Patents

Literature

336results about How to "Simple heat treatment process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

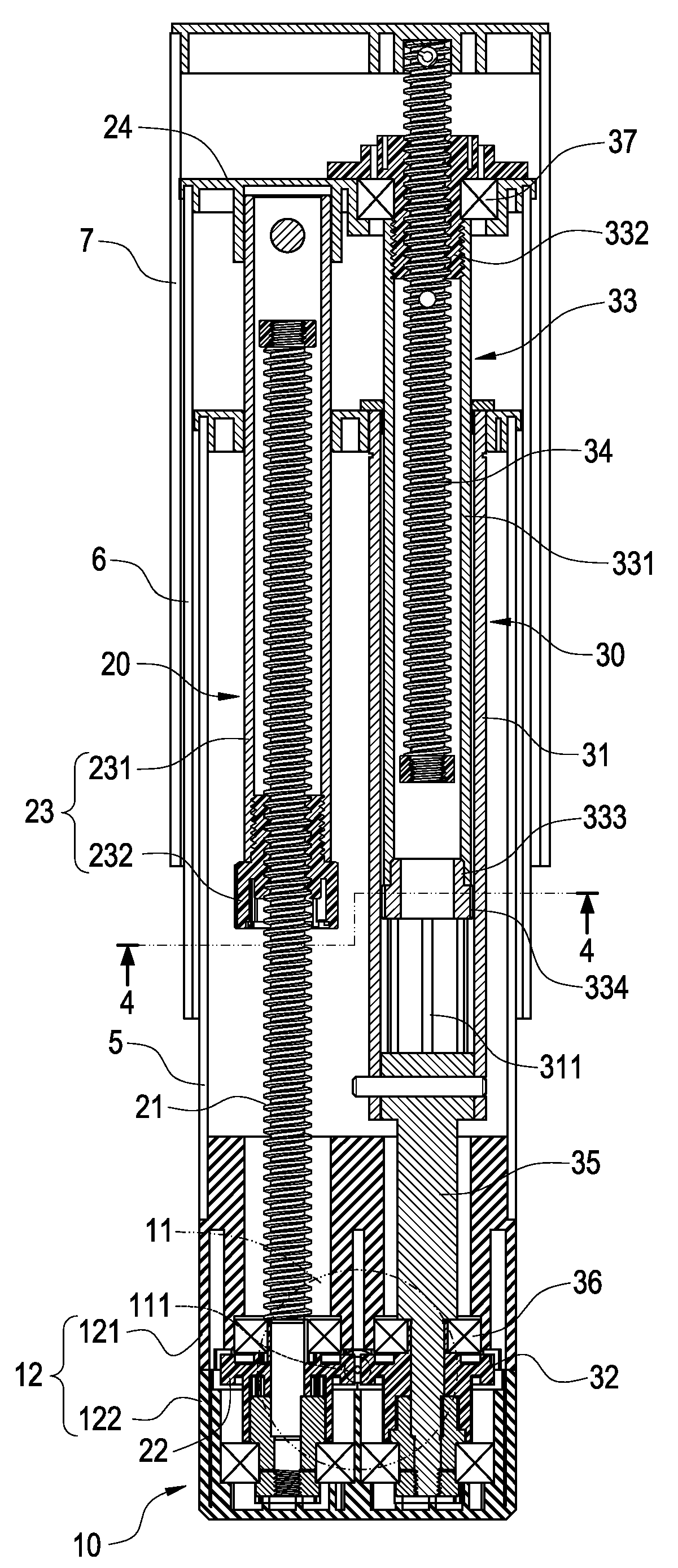

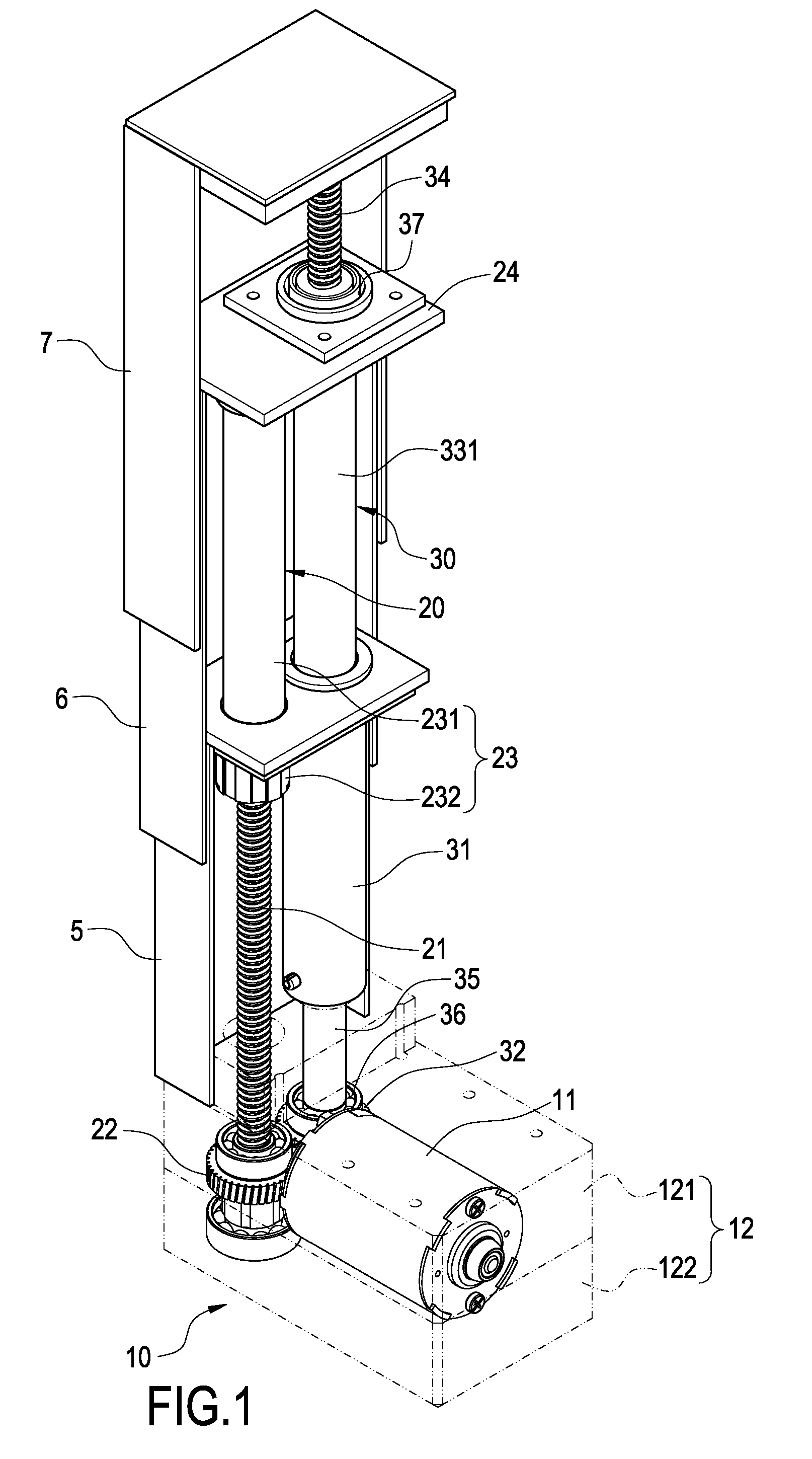

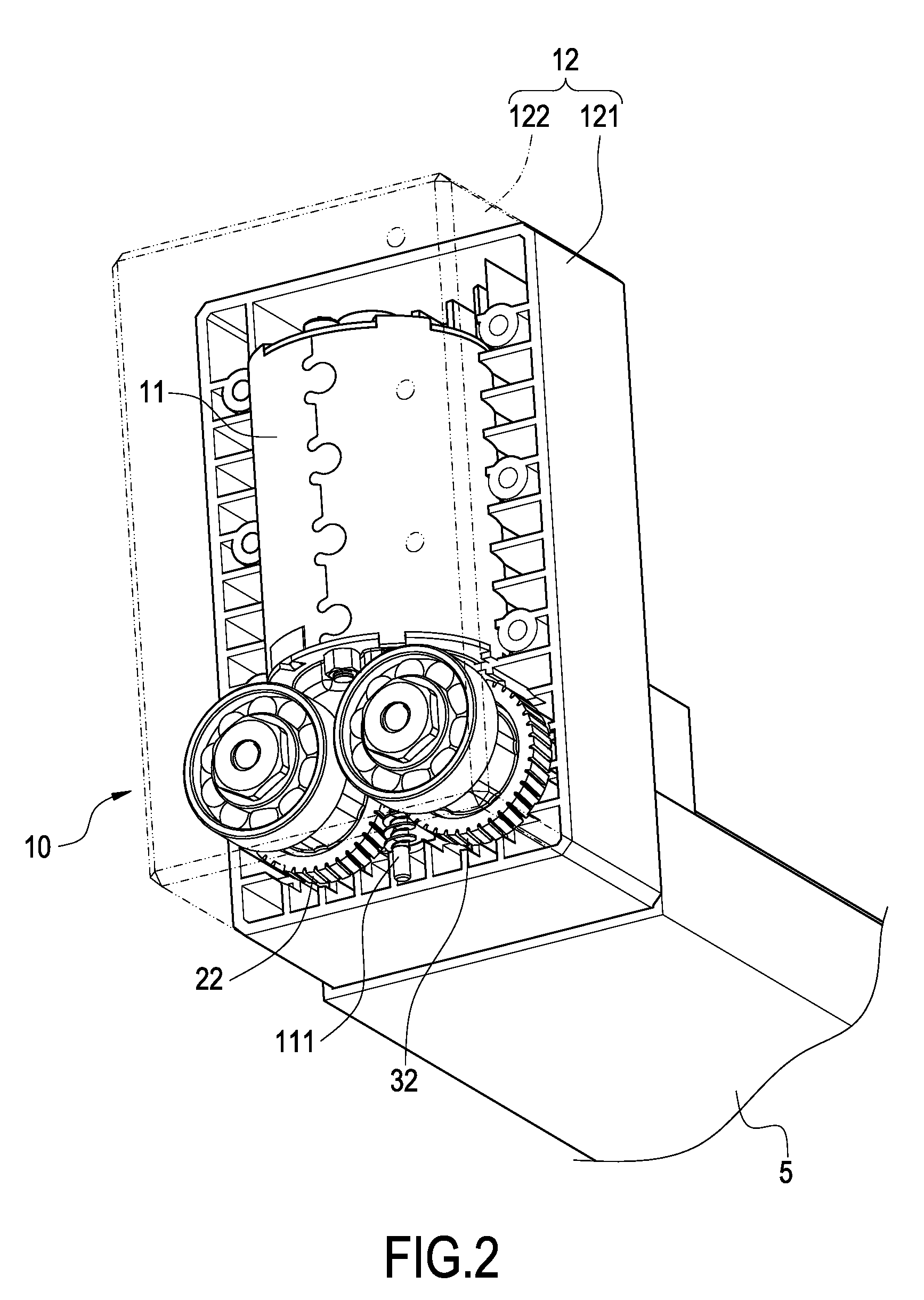

Lifting device having parallel double screw rods

ActiveUS7712389B2Improve the heating effectLow costToothed gearingsLifting devicesEngineeringScrew thread

A lifting device having parallel double screw rods includes a motor, a first transmission and a second transmission. The first transmission includes a screw rod driven by the motor and a telescopic tube assembly threadedly connected to the screw rod and linearly movable relative to the screw rod. The distal end of the telescopic tube assembly is fixedly connected on a connecting piece. The second transmission is provided at one side of the first transmission and parallel thereto. Further, the second transmission includes a sleeve driven by the motor to rotate, a telescopic tube assembly accommodated within the sleeve and axially movable relative to the sleeve, and a screw rod threadedly connected to the telescopic tube assembly and linearly movable relative to the telescopic tube assembly. The distal end of the telescopic tube assembly is connected to the connecting piece. With the above arrangement, each screw rod is interchangeable and the cost can be reduced.

Owner:TIMOTION TECH CO LTD

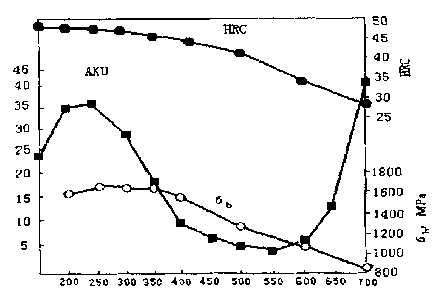

Micro-alloy chemical die steel and thermal treatment method thereof

InactiveCN101798657AEmission reductionSimple heat treatment processSolution treatmentChemical composition

The invention discloses a micro-alloy chemical die steel and a thermal treatment method thereof. The chemical die steel comprises the following chemical components in percent by weight: 0.7 to 0.9 percent of C, 0.15 to 0.25 percent of V or Nb, 1.0 to 2.0 percent of Cr, Mn, Si and Mo, common steel with more than or equal to 50ppm of O, N, S and P, and less than 50ppm clean steel. The thermal treatment method for the steel comprises the following steps: heating the steel to between 1,050 and 1,150 DEG C after hot rolling to perform solution treatment, quickly cooling the steel to 600 DEG C, transferring the steel to a 400 to 700 DEG C furnace to perform isothermal transformation, heating the steel to between 900 and 950 DEG C after machining, quenching the steel by oil, and finally tempering the steel at the temperature of between 150 and 200 DEG C. The invention discloses the high-quality chemical die steel with low alloy element content, advantages of saving sources and reducing carbon emission and wide application prospect in die and bearing industries.

Owner:戚正风 +1

Processing net forming integrated method for amorphous alloy workpiece

InactiveCN101164722ASolve the problem of inability to prepare structurally complex partsRealize the integration of preparation and processing net shapeTest sampleMolten alloy

The present invention relates to a preparation processing method of amorphous alloy workpiece. Said method includes the following steps: heating and melting alloy mother material, then pouring the molten alloy mother material into a breakable mould, after the molten alloy is cooled, an amorphous alloy can be obtained, after the mould is broken, cleaning the test sample so as to obtain the invented required workpiece.

Owner:BEIHANG UNIV

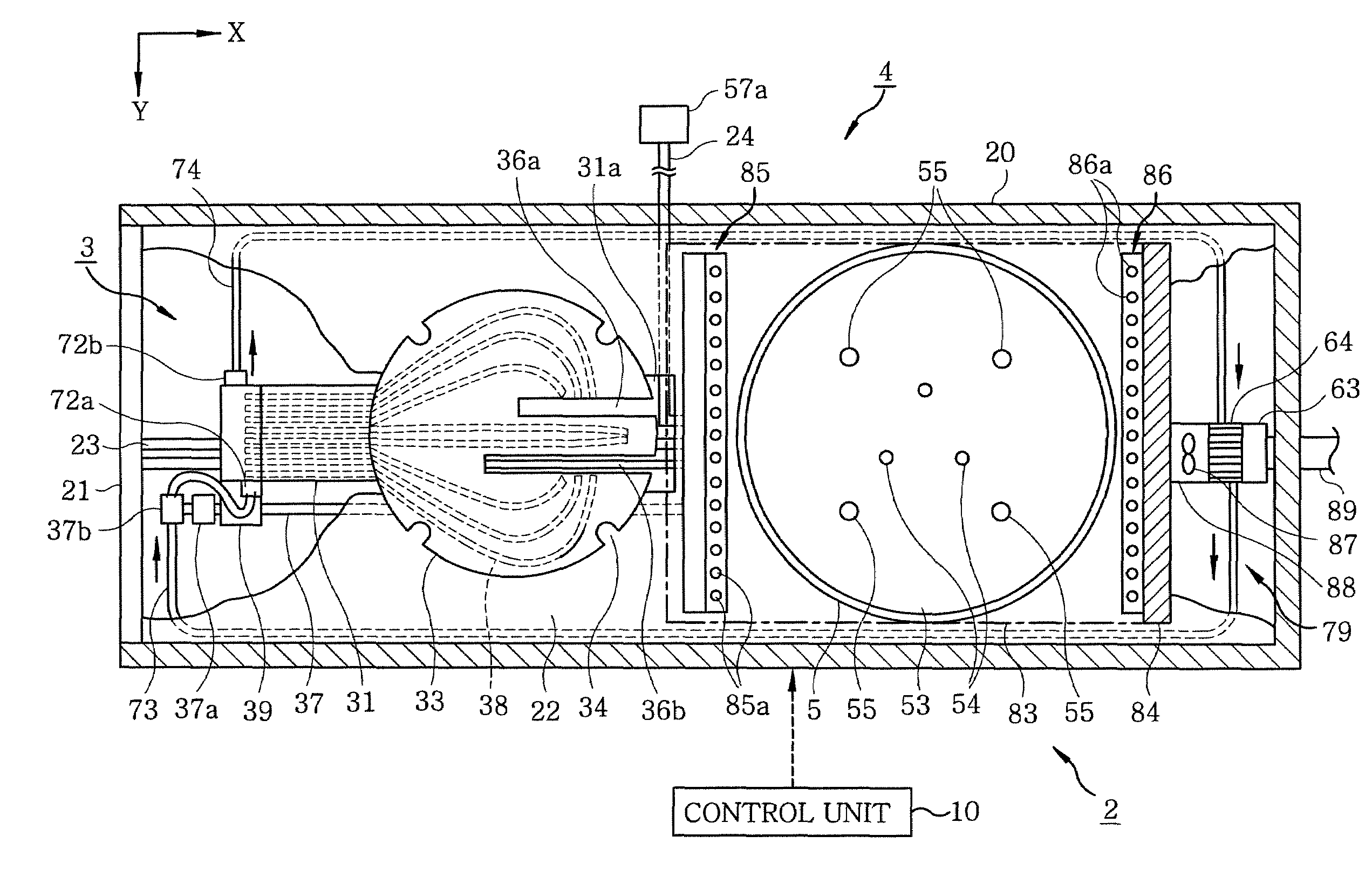

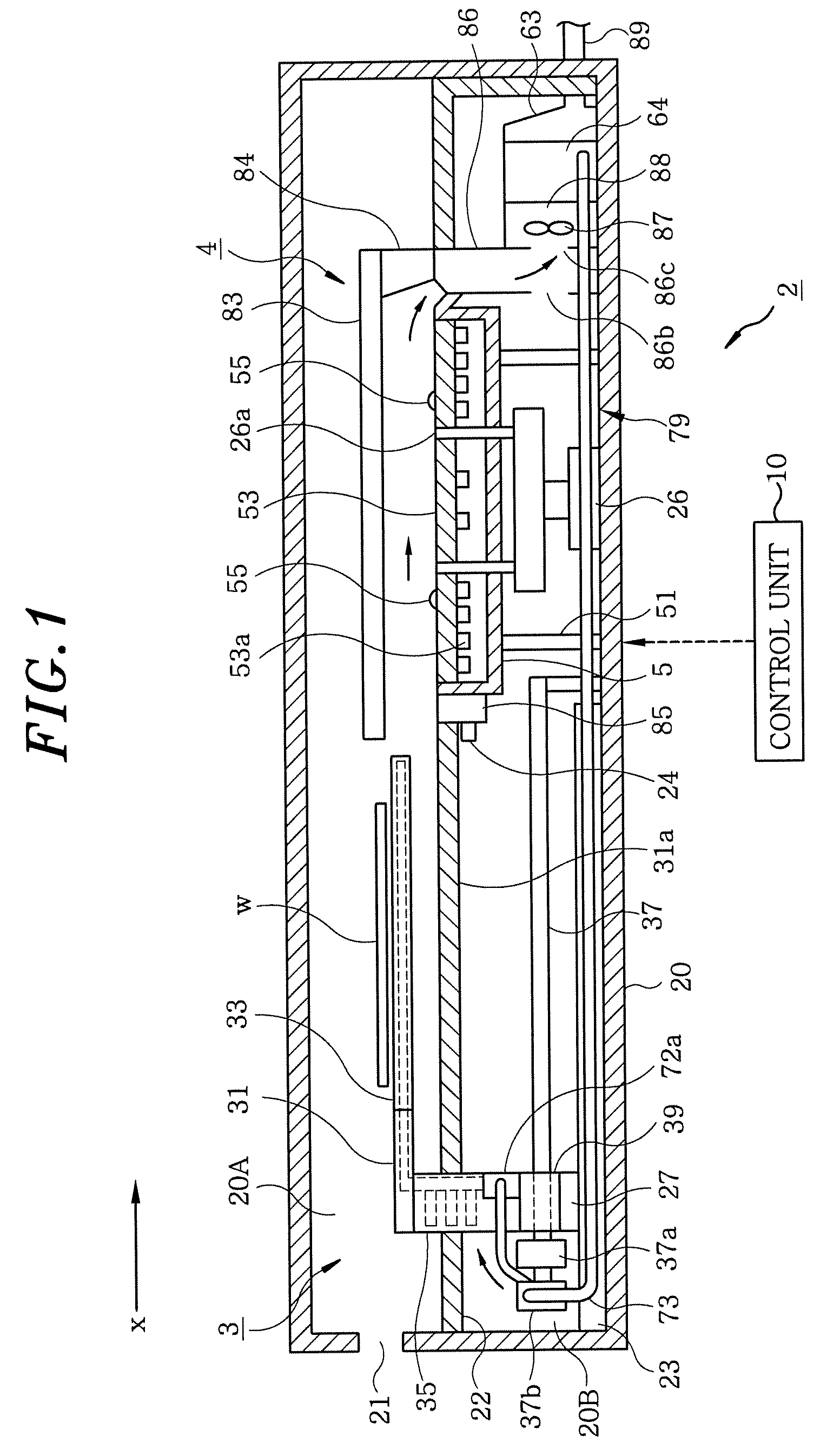

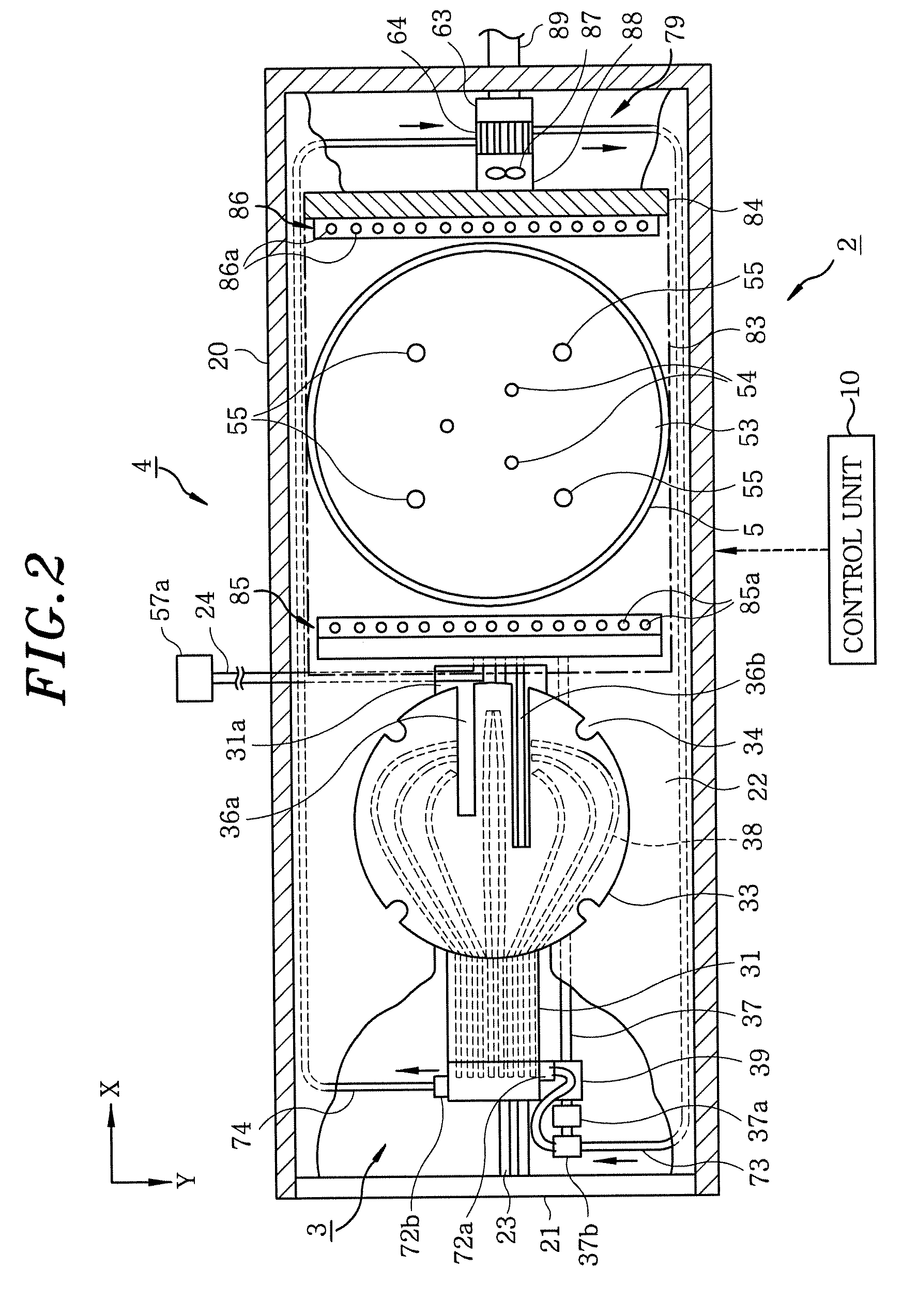

Heat treating apparatus, heat treating method, and storage medium

InactiveUS20070218706A1Promote exchangeEasy maintenanceMuffle furnacesElectric heatingCooling chamberEngineering

A heat treating apparatus includes a heating plate for heating a substrate coated with a coating liquid, a cooling plate for cooling the substrate and a heat pipe provided in the cooling plate, a cooling chamber being moved together with the cooling plate by the drive mechanism and accommodating a cooling liquid for cooling one end side of the heat pipe. The apparatus further includes a circulation passage provided in the heat treating apparatus to circulate the cooling liquid in the cooling chamber, a circulation pump for circulating the cooling liquid in the circulation passage; and a heat radiating member provided on the circulation passage to radiate the heat received by the cooling chamber to the outside of the heat treating apparatus.

Owner:TOKYO ELECTRON LTD

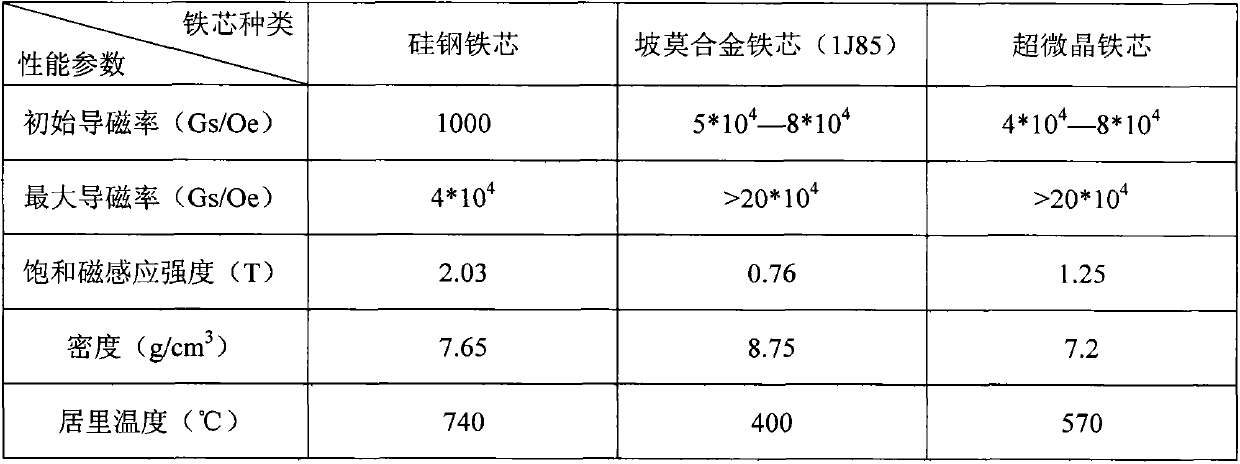

Magnetic core of low conductive magnet, manufacturing method and application thereof

ActiveCN103258612ALow coercivityStrong corrosion resistanceTransformers/inductances magnetic coresInductances/transformers/magnets manufactureAlloyAlternating current

The invention relates to a magnetic core of a low conductive magnet, a manufacturing method and and application thereof. The magnetic core of the low conductive magnet is made of ferromagnetic magnetically soft alloy, the molecular formula of the alloy is FeaMbCucSidBeM'fXg, wherein M represents Ni and / or Co, M' represents at least one element among V, Ti, Nb, Mo, Cr, Hf, Ta and W, and X represents P, Ge, C and impurities. With atomic percent as the unit, a, b, c, d, e, f and g meet the following conditions: b is larger than or equal to 5 and is smaller than or equal to 40, c is larger than or equal to 0.05 and is smaller than or equal to 1, d is larger than or equal to 1 and is smaller than or equal to 8, e is larger than or equal to 10 and is smaller than or equal to 20, f is larger than or equal to 0.5 and is smaller than or equal to 5, g is larger than or equal to 0 and is smaller than or equal to 0.5, d and e are larger than or equal to 10 and are smaller than or equal to 25, and a is equal to 100 minus b minus c minus d minus e minus f minus g. The microstructure of the using state of the alloy is an amorphous state. The magnetic core is low in magnetic conductivity, high in anti-saturation performance and high in modulation property to alternating current and direct current components. Further, a B-H loop line is of a linear shape, and the magnetic conductivity of the linear B-H loop line is high in modulation property in the alternating current and the direct current.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Bainite steel and bainite steel rail used for curve and heavy load steel rail, and production method thereof

ActiveCN101921971AHigh tensile strengthImprove uniformityFurnace typesHeat treatment furnacesHeavy loadImpurity

The invention discloses a bainite steel and a bainite steel rail used for a curve and a heavy load steel rail, and a heat treatment method thereof. The bainite steel contains the chemical elements by weight percent: 0.16-0.25% of C, 0.70-1.20% of Si, 2.10-2.40% of Mn, less than or equal to 0.025% of P, less than or equal to 0.015% of S, 0.6-1.2% of Cr, 0.15-0.40% of Mo, 0-0.7% of Ni and balance Fe and impurities which are treated by continuous casting, hot rolling and whole heat treatment. The invention can be used for the curve and the heavy load line steel rail, and prolongs the service life of the steel rail.

Owner:BEIJING TEYE IND & TRADE

Preparation method of nitrogen-doped carbon material

InactiveCN103730638AEasy to synthesizeAlleviate volume expansionCell electrodesCarbon compositesTin dioxide

The invention discloses a preparation method of a nitrogen-doped carbon material. The carbon material has a mesoporous structure and is doped with nitrogen, and the doping content of the nitrogen in the carbon material is controllable; a composite of the carbon material is modified by the carbon material; and the preparation method selects egg white as a raw material to form the nitrogen-doped carbon material through high-temperature calcination and carbonization in the inert atmosphere, and comprises steps as follows: (1), an egg white solution is taken as a solvent for material composition; (2), the egg white is steamed in boiling water and forms tin dioxide jelly similar to yellow cake; and (3), calcination is performed in the inert atmosphere to obtain the nitrogen-doped carbon material. with the adoption of the method, the nitrogen-doped carbon composite material with a carbon coating structure can be prepared, and the content of the nitrogen in the carbon material is controllable; and the prepared nitrogen-doped carbon composite material is suitable for being taken as a Li-ion electrode material, and is simultaneously applicable to the fields of corrosion resistance, gas absorption and the like.

Owner:JILIN UNIV

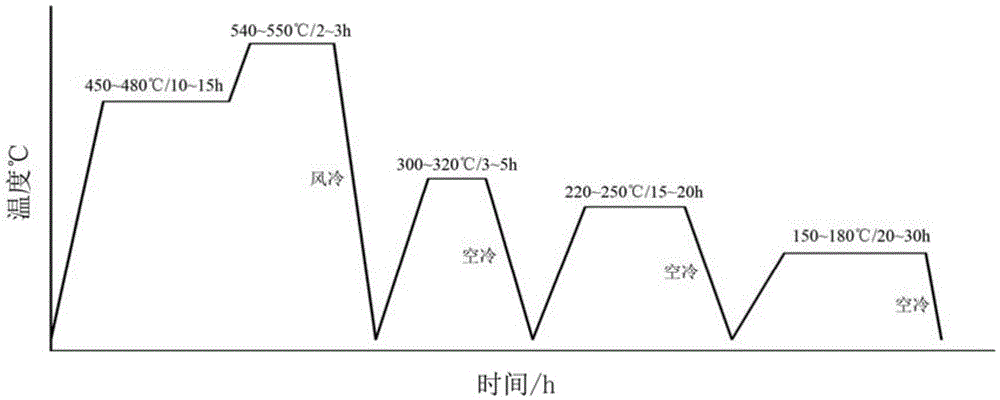

Heat treatment technology for improving mechanical properties of rare earth magnesium alloy castings

A heat treatment technology for improving mechanical properties of rare earth magnesium alloy castings is a heat treatment method which is used for carrying out staged solution and staged aging on Mg-Y-Nd magnesium alloy castings. Solution and aging are regarded as a whole body, namely, after being heated and subjected to primary solution and secondary solution sequentially, the castings are subjected to tertiary artificial aging sequentially, solution temperature, insulating time, aging temperature and insulating time are controlled, in a process of aging precipitation of strengthening phases containing Nd, a Y element is in a solution state, in a process of aging precipitation of a compound containing Y, a compound containing Nd cannot grow, the number of the strengthening phases subjected to aging precipitation is large, the strengthening phases are tiny, growth of crystal grains in a solution process is also avoided, and the mechanical properties of the alloys are improved. The heat treatment technology is simple, existing heat treatment equipment is not required to be modified, the mechanical properties of the obtained alloys are greater than those of alloys treated by a conventional method by at least 10%, industrial production is easy to implement, and a simple and efficient effective way is provided for improving the mechanical properties of the large-size rare earth magnesium alloy castings.

Owner:CENT SOUTH UNIV

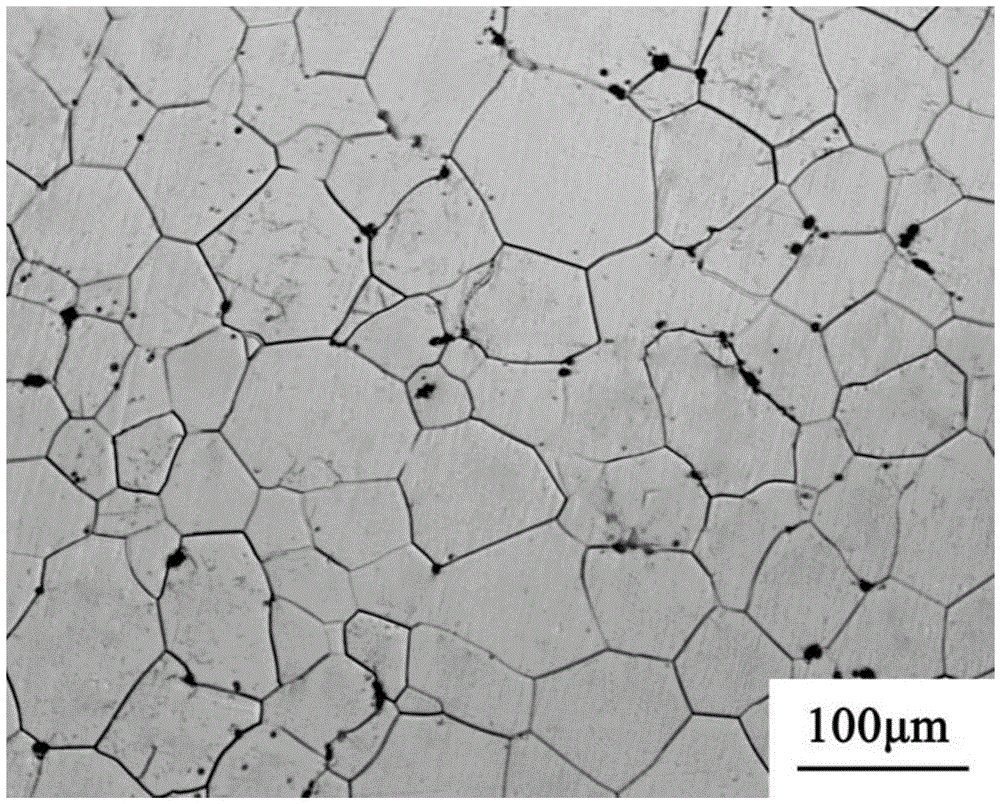

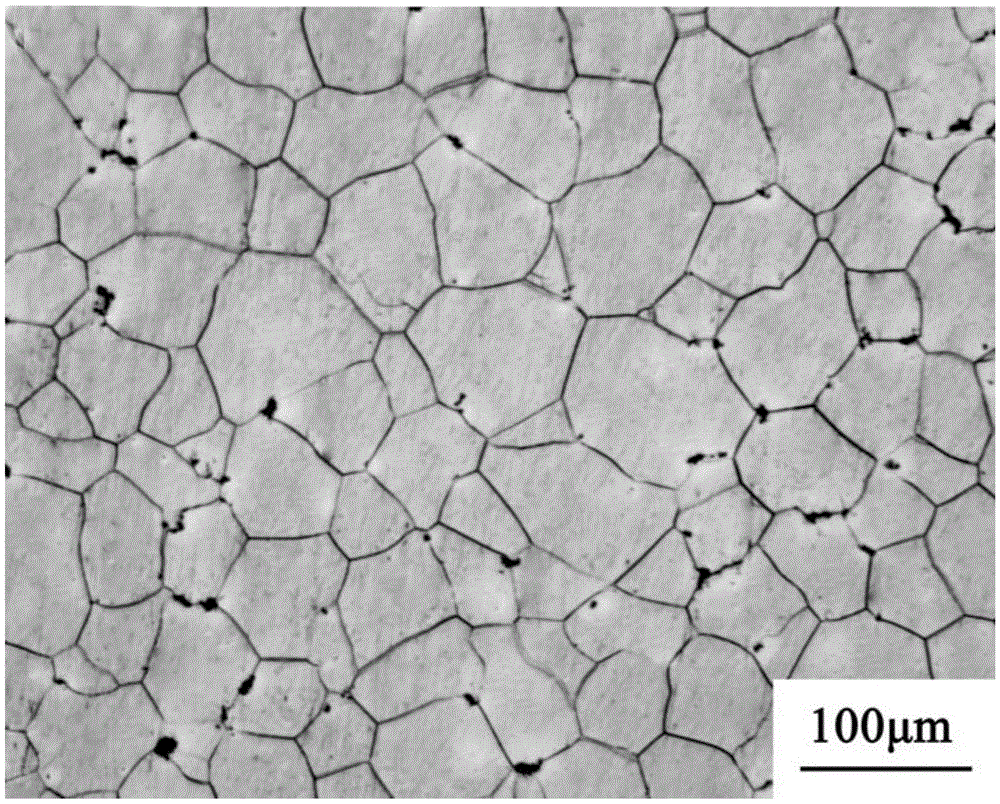

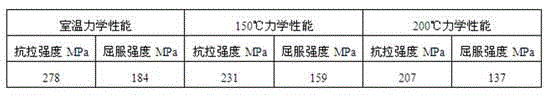

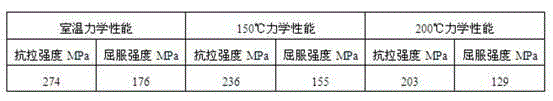

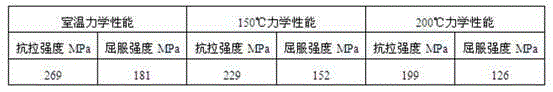

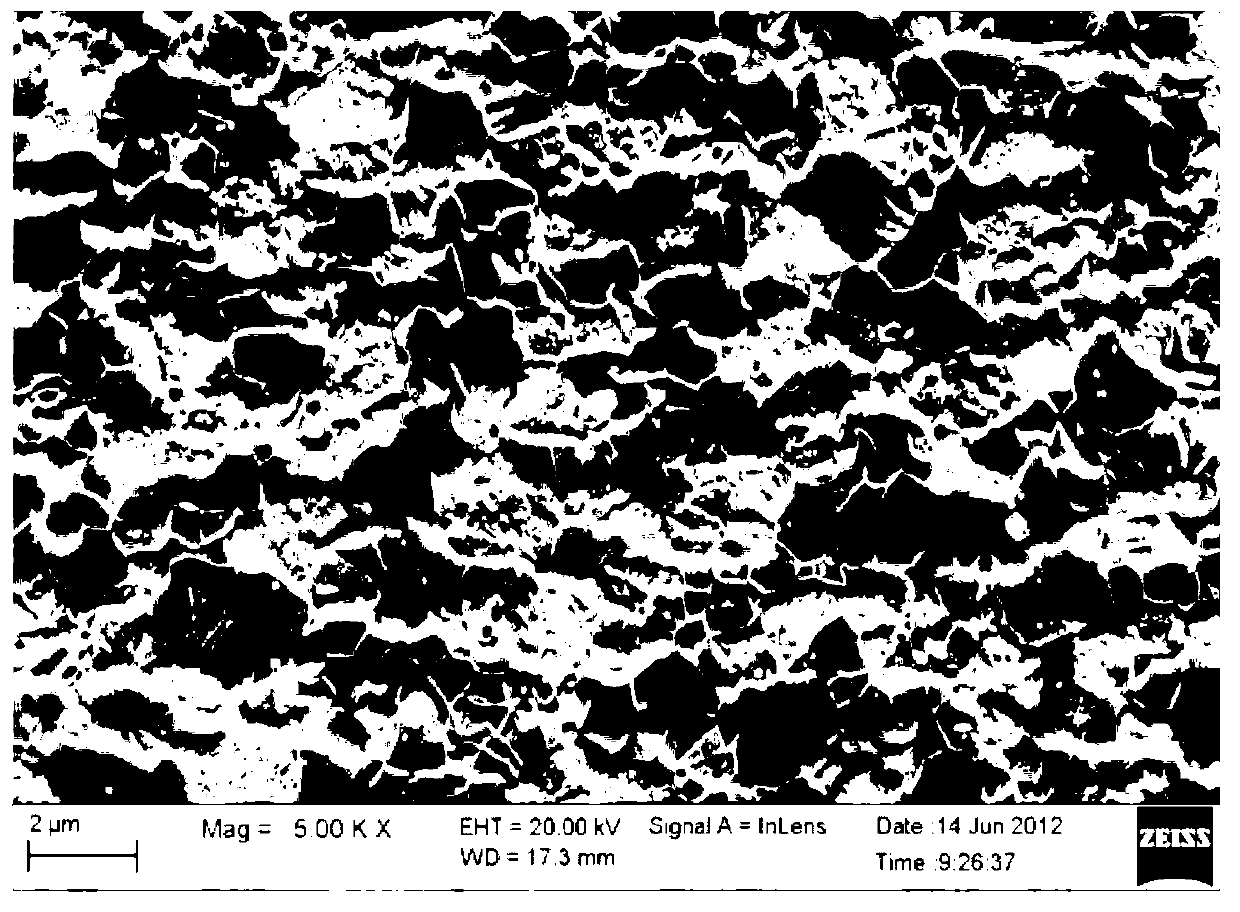

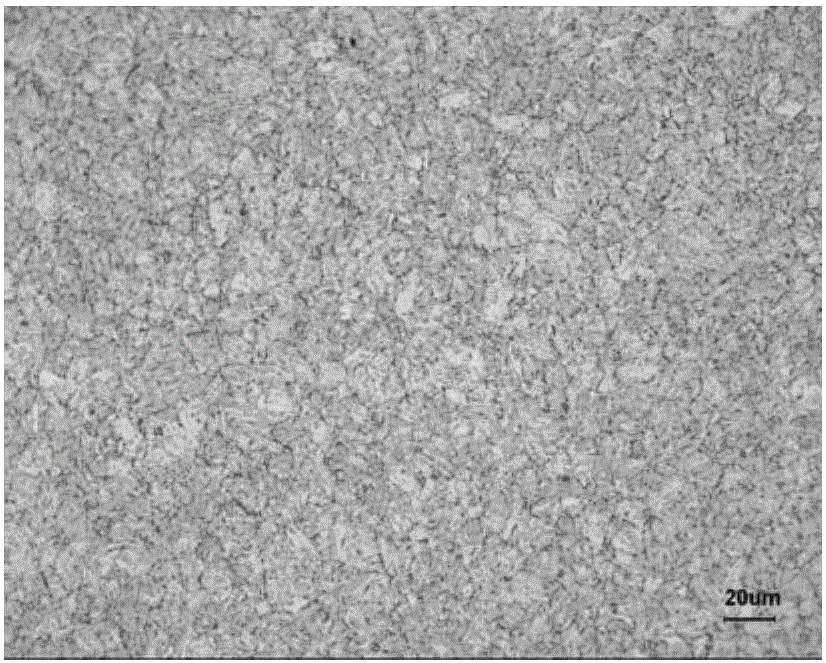

Low-cost multi-component heat-resistant magnesium alloy and preparation method of magnesium alloy

InactiveCN104694805AImprove plasticityImprove high temperature performanceHeat resistanceRoom temperature

The invention provides a low-cost multi-component heat-resistant magnesium alloy and a preparation method of the magnesium alloy. The low-cost multi-component heat-resistant magnesium alloy comprises the following components in percentage by weight: 4.2-6.7% of Al, 0.5-1.2% of Zn, 0.7-0.9% of Sr, 0.2-0.8% of Ca, 1.1-1.5% of Sn, 0.8-1.3% of Sb, 0.05-0.4% of Mn, 0.2-0.6% of Bi, 0.4-0.9% of Si and the balance of Mg. According to the low-cost multi-component heat-resistant magnesium alloy, a right amount of low-cost alloy elements such as Sr, Ca, Sn, Sb, Mn, Bi and Si are introduced; the high-temperature performance of the magnesium alloy can be remarkable improved; the application range of the magnesium alloy can be expanded; the magnesium alloy is low in cost, simple in smelting and heat treatment process and uniform in microscopic structure; the mechanical performance and the heat resistance of the alloy can be remarkably improved; after the alloy is solidified and aged, the maximum room-temperature tensile strength reaches 278MPa; the maximum tensile strength at 150 DEG C reaches 236MPa; the maximum tensile strength at 200 DEG C reaches 207MPa.

Owner:HENAN UNIV OF SCI & TECH

High-strength and high-plasticity medium manganese cold-roll steel sheet and manufacturing method thereof

InactiveCN103103438AImprove mechanical propertiesSimple and economical ingredientsTime rangeSheet steel

The invention discloses a high-strength and high-plasticity medium manganese cold-roll steel sheet and a manufacturing method thereof, and belongs to the technical field of metal material manufacturing. The high-strength and high-plasticity medium manganese cold-roll steel sheet comprises the following main components in percentage by mass: 0.15-0.25% of C, 7-8% of Mn, 1.2-1.8% of Si, and less than or equal to 0.05% of Al. The components are smelted and cast into a blank, and then the casting blank is subjected to multi-pass hot rolling so as to obtain a hot-rolled plate; the hot-rolled plate is subjected to intermediate heat treatment two times and two stages of cold rolling; the temperature of the intermediate heat treatment is 80-120 DEG C larger than Ar1, and the heat preservation time is 8 hours and above; in the two stages of cold rolling, the deformation is 30-50%; and the temperature of final heat treatment of the cold-roll steel sheet is Ar1+70 DEG C and above, and the annealing time ranges from 10 minutes to 2 hours. The cold-roll steel sheet disclosed by the invention is simple in preparation method, low in cost, and wide in application prospect. A prepared high-strength and high-plasticity medium manganese cold-roll steel sheet has excellent mechanical properties, and the product of strength and elongation of the cold-roll steel sheet can be up to 44.9 GPa*%.

Owner:UNIV OF SCI & TECH BEIJING

Steel for super-high-strength and super-high-toughness petroleum casing, petroleum casing and manufacturing method of petroleum casing

ActiveCN105002425AImprove toughnessSimple heat treatment processDrilling rodsFurnace typesChemical elementPetroleum

The invention discloses steel for a super-high-strength and super-high-toughness petroleum casing. The microstructure of the steel is a tempered sorbite. The chemical elements of the steel comprise, by mass, 0.1-0.22% of C, 0.1-0.4% of Si, 0.5-1.5% of Mn, 1-1.5% of Cr, 1-1.5% of Mo, 0.01-0.04% of Nb, 0.2-0.3% of V, 0.01-0.05% of Al, 0.0005-0.005% of Ca, the balance Fe and inevitable impurities. Correspondingly, the invention further discloses the petroleum casing made from the steel for the super-high-strength and super-high-toughness petroleum casing. Besides, the invention discloses a manufacturing method of the petroleum casing. The strength of the steel for the super-high-strength and super-high-toughness petroleum casing and the strength of the petroleum casing can be more than 155 ksi, the impacting toughness of the steel for the super-high-strength and super-high-toughness petroleum casing and the petroleum casing is 10% larger than the yield strength value of the steel for the super-high-strength and super-high-toughness petroleum casing and the petroleum casing, and super-high strength and super-high toughness match can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD +1

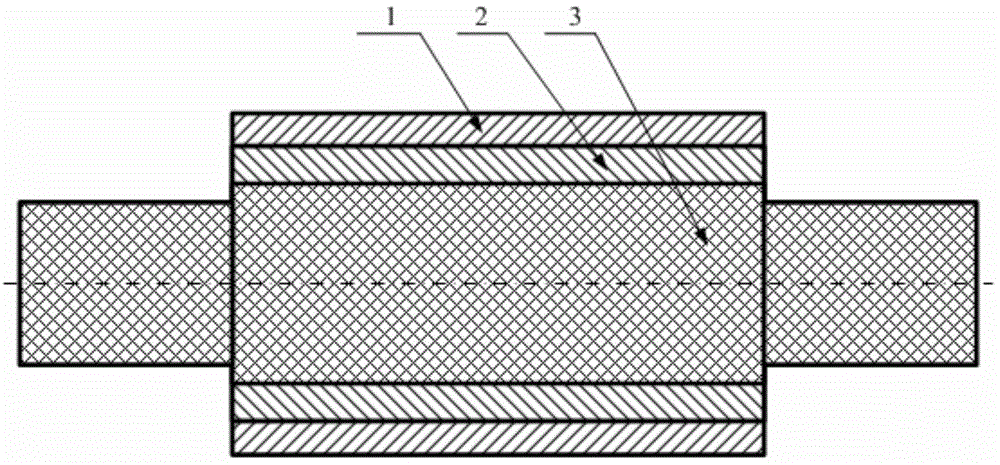

Wear-resisting roll used for steel rolling intermediate mill frame and manufacturing method thereof

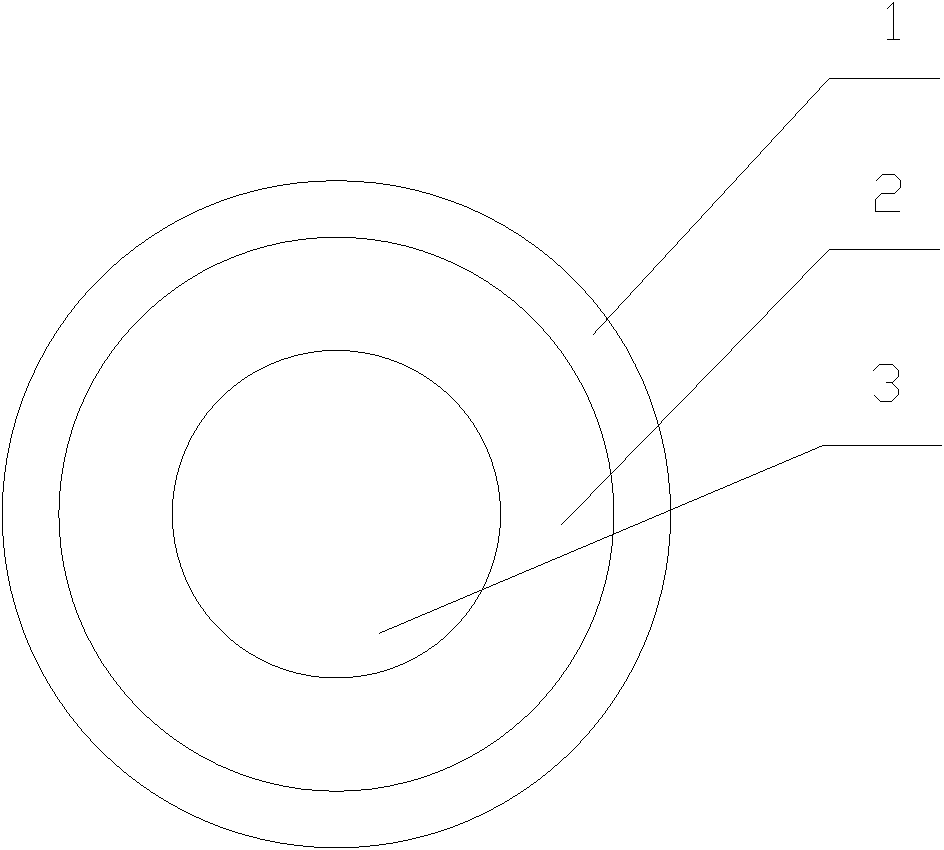

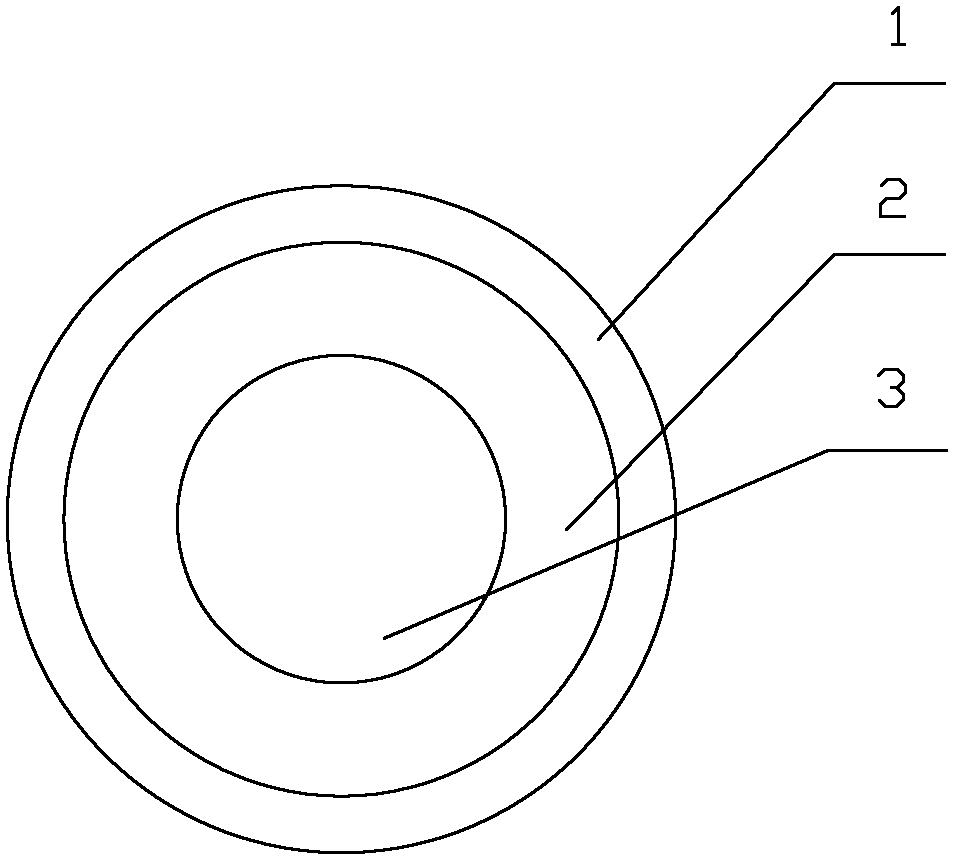

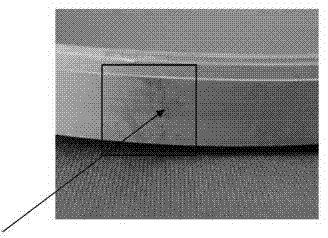

ActiveCN104148399ASimple heat treatment processShort heat treatment timeRollsMetal rolling arrangementsSocial benefitsAlloy

A wear-resisting roll used for a steel rolling intermediate mill frame and a manufacturing method thereof belong to the technical field of steel rolling. The wear-resisting roll is composed of outer layer alloy nodular cast iron, inner layer high strength gray iron and a hot rolled middle carbon round steel roll shaft with high strength. The outer layer alloy nodular cast iron and the inner layer high strength gray iron are formed through centrifugal casting in a composite mode, and the inner layer high strength gray iron is integrated with the hot rolled middle carbon round steel roll shaft with high strength, and the composite wear-resisting roll with high strength is obtained. The wear-resisting roll has the advantages of being simple and convenient in production process, long in service life, low in production cost and the like. In addition, good economic and social benefits are achieved through application and popularization.

Owner:枣庄瑞兴机械制造有限公司

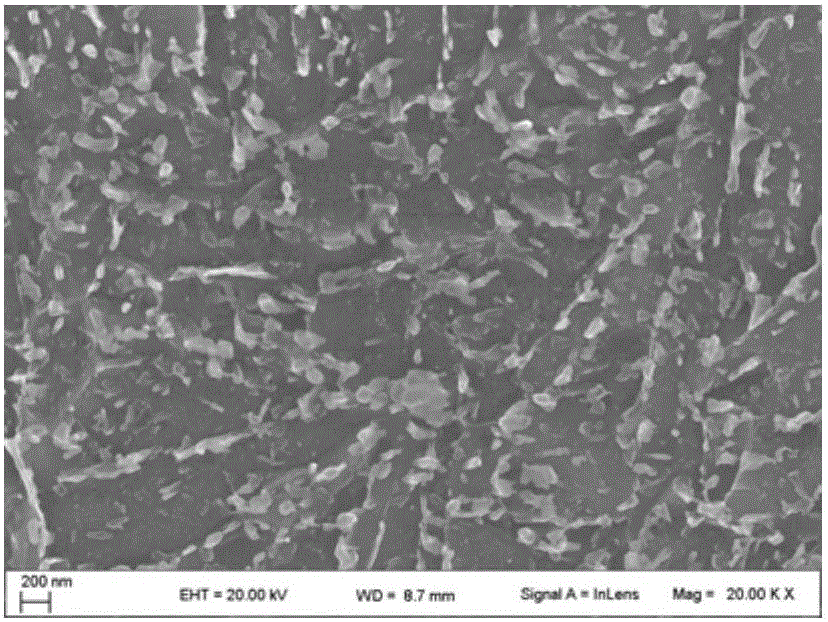

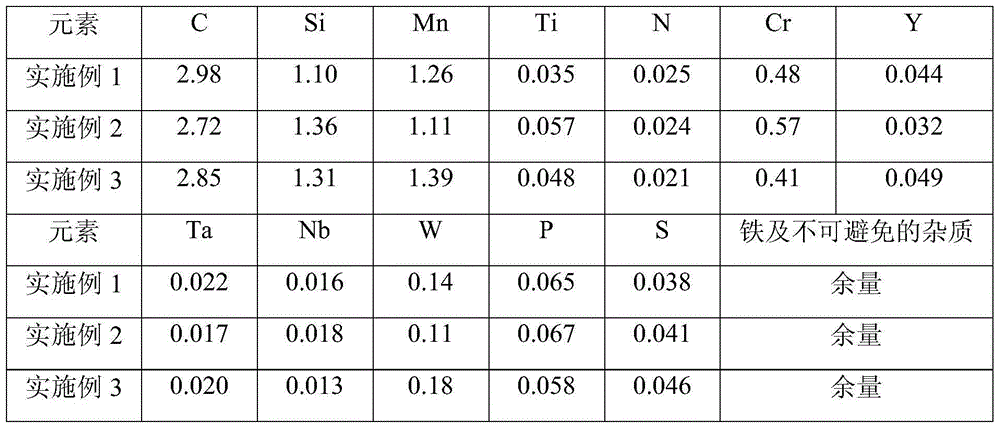

Industrial production method of chromium-free white cast iron with high wear resistance

The invention discloses an industrial production method of a chromium-free white cast iron with high wear resistance. The method comprises the following steps: the content of each component in the cast iron are (mass percent %): 2.8 to 3.1 of C, 0.8 to 1.4 of Si, 0.5 to 0.8 of Mn, 0.9 to 1.1 of Cu, 0.6 to 0.8 of Mo, 0.3 to 0.5 of V, 0.18 to 0.22 of B and the balance of Fe; the amounts of a modifier added in every 100 unit mass of the cast iron are: 0.6 to 1.0 of Re, 0.1 to 0.3 of Al, 0.1 to 0.3 of Nb and 0.1 of N; the raw materials for cast iron are added into a medium frequency induction furnace for melting, (bauxite is employed for producing crucible), the chromium-free cast iron is prepared, the modifier is added at the bottom of a ladle according to a proportion when the cast iron is casted; the obtained chromium-free cast iron is performed by a heat treatment, the chromium-free white cast iron with high wear resistance can be obtained; according to the method, the chromium element which is the cheapest can be removed, the performance of the obtained cast iron material of the invention can be reached to a performance of a high chromium cast iron through a heat treatment. A common stainless steel welding rod is employed for repair welding, so that the material cost is greatly reduced, and chromium-free white cast iron with high wear resistance is convenient for industrialized production.

Owner:CHANGCHUN UNIV OF TECH

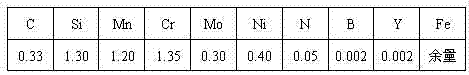

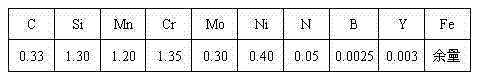

Boric low alloy wear resistant steel for pump

ActiveCN102367558AHigh strengthImprove wear resistanceProcess efficiency improvementTemperingWear resistant

The invention relates to the technical field of metal casting materials, and concretely relates to boric low alloy wear resistant steel for a pump. The steel is characterized in that the steel comprises the following chemical components: 0.33 wt% of C, 1.20 wt% of Mn, 1.30 wt% of Si, 1.35 wt% of Cr, 0.30 wt% of Mo, 0.40 wt% of Ni, 0.05 wt% of N, 0.002-0.0025 wt% of B, 0.002-0.003 wt% of Y, and the balance Fe and avoidless impurities. The boric low alloy wear resistant steel for the pump, which has the characteristics of high strength and hardness, and excellent tissue and performance, is obtained through molding a boric low alloy wear resistant steel casting with resin sand, and carrying out heat treatment consisting of quenching and tempering on the casting. The boric low alloy wear resistant steel of the invention has the advantages of high hardness, good toughness effect, high wear resistance, certain corrosion resistance, simple production technology, low production cost and the like.

Owner:SHANDONG SHUANGLUN

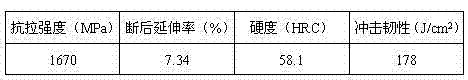

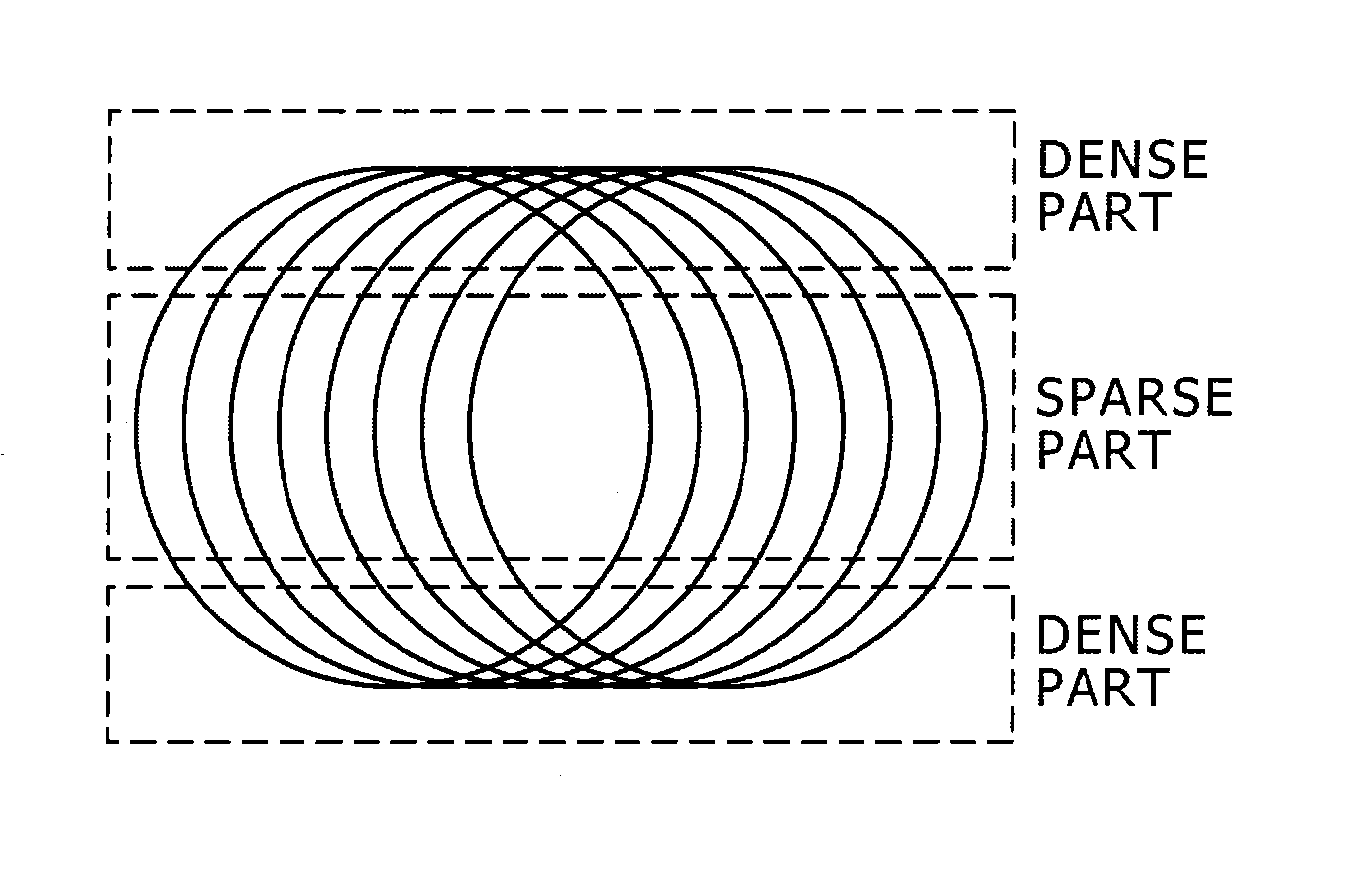

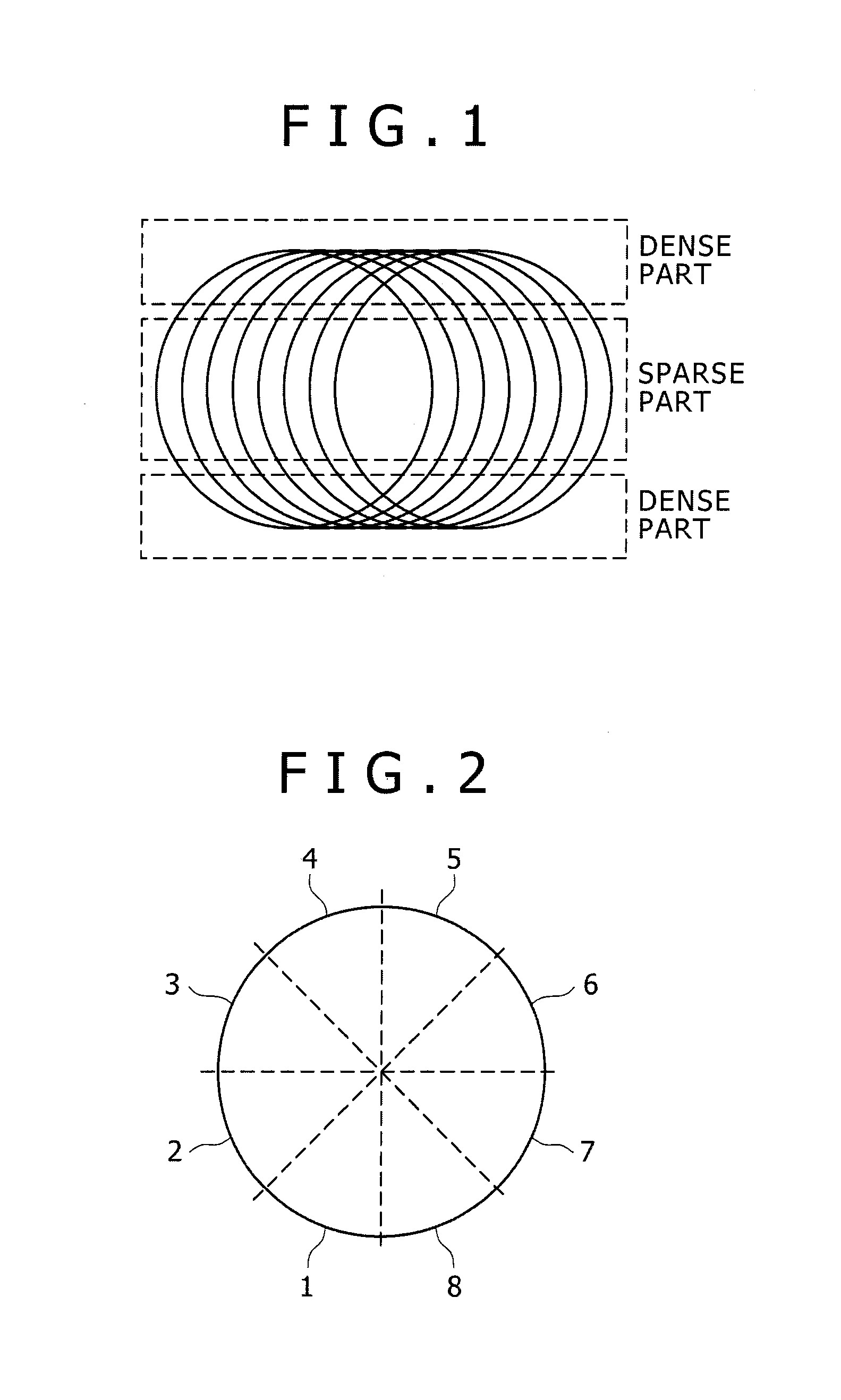

Steel wire rod for high-strength spring excellent in wire drawability, manufacturing method therefor, and high-strength spring

ActiveUS20130127100A1Deformation resistance increaseSatisfactory wire drawability and sv workabilityFurnace typesWire springsPearliteChemical composition

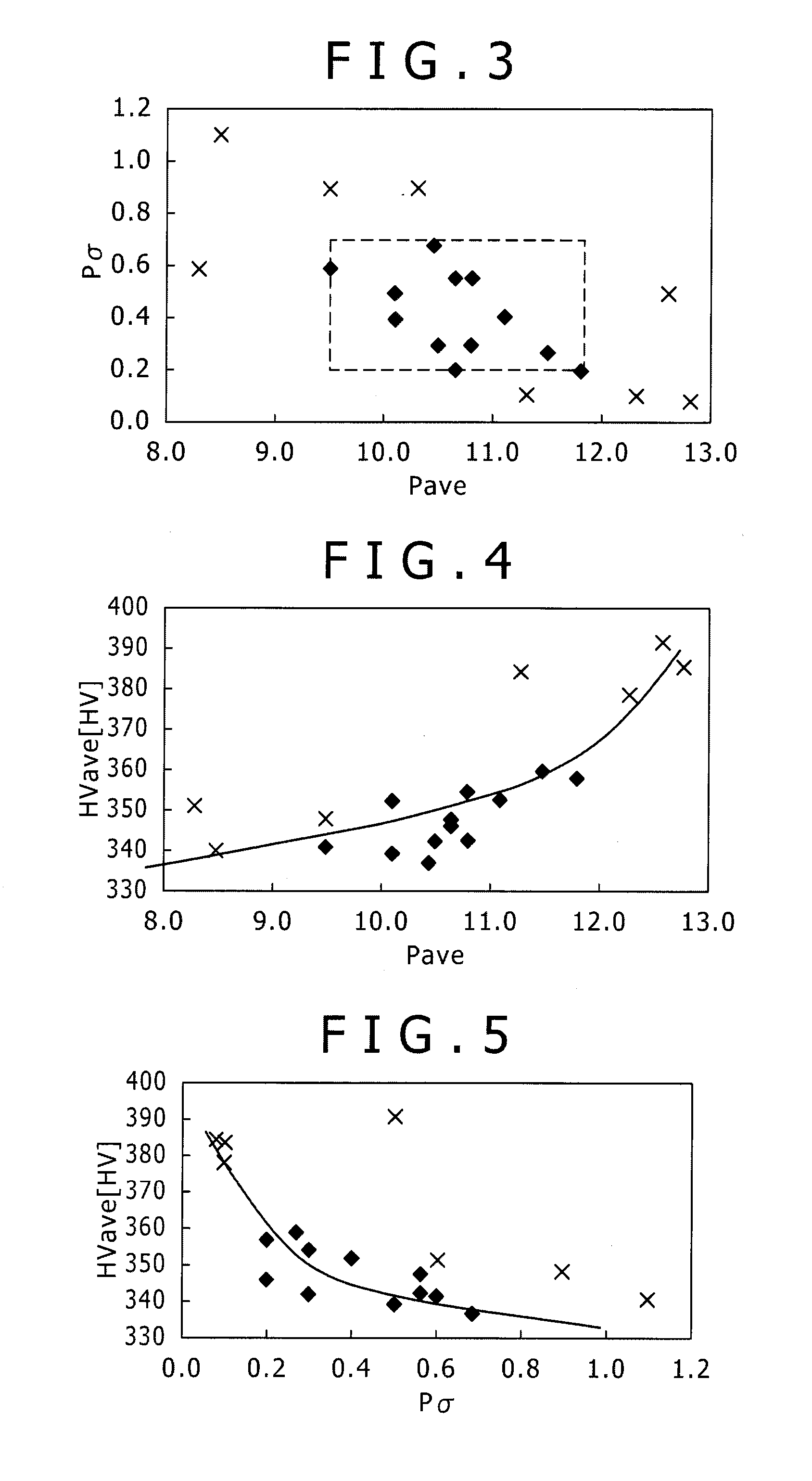

Provided are: a steel wire rod material for a high-strength spring, which does not undergo the increase in deformation resistance arising from the increase in hardness and can exhibit good wire-drawing processability and the like even when a heat treatment, which deteriorates productivity, is eliminated or a simplified and rapid heat treatment is employed instead; a useful method for producing the steel wire rod material for a high-strength spring; a high-strength spring produced using the steel wire rod material for a high-strength spring as a material; and others. This steel wire rod material for a high-strength spring is a steel wire rod material that has been hot-rolled already, and has a texture having a specified chemical composition and mainly composed of pearlite, wherein the average value (Pave) of the pearlite nodule size numbers and the standard deviation (Pσ) of the pearlite nodule size numbers fulfill the following formulae (1) and (2), respectively:9.5≦Pave≦12.0; (1)and0.2≦Pσ≦0.7 (2).

Owner:KOBE STEEL LTD

High-speed steel, extrusion roller containing high-speed steel and production method of extrusion roller

ActiveCN102251187AThere is no problem of poor roundnessSimple heat treatment processFurnace typesGrain treatmentsHigh-speed steelExtrusion

The invention discloses high-speed steel. The high-speed steel comprises the following components in percentage by weight: 1.0 to 2.0 percent of C, 0.3 to 1.0 percent of Si, 0.3 to 1.0 percent of Mn, 2.0 to 5.0 percent of Cr, 0.5 to 1.0 percent of Ni, 2.0 to 4.0 percent of Mo, 1.0 to 3.0 percent of V, 0.5 to 1.5 percent of W, and the balance of Fe. The invention also discloses an extrusion rollercontaining the high-speed steel and a production method of the extrusion roller. The high-speed steel disclosed by the invention has low cost and good abrasion resistance; and according to the extrusion roller containing the high-speed steel and the production method of the extrusion roller, the problems of a surfacing extrusion roller in the prior art are solved.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

Boron-containing multi-element low alloy wear resistant cast steel and preparing method thereof

InactiveCN101550518AHigh strengthImprove wear resistanceProcess efficiency improvementElectric furnaceWear resistantSilicon alloy

The invention discloses boron-containing multi-element low alloy wear resistant cast steel, and the chemical components (according to weight percentage) are as follows: 0.20 percent to 0.45 percent of C; 1.1 percent to 1.8 percent of Mn; 0.8 percent to 1.5 percent of Si; 0.3 percent to 1.2 percent of Cr; 0.05 percent to 0.20 percent of B; 0.08 percent to 0.30 percent of Ti; 0.03 percent to 0.20 percent of N; 0.05 percent to 0.15 percent of Ca; and 0.04 percent to 0.15 percent of K; and the balance is Fe and inevitable trace impurity. The preparing method adopts scrap steel, ferrosilicon, ferrochromium and ferromanganese as raw material, uses waste graphite electrode or pig iron to increase carbon, after the steel is melted and the ingredients of bath adjustment are qualified, the molten steel is heated to 1620 to 1660 DEG C, then calcium silicon alloy, ferroboron, ferrotitanium and nitrogen-containing ferrochrome are added before tapping, the material is moved out of the furnace, then yttrium-based rare earth magnesium alloy and potassium-containing substance are crushed into small pieces with the particle size of less than 15mm; after being dried at the temperature of 130 to 180 DEG C, the small pieces are positioned at the bottom of a pouring ladle, compound modification treatment is executed to the molten steel by adopting a ladle crushing method, the pouring temperature of the molten steel is 1480 to 1520 DEG C, casting parts are austenized under the condition of 830 DEG C to 1050 DEG C multiplied by (0.5 to 4)h and cooled fast, and then furnace cooling or air cooling is executed at the temperature of 150 DEG C to 300 DEG C after heat-preserving for 2 to 6 hours, therefore, the boron-containing multi-element low alloy wear resistant cast steel can be obtained.

Owner:西安国丰机械制造有限责任公司

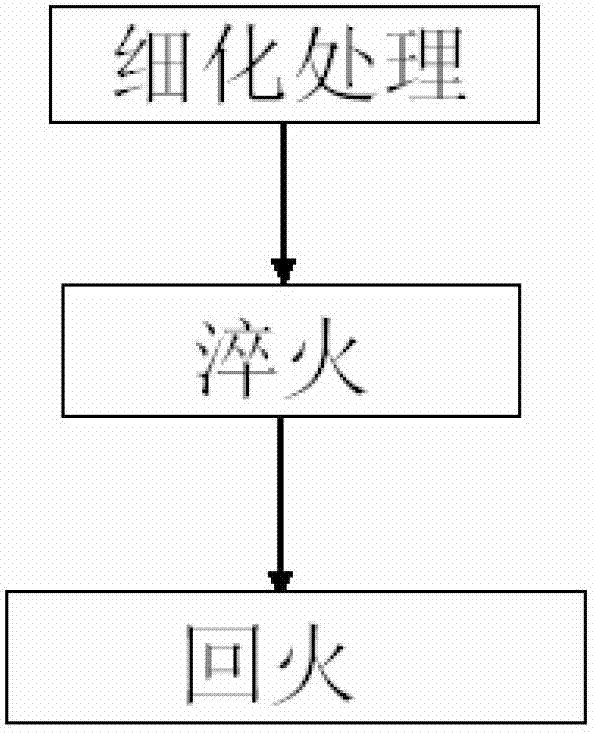

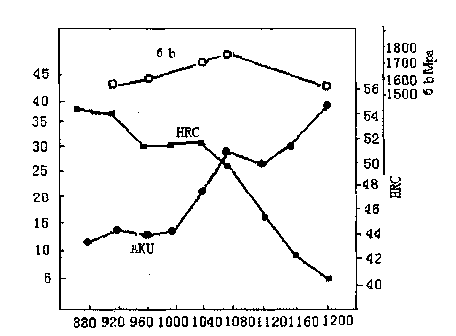

Method for refining 1Cr10Co6MoVNbN stainless steel forging grains

The invention relates to a method for refining 1Cr10Co6MoVNbN stainless steel forging grains. The method comprises: carrying out refinement, quenching and tempering on a forging, and reasonably controlling temperatures and thermal insulation times in various step to obtain the grain-refined stainless steel part. According to the present invention, one time heat treatment process for grain refining is added before the final part heat treatments of quenching and tempering are performed, such that the grains can be uniformly refined; when the temperature reaches the phase change temperature, the phase change occurs, such that the phase change stress is generated inside the system due to the phase change volume effect, the formed single-phase austenite generates slightly deformation, and the austenite is subjected to recrystallization so as to achieve the grain refinement effect, improve the qualification rate, and reduce a large amount of scrap loss.

Owner:AECC AVIATION POWER CO LTD

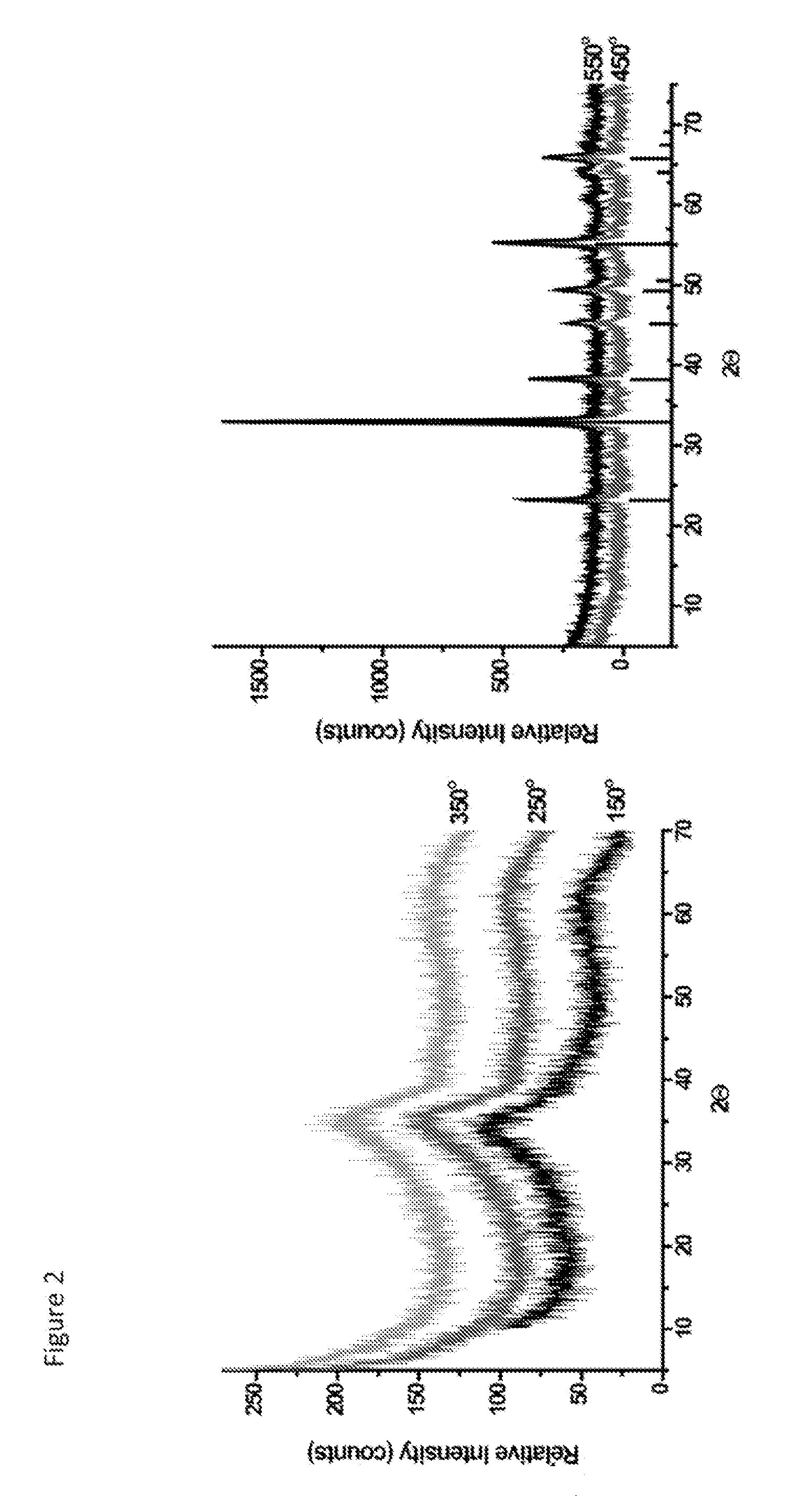

Production process of ultra-crystallite cutting iron core for split mutual inductor

ActiveCN103390492AThe process method is simpleLow costInductances/transformers/magnets manufactureCrystalliteInductor

The invention discloses a production process of an ultra-crystallite cutting iron core for a split mutual inductor. The production process comprises the following steps: a, placing an ultra-crystallite belt material iron core on a winding machine for winding into an iron core, and fixing by spot welding; b, thermally heating the iron core in a gradual temperature rising way, namely, heating to 380 DEG C and preserving heat for 10-50 minutes, heating to 450 DEG C and preserving heat for 10-50 minutes, and heating to 560-600 DEG C and preserving heat for 30-60 minutes; c, rapidly cooling by adopting air cooling till the temperature of the iron core is lowered to 300 DEG C, and controlling the time period from the end of the heat preservation to a moment when the temperature of the iron core falls below 300 DEG C to be within 45 minutes; d, reshaping the iron core, loading into a mold, putting into prepared paint together for soaking in vacuum, and hardening; e, cutting the cured iron core along a symmetrical center line, ensuring the flatness and smoothness of a notch, and eliminating scattering and burrs of the iron core; and f, testing and encapsulating. The process disclosed by the invention has the advantages that the method is simple, a thermal treatment process is improved, a paint soaking step is added, a low-cost and high-performance iron core can be realized, and a very remarkable effect is achieved.

Owner:河北申科电力股份有限公司 +5

Chromic-nickel-free high-strength high ductility structural steel and manufacturing method thereof

InactiveCN101082101AControl and optimize contentControl UniformityTemperature control deviceHeat treatment process controlNickel freeHeating temperature

The high strength and high toughness structural steel without Cr and Ni consists of C 0.24-0.30 wt%, Si 1.10-1.40 wt%, Mn 1.30-1.70 wt%, Mo 0.40-0.60 wt%, V 0.20-0.35 wt%, Al 0.015-0.050 wt%, Cu not more than 0.30 wt%, S not more than 0.012 wt%, P not more than 0.020 wt%, and Fe and inevitable impurities for the rest. Its production process includes the following steps: 1. smelting and casting ingot; 2. rolling in the heating temperature 1100-1180 deg.c, finishing temperature of 850-900 deg.c and cooling rate of 40-80 deg / hr; and 3. annealing at the temperature of 720+ / -10 deg.c for 8-10 hr, cooling to below 450 deg.c in the rate no higher than 30 deg / hr and discharging. The high strength and high toughness structural steel with cheap Si and Mn as main elements has yield strength not lower than 1170 MPa, tensile strength not lower than 1274 MPa, specific elongation not lower than 9 %, reduction of area not lower than 45 %, and impact toughness not lower than 62J.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Method for preparing low alloy high wear resistant cast steel plate

The present invention relates to a method for preparing a low alloy high wear resistant cast steel plate. The cast steel plate includes the following components: 0.25-0.35 wt% of C, 0.9-1.6 wt% of Si, 0.3-1.8 wt % of Mn, 0.7-1.0 wt% of Cr, 0.15-0.3 wt% of Mo, 0.05-0.35 wt% of Ti, 0.01-0.05 wt% of Nb, 0.05-0.25 wt% of V, 0.01-0.1 wt% of RE, no more than 0.03 wt% of P and S, and the balance Fe. The components are melted and molded, and then a processed ingot is placed therein for heating. When the temperature reaches 1050-1070 DEG C, the heat preservation lasts. After the completion of heat preservation, the ingot is placed into a 240-245 DEG C salt bath furnace for heat preservation. The ingot is finally cooled by the air. The casting and heat treatment process of the present invention is relatively simple, easily controlled, and low in cost, and the produced material has good strength and toughness.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

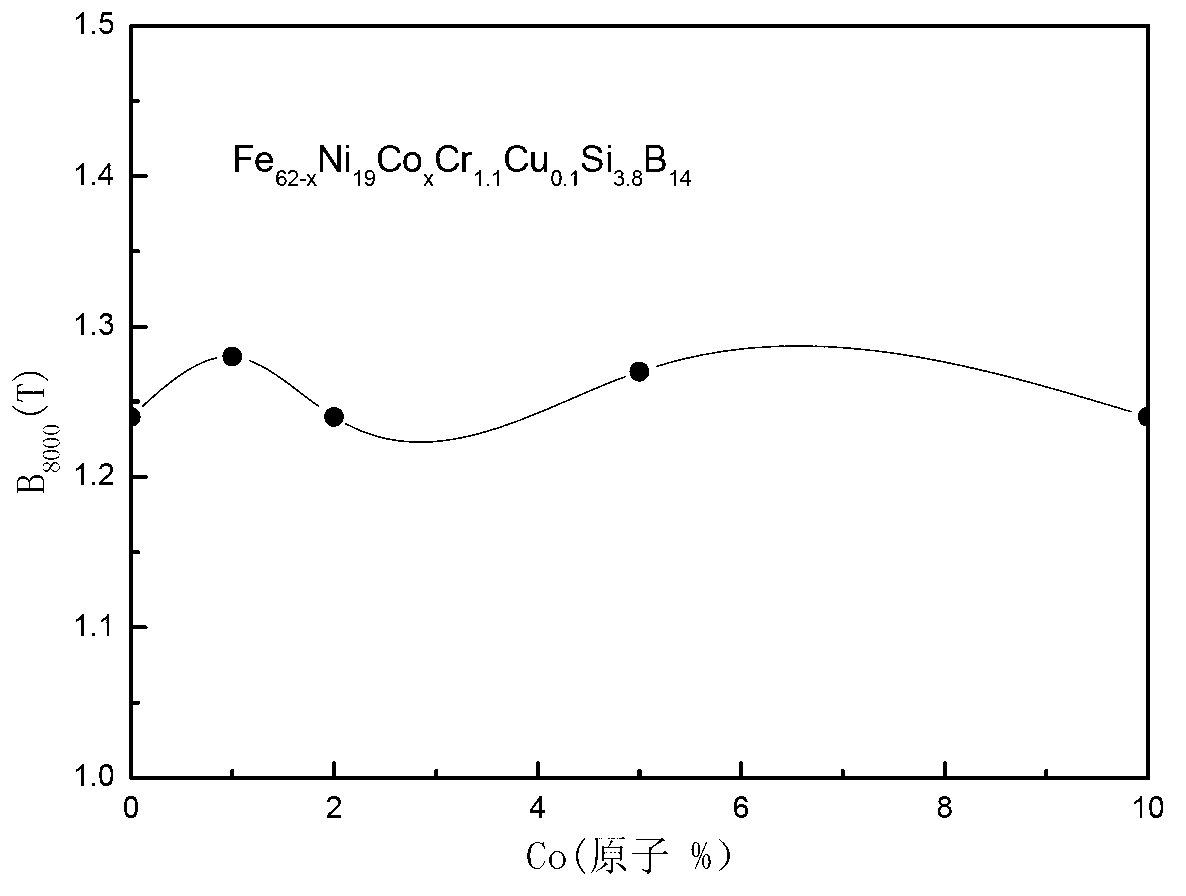

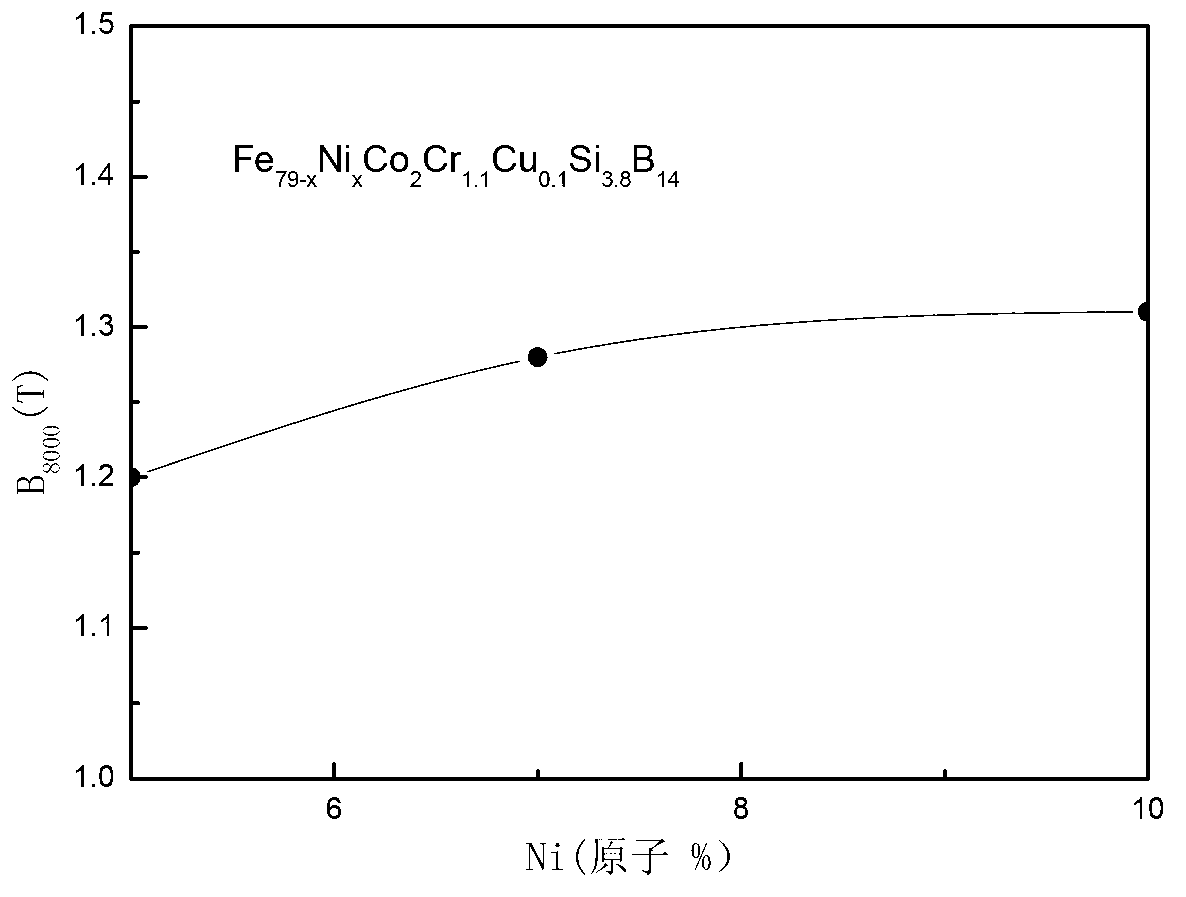

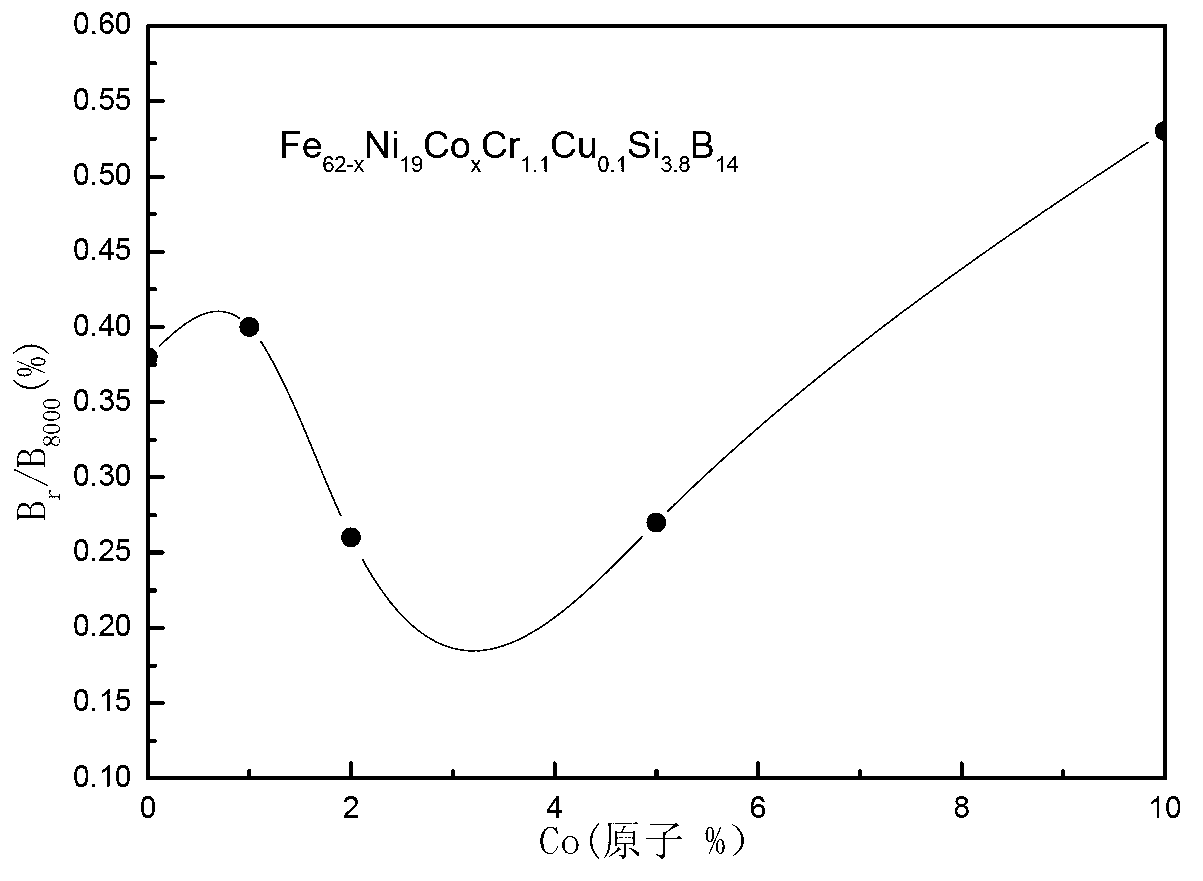

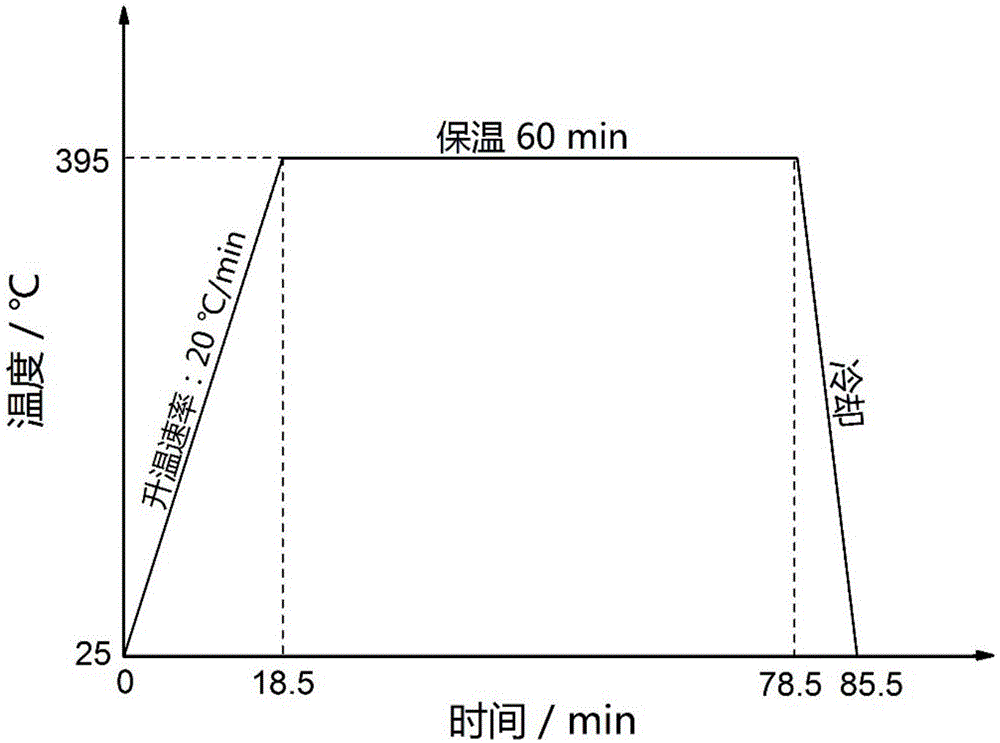

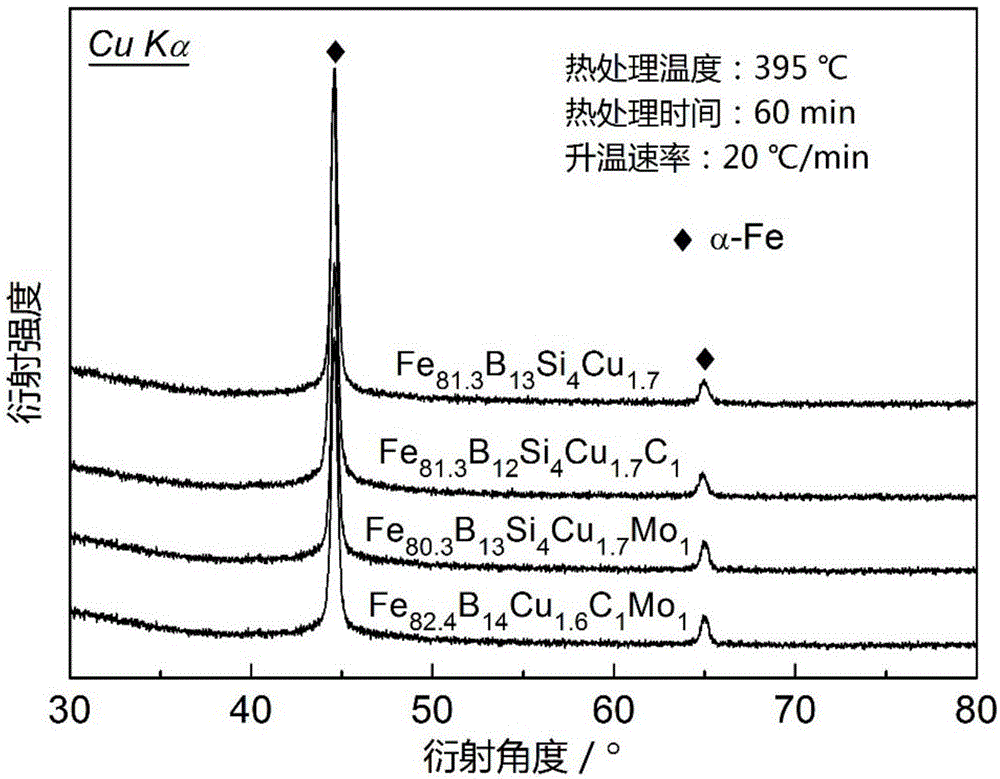

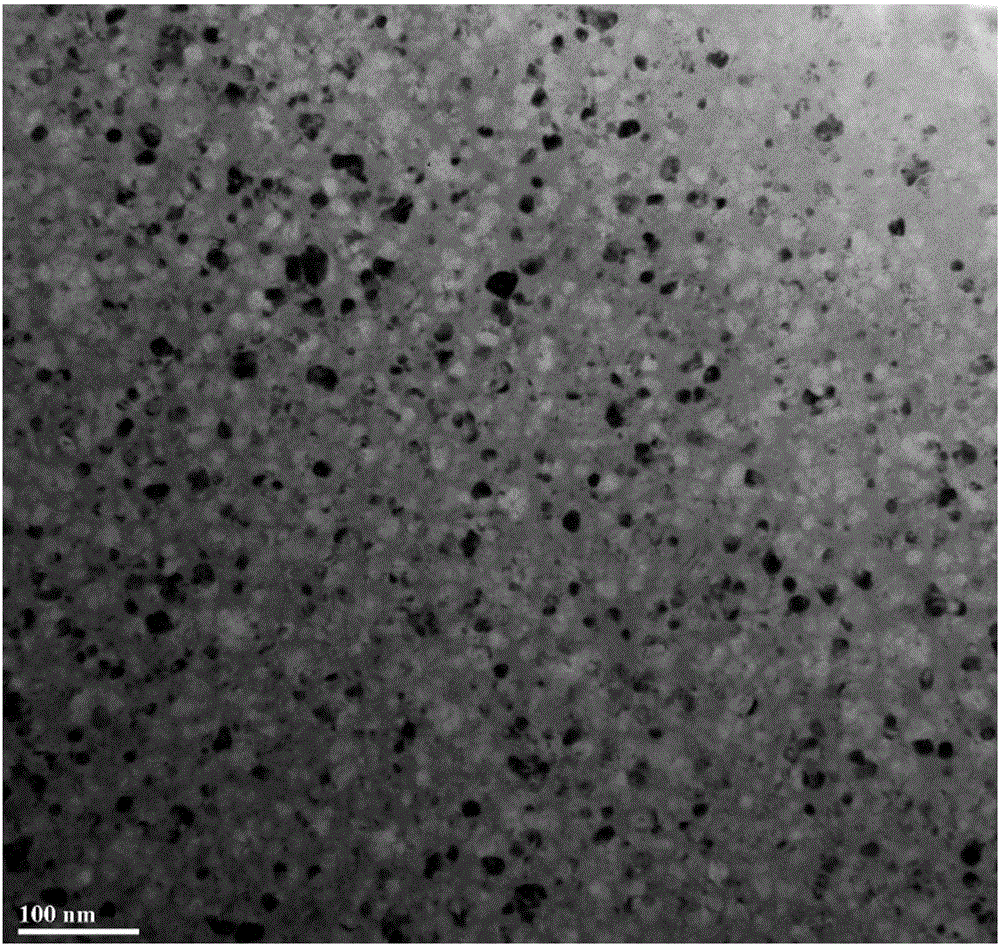

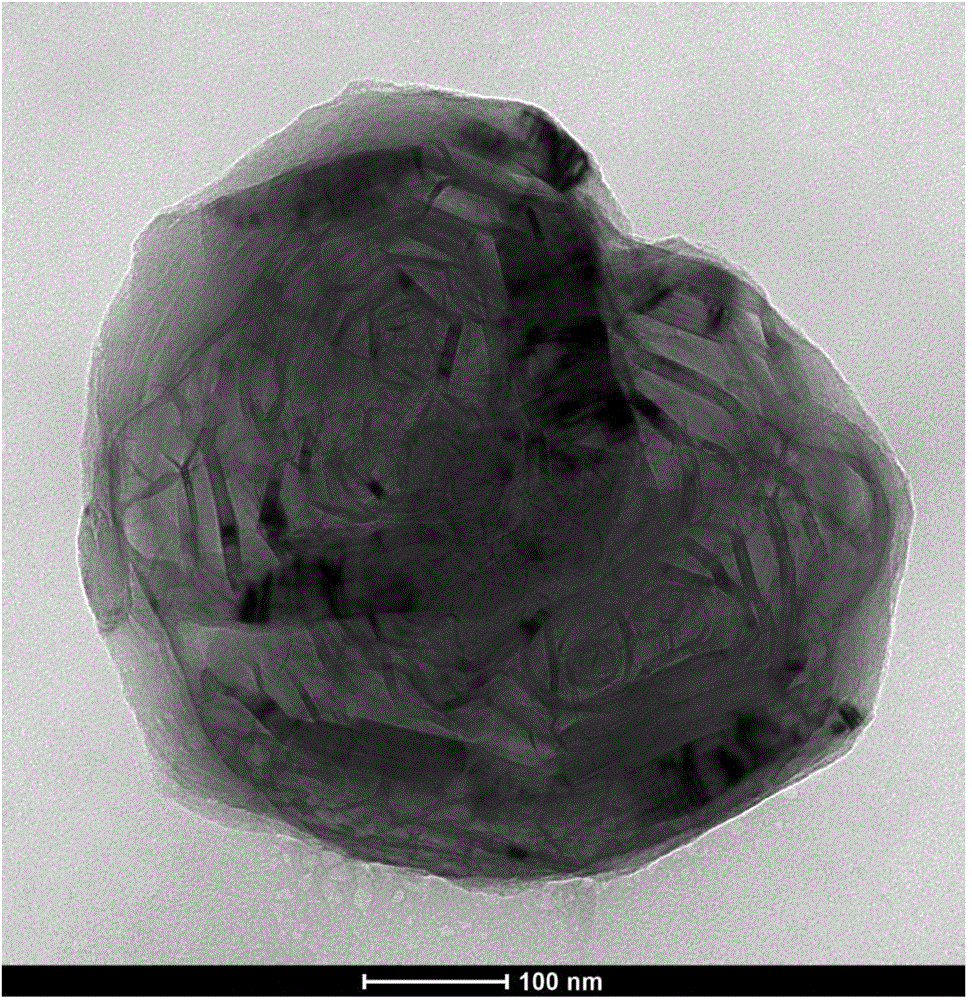

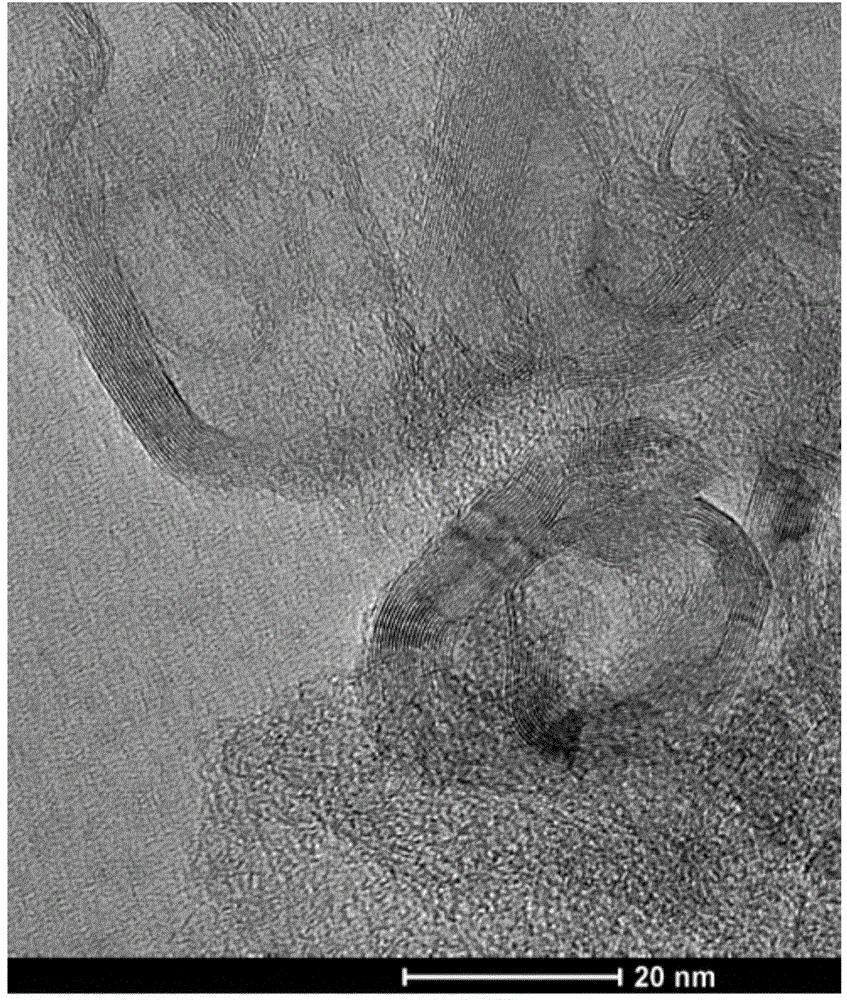

Nanocrystal magnetically soft alloy with high processing property and high saturation magnetic induction strength, and preparation method therefor

InactiveCN106373690AGood workmanshipHigh saturation magnetic inductionMagnetic materialsThermal insulationAlloy

The invention discloses a nanocrystal magnetically soft alloy with high processing property and high saturation magnetic induction strength, and a preparation method therefor, and belongs to the technical field of a new material. The chemical formula of the nanocrystal magnetically soft alloy is FeBSi<c>Cu<d>C<e>M<f>Z<g>, wherein M is at least one kind of elements Co or Ni; Z is at least one kind of elements Al, Cr, Mn, Ti, Nb, Ta or Mo; a, b, c, d, e, f and g are atomic percentage contents of corresponding elements, and satisfy the formula as follows: a+f is greater than or equal to 80 and less than or equal to 84; b is greater than or equal to 10 and less than or equal to 15; c is greater than or equal to 0 and less than or equal to 6; d is greater than or equal to 1.6 and less than or equal to 2.2; e is greater than or equal to 0 and less than or equal to 2; f is greater than or equal to 0 and less than or equal to 5; and g is greater than or equal to 0 and less than or equal to 2. The alloy is formed by uniformly dispersing an <alpha>-Fe phase, which is obtained by heat treatment of amorphous stripes and has the crystal grain sizes of less than 50nm, into residual amorphous phase tissues, wherein the saturation magnetic induction strength is greater than 1.7T, and the coercivity is less than 15A / m. The alloy has no volatile phosphorus element; in addition, the heat treatment process is simple, and high temperature-rise rate is not required; the heat treatment temperature range and the thermal insulation time range are wide; industrial production can be realized easily; and the nanocrystal magnetically soft alloy and the preparation method therefor are convenient to popularize and use.

Owner:DALIAN UNIV OF TECH

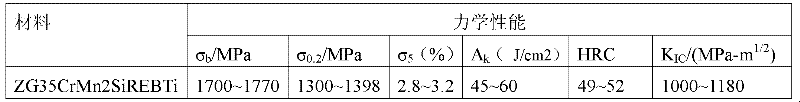

Martensite wear resistant steel and manufacturing method thereof

The invention relates to martensite wear resistant steel and a manufacturing method thereof. The martensite wear resistant steel comprises the following chemical components in percentage by mass: 0.30-0.35 % of C (Carbon), 0.6-1.2 % of Si (Silicon), 1.0-1.5 % of Mn (Manganese), 2.5-3.5 % of Cr (Chromium), 0.003-0.007 % of B (Boron), 0.03-0.06 % of Ti (Titanium), 0.1-0.15 % of Re (Rhenium), 0.01-0.03 % of Al (aluminum), not more than 0.035 % of S (Sulfur), not more than 0.035 % of P (Phosphorus) and the balance of Fe (Ferrum); and through a smelting process and a heat treatment process, the martensite wear resistant steel is obtained. In the manufacturing method of the martensite wear resistant steel, provided by the invention, precious alloy elements like Mo (Molybdenum), Ni (Nickel) and the like are not used; by using the martensite wear resistant steel prepared by the manufacturing method in the invention, the mechanical property can satisfy the national standard; moreover, compared with a high manganese steel, the martensite wear resistant steel has the advantage of obviously improving the corrosion resistance and increasing the operation time or the wear resistance by 1-3 times.

Owner:天津市蓟县东塔耐磨钢球厂

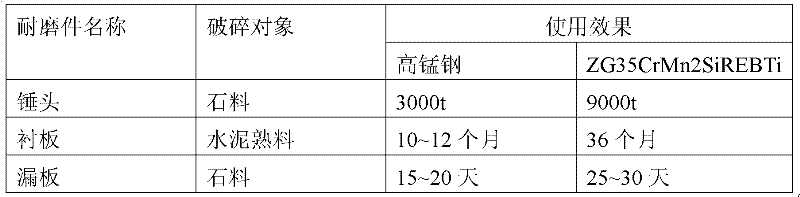

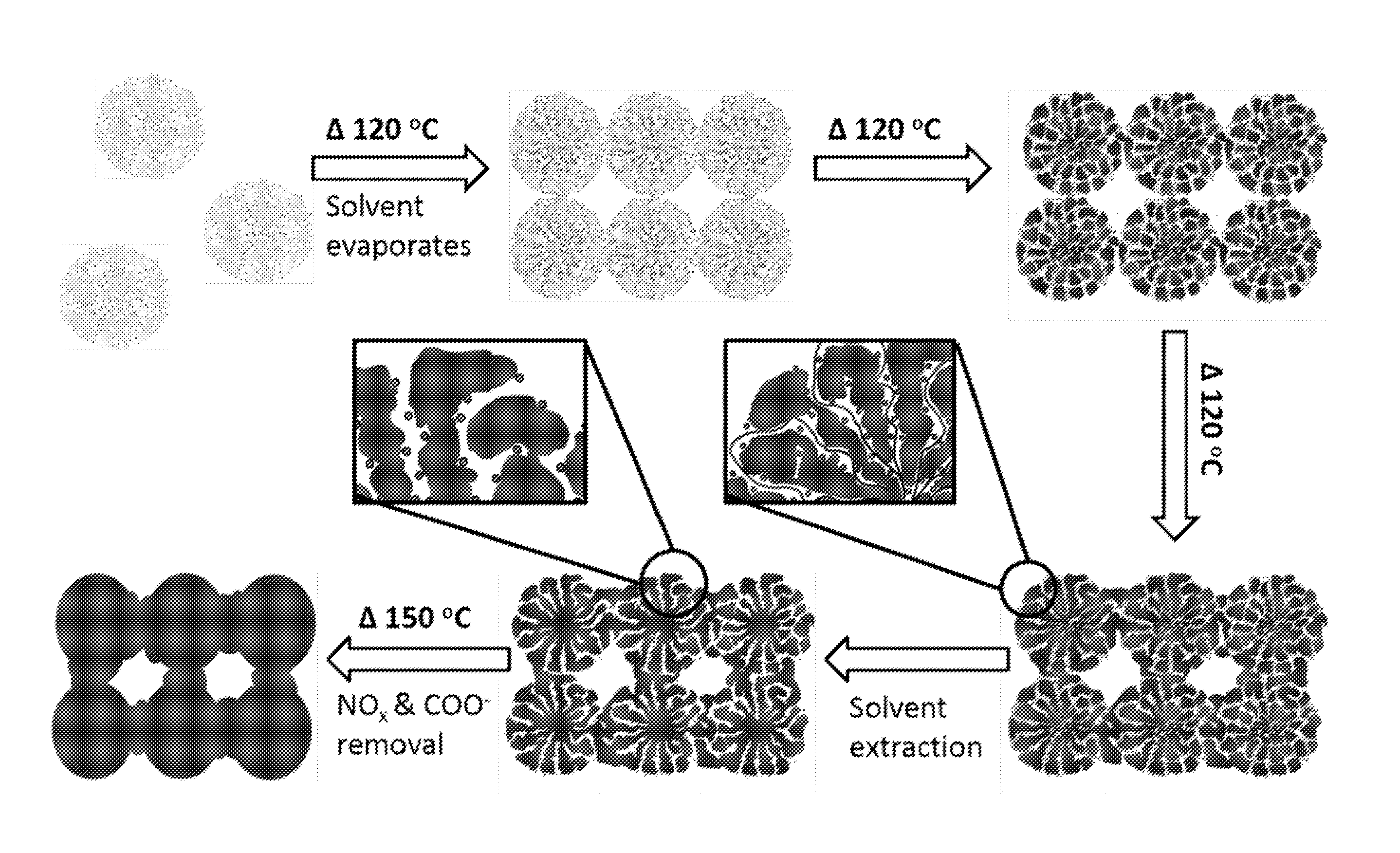

Mesoporous metal oxides and processes for preparation thereof

ActiveUS20140286846A1Simple heat treatment processDifferent porous structureSelenium/tellurium compundsCopper oxides/halidesLanthanideCrystallinity

A process for preparing a mesoporous metal oxide, i.e., transition metal oxide, Lanthanide metal oxide, a post-transition metal oxide and metalloid oxide. The process comprises providing a micellar solution comprising a metal precursor, an interface modifier, a hydrotropic ion precursor, and a surfactant; and heating the micellar solution at a temperature and for a period of time sufficient to form the mesoporous metal oxide. A mesoporous metal oxide prepared by the above process. A method of controlling nano-sized wall crystallinity and mesoporosity in mesoporous metal oxides. The method comprises providing a micellar solution comprising a metal precursor, an interface modifier, a hydrotropic ion precursor, and a surfactant; and heating the micellar solution at a temperature and for a period of time sufficient to control nano-sized wall crystallinity and mesoporosity in the mesoporous metal oxides. Mesoporous metal oxides and a method of tuning structural properties of mesoporous metal oxides.

Owner:UNIV OF CONNECTICUT

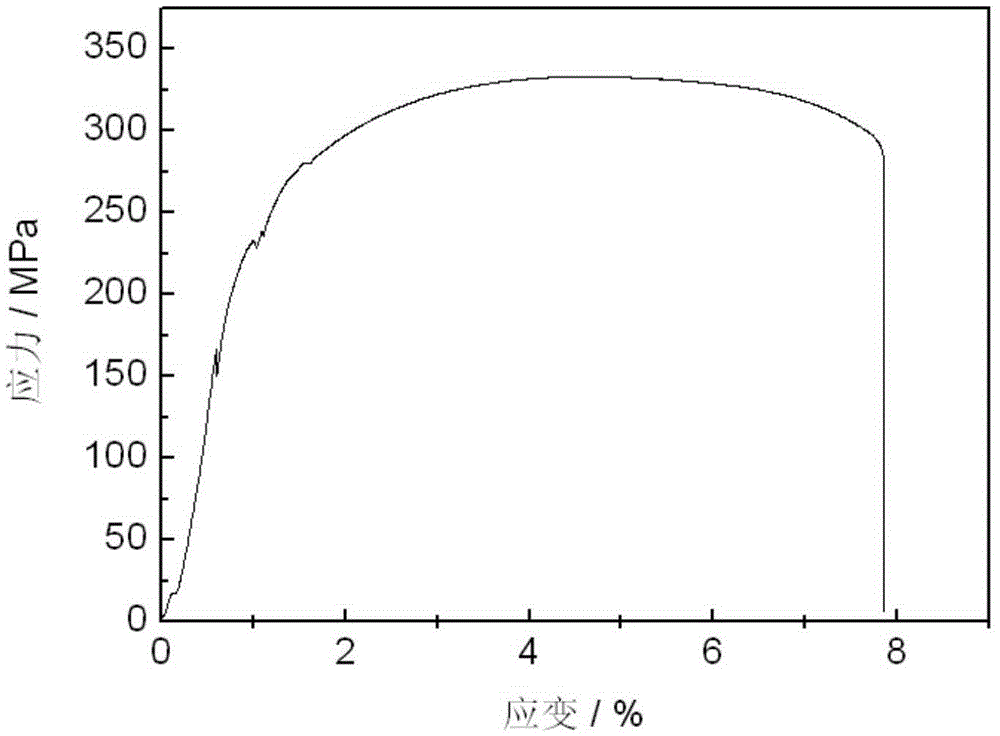

Heated and reinforced high-strength cast magnesium alloy and preparation method thereof

The invention provides a heated and reinforced high-strength cast magnesium alloy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 8.0-10.0 of Zn, 1.0-5.0 of Al, 1.0-5.0 of Sn, 0.1-1.0 of Cu, 0.3-0.8 of Mn, 0.3-0.5 of Ca, and the balance of Mg and inevitable impurity elements. According to the high-strength cast magnesium alloy, under a room-temperature stretch test, the tensile strength reaches 320-350 MPa, and the yield strength reaches 220-260 MPa. A heat treatment process of the magnesium alloy comprises solution treatment by 4-8 hours at a temperature of 330-380 DEG C, air cooling, aging by 8-16 hours at a temperature of 150-220 DEG C and obtaining of the high-strength cast magnesium alloy. The heat treatment process of the alloy is simple and easy to realize; and the aging treatment can form a lot of nanoscale strengthening phases in an alloy structure, so that the alloy strength can be prominently improved. The alloy contains no such noble metal as rare earth, and is an alloy system with low cost and wide applicability.

Owner:山东山科智镁新材料科技有限公司

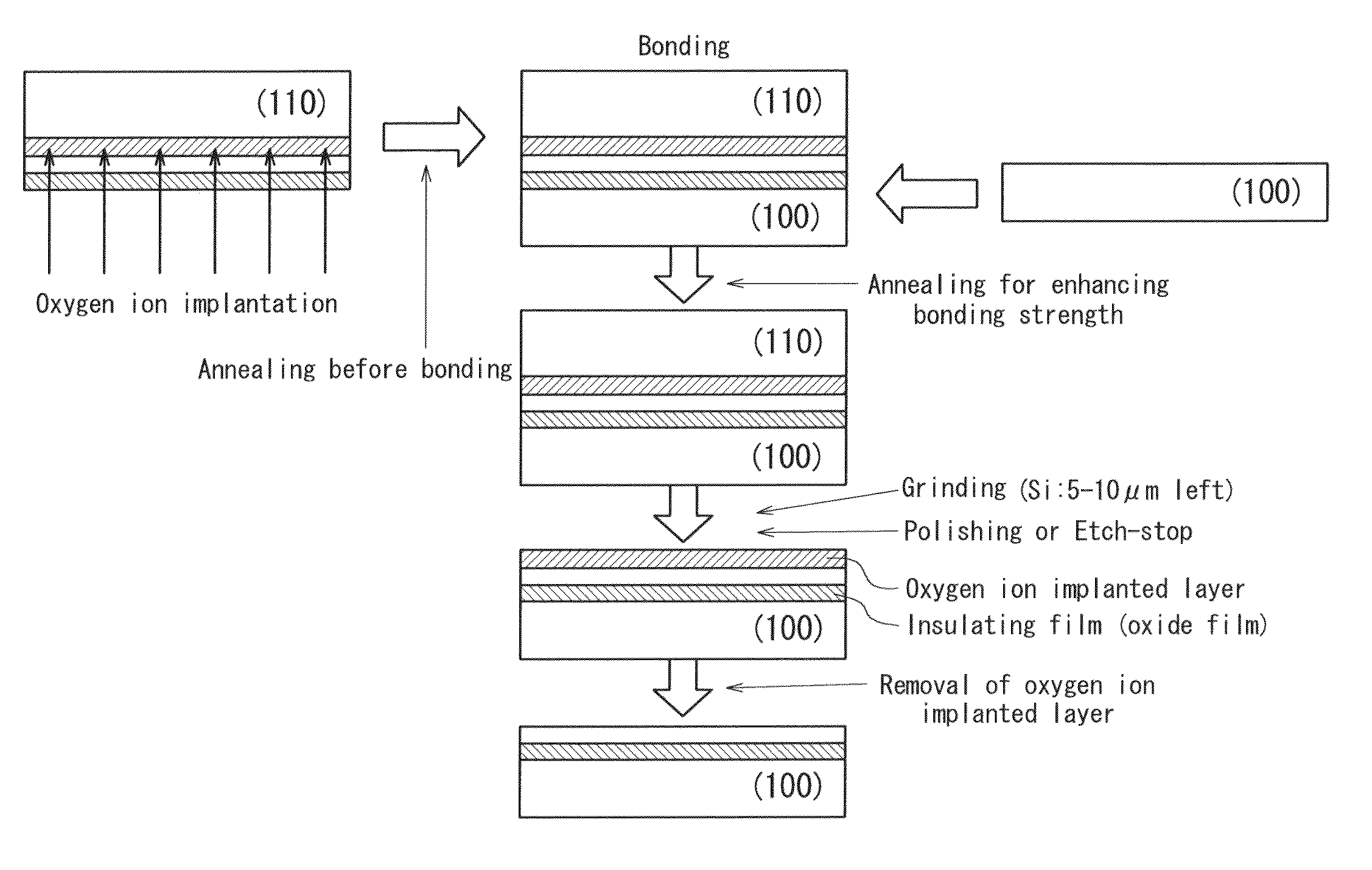

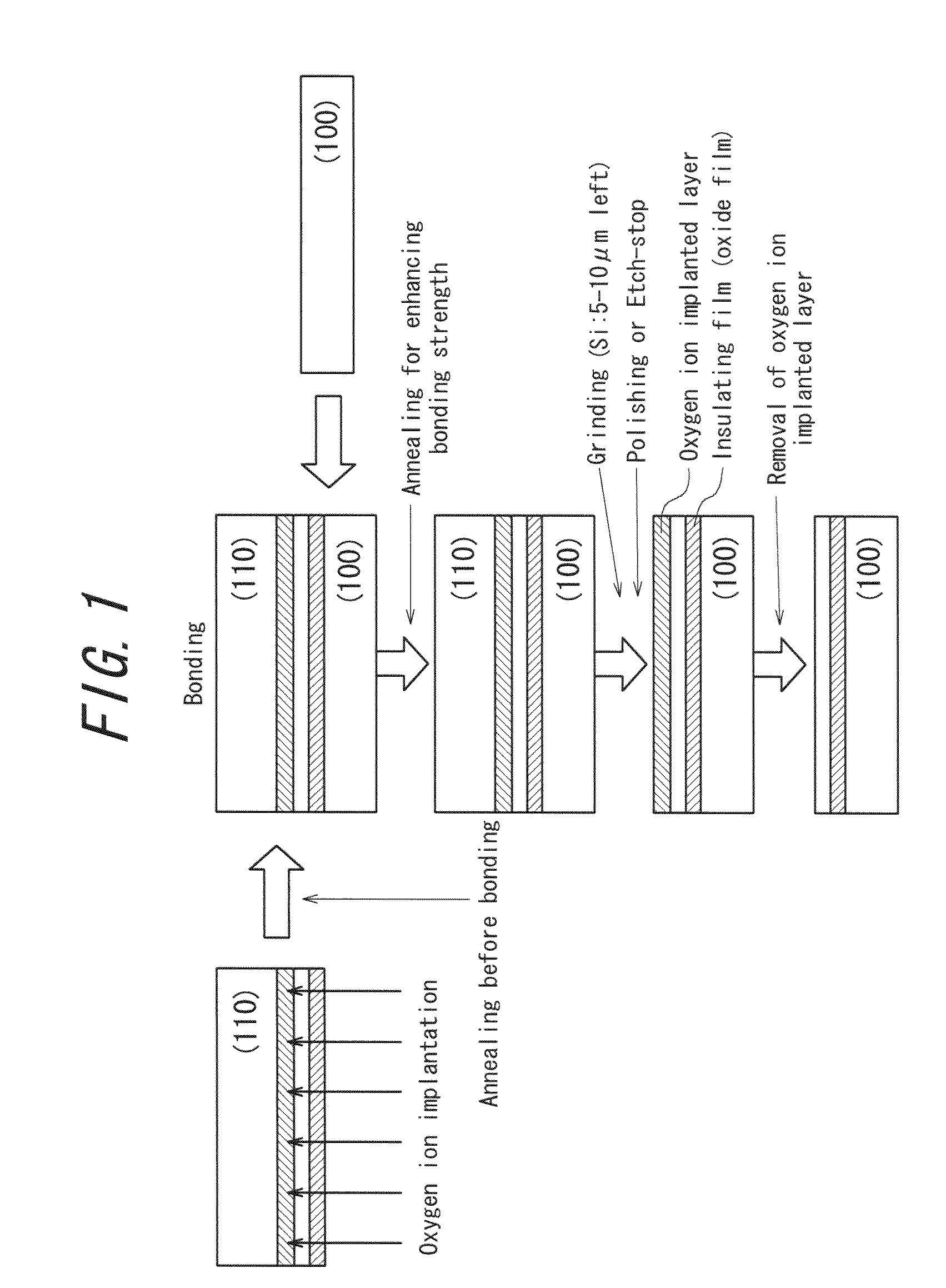

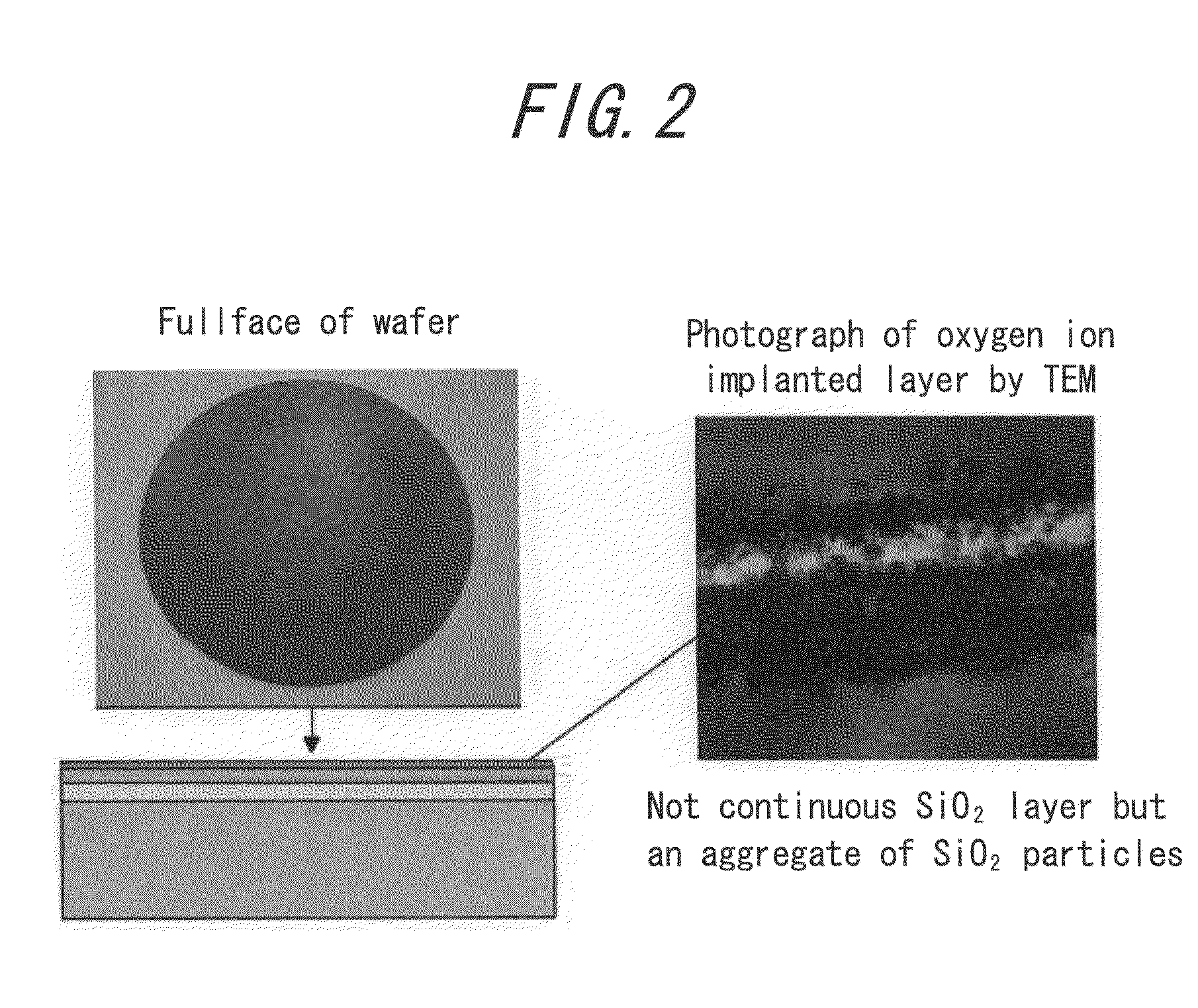

Method for producing bonded wafer

ActiveUS20090258475A1High bonding strengthSimple heat treatment processSemiconductor/solid-state device manufacturingOxygen ionsPhysical chemistry

Even if an oxygen ion implanted layer in a wafer for active layer is not a completely continuous SiO2 layer but a layer mixed partially with Si or SiOx, it is removed by here is provided a method for producing a bonded wafer in which it is possible to remove an oxygen ion implanted layer effectively as it is by repetitive treatment with an oxidizing solution and HF solution at a step of removing the oxygen ion implanted layer in a bonded wafer.

Owner:SUMCO CORP

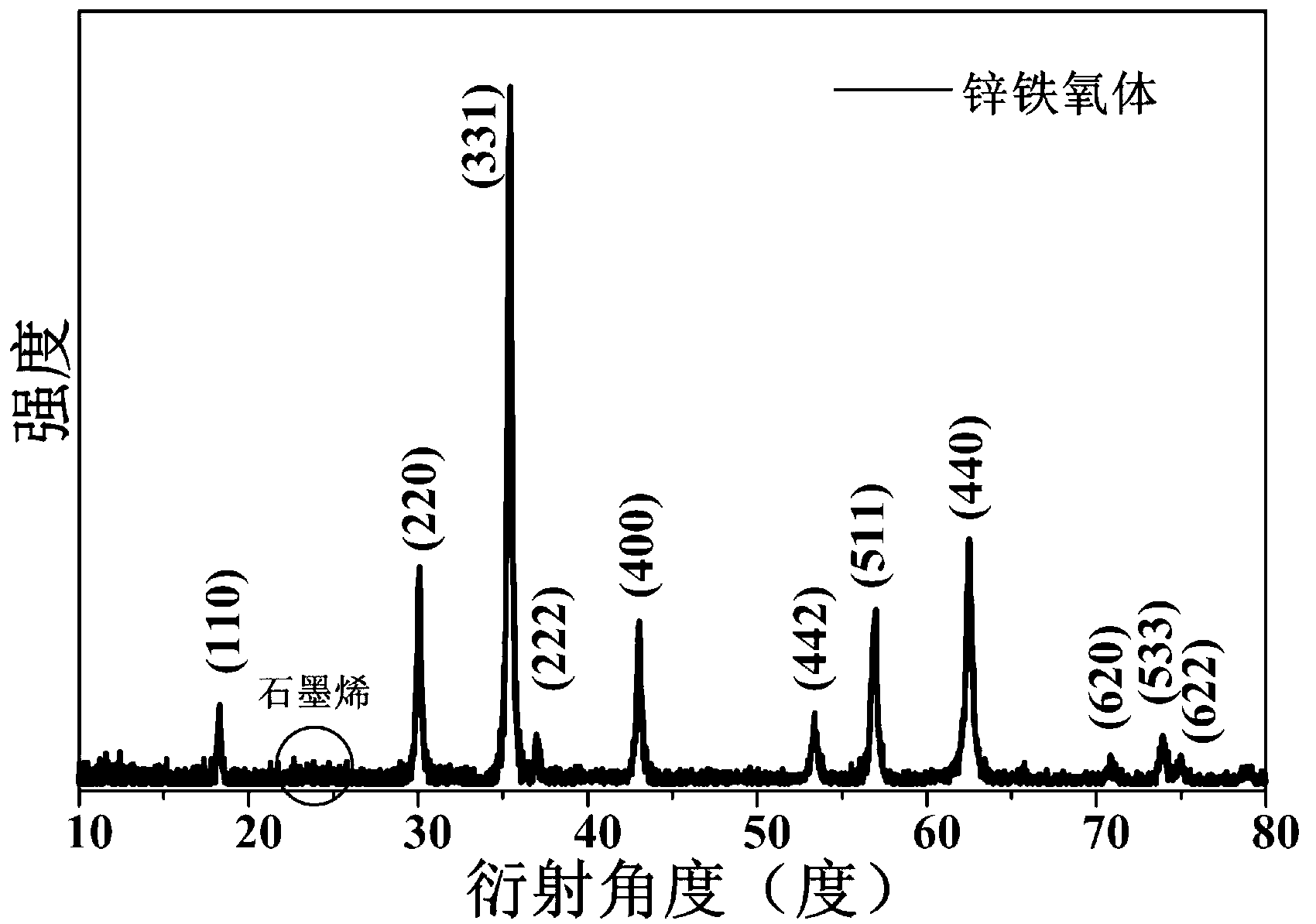

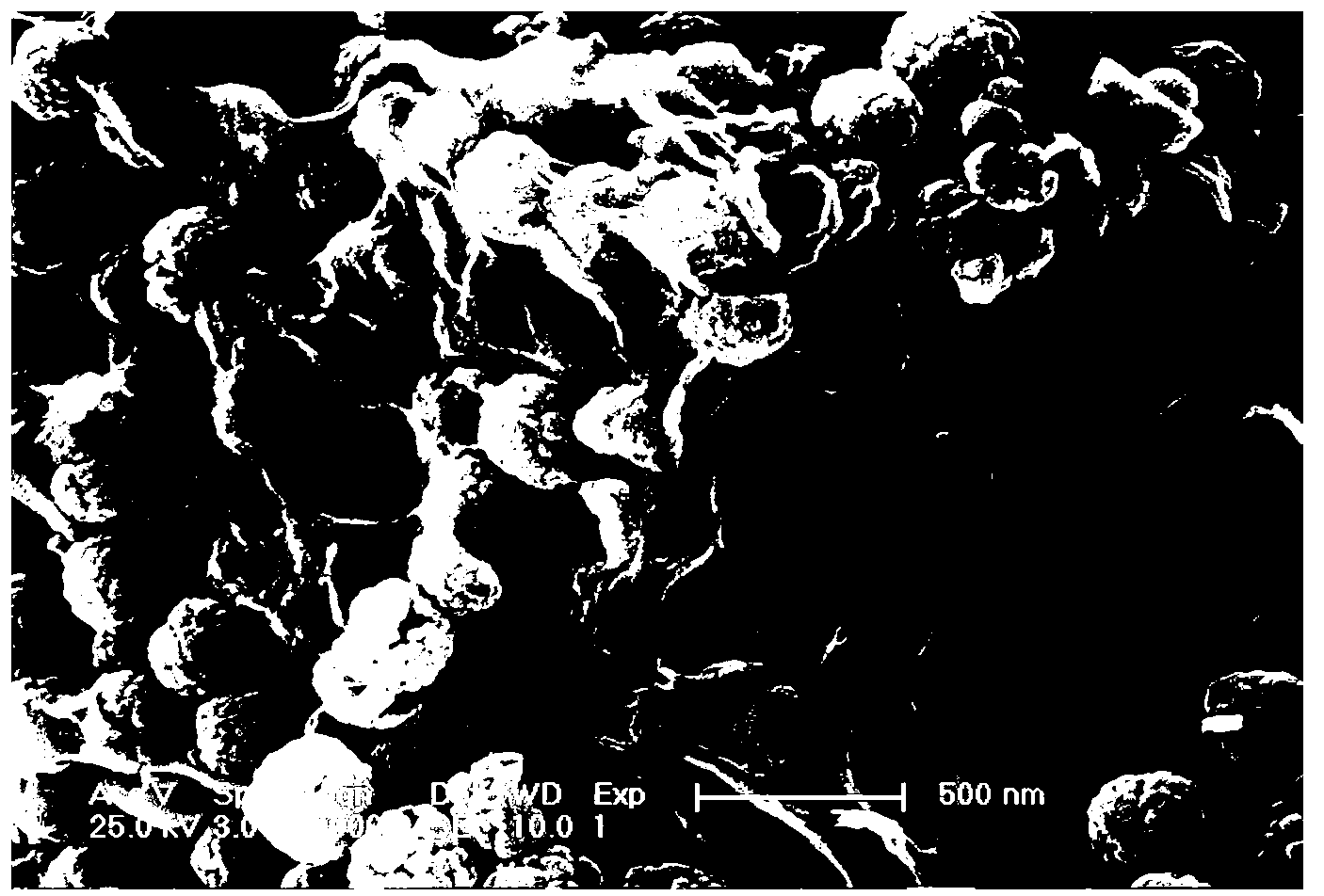

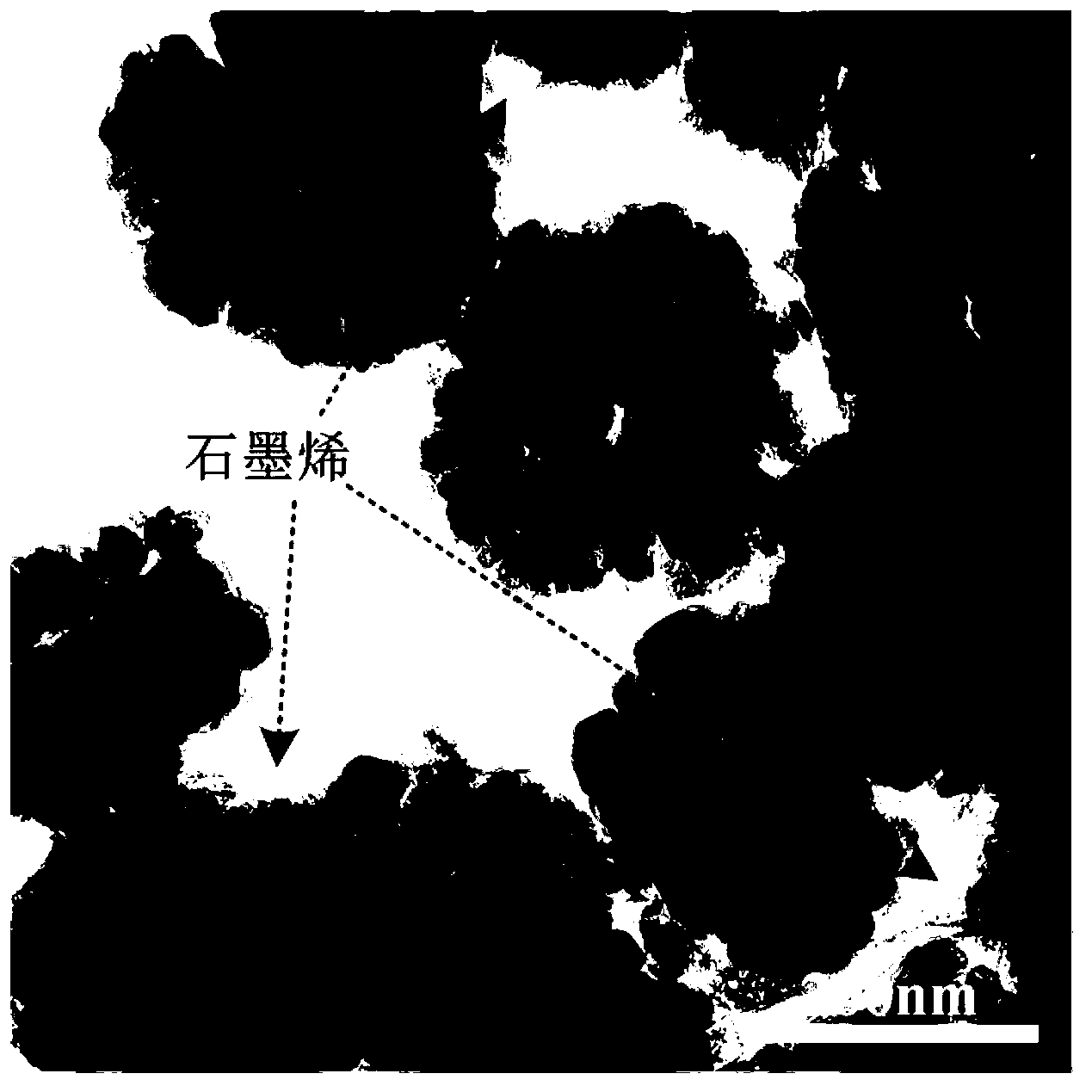

Method for preparing zinc ferrite coated by graphene

The invention discloses a method for preparing a zinc ferrite coated by grapheme. The grapheme coating process is guided by the self-assembly of nano-particles, the zinc ferrite is constituted by the self-assembly of the nano-particles, and the structure of the zinc ferrite is an assembly hollow sphere structure. Ethylene glycol is taken as a solvent, and a graphene oxide nanolayer, ferric chloride, zinc chloride and carbamide are taken as reactants. A dispersed solution is subjected to preheating, so that nano-particles to which graphene oxide is adhered are prepared. The nano-particles are heated for performing solvothermal reaction to enable the nano-particles to be self assembled and enable the graphene oxide to be reduced. After cooling, centrifugal separation, washing and drying, the zinc ferrite coated by grapheme is obtained. The method can be used for preparing a composite coated by the grapheme, wherein the composite coated by the grapheme has the advantages of even coating and controllability of the shape. In addition, the method has the characteristics of simplicity in manufacturing technique, environment friendliness and low cost.

Owner:JILIN UNIV

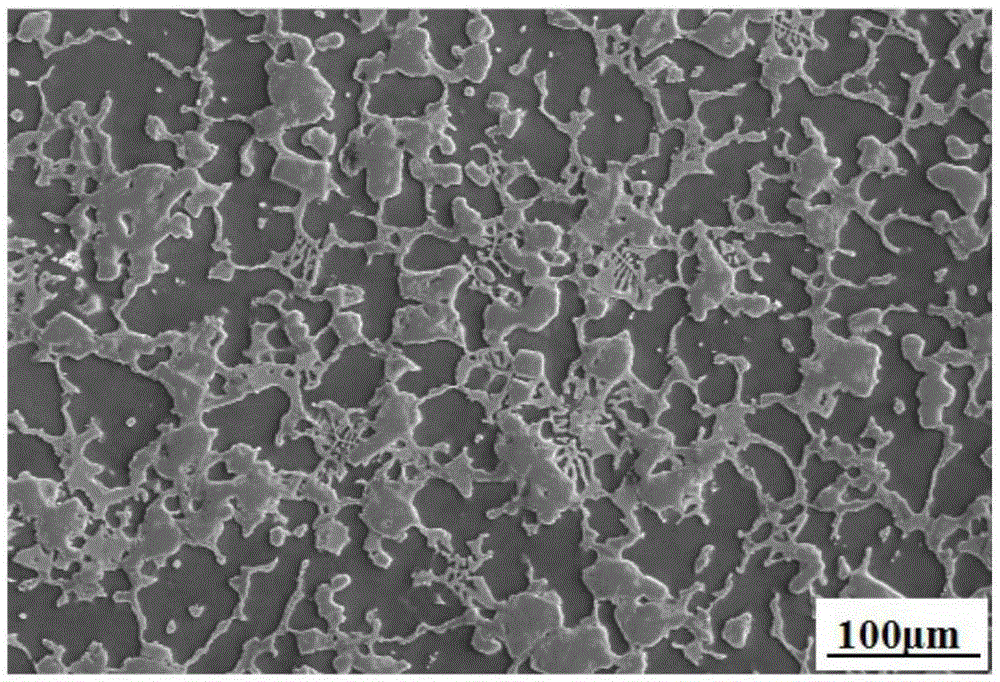

Nano-porous copper-loaded shape-controlled copper-based oxide composite as well as preparation method and application thereof

InactiveCN108597892AAvoid wastingSimple manufacturing processHybrid capacitor electrodesOxide compositeSupercapacitor

The invention relates to a nano-porous copper-loaded shape-controlled copper-based oxide composite as well as a preparation method and application thereof. The composite comprises an amorphous matrixat a core layer, nano-porous copper layers clamped at the two sides of the amorphous matrix and a copper-based oxide layer prepared through in situ oxidation, wherein the amorphous matrix is a TixCuyZrz alloy ingredient, x, y and z are atomic percents, x is more than or equal to 45 and less than or equal to 60, y is more than or equal to 40 and less than or equal to 50, z is more than or equal to1 and less than or equal to 5, and the sum of x, y and z is equal to 100; and the thickness of each nano-porous copper layer is 1.5-4[mu]m, ligament width is 32-55nm, and aperture size is 18-42nm. Theinvention simplifies preparation technology and avoids unnecessary energy waste, and copper-based oxides are generated through in situ oxidation on the surface of nano-porous copper and are firmly combined with a substrate, so that the composite can be taken as electrode slices of a supercapacitor independently.

Owner:HEBEI UNIV OF TECH

Preparation method of micro/nano graphene sheet

ActiveCN104831307ANo emissionsSimple processMaterial nanotechnologyElectrolysis componentsElectrolysisDistillation

The invention provides a preparation method of a micro / nano graphene sheet, which comprises the following steps: by using a graphite plate as a positive pole, an inert metal plate or graphite plate as a negative pole and ultrapure water or a benzene hexacarbonic acid solution as a electrolyte, carrying out electrolysis on graphite to obtain a micro / nano carbon material with the diameter of 10-500nm; and drying by distillation, and carrying out heat treatment at 400-600 DEG C in an argon or nitrogen atmosphere for 30-120 minutes to obtain the micro / nano graphene sheet with the thickness of 5-10nm. The method is simple in technique and convenient for operation, and is green and environment-friendly. The prepared graphene sheet has small diameter size.

Owner:SOUTHEAST UNIV

Ultra-low-carbon cryogenic steel and heat treatment technique thereof

The invention provides ultra-low-carbon cryogenic steel and a heat treatment technique thereof. The ultra-low-carbon cryogenic steel comprises the elements of, by mass, 0.005-0.01% of C, 1.0-4.5% of Ni, 6.0-12.0% of Mn, 1.0-3.0% of Al, 0.5-3.0% of Cu, 0.005% or less of P, 0.003% or less of S, 0.005-0.008% of N, 0.0005-0.002% of O and the balance Fe. According to the ultra-low-carbon cryogenic steel and the heat treatment technique thereof, through the TRIP effect of retained austenite and precipitation hardening of a nano-precipitate phase, the high-strength ultra-low-carbon nickel-saving nano-precipitate reinforced cryogenic steel is prepared and obtained, has good strength, excellent plasticity and good weldability and is low in cost, and the heat treatment technique is simple.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com