Patents

Literature

503 results about "Contaminated air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nose mask

Owner:BIO INT

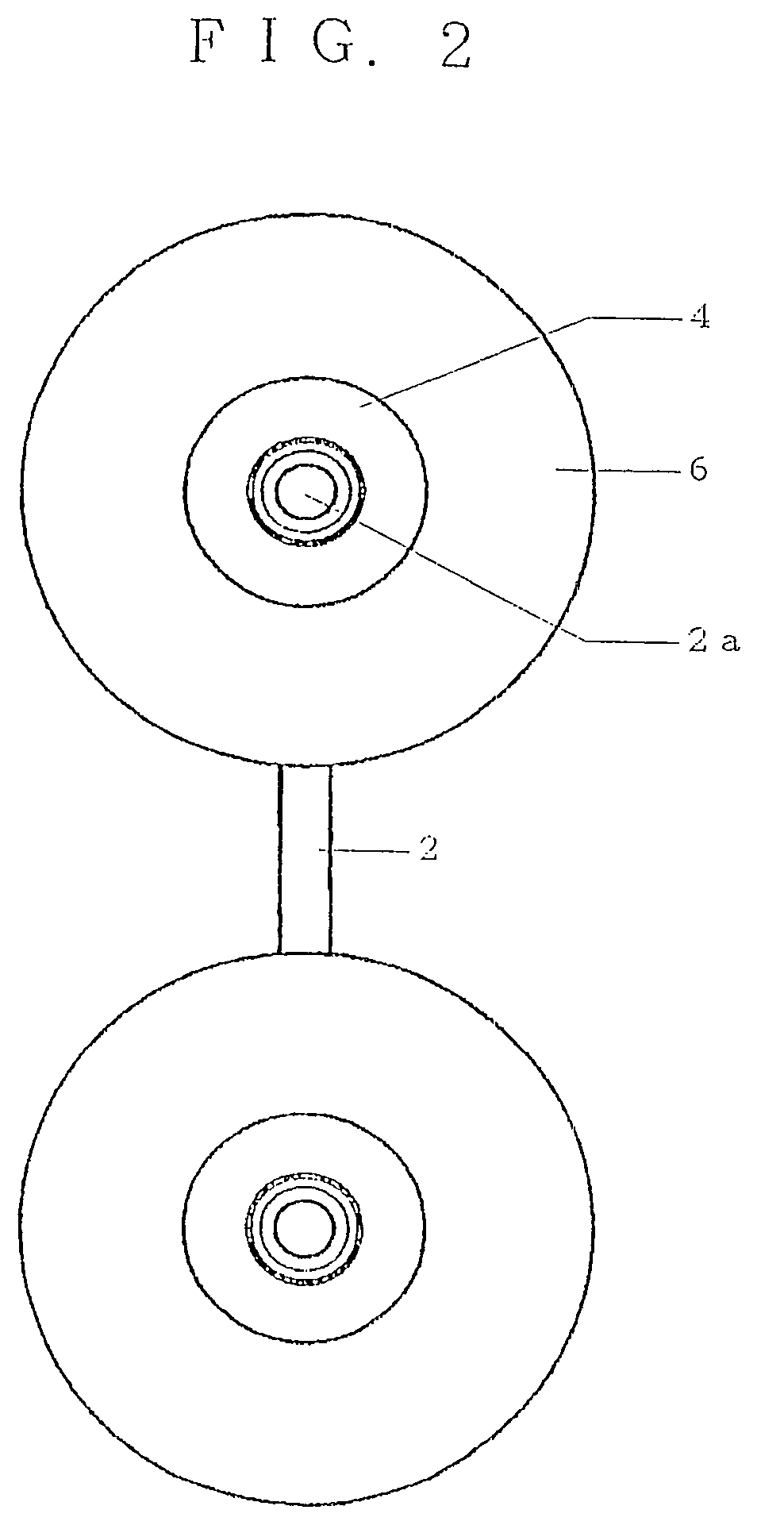

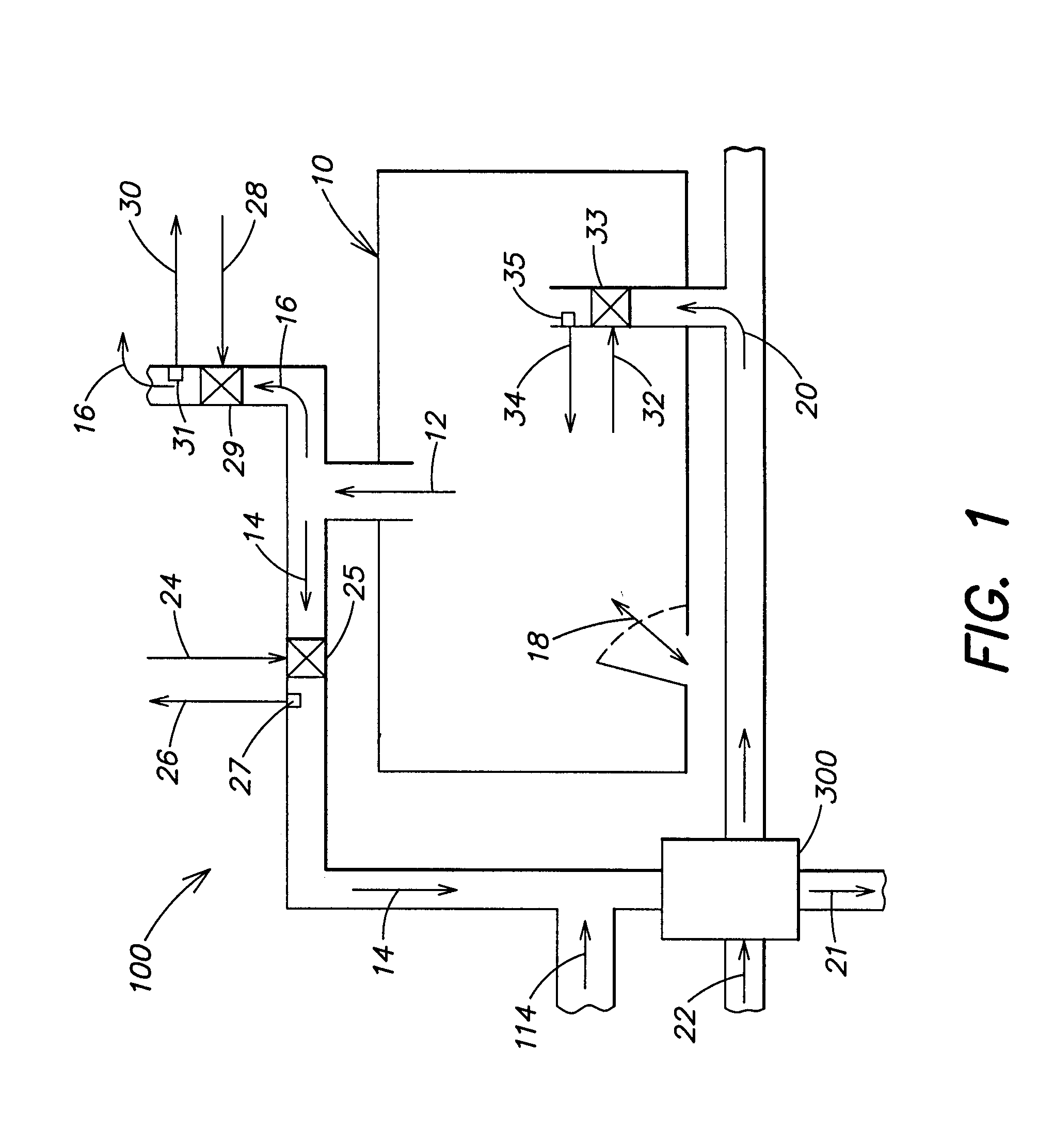

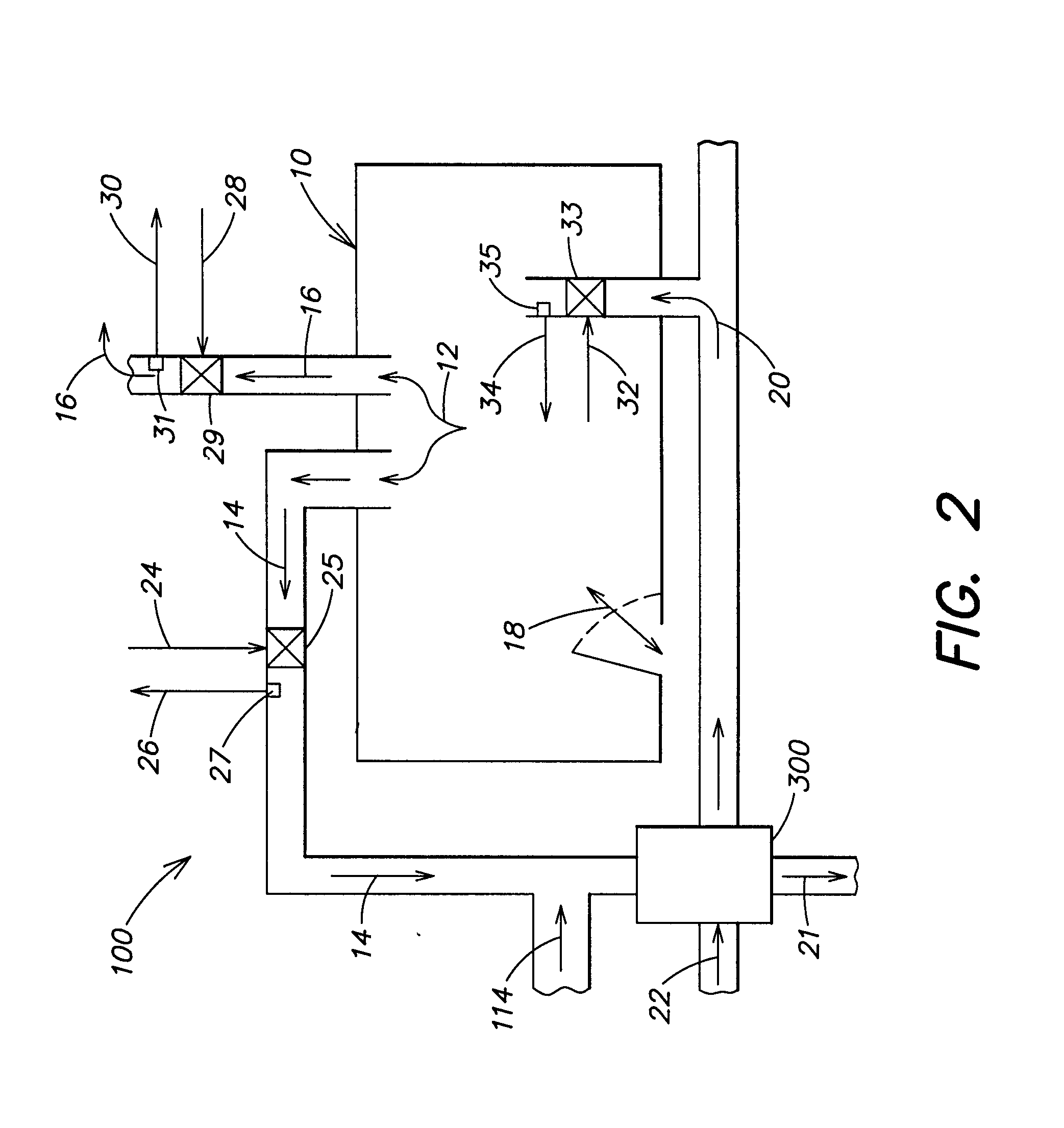

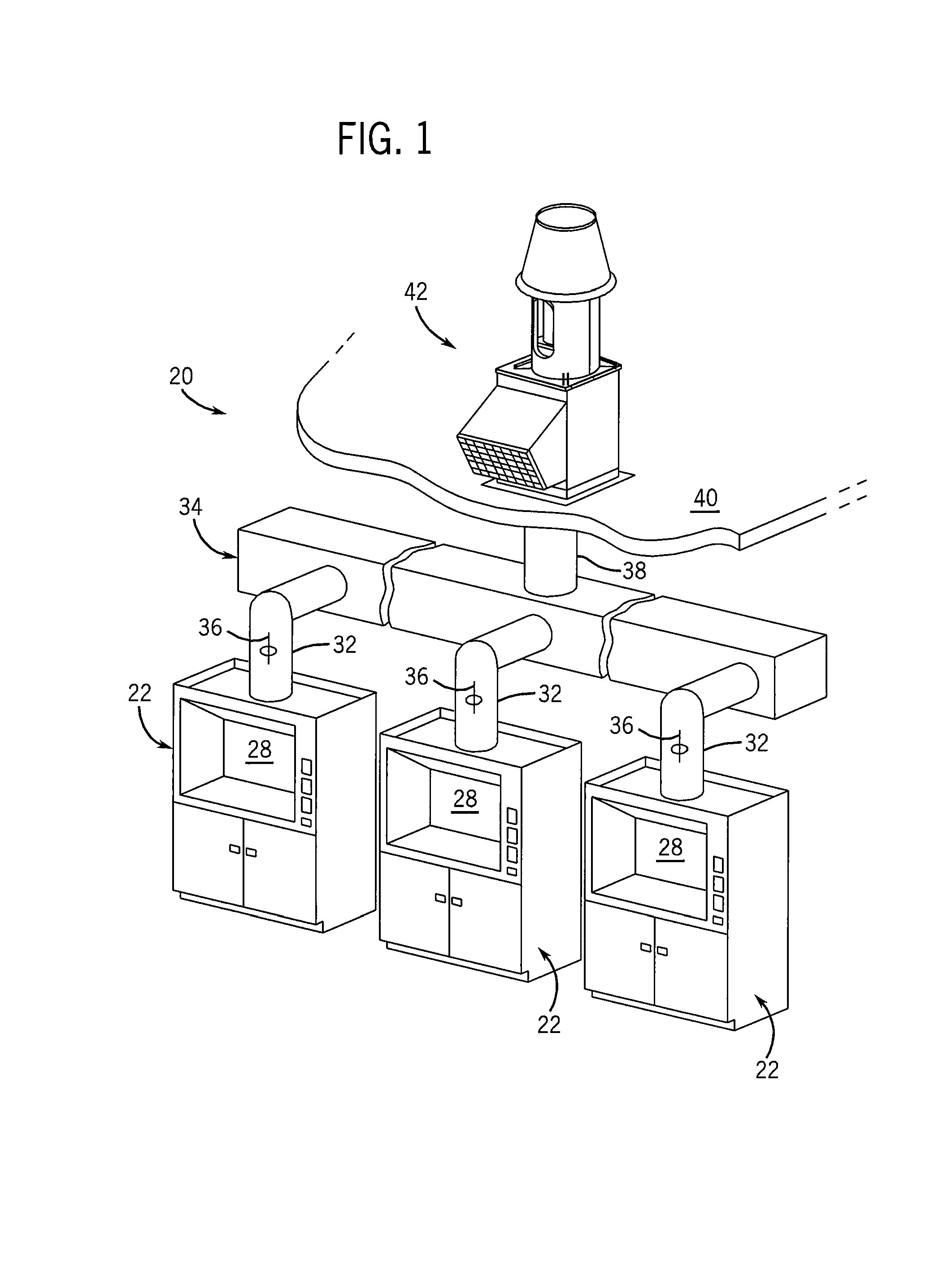

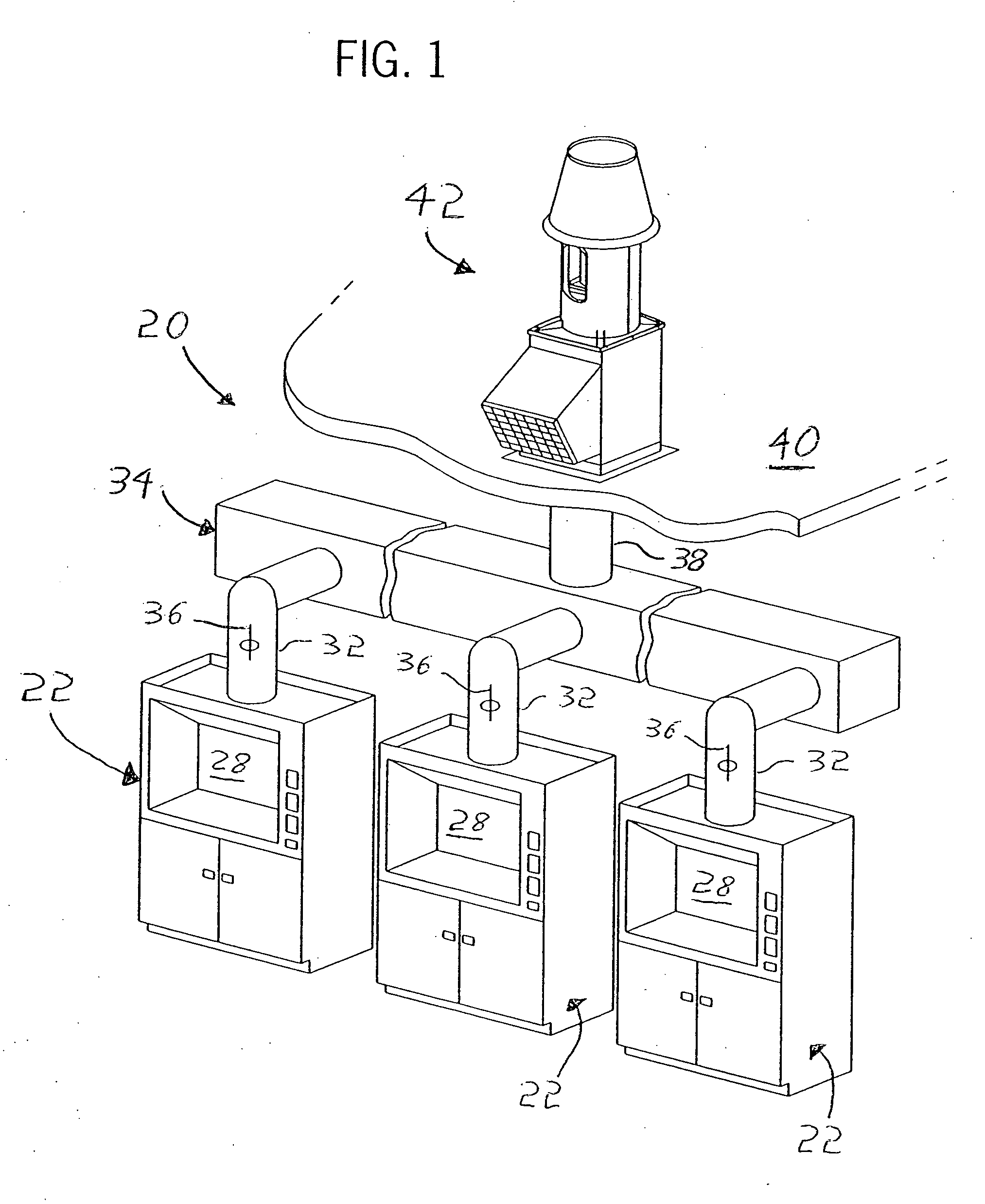

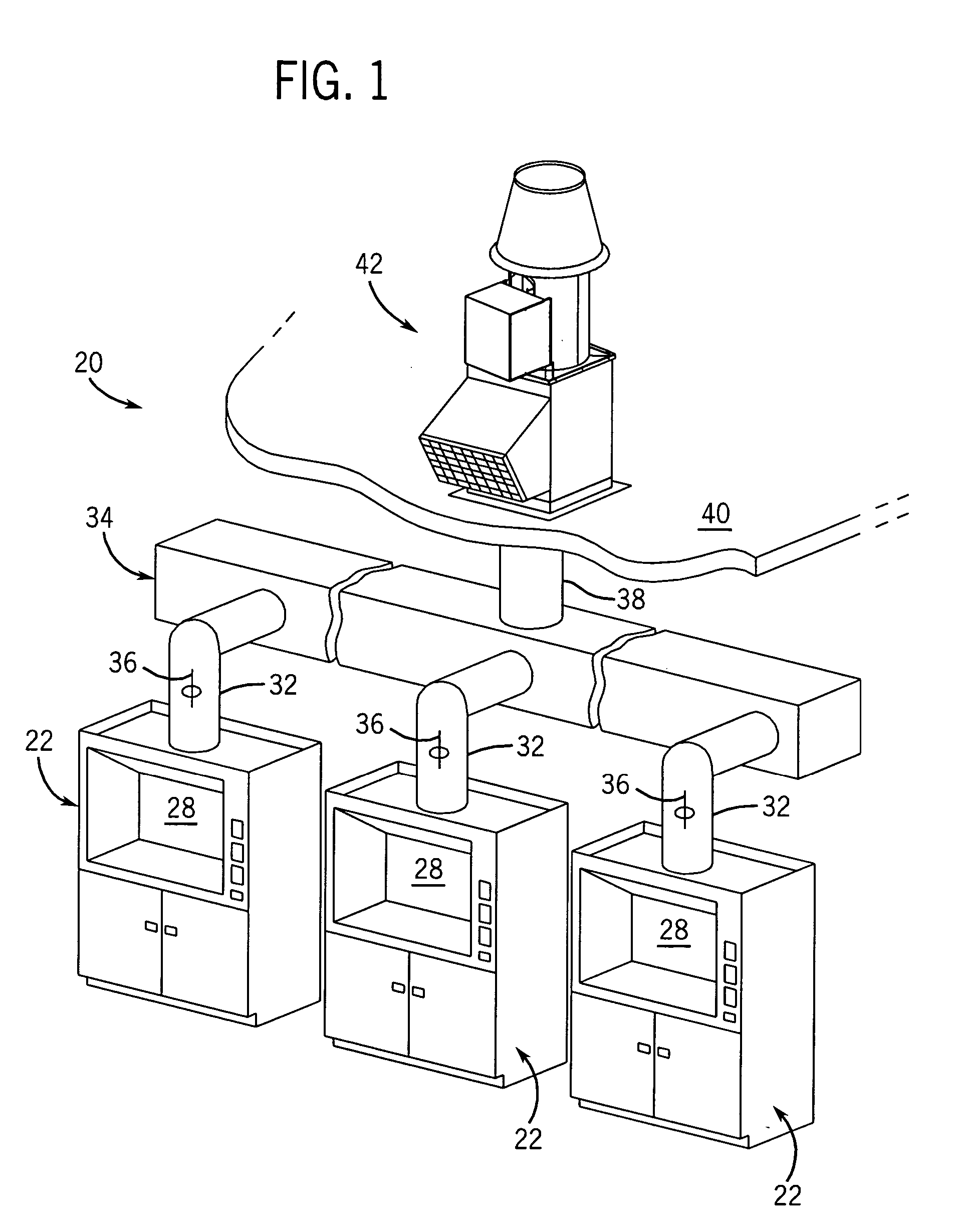

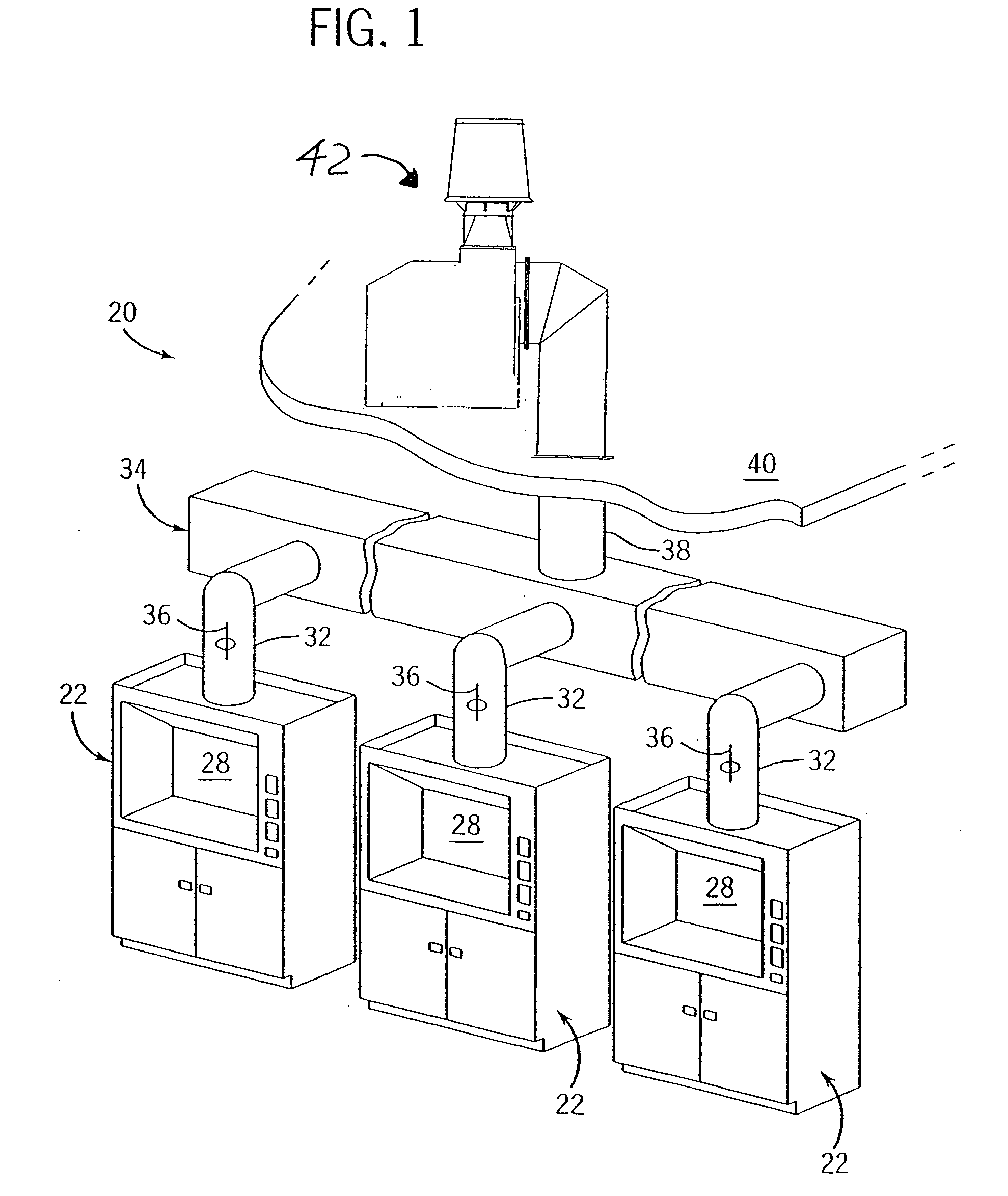

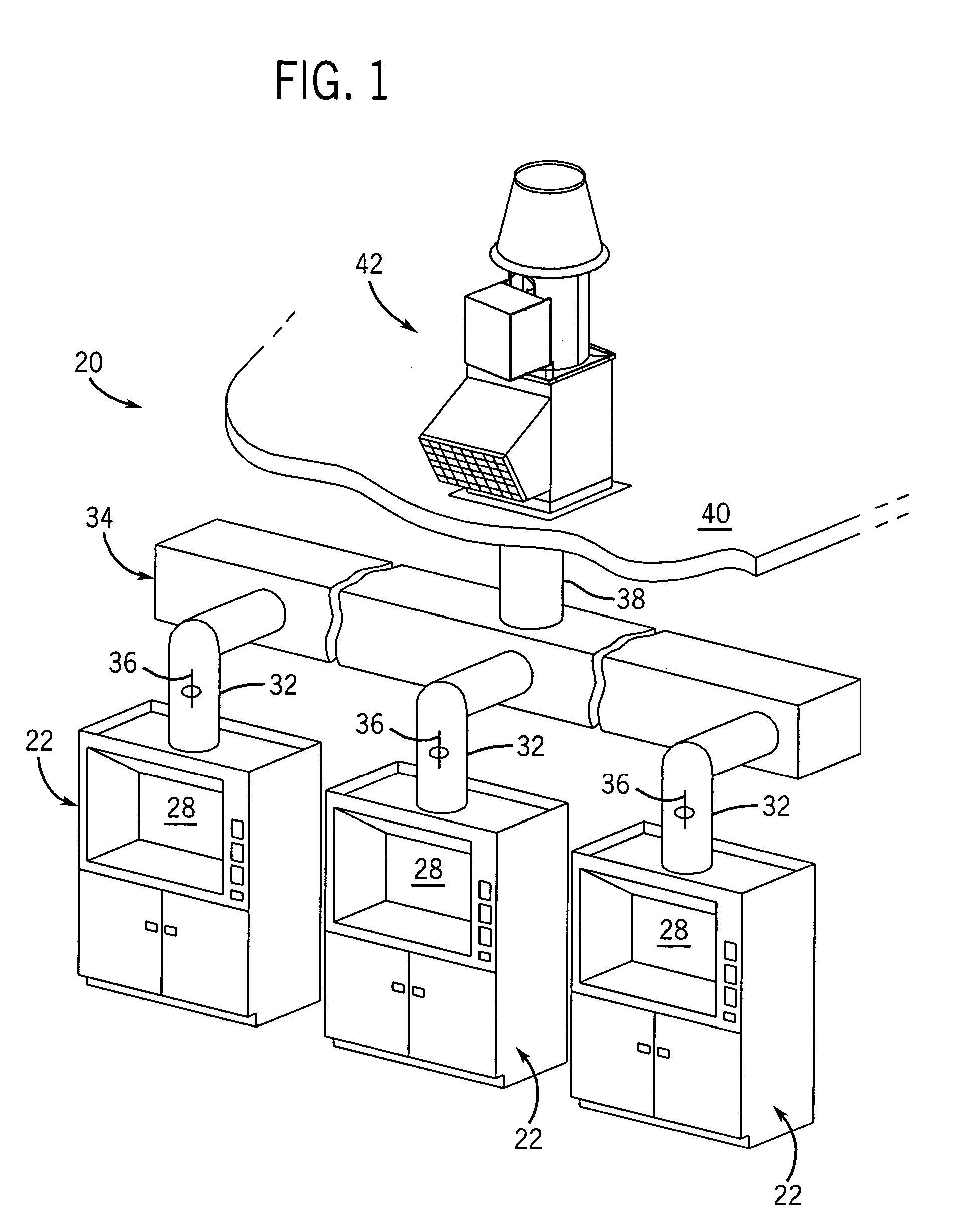

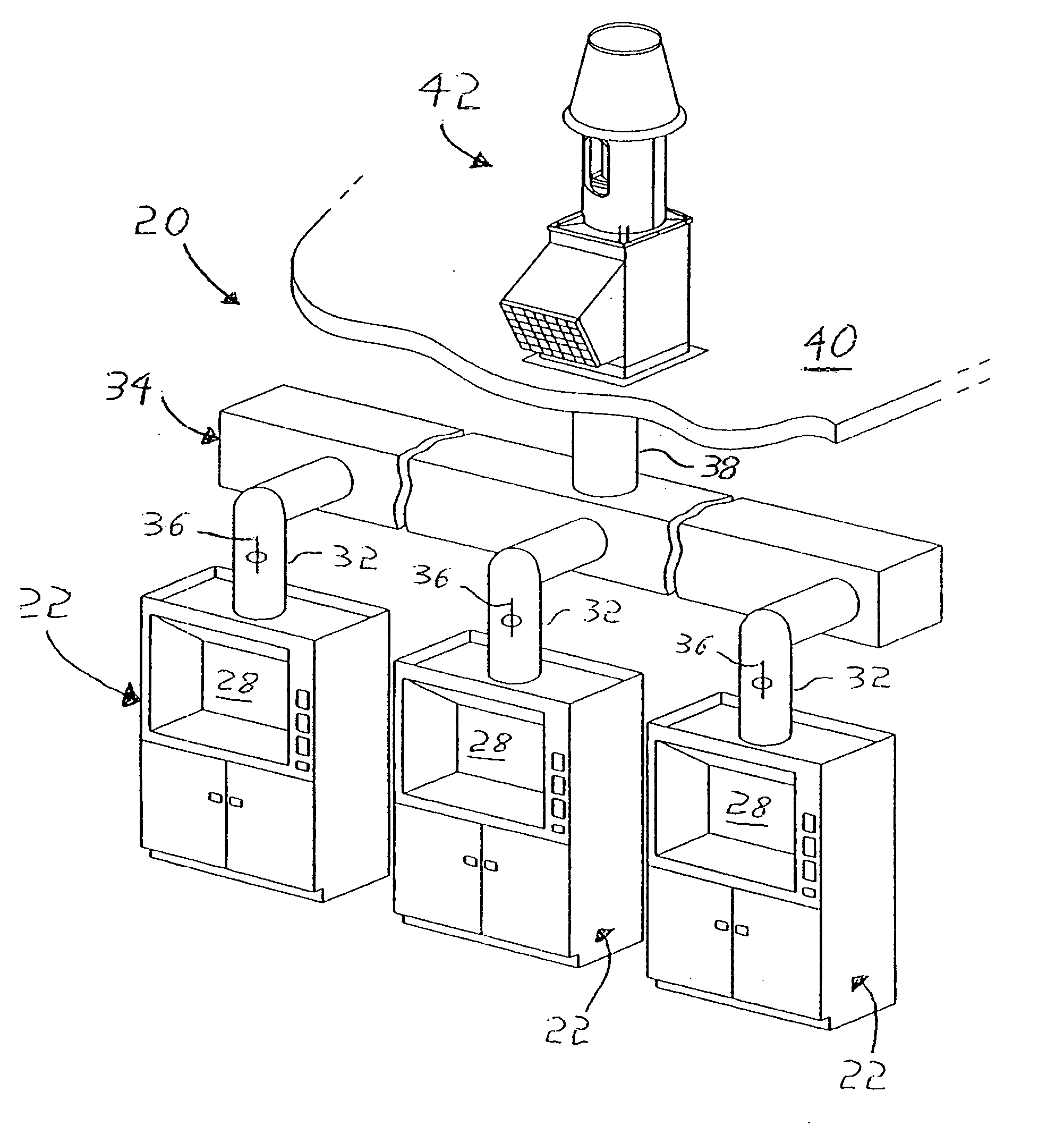

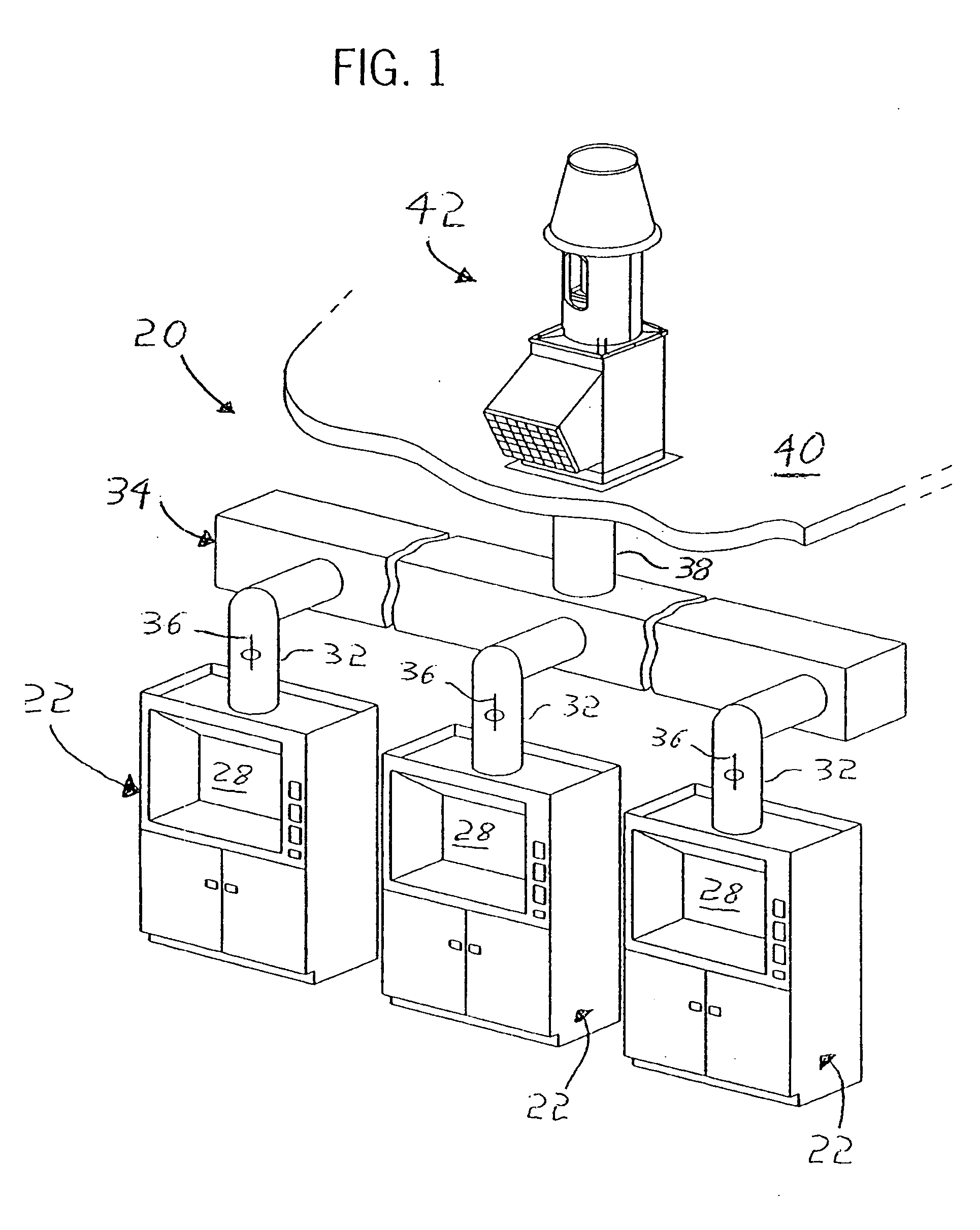

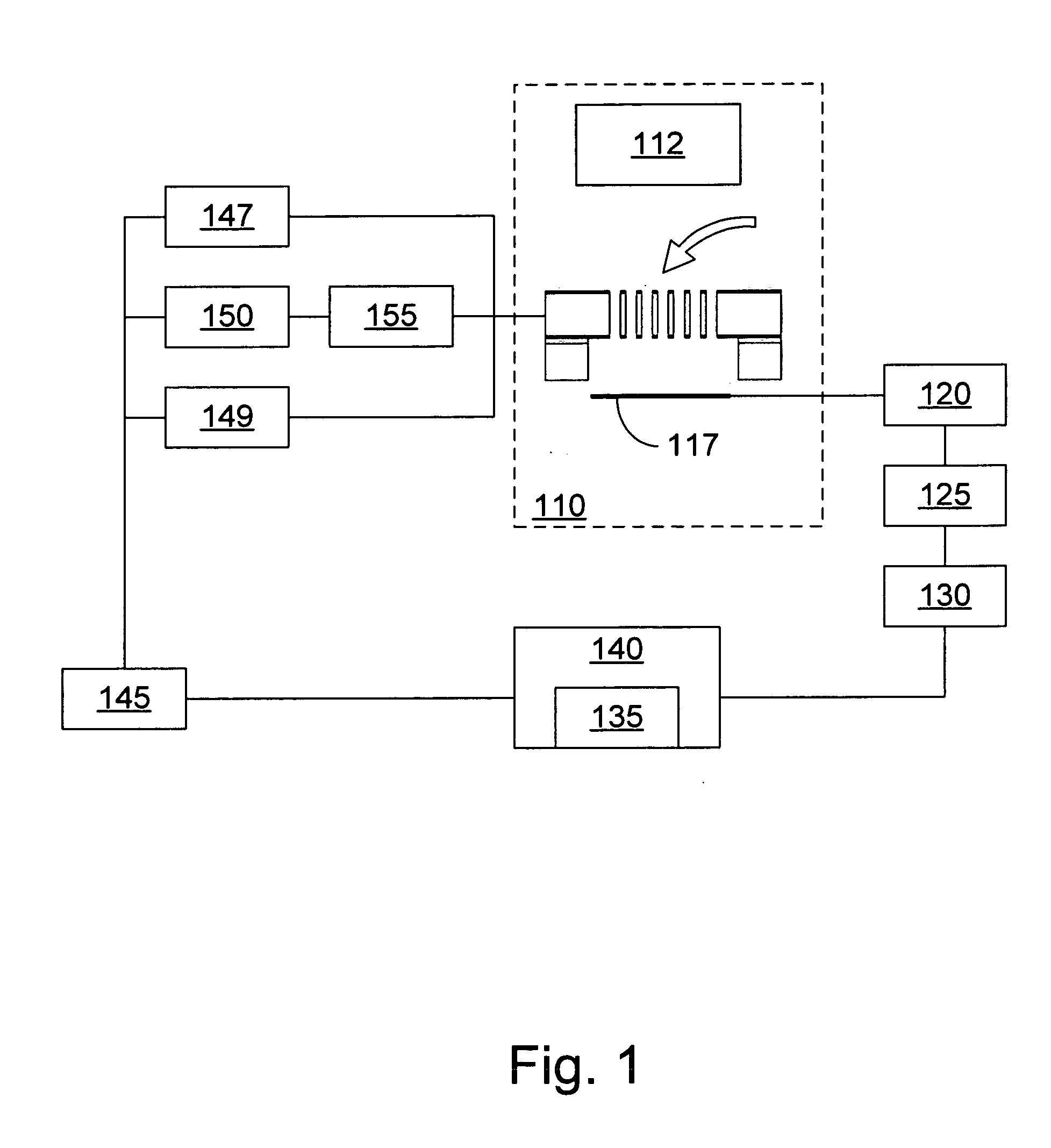

Methods and apparatus for recirculating air in a controlled ventilated environment

InactiveUS20020072322A1Human health protectionMechanical apparatusEnvironmental engineeringContaminated air

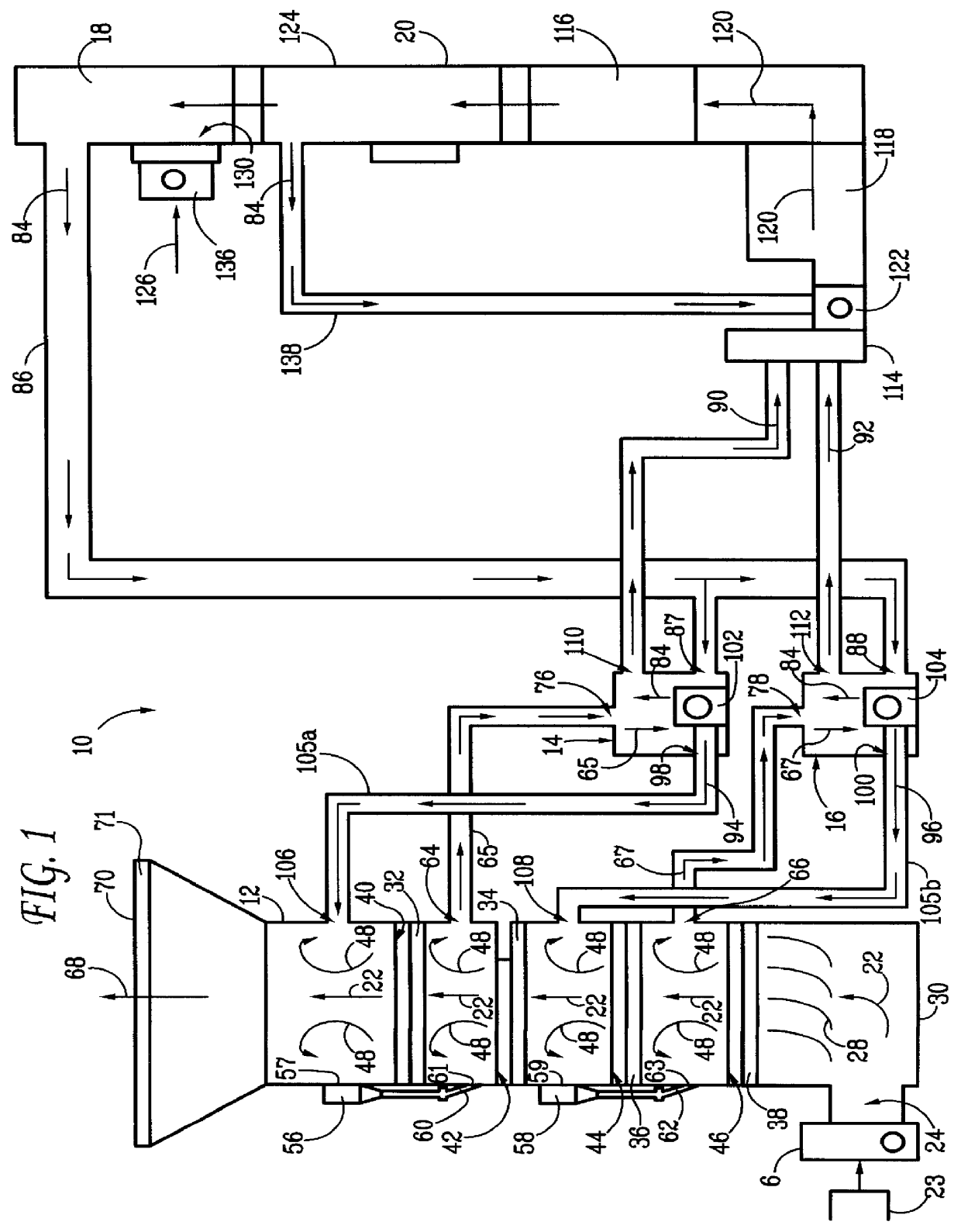

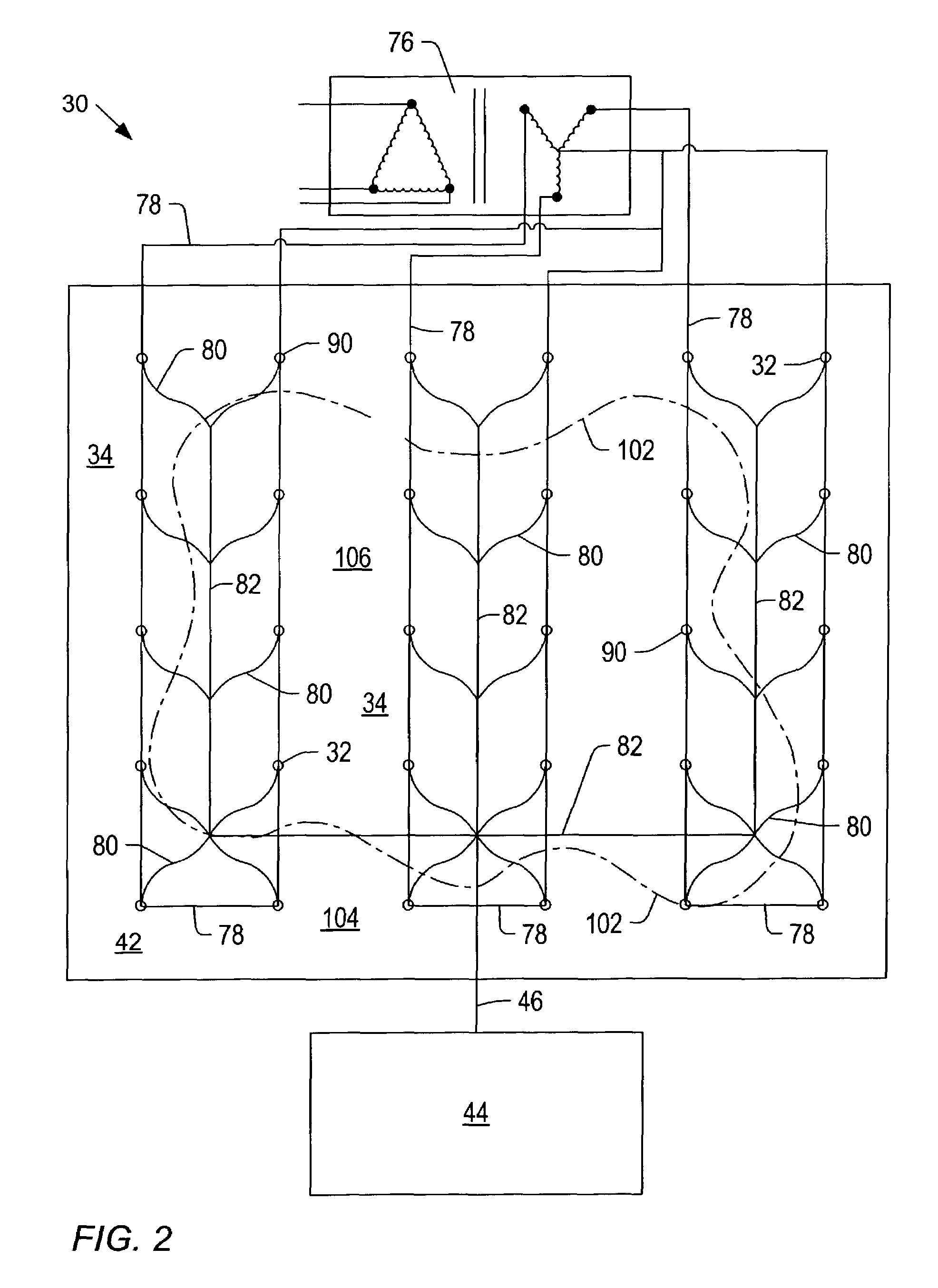

<heading lvl="0">Abstract< / heading> Methods and apparatus for recirculating air in a controlled ventilated environment. In one example, recirculation of air from one or more rooms in a multiple room ventilated environment having a common source of supply air is controlled such that minimum ventilation and thermal load requirements for each room are satisfied independently, so as to facilitate a reduction in the amount of fresh outside air required for the environment. In another example, the controlled airflows in each room may be based additionally on respective air quality levels of the air drawn from each room. In one aspect, if contaminants are detected in one or more rooms of the ventilated environment, the amount of air recirculated from a contaminated room back to the environment may be controlled based on a detected level of the contaminant and a dilution ratio of any returned contaminated air to the total uncontaminated air supplied to the environment.

Owner:PHOENIX CONTROLS

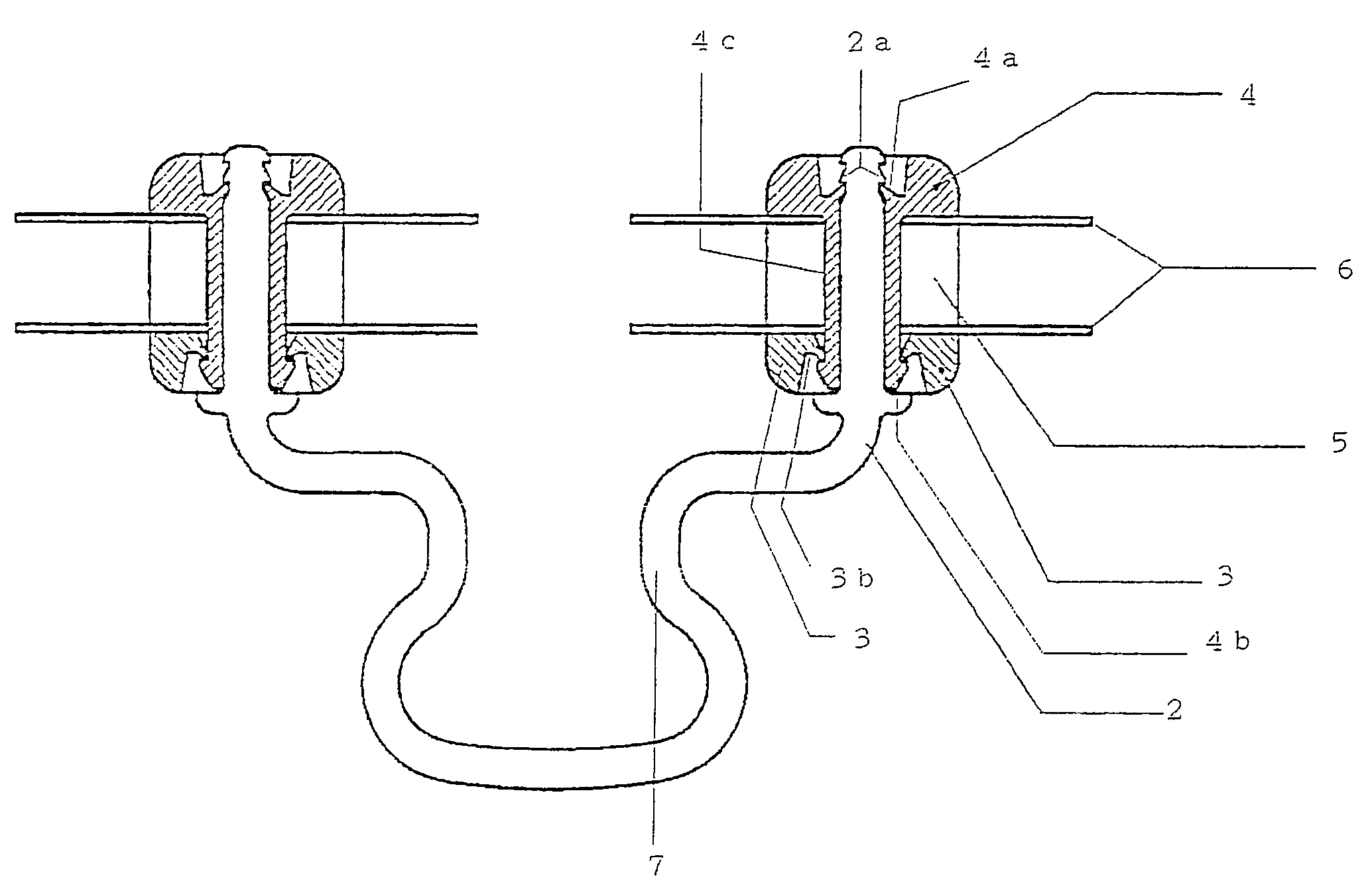

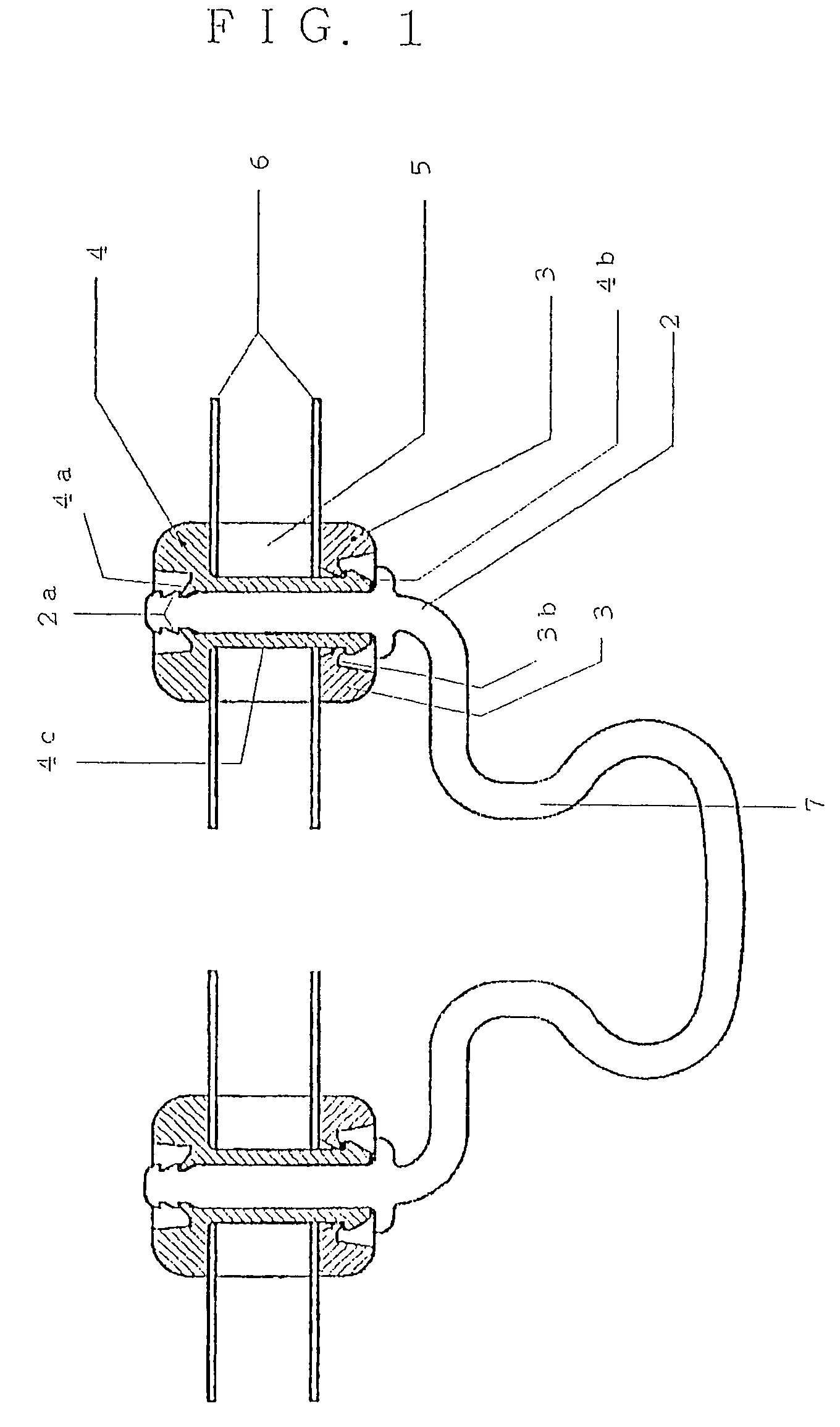

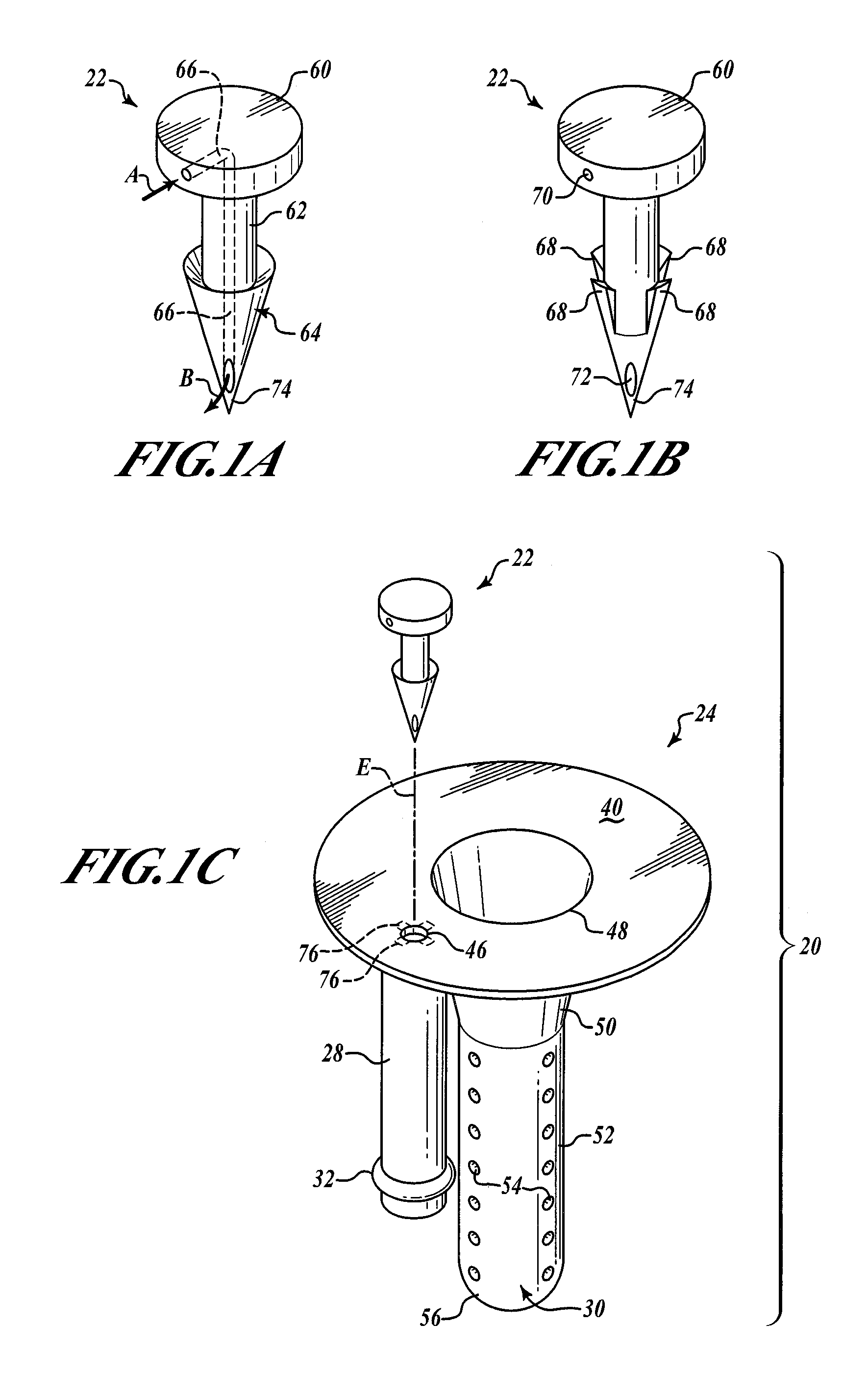

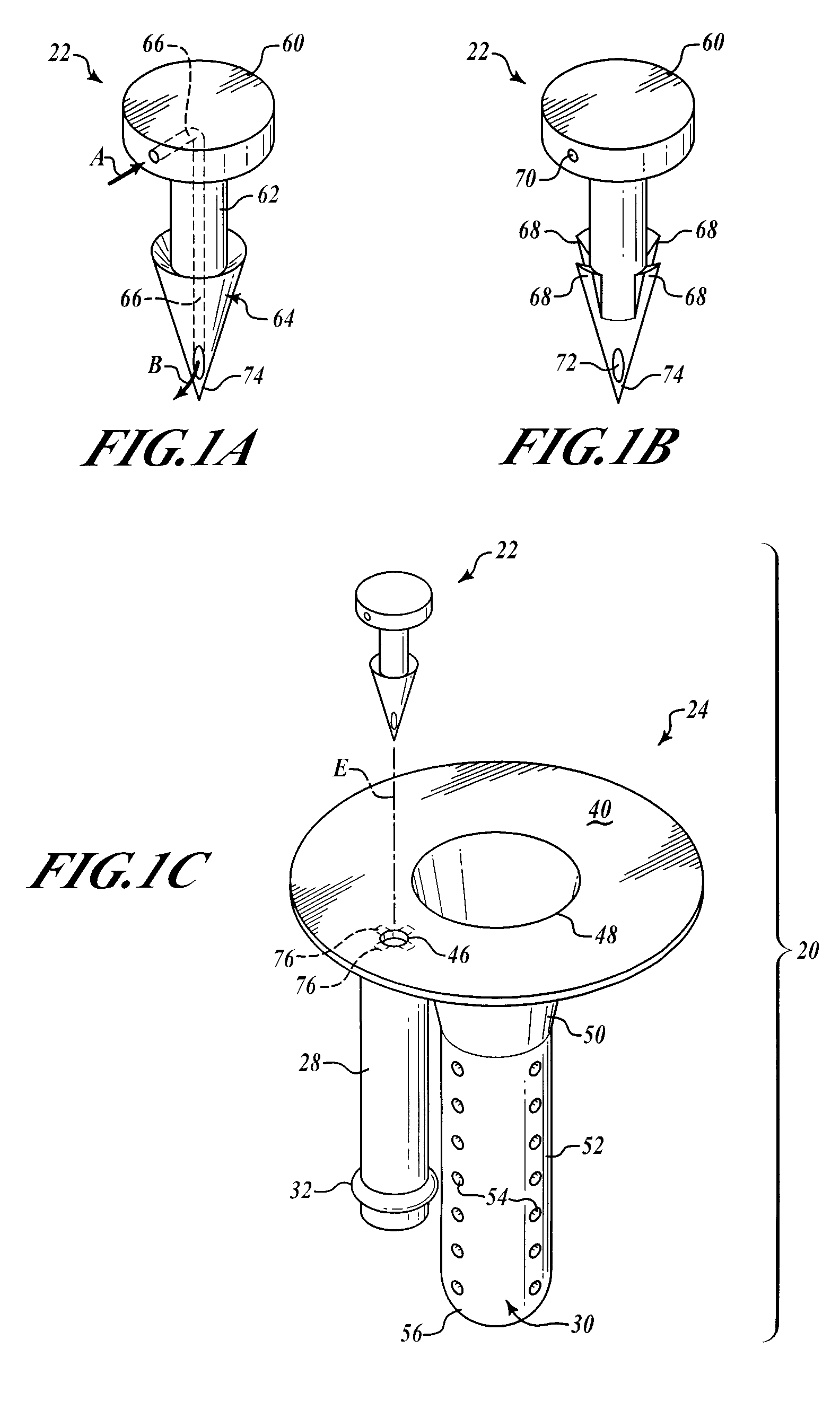

Vial assembly and method for reducing nosocomial infections

Vacuum break vial assembly and method for reducing the incidence of nosocomial infections, comprising a vial stopper having an apertured needle sheath, and a hole in the bottom of the vial fitted with a single or multi-part bladder-retaining plug / vent assembly. The vial has an aluminum cap holding a plastic flip-off top, removal of which permits access by hypodermic needle through the stopper into the needle sheath. No pre-pressurization of the vial by ambient contaminated air via the hypodermic can occur. Rather, the needle is inserted in the vial through the stopper and the medicinal fluid withdrawn. Air is inlet via a vent into the collapsed bladder secured in the bottom of the vial and the bladder expands to permit withdrawal of fluid into the hypodermic without vacuum lock. No air having pathogen vectors is introduced into the vial medicinal fluid, as the bladder isolates volume-compensating air from the medicinal fluid.

Owner:YANDELL MARION E

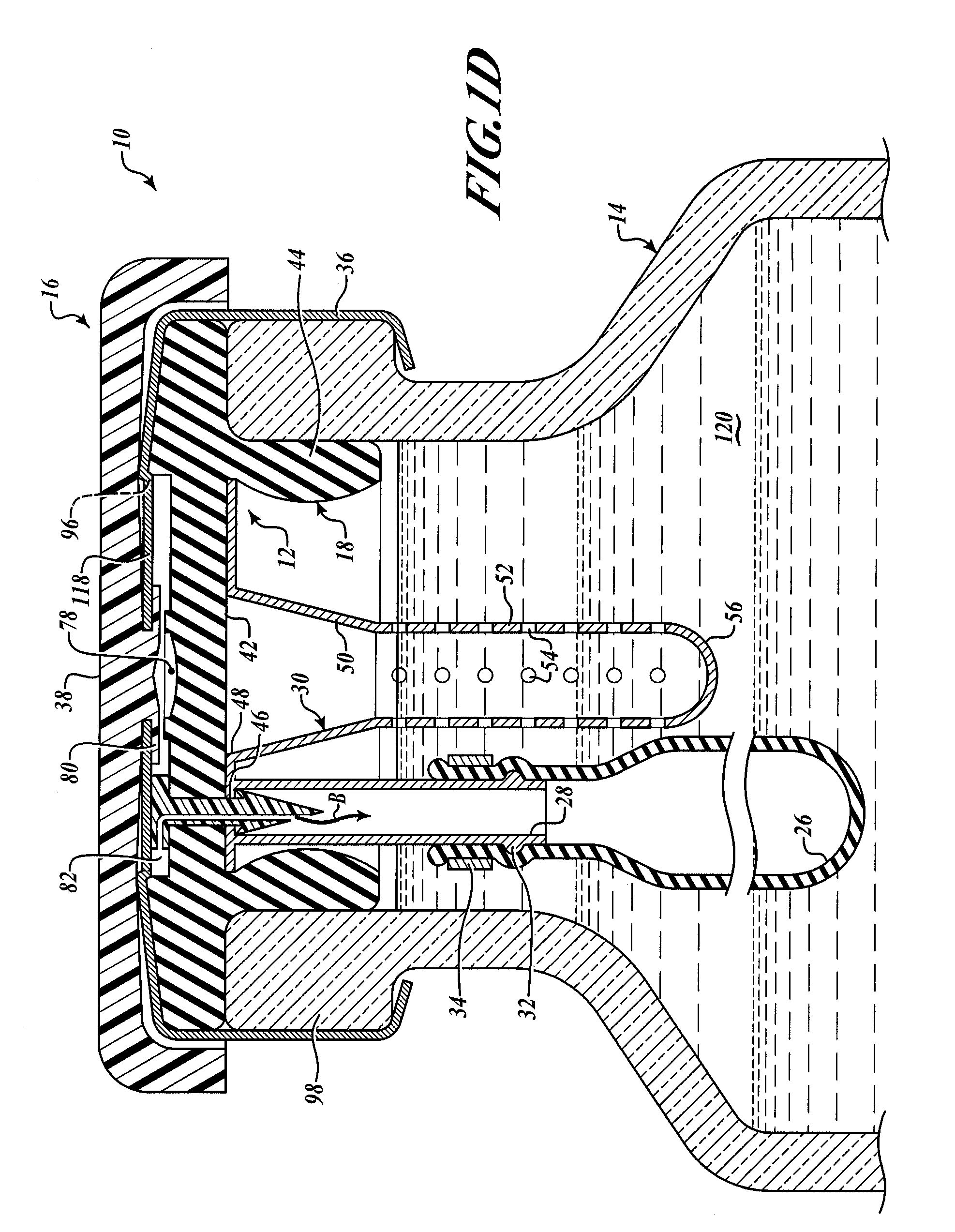

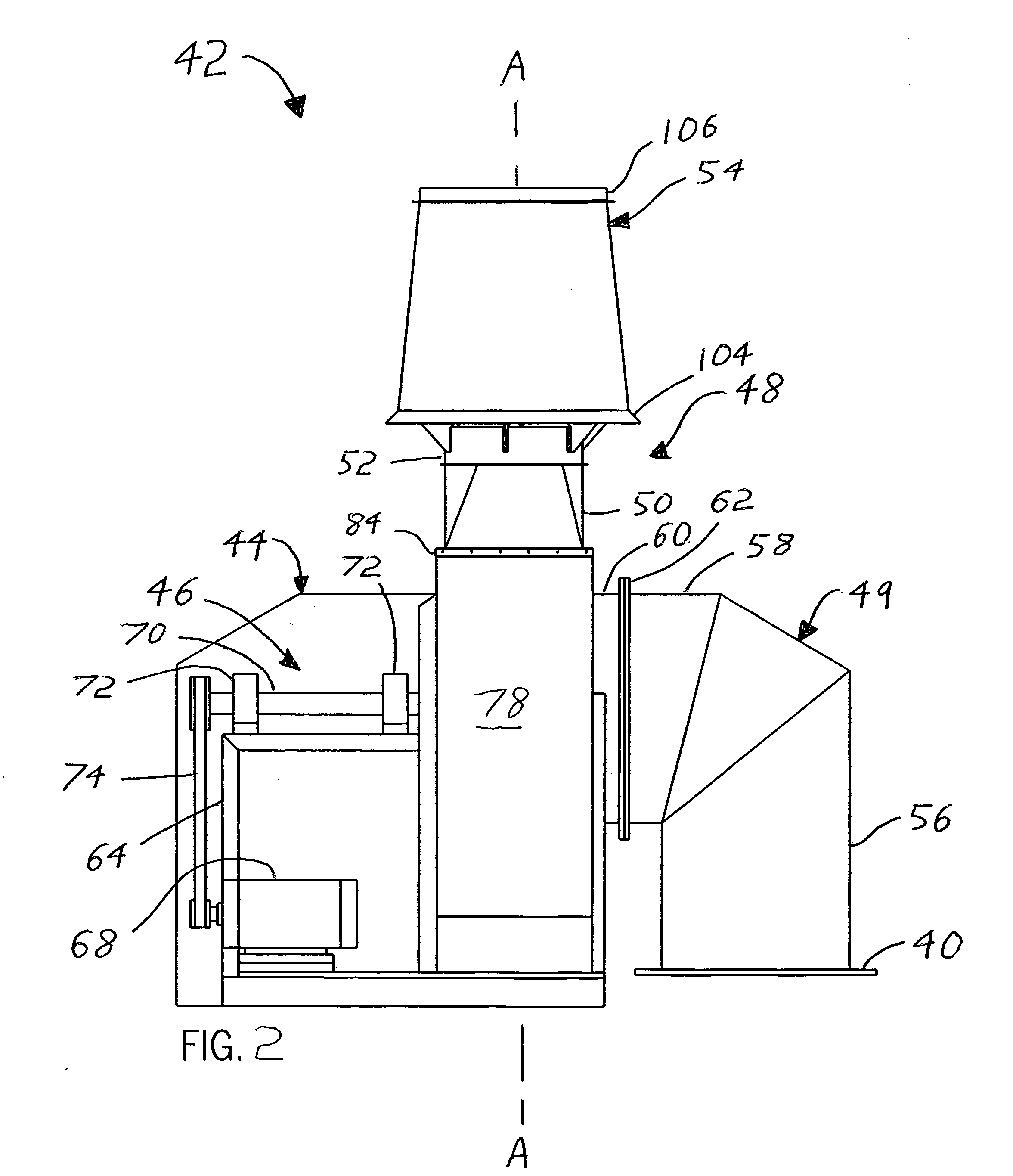

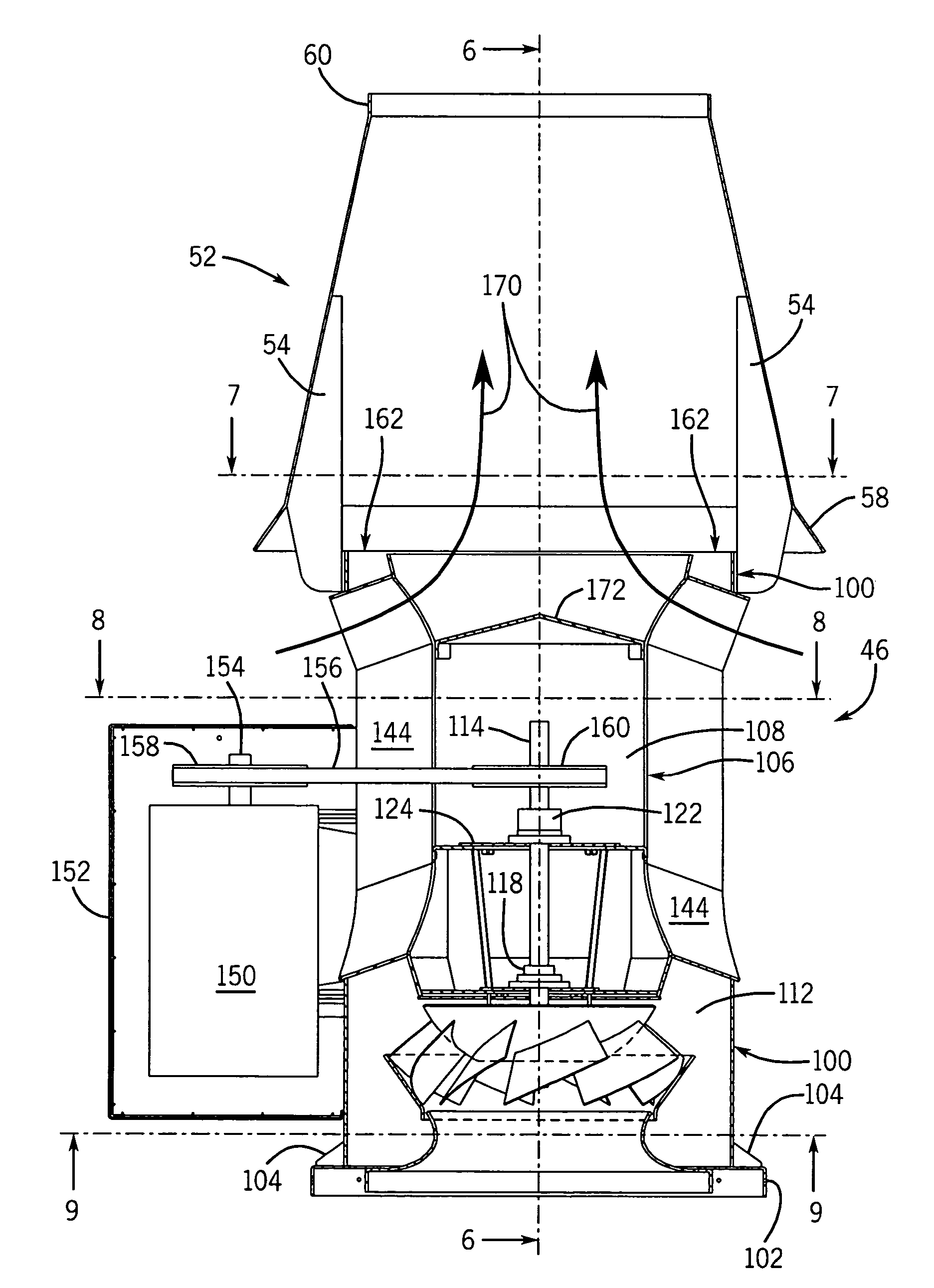

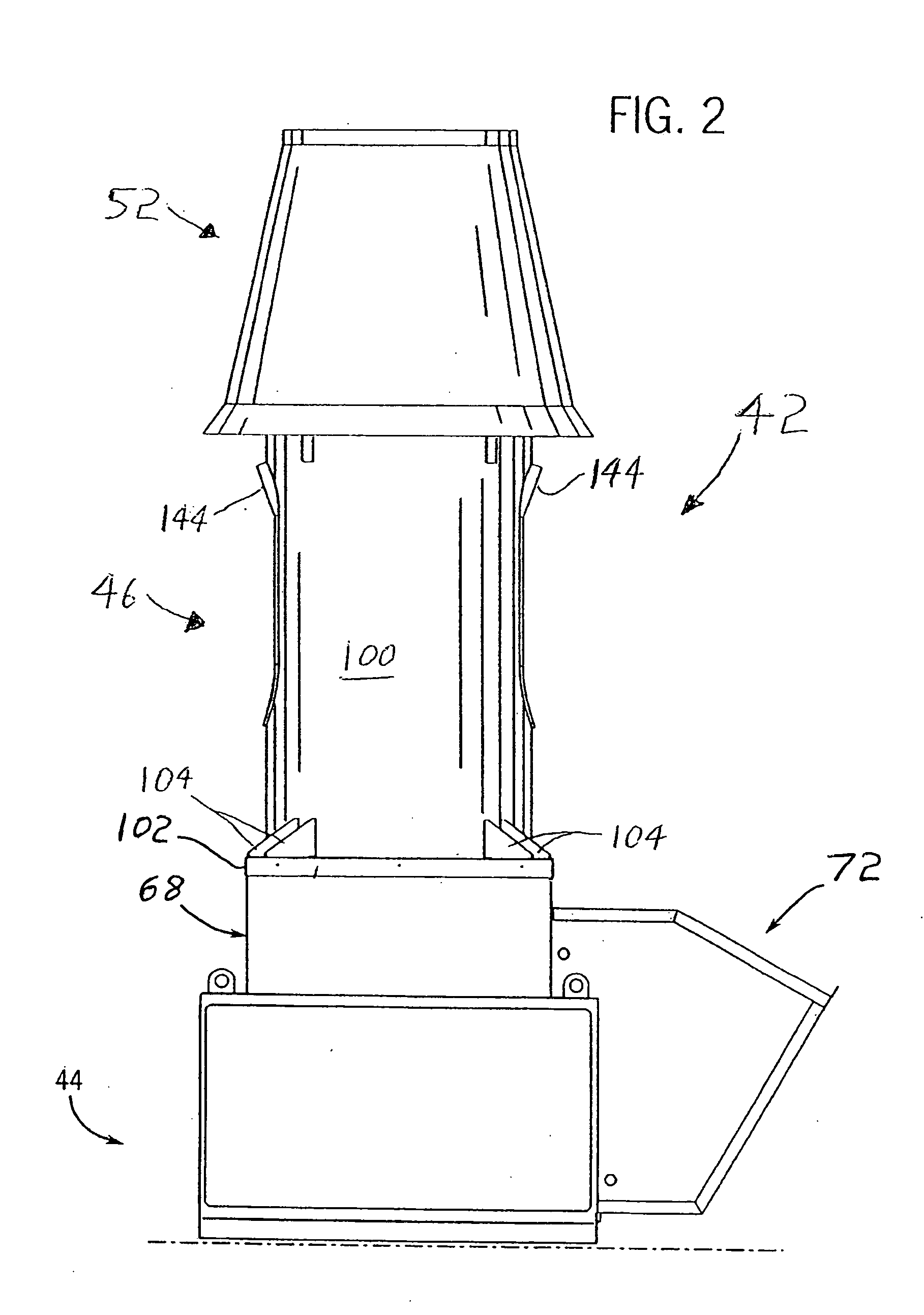

Exhaust fan assembly having flexible coupling

An exhaust assembly is provided for expelling contaminated air from a building. The assembly includes a plenum, a fan assembly attached to the plenum, and a windband mounted on top of the fan assembly. The fan assembly is constructed of cylindrical outer and inner walls which define a drive chamber and surrounding annular space. A fan driven by a motor whose shaft extends downward from the drive chamber draws exhaust air from the plenum and blows it up through the annular space to a nozzle at the top of the fan assembly. The motor is pivotally mounted inside the assembly to provide access to the motor components when it is desired to perform inspection and maintenance.

Owner:GREENHECK FAN

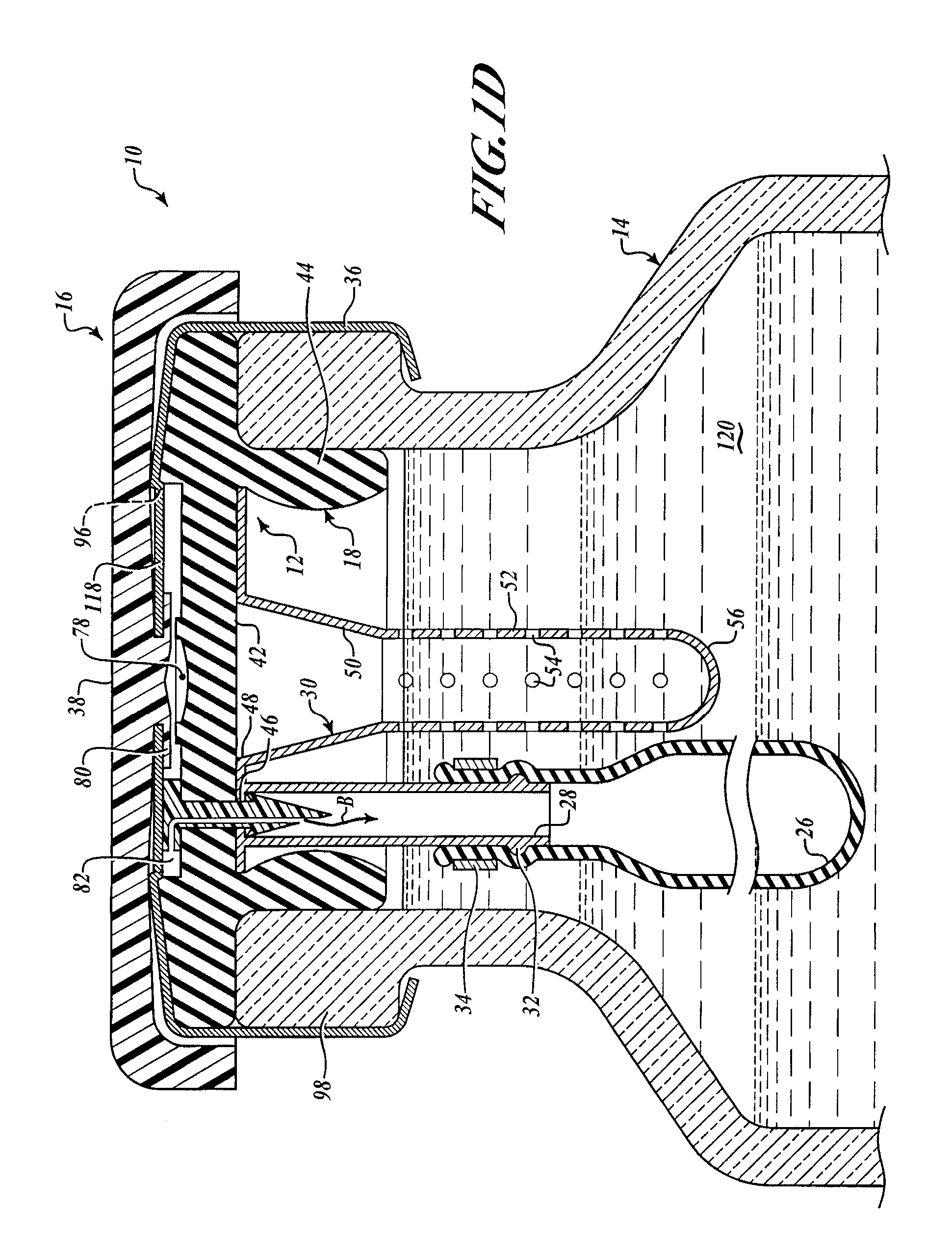

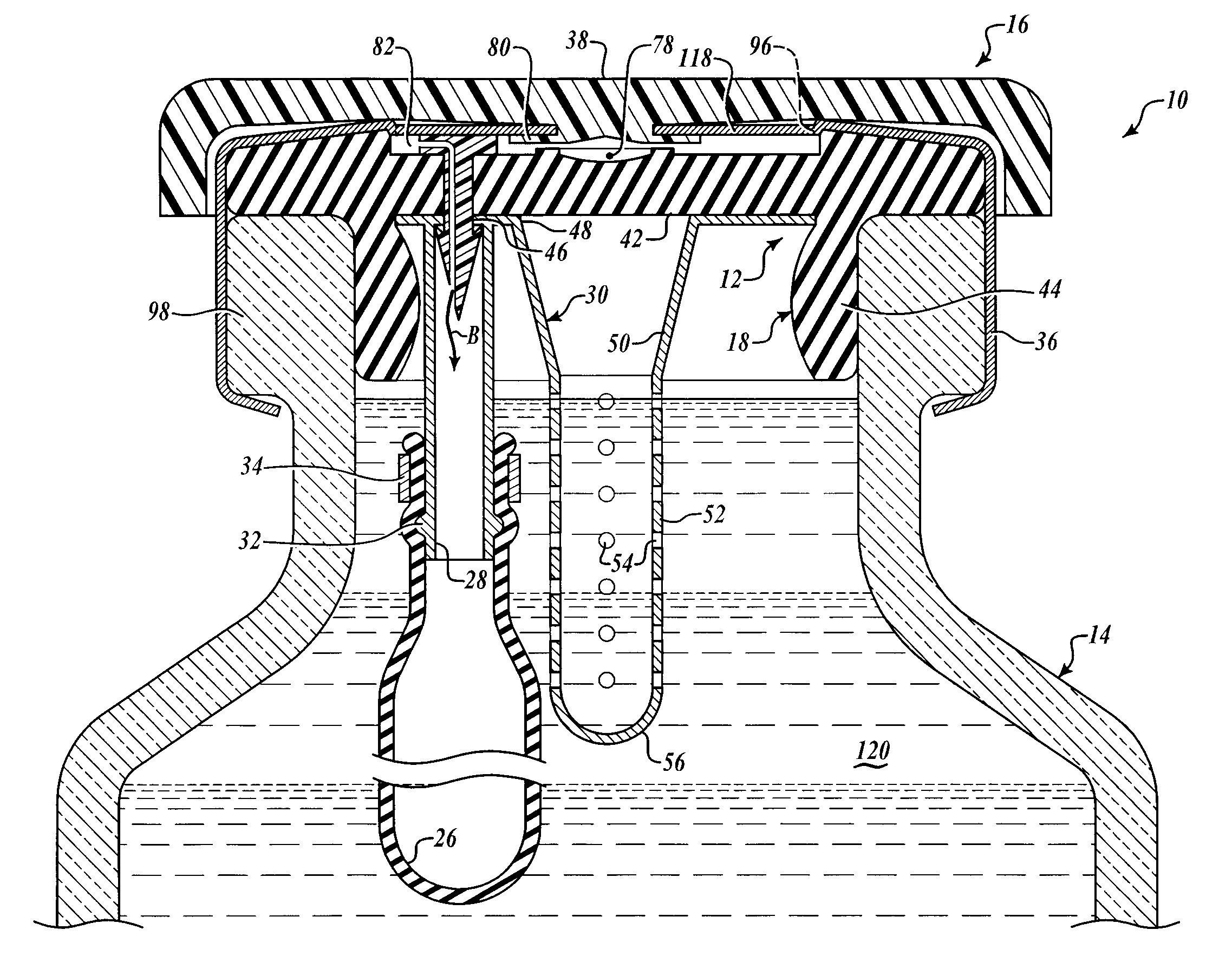

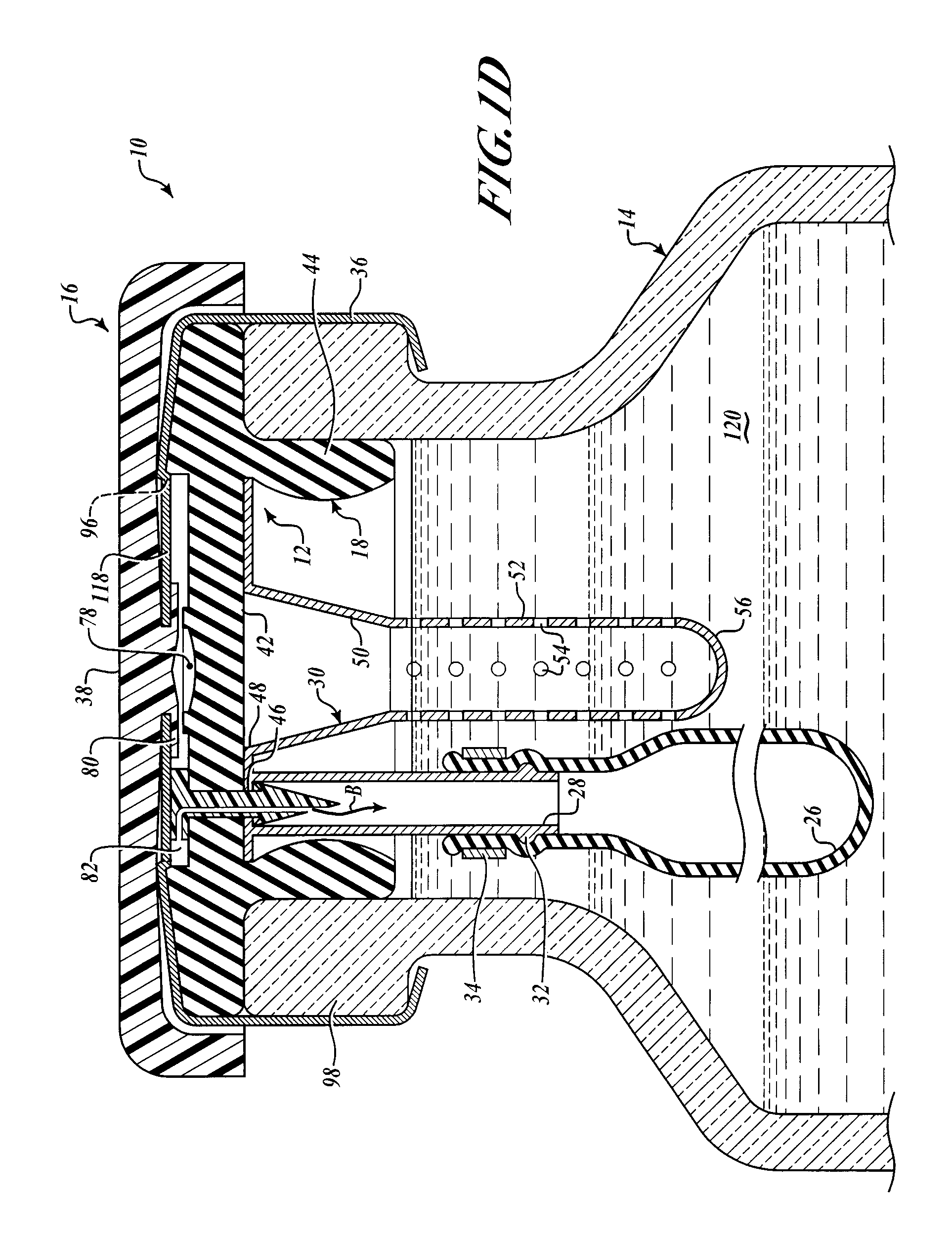

Deoiler for a lubrication system

ActiveUS7377110B2Reduce pressureHigh power settingPump componentsEngine fuctionsPositive pressureEngineering

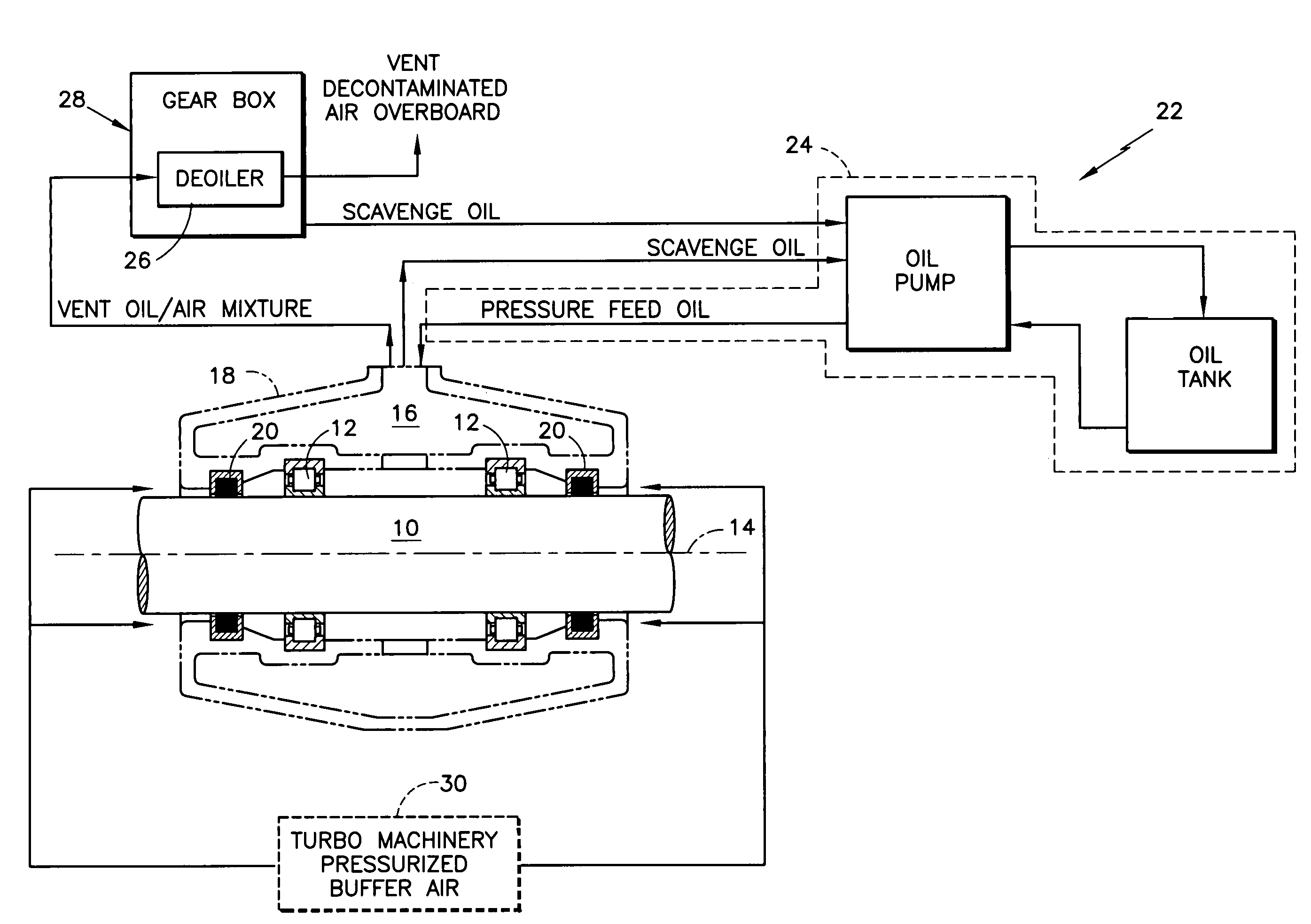

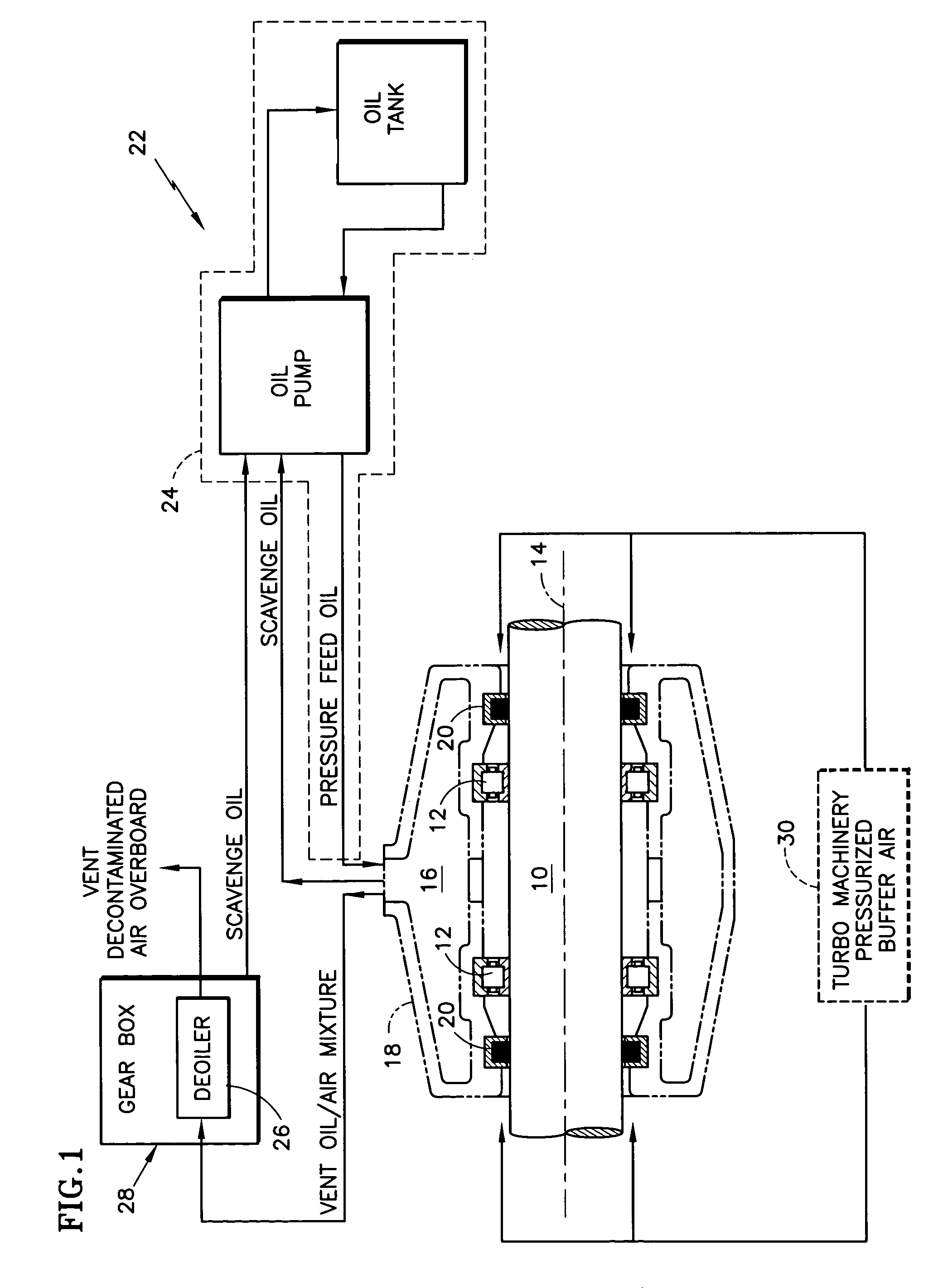

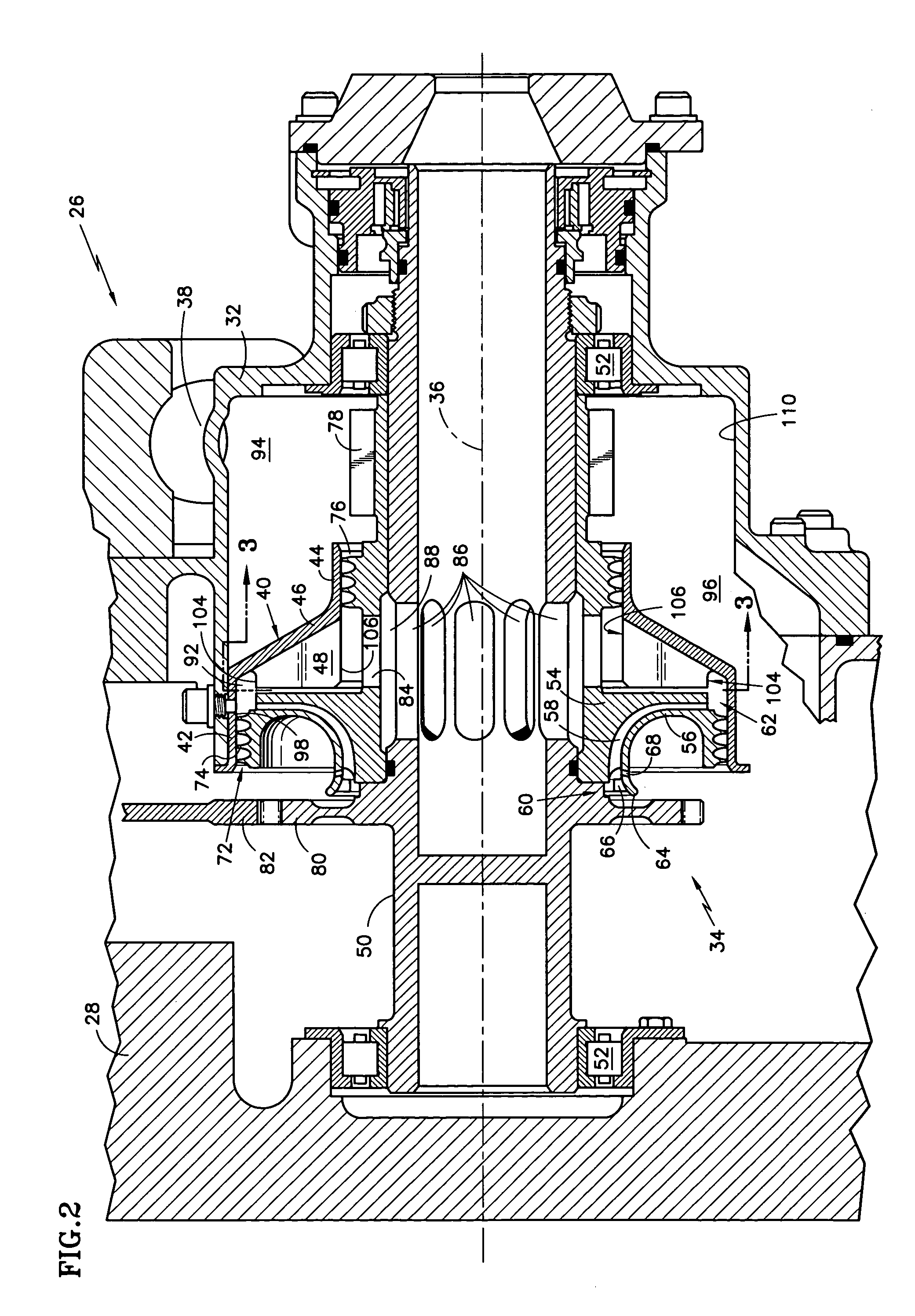

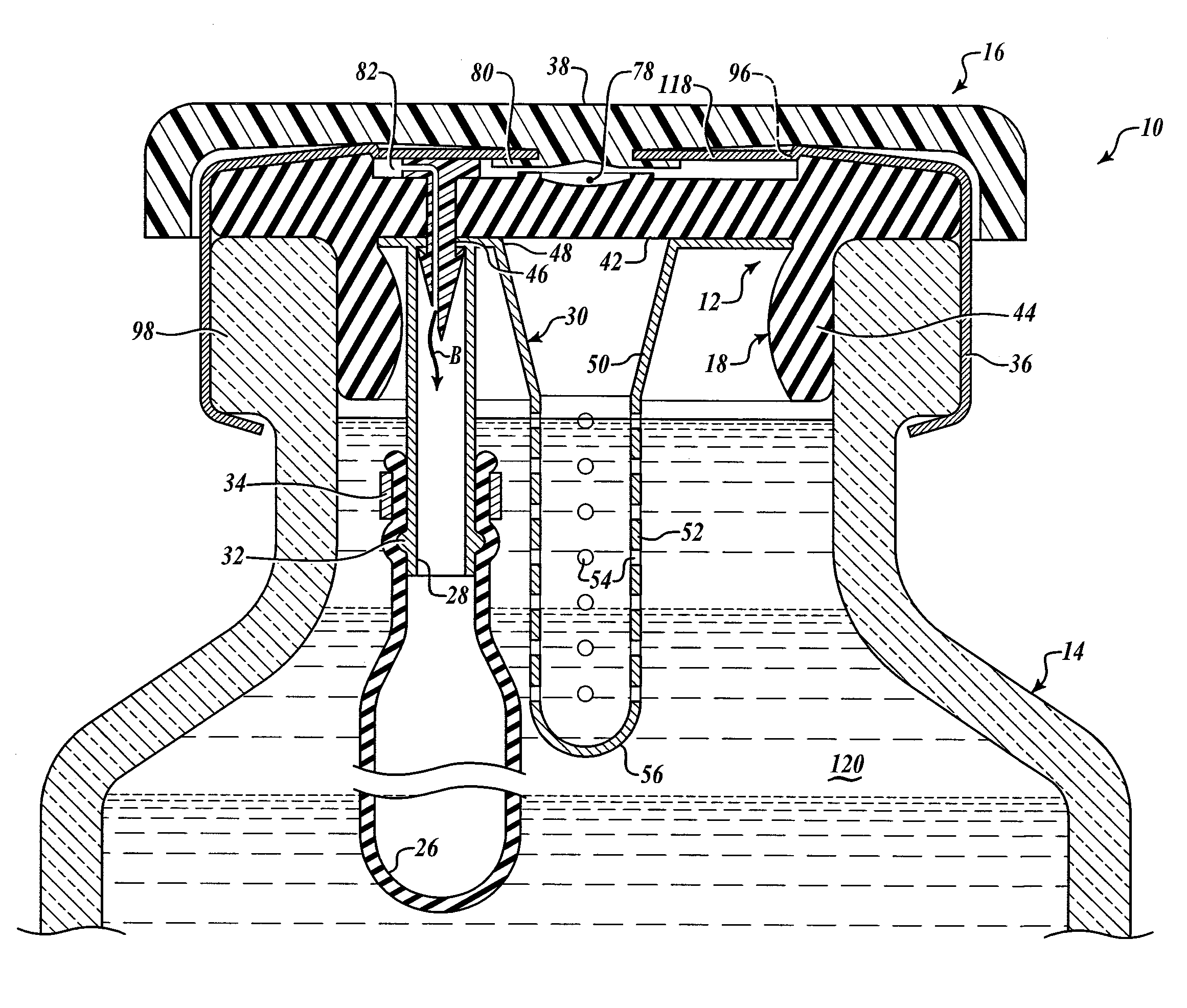

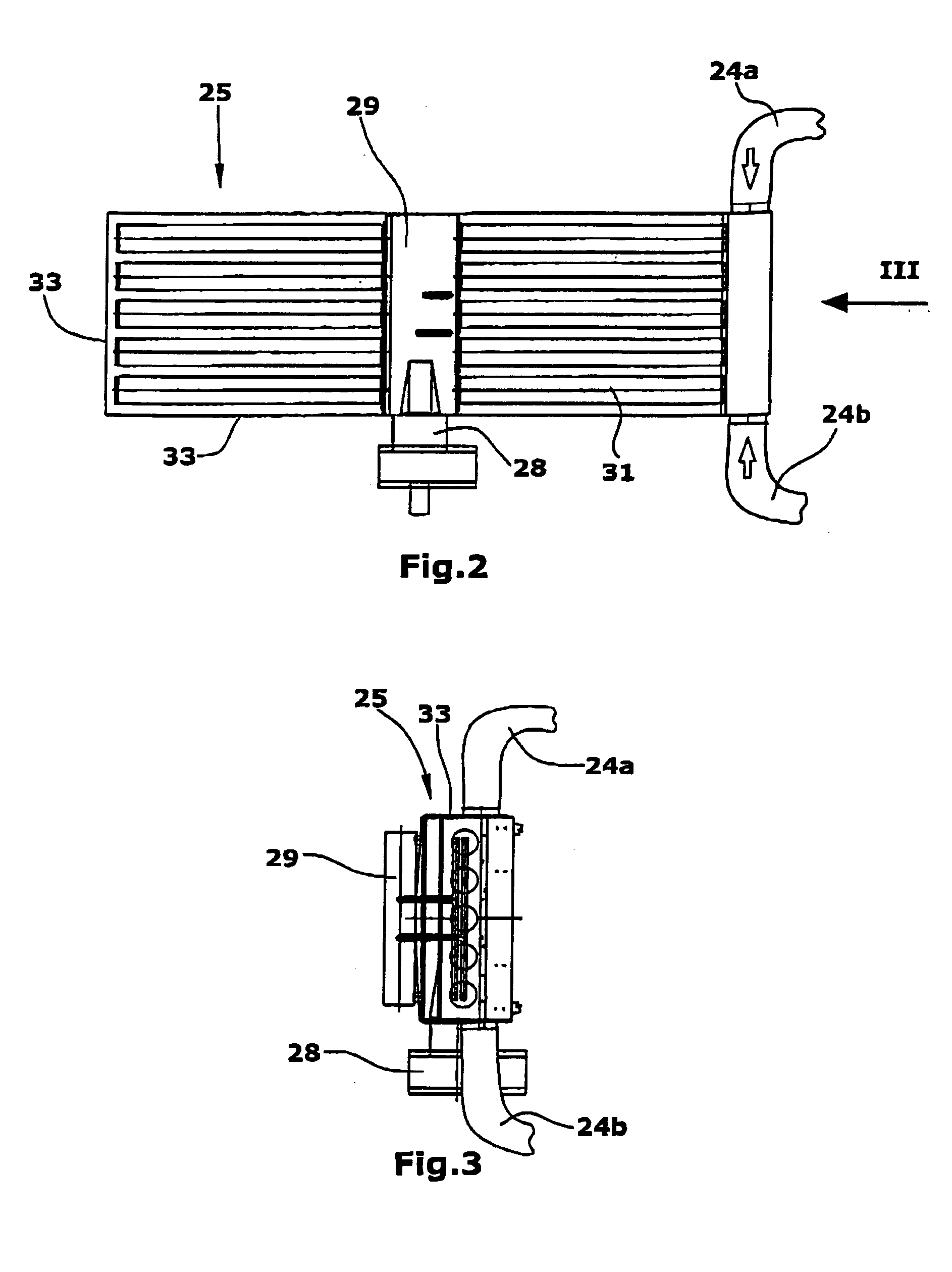

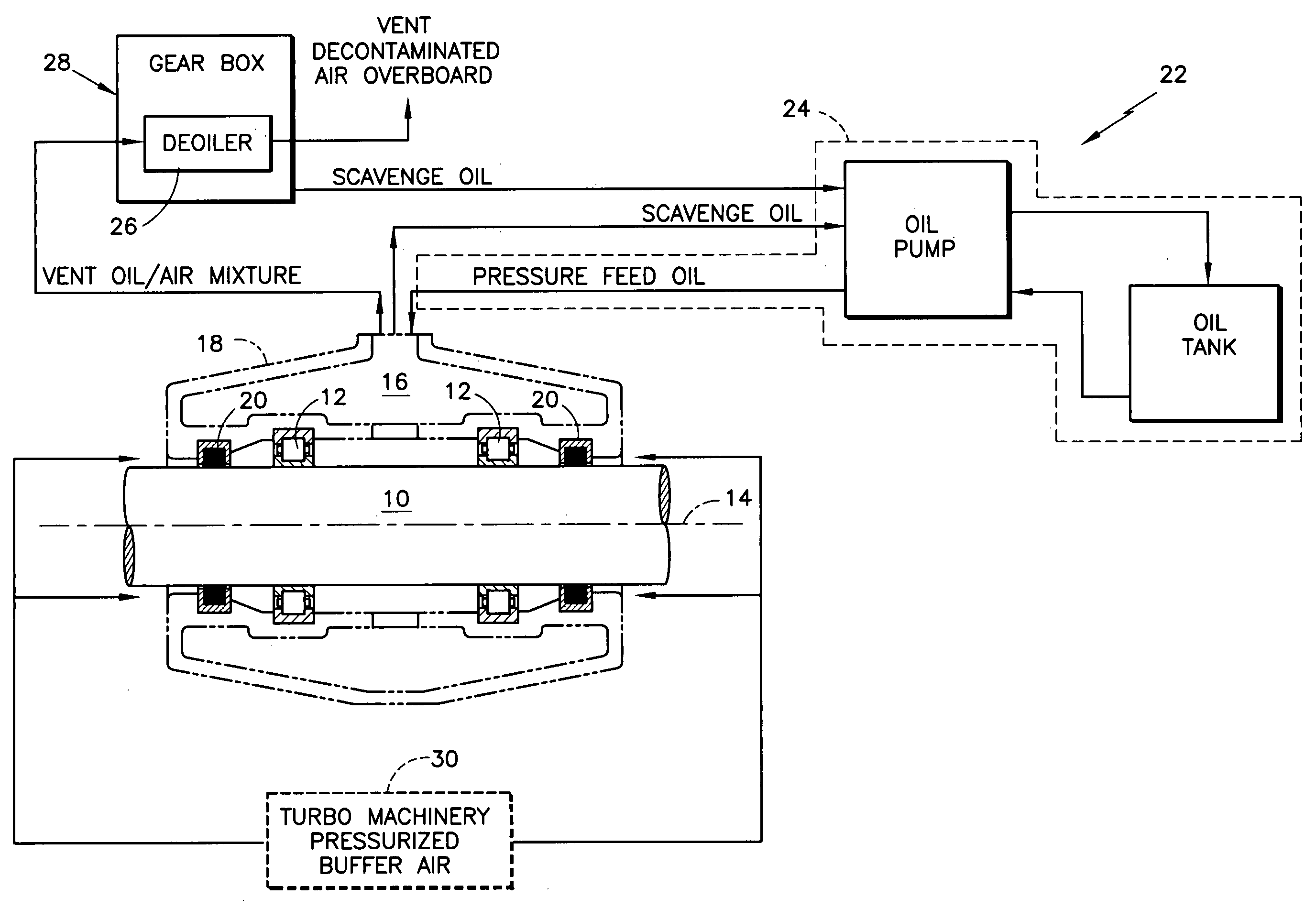

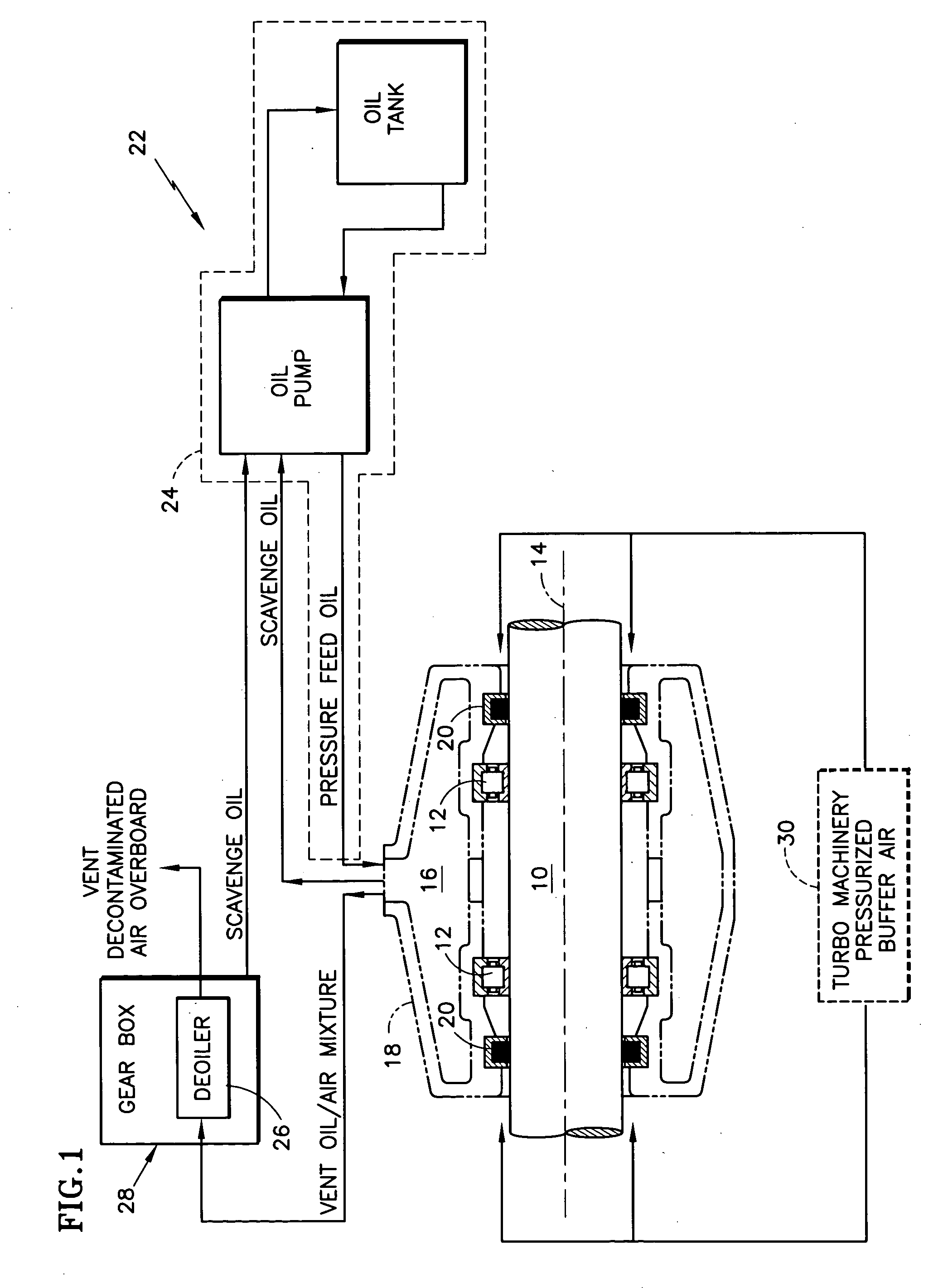

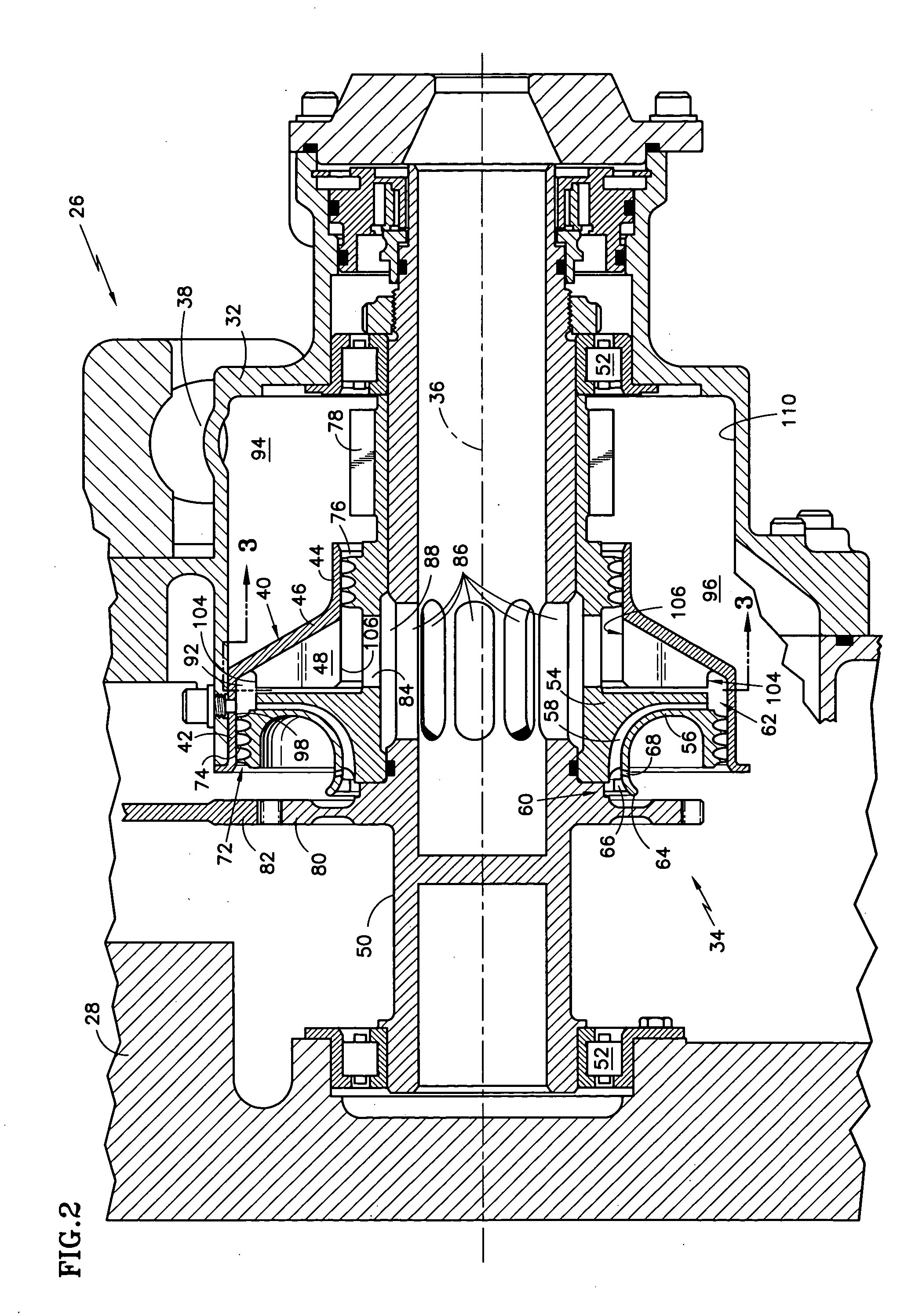

A deoiler 26 for separating oil from air contaminated with the oil has at least one separator for separating the oil from the air and also has a source of suction for reducing air pressure at the source of the air. In an exemplary embodiment, the deoiler 26 creates the suction at a first operating condition, but acts as a restrictor at a second operating condition. A deoiling method according to the invention creates suction at a first operating condition to reduce the air pressure at the source of the oil-contaminated air, establishes a flow restriction at a second operating condition to pressurize the air source, and encourages oil to separate from the air at both operating conditions. When used as a component of a turbine engine lubrication system 22, the source of contaminated air may be a buffered bearing compartment 16. The inventive deoiler ensures a positive pressure difference across the bearing compartment seals 20 at the engine's idle power setting without requiring the idle setting to be undesirably high, and without requiring the use of buffer air whose pressure at higher engine power is high enough to be detrimental. In an exemplary embodiment, the deoiler pressurizes the bearing compartment at higher power settings to resist excessive buffer air infiltration into the bearing compartment.

Owner:RTX CORP

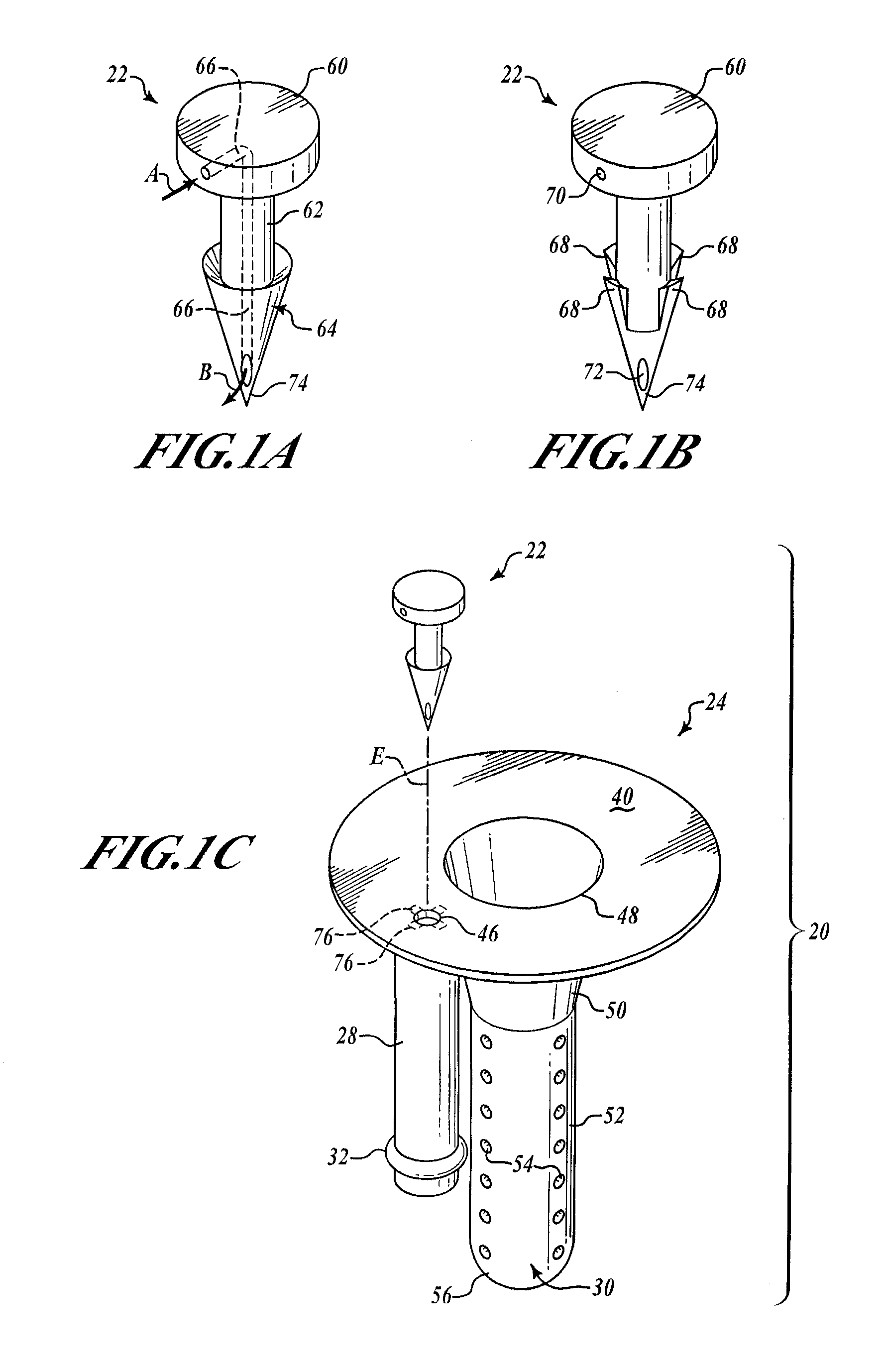

Vial assembly and method for reducing nosocomial infections

Vacuum break vial assembly and method for reducing the incidence of nosocomial infections, comprising a vial stopper having a 2-part withdrawn-fluid volume compensation assembly having a barbed vent element that secures an apertured needle sheath, a bladder-retainer tube and an expandable / unfoldable bladder. The vial has an aluminum cap holding a plastic flip-off top that removes a central portion of the cap to permit access by hypodermic needle through the stopper into the needle sheath. No pre-pressurization of the vial by ambient contaminated air via the hypodermic can occur. Rather, the needle is inserted in the vial through the stopper and the medicinal fluid withdrawn. Air is inlet into the separate bladder which expands to permit withdrawal of fluid into the hypodermic without vacuum lock. No air having pathogen vectors is introduced into the vial medicinal fluid as the bladder isolates volume-compensating air from the medicinal fluid. Plural embodiments are shown.

Owner:YANDELL MARION E

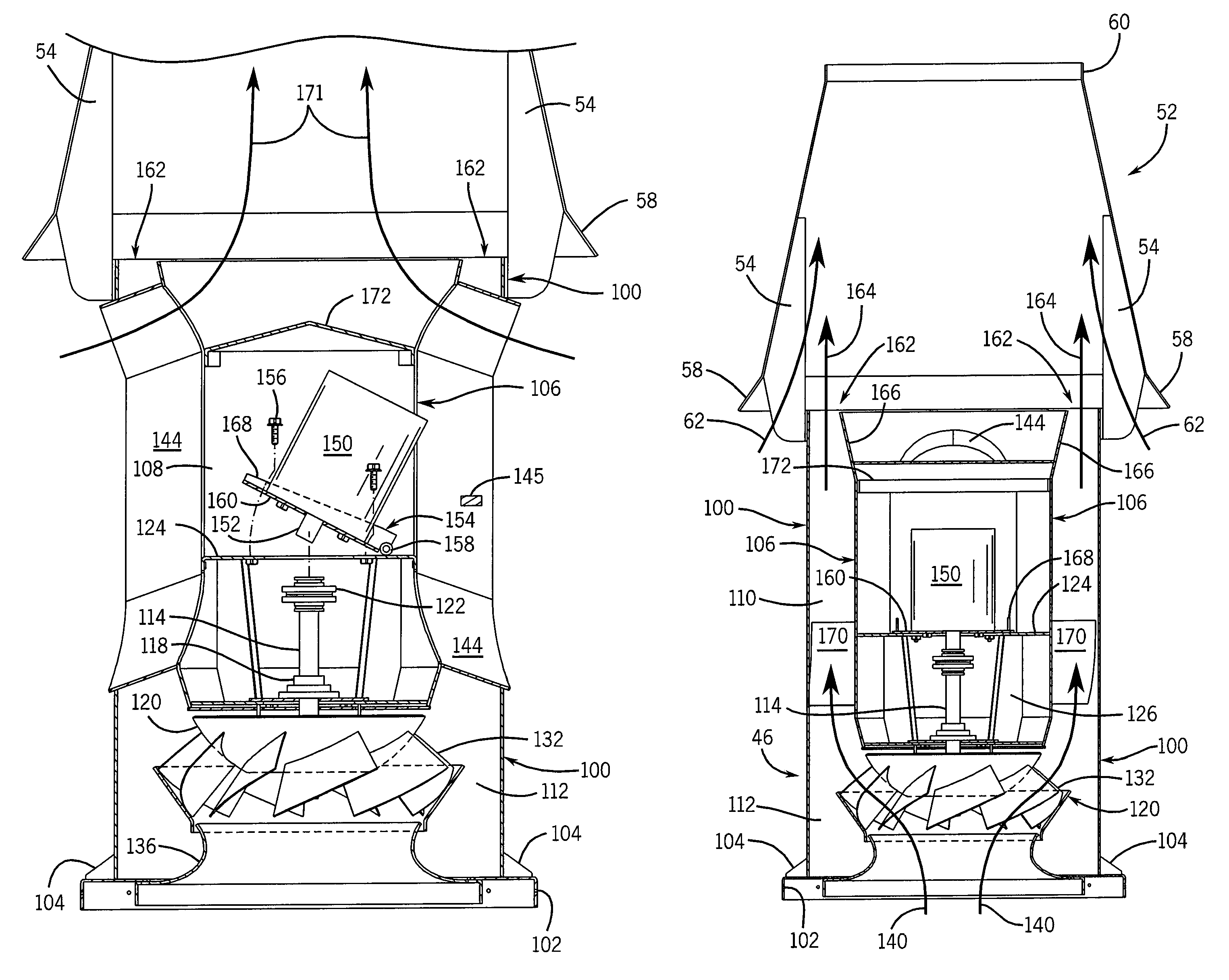

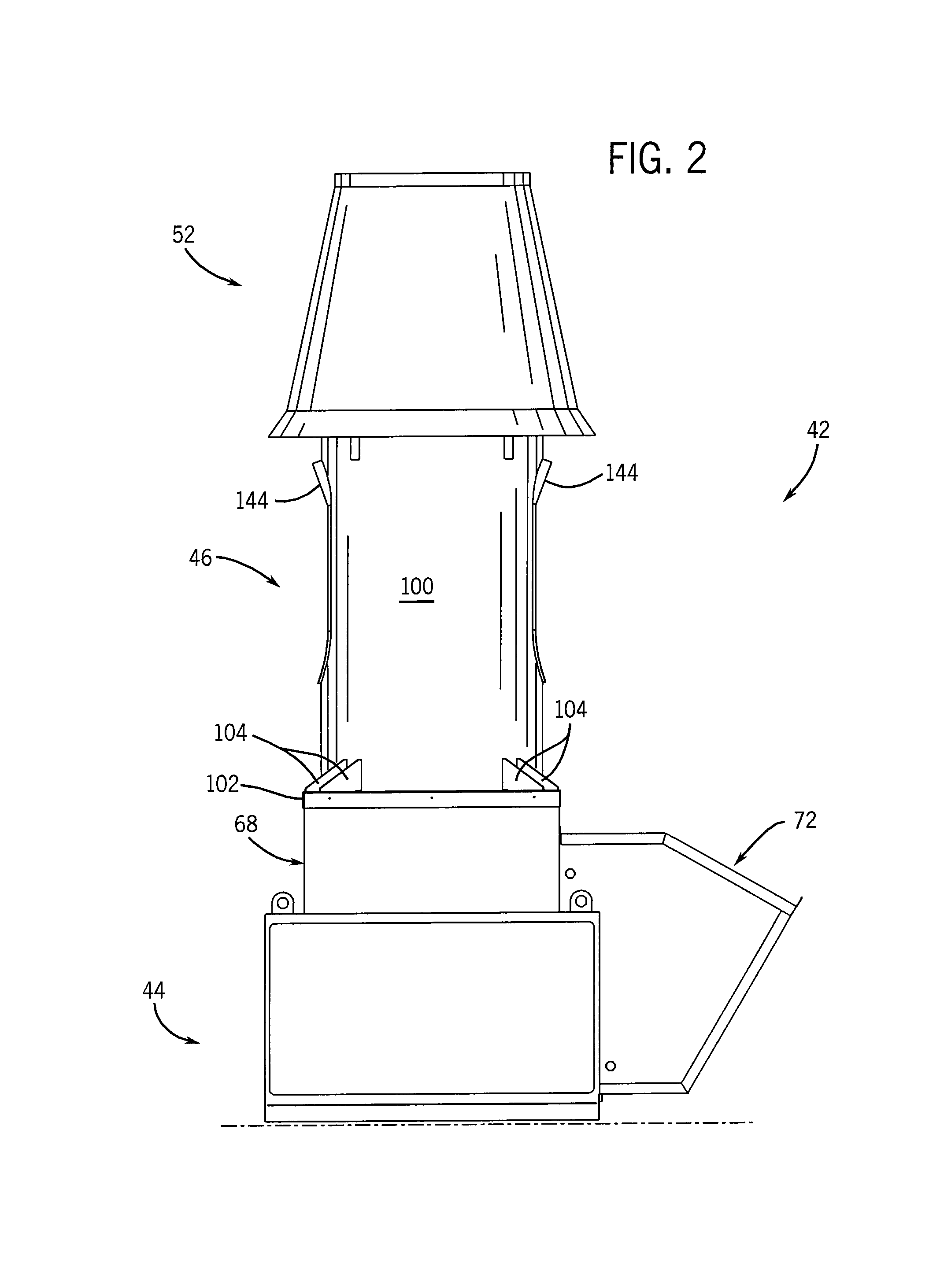

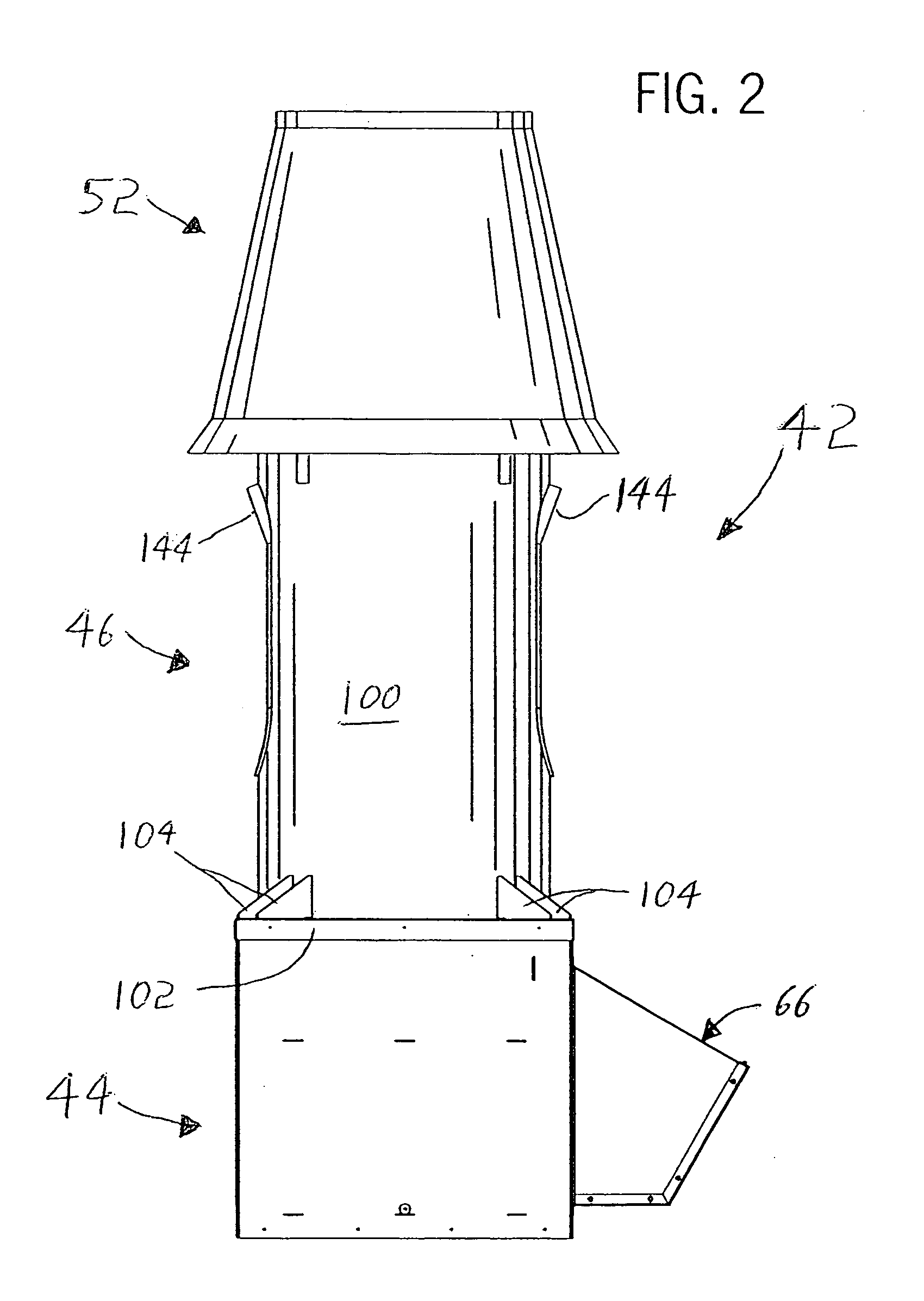

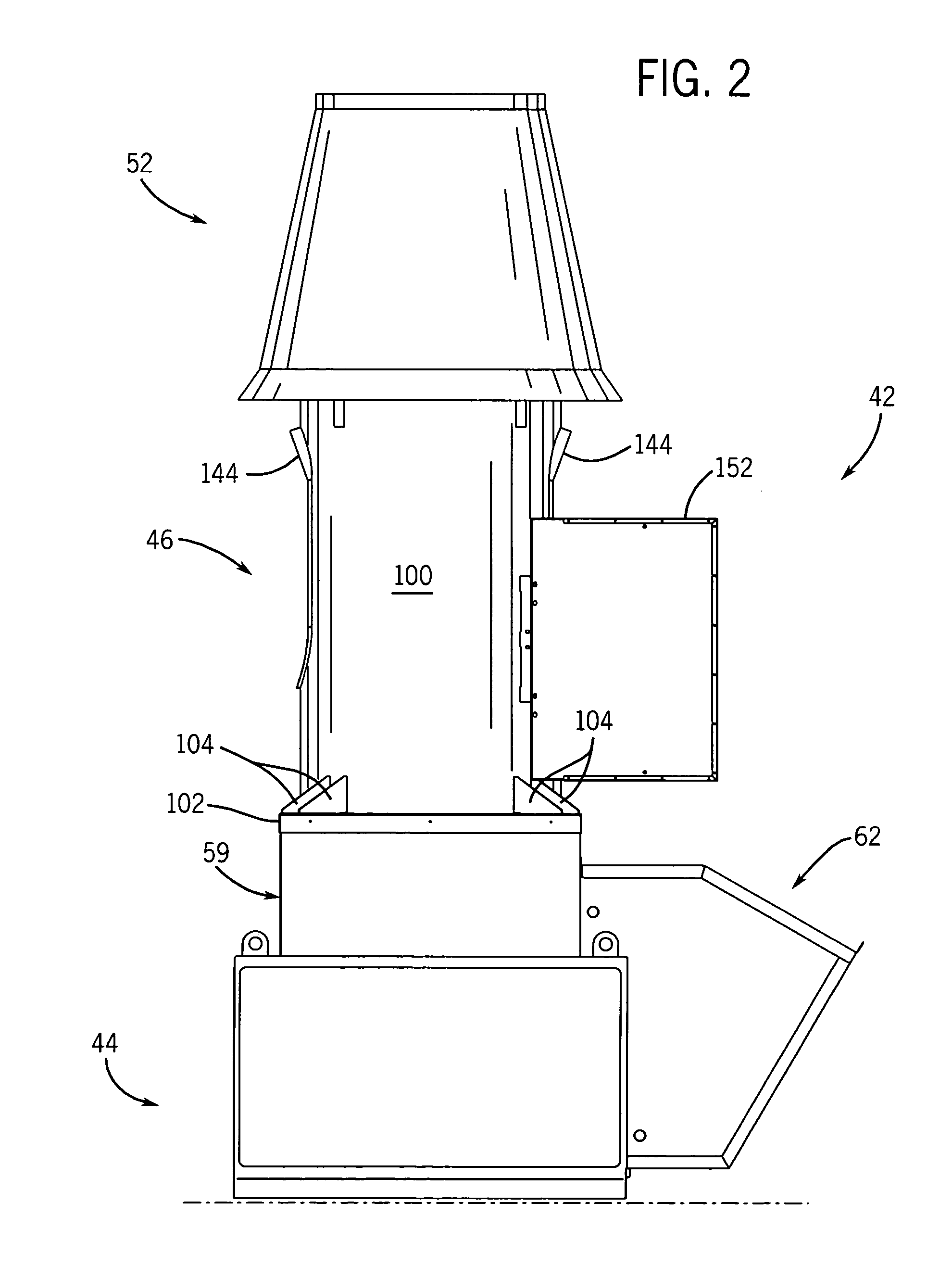

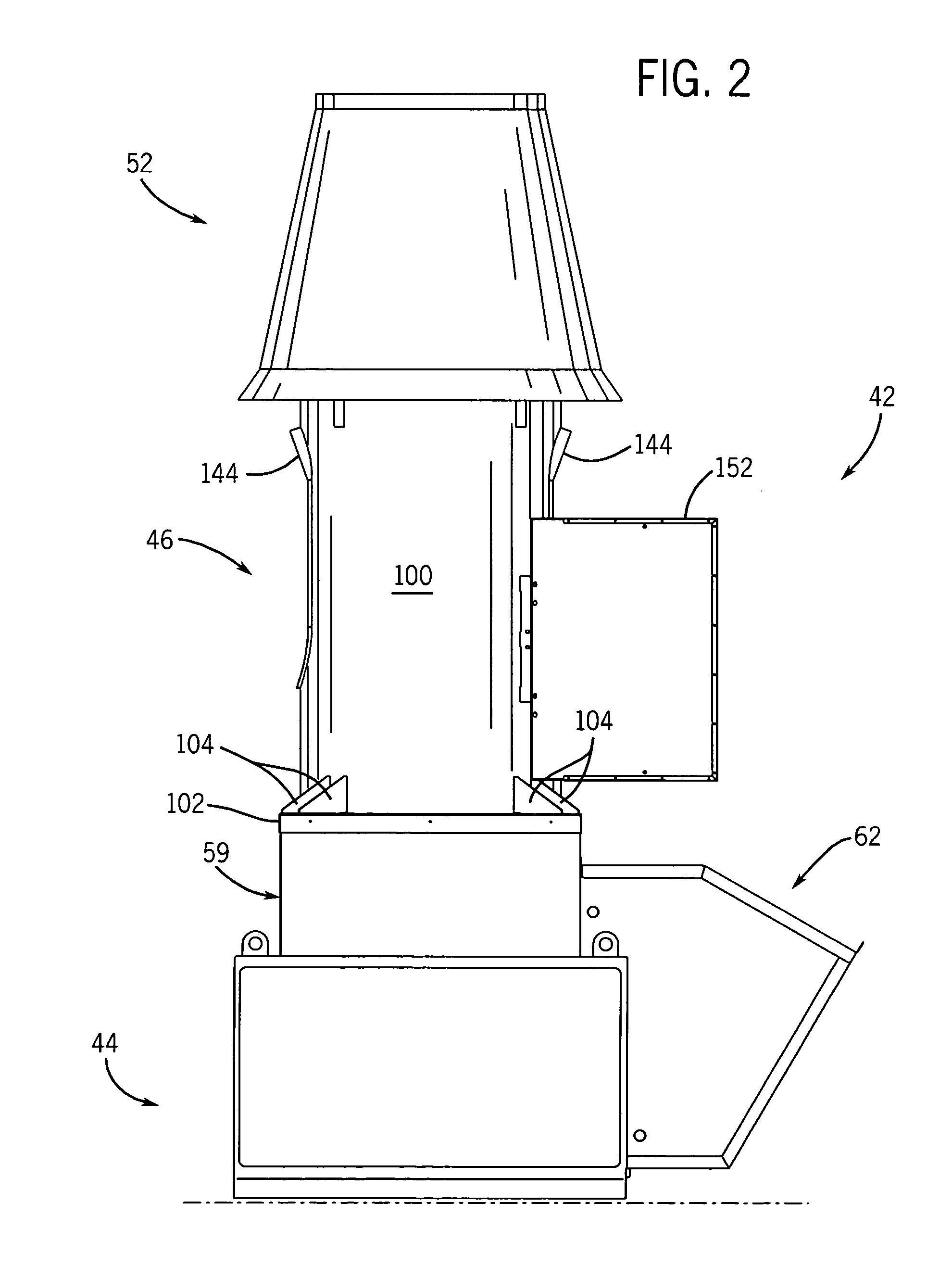

Pivotal direct drive motor for exhaust assembly

InactiveUS20050159101A1Lighting and heating apparatusHeating and ventilation casings/coversElectric machineEngineering

An exhaust assembly is provided for expelling contaminated air from a building. The assembly includes a plenum, a fan assembly attached to the plenum, and a windband mounted on top of the fan assembly. The fan assembly is constructed of cylindrical outer and inner walls which define a drive chamber and surrounding annular space. A fan driven by a motor whose shaft extends downward from the drive chamber draws exhaust air from the plenum and blows it up through the annular space to a nozzle at the top of the fan assembly. The motor is pivotally mounted inside the assembly to provide access to the motor components when it is desired to perform inspection and maintenance.

Owner:GREENHECK FAN

Vial assembly and method for reducing nosocomial infections

InactiveUS7789871B1Eliminate pollutionAvoid piercingClosuresDiagnosticsHypodermic needleHypodermoclysis

Vacuum break vial assembly and method for reducing the incidence of nosocomial infections, comprising a vial stopper having a 2-part withdrawn-fluid volume compensation assembly having a barbed vent element that secures an apertured needle sheath, a bladder-retainer tube and an expandable / unfoldable bladder. The vial has an aluminum cap holding a plastic flip-off top that removes a central portion of the cap to permit access by hypodermic needle through the stopper into the needle sheath. No pre-pressurization of the vial by ambient contaminated air via the hypodermic can occur. Rather, the needle is inserted in the vial through the stopper and the medicinal fluid withdrawn. Air is inlet into the separate bladder which expands to permit withdrawal of fluid into the hypodermic without vacuum lock. No air having pathogen vectors is introduced into the vial medicinal fluid as the bladder isolates volume-compensating air from the medicinal fluid. Plural embodiments are shown.

Owner:YANDELL MARION E

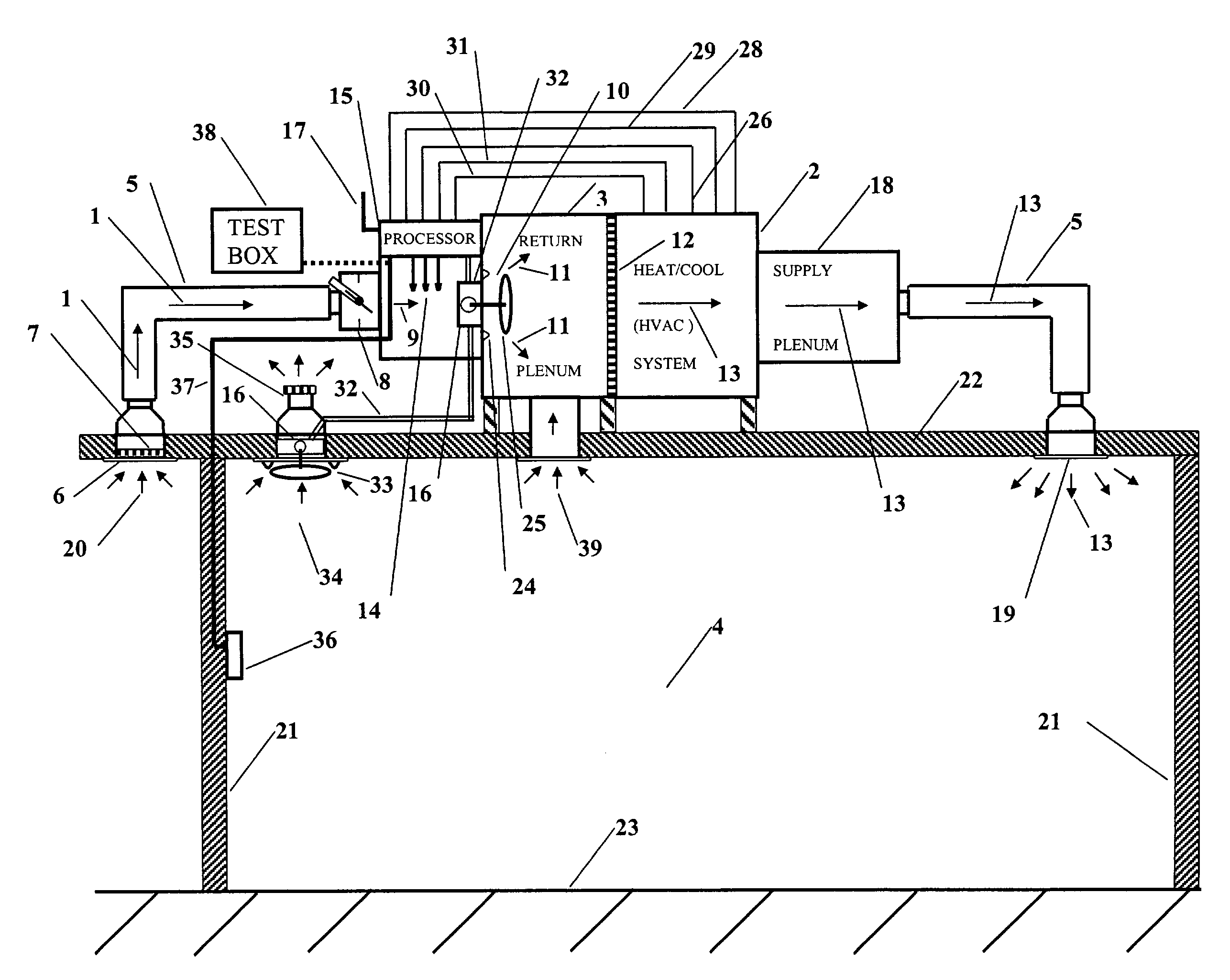

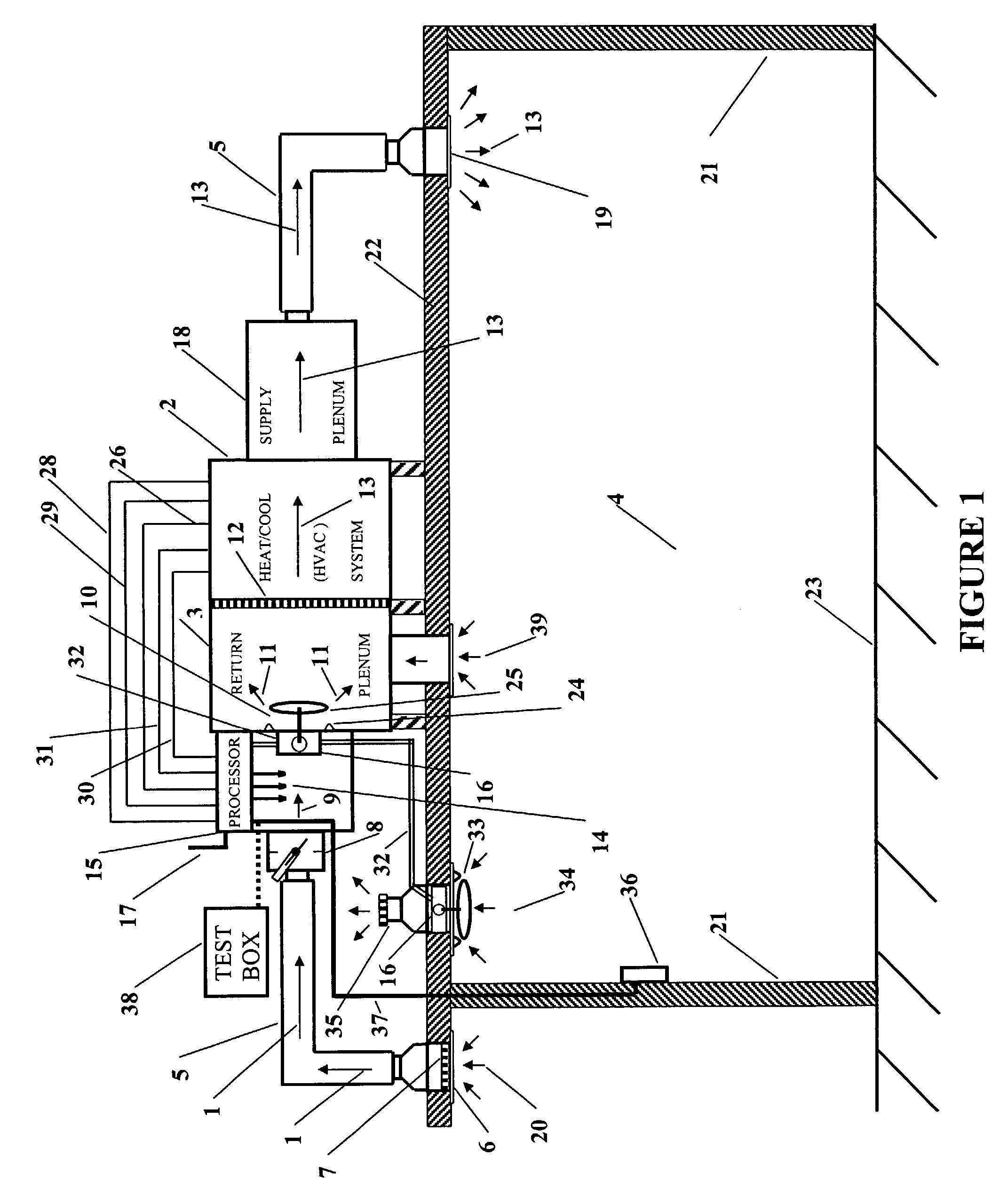

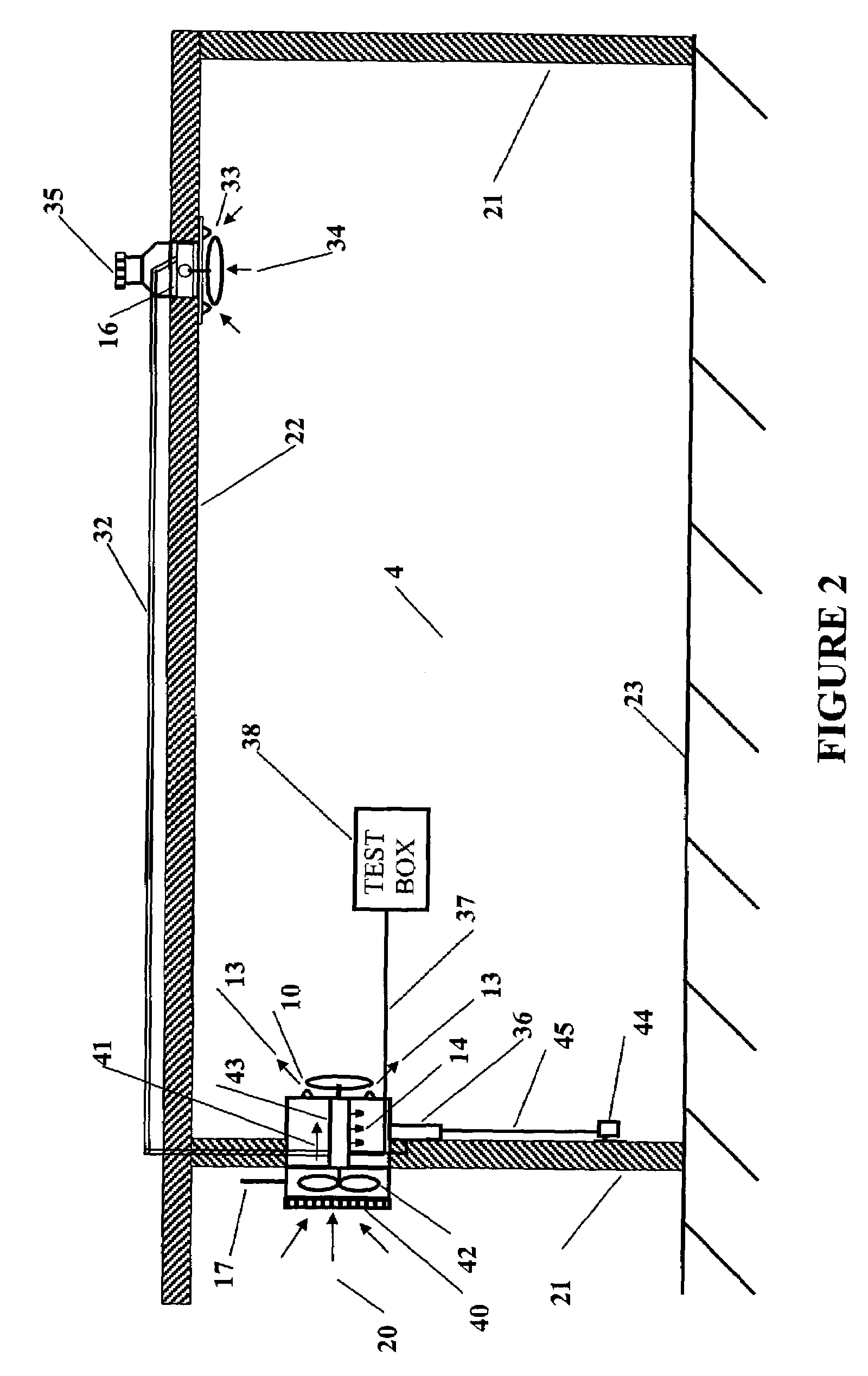

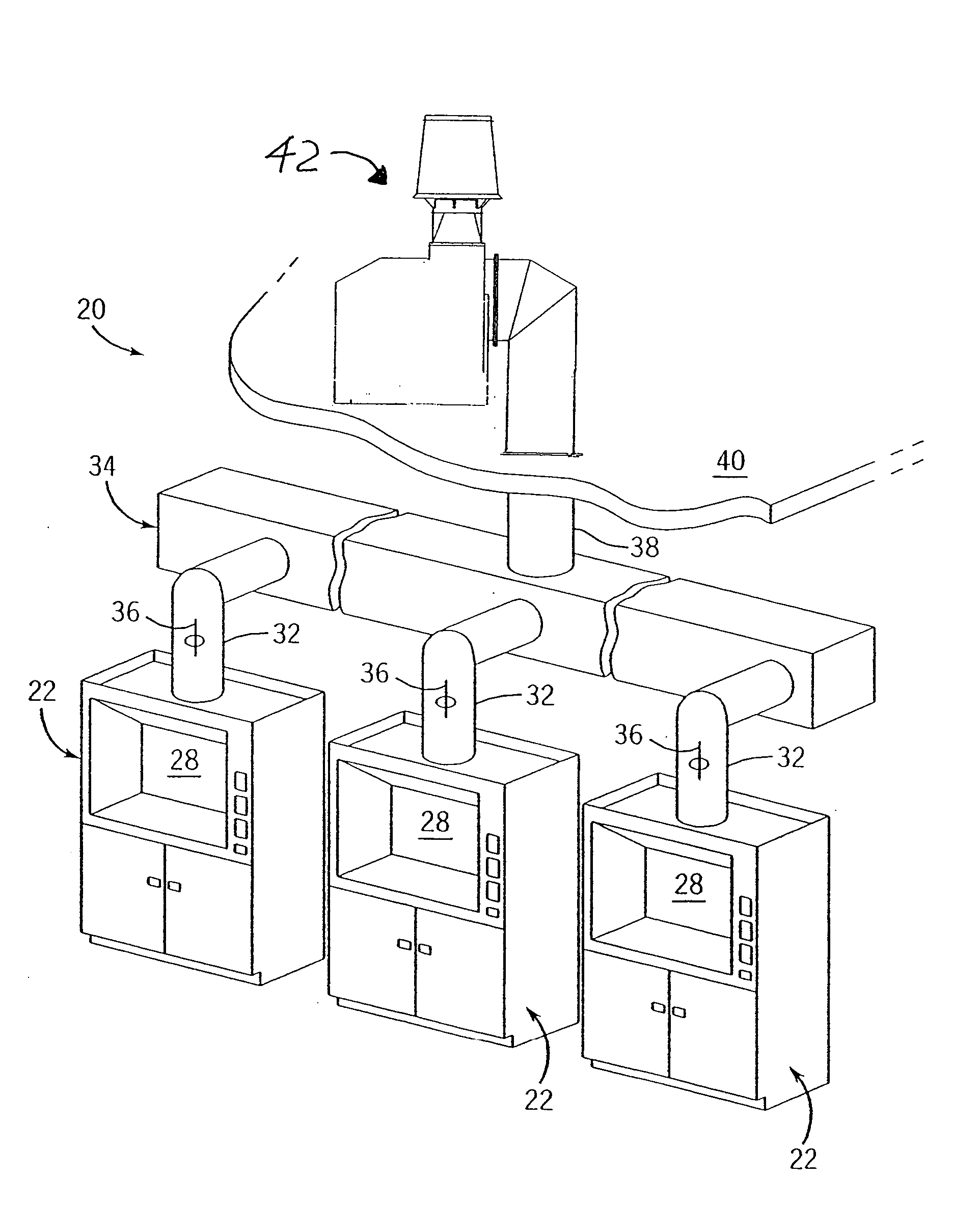

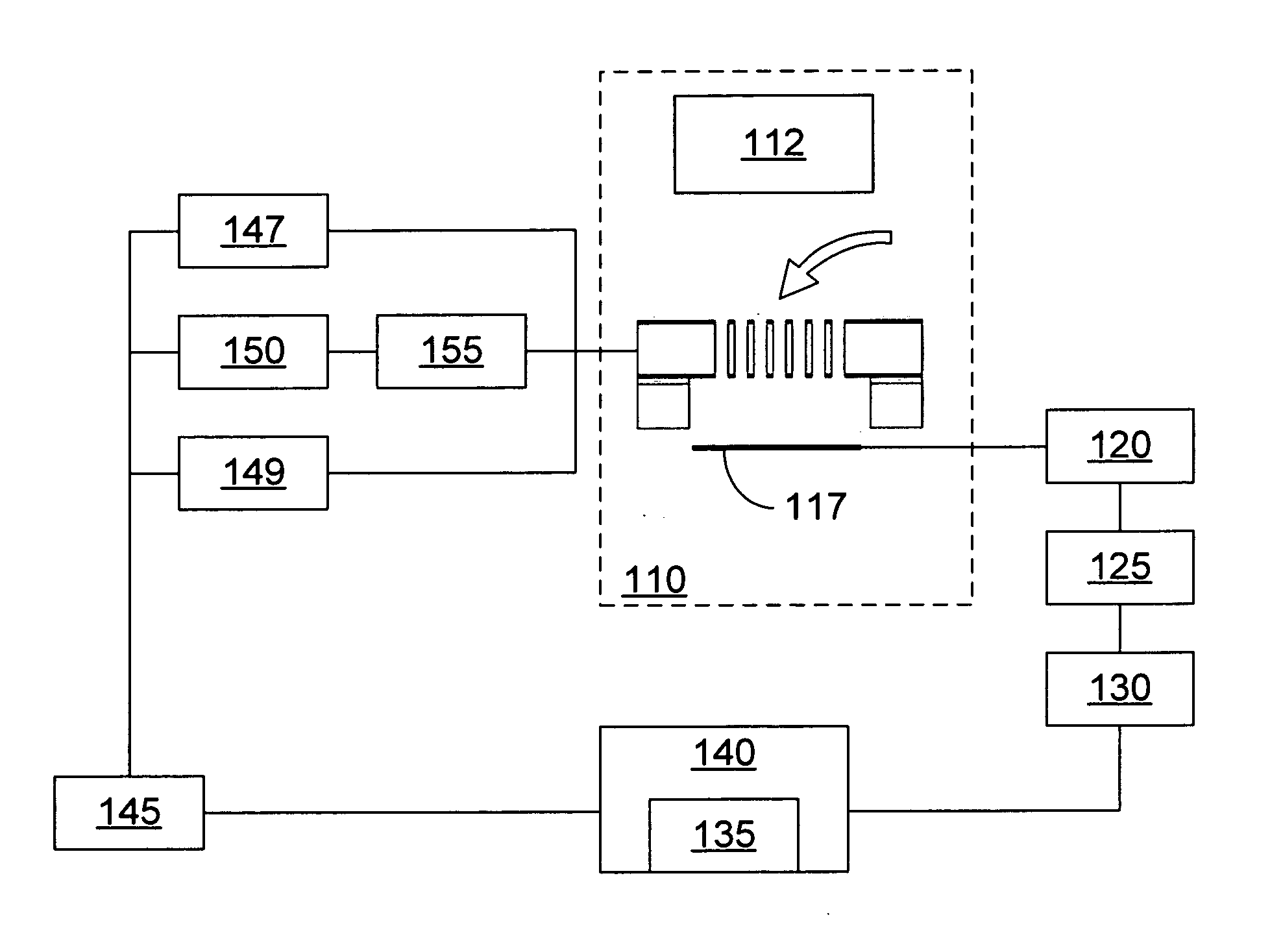

Method and apparatus for sampling and controlling ventilation airflow into a structure

InactiveUS7331852B2Mechanical apparatusSpace heating and ventilation safety systemsTelecommunications linkControl signal

A totally integrated ventilation system is contained in the outside air inlet stream. The system samples and controls ventilation airflow as it enters a structure. An air valve connecting the outside air inlet stream to the return plenum is controlled by a valve positioning device and a processor that monitors sensors located in the outside air inlet stream, air quality data provided by a telecommunications link and the HVAC system control signals. The air quality data includes locally broadcast air pollution data or air quality alert data related to accidents or terrorist attacks. The processor and valve positioning device simultaneously control a separate pressure relief valve that allows contaminated air to be exhausted from the structure. An alternate configuration uses a supplemental fan to introduce the outside air inlet stream directly into the structure where HVAC systems are not used. A status and control panel that provides an interface to the occupants or an automation system is provided along with a test box that can monitor the processor to determine the total volume of ventilation air introduced into the structure. This test data is used to program processor timing inputs to achieve desired ventilation results.

Owner:EZELL GEORGE D +1

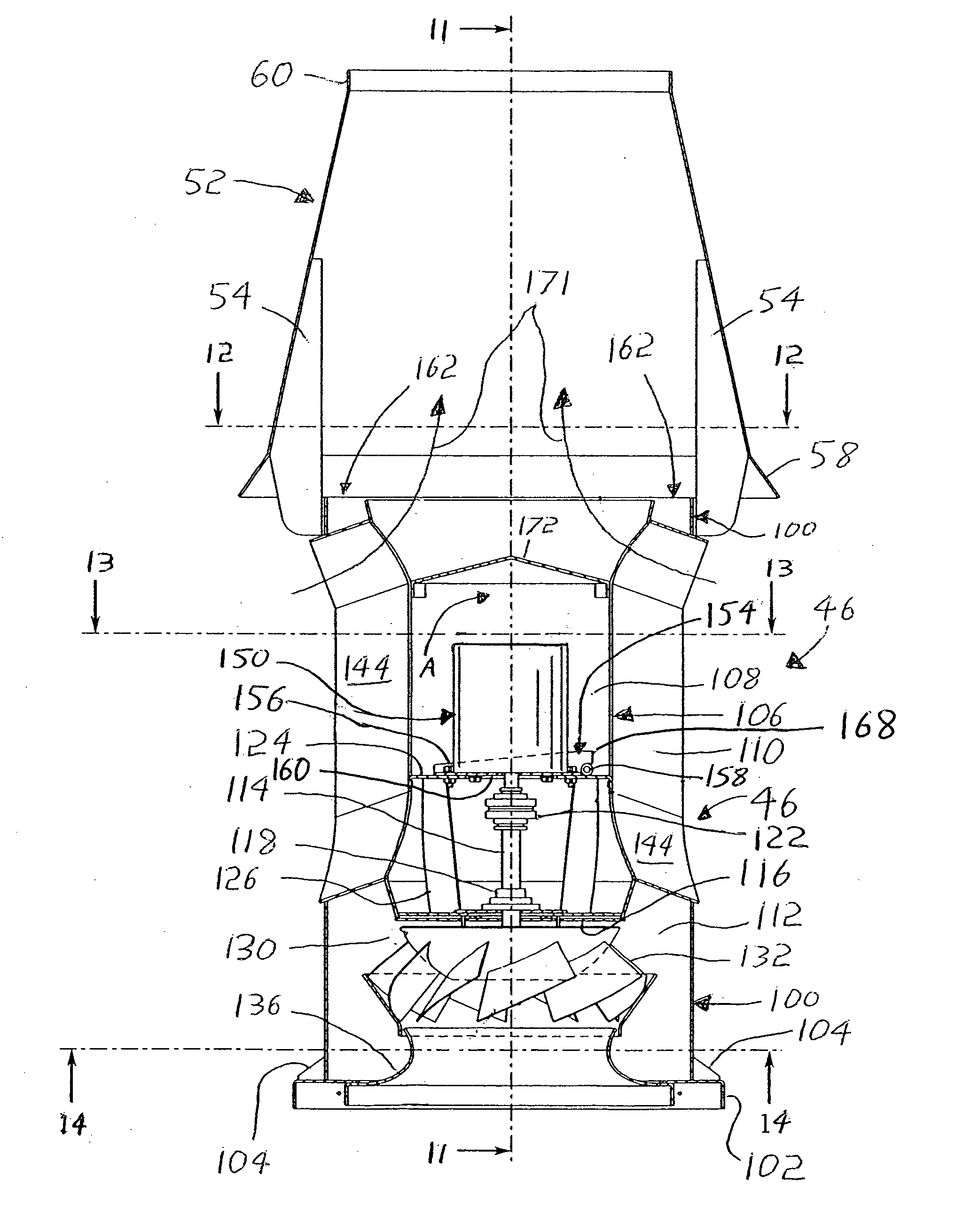

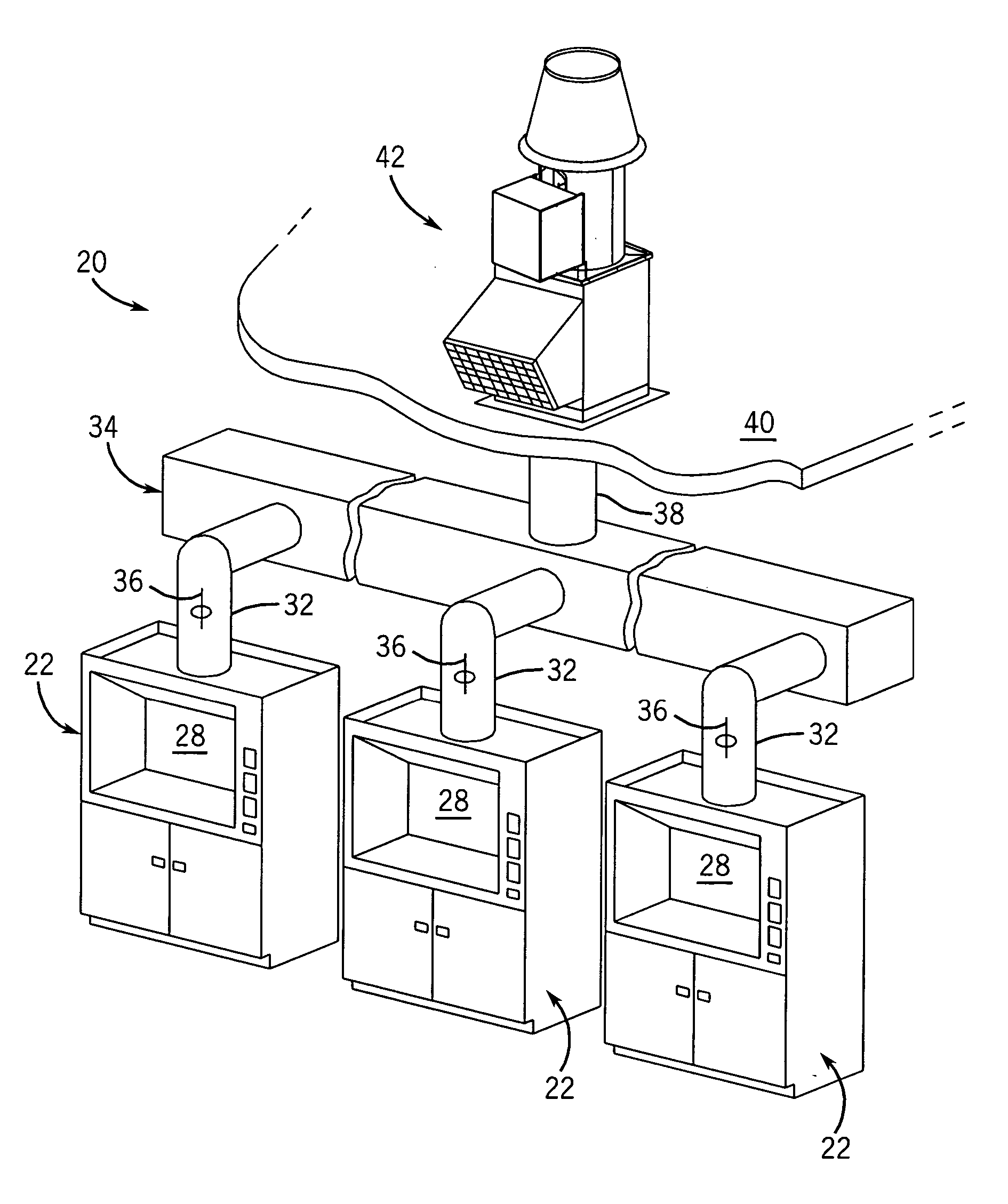

Exhaust fan assembly

ActiveUS20050170767A1Improve efficiencyEasy accessAir supply regulationDirt cleaningEngineeringContaminated air

Owner:GREENHECK FAN

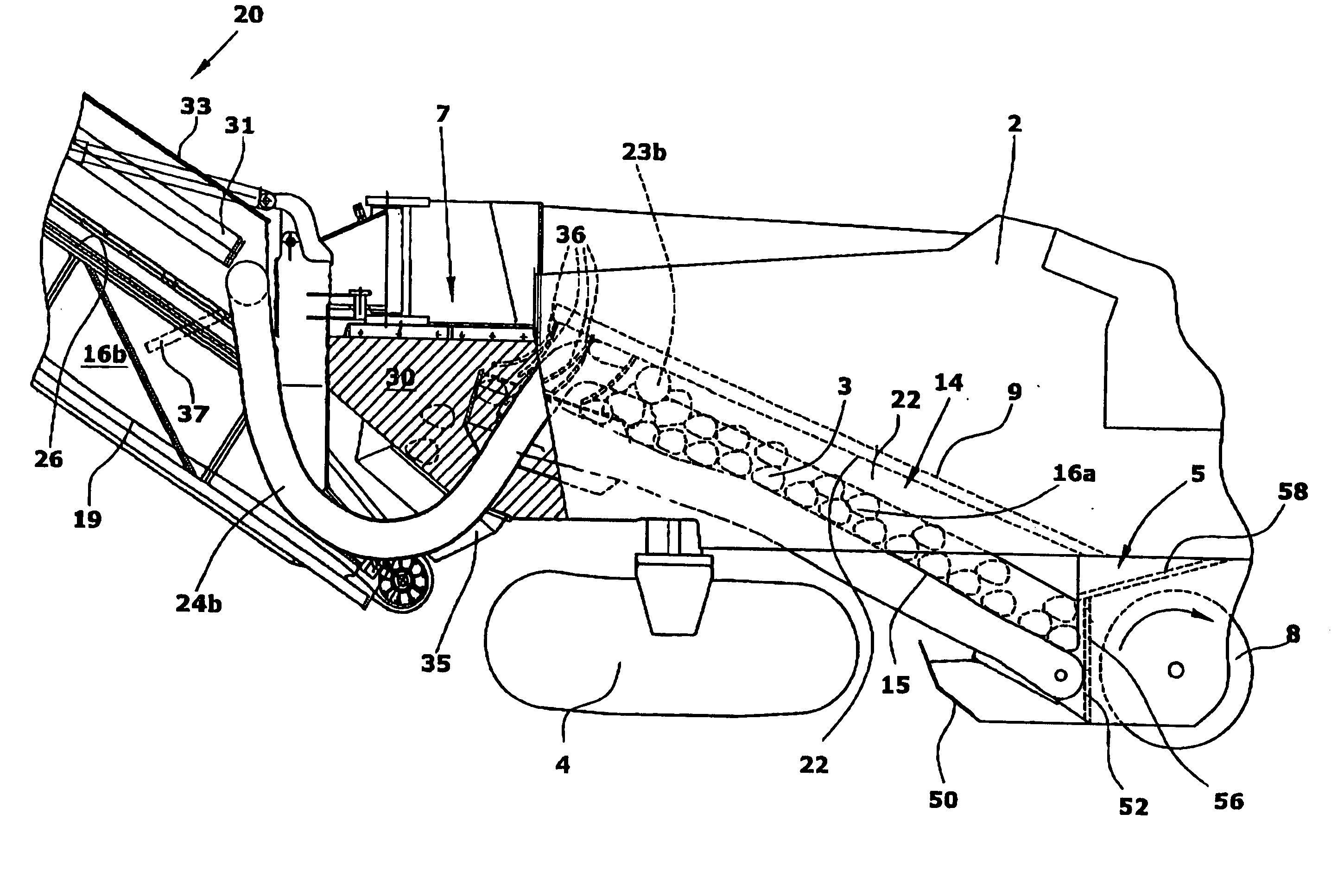

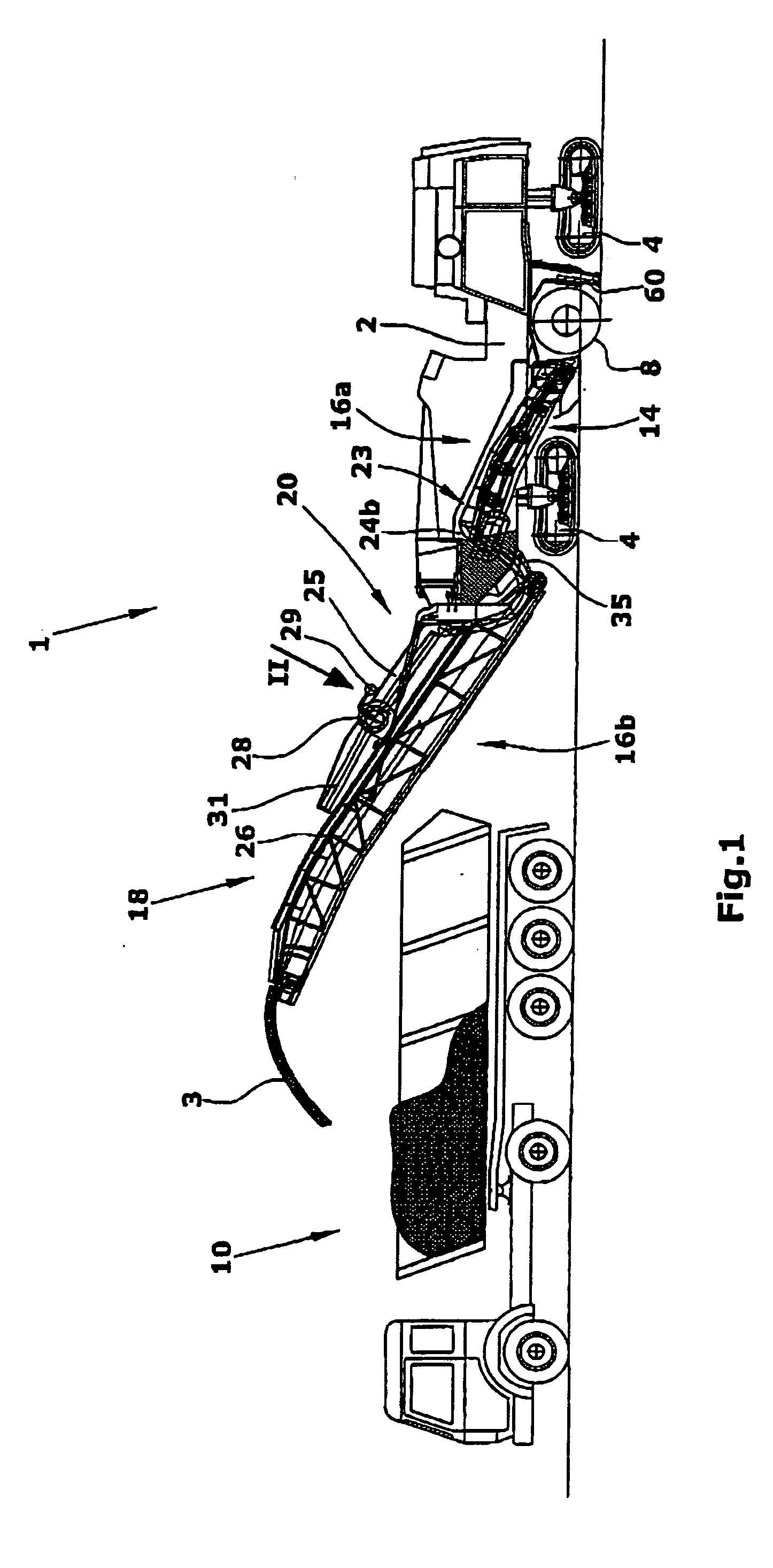

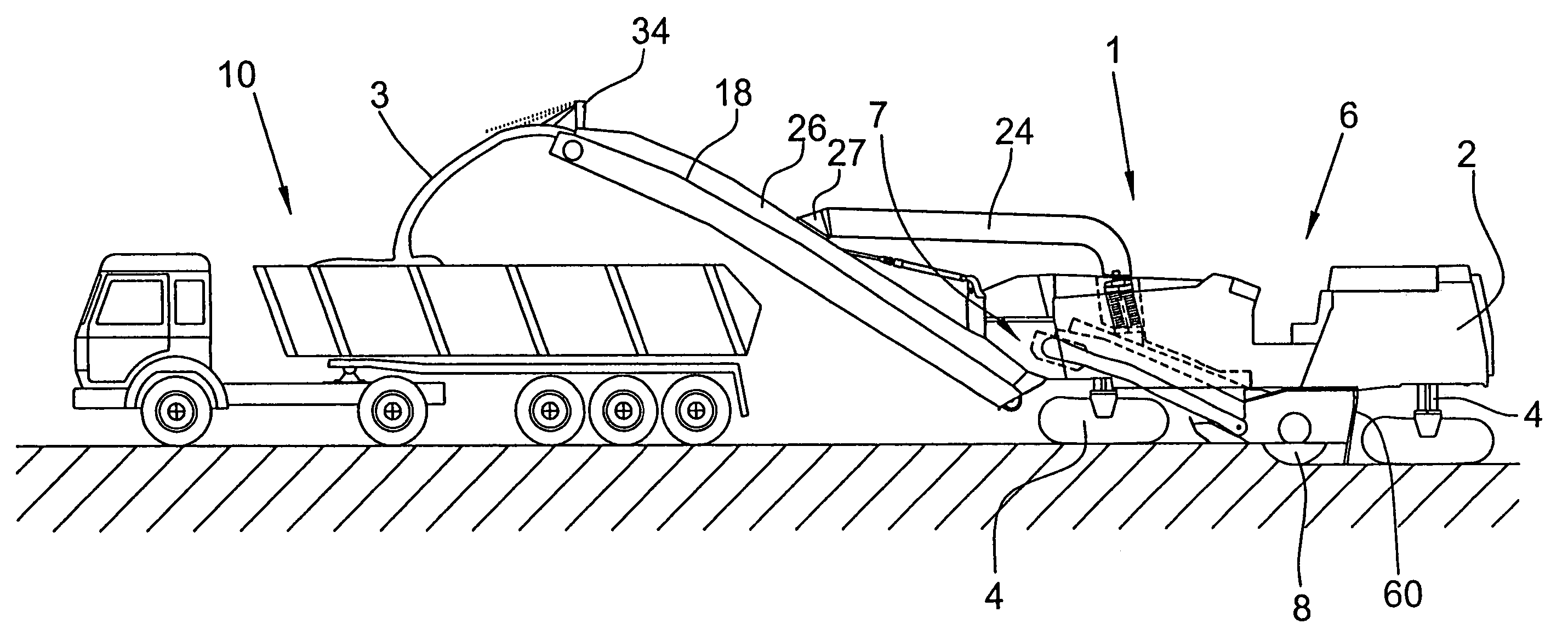

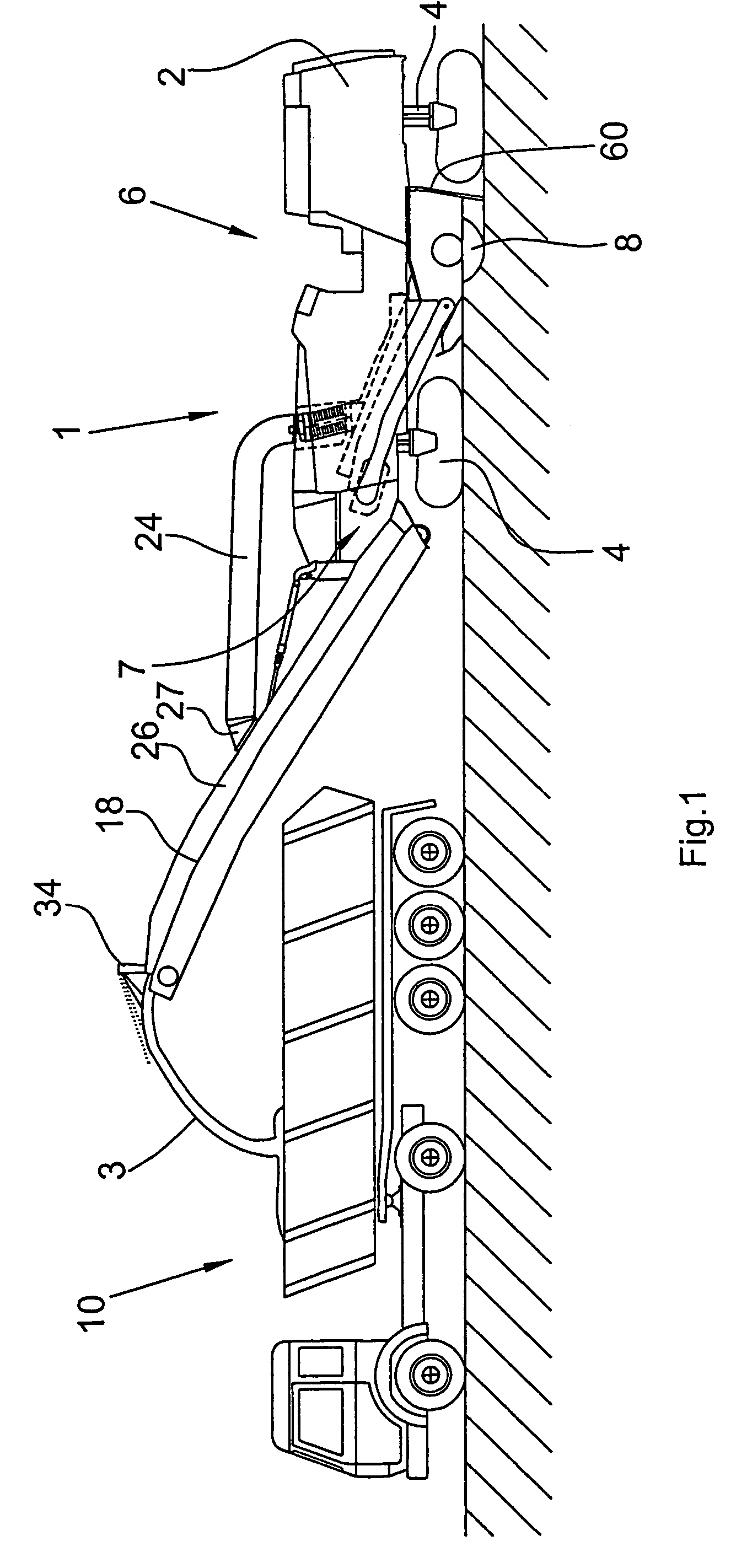

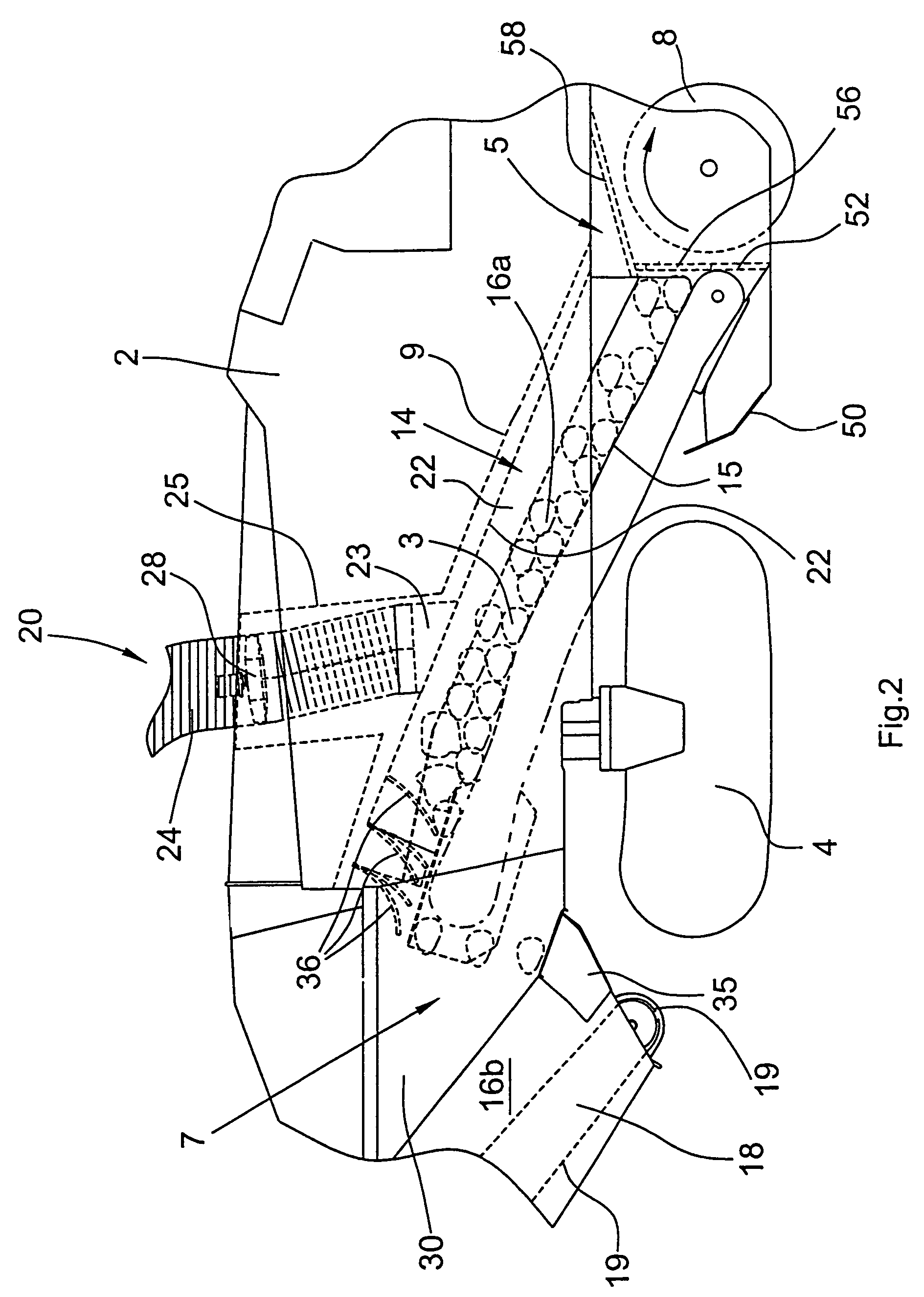

Milling machine as well as method for working ground surfaces

ActiveUS20050179309A1Inhibit currentEasy to useCombination devicesSlitting machinesEngineeringContaminated air

At a milling machine to work ground surfaces, with a machine frame, a milling drum supported at the machine frame, at least one transport device arranged at the machine frame which accepts the milled material from the milling drum, as well as with a suction device for the air polluted with dusts and vapors, whereby the milled material on the at least one transport device is enclosed by a channel, the suction device is connected to a rear channel section of the channel in the direction of the material transport and sucks off the air polluted during milling at the milling drum and in the rear channel section essentially in the direction of the material transport, it is provided that the suction device consists of a suction ventilator, a separator device for solids and a suction channel which is connected to the rear channel section, that the suction ventilator is arranged downstream of the separator device, and that the suction device disposes of the separated solids onto the transport device in a forward channel section in the direction of the material transport or into a collecting device, and the suction ventilator blows off the cleaned air into the environment.

Owner:WIRTGEN GMBH

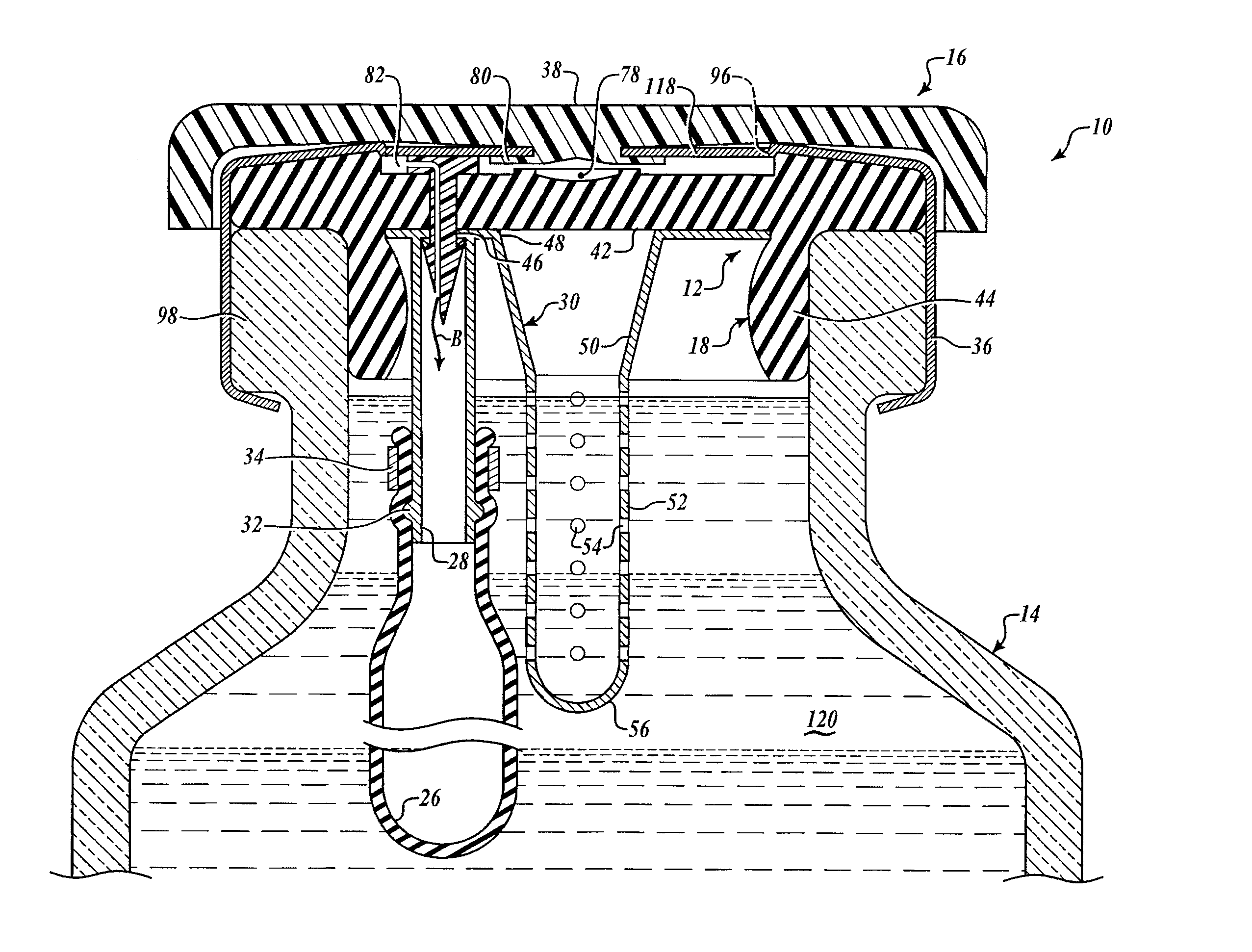

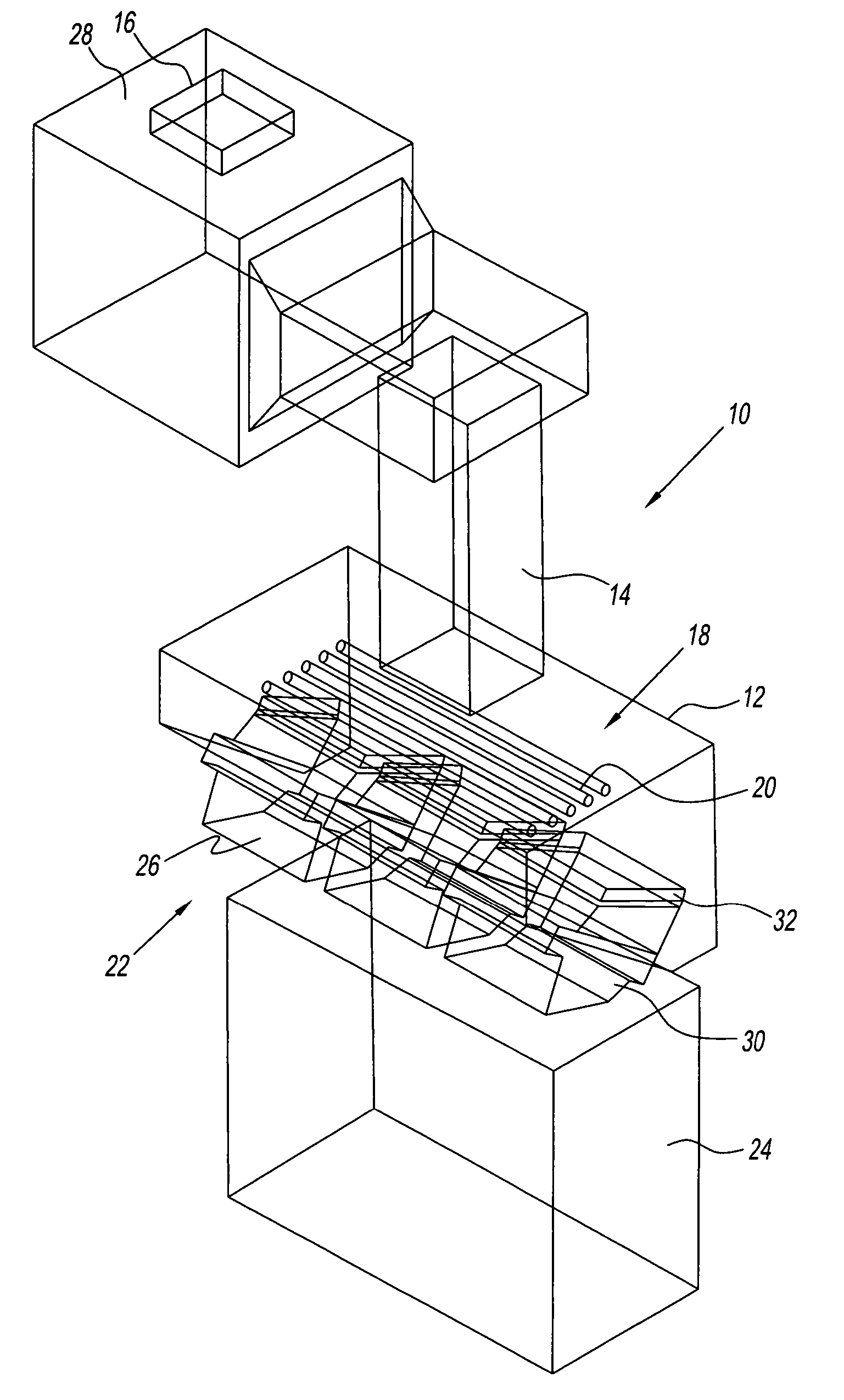

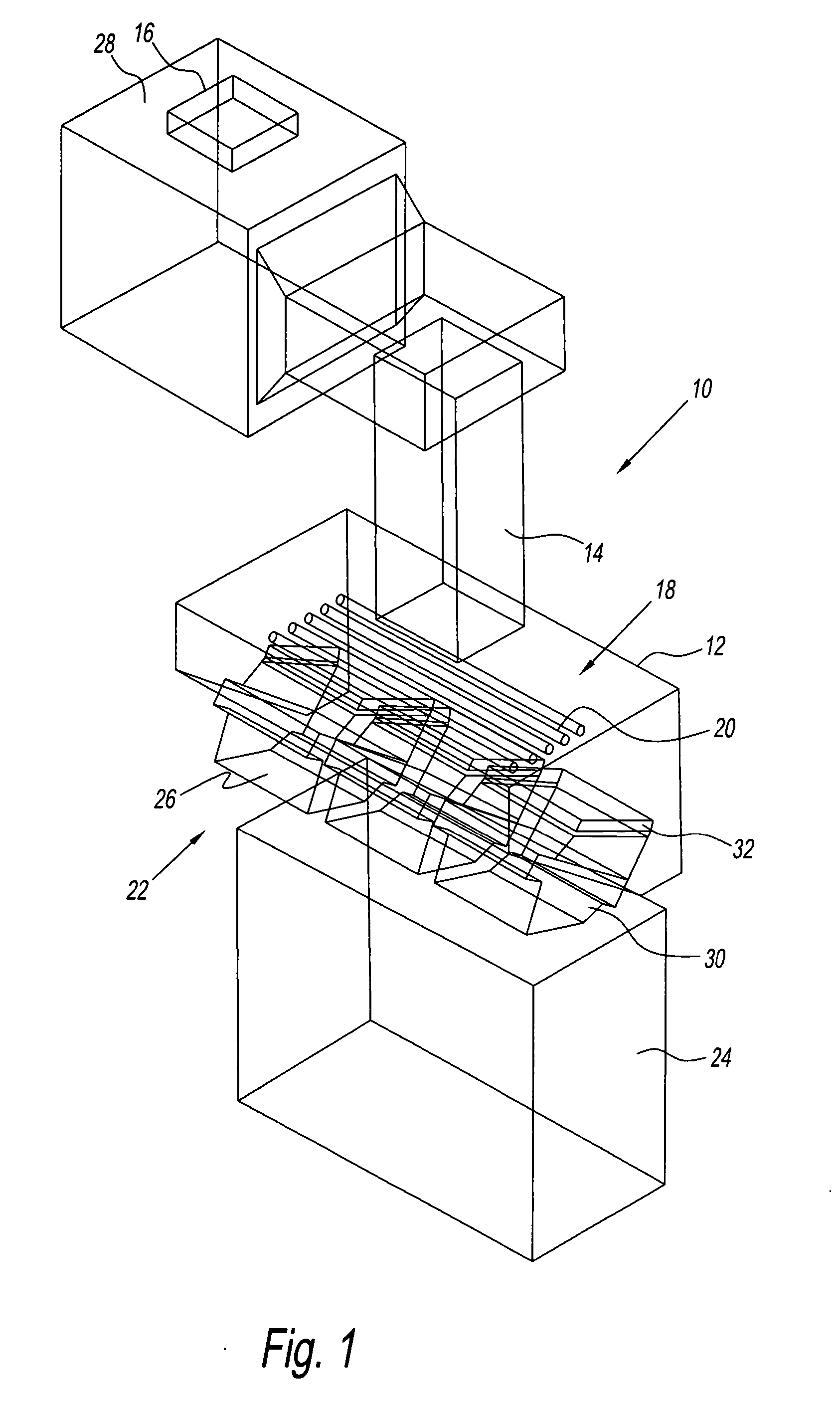

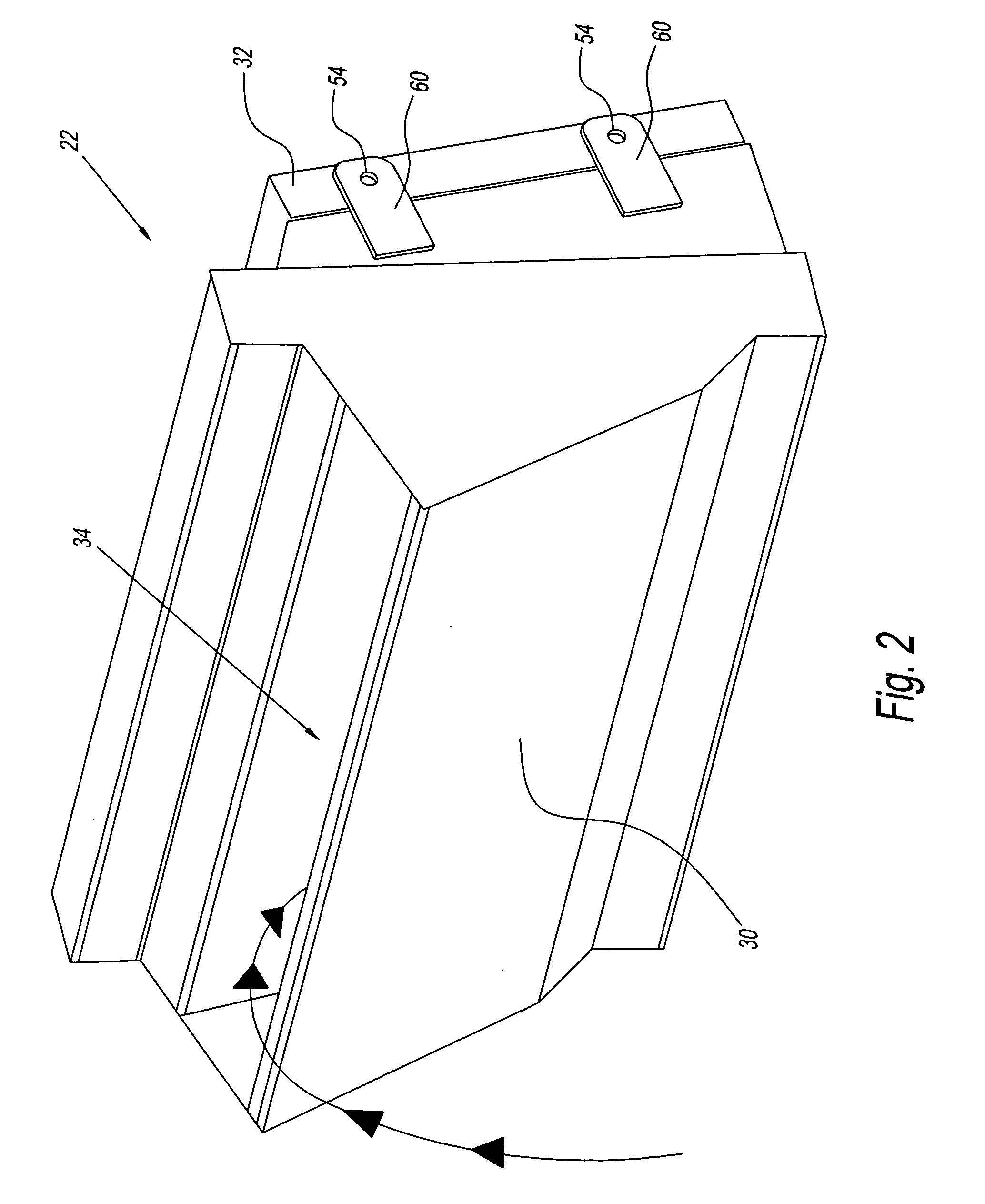

Deoiler for a lubrication system

ActiveUS20050217272A1Reduce pressureHigh power settingPump componentsEngine fuctionsSuction stressPositive pressure

A deoiler 26 for separating oil from air contaminated with the oil has at least one separator for separating the oil from the air and also has a source of suction for reducing air pressure at the source of the air. In an exemplary embodiment, the deoiler 26 creates the suction at a first operating condition, but acts as a restrictor at a second operating condition. A deoiling method according to the invention creates suction at a first operating condition to reduce the air pressure at the source of the oil-contaminated air, establishes a flow restriction at a second operating condition to pressurize the air source, and encourages oil to separate from the air at both operating conditions. When used as a component of a turbine engine lubrication system 22, the source of contaminated air may be a buffered bearing compartment 16. The inventive deoiler ensures a positive pressure difference across the bearing compartment seals 20 at the engine's idle power setting without requiring the idle setting to be undesirably high, and without requiring the use of buffer air whose pressure at higher engine power is high enough to be detrimental. In an exemplary embodiment, the deoiler pressurizes the bearing compartment at higher power settings to resist excessive buffer air infiltration into the bearing compartment.

Owner:RTX CORP

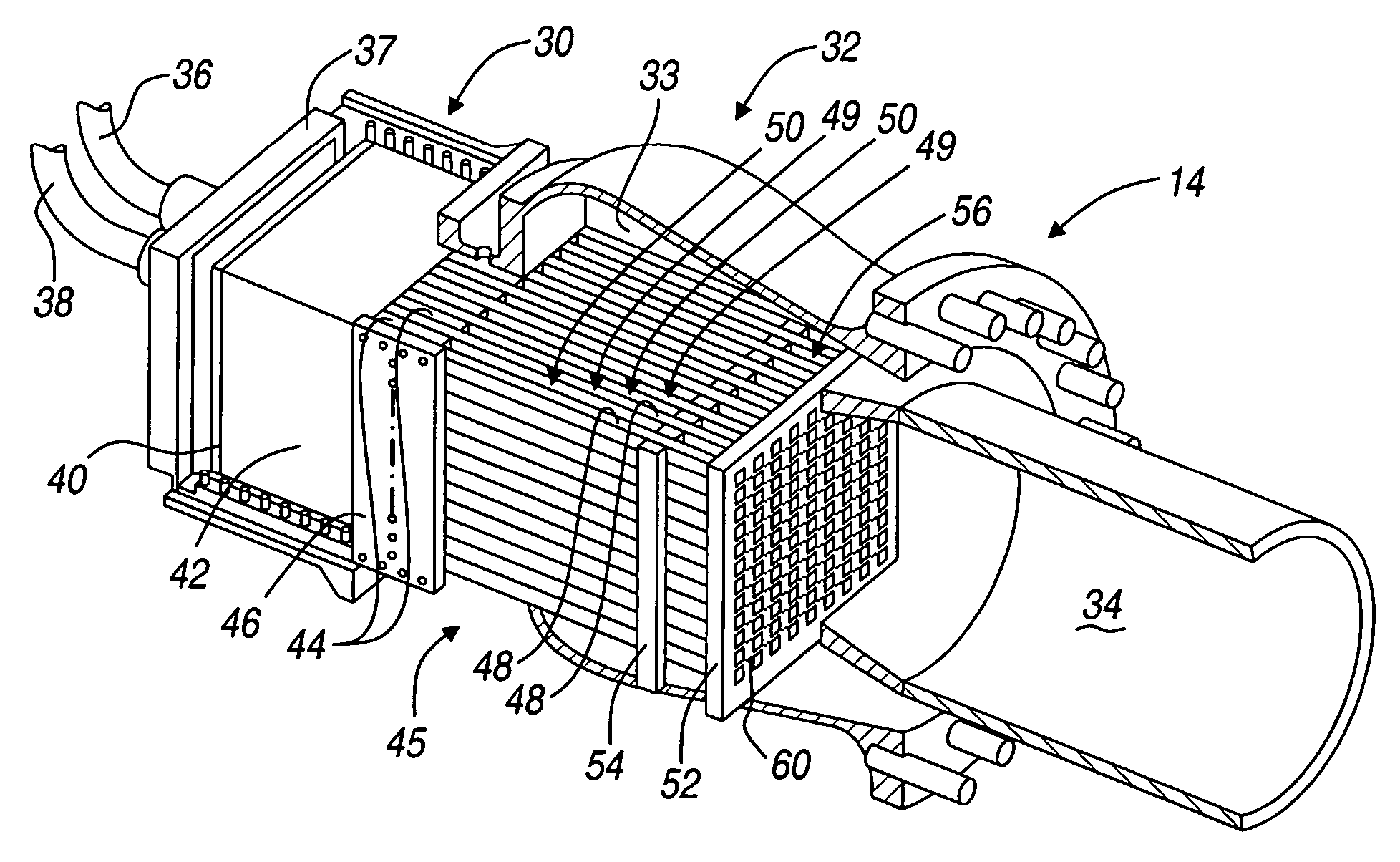

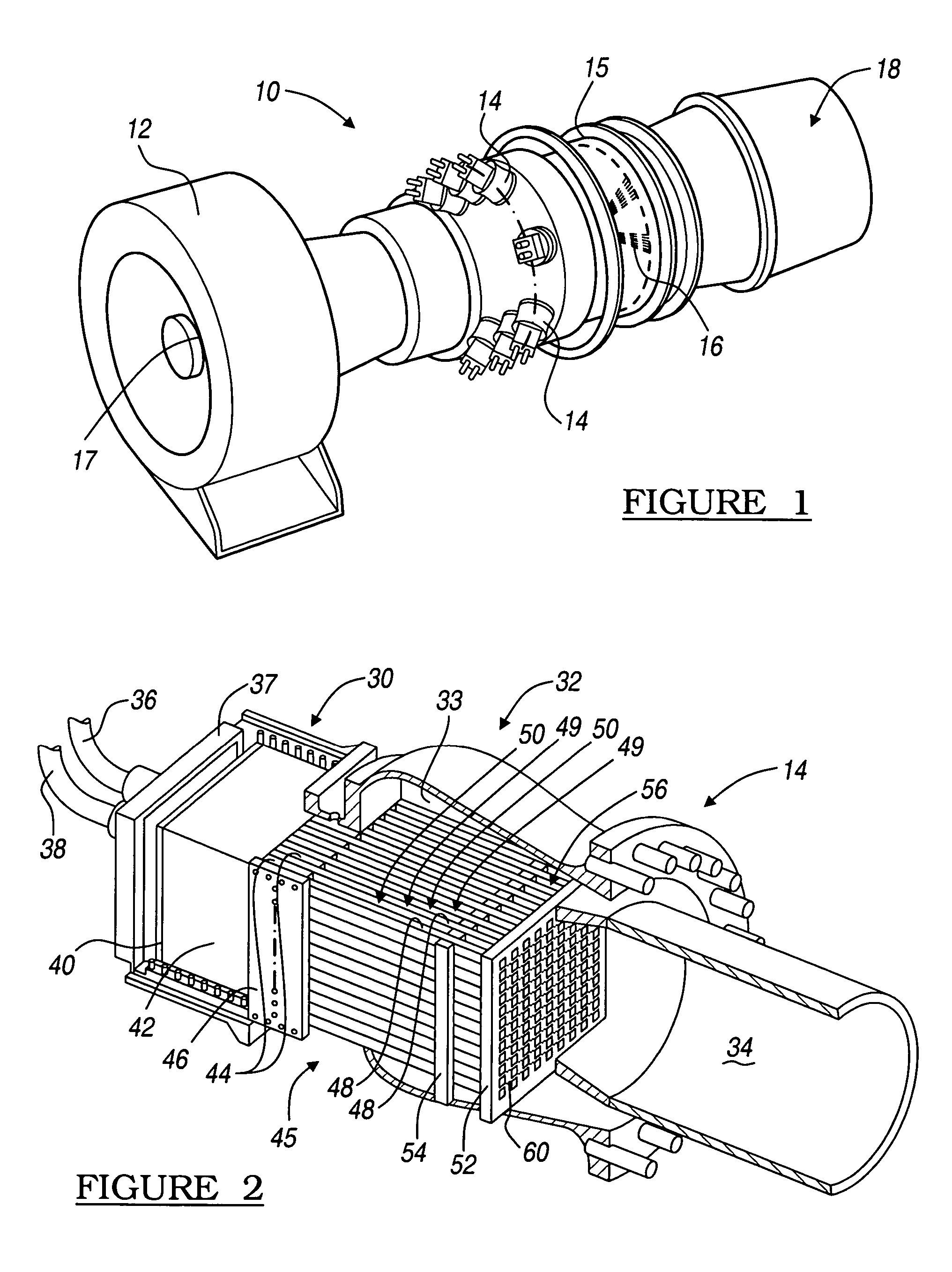

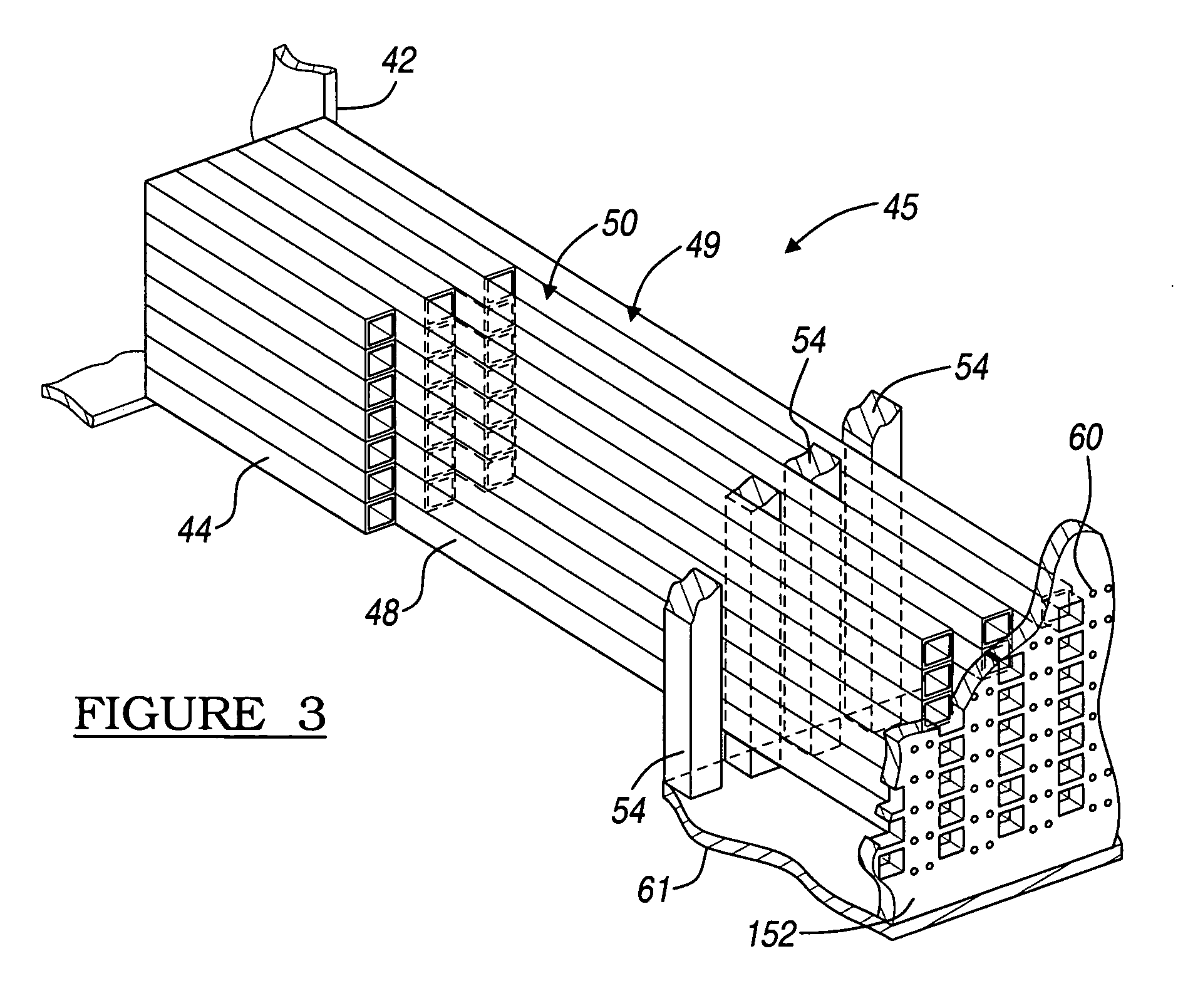

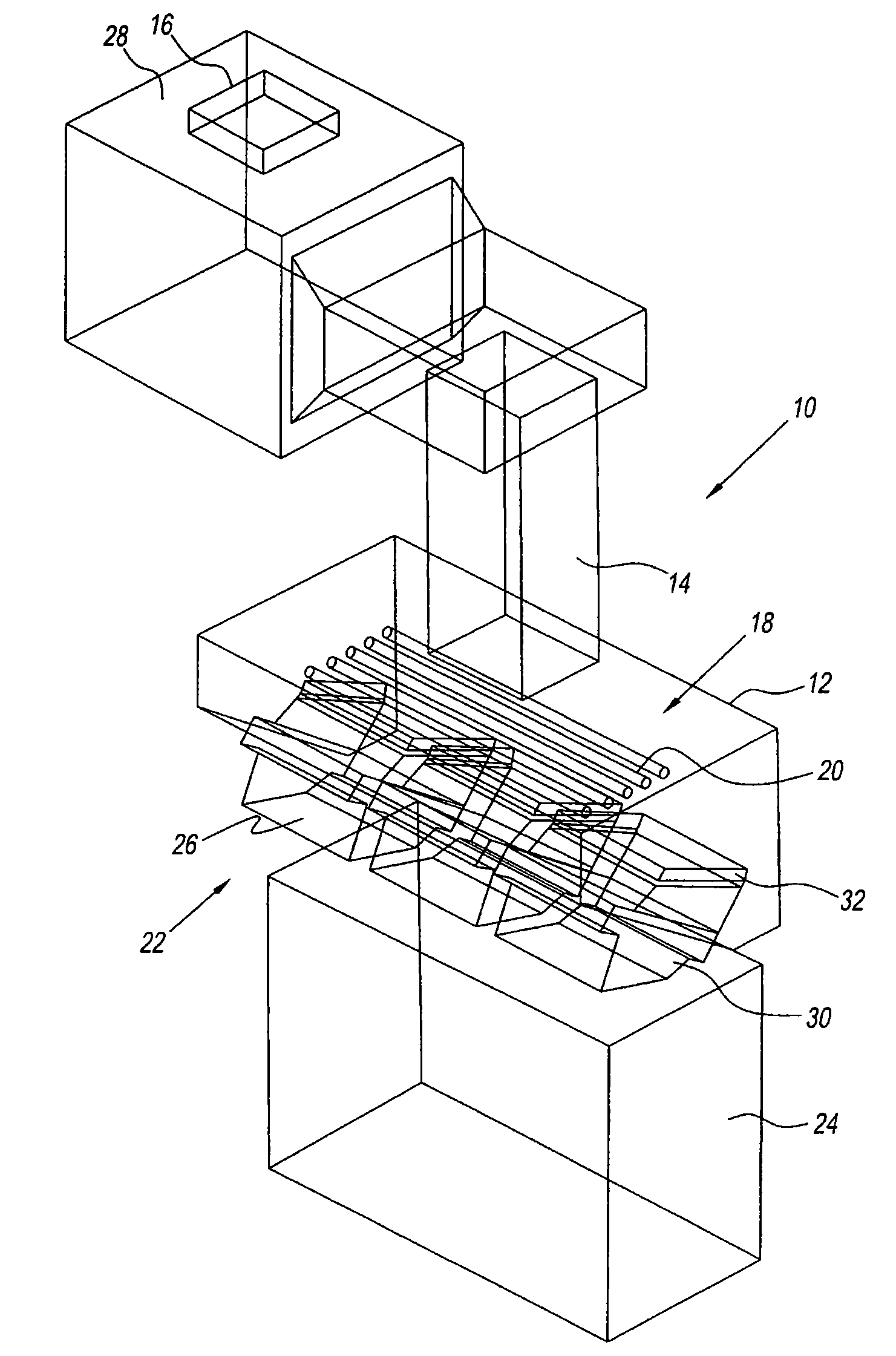

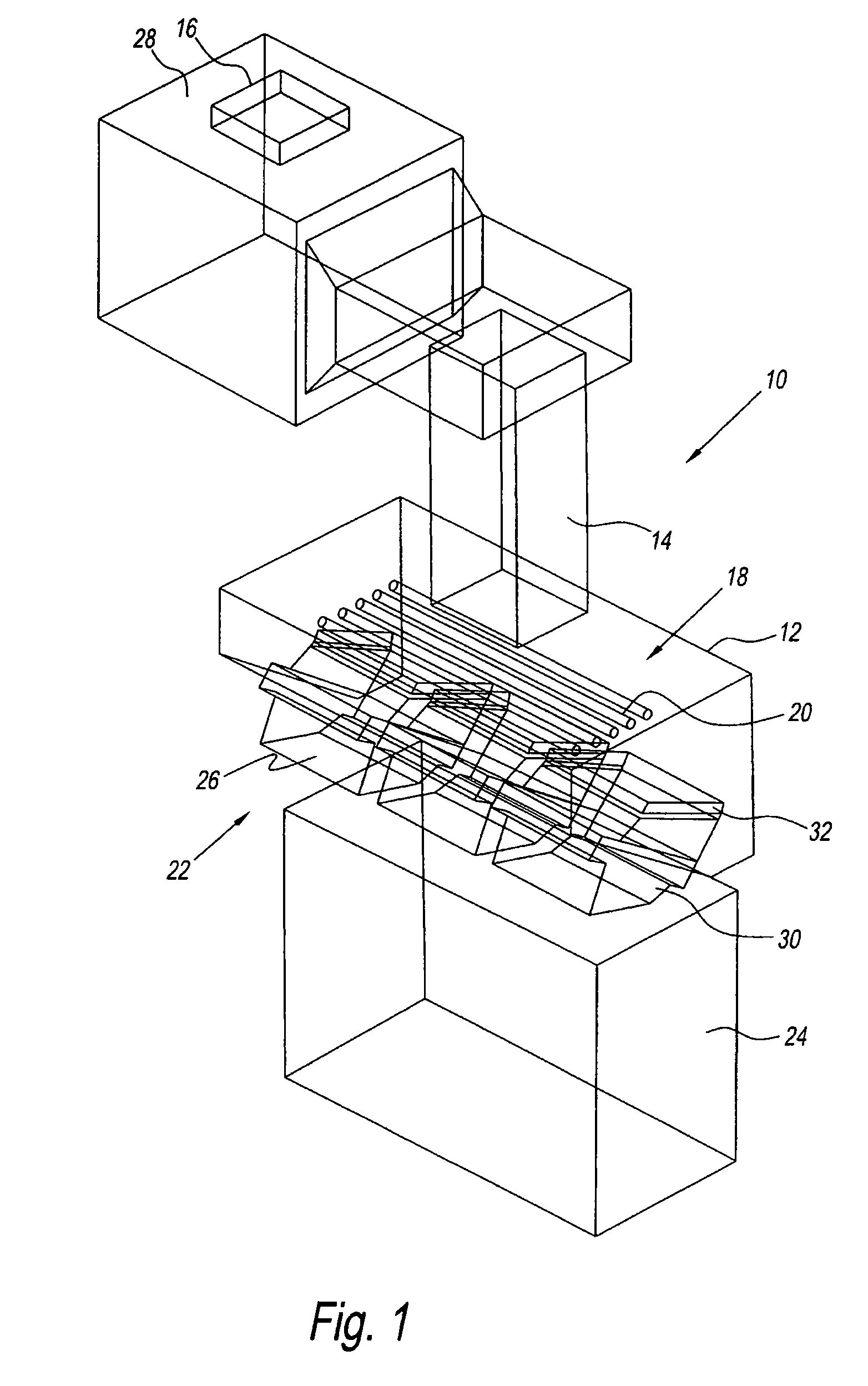

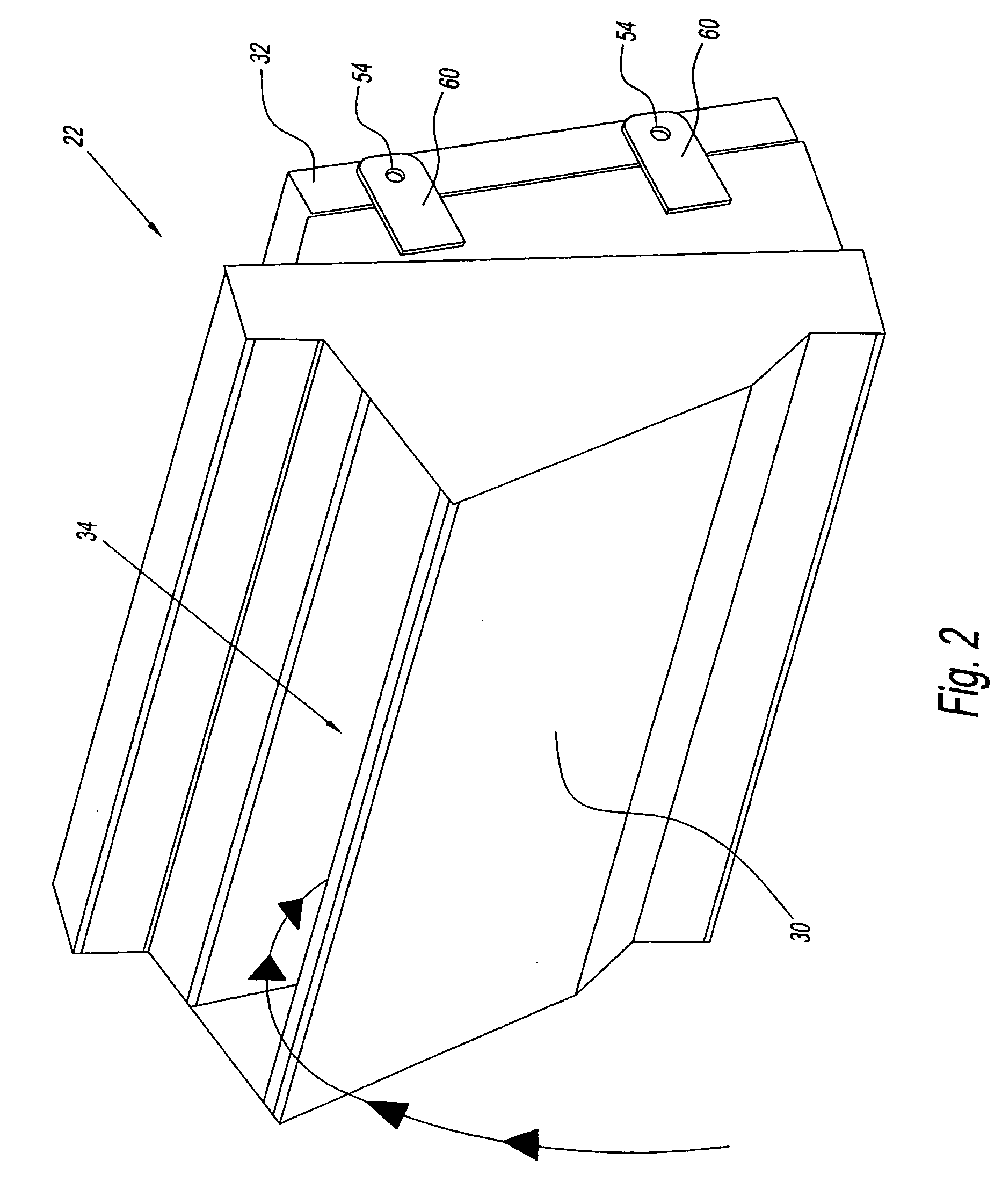

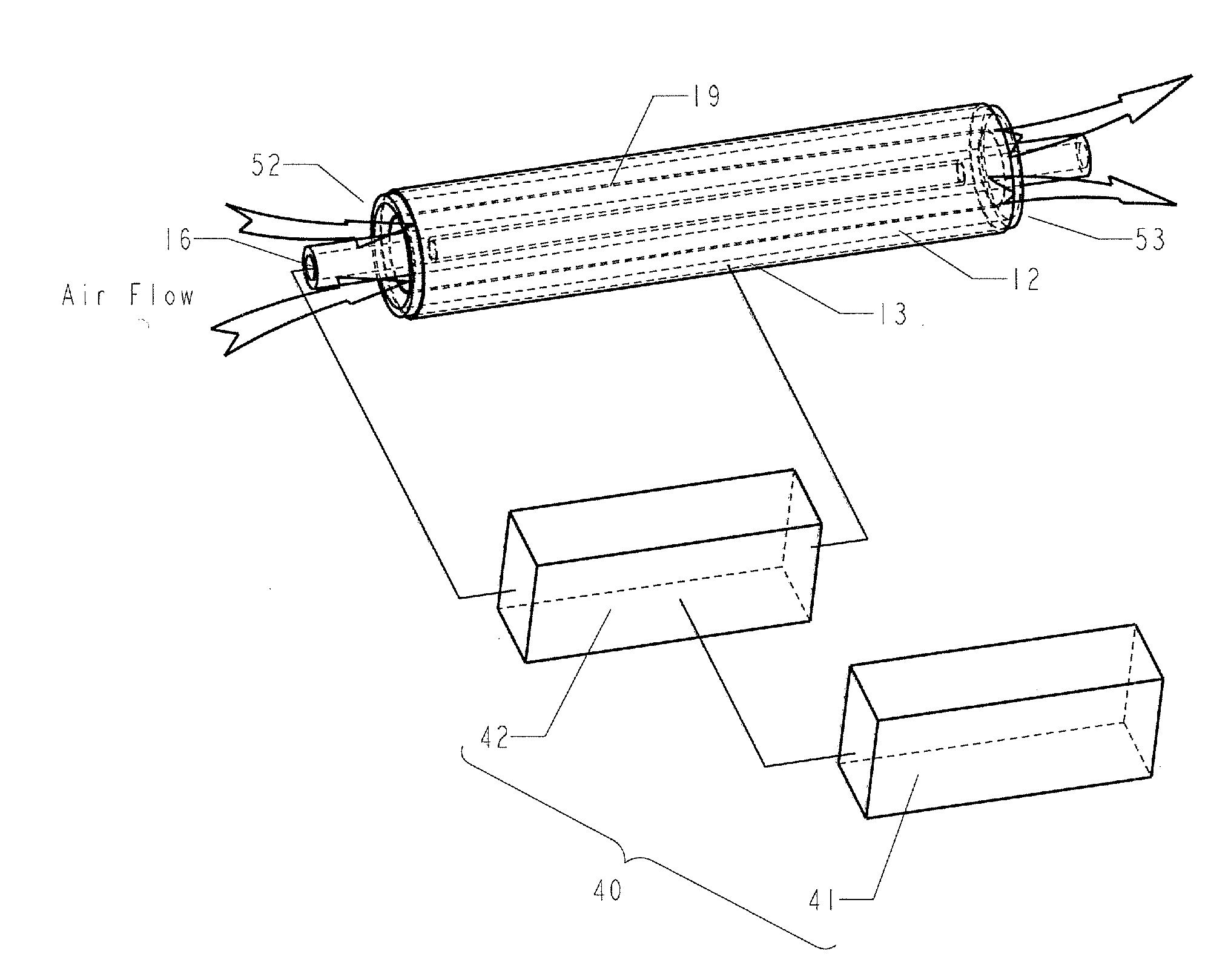

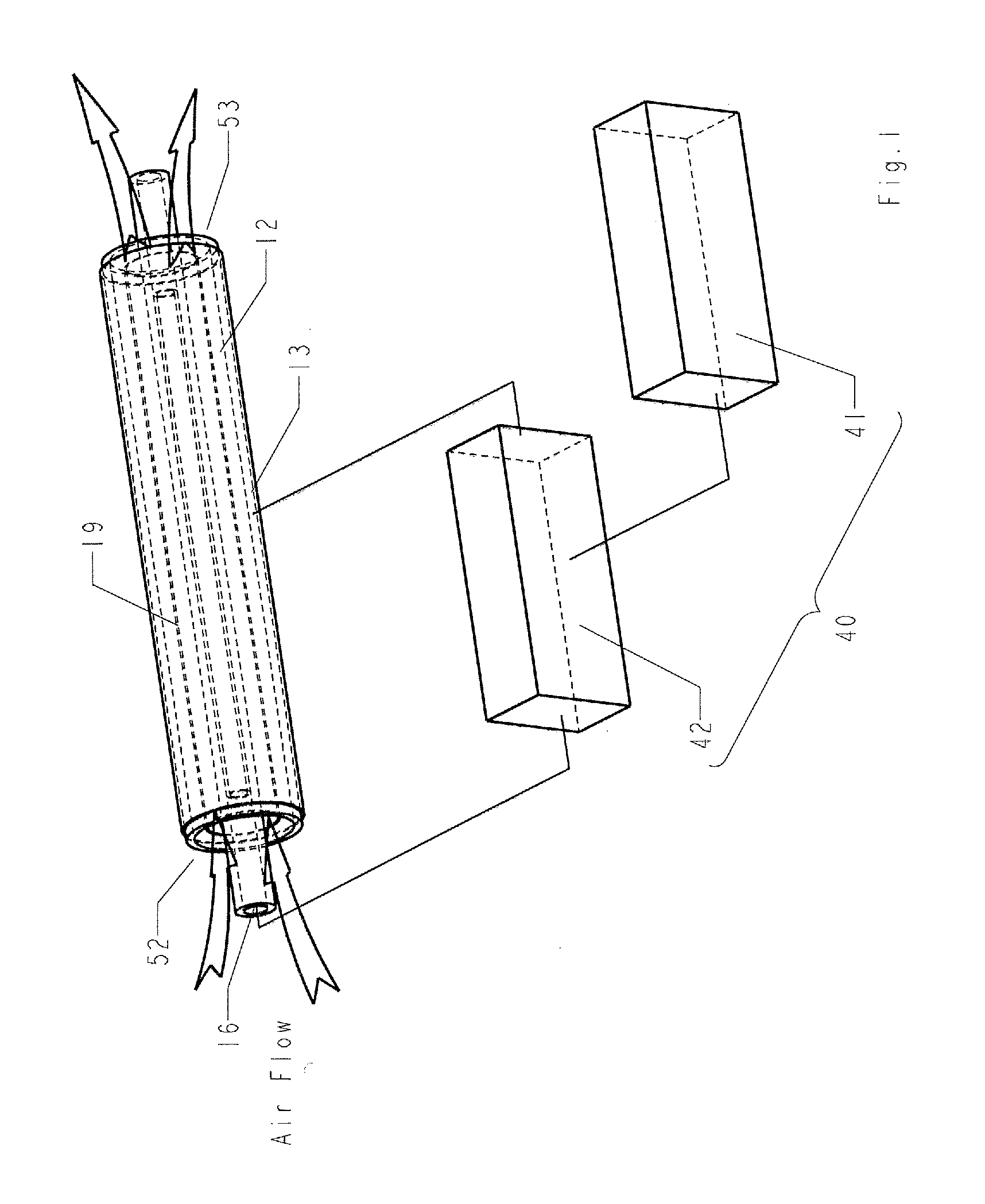

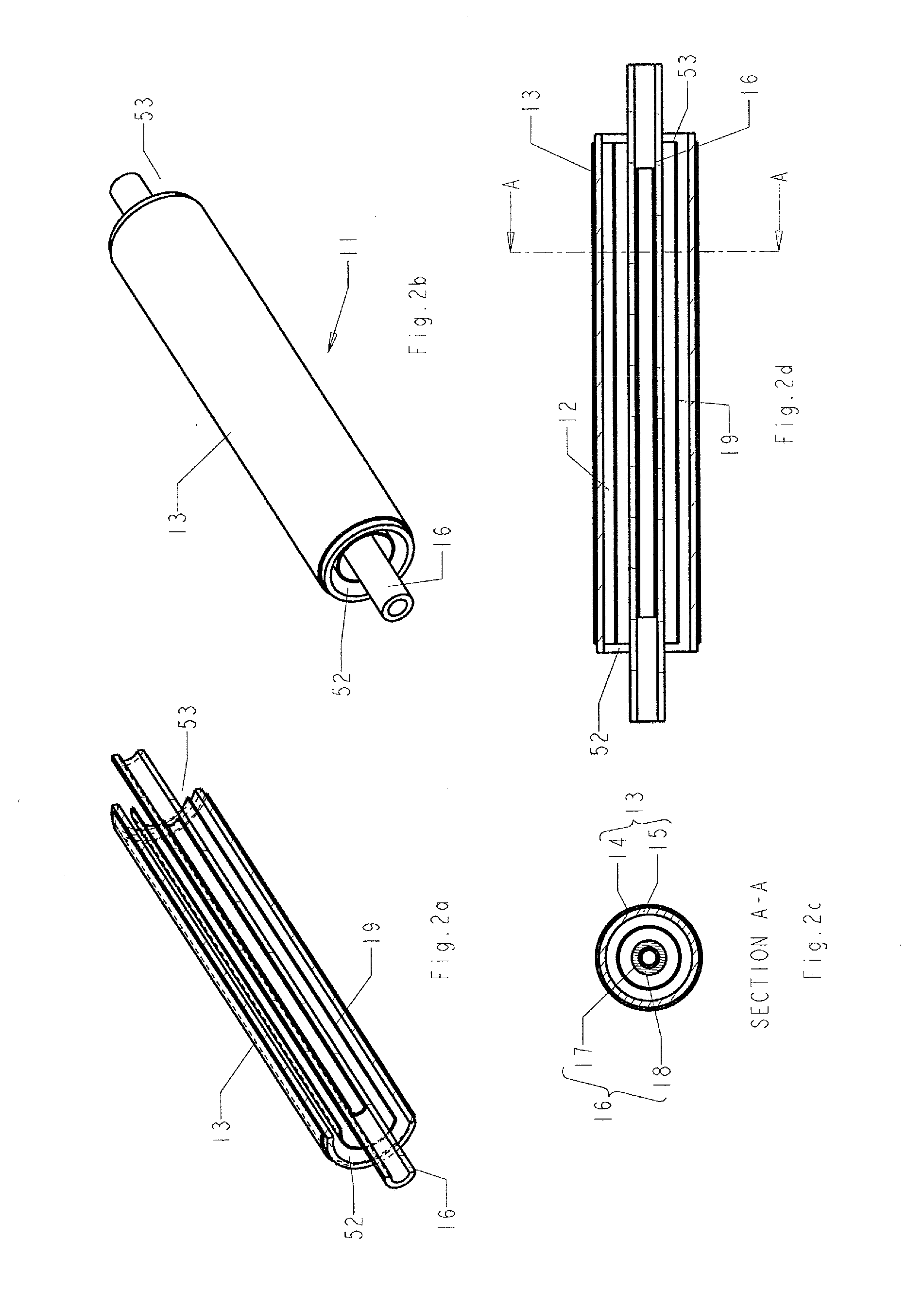

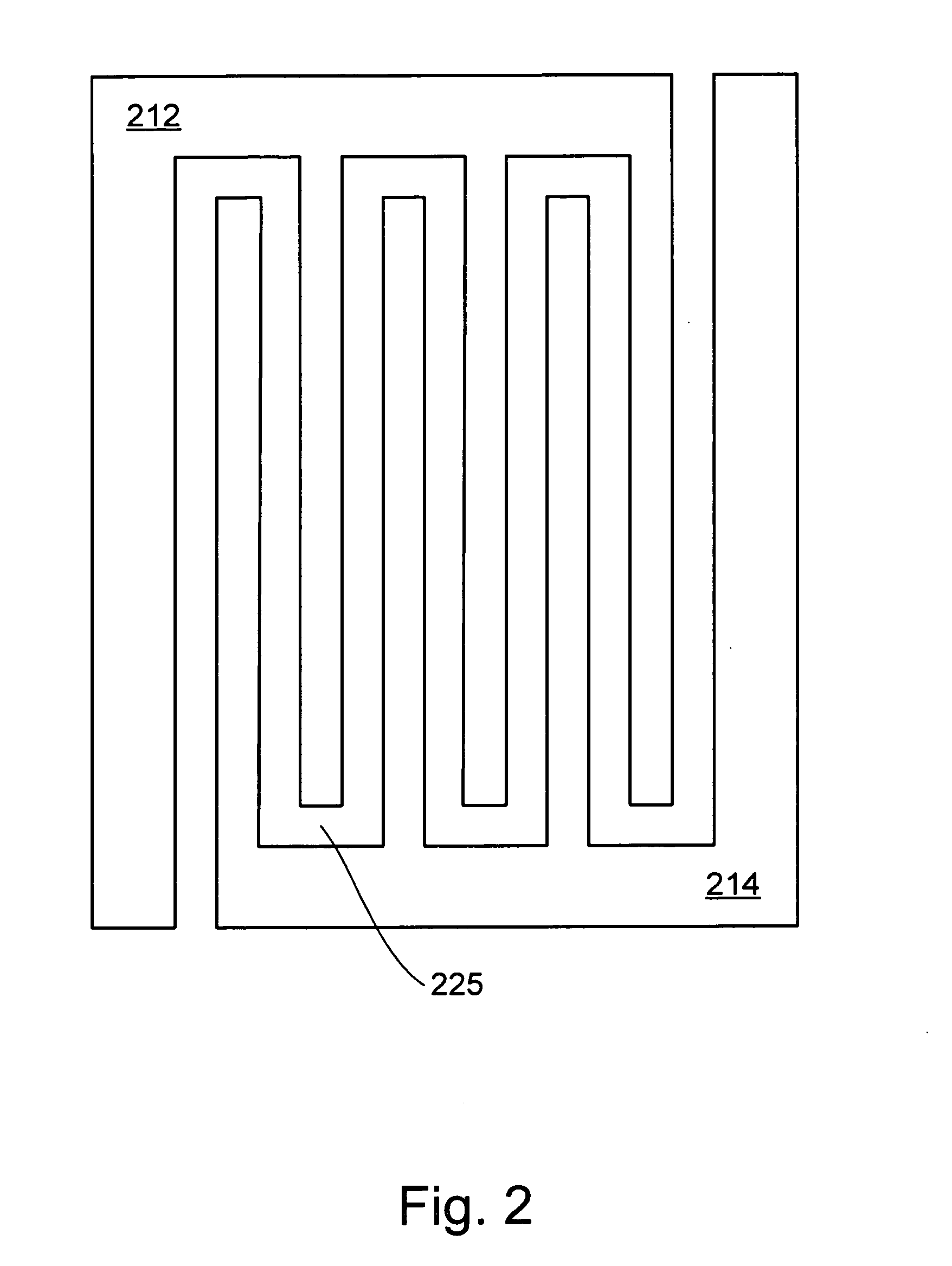

Apparatus and method for removing volatile organic compounds from a stream of contaminated air with use of an adsorbent material

InactiveUS6027550AImprove efficiencyReduce the amount requiredGas treatmentIsotope separationSorbentContaminated air

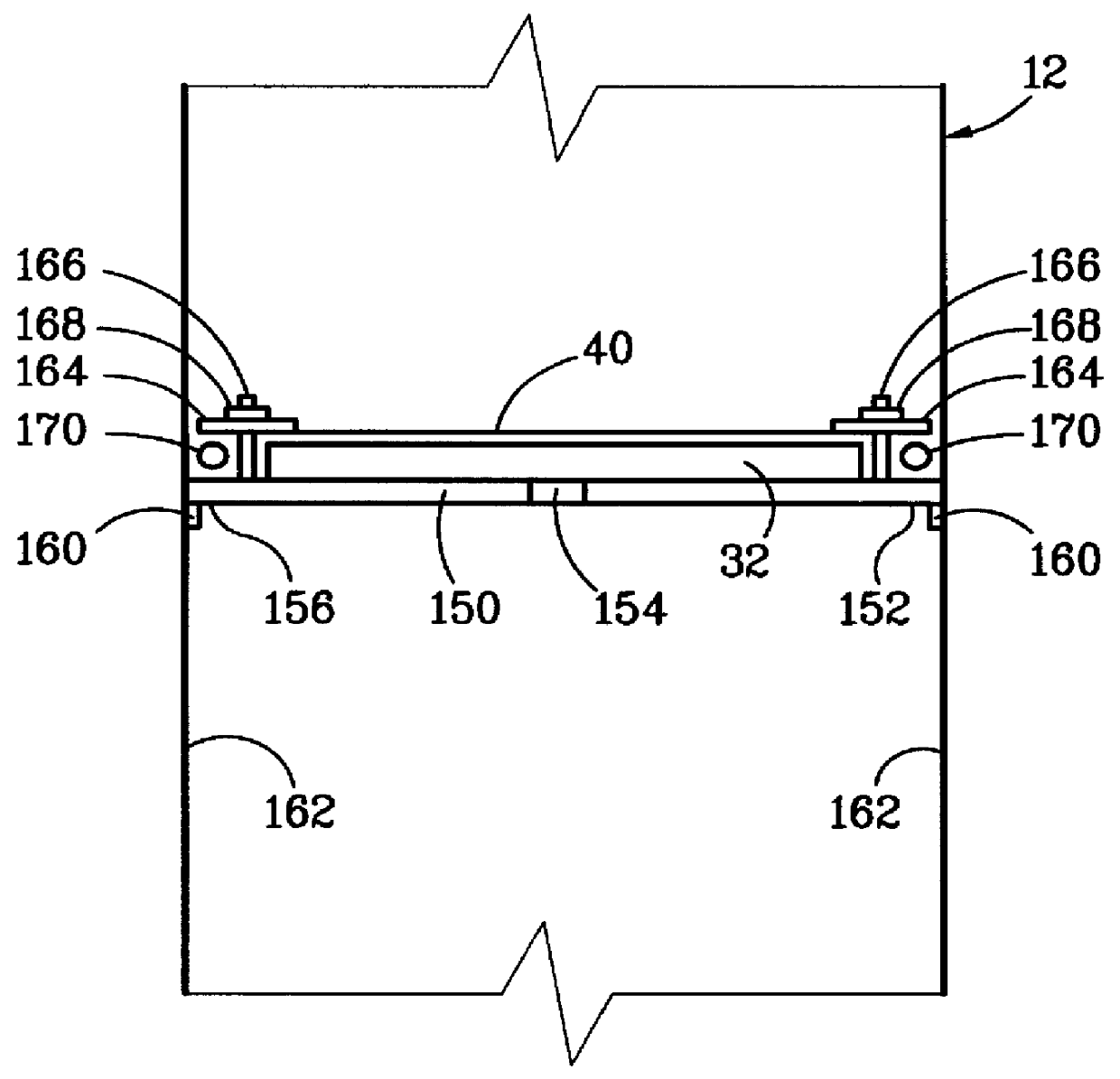

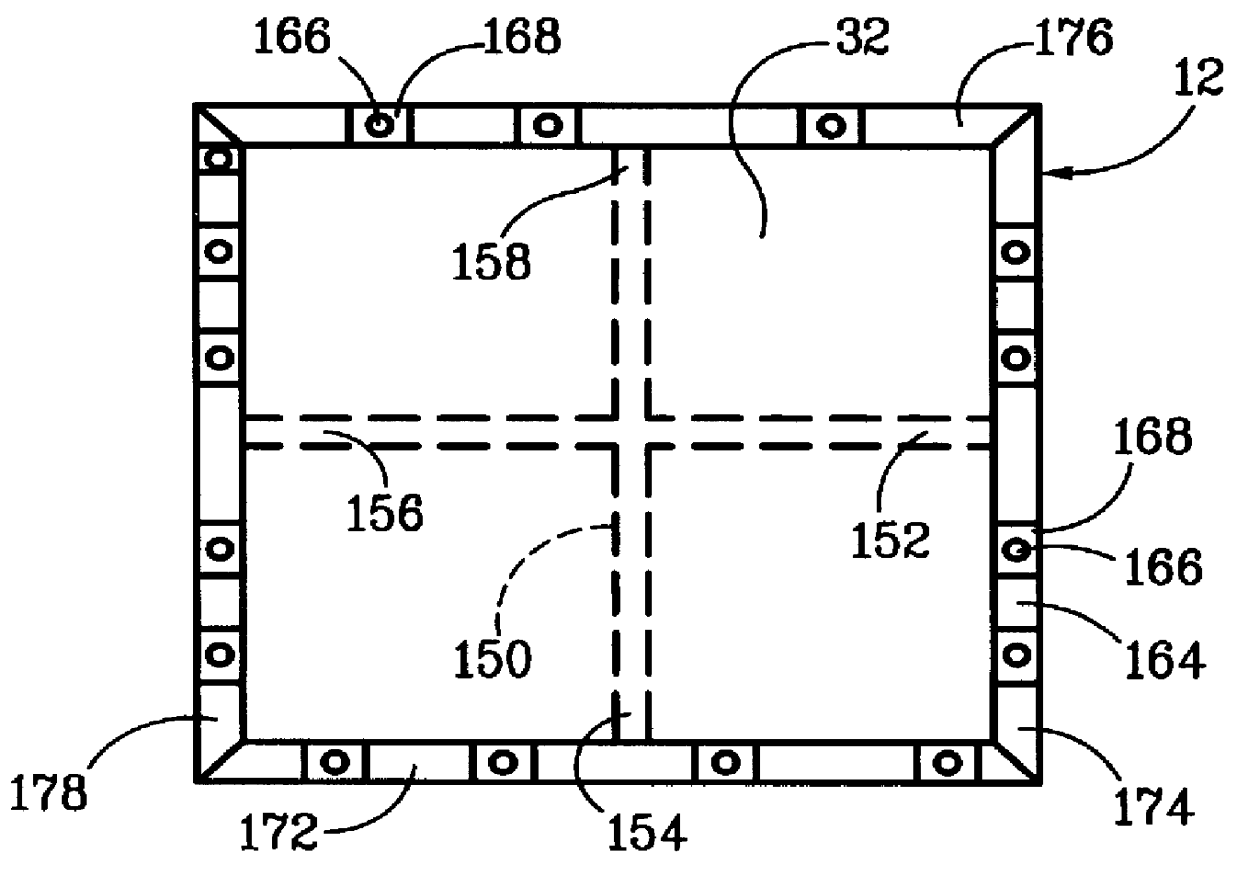

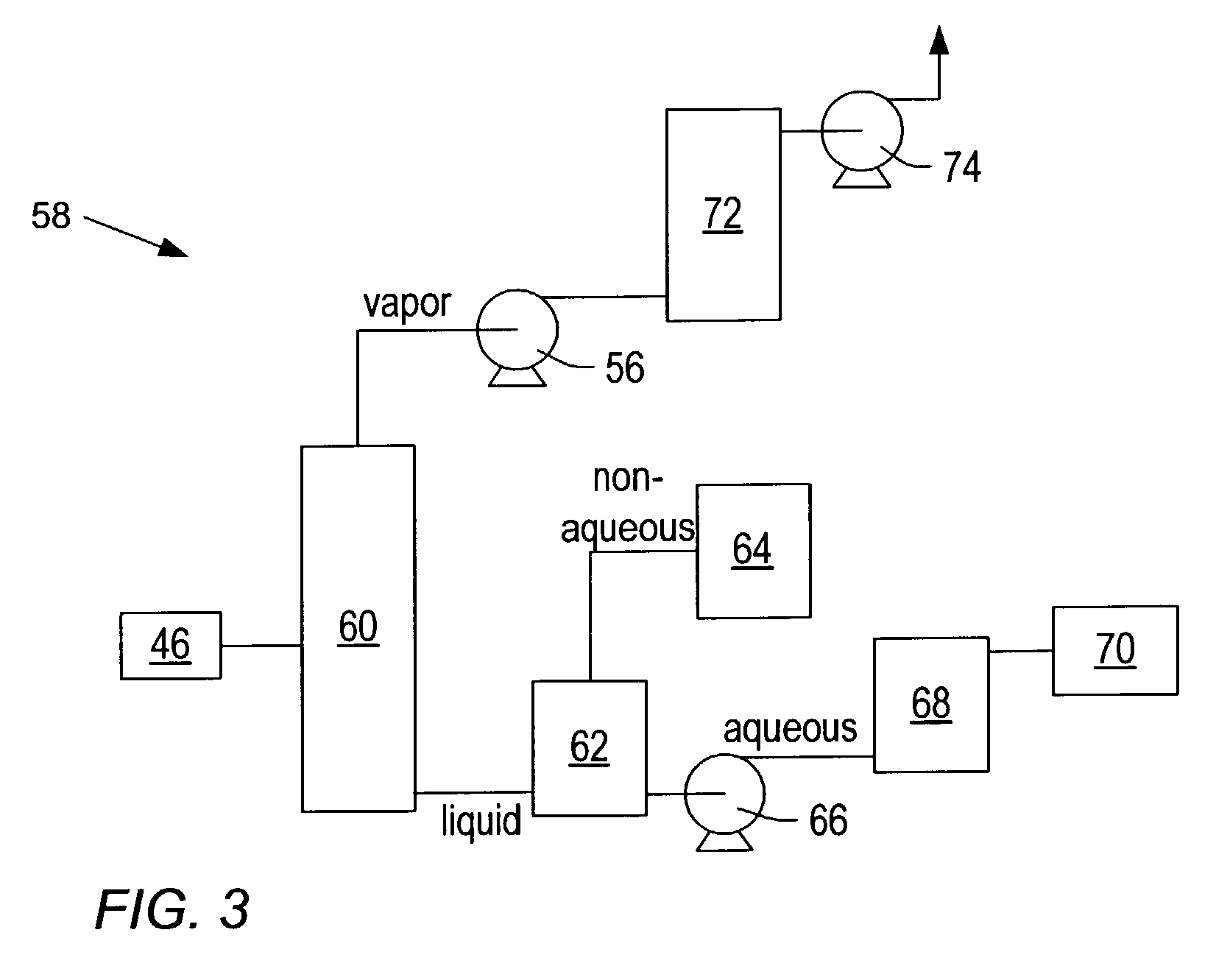

An apparatus and method for removing volatile organic compounds (VOCs) from a stream of contaminated air using an adsorbent material. The stream of contaminated air is introduced into an end of a first hollow member which contains the adsorbent material. A perforated member disposed within the hollow member is configured to increase the air stream velocity such that dispersed particles of the adsorbent material are entrained in the air stream. Entrainment of the adsorbent in the contaminated air stream facilitates efficient removal of the VOCs. The cleaned air stream exits from a second end of the first hollow member, and the adsorbent material, having a quantity of VOCs adsorbed thereon, is directed to a reconditioning apparatus wherein the VOCs are thermally desorbed. The reconditioned adsorbent material is then returned to the first hollow member.

Owner:TECHARMONIC

Soil remediation using heated vapors

ActiveUS7534926B2Reduce energy consumptionReduce the amount requiredGlass furnace apparatusContaminated soil reclamationSoil remediationPollution soil

Methods are provided for remediating contaminated soil. The methods may include collecting contaminated soil at a plurality of treatment sites. The contaminated soil at one or more of the plurality of treatment sites may be at least partially contained. Vapors produced from heating soil at one site may be used to heat contaminated soil at another site. A fluid directed to a portion of heated contaminated soil may accelerate heat transfer through the site of contaminated soil or through another site of contaminated soil. A method may include heating contaminated soil from more than one site at substantially the same time. Heating contaminated soil from more than one site at substantially the same time may include in situ and ex situ treatment at a common location.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Ultra-violet ventilation system having an improved filtering device

InactiveUS20050229922A1Reduce the amount requiredEasy to cleanMechanical apparatusDomestic stoves or rangesUltravioletContaminated air

An air ventilation system, comprising an air inlet for admitting contaminated air into the ventilation system, an air outlet for discharging decontaminated air from the ventilation, and an ultra-violet light source disposed therebetween. The ventilation system has a filter disposed upstream of the ultra-violet light source. The filter has a grease particle separator with at least two layers of expanded metal associated therewith. Each has a predetermined number of apertures forming a reticulum. A cartridge filter may be provided for each grease particle separator and disposed upstream thereof. Each cartridge filter and associated grease particle separator preferably forms an integral filtering unit and may be placed at any location of the system.

Owner:MAGNER ERIK +2

Method and apparatus for pollution control of confined spaces

A method of improve the removal of particulate matter, heavy metals, neutralizing acid, and kill microorganism pollutants, known to be in contaminated air volumes of occupied confined spaces, when exposed in close contact under pressure to a mixture of alkaline sorbent materials, having a known synergism between said pollutants using a self propelled fluidized bed reactor and packed bed filter apparatus system to optimize the contact collection efficiency of submicron particles and organic compounds.

Owner:AVINA DAVID CHRISTOPHER

Method and apparatus for injecting a fuel into a combustor assembly

InactiveUS20050076648A1Eliminating selectedTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorContaminated air

A combustor assembly including an injector element able to inject and substantially mix a fuel with a vitiated air stream, so that the substantially all of the fuel injected into the vitiated air stream reaches an auto ignition temperature before it combusts. Generally, the injector element expels the fuel from the injector orifice at a rate, a velocity, a trajectory, or a flow geometry able to mix the fuel with the vitiated air. Generally, the fuel is able to mix with the vitiated air in such a manner that the fuel is substantially mixed and no substantially high or substantially low concentrations of fuel exist in the air stream at the time that the fuel reaches the auto ignition temperature.

Owner:THE BOEING CO

Exhaust fan assembly

An exhaust fan assembly is provided for expelling contaminated air from a building. The assembly includes fan housing connected to the building via a duct. The fan housing contains a fan the draws air from the building through the duct. An extension is mounted to the outlet end of the fan housing, and has a cylindrical upper end connected to a nozzle. A windband is connected to the upper end of the nozzle, and provides an air entrainment path that allows ambient air to mix with the exhaust air prior to exiting through an exhaust fan assembly outlet.

Owner:GREENHECK FAN

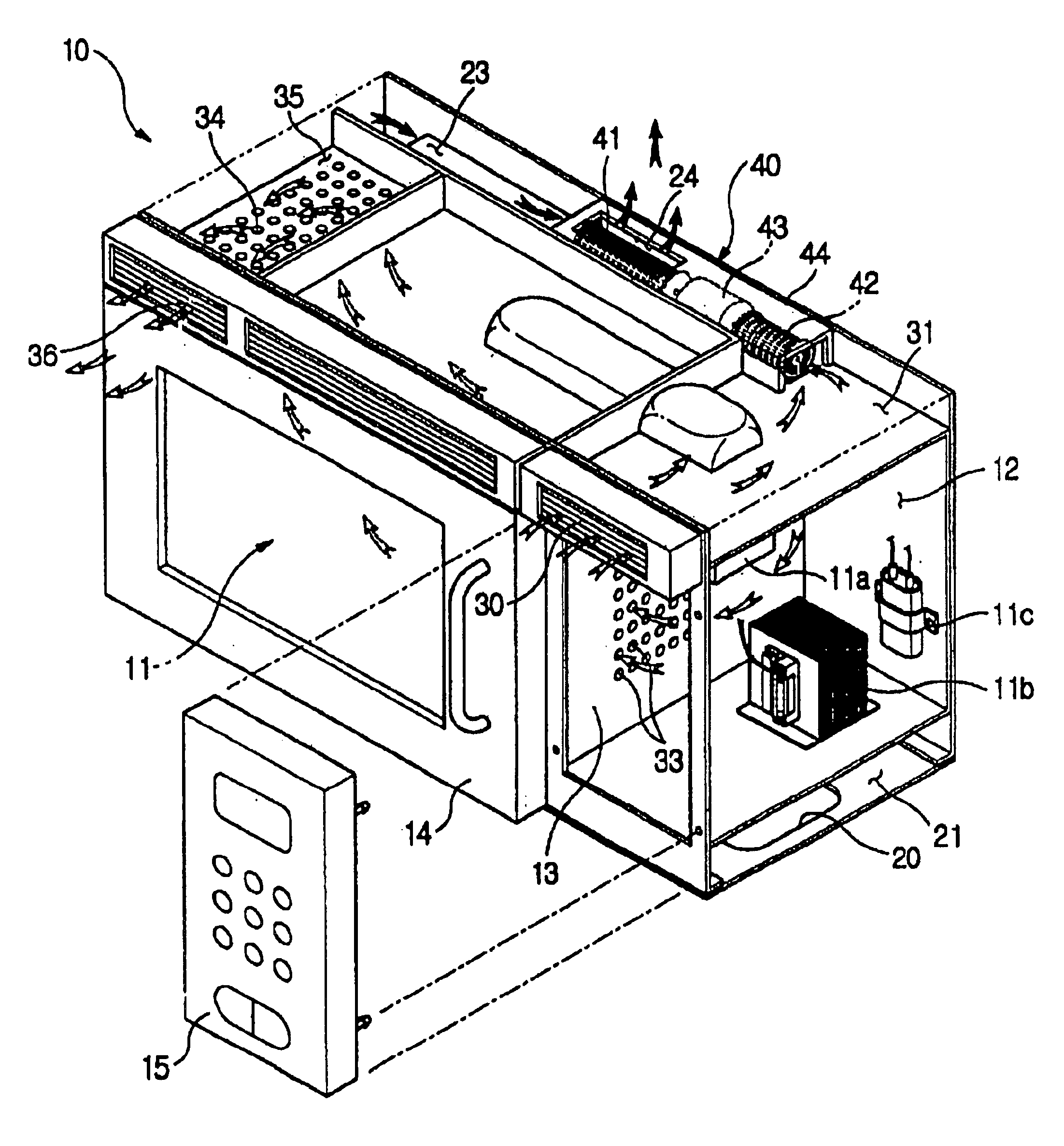

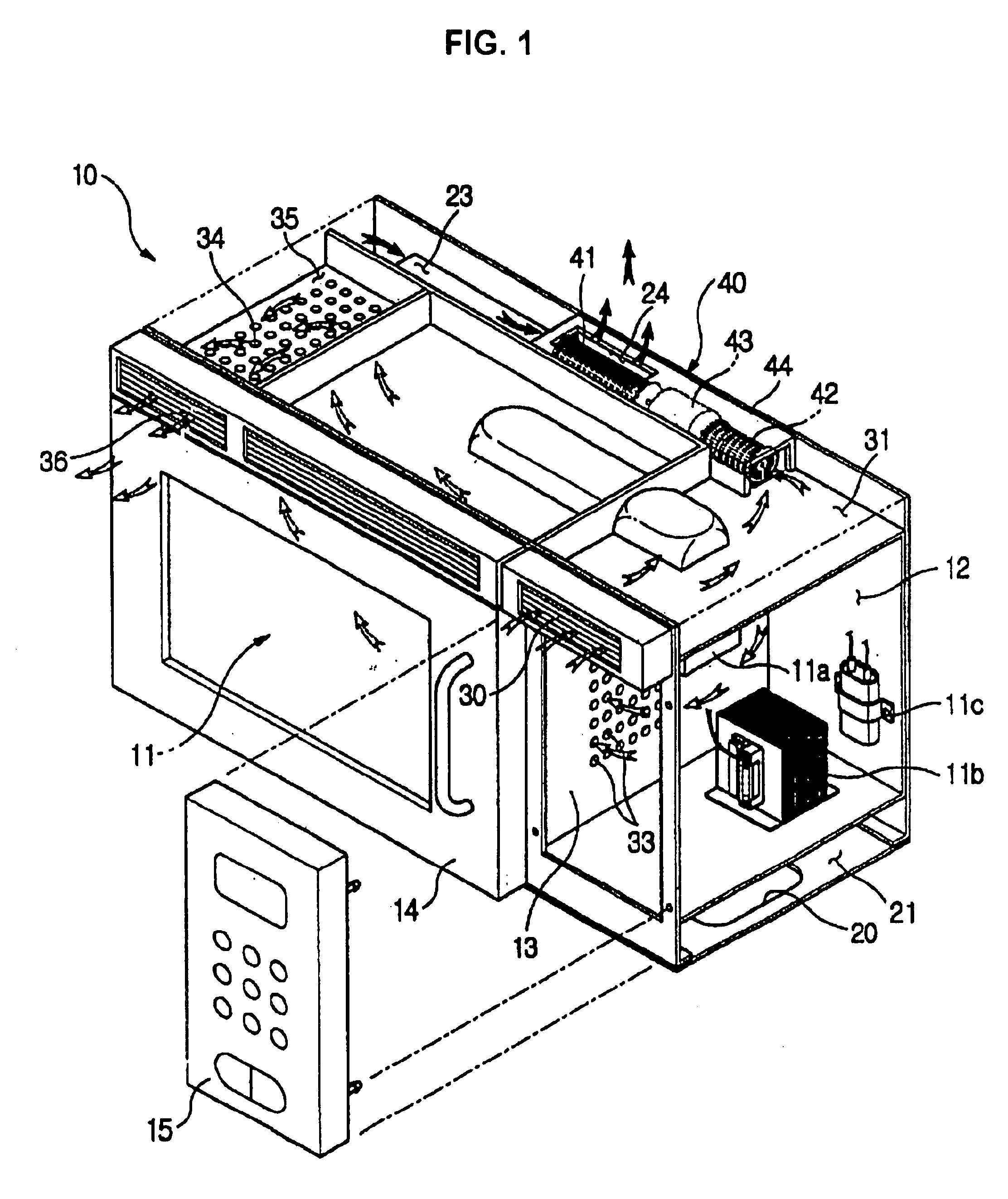

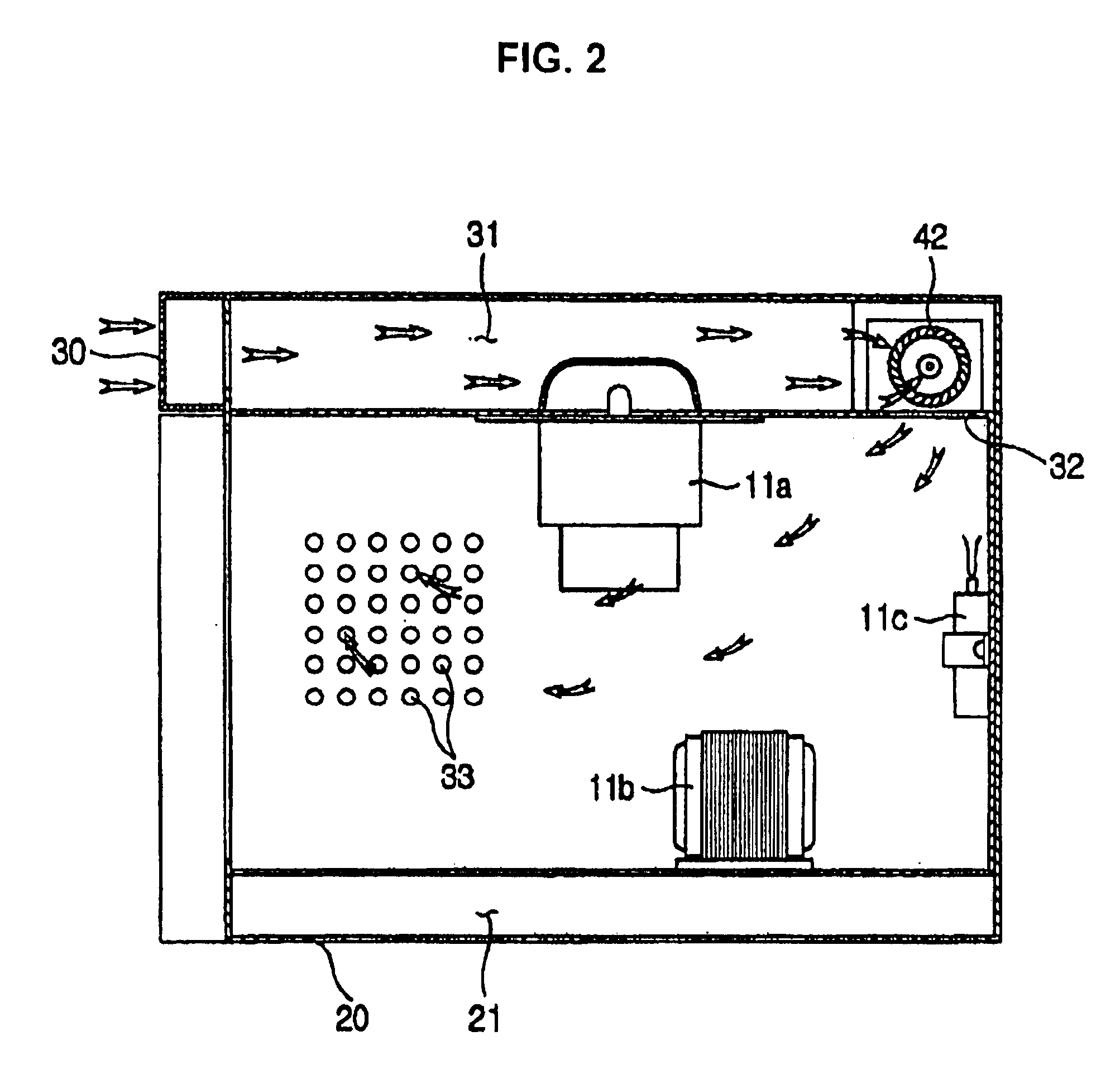

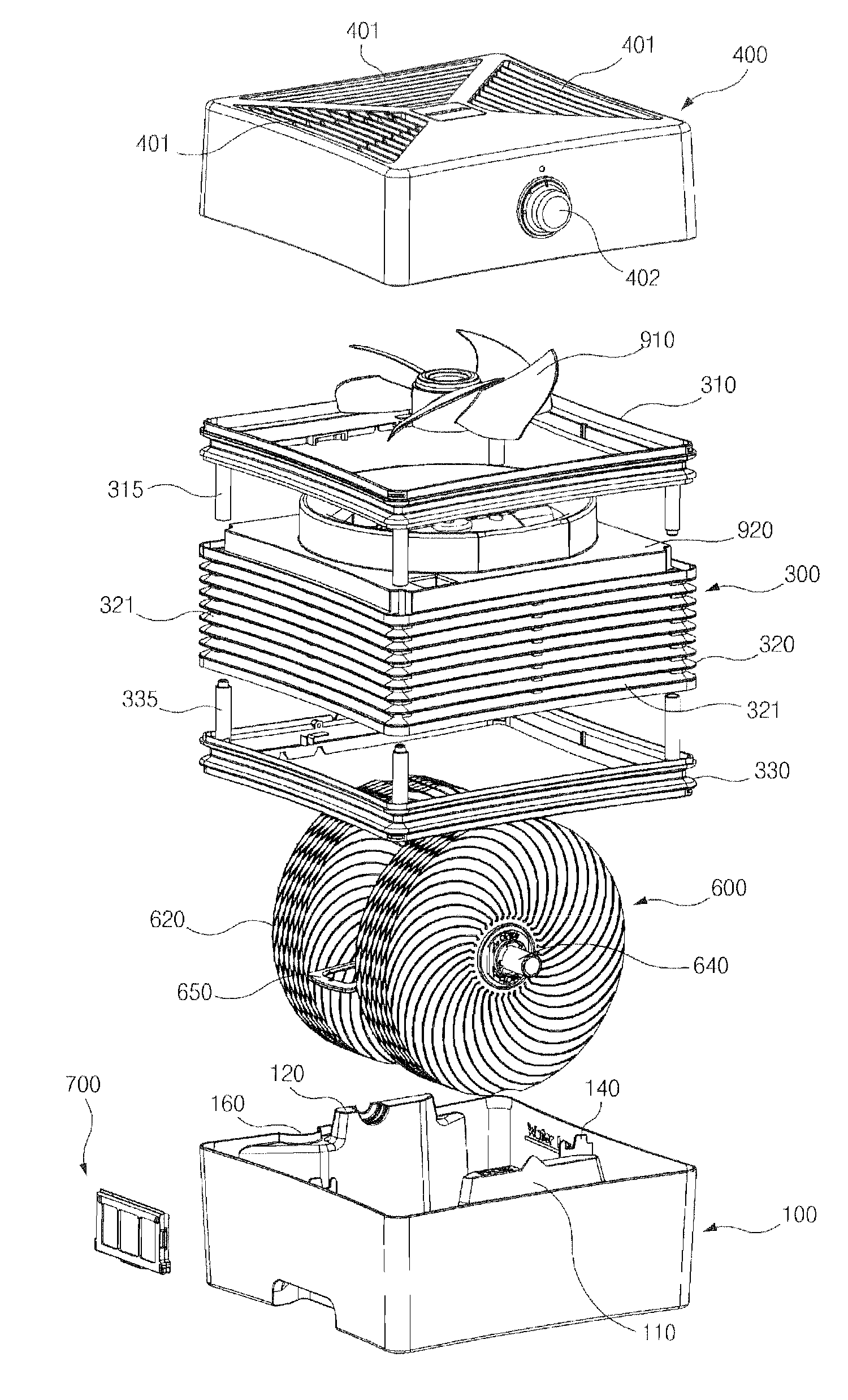

Exhaust and ventilation system for mountable type microwave oven

InactiveUS6864472B2Reduce in quantityImprove of manufactureDomestic stoves or rangesLighting and heating apparatusSuction forceMicrowave oven

A mountable type microwave oven including a blower fan assembly installed at a rear-upper portion of a cabinet to cool a machine room and ventilate a cooking chamber. The microwave oven includes a cabinet mounted on a wall of a cooking space, or under a storage cabinet, and having a cooking chamber to cook food therein and a machine room to house a plurality of electrical components, which are isolated from each other, an exhaust path to exhaust contaminated air generated from a cooking appliance installed below the wall-mounted microwave oven, a cooling-ventilation path to cool the machine room and to ventilate the cooking chamber, and a blower fan assembly including a drive motor having a pair of shafts to generate a rotating force, an exhaust fan joined to one shaft of the drive motor to generate a suction force and a propulsive force to cause the contaminated air to flow along the exhaust path, and a cooling-ventilation fan joined to the other shaft of the drive motor to generate suction and propulsive forces to cause air to flow along the cooling-ventilation path. Since the cooling-ventilation fan performs cooling of the machine room and ventilation of the cooking chamber, there is no need to provide an additional blower fan. Thus, the number of components of the microwave oven is reduced, thereby reducing production costs and improving productivity.

Owner:SAMSUNG ELECTRONICS CO LTD

Ultra-violet ventilation system having an improved filtering device

InactiveUS20080302247A1Easy to cleanReduce downtimeCombination devicesMechanical apparatusUltravioletContaminated air

An air ventilation system, comprising an air inlet for admitting contaminated air into the ventilation system, an air outlet for discharging decontaminated air from the ventilation, and an ultra-violet light source disposed therebetween. The ventilation system has a filter disposed upstream of the ultra-violet light source. The filter has a grease particle separator with at least two layers of expanded metal associated therewith. Each has a predetermined number of apertures forming a reticulum. A cartridge filter may be provided for each grease particle separator and disposed upstream thereof. Each cartridge filter and associated grease particle separator preferably forms an integral filtering unit and may be placed at any location of the system.

Owner:HALTON GROUP LTD

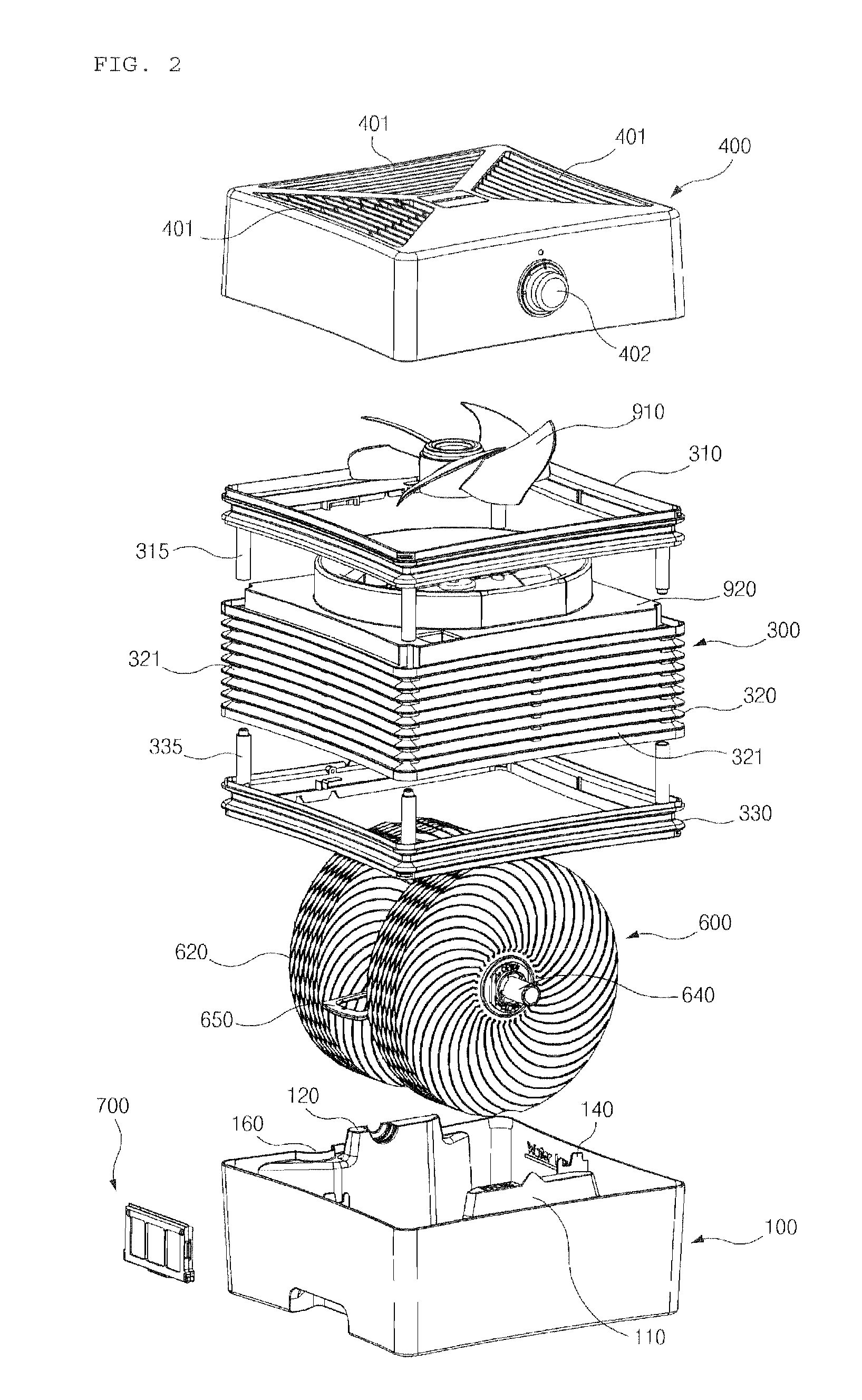

Air washer having humidifying function

InactiveUS20080127820A1Simple manufacturing processReduce weightCombination devicesMechanical apparatusEnvironmental engineeringContaminated air

An air washer adsorbs outside contaminated air to disks, which have water films formed thereon, and settles contaminants in water in a water reservoir, thus purifying and humidifying air.

Owner:WINIAMANDO

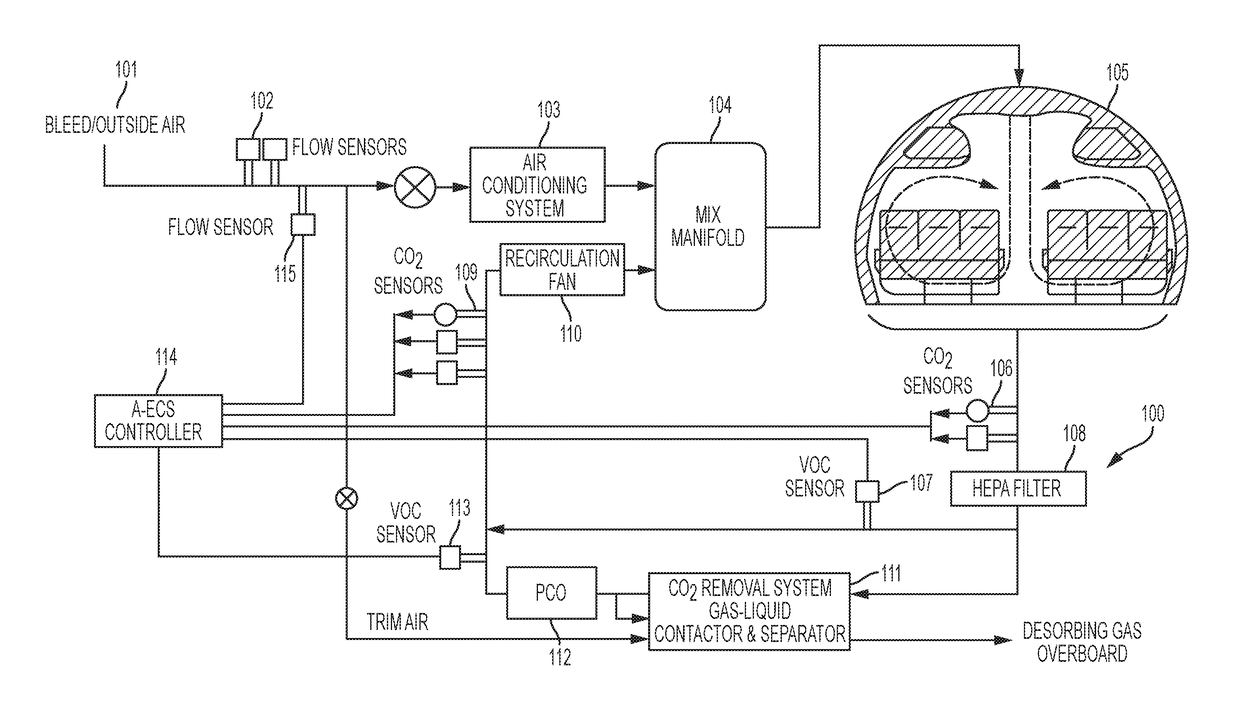

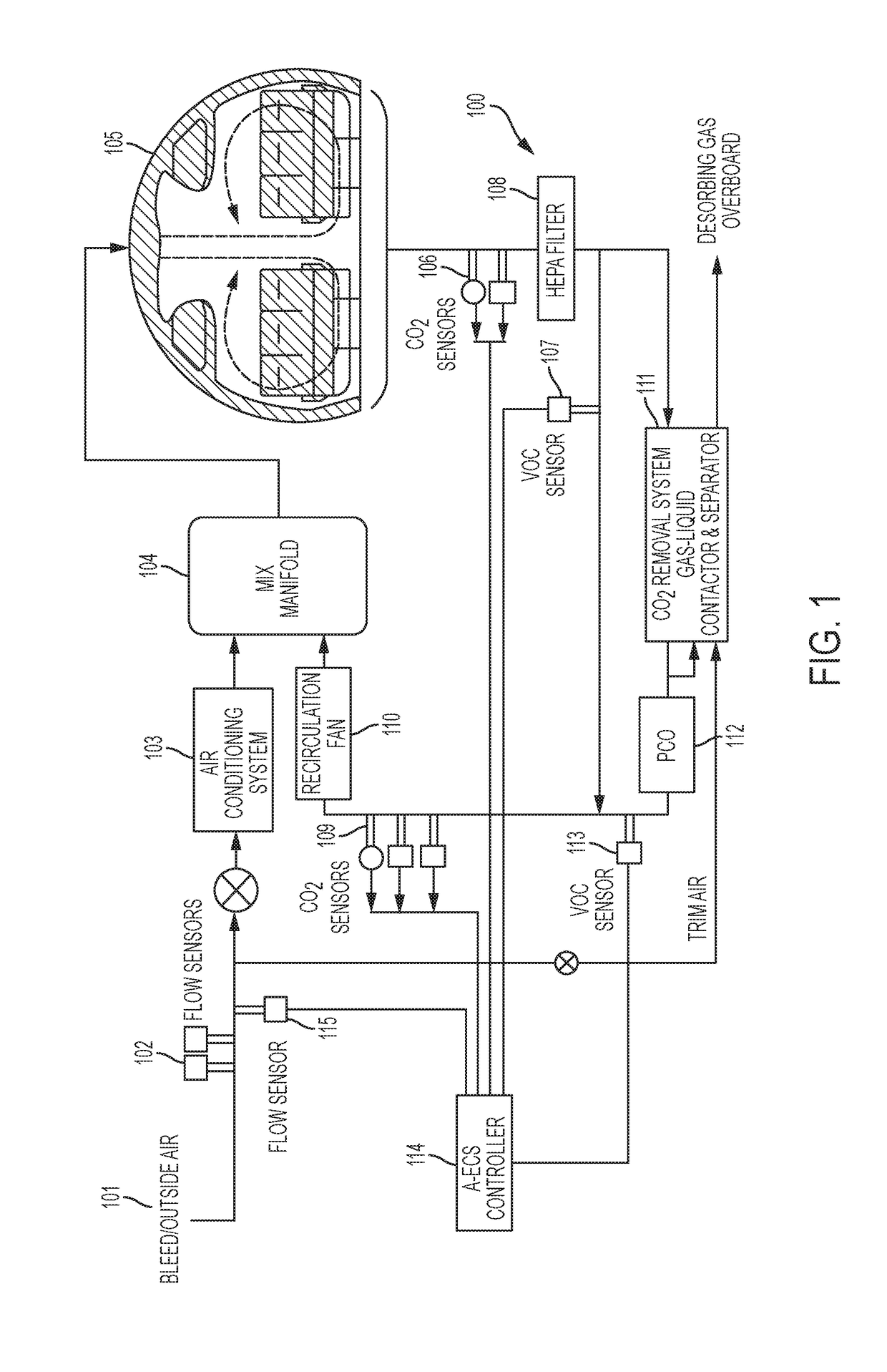

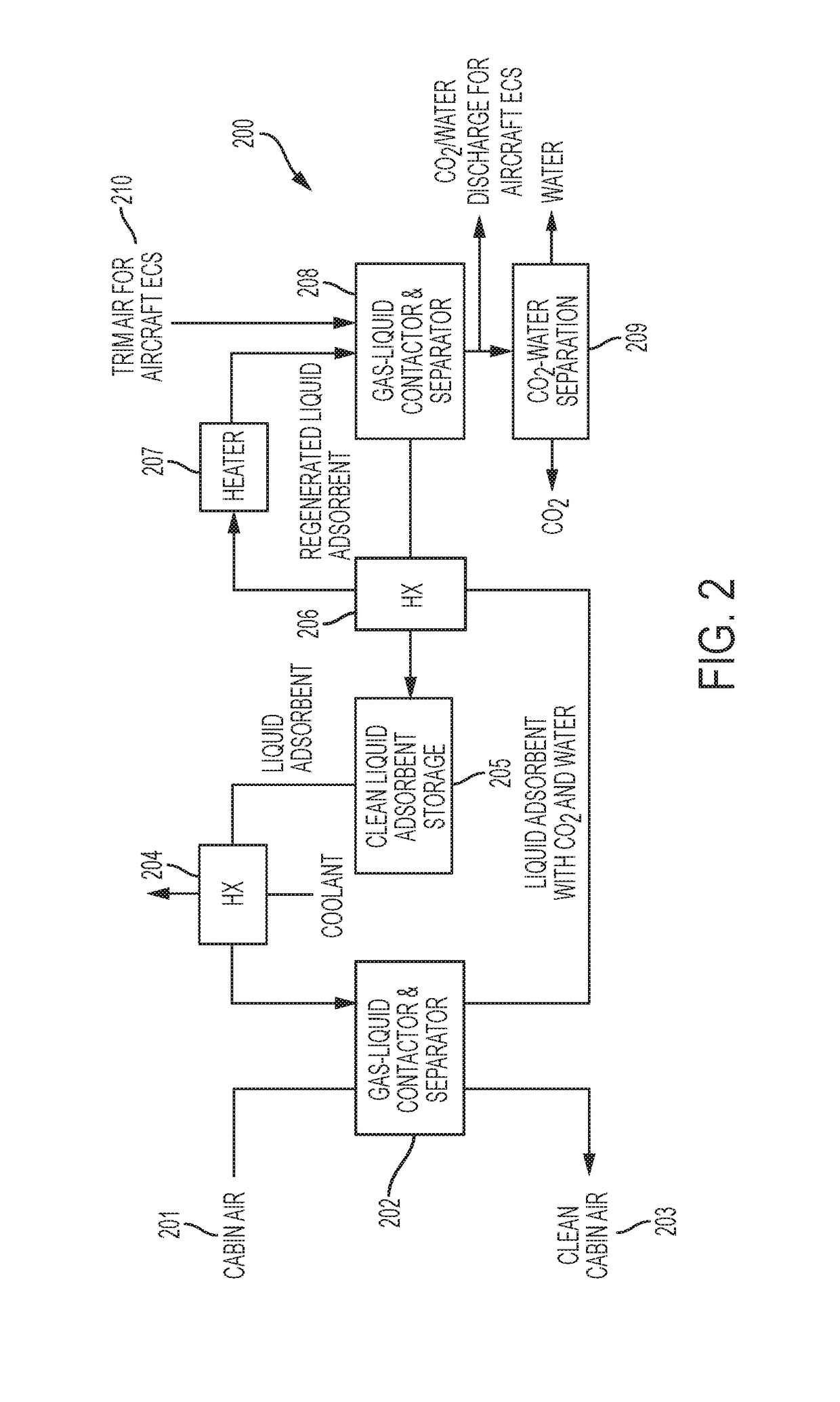

Apparatus and methods for enhancing gas-liquid contact/separation

ActiveUS20180056234A1Smooth connectionCosmonautic environmental control arrangementGas treatmentControl systemEnvironmental control system

An environmental control system includes an air conditioning subsystem; a mix manifold downstream of the air conditioning subsystem and upstream of an environment to be conditioned; and a contaminant removal subsystem downstream of the environment to be conditioned. The contaminant removal subsystem includes a first gas-liquid contactor-separator. The first gas-liquid contactor-separator includes a first rotating porous bed that provides a heat / mass transfer surface for contact between a contaminated air from the environment and a liquid absorbent.

Owner:HONEYWELL INT INC

Exhaust fan assembly

ActiveUS7682231B2Constant flow of airImprove efficiencyAir supply regulationDirt cleaningOperating energyContaminated air

An exhaust fan assembly is provided for expelling contaminated air from a building. The assembly includes a plenum, a fan assembly attached to the plenum, and a windband mounted on top of the fan assembly. The fan assembly is constructed of cylindrical outer and inner walls which define a bearing chamber and surrounding annular space. A fan driven by a shaft extending downward from the bearing chamber draws exhaust air from the plenum and blows it up through the annular space to a nozzle at the top of the fan assembly.

Owner:GREENHECK FAN

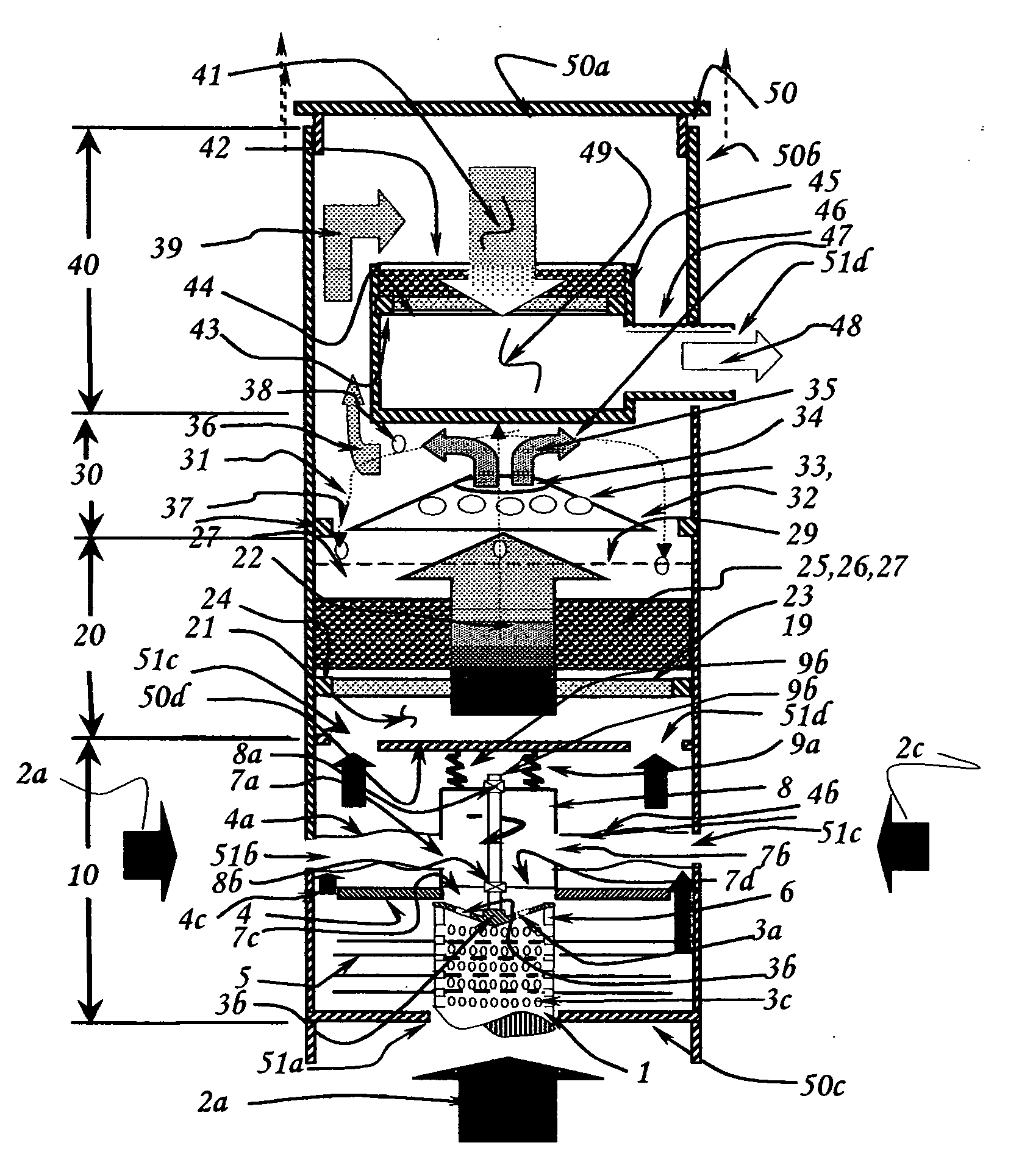

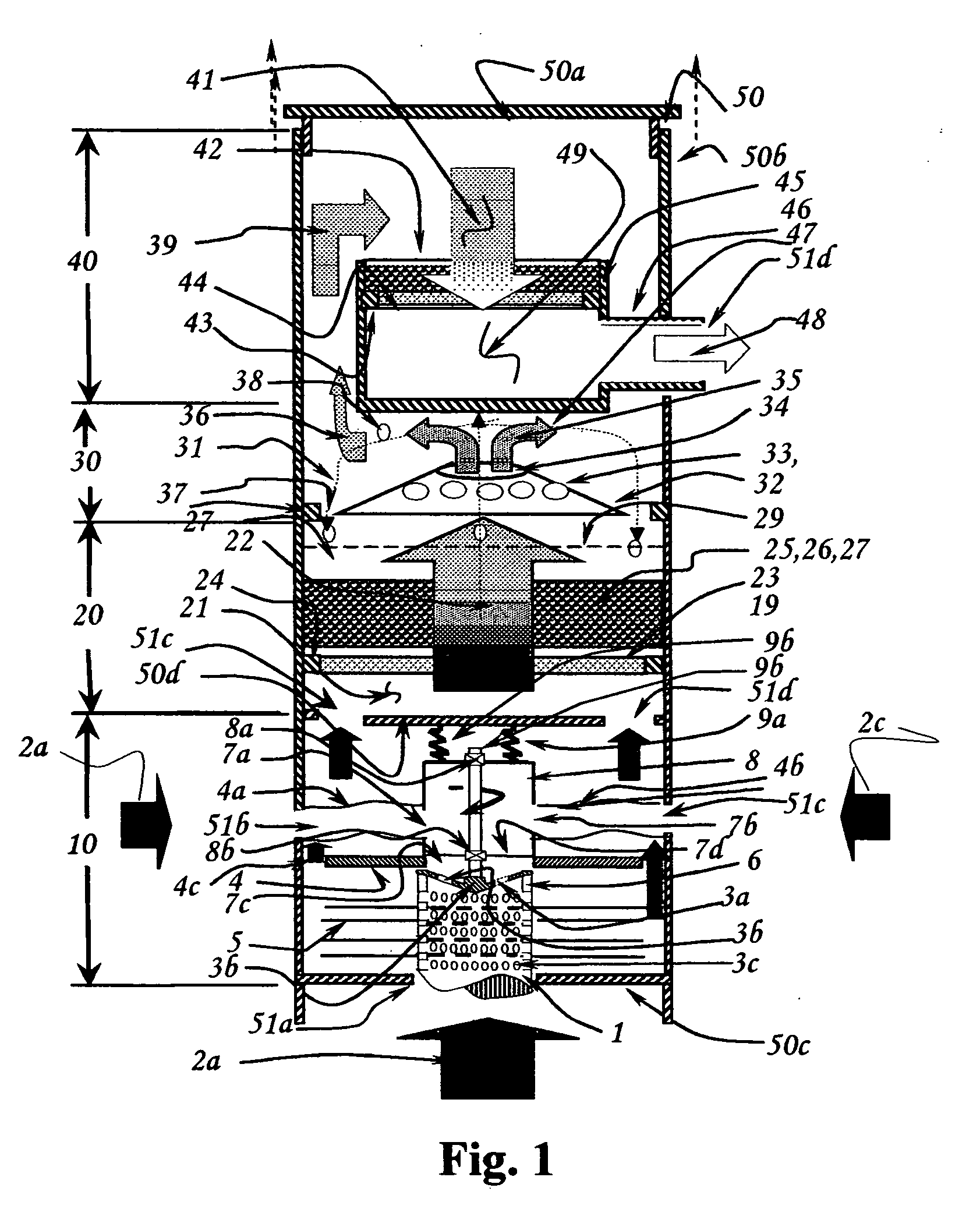

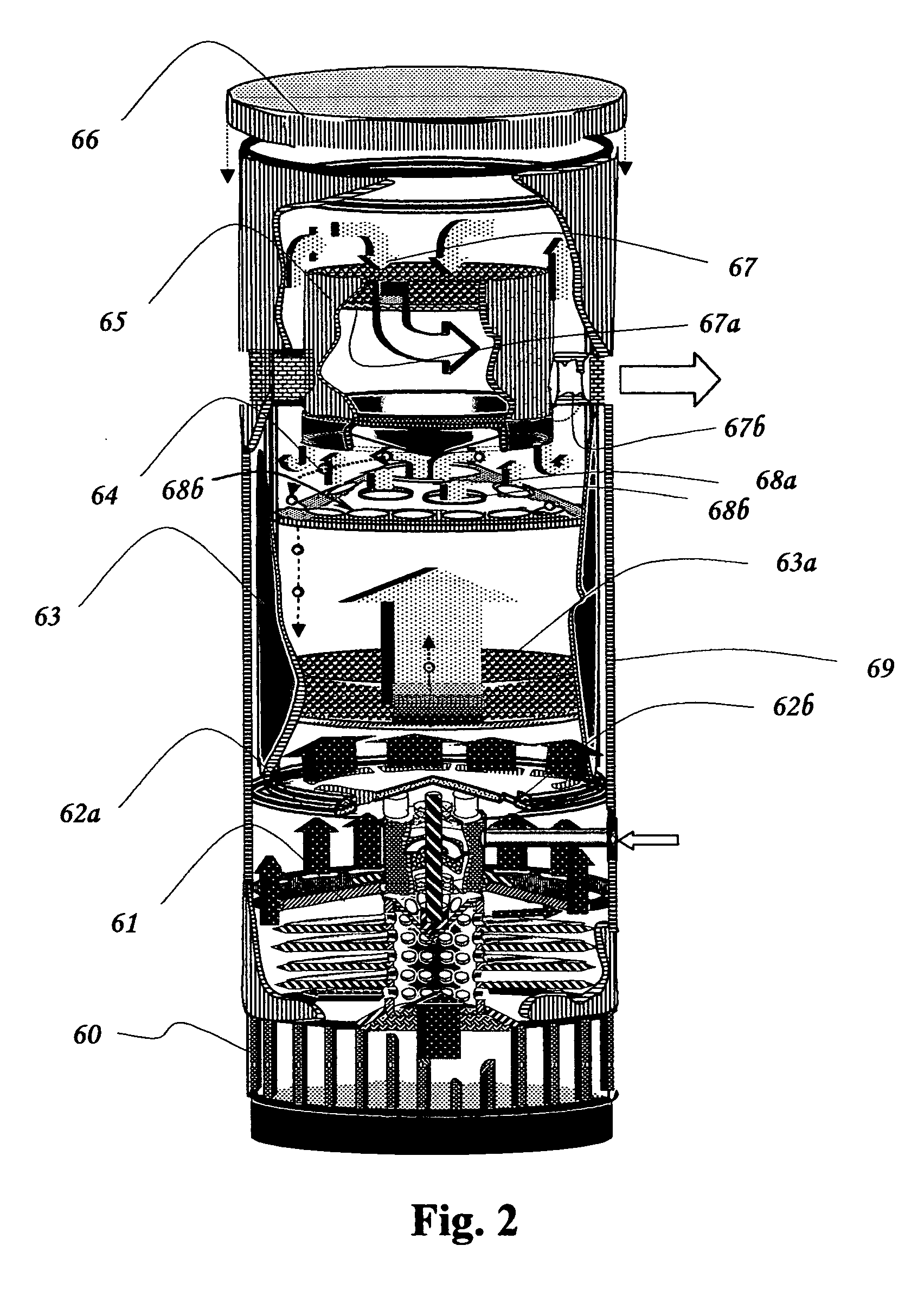

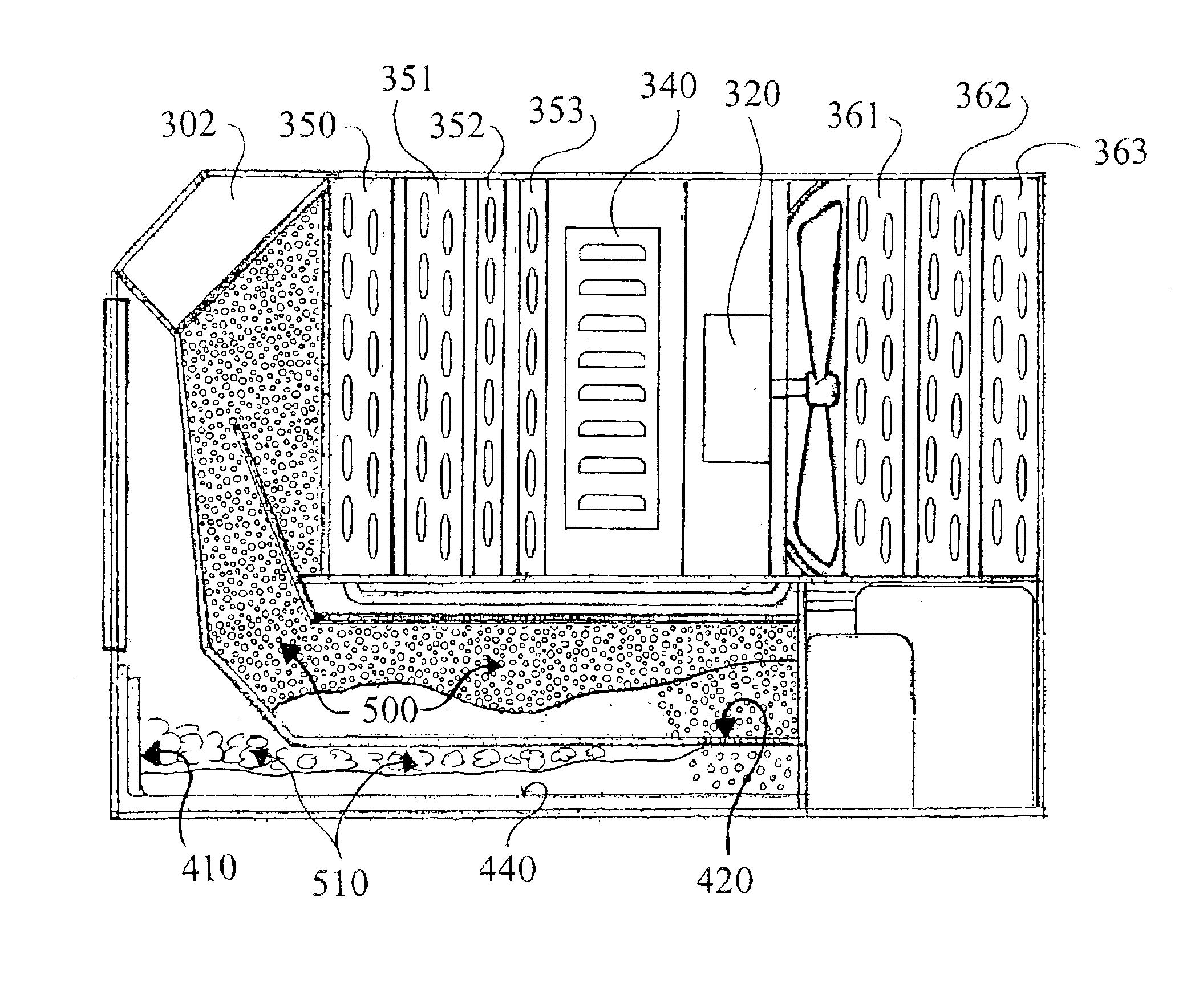

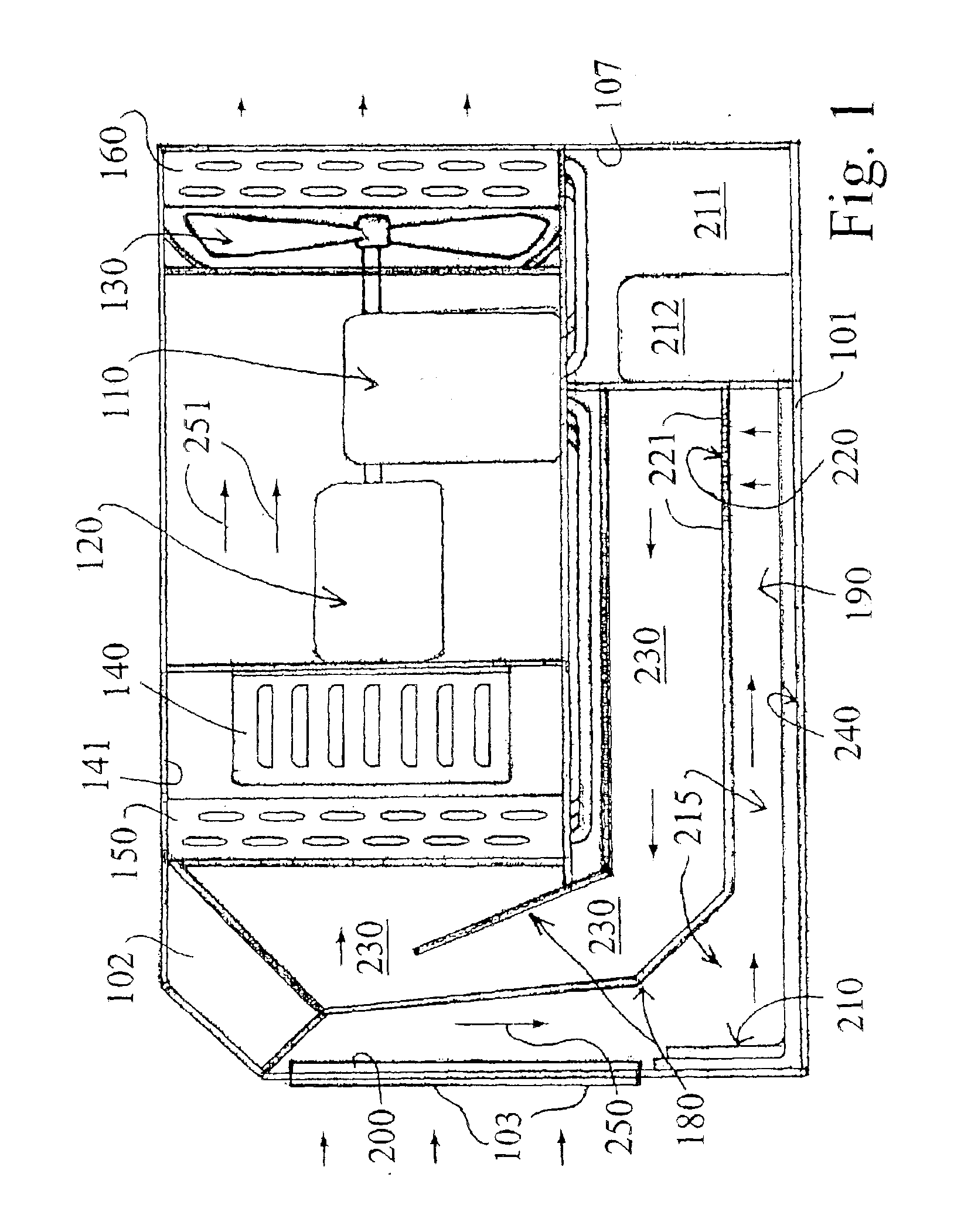

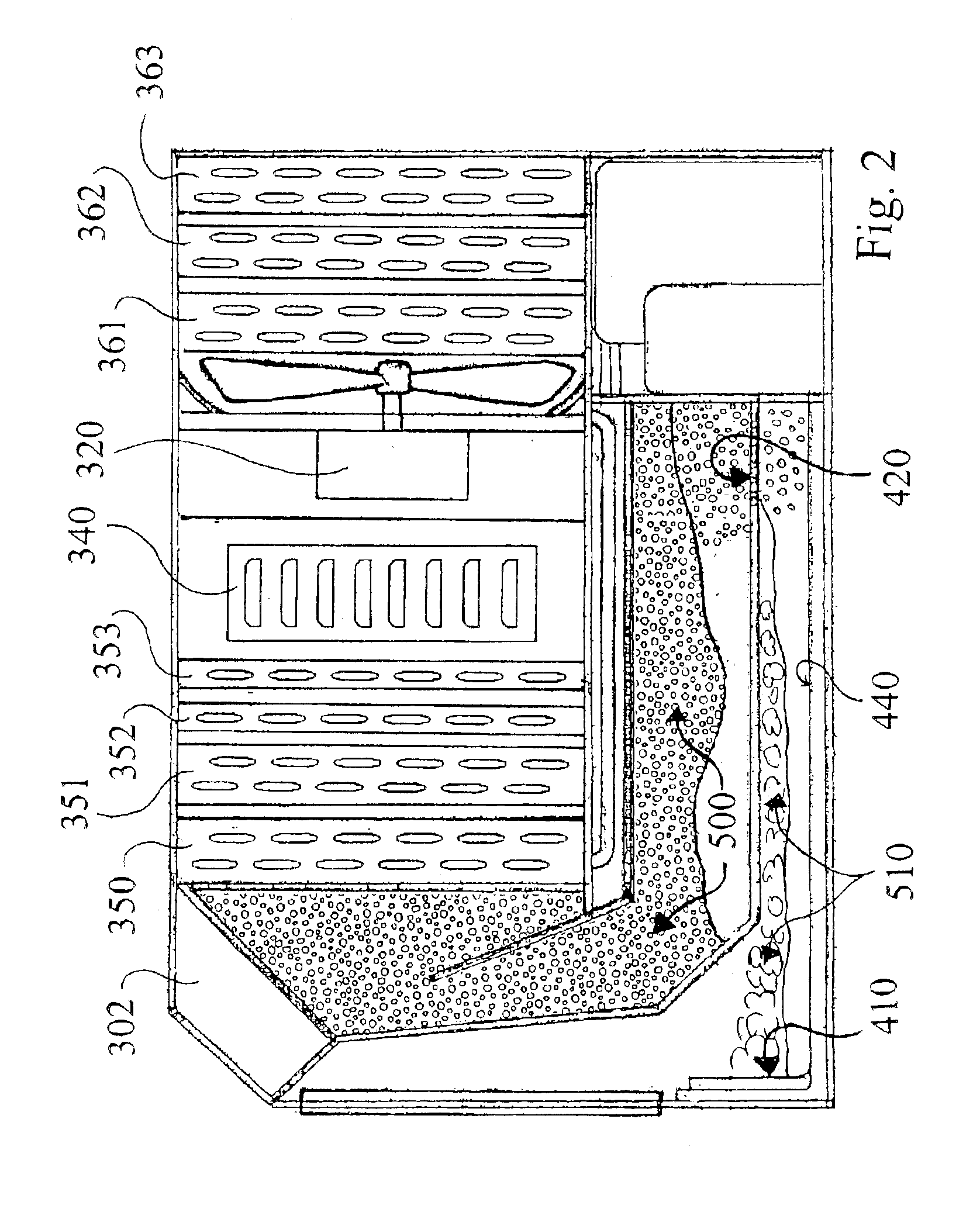

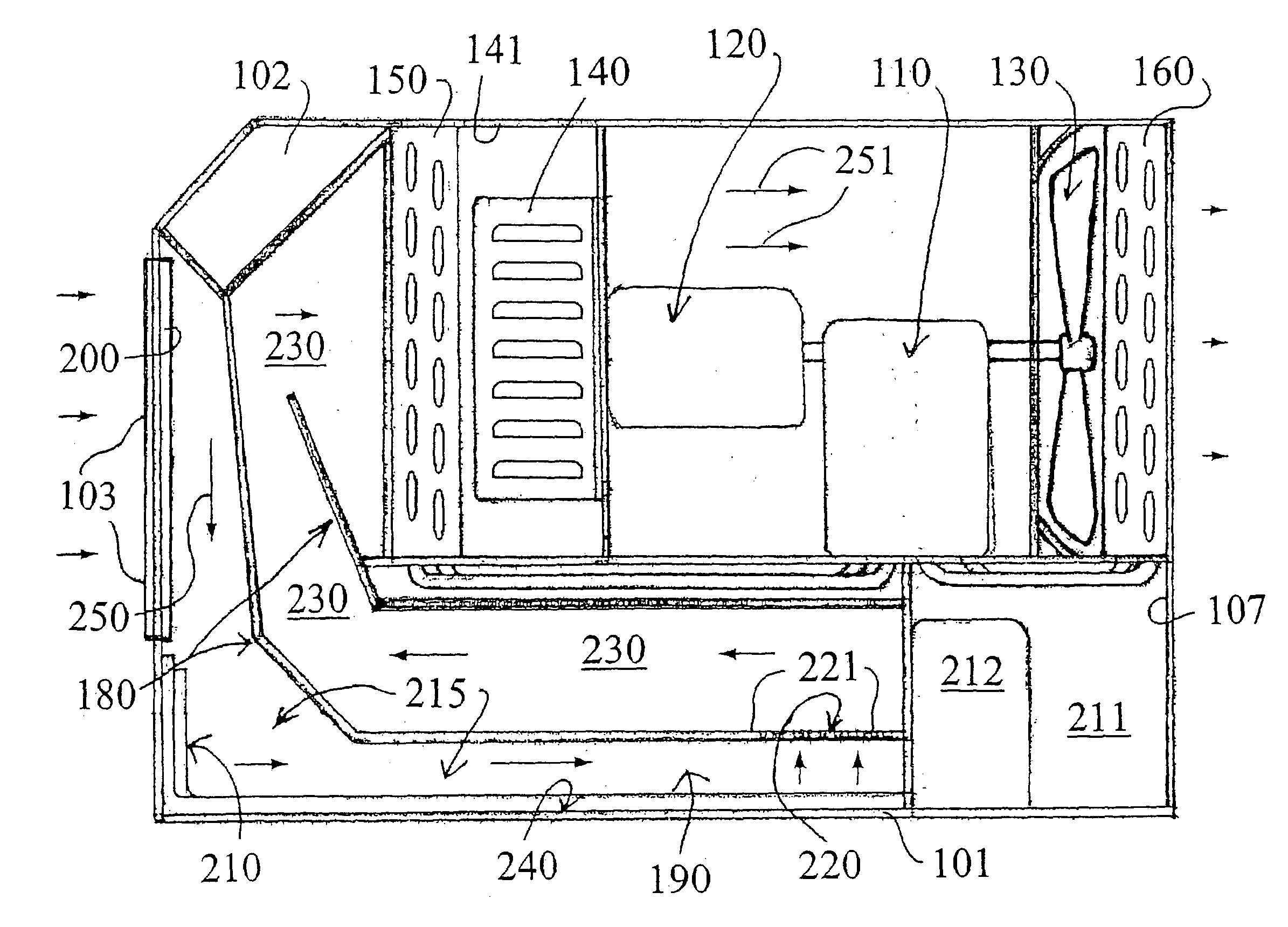

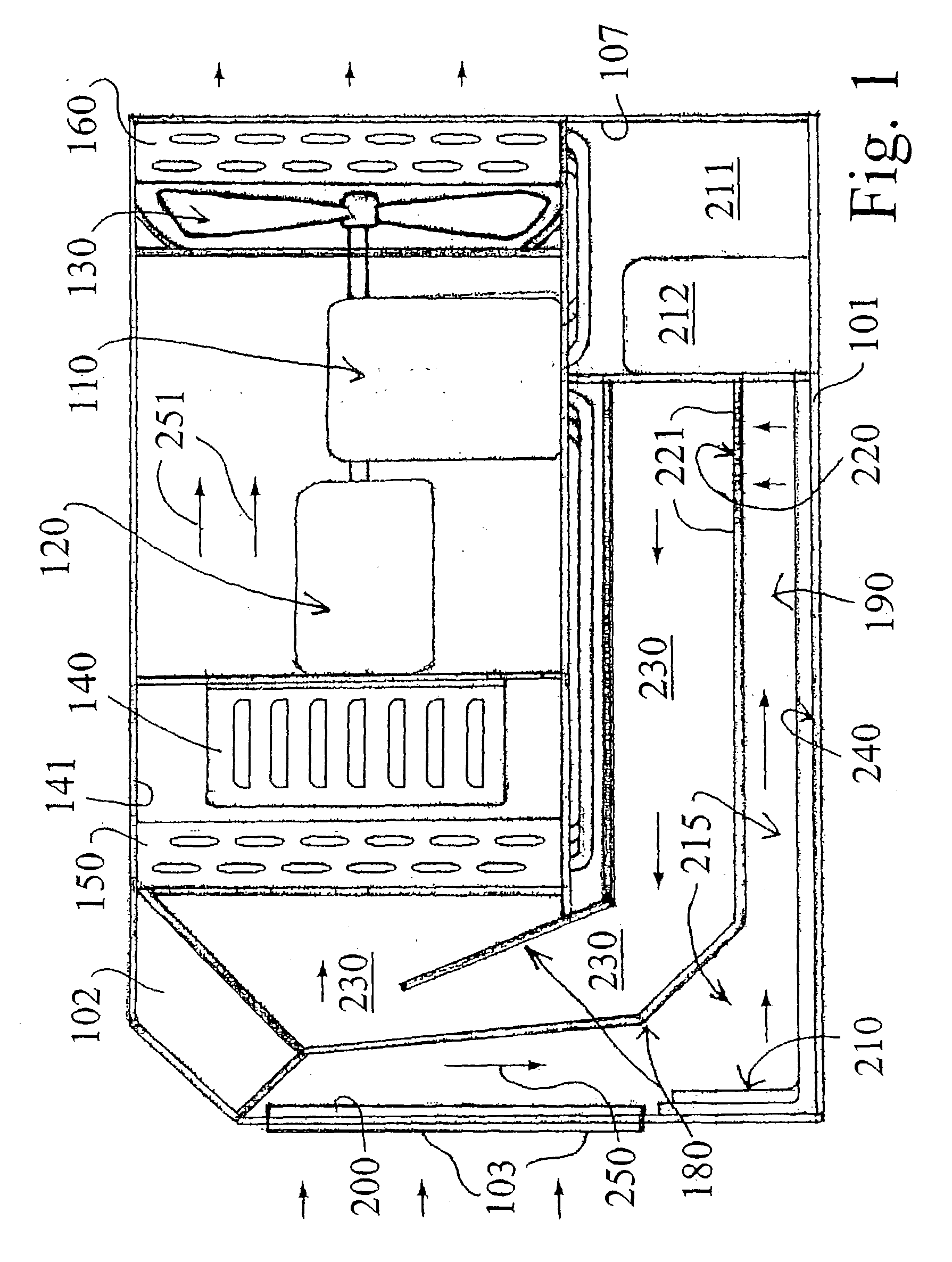

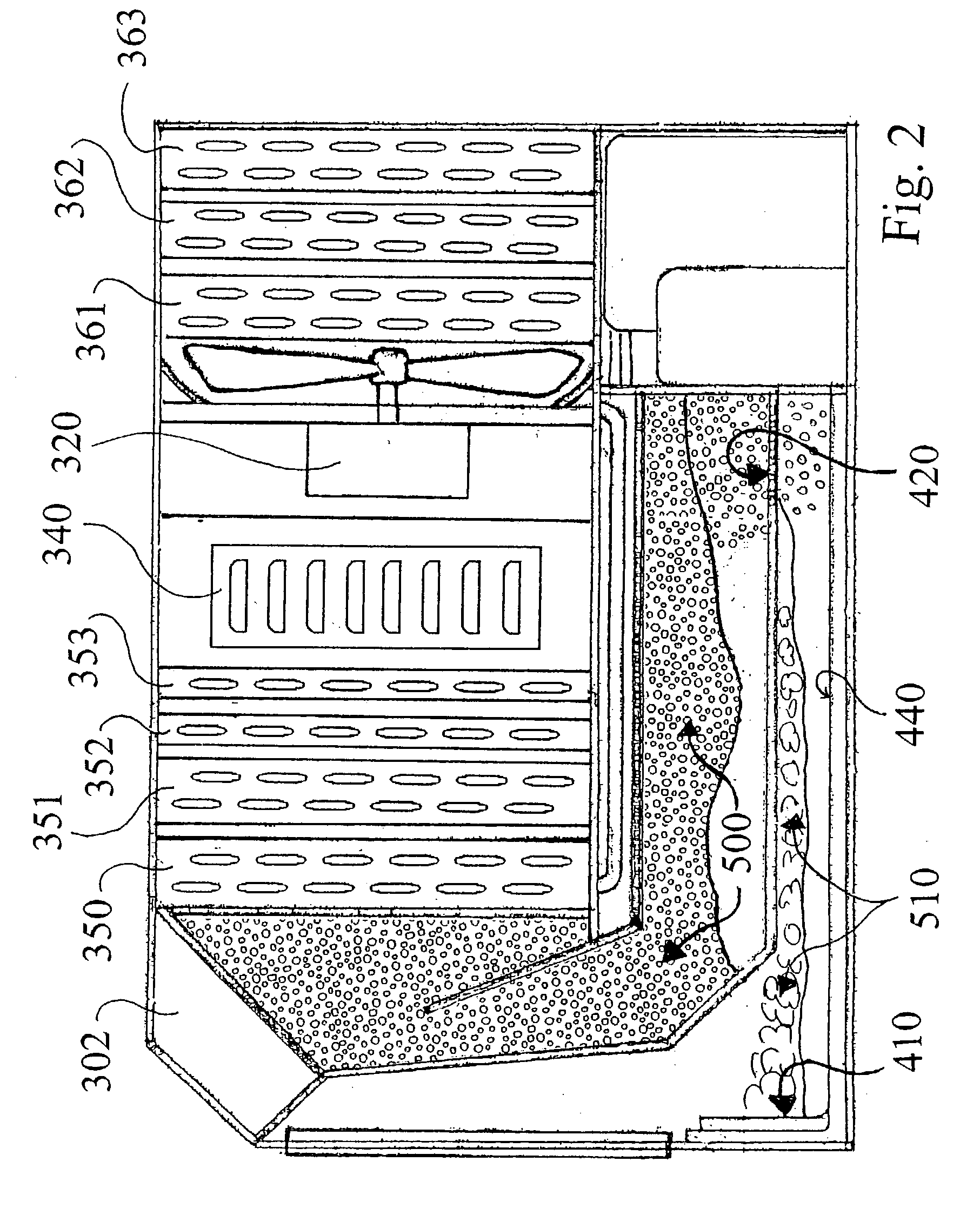

Method and apparatus for filtering an air stream using an aqueous-froth together with nucleation

InactiveUS6872240B2Efficient removalImprove filtering effectCombination devicesLiquid degasificationEngineeringAlternative methods

A method for urging contact between contaminants in an air stream and the wet surfaces of an aqueous-froth, and additional means of limiting the froth to a predetermined volume are provided. A wide spectrum of solution micro-droplet sizes (0.001 to 1000 micron) is introduced into a contaminated air stream. Micro-droplets suspended in the air stream remove contaminants by contact, collide and coalesce in the dynamics of the air stream and are removed by inertia. Smaller micro-droplets remain suspended in the air stream. The smallest micro-droplets evaporate, increasing the solution vapor pressure of the air stream. The humidified or saturated, contaminated air stream continuously expands the surface area of the solution reservoir exponentially into an aqueous froth of tiny bubbles. Airflow velocity drops in the micro-atmosphere inside each bubble of the froth. Contaminants and solution micro-droplets suspended in the air, inside the bubbles, settle out by the acceleration of gravity into the wet surfaces inside of each bubble. The froth is dewatered by condensation of the bubble walls, solution vapor, and micro-droplets, with trapped contaminants, onto the cold air, adjacent cold surfaces, and cold refrigerant coils. The liquid solution and contaminants drain from the refrigerant coils into the solution reservoir. Solution micro-droplets remaining in the air stream are drawn through a centrifugal blower / droplet separator and are thrown onto the blower housing to drain back into the solution reservoir. The air stream is passed through condensing refrigerant coils to reheat the air stream and reduce relative humidity. Variations including scaling, alternative methods of fogging, and additional applications are described.

Owner:IND CLIMATE SOLUTIONS INC

Diffusive plasma air treatment and material processing

InactiveUS20080056934A1Improve efficiencyMinimizationMechanical apparatusLighting and heating apparatusCatalytic functionEngineering

The Diffusive Plasma is for effective treatment of contaminated air and material processing. Air is purified and disinfected by passing through the diffusive plasma device which includes a reactor or a plurality of reactors arranged in parallel or series and is energized by a high voltage alternating current power supply. The diffuser, being electrically isolated, provides extra nucleation sites to initiate discharges. It serves to improve the generation of uniform and consistent plasma and to reduce the variation of discharge properties among the reactors. The addition of a diffuser, thereby, enhances the overall effectiveness of decomposing chemicals and destroying microbes to achieve high air treatment and material processing performance. The diffuser can be made of suitable filtering materials to additionally serve as a filter. By incorporating suitable catalytic materials with the diffuser, the reactor becomes a catalytic plasma reactor wherein the plasma environment provides enhanced catalytic functions. Effective plasma power deposition may be obtained by controlling the amplitude, waveform period and shape of the voltage applied to the electrodes of the reactor and hence the operation of the reactors with plasma discharged of selected conditions for optimizing the treatment and processing efficiency while minimizing the generation of unwanted bi-product gases. The present invention also relates to a method for effective air treatment and material processing.

Owner:ALPHATECH INT

Exhaust fan assembly having flexible coupling

An exhaust assembly is provided for expelling contaminated air from a building. The assembly includes a plenum, a fan assembly attached to the plenum, and a windband mounted on top of the fan assembly. The fan assembly is constructed of cylindrical outer and inner walls which define a drive chamber and surrounding annular space. A fan driven by a motor whose shaft extends downward from the drive chamber draws exhaust air from the plenum and blows it up through the annular space to a nozzle at the top of the fan assembly. The motor is pivotally mounted inside the assembly to provide access to the motor components when it is desired to perform inspection and maintenance.

Owner:GREENHECK FAN

Suction device and suction method for the disposal of dust in milling machines

InactiveUS7175364B2Lower requirementImprove efficiencyIn situ pavingsRoads maintainenceEngineeringMechanical engineering

Disclosed is an automotive milling machine for machining ground surfaces, comprising an engine frame (2), a movable milling drum (8) which is mounted on the engine frame (2), at least one conveying device (14, 18) which is arranged on the engine frame (2) and takes over the milled material (3) from the milling drum (8) at a transfer location (5), and a device (20) sucking off the air that is polluted with dust and fumes. The milled material (3) is enclosed by a duct (16, 16a, 16b) on the at least one conveying device (14, 18), said duct (16) being separated into two sections (16a, 16b). The suction device (20) is connected to the first section (16a) of the duct (16) downstream from the first transfer location (5) and sucks off the air that has been polluted during milling at the milling drum (8) as well as inside the first section (16a) of the duct (16) essentially in the direction in which the material is conveyed.

Owner:WIRTGEN GMBH

Method and apparatus for filtering an air stream using an aqueous-froth together with nucleation

InactiveUS20040020361A1Increase air volumeReduce humidityCombination devicesLiquid degasificationEngineeringAlternative methods

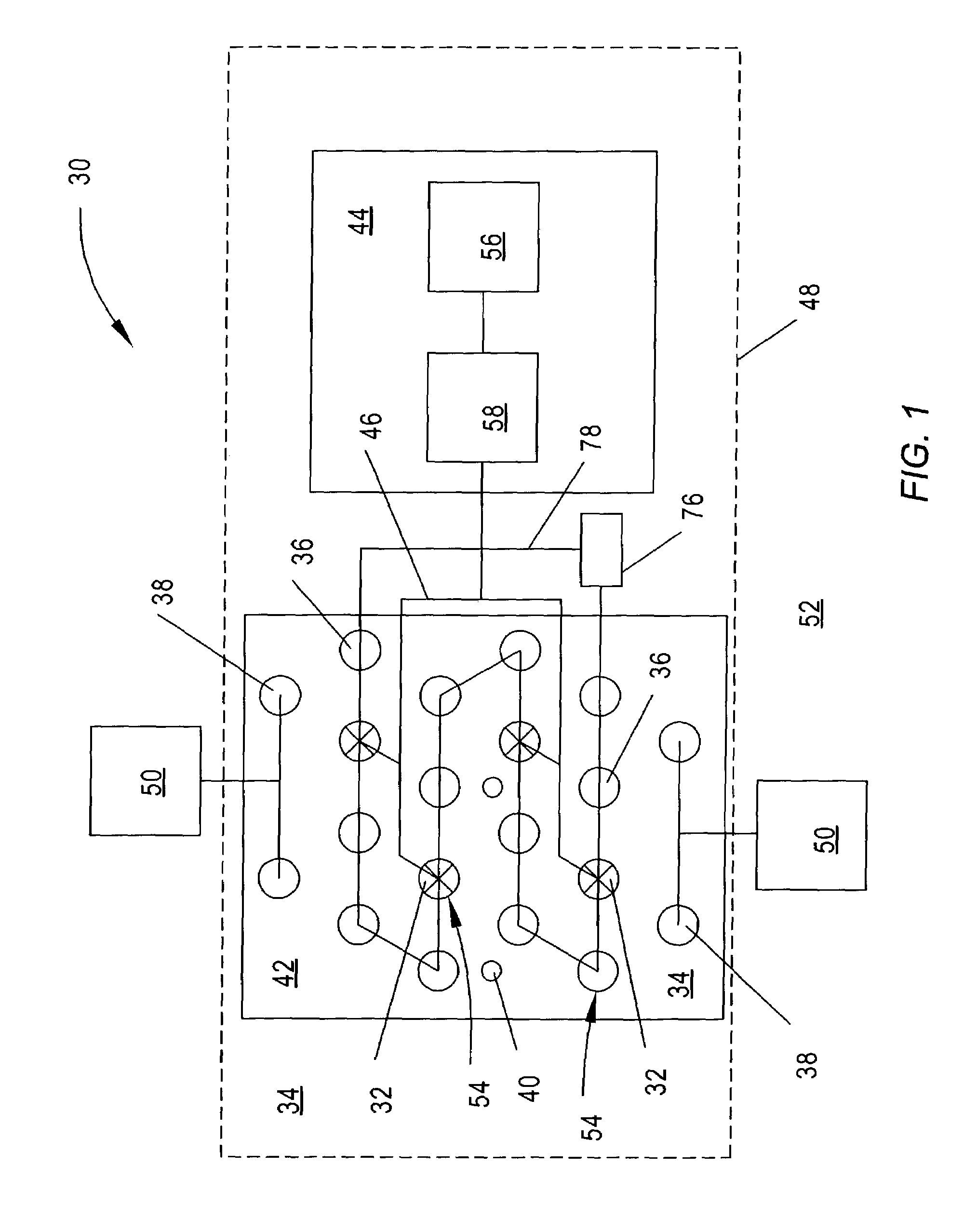

A method for urging contact between contaminants in an air stream and the wet surfaces of an aqueous-froth, and additional means of limiting the froth to a predetermined volume are provided. A wide spectrum of solution micro-droplet sizes (0.001 to 1000 micron) is introduced into a contaminated air stream. Micro-droplets suspended in the air stream remove contaminants by contact, collide and coalesce in the dynamics of the air stream and are removed by inertia. Smaller micro-droplets remain suspended in the air stream. The smallest micro-droplets evaporate, increasing the solution vapor pressure of the air stream. The humidified or saturated, contaminated air stream continuously expands the surface area of the solution reservoir exponentially into an aqueous froth of tiny bubbles. Airflow velocity drops in the micro-atmosphere inside each bubble of the froth. Contaminants and solution micro-droplets suspended in the air, inside the bubbles, settle out by the acceleration of gravity into the wet surfaces inside of each bubble. The froth is dewatered by condensation of the bubble walls, solution vapor, and micro-droplets, with trapped contaminants, onto the cold air, adjacent cold surfaces, and cold refrigerant coils. The liquid solution and contaminants drain from the refrigerant coils into the solution reservoir. Solution micro-droplets remaining in the air stream are drawn through a centrifugal blower / droplet separator and are thrown onto the blower housing to drain back into the solution reservoir. The air stream is passed through condensing refrigerant coils to reheat the air stream and reduce relative humidity. Variations including scaling, alternative methods of fogging, and additional applications are described.

Owner:IND CLIMATE SOLUTIONS INC

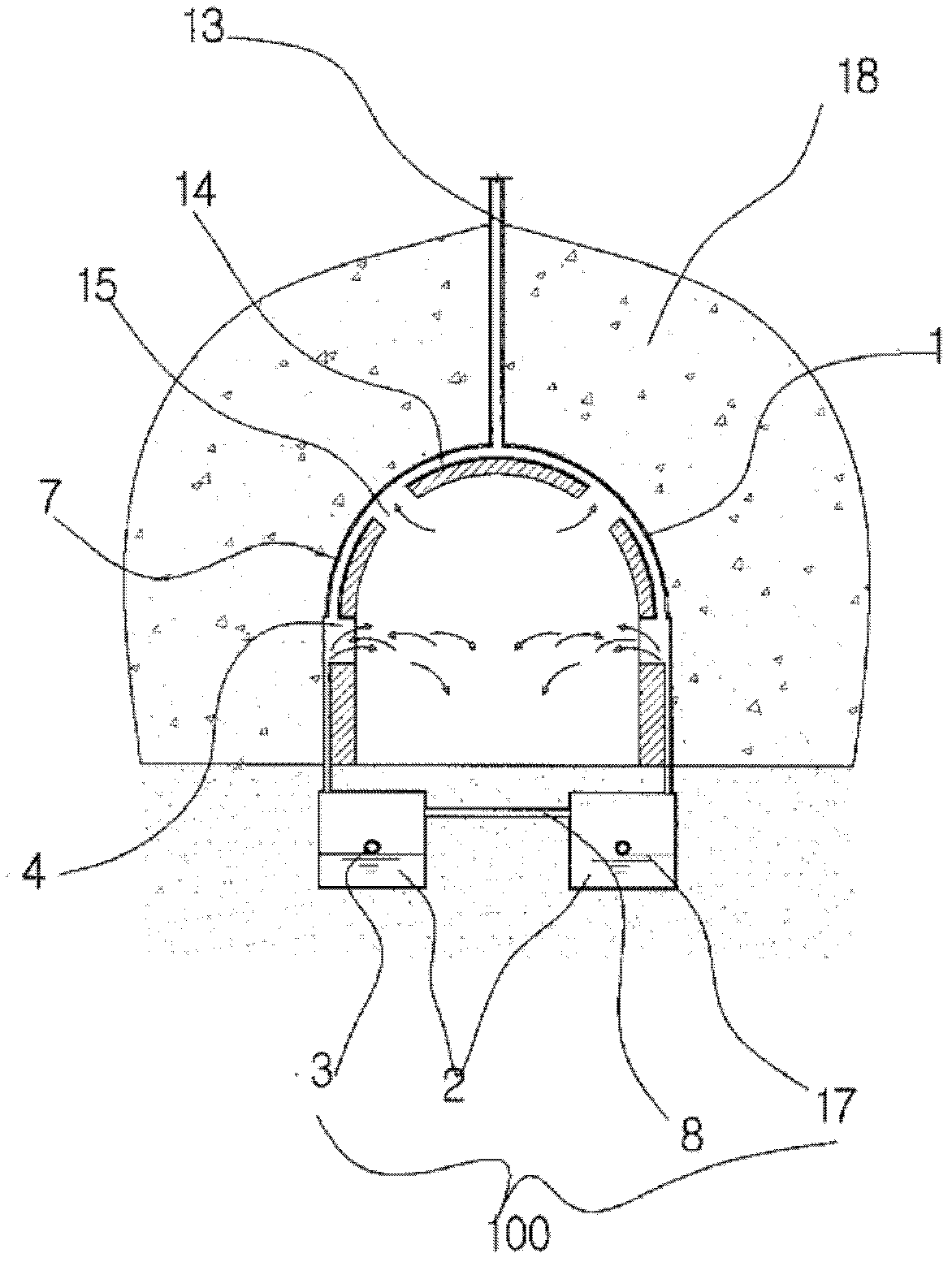

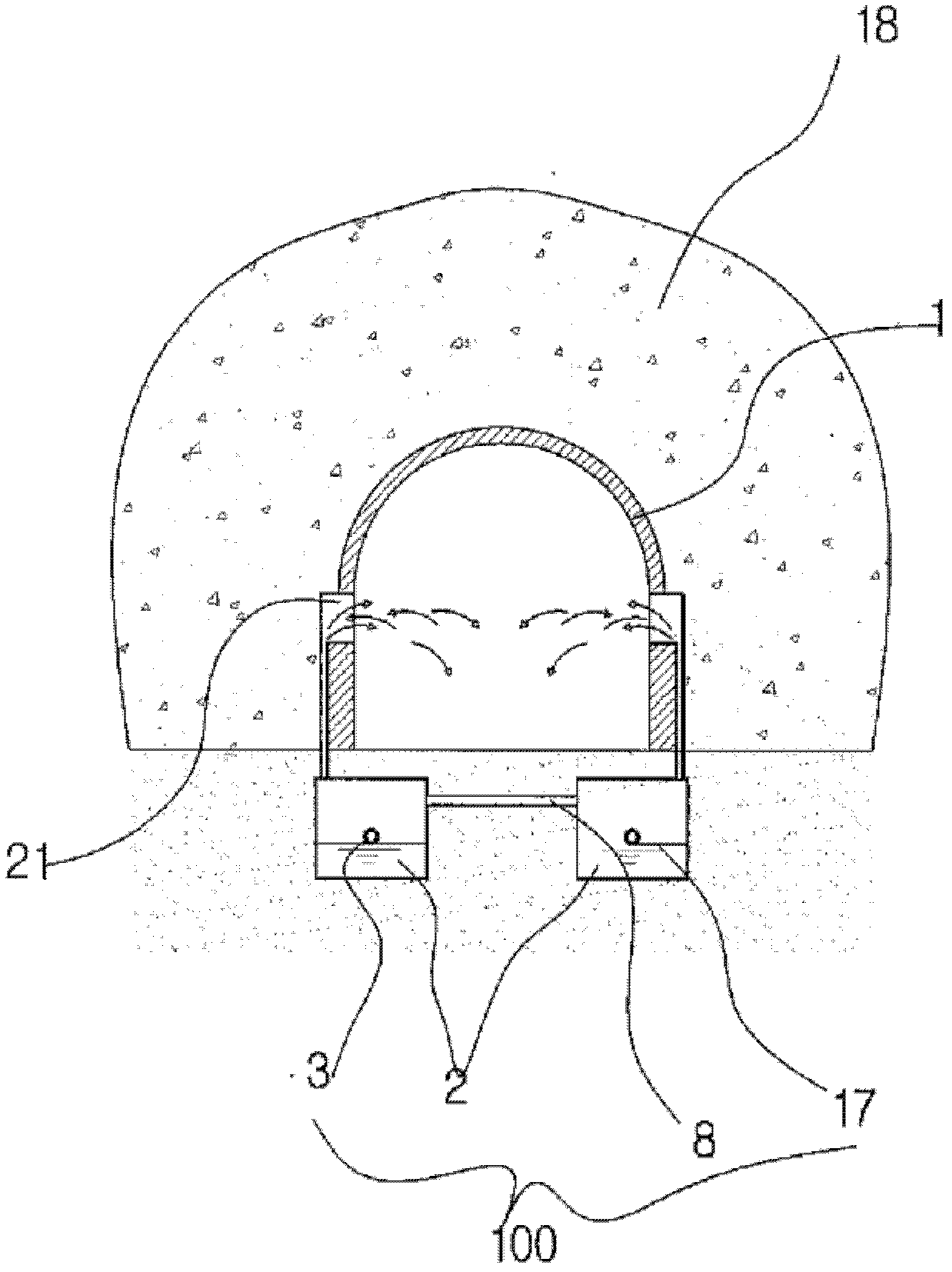

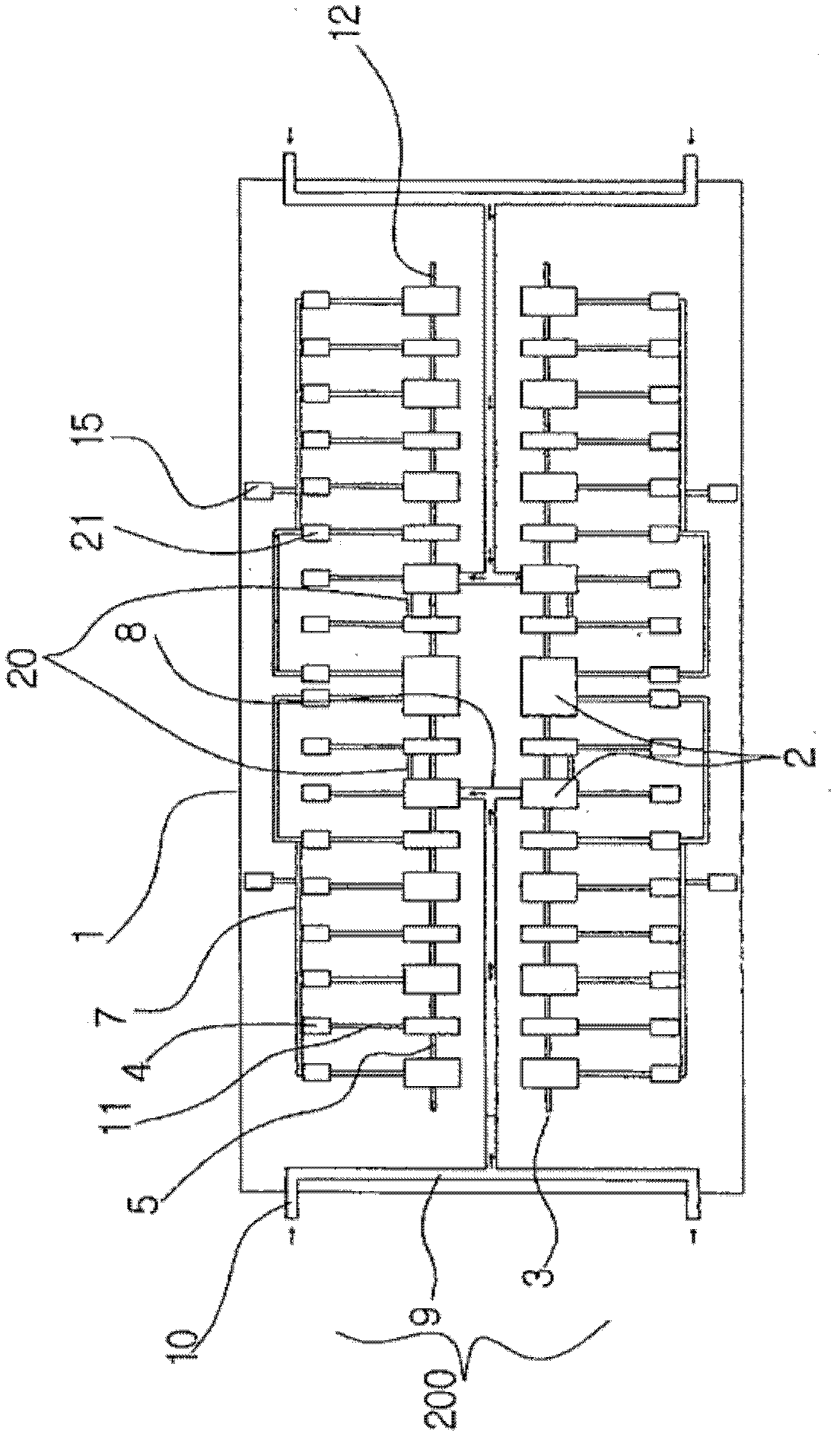

Tunnel air-exchange device using a natural air-exchange method

InactiveCN102482943AComfortable use environmentNo noiseMechanical apparatusLighting and heating apparatusEngineeringVentilation shaft

The present invention relates to a tunnel air-exchange device, and more specifically to one in which: the air inside normal tunnels including tunnels through which vehicles run is cleaned and polluted internal tunnel air is expelled to the outside, to which end cold air, supplied to water tanks of different sizes provided in line at set intervals in the floor inside the tunnel, is used to ensure that the heavy soot and gases in the polluted hot air generated by vehicles, are sucked into the water tanks while the lighter foul air is discharged through chimneys by convection, thereby creating a pleasant tunnel environment by always maintaining clean air inside the tunnel; and which also extinguishes fires by spraying fire-extinguishing water during tunnel fires. Accordingly, the present invention combines a chimney effect with natural convection provided by the water tanks to exchange the air inside the tunnel and naturally expel polluted air, which is in contrast to exhaust fans of the prior art because there is no generation of noise or heat, and expenses can be reduced since there is no electrical consumption.

Owner:李学守

Smart FAIMS sensor

InactiveUS20080017790A1Time-of-flight spectrometersMaterial analysis by electric/magnetic meansUltraviolet lightsInhaled air

There is no mask on the market or registered with the USPTO that uses ultraviolet light to kill air-borne viral and bacterial contaminants. The invention will ensure that if an individual must perforce be exposed to contaminated air as a result of natural or manmade events, then that individual will be able to use the Ultraviolet Light Assisted Protective Breathing Mask (the “ULAP Breathing Mask”) to kill whatever known or unknown viruses or bacteria may be in the vicinity. The ULAP Breathing Mask kills these contaminants before inhaled air ever reaches the filters. The prototype weighs approximately three pounds, and so is easily portable and is practical.

Owner:OWLSTONE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com