Patents

Literature

94 results about "UREA POWDER" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Urea is a colorless or white crystalline powder; it can also occur in the form of small white pellets.

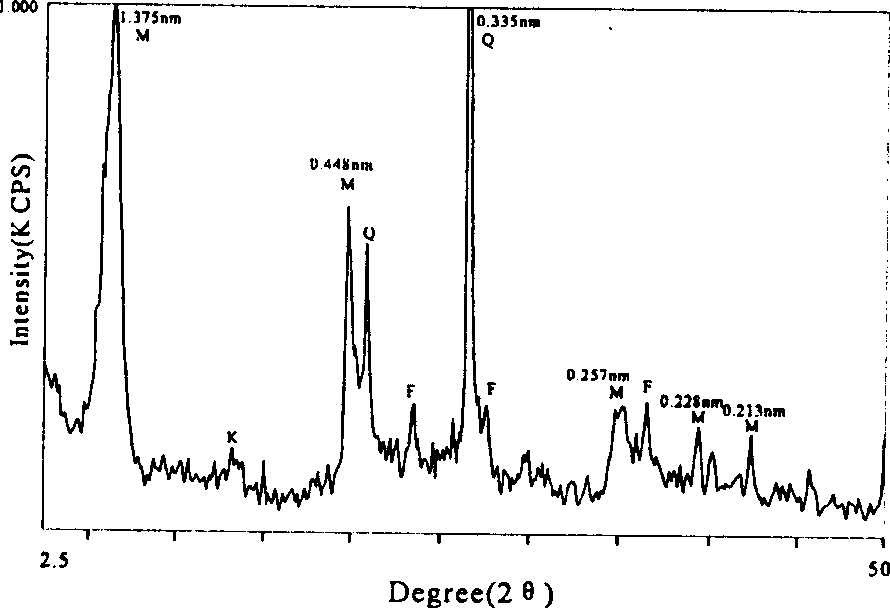

Method for preparing high-purity montmorillonite

The invention relates to a process for preparing high-purity montmorillonite, which consists of mixing alta-mud powder, sodium salt powder, and urea powder homogeneously, charging water into dispersible alta-mud, stirring for pulping, and carrying out centrifugal classification. The weight ratio of alta-mud powder, sodium salt powder and urea powder is 1:0.02-0.1:0.03-0.2.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

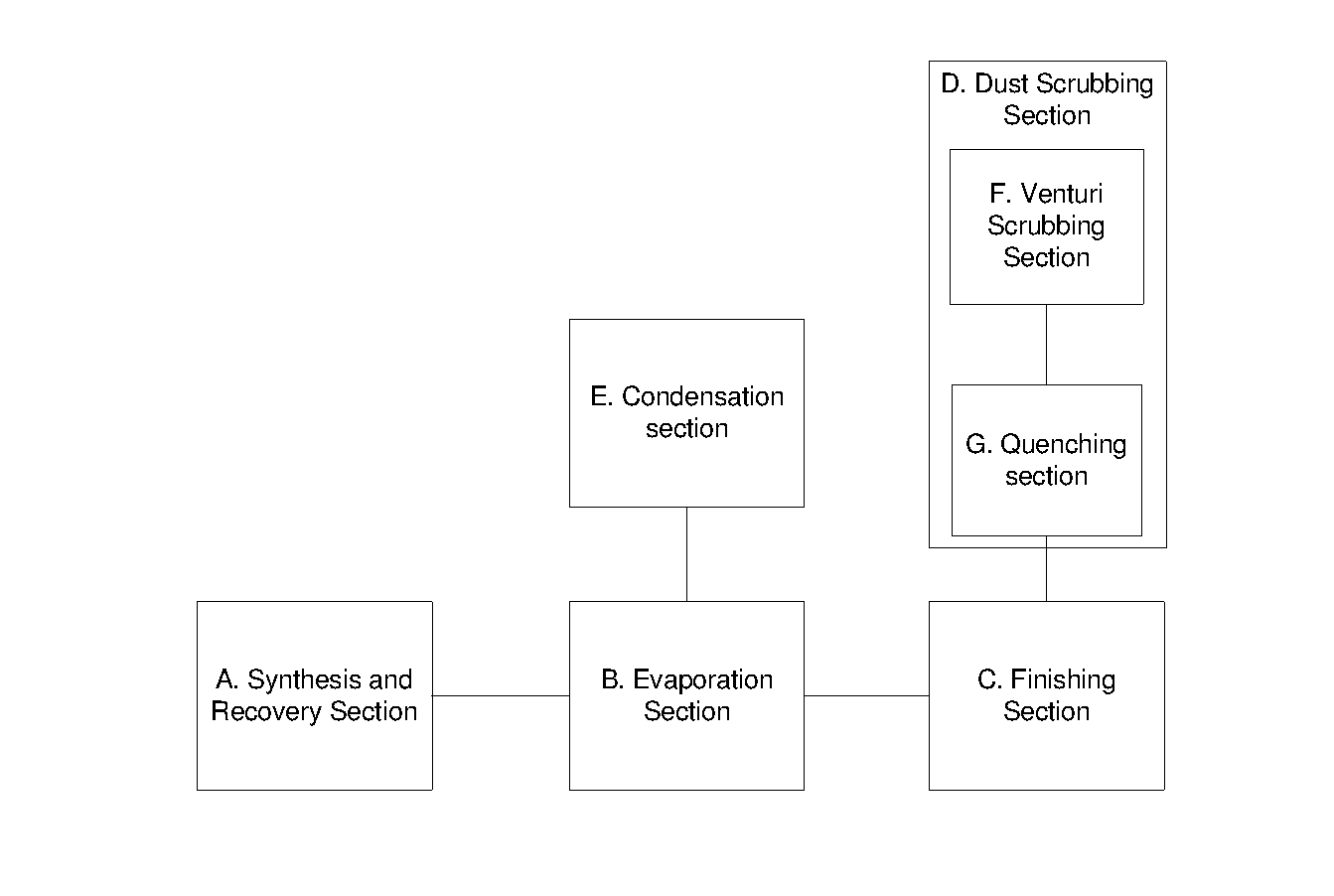

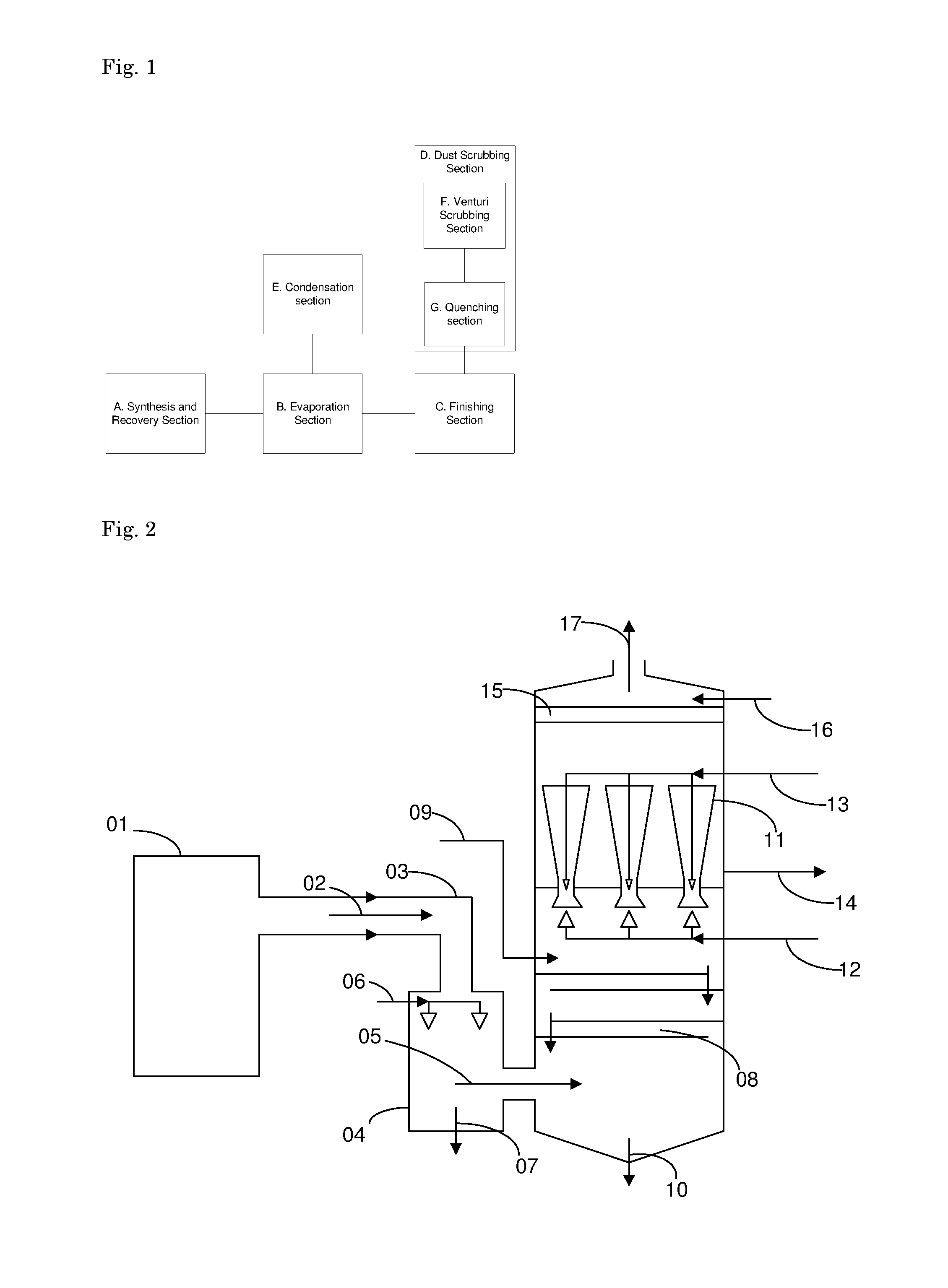

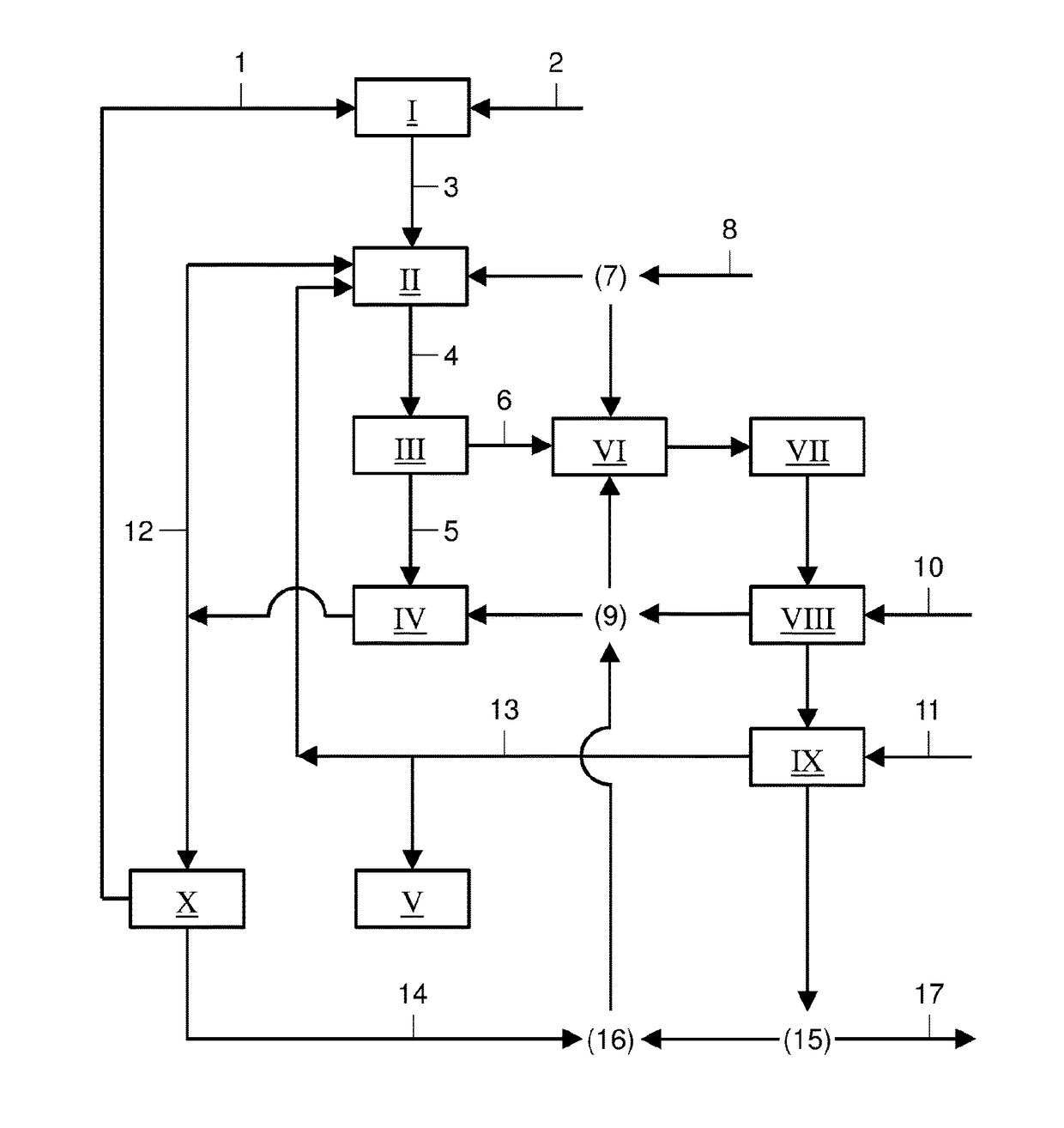

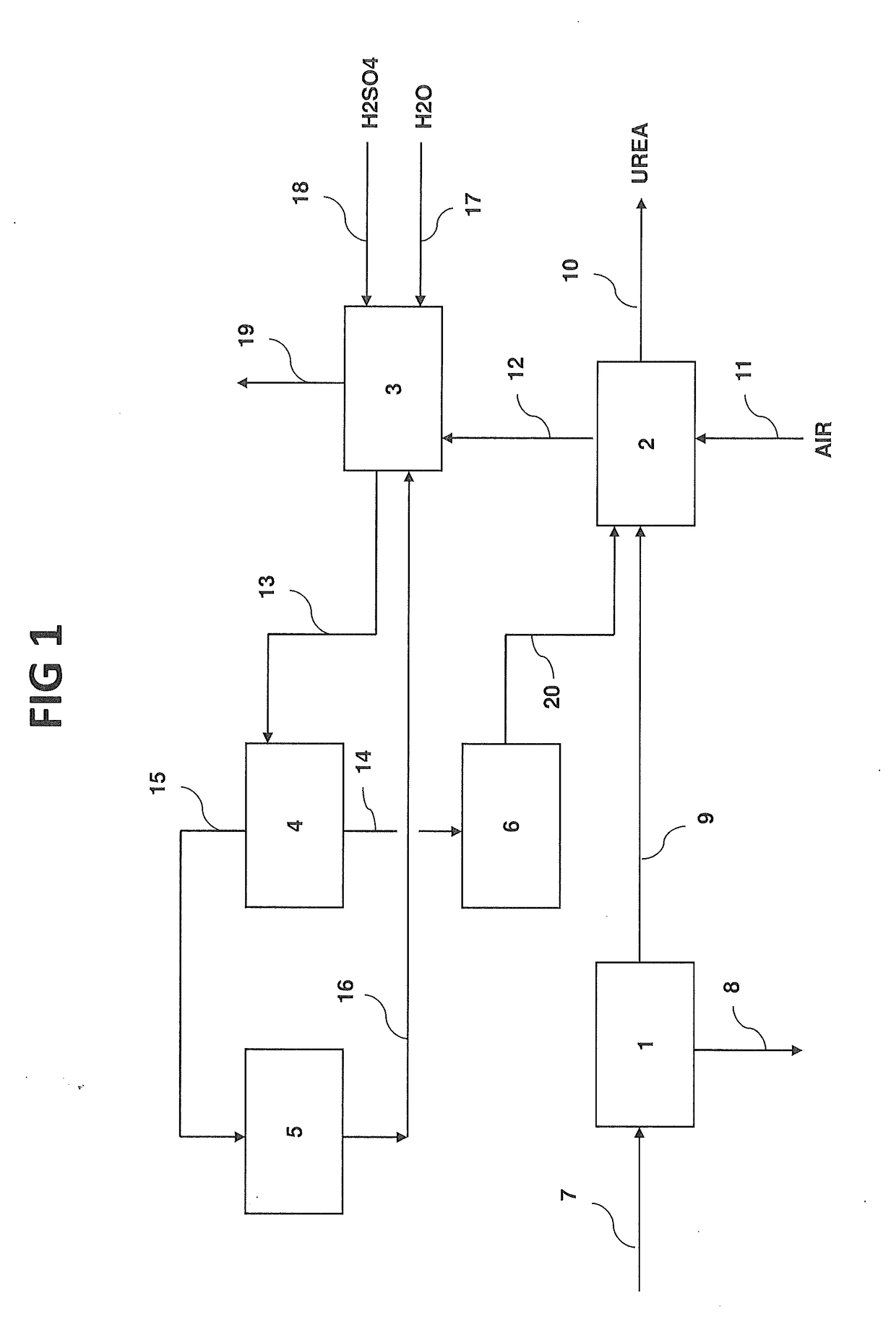

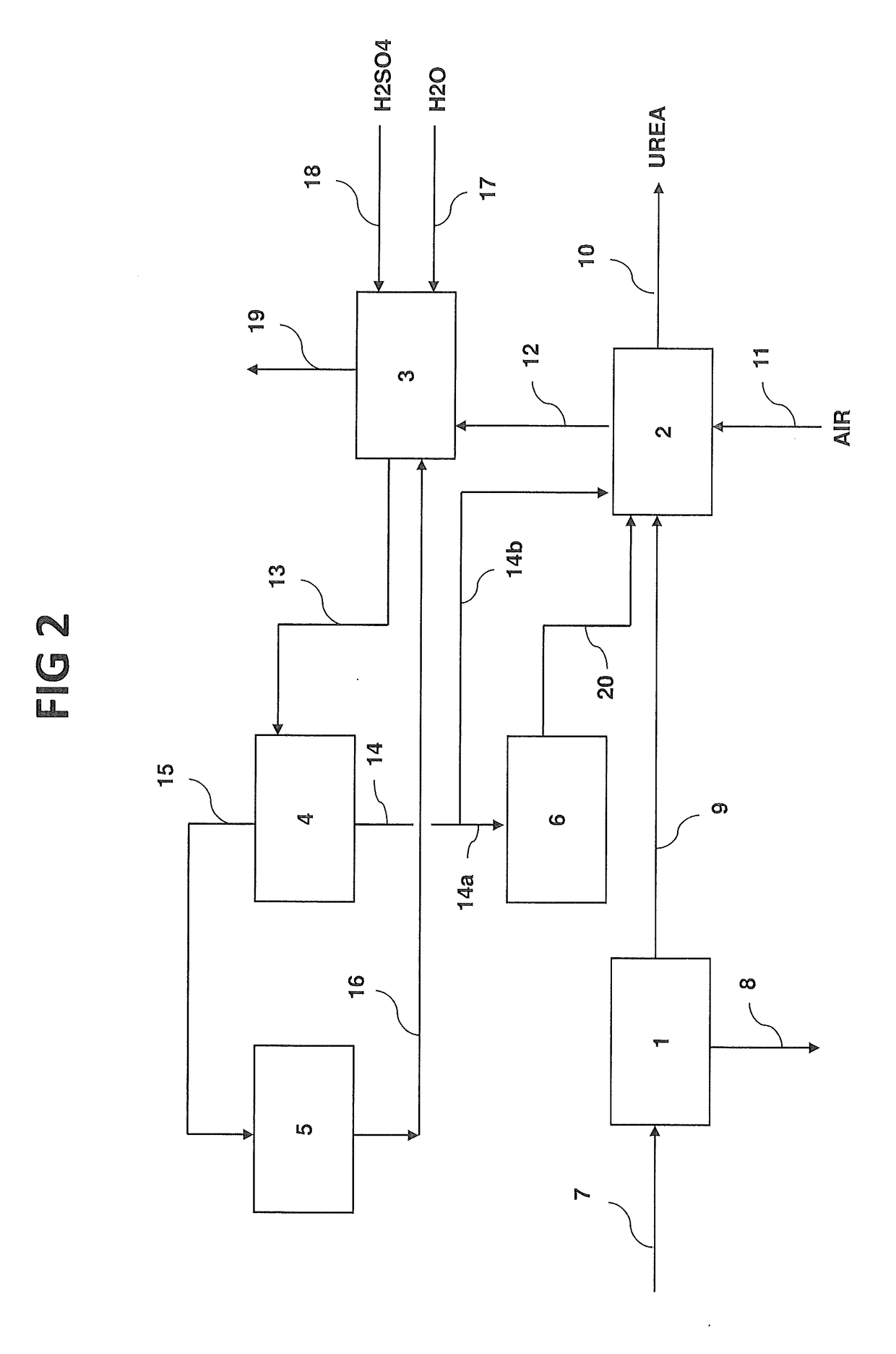

Removal of dust in urea finishing

Disclosed is a method for the removal of urea dust from the off- gas of a finishing section (1) of a urea production plant, the method comprises subjecting the off-gas to quenching with water (06) so as to produce quenched off-gas, and subjecting the quenched off-gas to scrubbing using at least one venturi scrubber (11). As a result, a lower pressure drop over the scrubber is attained, and a more efficient growth of urea particles, facilitating the removal thereof.

Owner:STAMICARBON BV

Process for preparing bentonite based sodium with high expension performance by drying method

Owner:湖北三鼎科技有限公司

SnS2/g-C3N4 composite nanosheet photocatalyst and preparation method thereof

InactiveCN103934012AImprove the performance of degrading organic dyesReduce chance of recombinationPhysical/chemical process catalystsWater bathsOrganic dye

The invention discloses a SnS2 / g-C3N4 composite nanosheet photocatalyst which is formed from two sheet layer materials, namely a SnS2 nanosheet and a g-C3N4 nanosheet. A preparation method of the composite nanosheet photocatalyst comprises the following main steps: putting tetrachlorostannane pentahydrate and a thioacetamide solution into a reaction kettle, performing hydrothermal reaction on the sealed reaction kettle in an electric dry oven, taking out a product, performing centrifugal separation to obtain a yellow precipitate, and washing and drying the product to obtain the SnS2 nanosheet; putting urea powder into a crucible, covering the crucible, and heating the covered crucible in a muffle furnace to obtain the yellow g-C3N4 nanosheet; and putting the SnS2 nanosheet and the g-C3N4 nanosheet into a methanol solution, ultrasonically treating in a water bath, magnetically stirring, removing methanol, putting into the reaction kettle, and heating the reaction kettle in the electric dry oven. The composite nanosheet photocatalyst can be used for effectively treating organic dye sewage; besides, the preparation method is simple and the cost is low.

Owner:DALIAN NATIONALITIES UNIVERSITY

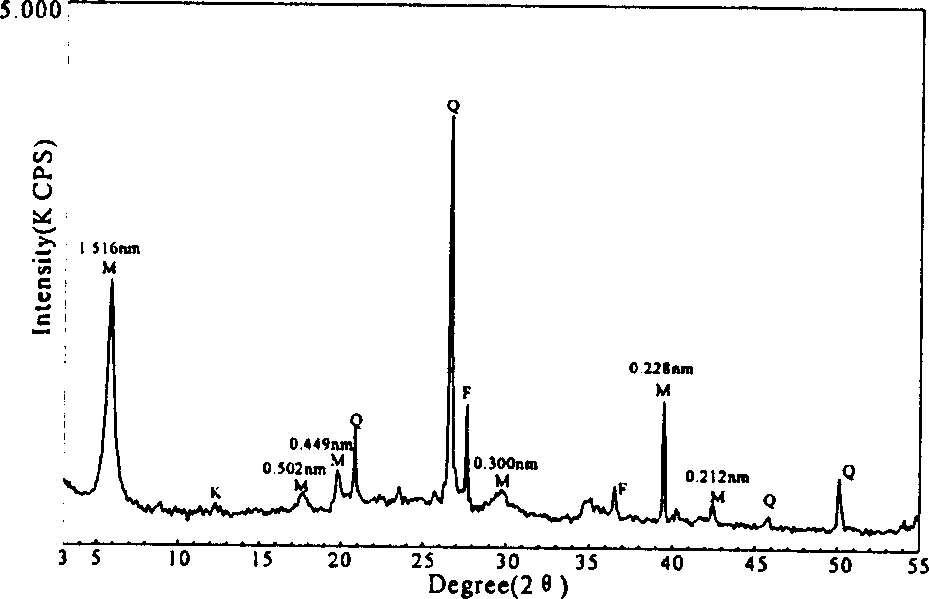

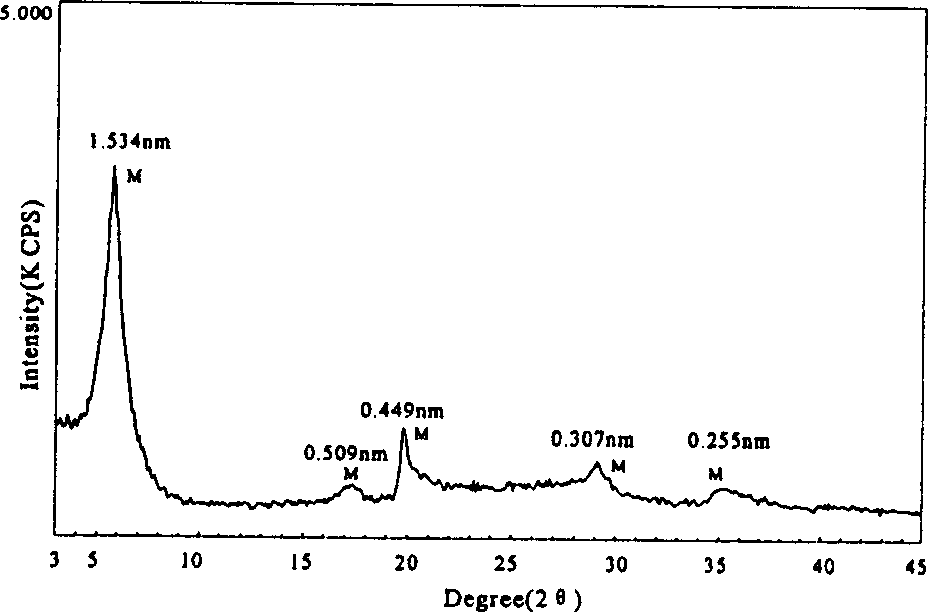

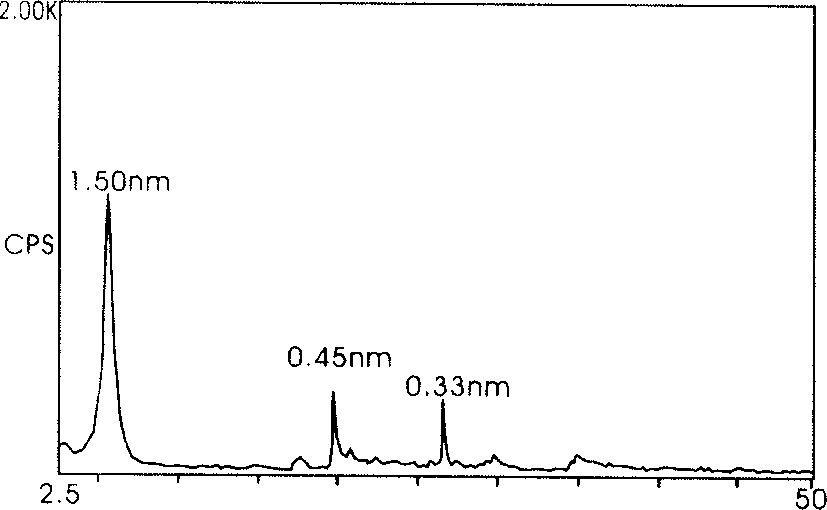

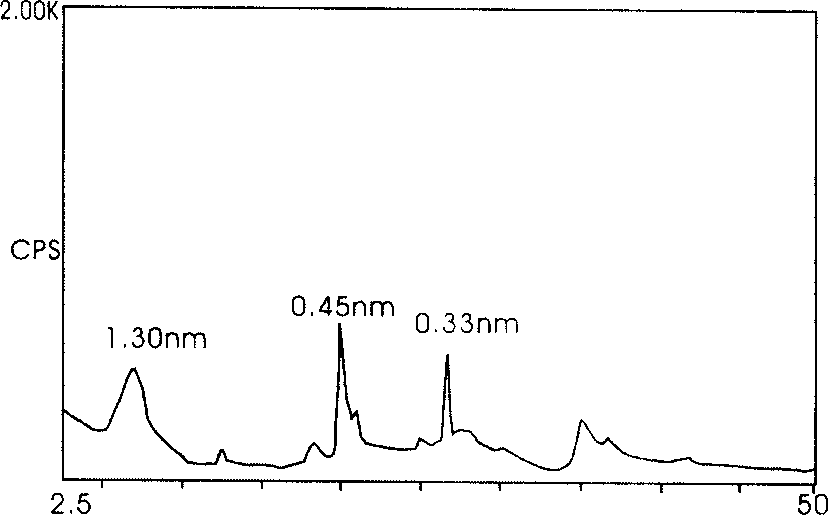

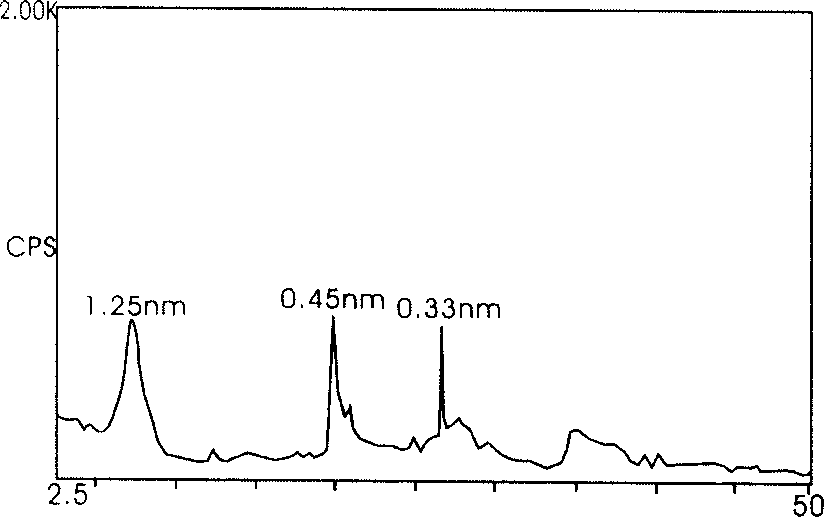

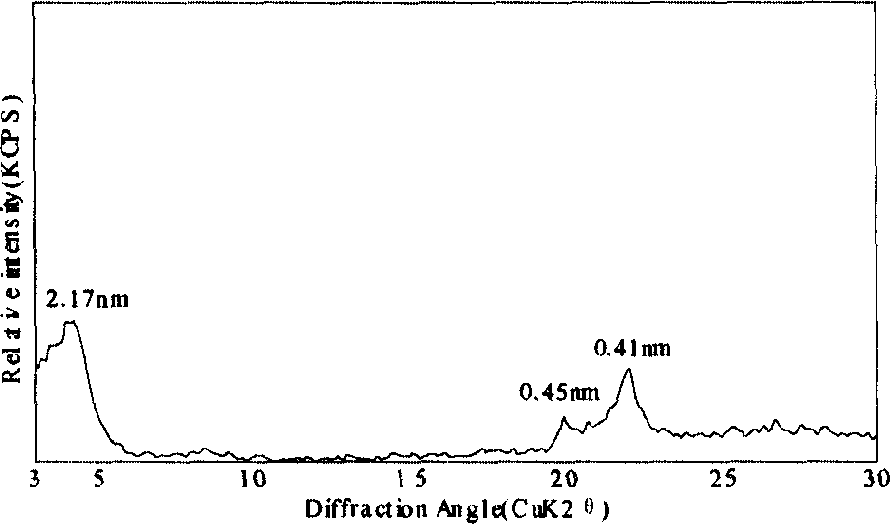

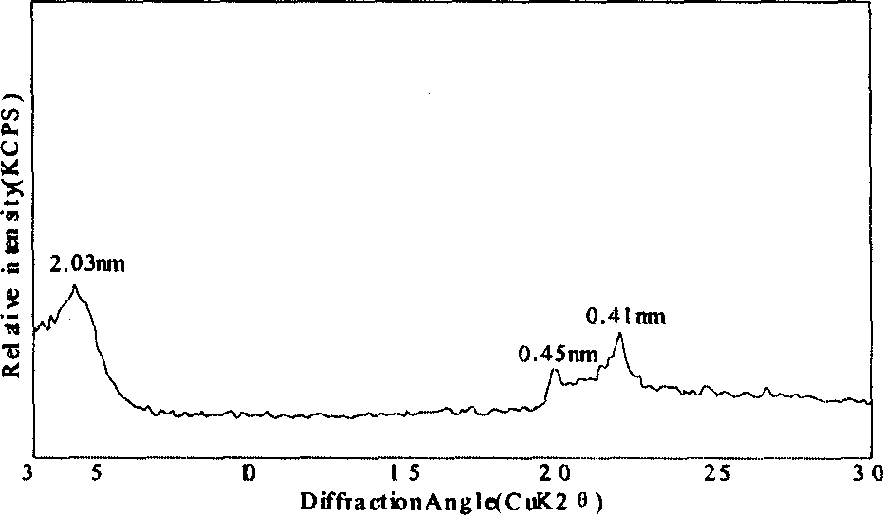

Dry method for preparing intercalation compound of monotomorillonite/urea

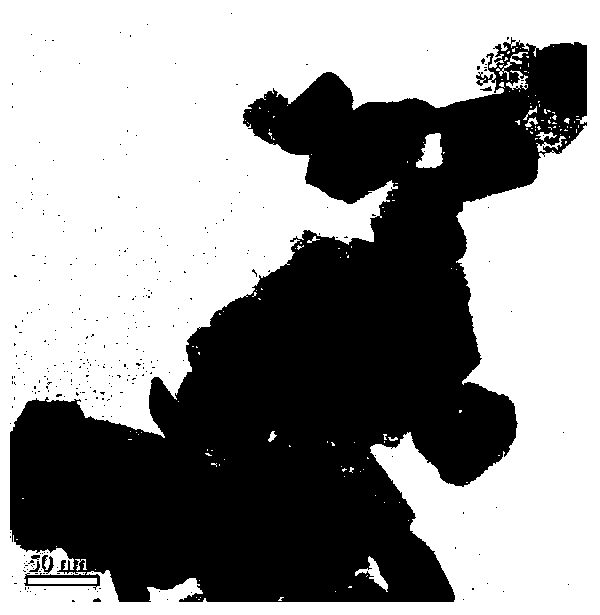

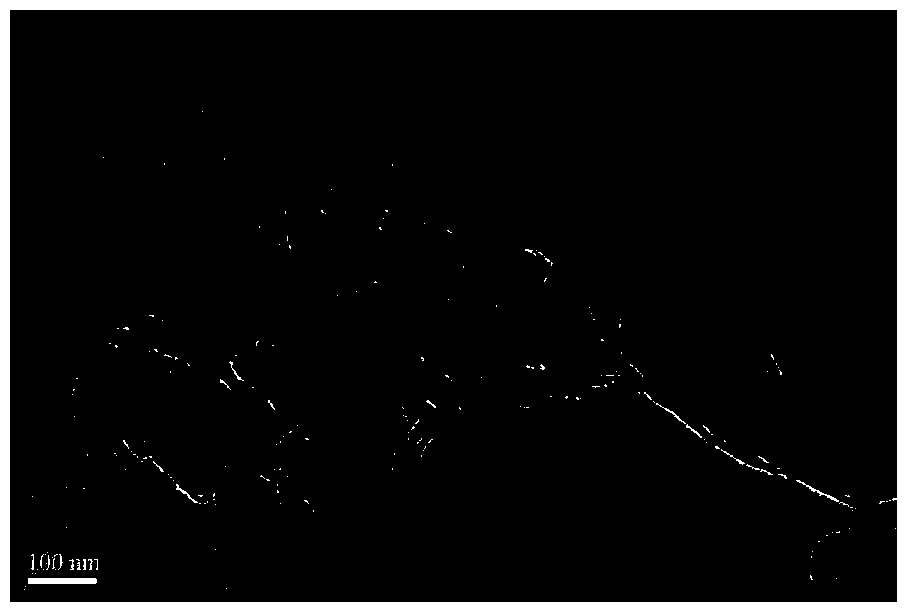

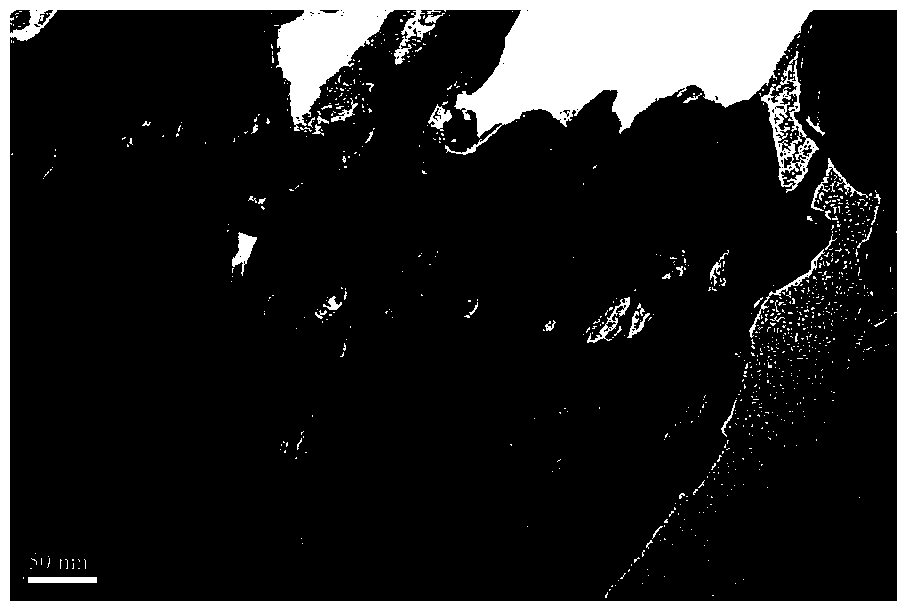

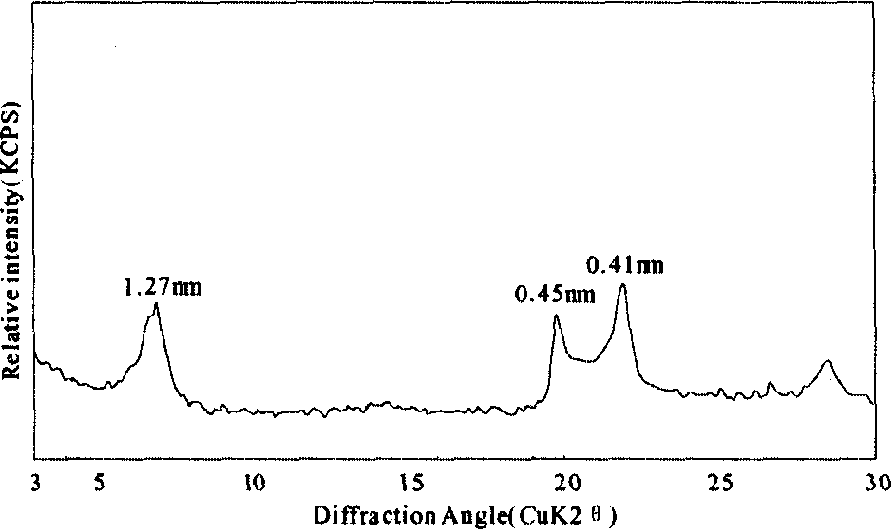

InactiveCN1563207ALow costOvercoming easy cakingInorganic pigment treatmentMontmorilloniteCrystal structure

A method for preparing intercalation composite of imvite / urea is featured as mixing sodium-base or calcium-base imvite powder material in diamemter of less than 45 micron m with urea powder uniformly, holding the mixture for 1-3 hr. at constant temperature to have urea molecule entered into interlayer of imvite crystal structure and obtaining the intercalation composite by expanding interlayer distance from 1.27nm-1.55 nm to 1.68 nm to 2.17 nm on imvite face.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

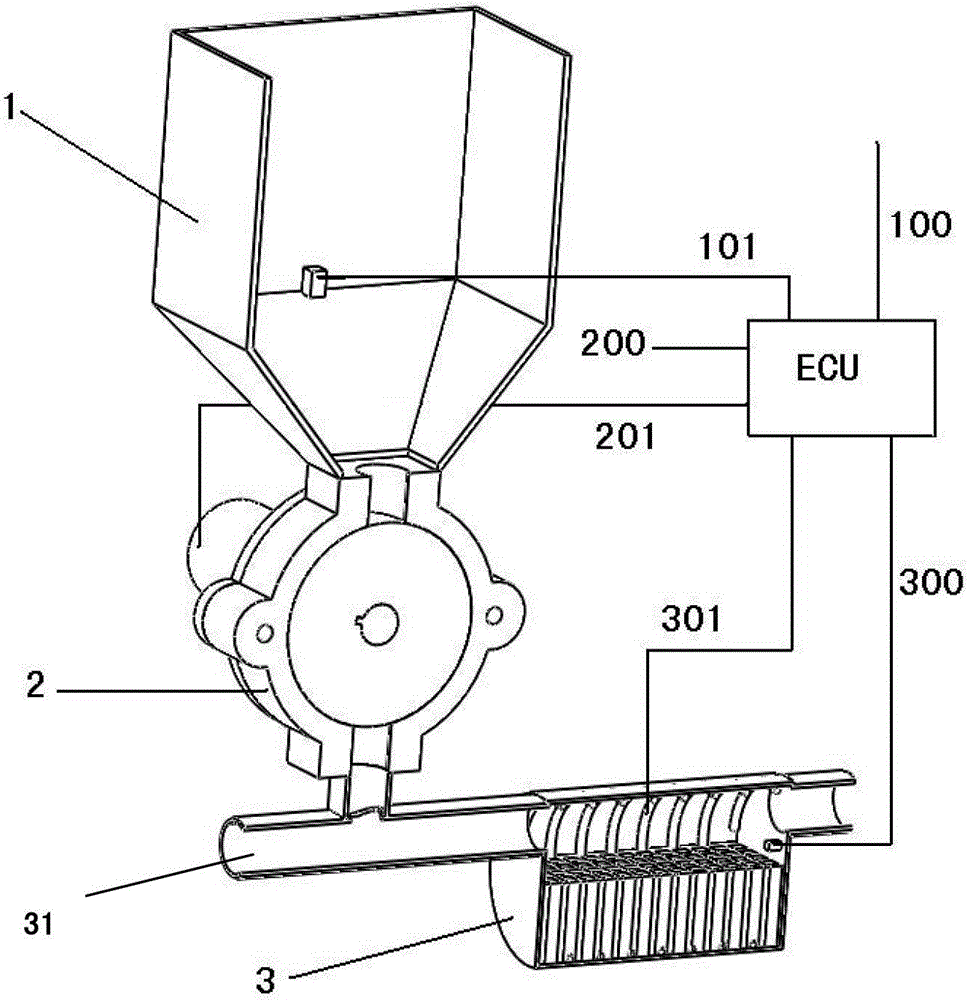

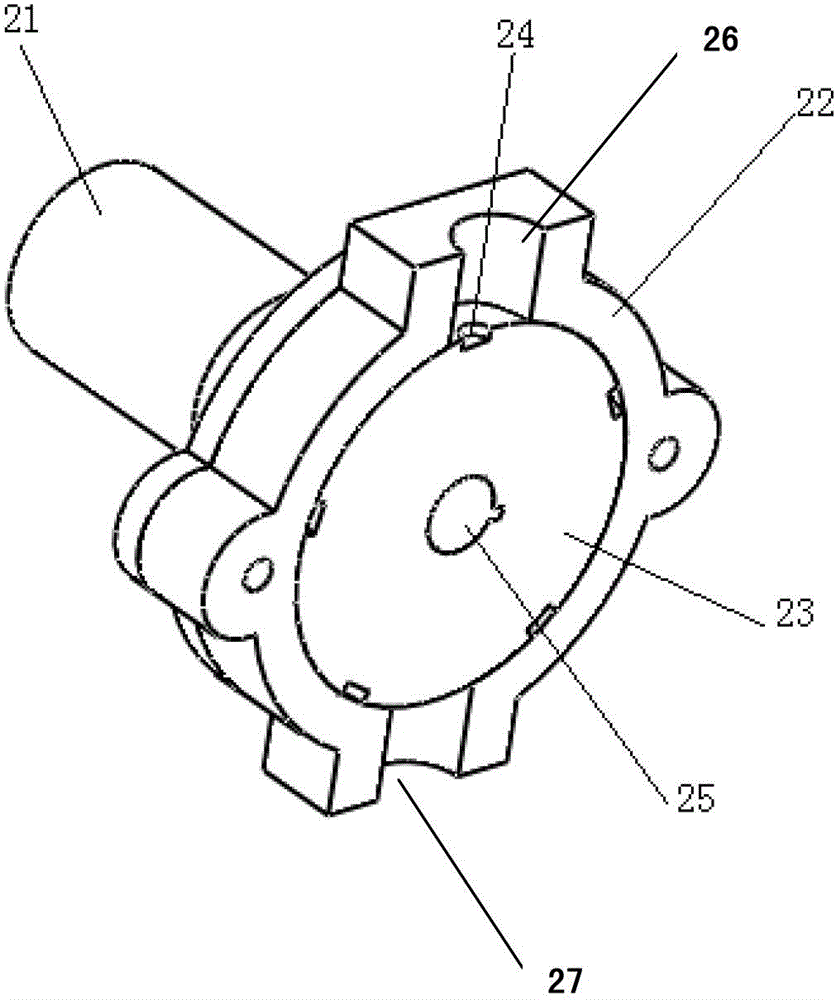

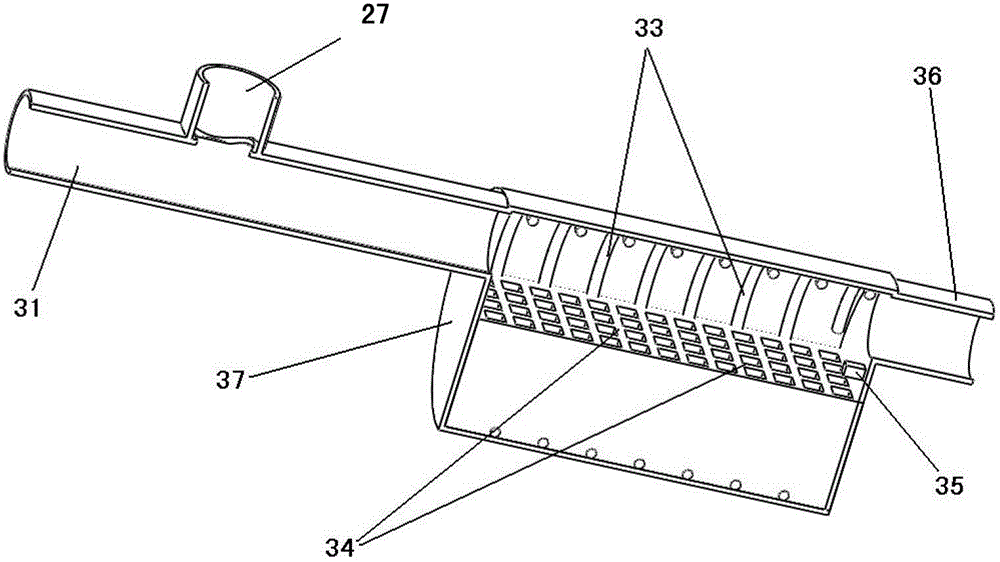

Device for quantitatively generating ammonia from solid urea

InactiveCN102943703ASolve the inconvenienceEffective use of momentumExhaust apparatusSilencing apparatusNitric oxideNitrogen oxide

The invention belongs to the technical field of denitration during a motor vehicle exhaust treatment process, and relates to a device for quantitatively generating ammonia from solid urea so as to reduce nitric oxides in motor vehicle exhaust. The device is composed of a solid urea storage tank, a solid urea quantitative lead-out device and a urea reaction cavity, wherein urea powder in the urea storage tank is accurately and quantitatively led out via the solid urea quantitative lead-out device, enters in an exhaust branch tube under the action of gravity, and is sprayed onto a urea catalyst carrier in the urea reaction cavity under the air injection function of the exhaust. The urea sprinkled on the surface of the catalyst carrier is rapidly reacted to generate ammonia in the presence of a catalyst, the generated ammonia is led out to an exhaust tube via an ammonia lead-out tube under the action of the exhaust flow, and enters into an SCR (selective catalytic reduction) reactor installed on the exhaust tube together with NOx in the exhaust, thus performing SCR reaction. Via the device, the disadvantages of the prior art in the field are solved to a certain extent; and the device has the advantages of low energy consumption, great efficiency, strong practicability, simple equipment, high safety, and the like.

Owner:JILIN UNIV

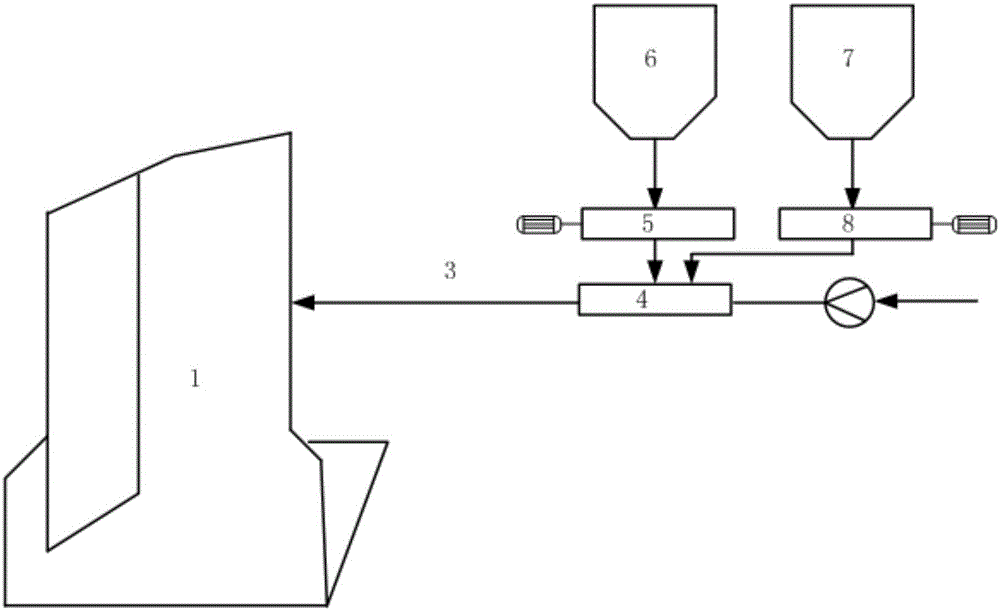

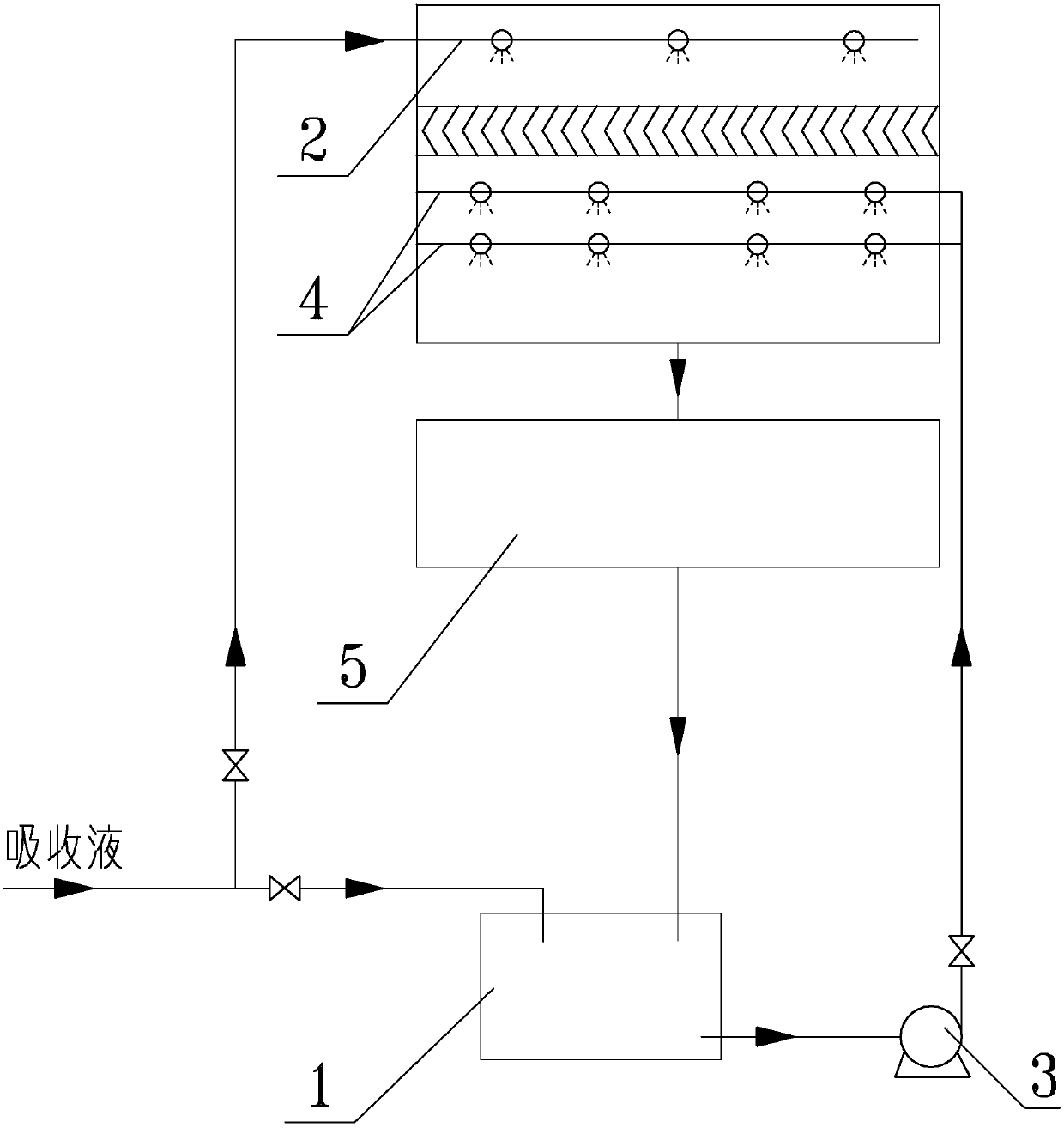

In-boiler desulfurization and denitration system and method for chain grate boiler

The invention discloses an in-boiler desulfurization and denitration system and method for a chain grate boiler. The system comprises the chain grate boiler, a feed bin and a smoke and powder mixer, wherein the feed bin is used for providing a space for containing a desulfurization agent and / or a denitration agent; the smoke and powder mixer is connected with the feed bin, a flue gas pipeline and the chain grate boiler respectively; flue gas is mixed with the desulfurization agent and the denitration agent in the smoke and powder mixer to provide power to deliver the desulfurization agent and the denitration agent to an injection pipeline component mounted in the chain grate boiler for injection; the desulfurization agent and the denitration agent are a calcium-based desulfurization agent and urea powder respectively. The desulfurization agent and the denitration agent are delivered into the chain grate boiler through the tail flue gas of the boiler, so that the urea powder can be effectively prevented from absorbing moisture for agglomeration; in addition, compared with that of hearth flue gas, the temperature and oxygen content of the tail flue gas are lower, so that an area of which the temperature is relatively proper and the oxygen concentration is relatively lower can be provided for denitration reaction in a higher-temperature area of a hearth, and the problems of instable hearth temperature, small reaction space and the like of the chain grate boiler can be solved.

Owner:SHANDONG SHENHUA SHANDA ENERGY ENVIRONMENTAL +1

Urea Compositions With Cooling Effect

The present invention includes a urea powder, the particles of which are encapsulated in a dimethicone and silica network, prior to being incorporated into anhydrous compositions. The encapsulated urea is capable of imparting a cooling activity to a topical composition. The invention also pertains to topical, cooling compositions containing an encapsulated urea. The encapsulated urea is new and its use to impart a cooling activity to topical anhydrous compositions is new. Topical, anhydrous compositions comprising the encapsulated urea are also new. Anhydrous compositions containing the urea are stable against hydrolysis that might otherwise occur due to the ambient humidity. Disclosed compositions create a clean and fresh feel for a user.

Owner:ELC MANAGEMENT LLC

Water-soluble compound fertilizer for activating soil and realizing no-tillage and preparation method for water-soluble compound

InactiveCN102329166ASolve the inconvenience of Shi Yi touching the branches and damaging the fruitSolution conditionsFertilizer mixturesSolubilityMonopotassium phosphate

The invention relates to a water-soluble compound fertilizer for activating soil and realizing no-tillage and a preparation method for the water-soluble compound. The water-soluble compound fertilizer is prepared from the following raw materials in percentage by weight: 15 percent of urea, 50 percent of monopotassium phosphate, 25 percent of humic acid and 10 percent of bacillus subtilis microbial inoculum. The preparation method comprises the following steps of: 1) crushing the urea; 2) culturing the bacillus subtilis microbial inoculum; 3) sequentially adding urea powder, the humic acid and the monopotassium phosphate into a continuous reaction kettle; 4) adding the bacillus subtilis microbial inoculum and performing secondary blending; and 5) packaging and warehousing. The invention has the advantages that: the fertilizer has quick action and long action, and can directly provide nutrition for crops and activate immobilized nutrition in the soil, activate the soil and inhibit bacteria in the soil, increase the yield and improve the quality, promote the development of root systems and improve the water and fertilizer retention capacity of soil, and effectively increase soil fertility and reduce the using amount of chemical fertilizers; and the water solubility of the product is over 98 percent, and the product is applied together with water or injected into the soil by using a fertilizing gun, is simple, convenient and easy, and is labor-saving and cost-saving.

Owner:张铭强

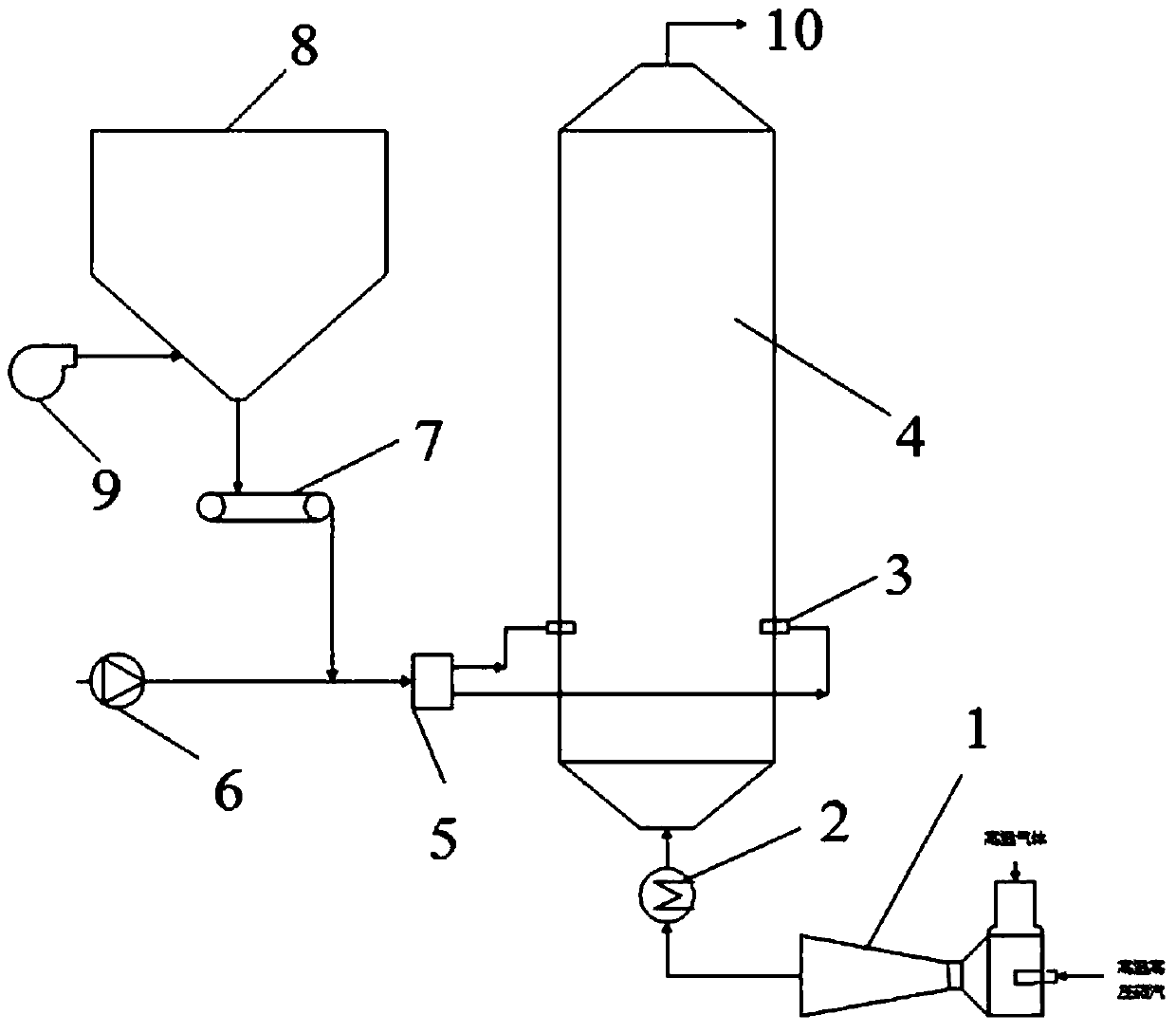

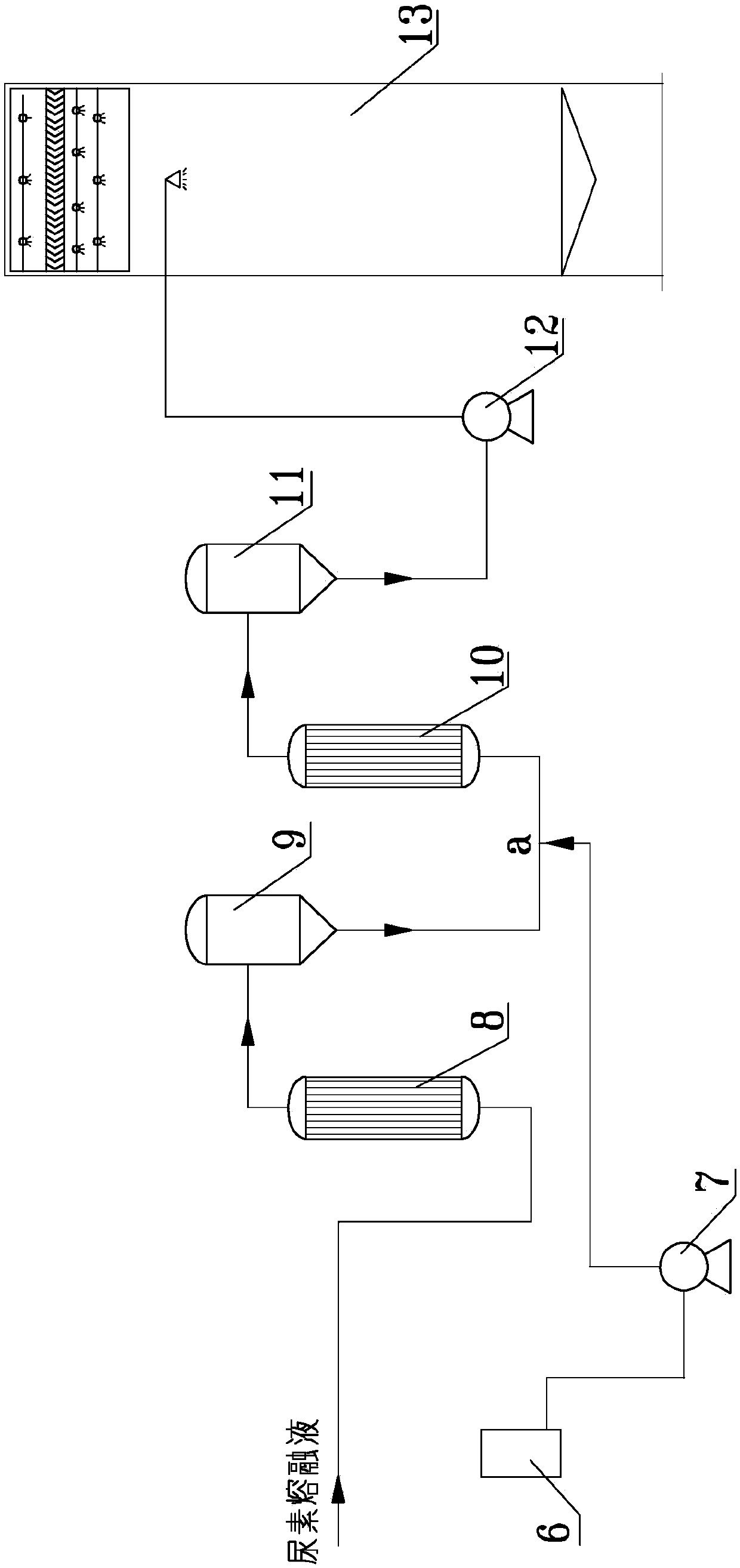

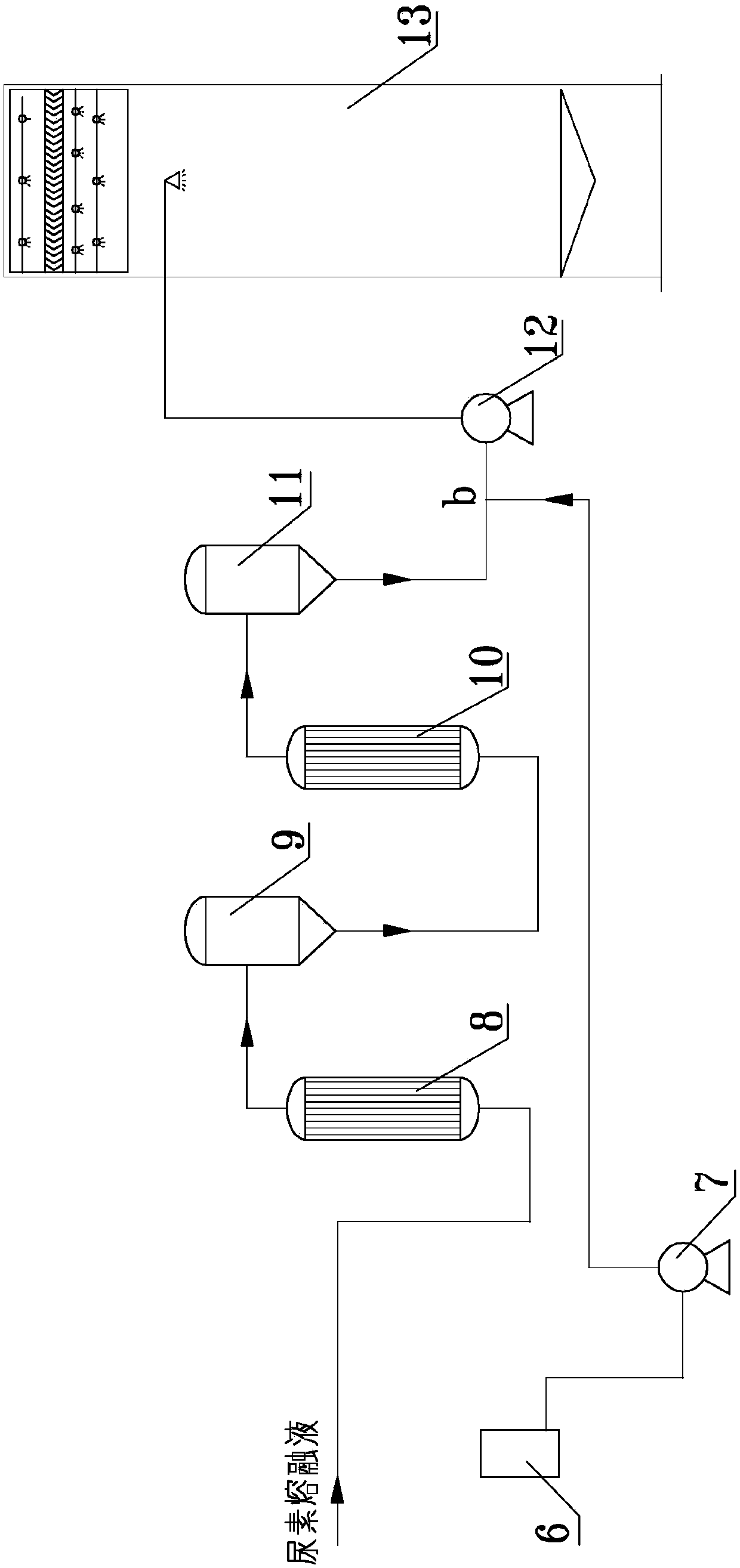

Dry type urea pyrolysis ammonia preparation system and method

PendingCN107739036AGuaranteed conversion rateReduce power consumptionChemical industryAmmonia preparation/separationWater vaporHigh pressure

The invention relates to a dry type urea pyrolysis ammonia preparation system and a dry type urea pyrolysis ammonia preparation method. The dry type urea pyrolysis ammonia preparation system is characterized by comprising an ejector, an electric heater, a power feeding opening, a pyrolyzing furnace, a distributor, a Roots blower, a metering feeding machine, a urea storage cabin and a fluidizationfan; an outlet of the ejector is connected with an inlet of the electric heater; an outlet of the electric heater is communicated with the bottom of the pyrolyzing furnace; an outlet of the fluidization fan is communicated with the bottom of the urea storage cabin; an outlet of the urea storage cabin is communicated with the metering feeding machine; a discharging opening of the metering feeding machine and an outlet of the Roots blower communicate with an inlet of the distributor after being merged; an outlet of the distributor is communicated with an inlet of the power feeding opening; an outlet of the power feeding opening is formed in the pyrolyzing furnace. According to the dry type urea pyrolysis ammonia preparation system and the dry type urea pyrolysis ammonia preparation method, urea solution is replaced by adopting urea powder; the system is simplified; the investment is reduced; pipeline corrosion and crystallization are avoided; high-temperature gas is pressurized by ejecting high-temperature high-pressure vapour, so that the system is energy-saving and reliable; meanwhile, water vapour and gas can be mixed uniformly, so that the conversion rate of urea pyrolysis is ensured.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

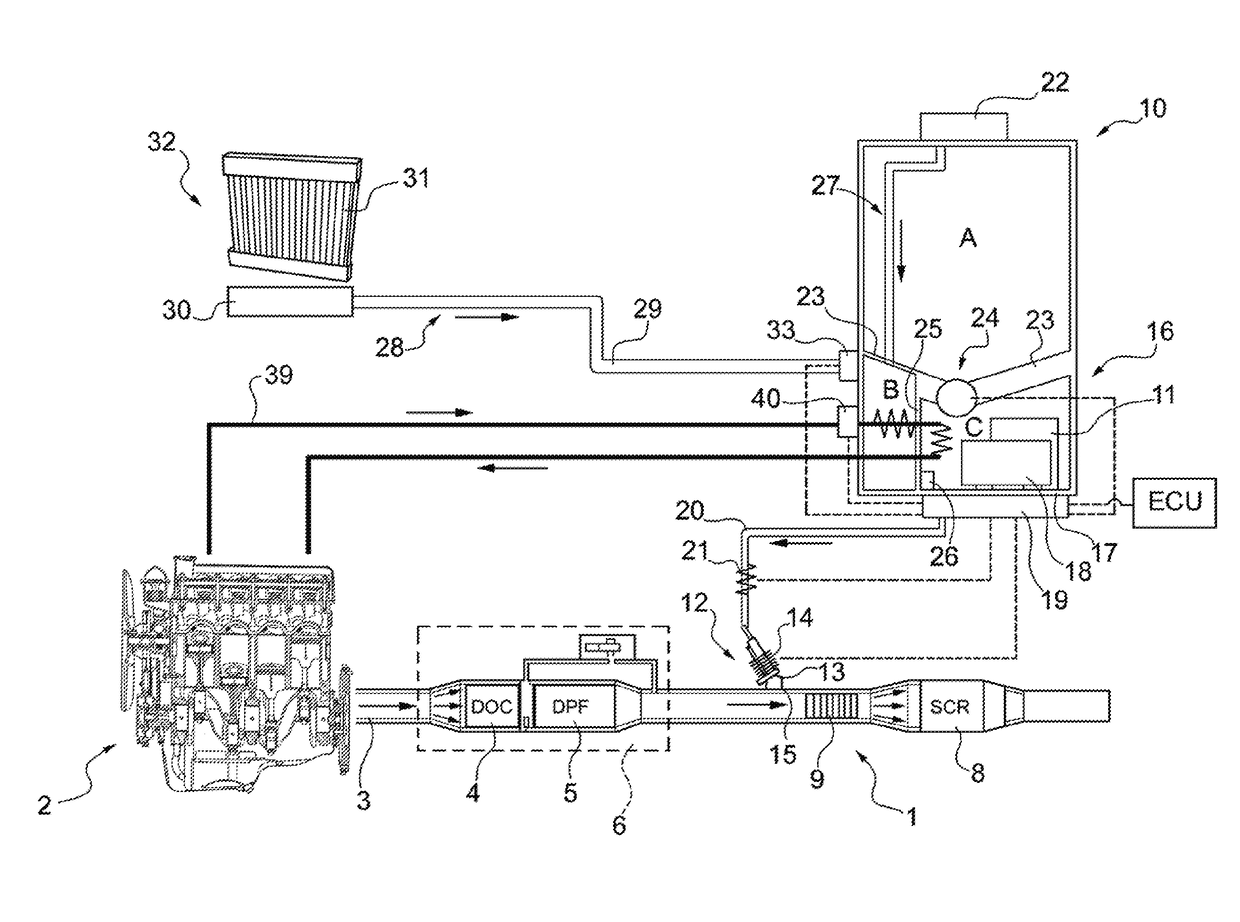

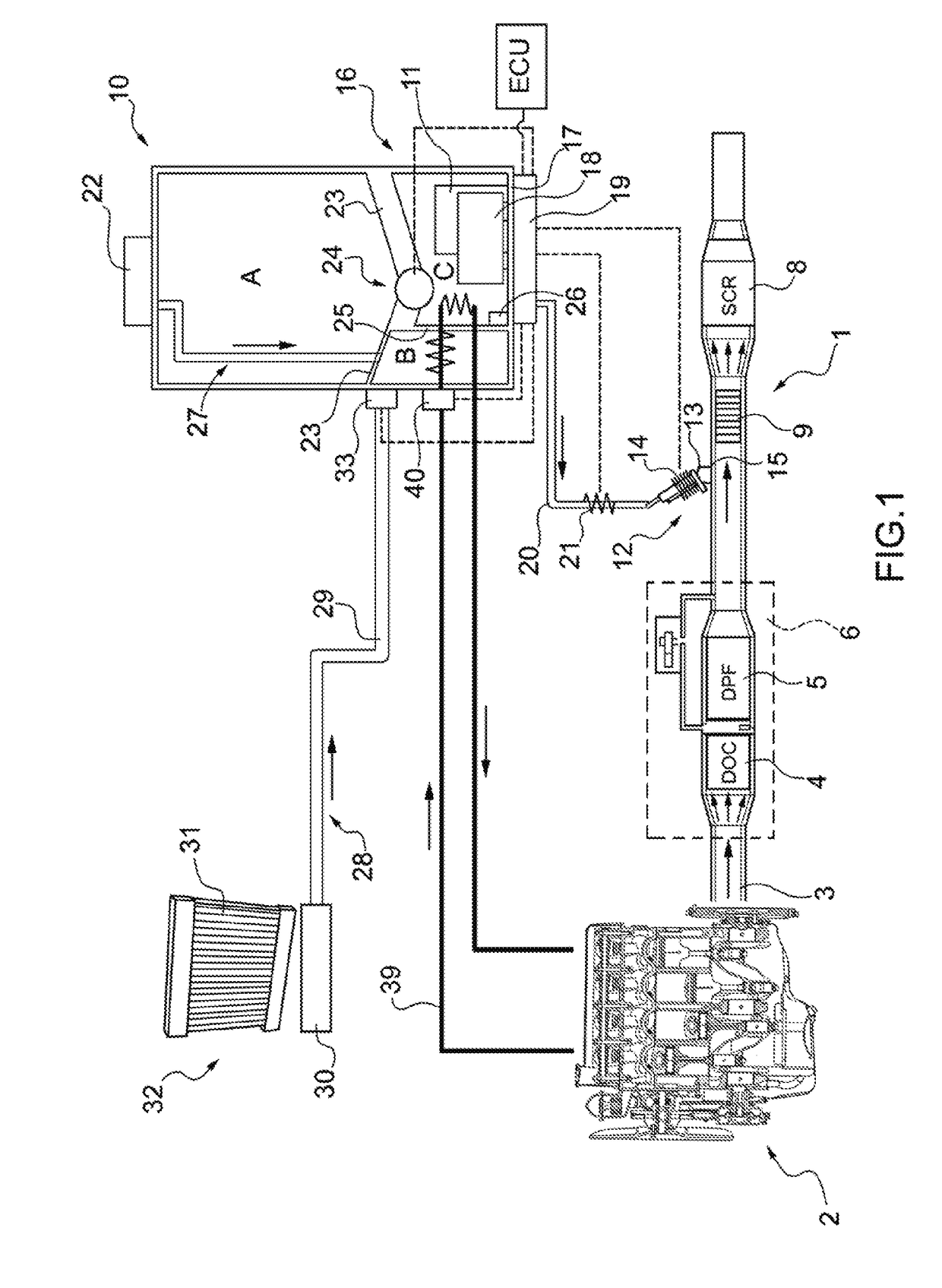

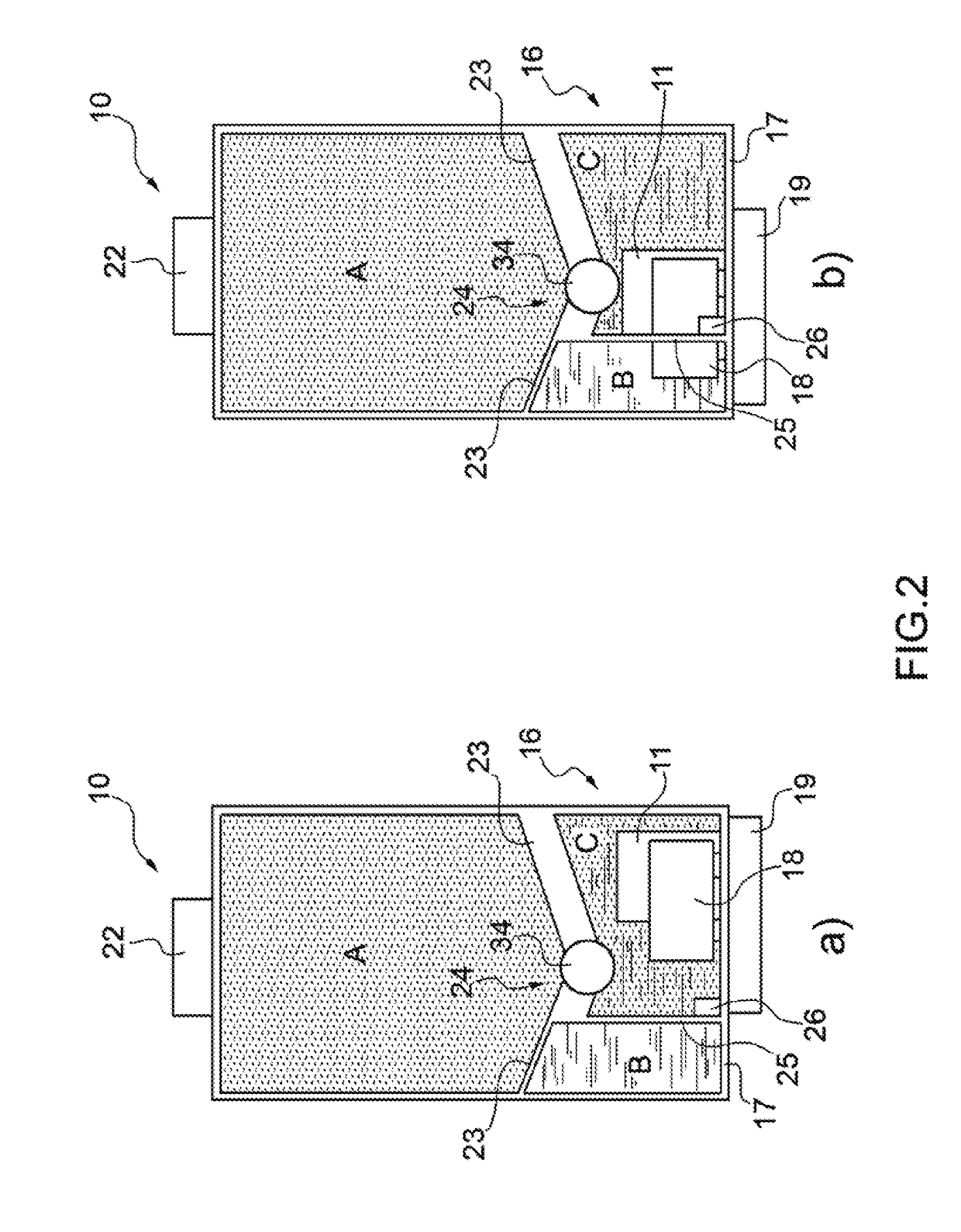

Method and apparatus to supply water to a tank of an exhaust system provided with exhaust gas after-treatment for a combustion engine

ActiveUS20180258812A1Small impactEasy to implementInternal combustion piston enginesExhaust apparatusCombustionWater volume

An exhaust system provided with exhaust gas after-treatment for a combustion engine comprising an exhaust pipe and a pumping device, which is buried inside the tank, from which it draws so as to feed a water solution of urea under pressure to an electromagnetic injector; the tank is supplied with urea powder and water, which are mixed on the inside so as to obtain a water solution of urea with a variable concentration; and a water supply circuit to supply water to the tank, which is provided with a first pipe, which draws the water from a basin and is regulated by a first valve, which allows water to be introduced into the tank, if necessary, or to be drained to the surrounding environment when the water quantity already contained in the tank is sufficient.

Owner:MARELLI EURO SPA

Removal of dust in urea finishing

ActiveUS20180326345A1Better addressUrea derivatives preparationOrganic compound preparationUreaChemistry

Disclosed is a method for the removal of urea dust from the off-gas of a finishing section of a urea production plant. the method comprises subjecting the off-gas to quenching with water so as to produce quenched off-gas. The quenched off-gas is subjected to humidification by mixing said quenched gas stream with a humidification fluid selected from (a) saturated steam and (b) superheated steam mixed with a second aqueous stream, so as to produce a humidified gas stream, subjecting said humidified gas stream to particle separation (i.e., dust removal) by means of a scrubbing liquid in which at least part of the particles in the gas stream are soluble.

Owner:STAMICARBON BV

Method for preparing high-nitrogen sulfonyl azophoska compound fertilizer

ActiveCN101337847AIncrease profitEvenly distributedFertiliser formsFertilizer mixturesPotassiumSlurry

The invention relates to a method for producing a high-N S-based NPK compound fertilizer from an S-based NPK compound fertilizer slurry and urea. The method comprises the following steps: drying the S-based NPK compound fertilizer slurry at a low temperature in an empty tower; mixing the dried NPK basal fertilizer powder with urea powder obtained by crushing granulated urea; granulating, drying at a low temperature, polishing and sieving to obtain the high-N S-based NPK compound fertilizer. Compared with the prior S-based compound fertilizer production method, the method has the advantages of high N content in the S-based NPK compound fertilizer product, large adjusting range of N content, less N loss in the production process, long time for crops in absorbing N in the fertilizer.

Owner:贵州西洋实业有限公司

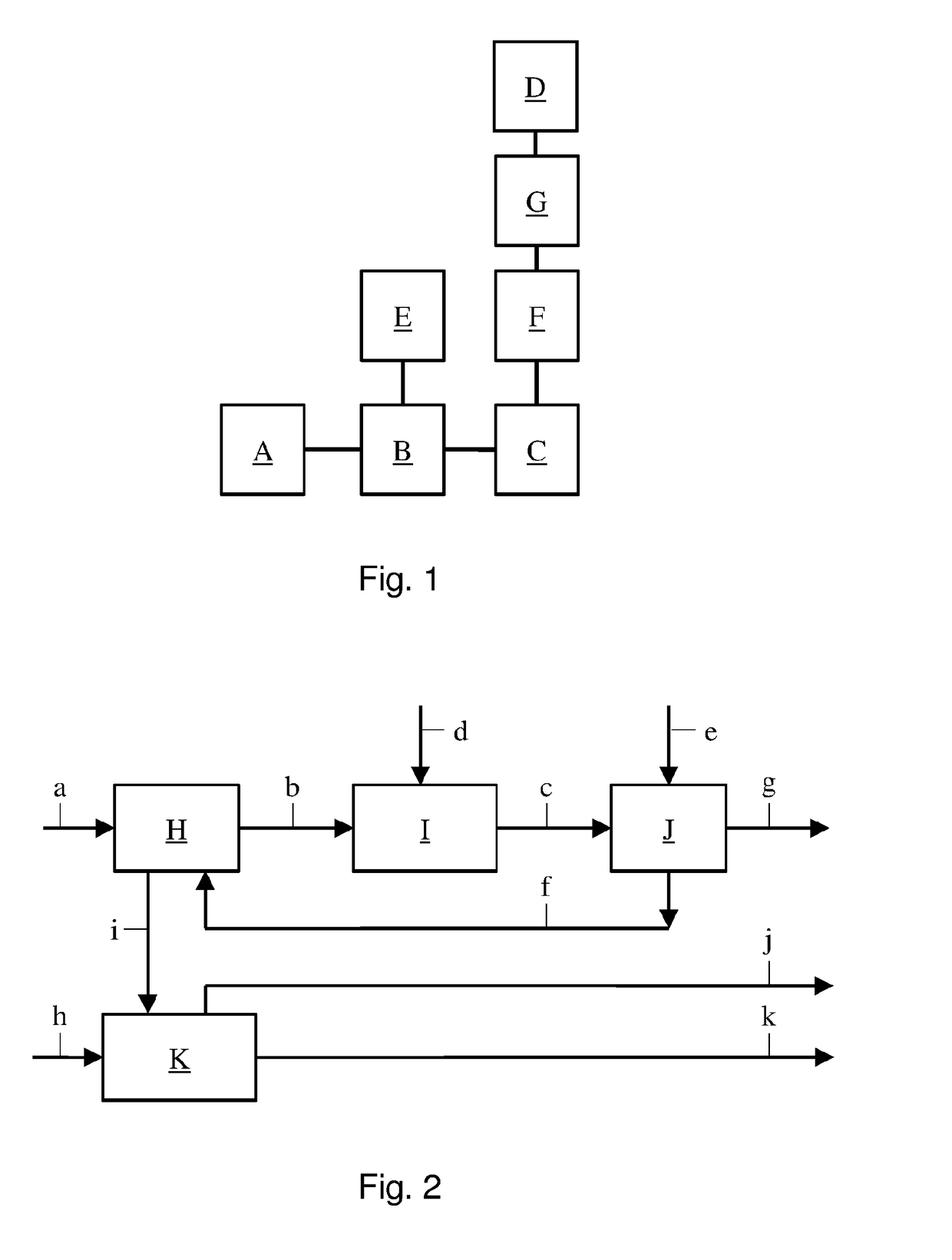

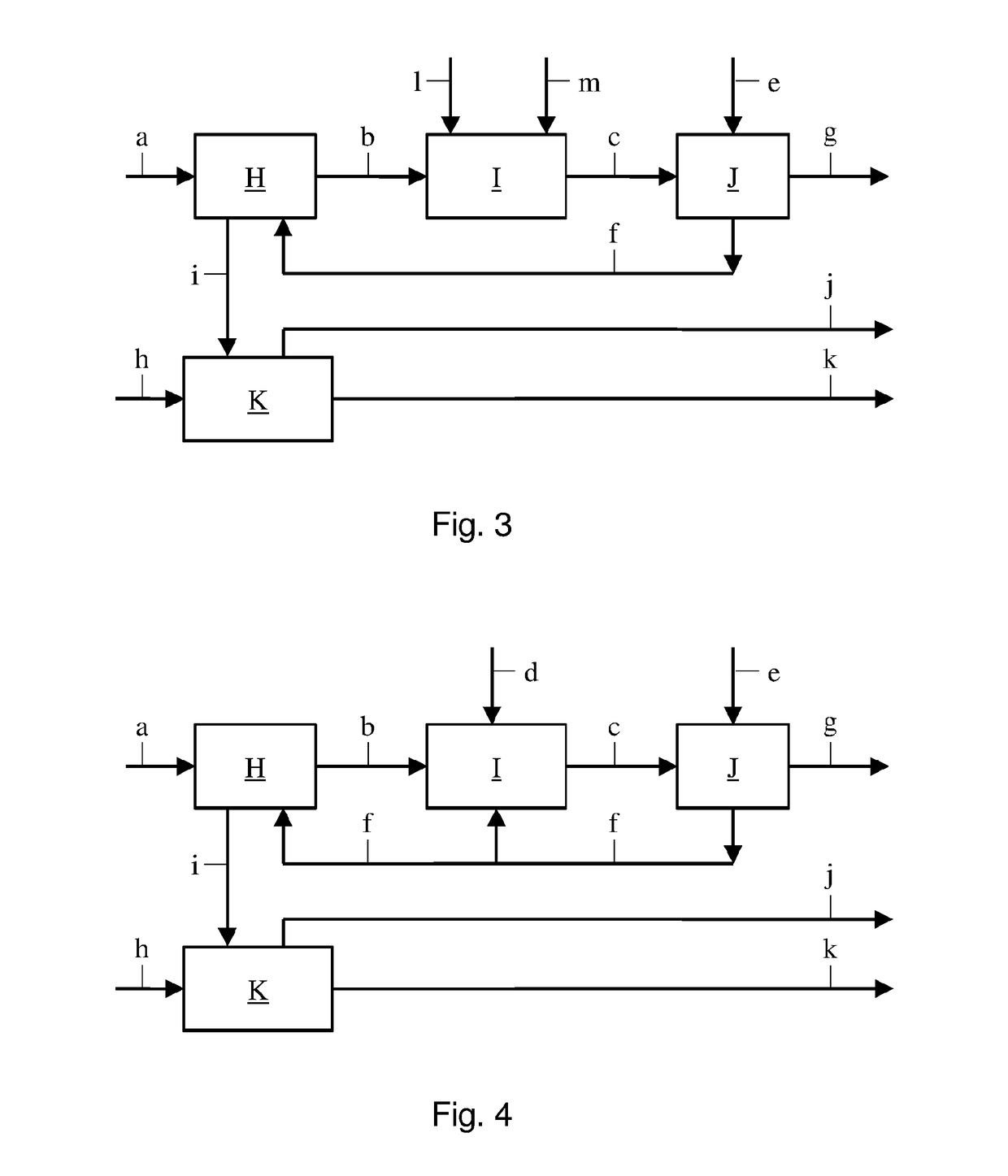

Urea finishing process with acid scrubbing

ActiveUS20170312717A1Urea crystallization temperatureLower evaporation temperatureUrea derivatives preparationMaterial granulation and coatingEvaporationWater flow

A process for the finishing of urea comprising: (a) removing water from an aqueous urea solution in a first evaporation and condensation section, obtaining a urea melt; (b) subjecting said urea melt to a finishing treatment comprising granulation and resulting in solid urea and air contaminated with urea dust and ammonia; (c) subjecting said contaminated air to acid scrubbing, producing an aqueous solution comprising urea and ammonium salts; (d) subjecting at least part of said aqueous solution to evaporation in a second evaporation section, obtaining a liquid stream comprising urea and ammonium salts and a gaseous stream; (e) condensing said gaseous stream in a second condensation section, obtaining a recycle aqueous stream; (f) using at least a part of said recycle aqueous stream for the scrubbing of contaminated air; (g) converting at least a portion of said liquid stream comprising urea and ammonium salts into solid particles, and (h) using said solid particles as seeds for the granulation; a corresponding urea plant and method of revamping a urea plant are also disclosed.

Owner:CASALE SA

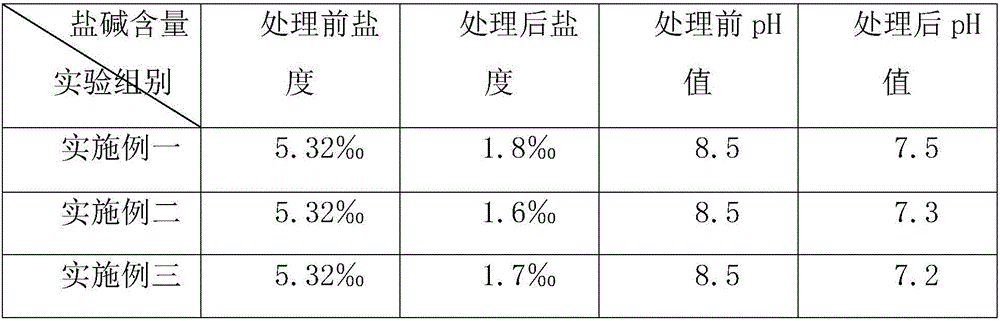

Improvement fertilizer for plantation of vines in saline land and improvement method thereof

InactiveCN106220411AWidely distributedEasy to neutralizeSuperphosphatesCalcareous fertilisersLivestock manureAcid substances

The invention specifically relates to an improvement fertilizer for plantation of vines in saline land, belonging to the field of improvement of saline land. The improvement fertilizer comprises the following raw materials by weight: 50 to 70 parts of crop straw gypsum urea powder, 40 to 60 parts of dried livestock manure, 35 to 65 parts of yellow mud powder, 50 to 60 parts of calcium superphosphate, 30 to 50 parts of ammonium chloride, 45 to 55 parts of pine needle mulch and 50 to 60 parts of diammonium phosphate. The invention also provides an improvement method by using the improvement fertilizer. The improvement method comprises the following steps: S1, land plowing; S2, application of acidic fertilizer; S3, preliminary improvement; and S4, salt leaching. Cheap production raw materials are included in the formula for the fertilizer, so production cost is low; the crop straw gypsum urea powder, the dried livestock manure and the pine needle mulch can produce organic acidic substances through fermentation; through laying in layers, the acidic substances can be widely distributed; and the method provided by the invention is simple, good in improvement effect and suitable for promotion and application.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Method for preparing glass microfibre reinforcement nano-hydroxyapatite biological composite coating

The invention relates to a method for preparing a glass microfibre reinforcement nano-hydroxyapatite biological composite coating, comprising the following steps of: firstly, mixing Ca(NO3)2.4H2O and (NH2)2HPO4 and adding distilled water to dissolve; then adding urea powder to make the mixture into mixed liquor; putting a generating head of a multi-frequency phonochemistry generator into the mixed liquor, filtering and drying after phonochemistry synthesis, then obtaining nano-HAp powder; dispersing the nano-HAp powder, analytically pure chitosan and glass microfibre in isopropanol, then obtaining suspending liquid; pouring the suspending liquid into a hydrothermal electrophoresis reaction kettle; putting the reaction kettle in a precise constant temperature oven, galvanizing and depositing; then drying and finally obtaining the composite coating. Nano-hydroxyapatite powder is prepared by using a phonochemistry synthesis method, and therefore, the prepared composite coating is compact and even, the crystalline phase of the coating is stable, the bonding strength can be greatly increased; and the expected bonding strength reaches 20-40MPa.

Owner:SHAANXI UNIV OF SCI & TECH

Cultivating method for direct sowing rice

ActiveCN106069435APlay a bactericidal effectShortened reproductive periodBiocideAlkali orthophosphate fertiliserPaddy fieldSowing

The invention provides a cultivating method for direct sowing rice. The cultivating method includes the steps that a rice field is treated and flattened, base fertilizer and a synergist are applied, and then sowing and irrigating are carried out, wherein the amount of the base fertilizer applied to each mu of the rice field is 50 kg, and the amount of the synergist applied to each mu of the rice field is 6 kg; 18-22 days after irrigating, 10 kg of urea powder with the nitrogen content being 46% is applied to each mu of the rice field; 28-32 days after irrigating, a first additive is applied to the rice field; 48-52 days after irrigating, a third additive is applied to the rice field; 73-77 days after irrigating, a second additive and the third additive are sequentially added to the rice field; 7 days after the former step is completed, the second additive is applied to the rice field again; 83-87 days after irrigating, the third additive is applied to the rice field; 93-97 days after irrigating, the third additive is applied to the rice field again. By means of the method, the growth period of traditional direct sowing rice can be shortened, diseases can be effectively resisted, and the yield per mu can be effectively increased.

Owner:刘俭

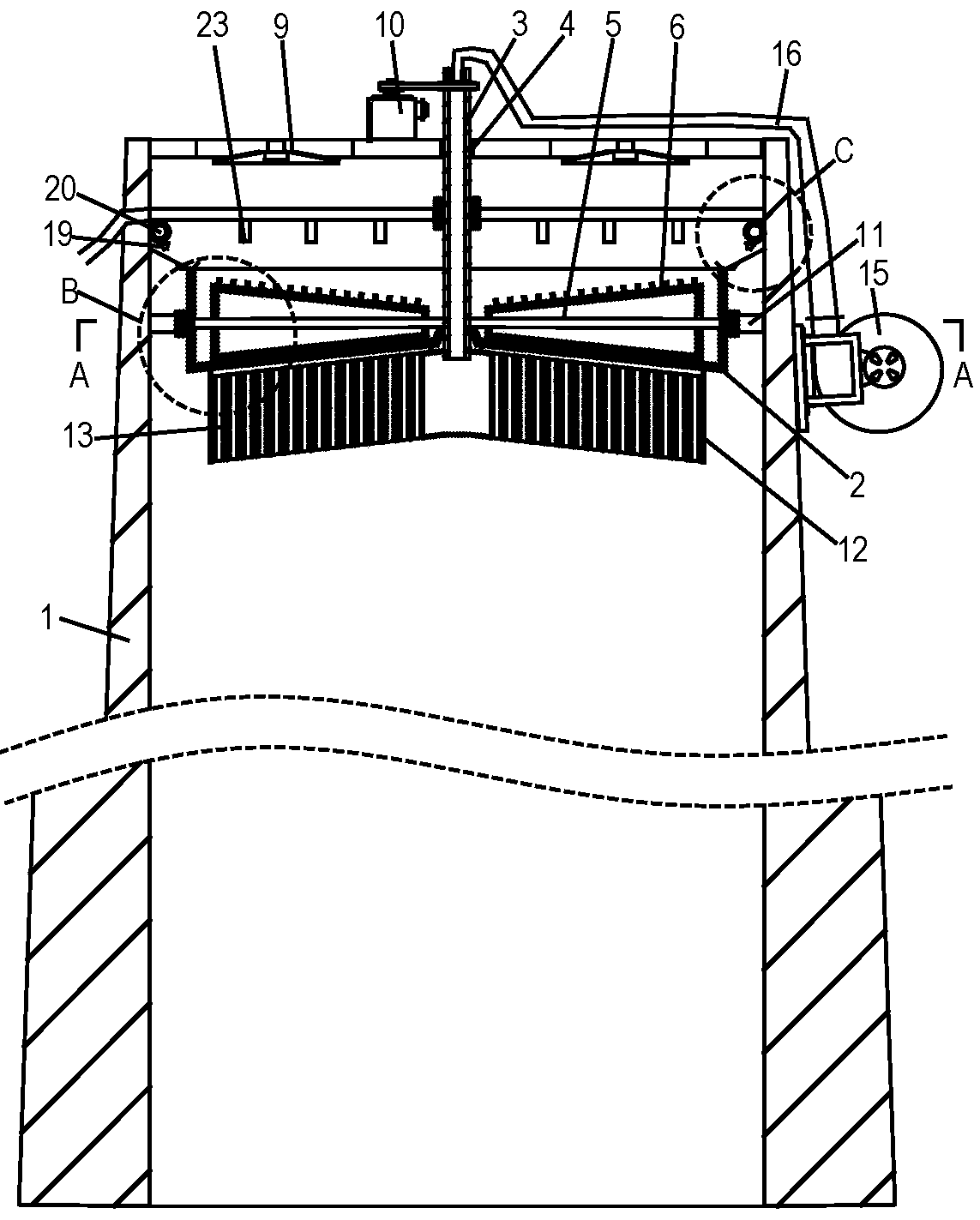

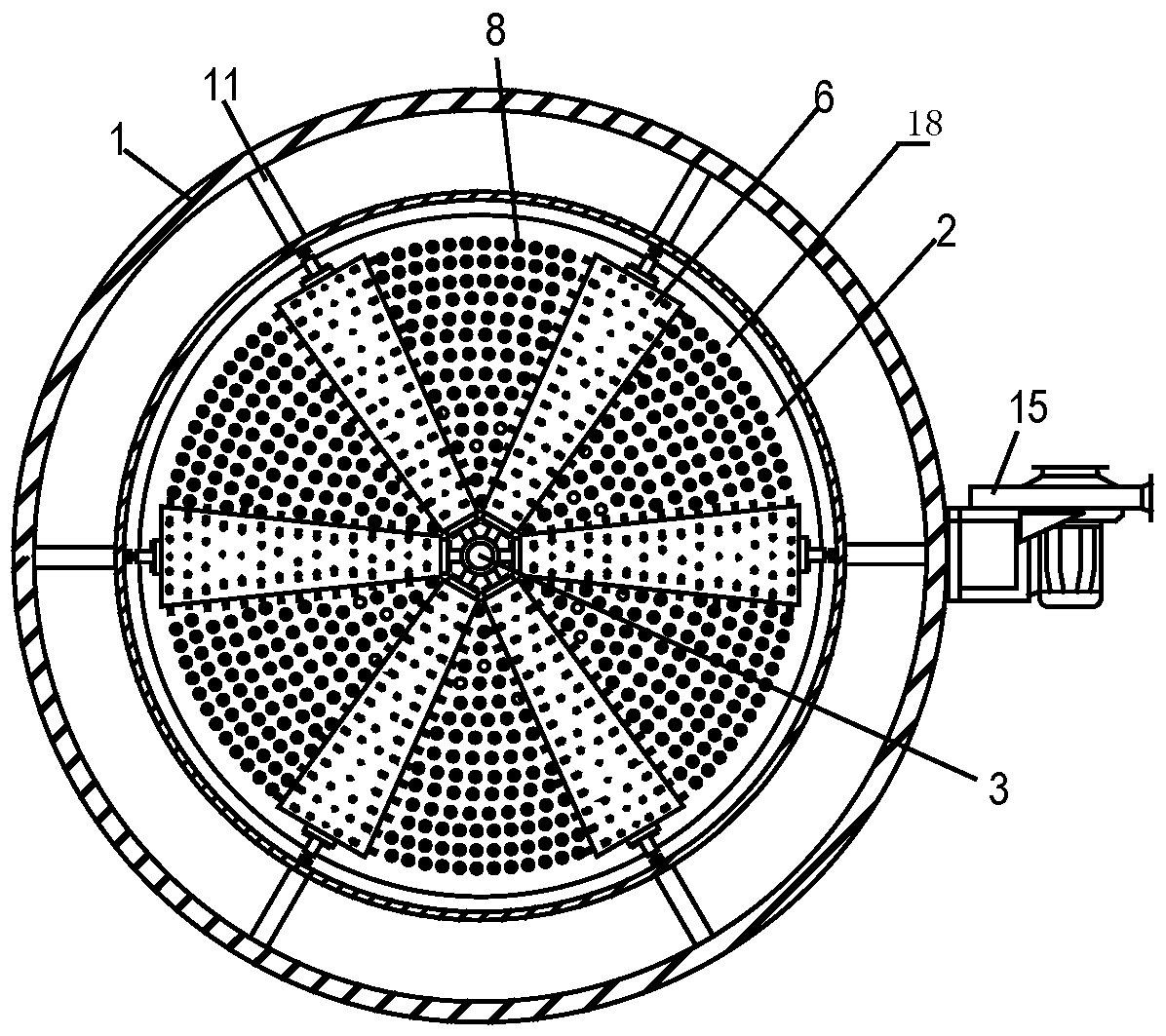

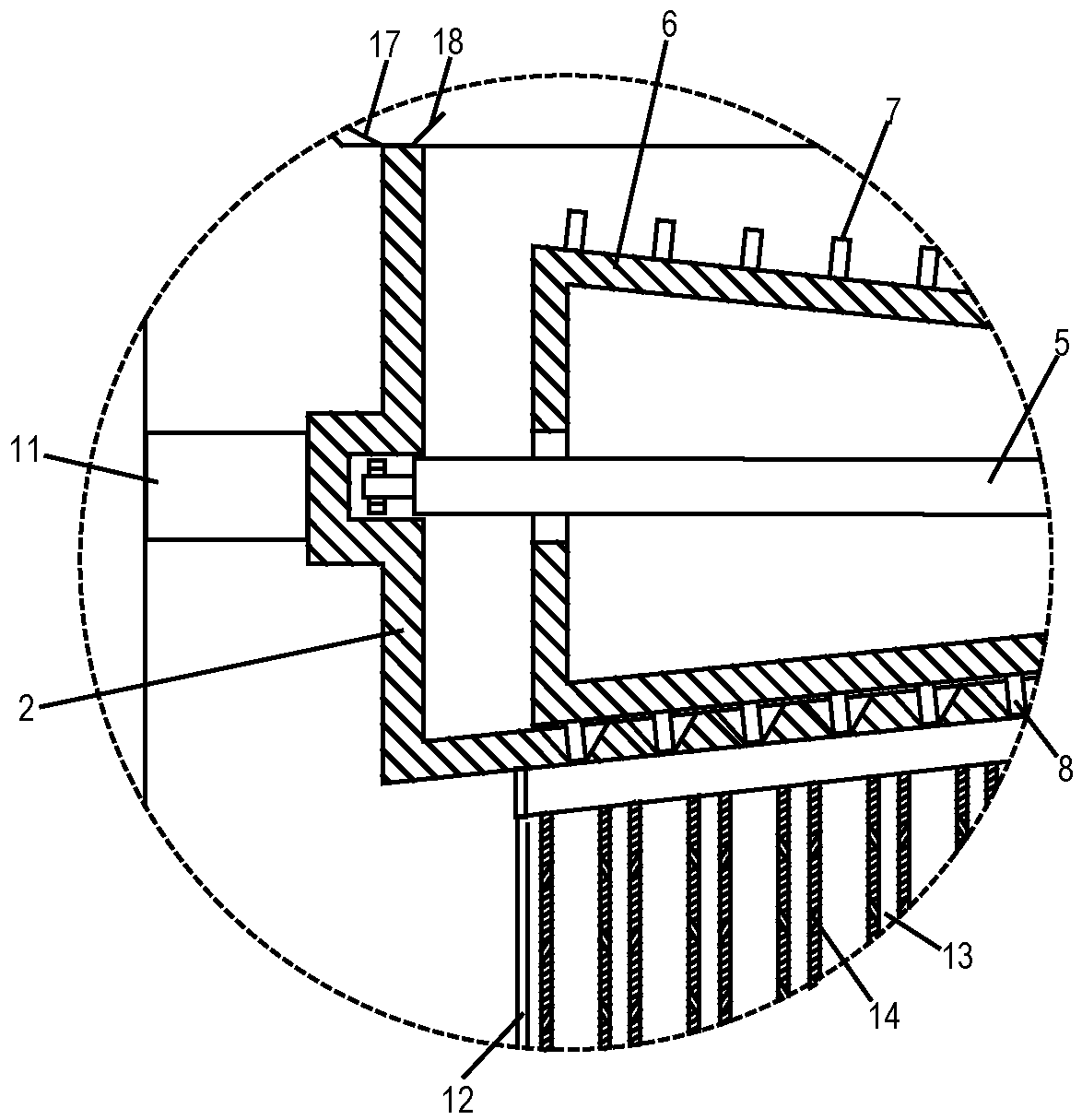

Urea granulating column with high yield

ActiveCN109126633AEasy to recycleIncrease contact areaGranulation by liquid drop formationGranulation by pressingEngineeringDistributor

The invention relates to a urea granulating column with high yield, comprising a column body and a distributor, as well as a squeezing disc that is arranged in the upper portion of the column body; ahollow shaft is arranged in the center of the squeezing disc; a plurality of horizontal center shafts are fixed evenly on the outer periphery of the hollow shaft, each horizontal hollow shaft is hinged to a squeezing roller in penetrating manner, and the bottom edges of each squeezing rollers are attached to the upper surface of the squeezing disc. The granulating blocking problem can be effectively solved by making use of squeezing granulation; each urea granule is squeezed to freely fall in an independent cooling tube; the urea granules are full and solid and have a stable falling trajectory; the urea granules never collide with and stick to other granules; column sticking to the granules is never caused, a water film on a film mesh spreads water so that contact area of the water with urea powder is enlarged, and dust collection effect is significant; the dissolved urea is easy to recycle; humidity in the column herein is unaffected and dust emission is reduced.

Owner:SHANDONG HUALU HENGSHENG CHEM IND

Microbial chemical fertilizer

InactiveCN106518540AImprove micro-ecological environmentBio-organic fraction processingExcrement fertilisersBiotechnologyMicroorganism

The invention discloses a microbial chemical fertilizer. The fertilizer is prepared from, by weight, 1-2 parts of bacillus amyloliquefaciens, 2-2.5 parts of bacillus mucilaginosus, 3-4 parts of urea powder, 3-5 parts of potassium sulfate, 4-5 parts of fermented chicken manure, 4-5 parts of distiller's grain, 0.5-1.25 parts of amino acid, 10-15 parts of fermented cow manure, 10-15 parts of fermented sheep manure, 10-15 parts of fermented duck manure, 100-200 parts of culture solution, 50-100 parts of straw powder, 50-100 parts of rice husk and the balance of deionized water. The fertilizer is prepared through the fermentation of compound microorganisms, can improve the micro-ecosystem of soil, and provide a beneficial condition for crop growth.

Owner:唐剑龙

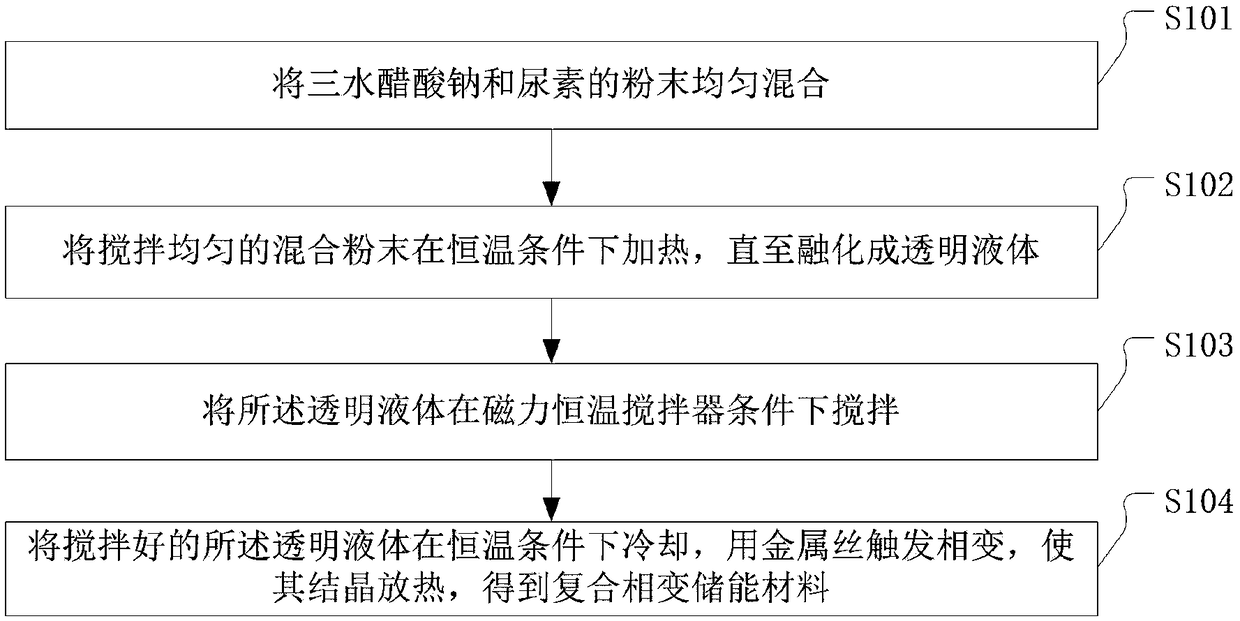

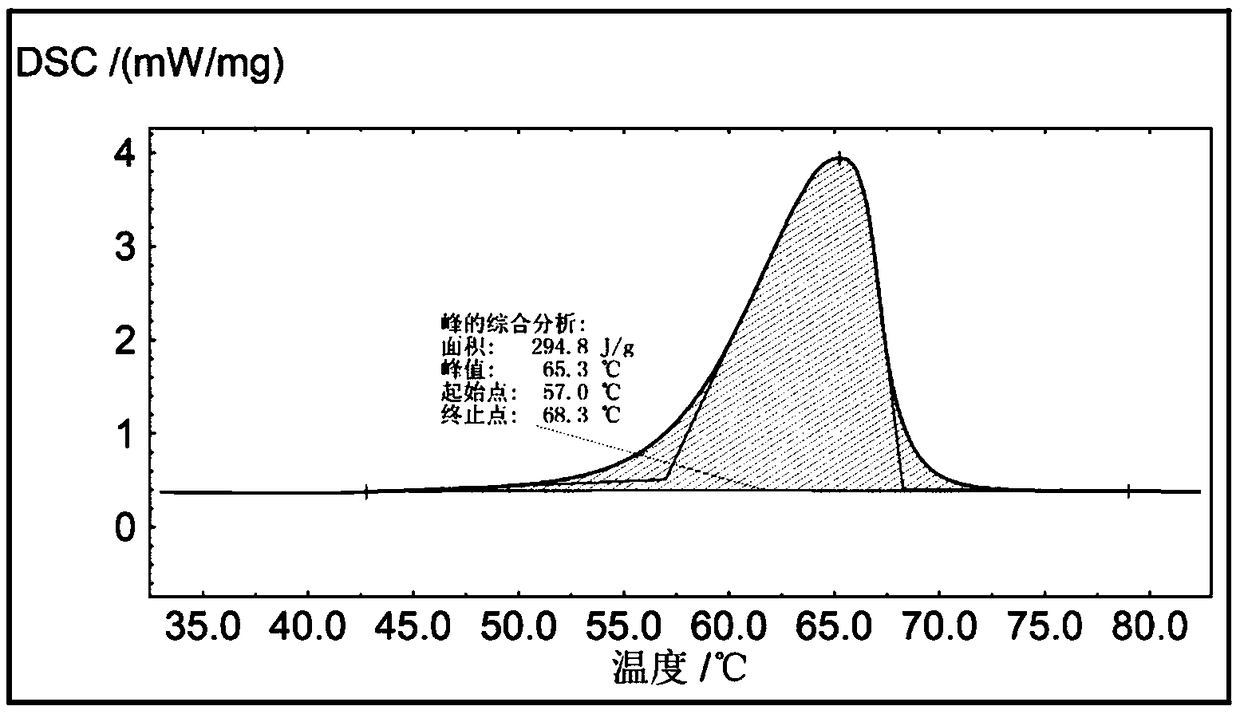

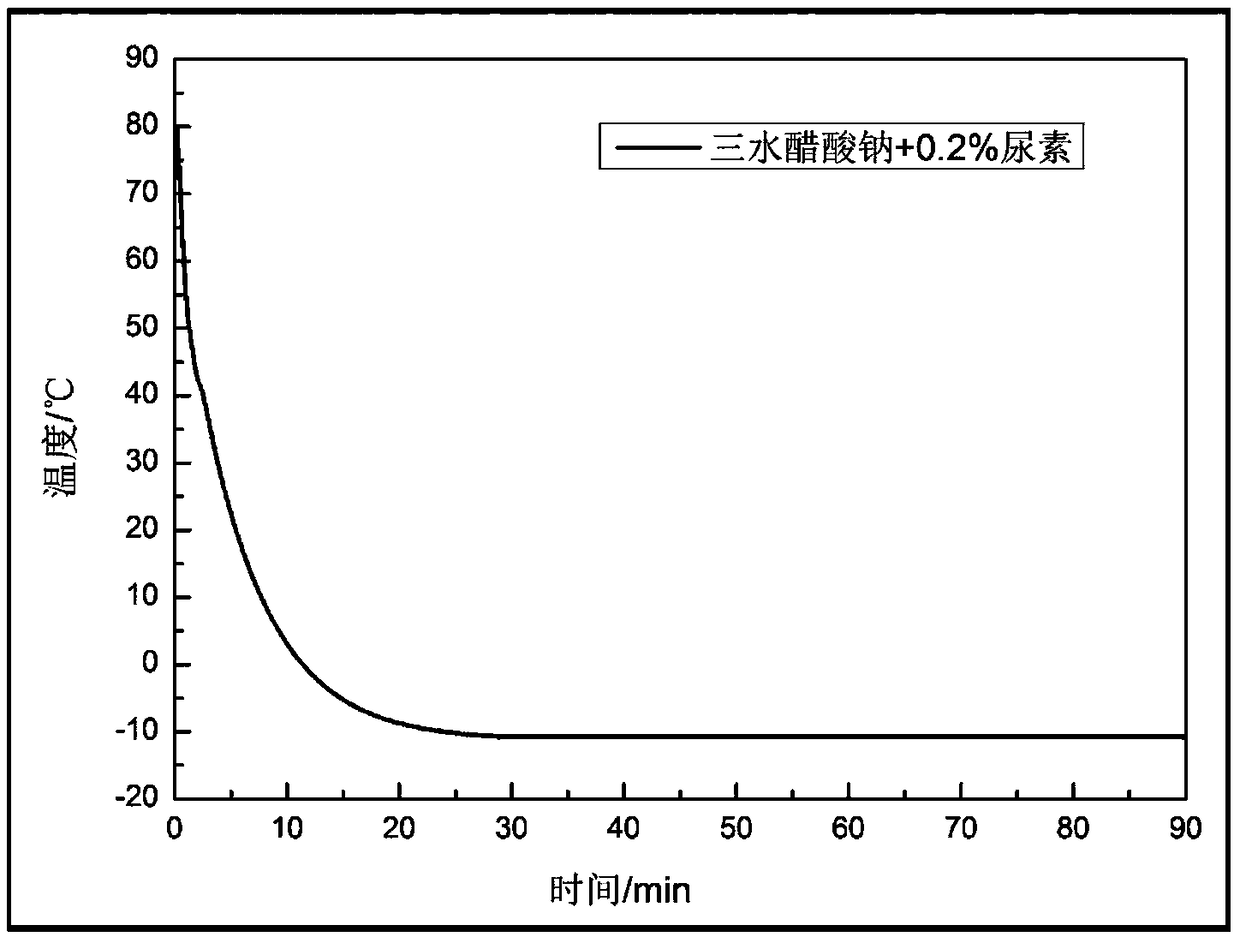

Phase change heat storage material based on sodium acetate trihydrate, preparation method and heat insulation material

InactiveCN109370537ALarge latent heat value of phase changeHigh thermal conductivityHeat-exchange elementsHeat conductingMaterials science

The invention discloses a phase change heat storage material based on sodium acetate trihydrate, a preparation method and a heat insulation material. The method includes the steps: uniformly mixing the sodium acetate trihydrate and urea powder; heating the uniformly stirred mixed powder at constant temperature until the mixed powder is melted into transparent liquid; stirring the transparent liquid by a magnetic constant temperature stirrer; cooling the stirred transparent liquid at constant temperature, triggering phase change by the aid of a metal wire, and enabling the transparent liquid tocrystallize and release heat to obtain a composite phase change energy storage material. By the aid of the embodiment, a phase change potential heat value of the sodium acetate trihydrate is effectively increased, the heat-conducting property of the material is improved, phase separation is relieved, reaction conditions are controllable, device requirements are simple, mass production is easily achieved, heat energy is stably stored, the utilization rate of the heat energy is increased, and environments are protected.

Owner:SHANGHAI MARITIME UNIVERSITY

Wheat straw type tobacco water-raised seedling substrate and preparation method thereof

InactiveCN106818442AMaximize added valueAvoid pollutionGrowth substratesCulture mediaBacillus licheniformisSnow mold

The invention discloses a preparation method of a wheat straw type tobacco water-raised seedling substrate. The preparation method comprises the following steps: spraying water to a straw pile body firstly, wherein the mass ratio of the water to straw is (0.8-1.2) to 1; dissolving urea powder accounting for 1-2 percent of the total mass of the straw into water, and spraying the dissolved urea powder into the straw pile body; taking 0.5 billion cfu / g of mixed bacterial agent of aspergillus niger and bacillus licheniformis, uniformly spraying the mixed bacterial agent into the straw pile body, wherein the mixed bacterial agent accounts for 0.1-0.5 percent of the total mass of the straw; scattering bean cake powder accounting for 2-4 percent of the total mass of the straw into the straw pile body to be fermented, and turning the pile for 45-60 days every 3-6 days to obtain a wheat straw fermentation broth; and mixing the following components in parts by weight: 50-80 parts of the wheat straw fermentation broth, 5-15 parts of vermiculite, 3-12 parts of perlite, 15-25 parts of carbonized rice hulls and 10-20 parts of fly ash to obtain the wheat straw type tobacco water-raised seedling substrate. The preparation method is simple in step, available in raw materials and low in cost. The seedling substrate is short in seedling time, high in seedling emergence rate and good in growth vigor of tobacco seedlings in the seedling formation period.

Owner:安徽莱姆佳生物科技股份有限公司

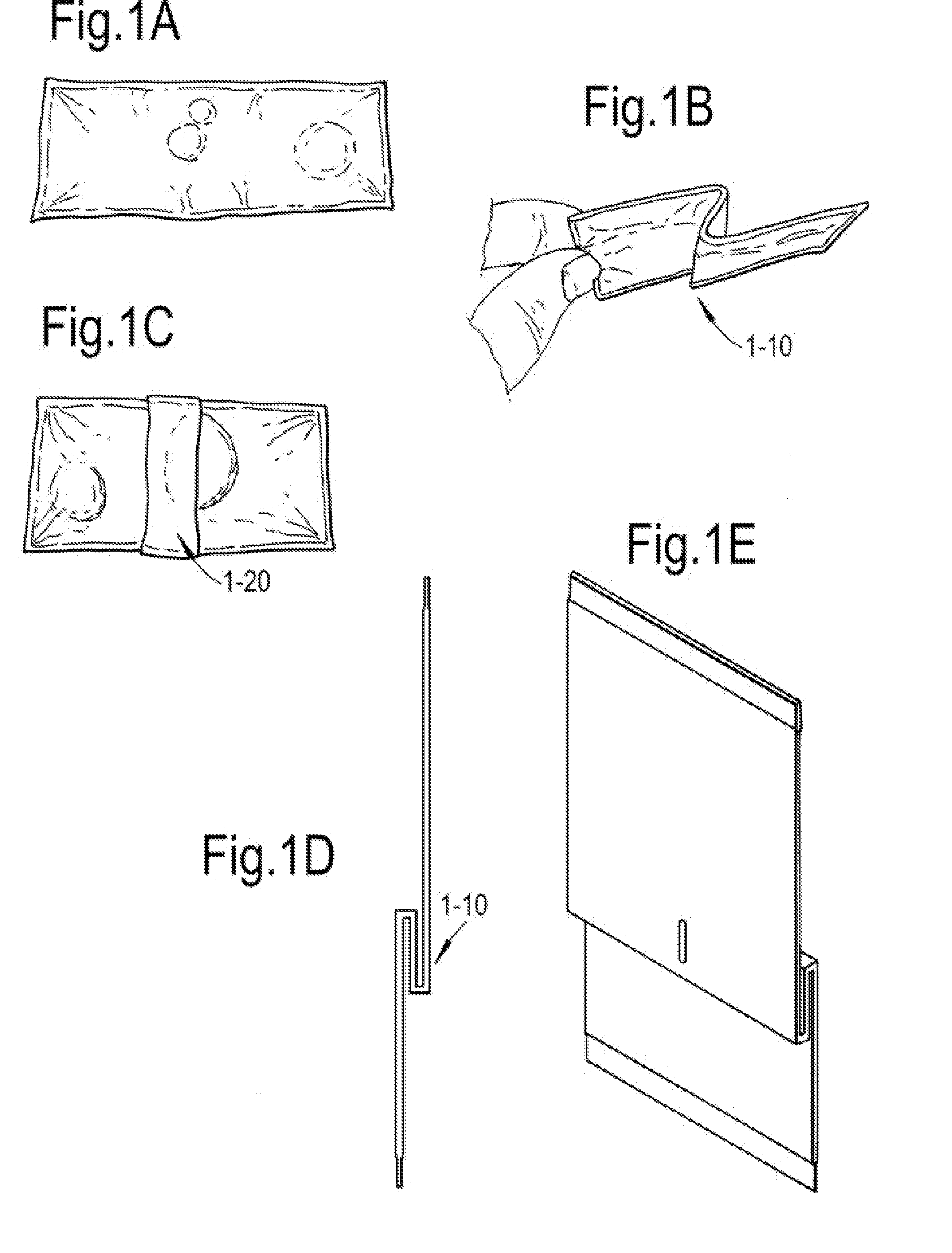

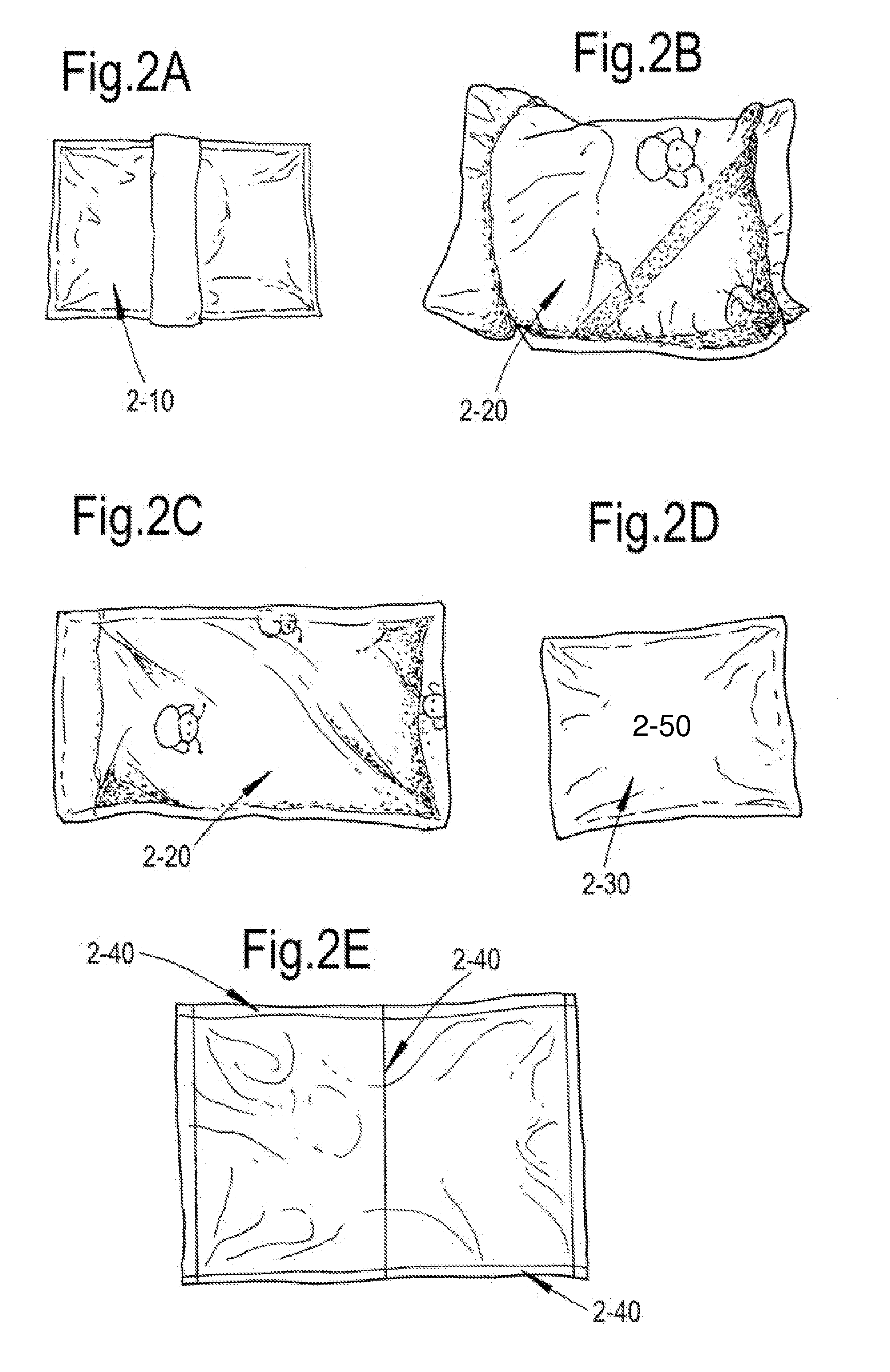

Coolant Device, Dispenser and Methods Background of the Invention

ActiveUS20150114858A1Easy to dispersePromotes rapid accessDomestic cooling apparatusLighting and heating apparatusSkin surfaceLateral extension

This invention provides a thin and discreet coolant device, and single and multiple unit dispenser containers containing the same. The coolant device comprises a first packet being comprised of a waterproof or water-resistant material containing water therewithin and further comprising a fold and further adapted to have a selectively permanent connection between external and internal layers of said fold, such that upon applying a force to laterally extend the ends of said packet, a rupture of said first packet occurs allowing for the leakage of the water contained therewithin. The coolant device further comprises a second packet which encases said first packet, comprising an exterior and interior layer, wherein said interior layer is comprised of an absorbant material and said exterior layer is comprised of a waterproof or water-resistant material and wherein an amount of powdered urea is located within an interior of said second packet. Upon lateral extension of the sides of the second packet, a rupture of said first packet occurs allowing for the leakage of the water contained therewithin and its exposure to said urea located within said second packet, which exposure results in an endothermic reaction resulting in an outer surface of said second packet becoming cooler to the touch than an outer surface temperature prior to said rupture. Use of the coolant devices to provide cooling to a skin surface on demand is described, as well.

Owner:ROTHENBERG SARAH

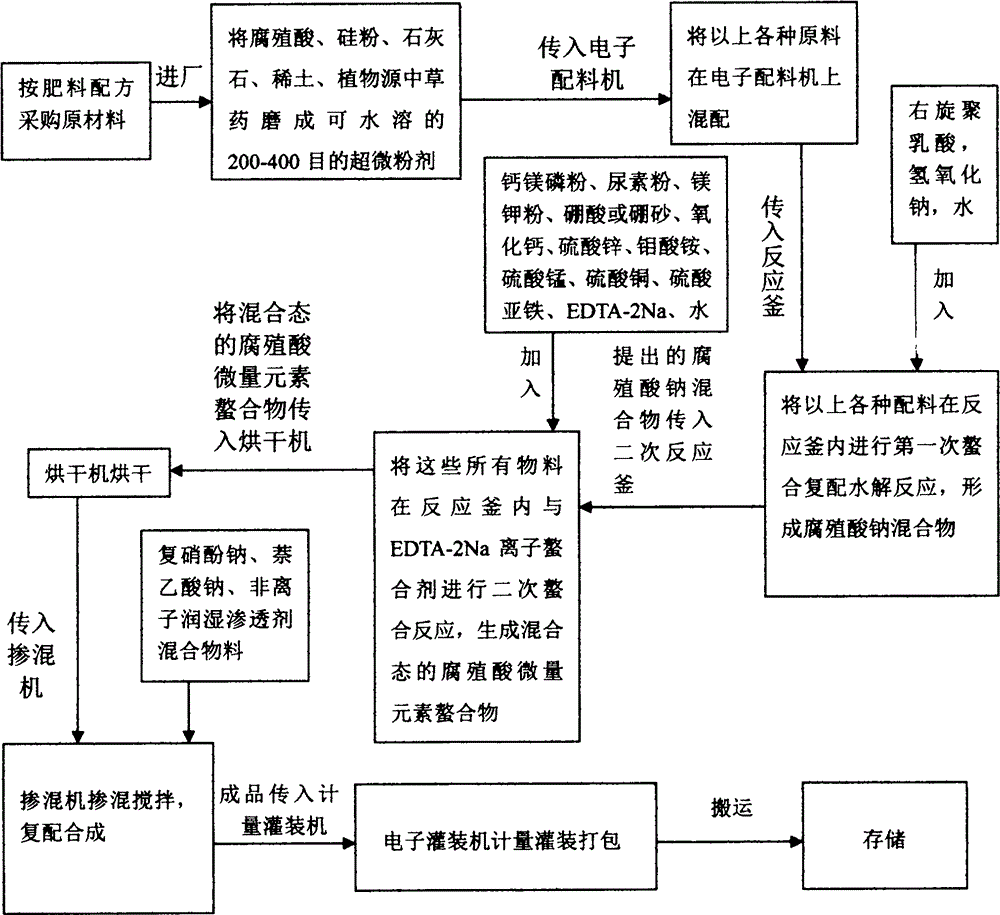

Humic acid dual-effect double-chelation multifunctional water-soluble fertilizer and manufacturing method thereof

The invention discloses a humic acid dual-effect double-chelation multifunctional water-soluble fertilizer and a manufacturing method thereof. The product is prepared by mixing humic acid powder, sodium hydroxide, silica powder, limestone powder, rare earth, calcium magnesium phosphorus powder, urea powder, magnesium kalium powder, boric acid (or borax), calcium oxide, zinc sulfate, ammonium molybdate, manganese sulfate, copper sulfate, ferrous sulfate and plant source Chinese herbal medicine (alums, nicotine, onions, sophora flavescens lectin, pyrethrin and a cedrela sinensis water extract) with compound sodium nitrophenolate, pimacol, PDLA, an ion chelating agent, a nonionic wetting agent and the like. The manufacturing method of the humic acid dual-effect double-chelation multifunctional water-soluble fertilizer comprises the steps that raw material powder is ground into 200-400-mesh water soluble powder and conveyed into a reaction kettle after being mixed, two-time chelation reactions are performed to generate a humic acid microelement chelate to be dried, compound sodium nitrophenolate, pimacol and the nonionic wetting agent are added and mixed, the product with the water solubility being 99.9% is produced, and packaging and delivery are performed after test qualification.

Owner:QIQIHAER JINDINGFENG MEDICAL STONE FERTILIZER IND CO LTD

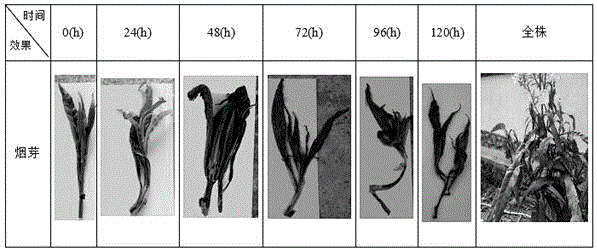

Urea paste tobacco suckercide and applying method thereof

InactiveCN105685073AGood effectReduce consumptionBiocidePlant growth regulatorsPesticide residueActive matter

Provided is urea paste tobacco suckercide. According to the suckercide, urea serves as bud removal active matter, paste serves as a carrier, and the suckercide is prepared from urea powder and the paste according to the mass ratio of 1:1. The paste is a pasty body formed in the way that flour and water are mixed in a pot according to the mass ratio of 1:8, and then the mixture is heated to 100 DEG C through an electric stove with the power of 500 W and boiled for 2 min. According to the applied technology, the suckercide is firstly prepared, then sprouting inhibition preparation is carried out, and a tobacco plant with tobacco sprouts emerging is selected as a treatment object; a row brush is dipped in urea paste prepared from the urea powder and the paste according to the proportion of 1:1 to directly smear the tobacco sprouts to form annular pesticide paste; checking is carried out once every 3-5 d after treatment, newly-grown tobacco sprouts are subjected to paste coating and sprout removal, and the aim of sprout inhibiting is achieved. The urea paste tobacco suckercide is harmless to people and livestock and obvious in effect, the tobacco sprouts wither to fall off after being smeared, consumption of potassium nutrients by the tobacco sprouts is reduced, and tobacco leave pesticide residues of chemical sprout removal are removed. The urea paste tobacco suckercide is suitable for all tobacco planting farmers and departments.

Owner:TONGREN CITY COMPANY OF GUIZHOU PROVINCE TOBACCO

Preparing method for nitrogen mixed titania light catalyst

InactiveCN1257013CEfficient purificationImprove environmental qualityPhysical/chemical process catalystsSolid state reaction methodVisible light photocatalytic

The invention discloses a preparation method of a nitrogen-doped titanium dioxide photocatalyst, which is used in the technical field of semiconductor photocatalysis. The invention adopts a solid phase reaction method to replace some oxygen elements in titanium dioxide with nitrogen, uses urea as a nitrogen source, and reacts with titanium dioxide powder or its precursor to generate nitrogen-doped titanium dioxide photocatalyst. The invention uses urea as nitrogen source, has simple process and safe operation. The bandgap width of the titanium dioxide photocatalyst is reduced by nitrogen doping, it has the ability to absorb visible light, the photocatalytic activity is improved, and it can effectively degrade pollutants and produce hydrogen by photolysis of water.

Owner:SHANGHAI JIAOTONG UNIV

Corn stalk coarse fodder anti-corrosive nourishing regulating agent and uses thereof

InactiveCN101326961AResistant to corruption, mildew and deteriorationHigh nutritional valueAnimal feeding stuffAccessory food factorsPropionateHigh water content

The invention relates to corn stalk crude feed anti-corrosive nutrition regulator and the application thereof, which relates to crude feed anti-corrosive nutrition regulator and the application thereof. The invention solves the problems that corn stalk crude feed in autumn and winter has high water content and cannot be packed, nutrient in the stalk is severely lost and is easy to be corroded, mouldy and go bad. The corn stalk crude feed anti-corrosive nutrition regulator of the invention consists of sodium diacetate powder, calcium propionate powder and urea powder. The application comprises the following steps: corn stalk is rubbed, and the corn stalk crude feed anti-corrosive nutrition regulator is evenly applied. The corn stalk crude feed in autumn and winter can be packed when the water content is high, is not easy to be corroded, mouldy and go bad, does not loss nutrient and improves the nutrition value of the corn stalk crude feed.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

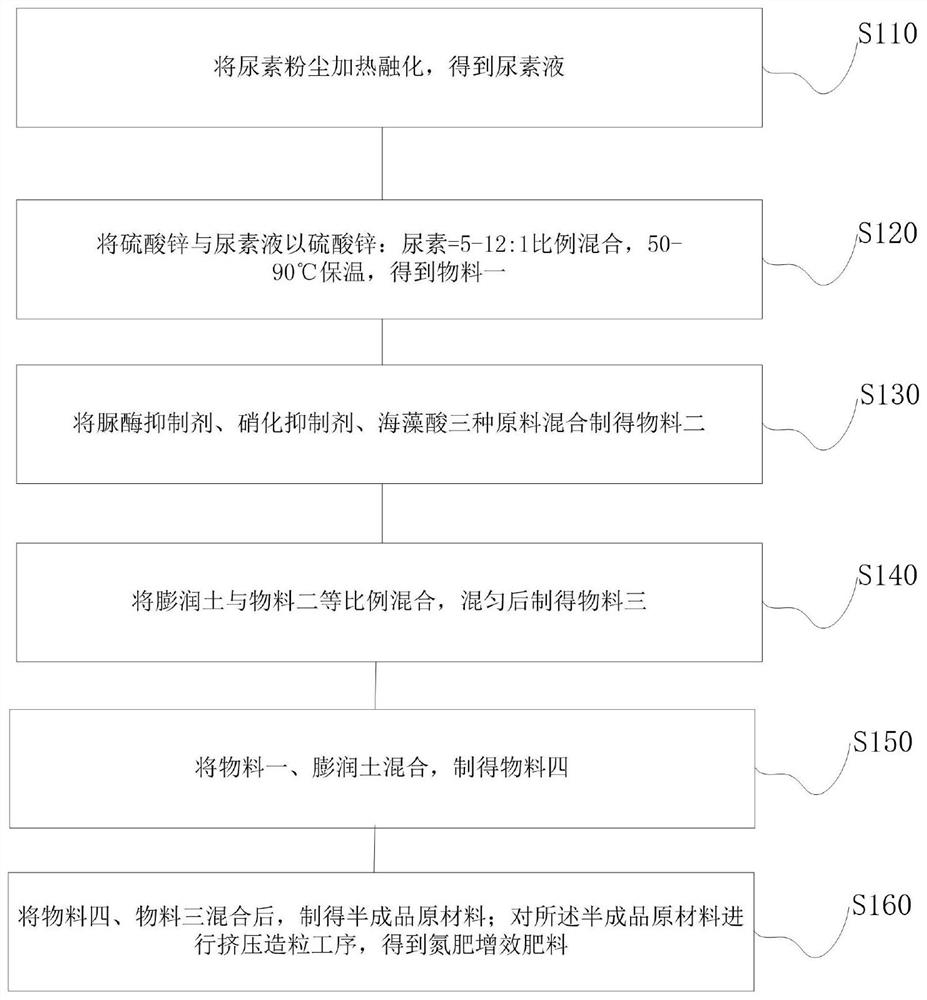

Nitrogen fertilizer synergistic fertilizer and preparation method thereof

InactiveCN112457116AAchieve long-term effectLow costAgriculture gas emission reductionOrganic fertilisersUrease enzymeEngineering

The embodiment of the invention provides a nitrogen fertilizer synergistic fertilizer and a preparation method thereof, and the preparation method comprises the following steps: heating and melting urea dust to obtain urea liquid; mixing zinc sulfate andtheurea liquid to obtain a material I; mixing three raw materials of urease inhibitor, nitrification inhibitor and alginic acid to obtain a material II; mixing bentonite and the material II in proportion, and uniformly mixing to obtain a material III; mixing the material I and bentonite to obtain a material IV; mixing the material IV and the material III to obtain a semi-finished product raw material; and carrying out extrusion granulation on the semi-finished product raw material to obtain the nitrogen fertilizer synergistic fertilizer. Inthe method, common urea or a common compound fertilizer taking urea as a nitrogen source is combined, so that the long-acting effect of the common fertilizer can be realized. Different from an existing stable urea product, the technology does not need to be combined with a urea system and can be independently used. Matched research of a stable urea production process is avoided, production is easy and convenient, the cost of auxiliaries and solvents can be reduced, and the burden of a system is reduced.

Owner:锦西天然气化工有限责任公司

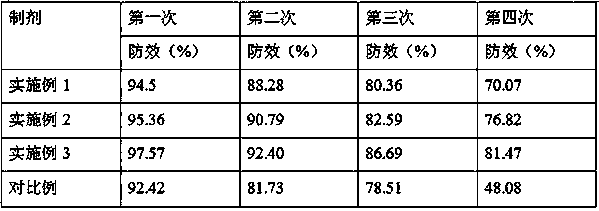

Preparation method of pesticide granules

InactiveCN108513976AImprove stress resistanceImprove efficacyBiocideAnimal repellantsPolyvinyl alcoholCarbide

The invention belongs to the technical field of pesticide and in particular relates to a preparation method of pesticide granules. The preparation method comprises the following steps: taking derris trifoliata and removing leaves; washing and rinsing with a sodium hypochlorite solution; then washing for 3 to 4 times to obtain treated derris trifoliate without the leaves; putting the derris trifoliate without the leaves into a solid culture medium and culturing; taking the biggest hyphae and mixing the biggest hyphae and a liquid culture medium; putting a mixture into a shaking table and fermenting; filtering to obtain filtered hyphae; crushing the filtered hyphae, sieving and drying to obtain a dry matter; mixing the dry matter and methanol; carrying out ultrasonic extraction and filtering; repeatedly extracting and combining filtrate; carbonizing pre-treated straws and mixing carbide and total filtrate; immersing and filtering to obtain a dried matter; mixing polyvinyl alcohol and water; heating to 70 to 80 DEG C; stirring and filtering to obtain filtrate; mixing the filtrate and urea powder; stirring and concentrating to obtain a concentered matter; mixing the dried matter and the concentered matter and conveying a mixture into an extruding and kneading device; then granulating, drying and separating and sieving to obtain the pesticide granules.

Owner:方建波

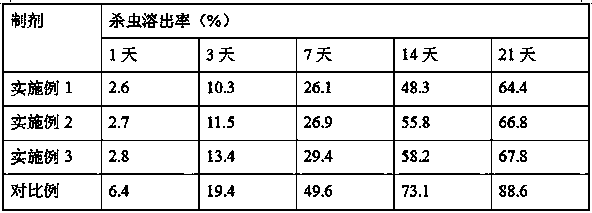

Preparation method of PAM (Polyacrylamide) enhancement nano-hydroxyapatite biological composite coating

The invention relates to a preparation method of a PAM (Polyacrylamide) enhancement nano-hydroxyapatite biological composite coating, comprising the following steps of firstly, dissolving Ca(NO3)2.4H2O and (NH2)2HPO4 into distilled water and preparing mixed liquor by putting a urea powder into the distilled water and uniformly stirring; secondly, filtering upper layer liquid after treating the mixed liquor by phonochemistrical synthesis and obtaining a nano-hydroxyapatite powder by vacuum drying; thirdly, obtaining a nano-hydroxyapatite suspension by scattering the nano-hydroxyapatite powder into isopropanol; fourthly, dissolving acrylamide into water and preparing AM solution by adding sodium sulfite and ammonium persulfate; and fifthly, treating a C / C substrate by ultrasonic waves after being put into the AM solution, fixing the treated C / C substrate on a cathode of a hydrothermal electrophoresis reactor, soaking the cathode into the nano-hydroxyapatite suspension, sealing the reactor, and obtaining the PAM (Polyacrylamide) enhancement nano-hydroxyapatite biological composite coating by electrophoretic deposition-heat treatment. The invention has the advantages of compact and uniform prepared composite coating and stable coating crystalline phase, can greatly enhance the bonding strength and has the expected bonding strength of 60-100MPa.

Owner:SHAANXI UNIV OF SCI & TECH

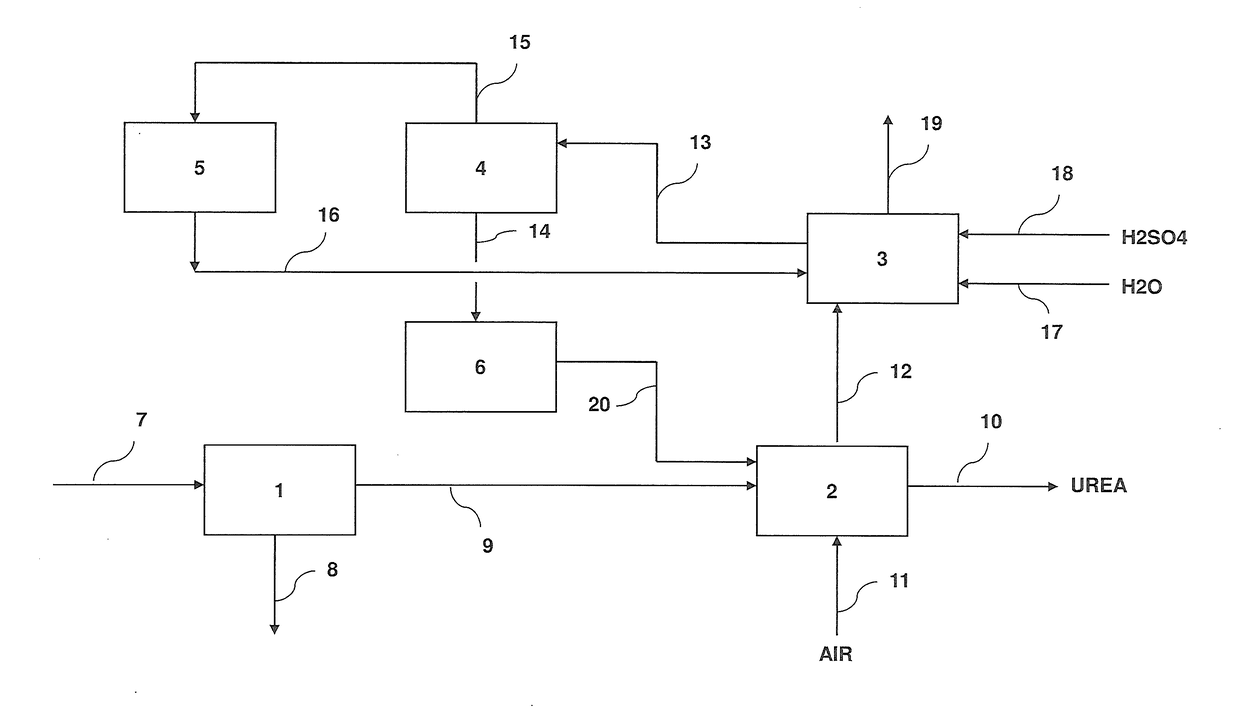

Method for removing free ammonia in urea powder

InactiveCN107759493AGood effectImprove removal efficiencyUrea derivatives preparationOrganic compound preparationOperabilityPollution

The invention discloses a method for removing free ammonia in urea powder. The method comprises the following steps: pumping a urea melted liquid into a melt pump after passing through a first-stage evaporator, a first-stage separator, a second-stage evaporator and a second-stage separator, then pumping an inorganic acid or organic acid solution in an acid storage tank into a pipeline between thefirst-stage evaporator separator and the second-stage evaporator or a pipeline between the second-stage evaporator separator and the melt pump after metering, and then pelleting into a pelleting towerafter passing through the melt pump. The free ammonia is removed by using acid-base neutralization, the effect is good, and the problem that the removal efficiency is low in a conventional method isavoided. While tail gas achieves the removal of free ammonia, nutrient elements such as sulfur element necessary for crop growth are added through the products of acid-base neutralization in urea product, the combination modes of elements such as nitrate nitrogen in the product are enriched, the functionality of the product is strengthened, the quality of the product is improved, the energy-savingand environmentally-friendly effects are improved, no secondary pollution is generated, the technology is simple, the operability is high, and the removal effect for free ammonia in urea particles ordust is obvious.

Owner:刘金成

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com