Preparation method of nitrogen-doped carbon material

A nitrogen-doped carbon and carbon material technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as difficulty in meeting the needs of high-capacity lithium-ion battery anode materials, reduce production costs, alleviate volume expansion, The effect of simple heat treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Stir the egg white liquid for 24 hours for homogenization, then filter to remove impurities, add 40 grams of egg white liquid to 30 ml of deionized water and stir to mix evenly;

[0025] (2) Heat the egg white solution in the steam of boiling water to denature and shrink the egg white molecules to form a colloid similar to a chicken cake;

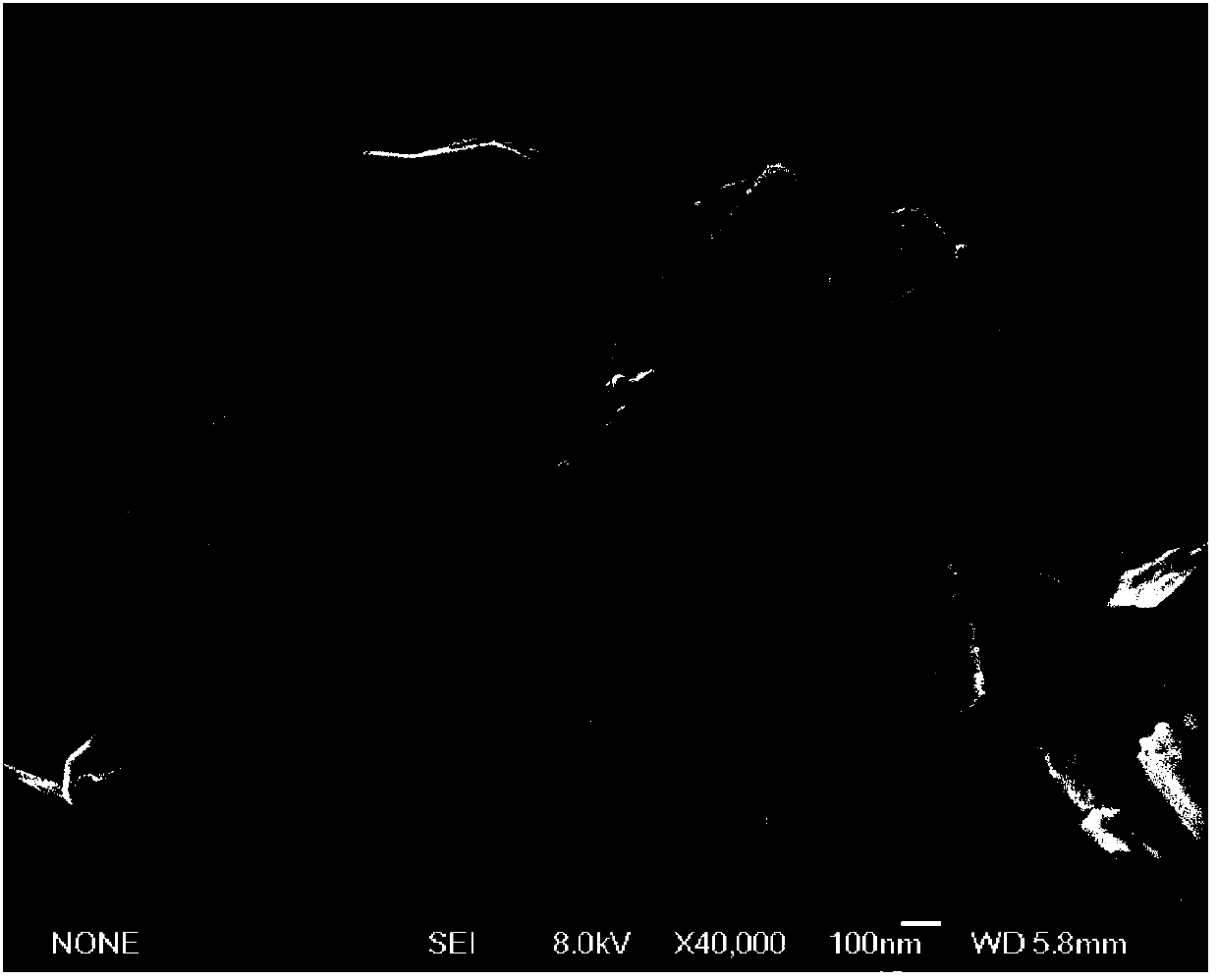

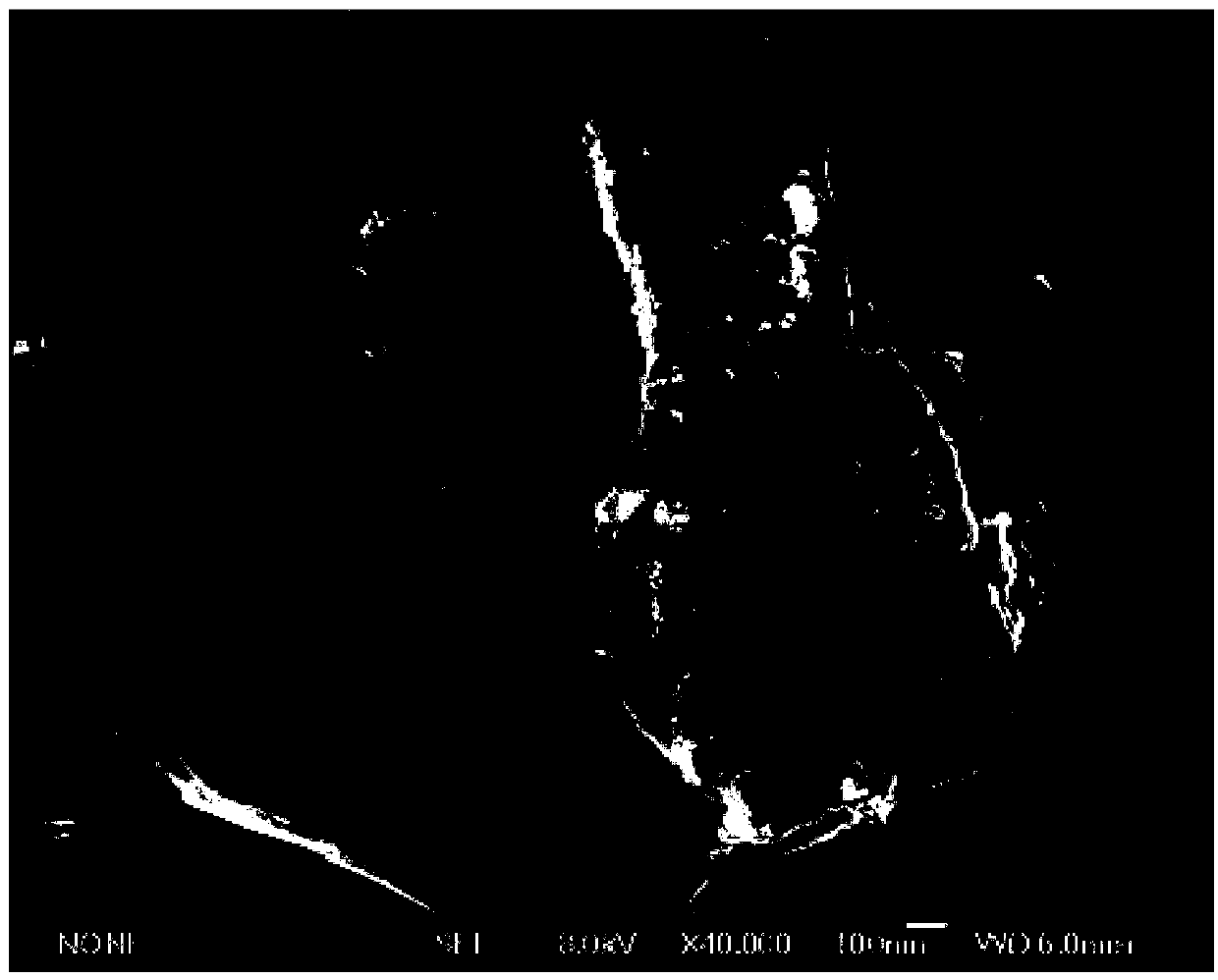

[0026] (3) Nitrogen-doped amorphous carbon can be obtained by calcining at 500°C for 3 hours under the protection of nitrogen;

Embodiment 2

[0028] (1) Take the egg white liquid and stir for 12 hours for homogenization, then filter to remove impurities, add 20 grams of egg white liquid to 20 ml of deionized water and mix well;

[0029] (2) Add 0.5 g of tin dioxide to the egg white solution, stir for 1 hour and then sonicate until uniformly dispersed;

[0030] (3) Heating the suspension in the steam of boiling water to denature and shrink the egg white molecules to form a colloid similar to a chicken cake;

[0031] (4) After centrifugation, washing and drying, the nitrogen-doped carbon-coated tin dioxide composite material can be obtained by calcining at 500°C for 6 hours under an inert atmosphere;

Embodiment 3

[0033] (1) Stir the egg white liquid for 48 hours for homogenization, then filter to remove impurities, dissolve 30 grams of egg white liquid into 30 ml of deionized water and mix well;

[0034] (2) Add 1 gram of glucose and 0.5 gram of tin dioxide to the egg white solution, stir for 1 hour and then sonicate until evenly dispersed;

[0035] (3) Heating the suspension in the steam of boiling water to denature and shrink the egg white molecules to form a colloid similar to a chicken cake;

[0036] (4) After drying, the nitrogen-doped carbon-coated tin dioxide composite material can be obtained by calcining at 600°C for 6 hours under an inert atmosphere;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com