Molten salt electrode boiler heat storage and power generation system

A technology of a power generation system and an electrode boiler, which is applied in the field of energy storage, can solve the problems of limited promotion and application, high cost, and no engineering promotion and application value, and achieves the effects of flexible operation mode, large heating power, and meeting heating requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

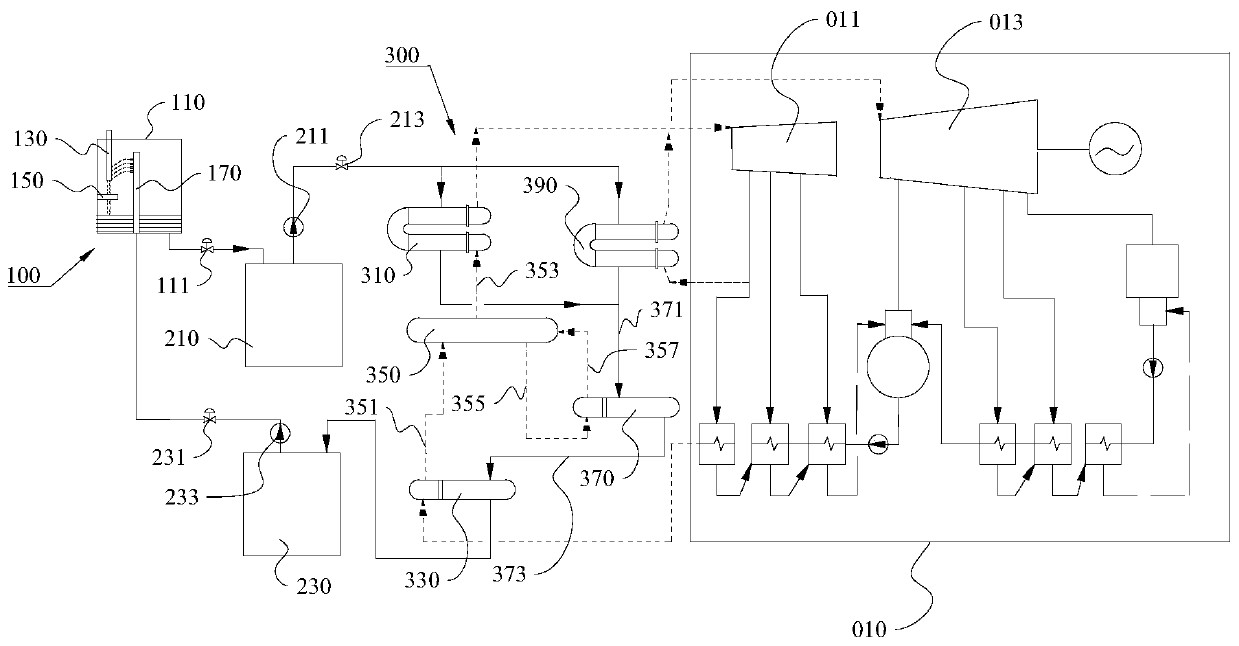

[0043] This embodiment provides a molten salt electrode boiler heat storage power generation system, please refer to figure 1 , this molten salt electrode boiler heat storage power generation system includes a heating part 100, a high temperature molten salt storage tank 210 and a heat utilization part 300;

[0044] The heating part 100 includes a furnace body 110, and a low-temperature molten salt supply head formed by a high-voltage electrode 130, a neutral electrode 150 and a molten salt distribution nozzle 170 arranged in the furnace body 110;

[0045] The high-voltage electrode 130 is used to connect to the power generation system, and the low-temperature molten salt supply head is used to fill the furnace body 110 with low-temperature molten salt;

[0046] One end of the high-temperature molten salt storage tank 210 is connected to the bottom of the furnace body 110, and the other end is connected to the heat utilization unit 300; The outlet regulating valve of the furn...

Embodiment 2

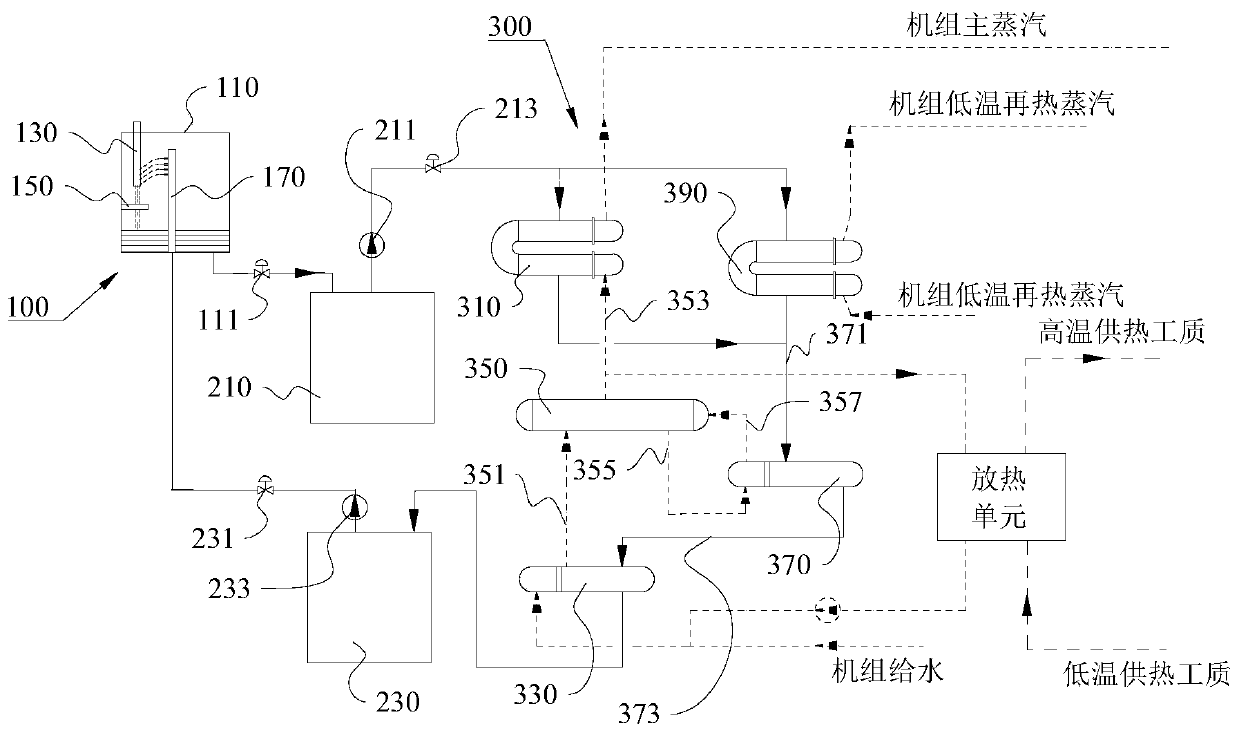

[0071] This embodiment provides a molten salt electrode boiler heat storage power generation system, please refer to figure 2The difference between this molten salt electrode boiler heat storage power generation system and the molten salt electrode boiler heat storage power generation system provided in Embodiment 1 is that when the heat storage unit provides power and external heat is required, the steam drum 350 is provided with a The seventh pipe 359 from which the saturated steam is drawn leads the saturated steam into the exothermic unit 320 , and in the exothermic unit 320 the temperature of the fluid used for industrial steam supply or heating is raised. After the saturated steam cools down and mixes with the unit feed water, it returns to the preheater 330 for the next cycle. When only heating is required and the heat storage unit is not required to generate electricity, the molten salt can be bypassed through the superheater 310 and the reheater 390, and the molten s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com