 3-6 parts of manganese dioxide, 4-9 parts of molybdenum tungstate, 2-6 parts of niobium phosphate, 1-4 parts of vanadium silicate, 2-5 parts of tin sulfate, 5-11 parts of Astragalus sinicus and 10-20 parts of ethyl orthosilicate. The ceramic material has the advantages of low heat expansion coefficient and high strength, the average heat expansion coefficient at 0-850 DEG C is 5.0-8.5 * 10<-7> / DEG C, and the flexural strength of the ceramic material at 0-850 DEG C is 95-105 Mpa.

Owner:苏州耐思特塑胶有限公司

A lead paste formulation for forklift truck battery and its preparation process

A lead paste formula for forklift truck battery and its preparation process are disclosed, 100 kg of lead powder, 11.5 kg of sulfuric acid, 12-13 kg of pure water, 80 g of chemical short fib, 300 g ofcalcium sulfate, 200 g of tin sulfate, 200 g of glycerol, 100 g of antifreeze and 0. 5-1 kg of cooling water; 100kg of lead powder, 11.5 kg of sulfuric acid, 10-11kg of pure water, 90g of semi-charcoal sawdust, 70g of sodium dodecyl sulfonate, 60g of pore-forming agent, 600g of tannin extract and 50g of diffusion agent; As that antifreeze is added in the invention, the lead paste is avoid from freezing in a cold area and can not work normally, and the charging acceptance capacity and the cycle life of the battery can be improved by adding tin sulfate.

Owner:安徽迅启电源科技有限公司

Mud-resistant polycarboxylic acid water reducer and preparation method thereof

The invention discloses a mud-resistant polycarboxylic acid water reducer which is prepared from the following components: allyl polyoxyethylene polyoxypropylene ether, components R, R1 and R2, a chain transfer agent, an initiating agent R3 and water, wherein the component R is one or more of maleic anhydride, sodium methallyl sulfonate, vinyl acetate, itaconic acid, itaconic anhydride and fumaric acid; R1 is one or a mixture of two of acrylic acid and methylacrylic acid; R2 is one or more of ascorbic acid, sodium formaldehyde sulfoxylate, ferrous sulfate, tin sulfate, sodium hypophosphite, sodium hydrogen sulfite and oxalic acid. The invention further discloses a preparation method for the mud-resistant polycarboxylic acid water reducer. The mud-resistant polycarboxylic acid water reducer has the following benefits: the water solubility and the steric hindrance of polycarboxylic acid are effectively kept; a large amount of non-hydrophilic structures on branch chains can be used for effectively preventing soil interlayer adsorption, so that the adsorption speed and effect are greatly reduced and the mud-resistant purpose is achieved.

Owner:SICHUAN TONGZHOU CHEM TECH

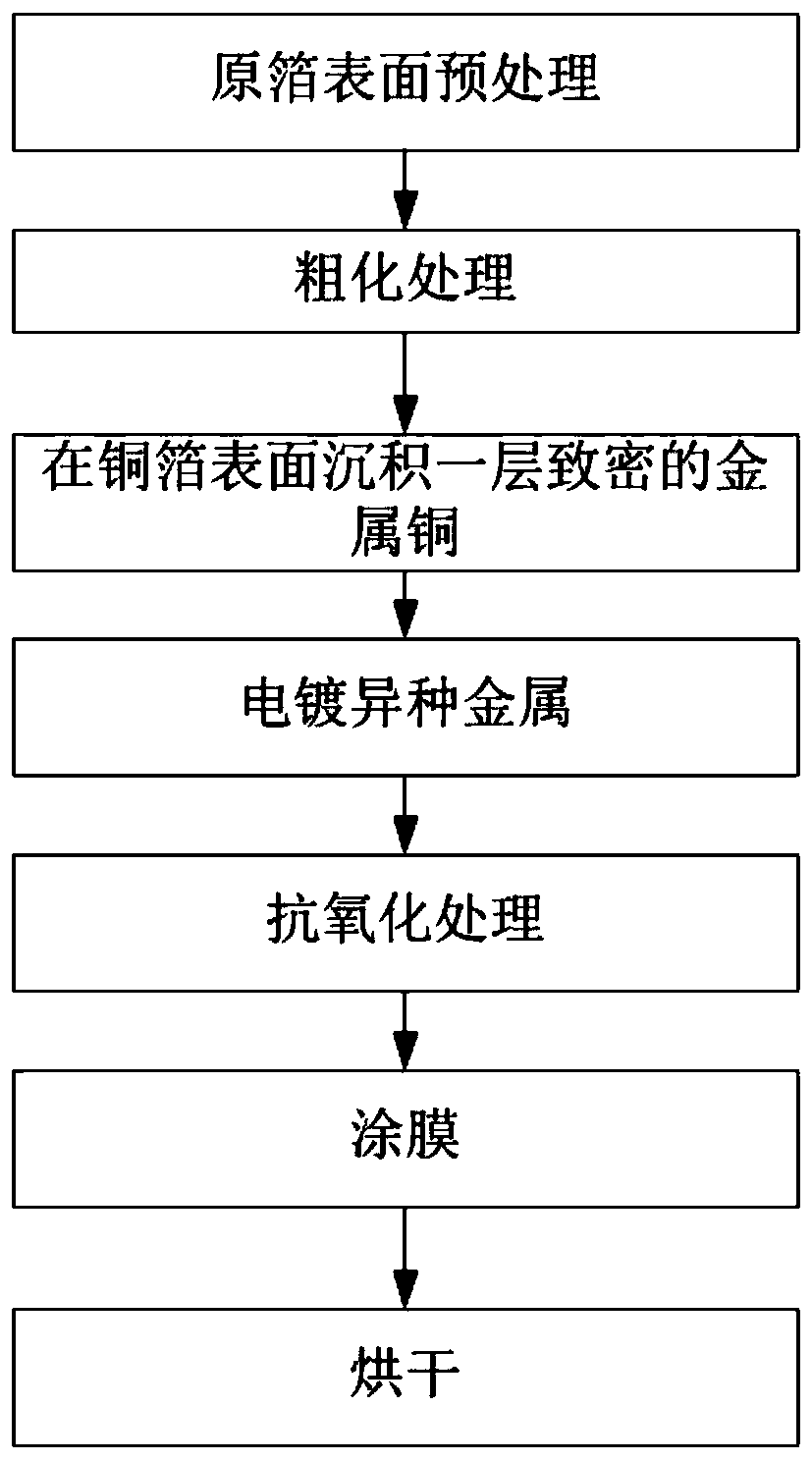

Electrolytic copper foil surface treatment technology

The invention discloses an electrolytic copper foil surface treatment technology. The technology comprises the follow steps of carrying out pretreatment; carrying out roughening, wherein roughening treatment is carried out on original foil subjected to pretreatment in a solution containing copper sulfate, sulphuric acid, sodium silicate and stannous sulfate; carrying out curing, wherein one layerof dense metallic copper is deposited in a gap between every two adjacent nodular particles of the copper foil subjected to roughening; carrying out electroplating of dissimilar metal, wherein in an inert gas atmosphere, the copper foil is heated to form a brass layer and then is subjected to antioxidant treatment, and antioxidant liquid is prepared by dissolving chromium trioxide and a glucose solution into water; soaking the obtained copper foil into the antioxidant liquid for one second to four seconds; carrying out coating, wherein a silane coupling agent is sprayed to the surface of the copper foil after the copper foil is subjected to antioxidant treatment, and then the copper foil is dried in an air-blowing manner; and carrying out oven drying. According to the electrolytic copper foil surface treatment technology, because the tin sulfate is added in an electroplating dissimilar metal technology to serve as an additive instead of arsenic in a traditional technology, the electrolytic copper foil surface treatment technology is friendly to the environment, and accords with the concept of green development.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com