Patents

Literature

215 results about "Ethylene urea" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

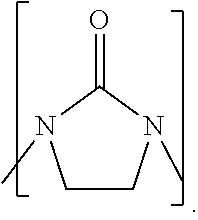

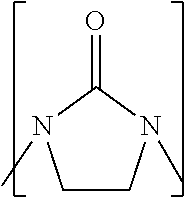

Ethylene urea. The Ethylene Urea 87% - also known as 2-Imidazolidinone hemihydrate – is mainly used in various kinds of formaldehyde removing formulations such as high effect formaldehyde removing detergents and long-term formaldehyde dissolution intermediates.

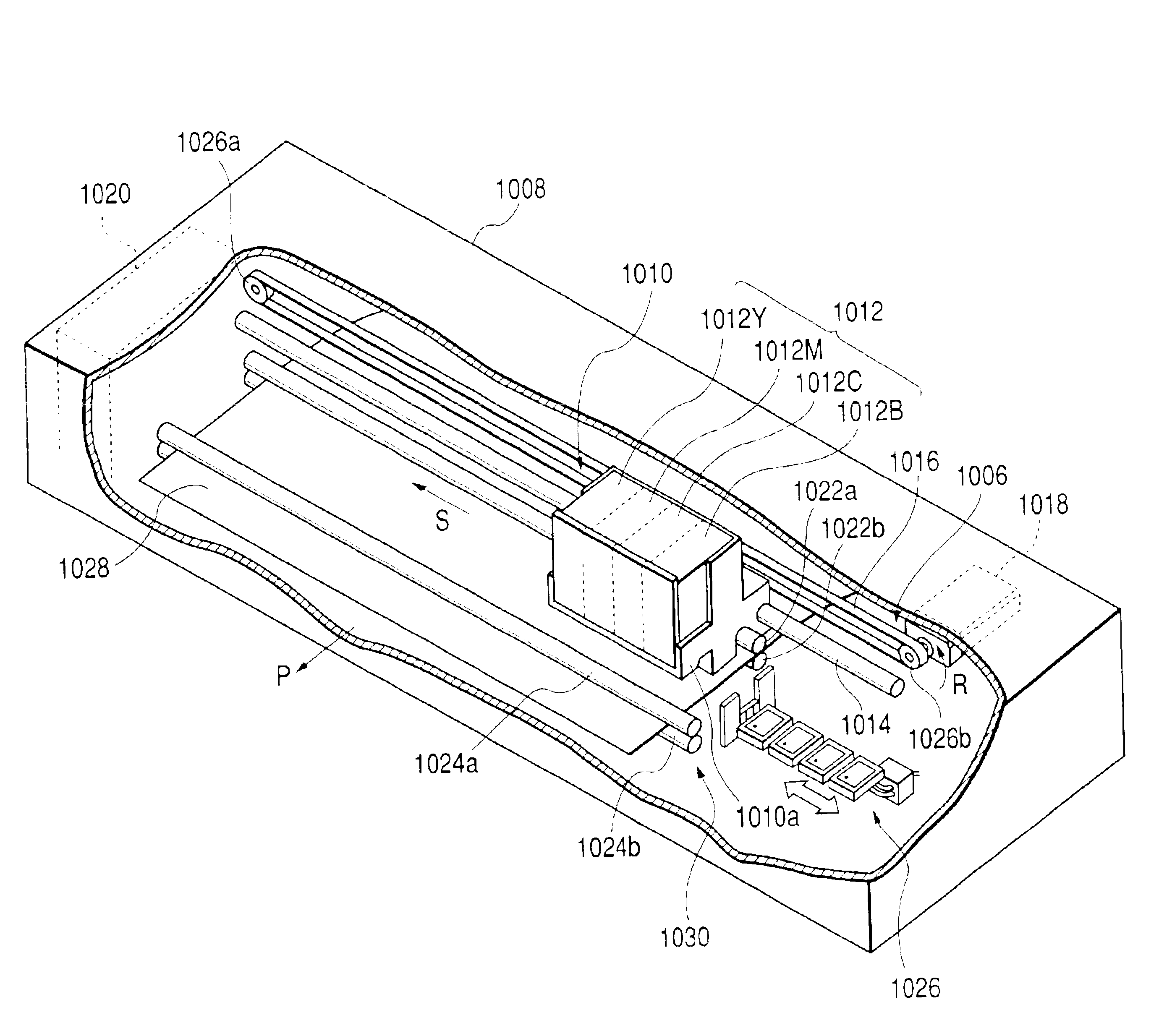

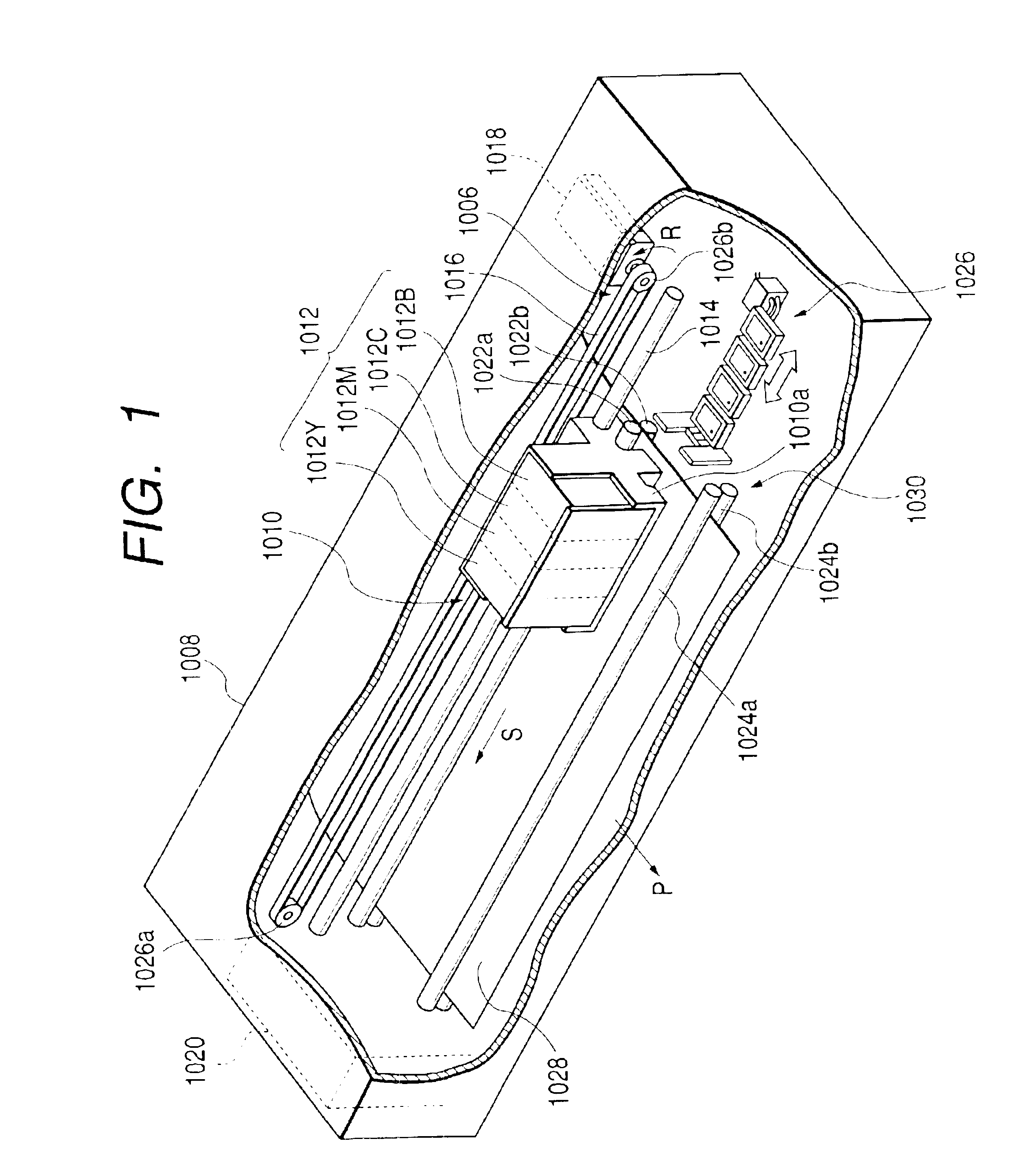

Ink, ink cartridge, recording unit, ink jet recording method, ink jet recording apparatus and method for stabilizing ink discharge

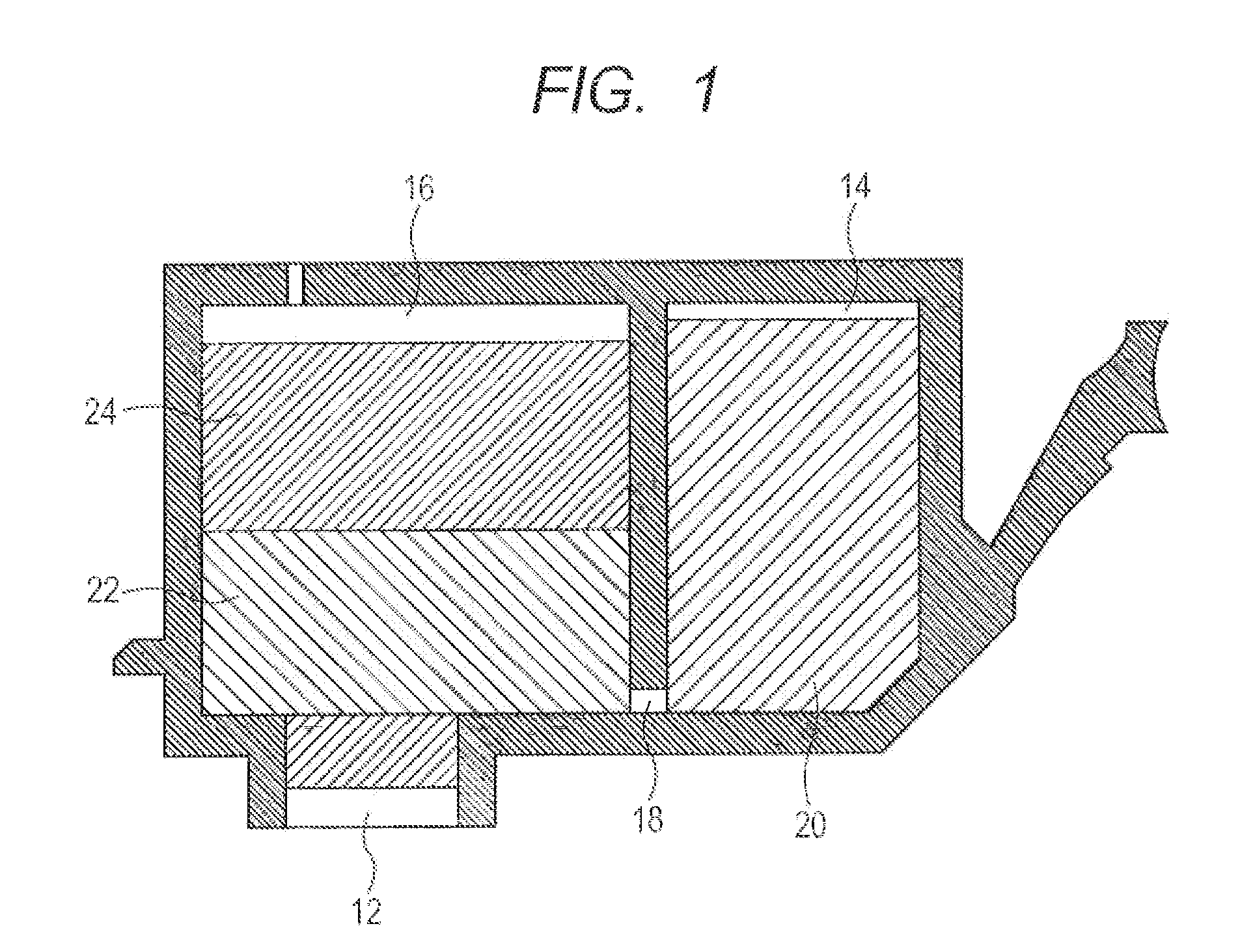

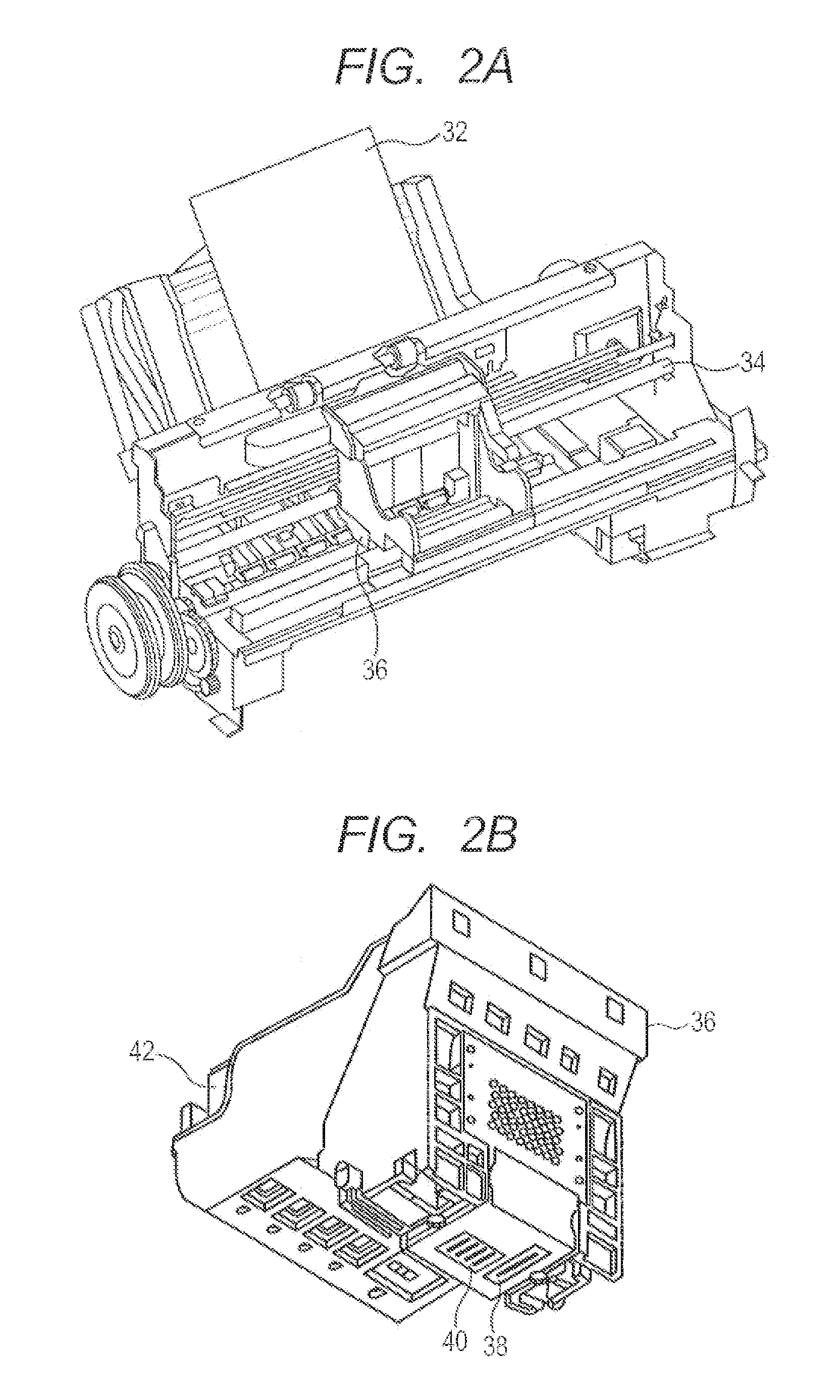

InactiveUS6874881B2Accurate imagingGood dispersionMeasurement apparatus componentsDuplicating/marking methodsWater insolubleEngineering

Provided is an ink-jet ink suitable for high speed printing and reduced ink ejection amount, wherein ink includes a water-insoluble coloring material dispersed in water with a resinous dispersant, glycerin, ethylene urea, and polyoxyethylene alkyl ether with HLB not lower than 13.

Owner:CANON KK

Finishing agent composition for cotton silk fabrics and production method of wash and wear cotton silk shirts

InactiveCN102634984AImprove breathabilityGood hygroscopicityVegetal fibresAnimal fibresEthylene ureaGlyoxal

The invention discloses a finishing agent composition for cotton silk fabrics and a production method of wash and wear cotton silk shirts. The finishing agent composition contains a finishing agent selected from dihydroxyl ethylene urea resin, butanetetracarboxylic acid, propanetricarboxylic acid, citric acid, polymaleic acid, glyoxal and glutaraldehyde, a polyurethane finishing agent and a catalyst. The wash and wear cotton silk shirts produced by the method can simultaneously have such advantages of cotton as good air permeability and strong moisture absorbability and such advantages of silk as good drapability, gloss and outstanding handfeel and can have excellent wash and wear effect while maintaining the peculiar handfeel of the cotton silk fabrics.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Maleic acid and ethylene urea containing formulation for removing residue from semiconductor substrate and method for cleaning wafer

InactiveUS6946396B2Efficient removalProvide performanceNon-ionic surface-active compoundsOrganic detergent compounding agentsResistMaleopimaric acid

Owner:NISSAN CHEM IND LTD

Water washable lithographic newspaper printing ink

A water washable lithographic newspaper ink comprising: a modified soybean oil based resin; pigment; an acid neutralizing agent; and a humectant. In addition, the ink according to the present invention may also comprise water, and a rewetting agent, preferably hydroxyethyl ethylene urea.

Owner:SUN CHEM CORP

Formaldehydeless permanent press finishing agent for fabric and preparation method and application thereof

ActiveCN101956322AOvercome lossImprove wrinkle resistanceVegetal fibresPotassium persulfatePolymer science

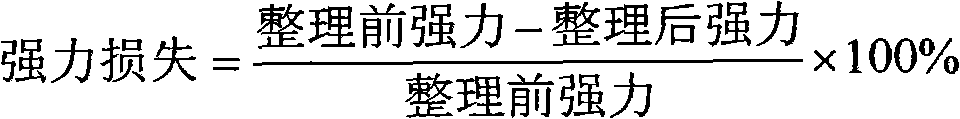

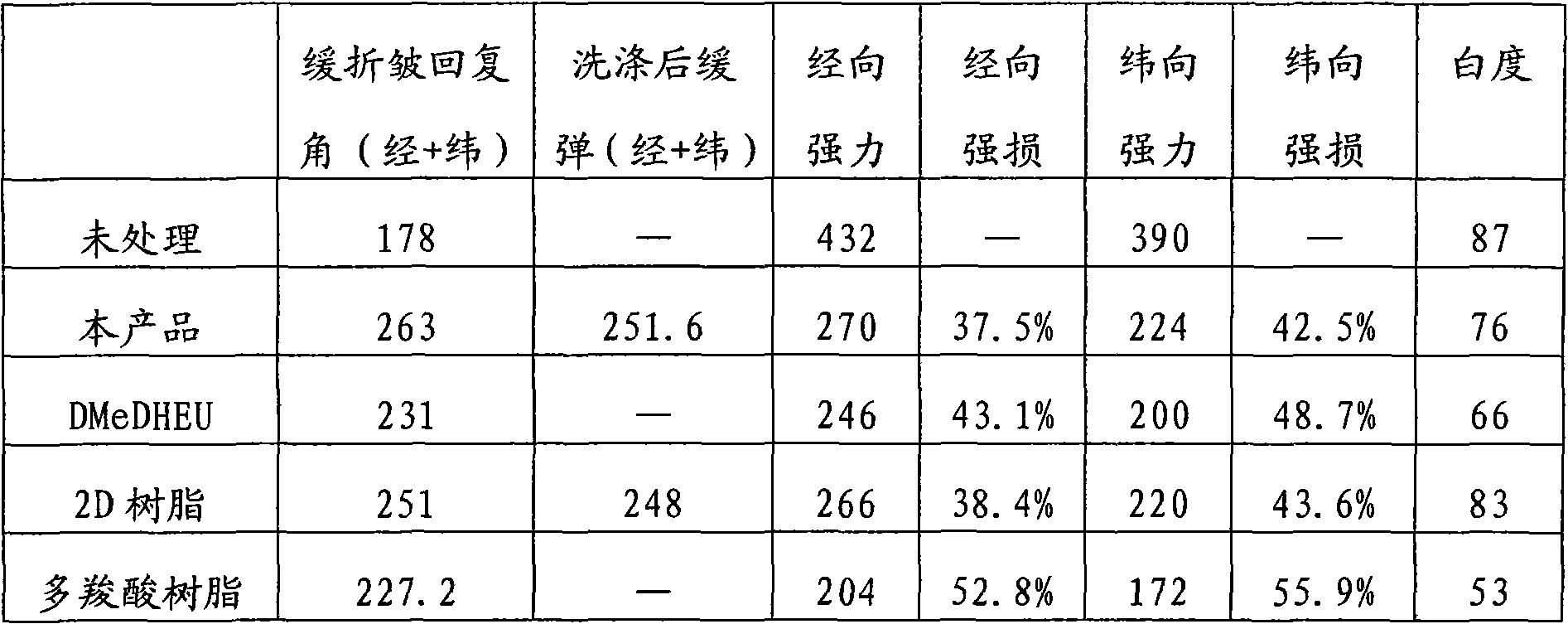

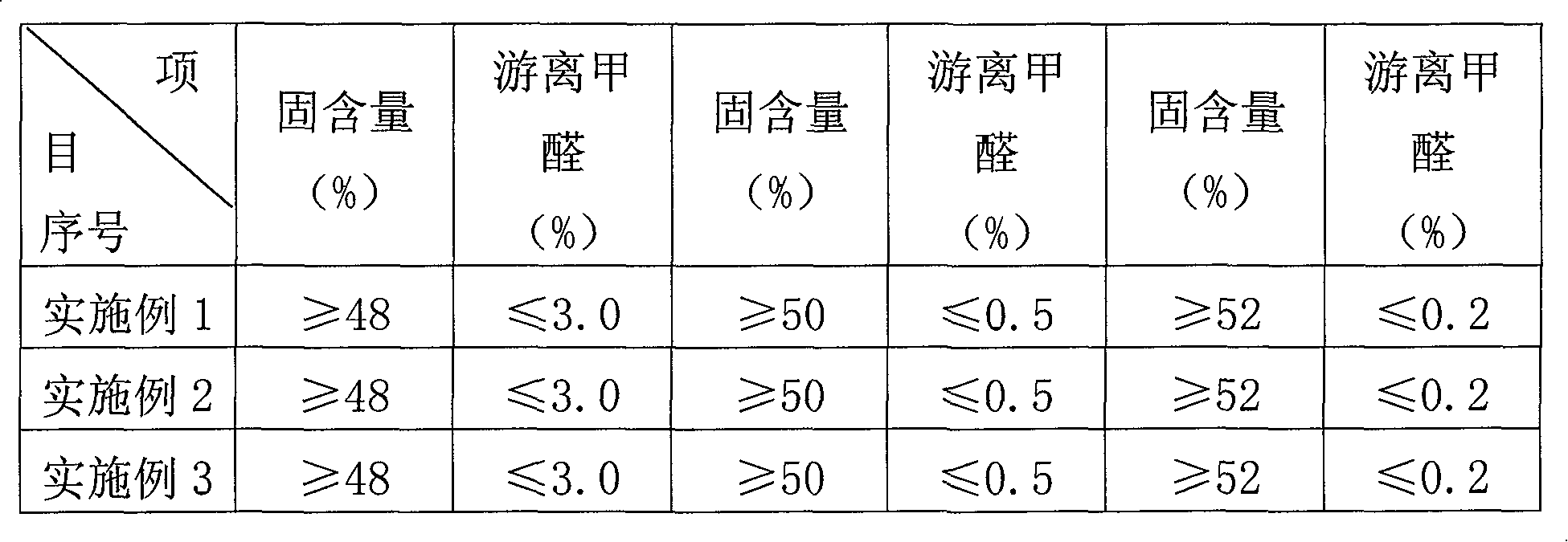

The invention discloses a novel formaldehydeless permanent press finishing agent for a fabric and a preparation method and application thereof. The formaldehydeless permanent press finishing agent for the fabric is prepared by performing a polymerization reaction on acrylamide, glyoxal, phthalic anhydride, sulfuric acid, potassium persulfate and the like. The product of the invention is mainly used for performing noniron finish on the fabric and improving the firmness of a dyed fabric and a printed fabric. Compared with the conventional N-methylol acrylamide resin, the permanent press finishing agent has prominent advantages of excluding of formaldehyde and crease resilience equivalent to or surpassing those of etherfied 2D (etherfied dimethylol dihydroxy ethylene urea) after being used for finishing a cotton fabric; and compared with the conventional formaldehydeless resin, the agent has the advantages of high crease resilience, strength loss less than that of a polycarboxylic formaldehydeless resin, cost lower than those of dimethylol dihydroxy ethylene urea (DMeDHEU) and butanetetracarboxylic acid (BTCA) and cost performance far higher than that of a polycarboxylic resin.

Owner:SICHUAN YIXIN TECH

Multifunctional eiderdown finishing agent

InactiveCN101130928AGood anti-moth effectGood deodorizing effectFibre treatmentAdjuvantEthylene urea

The present invention discloses a multifunctional down finishing agent, belonging to an adjuvant for treating down in the preparation process of down products. said down finishing agent composition contains (by weight portion) 0.5-2.5 portions of anti-bacterial anti-mildew agent, 0.5-2.5 portions of moth-proofing agent, 0.5-5 portions of film-forming agent, 1-8 portions of cross-linking agent, 20-90 portions of non-ionic surface active agent and 20-60 portions of water. The above-mentioned anti-bacterial anti-mildew agent is 2,4,4'-trichloro-2'-hydroxydiphenyl ether, the optimum moth-proofing agent is permethrin, the film-forming agent is acrylic composite resin, the cross-linking agent is melamine resin and / or dimethylol dihydroxy-ethylene urea and the described non-ionic surface active agent is methoxy polyethylene glycol and / or polyethylene glycol.

Owner:高德康 +1

Method for preparing urea-formaldehyde resin adhesive

InactiveCN101191043AImprove permeabilityGood water solubilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPotato starchEthylene urea

The invention discloses a preparation method for urea-formaldehyde resin adhesive, which is an adhesive produced by adopting ethylene urea, melamine or polyvinyl alcohol as formaldehyde catching agent and added with urea, potato starch residue and urea-formaldehyde resin to react. The invention has low formaldehyde content, can meet the requirement of low cost for composite sheet adhesive and has all excellent performances of urea-formaldehyde resin adhesive and the production cost is reduced; therefore, a practical adhesive that can be afforded entirely by each composite plate processing enterprises is obtained.

Owner:LANZHOU UNIVERSITY

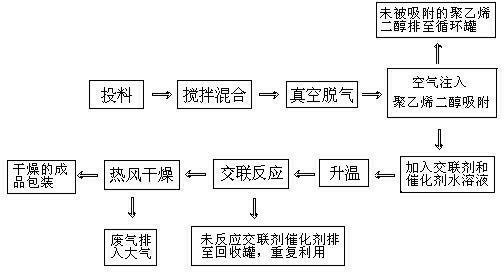

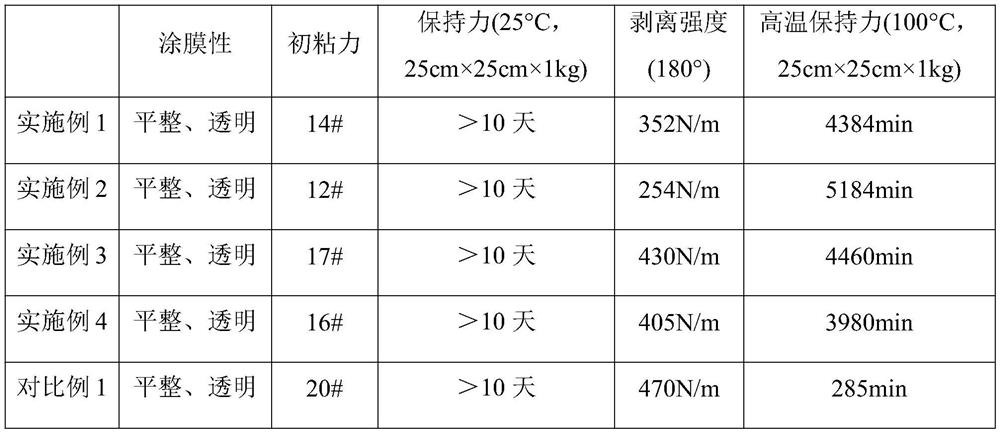

Polyacrylate, pressure-sensitive adhesive and preparation method

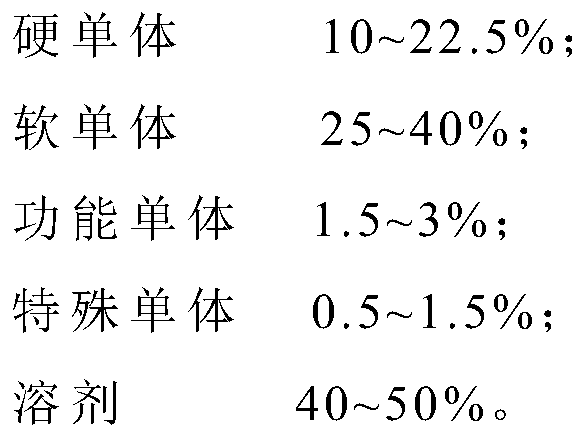

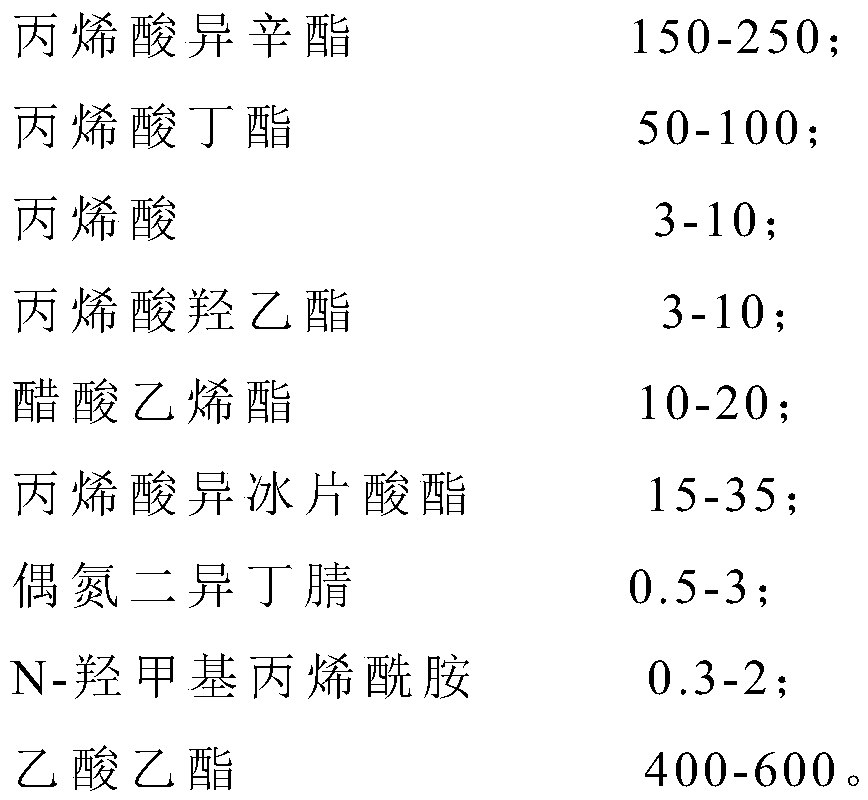

ActiveCN109762097AThe polymerization process is simpleHigh temperature resistance and good adhesionEster polymer adhesivesPressure sensitive film/foil adhesivesIsooctyl acrylateGlycidyl methacrylate

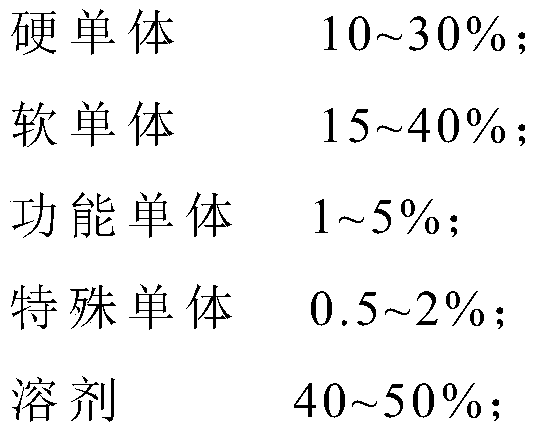

The invention relates to polyacrylate. Polyacrylate is synthesized from raw materials in percentage by mass as follows: 10%-30% of a hard monomer, 15%-40% of a soft monomer, 1%-5% of a functional monomer, 0.5%-2% of a special monomer and 40%-50% of a solvent, wherein the hard monomer comprises one or more of methyl acrylate, methyl methacrylate, vinyl acetate, acrylonitrile and isobornyl methacrylate; the soft monomer comprises one or more of ethyl acrylate, n-butyl acrylate, 2-ethylhexyl acrylate and n-propyl acrylate; the functional monomer comprises one or more of hydroxyethyl acrylate, acrylic acid, methacrylic acid, hydroxypropyl acrylate and 2-hydroxyethyl methacrylate; the special monomer comprises one or more of methacrylamido ethyl ethylene urea, hydroxyethyl methacrylate phosphate and glycidyl methacrylate. A pressure-sensitive adhesive has good high-temperature-resistant adhesive property, does no squeeze out, has no residue, has low cost and can be applied to masking tapesused in capacitor taping in the electronics industry as well as certain high-temperature-resistant adhesive tapes.

Owner:CYBRID TECHNOLOGIES INC

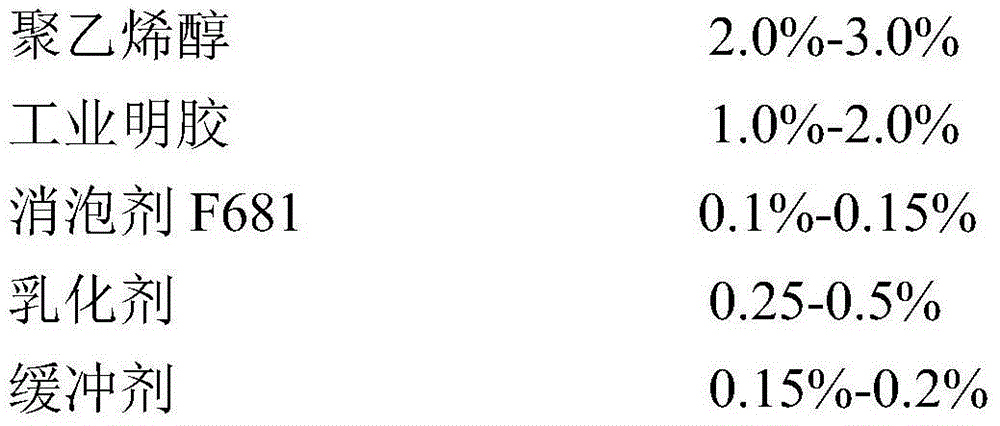

Water-based laminated adhesive and preparation method thereof

ActiveCN104263292AImprove adhesionLower surface energyEster polymer adhesivesAdhesive cementDiacetonamine

The invention discloses a water-based laminated adhesive and a production technique thereof. The water-based laminated adhesive mainly comprises deionized water, butyl acrylate, methyl methacrylate, acrylic acid, diisooctyl maleate, diacetone acrylamide, diamidohydrazine adipate, methacrylamido ethyl ethylene urea, an emulsifier, an initiator, a buffering agent, a defoaming agent, a film formation assistant and a preservative. A pre-emulsification technique is utilized to prepare the milk white liquid with blue fluorescence on appearance; the viscosity is 100-500 mPa.s, and the solid content is 48-55%; the film forming material is colorless and transparent, and the pH value is 7-9; the emulsion belongs to a self-crosslinking type; the macromolecules are automatically crosslinked in the compounding process, so the adhesive has high peel strength; and the emulsion has higher solid content, so the adhesive satisfies the requirement of dry-type composite quick drying.

Owner:浙江春雨新材料科技有限公司

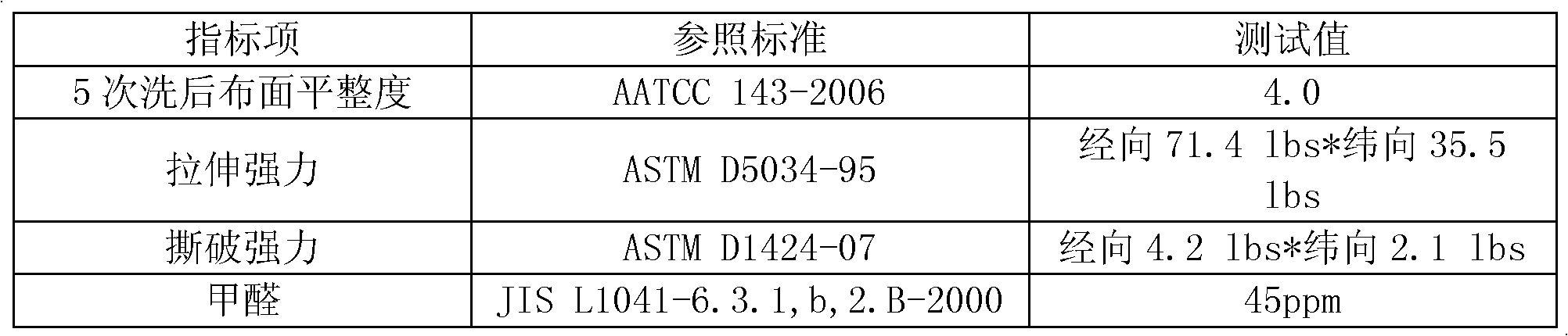

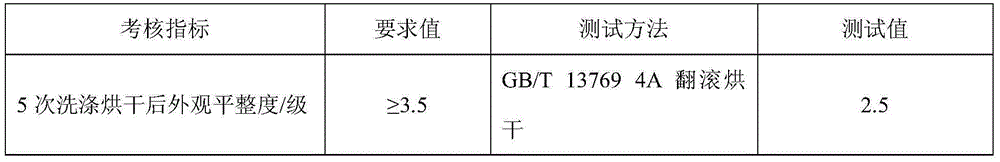

Finishing agent composition for cotton-silk fabrics and processing method of cotton-silk easy-care shirt

InactiveCN105133315AOvercome the defect of poor anti-slip performanceRetain moisture permeabilityVegetal fibresAnimal fibresAdditive ingredientMoisture permeability

The invention discloses a finishing agent composition for cotton-silk fabrics. The finishing agent composition comprises the following ingredients by weight: 120 to 180 parts of dihydroxy ethylene-urea resin, 10 to 60 parts of a powerful protecting agent, 10 to 50 parts of a smoothing agent, 30 to 80 parts of a softening agent, 10 to 25 parts of a catalyst, 5 to 10 parts of an anti-fraying agent, 1 to 5 parts of a penetrating agent, and 5 to 10 parts of a formaldehyde scavenger. The invention further provides a processing method of a cotton-silk easy-care shirt. The processing method of the cotton-silk shirt garment comprises the following steps: prewashing, drying, material spraying, pre-drying, pressing, baking, purified water washing, drying and moisture regaining, wherein the finishing agent composition is uniformly applied onto the cotton-silk easy-care shirt in the material spraying step. The finishing agent composition is used for finishing process of the cotton-silk fabrics, and can be used for overcoming the defect that the anti-sliding property of the cotton-silk fabrics is lowered after conventional easy-care treatment, reserving the own moisture permeability, air permeability and natural drapability of the cotton-silk fabrics, and enabling the cotton-silk fabrics to have relatively high easy-care property. Therefore, people can wear the shirt comfortably, and the shirt is easy to care. Moreover, the formaldehyde content of the finished cotton-silk easy-care shirt can be lower than the national standard.

Owner:NINGBO YOUNGOR TECH

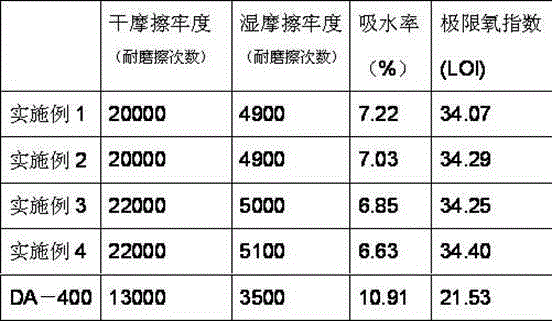

Electrostatic flocking adhesive for high fastness carpet and preparation method thereof

ActiveCN105294925ARaise the ratioImprove dry and wet rubbing fastnessEster polymer adhesivesPhosphoric Acid EstersPolymer science

The invention provides an electrostatic flocking adhesive for a high fastness carpet and a preparation method thereof. The raw materials comprise, by weight, 3.5-4.3 parts of a reactive anionic emulsifier, 25-27 parts of a reactive nonionic emulsifier, 3.9-4.1 parts of methacrylic acid polyether phosphate ester, 0.9-1.2 parts of itaconic acid, 4.9-5.1 parts of N-hydroxymethyl acrylamide, 0.9-1.2 parts of acrylamide, 1.5-2 parts of methacrylamide ethyl ethylene urea, 3.9-4.1 parts of methacrylic acid, 2.4-2.6 parts of hydroxyethyl methylacrylate, 3.9-4.1 parts of glycidyl methacrylate, 180-185 parts of n-butyl acrylate, 50-53 parts of acrylonitrile, 47-50 parts of methyl methacrylate, 1-1.1 parts of ammonium persulfate, 0.5-0.55 part of sodium bisulfite, and 258-272 parts of deionized water; a polymer emulsion formed by the seeded emulsion polymerization is supplemented with water solution containing 24-25 parts of ammonium polyphosphate and mixed to prepare the electrostatic flocking adhesive for high fastness carpet, wherein the adhesive has good wear resistance, moisture resistance and flame resistance.

Owner:LIAONING FIXED STAR FINE CHEM

Fabric anti-creasing agent and preparation method thereof

InactiveCN103668947ALong-lasting anti-wrinkleDurable ShrinkproofVegetal fibresAnimal fibresAcetic acidPolymer science

The invention discloses a fabric anti-creasing agent and a preparation method thereof. The fabric anti-creasing agent comprises the following raw materials in parts by mass: 15-20 parts of dihydroxy methyl dihydroxy ethylene urea, 5-8 parts of water-soluble polyurethane resin (WPU), 5-10 parts of sodium chloride, 20-25 parts of ethanol, 0.5-1 part of acetic acid, and 15-18 parts of water. The fabric anti-creasing agent disclosed by the invention has the advantages that the fabric is durable in resisting creases and shrinking, the fabric treated through the anti-creasing agent is flexible and smooth, stiff and wear-resisting. Furthermore, the treated fabric can eliminate the steps of washing and soaping, thereby saving manpower.

Owner:NANTONG TONGZHOU DISTRICT CHUANJIANG TOWN SUNWORLD DYNASTY HOME TEXTILE DESIGN STUDIO

Finishing agent composition for flax fabrics and processing method of flax easy-care shirt

InactiveCN105133344AOvercoming the hard feelingOvercome roughnessFibre treatmentDry-cleaning apparatus for textilesFoaming agentMoisture permeability

The invention discloses a finishing agent composition for flax fabrics. The finishing agent composition comprises the following ingredients by weight: 100 to 180 parts of dihydroxy ethylene-urea resin, 30 to 100 parts of a hydrophilic finishing agent, 10 to 60 parts of a powerful protecting agent, 5 to 25 parts of a catalyst, 1 to 5 parts of a penetrating agent, and 2 to 8 parts of an anti-fraying agent. The invention further provides a processing method of a flax easy-care shirt. The processing method comprises the following steps: prewashing, drying, material spraying, pre-drying, pressing, baking, water washing, drying and moisture regaining, wherein the finishing agent composition is uniformly applied onto the flax easy-care shirt in the material spraying step. The finishing agent composition is used for finishing process of flax fabrics, and can be used for overcoming the defect that the flax fabrics feel relatively hard and rough and are greatly lower in strength and wearing resistance after conventional easy-care treatment, reserving the own favorable moisture permeability, air permeability and natural antibiotic property of the flax fabrics to the utmost extent, and enabling the flax fabrics to have relatively high easy-care property. Therefore, people can wear the shirt comfortably, and the shirt is easy to care.

Owner:NINGBO YOUNGOR TECH

Maleic acid and ethylene urea containing formulation for removing residue from semiconductor substrate and method for cleaning wafer

InactiveUS20050096237A1Efficient removalLess corrosiveOrganic detergent compounding agentsNon-ionic surface-active compoundsResistCopper interconnect

A semiconductor wafer cleaning formulation for use in semiconductor fabrication comprising maleic acid and ethylene urea as essential components. The preferred formulation comprises maleic acid, ethylene urea, at least one carboxylic acid except maleic acid, at least one organic amine except ethylene urea and water The formulation can optionally comprise at least one selected from the group consisting of an organic solvent, a chelating agent and a surfactant. The formulation is suitably used for removal of residue from semiconductor wafers following a resist ashing process, particularly for removal of residue from wafers containing delicate copper interconnect and low-k or ultra low-k interlayer dielectrics structures. There is also provided a method for cleaning the wafer by using the formulation.

Owner:NISSAN CHEM IND LTD

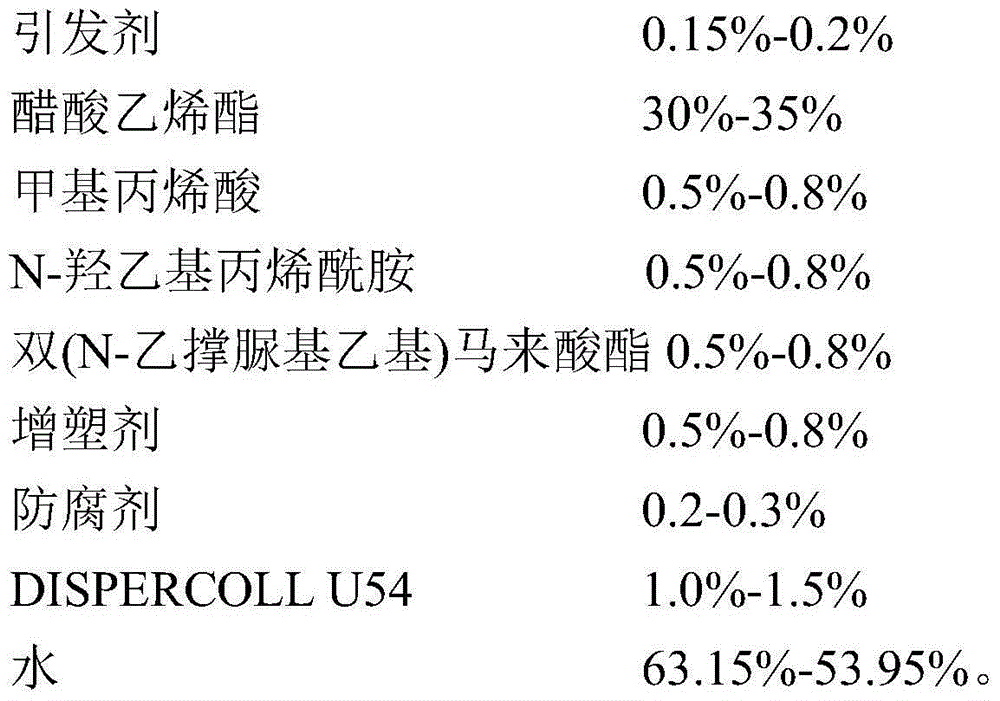

Repairable veneer adhesive and synthesizing method thereof

ActiveCN104140773AWith repair functionSolving the Repairability DilemmaMonocarboxylic acid ester polymer adhesivesMacromolecular adhesive additivesPolyurethane adhesiveEthylene urea

The invention discloses a repairable veneer adhesive and a synthesizing method thereof. The repairable veneer adhesive mainly comprises tap water, polyvinyl alcohol, technical gelatin, emulsifying agents, initiating agents, methylacrylic acid, N-hydroxyethyl acrylamide, vinyl acetate, double (N-ethylene-urea-based ethyl) maleate, Bayer waterborne polyurethane resin, plasticizers, buffering agents, antifoaming agents and preservatives. During preparation of the repairable veneer adhesive, firstly, the polyvinyl alcohol and the technical gelatin are used as protective adhesive bodies to synthesize self-crosslinking polyvinyl acetate copolymer modified emulsion, then, a thermal-activation-type polyurethane adhesive DISPERCOLLU54 is added into the copolymer emulsion, and finally, the veneer adhesive which is excellent in performance is prepared. The veneer adhesive has certain repairability. Compared with a traditional urea resin veneer adhesive, the adhesive prepared through the preparation method has the advantages of being repairable, convenient to use and harmless to the environment and human bodies.

Owner:TAIZHOU UNIV

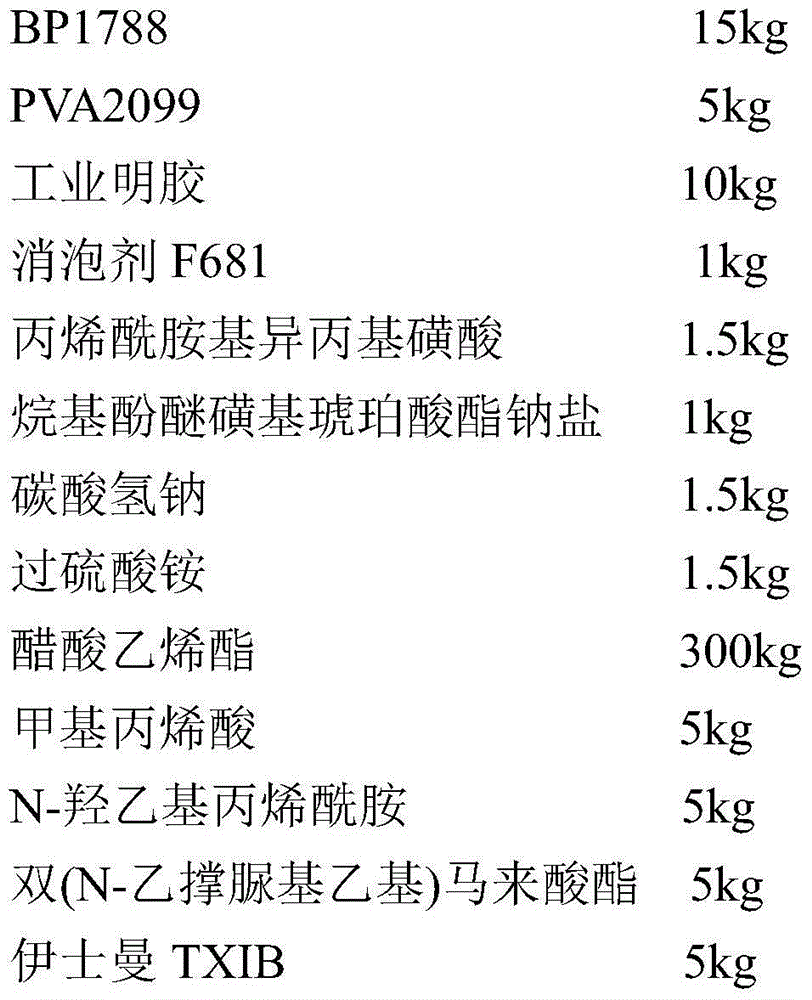

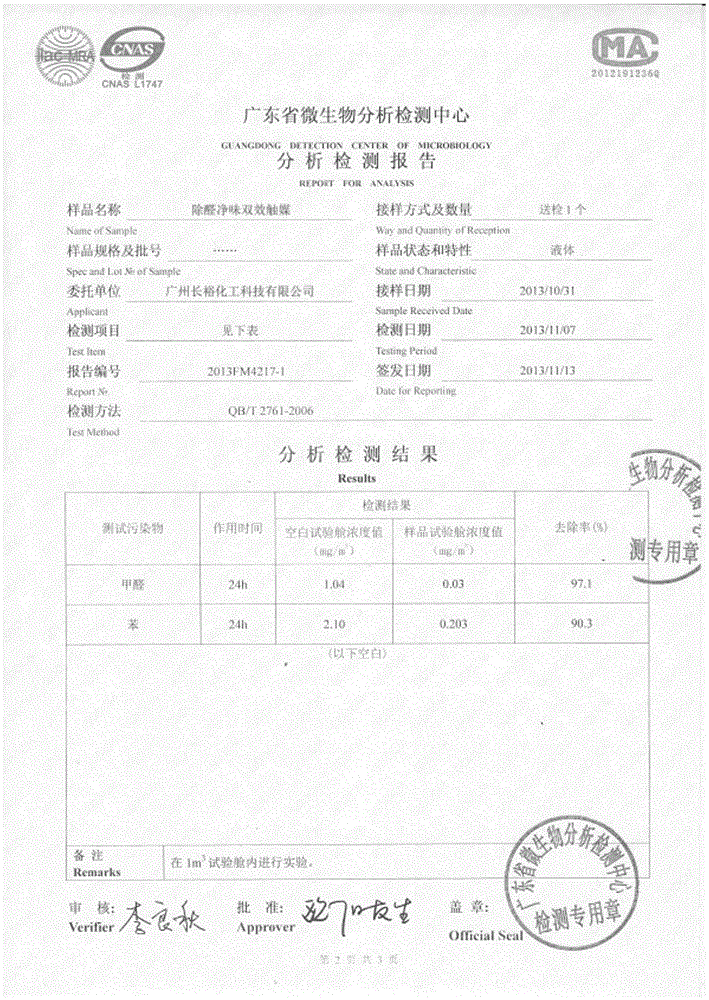

Formaldehyde-removal odor-removal double effect catalyst

InactiveCN105521827AImprove fixed energyReduce formaldehyde contentOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationEucalyptus oilEthylene urea

The invention discloses a formaldehyde-removal odor-removal double effect catalyst. The catalyst comprises, by weight, 5-10% of ethylene urea, 0.5-1% of chitosan quaternary ammonium salt, 1-2% of eucalyptus oil, 0.5-1% of azone, 2% of nanometer negative ion powder and the balance water. The formaldehyde-removal odor-removal double effect catalyst solves the problem that the traditional single ethylene urea hydrosolvent has good adhesion, a fast volatilization rate, short action time and a high cost.

Owner:GUANGZHOU CHANGYU CHEM TECH CO LTD

Oxidized graphene modified 3D printing resin and manufacturing method thereof

InactiveCN106543687AHigh strengthHigh temperature strengthAdditive manufacturing apparatusFoundryEthylene urea

The invention relates to the field of casting auxiliaries materials, in particular to a manufacturing method of an oxidized graphene modified 3D printing resin. The graphene modified 3D printing resin is prepared from, 7-13% of phenol, 1.5-2.5% of formic acid, 45-65% of furfuryl alcohol, 13-19% of formaldehyde, 7-13% of resorcinol, 3-7% of oxidized graphene, 0.5-1.5% of coupling agent and 0.5-1.5% of ethylene urea. Aimed at the problem in the prior art that a traditional resin for steel casting exits deficiences in 3D foundry sand printing, the oxidized graphene is creatively introduced, and thus the problem of sand burning in the steel casting is fundamentally solved; in addition, the oxidized graphene modified 3D printing resin can be used for conducting moulding on a sand mould with high heat resistance and high rigidity, can be used in a more complicated and thinner high-end casting, is stable in chemical properties, applicable to 3D printing technologies, high in strength of the foundry sand, simple and convenient to operate, and excellent in anti-sand burning performance.

Owner:GANSU KOCEL CHEM

Finishing process of garment fabric

InactiveCN104532562AImprove wrinkle resistanceImprove antibacterial propertiesFibre treatmentAcrylic resinEthylene urea

The invention discloses a finishing process of a garment fabric. The finishing process of the garment fabric comprises the following steps: (1) adding 3.4 parts by mass of trishydroxymethyl ethylene urea, 2.6 parts by mass of a dark plum extract and 1.7 parts by mass of acrylic resin into 12.9 parts by mass of deionized water, and uniformly stirring; (2) sequentially adding 2.3 parts by mass of waterborne polyurethane and 3.1 parts by mass of dodecyl trimethylammonium ammonium sulfate, further stirring until all the materials are uniformly mixed to prepare a finishing solution; and (3) padding the fabric in the finishing solution and drying at constant temperature. The fabric finished by the finishing process of the garment fabric is washable and is excellent in anti-crease performance and antibacterial performance.

Owner:CHANGSHU HUABO WOOLEN TEXTILE

Formaldehyde adsorbent and formaldehyde adsorbent preparation method

InactiveCN109173567AImprove adsorption capacityLarge adsorption capacityOther chemical processesAluminium silicatesActive componentSorbent

The invention relates to a formaldehyde adsorbent, the formaldehyde adsorbent comprises a carrier and an active component loaded on the carrier, the active component comprises ethyleneurea or its derivative, and ammonium phosphate; the mass ratio of the ethyleneurea or its derivative to ammonium phosphate is 1 to 20:1 to 20. The formaldehyde adsorbent of the invention has stable active componentsand high adsorption efficiency. The invention also relates to a preparation method of the formaldehyde adsorbent.

Owner:汤美英

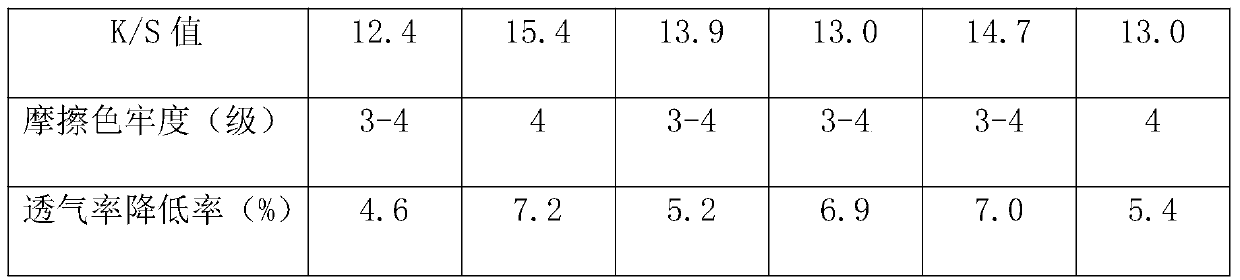

One-step dyeing method of porous cellulose microspheres-modified dyed cotton blended fabric

The invention provides a one-step dyeing method of a porous cellulose microspheres-modified dyed cotton blended fabric. The one-step dyeing method comprises the steps of soaking a polyester-cotton blended fabric in an alkaline pretreating solution containing hexadecyl trimethyl ammonium chloride, and padding to obtain a pretreated polyester-cotton blended fabric; adding cellulose fibers into a formate mixed liquid, heating, stirring for dissolving, adjusting pH to neutrality, dispersing in an aqueous solution to obtain a methylated cellulose microcrystalline solution, dropwise adding into acidic regenerating solution, curing, taking out cellulose nano hydrogel spheres, lyophilizing to obtain porous cellulose microspheres, dispersing in a solution containing dimethylol dihydroxy ethylene urea resin, mixing, soaking the pretreated polyester-cotton blended fabric under vibrating, and washing repeatedly to obtain a cellulose microspheres-modified polyester-cotton blended fabric; soaking the cellulose microspheres-modified polyester-cotton blended fabric in a dye, heating for dyeing, taking out, drying, and baking to obtain the dyed polyester-cotton blended fabric.

Owner:HUAIAN JIADE TEXTILE CO LTD

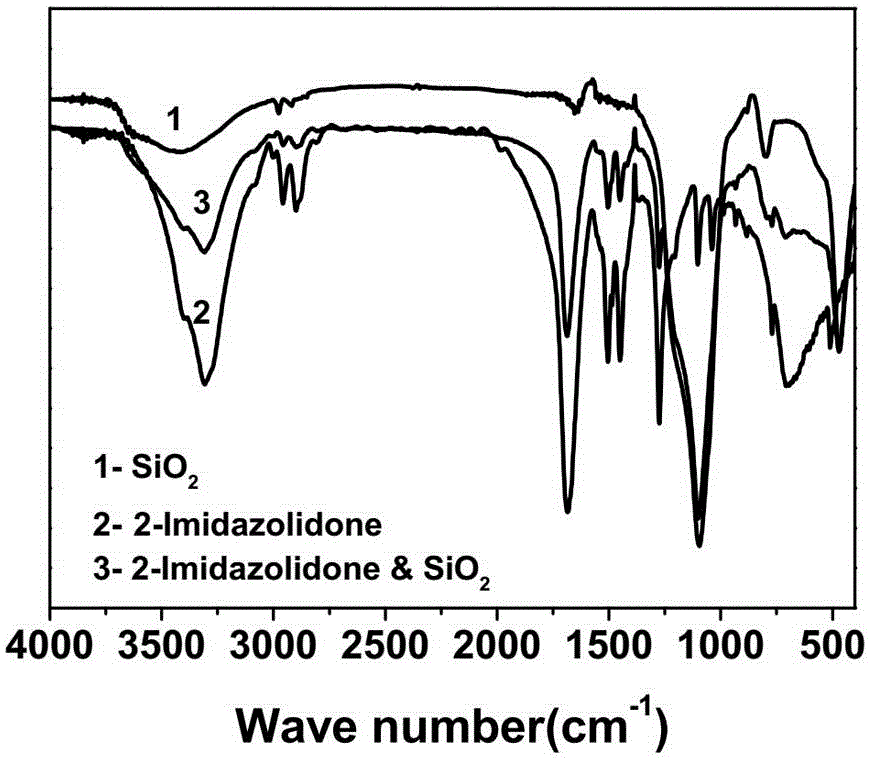

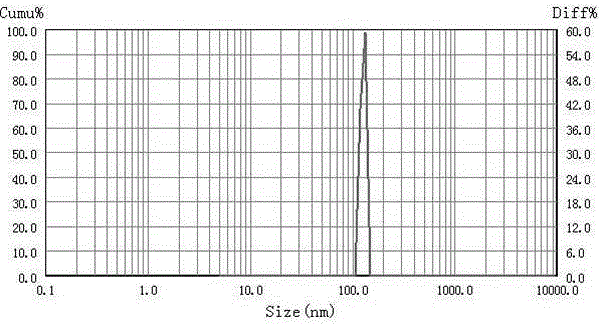

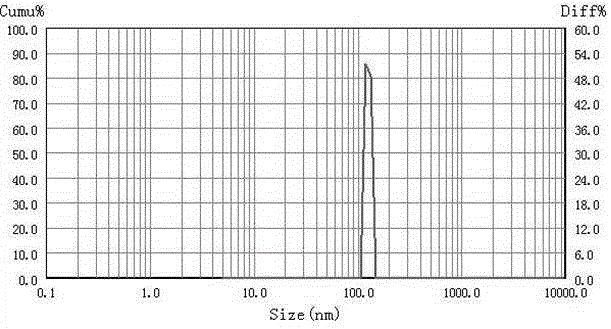

Ethylene urea composite nano-material for capturing formaldehyde and preparation method

ActiveCN106349797AImprove wear resistanceImprove adhesionGas treatmentDispersed particle separationSolubilityEthylene urea

The invention discloses an ethylene urea composite nano-material which is added to oil-based paint and has excellent formaldehyde capturing performance, and a preparation method of the ethylene urea composite nano-material. The technical method comprises the following steps: using an organic solvent as a solvent and a dispersion medium of ethylene urea; using silica, calcium carbonate, titanium dioxide, aluminum oxide and other inorganic nanometer materials with a particle size range of 30-500 nm as carriers; adjusting and controlling temperature and solubility of ethylene urea solution, and adding appropriate amount of a dispersion activating agent to prepare the ethylene urea composite nano-material which uses an inorganic nano-material as a core, uses ethylene urea as a shell, and has the particle size range of 50-1000 nm. The ethylene urea composite nano-material can be added to the oil-soluble paint to solve problems that ethylene urea is indissolvable and is easy to settle and stratify, and can be used for coating surfaces of indoor home furnishings made of artificial boards to effectively capture formaldehyde continuously released from the artificial boards, thereby reducing indoor formaldehyde exceeded pollution and protecting human health.

Owner:BEIJING UNIV OF CHEM TECH +1

Ink, ink cartridge and ink jet recording method

ActiveUS8932394B2Good light fastnessImprove stabilityDisazo dyesInksOrganic solventChemical compound

The present invention provides an ink jet ink that is capable of recording an image excellent in light resistance and ozone resistance and has excellent intermittent ejection stability. The ink jet ink contains a coloring material and a water-soluble organic solvent. The coloring material contains a compound represented by the following general formula (I), the water-soluble organic solvent contains ethylene urea end an alkanediol having 4 to 6 carbon atoms, and a content A (% by mass) of the coloring material, a content B (% by mass) of the ethylene urea and a content C (% by mass) of the alkanediol having 4 to 6 carbon atoms based on a total mass of the ink satisfy relationships of 0.20≦B / A≦10.0 and 0.10≦C / A≦10.0.

Owner:CANON KK

Modifying agent used for strengthening dimensional stability of compound wax emulsion of quick-growing wood

InactiveCN106363731APlay a stabilizing roleImprove impregnation modification rateWood treatment detailsPressure impregnationMicrocrystalline waxPolyvinyl alcohol

The invention discloses a modifying agent used for strengthening dimensional stability of compound wax emulsion of quick-growing wood. The modifying agent is prepared from the following raw materials in parts by weight: 3-3.5 parts of formaldehyde, 2-3 parts of urea, 1.5-2 parts of hexamethylenetetramine, 0.02-0.03 part of maleic anhydride, a proper amount of acetic acid, a proper amount of ammonia water, a proper amount of deionized water, 20-23 parts of dihydroxymethyl dihydroxyl ethylene urea with solid content being 42wt%, 1.5-2 parts of magnesium chloride hexahydrate, 10-11 parts of silica sol, 3-4 parts of paraffin, 2-3 parts of microcrystalline wax, 3-4 parts of fatty alcohol-polyoxyethylene ether and 2-2.5 parts of polyvinyl alcohol. The modifying agent disclosed by the invention is good in stability, is safe and environmentally-friendly and is suitable for industrial production; impregnation pressure treatment is carried out on the quick-growing wood, so that the modifying agent can penetrate into the wood to achieve waterproof and flexible effects, and therefore, the modified wood is not liable to crack, is resistant to moisture, is good in dimension stability; and furniture manufactured from the wood is strong and durable in use, is waterproof and mildew-proof, and can be used outdoors.

Owner:FUYANG WEIYE FURNITURE

Multifunctional finishing liquor for cotton and linen-cotton fabrics

The invention relates to a textile finishing liquor, especially to a multifunctional finishing liquor for cotton and linen-cotton fabrics. The finishing liquor provided by the invention is prepared from the following raw materials according to the following weight part ratio: modified triazine-5: fatty alcohol: trimethylol ethylene urea: citric acid: chitosan: water =1.0-5.0:0.2-1.2:20-35:10-20:20-30:500-700. By the adoption of the multifunctional finishing liquor, fabrics are comfortable to wear; the appearance of fabrics is flat and smooth; wrinkle resistant, bacterinertness and ultraviolet resistance are obviously raised; light fastness is also improved; it is not easy to generate static electricity; and changes of mechanical properties are within an acceptable range. The multifunctional finishing liquor for cotton and linen-cotton fabrics has advantages of scientific and reasonable formula, less amount, low cost, raised production efficiency and good stability.

Owner:李晓梅

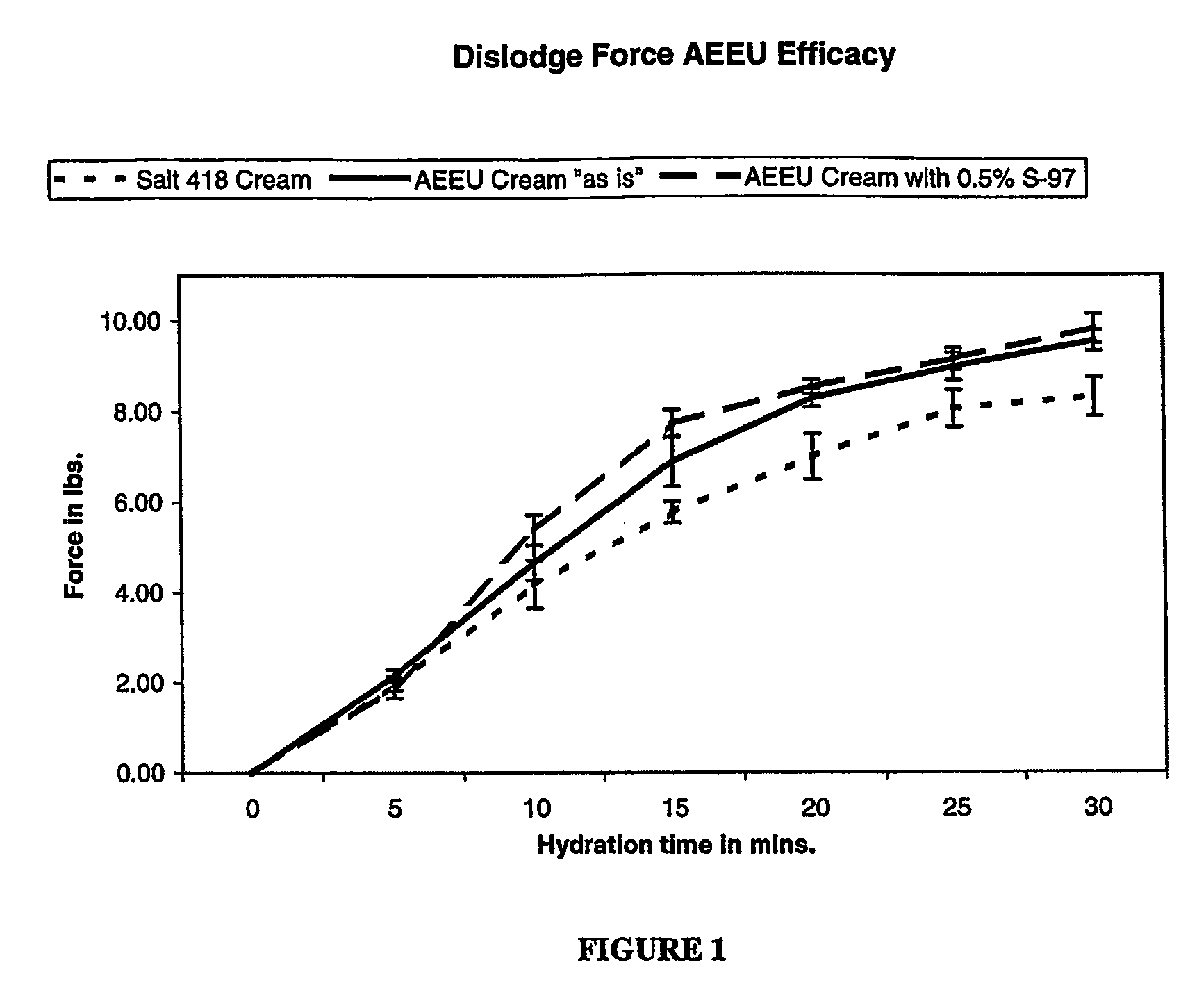

Denture adhesive

InactiveUS20060025494A1High affinityGood retention propertiesImpression capsDentistry preparationsPotassiumEthylene urea

Denture adhesive compositions with sufficient initial adhesion to the gums that build up enough cohesive strength upon hydration with saliva to withstand the stresses occurring during food mastication and cushions the gums from contact with the denture during chewing. The adhesive comprises a mixed partial salt of an amino ethyl ethylene urea substituted polyalkylvinylether / maleic acid copolymer wherein the cations of the salt are selected from the group consisting of zinc, calcium, magnesium, strontium, zirconium, sodium, and potassium.

Owner:SMITHKLINE BECKMAN CORP

Process for synthesizing polyethylene glycol (PEG) phase change thermal insulation material

The invention relates to a process for preparing a composite phase change energy storage material. The composite phase change energy storage material is prepared by coating polyethylene glycol 600 (PEG600) in micropores of expanded perlite, and performing cross-linking reaction on free hydroxy of dimethylol dihydroxy ethylene urea resin and the PEG600 and on the surfaces of the micropores of the expanded perlite for hole sealing to prevent the PEG600 from being lost. The selected phase change energy storage material PEG600 has the phase change temperature of about 20 DEG C, and is non-toxic, harmless, and low in price; micropores on the surface of the phase change energy storage material coated material are sealed by a hole sealing agent, so that the packaged phase change energy storage material is prevented from being leaked; and in addition, porous expanded perlite powder is adopted, so that the material is high in moisture absorption property.

Owner:PANJIN KELONG FINE CHEM

Green and low-toxicity formaldehyde scavenger and preparation method thereof

InactiveCN110801720AInhibition releasePrevent proliferationGas treatmentDispersed particle separationBiotechnologyActive agent

Owner:王再华

Easy-to-clean textile and applications thereof

ActiveCN103174033AGood removal effectImprove hydrophilicityVegetal fibresCarboxymethyl celluloseFiber

The invention discloses an easy-to-clean textile and applications of the easy-to-clean textile. The easy-to-clean textile is formed by 30-90% by weight of cotton staple fiber and 70-10% by weight of polyester staple fiber, a grafting reactant of N-hydroxymethyl dihydroxy ethylene urea and carboxymethyl cellulose sodium is at least attached on the cotton staple fiber, and hydrophilic polyester resin is at least attached on the polyester staple fiber. The collar dirt removal ability and the hydrophilic property of the obtained textile are excellent and the laundering durability is excellent.

Owner:TORAY IND INC

Water-based acrylate pressure-sensitive adhesive and preparation method thereof

InactiveCN113999632AHigh solid contentNo pollution in the processEster polymer adhesivesMethacrylateDiacetonamine

The invention discloses a water-based acrylate pressure-sensitive adhesive and a preparation method thereof. The pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 0.5 to 5 parts of acrylic acid or methacrylic acid, 30 to 50 parts of acrylate monomer, 1 to 10 parts of crosslinking functional monomer, 0.1 to 1 part of initiator, 0.5 to 5 parts of emulsifier, 0.01 to 0.5 part of buffering agent, 0.05 to 3 parts of molecular weight regulator, 0.5 to 10 parts of tackifying resin, 0.5 to 5 parts of pH regulator, 45 to 60 parts of deionized water and 0.5 to 5 parts of water-based additive, wherein the cross-linking functional monomer is at least one of beta-carboxyethyl acrylate, diacetone acrylamide, glycidyl methacrylate, acetoacetic acid ethyl methacrylate, methacrylamide ethyl ethylene urea, ethylidene urea ethyoxyl methacrylate and trimethylolpropane trimethacrylate; and the emulsifier comprises an anionic emulsifier and a nonionic emulsifier, and the weight percentage of the anionic emulsifier in the emulsifier is at least 10%. The water-based acrylate pressure-sensitive adhesive has the advantages of high peel strength, high retention, high adhesion and wide use temperature range.

Owner:ETERNAL CHEM (CHINA) CO LTD

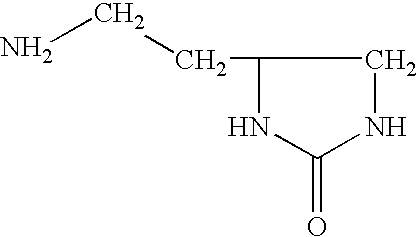

Process to prepare higher ethylene amines or urea derivatives thereof

ActiveUS20200207701A1Organic compound preparationAmino compound preparationUrea derivativesOxocarbon

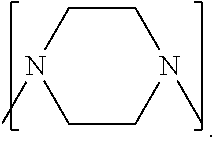

A process is provided for preparing ethylene amines of the formula NH2—(C2H4—NH—)pH wherein p is at least 2, or derivatives thereof wherein one or more units —NH—C2H4—NH— are present as a cyclic ethylene urea unitThe process includes reacting an ethanolamine-functional compound OH—(C2H4—NH—)qH or HO—(C2H4—NH)q—C2H4—OH wherein q is at least 1, and an amine-functional compound NH2—(C2H4—NH—)rH wherein r is at least 1, in the presence of a carbon oxide delivering agent and water, with a molar ratio of water:carbon oxide delivering agent of from about 0.01:1 to about 2:1.

Owner:AKZO NOBEL CHEM INT BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com