Preparation method of coated ternary nickel-cobalt-manganese lithium oxide positive electrode material

A technology of nickel-cobalt-manganese-lithium oxide and nickel-cobalt-manganese-lithium, applied in electrical components, battery electrodes, electrochemical generators, etc., can solve the problems of inability to effectively improve the high-temperature cycle performance of materials, low electronic conductivity and ion conductivity , to achieve the effect of improving high temperature cycle performance, improving processing performance and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

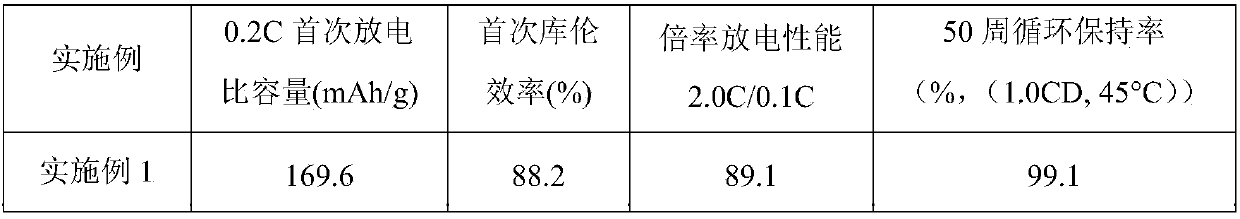

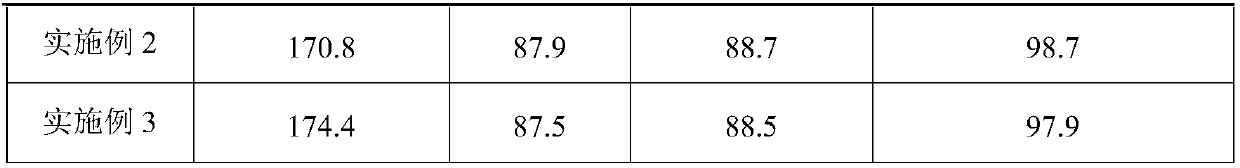

Embodiment 1

[0029] A method for preparing a coated ternary nickel-cobalt-manganese-manganese-lithium positive electrode material, comprising the following steps:

[0030] (1) Preparation of ternary nickel-cobalt-manganese-lithium precursor:

[0031] 1) Metal salt solution preparation: nickel sulfate 6 hydrate, cobalt sulfate 7 hydrate, and manganese sulfate 1 hydrate were added with water to prepare 2 mol / L salt solution respectively;

[0032] 2) Dilute lye preparation: dilute 30% concentrated sodium hydroxide lye (about 10.7M) into 4mol / L dilute lye;

[0033] 3) Preparation of dilute ammonia solution: dilute 22% concentrated ammonia water (about 12.5M) with water to prepare 2mol / L dilute ammonia solution.

[0034] Feed N into the 10L reactor 2 , first add 5L of 2mol / L dilute ammonia solution through a peristaltic pump as the bottom liquid, and respectively prepare the above nickel sulfate solution, cobalt sulfate solution and manganese sulfate solution according to the molar ratio of N...

Embodiment 2

[0040] A method for preparing a coated ternary nickel-cobalt-manganese-manganese-lithium positive electrode material, comprising the following steps:

[0041] (1) Preparation of ternary nickel-cobalt-manganese-lithium precursor:

[0042] 1) Metal salt solution preparation: nickel sulfate 6 hydrate, cobalt sulfate 7 hydrate, and manganese sulfate 1 hydrate were added with water to prepare a 2mol / L salt solution;

[0043] 2) Dilute lye preparation: dilute 30% concentrated sodium hydroxide lye into 4mol / L dilute lye;

[0044] 3) Preparation of dilute ammonia solution: dilute 20% concentrated ammonia water with water to prepare 0.5mol / L dilute ammonia solution;

[0045] Introduce N into the 10L reactor 2 , through the peristaltic pump, first add 2.5L of 0.5mol / L dilute ammonia solution as the bottom liquid, and use the co-precipitation method to separate the nickel salt solution, cobalt salt solution, and manganese salt solution according to the molar ratio of Ni:Co:Mn=5:2:3 Th...

Embodiment 3

[0051] A method for preparing a coated ternary nickel-cobalt-manganese-manganese-lithium positive electrode material, comprising the following steps:

[0052] (1) Preparation of ternary nickel-cobalt-manganese-lithium precursor:

[0053] 1) Metal salt solution preparation: nickel sulfate 6 hydrate, cobalt sulfate 7 hydrate, and manganese sulfate 1 hydrate were added with water to prepare a 2mol / L salt solution;

[0054] 2) Dilute lye preparation: dilute 30% concentrated sodium hydroxide lye into 5mol / L dilute lye;

[0055] 3) Preparation of dilute ammonia solution: dilute 22% concentrated ammonia water with water to prepare 1mol / L dilute ammonia solution;

[0056] Introduce N into the 10L reactor 2 , first add 3.5L of 1mol / L dilute ammonia solution as the bottom liquid through the peristaltic pump, and use the co-precipitation method to separate the nickel salt solution, cobalt salt solution, and manganese salt solution according to the molar ratio of Ni:Co:Mn=55:15:30 Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com