Patents

Literature

625 results about "Low elastic modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lower modulus of elasticity – A pliable substance that exhibits versatile mechanical characteristics All this mathematics talk can be a bit distracting, serving only to obscure real world functions. A softer material with a lower modulus of elasticity is rubber-like.

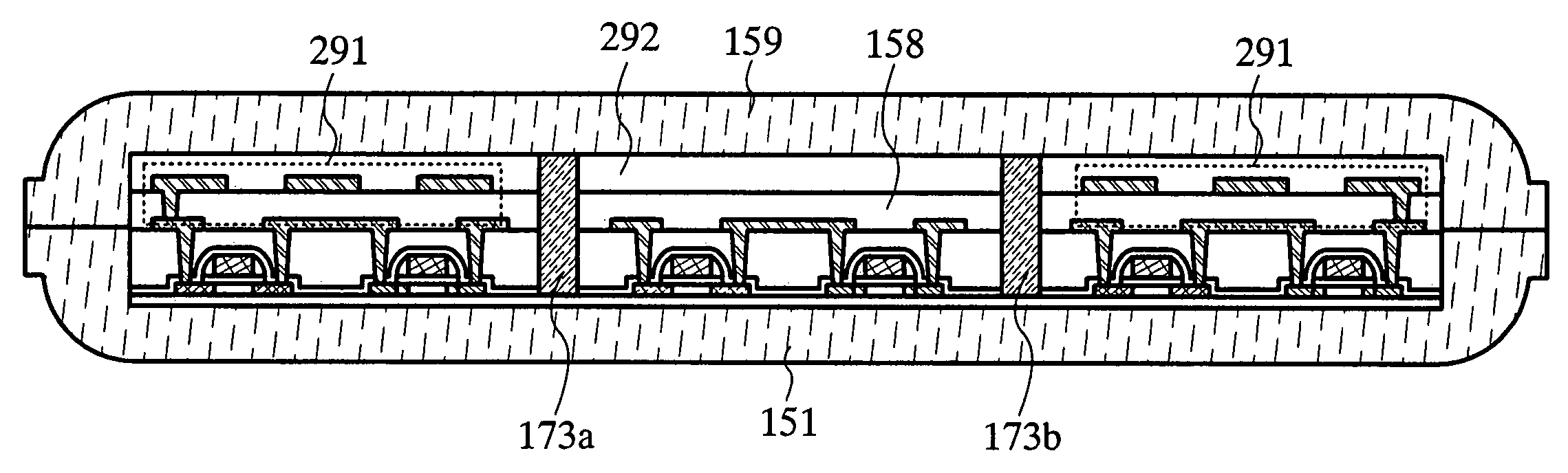

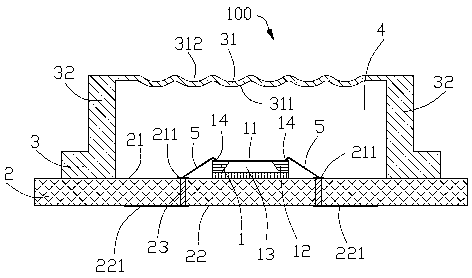

Semiconductor device and method for manufacturing the same

ActiveUS20090267225A1Reduce thicknessSmall sizeSemiconductor/solid-state device detailsSolid-state devicesShock resistanceDiffusion layer

In a semiconductor integrated circuit sandwiched between a pair of a first impact resistance layer and a second impact resistance layer, an impact diffusion layer is provided between the semiconductor integrated circuit and the second impact resistance layer. By provision of the impact resistance layer against the external stress and the impact diffusion layer for diffusing the impact, force applied to the semiconductor integrated circuit per unit area is reduced, so that the semiconductor integrated circuit is protected. The impact diffusion layer preferably has a low modulus of elasticity and high breaking modulus.

Owner:SEMICON ENERGY LAB CO LTD

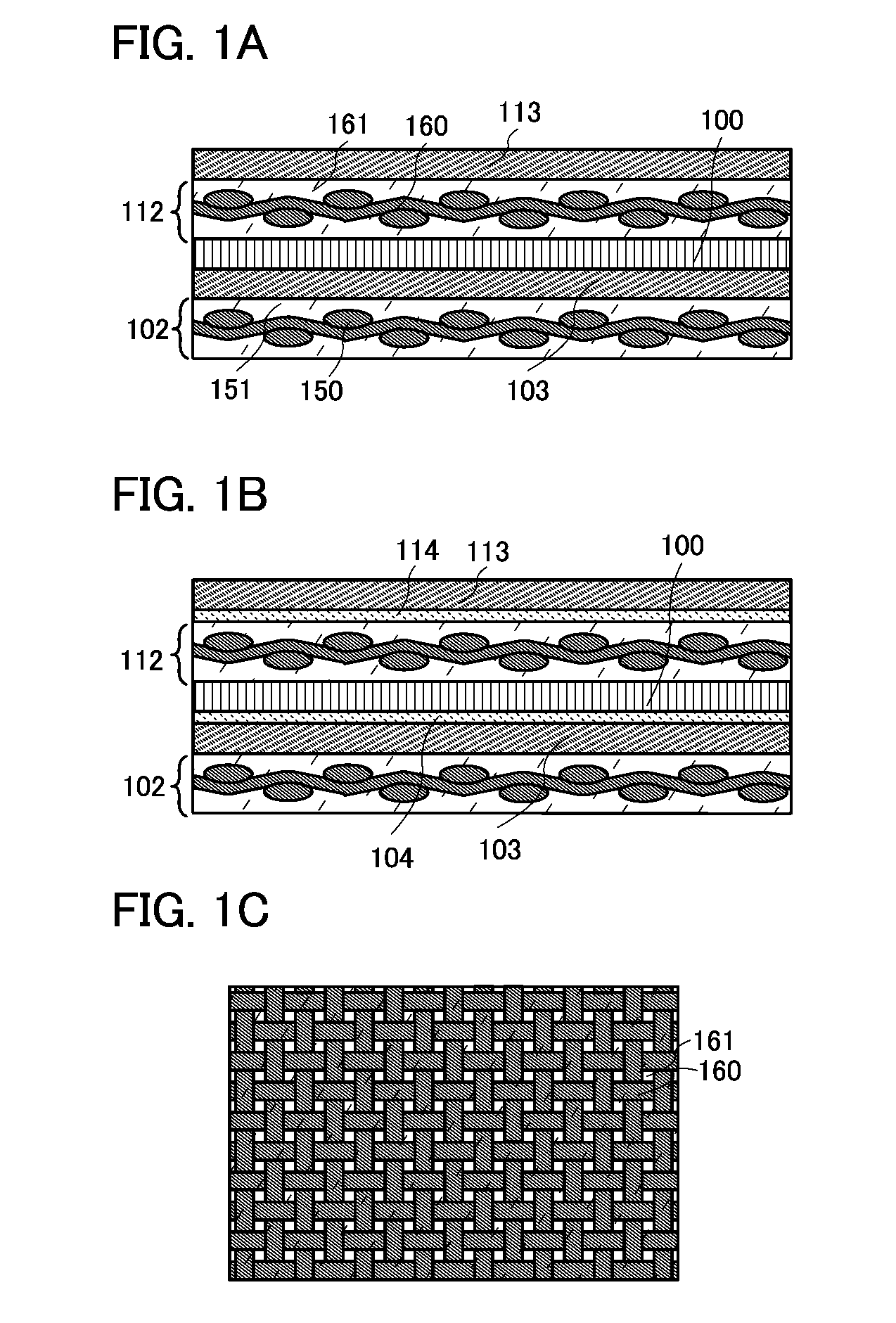

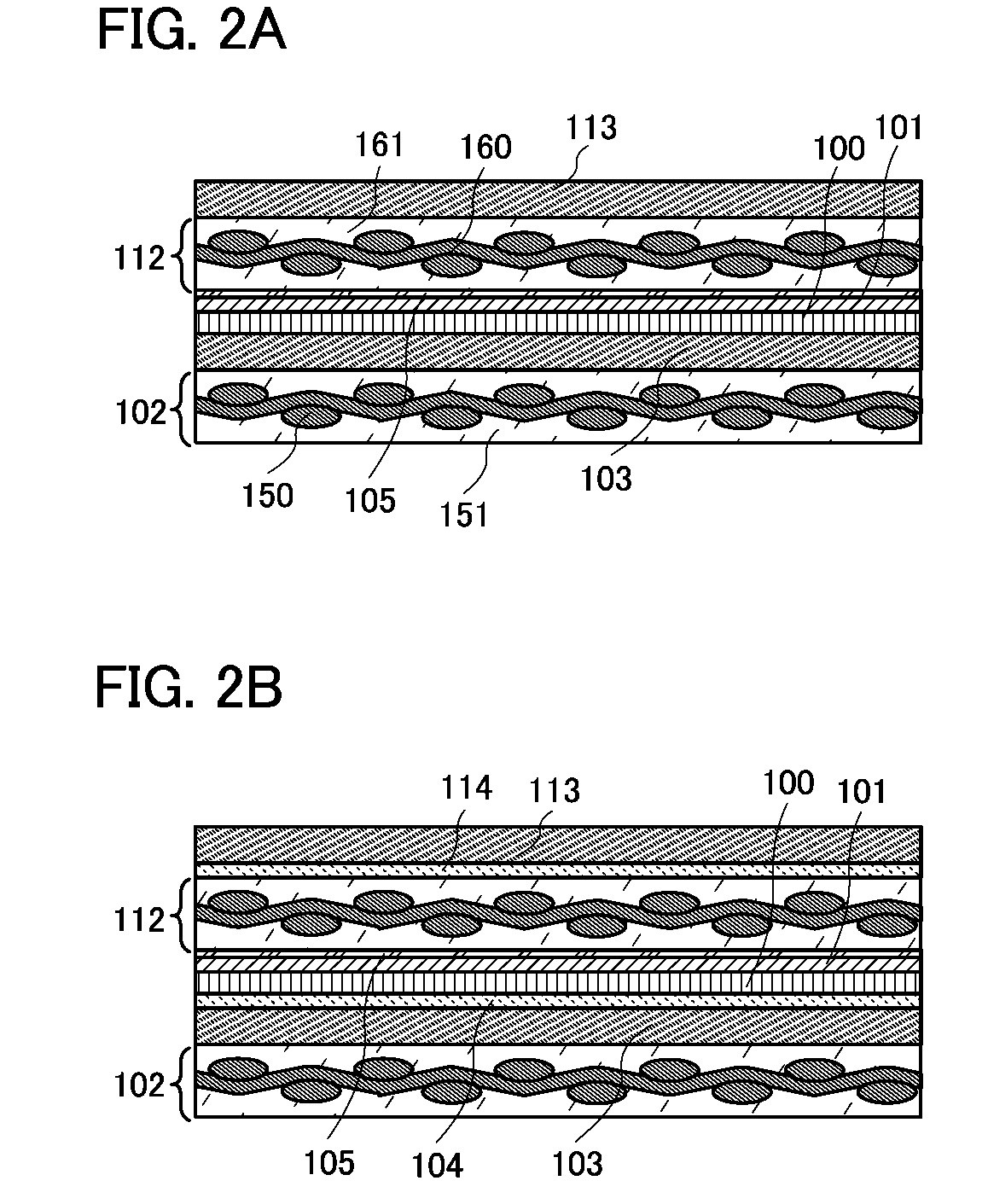

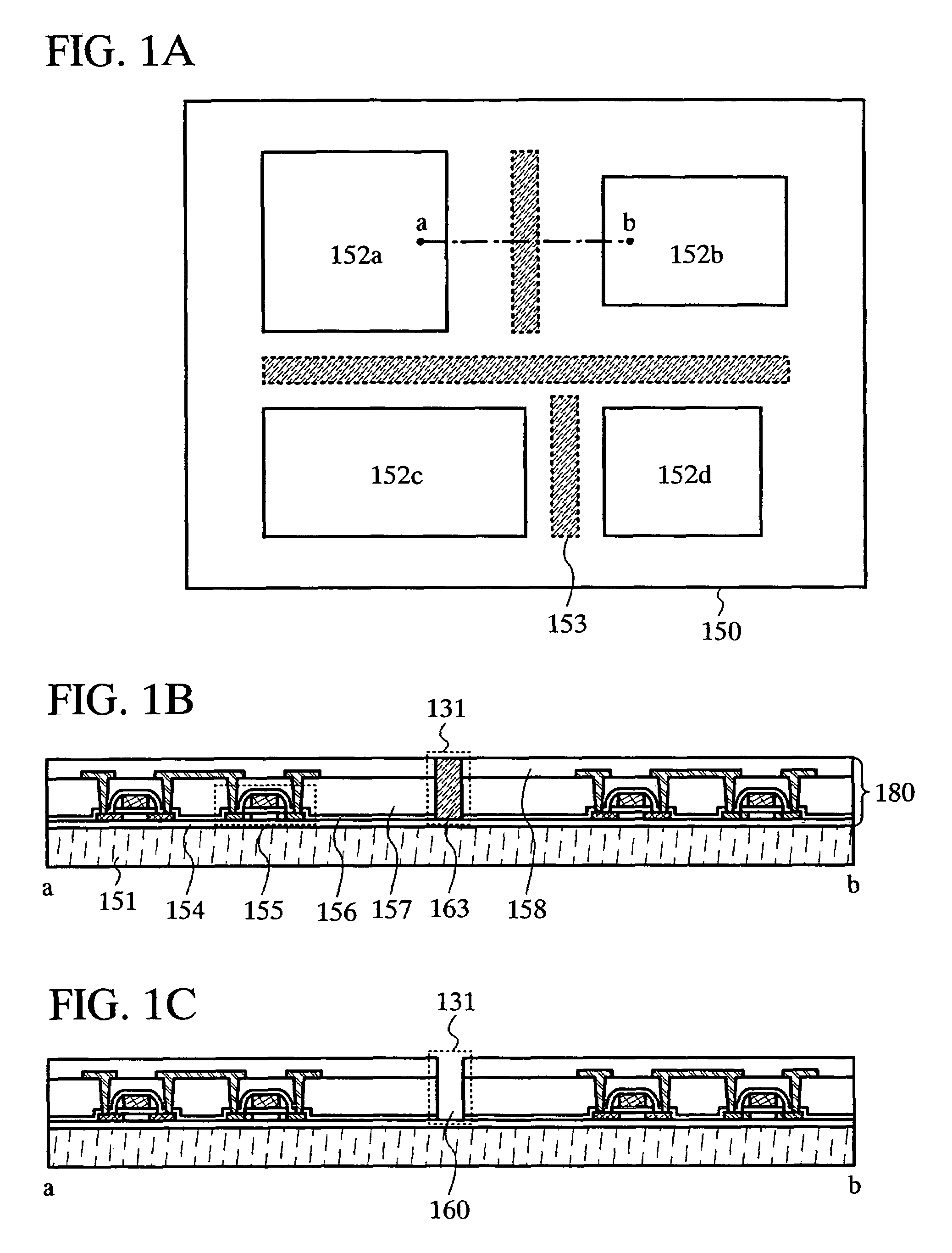

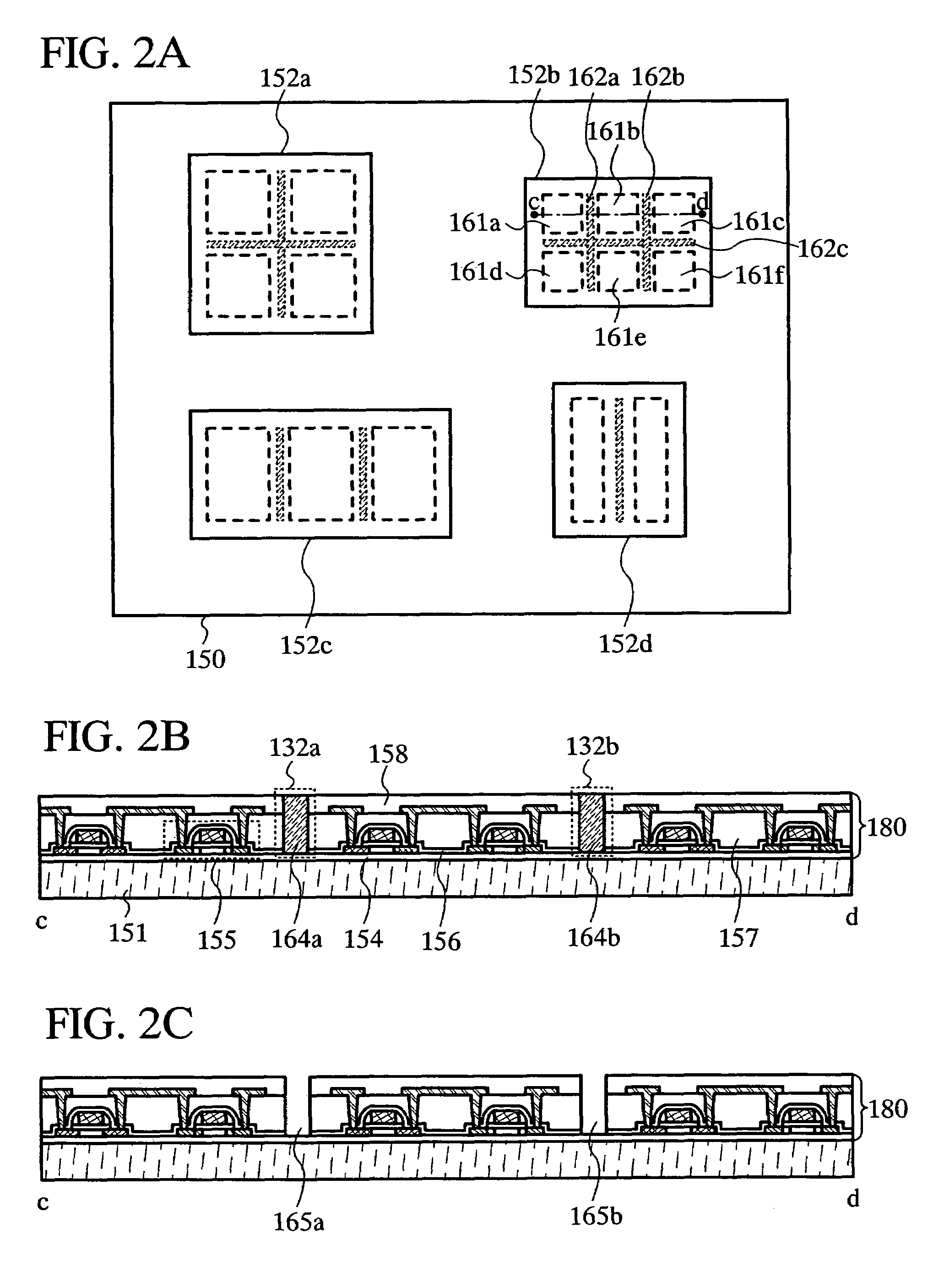

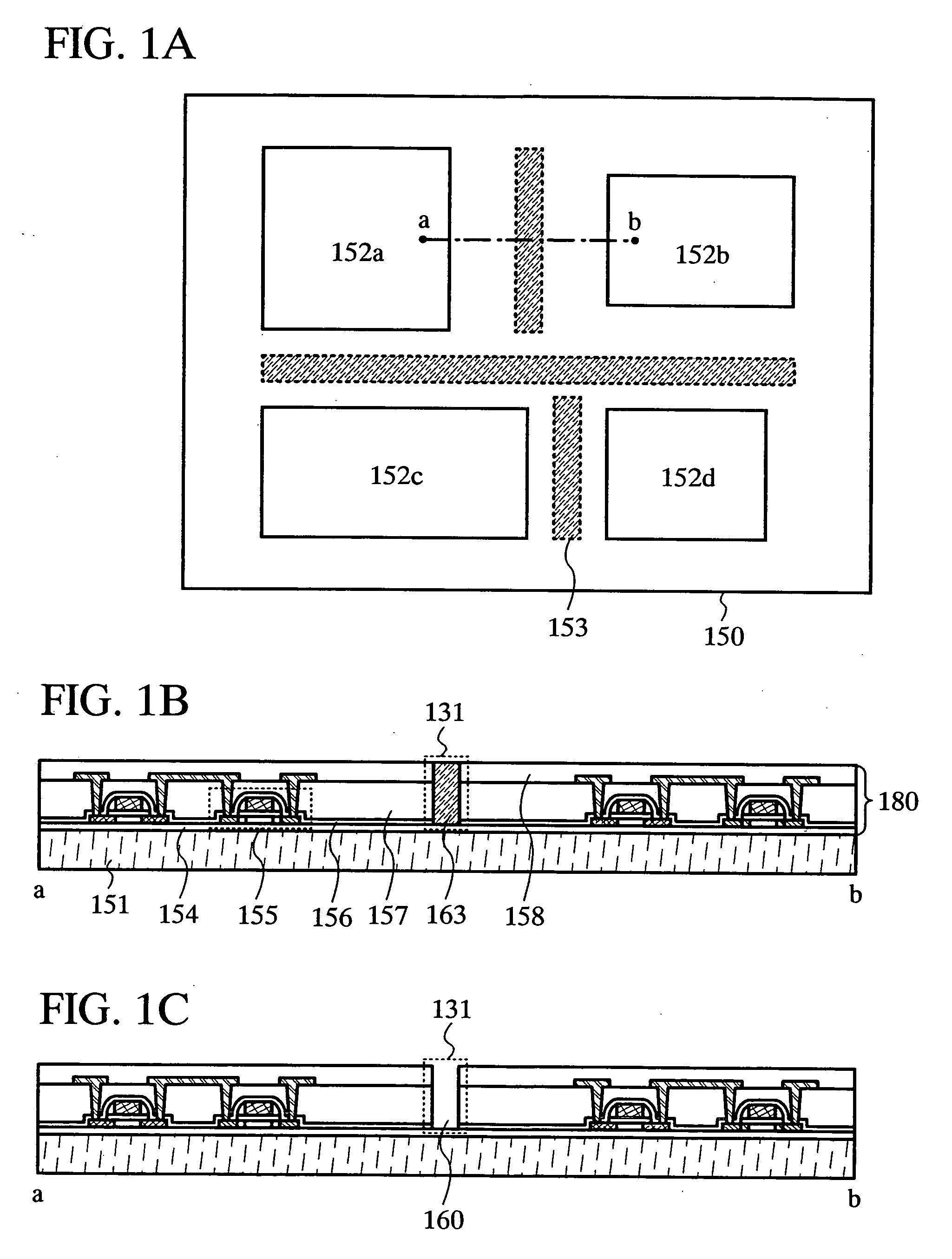

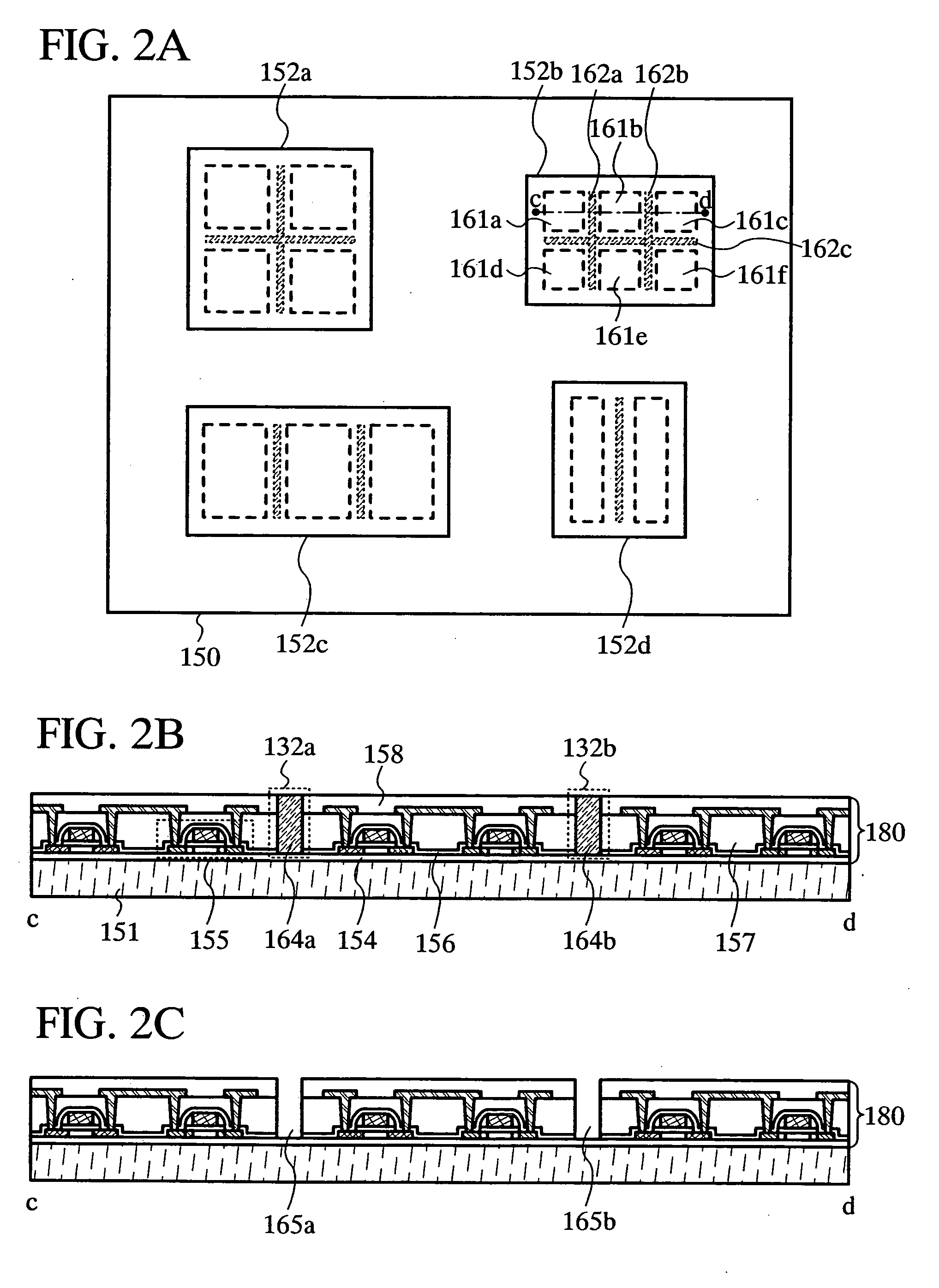

Semiconductor device and method for manufacturing the same

InactiveUS7566633B2Change flexibilityChange resistanceFinal product manufactureSolid-state devicesEngineeringGlass transition point

An object of the present invention is to provide a semiconductor device which has flexibility and resistance to a physical change such as bending and a method for manufacturing the semiconductor device. A semiconductor device of the present invention includes a plurality of transistors provided over a flexible substrate, each of which has a semiconductor film, a gate electrode provided over the semiconductor film with a gate insulating film therebetween, and an interlayer insulating film provided to cover the gate electrode, and a bending portion provided between the plurality of transistors, in which the bending portion is provided by filling an opening formed in the interlayer insulating film with a material having a lower elastic modulus, a material having a lower glass transition point, or a material having a higher plasticity than that of the interlayer insulating film.

Owner:SEMICON ENERGY LAB CO LTD

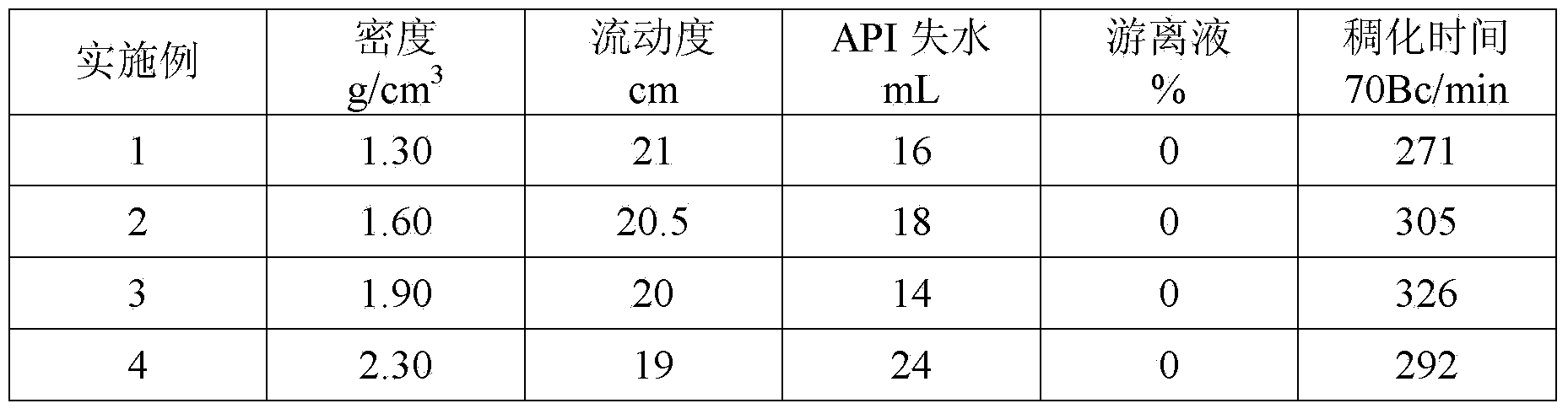

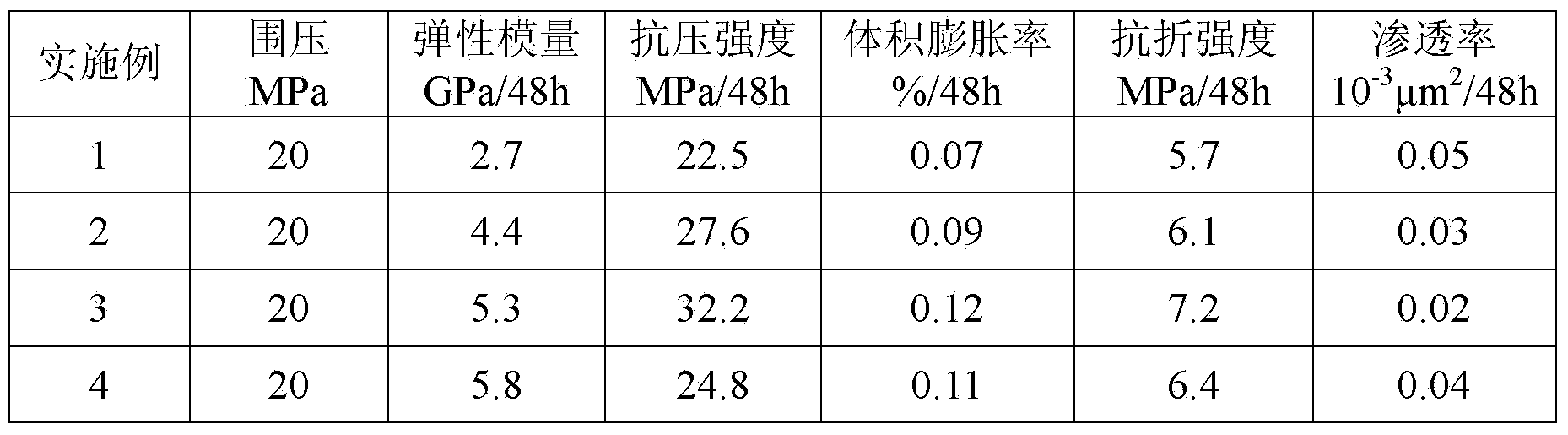

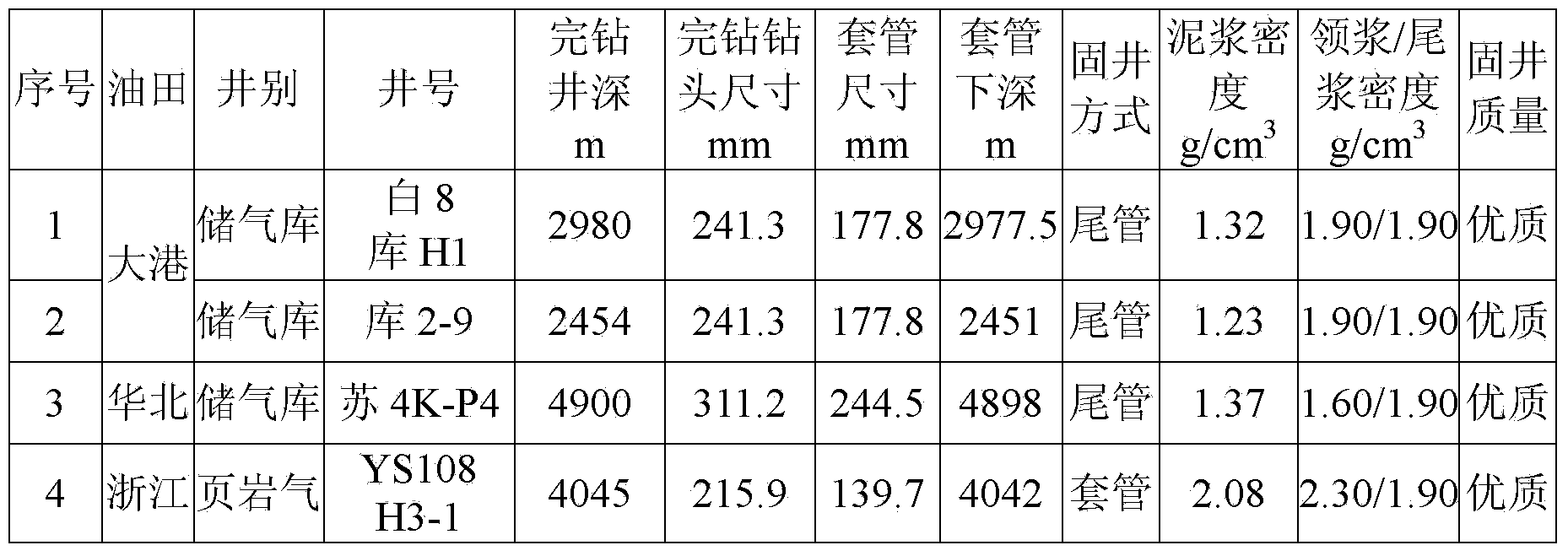

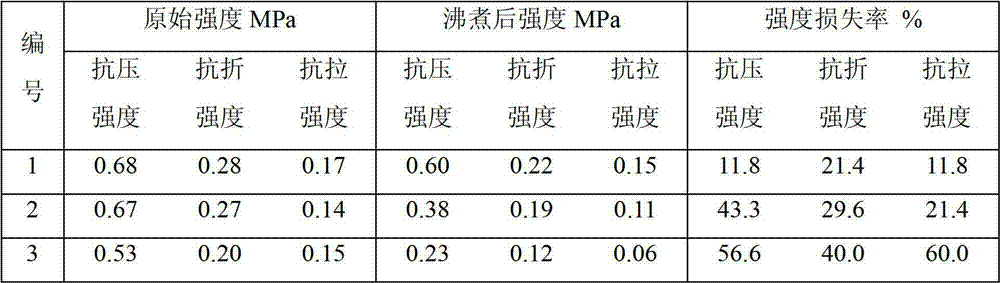

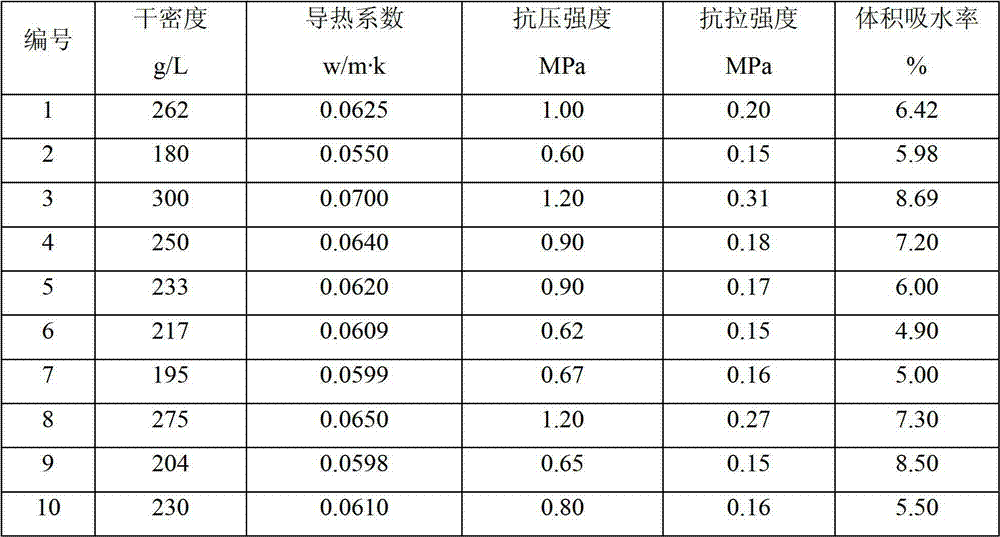

Expanded flexible well cementing grout and preparation method thereof

ActiveCN104371678ALow elastic modulusLower transfer coefficientDrilling compositionHorizontal wellsVolumetric Mass Density

The invention provides an expanded flexible well cementing grout and a preparation method thereof. The grout comprises the following components in parts by weight: 100 parts of cement, 6-14 parts of toughening material, 3-80 parts of reinforcing material, 8-120 parts of density modifier, 0.5-2.5 parts of suspension stabilizer, 20-40 parts of high-temperature stabilizer, 35-100 parts of distilled water, 0.5-2 parts of dispersant, 0.5-4 parts of fluid loss agent, 0.3-4 parts of retarder, 0.1-2 parts of foam inhibitor and 0.1-2 parts of defoamer. The invention further provides a preparation method of the expanded flexible well cementing grout. The grout has good sedimentation stability; and the set cement has the characteristics of micro expansion, high strength and low elasticity modulus, and can avoid the phenomena of micro cracks, micro annuluses, even fracture and the like caused by cement sheaths in subsequent operation of gas storage wells, shale gas wells, dense oil-gas horizontal wells and the like, thus realizing good zonal isolation and providing a technical support for long-term, safe and effective operation of oil-gas wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

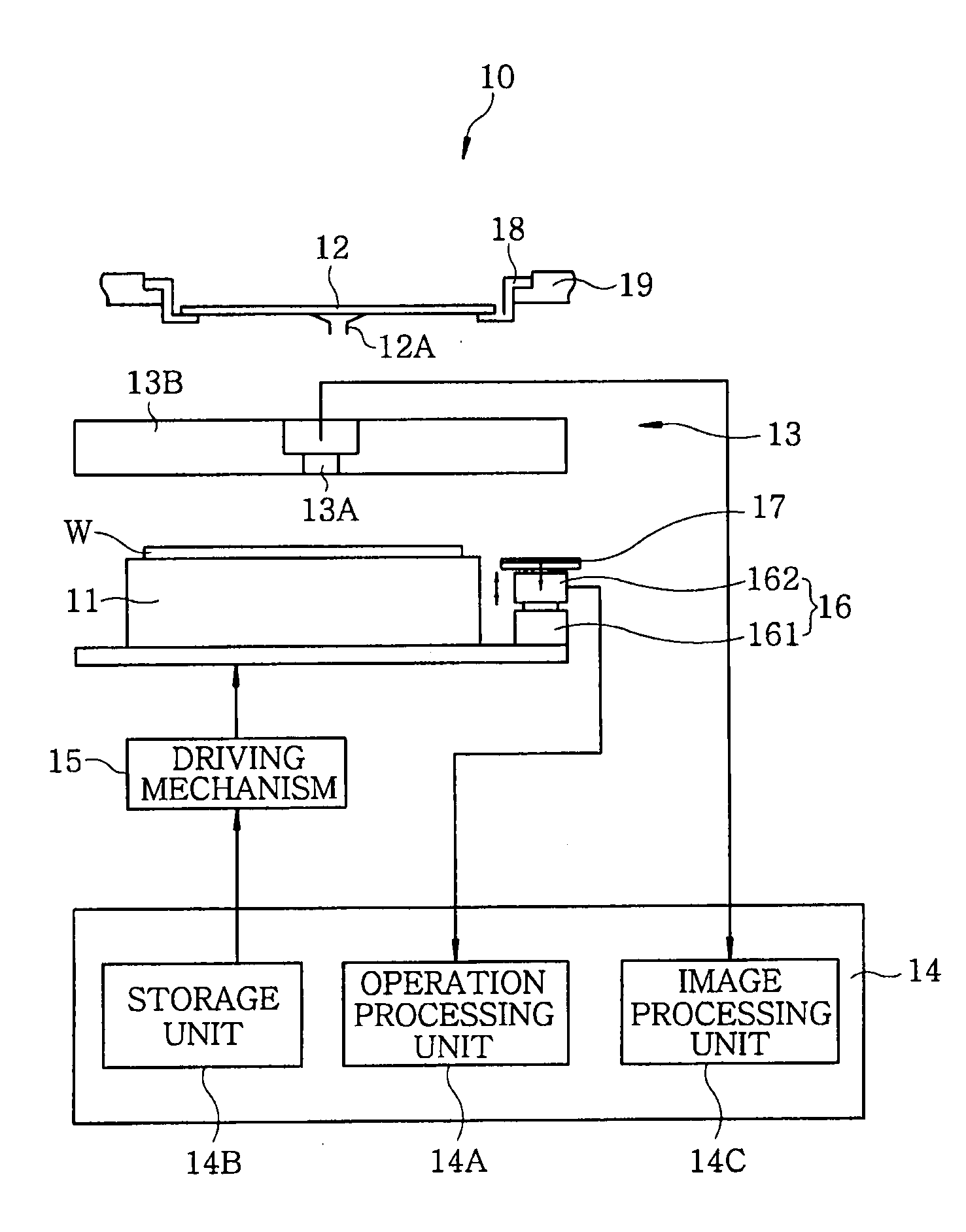

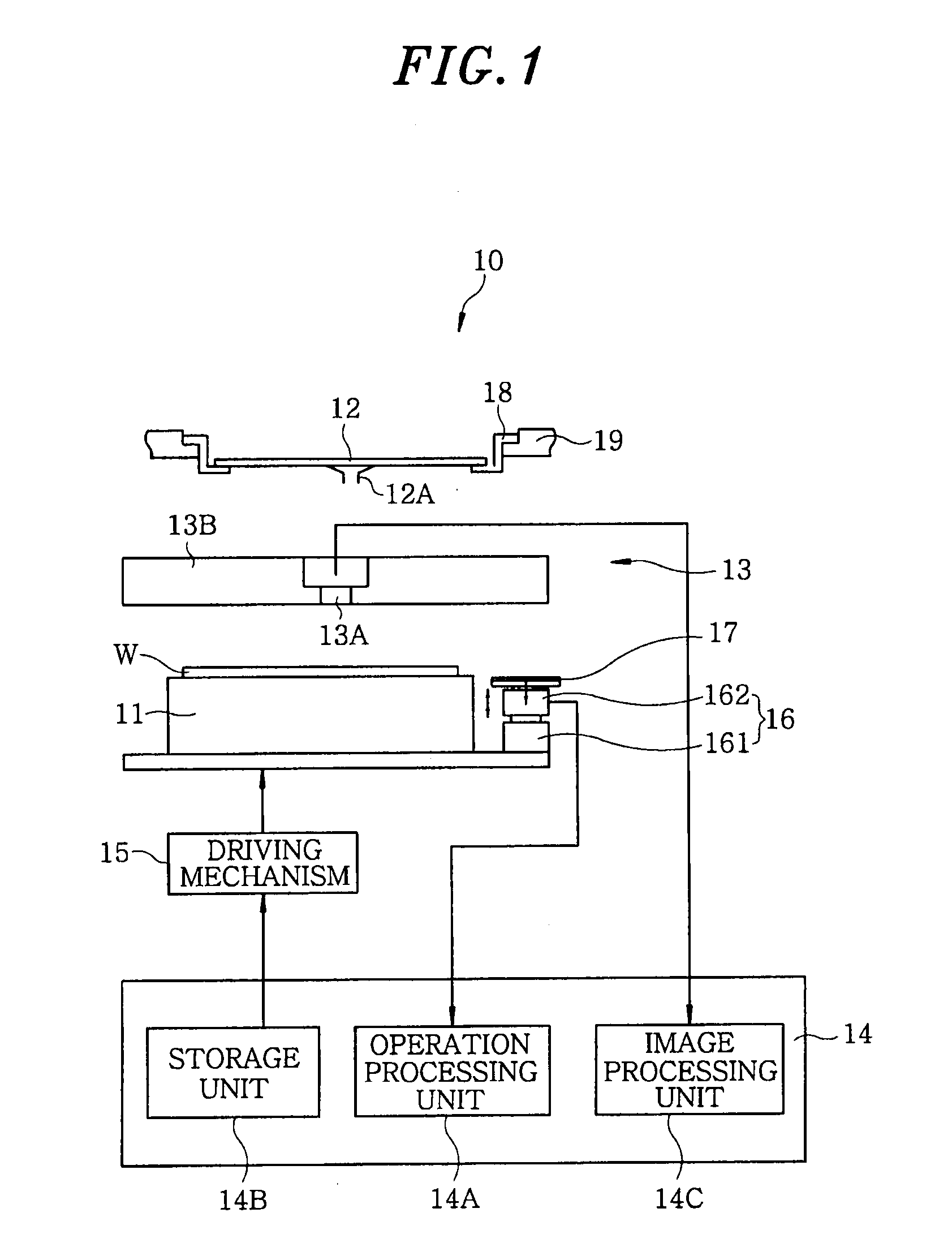

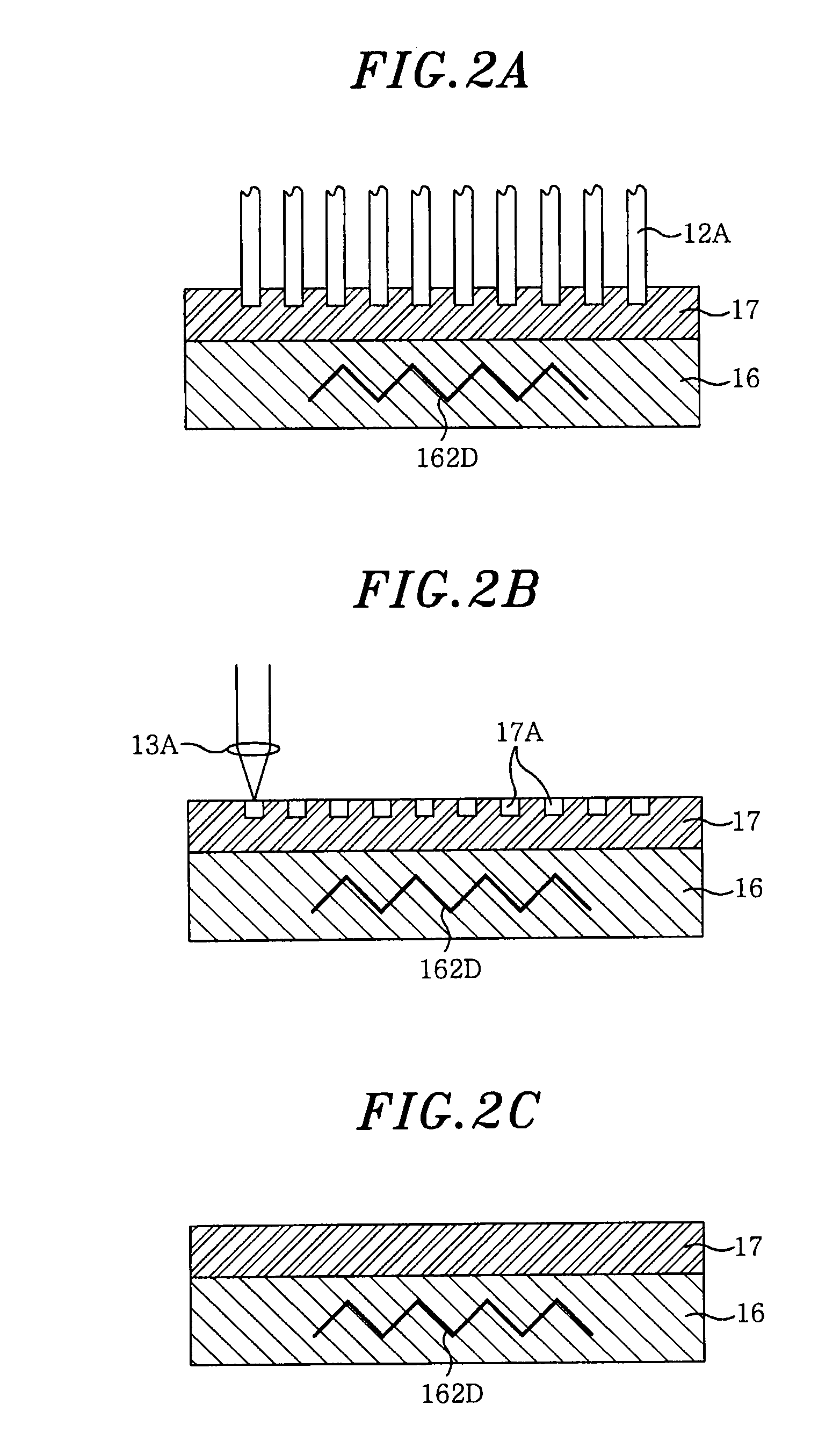

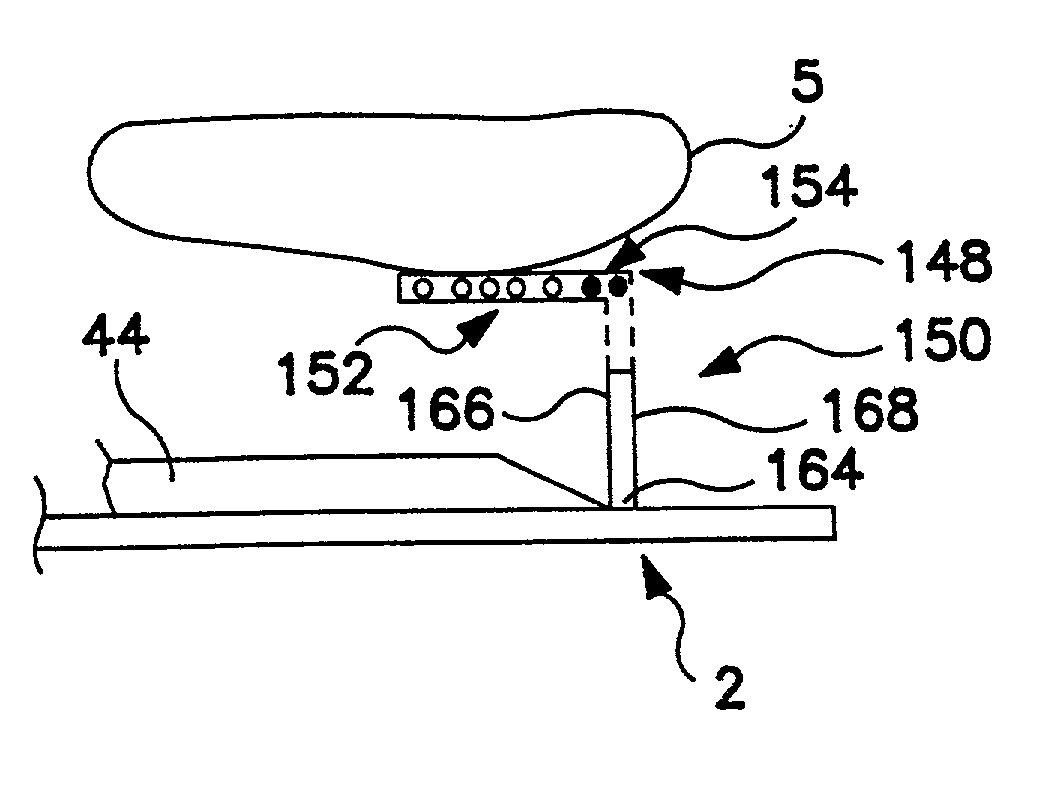

Needle trace transfer member and probe apparatus

ActiveUS20090212804A1Enhance inspection throughputReduce the effect of temperatureSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsVitrificationGlass transition

A needle trace transfer member to which needle traces of probes are transferred is installed at a movable mounting table to align the probes before electrical characteristics of a target object on the mounting table are inspected by bringing the probes into electrical contact with the target object. The needle trace transfer member is made of a shape memory polymer transformed reversibly and rapidly between a glass state with a high modulus elasticity and a rubber state with a low modulus of elasticity near its glass transition temperature. The glass transition temperature is set to a temperature close to a set temperature of the mounting table. The shape memory polymer is mainly made of polyurethane-based resin.

Owner:TOKYO ELECTRON LTD

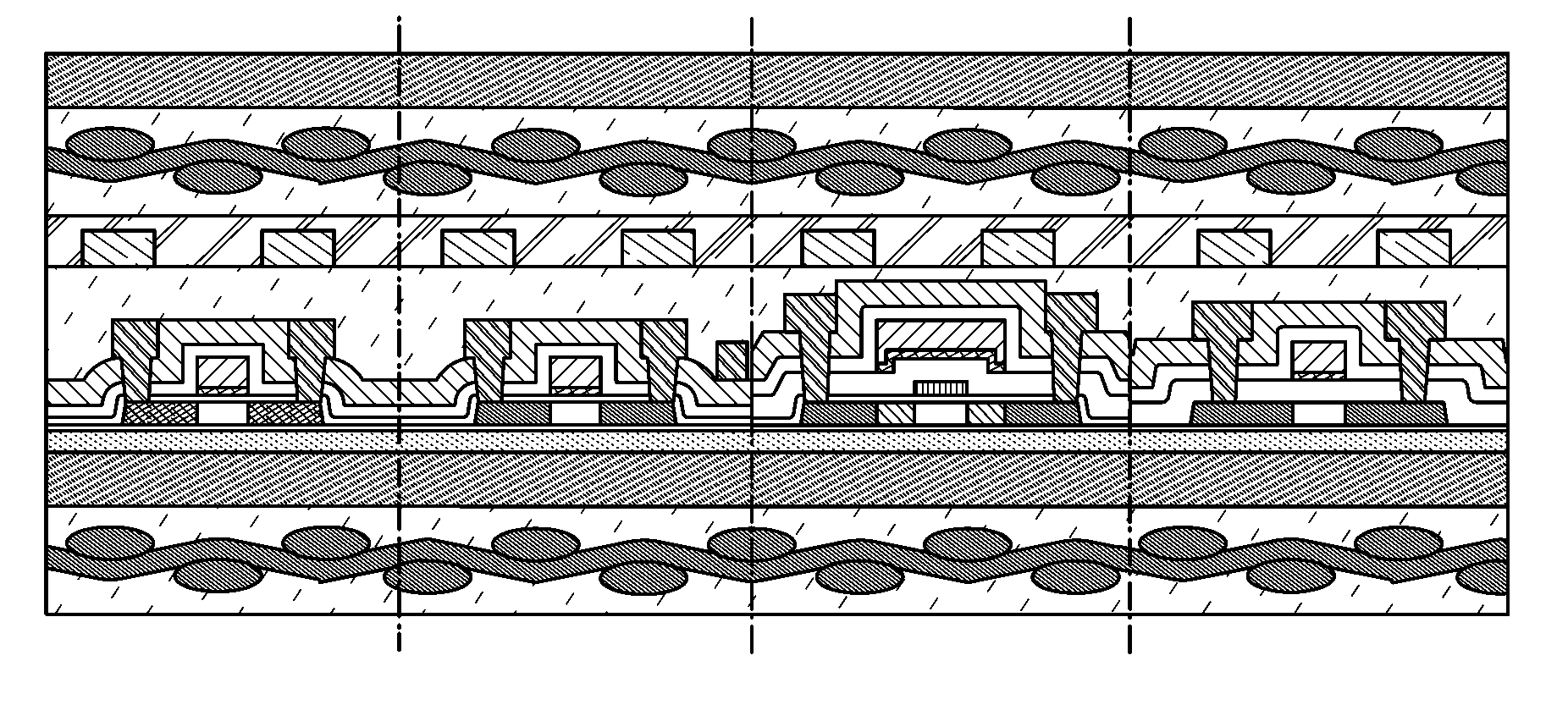

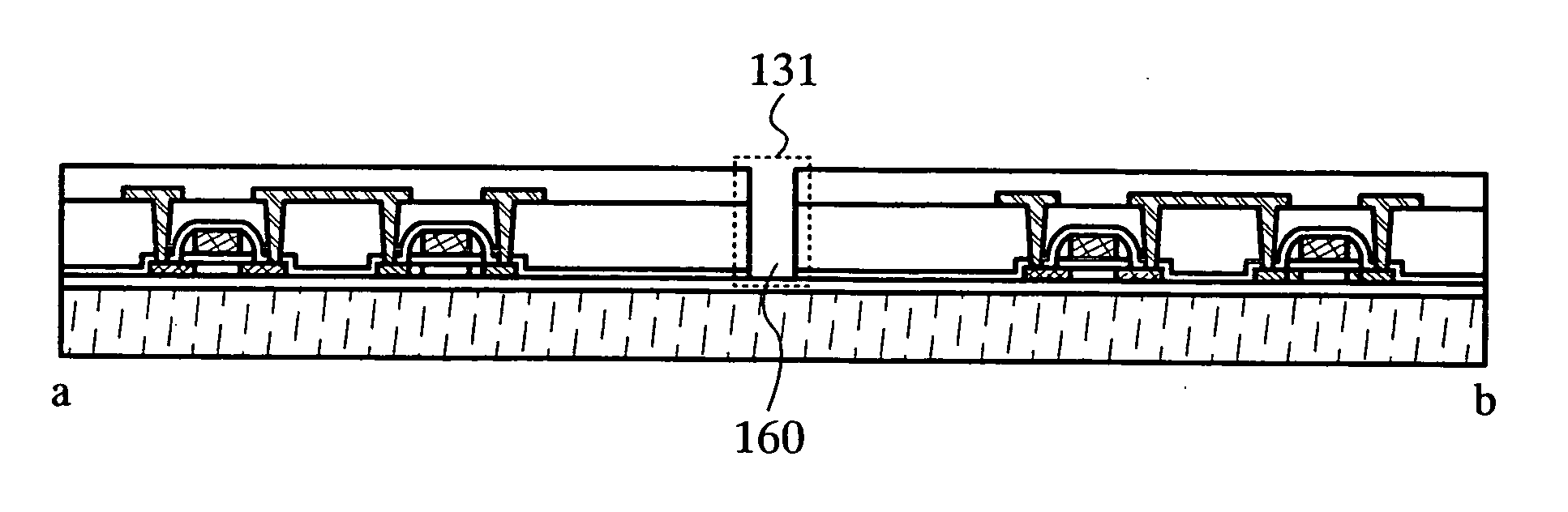

Semiconductor device and method for manufacturing the same

InactiveUS20060202206A1Less forceReduce stress exertedFinal product manufactureSolid-state devicesDevice materialGlass transition point

An object of the present invention is to provide a semiconductor device which has flexibility and resistance to a physical change such as bending and a method for manufacturing the semiconductor device. A semiconductor device of the present invention includes a plurality of transistors provided over a flexible substrate, each of which has a semiconductor film, a gate electrode provided over the semiconductor film with a gate insulating film therebetween, and an interlayer insulating film provided to cover the gate electrode, and a bending portion provided between the plurality of transistors, in which the bending portion is provided by filling an opening formed in the interlayer insulating film with a material having a lower elastic modulus, a material having a lower glass transition point, or a material having a higher plasticity than that of the interlayer insulating film.

Owner:SEMICON ENERGY LAB CO LTD

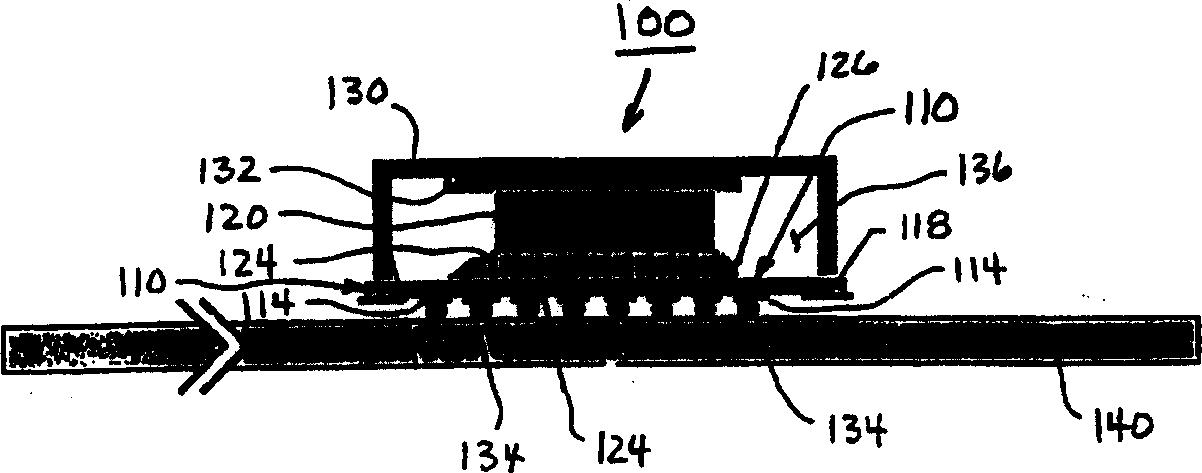

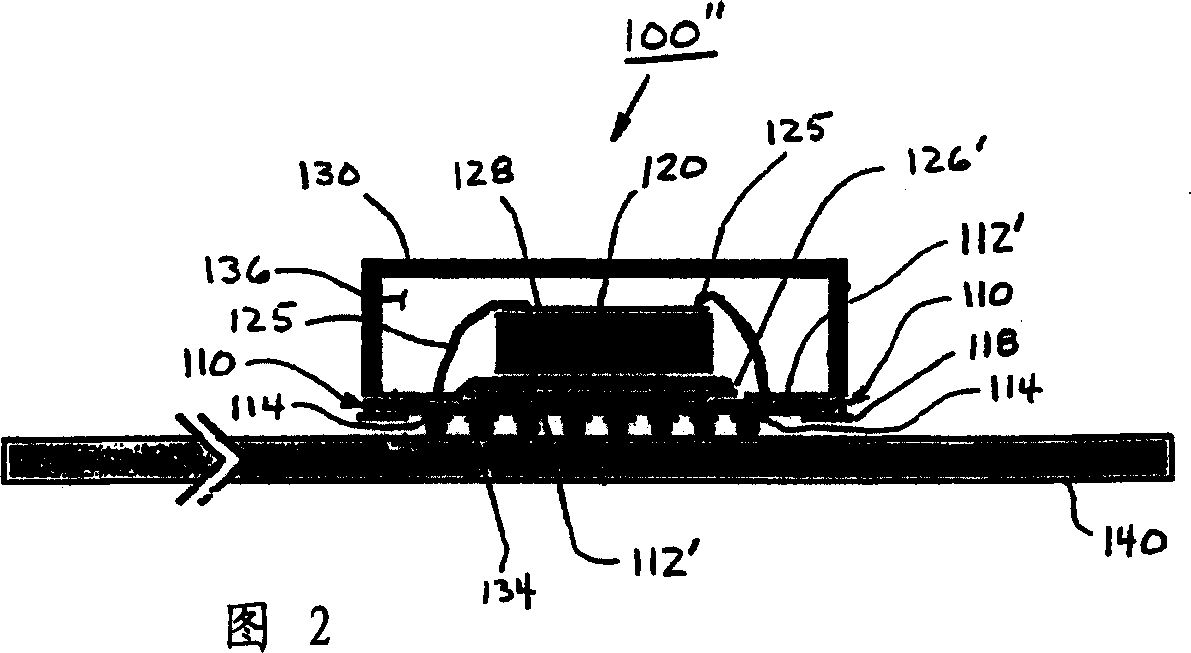

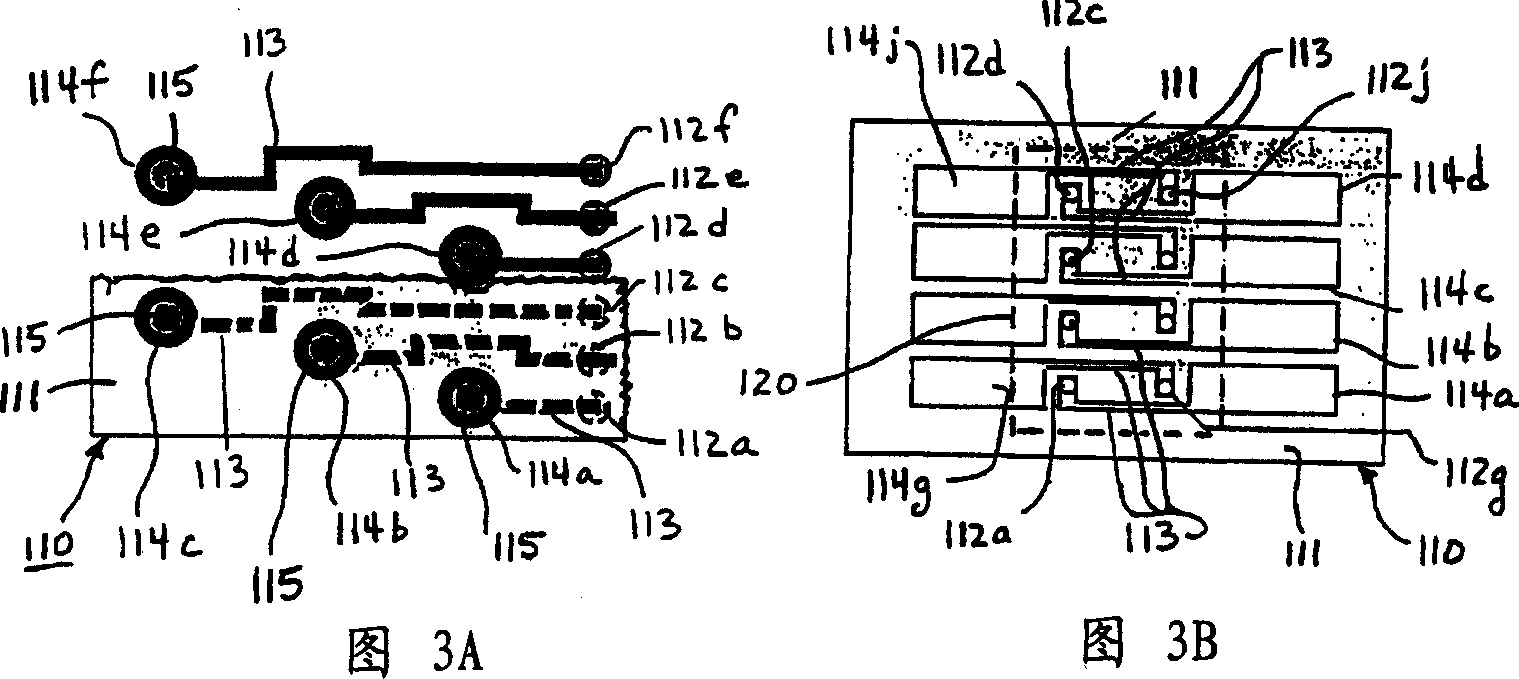

High-density electronic package and method for making same

InactiveCN1352804ARecord carriersSemiconductor/solid-state device detailsElectrical conductorHigh density

A high density electronic package includes a low-modulus-of-elasticity flexible adhesive interposer substrate to which an electronic device, such as a semiconductor chip or die or other component, is attached. The flexible adhesive interposer substrate includes a sheet or layer of a molecularly flexible adhesive having via holes therein in which are built up conductive vias to which contacts of the electronic device connect. A thin layer of metal foil on one surface of the flexible adhesive sheet is patterned to provide contacts and to connect electrically to the conductive vias. The electronic device may be covered by a lid or by an encapsulant attached to the flexible adhesive interposer substrate and / or the electronic device. An electronic package may include a plurality of electronic devices and respective flexible adhesive interposers that are electrically interconnected.

Owner:AMERASIA INT TECH

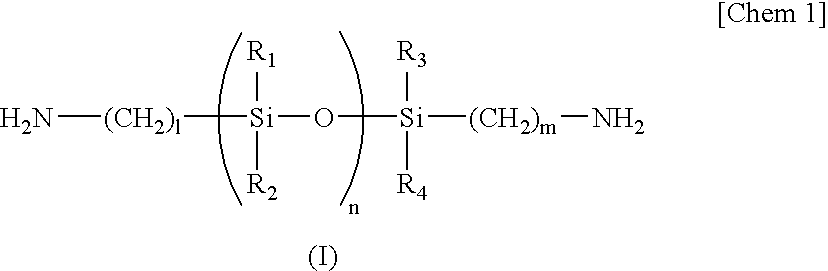

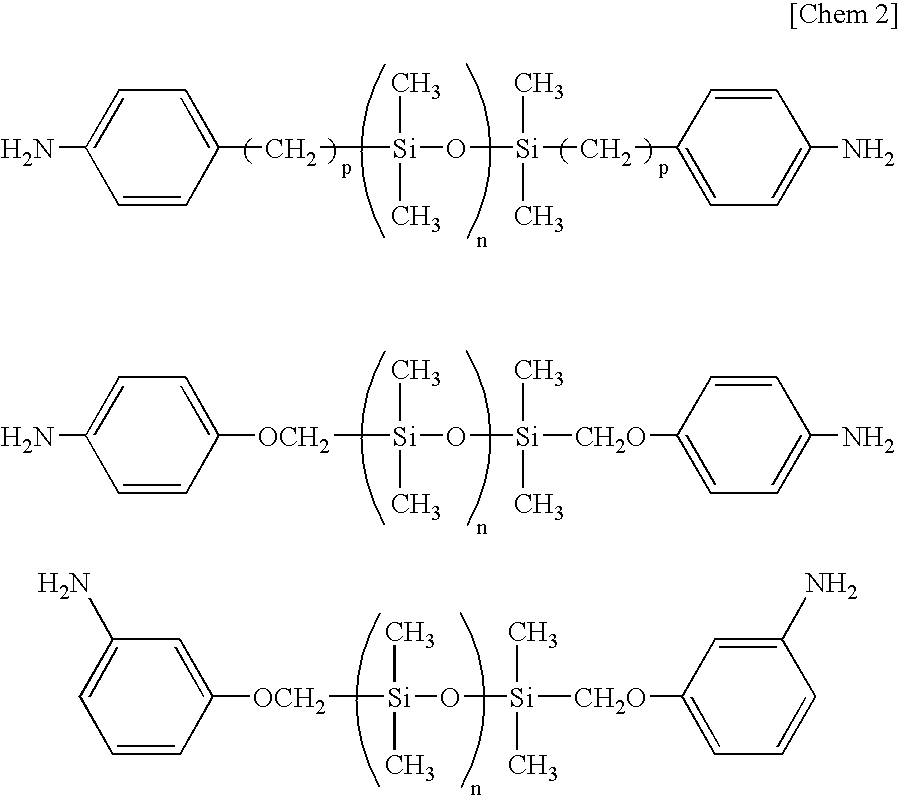

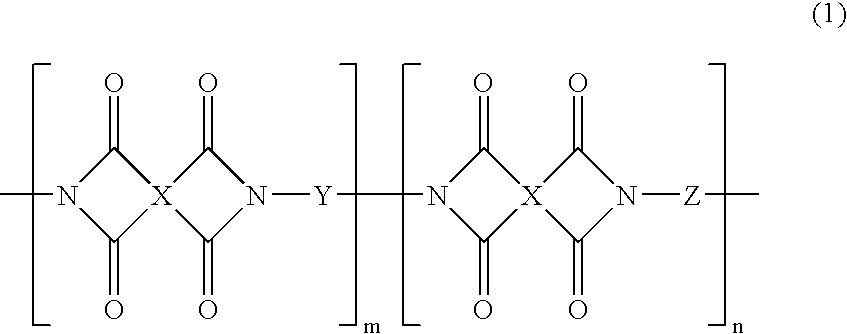

Block Copolymerized Polyimide Ink Composition for Printing

InactiveUS20080275181A1Strong adhesionLow modulusPrinted circuit aspectsSemiconductor/solid-state device manufacturingBenzoic acidSolvent

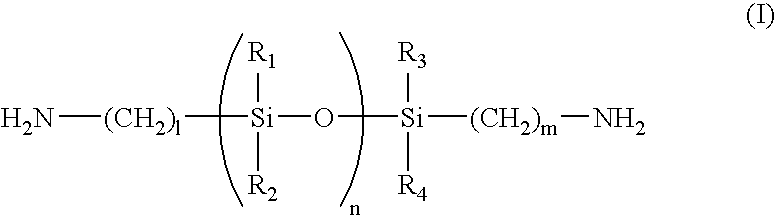

The object is to provide a polyimide ink composition having good printing properties and good continuous printing properties, which composition can be dried at a low temperature of not higher than 220° C., and which composition gives a coating film, after being dried, having excellent dimensional stability, heat resistance, low modulus of elasticity, flexibility, resistance to warping, chemical resistance, adhesiveness with substrates, and plating resistance. This object is accomplished by a polyimide ink composition for printing, comprising a mixed solvent containing an benzoic acid ester solvent and a glyme solvent, and a polyimide soluble in the mixed solvent; wherein the polyimide is obtained by polycondensing a polyimide oligomer with a tetracarboxylic dianhydride component(s) and / or a diamine component(s) having no siloxane bond in molecular skeleton thereof the polyimide oligomer being prepared by polycondensing a tetracarboxylic dianhydride component(s) and a diamine component(s) having siloxane bonds in molecular skeleton thereof in the presence of a base catalyst(s), or a mixed catalyst including a lactone(s) and / or an acidic compound(s) and a base(s); the content of the diamine component(s) having siloxane bonds based on the total diamine components being 15 to 85% by weight.

Owner:PI R & D +1

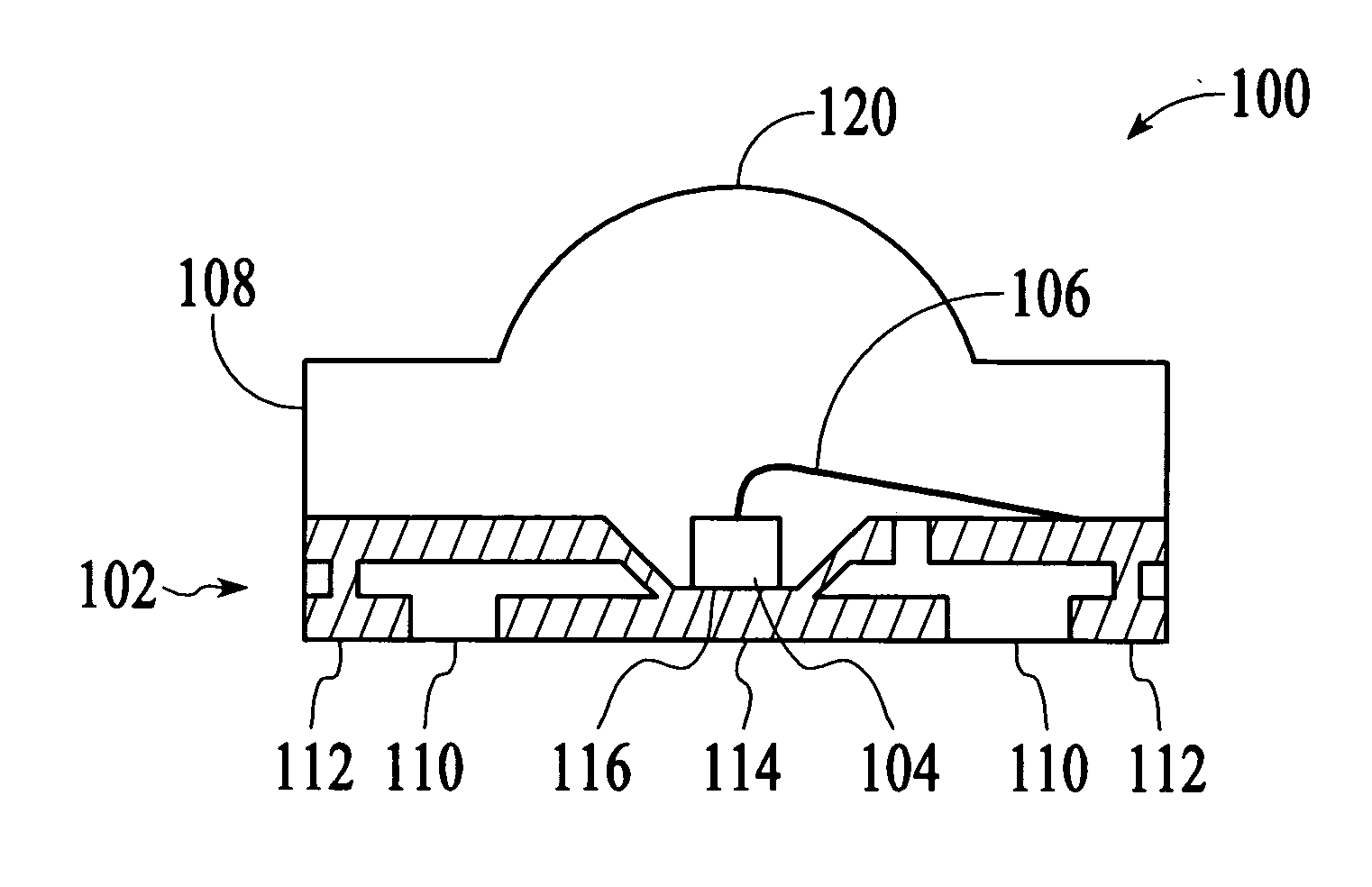

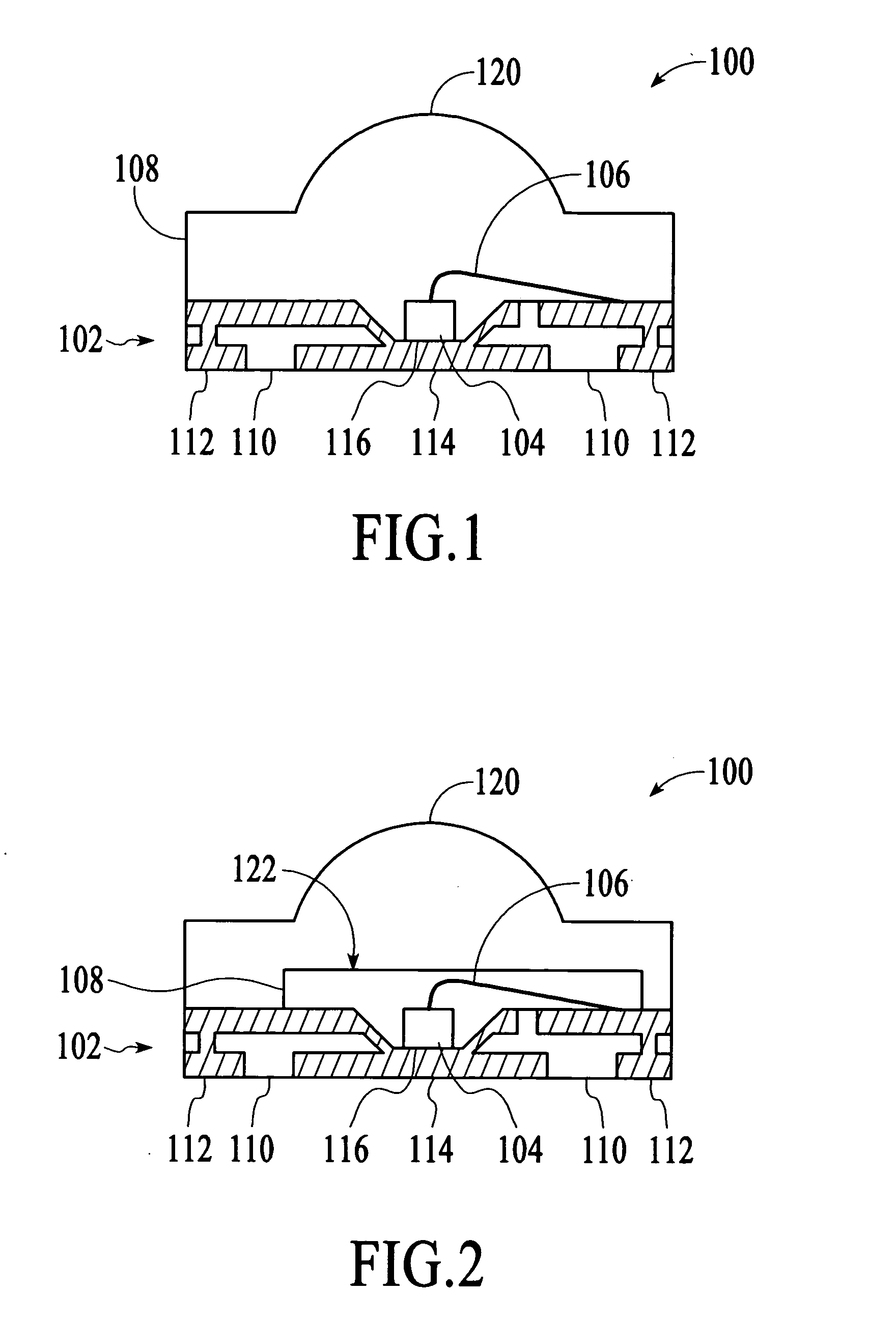

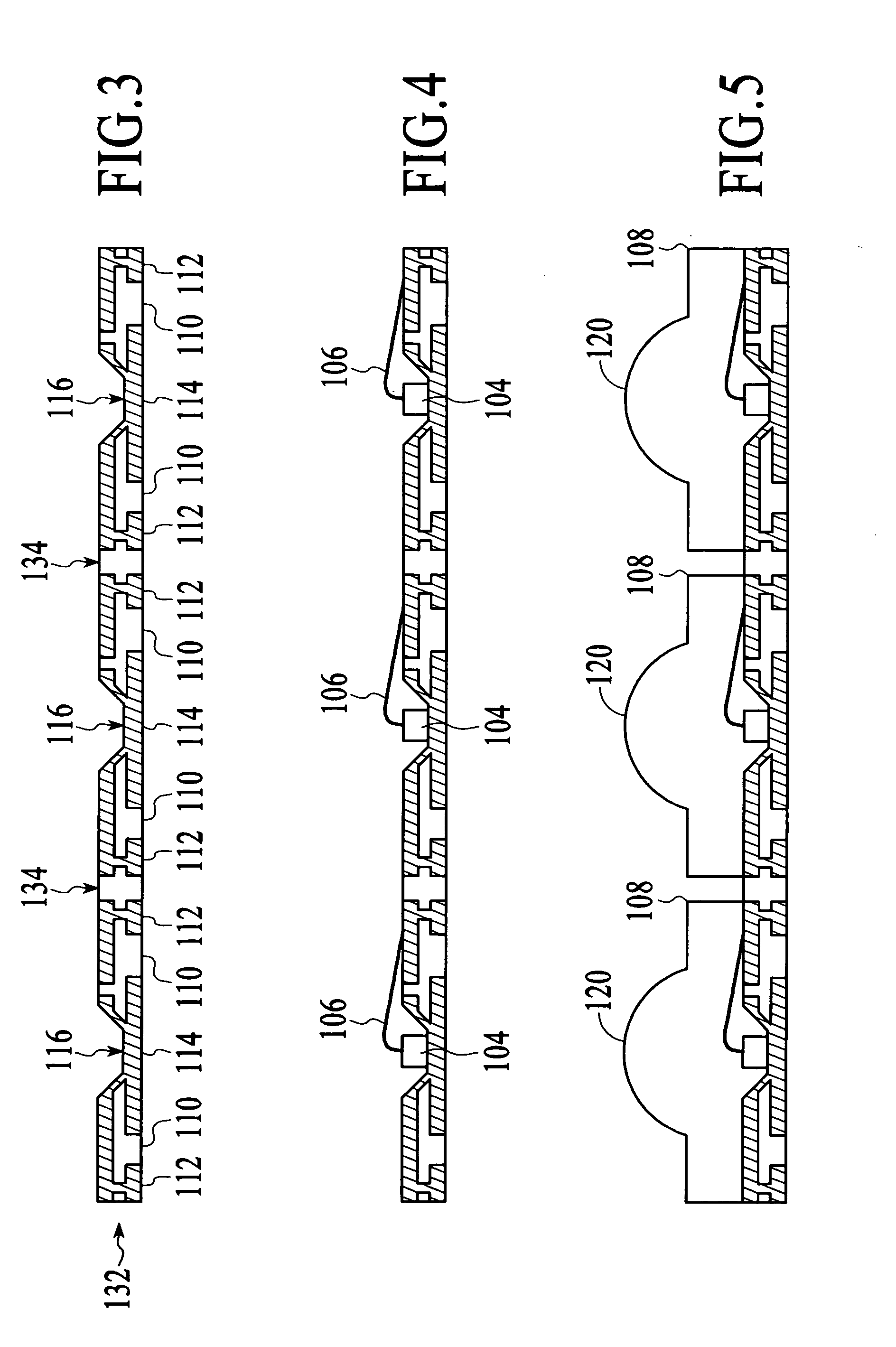

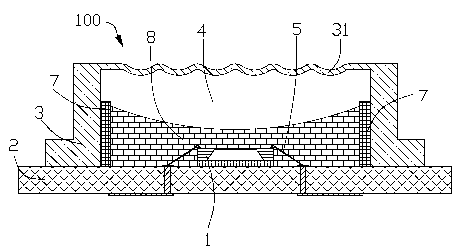

PCB-based surface mount LED device with silicone-based encapsulation structure

InactiveUS20050280016A1Reduce absorptionLow elastic modulusSolid-state devicesSemiconductor devicesLow elastic modulusEngineering

Owner:AVAGO TECH ECBU IP (SINGAPORE) PTE LTD

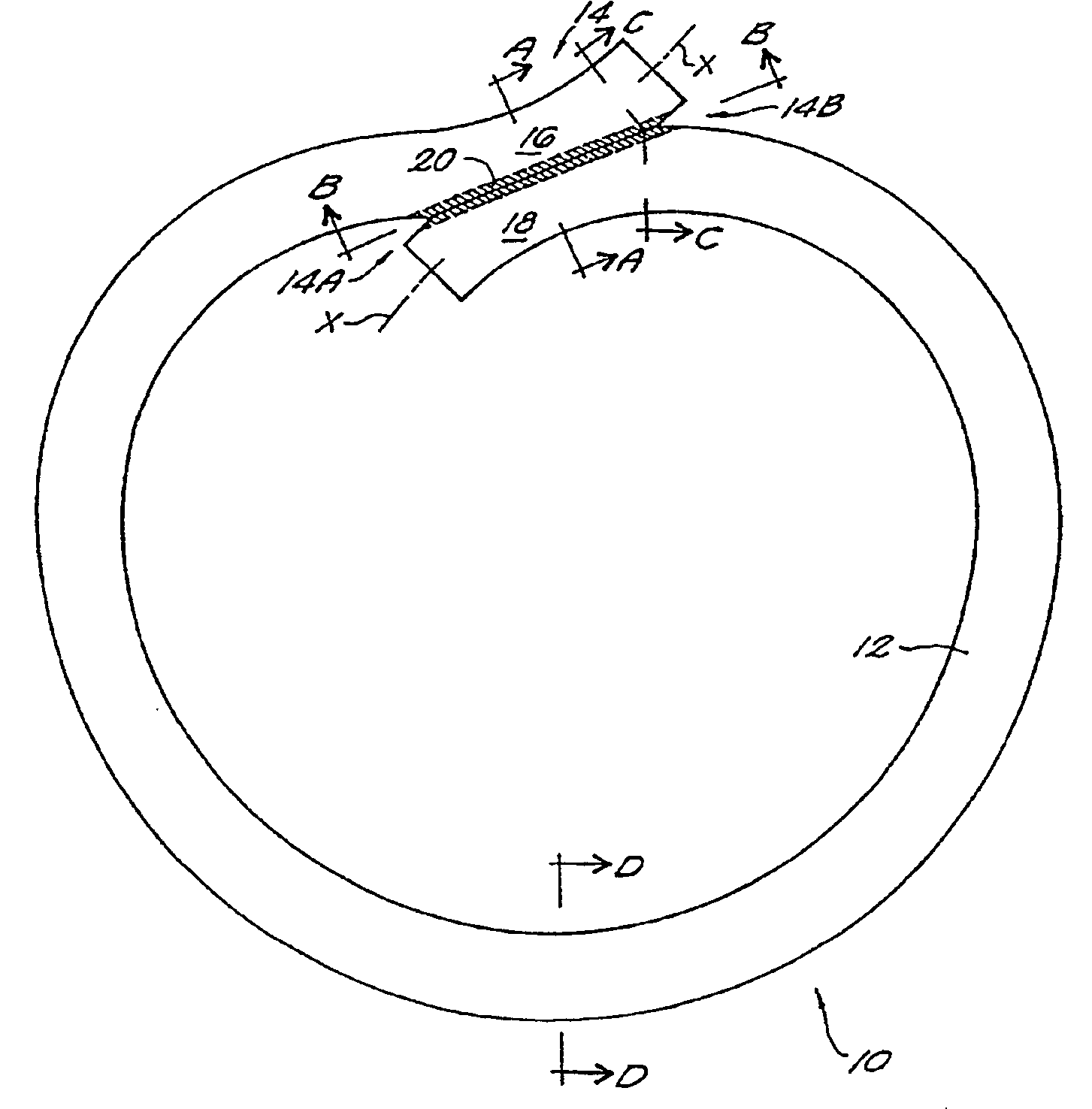

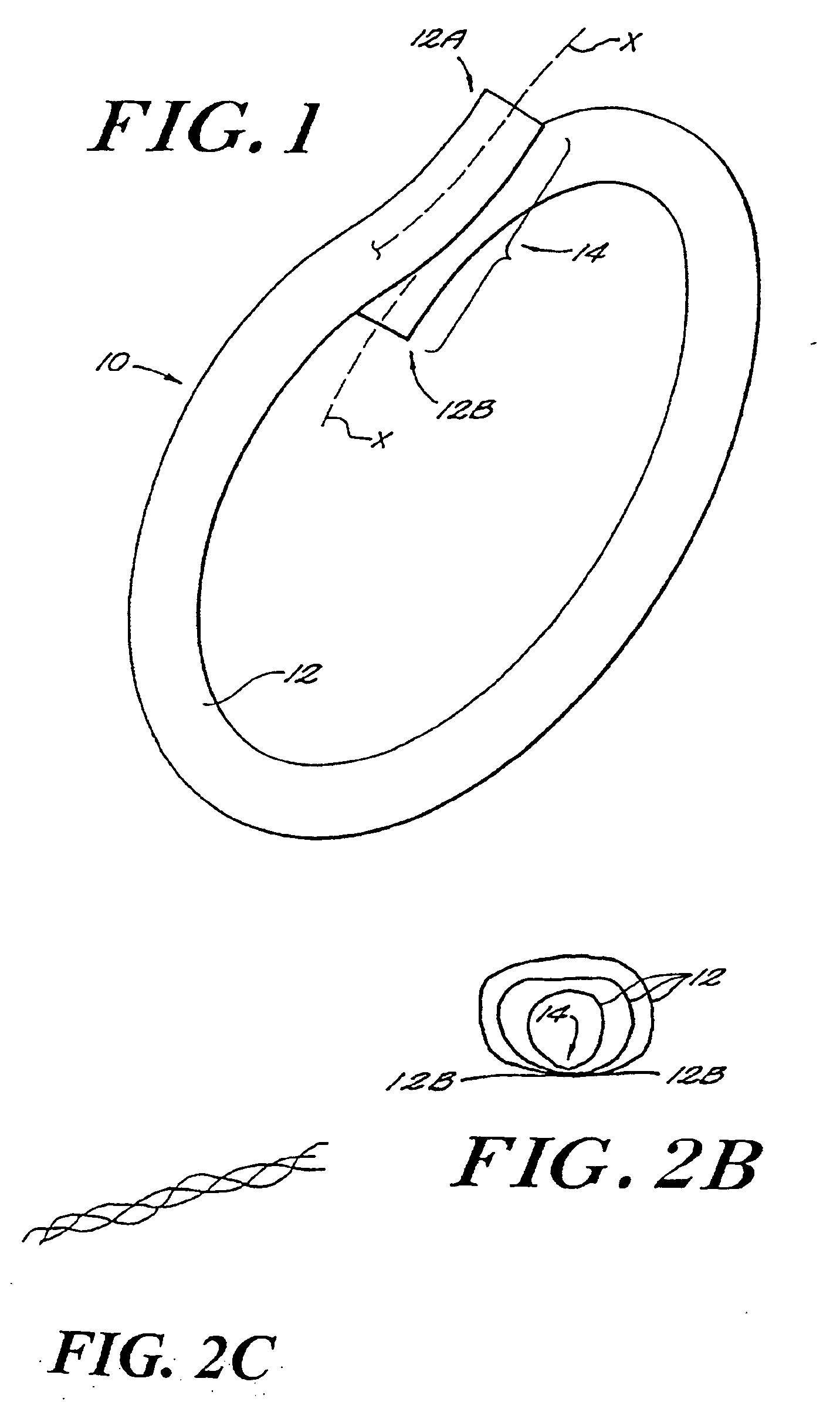

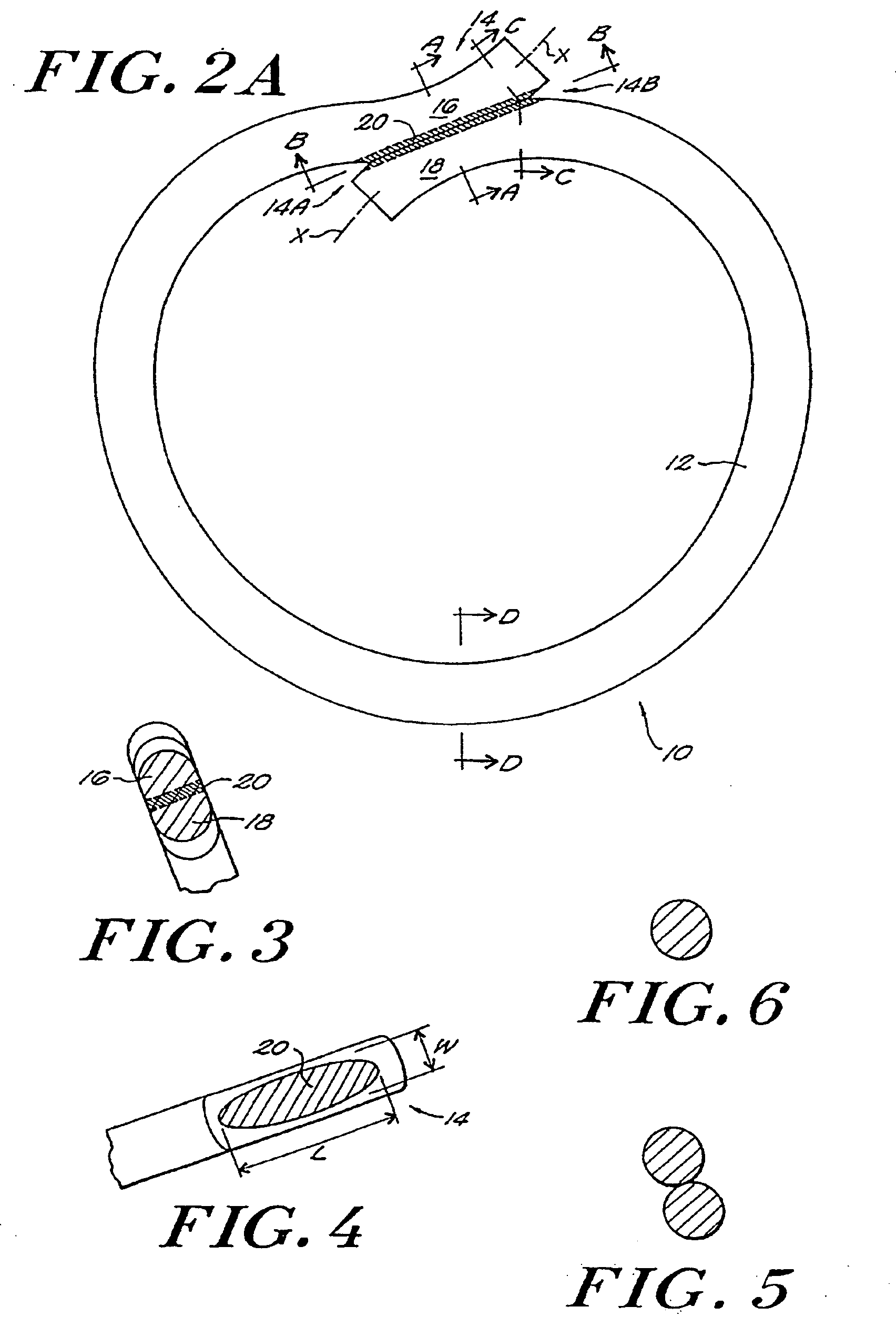

Fused loop of filamentous material and apparatus for making same

InactiveUS20050216058A1Maximize joint strengthSuture equipmentsSurgical needlesElastic fibresPolymer science

A method of forming an elastic cloth structure comprising fibers of synthetic, organic, relatively elastomeric polymer and fibers of a synthetic, organic, elongatable, but relatively nonelastic polymer. The relatively elastomeric fibers and the elongatable but relatively nonelastic fibers are forwarded for well dispersed random lay down of an unbonded web with random fiber crossings on a porous forming surface. Some of the fiber crossings are then bonded to provide a coherent bonded cloth web and the web is stretched to elongate some of the fibers in at least one direction. The web is then released so that retraction by the relatively elastomeric fibers provides looping and bunching of the elongated relatively nonelastic fibers to thereby provide a low modulus of elasticity in the direction in which the web was worked.

Owner:HOWMEDICA OSTEONICS CORP

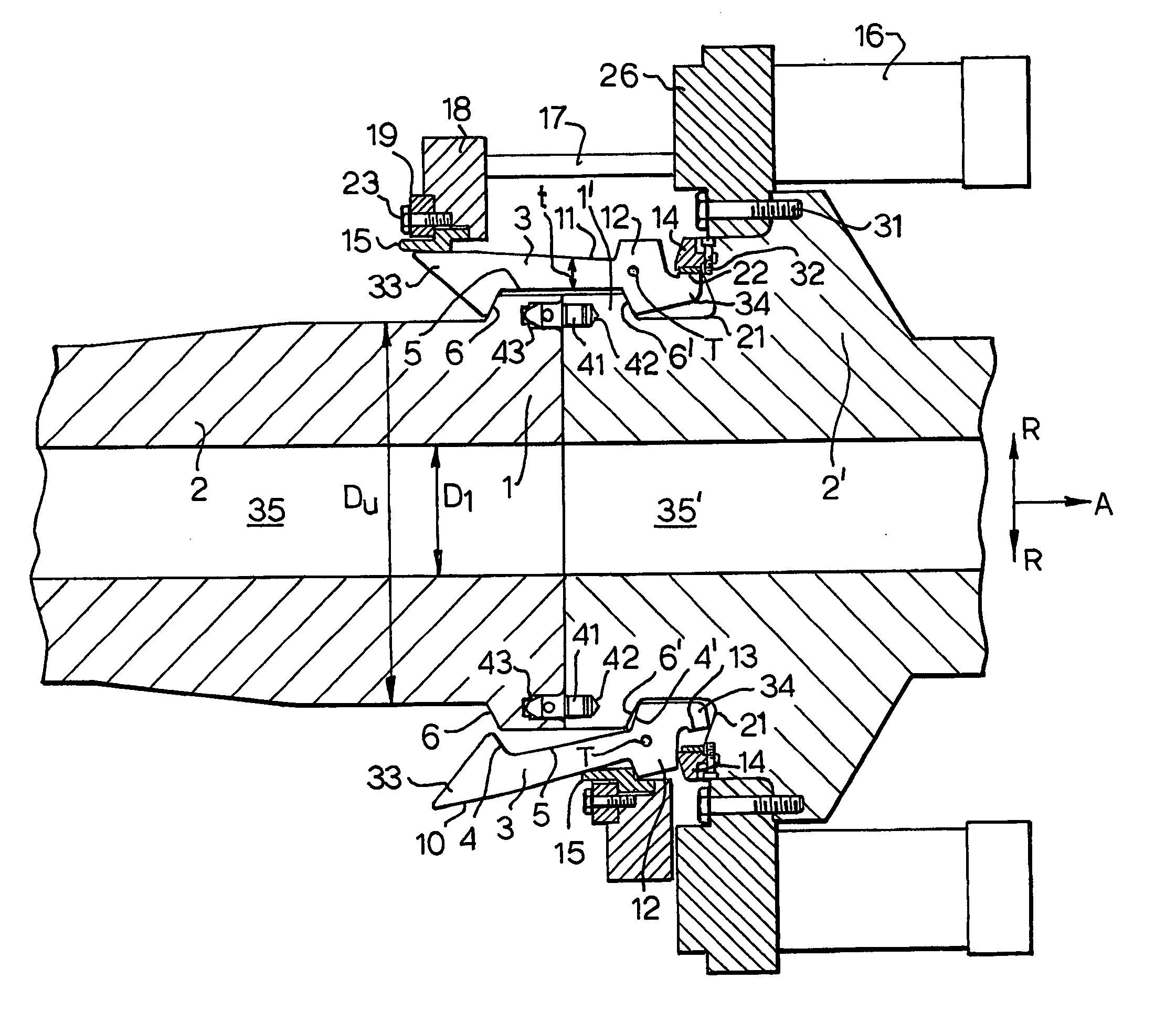

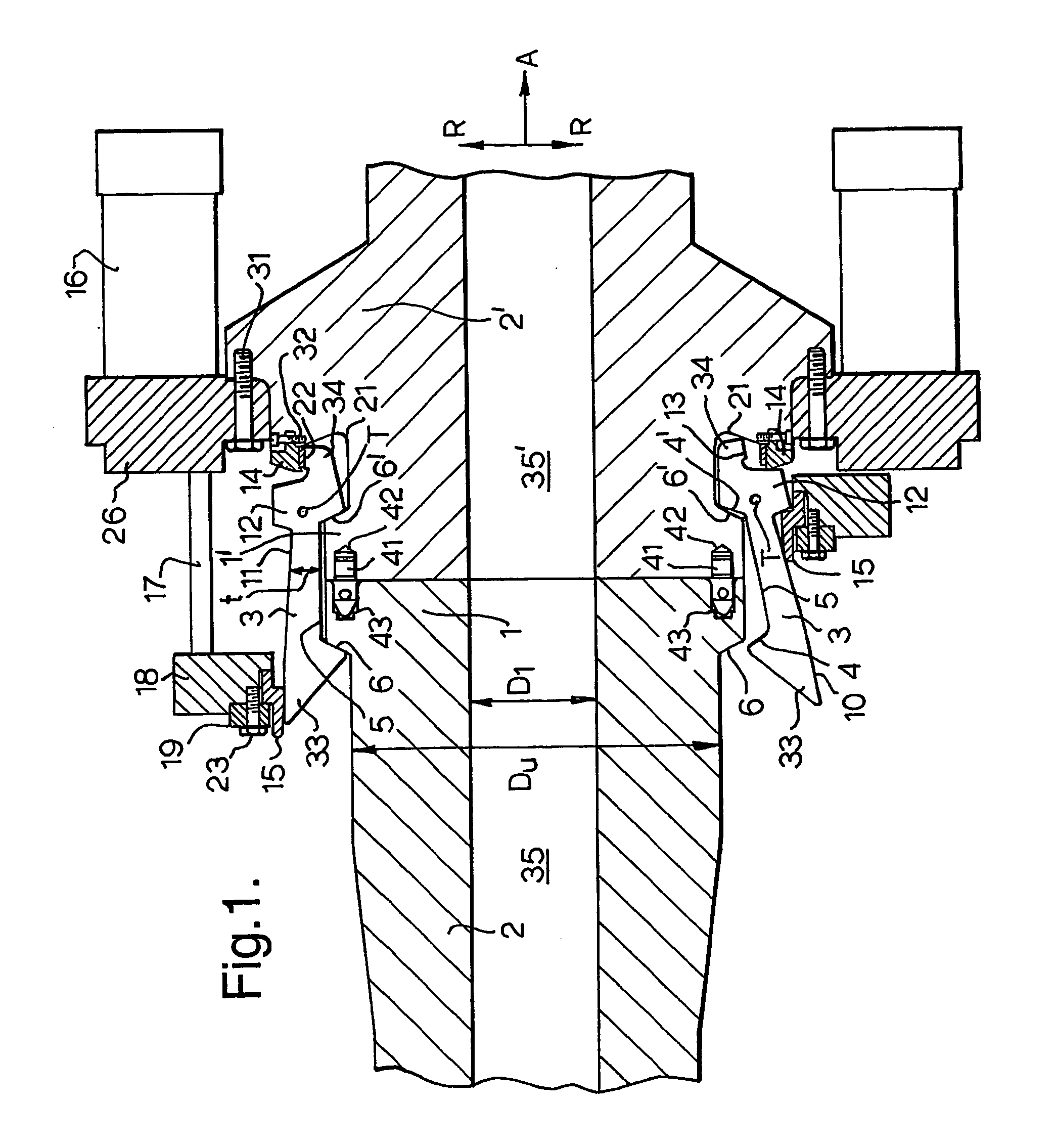

Mechanical joints for subsea equipment

InactiveUS20050146137A1Large dimensional toleranceExpand the scope of workSleeve/socket jointsPipe laying and repairJoint componentEngineering

A mechanical connector for oil and gas well apparatus applies a predetermined preload across the connection, the preload being adapted to accommodate relatively large dimensional tolerances in the loadpath of the connector preload by placing a component with a low modulus of elasticity within that load path. In one embodiment, the connector comprises fingers (3) of a pair of pipe flanges (1, 1′), a stationary retainer ring (14) against which a finger reaction surface (13) is pressed, a runner ring (15) located outside the fingers and movable lengthwise along the fingers by an actuator (16), the retainer ring and the runner ring having an elasticity that is so large that deviations in their elongation only have a small influence on the retainer ring and the runner ring radial pressure against the fingers and clamping forces of the fingers against the flanges. In a second embodiment, the connector comprises dogs (103, FIG. 4) located around the circumference of a first tubular joint component, a follower located outside the dogs (103) and movable axially of the dogs, the low elastic modulus component being a ring located in the loadpath below the dogs. In a third embodiment, the connector comprises a lockdown mechanism acting between nested components, the low elastic modulus component being an insert comprising a load shoulder transferring loads between the nested components.

Owner:FMC TECH INC

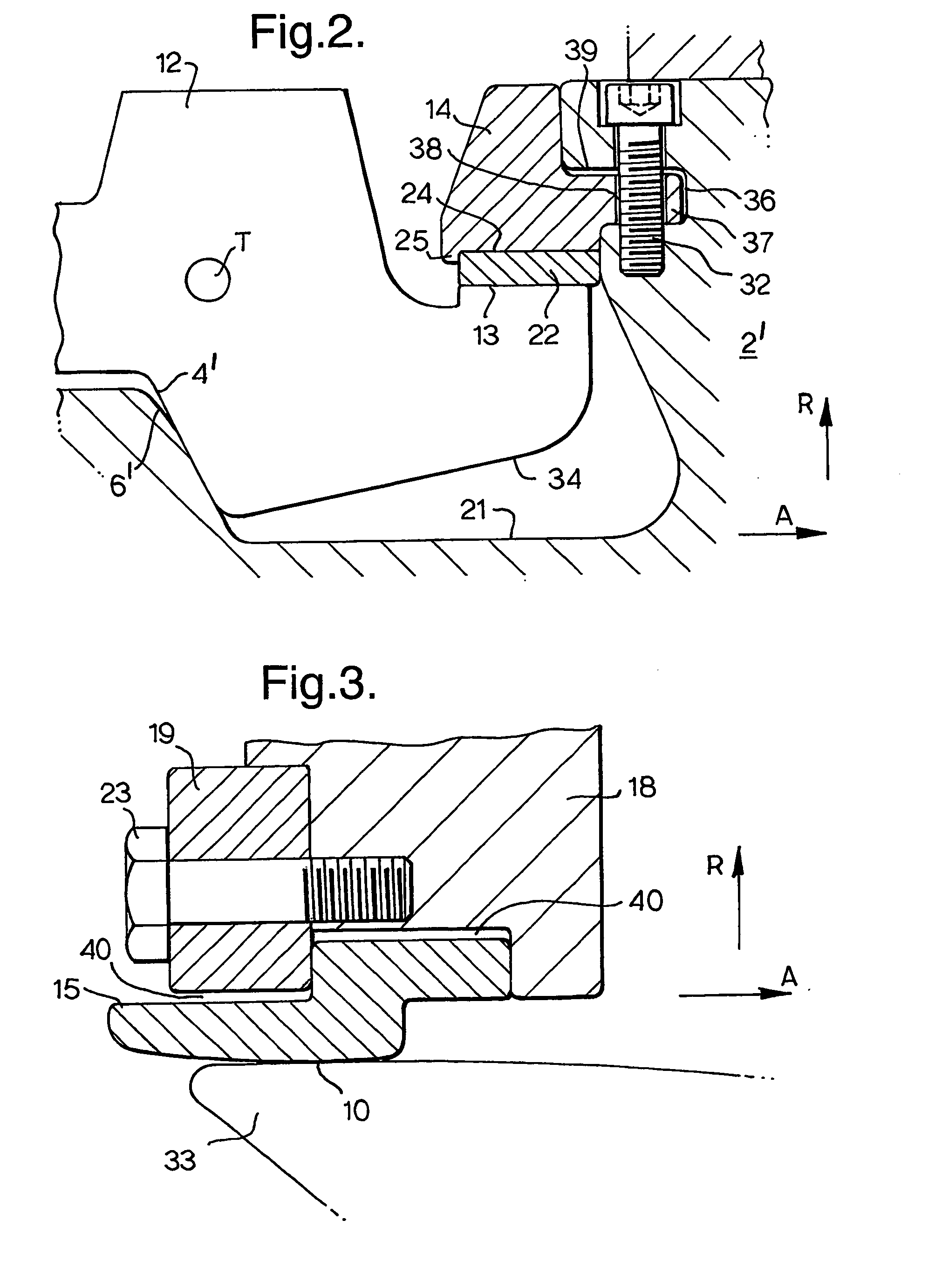

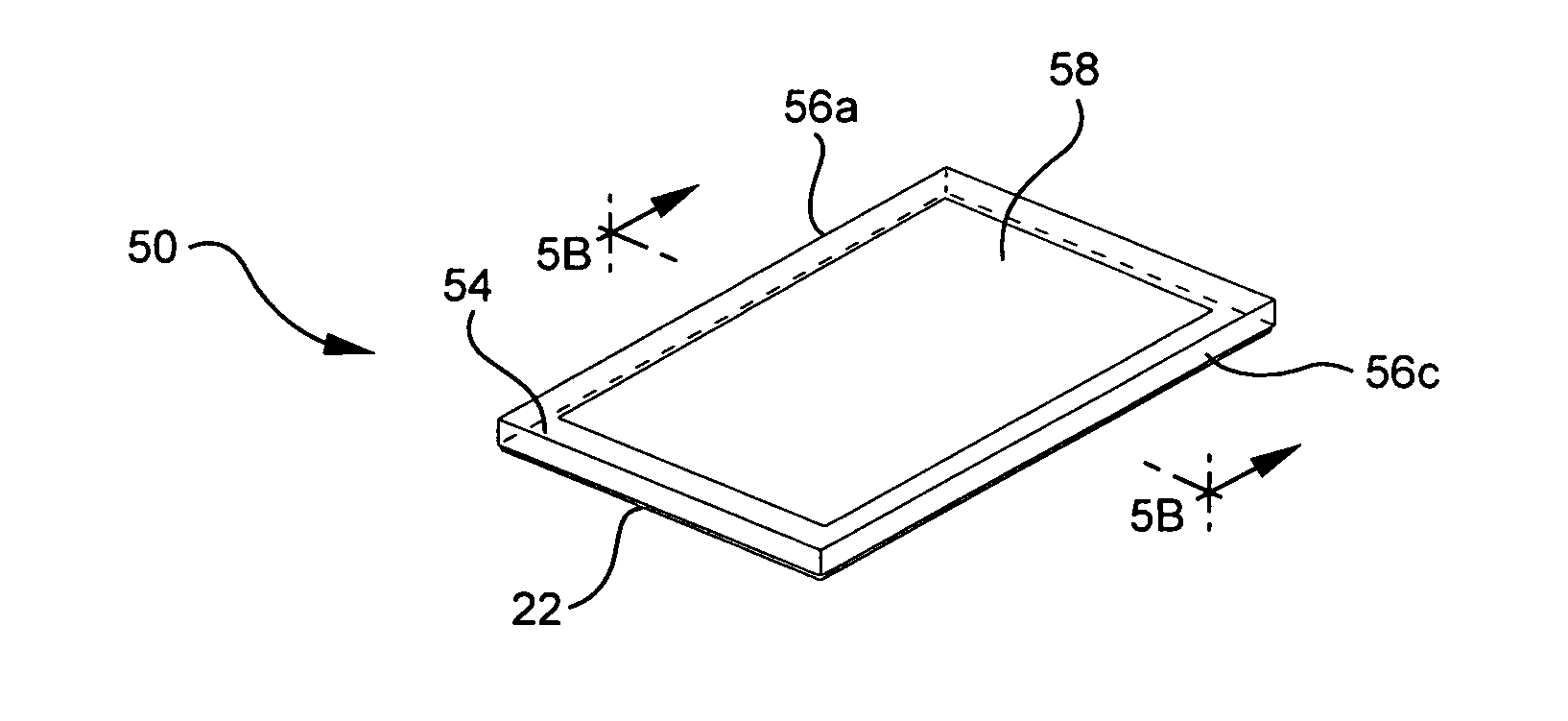

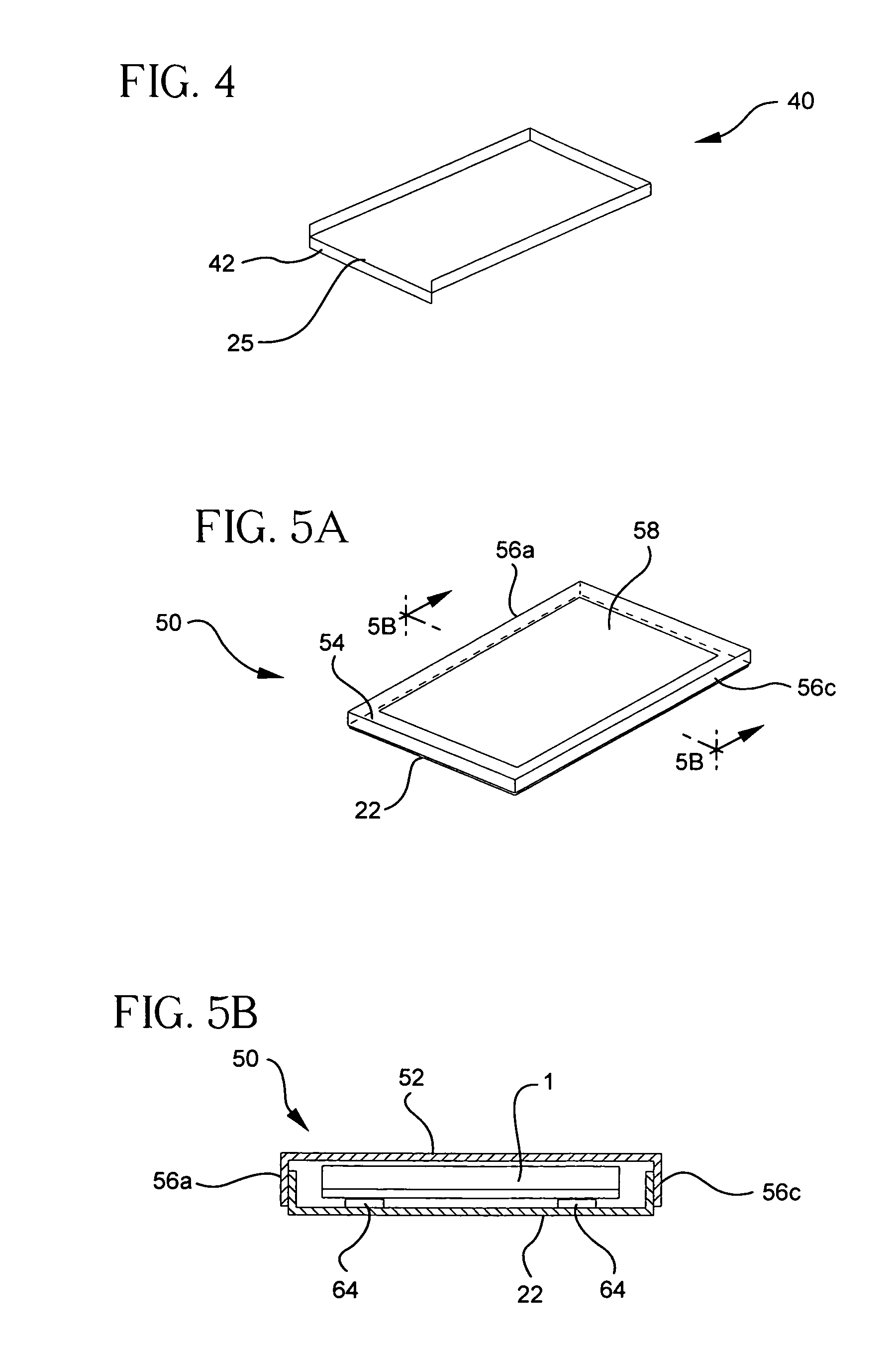

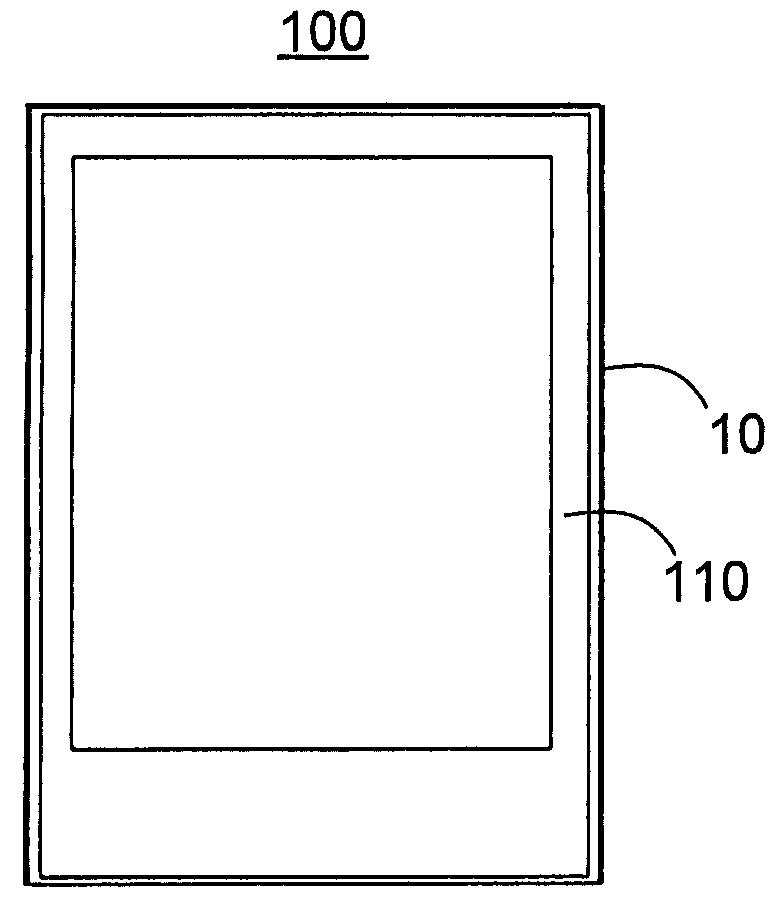

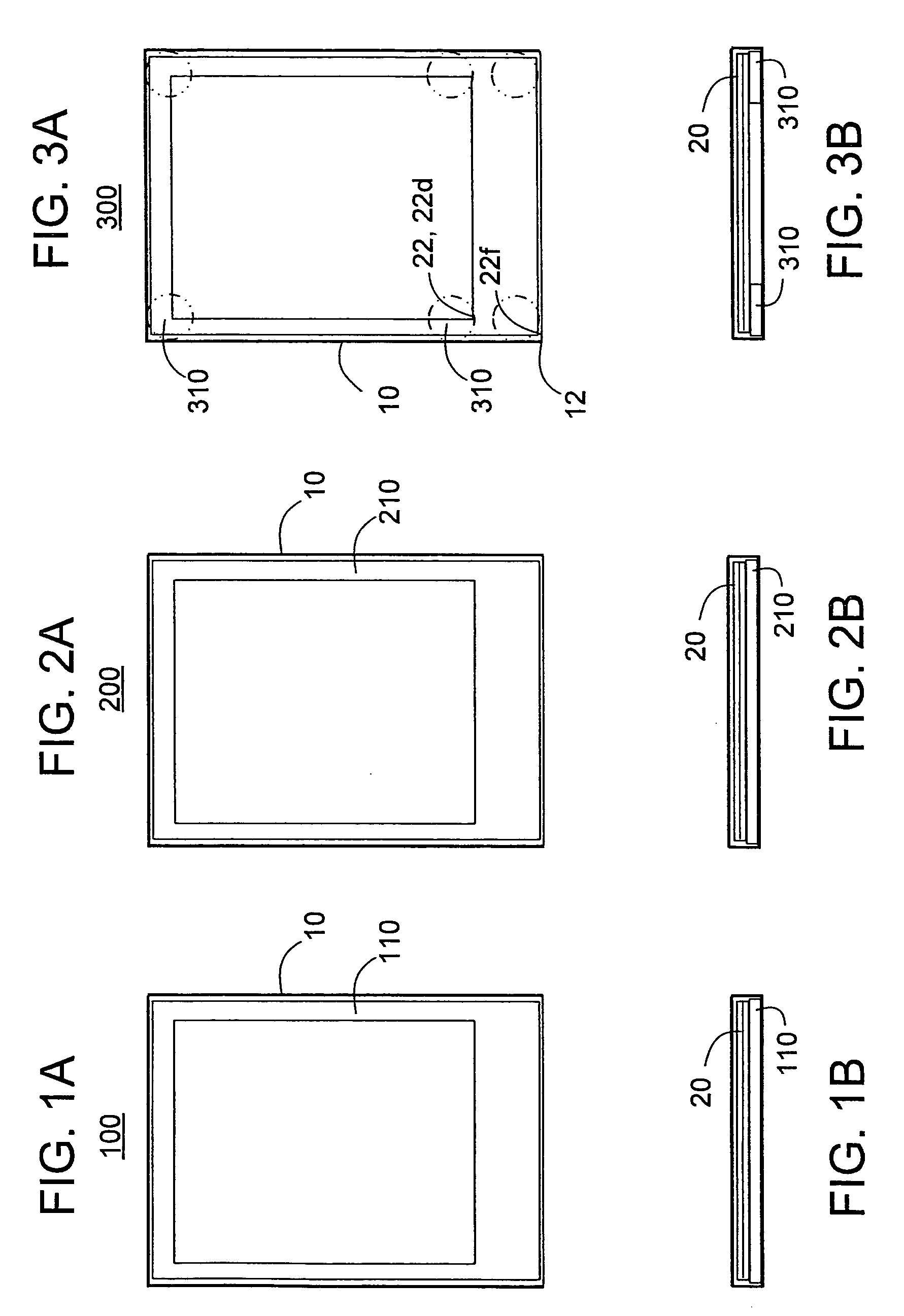

Bezel packaging for sealed glass assemblies and a glass assembly therefor

InactiveUS20110019351A1Reduce the likelihood of failureImprove integrityPlanar light sourcesStatic indicating devicesLeading edgeInter layer

Methods and assemblies related to frame or bezel packaging of a sealed glass assembly, such as a fit-sealed OLED device, such as an OLED display panel. The frame or bezel packaging may have one or more of (a) rounded or chamfered corners, (a) a cover, (b) a reinforced lead edge, (c) openings or cutouts in the back panel to conserve material and lighten the bezel, and (d) a shock absorbent intermediate layer of low modulus of elasticity material applied between the sealed glass assembly and the back and / or sides of the frame or bezel. The frame or bezel design may include a gap between the sealed glass assembly and the back panel of the bezel. The gap may be filled at least in part with low modulus of elasticity backing material. The glass package may have one or more of (a) rounded or chamfered corners, (b) rounded or chamfered edges, (c) a low modulus of elasticity material applied around its periphery or portions of its periphery, such as on the corners only, (d) a shortened lead end, and (e) a thickened lead end.

Owner:CORNING INC

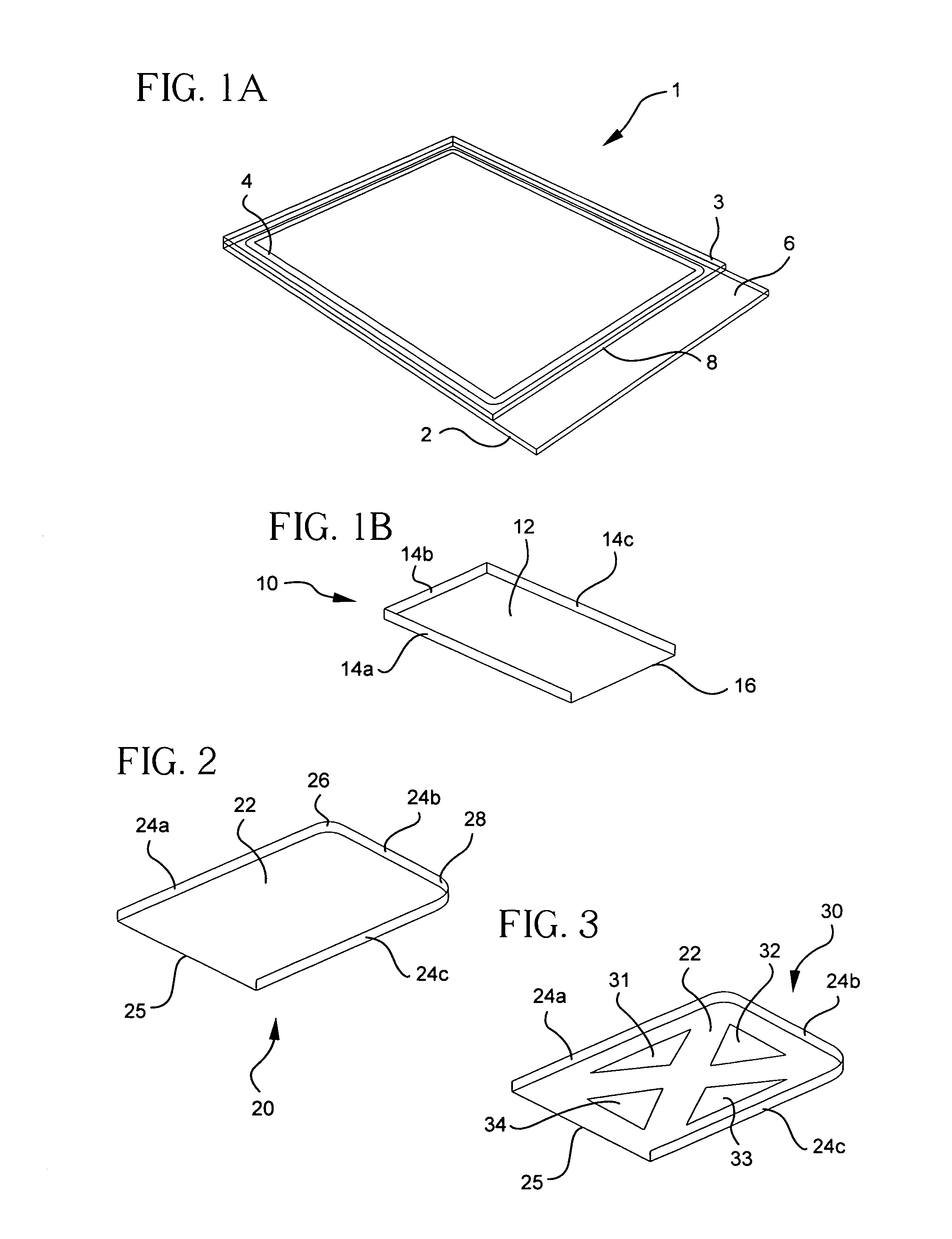

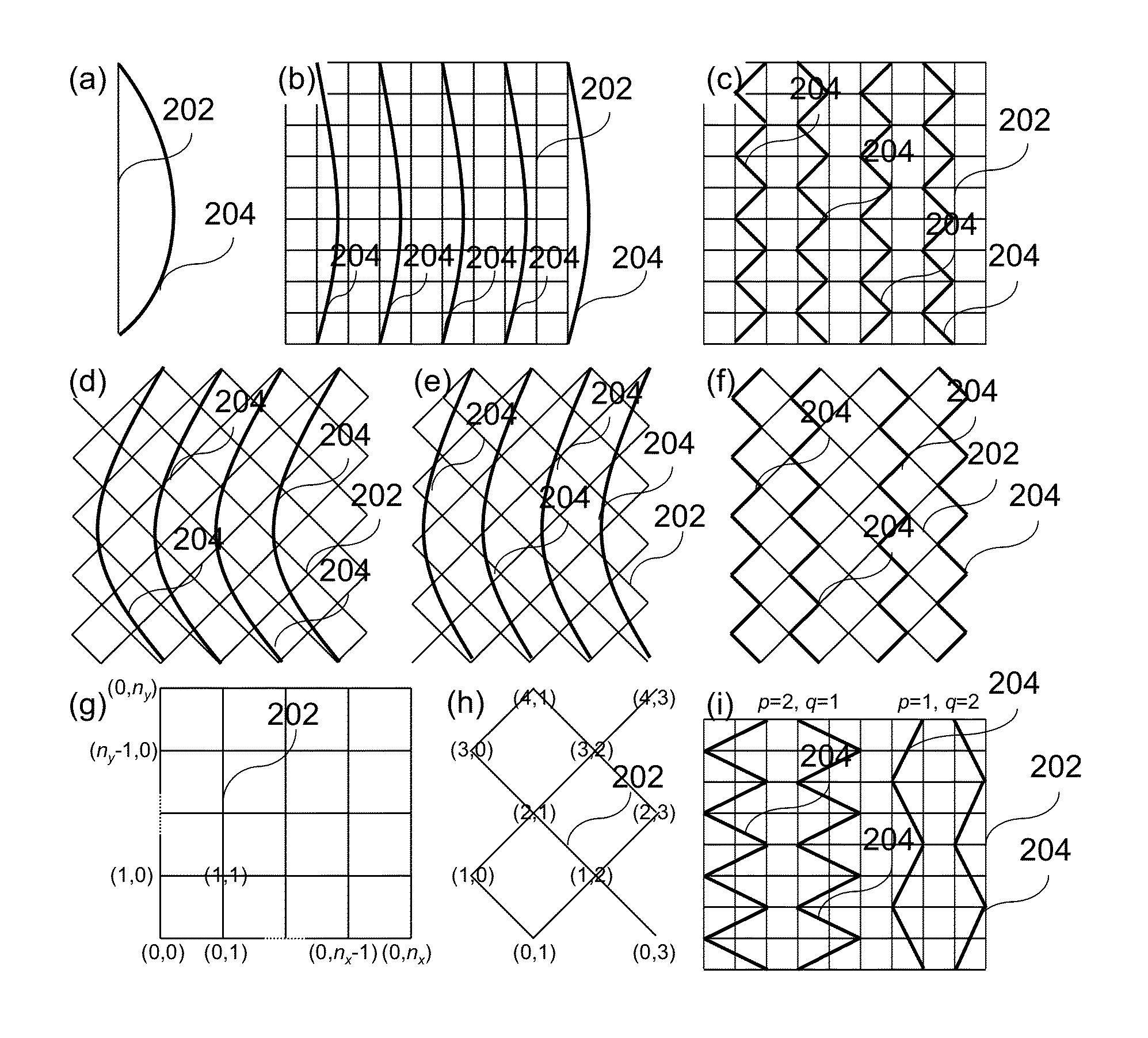

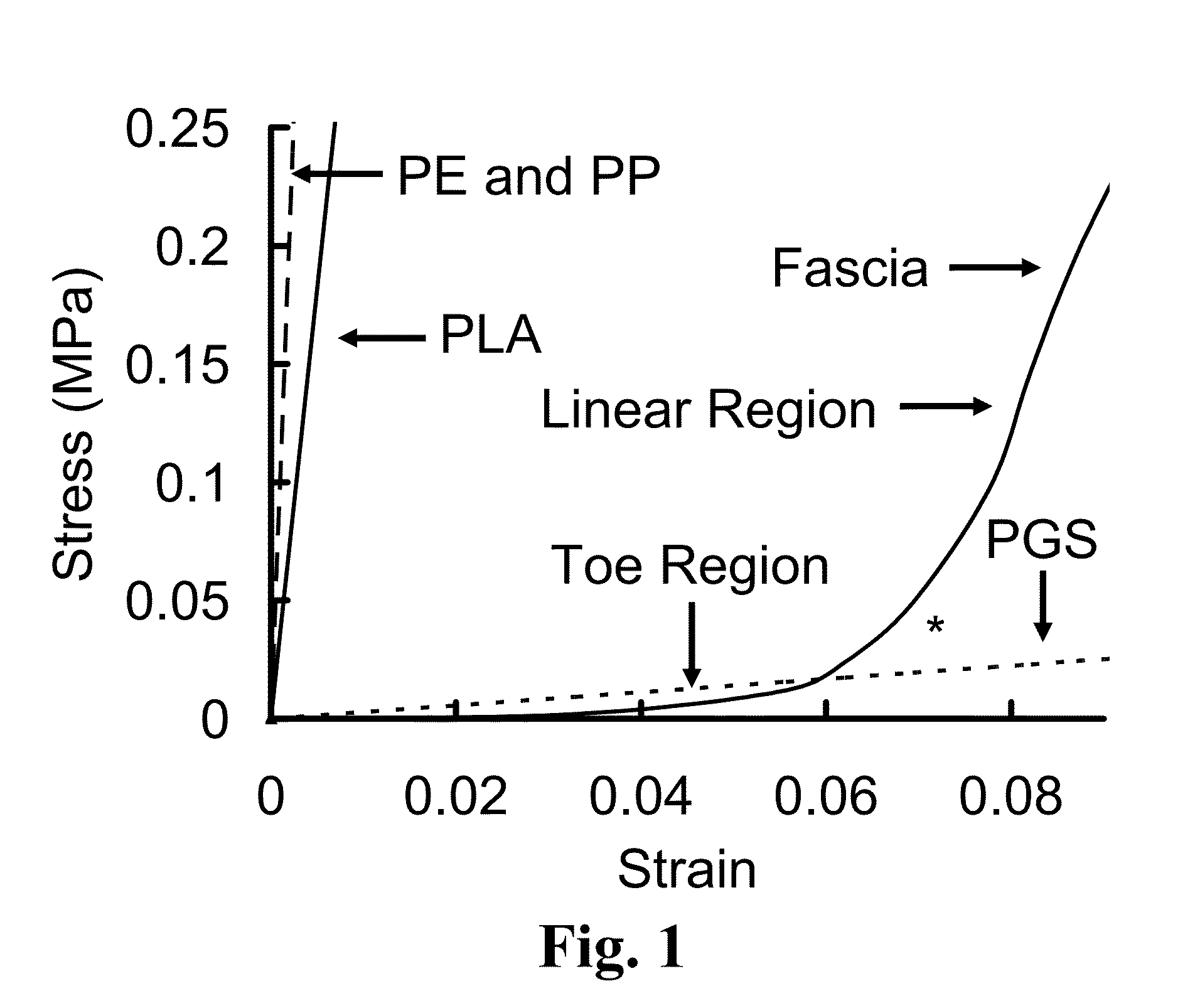

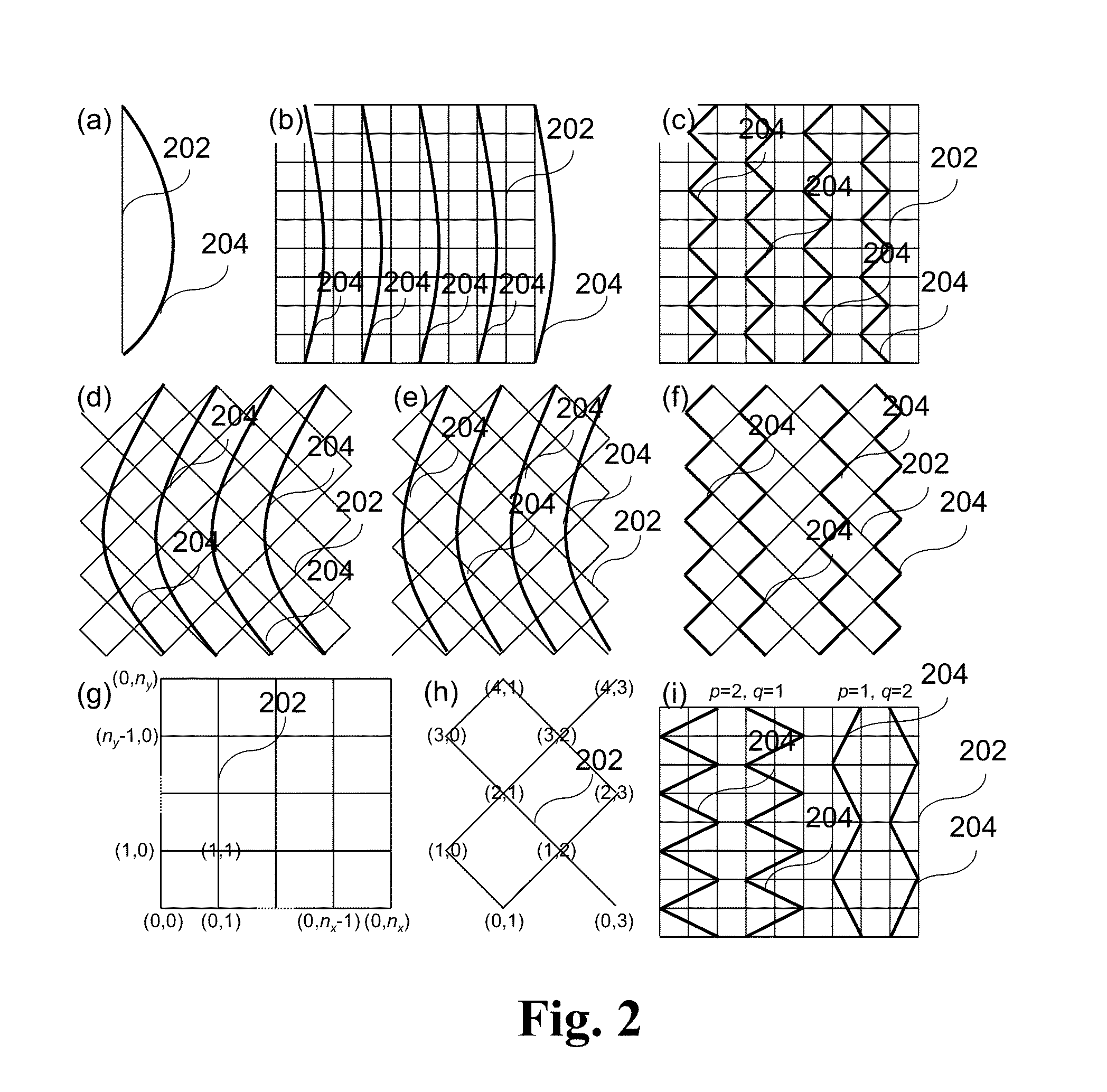

Biomimetic multiple strand fiber mesh and sutures

InactiveUS20130103079A1Lower elastic modulusHigh elastic modulusSuture equipmentsFiberMaterials science

A material comprising two or more fibers, wherein each of the fibers has a mechanical modulus, and the mechanical modulus of at least one fiber is higher than the mechanical modulus of another fiber. The higher modulus fiber has a longer length than the lower modulus fiber. In various embodiments, the higher modulus fiber is collagen mimetic and the lower modulus fiber is elastin mimetic. A suture is also described, comprising two or more fibers. At least one of the fibers is elastin-like and has a lower elastic modulus than another fiber that is collagen-like and has a higher elastic modulus. The higher modulus collagen-like fiber is longer than the lower modulus elastin-like fiber.

Owner:NOVO IP LLC

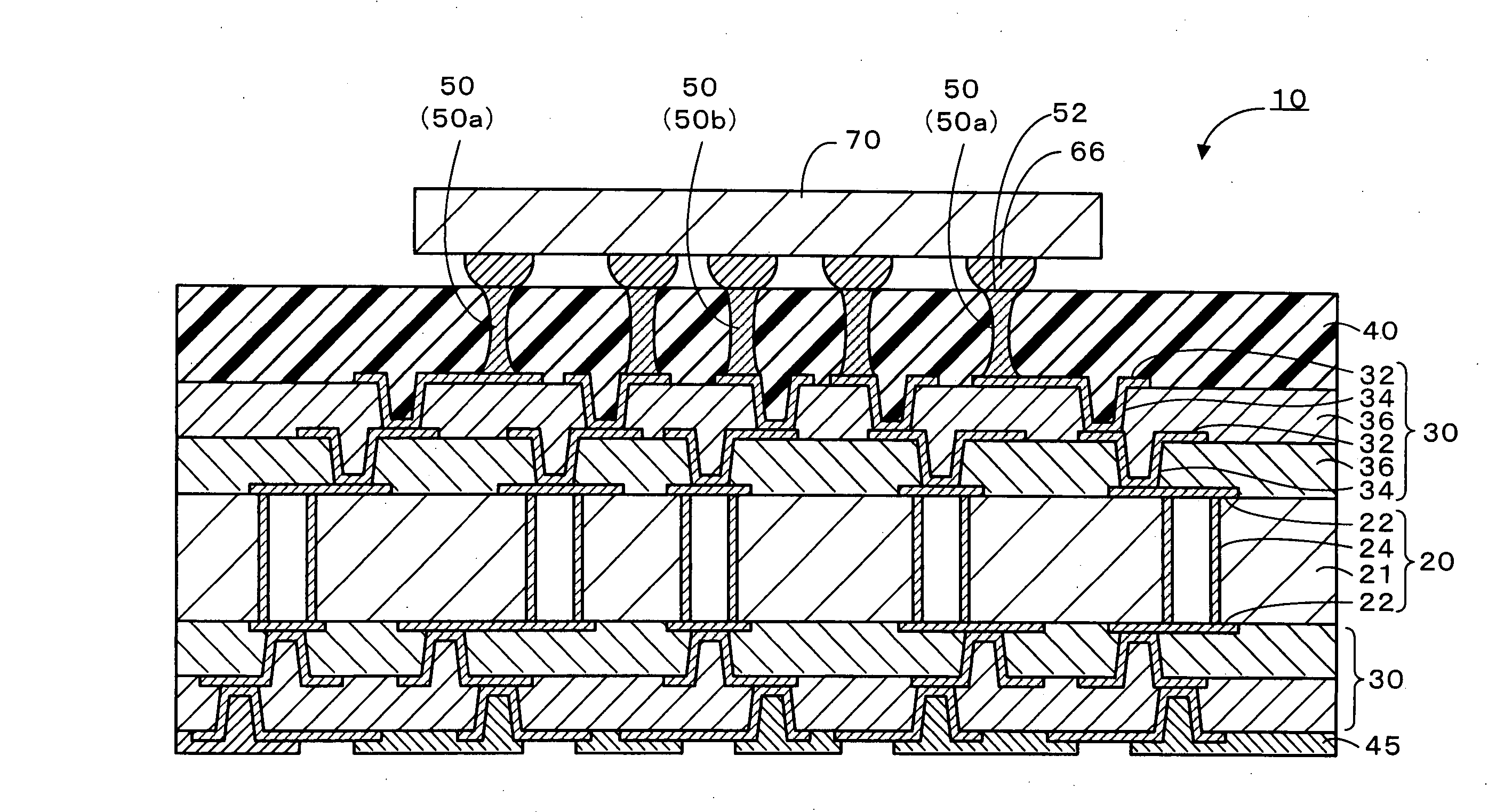

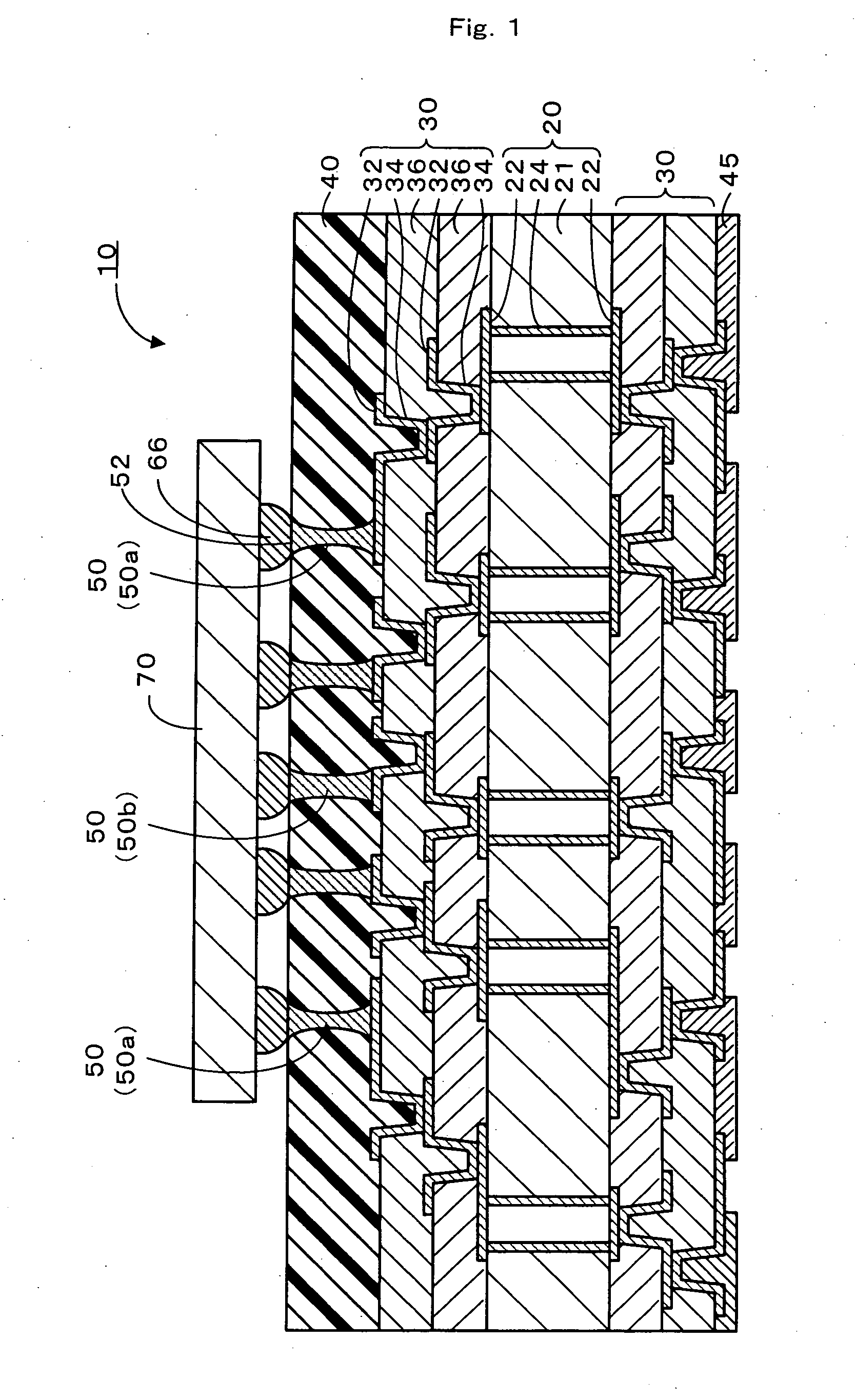

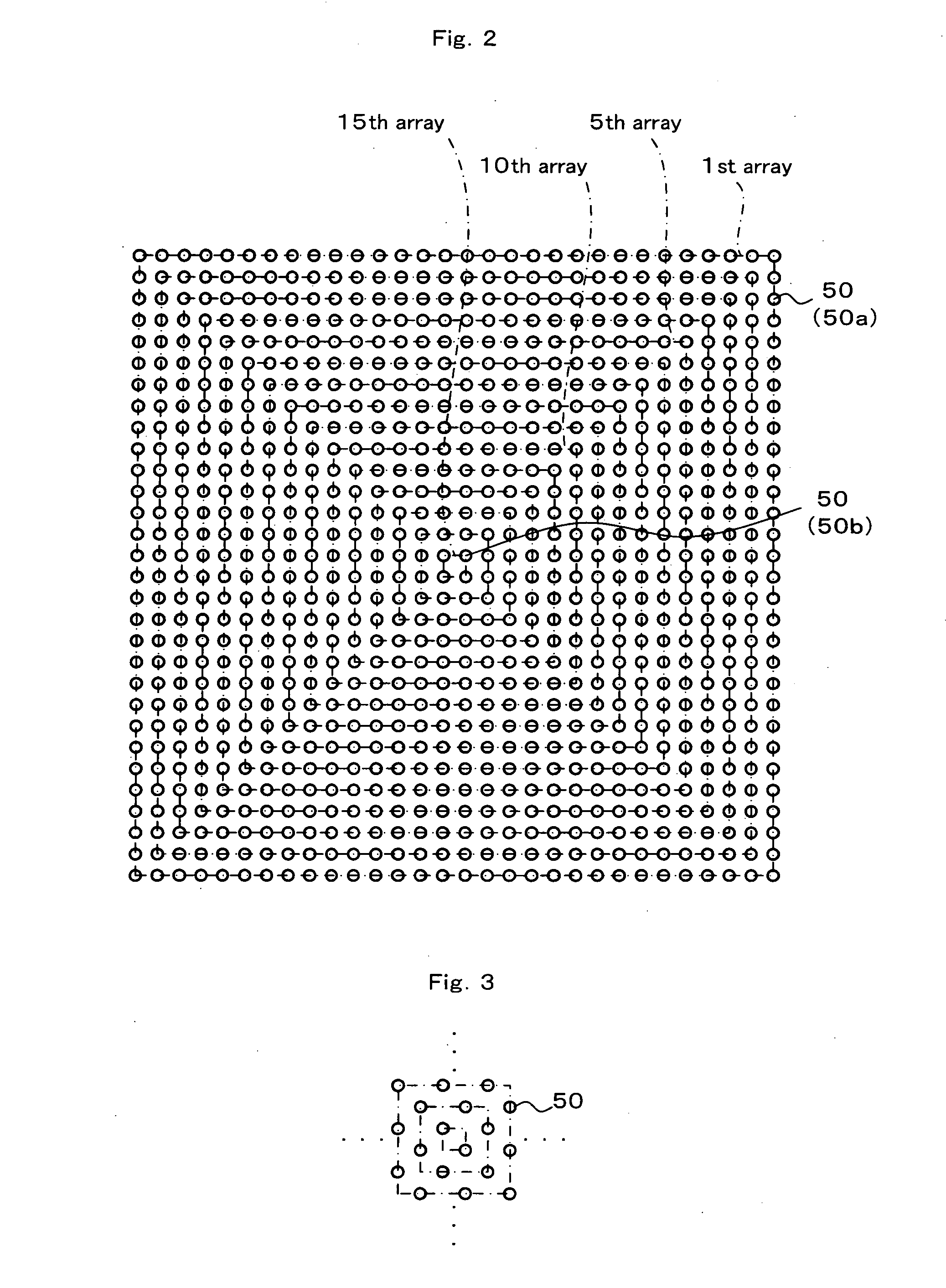

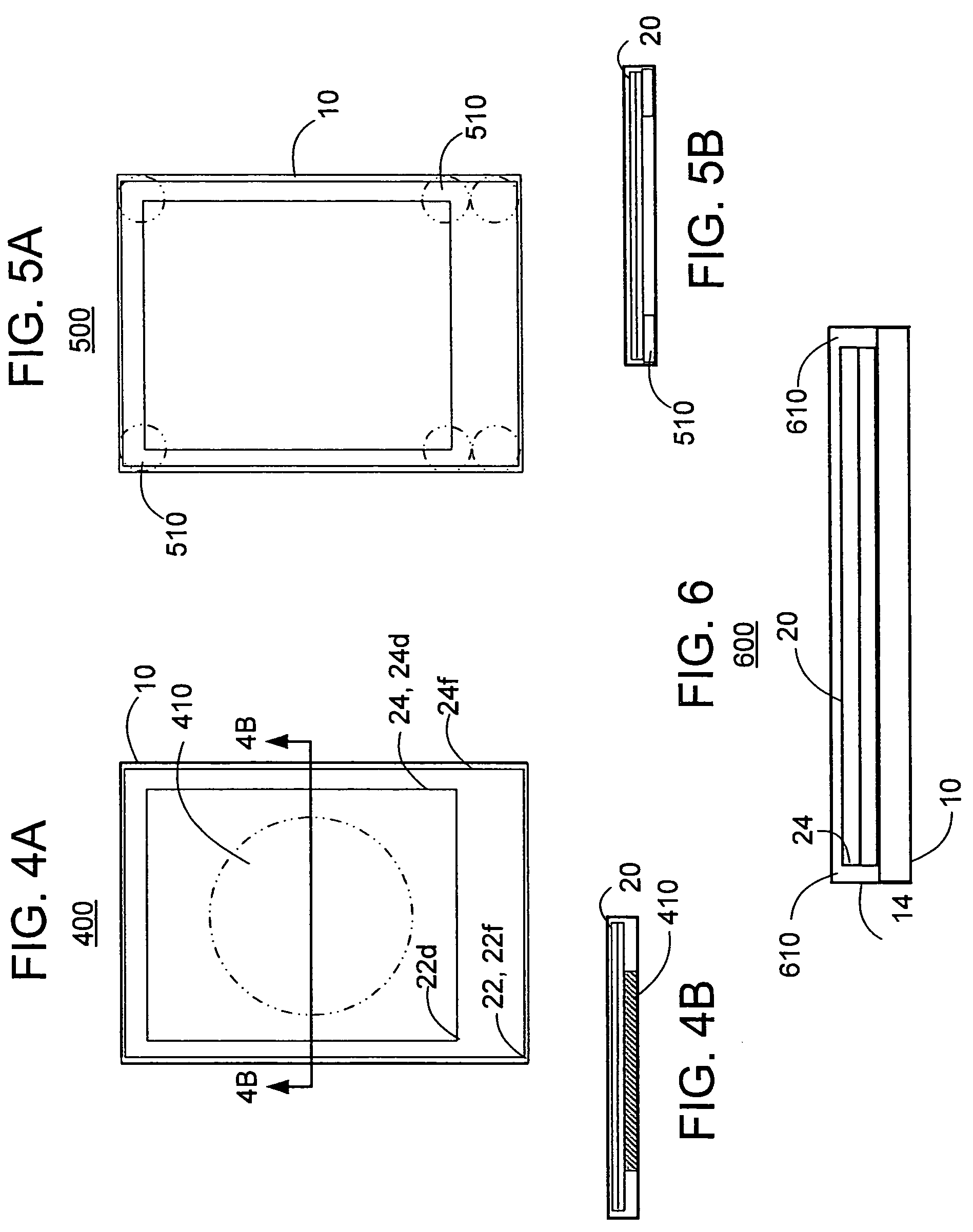

Multilayer printed wiring board

ActiveUS20060231290A1Sufficient effectSimple preparation processPrinted electric component incorporationSemiconductor/solid-state device detailsElectrical conductorLow elastic modulus

A multilayer printed wiring board 10 includes: a build-up layer 30 that is formed on a core substrate 20 and has a conductor pattern 32 disposed on an upper surface; a low elastic modulus layer 40 that is formed on the build-up layer 30; lands 52 that are disposed on an upper surface of the low elastic modulus layer 40 and connected via solder bumps 66 to a IC chip 70; and conductor posts 50 that pass through the low elastic modulus layer 40 and electrically connect lands 52 with conductor patterns 32. The conductor posts 50 have the aspect ratio Rasp (height / minimum diameter) of not less than 4 and the minimum diameter exceeding 30 μm, and the aspect ratio Rasp of external conductor posts 50a, which are positioned at external portions of the low elastic modulus layer 40, is greater than or equal to the aspect ratio Rasp of internal conductor posts 50b, which are positioned at internal portions of the low elastic modulus layer 40.

Owner:IBIDEN CO LTD

Wafer dicing/die bonding sheet

ActiveUS20040105990A1Avoid crackingAvoid separationSynthetic resin layered productsSolid-state devicesEpoxyHeat resistance

In a wafer dicing / die bonding sheet comprising a backing member, an adhesive layer, and a protective member, the adhesive layer is made of an adhesive composition comprising a phenolic hydroxyl radical-bearing polyimide resin, an epoxy resin, and an epoxy resin curing agent, the ratio of the total weight of the epoxy resin and the epoxy resin curing agent to the weight of the polyimide resin being from 0.1:1 to 3:1. Due to heat resistance, improved adhesive properties and a low modulus of elasticity, the wafer dicing / die bonding sheet is effective for reducing the warpage of a chip after die bonding.

Owner:SHIN ETSU CHEM IND CO LTD

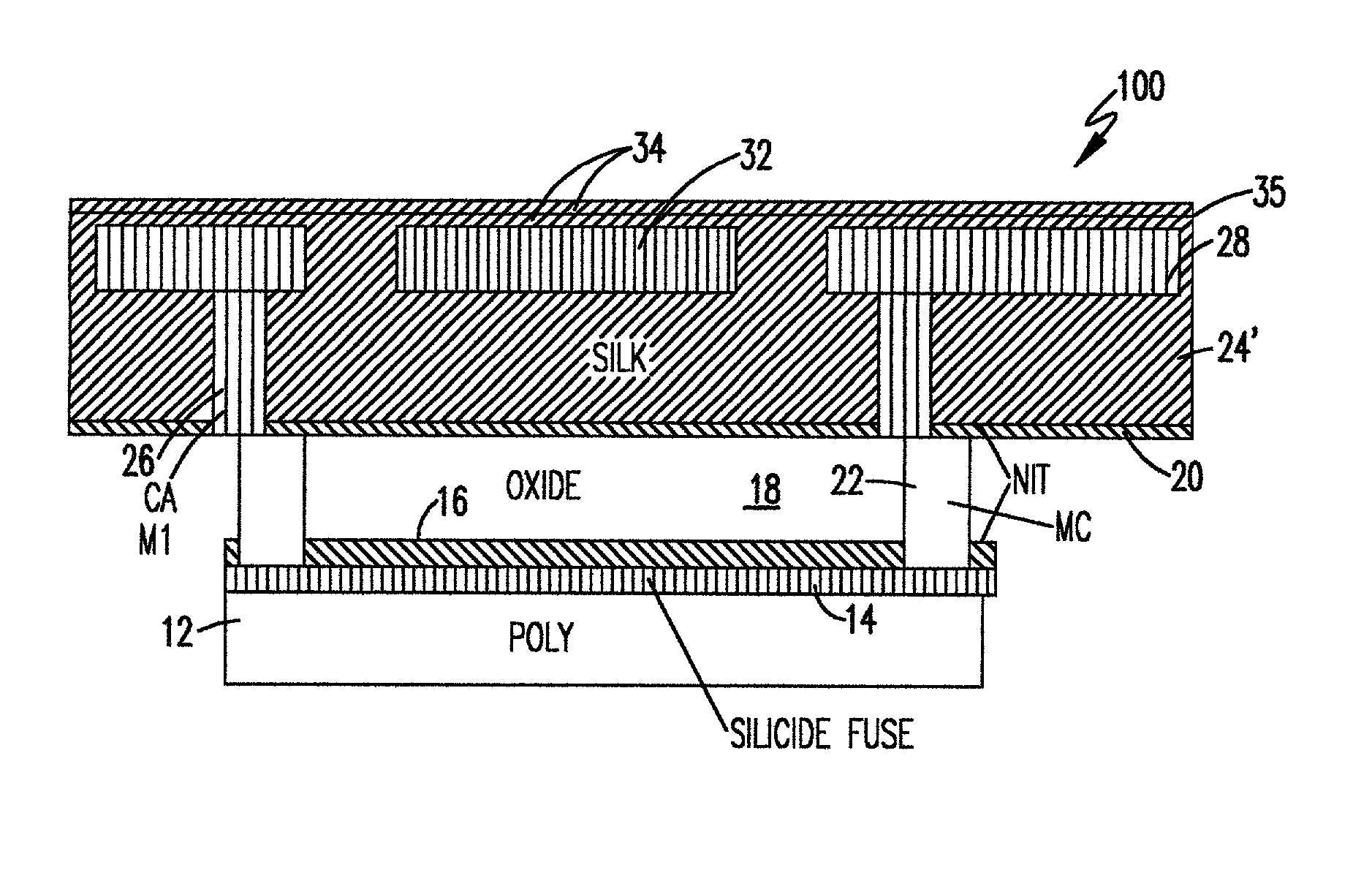

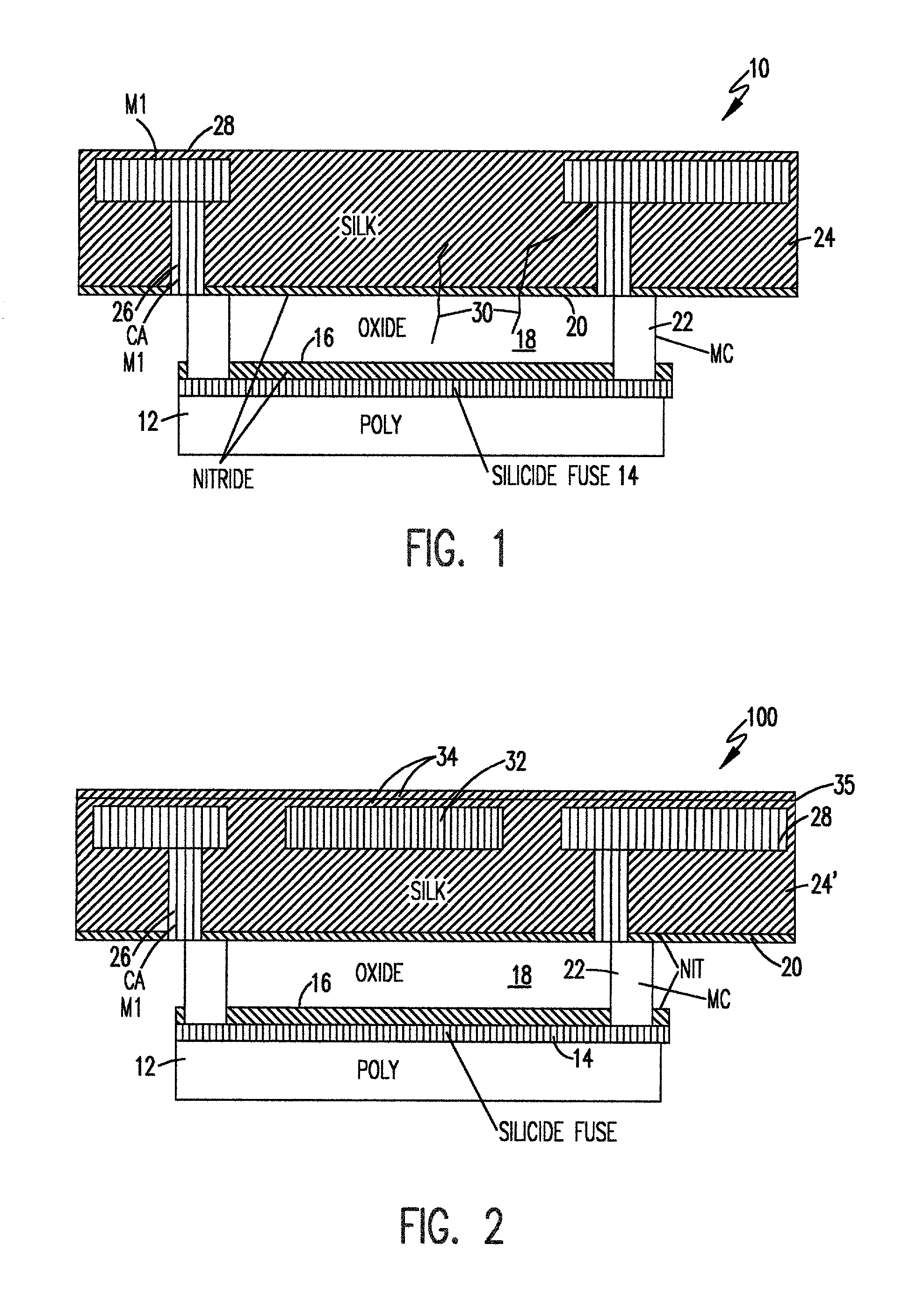

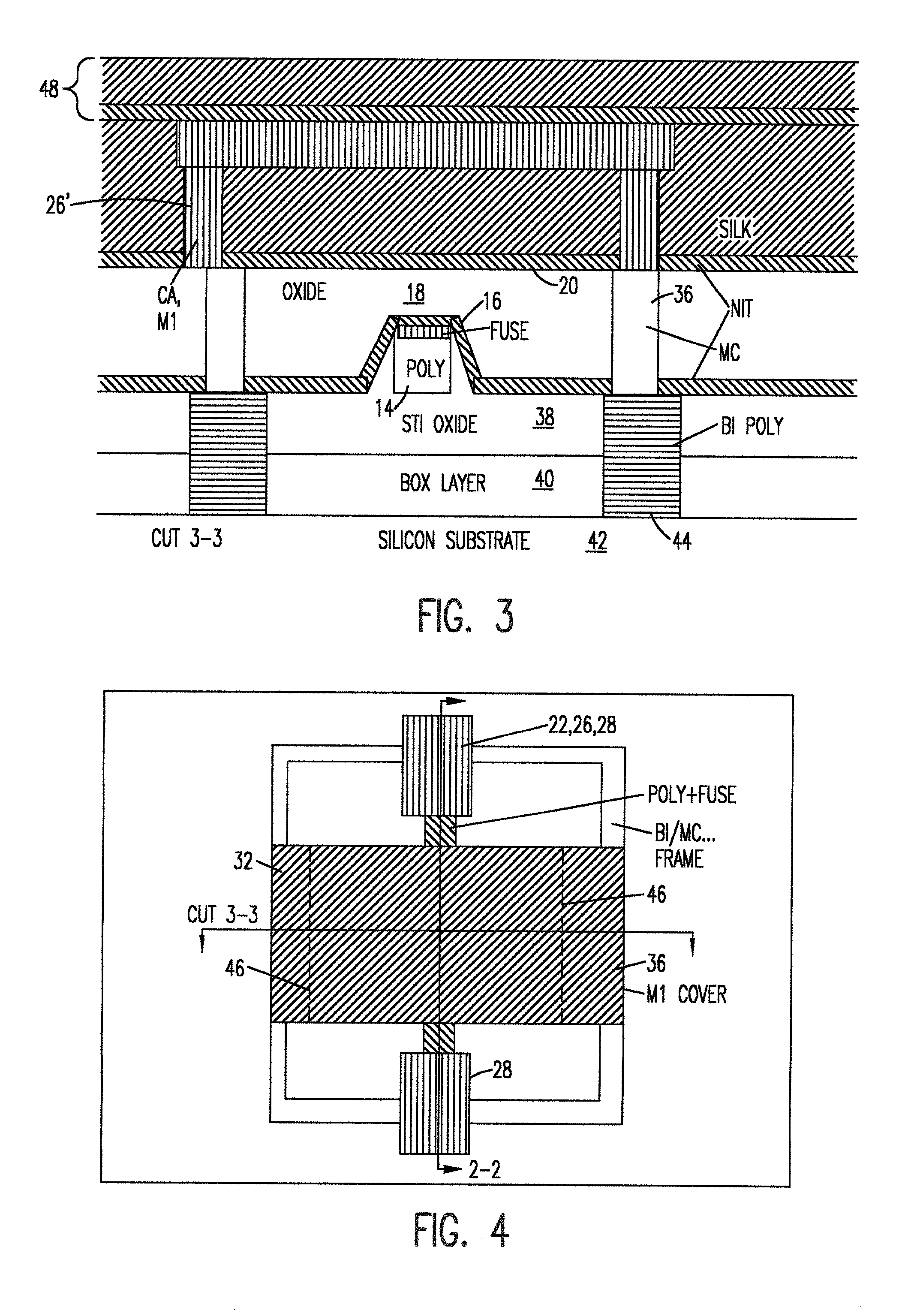

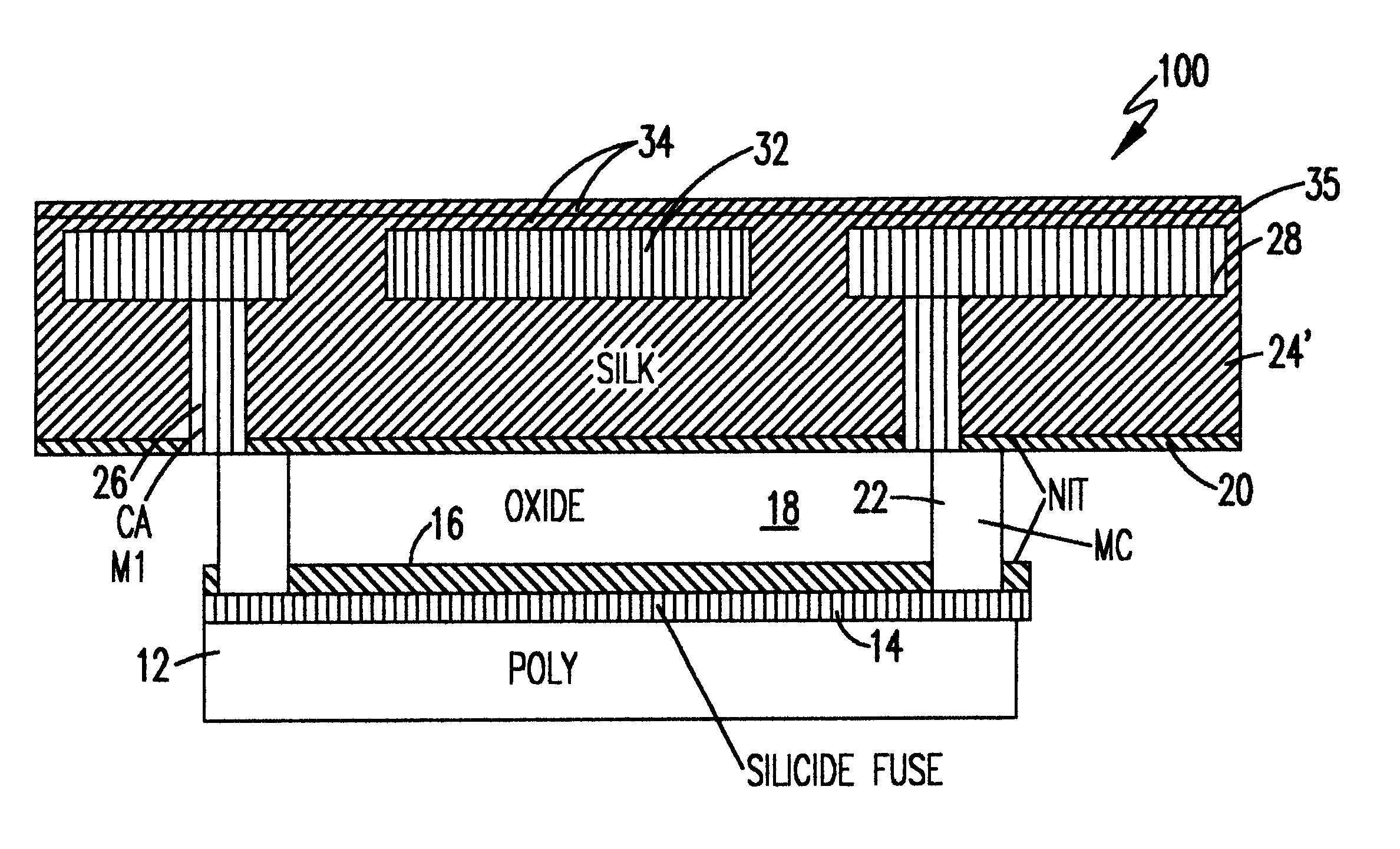

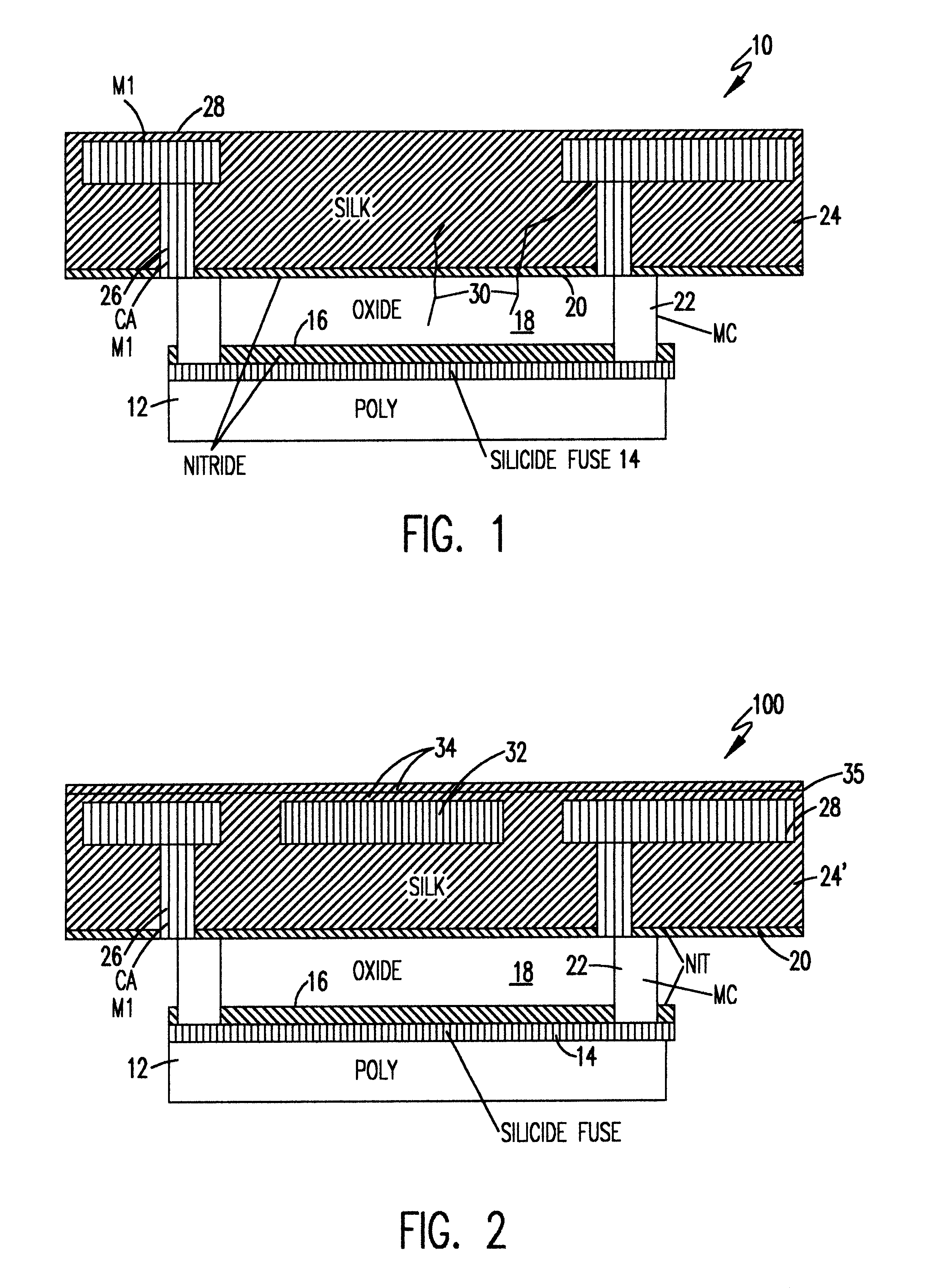

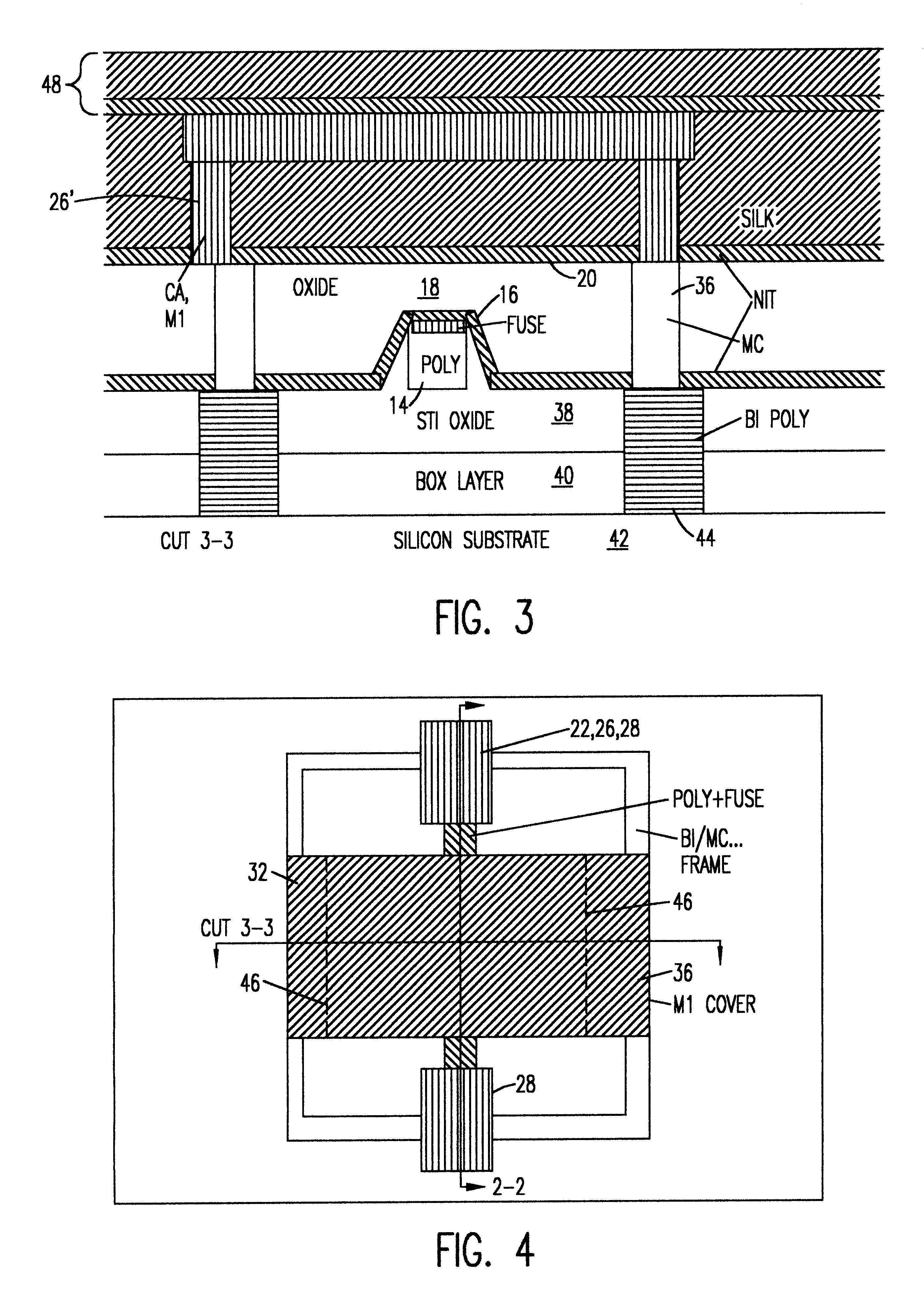

Fuse structure with thermal and crack-stop protection

InactiveUS20020113291A1Small sizeControl damageSemiconductor/solid-state device detailsSolid-state devicesConductive materialsMaterials science

Thermal degradation of a low-k organic dielectric material is avoided or limited in the proximity of a heat source such as a fusible element by overlaying the low-k material with a thermally conductive material and providing a low thermal resistance path from the thermally conductive material, possibly having a low modulus of elasticity, to a heat sink. The thermally conductive material thus provides crack-stop protection for further layers of an integrated circuit or interconnect structure above the fusible element by mechanical, chemical and thermal encapsulation of the heat source and low-k material.

Owner:GOOGLE LLC

Heat curable resin composition having a low elastic modulus, heat curable film using same, and cured products

InactiveUS20060079609A1Outstanding featuresLow elastic modulusSemiconductor/solid-state device detailsSolid-state devicesEpoxyHeat resistance

A heat curable resin composition having a low elastic modulus comprising (A) an epoxy resin, (B) crosslinked fine particles, and (C) a curing agent, which when cured with heat, produces a cured product having a elastic modulus of less than 1 GPa is provided. A cured product excelling in characteristics such as stress relaxation property (low stress properties), electric insulation properties, heat shock resistance, and heat resistance can be produced from the heat curable resin.

Owner:JSR CORPORATIOON

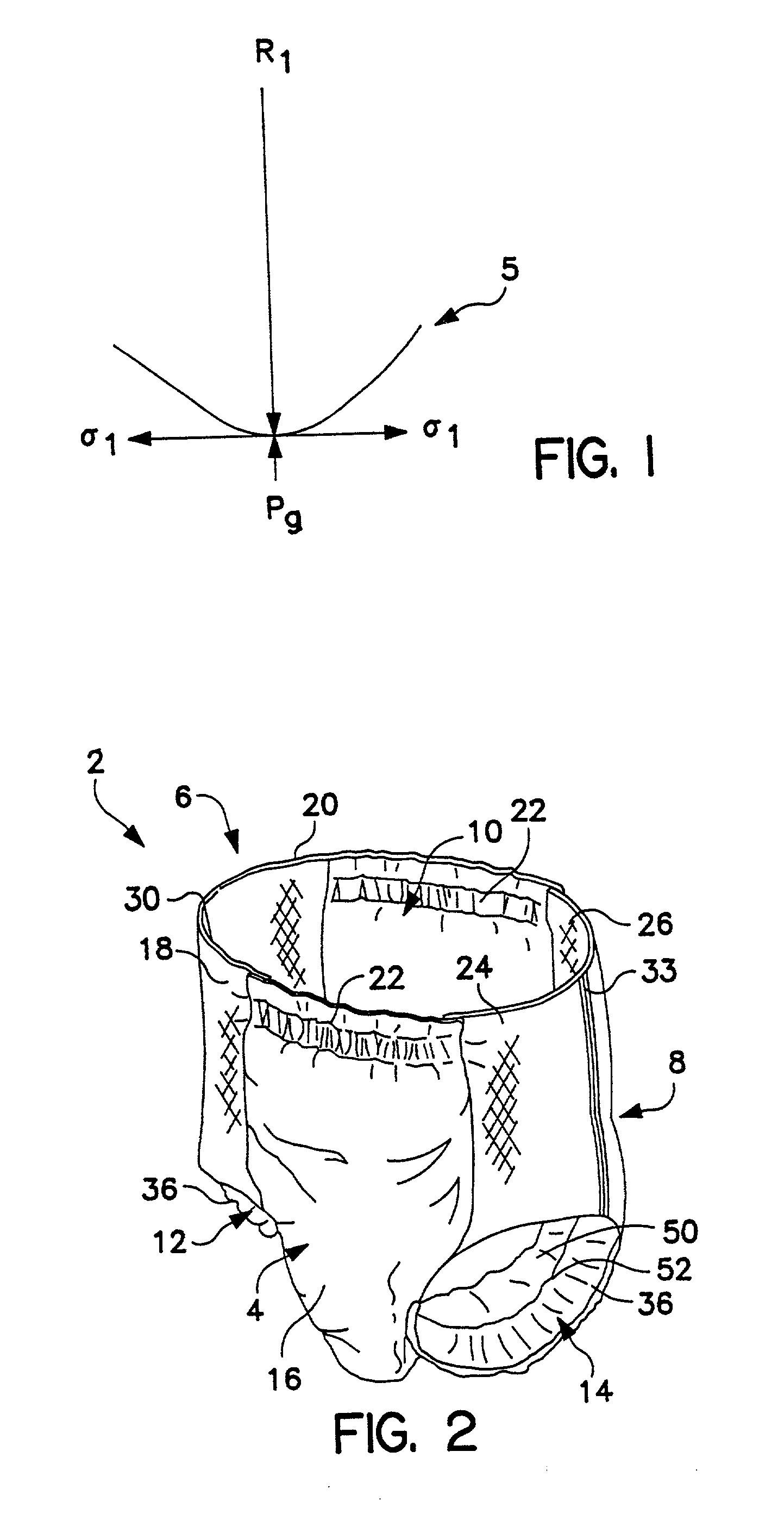

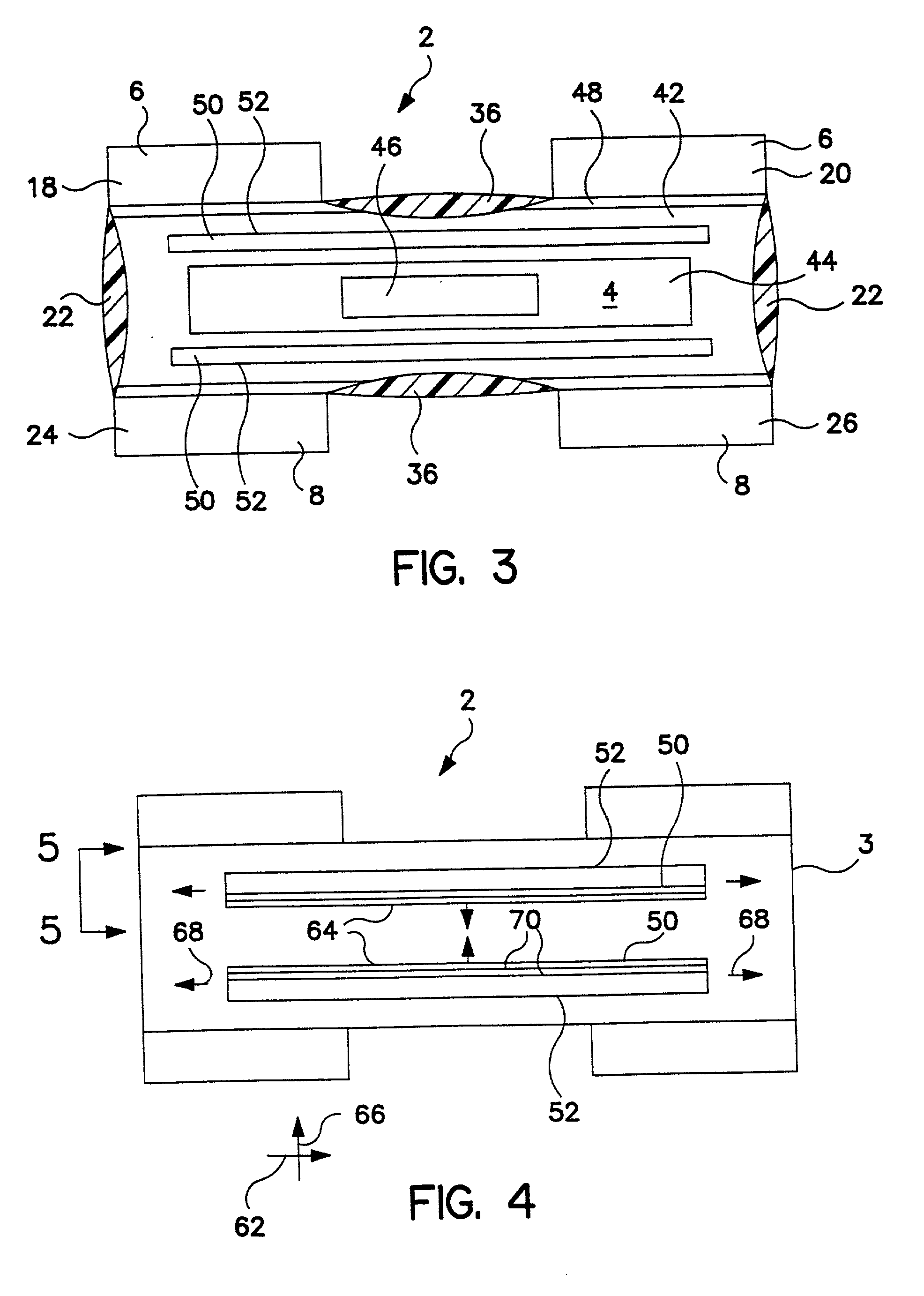

Body fluid sealing extensible gaskets for personal care products

A containment flap for an absorbent article, such as an incontinence garment, has elasticity in the long axis and extensibility of the flap with a low modulus of elasticity in its transverse direction. The long axis tension of the flap has a force vector normalized to the transverse direction when the flap is placed in curvature over the body of a wearer, thereby providing a force for extending the flap in the transverse direction to maintain contact with the body of the wearer when the garment begins to sag, such as may happen due to gravity when the garment is loaded with absorbed bodily fluids. Material suitable for constructing such flaps is further disclosed.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method of roll grinding

InactiveUS6988937B2Revolution surface grinding machinesOther chemical processesEngineeringGrinding wheel

Grinding of mill rolls is carried out with chatter resistant abrasive grinding wheels having relatively low elastic modulus values and relatively high burst speed values. Grinding operations may be carried out at high efficiency with controlled wheel vibration, thus generating optimum surface quality on the ground mill rolls.

Owner:SAINT GOBAIN ABRASIVES INC

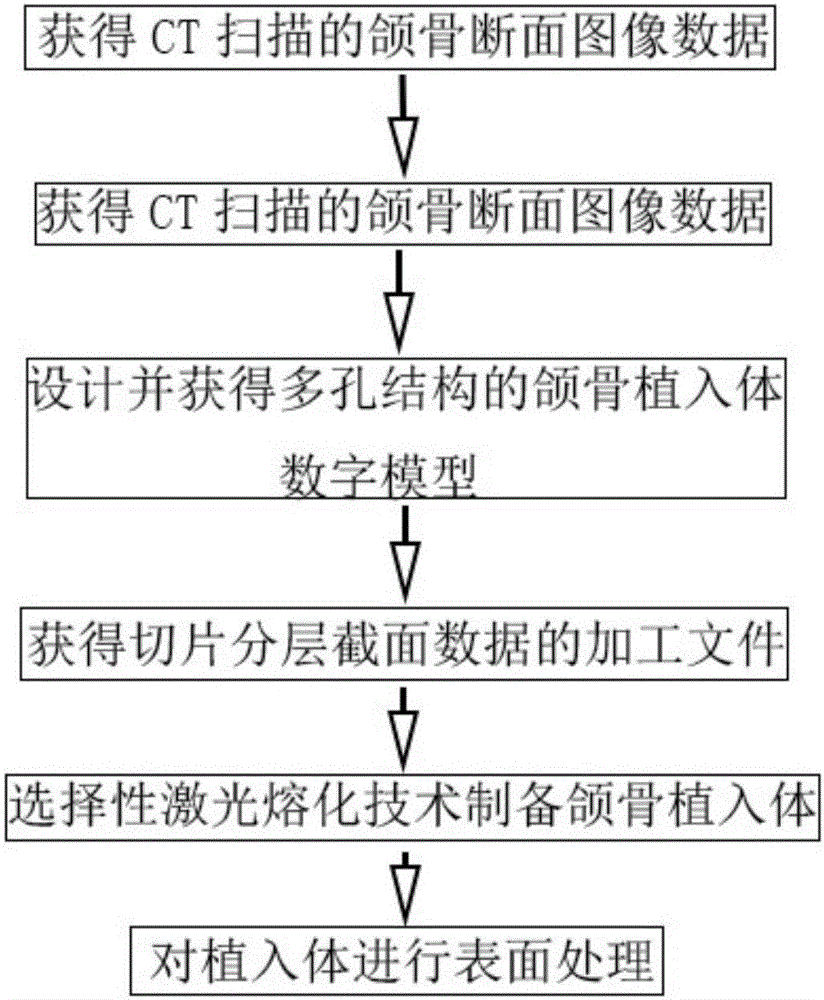

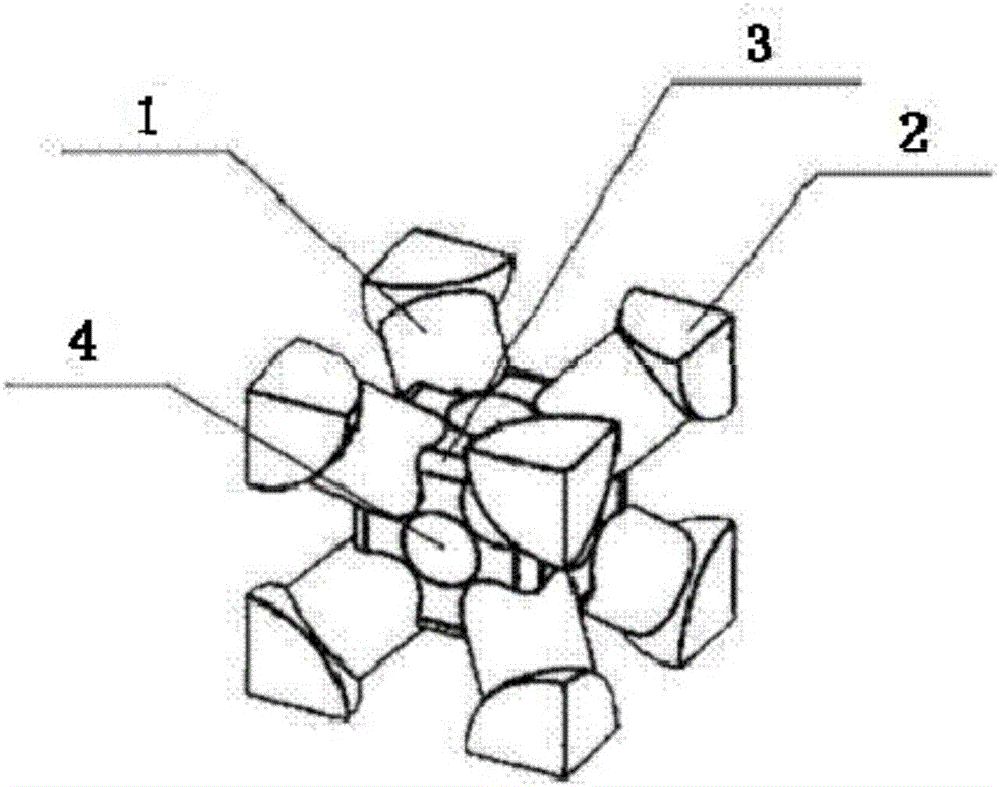

Low-elasticity-modulus titanium-based jawbone implant and preparation method thereof

InactiveCN104985183AMeet individual needsReduce concentrated stressBone implantStress concentrationPersonalization

The invention discloses a low-elasticity-modulus titanium-based jawbone implant and a preparation method of the implant. The preparation method mainly comprises the six steps that CT-scanned jawbone section image data are obtained; a rebuilt jawbone three-dimensional digital model is obtained; a jawbone implant digital model of a multi-hole structure is designed and obtained; a machining file of slice layered cross section data is obtained; the selective laser melting technology is adopted for preparing the jawbone implant; and surface treatment is carried out on the implant. The implant is used for treating a patient with jawbone defects, and the CAD digital design technology is used in the design of the implant; and jawbone repairing individualized design and multi-hole support structure design are combined, and through the selective laser melting technology, the low-elasticity-modulus titanium-based jawbone implant is prepared. The implant can meet the individual needs of the patient, and meanwhile can reduce the elastic modulus; and the problems of stress concentration and stress shielding of a traditional jawbone implant are solved, the preparation time is shortened, and the machining difficulty and the production cost are reduced.

Owner:东莞市唯信三维科技有限公司

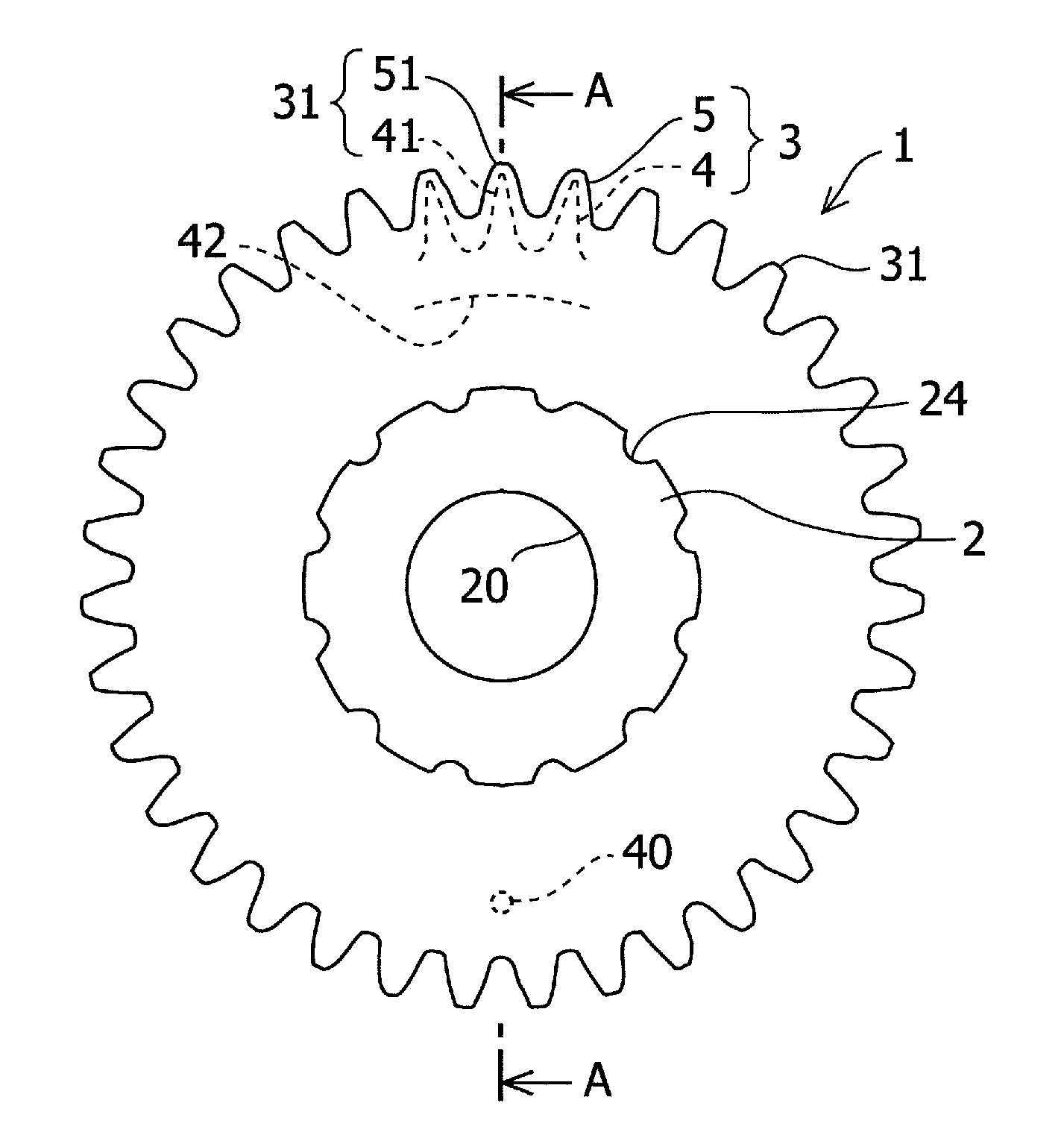

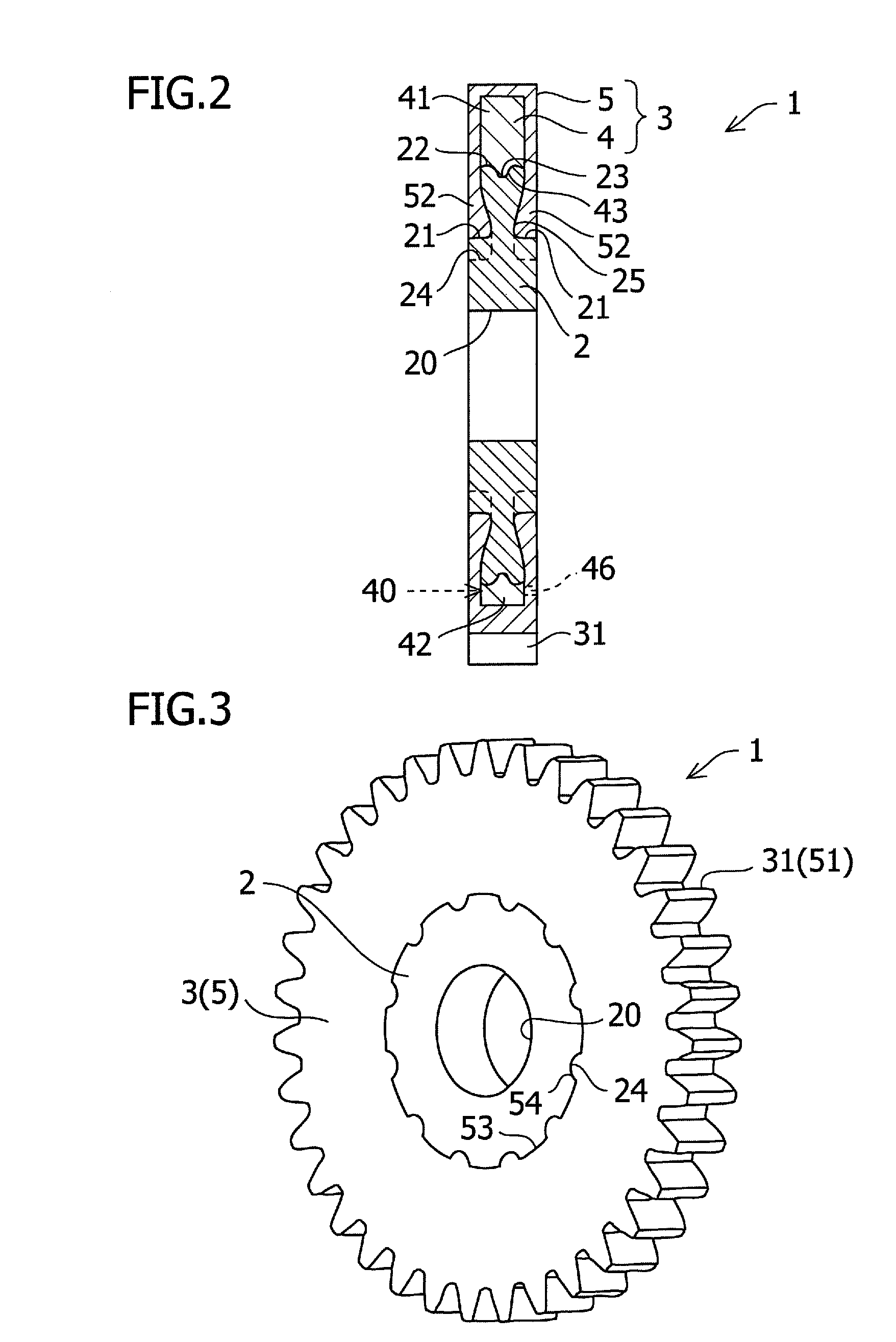

Plastic Gear

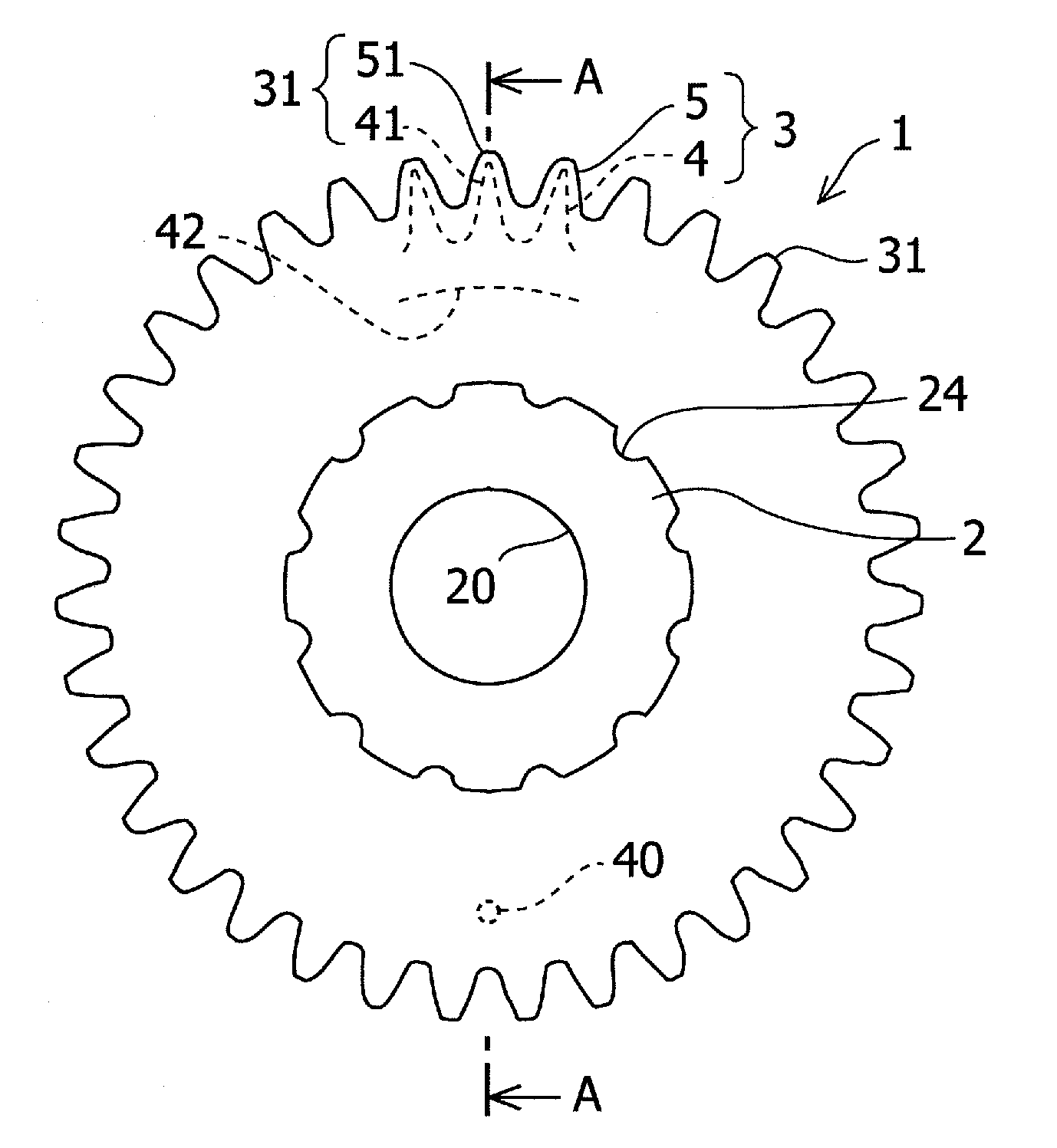

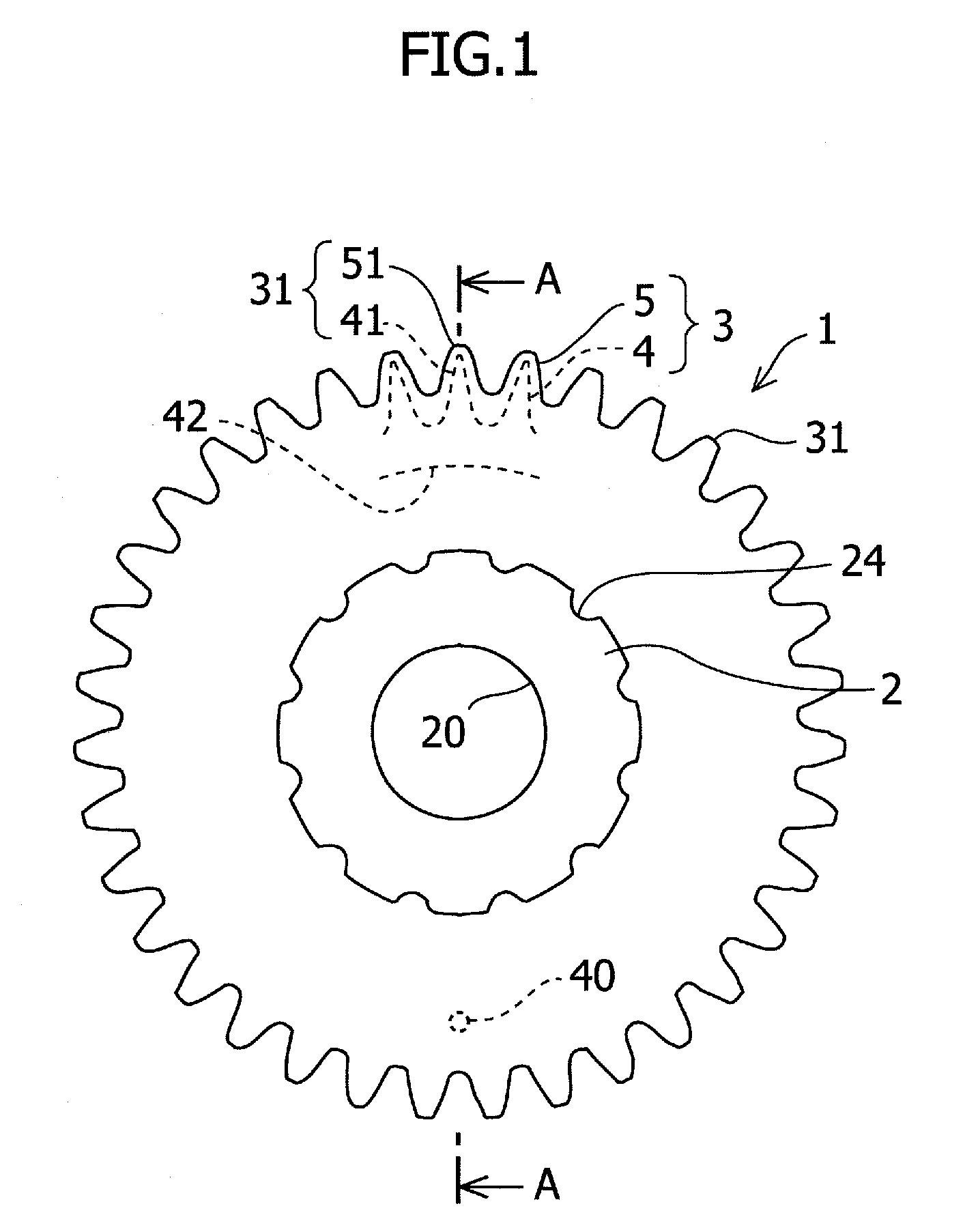

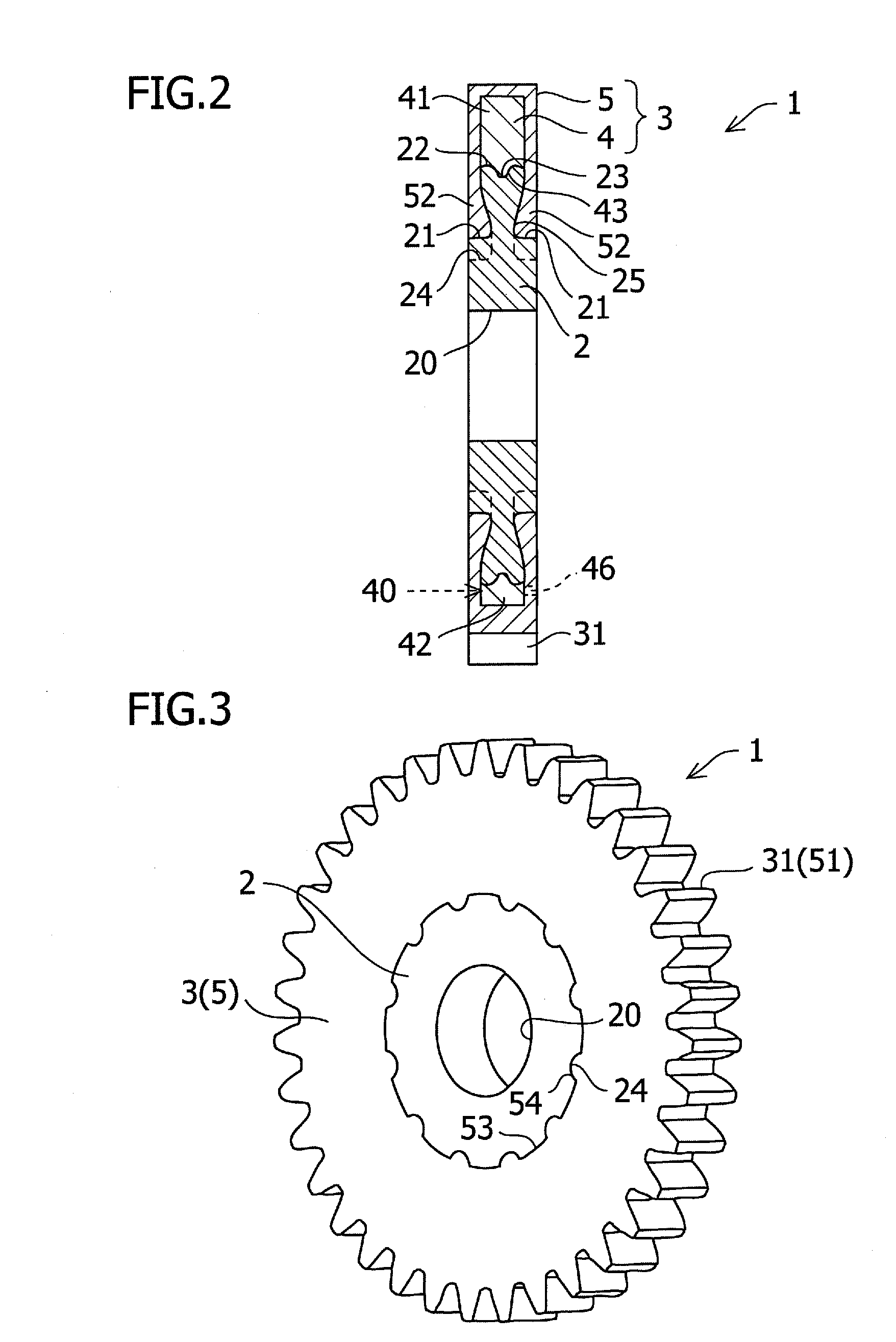

ActiveUS20080146402A1Improve impact resistanceReduce vibrationPortable liftingGearing detailsSurface layerPlastic materials

A plastic gear having a gear peripheral portion including a tooth portion is constituted by a plastic material, and a gear inner circumferential member with an annular shape or a disk shape is provided at the inner circumferential side of the gear peripheral portion. The gear peripheral portion includes an inner core and a surface layer member, the inner core being covered with the surface layer member and made of plastic with high elastic modulus and high strength, and the surface layer member being made of plastic with relatively low elastic modulus. The inner core is revolvably fitted around the gear inner circumferential member so as to revolve around the gear revolving axis, and an engaging portion is provided at an interface of the surface layer member and the gear inner circumferential member for preventing relative revolution around the gear revolving axis.

Owner:SUZUKI MOTOR CORP

Monomer, polymer, and ocular lens comprising the same

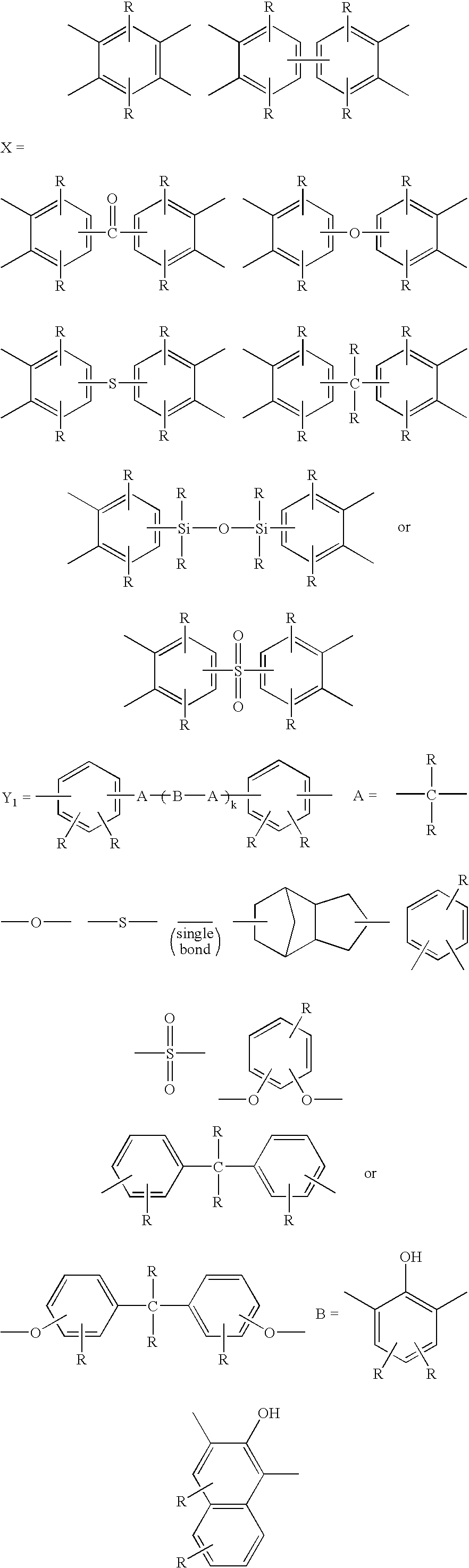

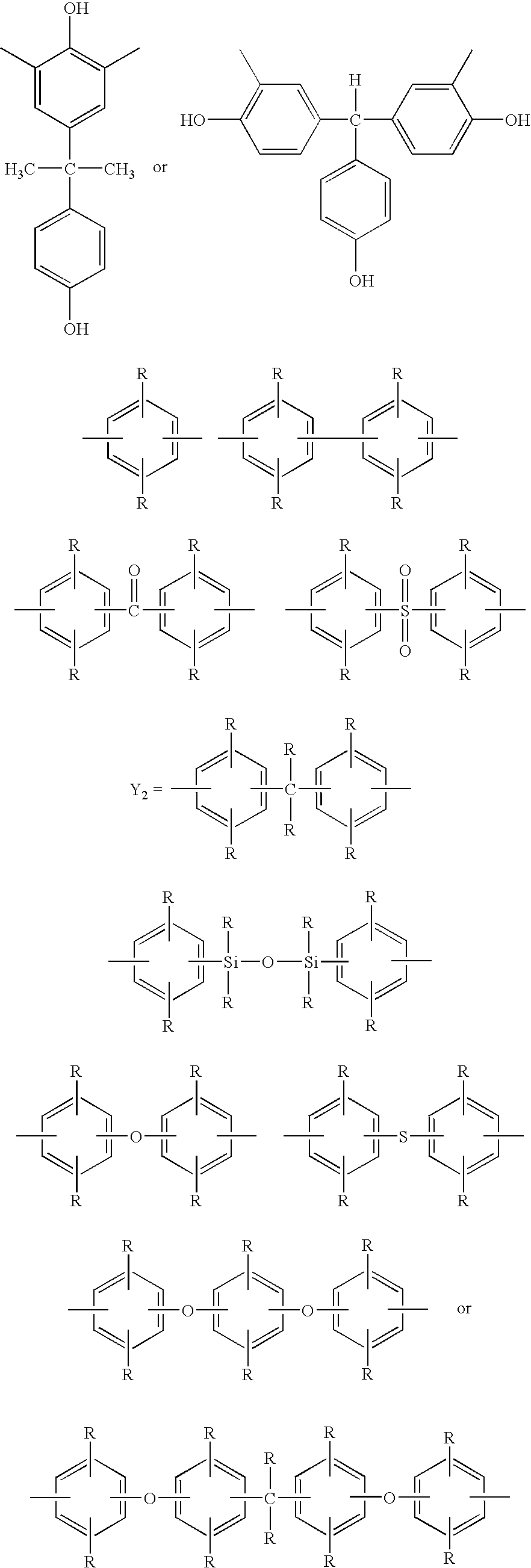

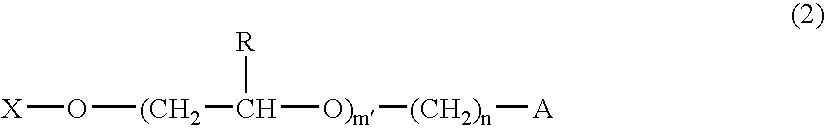

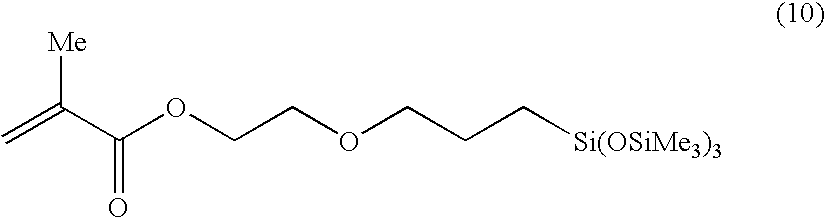

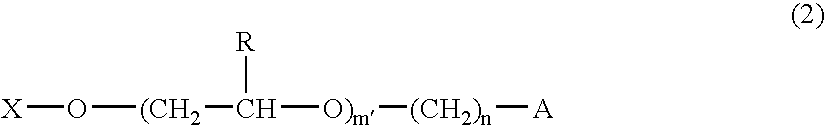

Monomers for polymers having high oxygen permeability, high water content and a low modulus of elasticity are provided, and polymers and ophthalmic lenses comprised of said monomers are provided. They are monomers represented by formula (1) or (2) below: X--O--(CH.sub.2CH.sub.2CH.sub.2O).sub.m--(CH.sub.2).sub.n--A (1) 1 wherein, X is a polymerizable group having carbon-carbon unsaturated bonds; A is a siloxanyl group; R is H or a methyl group; m is an integer of 1 to 10; m' is an integer of 2 to 10; and n is an integer of 2 to 10.

Owner:JOHNSON & JOHNSON VISION CARE INC

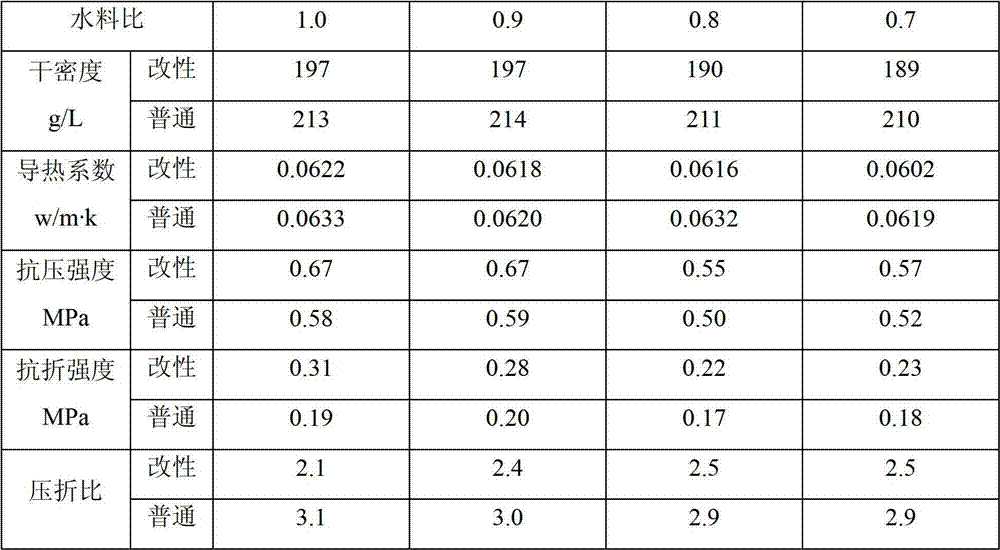

Dual organic modified cement-base expanded perlite fireproof thermal-insulation board and preparation method thereof

InactiveCN102815906AStrong resistance to deformationImprove crack resistancePolymer scienceCrack resistance

The invention relates to a dual organic modified cement-base expanded perlite fireproof thermal-insulation board and a preparation method thereof. The dual organic modified cement-base expanded perlite fireproof thermal-insulation board mainly comprises the following components in percentage by weight: 50-80% of organic modified expanded perlite, 20-35% of Portland cement, 5-10% of polymer emulsion, 0-3% of active filler and 0.5-1% of additive. The preparation method comprises the following steps: evenly mixing raw materials, adding water, stirring to obtain a semidry material, filling the semidry material into a mold, compacting into a fireproof thermal-insulation board, and finally, carrying out high temperature steam curing for several hours. The dual organic modified cement-base expanded perlite fireproof thermal-insulation board not only has the advantages of strong deformation resistance, favorable crack resistance, shock resistance, favorable weather resistance, long service life, favorable fire resistance (Grade A) and the like in the Portland cement-base expanded perlite inorganic thermal-insulation board, but also has the advantages of high strength, low density and low elastic modulus. The invention has the characteristic of high production efficiency, and can implement large-scale production.

Owner:宁波荣山新型材料有限公司

Plastic gear

ActiveUS7814809B2Improve impact resistanceReduce vibrationPortable liftingGearing detailsCircular discSurface layer

A plastic gear having a gear peripheral portion including a tooth portion is constituted by a plastic material, and a gear inner circumferential member with an annular shape or a disk shape is provided at the inner circumferential side of the gear peripheral portion. The gear peripheral portion includes an inner core and a surface layer member, the inner core being covered with the surface layer member and made of plastic with high elastic modulus and high strength, and the surface layer member being made of plastic with relatively low elastic modulus. The inner core is revolvably fitted around the gear inner circumferential member so as to revolve around the gear revolving axis, and an engaging portion is provided at an interface of the surface layer member and the gear inner circumferential member for preventing relative revolution around the gear revolving axis.

Owner:SUZUKI MOTOR CORP

Bezel packaging of frit-sealed OLED devices

InactiveUS20080120946A1Reduce the likelihood of failureHigh mechanical reliabilityElectroluminescent light sourcesSolid-state devicesFiberInter layer

Methods and assemblies relate to bezel packaging of a sealed glass assembly, such as a frit-sealed OLED device. The bezel packaging includes a shock absorbent intermediate layer of low modulus of elasticity material applied between the sealed glass assembly and the bezel. A bonding agent, which may include the low modulus of elasticity material and / or a separate bonding material, affixes the sealed glass assembly to the bezel. Bezel modifications may be made to stabilize the bezel. Exemplary bezel modifications include reinforced bezel side walls and supporting straps attached between bezel walls. The bezel design may include a gap between the edges of the sealed glass assembly and the bezel walls, so as to avoid direct contact therewith. The gap may be filled at least in part with low modulus of elasticity organic adhesive to provide additional shock absorbency. The low modulus of elasticity material may include foam, ceramic fiber cloth and / or a low modulus of elasticity polymeric organic coating.

Owner:CORNING INC

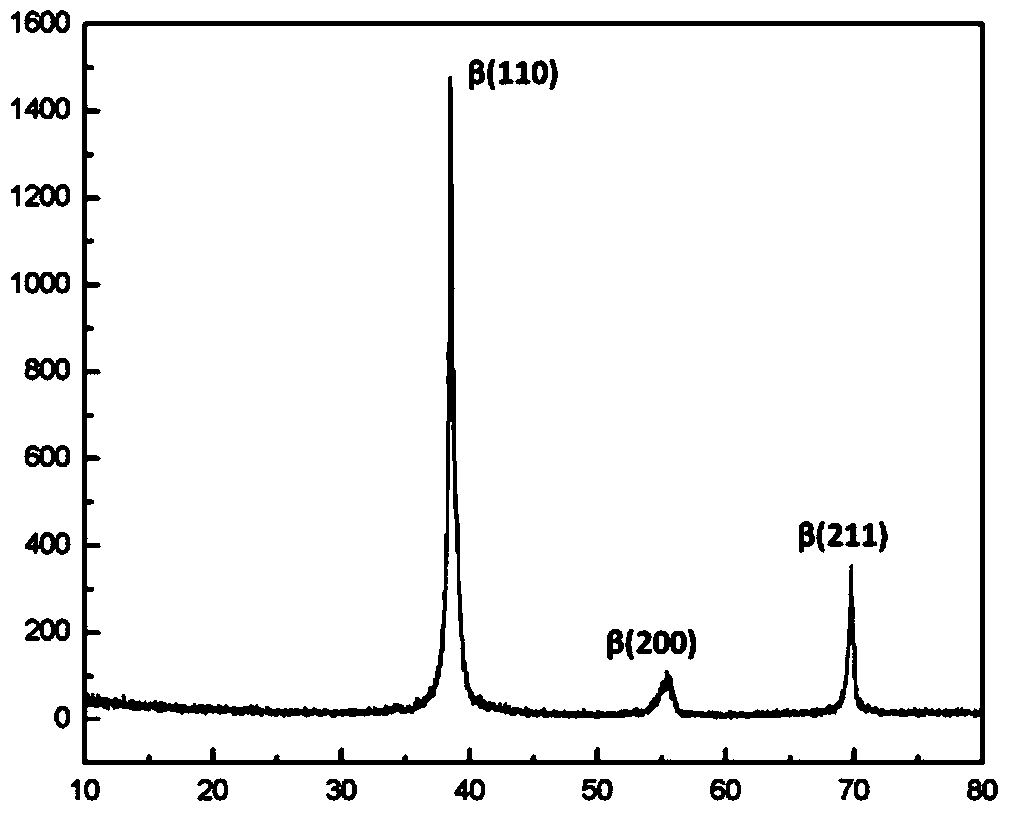

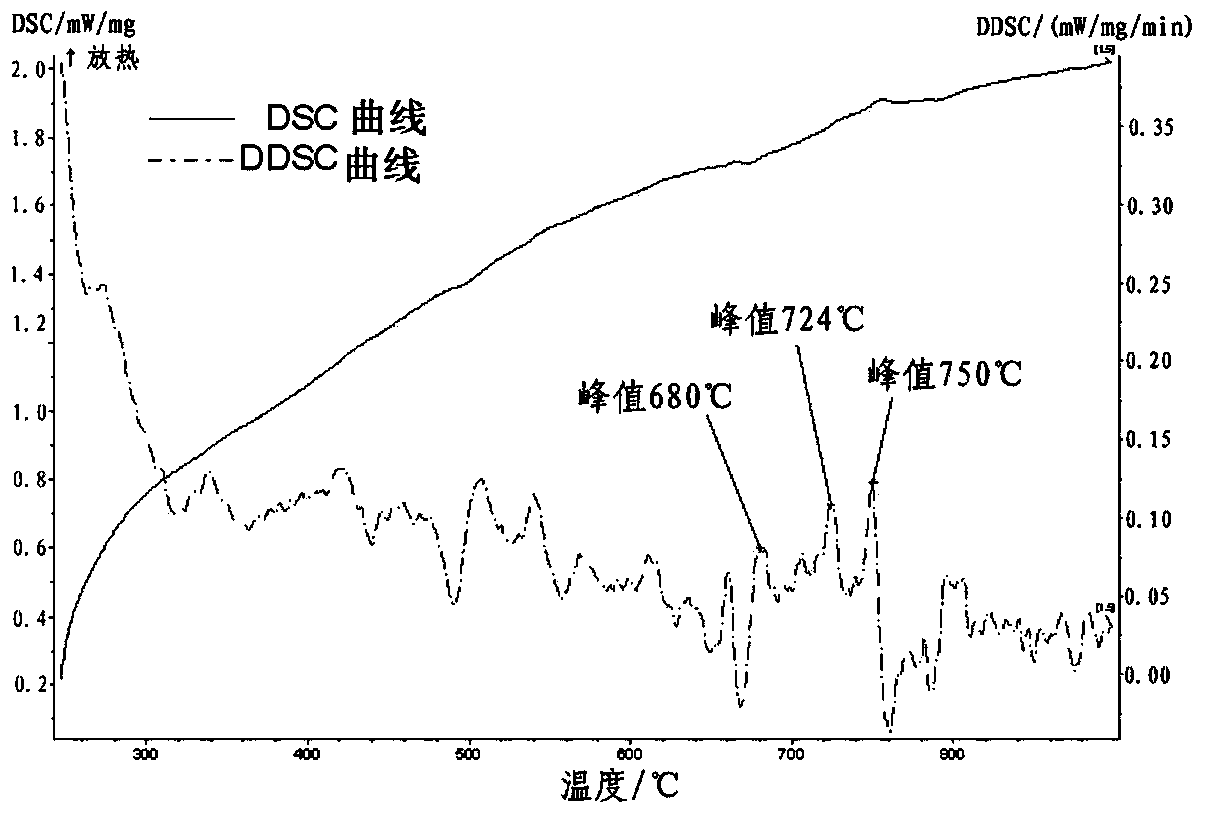

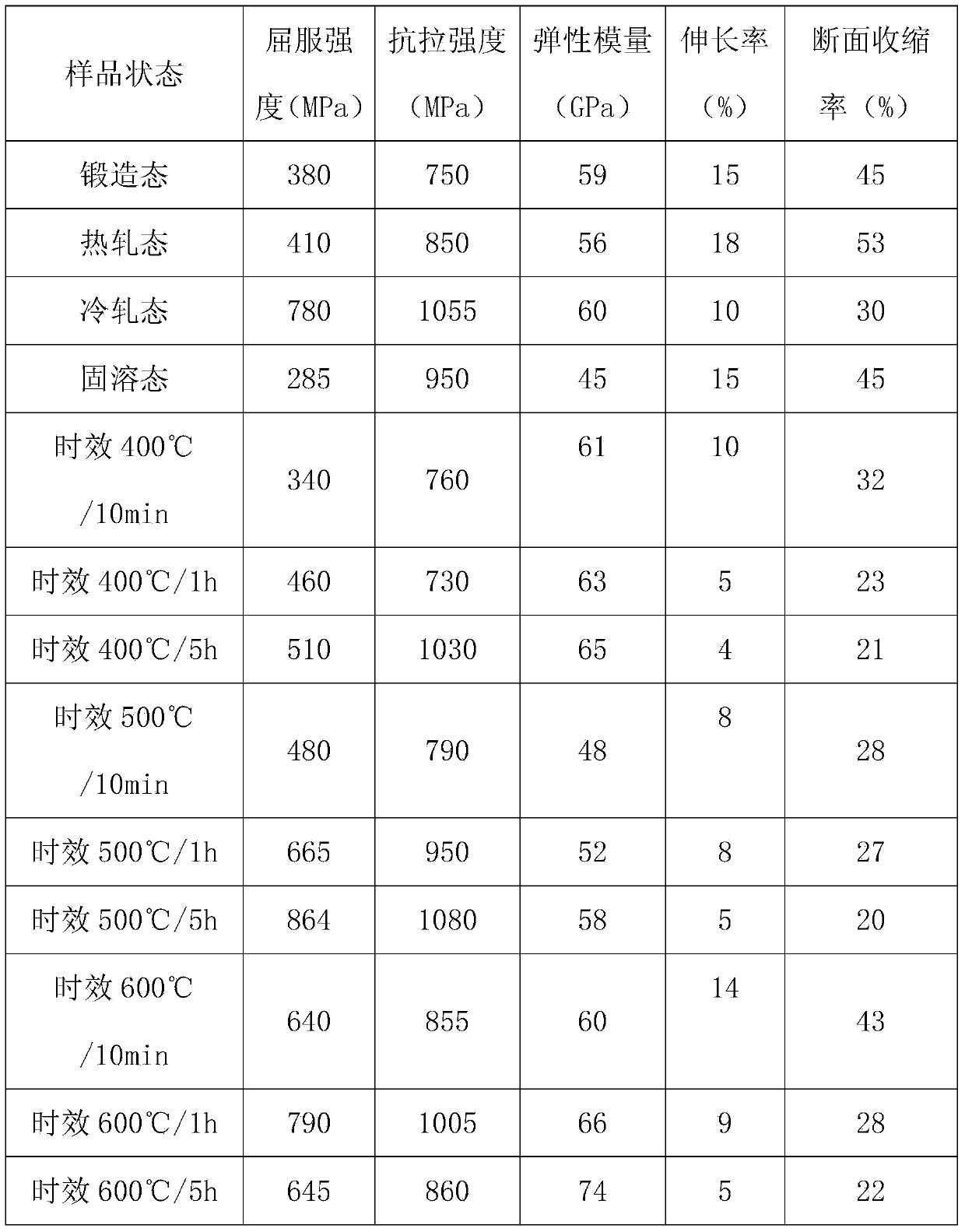

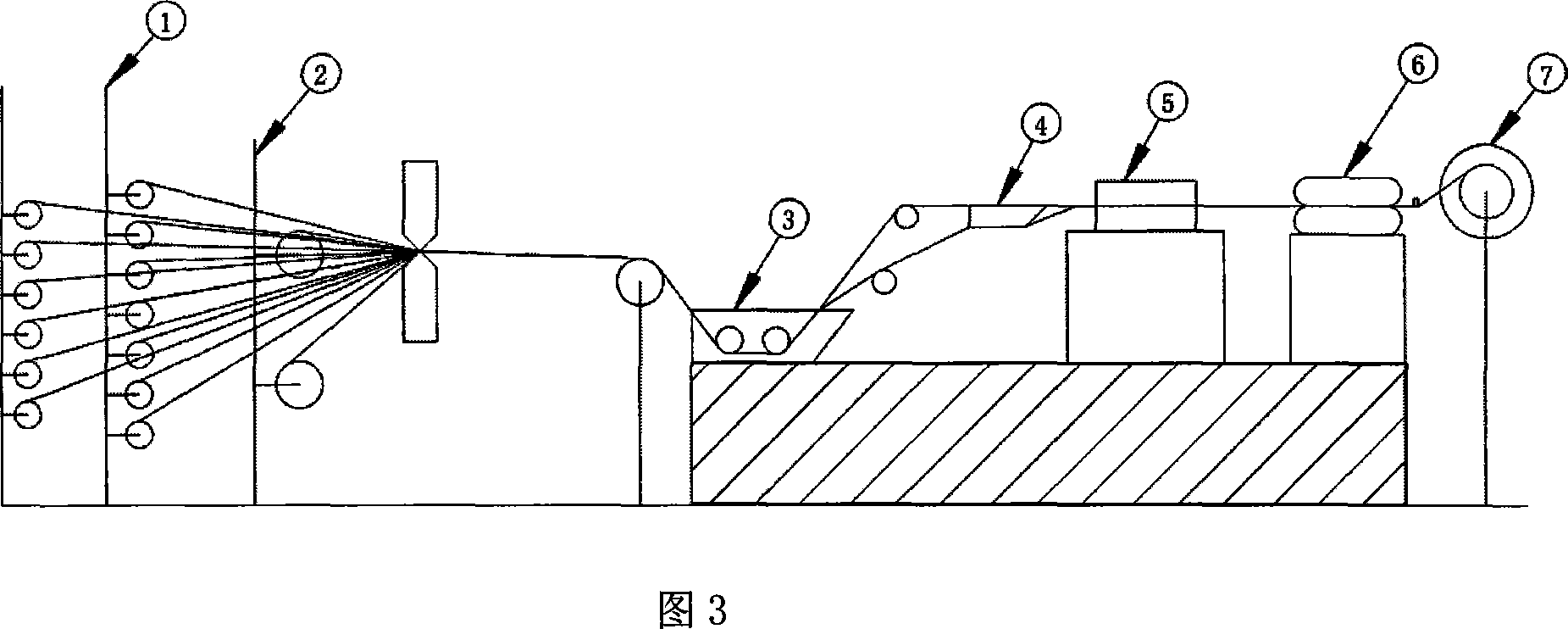

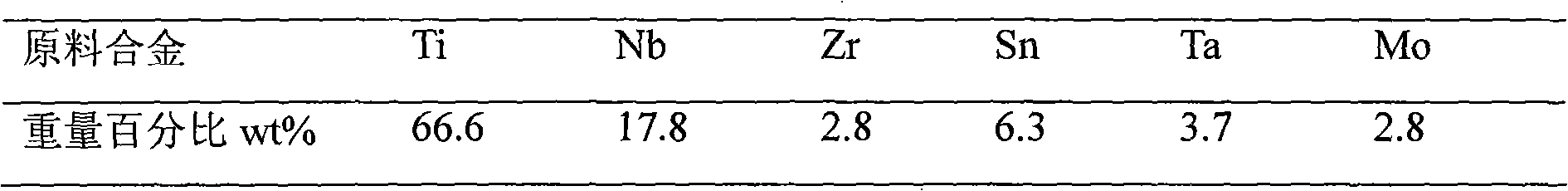

Metastable beta titanium alloy with low elastic modulus and preparing method thereof

The invention relates to a titanium alloy material, in particular to a multi-functional biomedical metastable beta titanium alloy material with excellent processing performance, and belongs to the technical field of titanium alloy material preparation. The alloy contains the following ingredients by mass: 18-27% of Nb, 0.5-2% of Mo, 3-5% of Zr, 7-9% of Sn, 0.1-0.3% of O and the balance of Ti. The titanium alloy has excellent comprehensive performance, and the strength and the elastic modulus of the alloy can be regulated through different thermal treatments. The elastic modulus E of the alloy is 40-7 3GPa, the yield strength sigma 0.2 is 260-864 MPa, the tensile strength sigma b is 686-1094 MPa, the elongation rate epsilon = 4-20%, and the facture surface shrinkage rate is 20-52%. The titanium alloy does not contain toxic elements, such as Al and V, and has excellent corrosion resistance, biocompatibility and cold processing performance. The titanium alloy can be used for manufacturing tissue repairing or substituting materials, such as artificial bones, artificial joints and bone plates.

Owner:BAOJI TITANIUM IND +1

Pressure sensor dielectric medium isolation packaging structure and packaging method of same

ActiveCN103257007AReduce manufacturing costFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsDielectricEngineering

The invention discloses a pressure sensor dielectric medium isolation packaging structure and a packaging method of the pressure sensor dielectric medium isolation packaging structure. The pressure sensor dielectric medium isolation packaging structure comprises a substrate, a cover body made of soft low-elasticity-modulus materials and a pressure sensor chip. The cover body and the substrate form an airtight cavity body together in order to accommodate the pressure sensor chip. When the pressure of a dielectric medium to be measured is acted on the cover body, the cover body deforms and accordingly compresses gas in the airtight cavity body to achieve balanced internal and external pressure. In the process, the dielectric medium to be measured is transmitted to a pressure sensitive membrane of the pressure sensor chip and accordingly the purpose that the pressure of pressure sensor chip and the pressure of the dielectric medium to be measured are separated is achieved. According to the pressure sensor dielectric medium isolation packaging structure and the packaging method of the pressure sensor dielectric medium isolation packaging structure, the pressure is transmitted by compressing the gas, and accordingly complex silicone oil filling procedures in a traditional silicone oil filling stainless steel packaging technology are avoided and manufacturing cost is greatly reduced.

Owner:MEMSENSING MICROSYST SUZHOU CHINA

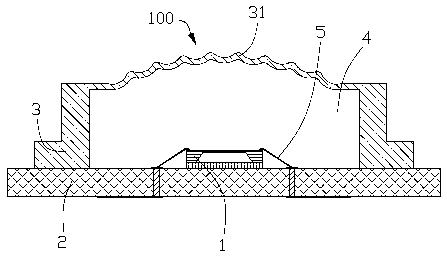

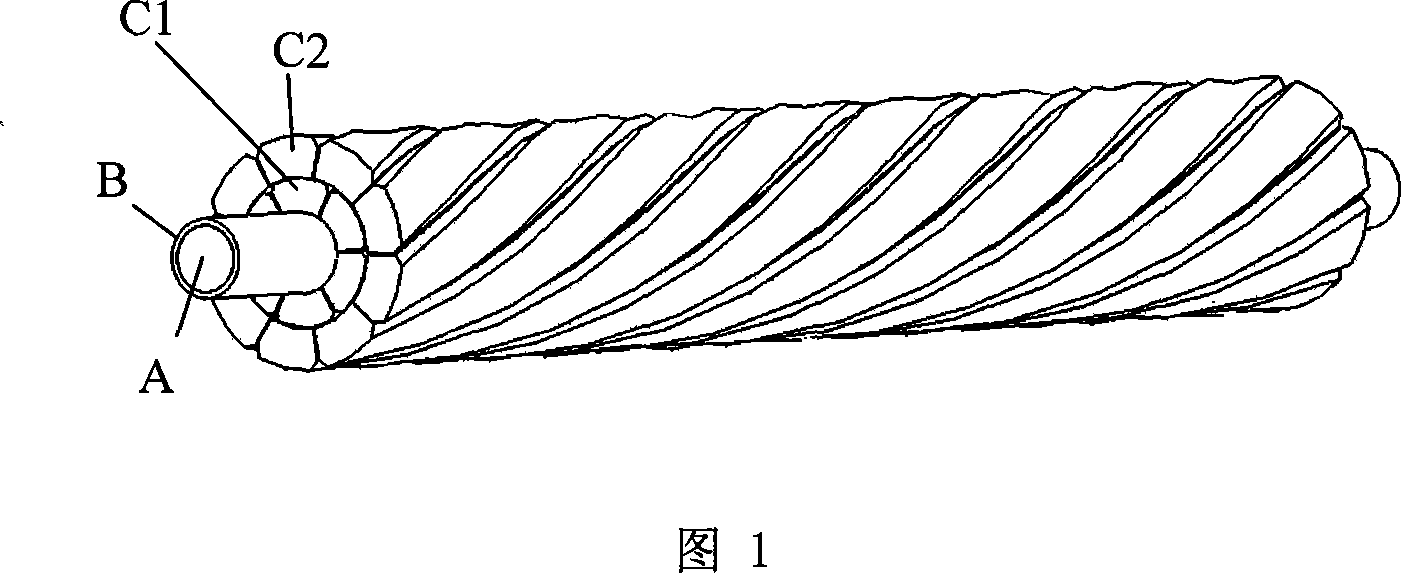

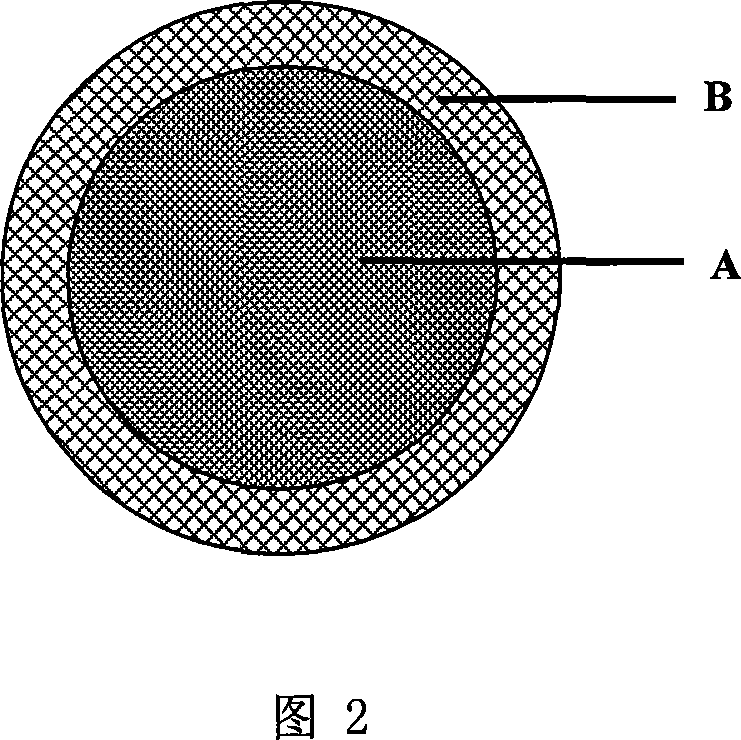

Heat-resisting and low expansion double capacity compound material core aluminum twisted wire and its making method

InactiveCN101034601AIncrease operating temperatureIncrease capacityNon-insulated conductorsPower cablesTextile fiberPower grid

The invention relates to a heat-resisting, low inflation double capacity compound material core aluminum stranded conductor and preparation method, the compound material core aluminum stranded conductor is composed of the compound material line core by the ultra long continual textile fiber heat-resisting resin and at least a section is tile shape pure aluminium or electric conduction outer layer with surround the aluminum alloy wire. Its preparation method is: Uses continuously pull-crowd craft to produce the excel in ultra long continual textile fiber strengthen the heat-resisting resin inner layer; Then through second time pull-crowd craft to cladding the outer layer which is formed by low elastical coefficient ultra long continual textile fiber strengthen the heat-resisting resin on the inner layer, namely makes the compound material line core; Again surrounds the tile shape pure aluminum or the aluminum alloy wire outside the compound material line core. The invention aluminum stranded conductor has low thermal-expansion coefficient, after enhances the conductor operating temperature the arc hang does not increase; the invention can long time safe working in 140degree centigrade, the aluminum, the aluminum alloy wire packing rate of the conductor layer is more than or equal to 90%, can double enhance the capacity of the electrical network transports.

Owner:NAT UNIV OF DEFENSE TECH +3

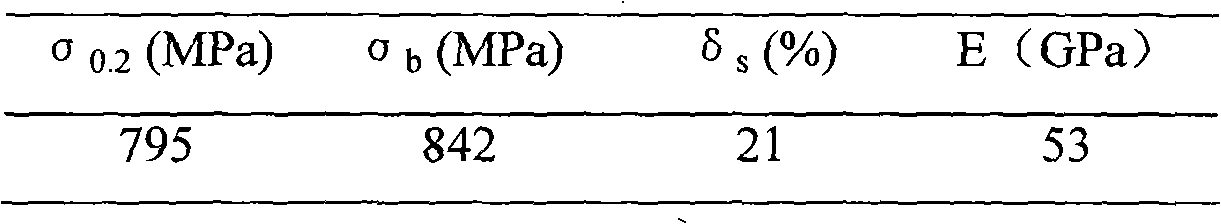

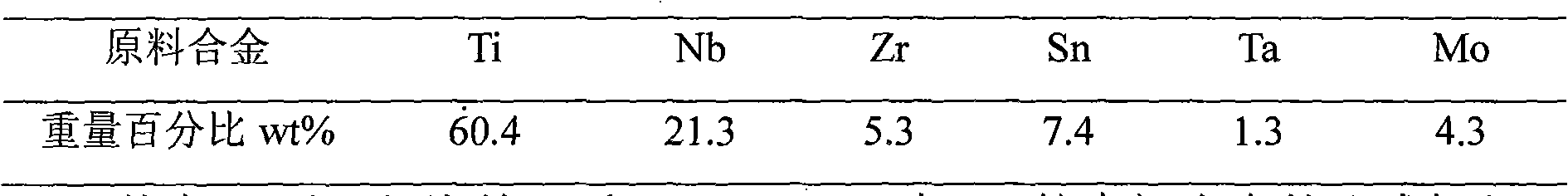

Biomedical beta-titanium alloy material and preparation method thereof

The invention relates to a biomedical beta-titanium alloy material with low elastic modulus. The preparation method for the material comprises the steps of raw material preparation, raw material smelting, cogging, forging and the like, namely the method comprises the following steps: preparing a raw material alloy of Nb, Zr, Sn, Ta, Mo and Ti according to a certain proportion, mechanically stirring and mixing the alloy, then pressing the alloy on a hydraulic press to form electrodes, and later smelting the electrodes in a vacuum consumable electro-arc furnace to obtain cast ingots of the beta-titanium alloy material; taking out the cast ingots with certain diameter, heating the cast ingots in a vacuum furnace and then preserving the heat, upsetting and drawing out the heated cast ingots on the hydraulic press or a forging device, and repeating the step twice to thrice to obtain a forging stock of the beta-titanium alloy material; heating the forging stock in the vacuum furnace and then preserving the heat, drawing out the heated forging stock on the hydraulic press or the forging device to obtain the biomedical beta-titanium alloy material with the elastic modulus E of 50 to 80GPa. The alloy has the characteristic of low elastic modulus, has good combination properties such as tensile strength, yield strength, corrosion resistance and the like, and does not contain toxic elements to human body.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Fuse structure with thermal and crack-stop protection

InactiveUS6653710B2Small sizeControl damageSemiconductor/solid-state device detailsSolid-state devicesConductive materialsMaterials science

Thermal degradation of a low-k organic dielectric material is avoided or limited in the proximity of a heat source such as a fusible element by overlaying the low-k material with a thermally conductive material and providing a low thermal resistance path from the thermally conductive material, possibly having a low modulus of elasticity, to a heat sink. The thermally conductive material thus provides crack-stop protection for further layers of an integrated circuit or interconnect structure above the fusible element by mechanical, chemical and thermal encapsulation of the heat source and low-k material.

Owner:GOOGLE LLC

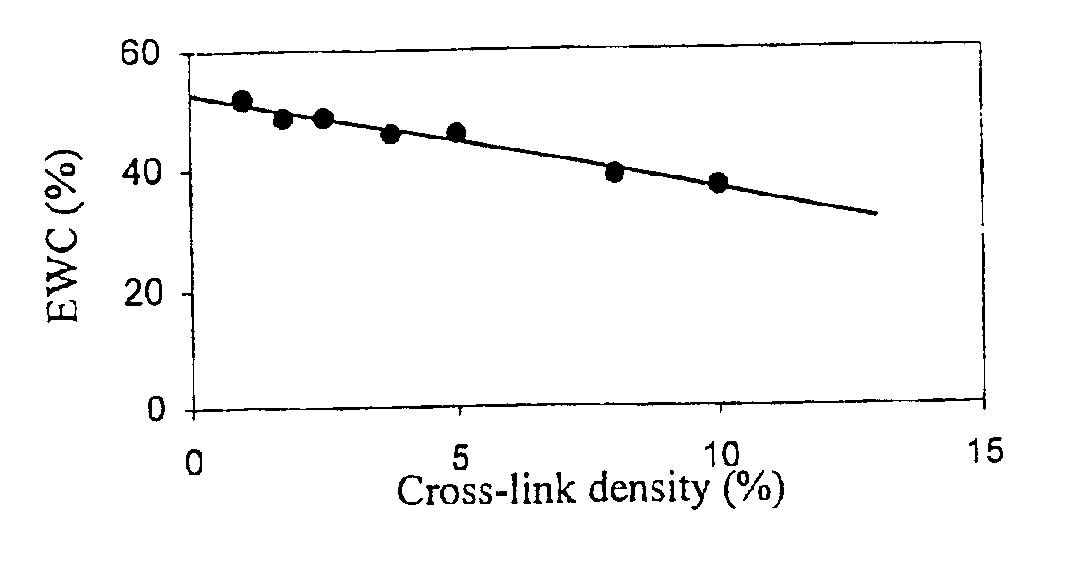

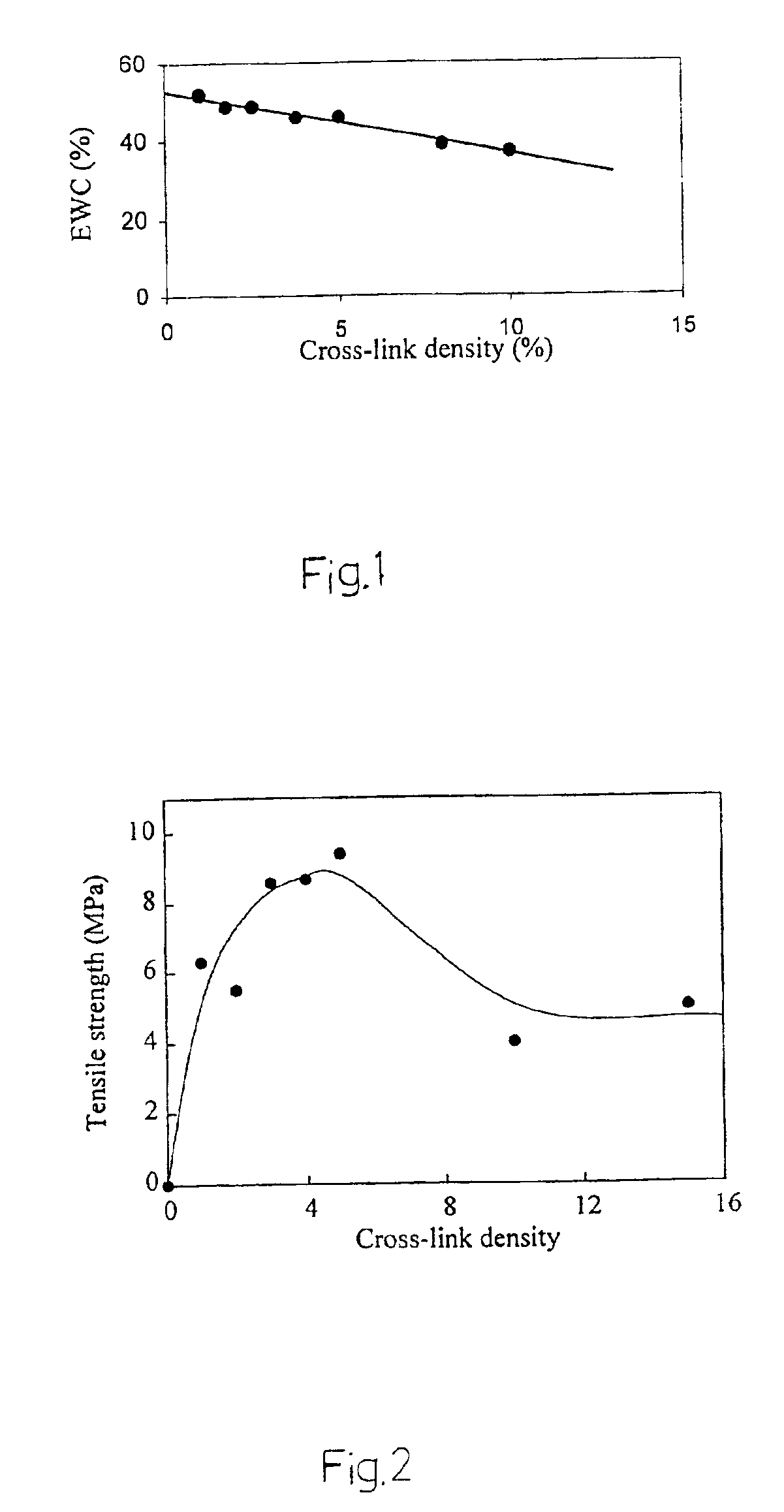

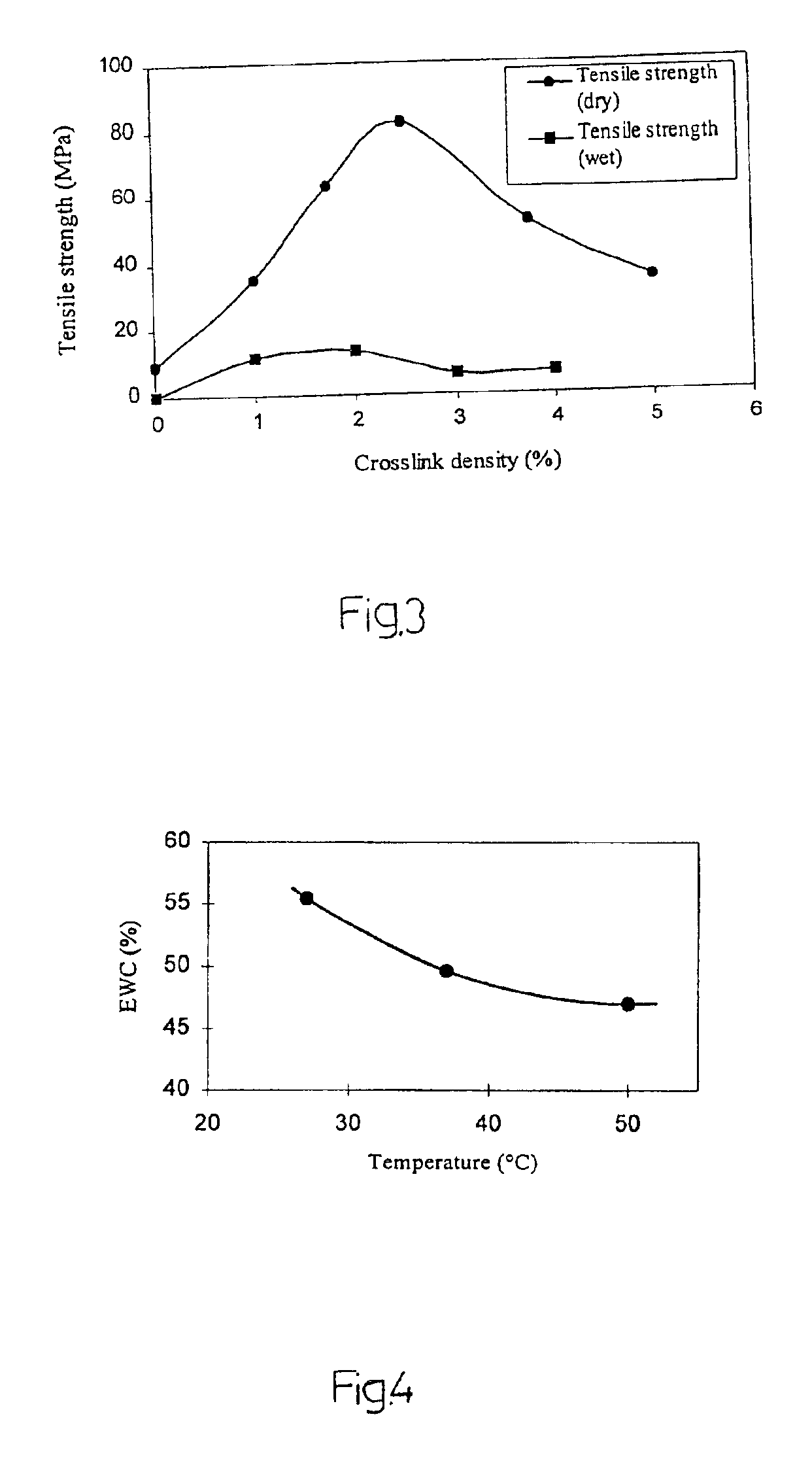

Hydrogels and methods for their production

InactiveUS6846875B2Advantageous mechanical characteristicHigh strengthPowder deliveryIntraocular lensHydrophilic polymersSolvent

The present invention relates to new hydrogels with improved mechanical properties and methods of their preparation. The hydrogels are formed from hydrophilic polymers having function hydroxyl groups and have low elasticity modulus typically less than about 10 kPa, a tensile strength above 1 MPa, an elongation above 50% which makes suitable as medical implants, in particular intraocular lenses. The hydrogels are prepared by a crosslinking method with a comparatively low concentration of hydrophilic polymer of a sufficiently high molecular weight dissolved in a good solvent.

Owner:AMO GRONINGEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com