Patents

Literature

277 results about "Turboexpander" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A turboexpander, also referred to as a turbo-expander or an expansion turbine, is a centrifugal or axial-flow turbine, through which a high-pressure gas is expanded to produce work that is often used to drive a compressor or generator.

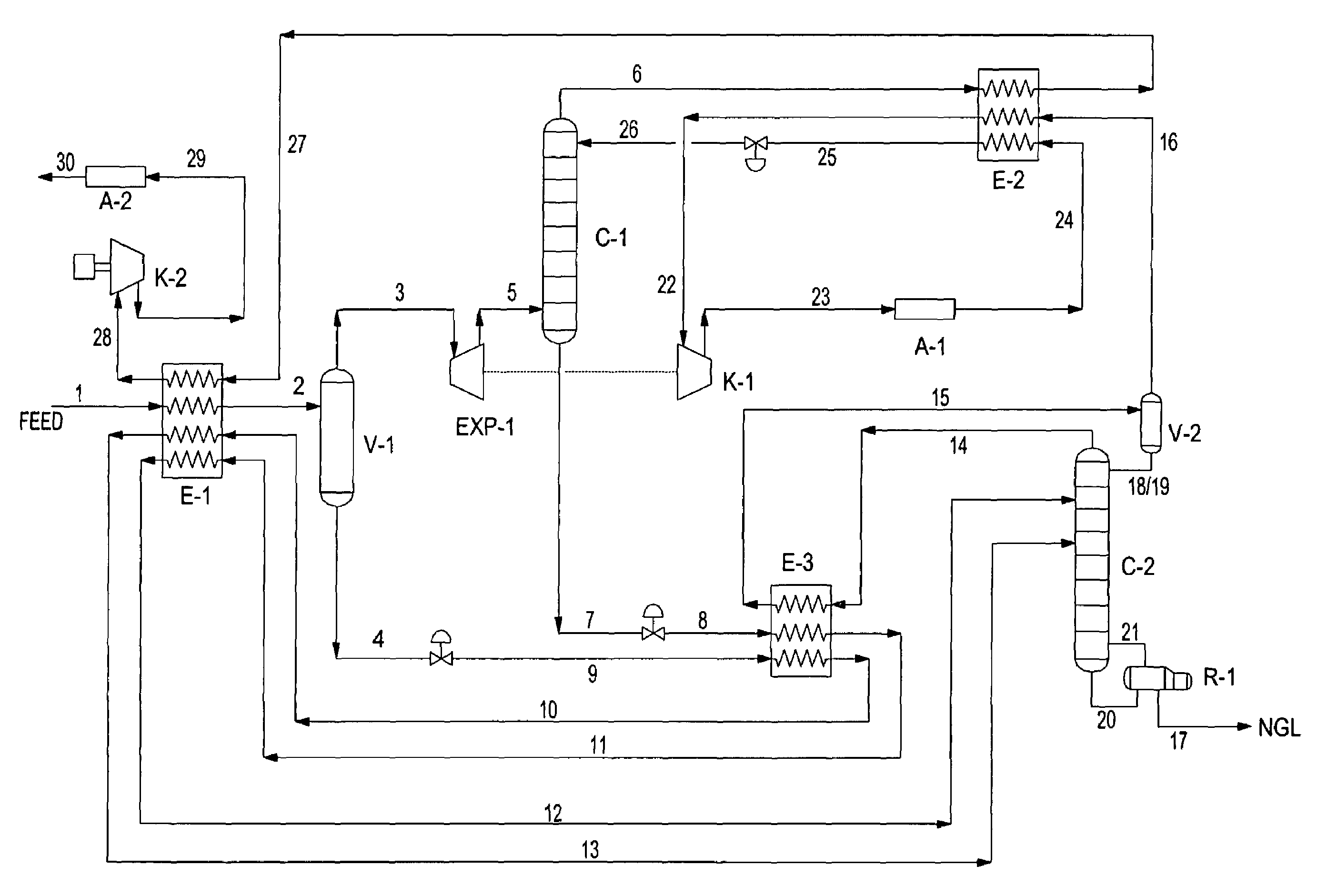

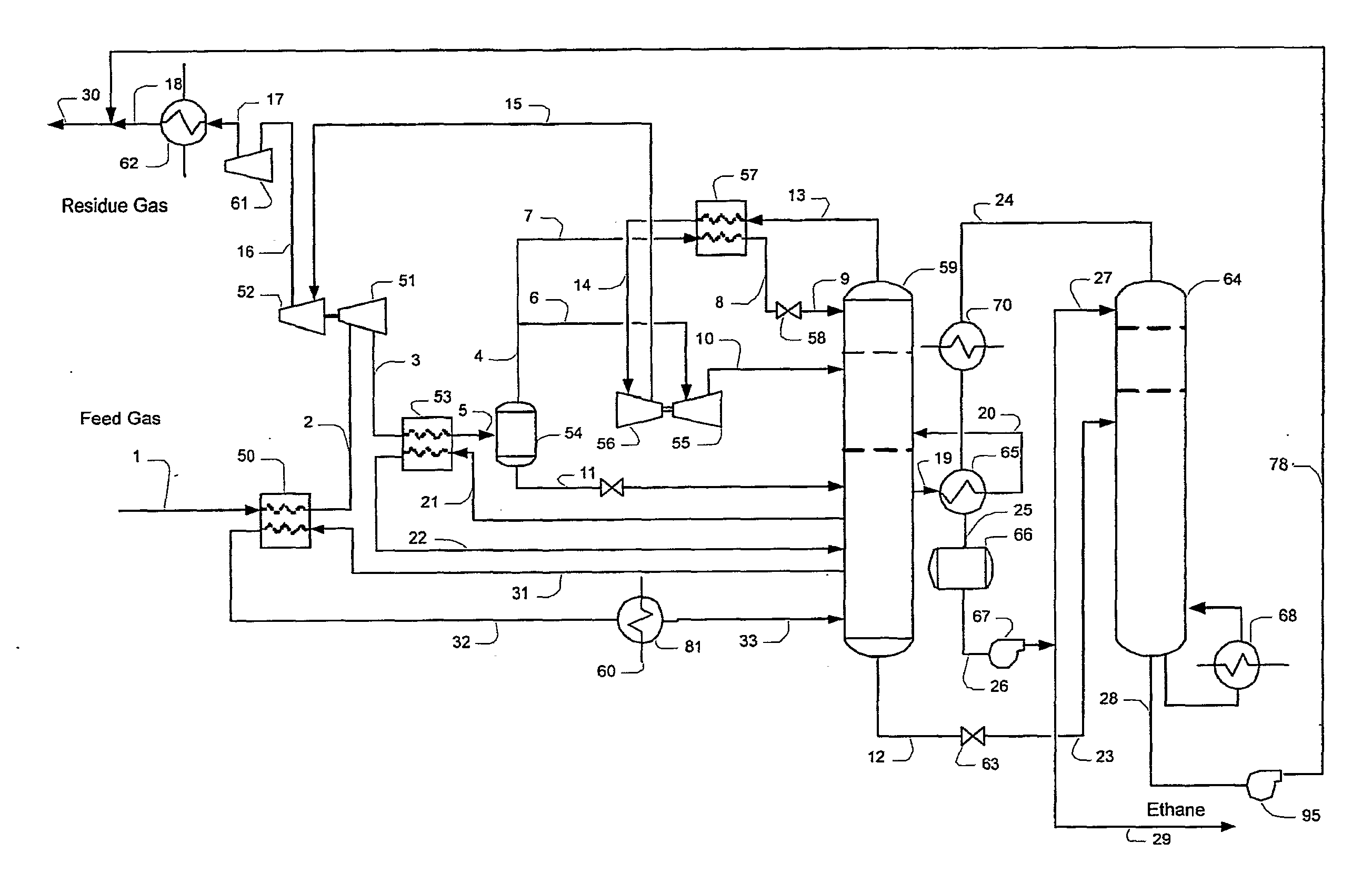

Ethane plus and HHH process for NGL recovery

InactiveUS7219513B1Good fractionation effectHeavy componentSolidificationLiquefactionFractionating columnPetrochemical

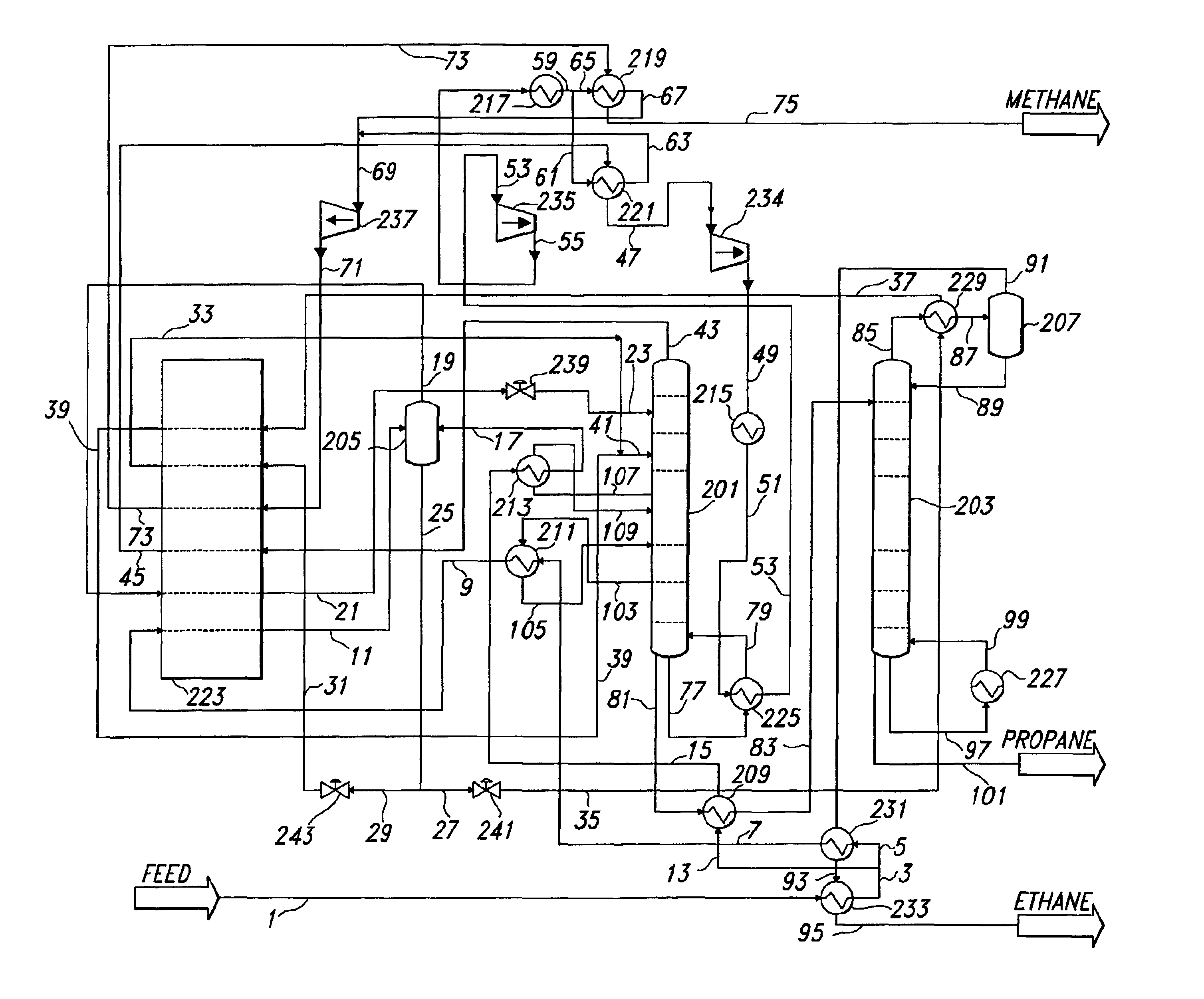

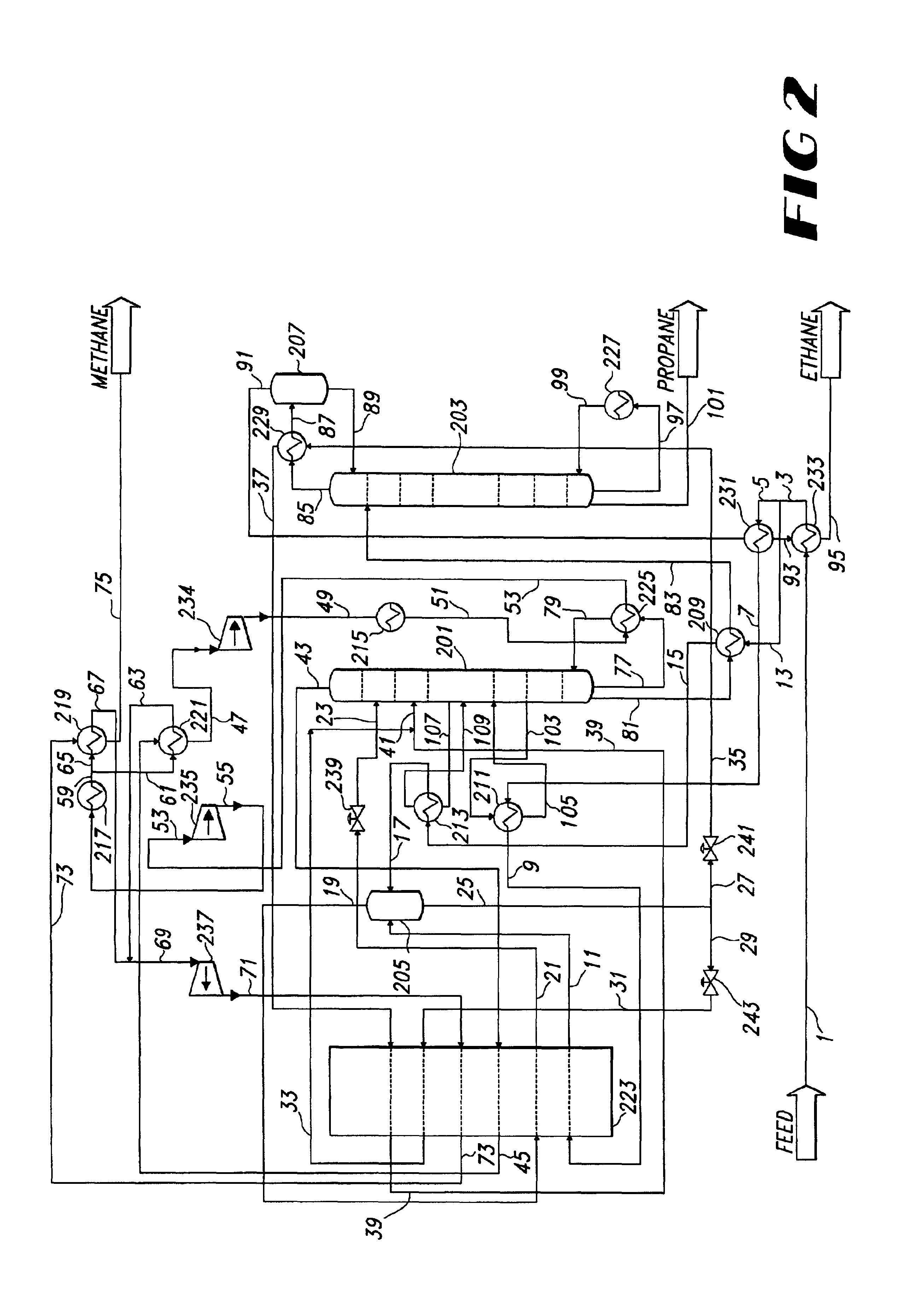

The present invention relates to methods for separating and recovering ethane, propane and heavier components from a feed gas, e.g. raw natural gas or a refinery or petroleum plant gas stream or a petrochemical plant gas stream. These methods employ a common new concept which is the use of the turbo-expander shaft compressor to generate the reflux requirement for the cryogenic absorber or distillation columns. The power of the turbo-expander which is absorbed by the shaft compressor is always high enough so that reflux generation by a specific gas compression through the expander shaft compressor and subsequent cooling, condensation and sub-cooling can always be easily maintained. The present invention allows for higher cryogenic absorber pressure and a lower demethanizer / de-ethanizer column pressure thus eliminating the common cryogenic pump at absorber bottom. The present invention ultimately results in a lower residue compression and utilities consumption. The present invention as such allows for a higher 99+% recovery of NGL from the feed gas stream.

Owner:MOSTAFA HUSSEIN MOHAMED ISMAIL

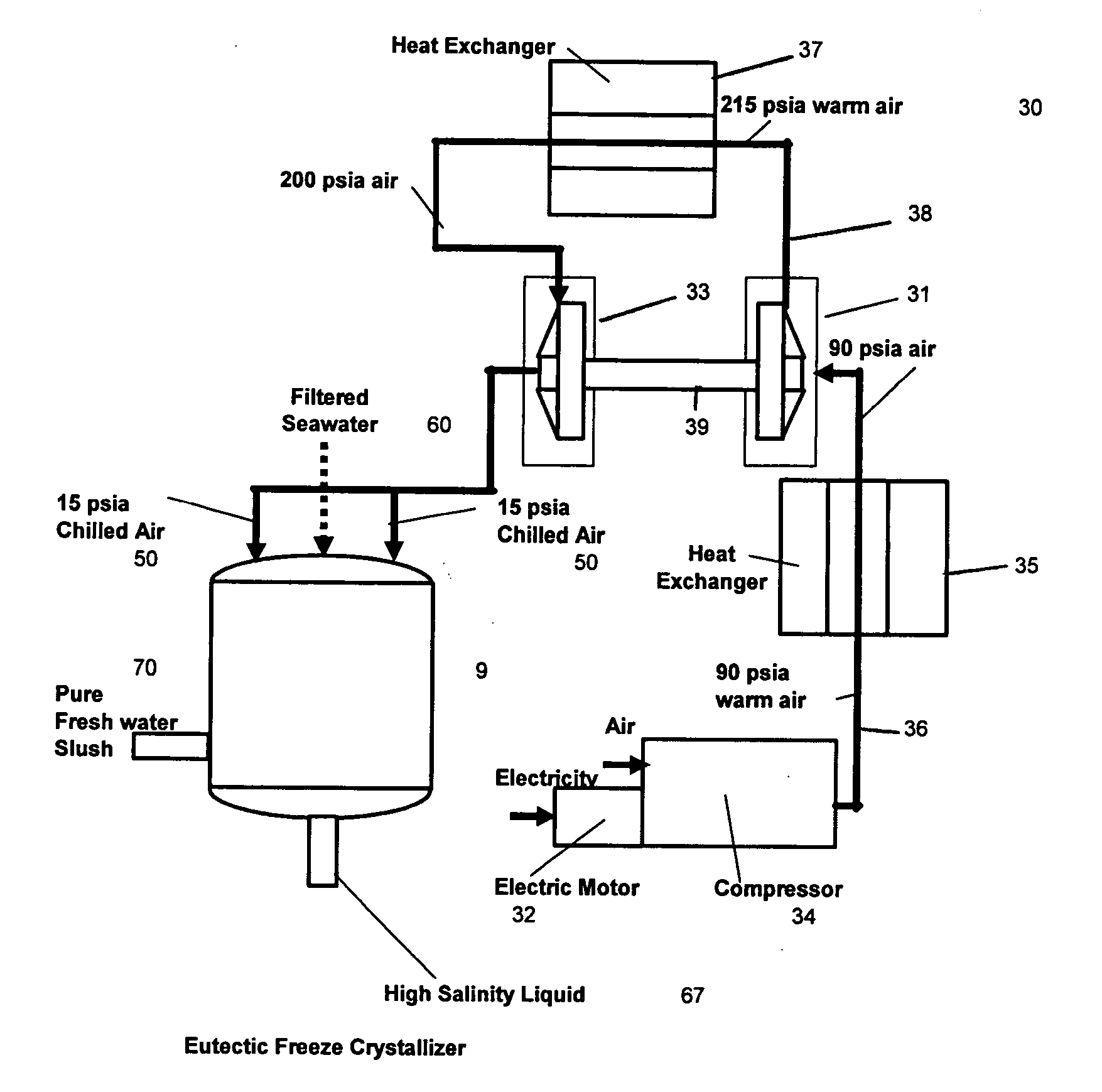

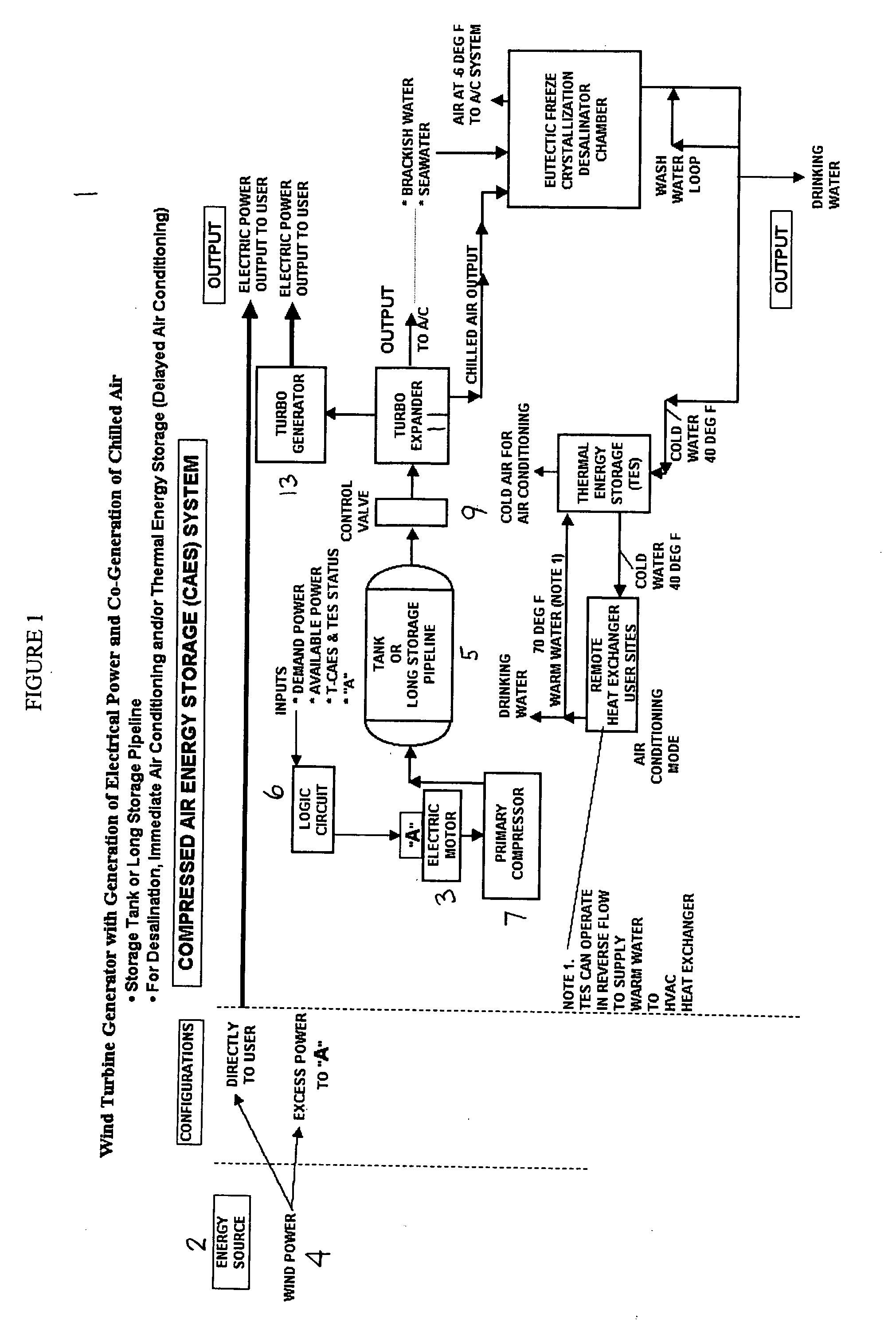

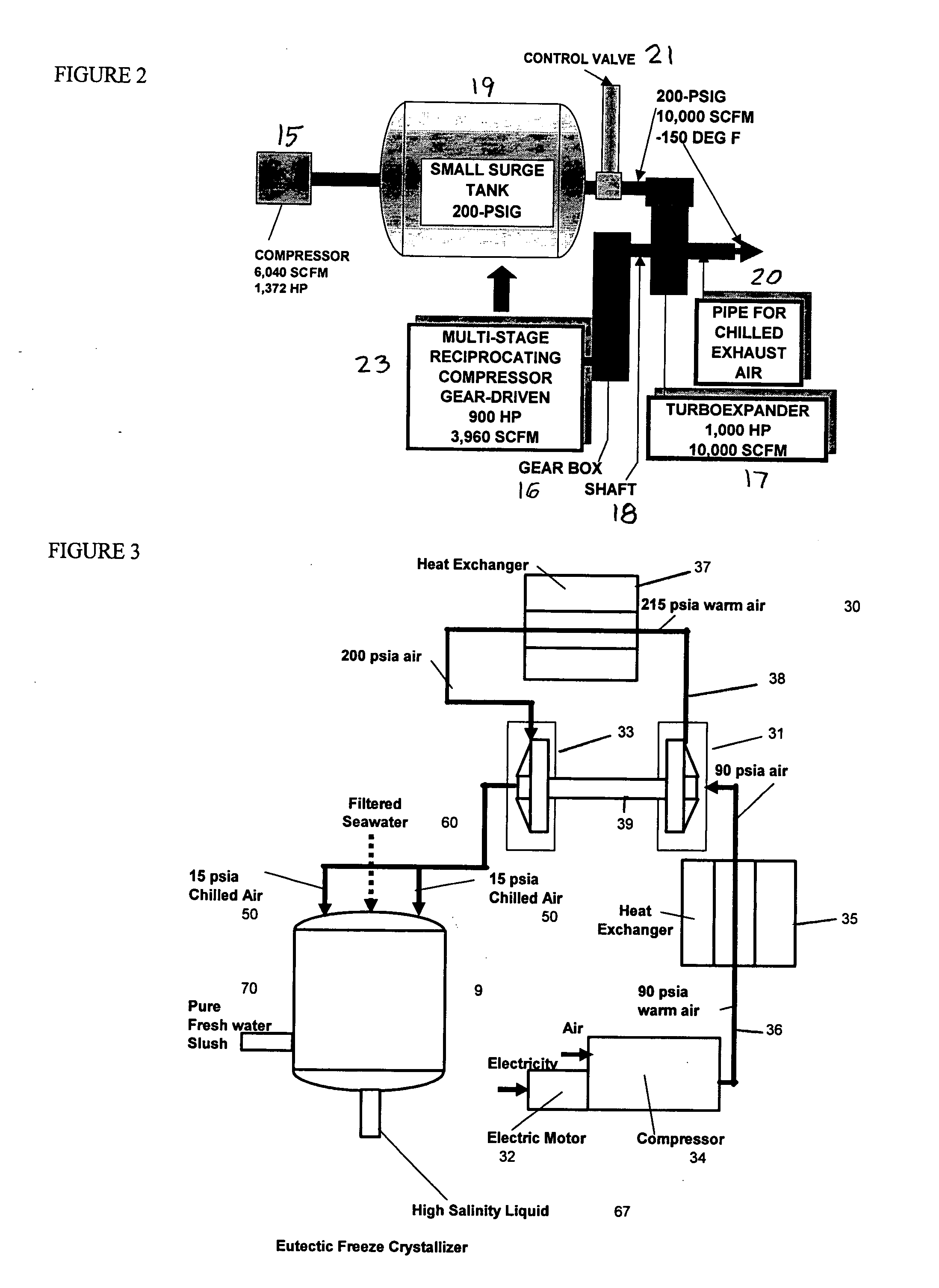

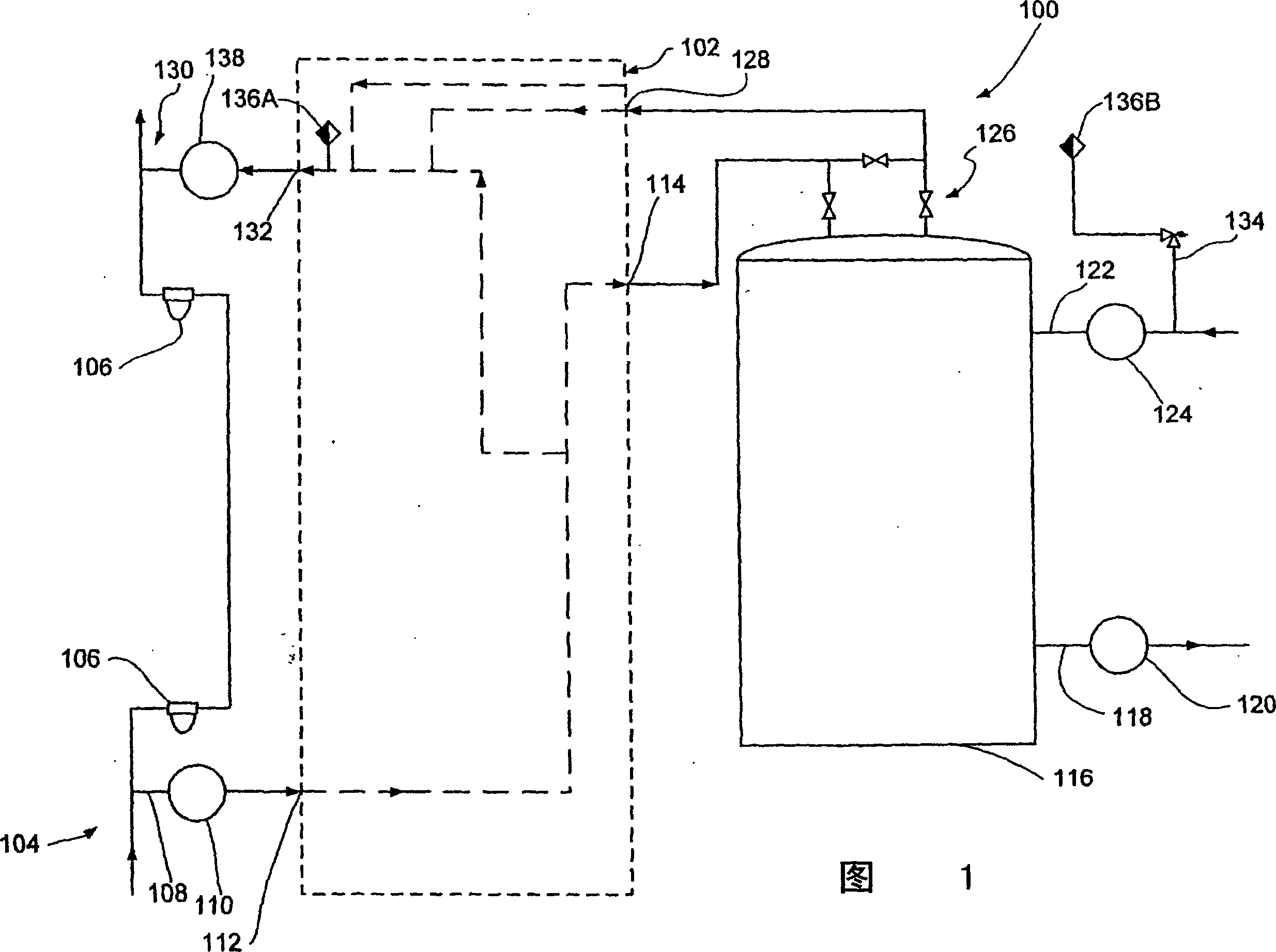

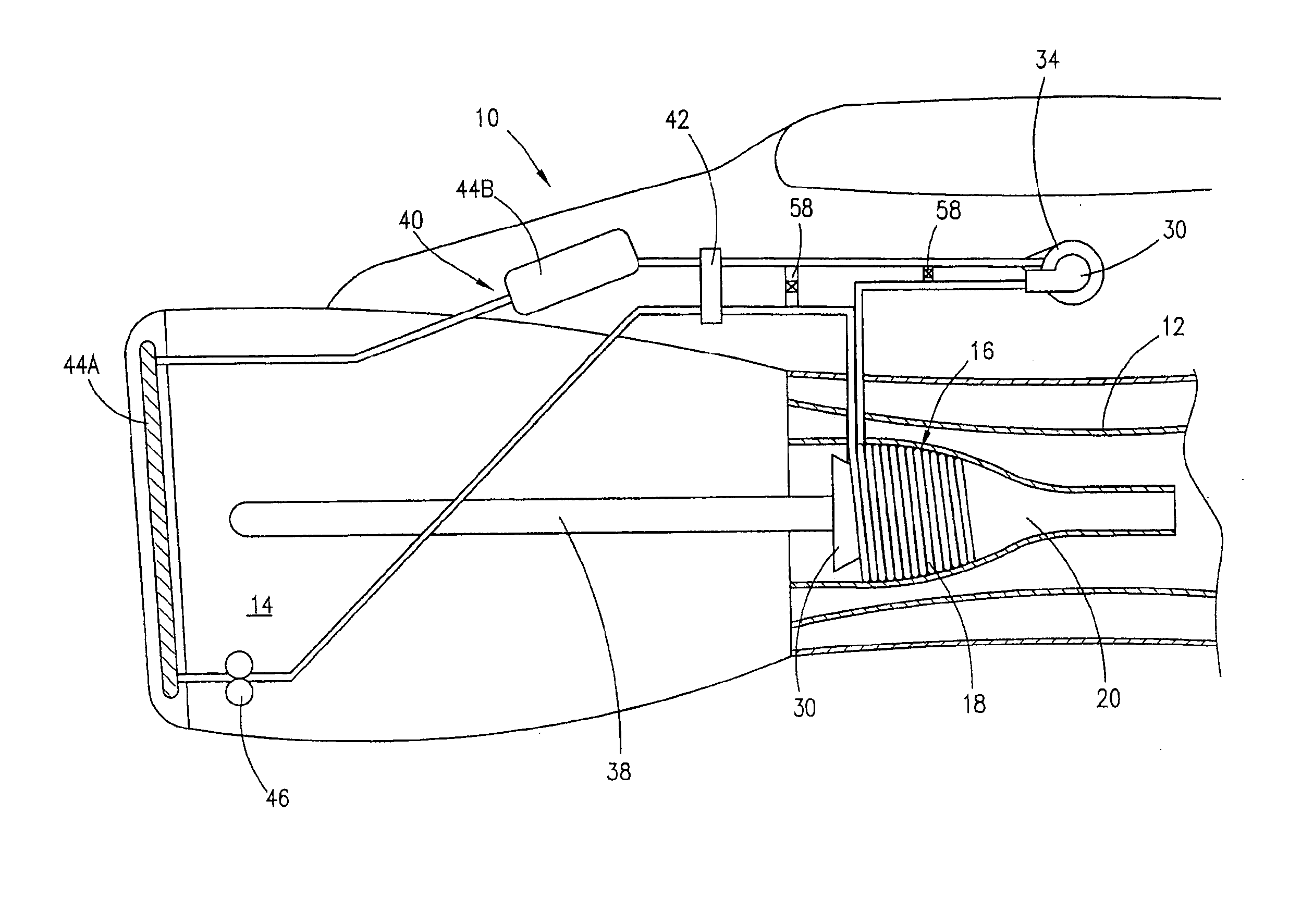

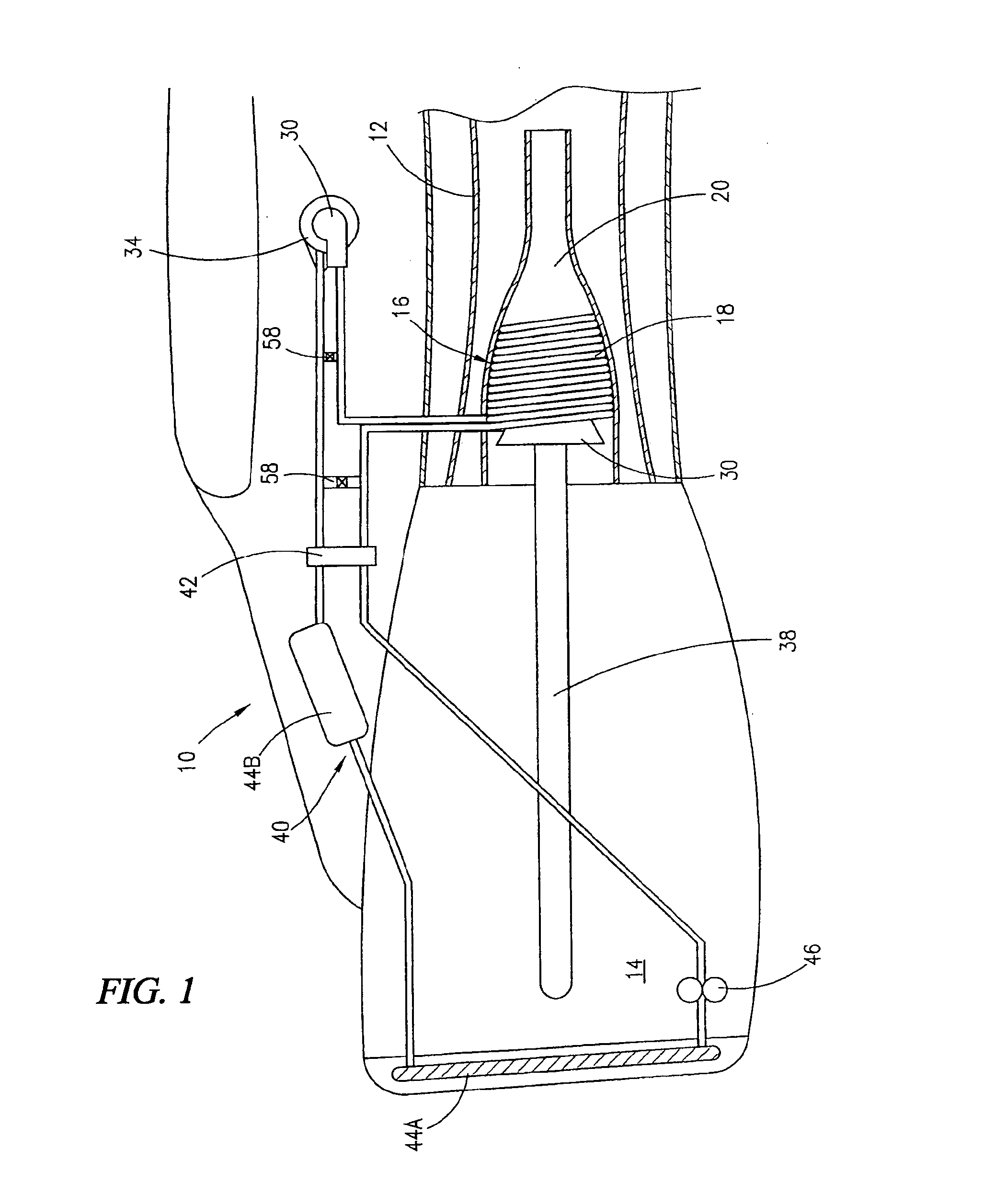

Desalination method and system using compressed air energy systems

InactiveUS20070295673A1Promote meltingFacilitate runoffWater treatment parameter controlWater cleaningSaline waterDesalination

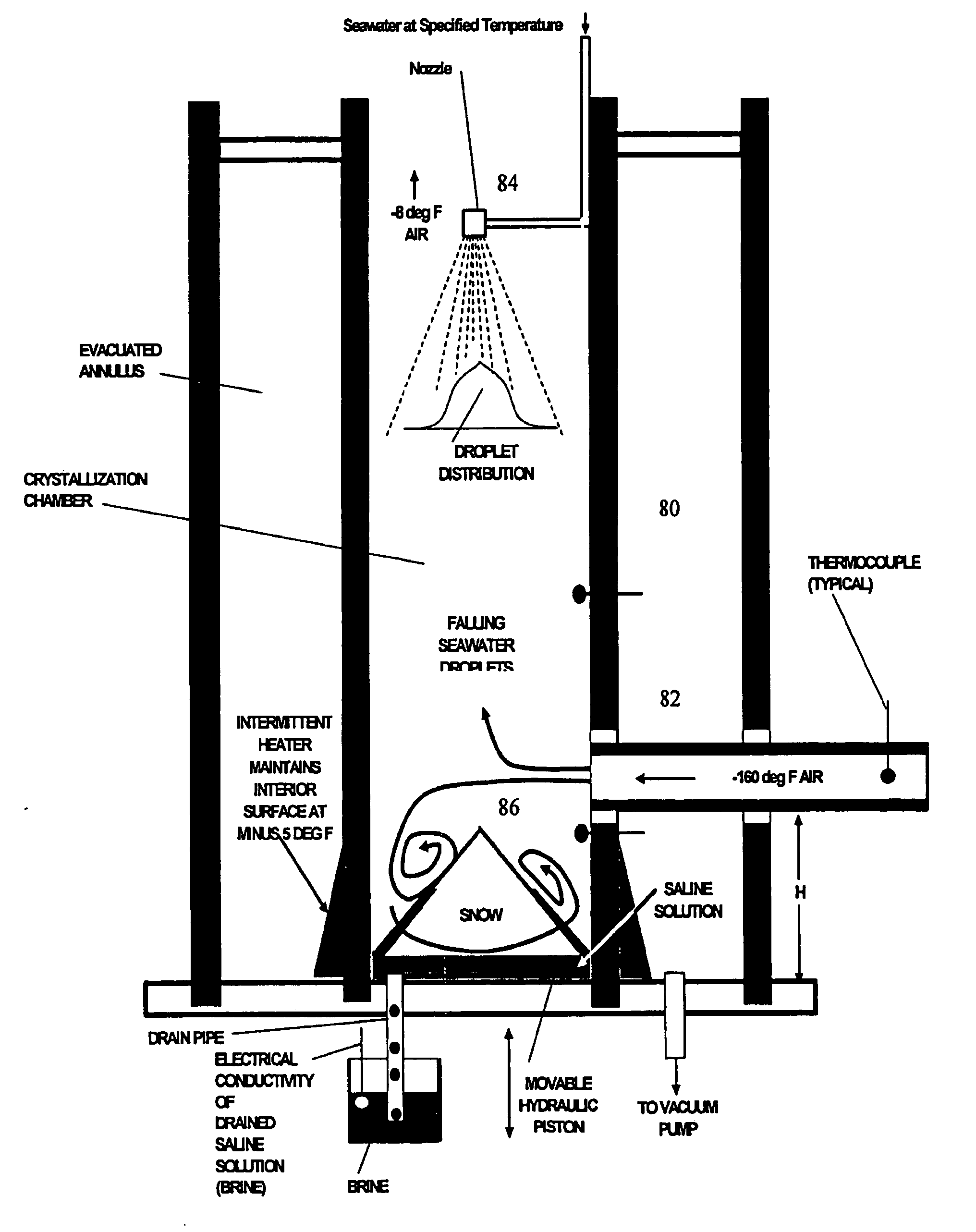

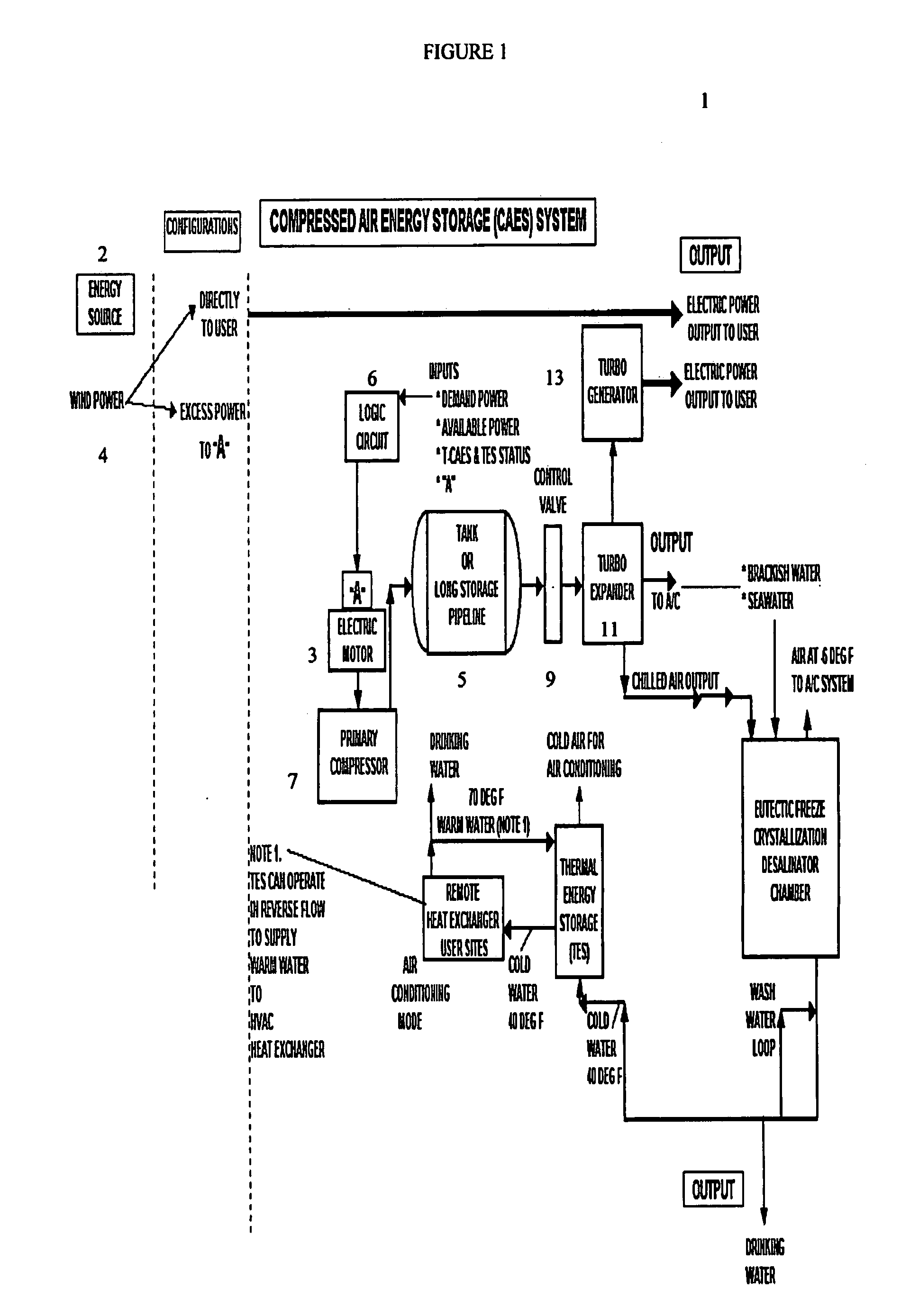

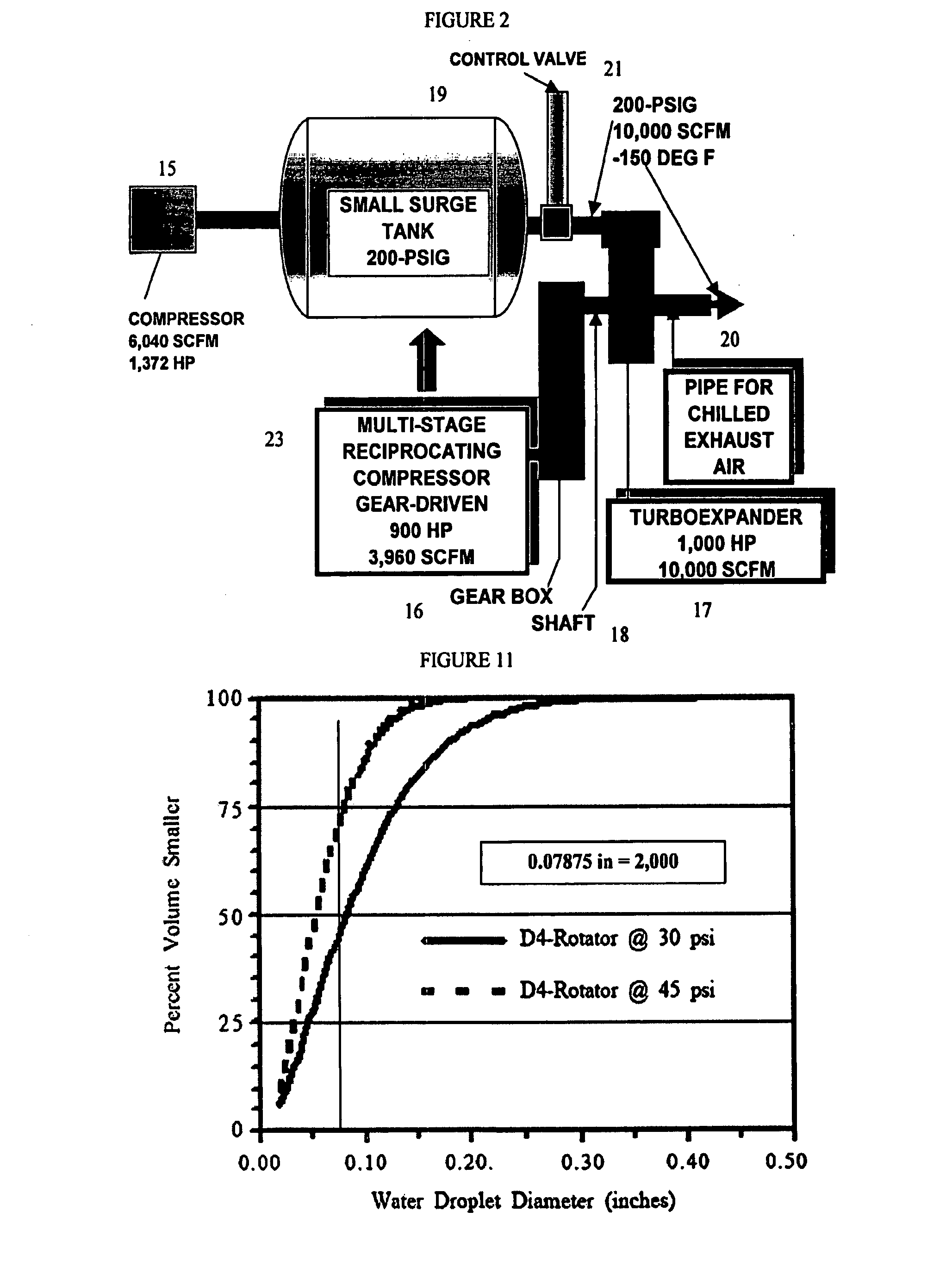

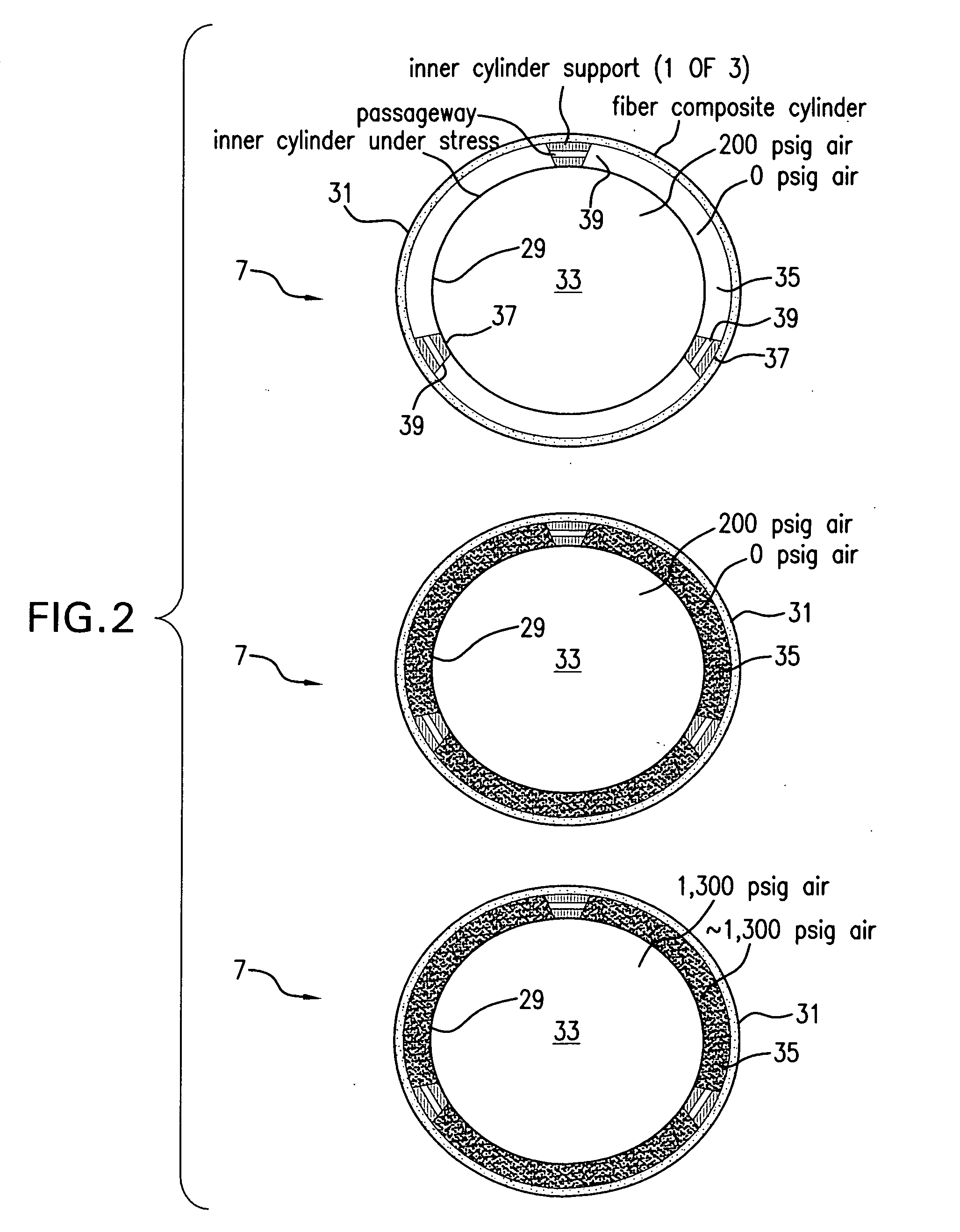

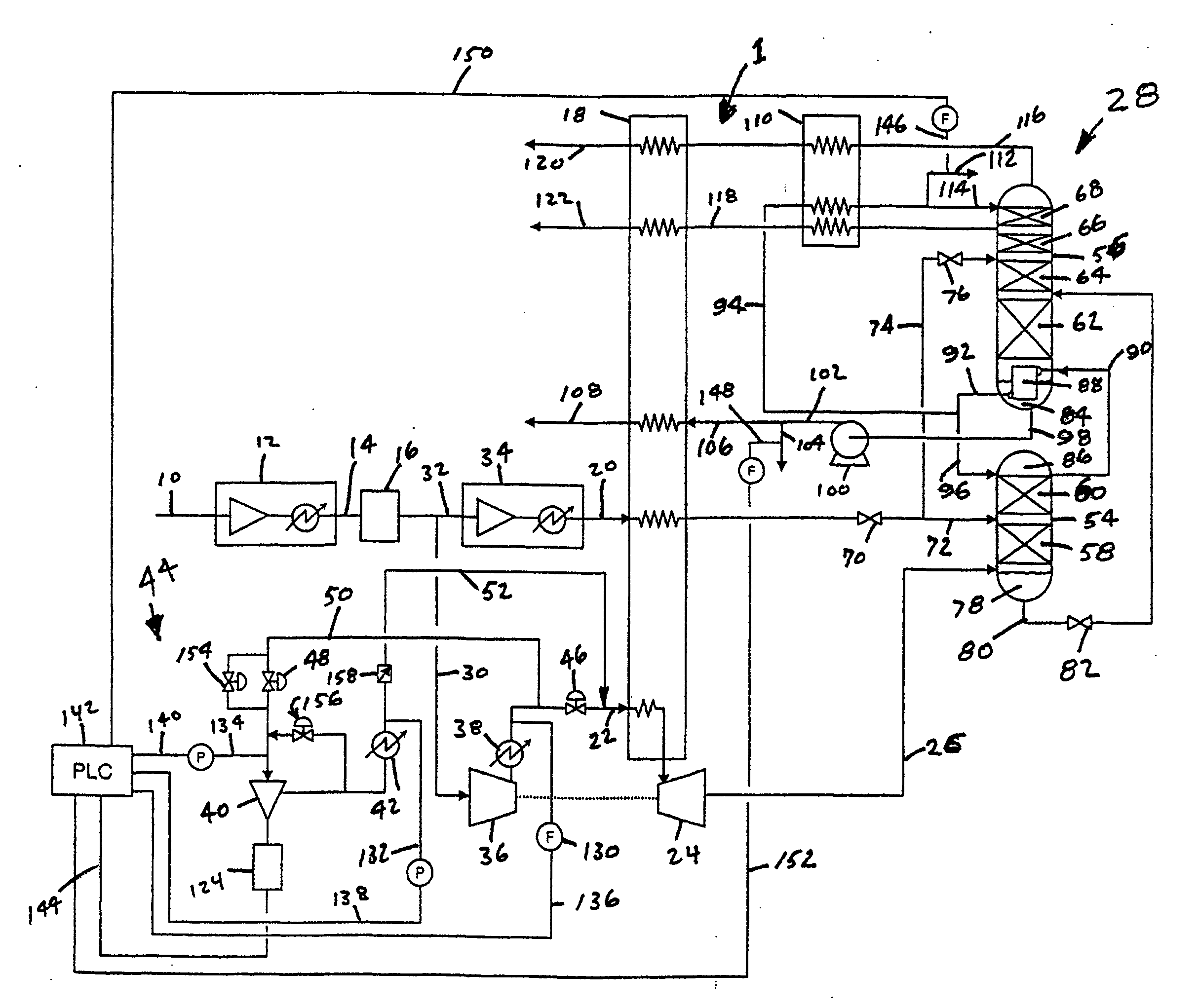

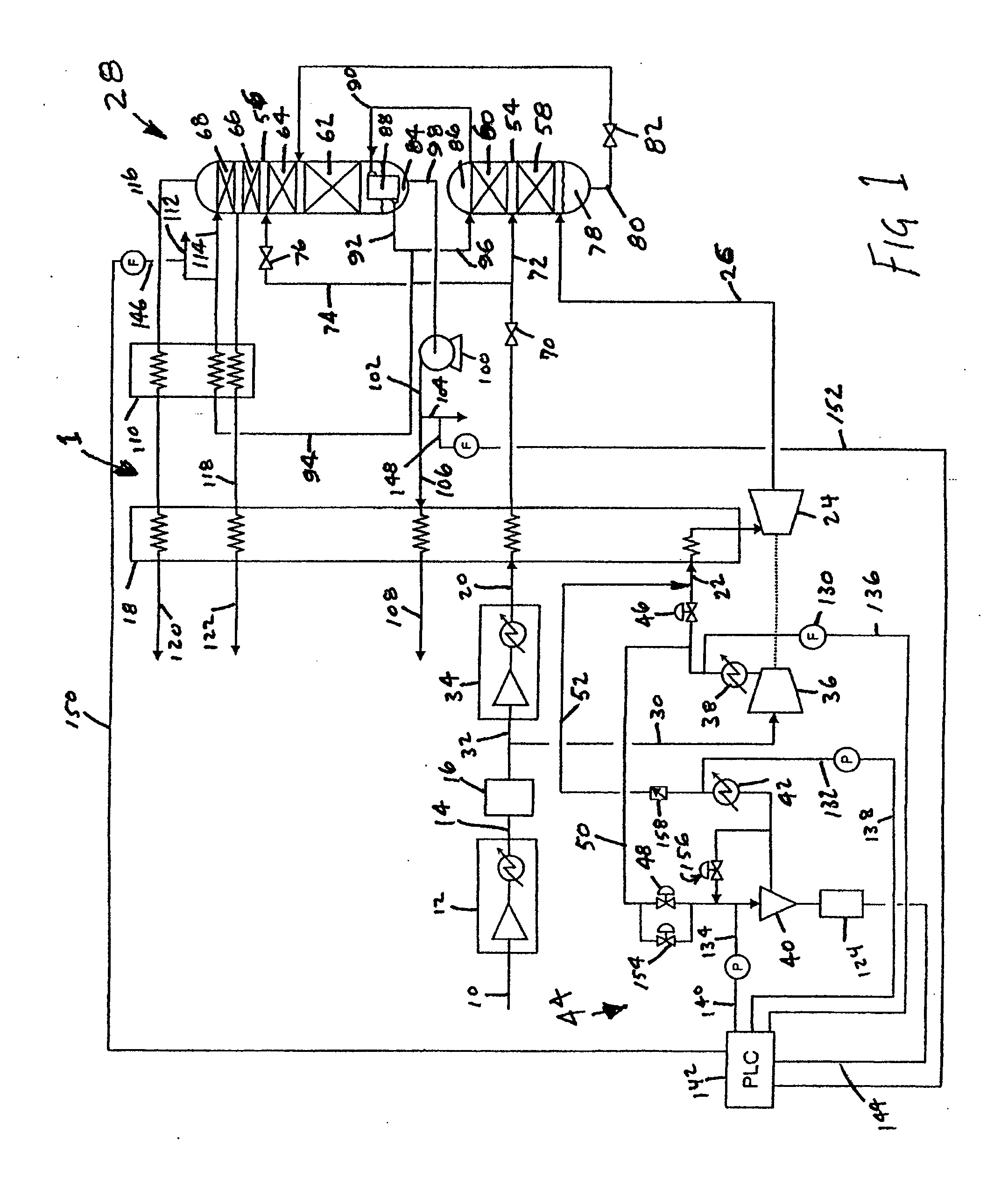

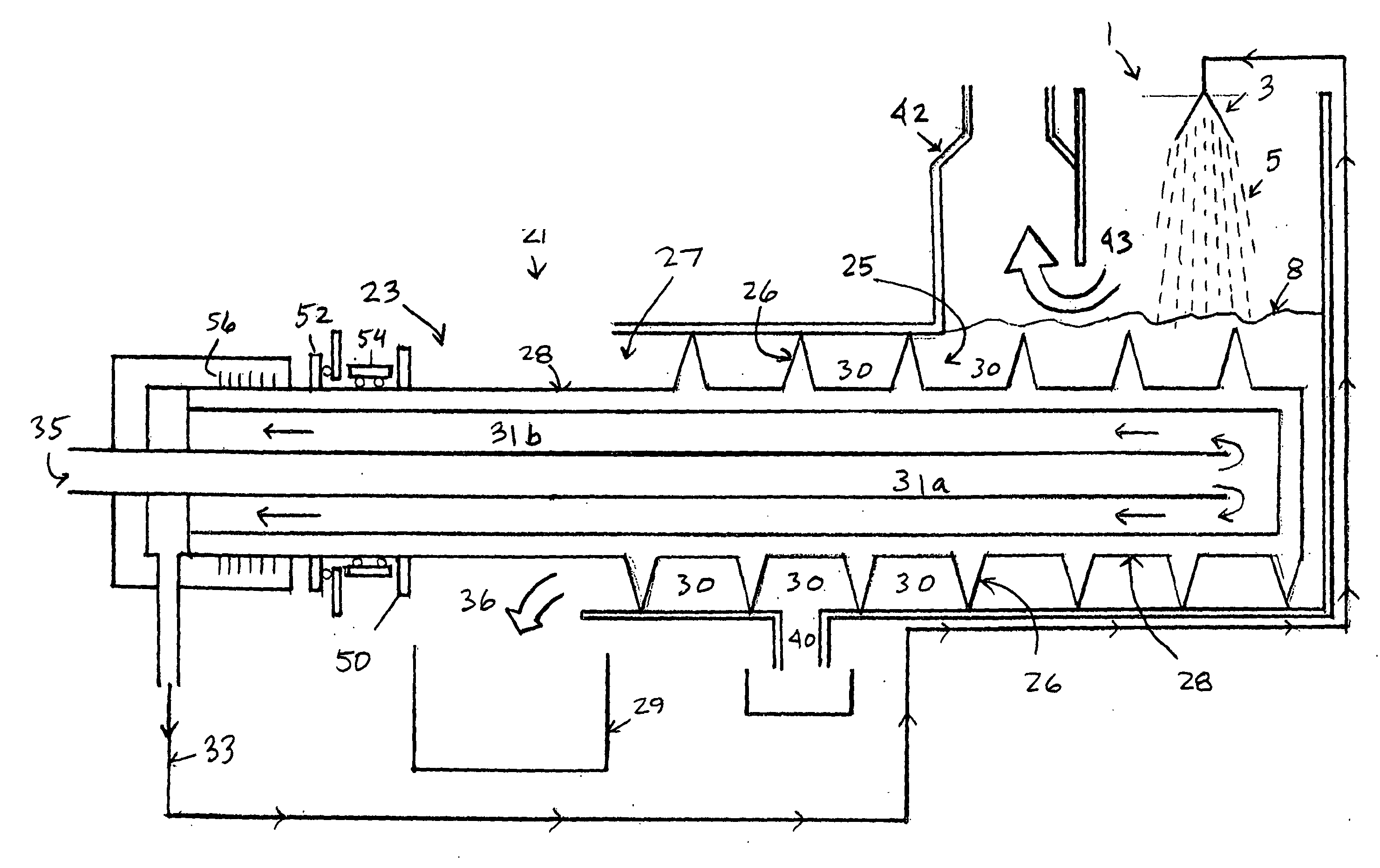

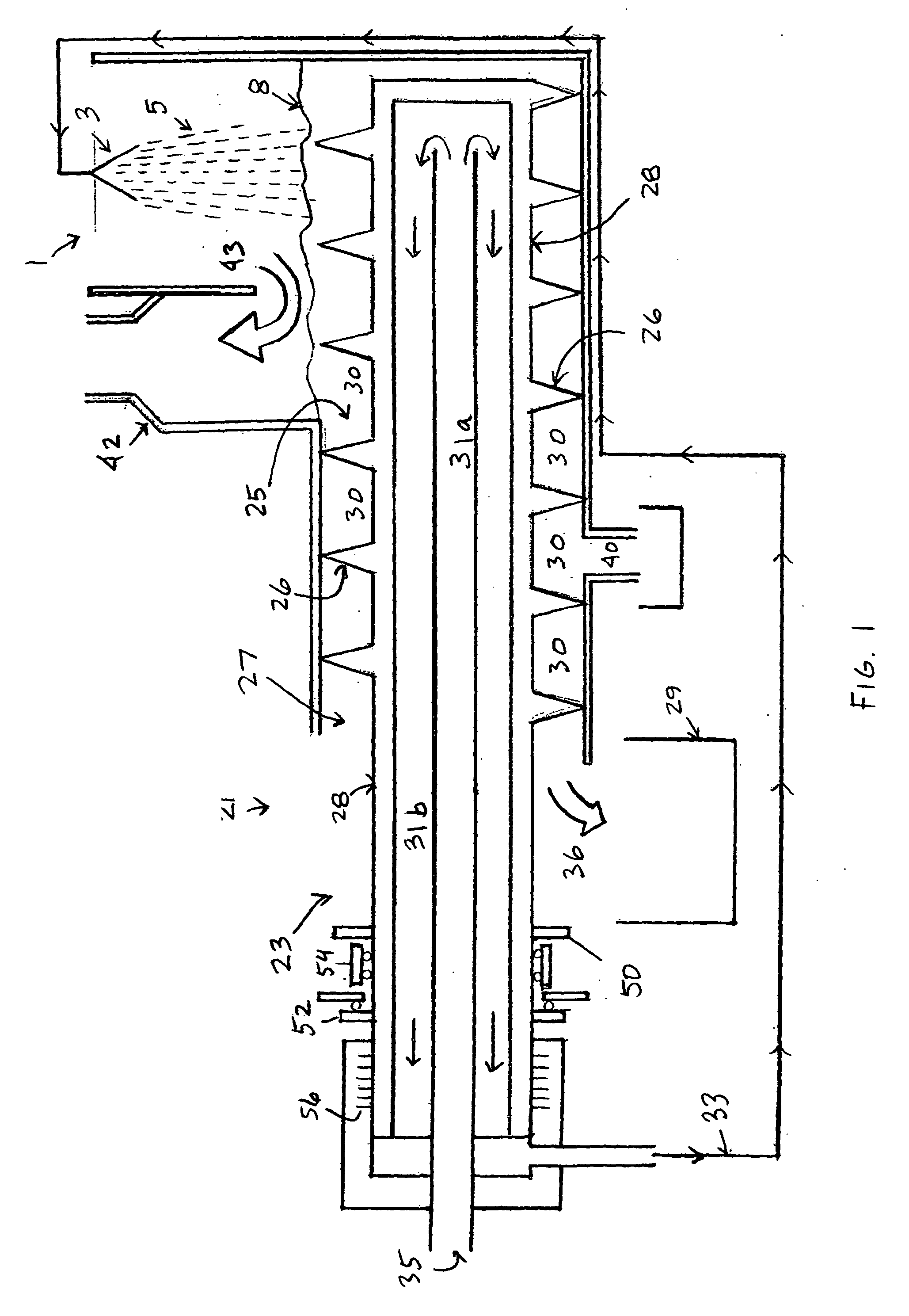

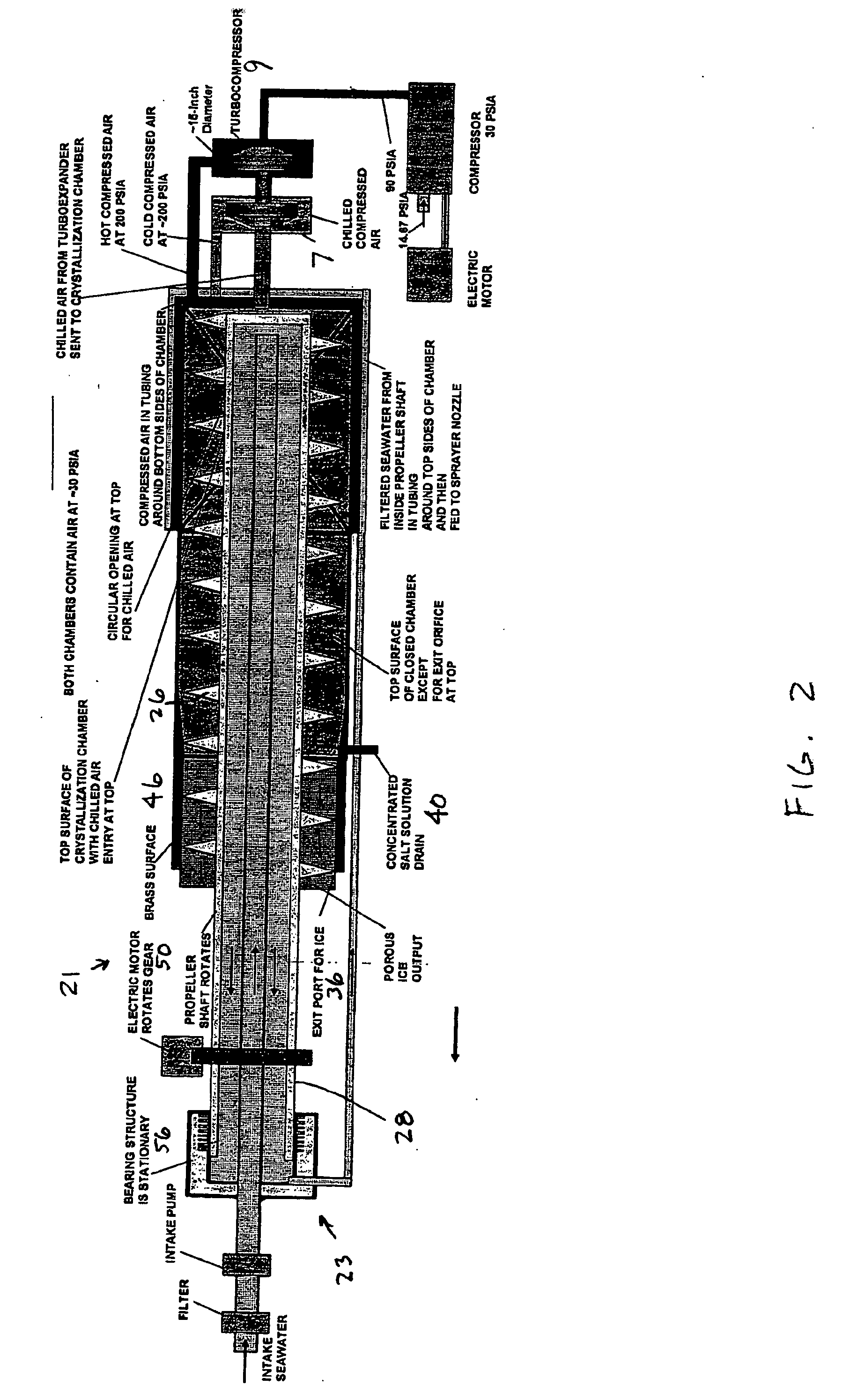

The invention relates to a desalination method and system that uses freeze crystallization technology that incorporates the use of compressed air energy as the source for freezing temperatures. When compressed air is released by a turbo expander, chilled air is produced as a by-product, wherein the chilled air is introduced into a crystallization chamber. Also injected into the chamber is a spray cloud of seawater droplets, which has been pre-chilled by heat exchange with the cold chamber walls, and which is then circulated and exposed to the chilled air in the chamber. The sizes of the droplets can vary, but are preferably predetermined, along with the relative temperatures, flows and speeds of the spray and chilled air, such that when the droplets are circulated within the chilled air, and settle at the bottom of the chamber, they are deposited at slightly above the eutectic temperature. This way, the ice / snow mass that forms at the bottom of the chamber will consist of frozen ice crystals, and a residue of salt water brine, which can runoff from the mass, either from the sides, or through any voids or channels that may form within the mass.

Owner:ENIS BEN M +1

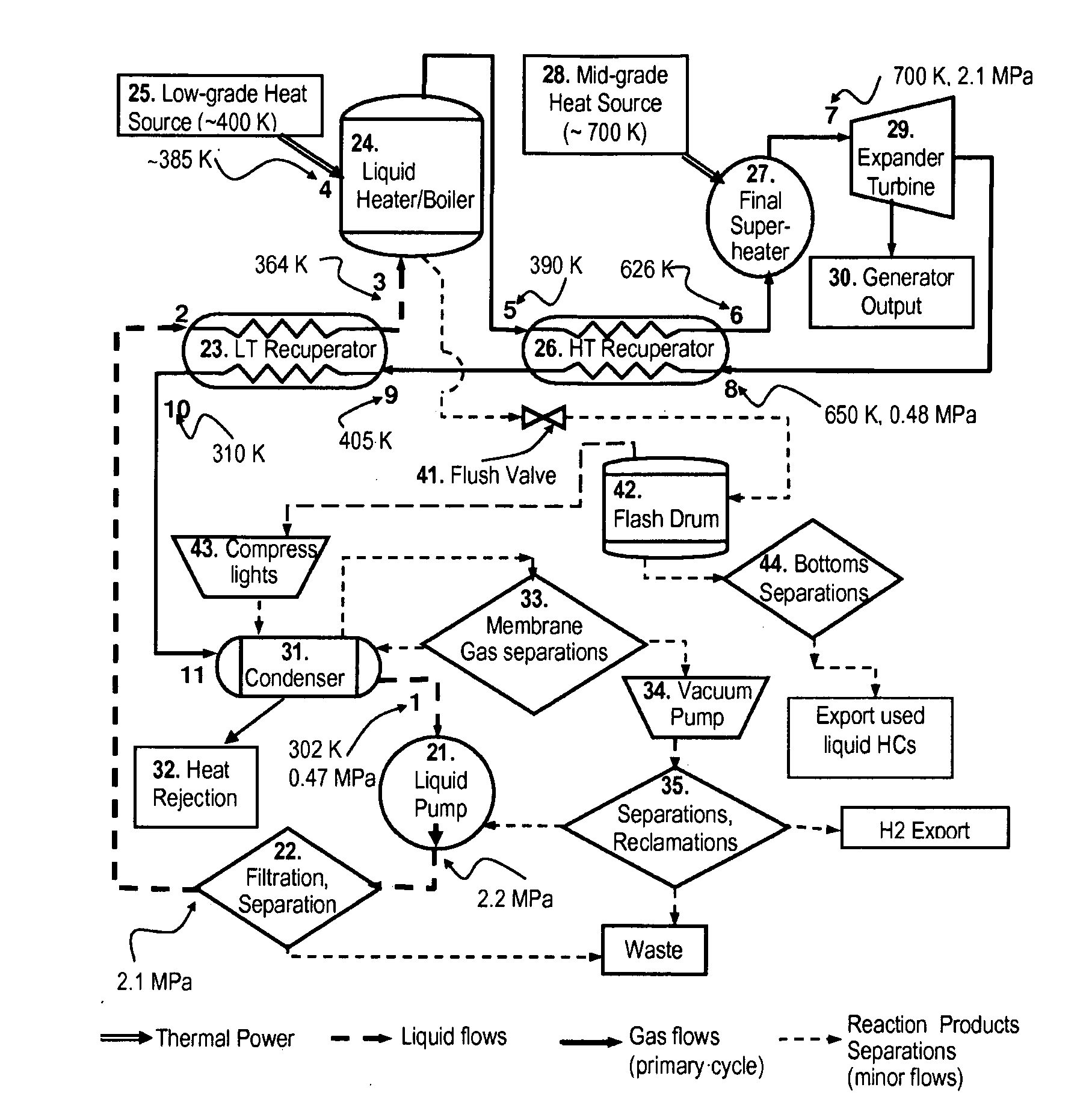

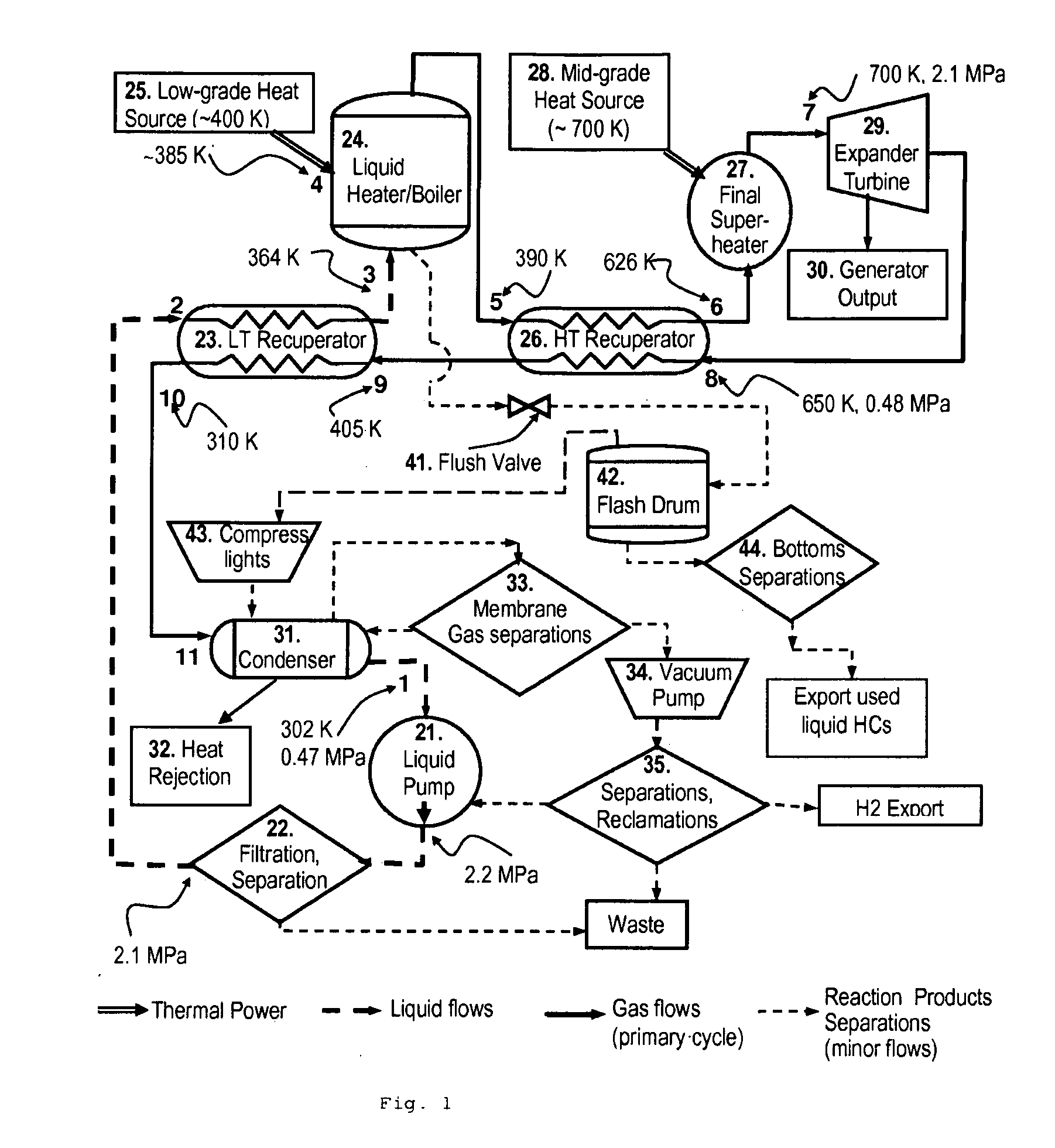

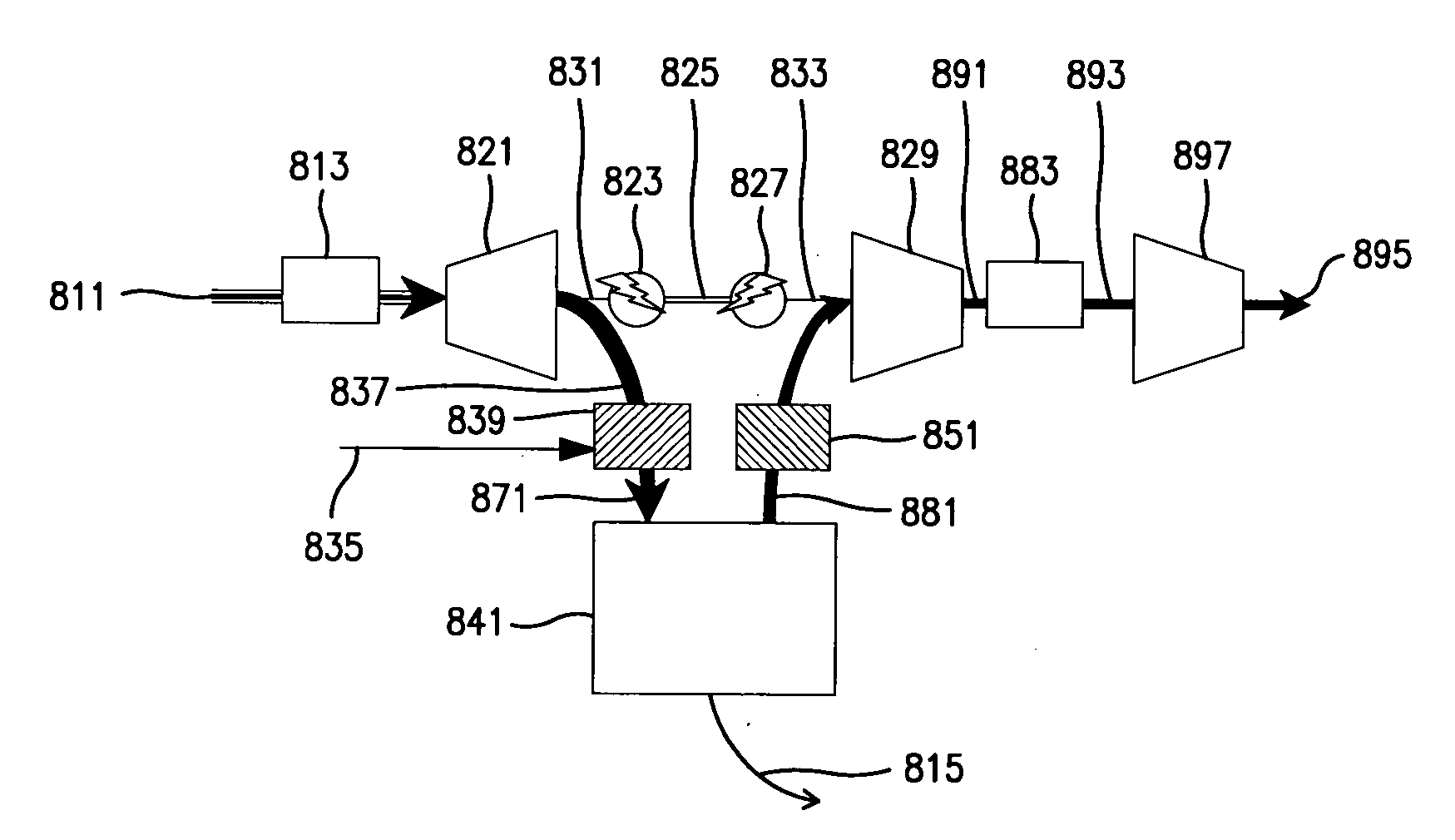

High-temperature dual-source organic Rankine cycle with gas separations

InactiveUS20100300093A1Increase temperatureMinimize timeAuxillary drivesInternal combustion piston enginesWorking fluidOrganic Rankine cycle

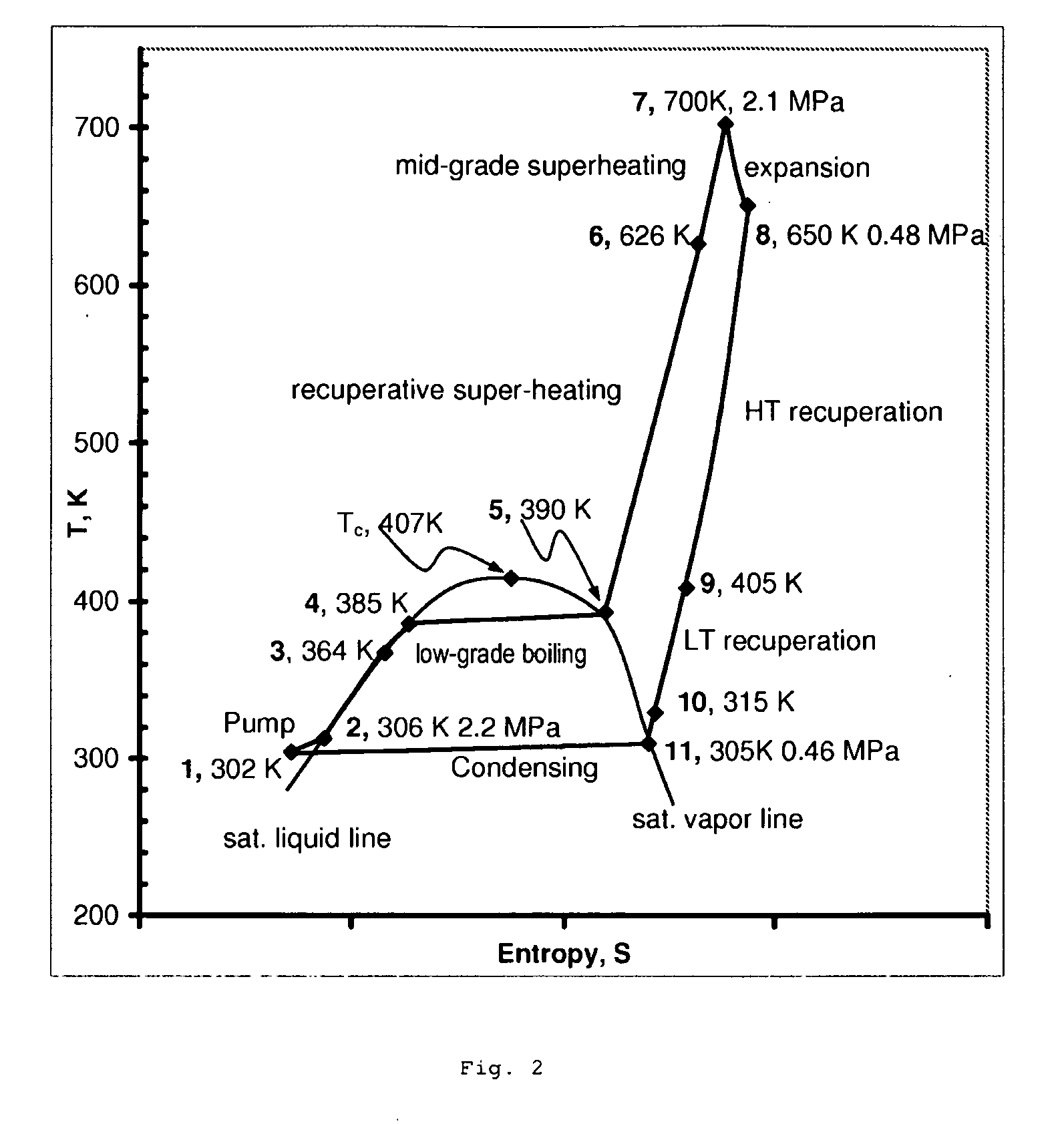

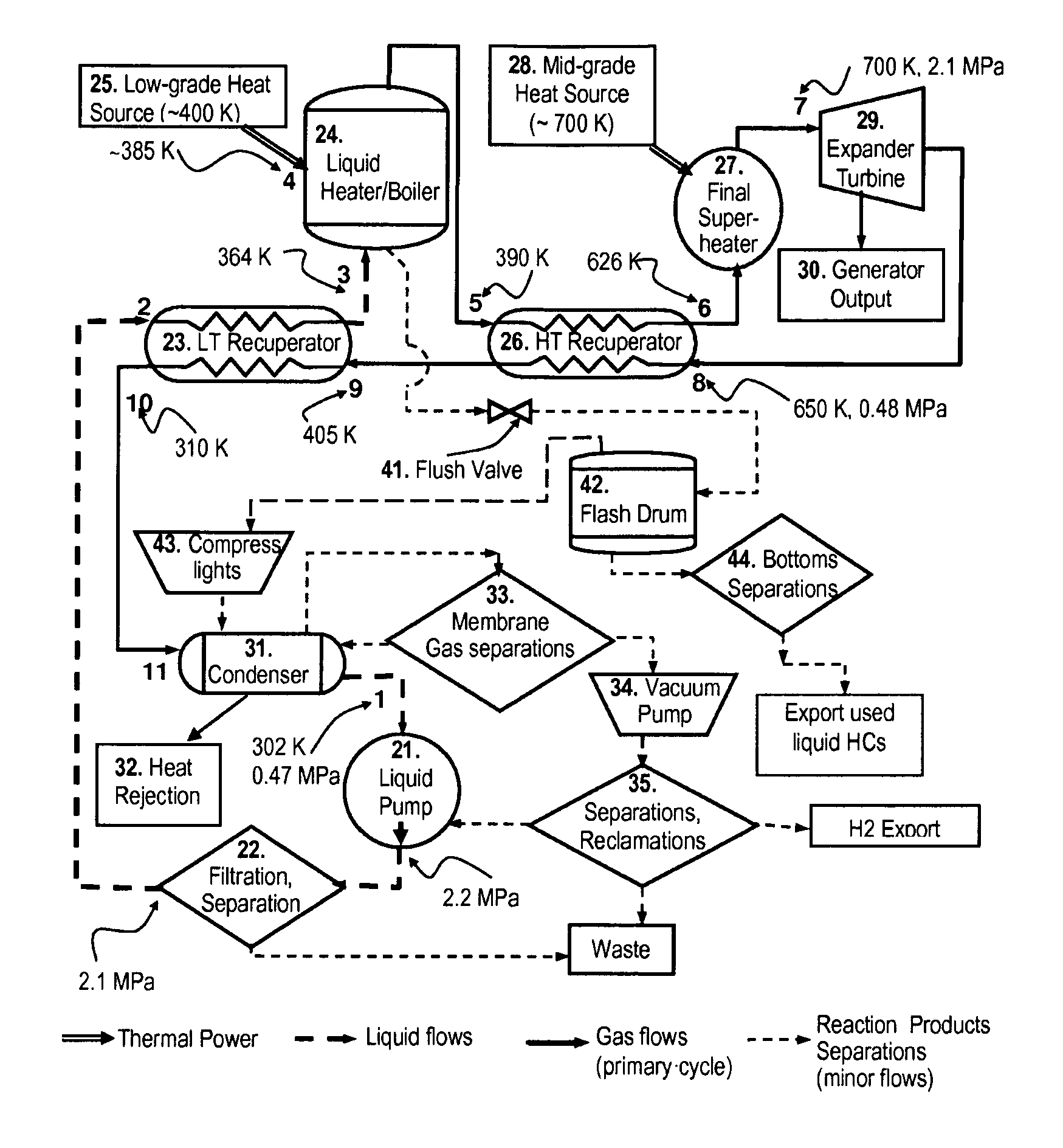

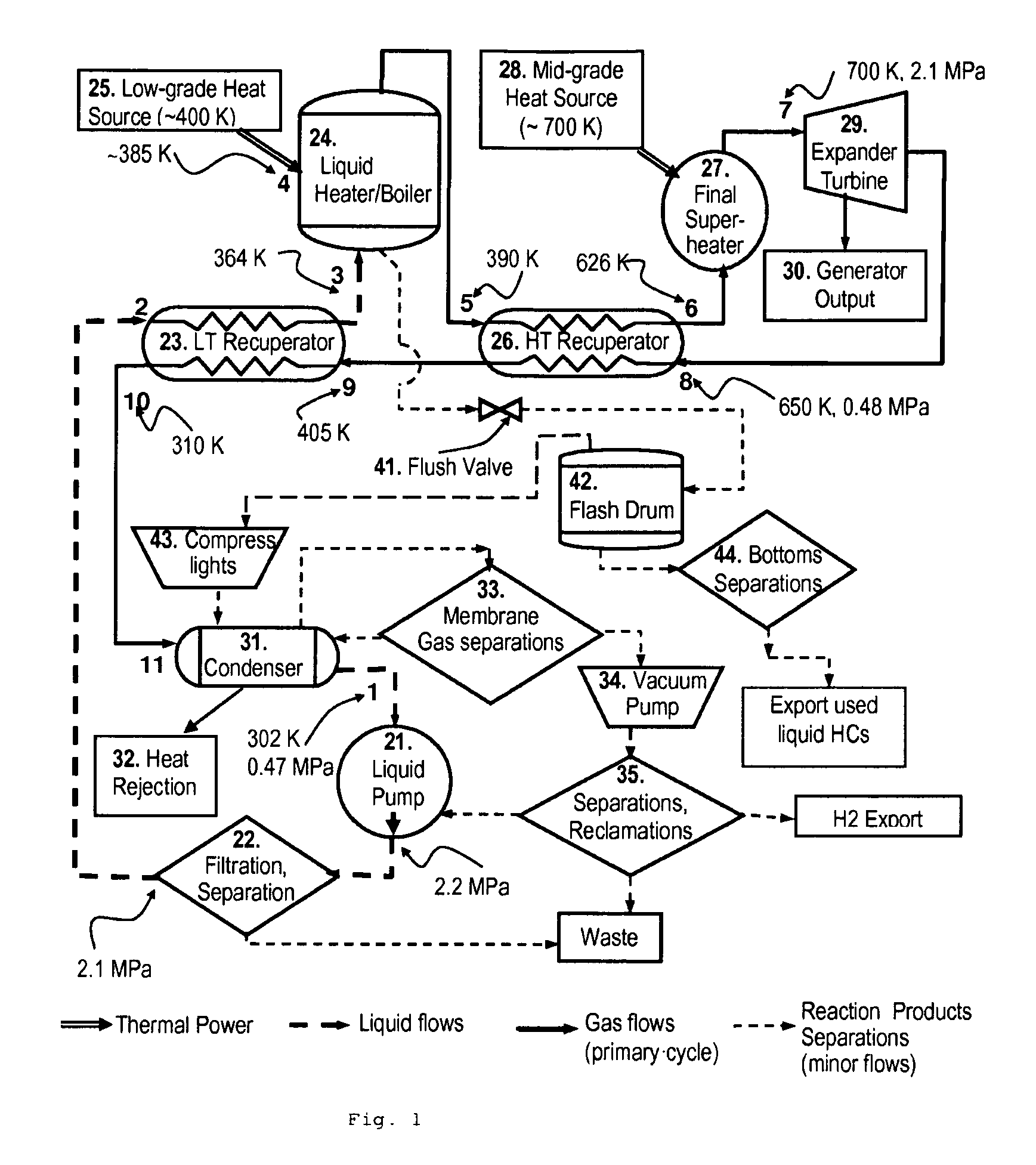

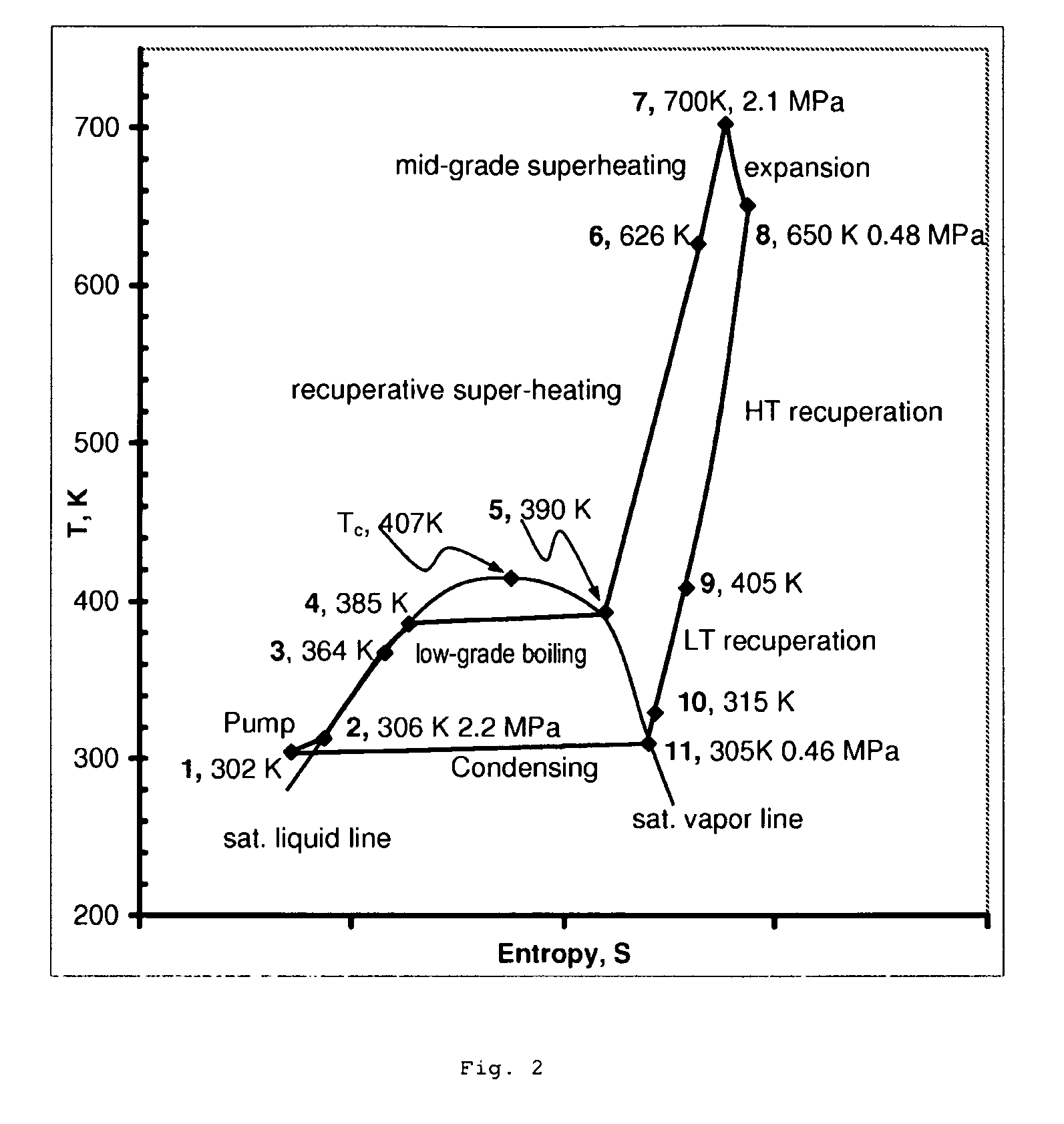

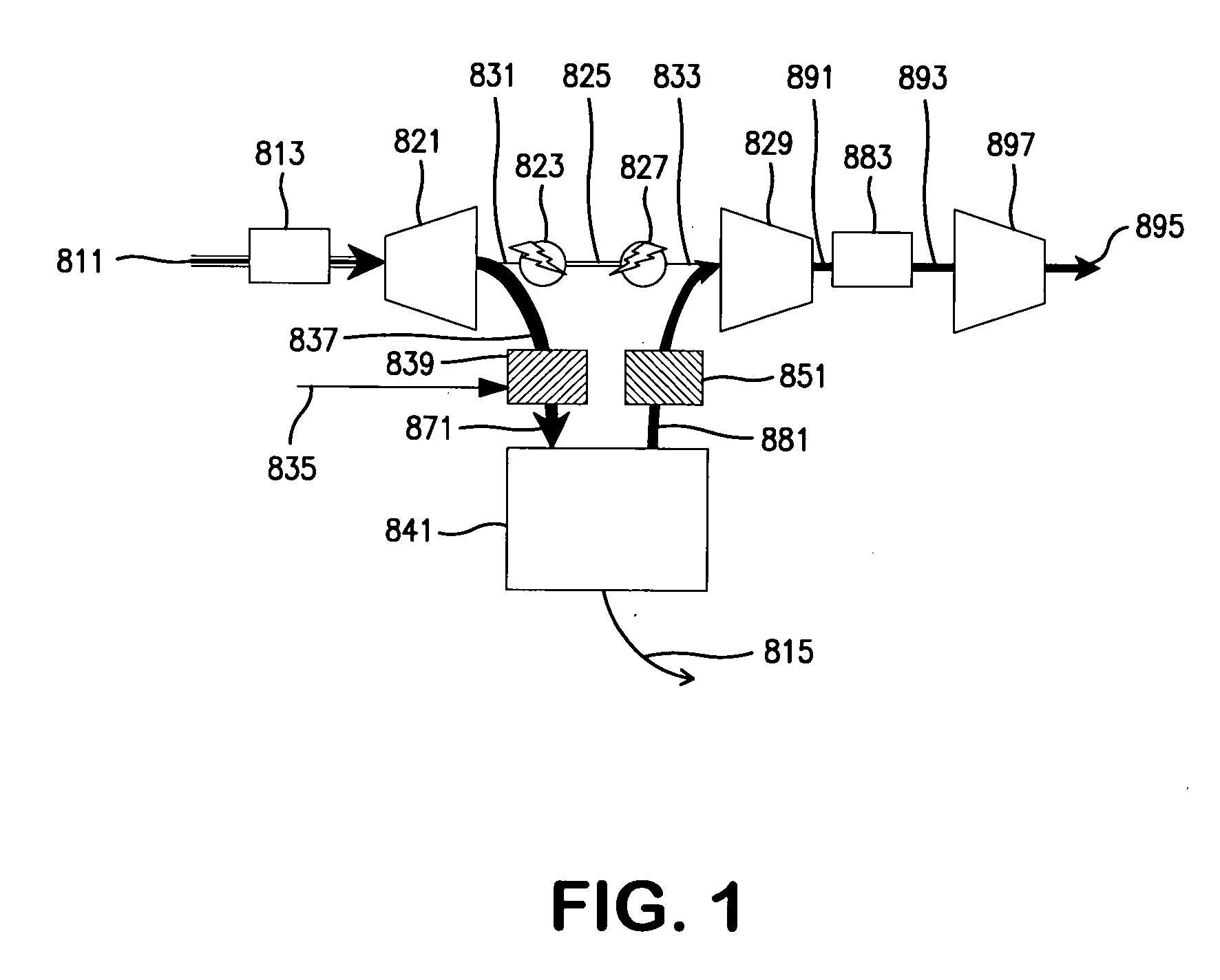

In a dual-source organic Rankine cycle (DORC), the condensed and slightly sub-cooled working fluid at near ambient temperature (˜300 K) and at low-side pressure (0.1 to 0.7 MPa) is (1) pumped to high-side pressure (0.5-5 MPa), (2) pre-heated in a low-temperature (LT) recuperator, (3) boiled using a low-grade heat source, (4) super-heated in a high-temperature (HT) recuperator to a temperature close to the expander turbine exhaust temperature using this exhaust vapor enthalpy, (5) further super-heated to the turbine inlet temperature (TIT) using a mid-grade heat source, (6) expanded through a turbine expander to the low-side pressure, (7) cooled through the HT recuperator, (8) cooled through the LT recuperator, (9) mostly liquefied and slightly subcooled in a condenser, and (10) the condensed portion is returned to the pump to repeat this cycle.

Owner:DOTY SCI

High-temperature dual-source organic Rankine cycle with gas separations

InactiveUS8046999B2Increase temperatureMinimize timeAuxillary drivesFrom solar energyWorking fluidOrganic Rankine cycle

In a dual-source organic Rankine cycle (DORC), the condensed and slightly sub-cooled working fluid at near ambient temperature (˜300 K) and at low-side pressure (0.1 to 0.7 MPa) is (1) pumped to high-side pressure (0.5-5 MPa), (2) pre-heated in a low-temperature (LT) recuperator, (3) boiled using a low-grade heat source, (4) super-heated in a high-temperature (HT) recuperator to a temperature close to the expander turbine exhaust temperature using this exhaust vapor enthalpy, (5) further super-heated to the turbine inlet temperature (TIT) using a mid-grade heat source, (6) expanded through a turbine expander to the low-side pressure, (7) cooled through the HT recuperator, (8) cooled through the LT recuperator, (9) mostly liquefied and slightly subcooled in a condenser, and (10) the condensed portion is returned to the pump to repeat this cycle.

Owner:DOTY SCI

Desalination Method and System Using Compressed Air Energy Systems

InactiveUS20100037653A1Facilitate runoffClean the ice massGeneral water supply conservationSeawater treatmentDesalinationSalt water

The invention relates to a desalination method and system that uses freeze crystallization technology that incorporates the use of compressed air energy as the source for freezing temperatures. When compressed air is released by a turbo expander, chilled air is produced as a by-product, wherein the chilled air is introduced into a crystallization chamber. Also injected into the chamber is a spray cloud of seawater droplets, which has been pre-chilled by heat exchange with the cold chamber walls, and which is then circulated and exposed to the chilled air in the chamber. The sizes of the droplets can vary, but are preferably predetermined, along with the relative temperatures, flows and speeds of the spray and chilled air, such that when the droplets are circulated within the chilled air, and settle at the bottom of the chamber, they are deposited at slightly above the eutectic temperature. This way, the ice / snow mass that forms at the bottom of the chamber will consist of frozen ice crystals, and a residue of salt water brine, which can runoff from the mass, either from the sides, or through any voids or channels that may form within the mass.

Owner:ENIS BEN M +1

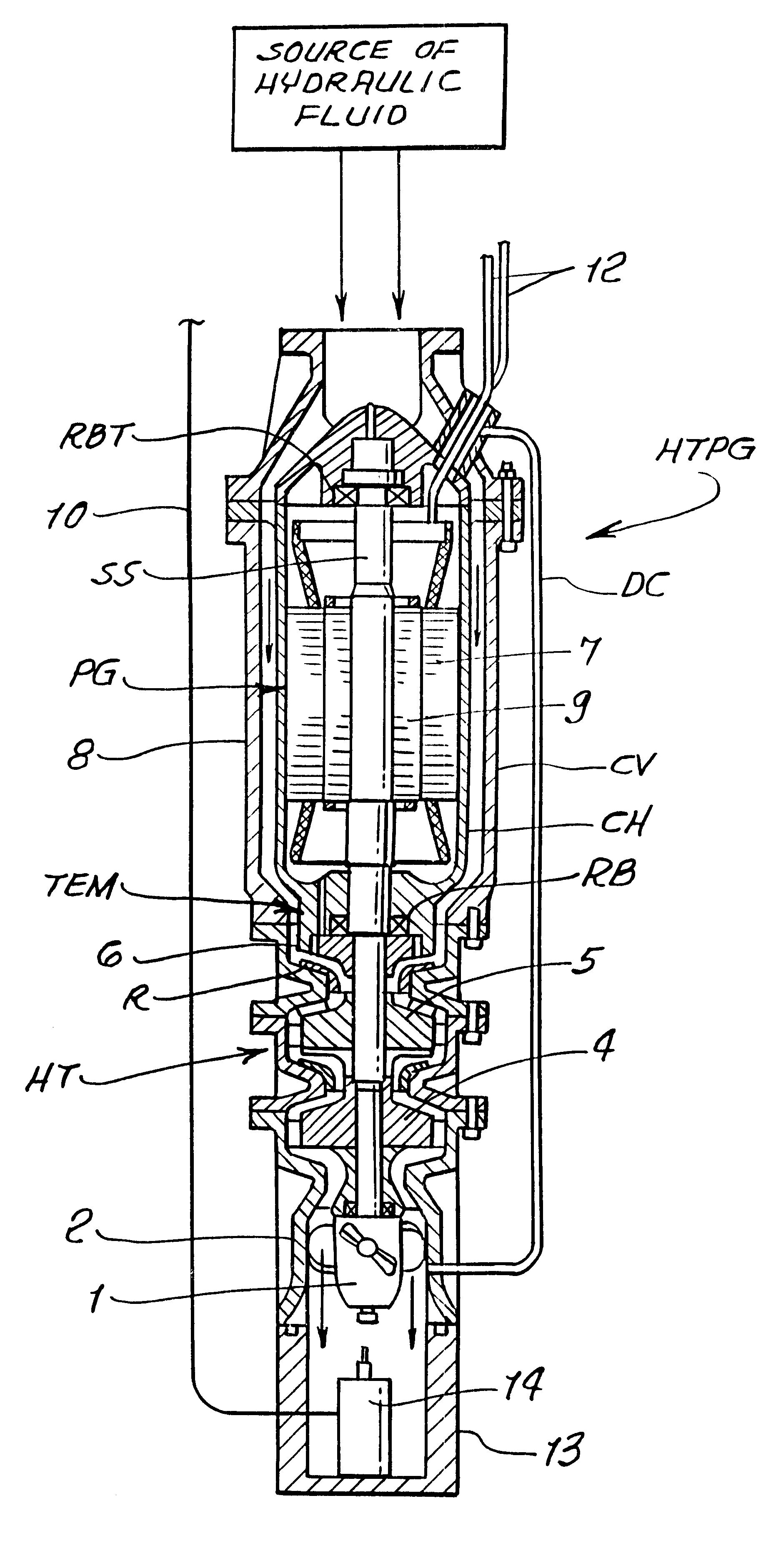

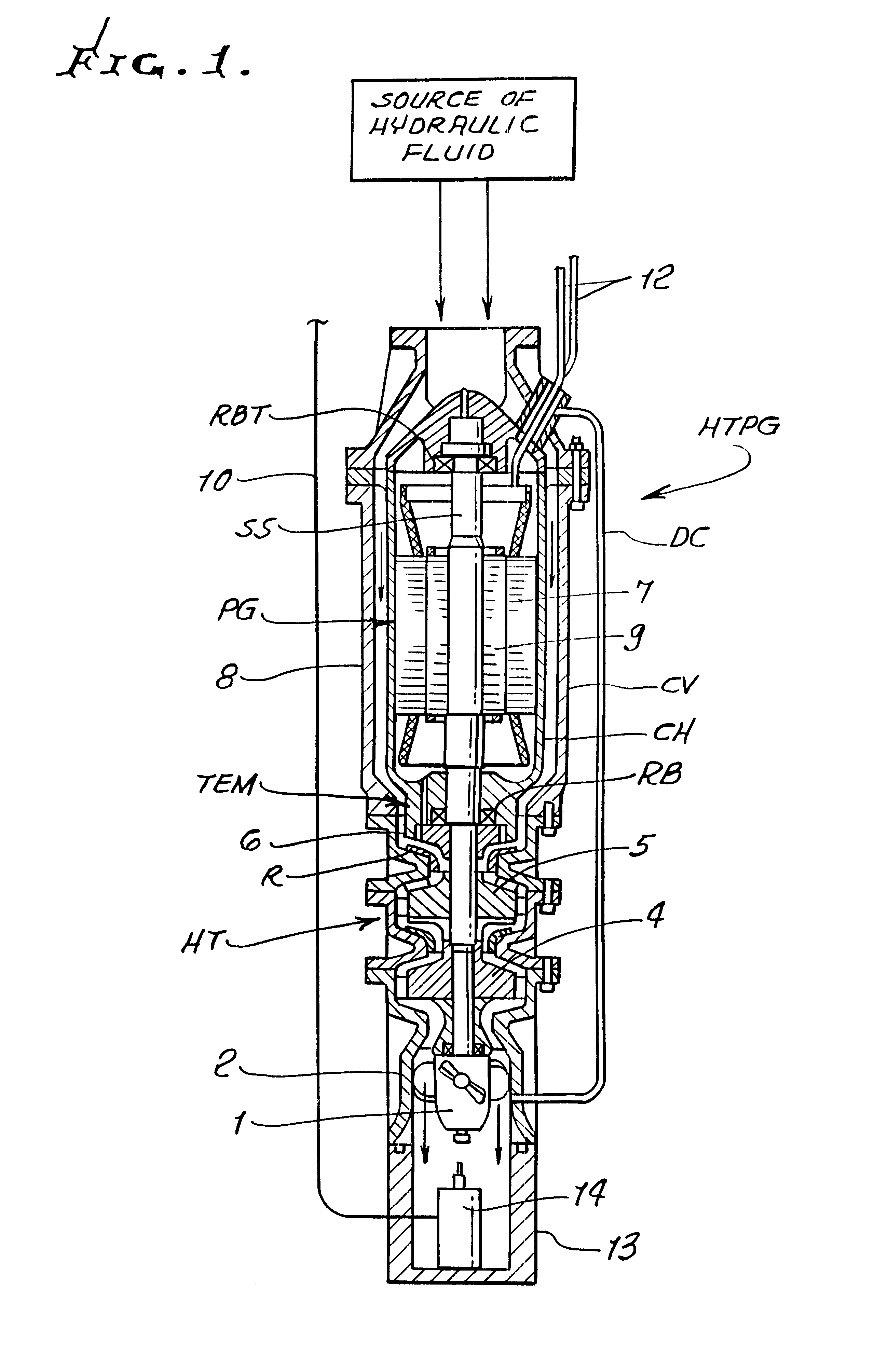

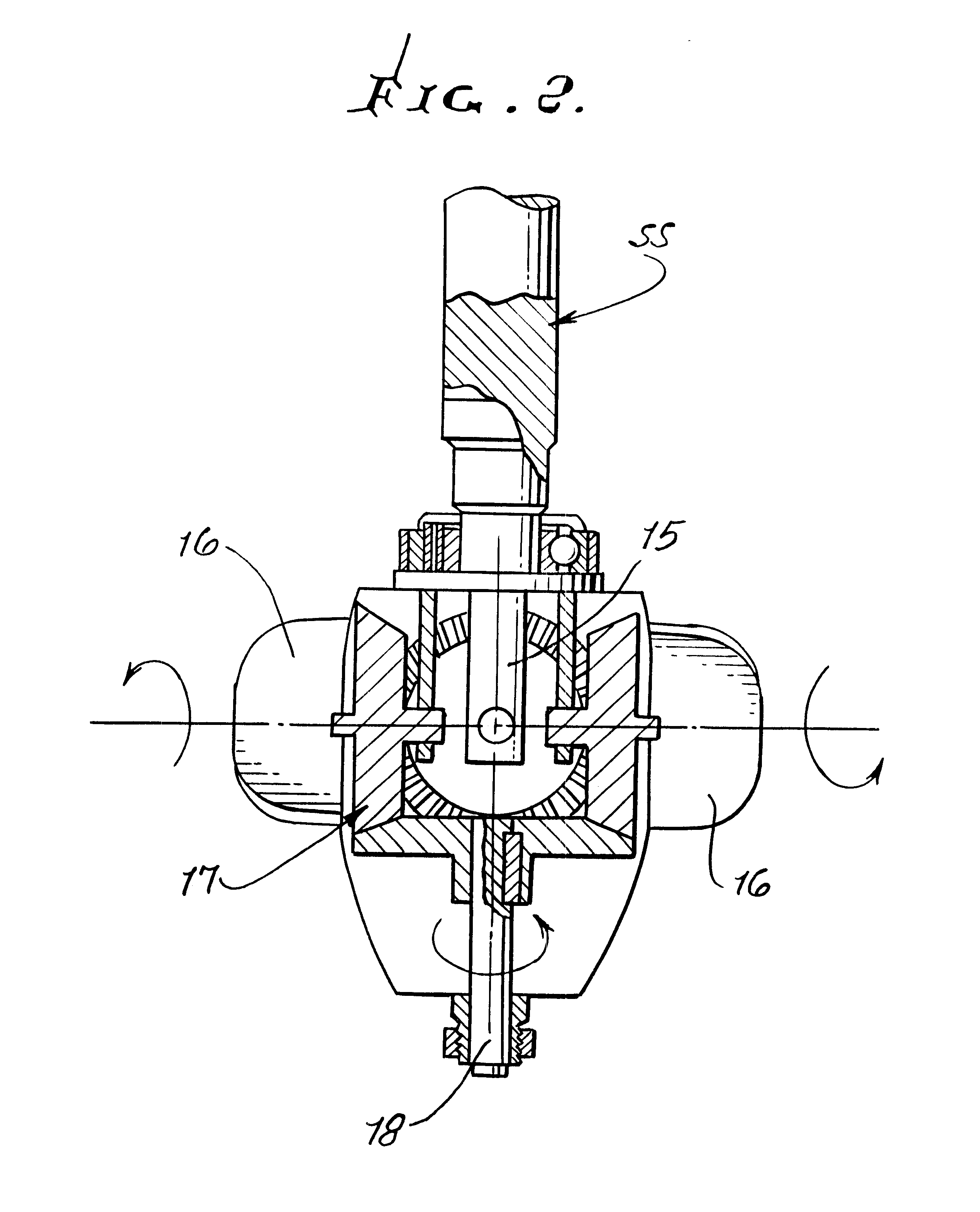

Dual type multiple stage, hydraulic turbine power generator including reaction type turbine with adjustable blades

InactiveUS6441508B1Maximize efficiencyConstant speedGas turbine plantsReaction enginesEngineeringHydraulic fluid

A hydraulic turbine power generator mounted on a single shaft wherein the hydraulic turbine means includes a plurality of reaction type turbine stages arranged to be in combination, rotatably responsive to the hydraulic fluid coupled to the turbines. One of the turbine stages having axial turbine runner means mounted to the single shaft and having a plurality of adjustable blades for permitting the pitch of the blades to be adjusted for controlling the effective operative fluid head to cause the shaft to rotate at a preselected speed and including means for adjusting the pitch of the adjustable blades. The turbine stages can be a Francis type turbine and a Kaplan type turbine. The hydraulic turbine power generator can be oriented in an upward direction to cause the fluid flow to travel upwardly through the turbine stages and function as a two phase turbine expander resulting in the separation of the liquid phase from the gas / vapor stage.

Owner:ELLIOTT CO

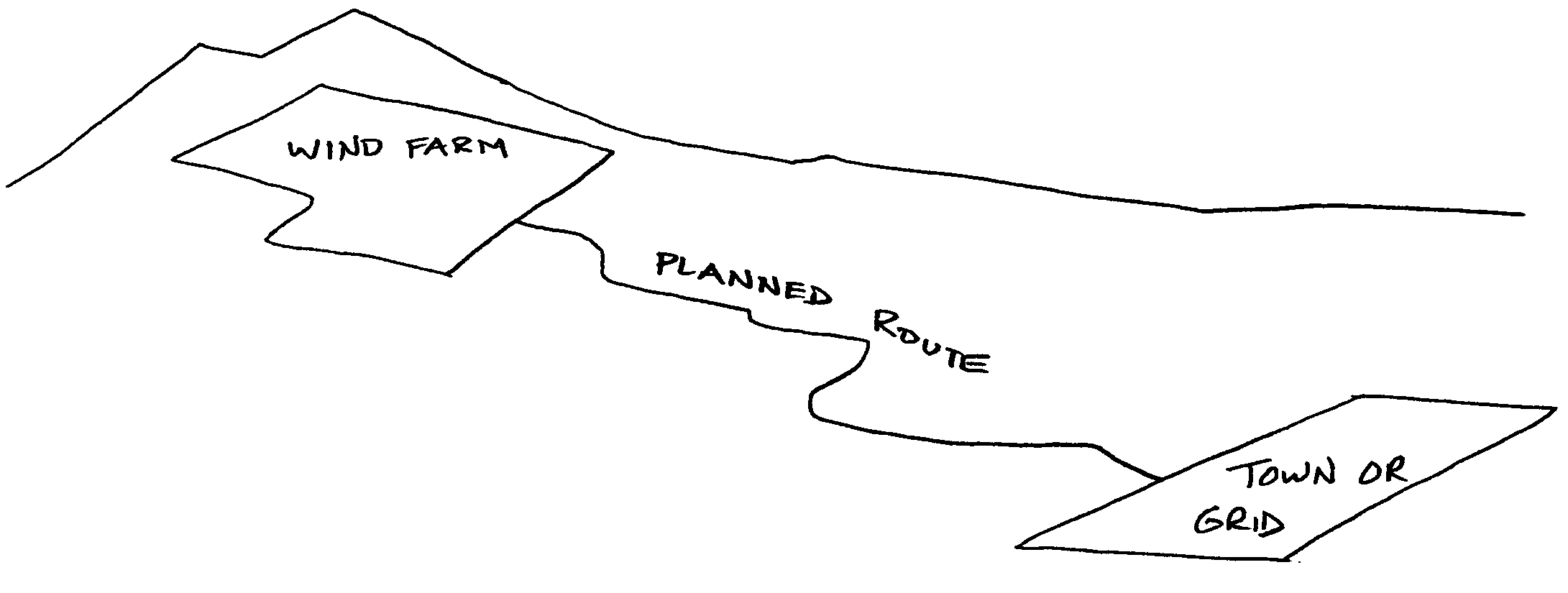

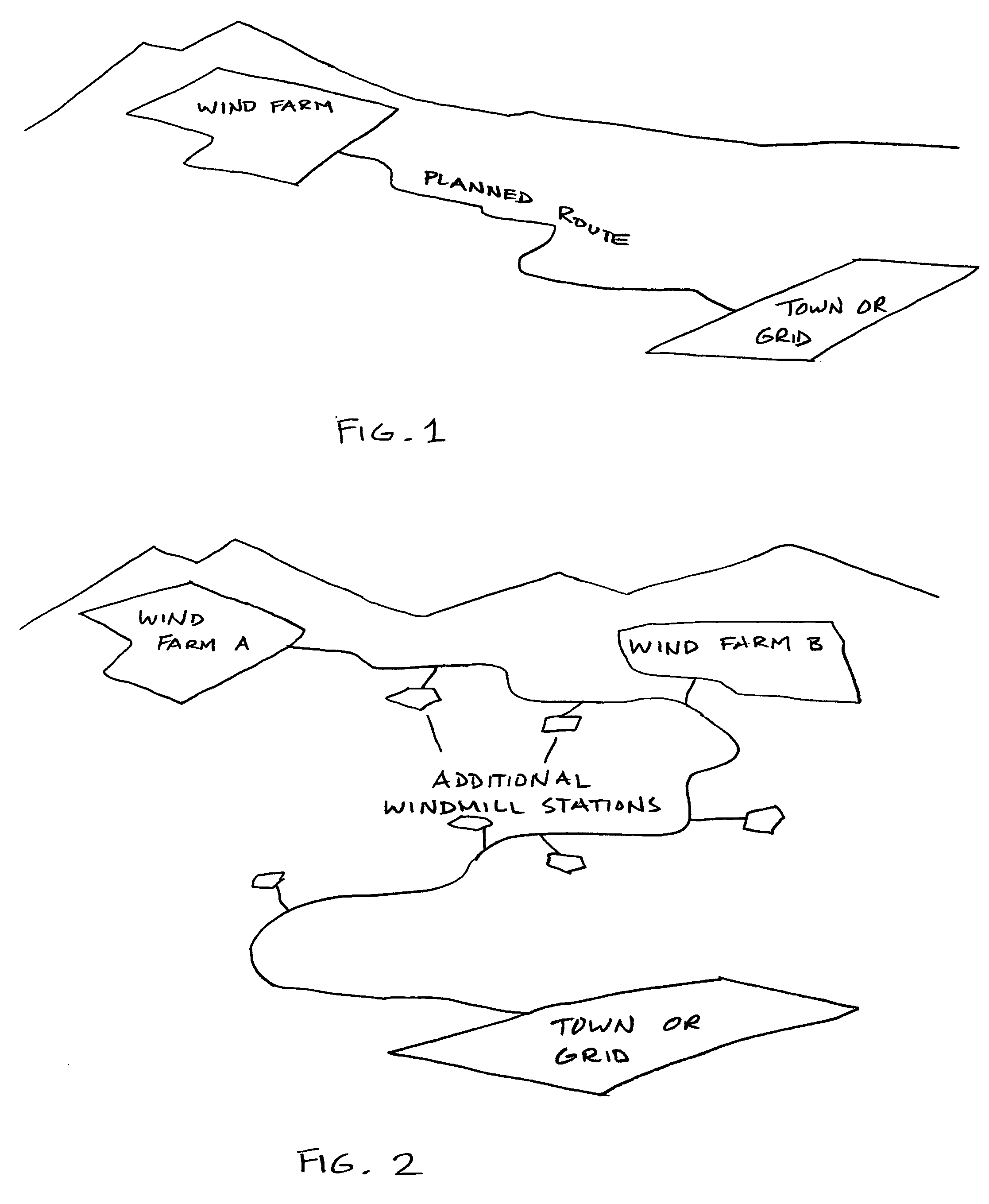

Method of storing and transporting wind generated energy using a pipeline system

InactiveUS20050016165A1Inhibit swellingEfficient designFluid couplingsWind energy with garvitational potential energyElectricityAlternator

The invention relates to a method of using a pipeline system for storing and transporting compressed air energy generated by wind turbines, wherein the pipeline preferably extends along a predetermined route, between a remote location where wind conditions are relatively consistent and predicable, and a power grid or community needing the power located a distance away. The remote location is preferably provided with a large number of windmill stations for generating electrical and mechanical energy, which is used to compress air into the pipeline. The route is preferably extended along an existing road or easement, and can incorporate abandoned existing piping when available. Turbo expanders and alternators are preferably provided at the user end of the pipeline, to release the compressed air and generate electricity for the grid or community.

Owner:ENIS BEN M +1

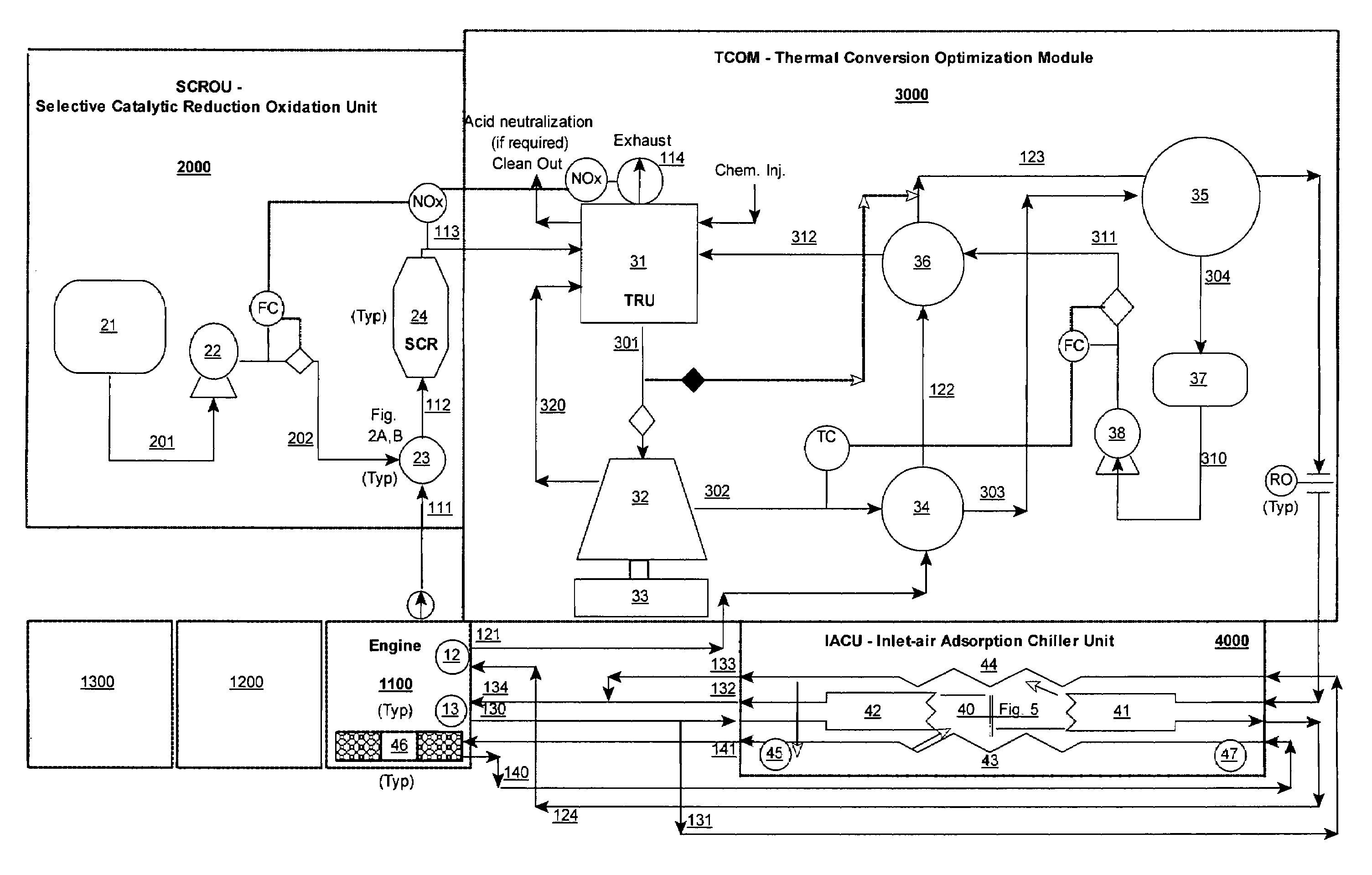

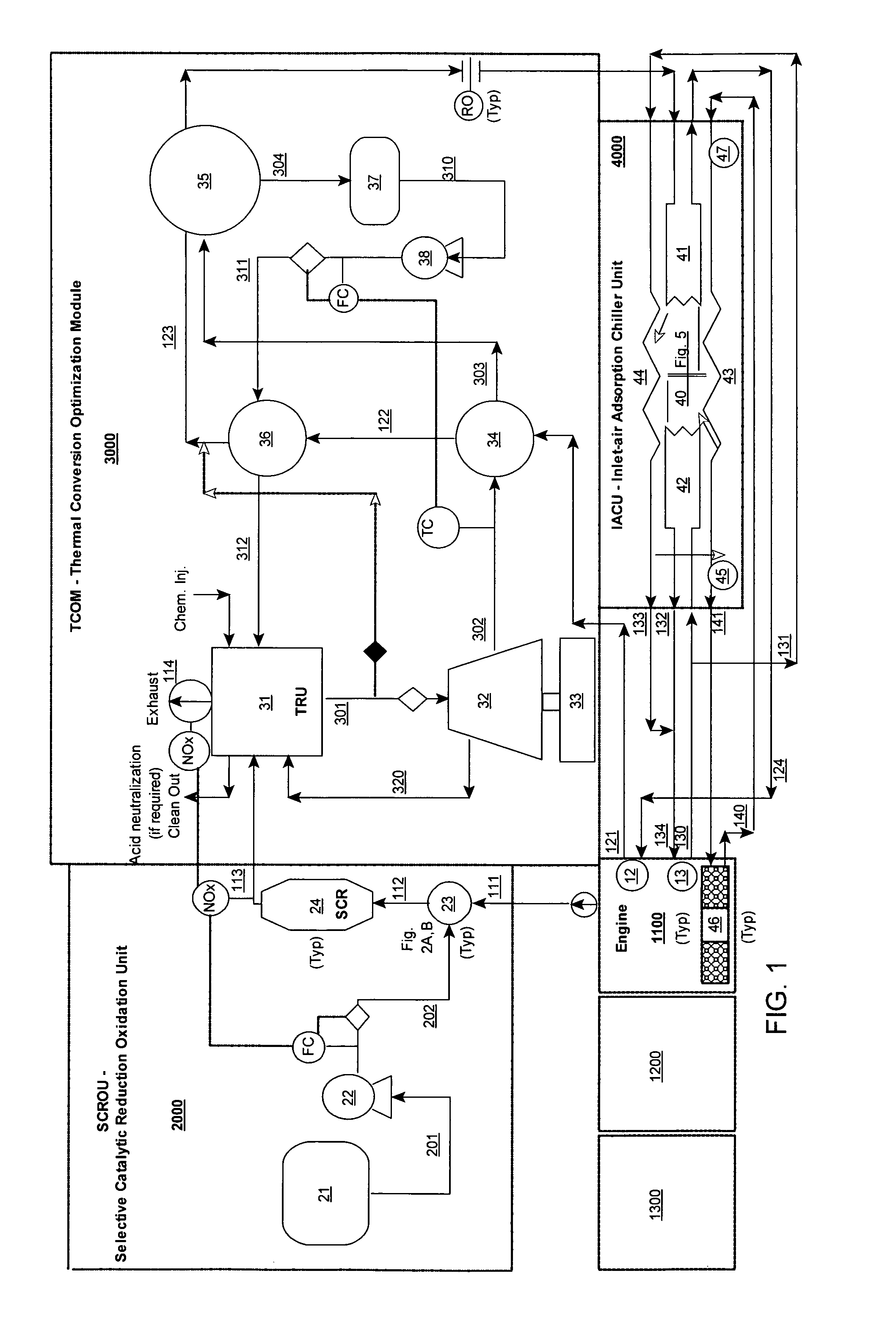

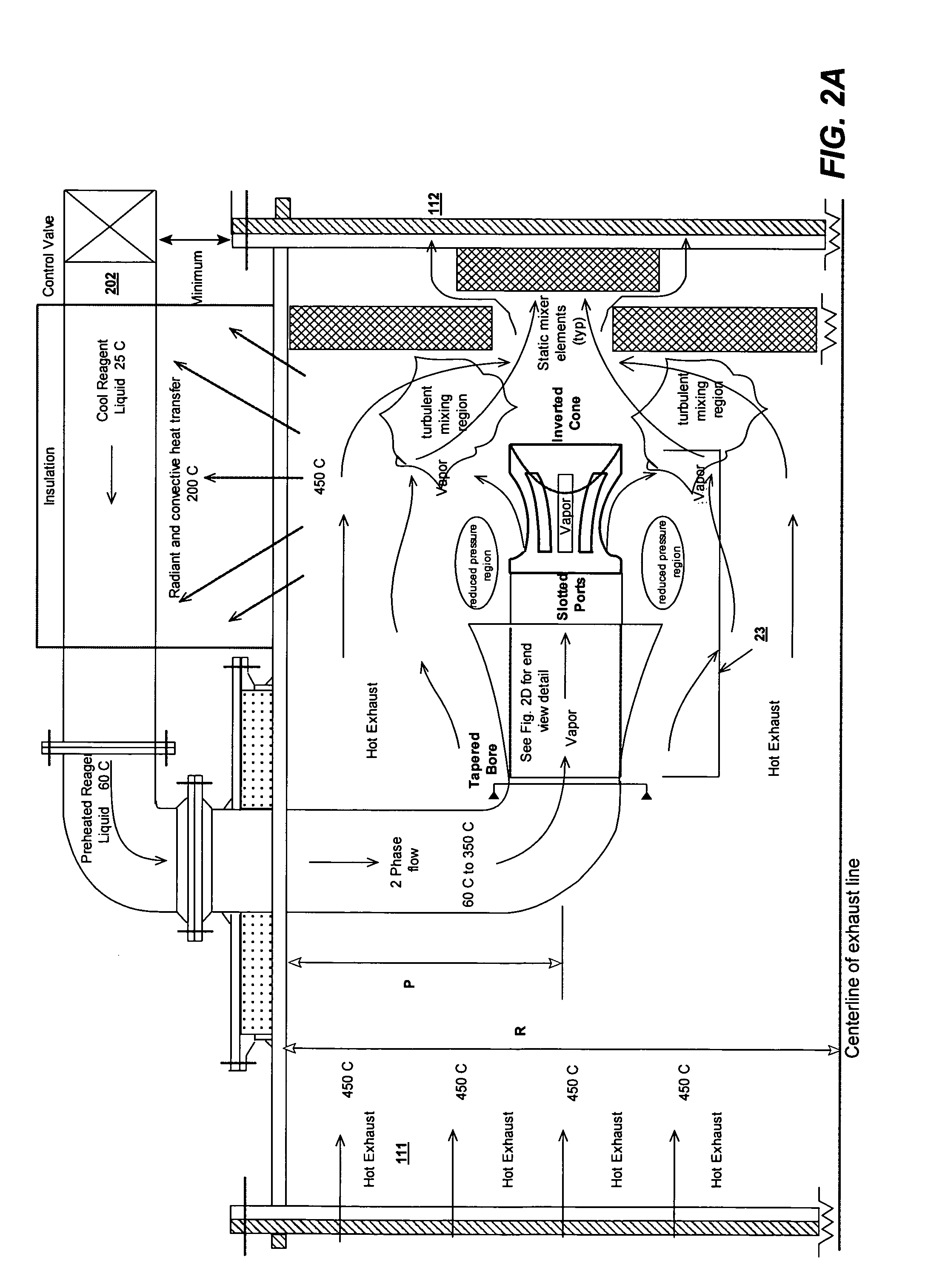

Energy recovery from waste heat sources

InactiveUS7469540B1Emission reductionResist acidic corrosionInternal combustion piston enginesExhaust apparatusThermal energyEngineering

In some embodiments, three integrated phases may be used to reduce emissions, convert thermal energy into electricity, and cool inlet combustion air. An ammonia injection system may be designed to eliminate extraneous equipment and hazardous re-circulation lines by directly vaporizing, injecting, and mixing ammonia using a specially designed nozzle. The second phase may include using a preheat / vaporizer / superheater exchanger to convert ammonia liquid into a superheated vapor that is then passed through a turbo-expander / generator to produce power. In some embodiments, the third phase may include inlet combustion air chilling.

Owner:KNAPTON BRENT WILLIAM +1

Removal of a target gas from a mixture of gases by swing adsorption with use of a turboexpander

The separation of a target gas selected from a high pressure gas mixture containing said target gas as well as a product gas using a swing adsorption process unit. A turboexpander is used upstream of the swing adsorber to reduce the pressure of the high pressure gas mixture. A compressor is optionally used downstream of the swing adsorber to increase the pressure of the target gas-containing stream for injecting into a subterranean formation.

Owner:EXXON RES & ENG CO

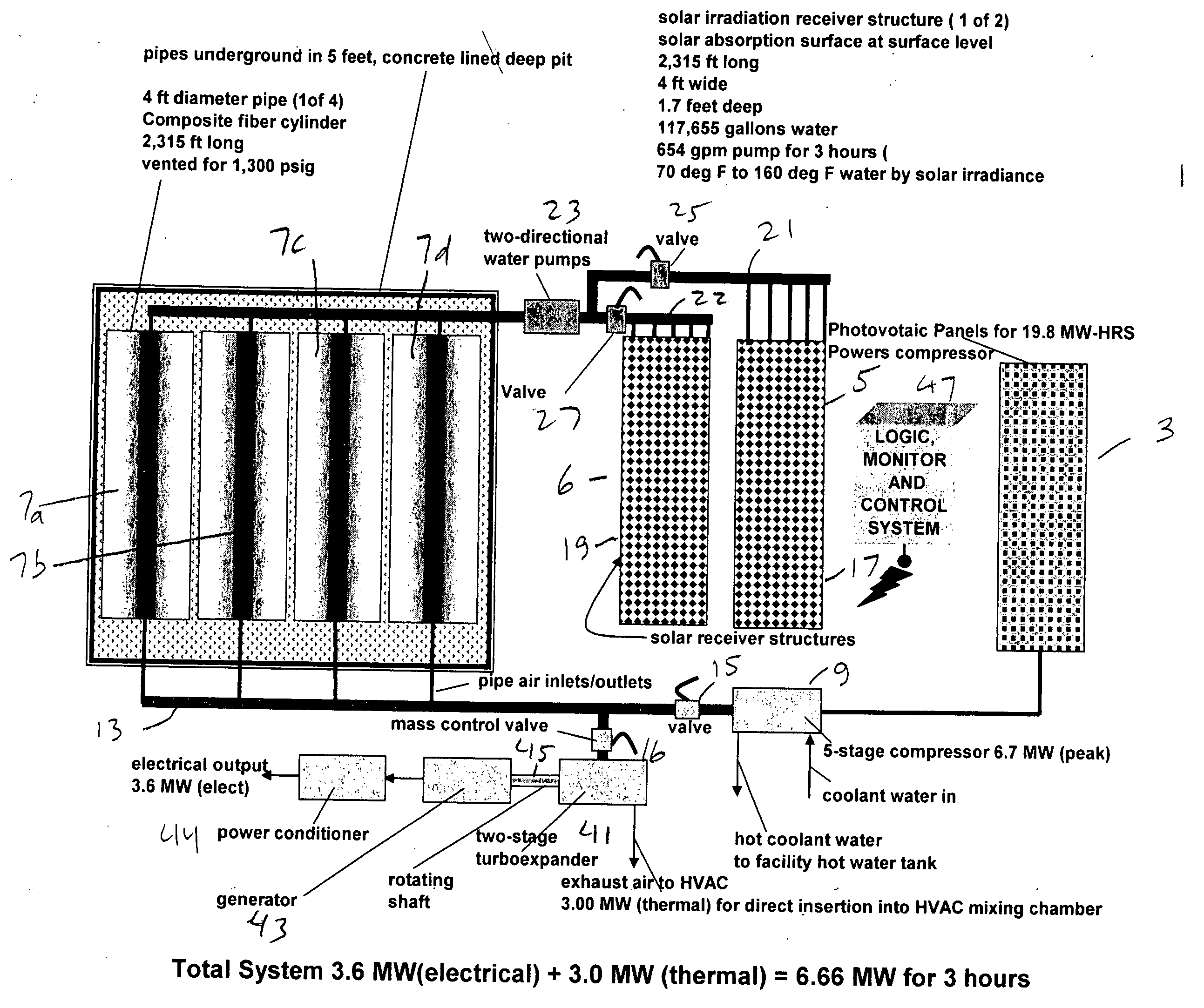

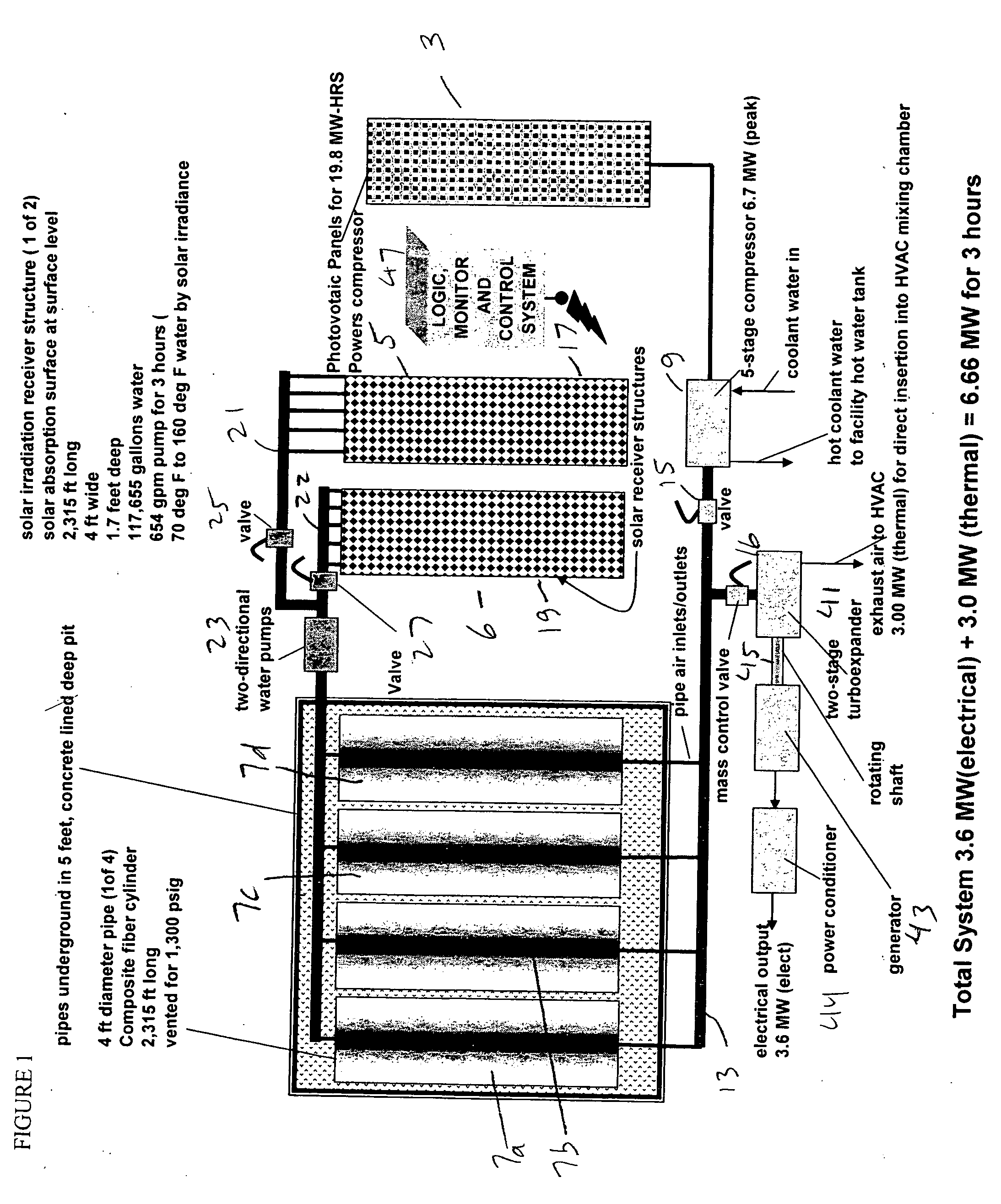

Method and apparatus for using solar energy to enhance the operation of a compressed air energy storage system

ActiveUS20090230696A1Reduce inconsistencyReduce inefficienciesSolar heating energyAuxillary drivesThermal energy storageCogeneration

The invention relates to a method and apparatus for using solar energy to enhance the efficiency of a compressed air energy storage system (and visa-versa). The apparatus comprises a photovoltaic panel to drive a compressor, which provides compressed air energy into an inner vessel housed within a storage tank. Two solar receiving panels are used to heat water which can be circulated and stored within an annulus surrounding the inner vessel, wherein the heated water can help regulate the temperature of the compressed air within the tank. This way, when air is released using a turbo expander, any excess temperature drops that can otherwise result from air expansion can be avoided. The overall system efficiency is enhanced by the chilled air by-product of the turbo expander which is used to generate more electrical power from an associated fuel-driven generator set, and / or by the waste heat from the compressor and from the generator set exhaust which is used in a Combined Heat and Power system (CHP) to power either a steam-driven generator set or an absorption chiller.

Owner:ENIS BEN M +1

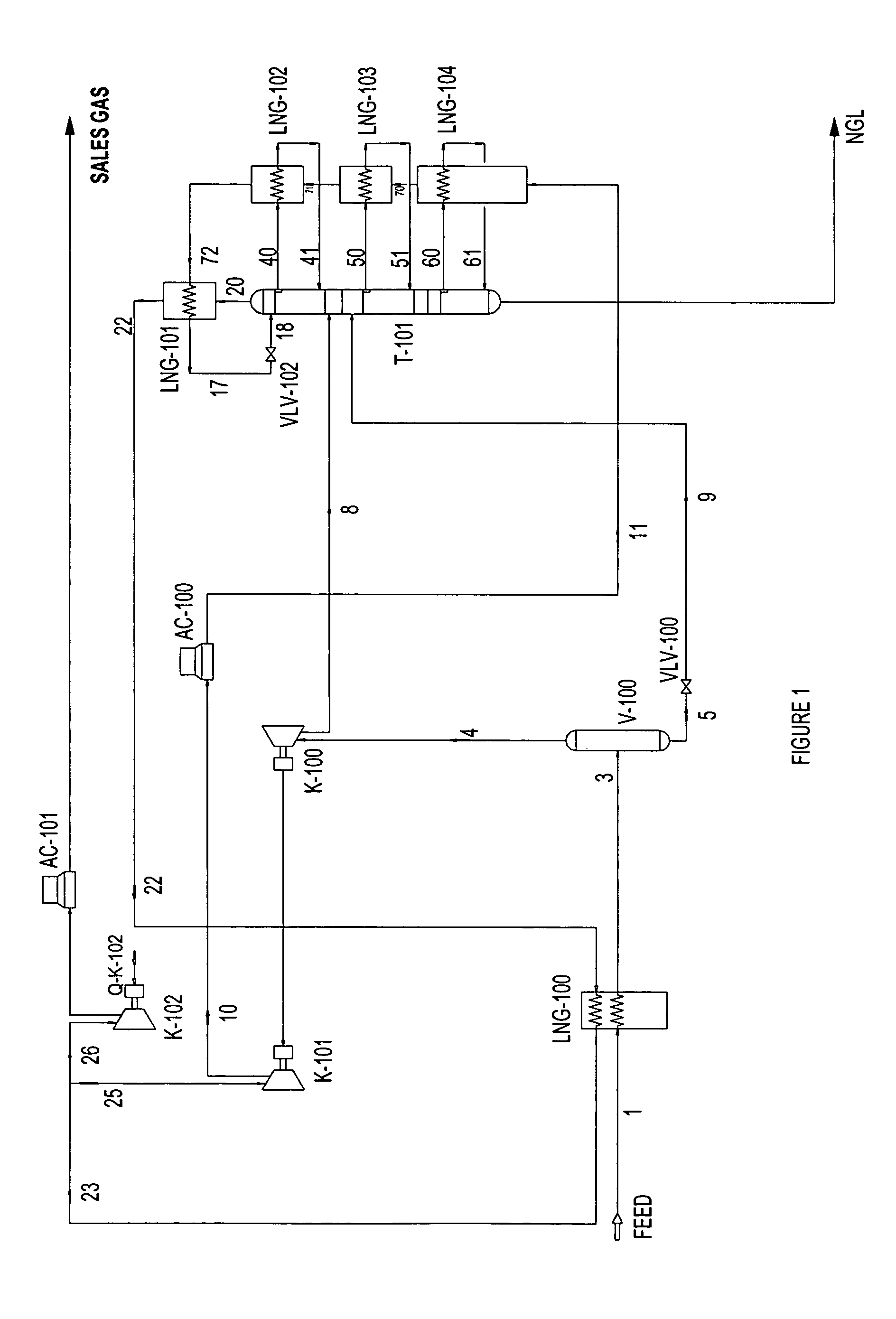

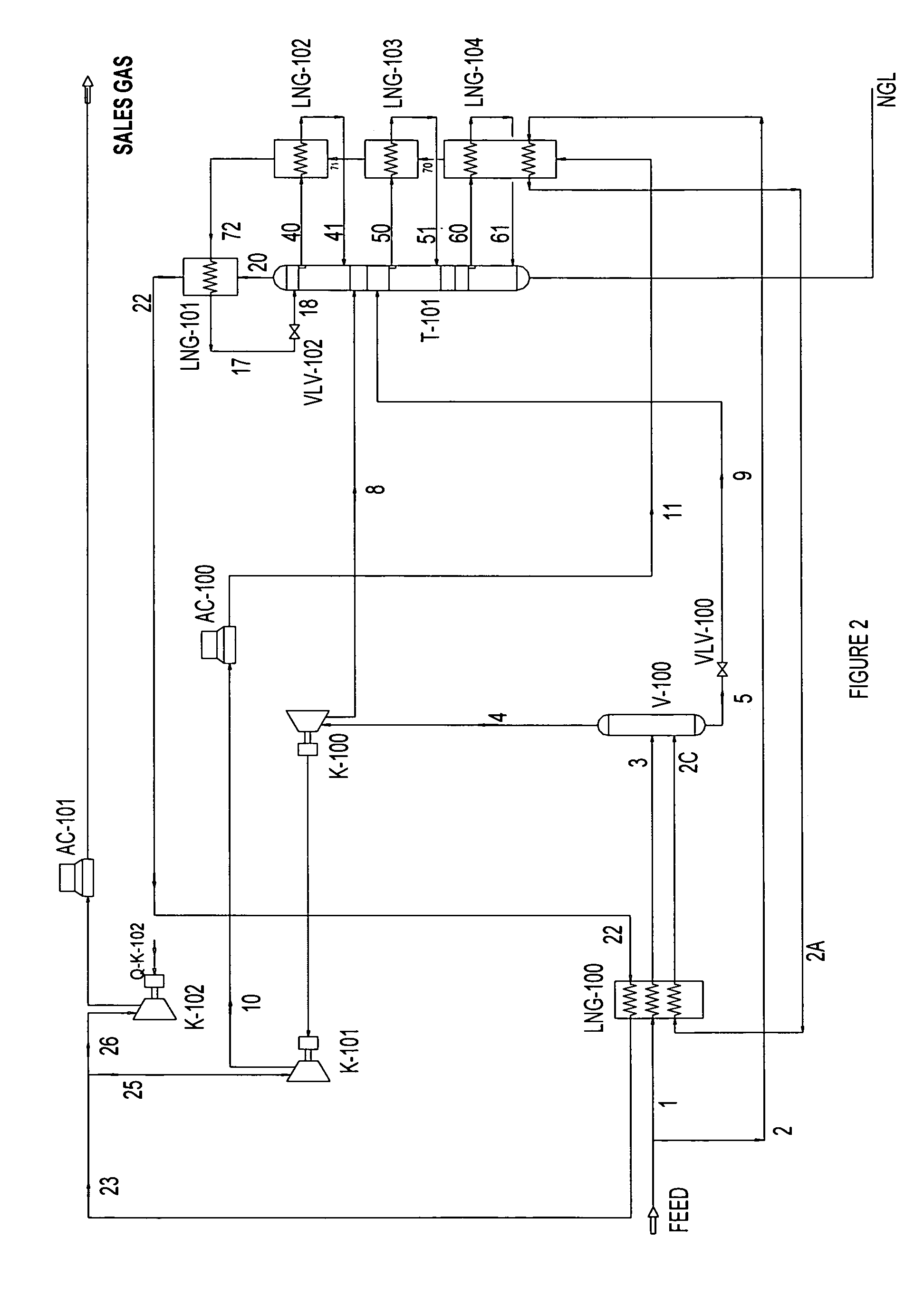

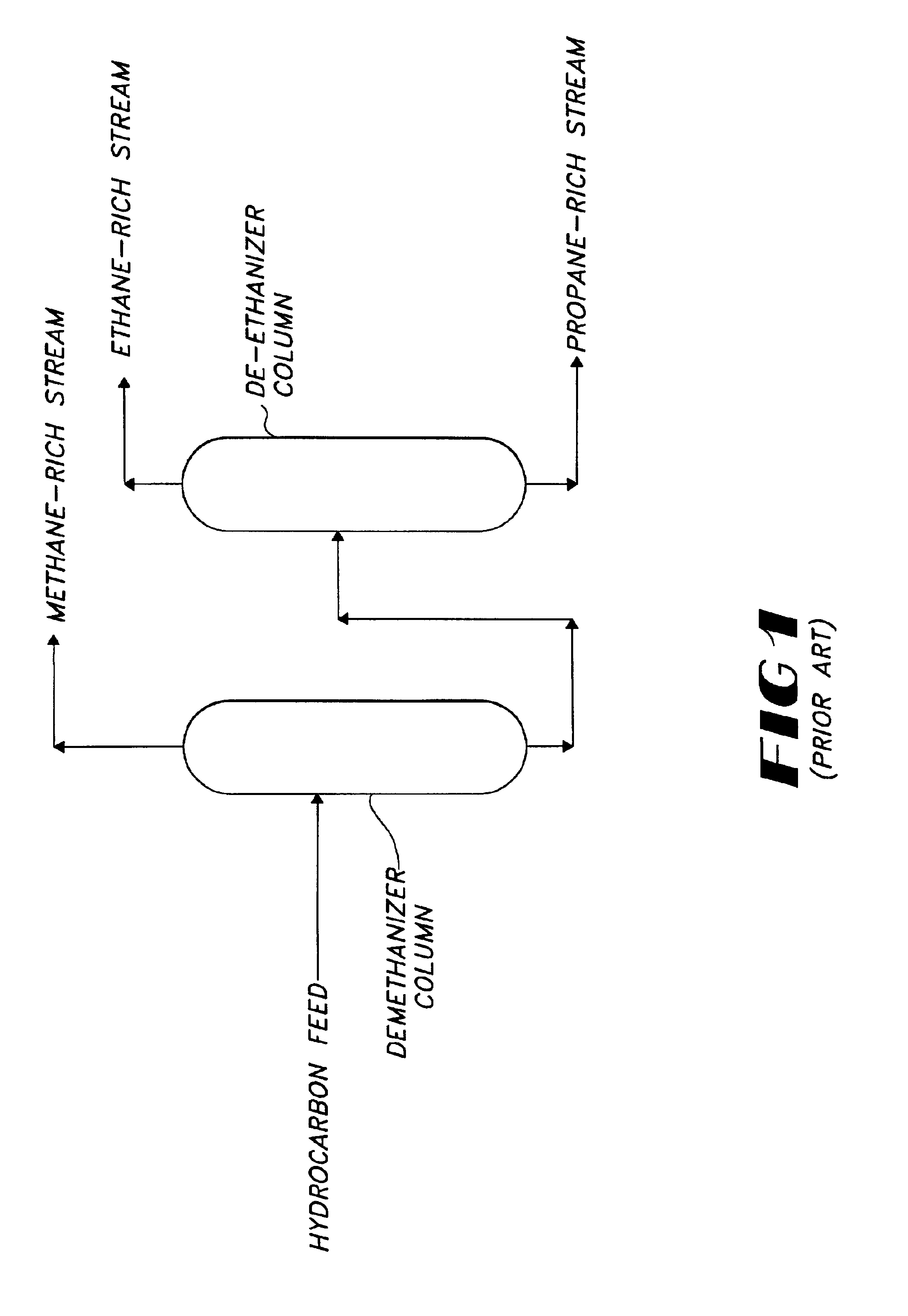

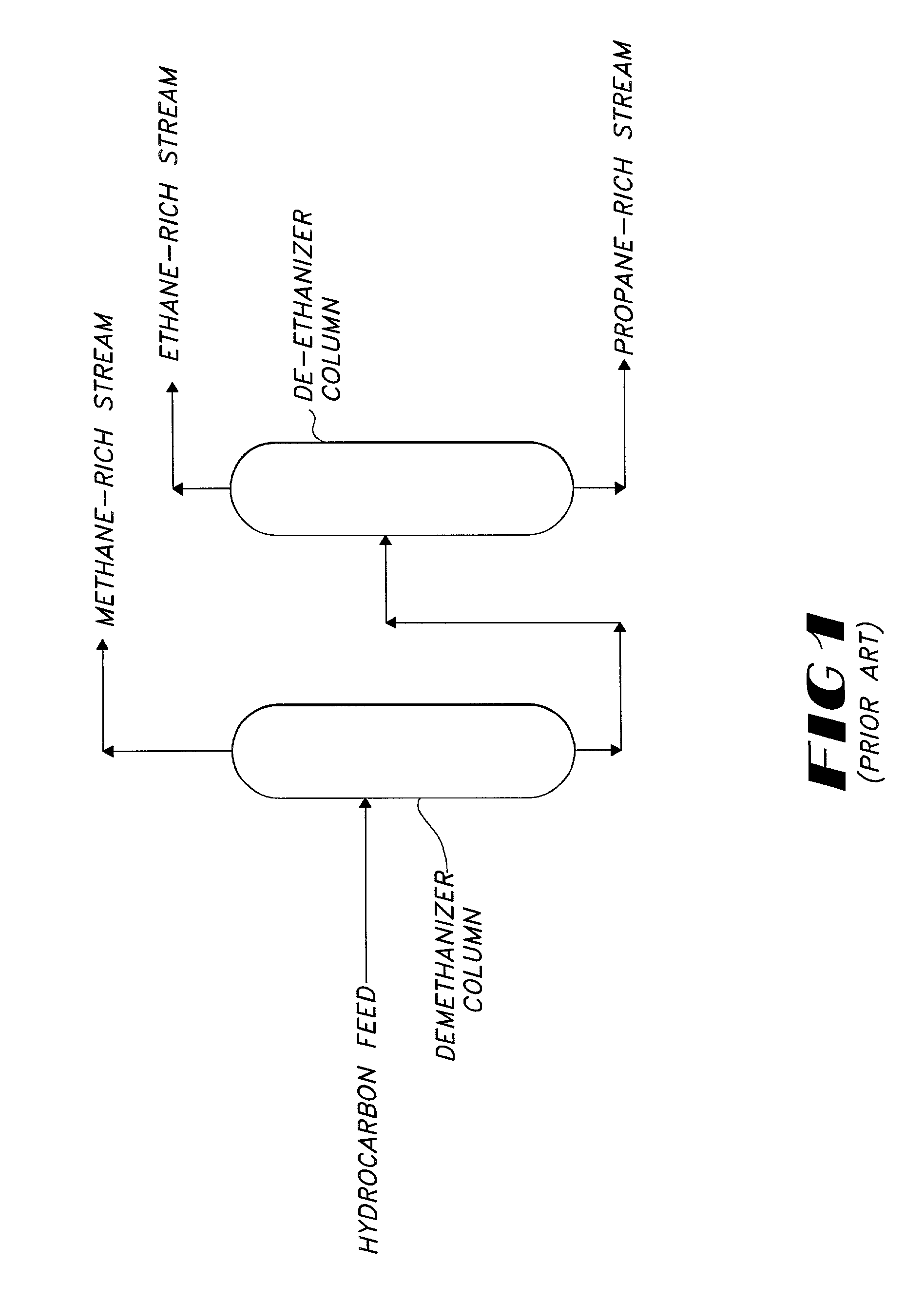

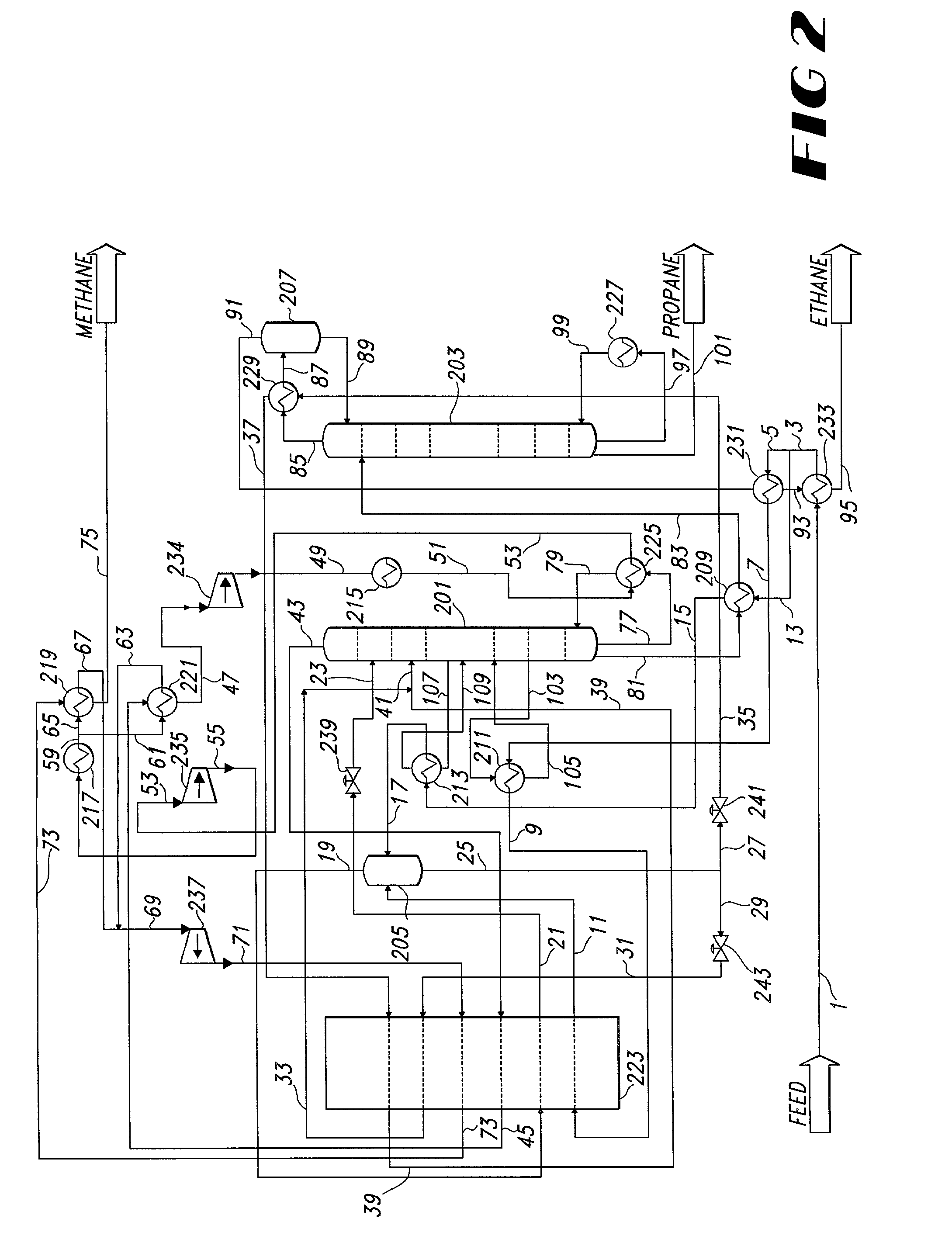

Ethane extraction process for a hydrocarbon gas stream

A process for ethane extraction from a gas stream based on turboexpansion and fractionation with no mechanical refrigeration is provided. The feed gas is sweetened and dehydrated by a conventional amine process and by a molecular sieve unit, to remove carbon dioxide and water. After this pretreatment, the feed gas undergoes to a series of cooling steps through a cryogenic brazed aluminum heat exchanger and fed to a demethanizer column. A stream rich in methane is recovered from the top of this column and fed to a centrifugal compressor and subsequently routed to a booster / turboexpander. The temperature of the methane gas is greatly reduced by the expansion allowing the cooled methane stream to be a cooling source for cryogenic heat exchanger. Feed for a de-ethanizer column comes from the bottom liquids of the de-methanizer column. Ethane is recovered overhead at the de-ethanizer column.

Owner:INELECTRA

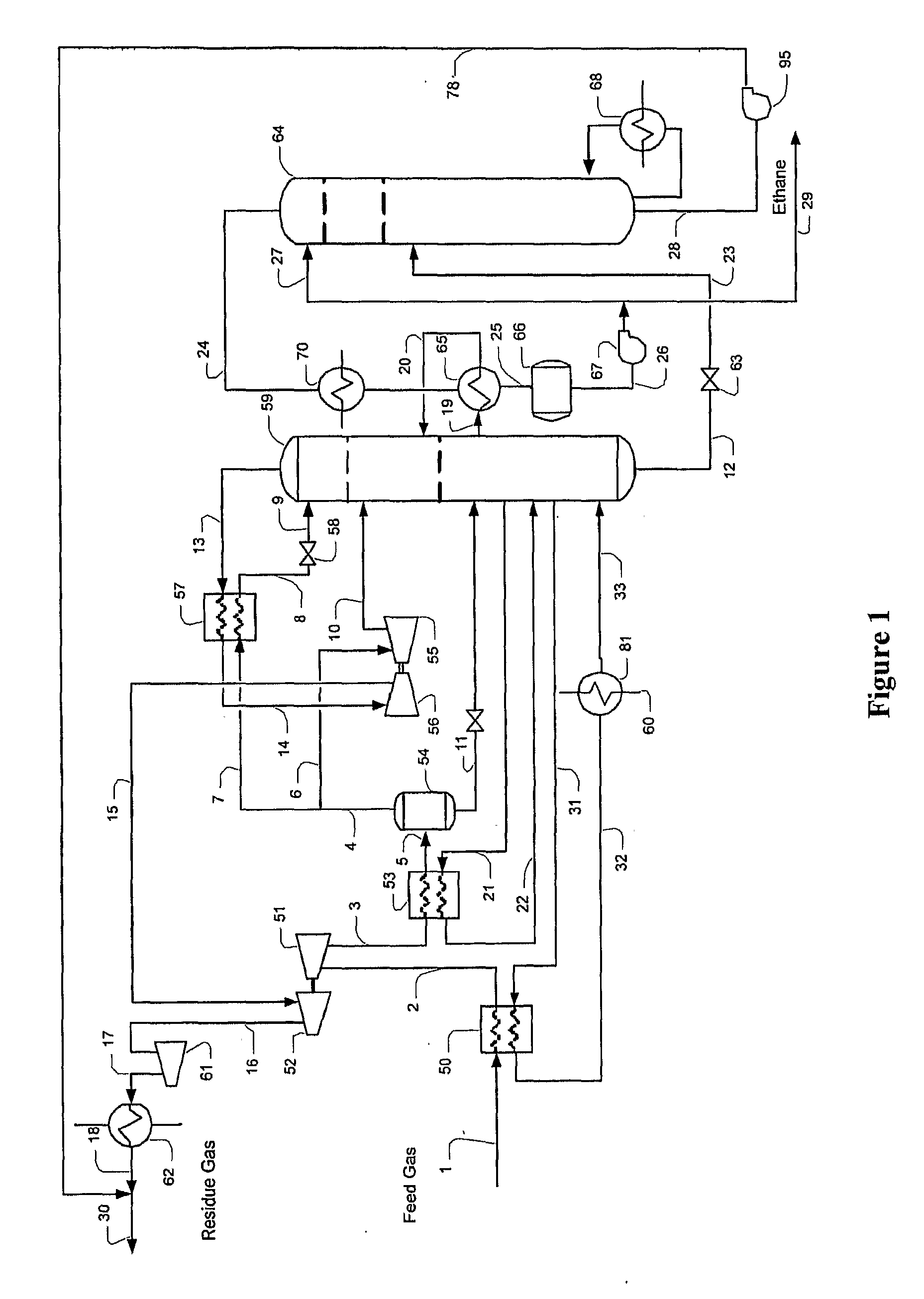

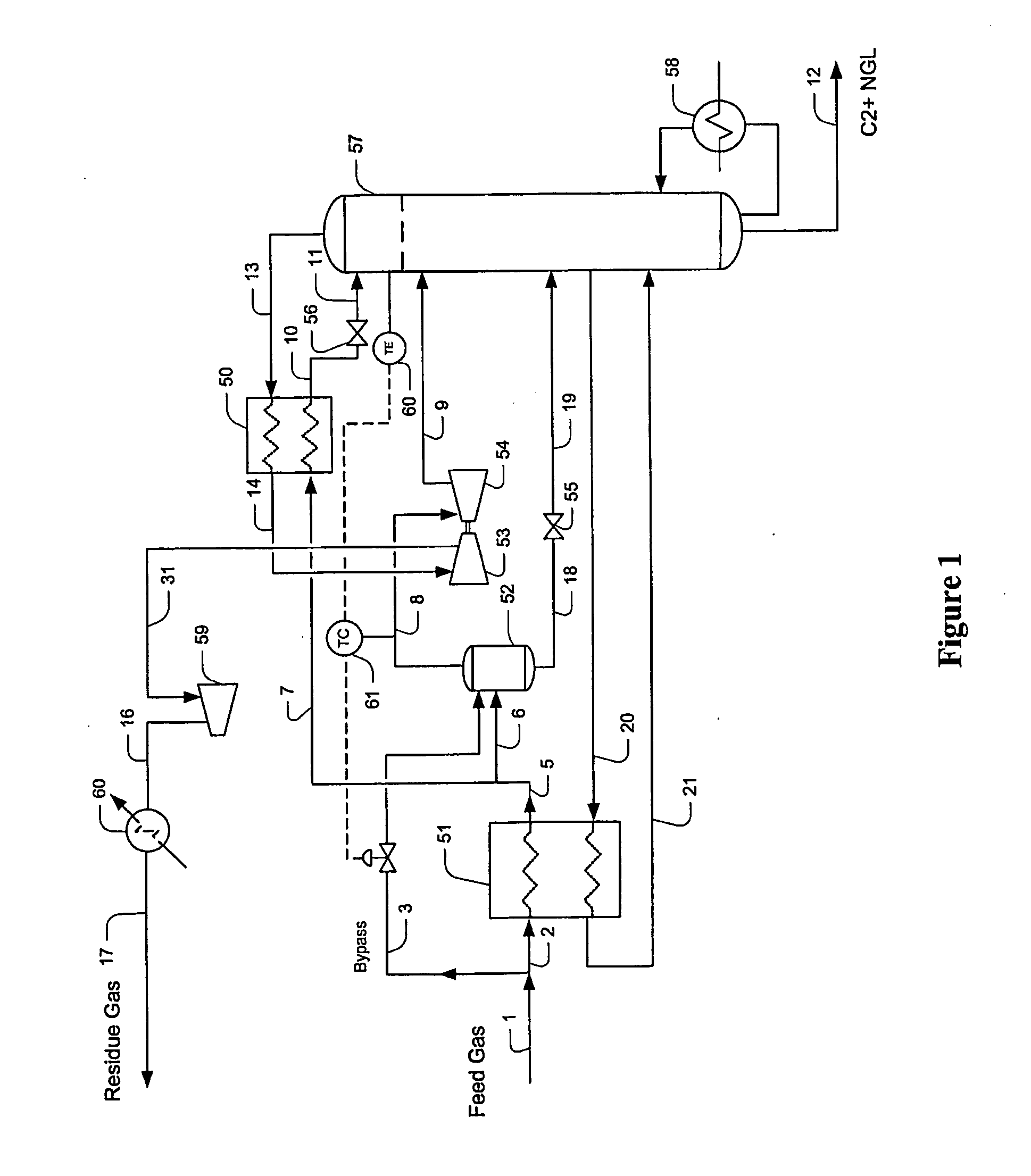

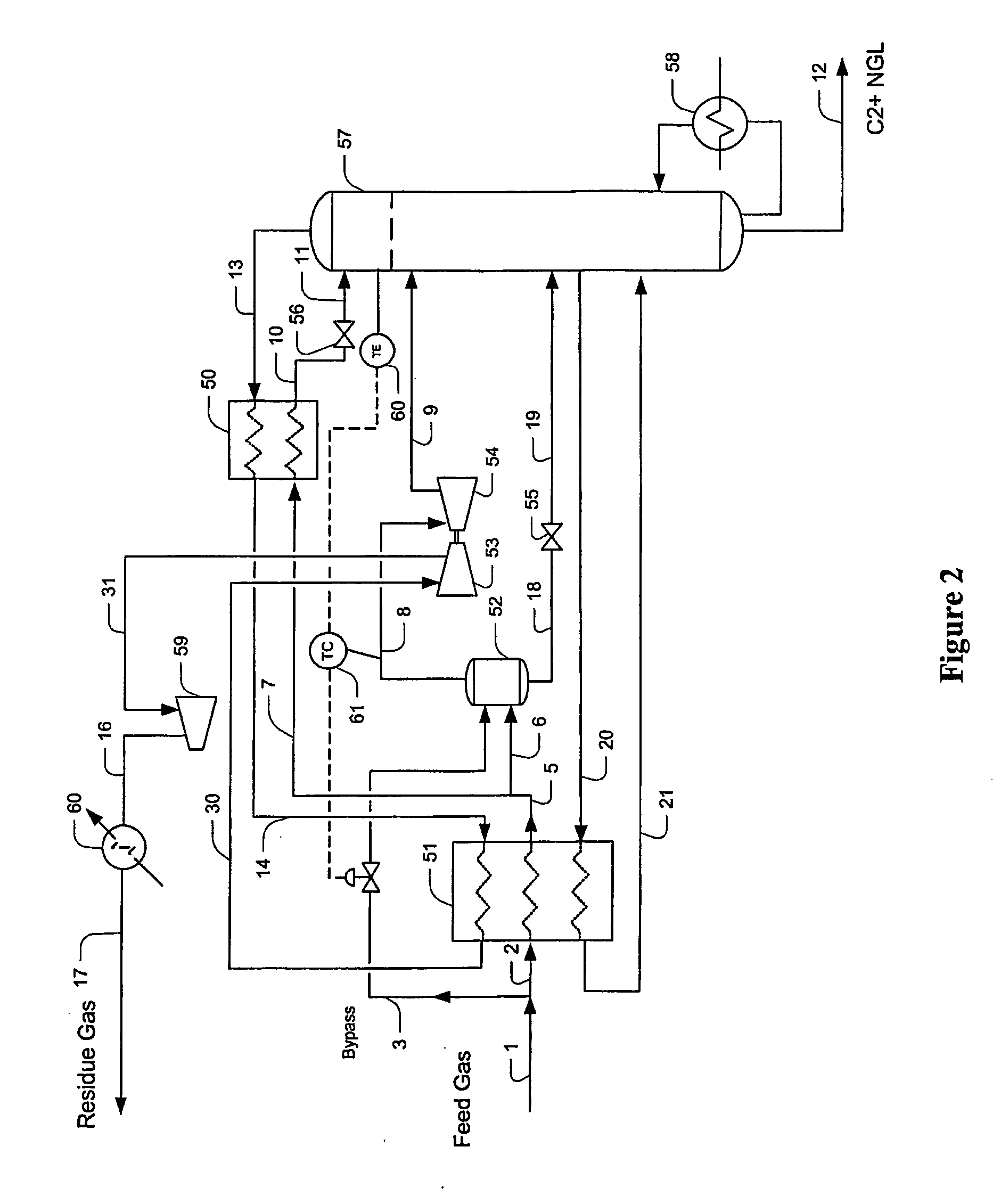

Ethane Recovery Methods And Configurations

ActiveUS20100011809A1Maximizing ethane recoveryIncrease pressureSolidificationLiquefactionRecovery methodEngineering

Contemplated methods and configurations use a cooled ethane and CO2-containing feed gas that is expanded in a first turbo-expander and subsequently heat-exchanged to allow for relatively high expander inlet temperatures to a second turbo expander. Consequently, the relatively warm demethanizer feed from the second expander effectively removes CO2 from the ethane product and prevents carbon dioxide freezing in the demethanizer, while another portion of the heat-exchanged and expanded feed gas is further chilled and reduced in pressure to form a lean reflux for high ethane recovery.

Owner:FLUOR TECH CORP

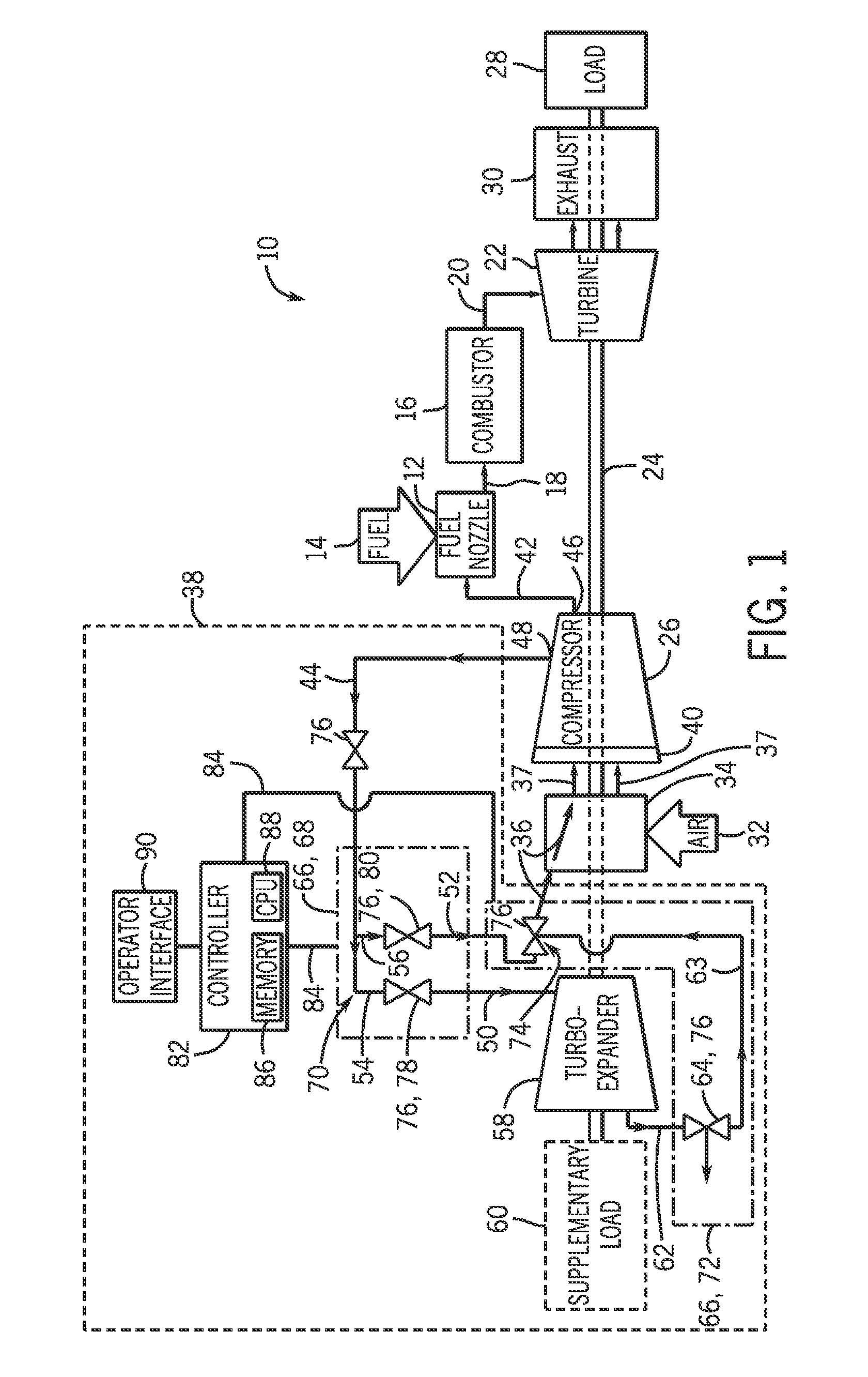

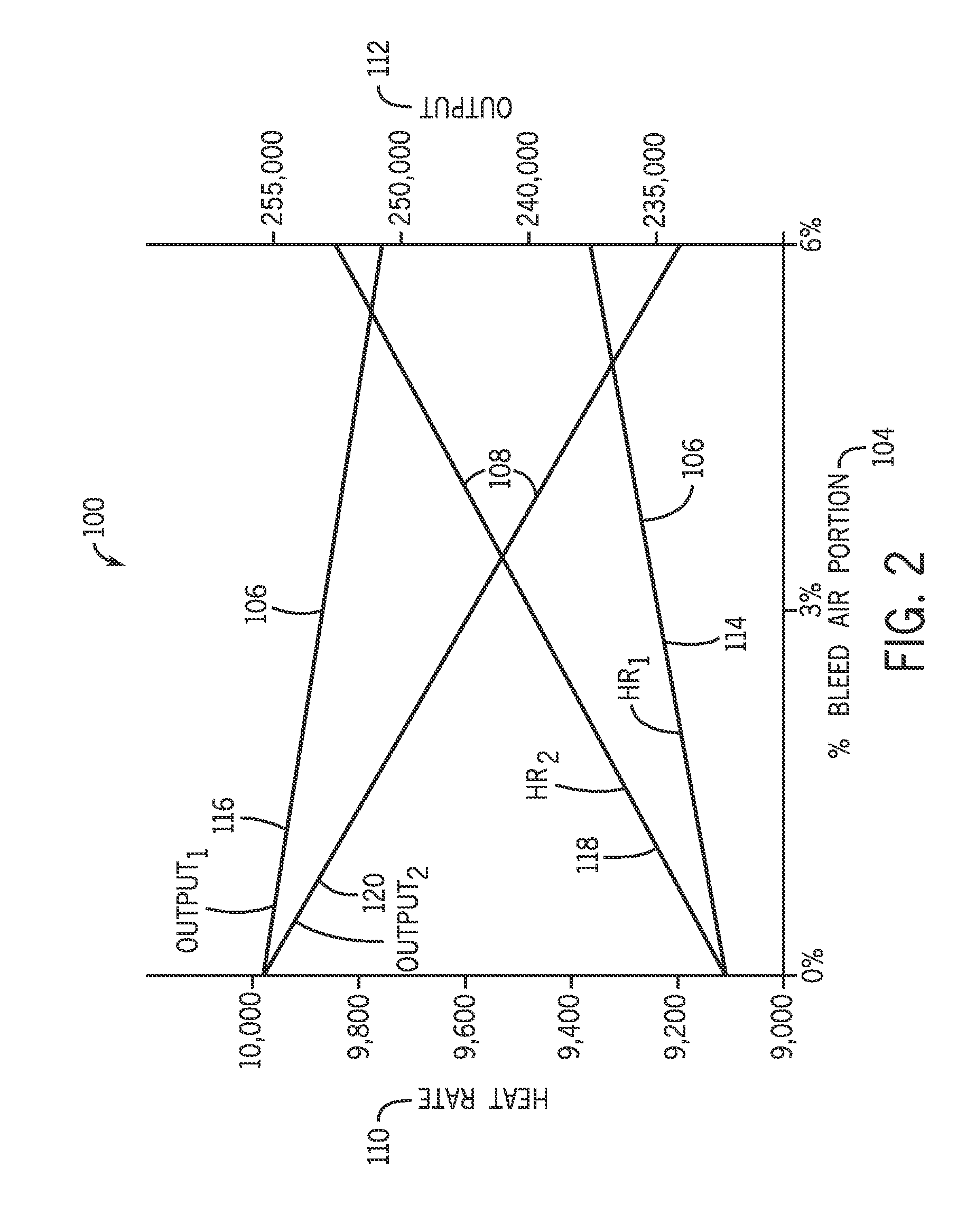

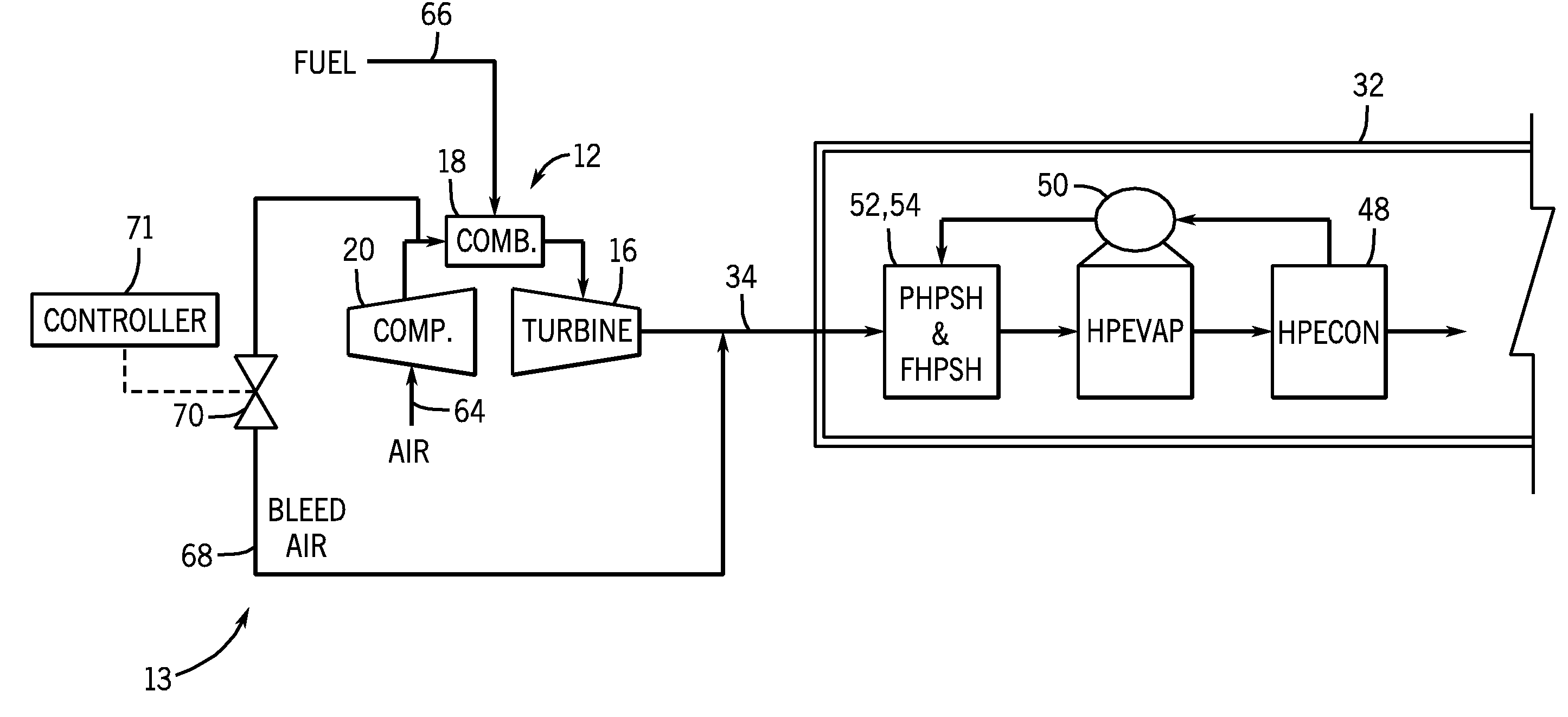

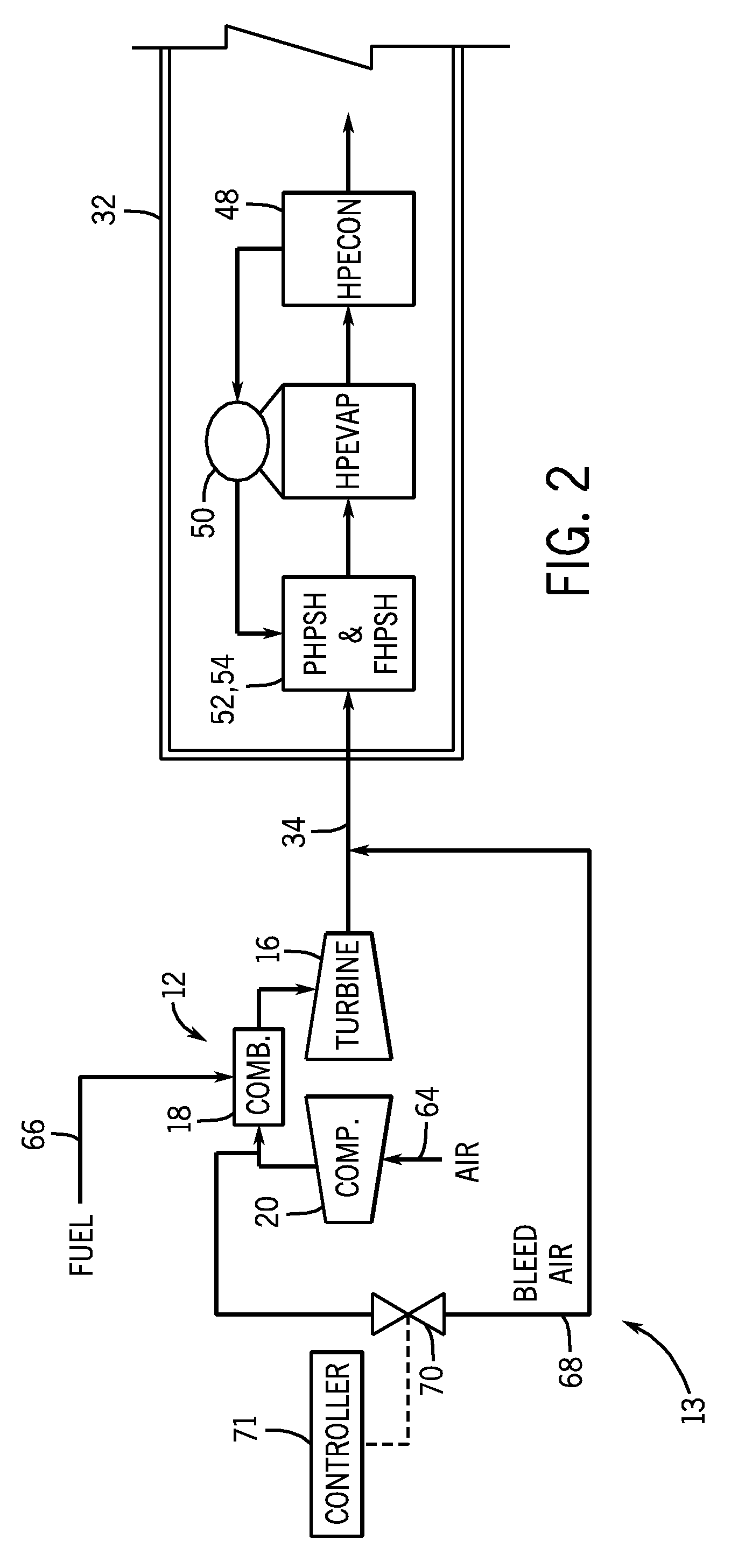

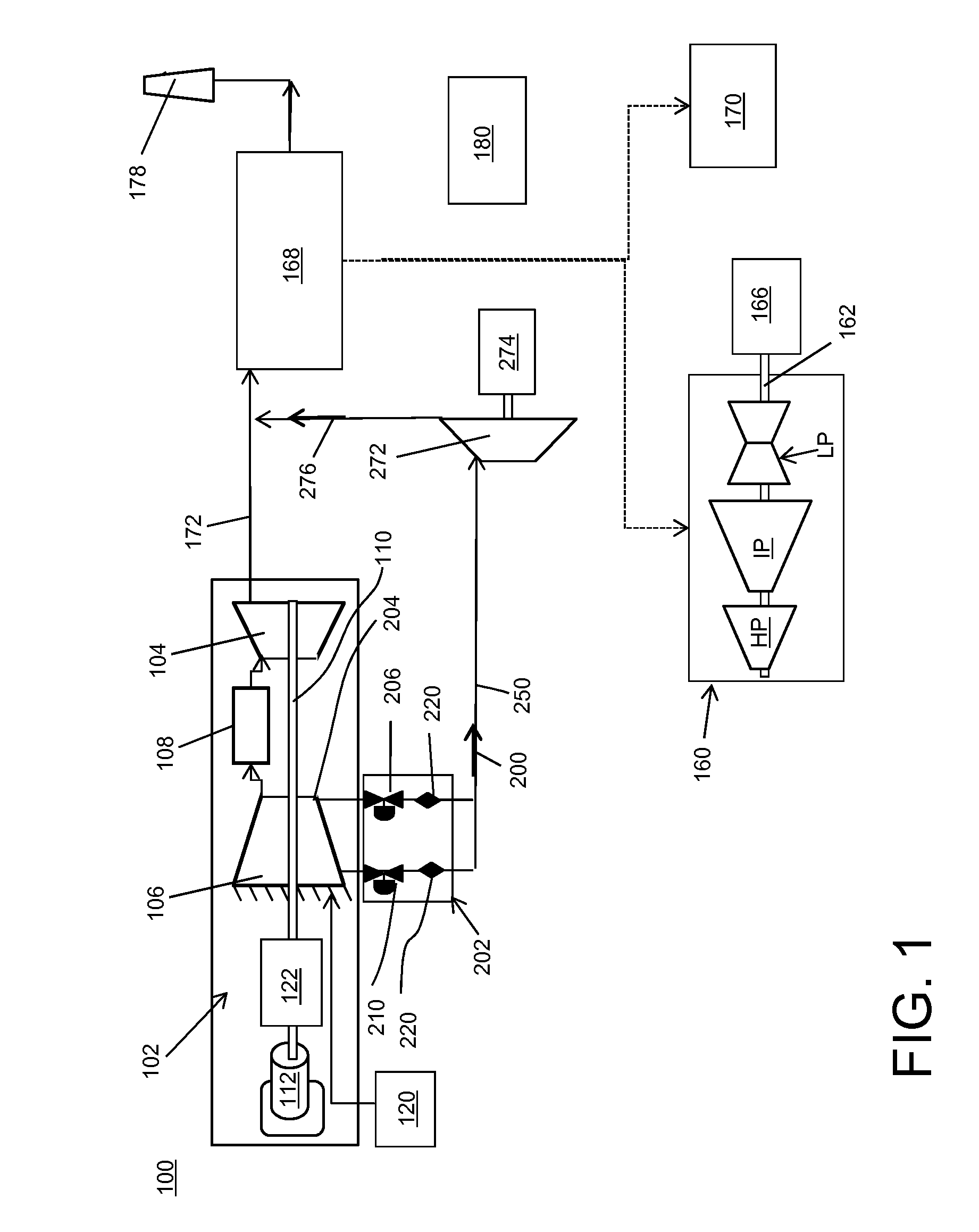

System and method for recirculating and recovering energy from compressor discharge bleed air

A system includes a gas turbine, an inlet bleed circuit, and a controller. The gas turbine includes a compressor and a turbine. The compressor is configured to produce pressurized air and bleed air. The turbine is configured to produce a first output. The inlet bleed circuit includes a turbo-expander configured to produce a second output from a non-zero first portion of the bleed air. The inlet bleed circuit is also configured to direct a part of the bleed air to an inlet of the compressor. The controller is configured to adjust the gas turbine and the inlet bleed circuit to control the second output of the turbo-expander.

Owner:GENERAL ELECTRIC CO

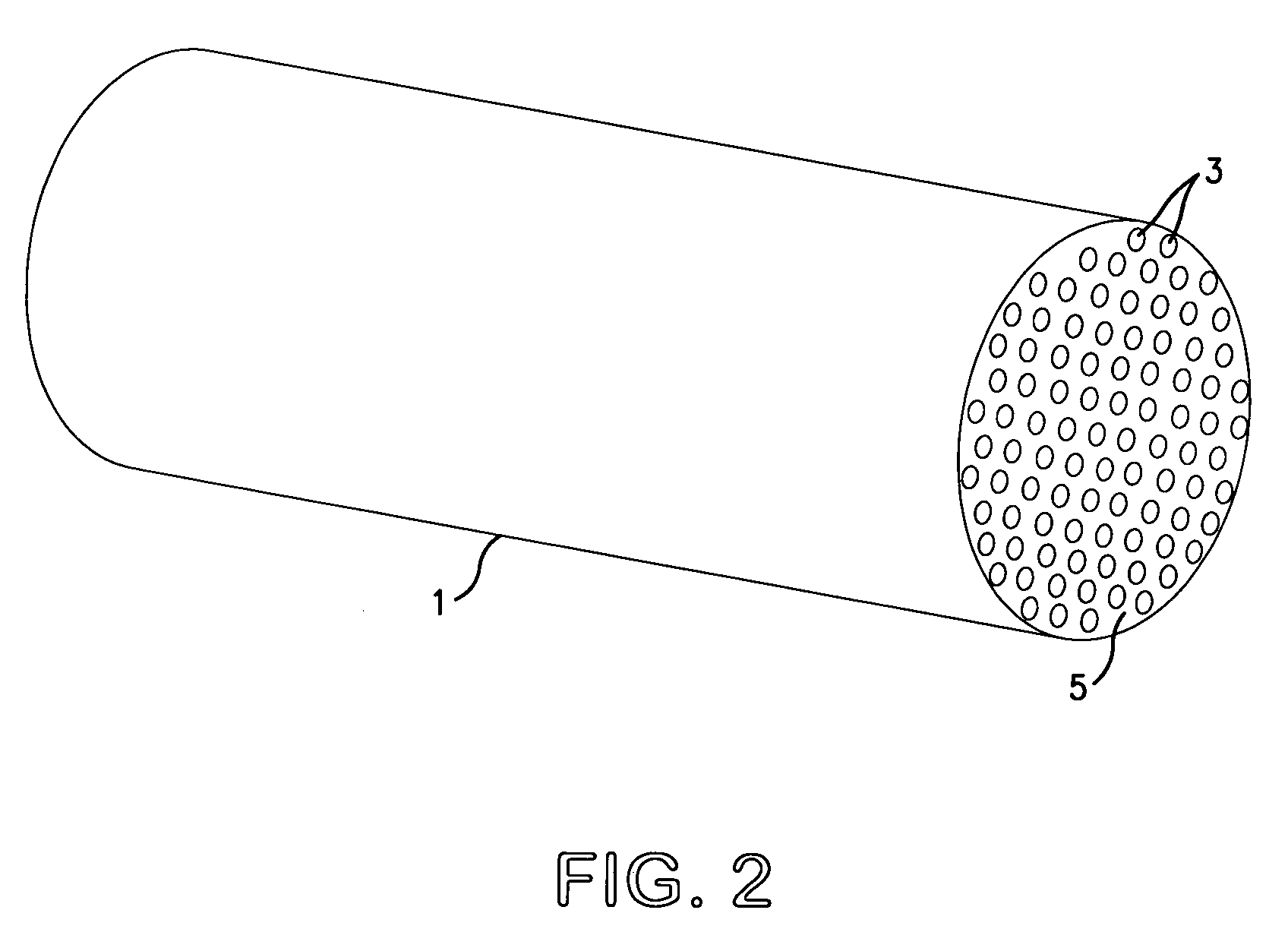

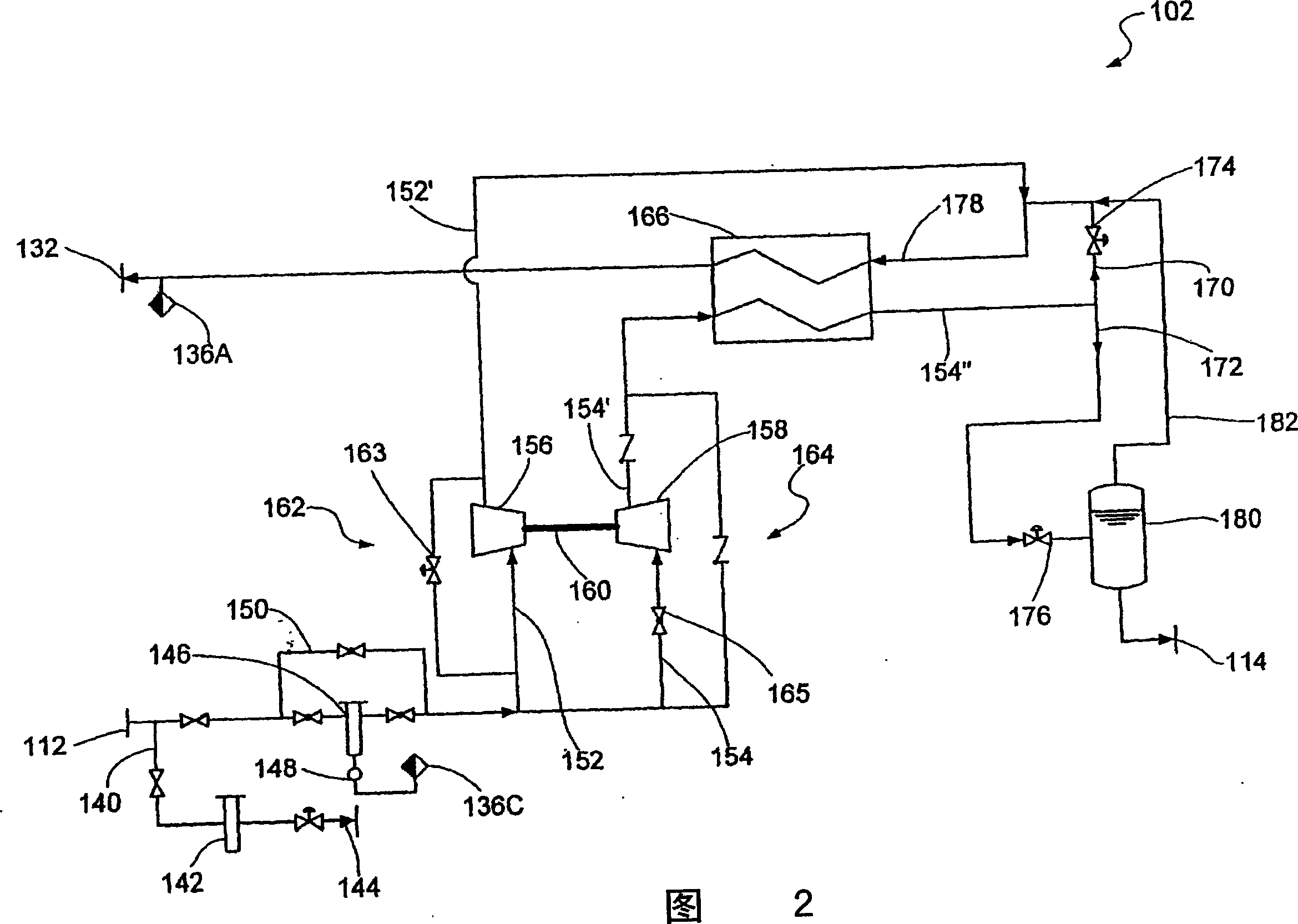

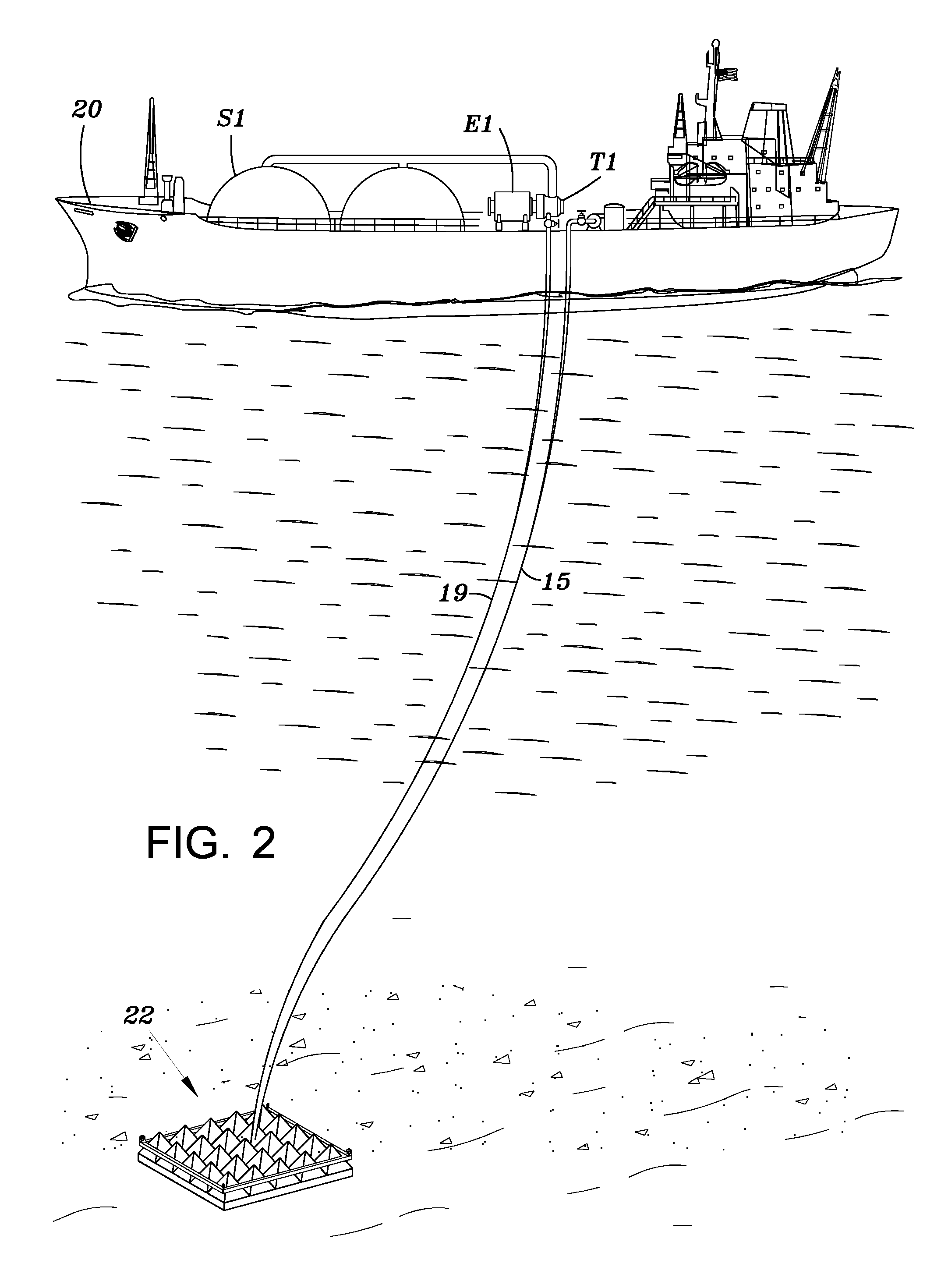

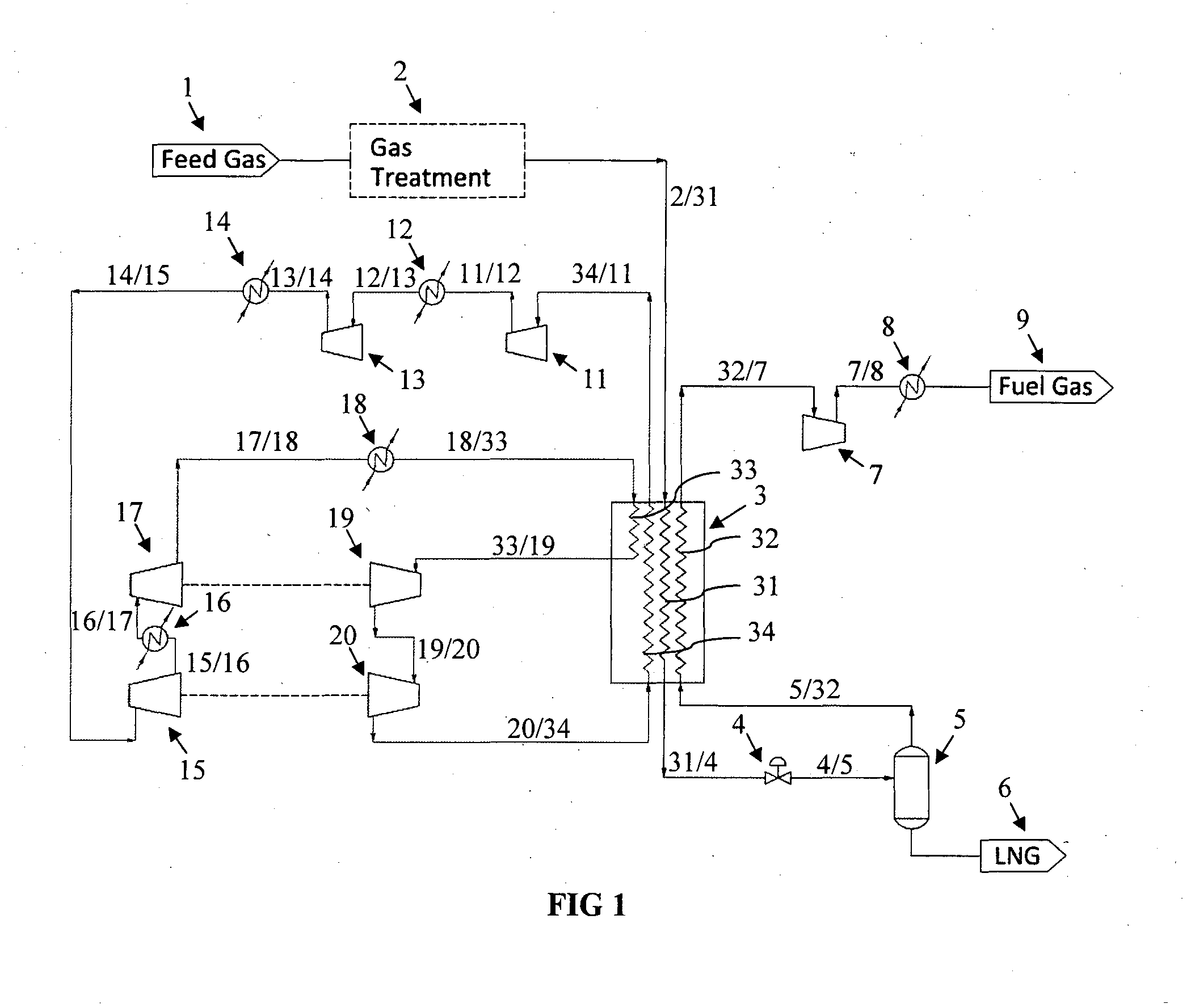

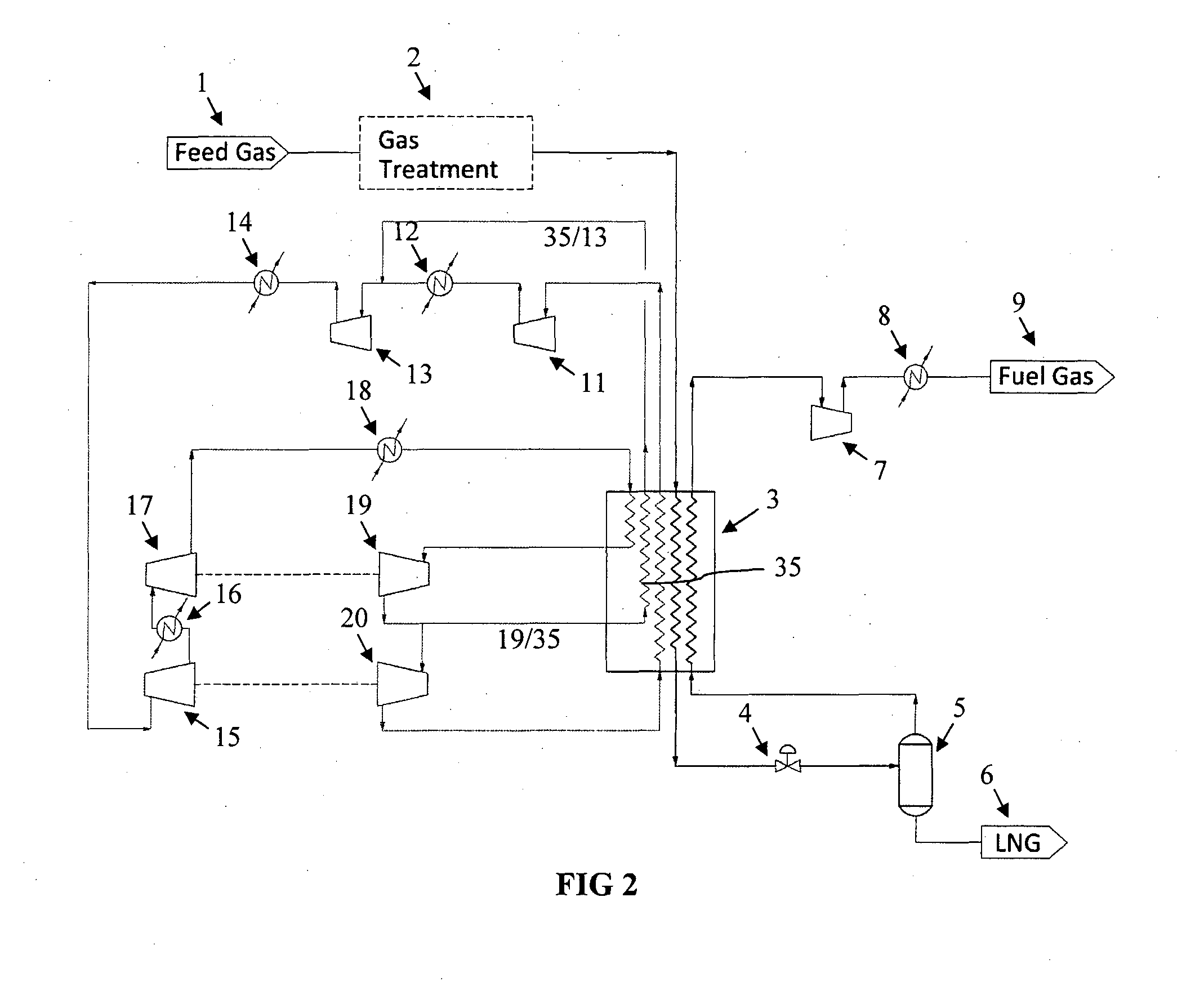

Apparatus for the liquefaction of natural gas and methods relating to same

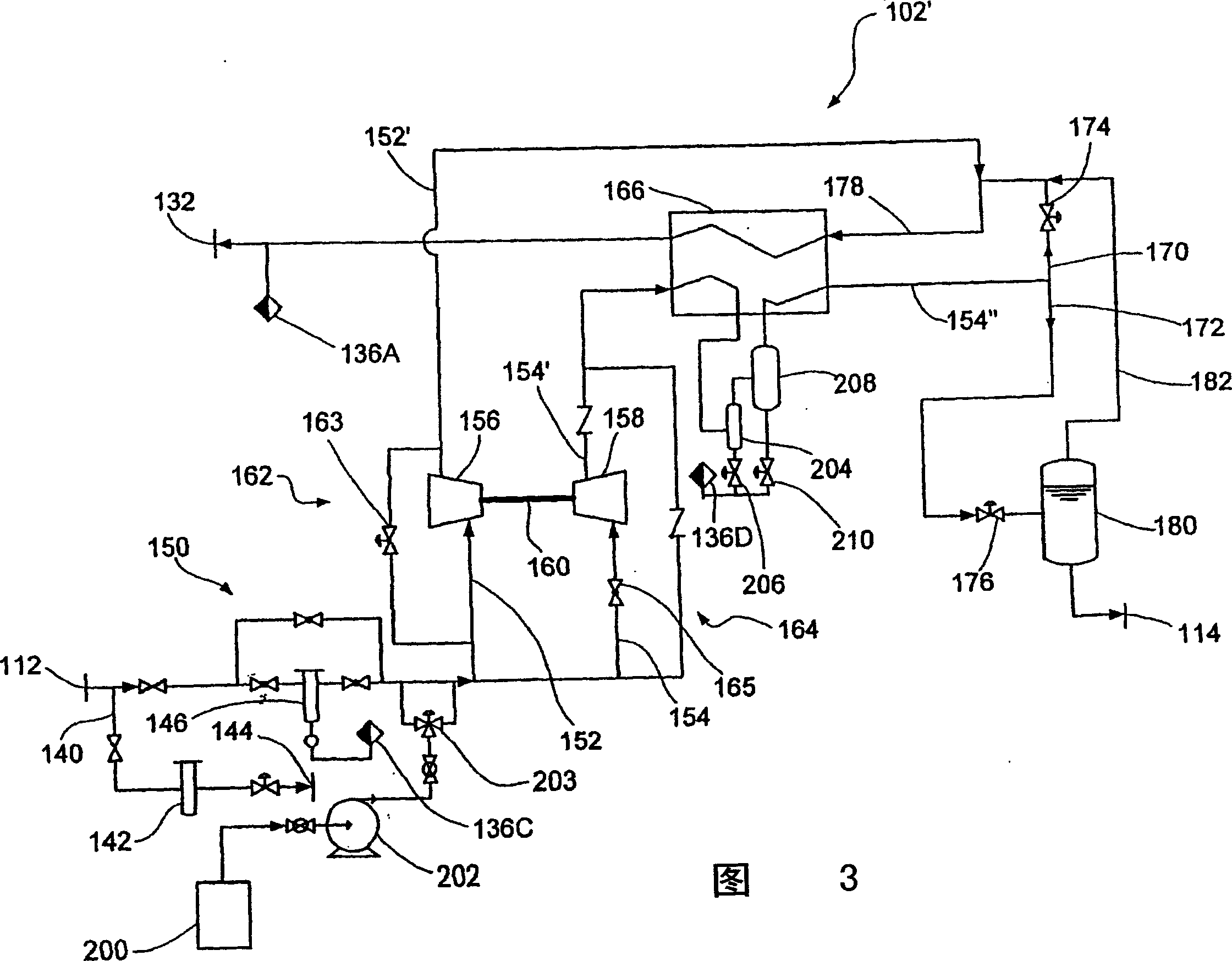

InactiveCN1615415ALow costReduce operating costsSolidificationLiquefactionProcess engineeringTurboexpander

A device and method for producing liquefied natural gas. The liquefaction unit can be connected to an unpurified natural gas source, such as a natural gas pipeline connection from a decompression station. A portion of the natural gas is withdrawn and split into a process stream (154) and a cooling stream (152). Cooling flow (152) is passed through turboexpander (156) to produce work output. The work output is used to drive the compressor (158) and compress the process flow. The compressed process stream is cooled, such as by the expanded cooling stream. The cooled and compressed process stream is split into first and second portions, and the first portion is expanded to liquefy the natural gas. Vapor is separated from liquid natural gas with a gas-liquid separator. A second portion of the cooled and compressed process stream is also expanded to cool the compressed process stream. The liquefaction process can also incorporate other components and technologies, including water purification cycles and carbon dioxide (CO2) purification cycles.

Owner:BECHTEL BWXT IDAHO

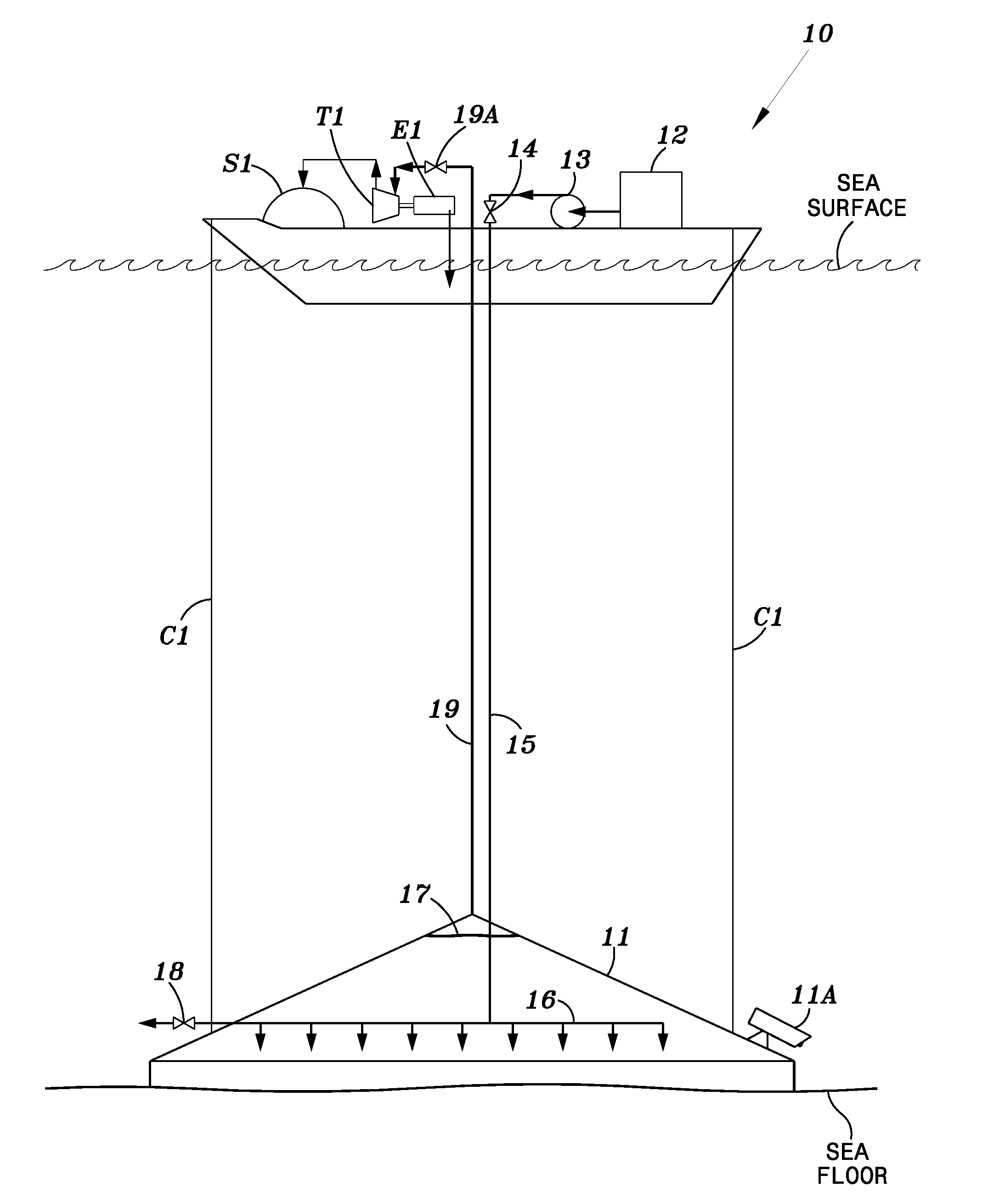

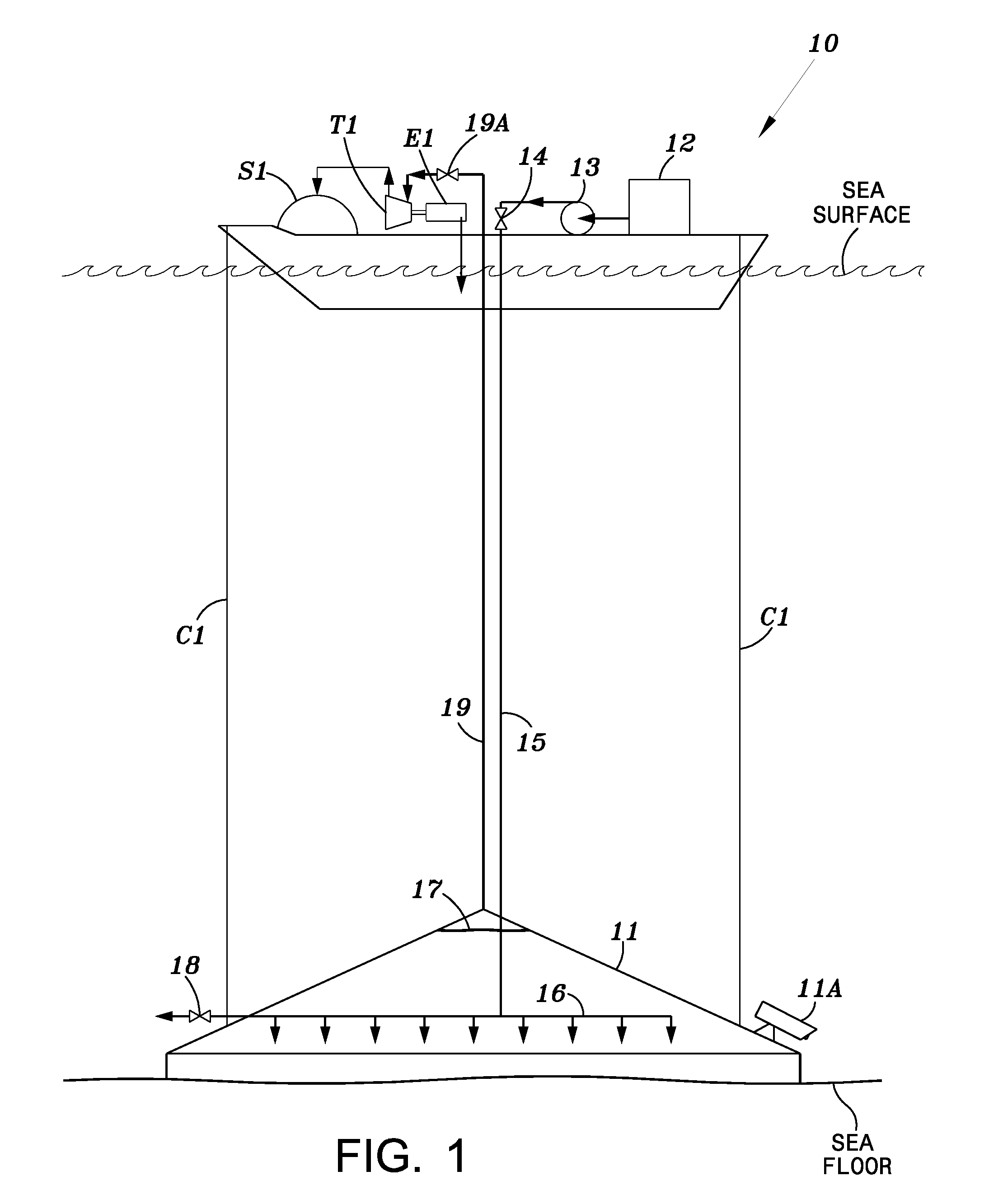

Method and apparatus for recovering methane from hydrate near the sea floor

Method and apparatus are disclosed for recovering natural gas from a hydrate deposit near or at the sea floor. A rigid dome structure, supported by a floating vessel and movable along the sea floor, is placed over the hydrate deposit. Heated sea water may be pumped from the floating vessel through headers and nozzles in the rigid dome structure. The heated sea water preferably fluidizes the marine sand containing hydrate, releasing gas in the hydrate. The gas is collected in the rigid dome structure and moved through a pipe to the floating vessel, where it may be processed through a turbo-expander and liquefied.

Owner:TEXAS A&M UNIVERSITY

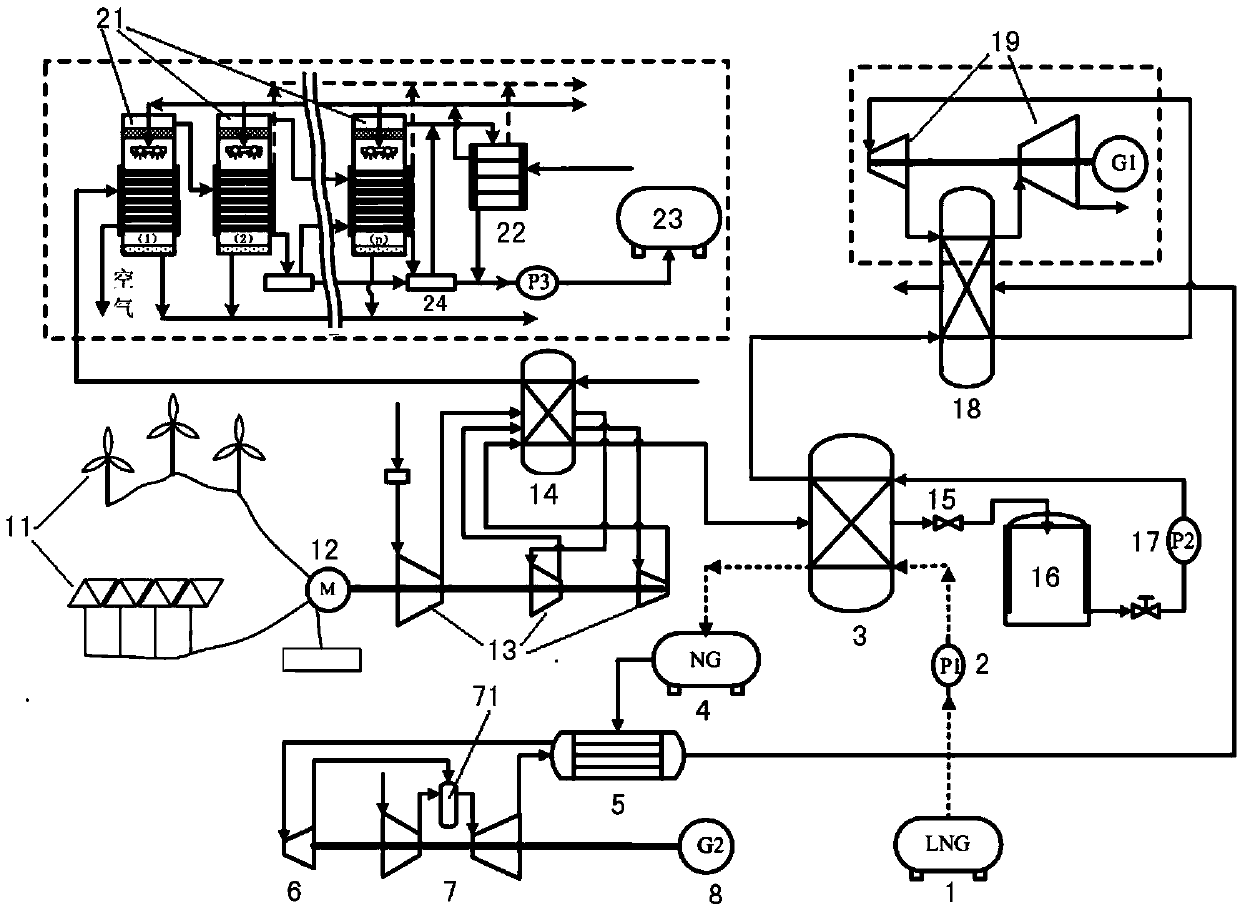

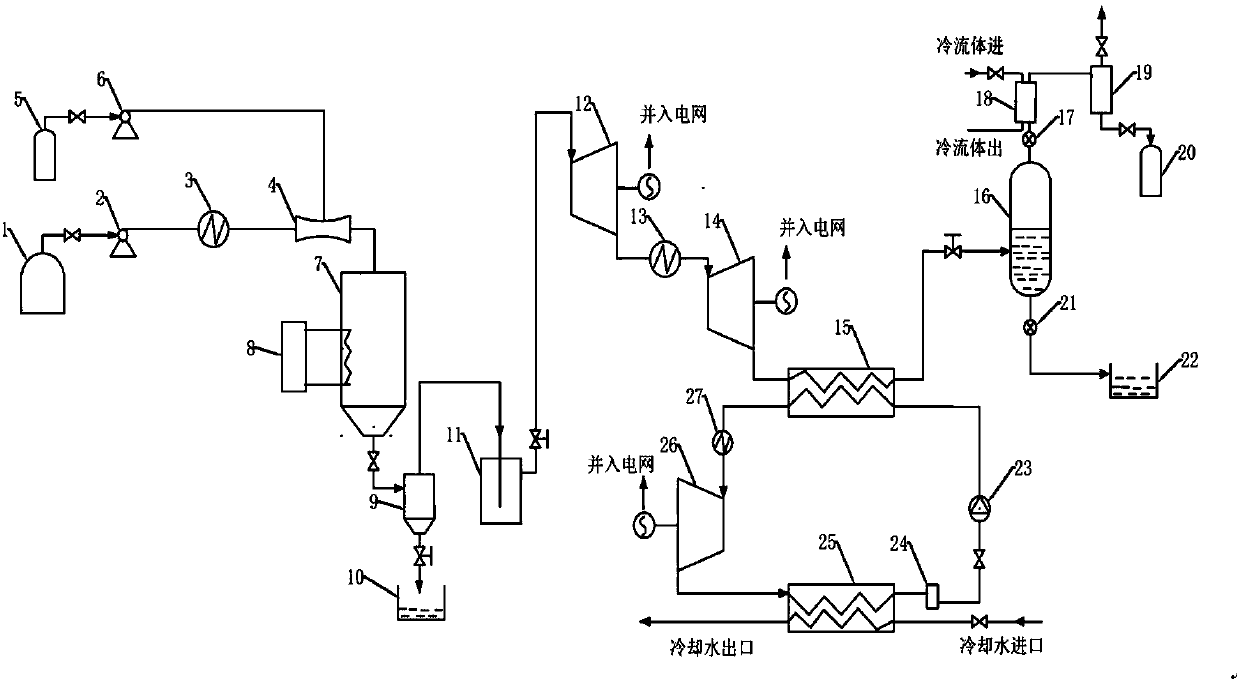

Island energy supply system with cold energy

ActiveCN103993920AImprove energy utilizationImprove economyFrom solar energyGeneral water supply conservationCombustion chamberDistillation

The invention relates to an island energy supply system with cold energy. The island energy supply system comprises an LNG power generation system unit, a renewable energy power generation and energy storage unit and a low-temperature multi-effect distillation seawater desalination system. The island energy supply system is a combination island energy supply system formed by power generation and energy storage systems in a combination mode based on an LNG power generator and unstable renewable energy such as wind energy, solar energy and wave energy. System waste heat is used as a heat source for a seawater desalination unit. During an energy storage process, stored LNG is converted into high-pressure natural gas (NG) by cold accumulation gasifying, the NG enters an NG storage tank and a pipe network system for storage and standby application, then air is subjected to compression, indirect cooling and cold accumulation, cold energy is recycled, and after throttling, liquidation storage is carried out. During a power using process, after high-pressure NG absorbs heat and is heated, the high-pressure NG enters a turbine expansion machine for working, then the NG enters a small gas turbine combustion chamber and burns with compressed air to drive a gas turbine to work, and liquid air is subjected to cold accumulation and gradual heat absorption temperature raising and then enters the turbine expansion machine for working. According to the energy supply system, on-island electricity energy and fresh water can be supplied at the same time, unstable renewable resources are converted into stable controllable generated power to be output, system efficiency is improved, power using cost is lowered, and compared with traditional island energy supply system, the island energy supply system has the great advantages.

Owner:鄂尔多斯大规模储能技术研究所 +1

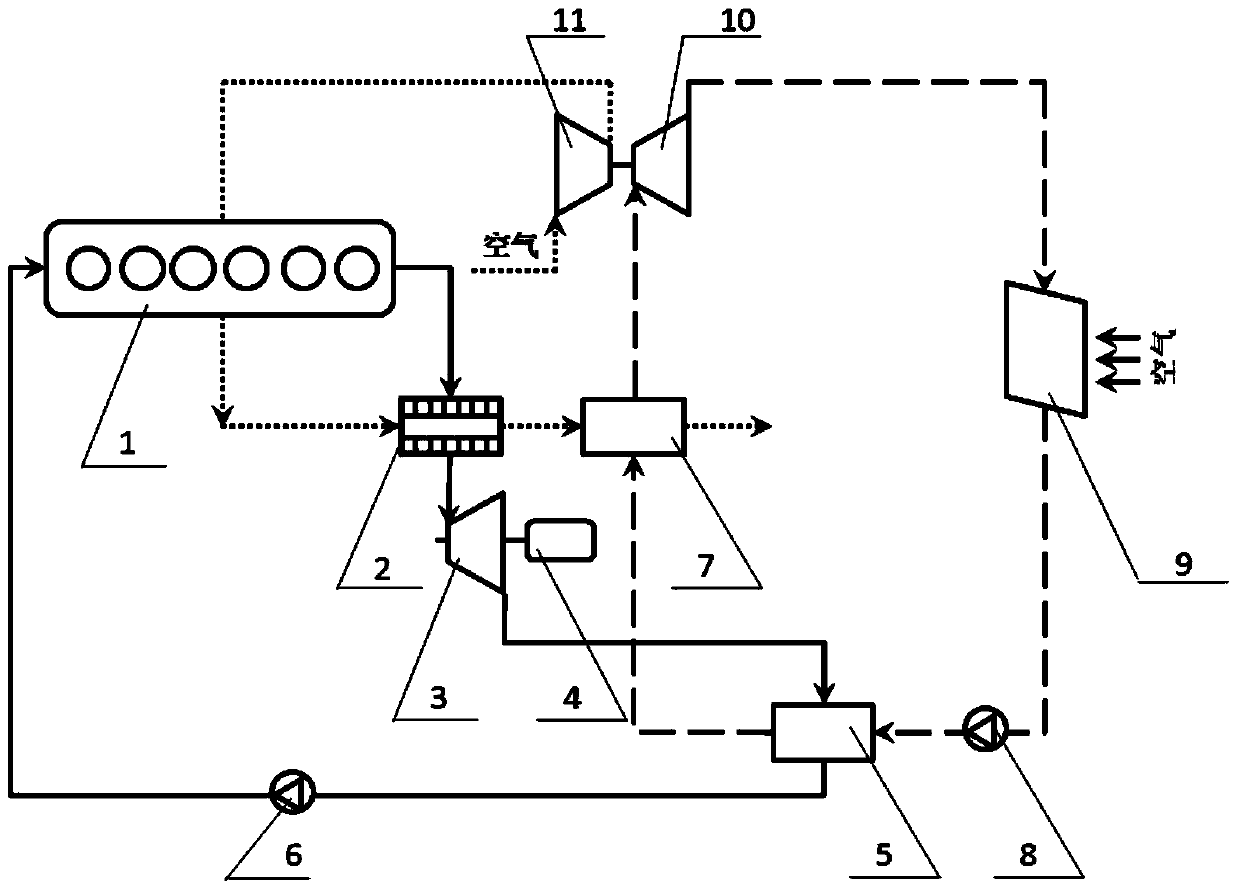

Internal combustion engine vapor supercharging waste heat recovery system

ActiveCN103742293AIncrease the effective working rangeEfficient use ofInternal combustion piston enginesEngine componentsWaste heat recovery unitOrganic Rankine cycle

The invention discloses an internal combustion engine vapor supercharging waste heat recovery system. According to the technical scheme, internal combustion engine cylinder sleeve cooling water is in tandem connection with the cold end of a thermoelectric generator, an expansion machine, a preheater and a circulating water pump sequentially through pipelines to form into a cooling water heat utilization circulating system; air performed air suction compression through a compressor is sent to an internal combustion engine; an exhaust pipe of the internal combustion engine is in tandem connection with the thermal end of the thermoelectric generator, the gas side of an evaporator sequentially to form into an exhaust thermal utilization system; a preheater is in tandem connection with the working medium side of the evaporator, a turbine expansion machine, the working medium side of the condenser and a working medium pump sequentially to form into an organic rankine cycle system; the compressor is in shaft connection with a turbo machine to form into a turbosupercharger. The internal combustion engine vapor supercharging waste heat recovery system has the advantages of breaking the temperature limit of the recycle source of the organic rankine cycle, recycling the waste heat energy of the exhaust and the cooling water, achieving efficient utilization of the waste heat, avoiding the condition that the exhaust energy is not enough to drive a supercharging system when the load is low, increasing the effective working range of the supercharging system and achieving the purpose of efficiently recycling the waste heat energy.

Owner:TIANJIN UNIV

Method for expanding compressor discharge bleed air

InactiveUS20100170218A1Turbine/propulsion engine coolingGas turbine plantsCombustion chamberBleed air

A method for recovering energy from bleed air from a compressor of a gas turbine is provided. The method includes directing bleed air from a compressor of a gas turbine into a cooling unit. The bleed air is compressed air from the compressor, and the bleed air is not directed into a combustion chamber of the gas turbine. The method also includes cooling the bleed air within the cooling unit. The method further includes expanding the cooled bleed air within a turbo-expander to generate power.

Owner:GENERAL ELECTRIC CO

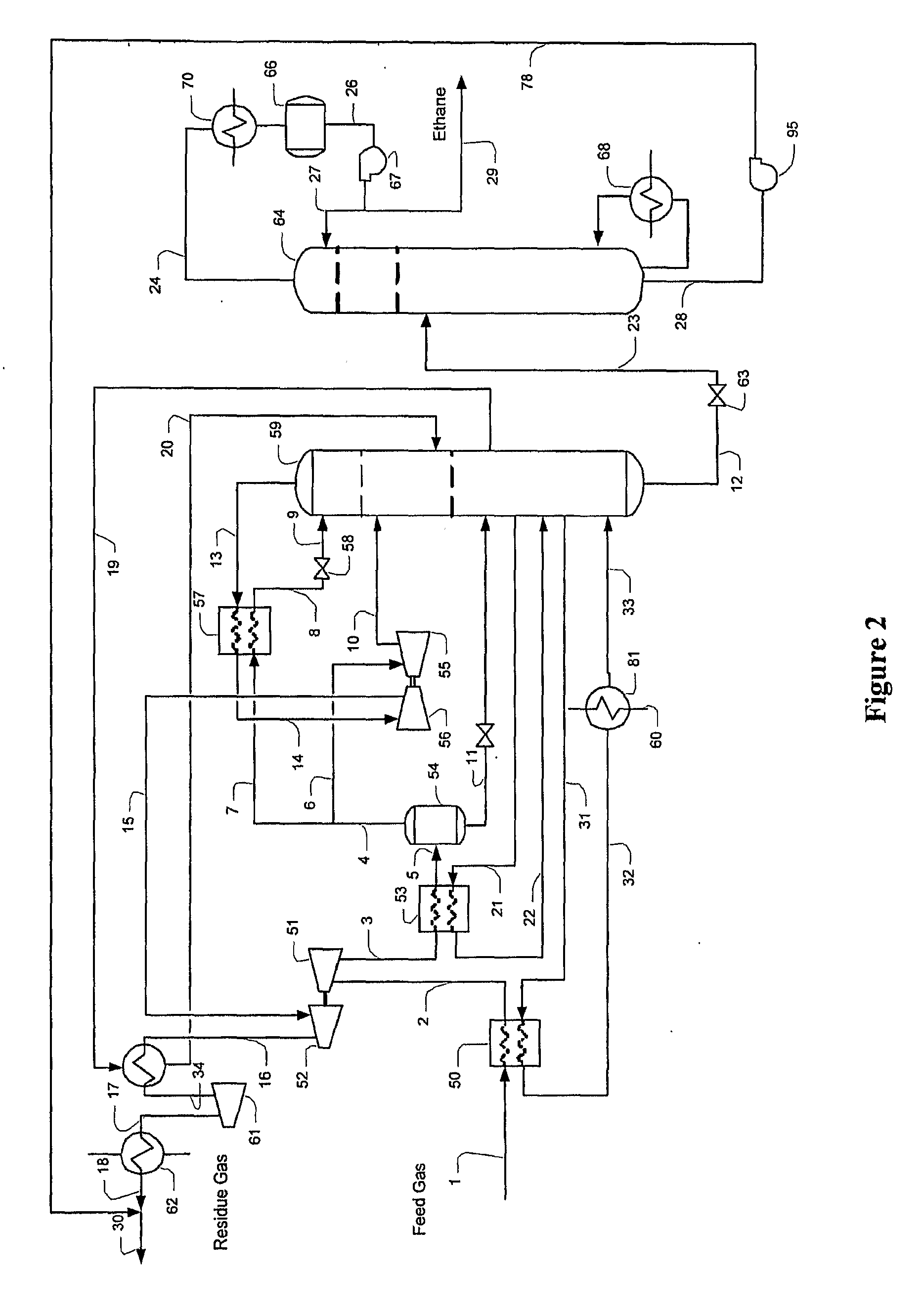

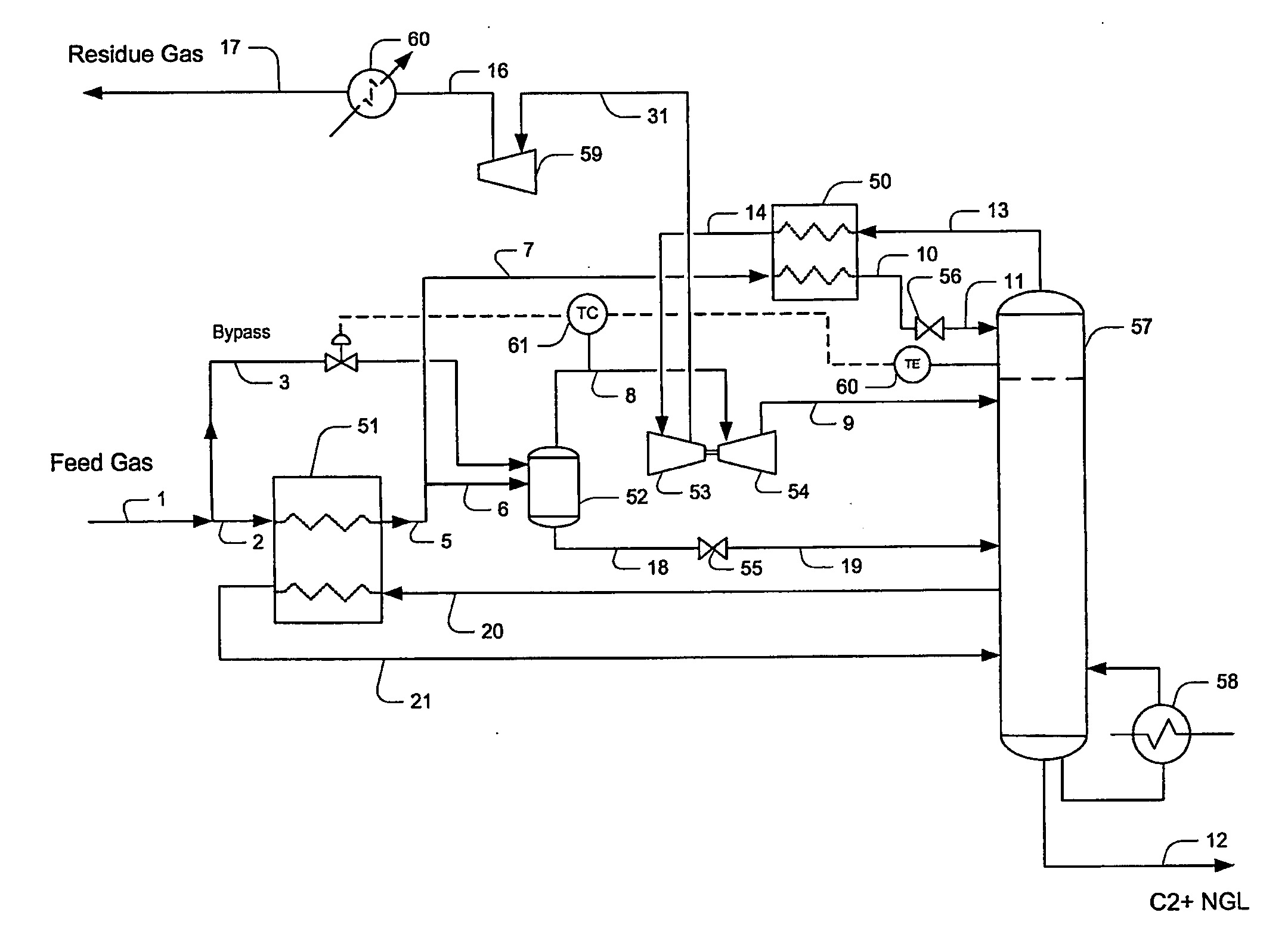

NGL Recovery Methods and Configurations

ActiveUS20100043488A1Increase power generationDesirable separationSolidificationLiquefactionRecovery methodProcess engineering

Contemplated NGL plants include a feed gas bypass circuit through which a portion of the feed gas is provided downstream to a vapor portion of the feed gas to thereby increase turbo expander inlet temperature and demethanizer temperature. Contemplated configurations are especially advantageous for feed gases with relatively high carbon dioxide content as they entirely avoid carbon dioxide freezing in the demethanizer, provide additional power production by the turboexpander, and recover C2+ components to levels of at least 80% while achieving a low carbon dioxide content in the NGL product.

Owner:FLUOR TECH CORP

Ethane extraction process for a hydrocarbon gas stream

A process for ethane extraction from a gas stream based on turboexpansion and fractionation with no mechanical refrigeration is provided. The feed gas is sweetened and dehydrated by a conventional amine process and by a molecular sieve unit, to remove carbon dioxide and water. After this pretreatment, the feed gas undergoes to a series of cooling steps through a cryogenic brazed aluminum heat exchanger and fed to a demethanizer column. A stream rich in methane is recovered from the top of this column and fed to a centrifugal compressor and subsequently routed to a booster / turboexpander. The temperature of the methane gas is greatly reduced by the expansion allowing the cooled methane stream to be a cooling source for cryogenic heat exchanger. Feed for a de-ethanizer column comes from the bottom liquids of the de-methanizer column. Ethane is recovered overhead at the de-ethanizer column.

Owner:INELECTRA

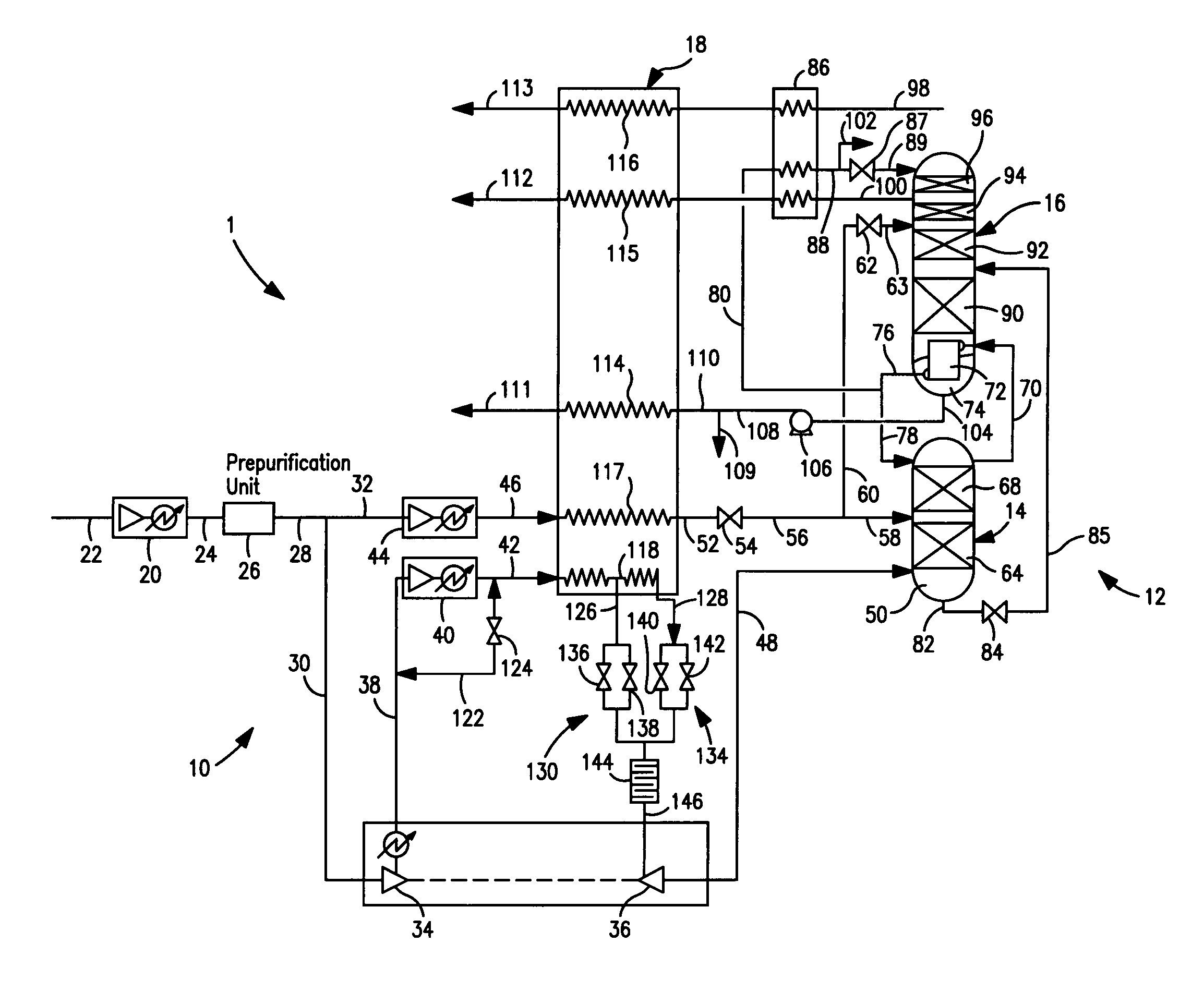

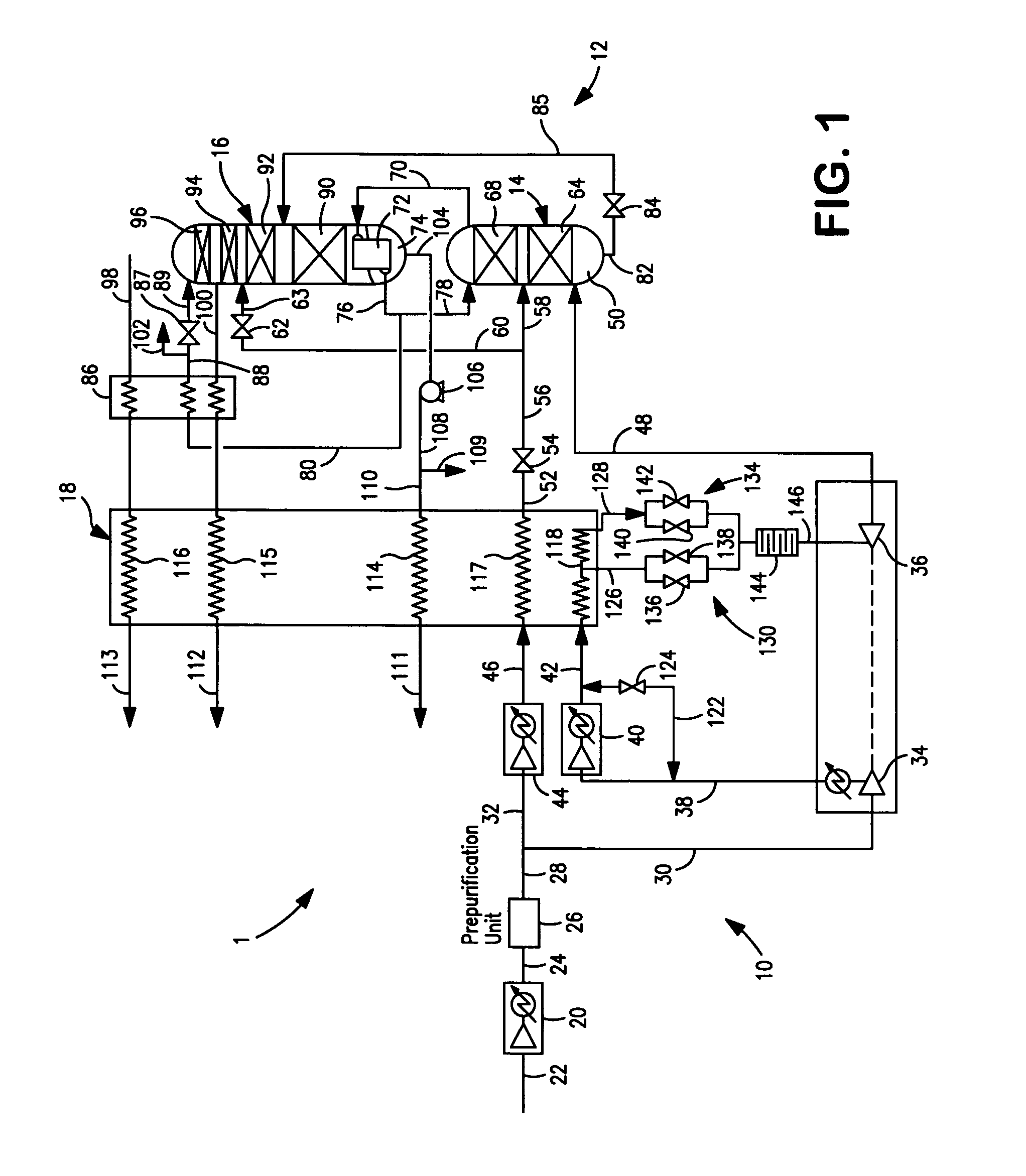

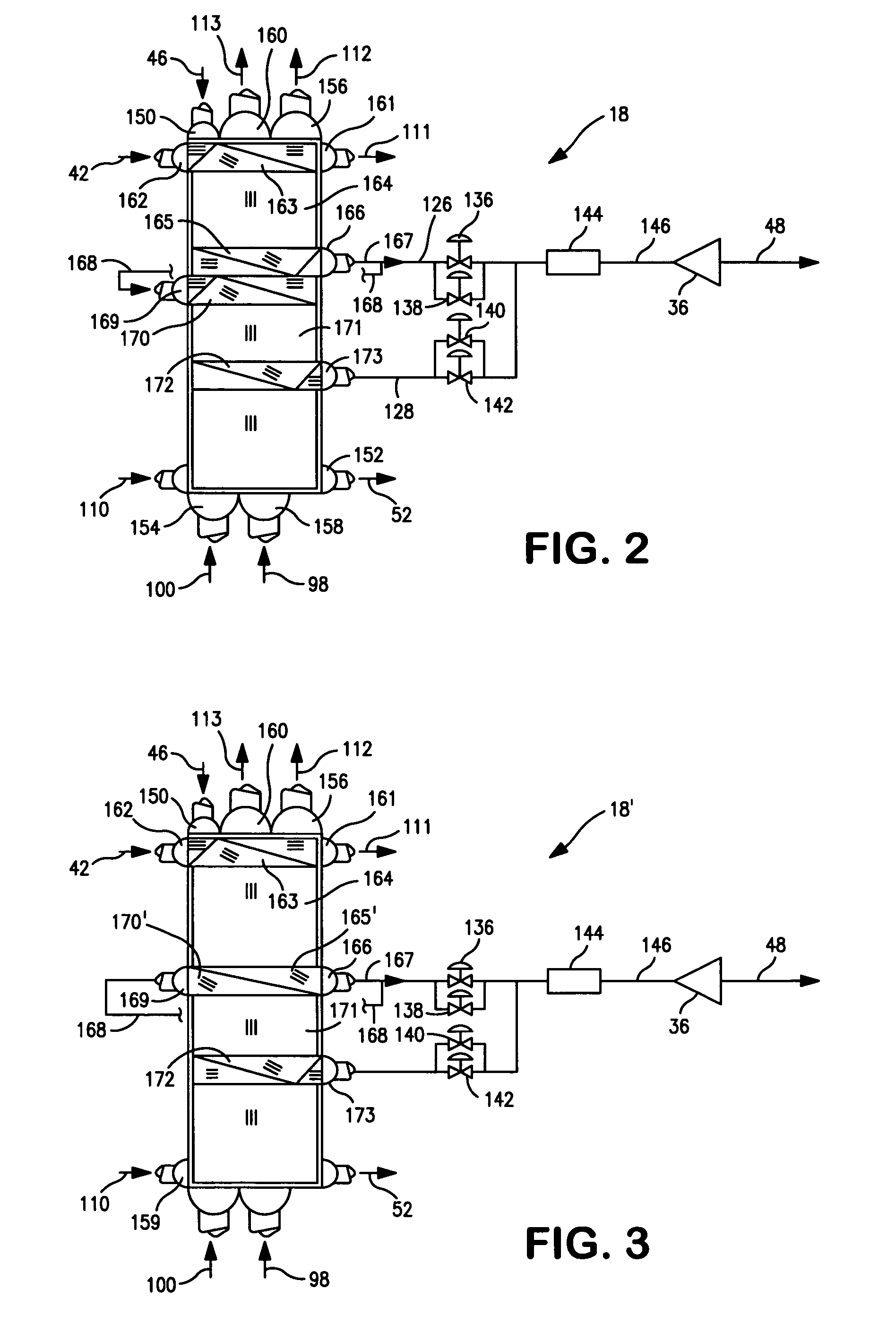

Distillation method and apparatus

InactiveUS20090241595A1High expansion rateIncrease chanceSolidificationLiquefactionLiquid productProduction rate

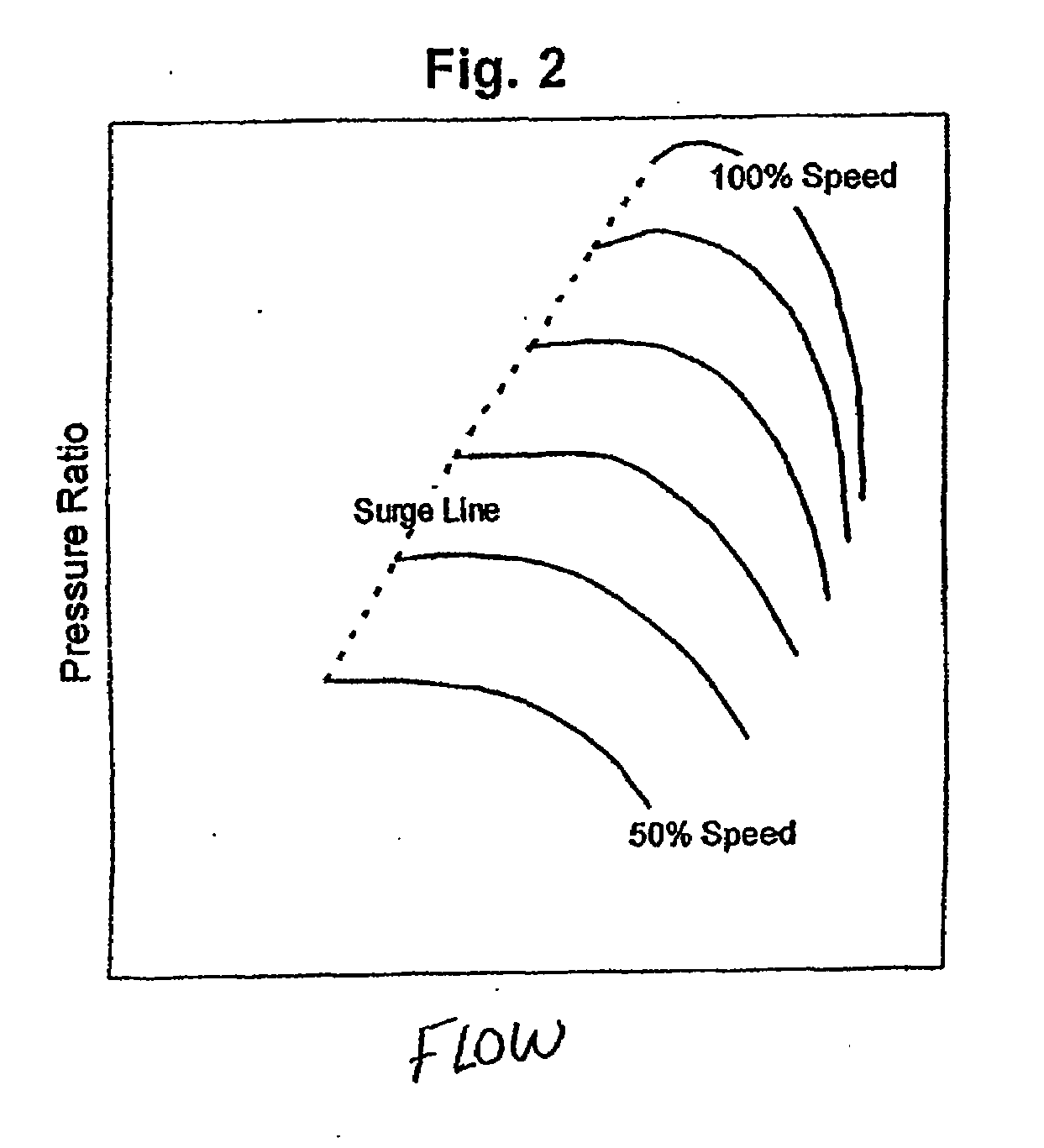

A distillation method and apparatus having application to the distillation of air in which liquid production make is varied by varying the pressure ratio across a turboexpander used in generating refrigeration. The pressure ratio is varied by varying the pressure of a compressed stream fed to the turboexpander. This is done by solely compressing such compressed stream by a first booster compressor during a low rate of production of liquid products. During a high rate of production of liquid products, the compressed stream is also compressed within a second booster compressor. The second booster compressor is driven by a variable speed drive to allow a variety of liquid production rates between the low level of liquid production and the high level of liquid production.

Owner:PRAXAIR TECH INC

Desalination method and system using a continuous helical slush removal system

ActiveUS20100018247A1Facilitates continuous removalReduce the temperatureWater treatment parameter controlGeneral water supply conservationSaline waterDesalination

The invention relates to a desalination method and system that uses freeze crystallization technology that incorporates the use of compressed air energy as the source for freezing temperatures. When compressed air is released by a turbo expander, chilled air is produced as a by-product, wherein the chilled air is introduced into a chamber, wherein a spray cloud of seawater droplets, which has been pre-chilled by heat exchange with the cold chamber walls, is then circulated and exposed to the chilled air in the chamber. The droplets then settle at the bottom of the chamber, wherein they are deposited at slightly above the eutectic temperature, to form an ice / brine slush mixture. A slush removal mechanism with a screw-like helical blade is provided to continuously remove the ice particles from the chamber.

Owner:ENIS BEN M +1

Supercritical-water-oxidation energy recovery system

PendingCN107935287AEmission reductionReduce energy inputWater/sewage treatment by centrifugal separationWater treatment parameter controlInorganic saltsSewage outfall

The invention discloses a supercritical-water-oxidation energy recovery system. The supercritical-water-oxidation energy recovery system disclosed by the invention has the beneficial effects that theoutlet end of a supercritical water oxidation reactor is connected with a high-pressure hydrocyclone, inorganic salts in reaction products in the supercritical water oxidation reactor are discharged from a sewage discharging port, high-pressure and high-pressure gas generated is exhausted into a buffering tank to carry out flat-pressing treatment, then the flatly-pressed gas passes through a high-pressure turboexpander and a low-pressure turboexpander in sequence to carry out residual-heat utilization for generating power, an outlet of the low-pressure turboexpander is connected with an evaporator, a Rankine circulation system is connected on the evaporator and is utilized for further utilizing residual heat of fluid passing through the evaporator, so that the energy input of the Rankine circulation system is reduced; the supercritical water oxidation system and a residual-heat and residual-pressure recovery system are fully combined, and heat energy and pressure energy of supercritical water oxidation products are fully utilized, so that the energy recovery and utilization rate of the supercritical water oxidation system is increased; carbon dioxide in the products is separated and recovered by utilizing a gas-liquid separator and a rectifying tower, so that the emission of greenhouse gas is reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Supercharged internal combustion engine system

InactiveUS20090259388A1Weight increaseHigh densityElectrical controlInternal combustion piston enginesCombustion chamberMechanical energy

A supercharged internal combustion engine system wherein during periods of high power demand the weight of combustion chamber charge is increased by cooling a portion of intake air in a turboexpander using high-pressure air from a storage tank. In addition to increasing engine output power, cold air intake also reduces engine pre-ignition (knocking) thereby reducing emissions. Mechanical energy produced during expansion of high-pressure air may be used to operate a turbocompressor, which compresses intake air and further increases charge weight. Effective supercharging is achieved even at low engine speeds. One of the objects of the invention is to obtain more power from small displacement ICE and thus providing automotive vehicles with sufficient acceleration in addition to good fuel economy. Another object of the invention is to enhance turbocharged engines and reduce their response lag. Air storage tank may be recharged using energy recovered during vehicle deceleration.

Owner:AGWEST

Separation method and apparatus

Separation method and apparatus for separating a gaseous mixture, for example, air, in a cryogenic rectification plant in which a compressed stream is divided into subsidiary streams that are extracted from a main heat exchanger of the plant at higher and lower temperatures. The two streams are then combined and expanded in a turboexpander to generate refrigeration for the plant. The flow rates of the two streams are adjusted to control inlet temperature of a turboexpander supplying plant refrigeration and to minimize potential deviation of the turboexpander exhaust from a saturated vapor state. Control of the expansion ratio can advantageously be applied to allow variable liquid production from the rectification plant.

Owner:PRAXAIR TECH INC

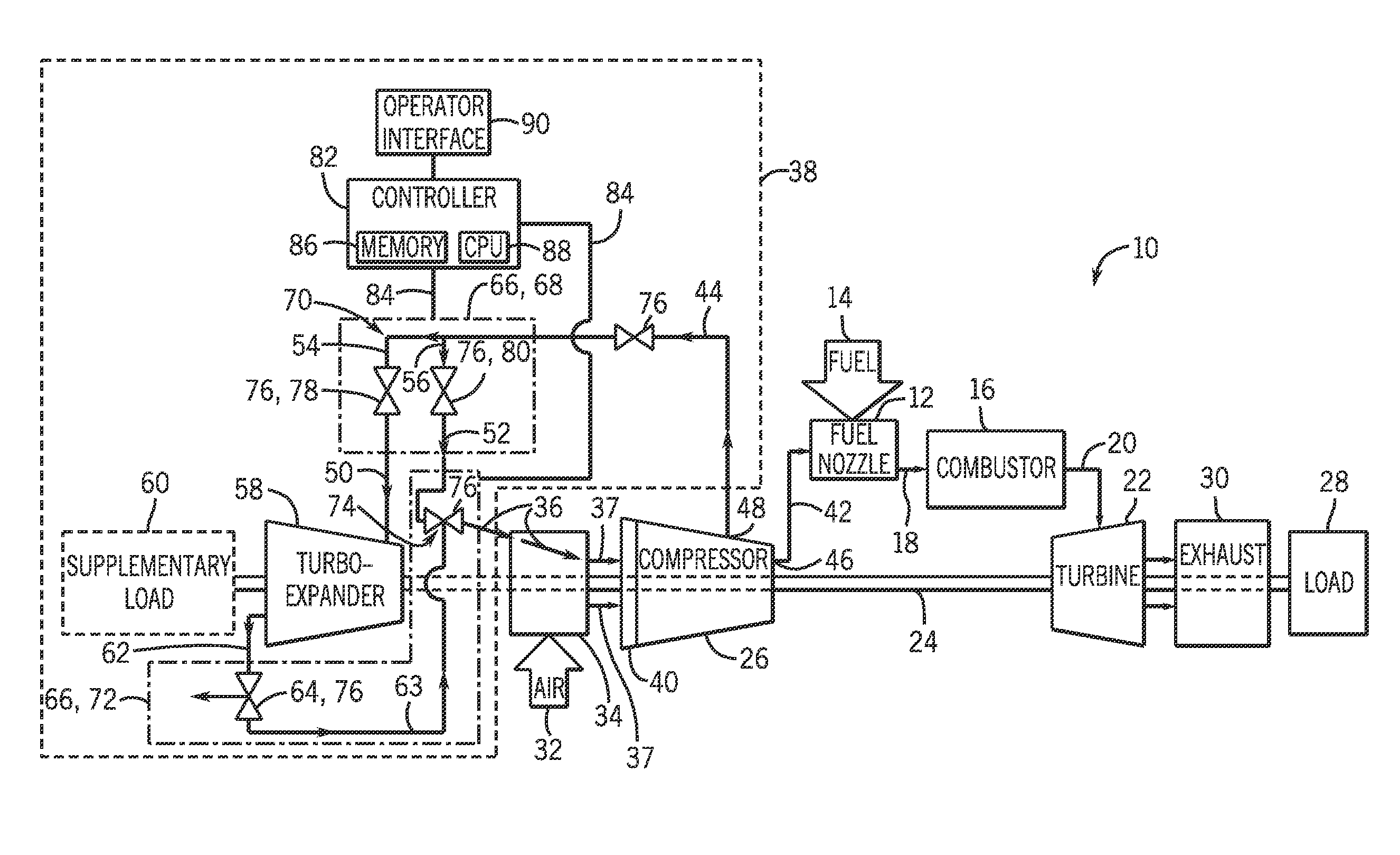

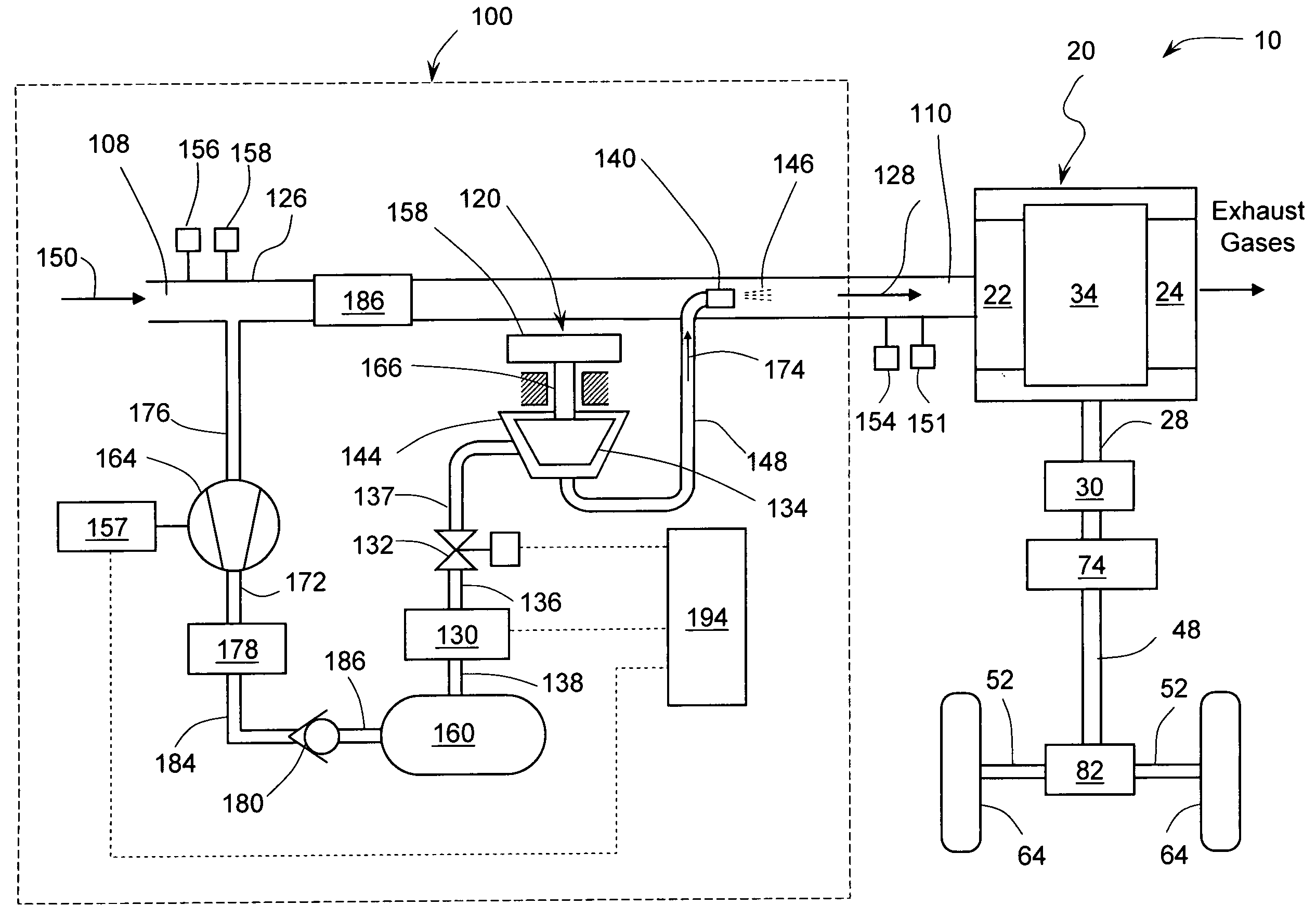

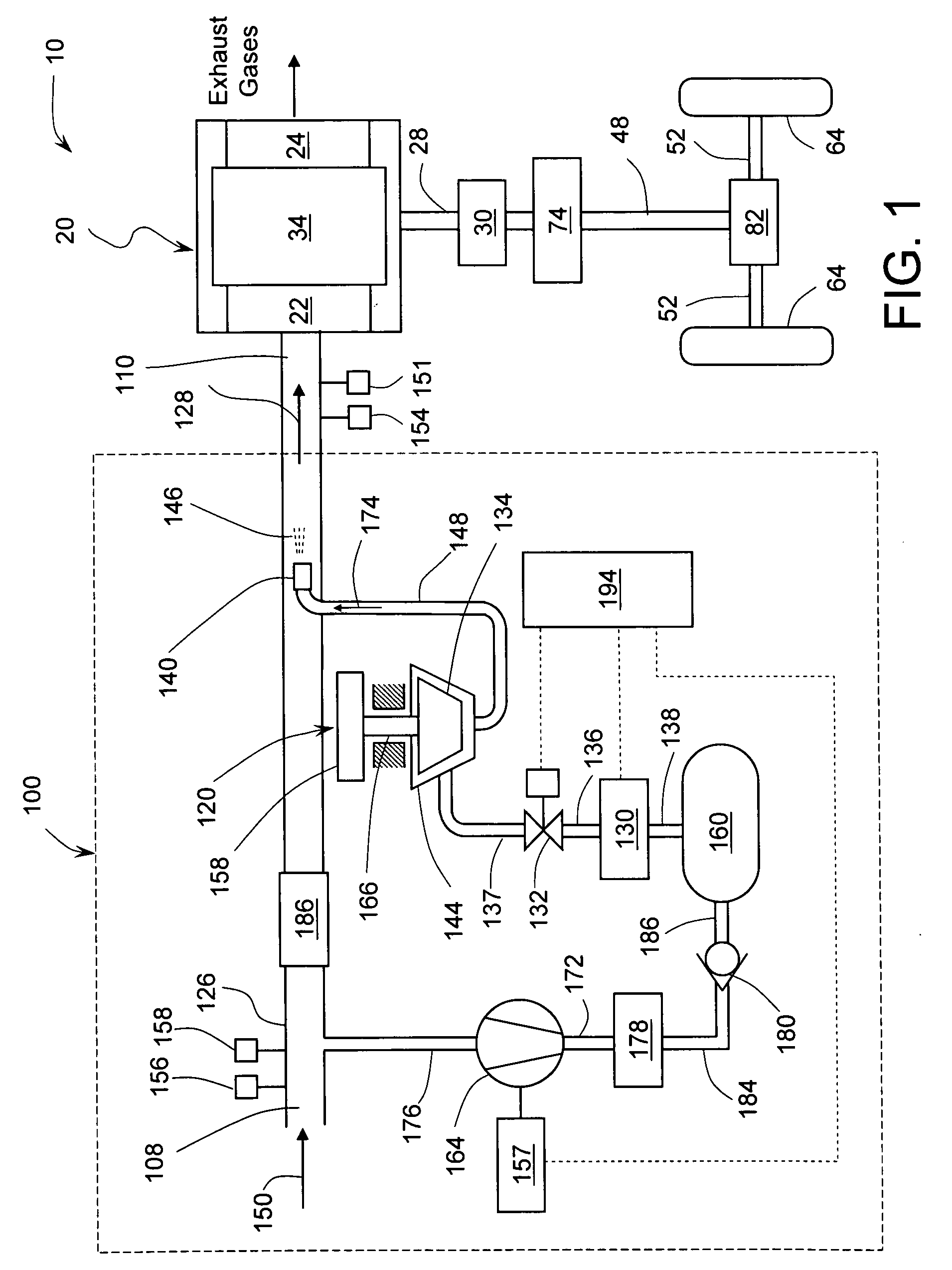

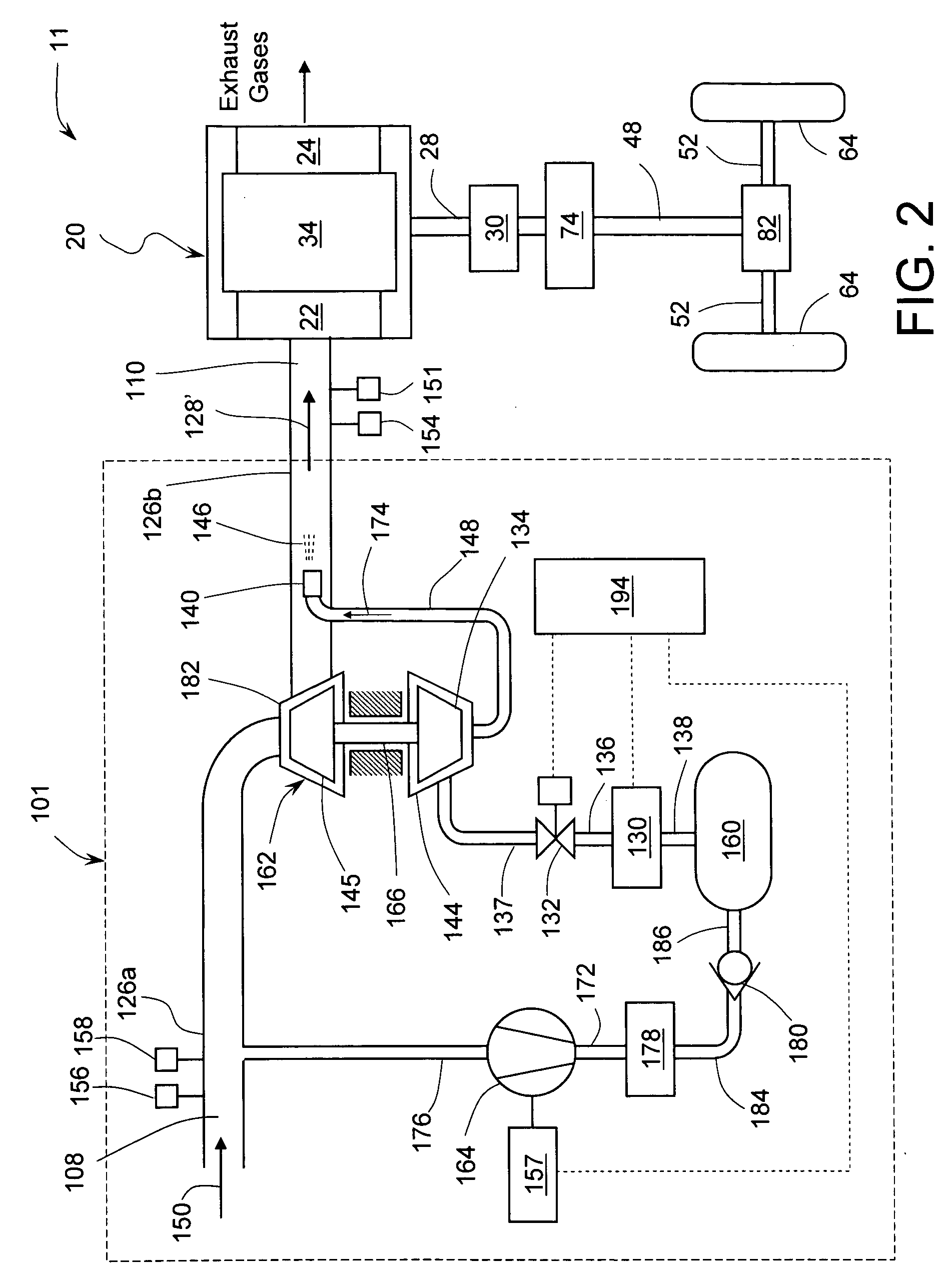

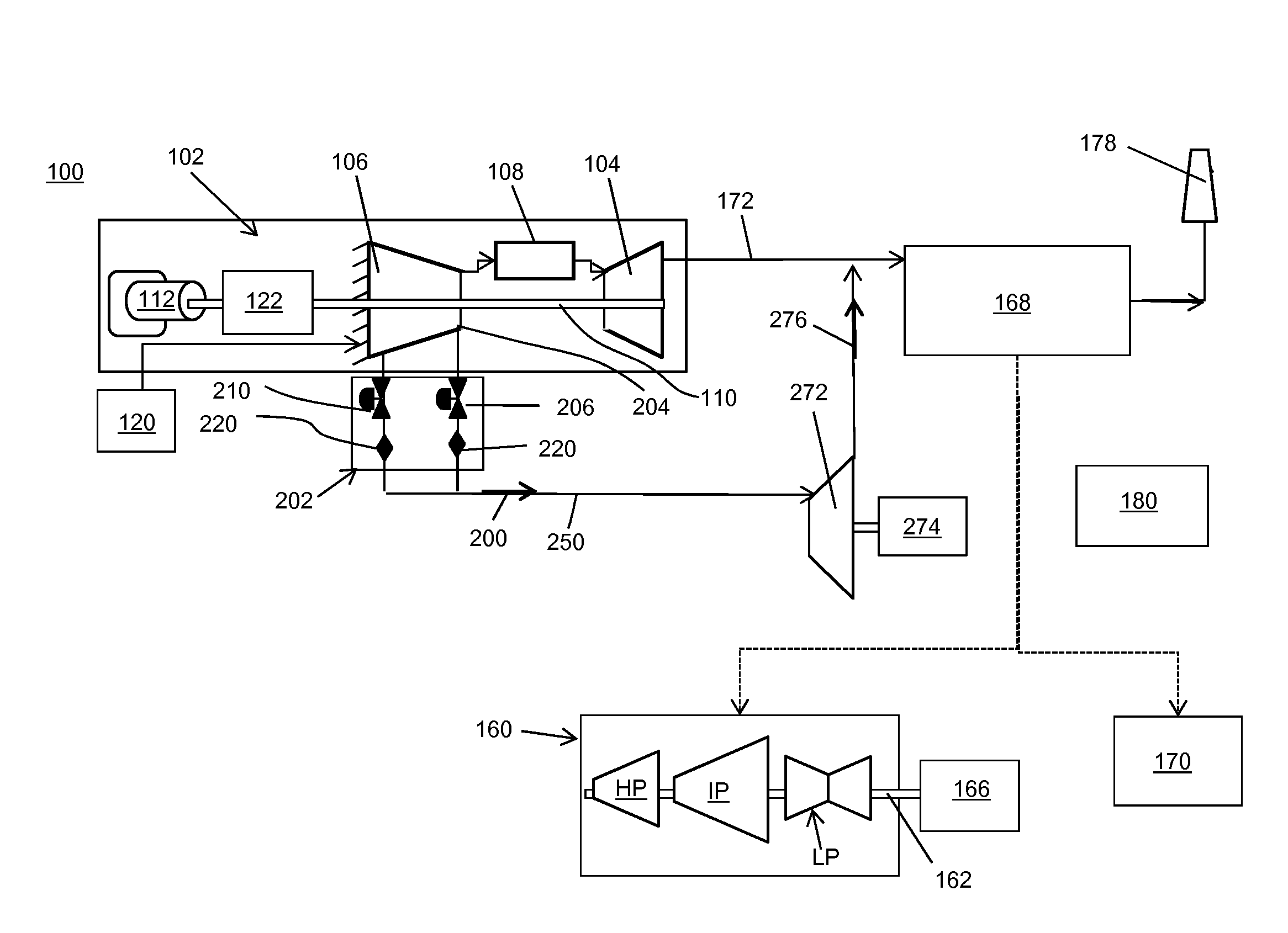

Power generation system having compressor creating excess air flow and turbo-expander for supplemental generator

A power generation system may include a gas turbine system including a turbine component, an integral compressor and a combustor to which air from the integral compressor and fuel are supplied. The combustor is arranged to supply hot combustion gases to the turbine component, and the integral compressor has a flow capacity greater than an intake capacity of the combustor and / or the turbine component, creating an excess air flow. A turbo-expander powers a generator. A first control valve controls flow of the excess air flow along an excess air flow path to the turbo-expander. An eductor may be positioned in the excess air flow path for using the excess air flow as a motive force to augment the excess air flow with additional air.

Owner:GENERAL ELECTRIC CO

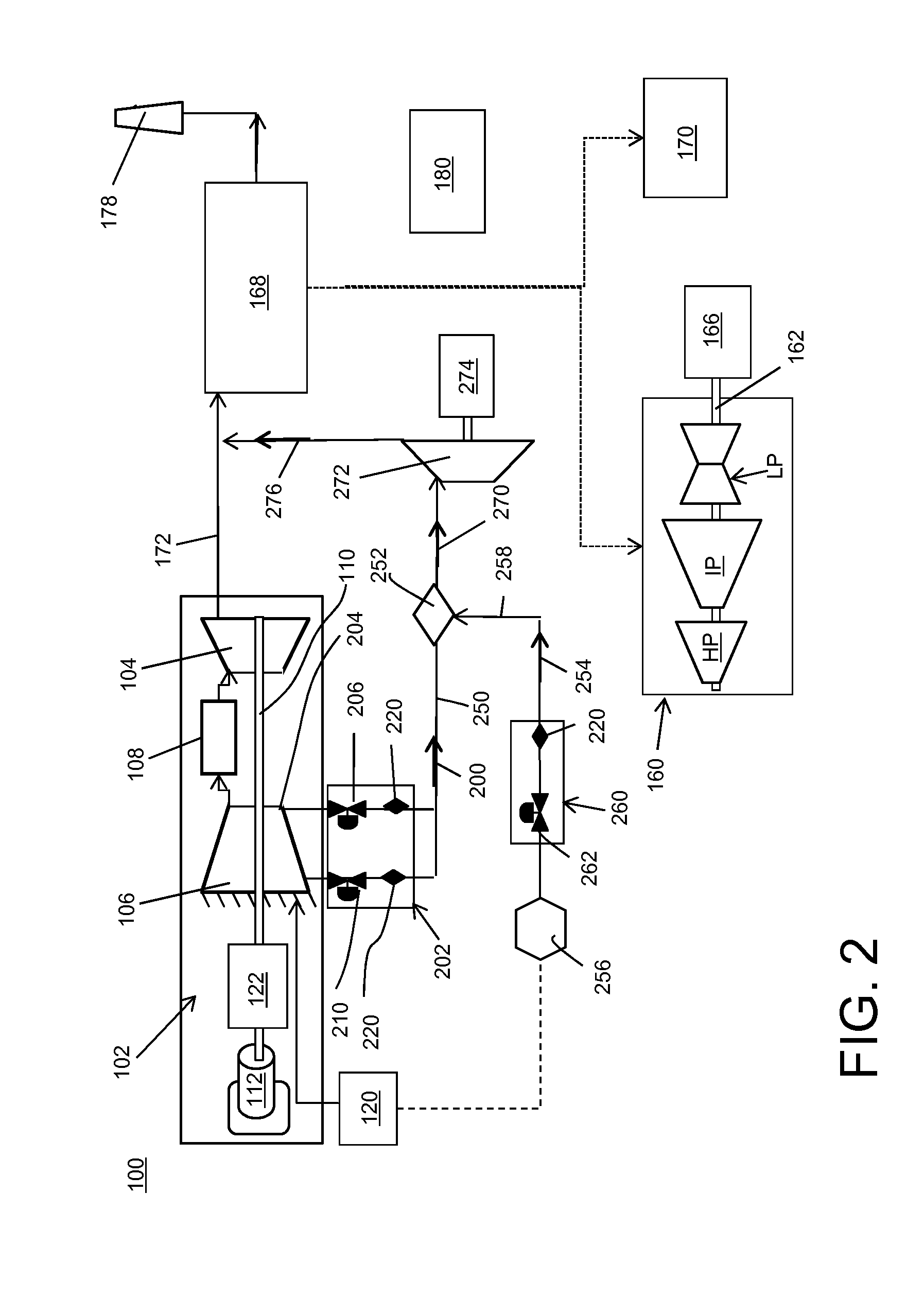

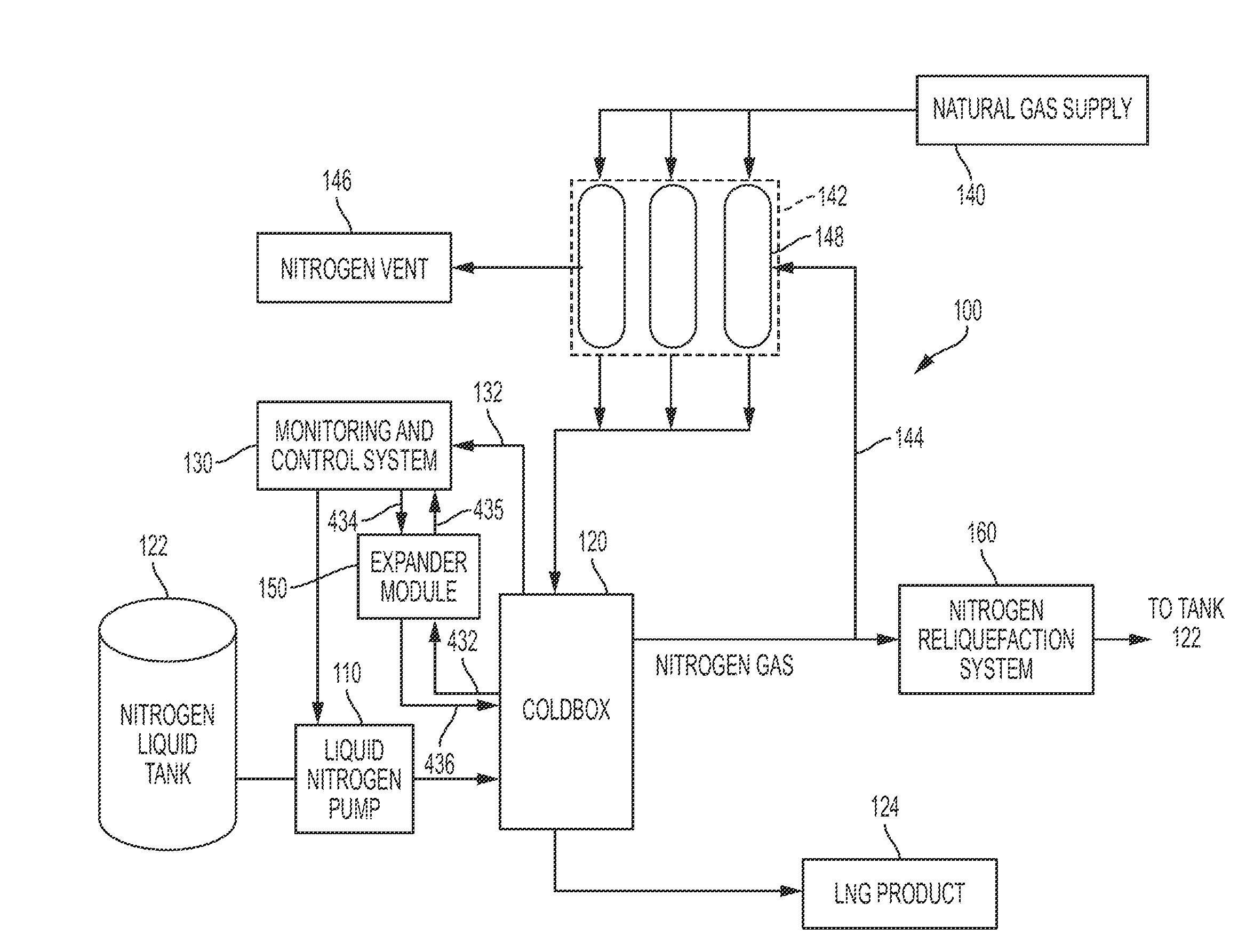

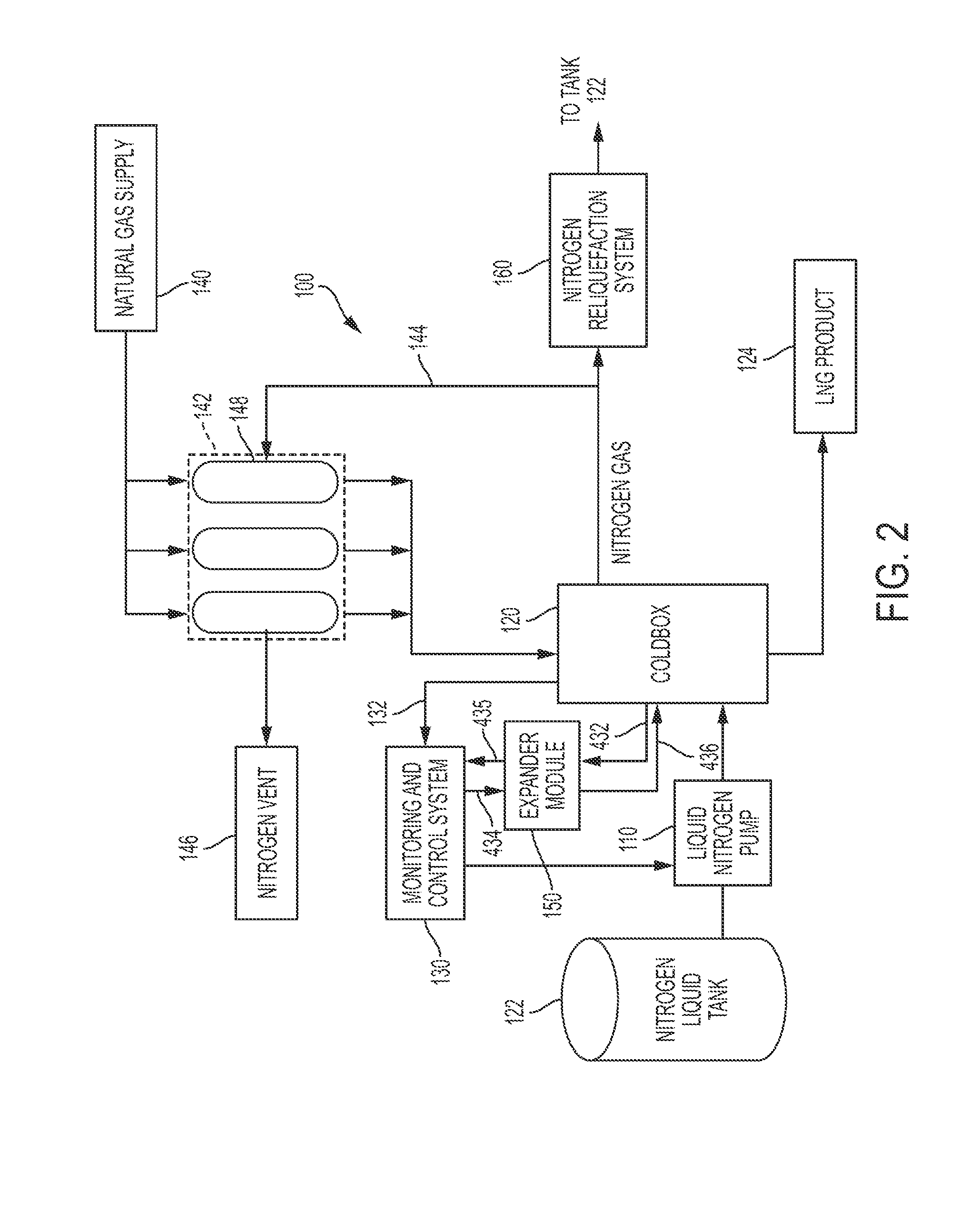

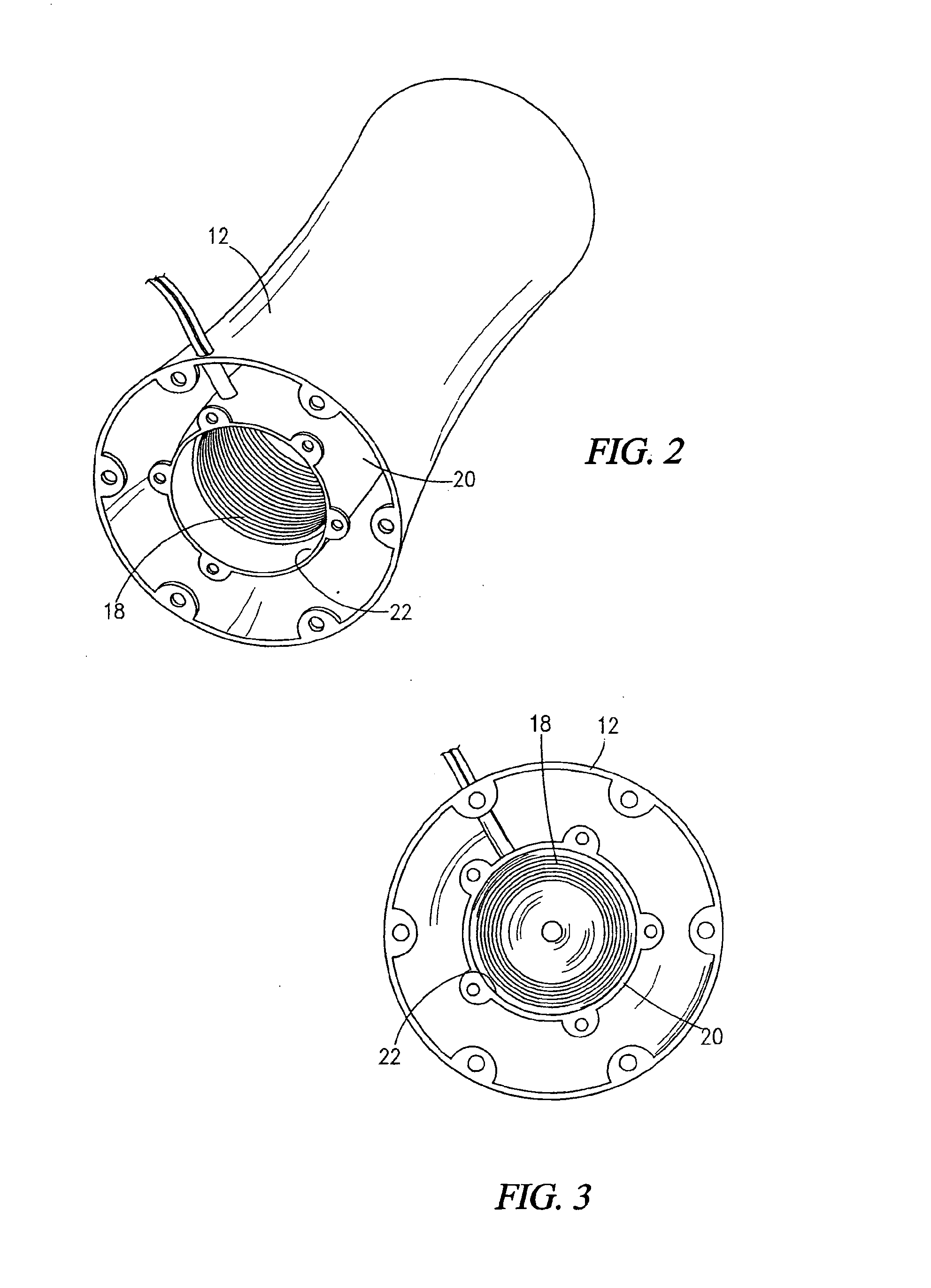

System and method for liquefying natural gas employing turbo expander

An improved system and method for liquefying natural gas employing liquid nitrogen is disclosed. The improved system and method lowers the nitrogen consumption rate by using an expander, for example, a radial inflow turbo-expander, on the nitrogen side. This reduction in nitrogen consumption rate substantially reduces system operating costs.

Owner:COSMODYNE

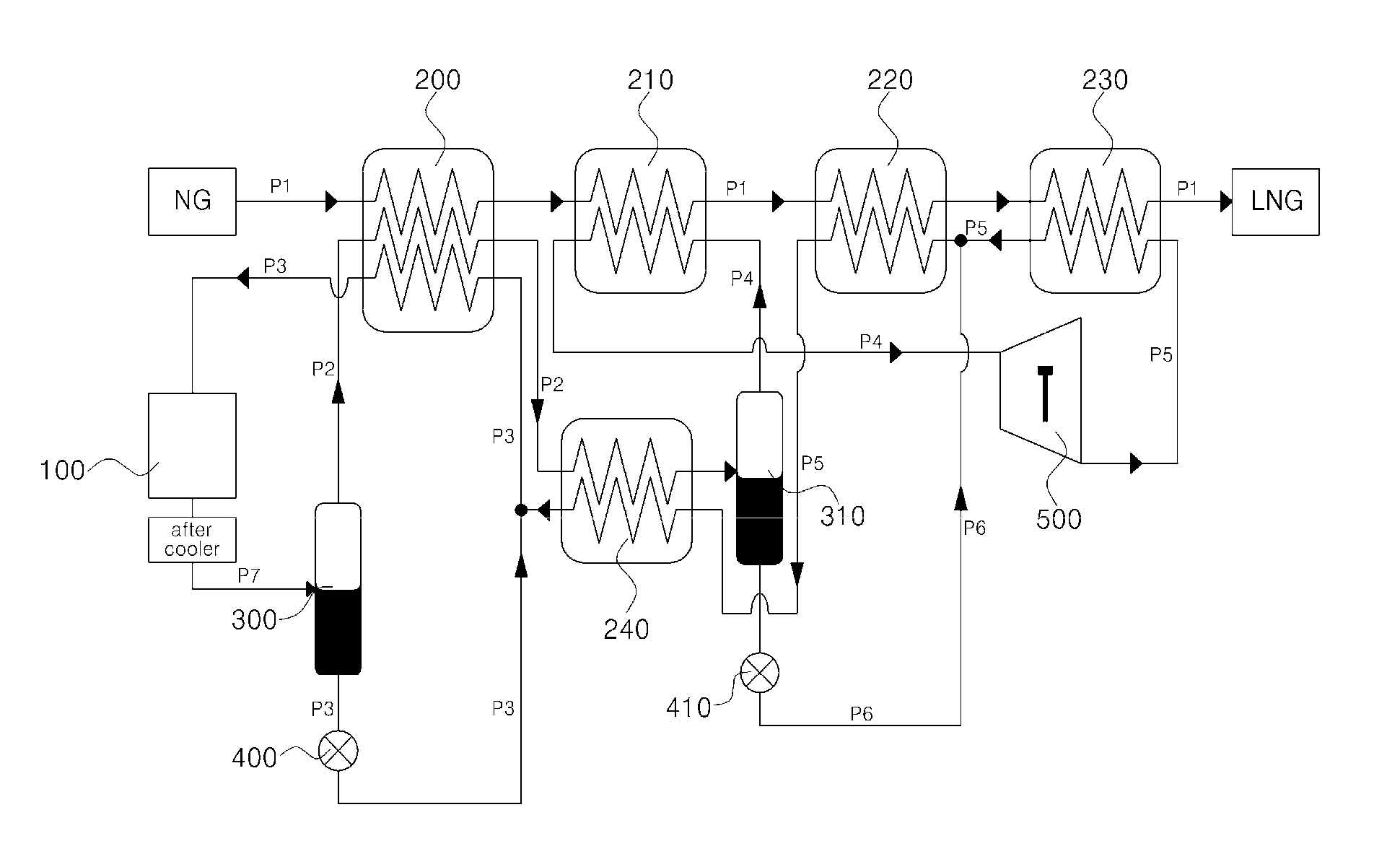

Natural Gas Liquefaction System with Turbine Expander and Liquefaction Method Thereof

InactiveUS20100024475A1Improve efficiencySolidificationLiquefactionVapor–liquid separatorTurboexpander

A natural gas liquefaction system with a turbine expander is provided that can improve the efficiency of the whole refrigeration cycle by using the turbine expander, instead of the throttling process that uses the conventional Joule-Thomson throttling valve that is used as a final throttling means in a conventional natural gas liquefaction system, and a liquefaction method thereof. The natural gas liquefaction cycle provided with the turbine expander of the present invention comprises a compressor 100, at least one vapor-liquid separator 300 or 310, a plurality of heat exchangers 200, 210, 220, 230 and 240, at least one Joule-Thomson throttling valves (below to be called JT valve) 400 and 410, a turbine expander 500, and connecting lines composed of plurality of pipes P1, P2, P3, P4, P5, P6 and P7 to connect these components.

Owner:KOREA ADVANCED INST OF SCI & TECH

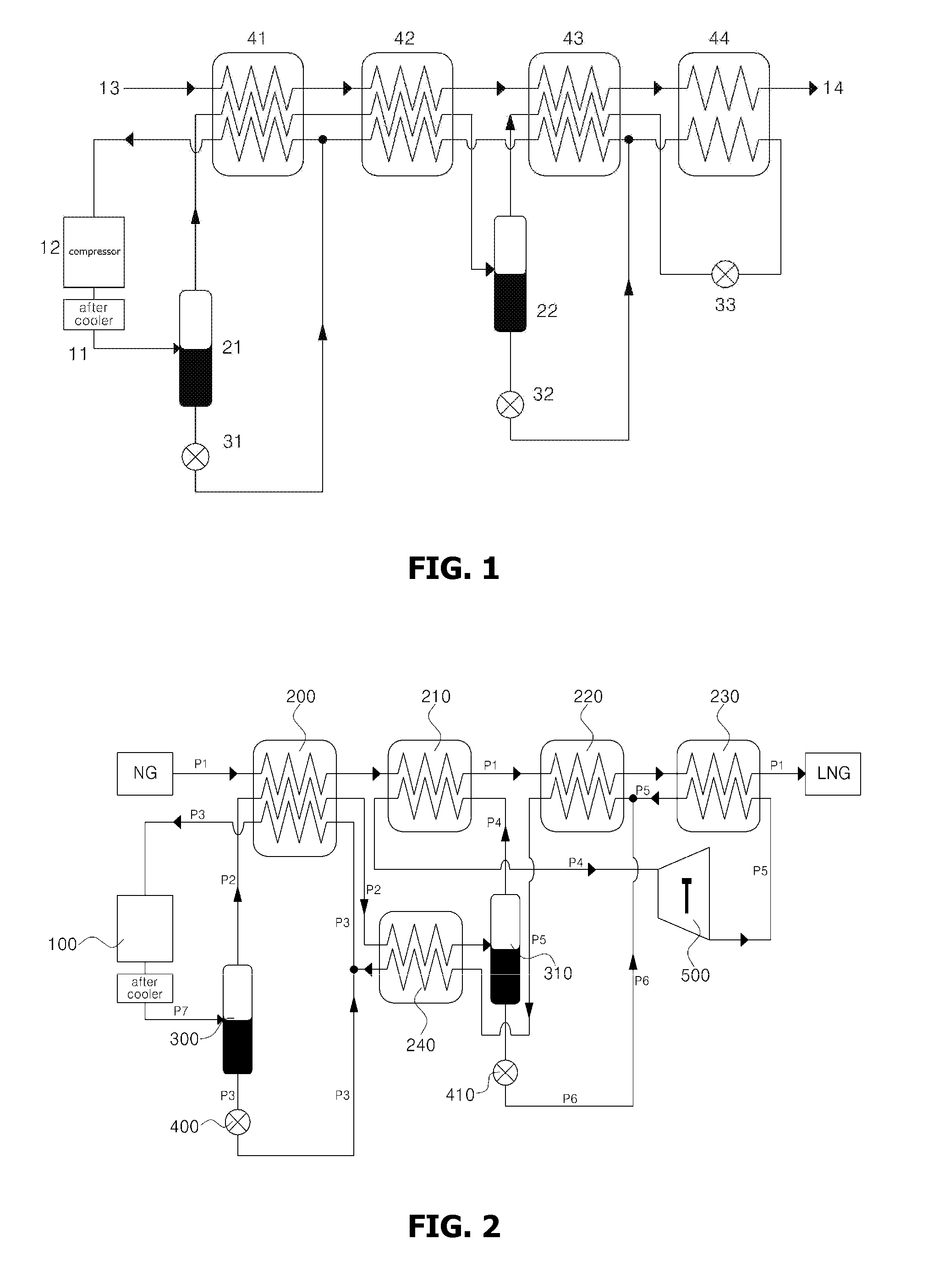

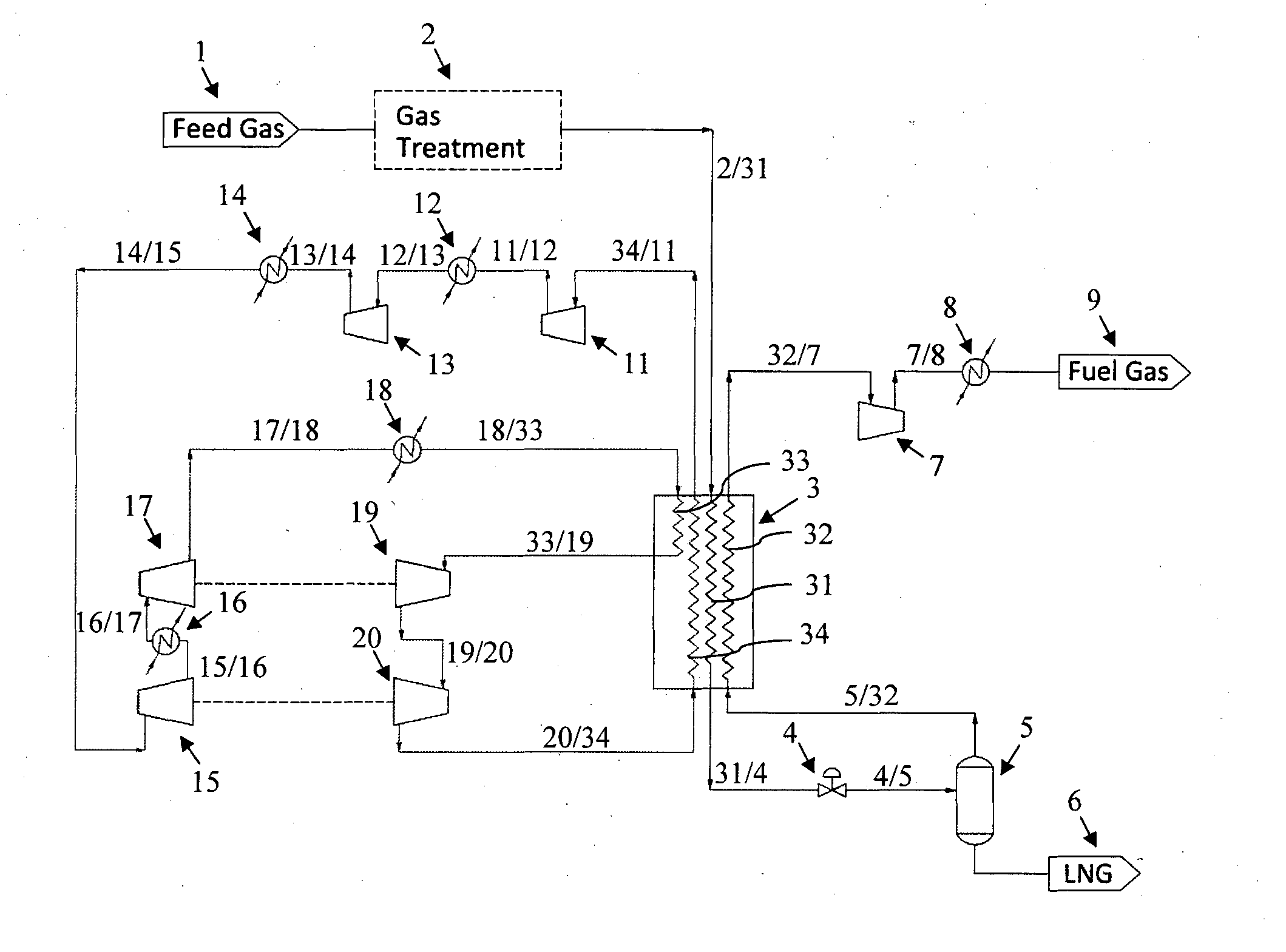

System And Method For Natural Gas Liquefaction

InactiveUS20150204603A1Improve cooling efficiencyReduce the temperatureSolidificationLiquefactionEngineeringTurboexpander

The present invention provides an LNG production system and method with improved refrigeration. The refrigeration is achieved by a refrigeration device comprising a plurality of refrigerant compressors (11, 13, 15, 17) configured into a series arrangement to perform multi-stage compressions of a refrigerant, a plurality of aftercoolers (12, 14, 16, 18) each of which being coupled to each of the plurality of refrigerant compressors to cool the compressed refrigerant, a plurality of turboexpanders (19, 20) coupled to the last aftercooler (18) and configured into a series configuration to perform multi-stage expansions of the compressed refrigerant, and a plurality of refrigerant heat exchange means (33, 34) coupled to both the first (11) of the plurality of refrigerant compressors and the last (20) of the plurality of turboexpanders, so that all components form a close refrigeration cycle.

Owner:KEPPEL OFFSHORE & MARINE TECH CENT PTE LTD

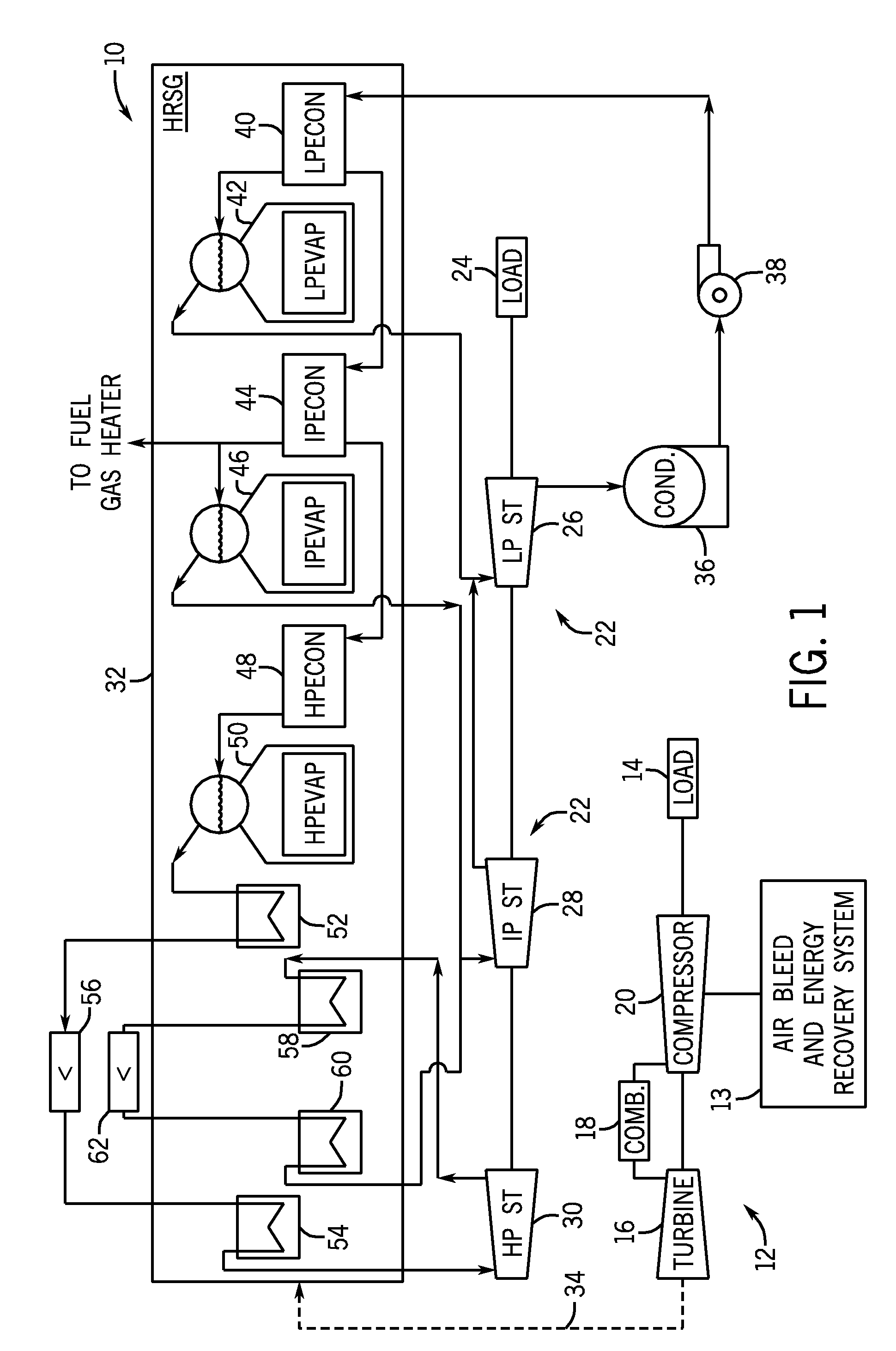

Heat Recovery System for a Gas Turbine Engine

InactiveUS20140190162A1Reduce fuel consumptionInternal combustion piston enginesTurbine/propulsion engine coolingEngineeringTurboexpander

A heat recovery system for an engine having an exhaust nozzle whereby exhaust gas is expelled, the heat recovery system comprising a heat exchanger disposed within the exhaust nozzle, heat exchanger containing a fluid, heat exchanger is further positioned to utilize heat energy from exhaust gas to vaporize fluid a turboexpander fluidly connected to heat exchanger and located downstream from heat exchanger, turboexpander further operatively connected to a utility a condenser fluidly connected to turboexpander and located downstream of turboexpander, and a pump fluidly connected to condenser and located between condenser and heat exchanger, pump is configured to direct fluid from condenser to heat exchanger; whereby operation of engine will generate heat energy in exhaust nozzle, vaporize fluid, and create a pressurized vapor which will drive turboexpander.

Owner:FLYSTEAM

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com