Activity increase agent for lead-acid storage battery

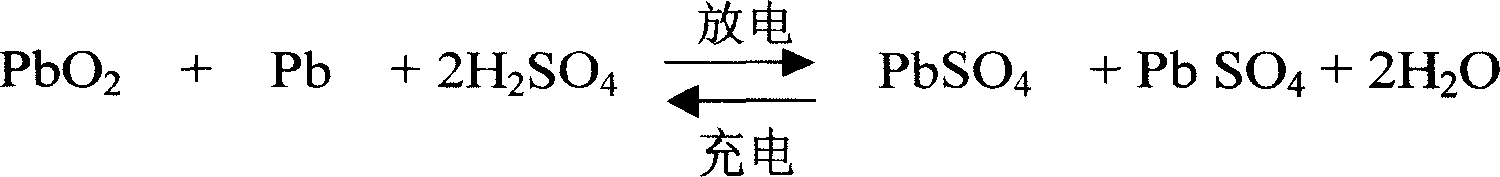

A battery, lead-acid technology, applied in the field of electrochemistry, can solve the problems of easy vulcanization of the battery plate, difficult to start the battery, long charging time, etc., to improve the continuous use performance, enhance the recovery and self-regeneration ability, and solve the problem of self-discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]Add 125 kg of distilled water to a 300 cubic meter enamel reaction kettle with stirring, slowly add 50 kg of sulfuric acid under continuous stirring, the temperature rises, and when the temperature drops to 25-30°C, add cobalt sulfate 1.4 in order kg, 1 kg of hydroxylamine sulfate, 5 kg of aluminum sulfate, 4 kg of cadmium sulfate, 2.7 kg of magnesium sulfate, and 3 kg of oxalic acid. In the process of adding raw materials, it is necessary to wait for the former raw material to dissolve before adding the latter.

Embodiment 2

[0044] The equipment and steps of this embodiment are the same as those in Embodiment 1. The raw materials are 135 kg of distilled water, 54 kg of sulfuric acid, 1.8 kg of cobalt sulfate, 1.3 kg of hydroxylamine sulfate, 9 kg of aluminum sulfate, 6 kg of cadmium sulfate, 3.7 kg of magnesium sulfate, oxalic acid 5 kg.

Embodiment 3

[0046] The equipment and steps of this embodiment are the same as those in Embodiment 1. The raw materials are 130 kg of distilled water, 52 kg of sulfuric acid, 1.6 kg of cobalt sulfate, 1.2 kg of hydroxylamine sulfate, 7 kg of aluminum sulfate, 5 kg of cadmium sulfate, 3.1 kg of magnesium sulfate, oxalic acid 4 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com