Household garbage gasification furnace with functions of regenerative high temperature air gasification and plasma smelting

A technology for high-temperature air and domestic waste, which is applied in the chemical industry, climate sustainability, and the manufacture of combustible gas, etc., and can solve problems such as the utilization of organic components that cannot be used in domestic waste, high temperature of pyrolysis gasification, and increased operating costs. Achieve the effects of improving energy utilization, improving quality, and solving dioxins and heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

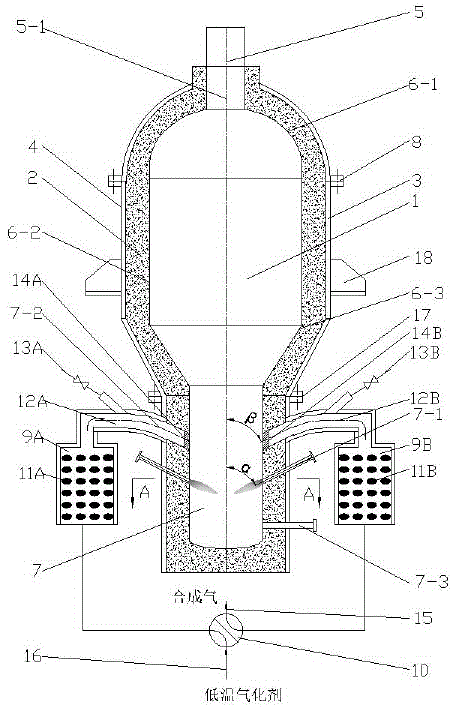

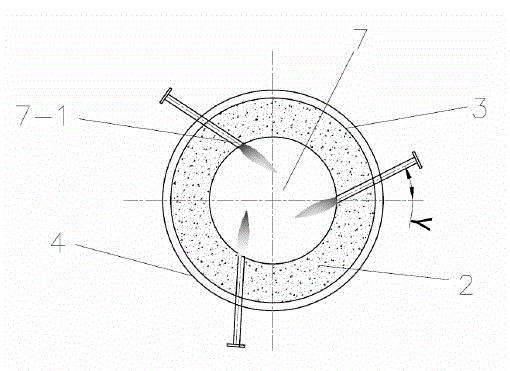

[0033] Such as Figure 1-2 As shown, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

[0034]The regenerative high-temperature air gasification and plasma melting domestic waste gasification furnace includes a plasma gasification reaction furnace and a regenerative heat exchange system. The plasma gasification reaction furnace includes garbage inlets at the top distributed sequentially from top to bottom 5, The pyrolysis and gasification reaction chamber 1 in the middle, and the ash melting chamber 7 in the lower part. The cylinder body of the ash melting chamber 7 is evenly arranged with a plurality of plasma torch installation ports 7-1 on the same horizontal plane. The plasma torch installation ports 7-1 are equipped with plasma torches, and two syngas outlets 7-2 on another horizontal plane are evenly arranged on the cylinder body of the ash melting chamber 7, and the syngas outlets 7-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com