Patents

Literature

115 results about "Hydroxylamine sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

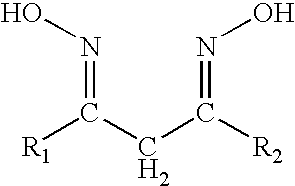

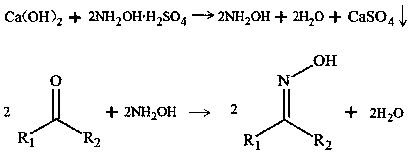

Hydroxylammonium sulfate is used in organic synthesis to convert aldehydes and ketones to oximes, carboxylic acids and their derivatives (e.g. esters) to hydroxamic acids, isocyanates to N-hydroxyureas and nitriles to amidoximes. Hydroxylammonium sulfate is also used to generate hydroxylamine-O-sulfonic acid from oleum or chlorosulfuric acid.

Fenton and Fenton-like system fortifier and using method thereof

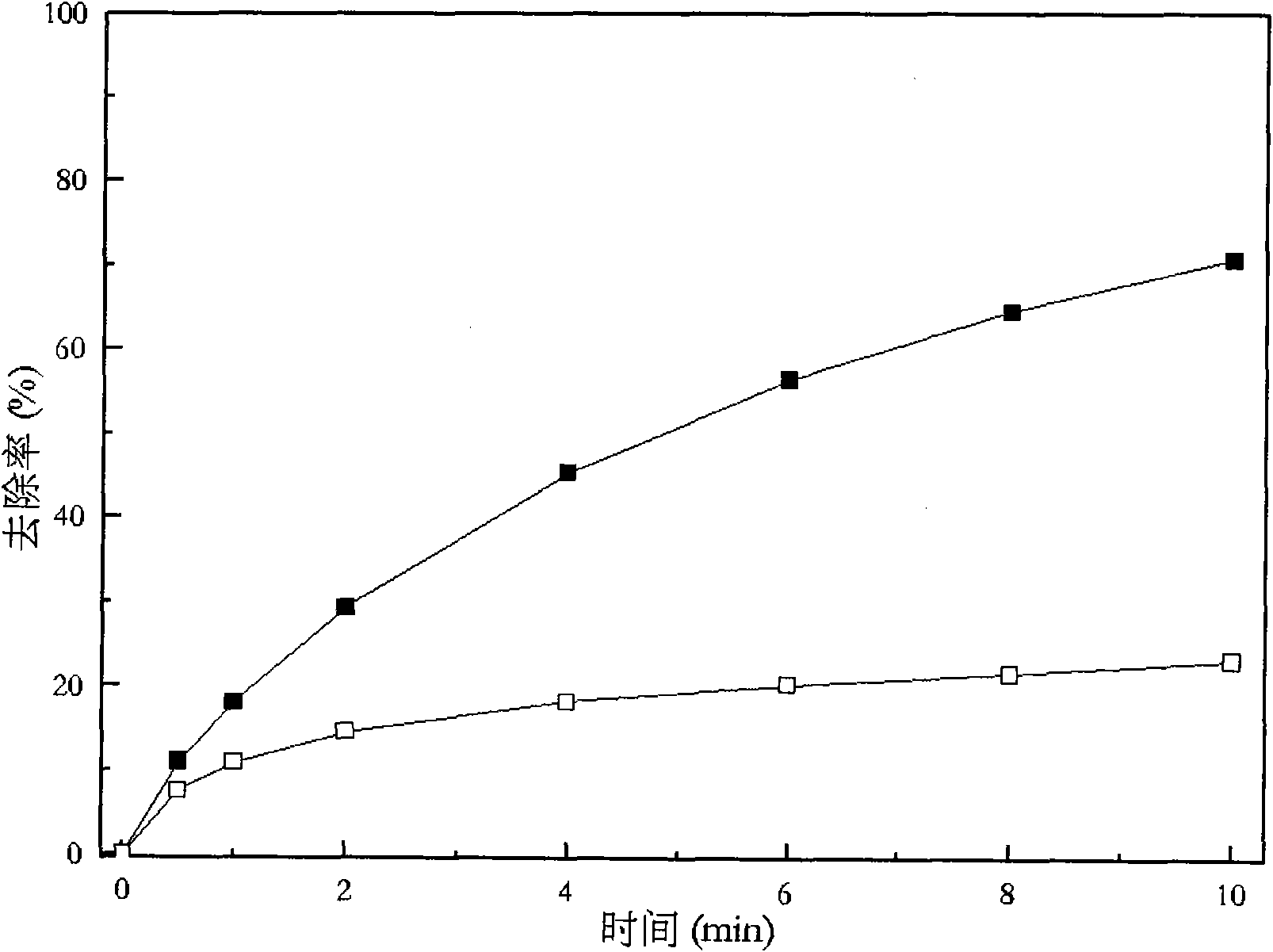

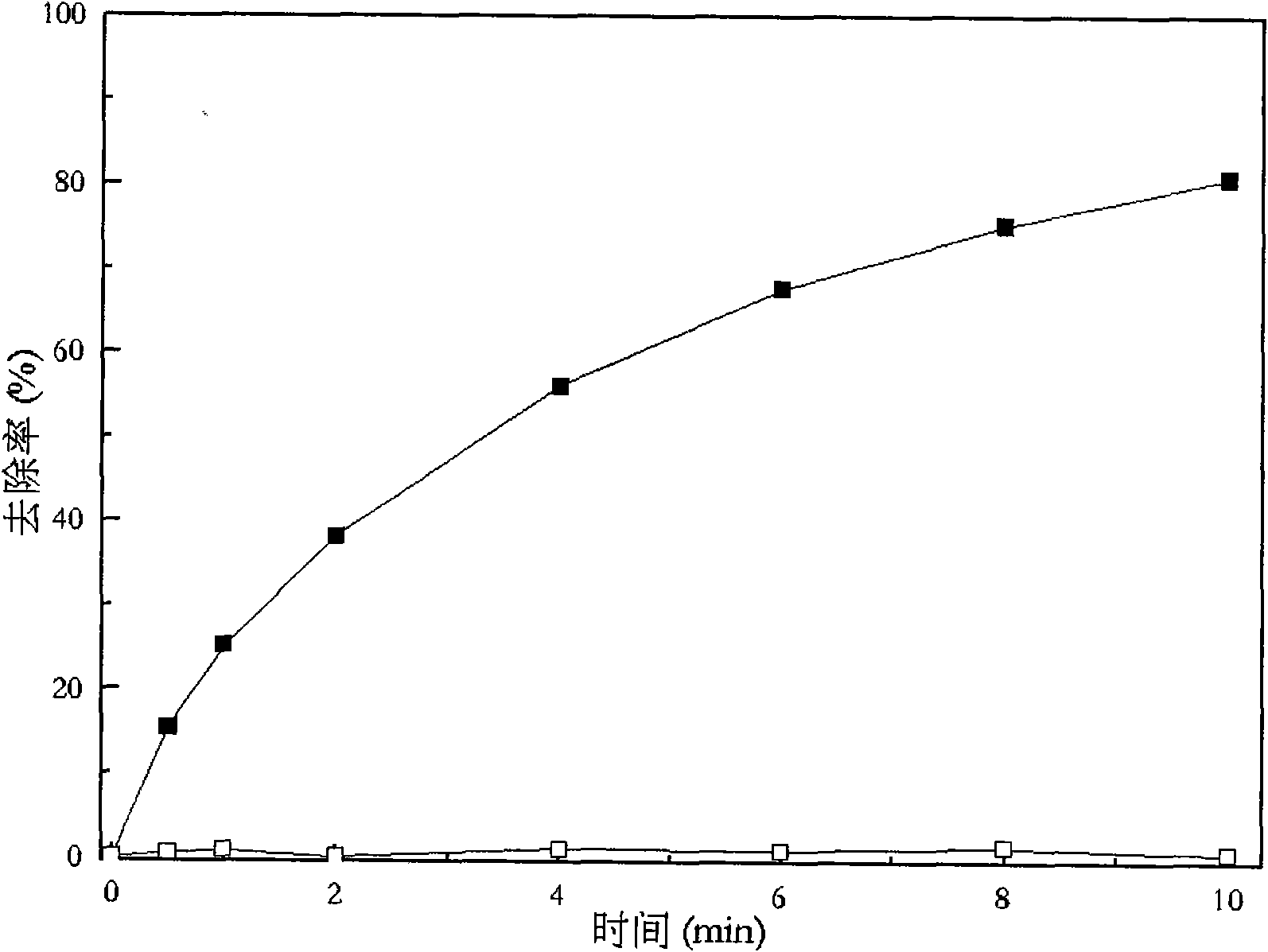

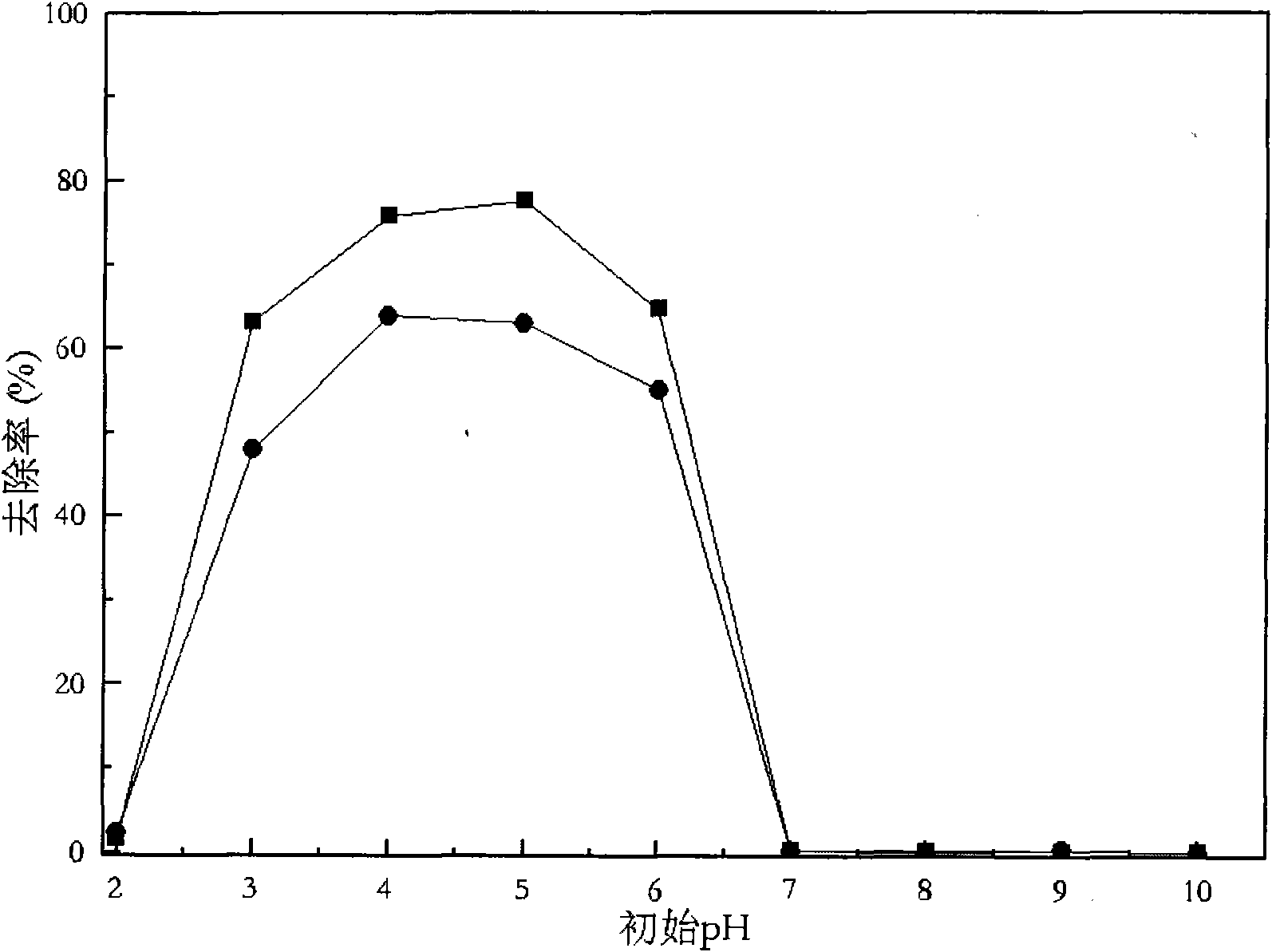

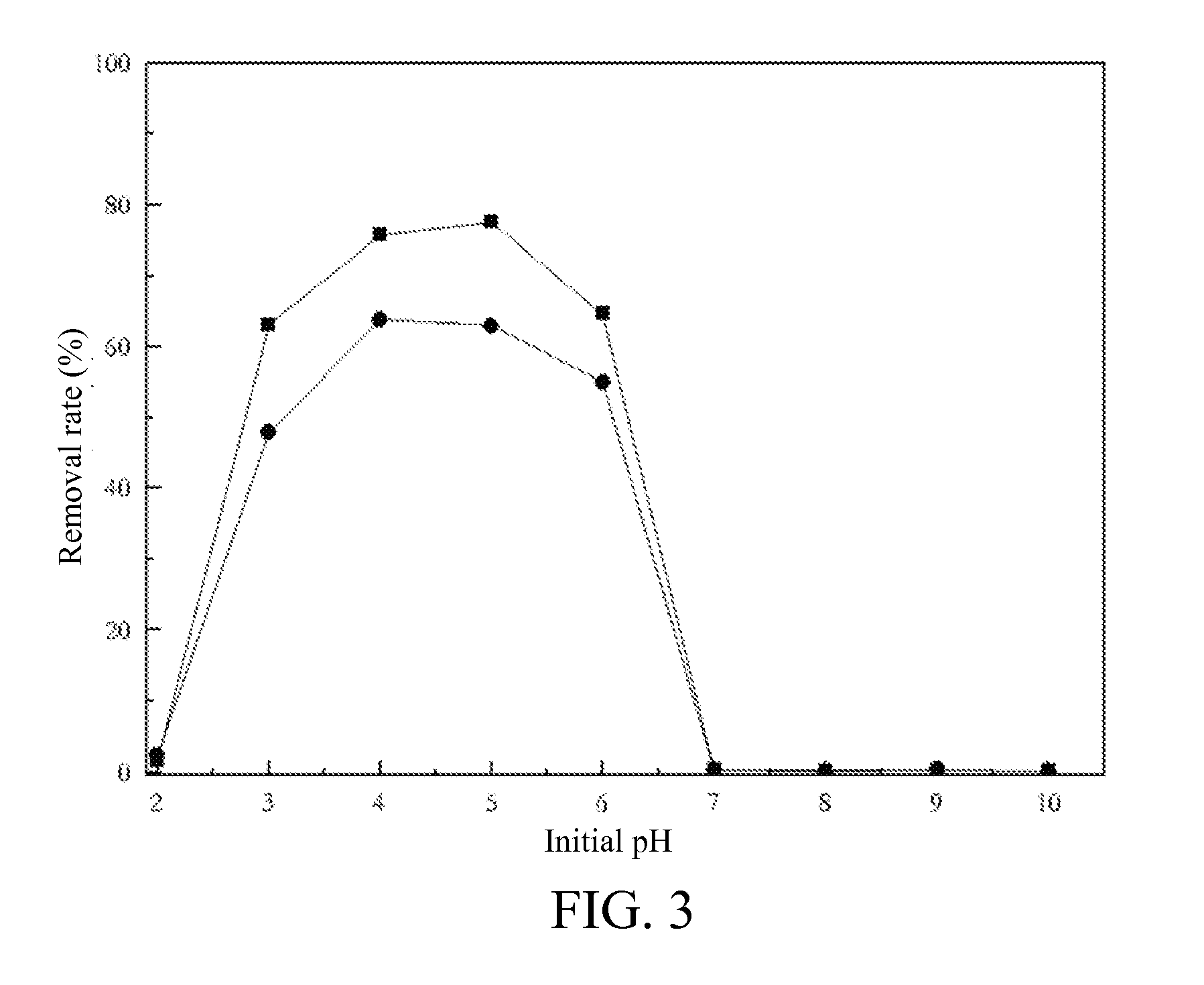

ActiveCN101792205AReduce dosageEasy to useWater treatment parameter controlWater treatment compoundsSulfite saltHydrazine compound

The invention provides a Fenton and Fenton-like system fortifier and a using method thereof, which relate to a water treating fortifier and a using method thereof and overcomes the defects that the pH value of the Fenton and Fenton-like system reaction water body is limited, the adding amount of Fe<2+> is overhigh in the Fenton reaction, and the reaction speed is low in Fenton-like reaction. The fortifier is selected from ascorbic acid, sodium sulfite, lithium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, hydroxylamine, hydroxyl-ammonium perchlorate, hydroxylamine sulfate, hydrazine, N,N-diethylhydroxylamine, carbohydrazide, ethanolamine, a hydroxylamine solution or N,N,N',N'-tetra substituted phenylenediamines. The using method has the following steps of: adding the Fenton and Fenton-like system fortifier, fortificated chemicals and peroxide into the treated water body; and then, uniformly stirring to react. The fortifier can accelerate the reaction of water treatment and decrease the using amount of the fortificated chemicals.

Owner:HARBIN INST OF TECH

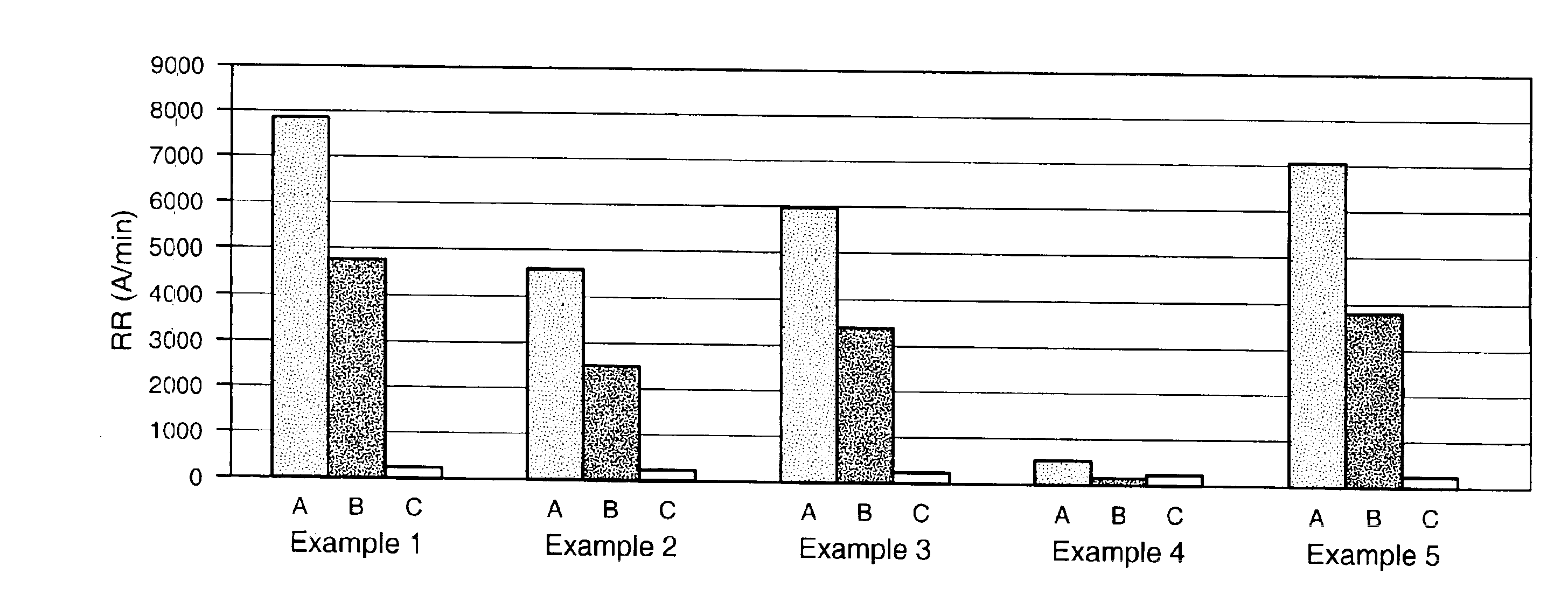

Anisotropic etching agent composition used for manufacturing of micro-structures of silicon and etching method

InactiveUS20070175862A1Reduce processing timeIncrease etch rateDecorative surface effectsSemiconductor/solid-state device manufacturingMicro structureTetramethylammonium hydroxide

An anisotropic etching agent composition for manufacturing of micro-structures of silicon comprising an alkali compound and hydroxylamines; an anisotropic etching method with the use of the etching agent composition. The alkali compound is preferably tetramethylammonium hydroxide, and the hydroxylamines is preferably at least one kind selected from the group consisting of hydroxylamine, hydroxylamine sulfate, hydroxylamine chloride, hydroxylamine oxalate, dimethyl hydroxylamine hydrochloride and hydroxylamine phosphate. An anisotropic etching property whose etching rate is different in crystal face orientation especially relating with etching technology with the use of manufacturing of micro-structures of silicon used as Micro Electro Mechanical Systems (MEMS) parts, semiconductor materials, etc is provided.

Owner:MITSUBISHI GAS CHEM CO INC

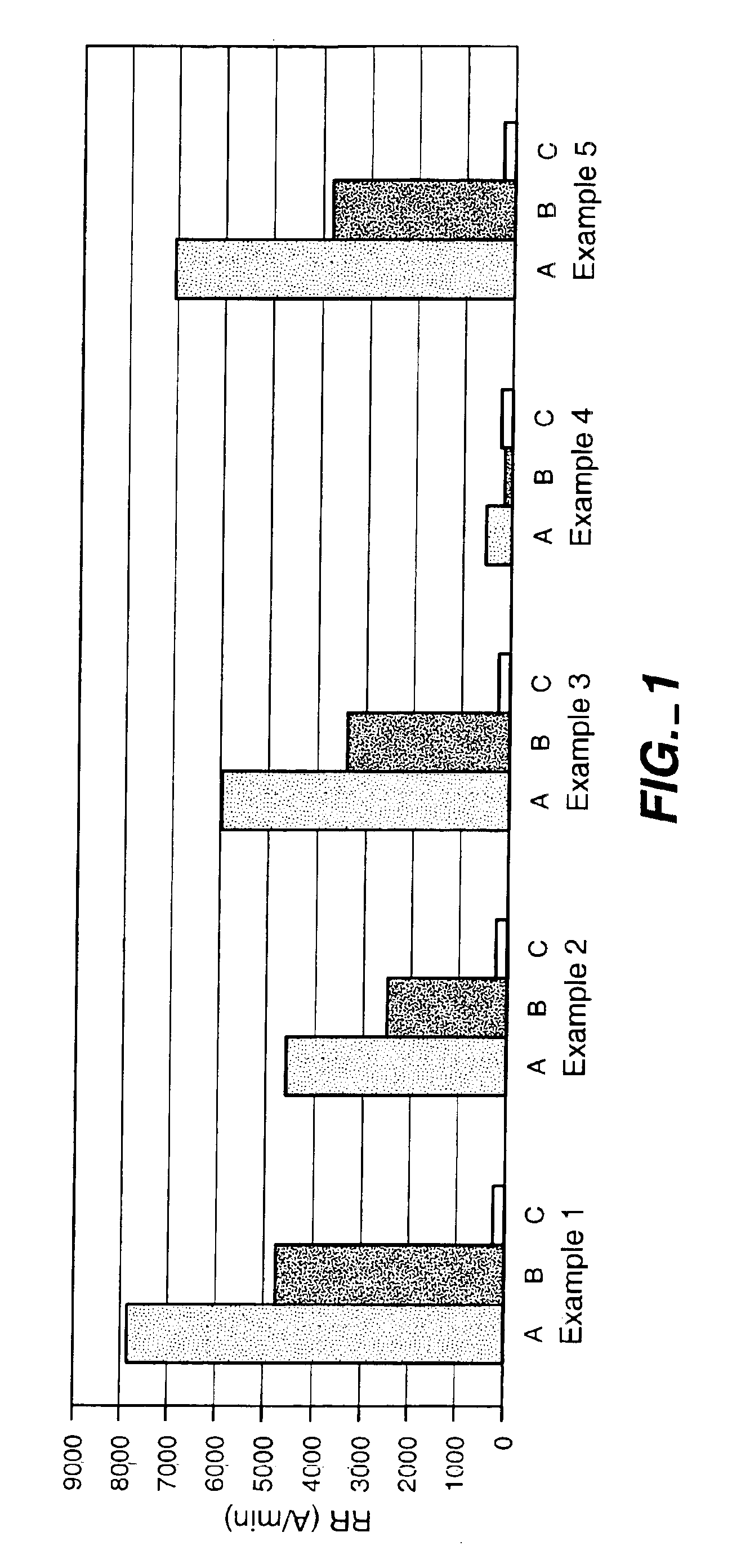

Compositions for chemical mechanical planarization of copper

InactiveUS6866792B2Other chemical processesSemiconductor/solid-state device manufacturingColloidal silicaNonane

The present invention relates chemical mechanical planarization (“CMP”) of copper surfaces and describes copper CMP slurries including an oxidizer, one or more hydroxylamine compounds and at least one abrasive. The hydroxylamine compositions can include hydroxylamine nitrate, hydroxylamine, hydroxylamine sulfate, hydroxyl ammonium salts and mixtures thereof. The oxidizers may further include citric acid as a complexing agent for copper. Sulfuric acid and / or nitric acid provide means for modifying the pH of the oxidizer so that the hydroxylamine chemistries are acidic. Some embodiments include corrosion inhibitors such as benzotriazole, 2,4-pentadione dioxime and / or 1,6-dioxaspiro[4,4] nonane 2,7-dione. Some embodiments also include a free radical inhibitor, advantageously hydrazine. Colloidal silica and milled alumina are used as typical abrasive components.

Owner:DUPONT AIR PRODS NANOMATERIALS +1

Preparation method for trapping agent for bauxite flotation

The invention relates to a preparation method for a trapping agent for bauxite flotation. The method is characterized by comprising the following steps of: undergoing a hydroxyl oximation reaction on a caustic soda solution, a hydroxylamine sulfate solution and methyl benzoate serving as raw materials to obtain a mixed solution containing sodium benzohydroxamic acid, sodium sulfate, methanol and water; and diluting the obtained mixed solution with water. The KL trapping agent prepared with the method has the advantages of high trapping capability, small using amount, good separating effect, effective reduction in chloride ions which are introduced into an alumina production flow, and effective reduction in corrosion of stainless steel equipment in ore dressing and the alumina production flow.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

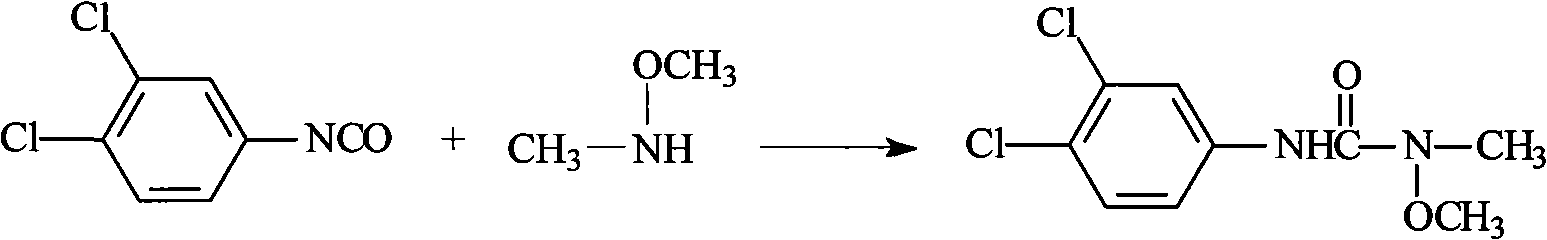

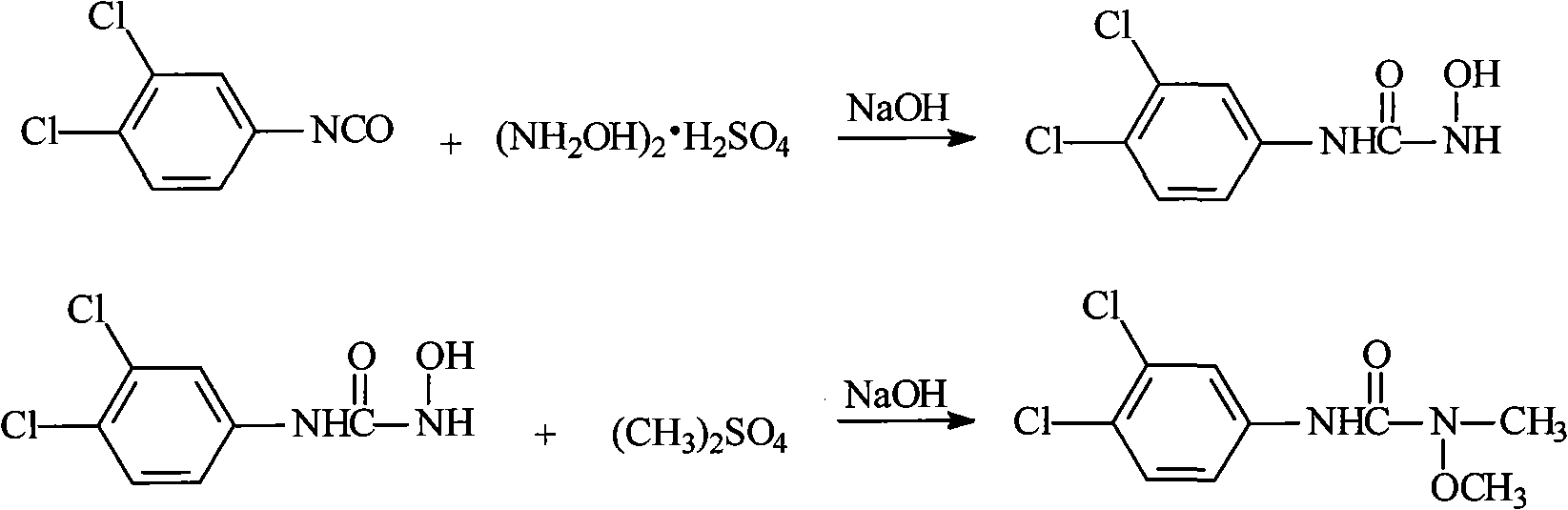

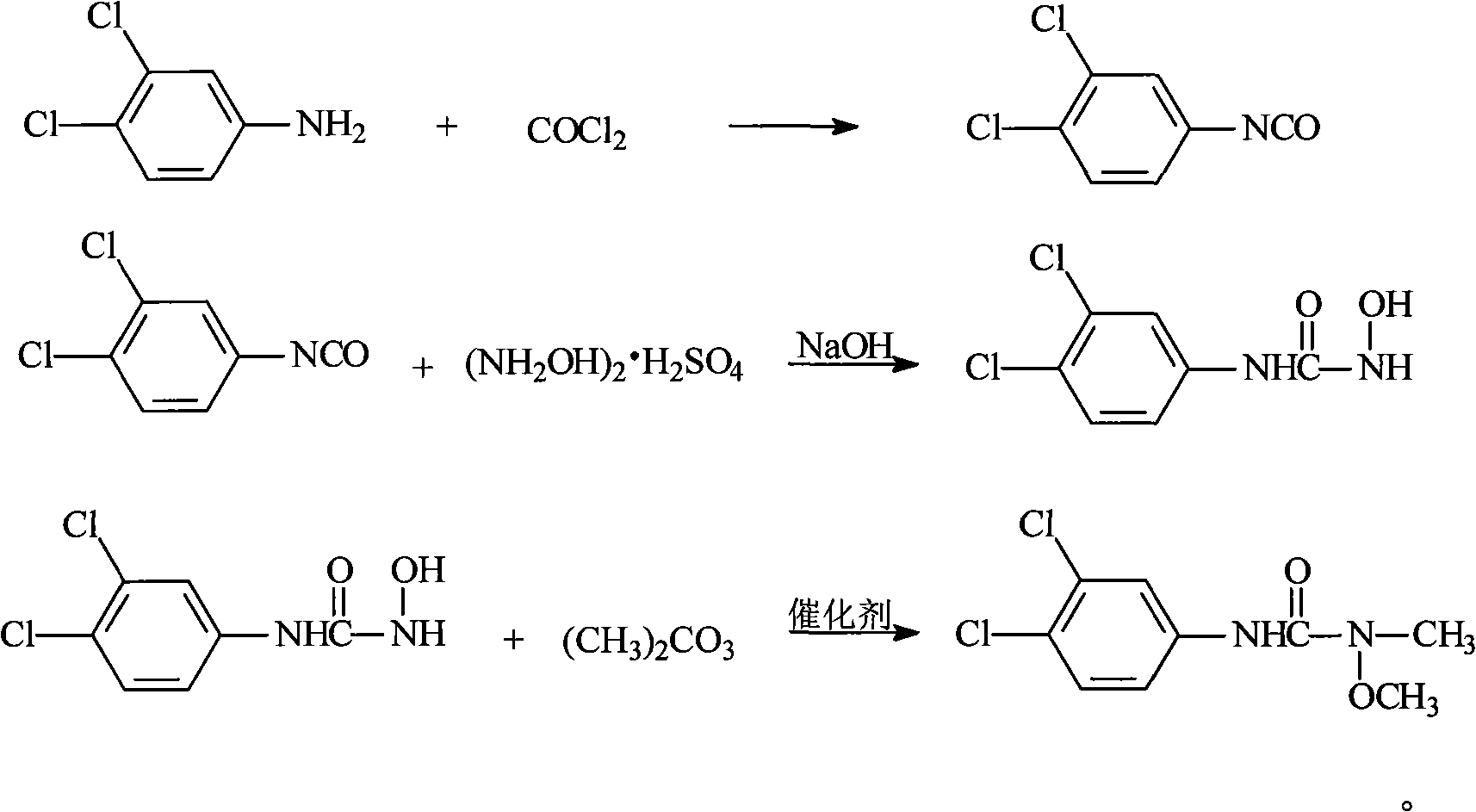

Method for preparing 3-(3,4-dichlorophenyl)-1-methoxy-1-methyl urea

ActiveCN101781236ANothing producedEasy to recycleUrea derivatives preparationOrganic compound preparationCarbonyl chlorideHydroxylamine sulfate

The invention discloses a method for preparing 3-(3,4-dichlorophenyl)-1-methoxy-1-methyl urea, which comprises the following steps: taking carbonyl chloride as an acylating agent to carry out an acylation reaction with 3,4-dichlorophenyl; obtaining 3,4-dichlorophenyl isocyanate; generating 1-hydroxy-3-(3,4-dichlorophenyl) urea by the reaction of 3,4-dichlorophenyl isocyanate and hydroxylamine sulfate or hydroxylamine hydrochloride under an alkaline condition; neutralizing 1-hydroxy-3-(3,4-dichlorophenyl) urea and alkali; and obtaining 3-(3,4-dichlorophenyl)-1-methoxy-1-methyl urea by a methylation reaction of 1-hydroxy-3-(3,4-dichlorophenyl) urea and dimethyl carbonate under the condition with a catalyst and a solution. The invention has less quantity of three wastes, high yield, good quality and complete reaction, and can reduce pollution and the cost.

Owner:JIANGSU KUAIDA AGROCHEM

Method for preparing salt of hydroxylamine by using 'coupling' technique of reactive extraction

This invention provides a method for preparing hydroxylamine salt by reaction-extraction 'coupled' technique. The method utilizes hydroxylamine hydrochloride and HNO3, H2SO4 or H3PO4 as the reactants to prepare hydroxylamine nitrate, hydroxylamine sulfate or hydroxylamine phosphate. During the reaction, a mixture of amide and diluting agent is utilized as the extraction phase to extract byproduct HCl generated during the reaction to obtain high-concentration hydroxylamine salt mother liquor. Then multi-stage cross-flow or vacuum distillation is performed to obtain concentrated hydroxylamine salt solution or crystal. During the reaction, byproduct inorganic acid can be extracted into the organic phase, which can reduce the amount of inorganic acid in aqueous phase, and break the previous thermodynamic equilibrium limit so that the reaction advances toward the positive reaction direction, and the yield is increased. The method has such advantages as simple process, few buproducts and easy operation, and is suitable for industrialization production.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of 3, 3', 4, 4'-biphenyltetracarboxylic dianhydride

InactiveCN110563678APrevent oxidationHigh yieldOrganic chemistryHydroxylamine sulfateHydroxylamine Hydrochloride

The invention discloses a preparation method of 3, 3', 4, 4'-biphenyltetracarboxylic dianhydride. The method includes the reactions of: (1) chlorination reaction: taking phthalic anhydride as the rawmaterial, adding a mixed solution of sodium hypochlorite aqueous solution and sodium hydroxide aqueous solution dropwise, carrying out chlorination reaction, and adjusting the pH value to generate 4-chlorophthalic acid monosodium salt; (2) coupling and hydrolysis: carrying out coupling reaction and hydrolysis reaction on the 4-chlorophthalic acid monosodium salt in the presence of a catalyst and acocatalyst under an alkaline condition to generate 3, 3', 4, 4'-biphenyltetracarboxylic acid sodium salt, wherein the catalyst is a palladium-carbon catalyst or a nickel-palladium-carbon catalyst, and the cocatalyst is hydroxylamine sulfate or hydroxylamine hydrochloride; and (3) acidification into 3, 3', 4, 4'-biphenyltetracarboxylic acid, and then drying and dehydration, thus obtaining 3, 3', 4, 4'-biphenyltetracarboxylic dianhydride. The method provided by the invention adopts phthalic anhydride as the raw material for reaction with sodium hypochlorite to synthesize 3, 3', 4, 4'-biphenyltetracarboxylic dianhydride, is low in production cost, avoids the use of potassium permanganate oxidation, simplifies the production process, and has small pollution, and high yield.

Owner:上海固创化工新材料有限公司

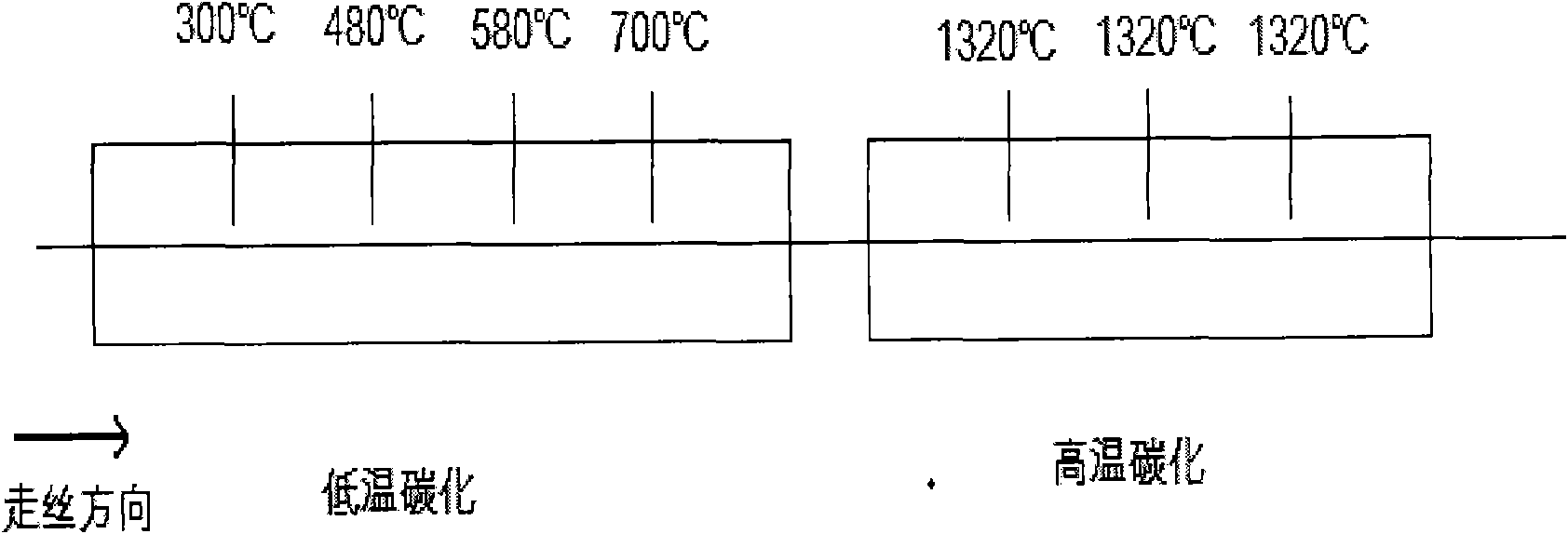

Method of preparing high strength carbon fibre

InactiveCN101550616AHigh tensile strengthReduce manufacturing costFibre chemical featuresFiberCarbon fibers

The present invention relate to a method of preparing high strength carbon fibre. First, dipping polyacrylonitrile fibre into 2-15 wt% hydroxylamine sulfate solution modifying agent to proceed modification, and proceeding washing and physical modification of densification to the polyacrylonitrile fibre, at last getting the high strength carbon fibre through pre-oxidation and carbonizing treatment. Thereby, obtaining a method of preparing high strength carbon fibre with advantages of convenient operation, simple apparatus, almost pollution-free to environment and low cost. The carbon fibre obtained by modification has a great improvement in tensile strength.

Owner:BEIJING UNIV OF CHEM TECH

Black phosphating liquid and use method thereof

ActiveCN102953055AStrong corrosion resistanceFast film formationMetallic material coating processesO-Phosphoric AcidHydroxylamine sulfate

The invention belongs to the technical field of metal surface treatment, and particularly relates to black phosphating liquid for phosphating the surface of alloy steel which does not need to be acid cleaned in preliminary treatment. The black phosphating liquid comprises components with the following weight percentage: 2 percent to 5 percent of acidic manganese phosphate, 2 percent to 4 percent of diammonium hydrogen phosphate, 1 percent to 3 percent of cobalt nitrate, 1 percent to 2 percent of guanidine nitrate, 0.5 percent to 1.5 percent of hydroquinone, 0.2 percent to 1 percent of hydroxylamine sulfate, 0.5 percent to 2 percent of phosphoric acid with the mass concentration being 80 percent to 90 percent, and the rest is pure water. Due to the use of the black phosphating liquid, the operation is simple, the stability is good, the film forming speed is high, a formed film is fine and uniform, the color is black, the film forming strength is high, the corrosion resistance is strong and the like, and the black phosphating liquid is applicable to the surface treatment of alloy steel parts of various models.

Owner:CHANGSHA WOER METAL SURFACE TECH

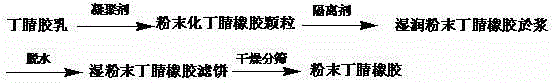

Production method for micro-crosslinking type powdered acrylonitrile-butadiene rubber containing middle and high content of nitrile

The invention relates to a production method for micro-crosslinking type powdered acrylonitrile-butadiene rubber containing middle and high content of nitrile. Firstly, nitrile rubber paste is synthetized, then agglomerated and isolated into powder, and finally dehydrated and dried. In the polymerization reaction stage, potassium carbonate is added as a reaction buffer agent, and diethylhydroxylamine, hydroxylamine sulfate, a mixed solution of potassium hydroxide and soft water are added as a composite terminating agent. In the isolation and powdering stage, WSL and DLTP are added as an antiager, monovalent sodium salts and divalent magnesium salts or monovalent sodium salts and divalent calcium salts are used as a coagulant, and the nitrile rubber paste is agglomerated and isolated into powder at 30-75 DEG C. The production process of the present invention is simple, easy to operate, low in production costs, small in energy consumption, and high in conversion rate which can reach more than 95%. The production method employs a new composite terminating agent, which is stable in mooney and good in termination effect. The powdered acrylonitrile-butadiene rubber is relatively fine, therefore dispersibility is improved during processing. The product is very good in heat resistance and wear resistance, and can meet the application requirements of train high friction brake block.

Owner:HUANGSHAN HUALAN TECH

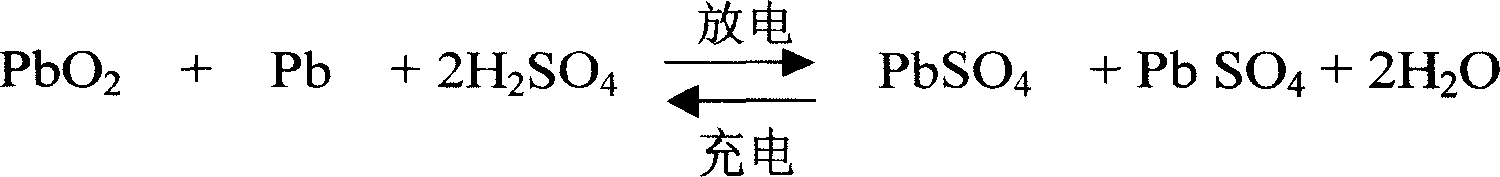

Activity increase agent for lead-acid storage battery

InactiveCN1960049ALarge capacityExtended service lifeLead-acid accumulatorsInternal resistanceEvaporation

The disclosed activator for lead-acid accumulator includes distilled water, sulfuric acid, cobalt sulfate, hydroxylamine sulfate, aluminum sulfate, cadmium sulfate, magnesium sulfate, and binary carboxylic acid. Advantages are: preventing pole plates from vulcanizing, increasing capacity and service life of accumulator, shortening time for charging accumulator, reducing evaporation of electrolyte in use, reducing internal resistance, avoiding overcharge. Moreover, the invention solves self-discharge issue of accumulator effectively.

Owner:蔡植如 +3

Phosphating process as cathode electrophoresis coating pretreatment

InactiveCN104250763ALower working temperatureReduce manufacturing costElectrophoretic coatingsMetallic material coating processesPhosphateAcid washing

The present invention discloses a phosphating process as a cathode electrophoresis coating pretreatment. The phosphating solution adopted by the process comprises: 33-37 g / L of zinc oxide, 123-127 g / L of 85% phosphoric acid, 12-14 g / L of nickel sulfate, 6-8 g / L of manganese carbonate, 5-7 g / L of potassium chlorate, 2-4 g / L of potassium fluoride, 9-11 g / L of hydroxylamine sulfate, 4-6 g / L of m-nitrobenzene sulfonic acid, 17-19 g / L of sodium citrate, 3-5 g / L of sodium polyphosphate, 0.5-1.5 g / L of triethanolamine, 1-2 g / L of phytic acid, 0.2-0.6 g / L of pentaerythritol phosphate, and the balance of water. The phosphating process comprises: carrying out acid washing, neutralization, deoiling degreasing, and water washing on a workpiece, immersing into a phosphating solution with temperature of 25-35 DEG C, a free acidity of 2-6 and the total acidity of 55-65, carrying out a reaction for 6-12 min, washing with water, and drying.

Owner:WUXI LUOSHE TECH VENTURE

Hypothermal nontoxic phosphatization liquid containing accelerant of hydroxylamine sulfate, and preparation method

InactiveCN1563491AReduce pollutionGood for healthMetallic material coating processesNitriteHydroxylamine sulfate

A low temperature atomic phosphide liquor containing hydroxylamine sulfate accelerant is composed of HNO3: 10-15ml / L, H3PO412-18ml / L, ZnO 8-12G / l, CuSO4, 5H2O 0.6-1.0G / l, HAS 2.0-4.0g / L, Na2 MoO4 2H2o 0.03-0.05%g / L, NaC103 0.8-1.3G / l, C6H8O7. H2O 2.0-3.0g / L characterizing in taking hydroxylamine sulfate accelerant as the master accelerant matched with other additives.

Owner:大连理工大学技术转移中心有限公司

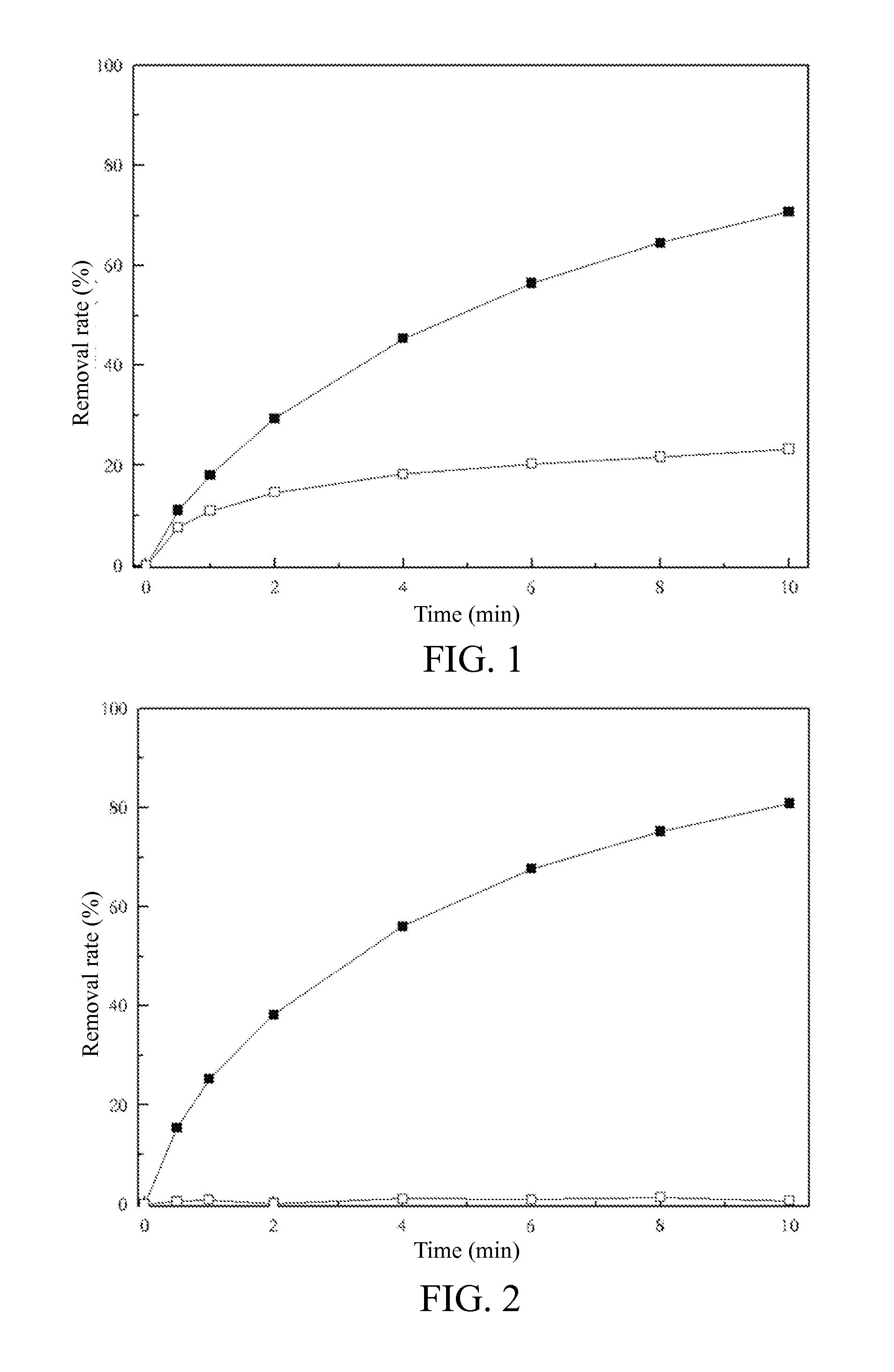

Fenton and Fenton-Like System Hardening Agent and Usage Thereof

InactiveUS20120305497A1Efficient use ofWide rangeWater treatment parameter controlOrganic chemistryHydrazine compoundSulfite salt

Fenton and Fenton-like system enhancing agent and the usage thereof are provided. It relates to a water treatment enhancer (enhancing agent) and the usage thereof. It widens water pH range of Fenton and Fenton-like system reaction. It reduces amount of Fe2+ required for Fenton reaction. It increases rate of Fenton-like reaction. The enhancing agent is selected from sodium sulfite, lithium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, hydroxylamine hydrochloride, hydroxylamine perchlorate, hydroxylamine sulfate, hydrazine, N,N-diethylhydroxylamine, amino ethanolamine, hydroxylamine solution or N,N,N′,N′-tetrasubstituted p-phenylenediamine. The method of use of enhancing agent comprises the steps of: adding Fenton or Fenton-like system enhancing agent, an agent for enhancement and hydrogen peroxide into water subject to treatment; and mixing and allowing reaction. The enhancing agent can increase the rate of reaction for the water treatment and reduce the dosage of the agent for enhancement.

Owner:HARBIN INST OF TECH

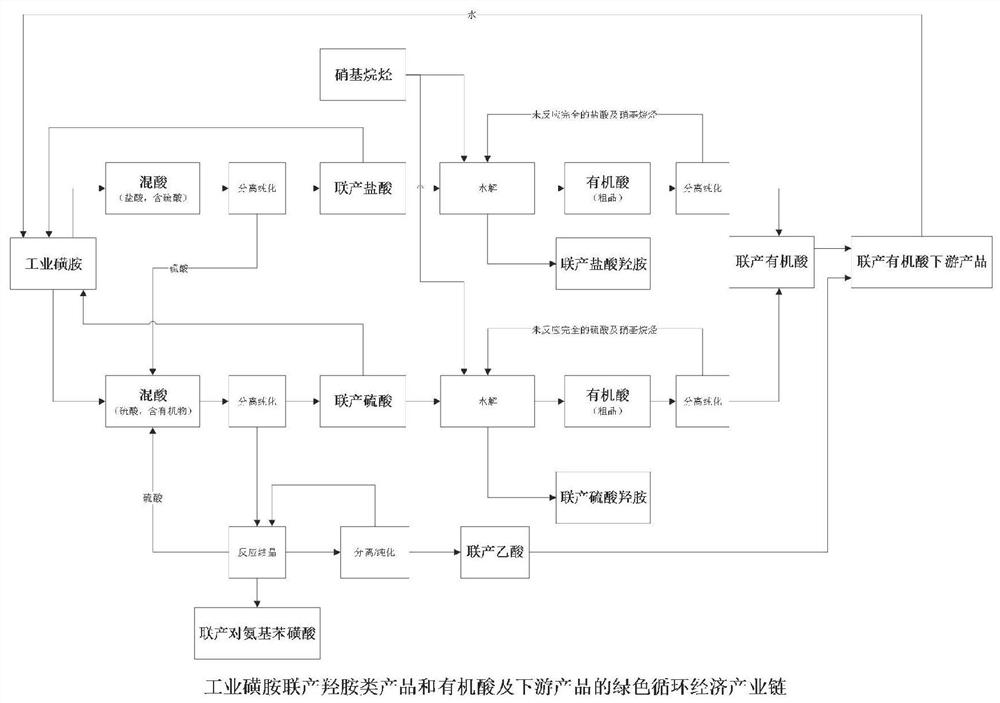

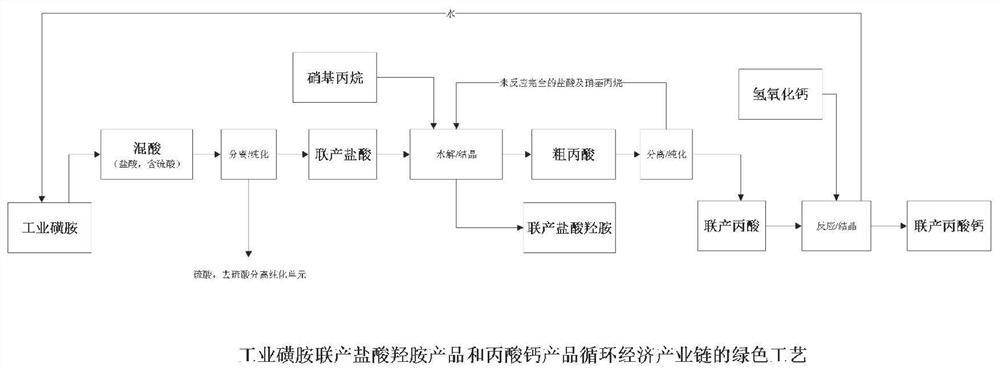

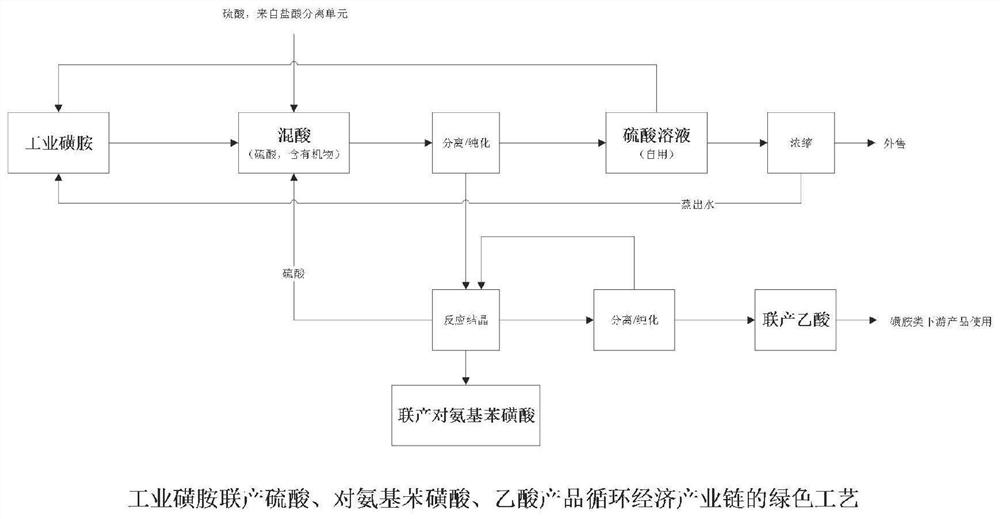

Green process of circular economy industry chain for co-production of industrial sulfanilamide and hydroxylamine products and organic acid downstream products

ActiveCN113321578ASolve the technical problems of separation and purificationHigh economic valueChlorine/hydrogen-chloride purificationOrganic compound preparationAlkaneNitroalkane

The invention provides a green process of a circular economy industry chain for co-production of industrial sulfanilamide and hydroxylamine products and organic acid downstream products. The process comprises the following steps that hydrochloric acid mixed acid is separated and purified to obtain sulfuric acid and co-produced hydrochloric acid, and the obtained sulfuric acid enters a sulfuric acid mixed acid treatment route; partial co-produced hydrochloric acid and nitroalkane are subjected to a hydrolysis reaction to obtain organic mixed acid and co-produced hydroxylamine hydrochloride, and the organic mixed acid is separated and purified to obtain co-produced organic acid; the sulfuric acid mixed acid is separated and purified to obtain organic matters and co-produced sulfuric acid; the organic matters are subjected to reactive crystallization to co-produce p-aminobenzene sulfonic acid; and partial co-production sulfuric acid and nitroalkane are subjected to a hydrolysis reaction to obtain a co-production hydroxylamine sulfate product and organic mixed acid, and the organic mixed acid is separated to obtain co-produced organic acid. According to the process, a green circular economy industrial chain of industrial sulfanilamide is realized, and meanwhile, a green circular economy industrial chain of hydroxylamine products and organic acid downstream products can be co-produced.

Owner:湖南吴赣药业有限公司

Environment-friendly type terminating agent for styrene butadiene rubber emulsion polymerization and preparation method thereof

ActiveCN103467656AImprove performanceMeet the needs of the production processPolymer scienceHydroxylamine sulfate

The invention discloses an environment-friendly type terminating agent for SBR (Styrene Butadiene Rubber) emulsion polymerization, wherein a raw material expression of the terminating agent is disubstituted alkyl dithiocarbamate of R2NCS2M; in the formula, A is alkyl with C1-C3, R is A-C6H4Cl or R is A-C6H5, M is a sodium salt or a potassium salt; an accelerant is isopropyl hydroxylamine sulfate. The ratio of the raw material: the accelerant: a dispersing agent: a chemical stabilizer is equal to 100: (1-20): 3: 6. The preparation method of the environment-friendly type terminating agent comprises the following steps of: preparing the raw material into 10-20 wt% aqueous liquor in a kettle; preparing the dispersing agent into 3wt% aqueous solution, and adding into the kettle under the stirring condition, uniformly stirring, adding 1-20 wt% accelerant aqueous liquor, uniformly stirring, adding the solid chemical stabilizer according to the ratio, and continuously stirring uniformly to prepare the environment-friendly type terminating agent which is uniform, transparent and stable. The raw material, an accelerant ratio as well as liquor components in the scheme are the same as those in a scheme II.

Owner:吉林市泷泽化工有限公司

Molybdate radical ion and nitrite radical ion concentration test card and its preparing method

InactiveCN1648642ASimple processLow costMaterial analysis by observing effect on chemical indicatorChemical methods analysisNitrite ionGallic acid ester

The present invention relates to a kind of molybdate radical ion and nitrite radical ion concentration test card and its preparation process. The test card includes test paper and standard color check card, and the test paper has molybdate radical ion indicating color developing paper sheet and nitrite radical ion indicating color developing paper sheet fixed on the base sheet. The molybdate radical ion indicating color developing paper sheet is prepared through soaking filter paper in mixed solution of gallic acid and hydroxylamine sulfate, drying and photophobic keeping; and the nitrite radical ion indicating color developing paper sheet is prepared through soaking filter paper in mixed solution ofaminobenzene sulfonic acid, dihydrochloride-1-naphthyl ethylene diamine and tartaric acid, drying and photophobic keeping. The present invention may be used in testing the concentration of molybdate radical ion and nitrite radical ion simultaneously.

Owner:WUHAN UNIV OF SCI & TECH

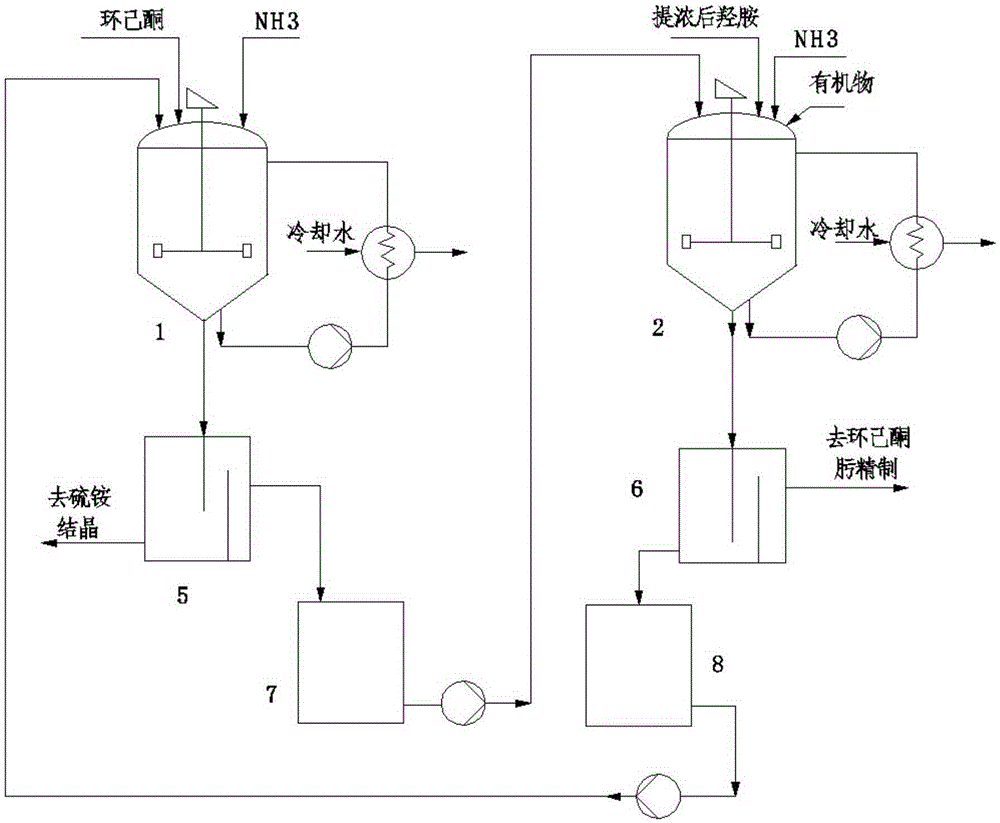

Cyclohexanone oxime synthesis method

ActiveCN105384656ALow Hydroxylamine Sulfate ConcentrationIncrease water contentOximes preparationSynthesis methodsHydroxylamine sulfate

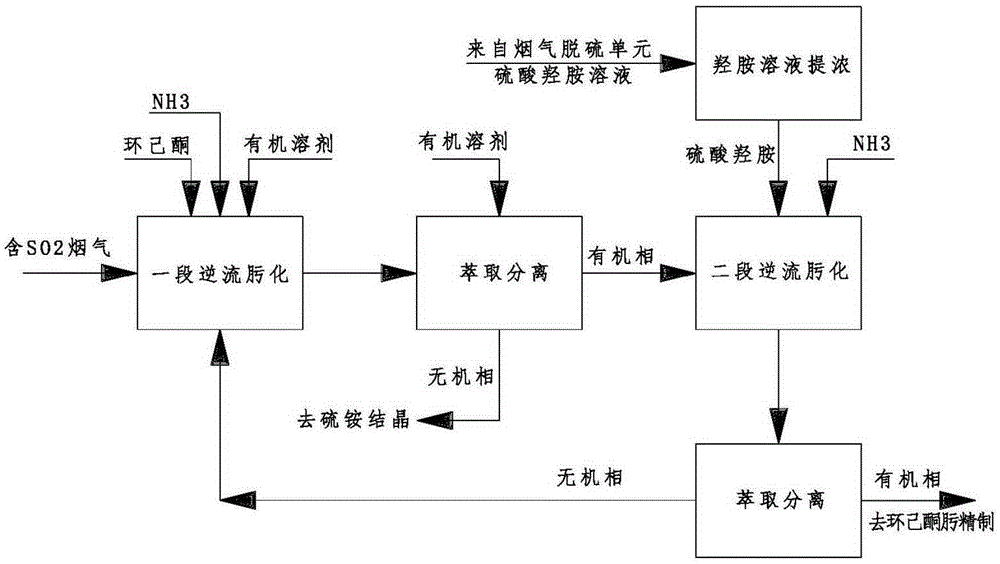

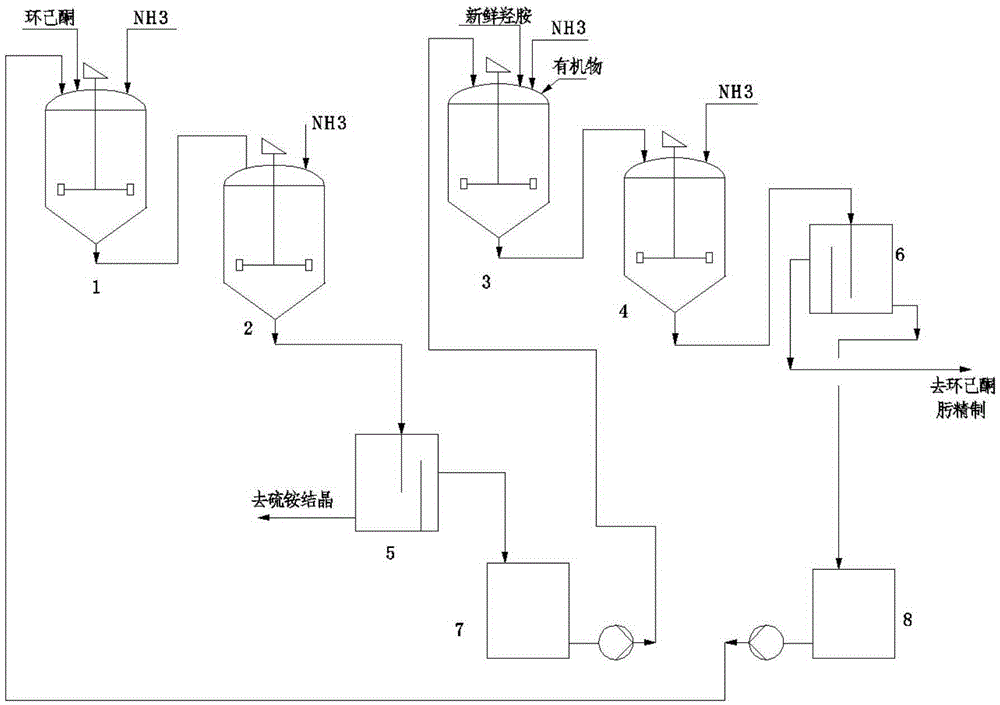

The invention discloses a cyclohexanone oxime synthesis method. In the process of preparing a flue gas desulfurization byproduct cyclohexanone oxime, sulfur dioxide in flue gas is absorbed by utilizing ammonia or ammonia water as an absorbent to prepare ammonium bisulfite, and the ammonium bisulfite serving as a raw material reacts with cyclohexanone by means of counter-current oximation to prepare cyclohexanone oxime. According to the method, by increasing the concentration of hydroxylamine sulfate and adding the organic solvent, the diffusion performance of a reaction system is improved and consumption of cyclohexanone is reduced; furthermore, due to the extraction effect of the organic solvent, the total content of cyclohexanone-oxime and cyclohexanone in the inorganic phase which leaves a cyclohexanone oxime synthesis system can be reduced to lower than 0.30wt%, and the yield of the cyclohexanone oxime synthesis reaction is increased.

Owner:SINOPEC NANJING ENG & CONSTR +1

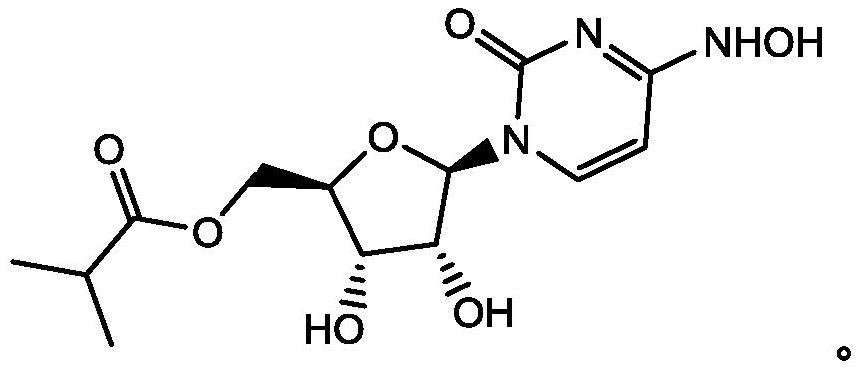

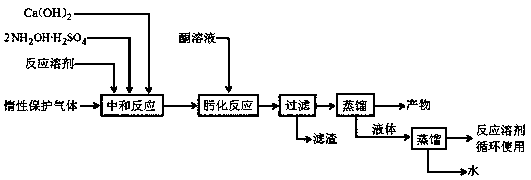

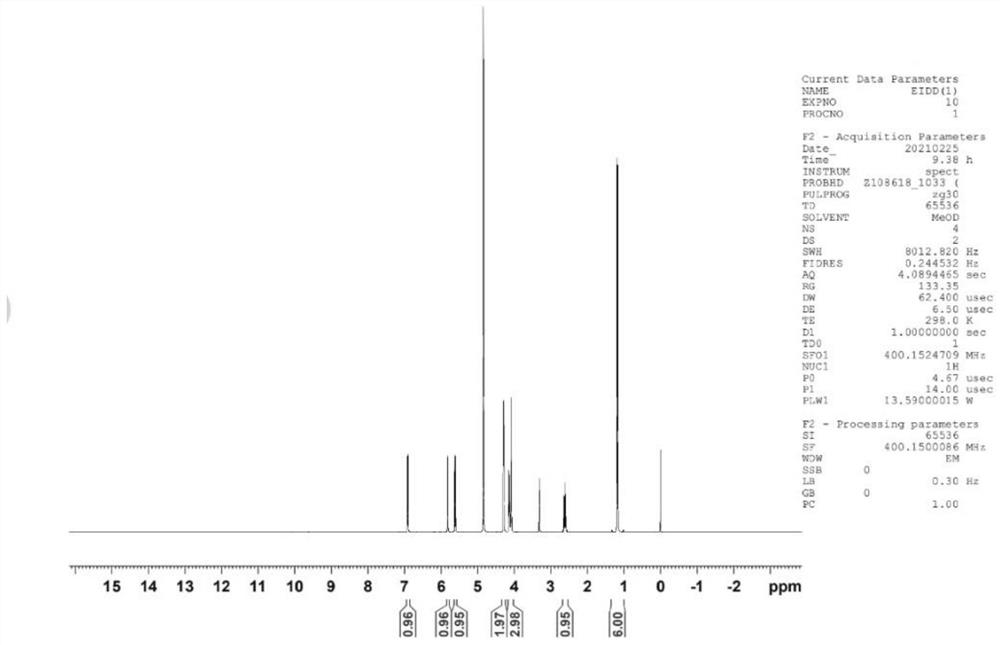

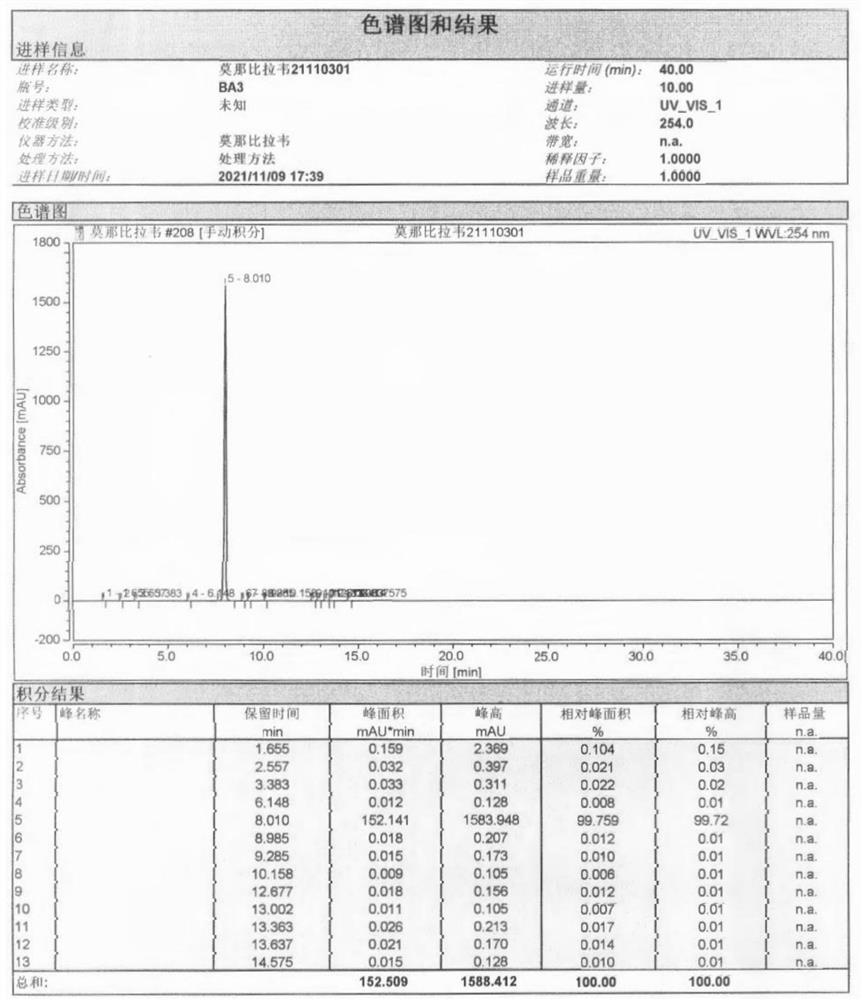

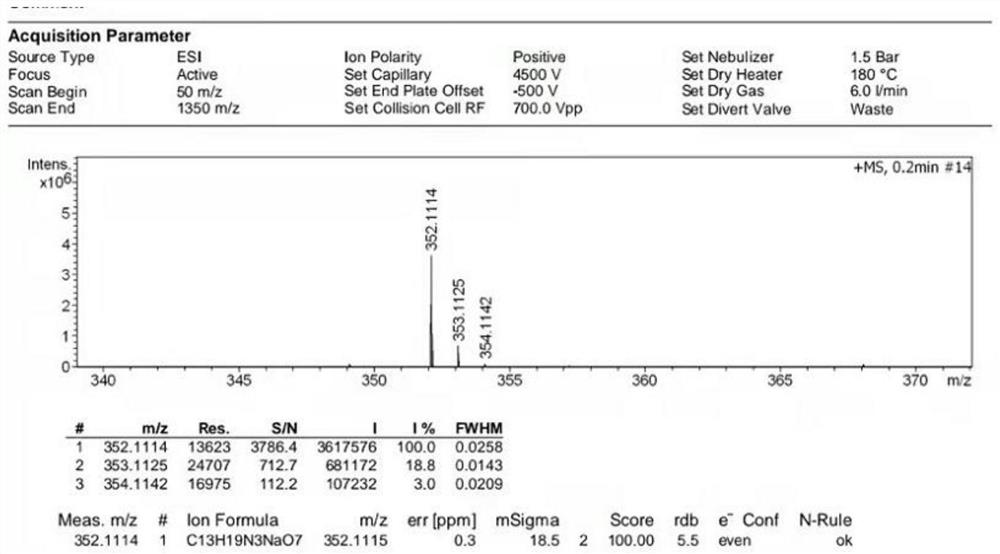

Preparation method of mupiravir

ActiveCN113956312AEfficient removalEliminate the refining stepSugar derivativesSugar derivatives preparationSodium acetateHydroxylamine sulfate

The invention discloses a preparation method of mupiravir, and belongs to the technical field of medicine preparation. The preparation method comprises the following steps: (1) adding a compound shown as a formula (I) into an alcohol solvent, adding water, sodium acetate and hydroxylamine sulfate, or adding water, sodium acetate and hydroxylamine hydrochloride, reacting, and performing post-treatment to obtain a compound shown as a formula (II); and (2) adding the compound of the formula (II) obtained in the step (1) into dichloromethane or trichloromethane, adding hydrochloric acid, reacting, and carrying out post-treatment and refining to obtain mupiravir. The preparation method is easy to operate, safe, environmentally friendly, low in cost and beneficial to large-scale production of products; the prepared product has high yield, and the purity reaches 99.8% or above; and the obtained product is suitable for production of bulk drugs.

Owner:SHANDONG CHENGCHUANG BLUE OCEAN PHARM TECH CO LTD

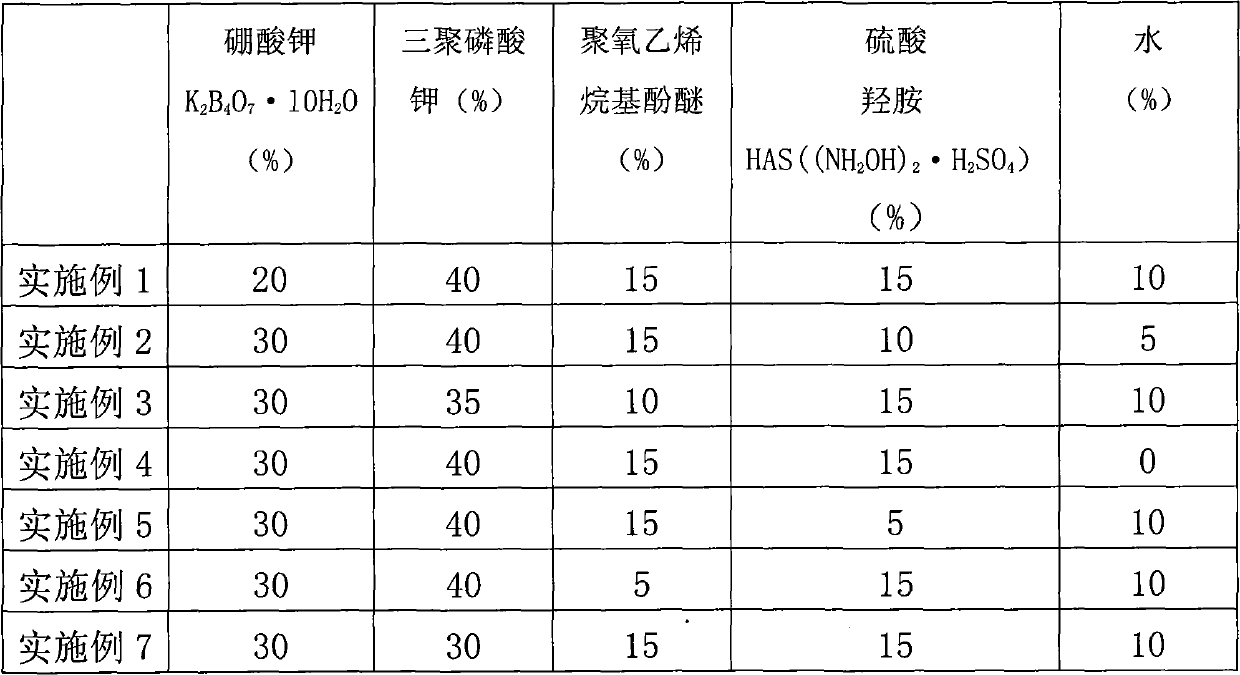

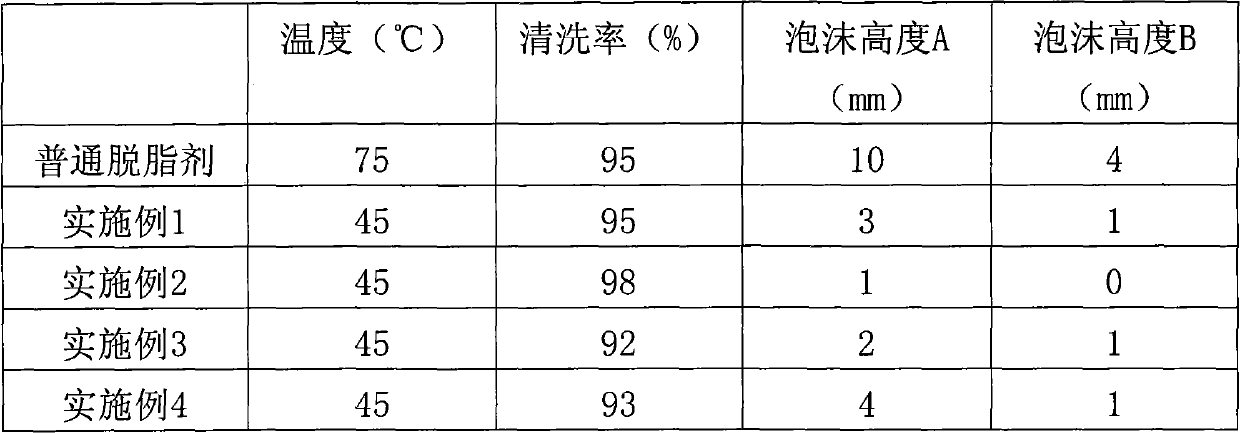

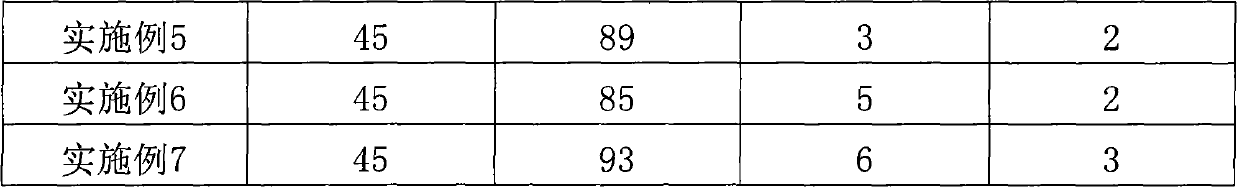

Low temperature and low foam electroplating degreasing additive agent

The invention discloses a low temperature and low foam electroplating degreasing additive agent, which comprises, by mass percentage, 20-30% of potassium boric, 30-40% of potassium tripolyphosphate, 5-15% of polyoxyethylene alkyl ether, 5-15% of hydroxylamine sulfate, and 0-10% of water. The invention overcomes the disadvantages that processing temperature is too high and foam generated is too much in the conventional pretreatment process of electroplating. The additive agent in the invention has a low processing temperature and excellent degreasing effect. Foam generated is little and disappears fast. Therefore, the additive agent is especially suitable for automatic spray pre-treatment, and is an ideal degreasing agent in the electroplate industry.

Owner:BAOSHAN IRON & STEEL CO LTD

Anti-aging and antibacterial medical rubber and preparation method thereof

InactiveCN106589635AImprove corrosion resistanceImprove antibacterial propertiesBoron carbideFlexural strength

The invention provides anti-aging and antibacterial medical rubber. The anti-aging and antibacterial medical rubber is prepared by, by weight, 60-80 parts of brominated butyl rubber, 8-15 parts of hydroxylamine sulfate, 20-30 parts of boron carbide, 25-35 parts of nano zinc carbonate, 20-30 parts of butyl rubber, 20-30 parts of resorcinol, 25-35 parts of lignin, 7-16 parts of cortex phellodendri extract, 10-15 parts of vulcanizing agent, 10-15 parts of accelerant, 6-10 parts of anti-aging agent mercapto benzimidazole, 10-15 parts of hydroxyl silicone oil and 18-28 parts of maleic anhydride, The medical rubber has the advantages that the medical rubber is good in corrosion resistance, antibacterial performance, anti-aging performance, solvent resistance, bending strength and tensile strength; by adding the butyl rubber, the resorcinol, the lignin and the anti-aging agent, rubber aging can be prevented effectively.

Owner:ANHUI RUIYAN NEW MATERIAL TECH RES INST

Foam sorting activator and application thereof

ActiveCN112246445AImprove hydrophobicityPlay a role in reduction modificationFlotationActive agentHydroxylamine sulfate

The invention discloses a foam separation activating agent, which comprises the following components in parts by weight: 0-10 parts of a soluble copper salt, 5-200 parts of an ammonium / amine salt and1-100 parts of a reducing active agent, wherein the soluble copper salt is selected from at least one of copper sulfate, copper nitrate, copper chloride or copper carbonate, the ammonium / amine salt isselected from at least one of ammonia water, ammonium carbonate, ammonium sulfate, ammonium chloride, diamine hydrogen phosphate, ammonium humate or ethylenediamine phosphate, and the reducing activeagent is selected from at least one of ascorbic acid, hydrazine hydrate, hydroxylamine hydrochloride or hydroxylamine sulfate. The foam separation activating agent is high in activating efficiency, stable and firm in activating effect, good in hydrophobicity of activated materials and high in flotation rate, can effectively improve the foam sorting capacity of the to-be-activated materials, and achieves the efficient foam separation and recycling of target components in the materials.

Owner:CHINA ENFI ENGINEERING CORPORATION

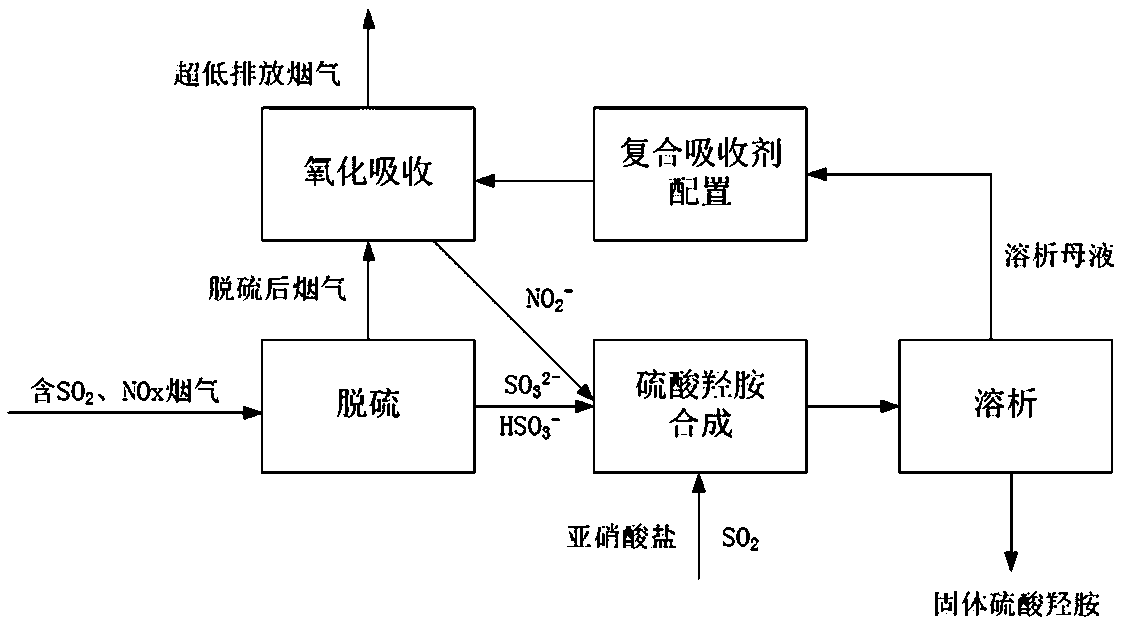

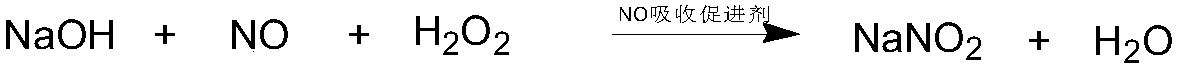

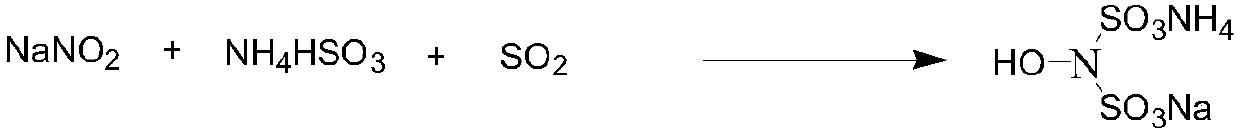

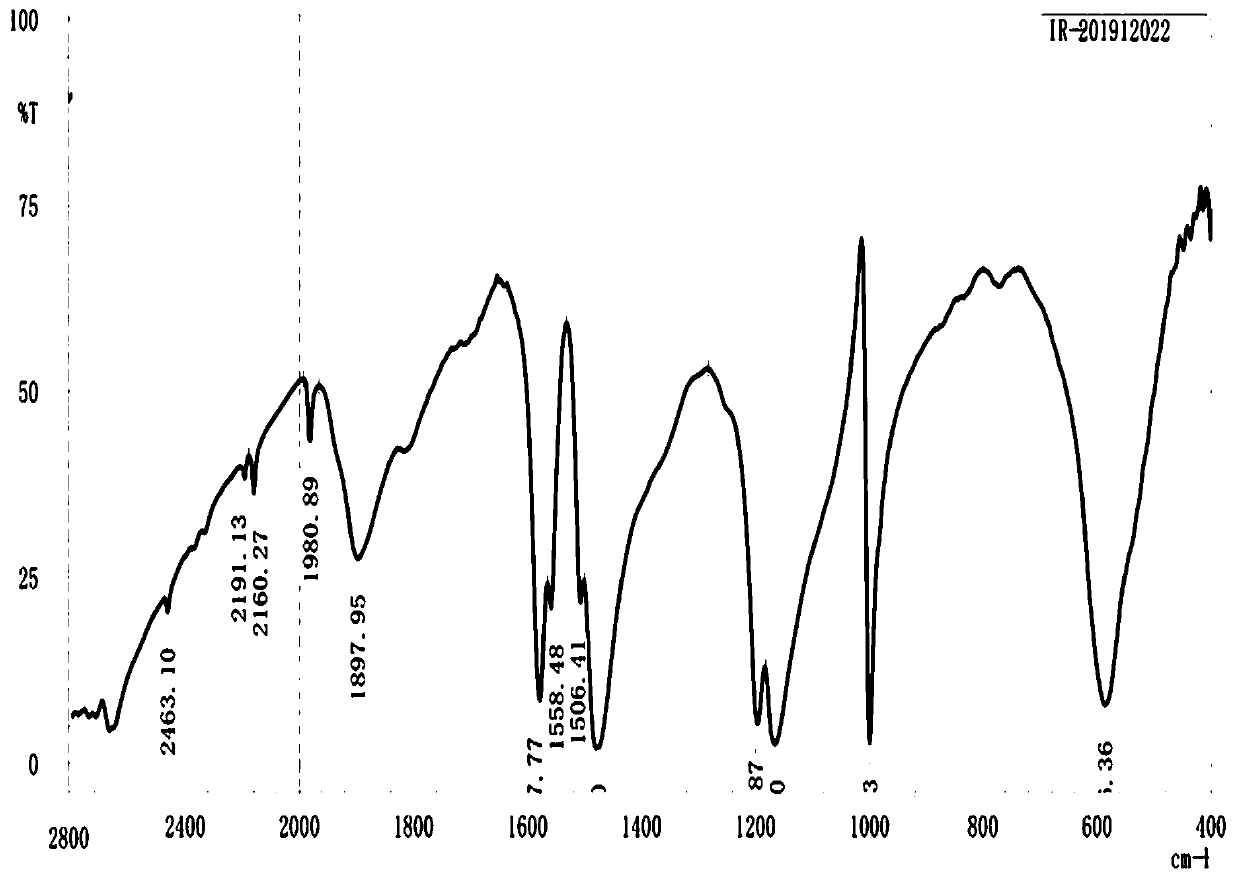

Method for cooperating flue gas desulfurization with denitrification to obtain byproduct hydroxylamine sulfate

InactiveCN107715670AIncrease oxidation rateIncrease usageDispersed particle separationHydroxylamineEconomic benefitsHydroxylamine sulfate

The invention provides a method for cooperating flue gas desulfurization with denitrification to obtain a byproduct hydroxylamine sulfate. The method comprises the following steps: step 1, a desulfurization section: enabling flue gas to enter a desulfurization device and carrying out circulating spraying on the flue gas by using circulating liquid to remove SO2, wherein the circulating liquid is adesulfurization agent ammonium sulfite solution; removing a main component SO2 in the flue gas, and after absorbing the SO2, the ammonium sulfite is converted into ammonium bisulfite; step 2, an oxidization absorption section; step 3, a synthesis section; step 4, a solid hydroxylamine sulfate preparation section: concentrating a hydroxylamine sulfate-containing solution obtained by the synthesissection, and treating by utilizing a dilution method to obtain solid hydroxylamine sulfate; step 4, a recirculating phase: mixing a dilution mother solution treated by step 4, an NaOH solution, an NOabsorption accelerant and hydrogen peroxide according to a ratio to obtain a compound absorbent; enabling the compound absorbent to enter the oxidization absorption section to realize recirculating utilization of the dilution mother solution. The method provided by the invention has the characteristics of safety, applicability and the like, has very good popularization and practical value, and hasgood economic benefit after being widely popularized and applied.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

Preparation method of hydroxylamine sulfate

ActiveCN106946234AImprove conversion rateHigh yieldChemical industryHydroxylamineFiltrationHydroxylamine sulfate

The invention belongs to the field of chemical engineering and relates to a preparation method of hydroxylamine sulfate. In the preparation method, sulfuric acid and ketoxime are employed as raw materials for producing the hydroxylamine sulfate in a reactive rectification system. The preparation method includes the steps of: (1) adding a sulfuric acid solution and ketoxime to the reactive rectification system to perform reactive rectification; (2) successively withdrawing a distillate from the column top of the reactive rectification system, when concentration of the hydroxylamine sulfate in the reaction liquid reaches 2-8.5 mol / L, performing crystallization and filtration at the same time; and (3) reducing the temperature of the reaction liquid and performing crystallization and filtration. The method for producing the hydroxylamine sulfate is greatly reduced in production energy consumption and achieves zero-emission of process wastewater.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of solid hydroxylamine sulfate

ActiveCN111285338AStrong complexing effectImprove adsorption capacityOther chemical processesOrganic compound preparationDoped grapheneHydroxylamine sulfate

The invention relates to the field of chemical engineering, and in particular, relates to a preparation method of solid hydroxylamine sulfate. According to the preparation method of the solid hydroxylamine sulfate through the reaction of sulfuric acid and diacetylmonoxime, conventional reagents are used in the method, no toxic raw material is used, the reaction process conditions are mild, the technological process is short, the production cost is low, a byproduct butanone can be generated, and the method is economical and environmentally friendly; the recyclable metal-doped graphene adsorbingmaterial is adopted, organic residues in a hydroxylamine sulfate solution can be efficiently adsorbed by utilizing a strong complexing effect between metal ions and diacetylmonoxime, and the method has the advantages of energy conservation, environmental protection and high utilization rate.

Owner:ZHEJIANG JINHUA NEW MATERIALS

Vulcanized black jean garment washing process

ActiveCN110117898AReduce riskSafe operating environmentLight resistant fibresDry-cleaning apparatus for textilesHydroxylamine sulfateDeodorant

The invention relates to a vulcanized black jean garment washing process. The vulcanized black jean garment washing process comprises the following steps of placing preprocessed jean garments into desizing solution for desizing treatment at 0-60 DEG C for 10-30 minutes, draining the desizing solution and washing the desized jean garments in clean water at room temperature; placing the desized jeangarments into enzyme solution for treatment at 30-40 DEG C for 15-60 minutes, draining the enzyme solution and washing the treated jean garments in clean water at room temperature; placing the treated jean garments in rinsing solution for treatment at 40-50 DEG C for 10-50 minutes, draining the rinsing solution and washing the rinsed jean garments in clean water at room temperature; adding dechlorinating deodorant into the rinsed jean garments for treatment at 30-40 DEG C for 5-15 minutes, draining the dechlorinating deodorant and washing the treated jean garments in clean water at room temperature; dewatering and drying the first-neutralized jean garments, spraying PP (polypropylene) solution onto the surface of the jean garments, then washing the jean garments in clean water; treating the PP-processed jean garments with hydroxylamine sulfate at 20-50 DEG C for 5-15 minutes, draining the hydroxylamine sulfate, and washing the treated jean garments in clean water at room temperature;processing, dewatering and drying the second-neutralized jean garments. Compared with the prior art, the vulcanized black jean garment washing process is environmentally friendly and safe, and the processed jean garments can be higher in performance.

Owner:FIBER CHEM BIOLOGICAL CHEM

New synthesis method of blocking agent for isocyanate-based cross-linking agents

InactiveCN108017556AImprove conversion rateReduce usageOximes preparationPaints for electrolytic applicationsCyclohexanoneFiltration

In the prior art, blocked isocyanates are widely used in the industry of coating materials, common isocyanate blocking agents mainly comprise oxime-based compounds, alcohol-based compounds, phenol-based compounds, beta-dicarbonyl compounds and other compounds, and the oxime-based compounds have characteristics of high reactivity, good storage stability and low unsealing temperature so as to be widely used. The invention discloses a new synthesis method of a blocking agent for isocyanate-based cross-linking agents, wherein the new synthesis method is a method for producing an oxime-based compound from a ketone-based compound. According to the new synthesis method, hydroxylamine sulfate is used as a raw material, and is added with butanone, acetone, cyclopentanone, cyclohexanone, butanedioneand 2-dioxocyclohexane solution in a dropwise manner in the presence of calcium hydroxide to prepare the product, wherein the reaction temperature is 20-130 DEG C, the reaction pressure is 0.05-0.3 MPa, and the reaction time is 2-15 h. According to the present invention, the new synthesis method has advantages of easily-available raw materials, simple process and equipment investment saving; themain component of the filtration residue is calcium sulfate so as to be industrially used, such that the advantages of economy, reasonability, VOC reducing and environmental protection are provided; and the conversion rate of the raw material is high, and the yield is increased.

Owner:SHENZHEN CHIBOOM TECH CO LTD

Hypothermal nontoxic phosphatization liquid containing accelerant of hydroxylamine sulfate, and preparation method

InactiveCN100339508CReduce pollutionGood for healthMetallic material coating processesNitriteHydroxylamine sulfate

A low temperature atomic phosphide liquor containing hydroxylamine sulfate accelerant is composed of HNO3: 10-15ml / L, H3PO412-18ml / L, ZnO 8-12G / l, CuSO4, 5H2O 0.6-1.0G / l, HAS 2.0-4.0g / L, Na2 MoO4 2H2o 0.03-0.05%g / L, NaC103 0.8-1.3G / l, C6H8O7. H2O 2.0-3.0g / L characterizing in taking hydroxylamine sulfate accelerant as the master accelerant matched with other additives.

Owner:大连理工大学技术转移中心有限公司

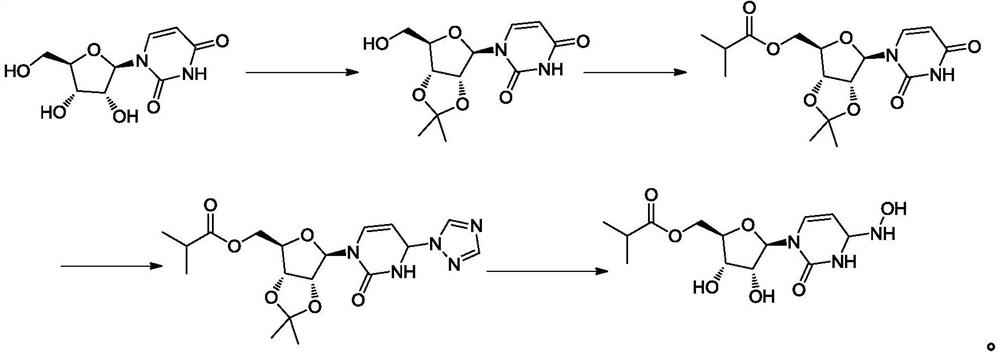

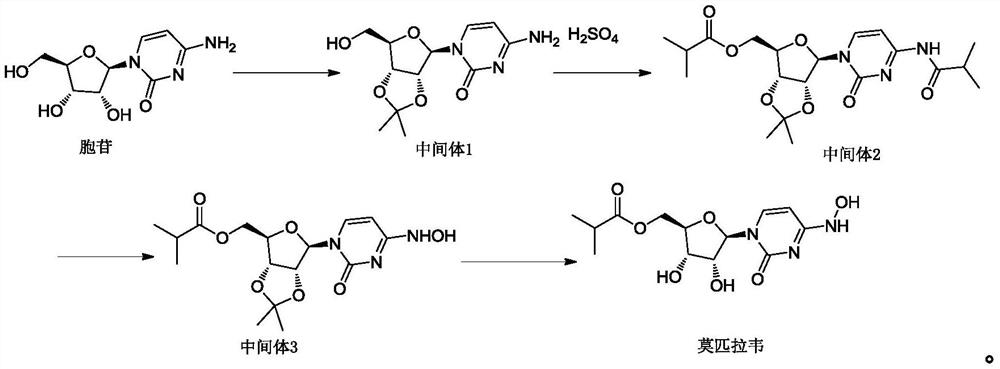

Preparation method of antiviral drug mupiravir

PendingCN114292303AReduce generationImprove route efficiencySugar derivativesAntiviralsAntiviral drugChemical compound

A preparation method of an antiviral drug mupiravir comprises the following steps: S1, synthesizing a compound 2: putting a compound 1 cytidine into a reaction container, and taking the compound 1 cytidine as a raw material; adding the solution 1 into the reaction container for replacement, and adding a protecting group DMF-DMA after three times of replacement; s2, synthesizing a compound 3; S3, synthesizing a compound 4; S4, synthesizing Molnupiravir: adding a solution 4 into a reaction system of the compound 4; the solution 4 comprises a reaction solvent and hydroxylamine sulfate; adding a pulping solvent into the intermediate 4, heating to 50 DEG C, and pulping for 30 minutes to obtain a product Molnupiravir; according to the preparation method, cytidine is taken as a starting raw material, DMF-DMA protecting groups are added, then esterification reaction, protecting group removal and hydroxyamination reaction are sequentially performed, a five-step one-pot method is realized, the route efficiency is effectively improved, the yield is increased, generation of three wastes is also effectively reduced, and the Molnupiravir with relatively high purity is obtained by finally purifying the system.

Owner:ANHUI HAIKANG PHARMA

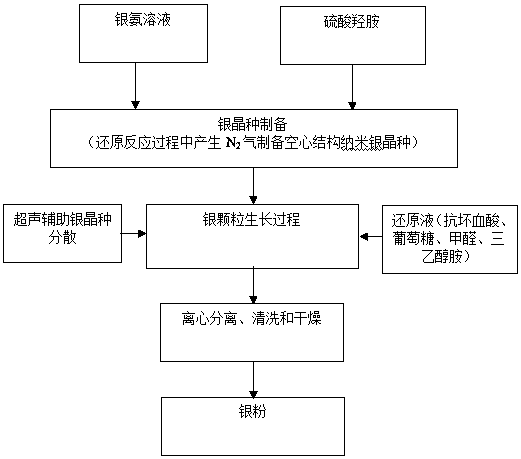

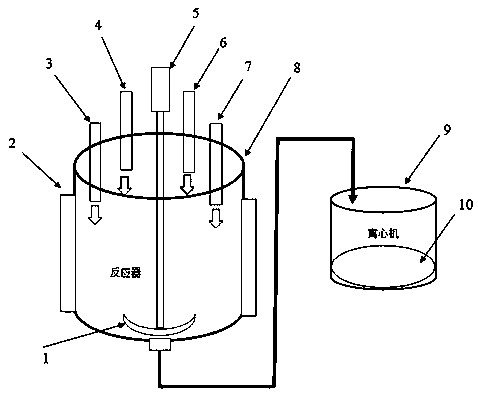

Preparation method of low-temperature sintered high-crystallinity silver powder

ActiveCN110102778ASolving the problem of mononuclear crystal growthSolving high sintering activationTransportation and packagingMetal-working apparatusMicro nanoHydroxylamine sulfate

The invention provides a preparation method of low-temperature sintered high-crystallinity silver powder, the preparation method comprises a process of obtaining metal silver particles from a silver ammonia solution by using a chemical reduction method in a reactor, the method comprises the following steps that a silver ammonia solution is used as an oxidizing agent, the hydroxylamine sulfate is used as a reducing agent, the hydroxylamine sulfate is added into the reactor in a jet flow mode to be fully mixed, micro-nano foams are formed in the solution environment by using N2 gas generated inthe reaction process, silver is deposited on the micro-nano foams, and a nano-silver seed crystal with a hollow structure is formed; then, one or more weak reducing agents are mixed and then are injected into the reactor, and meanwhile, an ultrasonic generator is adopted, reaction liquid in the reactor is dispersed through ultrasonic waves, so that the silver seed crystals are independently grownto form silver powder; and finally, the reaction liquid is carried out centrifugal separation, cleaning and drying to obtain the low-temperature sintered high-crystallinity silver powder. The production process is simple and stable, the production cost is low, the large-scale continuous industry can be realized, and the method can be widely applied to the production of various high-end conductivesilver paste.

Owner:上海镭立激光科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com