Method for surface modification of lithium cobaltate positive electrode material by phosphorus compound and lithium cobaltate positive electrode material

A cathode material and surface modification technology, applied in battery electrodes, electrochemical generators, structural parts, etc., can solve the problems of difficult regulation and complexity of process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

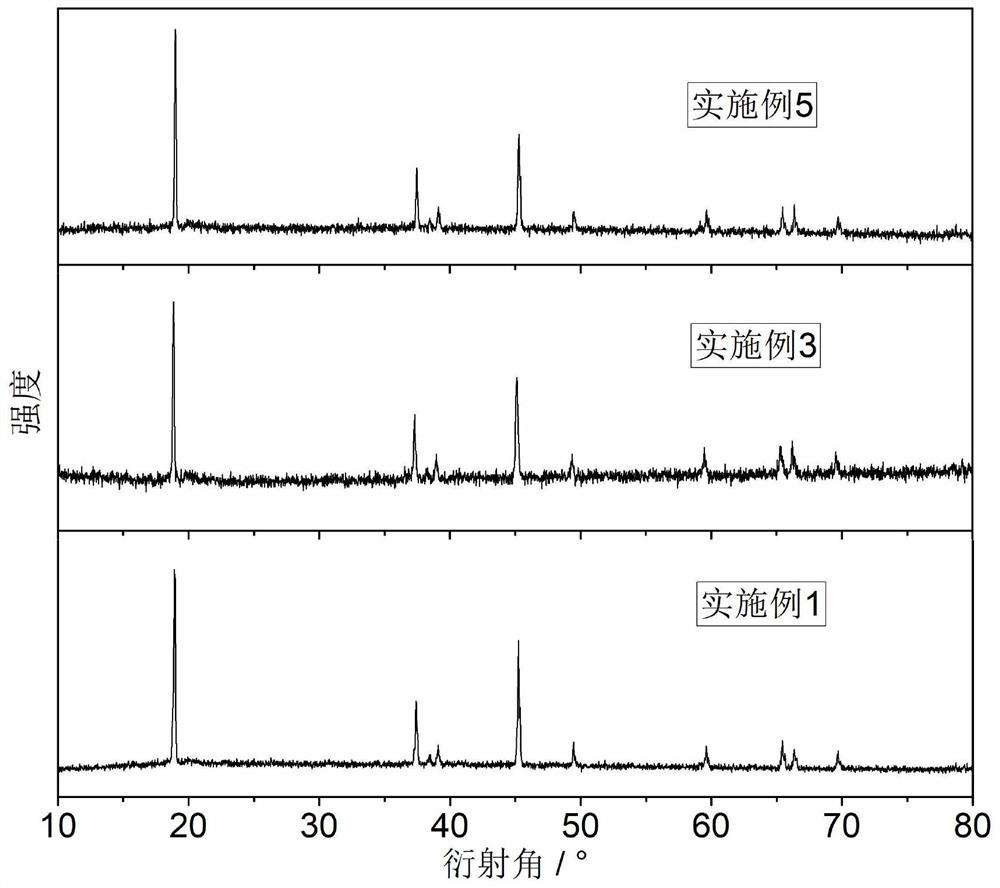

Embodiment 1

[0052] Mix 0.1g of sodium phosphate and 10g of lithium cobaltate in a ball mill, mill for 2 hours, heat at 400°C in air for 5-6 hours, and cool naturally to obtain a surface-modified lithium cobaltate material.

Embodiment 2

[0054] 0.2 g of sodium hypophosphite and 10 g of lithium cobaltate were ball-milled for 2 hours, heated at 200° C. in argon for 1 hour, and naturally cooled to obtain a surface-modified lithium cobaltate material.

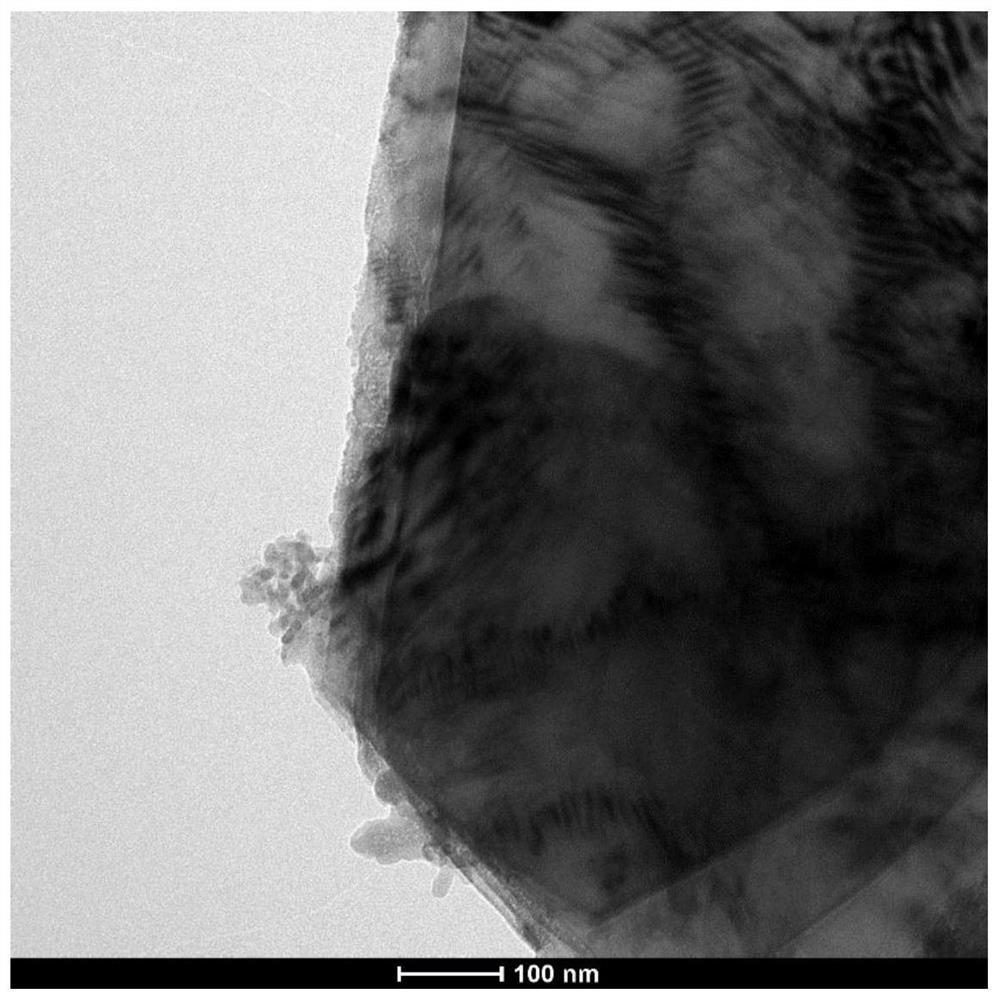

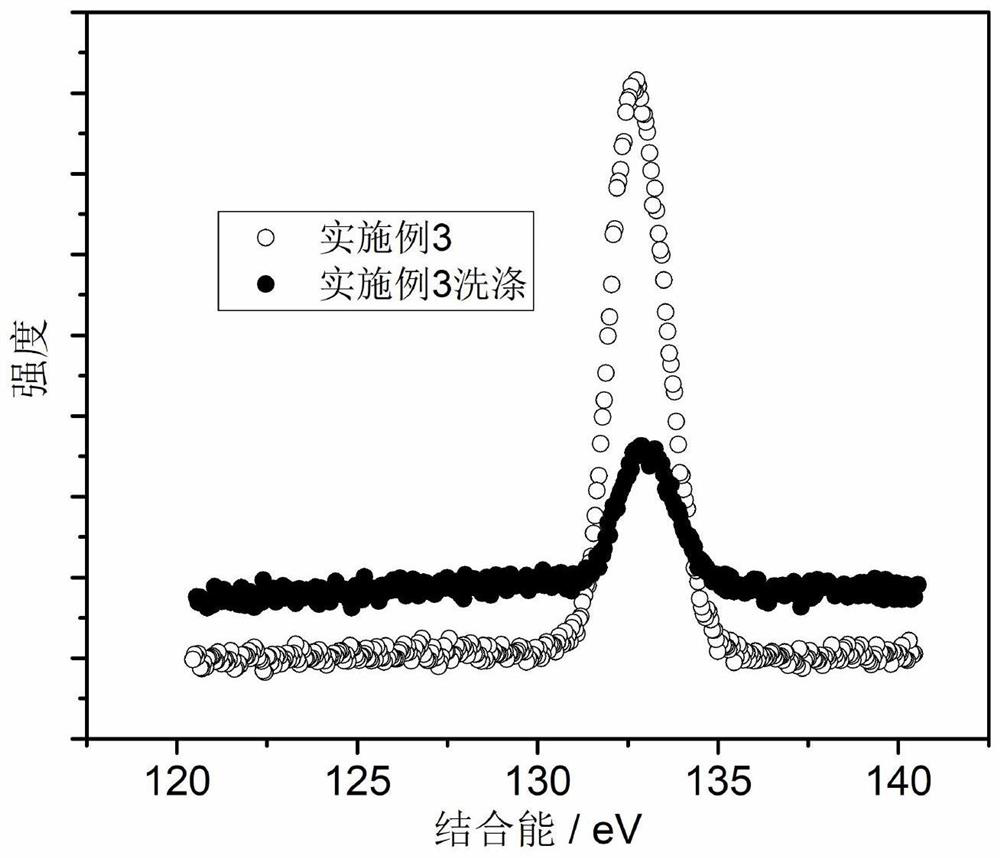

Embodiment 3

[0056] 0.5 g of sodium hypophosphite and 10 g of lithium cobaltate were mixed and ball-milled for 2 hours, heated at 500° C. in air for 2 hours, and naturally cooled to obtain a surface-modified lithium cobaltate material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com