Anti-stain and anti-fingerprint stainless steel plate and preparation method thereof

A stainless steel, fingerprint-resistant technology, used in chemical instruments and methods, layered products, metal layered products, etc., can solve problems such as poor anti-fouling, fingerprint resistance, good processing performance, and inability to meet usage requirements. , to achieve the effect of low cost, good performance and good anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

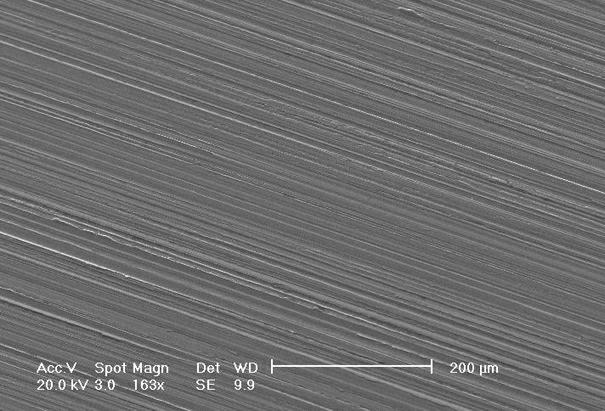

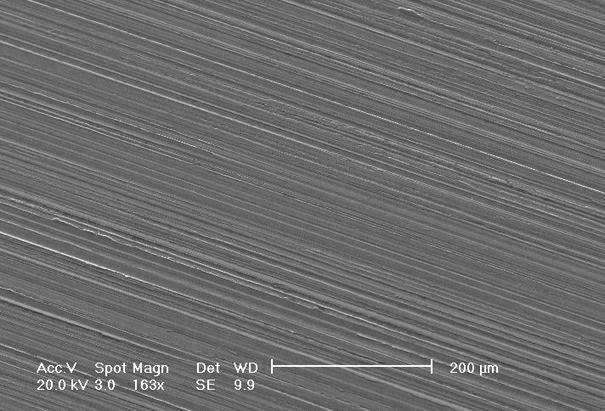

Image

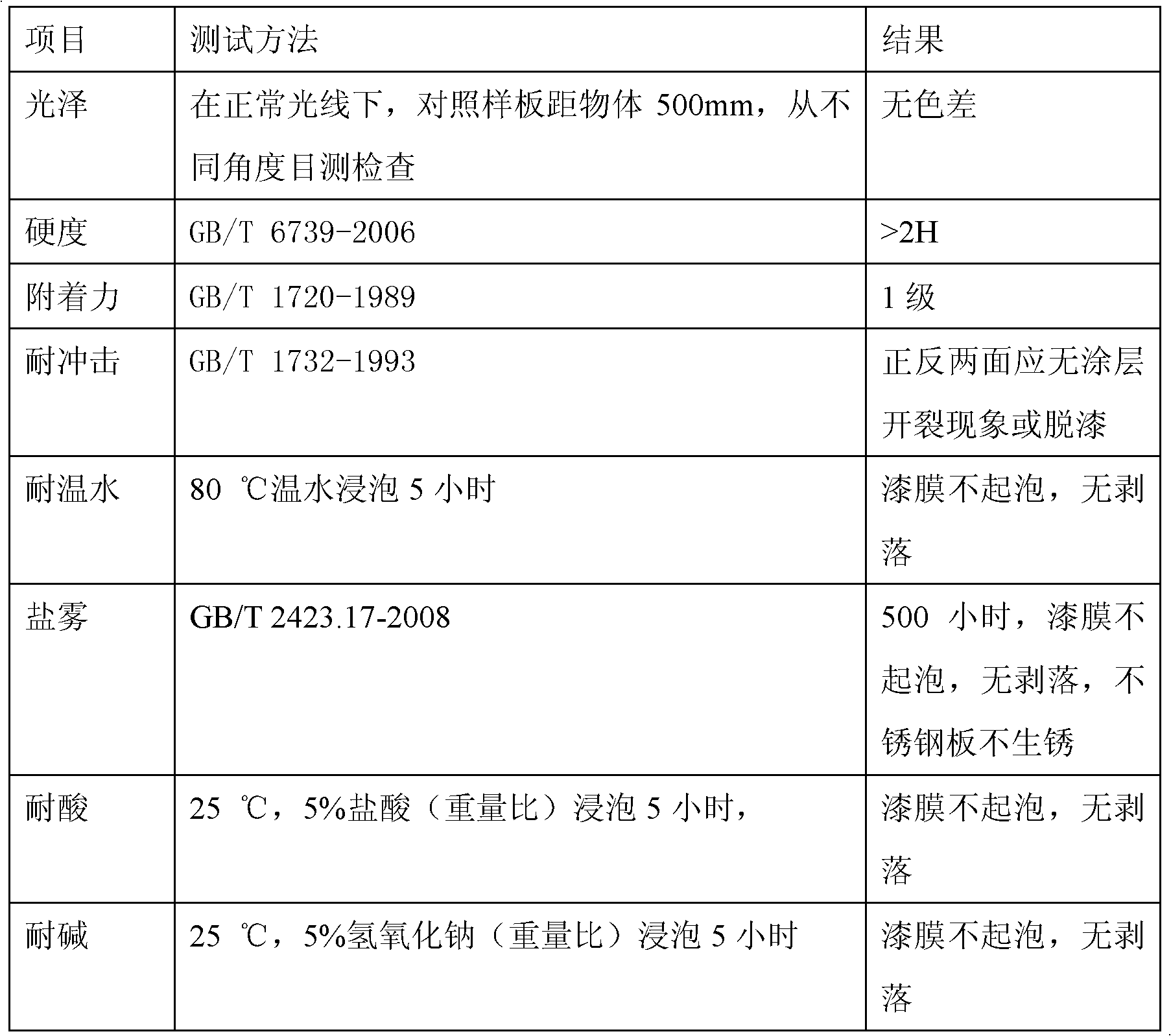

Examples

Embodiment 1

[0022] The acrylic composite resin is prepared by solution polymerization according to the following weight ratio: 30 parts of methyl methacrylate, 15-16 parts of methacrylic acid, 5 parts of butyl acrylate, 5-6 parts of acrylonitrile, 15-16 parts of hydroxyethyl acrylate , 6-7 parts of styrene, 1-2 parts of ammonium persulfate, 30 parts of butanol, 11 parts of butyl acetate. The obtained acrylic composite resin is dissolved in the solvent (not dried), and then add nano silicon dioxide 0.5, amino resin 15, epoxy resin 15, antirust agent 0.005, leveling agent 0.005, defoamer 0.005, dispersant 0.01, curing agent 30, ball milled for 1 hour, and mixed evenly to obtain a transparent solution. Film formers, fillers and additives are ball-milled and mixed uniformly to obtain the polymer coating of the present invention.

[0023] Immerse the 430 stainless steel plate in a pool containing a surface cleaning agent, wash it for 3 minutes, rinse it with tap water and deionized water thre...

Embodiment 2

[0025] In 100g of acrylic resin, add 100g of butanol to completely dissolve the acrylic resin, then add 1g of nano-zinc dioxide and 1g of nano-titanium dioxide, 10g of amino resin, 20g of epoxy resin, 0.005g of antirust agent, and 0.005g of leveling agent. 0.005g of defoaming agent, 0.01g of dispersant, 30g of curing agent, ball milled for 1 hour, and mixed uniformly to obtain a transparent solution.

[0026]Immerse the 430 stainless steel plate in a pool containing surface cleaning agent, wash it for 3 minutes, then rinse it with tap water and deionized water three times respectively, and after air drying for 10 minutes, apply the prepared coating material on the steel surface by roller coating , Cured at 190 degrees for 10 minutes, cooled naturally, and put into storage for quality inspection.

[0027] The particle diameter of the above-mentioned nano-inorganic nanoparticles is 50 nanometers, and the above-mentioned nano-inorganic nanoparticles are preferably treated with a ...

Embodiment 3

[0029] In 100g of acrylic resin, add 100g of butanol, after the acrylic resin is completely dissolved, add 0.5g of nano-titanium dioxide, 1g of nano-zinc oxide, 15g of amino resin, 15g of epoxy resin, 0.005g of antirust agent, 0.005g of leveling agent, 0.005g of defoaming agent, 0.01g of dispersant, 30g of curing agent, ball milled for 1 hour, and mixed uniformly to obtain a transparent solution.

[0030] Immerse the 430 stainless steel plate in a pool containing surface cleaning agent, wash it for 5 minutes, rinse it with tap water and deionized water three times, and dry it for 10 minutes, then apply the prepared coating material on the steel surface by roller coating , cured at 170 degrees for 15 minutes, cooled naturally, and put into storage for quality inspection. The above-mentioned nano-inorganic nanoparticles are better treated with a titanium ester coupling agent. The particle size of the nano-inorganic nanoparticles is 50 nanometers with a maximum component distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com