Patents

Literature

42results about How to "Reduce interface side reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

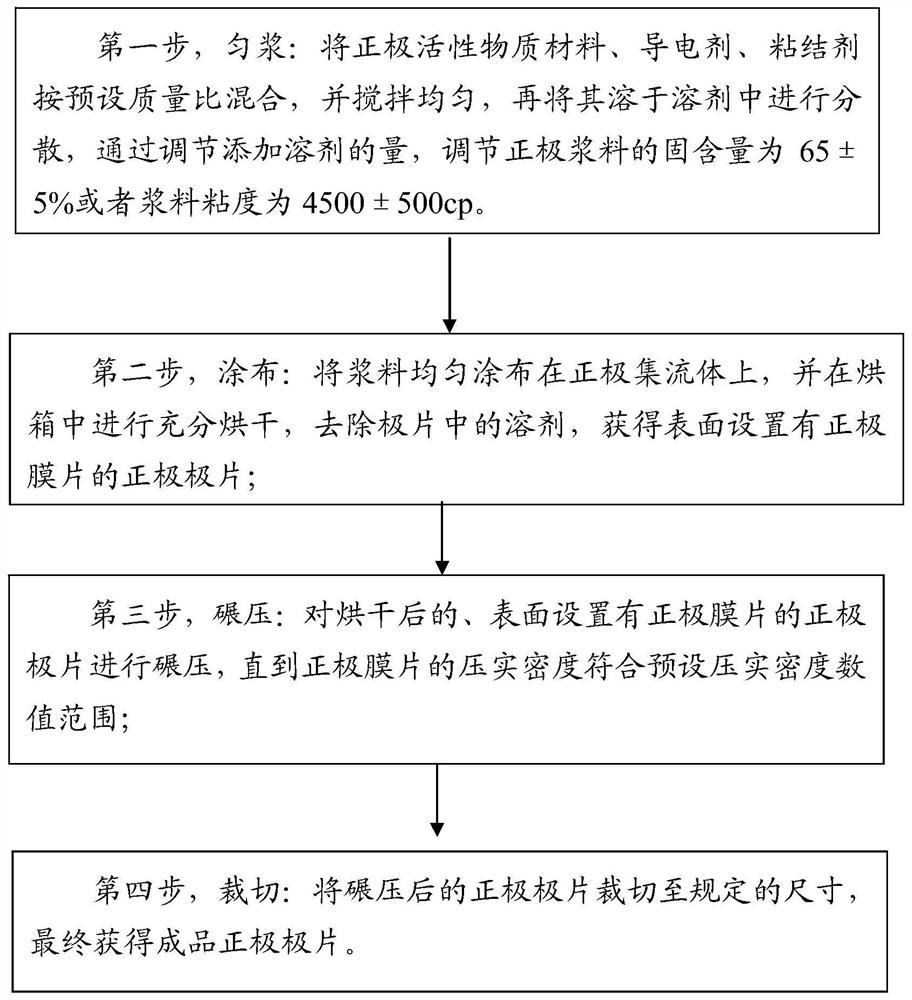

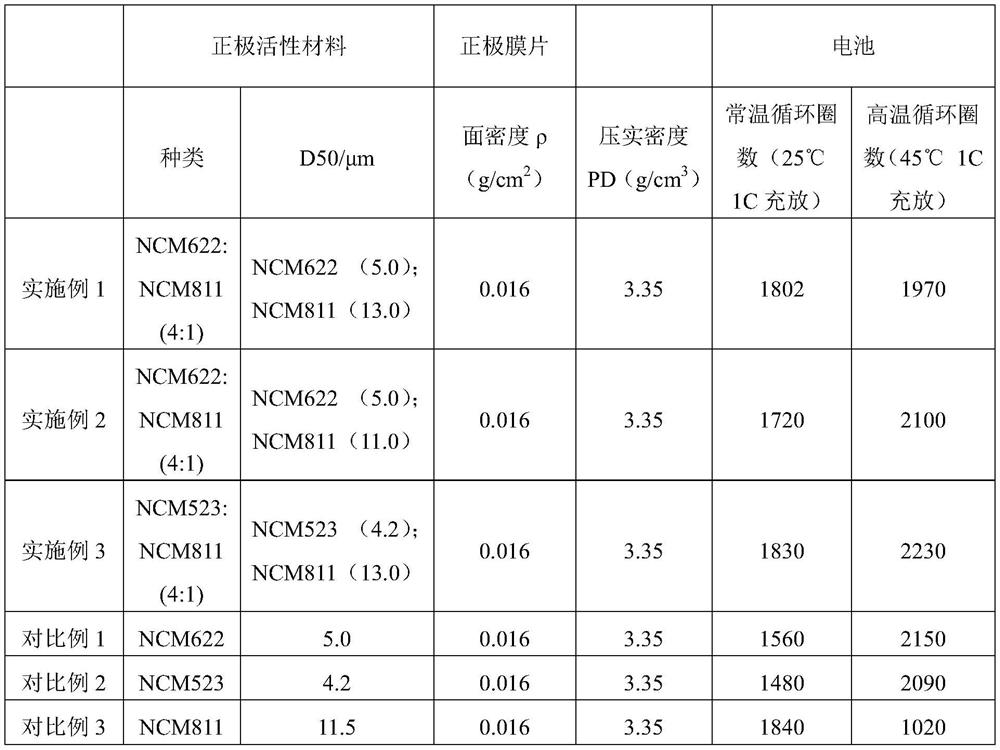

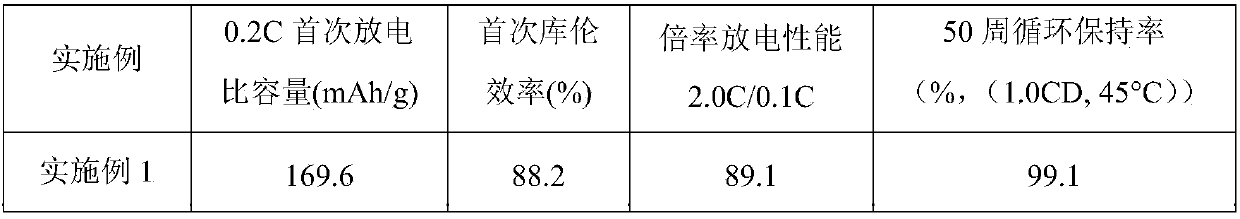

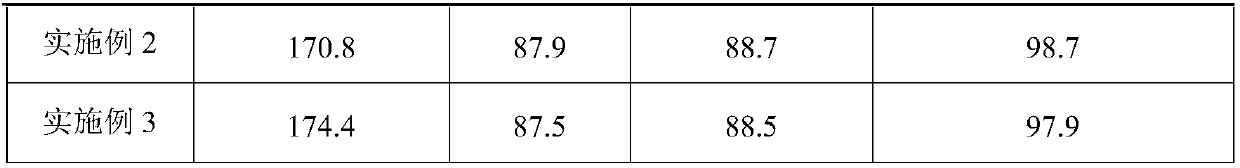

Positive pole piece and preparation method thereof and lithium ion secondary battery

PendingCN111640912AImprove thermal stabilityGood dynamic performanceSecondary cellsPositive electrodesSingle crystalPole piece

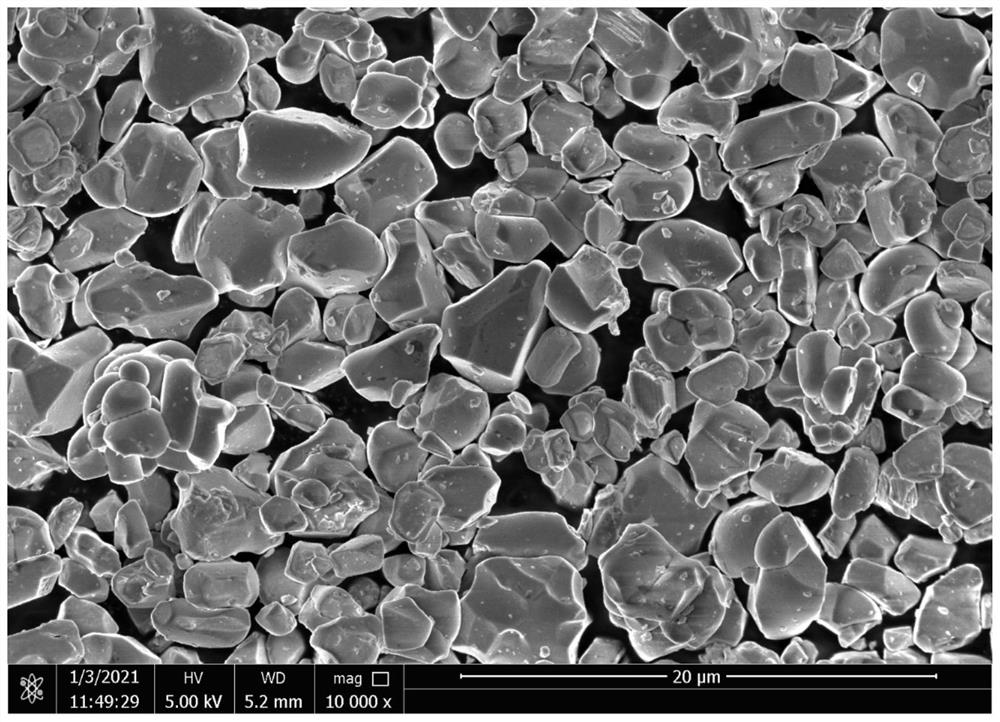

The invention discloses a positive pole piece which comprises a positive pole current collector and a positive pole diaphragm arranged on at least one surface of the positive pole current collector, and the positive pole diaphragm comprises a positive pole active substance; the positive electrode active substance comprises at least two lithium nickel cobalt manganese oxides LiNixCoyMn1-x-yO2 withdifferent morphologies and average particle sizes D50, wherein one type is primary particle single crystal LiNixCoyMn1-x-yO2, and the other type is secondary particle polycrystalline LiNixCoyMn1-x-yO2; the weight ratio [omega] of the single crystal to the polycrystalline LiNixCoyMn1-x-yO2 satisfies the relational expression: 0.1<=[omega]<=9. By adjusting the ratio of the primary particle single crystal to the secondary particle polycrystalline material and the nickel content, the positive pole piece can have better thermal stability and excellent dynamic performance, so that the lithium ion secondary battery based on the positive pole piece has the characteristics of long cycle life at normal temperature and high temperature.

Owner:LISHEN (QINGDAO) NEW ENERGY CO LTD

Preparation method of coated ternary nickel-cobalt-manganese lithium oxide positive electrode material

InactiveCN109638232AHigh ion conductivityImprove high temperature cycle performanceCell electrodesSecondary cellsLithium oxideElectrical conductor

The invention discloses a preparation method of a coated ternary nickel-cobalt-manganese lithium oxide positive electrode material. The preparation method comprises the following steps of (1) preparing a ternary nickel-cobalt-manganese lithium precursor; (2) preparing an oxide-coated ternary nickel-cobalt-manganese lithium precursor; and (3) preparing an ion conductor oxide-coated ternary nickel-cobalt-manganese lithium positive electrode material. By the preparation method of the positive electrode material, a lithium ion is easy to de-intercalate from a surface layer of the material, and thehigh-temperature circulation performance of the material is improved; a coating layer does not react with an electrolyte, interface side reaction caused by contact of the main body material and the electrolyte is reduced, and the safety of the material is improved; the processing performance of a pole plate during the uniform coating process is improved, and the high-temperature circulation performance of the material after being assembled into a battery is improved; and the prepared positive electrode material does not need to be subjected to a roasting process for two times, the energy consumption is reduced, and the cost is reduced.

Owner:宁夏汉尧富锂科技有限责任公司

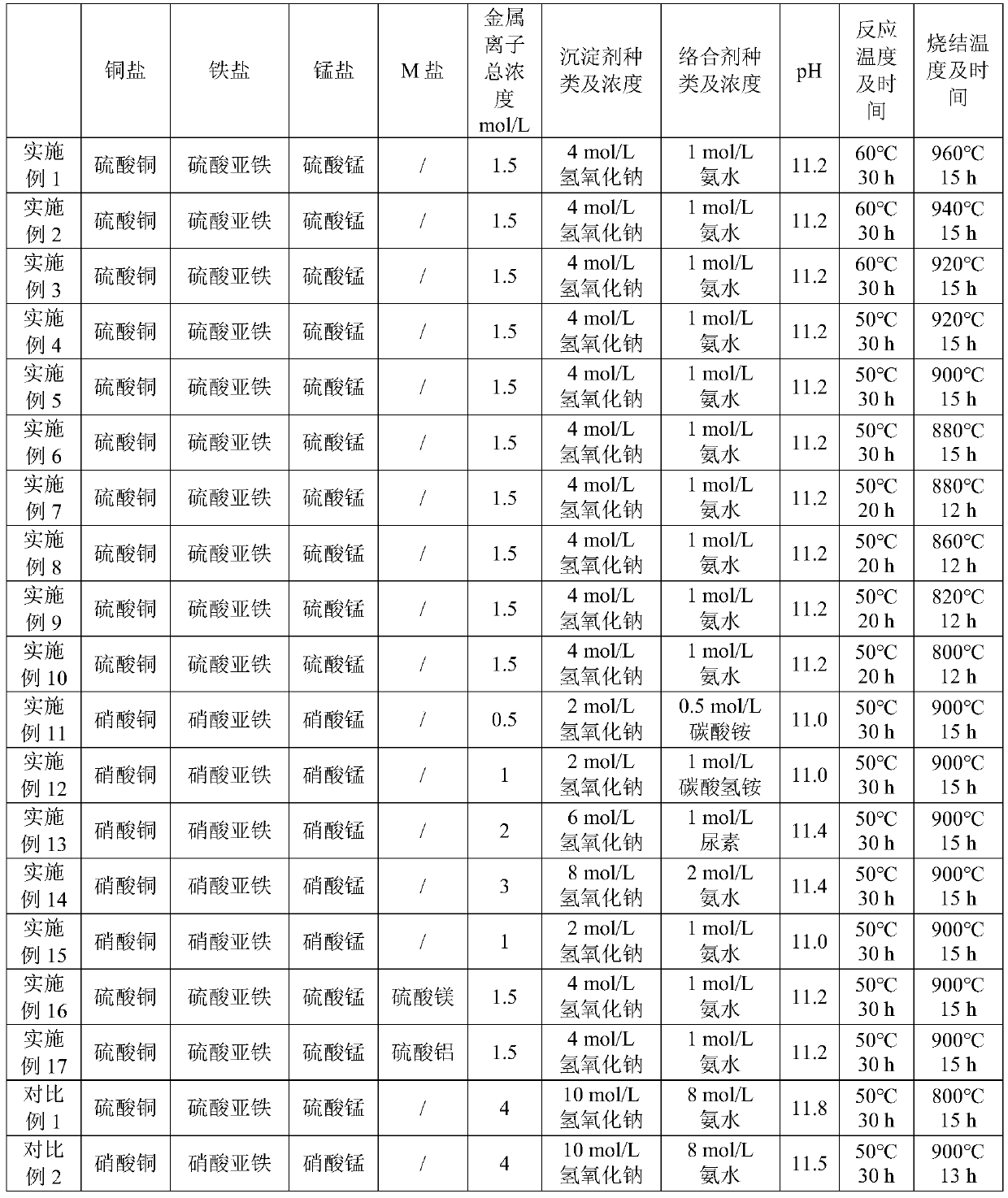

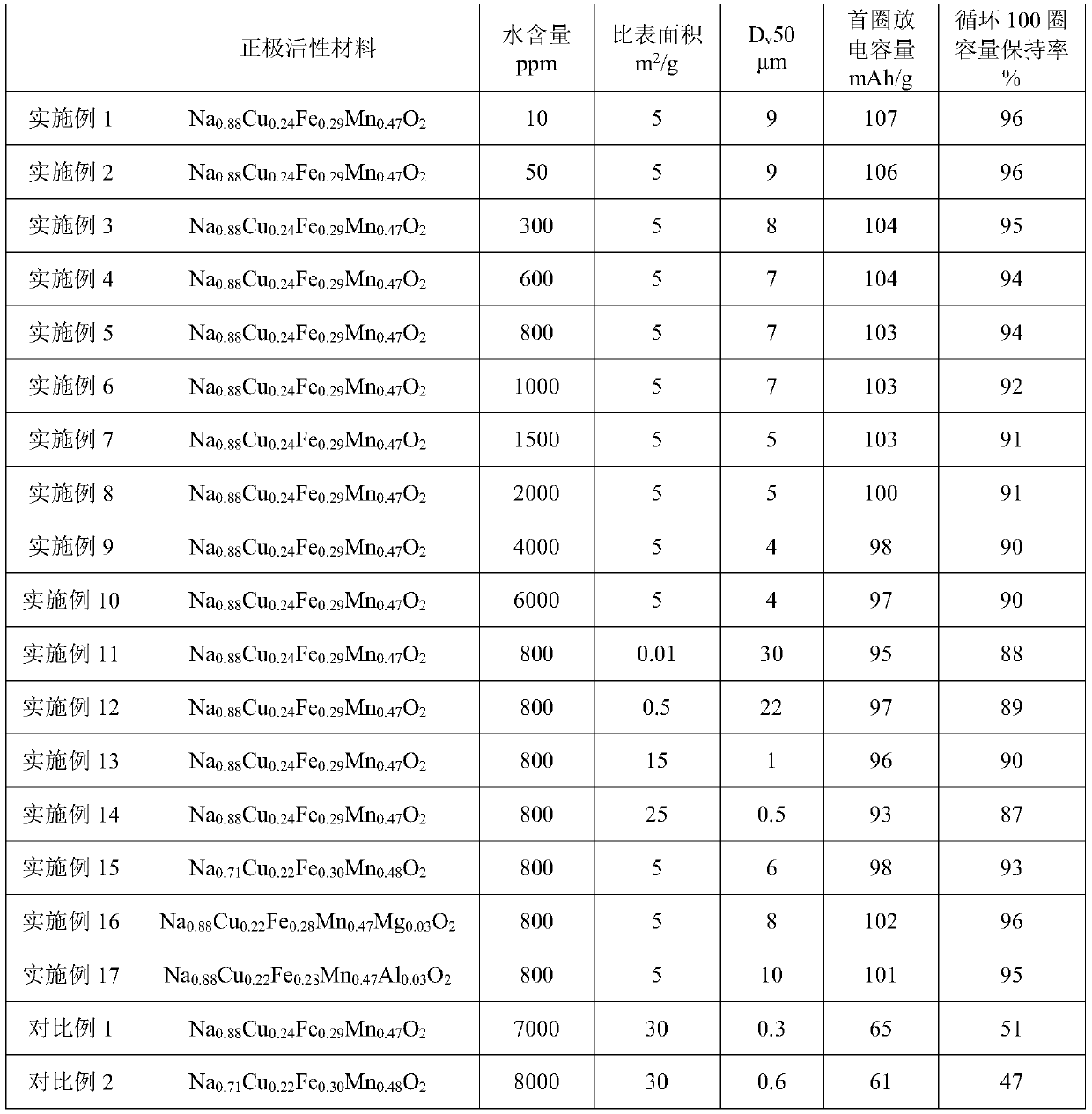

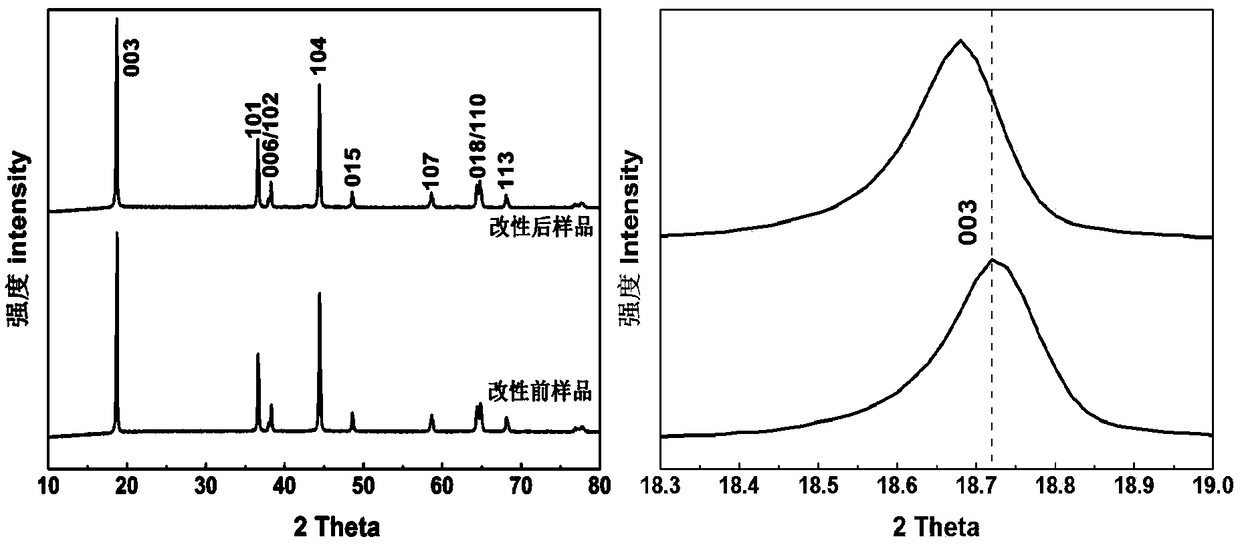

Positive electrode active material, positive electrode plate and sodium ion battery

PendingCN111435741AHigh charge and discharge capacityImprove cycle performanceSecondary cellsPositive electrodesPhysical chemistrySodium-ion battery

The invention discloses a positive electrode active material, a positive electrode plate and a sodium ion battery. The molecular formula of the positive electrode active material is Na<1-x>Cu<h>Fe<k>Mn<1>M<m>O<2y>, in the molecular formula, m is a transition metal site doping element, M is one or more of Li, Be, B, Mg, Al, K, Ca, Ti, Co, Ni, Zn, Ga, Sr, Y, Nb, Mo, In, Sn and Ba, 0<x<=0.33, 0<h<=0.24, 0<=k<=0.32, 0<l <=0.68, 0<=m<0.1, h+k+l+m=1 and 0<=y<0.2. The water content of the positive electrode active material is 6000 ppm or less. By adopting the positive electrode active material provided by the invention, the sodium ion battery has relatively high initial capacity, safety performance and cycle performance at the same time.

Owner:CONTEMPORARY AMPEREX TECH CO

A method for realizing ion doping and surface coating to modify ternary cathode material jointly by one-step method

ActiveCN109119611AInhibition transitionImprove cycle stabilityCell electrodesSecondary cellsCyclic processSolvent

The invention discloses a method for realizing metal ion doping and metal oxide surface coating to modify a ternary cathode material jointly by a one-step method, which comprises the following steps:S1. mixing a complexing agent and a ternary cathode material to be dissolved in a solvent, and continuing stirring reaction after ultrasonic wave treatment; 2, adding a metal ion salt solution to be doped and coated into the mixed solution in S1 drop by drop under the stirring state, and continuing stirring e reaction; S3, heating the mixed solution in S2, continuing stirring until the solvent iscompletely volatilized to obtain a mixed powder body; S4, calcinating the powder body obtained in S3 at 400-600 DEG C for 4-6h, and cooling to room temperature to obtain the modified material. The invention adopts a simple process and a method assisted by a complexing agent to prepare a modified ternary cathode material doped with elements on the surface layer and coated on the surface layer of the material in one step. Doping effectively inhibits the crystal structure transformation of the surface layer of the material during the cycle, and the coating layer prevents the direct contact with the electrolyte, inhibits the occurrence of side reactions, and improves the cycling stability of the material. By optimizing the synthesis process, the cost can be effectively saved, and the method has great application prospects.

Owner:GUANGDONG UNIV OF TECH

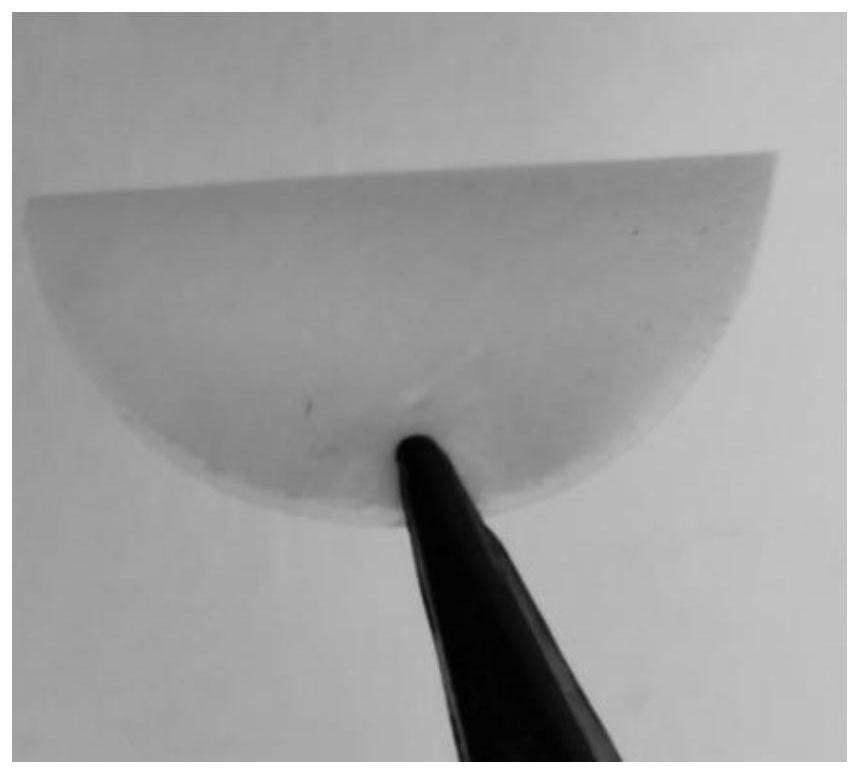

Flexible lithium metal negative electrode framework material as well as preparation method and application thereof

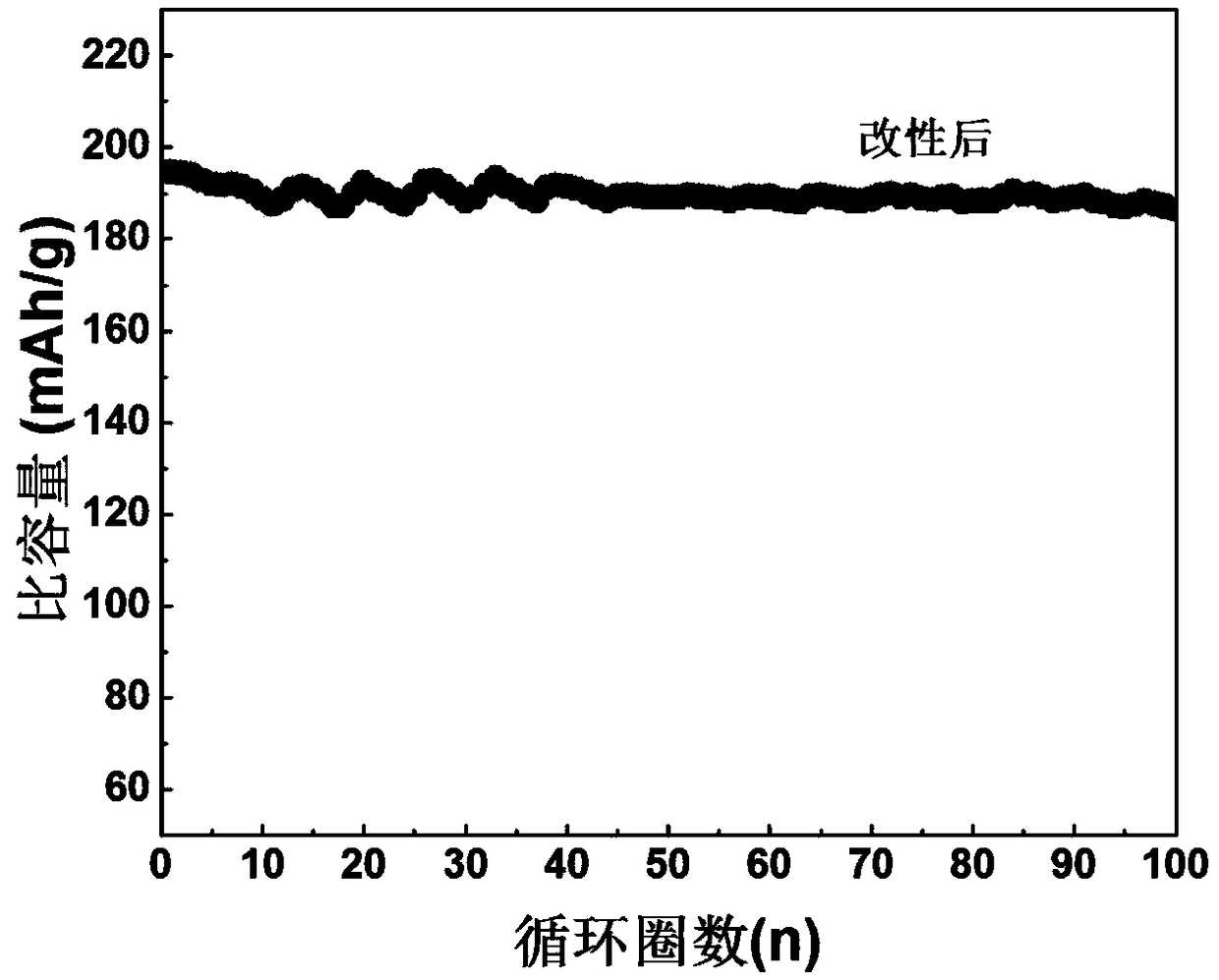

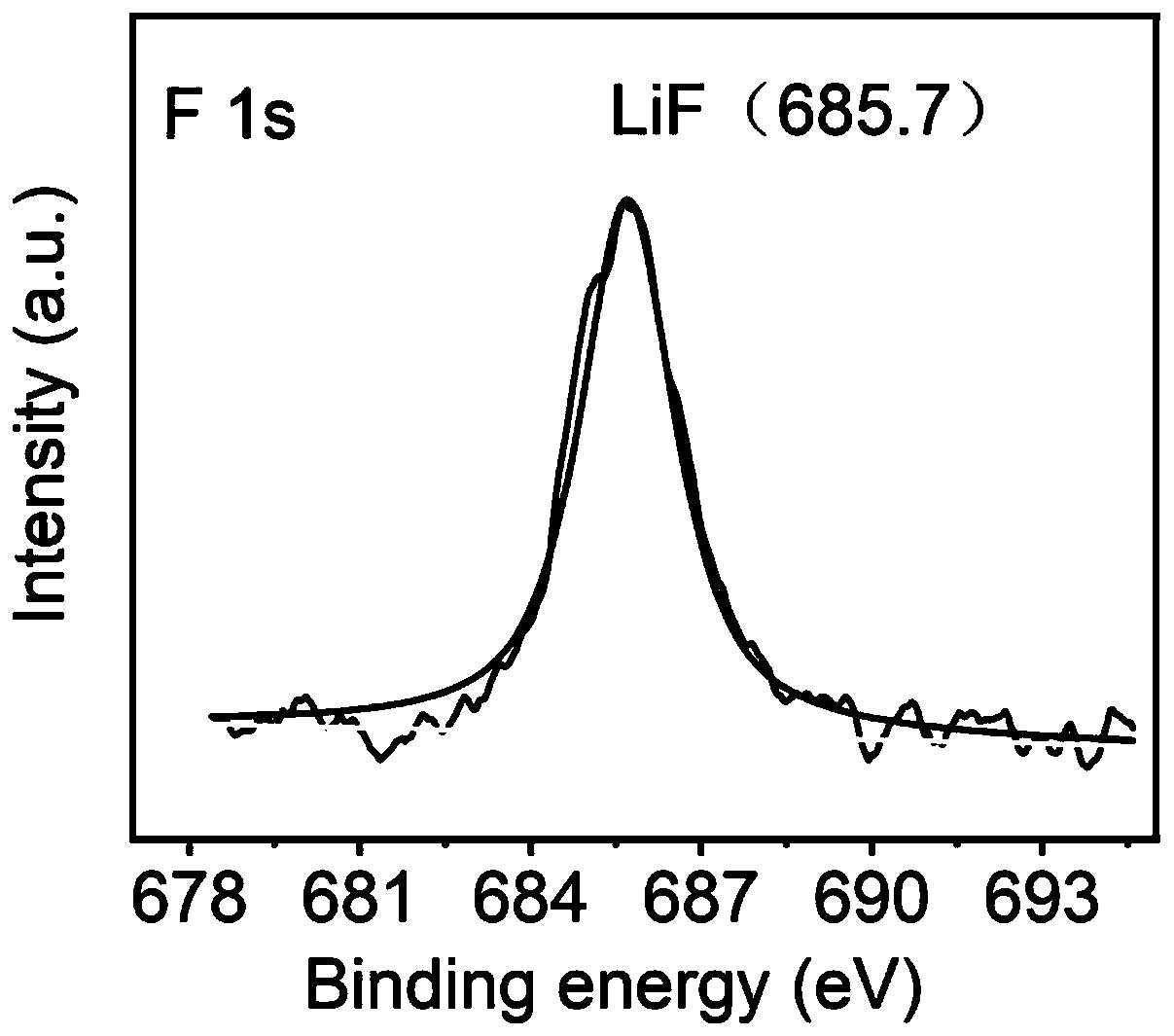

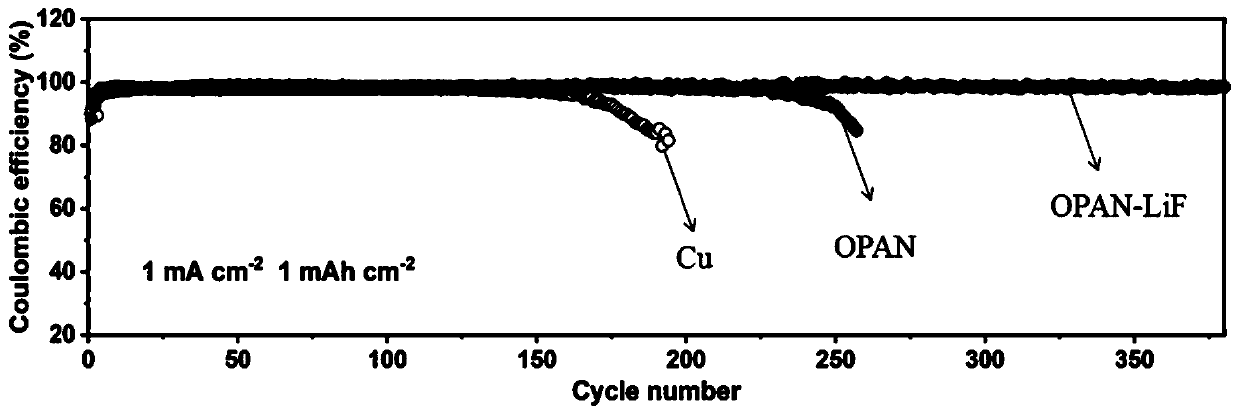

ActiveCN110993892AAlleviate volume expansionAveraged local ion concentrationNegative electrodesMonocomponent synthetic polymer artificial filamentLithium iron phosphateElectrical battery

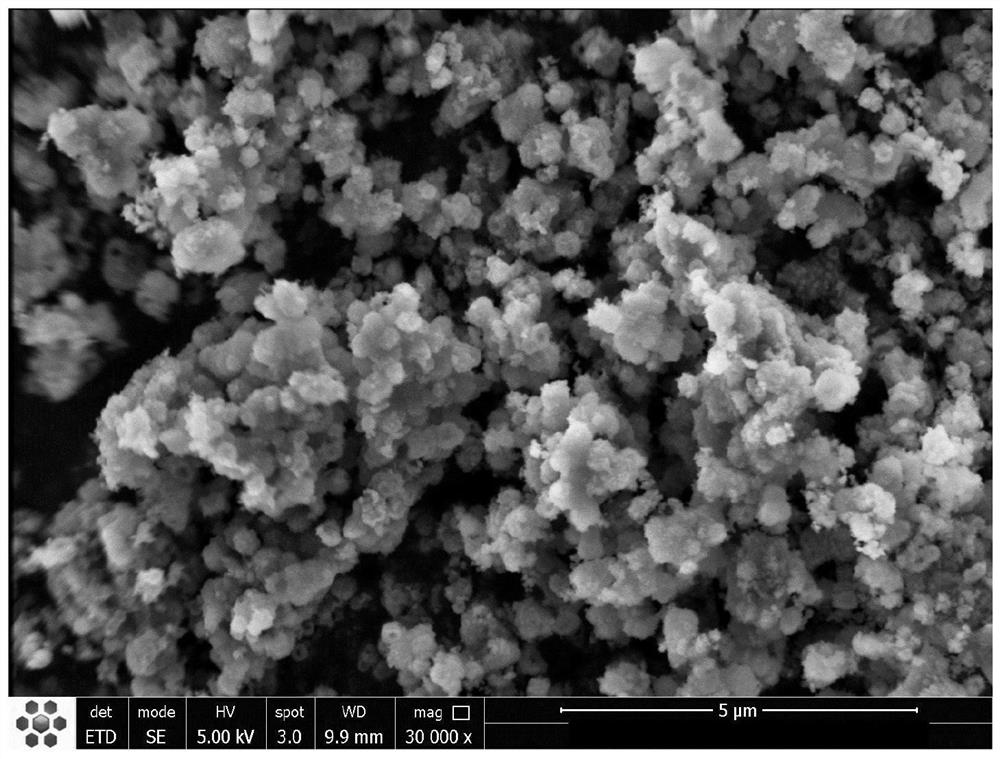

The invention discloses a flexible lithium metal negative electrode framework material as well as a preparation method and application thereof. The invention belongs to the field of lithium metal battery materials. The framework material is a three-dimensional nanofiber framework modified by lithium fluoride, the diameter of the three-dimensional nanofibers in the framework is 50-900 nm, the lithium fluoride particles are uniformly anchored in the three-dimensional nanofibers, the interiors of three-dimensional nanofiber frameworks are communicated and are three-dimensional and porous, the three-dimensional nanofiber frameworks have good flexibility and can be bent within 0-180 degrees, and the framework material is prepared from a high polymer mixed with the lithium fluoride particles through electrostatic spinning and heat treatment. The composite lithium metal negative electrode obtained by plating a flexible frameworkwith lithium shows good cycling stability during cycling, and ismatched with lithium iron phosphate to form a whole battery, under the condition of 5C, the capacity retention ratio can be 89% after 1600 circles, and the lithium metal battery obtained by using theframework can obtain high coulombic efficiency and long cycle life.

Owner:CENT SOUTH UNIV

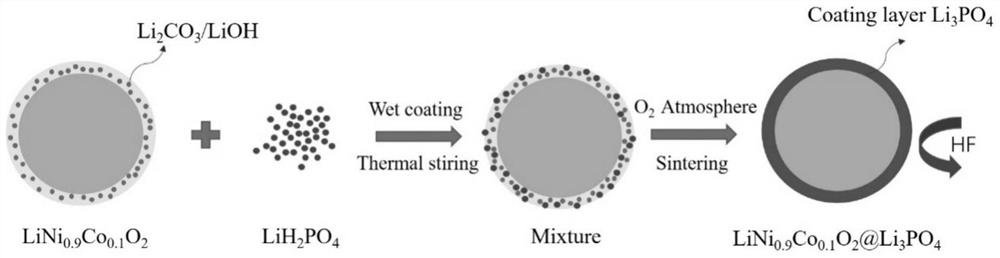

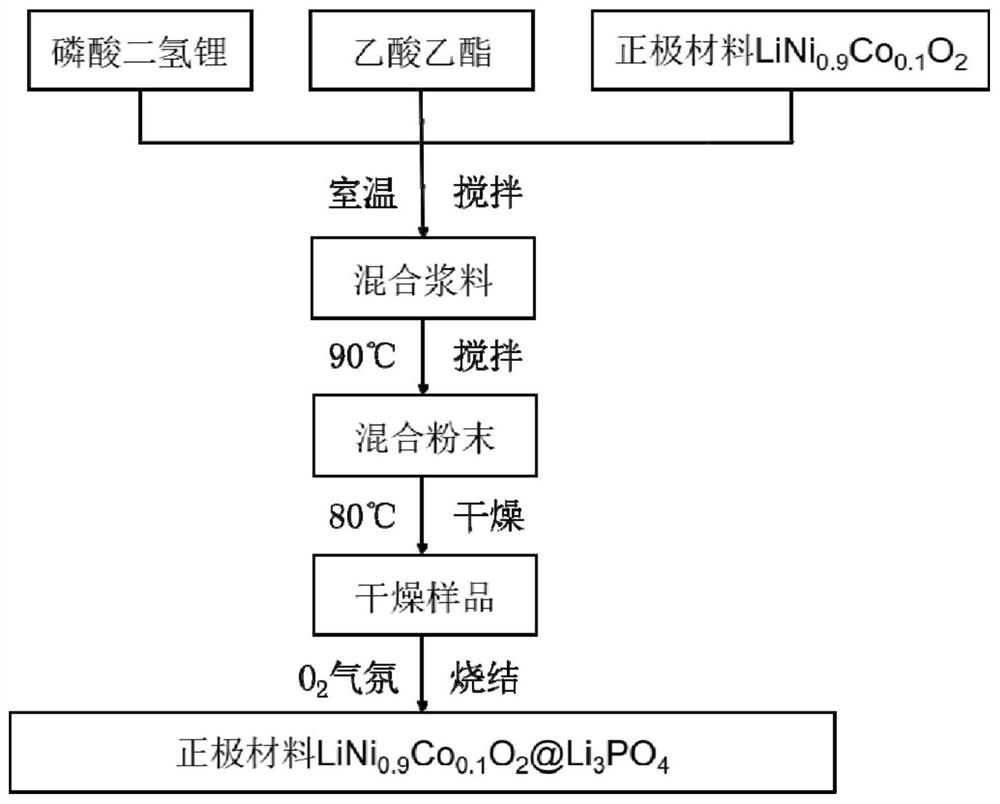

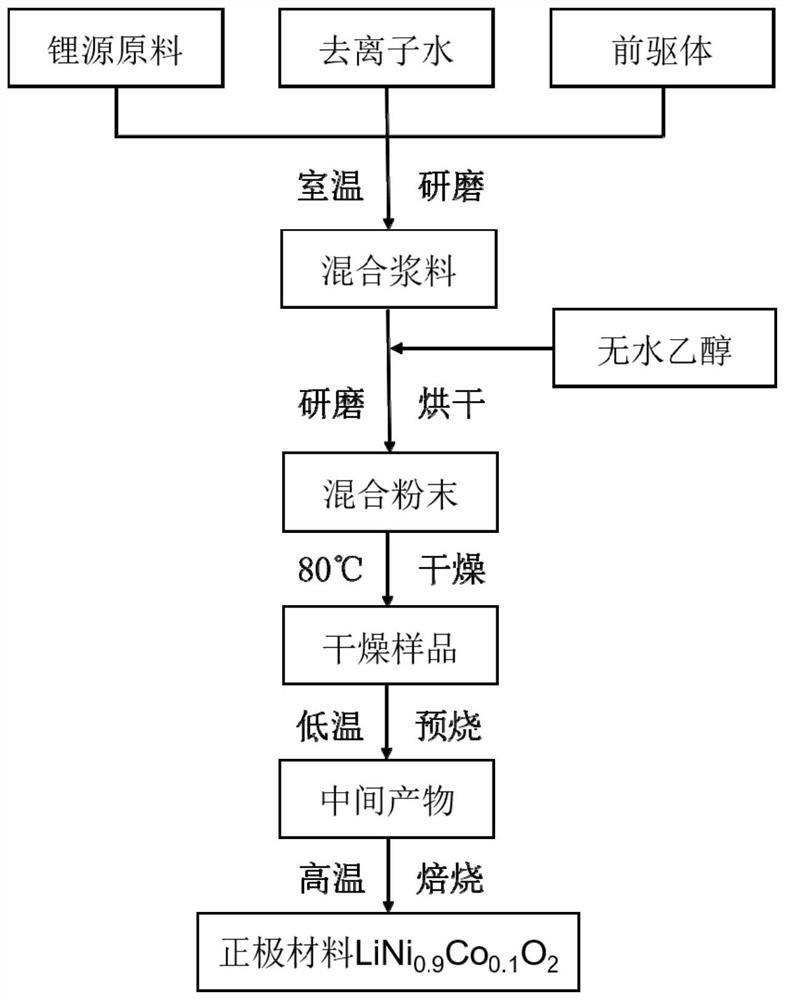

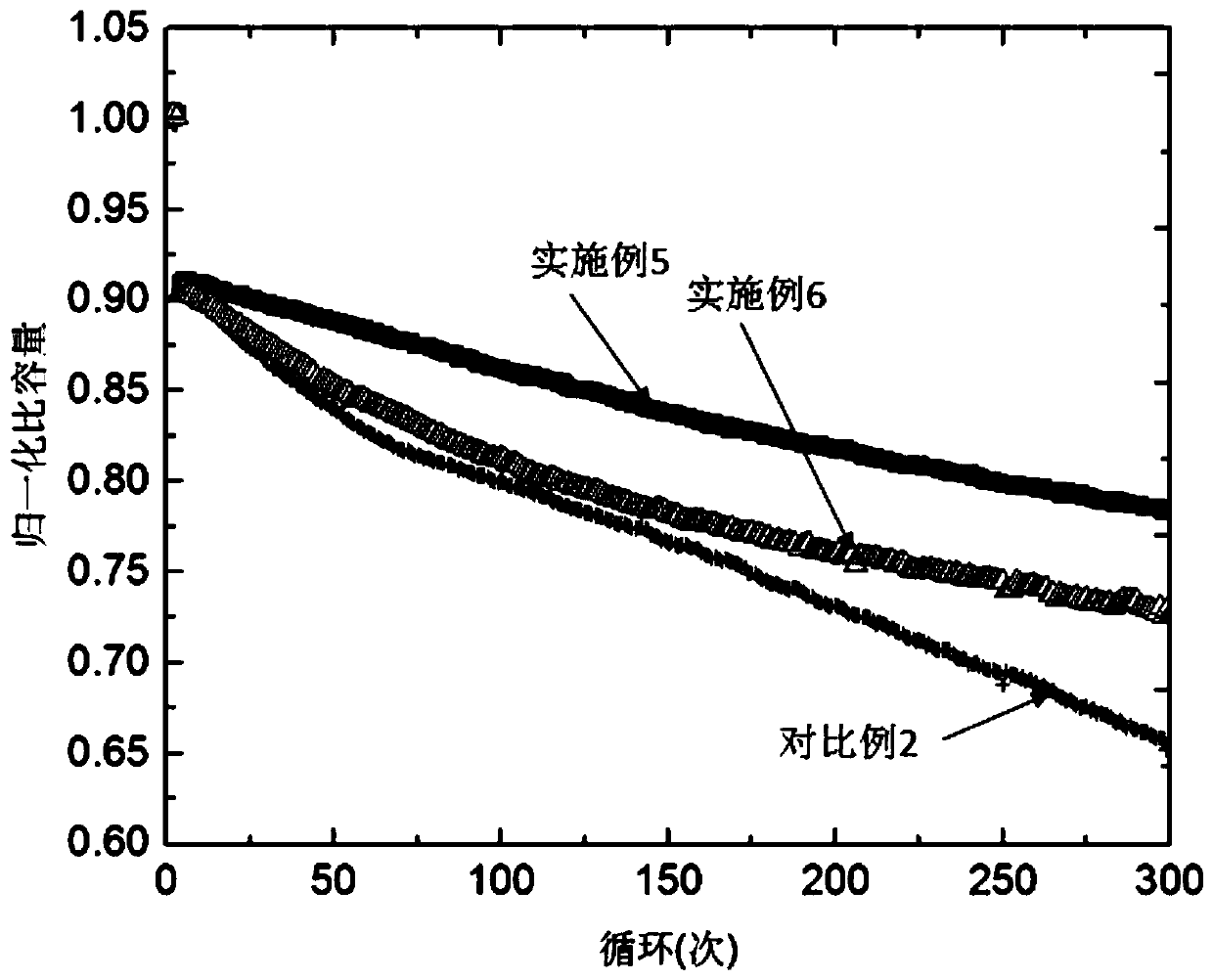

Lithium phosphate coated lithium ion battery high-nickel positive electrode material and preparation method thereof

PendingCN113328069AUniform particle size distributionSimple operation processSecondary cellsPositive electrodesElectrical conductorPhysical chemistry

The invention belongs to the technical field of preparation of a lithium ion battery high-nickel positive electrode material, and particularly provides a lithium phosphate coated lithium ion battery high-nickel positive electrode material and a preparation method thereof. The material and the preparation method are used for overcoming the defects of poor processing performance, harsh requirements on use environment, poor cycling stability, low first-circle coulombic efficiency and sharp reduction of high-temperature performance in the prior art. Lithium dihydrogen phosphate is taken as a coating raw material, and a fast ion conductor lithium phosphate coating layer is generated through in-situ reaction of lithium dihydrogen phosphate and residual alkali (LiOH and Li2CO3) on the surface of a parent material, so that lithium salt residues on the surface of the parent material are greatly reduced, the processing performance is improved, the requirement on a use environment is reduced, the ionic conductivity of the positive electrode material is increased, the number of lithium ions of the positive electrode material is increased, and phase change and interface side reaction are effectively inhibited, therefore, the lithium phosphate coated lithium ion battery high-nickel positive electrode material has excellent cycling stability and specific discharge capacity, and especially can maintain relatively good electrochemical performance at high temperature.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

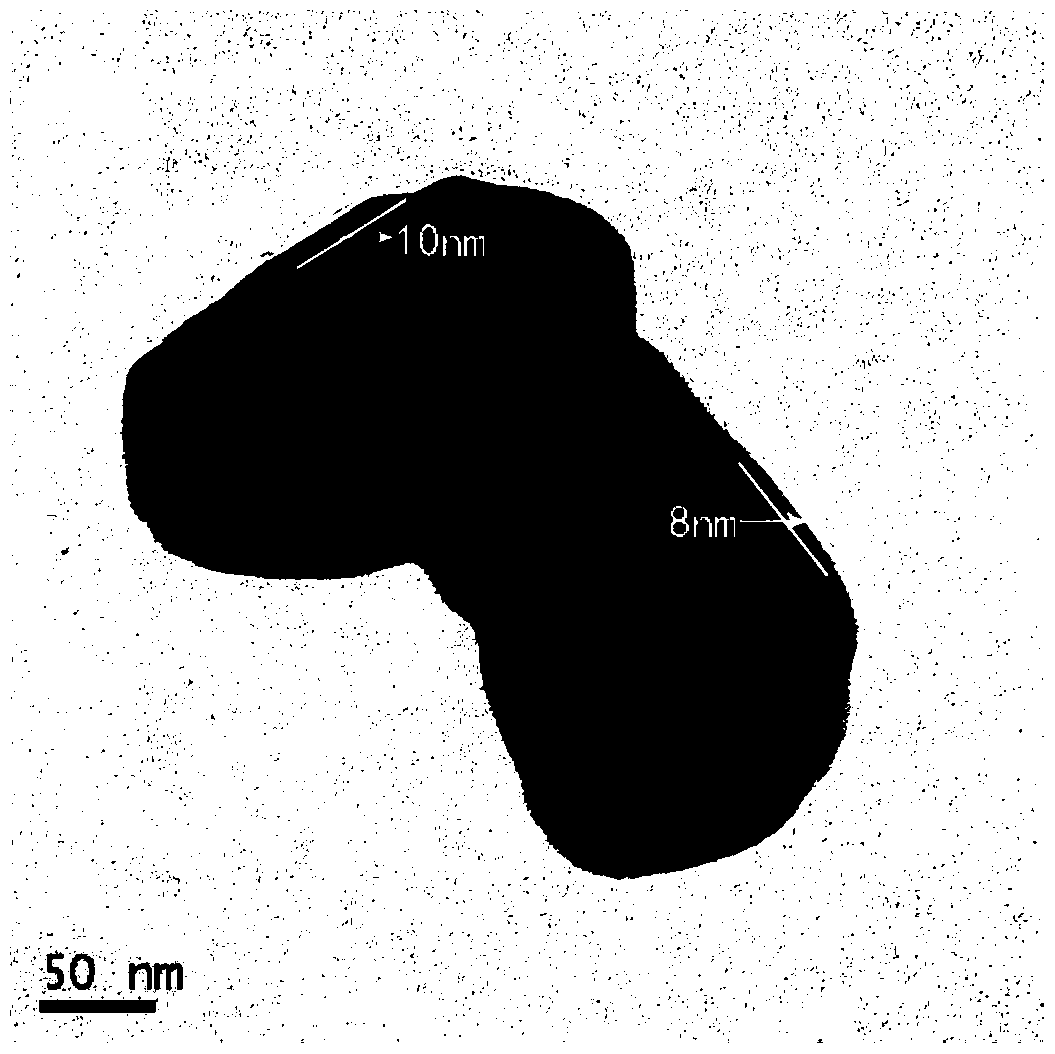

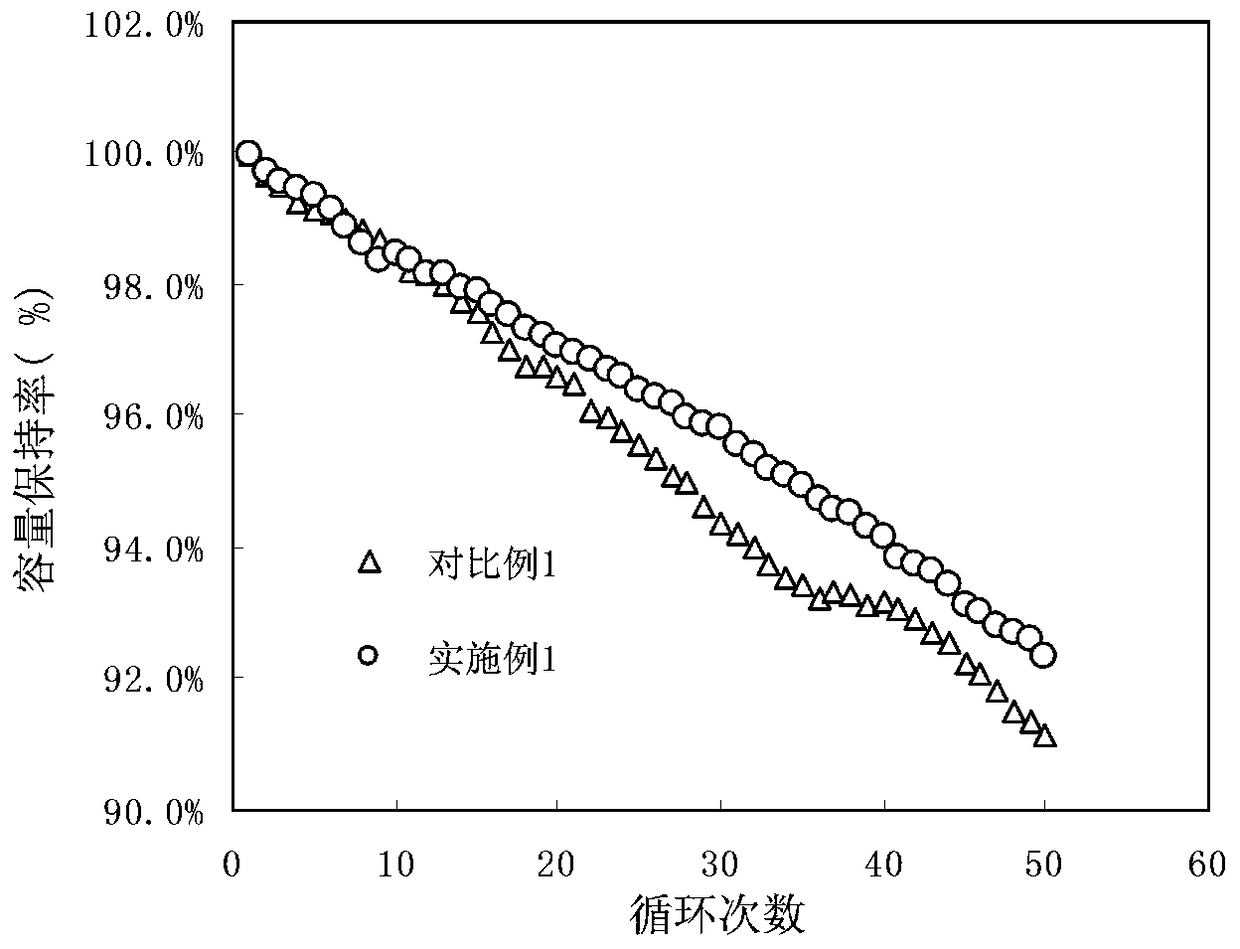

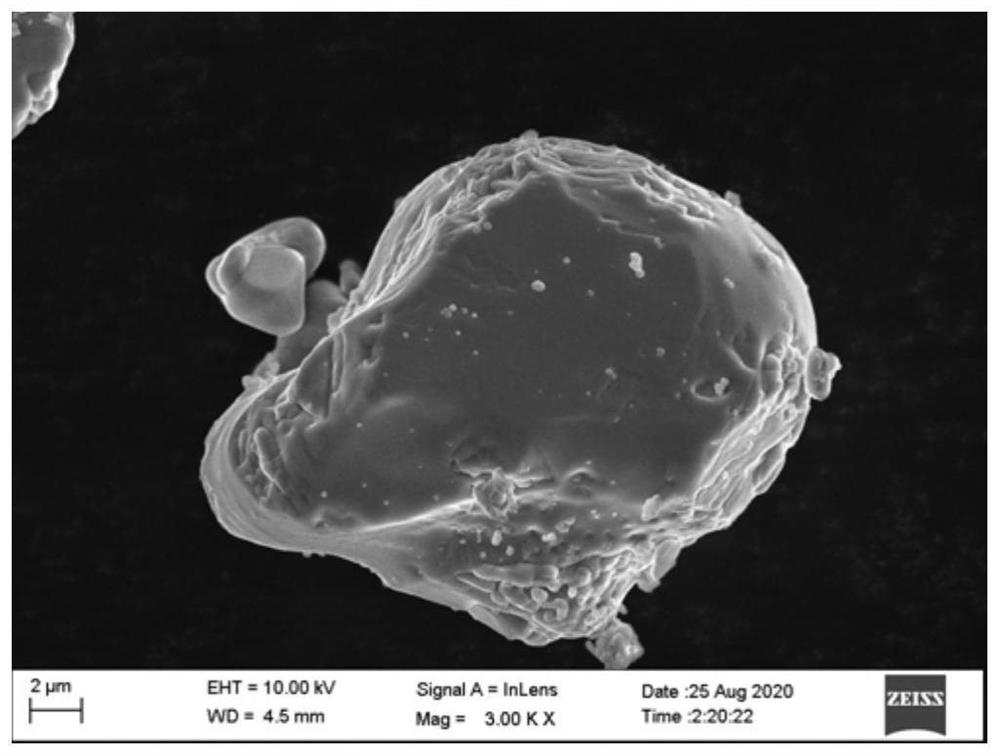

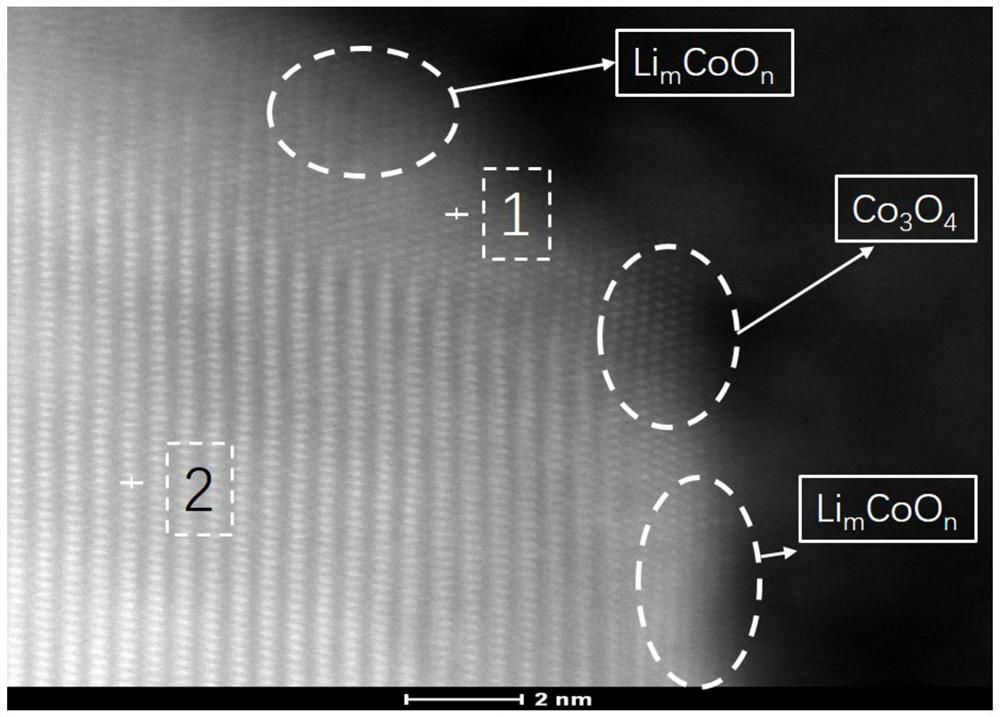

Electrode material, lithium ion battery and preparation method and application thereof

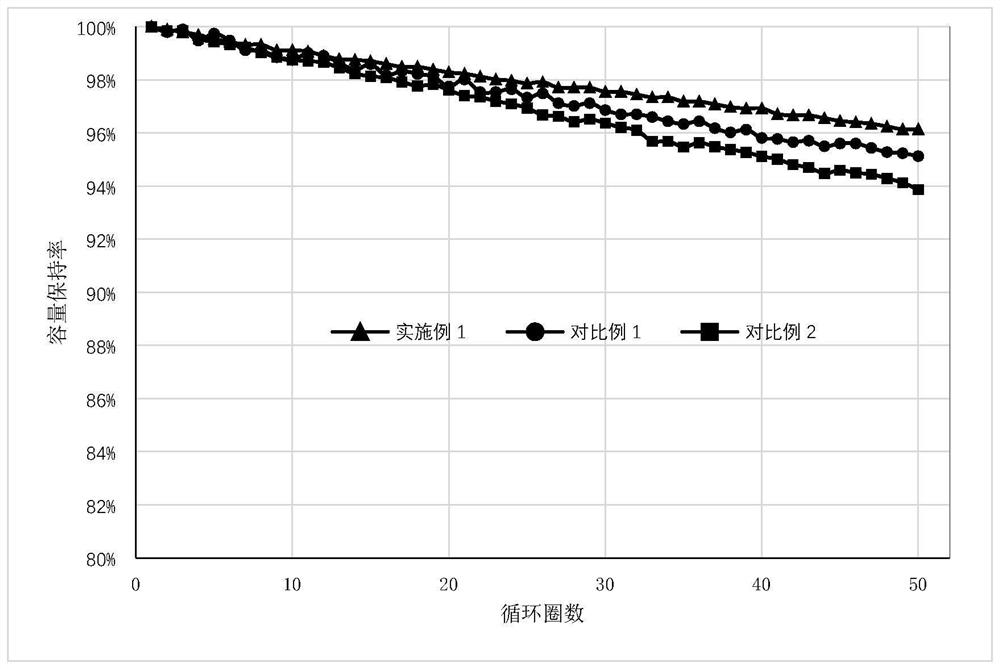

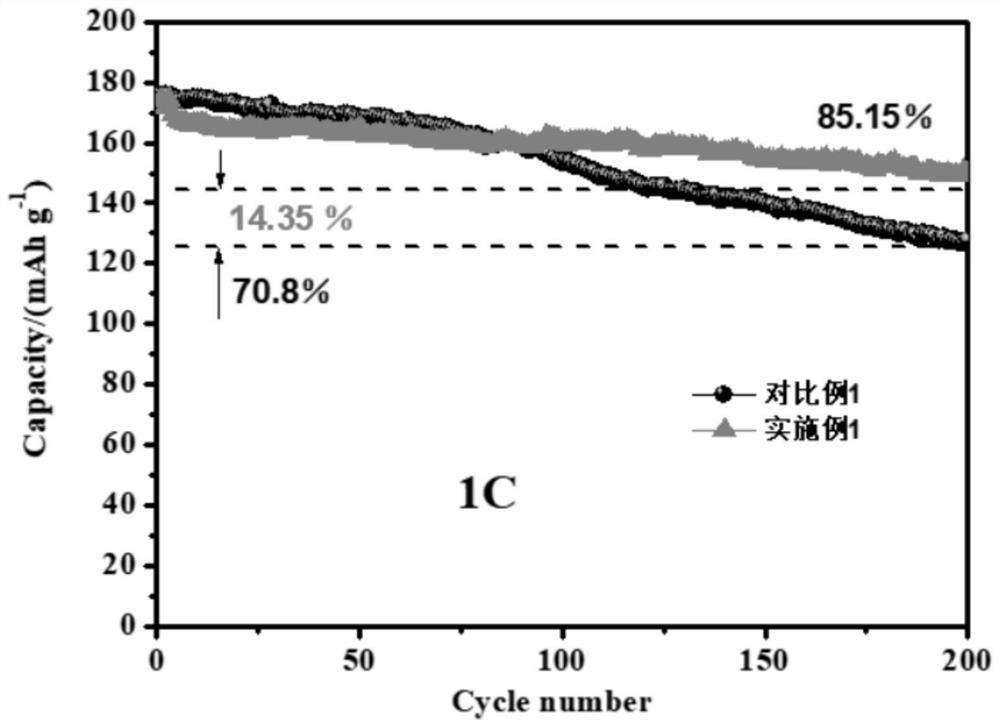

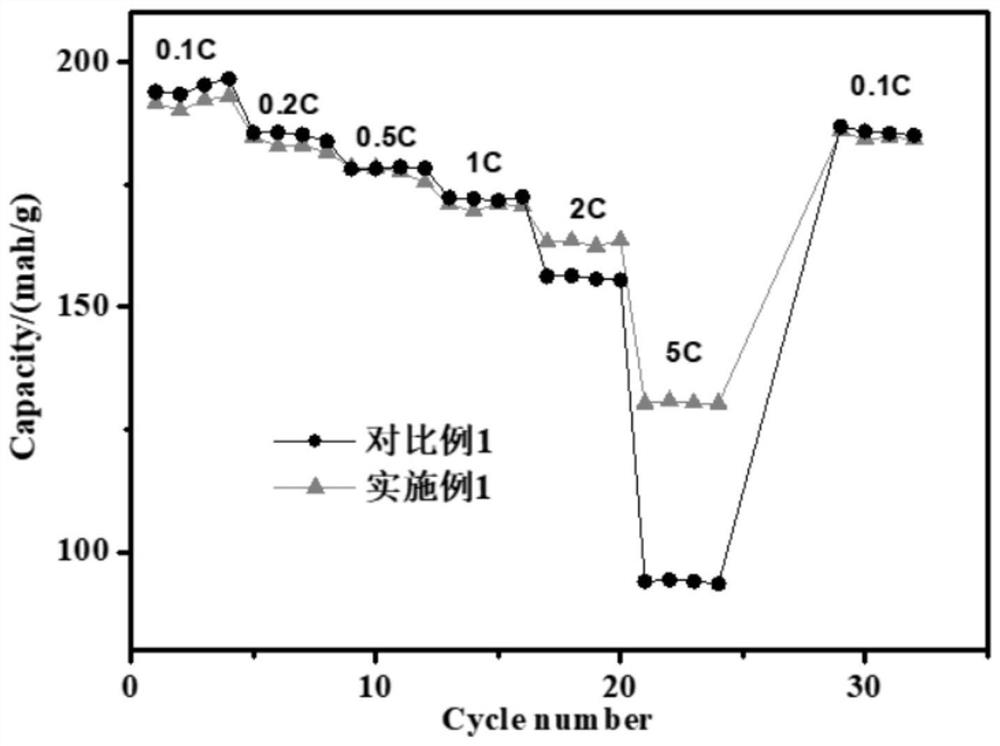

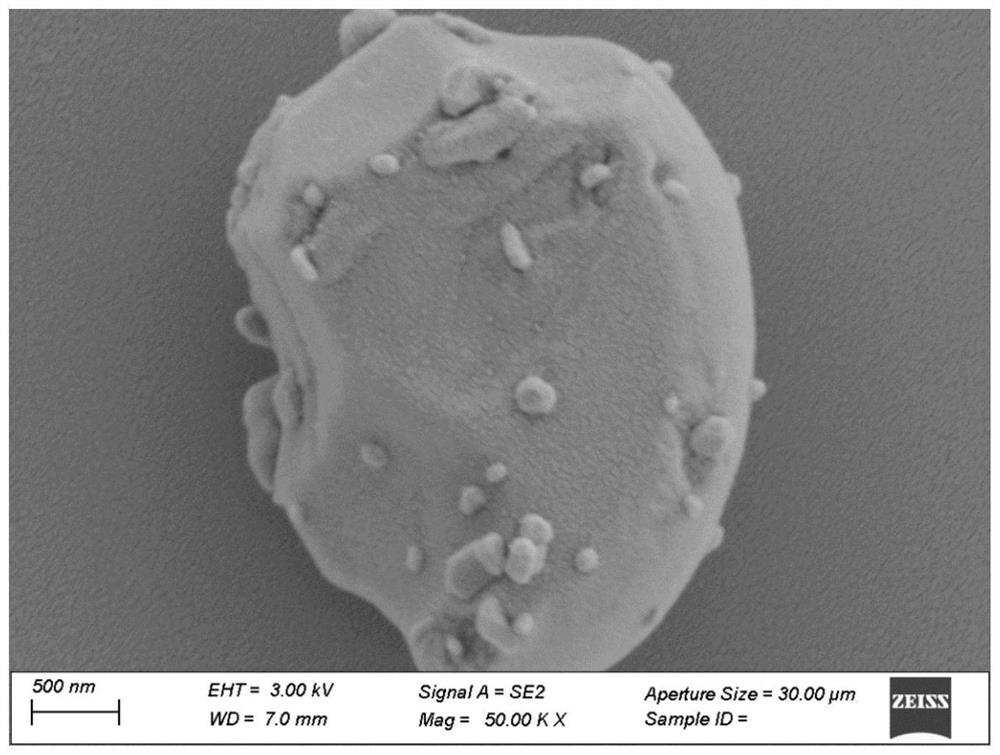

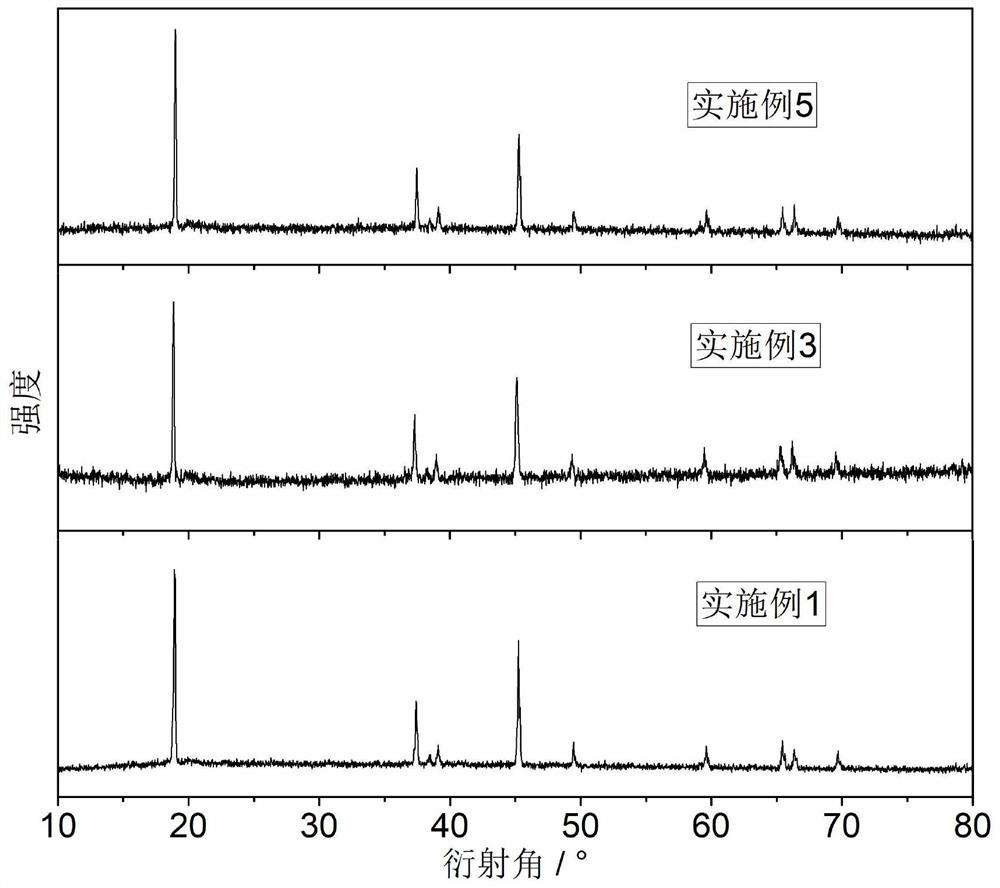

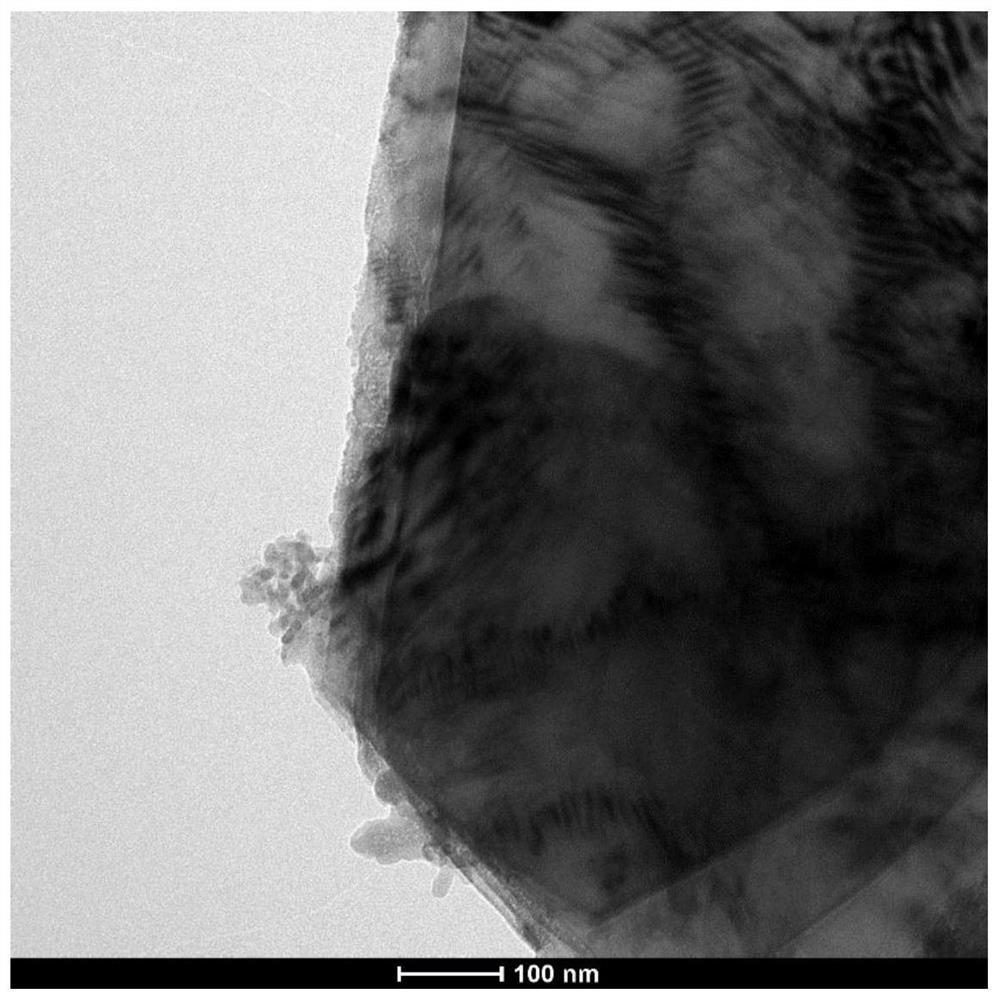

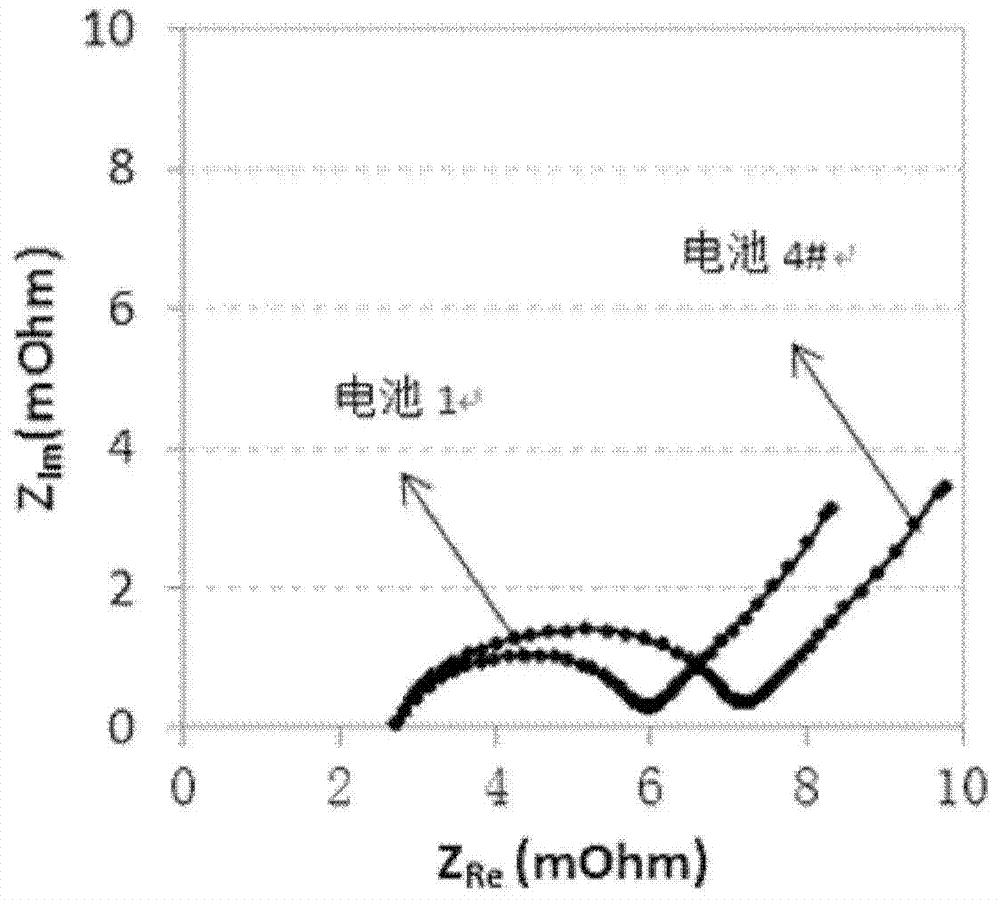

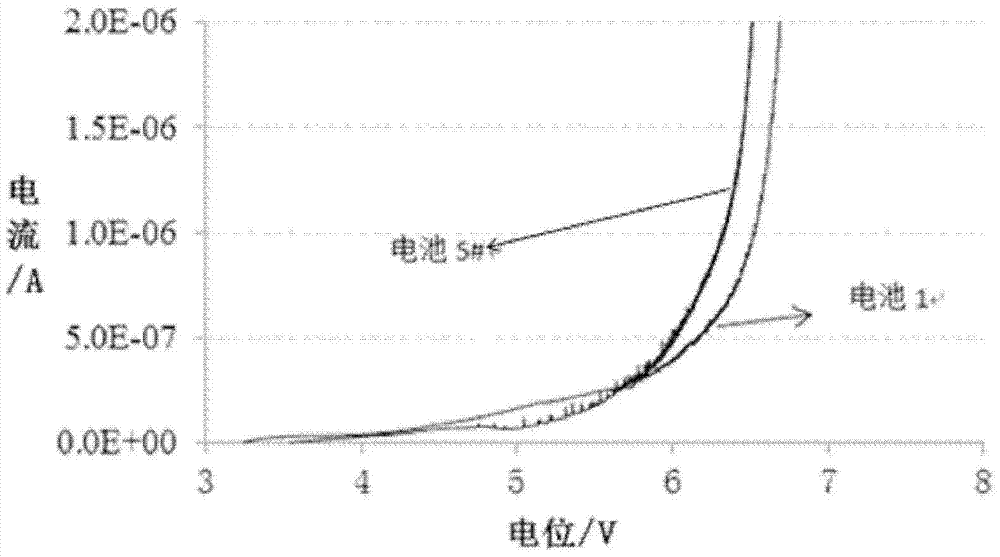

ActiveCN109786731AHigh capacity retentionReduce interface side reactionsCell electrodesSecondary cellsManganeseSodium-ion battery

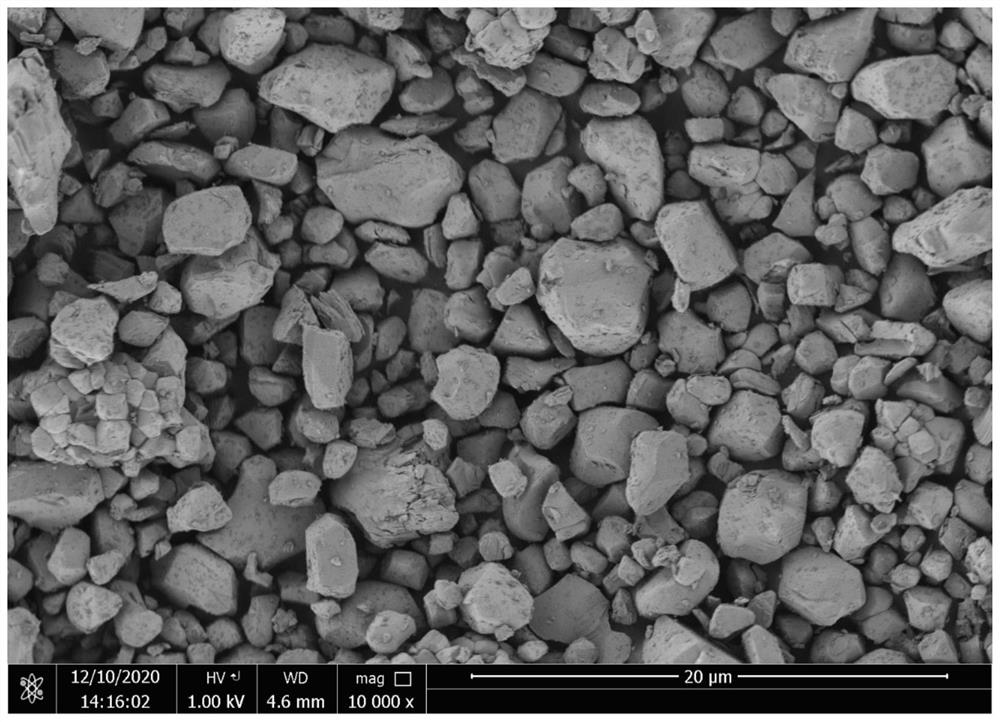

The invention discloses an electrode material, a lithium ion battery, a preparation method and application thereof. The preparation method comprises the following steps: calcining the mixture of a ternary precursor material, a seed crystal and a lithium ion-containing molten salt in an oxygen-containing atmosphere; wherein the molar ratio of the ternary precursor material to the seed crystal is 2:10-10: 1; the ternary precursor material is nickel-cobalt-manganese hydroxide or nickel-cobalt-aluminum hydroxide. The preparation method can control the average diameter of the obtained electrode material within a proper range, so that the interfacial side reaction of the electrode material in the battery cycle process is reduced, the capacity retention rate of the battery is further improved, and better rate capability and cycle stability are obtained.

Owner:SHANGHAI ZIJIAN CHEM TECH CO LTD

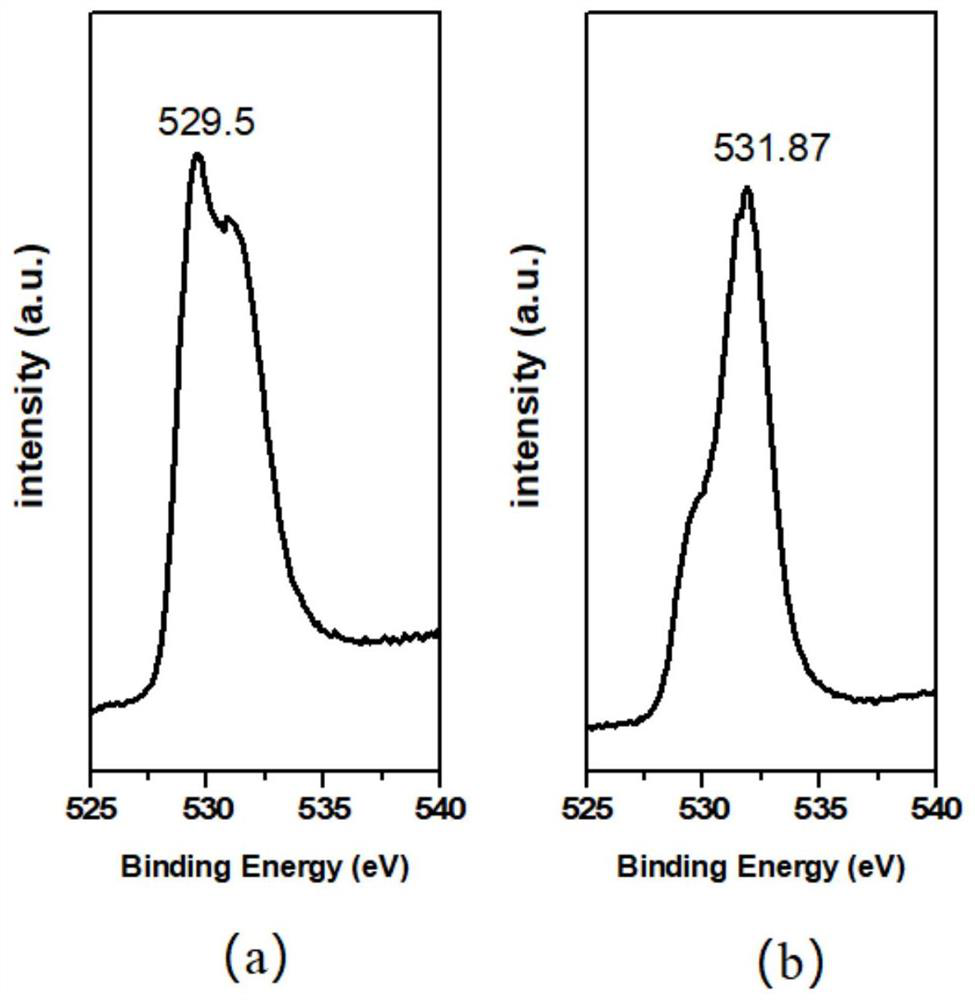

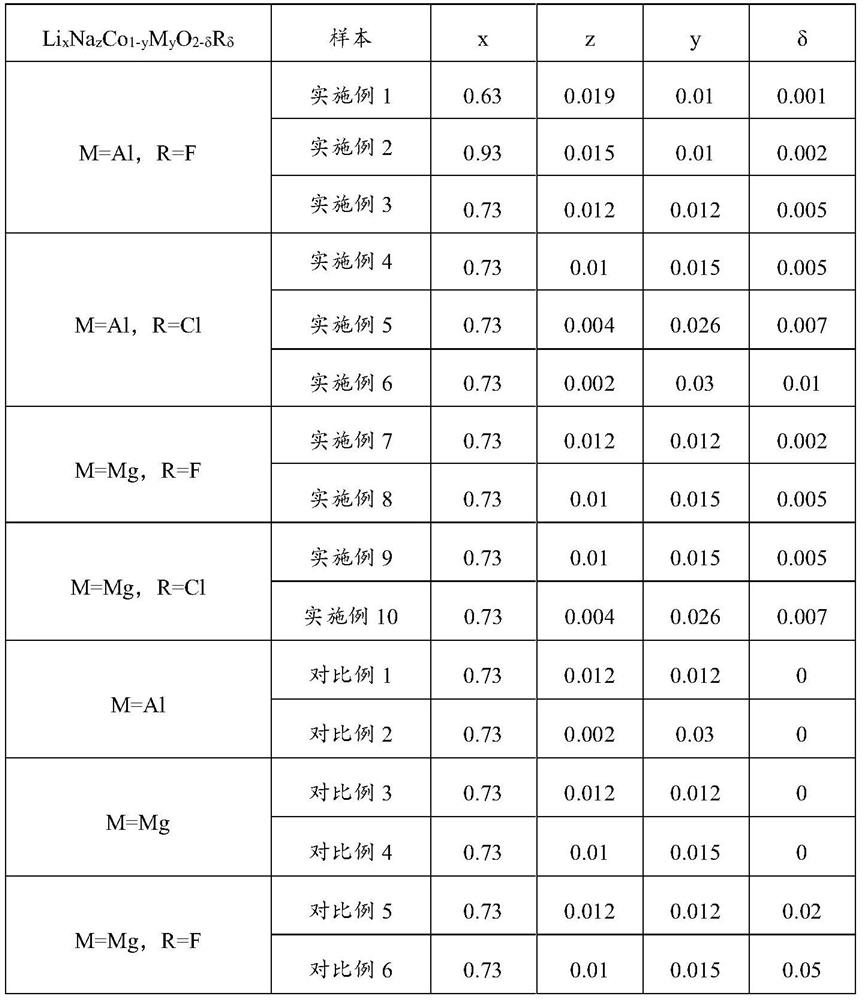

Positive electrode active material and electrochemical device

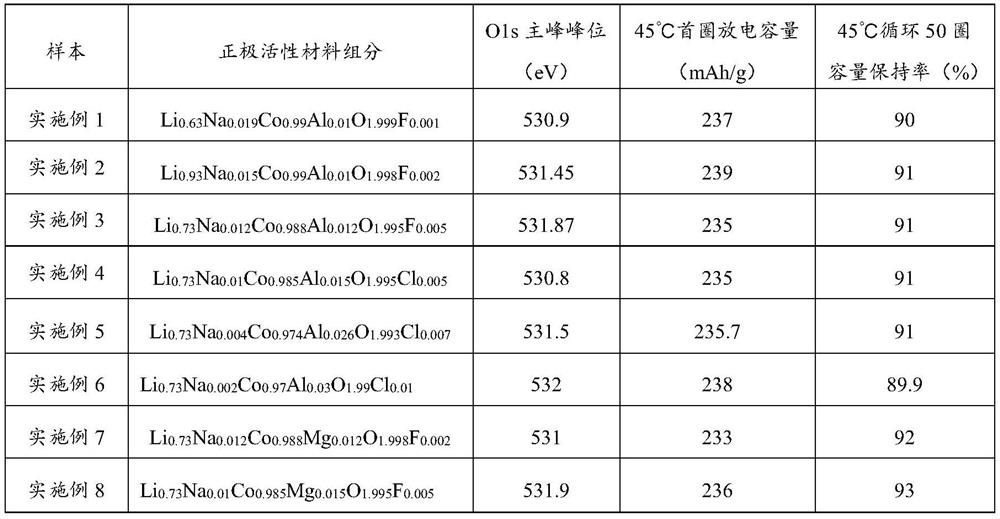

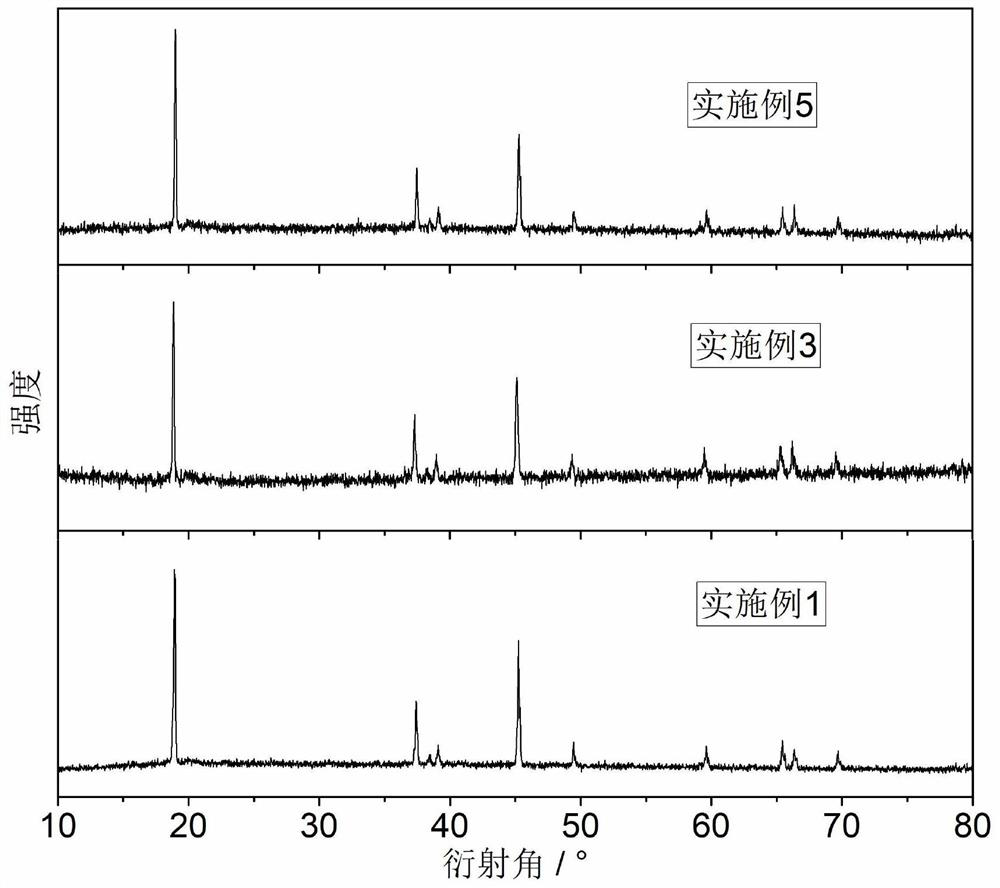

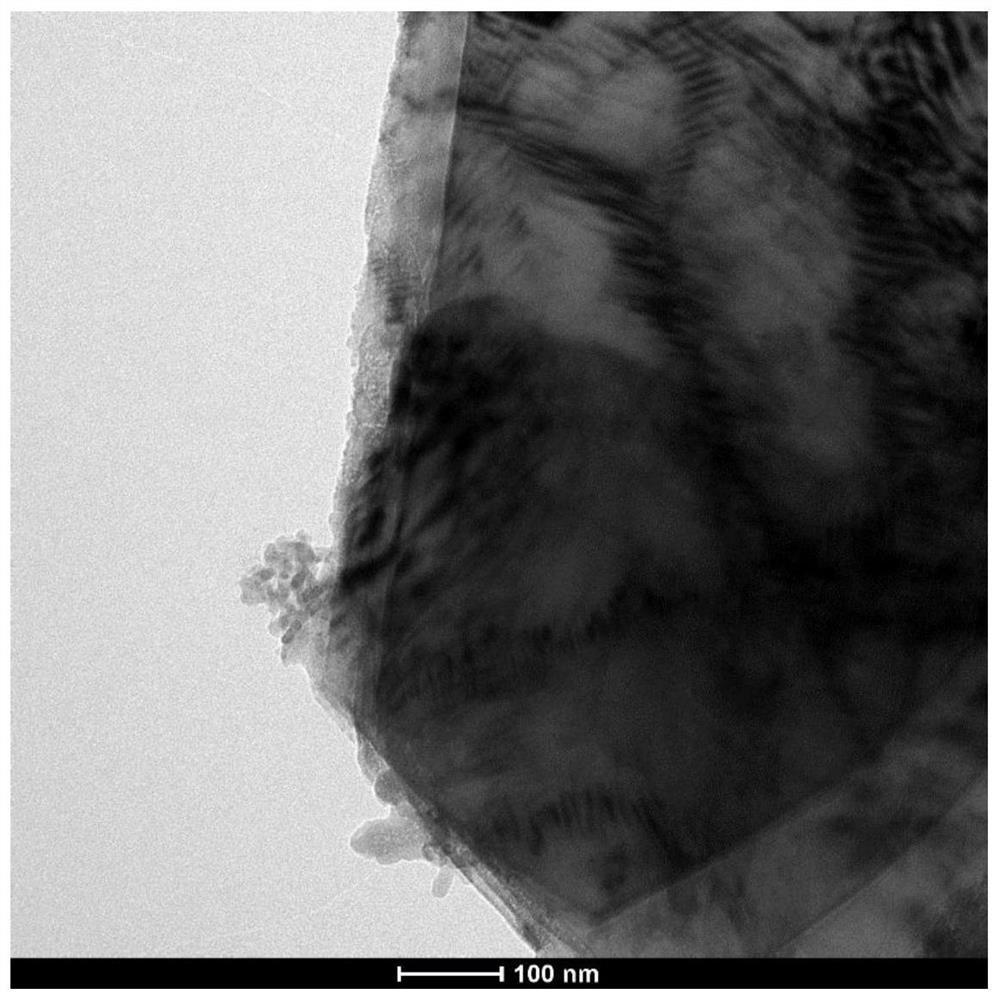

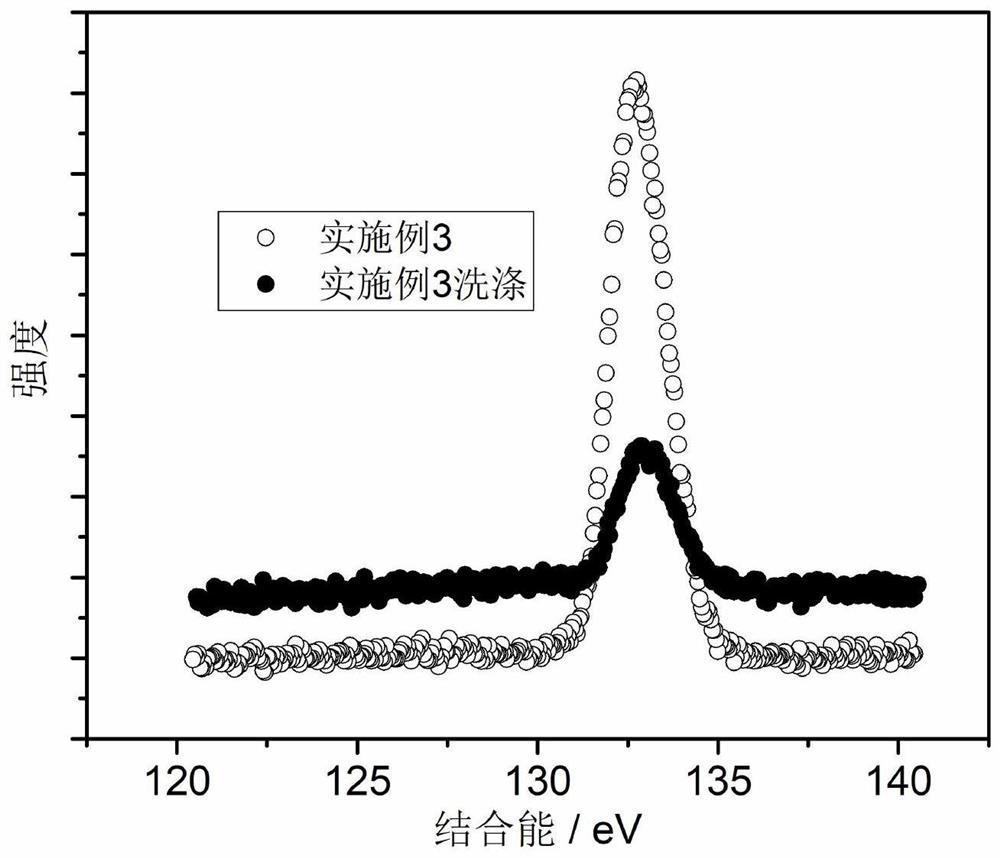

ActiveCN112331841AImprove structural stabilityAvoid damagePositive electrodesLi-accumulatorsPhysical chemistryCrystal structure

Provided are a positive electrode active material and an electrochemical device. The positive electrode active material is of a P63mc crystal structure and is a lithium transition metal composite oxide containing Co and an R element, wherein the M element includes at least one of Al, Mg, Ti, Mn, Fe, Ni, Zn, Cu, Nb, Cr, Y, or Zr, the R element includes at least one of F, Cl, and the R element is amolar content of nR; wherein the sum of the molar content of Co and the molar content of M is nCo+M, and the ratio delta of nR to nCo+M is larger than 0 and smaller than or equal to 0.01. The positiveelectrode active material disclosed by the invention is high in crystal structure stability, so that the cycle performance and the thermal stability of an electrochemical device are improved.

Owner:NINGDE AMPEREX TECH

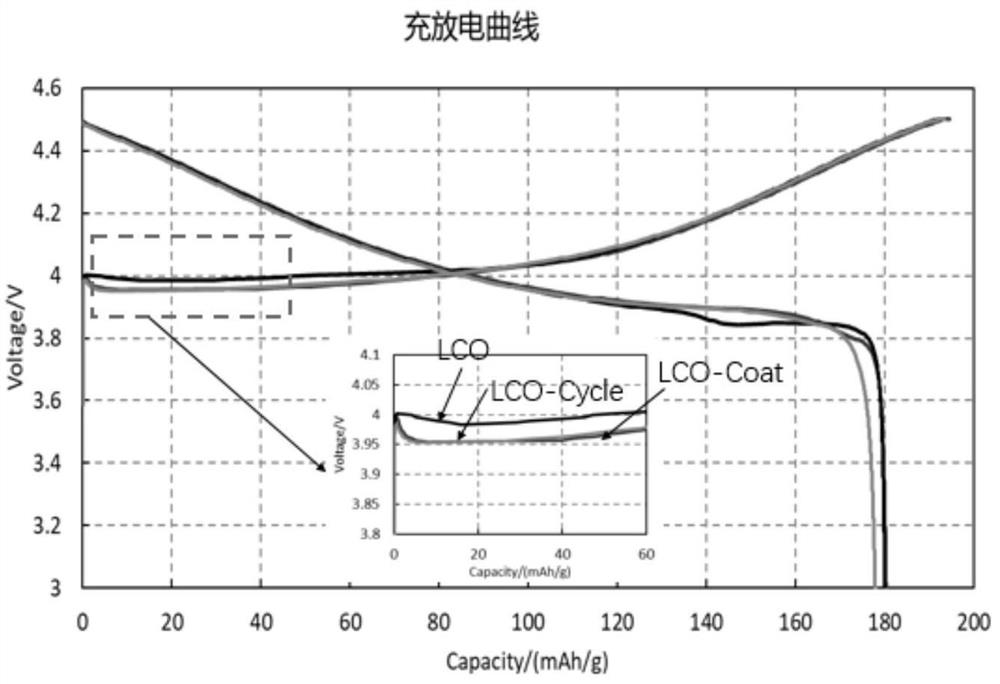

Method for modifying surface of lithium cobalt oxide positive electrode material by phosphorus-containing compound and lithium cobalt oxide positive electrode material

ActiveCN111916712ASimple processEasy to controlCell electrodesSecondary cellsElectrolytic agentPhysical chemistry

The invention provides a method for modifying the surface of a lithium cobalt oxide positive electrode material by a phosphorus-containing compound and the lithium cobalt oxide positive electrode material, and the method comprises the following steps: 1, by taking a lithium cobalt oxide powder material with a layered structure as a matrix, carrying out ball-milling mixing on the lithium cobalt oxide powder material and the phosphorus-containing compound according to a certain proportion to obtain a mixed powder material; 2, in an atmosphere protection environment, heating the mixed powder material to obtain the modified lithium cobalt oxide positive electrode material, wherein the interior of which is lithium cobalt oxide, the near surface of which comprises lithium cobalt oxide crystal lattices and phosphate radical bonds and the surface of which comprises an amorphous coating layer composed of metal ions and phosphate radical groups. According to the preparation method, a phosphorus-containing compound and lithium cobalt oxide are mixed and heated for process control and treatment, so the surfaces of lithium cobalt oxide particles are modified, and the stability of a lithium cobalt oxide structure is enhanced by doping phosphate radicals in surface crystal lattices; and the amorphous coating layer effectively protects the electrode electrolyte interface, reduces the interfaceside reaction, and improves the rate capability and the cycle performance.

Owner:NANJING UNIV OF SCI & TECH

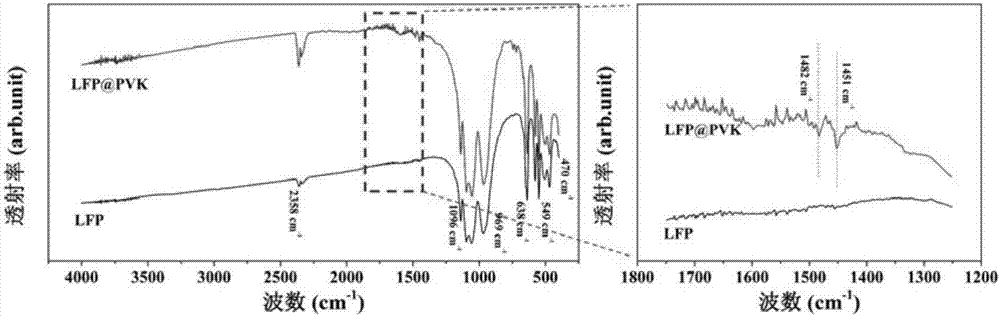

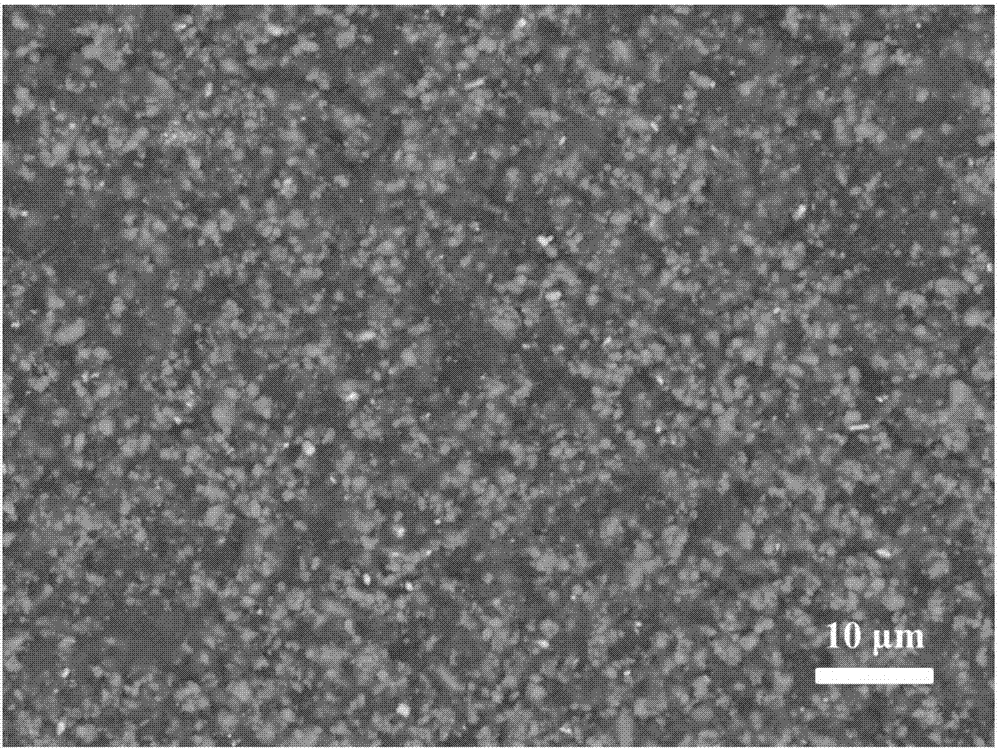

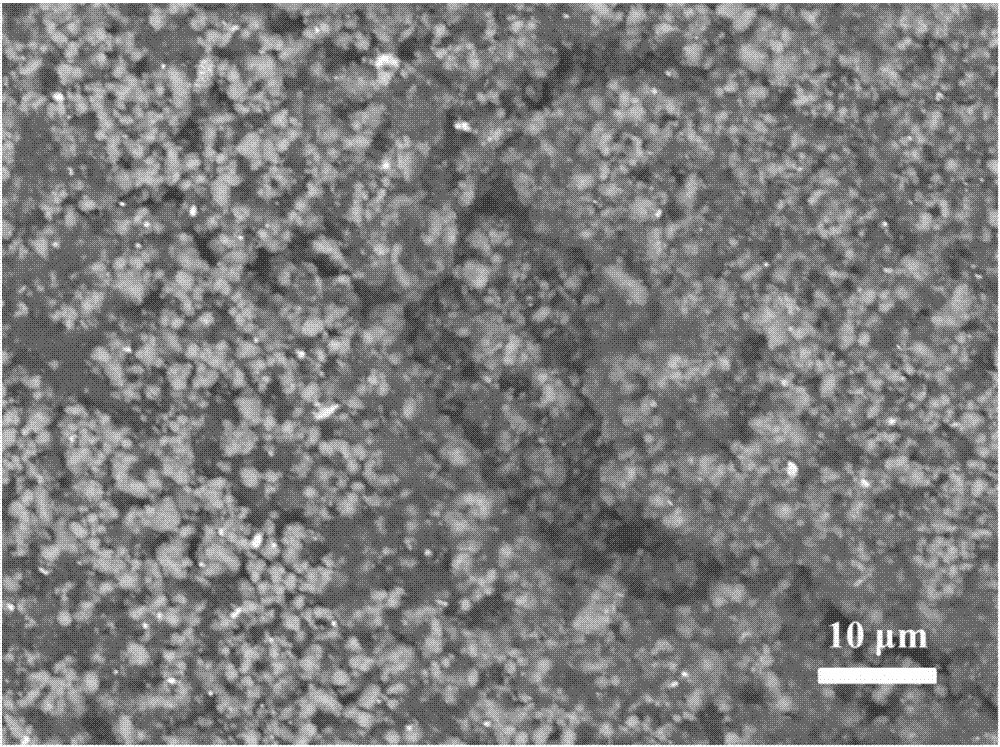

Preparation method of conductive polymer modified lithium ion battery positive pole piece

ActiveCN107507961AImproved magnification performanceImprove stabilityCell electrodesSecondary cellsCarbazoleConductive polymer

Belonging to the technical field of lithium ion batteries, the invention relates to a preparation method of a conductive polymer modified lithium ion battery positive pole piece. The method includes: coating a lithium ion battery positive active material surface with polyvinyl carbazole, then coating a current collector with the polyvinyl carbazole coated positive active material so as to obtain the lithium ion battery positive pole piece. According to the preparation method provided by the invention, the surface of the positive active material is coated with polyvinyl carbazole, thus effectively reducing the interface side reaction between the positive active material and an electrolyte solution, also ensuring Li<+> good transfer efficiency, simultaneously enhancing the electrical conductivity of the positive material, and prolonging the service life of the positive active material. By coating the current collector with the polyvinyl carbazole coated positive active material, the positive pole piece with excellent electrical properties, especially rate performance and stability can be obtained. And polyvinyl carbazole itself has certain caking properties, and can strengthen the oneness of the positive pole piece.

Owner:HENAN NORMAL UNIV

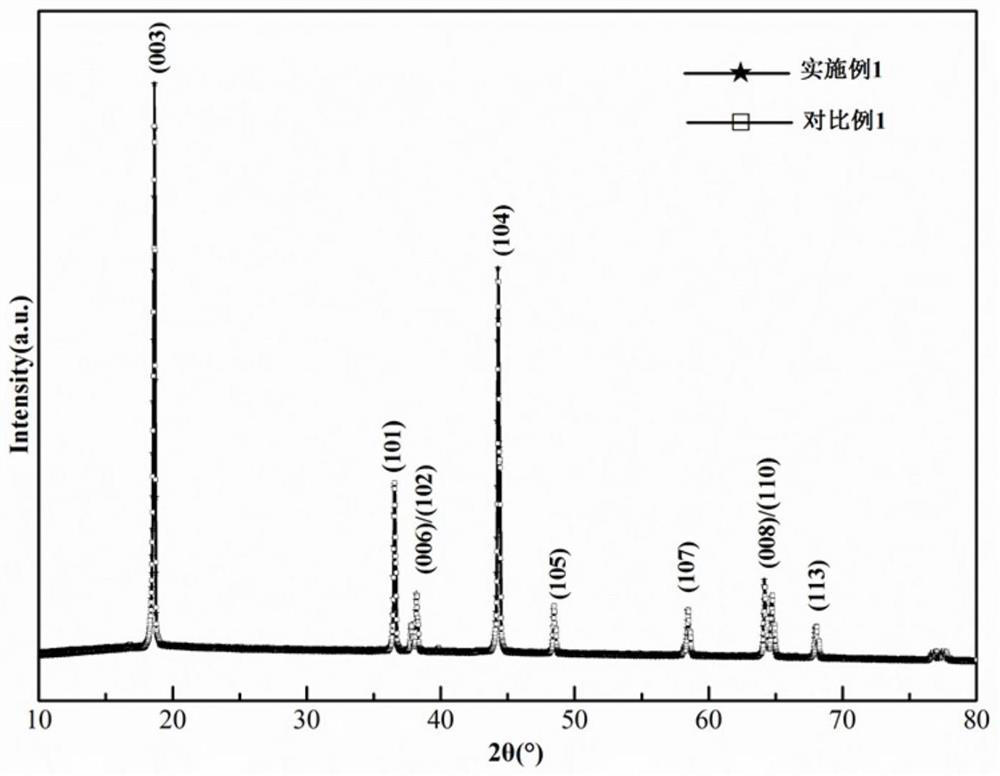

Monocrystal ternary positive electrode material as well as preparation method and application thereof

PendingCN114243014AImprove chemical performanceReduce residual lithium on the surfaceSecondary cellsPositive electrodesMetallurgyPhysical chemistry

The invention belongs to the technical field of lithium ion batteries, and discloses a single crystal ternary positive electrode material and a preparation method and application thereof, the chemical formula of the single crystal ternary positive electrode material is LiNixCoyMnzM (1-x-y-z) Oc (at) LiaNdOb, 0 < x < = 0.65, 0 < y < = 0.15, 0 < z < = 0.35, 0 < a < = 6, 0 < b < = 4, 1 < c < = 2, and 1 < = d < 2; m and N are at least one of Zr, Ni, Al, Cu, Co, Sr, Mn, Y, Ti, Mg, Mo, B, Sn, Fe, Zn, Si or W. The single-crystal ternary positive electrode material disclosed by the invention is a single-crystal material with a core-shell structure, and is low in surface residual lithium, stable in internal and external structures, high in energy density and excellent in cycle performance and dynamic performance.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Boron-doped lithium phosphate coated lithium ion battery positive electrode material and preparation method thereof

ActiveCN112599736AIncrease capacityImproved magnification performanceSecondary cellsPositive electrodesElectrical batteryPhysical chemistry

The invention discloses a boron-doped lithium phosphate coated lithium ion battery positive electrode material, which takes a layered structure oxide with high nickel content as a matrix, and the outer surface of the matrix is coated with a boron-doped Li3PO4 coating layer. The preparation method comprises the following steps: (1), adding a lithium source, a phosphorus source and a boron source into a high-pressure reaction kettle for hydrothermal reaction, and after the reaction is finished, performing cooling, washing, filtering and drying to obtain a coating agent; and (2), weighing a basematerial and the coating agent according to a stoichiometric ratio, uniformly performing mixing, and performing sintering to obtain the boron-doped lithium phosphate coated lithium ion battery positive electrode material. By introducing a proper amount of boron into the lithium phosphate coating layer of the lithium ion battery positive electrode material, the lithium ion conduction capability ofthe lithium ion battery positive electrode material is effectively improved, so that the positive electrode material coated with the coating layer shows relatively good capacity and rate capability and has a relatively low DCIR growth rate.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

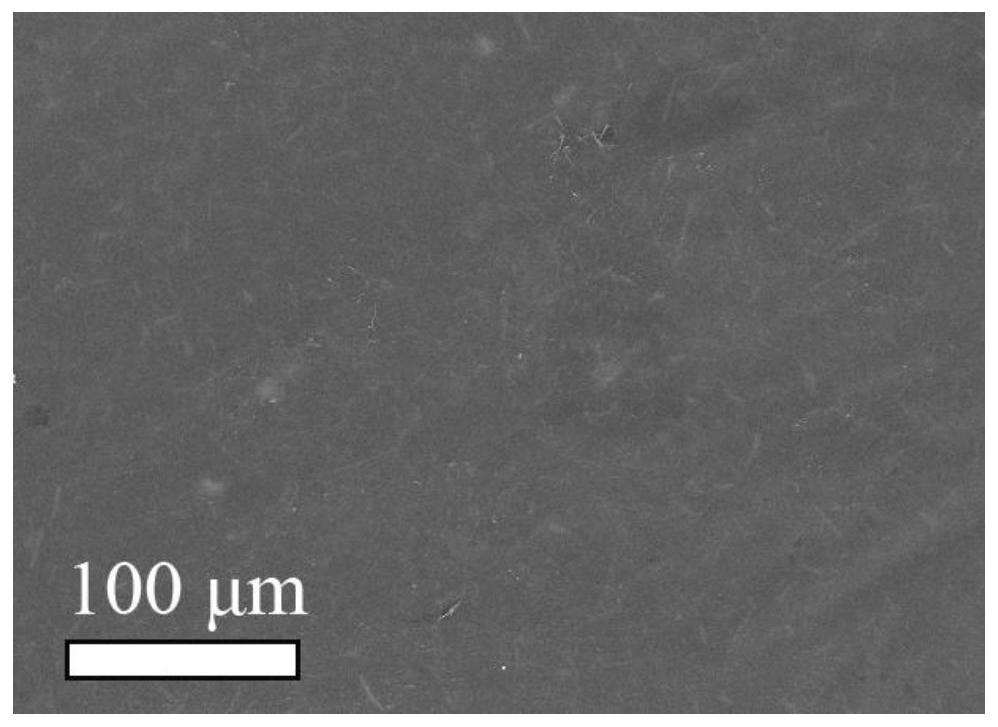

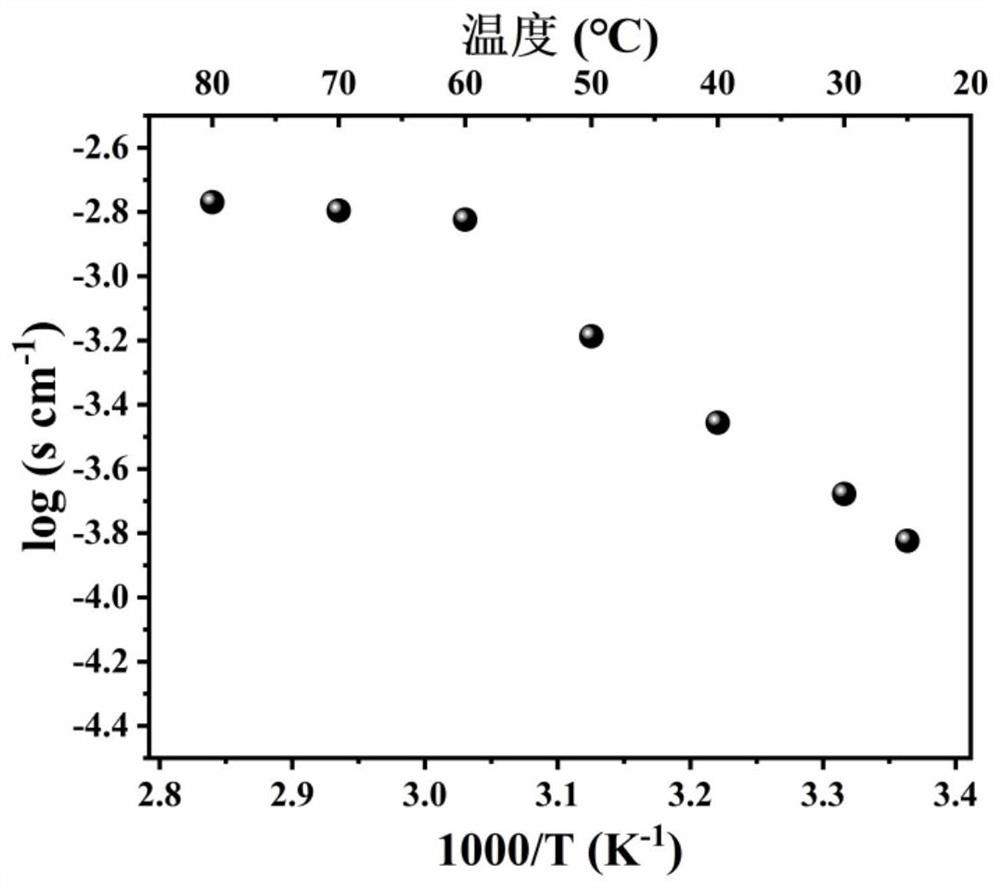

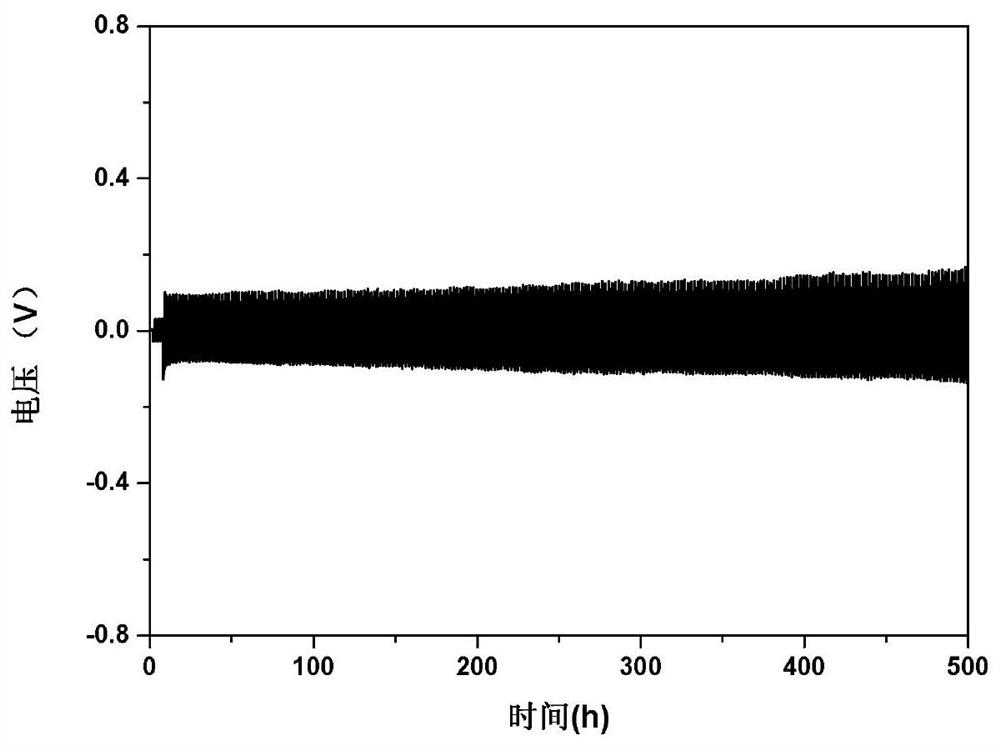

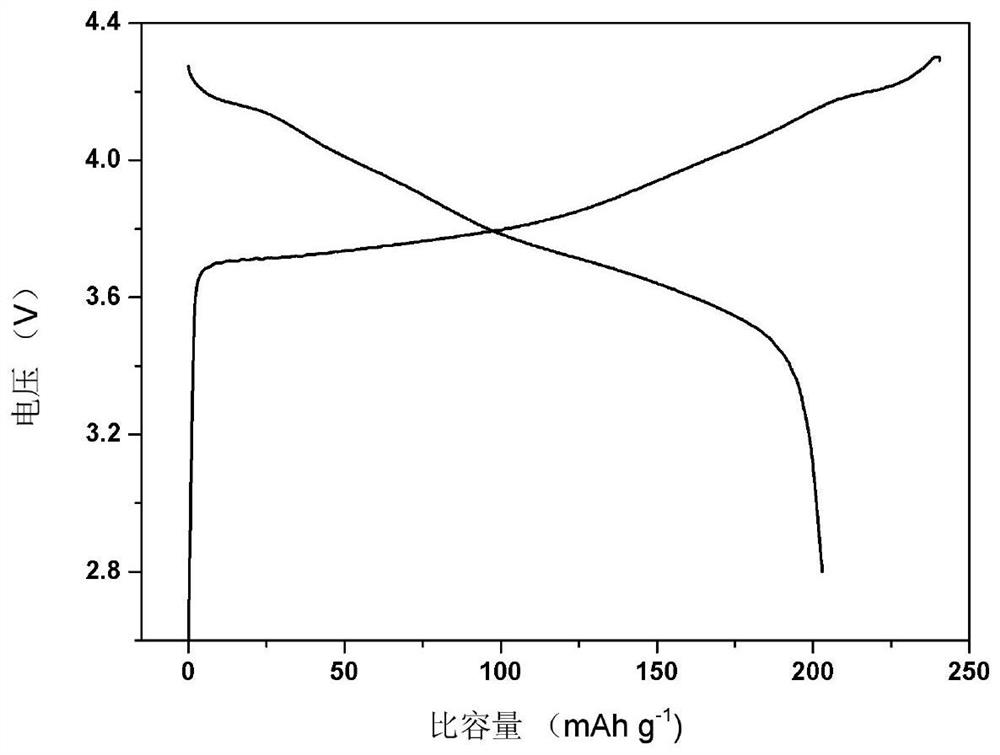

Inorganic/organic composite solid electrolyte and preparation method and application thereof

ActiveCN112909324AImprove cycle stabilityEvenly dispersedSolid electrolytesFinal product manufactureSolid state electrolyteElectrical conductor

The invention provides an inorganic / organic composite solid electrolyte preparation method, which comprises: mixing polyoxyethylene, a polyvinylidene fluoride-hexafluoropropylene copolymer, a sodium salt, a first filler and an organic solvent to obtain a first slurry, wherein the first filler is a P2 type layered oxide fast ion conductor modified by a silane coupling agent and the particle size of the first filler is 500 nm to 1.5 [mu] m; mixing polyoxyethylene, a polyvinylidene fluoride-hexafluoropropylene copolymer, sodium salt, a second filler and an organic solvent to obtain second slurry, wherein the second filler is a P2 type layered oxide fast ion conductor modified by a silane coupling agent and the particle size of the second filler is smaller than 500nm; coating a substrate with the first slurry, and drying to obtain a layer of solid electrolyte; and coating the second slurry on the surface of the layer of solid electrolyte, and drying to obtain the inorganic / organic composite solid electrolyte.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

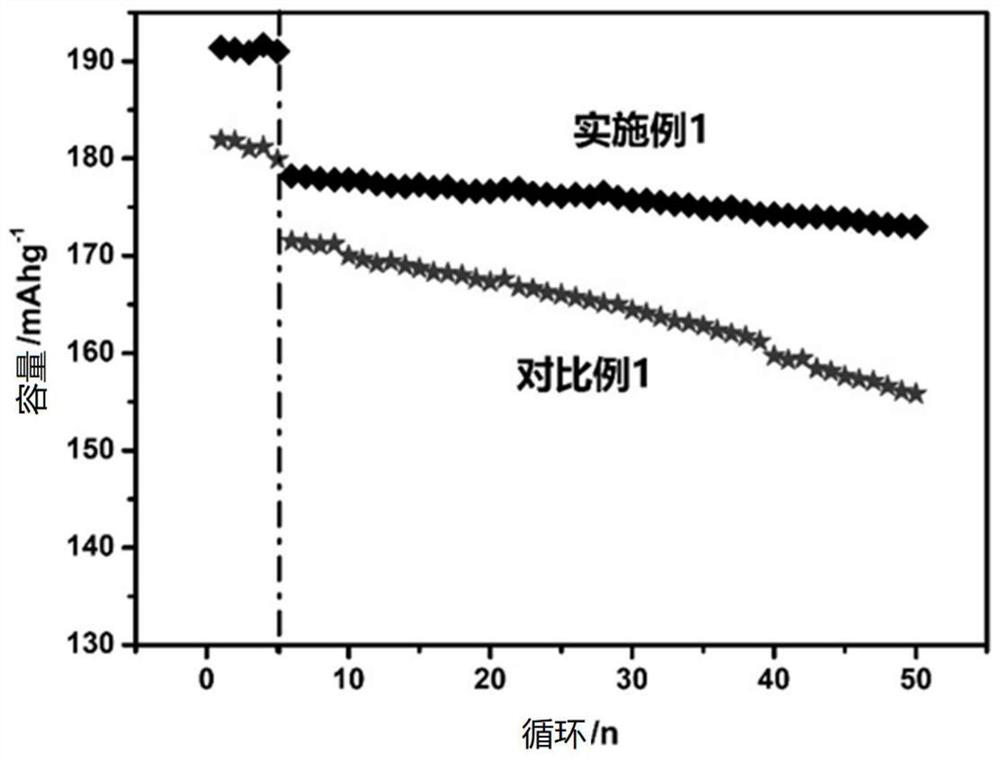

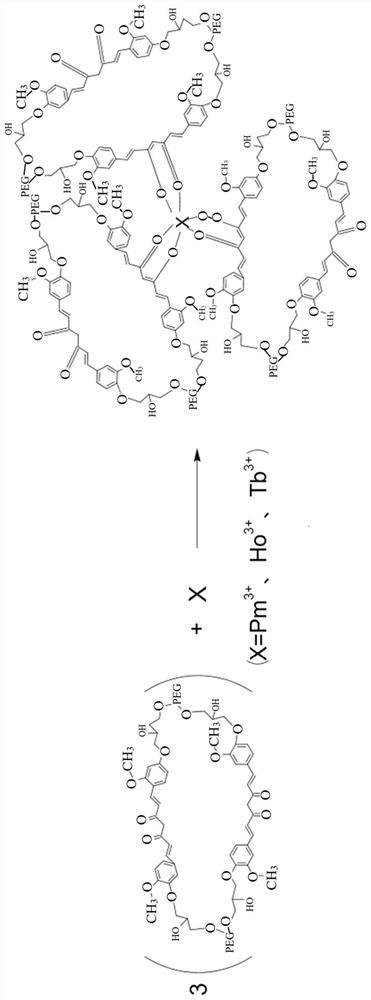

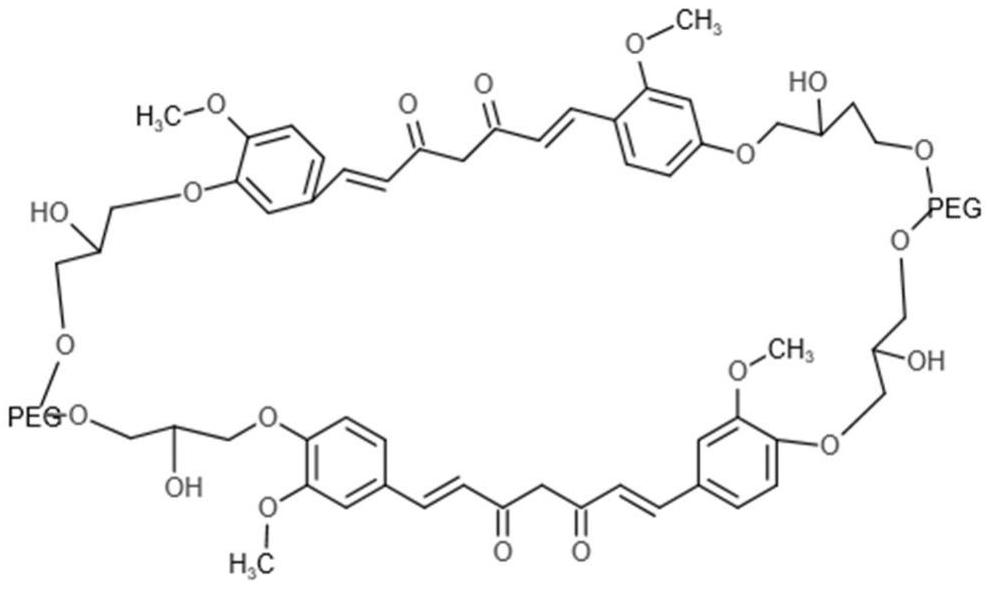

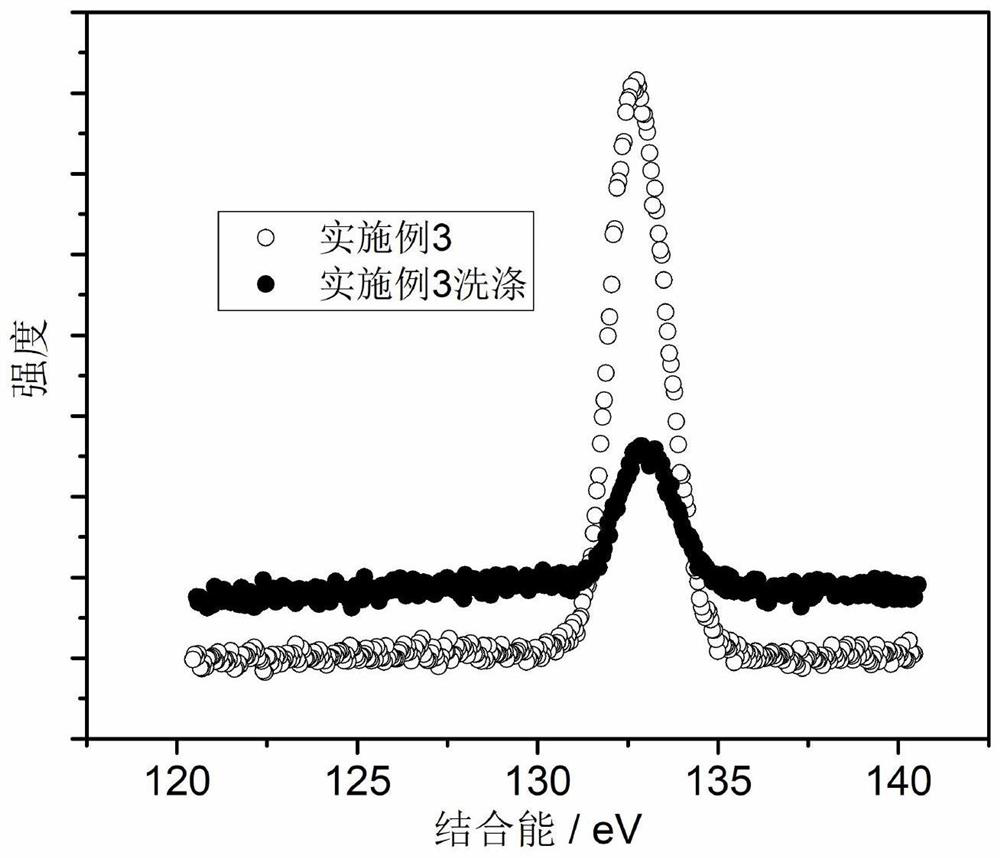

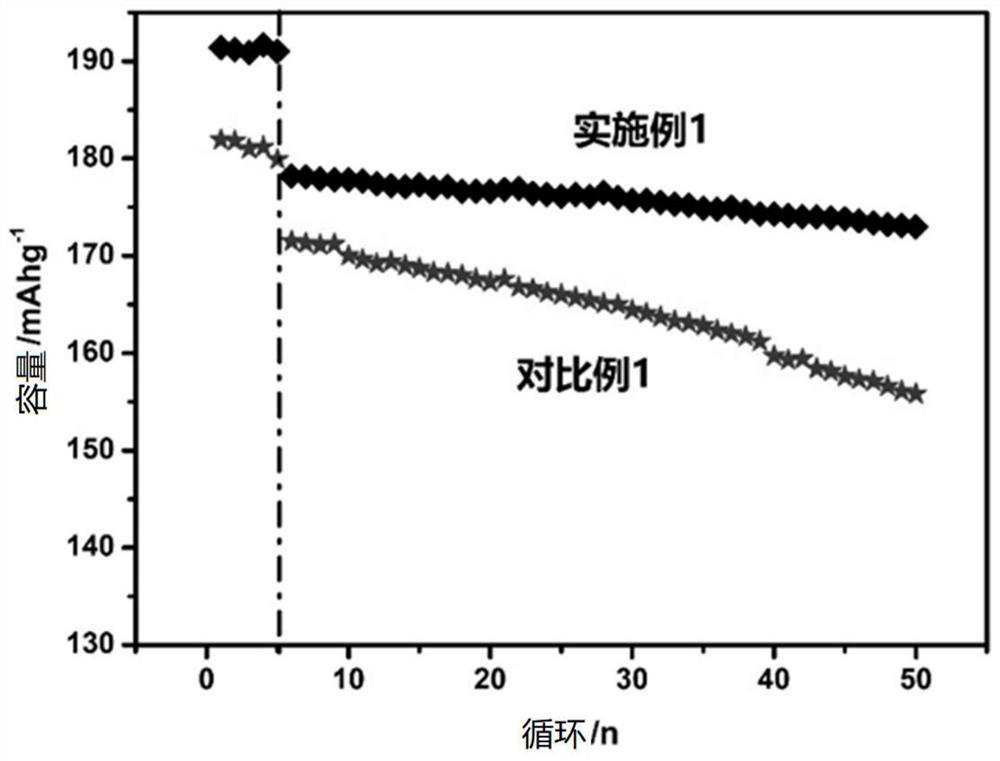

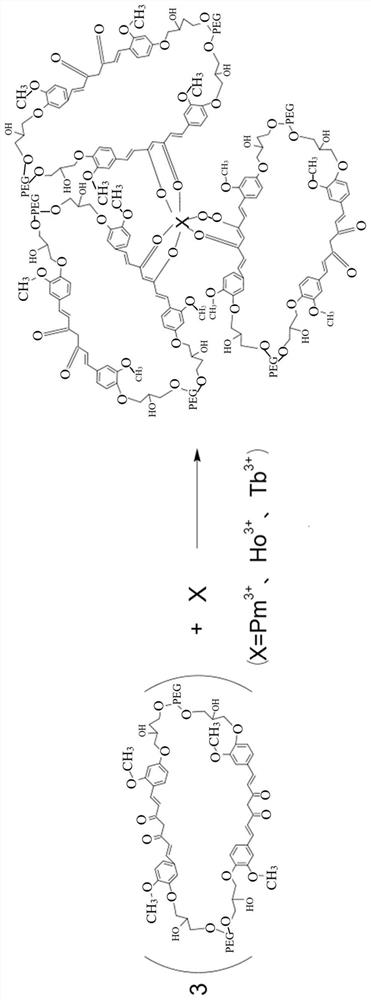

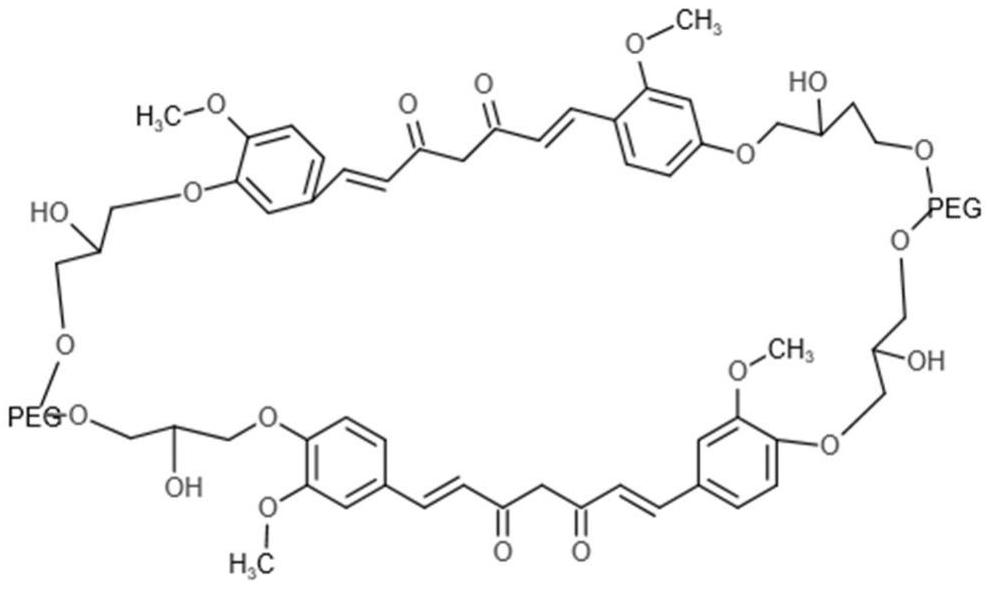

Modified single-crystal ternary positive electrode material and preparation method thereof

ActiveCN113571690AReduce residual alkaliReduce interface side reactionsSecondary cellsPositive electrodesElectrical batteryLanthanide

The invention discloses a modified single crystal ternary positive electrode material and a preparation method thereof. The traditional cross-linking agent is replaced by the hydrogen-bond interaction between the coordination bond formed by the unique beta-diketone group in curcumin and lanthanide series metal ions and the polymer chain, and the sulfonic acid type polymer with high elasticity and ductility is prepared; the generated sulfonic acid can effectively reduce the amount of residual alkali on the surface of the material, has high elasticity and ductility, and can effectively maintain the structure of the material in the repeated charging and discharging process of the battery, and the cycle performance of the battery can be improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Composite solid electrolyte membrane based on metal-organic framework material as well as preparation method and application of composite solid electrolyte membrane

ActiveCN113224383AImprove ionic conductivityRealization of chemically cross-linked polymeric networksFinal product manufactureElectrolyte accumulators manufactureSolid state electrolyteToluene diisocyanate

The invention discloses a composite solid electrolyte membrane based on a metal-organic framework material as well as a preparation method and application of the composite solid electrolyte membrane. The composite solid electrolyte membrane comprises a polymer network and lithium salt, wherein the polymer network is formed by polymerizing polyoxyethylene (PEO) and a metal-organic framework material (MOF) modified by toluene diisocynate (TDI), and the lithium salt is dispersed in the polymer network. According to the composite solid electrolyte membrane based on the metal-organic framework material as well as the preparation method and application of the composite solid electrolyte membrane of the invention, the toluene diisocynate is used as an intermediate, so that the MOF and the PEO are connected through chemical bonds, the ionic conductivity of lithium ions can be greatly enhanced, meanwhile, oxygenolysis of hydroxyl groups of the PEO under high voltage can be avoided, and the high-voltage electrochemical stability is remarkably improved. The preparation method is simple, easy to control, low in cost and easy to industrialize, and has a bright application prospect in the fields of high-specific-energy solid-state battery systems and flexible electronic energy storage devices.

Owner:CENT SOUTH UNIV

Flame-retardant solid-liquid mixed solid electrolyte, preparation method and lithium battery containing flame-retardant solid-liquid mixed solid electrolyte

ActiveCN113178617AGood ionic conductanceImprove ionic conductanceLi-accumulatorsSecondary cells servicing/maintenancePhosphoric Acid EstersPolymer network

The invention discloses a flame-retardant solid-liquid mixed solid electrolyte, a preparation method and a lithium battery containing the flame-retardant solid-liquid mixed solid electrolyte. The flame-retardant solid-liquid mixed solid electrolyte comprises a flame-retardant liquid phase component, a lithium salt and a polymer network structure, wherein the flame-retardant liquid phase component and the lithium salt are dispersed in the polymer network structure; the flame-retardant liquid phase component comprises a phosphorus-containing organic compound; the phosphorus-containing organic compound comprises phosphate ester, phosphite ester, phosphonate and halides thereof, and is efficient flame-retardant liquid; the high-molecular network structure is obtained by polymerizing high-molecular network structure monomers; and the polymer network structure monomer is selected from at least one of ester compounds containing C = C, and has high mechanical strength. According to the electrolyte obtained by the invention, the cycle performance and the safety performance of the battery can be well improved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

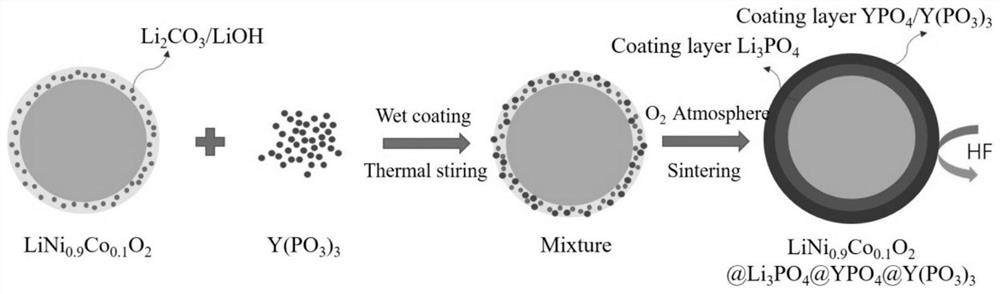

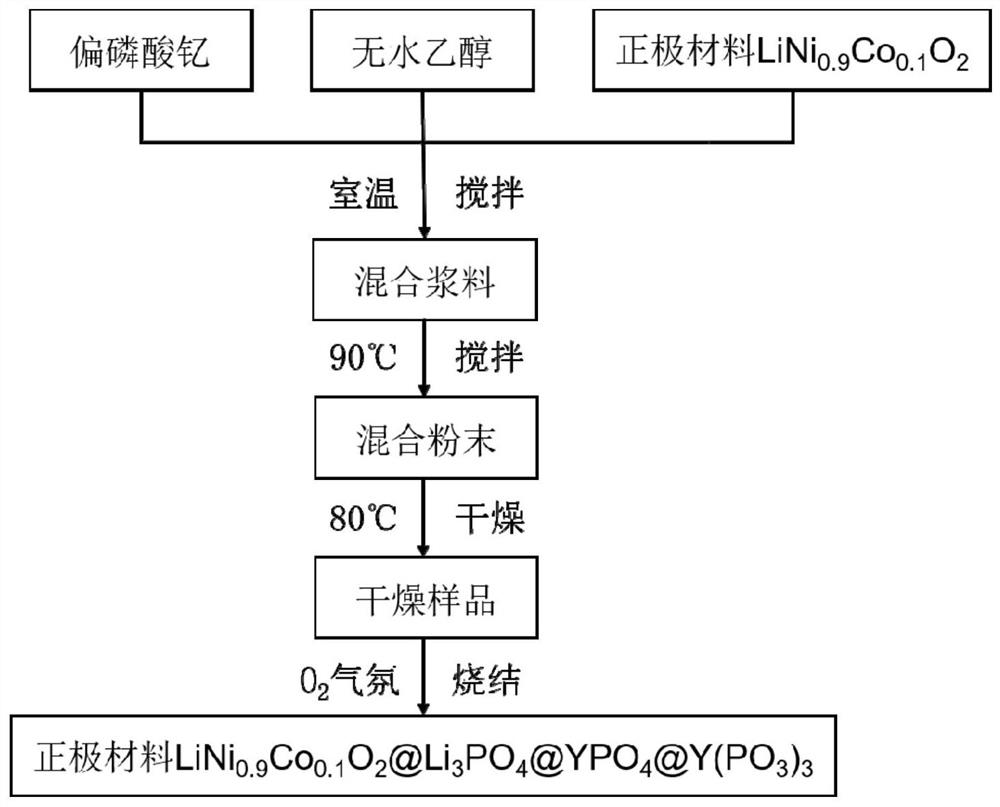

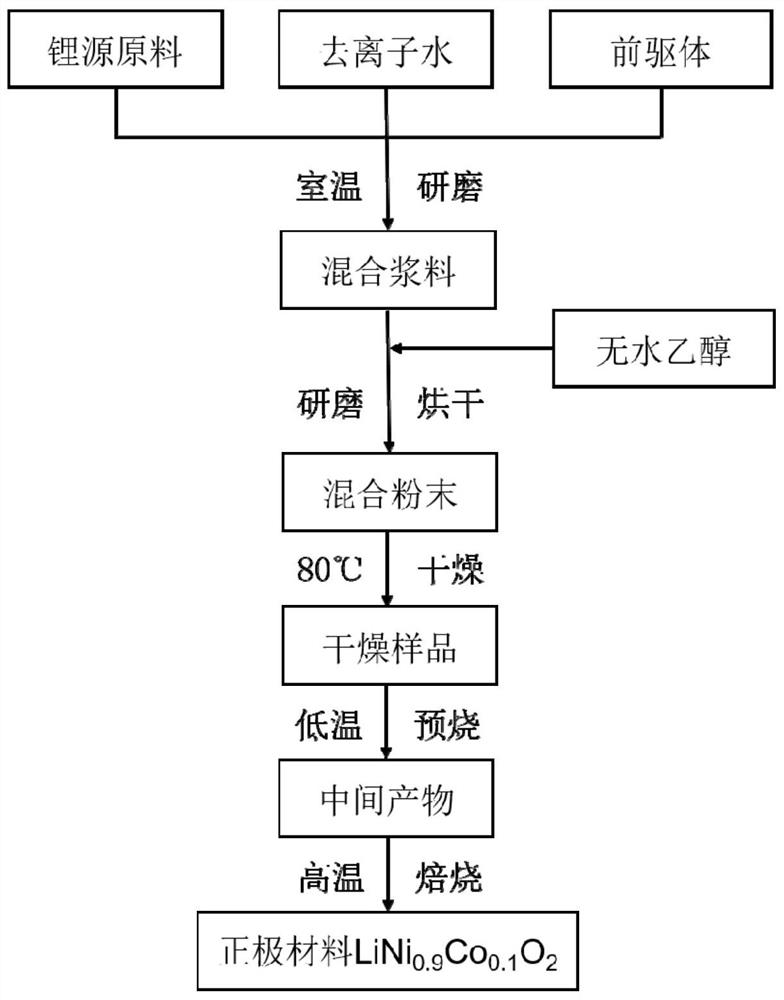

Composite phosphate coated lithium ion battery high-nickel positive electrode material and preparation method thereof

PendingCN113346055AUniform particle size distributionSimple operation processSecondary cellsPositive electrodesElectrical batteryPhysical chemistry

The invention belongs to the technical field of preparation of a lithium ion battery positive electrode material, and provides a composite phosphate coated lithium ion battery high-nickel positive electrode material and a preparation method thereof, which aim to overcome the defects of poor processability, harsh requirements on use environment, poor cycle stability, low first-circle coulombic efficiency, sharp reduction of high-temperature performance, poor safety and poor cycle life in the prior art. According to the composite phosphate coated lithium ion battery high-nickel positive electrode material, Yttrium metaphosphate Y(PO3) 3 is used as a coating raw material, and a composite multifunctional phosphate coating layer is generated through in-situ reaction of Y(PO3)3 and residual alkali (LiOH and Li2CO3) on the surface of a parent material, so that lithium salt residues on the surface of the parent material are greatly reduced, the processability is improved, the requirement on a use environment is reduced, the ionic conductivity of the positive electrode material is increased, and phase change and interface side reaction are effectively inhibited; therefore, the lithium phosphate coated lithium ion battery high-nickel positive electrode material has excellent specific discharge capacity and cycling stability, and especially can maintain relatively good electrochemical performance at high temperature.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

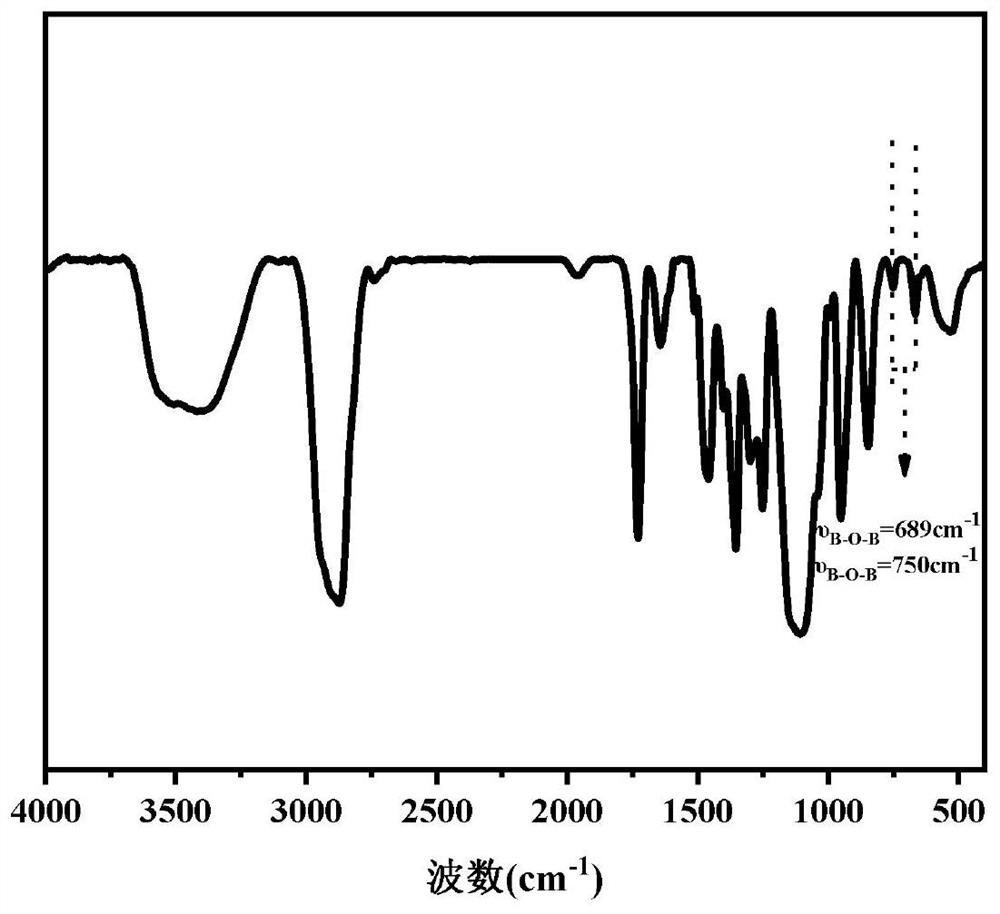

Boric acid ester cross-linked self-repairing polymer electrolyte and preparation method and application thereof

PendingCN114843599AImprove electrochemical performanceImprove mechanical propertiesSolid electrolytesFinal product manufactureMethacrylatePolymer science

The invention provides a preparation method of a boric acid ester cross-linked self-repairing polymer electrolyte, polyethylene glycol methyl ether methacrylate is selected as a monomer, crystallization is effectively inhibited, the electrochemical performance is improved, boric acid on a cross-linking agent structure containing boric acid is subjected to a condensation reaction to form boric acid ester, vacant p-orbit boron is introduced, and the self-repairing polymer electrolyte is prepared. Lithium ion conduction can be accelerated, a B-O covalent bond can be re-established through an ester exchange reaction of a dynamic boron ester bond, the polymer electrolyte has self-repairing capability, and the cross-linking density of a polymer chain segment can be effectively regulated and controlled by utilizing a cross-linking agent containing boric acid, so that the structure is regulated and controlled; the flexible, efficient, safe and stable boric acid ester cross-linked self-repairing polymer electrolyte is obtained. The polymer electrolyte prepared by the invention is amorphous, has a higher decomposition temperature, a glass transition temperature close to-45 DEG C and a potential stability window of 5.5 V or more, can be self-repaired after being cut and fused into a whole, and has good self-repairing property.

Owner:NANCHANG HANGKONG UNIVERSITY

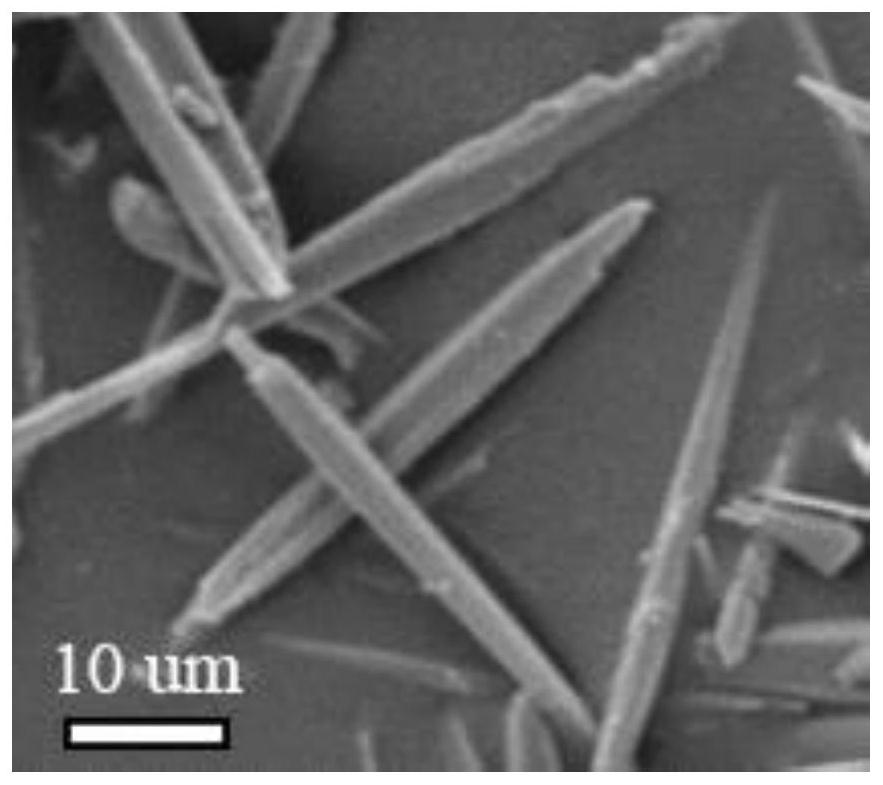

A modified single crystal multi-component positive electrode material and its preparation method

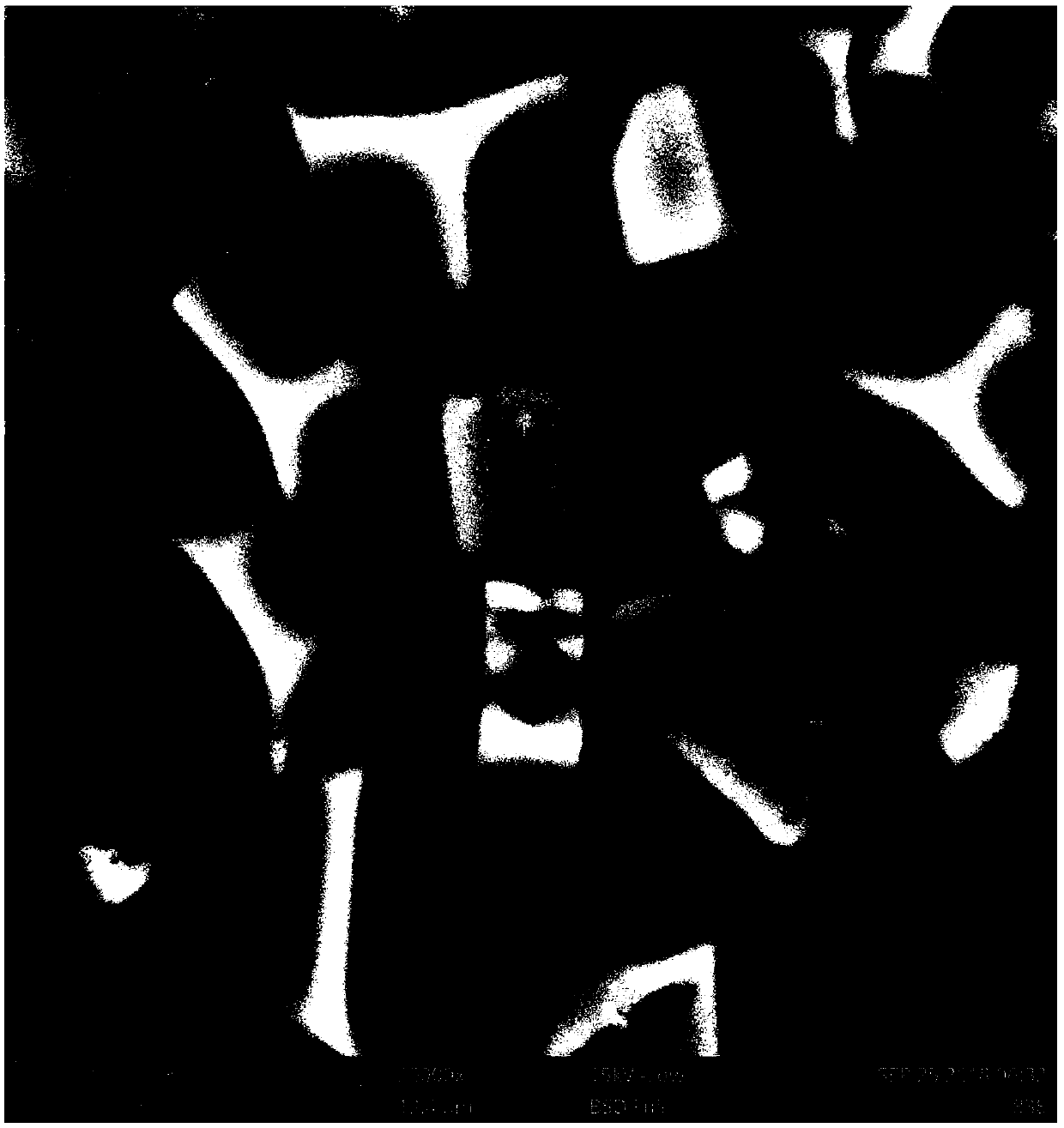

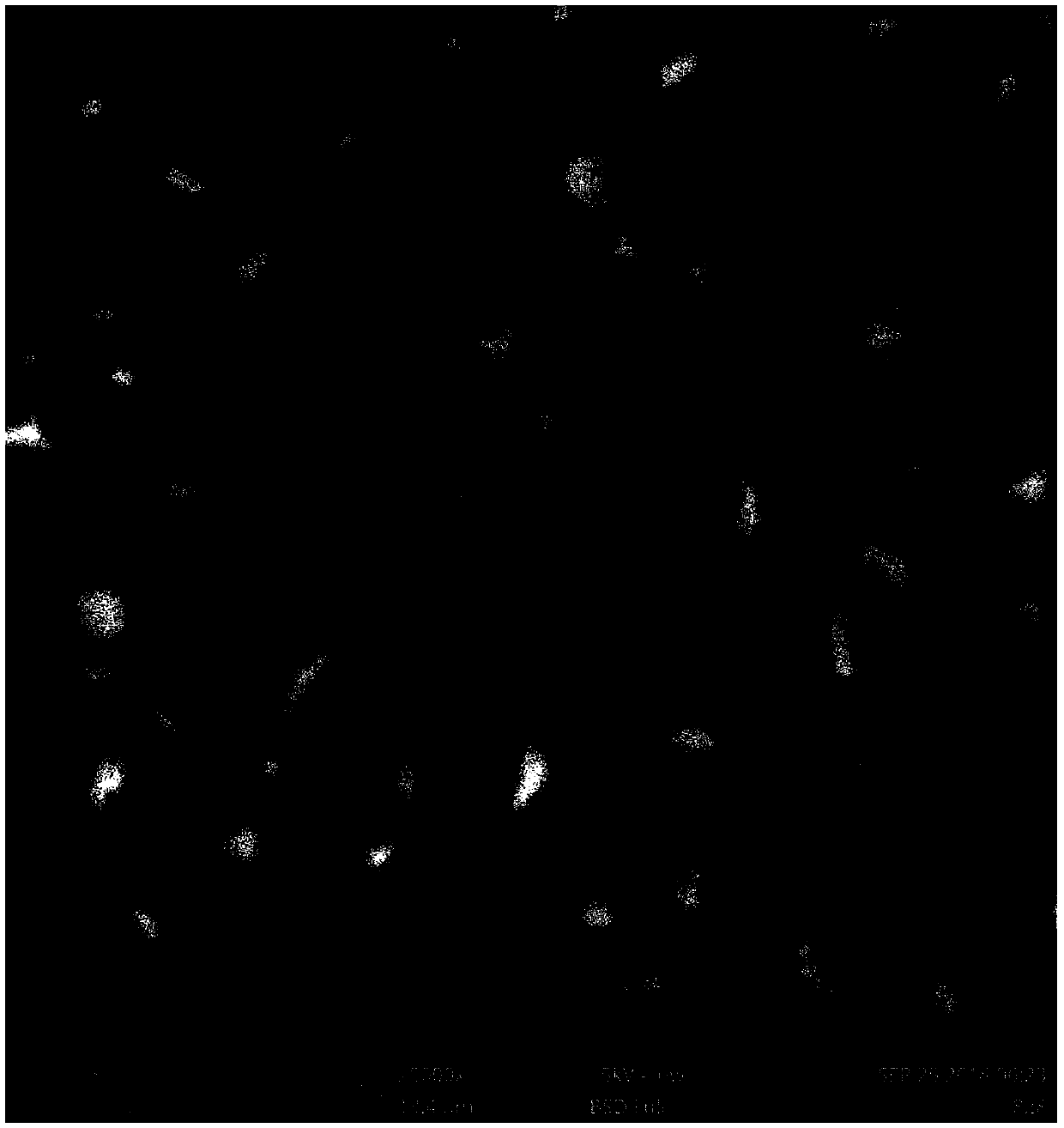

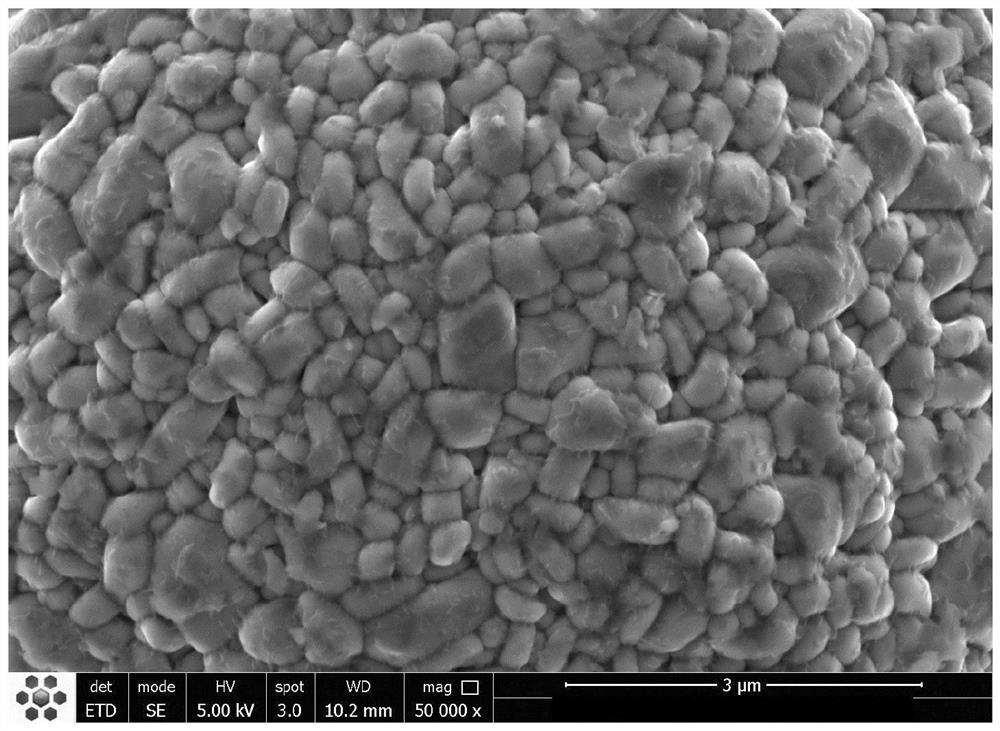

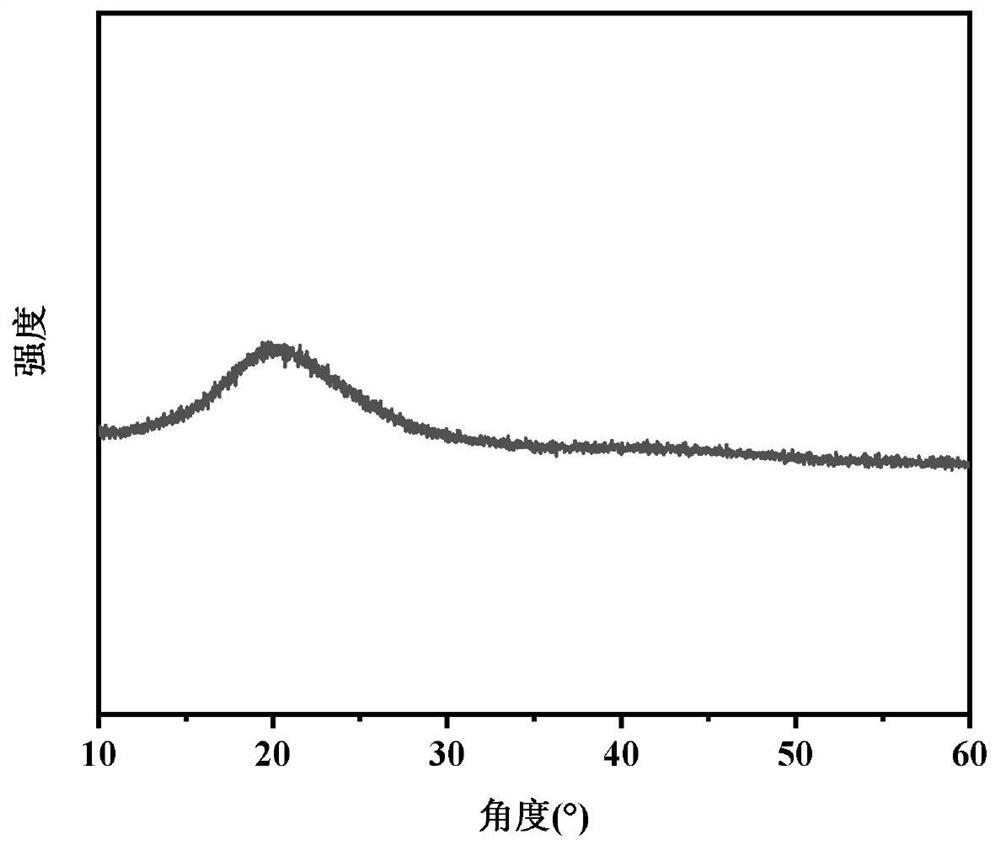

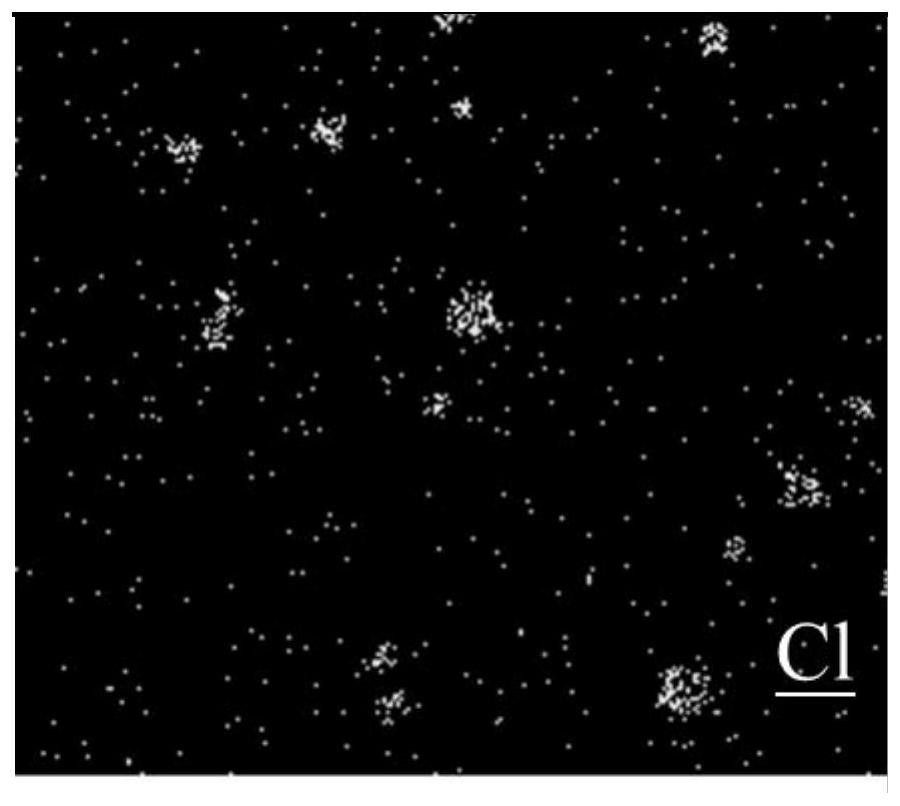

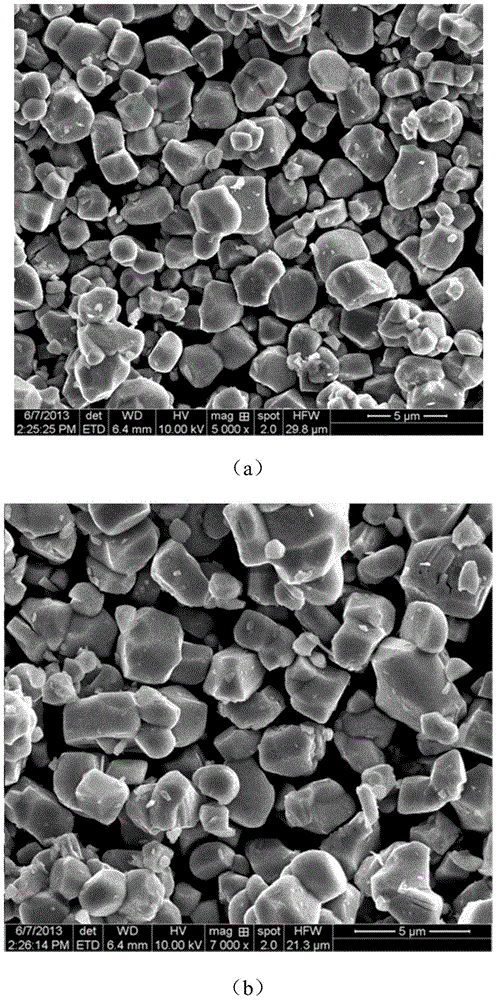

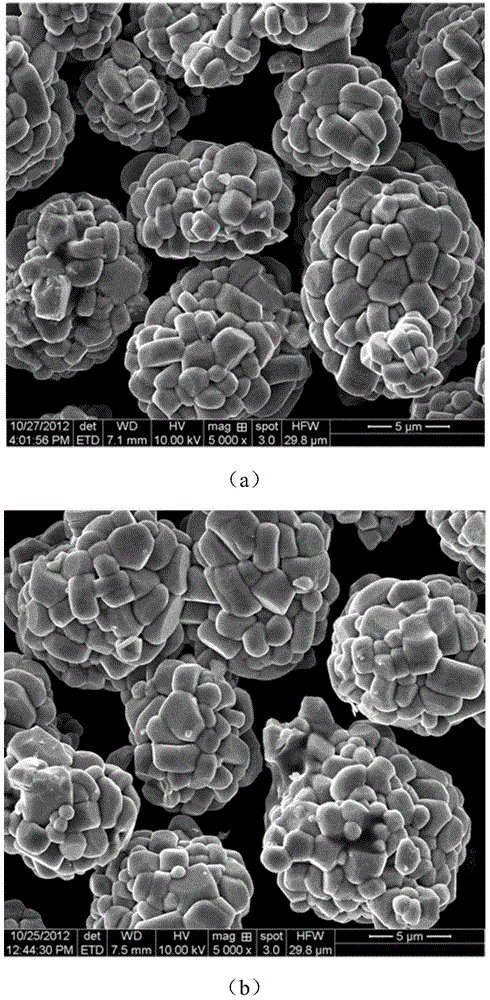

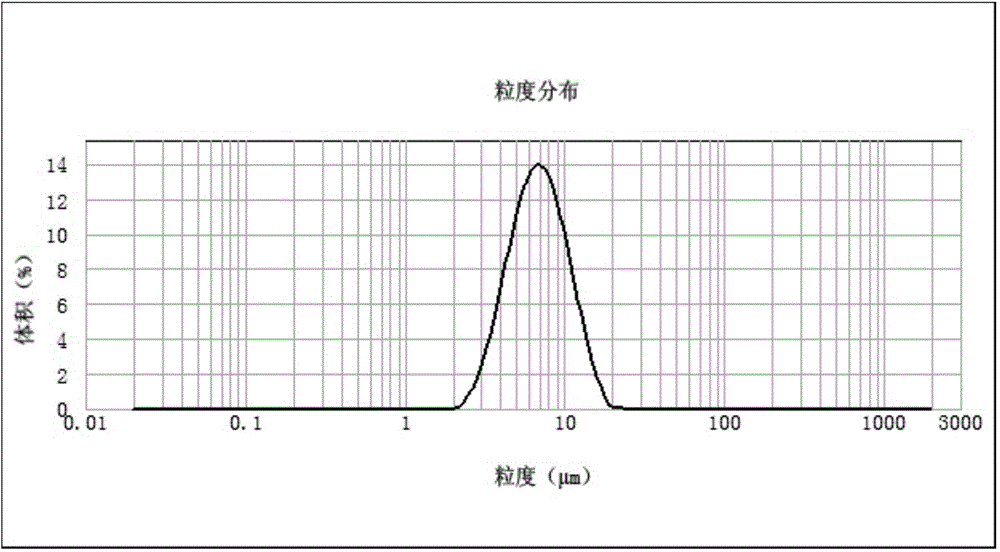

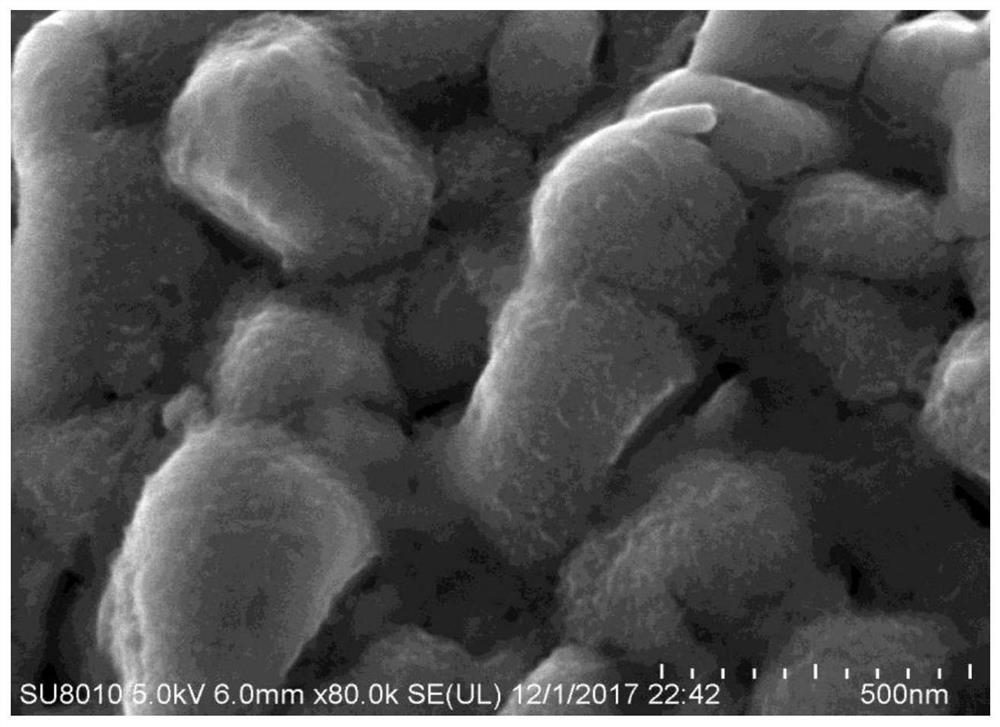

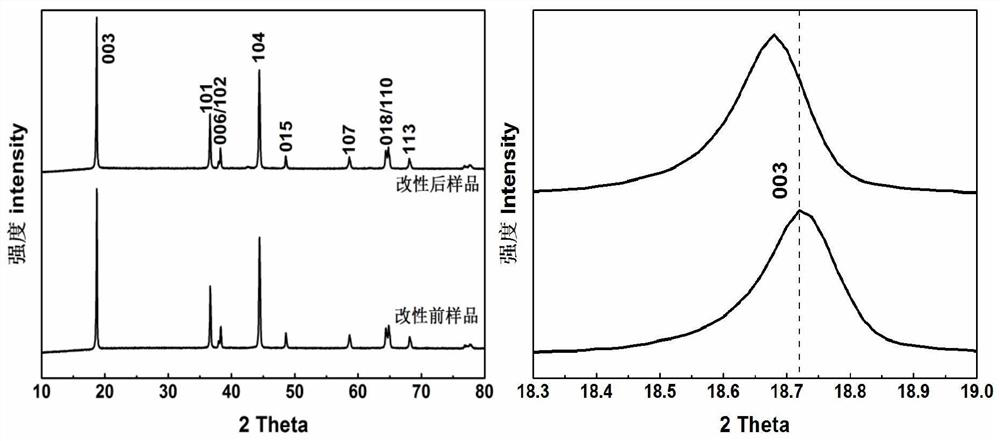

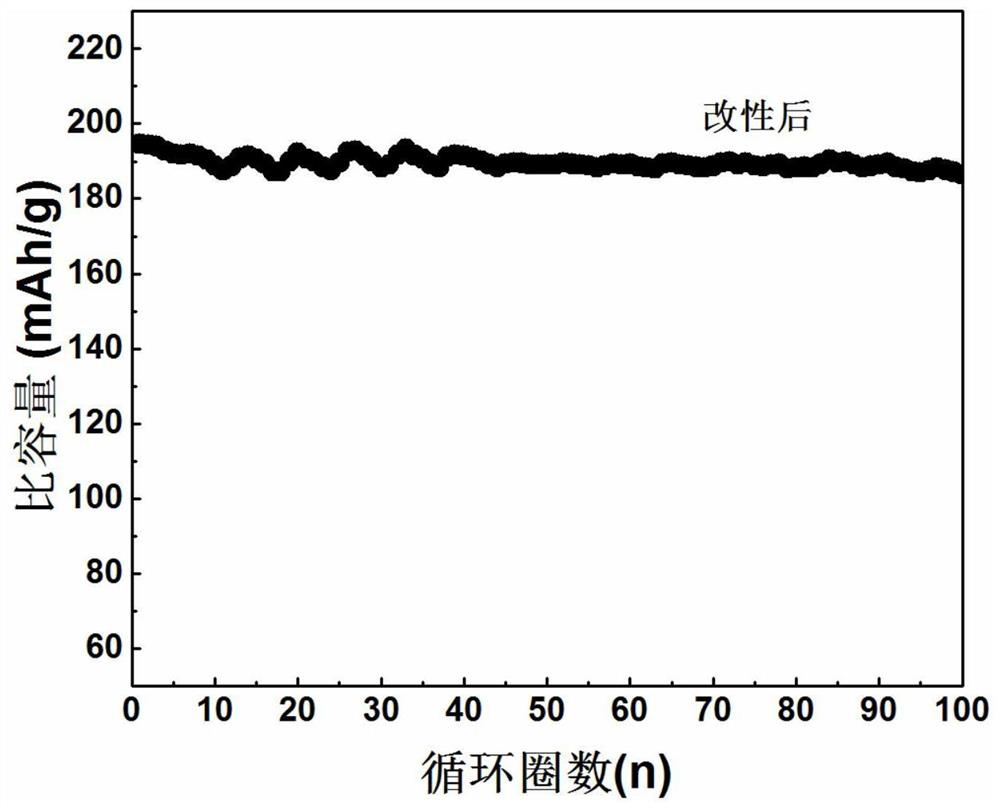

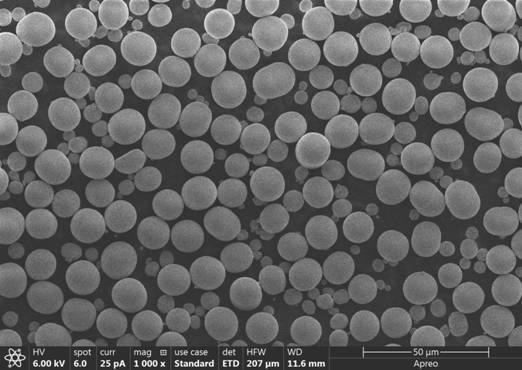

ActiveCN103413932BPromote directional growthHigh degree of monodispersityCell electrodesLithiumHigh energy

The invention discloses a modified single crystal type multielement anode material and a preparation method thereof. Lithium salt containing modified anions is dispersed to a water solution which contains dissolvable lithium salt and an organic pore-forming agent, a coprecipitation multihole precursor is added into the mixture, and then modified single crystal type multielement anode material which has the D50 equal to 2-30mu m and is quite high in monodispersity degree is successfully prepared through a 'once sintering' process. Compared with the prior art, the modified single crystal type multielement anode material provided by the invention has the following obvious advantages: (1) the 'once sintering' process is adopted, the technical route is simple, and the cost is reduced substantially; (2) the monodispersity degree of the prepared single crystal multielement anode material is quite high, the compaction density and the energy density are high, the high-temperature cycle performance is excellent, and the modified single crystal type multielement anode material can be applied to electric tools, such as high energy density type consume electronic products, electro-mobiles and the like.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

A one-step method for co-modifying ternary cathode materials by ion doping and surface coating

ActiveCN109119611BImprove stabilityImprove structural stabilityCell electrodesSecondary cellsElectrolytic agentSide reaction

The invention discloses a one-step method for realizing metal ion doping and metal oxide surface coating to jointly modify a ternary positive electrode material, comprising the following steps: S1. Mixing a complexing agent and a ternary positive electrode material into a solvent, Continue to stir the reaction after ultrasonic; S2. Add the metal ion salt solution to be doped and coated dropwise into the S1 mixed solution under stirring, and then continue to stir the reaction; S3. Heat the S2 mixed solution and continue to stir until the solvent is completely Volatilize to obtain a mixed powder; S4. Calcinate the powder obtained in S3 at 400-600° C. for 4-6 hours, and cool to room temperature to obtain a modified material. The invention adopts a simple process and selects a method assisted by a complexing agent to prepare a modified ternary positive electrode material whose surface layer is element-doped and surface-coated in one step. Doping effectively inhibits the transformation of the crystal structure of the surface layer of the material during the cycle, and the coating layer prevents direct contact with the electrolyte, inhibits the occurrence of side reactions, and improves the cycle stability of the material. By optimizing the synthesis process, the cost can be effectively saved, and the method has great application prospects.

Owner:GUANGDONG UNIV OF TECH

Metal lithium wire and preparation method thereof

ActiveCN111224091AImprove stabilityGuaranteed stabilityNegative electrodesSecondary cellsMetallic lithiumElectrolytic agent

The invention relates to a metal lithium wire and a preparation method thereof. The metal lithium wire has a one-dimensional linear structure, and the outer surface of the metal lithium wire is coatedwith a protective layer. The method takes a conductive array template as a deposition matrix, and the metal lithium wire is prepared in an organic electrolyte system through an electrochemical deposition method. The operation procedure at least comprises the following steps: 1) treating a deposition substrate; 2) performing electrochemical deposition of the metal lithium wire; 3) collecting the metal lithium wire; 4) performing high-temperature passivation treatment on the metal lithium wire. The metal lithium wire prepared by the method has a one-dimensional structure, the expansion and shrinkage of the volume of the metal lithium in the charging and discharging process can be buffered, and the surface coating protection layer can inhibit the reaction between the metal lithium and electrolyte or humid air; meanwhile, the preparation method is safe and simple, and the continuous production of preparation and coating of the metal lithium wire can be realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

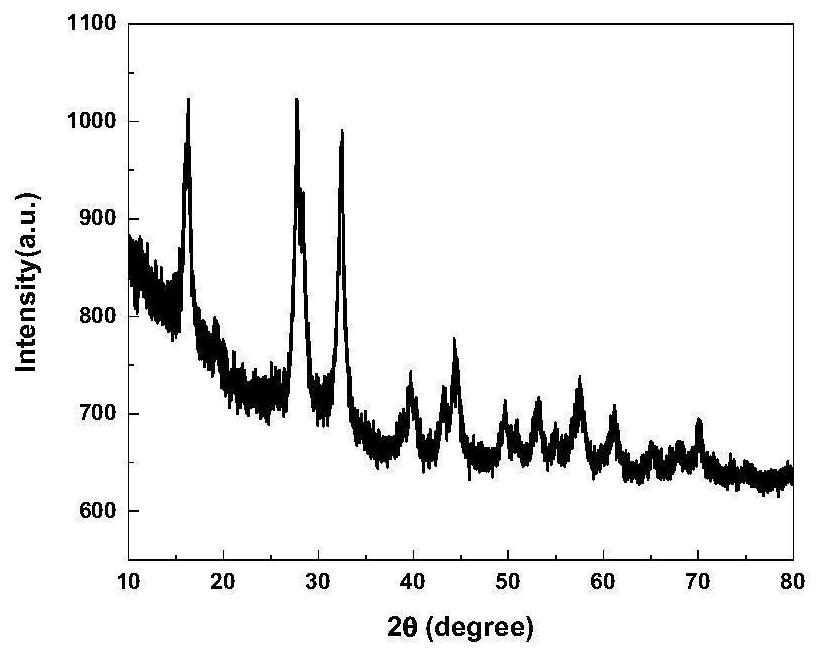

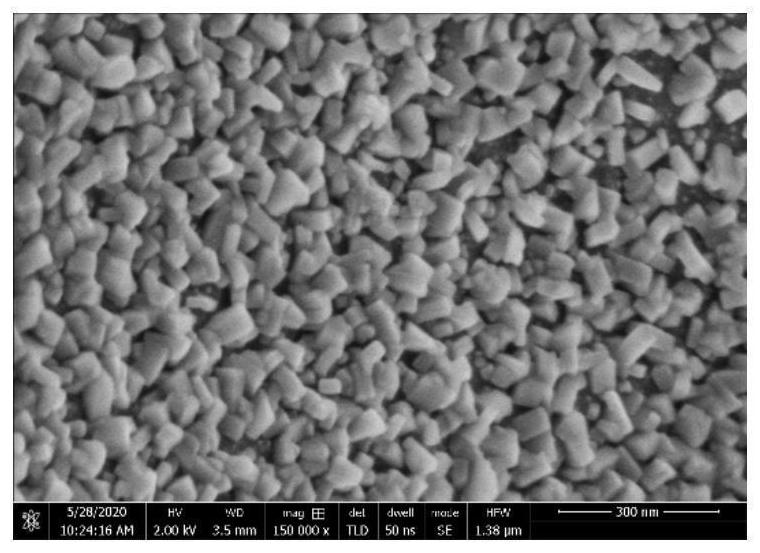

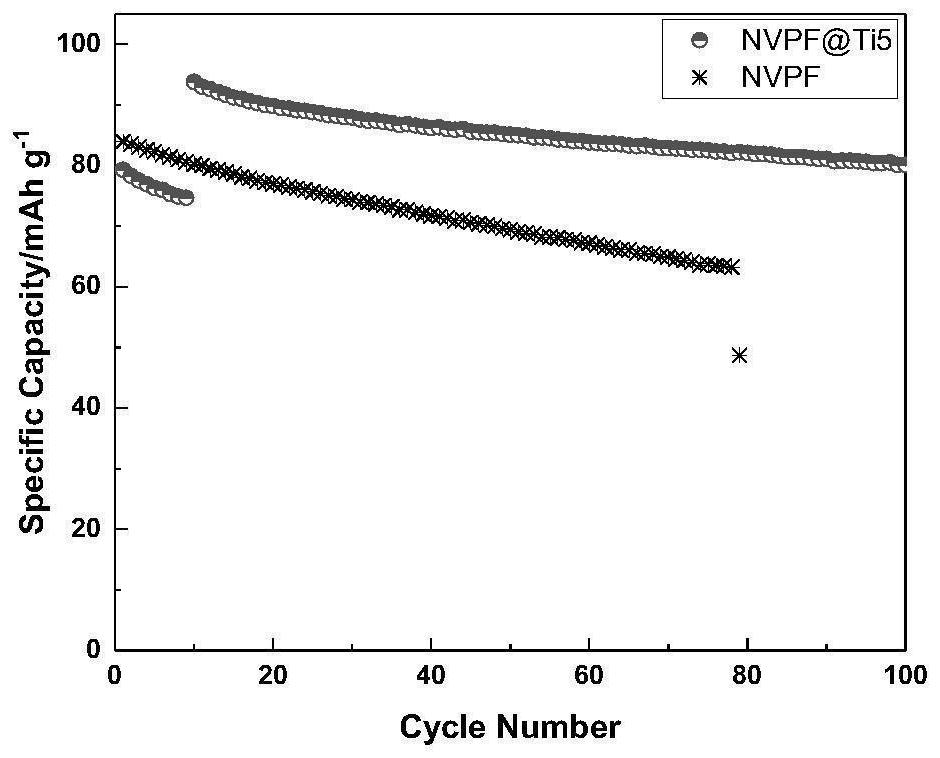

Sodium vanadium fluorophosphate electrode coated with metal oxide layer and preparation method thereof

ActiveCN112186135AImprove cycle stabilityHigh capacity retentionSecondary cellsVapour deposition manufacturingElectrical batteryPhysical chemistry

The invention provides a sodium vanadium fluorophosphate electrode coated with a metal oxide layer and a preparation method thereof, and the sodium vanadium fluorophosphate electrode coated with the metal oxide layer is obtained by depositing the metal oxide layer on a Na3V2(PO4)2F3 electrode slice through adoption of an atomic layer deposition method. The preparation method solves the problems ofV and F removal in the cyclic process of the positive electrode material for the sodium-ion battery, improves the cyclic stability of the material in the charge-discharge process, improves the capacity attenuation problem of the material, and has the advantages of uniform and compact coating layer, easily controlled coating amount and remarkably improved yield.

Owner:XI AN JIAOTONG UNIV

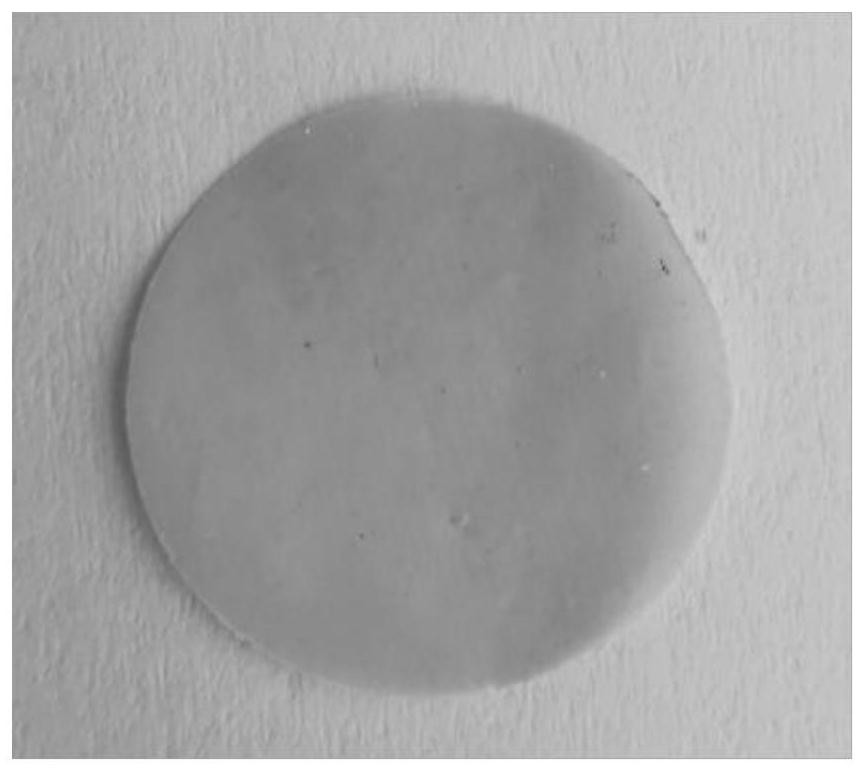

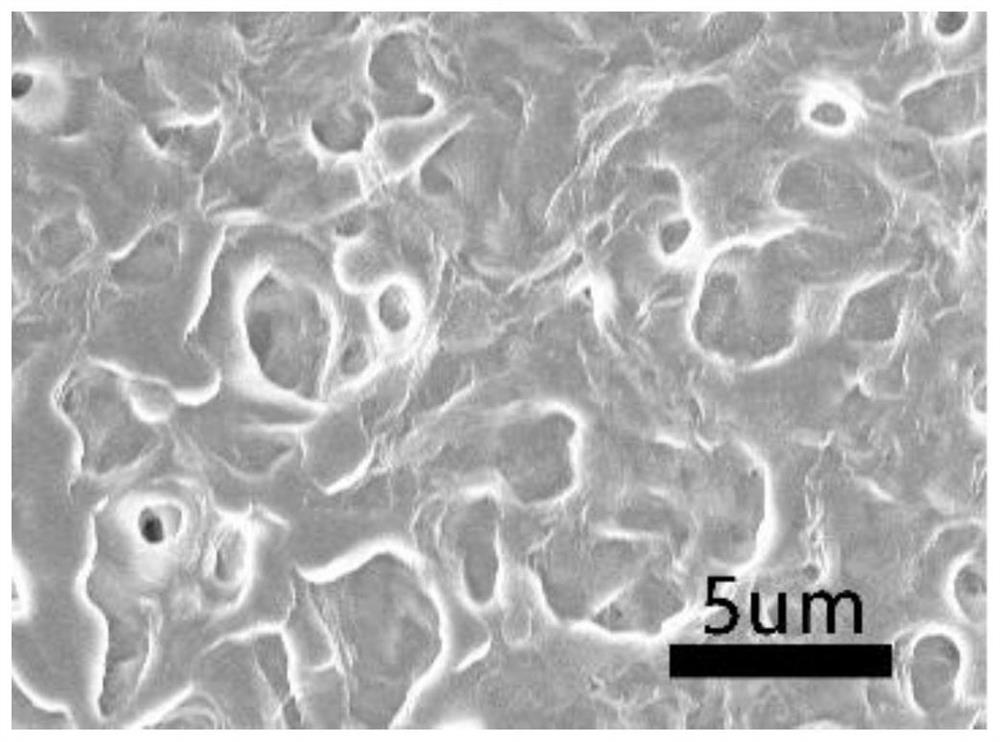

Preparation method of in-situ coated single-crystal high-nickel ternary positive electrode material

PendingCN114361441AControl particle sizePromote independent growthCell electrodesSecondary cellsLithium electrodeMicrowave sintering

The invention belongs to the technical field of lithium ion battery positive electrode materials, and particularly relates to a preparation method of a single-crystal high-nickel ternary positive electrode material for low-temperature sintering and in-situ coating. The preparation method comprises the following steps: mixing Ni0. 8Co0. 1Mn0. 1 (OH) 2 with a lithium source according to a certain proportion, simultaneously mixing a fluxing agent containing molybdenum and a fluxing agent containing vanadium, and calcining by using a microwave sintering furnace at a certain temperature to prepare the single crystal LiNi0. 8Co0. 1Mn0. 1 O2 material with in-situ coating layer lithium molybdenum vanadate. The direct contact between the electrolyte and the surfaces of the single-crystal LiNi < 0.8 > Co < 0.1 > Mn < 0.1 > O < 2 > particles can be prevented by coating the surfaces with the lithium molybdenum vanadate, so that unnecessary side reactions are reduced, the growth of a CEI film is prevented, and the structural stability of the single-crystal LiNi < 0.8 > Co < 0.1 > Mn < 0.1 > O < 2 > material is improved. And the lithium molybdenum vanadate is a fast ion conductor, so that the lithium ion de-intercalation capability can be enhanced, and the rate capability of the material is further improved.

Owner:JIANGSU UNIV

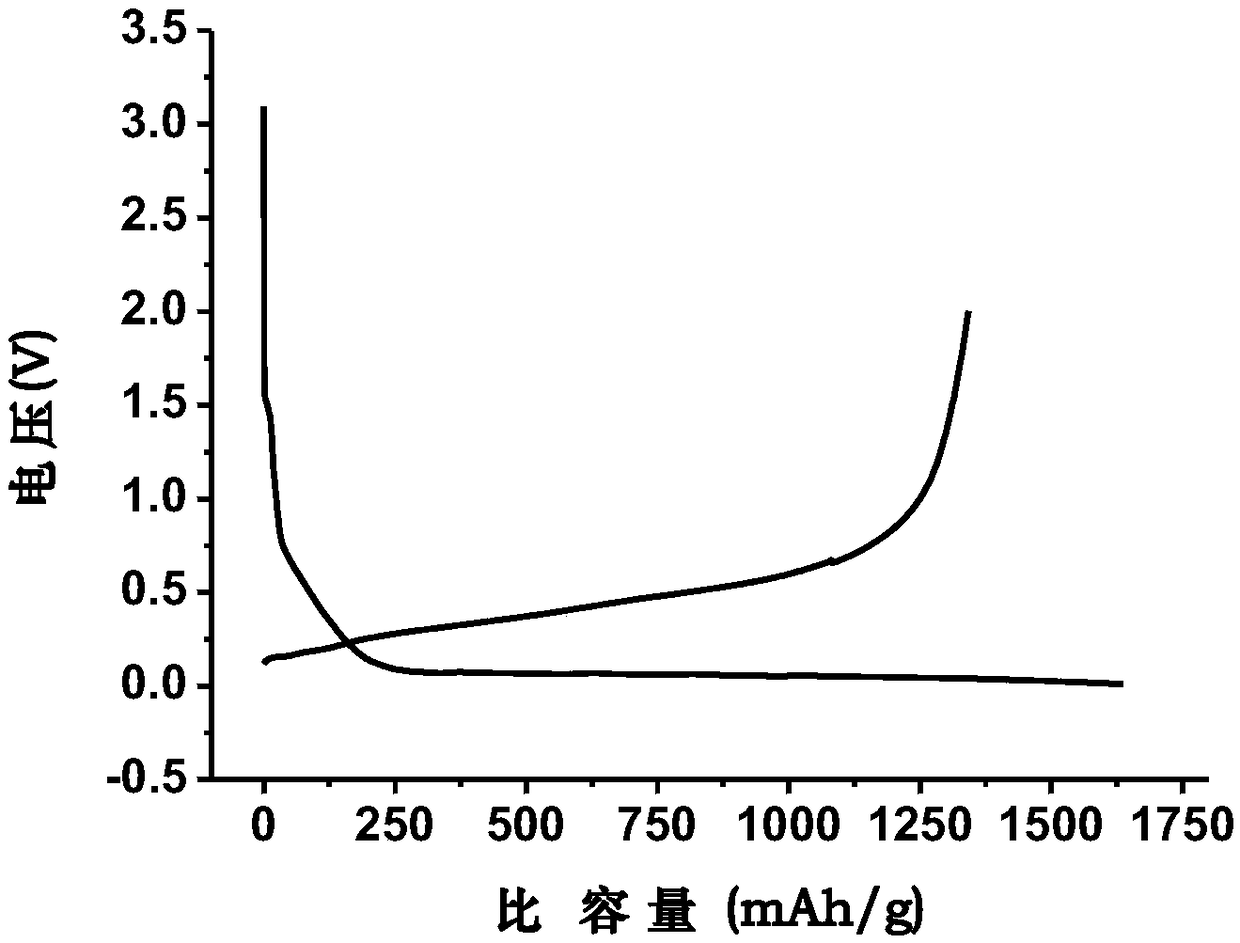

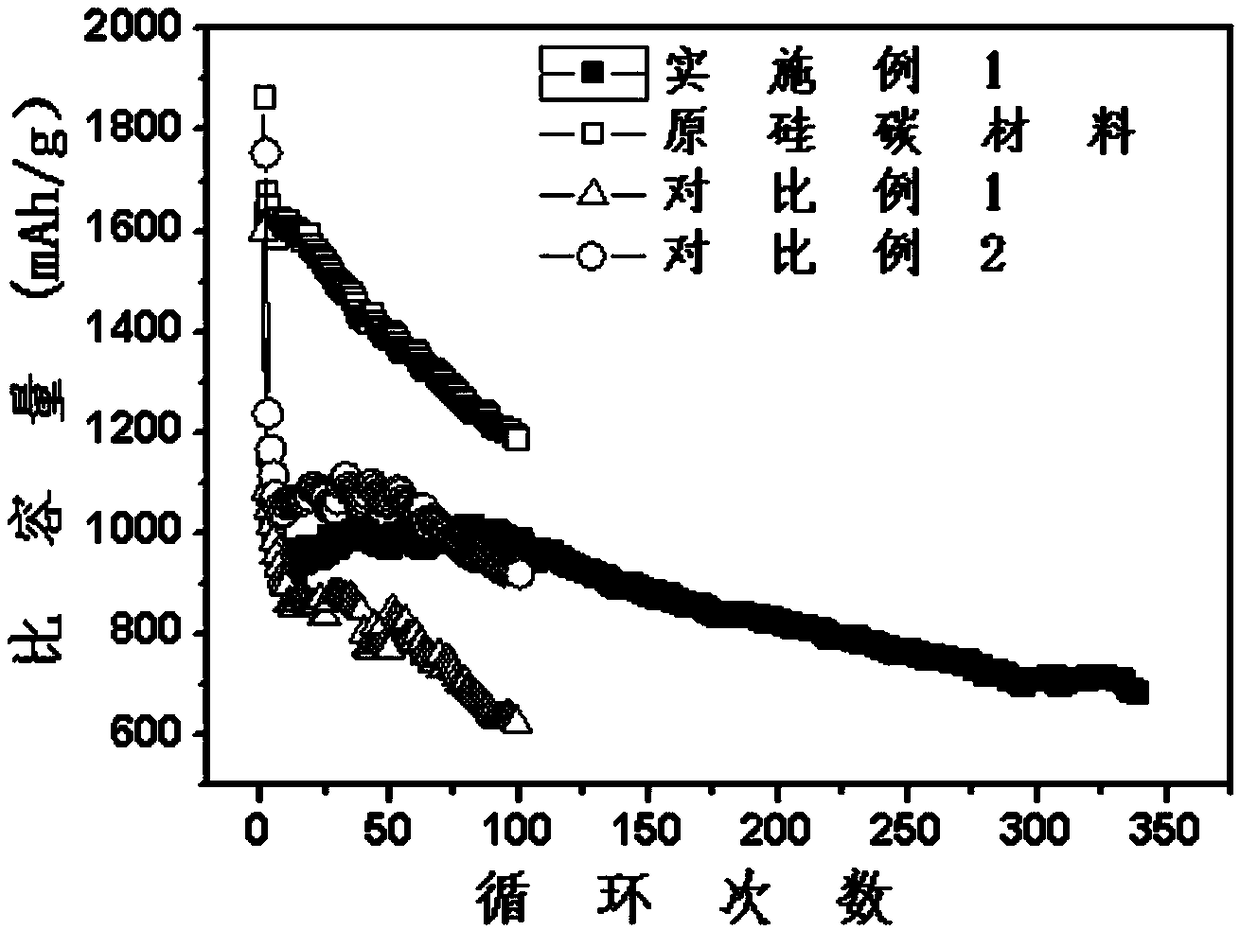

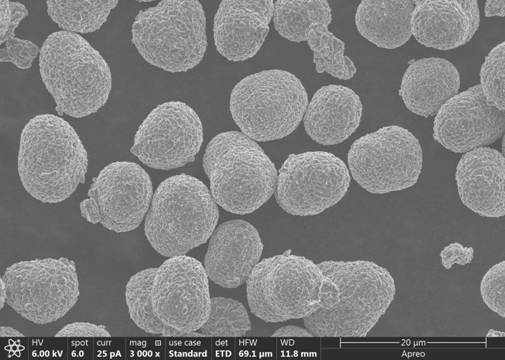

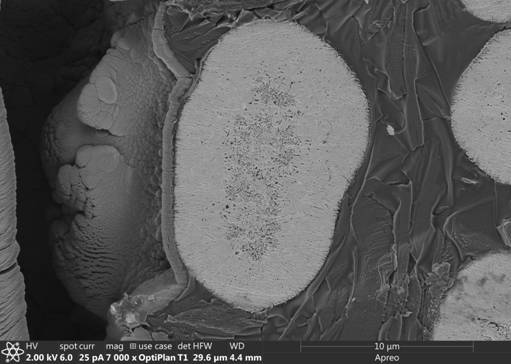

High-capacity negative electrode material as well as preparation method and application thereof

InactiveCN109378456AImprove cycle performanceImprove cycle lifeNegative electrodesSecondary cellsCarbon coatingElectrical battery

The invention provides a high-capacity negative electrode material as well as a preparation method and application thereof. The high-capacity negative electrode material is prepared by the following steps: by taking an M / C1 composite material as a precursor, coating a carbon material C2 in a manner of repeatedly performing liquid-phase dipping-heat treatment, thereby obtaining the product, whereinM is Si, Sn or AxOy; A is any one or more of Si, Sn, Mn, Fe, Co, Ni, Cu or Zn; and x / y is more than 0 and less than 2. The prepared high-capacity negative electrode material has the specific capacityof 600-1800mAh / g, and can be applied to lithium ion batteries or super-capacitors. According to the multi-step 'liquid-phase dipping-heat treatment' process, by virtue of 'multi-step' and 'liquid phase' operating manners, the complete carbon coating layer can be prepared on the premise of ensuring that a conductive network inside the high-capacity M / C1 material is invariable, and the cycle performance of the material is further improved.

Owner:SHAANXI COAL & CHEM TECH INST

Nickel-cobalt-boron precursor material and preparation method, nickel-cobalt-boron positive electrode material

ActiveCN114105156BImprove cycle performanceInhibition of microcracksSecondary cellsPositive electrodesIndiumCrystal plane

The invention belongs to the technical field of lithium ion battery materials, and discloses a nickel-cobalt-boron precursor material, a nickel-cobalt-boron positive electrode material, and a preparation method. The chemical formula of the nickel cobalt boron precursor material is Ni x Co y B z (OH) 2 , using the CASTEP software to calculate the surface energy of the (003) crystal plane of the precursor material to be 1.1 to 2.5 J / m 2 . In the process of preparing nickel-cobalt-boron precursor materials by co-precipitation, the temperature of the reaction system is controlled to be 30-90 °C, the pH value is 11-12.8, the concentration of the complexing agent is 5-8 g / L, and the stirring speed is 300-450 rmp , The solid content is 150~400 g / L. The nickel-cobalt-boron precursor material is calcined with lithium to obtain a positive electrode material, and the positive electrode material can be further coated with an indium coating having conductive ions. The positive electrode material prepared by the invention has excellent electrochemical performance.

Owner:ZHUJI PAWA NEW ENERGY

Method for surface modification of lithium cobaltate positive electrode material by phosphorus compound and lithium cobaltate positive electrode material

ActiveCN111916712BImprove stabilityProtection interfaceCell electrodesSecondary cellsElectrolytic agentLithium

The invention provides a method for modifying the surface of a lithium cobaltate positive electrode material with a phosphorus-containing compound and the lithium cobaltate positive electrode material, comprising the following steps: step 1, using a layered lithium cobaltate powder material as a matrix, and Compounds are ball milled and mixed according to a certain ratio to obtain a mixed powder material; step 2, heat the mixed powder material in an atmosphere protection environment to obtain a modified lithium cobaltate positive electrode material, the interior of which is lithium cobaltate, and the near surface Including lithium cobalt oxide lattice and phosphate root to form a bond, the surface includes an amorphous coating layer composed of metal ions and phosphate groups. The invention adopts process control and treatment of mixing and heating the phosphorus-containing compound and lithium cobaltate to modify the surface of lithium cobaltate particles, and utilizes the doping of phosphate on the surface lattice to enhance the stability of lithium cobaltate structure ; and effectively protect the electrode electrolyte interface by containing an amorphous coating layer, reduce interface side reactions, and improve rate performance and cycle performance.

Owner:NANJING UNIV OF SCI & TECH

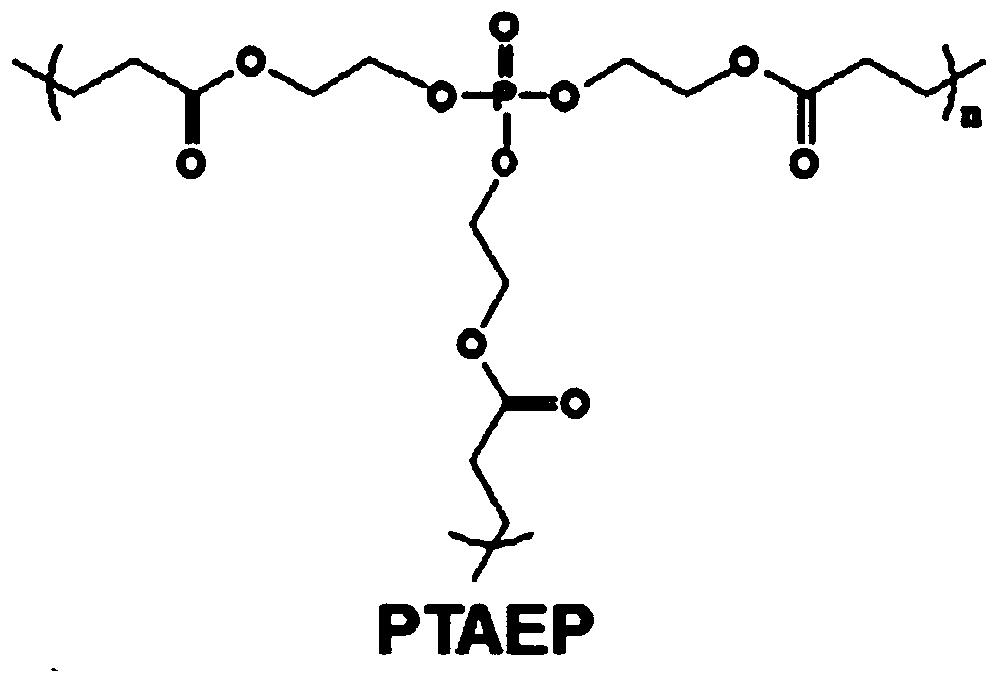

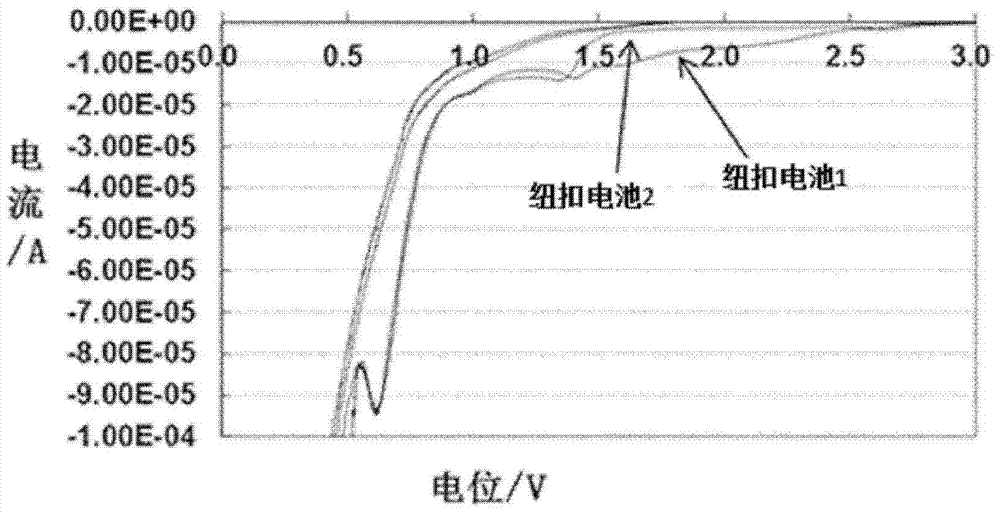

A kind of positive electrode of lithium ion battery coated with gel polymer and preparation method thereof

ActiveCN105226235BImprove conductivityImprove ionic conductivityCell electrodesPhosphateUltraviolet lights

A gel polymer coated lithium ion battery positive electrode and a preparation method therefor are disclosed. The lithium ion battery positive electrode comprises a positive electrode current collector, and a positive electrode active layer formed by a positive electrode active material, a conductive agent and a binder; the surface of the positive electrode active layer is coated by a layer of tri(di-acryloxyethyl) polyphosphoester gel polymer. The preparation method comprises the steps of mixing the positive electrode active material, the conductive agent and the binder firstly, taking N-methyl pyrrolidone as a solvent, uniformly stirring and coating on aluminum foils, and drying to obtain a positive plate A; placing the positive plate A into an acetone solution containing tri(di-acryloxyethyl) phosphate monomer and photoinitiator, and after fully volatizing the acetone solution, and obtaining a positive plate B; and exposing the positive plate B in ultraviolet light to obtain the lithium ion battery positive electrode. The lithium ion battery positive electrode of the invention is excellent in cycle performance and thermodynamic stability under higher cut-off voltage.

Owner:HUNAN SHANSHAN NEW ENERGY CO LTD

Electrolyte and lithium ion battery including the same

ActiveCN105261788BReduce interface side reactionsAvoid decompositionSecondary cellsOrganic electrolytesHigh temperature storageOrganic solvent

The invention relates to an electrolyte and a lithium ion battery including the same. The electrolyte comprises a lithium salt, an organic solvent, an additive A and an additive B, wherein the additive A is a dinitrile compound containing carbon-carbon double bonds; and the additive B is a silane phosphate compound and / or a silane boric acid ester compound. After the electrolyte provided by the invention is applied to the lithium ion battery, the high-temperature storage performance, the high-temperature cycle performance and the rate capability of the lithium ion battery can be improved.

Owner:NINGDE AMPEREX TECH

A kind of modified single crystal ternary cathode material and preparation method thereof

ActiveCN113571690BReduce residual alkaliReduce interface side reactionsSecondary cellsPositive electrodesElectrical batteryLanthanide

The invention discloses a modified single crystal ternary positive electrode material and a preparation method thereof. The present invention replaces the traditional cross-linking agent with the hydrogen bond between the coordination bond formed by the unique β-diketone group in curcumin and the lanthanide metal ion and the polymer chain, so as to obtain high elasticity and ductility. Sulfonic acid type polymer; the generated sulfonic acid can effectively reduce the amount of residual alkali on the surface of the material, and has both high elasticity and ductility, which can effectively maintain the structure of the material during the repeated charging and discharging of the battery, and improve the battery cycle performance. .

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Electrochemical device and electronic equipment containing it

ActiveCN112886002BIncrease energy densityImprove cycle stabilitySecondary cellsPositive electrodesEngineeringMaterials science

The present application relates to the technical field of energy storage, and in particular to an electrochemical device and electronic equipment containing it. The electrochemical device includes a positive electrode material, and the positive electrode material includes: an active material; and a first material located on the surface of the active material; wherein, the first material includes a second material with a lattice spacing of Å. The electrochemical device using the above positive electrode material can exhibit excellent cycle stability under high voltage, and can also improve the charge capacity and energy density.

Owner:NINGDE AMPEREX TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com