Ethylene urea composite nano-material for capturing formaldehyde and preparation method

A technology of composite nanomaterials and inorganic nanomaterials, applied in separation methods, chemical instruments and methods, coatings, etc., can solve the problems of poor ability to capture formaldehyde, low solubility, easy sedimentation and stratification, etc. Hardness and the effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

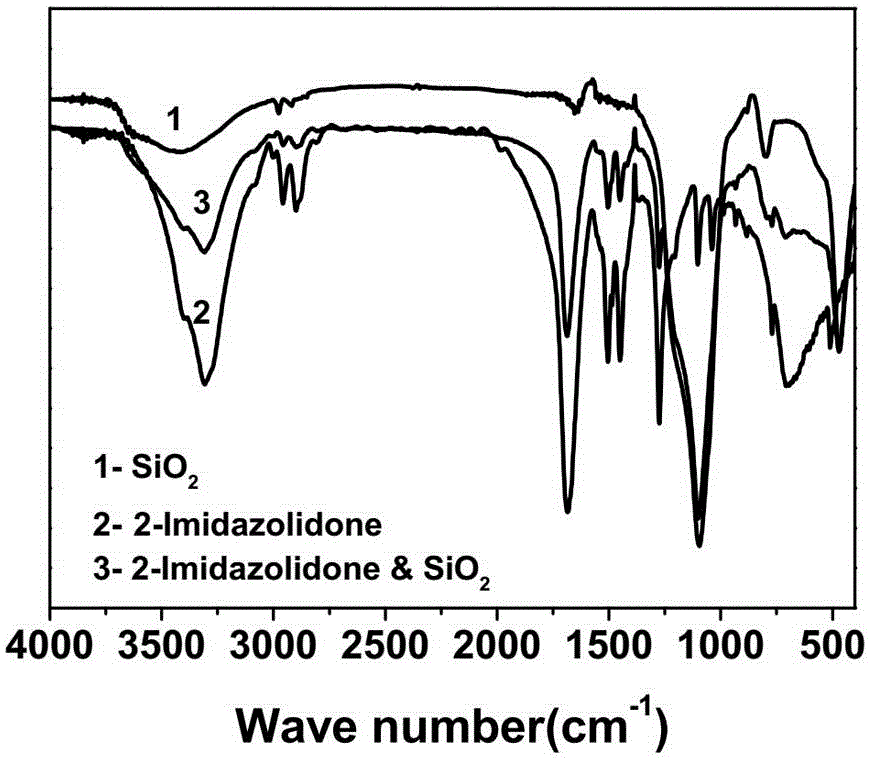

[0025] Pour 500 mL of industrial ethanol into the container of the colloid mill, add 300 g of nano-silica with a particle size of 30-150 nm, stir for 1 h, take out the silica paste, and store it in a container for later use.

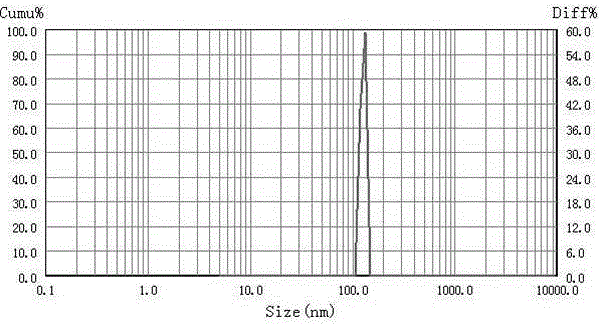

[0026] Take 20 g of the above silicon dioxide, disperse it evenly in 200 mL of ethanol by ultrasonic, add 20 g of ethylene urea particles, and put it in a water bath at 50 ° C for 20 min to dissolve completely, add 8 mL of dispersant sodium polyacrylate solution (20% ), cooled in an ice bath, stirred, and cooled to below 10°C to obtain a silica-ethylene urea composite nanomaterial with a particle size of 110-140 nm, dried at 70°C for 5 h, taken out, ground, weighed, and set aside.

[0027] The content of ethylene urea is about 45% by thermogravimetric analysis. Take a small amount of the above materials and disperse them into xylene and acetone solvents respectively, and let them stand for a month to observe the dispersion effect, which is uniform as befo...

Embodiment 2

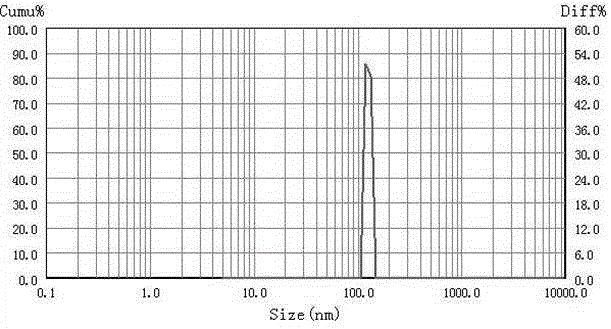

[0030] Pour 500 mL of industrial ethanol into the container of the colloid mill, add 300 g of calcium carbonate powder with a particle size of 50–100 nm, stir for 1 h, take out the calcium carbonate paste, and store it in a container for later use.

[0031] Take 100 g of the above calcium carbonate, ultrasonically disperse it in 1 L of ethanol, add 150 g of ethylene urea particles, and put it in a water bath at 50 ° C for 30 min to dissolve completely, add 8 mL of 1,6-hexanediol diacrylate solution (12%), cooled in an ice bath, stirred, and cooled to below 15°C to obtain calcium carbonate-ethylene urea composite nanomaterials with a particle size of 110-140 nm, dried at 70°C for 5 hours, taken out, ground, weighed, and set aside .

[0032] The content of ethylene urea is about 36% based on the data analyzed by thermogravimetric analyzer. Take a small amount of the above materials and disperse them in xylene and acetone solvent respectively, and let them stand for a month to ob...

Embodiment 3

[0035] Pour 500 mL of industrial ethanol into the container of the colloid mill, add 300 g of titanium dioxide powder with a particle size of 100-200 nm, stir for 1 h, take out the titanium dioxide paste, and store it in a container for later use.

[0036] Take 200 g of the above titanium dioxide, ultrasonically disperse it in 3 L of ethanol, add 400 g of ethylene urea particles, and put it in a water bath at 50 ° C for 20 min to dissolve completely, add 20 mL of polyamide solution (6%), and cool down in an ice bath , stirred, and cooled to below 15°C to obtain a titanium dioxide-ethylene urea composite nanomaterial with a particle size of 170-250nm, dried at 70°C for 5 hours, taken out, ground, weighed, and set aside.

[0037] The content of ethylene urea is about 33% based on the data analyzed by thermogravimetric analyzer. Take a small amount of the above materials and disperse them in xylene and acetone solvent respectively, and let them stand for a month to observe the dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com