Patents

Literature

145results about How to "Increase operating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wearable equipment, air conditioner control device, air conditioner control method and air conditioner

ActiveCN103982978ALow real-timeImprove accuracySpace heating and ventilation safety systemsLighting and heating apparatusInfraredEngineering

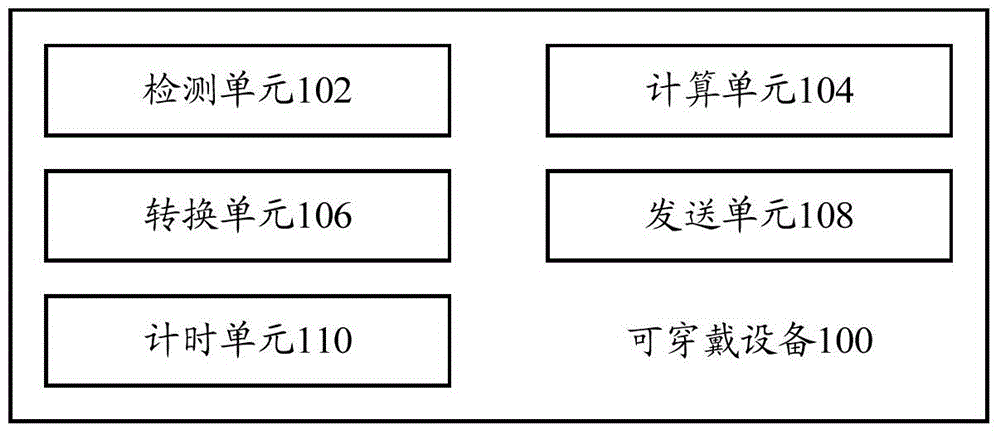

The invention provides wearable equipment, an air conditioner control device, an air conditioner control method and an air conditioner. The wearable equipment comprises a detection unit, a calculation unit, a conversion unit and a sending unit, wherein the detection unit is used for detecting the breathing frequency, body temperature and / or infrared heat generating amount of a user, the calculation unit is connected with the detection unit, and is used for converting the infrared heat generating amount into the heat radiating amount of the user, and calculating the difference between the heat radiating amount and the standard heat radiating amount, the conversion unit is connected with the detection unit and the calculation unit, and is used for converting the difference value into a heat radiating signal, and converting the breathing frequency and / or body temperature into a body function signal, and the sending unit is connected with the conversion unit, and is used for sending the heat radiating signal and / or the body function signal to the outside. By adopting the technical scheme, the running temperature of the air conditioner is adjusted according to the detected body condition information of the user, so the temperature adjusting of the air conditioner is more accurate, and then the temperature is suitable for different populations with different body conditions.

Owner:GUANGDONG MIDEA GRP WUHU REFRIGERATING EQUIP CO LTD +1

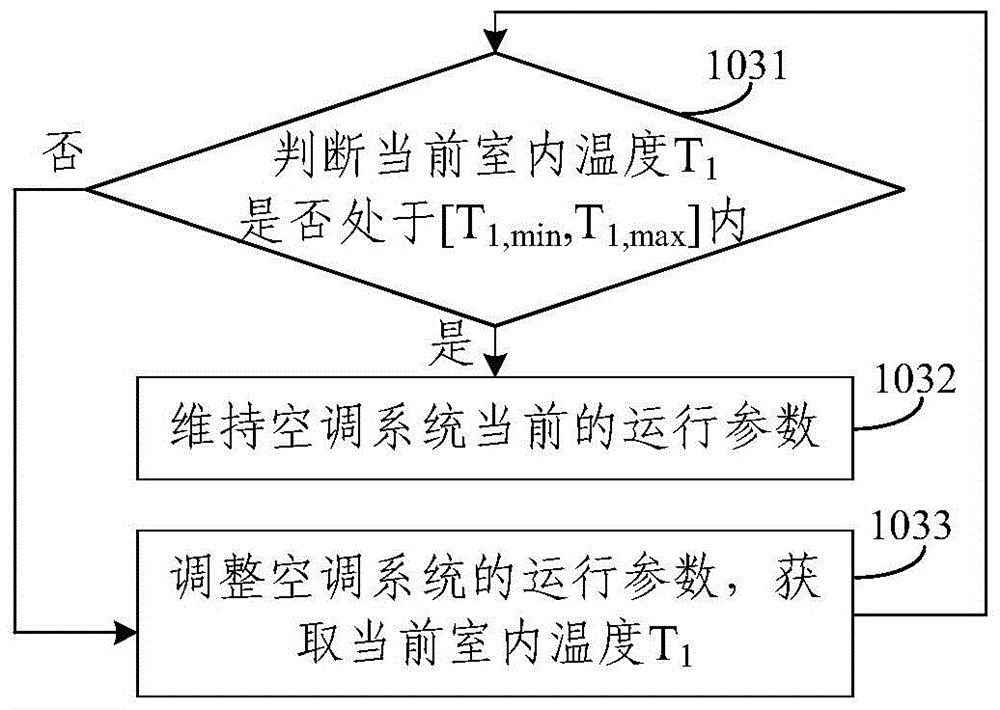

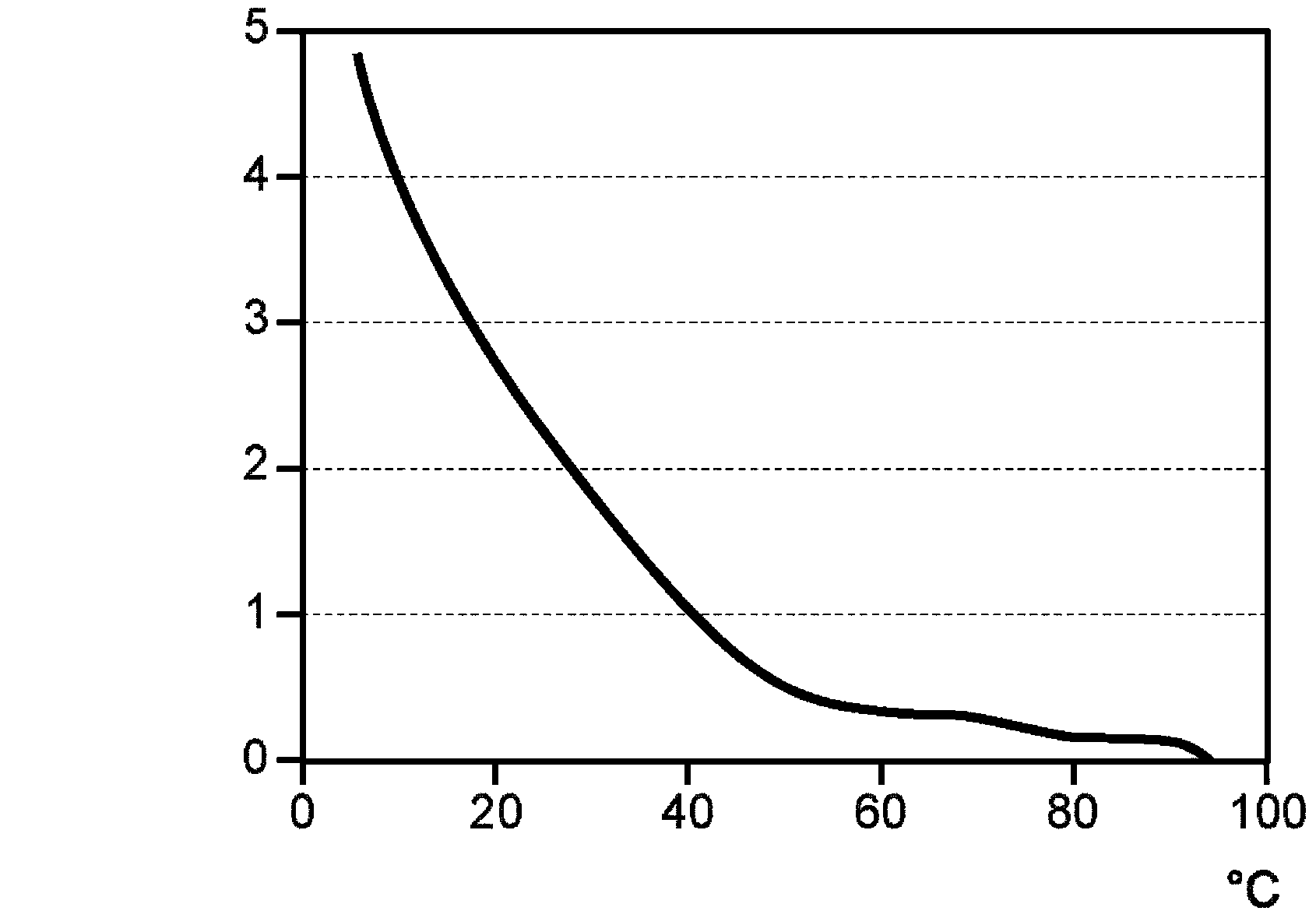

Comfort control method, controller and air-conditioning system

ActiveCN105222271AOptimal thermal comfortImprove comfort qualitySpace heating and ventilation safety systemsLighting and heating apparatusOutdoor temperatureEngineering

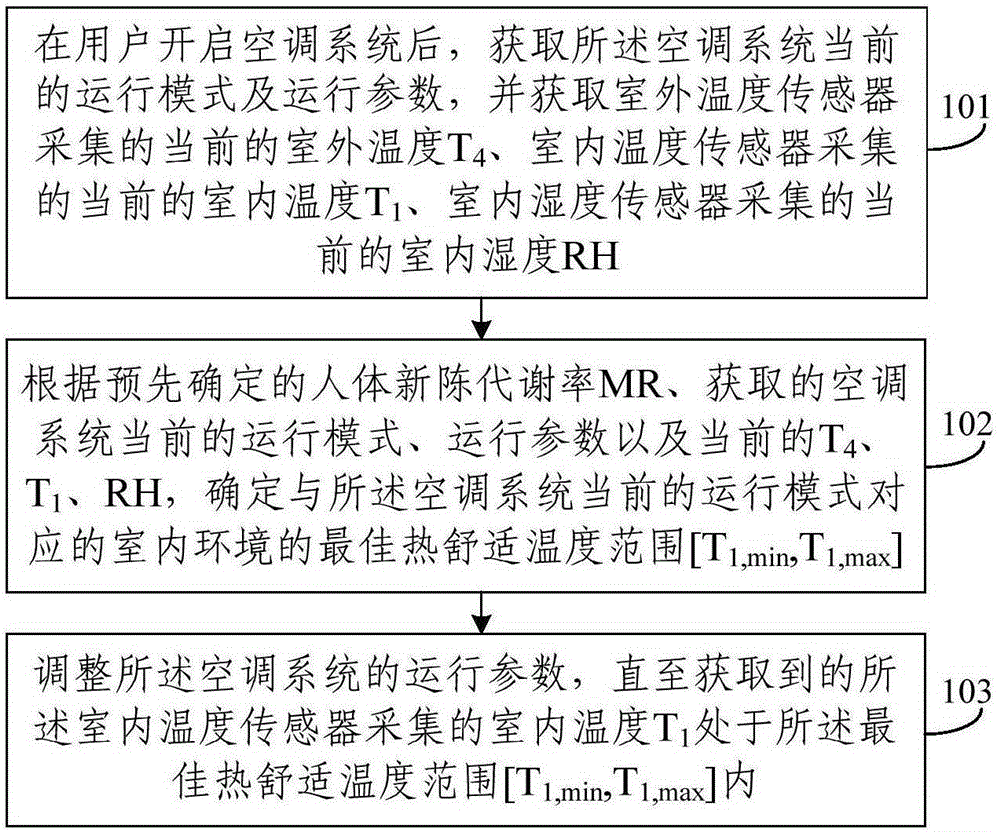

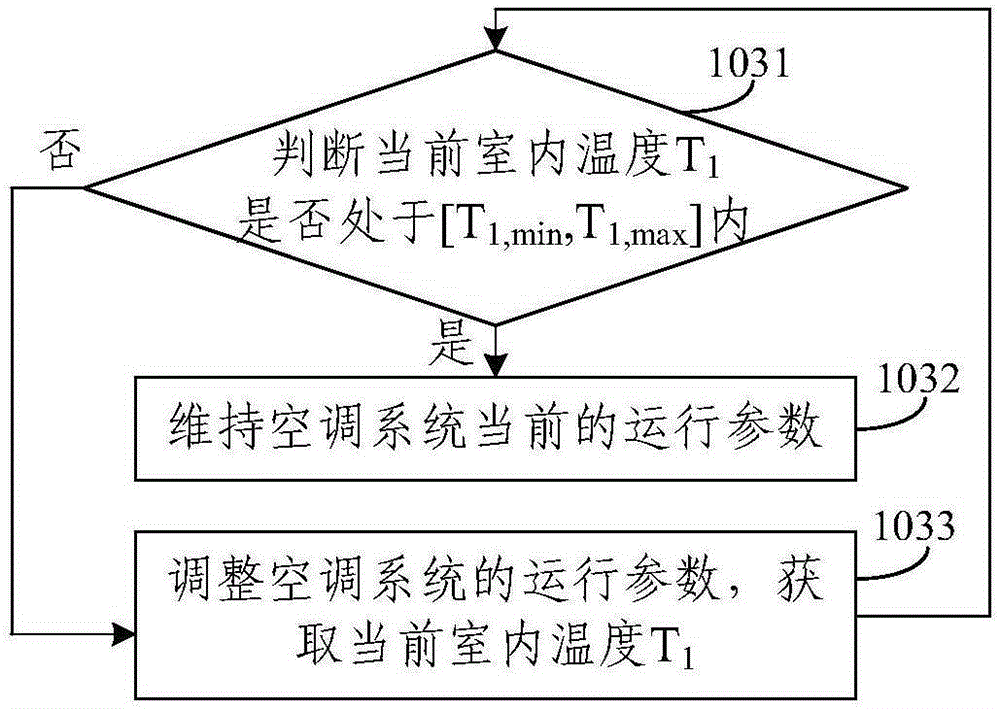

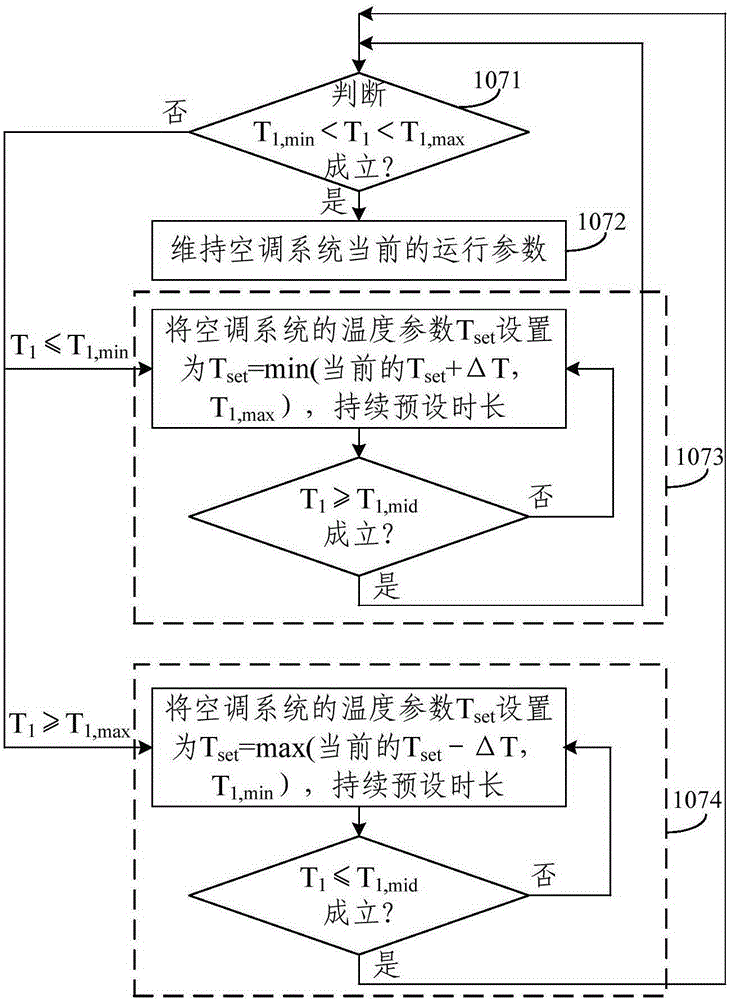

The invention discloses a comfort control method, a controller and an air-conditioning system. The comfort control method comprises the steps that after the air-conditioning system is started by a user, the current operating mode and operating parameters of the air-conditioning system are obtained, and the current outdoor temperature T4 acquired by an outdoor temperature sensor, the current indoor temperature T1 acquired by an indoor temperature sensor and the current indoor humidity RH acquired by an indoor humidity sensor are obtained; the optimum heat comfort temperature of range [T1, min,T1, max], corresponding to the current operating mode of the air-conditioning system, of the indoor environment is determined according to the human body metabolism rate MR determined in advance, the obtained current operating mode and operating parameters of the air-conditioning system, the current T4, the current T1 and the current RH; and the operating parameters of the air-conditioning system are adjusted till the obtained indoor temperature T1 acquired by the indoor temperature sensor is within the optimum heat comfort temperature range [T1, min,T1, max]. According to the comfort control method, the controller and the air-conditioning system, indoor users can be in the optimum heat comfort state by controlling indoor environment parameters.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

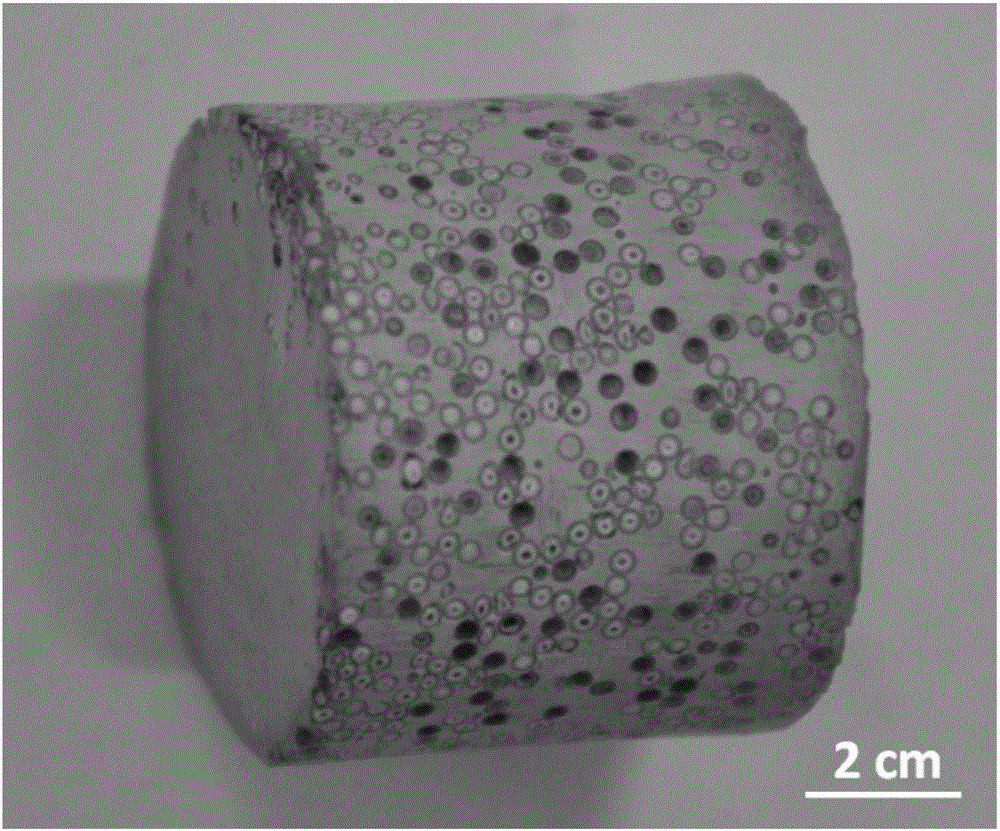

Full ceramic type covering fuel particle, preparation method of full ceramic type covering fuel particle and fuel element

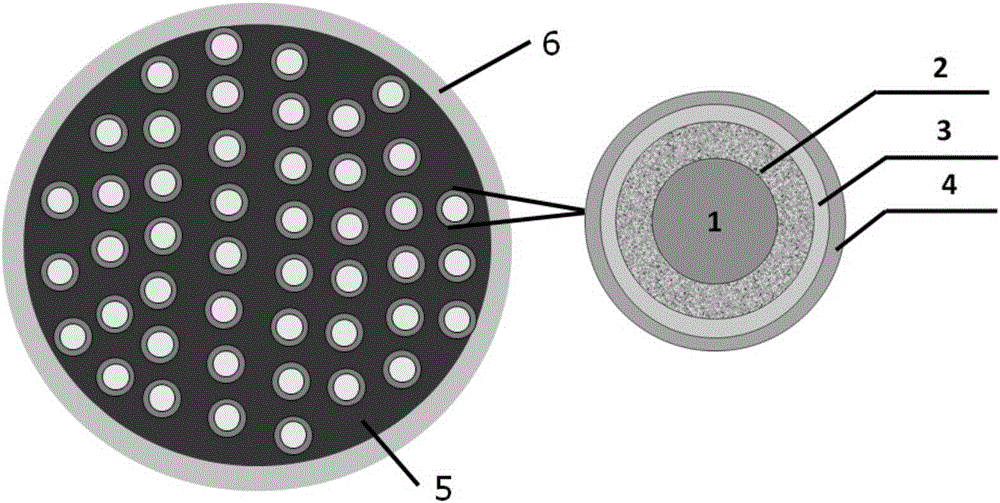

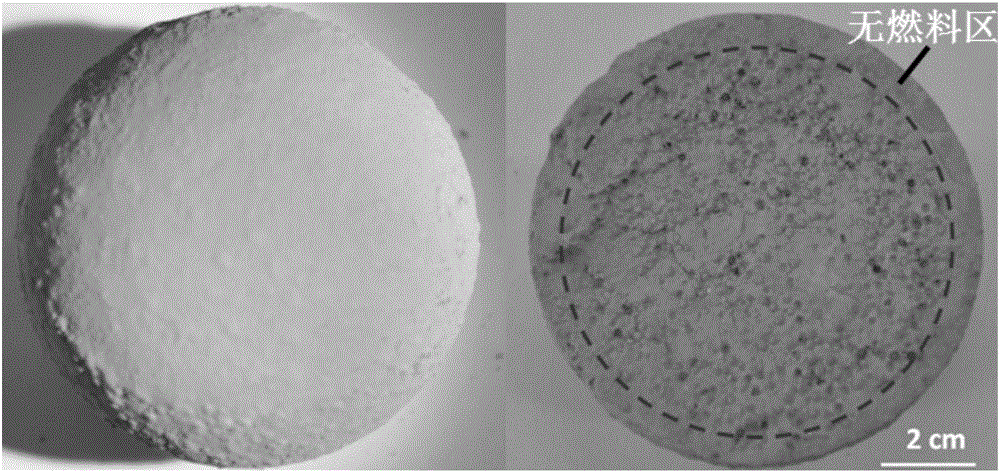

ActiveCN105185418ASimple processEasy to operateFuel elementsNuclear energy generationGas-cooled fast reactorMolten salt reactor

The invention relates to a full ceramic type covering fuel particle, a preparation method of the full ceramic type covering fuel particle and a fuel element prepared from the full ceramic type covering fuel particle. The full ceramic type covering fuel particle comprises a nuclear fuel core, a loose silicon carbide layer, a silicon carbide transition layer and a compact silicon carbide layer, wherein the loose silicon carbide layer, the silicon carbide transition layer and the compact silicon carbide layer sequentially cover the outside of the nuclear core. The full ceramic type fuel element is prepared by dispersing and distributing covering fuel particles in a silicon carbide substrate. When the fuel element provided by the invention is used, the problems of oxidation and corrosion of the existing covering fuel particles and the fuel element during air and water injection under the condition of reactor accidents can be solved. The fuel element can be used for the reactor types such as high-temperature air-cooled reactors, gas-cooled fast reactors, molten salt reactors, space reactors and pressurized water reactors.

Owner:TSINGHUA UNIV

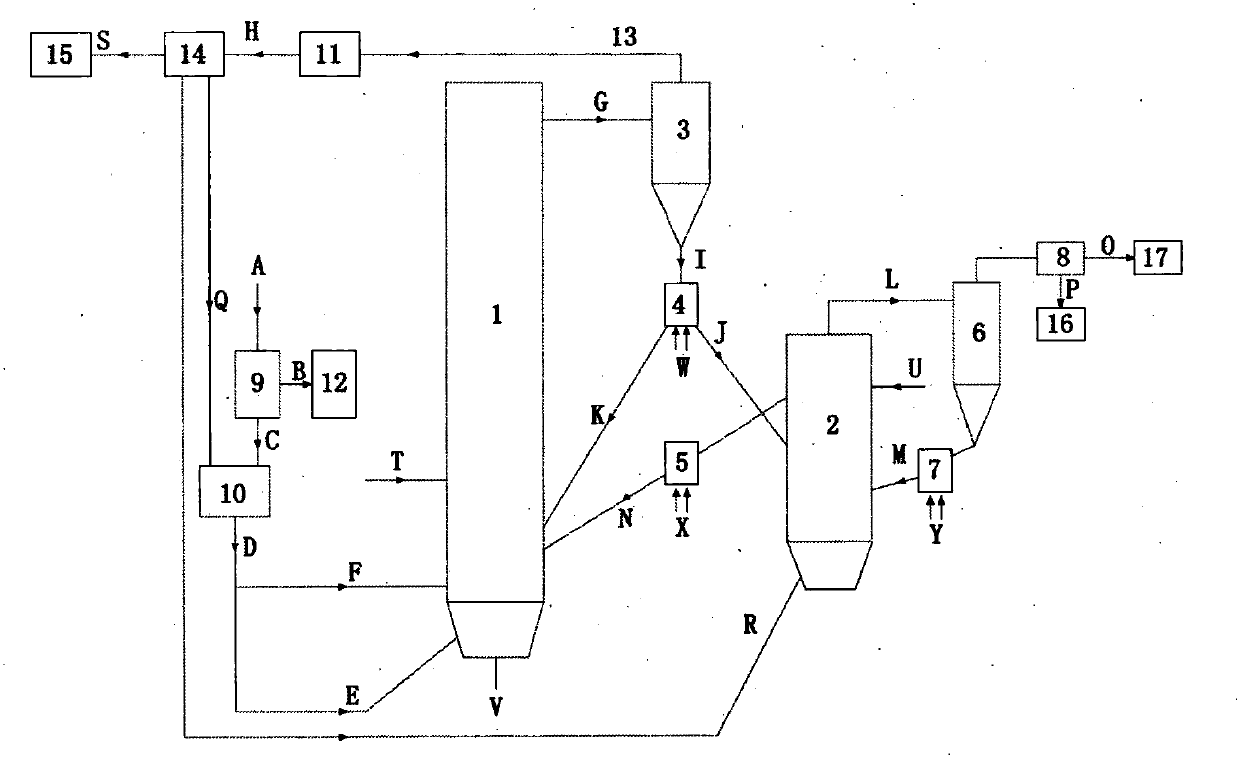

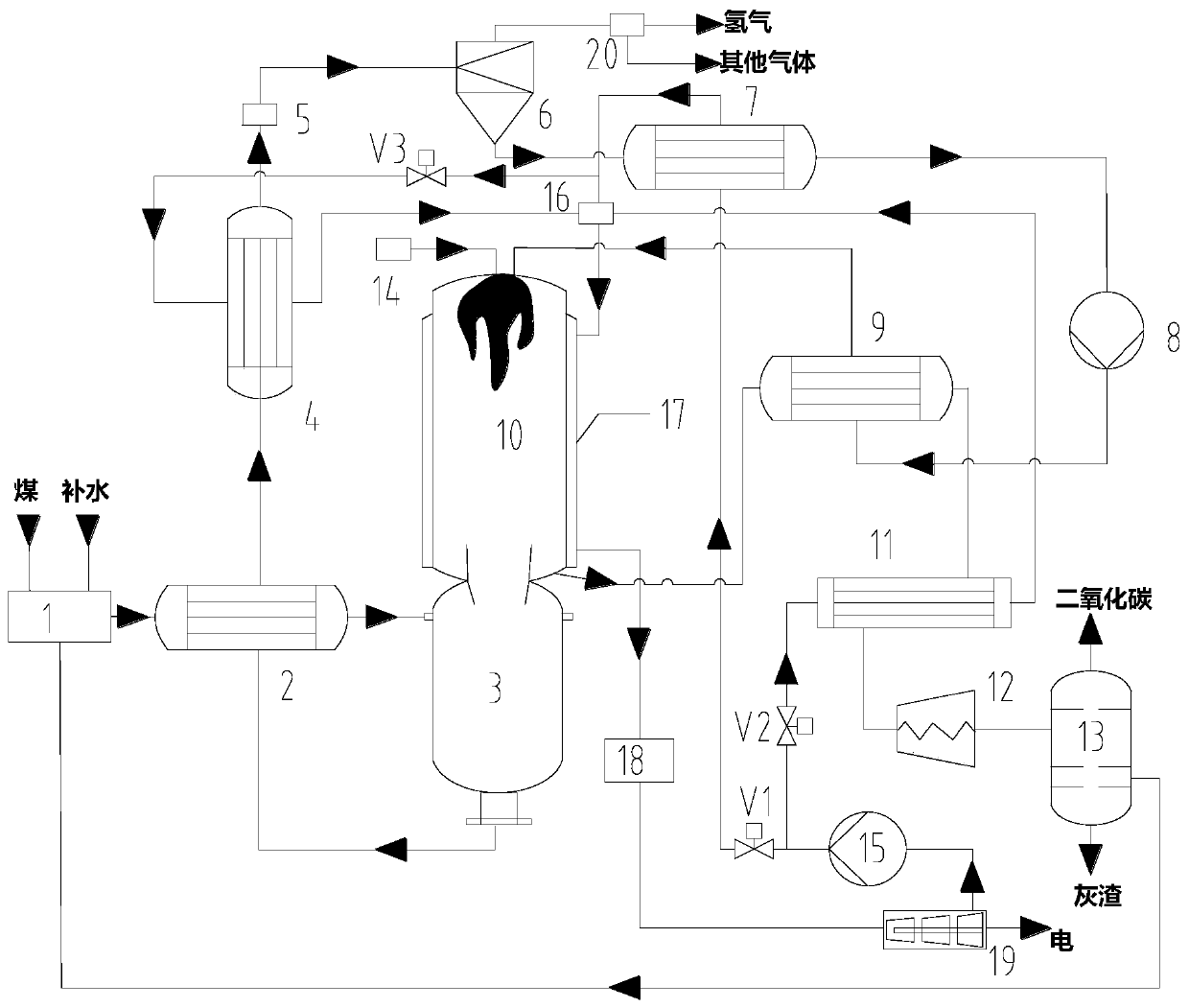

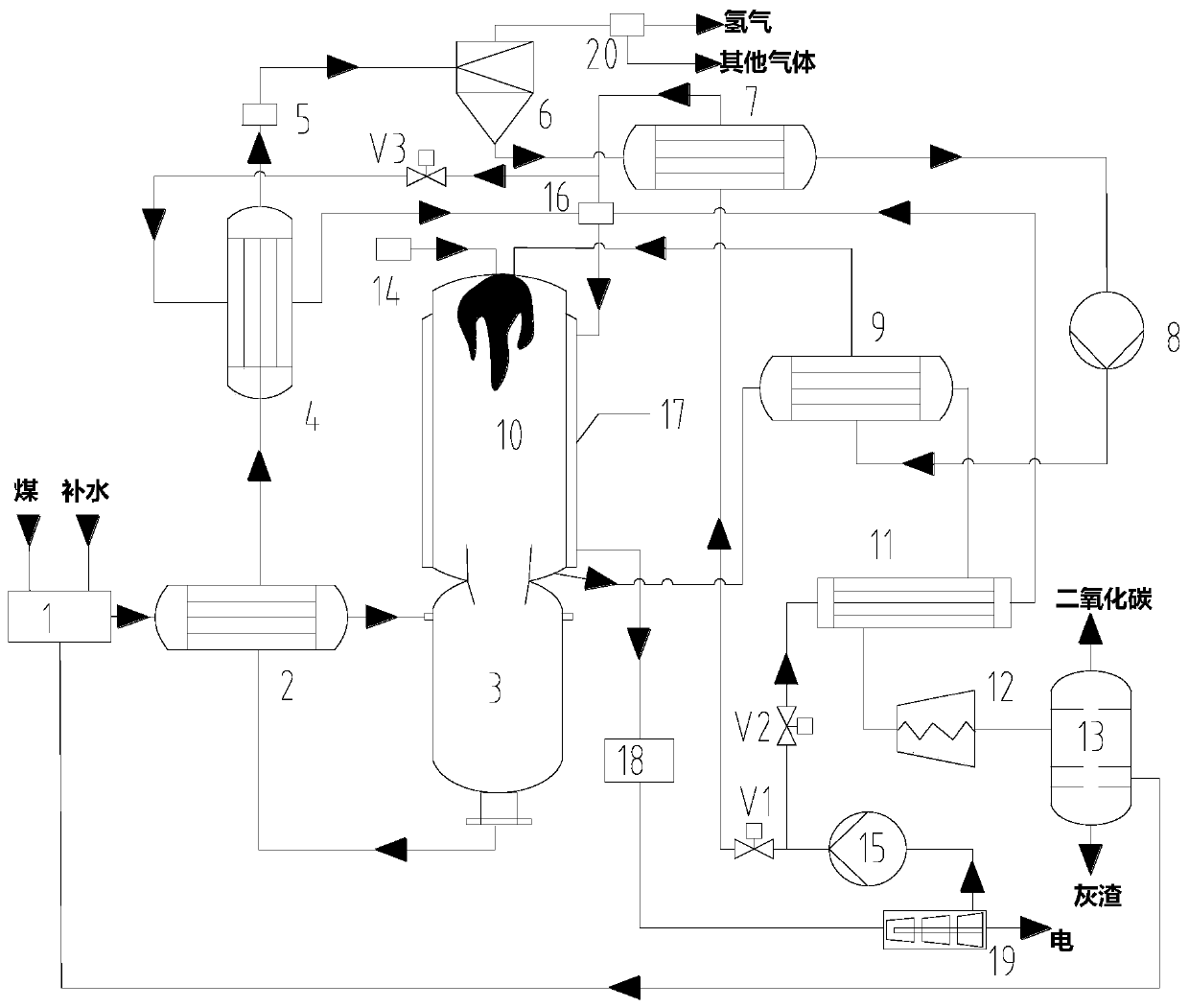

Oxygen-enriched combustion circulating fluidized bed poly-generation system and process

ActiveCN103742899AImprove utilization efficiencyIncrease operating temperatureNitrogen purification/separationFluidized bed combustionGeneration processFlue gas

The invention provides an oxygen-enriched combustion circulating fluidized bed poly-generation system. The oxygen-enriched combustion circulating fluidized bed poly-generation system comprises a circulating fluidized bed combustion furnace and a circulating fluidized bed gasification furnace, wherein the circulating fluidized bed combustion furnace is connected with a separator I, the separator I is connected with a flue at the tail and a two-way material control device, the two-way material control device is connected with the circulating fluidized bed combustion furnace and the circulating fluidized bed gasification furnace respectively, the circulating fluidized bed gasification furnace is connected with the circulating fluidized bed combustion furnace by a return feeder I, the circulating fluidized bed gasification furnace is connected with a ceramic dust collector and a coal gas purification system by a separator II, the flue at the tail is connected with a flue gas distribution valve by a glue gas dust-removal, desulfurization and denitration device, and an outlet of the flue gas distribution valve is divided into three paths. The invention also provides an oxygen-enriched combustion circulating fluidized bed poly-generation process. The oxygen-enriched combustion circulating fluidized bed poly-generation system has high fuel utilization rate, high coal gas yield, good tar quality, small pollutant discharge and low recycling cost, and fuel and flue gas at the tail can be utilized to the maximum extent.

Owner:SHANGHAI BOILER WORKS

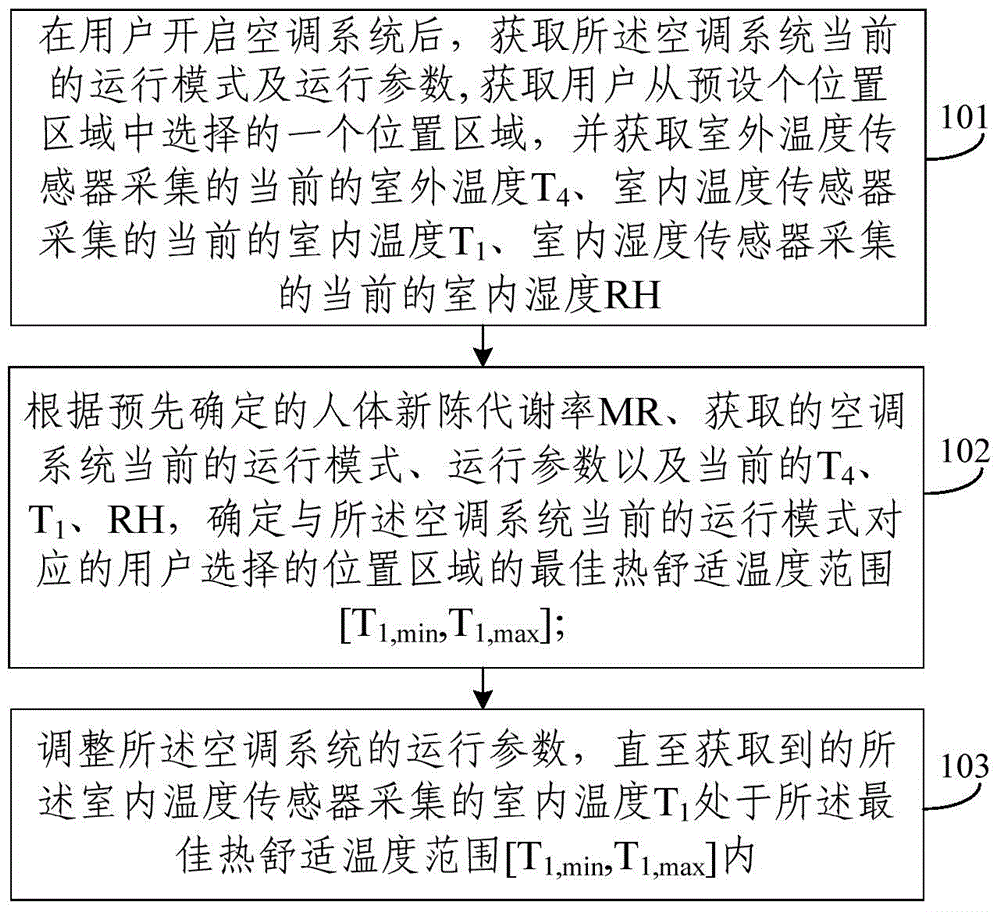

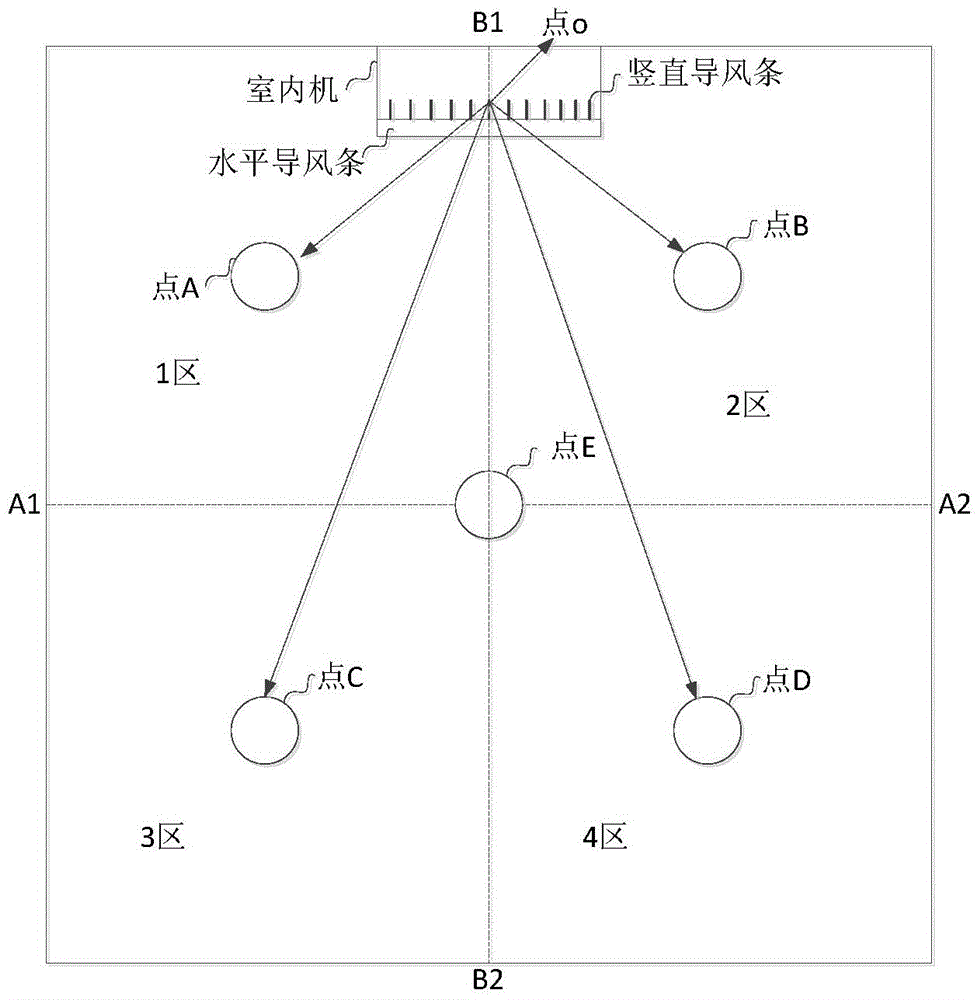

Comfort control method, controller and air-conditioning system

ActiveCN105222272AOptimal thermal comfortImprove comfort qualitySpace heating and ventilation safety systemsLighting and heating apparatusEngineeringOutdoor temperature

The invention discloses a comfort control method, a controller and an air-conditioning system. The comfort control method comprises the steps that the current operating mode and operating parameters of the air-conditioning system are obtained, a position area selected by a user is obtained, and the current outdoor temperature T4, the current indoor temperature T1 and the current indoor humidity RH are obtained; the optimum heat comfort temperature range, corresponding to the current operating mode of the air-conditioning system, of the position area selected by the user is determined according to the human body metabolism rate, the current operating mode and the operating parameters of the air-conditioning system and the current T4, T1 and RH; and the operating parameters of the air-conditioning system are adjusted till the obtained T1 is within the optimum heat comfort temperature range. According to the comfort control method, the controller and the air-conditioning system, by zoning an indoor space, comfort control is conducted in the area where the user is located so that indoor users in different positions can be in the optimum heat comfort state, and the comfort quality is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

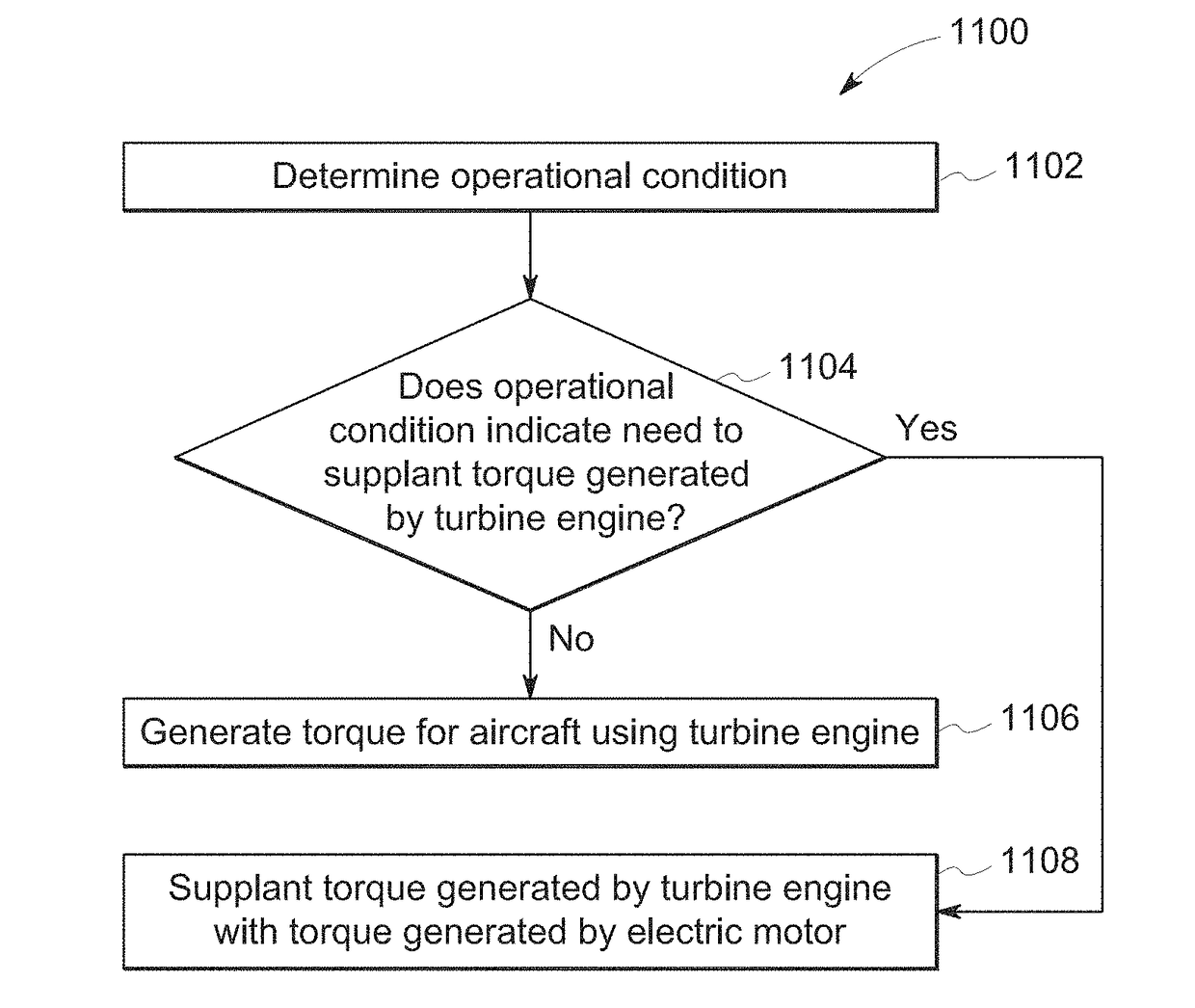

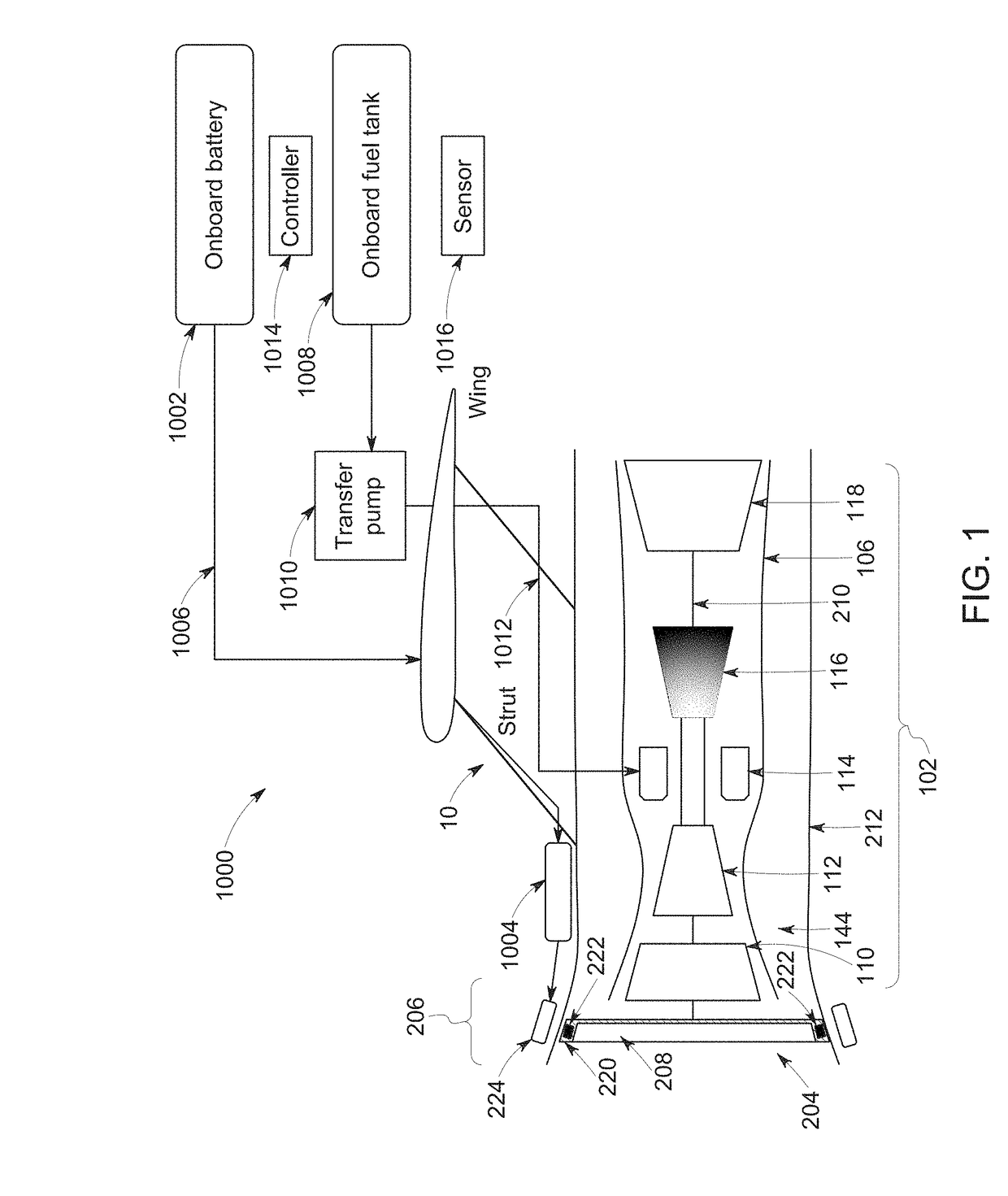

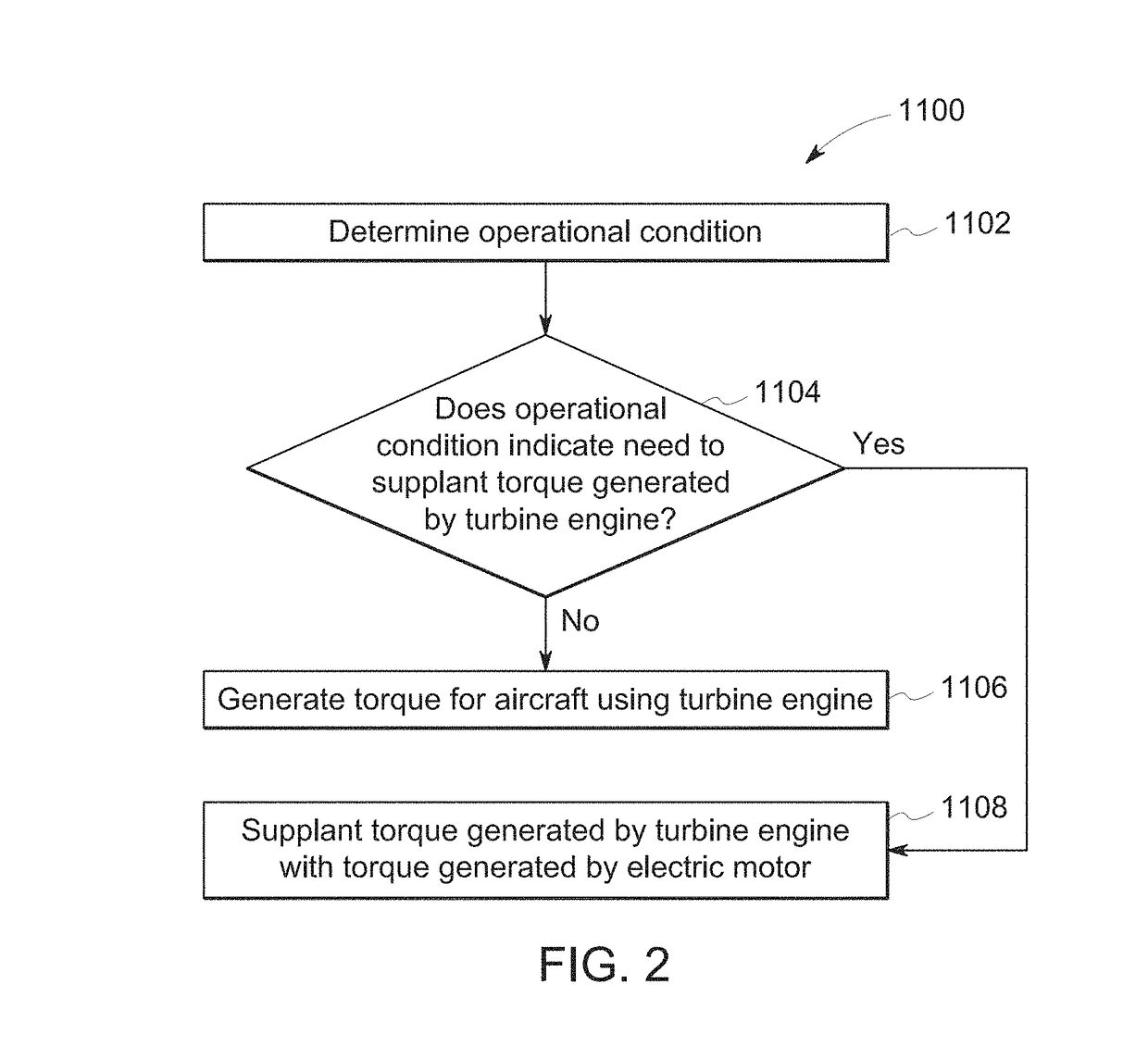

Propulsor assembly for an aircraft

ActiveUS20180229851A1Increase operating temperatureReduce and prevent increase operating temperatureMechanical power/torque controlJet type power plantsOperating temperatureFlight vehicle

An aircraft propulsor assembly includes a fan having a nacelle and plural fan blades radially disposed within the nacelle. The fan blades are configured to be rotated by torque generated by a turbine engine of an aircraft to generate thrust for propelling the aircraft. The assembly also includes an electric motor including a stator in the nacelle of the fan and a rotor in tips of two or more of the fan blades. The electric motor is configured to generate torque that also rotates the fan blades to generate thrust for propelling the aircraft. The assembly also includes a controller configured to reduce or prevent an increase in an operating temperature of the turbine engine of the aircraft by automatically supplanting at least some of the torque generated by the turbine engine with the torque generated by the electric motor.

Owner:GENERAL ELECTRIC CO

High-strength heat-resistant aluminum alloy single line and wire for smart power grid and processing process of single line

ActiveCN105369073AHigh strengthImprove the safety of useConductive materialInsulated cablesSmart gridPower grid

The invention discloses a high-strength heat-resistant aluminum alloy single line and wire for a smart power grid and a processing process of the single line. The high-stretching-rate high-strength heat-resistant aluminum alloy single line is prepared from, by weight percent, 0.05%-0.15% of Zr, 0.01%-0.30% of Y or La, 0.15%-0.30% of Fe, 0.01%-0.40 of Si, 0.01%-0.50% of Mg, 0.10% or less of other impurity elements and the balance aluminum. The strength of the wire formed by stranding single lines can be greatly increased, the draw-weight ratio can be increased, and the use safety of the wire can be improved; meanwhile, the operating temperature of the wire is greatly increased, the operating temperature of the wire is increased to 150 DEG C from conventional 70 DEG C, and therefore the carrying capacity is greatly improved; and the use requirements of high-capacity and large-span extra-high-voltage lines can be met.

Owner:FAR EAST CABLE +2

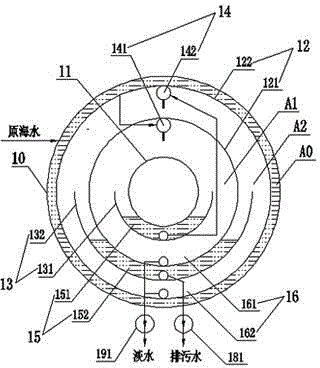

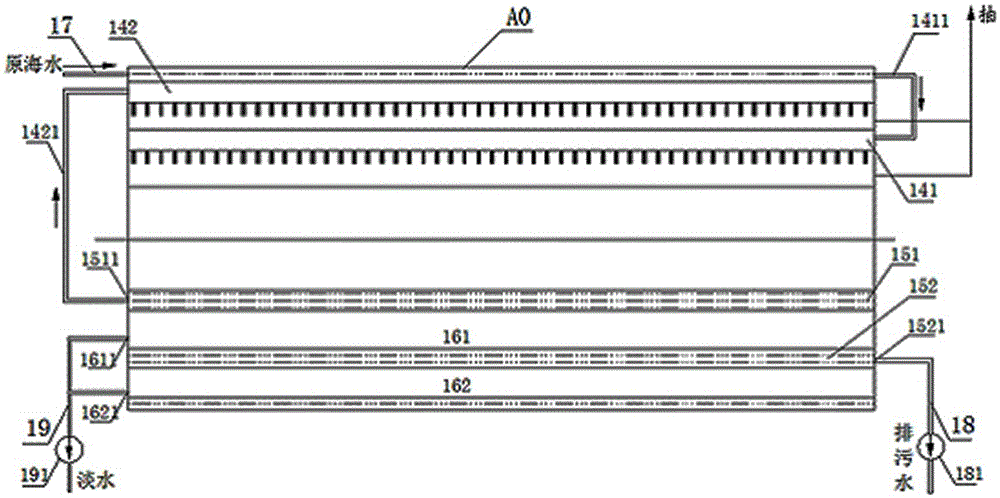

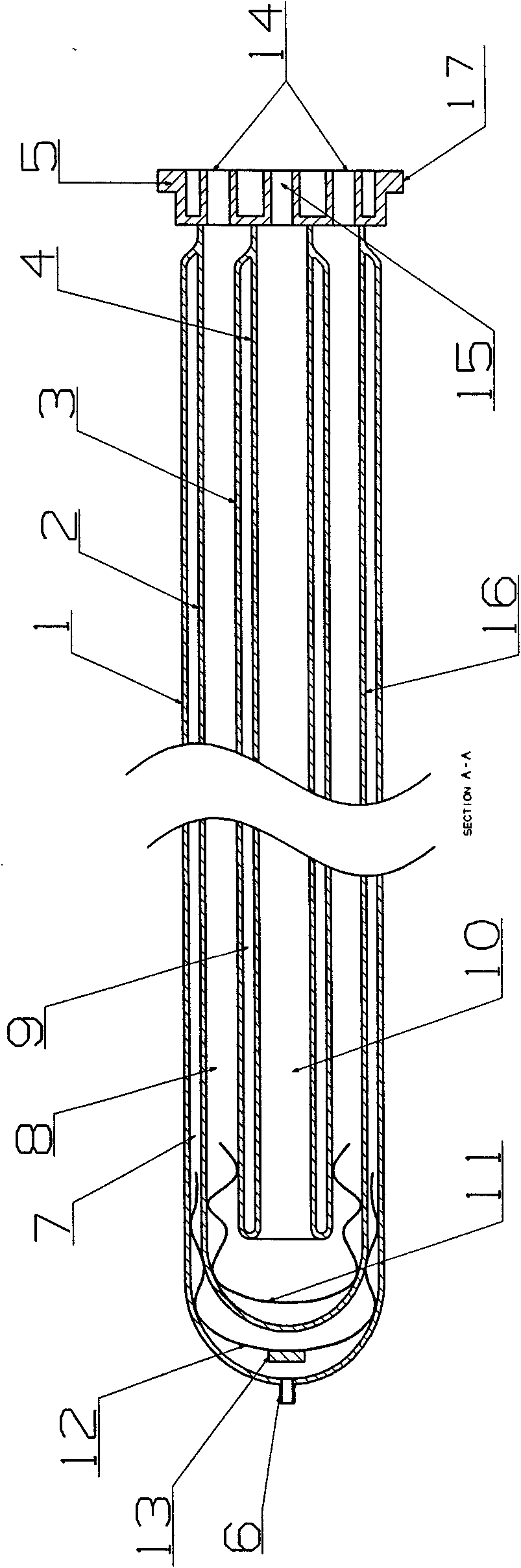

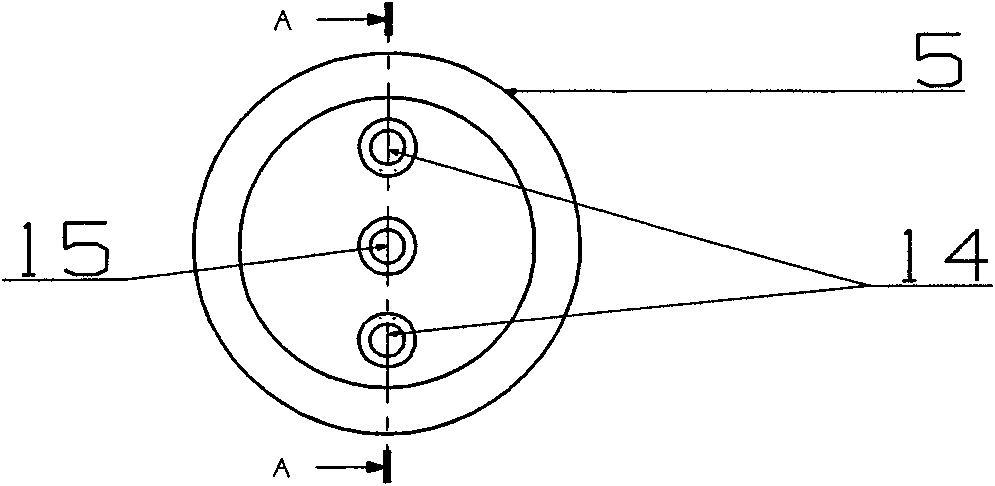

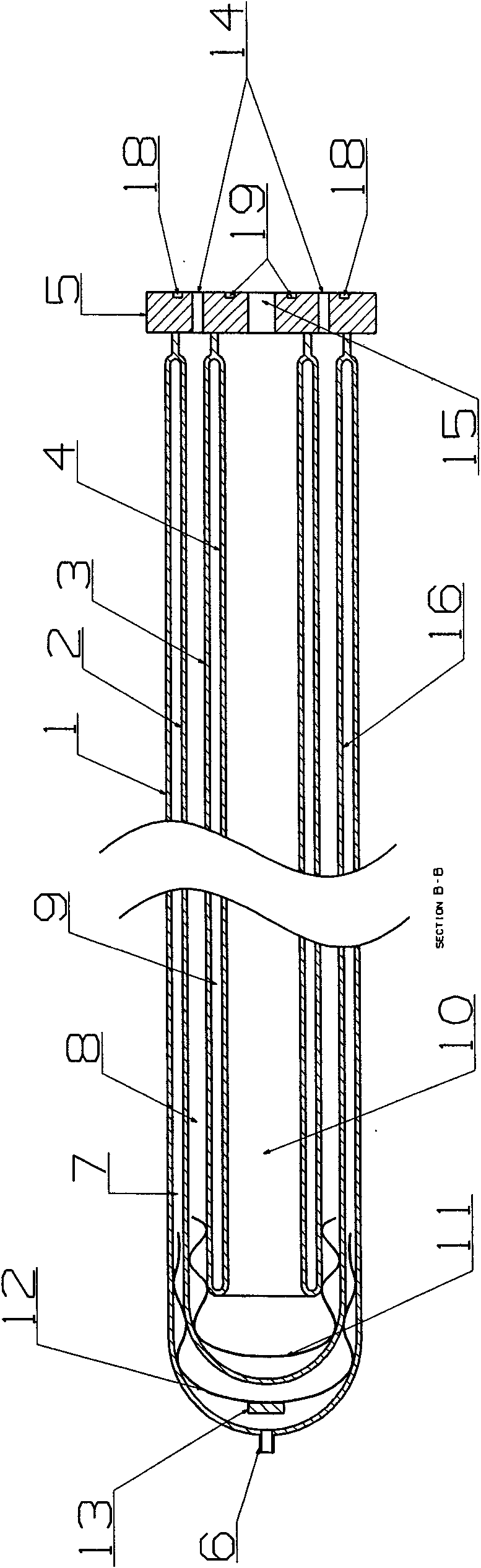

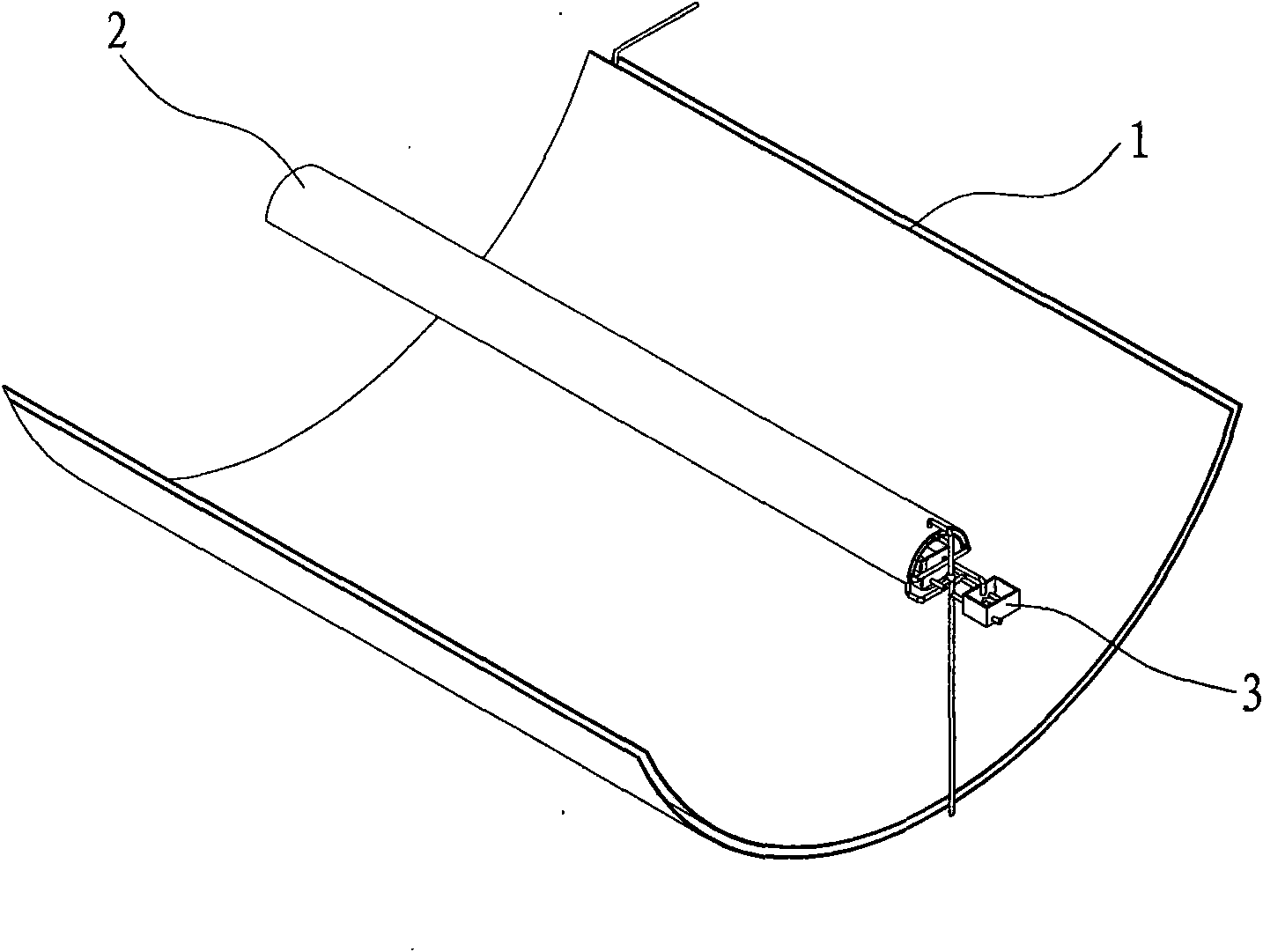

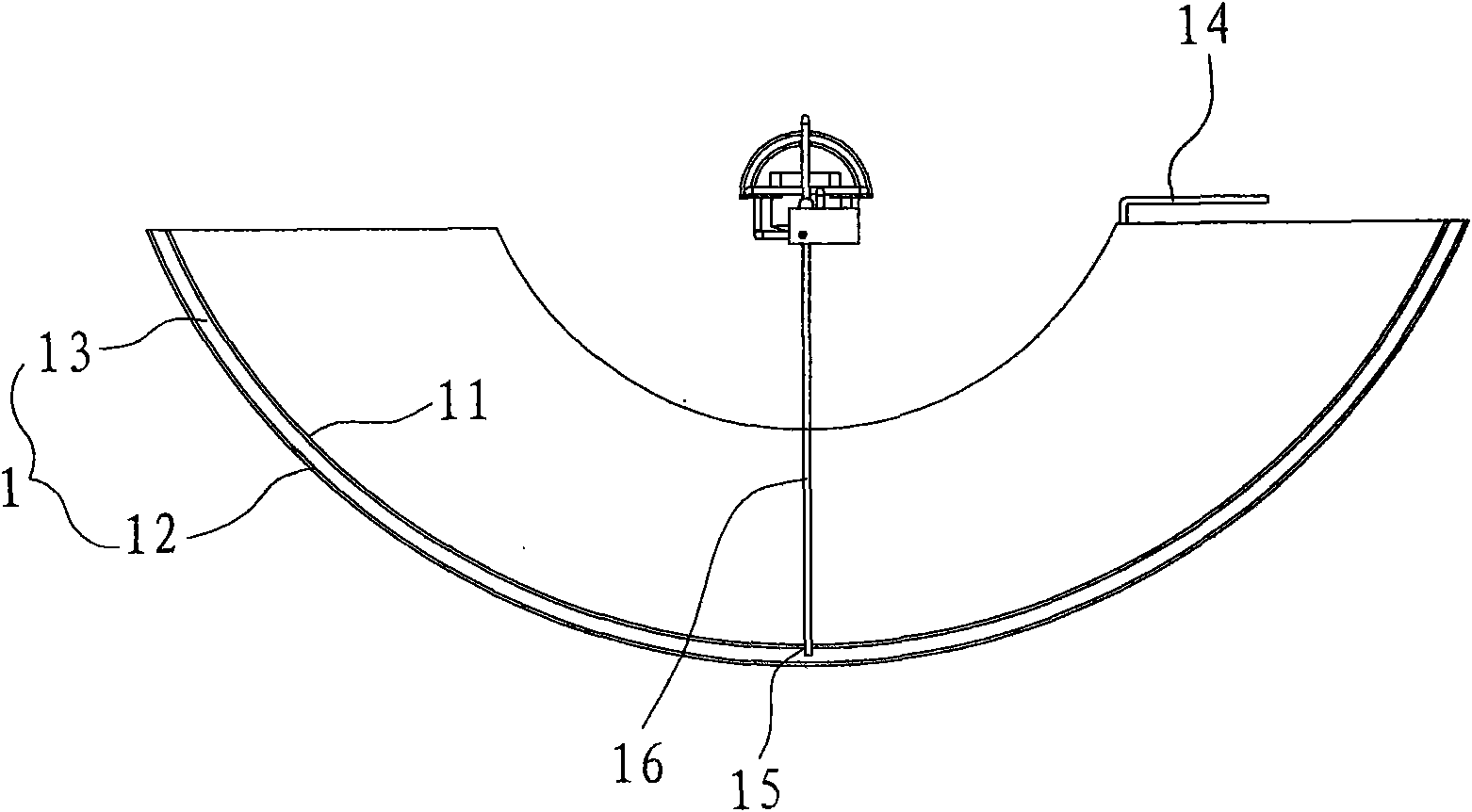

Loop heat pipe-type cylindrical solar seawater desalination device

ActiveCN104591327AIncrease heat transfer distanceHigh heat transferGeneral water supply conservationSeawater treatmentDistillationConcentration ratio

The invention discloses a loop heat pipe-type cylindrical solar seawater desalination device. The device comprises a cylindrical multiple-effect distiller, a light collection groove and a loop heat pipe. An evaporating pipe of the loop heat pipe is used as a solar heat collecting pipe and a condenser pipe of the loop heat pipe is used as a distiller heating pipe so that characteristics of good heat transfer performance and high integral efficiency are obtained. A heating pipe, a heat-transfer pipe, a semi-circular groove and a nozzle unit are tightly arranged in a heat-insulation cylinder inner-cavity so that a pre-heating chamber, a distillation chamber, a seawater tank and a fresh water tank are formed and thus the distiller structure is very compact, can be processed easily and is suitable for standard production. The distiller has the characteristics of repeated use of vaporization latent heat, reinforcement of inner heat and mass transfer processes and improvement of an operation temperature. The heat transfer areas of the distillation chamber are increased from inside to outside so that a small heat transfer temperature difference is kept, the whole distiller effective number is improved and a concentration ratio and a water yield are further improved. The loop heat pipe-type cylindrical solar seawater desalination device is suitable for low-cost modularization production and can be widely used in the field of solar energy seawater desalination.

Owner:JIMEI UNIV

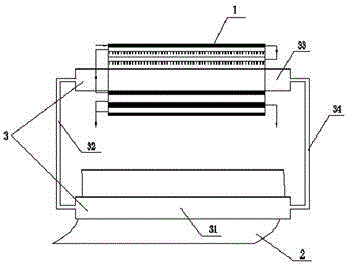

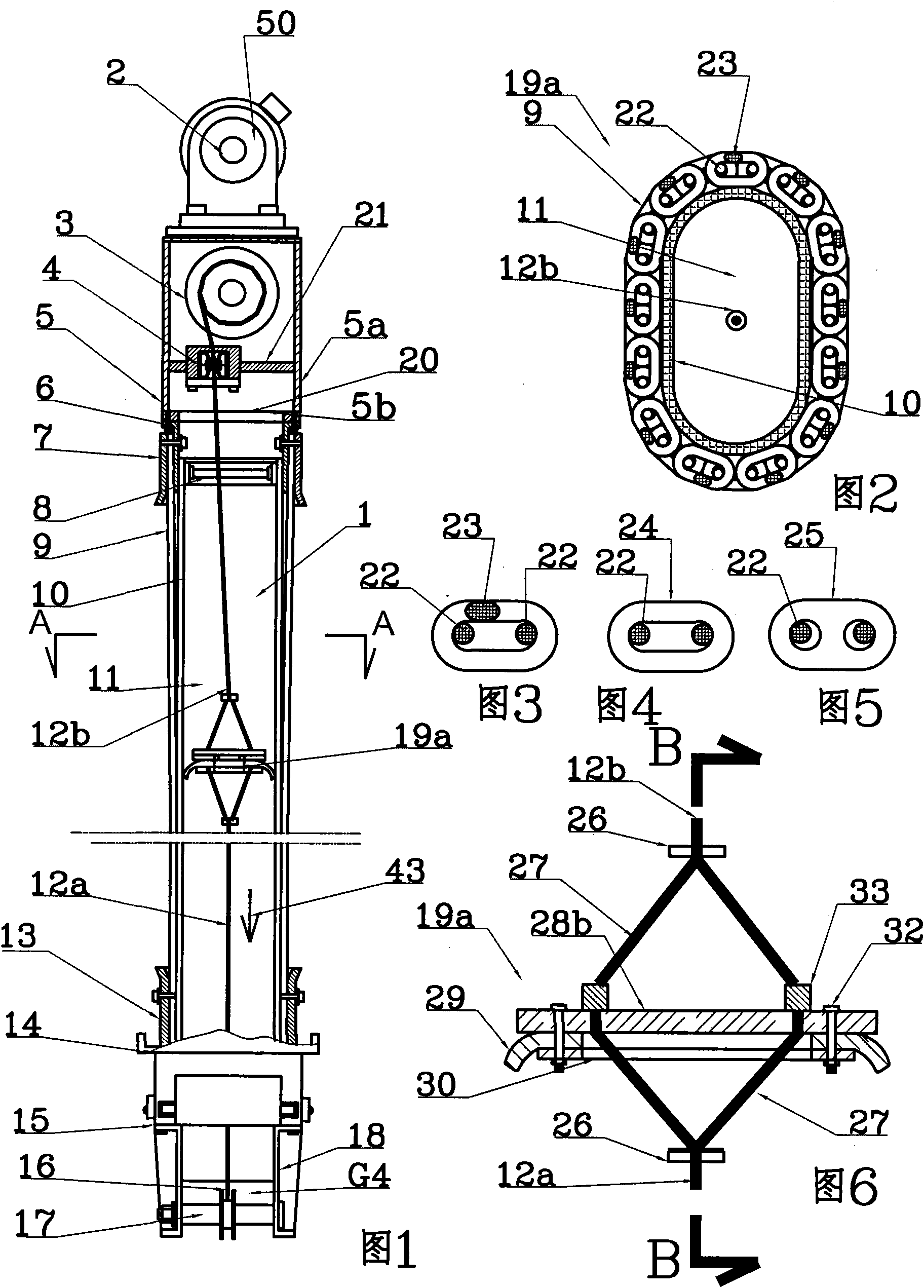

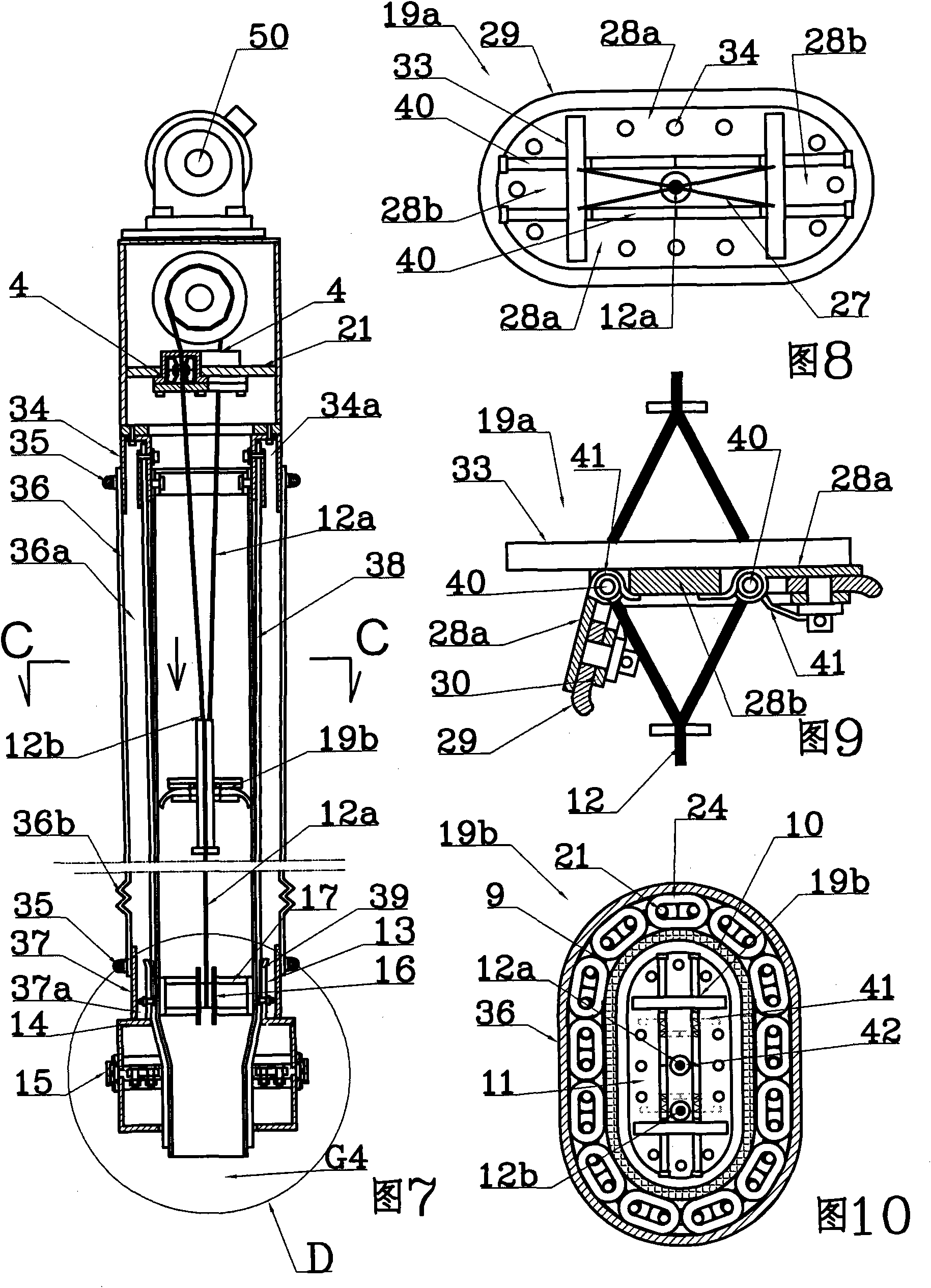

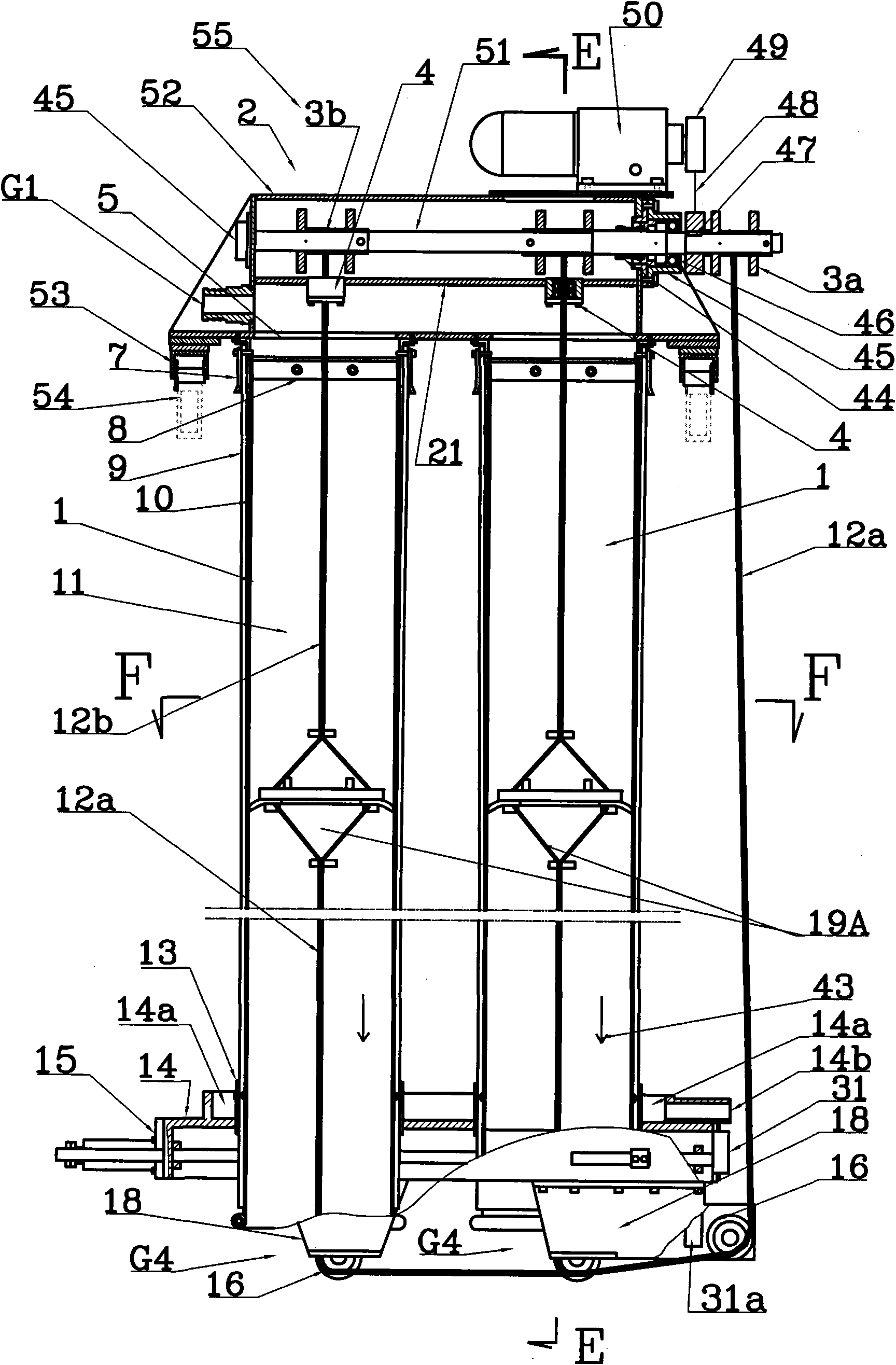

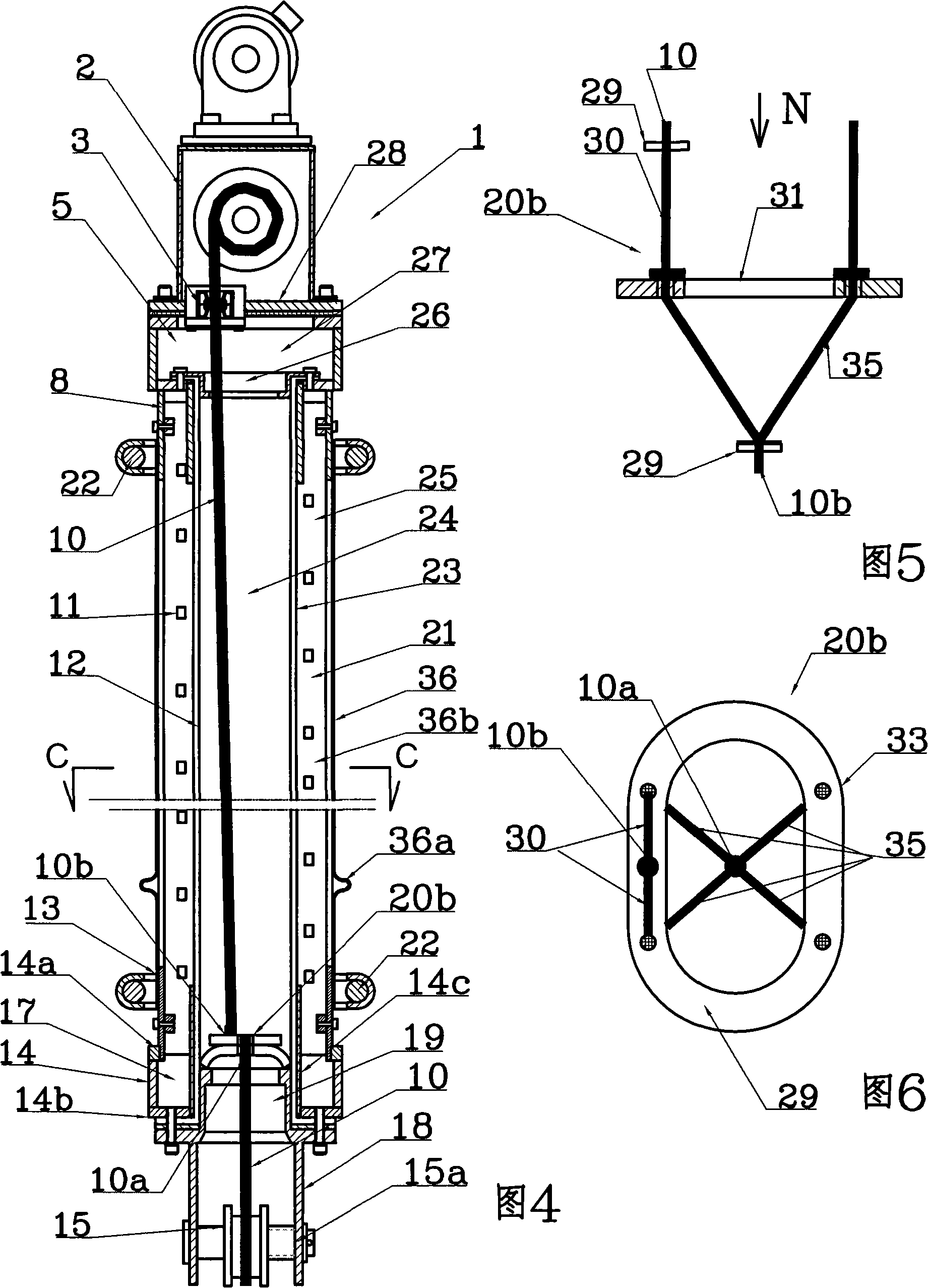

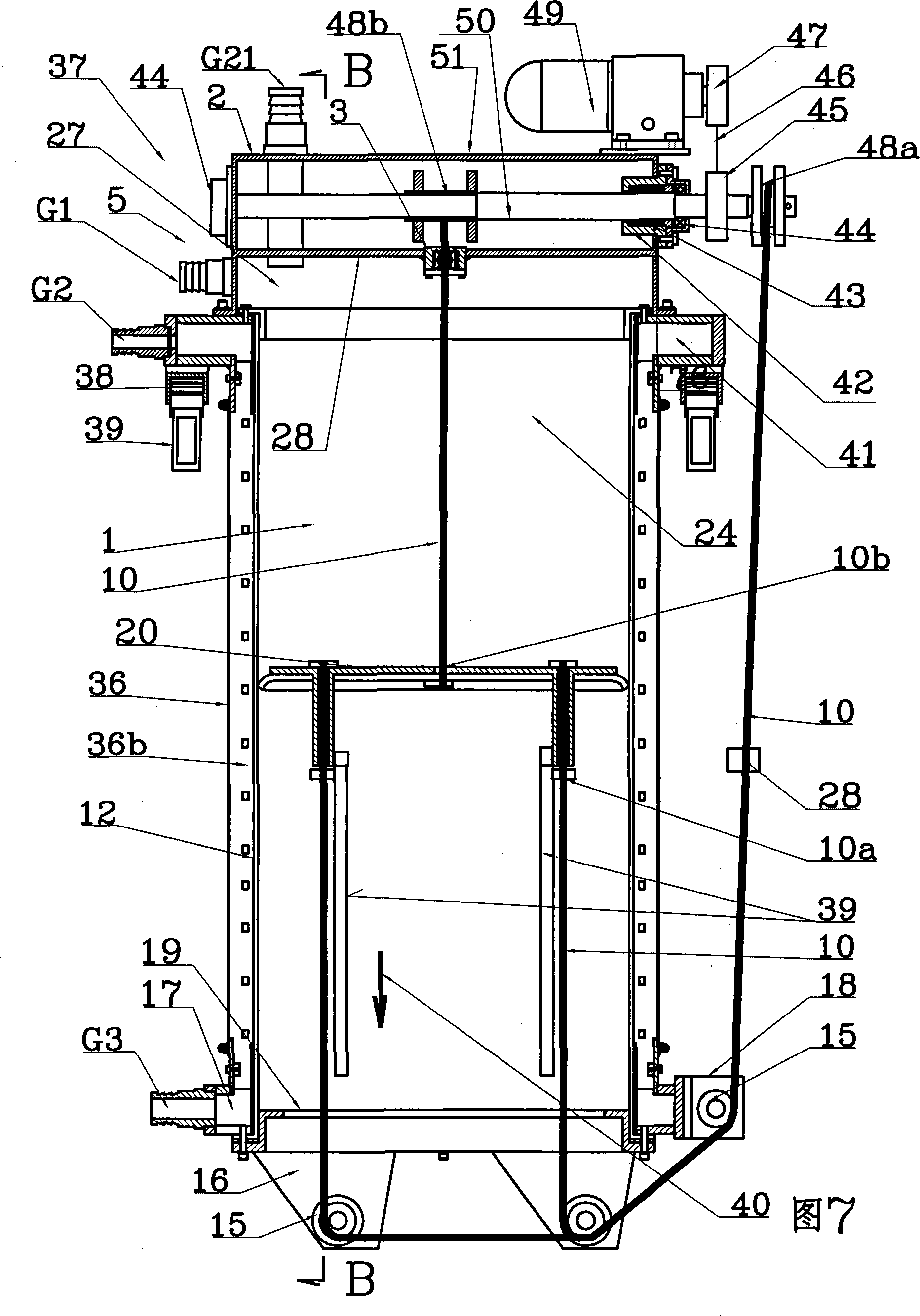

High-pressure compressing solid-liquid separation device of flexible pipe

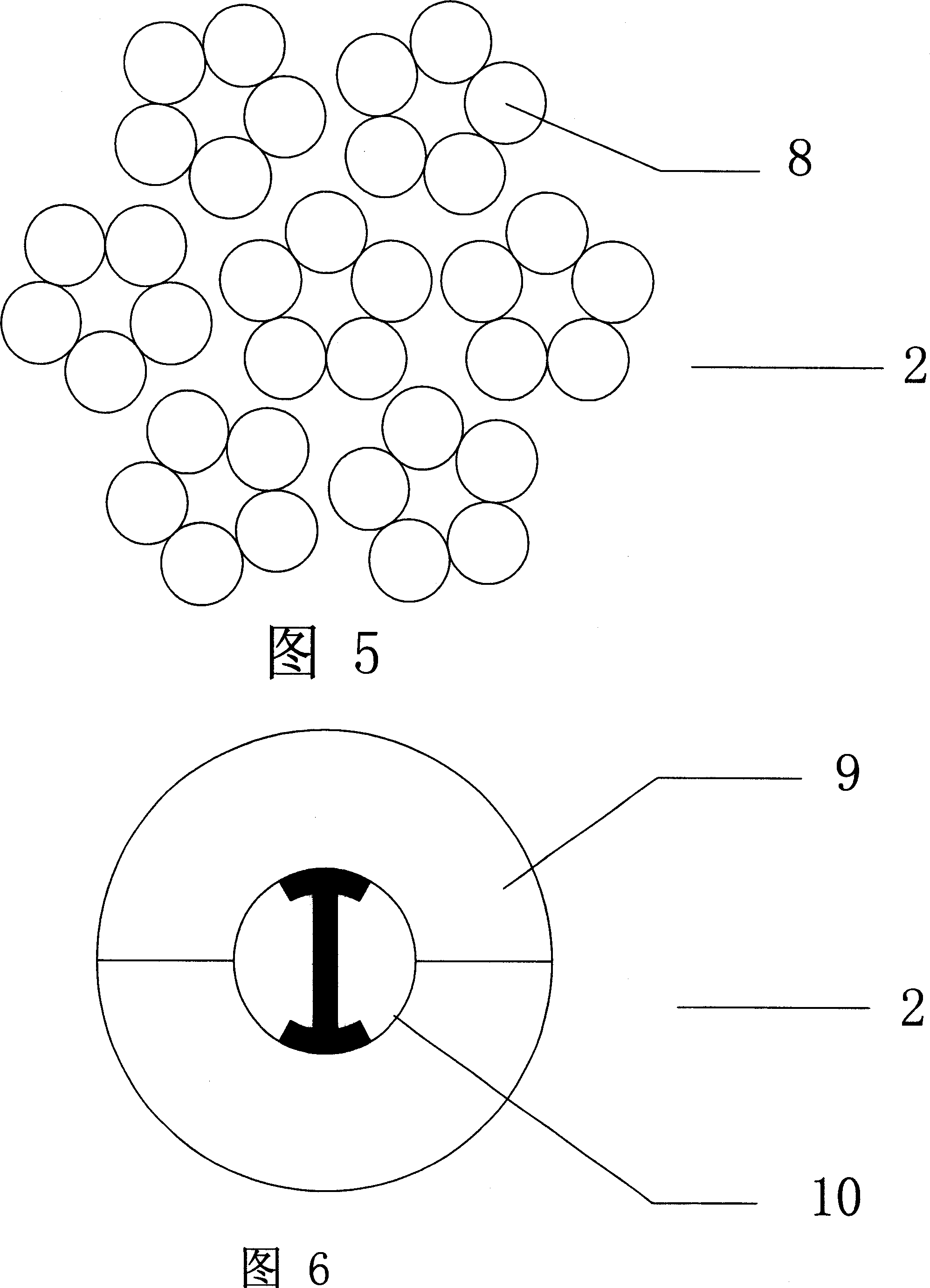

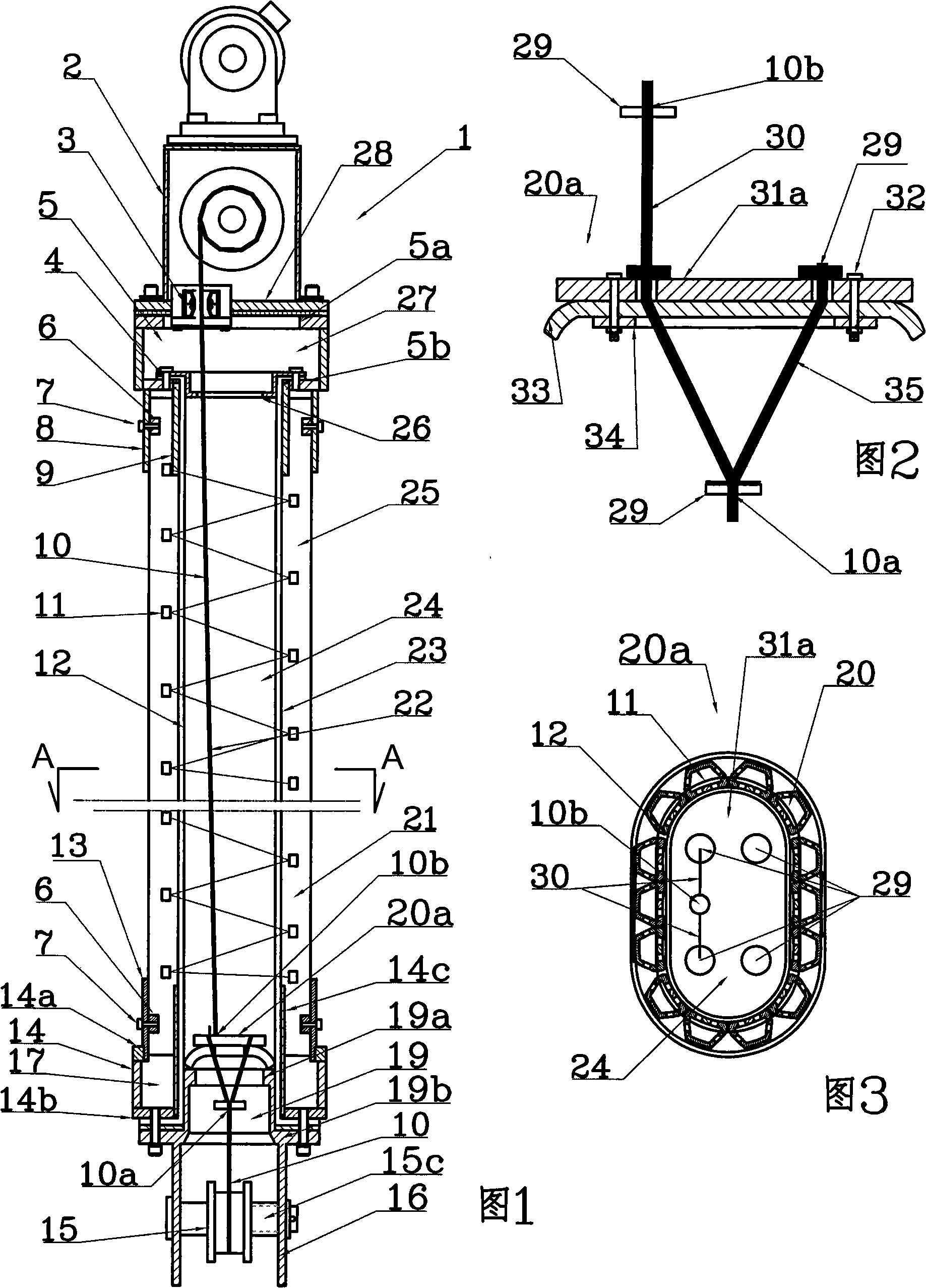

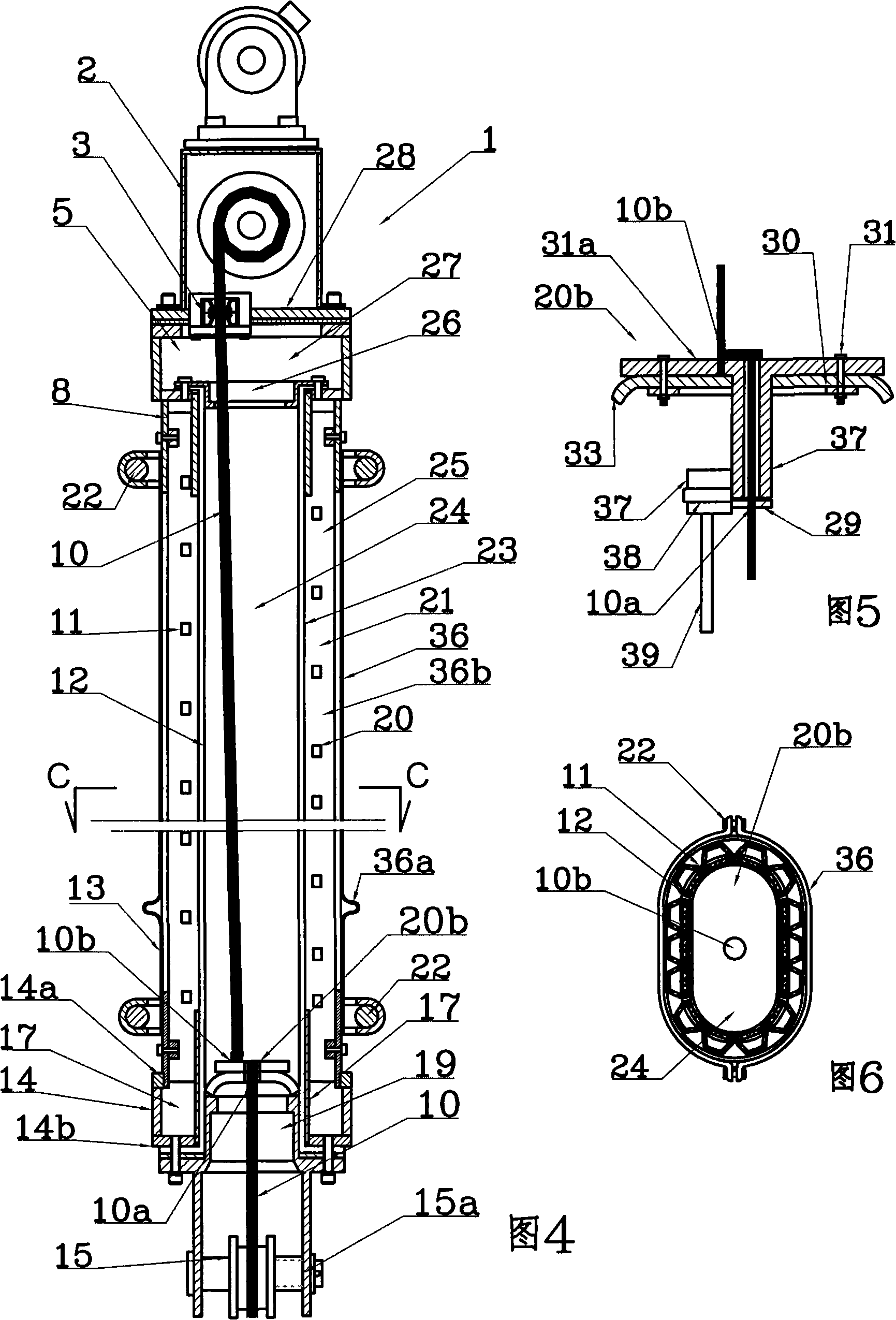

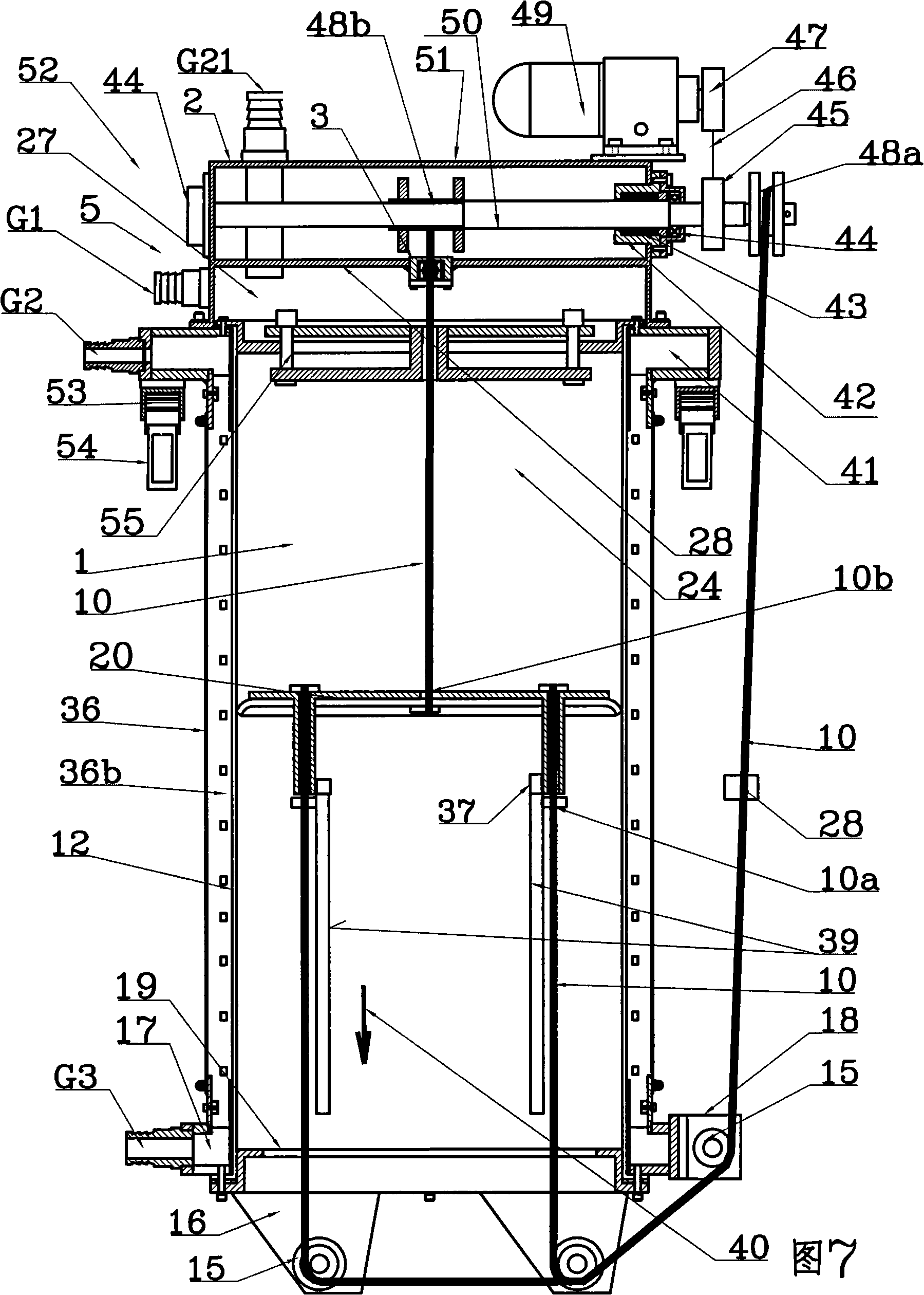

InactiveCN101574593AUniform humidityFast concentrationStationary filtering element filtersVolume variationFilter media

The invention relates to a high-pressure compressing solid-liquid separation device of a flexible pipe. Pipe-shaped filtering medium at the utmost outside layer adopts a steel wire braid conveyer belt, and filter residue left on the filtering medium is removed in filtering by using a piston scrapper plate; the solid-liquid separation is accomplished in compressing by utilizing the principle of filter chamber variable-volume compression, the filter chamber is almost close to zero in volume after volume variation, and does not need a high-pressure pump to convey raw materials and does not need an additional compression water pump system or compression compressed air system as the filter pushing force of a filter press; and a pressing assembly of a pressing application system adopts an pressing reinforced connection rod mechanism, not only the pushing force is increased by dozens of times, but also the pressure is maximal when the pressing stroke is over with the filter pressure up to 2.5MPa. The device can adopt repeated treading and filtering, the alternating change of the thickness and the thinness of the raw materials in compression improves the filtering speed, washing speed and efficiency; the humidity of a filter cake is uniform; the washing regeneration of filter mediums is automatically accomplished; the residue discharge is automatically accomplished; the production process can realize complete automazation, so that the energy consumption is reduced, and the production efficiency is higher; and the manufacture cost is low due to the utilization of screw rod for clamping and compression.

Owner:张民良

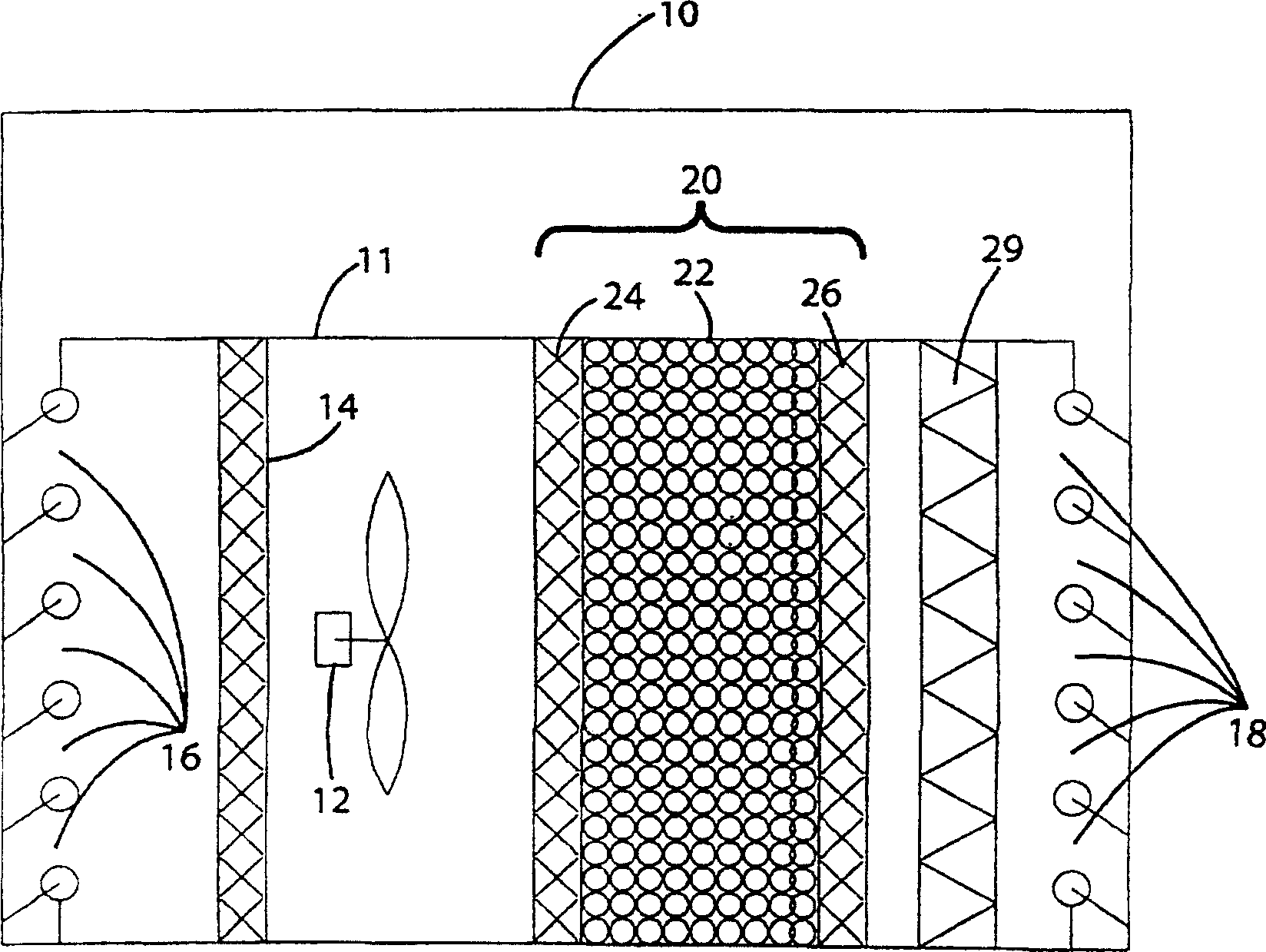

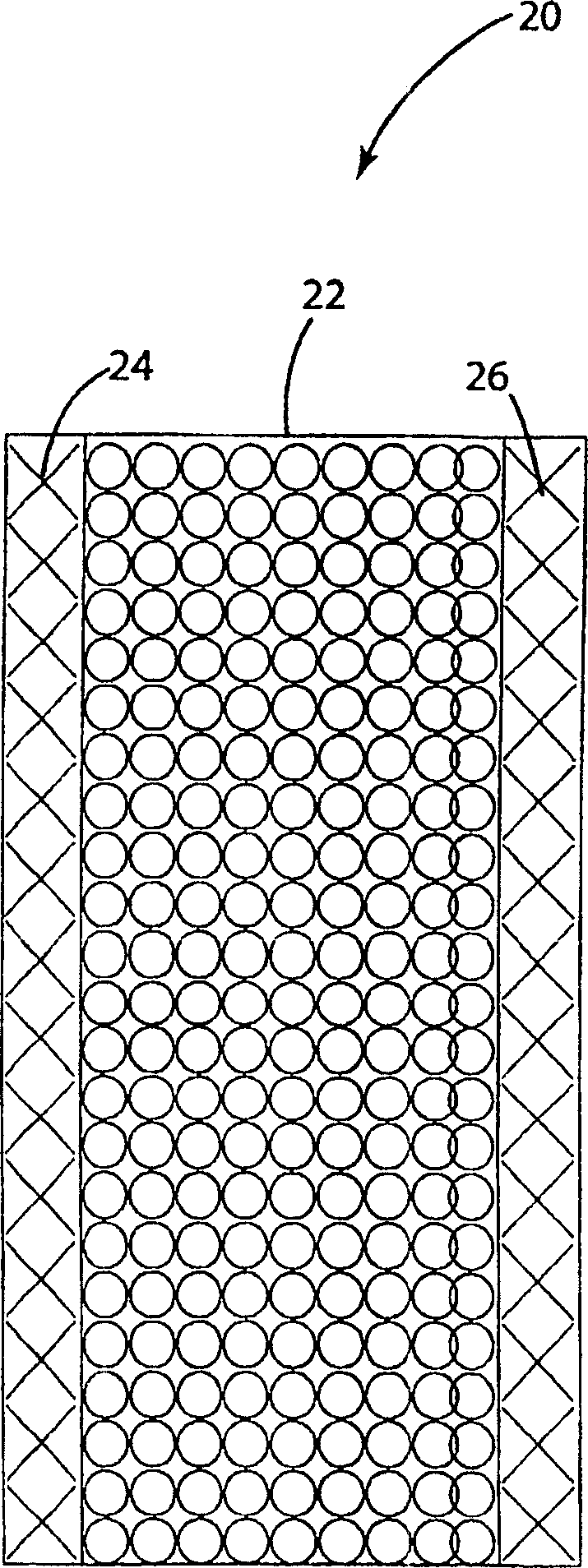

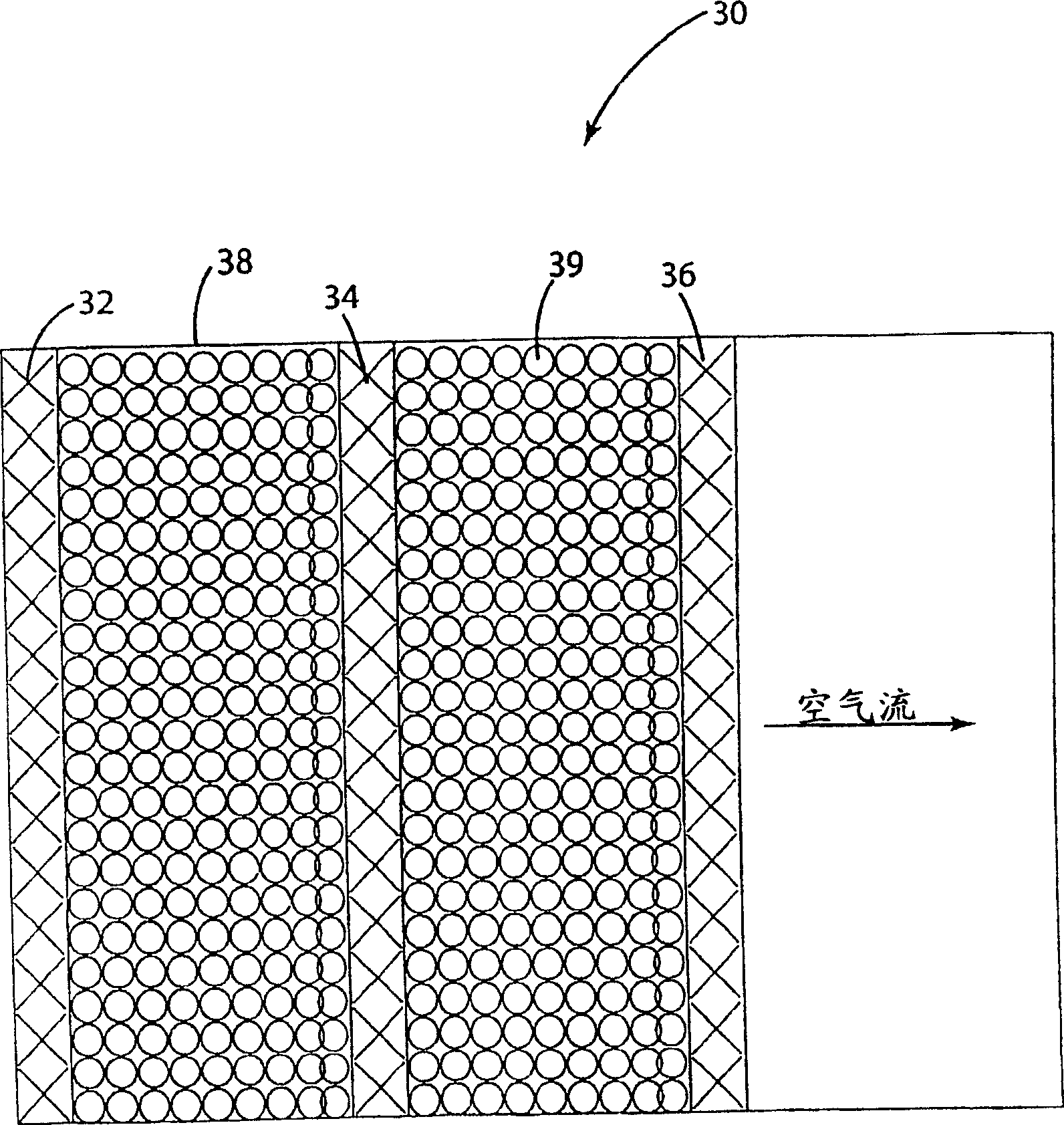

Nonthermal plasma air treatment system

InactiveCN1691966ALow costShort heating timeGas treatmentDispersed particle separationSorbentDesorption

A method and apparatus for reducing air contamination using a contaminant adsorbent to remove contaminants from air, and a nonthermal plasma to desorb and oxidize or detoxify the contaminants. The adsorbent may be comprised of a unique combination of a zeolite with a material having a high dielectric value. The power supply for the nonthermal plasma reactor is designed to seek and operate at the system resonant frequency. In one embodiment, the adsorbent material is separated from the nonthermal plasma reactor. In this embodiment, heat is applied to the adsorbent material to thermally desorb contaminants during a desorption / regeneration phase. Air is recirculated within the system to move desorbed contaminants from the adsorbent material to the nonthermal plasma reactor for decomposition. The recirculating air repeatedly moves contaminants through the reactor until they are destroyed or the desorption / regeneration phase is complete.

Owner:ACCESS BUSINESS GRP INT LLC

Full-glass dual-channel vacuum tube heat collector

InactiveCN101788198AIncrease operating temperatureLow costSolar heating energySolar heat devicesCollector deviceOperation mode

The invention discloses a full-glass dual-channel vacuum tube heat collector, which comprises an outer glass tube, a heat-absorbing glass tube, an isolating glass tube and an inner glass tube. The full-glass dual-channel vacuum tube heat collector is characterized in that: the tops of the outer glass tube, the heat-absorbing glass tube and the isolating glass tube are smelted and sealed on a glass flange at high temperature and a cavity among the outer glass tube, the heat-absorbing glass tube and the glass flange is vacuumized to form a vacuum cavity; an interlayer between the heat-absorbing glass tube and the isolating glass tube forms a heated channel and the interlayer between the isolating glass tube and the inner glass forms an insulating layer; the outer ring of the glass flange is provided with an outlet which is communicated with the heated channel and the middle of the glass flange is provided with an inlet which is communicated with an inflow channel. The full-glass dual-channel vacuum tube heat collector combines two operation modes of natural circulation and forced circulation, can be widely applied to the integration of building solar energy, can be applied to the solar energy power generation and has the advantages of novelty, simple operation, low fault and low cost.

Owner:吴艳频 +2

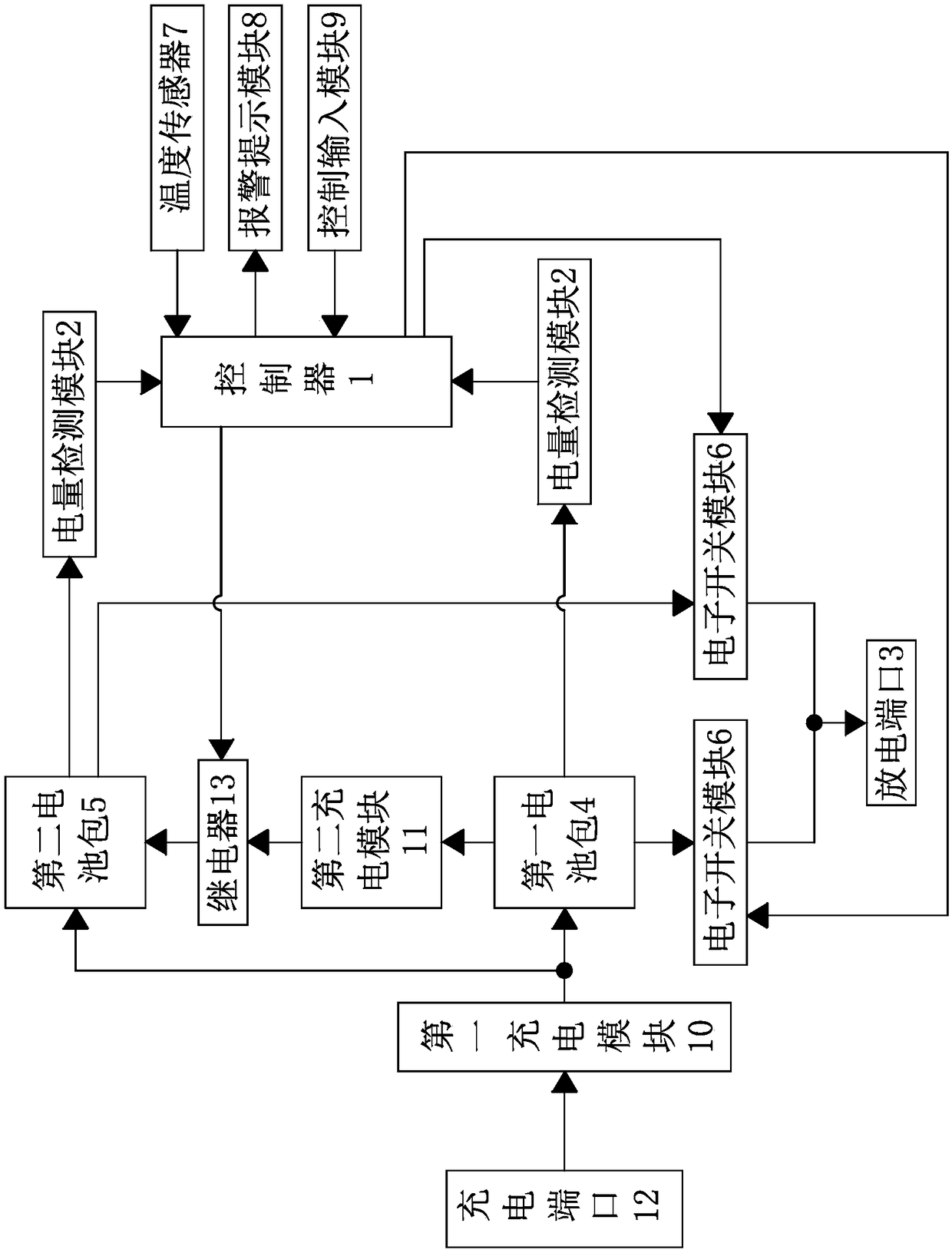

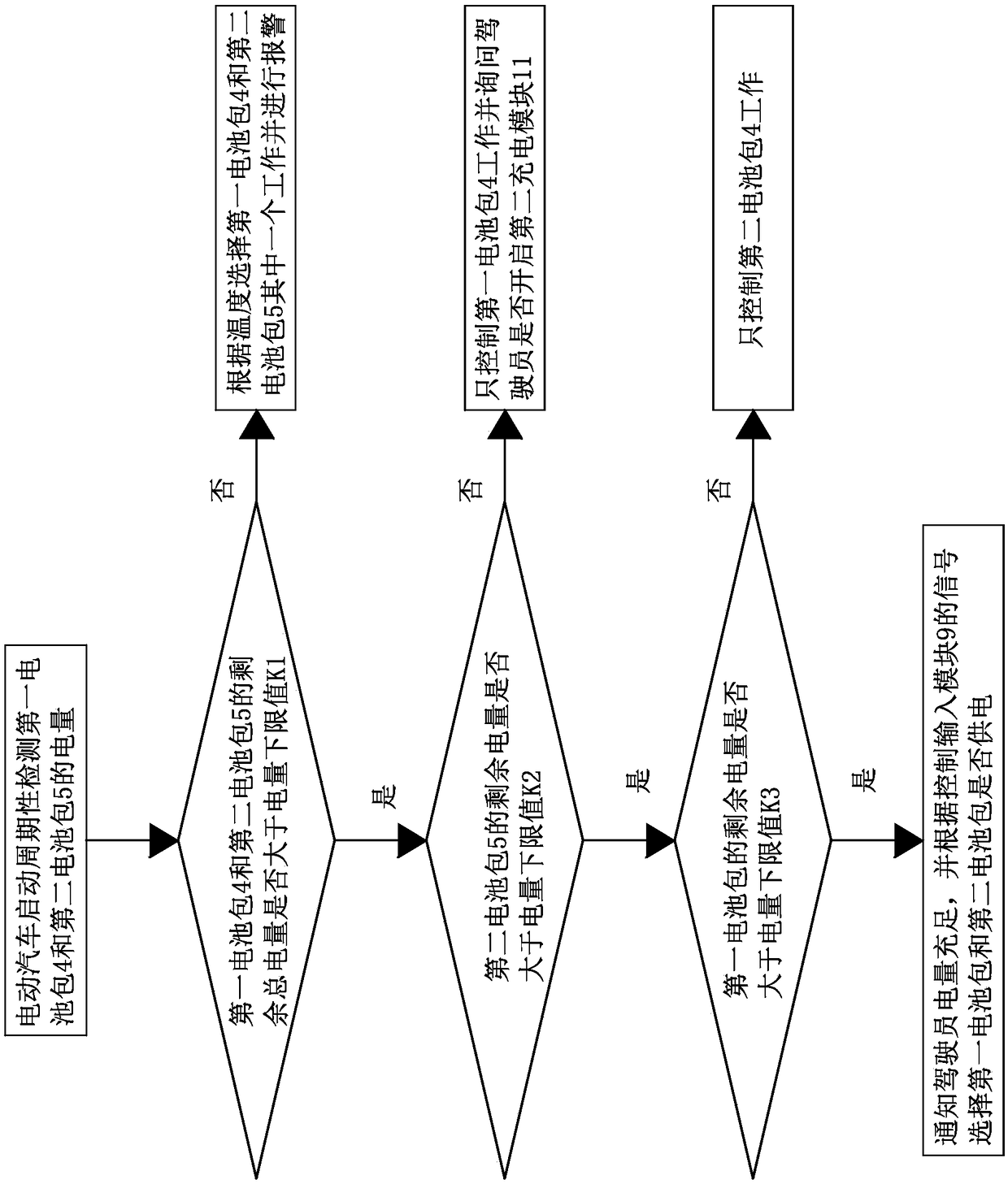

Changeable battery control system for electric automobile

ActiveCN108749617ALight in massEasy to operateVehicular energy storageElectric propulsionElectricityControl system

The invention provides a changeable battery control system for an electric automobile and belongs to the technical field of electric automobile battery changing. The problems that the power capacity of a fixedly arranged battery pack is hard to guarantee and the battery life cannot be rapidly prolonged in the prior art are solved. The changeable battery control system for the electric automobile comprises a controller, an electronic switch module, a detachable first battery pack, a fixed second battery pack, a first charging module, a charging port and a discharging port; and through the electronic switch module, the discharging port is supplied with power by using the first battery pack and / or the second battery pack. The changeable battery control system for the electric automobile further comprises a second charging module; the second charging module is supplied with power by using the first battery pack and used for charging the second battery pack; and the controller is used for controlling the second charging module and the electronic switch module. According to the changeable battery control system for the electric automobile, the power capacity in the fixedly arranged battery pack is preferentially kept.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD +1

Corrosion-proof vibration-proof wire

InactiveCN101145413AHigh tensile strengthSmall outer diameterInsulated cablesInsulated conductorsBreaking strengthElectrical conductor

The invention relates to an improvement of anti-corrosion and anti-vibration overhead power transmission cables for overhead power transmission lines and is characterized in that the reinforced inner core of the twisted cable is a fiber resin-molded elongated body and has a 0.5-8 mm distance to the innermost conductor of the twisted cable. The inventive wire has the advantages of self-damping vibration protection function, reduced weight of the reinforced core molded from resin mixed with carbon fiber and / or basalt fiber (50-70 percent of the steel-core anti-corrosion and anti-vibration cable core), increased tensile strength (up to 2000-6000MPa), maximum applied stress up to 60 percent of breaking strength, reduced base number or altitude of towers, larger construction span, large current capacity (about doubled), reduced construction cost (by 10-20 percent), and increased service life (by 20-30 years).

Owner:FAR EAST COMPOSITE TECH

Flexible tube side by side connected high-temperature, high-pressure squeezing and drying solid-liquid processing equipment

InactiveCN101352623AOvercome shear stressUniform humiditySemi-permeable membranesStationary filtering element filtersConnection typeSlag

The invention provides a flexible pipe parallel connection typed high-temperature and high-pressure squeezing and dry solid / liquid processing device; during the squeezing process, the solid / liquid separation is completed by a squeezing principle of changing volume of a filter chamber; the volume of the filter chamber can be near zero after the volume is changed; high pressure pump can not be needed to convey the raw material and additional squeezing water pump systems or squeezing air systems are not required to be taken as the filter pushing force of a press-filter; the mechanical pushing force is large and the pressurizing is quicker; repeated nipping filtration can be adopted; the washing filter slag is dipped; during the squeezing process, the alternative change of the thickness of the raw material improves the filtration speed, the washing speed and the efficiency; the humidity of a filter cake is uniform; the filtration and squeezing can be carried out at the same time when the vacuum or steam drying is carried out; the production quantity of each sequence batch is easily changed according to the requirement of production capability; the washing regeneration of the filter medium is automatically completed; the slag drainage is automatically completed; during the production process, various automatic protections can be adopted, thus completely realizing the automation, reducing the energy dissipation and having high production efficiency.

Owner:张民良

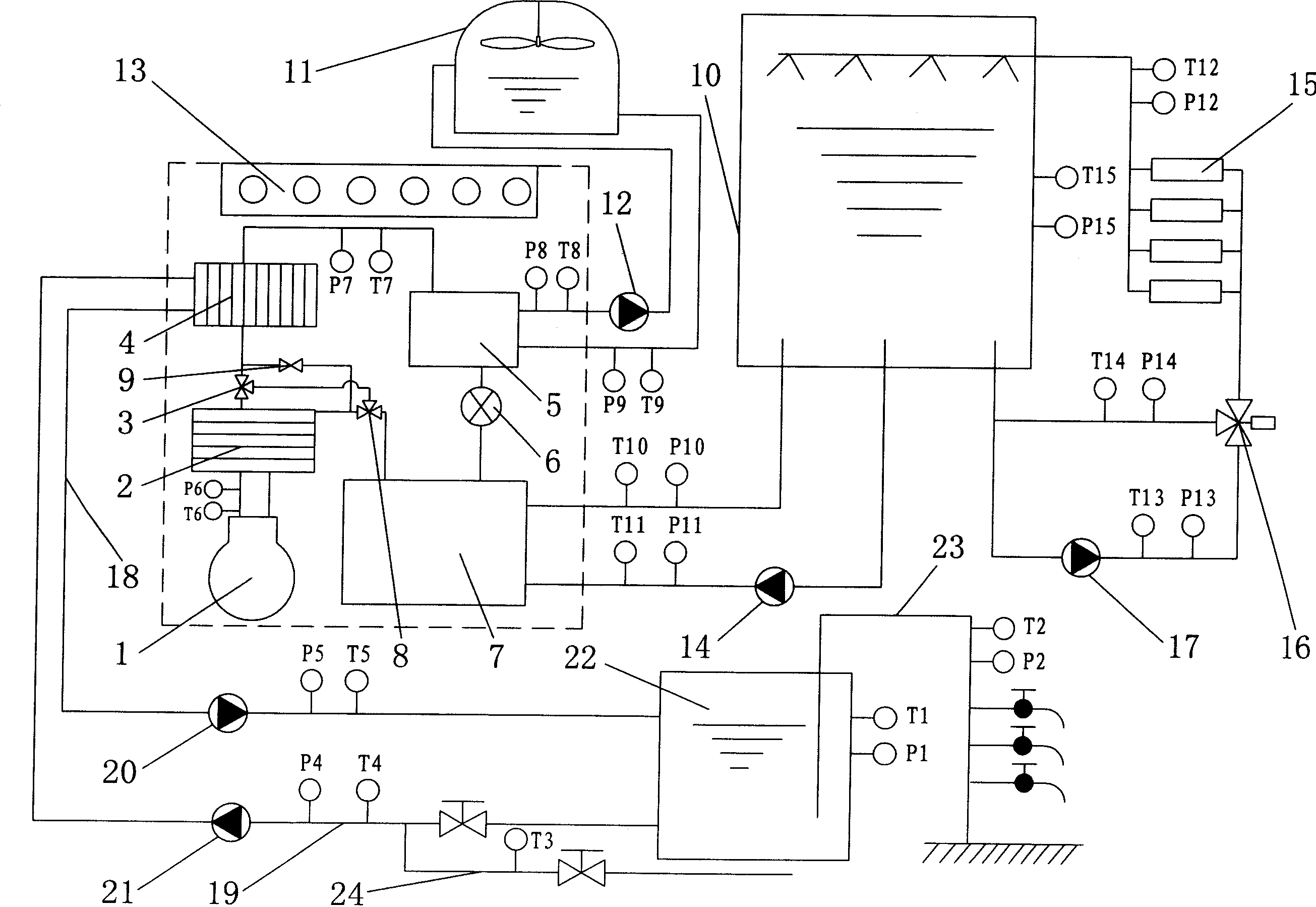

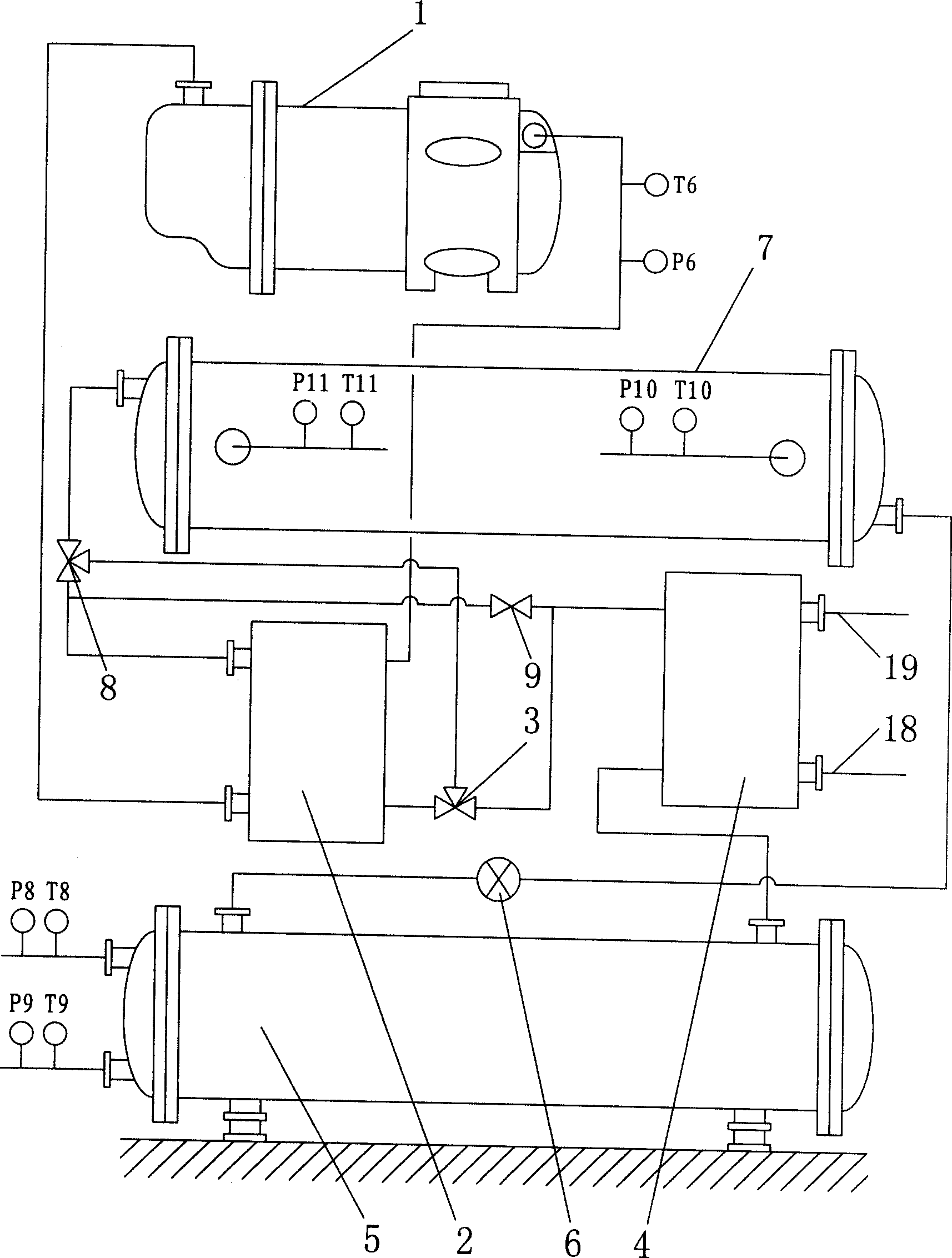

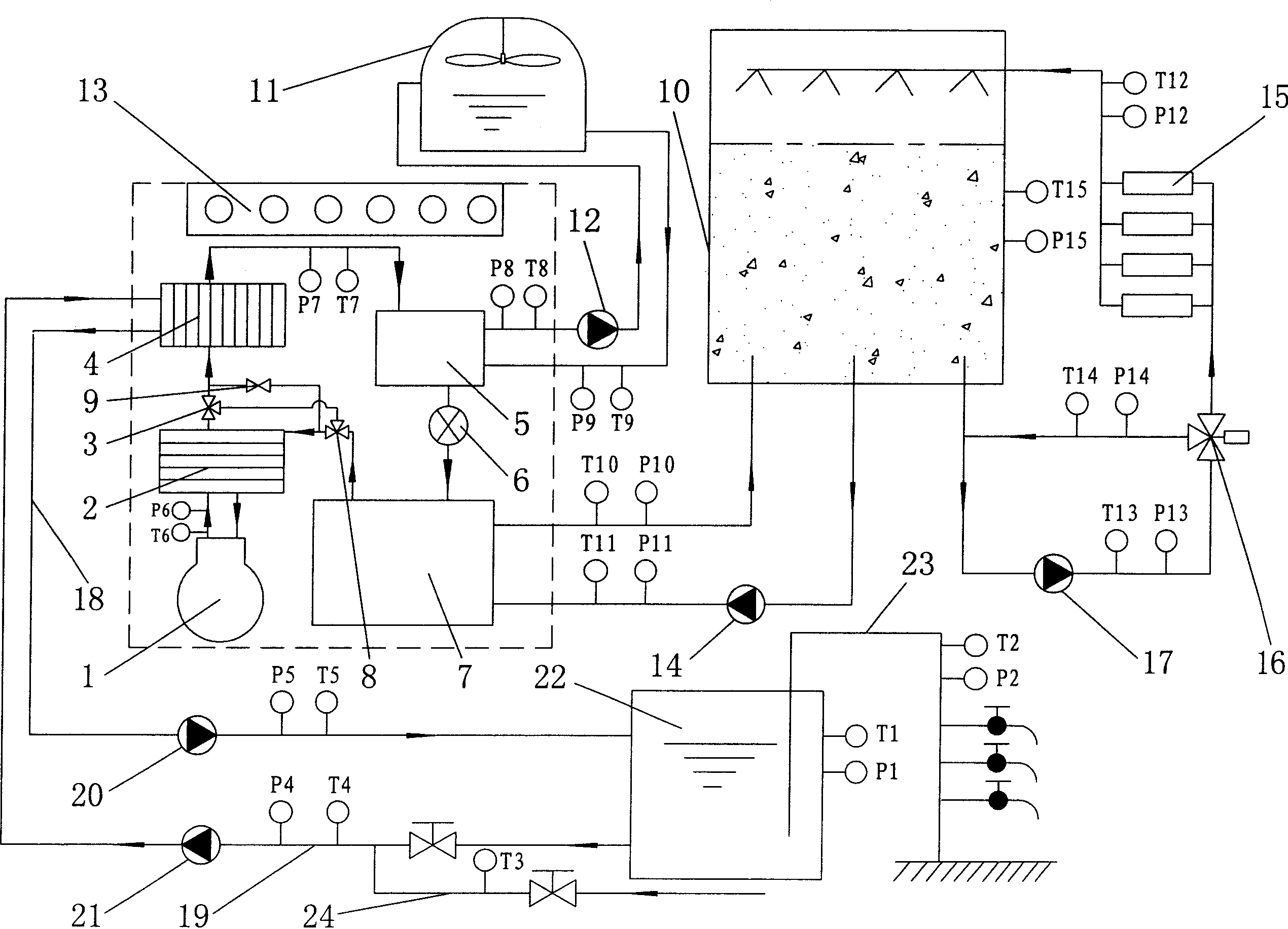

Ice-storage heat pump energy saving unit

ActiveCN1763460ARealize the heat pump functionAvoid pollutionHeat pumpsHeating and refrigeration combinationsWorking fluidAutomatic control

The invention discloses an ice-reservation heat pump energy-saving unit, which comprises the following parts: cold water unit, refrigerating working fluid cooling water circulation system, ice-reservation system, indoor cold-and-heat supply system and computer self-control device (13), wherein the cold water unit contains compressor (1), first heat-exchanger (5), electronic expansion valve (6), second heat-exchanger (7), plate-type refrigerating working fluid heat-exchanger (2), first electronic three-way valve (3), second electronic three-way valve (8), electromagnetic valve (9), which forms a loop through refrigerating working fluid pipe connection. The invention can be applied in the air-conditioner energy-saving domain widely.

Owner:中碳实业(珠海)有限公司

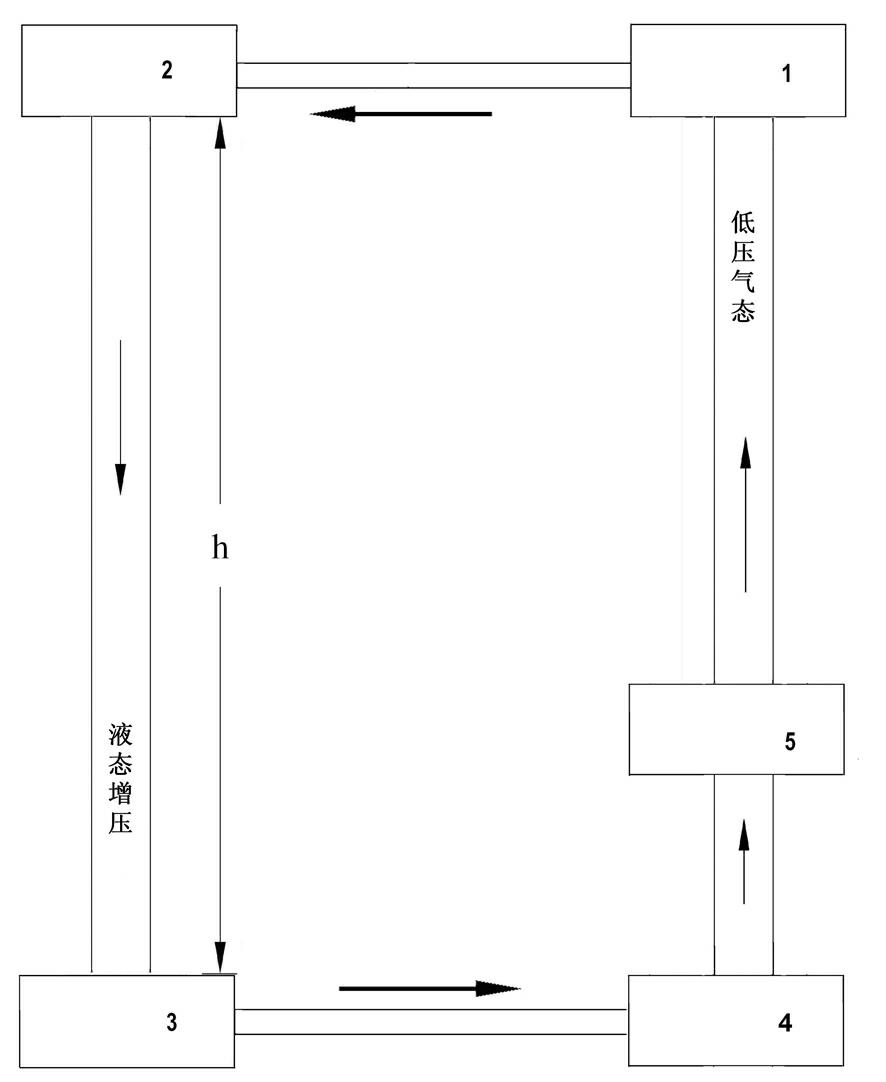

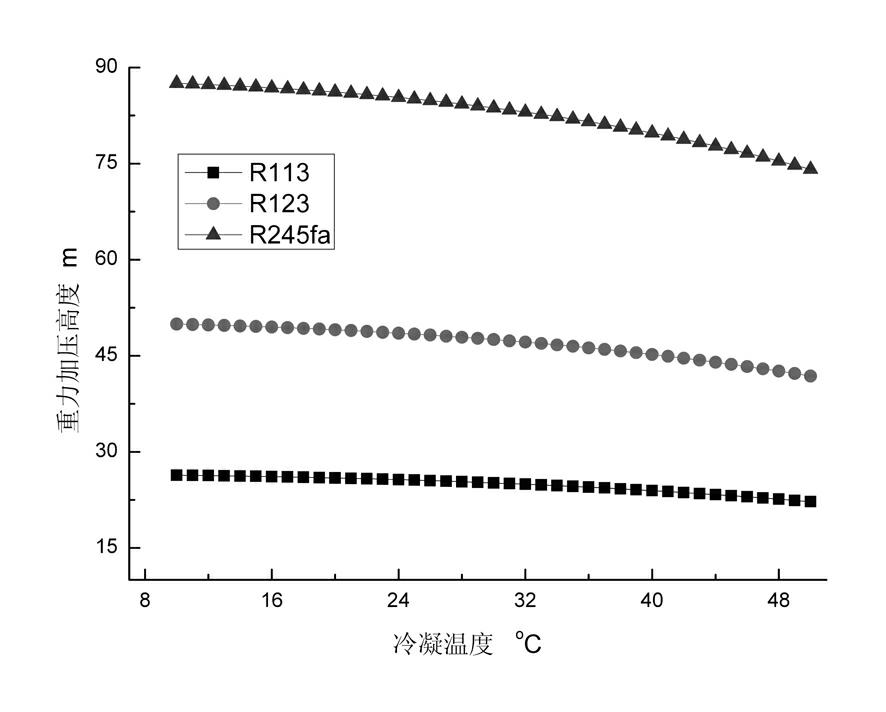

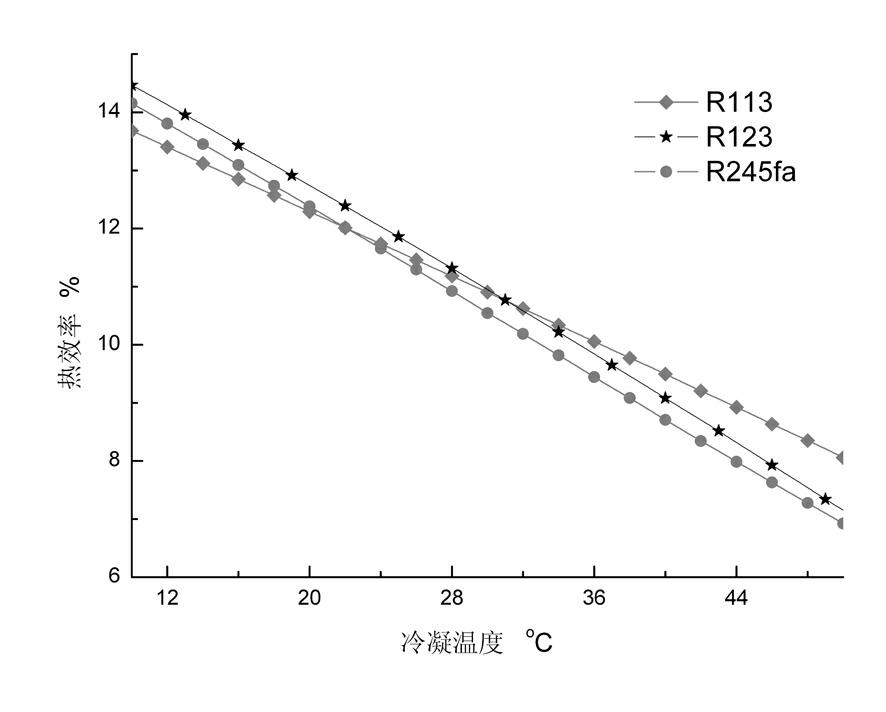

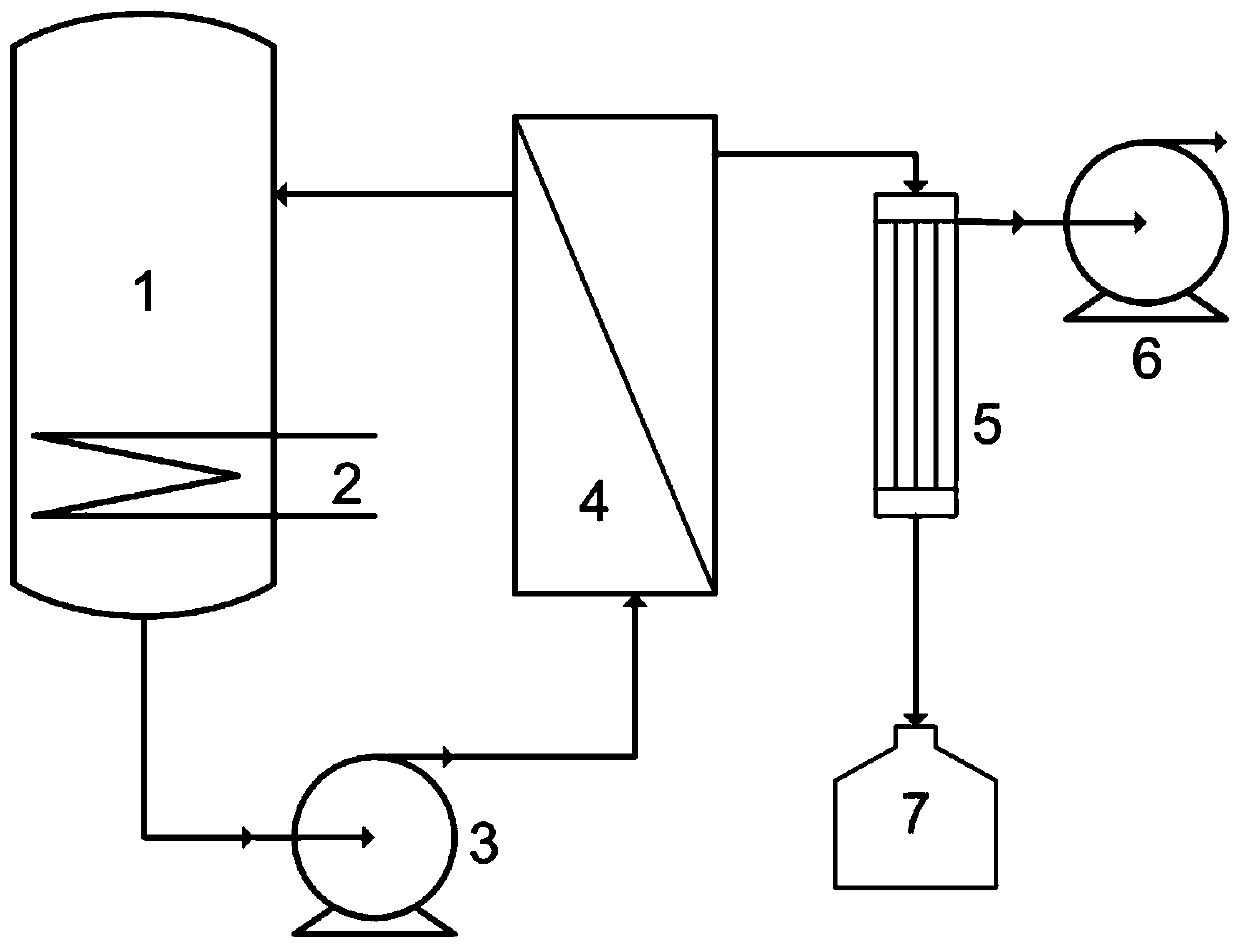

Organic working medium thermal power generation circulating system boosted by aid of gravity

InactiveCN102536365AIncrease operating temperatureIncrease operating pressureSteam engine plantsLiquid storage tankEngineering

The invention relates to an organic working medium thermal power generation circulating system boosted by the aid of gravity. A working medium outlet of an expansion machine of the system is communicated with a working medium inlet of a condenser via a pipeline, a working medium outlet of the condenser is communicated with an inlet of a liquid storage tank via a pipeline, an outlet of the liquid storage tank is communicated with a working medium inlet of an evaporator via a pipeline, a working medium outlet of the evaporator is communicated with an inlet of a gas storage tank via a pipeline, and an outlet of the gas storage tank is communicated with an inlet of the expansion machine via a pipeline; working medium is an organic matter; the locations of the condenser and the liquid storage tank are higher than the location of the evaporator by 5 meters to 200 meters in a gravity field; and average working temperature of the evaporator is higher than that of the condenser by 30 DEG C to 25 DEG C. A low working condition running characteristic of the organic working medium is combined with the gravity field, required evaporation pressure is provided for the organic working medium by the aid of the gravity, a pump is omitted in total circulation, and the structure is simple; and the organic working medium thermal power generation circulating system realizes simple and high-efficiency conversion between medium and low temperature grade thermal energy and mechanical energy, and has quite high technical feasibility and application prospect.

Owner:UNIV OF SCI & TECH OF CHINA

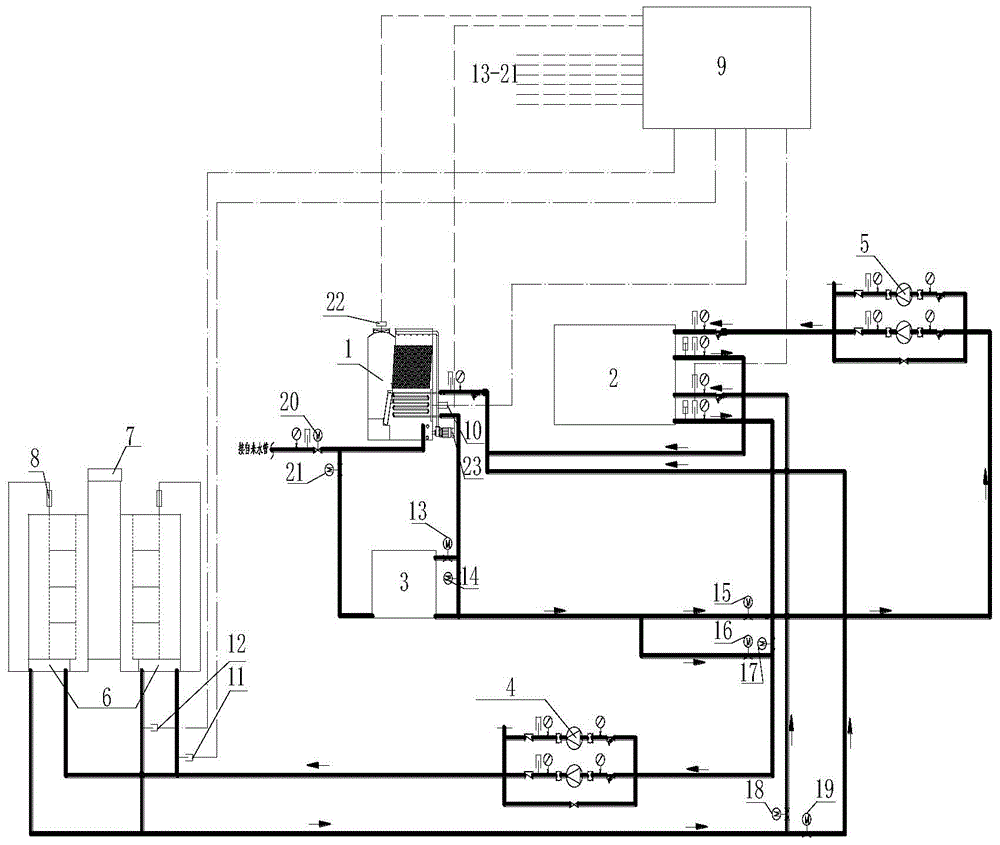

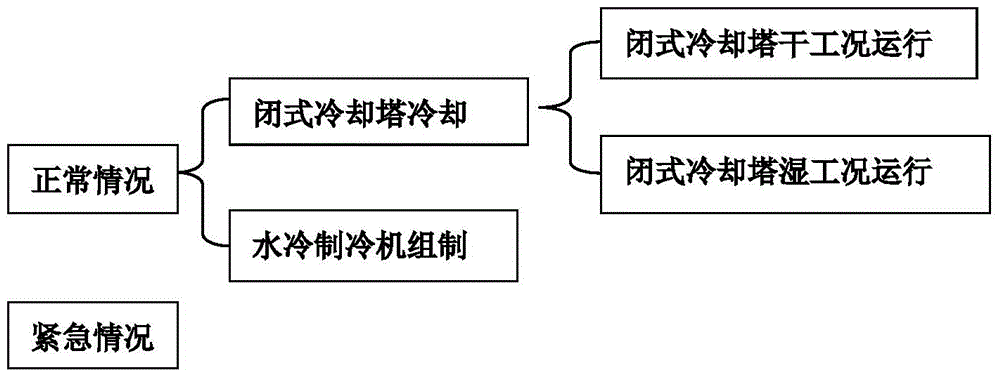

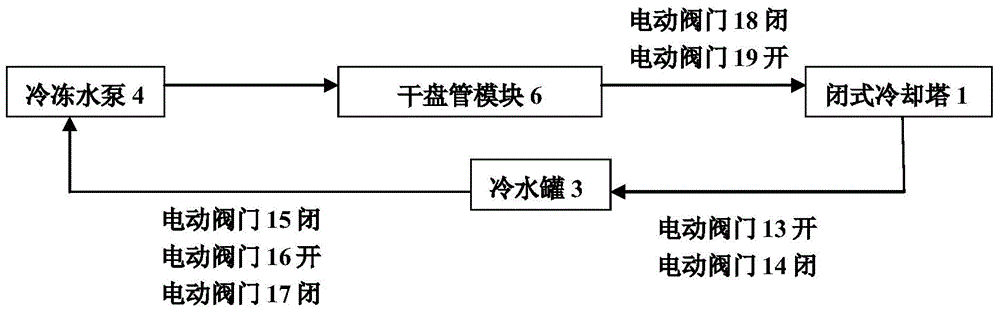

Heat humidity independently controlled air conditioning system applied to IDC machine room and refrigeration method

InactiveCN104456774AGuaranteed safe operationFlexible areaMechanical apparatusSpace heating and ventilation safety systemsCooling towerControl system

The present invention provides a heat humidity independently controlled air conditioning system applied to IDC machine room and a refrigeration method. The air conditioning system comprises a closed type cooling tower, a water-cooling refrigeration unit, a cold water tank, a refrigerated water pump, a cold water pump, a dry coil module, a fresh air dehumidification module, an exhaust device, an embedded control system, a closed cooling tower inlet air wet-and-dry-bulb temperature sensor, a dry coil module inlet water temperature sensor, and a dry coil module outlet water temperature sensor. The refrigeration method is as follow: when the dry bulb temperature of the outdoor air is lower than the criterion temperature 1, the closed type cooling tower operates in the dry conditions, the water-cooling refrigeration unit stops, and thus water and energy are saved; when the dry bulb temperature of the outdoor air is higher than the criterion temperature 1 and the wet bulb temperature is lower than the criterion temperature 2, the closed type cooling tower operates in the wet condition, the water-cooling refrigeration unit stops, and thus energy is saved; and when the wet bulb temperature of the outdoor air is higher than the criterion temperature 2, the water-cooling refrigeration unit operates and during the operation process the outlet water temperature is the criterion temperature 2, and thus energy is saved.

Owner:JIANGNAN UNIV

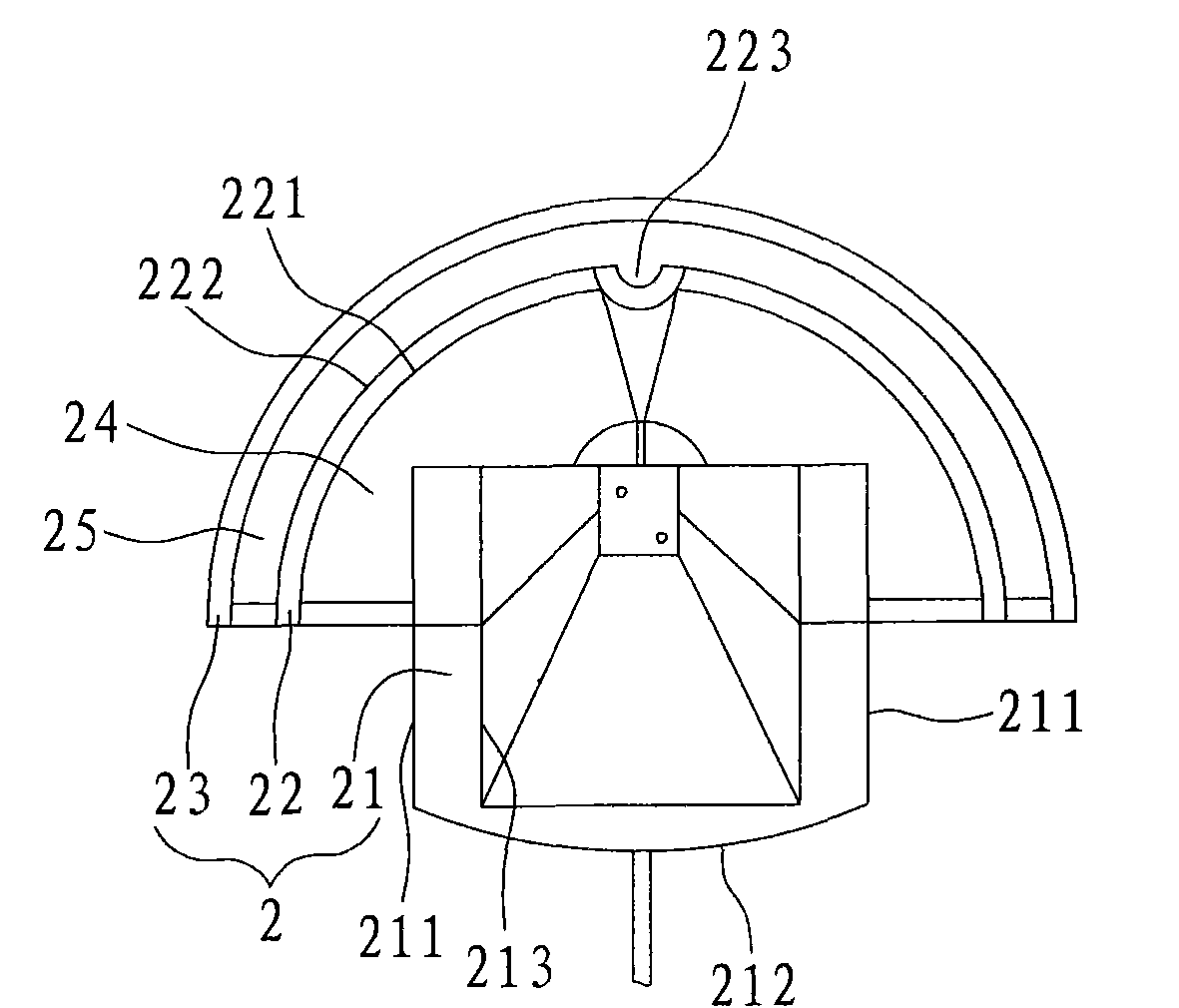

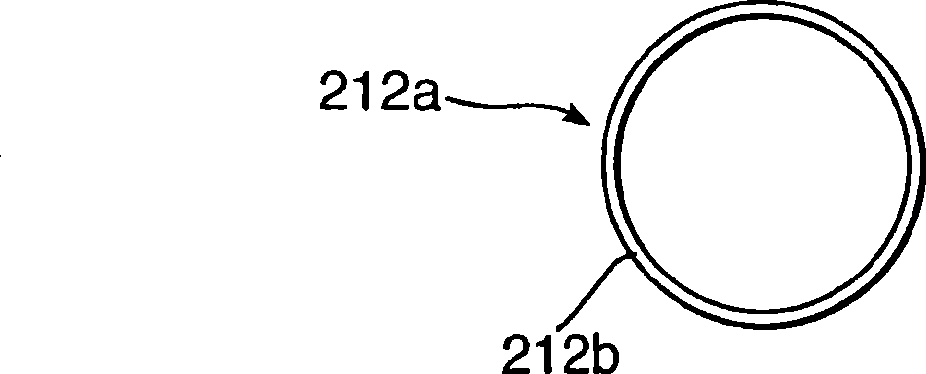

Novel solar seawater desalination system

InactiveCN101792190ARealize the purpose of reheat utilizationReduce heat lossSolar heating energyGeneral water supply conservationHigh energyWater vapor

The invention discloses a novel solar seawater desalination system. The system mainly comprises a condensing reflection slot, a seawater desalination device and a circulation water tank, wherein the seawater desalination device is arranged in the middle of the condensing reflection slot and is communicated with the hollow interlayer of the condensing reflection slot through a pipeline; and the circulation water tank is connected with the seawater desalination device through pipelines. The solar seawater desalination system improves energy flux density by using solar energy condensation, recycles water vapor latent heat of vaporization to heat seawater to be evaporated, improves energy utilization efficiency and operating temperature of the system by using the technology that a cooling water pipe recycles residual heat generating desalted water and the like and improves forced-convection heat transfer coefficients by adopting a cooling cover outer wall forced-convection heat transfer mode, and regulating flow velocity of a water pump so as to improve condensation effect of water vapor. The system has the characteristics of high energy utilization efficiency, large desalted water yield, investment saving, low energy consumption, simple structure, convenient operation, easy control and the like and is particularly suitable for low-cost and small-scale production.

Owner:JIMEI UNIV

Solar energy collection system

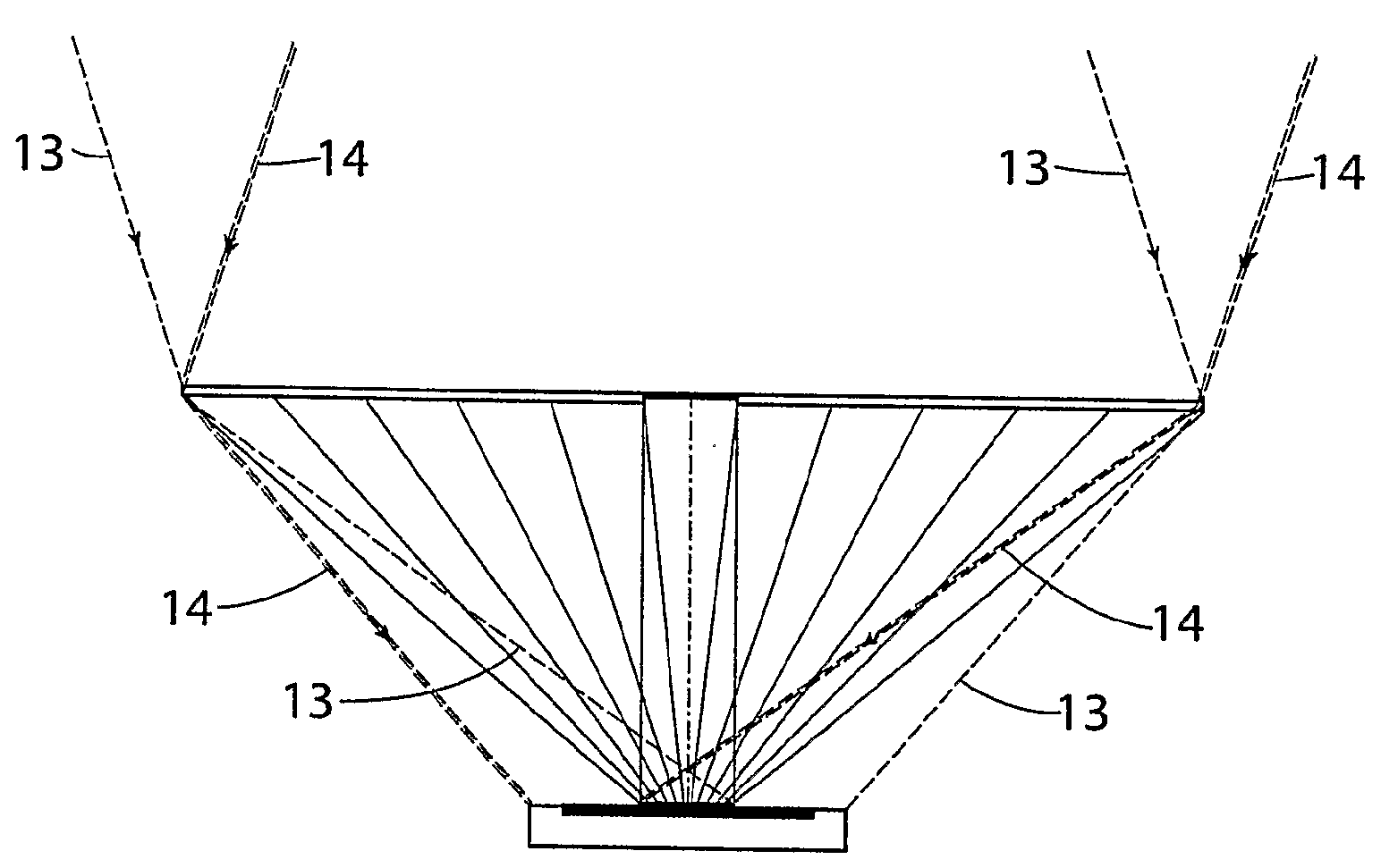

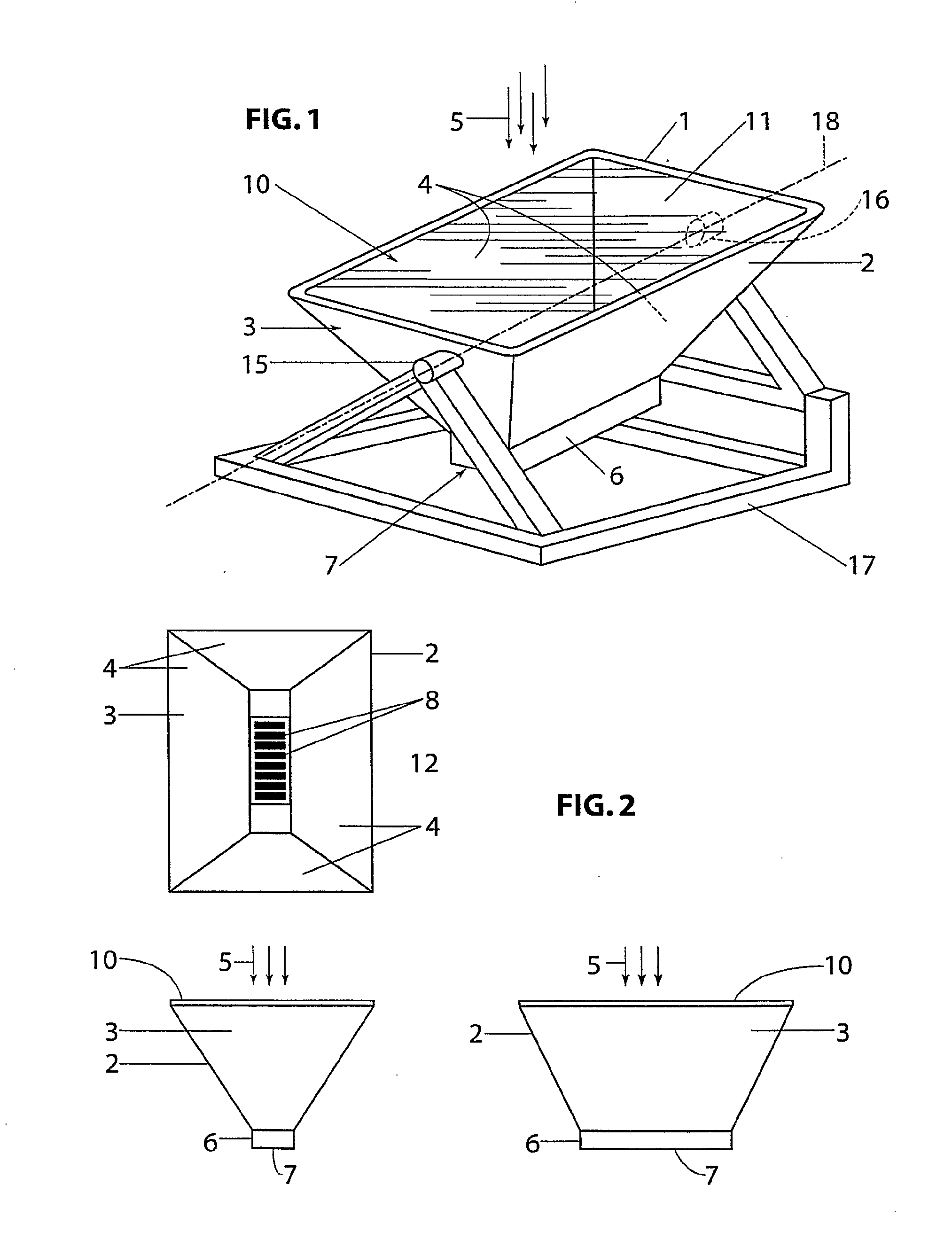

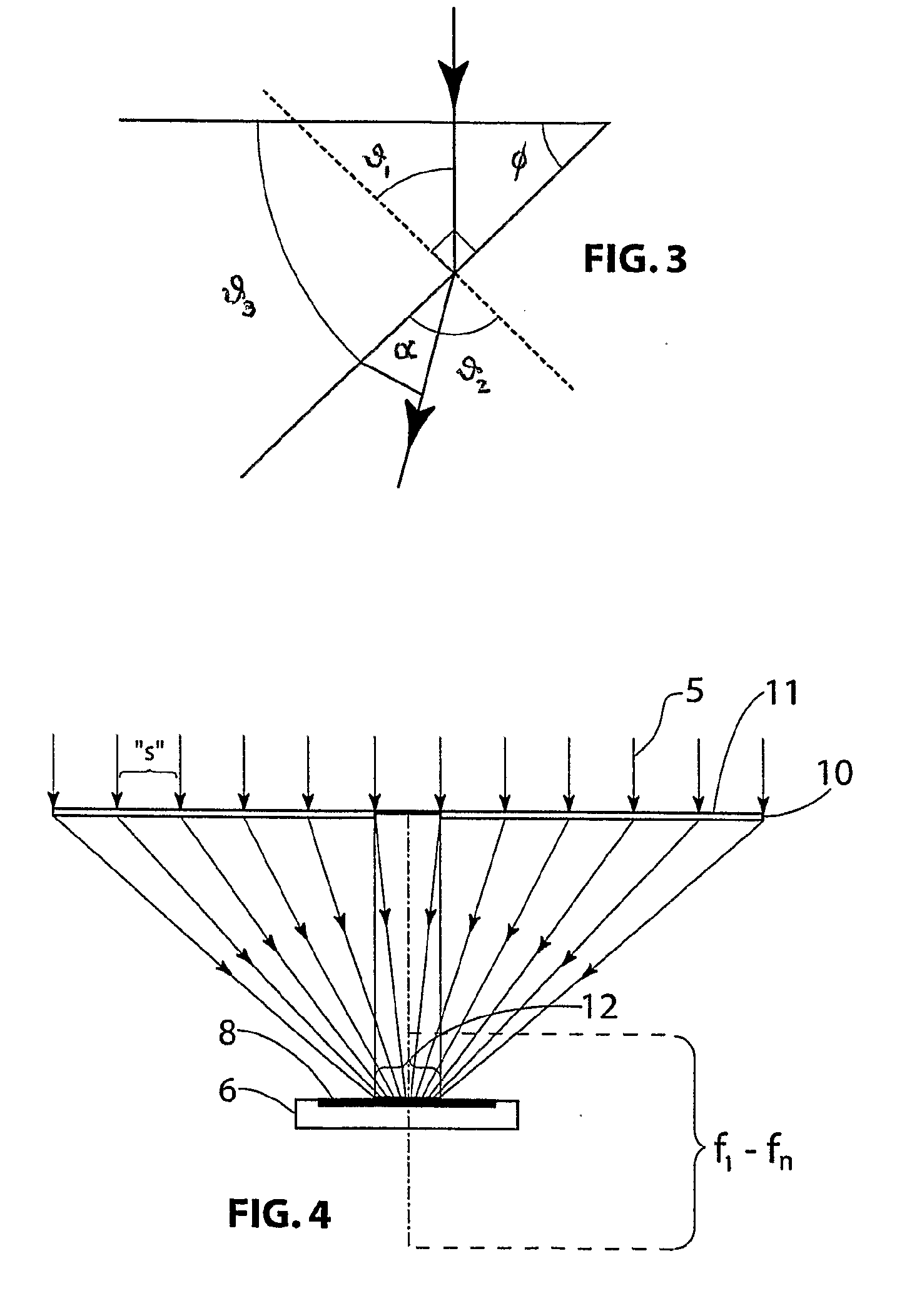

InactiveUS20090223553A1Increase working temperatureMinimal lossSolar heating energySolar heat collector controllersElectricityCollection system

A collector (2) for concentrating radiation (5), preferably solar radiation, and an energy collection system (1) that includes the collector, which concentrates the radiation along an elongate region of a body which converts the radiation into electrical and / or heat energy. A lens (10) is also disclosed for use in the system, which has a focal plane extending normally of the lens.

Owner:TECHN SOLAR

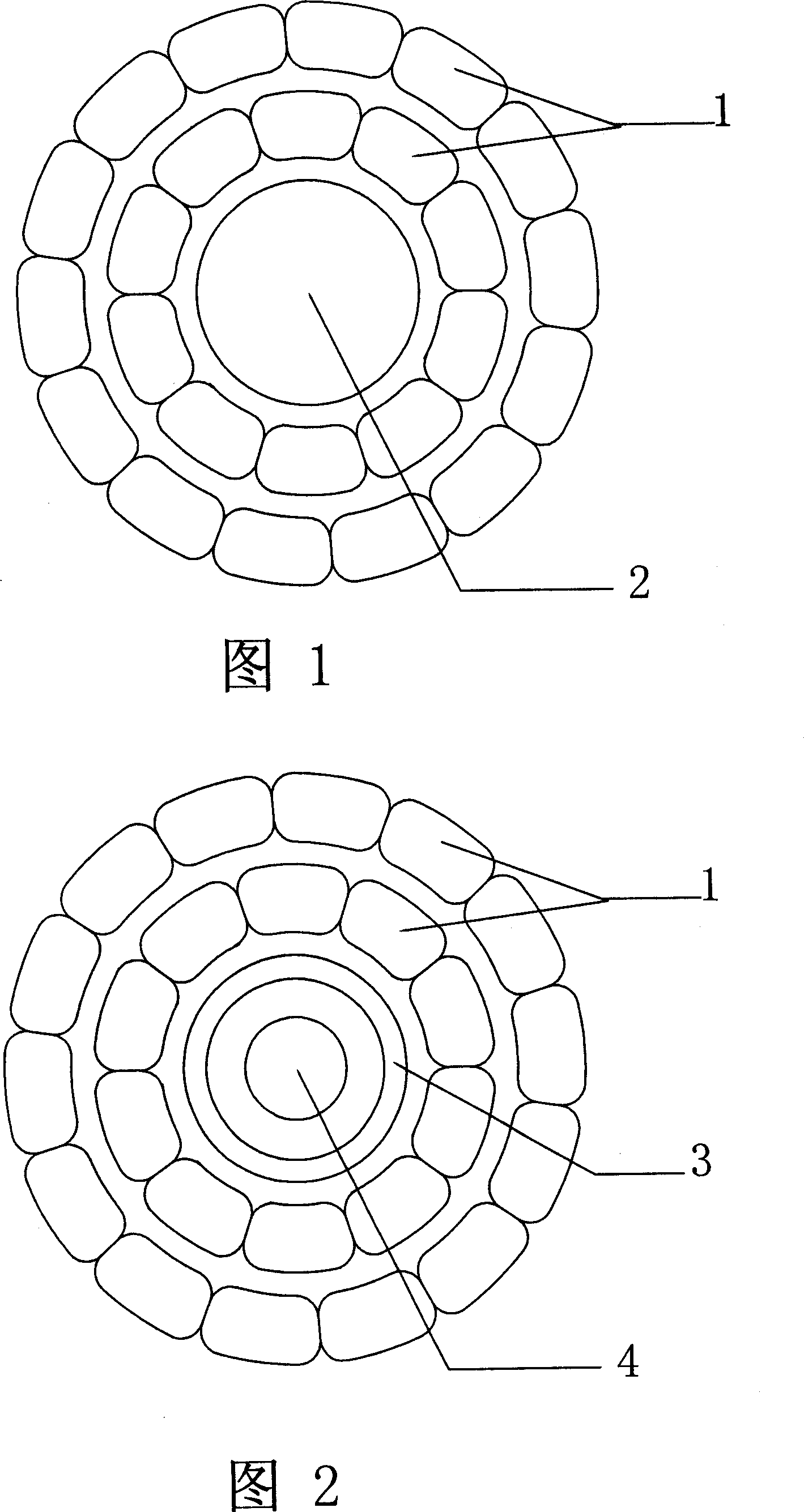

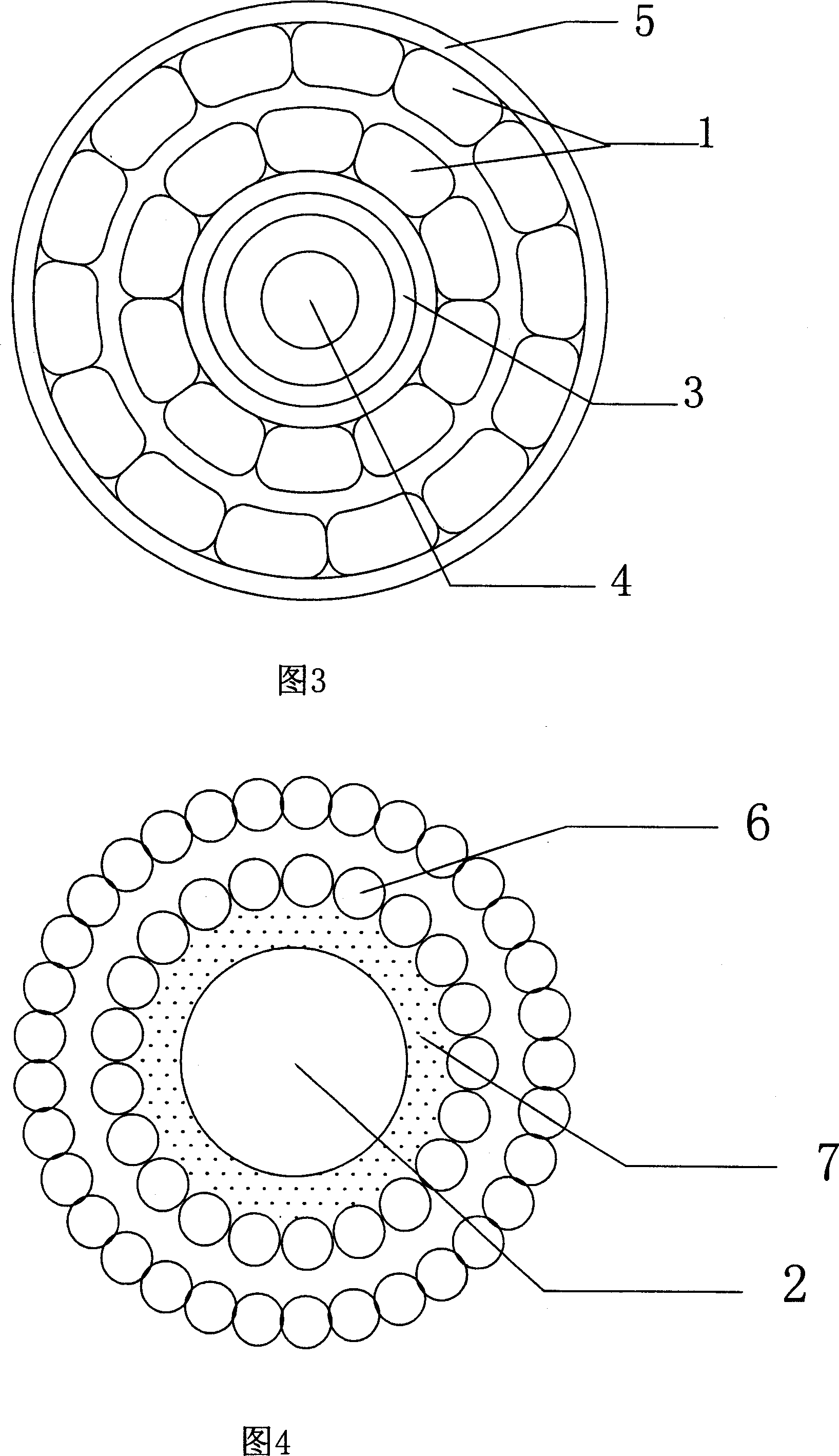

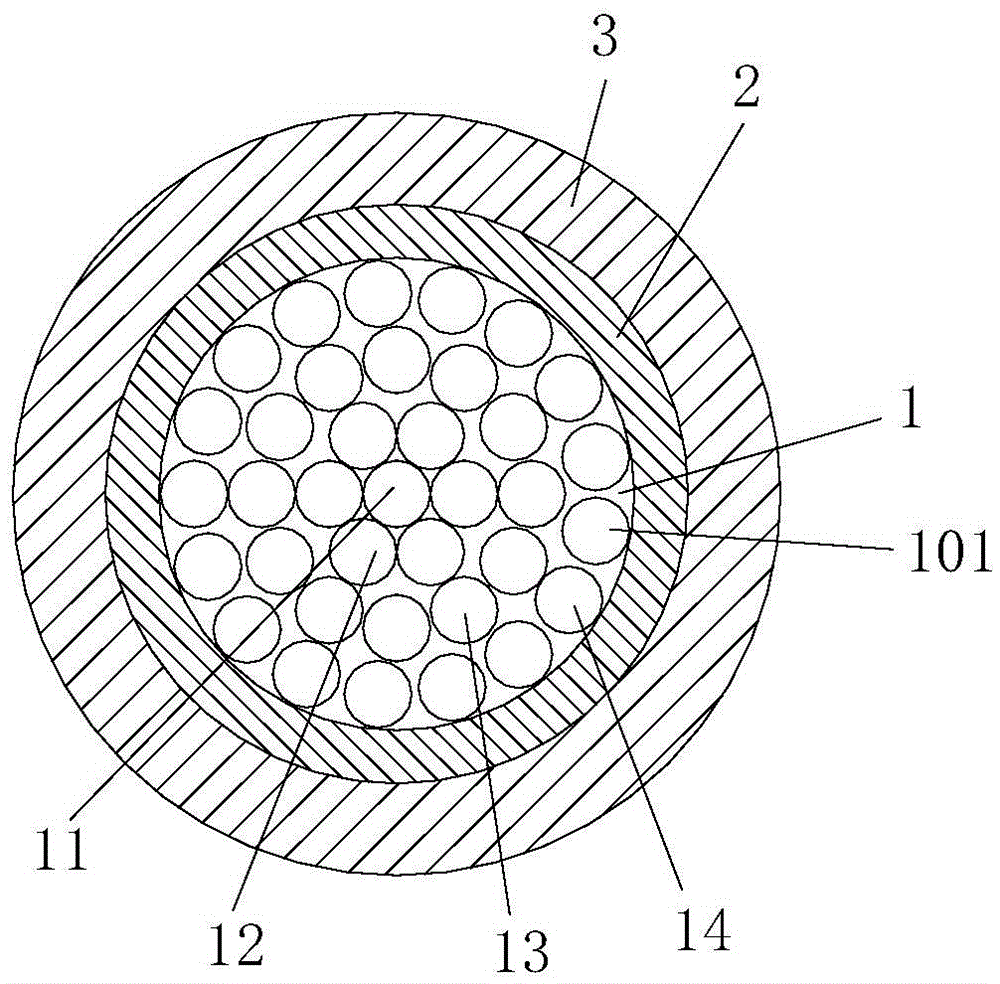

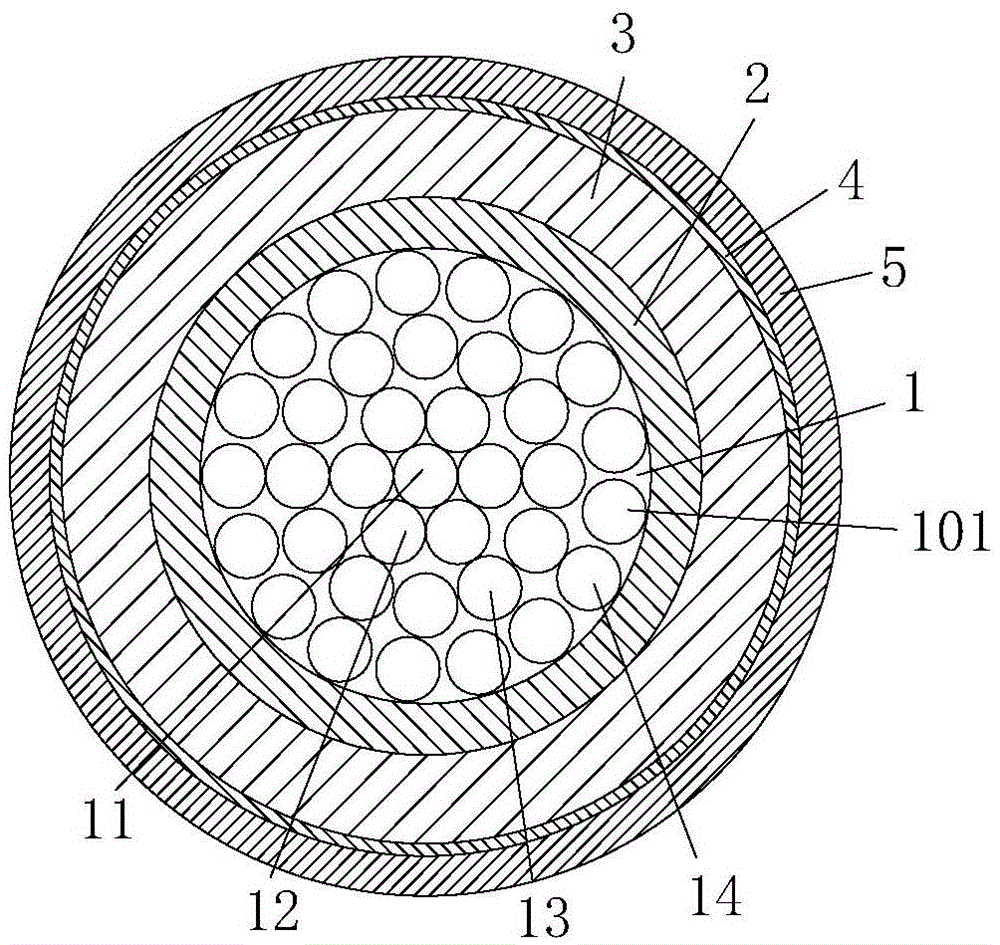

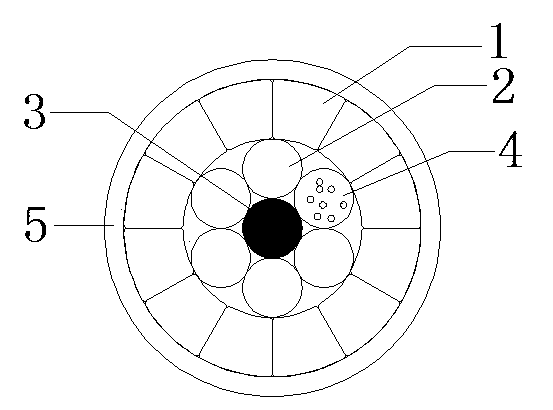

Insulating aerial aluminum alloy cable and preparation method thereof

ActiveCN105575460AGuaranteed temperatureIncrease operating temperatureConductive materialPower cables with screens/conductive layersPolyolefinCarrying capacity

The invention provides an insulating aerial aluminum alloy cable and a preparation method thereof. The cable comprises an aluminum alloy cable core, and a shielding layer and an insulating layer which are formed outside the aluminum alloy cable core from inside to outside in turn through extrusion. The shielding layer is formed by silane crosslinked polyolefin semi-conductive material through extrusion. The insulating layer is formed by silane crosslinked polyethylene material through extrusion or obtained through extrusion formation of the silane crosslinked polyethylene material and then irradiation processing. The aluminum alloy cable core has a compressive circular structure manufactured by 7-91 single heat-resistant aluminum alloy wires through twisting, and the cross section of the wires is circular. According to the cable, carrying capacity for transmission is enabled to be higher than original carrying capacity and cross section efficiency is enhanced for 40%-60% without changing the existing cable specifications. Reconstruction of old lines of existing urban and rural power grids can be facilitated, and reconstruction cost can be greatly reduced and reconstruction cost can be saved.

Owner:陕西永光电力电缆制造有限公司

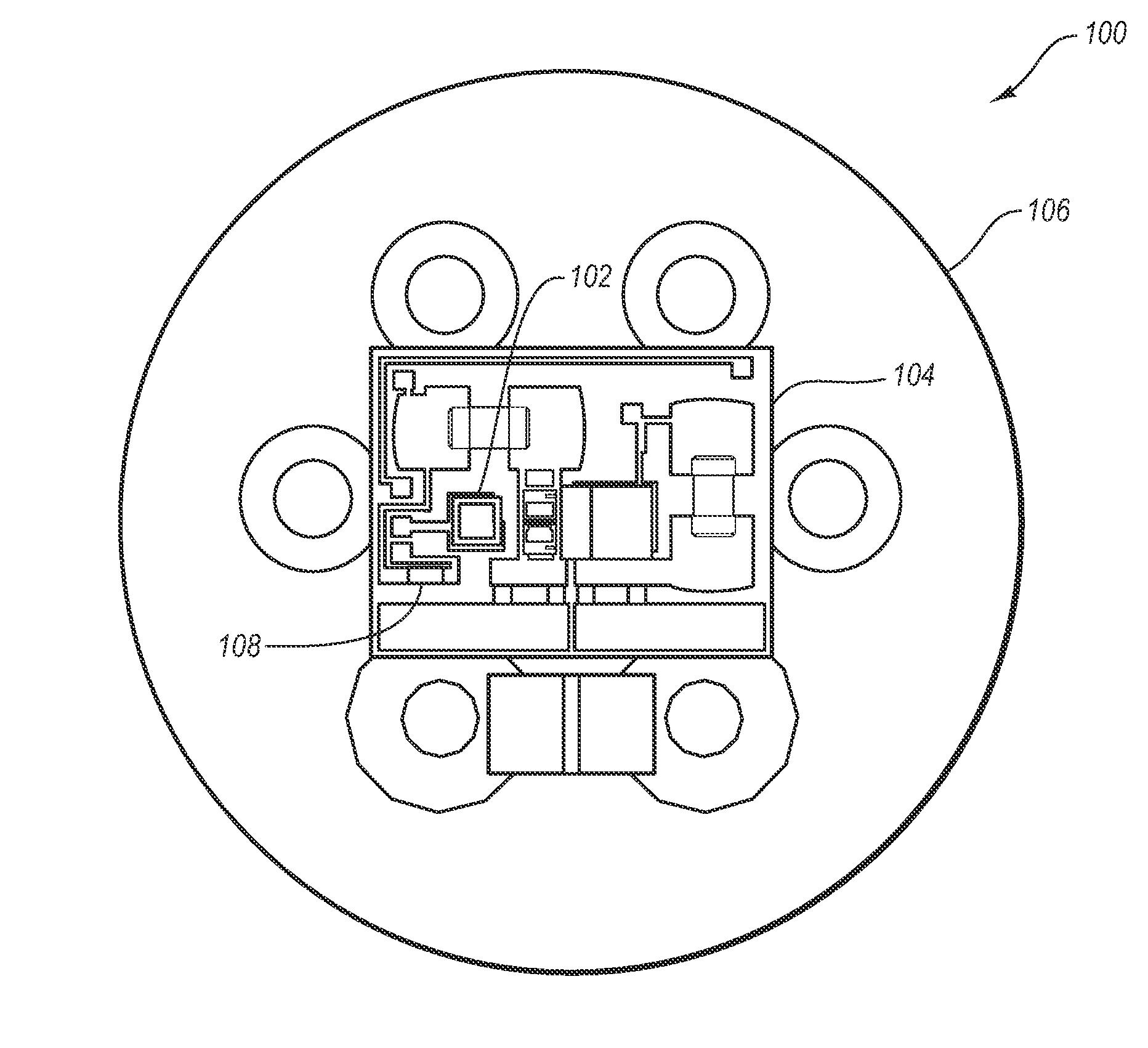

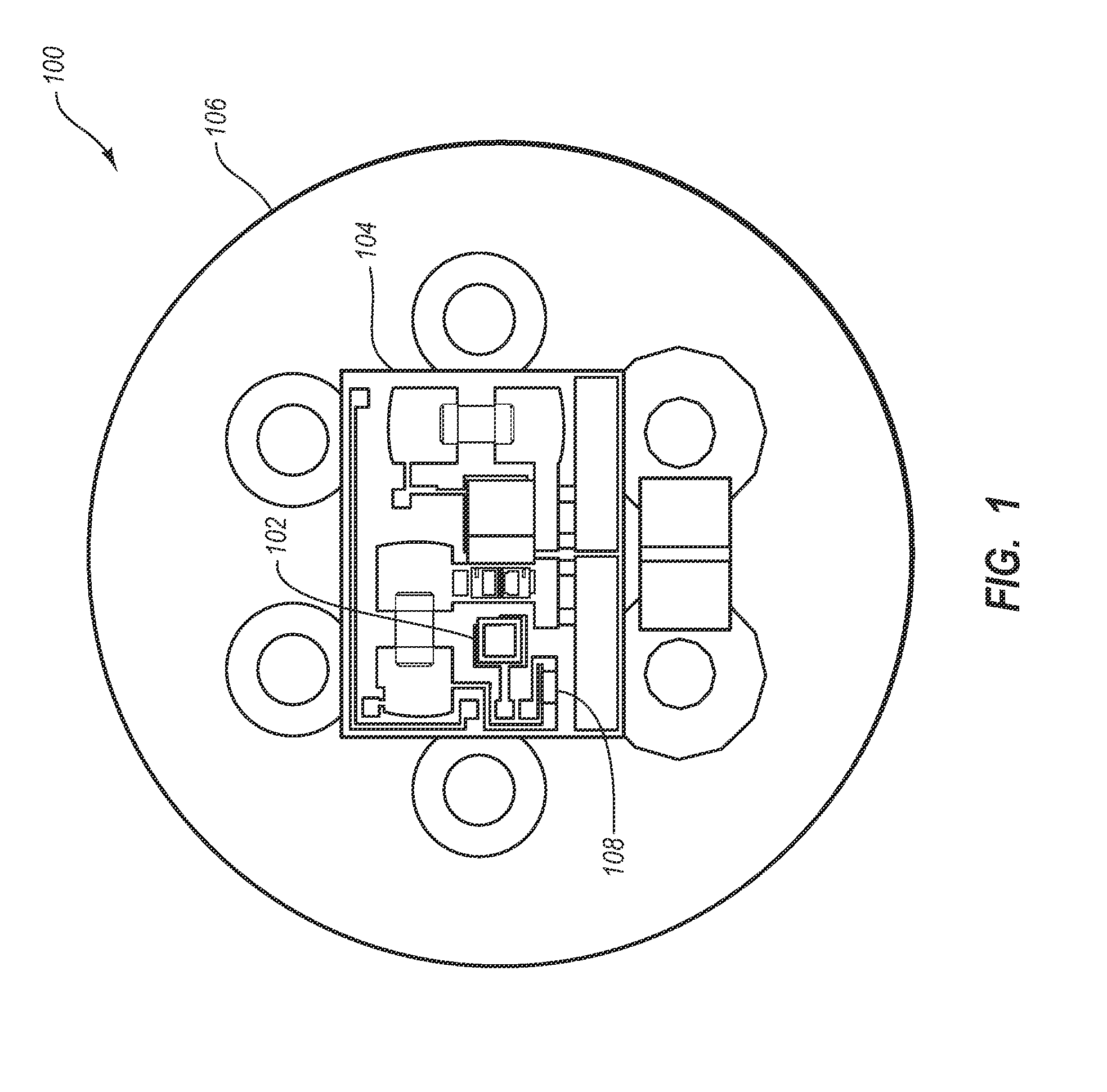

Resistive heating element for enabling laser operation

ActiveUS20080267233A1Increase operating temperatureLaser optical resonator constructionLaser cooling arrangementsOperating temperatureOperating temperature range

Heating resistor used to control laser operation. A laser package, such as a Transmitter Optical Subassembly (TOSA) includes a substrate. A laser is disposed on the substrate. A resistive heating element is disposed on the substrate with the laser. Control circuitry is connected to the resistive heating element. The control circuitry is configured to cause current flow through the resistive heating element based on temperature conditions. Current flow through the resistive heating element causes an increase in the operating temperature of the laser. This can be used to increase the effective operating temperature range of a laser.

Owner:II VI DELAWARE INC

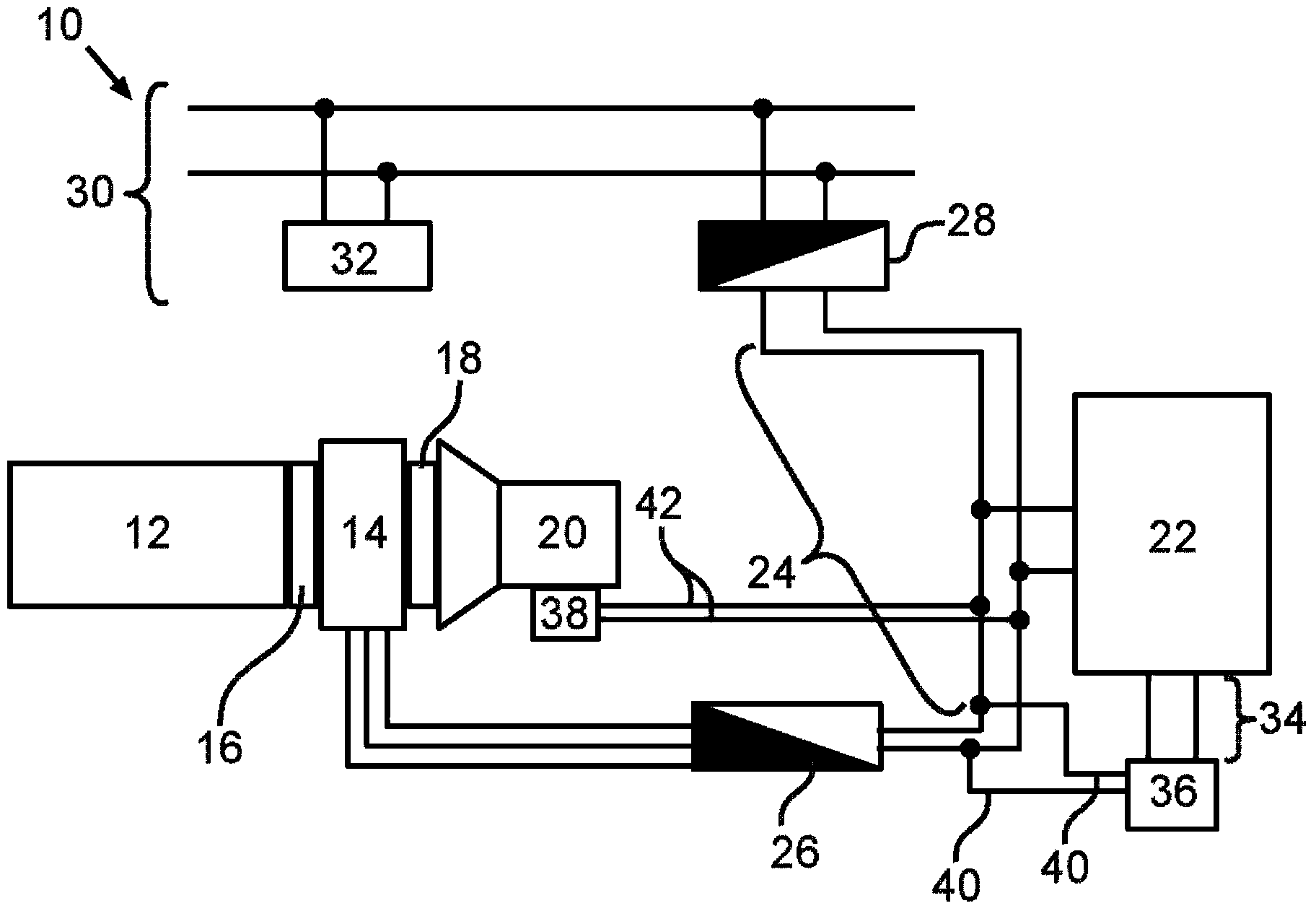

Method for operating motor vehicle with hybrid drive

ActiveCN103517843AAvoid energy lossReduce consumptionHybrid vehiclesAir-treating devicesElectricityOperating temperature

The invention relates to a method for operating a motor vehicle with a hybrid drive (10), in which at least one operating medium of the motor vehicle is heated to a predetermined desired temperature by means of a dielectric heating device (36, 38). By this means, immediately following a cold start of the motor vehicle, components through which the operating medium flows can be brought particularly rapidly to the optimum operating temperature thereof such that a particularly energy-saving operation of the motor vehicle is possible.

Owner:AUDI AG

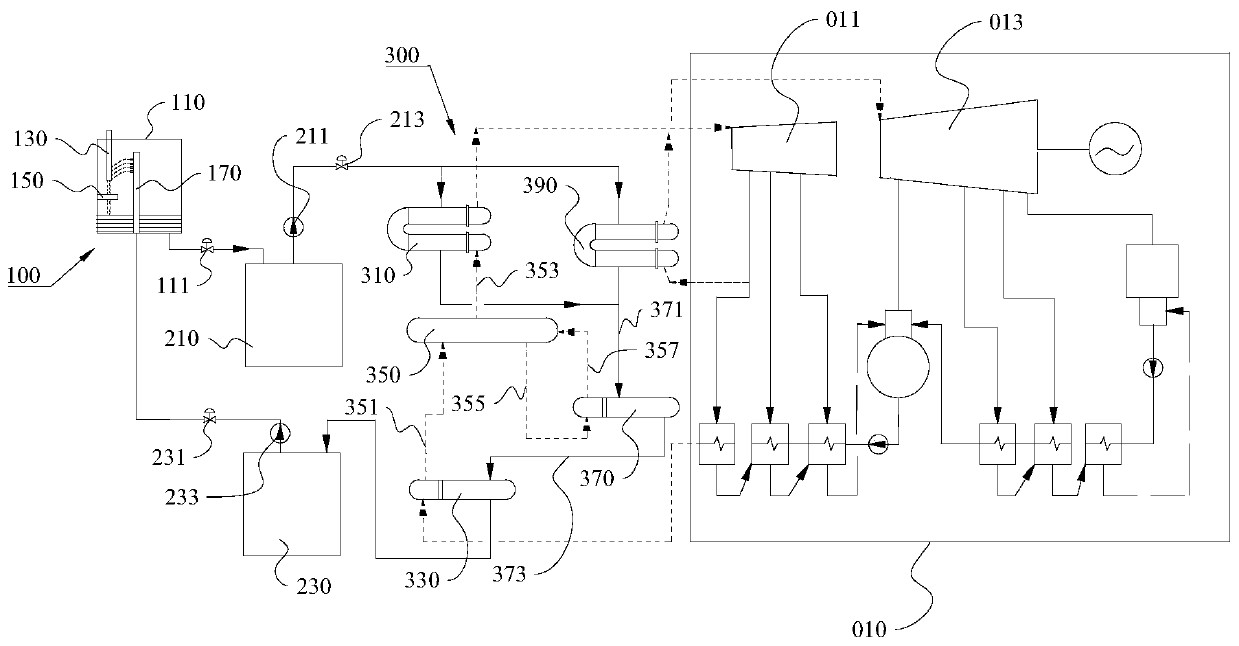

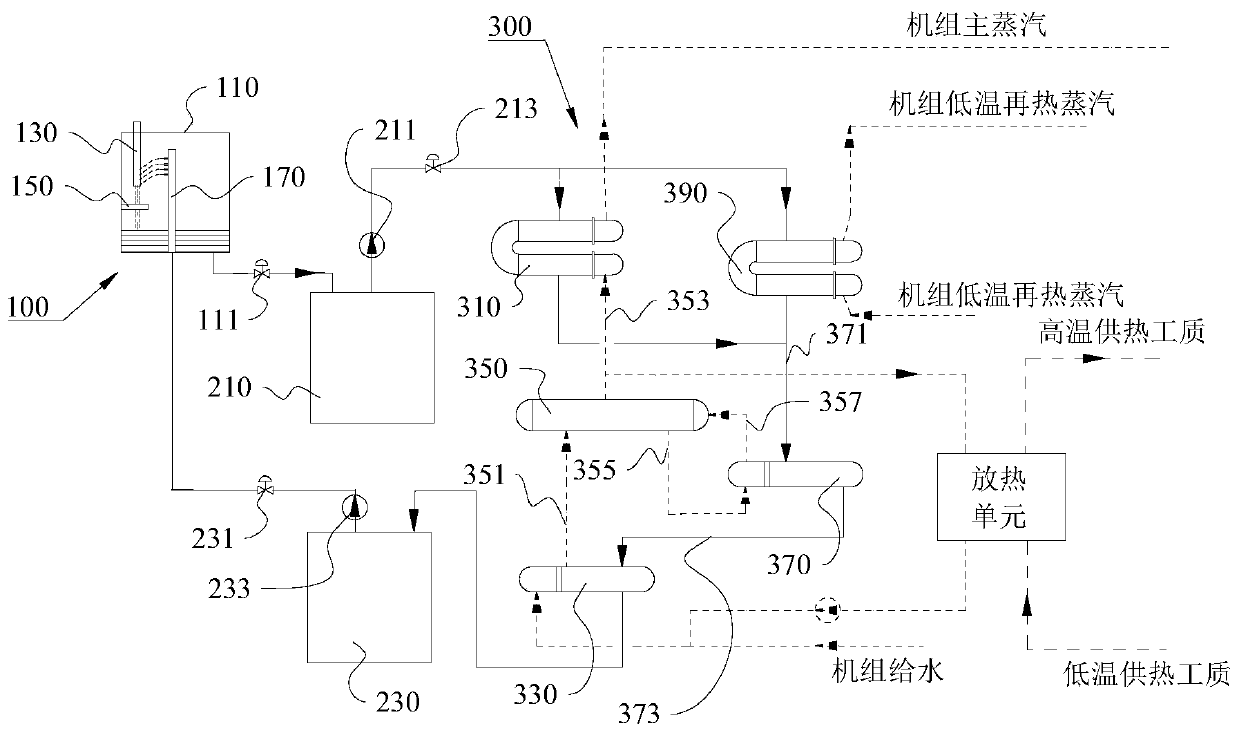

Molten salt electrode boiler heat storage and power generation system

InactiveCN111288428AAchieve large-scale storageImplement schedulingHeat storage plantsEnergy storageElectric powerBoiler (power generation)

The invention provides a molten salt electrode boiler heat storage and power generation system, and belongs to the field of energy storage. The system involves a heating part, a high-temperature molten salt storage tank and a heat utilization part; the heating part comprises a boiler body, a high-voltage electrode, a neutral electrode and a low-temperature molten salt supply head, wherein the high-voltage electrode, the neutral electrode and the low-temperature molten salt supply head are arranged in the boiler body, the high-voltage electrode is used for being connected with a power generation system, and the low-temperature molten salt supply head is used for filling the boiler body with low-temperature molten salt; one end of the high-temperature molten salt storage tank is connected with the bottom of the boiler body, and the other end of the high-temperature molten salt storage tank is connected with the heat utilization part; and the heat utilization part is used for carrying outheat exchange on the molten salt sent out by the high-temperature molten salt storage tank and a water working medium for pushing the steam turbine to act, and sending the cooled molten salt back tothe boiler body. Wind power photovoltaic curtailed electricity is used for heating the molten salt and storing heat in the off-peak period of electricity utilization, and high-temperature molten saltis used for heating feed water to generate high-temperature and high-pressure steam in the peak period of electricity utilization, so that the steam turbine is pushed to act, he stored heat is converted into electric energy to be output, and the curtailed wind and light can be effectively consumed to realize large-scale storage and scheduling of non-water renewable energy power.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Energy gradient utilization system and method for supercritical water gasification hydrogen production process

PendingCN111171875ARelease fullyEfficient use ofGasification processes detailsBulk chemical productionCombustionEngineering

The invention discloses an energy gradient utilization system and method for a supercritical water gasification hydrogen production process. The system comprises a supercritical hydrothermal combustion reactor and a supercritical water gasification reactor. A bottom outlet of the supercritical water gasification reactor is connected to an inlet of a gas-phase separator through a hot fluid side ofa first preheater, a hot fluid side of a temperature regulator and a pressure regulator. A bottom outlet of the gas-phase separator is connected to a top inlet of the supercritical hydrothermal combustion reactor through a hot fluid side of a first heat regenerator, a booster pump and a cold fluid side of a second preheater. The bottom center of the supercritical hydrothermal combustion reactor iscommunicated with the supercritical water gasification reactor through a flow guide piece. An outlet of a water feeding pump and a cold fluid side outlet of the first heat regenerator are both divided into two paths, provide cold fluid respectively and finally send the cold fluid to a first inlet of a mixer. An outlet of the mixer is connected with an efficient cooling jacket, an outlet of the efficient cooling jacket is connected with an inlet of a steam turbine through a temperature and pressure regulator, and an outlet of the steam turbine is connected with an inlet of the water feeding pump. According to the invention, comprehensive gradient utilization of pressure energy and heat energy in the coal gasification hydrogen production process is achieved.

Owner:XI AN JIAOTONG UNIV

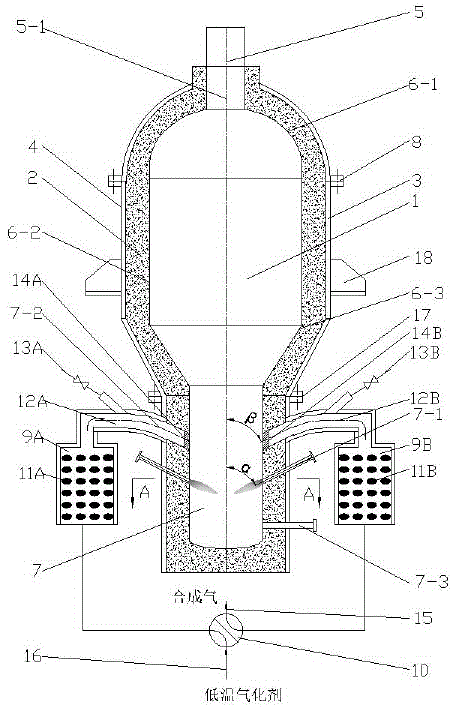

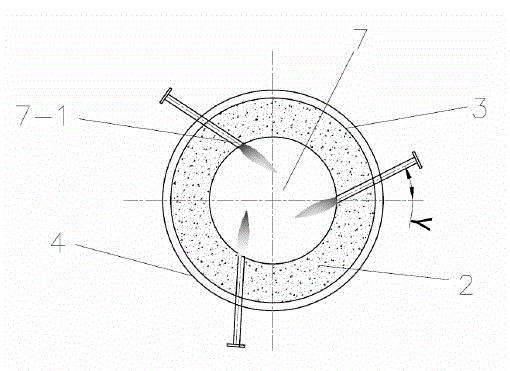

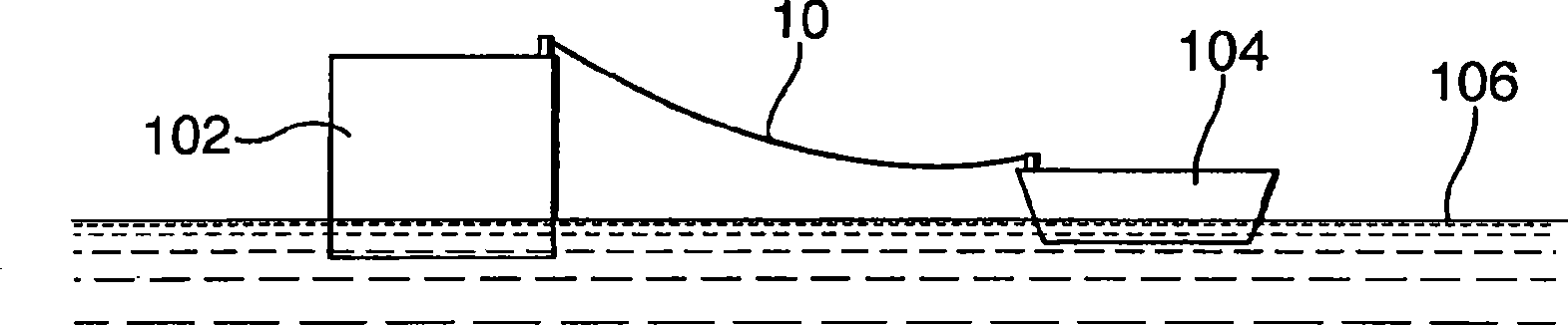

Household garbage gasification furnace with functions of regenerative high temperature air gasification and plasma smelting

InactiveCN104974795AIncrease profitIncrease operating temperatureChemical industryCombustible gas productionProcess engineeringDomestic waste

The invention discloses a household garbage gasification furnace with the functions of regenerative high temperature air gasification and plasma smelting. The gasification furnace comprises a plasma gasification reaction furnace and a regenerative heat exchange system, wherein gasification reaction is carried out in the plasma gasification reaction furnace; the regenerative heat exchange system is installed on a lower segment of the plasma gasification reaction furnace and comprises two regenerative chambers, regenerators, two synthesis gas passages and a four-way reversing valve; the two regenerative chambers are symmetrically arranged at the two sides outside the plasma gasification reaction furnace and are filled with the regenerators; the tops of the regenerative chambers are connected with synthesis gas outlets of the plasma gasification reaction furnace by the synthesis gas passages, and the bottoms of the regenerative chambers are connected with the four-way reversing valve by pipelines. The household garbage gasification furnace has the beneficial effects that the sensible heat of pyrolysis and gasification gas is recovered by heating gasification air by adopting synthesis gas produced by the plasma gasification reaction furnace to increase the energy utilization rate; the regenerative heat exchange system is adopted for regenerative heat exchange, thus increasing the household garbage conversion rate and the heat value of produced gas and reducing the power consumption of a plasma torch.

Owner:中国东方电气集团有限公司

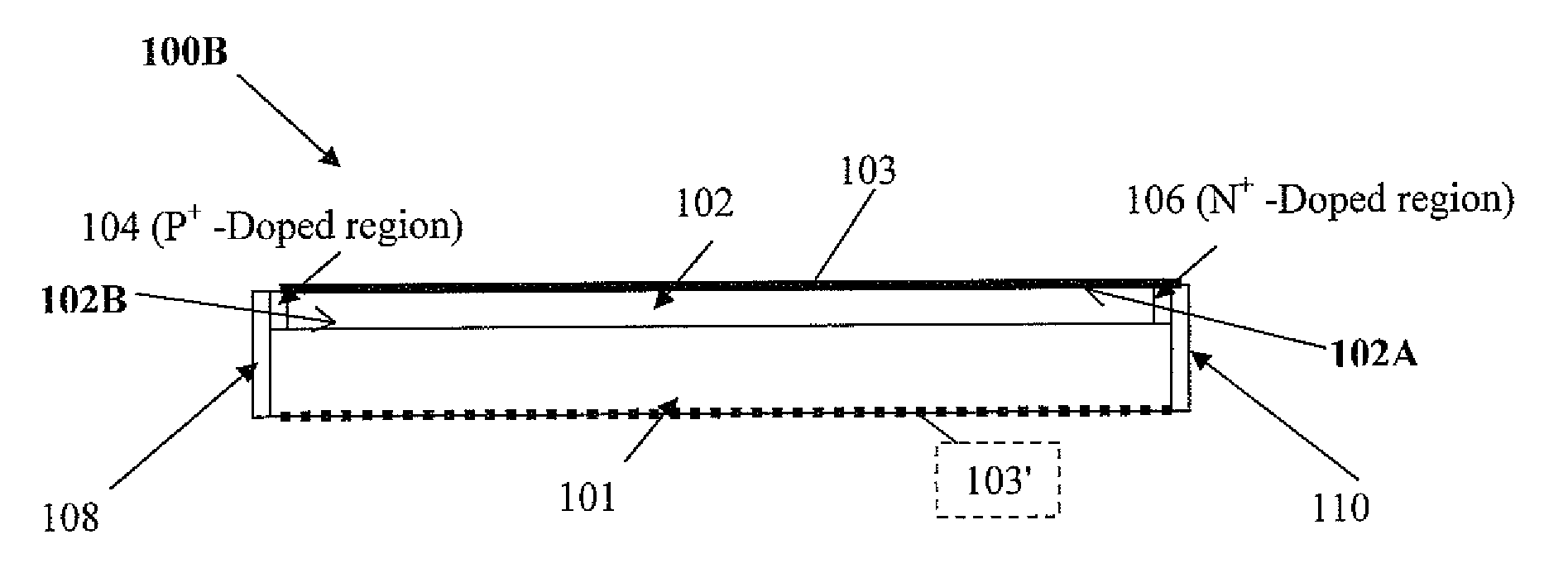

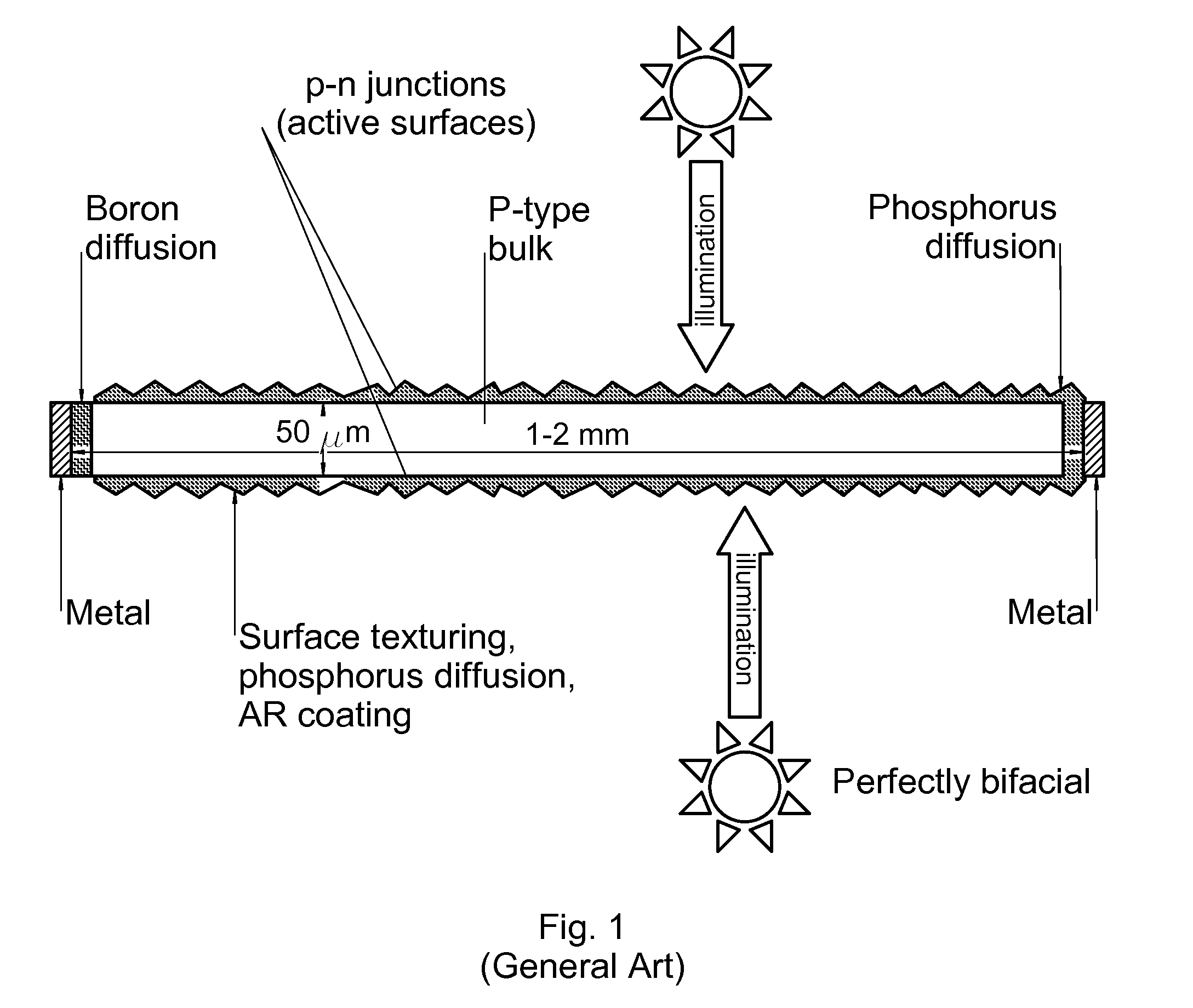

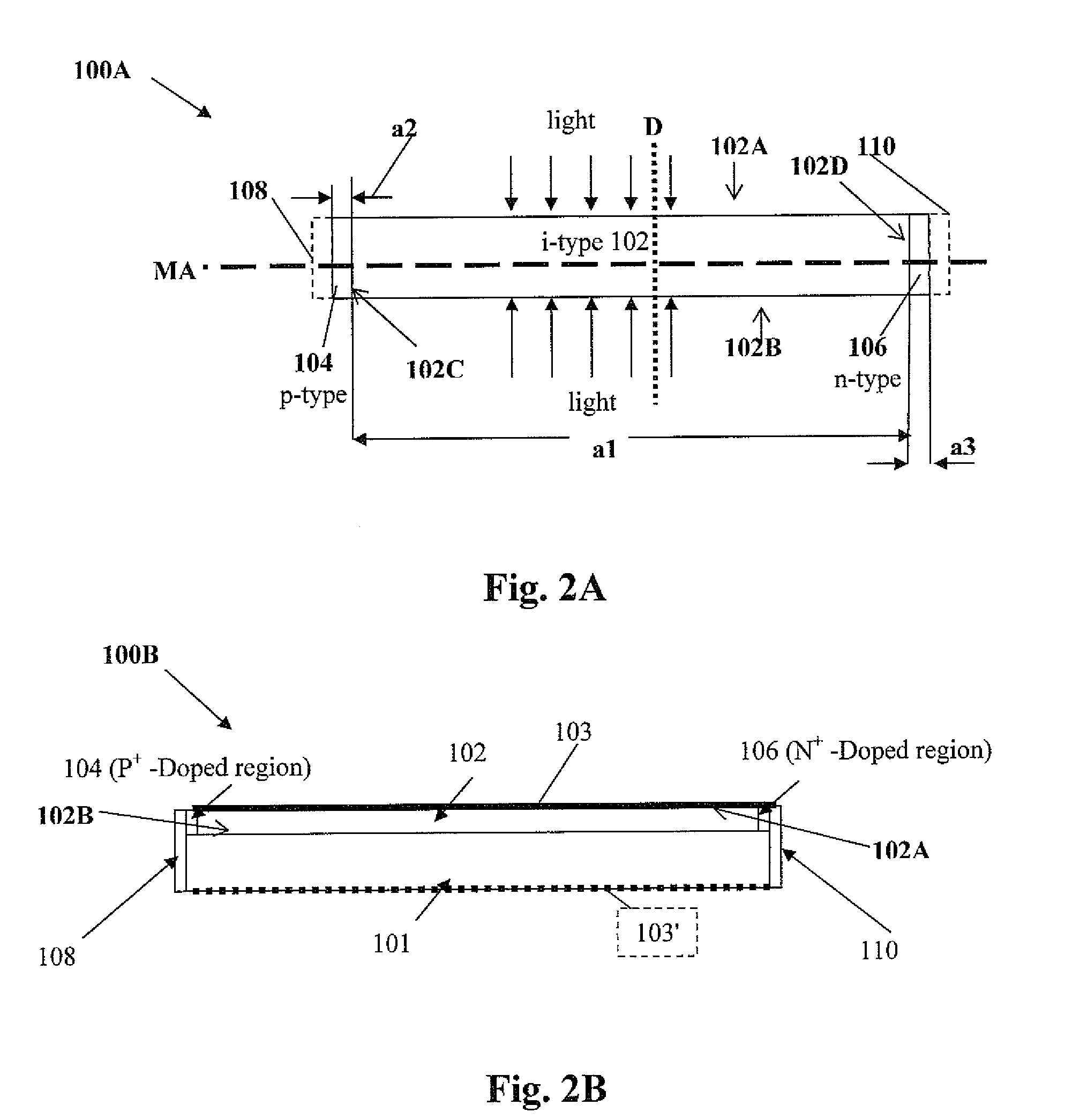

Photoelectric structure and method of manufacturing thereof

InactiveUS8080856B2Significant utilityLow costSolid-state devicesSemiconductor/solid-state device manufacturingCharge carrierElectromagnetic radiation

Owner:GOLAN GADY +2

Reinforced optical fiber composite high-temperature-resistant overhead insulating cable

The invention discloses a reinforced optical fiber composite high-temperature-resistant overhead insulating cable which comprises a carbon fiber composite reinforced core. A plurality of round flexible aluminum wires and a stainless steel sleeve light unit are stranded on the outer side of the carbon fiber composite reinforced core in a concentric mode. A plurality of special-shaped flexible aluminum monofilaments which are distributed in a round shape are arranged on the outer sides of the round flexible aluminum wires and the outside of the stainless steel sleeve light unit, and a high-temperature-resistant insulating layer is arranged on the outer sides of the special-shaped flexible aluminum monofilaments. The reinforced optical fiber composite high-temperature-resistant overhead insulating cable is simple in structure, long in service life and suitable for reconstruction and construction of power grid overhead lines in urban and rural areas, can bear the tension strength of 2400Mpa, allows long-time operation temperature to be more than 180 DEG C, has communication and monitoring functions, can effectively solve the dropping problem of the cable, and guarantees safe operation of lines.

Owner:HENAN KOSEN CABLE

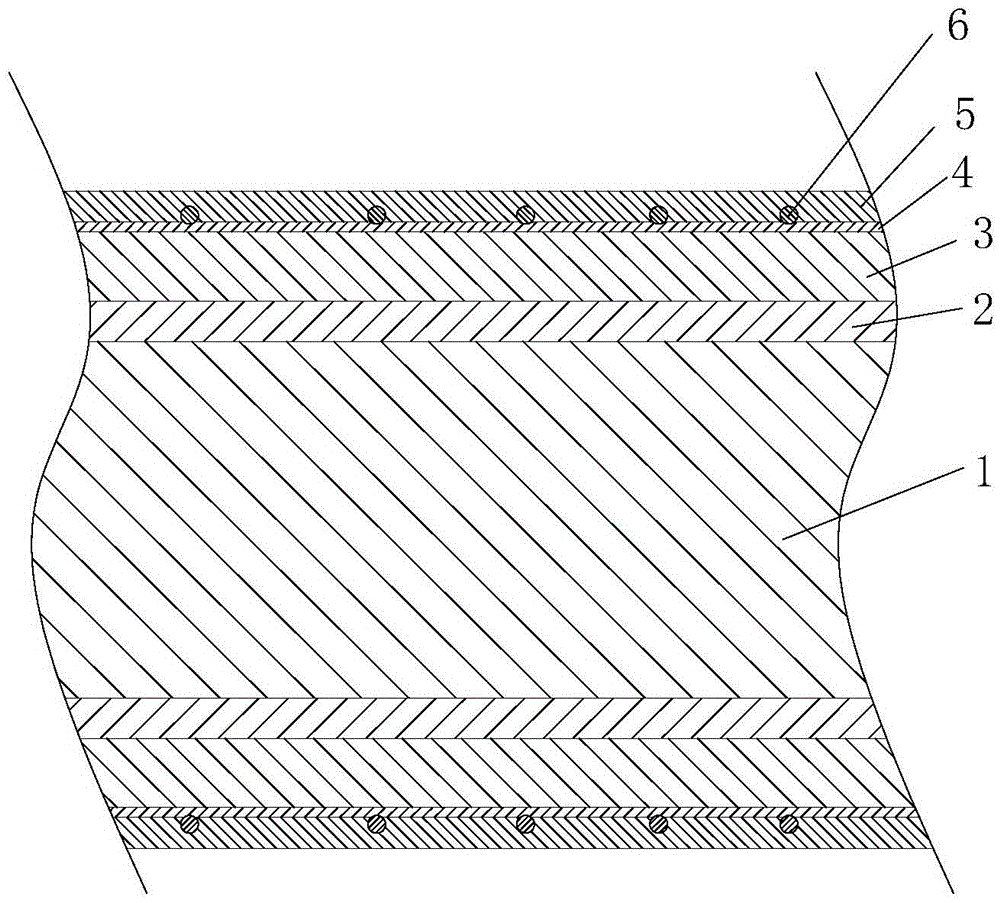

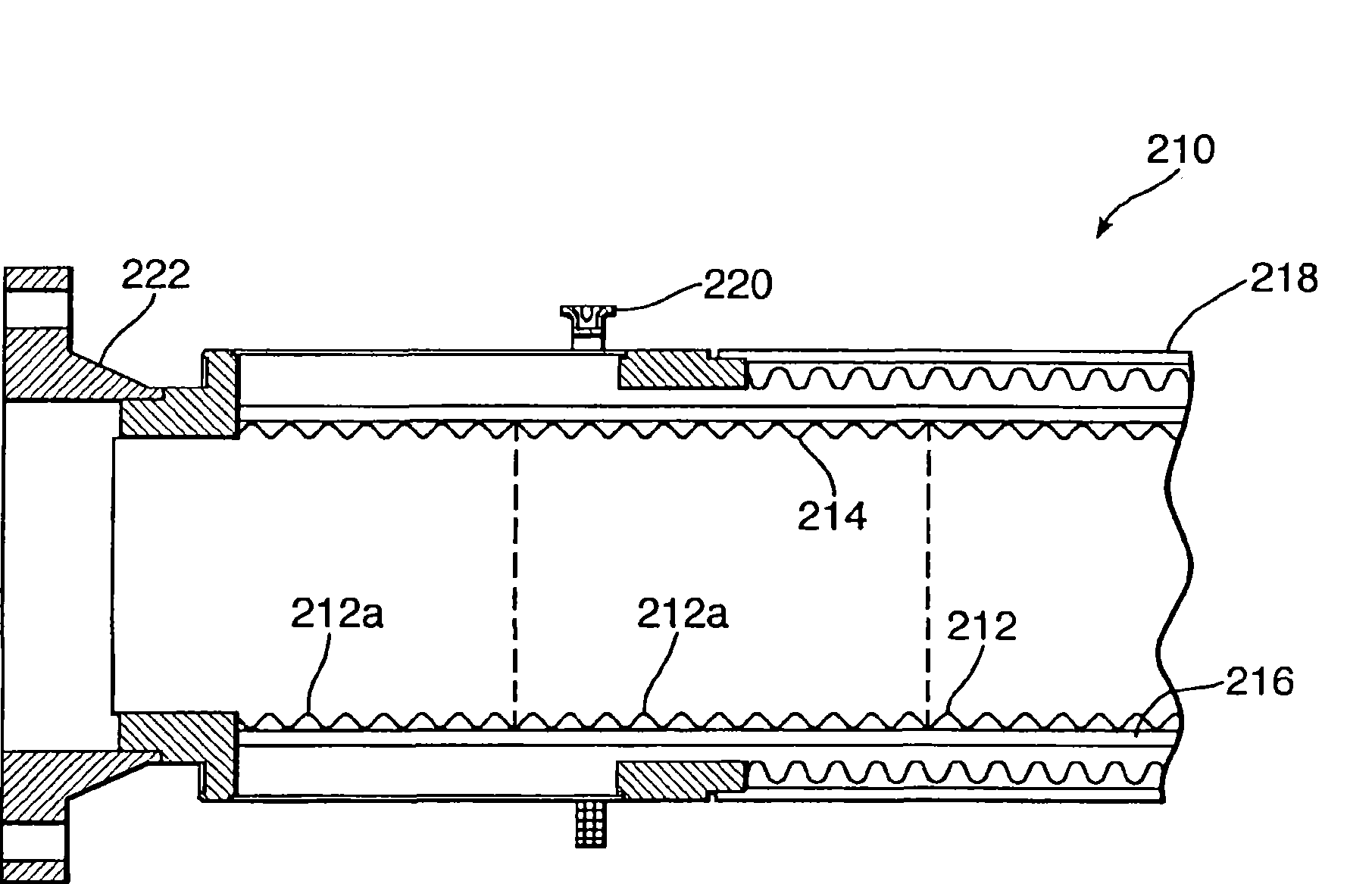

Improvements relating to hose

InactiveCN101523105AIncrease operating temperatureHigh or low operating temperatureFlexible pipesTubular articlesEngineeringBellows

The invention relates to bellows hose, which is capable of being used without leakage, and which has a longer length and / or diameter than has been previously achievable. A bellows hose (210) comprises an inner tubular bellows (212) and an outer tubular bellows (214). An insulation layer (216) is provided between the bellows (212 and 214). An armoured layer (218) is provided around the outer bellows (214), to improve the insulation further. The hose can have length above 30m and a diameter above 400mm. A method of, and apparatus for, making the hose are also described, which involves the use of a non-metallic mandrel.

Owner:BHP PETROLEUM

High-speed filtering, high-temperature, high-pressure squeezing and drying flexible tube type solid-liquid processing equipment

InactiveCN101352624ARelieve pressureUniform humiditySemi-permeable membranesStationary filtering element filtersSlagHigh pressure

The invention provides a high-speed filtration and high-temperature and high-pressure squeezing and drying flexible pipe typed solid / liquid processing device; during the filtrating process, a piston slag scraper is used for removing the filtrated slag remained on the filter medium and replace a compressor and a filter machine at the same time; during the squeezing process, the solid / liquid separation is completed by a squeezing principle of changing volume of a filter chamber; the volume of the filter chamber can be near zero after the volume is changed; high pressure pump can not be needed to convey the raw material and additional squeezing water pump systems or squeezing air systems are not required to be taken as the filter pushing force of a press-filter; the mechanical pushing force is large and the pressurizing is quicker; repeated nipping filtration can be adopted; the washing filter slag is dipped; during the squeezing process, the alternative change of the thickness of the raw material improves the filtration speed, the washing speed and the efficiency; the humidity of a filter cake is uniform; the filtration and squeezing can be carried out at the same time when the vacuum or steam drying is carried out; the production quantity of each sequence batch is easily changed according to the requirement of production capability; the washing regeneration of the filter medium is automatically completed; the slag drainage is automatically completed; during the production process, automation can be completely realized, the energy dissipation is reduced and the production efficiency is high.

Owner:张民良

Recovery method of N-methyl pyrrolidone

PendingCN110759844AReduce concentration polarizationReduce or even eliminate concentration polarizationOrganic chemistryPyrrolidinonesMethyl palmoxirate

The invention provides a recovery method of N-methyl pyrrolidone. The method is characterized by comprising the following steps: heating an N-methyl pyrrolidone material liquid with the water contentof 1-50 wt.% in a circulating tank to 30-190 DEG C; introducing the heated N-methyl pyrrolidone material liquid into a pervaporation membrane assembly to make water in the material liquid be separatedfrom the material liquid side of the pervaporation membrane and enter the permeation side, wherein the pervaporation membrane assembly comprises 1-3000 organic-inorganic or inorganic-organic hybrid membrane single-pass pipes or multi-pass pipes, an absolute pressure of the permeation side is set to be 100-15000 Pa, and a membrane feeding speed of the material liquid is set to be 0.15-1.6 m / s; after the material liquid passes through the pervaporation membrane assembly, making the material liquid on the material liquid side return to the circulating tank, and making the water on the permeationside be condensed and recovered; and performing circulation for multiple times on the material liquid in the circulating tank to obtain recovered N-methyl pyrrolidone.

Owner:HYLEIN ENERGY & ENVIRONMENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com