Patents

Literature

277 results about "Material line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

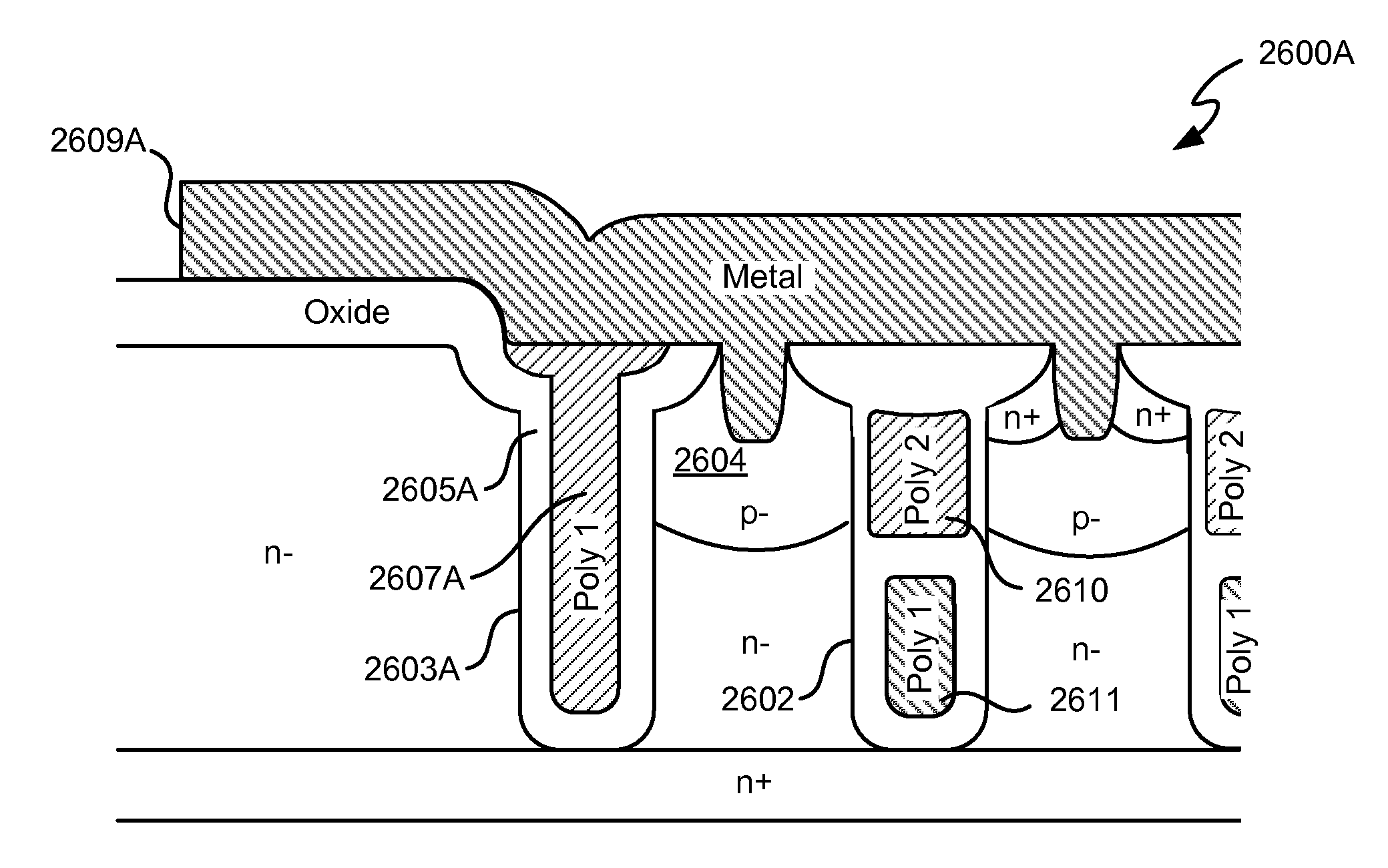

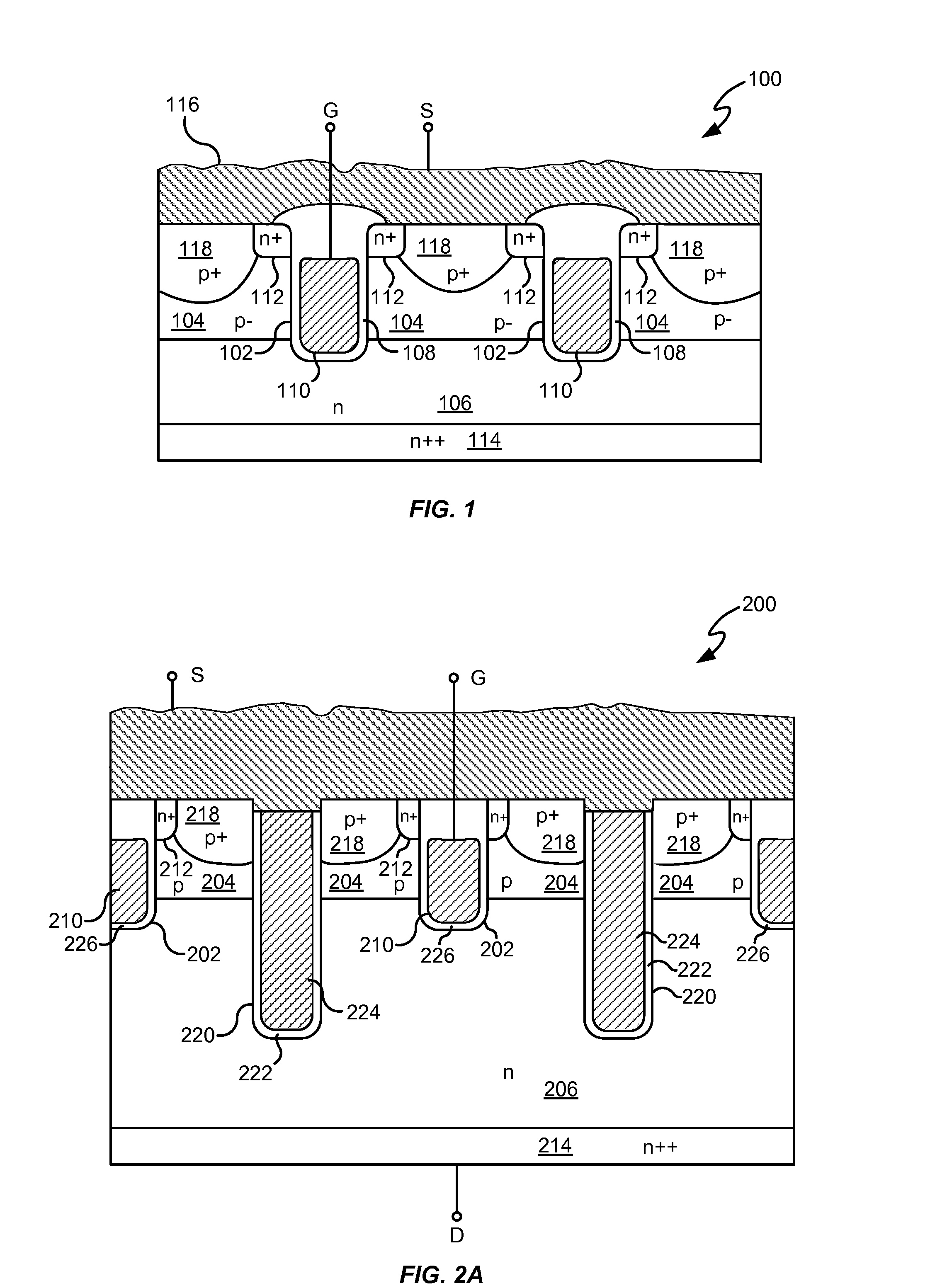

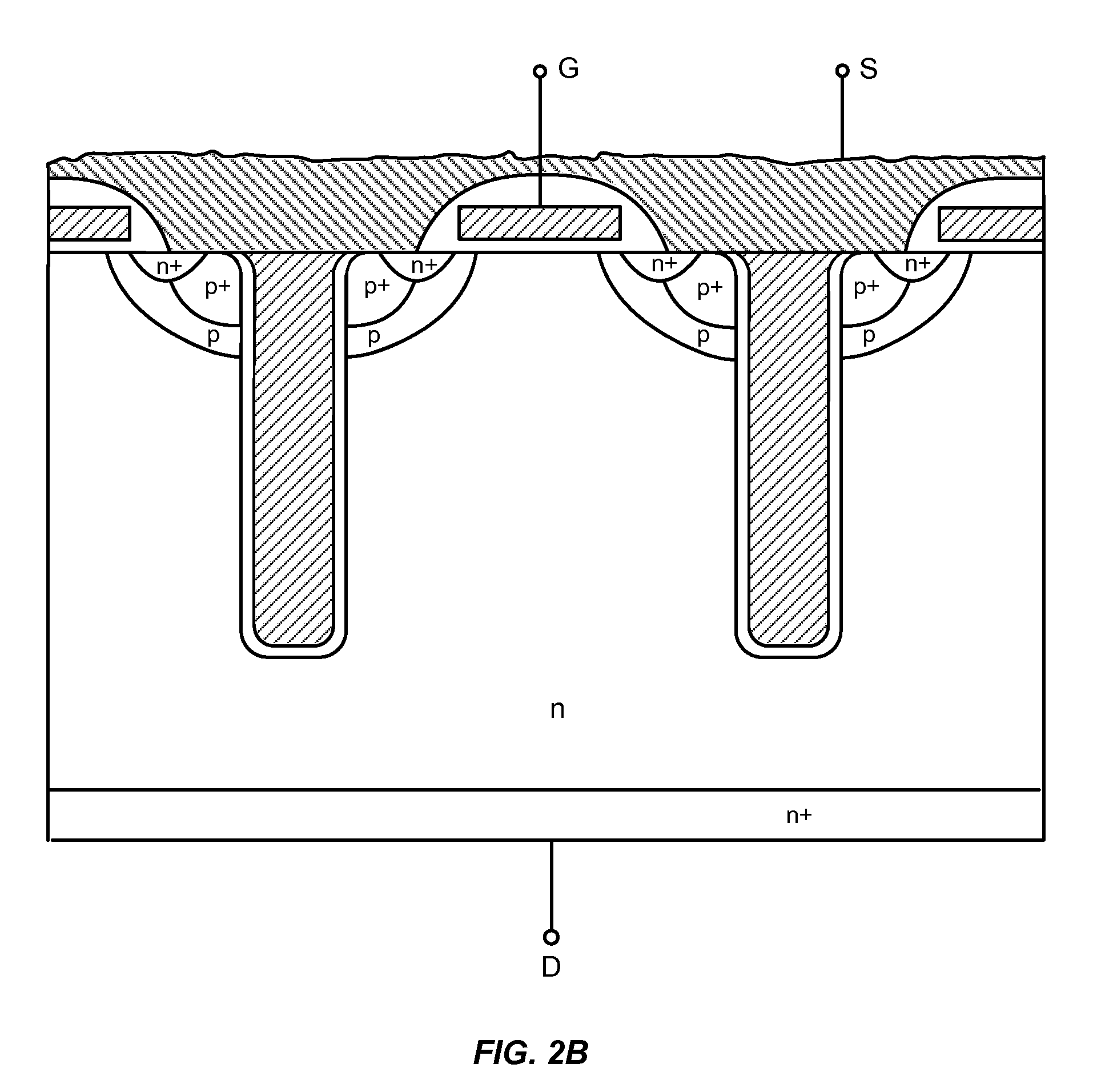

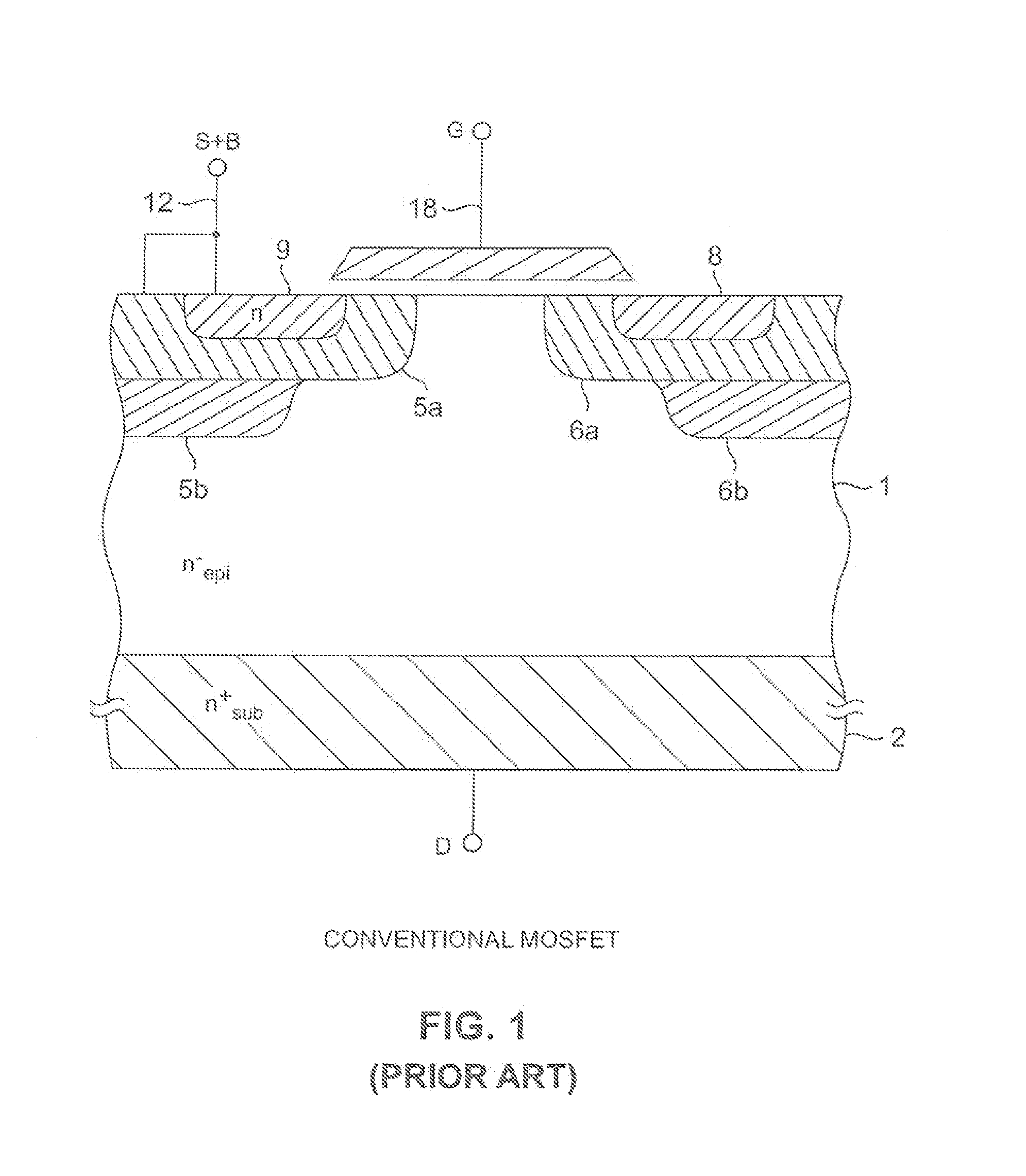

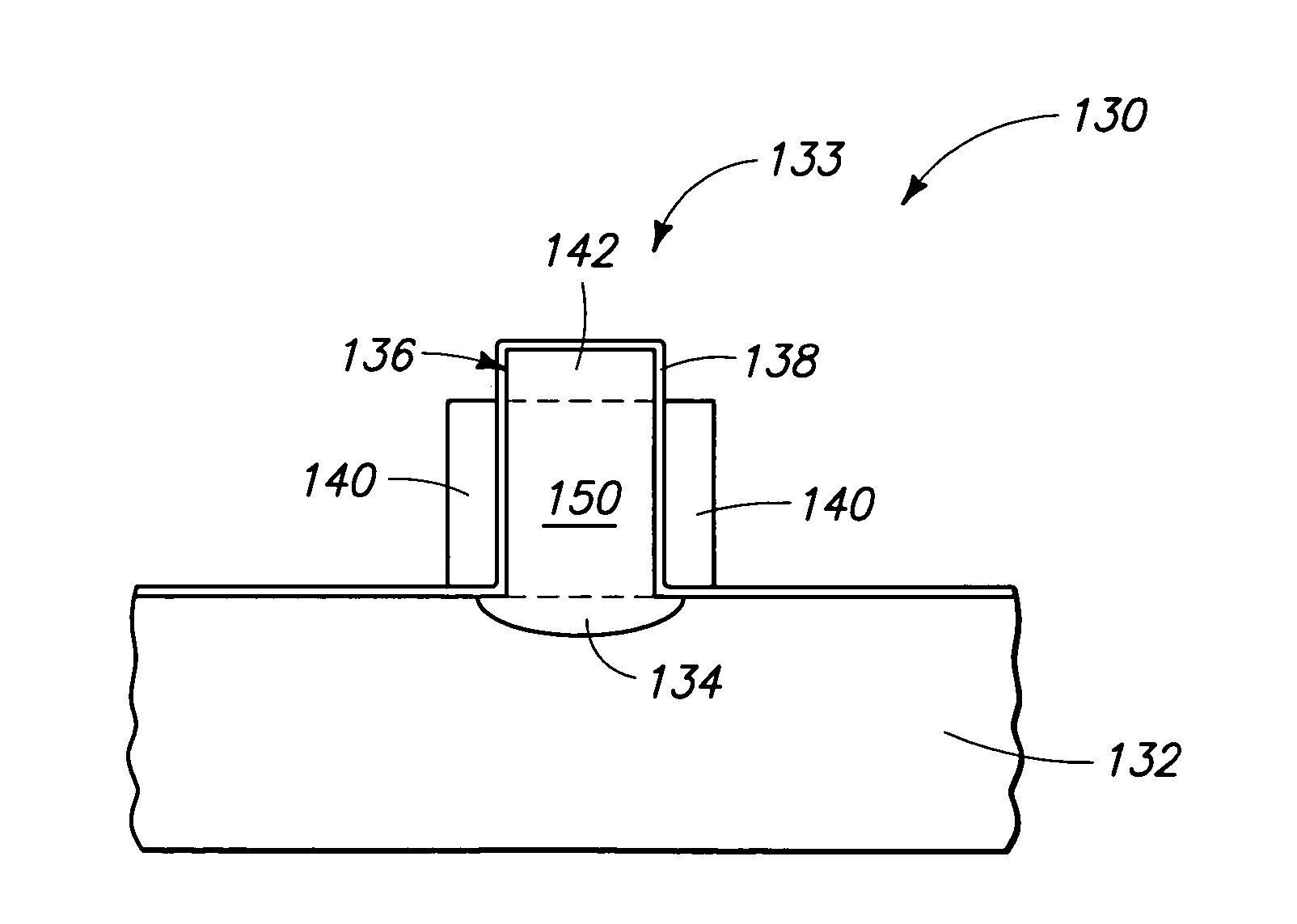

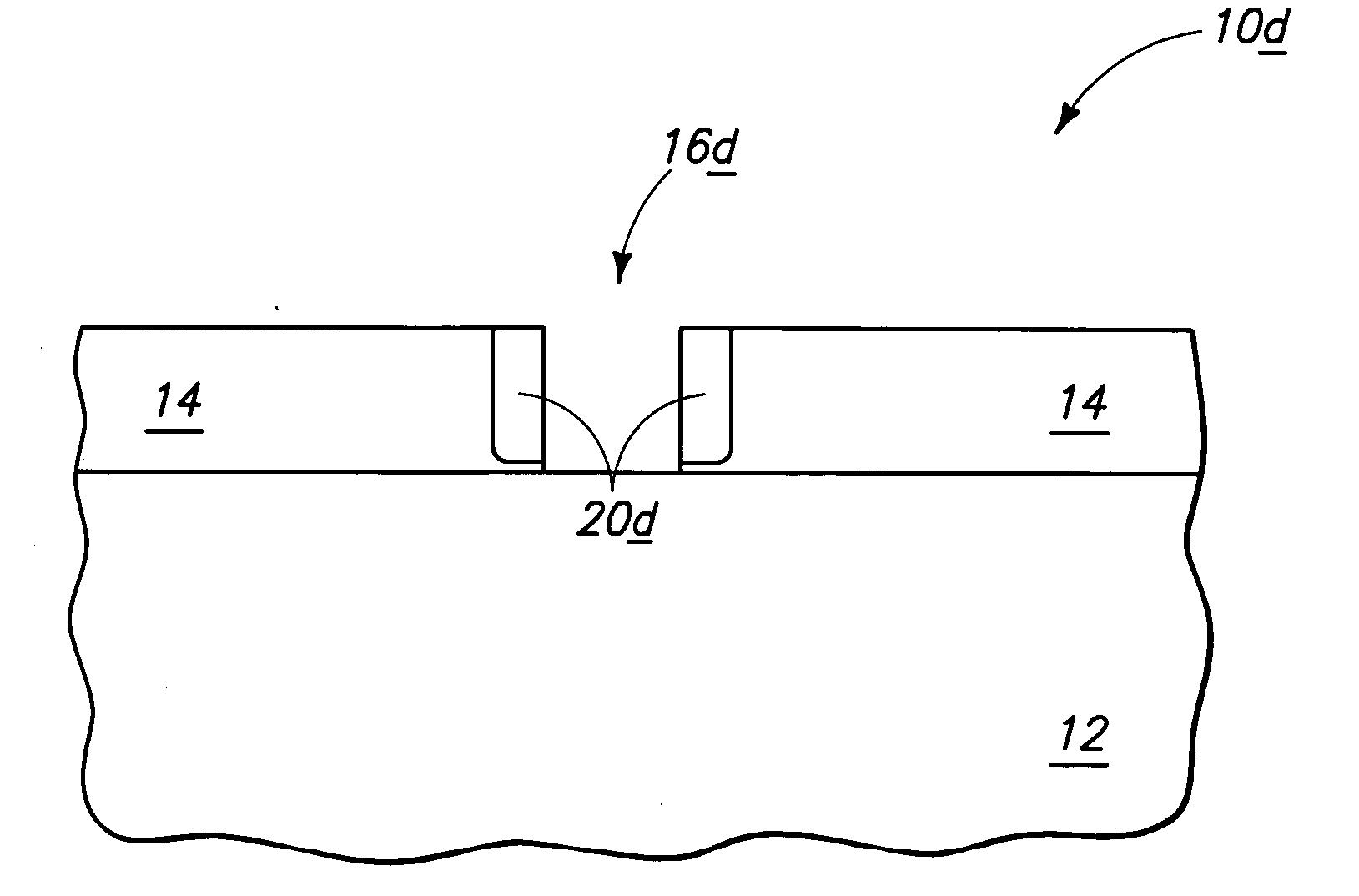

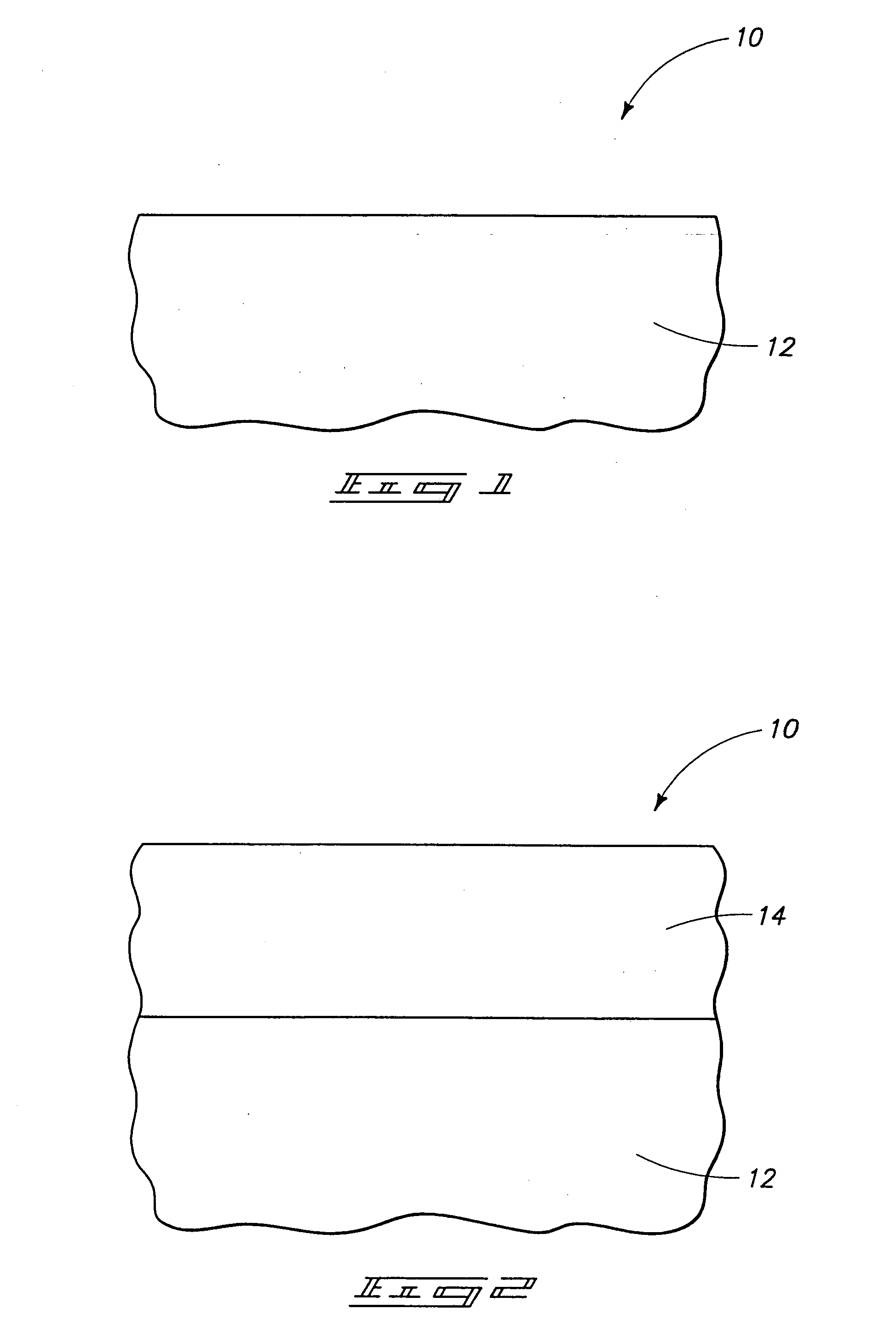

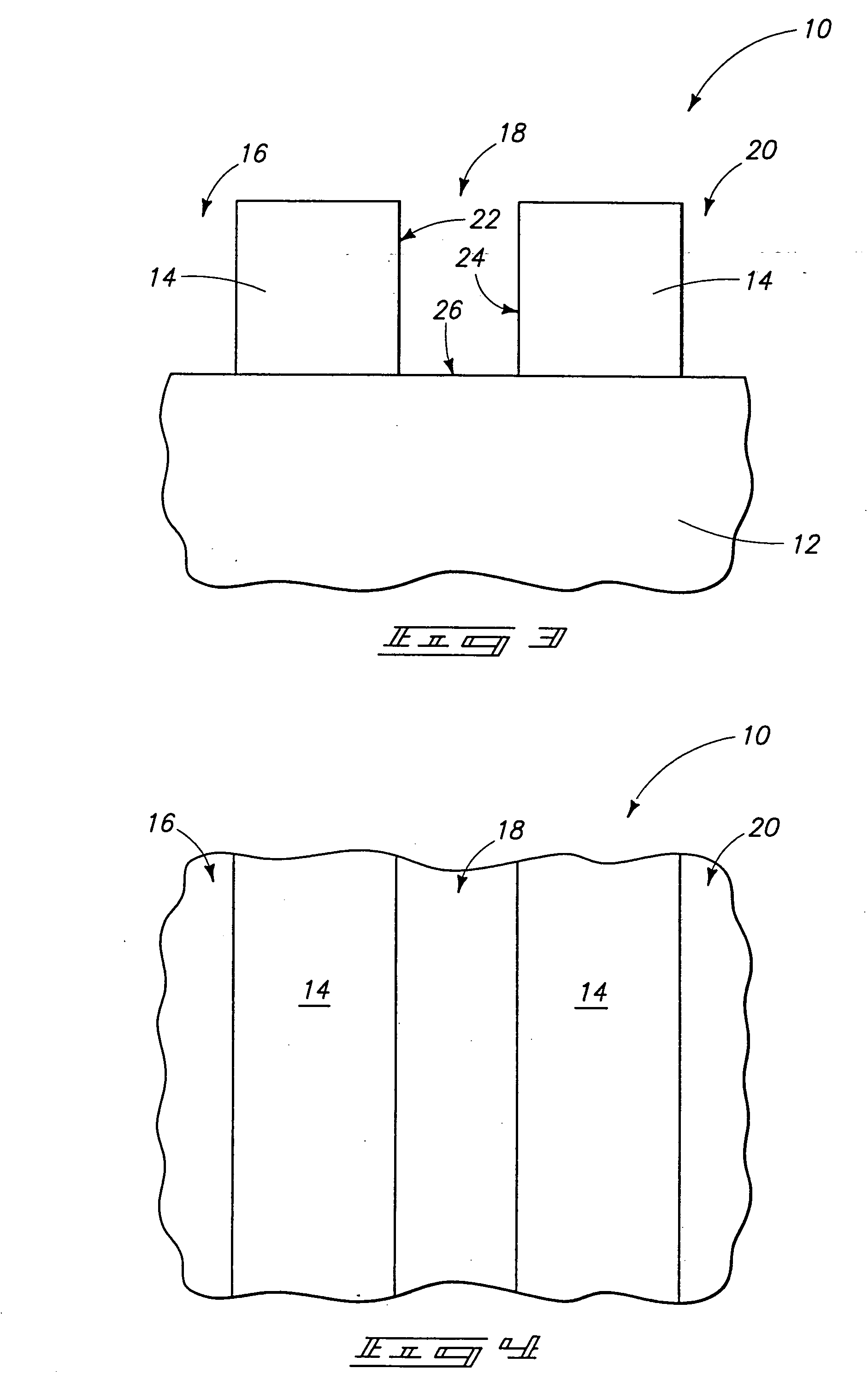

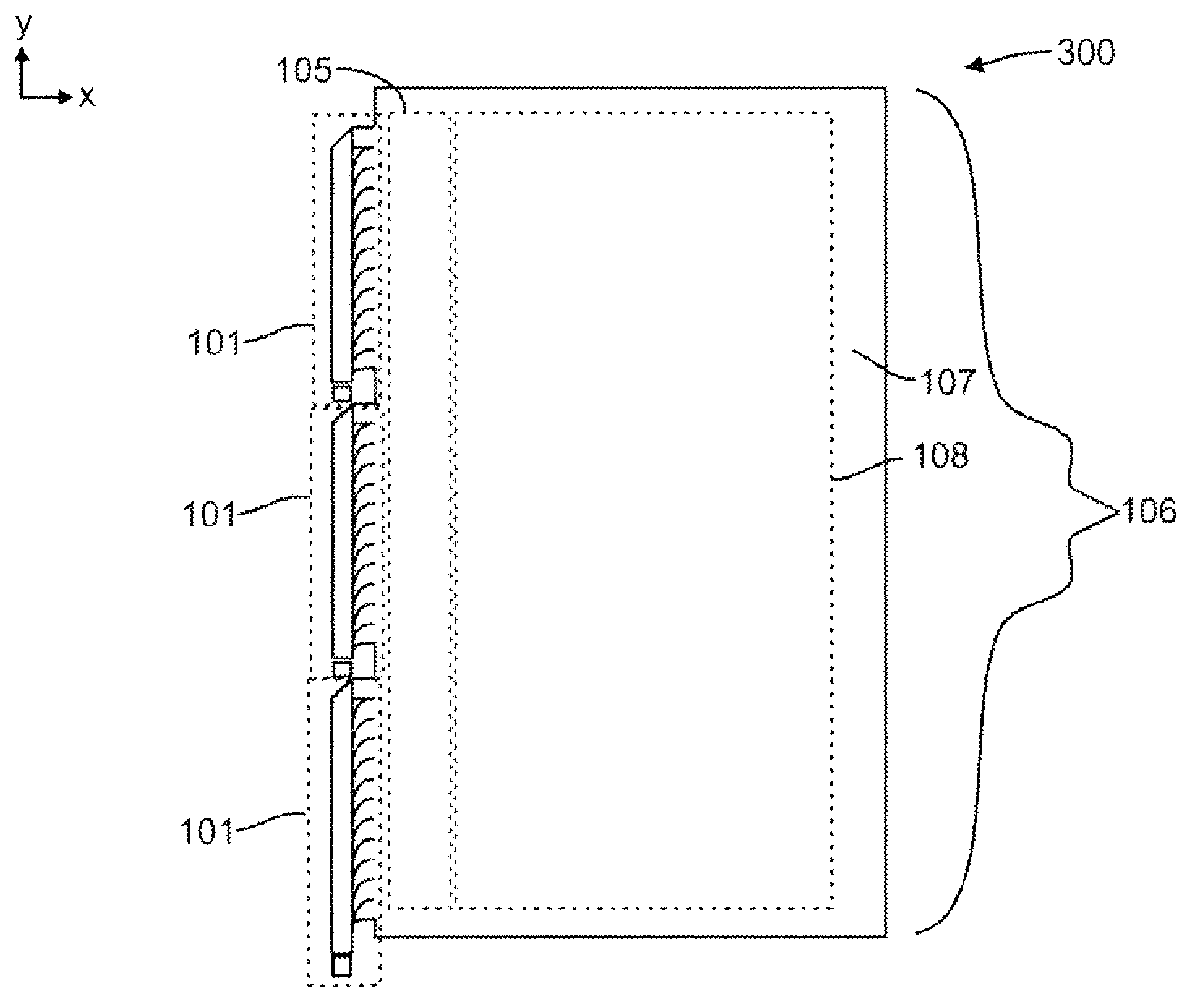

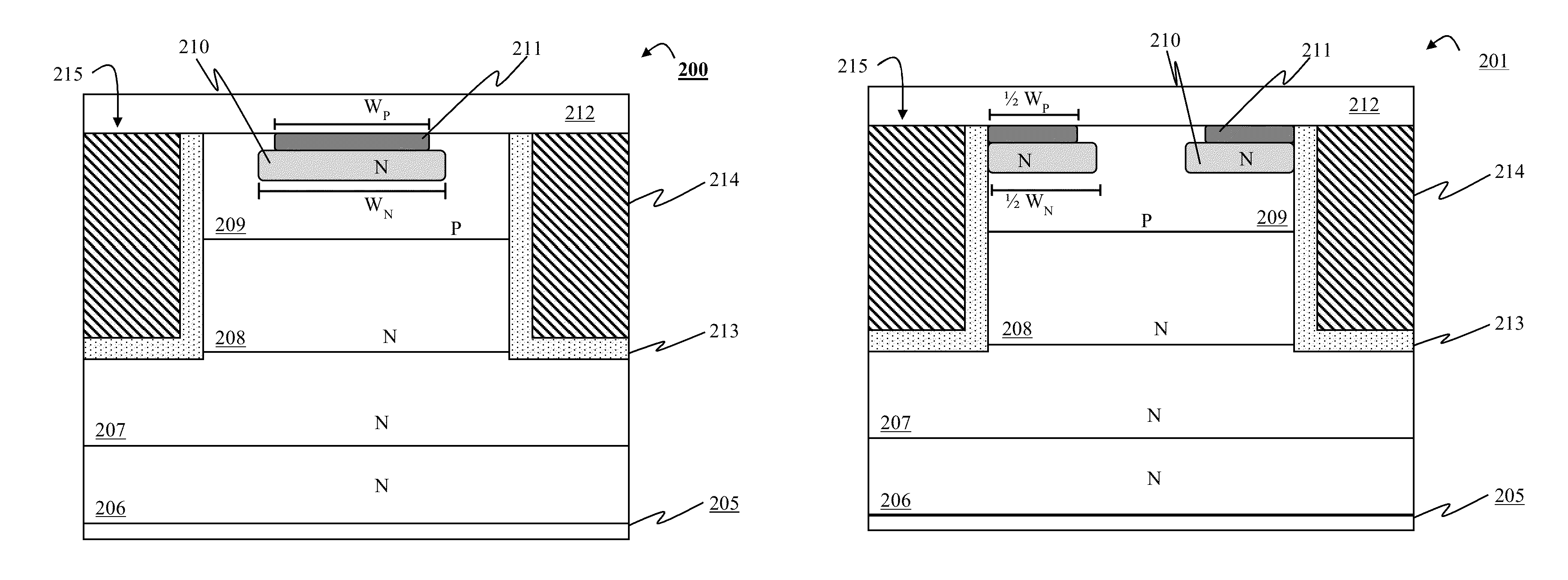

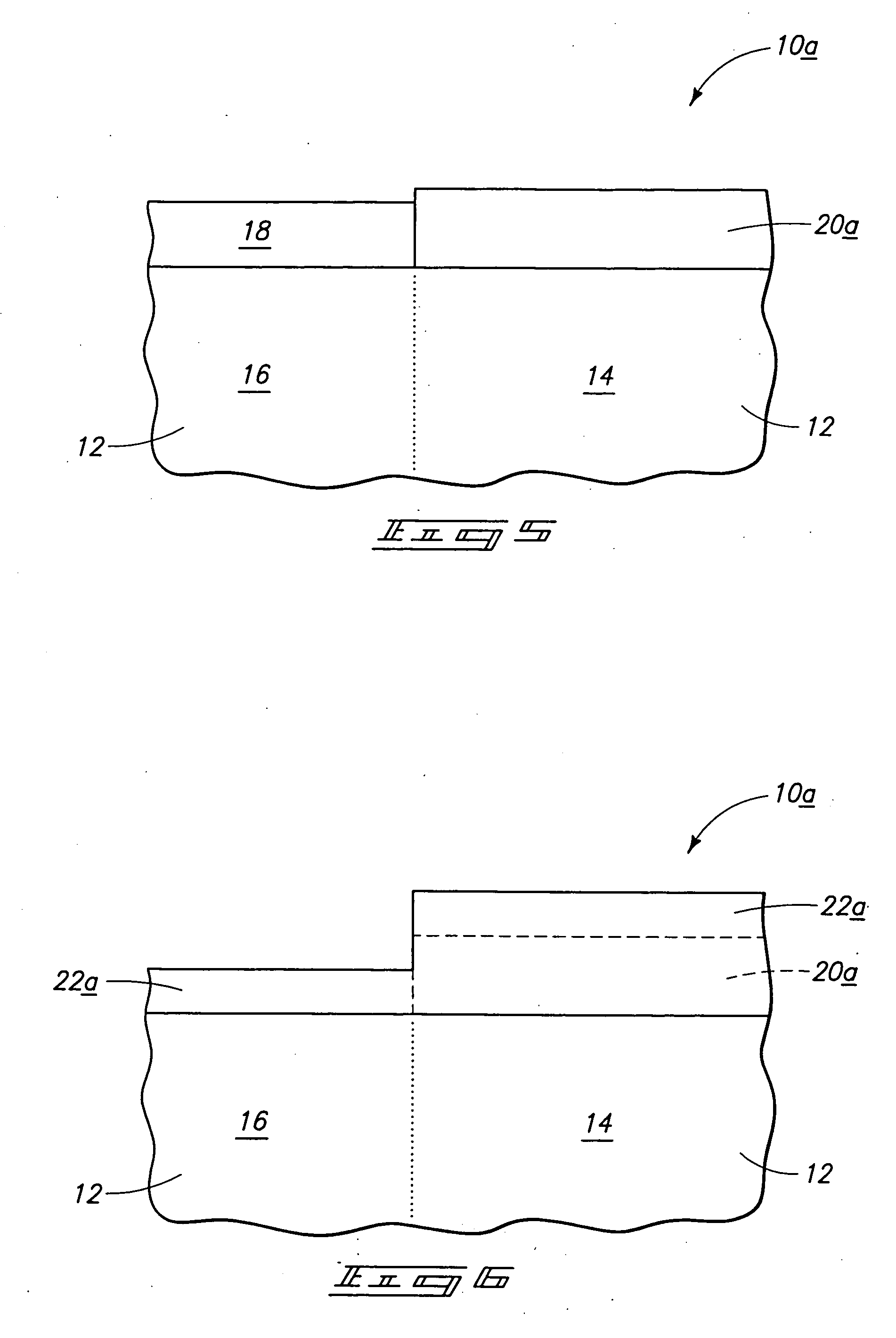

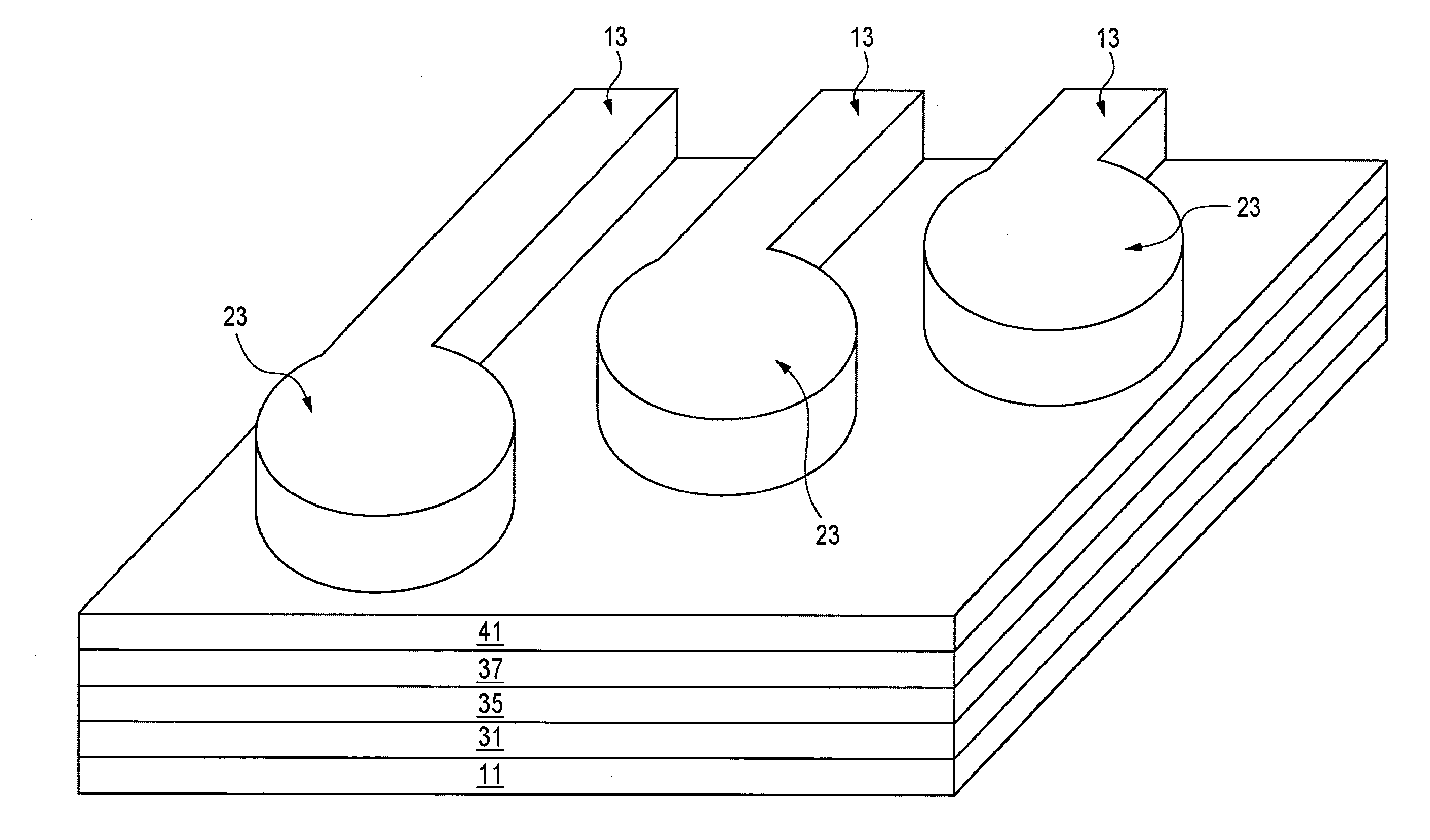

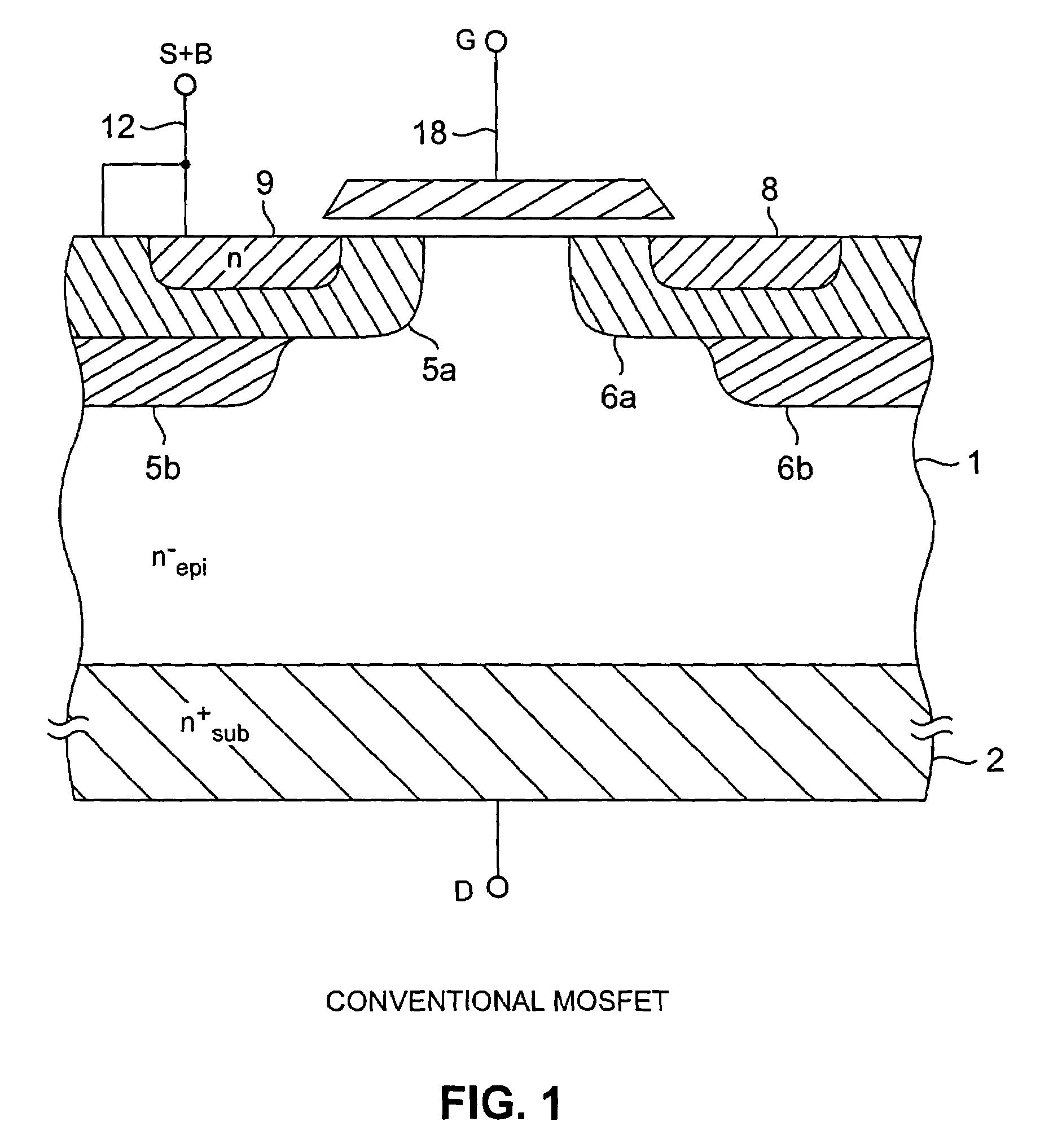

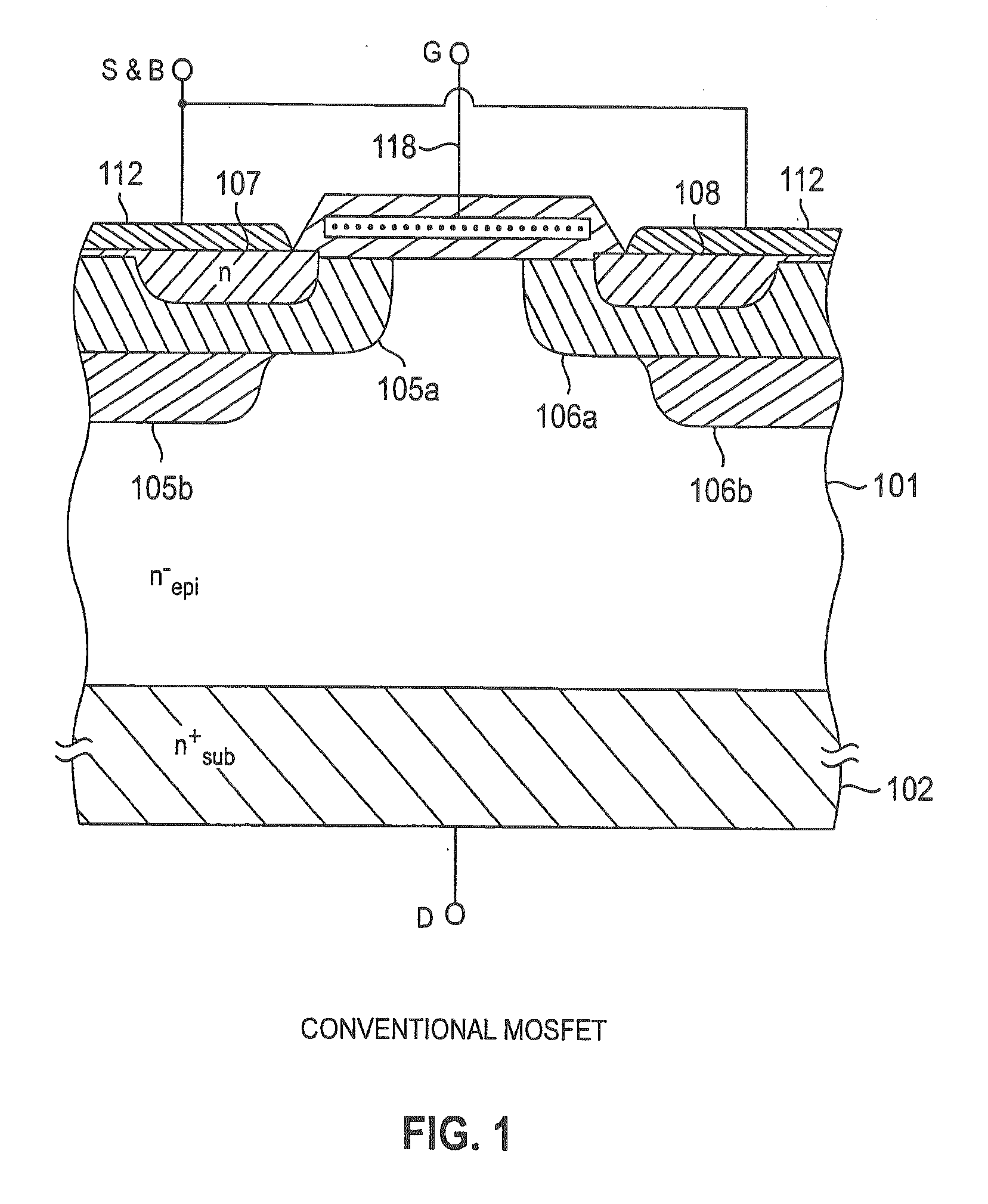

Power Semiconductor Devices Having Termination Structures and Methods of Manufacture

InactiveUS20080135931A1Simple structureEasy to packTransistorEfficient power electronics conversionPower semiconductor deviceDielectric

A semiconductor power device includes a drift region of a first conductivity type, a well region extending above the drift region and having a second conductivity type opposite the first conductivity type, an active trench extending through the well region and into the drift region, source regions having the first conductivity type formed in the well region adjacent the active trench, and a first termination trench extending below the well region and disposed at an outer edge of an active region of the device. The sidewalls and bottom of the active trench are lined with dielectric material, and substantially filled with a first conductive layer forming an upper electrode and a second conductive layer forming a lower electrode, the upper electrode being disposed above the lower electrode and separated therefrom by inter-electrode dielectric material. The first termination trench can be lined with a layer of dielectric material that is thicker than the dielectric material lining the sidewalls of the active trench, and is substantially filled with conductive material.

Owner:SEMICON COMPONENTS IND LLC

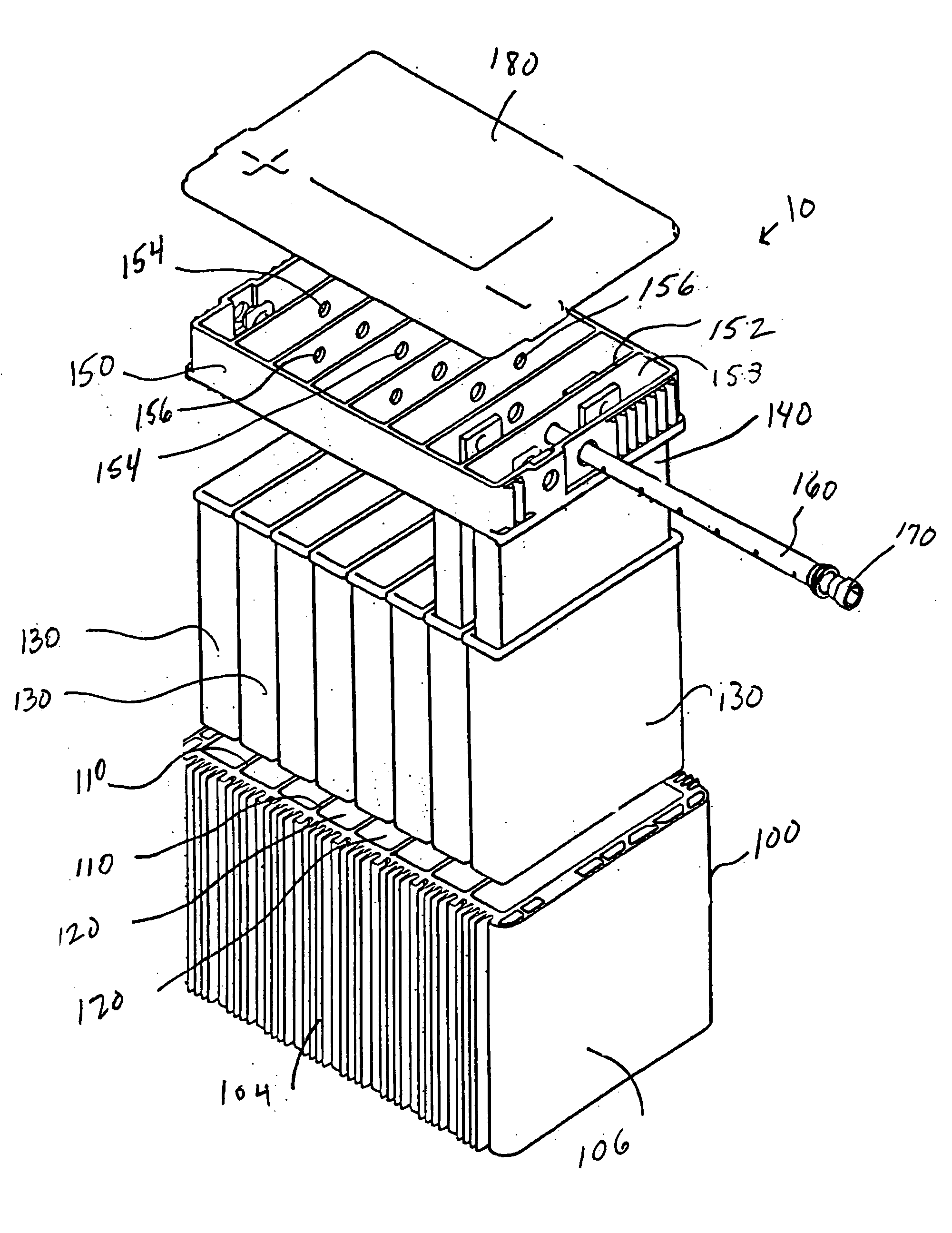

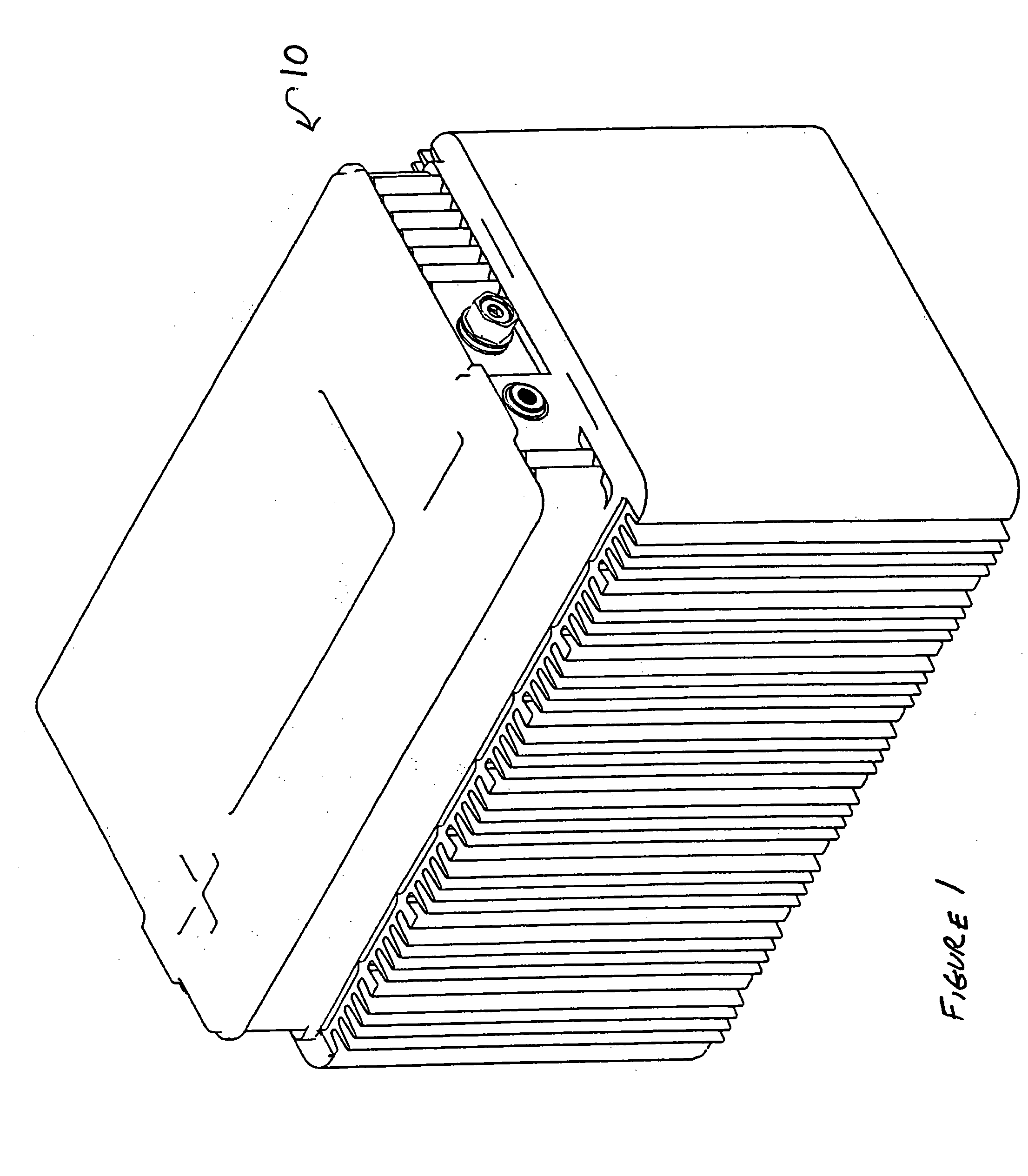

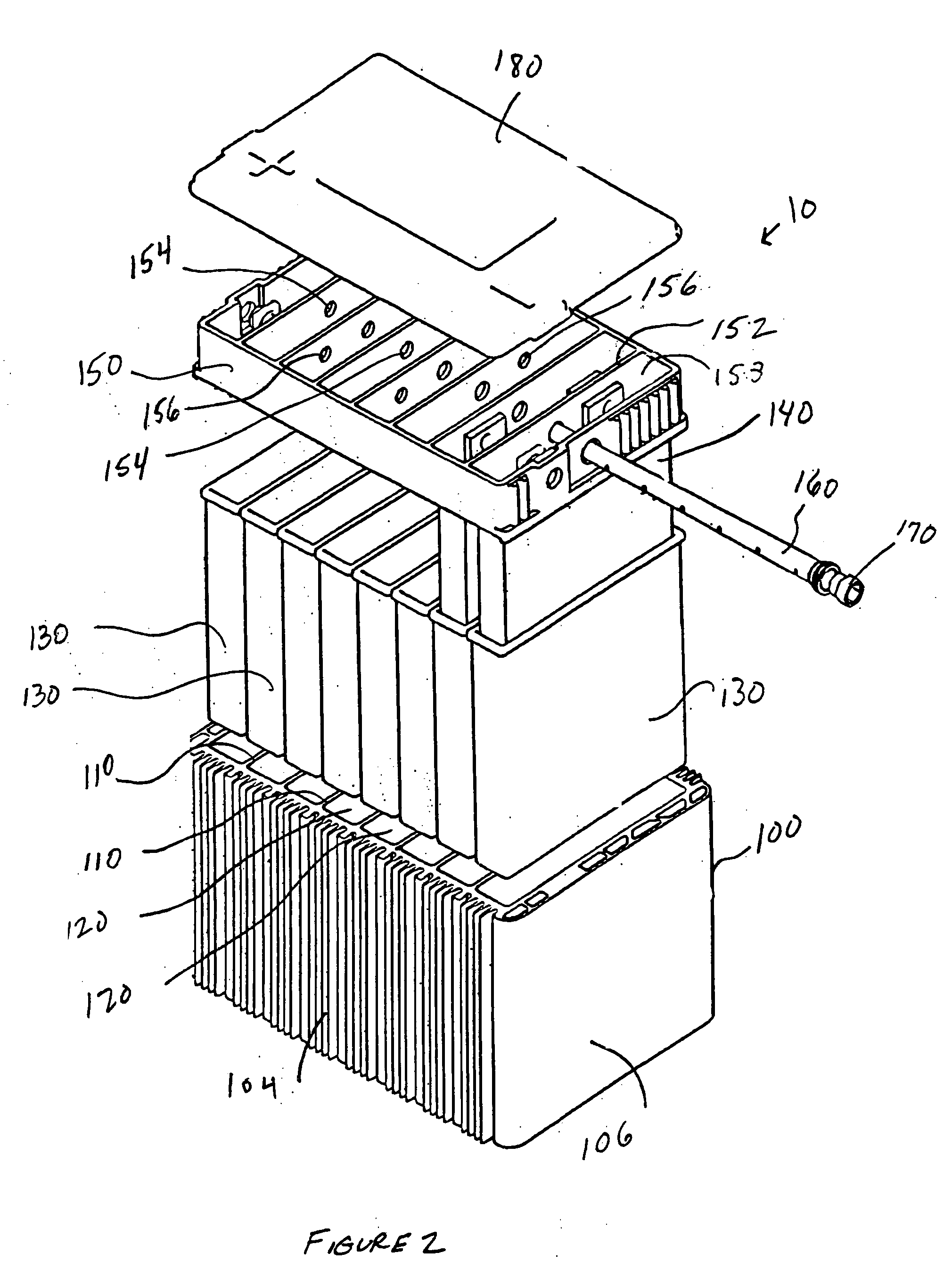

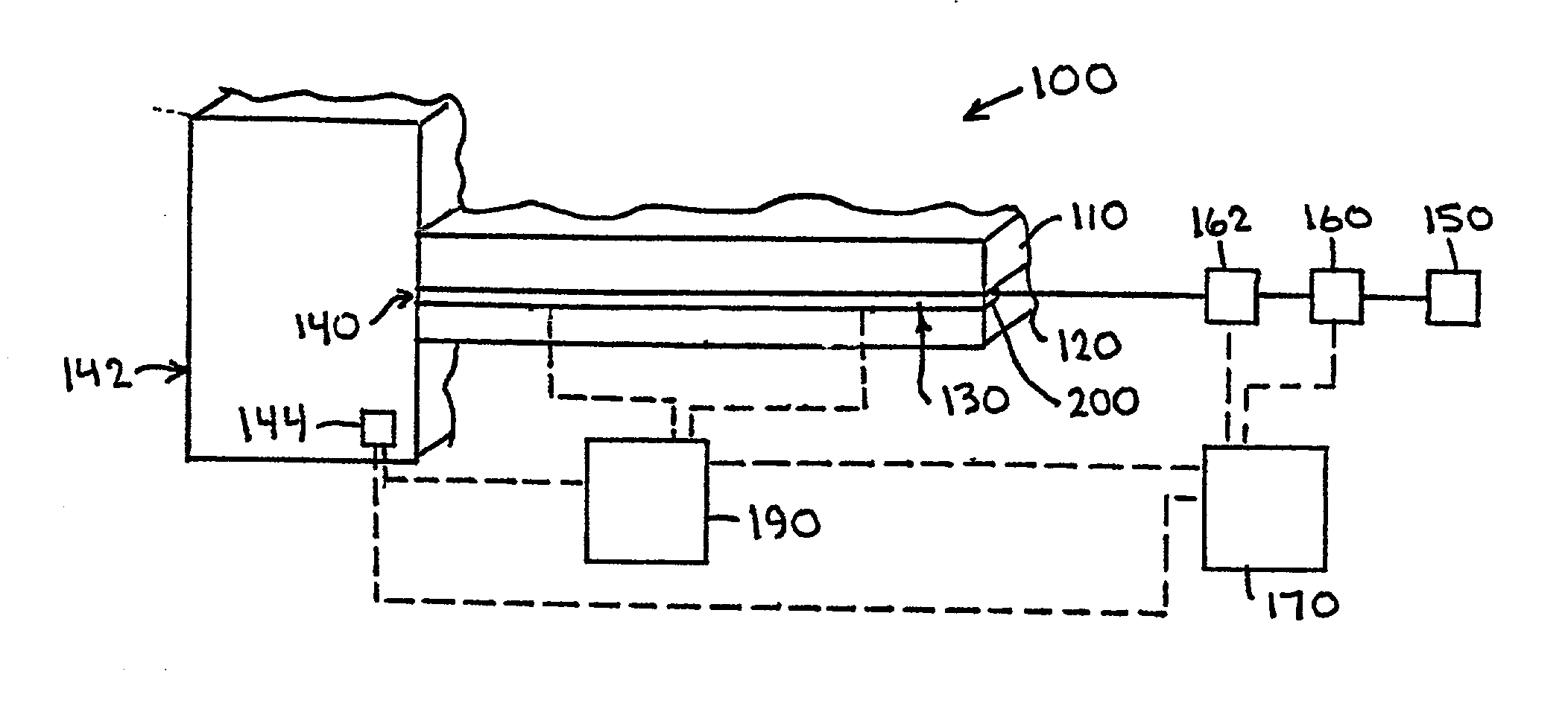

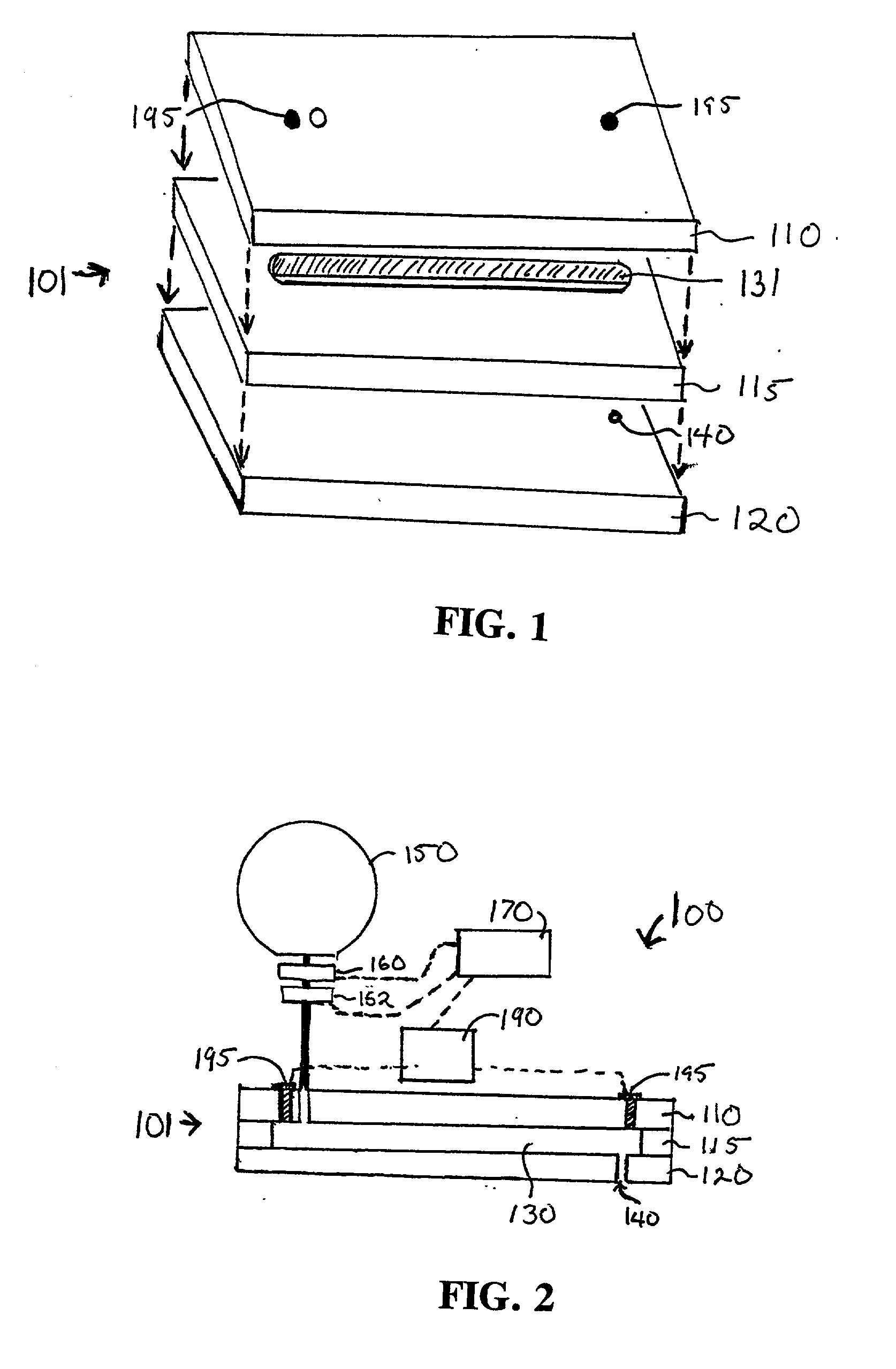

Battery assembly with heat sink

InactiveUS20050255379A1Improve thermal conductivityJackets/cases materialsFlat cells groupingEngineeringElectrochemical cell

A multi-cell battery comprising a housing having one or more partitions dividing the housing into a plurality of regions. A dielectric material lines the surfaces of the housing within each of the regions and an electrochemical cell is disposed within each of the regions. The housing is used as a heat sink to draw heat away from the individual electrochemical cells during operation.

Owner:OVONIC BATTERY CO INC

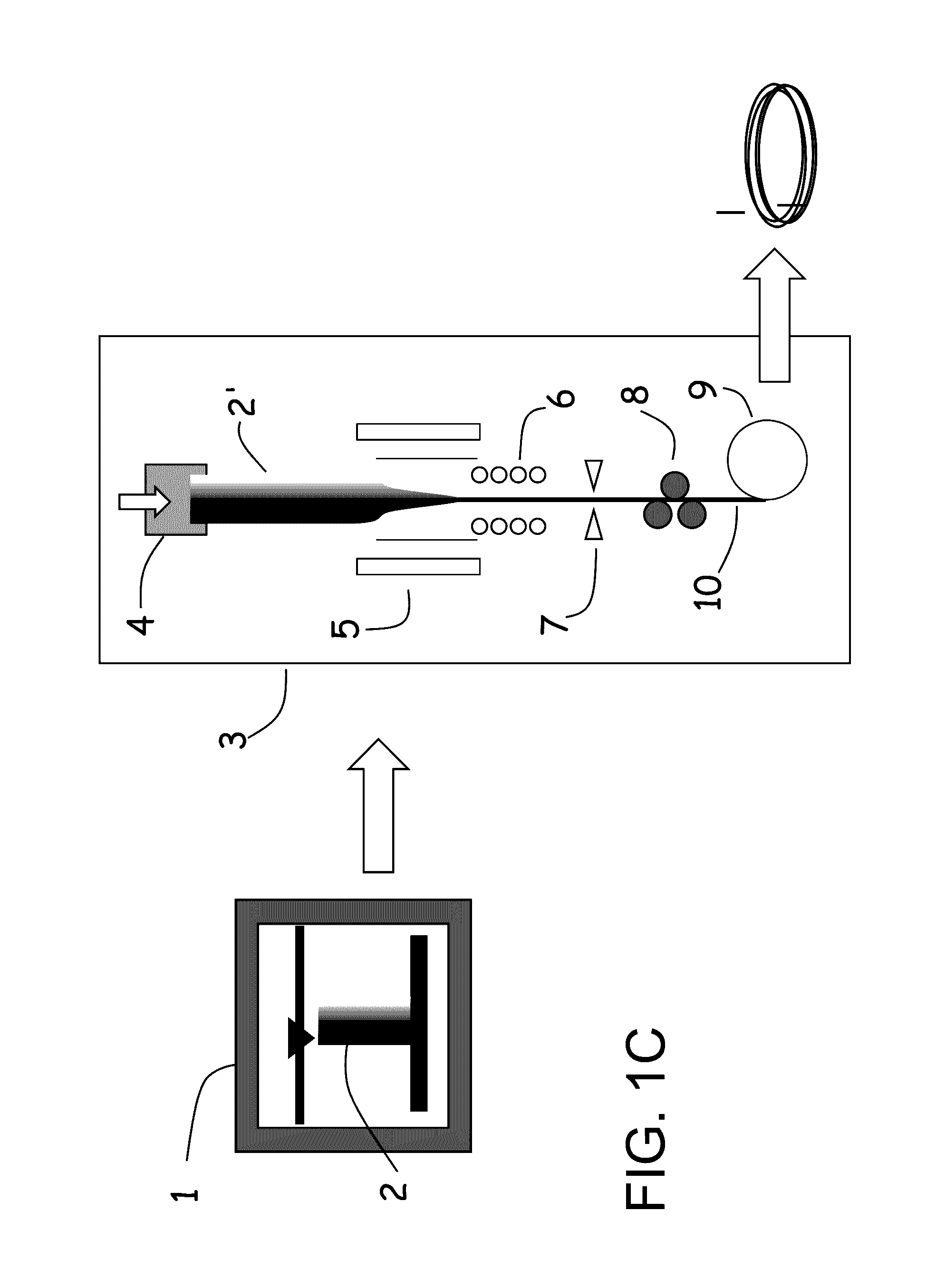

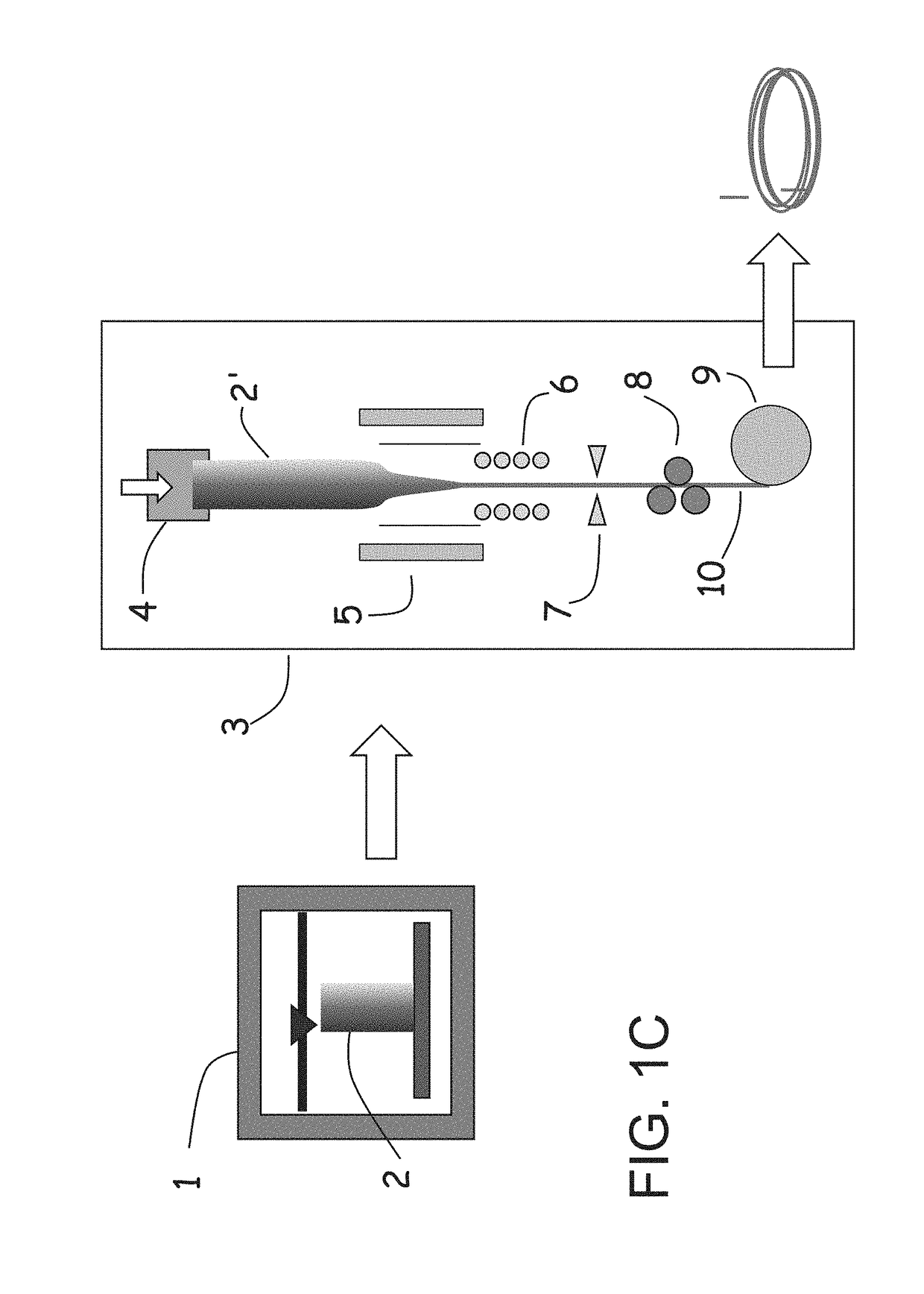

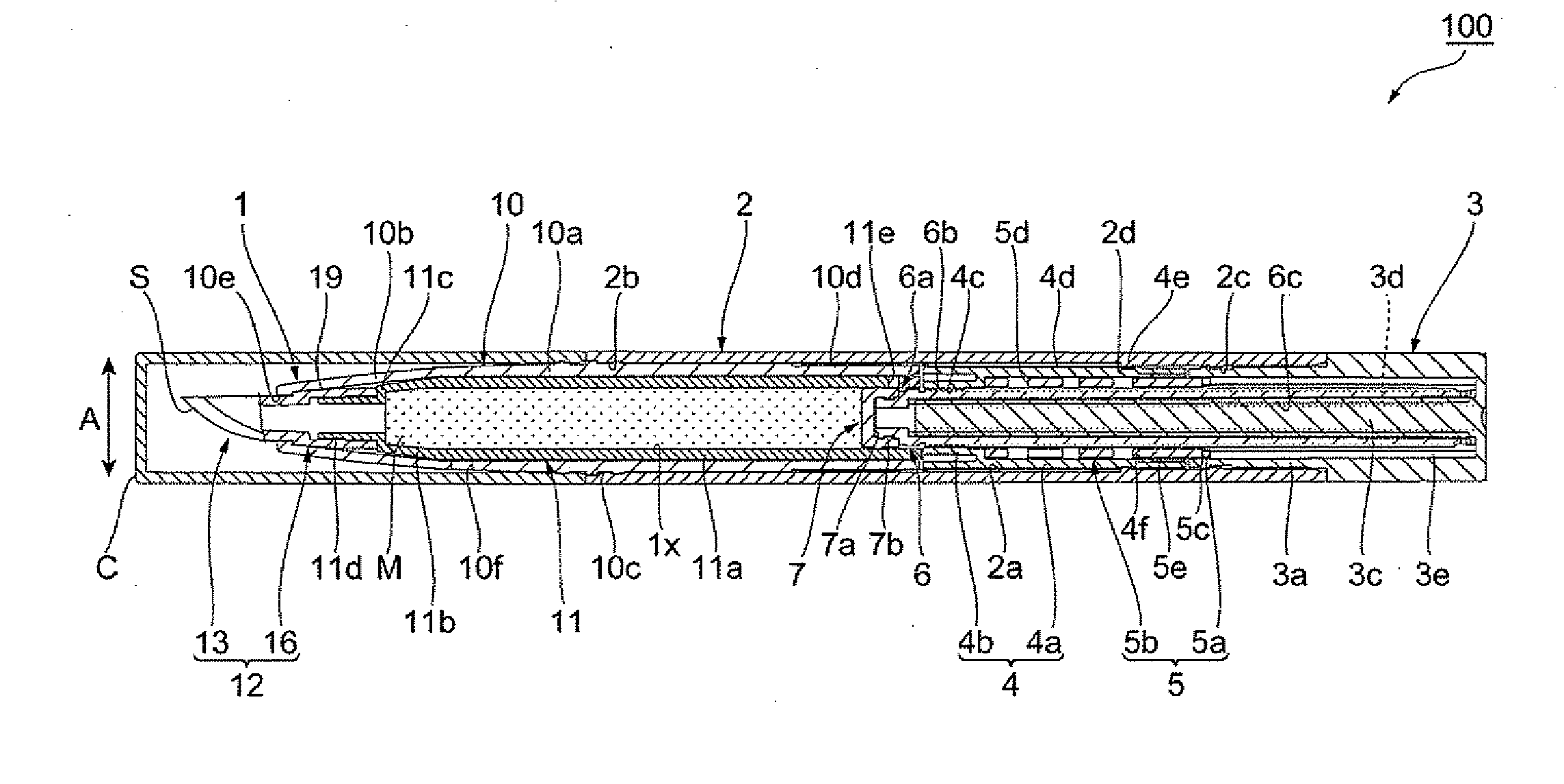

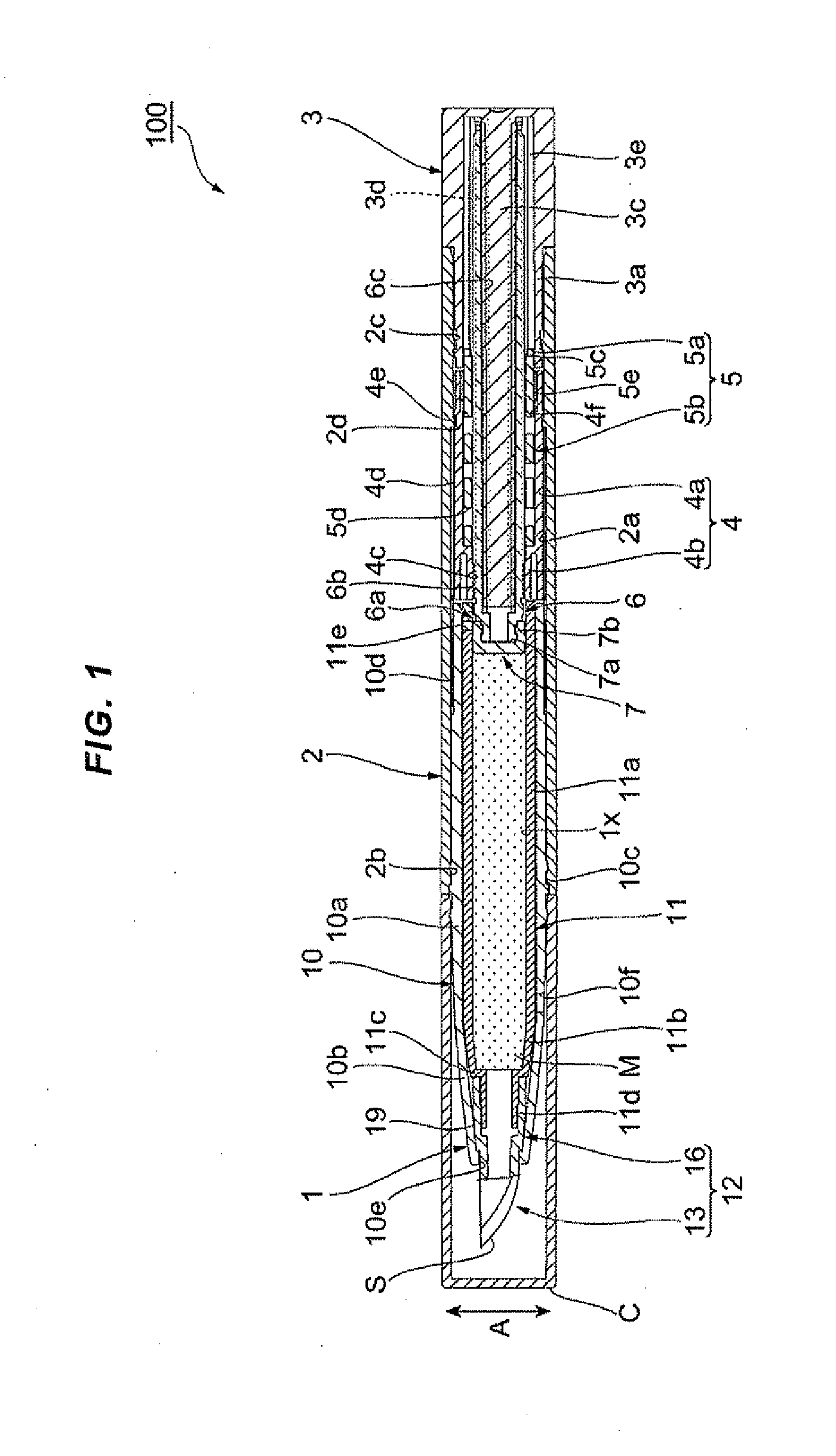

Resistive heater formed inside a fluid passage of a fluid vaporizing device

InactiveUS20030106551A1RespiratorsLiquid spraying apparatusElectrical resistance and conductanceBiomedical engineering

A fluid vaporizing device such as an aerosol generator having a tubular heater in the form of thin film of resistance heating material lining a fluid passage and method for forming the tubular heater within the fluid passage. The tubular heater can be heated to volatilize a fluid within the passage. The fluid vaporizing device can be used for the generation of aerosols containing medicated material.

Owner:PHILIP MORRIS USA INC

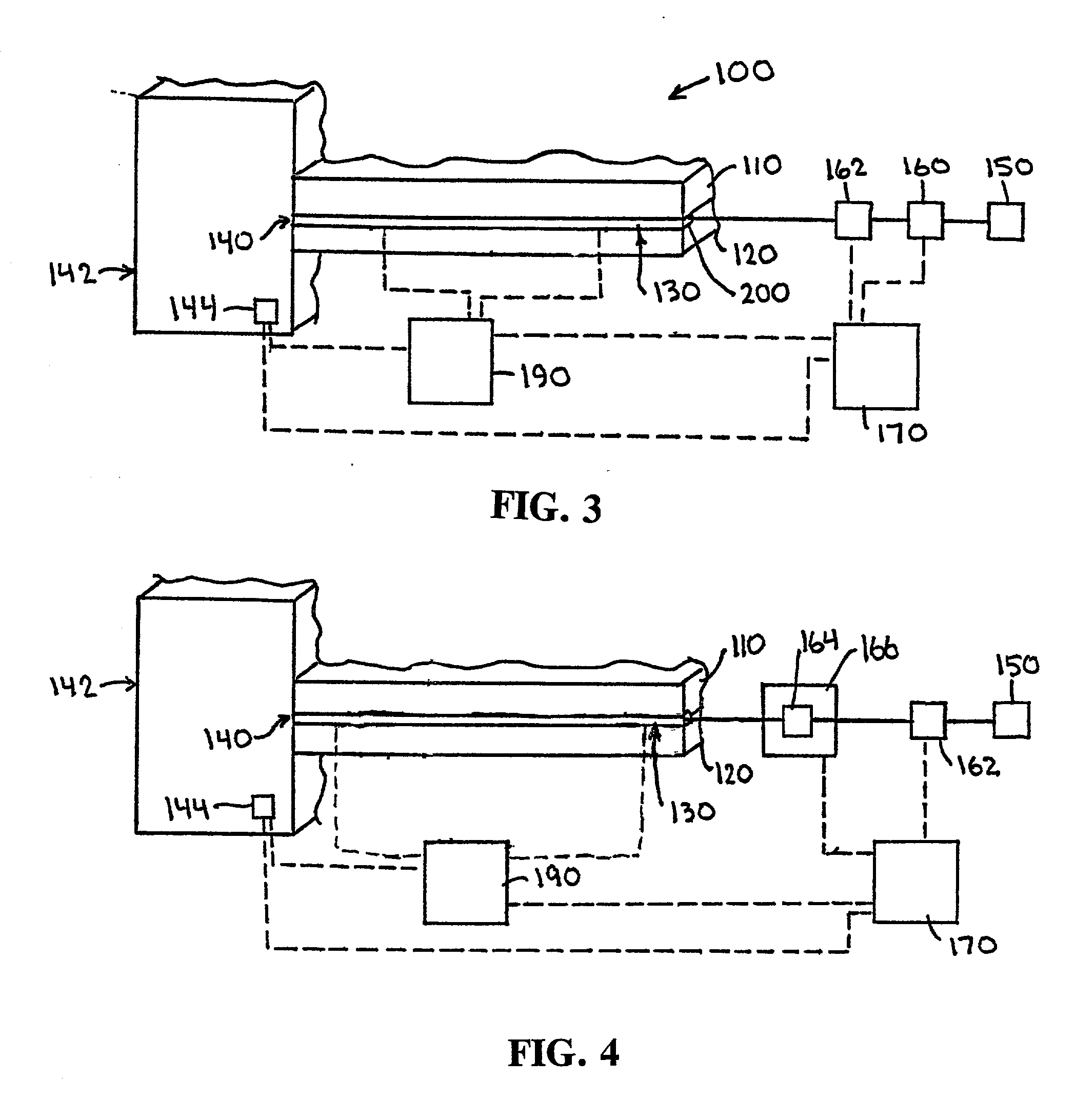

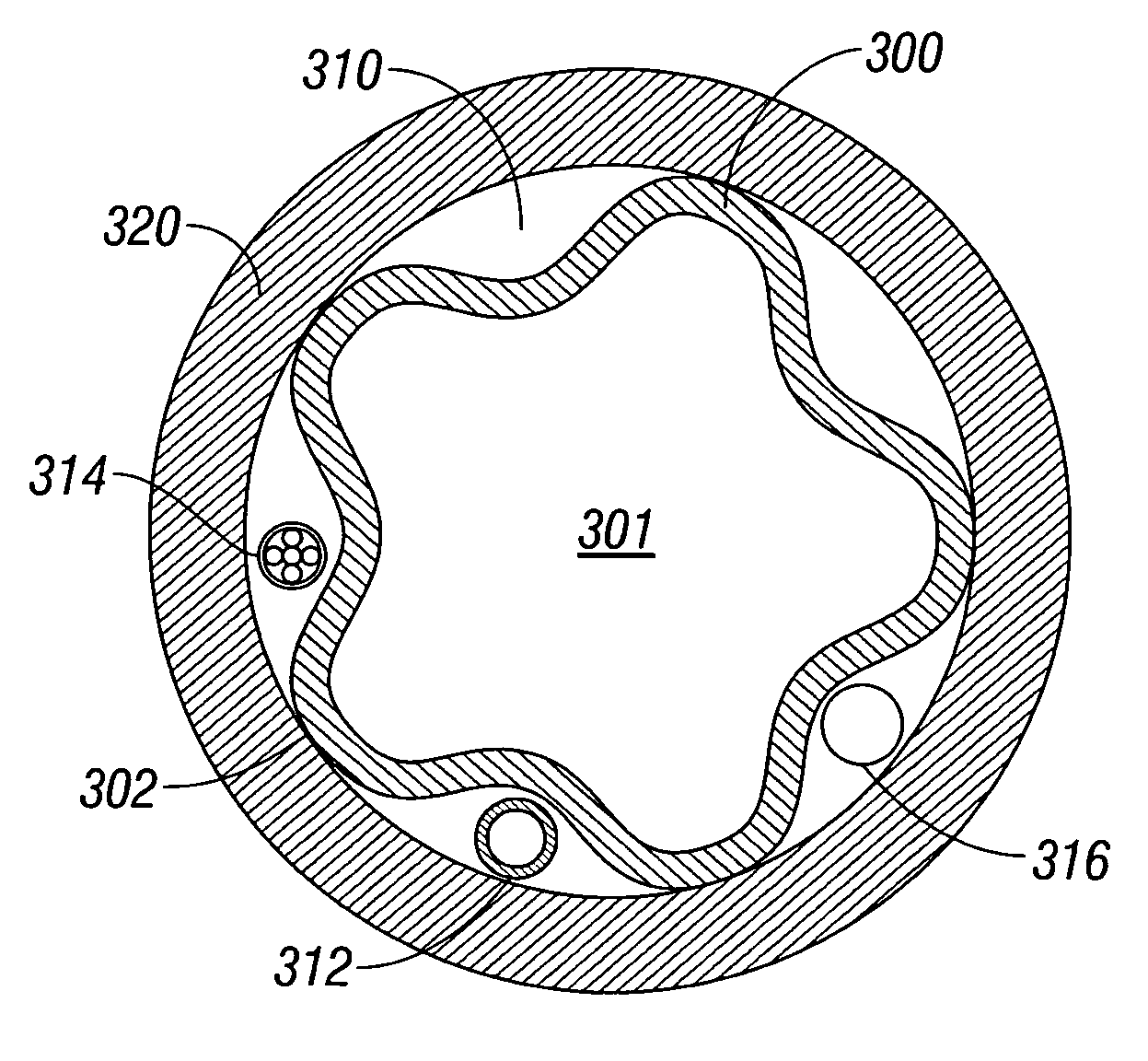

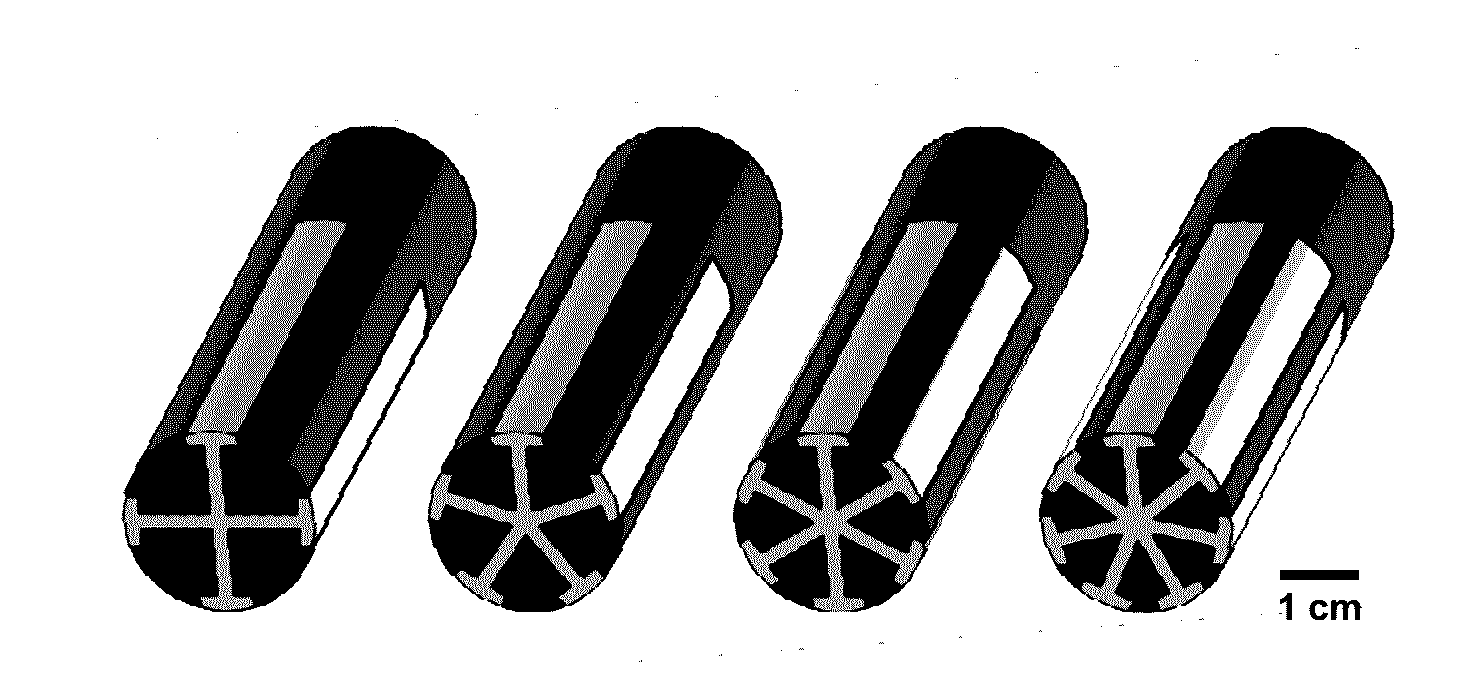

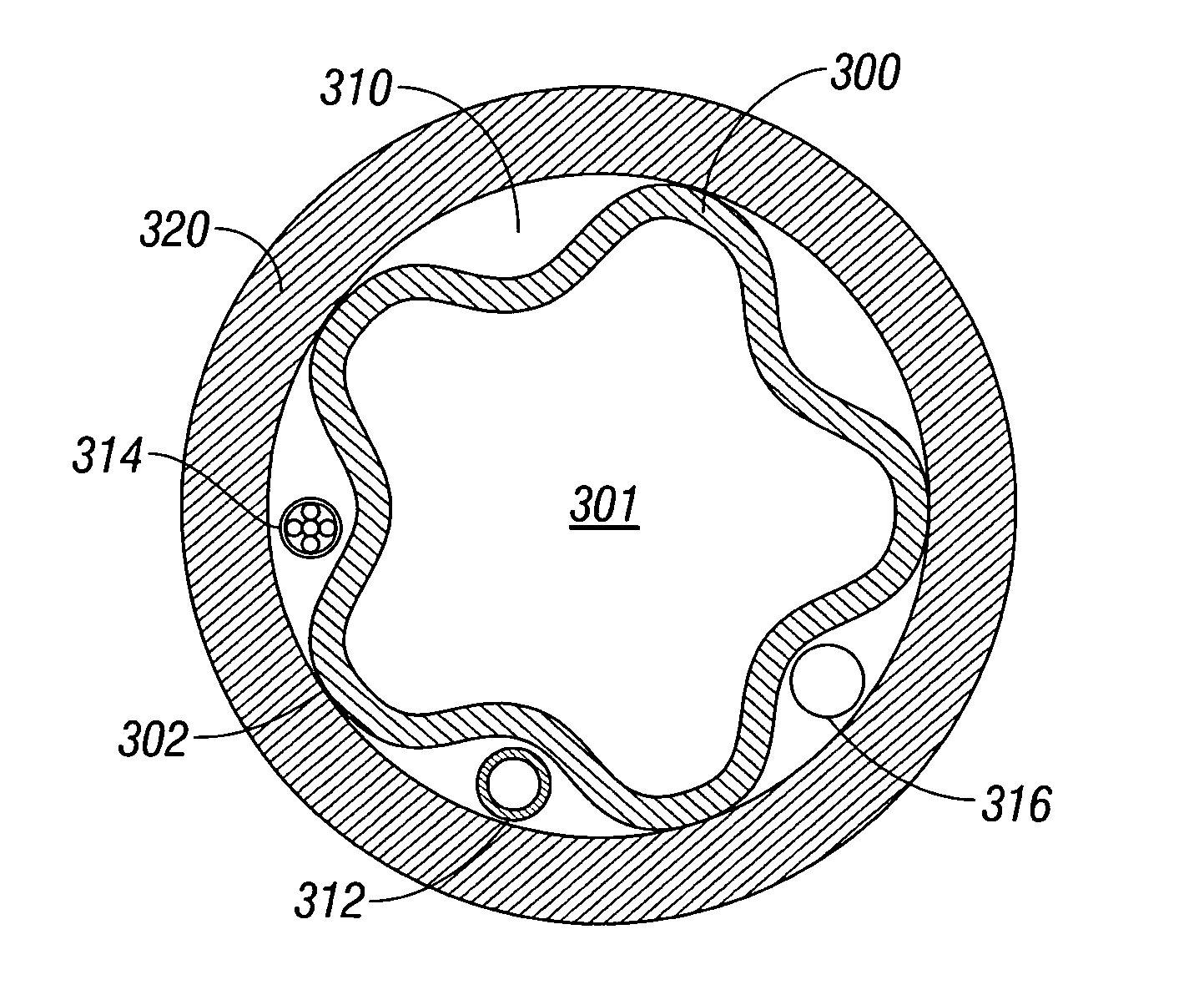

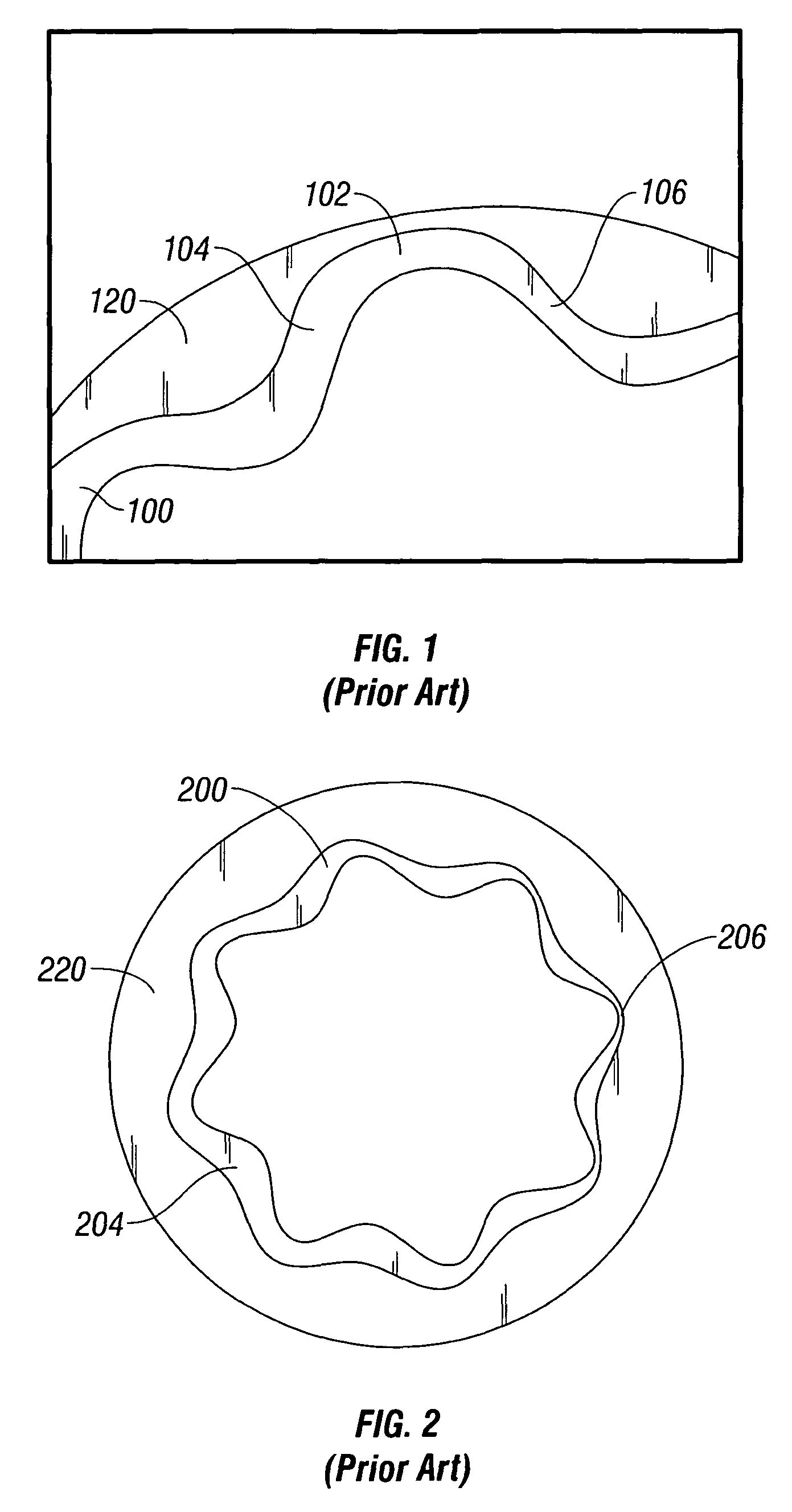

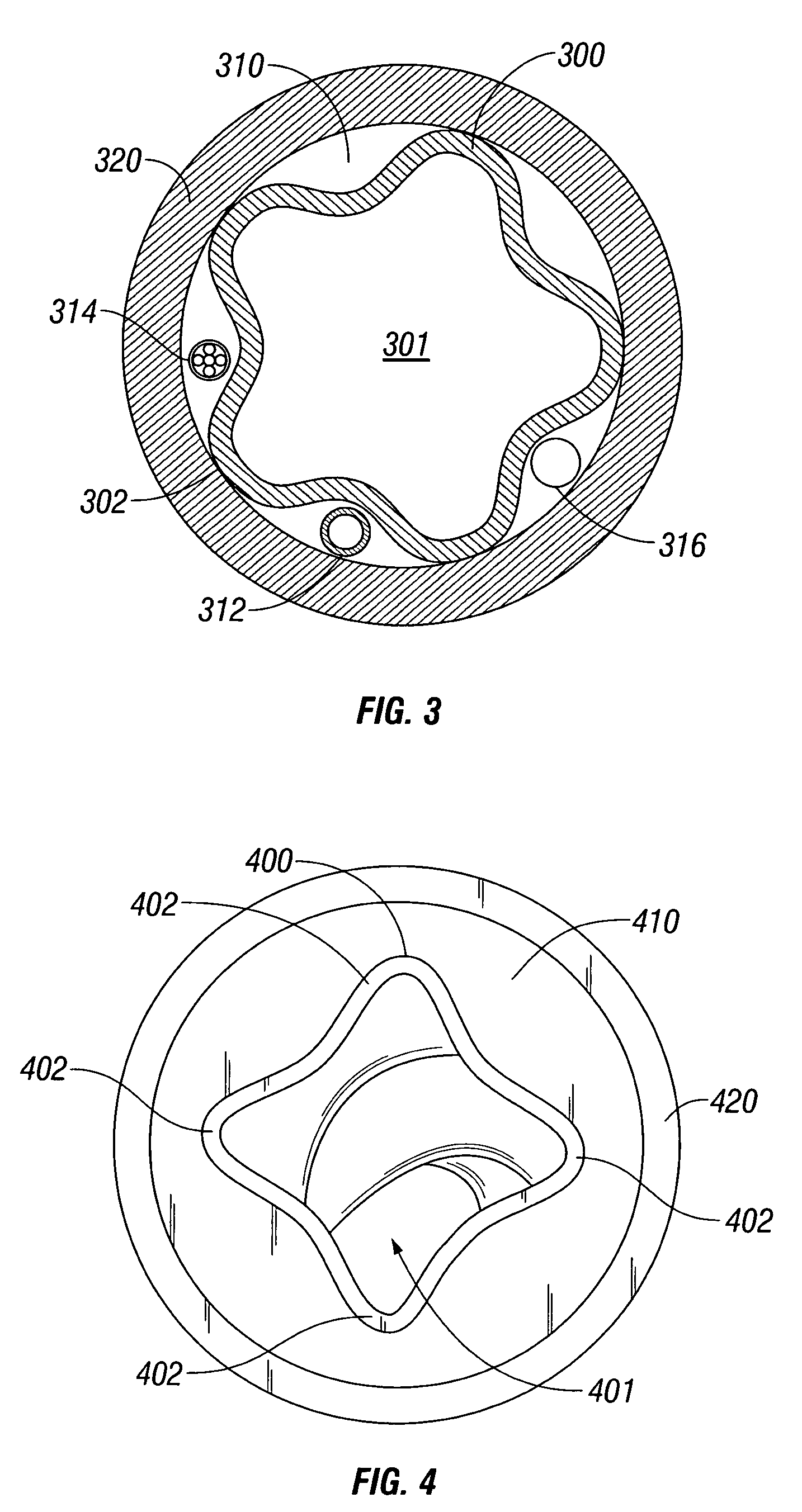

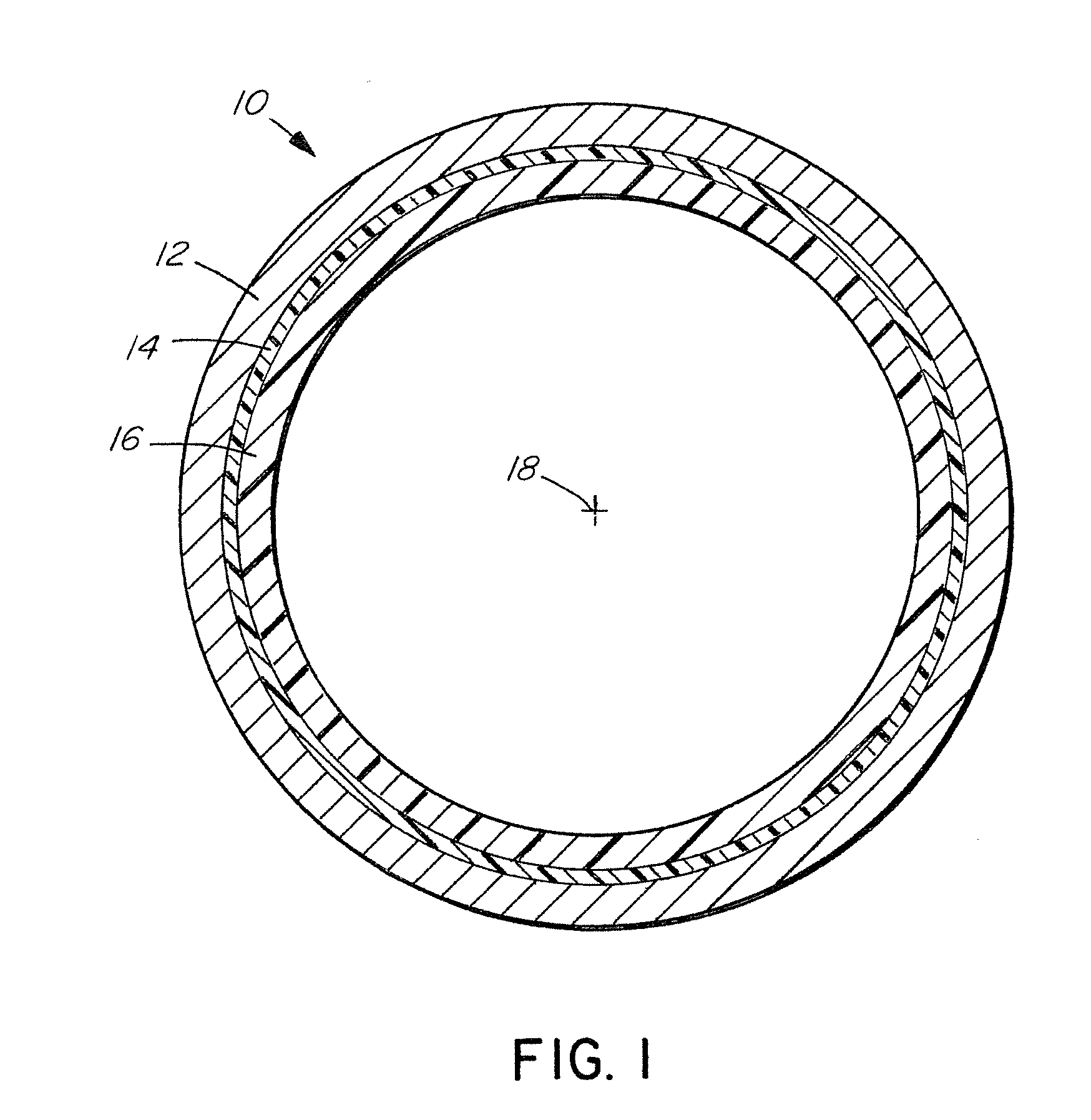

Controlled thickness resilient material lined stator and method of forming

InactiveUS20080025859A1Oscillating piston enginesEngine of intermeshing engagement typeStatorMaterial line

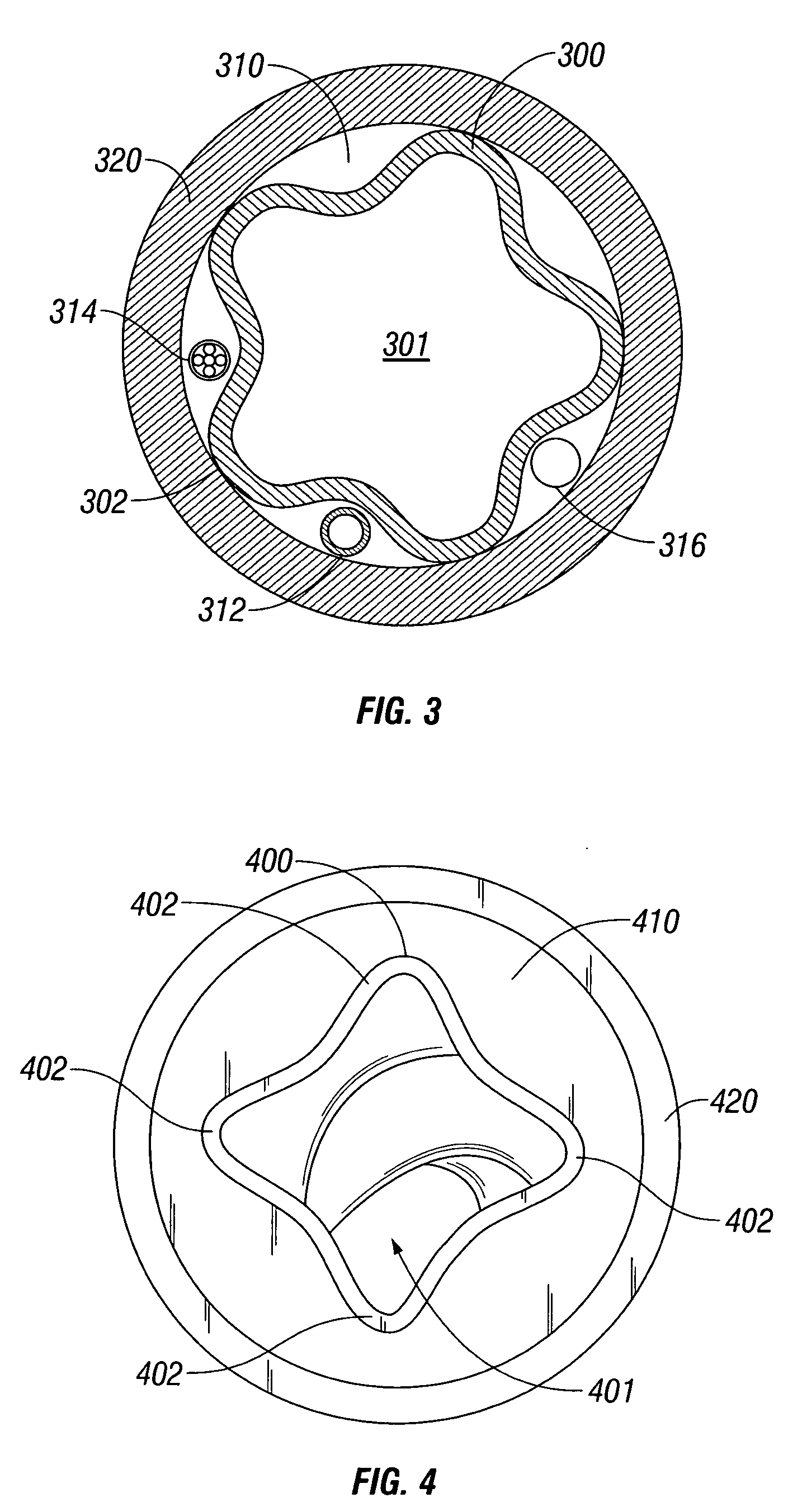

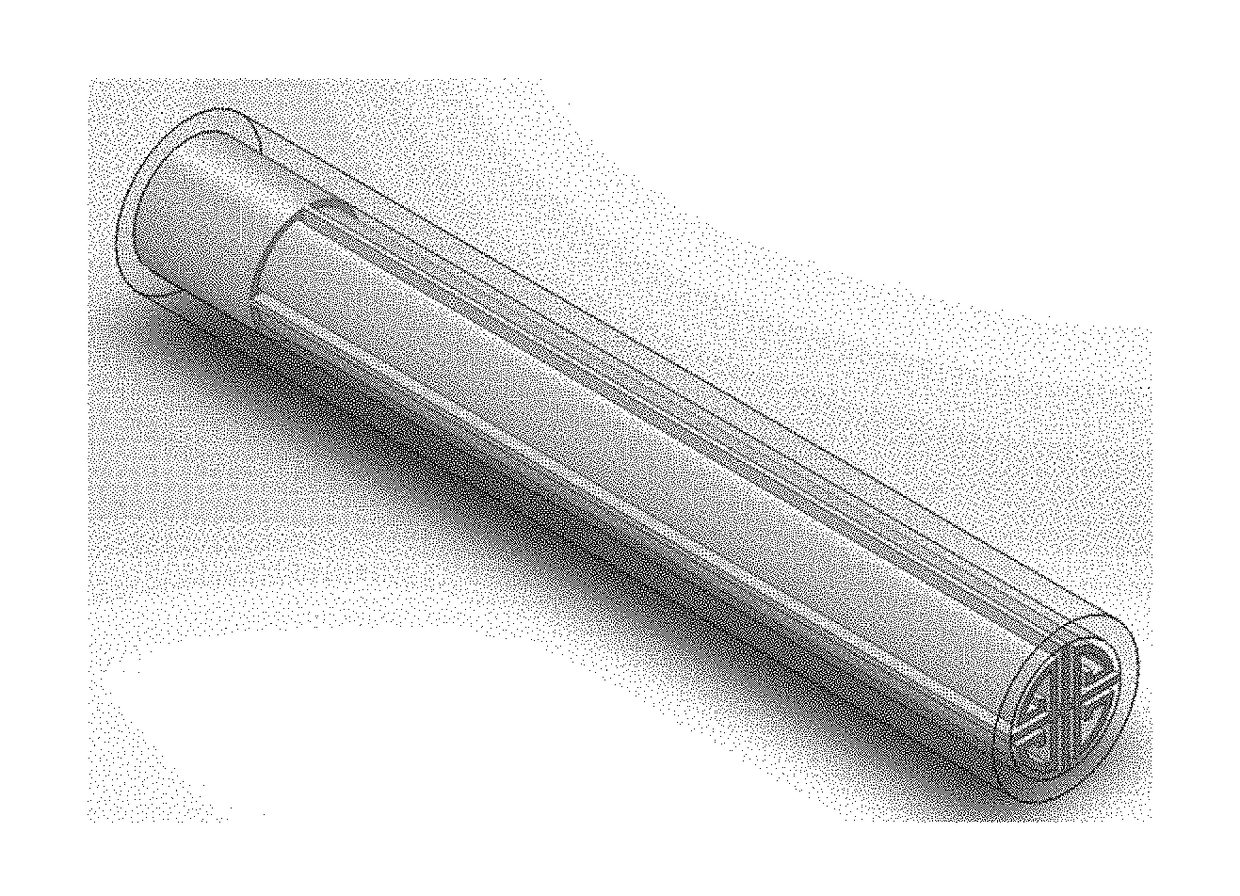

The present invention relates to a resilient material lined stator and method of forming. A method of forming a resilient material lined stator can include disposing a resilient material tube 400 with a profiled helical inner surface 401 into the bore of a body 420. A cast material 410 can be disposed therebetween. The cast material 410 can bond to the body 420 to form a resilient material lined stator or the body 420 can be removed. The cast material 310 can include a conduit 312 or conductor 314 extending therethrough. The cast material 310 can include a pathway 316 formed therethrough. The resilient material can be an elastomer.

Owner:SCHLUMBERGER TECH CORP

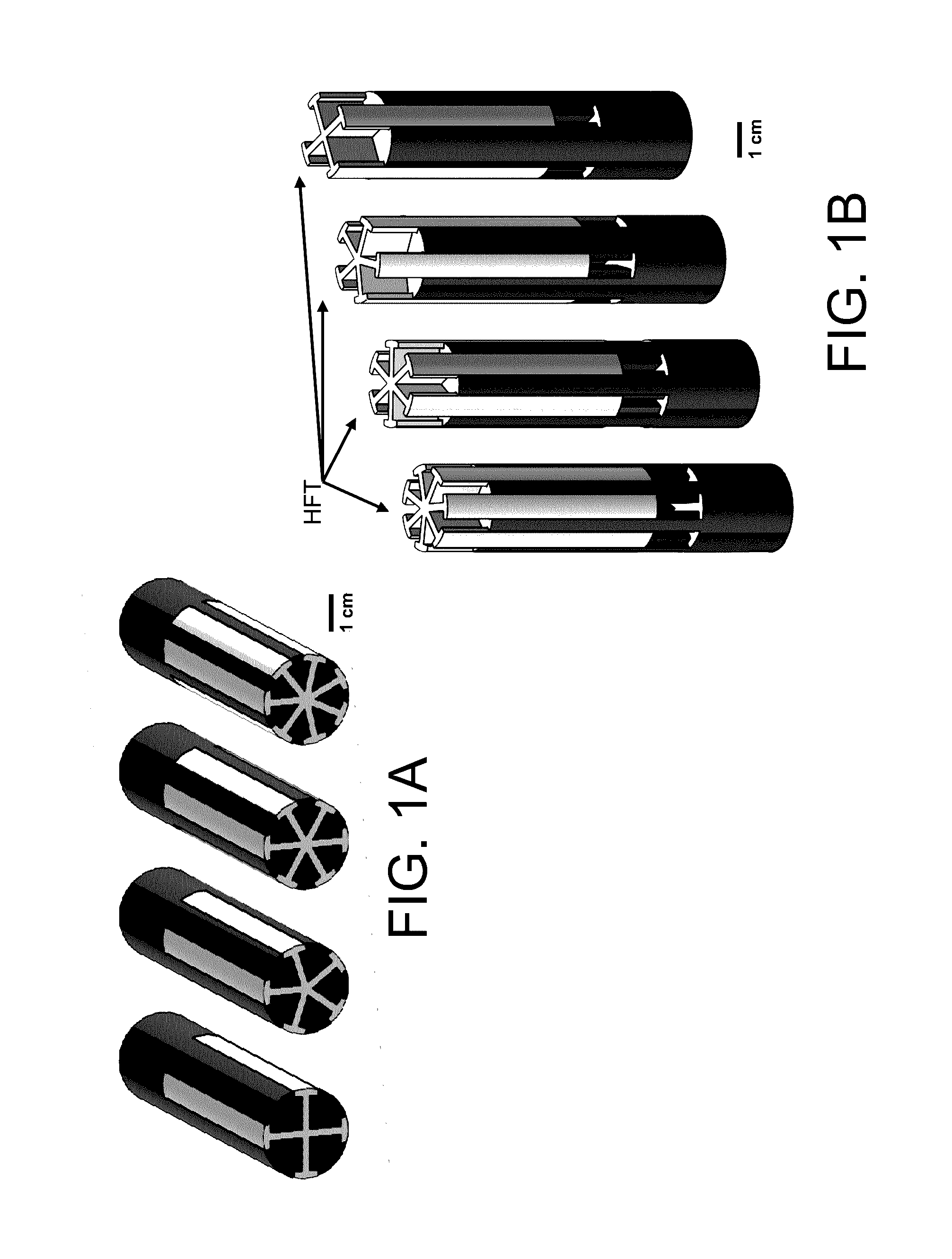

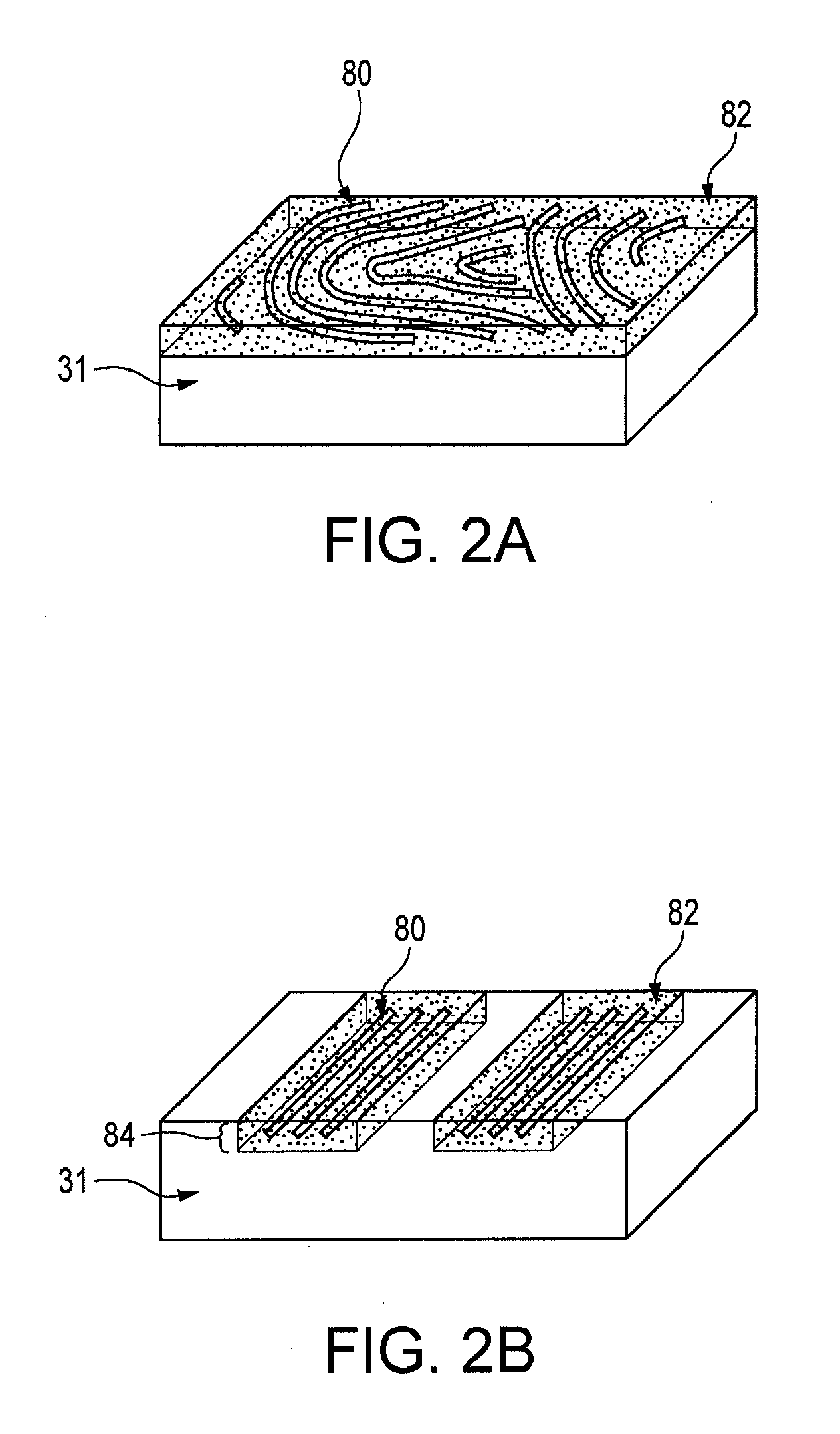

Microstructured materials

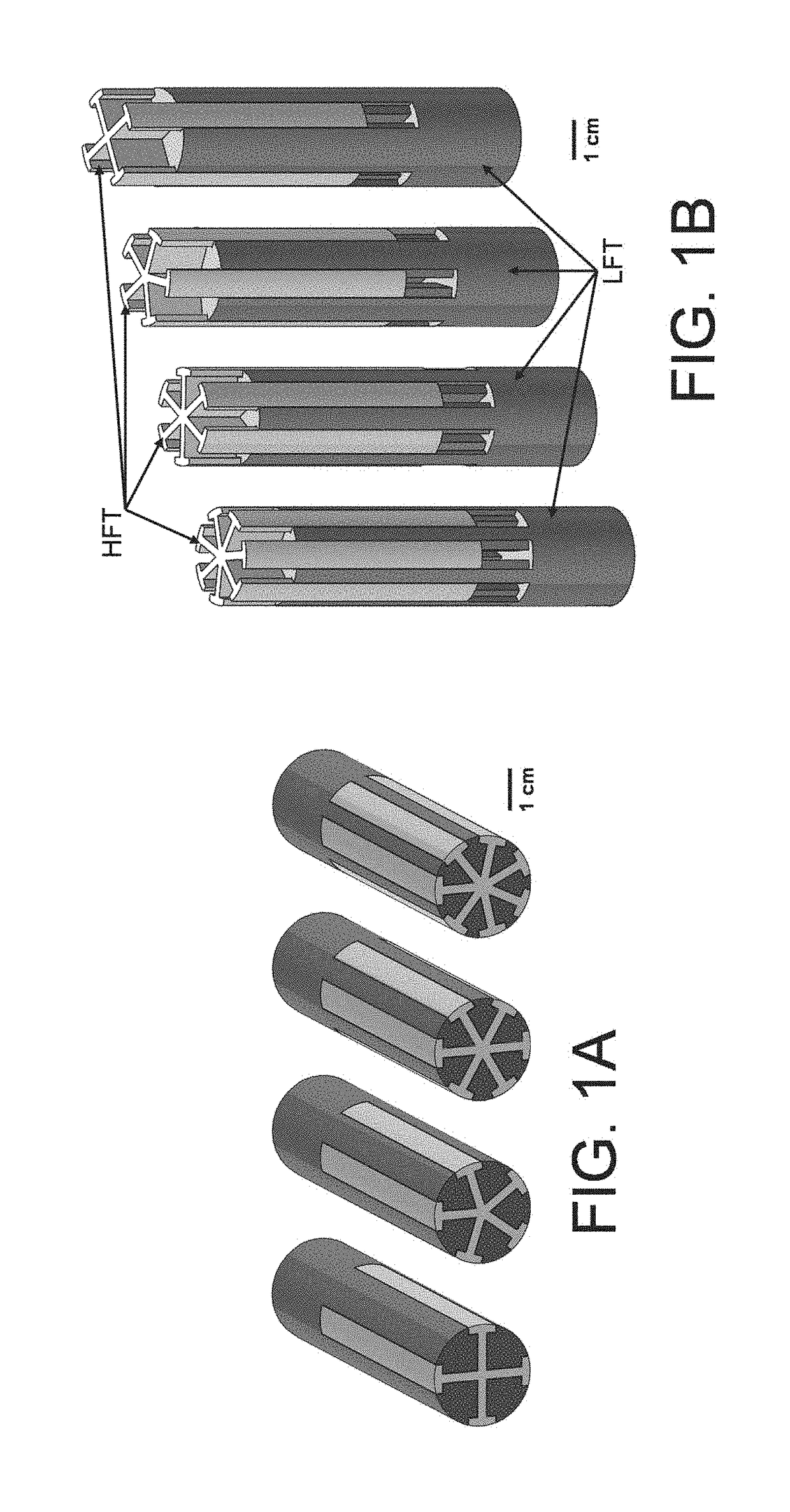

ActiveUS20160281267A1Maintain dimensional stabilityHigh propertyAdditive manufacturing apparatusOptical articlesFiberGeometric stability

A thermoplastic filament comprising multiple polymers of differing flow temperatures in a regular geometric arrangement, and a method for producing such a filament, are described. Because of the difference in flow temperatures, there exists a temperature range at which one polymer is mechanically stable while the other is flowable. This property is extremely useful for creating thermoplastic monofilament feedstock for three-dimensionally printed parts, wherein the mechanically stable polymer enables geometric stability while the flowable polymer can fill gaps and provide strong bonding and homogenization between deposited material lines and layers. These multimaterial filaments can be produced via thermal drawing from a thermoplastic preform, which itself can be three-dimensionally printed. Furthermore, the preform can be printed with precisely controlled and complex geometries, enabling the creation of monofilament and fiber with unique decorative or functional properties.

Owner:US SEC THE ARMY THE

Method of forming controlled thickness resilient material lined stator

InactiveUS7739792B2Oscillating piston enginesEngine of intermeshing engagement typeElastomerElectrical conductor

The present invention relates to a resilient material lined stator and method of forming. A method of forming a resilient material lined stator can include disposing a resilient material tube 400 with a profiled helical inner surface 401 into the bore of a body 420. A cast material 410 can be disposed therebetween. The cast material 410 can bond to the body 420 to form a resilient material lined stator or the body 420 can be removed. The cast material 310 can include a conduit 312 or conductor 314 extending therethrough. The cast material 310 can include a pathway 316 formed therethrough. The resilient material can be an elastomer.

Owner:SCHLUMBERGER TECH CORP

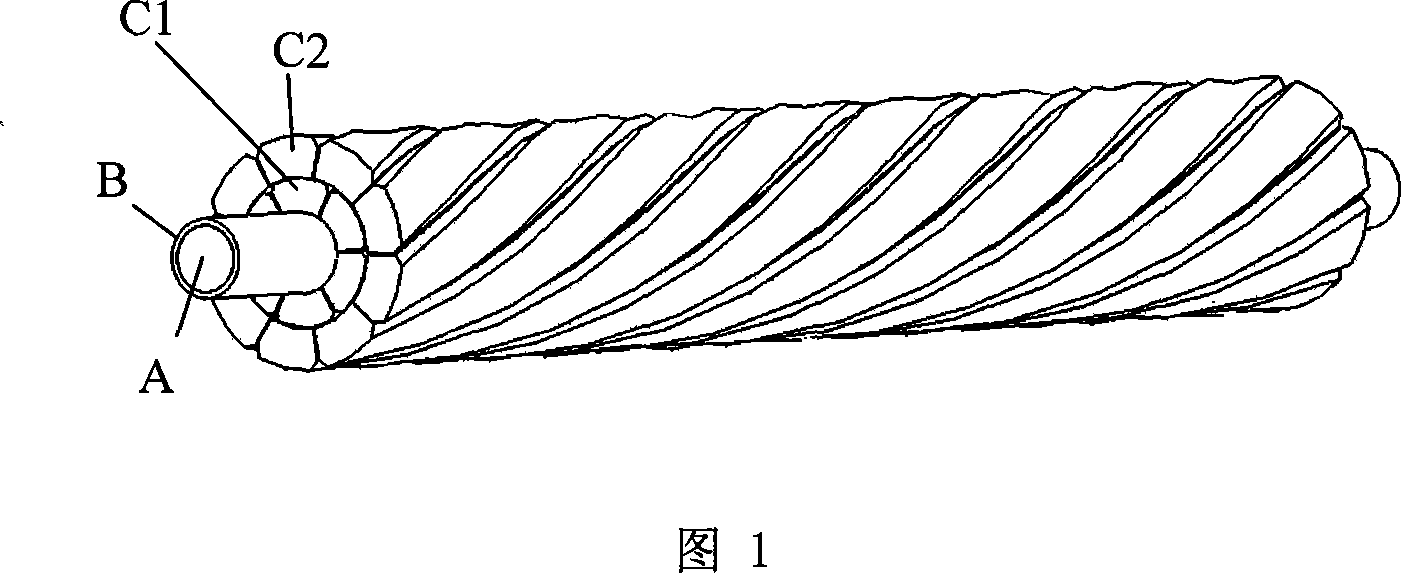

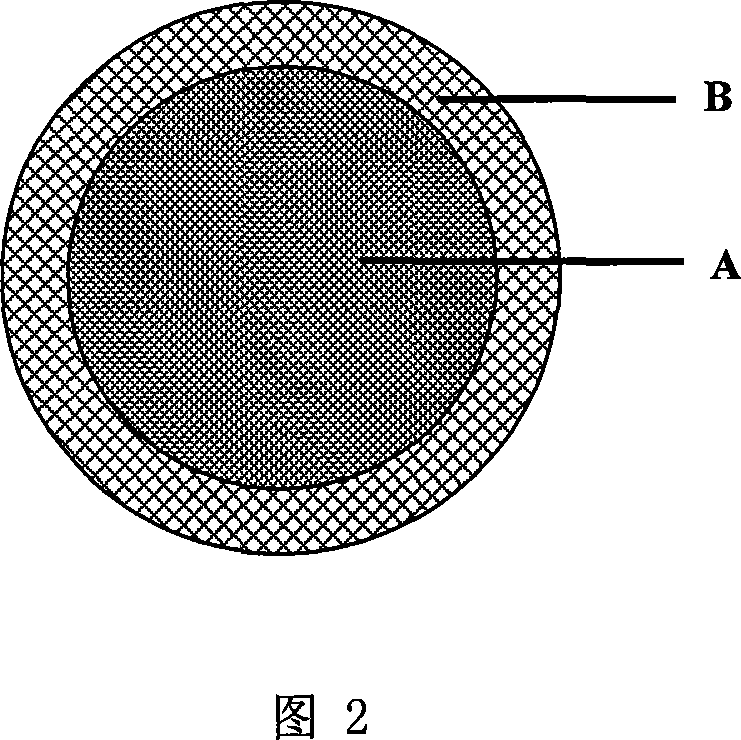

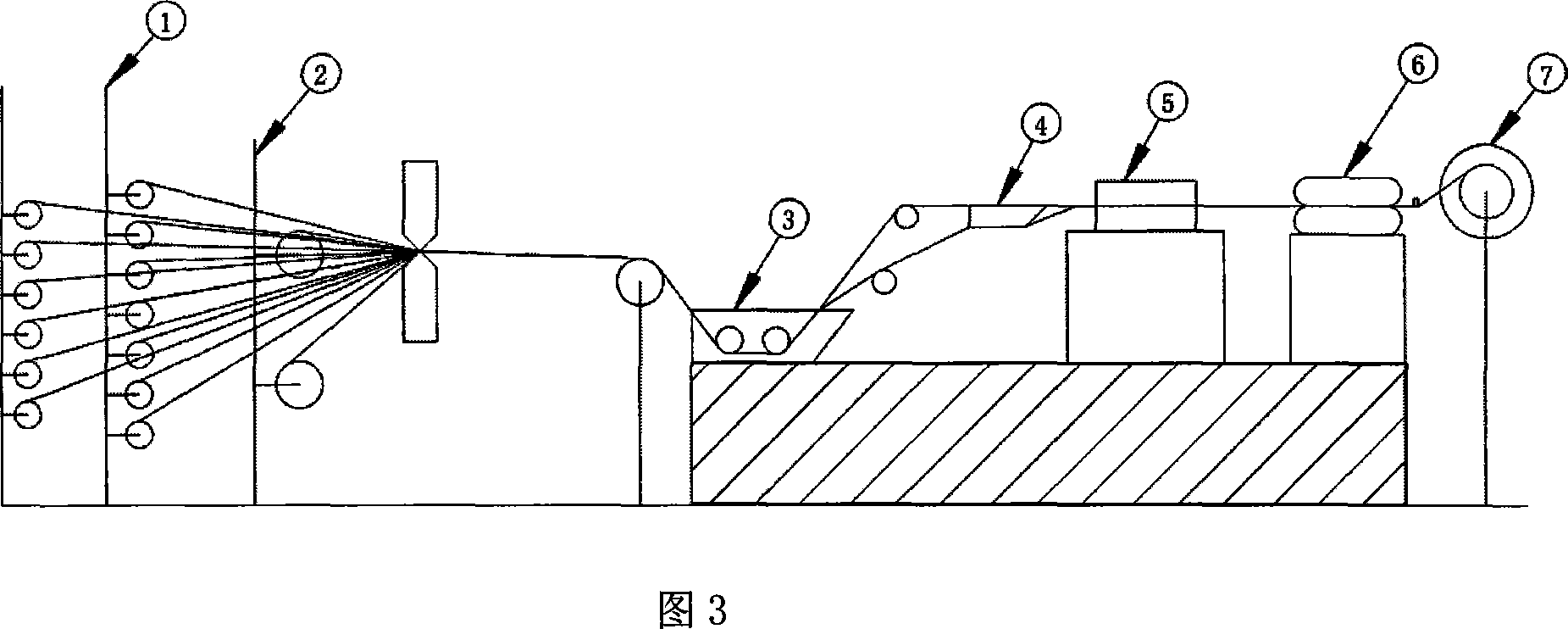

Heat-resisting and low expansion double capacity compound material core aluminum twisted wire and its making method

InactiveCN101034601AIncrease operating temperatureIncrease capacityNon-insulated conductorsPower cablesTextile fiberPower grid

The invention relates to a heat-resisting, low inflation double capacity compound material core aluminum stranded conductor and preparation method, the compound material core aluminum stranded conductor is composed of the compound material line core by the ultra long continual textile fiber heat-resisting resin and at least a section is tile shape pure aluminium or electric conduction outer layer with surround the aluminum alloy wire. Its preparation method is: Uses continuously pull-crowd craft to produce the excel in ultra long continual textile fiber strengthen the heat-resisting resin inner layer; Then through second time pull-crowd craft to cladding the outer layer which is formed by low elastical coefficient ultra long continual textile fiber strengthen the heat-resisting resin on the inner layer, namely makes the compound material line core; Again surrounds the tile shape pure aluminum or the aluminum alloy wire outside the compound material line core. The invention aluminum stranded conductor has low thermal-expansion coefficient, after enhances the conductor operating temperature the arc hang does not increase; the invention can long time safe working in 140degree centigrade, the aluminum, the aluminum alloy wire packing rate of the conductor layer is more than or equal to 90%, can double enhance the capacity of the electrical network transports.

Owner:NAT UNIV OF DEFENSE TECH +3

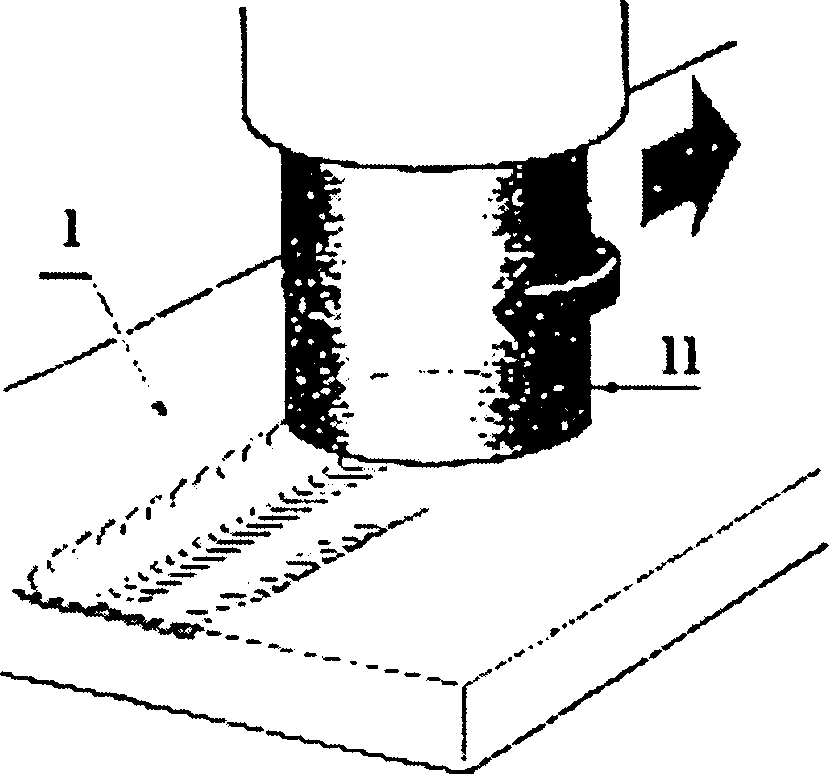

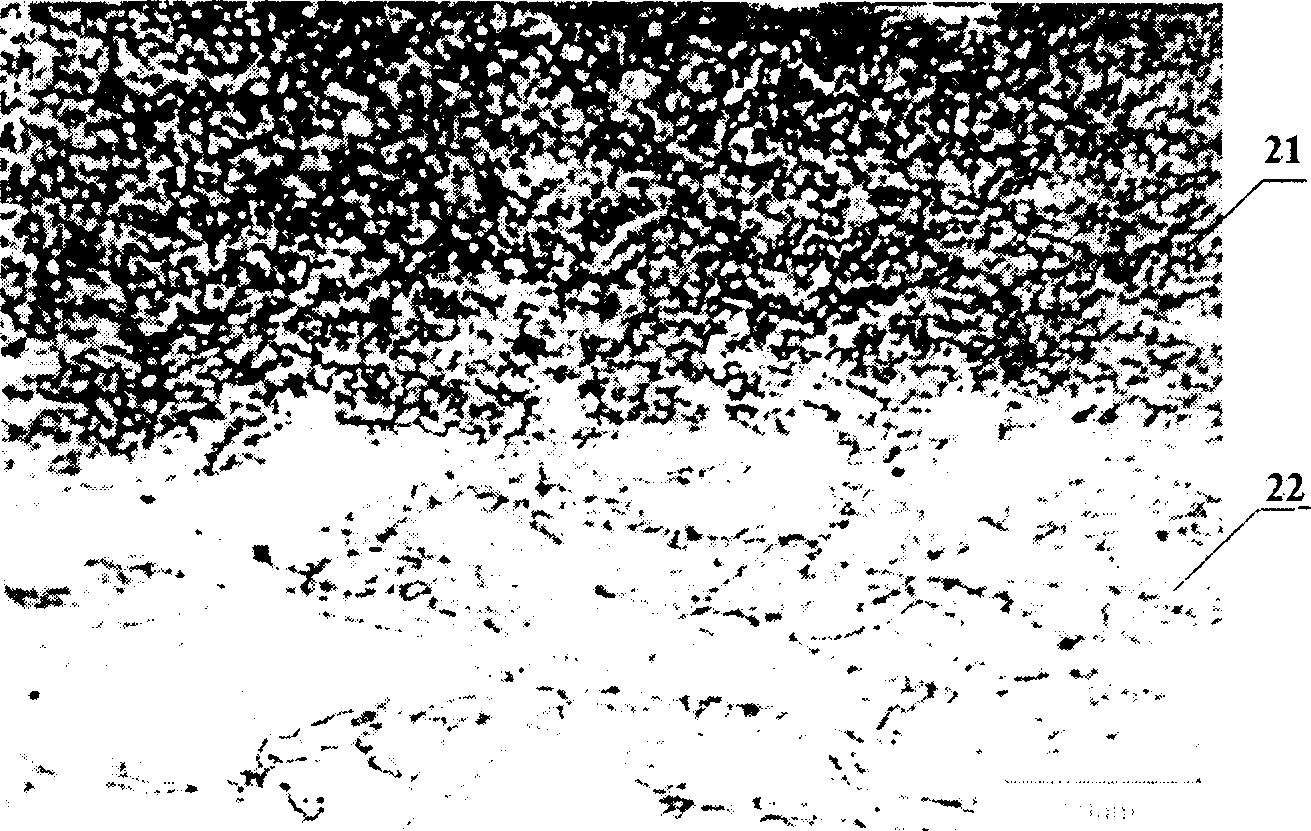

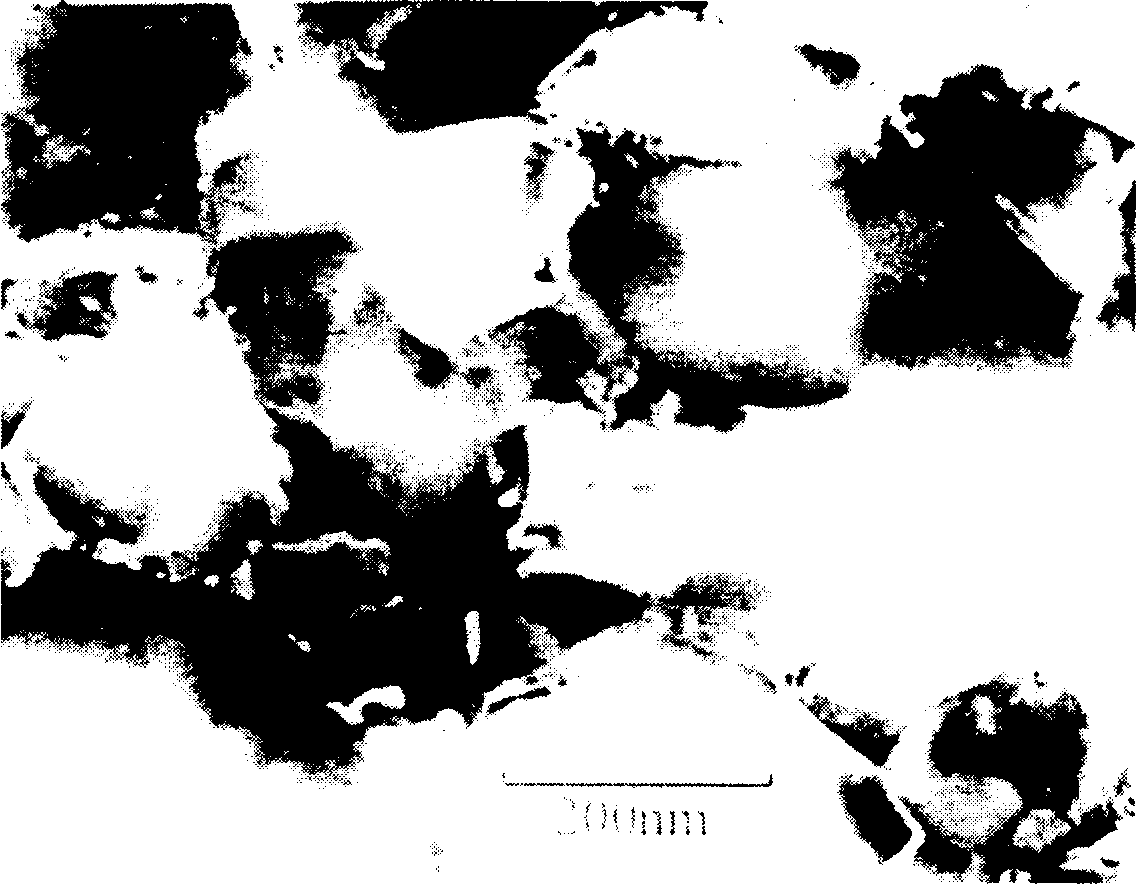

Method for preparing super fine crystal material

A process for preparing large-area or rod-shaped ultrafine-grain crystal material by the transfer method in strong deformation region features that A pression-torsion head pressing on a planar metal material is rotating at a certain speed while transversely moving to treating the surface of the material line by line, breaking the metallic crystal grains and generating large-area ultrafine-grain crystal material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

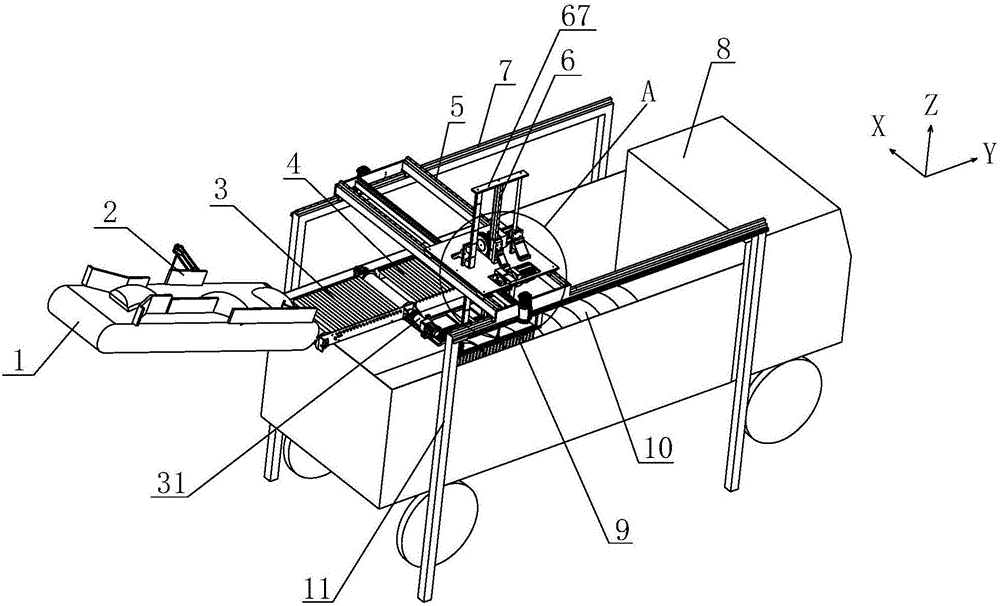

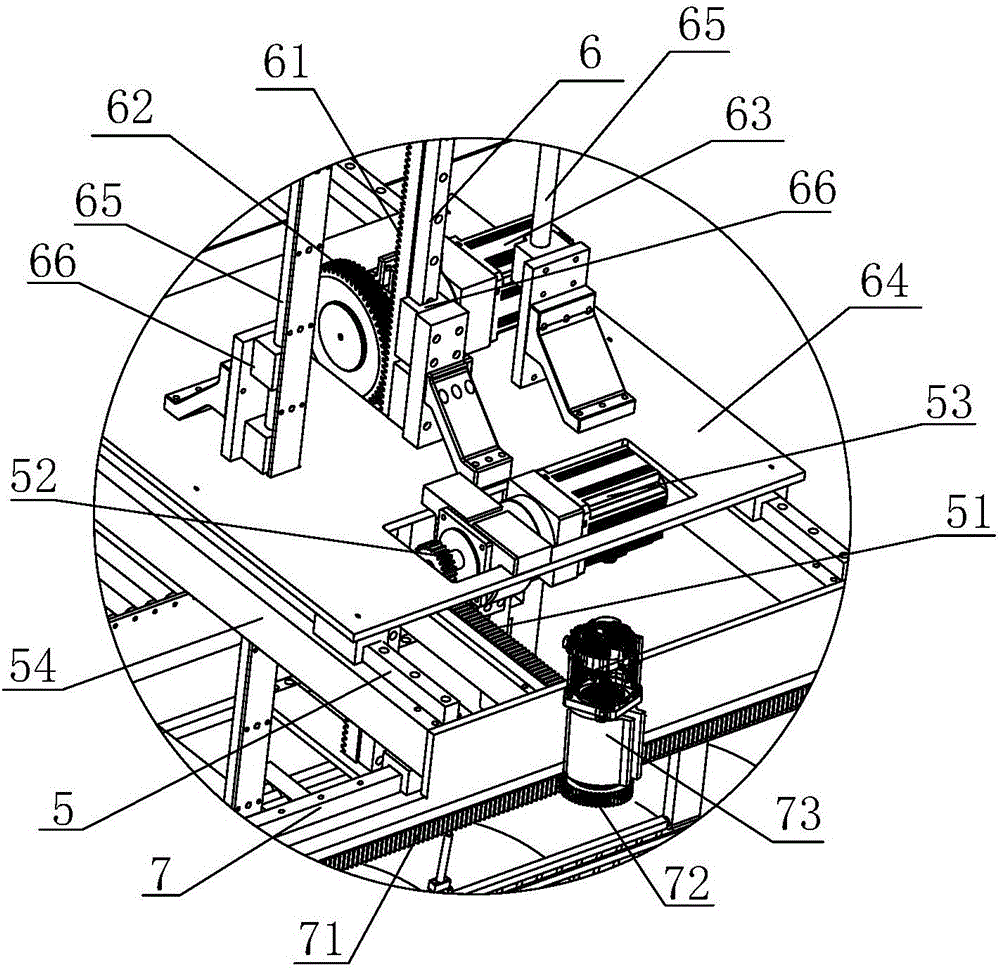

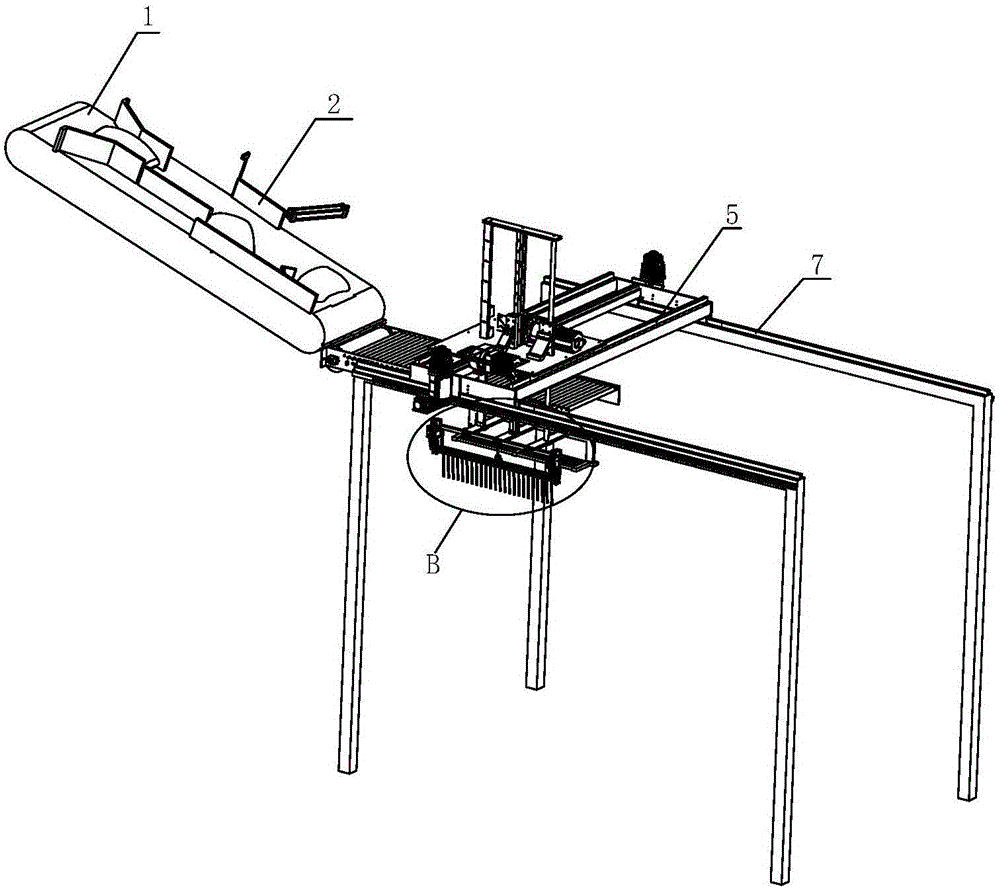

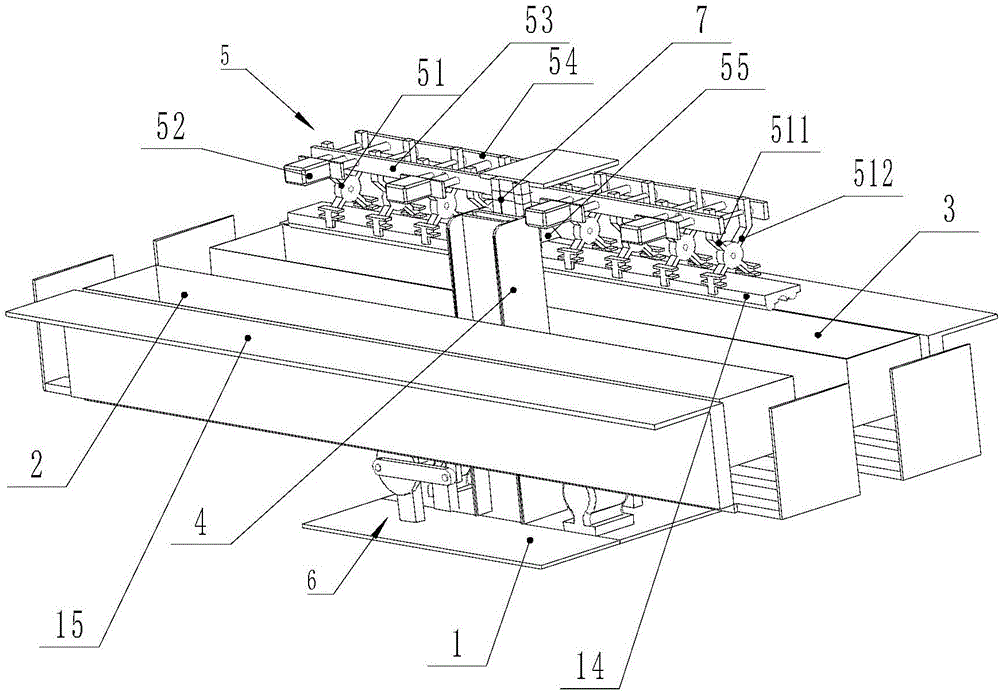

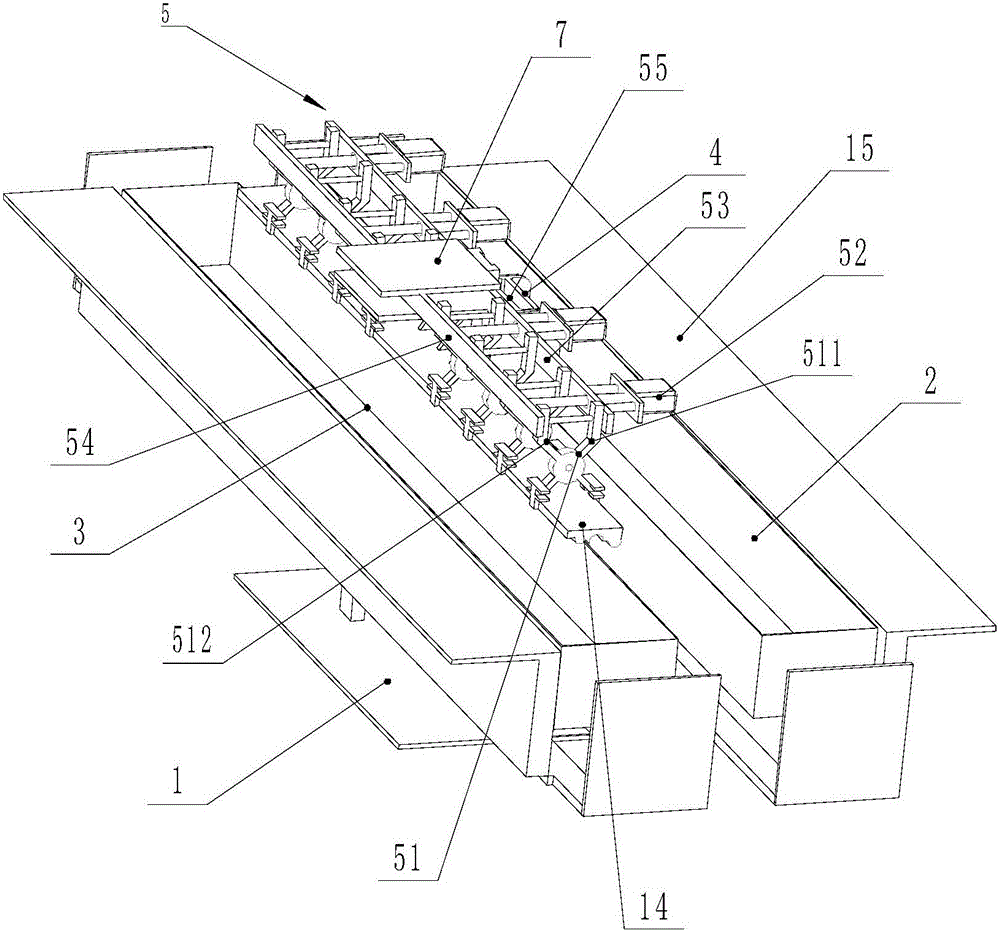

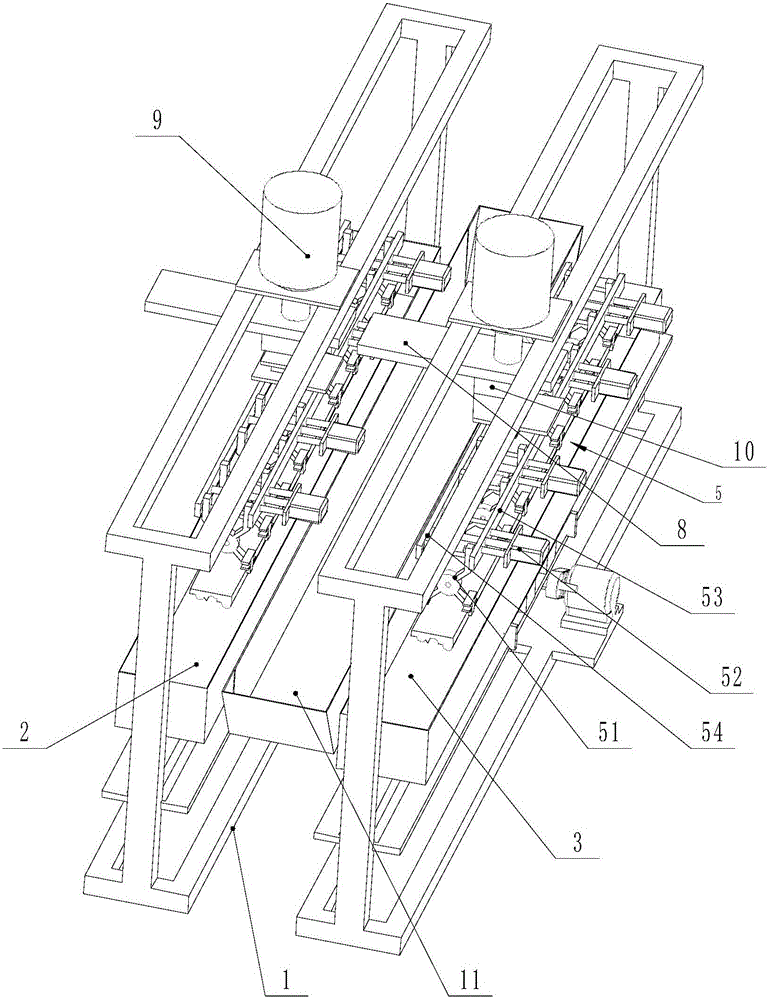

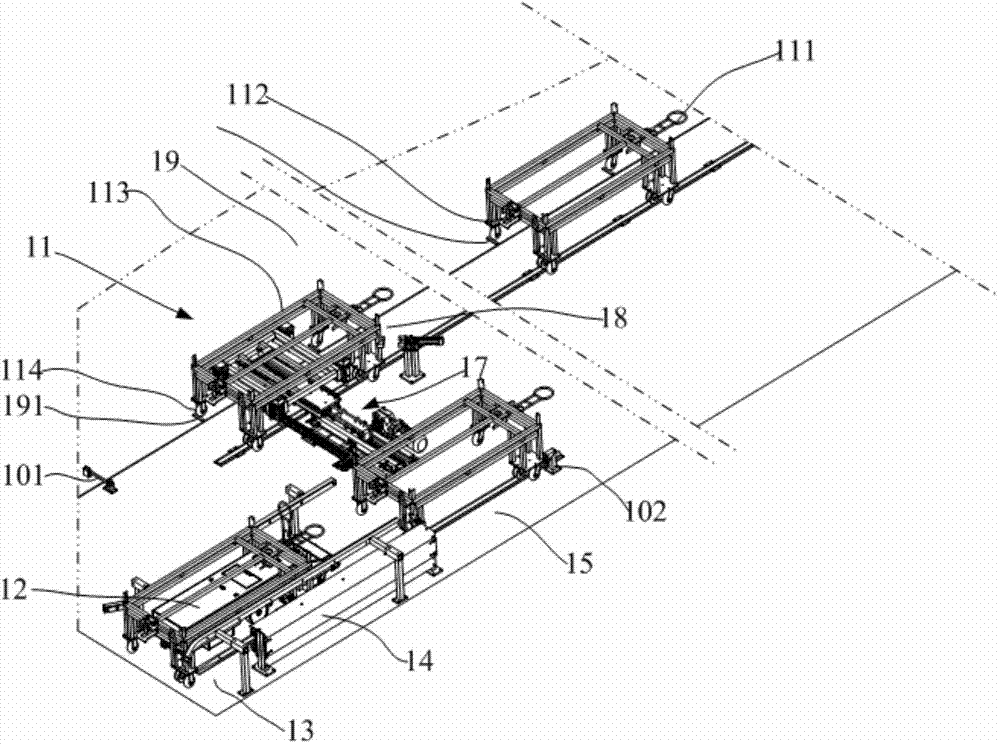

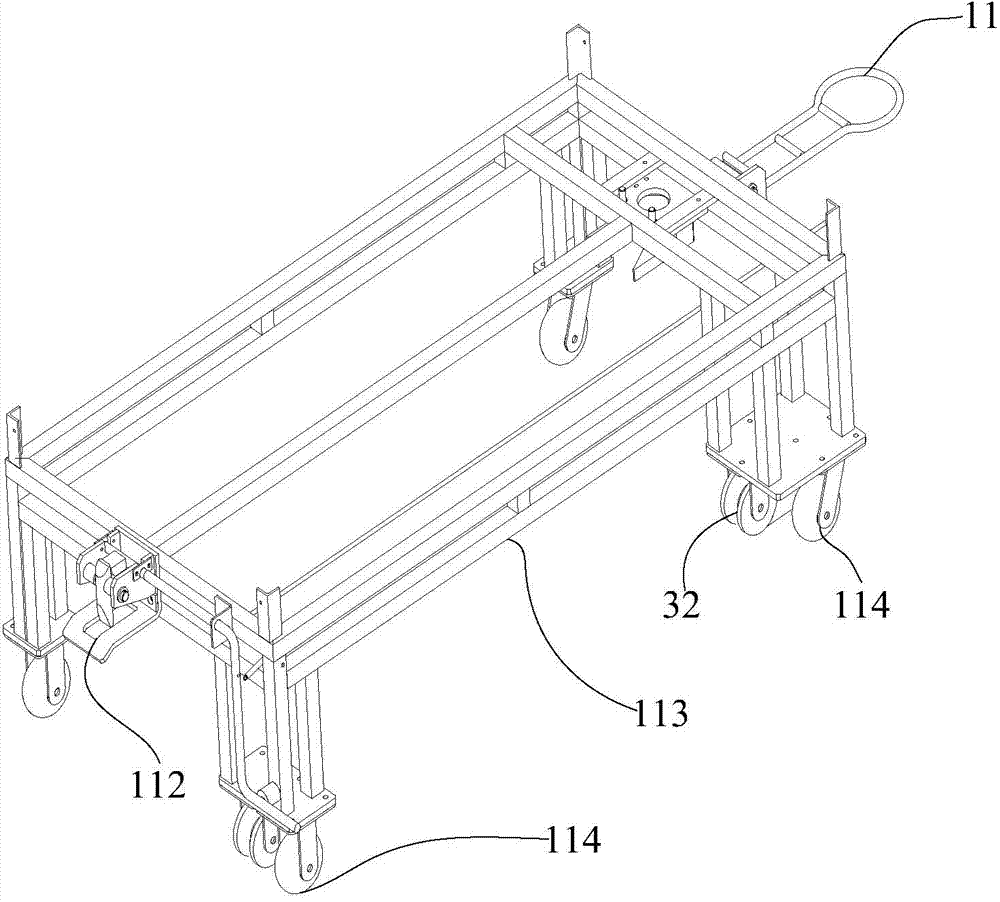

Automatic loading machine for bagged materials

ActiveCN106276323APrecise blanking and palletizingImprove palletizing efficiencyLoading/unloadingEngineeringAutomation

The invention provides an automatic loading machine for bagged materials. The automatic loading machine for the bagged materials comprises supporting frames for being mounted on two sides of a transportation vehicle, an incoming material line for transmitting material bags, a buffer shaping line and a positioning line, and also comprises a Y-direction translation mechanism mounted on the supporting frames, an X-direction translation mechanism mounted on the Y-direction translation mechanism and a Z-direction translation mechanism mounted on the X-direction translation mechanism, wherein a material lifting frame and a material falling frame are mounted at the lower end of the Z-direction translation mechanism; the material lifting frame is used for lifting up the material bags on the positioning line; the material falling frame is used for receiving the material bags which fall off from the material lifting frame and placing the material bags on the transportation vehicle. The automatic loading machine for the bagged materials can precisely control the space position of the material lifting frame and the material falling frame through the three translation mechanisms, so that the materials can fall precisely. The automatic loading machine for the bagged materials realizes high automation without manual participation, so the stacking and loading efficiency of the material bags can be effectively improved.

Owner:重庆南商机器人科技有限公司

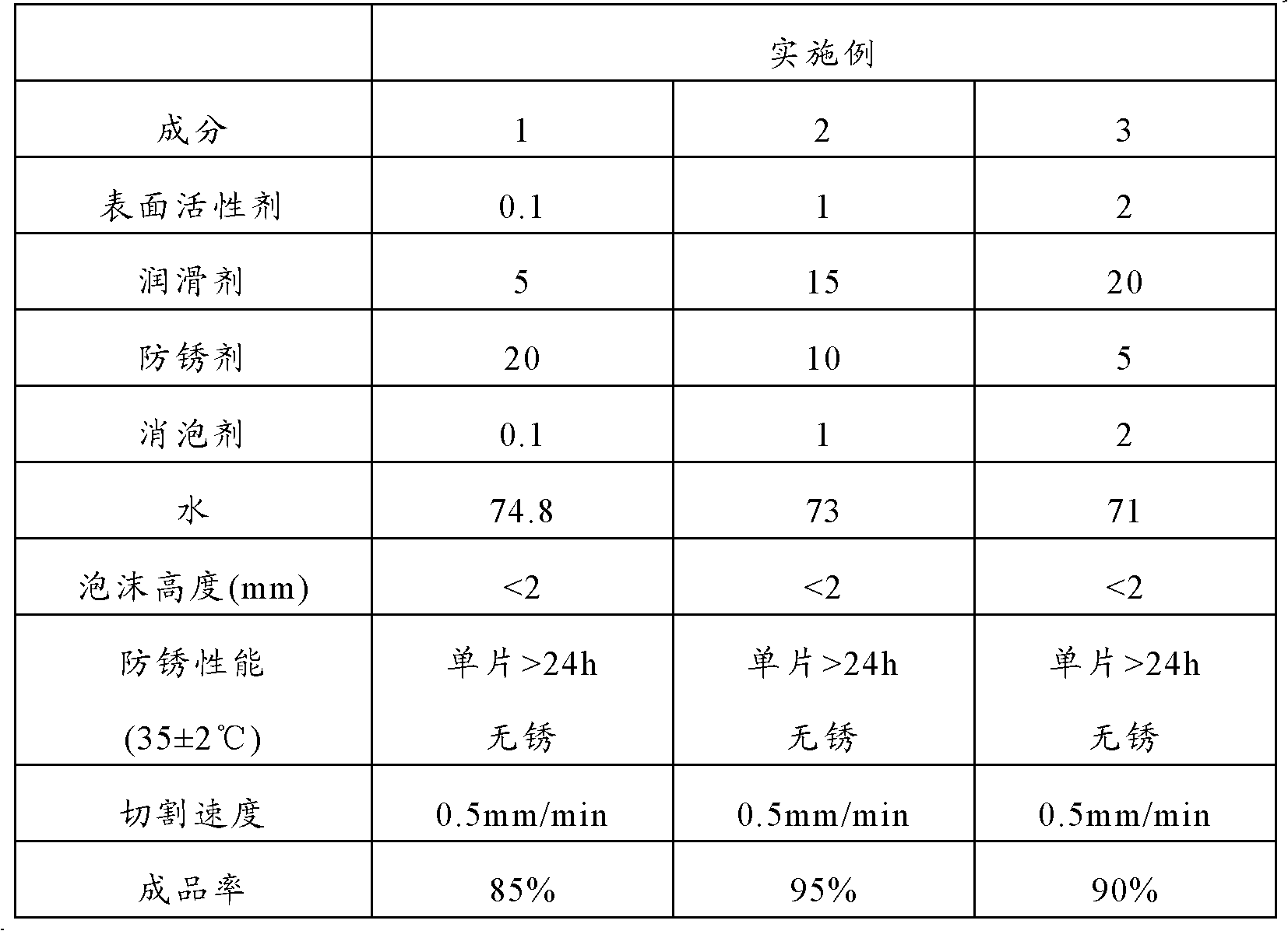

Water-soluble cooling liquid for fixed abrasive material line cutting, and preparation method thereof

ActiveCN103013638ADoes not increase viscosityImprove the lubrication effectLubricant compositionMaterials scienceCutting fluid

The present invention provides a water-soluble cutting liquid for fixed abrasive material line cutting, wherein the water-soluble cutting liquid is characterized by comprising, by weight, 0.1-10% of an non-ionic surfactant, 2-20% of an anti-rust sterilization agent, 4-20% of a lubricant, 0.1-2% of an antifoaming agent, and the balance of water. According to the present invention, the cutting liquid with performances of wetting, cleaning, cooling and rust resistance is achieved, is applicable for fixed abrasive material line cutting, and has characteristics of simple process and operation, no corrosion, no bubbling, no rust, no harm on human body, and low cost. The present invention further provides a preparation method for the water-soluble cooling liquid for fixed abrasive material line cutting.

Owner:ZHEJIANG SHUNLIAN INTELLIGENT EQUIP CO LTD

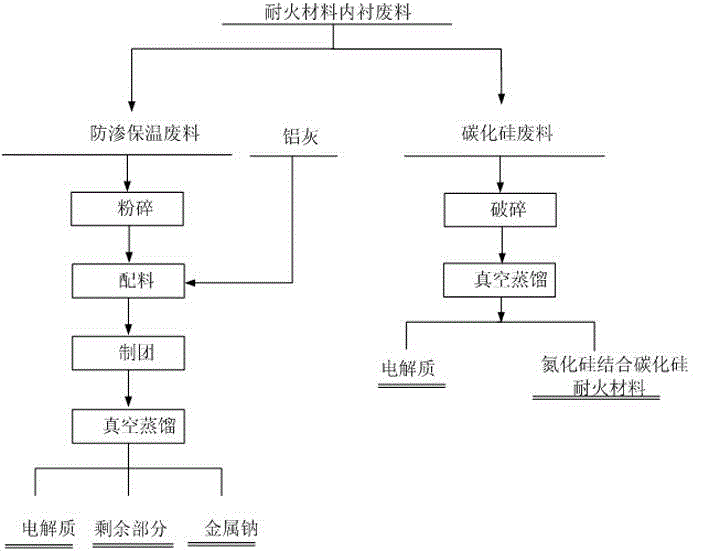

Recovery treatment method of electrolytic aluminum ash and refractory material lining waste

The invention discloses a recovery treatment method of electrolytic aluminum ash and a refractory material lining waste; the refractory lining waste is divided into an impermeable insulation waste and a silicon carbide waste; and the method comprises the following steps: (1) the impermeable insulation waste is crushed and levigated to mix with the aluminum ash to press a pellet; (2) vacuum distillation: electrolyte and metal sodium are crystallized on a crystallizer; the remainder part has main components of Al2O3 and SiO2; the silicon carbide waste is distilled at a temperature of 1000-1200 DEG C in vacuum after being crushed; the electrolyte is crystallized on the crystallizer; and the remainder part is a silicon nitride and silicon carbide refractory material. The method is simple in flow; the useful components can be fully recycled; the recovery cost is low; and meanwhile, the environmental pollution is reduced, so that the application prospect is excellent.

Owner:NORTHEASTERN UNIV

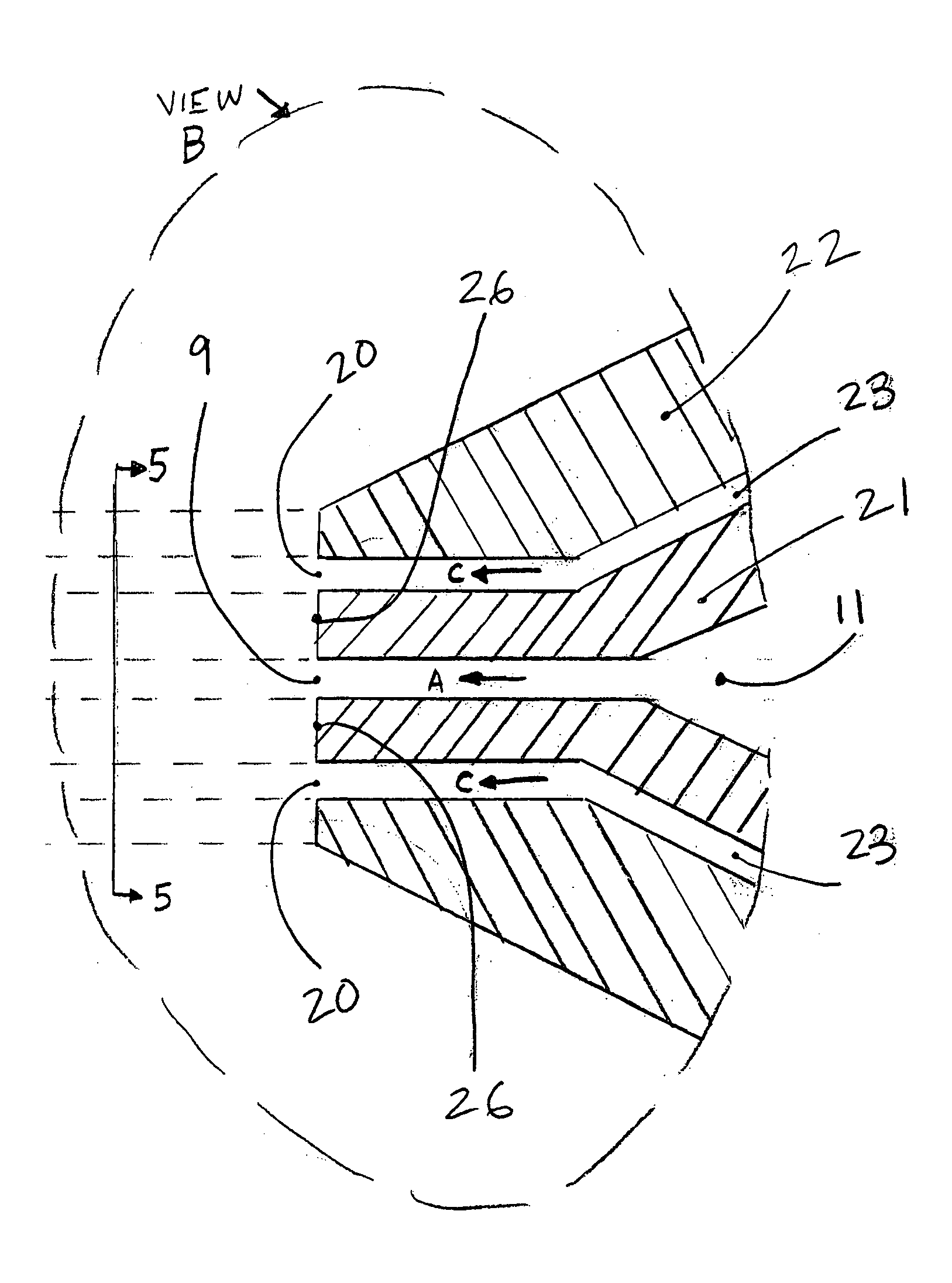

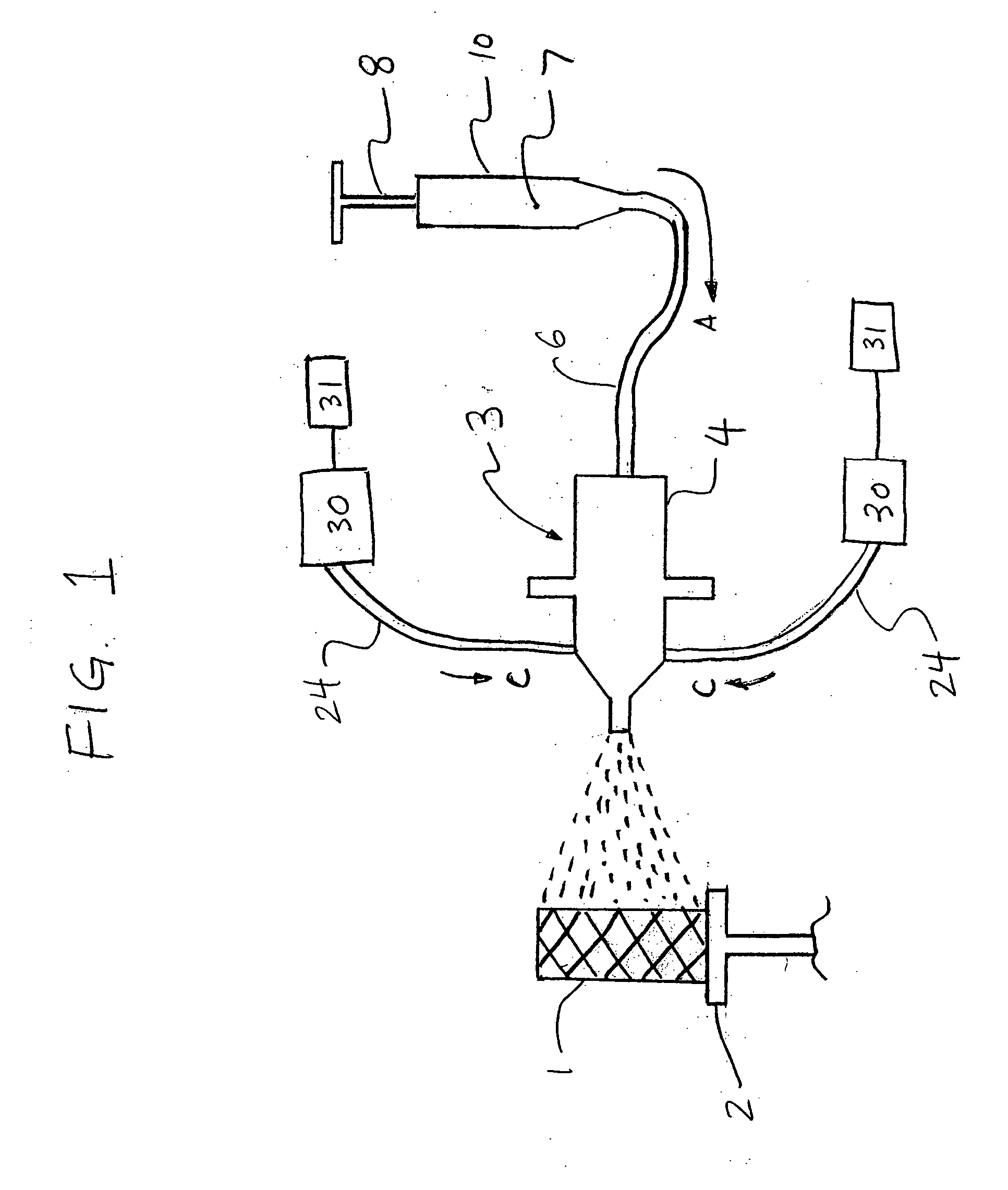

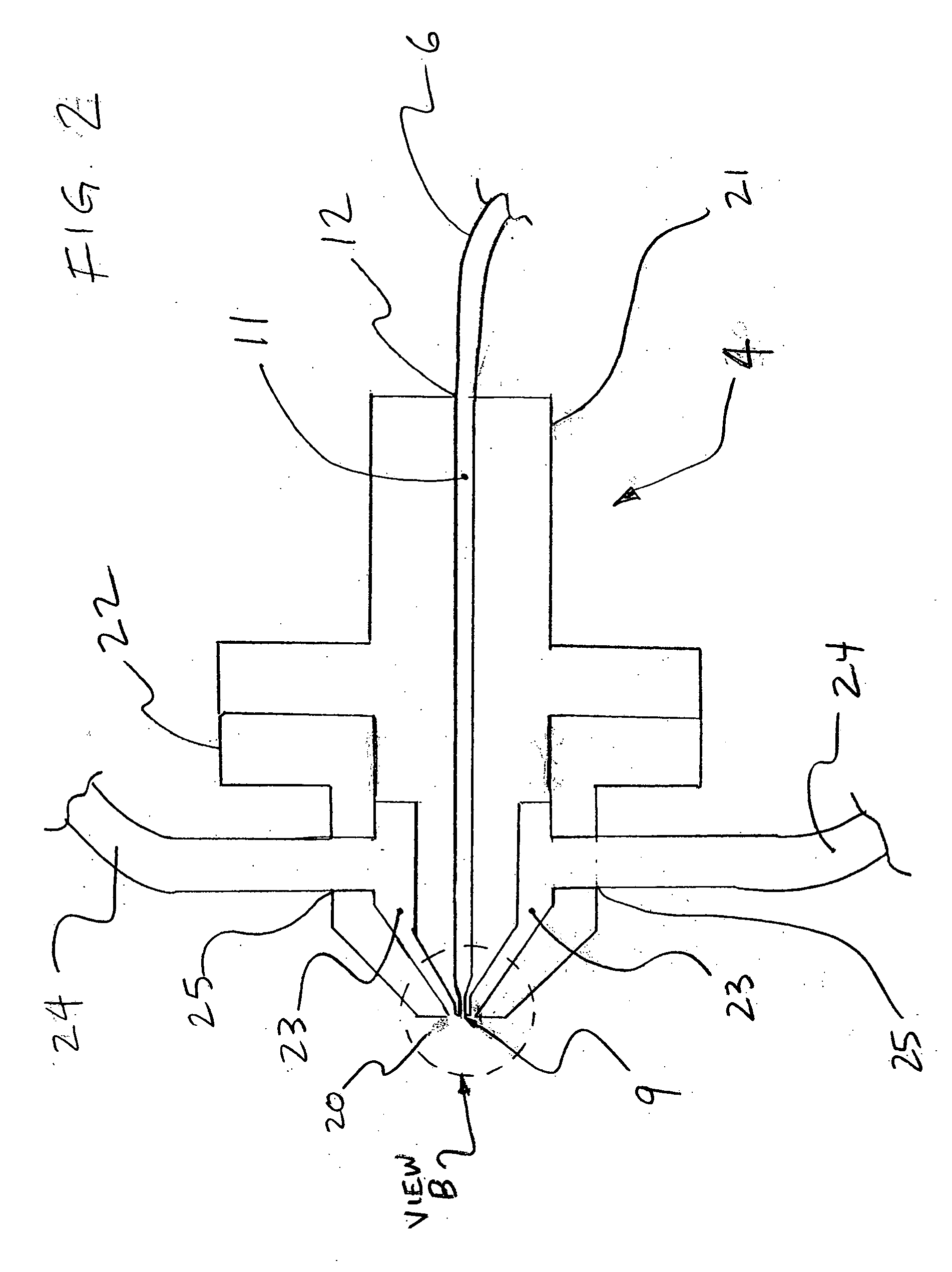

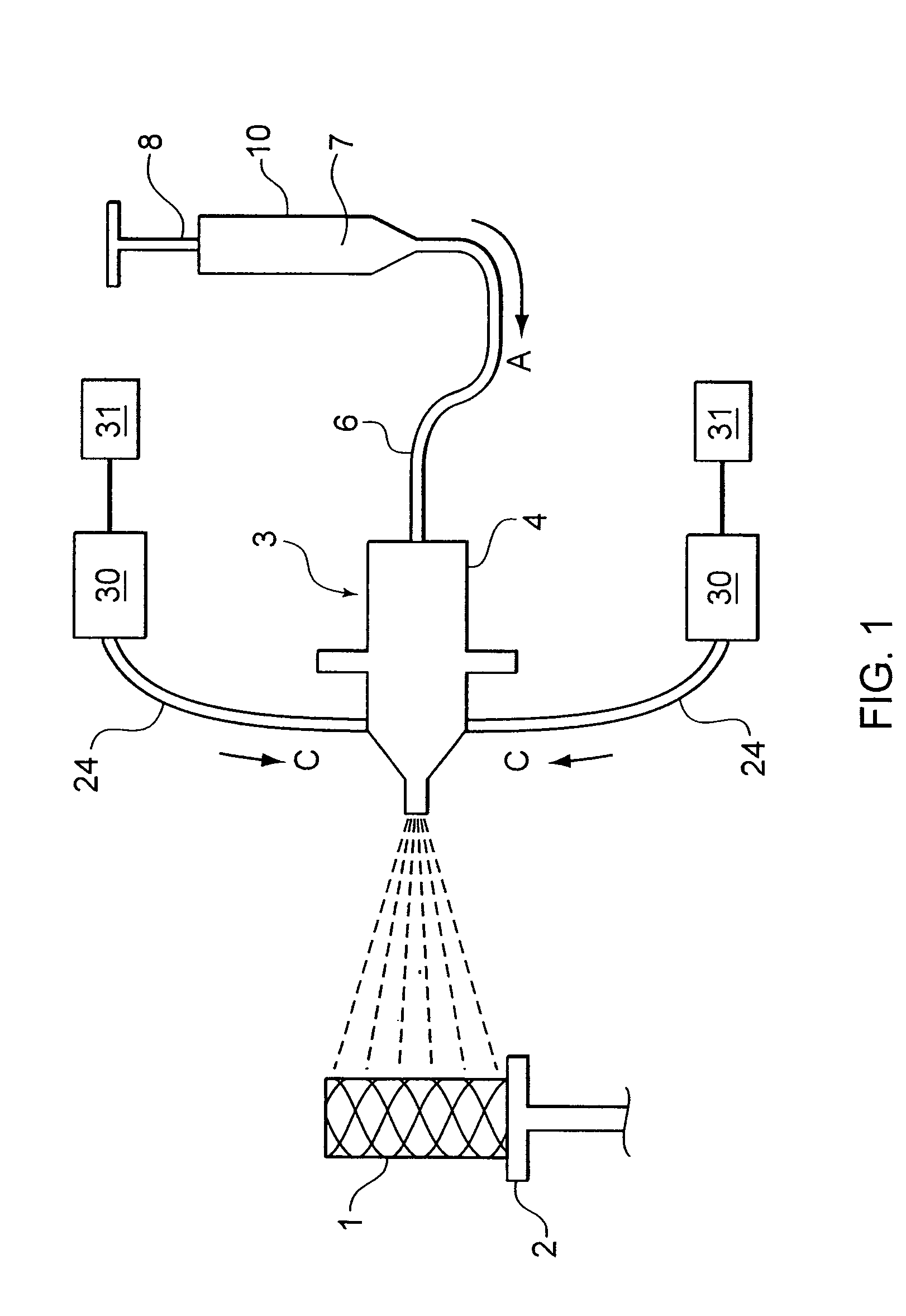

Method for fine bore orifice spray coating of medical devices and pre-filming atomization

ActiveUS20050202156A1Reduce vibrationStabilize spray plumePharmaceutical containersPretreated surfacesSpray coatingDroplet size

A method for spray deposition of small targets, such as medical devices like stents. The method includes the steps of positioning a spray nozzle body, which has a fine bore diameter to pressurize the coating material within the nozzle body, near a medical device, and dampening vibration of the nozzle body during operation by maintaining a steady back pressure in the coating material line sufficient to eliminate or minimize vibration modes from external and internal sources; and stabilizing the spray coating plume. In another embodiment, a coating method is disclosed in which a finer atomized spray droplet size is achieved by pre-filming the coating material onto a flat face before entraining the coating material within the atomizing fluid, which improves manufacturing repeatability, reduces coating variances, and increases therapeutic dosage predictability. In certain embodiments of the invention, the coating materials include therapeutic agents and biologically active materials.

Owner:BOSTON SCI SCIMED INC

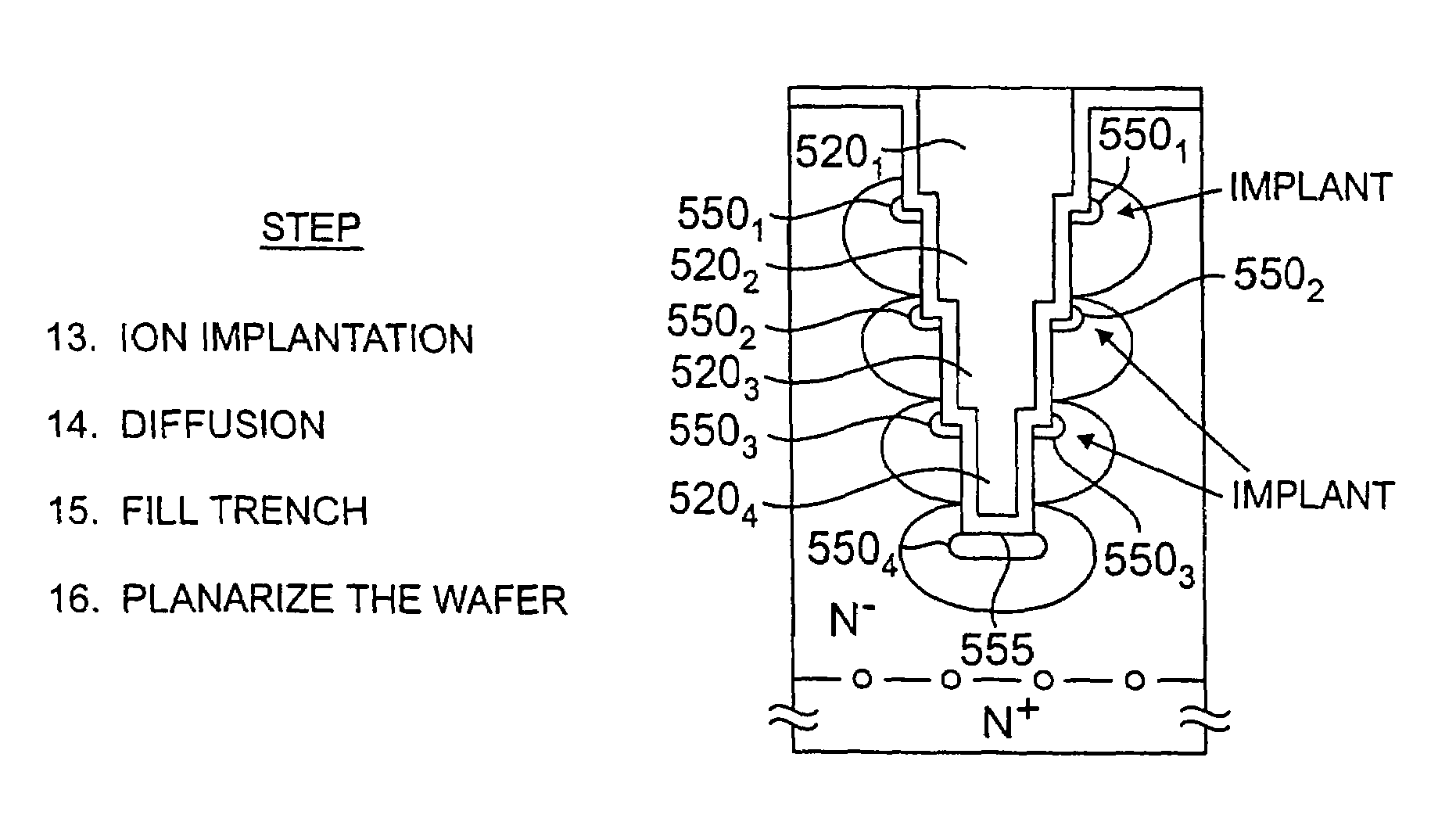

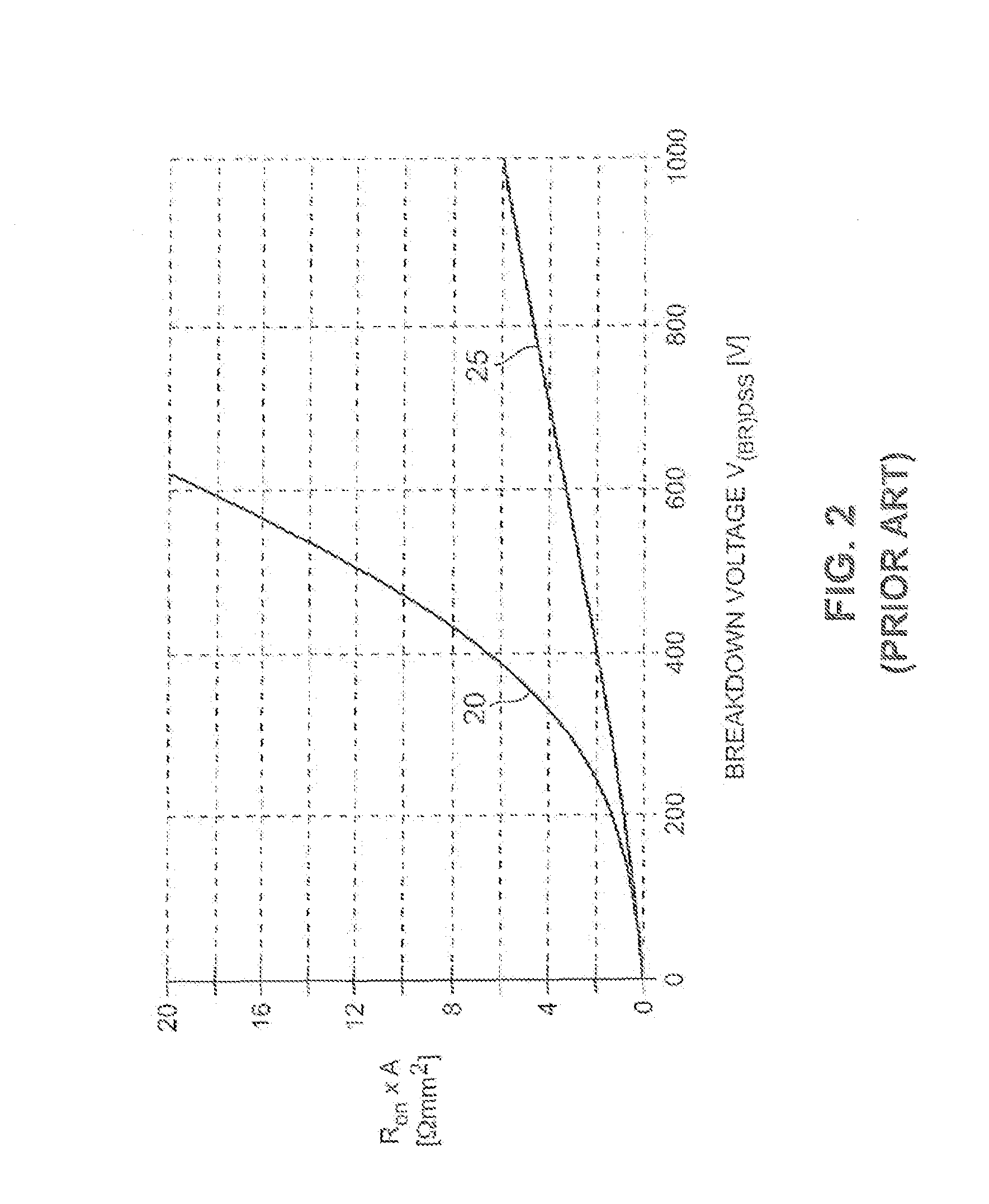

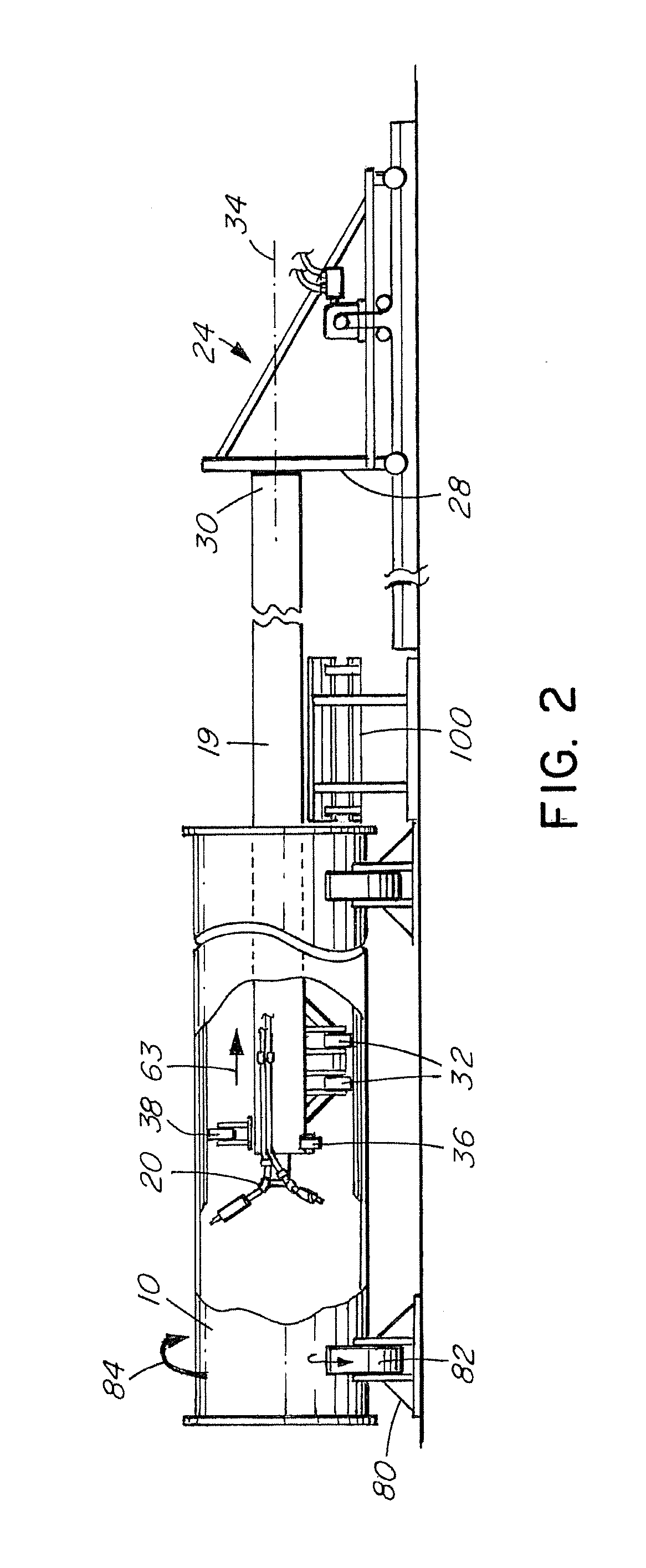

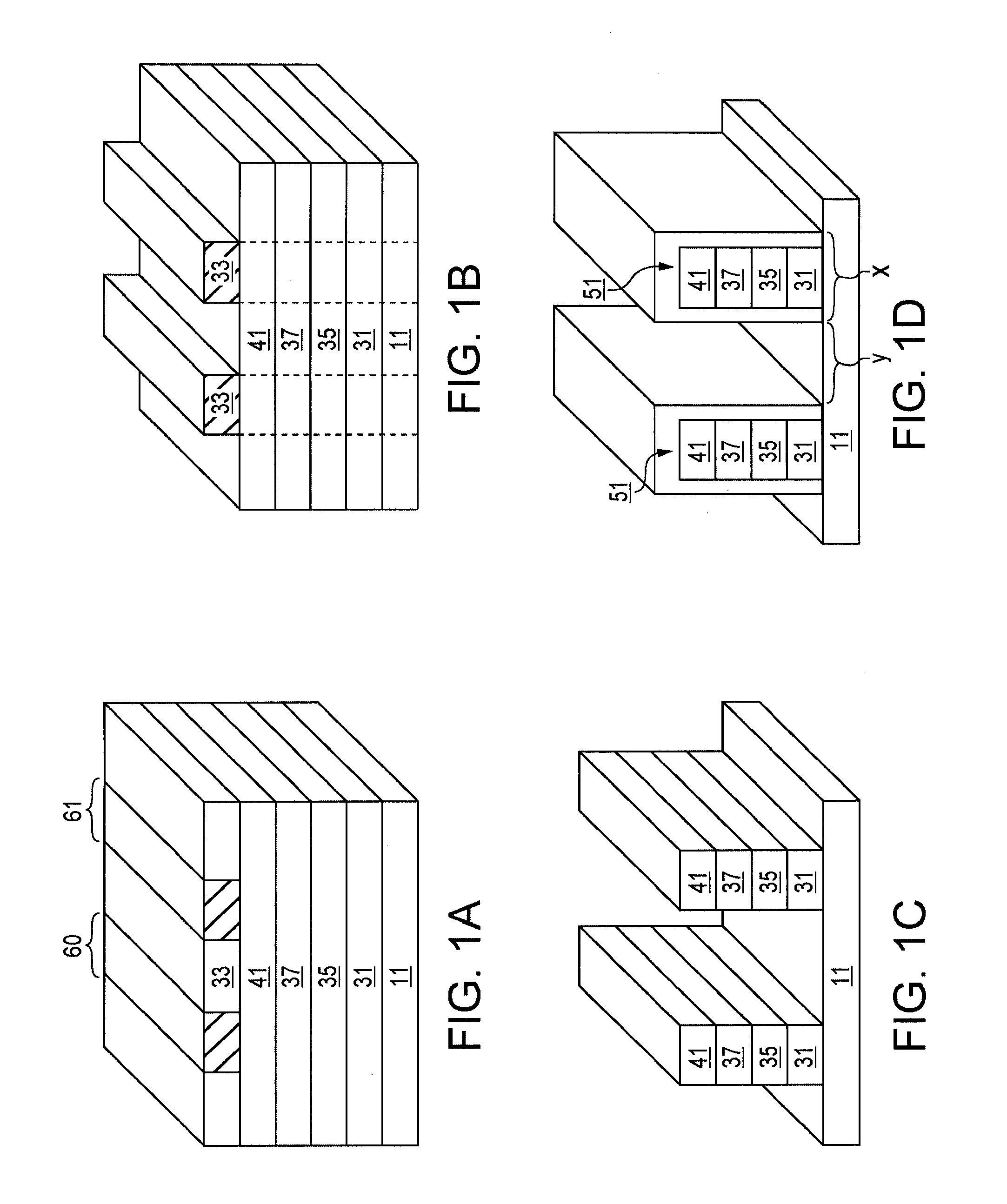

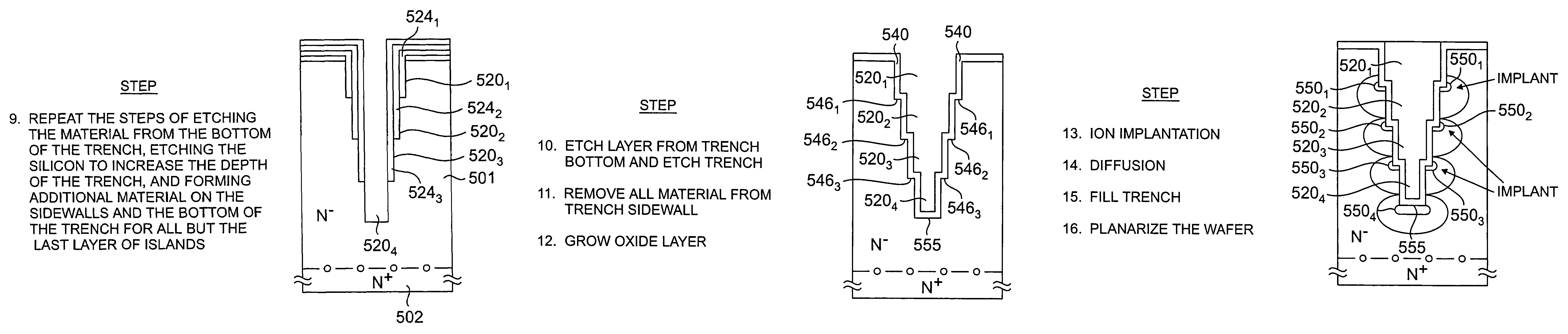

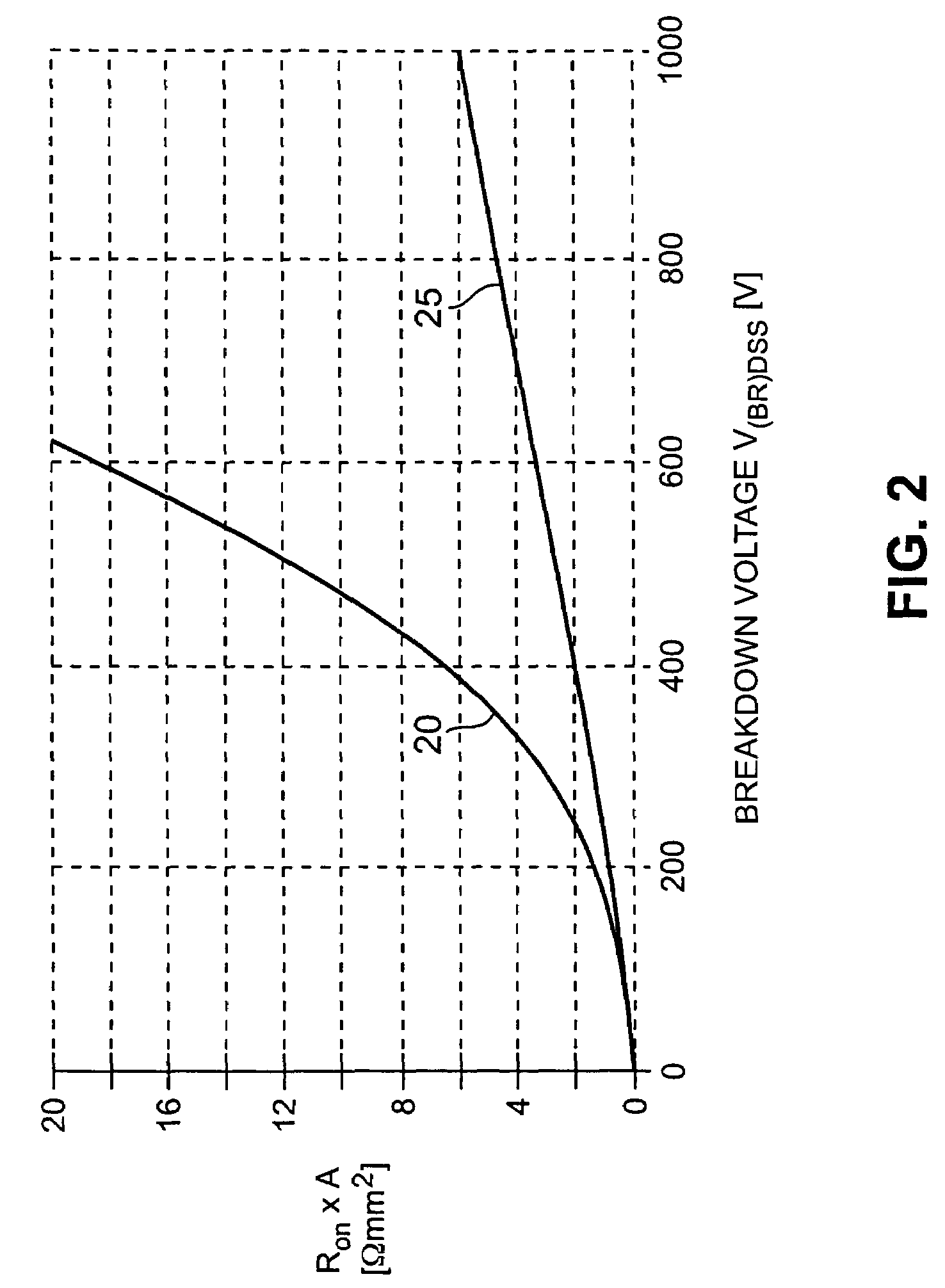

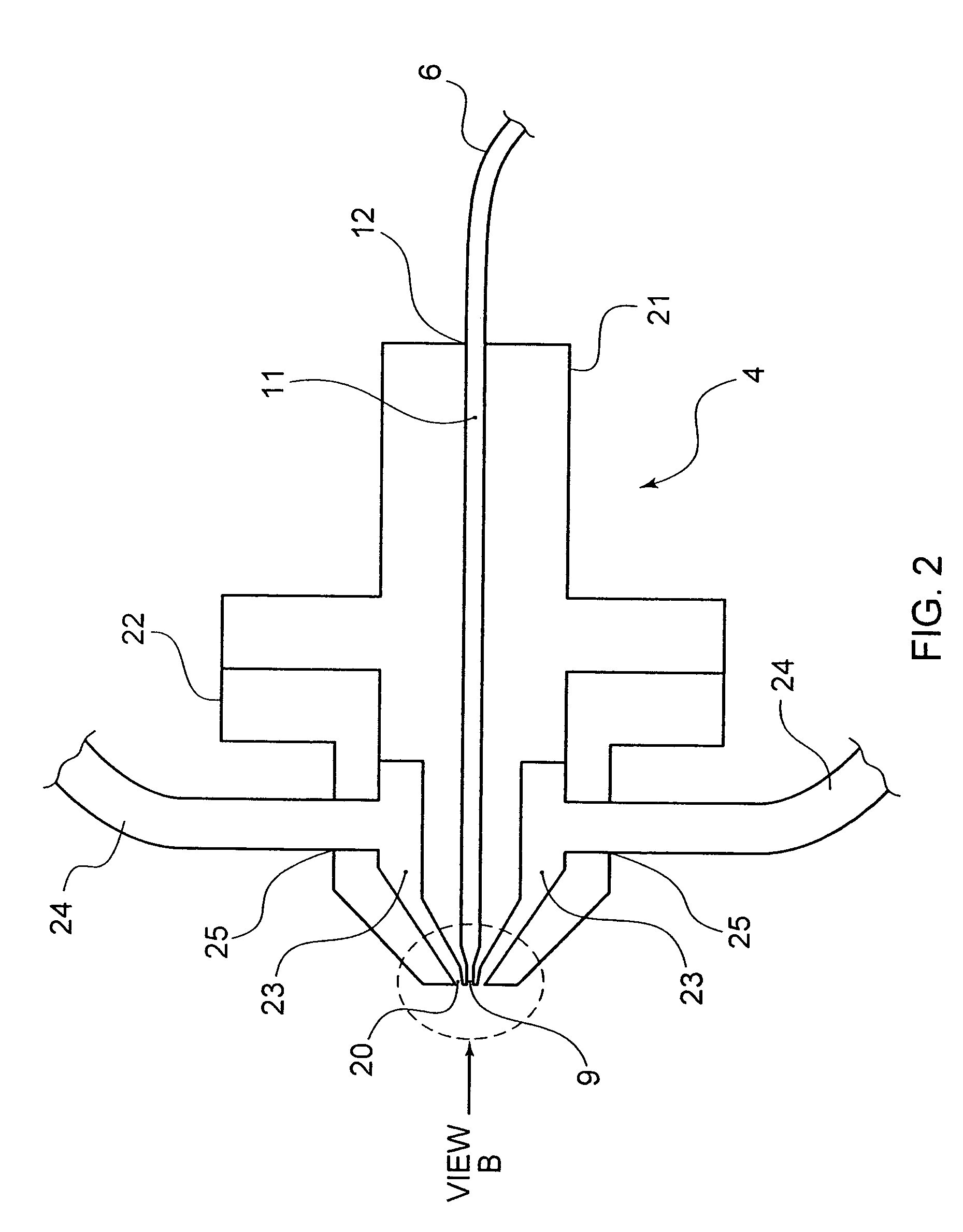

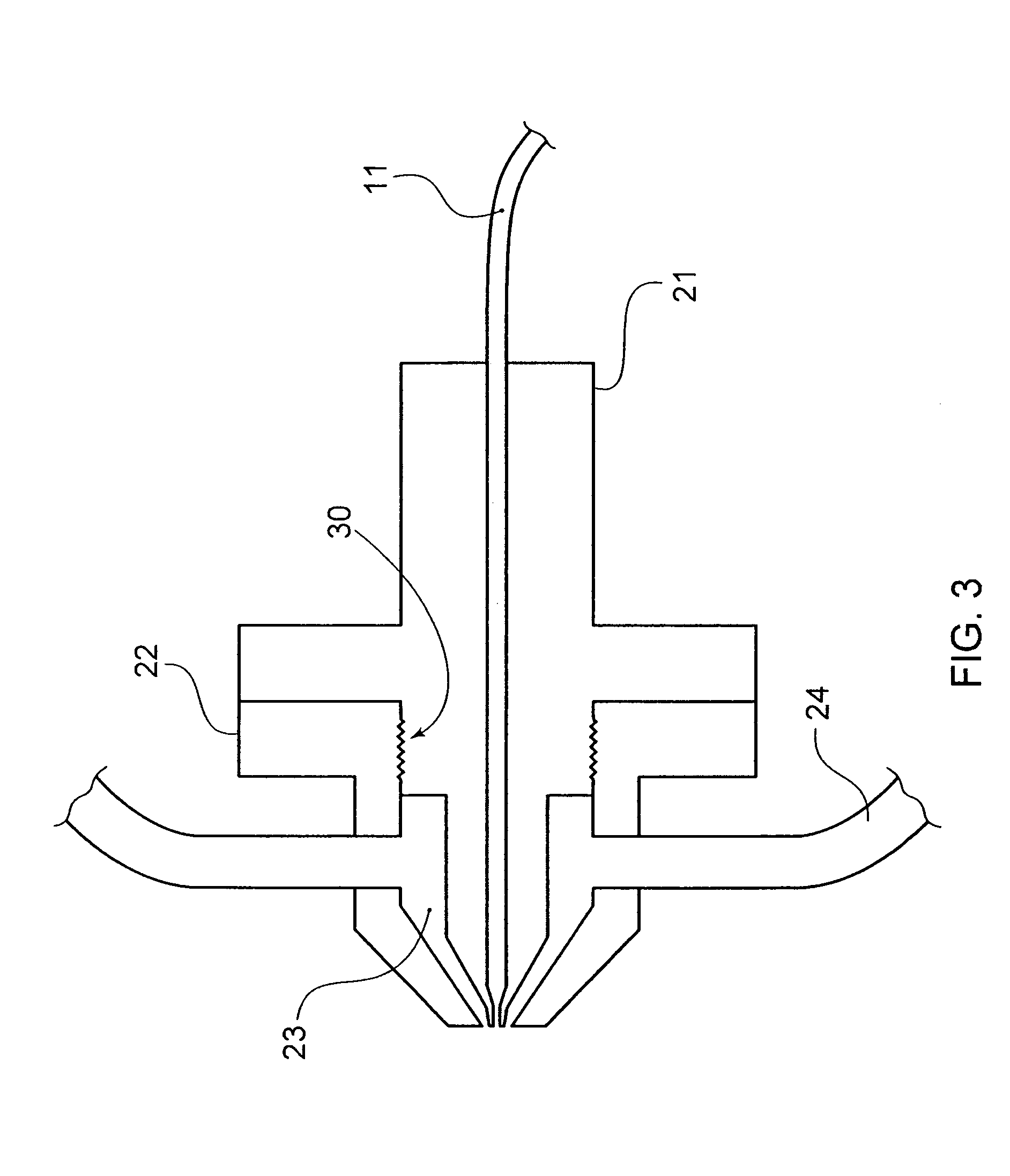

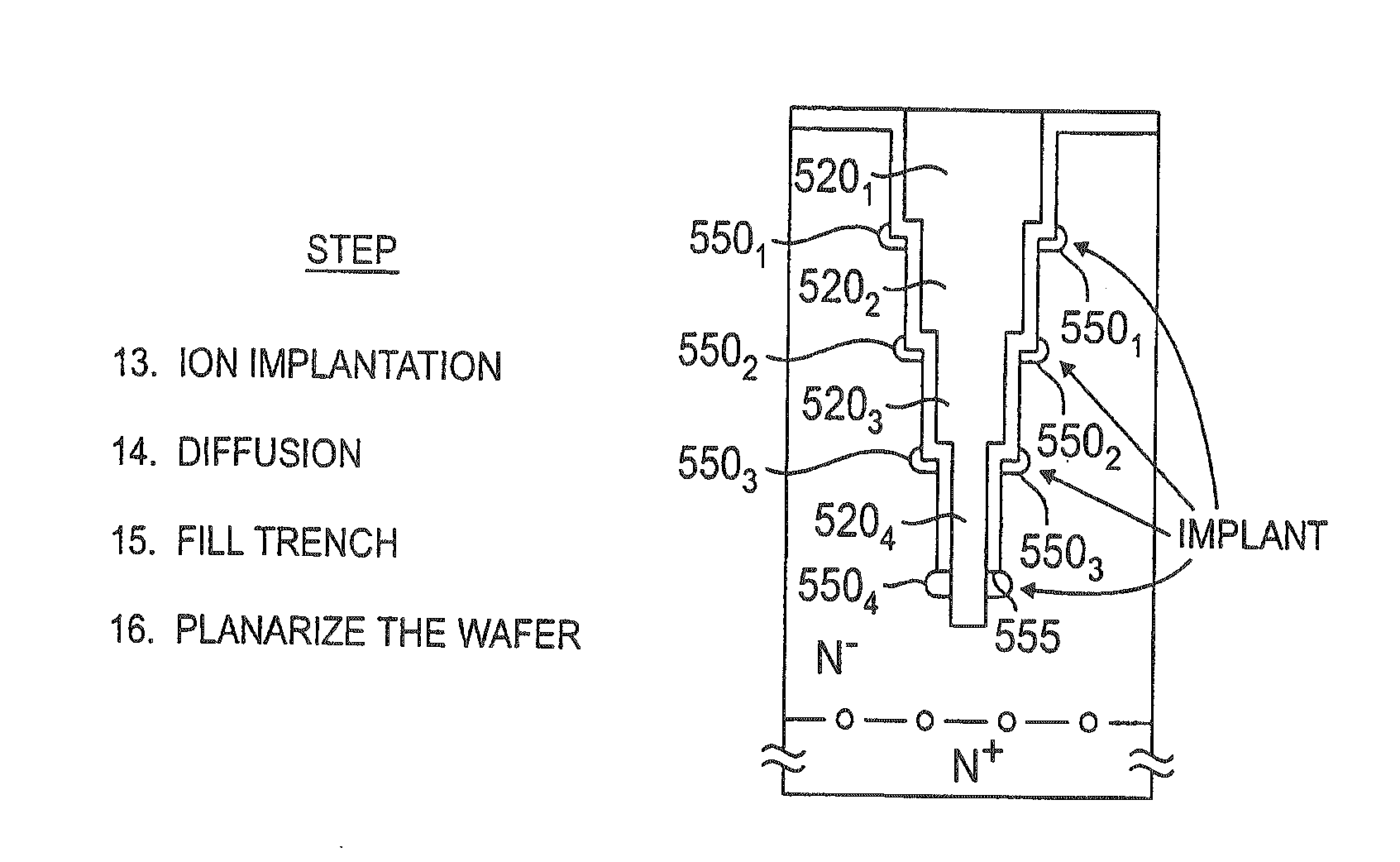

Power semiconductor device having a voltage sustaining region that includes doped columns formed by terraced trenches

InactiveUS7586148B2Semiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceDopant

A method is provided for forming a power semiconductor device. The method begins by providing a substrate of a first conductivity type and forming a voltage sustaining region on the substrate. The voltage sustaining region is formed in the following manner. First, an epitaxial layer is deposited on the substrate. The epitaxial layer has a first or a second conductivity type. Next, at least one terraced trench is formed in the epitaxial layer. The terraced trench has a trench bottom and a plurality of portions that differ in width to define at least one annular ledge therebetween. A barrier material is deposited along the walls and bottom of the trench. A dopant of a conductivity type opposite to the conductivity type of the epitaxial layer is implanted through the barrier material lining the annular ledge and at the trench bottom and into adjacent portions of the epitaxial layer to respectively form at least one annular doped region and another doped region. The dopant is diffused in the annular doped region and the another doped region to cause the regions to overlap one another, whereby a continuous doped column is formed in the epitaxial layer. A filler material is deposited in the terraced trench to substantially fill the terraced trench. Finally, at least one region of conductivity type opposite to the conductivity type of the epitaxial layer is formed over the voltage sustaining region to define a junction therebetween.

Owner:GEN SEMICON

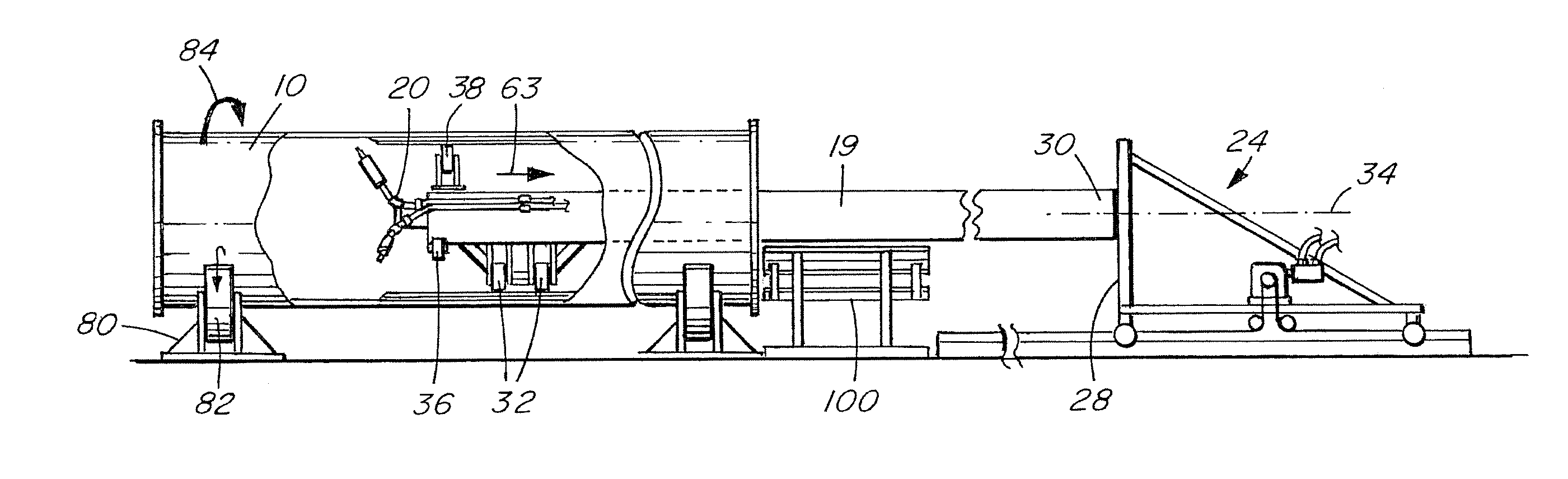

Refractory material removal system and method

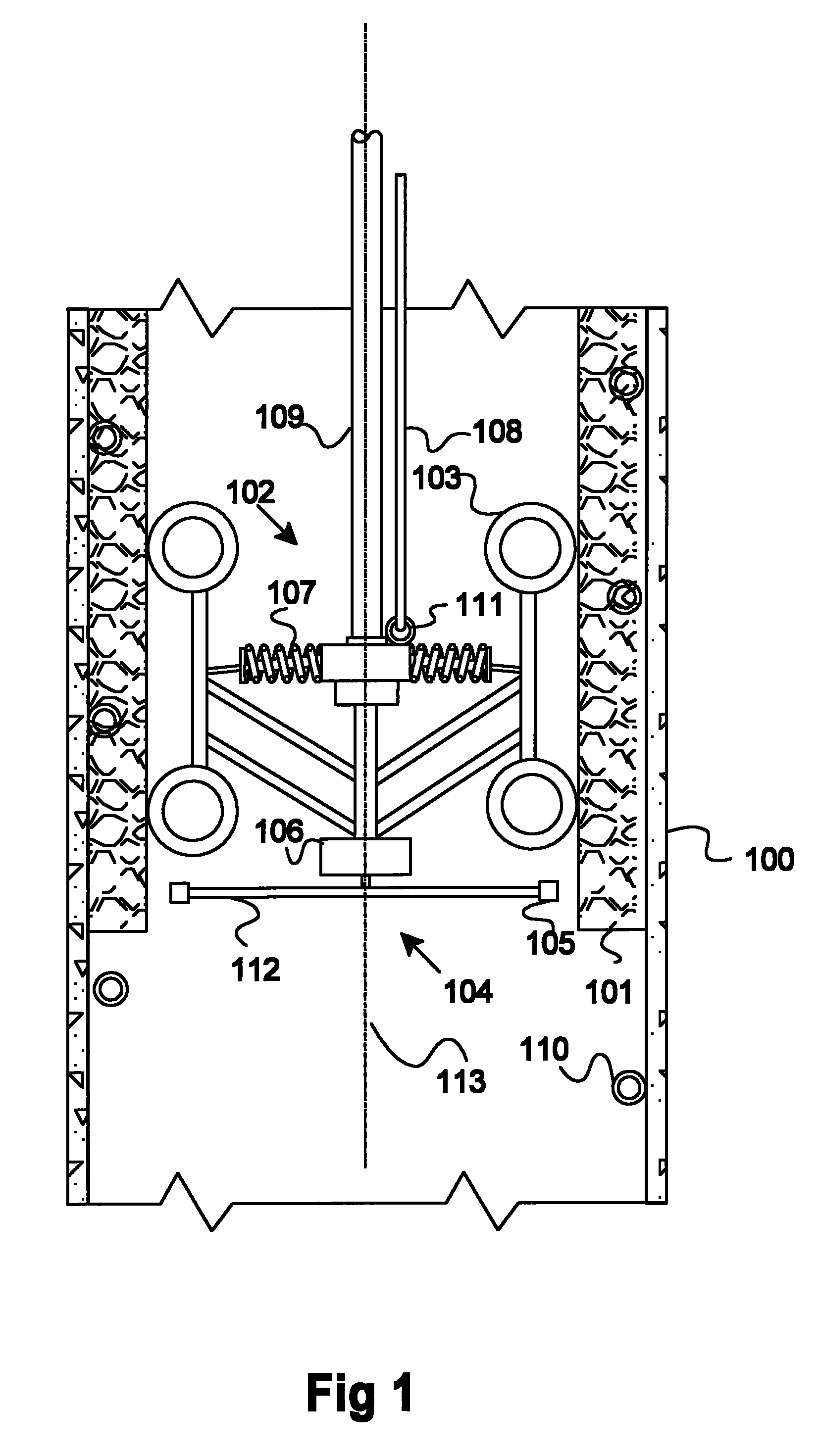

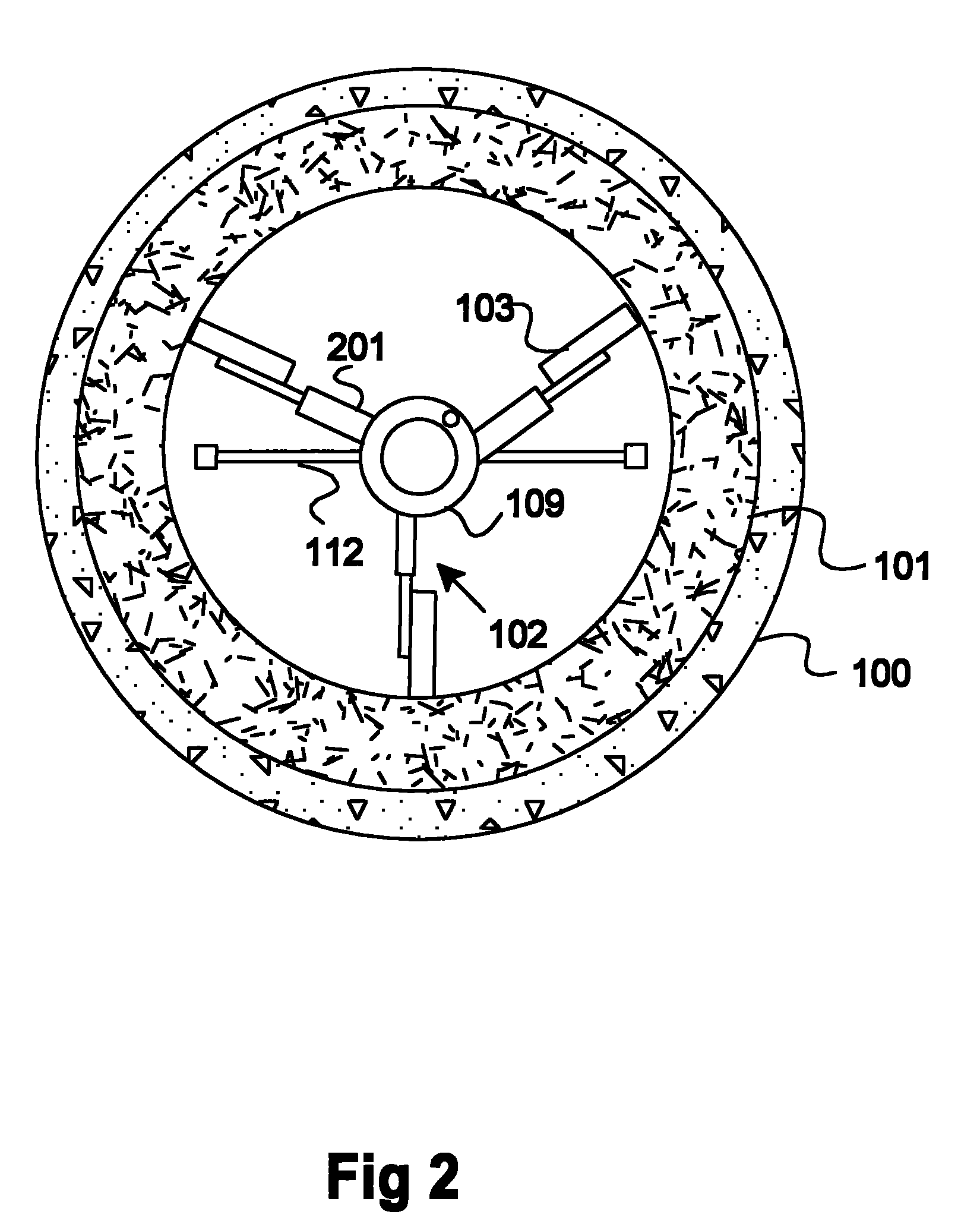

Apparatus for removing refractory lining the inside of a cylindrical structure comprising a traveler received within the structure and movable along its length and having a securing means, a rotatable nozzle assembly connected to the traveler, the nozzle assembly comprising one or more nozzle lines each terminating in a nozzle head that rotates, the nozzle assembly being configured in a manner that each nozzle head is suitably spaced from the refractory to be able to deliver a jet of fluid under pressure to the refractory, a nozzle rotation means for rotating the nozzle assembly, and a conduit means in fluid communication with the nozzle assembly suitable for delivering a flow of fluid to the nozzle assembly under sufficient pressure to cut the refractory material lining the structure. A method employing the apparatus for removing refractory.

Owner:MAC & MAC HYDRODEMOLITION

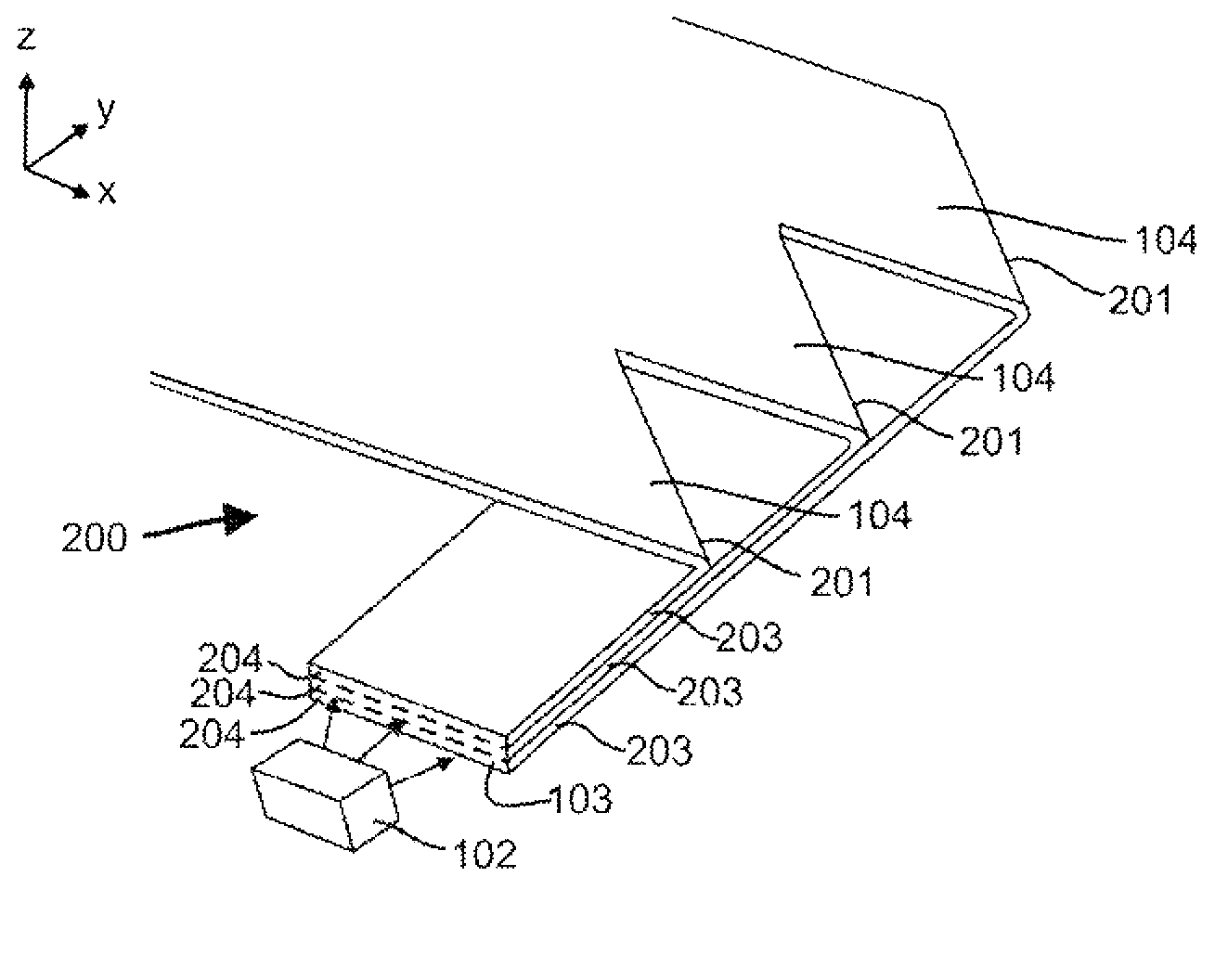

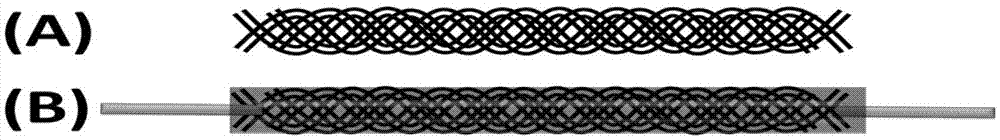

Multi-material polymer filament for three-dimensional printing co-drawn with functional or structural thread

ActiveUS20180087189A1Reduce surface roughnessMaintain geometric accuracyAdditive manufacturing apparatusFilament/thread formingMulti materialFiber

A thermoplastic filament comprising multiple polymers of differing flow temperatures in a geometric arrangement and an interior channel containing a structural or functional thread therein is described. A method for producing such a filament is also described. Because of the difference in flow temperatures, there exists a temperature range at which one polymer is mechanically stable while the other is flowable. This property is extremely useful for creating thermoplastic monofilament feedstock for three-dimensionally printed parts, wherein the mechanically stable polymer enables geometric stability while the flowable polymer can fill gaps and provide strong bonding and homogenization between deposited material lines and layers. These multimaterial filaments can be produced via thermal drawing from a thermoplastic preform, which itself can be three-dimensionally printed. Furthermore, the preform can be printed with precisely controlled and complex geometries, enabling the creation of a filament or fiber with an interior thread contained within the outer, printed filament or fiber. This thread adds structural reinforcement or functional properties, such as electrical conductivity or optical waveguiding, to the filament.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

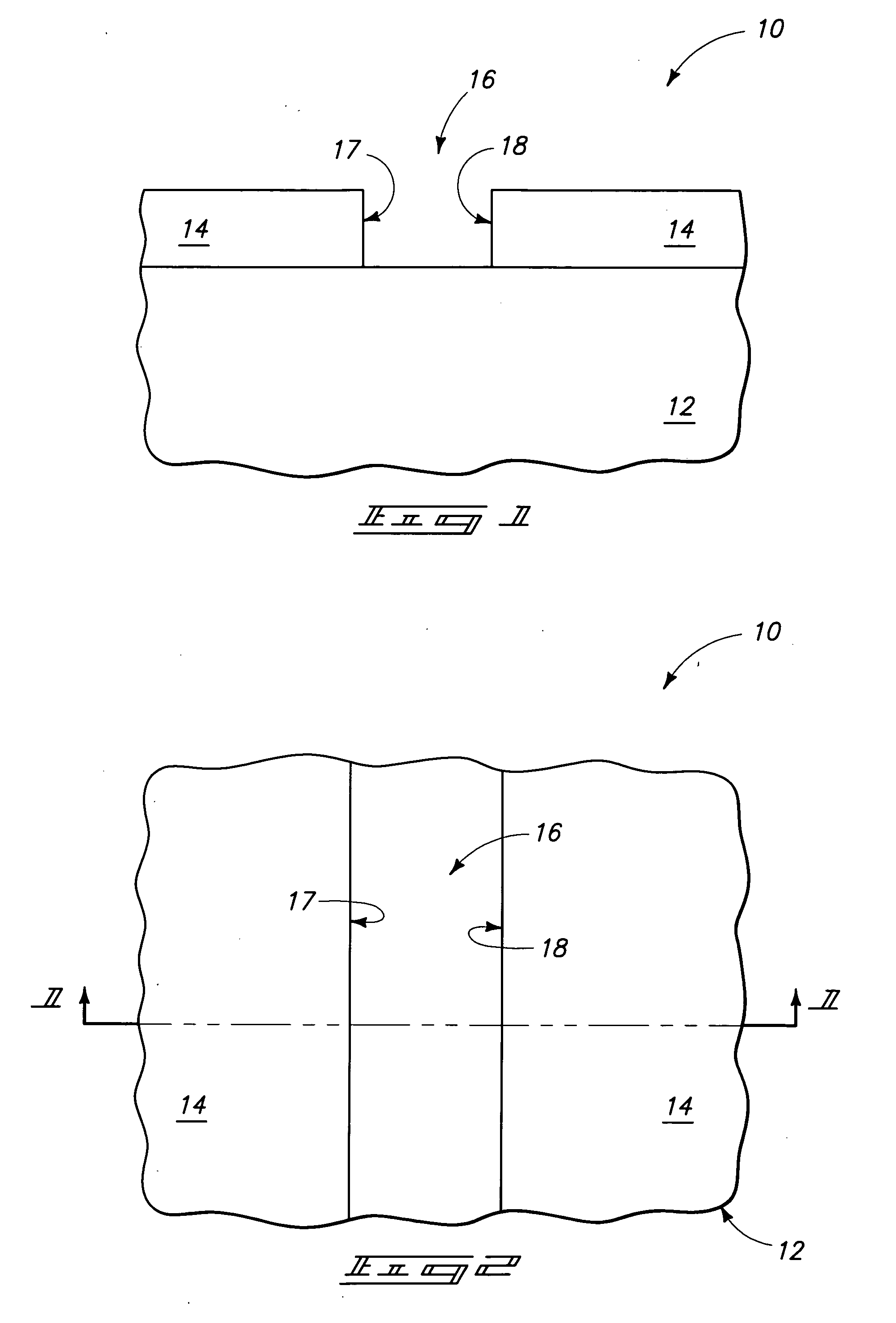

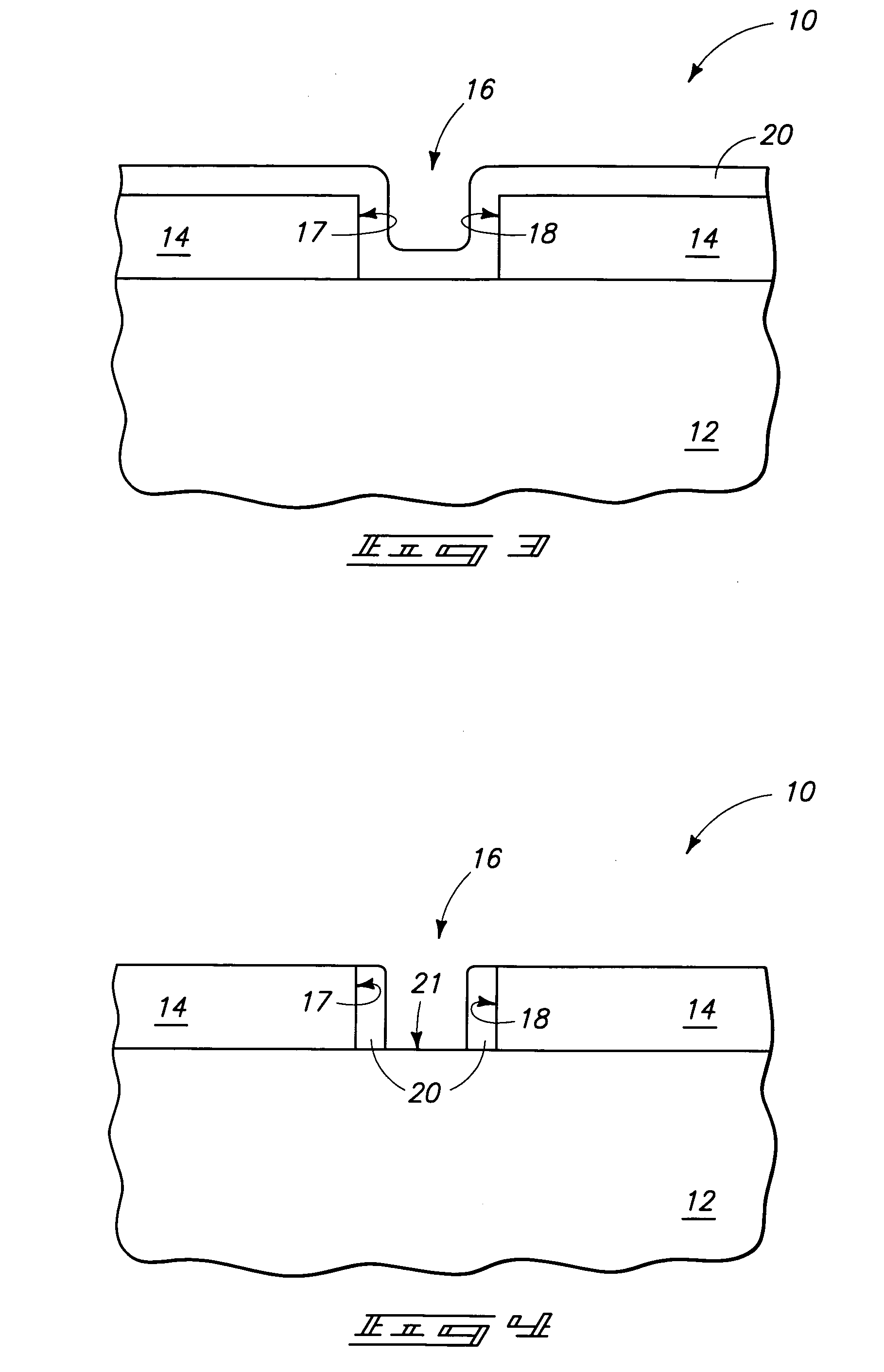

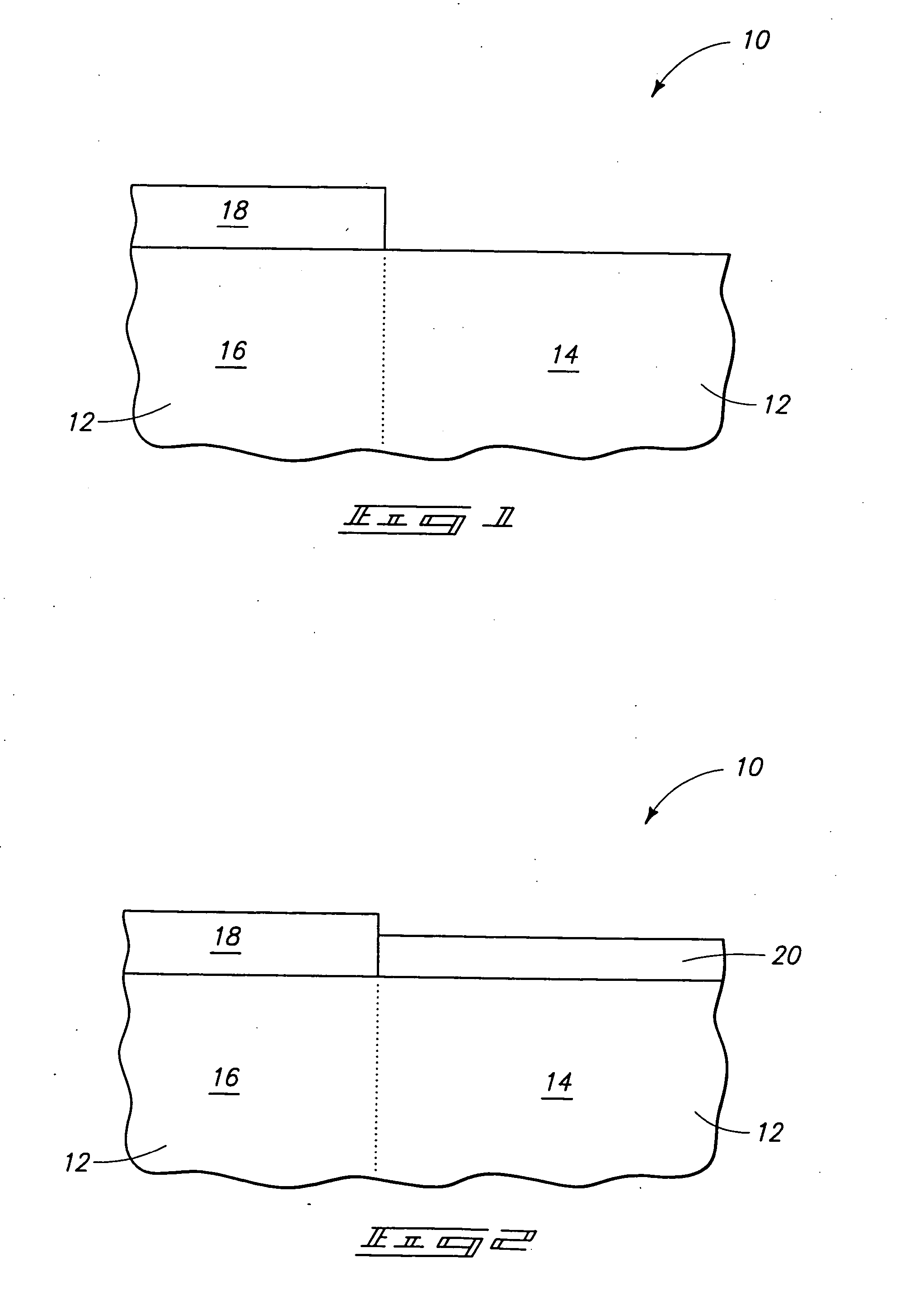

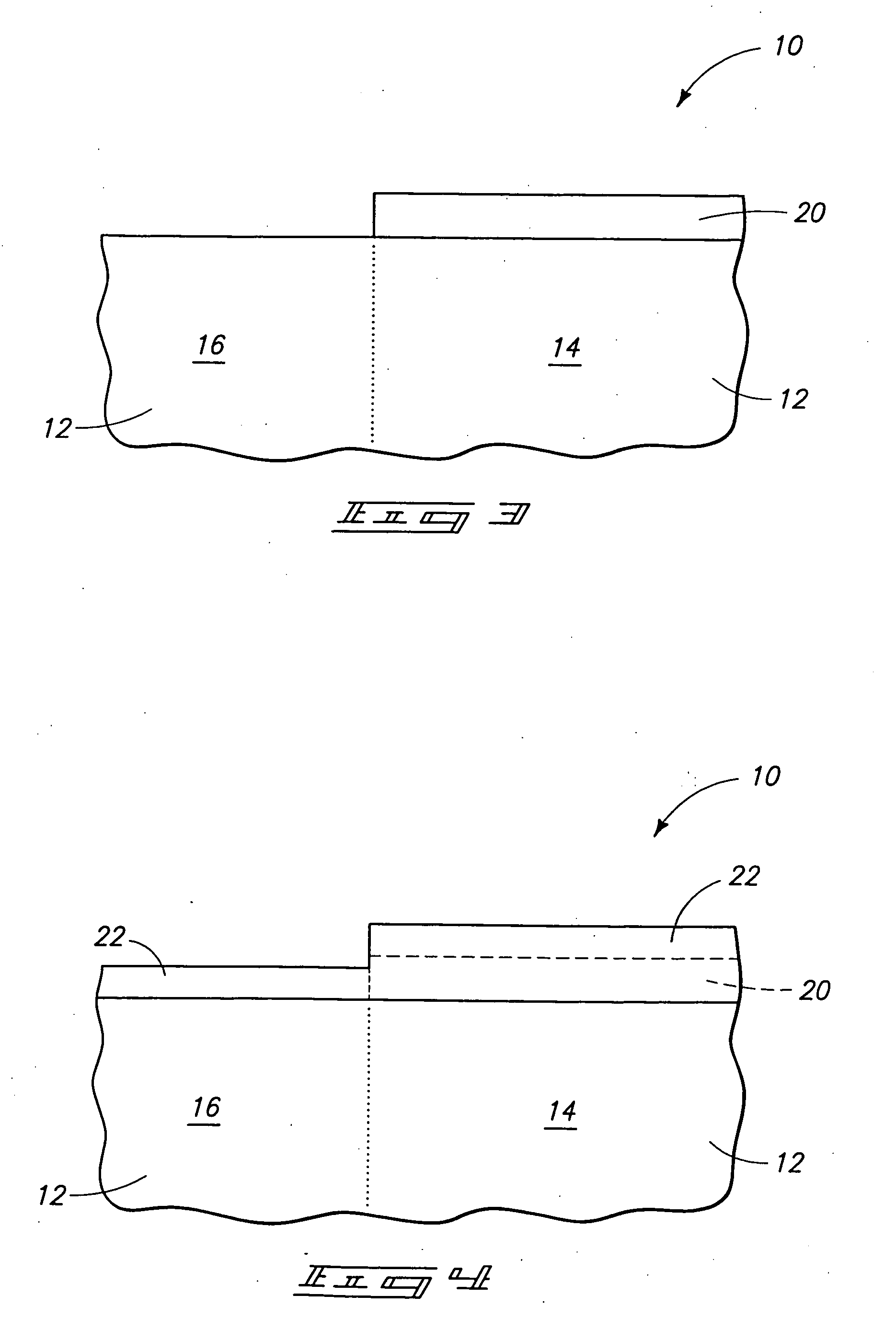

Methods of forming layers comprising epitaxial silicon

ActiveUS20060264010A1Semiconductor/solid-state device manufacturingSemiconductor devicesSingle crystalSilicon

The invention includes methods of forming layers comprising epitaxial silicon. In one implementation, an opening is formed within a first material received over a monocrystalline material. Opposing sidewalls of the opening are lined with a second material, with monocrystalline material being exposed at a base of the second material-lined opening. A silicon-comprising layer is epitaxially grown from the exposed monocrystalline material within the second material-lined opening. At least a portion of the second material lining is in situ removed. Other aspects and implementations are contemplated.

Owner:MICRON TECH INC

Methods of forming layers comprising epitaxial silicon

ActiveUS20060046440A1Semiconductor/solid-state device manufacturingSemiconductor devicesSingle crystalSilicon

The invention includes methods of forming layers comprising epitaxial silicon. In one implementation, an opening is formed within a first material received over a monocrystalline material. Opposing sidewalls of the opening are lined with a second material, with monocrystalline material being exposed at a base of the second material-lined opening. A silicon-comprising layer is epitaxially grown from the exposed monocrystalline material within the second material-lined opening. At least a portion of the second material lining is in situ removed. Other aspects and implementations are contemplated.

Owner:MICRON TECH INC

Stone material line polisher and polishing method thereof

ActiveCN105108629AHigh degree of automationQuickly achieve coarse grindingEdge grinding machinesPolishing machinesEngineeringMaterial line

The invention discloses a stone material line polisher. The stone material line polisher comprises a rack. Material troughs are installed on the rack. Abrasive used for conducting contact polishing on the face to be polished of stone material is contained in the material troughs. A vertical slide seat is further installed on the rack vertically in a sliding mode. The vertical slide seat is connected with a vertical driving device. A clamping assembly transversely clamping or unclamping the stone material is installed on the vertical slide seat. The stone material clamped by the clamping assembly is located in the material troughs. The material troughs are driven by a horizontal reciprocating driving device to slide longitudinally in a reciprocating mode, or the clamping assembly is driven by the horizontal reciprocating driving device to slide longitudinally in a reciprocating mode. According to the polisher, rapid polishing of the stone material can be achieved, and meanwhile, rapid discharge is further achieved.

Owner:湖南省恒鑫新材料科技有限公司

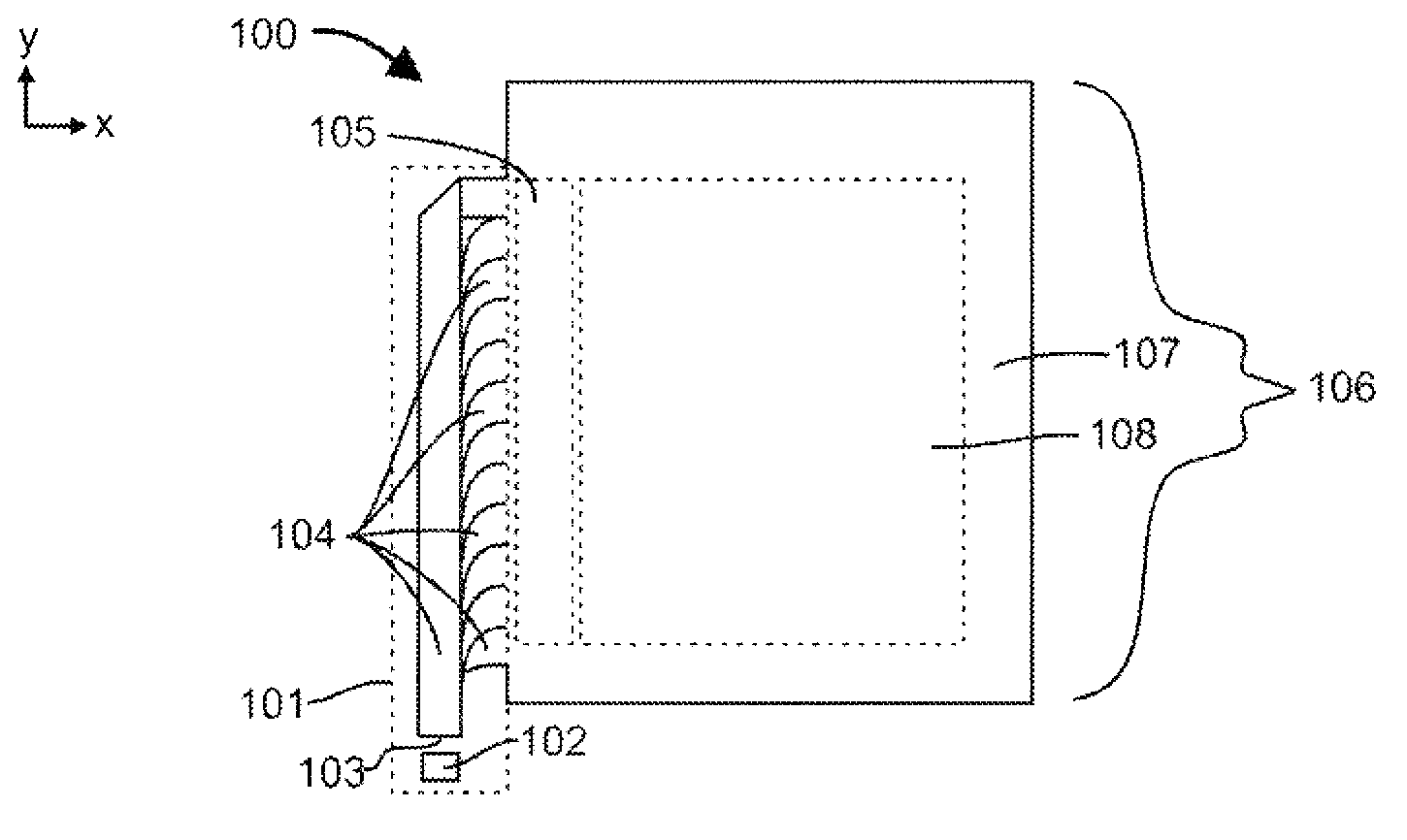

Sign comprising a film-based lightguide

InactiveCN102918435APoint-like light sourceEnergy saving control techniquesGraphicsAbsorbent material

A device includes a light transmitting film defining a lightguide region. A first region is defined within the lightguide region representing a region of one or more of an indicia, a graphic, and an image that is visible by light extraction when illuminated by light propagating within the film in a waveguide condition, wherein the first region includes a plurality of light extraction features that redirect a portion of light traveling within the film in a waveguide condition out of a first face of the opposing faces of the film in the first region, and the first region has a luminance less than 50 cd / m2 when illuminated with 1000 lux of diffuse light when disposed on an opening of a light trap box comprising a plurality of walls and a black, light absorbing material lining the plurality of walls. A method of making or producing a device is also disclosed.

Owner:FLEX LIGHTING II

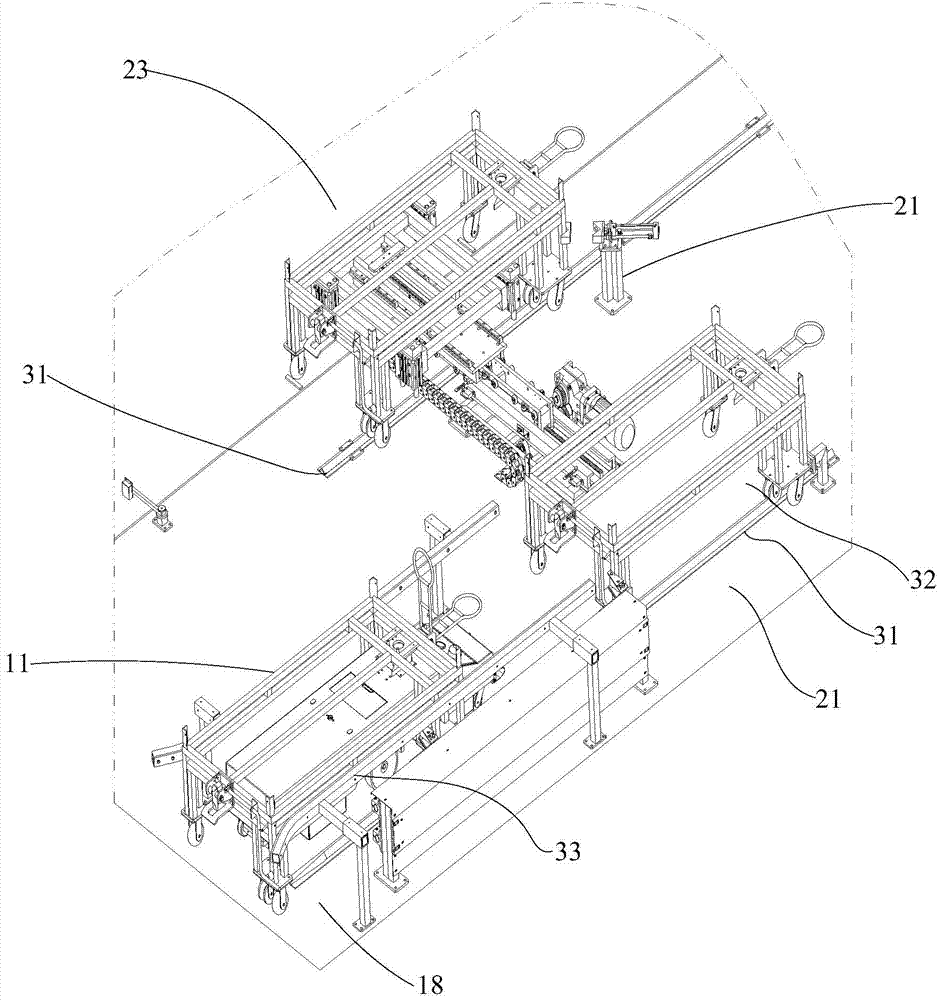

Automatic material line-following conveying system

The invention discloses an automatic material line-following conveying system, and relates to the technical field of material conveying. The automatic material line-following conveying system aims to solve the problem that an automatic material line-following conveying system in the prior art needs a plurality of operating workers and is limited by the space and arrangement of a production workshop. The automatic material line-following conveying system comprises a material trolley set. An automatic guide trolley guides the material trolley at the forefront portion to a first position and is separated from the material trolley set at the first position. A lateral moving unit is arranged on the right side of the material trolley set and can move the material trolley at the forefront portion from the first position to a second position in the moving direction of the material trolley. When the material trolley at the forefront portion is arranged at the second position, a horizontal moving unit is arranged on the right side of the material trolley at the forefront portion and can lift the material trolley at the forefront portion to a certain height and move the material trolley at the forefront portion to a third position. The third position is reserved on a sliding plate, and then the horizontal moving unit returns to an initial position. The automatic material line-following conveying system further comprises a controller and a plurality of sensors electrically connected with the controller, and the sensors are used for determining the positions where the material trolleys are located and sending signals to the controller.

Owner:精诚工科汽车系统有限公司

Method and apparatus for high pressure water treatment of the inside of a pipe section

Material lining the inside surface of a section of pipe is removed by a hydrodemolition nozzle assembly mounted on a working end of an elongated boom. The opposed end of the boom is supported outside the pipe on a movable support for inserting and retracting the boom from the inside of the pipe. The nozzles remove the liner while the working end of the boom is supported by a wheel resting on the liner that has not yet been removed and that rolls along the inside liner as the pipe is made to revolve around the boom. The nozzles are oriented to eject the liner and water downstream and away from the boom.

Owner:MAC & MAC HYDRODEMOLITION

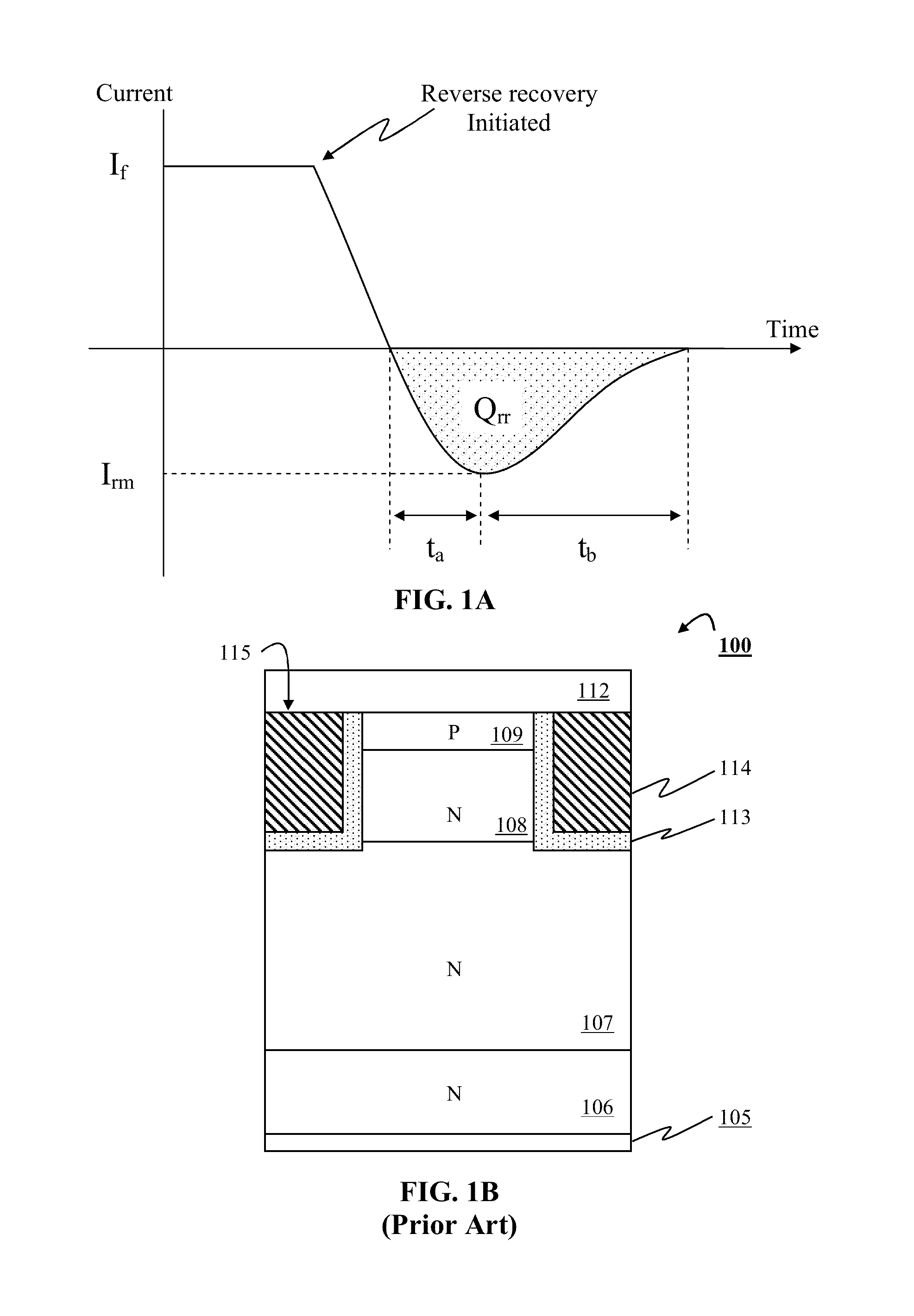

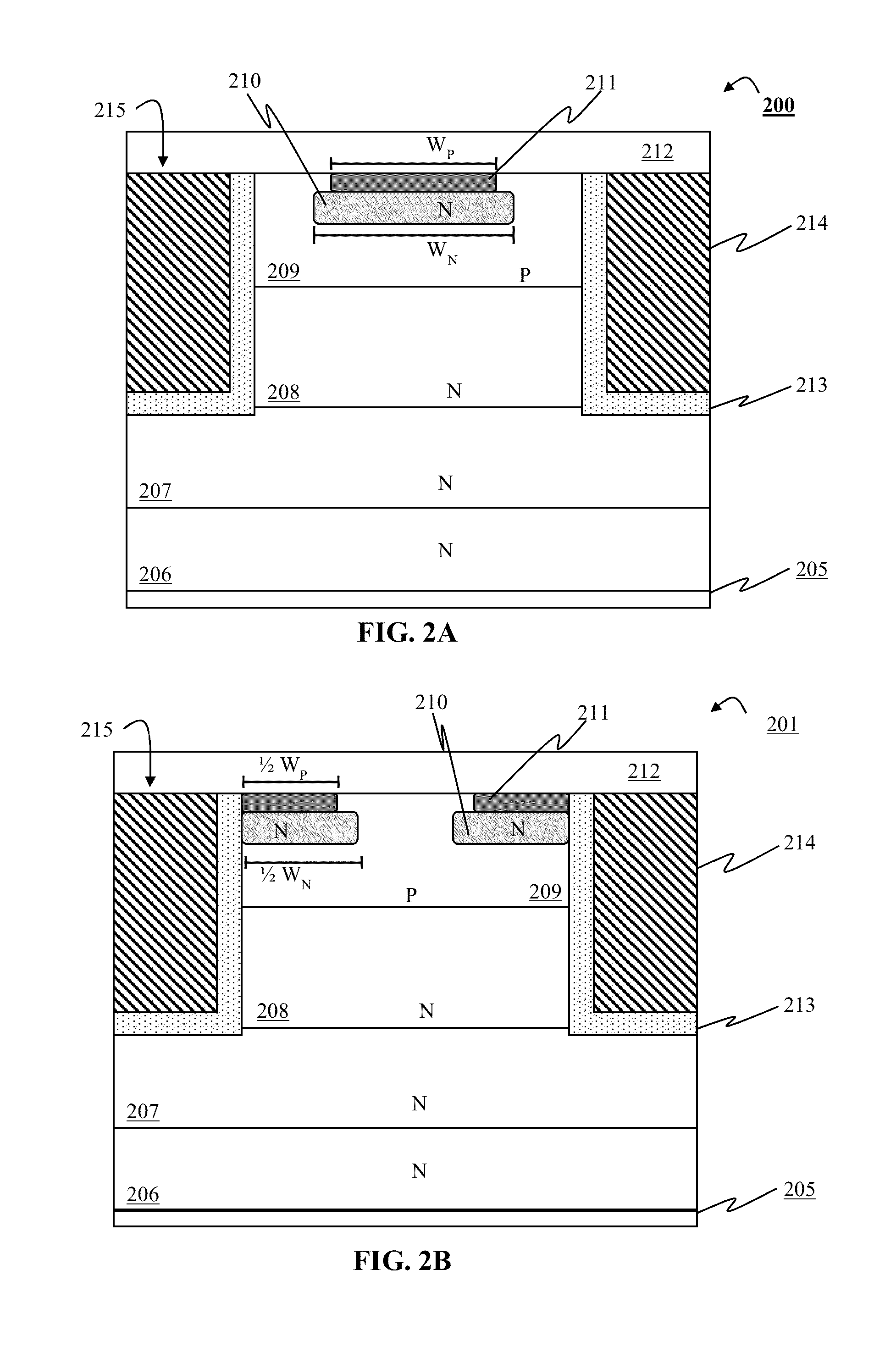

High voltage fast recovery trench diode

ActiveUS8710585B1Semiconductor/solid-state device detailsSolid-state devicesElectricitySubject matter

Aspects of the present disclosure describe high voltage fast recovery trench diodes and methods for make the same. The device may have trenches that extend at least through a top P-layer and an N-barrier layer. A conductive material may be disposed in the trenches with a dielectric material lining the trenches between the conductive material and sidewalls of the trenches. A highly doped P-pocket may be formed in an upper portion of the top P-layer between the trenches. A floating N-pocket may be formed directly underneath the P-pocket. The floating N-pocket may be as wide as or wider than the P-pocket. It is emphasized that this abstract is provided to comply with rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:ALPHA & OMEGA SEMICON INC

Methods of forming a layer comprising epitaxial silicon, and methods of forming field effect transistors

ActiveUS20060051941A1Semiconductor/solid-state device manufacturingSemiconductor devicesSingle crystalField-effect transistor

The invention includes methods of forming layers comprising epitaxial silicon. In one implementation, an opening is formed within a first material received over a monocrystalline material. Opposing sidewalls of the opening are lined with a second material, with monocrystalline material being exposed at a base of the second material-lined opening. A silicon-comprising layer is epitaxially grown from the exposed monocrystalline material within the second material-lined opening. At least a portion of the second material lining is in situ removed. Other aspects and implementations are contemplated.

Owner:MICRON TECH INC

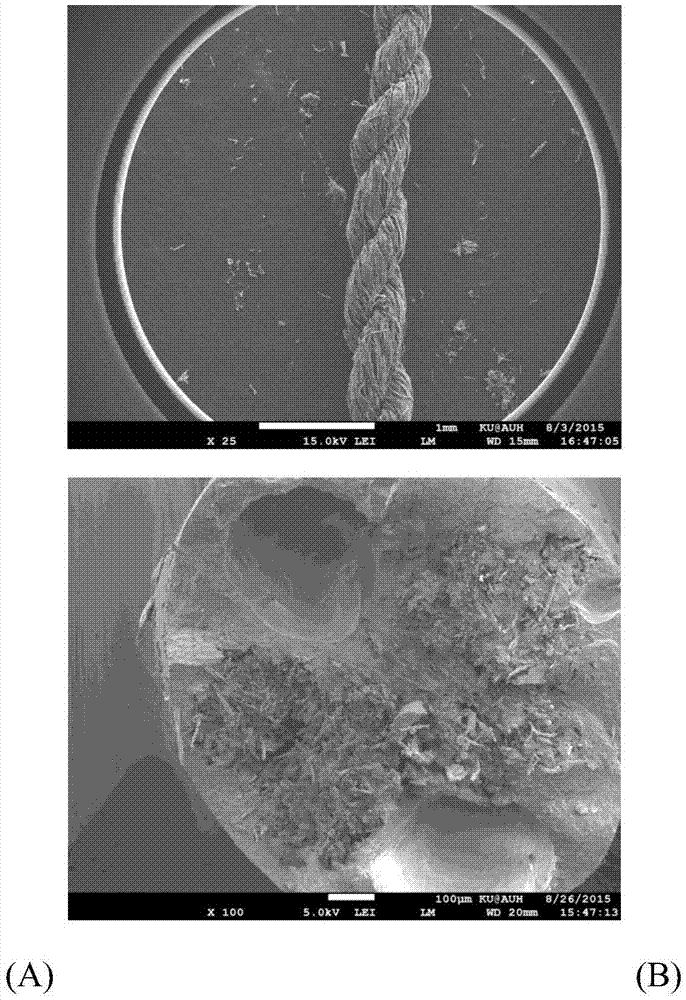

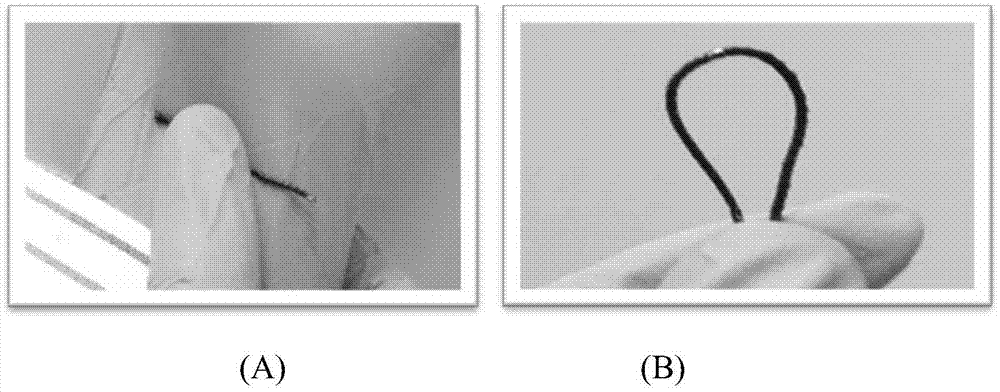

Preparation method of piezoresistance type linear flexibility stress sensor

InactiveCN105444928ASimple preparation processLow costForce measurement using piezo-resistive materialsThroatAdhesive

The invention provides a preparation method of a linear flexibility stress sensor with high sensitivity. The preparation method comprises the steps: 1) performing 0.5-5 hours of splitting processing on a biomass line with a 0.2-5mm diameter under the vacuum or inert atmosphere protection and under the 700-1000DEG C high temperature to prepare linear stress sensitive materials; 2) dividing the linear stress sensitive materials into 0.5-10cm line segments, wherein two ends of each line segment are connected with a 0.03-0.5mm conductive electrode through conductive silver adhesives; and 3) dipping and coating the surface of each stress sensitive material line segment connected with the electrodes with polymethyl siloxane resin, and performing vacuum defoamation and resin solidification to prepare a linear flexibility stress sensor. The linear flexibility stress sensor belongs to the piezoresistance type, and is small in volume and convenient to use, that is, the sensor can be used independently and can also be used after being integrated with textile fabrics. The linear flexibility stress sensor can also be used for acquisition of data of respiration, pulse, heartbeat and throat vibration of a human body, and can effectively monitor the physiological signals related with human health.

Owner:CHONGQING UNIV

Six-series high-surface mobile phone aluminum alloy shell and production method of aluminum alloy thin plate

The invention provides a six-series high-surface mobile phone aluminum alloy shell. The six-series high-surface mobile phone aluminum alloy shell is obtained by carrying out stamping, machining and oxidization on an aluminum alloy plate, and the aluminum alloy is an aluminum alloy 6061. Starting from the raw material of the aluminum alloy plate of the mobile phone aluminum alloy shell, by combining the strength requirement of the mobile phone aluminum alloy shell and the appearance requirement of the high surface, special selection is carried out on the type of the aluminum alloy, the components of the aluminum alloy are creatively selected and combined and supplemented by specific proportion contents, the specific aluminum alloy 6061 is selected as the aluminum alloy plate, and thereforethe material line defect and the black line defect are eliminated from the basic aluminum alloy plate, the rejection rate caused by the material line defect and the black line defect is greatly reduced, the working procedures are simple and suitable for application and popularization of industrial mass production, and important actual significance and market prospects are achieved.

Owner:SOUTHWEST ALUMINUM GRP

Method for providing electrical connections to spaced conductive lines

ActiveUS20100295183A1Semiconductor/solid-state device detailsSolid-state devicesElectrical conductorElectrical connection

An integrated circuit and a method of formation provide a contact area formed at an angled end of at least one linearly extending conductive line. In an embodiment, conductive lines with contact landing pads are formed by patterning lines in a mask material, cutting at least one of the material lines to form an angle relative to the extending direction of the material lines, forming extensions from the angled end faces of the mask material, and patterning an underlying conductor by etching using said material lines and extension as a mask. In another embodiment, at least one conductive line is cut at an angle relative to the extending direction of the conductive line to produce an angled end face, and an electrical contact landing pad is formed in contact with the angled end face.

Owner:MICRON TECH INC

Power semiconductor device having a voltage sustaining region that includes terraced trench with continuous doped columns formed in an epitaxial layer

InactiveUS7084455B2Semiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceDopant

A method is provided for forming a power semiconductor device. The method begins by providing a substrate of a first conductivity type and forming a voltage sustaining region on the substrate. The voltage sustaining region is formed in the following manner. First, an epitaxial layer is deposited on the substrate. The epitaxial layer has a first or a second conductivity type. Next, at least one terraced trench is formed in the epitaxial layer. The terraced trench has a trench bottom and a plurality of portions that differ in width to define at least one annular ledge therebetween. A barrier material is deposited along the walls and bottom of the trench. A dopant of a conductivity type opposite to the conductivity type of the epitaxial layer is implanted through the barrier material lining the annular ledge and at the trench bottom and into adjacent portions of the epitaxial layer to respectively form at least one annular doped region and another doped region. The dopant is diffused in the annular doped region and the another doped region to cause the regions to overlap one another, whereby a continuous doped column is formed in the epitaxial layer. A filler material is deposited in the terraced trench to substantially fill the terraced trench. Finally, at least one region of conductivity type opposite to the conductivity type of the epitaxial layer is formed over the voltage sustaining region to define a junction therebetween.

Owner:GEN SEMICON

Method for fine bore orifice spray coating of medical devices and pre-filming atomization

ActiveUS6979473B2Stable spray plumeIncrease back pressurePharmaceutical containersPretreated surfacesSpray coatingDroplet size

A method for spray deposition of small targets, such as medical devices like stents. The method includes the steps of positioning a spray nozzle body, which has a fine bore diameter to pressurize the coating material within the nozzle body, near a medical device, and dampening vibration of the nozzle body during operation by maintaining a steady back pressure in the coating material line sufficient to eliminate or minimize vibration modes from external and internal sources; and stabilizing the spray coating plume. In another embodiment, a coating method is disclosed in which a finer atomized spray droplet size is achieved by pre-filming the coating material onto a flat face before entraining the coating material within the atomizing fluid, which improves manufacturing repeatability, reduces coating variances, and increases therapeutic dosage predictability. In certain embodiments of the invention, the coating materials include therapeutic agents and biologically active materials.

Owner:BOSTON SCI SCIMED INC

Method for fabricating a power semiconductor device having a voltage sustaining layer with a terraced trench facilitating formation of floating islands

InactiveUS20080142880A1Semiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceDopant

A method is provided for forming a power semiconductor device. The method begins by providing a substrate of a second conductivity type and then forming a voltage sustaining region on the substrate. The voltage sustaining region is formed by depositing an epitaxial layer of a first conductivity type on the substrate and forming at least one terraced trench in the epitaxial layer. The terraced trench has a plurality of portions that differ in width to define at least one annular ledge therebetween. A barrier material is deposited along the walls of the trench. A dopant of a second conductivity type is implanted through the barrier material lining the annular ledge and said trench bottom and into adjacent portions of the epitaxial layer. The dopant is diffused to form at least one annular doped region in the epitaxial layer and at least one other region located below the annular doped region. A filler material is deposited in the terraced trench to substantially fill the trench, thus completing the voltage sustaining region. At least one region of the second conductivity type is formed over the voltage sustaining region to define a junction therebetween.

Owner:VISHAY GENERAL SEMICONDUCTOR LLC

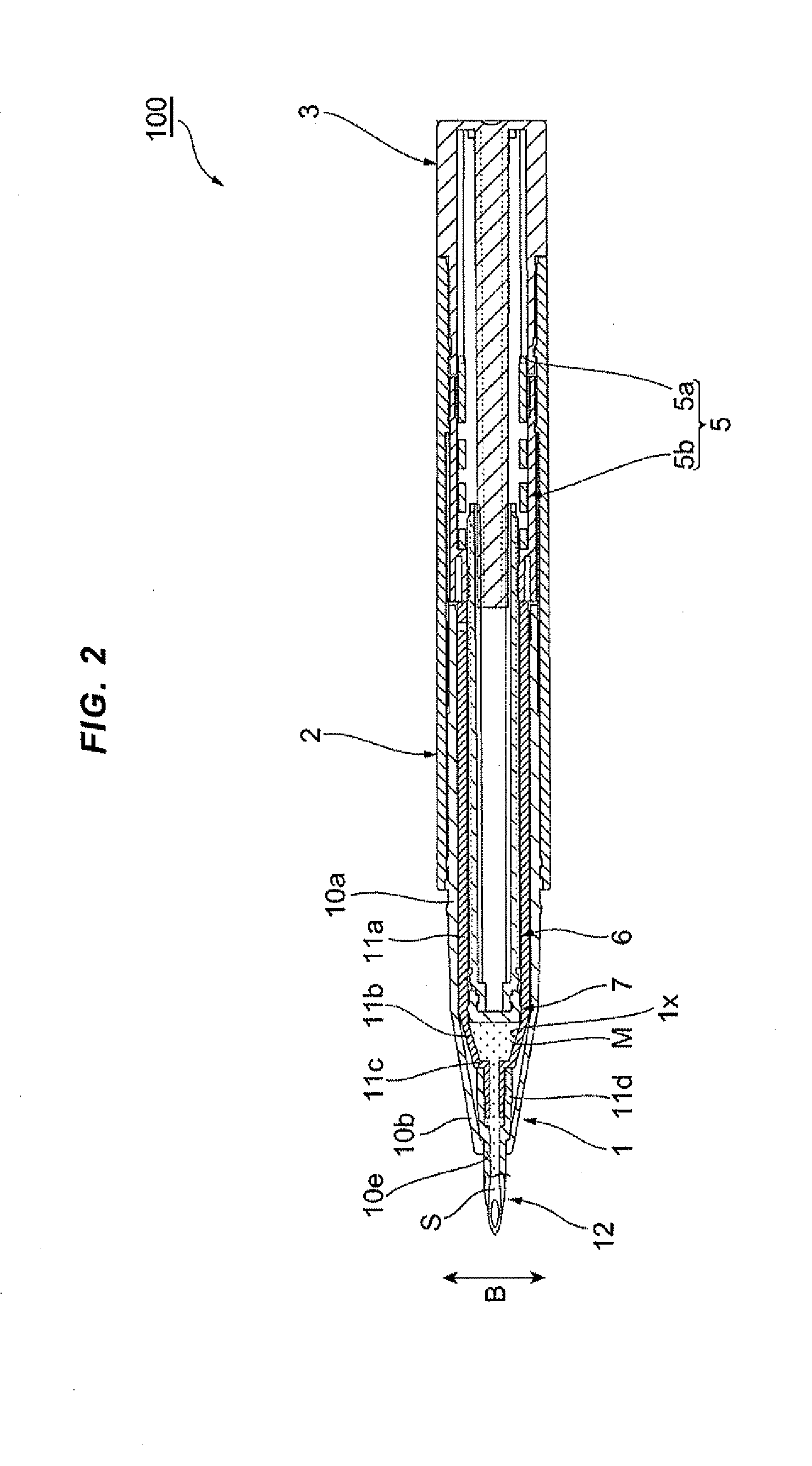

Cosmetic material application container

ActiveUS20120076568A1Easily drawnDrawing difficultLiquid surface applicatorsCarpet cleanersLong axisSoft materials

The invention provides a cosmetic material application container which can stably and easily draw a cosmetic material line, and is structured to discharge a cosmetic material in a filling region from a pen point portion formed by a soft material. A pen point portion shape is three-dimensionally formed by structuring a flat column body by a flat base end shape and a leading end shape provided closer to a leading end side than the base end shape, setting such an arcuate curve as to incline while heading for a base end side from one intersecting point between an outer edge of the leading end shape and a long axis (L2) and bulge to the leading end side, on a plane including a long axis (L1) and the long axis (L2), and cutting the flat column body by a cut surface passing through the curve.

Owner:TOKIWA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com