Manganese dioxide battery based on electrochemical metallurgy principle

A manganese dioxide battery and manganese dioxide electrode technology, which is applied in secondary batteries, electrochemical generators, battery electrodes, etc., can solve the problems of increasing battery cost, limiting battery energy density, and zinc cannot exist stably, and achieve high Energy density, high cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

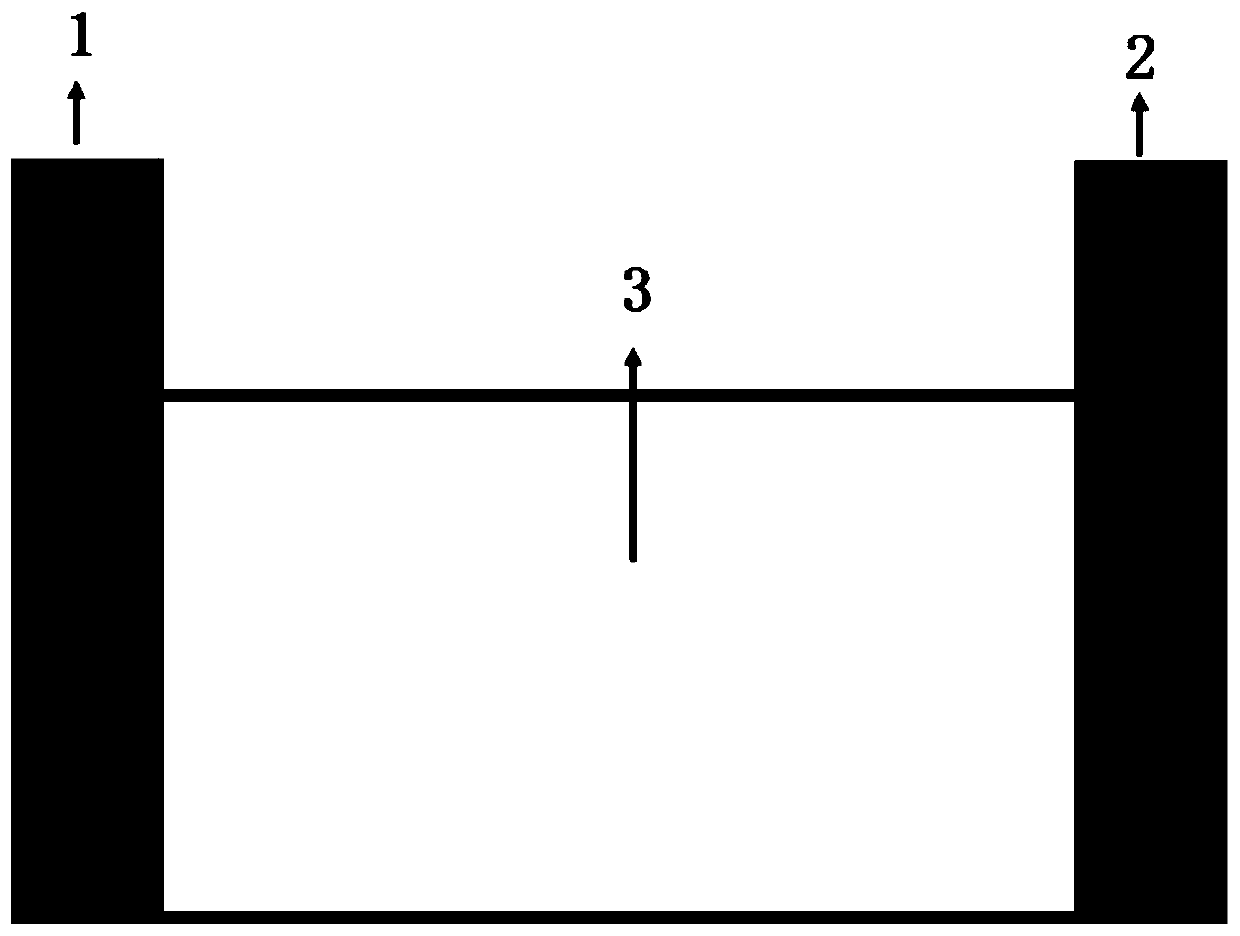

Image

Examples

Embodiment 1

[0033] A manganese dioxide battery based on the principle of electrochemical metallurgy, using tin as the negative electrode based on the electrochemical metallurgical reaction. An aqueous solution of 3 mol / L sulfuric acid + 0.1 mol / L manganese sulfate + 0.1 mol / L tin sulfate is used as the electrolyte. Among them, the hydrogen ion concentration is about 6mol / L. Manganese dioxide was used as the positive electrode. The open circuit voltage of the obtained battery is about 1.4V, and can be cycled stably for more than 300 cycles.

Embodiment 2

[0035] A manganese dioxide battery based on the principle of electrochemical metallurgy, using cadmium as the negative electrode based on the electrochemical metallurgical reaction. An aqueous solution of 3mol / L sulfuric acid+0.1mol / L manganese sulfate+0.1mol / L cadmium sulfate is used as the electrolyte. Among them, the hydrogen ion concentration is about 6mol / L. Manganese dioxide was used as the positive electrode. The open circuit voltage of the obtained battery is about 1.7V, and can be cycled stably for more than 200 cycles.

Embodiment 3

[0037] A manganese dioxide battery based on the principle of electrochemical metallurgy, using tin as the negative electrode based on the electrochemical metallurgical reaction. An aqueous solution of 5 mol / L sulfuric acid + 0.1 mol / L manganese sulfate + 0.1 mol / L tin sulfate is used as the electrolyte. The hydrogen ion concentration is about 10mol / L. Manganese dioxide was used as the positive electrode. The open circuit voltage of the obtained battery is about 1.5V, and can be cycled stably for more than 200 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com