Patents

Literature

162 results about "Cadmium sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cadmium sulfate is the name of a series of related inorganic compounds with the formula CdSO₄·xH₂O. The most common form is the monohydrate CdSO₄·H₂O, but two other forms are known CdSO₄·⁸⁄₃H₂O and the anhydrous salt (CdSO₄). All salts are colourless and highly soluble in water.

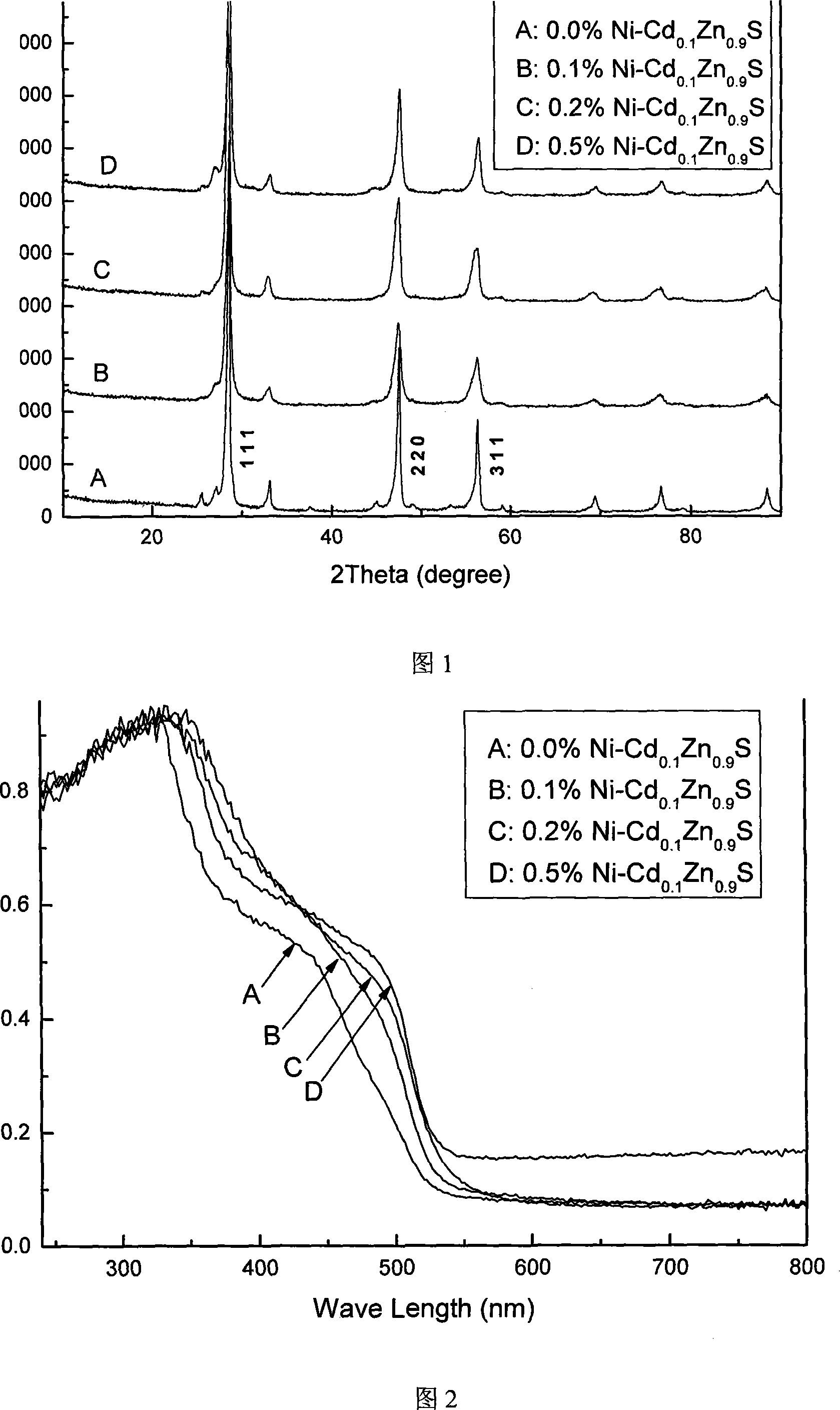

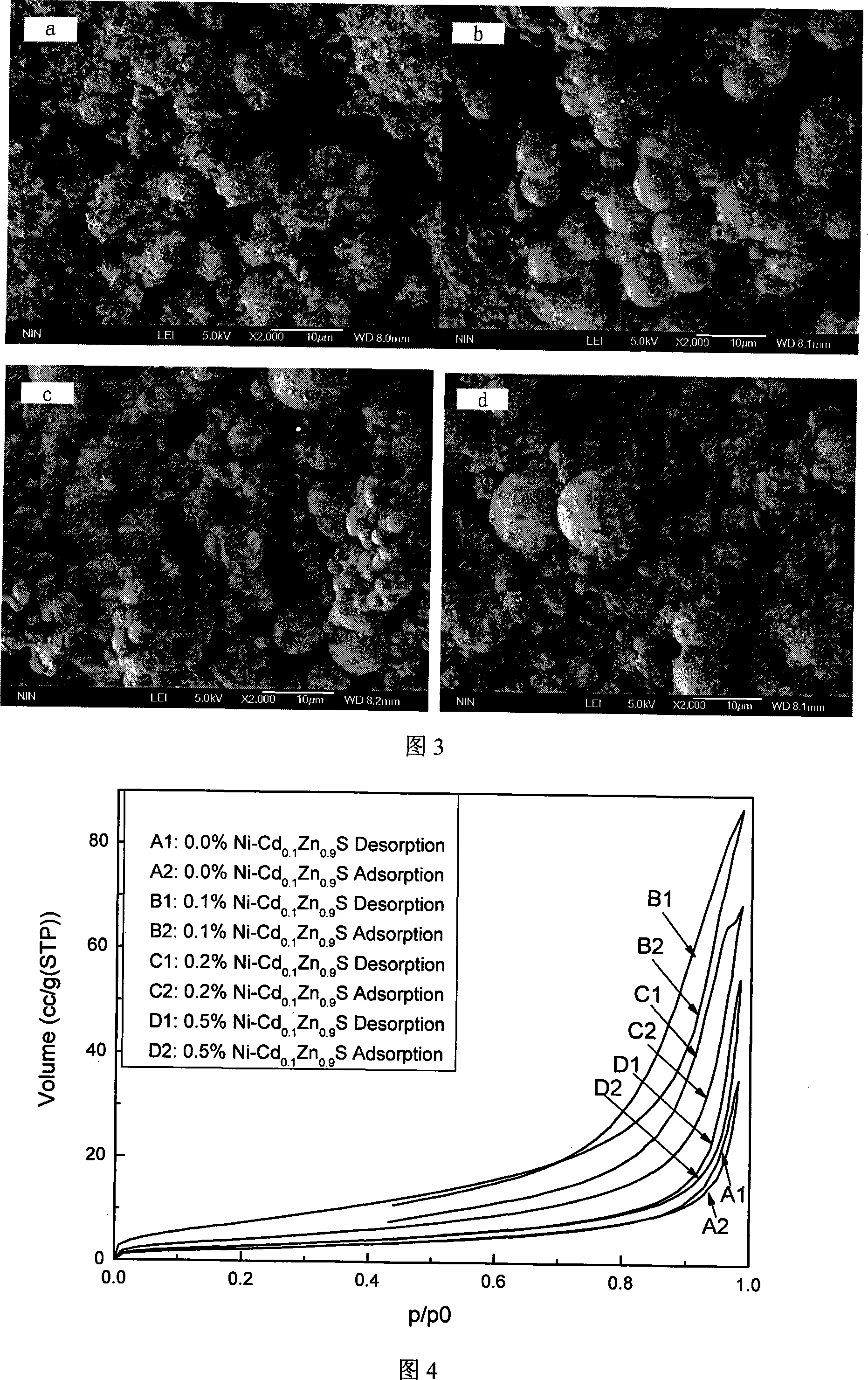

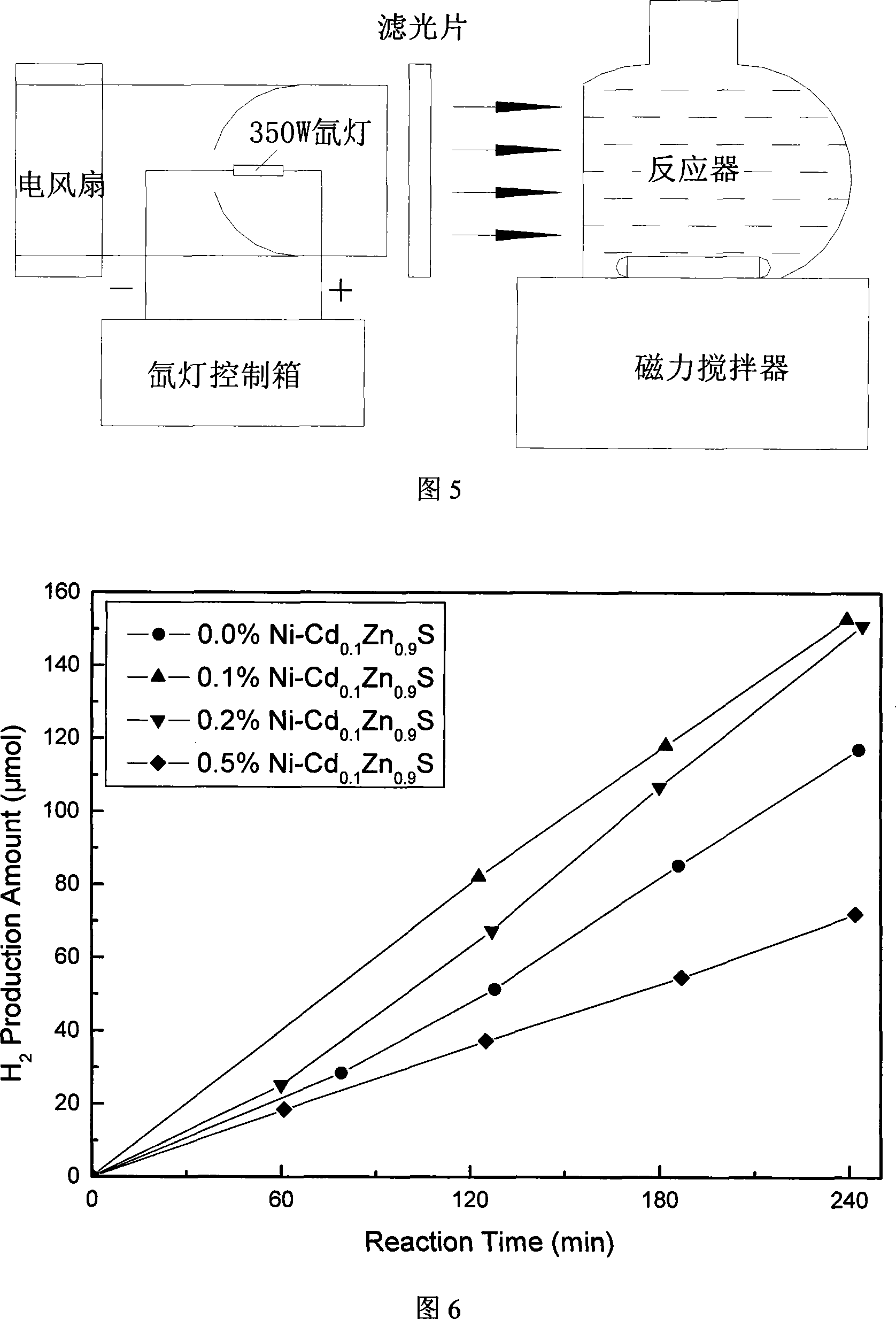

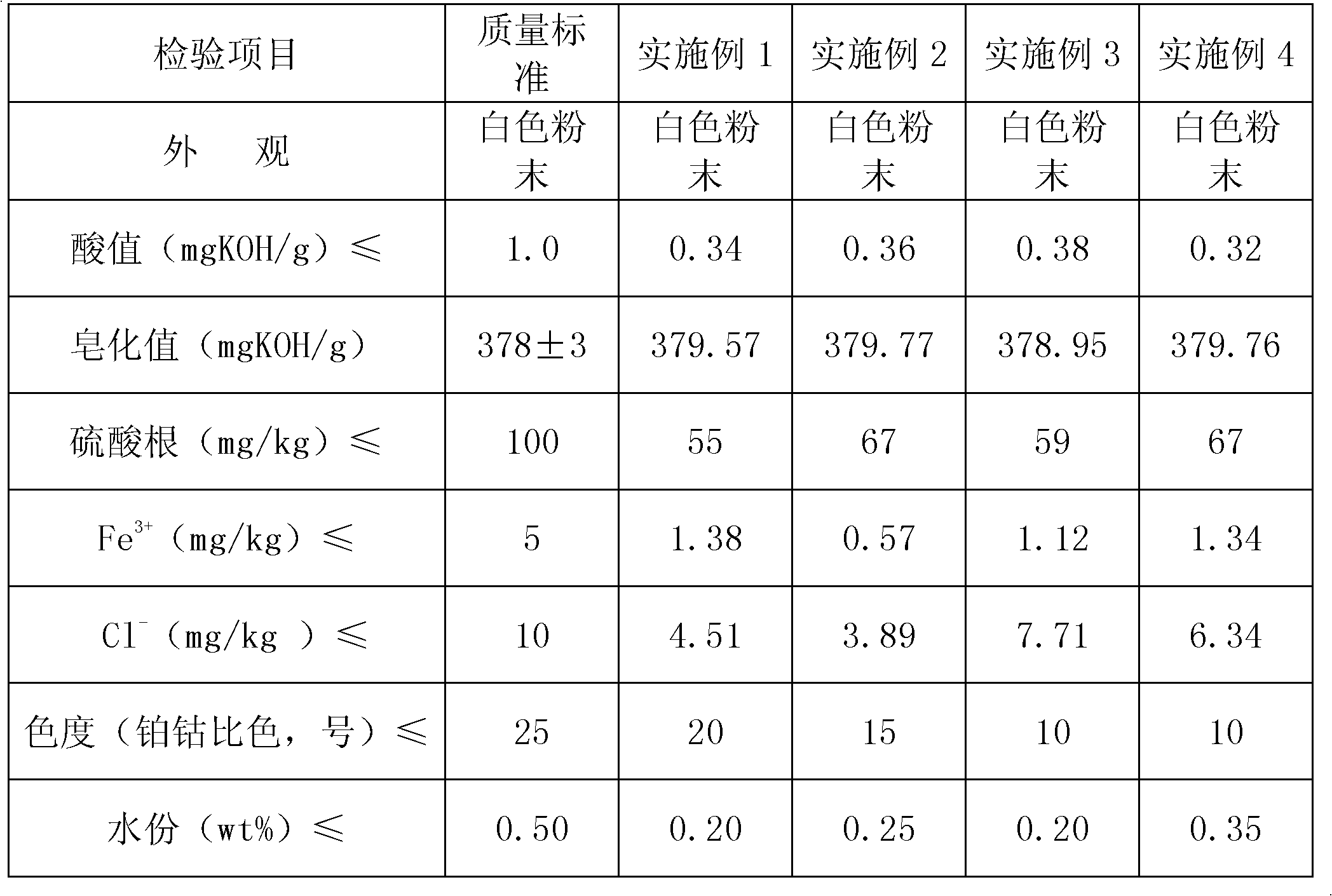

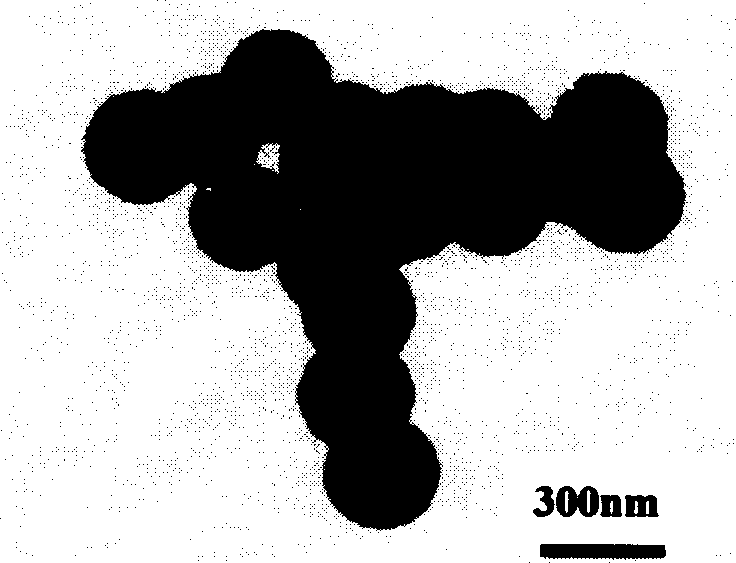

Ni doping Cd*.Zn*.*S micrometre ball photocatalyst and preparation method

ActiveCN101157044AImprove hydrogen production activityHigh activityPhysical/chemical process catalystsHydrogen productionPhotocatalytic water splittingPhotocatalytic reaction

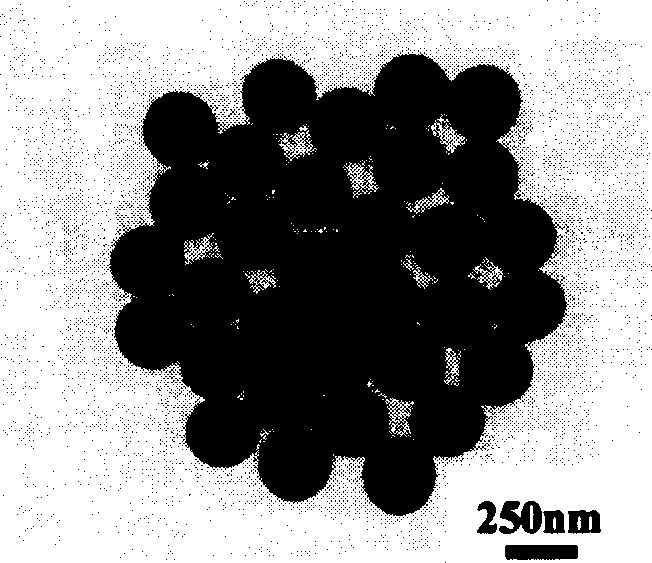

The invention discloses Ni-doped Cd0.1Zn0.9 S microsphere photocatalyst and the preparation method thereof, the particle shape of the produced photocatalyst is a microsphere formed by nanometer crystals, and the doping amount of Ni is 0.1 percent to 0.5 percent of the weight of the catalyst. The invention has the preparation method that zinc sulfate, cadmium sulfate, nickel nitrate, and thioacetamide are taken as raw materials to form mixed solution which is sealed in a hydrothermal caldron and then laid in a baking oven to be insulated, naturally cooled to the room temperature, a resultant is obtained through cleaning, drying, and grinding. The Ni-doped Cd0.1Zn0.9S microsphere photocatalyst is prepared by the invention, and the anti-surface oxidation capability in air and the photo-corrosion resistant capability in the photocatalytic reaction are evenly enhanced greatly. Because the particle of the photocatalyst is microsphere-shaped, the photocatalytic activity for photocatalytic water splitting into hydrogen of visible light of the catalyst is greatly enhanced, and the highest hydrogen production rate reaches 191.01 micromole / (g*h). The quantum efficiency reaches 6.77 percent at the 420 nm position. After Pt of 0.6 wt percent is loaded, the highest hydrogen production rate reaches 585.45 micromole / (g*h), which is three times than the hydrogen production rate when the Pt is not loaded. The quantum efficiency reaches 15.9 percent at the 420 nm position, the activity is high, and the stability is good.

Owner:XI AN JIAOTONG UNIV

Comprehensive waste cell utilizing treamtent process

InactiveCN1349271ANo secondary pollutionSimple methodSolid waste disposalReclaiming serviceable partsCadmium sulfateSulfate

The invention is to process various kinds of waste battery in classifications and uses chemical or physical method to extract zinc salt, chalcanthite, carbon black, manganese bioxide and mercury etc.from zinc-manganese battery, ferrisulphas, potion and nickel sulfate etc. from ferronickel battery, potion, cadmium sulfate and nickel sulfate etc. from cadmium-nickel battery, potion, silver salf and white copperas etc. from silver-zinc battery. Said technology can be used to proces waste battery and make the resource obtd. fully utilization. The advantages are: simple and reasonable processing technology and low cost, no three waste problem, no secondary pollution.

Owner:王宗良 +1

Method for synthesizing dimethyl isophthalate-5-sodium sulfonate

ActiveCN102633693AReduce usageImprove conversion rateSulfonic acids salts preparationSulfonateCadmium sulfate

The invention discloses a method for synthesizing dimethyl isophthalate-5-sodium sulfonate. Dimethyl isophthalate-5-sodium sulfonate is prepared by steps of sulfonation reaction, esterification, neutralization reaction and aftertreatment with isophthalic acid and fuming sulfuric acid serving as raw materials, wherein the sulfonation reaction is completed in three reaction temperature zones, different catalysts are used in different reaction temperature zones, cadmium sulfate is used as the catalyst at the temperature ranging from 150 DEG C to 159 DEG C, SiO2 is used as the catalyst at the temperature ranging from 160 DEG C to 169 DEG C, and mercuric sulfate is used as the catalyst temperature ranging from 170 DEG C to 181 DEG C. By the method, sulfonation reaction effect is improved, conversion rate of isophthalic acid is increased, sulfonation reaction temperature is lowered while sulfonation reaction time is shortened, reaction by-products including disulfonate, polymer and sulfone compounds are greatly reduced, product purity is improved while product yield is increased, and further, usage of fuming sulfuric acid and usage of sodium carbonate in a subsequent neutralization procedure are reduced, so that production cost is reduced.

Owner:WEIFANG WORLD CHEM

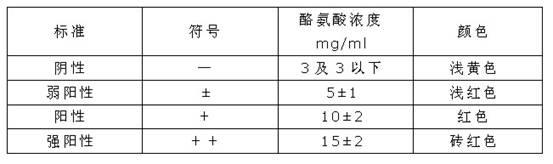

Hydroxyphenylalanine urine detection reagent and preparation method thereof

InactiveCN102368069AMeeting the needs of broad-spectrum screeningHigh broad spectrumMaterial analysisNitrateCadmium sulfate

The invention relates to an external detection reagent for clinic diagnosis, particularly to a hydroxyphenylalanine urine detection reagent which is a determination reagent for metabolic disorder in the body and its preparation method. The urine detection reagent is prepared by respectively dissolving Hg2<+>, Hg<2+>, Ni<2+> and Cd<2+> in corresponding acid solutions and mixing in proportion. The mercuric sulfate as a donor of Hg<2+> is dissolved in a sulfuric acid solution, the mercurous nitrate as a donor of Hg2<+> is dissolved in a nitric acid solution, the nickel sulfate as a donor of Ni<2+> is dissolved in distilled water, and the cadmium sulfate as a donor of Cd<2+> is dissolved in a nitric acid solution. The invention overcomes the defects and disadvantages existing in the prior art, and the detection reagent is a urine analysis reagent for metabolic disorder with novel formula and has high stability, sensitivity and wide application range.

Owner:吉林生物研究院有限公司

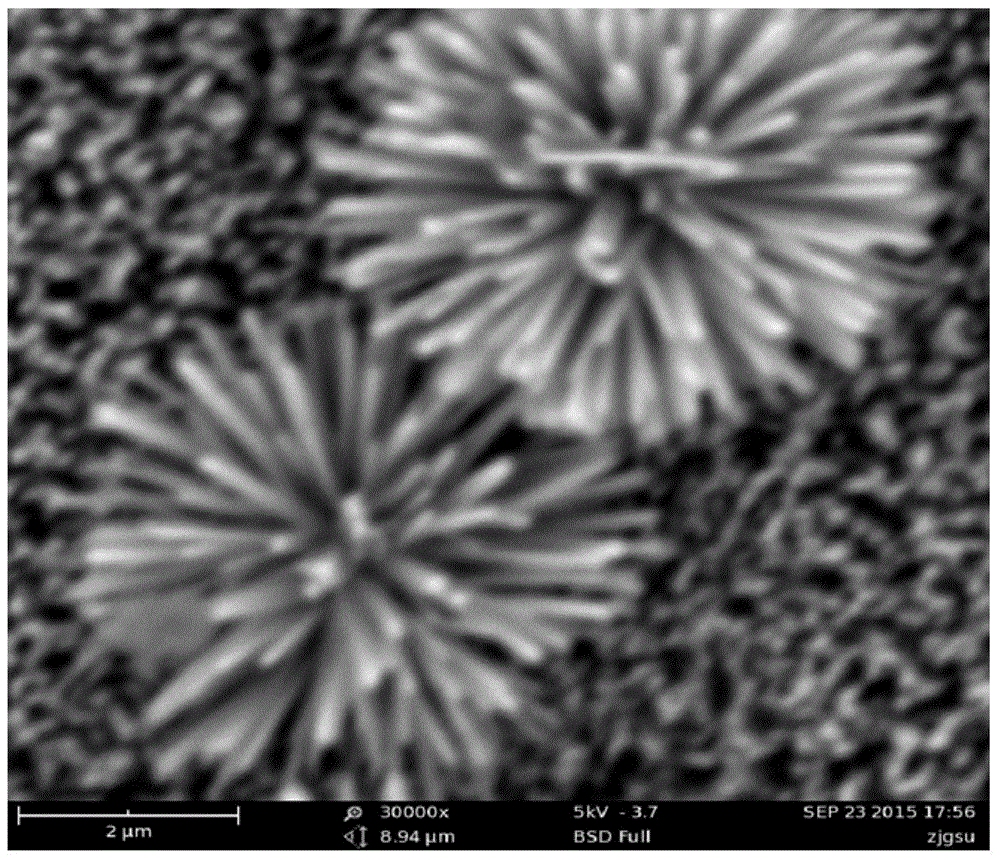

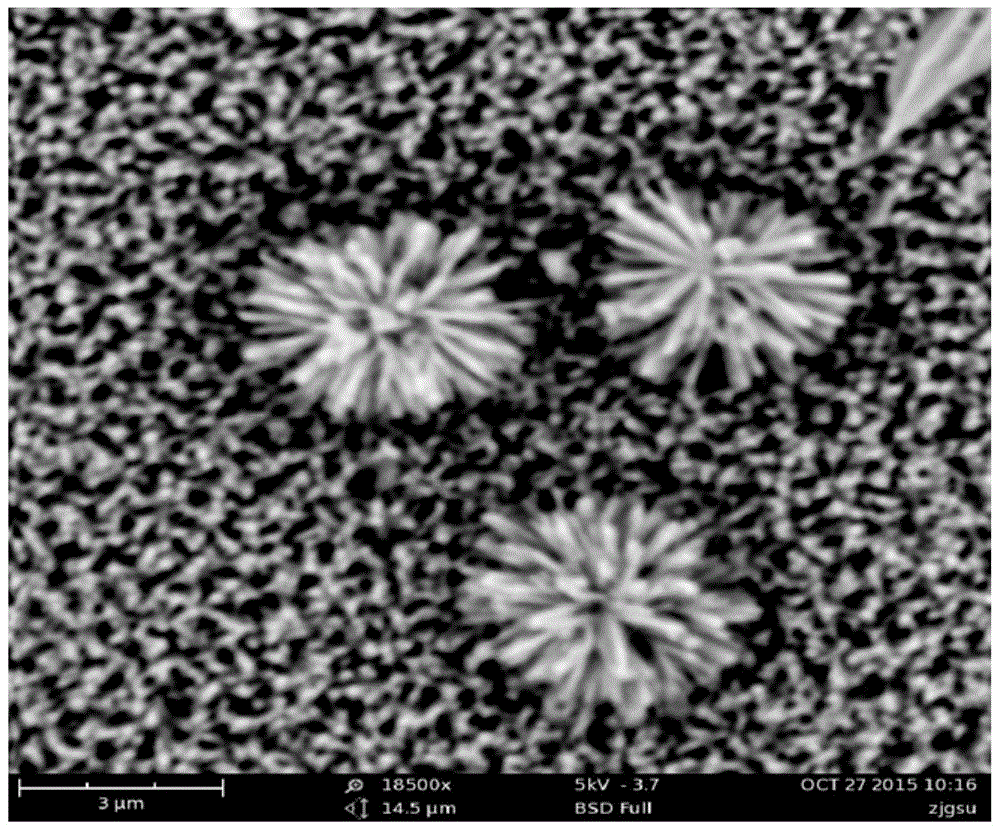

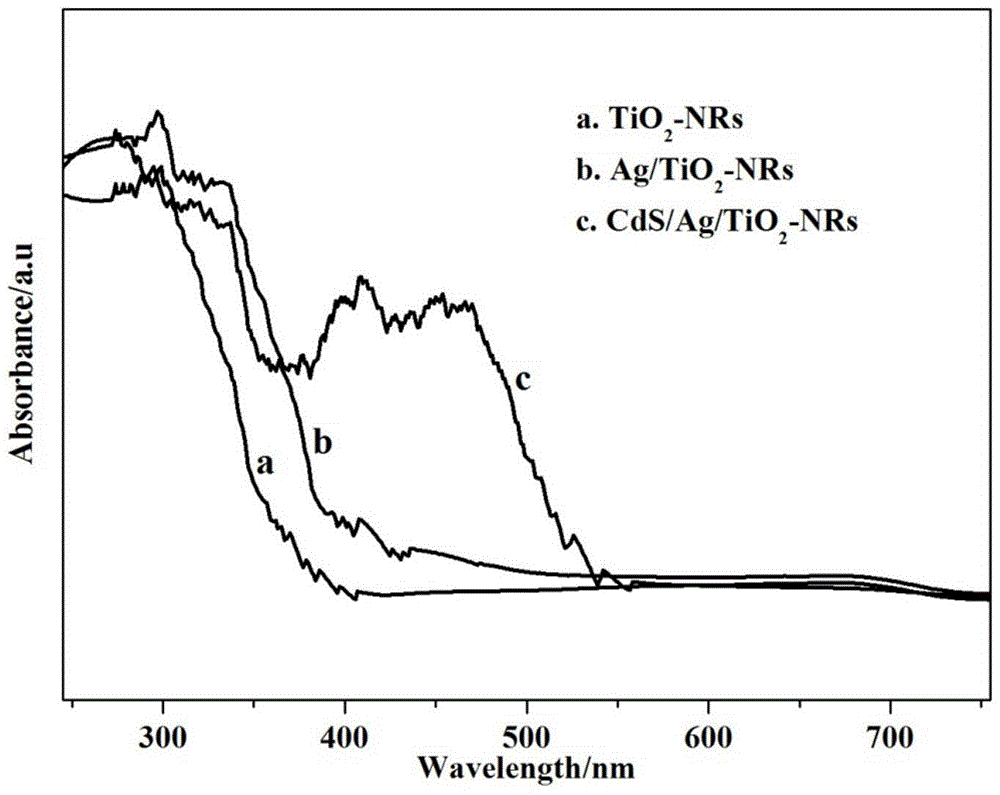

Composite titanium dioxide nanoflower photoelectrocatalysis material and preparation and application thereof

ActiveCN105727998APromote absorptionFull hydrogen productionMaterial nanotechnologyPhysical/chemical process catalystsWater bathsThiourea

The invention relates to a composite titanium dioxide nanoflower photoelectrocatalysis material and preparation and application thereof.Preparation includes the following steps that 1, tetrabutyl titanate is added into a hydrochloric acid solution and mixed uniformly, then the mixed solution is moved into a high-pressure reactor, cleaned FTO conducting glass is soaked in reaction fluid in the high-pressure reactor with the conducting face facing upwards, and an FTO electrode with supported nanoflower-shaped titanium dioxide is obtained through heat treatment; 2, precious metal nanometer points are deposited on FTO through a continuous ion layer adsorption method to obtain a titanium dioxide nanoflower electrode with supported precious metal nanometer points; 3, the titanium dioxide nanoflower electrode with the supported precious metal nanometer points is soaked in an ammonia solution where cadmium sulfate and thiourea are dissolved, water-bath heating is conducted for 10-15 min with the supporting face facing upwards, and the product is taken out and calcined to obtain the titanium dioxide nanoflower photoelectrocatalysis material coated with a precious metal nanometer point cadmium sulfide film.The preparing method is simple, and the prepared catalysis material is good in performance and has higher hydrogen generation capacity when applied to hydrogen generation.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

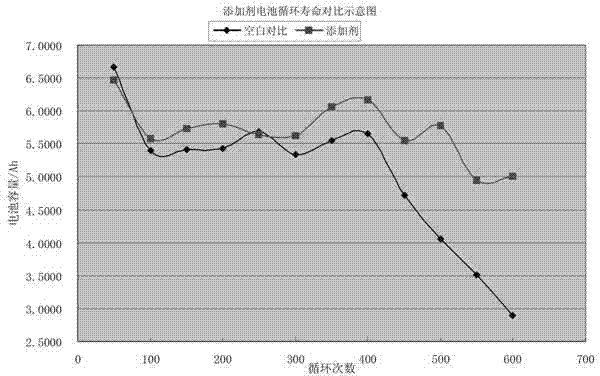

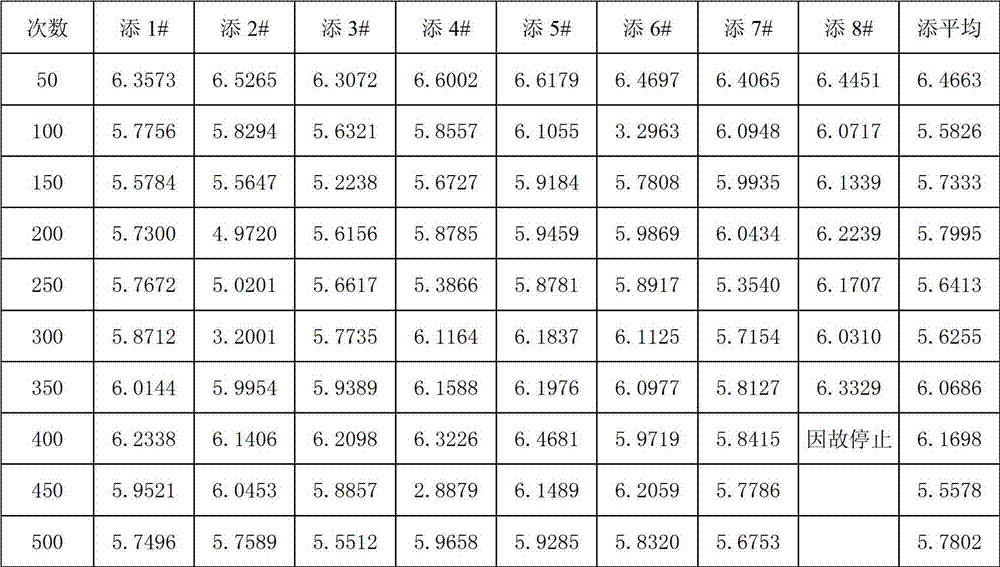

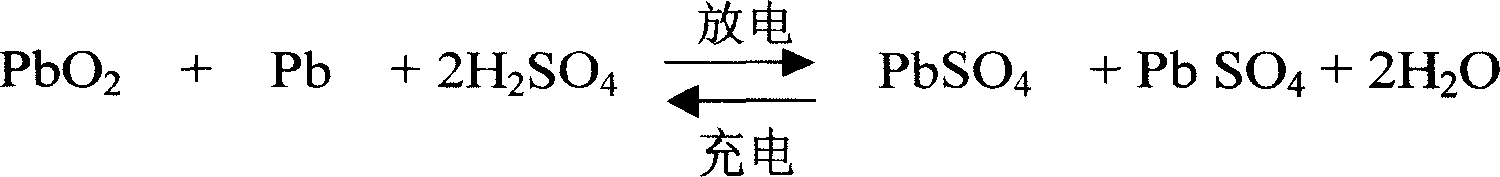

Lead acid storage battery electrolyte additive and preparation method thereof

ActiveCN103050738ALower internal resistanceReduce heatLead-acid accumulatorsEthylenediamineInternal resistance

The invention discloses a lead acid storage battery electrolyte additive and a preparation method thereof. Concentrated sulphuric acid is added into a certain quantity of purified water obtained through ion exchange to prepare dilute sulfuric acid, EDTA (Ethylene Diamine Tetraacetic Acid), aluminum sulfate, sodium sulfate, cadmium sulfate, stannous sulfate, magnesium sulfate, cobaltous sulfate, copper sulfate and potassium sulfate are added into 1L dilute sulfuric acid, which is taken out and heated, step by step according to the formula quantity, and the mixture is fully stirred and cooled to the room temperature to obtain the lead acid storage battery electrolyte additive. According to the invention, the cycle life of a traditional storage battery is remarkably improved, lead dendritic crystals in the battery are effectively prevented from short circuit, the internal resistance of the battery in the later period of cycle life is reduced, the charge acceptance capability is improved, water loss during charging is reduced, heat generated during battery charging is decreased and the battery is protected against thermorunaway. The lead acid storage battery electrolyte additive is suitable for various lead acid storage batteries, such as lead acid storage batteries for starting up automobiles and motorcycles, deep-cycle batteries and AGM (Absorptive Glass Mat) valve-regulated sealed lead acid storage batteries for power vehicles, flat-plate / tubular flooded storage batteries and flat-plate / tubular colloid storage batteries and the like.

Owner:易德维能源科技(深圳)有限公司

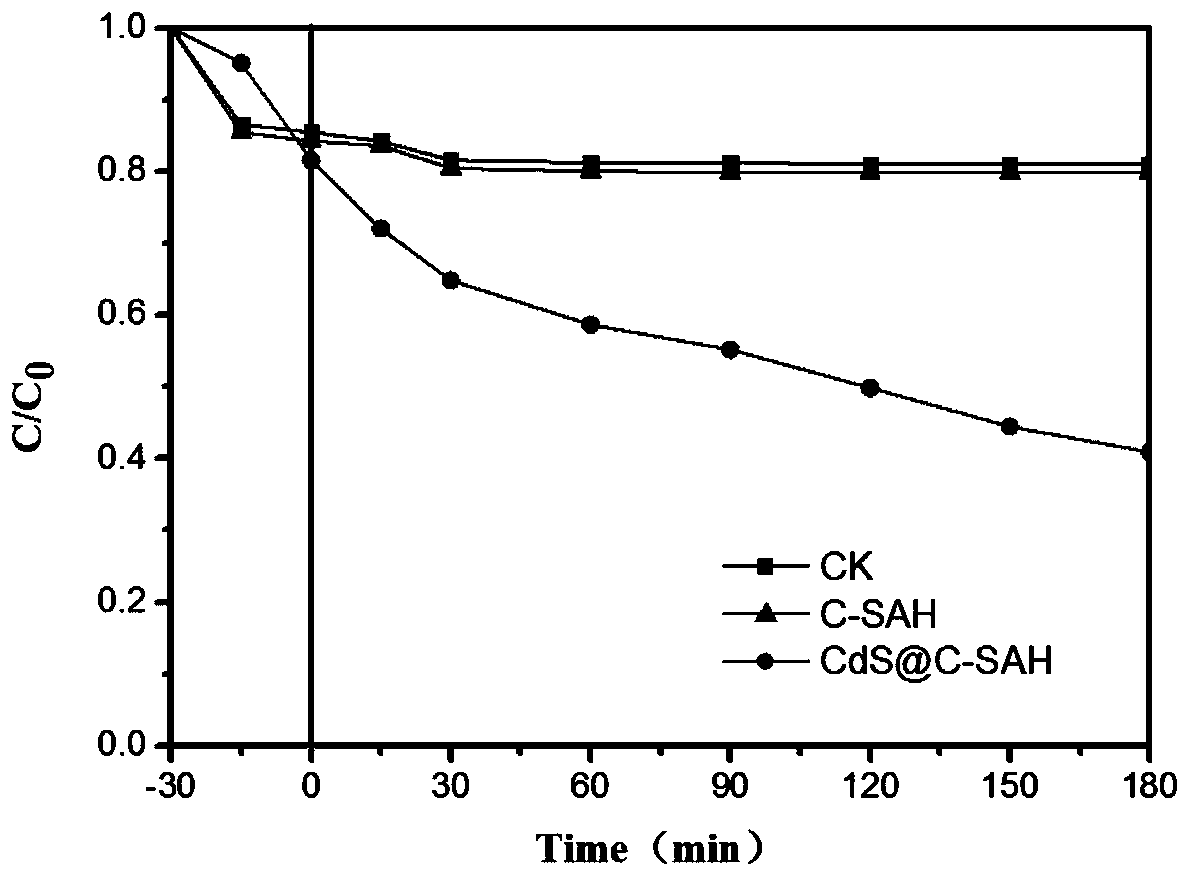

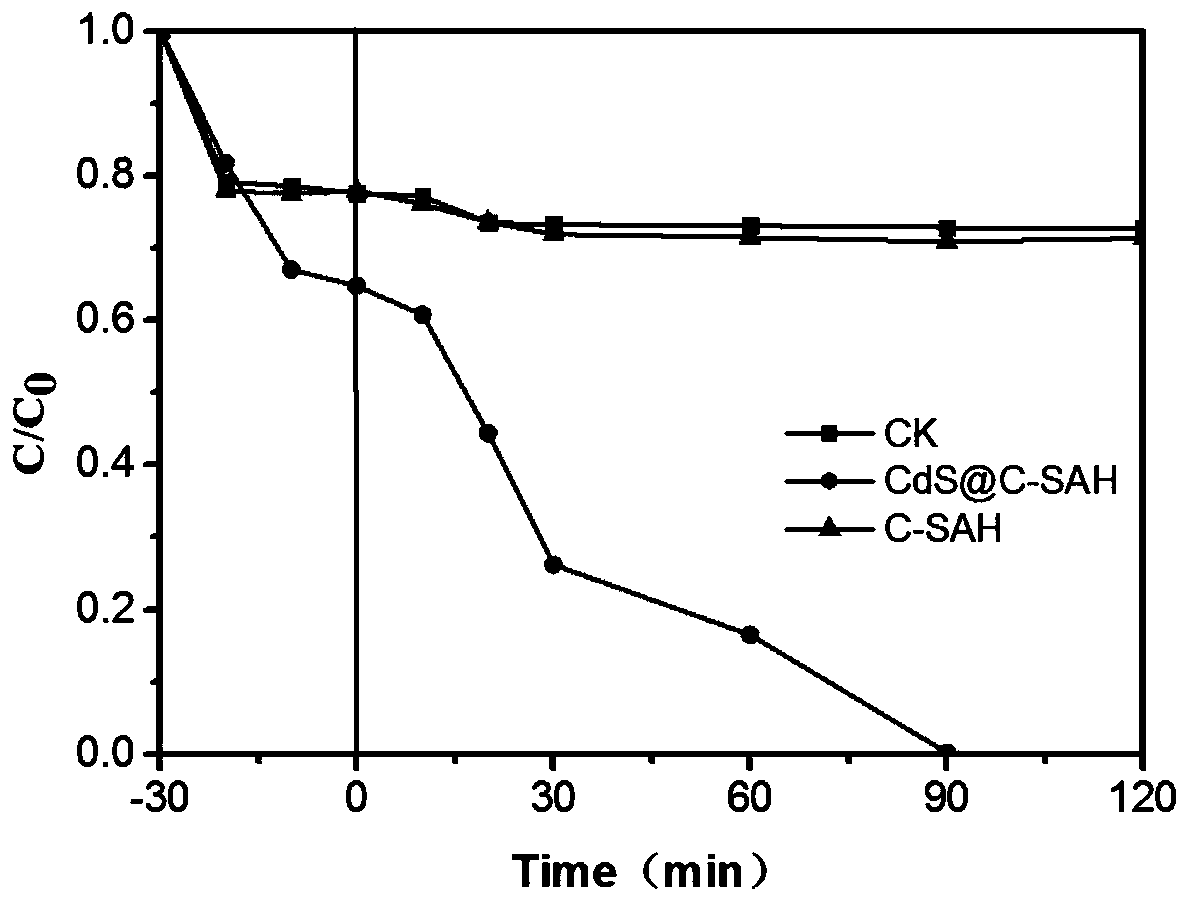

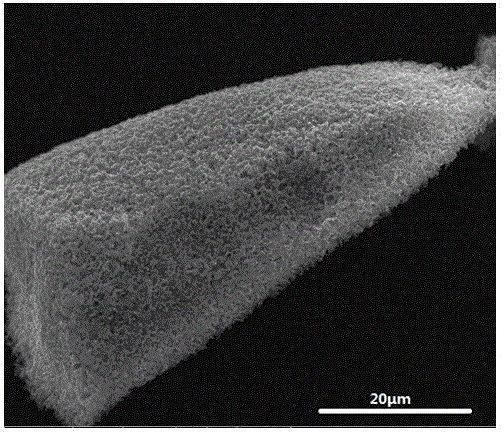

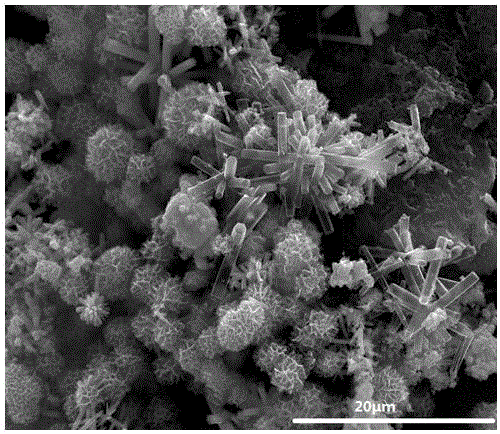

Method for preparing photocatalytic material from cadmium hyperaccumulator and application

ActiveCN109794262ARealize full resource utilizationRealize high-value recyclingPhysical/chemical process catalystsWater/sewage treatment by irradiationCadmium sulfateHyperaccumulator

The invention discloses a method for preparing a photocatalytic material from a cadmium hyperaccumulator and application. A cadmium-enriched hyperaccumulator harvested product is converted into a carbon loaded cadmium sulfate photocatalytic material with the small forbidden band width and efficient photocatalytic activity, full-dose recycling and high-value recycling of the cadmium hyperaccumulator can be achieved, the problems of high cost and secondary environment contamination for cadmium contaminated site plant repairing are solved, and application and popularization of the cadmium hyperaccumulator in soil contamination repairing are promoted.

Owner:FUJIAN AGRI & FORESTRY UNIV

Red infrared-penetrating quartz tube and preparation method thereof

The invention discloses a red infrared-penetrating quartz tube. Highly-pure arenaceous quartz is used as a basic material in part by weight, and 8-10% of colorant by weight is added, wherein the colorant comprises cuprous oxide (Cu2O), manganese dioxide (MnO2), selenium (Se), cadmium sulfate octahydrate (3Cd2SO4.8H2O), aluminium hydroxide (Al(OH)3), stannous chloride dehydrate (SnCl2.2H2O), samarium chloride (SmCl3) and antimony oxide (Sb2O3). The red infrared-penetrating quartz tube which is formed by drawing by adopting a preparation technique for tube wall integral coloring has favorable uniformity and toughness, strong compression resistance and wide light-absorbing range, has the characteristics of high temperature resistance and stable filtering property, and absorbs visible light and penetrates the near infrared ray of 800-2500nm. The invention has the spectral characteristics of 400nm penetration rate T being less than or equal to 14%, 700nm penetration rate T being less than or equal to 6.0% and 1100nm penetration rate T being more than or equal to 85.0% when the thickness of a sample is 1.0 mm.

Owner:LIANYUNGANG HONGYANG QUARTZ PROD

Method for preparing GO-CdS-ZnO-porous silicon composite photocatalyst

ActiveCN106582717AExpand the scope of absorptionEfficient separationPhysical/chemical process catalystsWater/sewage treatment by irradiationCadmium sulfateThiourea

The invention discloses a method for preparing a GO-CdS-ZnO-porous silicon composite photocatalyst. The method comprises the steps: (1) preparing porous silicon by adopting a metal nanoparticle assisted etching method; (2) preparing a graphene oxide dispersion solution; (3) adding the porous silicon into a ZnO precursor solution, carrying out stirring, carrying out ultrasonic dispersion, and carrying out a reaction with a zinc nitrate solution containing PVA, which serves as a dispersant, and urotropine which serves as a complexing agent, so as to obtain a ZnO-porous silicon material; and (4) adding the graphene oxide dispersion solution and the ZnO-porous silicon into cadmium sulfate, which serves as a cadmium source, and thiourea which serves as a sulfur source, carrying out a reaction in an autoclave, and carrying out flushing and drying after the reaction is completed, thereby obtaining the GO-CdS-ZnO-porous silicon composite photocatalyst.

Owner:KUNMING UNIV OF SCI & TECH

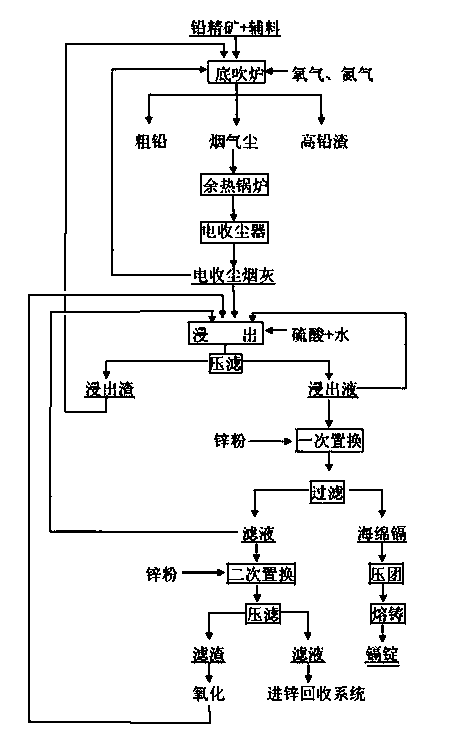

Method for enriching and recycling cadmium from lead smelting system

ActiveCN103740945AEffective enrichment and separationReduce acidityProcess efficiency improvementLead smeltingNon-ferrous extractive metallurgy

The invention belongs to a non-ferrous metal metallurgy industry and particularly relates to a method for enriching and recycling cadmium from a lead smelting system. The method comprises the following steps: matching a lead concentrate with auxiliary materials and returned low-cadmium smoke and dust, and adding desulfurization smelting lea of a bottom blowing furnace; circularly enriching the cadmium in electric dust-collection smoke and dust in a form of cadmium sulfate; when the cadmium content of the electric dust-collection smoke and dust is 5%-28%, leaching by using water or dilute sulfuric acid to separate the cadmium; displacing a leaching solution by using zinc powder to produce cadmium sponge and further producing rough cadmium and fine cadmium; and taking a solution obtained by displacing the cadmium as a raw material for producing nano zinc oxide, zinc sulfate monohydrate and zinc sulfate heptahydrate to recycle zinc. The lead is enriched in leached dreg in a leaching process so that the lead can be conveniently returned back to a lead system to be smelted and recycled. According to the method, a bottom blowing smelting technology is adopted; when the lead is smelted, the cadmium in the raw material is efficiently enriched and converted into a water-soluble cadmium salt; a technological process is shortened and conditions for directly enriching, separating and recycling the lead and the cadmium are provided; the dispersion of the lead when the cadmium is recycled by a wet method is avoided and the production cost is reduced.

Owner:HENAN YUGUANG GOLD & LEAD

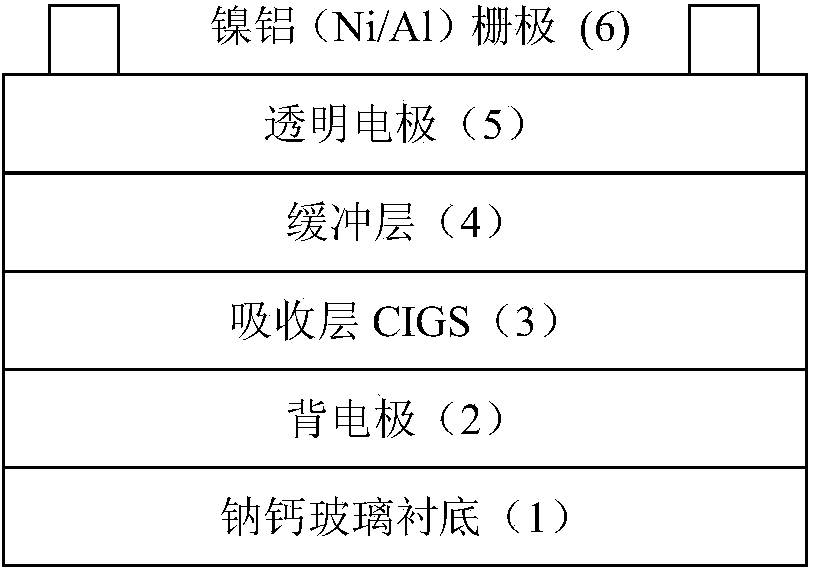

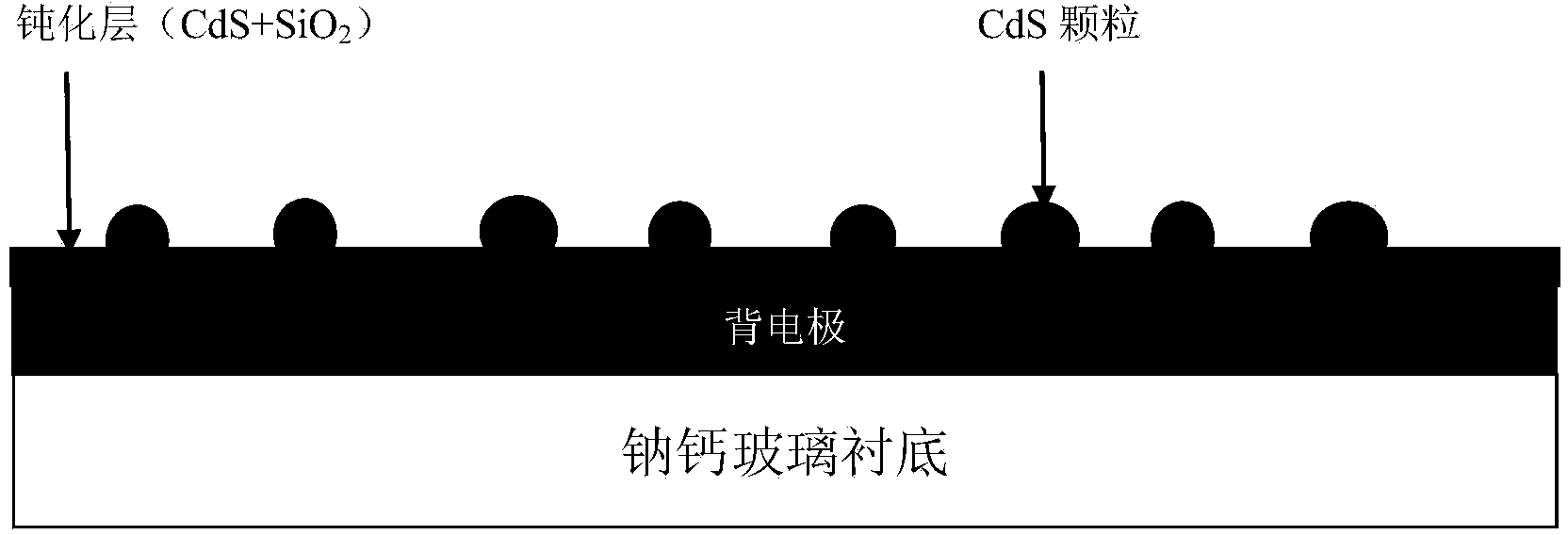

Surface passivation technology capable of improving performance of copper indium gallium selenium thin-film solar cells

InactiveCN104143587AInhibitory inhibitory complexImprove efficiencyFinal product manufacturePhotovoltaic energy generationIndiumThiourea

Copper indium gallium selenium (CIGS for short) thin-film solar cells have many advantages, and are one part, with the most development potential, of the solar cell technology. The invention relates to a method for passivating the interface between a back electrode and absorption layer CIGS in each CIGS solar cell, recombination of carriers on the interface is restrained, and thus the performance of the CIGS device is improved. The method includes the steps that after a solution with cadmium sulfate, thiourea and ammonia water mixed is heated for 2 min to 10 min, a substrate with a back electrode layer deposited is placed in the solution, heating is continued for 2 min to 10 min, and then a cadmium sulfide layer containing large particles is grown; a silicon dioxide layer is grown on the cadmium sulfide layer to serve as an insulation passivation layer, the large particles of cadmium sulfide are removed with an ultrasonic method, and then a passivation layer with nanostructure holes is formed; a CIGS absorption layer is further grown on the passivation layer, and then the absorption layer and the back electrode can make point contact. The open-circuit voltage and the fill factor of the CIGS solar cells prepared with the technology are increased, and the photoelectric conversion efficiency of the CIGS solar cells prepared with the technology is improved.

Owner:SUZHOU RUISHENG SOLAR ENERGY TECH

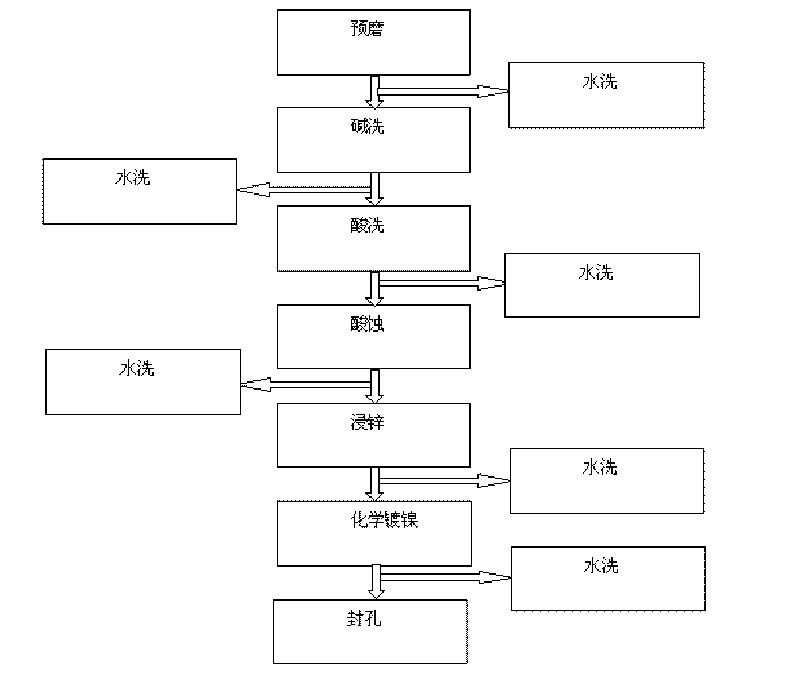

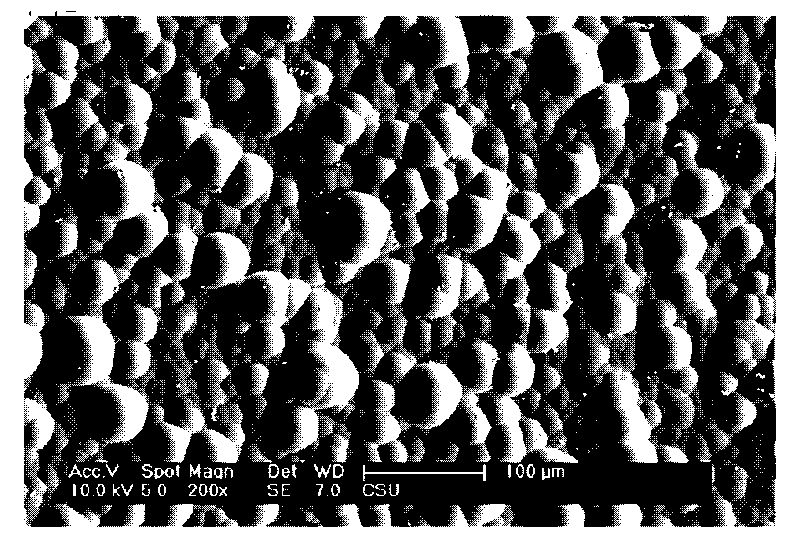

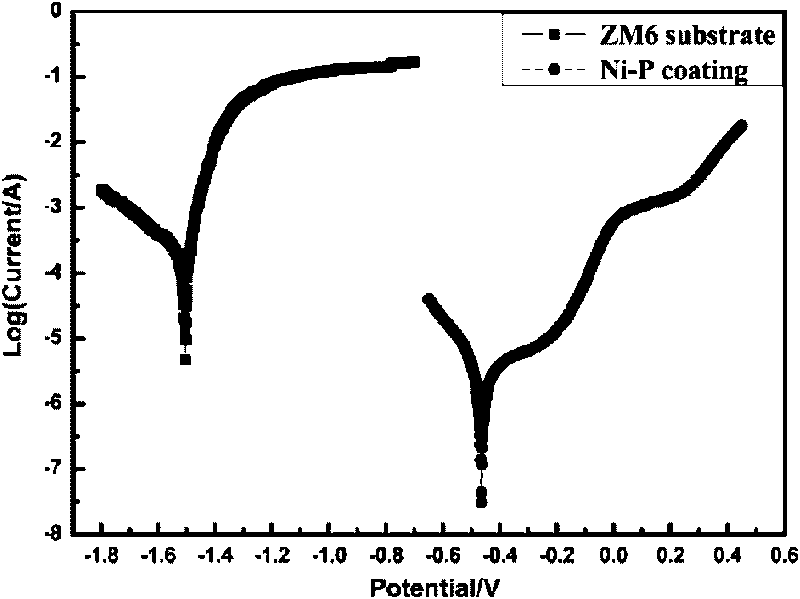

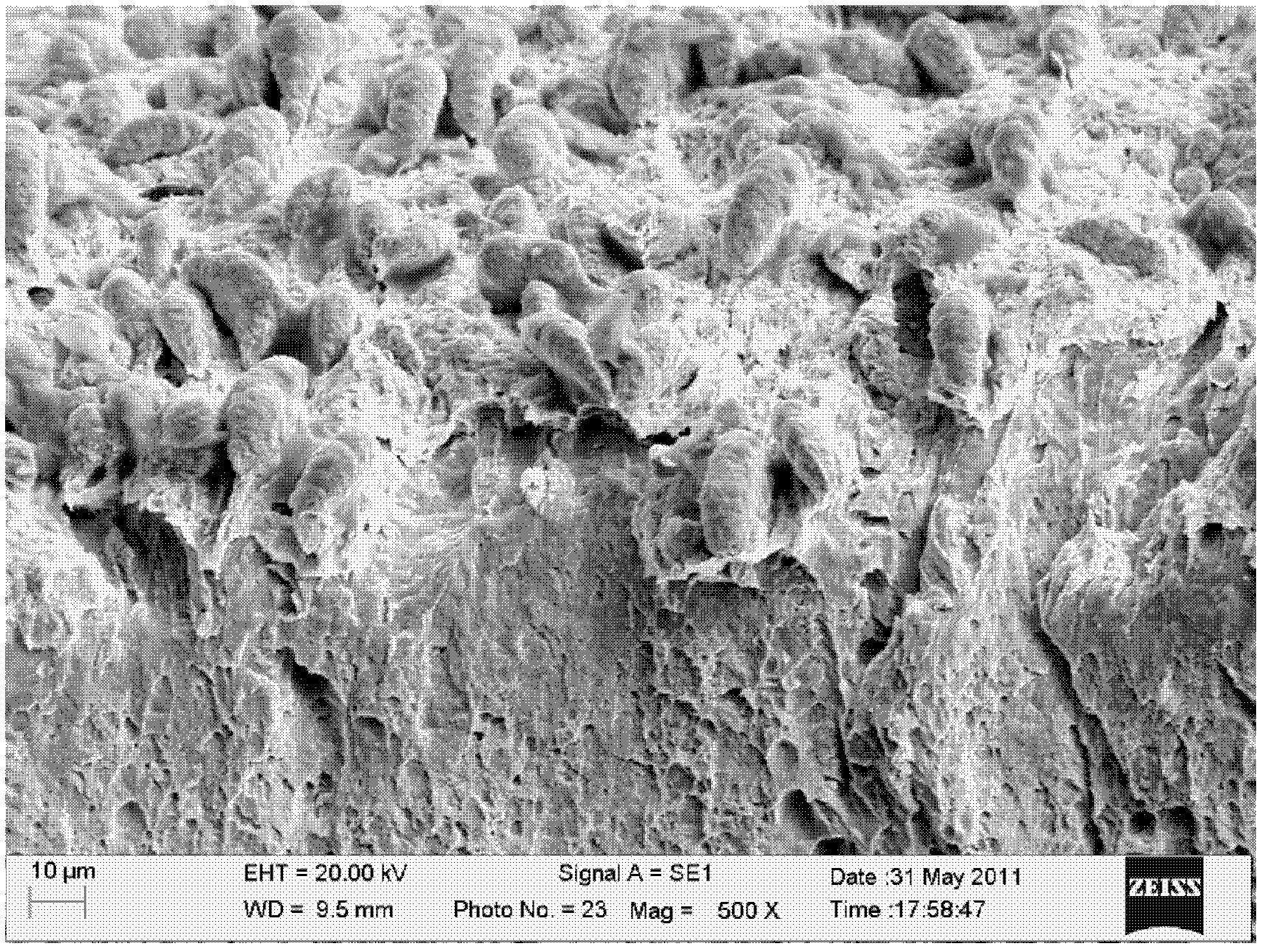

Chemical nickel-plating method for ZM6 magnesium alloy

InactiveCN101717926AImprove corrosion resistanceLess corrosiveLiquid/solution decomposition chemical coatingAcid etchingAcid washing

The invention relates to a method for chemically plating nickel to a ZM6 magnesium alloy. The method comprises the steps of performing pretreatment on a magnesium alloy matrix before plating and then performing chemical nickel plating to deposit a chemical nickel-plating layer, wherein the pretreatment before plating comprises four steps, namely alkali washing, acid washing, acid etching and zinc dipping; and the chemical nickel-plating layer is obtained by adopting basic nickel carbonate serving as a main salt, sodium hypophosphite serving as a reducing agent, hydrofluoric acid serving as a corrosion inhibitor, lactic acid serving as a complexing agent and mixed solution of cadmium sulfate and potassium iodate serving as a brightening agent and a stabilizing agent. The bright and flat nickel-plating layer can be obtained by plating at the temperature of about 85 DEG C after the zinc dipping of a plated piece. The method is suitable for chemically plating the nickel to the ZM6 magnesium alloy material to achieve the aim of protecting the ZM6 magnesium alloy. The method has the advantages of high plating speed and good protection.

Owner:CENT SOUTH UNIV

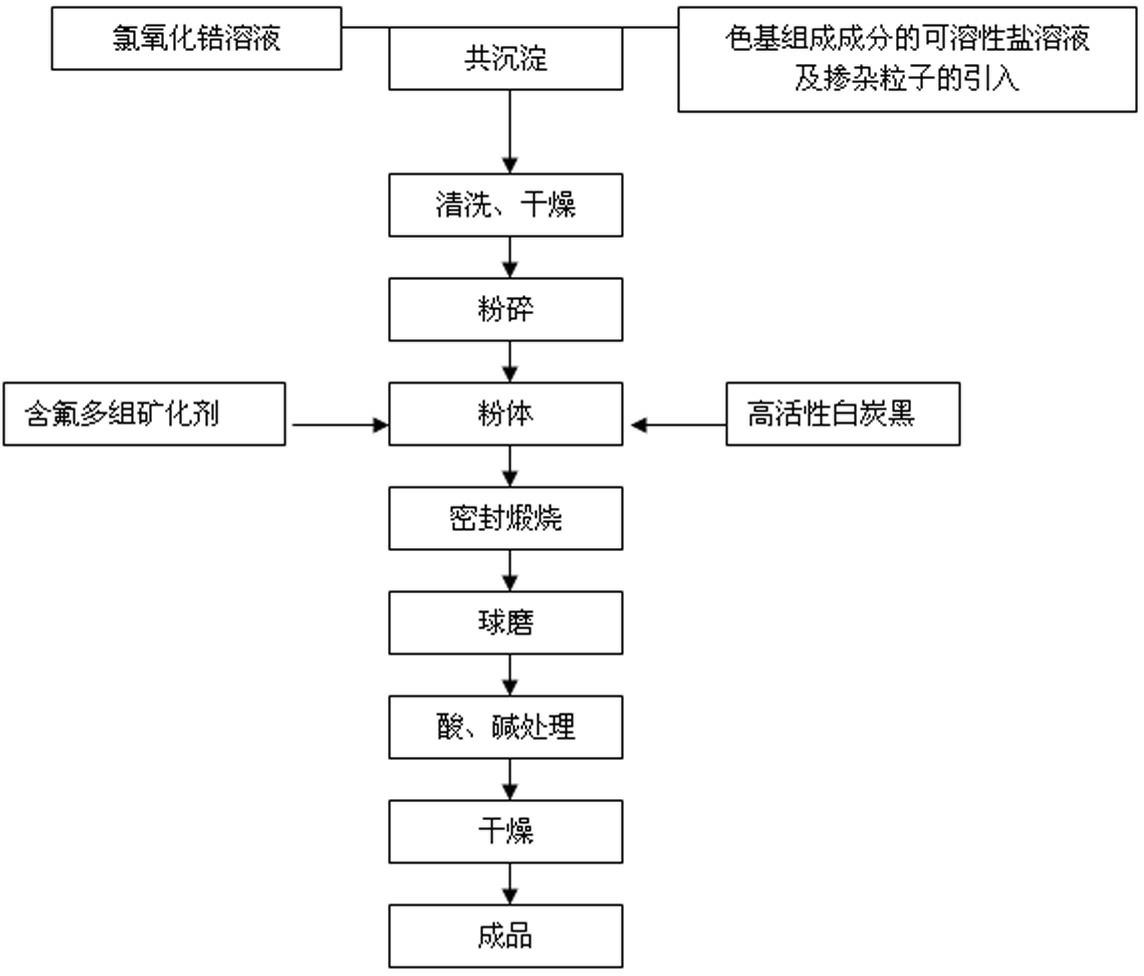

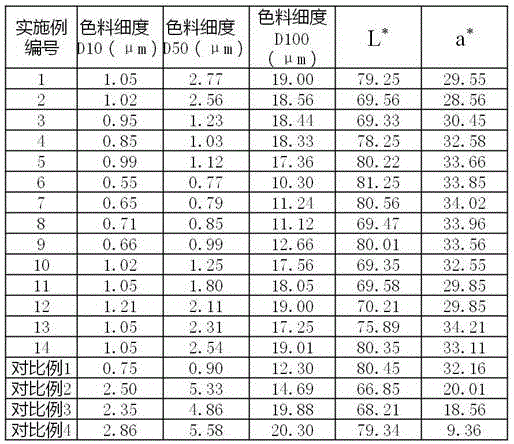

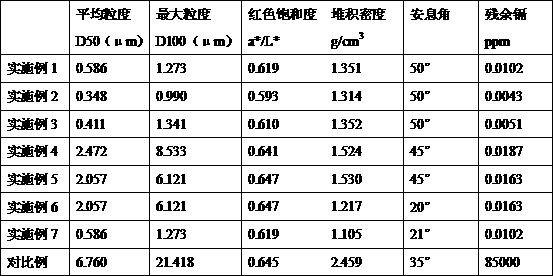

Zirconium silicate coated cadmium yellow ceramic pigment and preparation method thereof

The invention discloses a method for preparing a zirconium silicate coated cadmium yellow ceramic pigment. The method comprises the following steps of: (1) dissolving zirconium oxychloride and cadmium sulfate into water in the molar ratio of (1.3-1.5):(0.13-0.15) to prepare a 27-45% solution A; (2) dissolving sodium sulfide, sodium metasilicate pentahydrate and sodium hydroxide in the molar ratio of (0.25-0.35 ):(1.13-1.23):(0.31-0.35) into water to prepare a 7-15% solution B; (3) stirring the solution B, titrating by using the solution A, and carrying out neutralization reaction until the pH value reaches 8.0-8.5; (4) filtering by pressing after the reaction finishes, and drying until the content of water is less than 4%; (5) grinding the dried substance until the finesses reaches 400-500 meshes; (6) mixing 100 parts by weight of ground dried substance with 3-5 parts by weight of a mineralizing agent uniformly, calcining at the temperature of 1,000-1,050 DEG C, mixing 45-55 parts by weight of a calcination product with 25-35 parts by weight of 45-55% sulfuric acid, soaking the mixture for 20-48 hours, washing with water until the mixture is neutral, grinding until the finesses D90 reaches 22-28mum, and drying to obtain the zirconium silicate coated cadmium yellow ceramic pigment.

Owner:佛山市南海万兴材料科技有限公司

Chemical plating method for quartz fiber surface

The invention relates to a chemical plating method for a quartz fiber surface. The plating solution consists of 24g / L of nickel chloride hexahydrate, 10g / L of sodium hypophosphite, 10g / L of potassium borohydride, 24mL / L of ethylenediamine and 0.6mg / L of cadmium sulfate. Chemical plating is performed when the pH of the plating solution is equal to 13 to 14 and the temperature is 90 DEG C. Nickel-phosphorus-boron alloy is chemically plated on the quartz fiber surface to improve the hardness and the electric conductivity of the fiber.

Owner:成都亨通光通信有限公司

Preparation method of electroplated cadmium coating for metalwork

The invention relates to a preparation method of an electroplated cadmium coating for metalwork, belonging to the field of chemical industry, and comprising the following steps of: degreasing and cleaning metalwork to be electroplated by an ultrasonic cleaner, then finely sanding the metalwork, cleaning the surface of the metalwork with clear water and alcohol in sequence, drying the metal surface to remove the alcohol from the surface of the metalwork; and electroplating by a plating solution composed of cadmium sulfate, nickel sulfate, potassium hydroxide, a complexing agent and an auxiliary complexing agent. The preparation method provided by the invention has the advantages that the metalwork is easy to treat, the formula of the plating solution is simple, operation and maintenance are easy, harmful substances such as cyanogen and the like are not contained, and environmental protection is benefited. In addition, the bonding quality between a plated coating and a substrate is good without cracking or damage.

Owner:UNIV OF SCI & TECH BEIJING

Prepn of nano cadmium sulfide/polystyrene core-shell microsphere

During the preparation of nano cadmium sulfide / polystyrene core-shell microsphere, polystyrene microsphere is first prepared through emulsion polymerization, which includes mixing decompress distilled styrene, lauryl sodium sufate, potassium persulfate and twice deionized water in certain proportion, leading in nitrogen while fast raising the temperature to 80 deg.c for reaction, demulsification with sodium chloride solution, filtering, washing and drying; the polystyrene microsphere is then mixed with sulfur source and cadmium source in some solvent and the mixture is heated to prepare the nano cadmium sulfide / polystyrene core-shell microsphere. The cadmium source is cadmium chloride with crystal water, cadmium caetate with crystal water, cadmium sulfate or cadmium nitrate; the sulfur source is thiacetamide, sulfourea, carbon disulfide or ammonium sulfide; and the solvent is ethanol, water or ammonia water. The microsphere is homogeneous in size and has compact shell.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing yellow pigment by using commonly used color development for replacing rare-earth element praseodymium and vanadium color development

ActiveCN102627478AAchieve chemical stabilityImprove temperature resistanceRare-earth elementZirconium oxychloride

The invention belongs to the technical field of ceramic coloring and pigment and particularly relates to a method for preparing yellow pigment by using commonly used color development for replacing rare-earth element praseodymium and vanadium color development. The method is mainly characterized in that zirconium oxychloride, cadmium sulfate, sodium sulfide, high-activity white carbon black, fluorine-containing multi-component mineralizer, caustic soda flakes and zinc chloride or ferrous chloride are used as raw materials, a technique of doping zinc ions and iron ions in envelope cadmium sulfide pigment is adopted, a solid-liquid combination method is adopted for introducing precursors, novel mineralizer is introduced during high-temperature sintering and the yellow pigment which can replace the rare-earth element praseodymium and the vanadium color development is prepared. The resistant temperature of a product can be improved by 30-50 DEG C on the basis of the resistant temperature of the original zirconium-praseodymium yellow and vanadium-zirconium yellow, the dissolved quantity of cadmium can fully satisfy the international standard, the grain shape is more evenly and grains are spherically distributed and the color development effect is two times of the color development effect of the original product.

Owner:JIANGXI JINHUAN PIGMENTS

Artistic pigment and preparation method thereof

The invention belongs to the technical field of pigments, and concretely relates to an artistic pigment and a preparation method thereof. The artistic pigment comprises ochre, calcium carbonate, sodium benzoate, mercury sulfide, cadmium sulfate, a polyurethane modified epoxy resin emulsion, pigment powder, distilled water, a thickening agent and a color micro-particle. Calcium carbonate included in the pigment guarantees the strong water resistance of the pigment; the thickening agent makes the pigment be difficult to fade and makes picture scrolls have high quality; and a color micro-particle is added to make the pigment have deep coloring and to make the picture scrolls have high quality. The artistic pigment has the advantages of simple preparation process, use convenience, difficult fading of the pigment coated on the picture scrolls, and suitableness for being popularized and used in relevant fields.

Owner:ZIBO VOCATIONAL INST

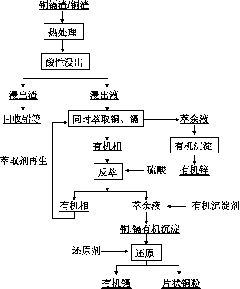

Treatment method of wet method zinc smelting by-products

InactiveCN101824541AAchieve separationSimple post-processingProcess efficiency improvementCadmium sulfateOrganic solvent

The invention discloses a treatment method of wet method zinc smelting by-products, which comprises the following steps: firstly, using a sulfuric acid solution for leaching heat treated copper-cadmium slag or copper-rich slag; then, using an organic solvent extraction method for extracting copper and cadmium at the same time from leach liquor to obtain copper-cadmium-rich organic phase zinc-sulfate-containing faffinate; using sulphuric acid for carrying out back extraction on the copper-cadmium-rich organic phase to obtain a mixed solution of copper sulfate and cadmium sulfate; then, adding a proper amount of organic precipitant into the mixed solution to obtain a mixture of organic precipitates of the copper and the cadmium; separating and washing the copper and cadmium precipitates; and adding a reducing agent solution for carrying out reduction reaction to respectively obtain sheet type copper powder and organic cadmium products. The invention realizes the value adding utilization of wet method zinc smelting by-products, reduces the treatment cost of the zinc smelting by-products, and reaches the goals of discharge reduction and yield improvement.

Owner:河池市津泰资源再生有限公司

Activity increase agent for lead-acid storage battery

InactiveCN1960049ALarge capacityExtended service lifeLead-acid accumulatorsInternal resistanceEvaporation

The disclosed activator for lead-acid accumulator includes distilled water, sulfuric acid, cobalt sulfate, hydroxylamine sulfate, aluminum sulfate, cadmium sulfate, magnesium sulfate, and binary carboxylic acid. Advantages are: preventing pole plates from vulcanizing, increasing capacity and service life of accumulator, shortening time for charging accumulator, reducing evaporation of electrolyte in use, reducing internal resistance, avoiding overcharge. Moreover, the invention solves self-discharge issue of accumulator effectively.

Owner:蔡植如 +3

Composite dechlorination agent for removing high-concentration chlorine-containing wastewater and application method thereof

InactiveCN102464392AReduce dosageLow running costWater contaminantsWater/sewage treatmentCompound organicMethylene Dichloride

The invention discloses a composite dechlorination agent for removing high-concentration chlorine-containing wastewater and an application method thereof, which belong to the field of sewage treatment in environment protection. The composite dechlorination agent is prepared by compounding organic acids and inorganic salts, wherein the organic acids include two or more than two of nicotinic acid, citric acid, succinic acid, beta-ketoglutaric acid, and ketosuccinic acid; the inorganic salts include one or two of mercury sulfate, cadmium sulfate and copper sulfate; and the weight percentages of the organic acids and inorganic salts are 15-80% and 20-85% respectively. The application method comprises the steps of: adding the prepared composite dechlorination agent in percentage by weight of 0.05-0.5% into the high-concentration chlorine-containing wastewater and continuously stirring for 10-30min; adding a methylene dichloride solvent; standing for layering, separating, and subjecting obtained wastewater to air flotation treatment; and finally scraping off a layer of residue floating on the surface of the wastewater by a residue scraping machine to obtain the dechlorinated wastewater as the yielding water, wherein the dechlorinated wastewater can be lower than the national emission standard I. The composite dechlorination agent and the application method disclosed by the invention have the characteristics of simple technological process, smaller dosage of chemical agent, lower running expense, no sludge, high removal rate of chlorine ions in the wastewater, and the like; and the removal rate of chlorine ions in the wastewater can reach above 99.9%.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

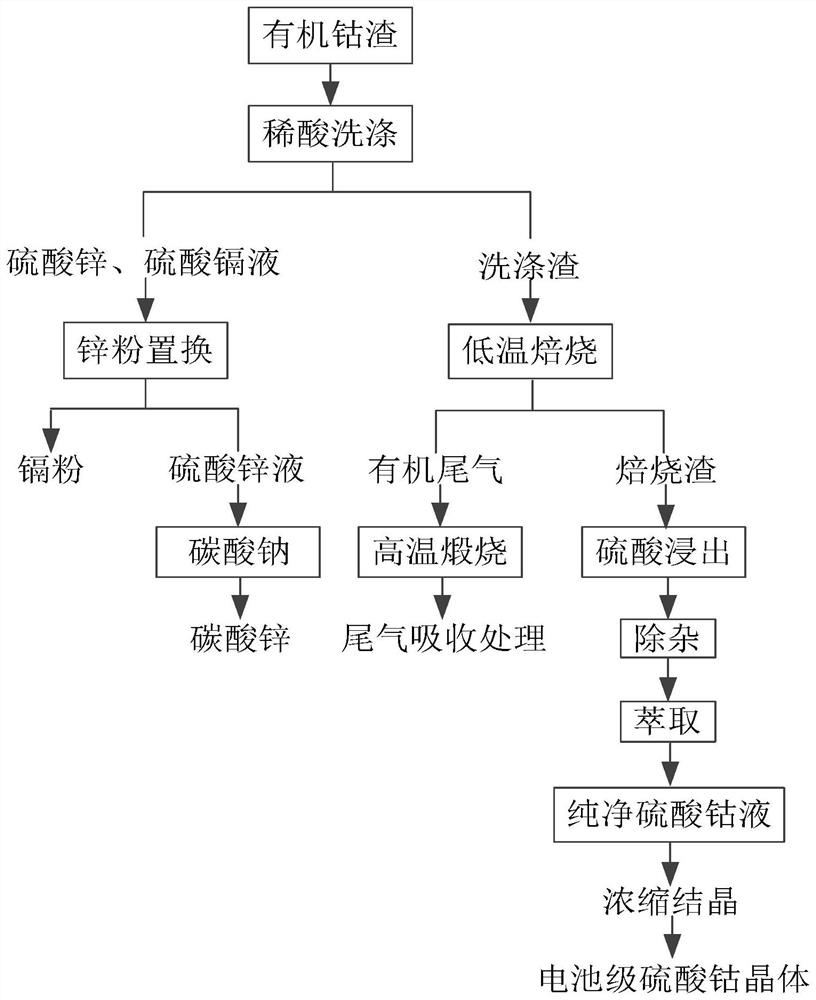

Method for producing cobalt sulfate by utilizing organic cobalt slag of zinc smelting plant

PendingCN112520790ADifficult to handleFully recycleCobalt sulfatesZinc compoundsSulfate zincZinc smelter

The invention discloses a method for producing cobalt sulfate by utilizing organic cobalt slag of a zinc smelting plant, and belongs to the field of non-ferrous metal hydrometallurgy. The method comprises the following steps: firstly, washing organic cobalt slag of a zinc smelting plant with dilute acid, enabling zinc and cadmium in the organic cobalt slag to react with dilute sulfuric acid to generate zinc sulfate and cadmium sulfate, enabling the zinc sulfate and cadmium sulfate to enter a solution, performing filtering, and recycling the solution to obtain cadmium powder and zinc carbonate;carrying out low-temperature roasting on the filter residues, carrying out high-temperature roasting on organic tail gas obtained by low-temperature roasting, carrying out high-temperature decomposition on the organic tail gas, carrying out cyclic absorption tail gas treatment through alkali liquor, carrying out low-temperature roasting to obtain cobalt oxide slag, performing leaching through sulfuric acid to obtain a solution containing cobalt sulfate, carrying out P204 extraction to deeply remove impurities, completely removing the impurities, extracting cobalt by using P507 to obtain a high-purity cobalt sulfate solution, and performing evaporation, concentration and crystallization to obtain a battery-grade cobalt sulfate crystal product. The application of the method develops a new cobalt raw material source for the field of non-ferrous metal hydrometallurgy, and the method has remarkable economic value and social value.

Owner:MEISHAN SHUNYING POWER BATTERY MATERIALS CO LTD

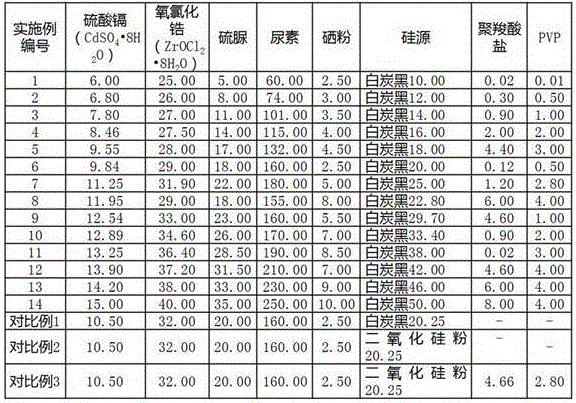

Cadmium sulfoselenide occlusion pigment, ceramic ink and preparation method of cadmium sulfoselenide occlusion pigment

ActiveCN106590031ABright and full colorAvoid cloggingPigmenting treatmentInksThioureaCarboxylic salt

The invention discloses a cadmium sulfoselenide occlusion pigment. The powder fineness of the pigment is 0.5 to 3 [mu]m. The invention further provides a method for preparing the cadmium sulfoselenide occlusion pigment. The method comprises the following steps: mixing and stirring cadmium sulfate, zirconium oxychloride, selenium, thiourea, urea, white carbon black, poly-carboxylate and polyvinyl pyrrolidone, which are adopted as raw materials, to be dissolved in water, loading a solution in a reaction kettle, performing reaction for 5 to 24h under the conditions of temperature of 60 to 200 DEG C and rotating speed of 100 to 300r / min, performing natural cooling to obtain a pigment precursor after reaction, and executing washing, firing and drying steps to obtain a cadmium sulfoselenide occlusion pigment finished product. The molar ratio of the cadmium sulfate to the zirconium oxychloride to the thiourea to the urea to selenium powder to water glass to the poly-carboxylate to the polyvinyl pyrrolidone is (6-15):(25-40):(5-35):(60-250):(2.5-10):(25-50):(0.02-8.0):(0.01-4.0).

Owner:FOSHAN HUAYI CERAMIC COLORS CO LTD

Preparation method and application of CdIn2S4-graphene composite photocatalyst

InactiveCN104857975AEfficient separationImprove photocatalytic activityPhysical/chemical process catalystsOrganic compound preparationPhotocatalytic water splittingFiltration

The invention discloses a preparation method and application of a CdIn2S4-graphene composite photocatalyst with visible-light response. The preparation method comprises the following preparation steps: placing graphite oxide in a reductive alcohol agent for ultrasonic dispersion; adding cadmium sulfate and indium chloride into the reductive alcohol agent and carrying out stirring to dissolve cadmium sulfate and indium chloride; mixing the two obtained systems and adding thioacetamide; transferring the obtained mixture to a hydro-thermal kettle for a reaction; and after completion of the reaction, subjecting the obtained product to vacuum filtration, washing and vacuum drying so as to obtain the CdIn2S4-graphene composite photocatalyst. According to the invention, graphene is used as a carrier and the CdIn2S4-graphene composite photocatalyst is prepared in one step by using a solvothermal method. The composite photocatalyst is mainly applied to conversion and utilization of solar energy, e.g., hydrogen production through photocatalytic water splitting and photocatalytic reduction of CO2.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Zirconium silicate covered cadmium selenide sulfide pigment for ceramic inkjet printing or ceramic dry blending and preparation method thereof

The invention discloses zirconium silicate covered cadmium selenide sulfide pigment for ceramic inkjet printing or ceramic dry blending and a preparation method thereof. The preparation method comprises the following steps: firstly, slowly dropwise adding a water glass or sodium silicate solution into strong acid to form a weak acidic solution with the pH (Potential of Hydrogen) of 2 to 4; slowlydropwise adding weak alkali into a strong acidic mixed solution of zirconium oxychloride, cadmium sulfate, thiourea and ammonium fluoride to form a weak acidic solution with the pH of 2 to 4; then mixing the two weak acidic solutions and adding ultrafine selenium powder and a dispersant to form semi-transparent gel; drying and calcining to obtain the pigment for the ceramic inkjet printing; addingtrace metal ions into the mixed solution to further control the granularity of the pigment, and carrying out surface modification to obtain the ceramic for the ceramic dry blending. According to thezirconium silicate covered cadmium selenide sulfide pigment disclosed by the invention, a condition that reaction cannot be controlled when direct contact between strong acid and strong alkali is violent is avoided, so that reactants are blended in a molecule grade under a solution state to form the gel with extremely high reaction activity and the calcining temperature of about 200 DEG C is reduced; the pigment has small granularity and the environment protection and production and safety advantages are remarkable.

Owner:JIANGXI JINHUAN PIGMENTS

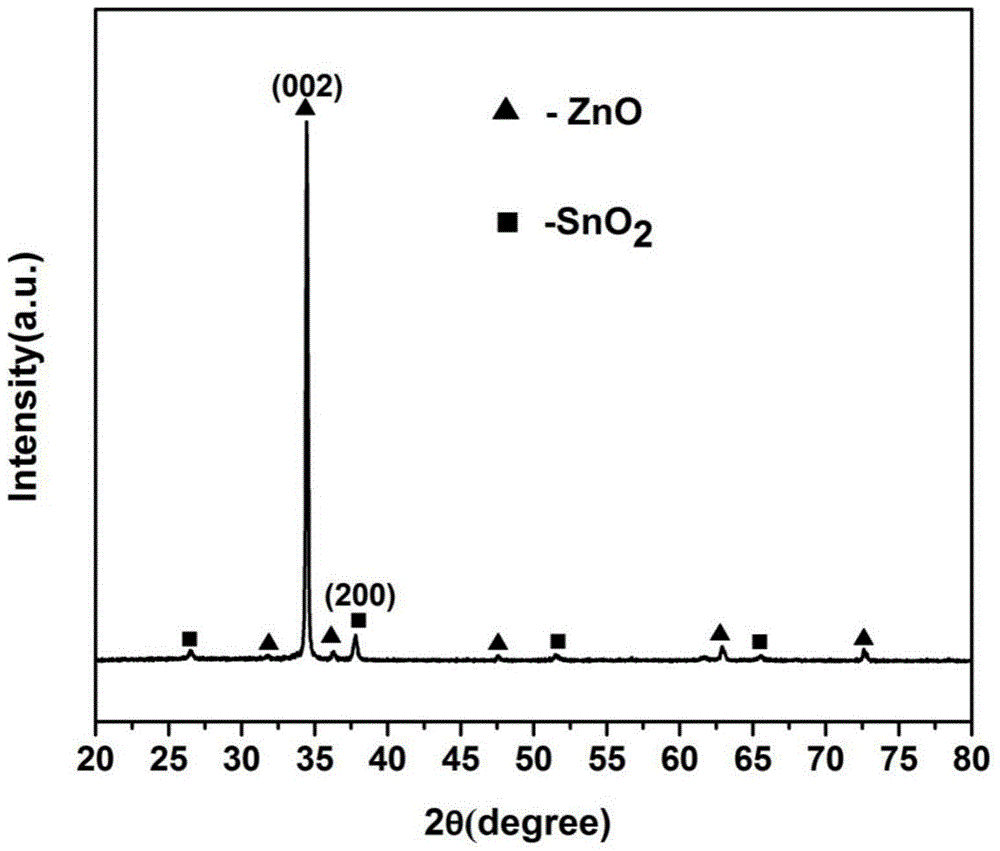

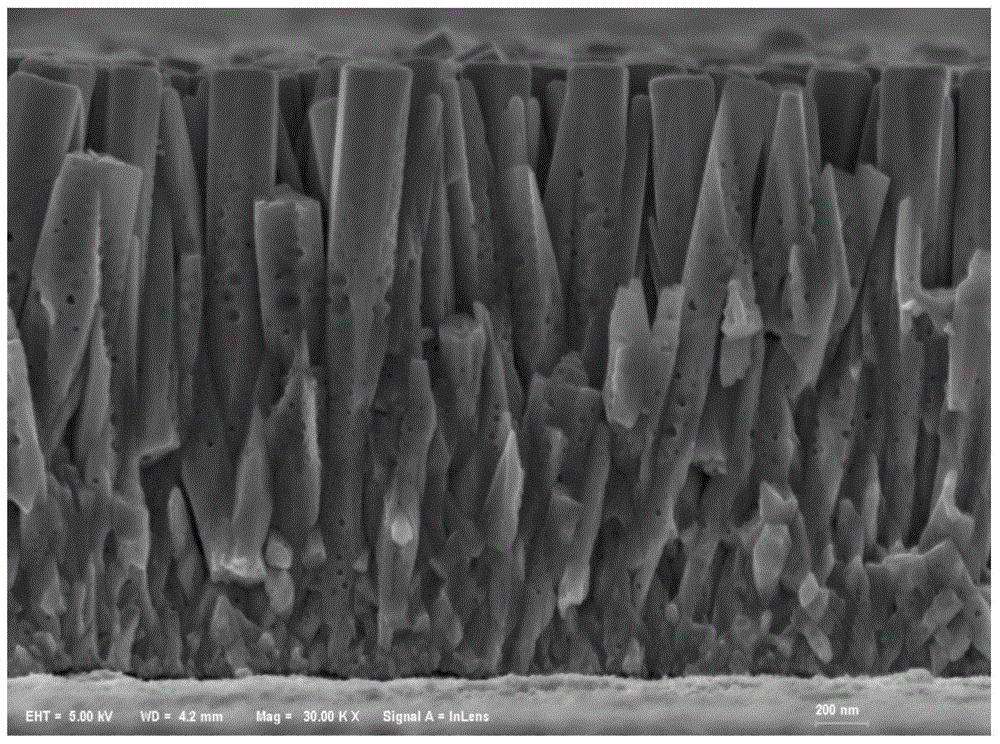

Method for in-situ preparation of porous structure zinc oxide nanometer rod array

ActiveCN105836789AImprove adsorption capacityHigh purityMaterial nanotechnologyZinc oxides/hydroxidesZinc Acetate DihydrateZinc oxide nanorod

The invention discloses a method for in-situ preparation of a porous structure zinc oxide nanometer rod array. The method comprises preparing a zinc oxide precursor solution from a zinc acetate dihydrate, methanol and ammonium acetate, cleaning a substrate, dipping the substrate in the zinc oxide precursor solution, carrying out multiple drawing film formation, carrying out drying and annealing treatment to obtain a high purity zinc oxide film crystal seed layer, carrying out crystal seed layer growth in a growth solution of a zinc acetate dehydrate, cadmium sulfate, deionized water and ethene diamine multiple times, and carrying out cleaning and annealing treatment to obtain a directionally arranged porous structure zinc oxide nanometer rod array. The porous structure zinc oxide nanometer rod array has a large specific surface area and provides more spaces for molecule adsorption. The method has a low cost and low equipment requirements and is suitable for a large-area substrate.

Owner:WUHAN UNIV OF TECH

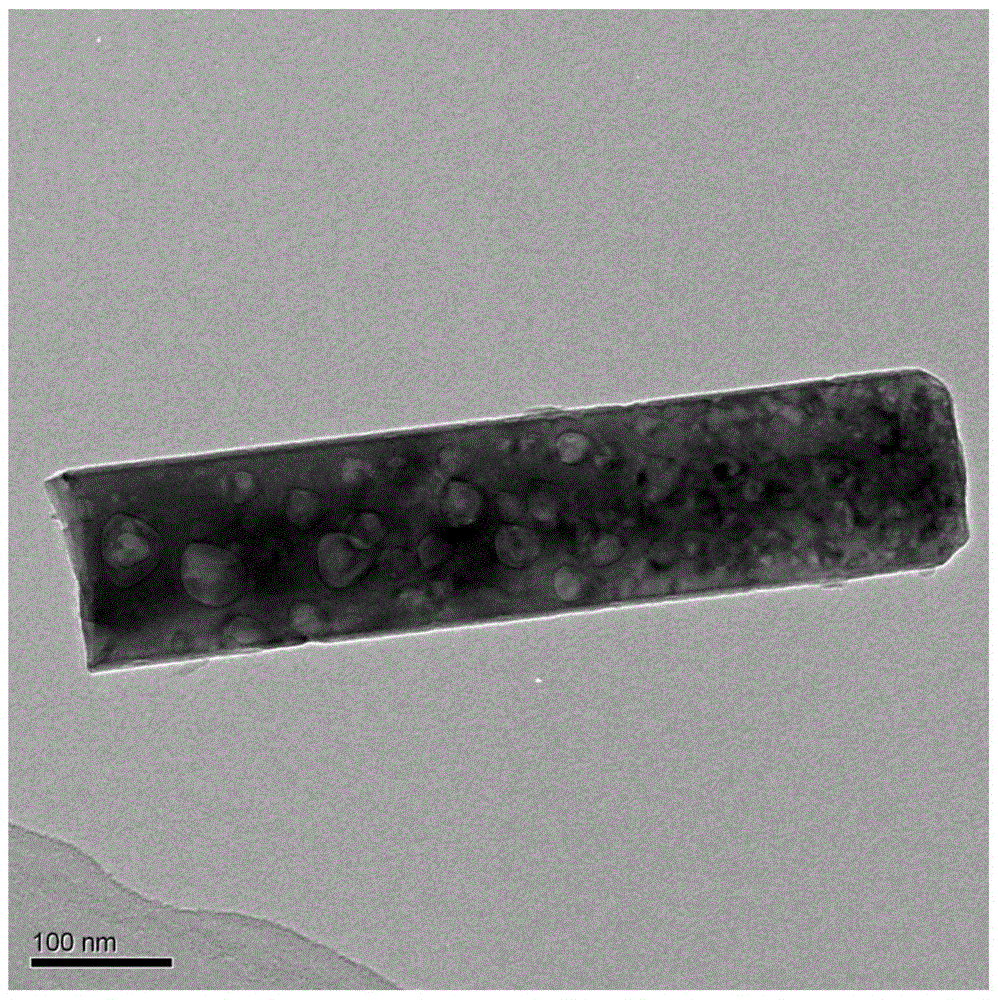

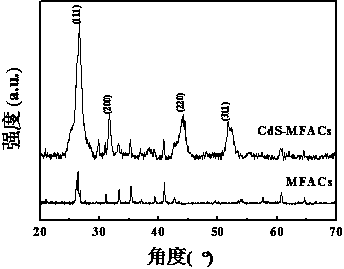

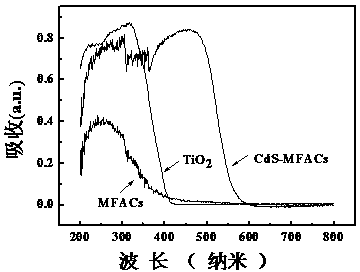

Preparation method of catalyst capable of magnetic separation

InactiveCN104043462AAvoid secondary pollutionCatalyst carriersWater/sewage treatment by irradiationPtru catalystCarboxyl radical

The invention relates to a preparation method of a catalyst capable of magnetic separation, and belongs to the technical field of environmental material preparation. The preparation method of the catalyst capable of magnetic separation comprises the following steps: by adopting a chemical precipitation method, firstly, screening and modifying coal ash to prepare carboxyl magnetic pulverized coal ash, then mixing uniformly carboxyl magnetic pulverized coal ash, water, cadmium sulfate, thiourea and ammonium hydroxide, introducing nitrogen to react to prepare a CdS-MFACs composite photocatalyst. The preparation method of the magnetic separation catalyst has a relatively degrading effect on antibiotics in waste water, and the main action mechanism for degrading danofloxancin mesylate by the CdS-MFAs composite photocatalysis is discussed by observing the degrading process. The preparation method of the magnetic separation catalyst has the technical advantages that the load-type photocatalyst improves the utilization ratio of the photocatalyst, and reduces secondary pollution caused by using the catalyst in the using process; especially, industrial waste material magnetic pulverized coal ash is adopted as a base body material, not only is the effect of treating waste by waste reached, but also the photocatalyst reclaimed by an applied magnetic field can be prepared simply and easily, and great convenience is provided for the preparation and reclamation of a magnetic photocatalyst.

Owner:JIANGSU UNIV

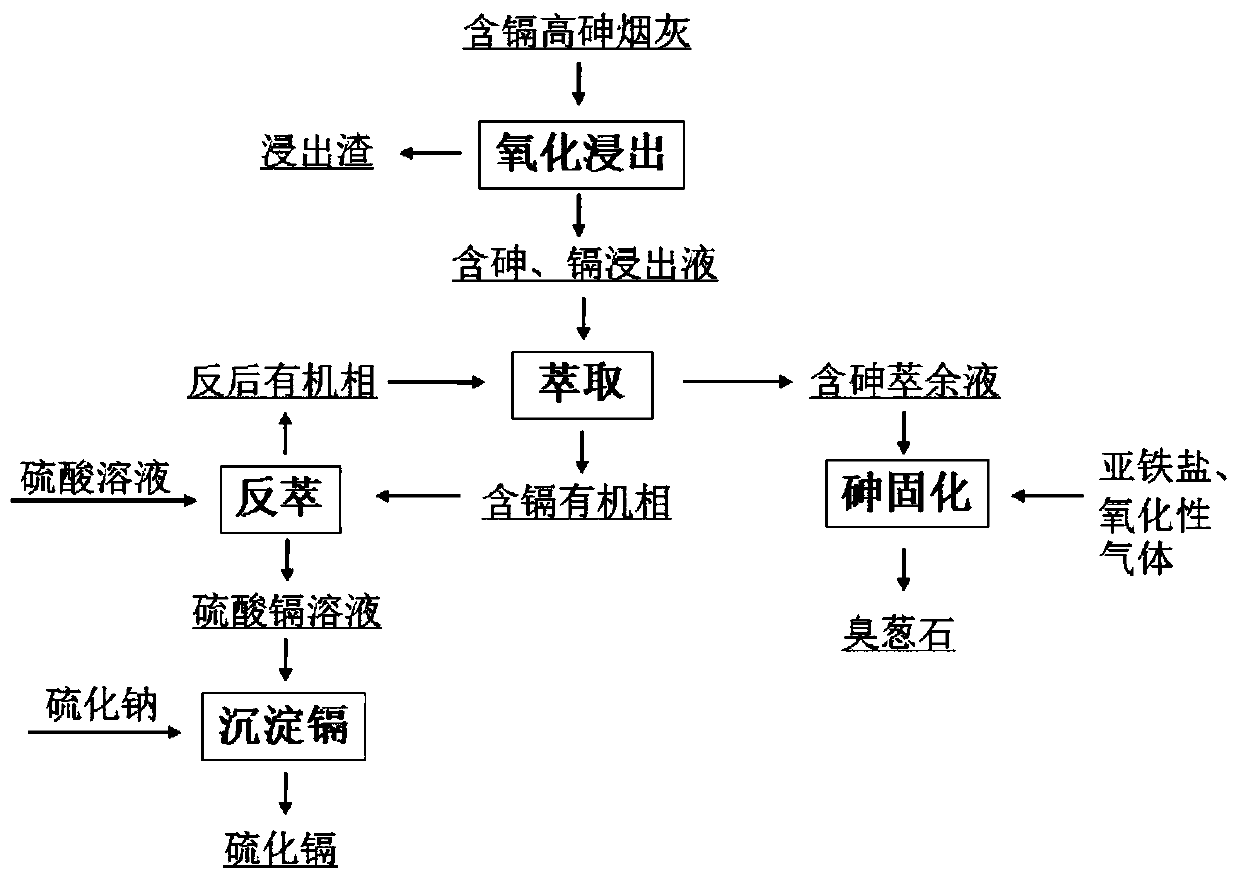

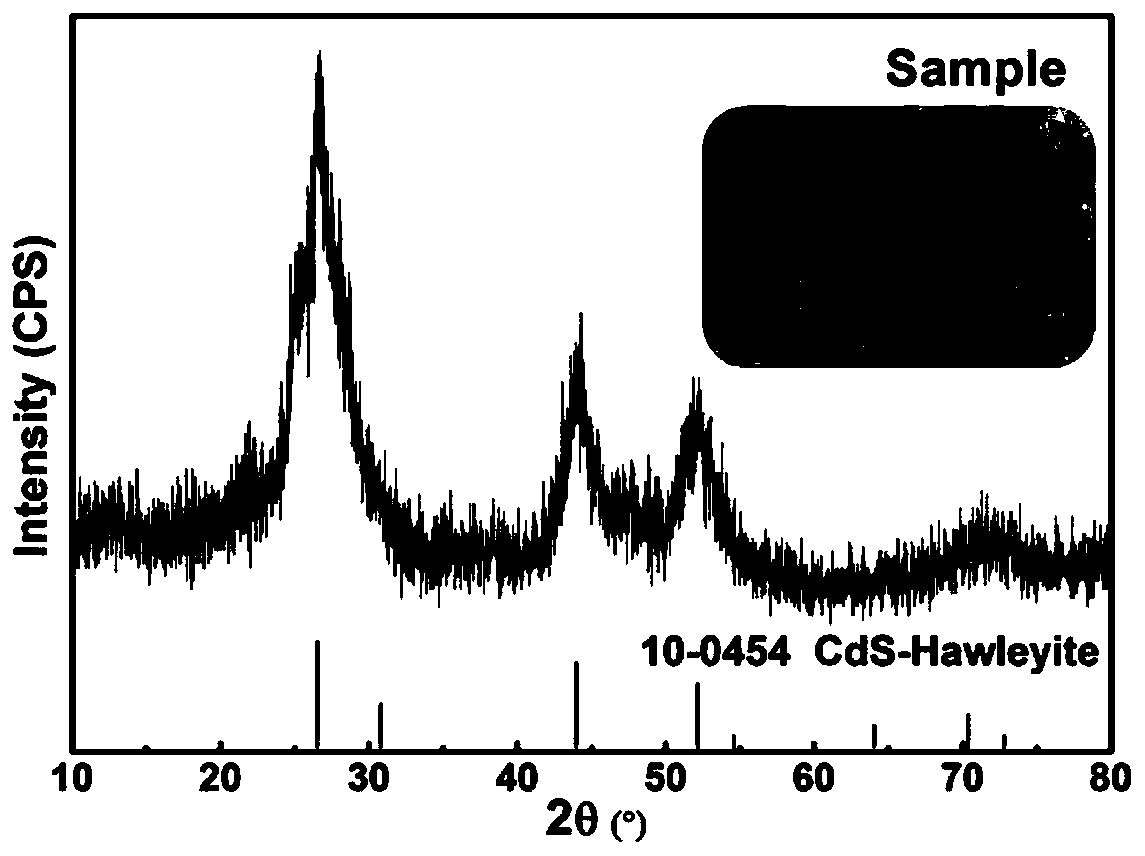

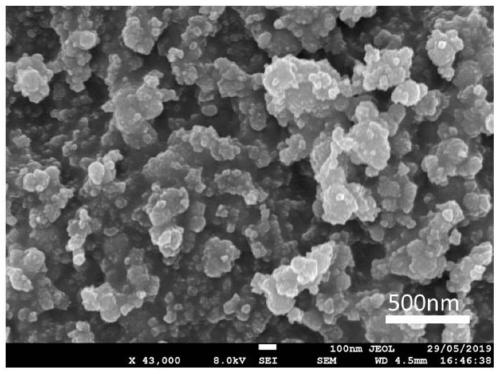

Method of recovering cadmium from cadmium-containing high-arsenic soot

ActiveCN111041221AHardened securityCuring Handling SafetyIron compoundsProcess efficiency improvementFerrous saltsSoot

The invention discloses a method of recovering cadmium from cadmium-containing high-arsenic soot. The method includes the following steps of firstly, oxidizing leaching, wherein oxidizing leaching isperformed on the cadmium-containing high-arsenic soot, and filtering is performed to obtain a leachate containing cadmium and arsenic and leach residues containing valuable metals; secondly, extracting, wherein extracting is performed on the leachate containing cadmium and arsenic after the pH is adjusted to be 2.5-3.0, and a cadmium-containing organic phase and a arsenic-containing extraction solution are obtained; thirdly, reverse extracting, wherein a cadmium sulfate solution is obtained after reverse extracting is performed on the cadmium-containing organic phase through a sulfuric acid solution; fourthly, cadmium precipitation, wherein precipitation reaction is performed on the cadmium sulfate solution through sodium sulphide to obtain cadmium sulfide; and fifthly, arsenic curing, wherein soluble ferrite is added to the arsenic-containing extraction solution, a gaseous oxidant is introduced for reaction, and scorodite crystals are obtained. According to the method, cadmium in thecadmium-containing high-arsenic soot is effectively extracted through an extracting method, cadmium is separated from lead, iron, bismuth and the like, meanwhile the safe disposal of arsenic is realized, highly toxic arsine gas is prevented from being generated in the technological process, and the method is economical and friendly to the environment.

Owner:CENT SOUTH UNIV

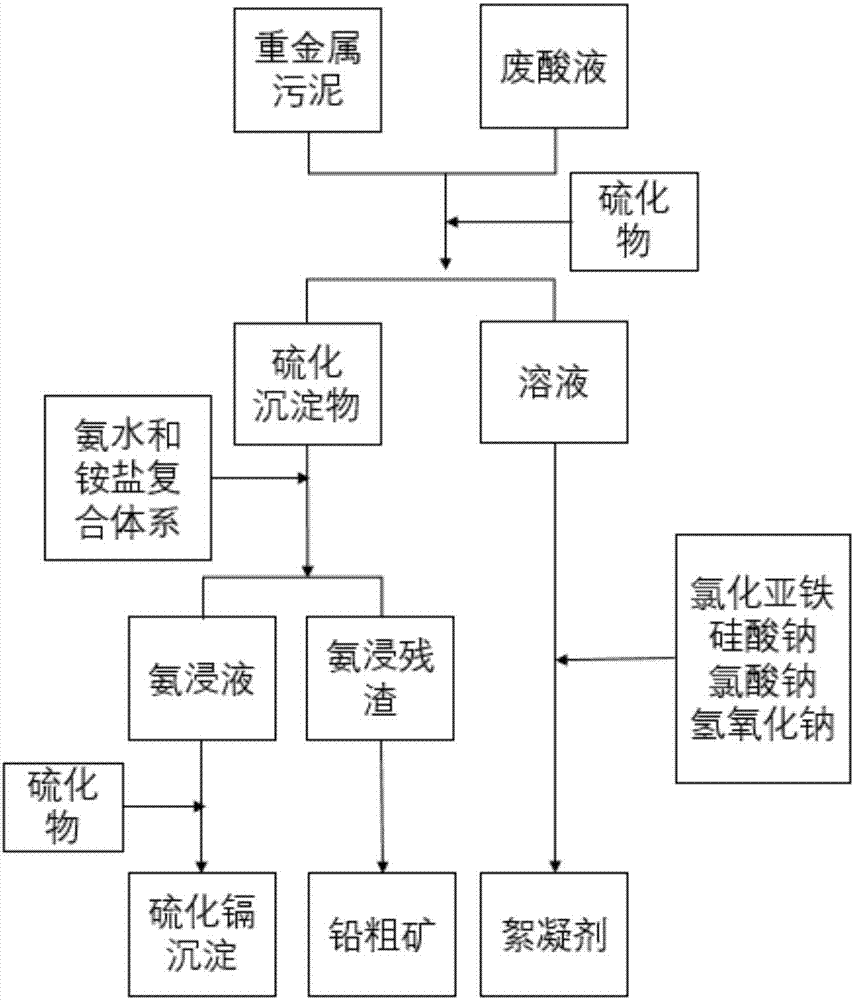

Method for preparing polysilicate iron flocculating agent from iron-containing heave metal sludge, and recycling treatment method of heavy metal sludge

ActiveCN107226599AAvoid it happening againWon't interfereSludge treatmentSpecific water treatment objectivesTreatment effectSludge

The invention discloses a method for preparing polysilicate iron flocculating agent from iron-containing heave metal sludge, and a recycling treatment method of the heavy metal sludge, and belongs to the technical field of environmental protection. The preparation method comprises the following steps: dissolving the heavy metal sludge by using waste acid liquid, and adding sulfide to remove cadmium and lead ions from the solving liquid to obtain complexing precipitate and iron-containing flocculating agent preparation liquid; treating the complexing precipitate by an ammonia leaching method to obtain cadmium-containing ammonia leaching liquid and ammonia leaching residue, adding sulfide into the ammonia leaching liquid to obtain cadmium sulfate precipitate, and taking the ammonia leaching residues as lead coarse ore; supplementing ferrous chloride for the iron-containing flocculating agent preparation liquid, adding sodium silicate and sodium chlorate, completely mixing, adjusting the basicity, carrying out reaction, allowing standing still and curing to obtain curing liquid, and then obtaining the polysilicate iron flocculating agent. The flocculating agent prepared by the method is good in treatment effect, high in settling velocity, small in use amount and simple in production flow, can realize reduction, harmlessness and recycling of the heavy metal sludge, and has good economic benefit and environmental benefit.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

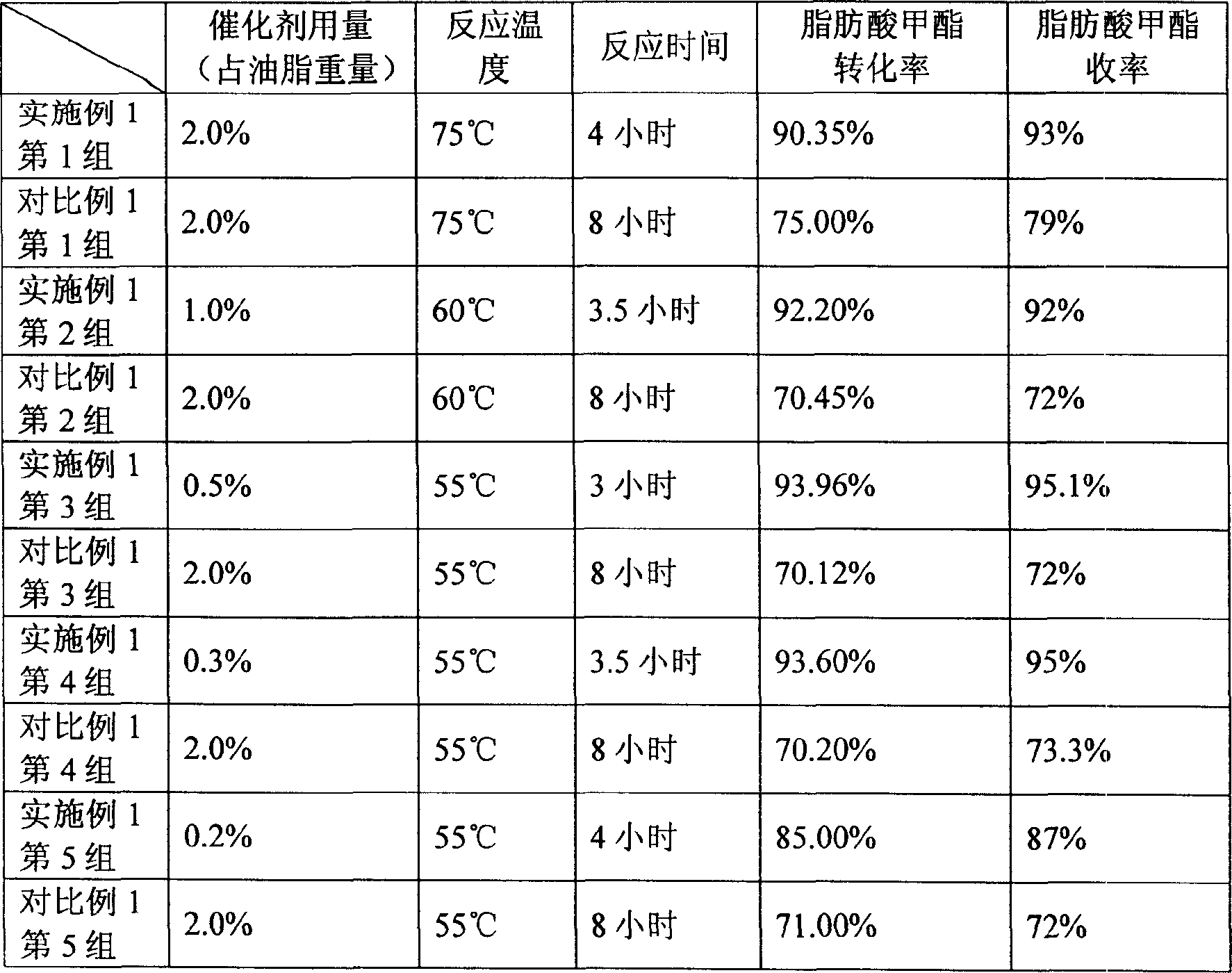

Esterification catalyst for preparing biological diesel oil by animal plant lipid and application method

InactiveCN1793288AHigh yieldReduce manufacturing costBiofuelsLiquid hydrocarbon mixture productionOil and greaseReaction temperature

The invention relates to esterifying reaction catalyst used animal and vegetable grease to manufacture biological diesel oil. It belongs to using anima and vegetable grease to manufacture biological diesel oil technique field. The catalyst includes A, B, and C three components; the A can be one or many of cadmium sulfate, zinc sulphate, or aluminium sulphate; the B is sulfuric acid quadric-ammino combine copper; the C is chromic oxide and aluminium sulfide. The invention also offers the manufacturing method. The esterifying reaction catalyst can effectively control the reaction direction to make the reversible reaction toward producing fatty acid methyl ester to make fatty glyceride esterifying ratio reach above 90%. Compared with the catalyst and application method, the invention can reduce catalyst reaction temperature, shorten catalyst reaction time, reduce end product processing program, and effectively increase biological diesel oil production quality, and reduce the fabrication cost.

Owner:赵金玉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com