High-density electronic package and method for making same

A technology of electronic packaging and electronic devices, applied in the field of electronic device packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

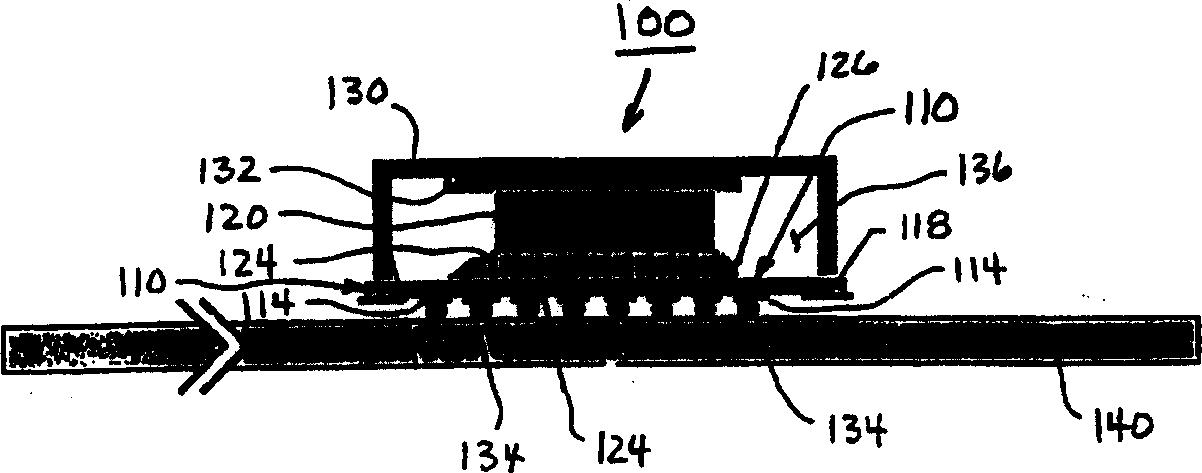

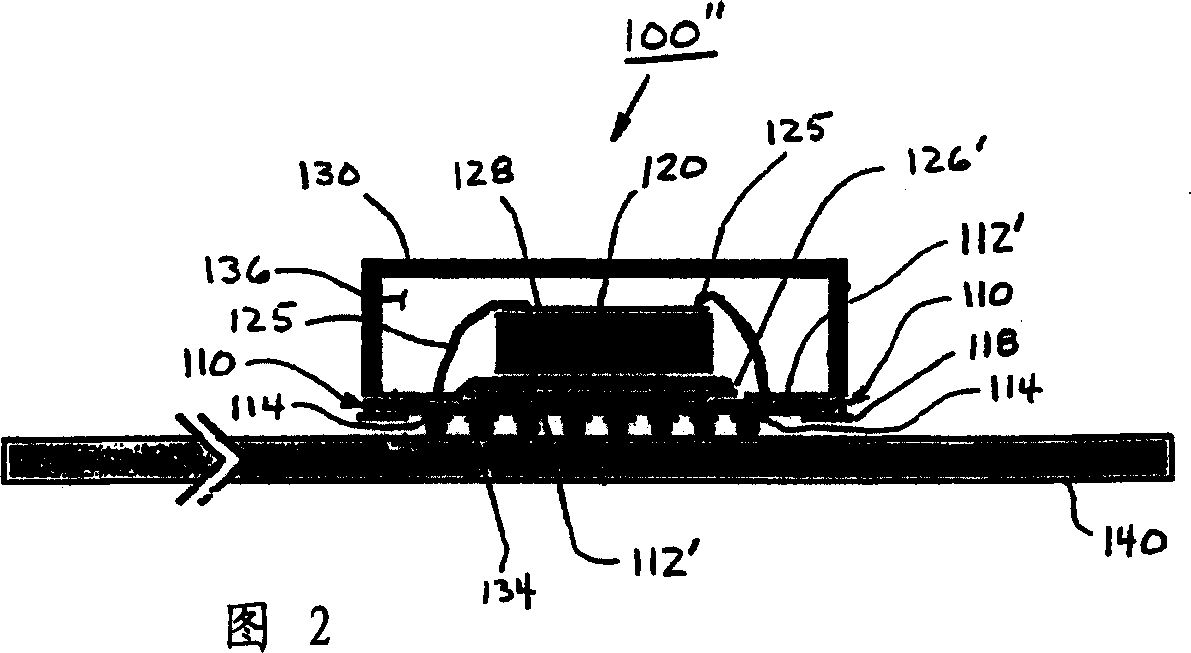

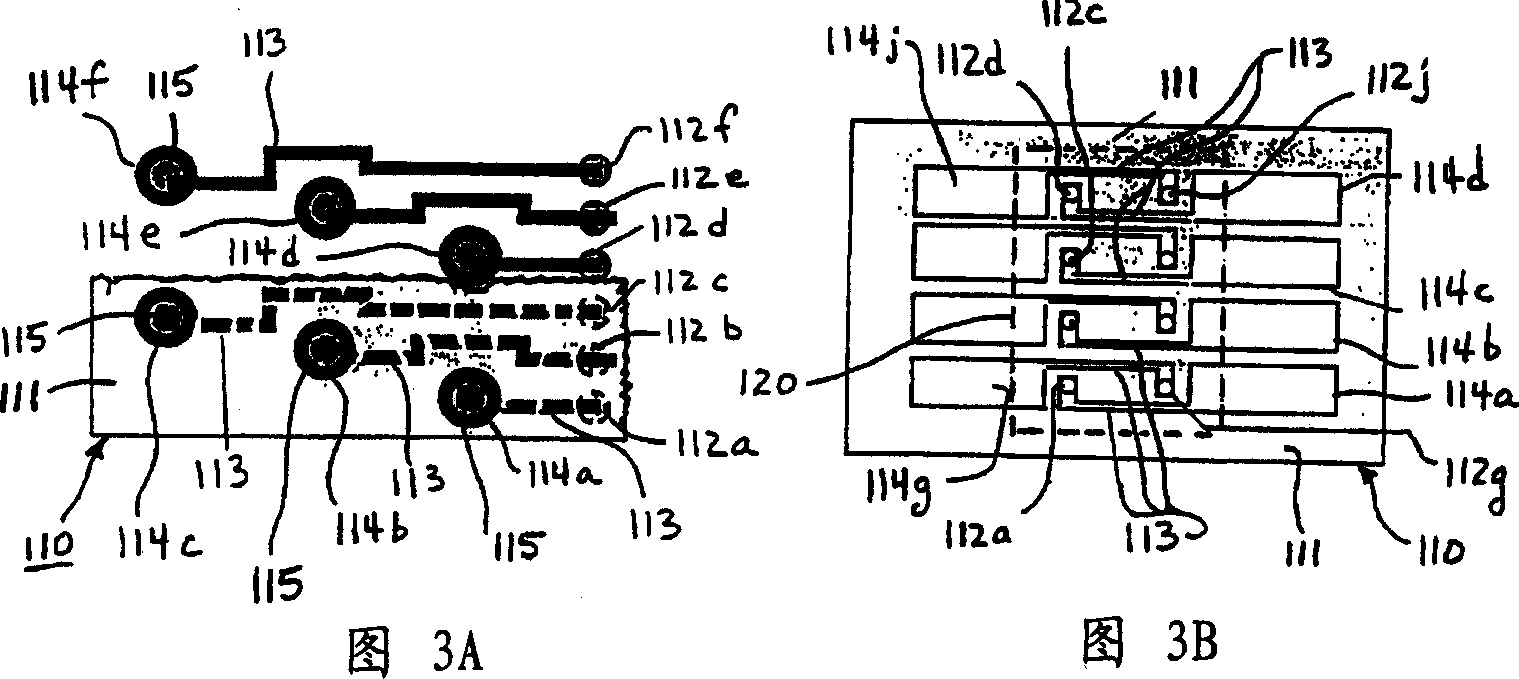

[0031] Electronic packaging is subject to heat-induced forces and moisture sealing. Each device package consists of a semiconductor chip or die, which is attached to an intermediate stack substrate, such as an FR4 stack, by die glue. Fine gold or aluminum bond wires connect the connection terminals of the semiconductor chip to corresponding conductors on the substrate, which is connected to the underlying substrate by a connection that may be a solder or conductive adhesive conductor. Semiconductor chips and bond wires are typically encapsulated with a molded encapsulant or covered with a cover that provides mechanical support and moisture barrier.

[0032] Mechanical stresses arise due to differences in coefficient of thermal expansion (CTE) and high modulus of elasticity (ME), ie stiffness, of the different materials used in such modules. The silicon semiconductor die has a CTE of about 3 ppm / °C, the adhesive has a CTE of about 40 ppm / °C, the substrate has a CTE of about 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com