Sulfate dispersion chromate reducer

A sulfate and reducing agent technology, used in the field of reducing chromate in cement, cement additives, and solid sulfate particles, can solve problems such as hindering tin sulfate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Formulation of the tin sulfate composition of the present invention: tin sulfate particles (56 gm) and eutan gum base VMA (44 gm) were mixed together. The VMA is available from Grace Construction Products under the trade name V-MAR(R) 3. Other suitable VMAs may include xanthan gum, wenlai gum, and cellulose ethers, preferably dispersed in water with an optional dispersant.

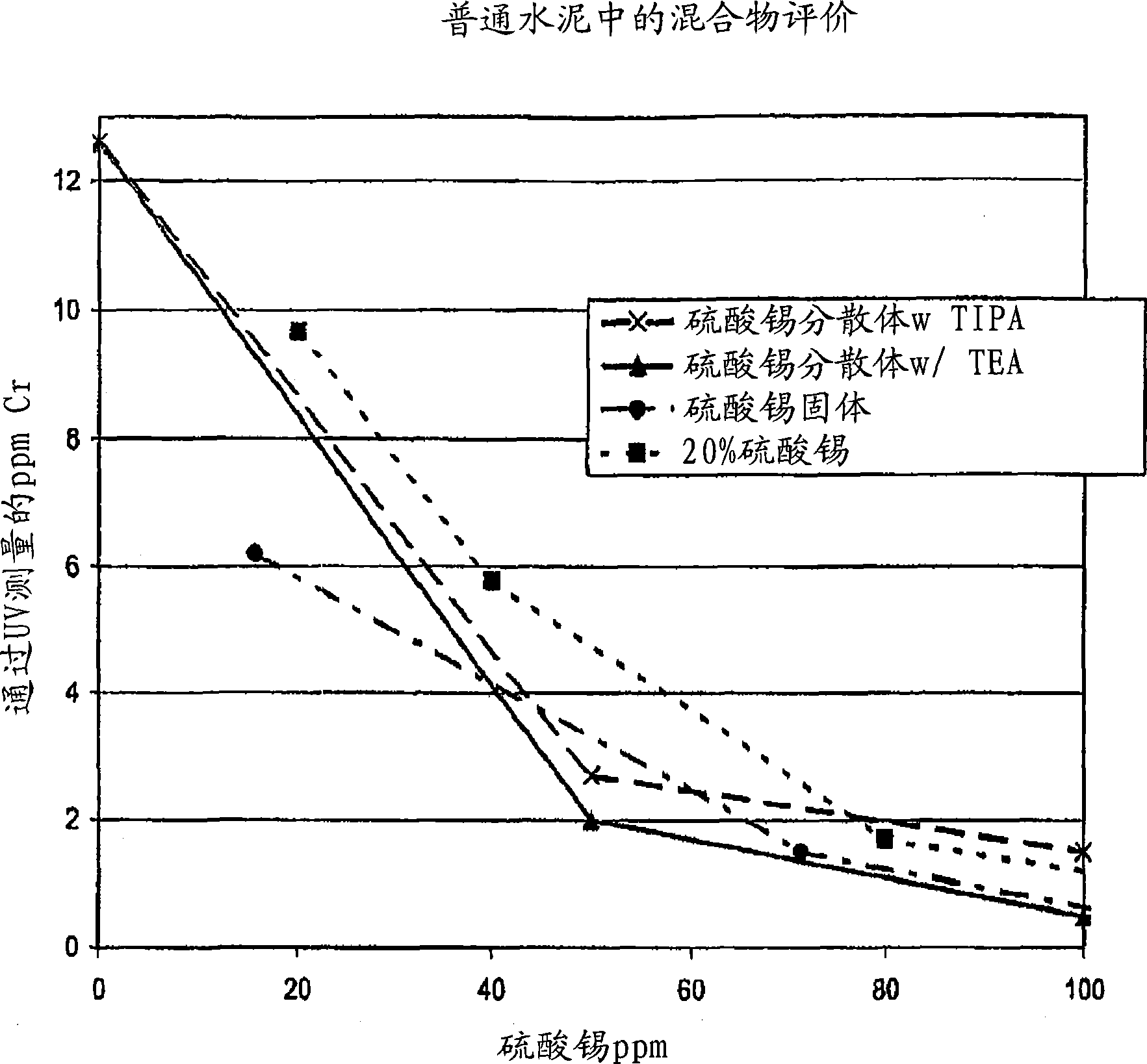

[0067] Table 1 shows the performance comparison between tin sulfate solid, tin sulfate dispersion and tin sulfate solution. All additives were interground into slag cement prepared in a laboratory ball mill. In the cement prepared in the laboratory, the proportions of the various materials were as follows: 70% cement clinker, 25% slag, 2.8% gypsum, 1.9% stucco. Abrasives were prepared at ambient temperature.

[0068] The additive amounts of chromate reducing additives are shown in Table 1. Dosages of active tin sulfate moieties are also given. The soluble ppm Cr (measured as chromate) is given ...

Embodiment II

[0073] Similar experiments were carried out using cement with the following composition percentages: 95% cement clinker, 2.8% gypsum, 1.9% stucco. The respective chromate reduction properties of the samples are shown in Table 2.

[0074] Chromate Reducing Additives

Embodiment III

[0076] Another test was carried out using a cement having the following composition percentages: 65% cement clinker, 7.5% slag, 15.1% limestone, 7.5% natural pozzolan, 2.8% gypsum and 1.9% stucco, the percentages being calculated on a total weight basis. In this case, 200 ppm tin sulfate delivered in dispersion performed comparable to 300 ppm tin sulfate delivered in solution in heat treated cement. The results are shown in Table 3.

[0077] Chromate Reducing Additives

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com