Flexible lithium metal negative electrode framework material as well as preparation method and application thereof

A lithium metal negative electrode and skeleton material technology, which is applied to the flexible lithium metal negative electrode skeleton material and its preparation. The application field of the flexible lithium metal negative electrode skeleton material in the lithium metal battery negative electrode field can solve the problems of battery cycle performance degradation and thermal failure. , to achieve the effect of low material cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The invention provides a method for preparing a flexible lithium metal negative electrode framework material, comprising the following steps:

[0038] (1) Mix 1g of lithium fluoride particles with 20ml of alcohol and then perform high-performance ball milling. During the ball milling process: use large ball milling beads with a diameter of 9mm and small ball milling beads with a diameter of 4mm, and the ratio of the numbers is 1:12. The ball milling beads are made of stainless steel balls, the milling medium is alcohol, the ball-to-material ratio is 30:1, and the milling time is 3 hours;

[0039] Then crush the ball-milled lithium fluoride particles with a cell disruptor for 30 minutes, and then dry them in a blast drying oven at 60°C for 12 hours to obtain the processed lithium fluoride particles;

[0040] (2) Dissolve 0.1 g of the above-mentioned treated lithium fluoride particles and 0.8 g of polyacrylonitrile (PAN, Mw=130,000) in 10 mL of DMF, and rotate and stir at...

example 1

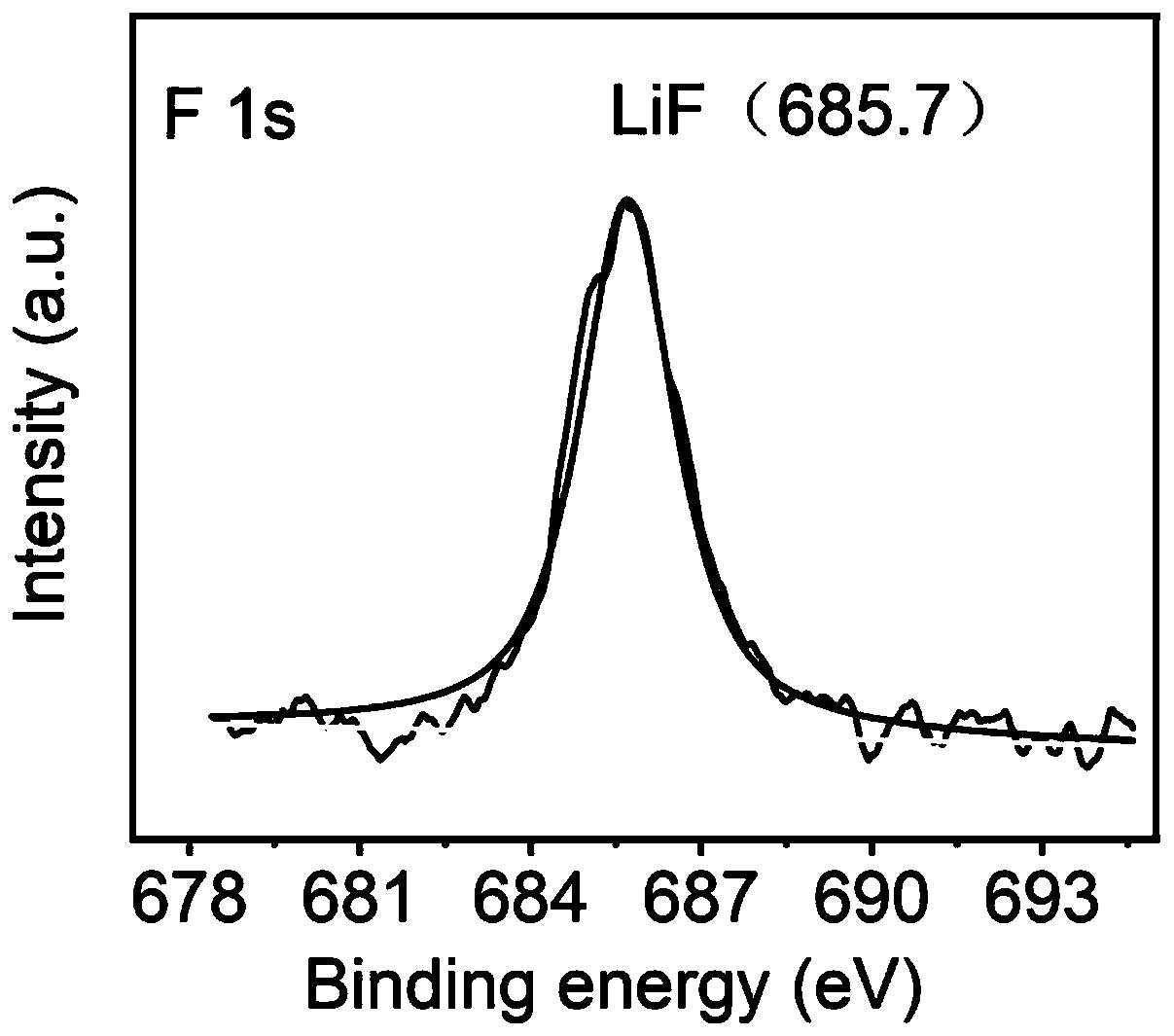

[0042] The high-resolution figure of the material that example 1 makes is as figure 1 As shown, the fiber diameter of lithium fluoride-modified oxidized polyacrylonitrile nanofiber framework (OPAN-LiF) is about 300 nm, and the internal three-dimensional crosslinking. The XPS F 1s spectrum of the material that embodiment 1 makes is as figure 2 shown.

Embodiment 2

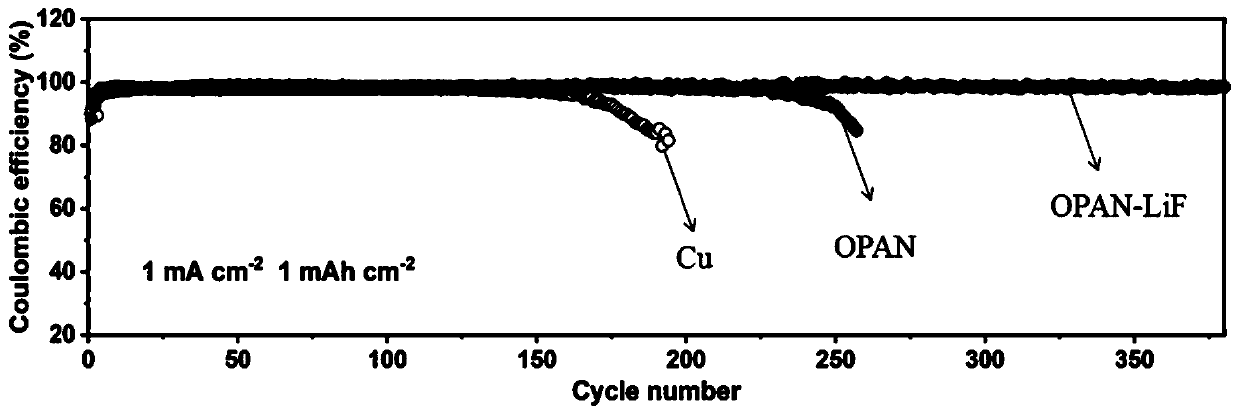

[0049] In order to test the inhibitory effect of the OPAN-LiF framework material on the growth of lithium dendrites and the improvement of the Coulombic efficiency, a lithium-copper half-cell was assembled for testing. Place the obtained OPAN-LiF pole piece on the top of the copper foil, use metal lithium as the counter electrode, and the electrolyte solution is 1M lithium bistrifluoromethanesulfonylimide (LiTFSI) dissolved in 2% LiNO 3 1,3-dioxolane (DOL) / ethylene glycol dimethyl ether (DME) (1:1w / w).

[0050] The assembled half-cells were tested at a current density of 1 mA cm -2 , surface capacity 1mAh cm-2 Under the condition of , its cycle number-coulombic efficiency curve see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com