Composite diaphragm for alkali metal battery and preparation and application thereof

A technology of alkali metal batteries and composite diaphragms, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of diaphragm shrinkage and deformation, increase thermal runaway, and cannot be retained, so as to improve battery efficiency and life, high mechanical Powerful, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

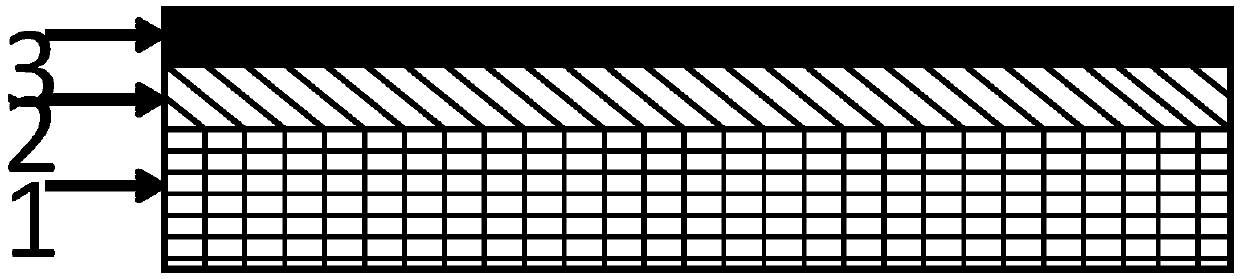

[0022] 1) Al that will be coated with a thickness of 2 microns, a porosity of 40%, and a pore size distribution of 0.05-0.1 microns 2 o 3 PP / PE / PP porous film with a thickness of 16 microns, a porosity of 38%, and a pore size distribution of 0.05-0.1 microns (purchased from Shenzhen Kejingzhida Technology Co., Ltd.) of the ceramic coating enters the magnetron sputtering chamber in the form of roll-to-roll in vivo;

[0023] 2) Put lithium phosphate, lithium silicate, and lithium fluoride sputtering targets into 1, 2, and 3 magnetron sputtering targets respectively;

[0024] 3) Set the sputtering parameters: the sputtering vacuum is 1.4Pa, the reaction gas is nitrogen, the deposition power is 120W for target position 1, 90W for target position 2, 70W for target position 3, and the deposition time is 15 minutes;

[0025] 4) Vacuum-deposit an amorphous alkali metal ion conductor inorganic solid layer on the ceramic coating side of the ceramic coating organic diaphragm, and the i...

Embodiment 2

[0027]1) PP / PE / PP coated with a boehmite ceramic coating with a thickness of 2 microns, a porosity of 35%, and a pore size distribution of 0.05-0.1 microns with a thickness of 25 microns, a porosity of 50%, and a pore size distribution of 0.05-0.08 microns Porous film (purchased from Shenzhen Kejing Zhida Technology Co., Ltd.) enters the magnetron sputtering chamber in the form of roll-to-roll;

[0028] 2) Put the sodium phosphate, germanium oxide, and sodium iodide sputtering targets on the 1, 2, and 3 magnetron sputtering target positions respectively;

[0029] 3) Set the sputtering parameters: the sputtering vacuum is 1.5Pa, the reaction gas is nitrogen, the deposition power is 150W for target position 1, 100W for target position 2, 80W for target position 3, and the deposition time is 12 minutes;

[0030] 4) Vacuum-deposit an amorphous alkali metal ion conductor inorganic solid layer on the ceramic coating side of the ceramic coating organic diaphragm, and the inorganic so...

Embodiment 3

[0032] 1) Al that will be coated with a thickness of 2 microns, a porosity of 40%, and a pore size distribution of 0.05-0.1 microns 2 o 3 PP / PE / PP porous film with a thickness of 16 microns, a porosity of 38%, and a pore size distribution of 0.05-0.1 microns (purchased from Shenzhen Kejingzhida Technology Co., Ltd.) of the ceramic coating enters the magnetron sputtering chamber in the form of roll-to-roll in vivo;

[0033] 2) Put the lithium phosphate, germanium oxide, and lithium chloride sputtering targets on the 1, 2, and 3 magnetron sputtering target positions respectively;

[0034] 3) Set the sputtering parameters: the vacuum degree of sputtering is 0.8Pa, the reaction gas is nitrogen, the deposition power is 90W for the first target position, 60W for the second target position, 50W for the third target position, and the deposition time is 10 minutes;

[0035] 4) Vacuum-deposit an amorphous alkali metal ion conductor inorganic solid layer on the ceramic coating side of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com