Patents

Literature

54 results about "Power deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

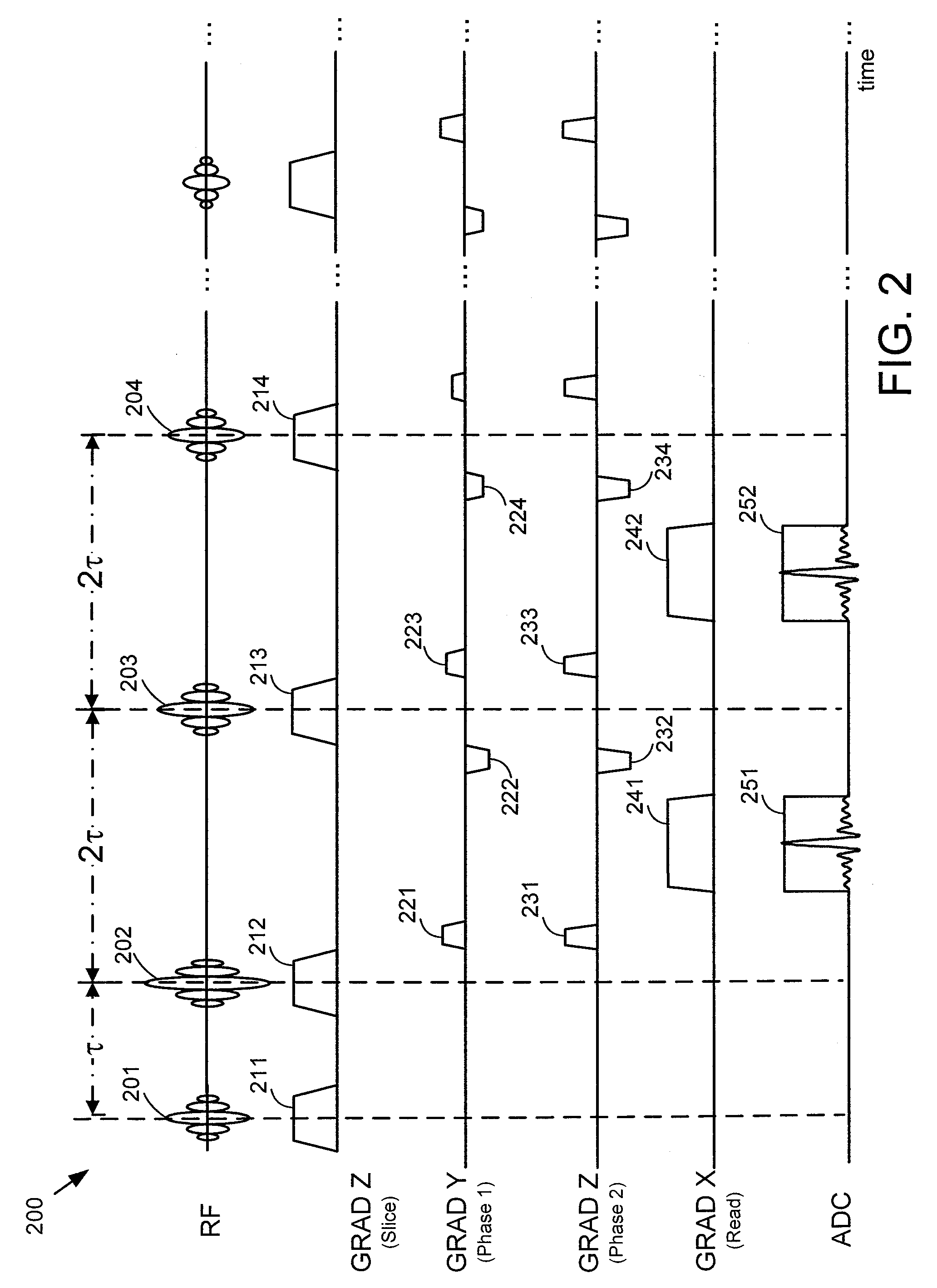

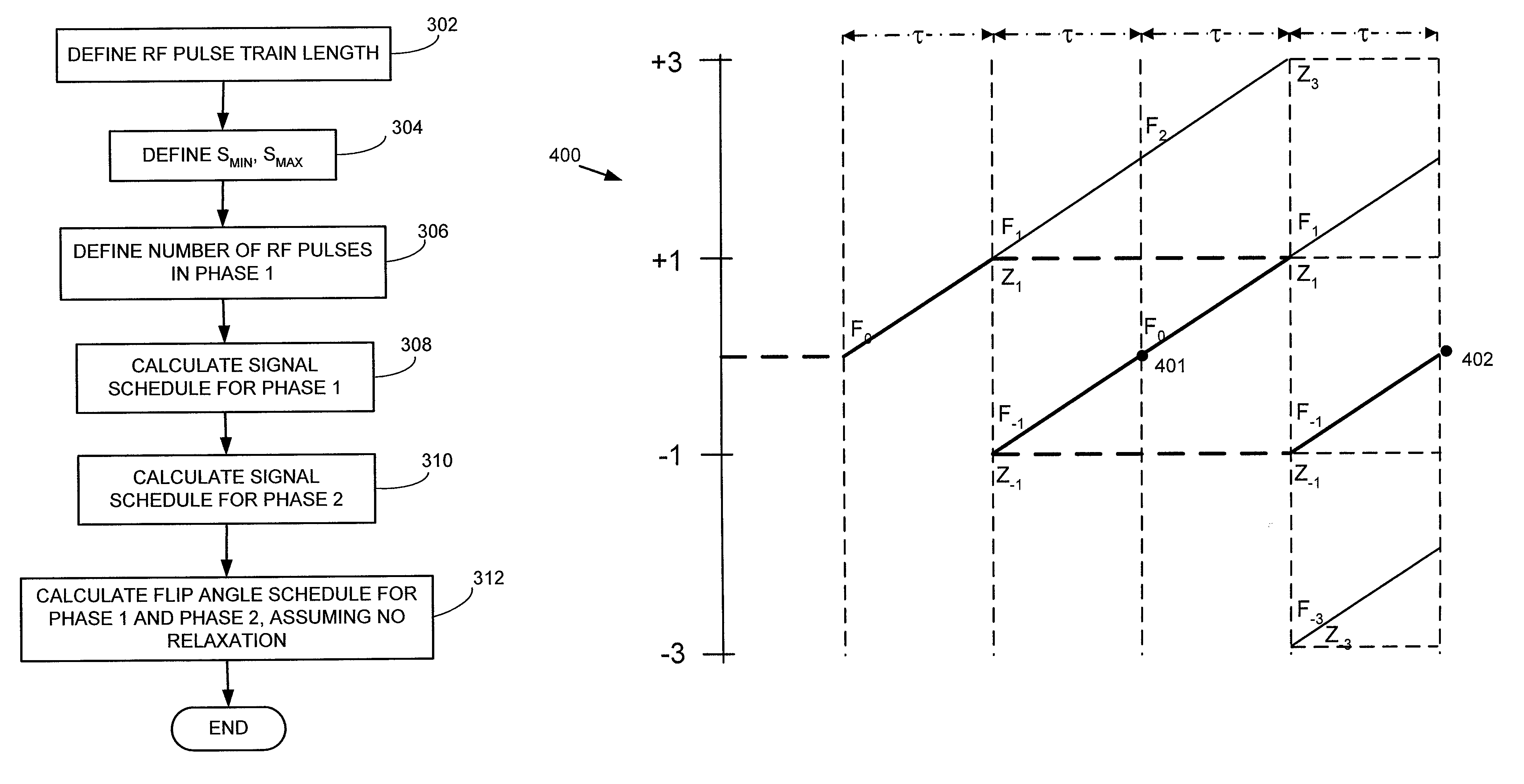

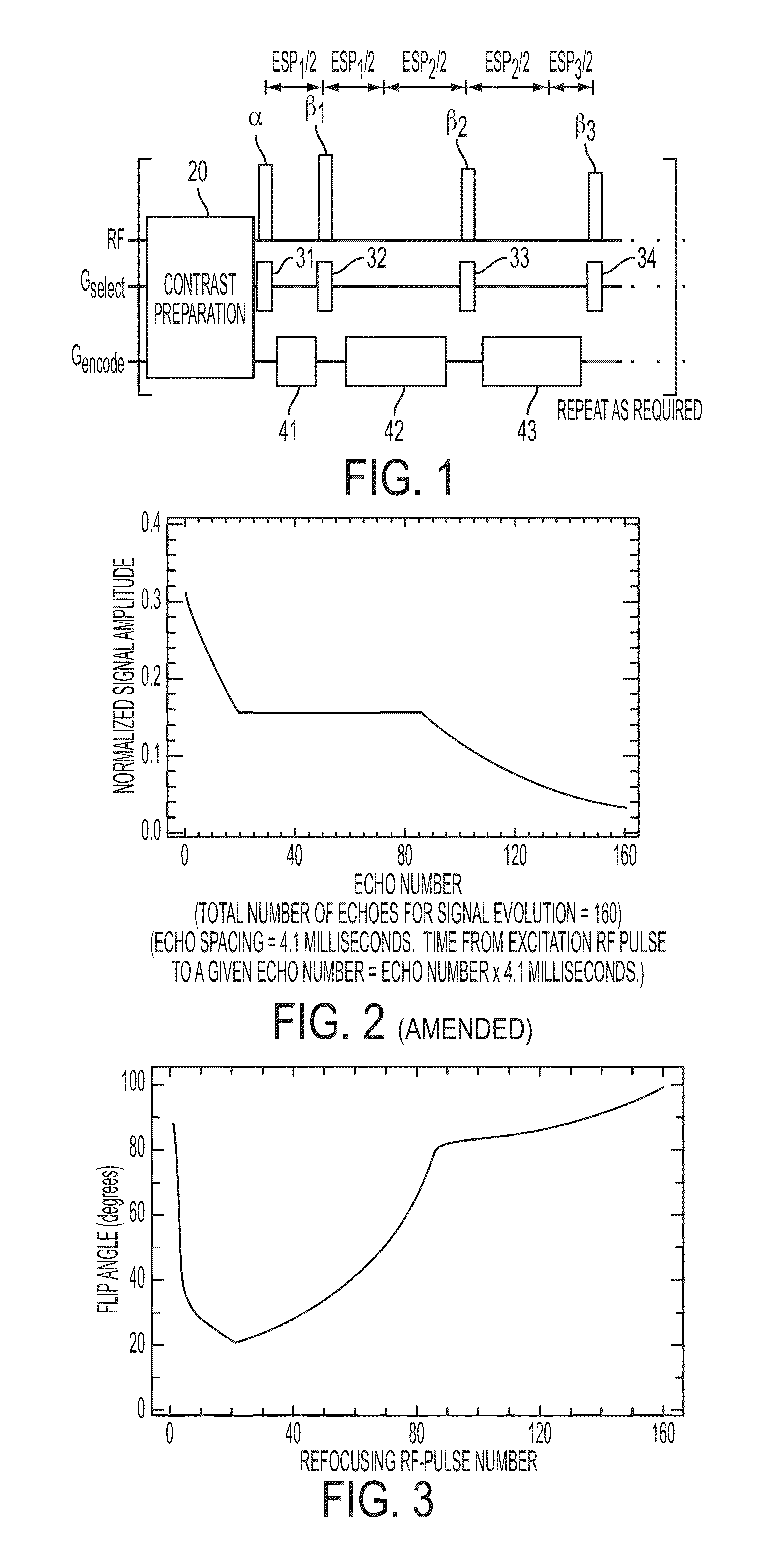

Method and apparatus for generating a flip angle schedule for a spin echo train pulse sequence

ActiveUS20080319301A1Reduced refocusing flip angleMagnetic measurementsDiagnostic recording/measuringTarget signalPulse sequence

Owner:GENERAL ELECTRIC CO

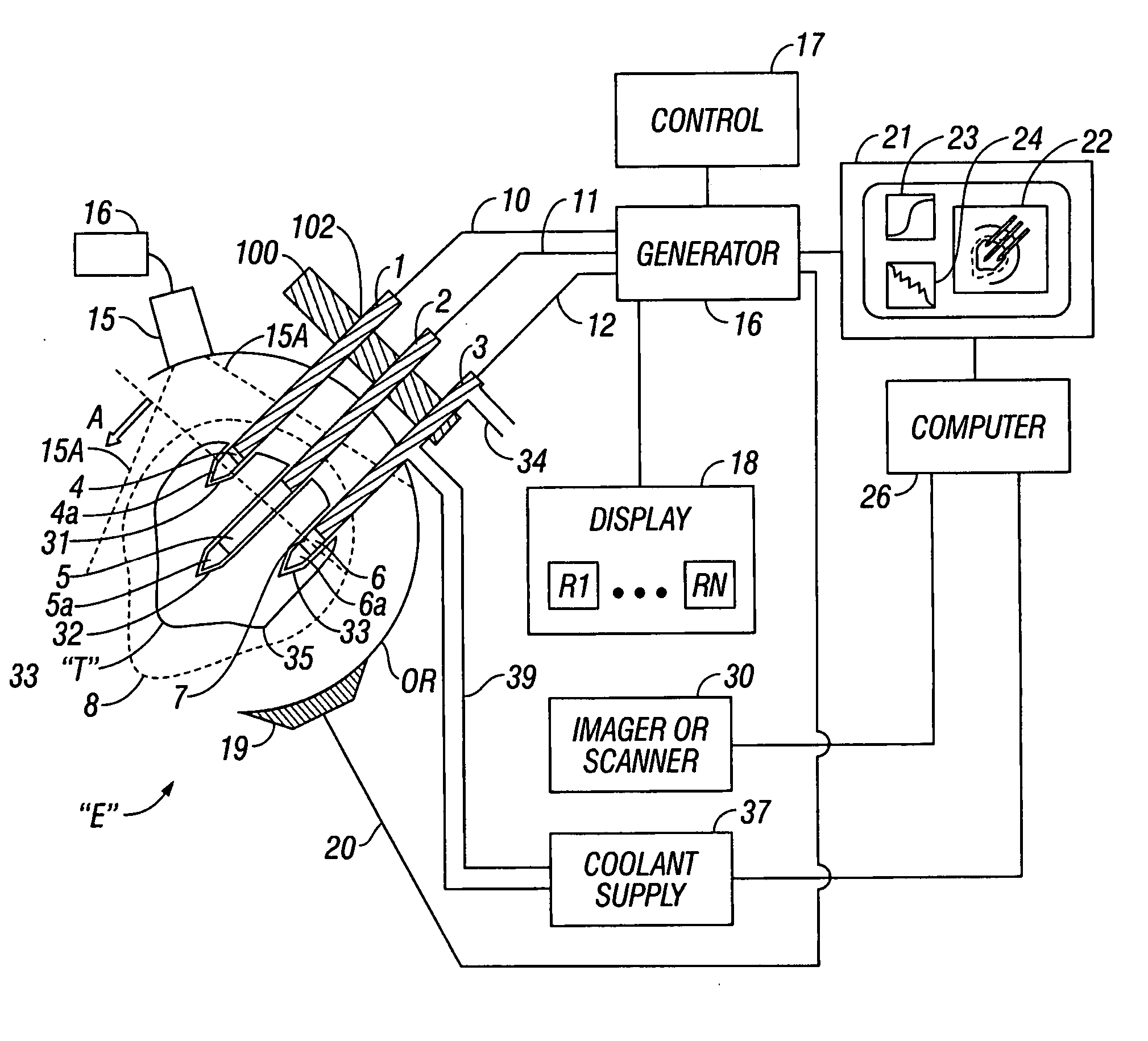

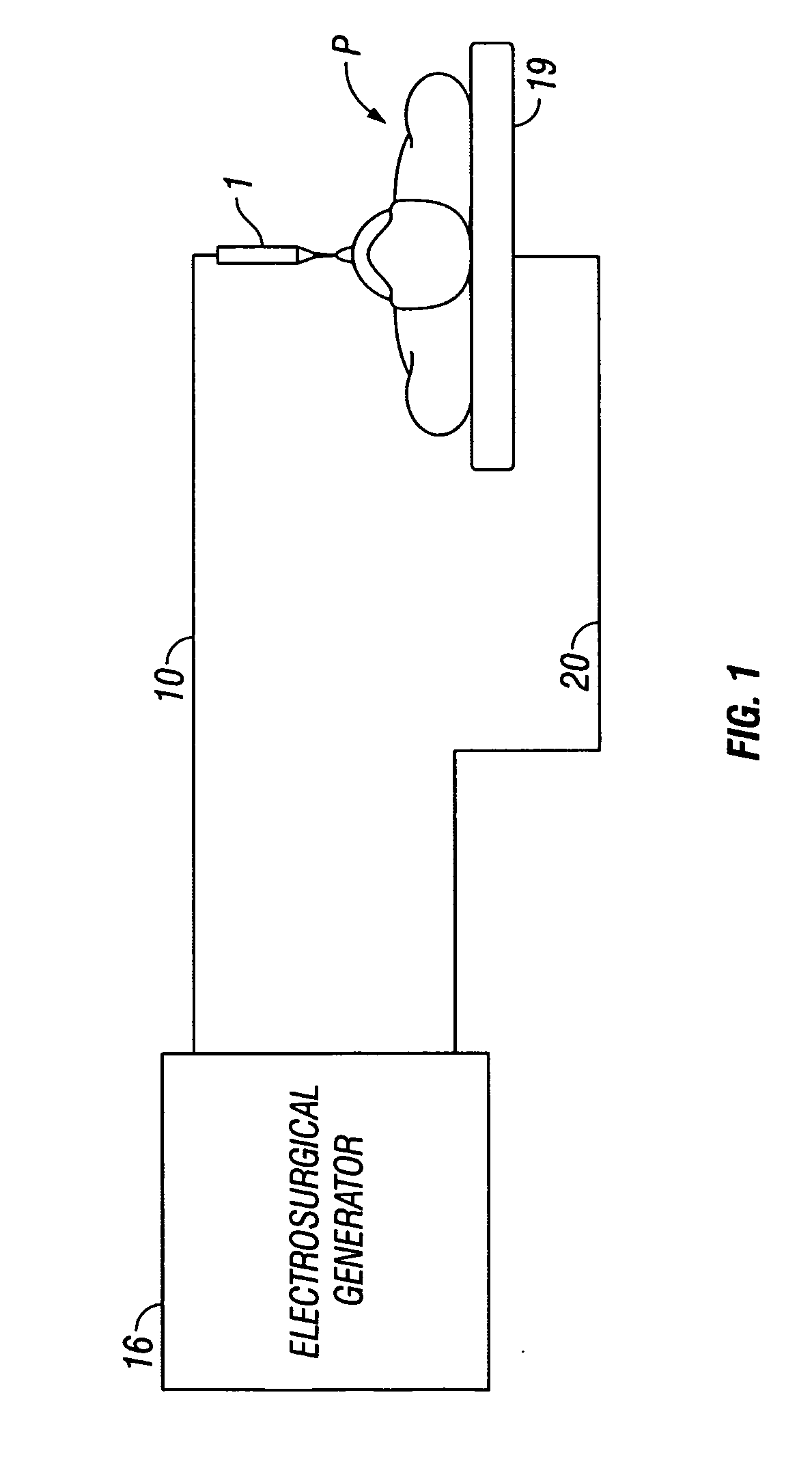

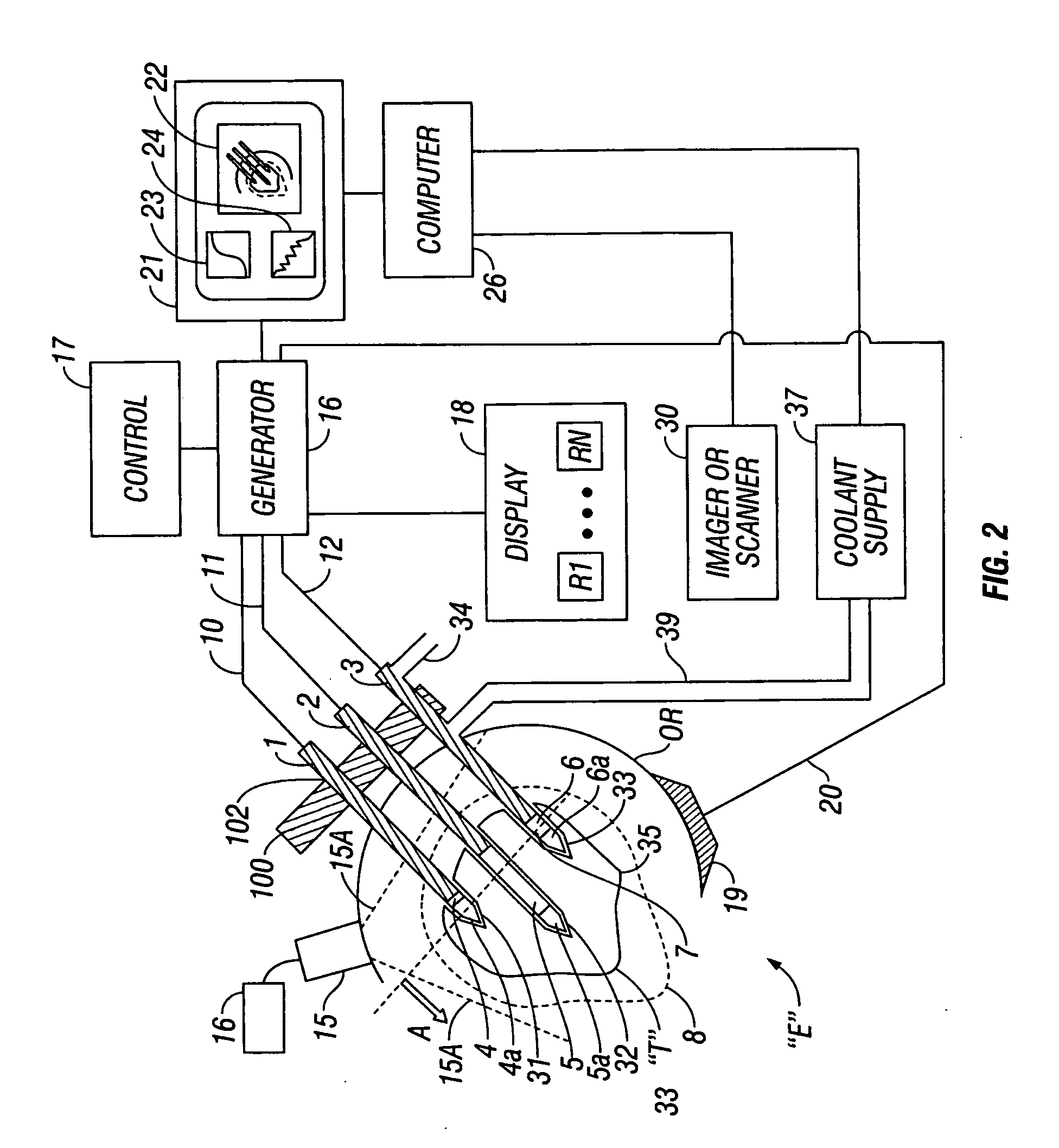

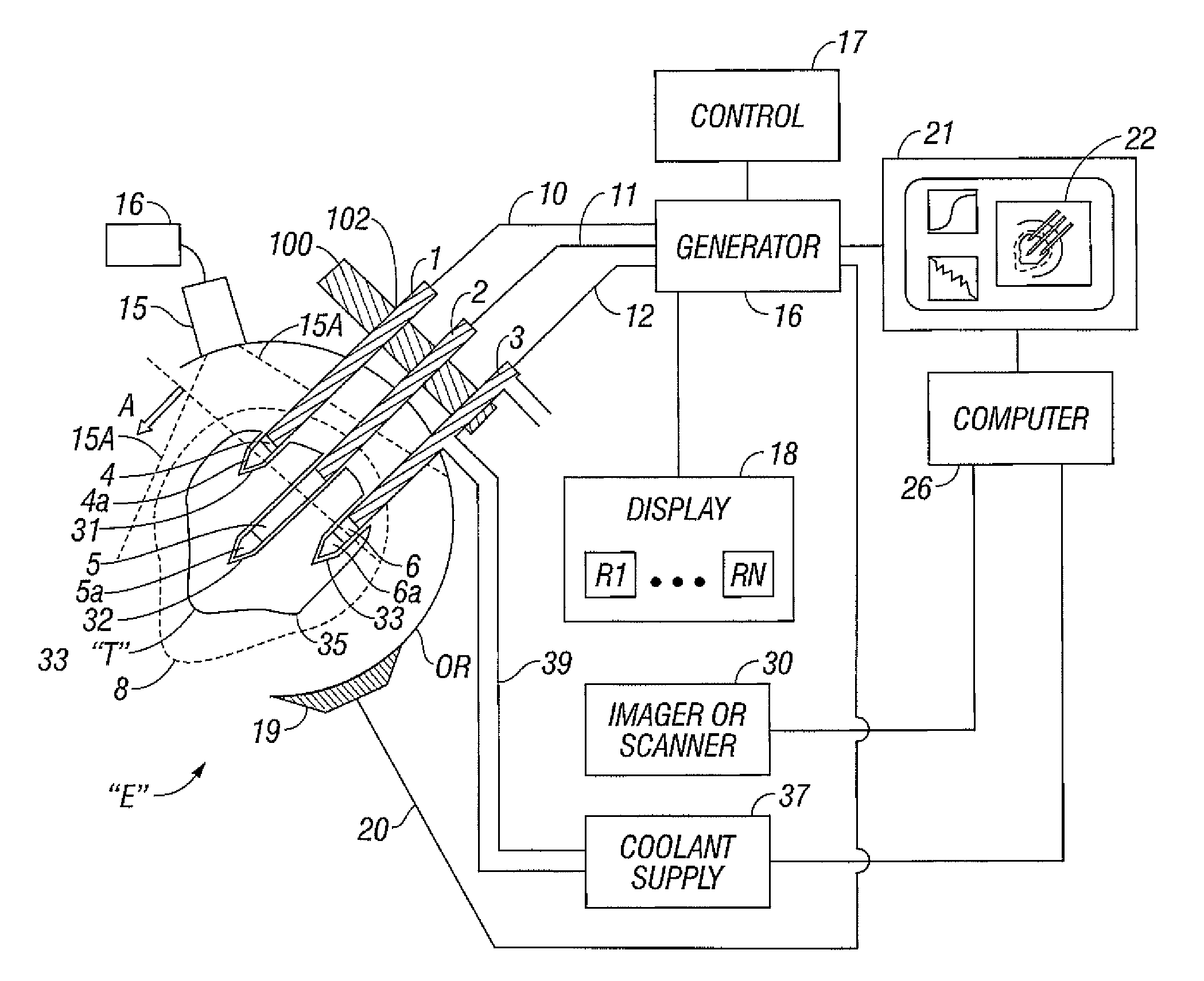

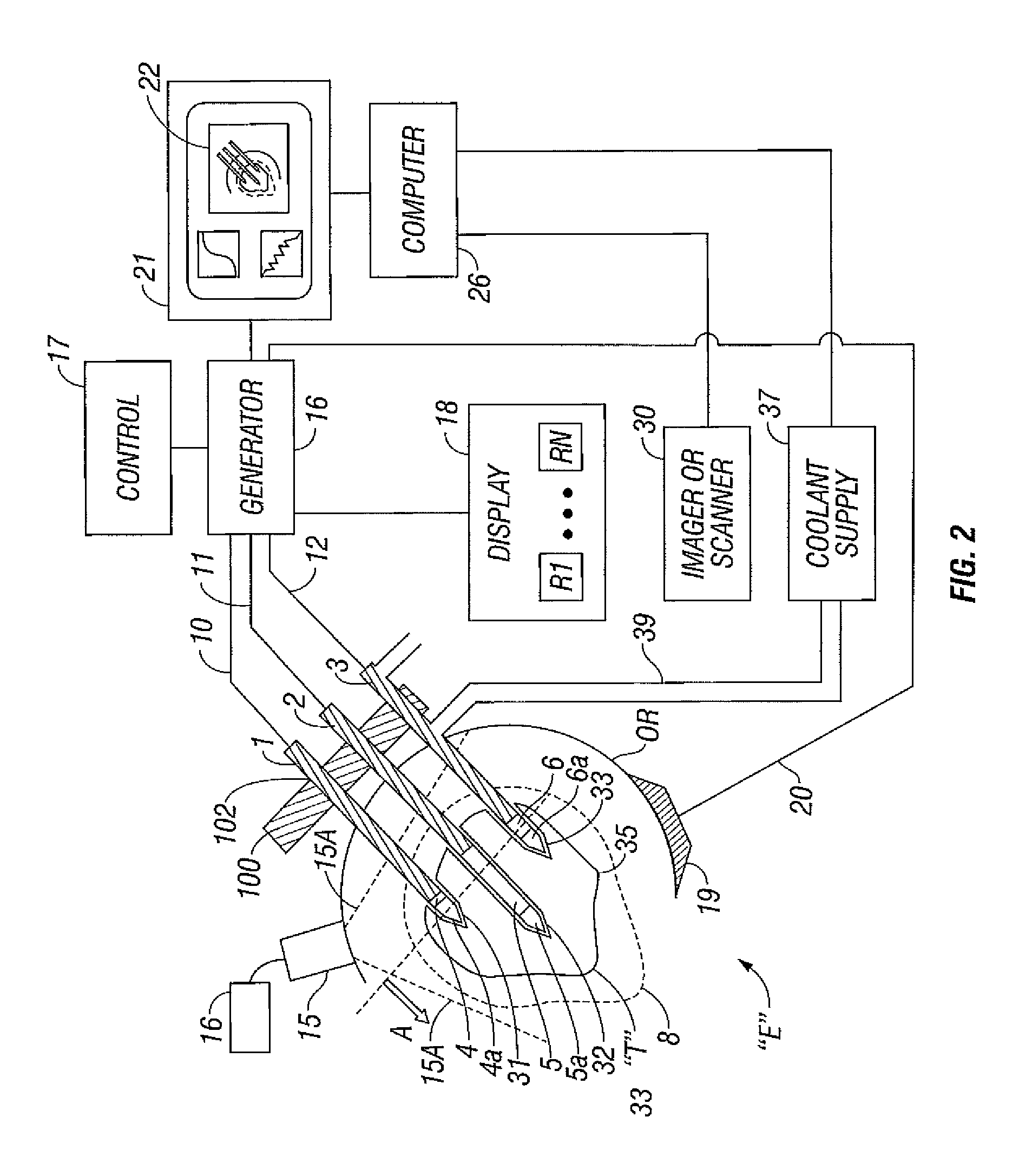

System and method for ablating tissue

ActiveUS20070250054A1Produced in volumeDiagnosticsSurgical needlesElectrical connectionPower deposition

An electrosurgical system and method for performing an electrosurgical procedure are disclosed. The electrosurgical system includes a high frequency generator to supply energy, the generator including one or more electrical connections. The system also includes one or more instruments configured to be inserted into tissue of the patient's body having a hardened tissue volume. The instruments are configured to penetrate the hardened tissue volume to create at one or more orifices defined therein. The instruments are also configured to selectively encapsulate one or more active electrodes that are coupled to the electrical connections. Each of the electrodes has an elongated shaft terminating in an exposed, conductive tip. The electrodes are configured to be inserted into the tissue of the patient's body and into the hardened tissue volume through the orifices to subsequently apply energy from the high frequency generator to the exposed, conductive tip to induce a coherent heating effect in the hardened tissue volume from power deposition therein, thereby producing a heat ablation volume in the hardened tissue volume.

Owner:COVIDIEN AG

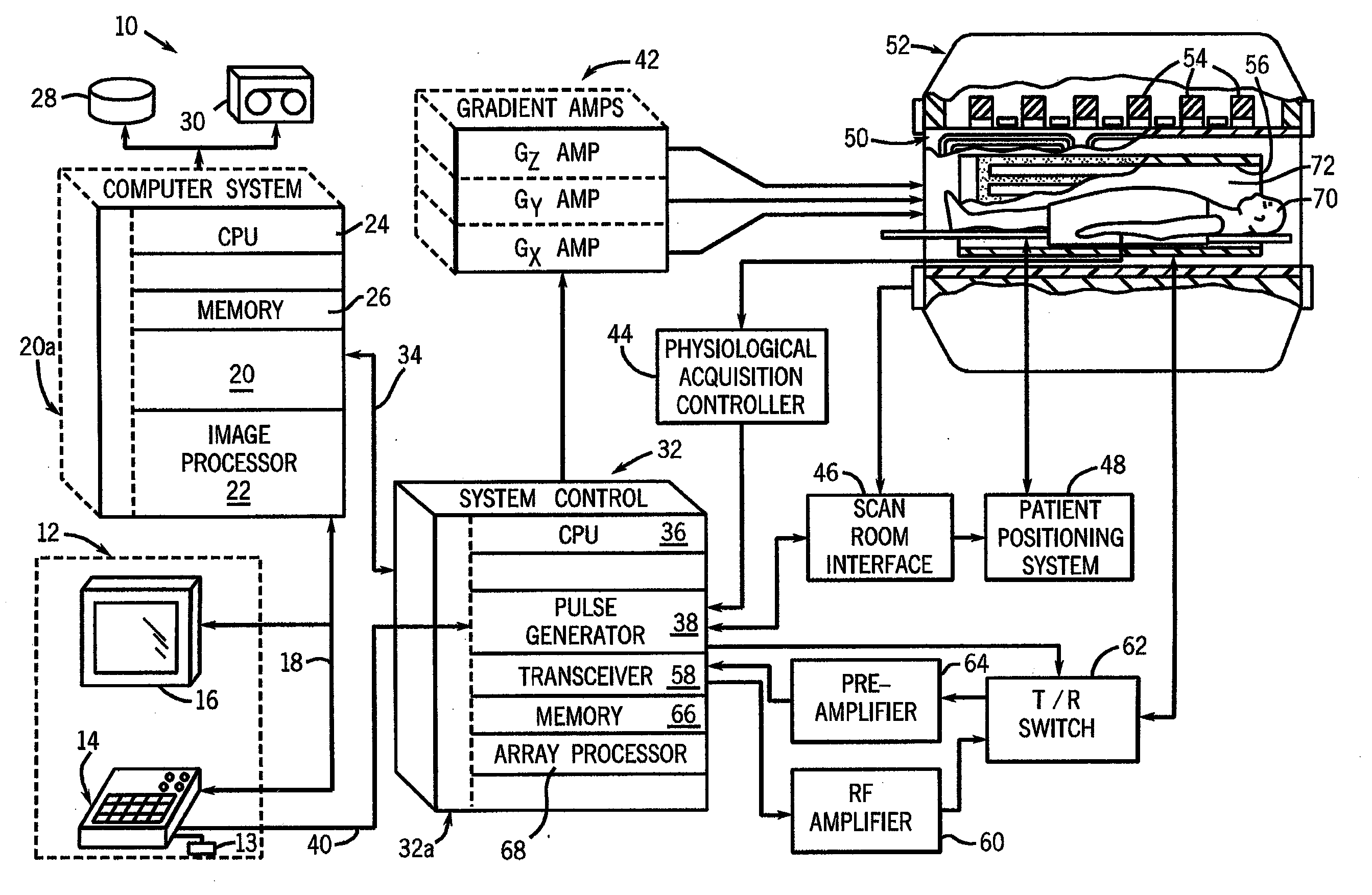

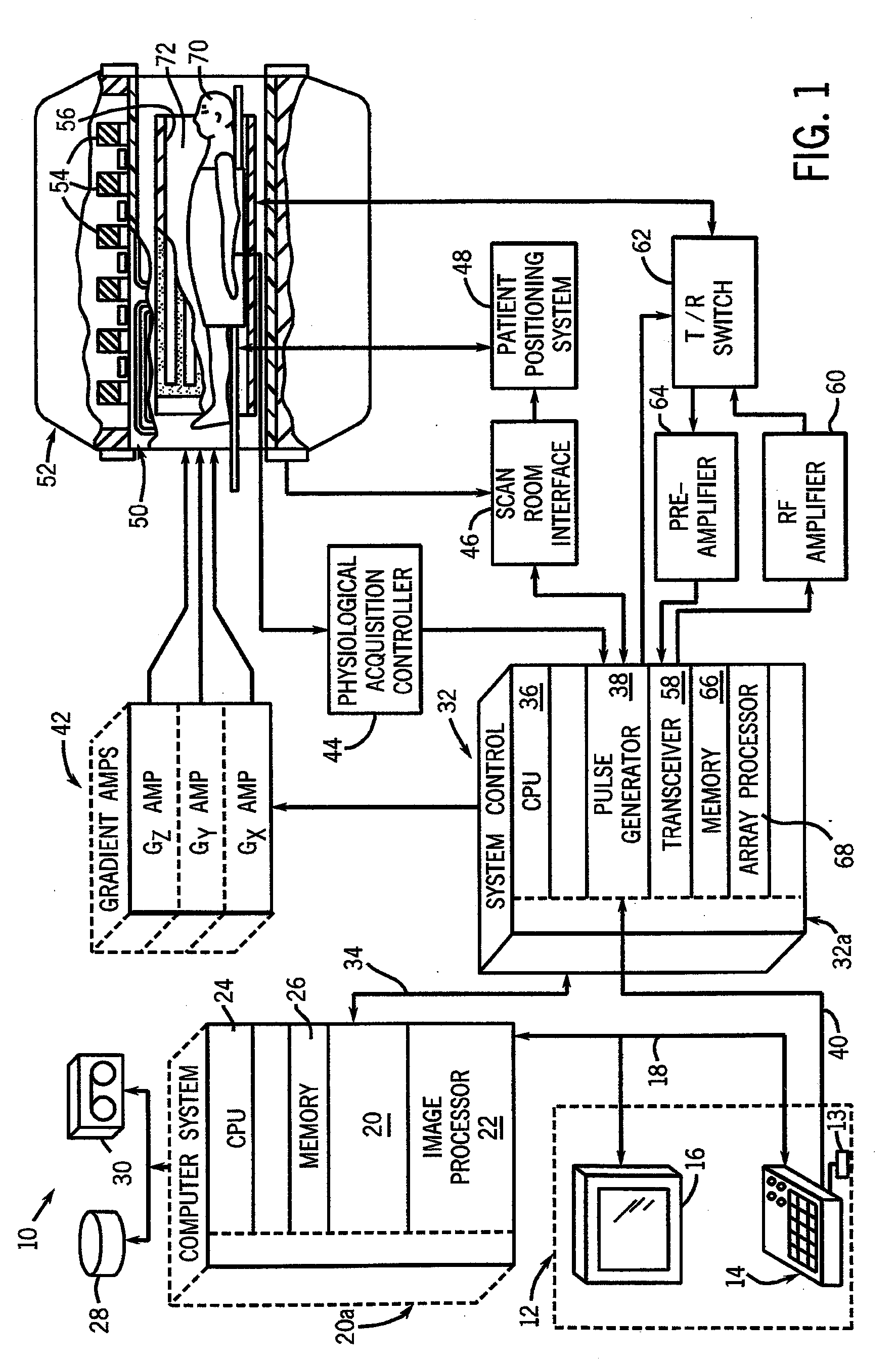

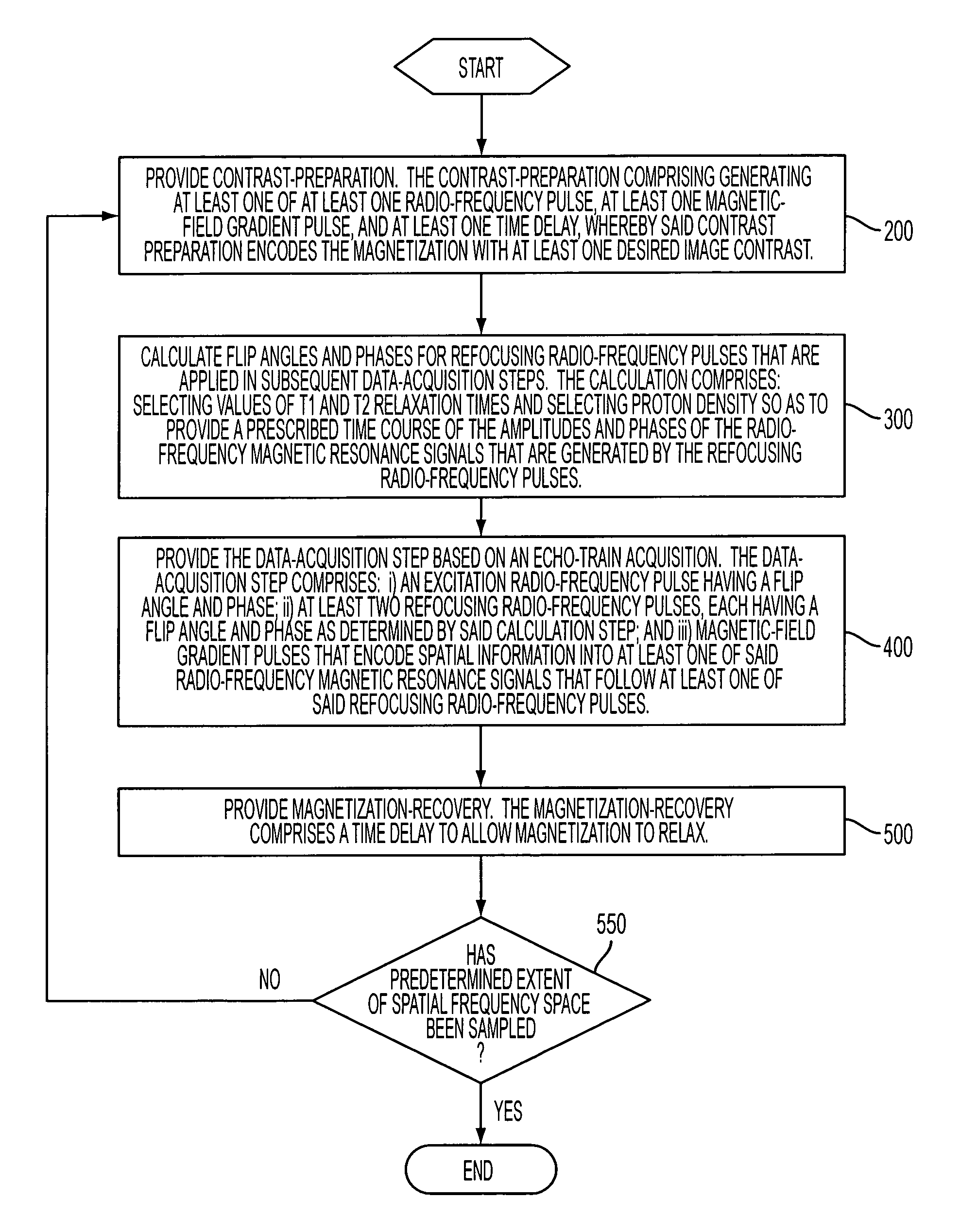

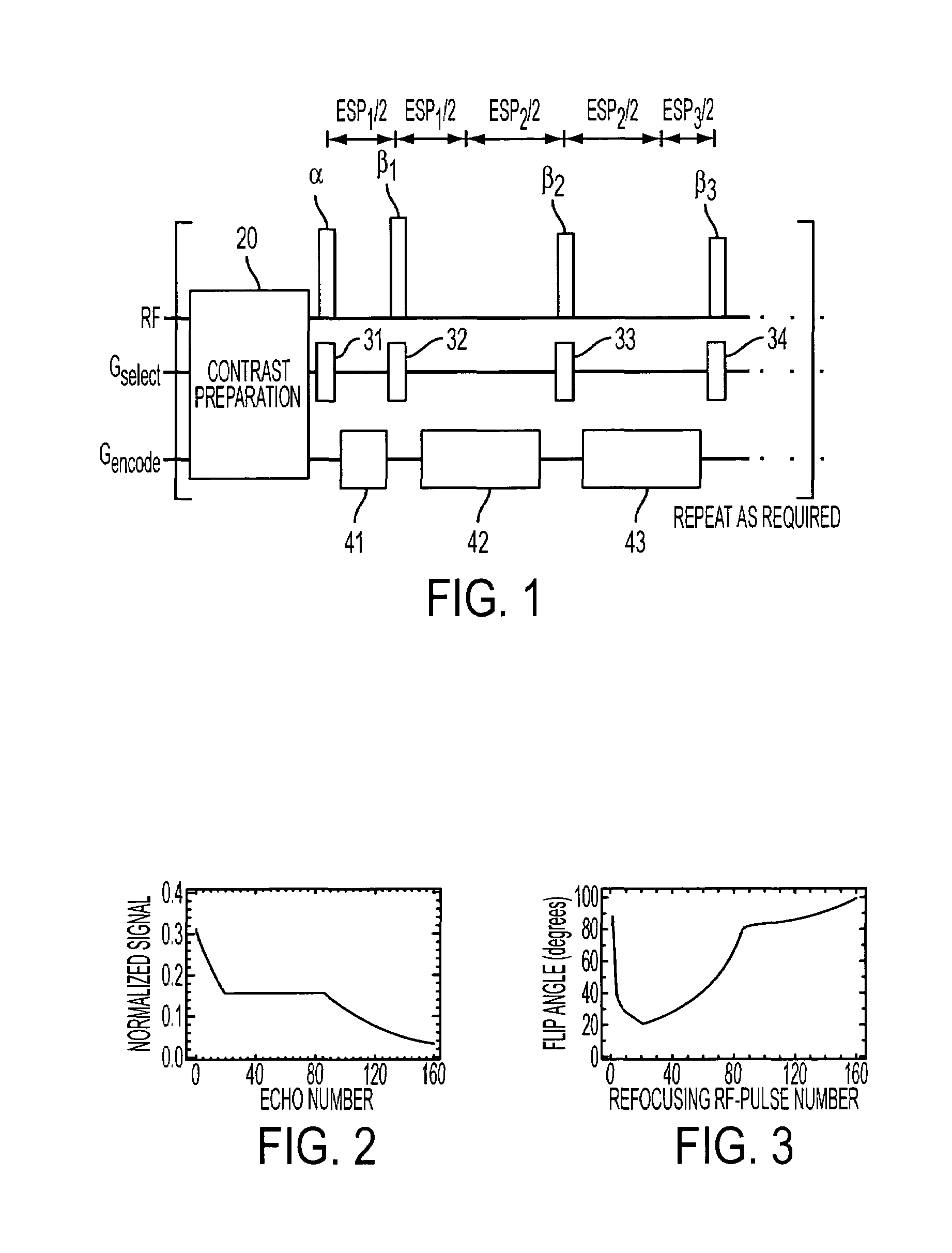

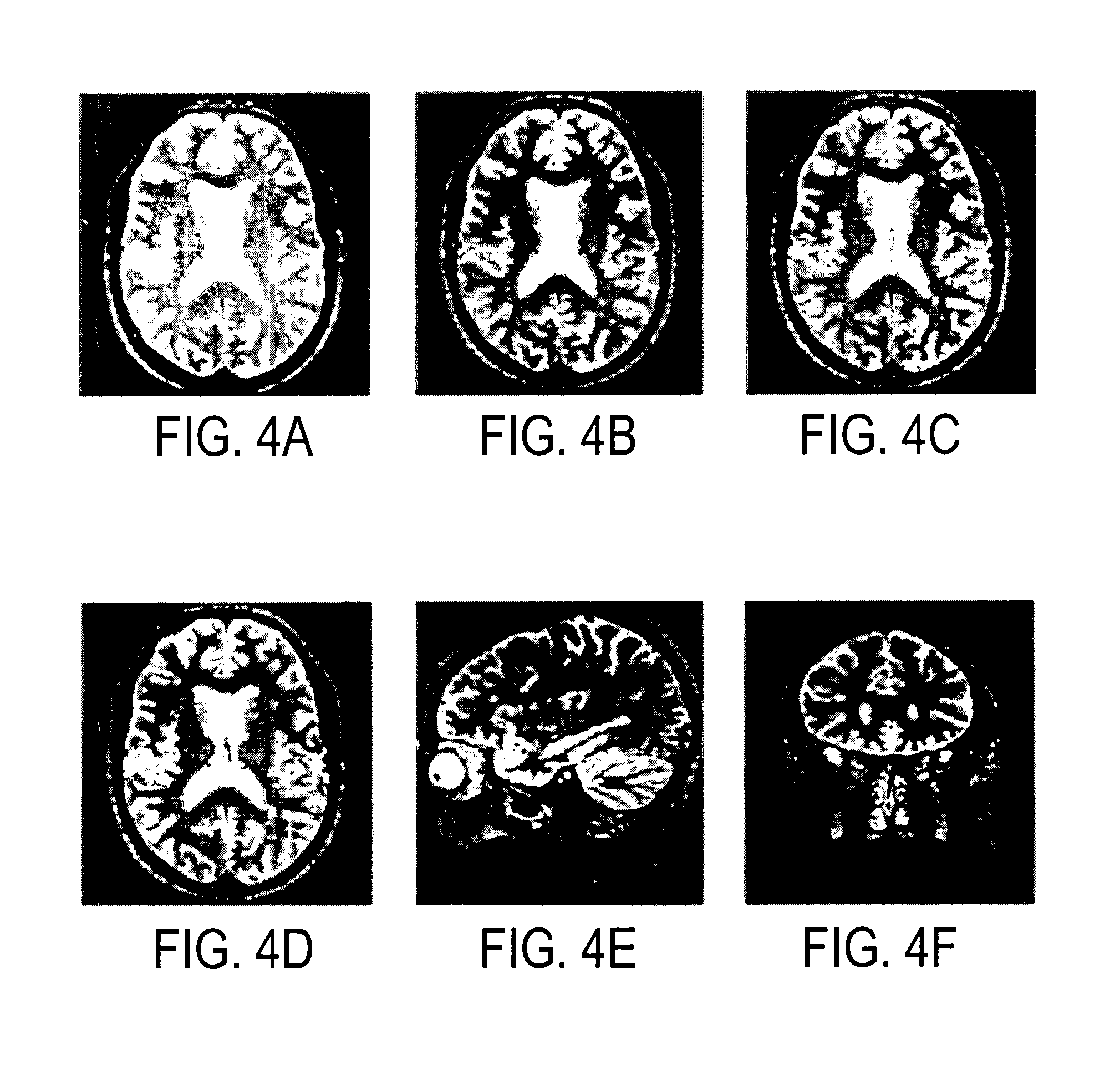

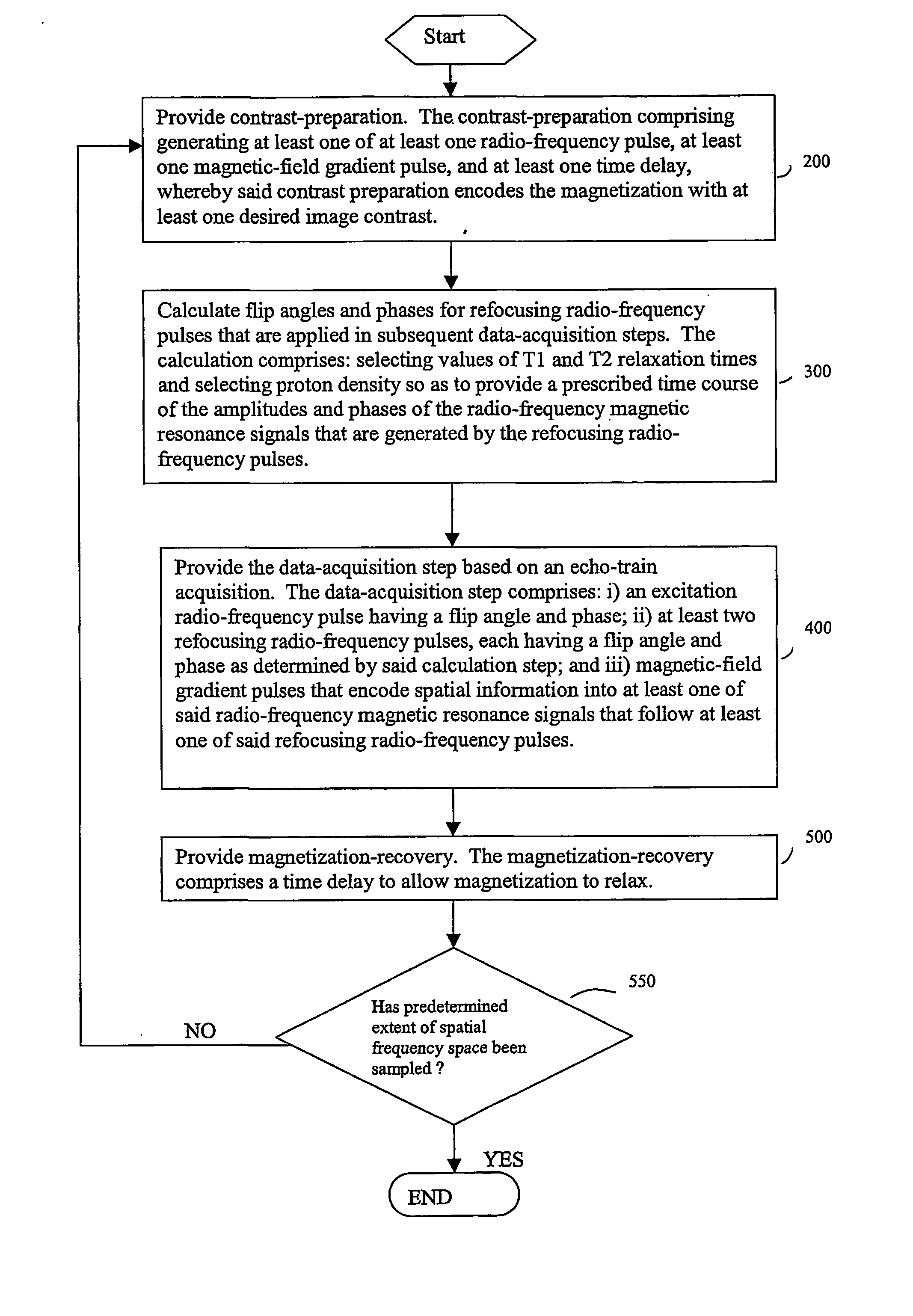

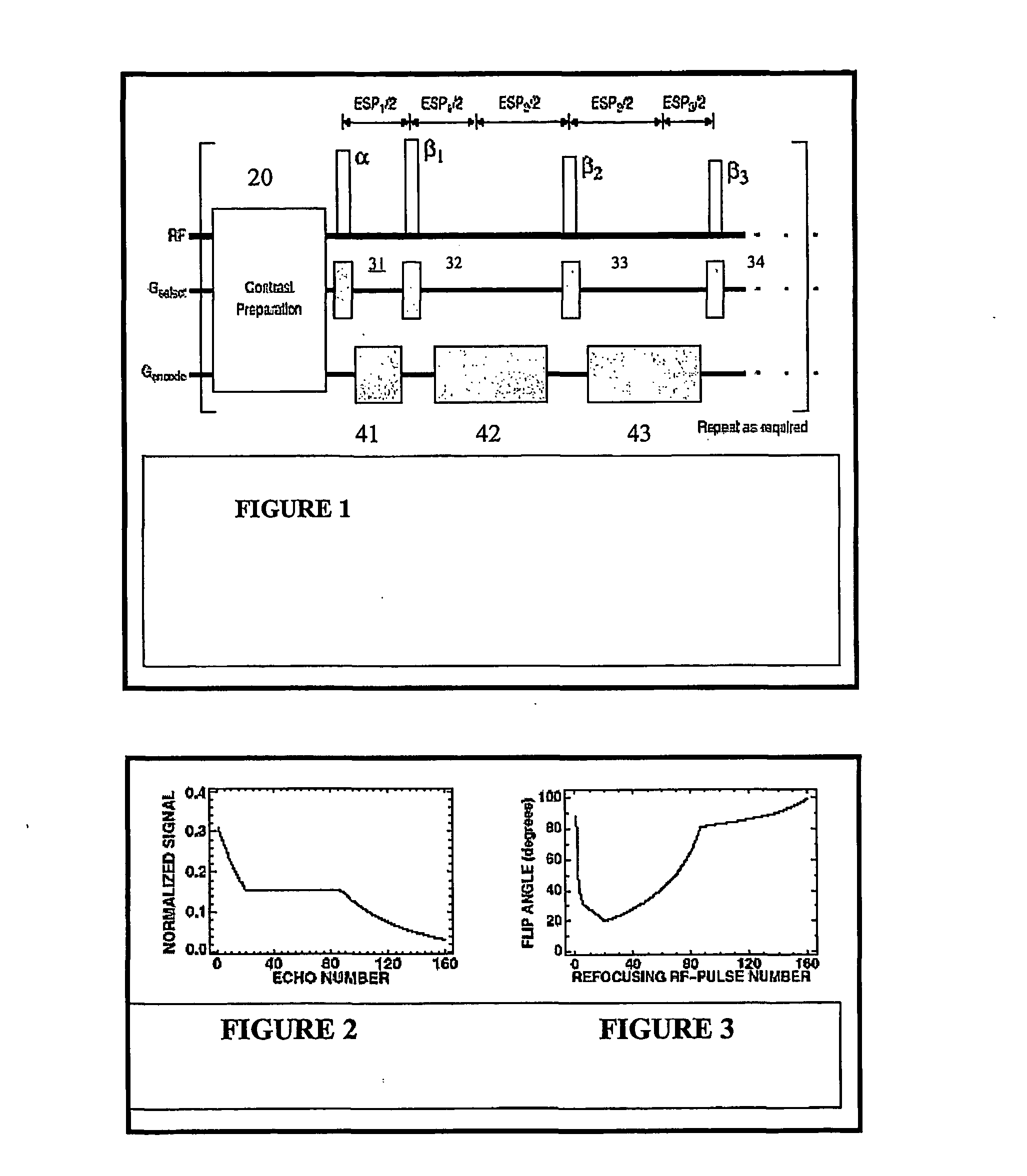

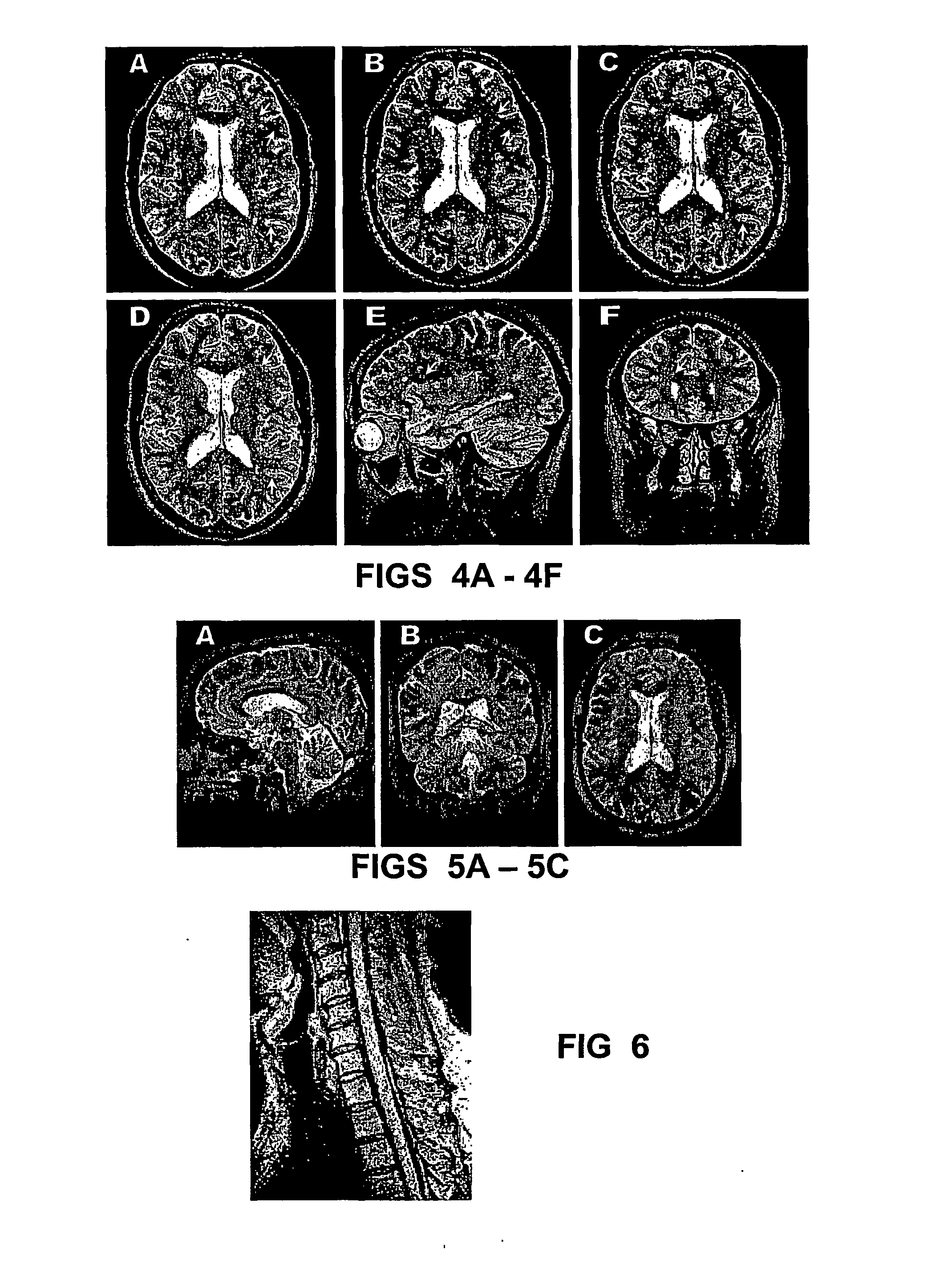

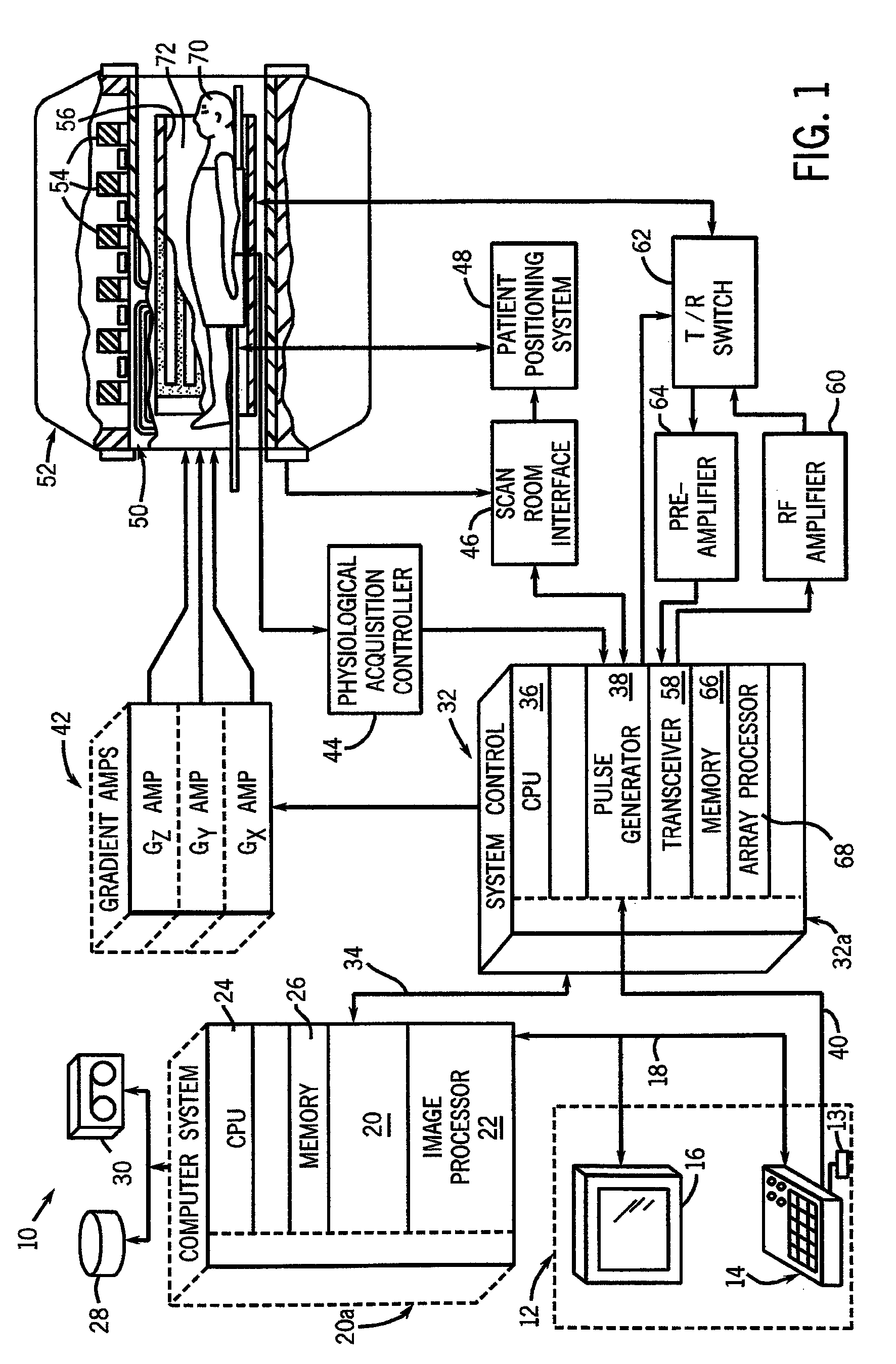

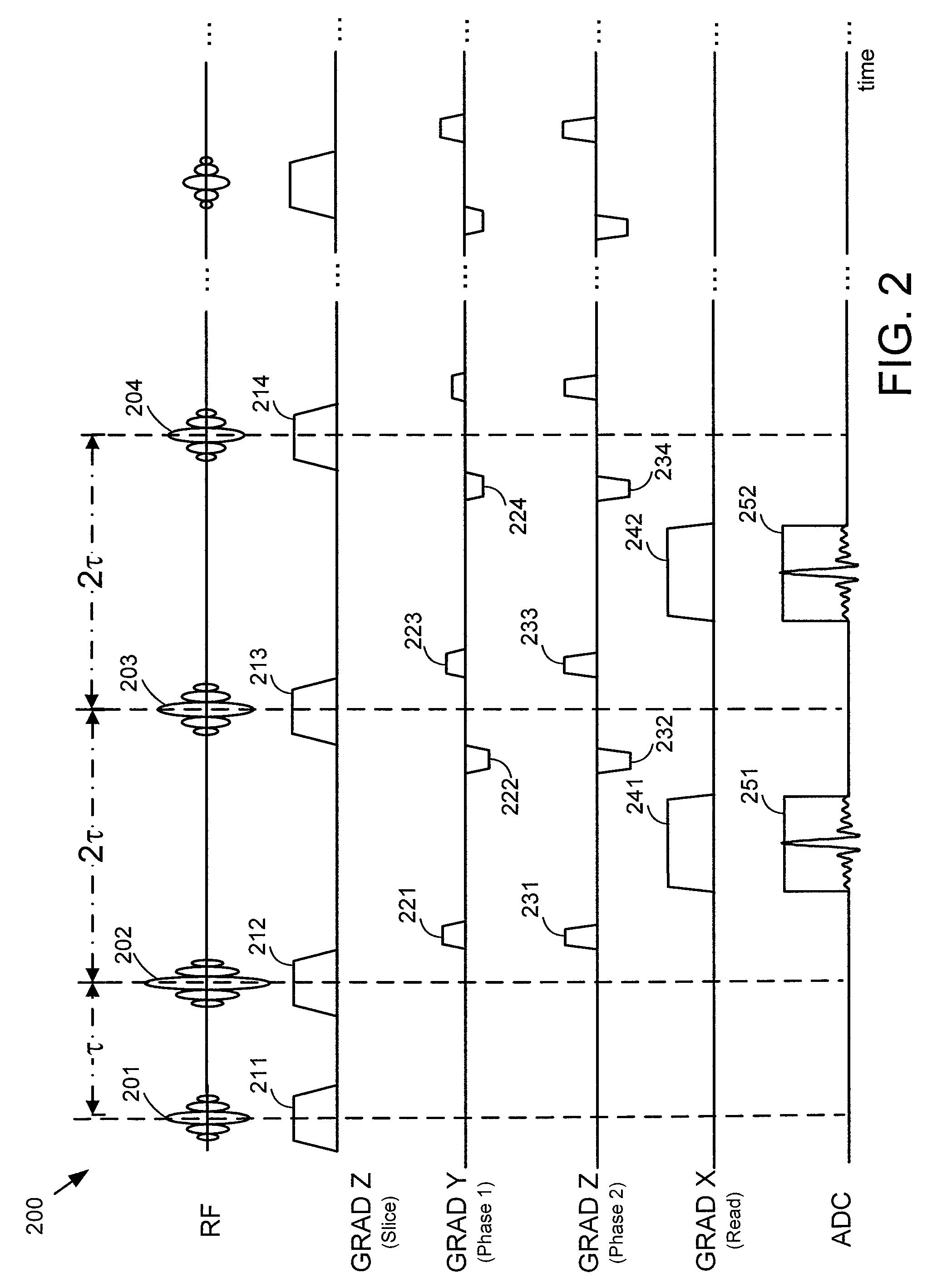

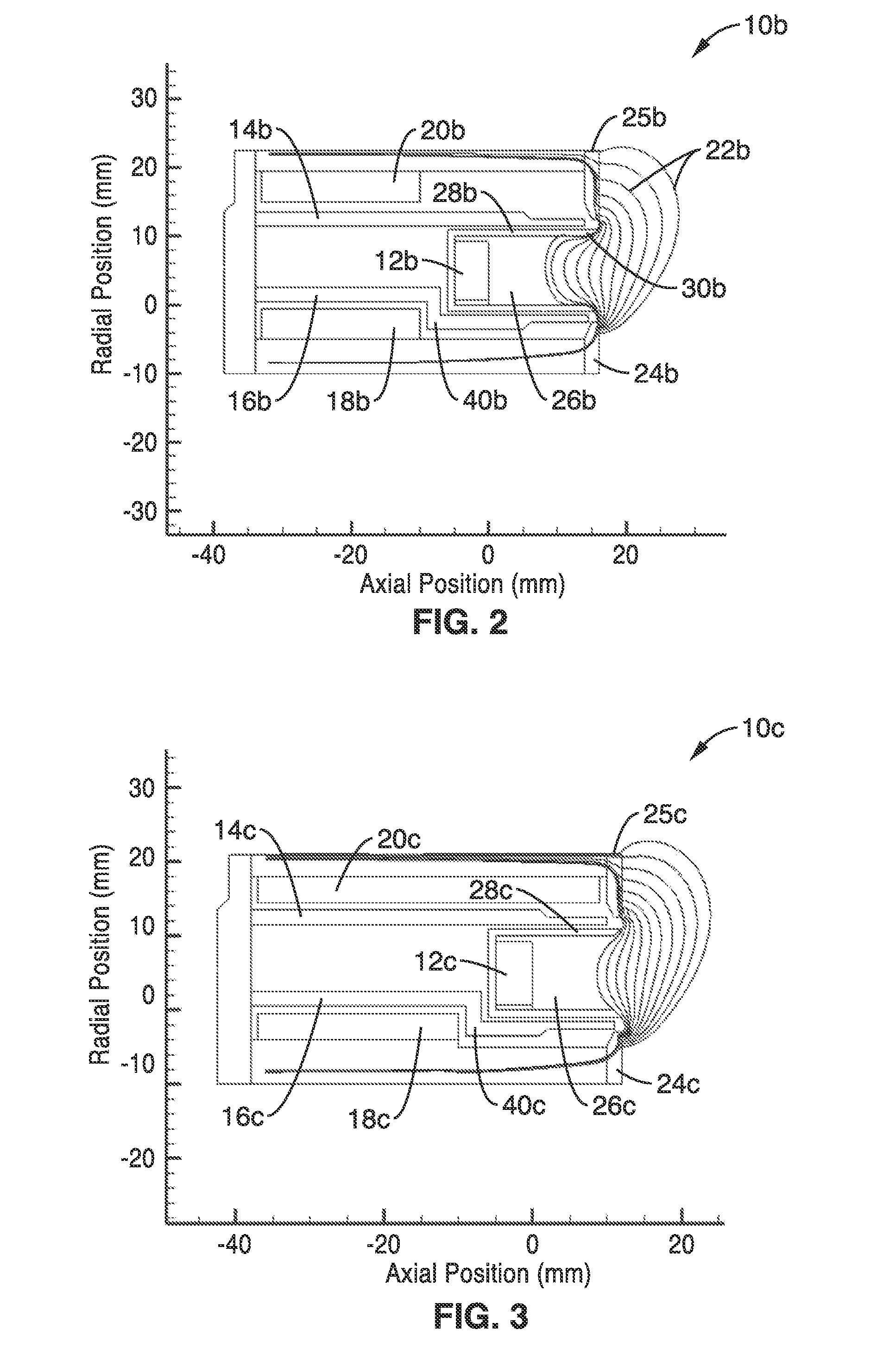

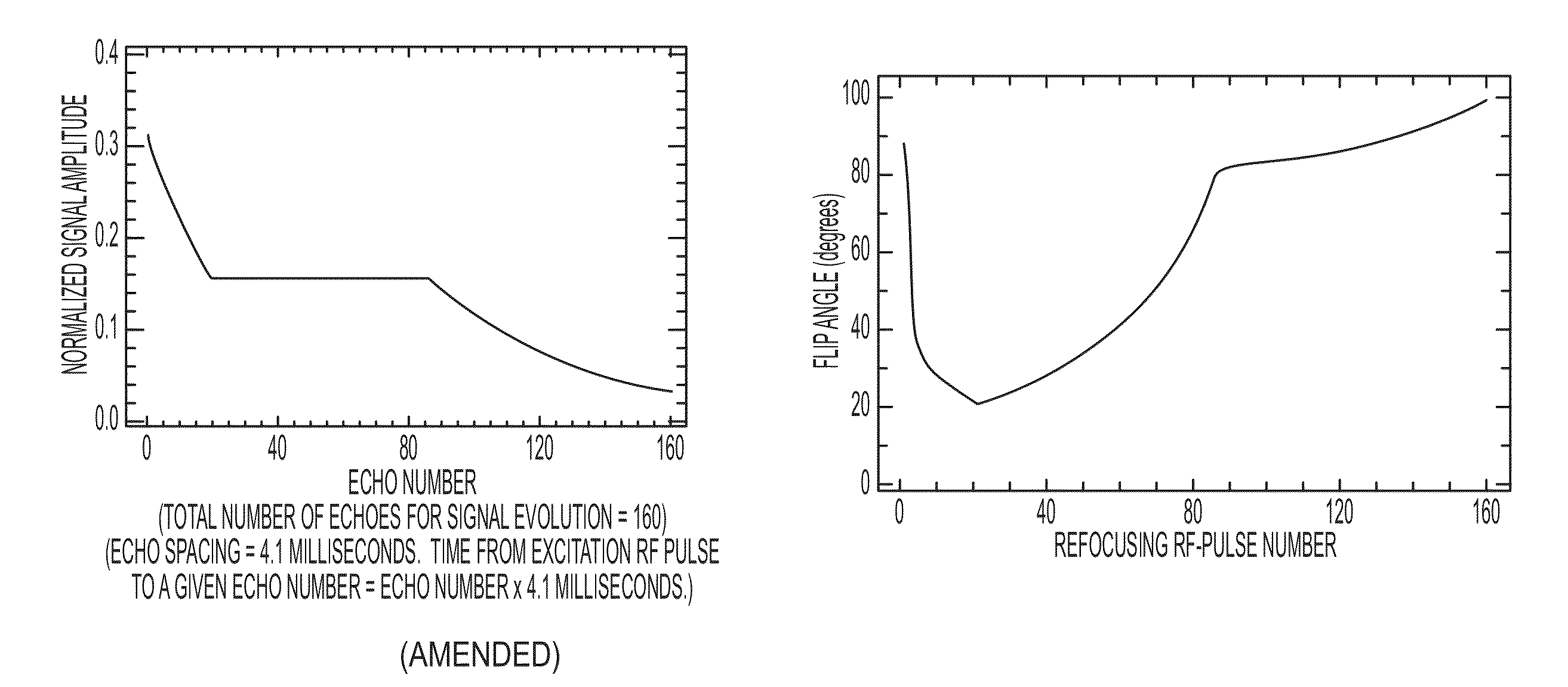

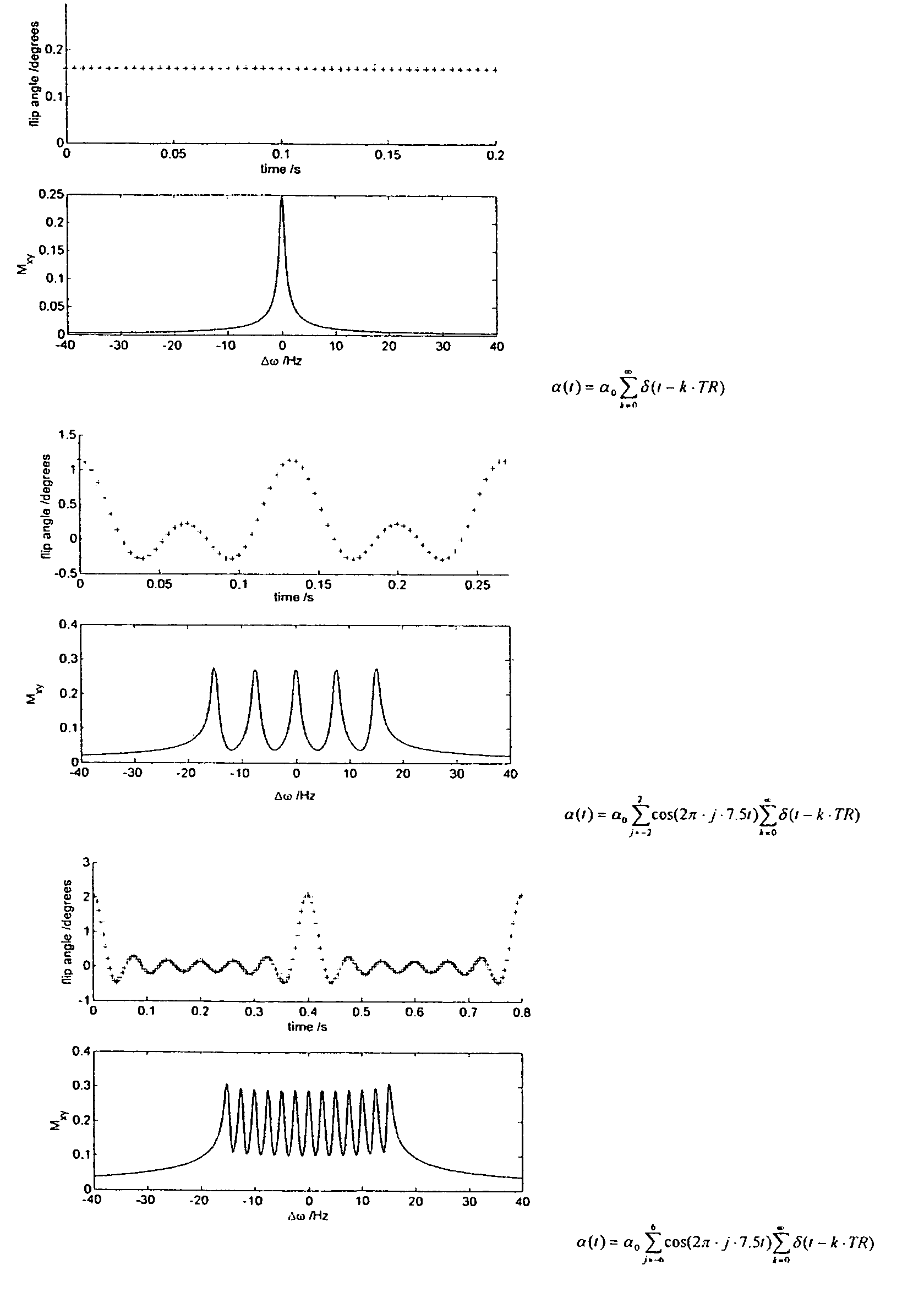

Method and apparatus for spin-echo-train MR imaging using prescribed signal evolutions

InactiveUS7164268B2Extended durationShorten Image Acquisition TimeDiagnostic recording/measuringMeasurements using NMR imaging systemsHigh fieldMagnetic resonance technique

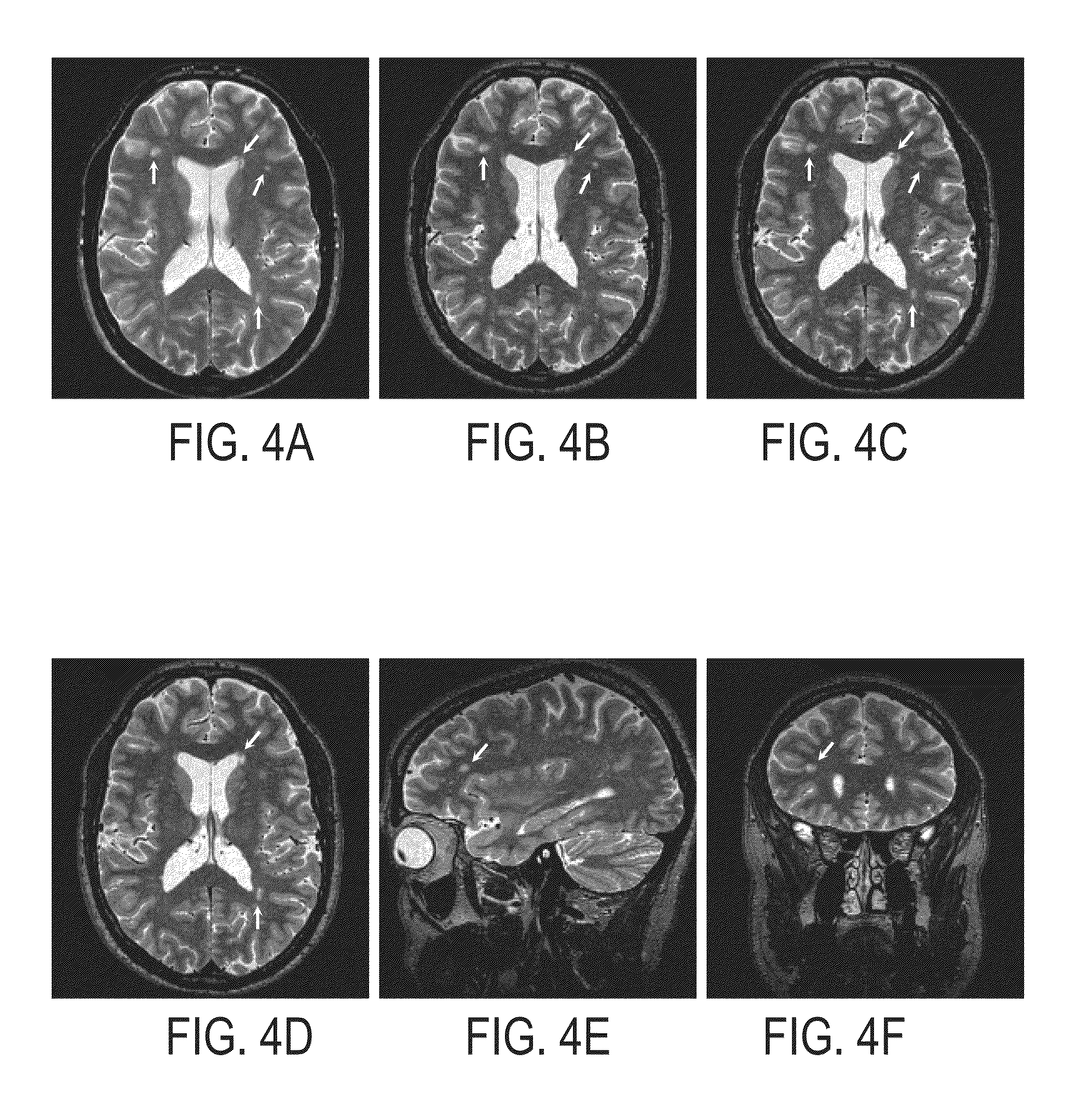

A magnetic resonance imaging “MRI” method and apparatus for lengthening the usable echo-train duration and reducing the power deposition for imaging is provided. The method explicitly considers the t1 and t2 relaxation times for the tissues of interest, and permits the desired image contrast to be incorporated into the tissue signal evolutions corresponding to the long echo train. The method provides a means to shorten image acquisition times and / or increase spatial resolution for widely-used spin-echo train magnetic resonance techniques, and enables high-field imaging within the safety guidelines established by the Food and Drug Administration for power deposition in human MRI.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

System and method for ablating tissue

An electrosurgical system and method for performing an electrosurgical procedure are disclosed. The electrosurgical system includes a high frequency generator to supply energy, the generator including one or more electrical connections. The system also includes one or more instruments configured to be inserted into tissue of the patient's body having a hardened tissue volume. The instruments are configured to penetrate the hardened tissue volume to create at one or more orifices defined therein. The instruments are also configured to selectively encapsulate one or more active electrodes that are coupled to the electrical connections. Each of the electrodes has an elongated shaft terminating in an exposed, conductive tip. The electrodes are configured to be inserted into the tissue of the patient's body and into the hardened tissue volume through the orifices to subsequently apply energy from the high frequency generator to the exposed, conductive tip to induce a coherent heating effect in the hardened tissue volume from power deposition therein, thereby producing a heat ablation volume in the hardened tissue volume.

Owner:COVIDIEN AG

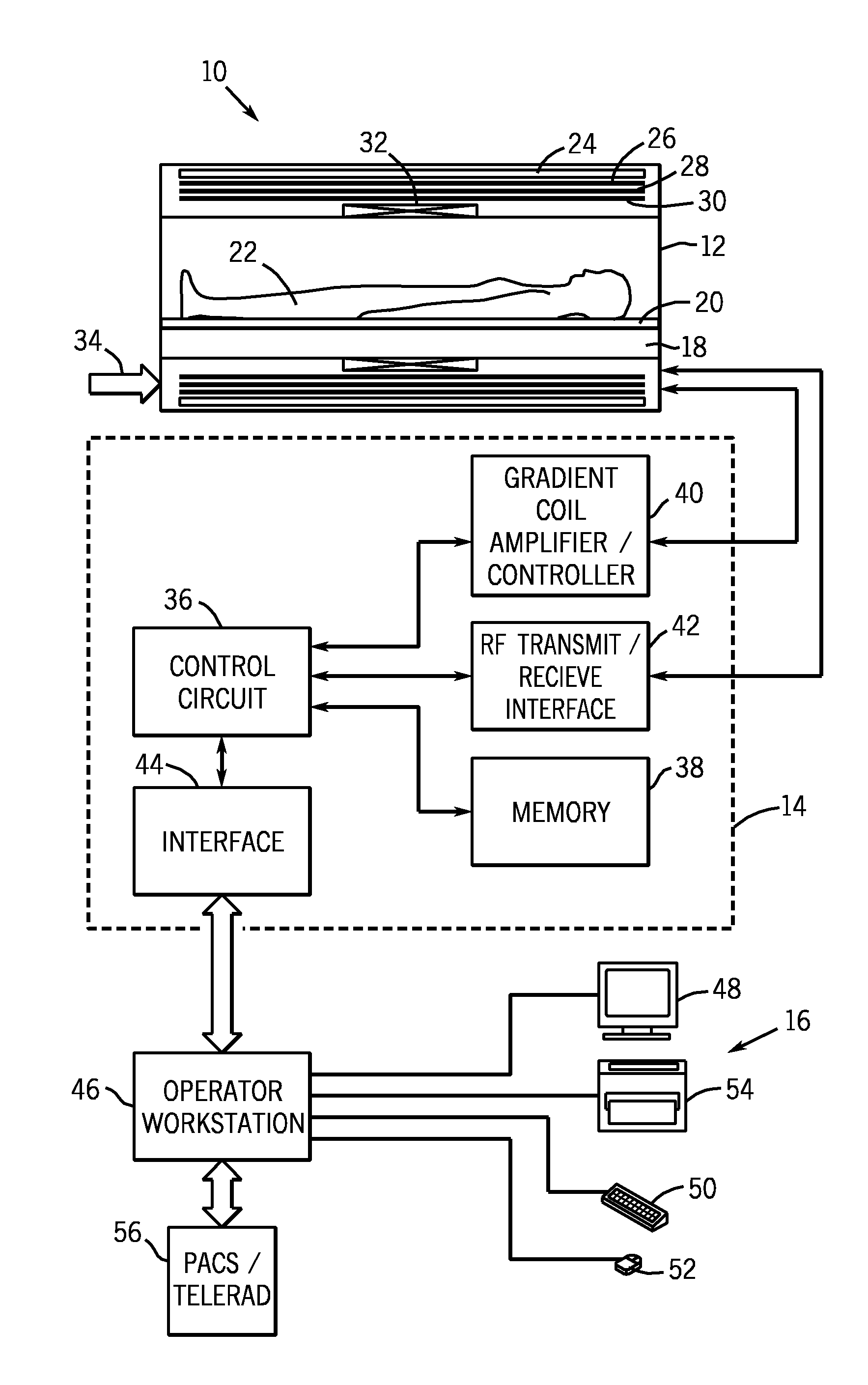

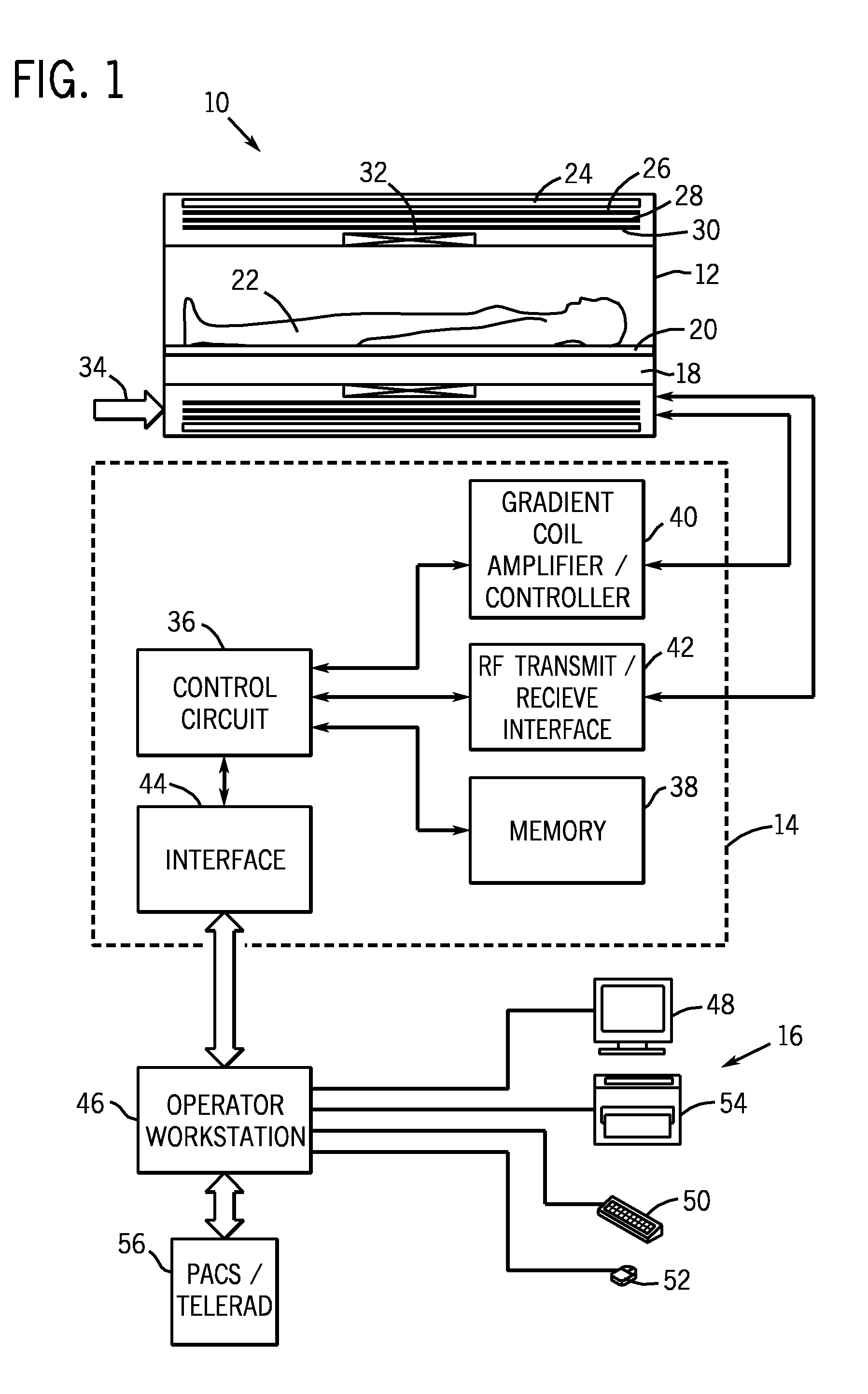

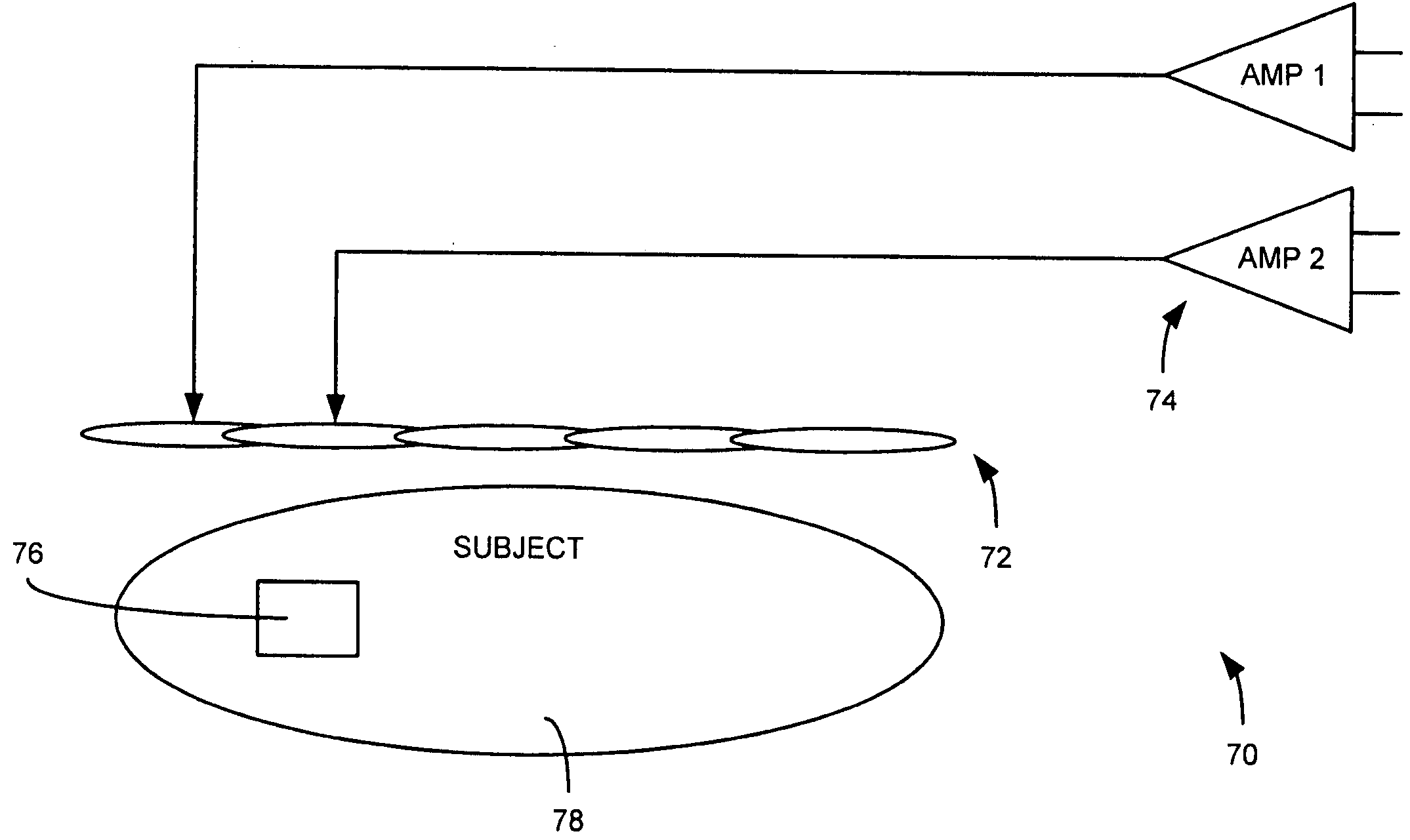

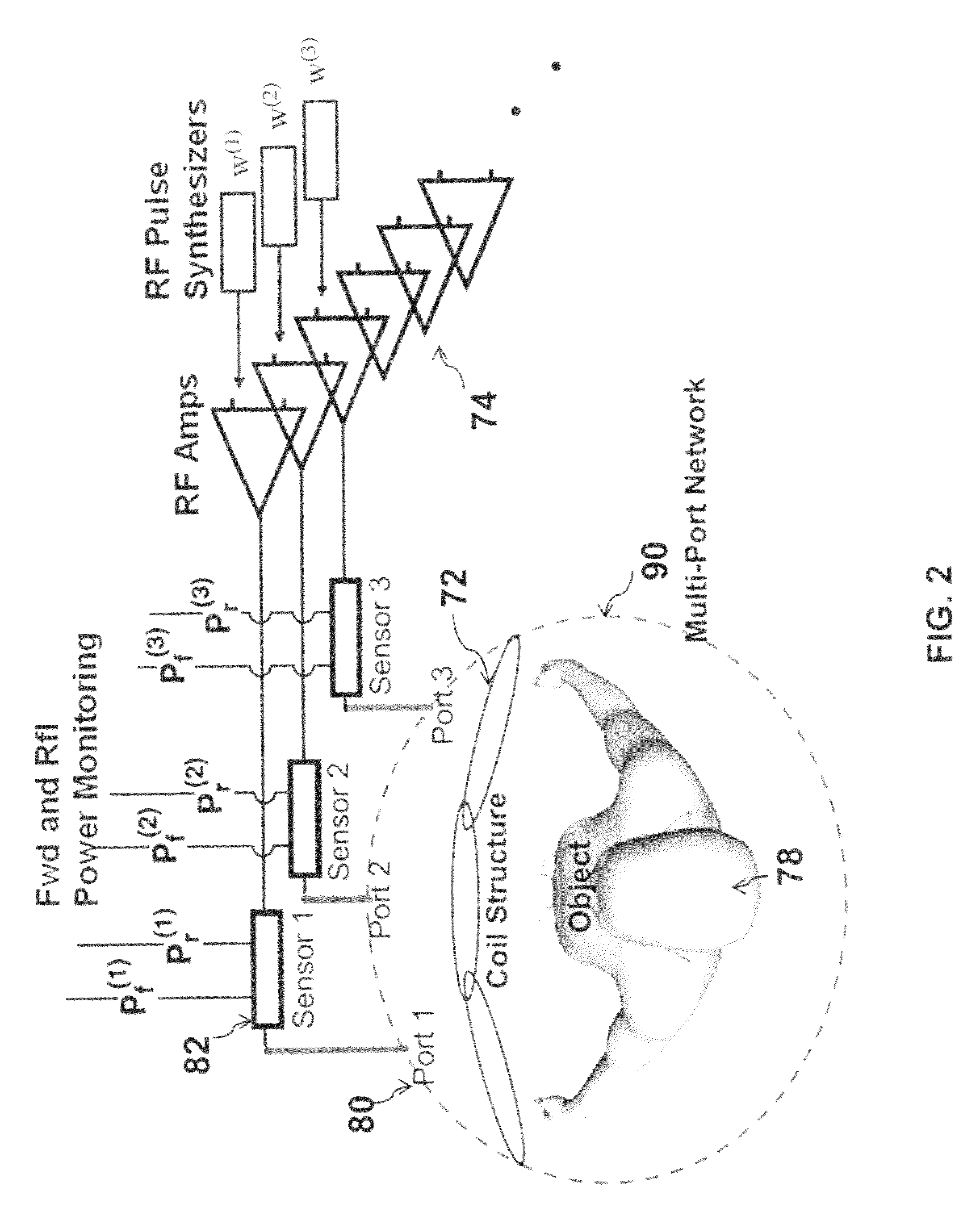

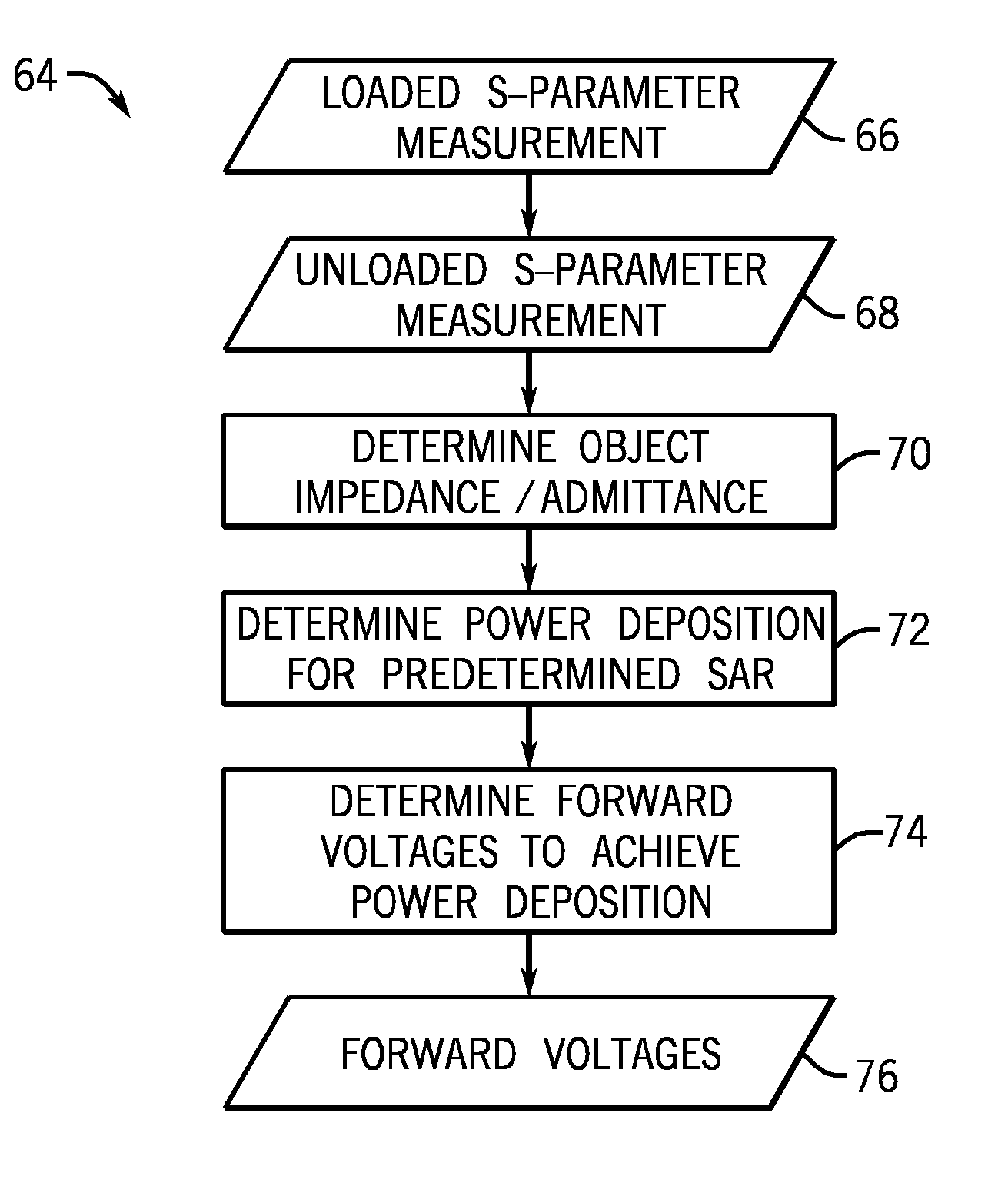

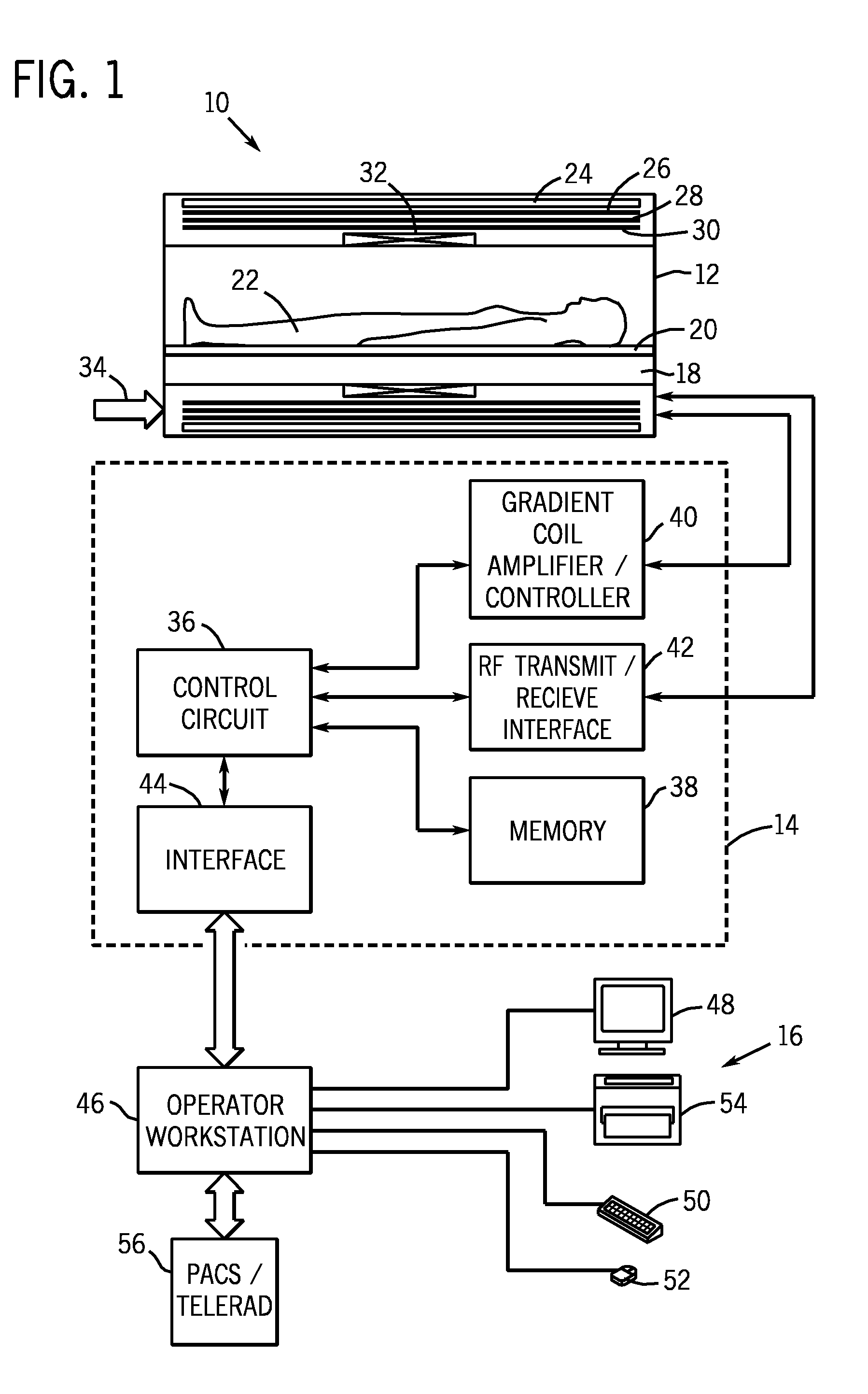

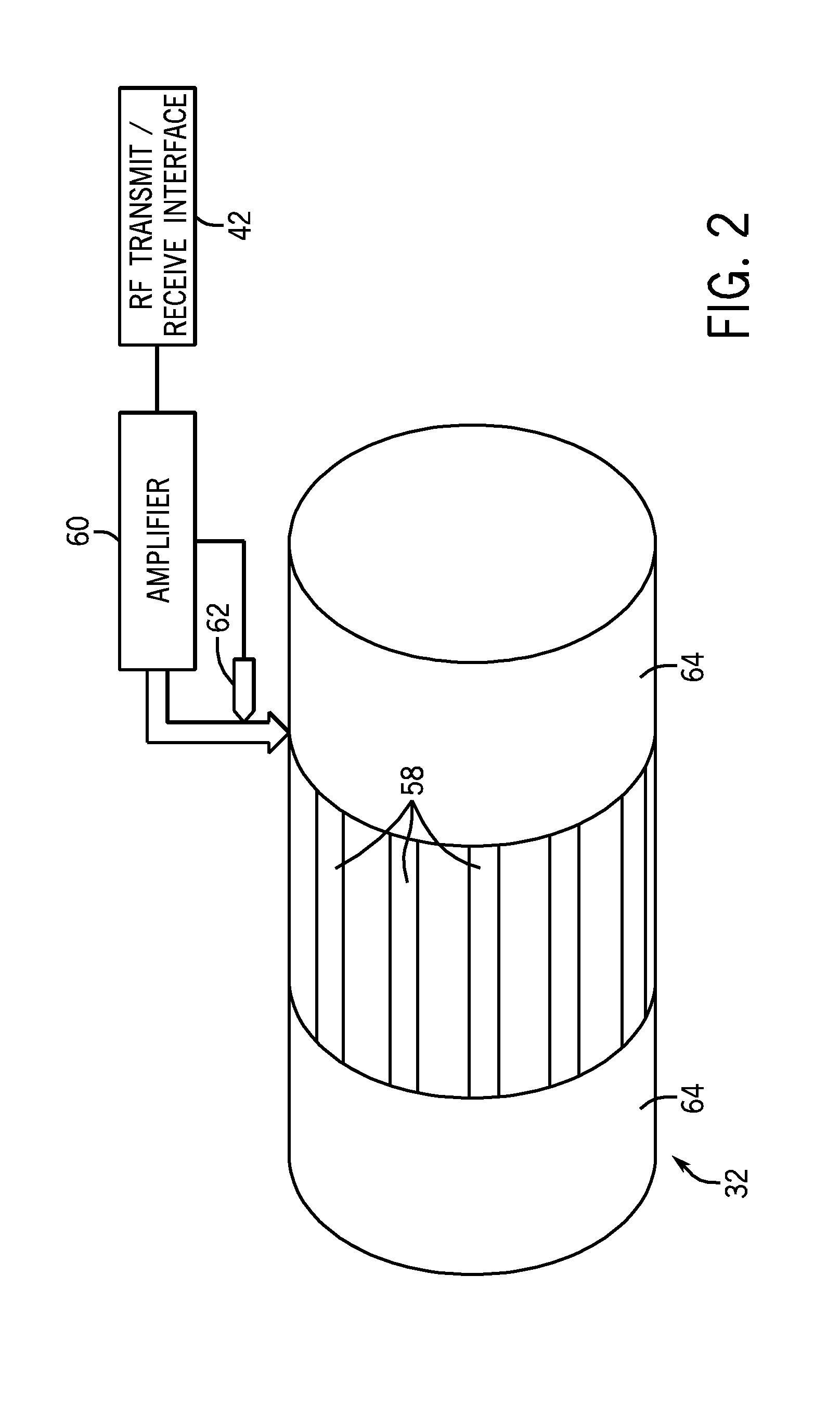

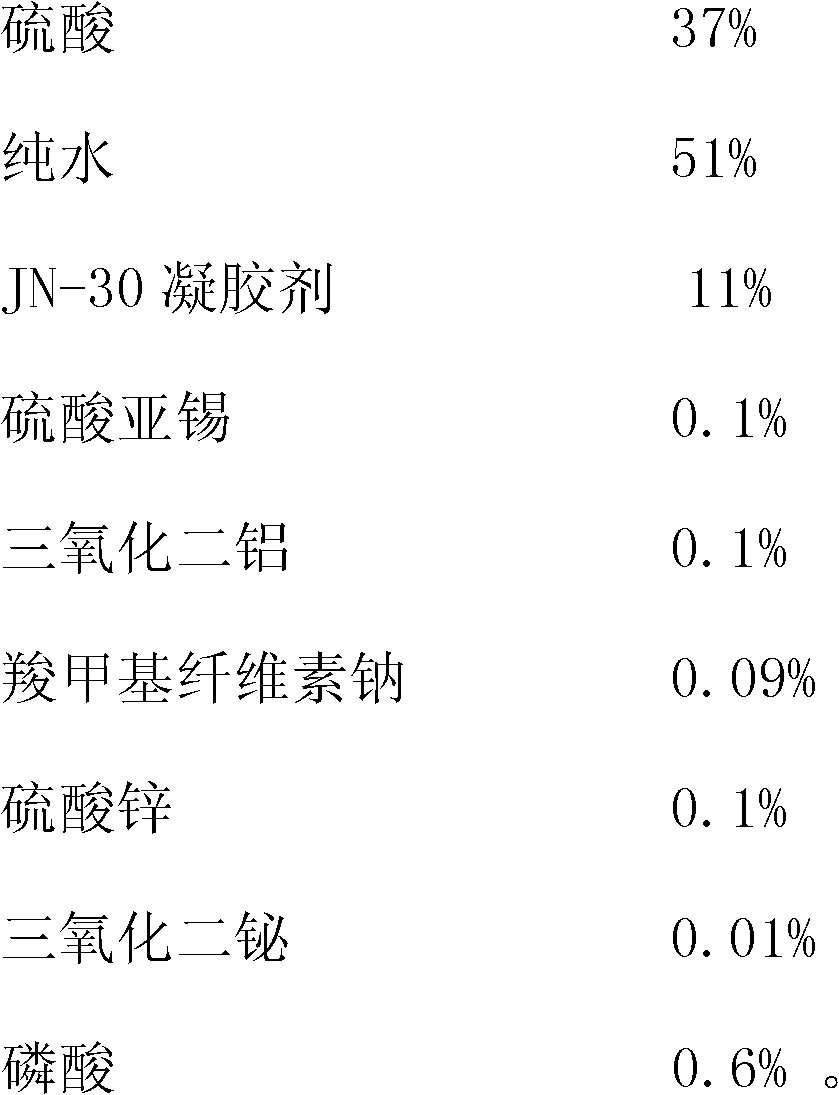

Using s-parameter measurements to manage SAR and transmit gain

ActiveUS20100244840A1Electric/magnetic detectionMeasurements using magnetic resonanceAudio power amplifierEngineering

Systems and methods for controlling a magnetic resonance imaging system are provided. In one embodiment, a magnetic resonance imaging system includes a radio frequency coil with a plurality of conductive coil elements, control circuitry that determines, based at least in part on a measurement of scattering parameters, a plurality of forward voltages that will cause power deposition into an object within a predetermined specific absorption rate, and an amplifier configured to apply the determined plurality of forward voltages respectively to the plurality of coil elements. The control circuitry may determine the plurality of forward voltages based at least in part on an unloaded measurement of scattering parameters and a loaded measurement of scattering parameters.

Owner:GENERAL ELECTRIC CO

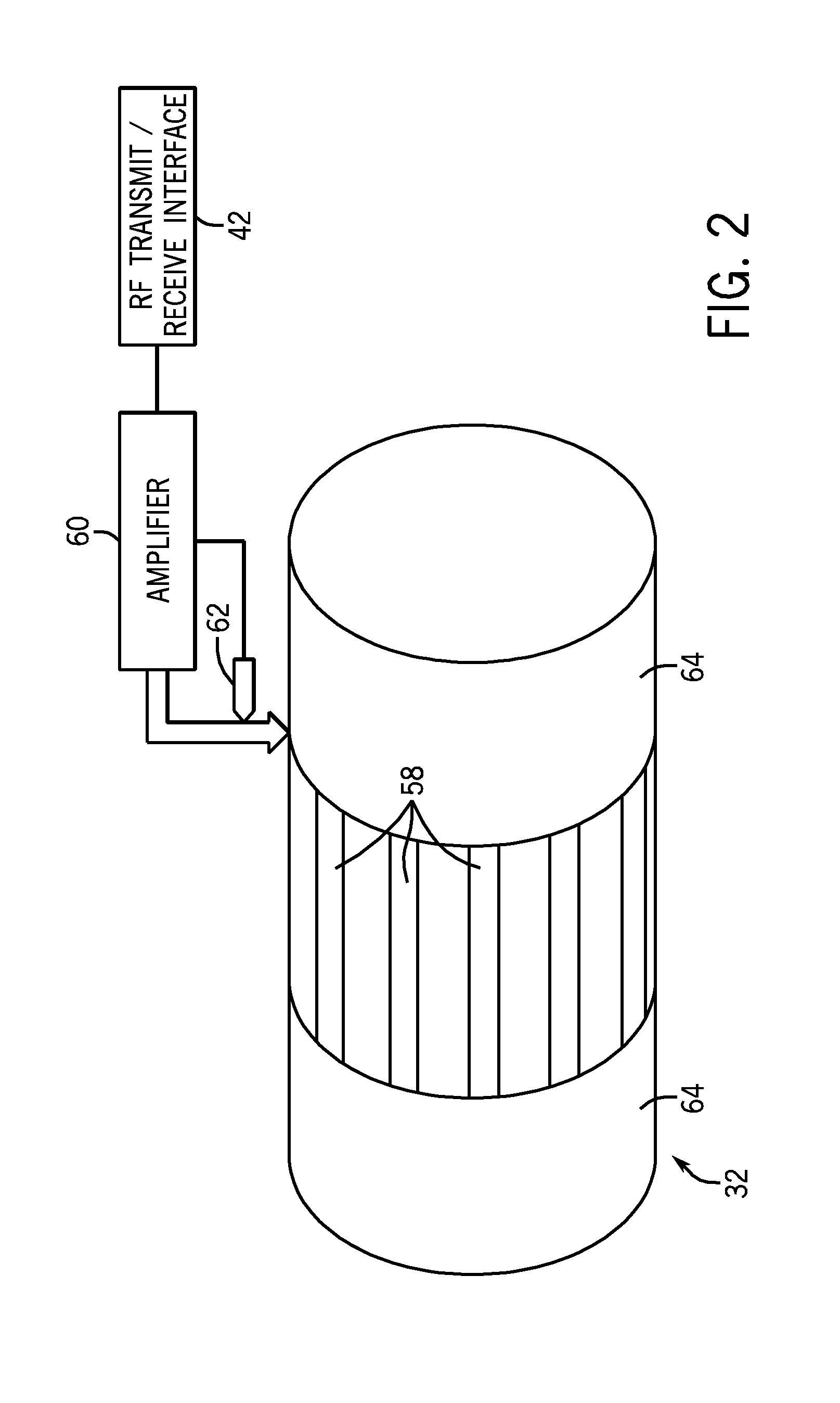

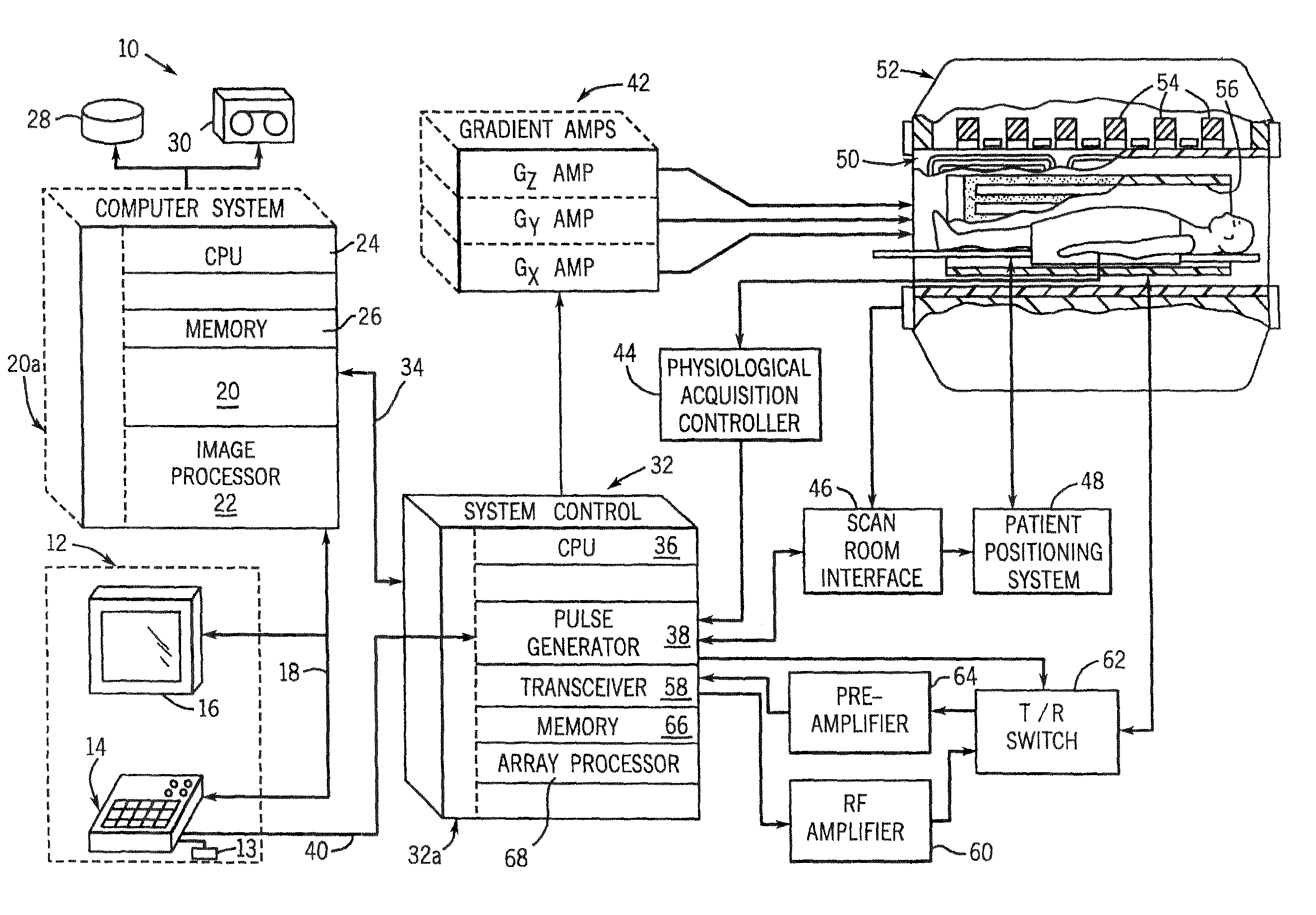

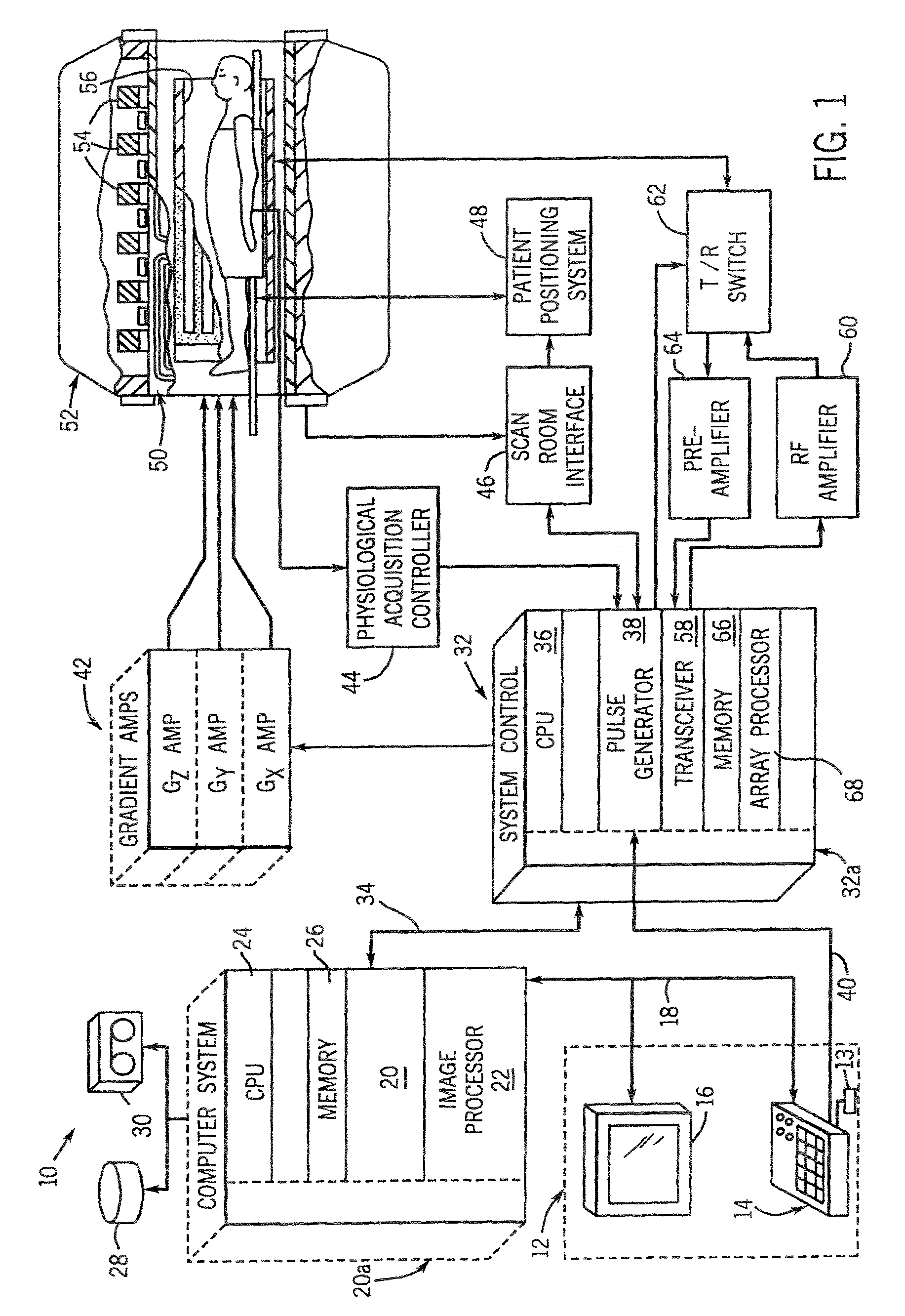

Method and apparatus to reduce RF power deposition during MR data acquisition

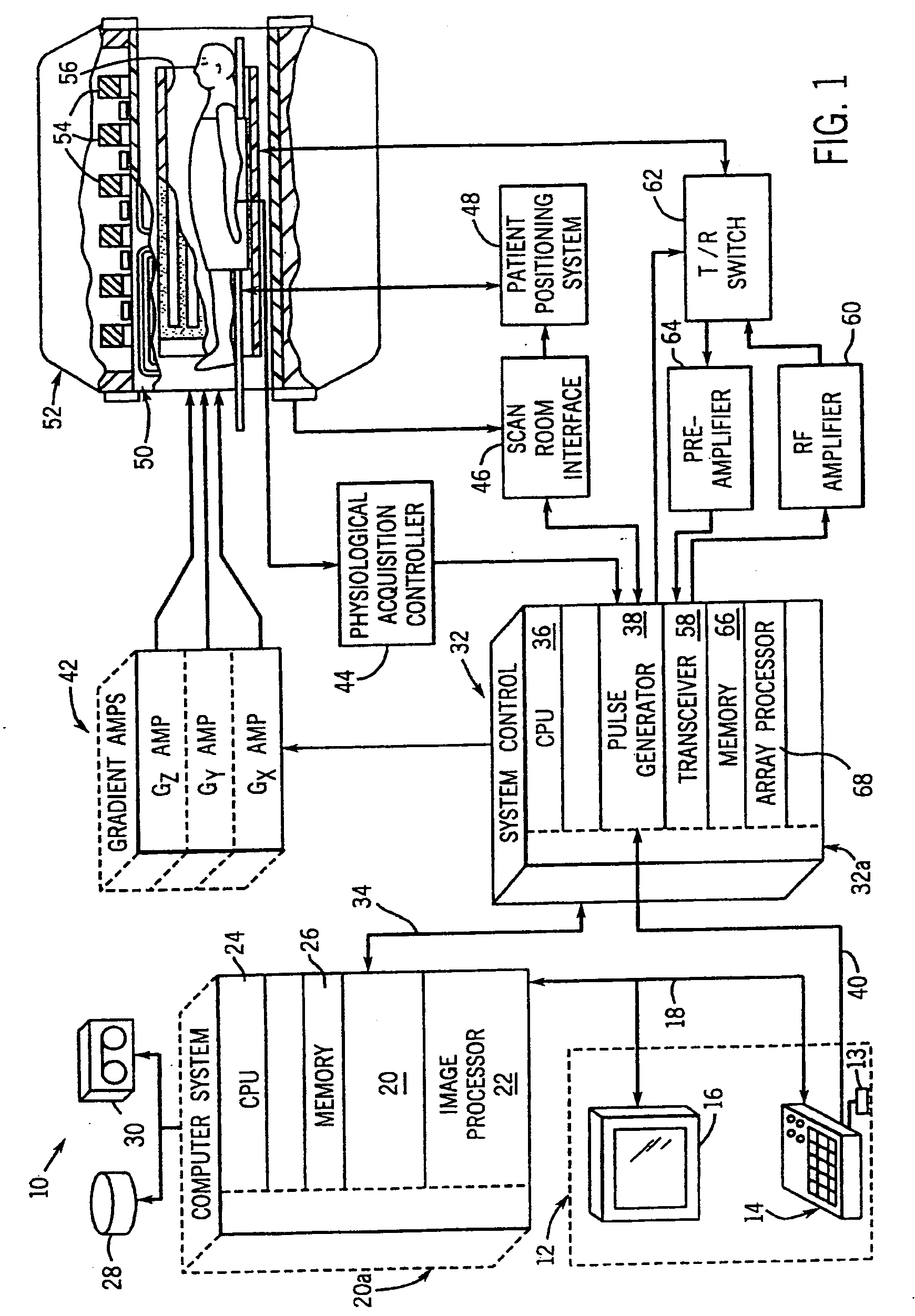

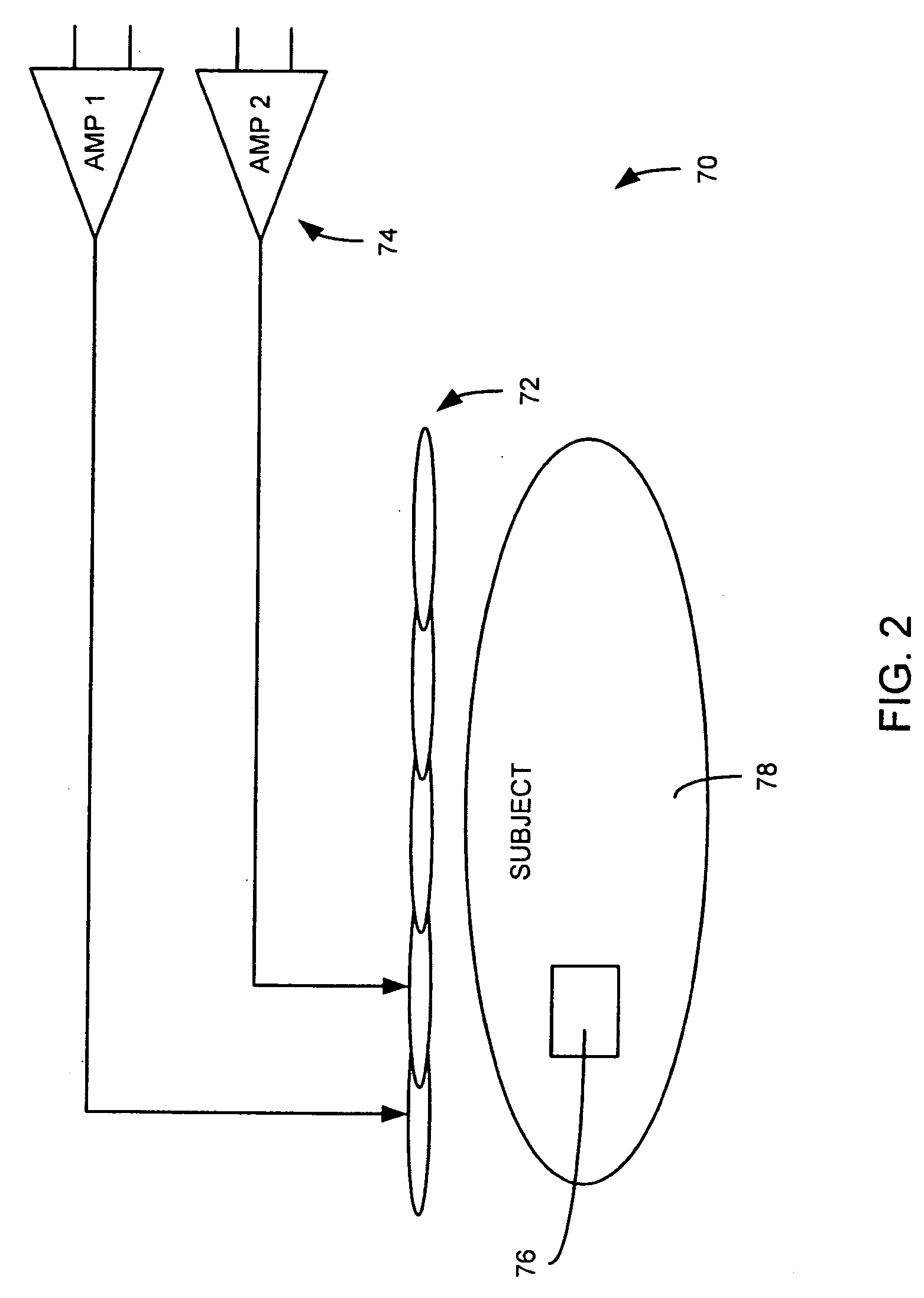

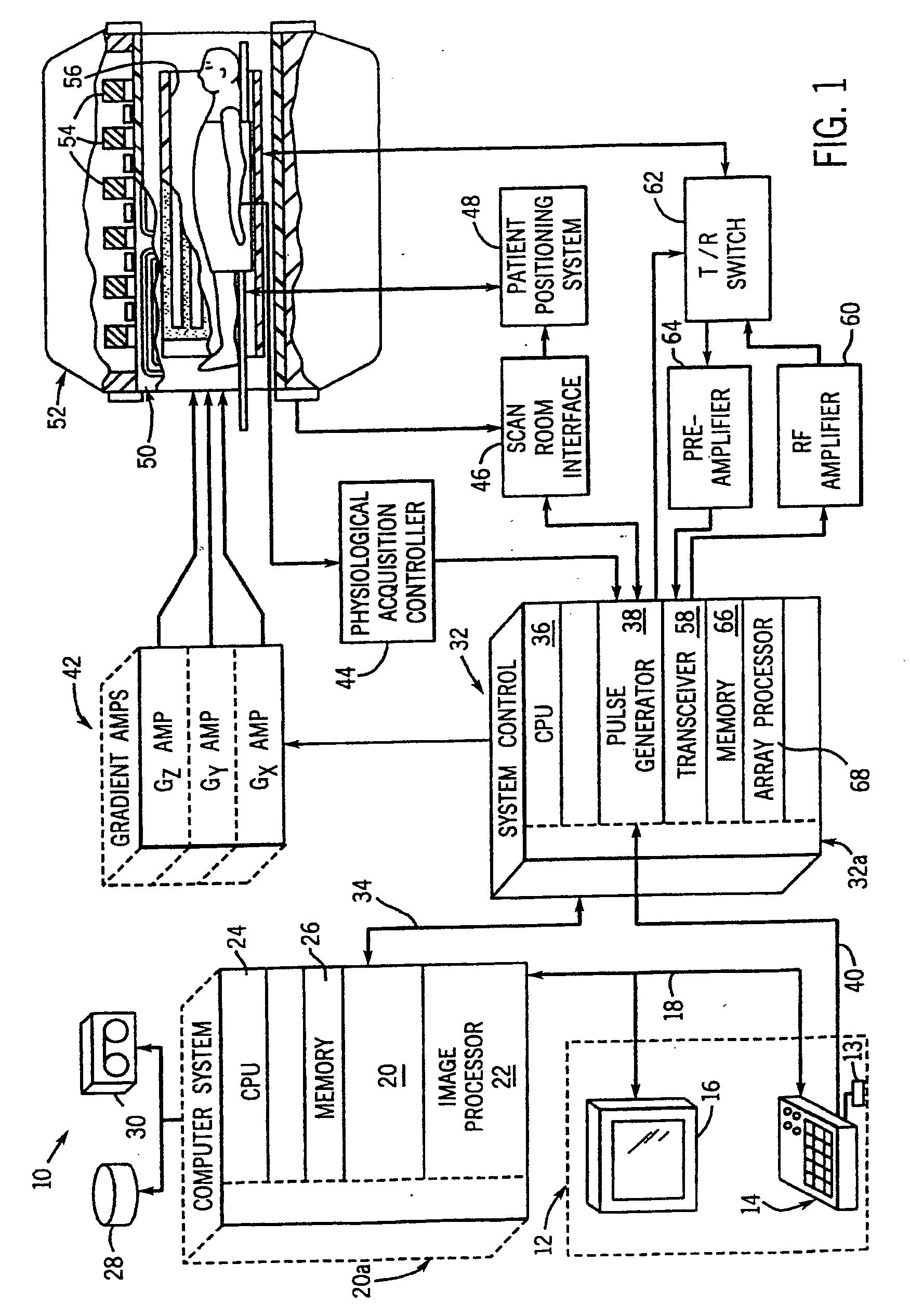

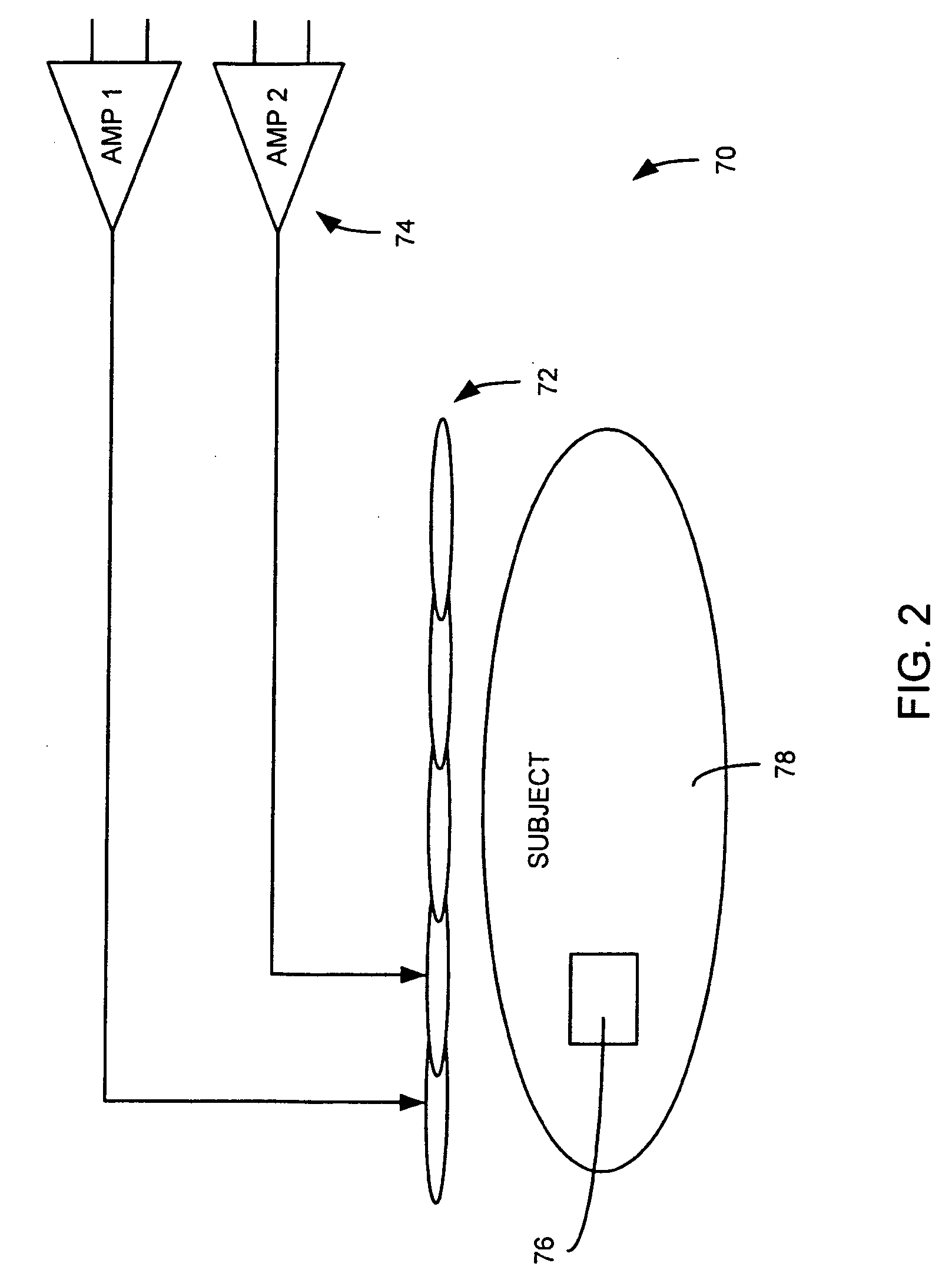

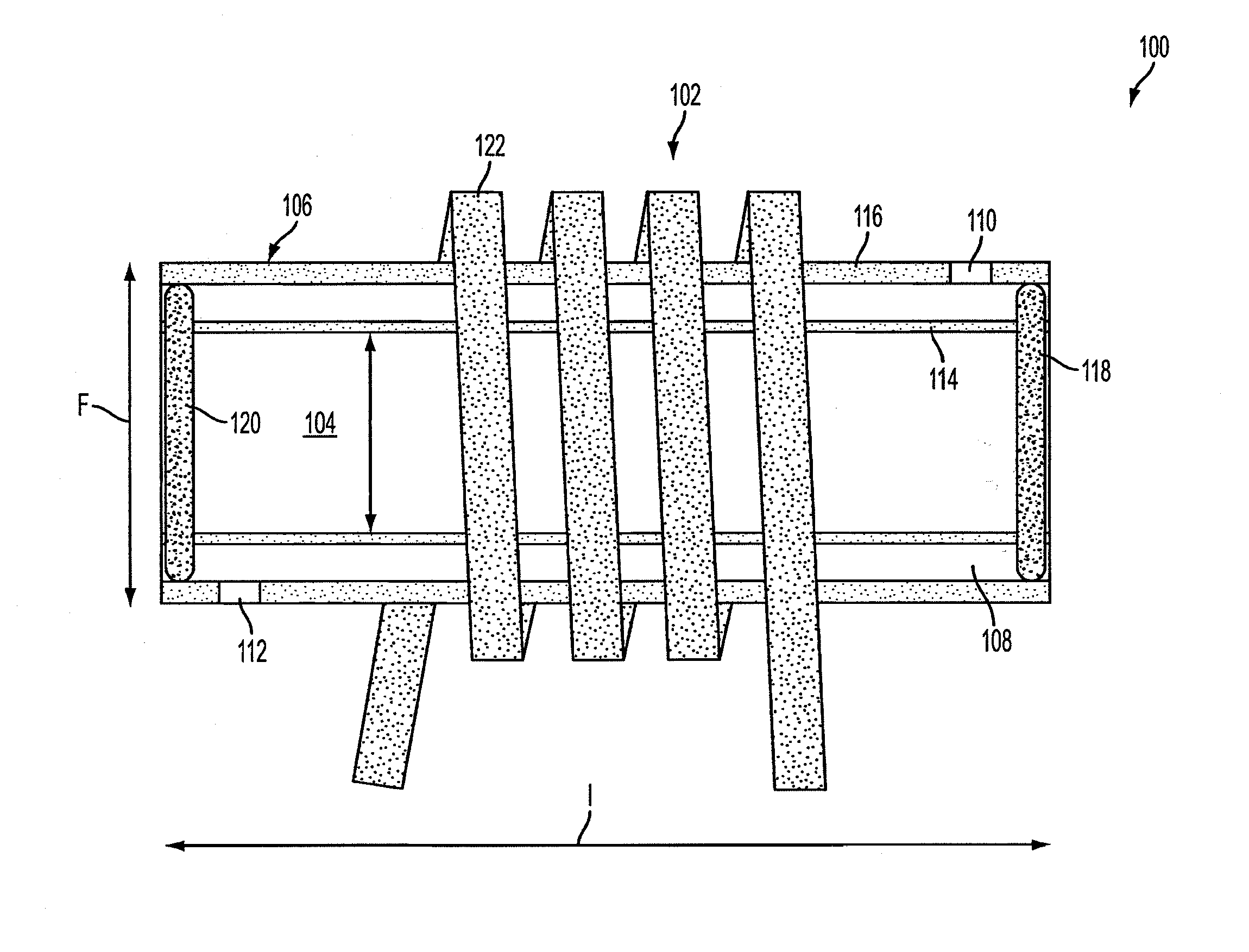

ActiveUS20050110487A1Efficient managementFaithful productionDiagnostic recording/measuringSensorsAudio power amplifierCoil array

A system composed of multiple transmit coils with corresponding RF pulse synthesizers and amplifiers is disclosed. A method of designing RF pulses specific to each transmit coil to dynamically control RF power deposition across an imaging volume is also disclosed, where parallel excitation with the transmit coils allows for management of RF power deposition on a subject while facilitating faithful production of a desired excitation profile. The present invention also supports reduction in scan time and is applicable to any coil array geometry.

Owner:GENERAL ELECTRIC CO

Method and apparatus for spin-echo-train MR imaging using prescribed signal evolutions

InactiveUS20040051527A1Measurements using NMR imaging systemsElectric/magnetic detectionHigh fieldMagnetic resonance technique

A magnetic resonance imaging "MRI" method and apparatus for lengthening the usable echo-train duration and reducing the power deposition for imaging is provided. The method explicitly considers the t1 and t2 relaxation times for the tissues of interest, and permits the desired image contrast to be incorporated into the tissue signal evolutions corresponding to the long echo train. The method provides a means to shorten image acquisition times and / or increase spatial resolution for widely-used spin-echo train magnetic resonance techniques, and enables high-field imaging within the safety guidelines established by the Food and Drug Administration for power deposition in human MRI.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Method and apparatus for generating a flip angle schedule for a spin echo train pulse sequence

Owner:GENERAL ELECTRIC CO

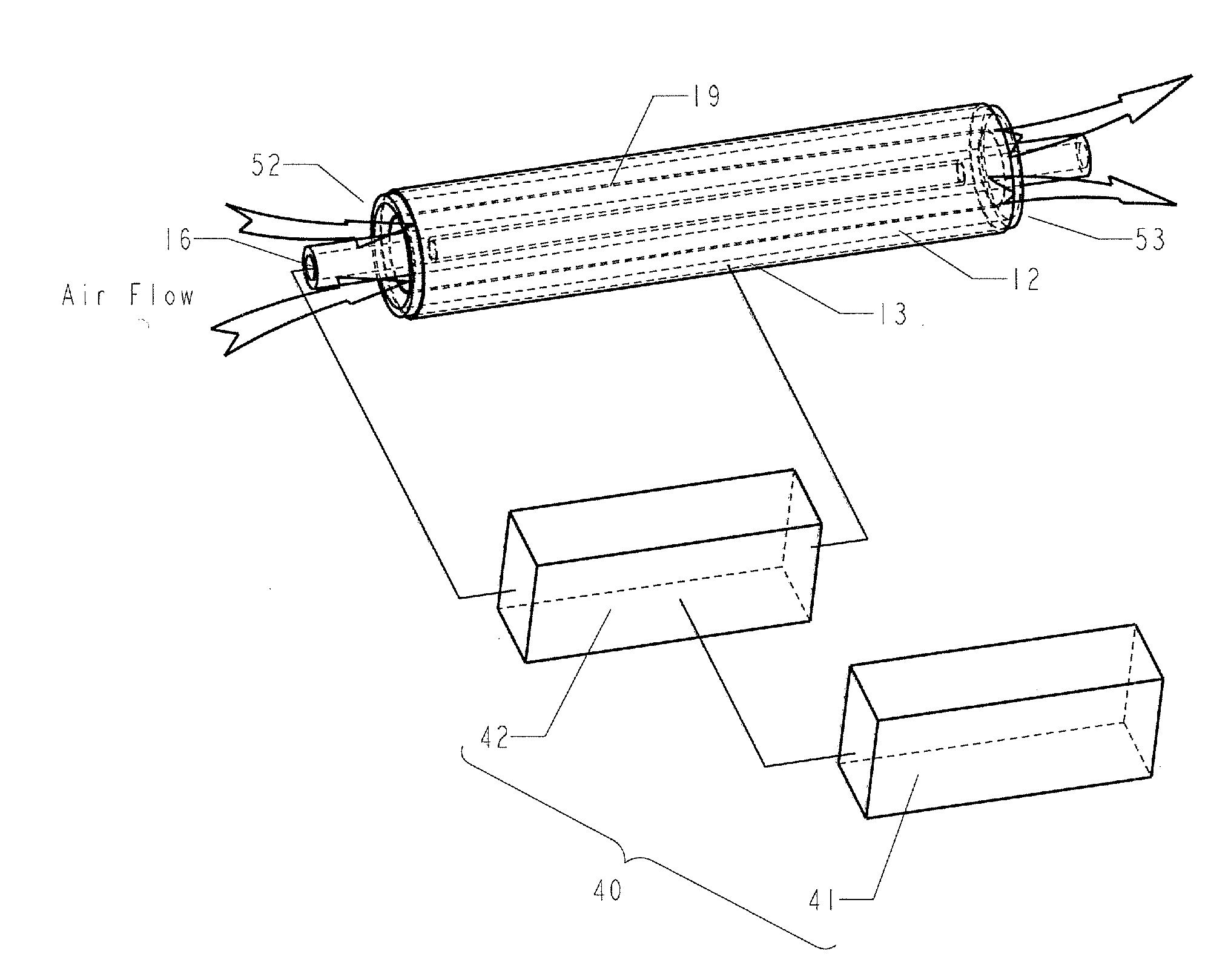

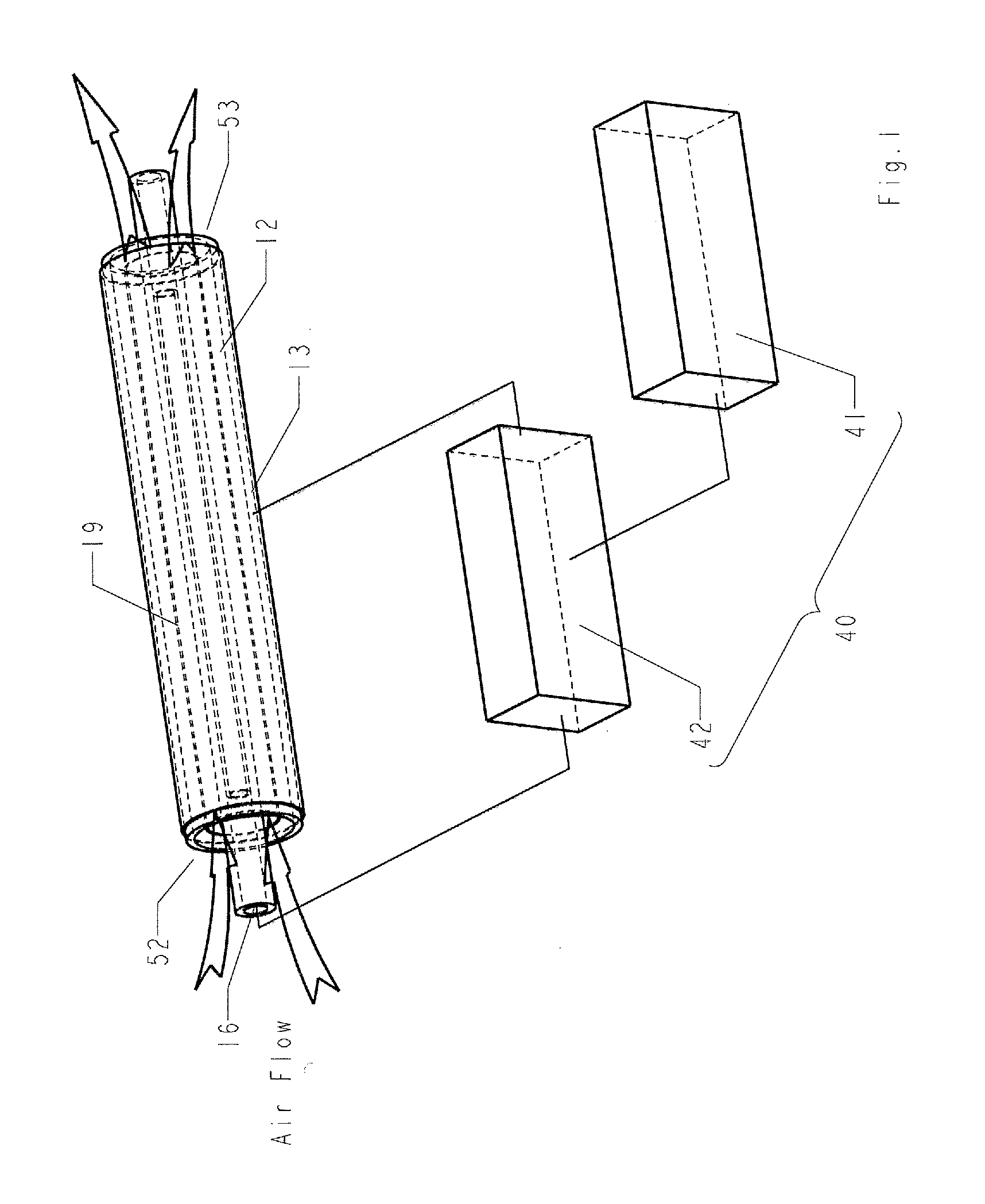

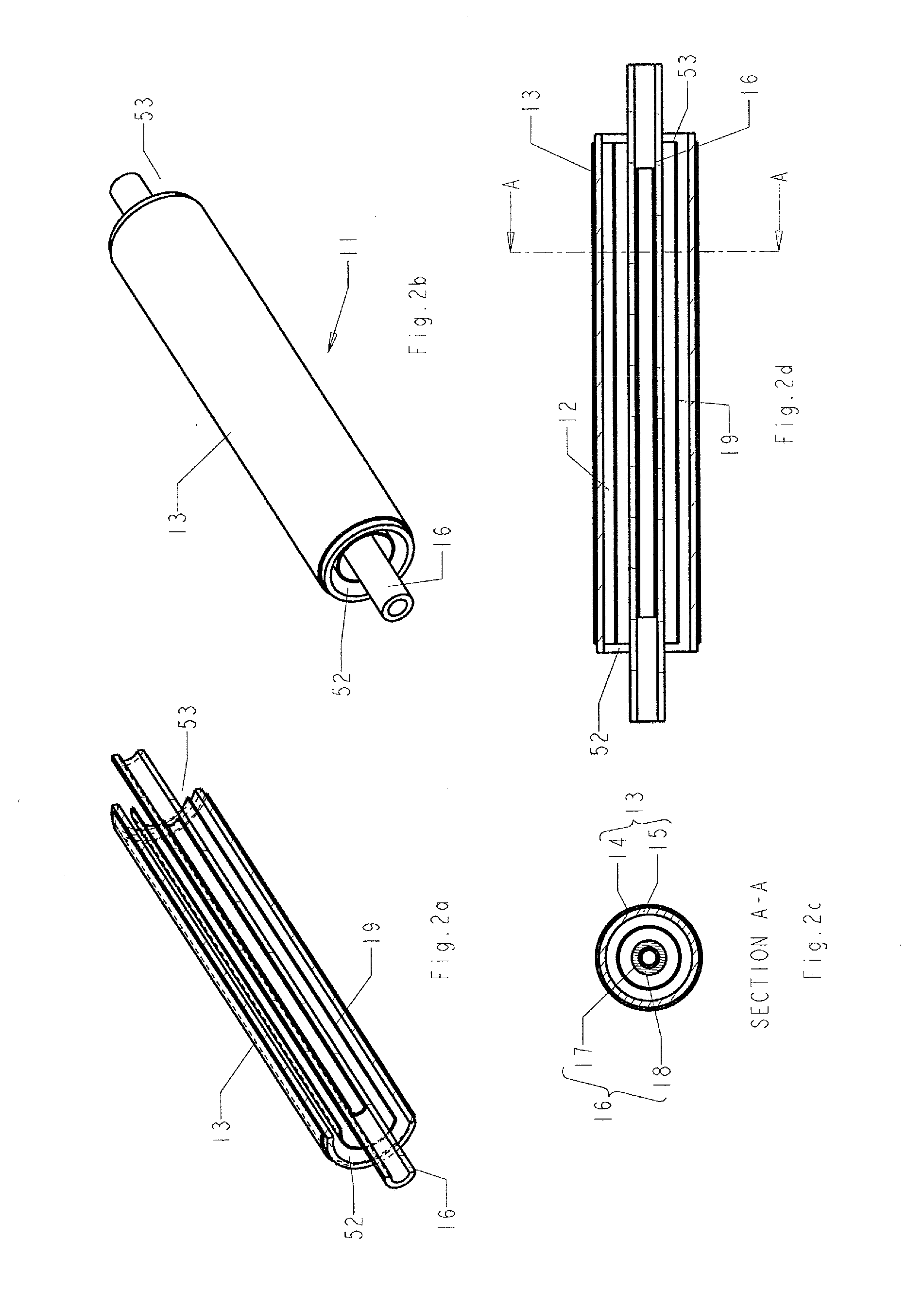

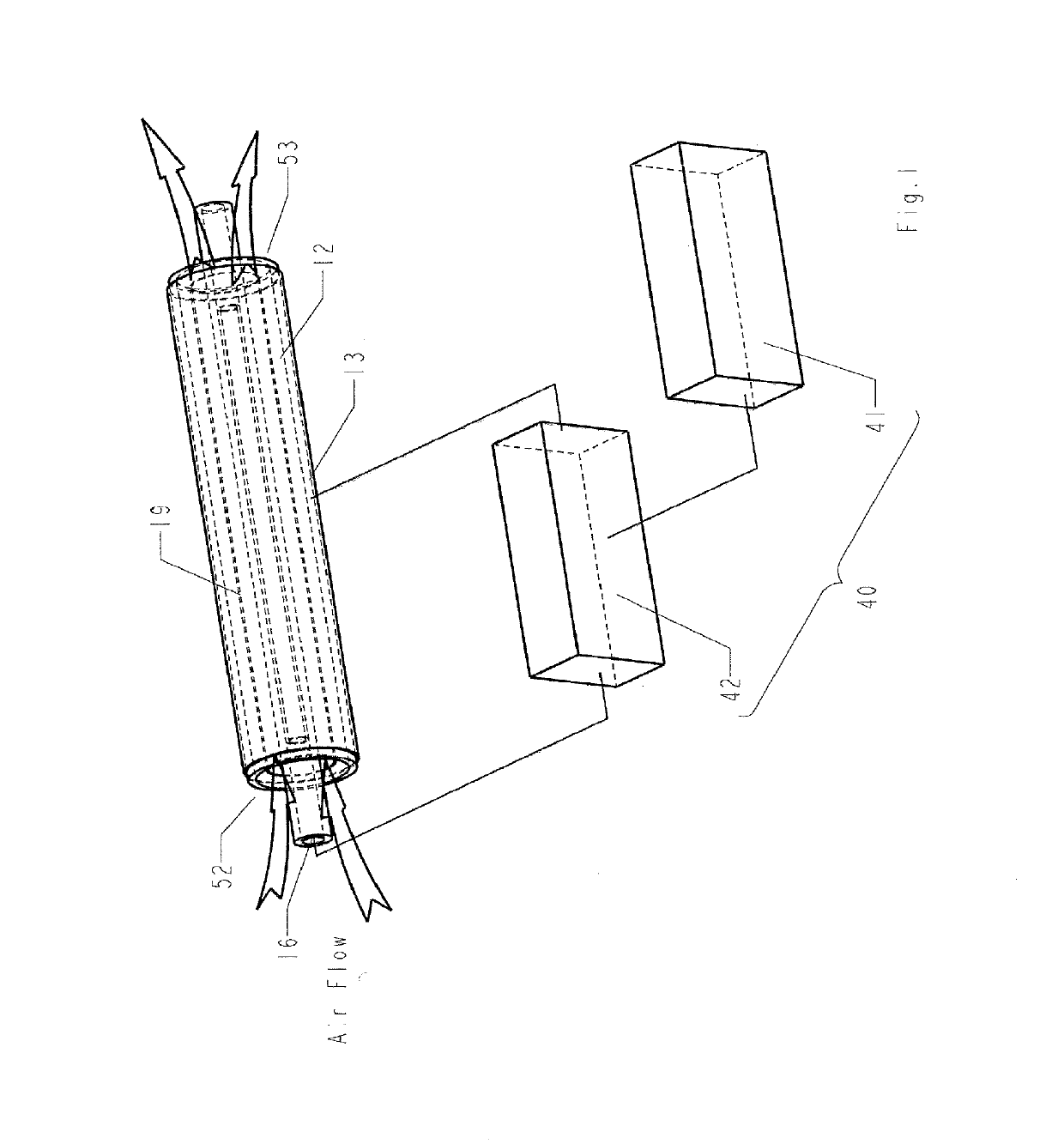

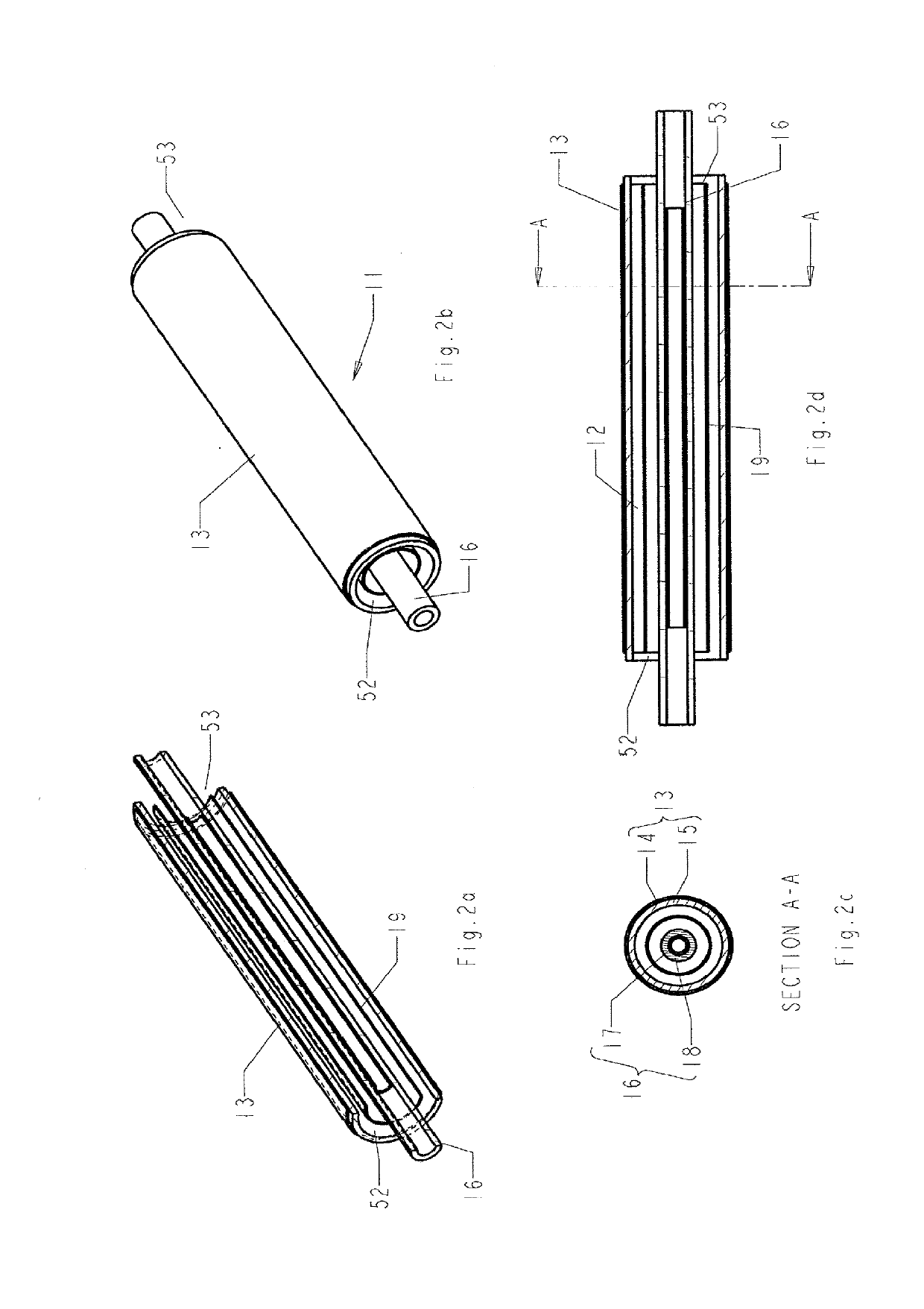

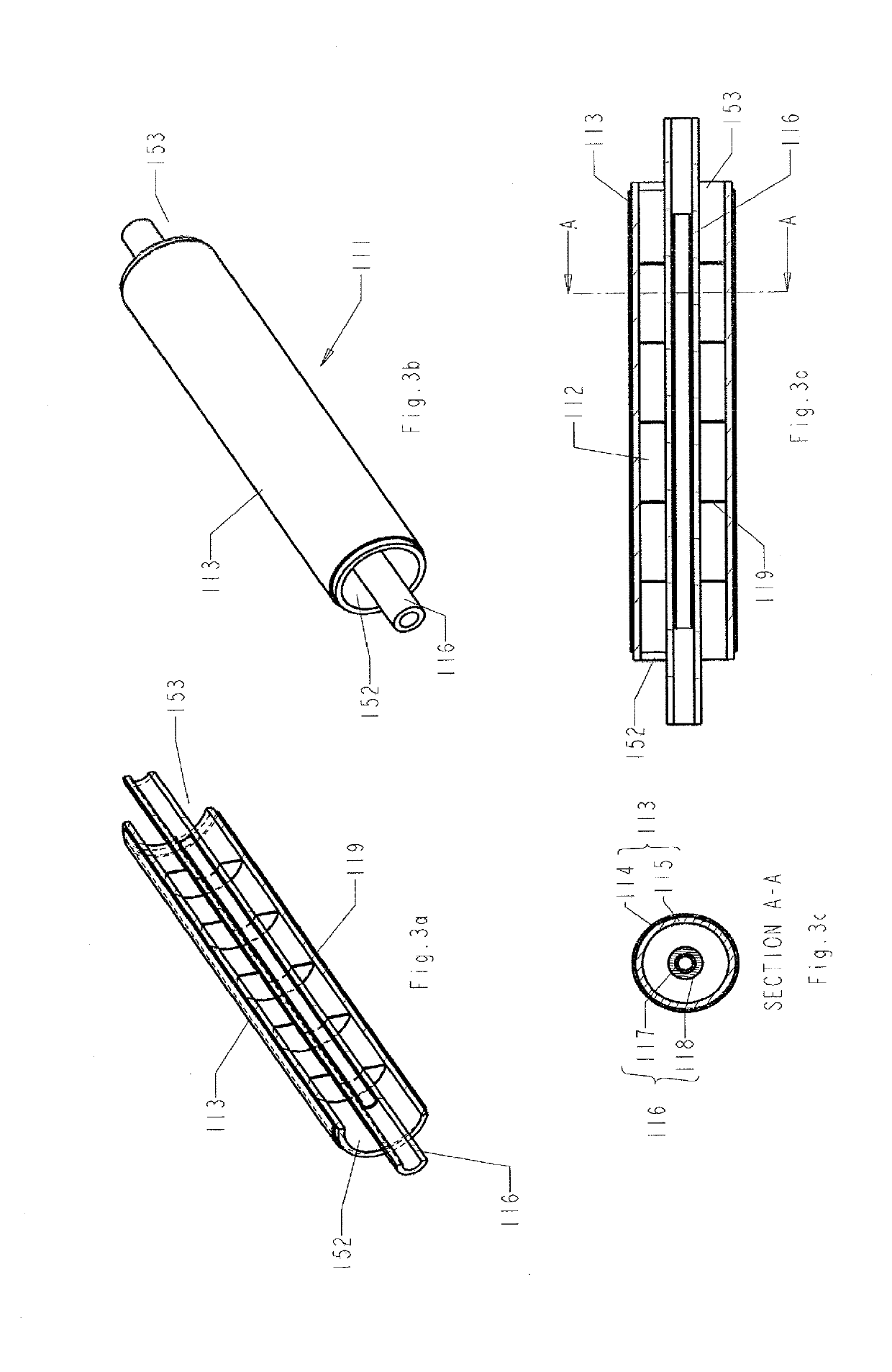

Diffusive plasma air treatment and material processing

InactiveUS20080056934A1Improve efficiencyMinimizationMechanical apparatusLighting and heating apparatusCatalytic functionEngineering

The Diffusive Plasma is for effective treatment of contaminated air and material processing. Air is purified and disinfected by passing through the diffusive plasma device which includes a reactor or a plurality of reactors arranged in parallel or series and is energized by a high voltage alternating current power supply. The diffuser, being electrically isolated, provides extra nucleation sites to initiate discharges. It serves to improve the generation of uniform and consistent plasma and to reduce the variation of discharge properties among the reactors. The addition of a diffuser, thereby, enhances the overall effectiveness of decomposing chemicals and destroying microbes to achieve high air treatment and material processing performance. The diffuser can be made of suitable filtering materials to additionally serve as a filter. By incorporating suitable catalytic materials with the diffuser, the reactor becomes a catalytic plasma reactor wherein the plasma environment provides enhanced catalytic functions. Effective plasma power deposition may be obtained by controlling the amplitude, waveform period and shape of the voltage applied to the electrodes of the reactor and hence the operation of the reactors with plasma discharged of selected conditions for optimizing the treatment and processing efficiency while minimizing the generation of unwanted bi-product gases. The present invention also relates to a method for effective air treatment and material processing.

Owner:ALPHATECH INT

Method and apparatus to reduce RF power deposition during MR data acquisition

InactiveUS20050134267A1Efficient managementFaithful productionDiagnostic recording/measuringMeasurements using NMR imaging systemsAudio power amplifierCoil array

A system composed of multiple transmit coils with corresponding RF pulse synthesizers and amplifiers is disclosed. A method of designing RF pulses specific to each transmit coil to dynamically control RF power deposition across an imaging volume is also disclosed, where parallel excitation with the transmit coils allows for management of RF power deposition on a subject while facilitating faithful production of a desired excitation profile. The present invention also supports reduction in scan time and is applicable to any coil array geometry.

Owner:GENERAL ELECTRIC CO

Magnetically shielded miniature hall thruster

InactiveUS20150128560A1Eliminates effect of ion bombardment erosionLonger thruster lifetimeMachines/enginesUsing plasmaElectron temperatureErosion rate

Magnetically shielded miniature Hall thrusters are disclosed that use a unique magnetic field topology that prevents the magnetic field lines from intersecting the discharge channel walls in the acceleration region of the thruster. Instead, the lines of force originating from both the inner and outer pole pieces curve around the downstream edges of the discharge channel and follow the channel walls towards the anode. This unique field topology results in low electron temperature at the discharge channel walls while eliminating strong electric field components that would otherwise lead to high erosion rates and power deposition from ion acceleration into the channel walls.

Owner:RGT UNIV OF CALIFORNIA

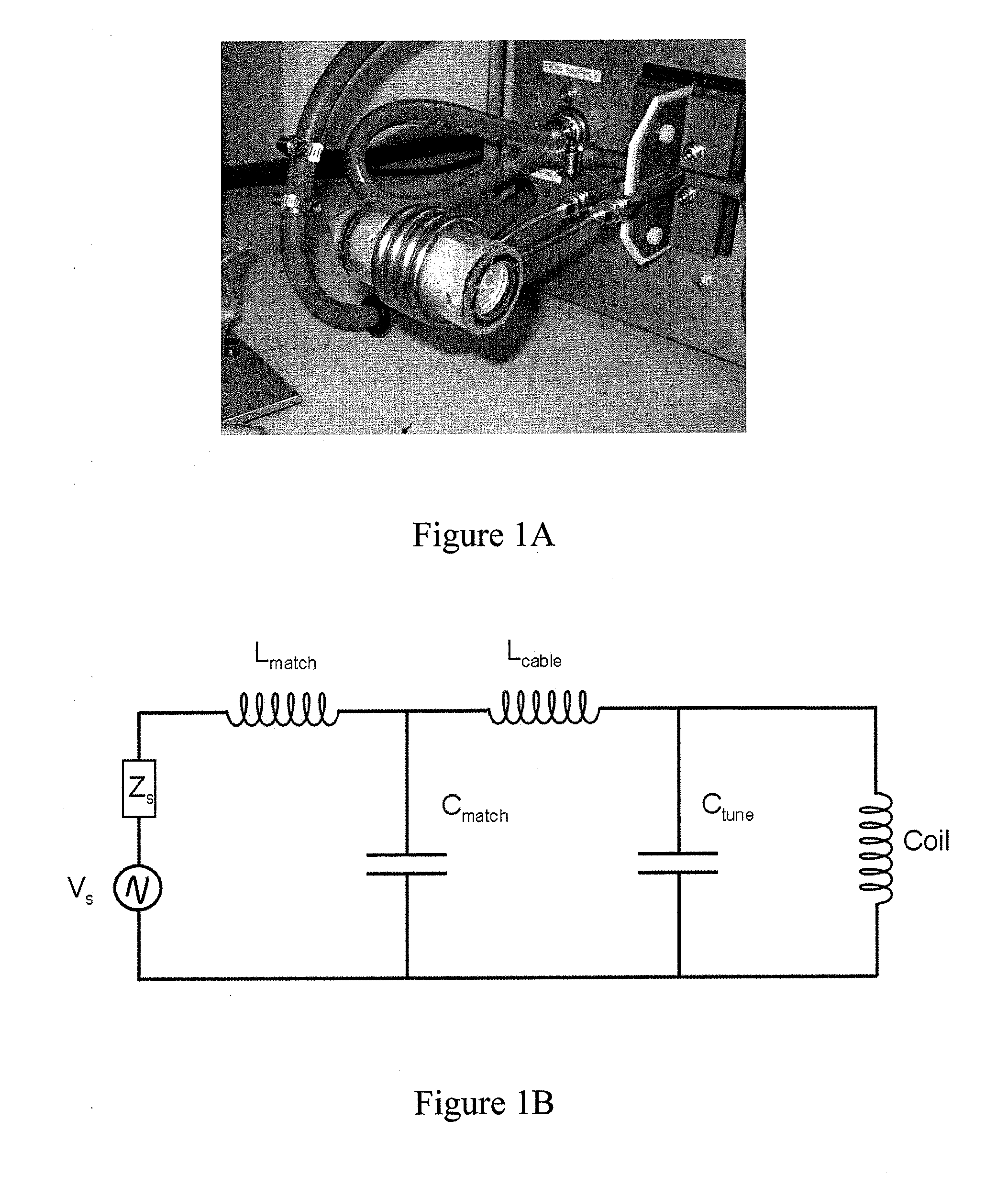

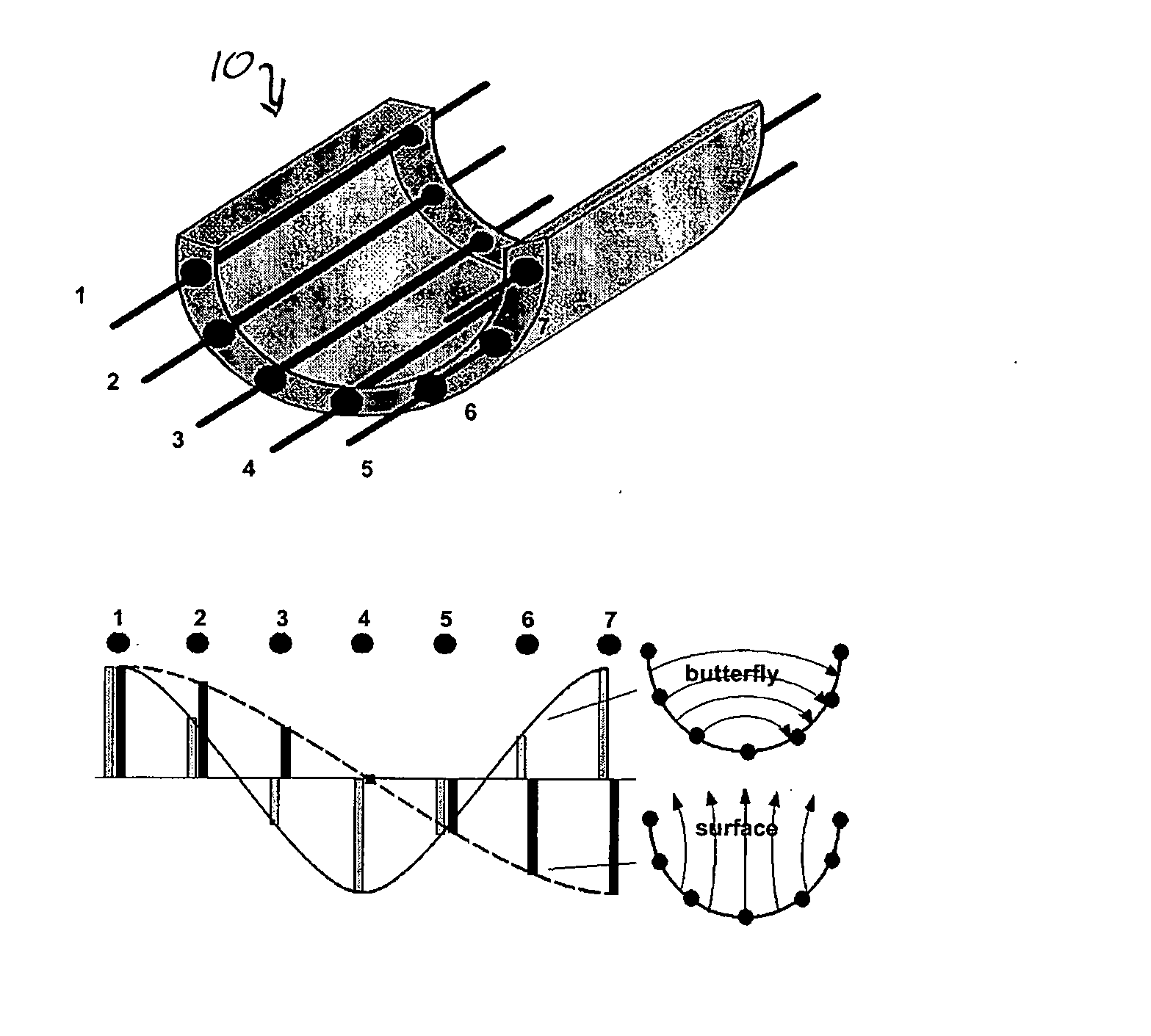

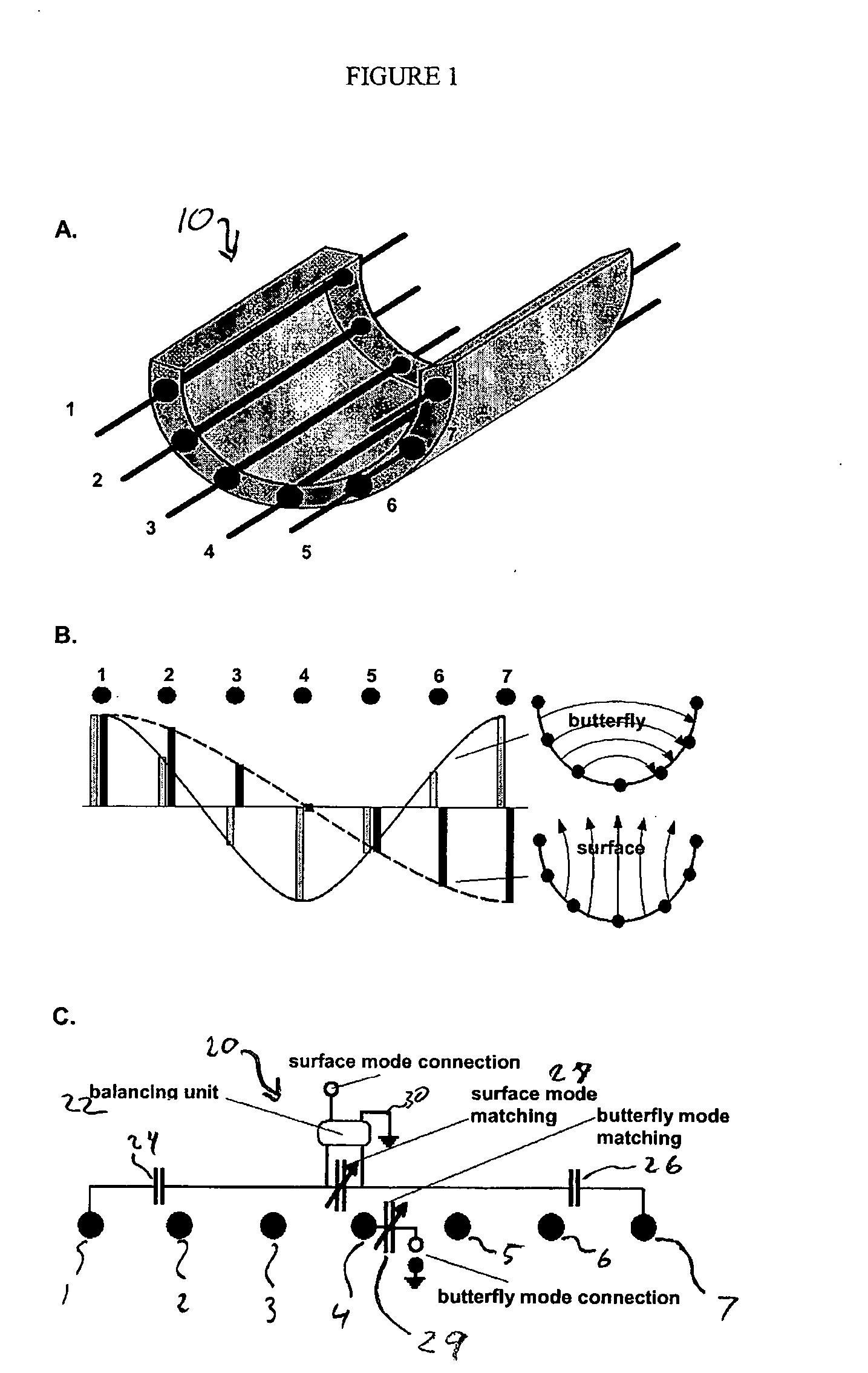

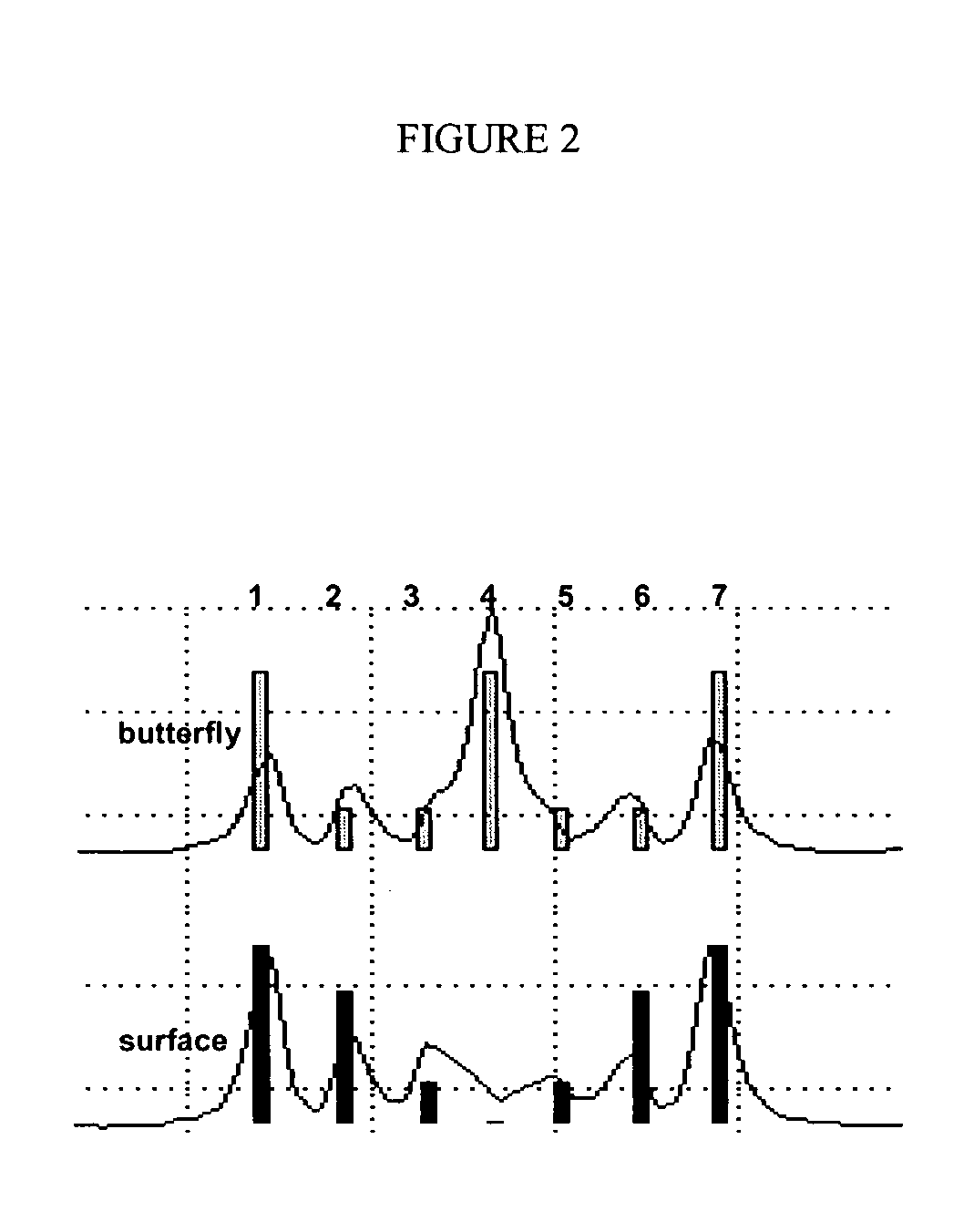

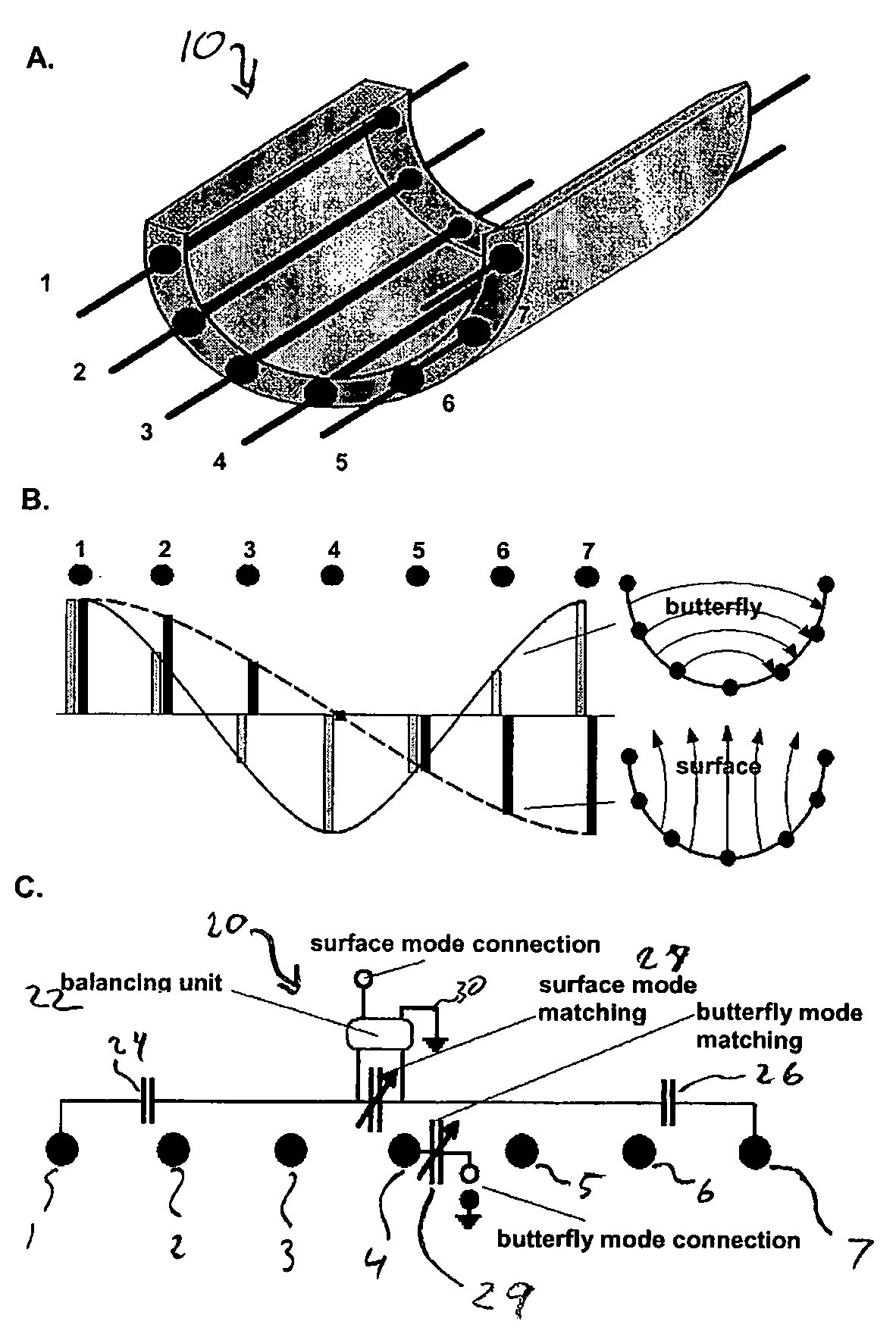

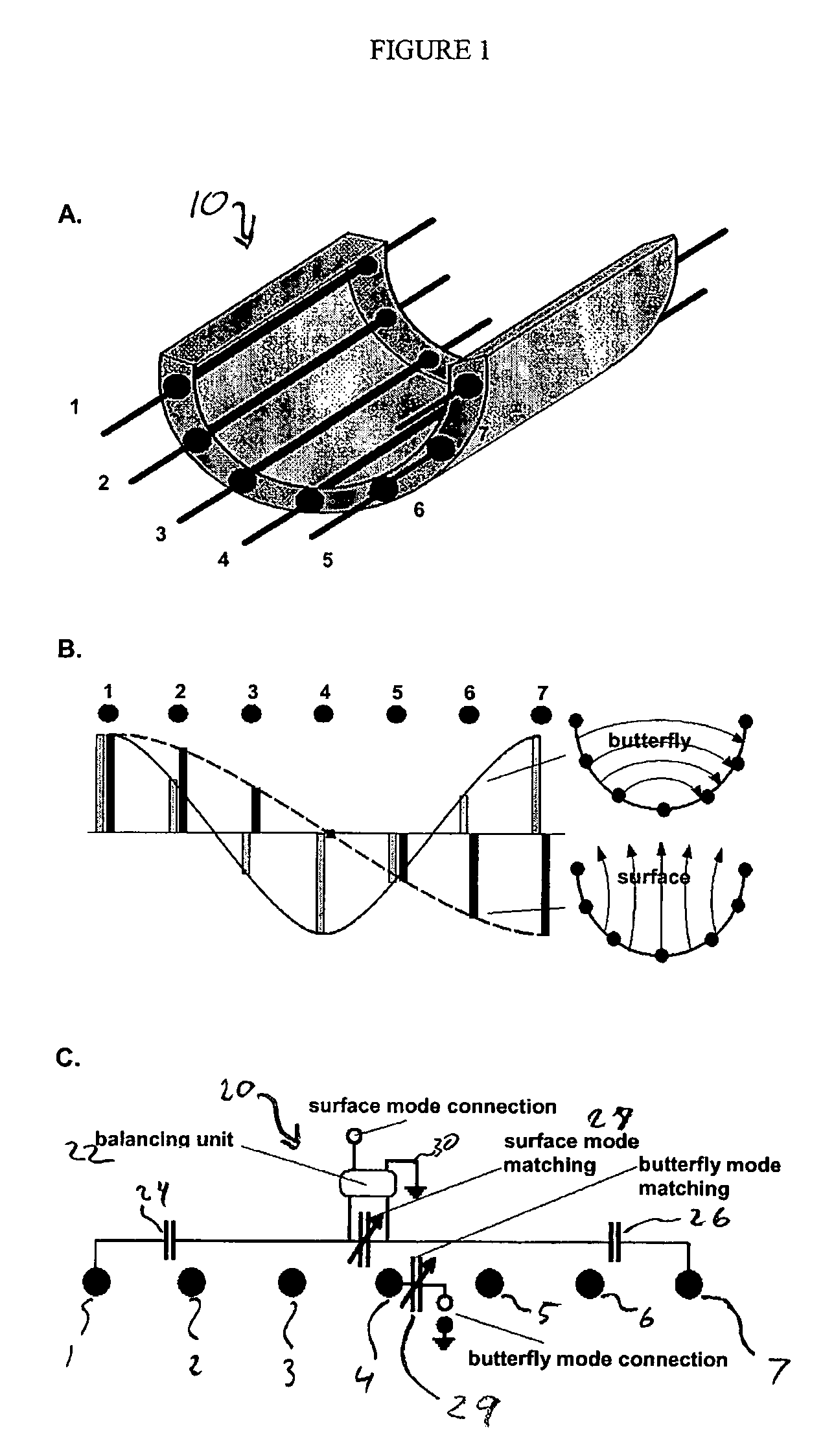

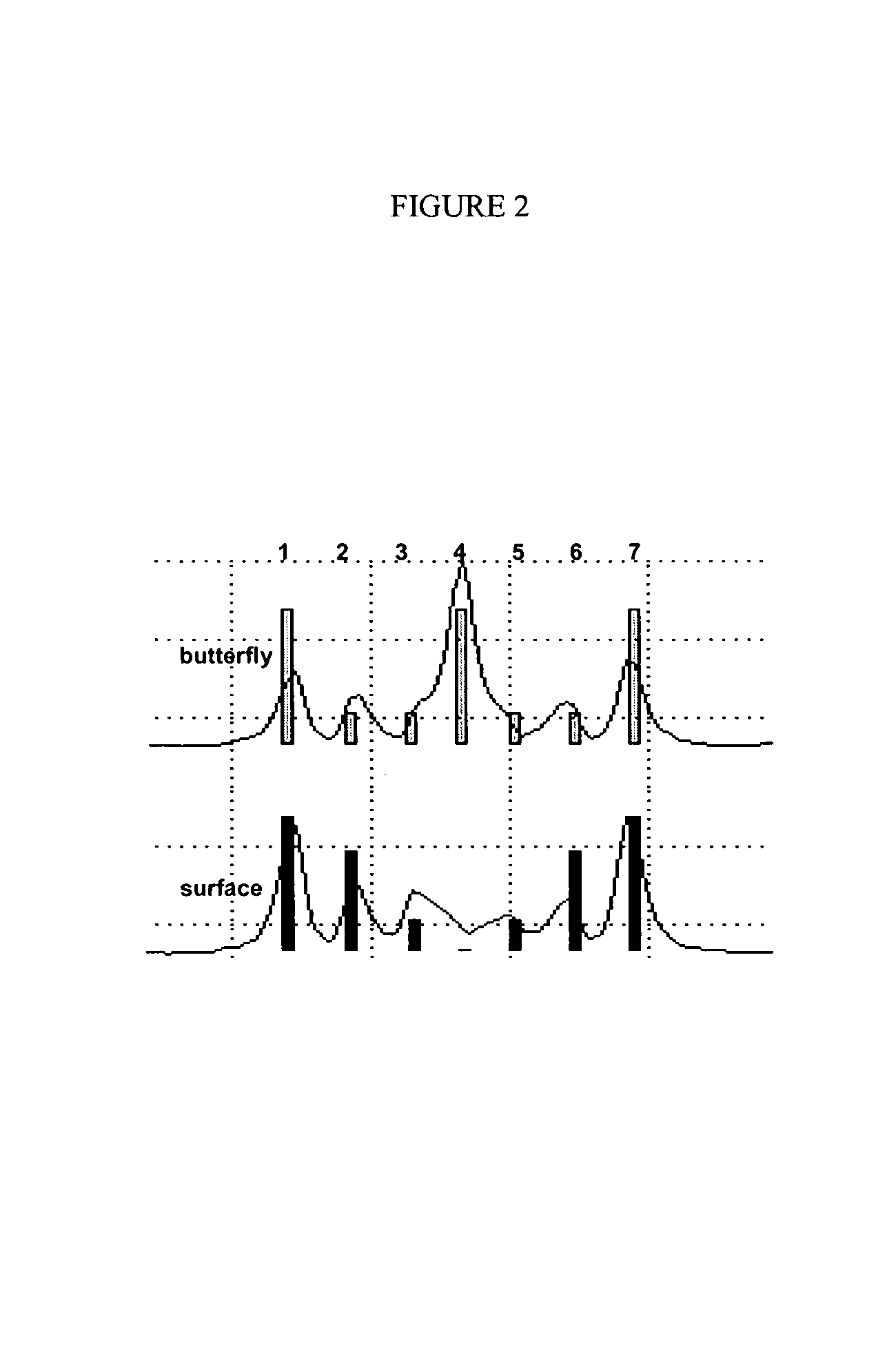

Multi-port RF systems and methods for MRI

Optimizing RF coil currents' magnitude / phase relationship, temporal modulation and spatial distribution is crucial to MR imaging performance. One key aspect for the optimization is the knowledge of B1 spatial distribution and RF power deposition associated with a coil current pattern or a source configuration, and the use of the knowledge in the optimization. Another key aspect for the optimization is a hardware infrastructure that facilitates the optimization, with, specifically, a coil structure that supports flexible current path control. The present invention relates to calibration methods and multi-channel parallel RF transmit / receive coil assemblies that improve the performance of MR imaging by addressing both aspects.

Owner:ZHU YUDONG

Using S-parameter measurements to manage SAR and transmit gain in MRI

Systems and methods for controlling a magnetic resonance imaging system are provided. In one embodiment, a magnetic resonance imaging system includes a radio frequency coil with a plurality of conductive coil elements, control circuitry that determines, based at least in part on a measurement of scattering parameters, a plurality of forward voltages that will cause power deposition into an object within a predetermined specific absorption rate, and an amplifier configured to apply the determined plurality of forward voltages respectively to the plurality of coil elements. The control circuitry may determine the plurality of forward voltages based at least in part on an unloaded measurement of scattering parameters and a loaded measurement of scattering parameters.

Owner:GENERAL ELECTRIC CO

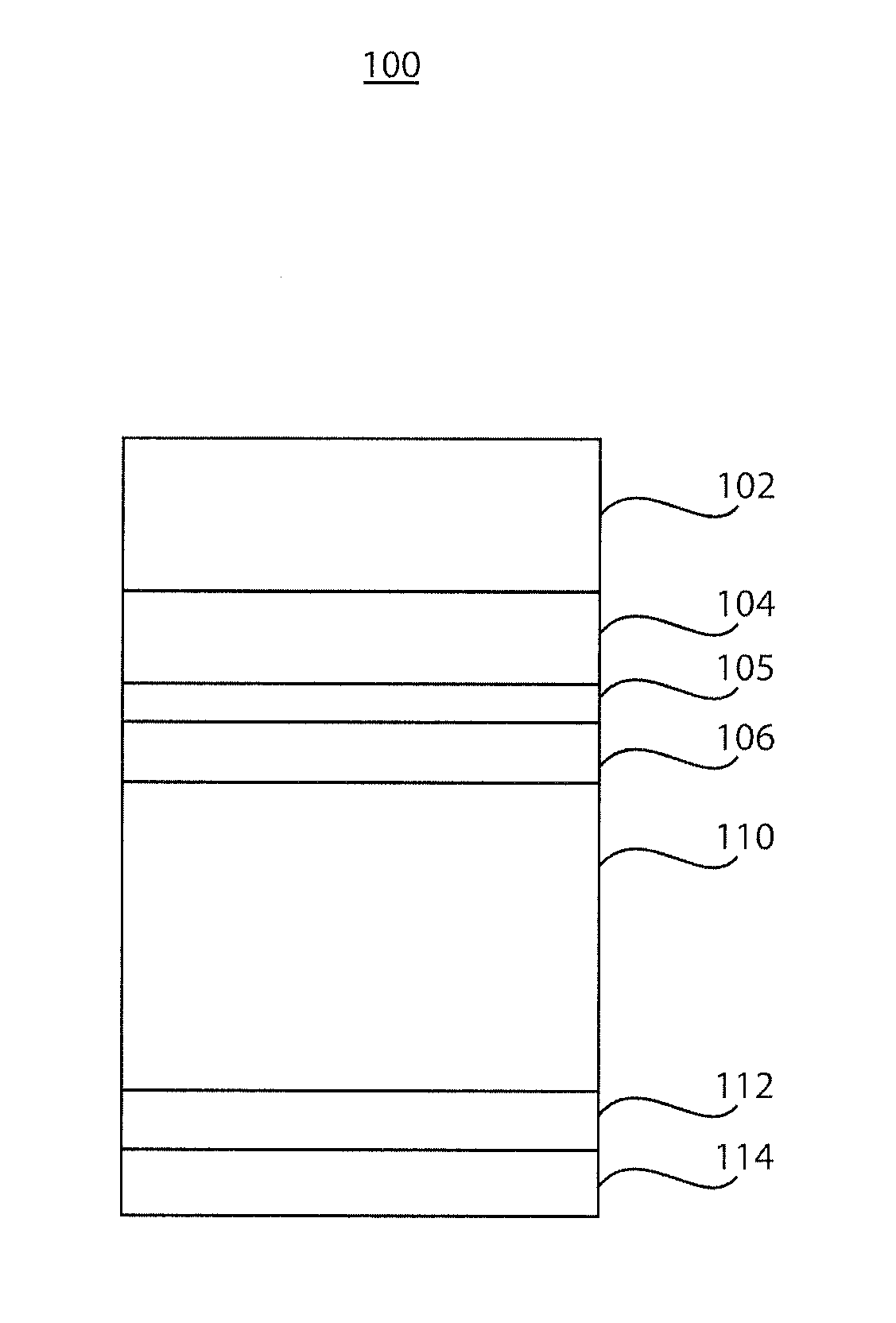

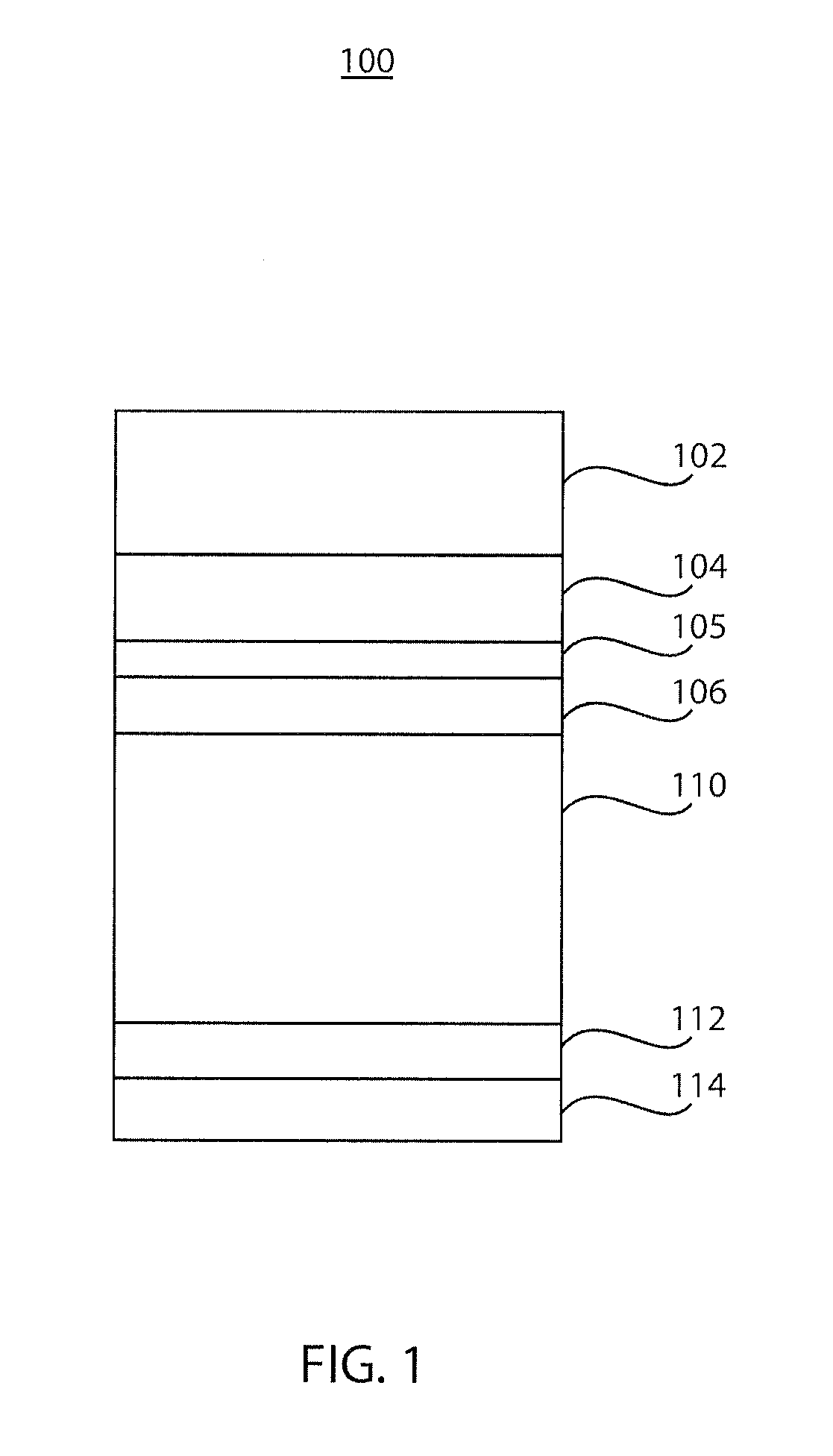

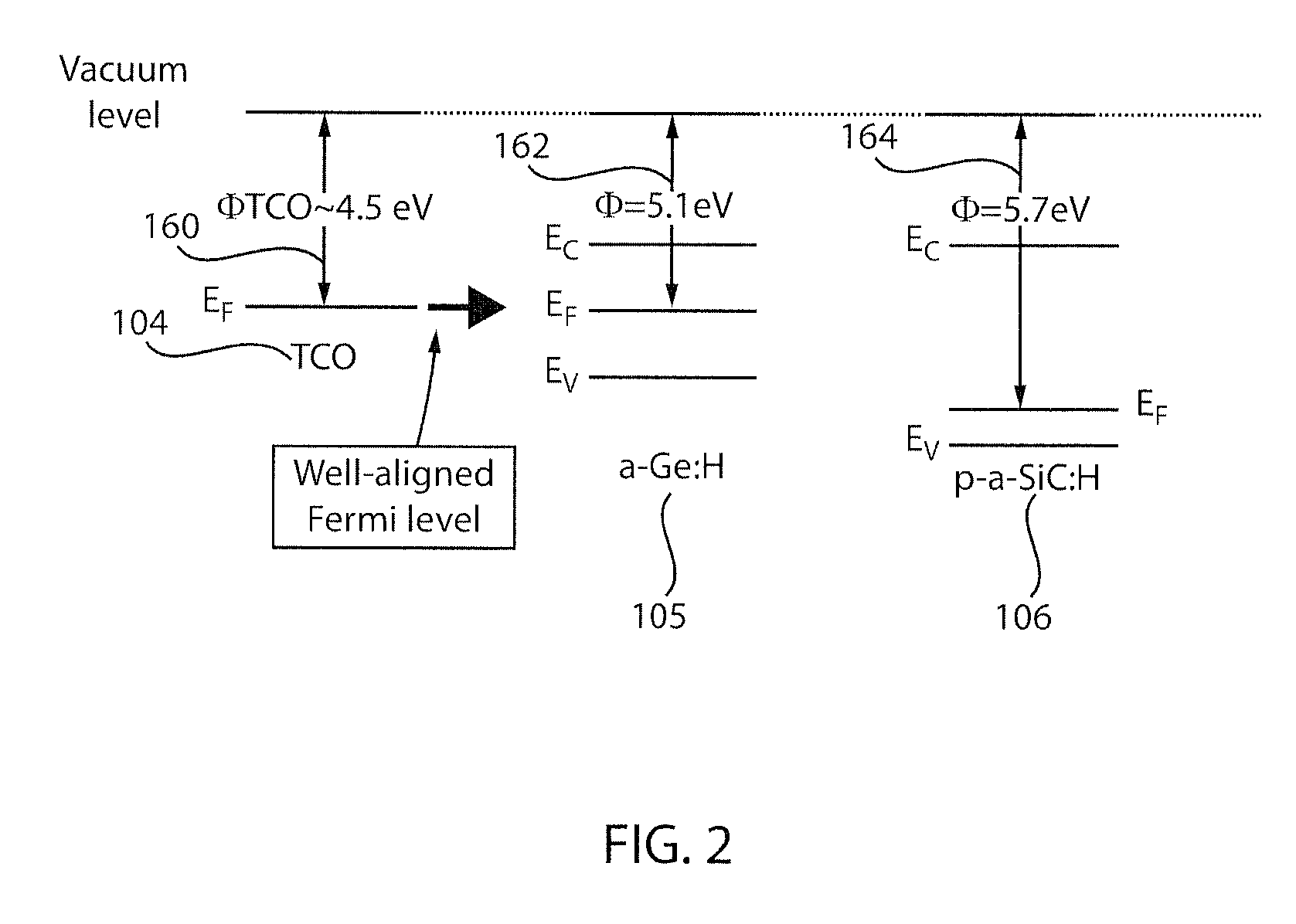

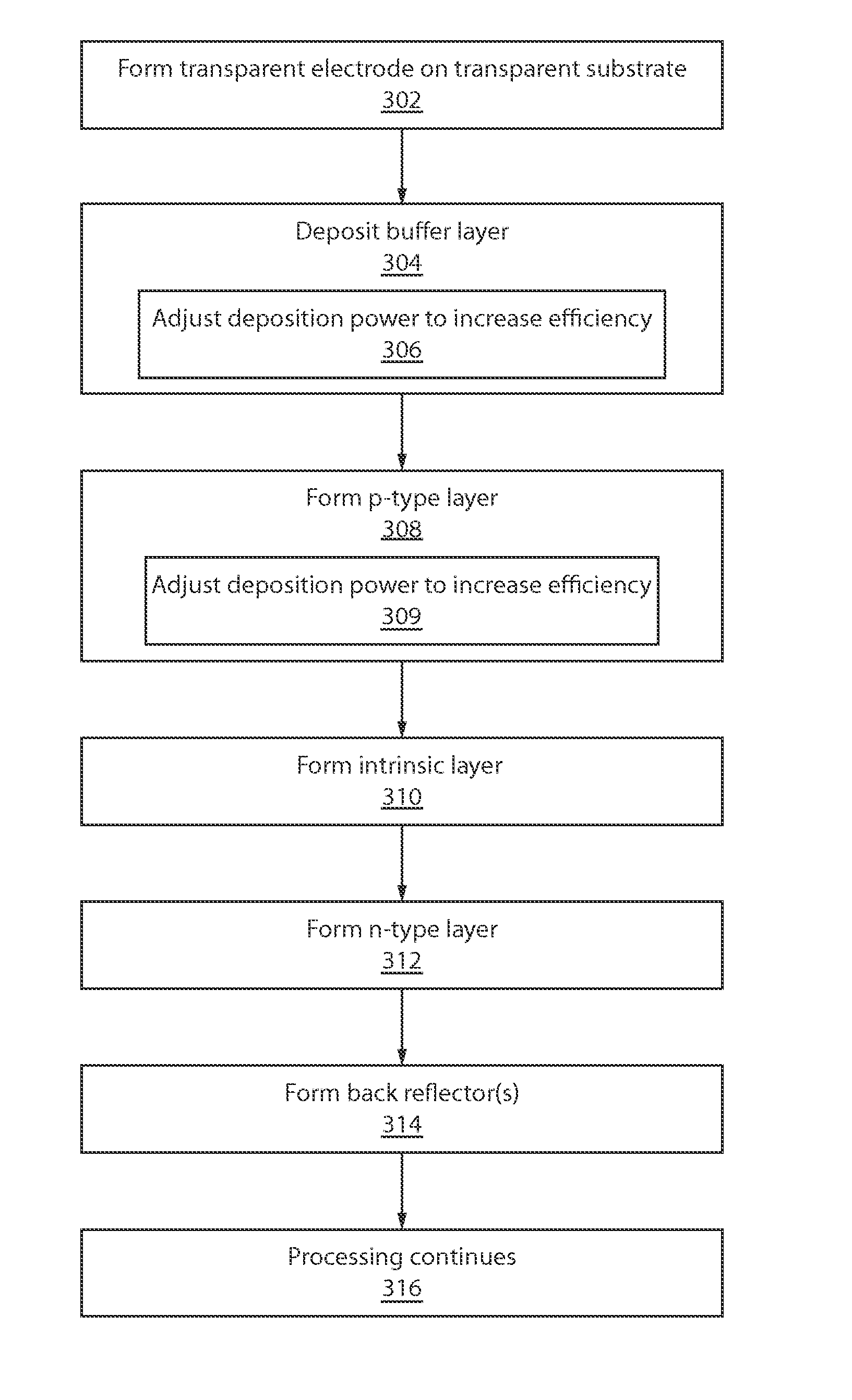

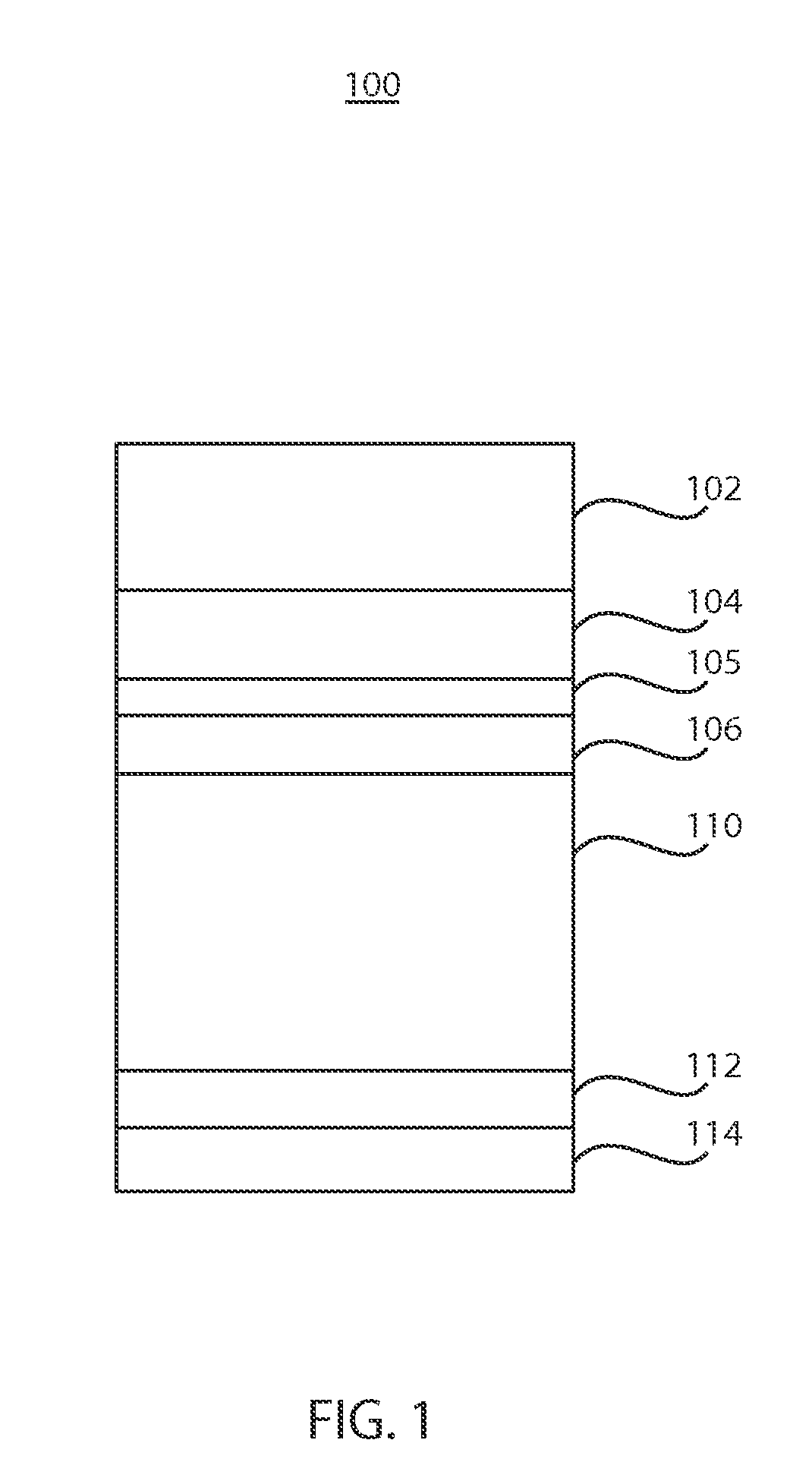

Reduced light degradation due to low power deposition of buffer layer

ActiveUS20130221464A1Improve the immunityFinal product manufactureSemiconductor/solid-state device manufacturingWork functionPower deposition

Methods for forming a photovoltaic device include forming a buffer layer between a transparent electrode and a p-type layer. The buffer layer includes a work function that falls substantially in a middle of a barrier formed between the transparent electrode and the p-type layer to provide a greater resistance to light induced degradation. An intrinsic layer and an n-type layer are formed over the p-type layer.

Owner:IBM CORP

Method and apparatus for spin-echo-train MR imaging using prescribed signal evolutions

InactiveUSRE45725E1Shorten Image Acquisition TimeExtended durationDiagnostic recording/measuringSensorsHigh fieldMagnetic resonance technique

A magnetic resonance imaging “MRI” method and apparatus for lengthening the usable echo-train duration and reducing the power deposition for imaging is provided. The method explicitly considers the t1 and t2 relaxation times for the tissues of interest, and permits the desired image contrast to be incorporated into the tissue signal evolutions corresponding to the long echo train. The method provides a means to shorten image acquisition times and / or increase spatial resolution for widely-used spin-echo train magnetic resonance techniques, and enables high-field imaging within the safety guidelines established by the Food and Drug Administration for power deposition in human MRI.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

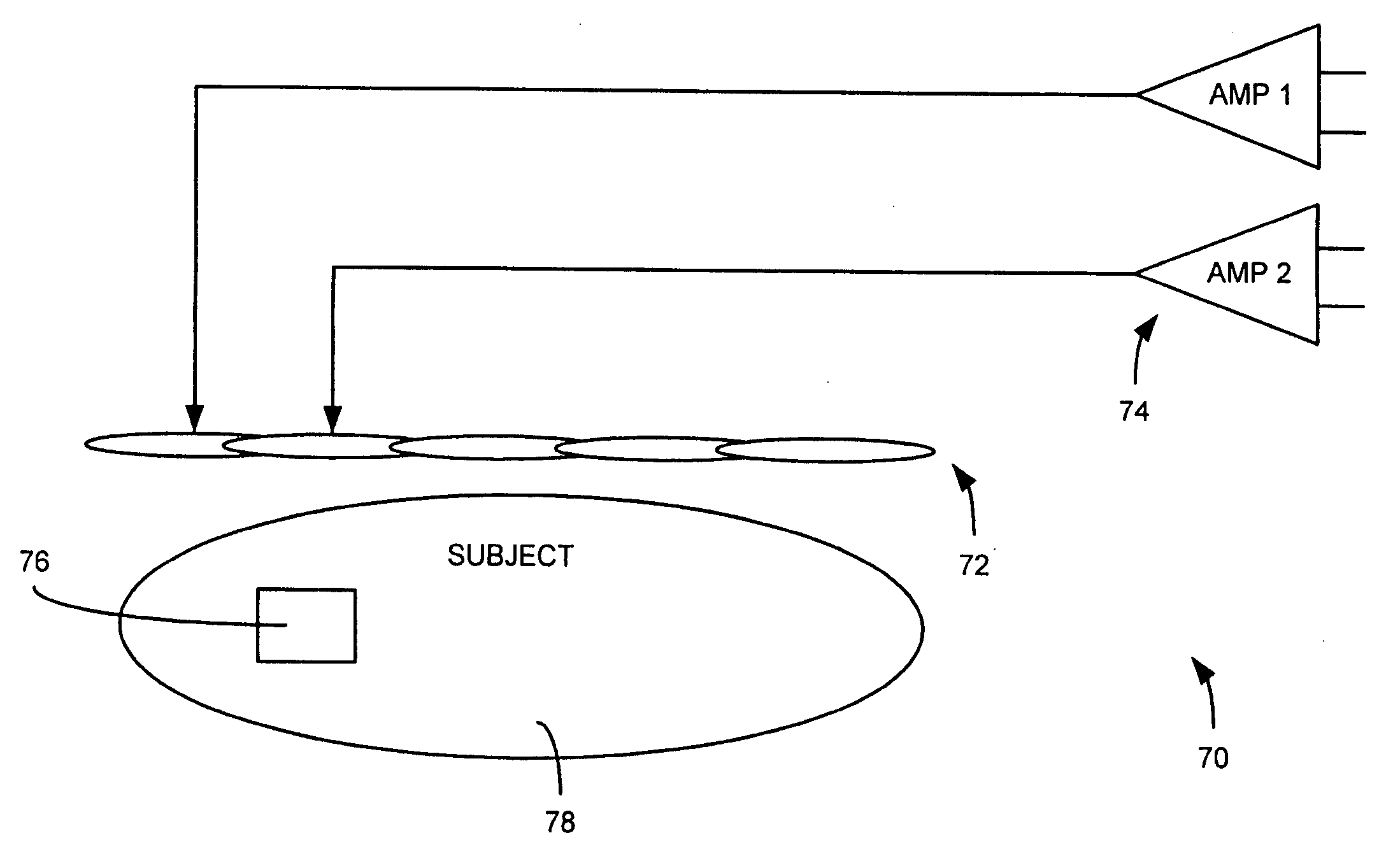

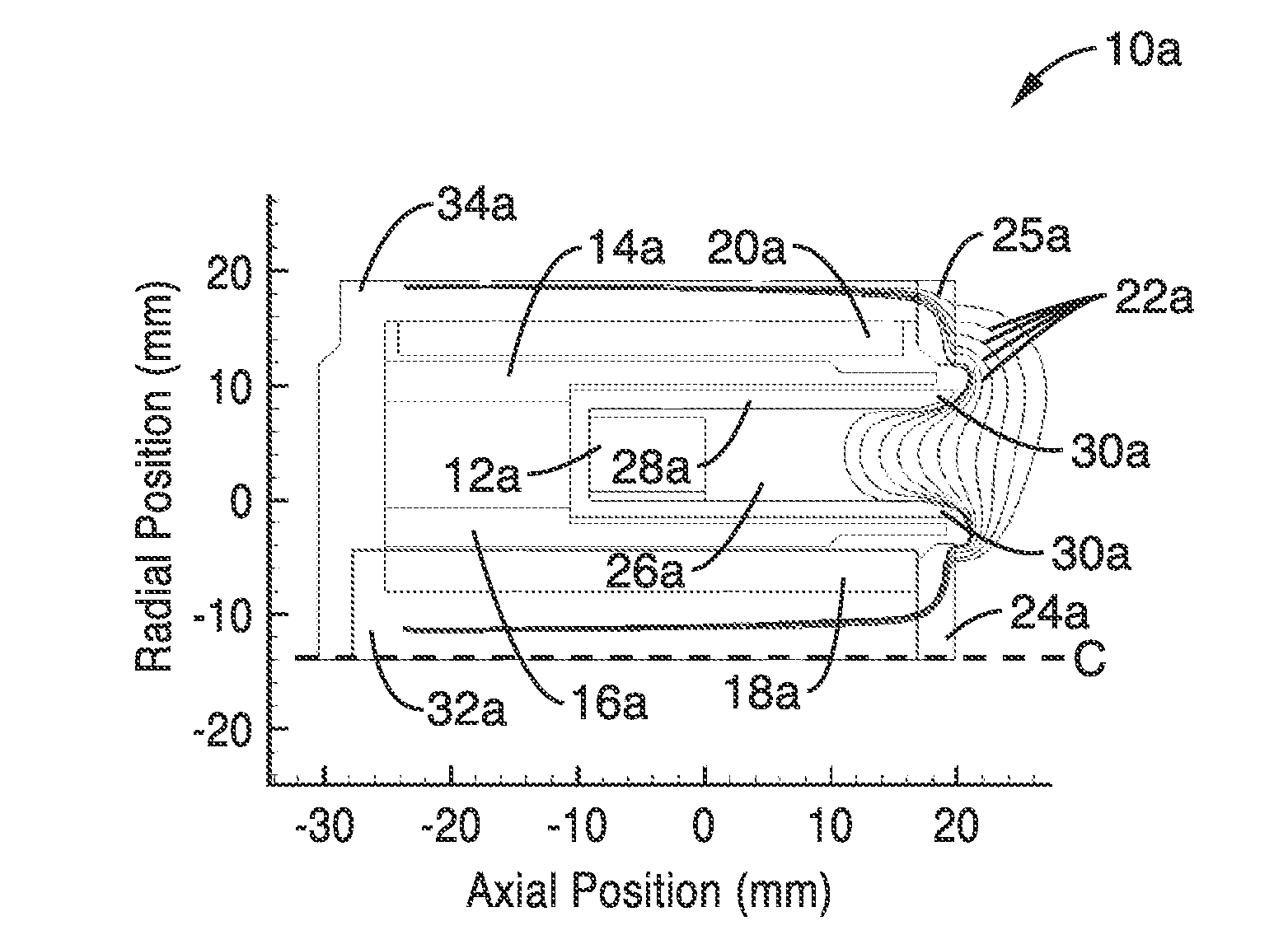

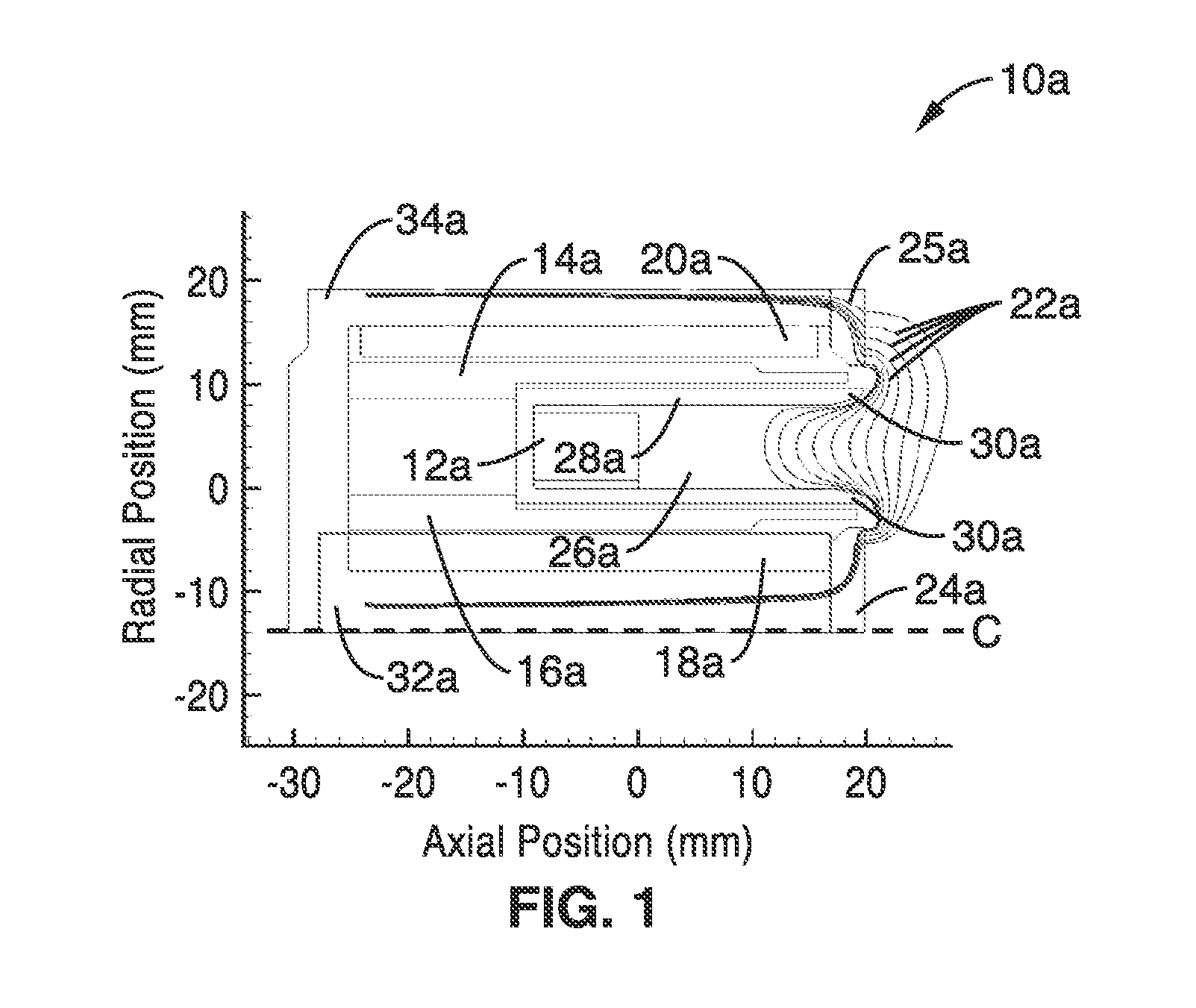

Systems and Methods to Reduce Power Deposition in Tissue Exposed to Radio Frequency Electromagnetic Fields

ActiveUS20120265000A1Reduces power depositionReduce depositionElectrotherapyMagnetic measurementsRadiofrequency electromagnetic radiationElectromagnetic radiation

An apparatus for exposing a region of interest of an object, animal or person to an alternating magnetic field has a source of radio-frequency electromagnetic radiation arranged to provide the alternating magnetic field in an exposure volume defined by the apparatus, and a shield arranged between the source of radio-frequency electromagnetic radiation and the exposure volume. The shield includes a material that has a sufficient thickness and arrangement to reduce power deposition to at least regions outside of the region of interest of the object, animal or person during exposure in the exposure volume.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

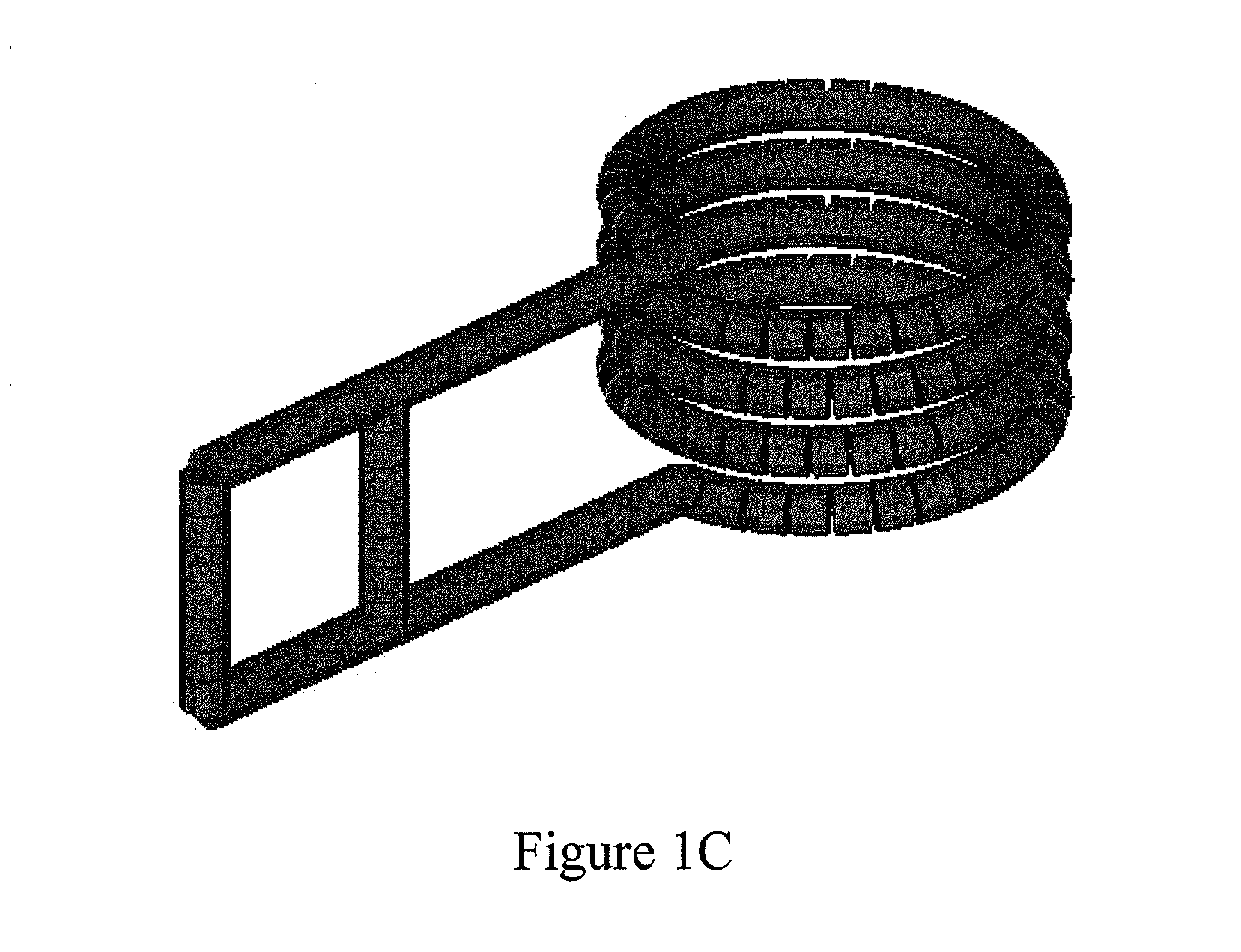

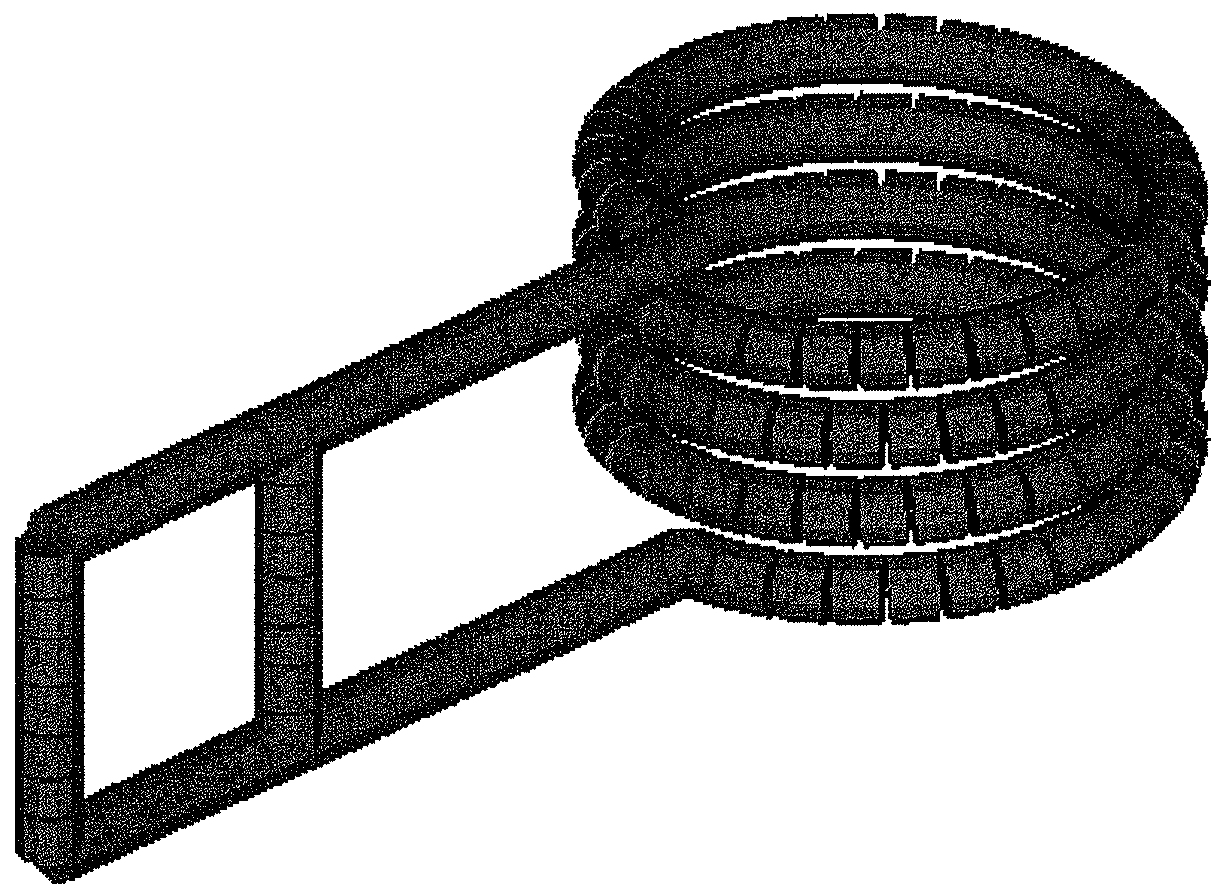

Open half volume quadrature transverse electromagnetic coil for high field magnetic resonance imaging

InactiveUS20050253581A1Electric/magnetic detectionMeasurements using magnetic resonancePatient comfortHigh field magnetic resonance imaging

A half-volume quadrature TEM coil high field (>3 T) imaging applications. This novel coil produces a sufficiently large homogeneous B1 field region for the use as a volume coil. It provides superior transmission efficiency, resulting in significantly lower power deposition, as well as greater sensitivity and improved patient comfort and accessibility compared with conventional full-volume coils. Additionally this coil compensates the RF penetration artifact that distorts high-field images recorded with linear surface and volume coils. These advantages make it potentially possible to apply the device as an efficient transmit / receive body coil at high fields, where the use of the full-volume coils is complicated by the excessive power deposition and low sensitivity.

Owner:ALBERT EINSTEIN COLLEGE OF MEDICINE INC

Method for performing thermal spraying by using ceramic powder

InactiveCN102505105AIncrease profitStable spraying powerMolten spray coatingCoated surfaceThermal spraying

The invention relates to a thermal spraying method in the field, in particular to a method for performing thermal spraying by using ceramic powder. The method comprises the following steps of: 1) heating and melting or softening the ceramic powder by a heat source; 2) spraying the ceramic powder which is heated and molten or softened in step 1) onto the surface of a matrix; and 3) cooling, solidifying and forming, wherein the particle size of the ceramic powder is 20 to 40mu m. According to the method for performing thermal spraying by using the ceramic powder, the utilization rate of the ceramic powder is improved by performing thermal spraying by using the ceramic powder with the particle size of between 20 and 40mu m; a ceramic coating is compact and uniform; the spraying power is stable; the method can be easily operated by workers; the phenomenon that the surface of the coating is bumpy because the ceramic powder has larger particles and cannot be molten is avoided; and the roughness is less than or equal to 0.2mu m, so that the surface roughness of the coating is greatly reduced. The hardness of the coating is 850 to 1,000HV, the powder deposition efficiency is over 60 percent, and the harness of the coating and the power deposition efficiency are remarkably improved.

Owner:JIANGSU WUJIN HYDRAULIC HOIST

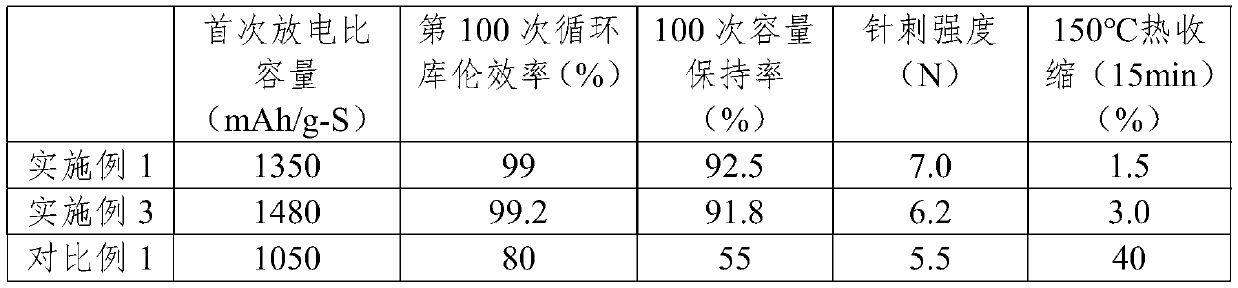

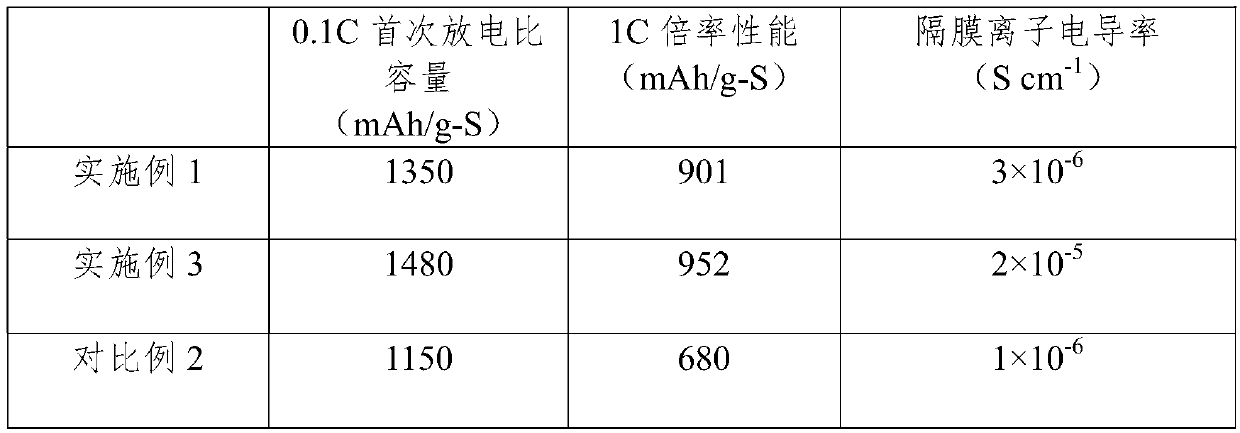

Composite diaphragm for alkali metal battery and preparation and application thereof

ActiveCN110707267AHigh ion conductivityHigh mechanical strengthSecondary cellsCell component detailsCeramic coatingPhysical chemistry

The invention relates to a composite diaphragm for an alkali metal battery and a preparation method of the composite diaphragm. The composite diaphragm comprises an organic diaphragm matrix layer coated with a ceramic coating and an amorphous alkali metal ion conductor inorganic solid layer, and the preparation method is a vacuum physical deposition method and comprises the following steps of passing an organic diaphragm substrate through a vacuum deposition cavity in a roll-to-roll mode, wherein the vacuum degree of a vacuum box body is 0.5-5 Pa, the reaction gas is nitrogen, the deposition power supply power is 30-180 W, the deposition time is 5-30 min; and depositing to prepare the composite diaphragm. The deposited inorganic solid layer is compact and non-porous, so that the diaphragmhas very strong mechanical property and high-temperature resistance, and the internal short circuit caused by the battery impurities and the metal dendrites and the thermal deformation of the batterydiaphragm can be effectively prevented. Meanwhile, the inorganic solid layer has the alkali metal cation high-speed conduction performance, stability in air and a hetero-ion blocking function, so thatthe safety performance and the cycle life of the battery can be remarkably improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

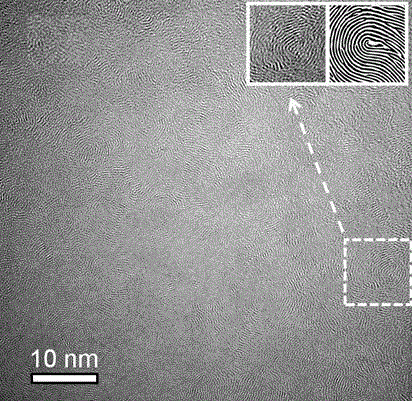

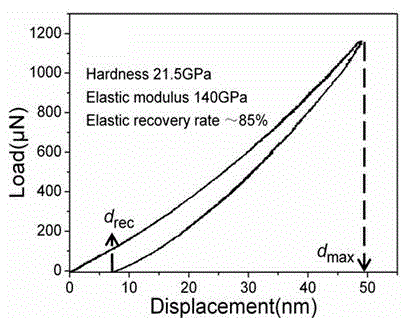

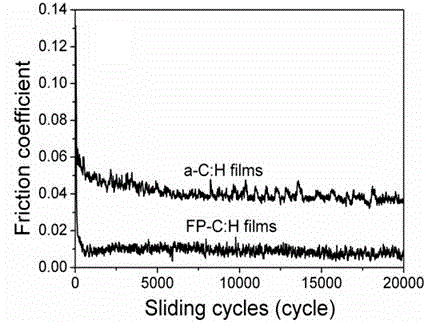

Low-temperature vapor deposition method for carbon-based super-lubricating thin film with onion structure

ActiveCN105779950AImprove mechanical propertiesUniform mechanical propertiesVacuum evaporation coatingSputtering coatingAlcoholPhysical chemistry

The invention relates to a low-temperature vapor deposition method for a carbon-based super-lubricating thin film with an onion structure. The method comprises the following steps of (1) carrying out ultrasonic cleaning on silicon substrate by using acetone and absolute ethyl alcohol, and transferring the silicon substrate to a coating cavity; (2) vacuumizing until the vacuum degree is smaller than 4.0*10<-3> Pa; (3) cleaning under the following conditions: introducing Ar until the air pressure is 2-3 Pa, applying a negative bias voltage of -1000 to -1200 V to the silicon substrate to carry out plasma glow cleaning for 10 min; and (4) depositing the carbon-based super-lubricating thin film with the onion structure, namely keeping the bias voltage at -500 to -1000 V, the frequency at 3.5 KHz and the duty ratio at 15-25%; and keeping the air flow of Ar at 80-200sccm, the CH4 flow at 40-50sccm, the air pressure at 0.45-0.5 Pa, the target power at 800-900 W, the deposition time within 1 h and the deposited thin film thickness at about 1 mu m in the deposition process. The carbon-based super-lubricating thin film with the onion structure, prepared by using the low-temperature vapor deposition method, has the advantages of high hardness, excellent chemical inertness, low frictional coefficient, good wear resistance and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Open half volume quadrature transverse electromagnetic coil for high field magnetic resonance imaging

InactiveUS6980003B2Electric/magnetic detectionMeasurements using magnetic resonancePatient comfortHigh field magnetic resonance imaging

A half-volume quadrature TEM coil high field (>3 T) imaging applications. This novel coil produces a sufficiently large homogeneous B1 field region for the use as a volume coil. It provides superior transmission efficiency, resulting in significantly lower power deposition, as well as greater sensitivity and improved patient comfort and accessibility compared with conventional full-volume coils. Additionally this coil compensates the RF penetration artifact that distorts high-field images recorded with linear surface and volume coils. These advantages make it potentially possible to apply the device as an efficient transmit / receive body coil at high fields, where the use of the full-volume coils is complicated by the excessive power deposition and low sensitivity.

Owner:ALBERT EINSTEIN COLLEGE OF MEDICINE OF YESHIVA UNIV

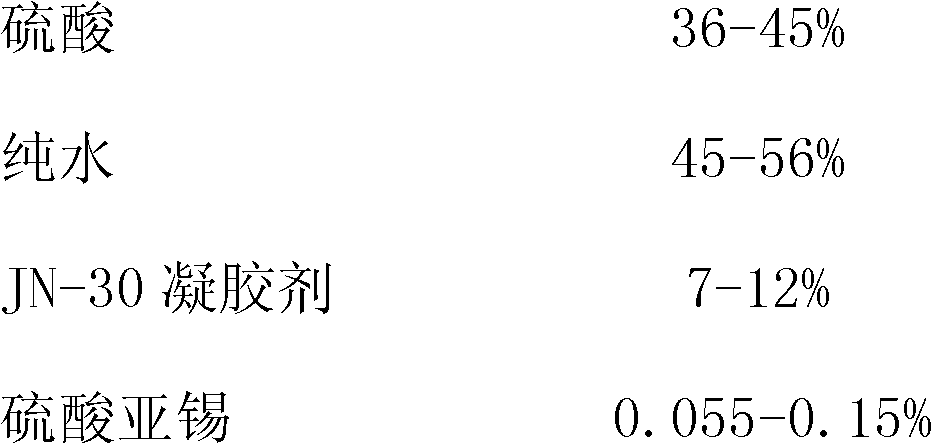

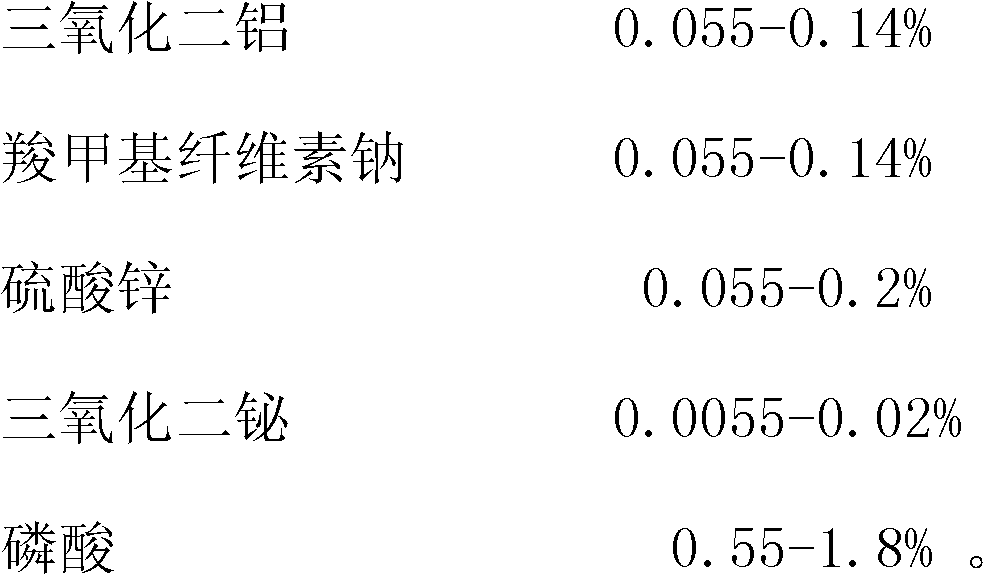

Colloidal electrolyte for starting type battery

The invention provides colloidal electrolyte for a starting type battery, which comprises the following components by mass percent: 36 to 45 percent of sulfuric acid, 45 to 56 percent of purified water, 7 to 12 percent of JN-30 gelata, 0.055 to 0.15 percent of stannous sulfate, 0.055 to 0.14 percent of aluminium sesquioxide, 0.055 to 0.14 percent of sodium salt of carboxy methyl-cellulose, 0.055 to 0.2 percent of zinc sulfate, 0.0055 to 0.02 percent bismuth trioxide, and 0.55 to 1.0 percent of phosphoric acid. The colloidal electrolyte is better in runnability before being added into the battery, after being added into the battery, the colloidal electrolyte is changed to be non-liquid jelly type gel through electrolysis, water loss is avoided, the problem of removed power deposition in conventional electrolyte caused by rocking and impacts of heavy current can be solved, and the service life of the battery is prolonged.

Owner:CHAOWEI POWER CO LTD

Systems and methods to reduce power deposition in tissue exposed to radio frequency electromagnetic fields

ActiveUS9333369B2Reduce depositionElectrotherapyMagnetic measurementsRadiofrequency electromagnetic radiationElectromagnetic radiation

An apparatus for exposing a region of interest of an object, animal or person to an alternating magnetic field has a source of radio-frequency electromagnetic radiation arranged to provide the alternating magnetic field in an exposure volume defined by the apparatus, and a shield arranged between the source of radio-frequency electromagnetic radiation and the exposure volume. The shield includes a material that has a sufficient thickness and arrangement to reduce power deposition to at least regions outside of the region of interest of the object, animal or person during exposure in the exposure volume.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

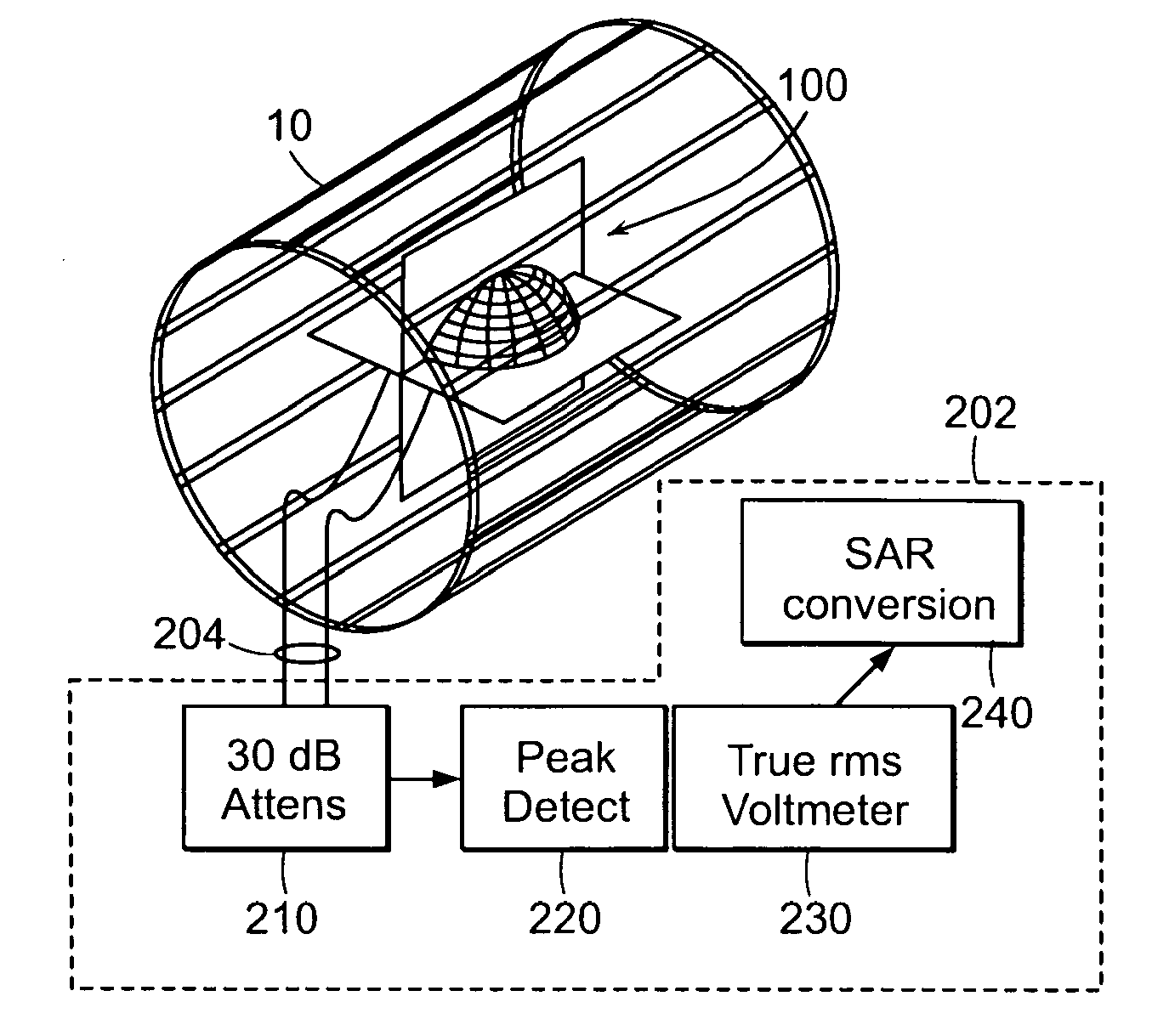

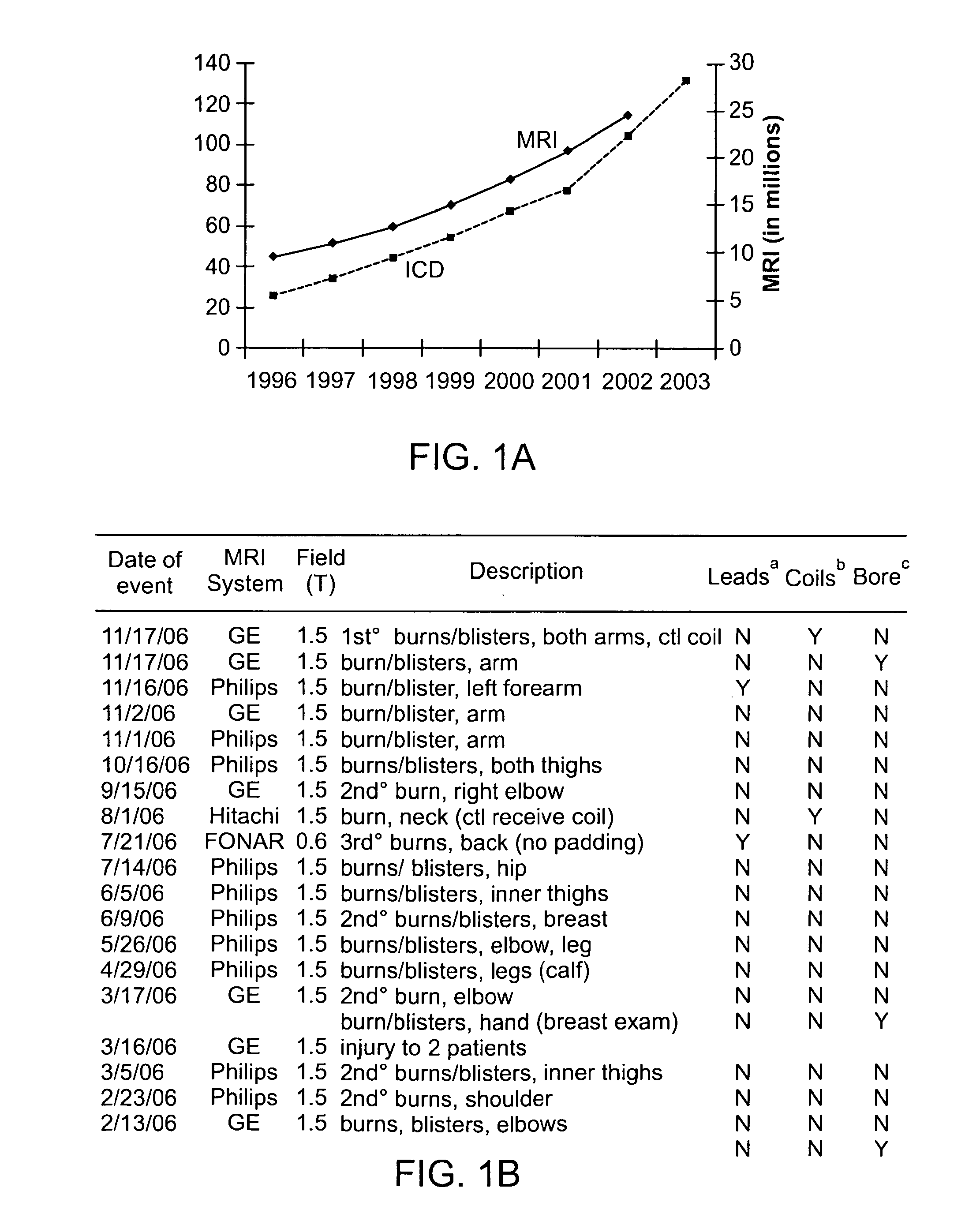

SAR dosimeter for RF power deposition in MRI and methods and systems related thereto

Featured is a dosimeter device that measures SAR deposited by RF power deposition during MRI of a specimen. Such a dosimeter device includes a transducer that is configured to present a load to the MRI scanner in which the transducer is located and to provide an output representative of signals induced in the transducer. The transducer also is configured so that the presented load is substantially equivalent to another load which would be presented by the specimen during MRI of the specimen. Such a transducer also is configured so as to generate an MRI signal that is sufficient to allow the MRI scanner to adjust the RF power to a value substantially equal to that of the specimen. Also featured are methods for measuring SAR deposited by RF power deposition and apparatuses or system embodying such a dosimeter device.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Diffusive plasma air treatment and material processing

InactiveUS20190287763A1Improve efficiencyMinimizationGas treatmentElectric discharge tubesCatalytic functionEngineering

The Diffusive Plasma is for effective treatment of contaminated air and material processing. Air is purified and disinfected by passing through the diffusive plasma device which includes a reactor or a plurality of reactors arranged in parallel or series and is energized by a high voltage alternating current power supply. The diffuser, being electrically isolated, provides extra nucleation sites to initiate discharges. It serves to improve the generation of uniform and consistent plasma and to reduce the variation of discharge properties among the reactors. The addition of a diffuser, thereby, enhances the overall effectiveness of decomposing chemicals and destroying microbes to achieve high air treatment and material processing performance. The diffuser can be made of suitable filtering materials to additionally serve as a filter. By incorporating suitable catalytic materials with the diffuser, the reactor becomes a catalytic plasma reactor wherein the plasma environment provides enhanced catalytic functions. Effective plasma power deposition may be obtained by controlling the amplitude, waveform period and shape of the voltage applied to the electrodes of the reactor and hence the operation of the reactors with plasma discharged of selected conditions for optimizing the treatment and processing efficiency while minimizing the generation of unwanted bi-product gases. The present invention also relates to a method for effective air treatment and material processing.

Owner:ALPHATECH INT

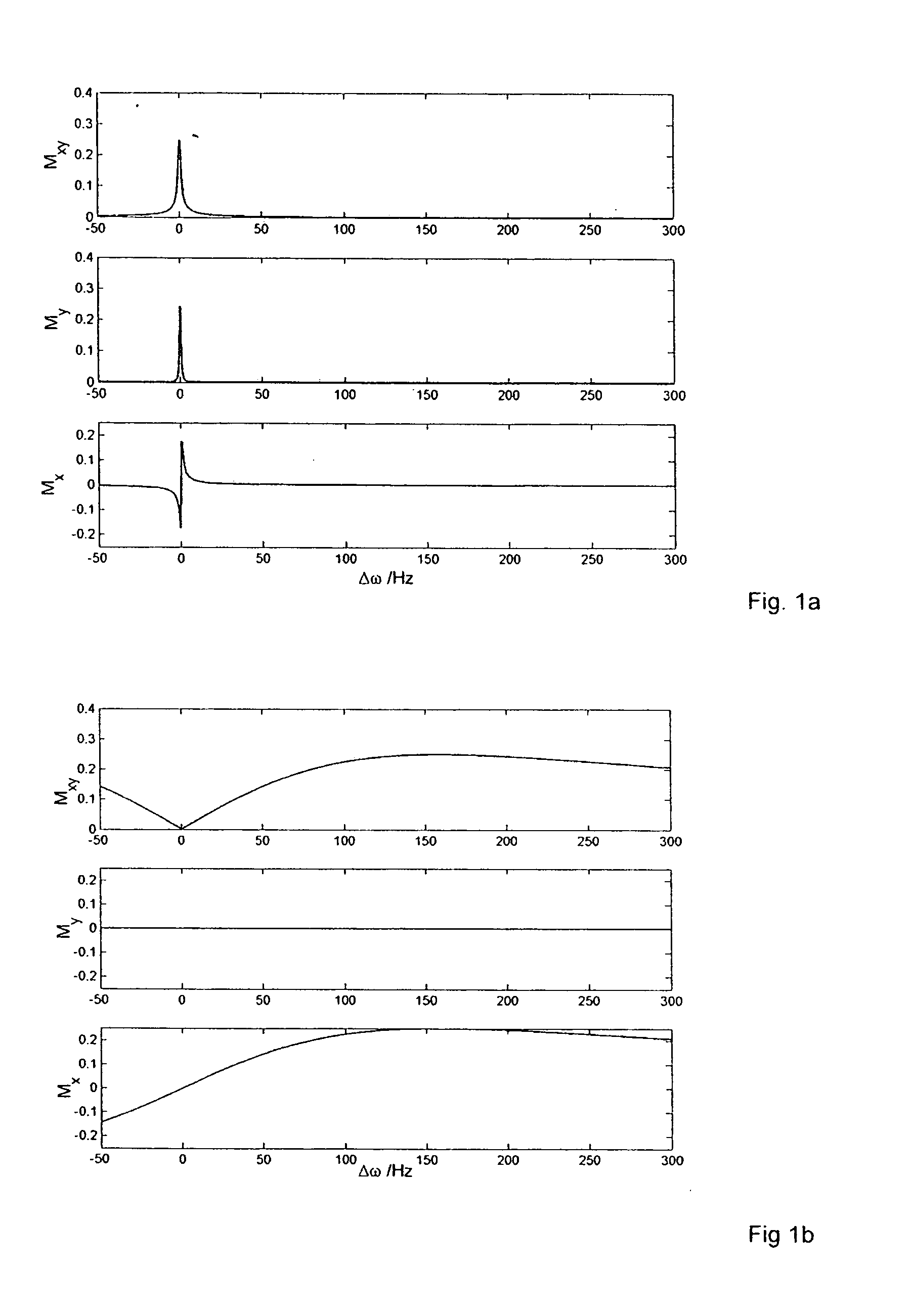

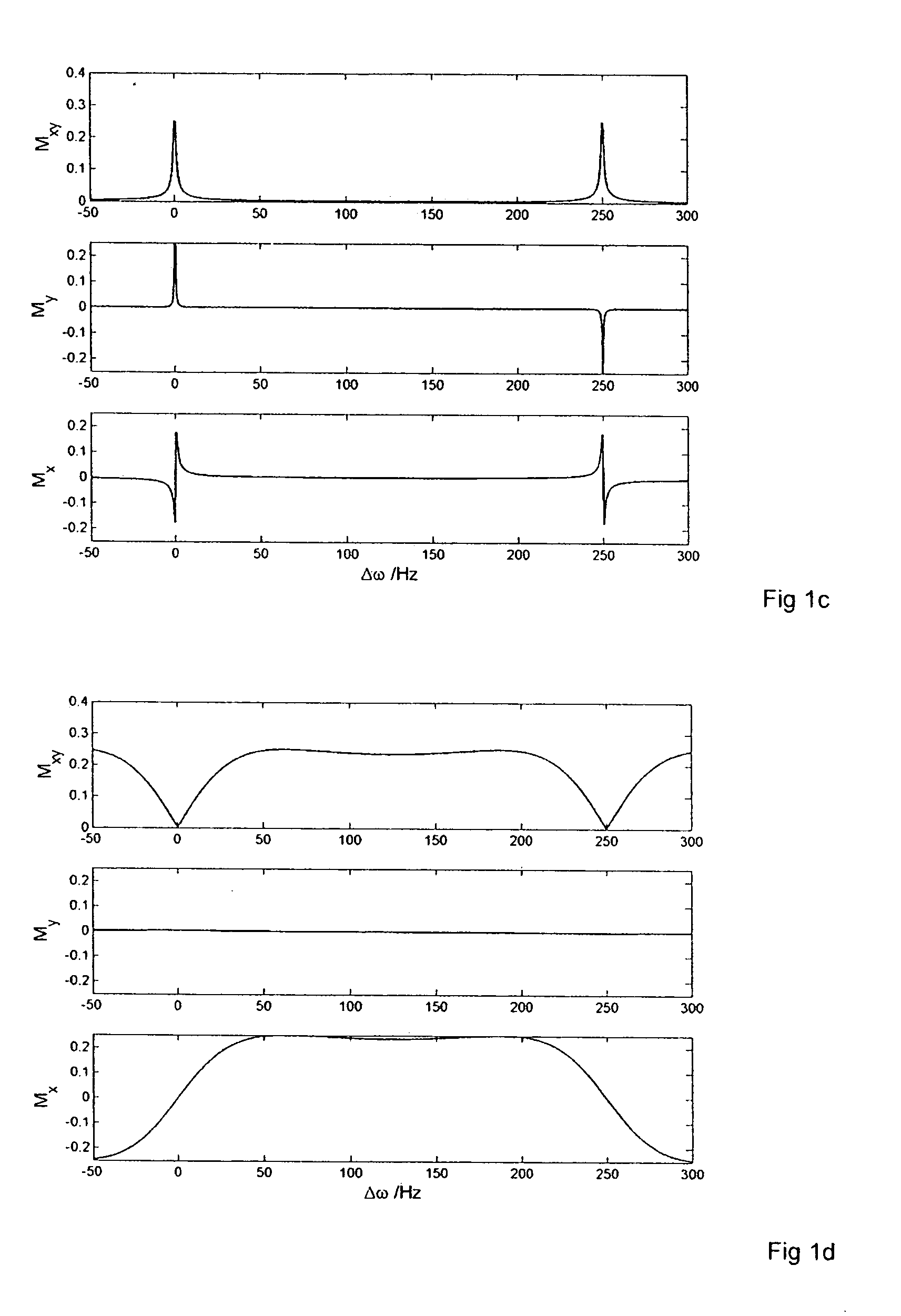

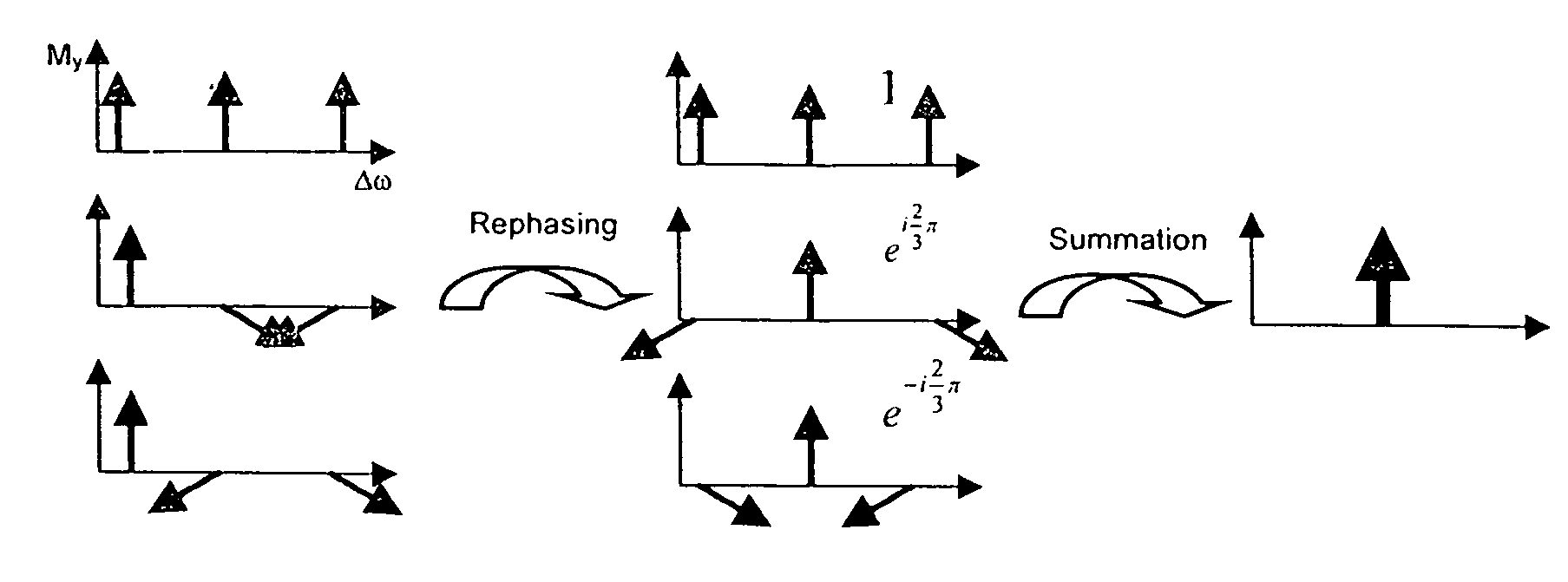

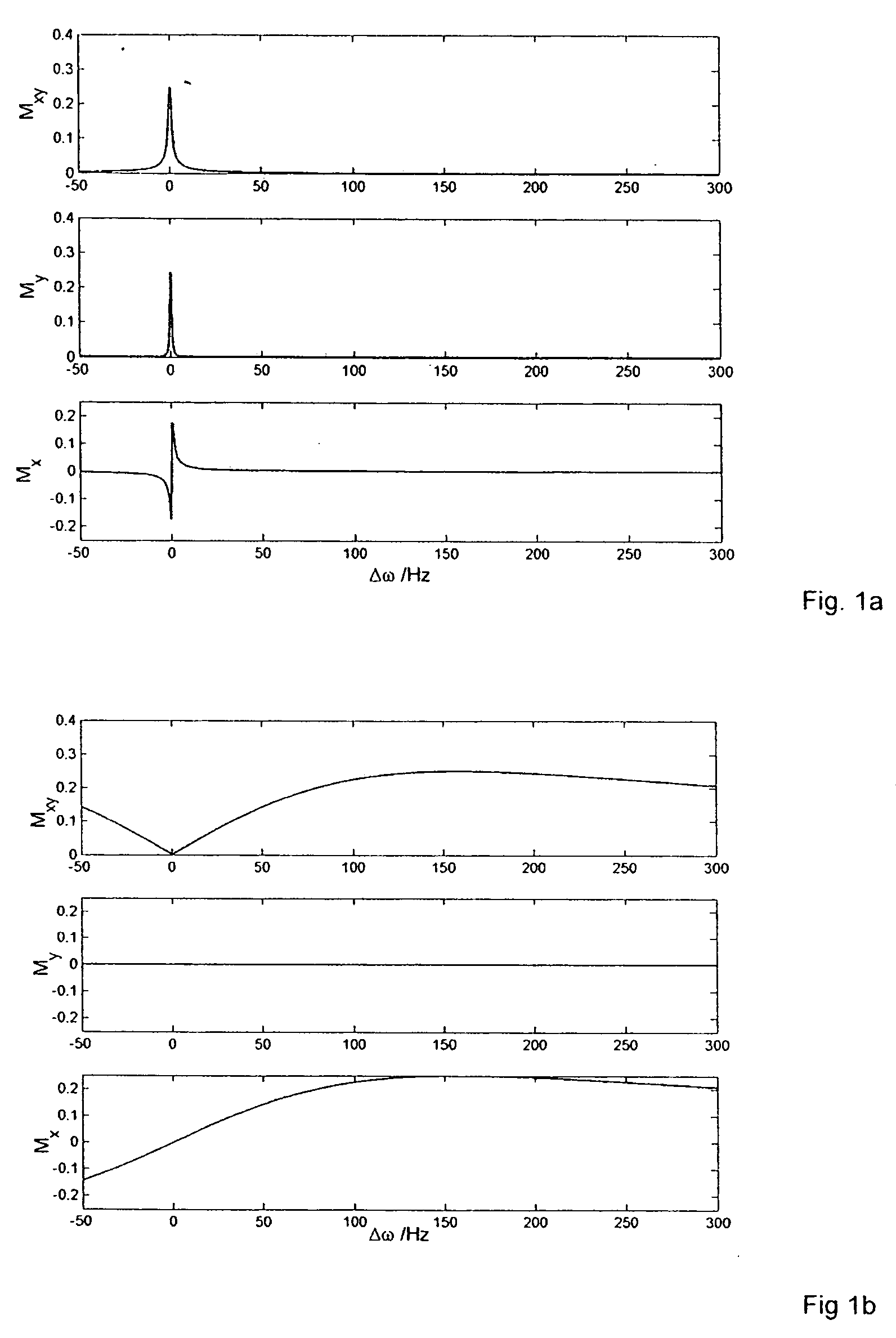

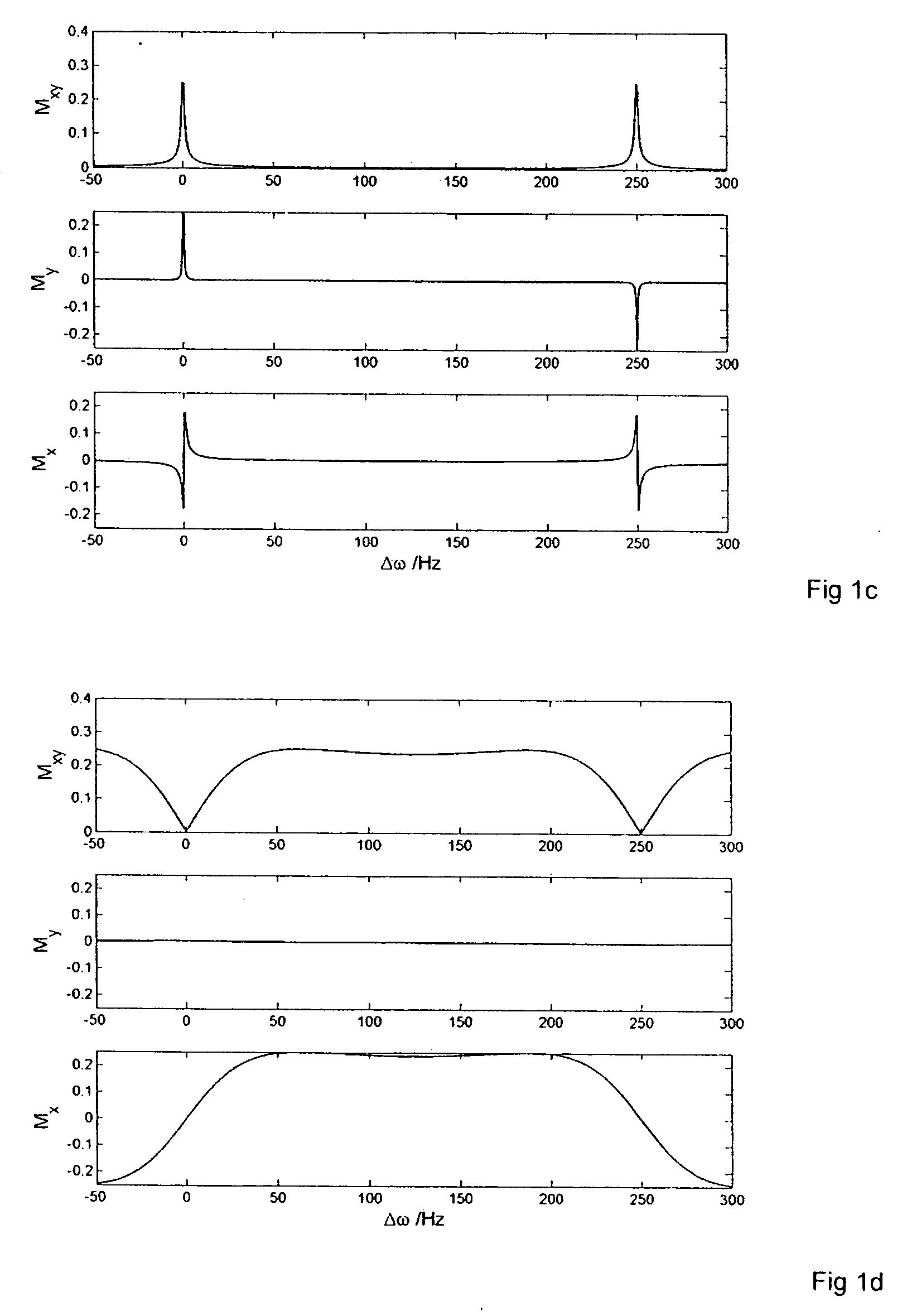

Measuring method of spatially resolved frequency selective images

InactiveUS7167003B2Quick measurementFacilitates precise limitation of NMR measurementMeasurements using NMR imaging systemsElectric/magnetic detectionResonance lineRadio frequency

The present invention describes a magnetic resonance imaging method wherein spatially resolved frequency sensitive image data are collected by means of free precession sequences employing very small radio frequency (RF) excitation pulses per unit time which result in highly frequency selective steady-state signals dominated by linear properties of the system, for which the superposition principle holds. By appropriate linear combination of steady state signals of N different frequencies, N resonance lines can be acquired simultaneously. This method allows spectroscopic recordings with very low RF power deposition which renders the method suitable for applications at high static magnetic field strengths.

Owner:UNIV ZURICH +1

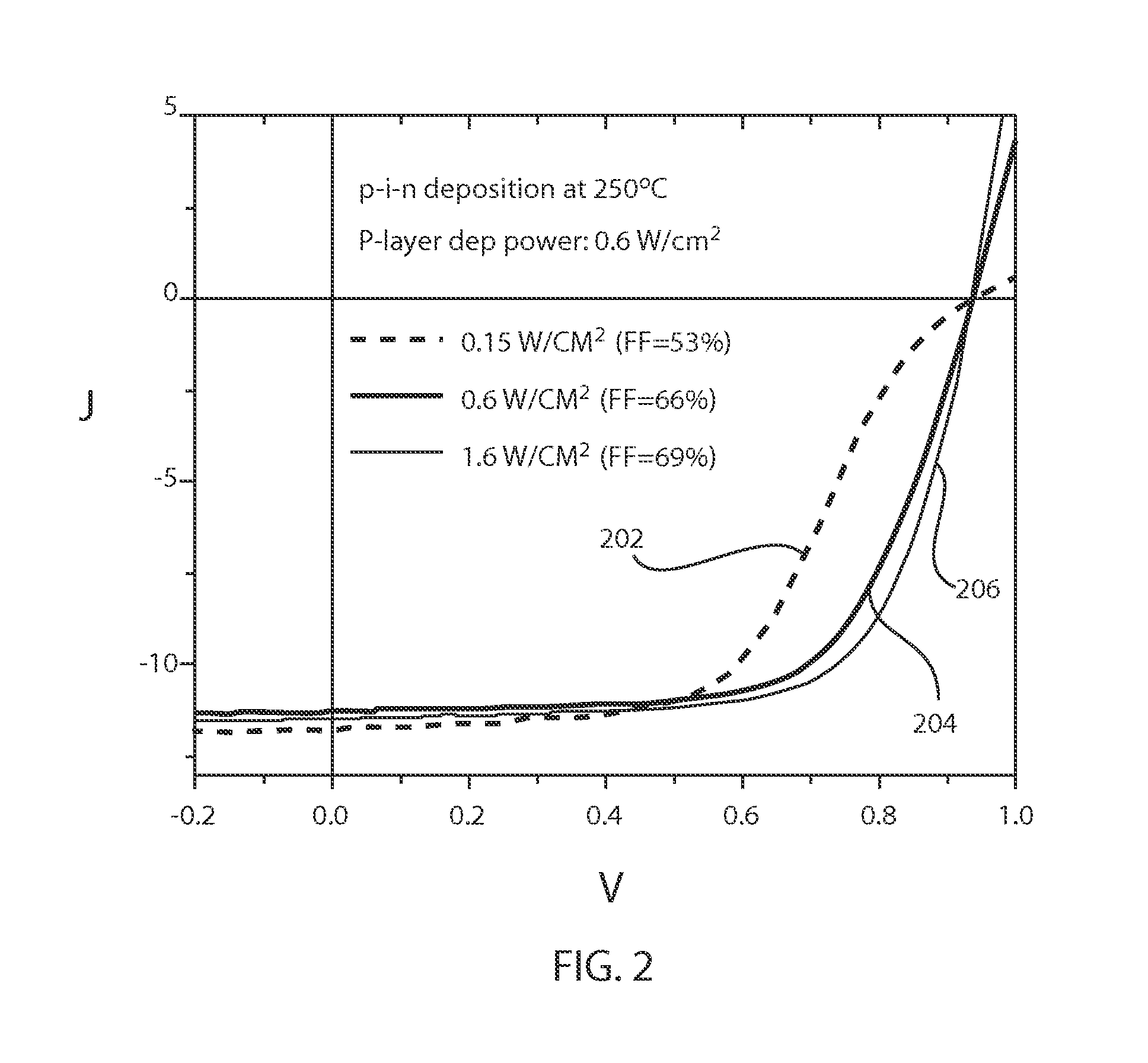

Enhancing efficiency in solar cells by adjusting deposition power

InactiveUS20140120655A1Improve equipment efficiencySemiconductor/solid-state device manufacturingChemical vapor deposition coatingPhysical chemistryEngineering

Methods for forming a photovoltaic device include adjusting a deposition power for depositing a buffer layer including germanium on a transparent electrode. The deposition power is configured to improve device efficiency. A p-type layer is formed on the buffer layer. An intrinsic layer and an n-type layer are formed over the p-type layer.

Owner:INT BUSINESS MASCH CORP +1

Measuring method of spatially resolved frequency selective images

InactiveUS20060043971A1Facilitates precise limitation of NMR measurementControl volumeMeasurements using NMR imaging systemsElectric/magnetic detectionResonance lineRadio frequency

Owner:UNIV ZURICH +1

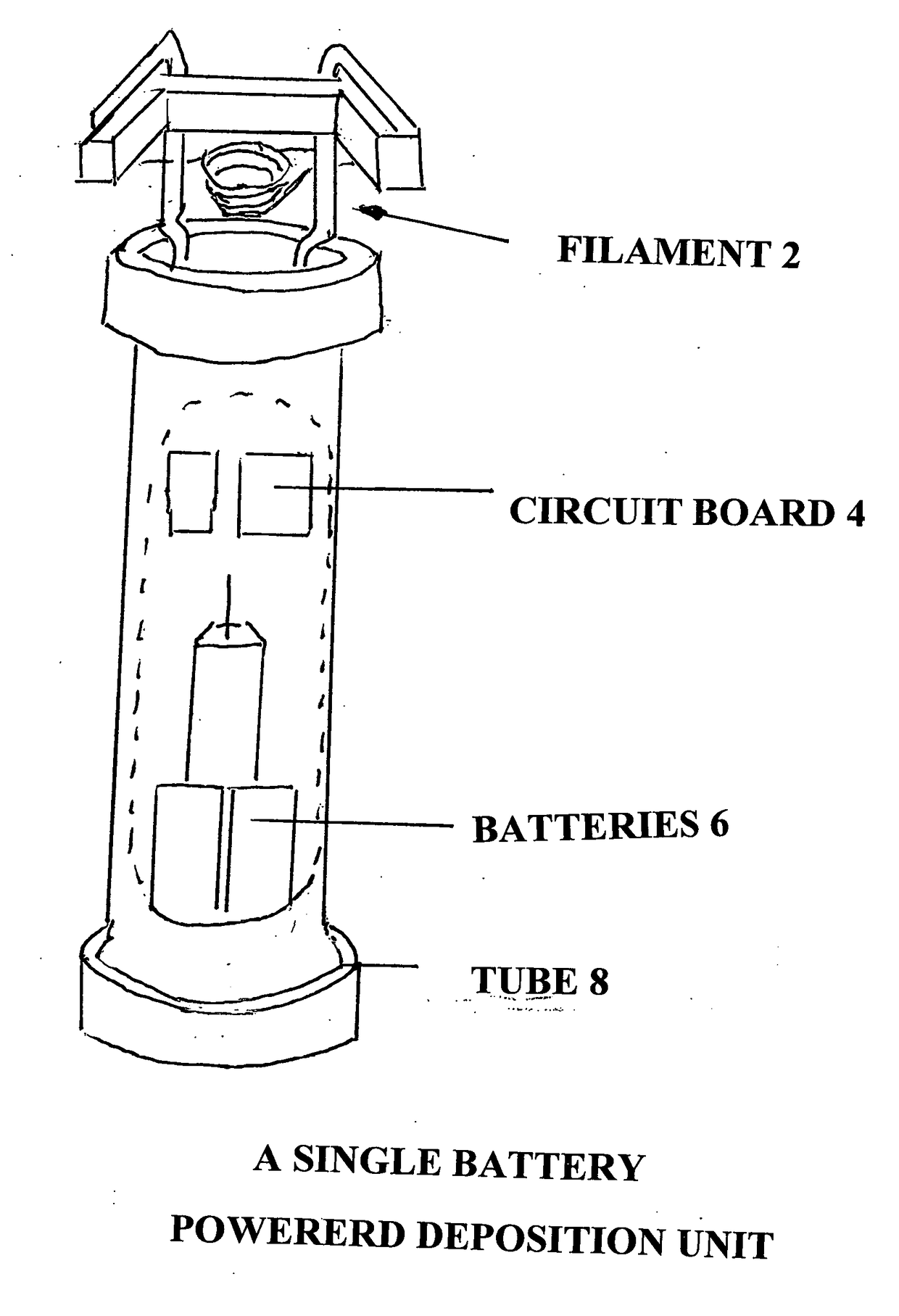

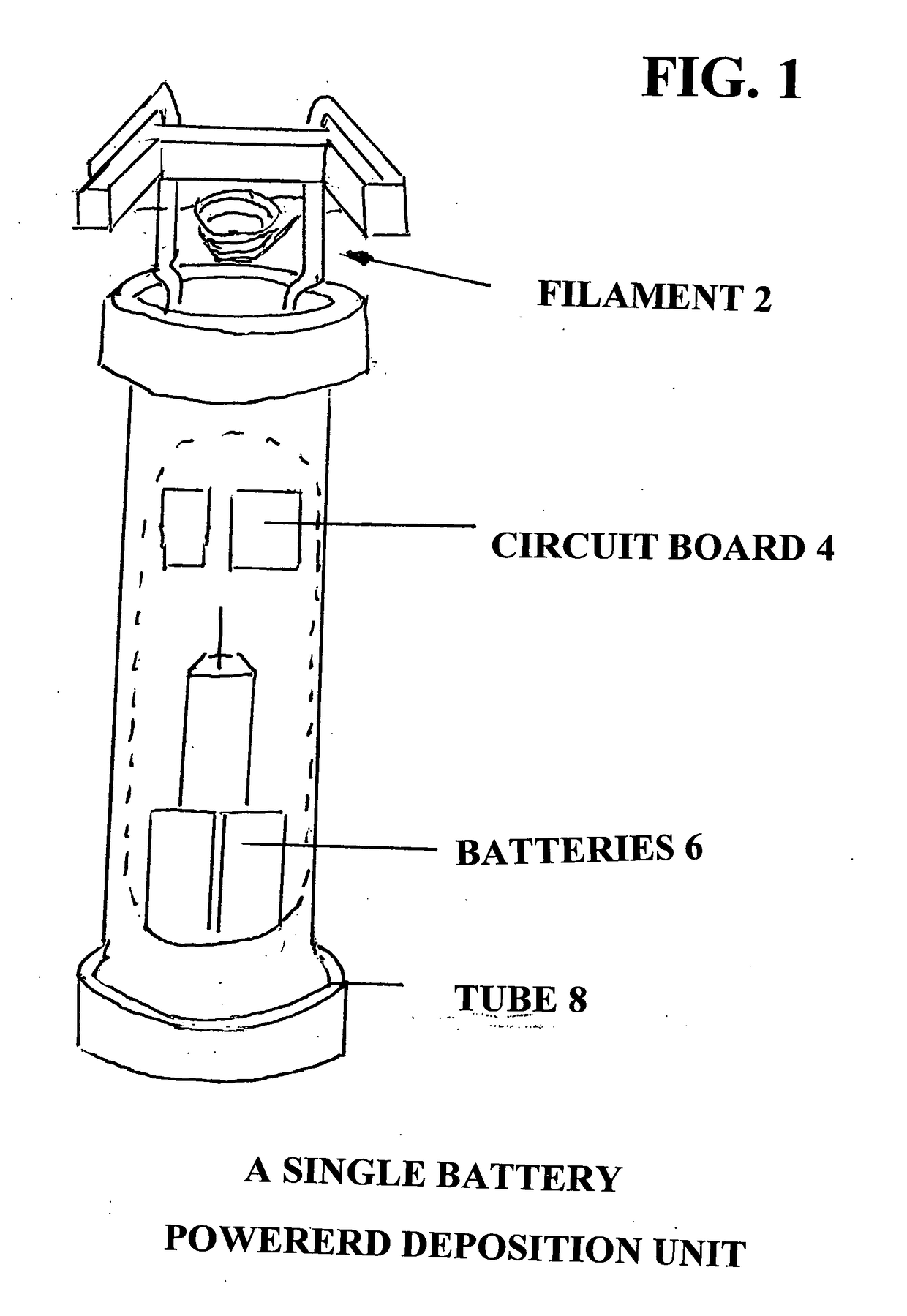

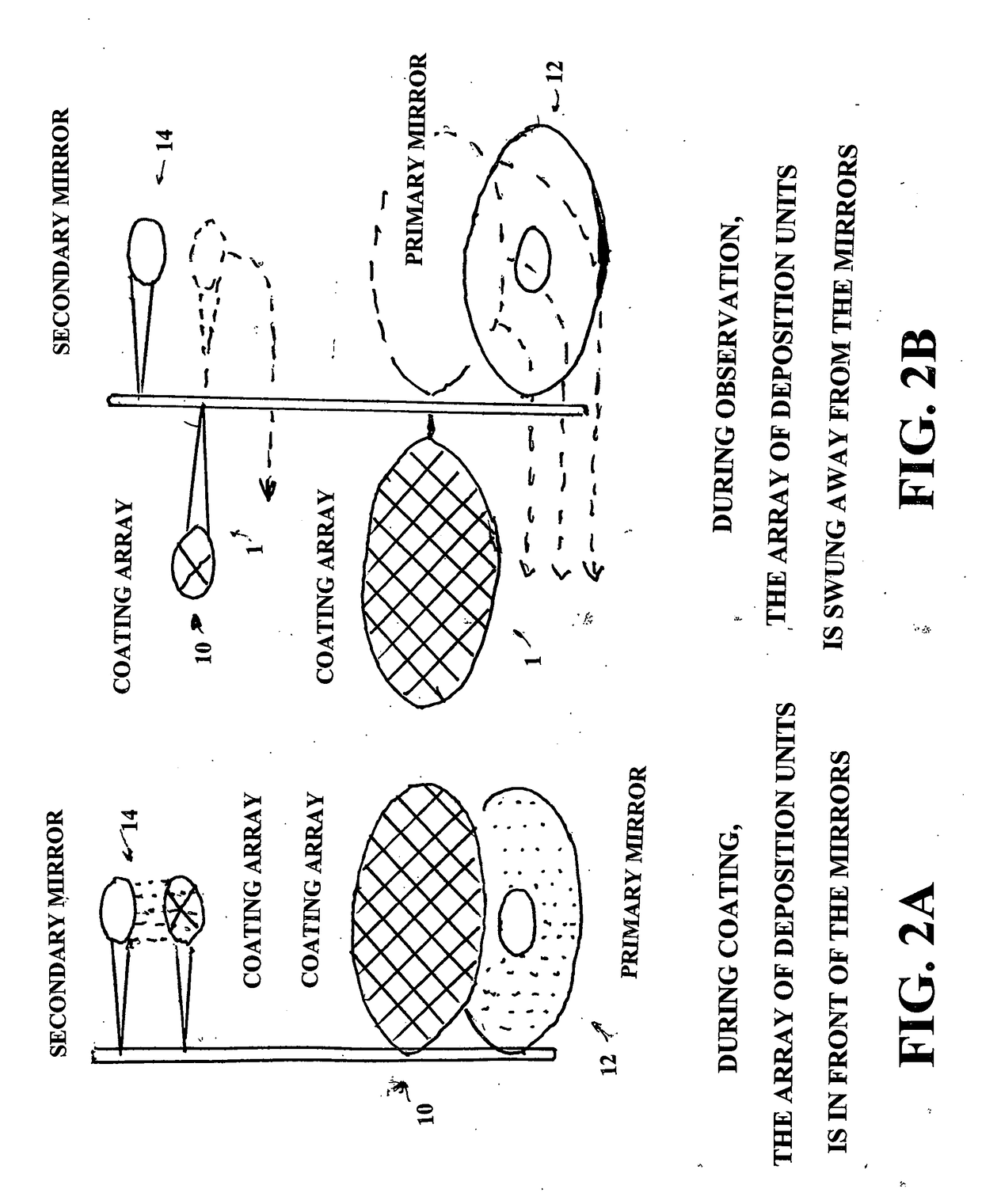

Battery-Powered deposition system and process for making reflective coatings

InactiveUS20180217304A1Minimize tungstenHeating fastMirrorsVacuum evaporation coatingElectrical batteryAlloy

A battery powered deposition system and process for applying aluminum, silver, and SiO films (and their derivatives such as aluminum oxide, aluminum nitride and silicon dioxide) especially for making broadband reflective coatings for mirrors. One or more filaments are wetted with a filament wetting material such as aluminum or a silver alloy. In a preferred embodiment filaments are heated quickly to a high temperature with an array of batteries and the filament wetting material is deposited as a reflective coating on the mirror.

Owner:SHEIKH DAVID

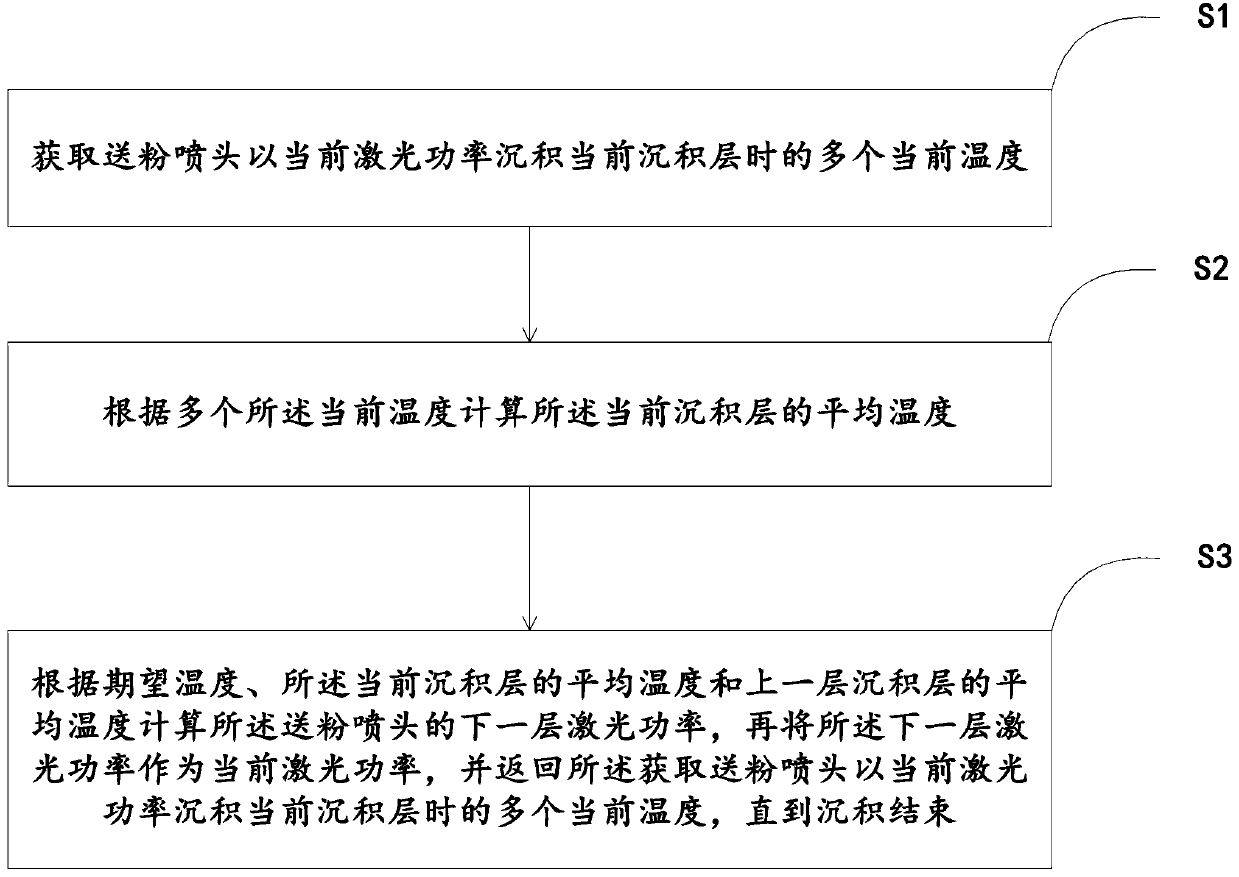

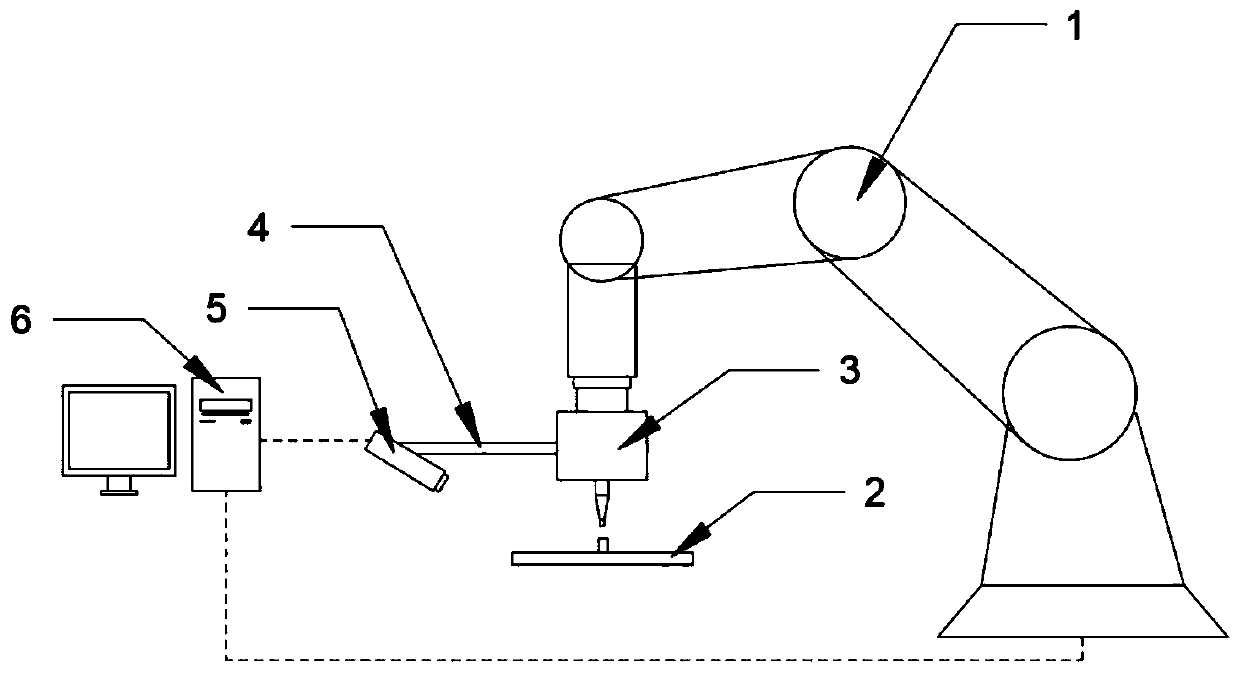

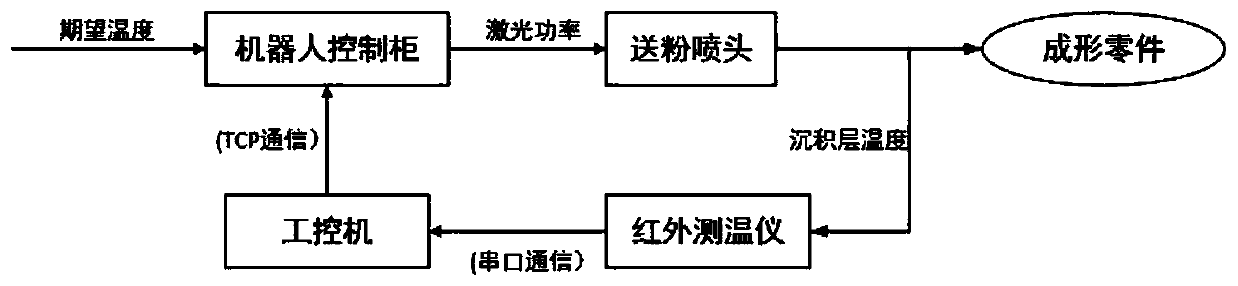

Laser metal additive deposition temperature control method and system

InactiveCN111545937AHigh control precisionAdditive manufacturing apparatusLaser beam welding apparatusDeposition temperatureTemperature control

The invention relates to a laser metal additive deposition temperature control method and system. The laser metal additive deposition temperature control method comprises the following steps that a plurality of current temperatures are acquired when a powder feeding nozzle deposits a current deposition layer at current laser power, wherein the plurality of current temperatures are obtained by performing temperature acquisition on sediments sprayed by the powder feeding nozzle in a set range in a process of forming the current deposition layer; the average temperature of the current depositionlayer is calculated according to the plurality of current temperatures; the laser power of the next layer of the powder feeding nozzle is calculated according to the expected temperature, the averagetemperature of the current deposition layer and the average temperature of the previous deposition layer, the laser power of the next layer is taken as the current laser power, and a plurality of current temperatures obtained by the powder feeding nozzle is returned when the powder feeding nozzle deposits the current deposition layer at the current laser power until deposition ends. According to the laser metal additive deposition temperature control method and system, the control precision of the laser metal additive deposition temperature is improved.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com