Solidified composite electrolyte and preparation method thereof

A composite electrolyte, solid-state technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of complex preparation methods of gel polymer electrolytes, wide electrochemical windows, and complex preparation methods, and achieve wide electrochemical performance. Stable window, improved overall performance, and the effect of large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Preparation of in situ gel composite electrolyte

[0054] Under the protection of argon with a purity of ≥99%, 1 g of lithium bistrifluoromethanesulfonimide was dissolved in 5.15 g of N-methyl, propylpiperidine bistrifluoromethanesulfonimide salt ionic liquid to form Lithium-ion conductive ionic liquid electrolyte, measure 2.45ml of tetraethyl orthosilicate and 0.24ml of dibutyl phosphate and mix them, add 4.0ml of formic acid and stir for 10min to obtain a transparent mixed solution, add the mixed solution to the ionic liquid electrolyte and mix, The gel composite was obtained by aging for 12 hours under the protection of argon, and the gel composite was vacuum-dried at 80° C. for 48 hours to obtain an in-situ gel composite electrolyte.

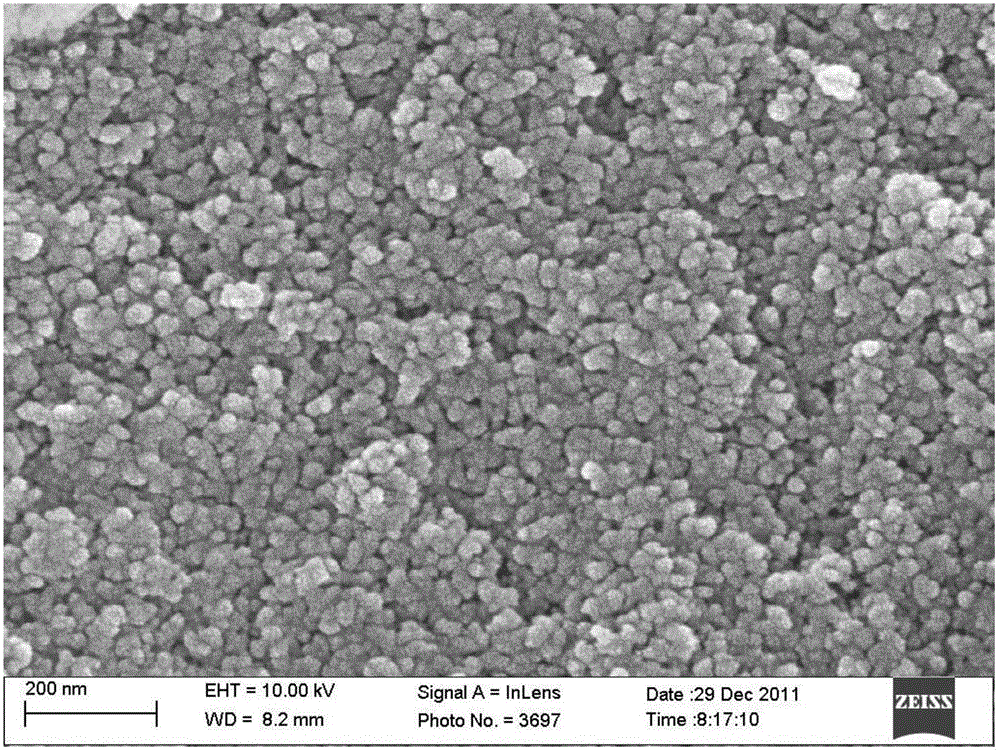

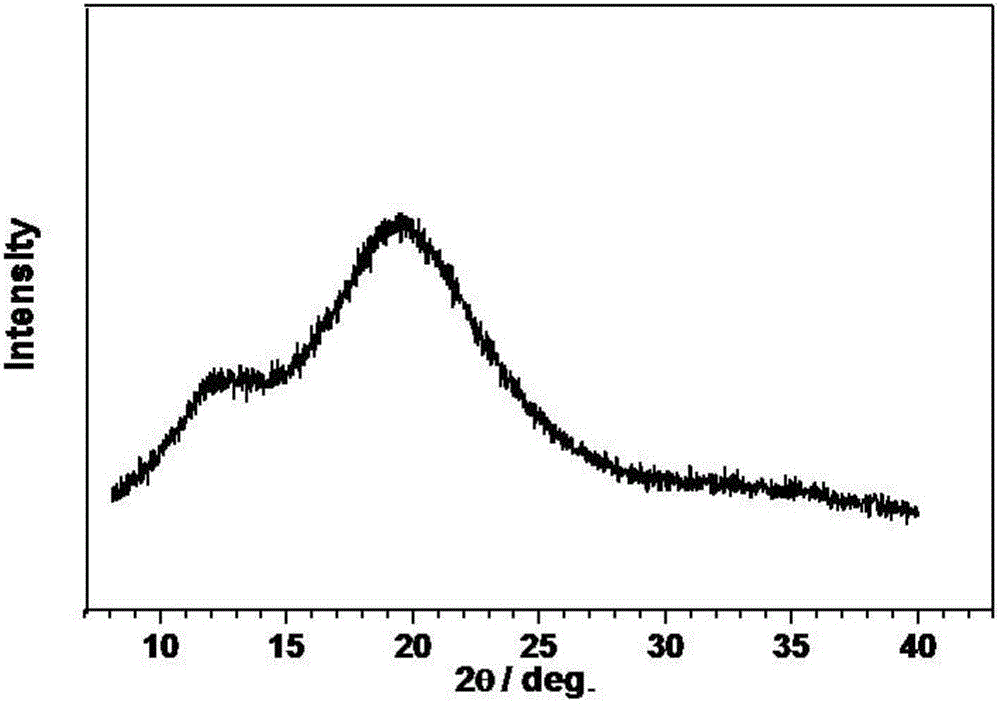

[0055] It can be seen from the SEM test that the in-situ gel composite electrolyte prepared in Example 1 has a rich nanoporous network structure, and the ionic liquid electrolyte is confined in it in situ; the TG test shows that t...

Embodiment 2

[0063] (1) Preparation of in situ gel composite electrolyte

[0064] Under the protection of argon with a purity of ≥99%, 1 g of lithium bistrifluoromethanesulfonimide was dissolved in 5.15 g of N-methyl, propylpiperidine bistrifluoromethanesulfonimide salt ionic liquid to form Lithium-ion conductive ionic liquid electrolyte, measure 1.36ml of tetraethyl orthosilicate and 1.20ml of dibutyl phosphate, mix them, add 4.0ml of formic acid and stir for 10min to obtain a transparent mixed solution, add the mixed solution to the ionic liquid electrolyte and mix, The gel composite was obtained by aging for 12 hours under the protection of argon, and the gel composite was vacuum-dried at 80° C. for 48 hours to obtain an in-situ gel composite electrolyte.

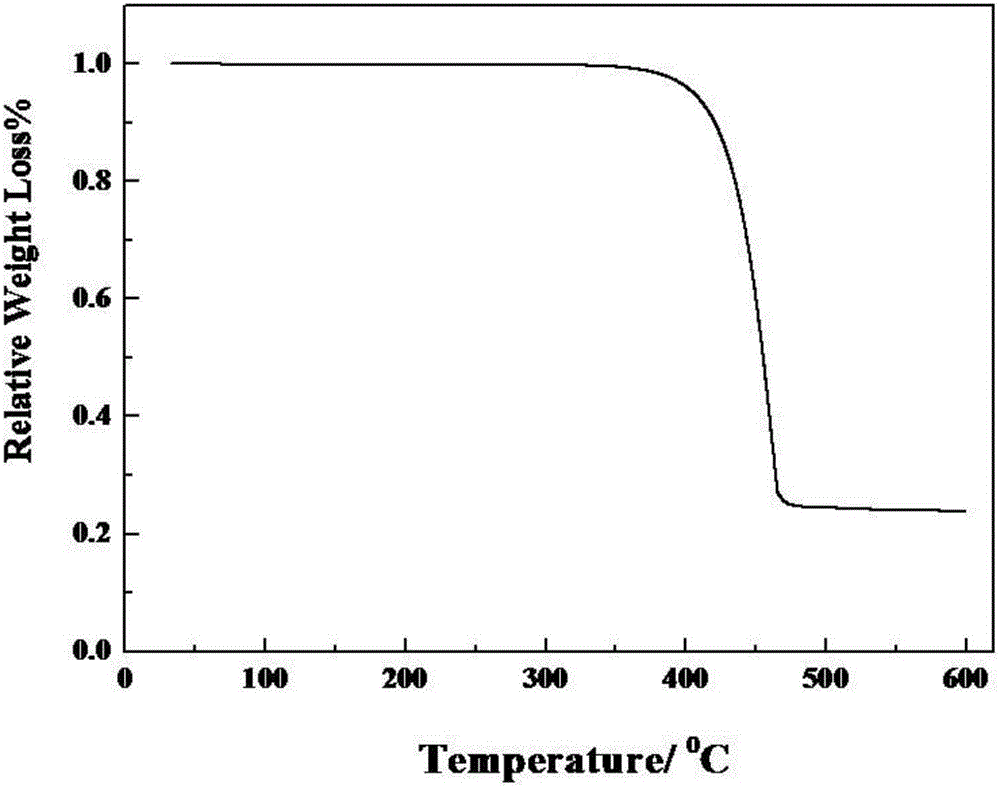

[0065] figure 1 It shows that the in situ gel composite electrolyte prepared in Example 2 has a rich porous network and nanoparticle structure, and the ionic liquid electrolyte is confined in situ; figure 2 The middle TG test curv...

Embodiment 3

[0073] (1) Preparation of in situ gel composite electrolyte

[0074] Under the protection of argon with a purity of ≥99%, 1 g of lithium bistrifluoromethanesulfonimide was dissolved in 5.15 g of N-methyl, propylpiperidine bistrifluoromethanesulfonimide salt ionic liquid to form Lithium-ion conductive ionic liquid electrolyte, measure 0.27ml of tetraethyl orthosilicate and 2.17ml of dibutyl phosphate to mix, then add 4.0ml of formic acid and stir for 10min to obtain a transparent mixed solution, add the mixed solution to the ionic liquid electrolyte and mix, in The gel composite was obtained by aging for 12 hours under the protection of argon, and the gel composite was vacuum-dried at 80° C. for 48 hours to obtain an in-situ gel composite electrolyte.

[0075] It can be seen from SEM detection that the in-situ gel composite electrolyte prepared in Example 3 has a rich nanoporous network structure, and the ionic liquid electrolyte is confined in situ; TG shows that the initial t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com