Patents

Literature

387 results about "Polyoxyethylene alkyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

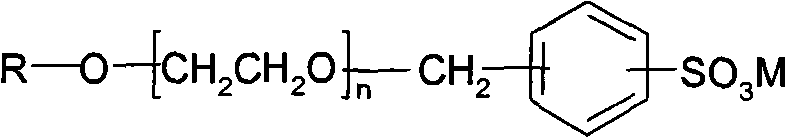

Polyoxyethylene alkyl ethers, CnEm, are nonionic surfactants made of an alkyl chain with n methylene groups and a hydrophilic part with m oxyethylene units. CnEm nonionic surfactants are very useful in chemical analysis. The commercially available products are often a mixture of several CnEm molecules with different m values.

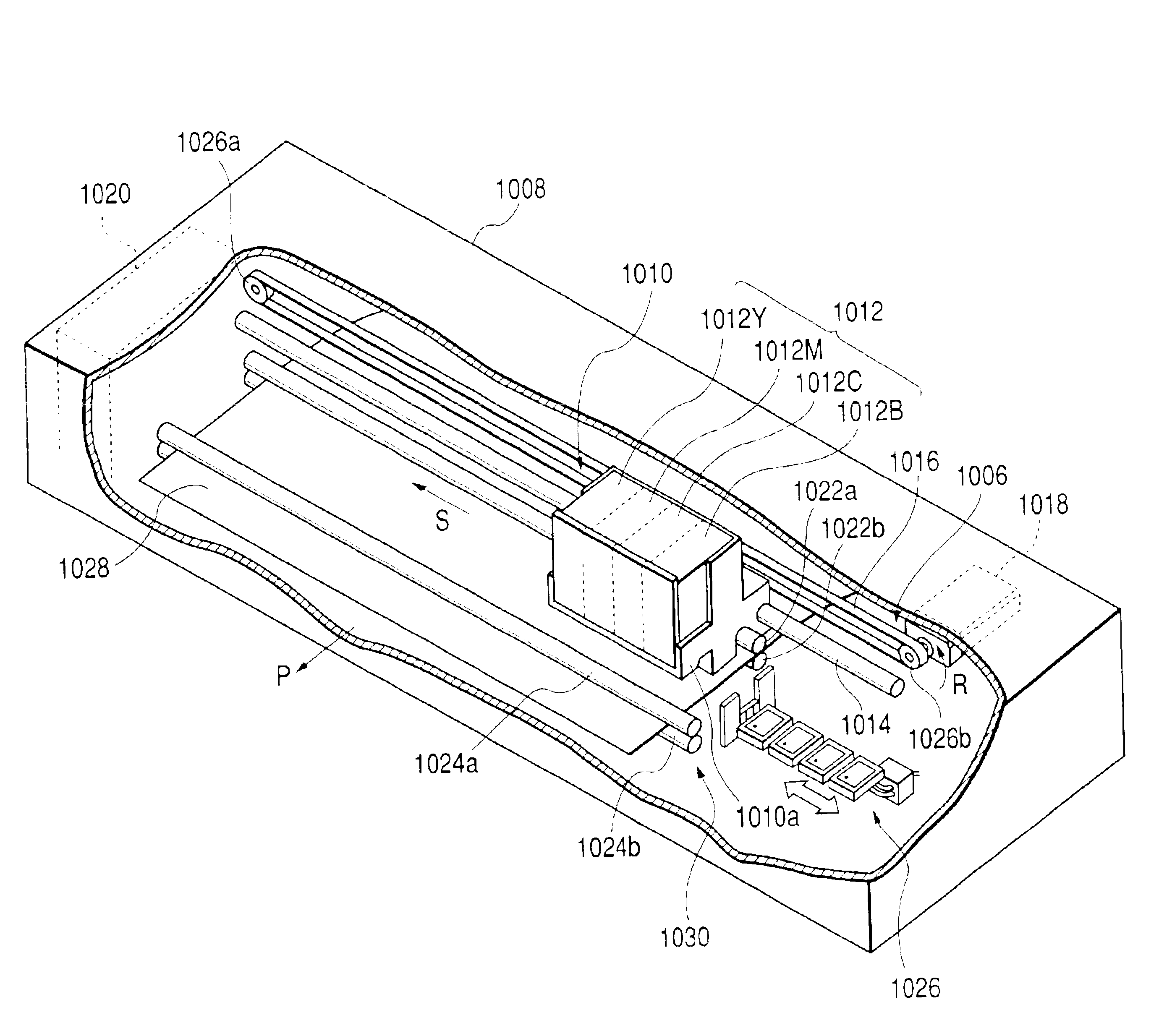

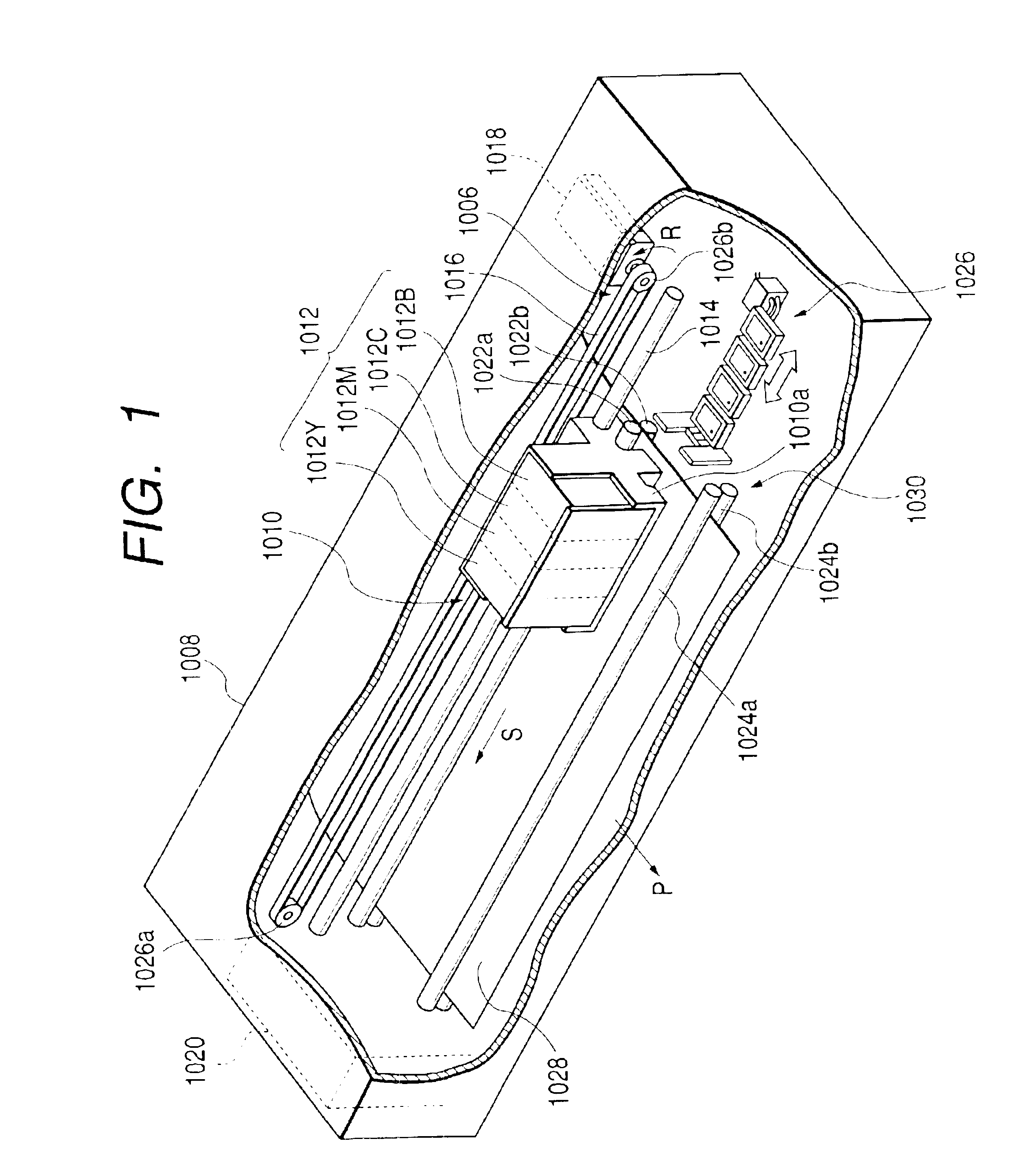

Ink, ink cartridge, recording unit, ink jet recording method, ink jet recording apparatus and method for stabilizing ink discharge

InactiveUS6874881B2Accurate imagingGood dispersionMeasurement apparatus componentsDuplicating/marking methodsWater insolubleEngineering

Provided is an ink-jet ink suitable for high speed printing and reduced ink ejection amount, wherein ink includes a water-insoluble coloring material dispersed in water with a resinous dispersant, glycerin, ethylene urea, and polyoxyethylene alkyl ether with HLB not lower than 13.

Owner:CANON KK

Anti-emulsification water-soluble metal washing agent

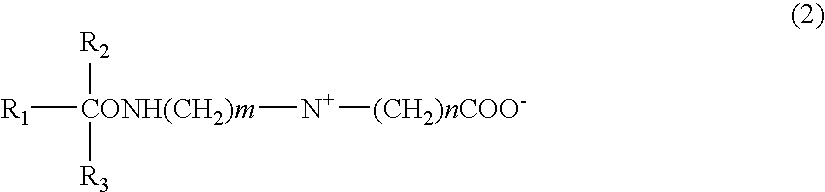

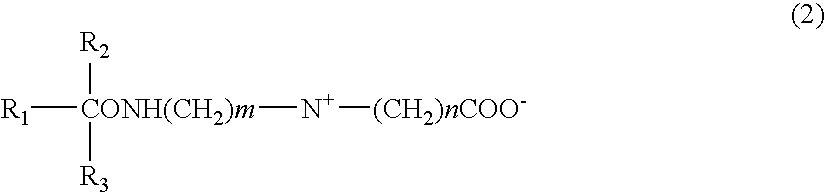

The invention relates to an anti-emulsification water-soluble metal washing agent. Every 100 parts of the anti-emulsification water-soluble metal washing agent include the following components according to parts by weight: 3-7 non-ionic surfactant, 3-7 bi-ion active agent, 1-5 chelator, 1-5 rust preventive, 5-10 inorganic builder and the balance water, wherein the non-ionic surfactant is any one of fatty amine polyoxypropylene ether, alkylphenol ether and fatty amine polyoxyethylene alkyl ether ammonium sulfate, the bi-ion active agent is any one of alkyl dimethylin acetic acid betaine, lauramidopropyl betaine and cocamidopropyl betaine, the chelator is any one of sodium citrate, ethylenediaminetetraacetic acid tetrasodium salt and nitrilotriacetic acid sodium salt, the rust preventive is any one of sodium borate, sodium nitrite, sodium benzoate and long carbon chain carboxylic acid amine, and the inorganic builder is any one of trisodium phosphate, sodium metasillcate, sodium carbonate, sodium bicarbonate and sodium hydroxide. The anti-emulsification water-soluble metal washing agent has the advantage of higher cleaning capacity and reutilization capacity.

Owner:NANJING KERUN LUBRICANTS

Nonionic surfactant foaming agents for foaming cosmetic compositions

InactiveUS6231844B1Stable and clear concentrationImprove production stabilityCosmetic preparationsHair removalFoaming agentEther

Cosmetic foaming compositions and hair mousse compositions employ a foaming agent comprising a mixture of first and second nonionic surfactants and having a total HLB as measured by the Griffin method of at least 12. The first nonionic surfactant is selected from defined polyoxyethylene alkyl ether surfactants, polyoxyethylene alkenyl ether surfactants, polyoxypropylene polyoxyethylene ether surfactants, and mixtures thereof; and the second nonionic surfactant is selected from defined polyoxyethylene long chain alkyl fatty acid or benzene ether surfactants, polyoxyethylene ether surfactants, polyoxypropylene ether surfactants, and mixtures thereof.

Owner:THE PROCTER & GAMBLE COMPANY

High solid content vinyl acetate-ethylene copolymer emulsion and method for synthesizing the same

ActiveCN101200518AReduce consumptionIncrease the conversion rate of the polymerization reactionMonocarboxylic acid ester polymer adhesivesSodium bicarbonatePhenol

The present invention relates to high solid content vinyl acetate-ethylene copolymer latex for binder and the synthetic method, including 55 to 75 portion of vinyl acetate, 24 to 45 portion of ethylene, 3 to 5 portion of N-methylol acrylamide, 2 to 4 portion of PVA1788 and PVA0588, 0.4 to 1.0 portion of the compound of nonionic emulsifying agent nonyl phenol polyoxyethylene alkyl ether and anion emulsifying agent alkyl sulphate with 2:1 mixture ratio, 0.2 to 1.0 portion of 35 percents oxydol with 1:1 mixture ratio, 0.05 to 0.4 portion of formol zinc sulphate, 0.1 to 0.5 portion of ferrous sulphate, 0.5 to 1.0 portion of regular dodeca-carbon thiol-alcohol, 0.05 to 0.35 portion of potassium phosphate, 0.1 to 0.5 portion of sodium bicarbonate and 45 to 55 portion of de-ionized water. With the adoption of latex polymerization, low-residual monomer VAE latex with solid content more than 65 percents is synthesized, which is used as binder to be applied in timber processing industry and packaging industry.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

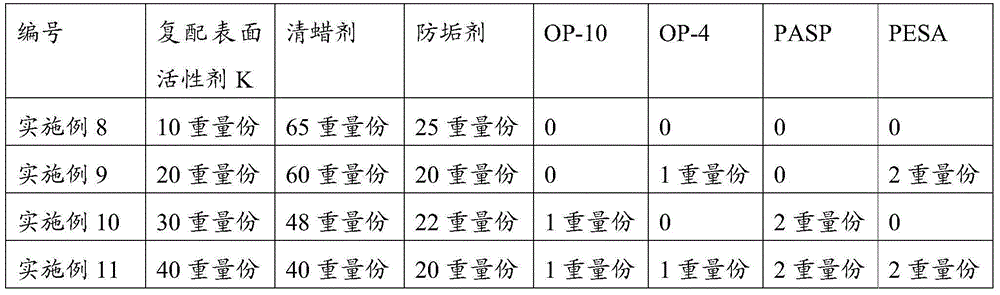

A soluble antiscale wax control ball

ActiveCN105441051ASolubleImprove wax removal effectDrilling compositionCarvacryl acetateCleansing Agents

A soluble antiscale wax control ball is disclosed. The soluble antiscale wax control ball comprises surfactants, wax cleaning agents and an antiscale agent RX-613. The surfactants comprise sodium alkylbenzenethiosulphonate, Ninol and polyoxyethylene alkyl ether. The wax cleaning agents comprise ethylene-vinyl acetate copolymer and polyethylene. The soluble antiscale wax control ball is advantaged by being soluble and having functions of preventing scaling and wax precipitation of pipelines, being capable of not blocking pipelines, and the like. The soluble antiscale wax control ball can dissolve old scale into crude oil and can prevent crude oil components from scaling onto walls of pipelines, and therefore problems of mechanical wax-cleaning antiscale balls at present, such as pipeline blockage and high running costs, which are caused by pipeline transfiguration, and the like are overcome. Experiment research shows that the soluble antiscale wax control ball can achieve wax-cleaning effects of rubber balls in site and has multiple functions comprising chemical wax cleaning and scale prevention, the comprehensive wax cleaning rate is 85.2%, and the antiscale rate is 82.18%.

Owner:PETROCHINA CO LTD

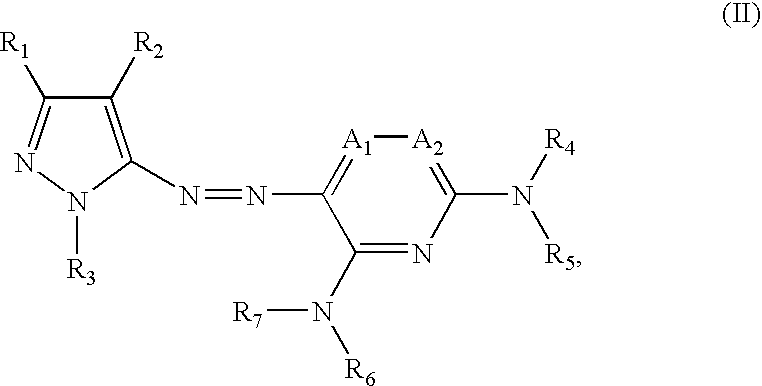

Liquid pesticide composition

InactiveUS6664213B1Improve biological effectGood storage stabilityBiocideDead animal preservationBULK ACTIVE INGREDIENTActive ingredient

A novel liquid pesticide composition comprising a pesticidally active ingredient and a polyoxyethylene alkyl ether which has the following features (a) and (b): (a) an HLB value of 6 to 13.5; and (b) a content of 10 to 50 wt % based on the liquid pesticide composition.

Owner:NISSAN CHEM IND LTD

Foaming agent composition used for high temperature and high salt oil reservoir

Owner:CHINA PETROLEUM & CHEM CORP +1

Foam drainage gas recovery method for natural gas horizontal well

InactiveCN102587865AThe effect of drainage and gas recovery is obviousSimple and safe operationFluid removalDrilling compositionRecovery methodPolyethylene glycol

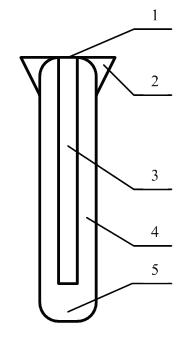

The invention relates to a foam drainage gas recovery method used for a natural gas horizontal well. The method is capable of injecting a foam scrubbing agent into the bottommost end of a gas well shaft, so that the whole shaft is filled with foam fluid and optimal drainage gas recovery effect is achieved. The technical scheme of the method comprises the following steps: firstly, manufacturing a dynamical underground foam scrubbing bar which consists of a gas nozzle, a tail wing, a boosting agent, a shell and a protection head sleeve, wherein the material for manufacturing the tail wing, the shell and the protection head sleeve is the solid foam scrubbing agent which consists of polyoxyethylene alkyl ethers, polyethylene glycol, urea, imidazoline, sodium dodecyl benzene sulfonate and saturated alcohol sulfate; and the boosting agent is one of dry ice, sodium hydride or potassium oxide; and secondly, throwing the dynamical underground foam scrubbing bar to the bottom of the well, wherein the boosting agent is in contact with water to generate a large amount of gas, so that the foam scrubbing bar is pushed to the bottommost end; and as the foam scrubbing agent is dissolved, a large amount of foam is formed to achieve the optimal effect of drainage gas recovery. The method disclosed by the invention has a wide application range without any wellhead equipment and energy, is simpleand safe in operation, low in cost and has no pollution to the environment.

Owner:SOUTHWEST PETROLEUM UNIV

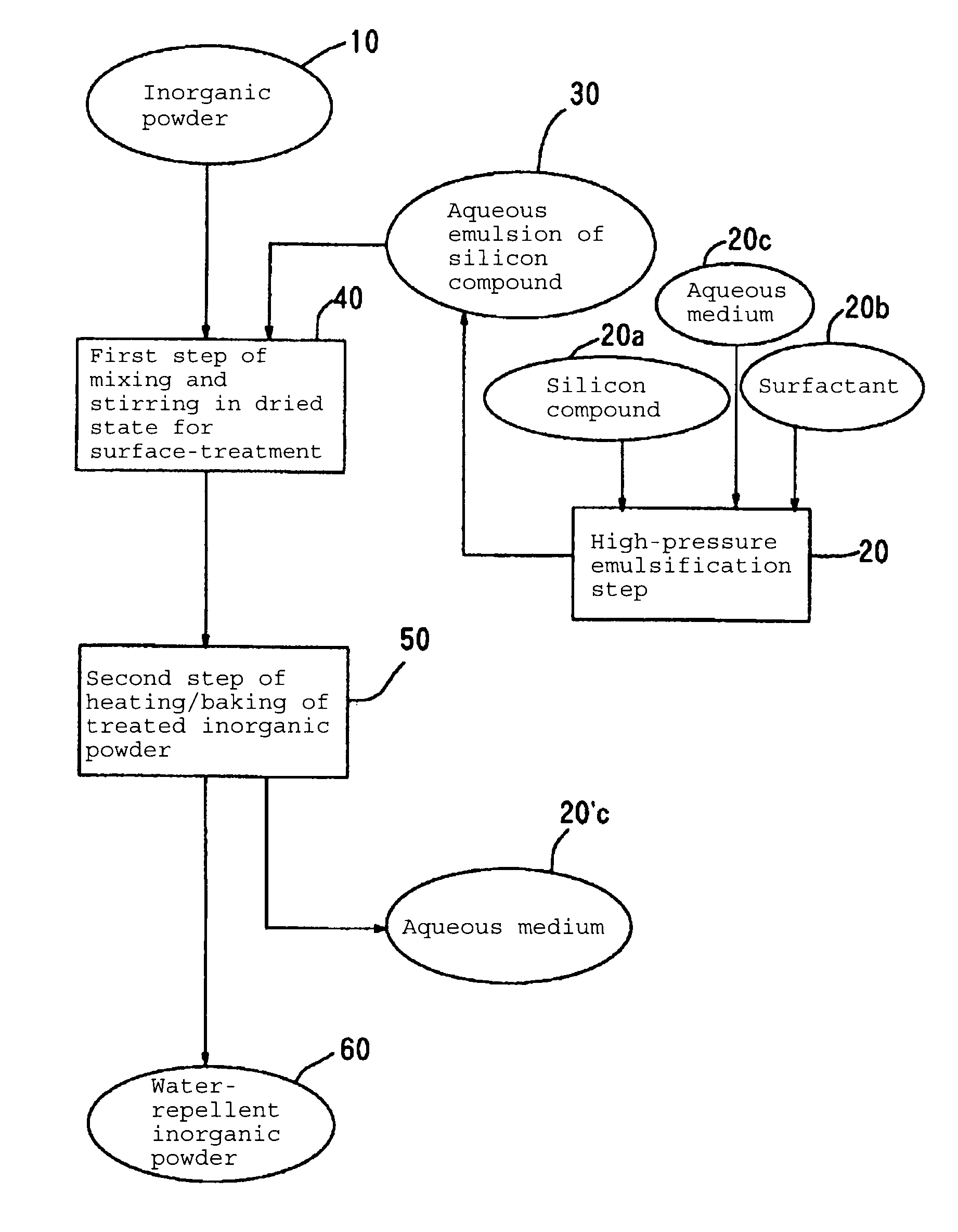

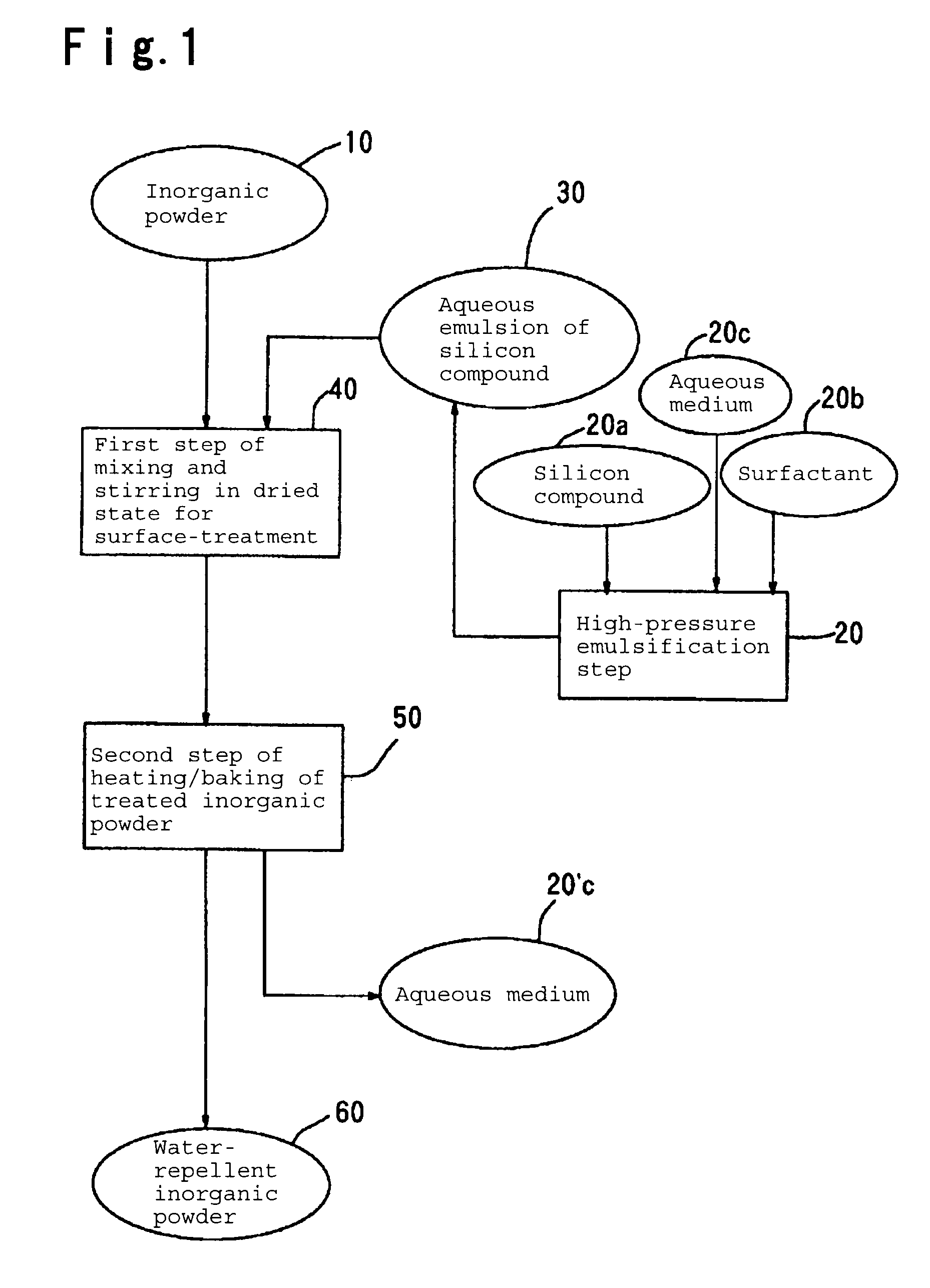

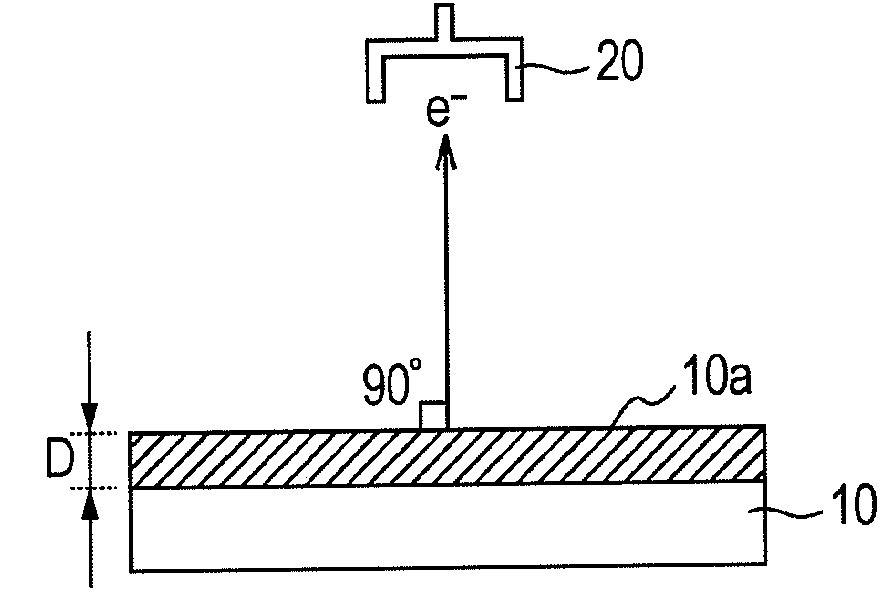

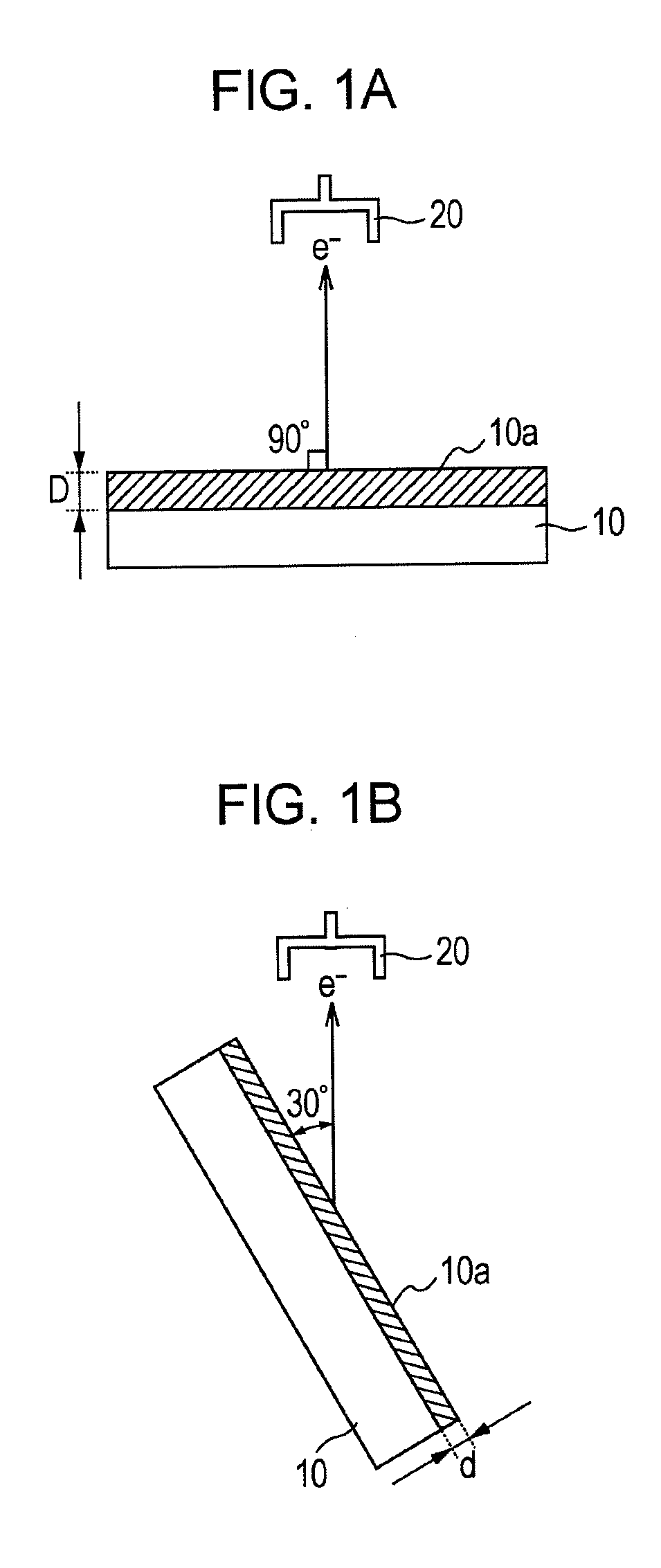

Water-repellent inorganic powder and process for its production

InactiveUS20080269358A1Stable water repellencyEffective treatmentMaterial nanotechnologySilicaEpoxyPolyethylene glycol

To provide a stable water-repellent inorganic powder which is substantially free from re-dissolution of a silicon compound used for surface treatment whether an organic solvent is polar or non-polar.A water-repellent inorganic powder which is surface-treated with a silicon compound, wherein the silicon compound is one having a group reactive with the inorganic powder, and when the inorganic powder is dispersed in any of polar organic solvents and non-polar organic solvents, the retention of the silicon compound is at least 90%. Preferably, the silicon compound is an aqueous emulsion of any of methylhydrogen silicone oil, alkoxy-modified silicone oil, amino-modified silicone oil, epoxy-modified silicone oil, polyether-modified silicone oil or carboxyl-modified silicone oil, and to the aqueous emulsion, at least one surfactant selected from the group consisting of a sorbitan fatty acid ester type, a polyoxyethylene sorbitan fatty acid ester type, a polyethylene glycol fatty acid ester type, a polyoxyethylene fatty acid ester type, an N-acylamino acid type, a polyoxyethylene alkyl ether type and a polyoxyethylene alkylphenyl ether type, is incorporated.

Owner:AGC SI TECH

Water-Based Ink Set For Ink-Jet Recording

ActiveUS20070186812A1Improves not recovery performanceImprove the problemDuplicating/marking methodsInksWater basedMagenta

Owner:BROTHER KOGYO KK

A water-based metal cleaning agent and a preparing method thereof

InactiveCN107779893AThe formula is scientific and reasonableStrong degreasing abilityWater basedSodium stearate

A water-based metal cleaning agent and a preparing method thereof are disclosed. The cleaning agent includes, by weight, 15-20 parts of polyoxyethylene alkyl ether, 15-20 parts of octylphenol polyoxyethylene ether, 10-12 parts of sodium citrate, 10-12 parts of sodium stearate, 10-15 parts of sodium dodecyl sulfonate, 8-15 parts of triethanolamine oleate, 15-20 parts of coconut fatty acid diethanolamide, 3-5 parts of sodium silicate, 3-5 parts of carboxymethylcellulose, 2-4 parts of a defoamer and 80-100 parts of water. The polyoxyethylene alkyl ether, the octylphenol polyoxyethylene ether, thesodium dodecyl sulfonate are firstly dissolved into the water, then the sodium citrate, the sodium stearate, the sodium silicate, the triethanolamine oleate, the coconut fatty acid diethanolamide andthe carboxymethylcellulose are added in order according to the ratio, the mixture is stirred until the mixture is in a semitransparent state, finally the defoamer is added into the mixture, and the mixture is fully stirred. The cleaning agent is scientific and reasonable in formula, high in cleaning power, safe, environmentally friendly, simple and convenient to operate and low in cost.

Owner:天佑京铁轨道技术有限公司 +1

Topical spray for burn treatment and anti-infection

InactiveUS6987133B2Function increaseReduce disadvantagesBiocideCosmetic preparationsCross-linkAntimicrobial drug

This invention relates to a topical spray preparation for burn treatment and microbial infections on human being or animals. This non-aerosol preparation contains an antimicrobial drug, i.e., silver sulfadiazine, as is dispersed or solubilized in a cream or lotion base matrix which can be sprayed directly from a common trigger spray device. The key component of the matrix can be characterized by it having a suitable molecular weight polymer of cross-linked acrylic acid, such as Carbomers or non-ionic surfactants such as polyoxyethylene alkyl ethers, or any combination of the above materials.

Owner:SAGE PHARMA

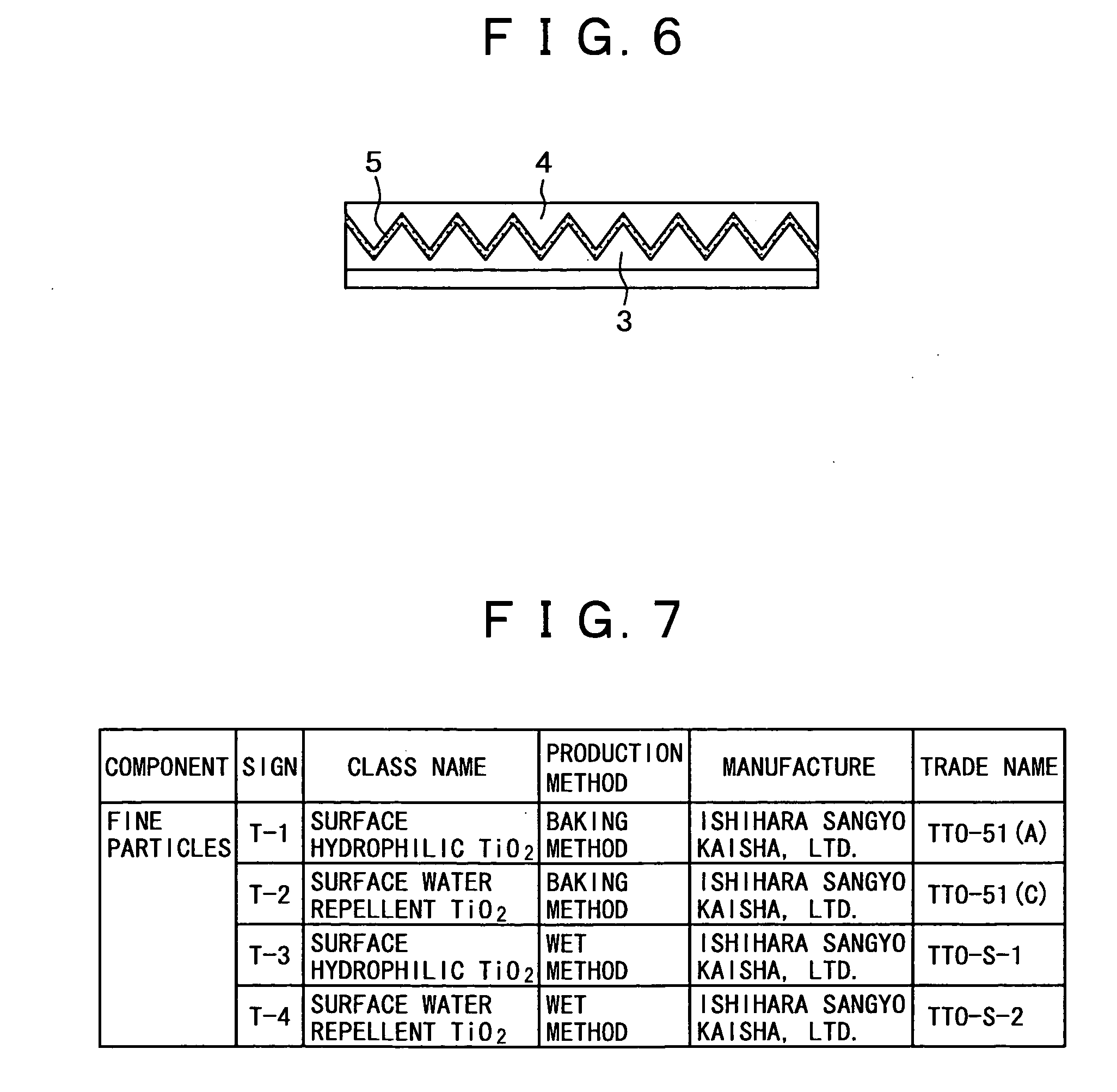

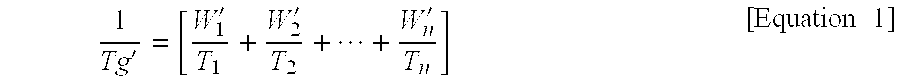

Fine particle dispersion composition, optical component, optical film laminate, polarization splitting device, and method for manufacturing the optical component

InactiveUS20050163971A1Avoid it happening againExcels in environmental durabilityLiquid surface applicatorsSynthetic resin layered productsO-Phosphoric AcidOrganic solvent

The invention provides a fine particle dispersion composition that does not depend on a curing method and that has adaptability to the curing methods and versatility and can provide a highly transparent optical component, an optical component using the fine particle dispersion composition and a method of manufacturing the same, and an optical film laminate using the optical component, and also provides a polarization splitting device using the optical component. In order to achieve the above, there is provided an optical component, which is obtained by curing a fine particle dispersion composition, which comprises metal-oxide fine particles, an organic resin material adapted to cure by absorbing energy, one of a polyoxyethylene alkyl ether phosphoric acid-based surfactant and a polyoxyethylene alkyl ether carboxylic acid-based surfactant, each of which has a molecular weight of 500 or more, and an organic solvent.

Owner:SONY CORP

Cleaning agent for treating oily sludge by using hot washing method and preparation method of cleaning agent

InactiveCN102826728AEasy to cleanHigh recovery rateSludge treatmentFatty/oily/floating substances removal devicesSludgeCleansing Agents

The invention relates to a cleaning agent for treating oily sludge by using a hot washing method and a preparation method of the cleaning agent. The cleaning agent comprises the following components in percentage by weight: 10-20 percent of polypropylene oxide and polyoxyethylene phenolic resin ether, 20-30 percent of sodium dodecyl benzene sulfonate, 1-5 percent of polyoxyethylene alkyl ether sulfate (AES), 5-10 percent of sodium hydroxide, 5-10 percent of methanol and the balance of water. The preparation method of the cleaning agent comprises the following steps of: adding the polypropylene oxide and polyoxyethylene phenolic resin ether and the sodium dodecyl benzene sulfonate into an enamel reactor; adding water under continuously stirring; gradually adding the AES after 30 minutes; continuously stirring for 60 minutes and then opening cooling water; continuously stirring and sequentially adding the sodium hydroxide and the methanol; and simultaneously stirring and cooling for 40 minutes. According to the cleaning agent, the double functions of demulsifying and cleaning are achieved, the separation effect of oil, water and sludge can be improved and oil in the hot washing water and oil in the finally-treated sludge are reduced.

Owner:PETROCHINA CO LTD +2

Emulsion for vibration damping materials

InactiveUS20070049697A1Good vibration reduction effectImproving skinning propertyOther chemical processesTransportation and packagingDiphenyl etherEmulsion

To provide an emulsion for vibration damping materials: excellent in vibration damping property in a wide temperature range, drying property, and mechanical stability; and capable of improving skinning property of the coating film surface. An emulsion for vibration damping materials, comprising an emulsion produced using an anionic emulsifier, wherein the anionic emulsifier is at least one selected from the group consisting of polyoxyethylene alkyl ether sulfate ester salts, alkyl diphenyl ether disulfonates, and alkenyl disuccinates, and a use amount of the anionic emulsifier is 1.0 part or more relative to 100 parts by weight of a total amount of a monomer component used for producing the emulsion.

Owner:NIPPON SHOKUBAI CO LTD

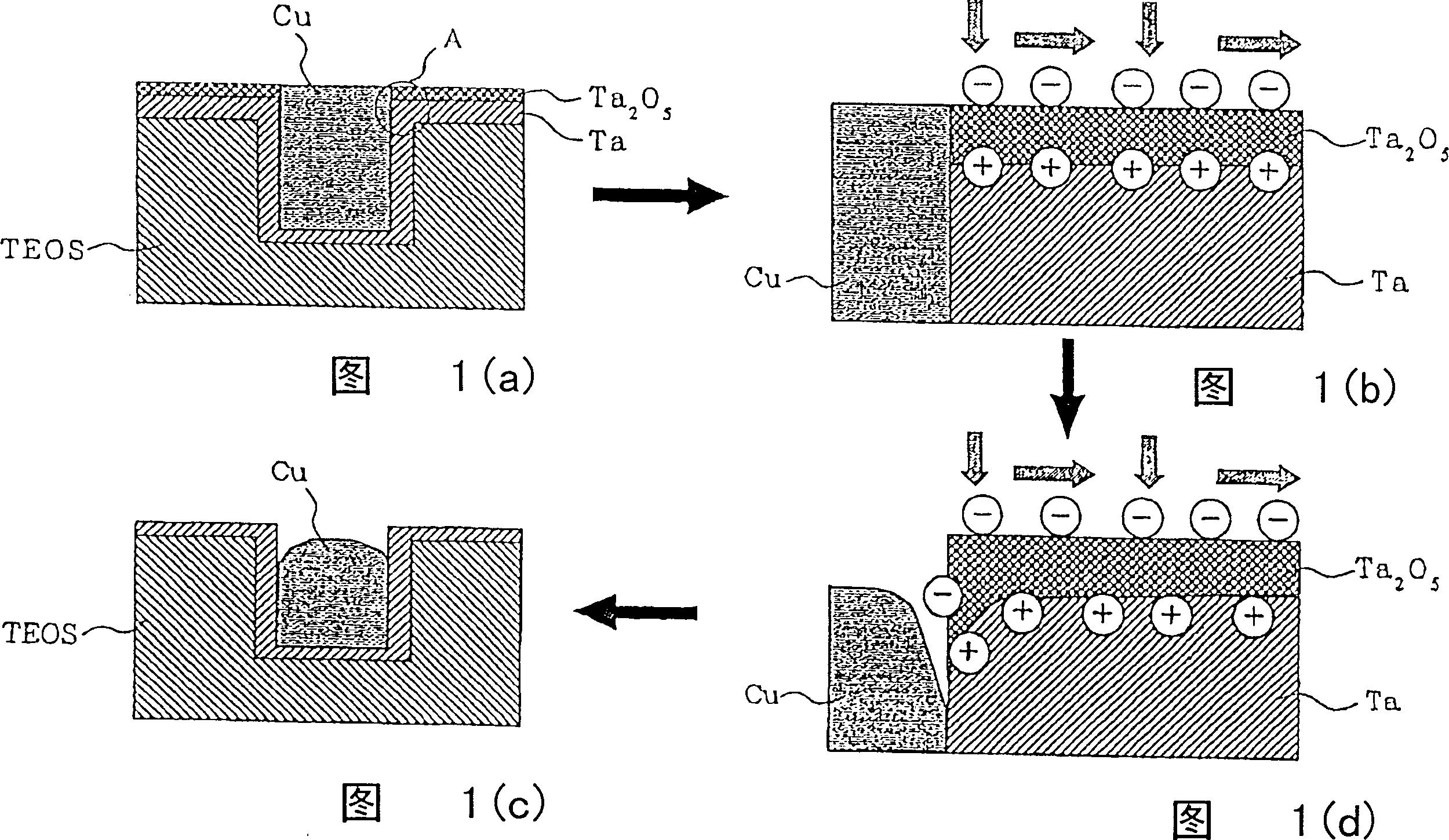

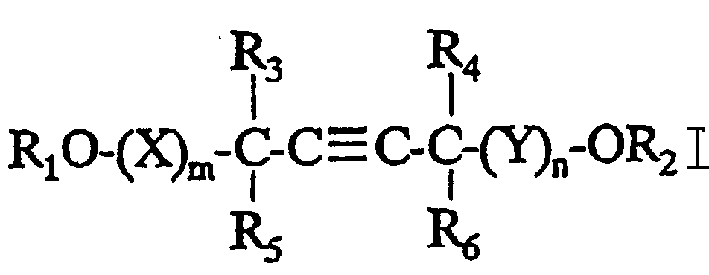

Polishing composition and its polishing method

InactiveCN1398939ADoes not impair the grinding rateOther chemical processesSemiconductor/solid-state device manufacturingPolyethylene oxideSilicon dioxide

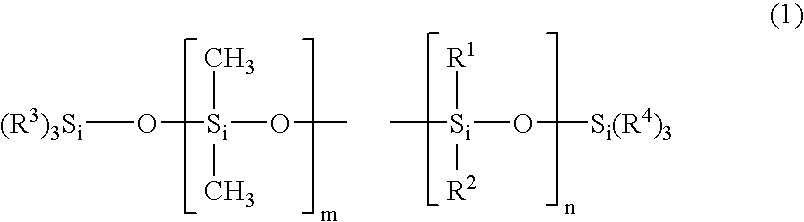

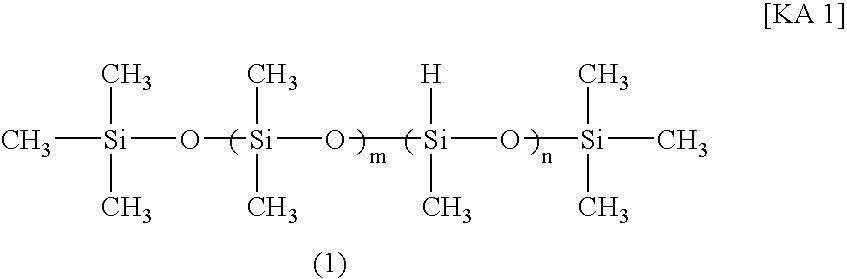

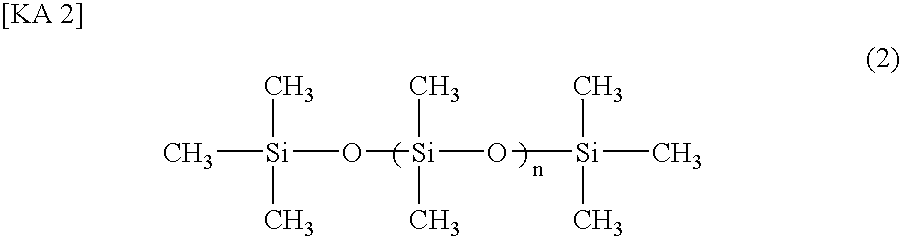

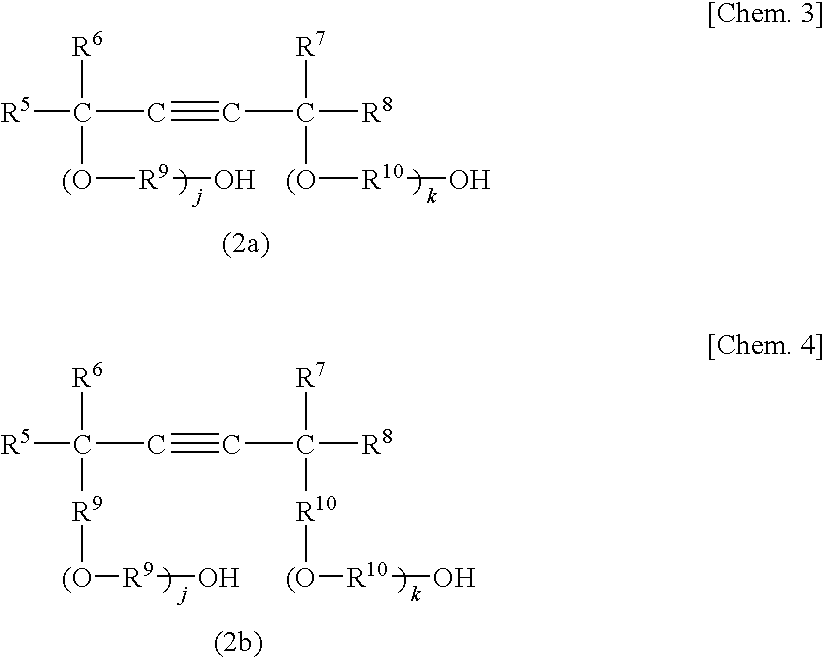

A polishing composition comprising: (a) at least one abrasive selected from the group consisting of silicon dioxide and aluminum oxide, (b) at least one organic compound selected from the group consisting of a polyethylene oxide, a polypropylene oxide, a polyoxyethylene alkyl ether, a polyoxypropylene alkyl ether, a polyoxyethylenepolyoxypropylene alkyl ether and a polyoxyalkylene addition polymer having a C IDENTICAL C triple bond, represented by the formula (1): <CHEM> wherein each R1 to R6 is H or a C1-10 alkyl group, each X and Y is an ethylene-oxy group or a propylene-oxy group, and each of m and n is a positive number of from 1 to 20, (c) at least one polishing accelerating compound selected from the group consisting of citric acid, oxalic acid, tartaric acid, glycine, alpha -alanine and histidine, (d) at least one anticorrosive selected from the group consisting of benzotriazole, benzimidazole, triazole, imidazole and tolyltriazole, (e) hydrogen peroxide, and (f) water.to

Owner:FUJIMI INCORPORATED

Biological enzyme deinking method for waste paper

InactiveCN1594729AIncrease the reaction concentrationHigh catalytic efficiencyFats/resins/pitch/waxes removal in pulpPaper recyclingFiltrationSewage

Provided is a biological enzyme deinking method for waste paper, in which flotation applies polyoxyethylene alkyl ether as flotation auxiliary, deinking process applies compound enzyme as deinking agent. The method improves the white content of the regenerated pulp by chemistry method, which is enhanced to 5-8% higher, and the COD value of the discharged sewage reduced more than 60%. The paper pulp filtration performance is further increased and the strength is similar, thus it can meet requirement of making different papers.

Owner:ENZYME ENG INST SHAANXI PROVINCE ACAD OF SCI

Fluoropolymer dispersion and electrode composition containing same

InactiveUS7659335B2Improve stabilityHigh viscosityCell electrodesFilm/foil adhesivesFluoropolymerSURFACTANT BLEND

A composition comprising an aqueous dispersion of fluoropolymer particles stabilized with a polyoxyethylene alkyl ether surfactant having a polydispersity index, Mw / Mn, of 1.15 or less, useful in compositions comprising electrode material.

Owner:DUPONT MITSUI FLUOROCHEMICALS CO LTD

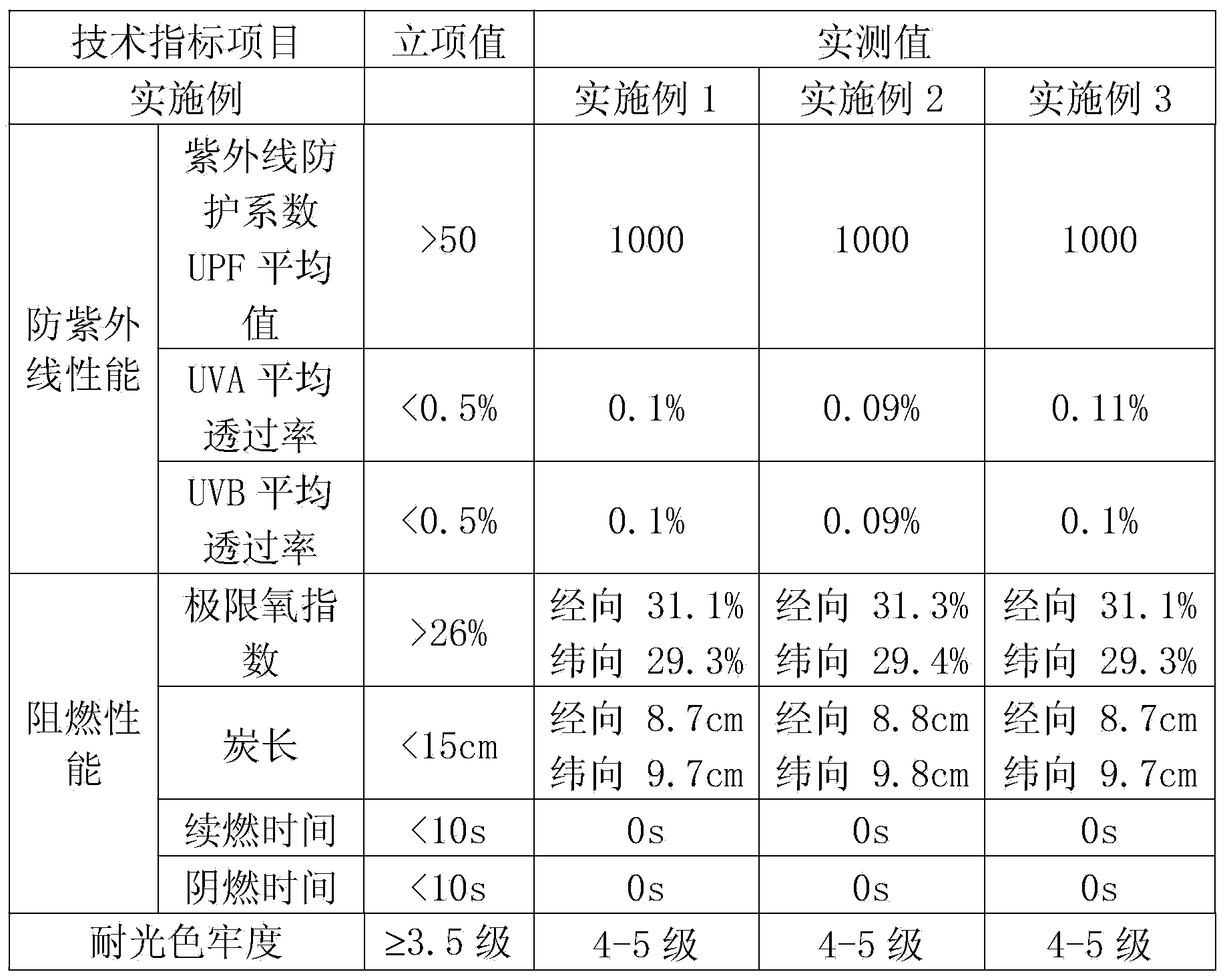

Production process for anti-ultraviolet flame-retardant light-resistant curtain shell fabric

The invention discloses a production process for an anti-ultraviolet flame-retardant light-resistant curtain shell fabric. The production process comprises the following steps: mixing and spinning flame-retardant polyester fiber, polyacrylonitrile fiber, refined sulfur cotton and flame-retardant nylon into yarns; spinning the yarns into a semi-finished shell fabric; padding the semi-finished shell fabric into a finishing solution for padding, and then drying and cooking the semi-finished shell fabric to obtain a finished curtain shell fabric, wherein the finishing solution comprises a coating, a Gemini cationic softener, a flame retardant, a micro-nano-oxide, polyoxyethylene alkyl ether sulfonates succinate and the like; the flame retardant is obtained by synthesizing trimethylolpropane, trimethyl phosphate and trimethyl phosphate in the molar ratio of 1:1:1; and the Gemini cationic softener is obtained by synthesizing stearyl amidopropyl dimethyl amine and bis(2-chloroethyl) ether in the molar ratio of 2:1. The curtain shell fabric prepared by the method has high ultraviolet resistance, high light resistance and high flame retardant performance.

Owner:ZHEJIANG HUIDE NEW MATERIAL

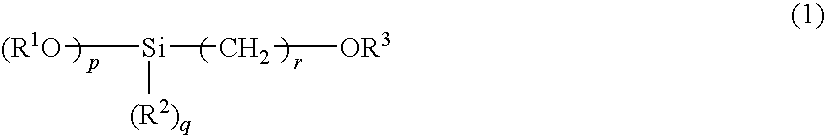

Water-resistant aluminum pigment, water-resistant aluminum pigment dispersion, aqueous ink composition containing the aforementioned, and method for producing water-resistant aluminum pigment dispersion

InactiveUS20100251929A1Good water dispersibilityAvoid whiteningMaterial nanotechnologyDuplicating/marking methodsOrganic solventPhosphate

A method for producing a water-resistant aluminum pigment dispersion includes (a) adding a treatment agent containing a compound of general formula (1) described below to an aluminum pigment dispersion containing aluminum pigment particles dispersed in an organic solvent and reacting a hydroxy group present on a surface of each of the aluminum pigment particles with the compound of general formula (1) described below to form a film on the surface of each aluminum pigment particle, (b) removing at least a portion of the organic solvent, and (c) adding an aqueous solution containing at least one selected from polyoxyethylene alkyl ether phosphate and salts thereof,(wherein p represents an integer of 1 to 3, q represents an integer that satisfies the equation p+q=3, r represents an integer of 2 to 10, R1 and R2 each independently represent an alkyl group having 1 to 4 carbon atoms, and R3 represents an acrylic group, an acryloyl group, or a methacryloyl group).

Owner:SEIKO EPSON CORP

Ultrahigh-toughness concrete and production method thereof

The invention discloses an ultrahigh-toughness concrete and a production method thereof. The ultrahigh-toughness concrete is produced by proportionally mixing Portland cement, slag aggregate, steel fiber, silicon powder, flyash beads, lithium salt residue, latex, rubber powder, a nano waterborne binder, graphene-modified glass fiber, trimethylolpropane, sulfoaluminate clinker, a defoaming agent, polyoxyethylene alkyl ether, p-toluenesulfonic acid, nano silicon particles, nano calcium carbonate, elastic silicone acrylic emulsion, methyl N,N-dihydroxyethyl-3-aminopropanoate, water and a polycarboxylate superplasticizer. The ultrahigh-toughness concrete produced herein has high compressive strength, high tensile strength and lasting ultrahigh ductility and has good energy-dissipating capacityand elastic modulus.

Owner:TANGSHAN COLLEGE

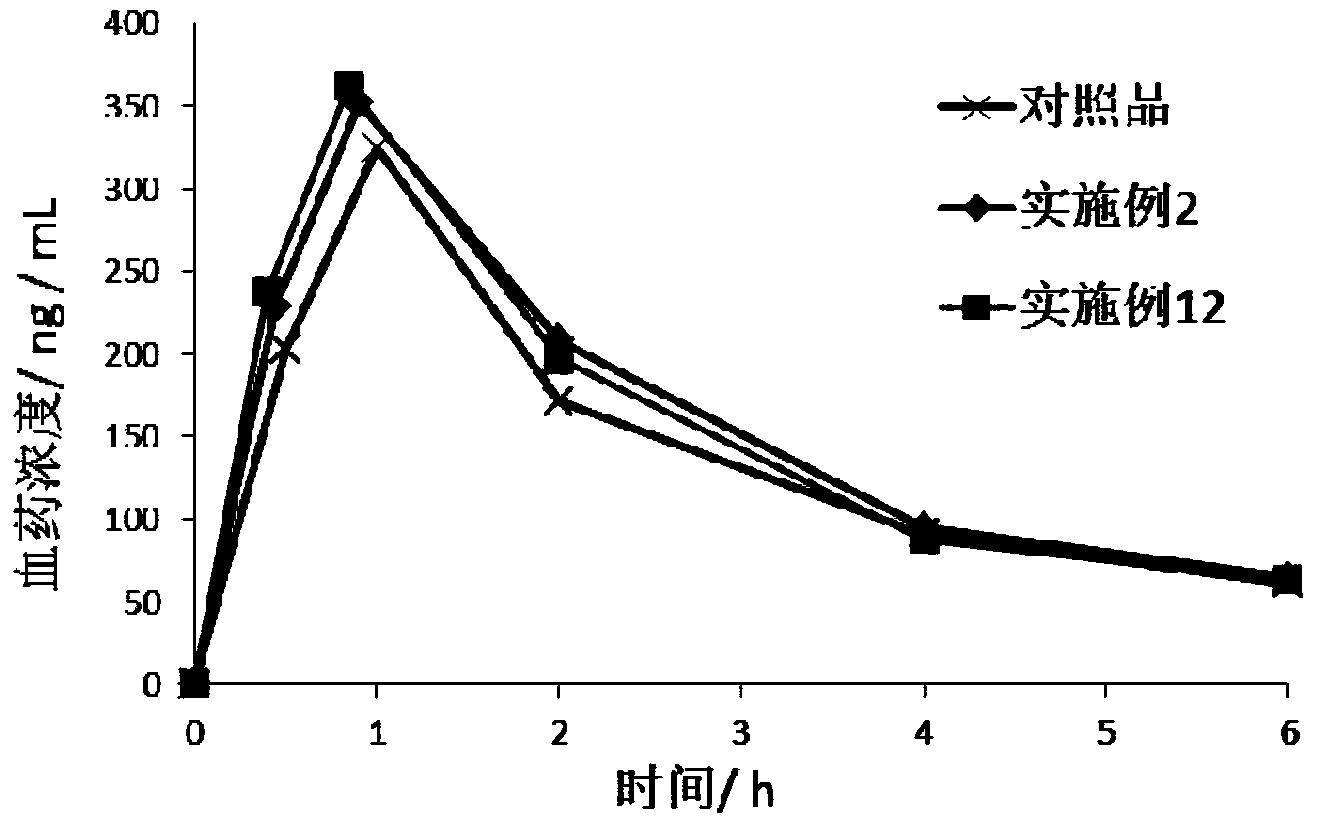

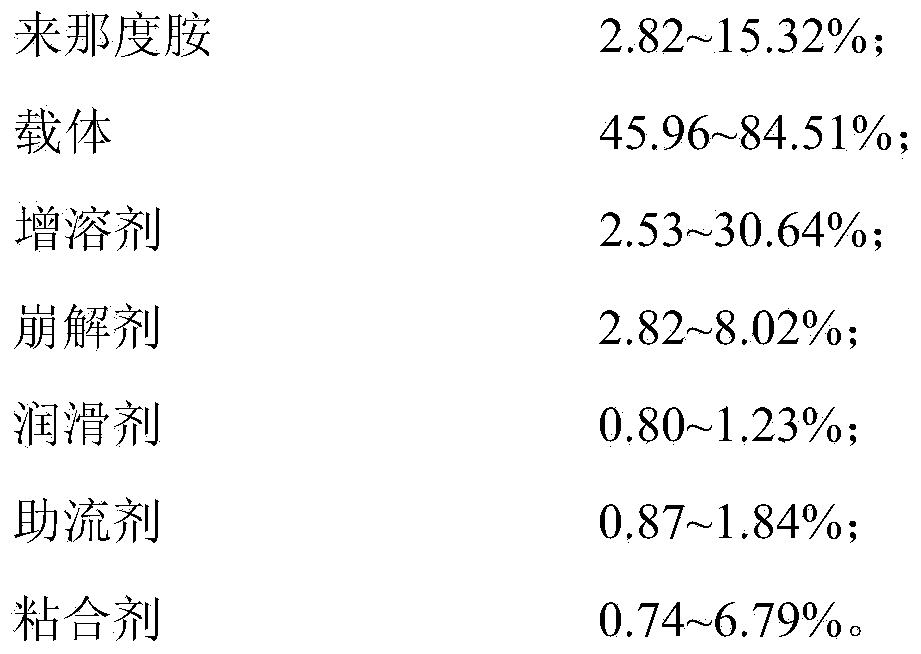

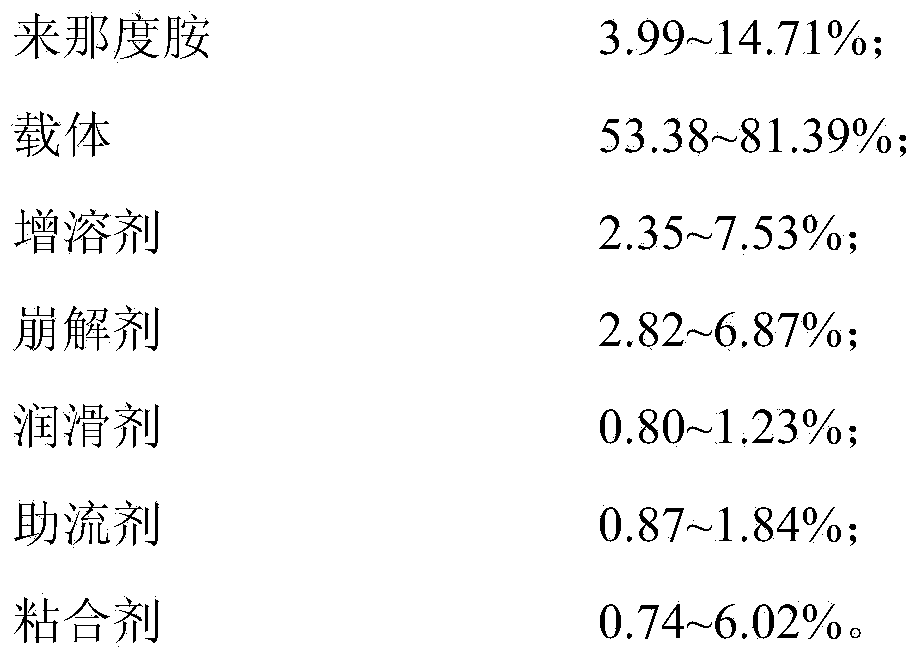

Composite for treating myelodysplastic syndrome and preparation method thereof

ActiveCN103705485ASimple granulation processControllable flyingOrganic active ingredientsPill deliverySolubilityAdhesive

The invention discloses a composite for treating myelodysplastic syndrome. The composite comprises the following components: lenalidomide, a carrier, a solubilizing agent, a disintegrating agent, a lubricating agent, a flow aid and an adhesive, wherein the carrier is a mixture of any one or several of a high-molecular water-soluble polymer, a water-soluble small molecule compound, a hydrophilic auxiliary material and an inorganic carrier; the solubilizing agent is a mixture of one or several of lauryl sodium sulfate, poloxamer, beta. cyclodextrin and a derivative thereof, polysorbate and polyoxyethylene alkyl ether. The invention also provides a preparation method of the composite, and the preparation method comprises the steps of grinding, mixing, dry granulation, total mixing and tabletting or capsule filling. The preparation method disclosed by the invention effectively enhances the water solubility and bioavailability of the lenalidomide; the dry granulation preparation process simplifies the preparation steps, reduces the cost, saves the energy resources, reduces the labor expenditure and realizes the energy conservation and environment protection in production.

Owner:AC PHARMA CO LTD

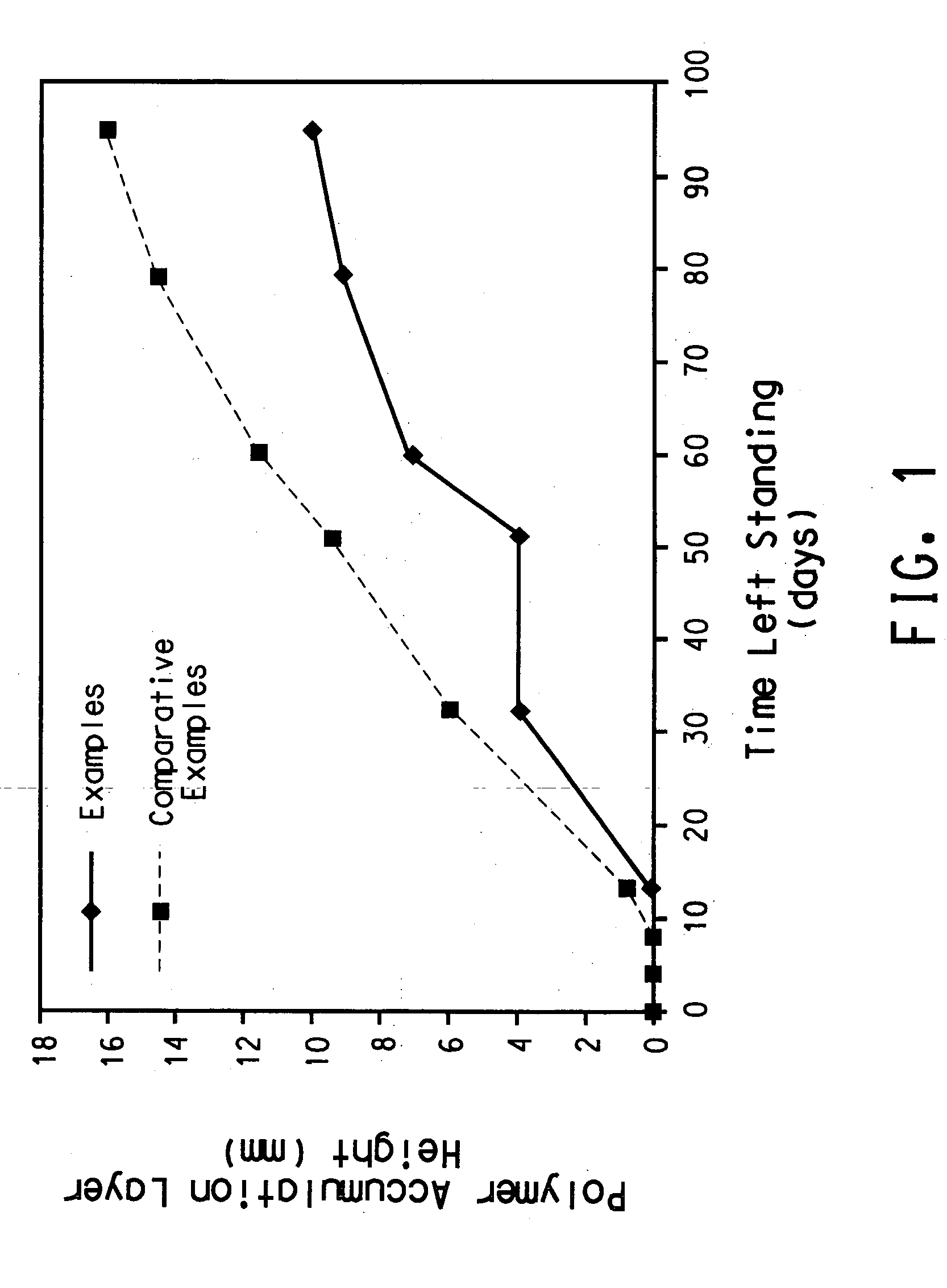

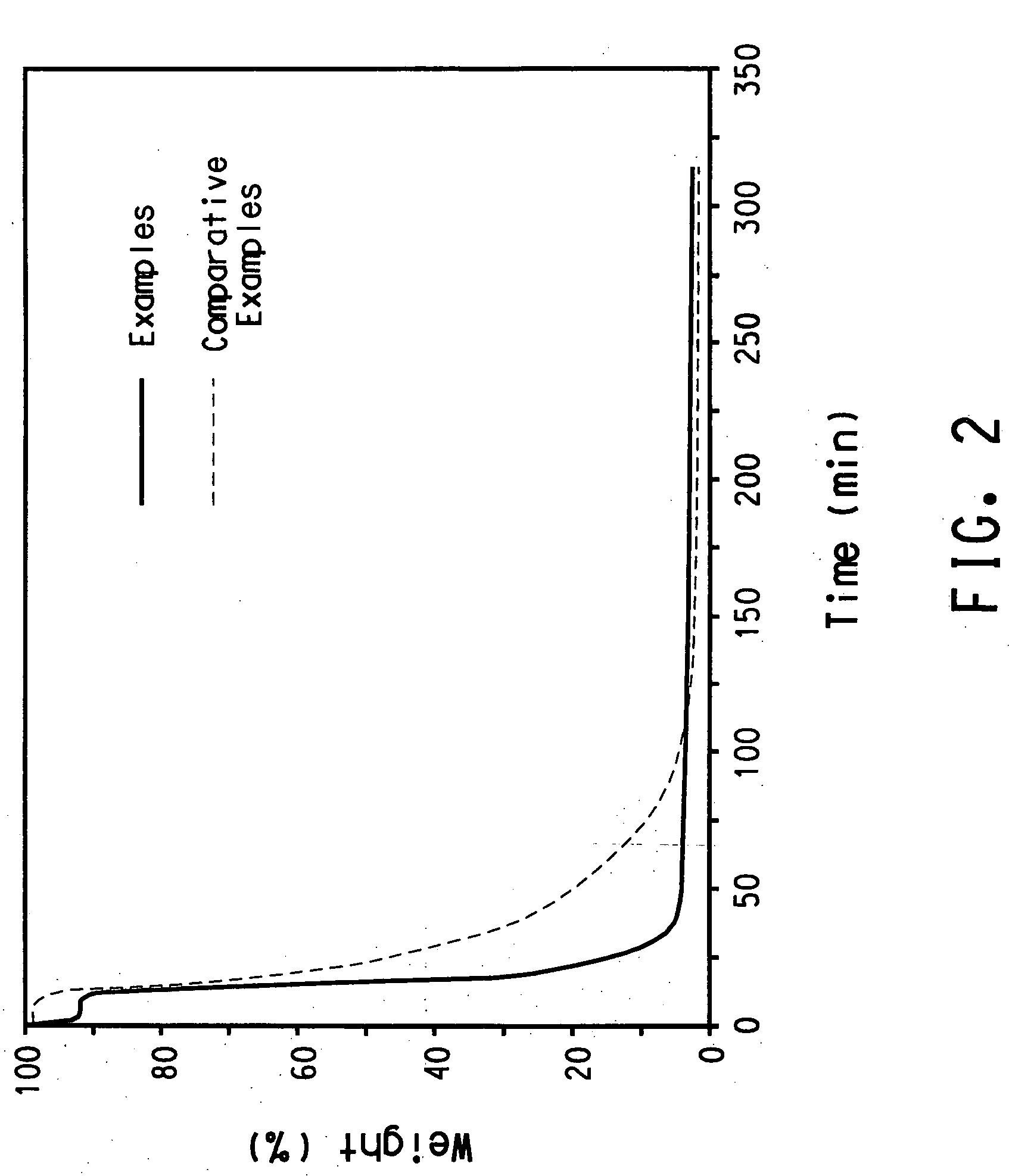

Fluoropolymer dispersion and electrode composition containing same

InactiveUS20060078800A1Good for volatilizationSuperior sedimentation stabilityCell electrodesFilm/foil adhesivesFluoropolymerSURFACTANT BLEND

A composition comprising an aqueous dispersion of fluoropolymer particles stabilized with a polyoxyethylene alkyl ether surfactant having a polydispersity index, Mw / Mn, of 1.15 or less, useful in compositions comprising electrode material.

Owner:DUPONT MITSUI FLUOROCHEMICALS CO LTD

Method of determining substrate contained in hemoglobin-containing sample

InactiveUS20070154976A1Accurate measurementReduce distractionsMicrobiological testing/measurementBiological testingActive agentSuccinic acid

The present invention provides a convenient, efficient method for determining a substrate contained in a hemoglobin-containing sample and a reagent therefor, which can be employed for a variety of automatic analyzers while reducing interference of hemoglobin contained in the sample. A method for determining a substrate contained in a hemoglobin-containing sample through reaction of an oxidase with the substrate and optical measurement of the produced hydrogen peroxide by use of a peroxidase and an oxidizable color producing reagent, characterized in that the hemoglobin-containing sample is treated with an anionic surfactant selected from among a polyoxyethylene alkyl ether sulfate salt, a polyoxyethylene alkylphenyl ether sulfate salt, a polyoxyethylene alkyl ether phosphate, a polyoxyethylene alkyl sulfosuccinate, a polyoxyethylene alkyl ether carboxylate salt, a polyoxyethylene alkyl ether sulfonate salt, triethanolamine lauryl sulfate, an alkyl sulfosuccinate, and an alkylphenyl ether sulfonate salt.

Owner:SEKISUI MEDICAL CO LTD

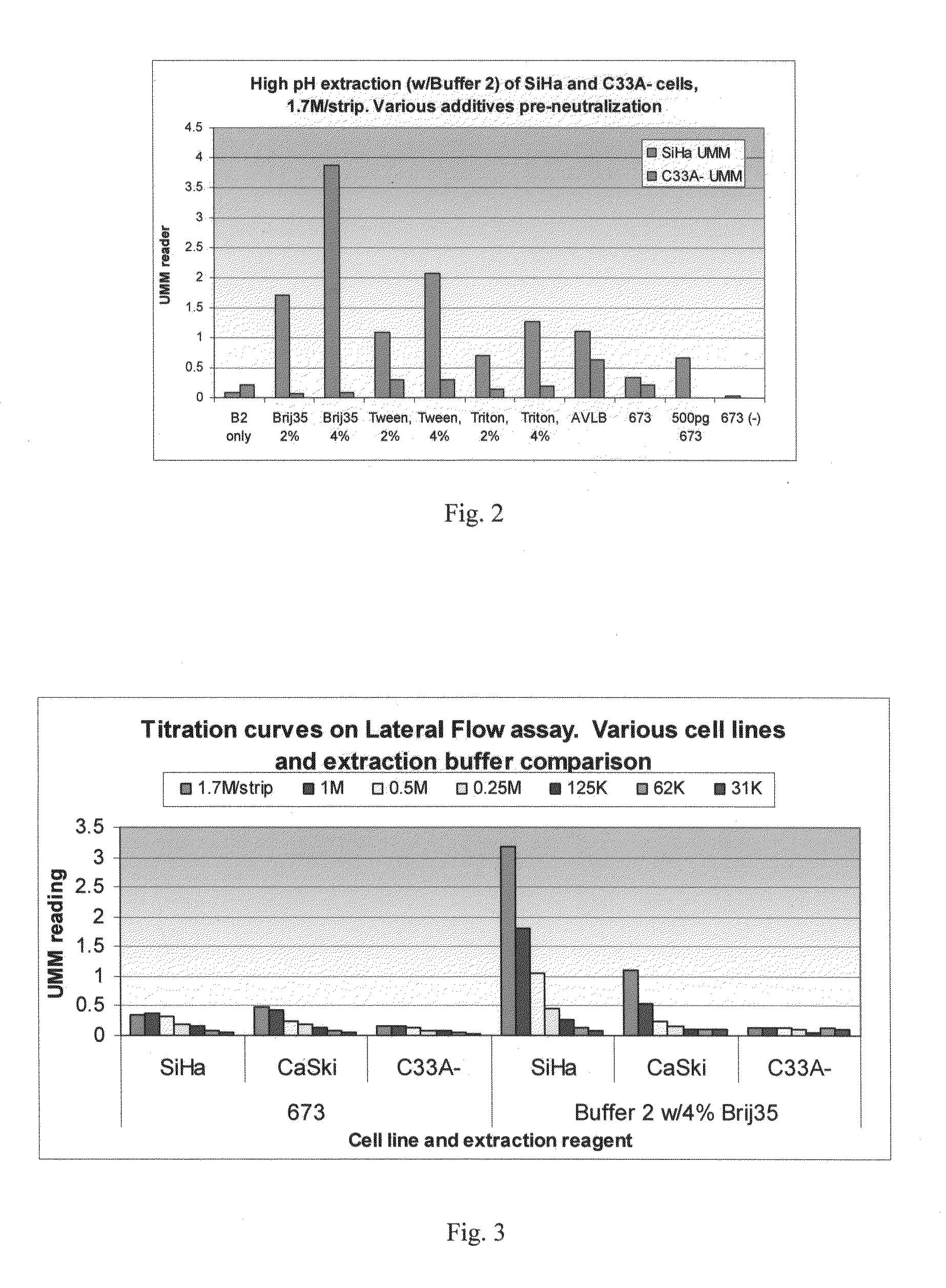

Method of efficient extraction of protein from cells

ActiveUS20090123910A1Microbiological testing/measurementPreparing sample for investigationProtein targetIntermediate composition

Methods for producing a protein extract from cells, such as cells or cellular samples containing viral proteins, are provided. In general terms, the methods may involve: increasing the pH of the cells to a pH of at least about pH 10.0 to produce an intermediate composition, and then, in the presence of a non-ionic detergent such as a polyoxyethylene alkyl ether, neutralizing the pH of the intermediate composition to produce the protein extract. Such methods can be used in conjunction with methods for detecting one or more target proteins in a sample, such as viral proteins. Systems, kits and compositions for practicing the subject methods are also provided.

Owner:ARBOR VITA CORP +1

Oil-Based White Ink for Ink Jet Recording

ActiveUS20080194754A1Improve anti-settling performanceEasy to demouldMeasurement apparatus componentsDuplicating/marking methodsOrganic solventPhenyl Ethers

The present invention relates to an ink jet ink which is an oil-based white ink for ink jet recording containing (a) titanium oxide having an average particle size of 0.15 to 0.25 μm, (b) a resin, (c) an organic solvent and (d) a nonionic surfactant, wherein the nonionic surfactant comprises at least one member selected from polyoxyethylene alkyl ethers and polyoxyethylene phenyl ethers. According to the invention, there can be provided an oil-based white ink for ink jet recording which is excellent in ejection stability and in recovery properties after standing for a long period of time.

Owner:SEIKO EPSON CORP +1

Electroless plating liquid

InactiveUS20090088511A1Improve stabilityUniformly formedConductive materialSemiconductor/solid-state device manufacturingPhosphoric Acid EstersTectorial membrane

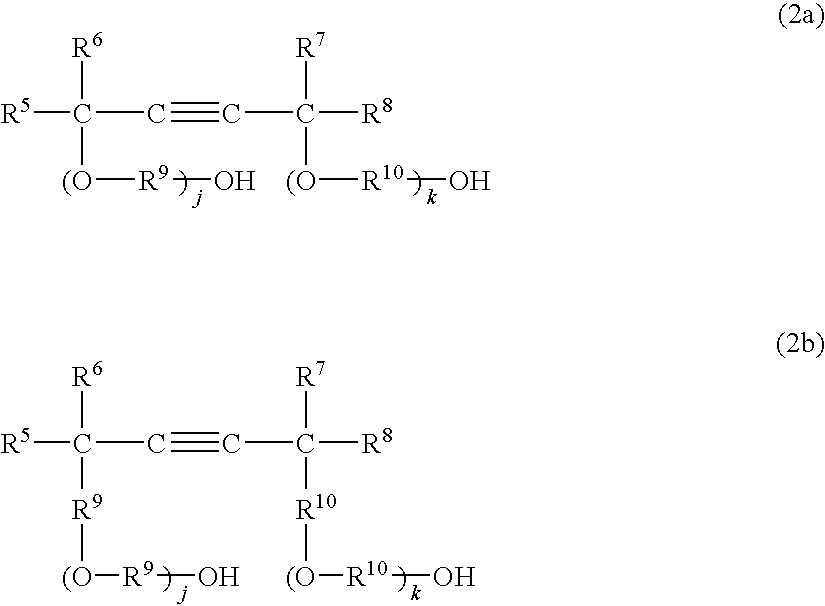

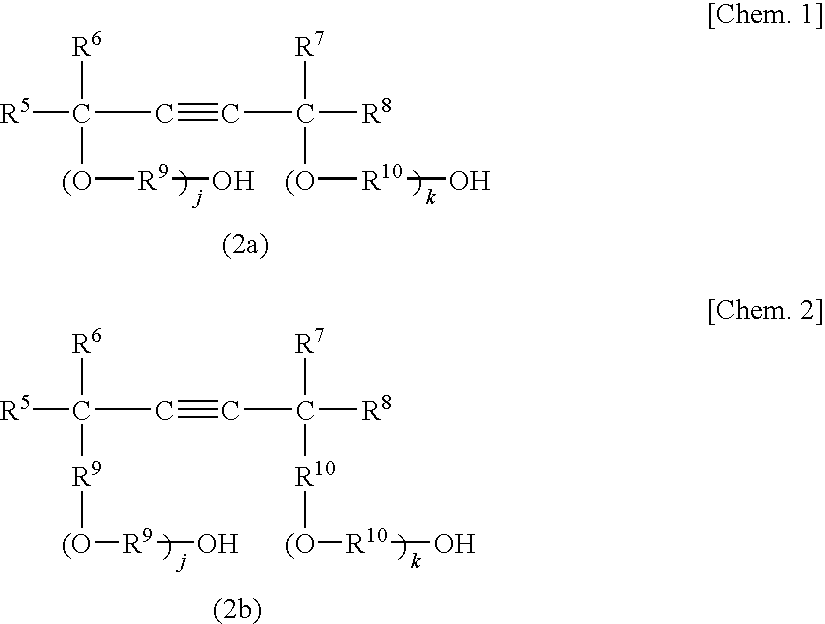

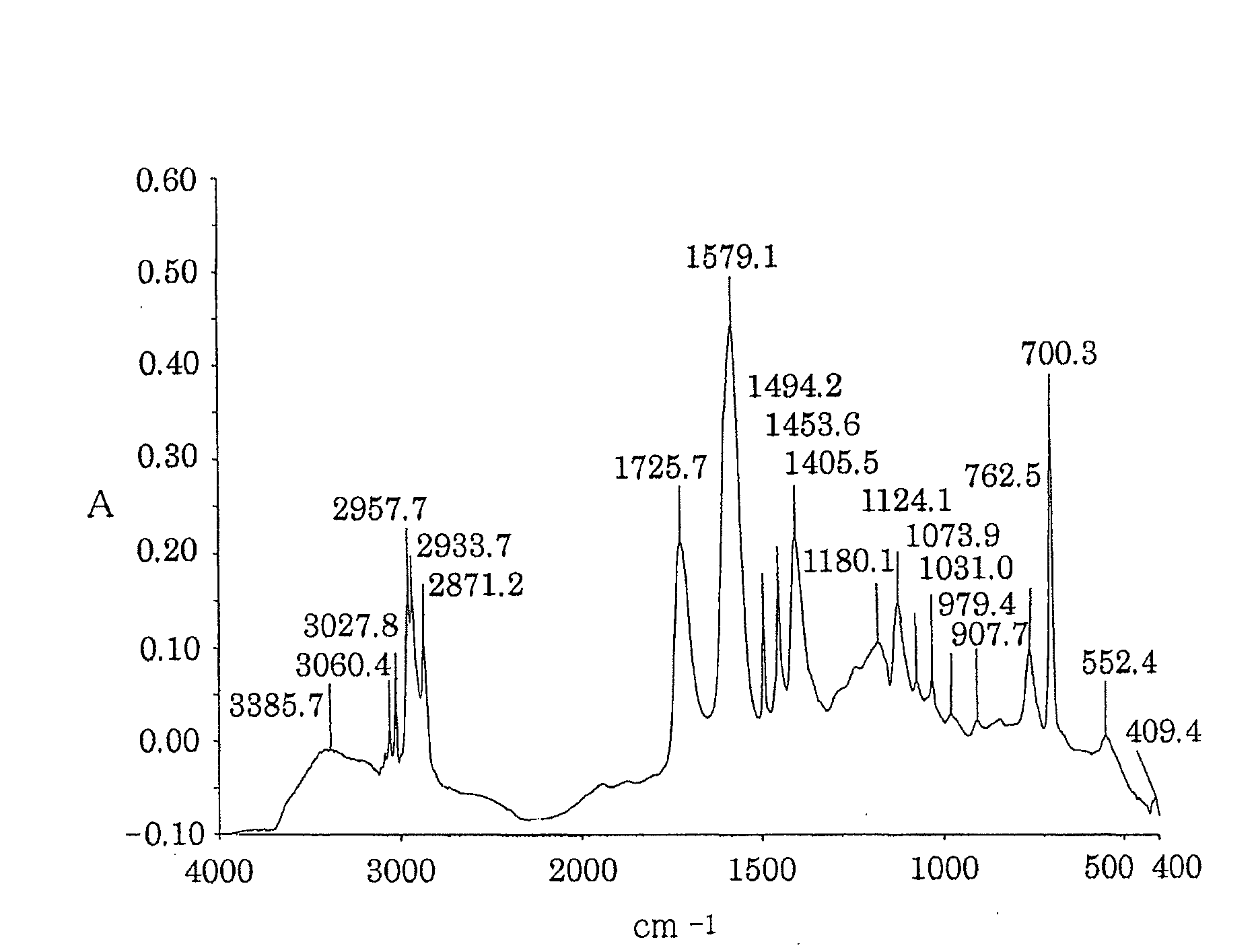

The electroless plating solution of the present invention is an electroless plating solution used for selectively forming a protective film on a surface of an exposed wiring in the production of a semiconductor device having a wiring structure, whereinthe electroless plating solution includes a cobalt ion, an ion of a second metal other than cobalt, a chelating agent, a reducing agent, a surface active agent and a specific tetraalkylammonium hydroxide, andthe surface active agent is selected from the group consisting of a compound represented by the following formula (2a) or (2b), a sulfonic acid type anionic surface active agent, a polyoxyethylene alkyl ether phosphoric ester and a polyoxyalkylene monoalkyl ether,wherein R5 to R8 are each a hydrogen atom or a specific alkyl group, R9 and R10 are each an alkylene group of 2 to 5 carbon atoms, j and k are each independently an integer of not less than 1, and the sum of j and k is 2 to 50.According to the present invention, a protective film uniformly having a diffusion-preventing ability can be formed on a copper wiring with high selectivity.

Owner:JSR CORPORATIOON

Aqueous-dispersion-type pressure-sensitive adhesive composition and pressure-sensitive adhesive sheet

InactiveUS20090186221A1Excellent stability against mechanical shearImprove productivityNatural rubber adhesivesLayered productsEmulsionPolymer science

The present invention provides an aqueous-dispersion-type pressure-sensitive adhesive composition and a pressure-sensitive adhesive sheet formed thereof. This composition comprises a rubber latex, a tackifier resin emulsion, a dispersant composed primarily of a polycarboxylic acid (salt) having a hydrophobic side chain, and an emulsifier composed primarily of a polyoxyethylene alkyl ether sulfuric acid ester having an average polymerization degree of 16 to 80. A preferred dispersant contains carboxyl group at 2 to 6 mmol / g and an aqueous solution thereof at 1% by mass has a surface tension of 25 to 45 mN / m.

Owner:NITTO DENKO CORP

Cream-type skin cleansing composition

InactiveUS20070232508A1Easy to useNot to impair effectCosmetic preparationsHair removalPolyolAlcohol

A cream-type skin cleansing composition containing substantially no polyhydric alcohol, which weakly acidic with a pH of 4.0 to 6.0, and soft and smooth with a whity appearance is provided, which is excellent in foamability as well as rinsability and in feeling during application, but avoids from becoming hard at low temperatures, and which can be readily prepared by using a common simple mixer, which contains an N-long-chain acylglycine or a salt thereof, a polyoxyethylene alkyl ether sulfate salt, a betaine type amphoteric surfactant, an inorganic or organic salt and water at a specified amounts and pH.

Owner:AJINOMOTO CO INC

Digesting assistant in use for making paper

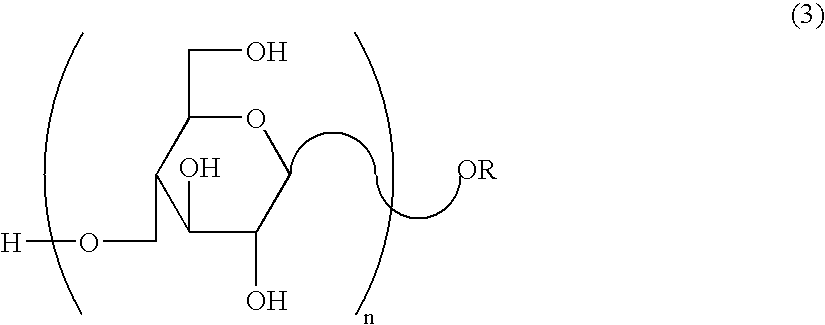

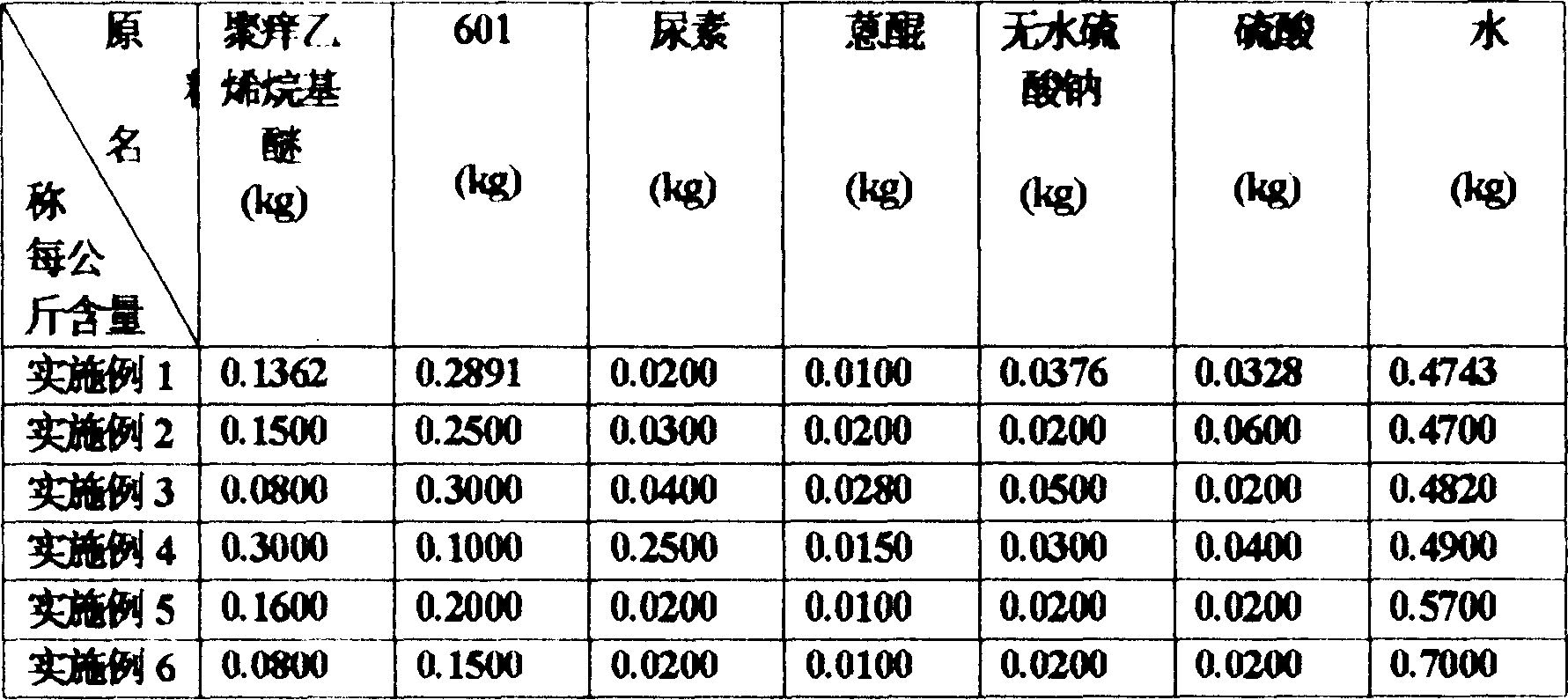

InactiveCN1540091AHigh yieldReduce appearance colorCellulose material pulpingDigestionSODIUM SULFATE ANHYDROUS

A digestion aid for making paper is prepared from polyoxyvinyl alkylether, sodium alkylsulfonate, urea, anthraquinone, anhydrous sodium sulfate, sulfuric acid and water. Its advantages are high output rate and whiteness of pulp and short digestion time.

Owner:OUPULONG CHEM ENG SCI TECH GUANGZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com