Low temperature and low foam electroplating degreasing additive agent

An additive and low-temperature technology, which is applied in the field of chemical cleaning and degreasing of metal materials, can solve problems such as unknown composition, increased material operating costs, and severe foam, and achieves low production costs, less foam, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments.

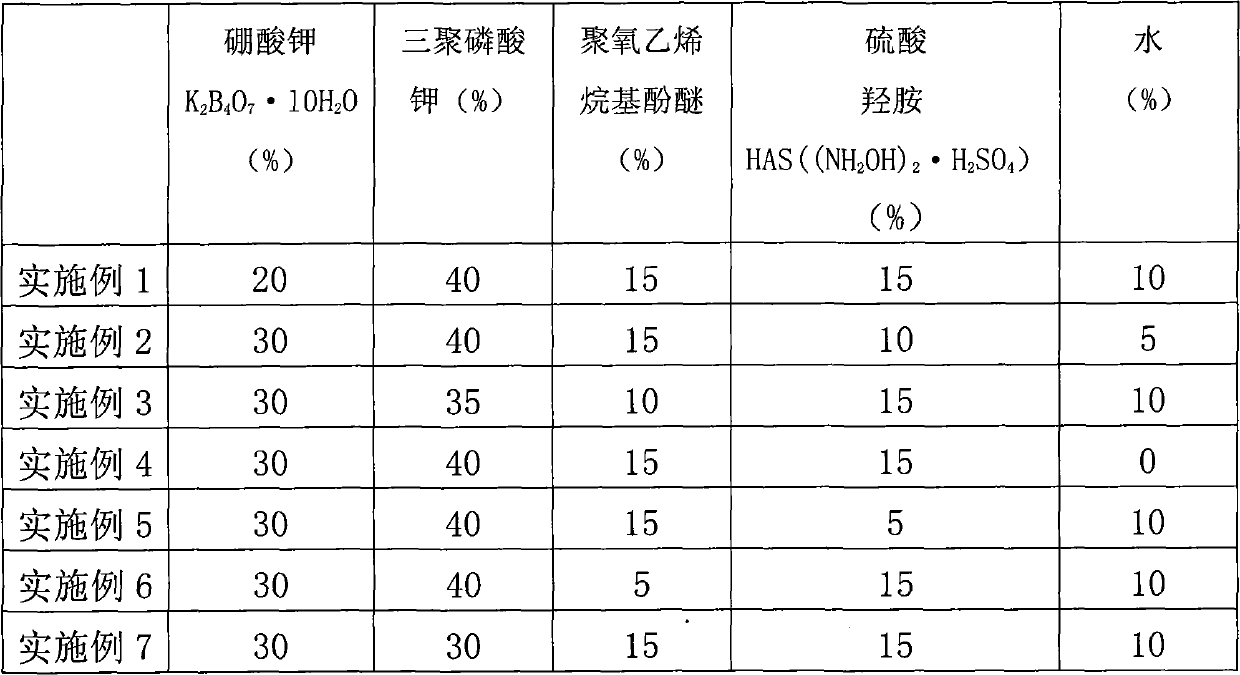

[0025] According to the present invention, 7 kinds of additives with different mass percentages of chemical components were produced, and comparative tests were carried out respectively. The specific formulations thereof are shown in Table 1.

[0026]

[0027] The chemical component mass percent of each additive in the embodiment of the present invention 1-7 in table 1

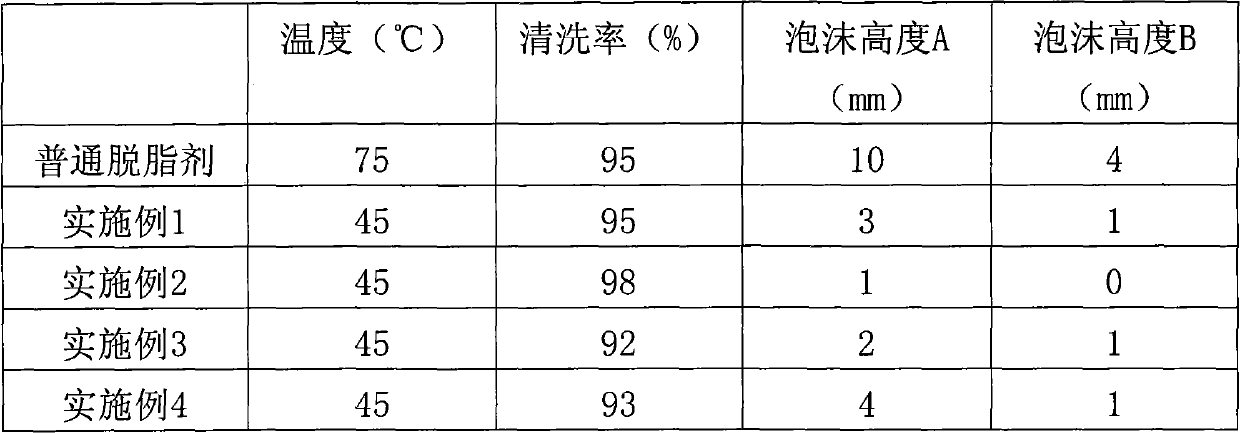

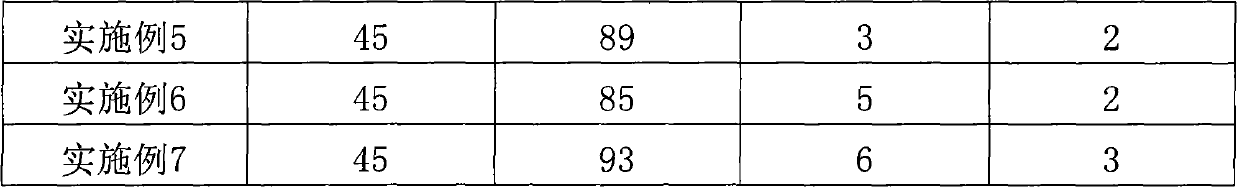

[0028] Table 2 shows the measurement results of the comparison test between the degreasing low-temperature low-foaming additive and the common degreasing agent in Examples 1-7 of the present invention.

[0029]

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com