Patents

Literature

208 results about "Nickel free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smelting method for medium-thin wall cast-state nickel-free low-temperature ductile cast iron

ActiveCN102690986AImprove densification performanceImprove roundnessIntermediate frequencyStress relief

The invention relates to a smelting method for medium-thin wall cast-state nickel-free low-temperature ductile cast iron. The medium-thin wall cast-state nickel-free low-temperature ductile cast iron comprises the following chemical components in percentage by mass: 3.5-4.1 percent of C, 1.7-2.2 percent of Si, 0.10-0.25 percent of Mn, not more than 0.035 percent of P, not more than 0.020 percent of S, 0.015-0.030 percent of Re, 0.025-0.045 percent of Mg, 0-0.20percent of Cu, less than 0.1 percent of residual element, and Fe in balancing amount. The medium-thin wall cast-state nickel-free low-temperature ductile cast iron is obtained by mixing furnace materials and carrying out high-temperature smelting in an intermediate-frequency furnace, modularization and inoculation treatment and casting and heat-insulating treatment on the mixed furnace materials. Cast iron products obtained by adopting the smelting method disclosed by the invention obtain normal-temperature mechanical property and low-temperature mechanical property under the cast state conditions; complex medium-thin wall parts are required to be subjected to low-temperature stress relief annealing; and simple medium-thin wall parts are free from being annealed, so that the production cost is greatly reduced, the production period is greatly shortened and the production efficiency is increased.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

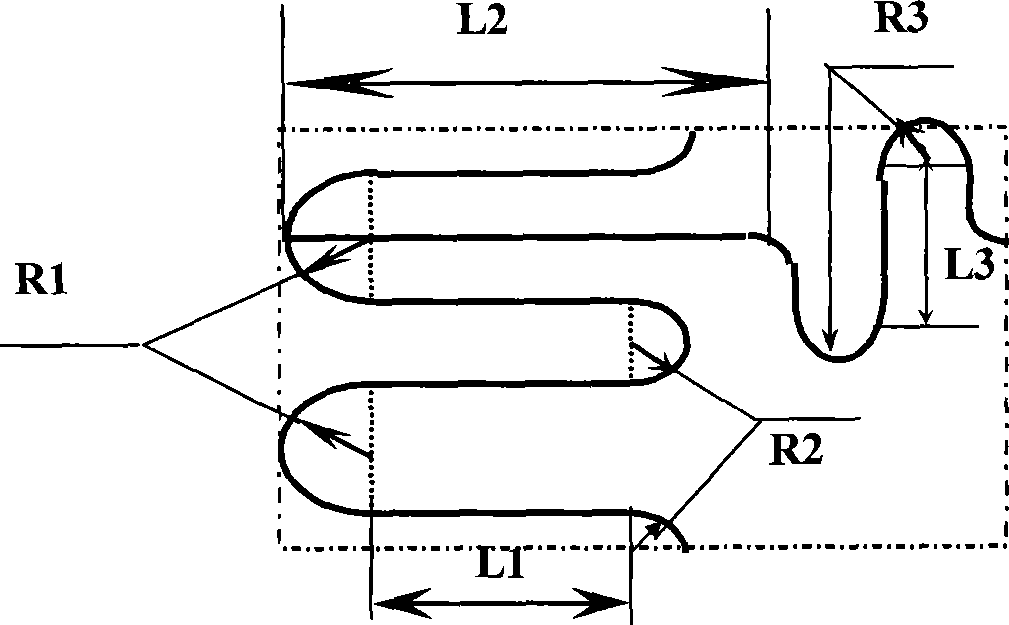

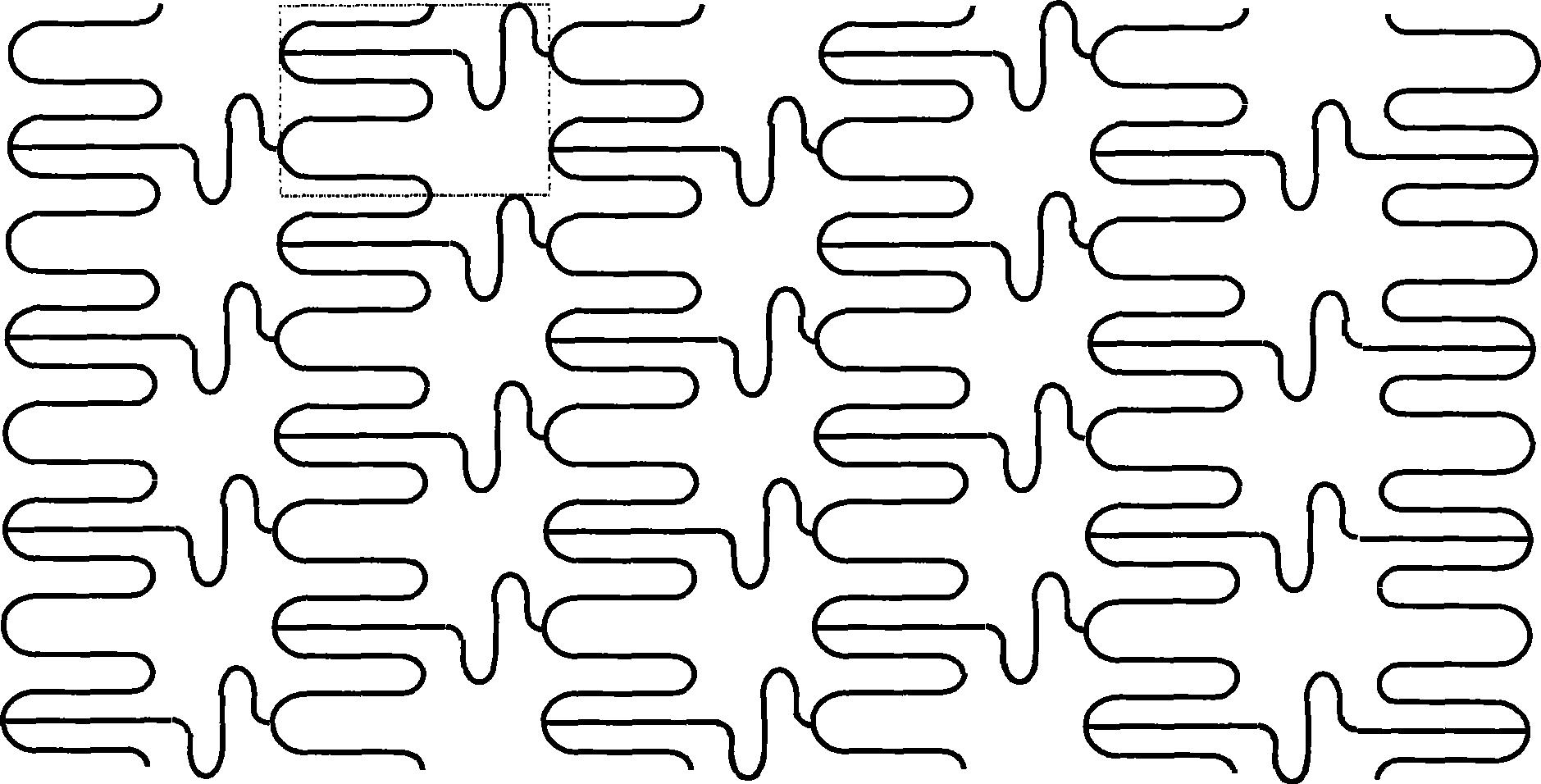

Anti-coagulation stainless steel coronary arterial bracket and uses thereof

ActiveCN101385669AAvoid postoperative restenosisGood biological compatibilityStentsProsthesisMedicineWhole body

The invention relates to a medical apparatus, in particular to an anticoagulant stainless steel coronary support which is made from a high-nitrogen nickel-free austenitic stainless steel material with good blood compatibility. The support is of tubular structure with a mesh surface which is formed by orderly arranging a unit figure on the side surface of a tube along the circumference and axial direction, the primary supporting function is provided by U-shaped corrugated mesh wires extending along the axial direction, the corrugated mesh wires are connected into a whole body by soft mesh wires arranged at intervals, and the diameter of the mesh wire (width or thickness) is 40-100mum; and the surface of the support is passivated and coated with a medication. The anticoagulant stainless steel support has the advantages of good mechanical properties, good flexibility and good anticoagulant property, and can be used as a support for cardiovascular and cerebrovascular systems or a support for other cavity bodies.

Owner:ZHONGKE YIAN MEDICAL TECH BEIJING CO LTD

Method for preparing high nitrogen and nickel-less austenitic stainless steel

The invention provides a method for smelting and manufacturing a high-nitrogen nickel-free austenitic stainless steel under normal pressure. The method comprises the following: a step of rapidly adding high-nitrogen alloy before or when the refined Cr-Mn base steel to be poured is poured; a step of stirring the mixture rapidly; a step of quickly casting the steel liquid which is not or little dissolved in the high-nitrogen alloy to make blank material; a step of dealing with the blank material through thermal deformation process and solution treatment to obtain the single phase austenitic stainless steel with 0.6-1.2 weight percent of nitrogen. The method can be carried out under the normal pressure without being smelted at high pressure. Moreover, the method has the advantages of low cost, high efficiency, simple process and accurate control of N, can produce various profiles and is suitable for the mass production.

Owner:上海莅辰企业管理中心(有限合伙)

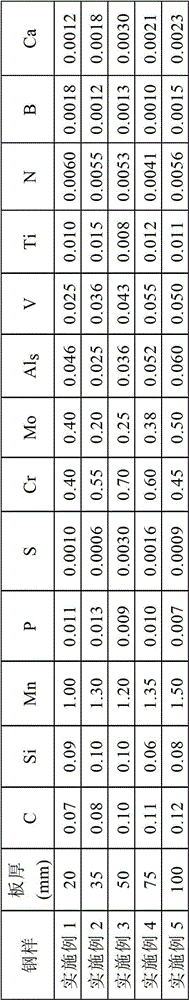

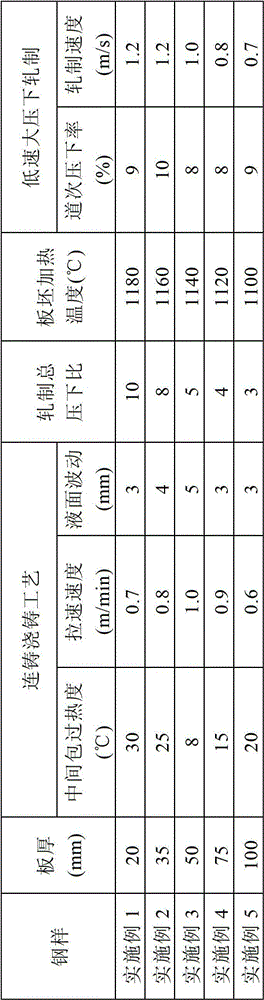

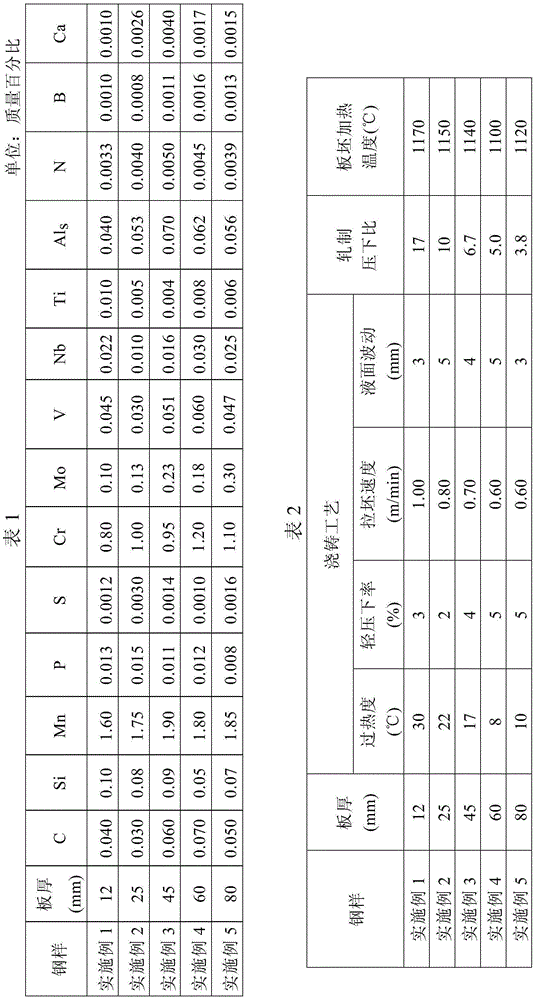

Nickel-free high-toughness 80kg-grade high-strength steel and manufacturing method thereof

ActiveCN102719757ASimple welding processHigh strengthHeat treatment process controlNickel freeToughness

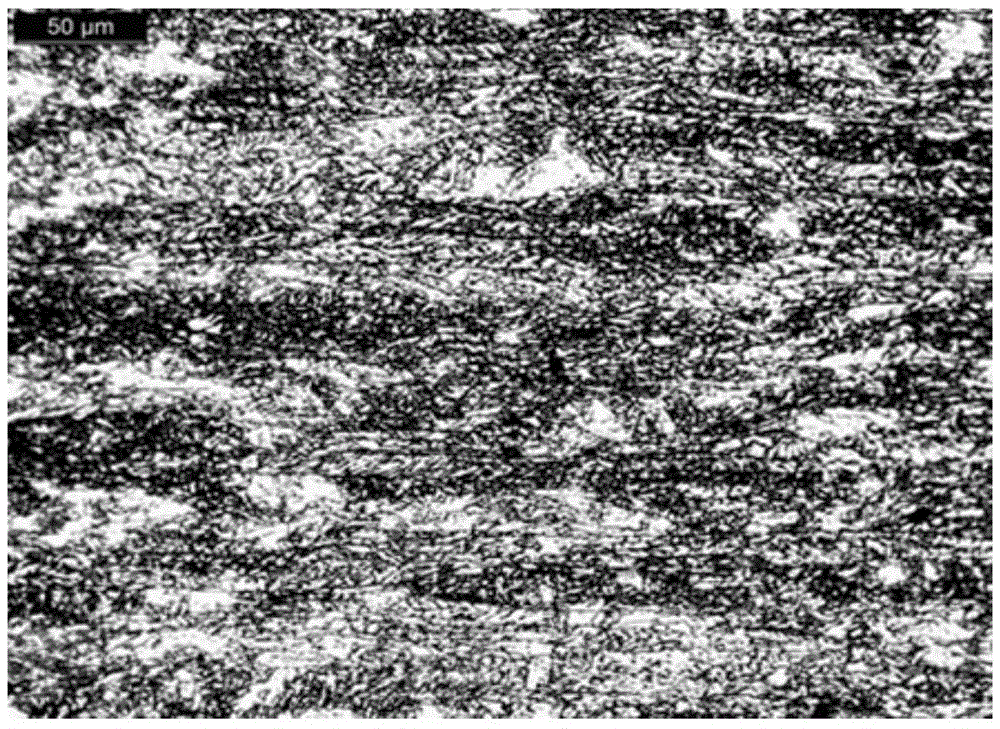

The invention relates to nickel-free high-toughness 80kg-grade high-strength steel and a manufacturing method thereof. A component system of ultralow C, ultralow Si, medium Mn and Ti, V and B microalloy steel is used as a basis; the acid-soluble Als content in steel is properly improved, the Als is not less than 10*[(%Ntotal)-0.292(%Ti)], Mn / C is not less than 12, (%C)*(%Si) is not more than 0.01, and [(%Cr)+1.3(%Mo)]*[(%V)+(%C)] is not less than 0.087; Ca treatment is carried out, the Ca / S ratio is 1.00-3.00, and (%Ca)*(%S)<0.18> is not more than 2.5*10<-3>; F*DI index number * zeta is not less than 2.0* finished steel plate thickness, wherein zeta is on-line DQ (direct quenching) hardenability contribution factor, and F is B element hardenability contribution factor; DQ (thermo mechanical control process: TMCP) and off-line tempering process (T) are optimized; the microscopic structure of the steel plate is fine low-carbon tempered martensite and tempered lower bainite; the steel has the average colony size below 20 mu m, has excellent strength and plasticity and strong toughness, and is particularly suitable for hydroelectric pressure water pipes, steel branch pipes, scrolls, ocean platforms, large-sized engineering machines and other large-sized steel structures and equipment.

Owner:BAOSHAN IRON & STEEL CO LTD

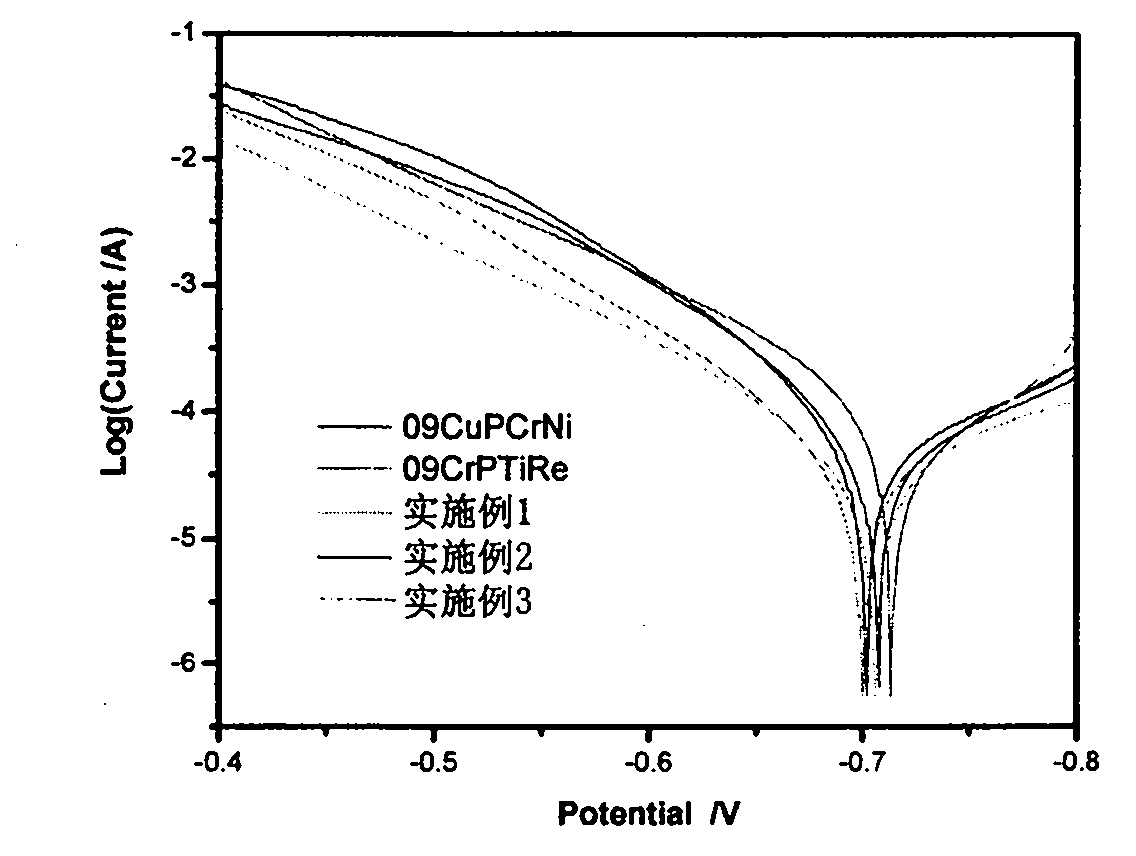

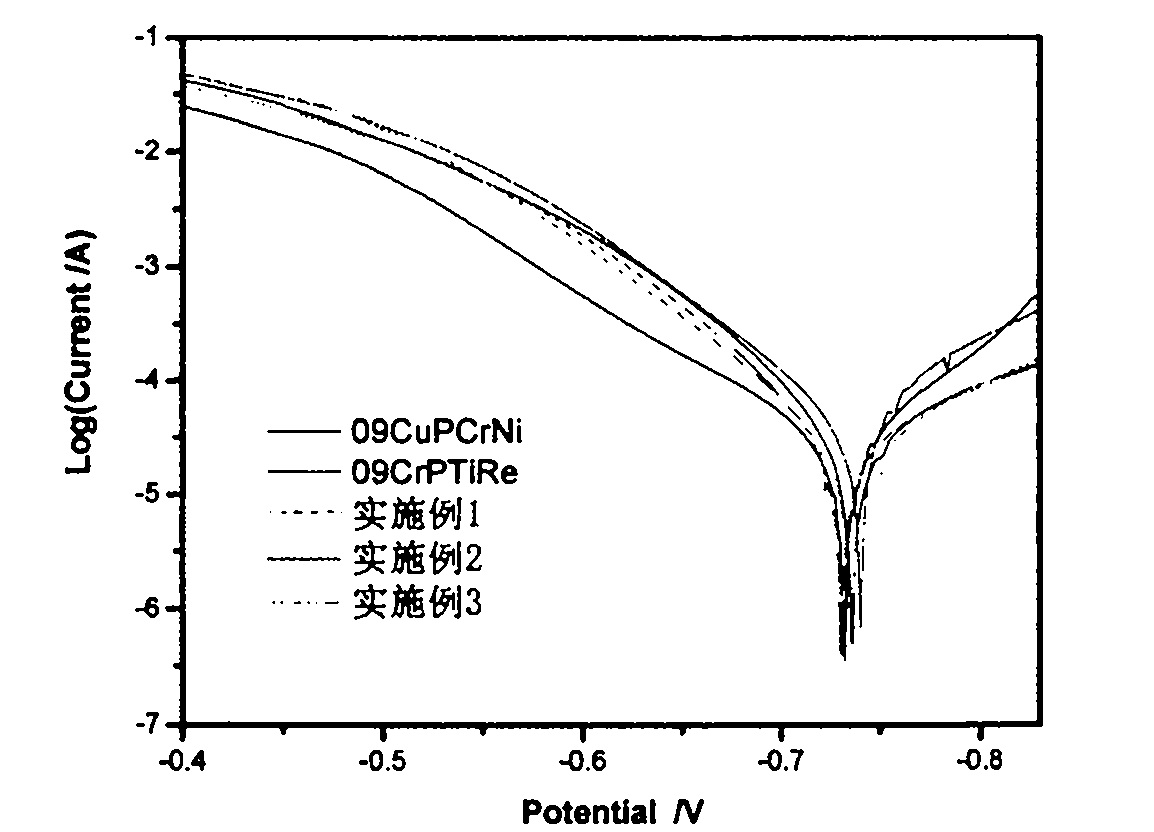

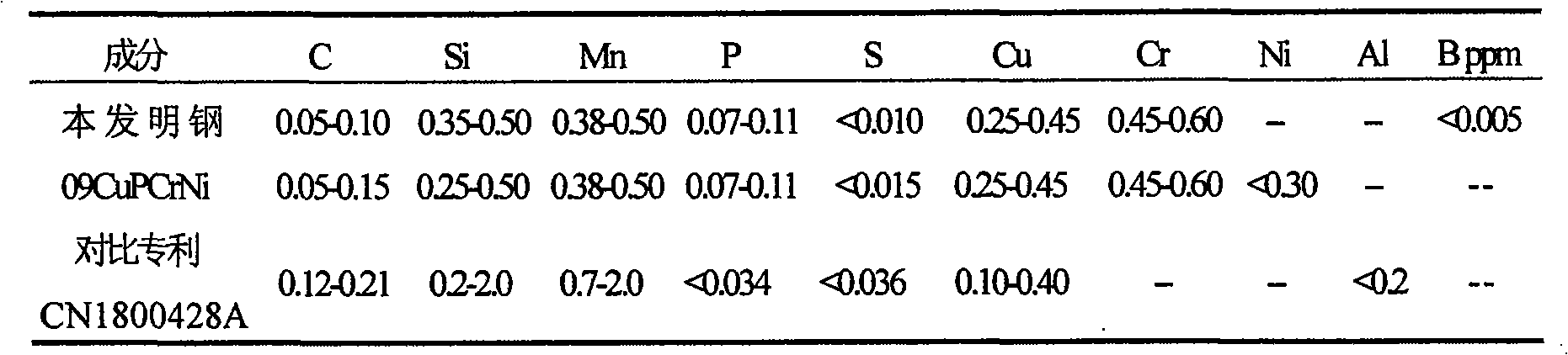

Nickel-free weather-resistant steel and method for preparing hot rolled plate thereof

ActiveCN101864538AAccelerated corrosionQuality improvementWork treatment devicesMetal rolling arrangementsThin slabNickel free

The invention provides nickel-free weather-resistant steel and a method for preparing a hot rolled plate thereof, and mainly solves the technical problems of high cold crack index, not very good welding performance and the like due to high C, Si and Mn content of the conventional nickel-free weather-resistant steel. The technical scheme is that: the weather-resistant steel comprises the following alloying ingredients in percentage by weight: 0.05 to 0.10 percent of C, 0.35 to 0.50 percent of Si, 0.38 and 0.50 percent of Mn, 0.07 to 0.11 percent of P, less than 0.010 percent of S, 0.45 to 0.60 percent of Cr, 0.25 to 0.45 percent of Cu, 0 to 50ppm of B, and the balance of Fe. The nickel-free weather-resistant steel of the invention is mainly used for replacing high-grade 09CuPCrNi weather-resistant steel.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD +1

Method for preparing nitrogen-contained ODS (oxide dispersion strengthened) nickel-free austenite alloy by mechanical alloying process

The invention discloses a method for preparing nitrogen-contained ODS (oxide dispersion strengthened) nickel-free austenite alloy by a mechanical alloying process, which comprises the following steps of: mixing pure metal element powder of Fe, Cr, Mn, W, Ti and Al and nanometer Y2O3 powder in the following mass ratio: 17-20% of Cr, 18-22% of Mn, 1.5-2.5% of W, 2-4% of Al, 0.5-1.0% of Ti, 0.3-0.6% of Y2O3 and the balance of Fe; loading into a ball-milling tank of a horizontal planetary high-energy ball mill; after the is vacuumized, filling the ball-milling tank with high-purity nitrogen; controlling the pressure at 0.1-1atm; carrying out ball milling for 30-90 hours, wherein the ball mill is shut down for 1 hour in every five hours of ball milling; obtaining the ODS nickel-free austenite alloy powder of which the nitrogen content is 0.1-0.8%; and sintering to obtain the ODS nickel-free austenite alloy. According to the nickel-free austenite alloy, the solid solution strengthening of nitrogen and oxide dispersion strengthening can be simultaneously realized, and the service capability of the nickel-free austenite stainless steel under the high-temperature environment can be improved to a great extent.

Owner:UNIV OF SCI & TECH BEIJING

Medical high-nitrogen nickel-free austenitic stainless steel material and production method thereof

ActiveCN102888566AImprove long-term use safetyImprove wear and corrosion resistanceProsthesisNickel freeWear resistance

The invention relates to a medical high-nitrogen nickel-free austenitic stainless steel material and a production method thereof. The material is a single-phase austenite structure and comprises the following components by weight percent: 15-18% of Cr, 10-16% of Mn, 1.5-2.5% of Mo, 0.4-0.7% of N, 0.02-0.08% of RE, less than or equal to 0.06% of unavoidable impurities and the balance of Fe. The material is free of toxic nickel, has good cytotoxicity and pyrogenic testing performances, excellent mechanical performance, higher abrasion resistance and good corrosion resistance, especially spot corrosion resistance and intergranular corrosion resistance.

Owner:CHONGQING MATERIALS RES INST

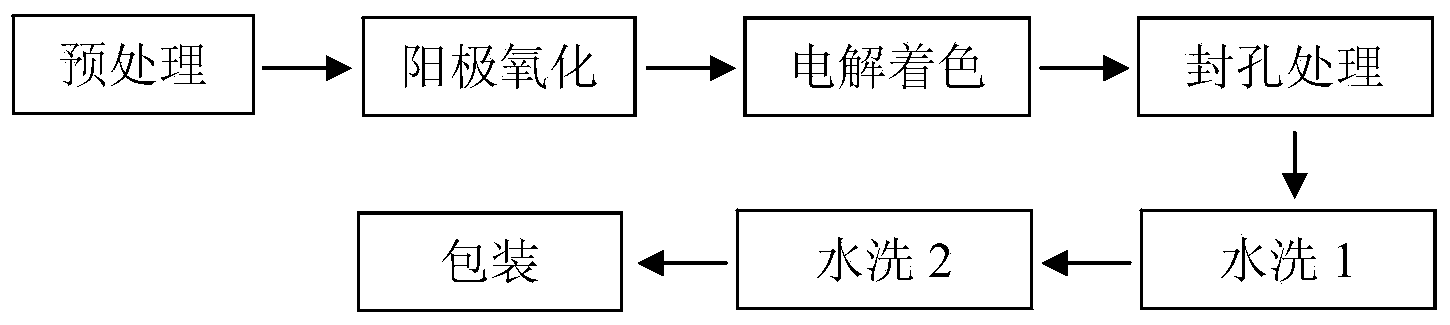

Aluminum alloy oxide film nickel-free normal-temperature sealing process and sealing agent

InactiveCN104342736AEasy to handleCreate pollutionSurface reaction electrolytic coatingNickel freeMaterials science

The invention provides a normal-temperature sealing agent which can obtain oxide film sealing performance and corrosion resistance equivalent or superior to that by using a nickel-containing oxide film sealing agent, is easy to use, does not contain heavy metal, is simple in wastewater treatment and does not cause environmental pollution. The aluminum alloy oxide film nickel-free normal-temperature sealing agent contains at least one of compound A selected from water-soluble titanium compound or water-soluble zirconium compound and an organic compound B which is used as a stabilizer and is provided with a plurality of functional groups, wherein the content of the compound A is 0.1-50mmol / L; the content of the organic compound B is 2.5-10 times of the content of the compound A. The sealing agent further comprises accelerant with content of 0.1-5.0g / L and PH buffering agent with content of 1.0-20.0g / L.

Owner:湖州织里天荣铝材添加剂厂

Nickel-free micro-alloy low-temperature pressure vessel steel and manufacturing method thereof

ActiveCN101082104AHigh strengthImprove low temperature toughnessTemperature control deviceElongation control deviceSheet steelNickel free

The microalloy steel without Ni for low temperature pressure container consists of C 0.04-0.08 wt%, Si less than 0.6 wt%, Mn 1.0-1.6 wt%, Nb 0.010-0.030 wt%, Ti 0.005-0.030 wt%, V less than 0.070 wt%, Al 0.004-0.060 wt%, N less than 0.008 wt%, P less than 0.015 wt%, S less than 0.010 wt%, and Fe and inevitable impurity for the rest. By means of reasonable alloy component design and technological process including TMCP rolling, the steel plate has yield strength up to 360 MPa, tensile strength over 490 MPa, high low temperature impact toughness, excellent plasticity and welding performance, low production cost and short production period.

Owner:BAOSHAN IRON & STEEL CO LTD

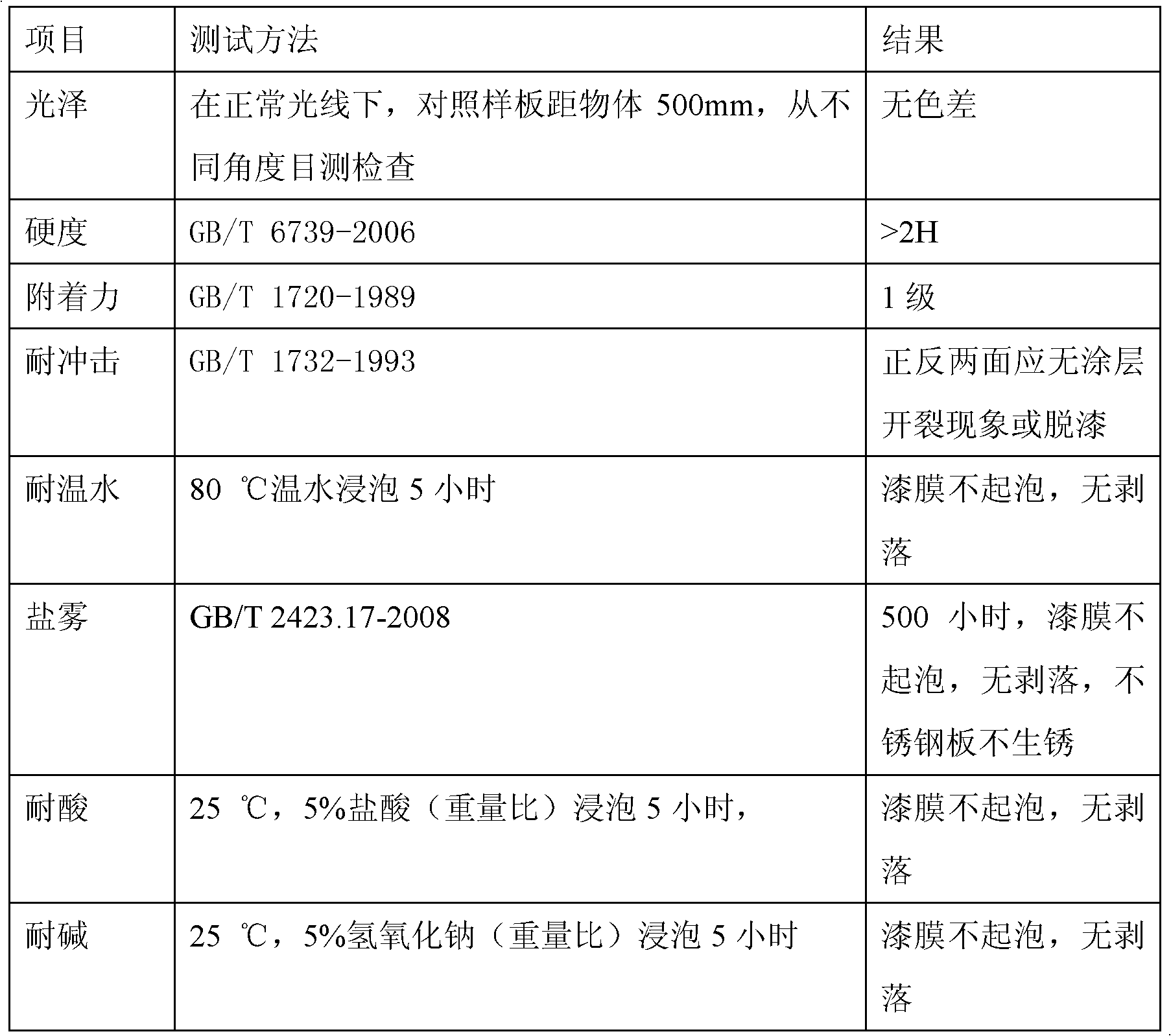

Anti-stain and anti-fingerprint stainless steel plate and preparation method thereof

ActiveCN102602079AReduce pollutionImprove anti-corrosion performanceSynthetic resin layered productsMetal layered productsEpoxyAcrylic resin

The invention provides an anti-stain and anti-fingerprint stainless steel plate and a preparation method thereof. The anti-stain and anti-fingerprint stainless steel plate consists of a stainless steel plate and a polymer coating layer material, wherein the stainless steel plate comprises austenite stainless steel and low-nickel or nickel-free ferrite stainless steel, and the polymer coating layer material is mixed by acrylic resin, film forming matter, inorganic nano filler, solvent and accessory ingredient; and the film forming matter comprises amino resin and epoxy resin. The preparation method comprises the following steps of: dissolving crylic acid composite resin in the solvent, adding the film forming matter, the inorganic nano filler and the accessory ingredient, and evenly mixing in a ball-milling way to prepare the coating material; and forming the coating layer on the stainless steel plate by the coating material, and solidifying the coating layer, wherein the thickness of the coating material is 1-10 micrometer(s).

Owner:HAIMEN SENDA DECORATION MATERIAL CO LTD

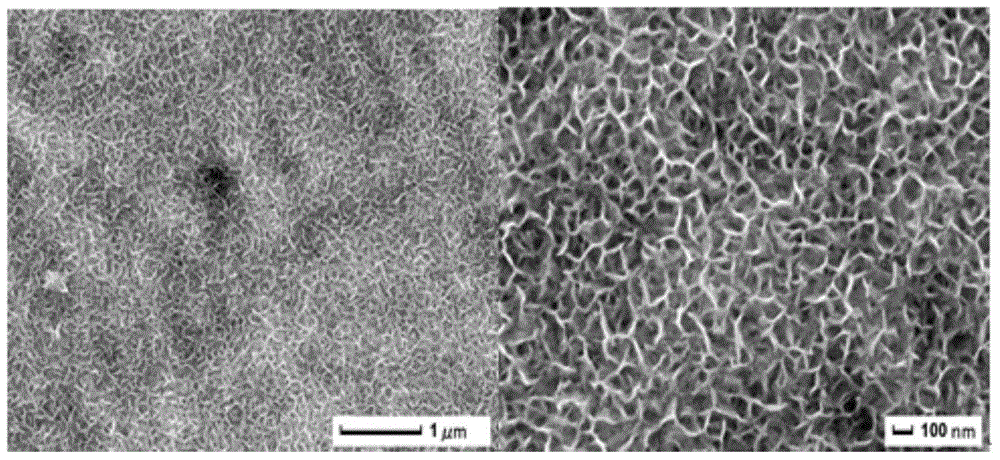

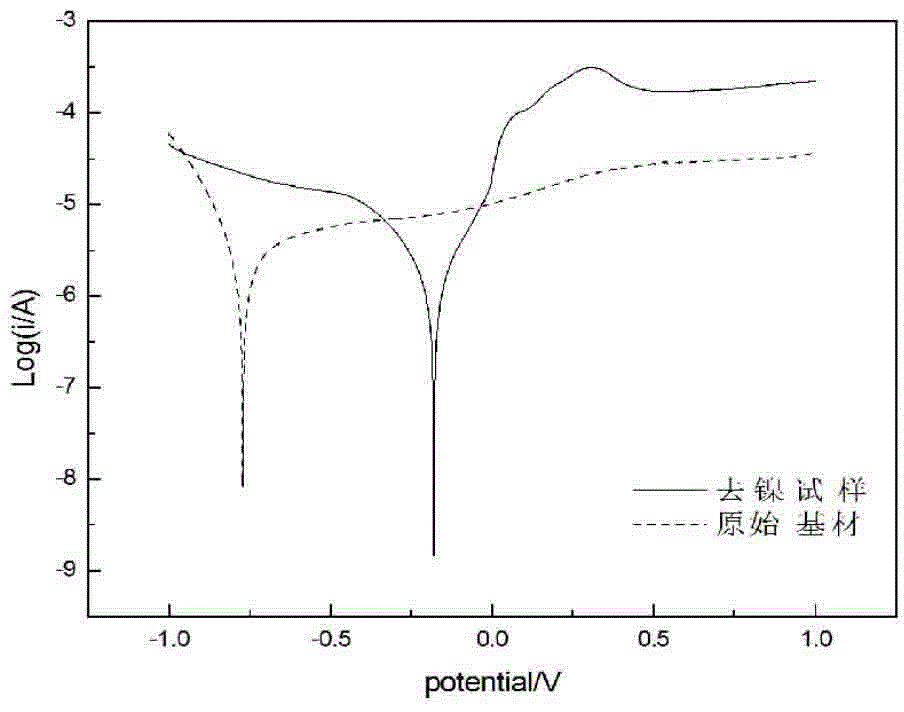

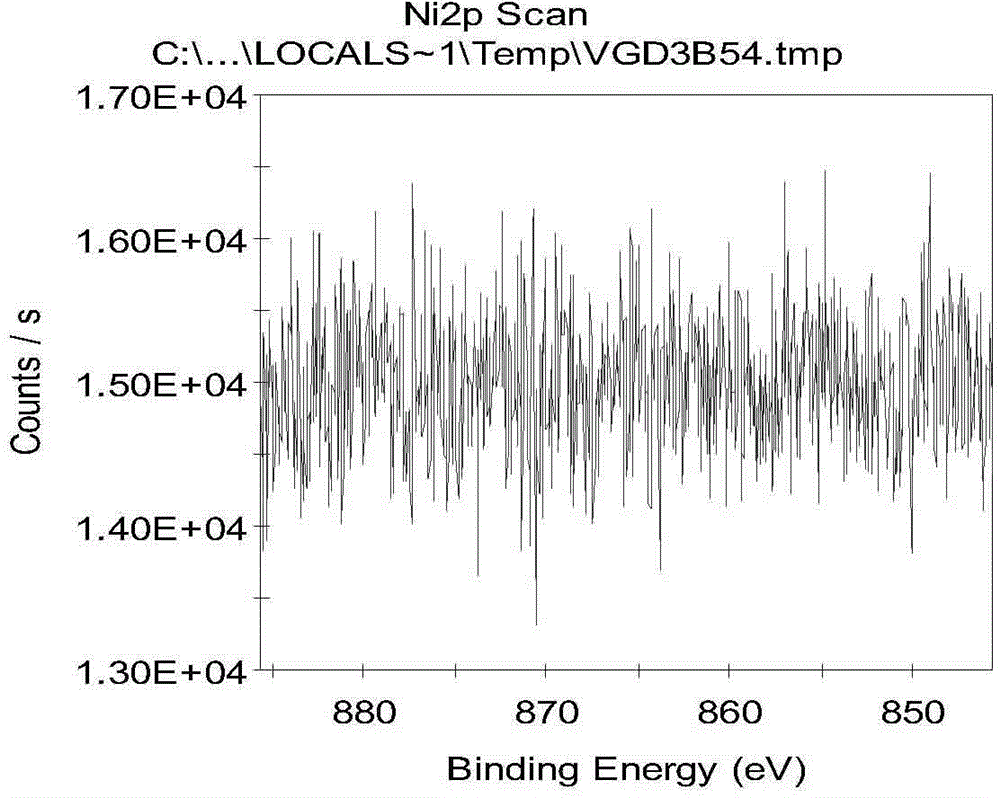

Production method of nickel-titanium alloy surface nickel-free layer

The invention provides a production method of a nickel-titanium alloy surface nickel-free layer, and relates to the fields of surface engineering technologies and biomaterials. The method comprises the following steps: pre-treating nickel-titanium alloy, and placing the nickel-titanium alloy in an alloy removal treatment fluid to carry out a reaction in order to obtain nickel-titanium alloy with the surface being a nickel-free layer. The nickel-titanium alloy with the surface being the nickel-free layer has high corrosion and blood coagulation resistance to meet special demands of intravascular stents, cardiac valves and other human body intervention materials.

Owner:WUXI SHENKANG MECHANICAL EQUIP

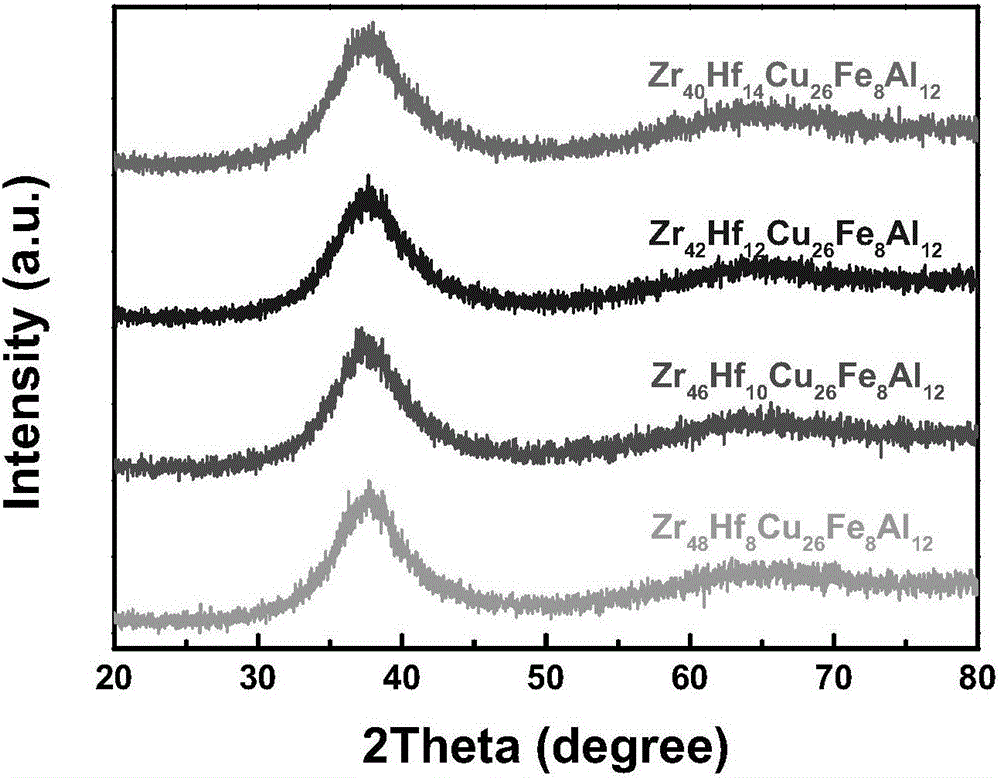

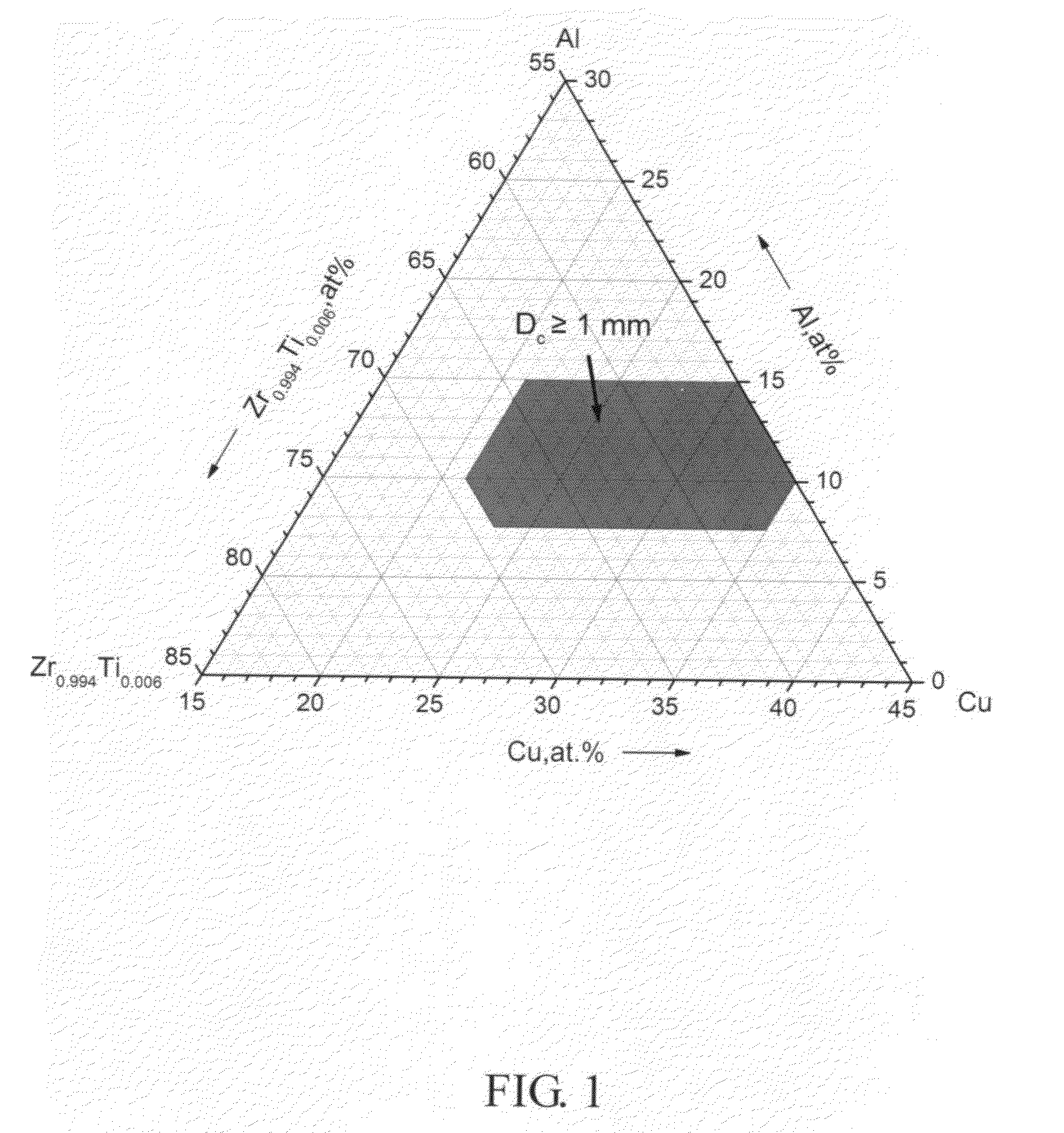

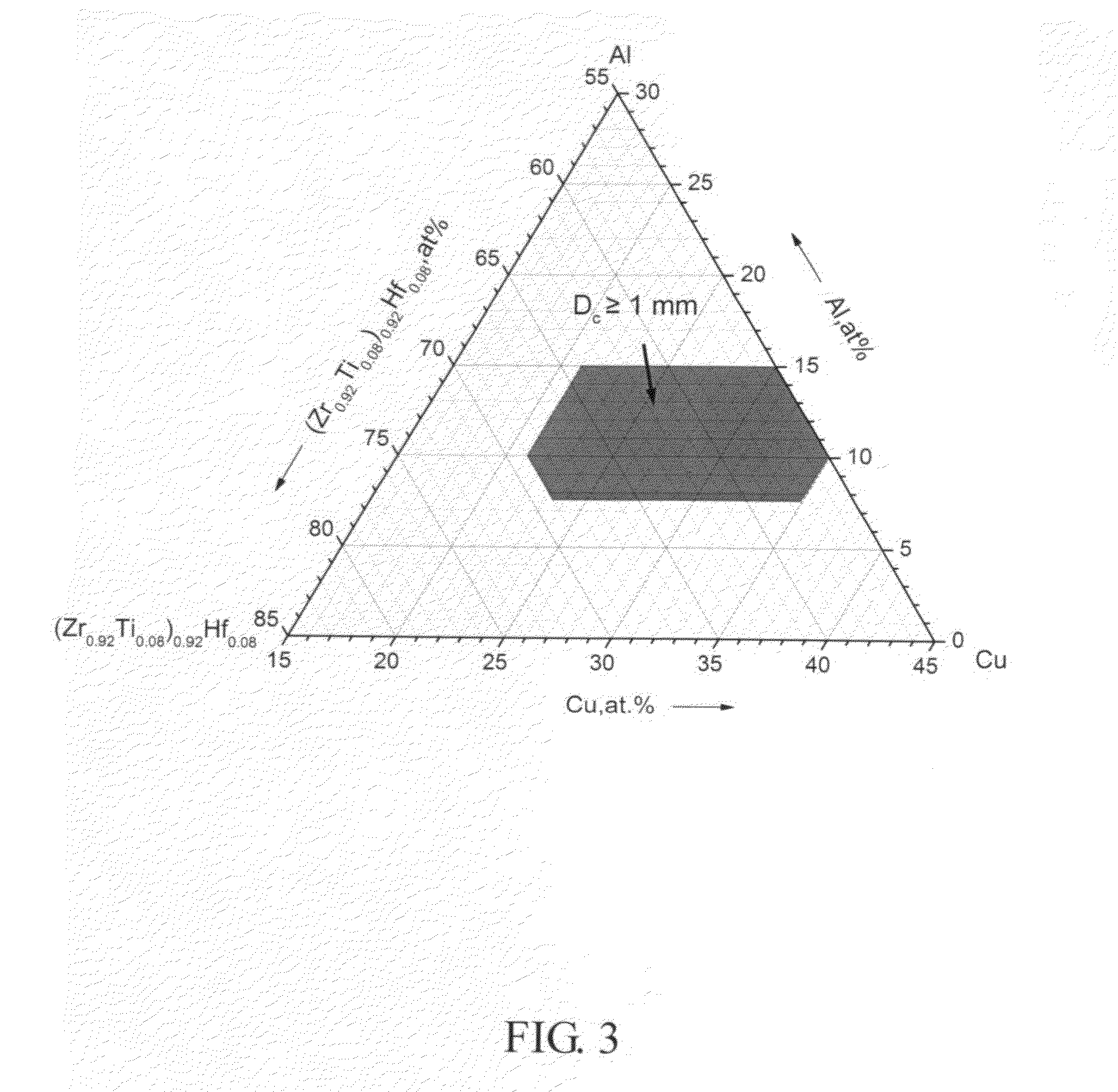

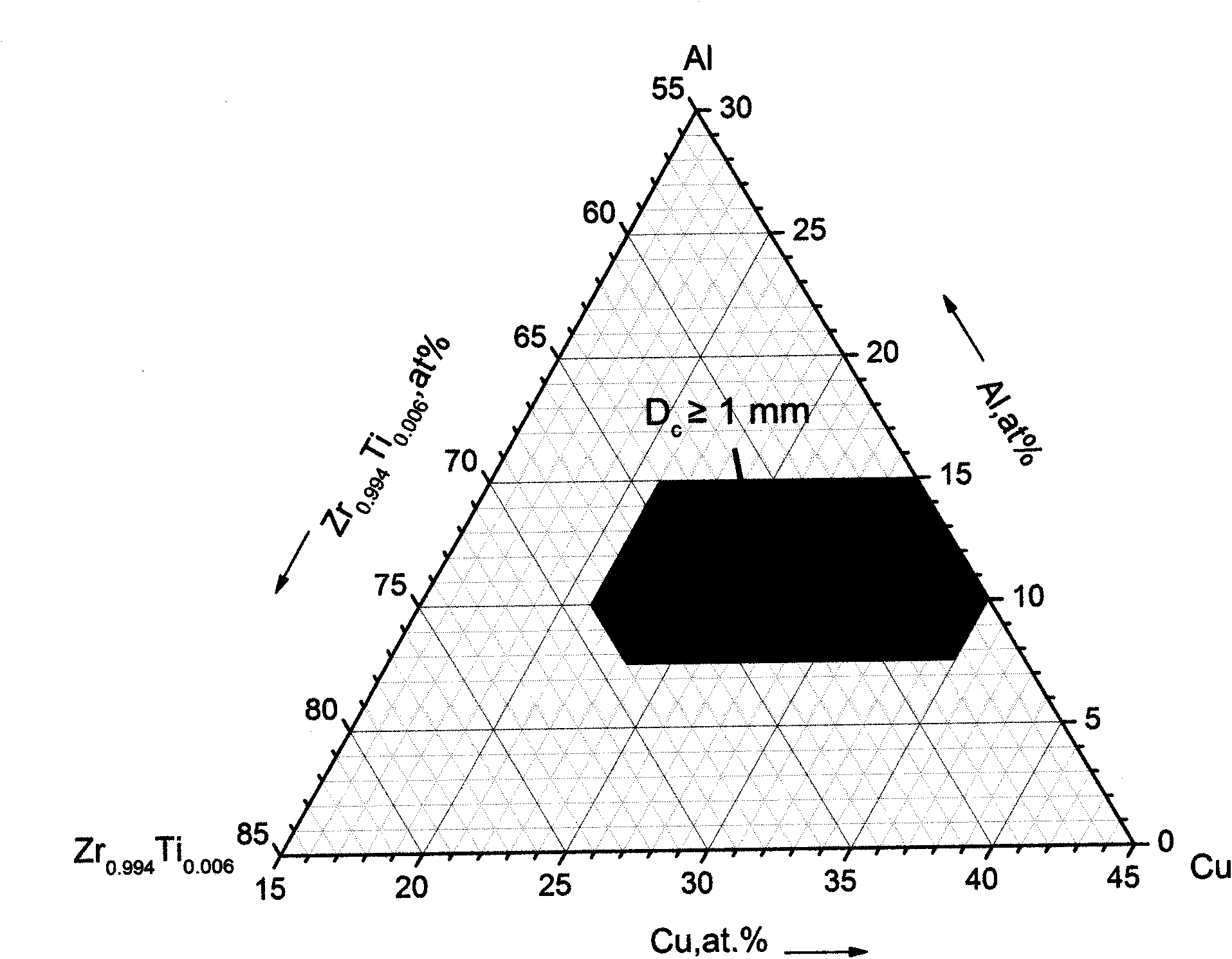

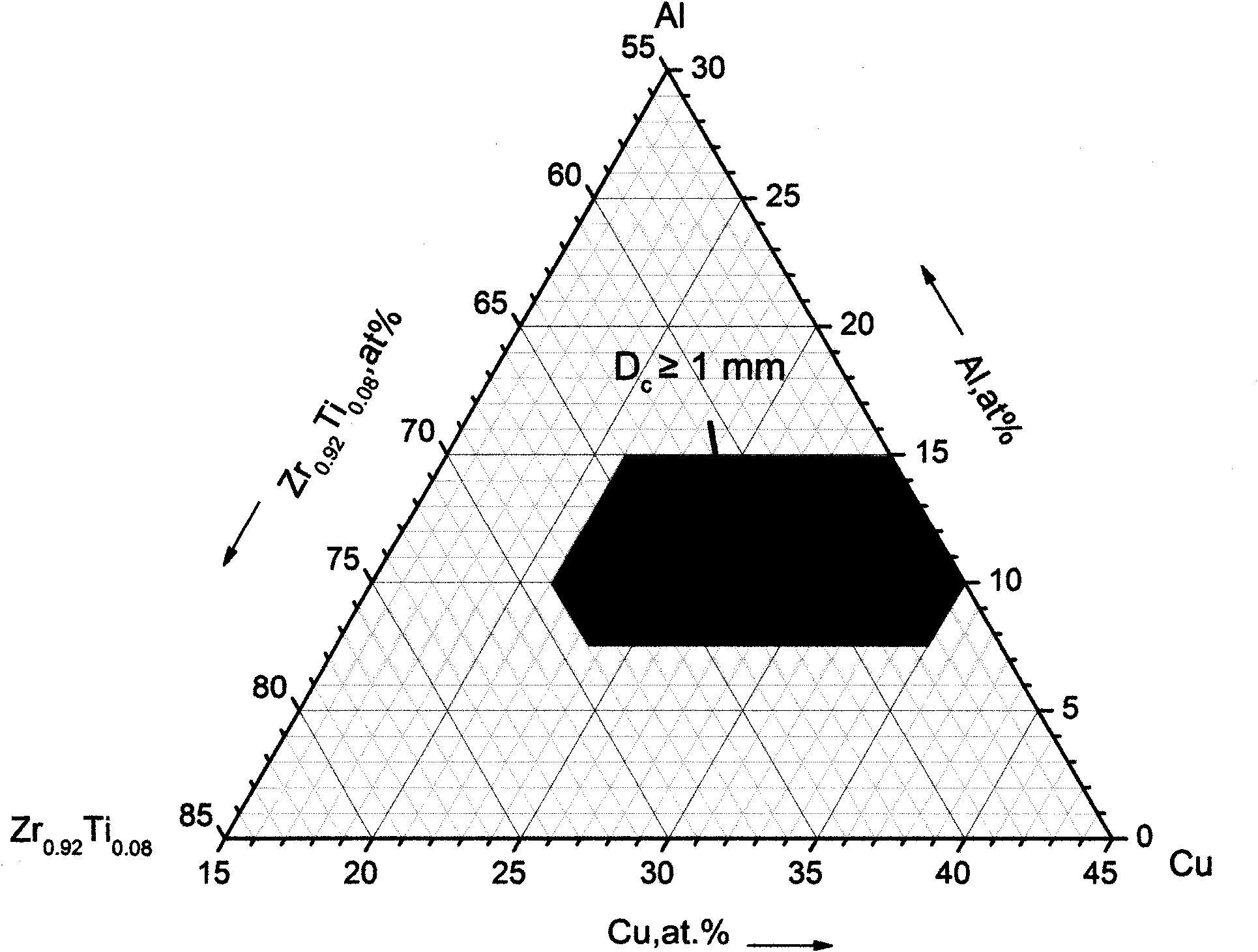

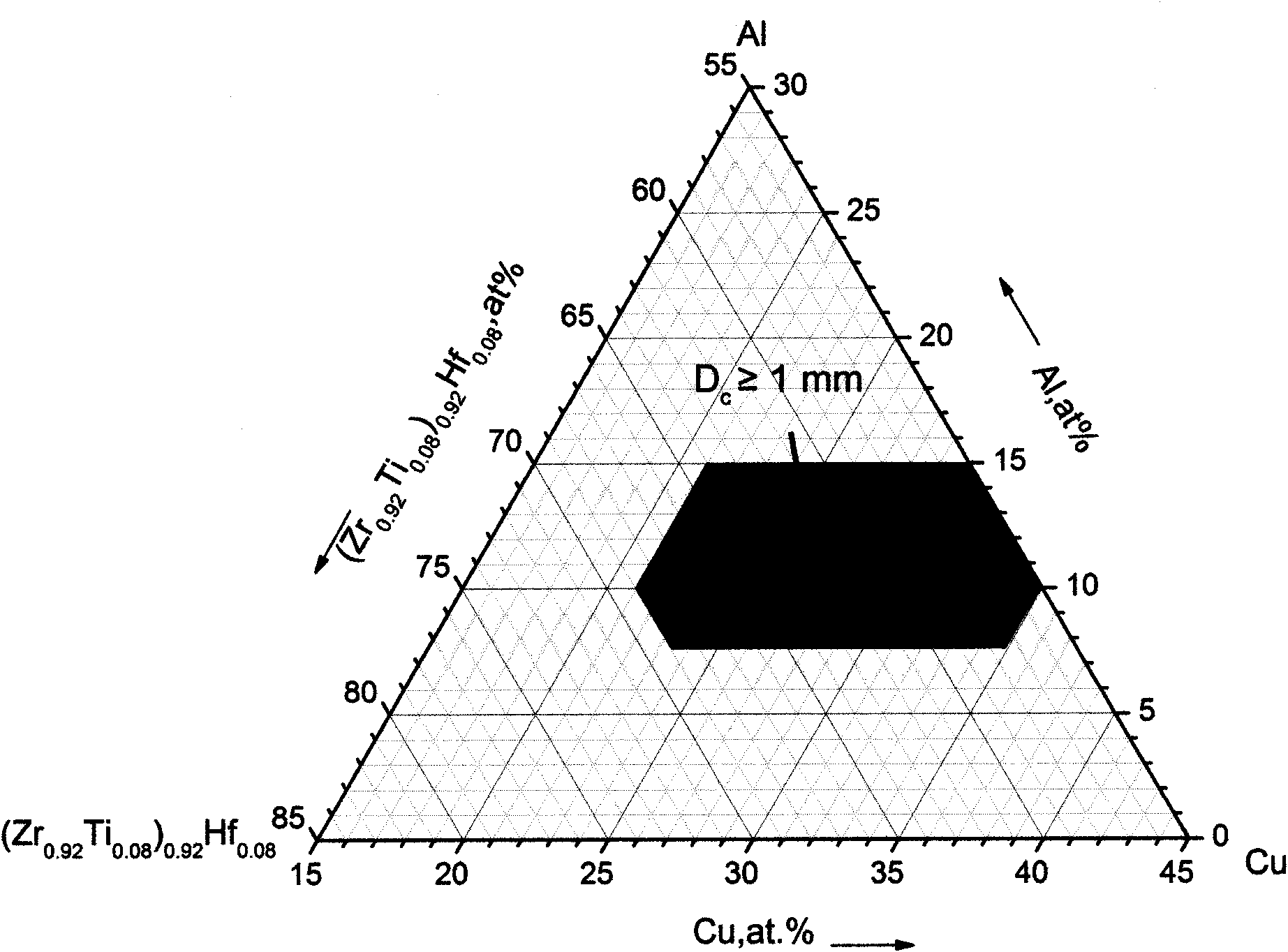

Beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and preparation method thereof

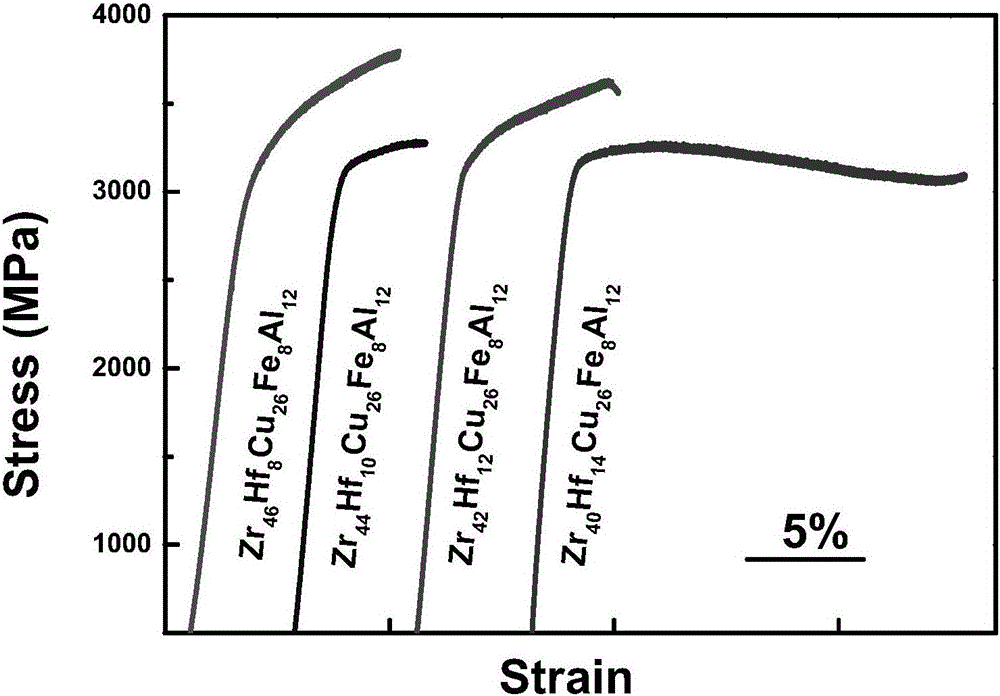

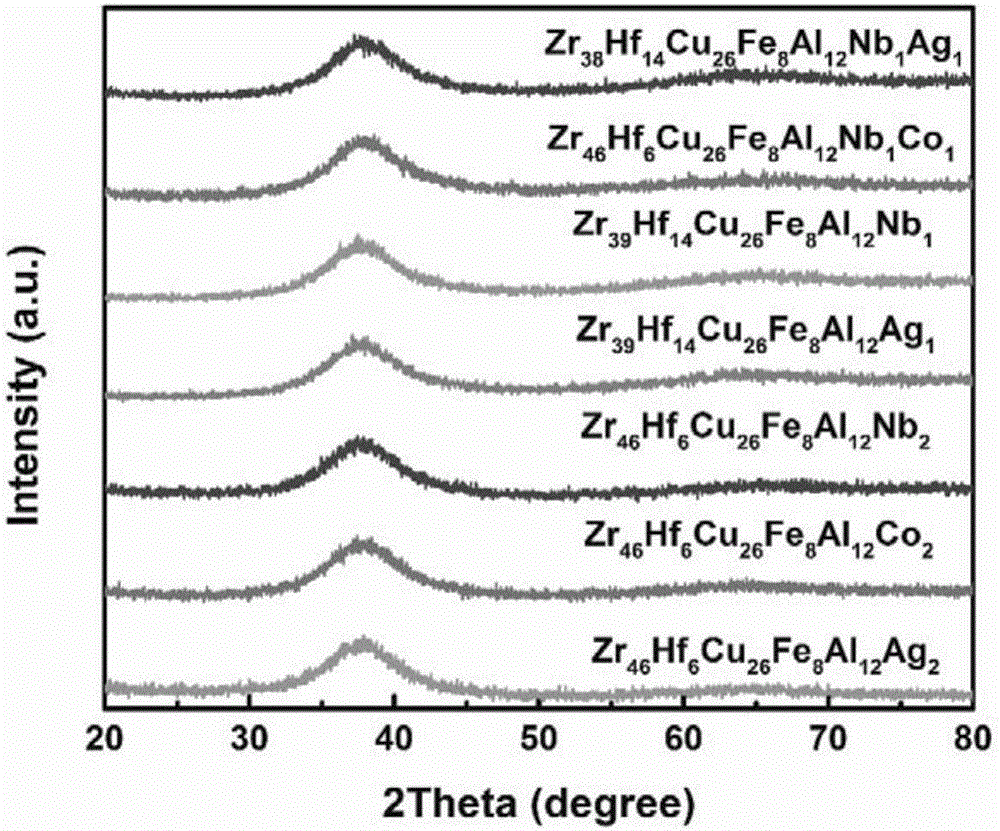

ActiveCN106756647AGood biocompatibilityWide temperature range of subcooled liquid phase regionBiocompatibility TestingNickel free

The invention provides a beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and a preparation method thereof. The alloy comprises, by atom, 38-50% of Zr, 2-15% of Hf, 20-30% of Cu, 5-10% of Fe, 10-15% of Al, 0-5% of Co, 0-5% of Ag and 0-5% of Nb. The electric arc melting copper mould casting method is adopted for preparation. The amorphous alloy is free of metal elements such as Be and Ni, and biocompatibility of the zirconium-base alloy is improved. The high amorphous forming capacity is achieved, and the zirconium-base block body amorphous alloy with the critical size being no less than 5 mm can be prepared through the copper mould casting method. According to the beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy, high hardness is achieved, and vickers hardness is larger than 540 Hv; the plastic deformation capacity being larger than 3% is achieved; and the super-cooled liquid phase region range is wide and reaches 92 K at most. The beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and the preparation method thereof has very wide application prospects in the fields of biomedical materials such as a precise complex medical component, a joint prosthesis and a human skeleton.

Owner:UNIV OF SCI & TECH BEIJING

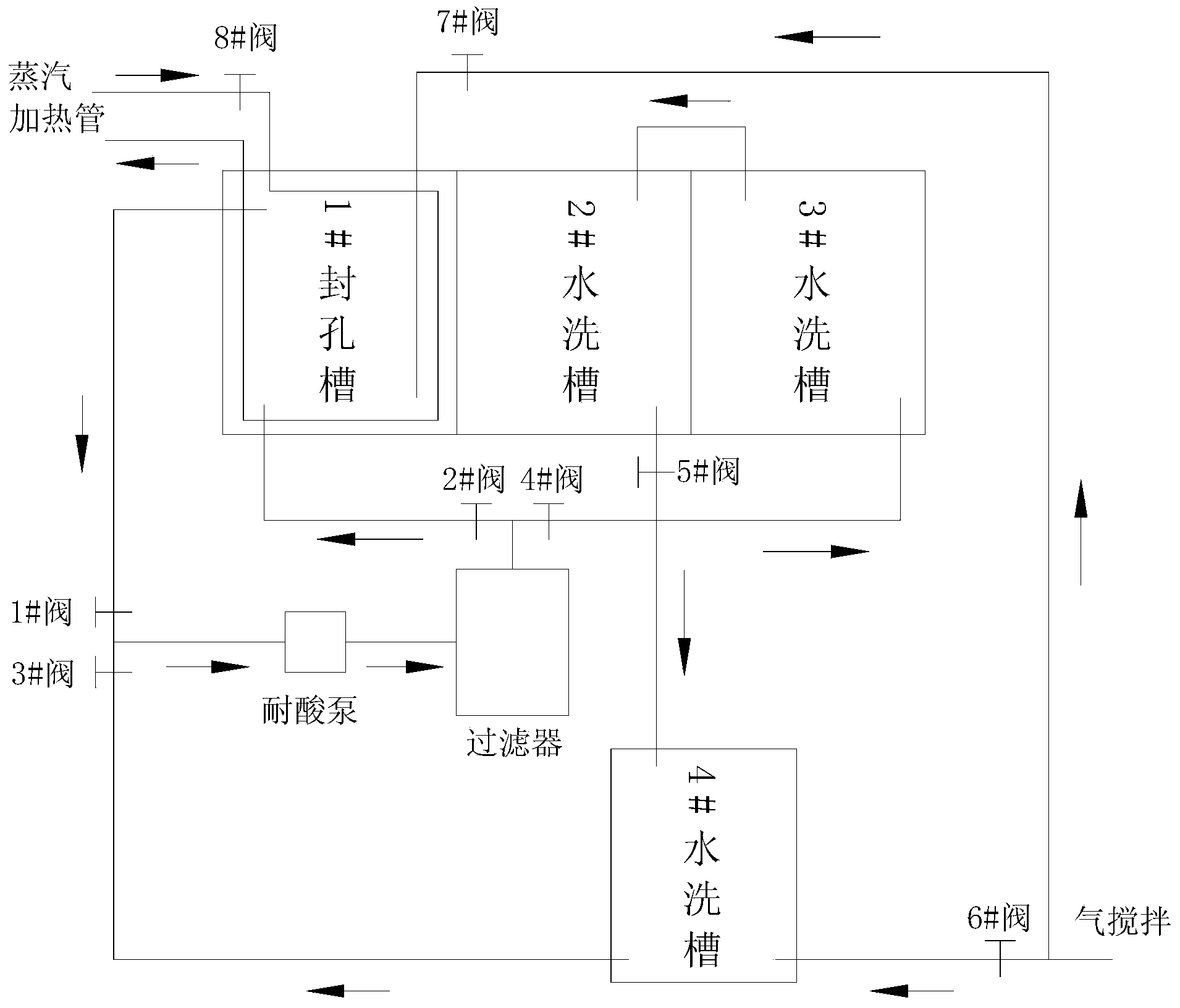

Nickel-free hole sealing agent for aluminum alloy and hole sealing treatment process of agent

ActiveCN103590086AEliminate pollutionSolve the problem of decomposition and precipitationSurface reaction electrolytic coatingNickel saltWater quality

The invention discloses a nickel-free hole sealing agent for an aluminum alloy. The nickel-free hole sealing agent comprises water solutions of fluorotitanic acid, a corrosion inhibitor and a chelating agent, wherein on the basis of the volume of the hole sealing agent, the concentration of the fluorotitanic acid is 6.0-9.0 g / L, the concentration of the corrosion inhibitor is 1.0-3.0 g / L and the concentration of the chelating agent is 1.0-3.0 g / L. The hole sealing agent takes the fluorotitanic acid as the main ingredient, and pollution of nickel salt to the aluminum alloy and the water quality is eliminated from the source. The invention further provides a hole sealing treatment process using the nickel-free hole sealing agent for the aluminum alloy. The operation is simple, energy conservation and environment protection are realized, waste water is easy to treat, the hole sealing agent is suitable for large-scale production, nickel pollution in the building aluminum alloy finished surface treatment process, the aluminum alloy using process and the waste treatment process is completely ended, and the bottleneck problem about restricting the industry development over the years is solved.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

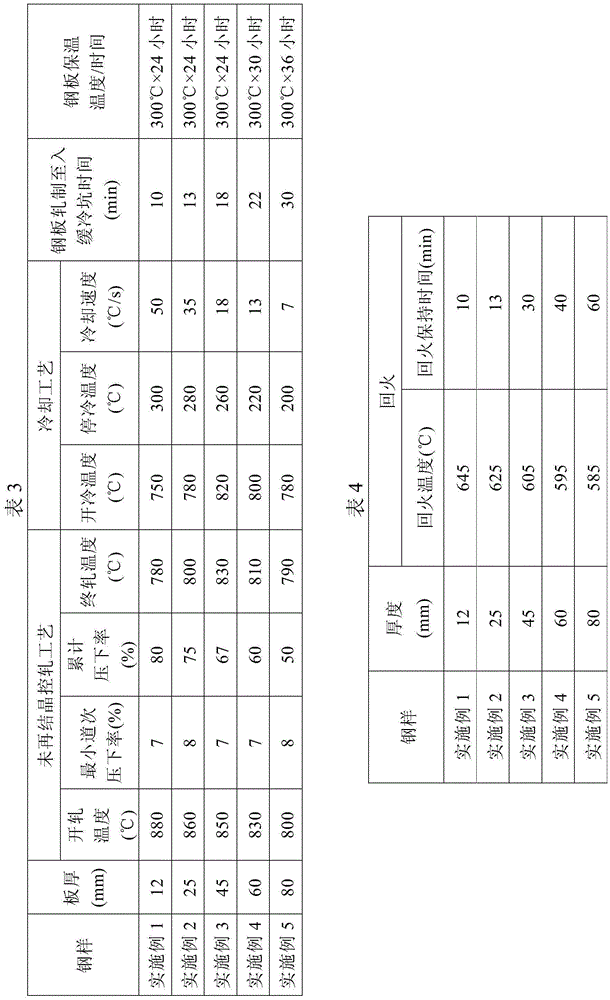

Steel plate with super-low cost, 800MPa-grade high toughness and excellent weldability and manufacture method thereof

The invention provides a steel plate with super-low cost, 800MPa-grade high toughness and excellent weldability and a manufacture method thereof. According to the manufacture method, metallurgical technical control methods of selecting super-low C-super-low Si-high Mn-highAls-(low Mo+high Cr) alloying-(Ti+Nb+V+B)microalloying composition system as basis, properly increasing the content of acid solution Als in steel, performing Ca treatment and leading the value of [(%C)+(%Mn) / 6+(%Si) / 24+(%Ni) / 40+(%Cr) / 5+(%Mo) / 4+(%V) / 14+7.3(%B)]*V cooling speed / (T starting cooling temperature-T terminating cooling temperature)*t to be more than or equal to 0.60 and less than or equal to 1.00, and the like are adopted, a specific controlled-rolling and online tempering process is optimized, the tempered steel plate has excellent weldability while the strength, low-temperature toughness, obdurability and plasticity of the tempered steel plate are matched, the problem of the weldability of a nickel-free tempered steel plate can be successfully solved, the welding HAZ has high strength, high toughness and excellent plasticity. The steel plate is especially suitable for hydroelectric pressure pipelines / volute casings / steel bifurcated pipes, marine platforms, large maritime working machinery and other large steel structures and equipment.

Owner:BAOSHAN IRON & STEEL CO LTD

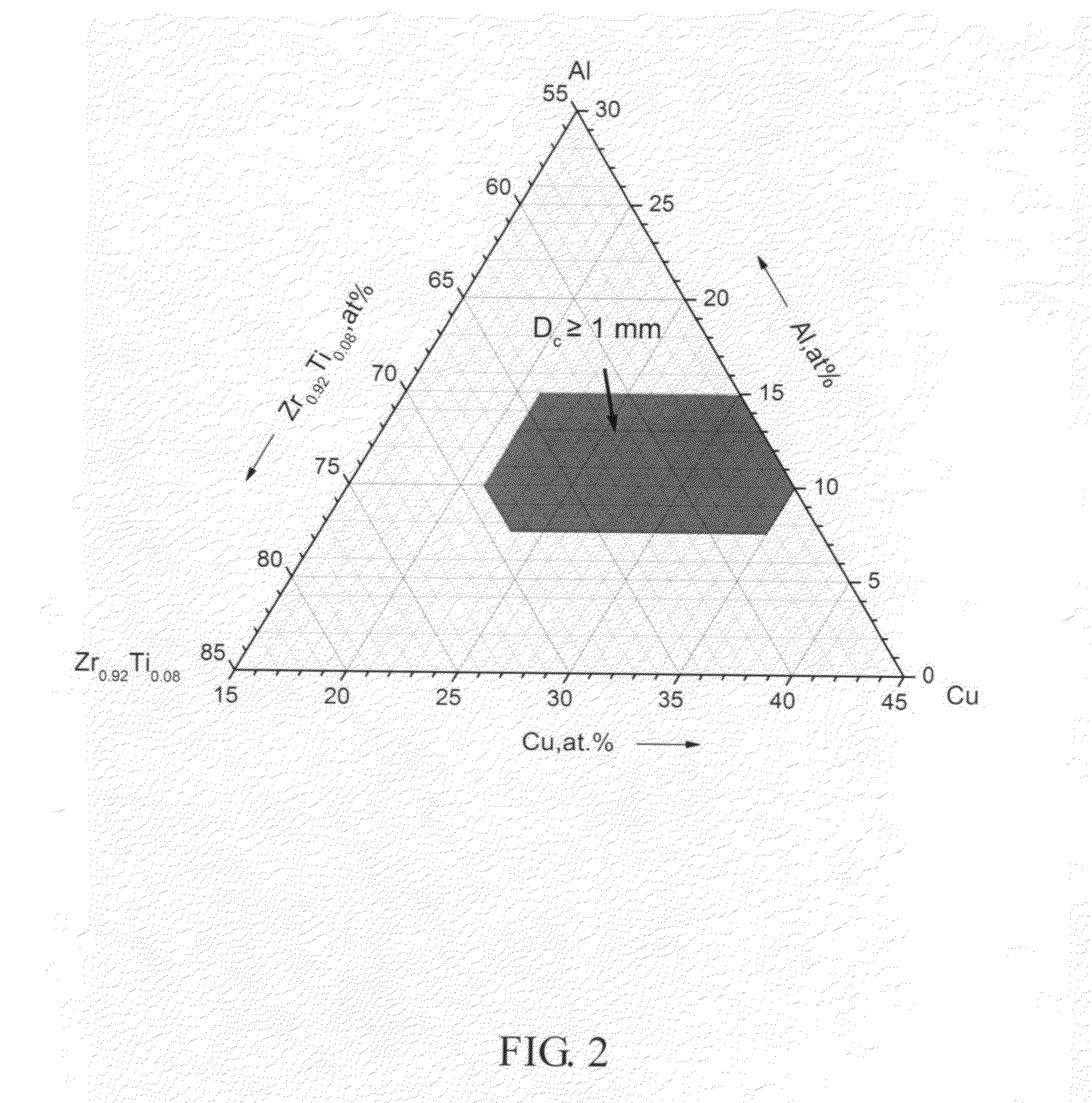

Amorphous nickel-free zirconium alloy

An amorphous Nickel-Free Zirconium alloy which is readily formed through copper mold casting, comprising a composition consisting of four elements in which the first element is Zr, the second element is Ti, the third element is Cu and the fourth element is Al, wherein an atomic percent of the first to the fourth elements in the composition are represented by a, b, c and d respectively, wherein a=45˜69%, b=0.25˜8%, c=21˜35%, and d=7.5˜15%, where a sum of a, b, c and d is smaller than or equal to 100%. The composition of the amorphous alloy within the above range is melted in a copper mold to form bulk amorphous materials or parts which have characteristics of high tensile strength, high fracture toughness, low Young's modulus and high corrosion resistance.

Owner:INST OF METAL RES CHINESE ACADEMY OF SCIENECE

High temperature durable, oxidation resistant and lead nickel free conductor pulp and preparing method thereof

InactiveCN101290817AImprove antioxidant capacityReduce manufacturing costNon-conductive material with dispersed conductive materialCable/conductor manufactureMean diameterElectrical conductor

The invention discloses high temperature-resisting antioxidative leadless nickel conductor slurry. The compositions in percentage by weight of the slurry are: 50 to 70 percent of nickel powder, 1 to 5 percent of antioxidative protective agent, 5 to 15 percent of inorganic agglomerant and 15 to 30 percent of organic carrier. The compositions are evenly mixed and ground to obtain leadless nickel conductor slurry product with granularity less than 15mu m and viscosity of between 65 and 75 Pa.s, wherein the nickel powder is selected from spherical nickel powder with the mean diameter of between 0.1 and 2.0 mu m; the antioxidative protective agent is selected from one sort or more than one sort of B, Cr and Y which are spherical micropowder with the mean diameter less than 1mu m; and the inorganic agglomerant is leadless glass powder. The slurry product has excellent high temperature-resisting antioxidative performance and is suitable for sintering under atmospheric condition with the antioxidative temperature adjusted between 800 and 900 DEG C. Moreover, the slurry has simple preparation process, low production cost and energy conservation and is propitious to environmental protection.

Owner:HUAZHONG UNIV OF SCI & TECH

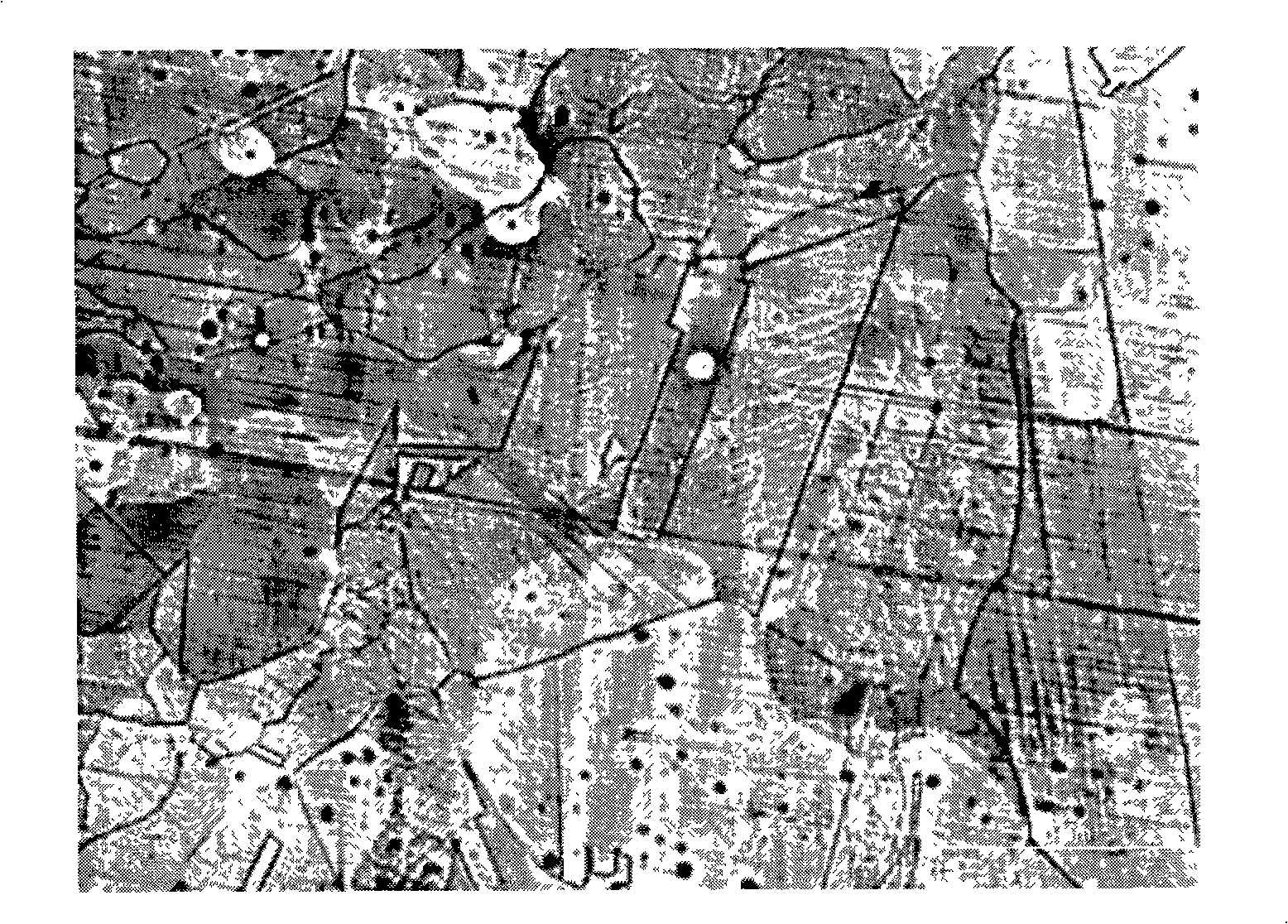

Chromic-nickel-free high-strength high ductility structural steel and manufacturing method thereof

InactiveCN101082101AControl and optimize contentControl UniformityTemperature control deviceHeat treatment process controlNickel freeHeating temperature

The high strength and high toughness structural steel without Cr and Ni consists of C 0.24-0.30 wt%, Si 1.10-1.40 wt%, Mn 1.30-1.70 wt%, Mo 0.40-0.60 wt%, V 0.20-0.35 wt%, Al 0.015-0.050 wt%, Cu not more than 0.30 wt%, S not more than 0.012 wt%, P not more than 0.020 wt%, and Fe and inevitable impurities for the rest. Its production process includes the following steps: 1. smelting and casting ingot; 2. rolling in the heating temperature 1100-1180 deg.c, finishing temperature of 850-900 deg.c and cooling rate of 40-80 deg / hr; and 3. annealing at the temperature of 720+ / -10 deg.c for 8-10 hr, cooling to below 450 deg.c in the rate no higher than 30 deg / hr and discharging. The high strength and high toughness structural steel with cheap Si and Mn as main elements has yield strength not lower than 1170 MPa, tensile strength not lower than 1274 MPa, specific elongation not lower than 9 %, reduction of area not lower than 45 %, and impact toughness not lower than 62J.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Nickel-free black tin cobalt alloy plating solution and electroplating technology by using same

The invention relates to a nickel-free black tin cobalt alloy plating solution and an electroplating technology by using same. The parameters and contents of all components of the plating solution are as follows: the content of tin ions in a tin salt is 0.05-6g / L; the content of cobalt ions in a cobalt salt is 0.05-0.8g / L; the content of third metallic ions is 0.02-50g / L; the content of a complexing agent is 0.1-180g / L; the content of a blacking agent is 0.1-50g / L; the content of a PH buffer is 5-300g / L; the baume degree of the plating solution is 6-250; the temperature is 20-55 DEG C; and PH is 9-13. According to the technology provided by the invention, tin is taken as a main alloy layer and few cobalt and third and fourth metal ions are added in tin to form a ternary or quaternary alloy system; the cobalt content in the common black tin cobalt alloy plating solution excesses 8g / L, but the cobalt content is reduced to 0.05g / L according to the new electroplating technology provided by the invention; the special biodegradable or non-biodegradable stabilizing complexing agent and PH buffer are used, so that the production cost is lowered; and the nickel-free black tin cobalt alloy plating solution meets the limitation requirement on CO in the European Union Rosh standard, Germany LMBG standard, Mattel children toy standard, European Oeko-Tex Standard 100 standard and the like.

Owner:杜强

Cyanide-free and nickel-free electroplating method for copper-tin alloy

InactiveCN104674314AReduce poisonHelp the marketLiquid/solution decomposition chemical coatingSuperimposed coating processCopper platingCyanide

The invention discloses a cyanide-free and nickel-free electroplating method for a copper-tin alloy. The method comprises the following steps: sequentially performing chemical copper plating, cyanide-free copper electroplating, sulfate copper electroplating, cyanide-free copper-tin alloy electroplating and lead-free chromium electroplating on a base material, wherein the electroplating solution of cyanide-free copper electroplating comprises 10-20g / l copper pyrophosphate and 230-280g / l sodium pyrophosphate; the electroplating solution of cyanide-free copper-tin alloy electroplating comprises 240-280g / l potassium pyrophosphate, 12-17g / l copper pyrophosphate and 10-20g / l sodium stannate; and the electroplating solution of lead-free chromium electroplating comprises 20-24g / l trivalent chromium and 65-85g / l boric acid. The electroplated parts are subjected to non-phosphorus oil removal, chemical copper plating, cyanide-free copper preplating, sulfate copper plating, cyanide-free copper-tin alloy plating and lead-free chromium plating, the requirement of constructing environment protection industry and intensive economy in China is met, cancerogenic substances are not contained in production, and the environmental pollution is further reduced.

Owner:温兵

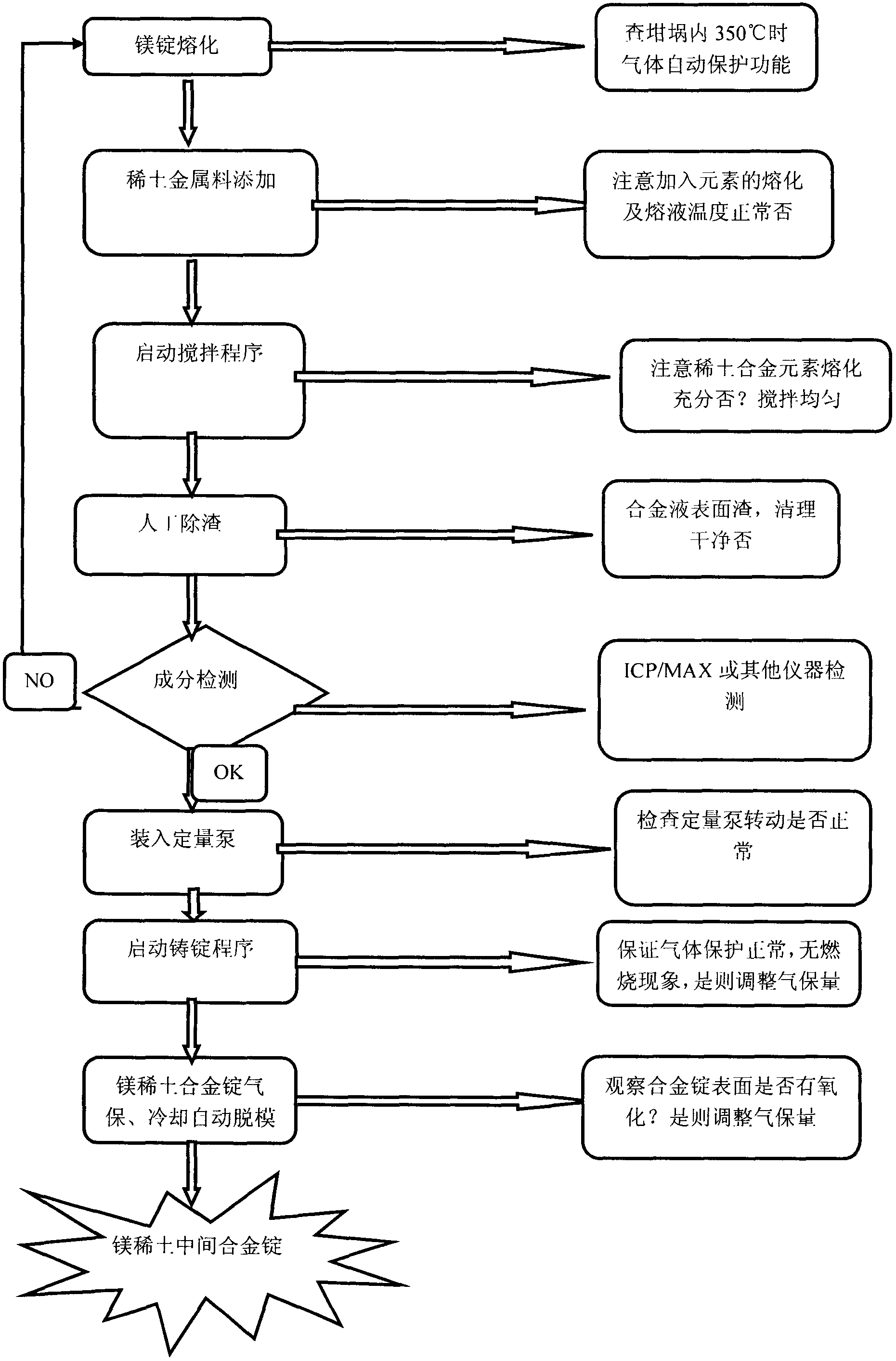

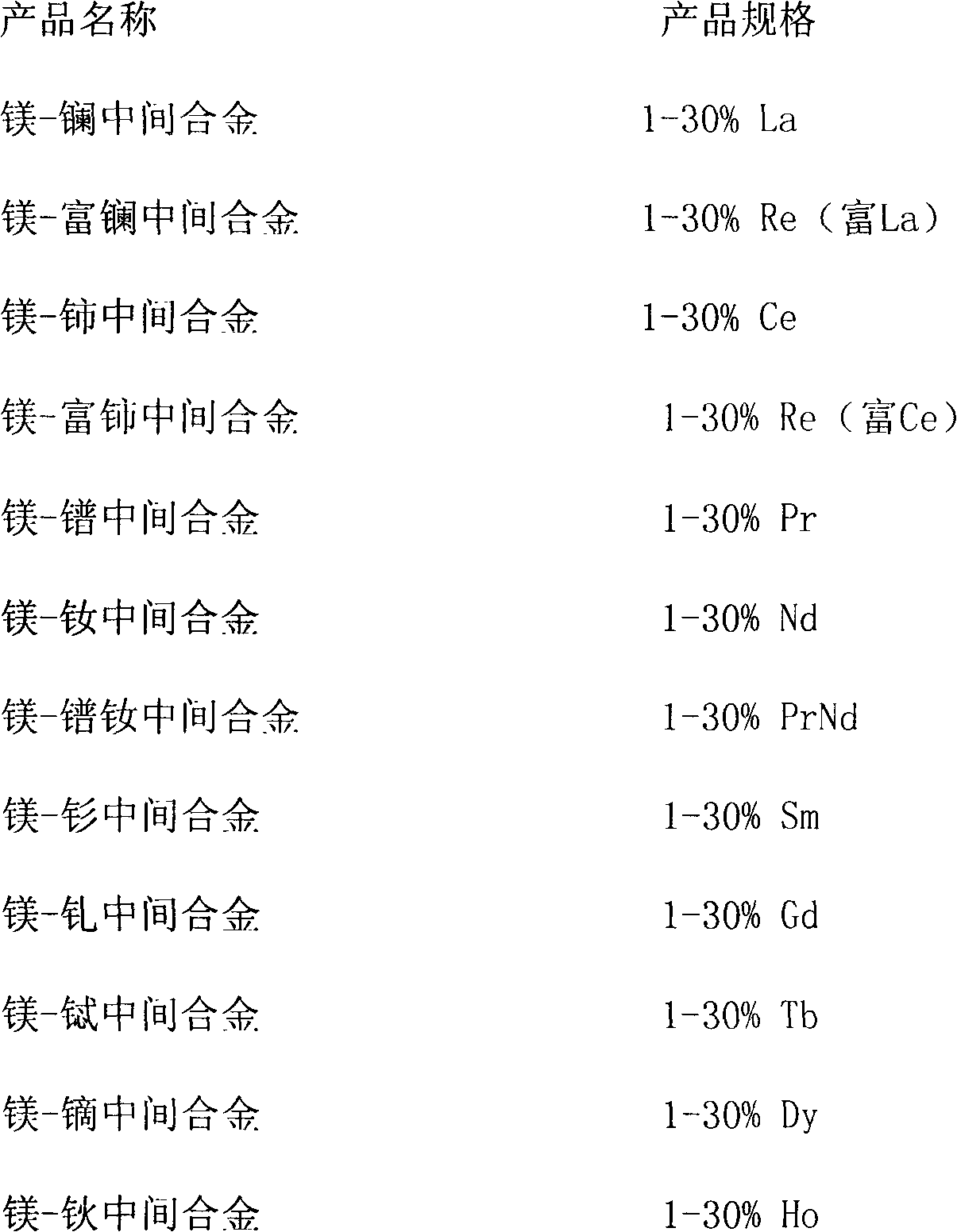

Method for continuously and automatically producing magnesium-rare earth intermediate alloys

ActiveCN103540777ASafe and efficient productionNo pollution in the processMolten metal pouring equipmentsRare earthNickel free

The invention discloses a method of continuously and automatically producing 16 magnesium-rare earth intermediate alloys such as a magnesium-neodymium intermediate alloy. The method comprises the following steps: after melting a magnesium ingot raw material by a finery, adding a rare earth metal material, manually deslagging, and automatically stirring and homogenizing by a system, and sampling and testing alloy components which are qualified; then pouring an alloy liquid to an ingot case of a pig moulding machine through a metering pump to form a continuous and automatic ingot casting; and cooling the alloy liquid to form standard magnesium-rare earth intermediate alloys. The key point of the invention is as follows: the method is applicable to continuous and automatic ingot casting production of 16 magnesium-rare earth intermediate alloys such as the magnesium-neodymium intermediate alloy, so that the labor intensity of production is reduced, and the production safety is greatly improved in anhydrous environment production. The produced product is consistent and high in yield. According to a crucible manufactured by a nickel-free high temperature alloy steel plate, carbon content is not introduced in the production process, the production efficiency is high, and the method is applicable to continuous production on a large scale, free from environmental pollution. Waste residues can be recycled, thereby truly realizing safe and efficient production of the magnesium-rare earth intermediate alloys on a large scale.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

High-nitrogen nickel-free antibacterial stainless steel watch case and manufacturing method thereof

InactiveCN105921755AExert antibacterial effectHigh hardnessElectronic time-piece structural detailsTransportation and packagingInternational marketHardness

The invention discloses a high-nitrogen nickel-free antibacterial stainless steel watch case and a manufacturing method thereof. According to the high-nitrogen nickel-free antibacterial stainless steel watch case disclosed by the invention, Ag is combined with high nitrogen, so the antibacterial effect of Ag can be played, and the hardness and wear resistance of the watch case can be improved as well, therefore the high-nitrogen nickel-free antibacterial stainless steel watch case has a huge market value. According to the watch case disclosed by the invention, nickel element in the watch case is removed, the requirements of European Union ROSH environmental protection certification are fully carried out, so harms caused by nickel allergy are reduced to zero; moreover, the safety of the watch case is improved, and a quite good foundation is laid for China-made watch cases to break into and occupy international markets. Besides, according to the high-nitrogen nickel-free antibacterial stainless steel watch case disclosed by the invention, the mechanical properties of stainless steel are improved, good toughness and plasticity of the stainless steel are maintained; the strength of the stainless steel can be further improved; the yield strength can be higher than 2Gpa; the wear resistance of the stainless steel watch case is improved as well.

Owner:依波精品(深圳)有限公司

Practical nickel-free sealing agent for aluminum alloy anodic oxidation

InactiveCN103668387ANon-toxicGood sealingSurface reaction electrolytic coatingCobalt acetateEcological environment

The invention provides a practical nickel-free sealing agent for aluminum alloy anodic oxidation, which is prepared by compounding primary salt sodium acetate, secondary salt cobalt acetate and a penetrant sorbitol in combination with an assistant. The physical state is powder or water. The practical nickel-free sealing agent for aluminum alloy anodic oxidation, provided by the invention, is affordable and non-toxic to the ecological environment, and realizes an equivalent effect as nickel salt sealing; the sealing effect on an organic dyed film (red or yellow) is better than that of a nickel salt sealing agent.

Owner:台山市科美化学工业有限公司

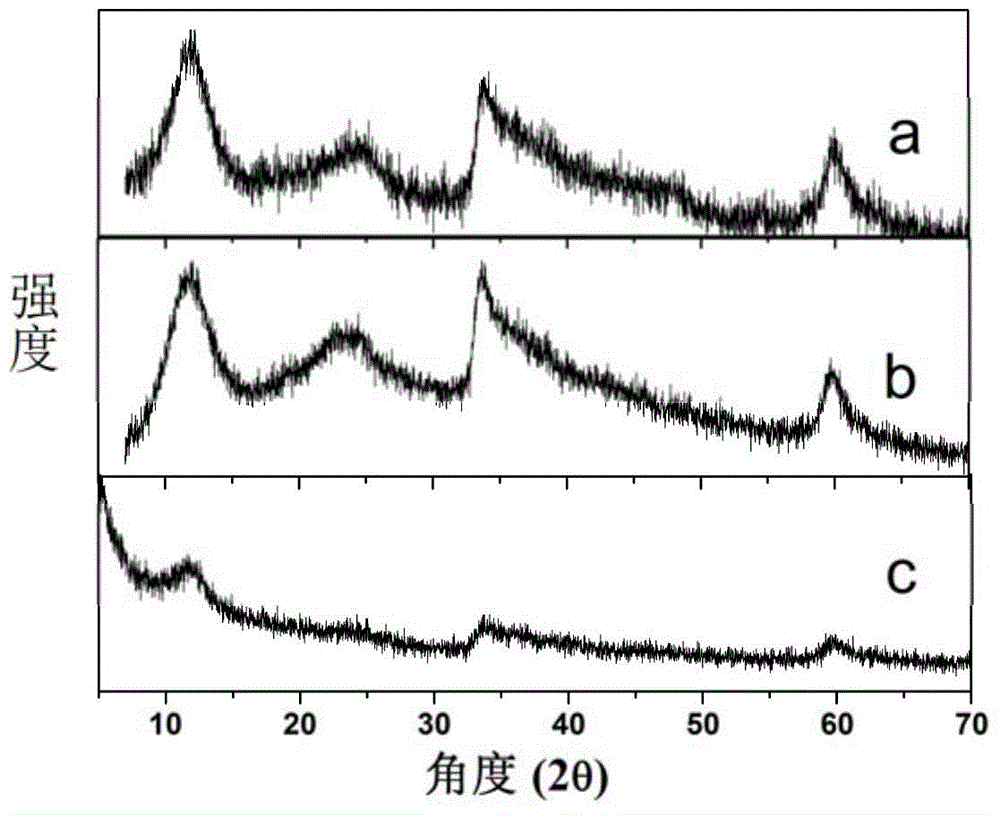

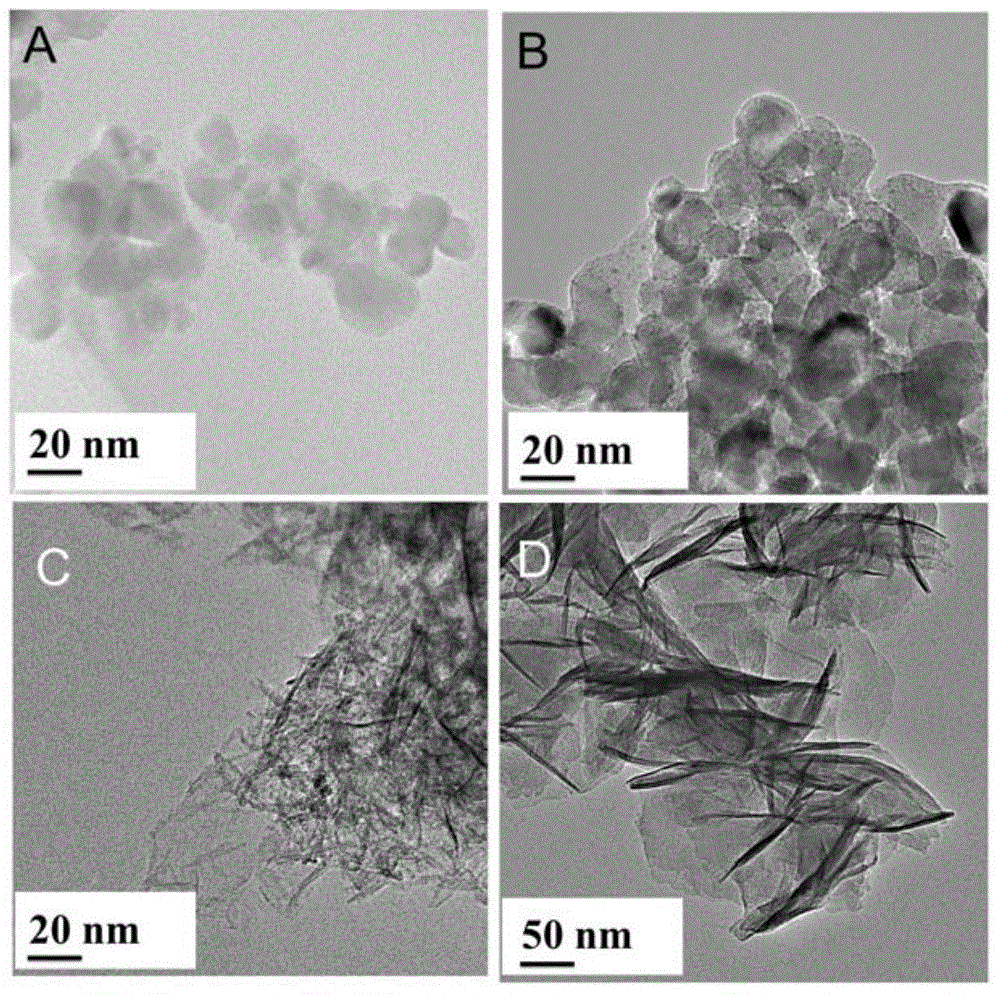

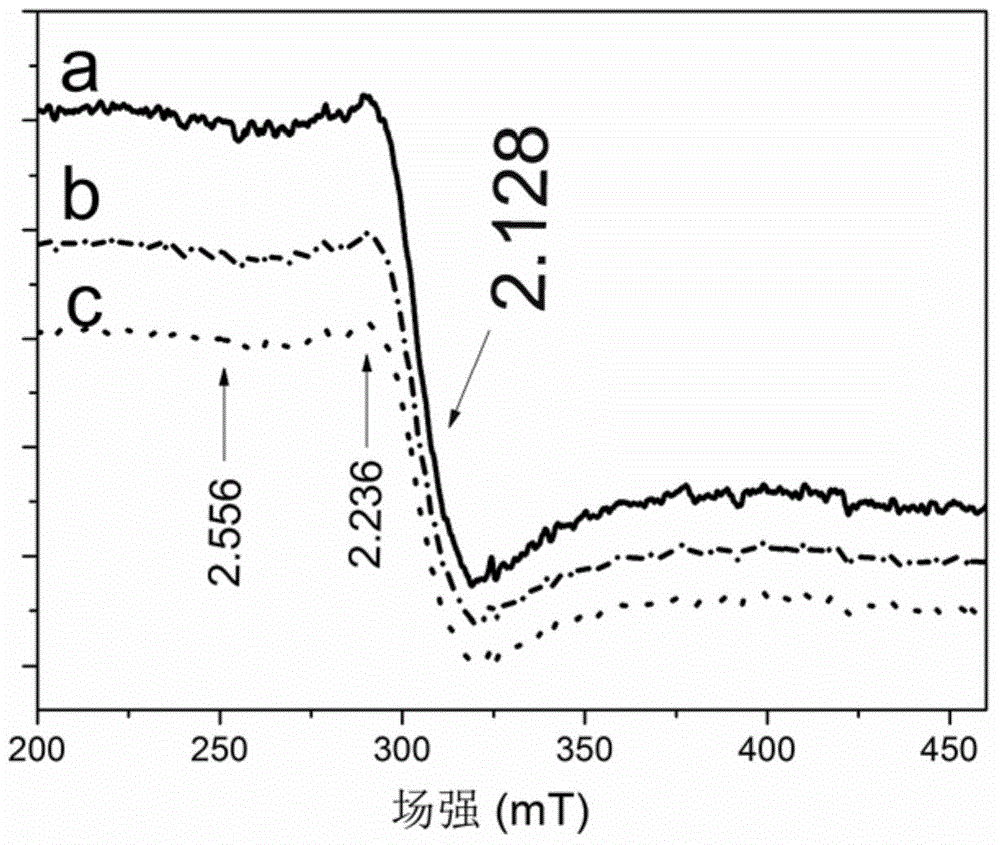

Trivalent-nickel-doped nickel-based hydrotalcite nanometer sheet, preparation method thereof, and application of nano-sheet to supercapacitor

ActiveCN105399145AImprove performanceMild preparation conditionsMaterial nanotechnologyHybrid capacitor electrodesCapacitanceNickel free

The invention discloses a high-activity trivalent-nickel-metal-doped nanometer nickel-based hydrotalcite material in a nickel-based electrode material, and a preparation method of the nanometer nickel-based hydrotalcite material. A micro-emulsion confined synthetic method is adopted, is mild in preparation condition and easy for industrial massive production when compared with a traditional preparation method, and provides a feasible method and thought for synthesis of a trivalent-nickel material. The synthesized trivalent-nickel-doped hydrotalcite material is remarkably excellent in capacitance with respect to a supercapacitor. The capacitance can reach 2810 F / g (in a condition of a discharge current being 1.5 A / g), and is 28 times as much as the capacitance (being 100F / g) of a trivalent-nickel-free hydrotalcite material. The trivalent-nickel-doped hydrotalcite material still maintains an excellent charging and discharging effect and is superior in stability under a large electric current. A series of supercapacitor electrode materials doped with trivalent nickel is greatly superior to a traditional Ni-based electrode material, is simple in synthetic method, operation, and processes, and is easy for massive production.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

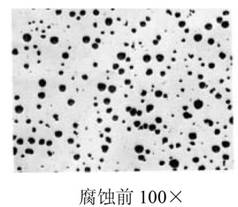

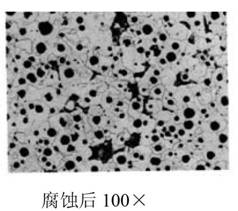

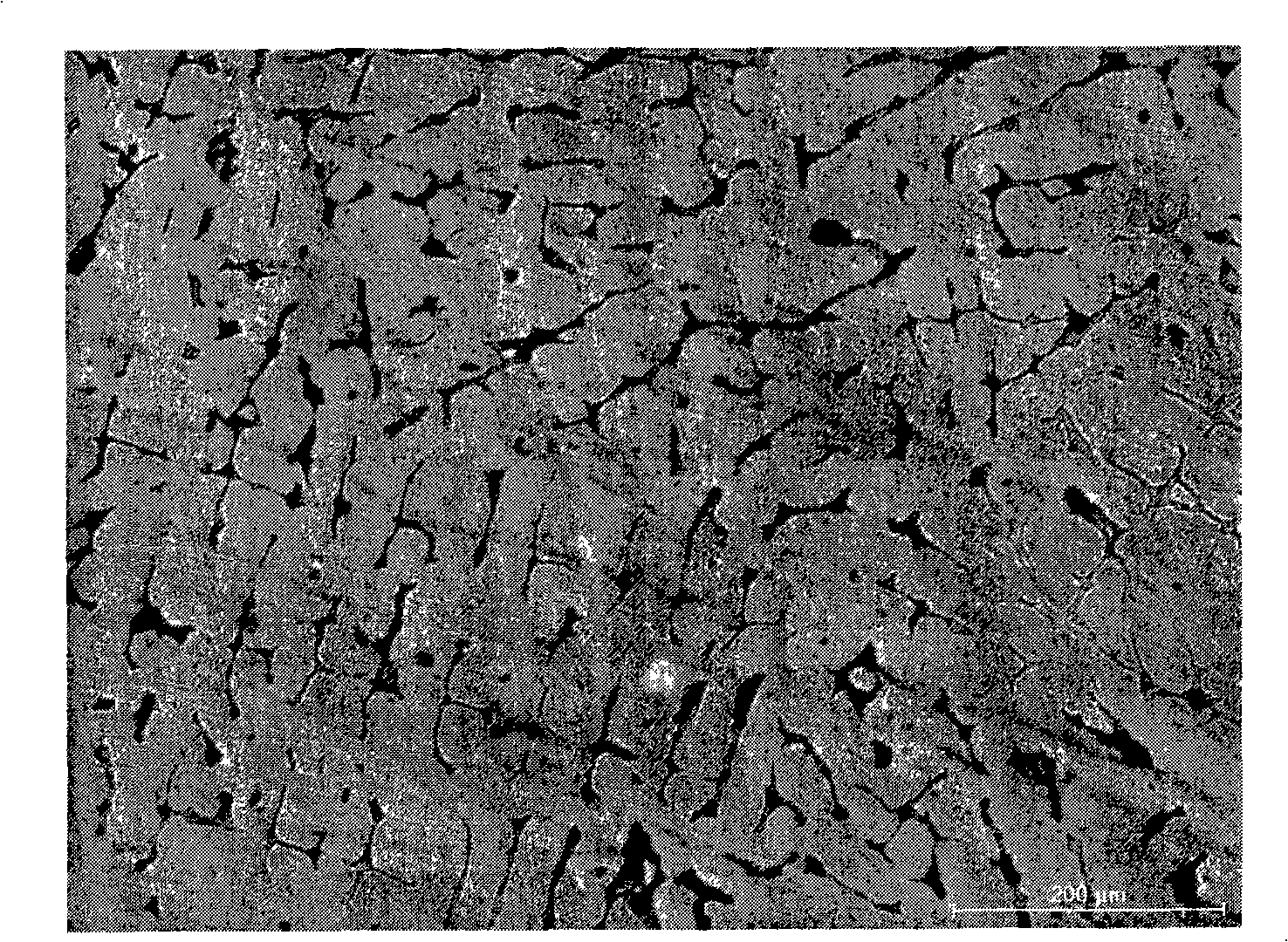

Cobalt-nickel-free based alloy for strengthening coating of sealing surface of nuclear power valve

InactiveCN101717881ASmall and dense tissueImprove mechanical propertiesMetallic material coating processesNuclear powerNickel free

The invention discloses a cobalt-nickel-free based alloy for a strengthening coating of a sealing surface of a nuclear power valve. The alloy contains the following components by weight percentage: 37.5%-38.5% of chromium, 5.0-6.0 % of carbon, 2.0%-2.5% of silicon, 1.0%-1.5% of boron, 0.5%-1.5% of yttrium oxide and the balance of nickel. The mixing alloy powder is compounded, and the strengthening coating is prepared by a laser cladding technology. The obtained cobalt-nickel-free based alloy strengthening coating of the sealing surface of the nuclear power valve has the relative parameters as follows: the average hardness HRC is 45-50, and is 39-43 higher than the traditional cobalt-nickel alloy coating; the grain size is 11-12, and is finer than the traditional plasma spray-welding coating of 9-10 and the flame surfacing welding layer of 8-9, which is favorable for the comprehensive mechanical property correspondingly; the combined bandwidth of the coating and the base body is 25-40 mum, and is compacter than the traditional plasma spray-welding combined band with the width of 80-120 mum and the flame surfacing welding combined band with the width of 20-300 mum. The invention has the advantages of saving of noble metal, i.e. cobalt, cost reduction, simple preparation technology, conformance to special requirement of nuclear environment, and the like.

Owner:SUZHOU UNIV +1

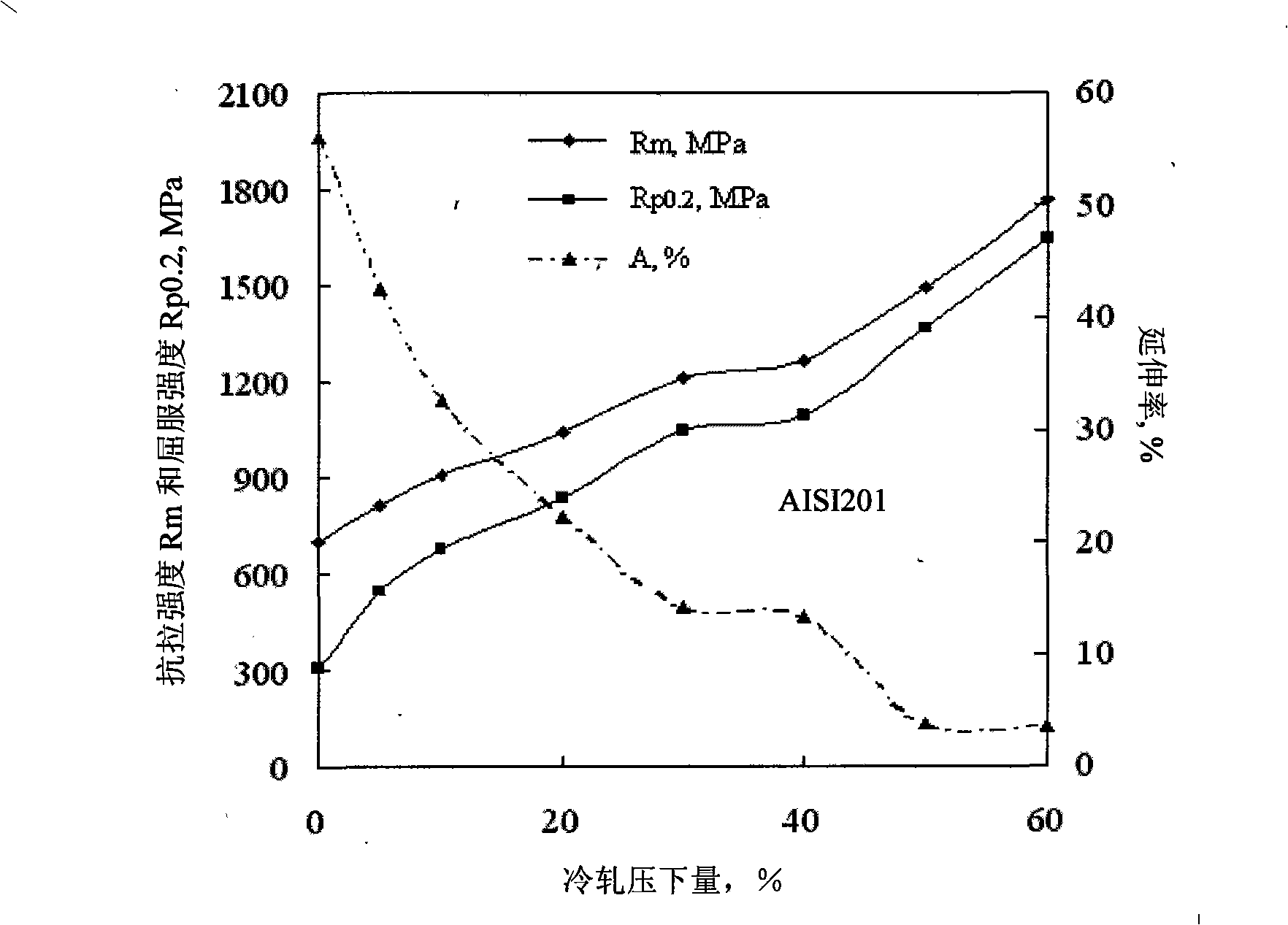

Nickel-free metastable austenitic stainless steel with TRIP effect

The invention provides nickel-free metastable austenitic stainless steel with TRIP effect. The nickel-free metastable austenitic stainless steel comprises the following chemical composition in percentage by weight: 0.08-0.15 percent of C, less than 1 percent of Si, 8-10 percent of Mn, 15-16.5 percent of Cr, 0.15-0.30 percent of N, less than 0.03 percent of P, less than 0.02 percent of S, and the balance being Fe and inevitable impurities. The nickel-free metastable austenitic stainless steel can improve the strength of steel through cold working, ensures that material has wider strength range so as to meet various working condition demands, is especially suitable for weak corrosive environments, such as traffic, construction, hardware and other fields, and can partially replace AISI304, AISI301, AISI201 and other austenitic stainless steel with high nickel content so as to save noble metal nickel.

Owner:BAOSHAN IRON & STEEL CO LTD

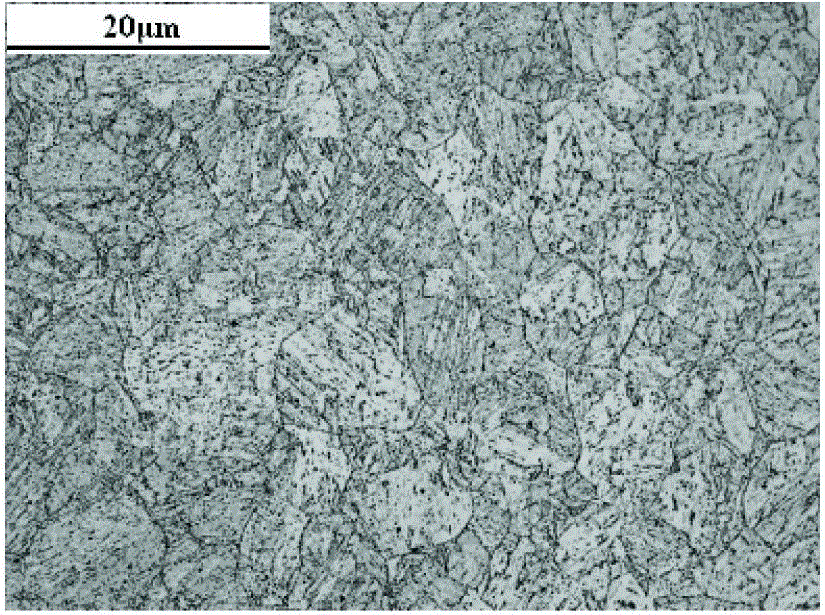

Nodular cast iron roller of hot rolled seamless steel tube tandem mill and preparation method thereof

ActiveCN102330013ASufficiently prone to chipping issuesPrevents prone to chipping problemsFoundry mouldsFurnace typesChromium freeNickel free

The invention discloses a nodular cast iron roller of a hot rolled seamless steel tube tandem mill and a preparation method thereof. The method comprises the following steps of: according to the structural shape of the roller, selecting a composite sand mold, the circular sections of which have nearly equal thickness; selecting a raw material with low alloy content for smelting; controlling the casting solidification time within 2 hours; performing isothermal quenching on a roller casting blank; and finally, performing finish machining and inspection on the roller. The invention simultaneously provides the nickel-free and chromium-free nodular cast iron roller of the hot rolled seamless steel tube tandem mill, designed by using low-molybdenum alloy reduced components. By the method, the nodular cast iron roller of the hot rolled seamless steel tube tandem mill, satisfying the service condition, is manufactured; the roller is prevented from cracking in use; consumption of noble metals such as nickel, chromium and molybdenum and energy is reduced; and the manufacturing and using costs of an enterprise are reduced.

Owner:SHANDONG SIFANG STEEL PIPE EQUIP MFG

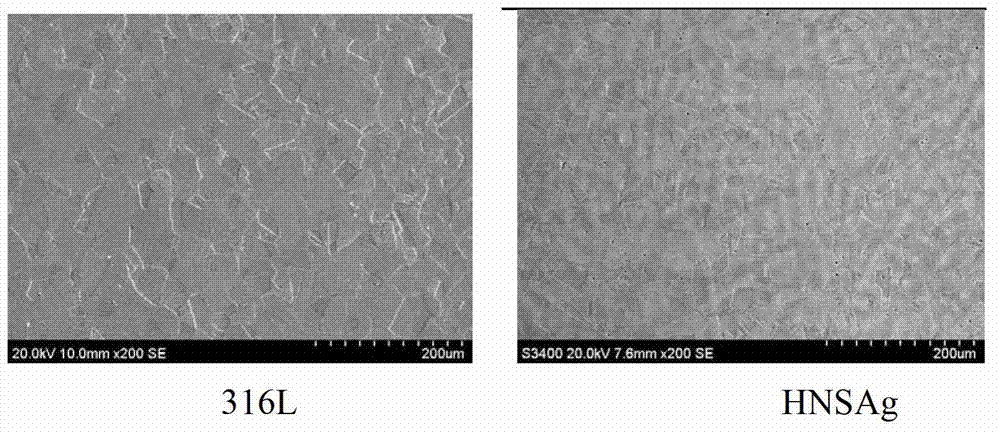

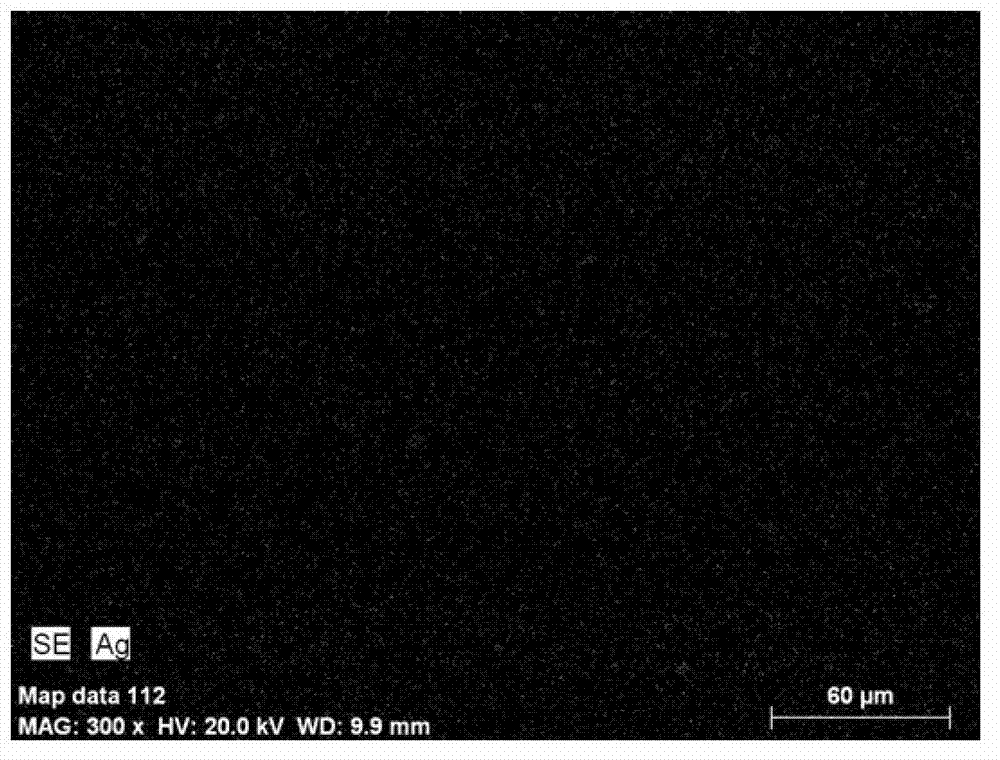

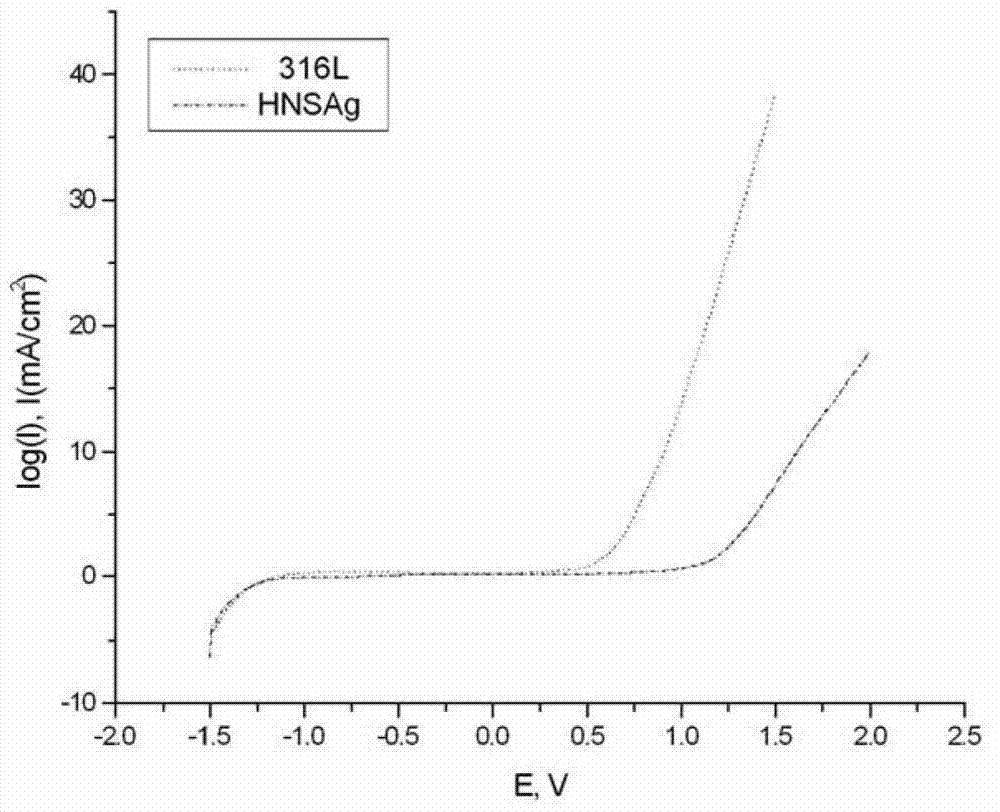

High-nitrogen nickel-free austenite antibacterial stainless steel (HNSAg) and manufacturing method thereof

ActiveCN103045951AImprove toughness and plasticityMeet processing requirementsChromium nickelNiobium

The invention discloses high-nitrogen nickel-free austenite antibacterial stainless steel (HNSAg) and a manufacturing method thereof. The stainless steel comprises carbon, silicon, manganese, chromium, molybdenum, copper, nitrogen, niobium, silver and the balance of iron by weight percent; the high-nitrogen nickel-free austenite antibacterial stainless steel (HNSAg) is of a single austenite structure after subjected to solution treatment, and is excellent in pitting corrosion resistance in a non-microorganism environment and good in bacterial resistance and microorganism corrosion resistance in a microorganism environment; the antibacterial rate of the stainless steel on staphylococcus aureus and escherichia coli reaches more than 93%; the nickel release risk is inexistent; the manganese release rate in artificial saliva and sweat is much lower than the acceptable daily intake standard; the stainless steel can be used as a biomedical material; and the metal toxicity risk is inexistent. The high-nitrogen nickel-free austenite antibacterial stainless steel (HNSAg) is very good in flexibility and plasticity, can meet the processing requirements of fine parts such as jewelries and the like, and is superior to chromium-nickel austenite antibacterial stainless steel of 316 L and the like in overall performance.

Owner:郭强

Nickel-free zirconium alloy with amorphous structure easily formed by pouring melt copper mould

The invention relates to a nickel-free zirconium alloy with an amorphous structure easily formed by pouring a melt copper mould. The alloy comprises four components, namely, Zr, Ti, Cu and Al, wherein the atom percentages of the four components in the whole alloy are respectively a, b, c and d, and a is 45-69%, b is 0.25-8%, c is 21-35%, d is 7.5-15%, and the sum of a, b, c and d is less than or equal to 100%. The alloy melt is poured to an inner cavity of a copper mould, and then a bulk material or part with the amorphous structure is formed. The amorphous zirconium alloy provided by the invention has the characteristics of high breakage strength, high tenacity, low elastic modulus and corrosion resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

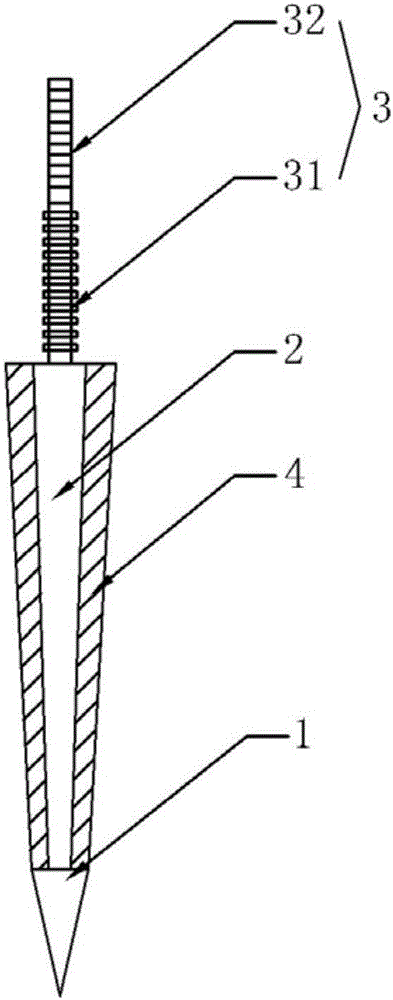

Manufacturing method of root canal filling tip

ActiveCN106377434AGood biocompatibilityEasy to useImpression capsDentistry preparationsGutta-perchaBiocompatibility Testing

The invention provides a manufacturing method of a root canal filling tip, and belongs to the field of medical equipment. The manufacturing method of the root canal filling tip comprises the following steps: step 1, selecting a medical vanadium-free nickel-free titanium alloy wire as a raw material; step 2, processing a first end of the vanadium-free nickel-free titanium alloy wire into a cone to form a closed section; step 3, processing a filling section from a thick end of the closed section on the vanadium-free nickel-free titanium alloy wire; step 4, cutting into a plurality of scale lines from one end of the filling section on the vanadium-free nickel-free titanium alloy wire to form a depth measuring section; and step 5, manufacturing a mould with a mould cavity, putting the filling section in the center of the mould cavity of the mould, and injecting heated gutta-percha into the mould cavity to enable the gutta-percha to uniformly wrap the periphery of the filling section. The root canal filling tip manufactured by the manufacturing method provided by the invention adopts the vanadium-free nickel-free titanium alloy wire as the raw material, has high biocompatibility and is safe to use; and the root canal filling tip adopts an integrally formed structure, avoids welding and prevents harmful substances in a welding flux from permeating a human body.

Owner:莫总鸣

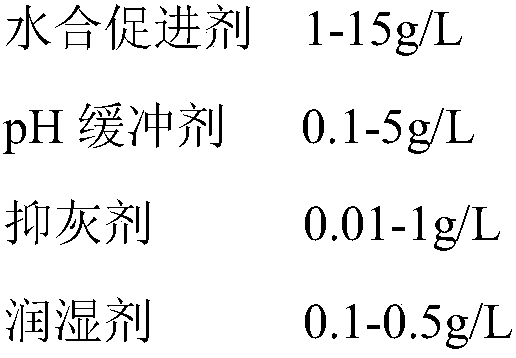

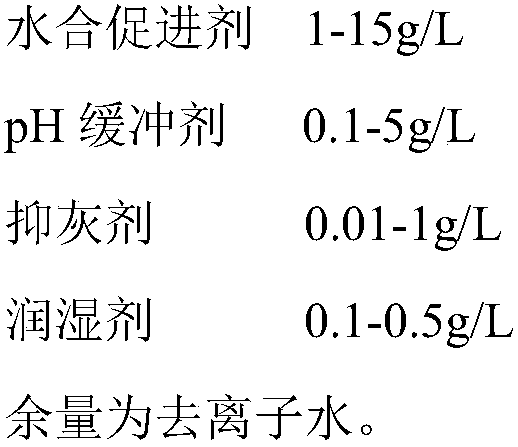

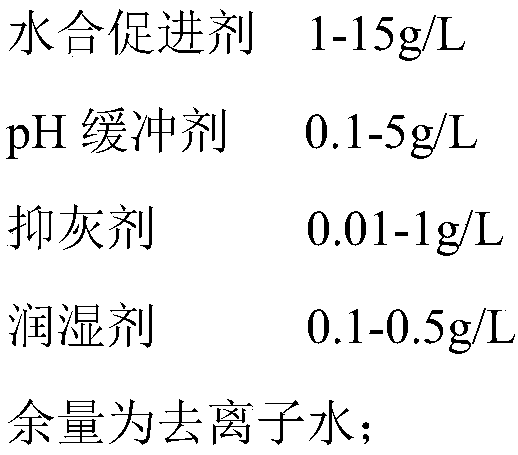

Nickel-free and fluoride-free sealing agent for aluminum and aluminum alloy anode oxide films

InactiveCN108018591AAvoid pollutionImprove corrosion resistanceSurface reaction electrolytic coatingWastewaterNickel free

The invention discloses a nickel-free and fluoride-free sealing agent for aluminum and aluminum alloy anode oxide films. The sealing agent is prepared from the following components of 1-15g / L of a hydration accelerant, 0.1-5g / L of a pH buffer agent, 0.01-0.1g / L of an ash inhibitor, 0.1-0.5g / L of a wetting agent and the balance deionized water. The sealing agent has the advantages that heavy metalpollution in wastewater treatment can be avoided, in addition, the oxide films with good corrosion resistance can be obtained, the experimental requirement of GB / T 8753.1-2005 phosphochromic acid canbe met, the films are uniform and smooth, the dye speck resistance performance is good, and hole sealing of the natural-color anode oxide film and the dyed anode oxide film can be simultaneously realized; and a concentrated formula is provided, a preparation method is simple, and the operation is convenient.

Owner:HANGZHOU WIN WIN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com